Synthesis method of high-purity chlorosulfonyl isocyanate

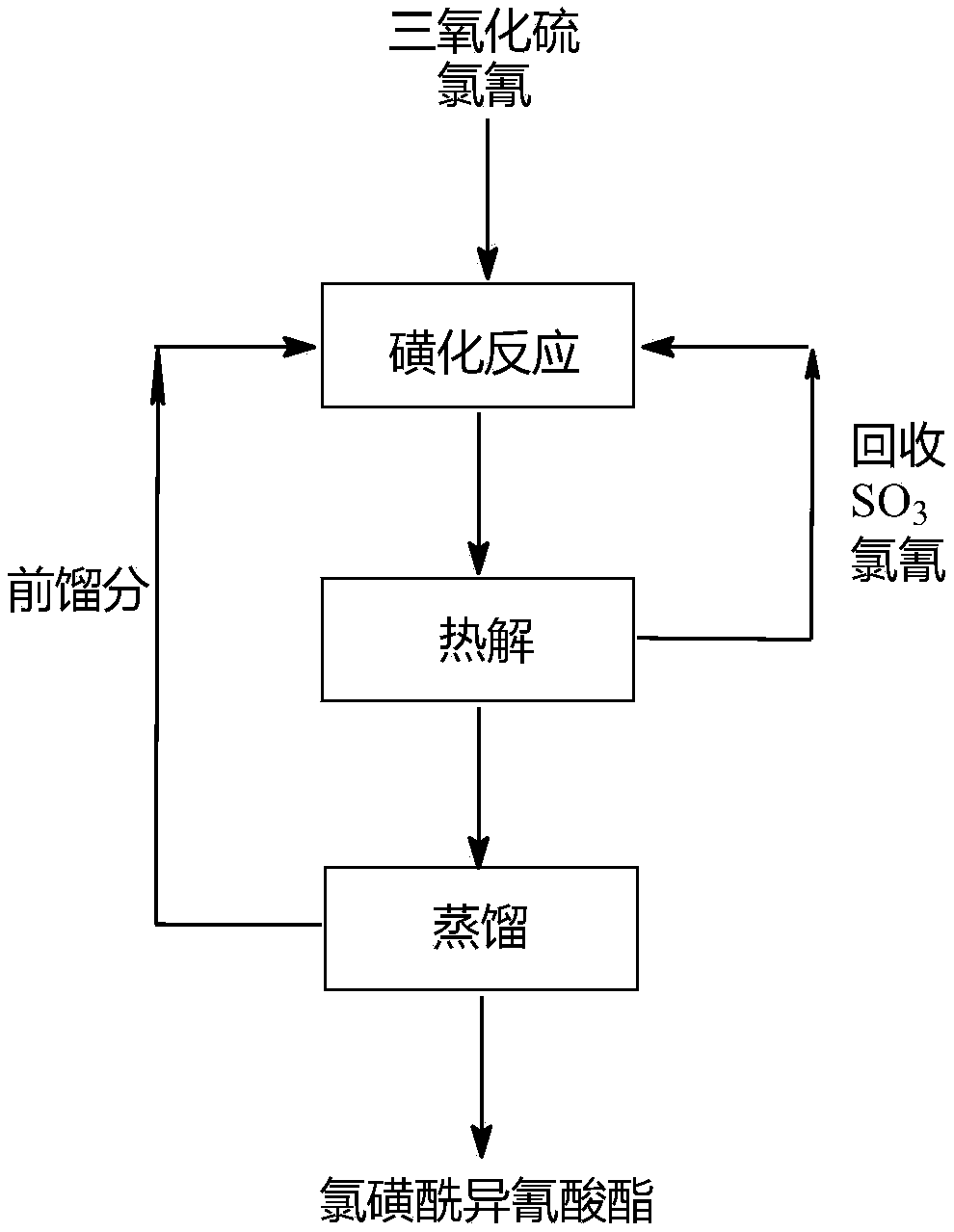

A technology of chlorosulfonyl isocyanate and synthesis method, which is applied in the preparation of sulfonic acid amide, organic chemistry, etc., can solve the problems of unsuitability for industrial production, inability to run for a long time, and harsh reaction conditions, so as to reduce energy consumption and labor costs, and improve production efficiency. The process is safe and reliable, and the effect of avoiding the use of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

