Production method of terpene resin

The technology of a terpene resin and a production method is applied in the production field of terpene resin, and can solve the problems of undiscovered manufacturing process technology, large fluctuation of reaction temperature, unstable operation of equipment, etc., and achieves increased daily output, mild and uniform reaction, The effect of smooth operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

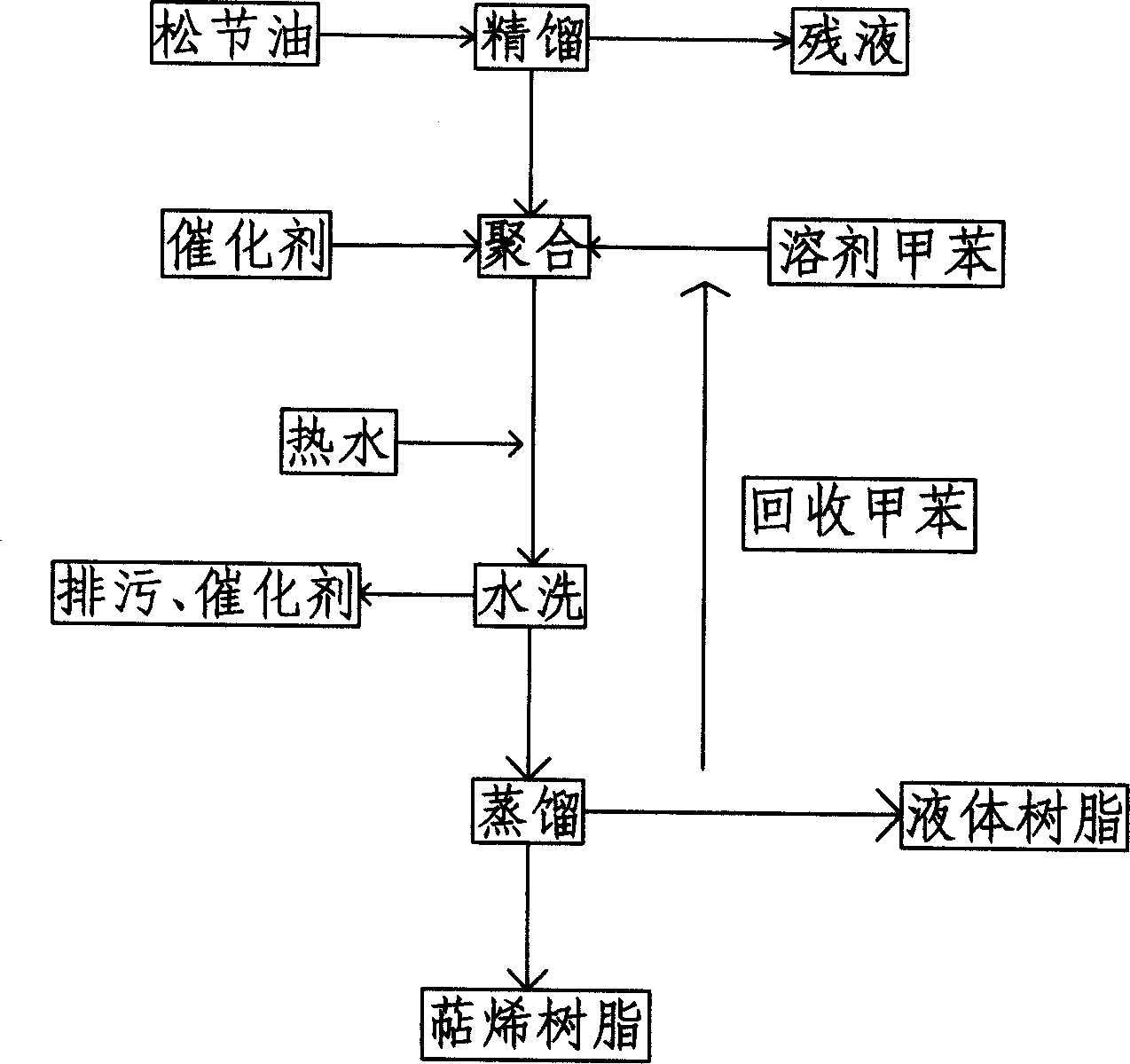

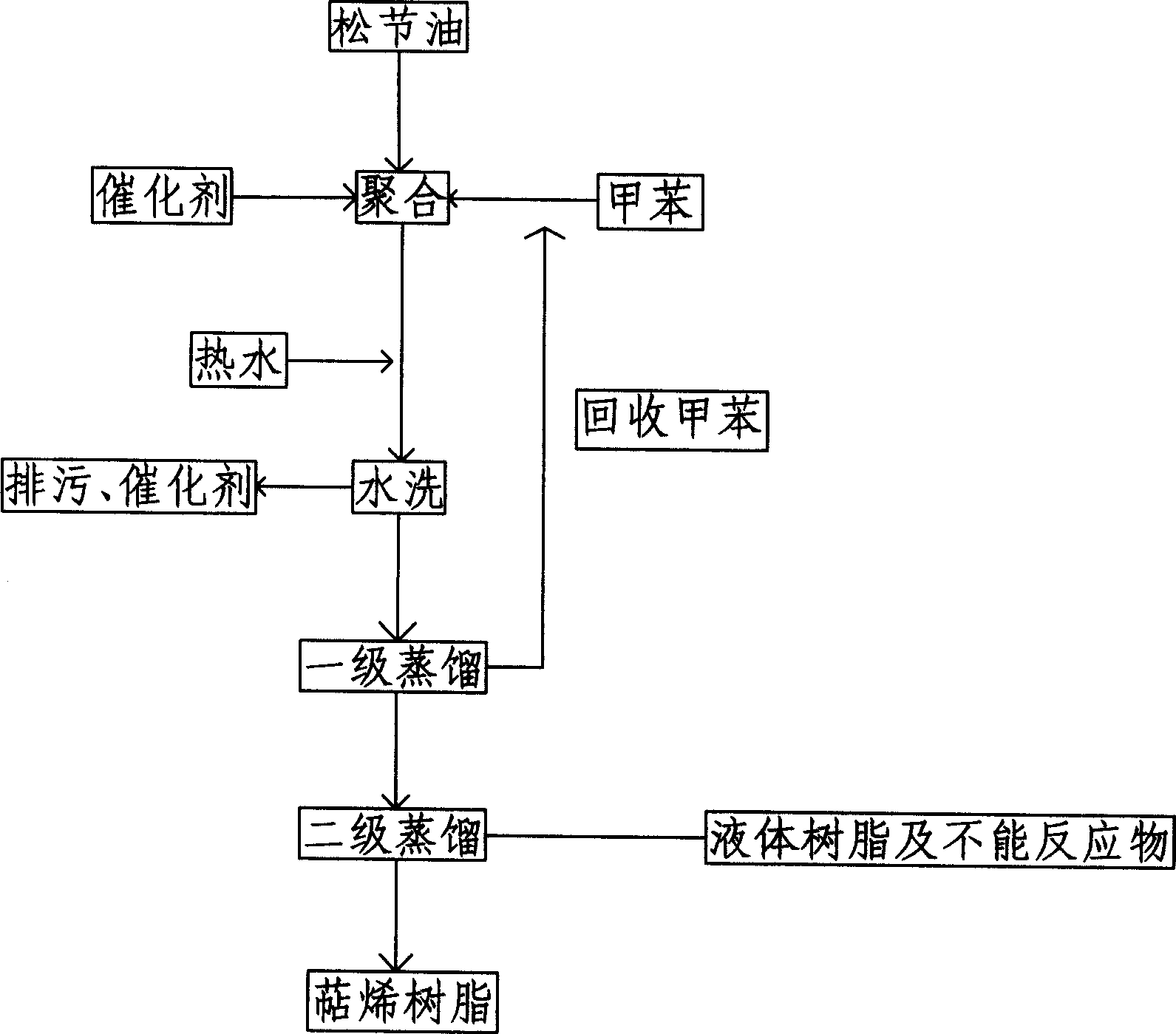

[0016] The idea of the present invention is to reduce the production cost and increase the yield of high-quality terpene resin and overall quality by reducing the process, reducing the requirements for raw materials and improving the process.

