Patents

Literature

139results about How to "Shorten distillation time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pine gum processing method and equipment

InactiveCN101343509AIncrease productionRosin quality improvementNatural resin purificationTurpentineRosin

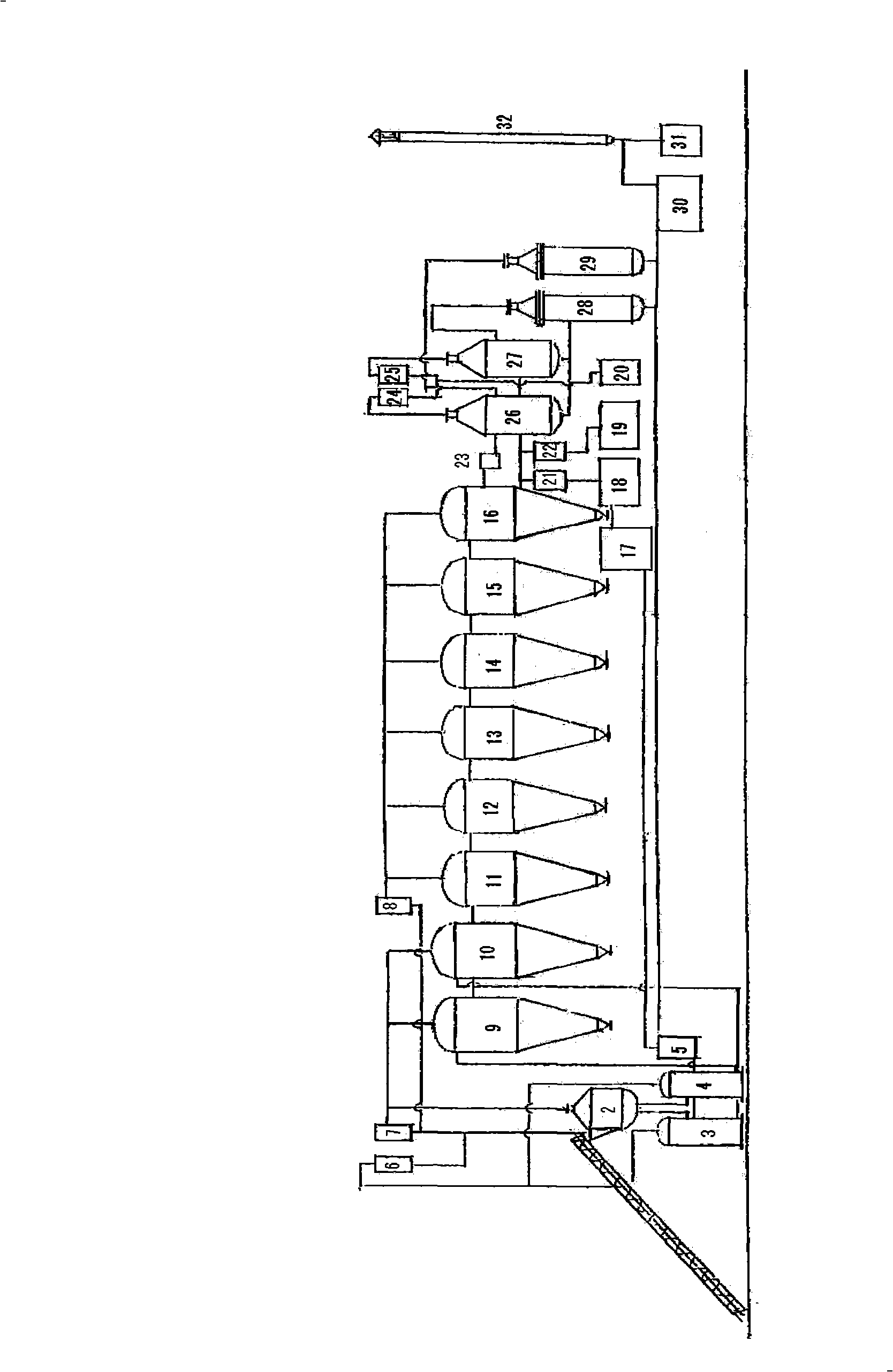

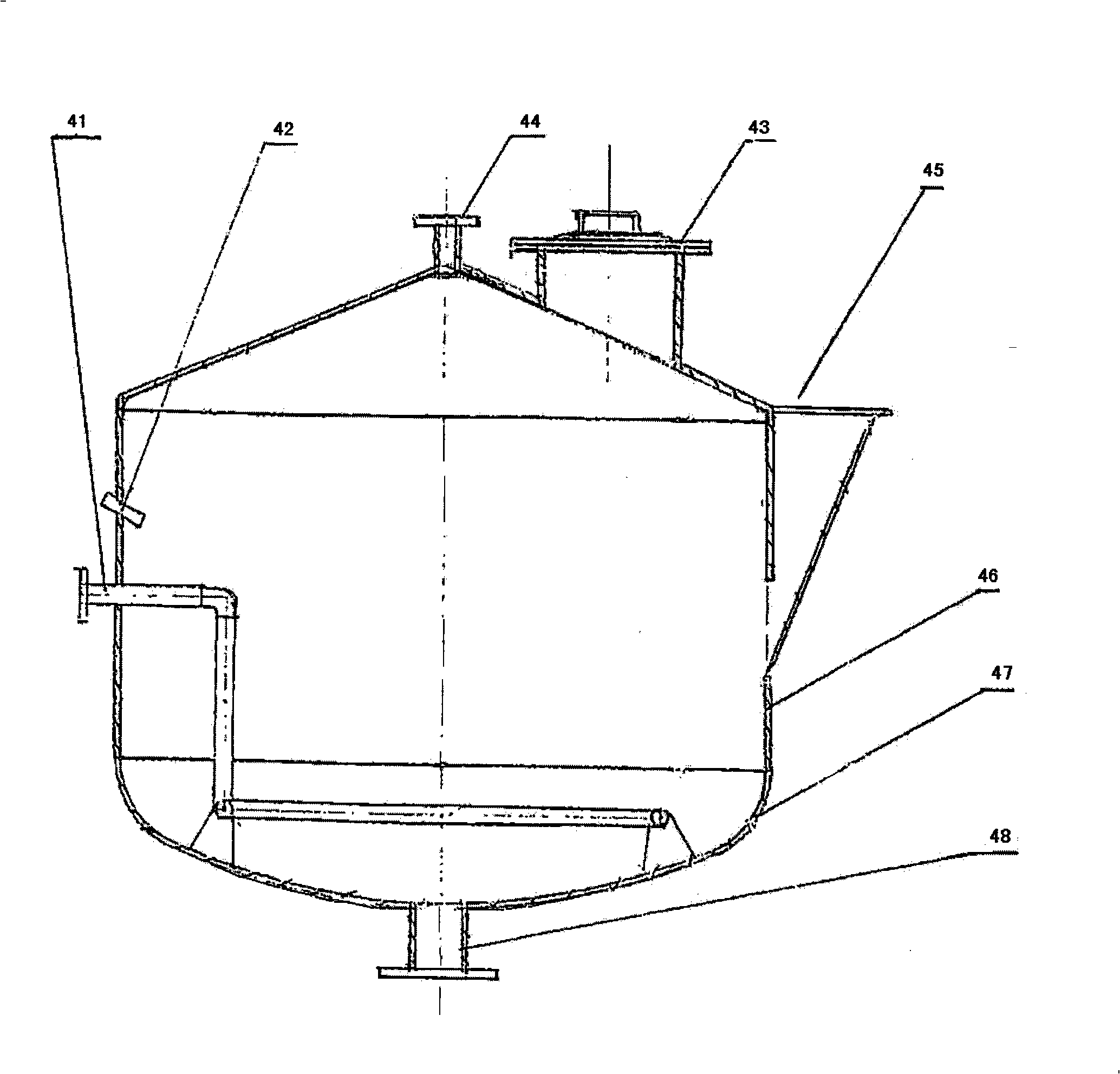

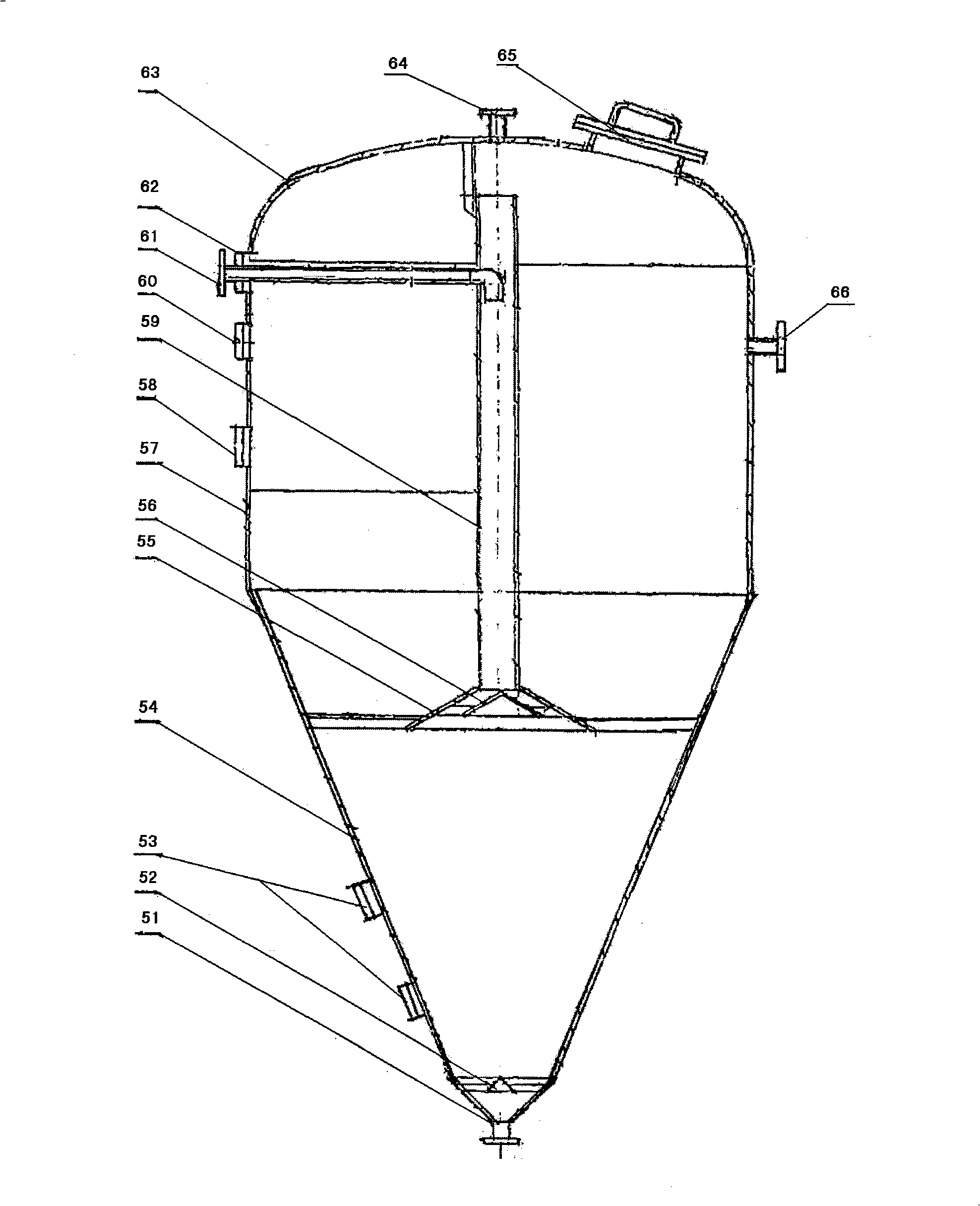

The invention discloses a processing technology of turpentine by a steaming process and the device. The invention adopts the technology that the turpentine is previously preheated and then dissolved, the dissolved turpentine enters into the clearing procedure after adopting the transitional clearing step, the turpentine liquid is preheated after being filtered, then oil gas and colophony are distilled out, turpentine oil is obtained through the condensation of the oil gas, and the distilled high-temperature tail gas and oil gas are recovered to preheat the turpentine and the turpentine liquid; the device adopts that a turpentine preheating pot is arranged in front of a liquating pot; a transitional clarifying kettle is arranged before a clarifying kettle; a distilling and preheating pot is arranged between a turpentine liquid filter and a distillatory kettle. Compared with the prior discontinuous process technology, the processing technology can greatly increase the production, the quality of the colophony is greatly improved, more than 98 percent of the colophony can reach the special grade and the first-grade, the distilling degree of the top grade turpentine reaches 97 percent, half of the standard coal consumed by one ton of colophony is approximately saved, half of the steam and the cooling water are also reduced, and the energy saving and consumption reducing effects are remarkable.

Owner:李国鸿

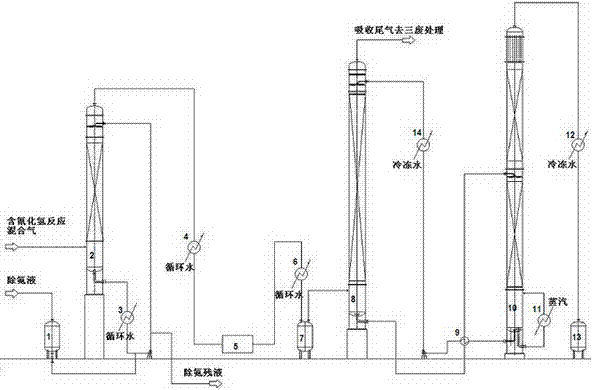

Method for purifying hydrocyanic acid from mixed gas containing hydrocyanic acid

InactiveCN102502707AImprove purification efficiencyReduce cooling energy consumptionHydrogen cyanide preparation/purification/separationAcid waterAqueous solution

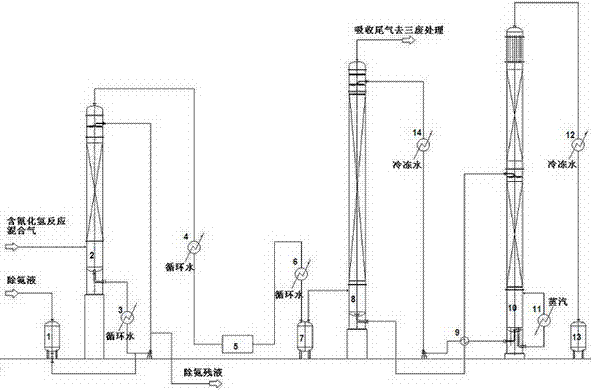

The invention discloses a method for purifying hydrocyanic acid from mixed gas containing the hydrocyanic acid, which comprises an absorption step and a rectification step, wherein in the absorption step, pressurizing the mixed gas containing the hydrocyanic acid to 0.11-1.5 MPa, then cooling to 10-80 DEG C, introducing into a pressure absorption tower, and pressurizing and absorbing the hydrocyanic acid in the mixed gas with absorption liquid, i.e. acidic aqueous solution with a pH value of 1-6 under the conditions that the pressure in the tower is 0.11-1.0 MPa, and the temperature is 0-60 DEG C to obtain hydrocyanic acid absorption liquid. The method has the beneficial effects that the existing atmospheric absorption method is replaced by a pressure absorption method to absorb the hydrocyanic acid in the mixed gas containing the hydrocyanic acid; the absorption temperature can be improved to 60 DEG C; the concentration of the hydrocyanic acid in the hydrocyanic acid absorption liquid can be improved by 3-10 times, so that the purifying efficiency of the hydrocyanic acid can be remarkably improved; and meanwhile, the energy consumption is greatly reduced and can be reduced by 80 percent to a maximum extent.

Owner:CHONGQING UNISPLENDOUR CHEM

Method for extracting cinnamon oil

InactiveCN102559384AEasy to separateShorten distillation timeEssential-oils/perfumesFatty-oils/fats productionChinese cinnamonCinnamon Oil

The invention relates to a method for extracting cinnamon oil from dry branches and leaves of cinnamon. By the method, the extraction time can be shortened, oil yield can be improved, energy consumption can be reduced, and the production cost can be reduced. according to the method, a surfactant is used as a leaching adjuvant in a water vapor distillation method, the water-wetting of surfaces of the branches and leaves of the cinnamon is accelerated under the action of wetting, permeation and solubilization of the surfactant, and the water permeates through plant cells, so that essential oil inside the plant cells is carried away from the cells; and the essential oil is subjected to exchange by heat energy in a system, so that the essential oil is azeotropic with water vapor to be distilled with the water vapor, and the distilled essential oil is condensed, cooled and subjected to centrifugal sedimentation to obtain the cinnamon oil. According to the method, the distillation time is short, so the change of heat sensitive chemical ingredients in the essential oil due to long-term heating is avoided, and the influence on aroma of the essential oil due to the coking of plant raw materials caused by overheating is also avoided. The cinnamon oil is light in color and pure in aroma, and does not have the smell of scorching.

Owner:GUANGXI SANPOTEL HEALTH IND CO LTD

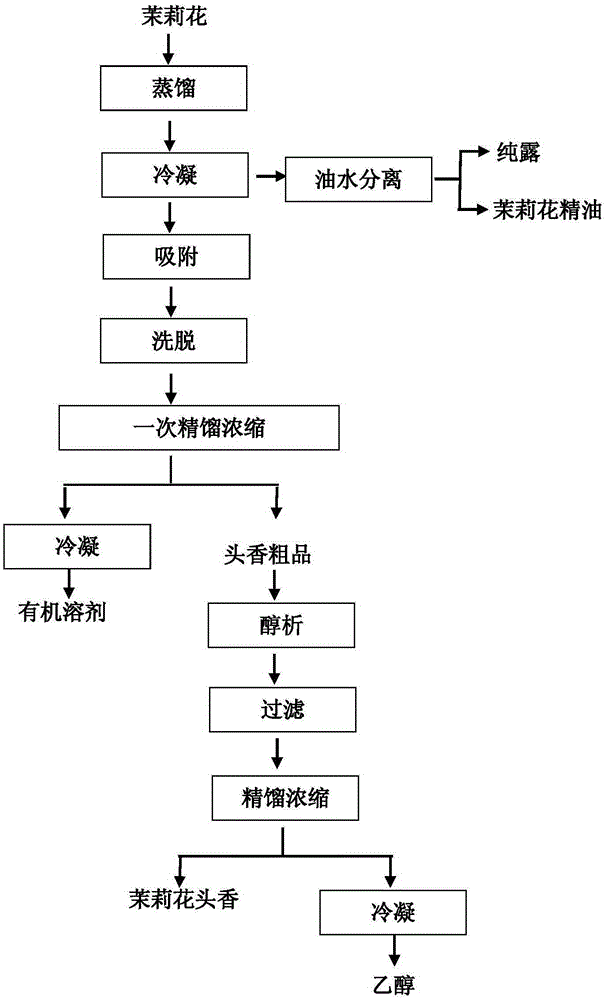

Method for extracting essential oil and headspace volatile of arabian jasmine flower

InactiveCN105296162AOvercome technical problemsLower distillation temperatureEssential-oils/perfumesOrganic chemistryHorticulture

The invention discloses a method for extracting essential oil and headspace volatile of arabian jasmine flowers. The method comprises the steps of distilling, condensing, oil water separating, adsorbing, primary rectifying concentrating, alcohol precipitating, secondary rectifying concentrating and the like. According to the method, in a vacuum state, vapor is adopted to distill the essential oil of the arabian jasmine flowers, distilling temperature is reduced, distilling time is shortened, the use rate of equipment is improved, the quality and yield of the essential oil of a product are improved, the production cost is reduced, and the technical problems of the existing traditional solvent method and supercritical carbon dioxide method are overcome. The headspace volatile of the arabian jasmine flowers is obtained by concentrating of a rectifying tower, and compared with the existing reduced pressure distillation, the method has the advantages that the loss of easy-to-volatile headspace volatile component is reduced, and the purity of the headspace volatile can be improved. By using the method in the invention to extract the essential oil and headspace volatile of the arabian jasmine flowers, the yields are respectively 0.23-0.28% and 5.5-6.0% and the yields of the respective components are obviously improved.

