Patents

Literature

83 results about "Cyanogen chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cyanogen chloride is a toxic chemical compound with the formula NCCl. This linear, triatomic pseudohalogen is an easily condensed colorless gas. More commonly encountered in the laboratory is the related compound cyanogen bromide, a room-temperature solid that is widely used in biochemical analysis and preparation.

Broad spectrum filter system including tungsten-based impregnant and being useful for filtering contaminants from air or other gases

InactiveUS7004990B2Broad filtering capabilitySatisfactory performanceGas treatmentOther chemical processesFilter systemFilter media

Owner:3M INNOVATIVE PROPERTIES CO

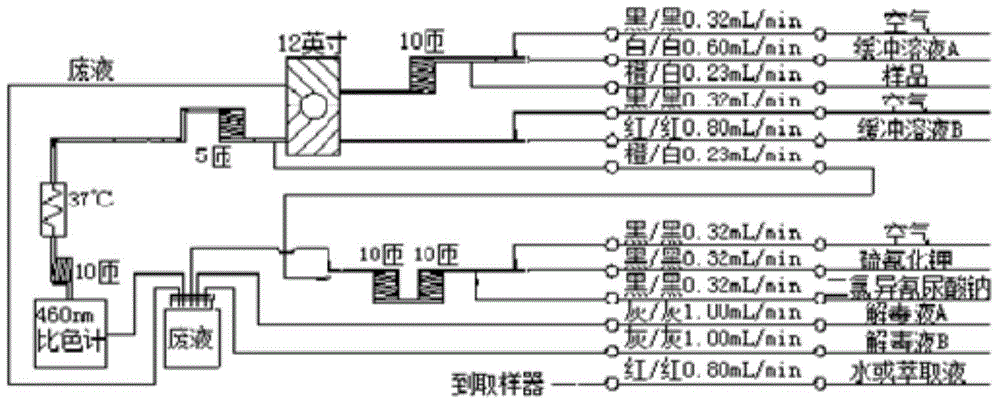

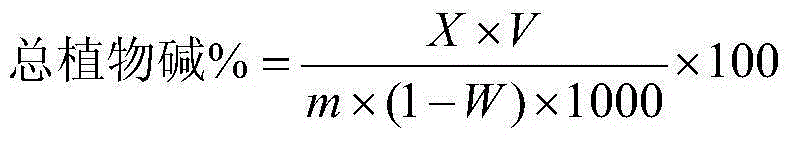

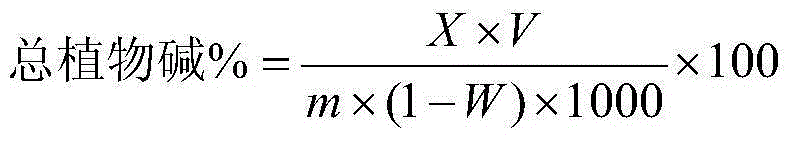

Continuous flow method for measuring total alkaloid in tobacco or tobacco products

ActiveCN104132937AGuaranteed pHWill not be affected by acid and alkali environmentMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationPotassium thiocyanateContinuous flow

The invention provides a continuous flow method for measuring total alkaloid in tobacco or tobacco products. In the method, potassium thiocyanate and sodium dichloro isocyanurate are adopted to carry out reactions to generate cyanogen chloride on line. The cyanogen chloride can carry out reactions with total alkaloid (calculated in the form of nicotine) in tobacco or tobacco products to break off the pyridine rings of nicotine, and then further carries out reactions with p-aminobenzene sulfonic acid. The reaction products are measured by a chromometer at 460 nm. The method uses a buffer system to control the pH value of the reaction system in a range of 6.0 to 7.5, and the buffer system is composed of a buffer solution A and a buffer solution B. The buffer solution A is prepared by the following steps: weighing disodium hydrogen phosphate and trisodium phosphate, placing the weighed substances in a beaker, dissolving the substances with water, transferring the solution to a volumetric flask (1L), and adding water into the volumetric flask until the water reaches the scale. The buffer solution B is prepared by the following steps: weighing p-aminobenzene sulfonic acid, disodium hydrogen phosphate, sodium dihydrogen phosphate, and sodium citrate, placing the weighed substances into a beaker, dissolving the substances with water, transferring the solution to a volumetric flask (1L), and then adding water into the volumetric flask until the water reaches the scale.

Owner:CHINA NAT TOBACCO QUALITY SUPERVISION & TEST CENT

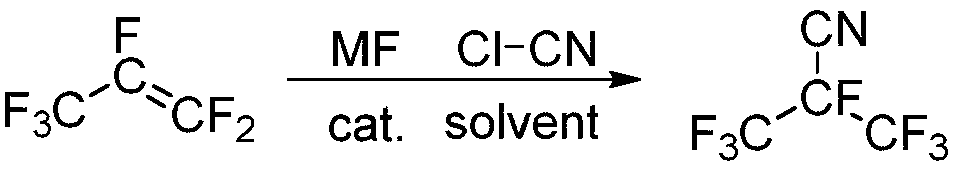

Preparation method of perfluoronitrile type compound

ActiveCN108863847AHigh yieldHigh purityCarboxylic acid nitrile preparationOrganic compound preparationOrganic synthesisPotassium

The invention relates to the technical field of organic synthesis and in particular relates to a preparation method of a perfluoronitrile type compound. The invention discloses the preparation methodof the perfluoronitrile type compound; the preparation method comprises the following step: taking a perfluoroalkene type compound, metal fluoride and cyanogen chloride to react under nitrogen gas orinert gas displacement and protection, so as to obtain the perfluoronitrile type compound. The preparation method adopts a one-pot method to synthesize the perfluoronitrile type compound and is simpleto operate; a byproduct of the reaction is sodium chloride or potassium chloride and has no pollution to the environment; post-treatment is easy to operate. Furthermore, the perfluoronitrile type compound prepared by the preparation method has high yield and the highest yield is 82.1 percent; the perfluoronitrile type compound has high purity and the purity is higher than 99.3 percent; the technical problems that an existing perfluoronitrile type compound has relatively low yield and is uneconomical are solved.