[0017] The following are non-limiting examples of the present invention, and specific data and proportions can be adjusted in real time according to actual conditions without any critical influence on the results.

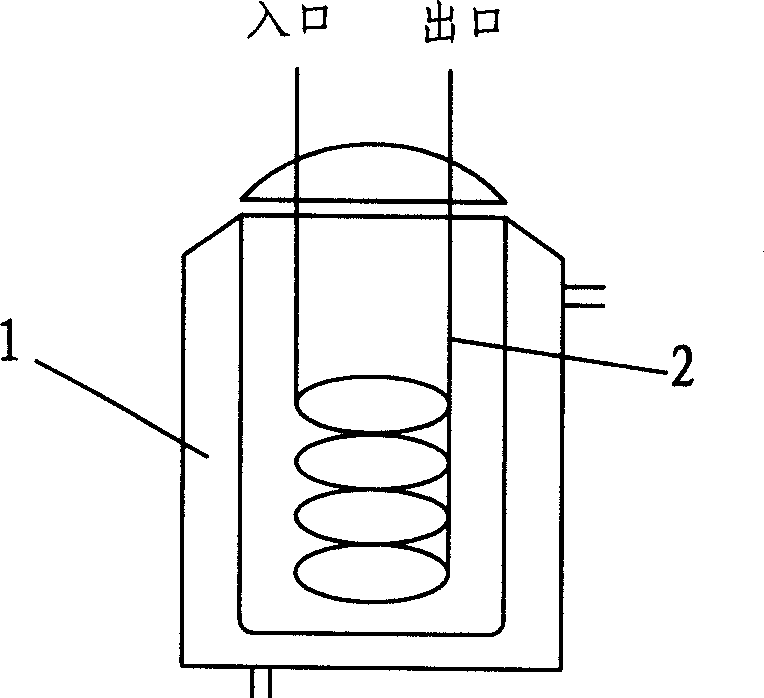

[0018] First prepare the raw material turpentine, toluene and catalyst aluminum trichloride in a ratio of 100:80:6.5, first put the toluene and catalyst aluminum trichloride into the reaction kettle, then slowly add turpentine, and the reaction temperature is controlled at minus 5 ~0°C, until the polymerization reaction ends 30 minutes after the turpentine is added; at this stage, the rectification process in the traditional process is eliminated, and the solvent toluene is replaced by industrial toluene, which reduces one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com