Owner:GUANGXI FORESTRY RES INST

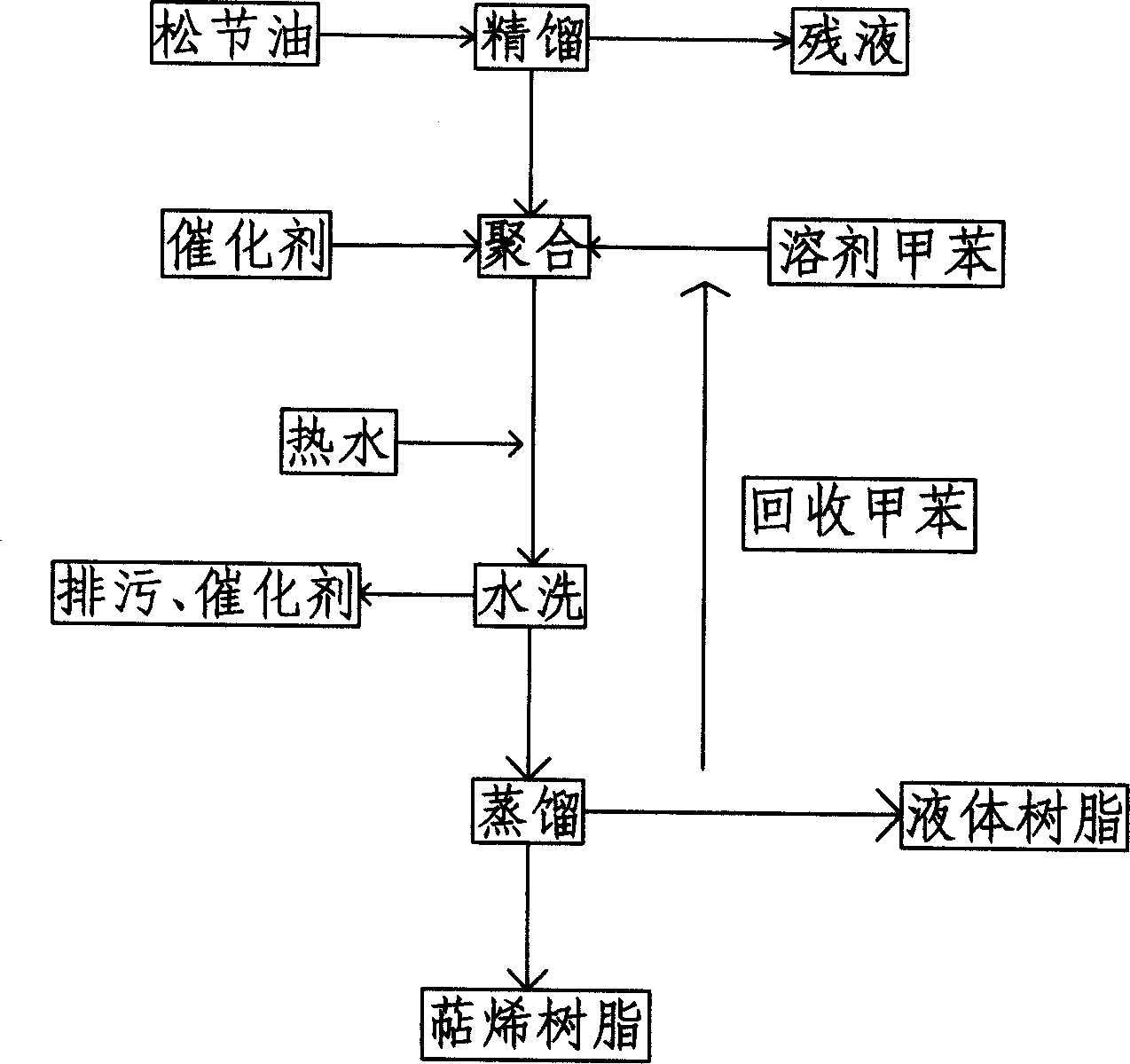

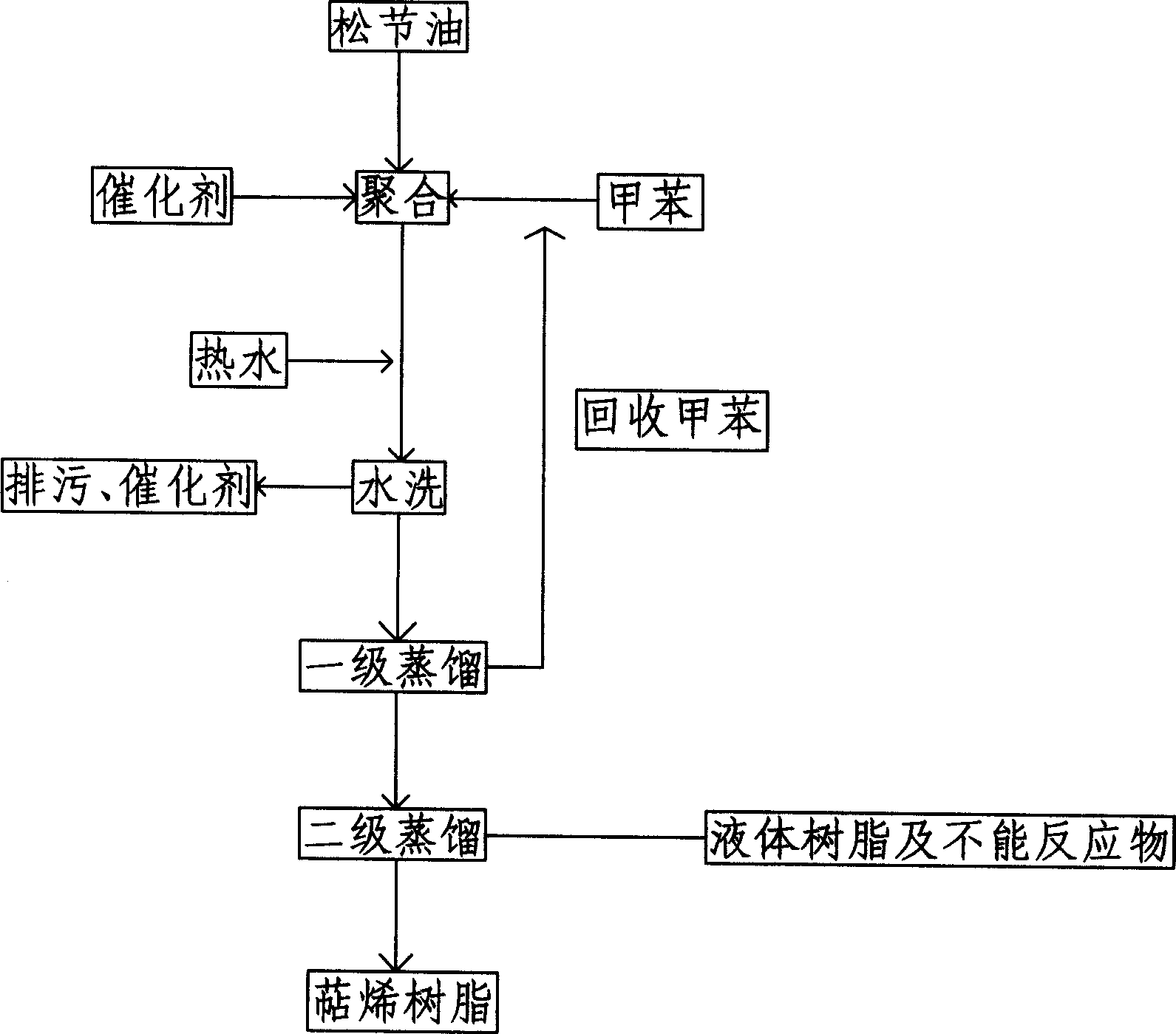

Production method of terpene resin

InactiveCN1631916AMild and even reactionThe reaction temperature fluctuation range is smallAluminium chlorideDistillation

A method for producing terpine resin has the steps follows: turpentine oil, toluene, catalyst aluminium chloride have polymerization in the wash the mixed outcome with hot water for draining the catalyst and waste out, then distil the outcome, recycle toluene and clear the liquid resin and the material which did not join the reaction in the course of distillation, then the toluene is made. The reactor includes enamel glass and inside cooling device which is steelless pipe groups filled with saturated salt solution of indoor temperature in the polymerization. The invention has friendly reaction, small fluctuating range of temperature, stable operation, productiving being raised by 20%, fewer equipments, low cost fir energy and production good economic benefit.

Owner:蓝运泉

Steam distillation aromatic essential oil equipment

ActiveCN103740468AAvoid overall overheatingAvoid burnsEssential-oils/perfumesWater vaporSteam distillation

The invention discloses steam distillation aromatic essential oil equipment. The equipment comprises a distillation kettle, a complex distillation column, a goose neck pipe, a cooler and an oil-water separator, wherein a double-layer hollow steam coil pipe is horizontally and fixedly arranged at the bottom in the kettle body of the distillation kettle; the inner pipe of the double-layer hollow steam coil pipe is connected with steam outlet pipes which are distributed annularly and are communicated with the inner pipe of the double-layer hollow steam coil pipe and penetrate through the outer pipe of the double-layer hollow steam coil pipe in a liquid sealing way; the included angle between the extension lines of the steam outlet pipes and the vertical axis in the kettle body of the distillation kettle is 30 to 40 degrees. The steam distillation aromatic essential oil equipment has the benefits that the outer pipe of the hollow steam coil pipe can be prevented from being overheated, and the aromatic petals in contact with the outer pipe are prevented from being burnt, so that the aroma quality of the aromatic essential oil is improved; the steam sprayed from the steam outlet pipes drives the aromatic petals and water to move in the spraying direction of the steam and to roll downward along the inner wall of the kettle body of the distillation kettle, so that the aromatic petals are steamed and cooked uniformly, the distillation time is shortened, and the oil yield is improved.