Owner:GUANGDONG POWER GRID CO LTD +1

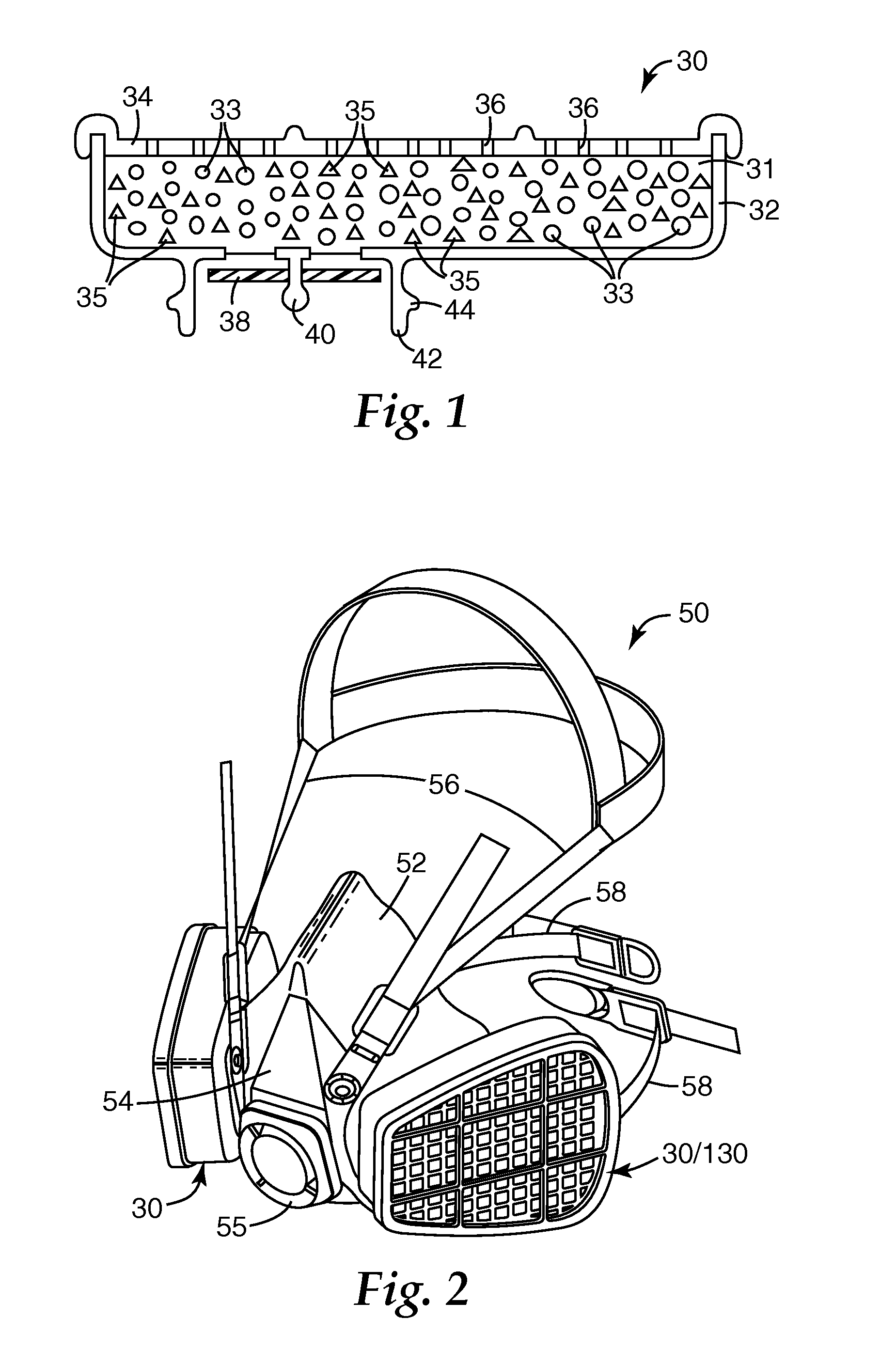

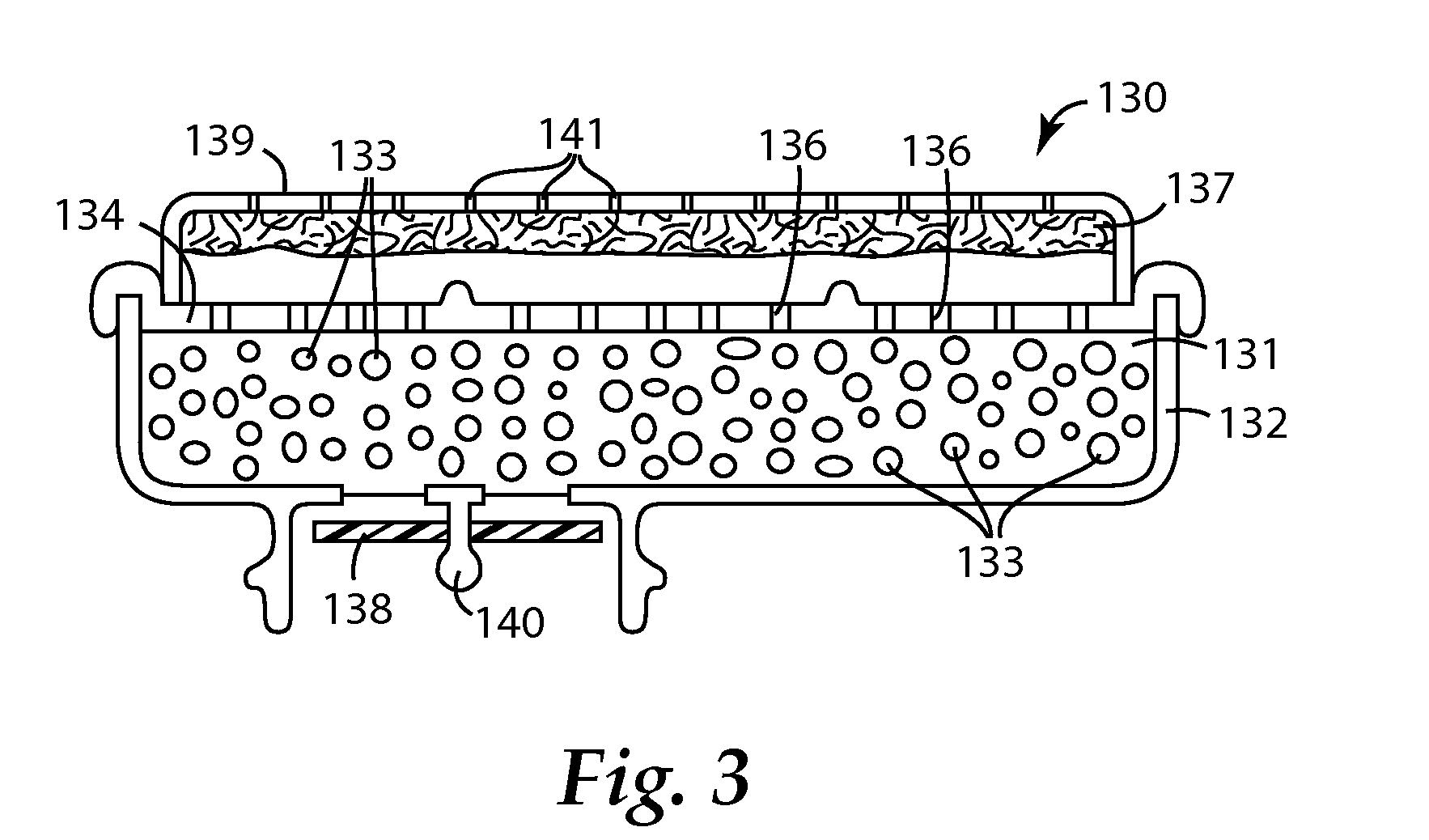

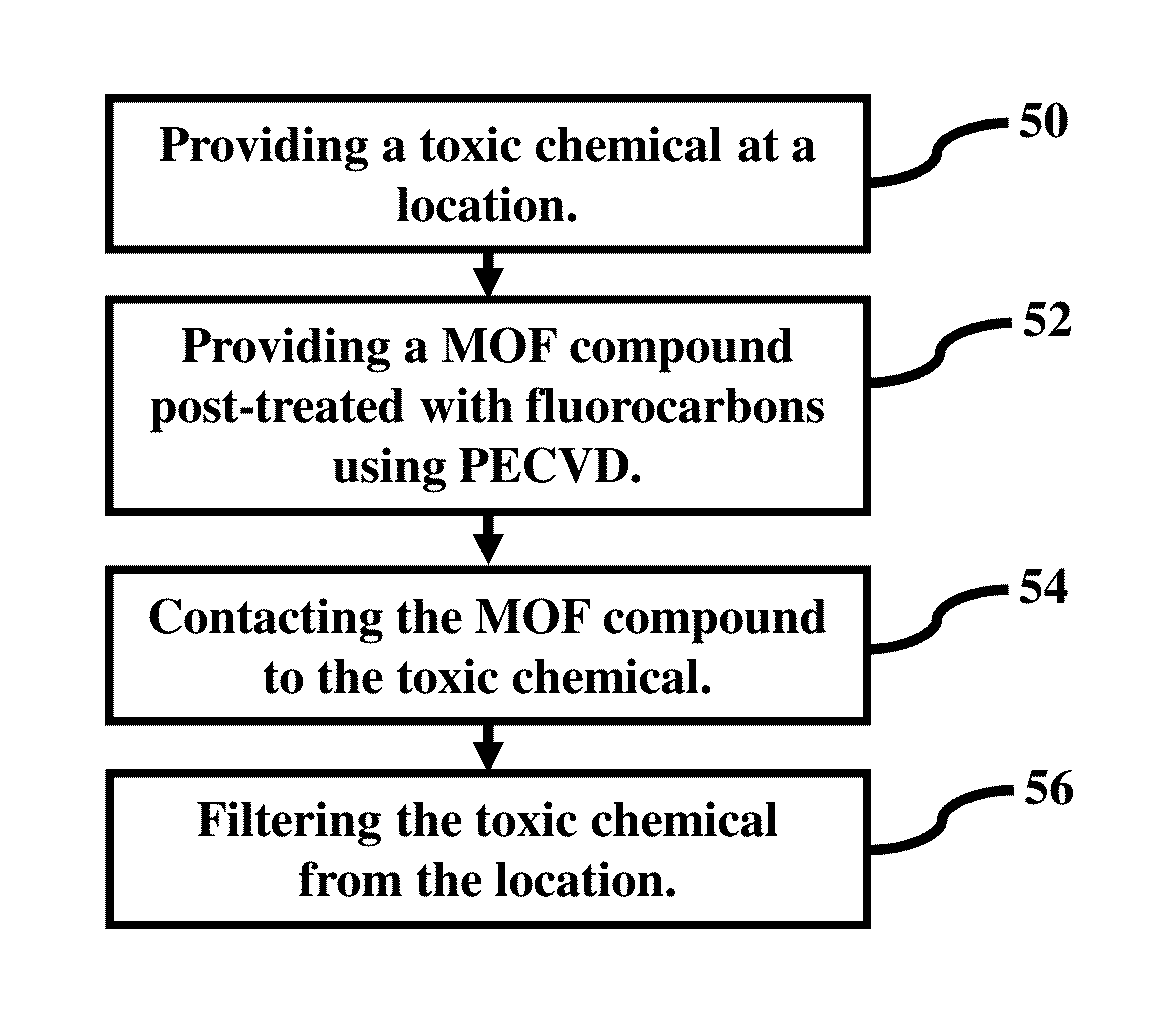

Removal of toxic chemicals using metal-organic frameworks (MOFs) post-treated via plasma-enhanced chemical vapor deposition (PECVD) with fluorocarbons

A system and method of filtering comprising adsorbing a toxic chemical using a metal-organic framework (MOF) compound that has been post-treated with fluorocarbons using plasma-enhanced chemical vapor deposition (PECVD). The toxic chemical may comprise any of ammonia and cyanogen chloride. Furthermore, the toxic chemical may comprise any of an acidic / acid-forming gas, basic / base-forming gas, oxidizer, reducer, and organic gas / vapor. The toxic chemical is physically adsorbed by the MOF compound. Moreover, the toxic chemical interacts with unsaturated metal sites within the MOF. Additionally, the MOF compound may comprise any of Cu-BTC, MOF-177, and an isoreticular metal-organic framework (IRMOF) compound. The MOF compound may comprise a metal-carboxylate bond. Additionally, the MOF compound may be unstable in the presence of moisture.

Owner:UNITED STATES OF AMERICA

Adducts of amines and polycarboxylic acids, and filter media comprising such adducts

InactiveUS20110171076A1Reduce volatilityUndesirable side-effectOrganic chemistryOther chemical processesFilter mediaFilter system

Herein are disclosed adducts of amines and polycarboxylic acids, and methods of making such adducts. Such adducts can be used to remove cyanogen chloride. Also disclosed are methods of providing such adducts on supports to form filter media. Also disclosed are methods of combining such filter media with catalysts and / or with porous polymeric webs to form filter systems.

Owner:3M INNOVATIVE PROPERTIES CO

Removal of toxic chemicals using metal-organic frameworks (MOFs) post-treated via plasma-enhanced chemical vapor deposition (PECVD) with fluorocarbons

ActiveUS9216404B1Other chemical processesSolid sorbent liquid separationForming gasMetal-organic framework

A system and method of filtering comprising adsorbing a toxic chemical using a metal-organic framework (MOF) compound that has been post-treated with fluorocarbons using plasma-enhanced chemical vapor deposition (PECVD). The toxic chemical may comprise any of ammonia and cyanogen chloride. Furthermore, the toxic chemical may comprise any of an acidic / acid-forming gas, basic / base-forming gas, oxidizer, reducer, and organic gas / vapor. The toxic chemical is physically adsorbed by the MOF compound. Moreover, the toxic chemical interacts with unsaturated metal sites within the MOF. Additionally, the MOF compound may comprise any of Cu-BTC, MOF-177, and an isoreticular metal-organic frame work (IRMOF) compound. The MOF compound may comprise a metal-carboxylate bond. Additionally, the MOF compound may be unstable in the presence of moisture.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