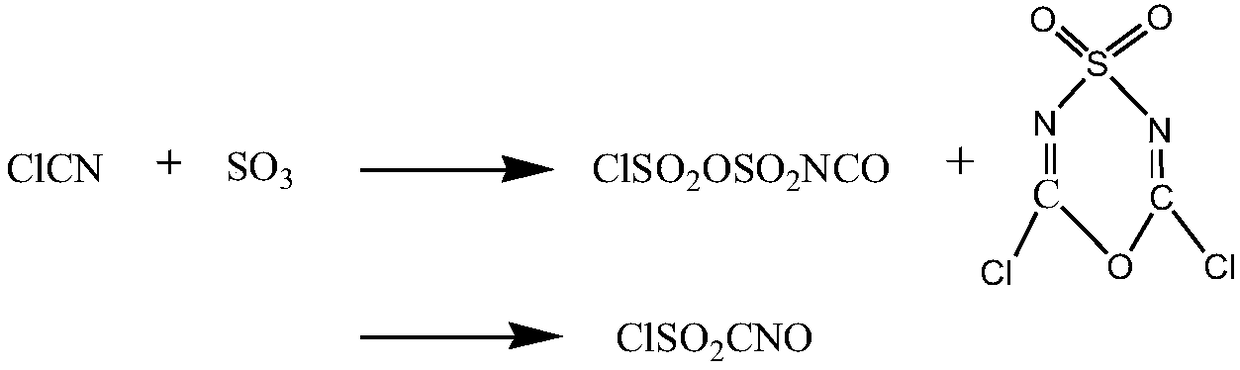

Method used

Image

Examples

Embodiment 1

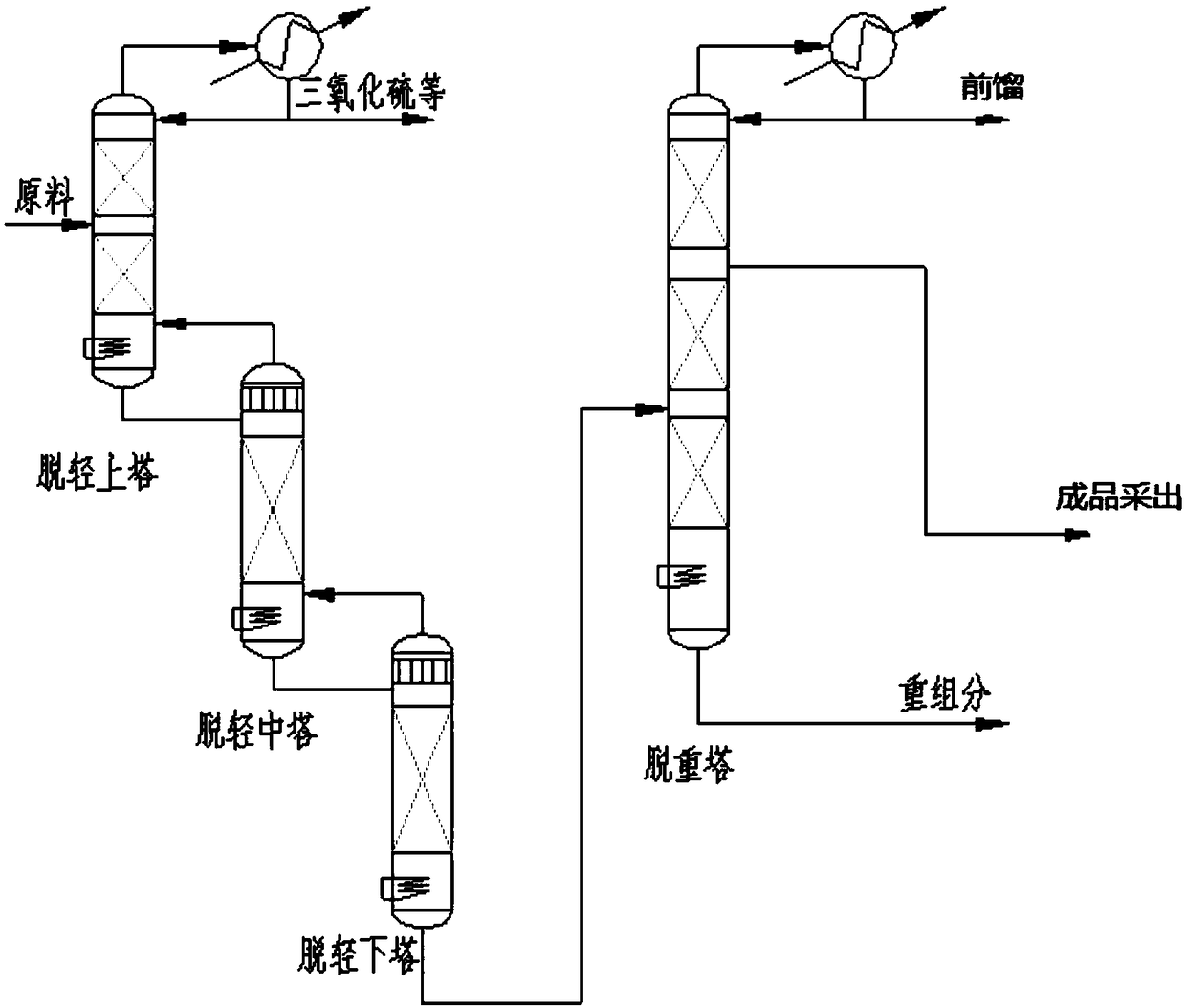

[0046] The present embodiment provides a continuous distillation system comprising:

[0047]The light removal upper tower, the light removal middle tower and the light removal lower tower connected successively from top to bottom, the middle part of the light removal upper tower is provided with a feed liquid inlet;

[0048] A weight-removing tower in which the liquid inlet is connected to the liquid outlet of the lower tower. The upper part of the weight-removing tower is provided with an outlet for fractions before distillation. The middle part of the weight-removing tower is provided with a finished product outlet. Heavy components are exported.

[0049] The upper light removal tower, the middle light removal tower, the lower light removal tower and the heavy weight removal tower are packed towers, and the filler is selected from 700Y wire mesh corrugated packing.

[0050] Wherein, the packing in the light removal upper tower is arranged in sections, the packing in the lig...

Embodiment 2

[0063] Add 20mL of chlorosulfonic acid isocyanate into the reaction device as a reaction solvent, and then feed in a certain amount of sulfur trioxide 80.06g and cyanogen chloride 61.47g at the same time, and keep the temperature at 30°C for reaction. Raise the temperature of the reaction solution to 120°C for thermal decomposition, recover sulfur trioxide, and pass it into the next sulfonation reaction. The thermally decomposed reaction liquid is rectified, and the reaction liquid is carried out by means of continuous distillation. While feeding the material, heat the bottom of the light removal lower tower, and then open the light middle tower and the light removal upper tower to heat. When the pressure in the kettle reaches 1.7Mpa and the temperature at the top of the tower reaches 95°C, reflux for 2 hours to ensure thermal decomposition After it is fully completed, the feed is continuously re-fed, and the front fraction and the finished product are continuously extracted a...

Embodiment 3

[0065] Add 20mL of the fraction before the batch to the reaction device as a reaction solvent, and then feed 80.06g of sulfur trioxide, 61.47g of cyanogen chloride and recovered gas at the same time according to a certain amount, and keep the temperature at 34°C for reaction. The temperature of the reaction solution is raised to 100°C for thermal decomposition, and sulfur trioxide is recovered. The thermally decomposed reaction liquid is rectified, and the reaction liquid is carried out by means of continuous distillation. While feeding the material, heat the bottom of the light removal lower tower, and then open the light middle tower and the light removal upper tower to heat. When the pressure in the kettle reaches 1.5Mpa and the temperature at the top of the tower reaches 93°C, reflux for 2 hours to ensure thermal decomposition After it is fully completed, the feed is continuously re-fed, and the forward distillation and the finished product are continuously extracted at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com