Owner:郭永来

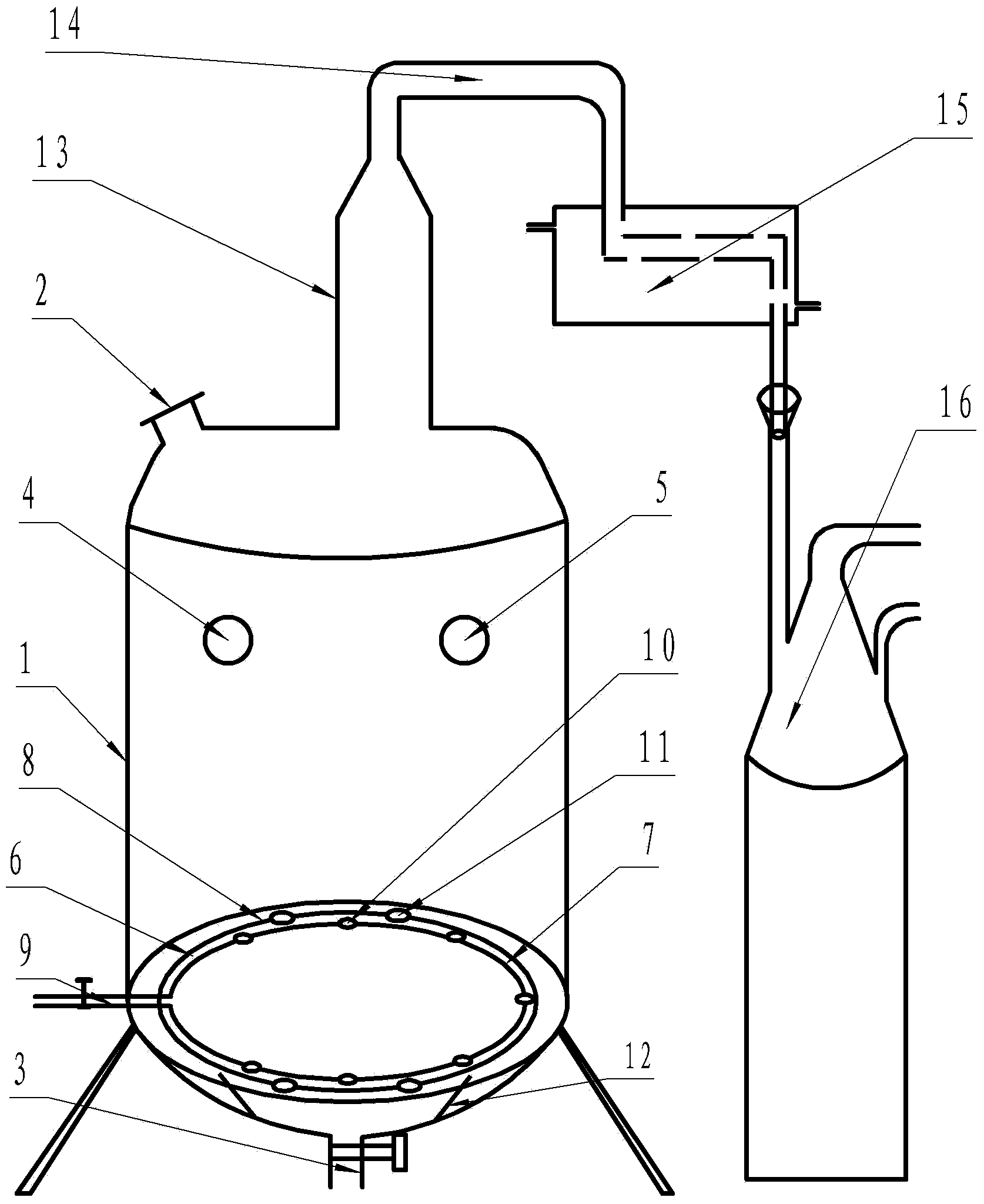

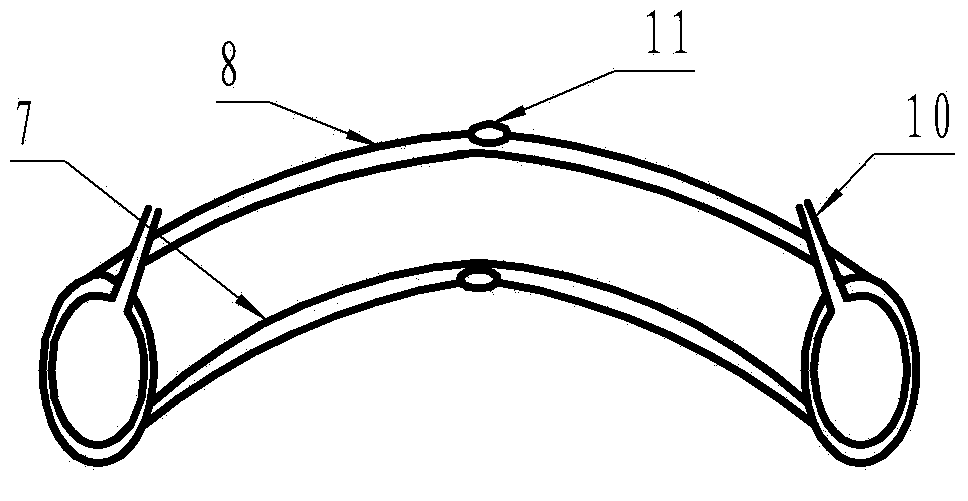

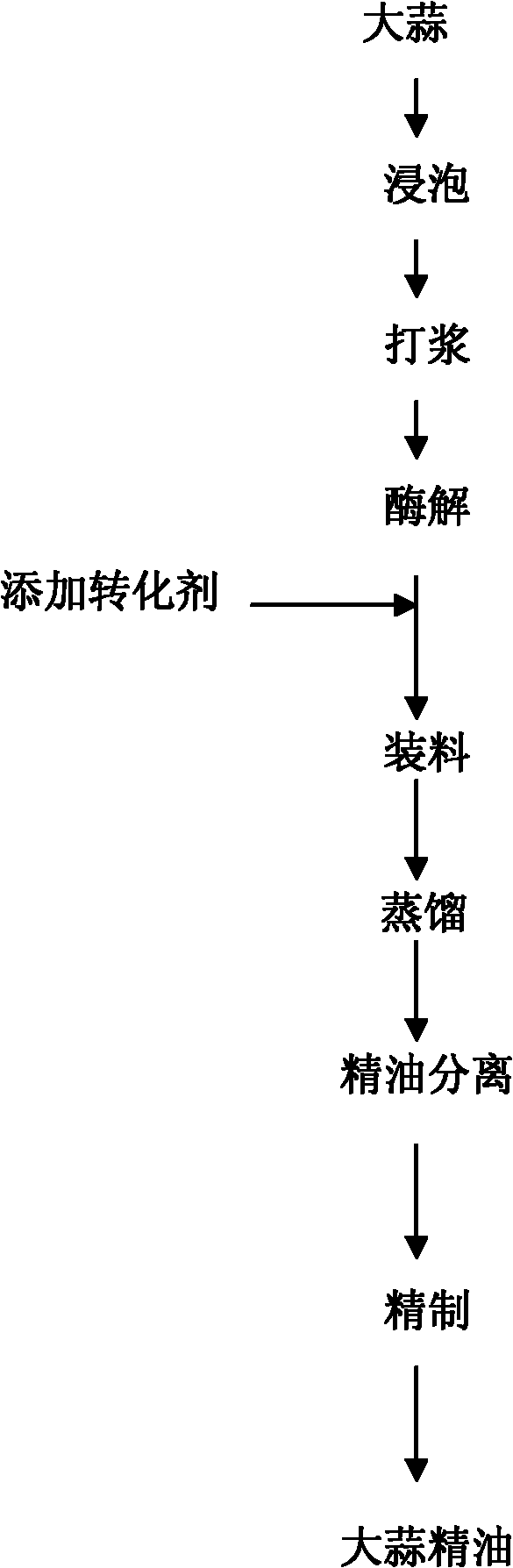

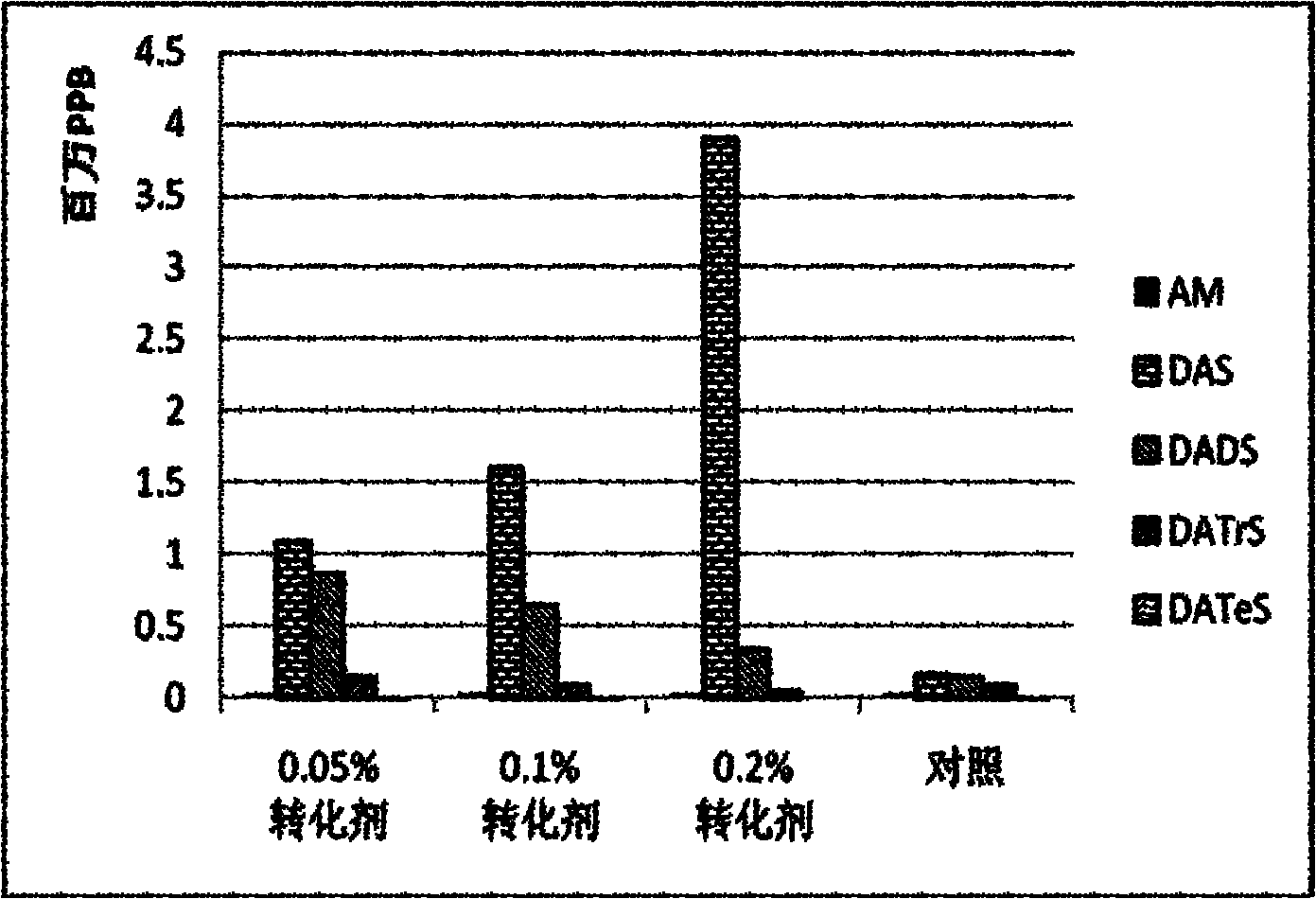

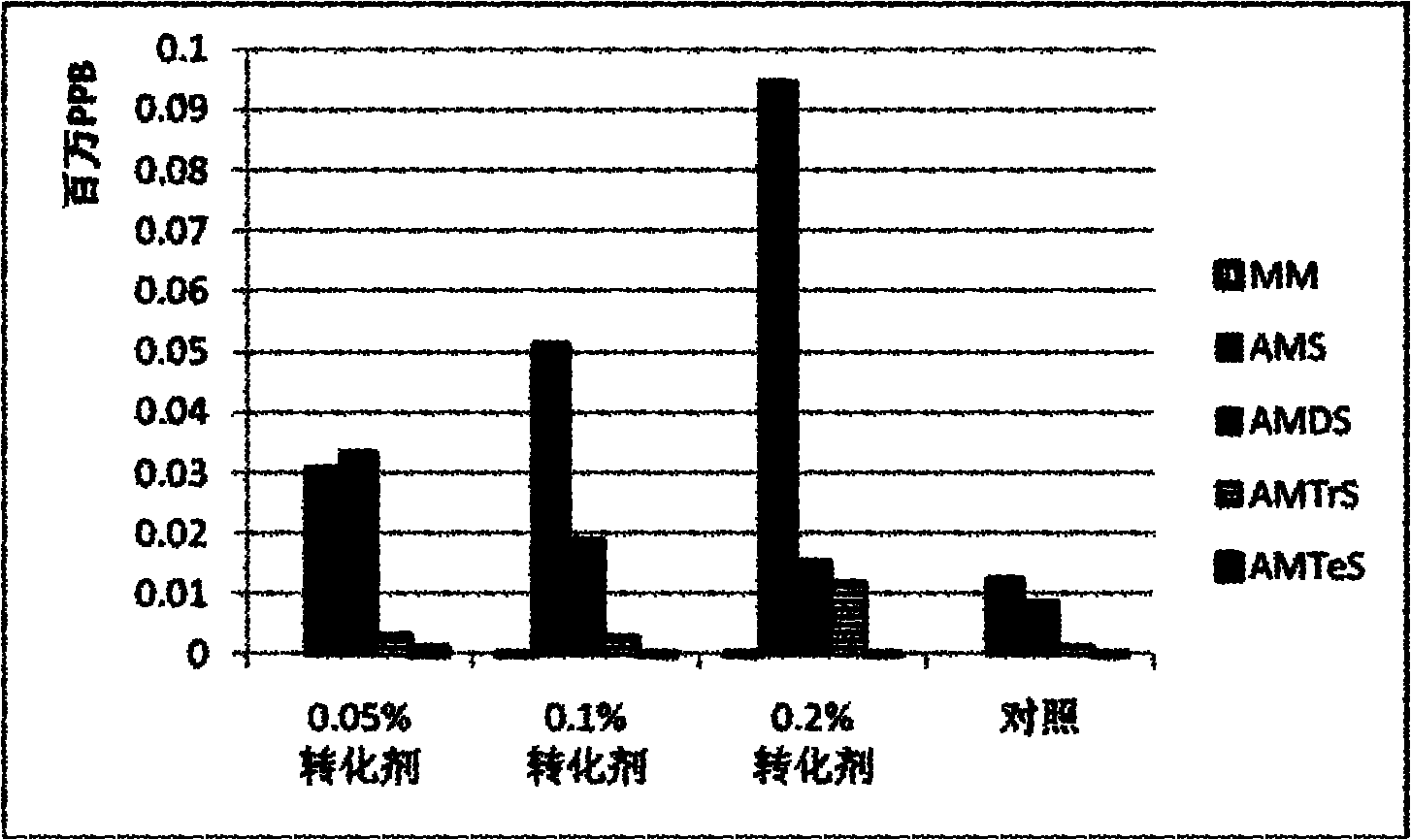

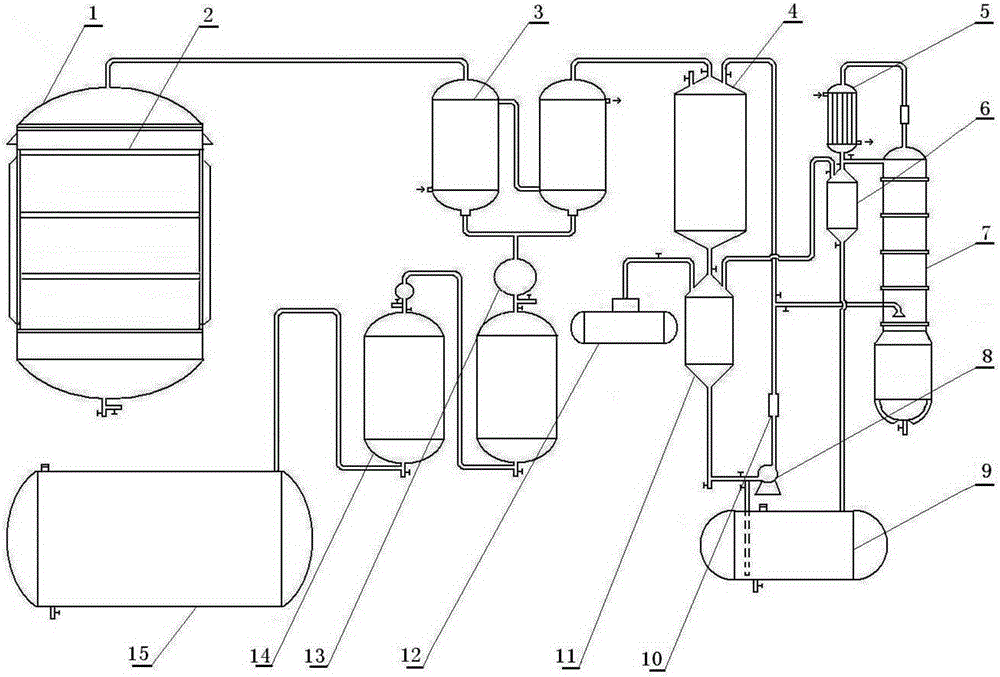

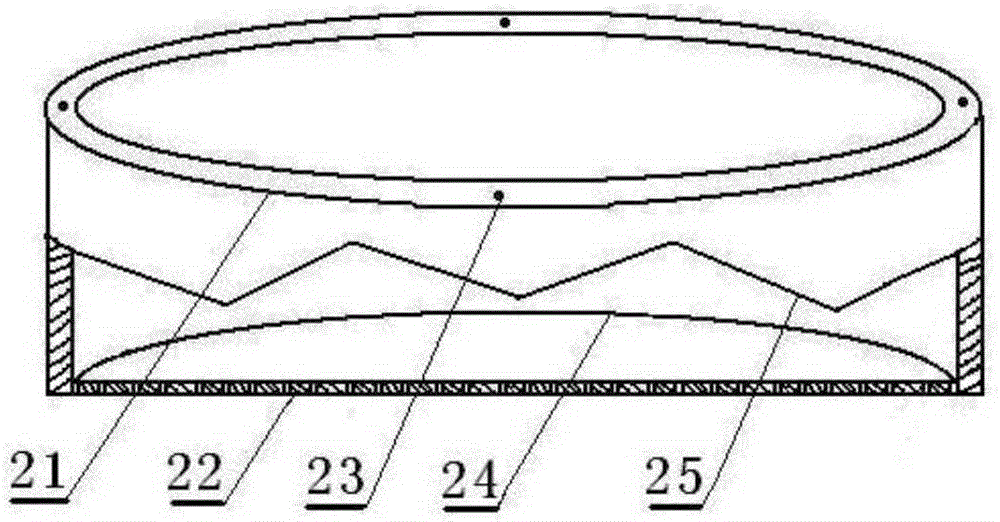

Method for improving garlic oil yield

The invention discloses a method for improving garlic oil yield, which comprises: soaking fresh garlic or dry garlic slices in water; stirring for removing impurities such as soil; feeding the fresh garlic or dry garlic slices in a pulping machine and crushing; adding an allinase activity regulator; performing enzymolysis; adding a transforming agent; feeding; distilling; feeding distillate into distilling equipment; taking an oil phase out, wherein the oil phase is coarse garlic oil; drying the garlic oil by a silicagel column; and removing residual moisture and obtaining the garlic oil. Themethod has the main advantages that: when the proper transforming agent is added, the distillation time is reduced by 20 percent, the garlic oil yield is improved to 1 to 3 times, and the content of each of the components such as diallyl disulfide, diallyl trisulfide, diallyl sulfide, allyl methyl sulfide, allyl methyl disulphide, allyl methyl trisulphide, propenethiol and methyl merecaptan is improved to over 3 times; and equipment investment is not increased, as only a proper amount transforming agent is added on the basis of the original distillation garlic oil production line.

Owner:JINAN UNIVERSITY

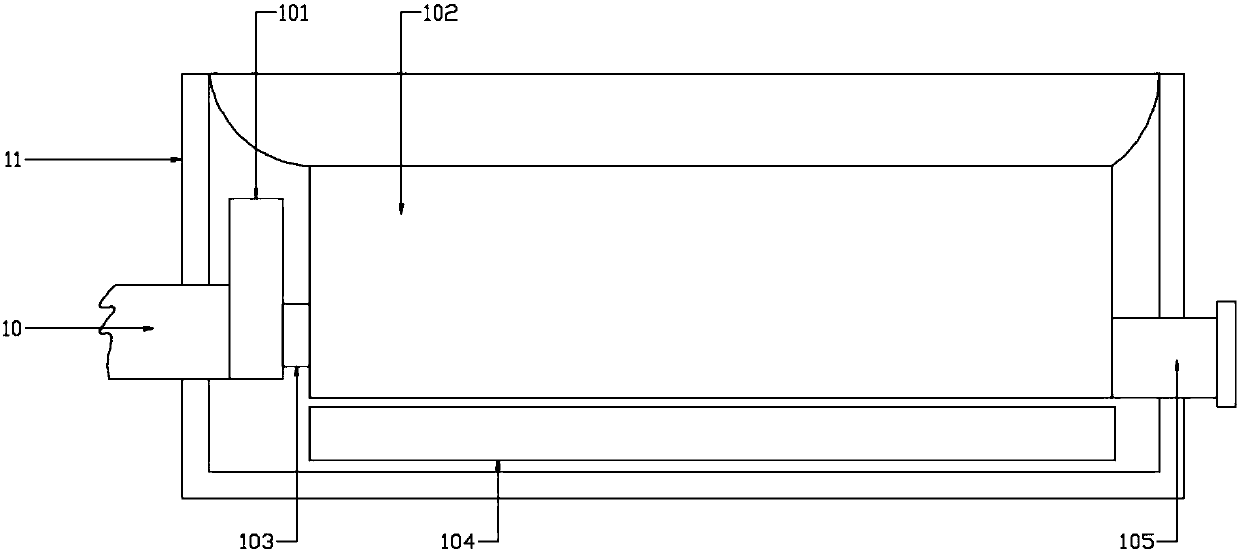

Extraction equipment for fragrant plant essential oil and headspace volatile

InactiveCN105296163AEasy to recycleTechnical Difficulties in Overcoming LossEssential-oils/perfumesAlembicOrganosolv

The invention discloses extraction equipment for fragrant plant essential oil and headspace volatile. The extraction equipment comprises an alembic, a condenser I, an oil-water separator, an adsorber, a liquid pump and a rectifying tower, wherein a material steaming basket is arranged inside the alembic; the condenser I is connected with the alembic; the oil-water separator is connected with a liquid delivery pipe at the bottom of the condenser I; the adsorber is connected with the top of the condenser I; the bottom of the adsorber is connected with a headspace volatile elution gathering tank; the top of the headspace volatile elution gathering tank is connected with a vacuum system and the top of an organic solvent gathering tank; a feed port of the liquid pump is connected with a discharge port of the headspace volatile elution gathering tank through a valve; a discharge port of the liquid pump is connected with a feed port of the rectifying tower and the top of the adsorber by valves. The extraction equipment disclosed by the invention not only can well recycle the headspace volatile, but also has the advantages of high oil extraction rate, low energy dissipation, simple operation, low equipment cost and the like, the extraction equipment can easily realize industrialized production, has very good social and economical benefit.

Owner:GUANGXI FORESTRY RES INST

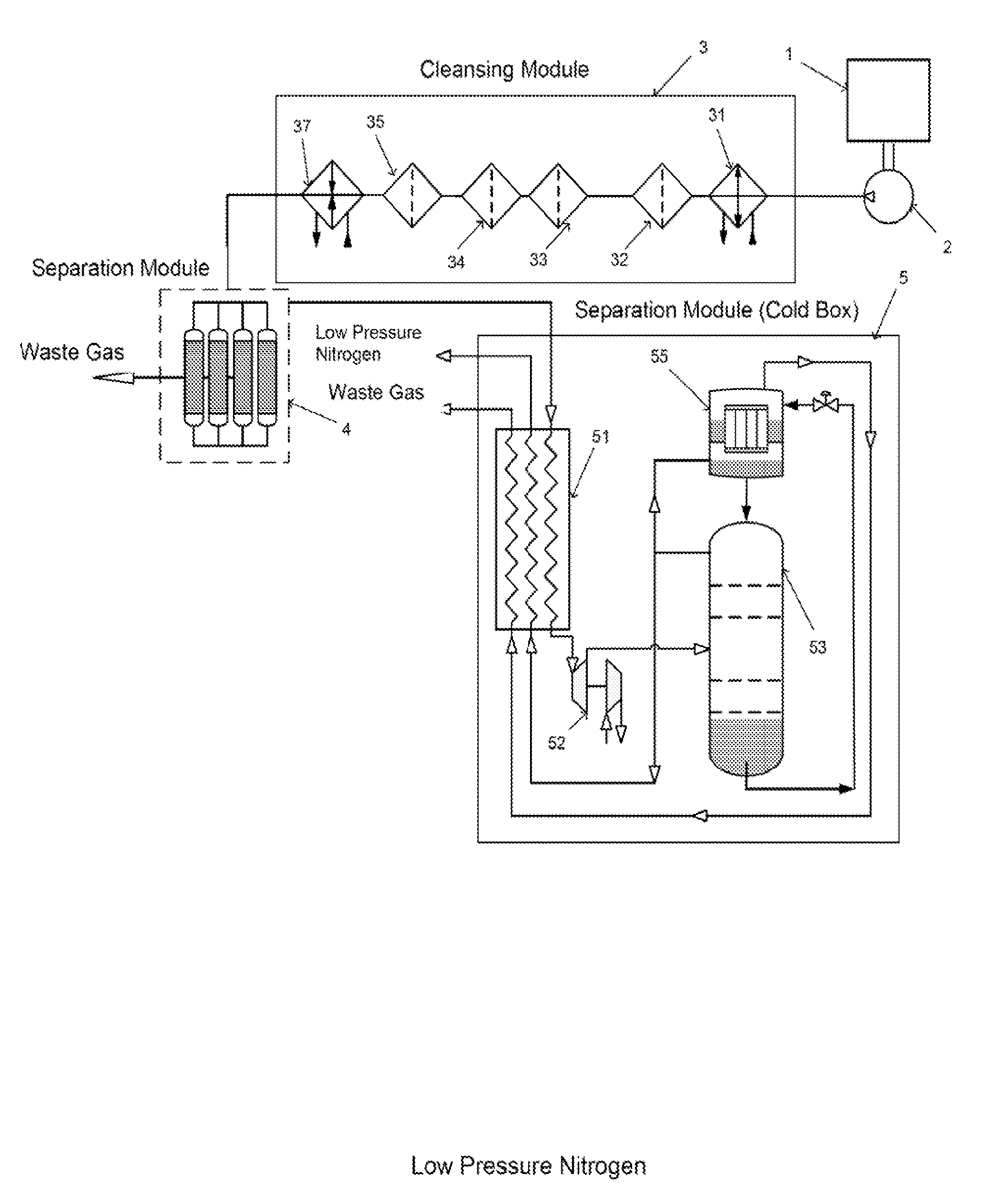

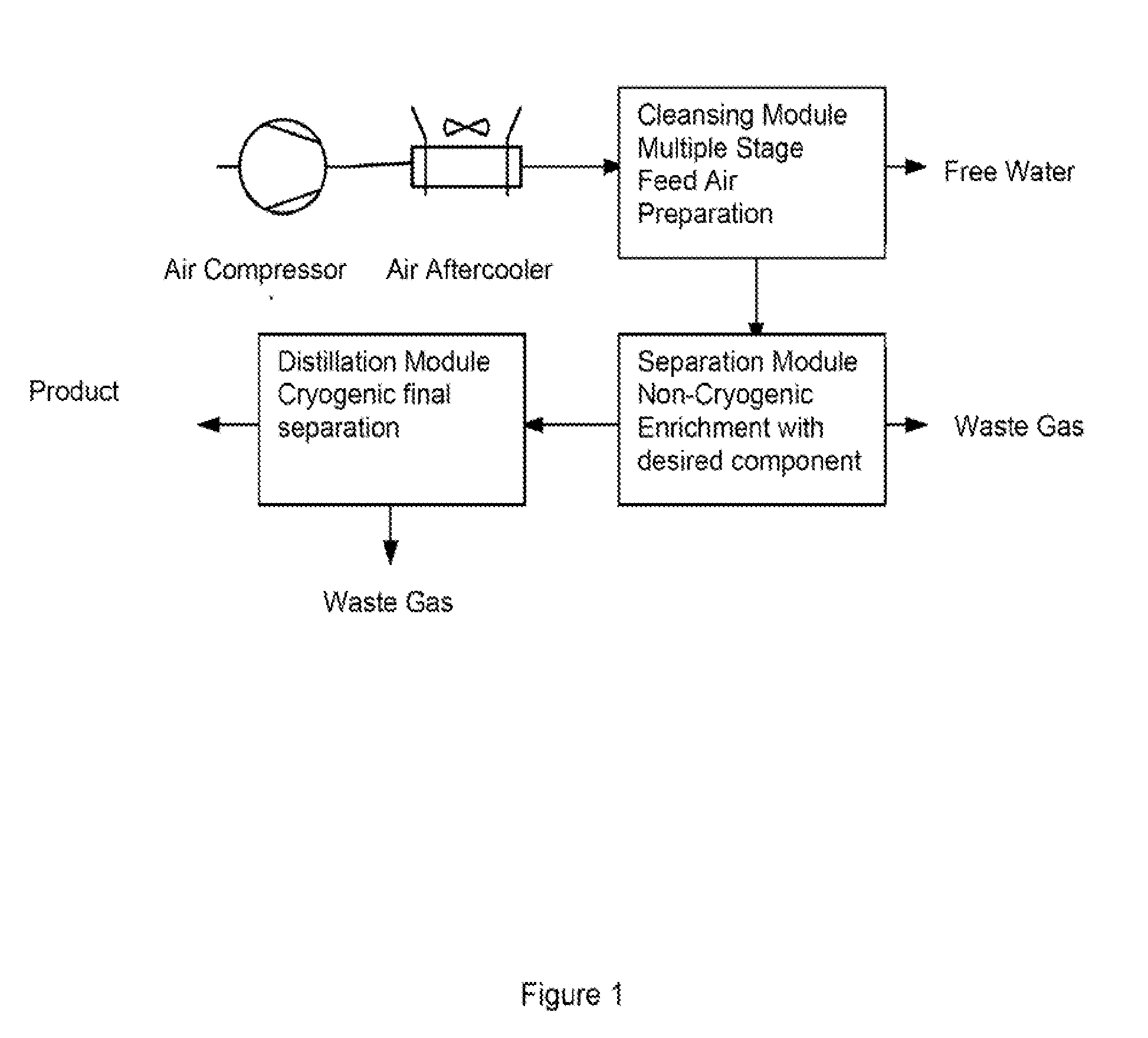

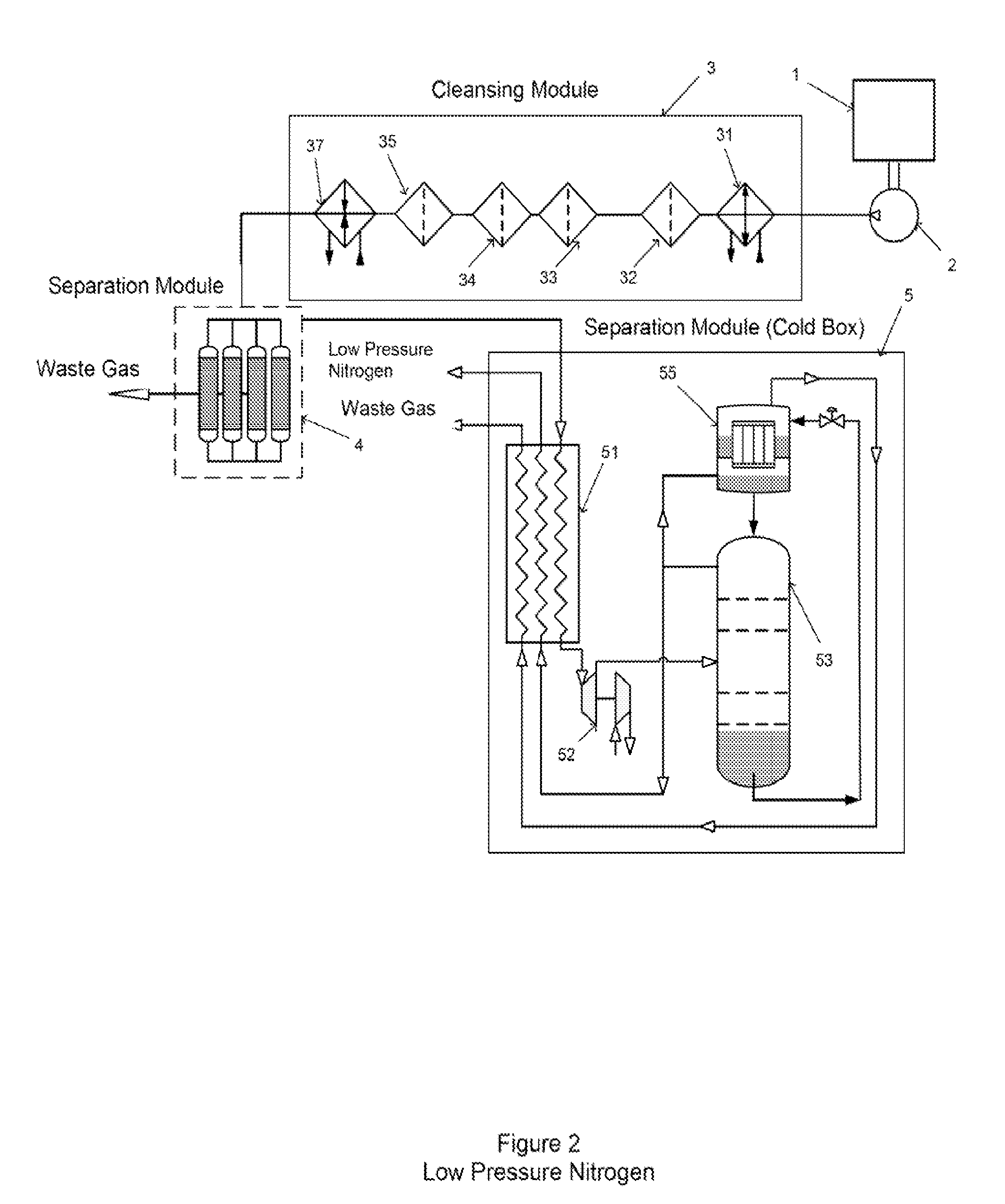

Hybrid Air Separation Method with Noncryogenic Preliminary Enrichment and Cryogenic Purification Based on a Single Component Gas or Liquid Generator