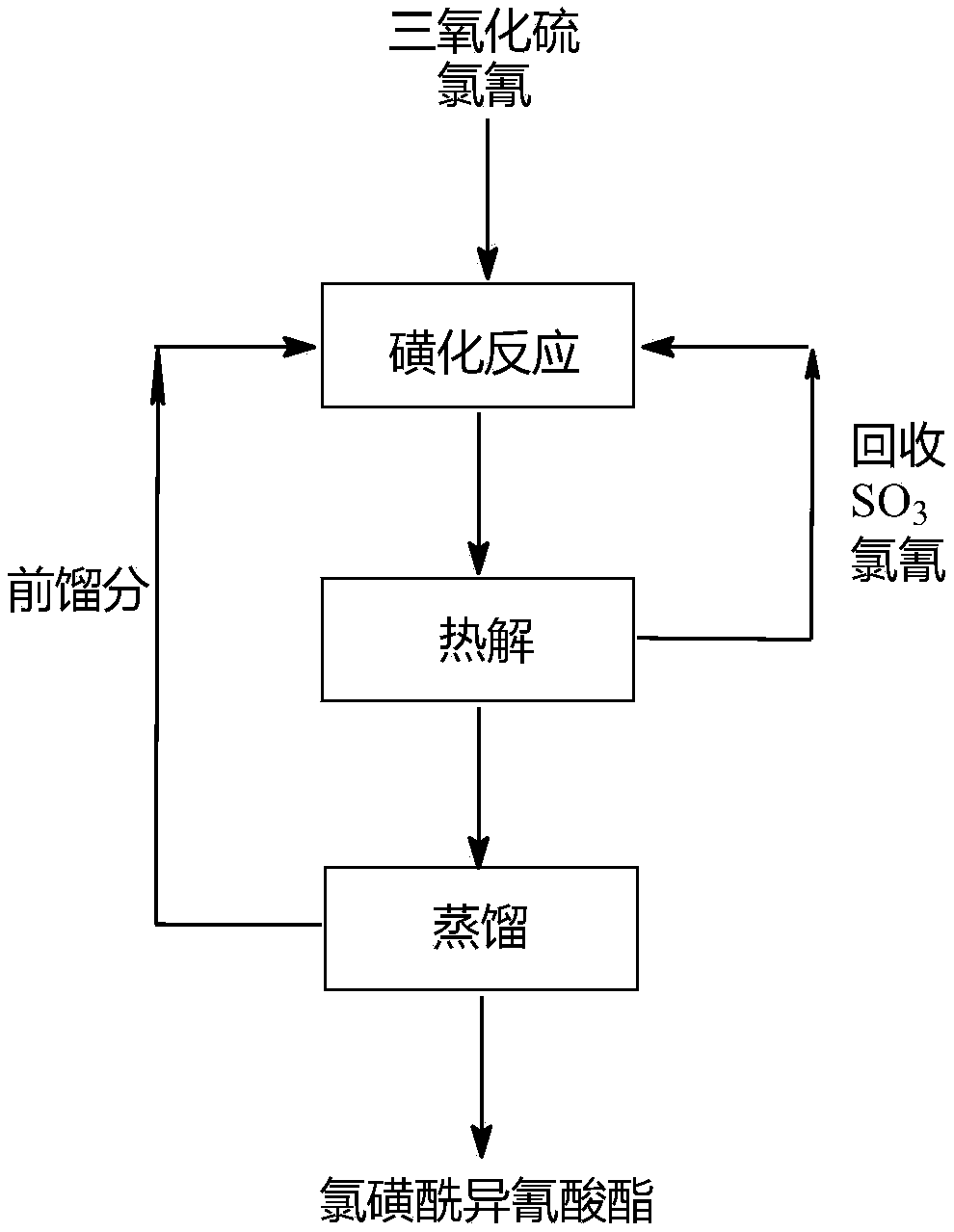

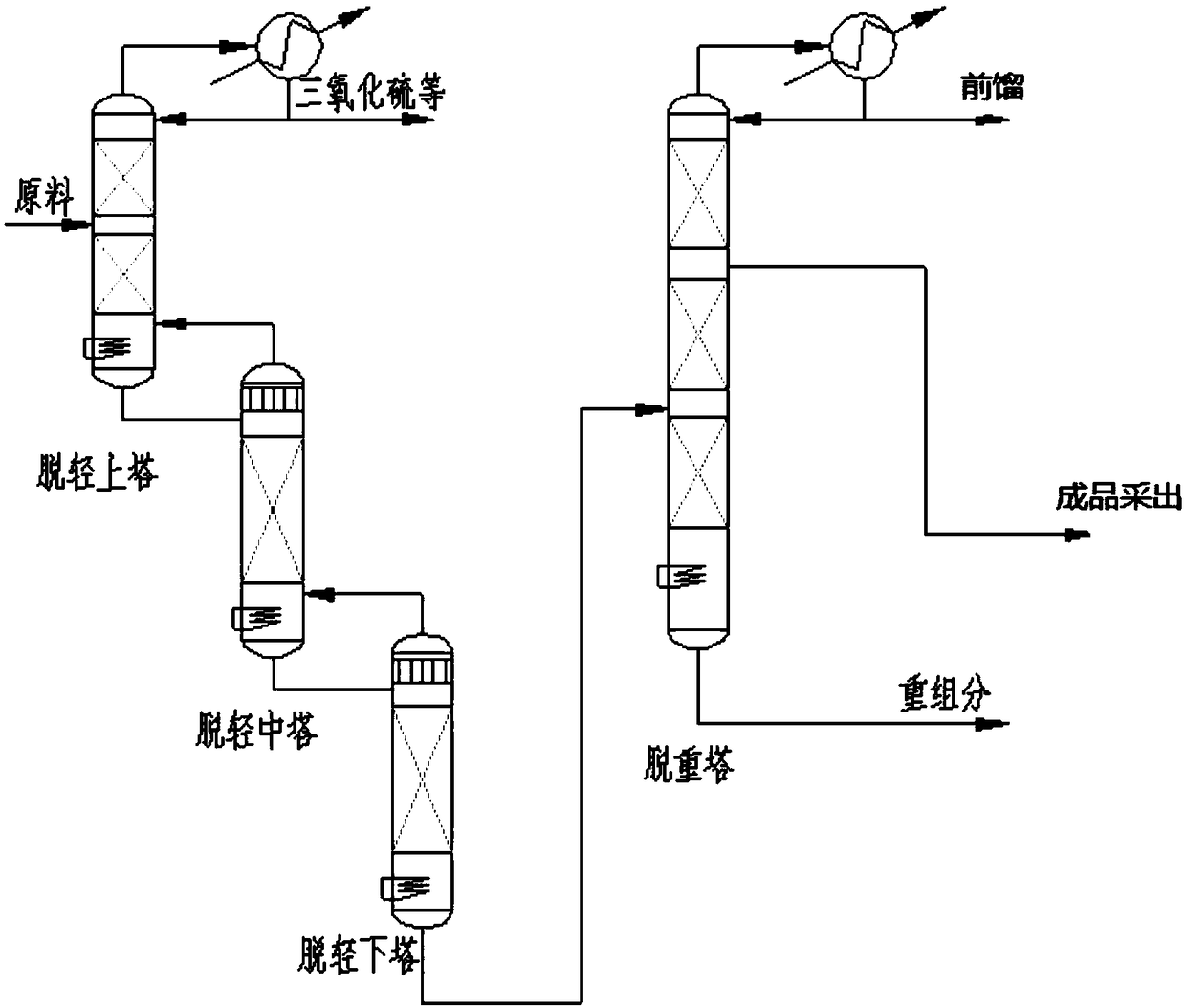

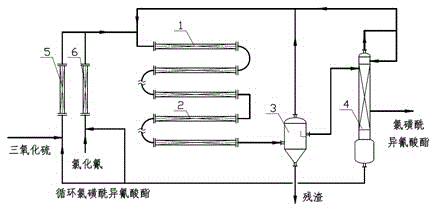

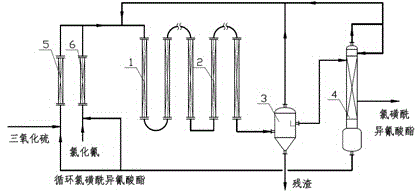

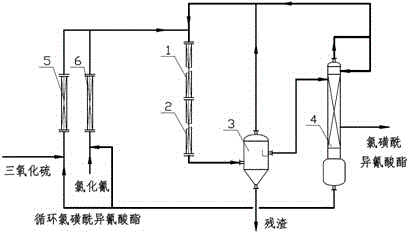

Manufacturing method of chlorosulfonyl isocyanate

ActiveCN101891657AReduce consumptionReduce manufacturing costSulfonic acid amide preparationSodium cyanideSolvent

The invention relates to a manufacturing method of chlorosulfonyl isocyanate, in particular to a method of taking cyanogen chloride, sulfuric anhydride and a sodium hydride water solution as raw materials to produce chlorosulfonyl isocyanate with high efficiency and low consumption. The manufacturing method of chlorosulfonyl isocyanate comprises the following steps: simultaneously adding liquid chlorine and a sodium cyanide water solution to a chlorination reactor for chlorination reaction; then preparing pure liquid cyanogen chloride by cooling, drying and refining; then adding the cyanogen chloride and the sulfuric anhydride which are respectively dissolved in inert solvents in equal mole ratio to the reactor; preparing the crude product of chlorosulfonyl isocyanate by reaction at low temperature; and preparing the finished product of chlorosulfonyl isocyanate by desolventizing, thermal decomposition and rectifying. The invention has simple method and easy implementation, the traditional production process is changed, and the liquid chlorine is not gasified and directly reacts with the sodium cyanide water solution to prepare the cyanogen chloride, thereby simplifying the process, greatly improving the yield and quality of the product, reducing the energy consumption, reducing the production cost of enterprises, and being an ideal manufacturing method of the chlorosulfonyl isocyanate.