Large quantities of high purity and high pressure nitrogen or oxygen gas are produced using a portable system. A PSA, VSA, TSA, or permeable membrane system cleans the air of water and carbon dioxide, as normally required by the cryogenic distillation cycle, but additionally, a significant amount of the oxygen or nitrogen is also removed, depending on the desired produced gas. The removal of the oxygen or nitrogen before the cryogenic process permits the distillation column to be significantly shorter than would otherwise be required. This in turn reduces the size of the equipment such that it can easily be transported and setup. Additionally, a high pressure liquid pump is used to boost the pressure of the nitrogen or oxygen immediately before it goes through the last pass of the cryogenic heat exchanger where the liquid is vaporized and the incoming gas is cooled.

Owner:INNOVATIVE NITROGEN SYST

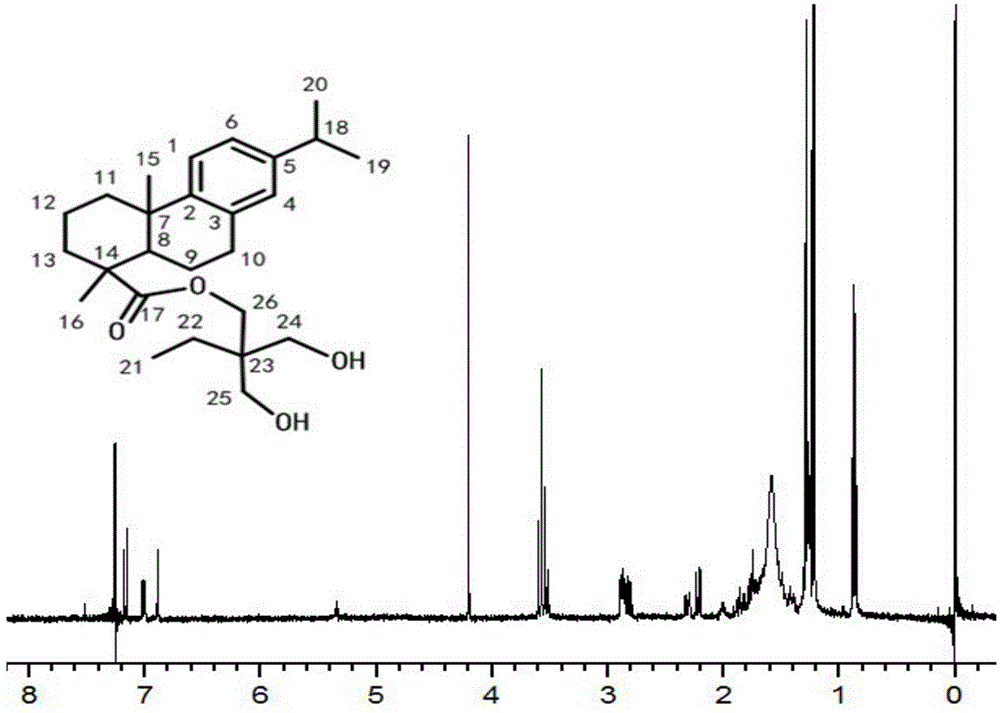

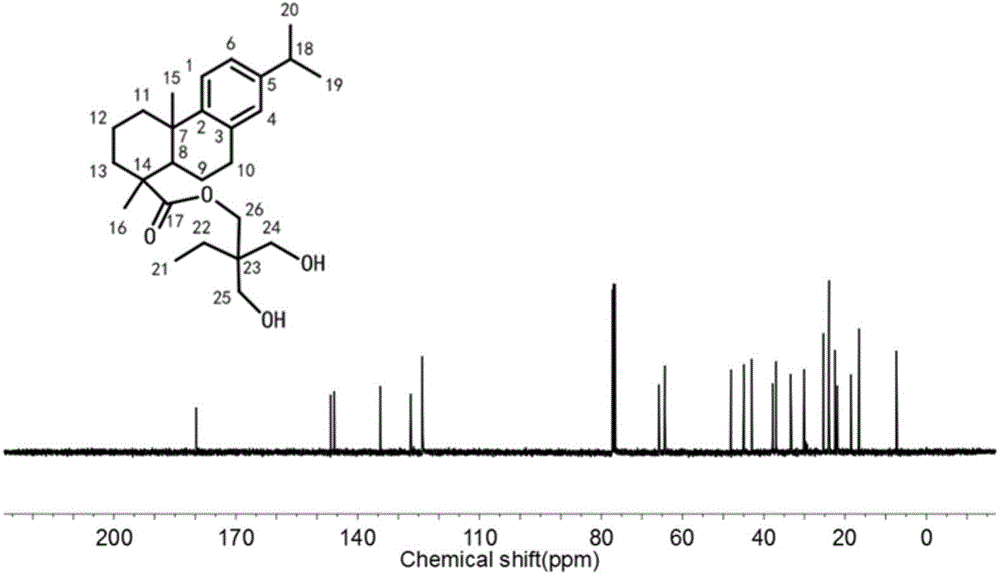

Rosin triol ester as well as preparation method and application thereof

InactiveCN104693024ABiodegradableLow costOrganic compound preparationTransportation and packagingTrimethylolpropaneTriol

The invention discloses a rosin triol ester and a preparation method therefore. The chemical name of the rosin triol ester is trimethylolpropane dehydroabietyate. The preparation method of the rosin triol ester comprises the following steps: by taking dehydroabietic acid and trimethylolpropane as the raw materials, EDC / DMAP as the catalysts, and any one of methylene chloride, tetrahydrofuran and N,N-dimethyl formamide as the solvent, performing an esterification reaction at normal temperature to synthesize the trimethylolpropane dehydroabietyate. The esterification method is completed in one step; the steric hindrance can be effectively overcome; the yield is high; the reaction is performed at room temperature so that the energy consumption can be reduced; the byproducts are soluble in water and easy to purify; the smell is light and few three wastes are generated; and the solvent selection range is wide. The ester prepared by use of the method is wide in use, and can be used as plasticizers and modifiers of various resins, excellent adhesives for pressure-sensitive and thermosensitive adhesive tapes, hot melt coatings, surface activators and pharmaceutical vectors.

Owner:GUANGXI UNIV FOR NATITIES

Method for producing 2-butenoic acid

ActiveCN101979371AWell mixedIncrease reaction pressureOrganic compound preparationChemical/physical/physico-chemical nozzle-type rreactors2 Butenoic AcidsOxygen

The invention provides a method for producing 2-butenoic acid, which comprises the following steps: preparing mixed feed liquid from 2-butenoic aldehyde, normal hexane and water in a weight ratio of 1:1:0.05-0.08; mounting an ejector pump on an oxidation reaction kettle for spraying the mixed feed liquid into the oxidation reaction kettle; introducing oxygen into the oxidation reaction kettle to perform a reaction under a condition that the reaction pressure in the oxidation reaction kettle is 0.1 to 0.6MPa and a condition that the temperature is 25 to 35 DEG C to obtain oxidation reaction solution; distilling the oxidation reaction, distilling the remaining 2-butenoic aldehyde under a reduced pressure, recovering the 2-butenoic aldehyde, distilling the remaining normal hexane at normal pressure and obtaining filtrate; and cooling the filtrate to -5 DEG C to 5 DEG C, precipitating, crystallizing and filtering and drying the crystals to obtain the 2-butenoic acid product. The production method has the advantages that: the reaction speed is high; the product yield is high; the energy consumption is small; and the quality of the product obtained is high.

Owner:HENAN ZAITI BIO TECH

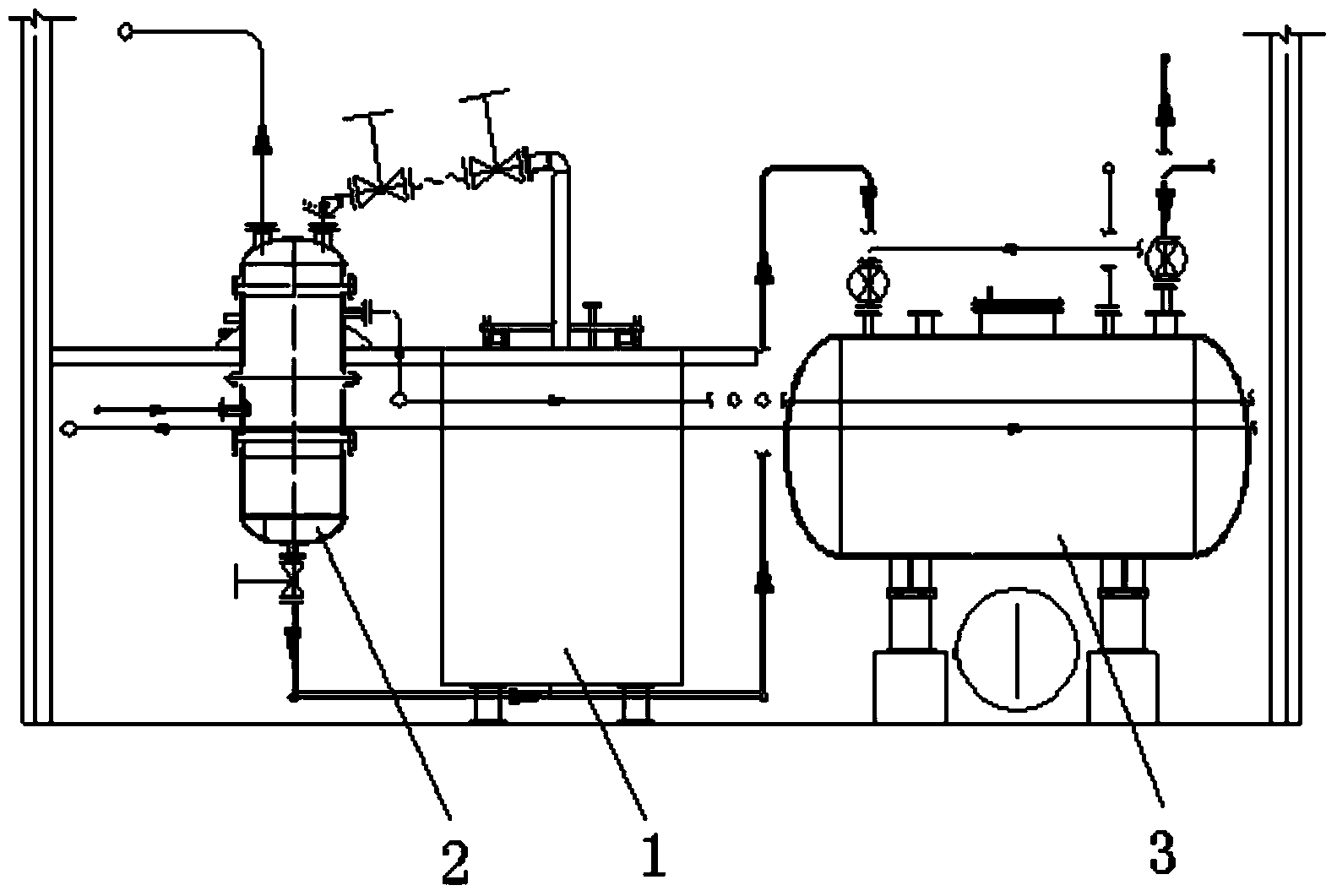

Recovery process and apparatus for solid state metal sodium waste residue

ActiveCN103667708AHigh recovery rateReduce energy consumptionProcess efficiency improvementResource savingToxic industrial waste

The present invention relates to a recovery process and an apparatus for solid state metal sodium waste residue. The process is characterized by comprising: placing solid state metal sodium waste residue into a heating furnace (1) to carry out high temperature heating to obtain sodium vapor so as to separate sodium and other elements through distillation separation, carrying out condensation on the sodium vapor to obtain liquid state sodium, and conveying the liquid state sodium to a sodium casting machine to cast sodium. According to the present invention, the sodium residue distillation method is adopted to recover and utilize the metal sodium from the sodium residue so as to provide characteristics of low energy consumption, high yield and the like; the raw materials use the industrial waste so as to achieve resource saving and created economic benefits; trial results prove that purity of the metal sodium produced by using the process can be 99.9%, and is higher than purity 99.7% of the metal sodium produced by using the original process; and continuous vacuum pumping is designed in the distillation process so as to enhance a sodium residue recovery rate, shorten a distillation time and meet the optimum process conditions of continuous production.

Owner:中盐内蒙古化工钠业有限公司 +1

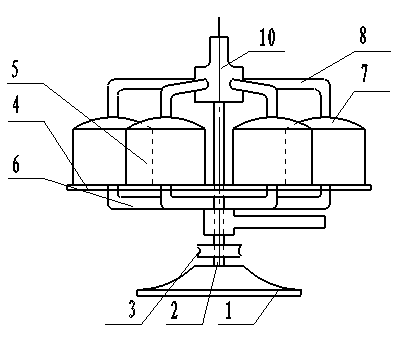

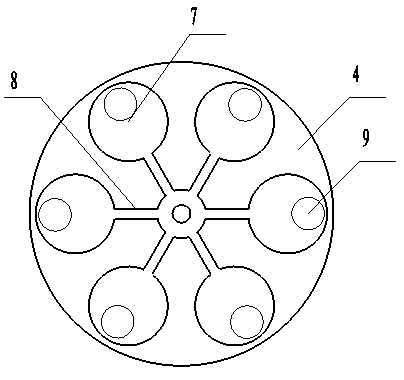

Alcohol distilling device

InactiveCN103657124AReduce volumeFully distilledAlcoholic beverage preparationDistillation separationDrive wheelAqueous alcohol

The invention relates to an alcohol distilling device. The alcohol distilling device comprises a fixed disc, a transmission shaft and a driving wheel, wherein one end of the transmission shaft is movably mounted on the fixed disc, and the driving wheel is mounted on the transmission shaft and is controlled by the driving device; a positioning disc is fixed on the transmission shaft; at least two steaming pots are mounted on the positioning disc, a high-temperature steam delivery pipe communicated with a high-temperature steam source is connected to the lower part of each steaming pot, movable steaming pot covers above the steaming pots are respectively connected with alcohol steam delivery pipes, and the tail end of each alcohol steam delivery pipe is communicated with an alcohol steam outlet. According to the alcohol distilling device, multiple steaming pots are used for replacing the single steaming pot for distilling, so that the volume of fermentation materials in the single steaming pot is reduced, the distilling is thorough, the distilling time is shortened, and the distilling efficiency is increased.

Owner:山西鼎圣精工机械制造股份有限公司

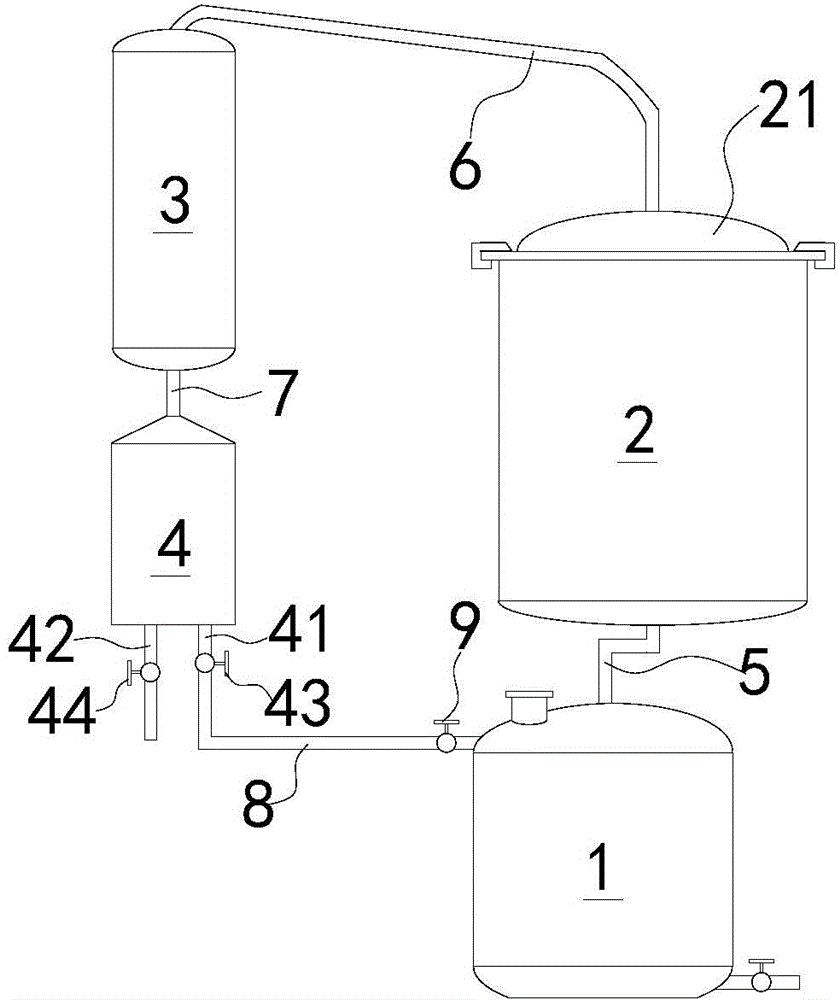

Vegetable oil extracting device

InactiveCN104419524AHeating fastImprove oil yieldEssential-oils/perfumesFatty-oils/fats productionVegetable oilBoiling point

The invention discloses a vegetable oil extracting device and aims at providing a vegetable oil extracting device which is simple in structure and convenient to operate. The vegetable oil extracting device comprises a steam generator, a distilling still, a condenser and an oil-water separator, wherein a water draining tube and an oil removing tube are arranged at the lower end of the oil-water separator, a first valve is arranged on the water draining tube, and a second valve is arranged on the water removing tube; a first branch tube communicated with the bottom of the distilling still is arranged at the upper end of the steam generator; a hose communicated with an inlet of the condenser is arranged on the end cover of the distilling still; a second branch tube communicated with an inlet of the oil-water separator is arranged in the outlet of the condenser; and a third branch tube communicated with the upper part of the steam generator is arranged in an outlet of the water draining tube of the oil-water separator. The vegetable oil extracting device is used for heating and distilling materials in the distilling still by virtue of the steam generated in the steam generator. The vegetable oil extracting device disclosed by the invention is high in distilling speed, capable of shortening the distilling time and lowering the energy consumption. Moreover, components with a high boiling point can be steamed out of the high temperature steam, and the oil extraction rate is high.

Owner:KUNMING OCEAN DEW BIOLOGICAL TECH

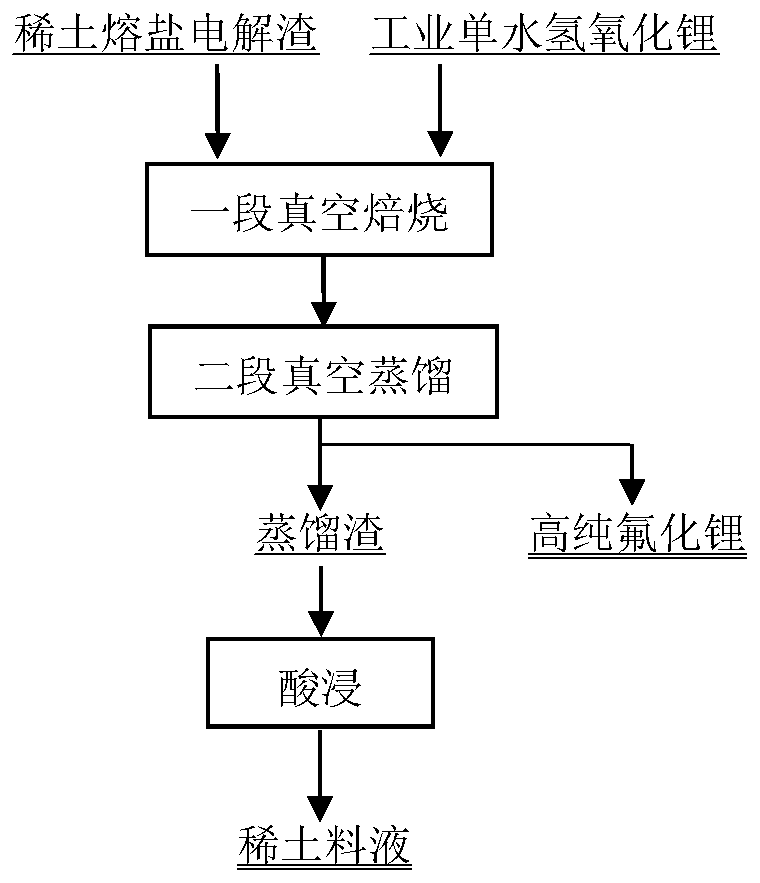

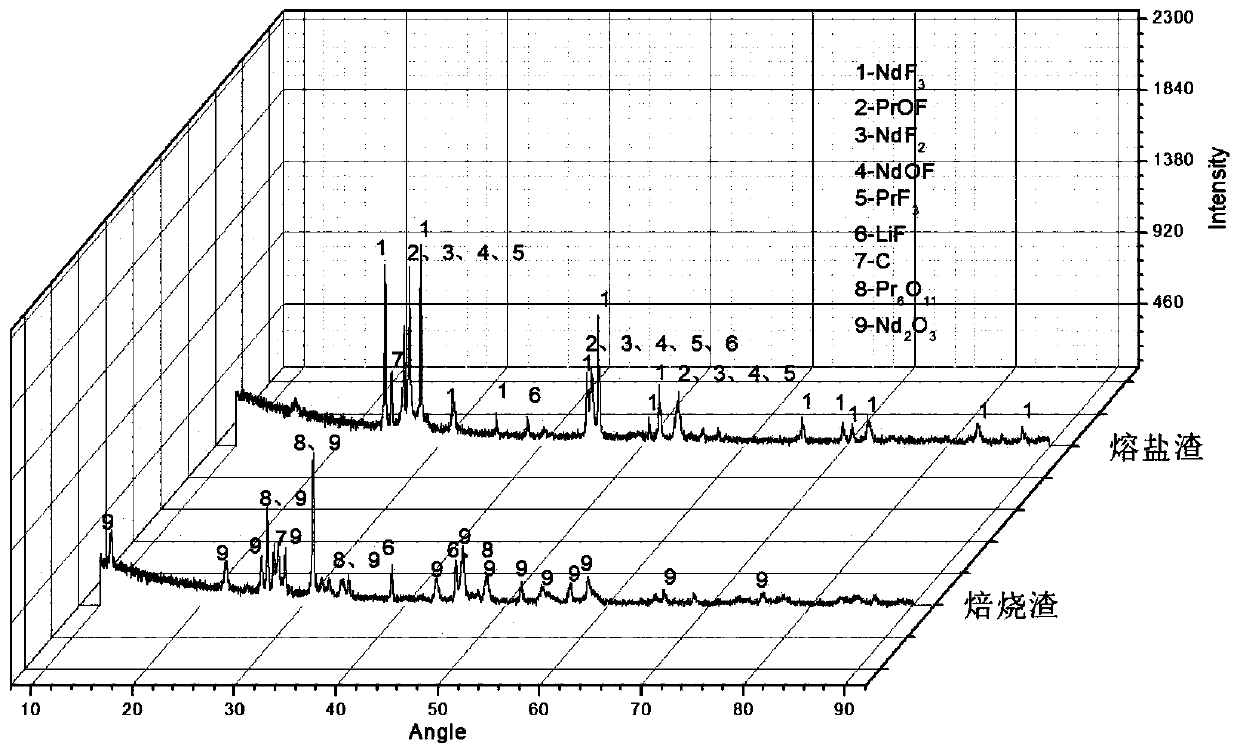

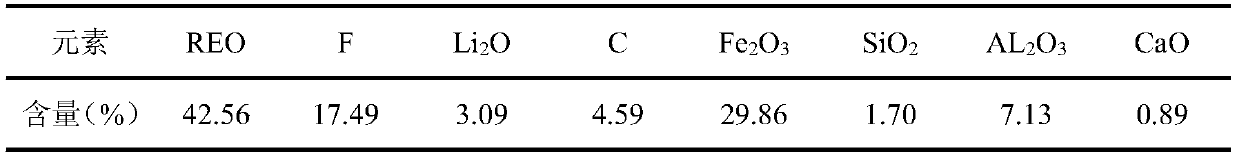

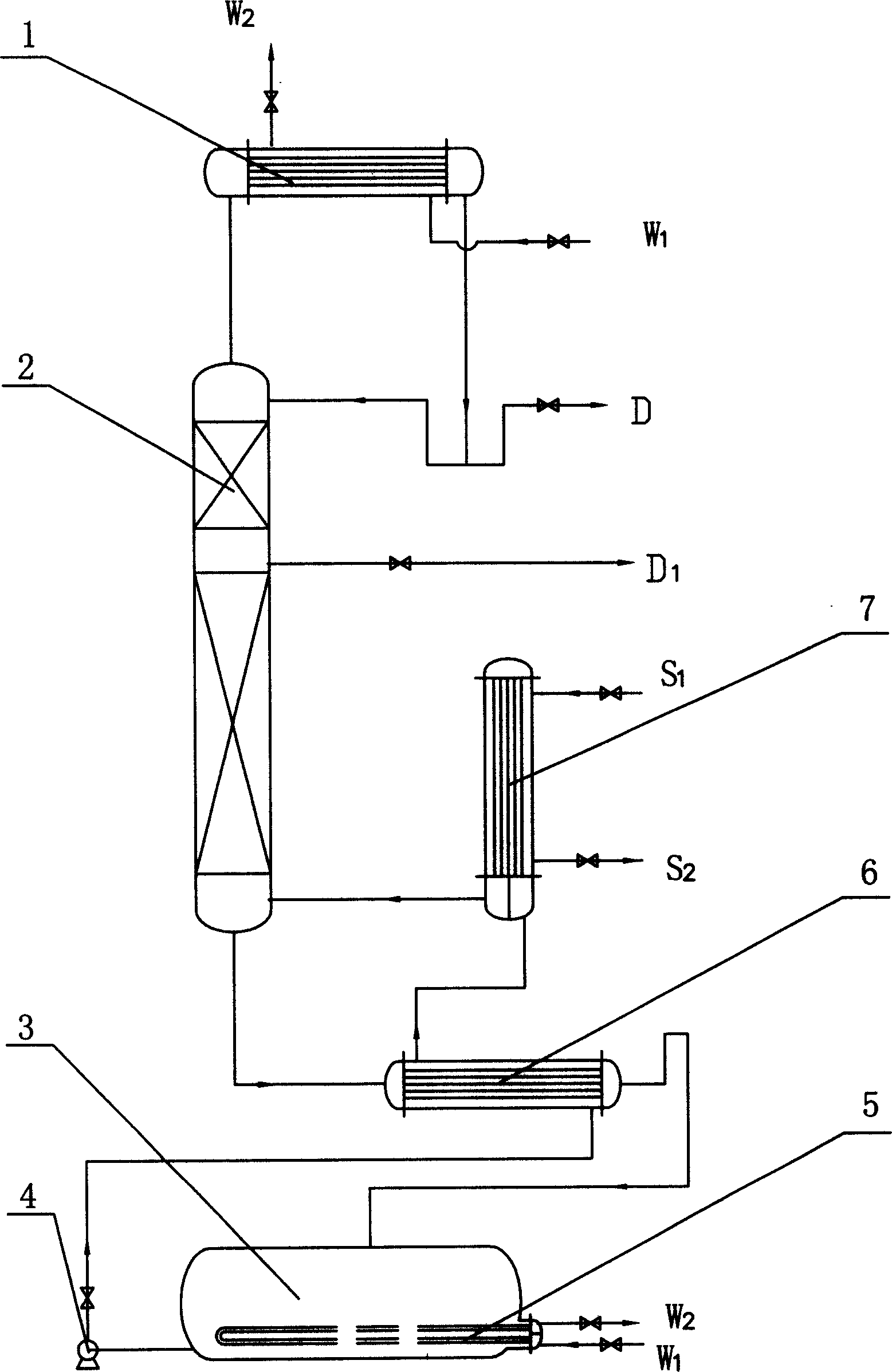

Method for efficiently recovering valuable elements from rare earth molten salt electrolytic slag

ActiveCN111534701AReduce vacuum distillation temperatureClean separationAlkali metal fluoridesProcess efficiency improvementSlagProcess engineering

The invention discloses a method for efficiently recovering valuable elements from rare earth molten salt electrolytic slag. According to the method for efficiently recovering the valuable elements from the rare earth molten salt electrolytic slag, the rare earth molten salt electrolytic slag is uniformly mixed with a lithium source to obtain a mixture; and the mixture is sequentially subjected toone-stage vacuum roasting and two-stage vacuum distillation to obtain high-purity lithium fluoride. The method for efficiently recovering the valuable elements from the rare earth molten salt electrolytic slag is based on the characteristics that a melting boiling point of the lithium fluoride is lower than that of rare earth fluoride and the vapor pressure of the lithium fluoride is higher thanthat of the rare earth fluoride, the less volatile rare earth fluoride in the slag is converted into volatile lithium fluoride through the one-stage vacuum roasting firstly, then fluorine resources are recovered in the form of the lithium fluoride through the two-stage vacuum distillation process, so that vacuum distillation temperature, distillation time and distillation energy consumption can beeffectively reduced, clean separation of fluorine and rare earth in the slag is realized, a comprehensive recovery rate of the fluorine and the rare earth is further improved, green high-value comprehensive recycling of the rare earth, the lithium and the fluorine resources in the rare earth molten salt electrolytic slag is realized, and the comprehensive recovery rate of the rare earth and fluorine elements can reach more than 99% at the highest.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

Thermosensitive material intermittent rectifying process having side material output and tower kettle cold material storage

An intermittent rectifying system with side discharge and cold storage of material on top for the thermosensitive material is composed of cold storaging tower still, rectifying tower with side discharging, condenser, cooler, shielding pump and evaporator. The thermosensitive material is stored in cold state. Its advantages are short rectifying time, low thermodecomposing rate of raw material, and high purity and output rate of product.

Owner:TIANJIN UNIV

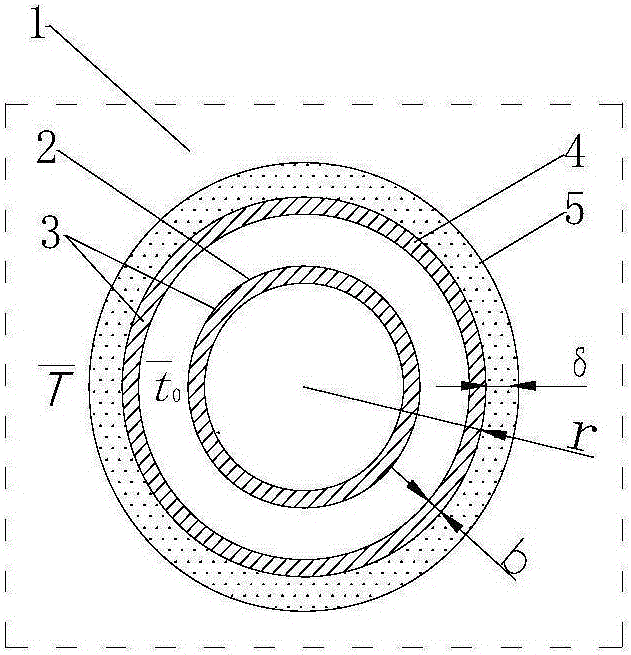

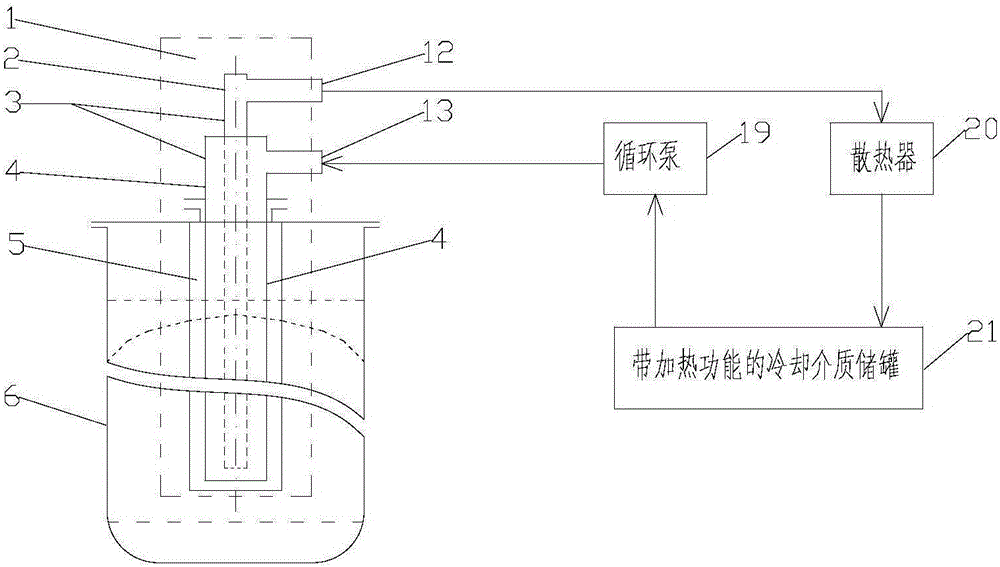

Tubular heat exchanger with inert coating layer and application to titanium sponge production

ActiveCN105925820AIncrease productivityImprove reduction efficiencyStationary tubular conduit assembliesTitanium tetrachlorideMagnesium

The invention discloses a tubular heat exchanger with an inert coating layer and application to titanium sponge production. The tubular heat exchanger can be used for quickly rejecting heat generated from a magnesiothermic reduction reaction and gathered in a liquid magnesium central area, so that the titanium tetrachloride feeding amount can be multiplied; meanwhile, the inert coating layer on the surface of the tubular heat exchanger always remains in a solidification state, thereby preventing formation, deposition and attachment of a titanium crystal on the metal surface of the tubular heat exchanger, and preventing bonding of a titanium lump and the metal surface of the tubular heat exchanger; and after the reduction is finished, the coating layer is melted and drops off, and a cavity is formed in the axis position of the titanium lump, so that the titanium sponge distillation period can be shortened by half or above. By adoption of the tubular heat exchanger provided by the invention, the titanium sponge production efficiency is multiplied, the power consumption cost is greatly reduced, and a prerequisite is provided for further enlargement of a furnace profile.