Owner:营口昌成新材料科技有限公司

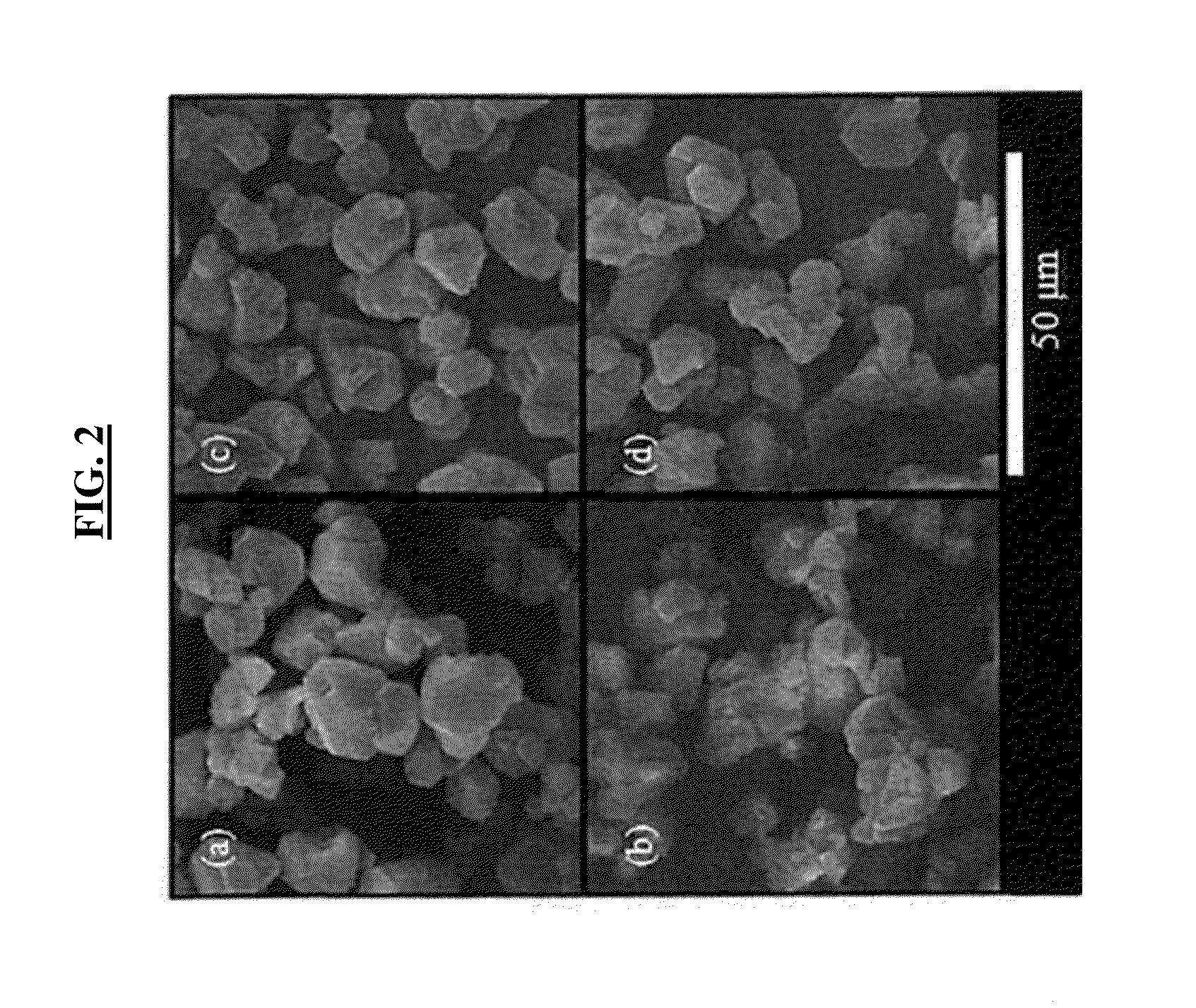

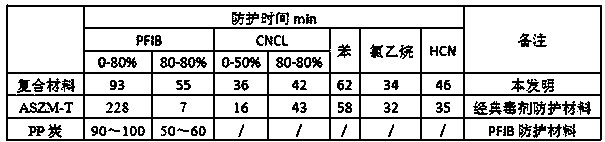

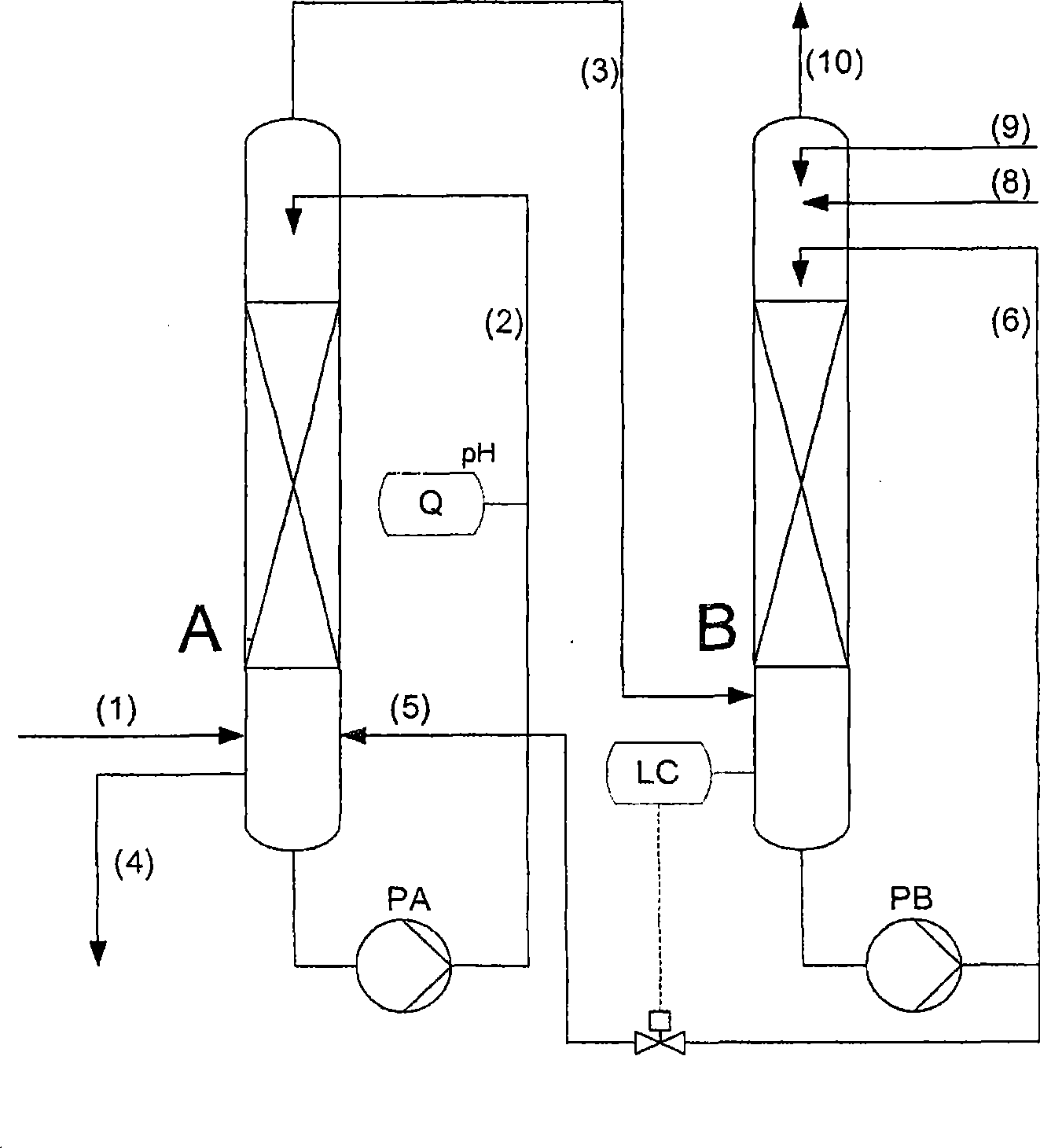

Composite type protective material for comprehensive toxicant prevention

InactiveCN103721367ALarge specific surface areaReasonable pore structure distributionChemical protectionActivated carbonToxicant

The invention relates to a toxicant prevention material, particularly to a composite type protective material for comprehensive toxicant prevention. The material comprises activated carbon serving as a carrier and an impregnant adsorbed by the activated carbon, wherein the impregnant comprises 7%-10% (by weight) of Cu, 1%-2% (by weight) of Mo, 0.6%-3% (by weight) of an active component additive Ag, 0.4%-1% (by weight) of Zn and 5%-10% (by weight) of a multi-amine compound TEDA (triethylene diamine). The material is reasonable in design, and the composite type protective material capable of effectively protecting against various toxicants such as classic toxicants of HCN (hydrogen cyanide) and CNCL (cyanogen chloride), a penetrating toxicant of perfluoroisobutylene and the like, is developed.

Owner:SHANXI XINHUA CHEM

Broad spectrum filter system including tungsten-based impregnant and being useful for filtering contaminants from air or other gases

ActiveUS20050183577A1Broad spectrum filtering performanceCompact and convenient to useCombination devicesGas treatmentFilter mediaFilter system

Filter systems that are effective against a broad range of contaminants including HCN, cyanogen chloride (CK), acid contaminants. and basic contaminants such as ammonia without the need (but with the option, if desired) for using molybdenum or chromium containing materials. The filtering systems of the present invention include a tungsten-based material and other impregnants incorporated into a substrate such as filter media particles.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one

ActiveCN101417951ARich sourcesReduce manufacturing costOrganic compound preparationAmino compound preparationSodium bicarbonateSulfite salt

The invention discloses a preparation method of 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone, which is an intermediate for the synthesis of antiviral medicine carbonyl ring nucleoside, which is characterized in that, an aqueous solution prepared by anhydrous sodium sulfite and sodium bicarbonate is added to a reactor; the temperature is controlled between 0 to 60 DEG C; a fixed amount of methanesulfonyl chloride is added by dropping, and the temperature is maintained to react for 2 to 4 hours to prepare methyl sulfonate solution; a fixed amount of ether solvent is added to the solution, and under a temperature ranging from 10 to 60 DEG C, cyanogens chloride is added; after 4 to 6 hours reaction, cyclopentadienyl is added by dropping; the pH value of the reaction solution is controlled between 1.5 to 3 to react for 3 to 5 hours; then sodium hydroxide is used for regulating the pH value to 7 to 9; after standing, the ether solvent is separated, and a fixed amount of methyl chloride is used for separated extraction 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone; the methyl chloride is distilled and a crude product is obtained; the crude product is decolorized by activated carbon and recrystallized in ether solvent; 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone with a purity of more than 99.6 percent is obtained after drying. The preparation method has the advantages of rich raw material sources, low cost, simple technological process, small emission of three wastes, benefits for industrial production and other advantages.

Owner:JILIN PURUITE BIOTECH CO LTD

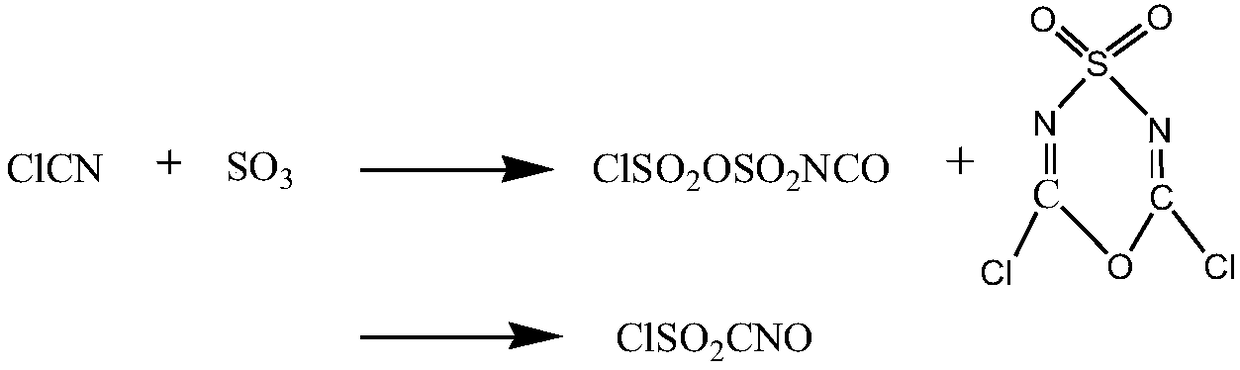

Synthesis method of high-purity chlorosulfonyl isocyanate

ActiveCN109400506AIncrease profitReduce usageSulfonic acid amide preparationPositive pressureSynthesis methods

The invention provides a synthesis method of high-purity chlorosulfonyl isocyanate. The synthesis method includes the steps that (A) under the condition of a diluent, sulfur trioxide and cyanogen chloride are subjected to sulfonation reaction to obtain a reaction solution; (B) the reaction solution is subjected to thermal decomposition reaction to obtain a reaction solution after thermal decomposition; (C) the reaction solution after thermal decomposition is subjected to positive pressure continuous distillation to obtain the high-purity chlorosulfonyl isocyanate and a distillate before distillation; and the diluent is selected from the chlorosulfonyl isocyanate or the distillate before distillation. According to the synthesis method of the high-purity chlorosulfonyl isocyanate, the totalyield of the process is increased; the distillate before distillation is used as a reaction solvent, use of a high boiling point solvent is avoided, in the pyrolysis process, the cyanogen chloride andthe sulfur trioxide are partially recovered, thus the utilization rate of raw materials is increased, and the production cost is lowered; and meanwhile, the rectification process is conducted throughthe mode of positive pressure distillation and continuous feeding, the yield of products is greatly increased, the distillation time is shortened, energy consumption and labor costs are lowered, andthe synthesis method of the high-purity chlorosulfonyl isocyanate is suitable for industrial mass production.

Owner:四平市精细化学品有限公司

Method for producing chlorosulfonyl isocyanate by taking cyanogen chloride and sulfur trioxide as raw materials

InactiveCN104447438AUniform and controllable residence timeEnhanced mass transferOrganic compound preparationSulfonic acid amide preparationCyanogen halideImpurity

The invention relates to a method for producing chlorosulfonyl isocyanate by taking cyanogen chloride and sulfur trioxide as raw materials, belonging to the methods for producing chlorosulfonyl isocyanate. The method comprises the following steps: feeding the raw materials into a tubular reactor at a theoretical molar ratio, enabling the raw materials to react continuously in the tubular reactor, feeding the by-products of reaction into a tubular thermal decomposition reactor of by-products, continuously converting the by-products of reaction to the desired product, separating the crude product, and purifying to obtain the high-purity chlorosulfonyl isocyanate. The method provided by the invention can realize the production of the chlorosulfonyl isocyanate through continuous reaction in the tubular reactor, and the method has the advantages of low investment in devices, high production efficiency and strong production capacity. The advanced production process is adopted to produce the chlorosulfonyl isocyanate, a few by-products are generated during reaction in the tubular reactor, and the by-products can be completely converted into the target product through thermal decomposition reaction. No by-product is sent out of the bound in addition to the impurities involved into the raw materials in the production process, the utilization rate of the raw materials is high, the product has high quality, the production process is stable, and the method is easy to operate and has large operating flexibility.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

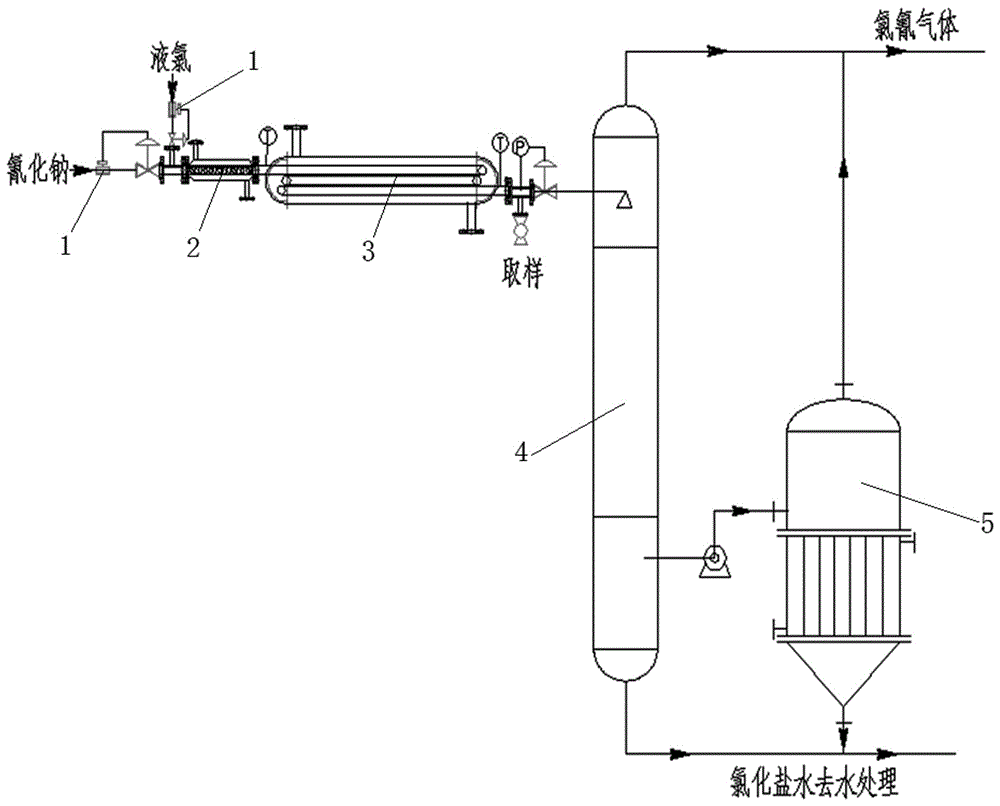

Method for producing cyanogen chloride by using tubular reactor

InactiveCN106395861AReduce investmentIncrease productivityCyanogen halogenidesDesorptionReaction temperature

The invention relates to the technical field of the synthesis of fine chemical intermediates, particularly relates to the technical field of the production of cyanogen chloride, and discloses a method for producing the cyanogen chloride by using a tubular reactor. The method comprises the following steps of mixing liquid chlorine with a sodium cyanide aqueous solution according to the mole ratio of sodium cyanide to the liquid chlorine, which is 1 to (0.9 to 1.2), controlling the temperature of obtained mixed liquor to be 20 to 50 DEG C, afterwards, introducing the mixed liquor into the tubular reactor to react, controlling the pressure of the tubular reactor to be 0.1MPa to 2.0MPa, and controlling reaction temperature to be 20 to 60 DEG C, wherein the residence time of the reaction is 10s to 600s; discharging material liquid after the completion of the reaction into a desorption tower from the tail end of the tubular reactor, and controlling the temperature of the desorption tower to be 20 to 60 DEG C, so as to obtain a pure cyanogen chloride gas through desorption and drying. By using the method provided by the invention, the production efficiency can be improved; the method has the advantages that the production yield is high and further the reactor is simple.