Owner:王进民

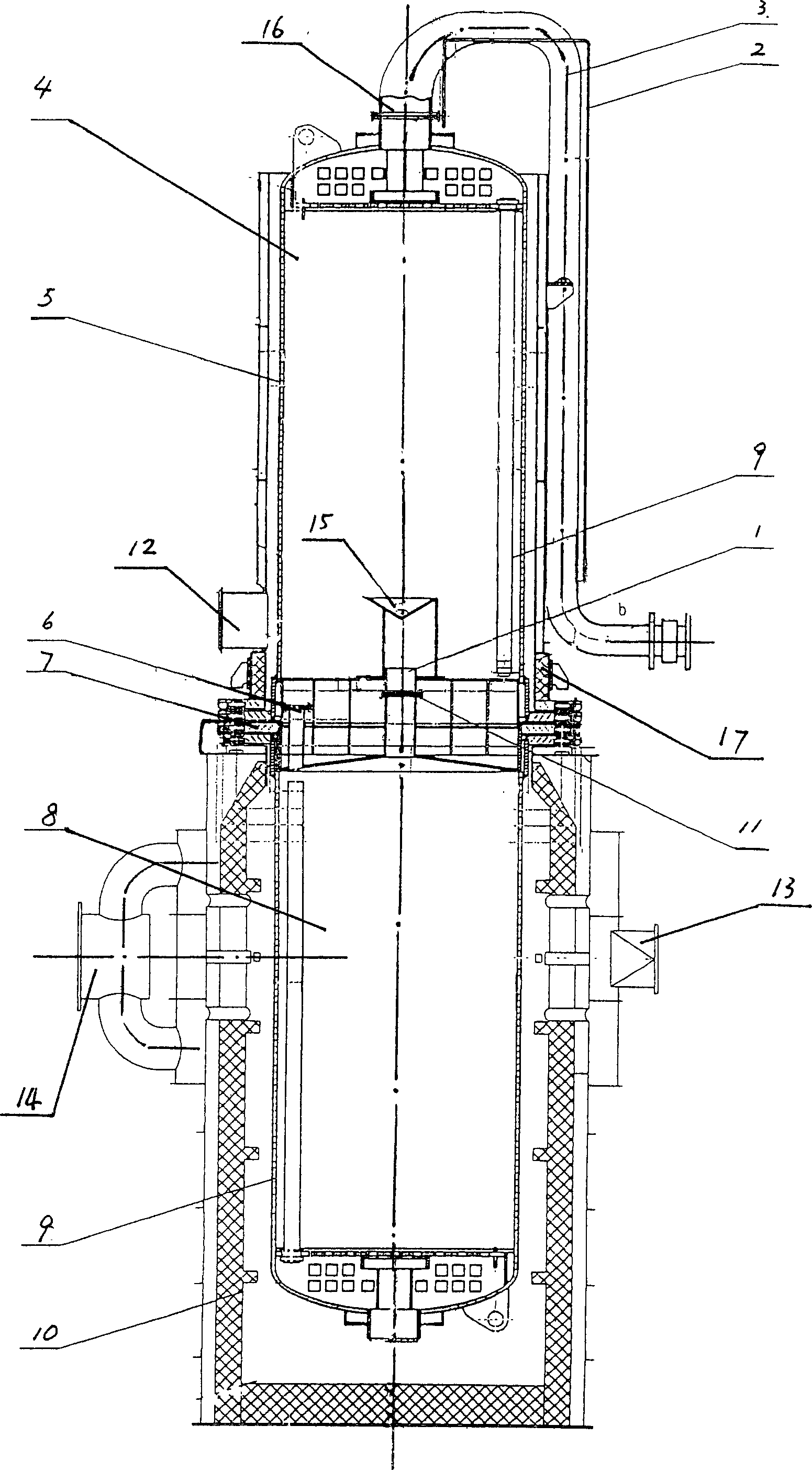

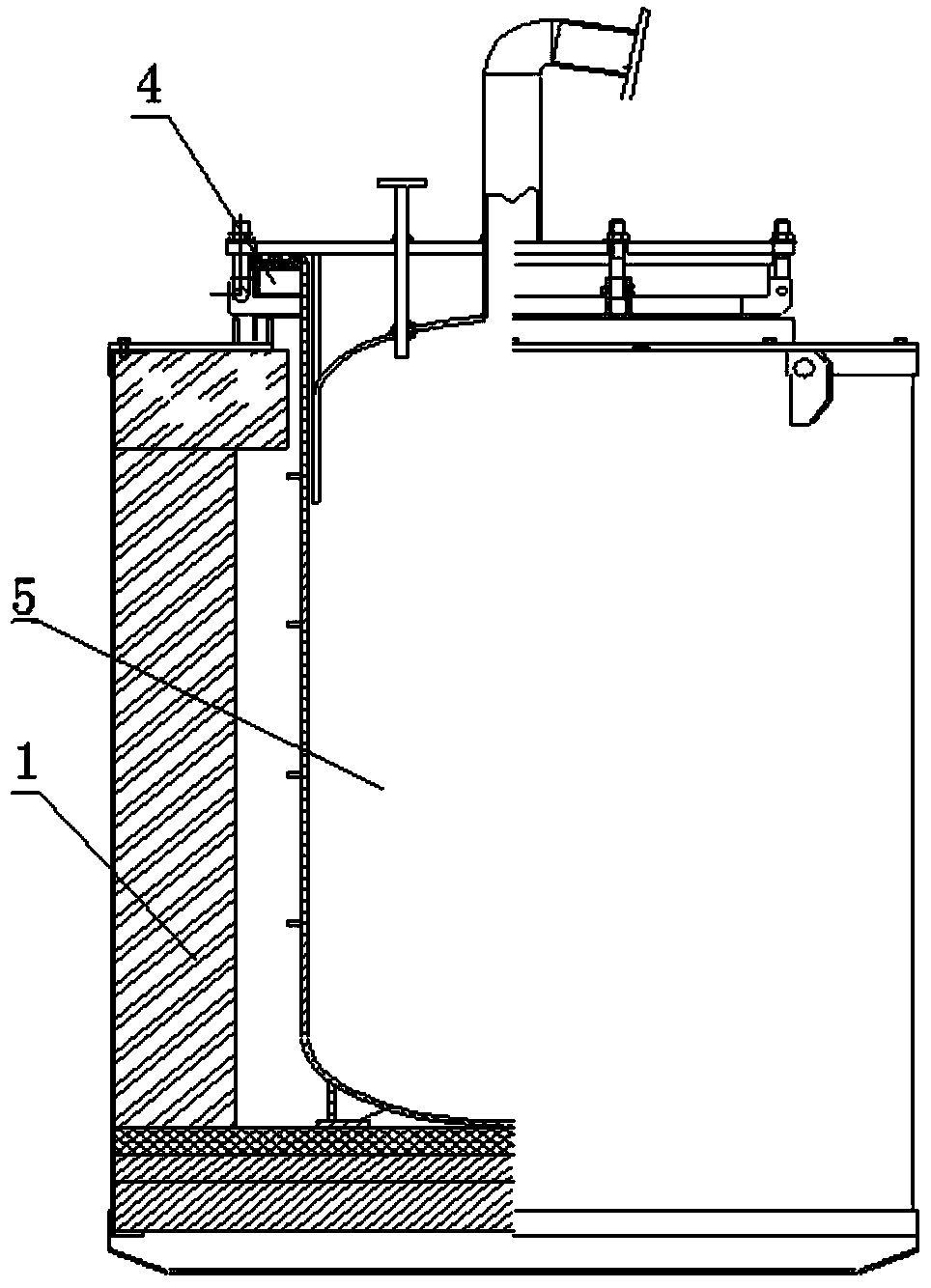

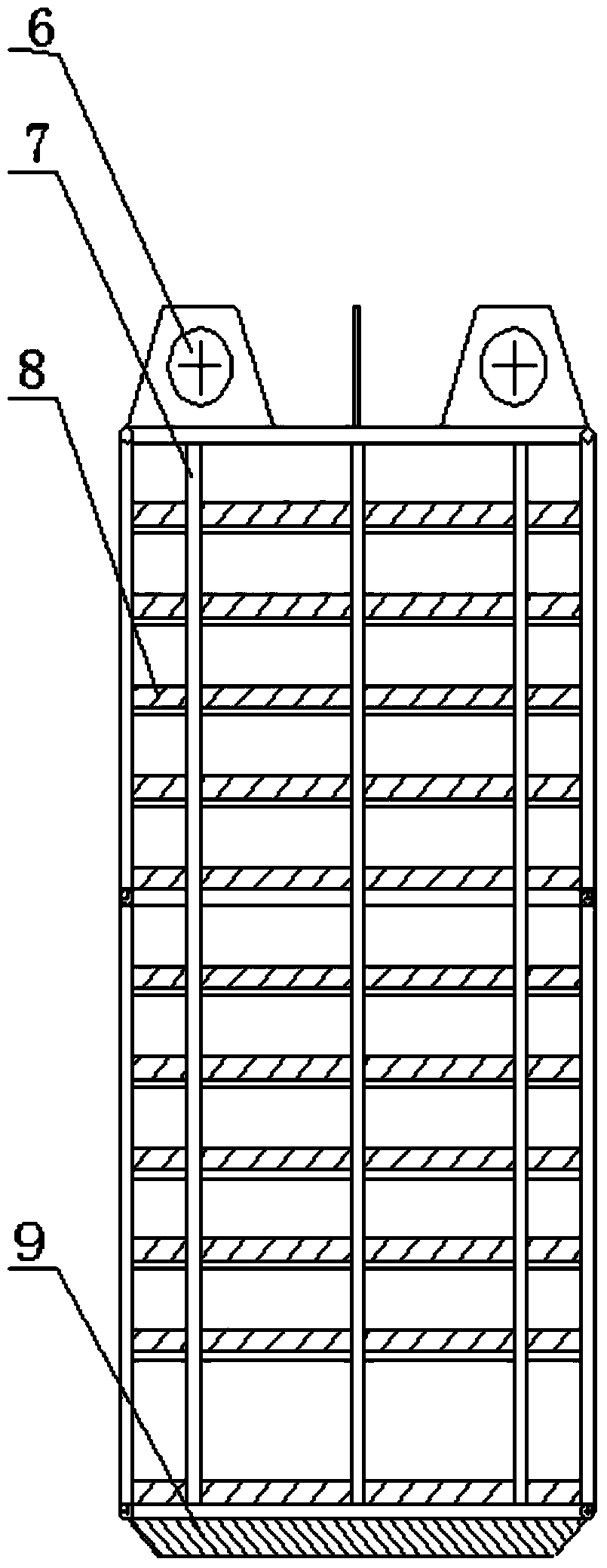

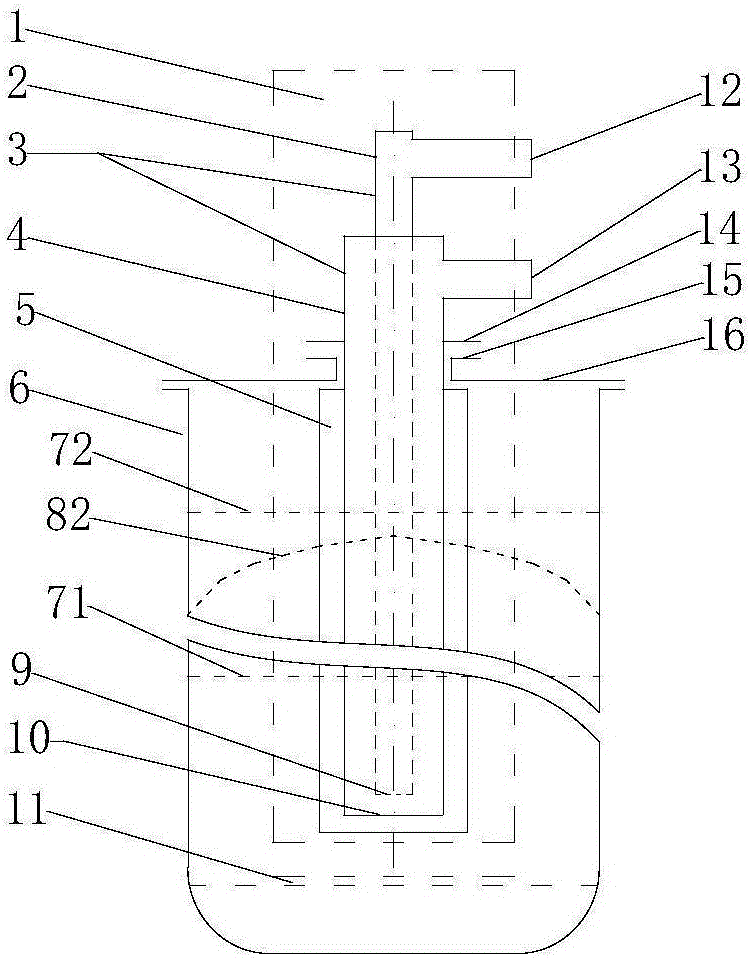

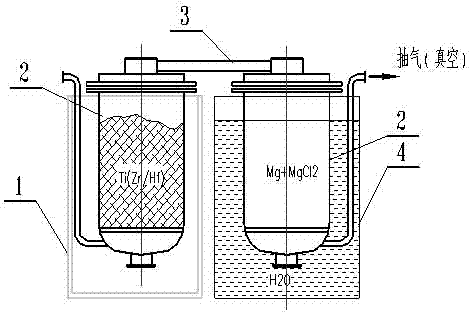

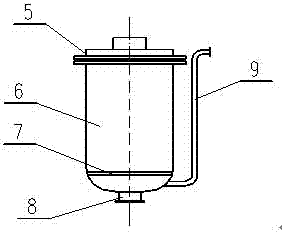

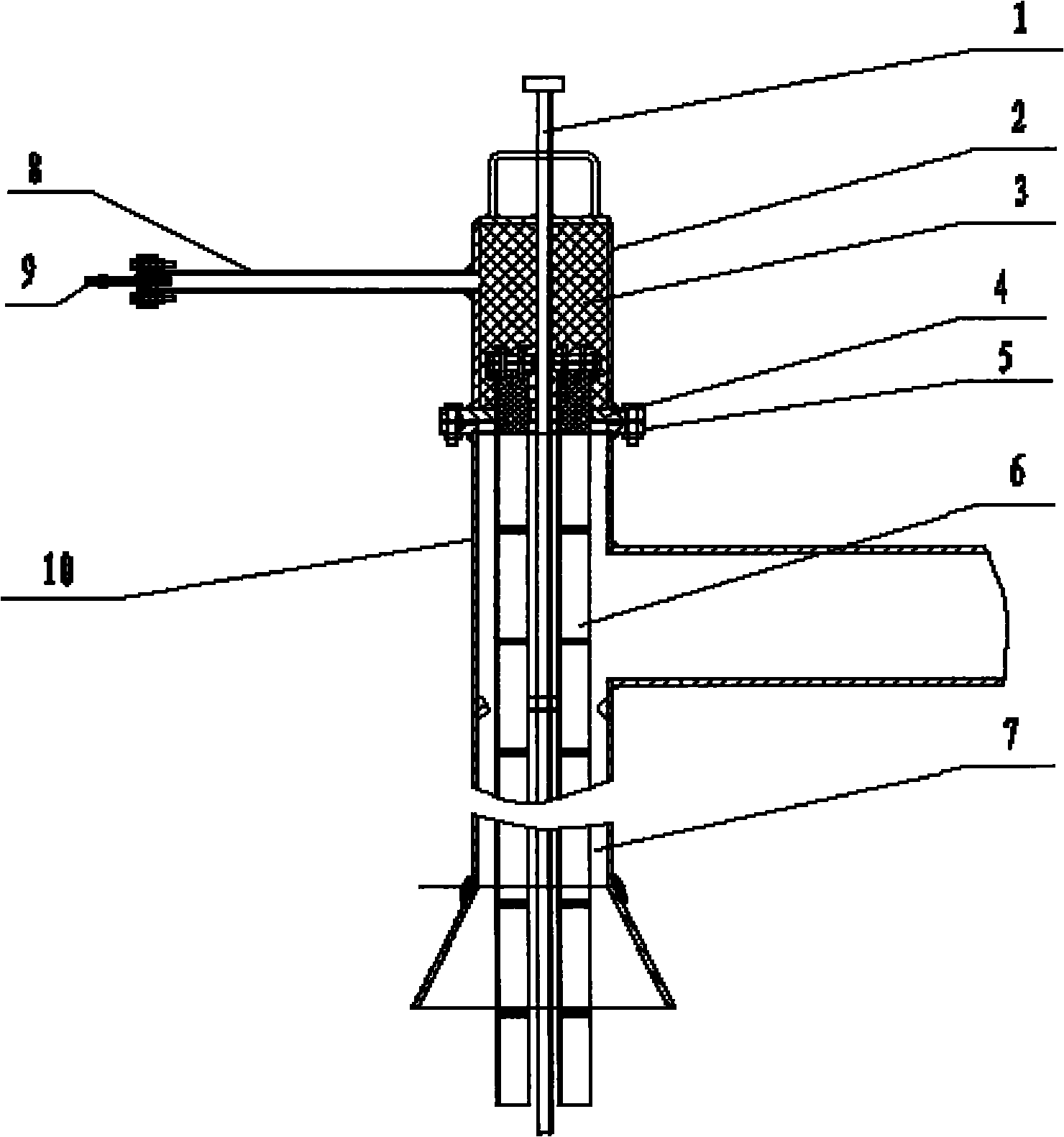

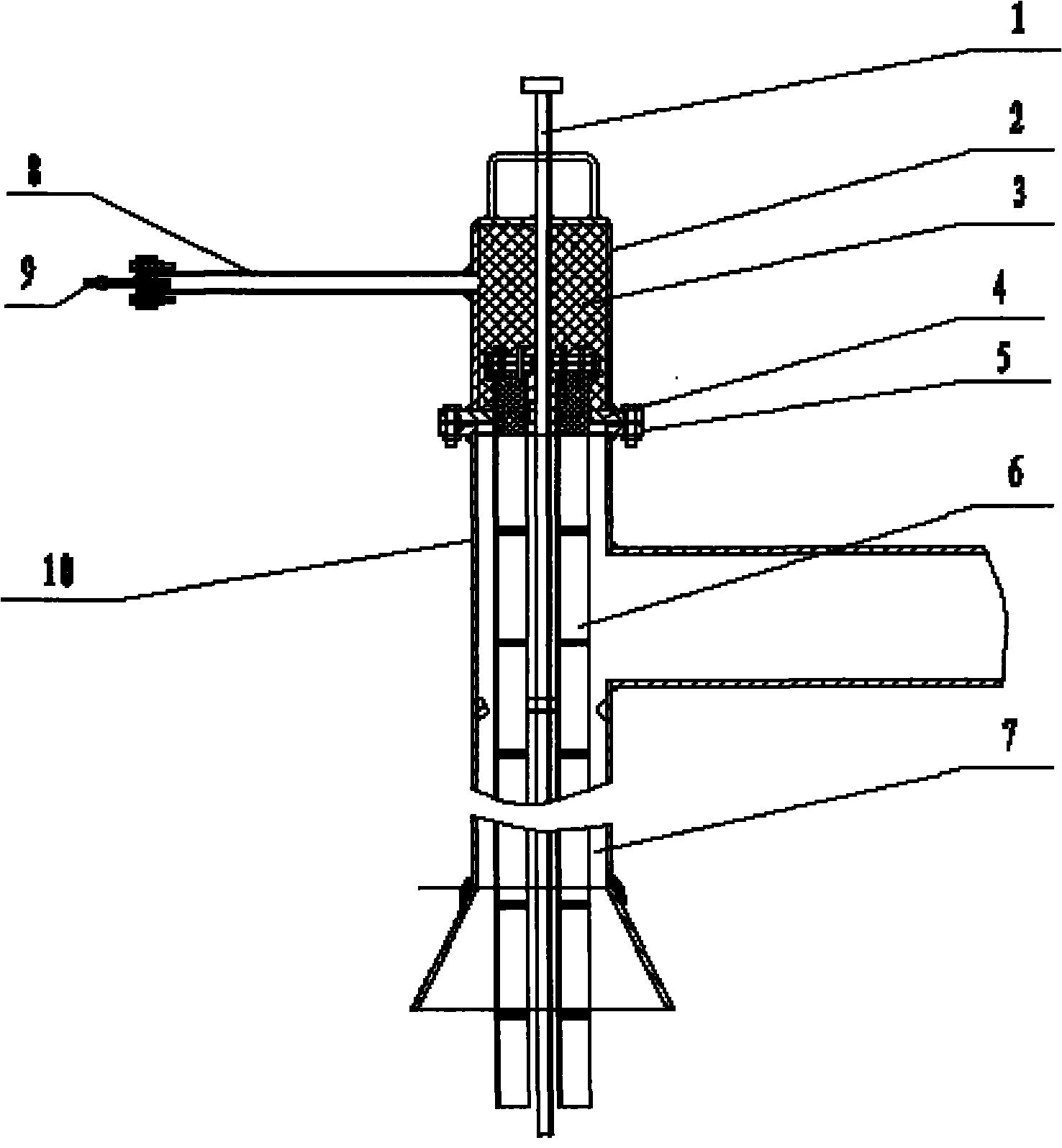

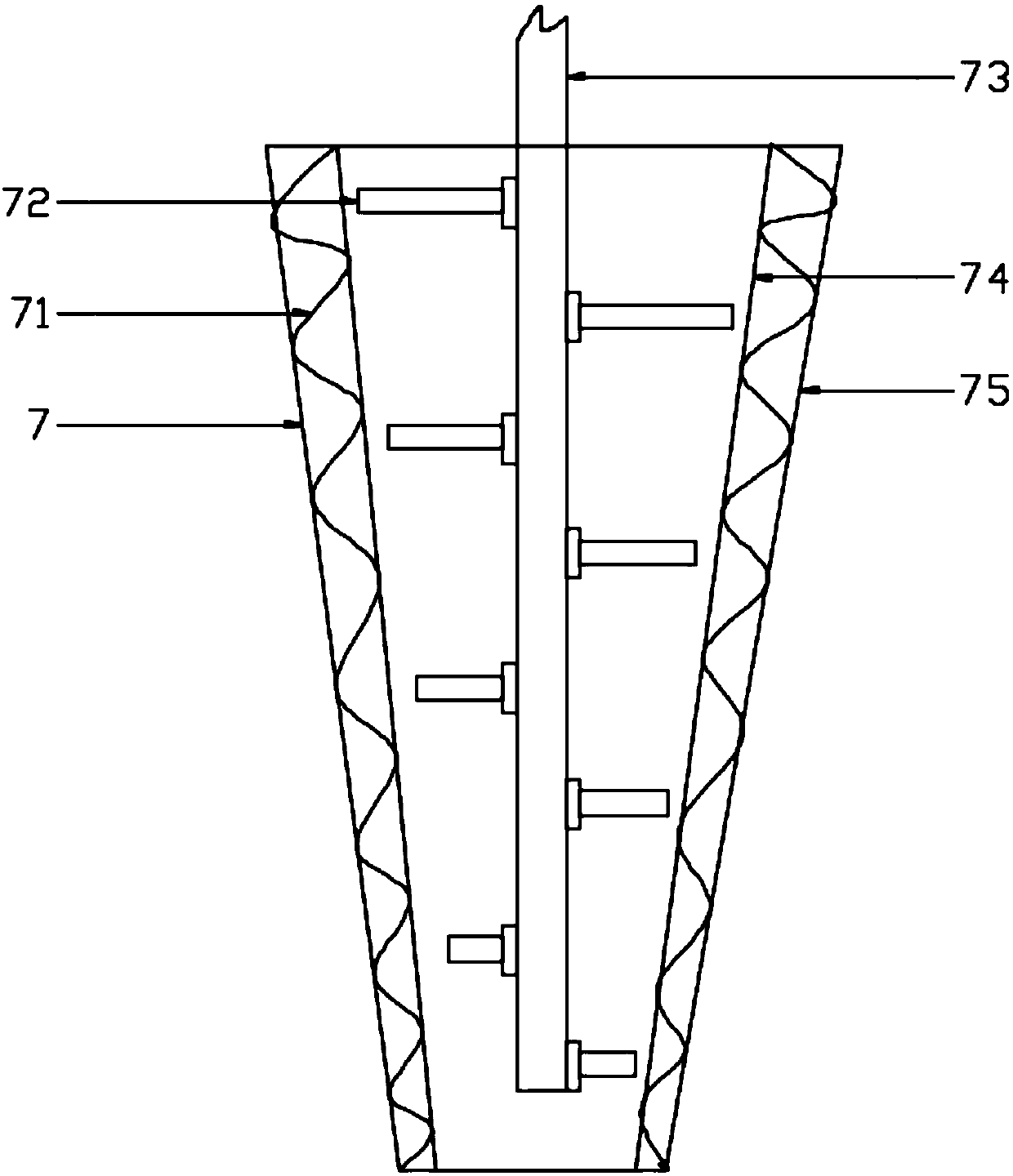

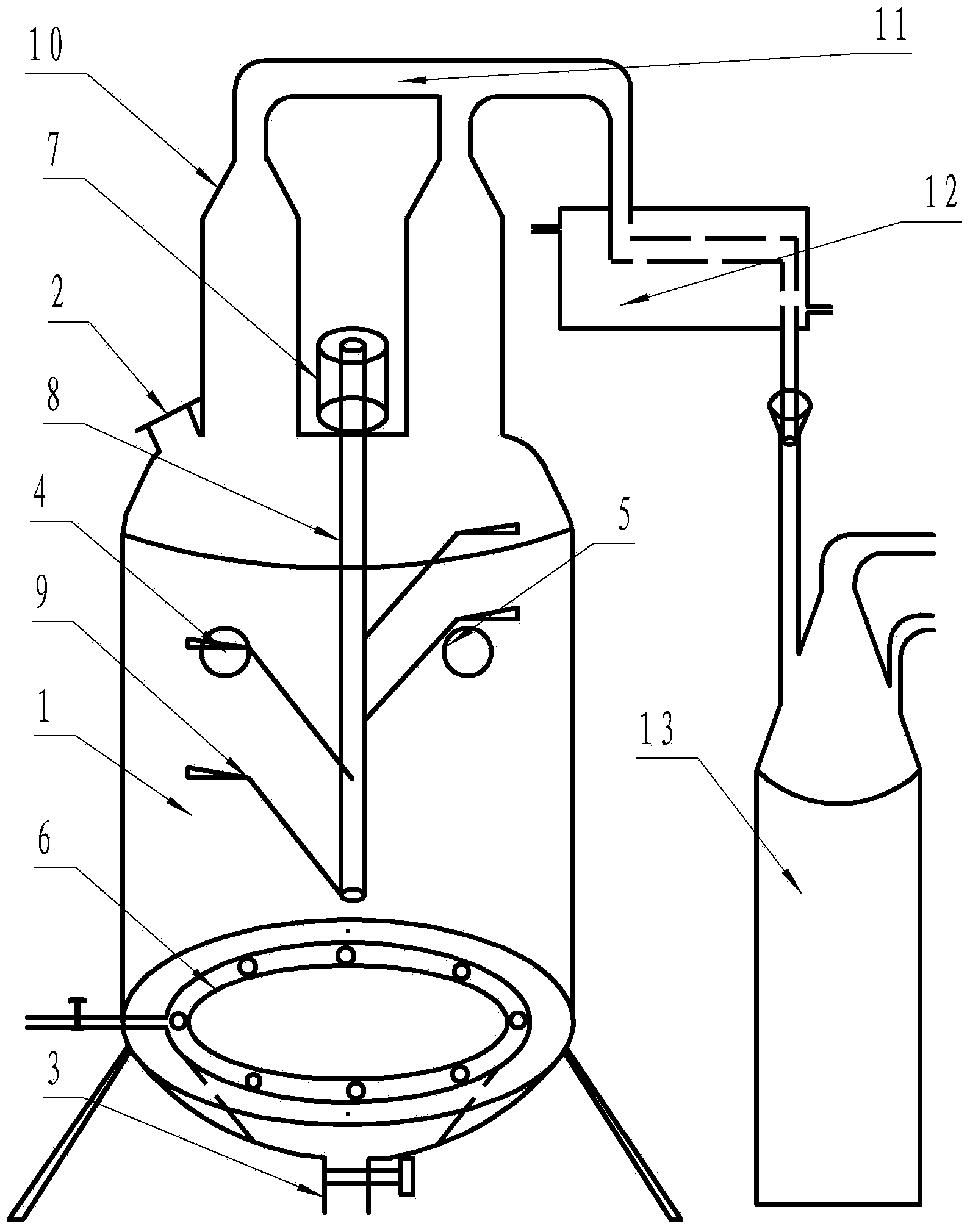

Sponge titanium and sponge zirconium reduction distillation equipment

The invention discloses sponge titanium and sponge zirconium reduction distillation equipment. The equipment comprises two reduction reactors (2), one reduction reactor (2) is arranged in a reduction distillation furnace (1), the other reduction reactor (2) is arranged in a cooler (4); and the upper ends of the two reduction reactors (2) are connected through a channel heater (3). Each reduction reactor (2) comprises a reactor cover (5) a reactor cylinder (6), and a filter plate (7), and a product discharge opening (8) is arranged on the center of the bottom of the reduction reactor (2). The lower end of the reduction reactor (2) is provided with a magnesium chloride discharge pipe (9). The conventional reduction distillation reactor is simplified, the magnesium chloride discharge pipe is taken as the vacuum gas discharge pipe, the condensation distance of the magnesium and magnesium chloride is prolonged, the cooling efficiency is increased, and the distillation period and energy consumption are reduced.

Owner:GUIYANG AL-MG DESIGN & RES INST

Anti-blocking tube heating device for sponge production

InactiveCN101812601ASolve the problem of pipe blockageReduce the number of open checksInsulation layerDistillation

The invention discloses an anti-blocking tube heating device for sponge production. The heating device consists of a temperature measuring tube, a sleeve, a heat insulation layer, a sleeve flange, an inverse U-shaped connecting tube, an inverse U-shaped connecting tube flange, a U-shaped resistance wire, two heat radiation sleeves, a contact rod sleeve and a contact rod, wherein one end of the heat radiation sleeve is closed and provided with a pore communicated with the inverse U-shaped connecting tube at the position close to the inverse U-shaped connecting tube flange; the U-shaped resistance wire is arranged inside the heat radiation sleeve, the heat insulation layer is formed in the sleeve, and the sleeve is sealed through the sleeve flange and the inverse U-shaped connecting tube flange; and a U-shaped resistance wire binding post is connected with the contact rod, and the contact rod is sealed in the contact rod sleeve. The heating device effectively solves the problem that a passageway standpipe at the distillation stage of the titanium sponge production is blocked, shortens the distillation time, reduces the times of opening a condenser for examination, reduces the probability of air inlet pollution of a titanium sponge product, saves energy, reduces consumption, and prolongs the service life of the product by about 2 to 3 times.

Owner:洛阳双瑞万基钛业有限公司

Production method of persimmon liquor

The invention relates to a production method of persimmon liquor, the production method is characterized by comprising the following steps: 1, selecting whole fruit of a persimmon and cleaning the whole fruit; 2, performing carbon dioxide deastringency under a sealed condition; 3, crushing; 4, adding yeast; 5, performing solid state fermentation; 6, distilling; 7, performing secondary distillation; 8, put the distilled persimmon into a jar for aging; the next step is that the distilled persimmon is fermented at above 15 DEG C for 30 days; the further step is that the distilled persimmon is mixed with wine stillage to stir and distill. According to the production method of persimmon liquor provided by the invention, the liquor taste is improved and the grade is raised.

Owner:陈金明

Method for detecting volatile phenol content of water

InactiveCN104374728AThe analysis result is accurateShorten distillation timeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsVolatile phenolsDistillation