Owner:HEBEI LINGANG CHEM

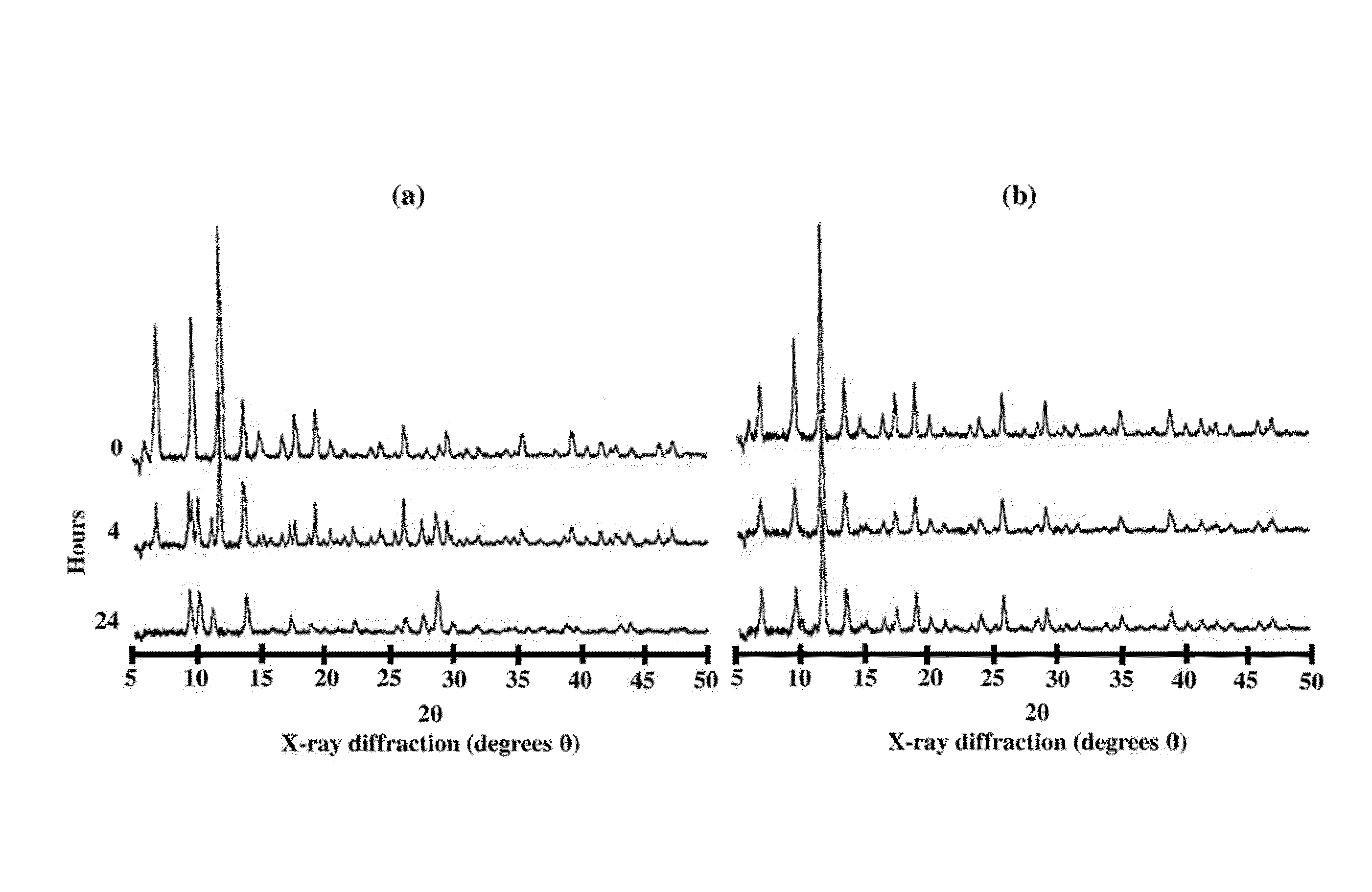

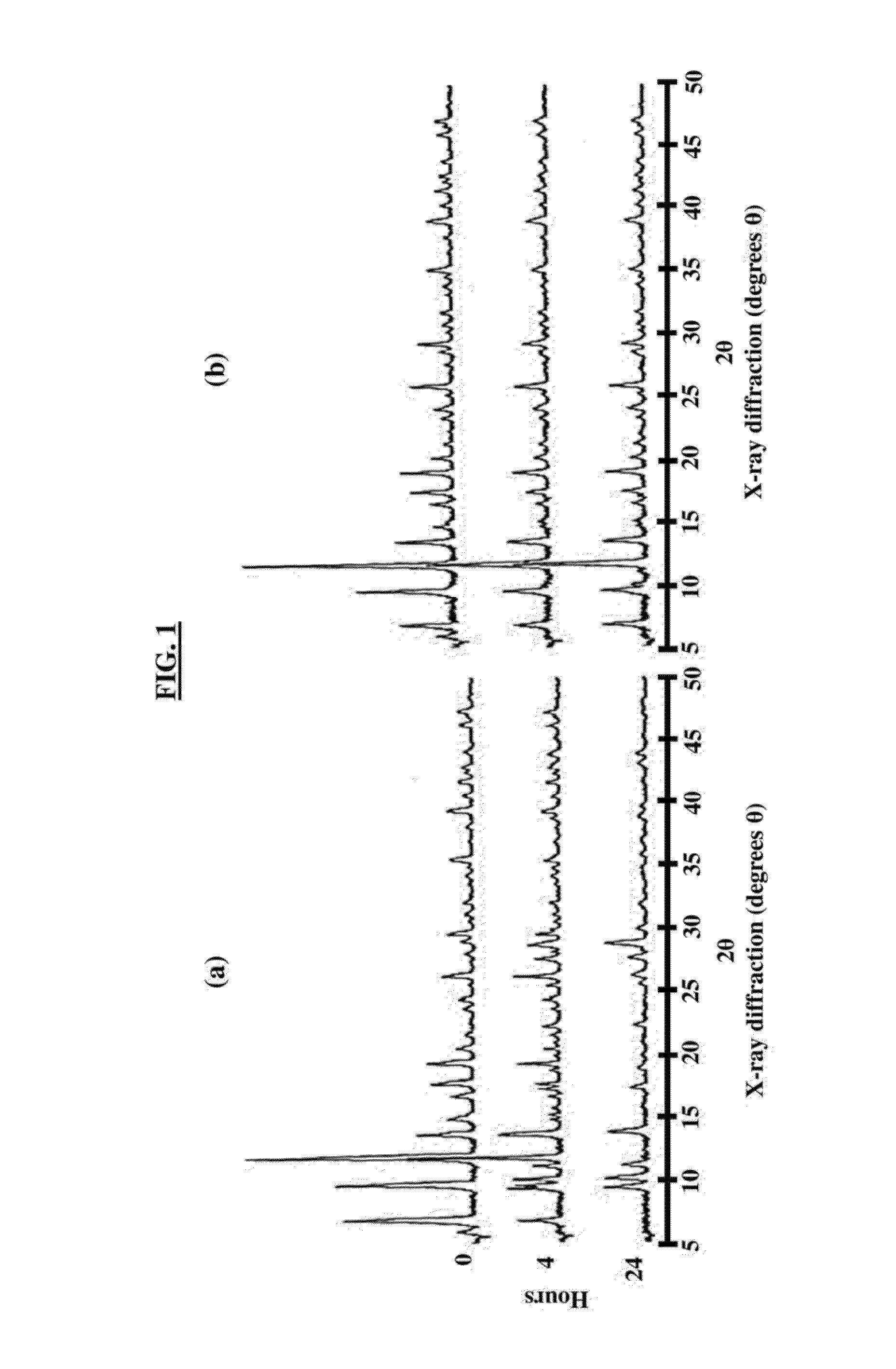

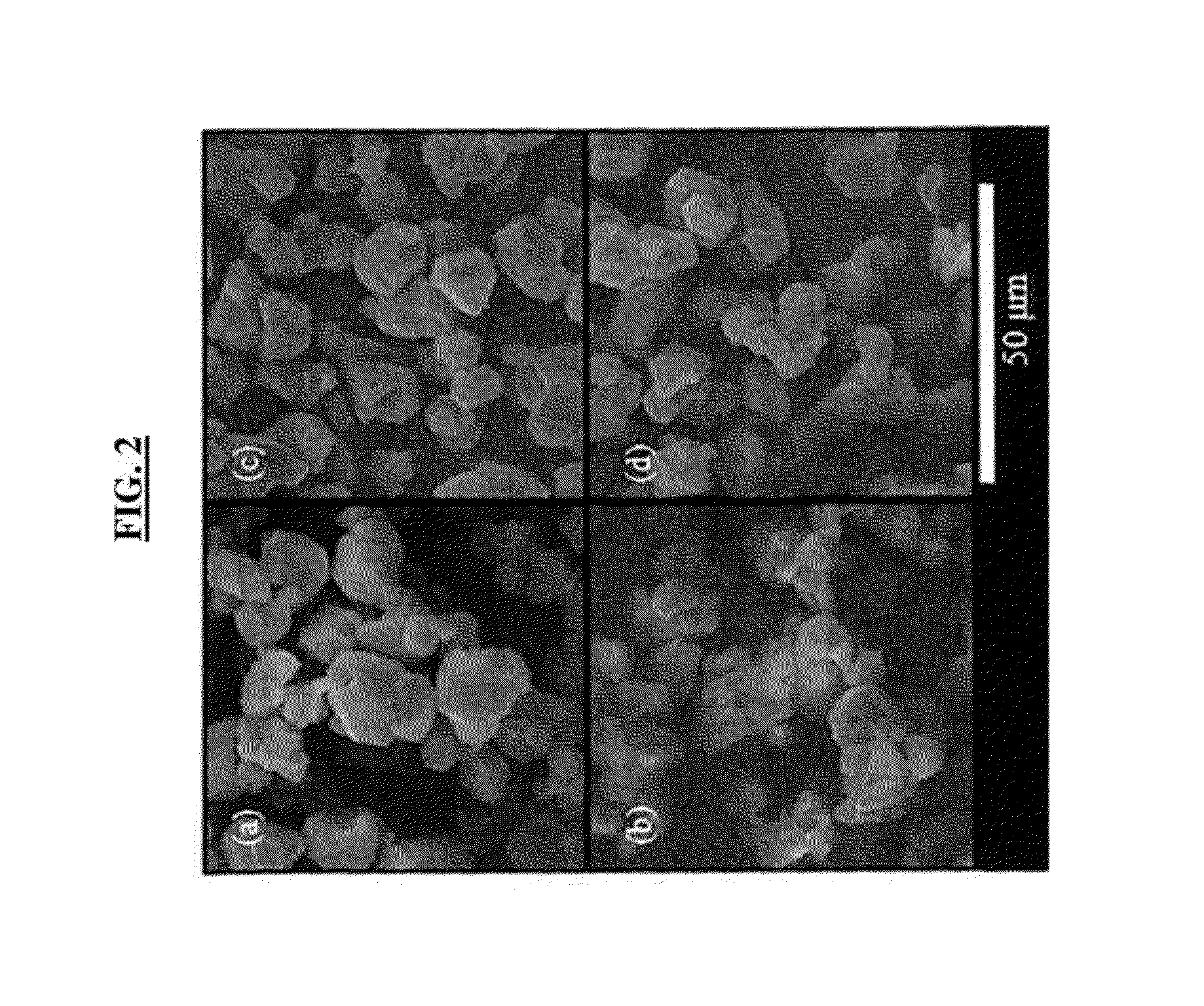

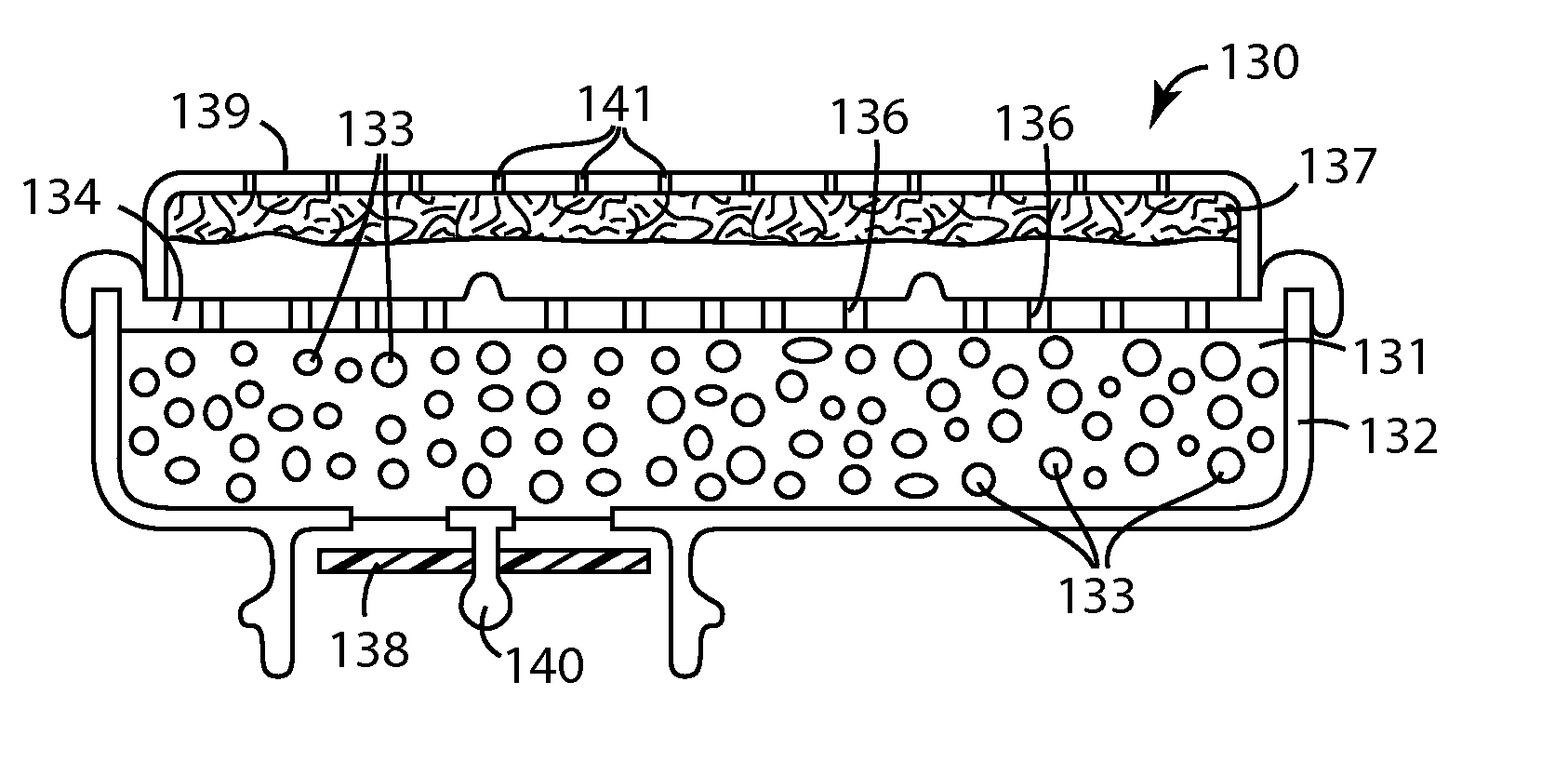

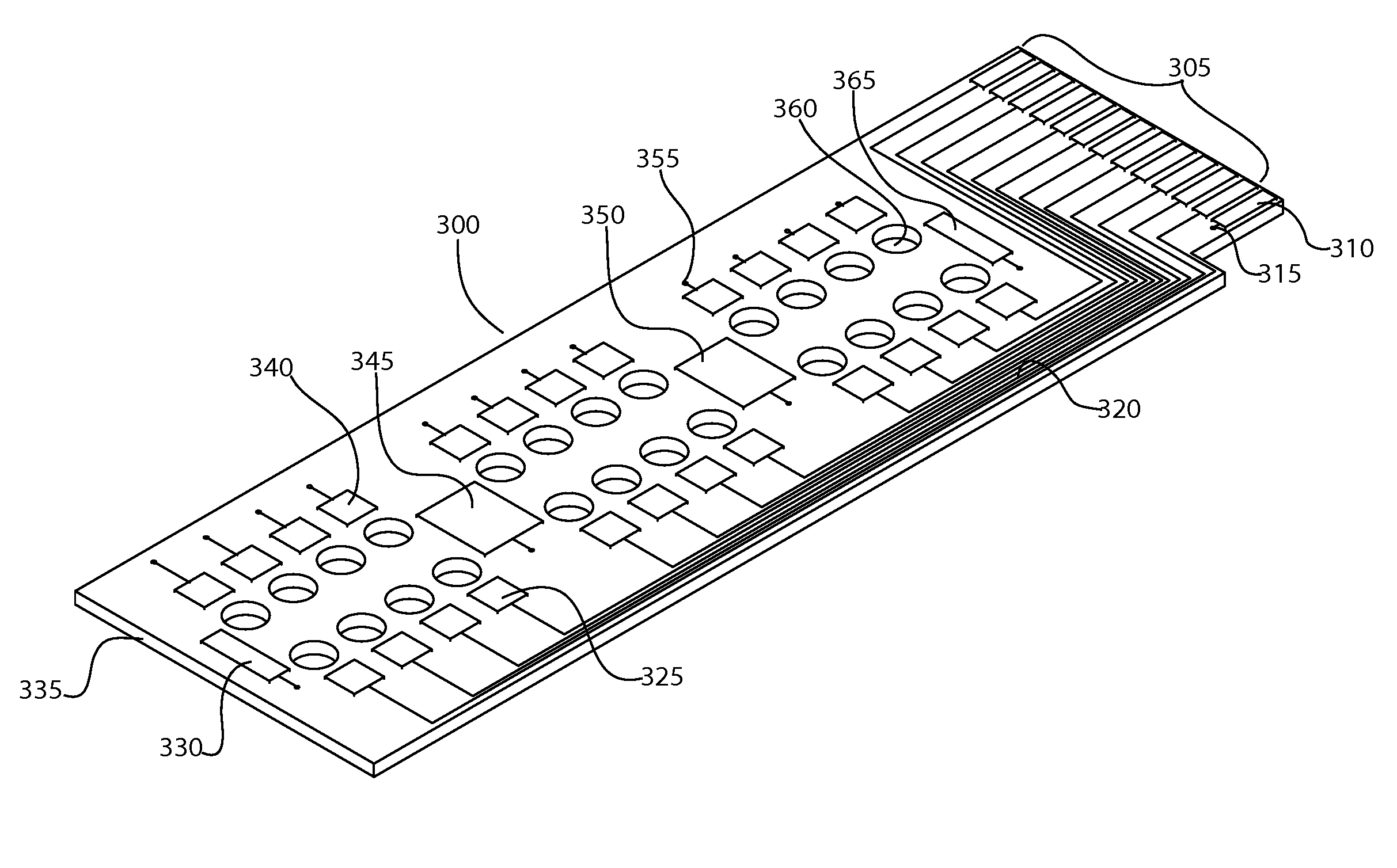

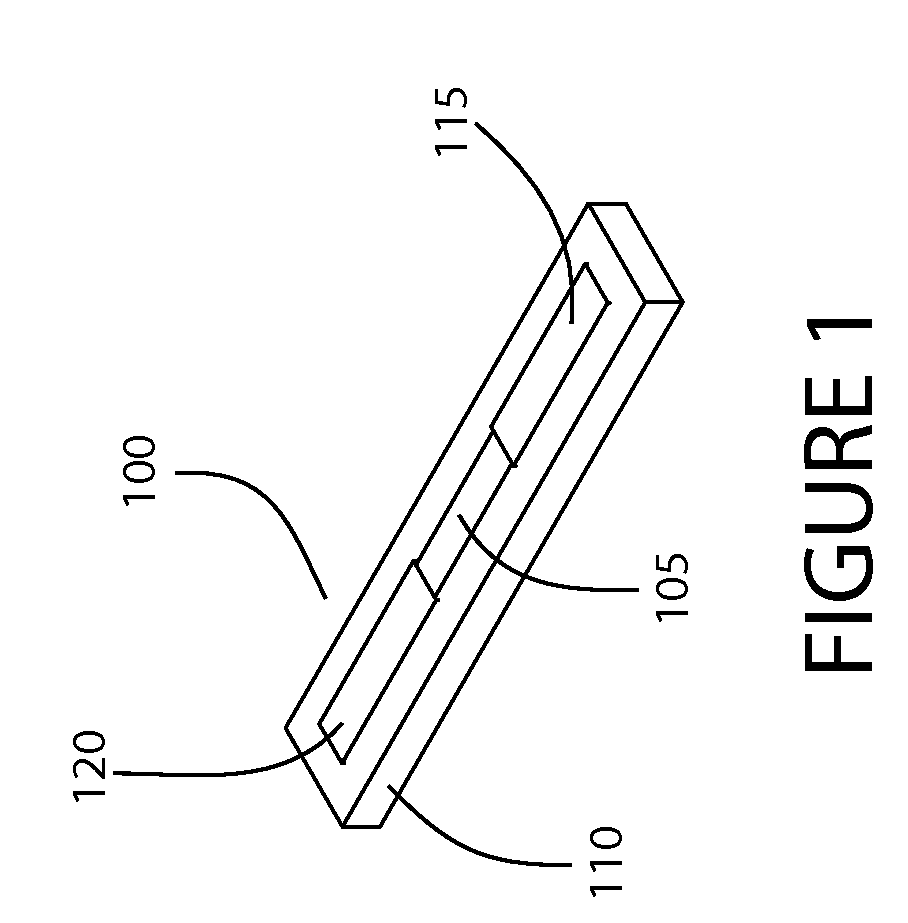

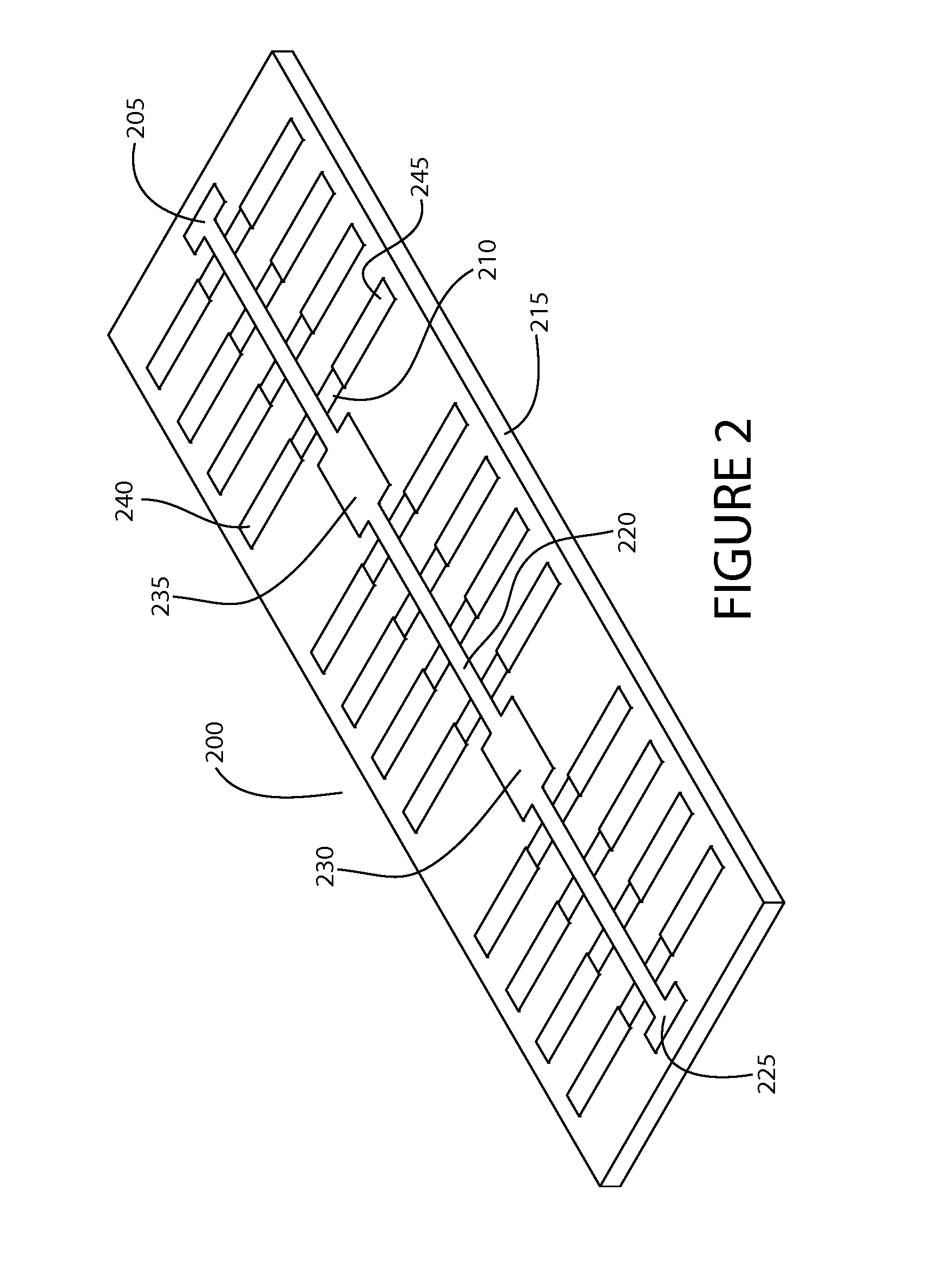

Nanocrystalline indium tin oxide sensors and arrays

ActiveUS20100279425A1Material thermal conductivityBiological testingSensor arrayMethyl thiophosphate