The invention discloses a method for detecting volatile phenol content of water and belongs to the field of environment sample detection methods. The method comprises the following steps of taking a water sample, adding a methyl orange indicator into the water sample, adjusting the water sample to orange red or red color solution by a phosphoric acid solution, pouring a copper sulphate solution into the water sample, carrying out heating distillation, collecting the distillate by a volumetric flask with a sodium hydroxide solution, washing the wall of a condenser tube by desalinized water, adding a washing liquid into the same volumetric flask, carrying out dilution by desalinized water to obtain a solution having a desired volume, pouring the distillate into a colorimetric pipe, adjusting the pH of the solution to less than 7 by a hydrochloric acid solution, determining distillate absorbance by the obtained acidic solution as a reference solution and calculating phenol content corresponding to the absorbance according to a standard curve regression equation. The method has a phenol recovery rate more than 94.0%, lowest detection limit of 0.1mg / L, standard deviation of 0.05 and a variation coefficient of 3%, and has the characteristics of high accuracy, high repeatability, operation simpleness and low detection limit.

Owner:SHAANXI HUALU CHEM ENVIRONMENTAL PROTECTION

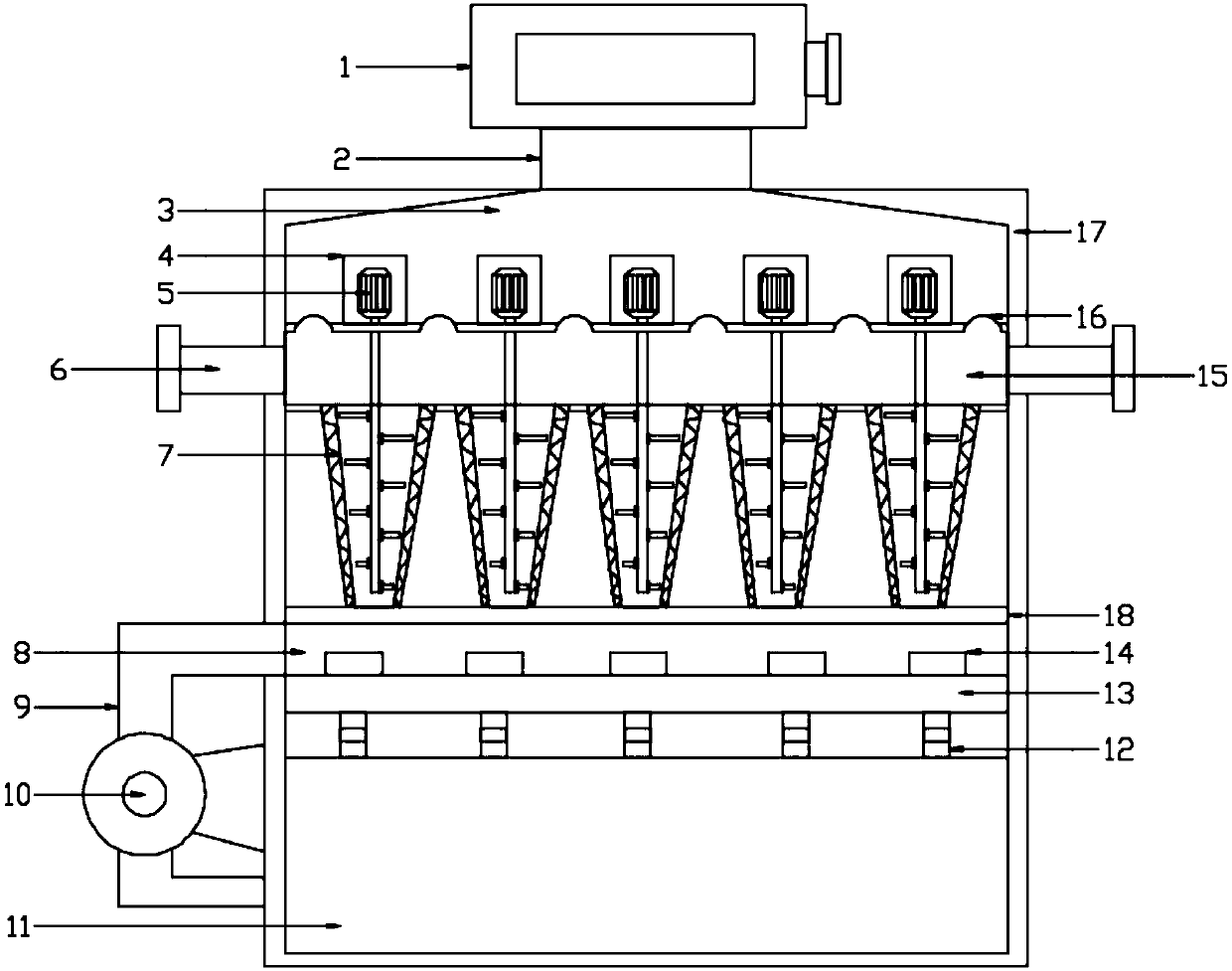

Distillation equipment for chemical production

InactiveCN107596717APrevent liquefactionIncrease contact areaDistillation regulation/controlFractional distillationGas phaseDistillation

The invention discloses distillation equipment for chemical production. The distillation equipment comprises a cavity, pre-heating pipes, a liquid outlet cavity layer, a distillation box and a liquidinlet cavity layer, wherein the cavity is arranged at the inner side of the top of an equipment shell; air outlet pipes which are distributed in an array are arranged at the top of the liquid inlet cavity layer; the upper ends of the air outlet pipes are communicated with the cavity; a liquid inlet pipe is arranged at each of the left and right sides of the liquid inlet cavity layer; each pre-heating pipe is provided with an inner-layer pipe and an outer-layer pipe sleeves each inner-layer pipe; heating wires are arranged between the inner-layer pipes and the outer-layer pipes; each inner-layer pipe is internally provided with a rotary shaft; aeration heads which are distributed in the array are arranged at the bottom of the liquid outlet cavity layer; the distillation box is internally provided with a liquid collection cavity; third connection pipes which are distributed in the array are arranged at the right side of the liquid collection cavity; the right sides of the third connection pipes are connected with flow dividing distillation pipes; heating plates are arranged at the lower ends of the flow dividing distillation pipes. The distillation equipment for the chemical production, disclosed by the invention has the advantages that the heating area is increased, the efficient distillation is realized, the distillation time is shortened and the purity is high; liquefaction ina gas phase mass transferring process can be avoided through pre-heating.

Owner:山东聚恒能源设备有限公司

Steam distillation aromatic essential oil device

The invention discloses a steam distillation aromatic essential oil device. The device comprises a distillation kettle, complex distillation columns, a goose neck pipe, a cooler and an oil-water separator, wherein a steam coil pipe which is in liquid sealing connection with the kettle body is fixedly arranged at the bottom of the kettle body in the distillation kettle; a stirring device with a power device is fixedly arranged at the middle position between the complex distillation columns arranged on the kettle top of the distillation kettle; the rotating shaft of the stirring device extends into the distillation kettle in a liquid sealing way; strip-shaped stirring blades are sequentially fixedly arranged on the rotating shaft extending into the distillation kettle in a spiral way. The steam distillation aromatic essential oil device has the benefits that the stirring device with a speed regulating device is started in the distilling process of aromatic essential oil, and the strip-shaped stirring blades are stirred, so that the mixture of aromatic flowers and water in the distillation kettle is circulated vertically; therefore, the water and the aromatic flowers in the distillation kettle are stirred uniformly and are soaked, steamed and cooked sufficiently, the distillation time is shortened by 0.5 to 1.0 hour, and the oil yield of the aromatic essential oil is improved.

Owner:郭永来

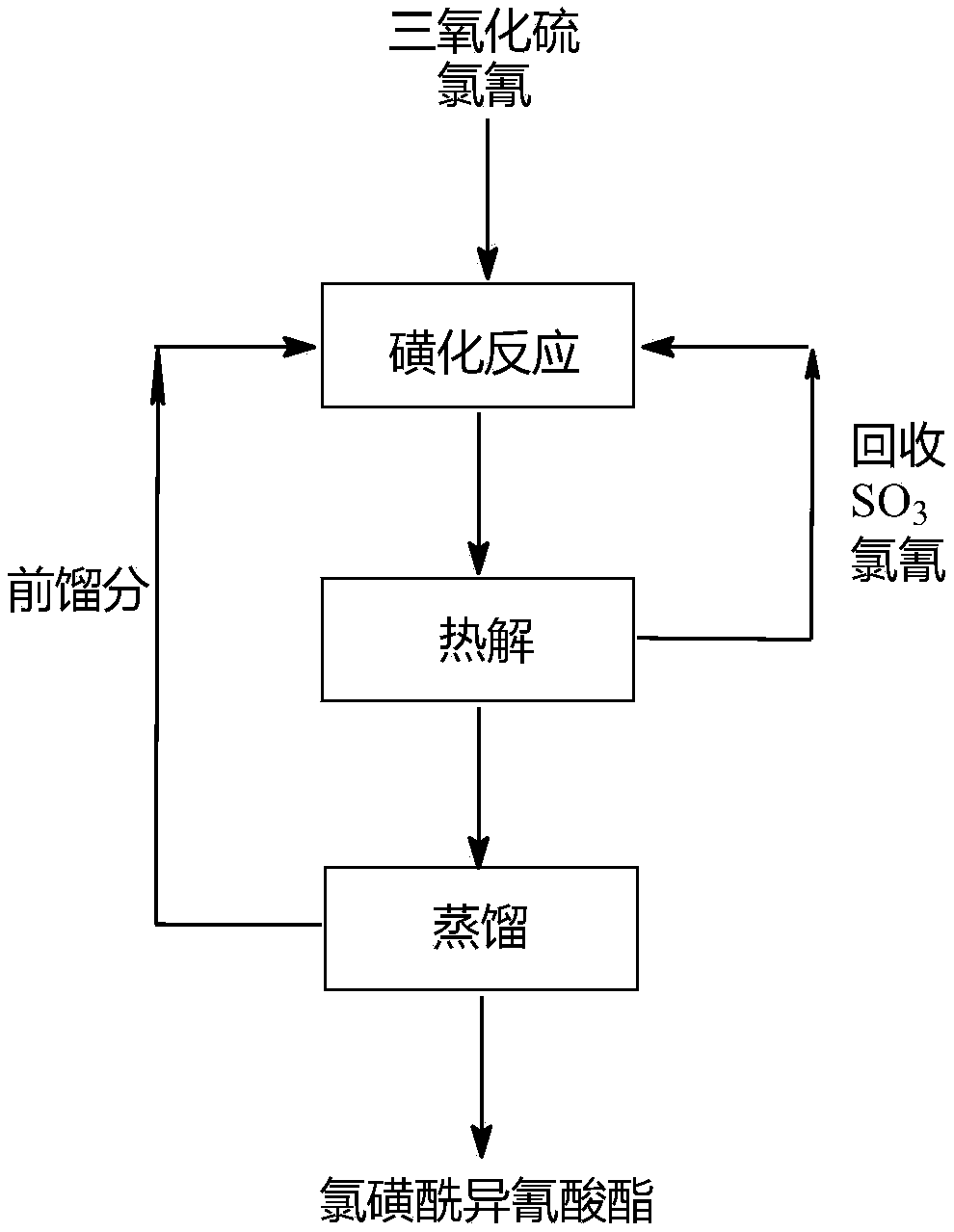

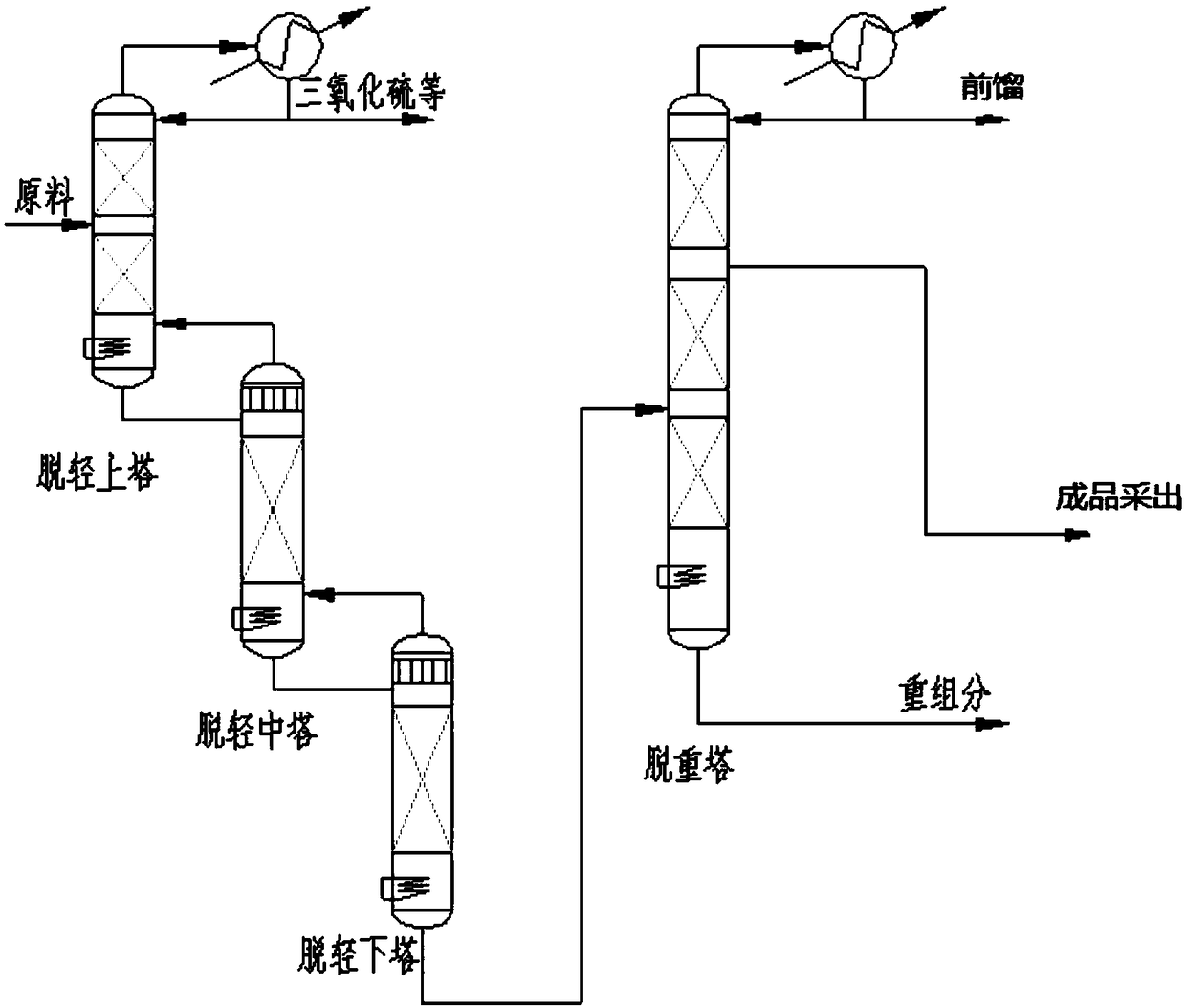

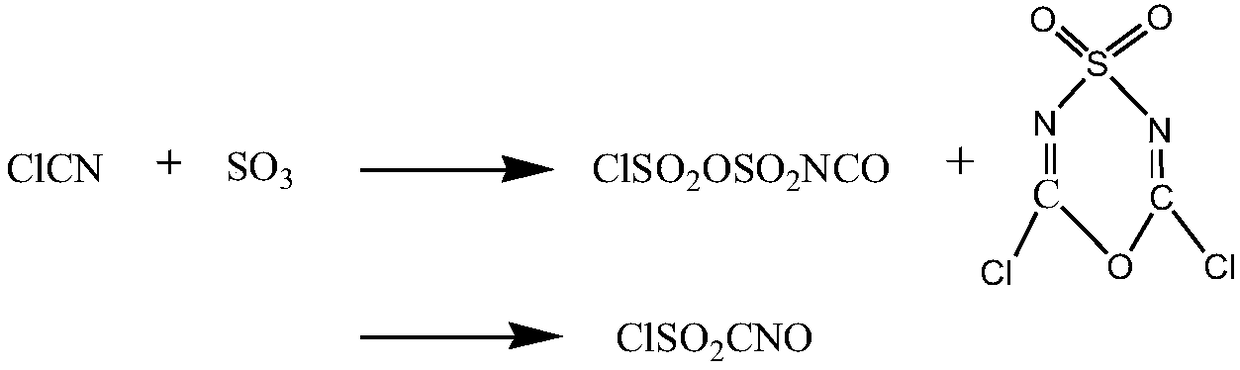

Synthesis method of high-purity chlorosulfonyl isocyanate

ActiveCN109400506AIncrease profitReduce usageSulfonic acid amide preparationPositive pressureSynthesis methods

The invention provides a synthesis method of high-purity chlorosulfonyl isocyanate. The synthesis method includes the steps that (A) under the condition of a diluent, sulfur trioxide and cyanogen chloride are subjected to sulfonation reaction to obtain a reaction solution; (B) the reaction solution is subjected to thermal decomposition reaction to obtain a reaction solution after thermal decomposition; (C) the reaction solution after thermal decomposition is subjected to positive pressure continuous distillation to obtain the high-purity chlorosulfonyl isocyanate and a distillate before distillation; and the diluent is selected from the chlorosulfonyl isocyanate or the distillate before distillation. According to the synthesis method of the high-purity chlorosulfonyl isocyanate, the totalyield of the process is increased; the distillate before distillation is used as a reaction solvent, use of a high boiling point solvent is avoided, in the pyrolysis process, the cyanogen chloride andthe sulfur trioxide are partially recovered, thus the utilization rate of raw materials is increased, and the production cost is lowered; and meanwhile, the rectification process is conducted throughthe mode of positive pressure distillation and continuous feeding, the yield of products is greatly increased, the distillation time is shortened, energy consumption and labor costs are lowered, andthe synthesis method of the high-purity chlorosulfonyl isocyanate is suitable for industrial mass production.

Owner:四平市精细化学品有限公司

Method for extracting cinnamomum camphora essential oil through two-stage continuous pressure-variable steam distillation

InactiveCN108179068AEfficient extractionHigh yieldEssential-oils/perfumesCinnamomum camphoraSteam pressure

The invention discloses a novel method for extracting cinnamomum camphora essential oil through two-stage continuous pressure-variable steam distillation. The method comprises the following specific flow path: adding cinnamomum camphora branches and leaves into a distillation kettle, then closing a feed port of the distillation kettle, and introducing steam from the bottom of the kettle for starting a steam distillation process. The steam pressure of introduced steam is adjusted by a steam pressure adjusting device; the distillation process comprises two continuous distillation stages; in thefirst stage, the steam pressure of the introduced steam is controlled to be 0.3-0.6MPa, and the distillation time is 3-10 min; in the second stage, the steam pressure of the introduced steam is controlled to be 0.05-0.2MPa, and the distillation time is 70-120min. Compared with the existing steam distillation method, the method has the advantages as follows: the steam consumption is reduced, the production energy consumption is reduced, the distillation time is short, and the yield of the essential oil is high, the production efficiency of the cinnamomum camphora essential oil is improved, andthe extraction cost of the cinnamomum camphora essential oil is reduced.

Owner:JIANGXI AGRICULTURAL UNIVERSITY

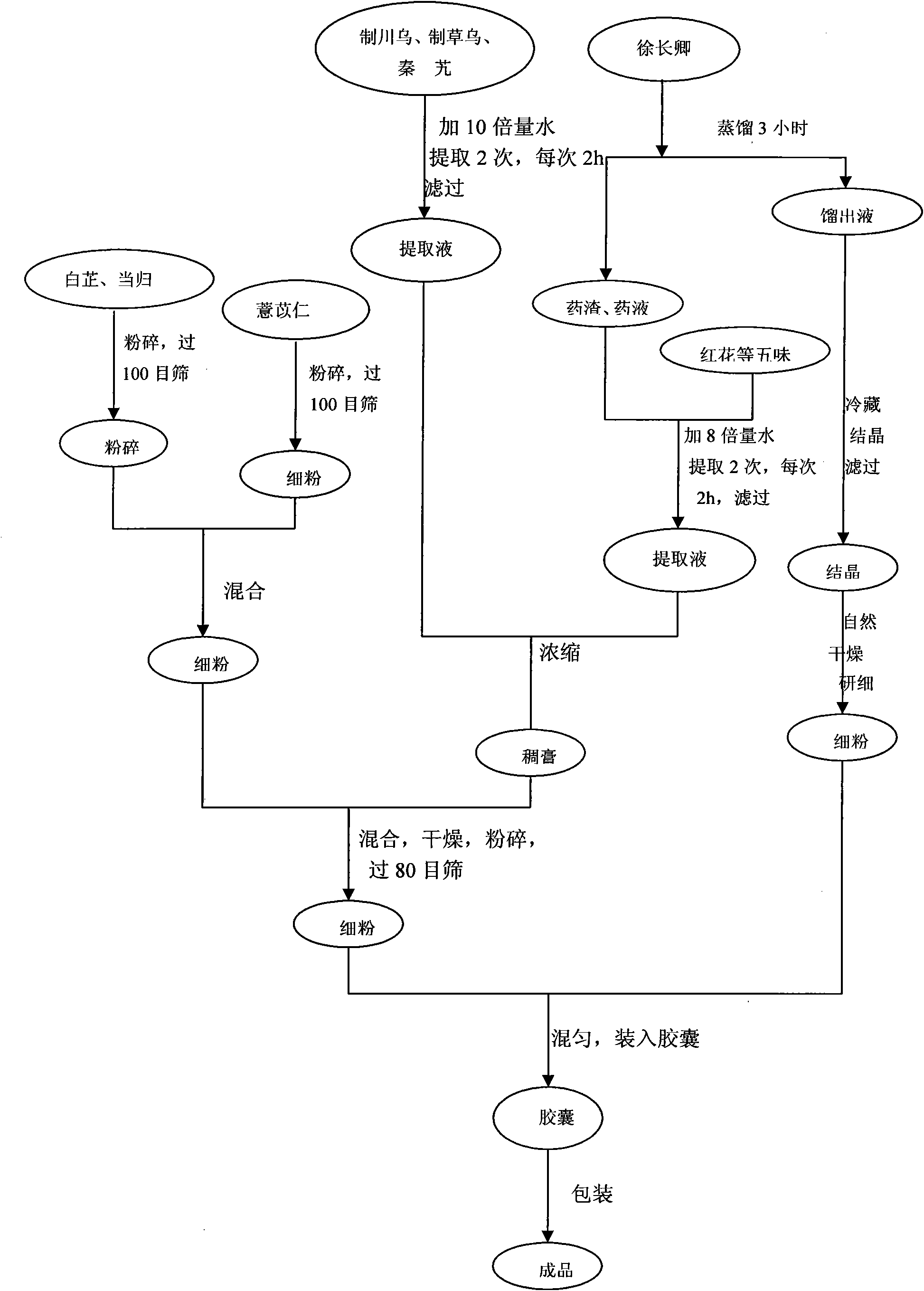

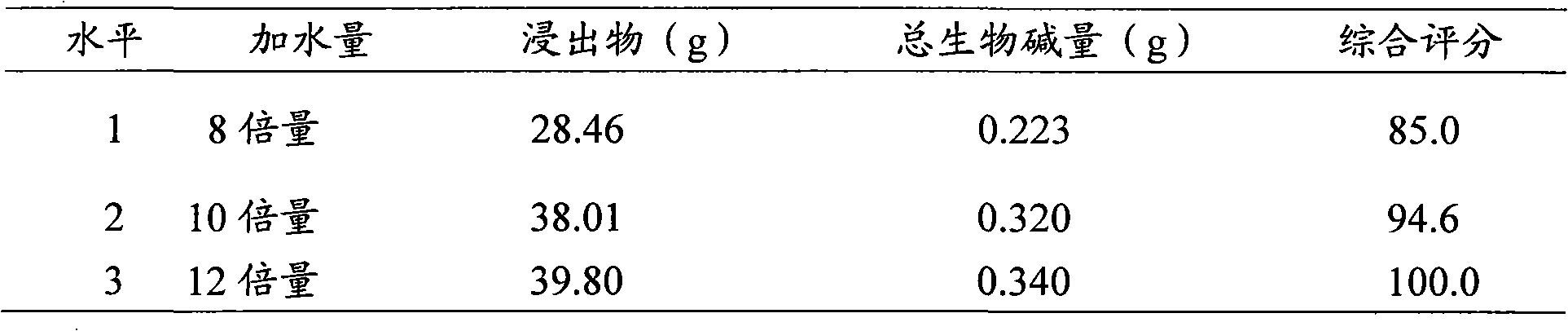

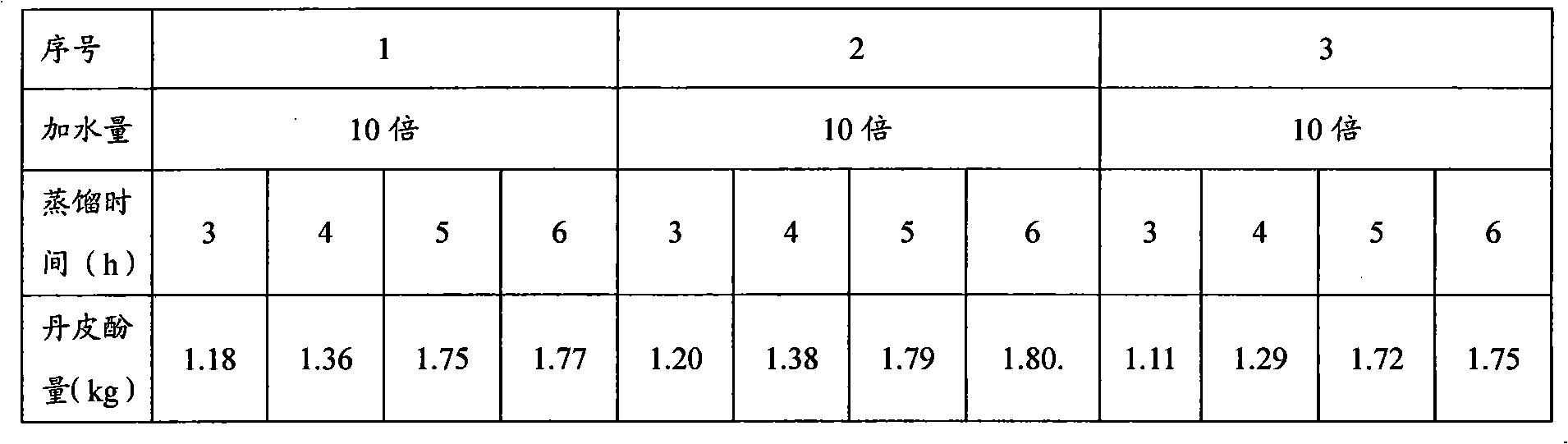

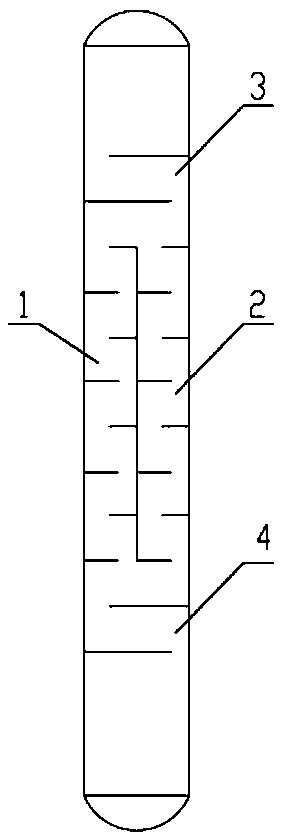

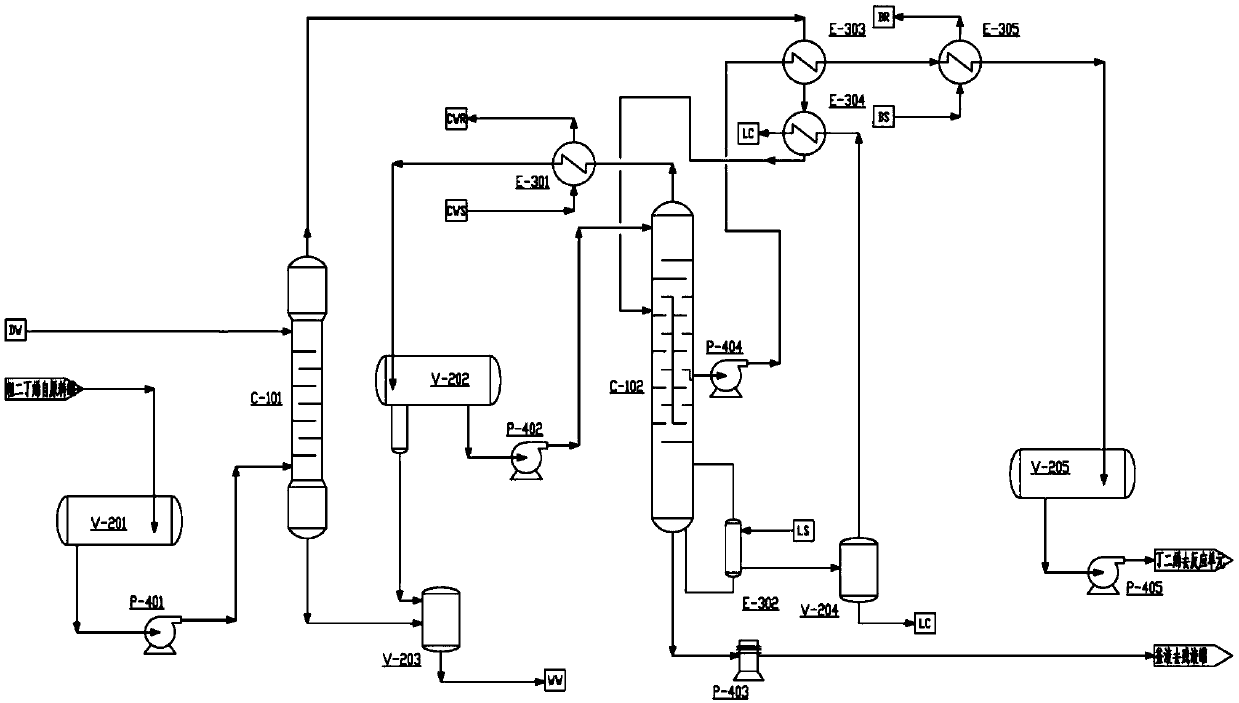

Production method of bone spur pain-eliminating capsule

ActiveCN101856472AHigh yieldToxic and side effectsNervous disorderAntipyreticMedicineEconomic benefits

The invention relates to a production method of a bone spur pain-eliminating capsule, which comprises the steps of treating dahurian angelica root, Chinese angelica and semen coicis, treating radix aconiti preparata, radix aconiti agrestis praeparata and gentiana macrophylla, treating paniculate swallowwort root and other steps. By adopting the method, the yield of paeonol in the paniculate swallowwort root is greatly increased, the water consumption during extraction is greatly reduced, the distillation time is greatly shortened and the energy consumed for extraction is remarkably reduced and the utilization rate of the equipment is remarkably improved. Therefore, the invention has unexpected technical effects, remarkable economic benefits and wide application prospect.

Owner:中山市恒生药业有限公司

Butadiene refining method and butadiene refining device

PendingCN111333480AShorten distillation timeReduce the possibility of copolymerizationDistillation purification/separationHydrocarbonsButadiene DioxideProcess engineering

The invention discloses a butadiene refining method and a butadiene refining device. The method comprises the following steps: firstly, extracting crude butadiene by adopting a water scrubber to remove impurities; feeding the washed crude butadiene into a pre-fractionating tower of a dividing wall tower, with a main fractionating tower being at the other side of the dividing wall tower, extractingrefined butadiene from the main fractionating tower side line of the dividing wall tower, extracting a gas phase from the top of the dividing wall tower, after condensation phase splitting, extracting a water phase, completely returning the oil phase, and discharging residual liquid rich in heavy components from the bottom of the dividing wall tower. According to the method, the existing technological process is optimized, the butadiene rectification time is shortened, the possibility of butadiene copolymerization is reduced, and the quality of refined butadiene and the yield of butadiene areremarkably improved; meanwhile, the butadiene dividing wall tower is used as refining equipment, one dividing wall tower realizes the separation function of two conventional rectifying towers, and the device investment and the operation cost are reduced. In addition, a heat exchange system is optimized, steam consumption is greatly reduced, and the method and the device have remarkable practicability and economic benefits.

Owner:TIANJIN PULAI CHEM TECH

Industrial production method of 2,6-difluoroaniline

InactiveCN112457198AAvoid heat damageReaction is easy to controlAmino compound purification/separationPreparation by rearrangement reactionsDiaphragm pumpSodium chlorate

The invention discloses an industrial production method of 2,6-difluoroaniline, wherein the industrial production method comprises the following steps: S1, preparation of a solution: mixing a sodium hydroxide aqueous solution and 2,6-difluorobenzamide to obtain a solution 1, and taking a sodium hypochlorite aqueous solution as a solution 2; S2, equipment building: connecting reaction kettles 1 and2 with a reaction kettle 3 through diaphragm pumps 1 and 2 respectively, and connecting the reaction kettle 3 with a reaction kettle 4 through an overflow pipe; S3, degradation reaction: simultaneously pumping the solution 1 and the solution 2 into the reaction kettle 3 by using the diaphragm pumps 1 and 2, and enabling a reaction liquid to flow out of an overflow pipe to the reaction kettle 4; S4, primary distillation: evaporating the product 2,6-difluoroaniline to a receiving kettle along with water vapor in the overflow pipe; and S5, rectifying of a crude product: rectifying after a liquidin the receiving kettle is layered. The CSTR mode is adopted to control the addition amount and time of the reaction liquid, so that the reaction is more controllable, and the problems of product heating damage and easy material flushing in the production process caused by violent material heat release in traditional kettle type reaction are avoided.

Owner:南京硕达生物科技有限公司

Method for producing 2-butenoic acid

ActiveCN101979371BWell mixedIncrease reaction pressureOrganic compound preparationChemical/physical/physico-chemical nozzle-type rreactors2 Butenoic AcidsOxygen

The invention provides a method for producing 2-butenoic acid, which comprises the following steps: preparing mixed feed liquid from 2-butenoic aldehyde, normal hexane and water in a weight ratio of 1:1:0.05-0.08; mounting an ejector pump on an oxidation reaction kettle for spraying the mixed feed liquid into the oxidation reaction kettle; introducing oxygen into the oxidation reaction kettle to perform a reaction under a condition that the reaction pressure in the oxidation reaction kettle is 0.1 to 0.6MPa and a condition that the temperature is 25 to 35 DEG C to obtain oxidation reaction solution; distilling the oxidation reaction, distilling the remaining 2-butenoic aldehyde under a reduced pressure, recovering the 2-butenoic aldehyde, distilling the remaining normal hexane at normal pressure and obtaining filtrate; and cooling the filtrate to -5 DEG C to 5 DEG C, precipitating, crystallizing and filtering and drying the crystals to obtain the 2-butenoic acid product. The production method has the advantages that: the reaction speed is high; the product yield is high; the energy consumption is small; and the quality of the product obtained is high.

Owner:HENAN ZAITI BIO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com