A sensor for sensing gaseous chemicals includes a substrate, a variable resistance nanocrystalline ITO thin film formed on the substrate, and electrodes electrically coupled to the thin film. A sensor array assembly includes a sensor slide and a perforated interface circuit. The interface circuit abuts and electrically couples the sensor slide. The sensor slide includes several spaced apart ITO film strips formed on a slide substrate. A common electrode is electrically coupled to a common portion of each ITO film strip providing an electrically conductive path across the common portions of each of the plurality of spaced apart ITO film strips. A discrete electrode is electrically coupled to a discrete portion of each ITO film strip. The interface circuit is configured to abut and electrically couple to the sensor slide. A conductive discrete electrode pad electrically couples each of the plurality of discrete electrodes of the sensor slide to discrete terminals on the interface circuit. A conductive common electrode pad is associated with and electrically couples the common electrode of the sensor slide to a common electrode on the interface circuit. Apertures in the interface circuit expose the thin film to the environment. Resistance changes in a detectible manner upon exposure to sensible chemicals at ambient temperature, such as 1,2,2-Trimethylpropyl methylphosphonofluoridate (soman, GD), O-Ethyl S-(2-isopropylaminoethyl) methylphosphonothiolate (VX), distilled bis(2-chloroethyl) sulfide (mustard, HD), carbonyl chloride, Phosgene (CG) and cyanogen chloride (CK), ozone, carbon monoxide, carbon dioxide, acetylene, propane, ammonia, sulfur dioxide, ethanol, methanol, volatile organic compounds and industrial toxic chemicals.

Owner:NORTH FLORIDA UNIV OF

Process for preparing phenol addition compound cyanate of dicyclopentadiene

InactiveCN1569822AImprove qualityLow dielectric constantOrganic chemistryDielectric lossCyanate compound

The invention discloses a process for preparing phenol addition compound cyanate of dicyclopentadiene which comprises first preparing cyanogen chloride, then further obtaining cyanate. The cyanate of dicyclopentadiene obtained has high quality, after being poured in to trimer resin, the dielectric constant is < 3, the dielectric loss is less than 0.0022.

Owner:上海慧峰化工科技有限公司

Method for Producing Chlorosulfonyl Isocyanate

ActiveUS20070286789A1Easy to controlSulfonic acid amide preparationCyanic/isocyanic acidSulfur trioxideChlorosulfonyl isocyanate

A method for producing chlorosulfonyl isocyanate by reaction of sulfur trioxide with cyanogen chloride, wherein chlorosulfonyl isocyanate or a solution including chlorosulfonyl isocyanate is used as a reaction solvent, sulfur trioxide and cyanogen chloride which are respectively diluted with the chlorosulfonyl isocyanate or the solution including chlorosulfonyl isocyanate are added at the same time to a reaction system in an almost equimolar amount under reflux. By the production method of present invention, chlorosulfonyl isocyanate can be produced from sulfur trioxide and cyanogen chloride in which the yield of the chlorosulfonyl isocyanate is high, the method has excellent operability, number of equipments is reduced, and time for controlling the temperature is saved.

Owner:NIPPON SODA CO LTD

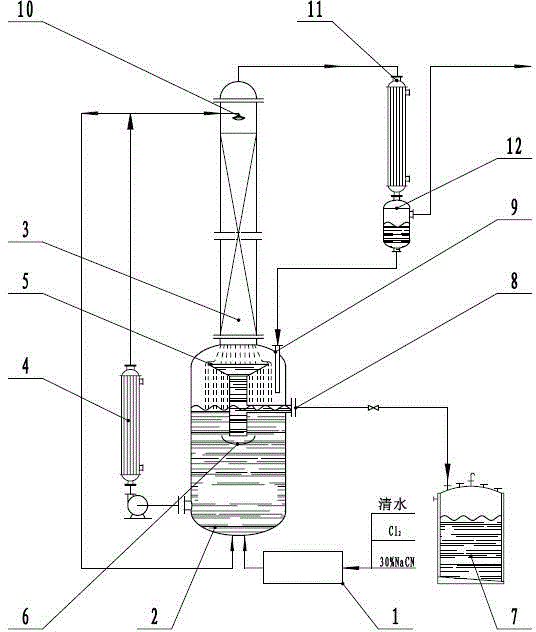

Chlorination reaction device and chlorination reaction technology for preparing cyanogen chloride

The invention provides a chlorination reaction device and a chlorination reaction technology for preparing cyanogen chloride. Chlorination reaction is carried out at a relatively low temperature in the divided three steps of pre-reaction, intermediate reaction and post-reaction. Cyanide is almost completely consumed, and the product residence time is shortened by the technology, so that unnecessary side reactions can be removed, and the raw material yield is maximized.

Owner:营创三征(营口)精细化工有限公司

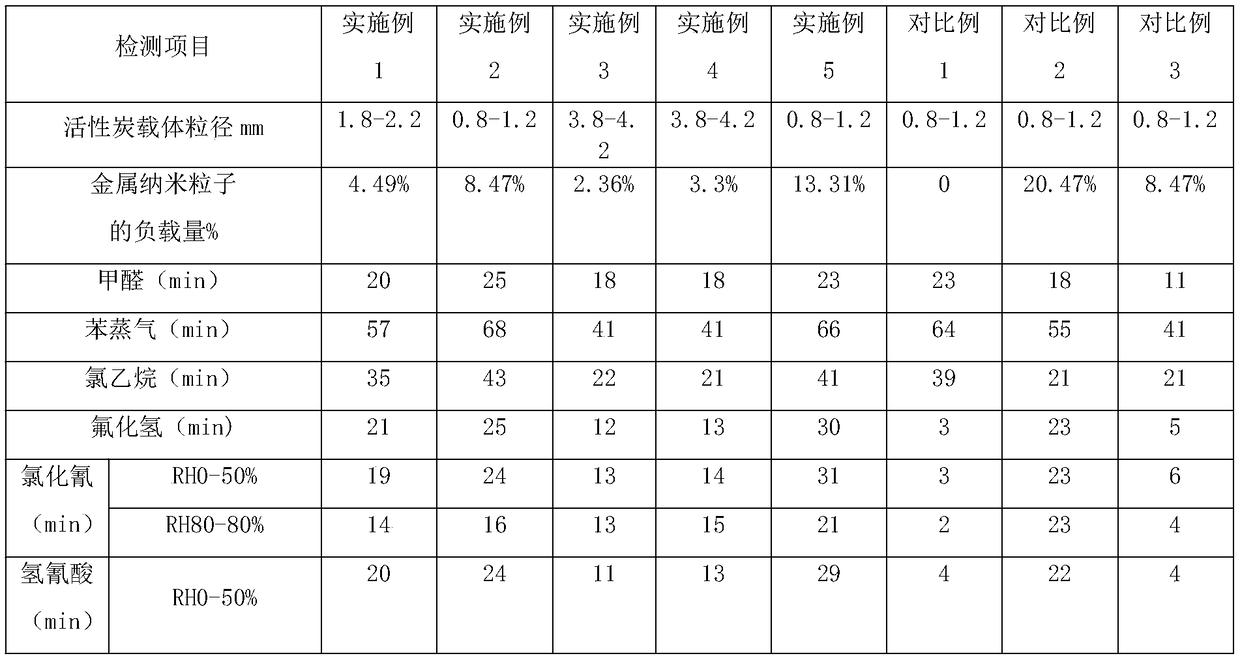

Preparation method of composite type protective material for comprehensive toxicant prevention

InactiveCN103721366AWith comprehensive filtering effectAchieve compositeChemical protectionToxicantHCN poisoning

The invention relates to a toxicant prevention material, particularly to a preparation method of a composite type protective material for comprehensive toxicant prevention. The method comprises the steps as follows: (1) the composite type protective material for the comprehensive toxicant prevention comprises activated carbon serving as a carrier and an impregnant adsorbed by the activated carbon, wherein the impregnant comprises 7%-10% (by weight) of Cu, 1%-2% (by weight) of Mo, 0.6%-3% (by weight) of an active component additive Ag, 0.4%-1% (by weight) of Zn and 5%-10% (by weight) of a multi-amine compound TEDA (triethylene diamine); the content of basic cupric carbonate, ammonium molybdate, silver nitrate and zinc carbonate of the impregnant of active components are calculated according to the content of the active components such as the Cu, the Mo, the Ag and the Zn respectively. The method is reasonable in design, and the composite type protective material capable of effectively protecting against various toxicants such as classic toxicants of HCN (hydrogen cyanide) and CNCL (cyanogen chloride), a penetrating toxicant of perfluoroisobutylene and the like, is developed.

Owner:SHANXI XINHUA CHEM

Method for purifying waste gases produced during the production of cyanuric chloride

InactiveCN101455937AReduce the burden onReduce technical complexityOrganic chemistryDispersed particle separationExhaust gasCyanogen chloride

The invention relates to a method for purifying waste gases produced during the production of cyanuric chloride. In the first step, the waste gas is treated with a weak alkaline, aqueous solution that contains hypochlorite and is treated, in the second step, with a strongly alkaline, aqueous solution. The harmful substances chlorine cyanide and chlorine are practically quantitatively bonded without it leading to a high contamination of waste water.

Owner:EVONIK DEGUSSA GMBH

Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one

ActiveCN101417951BRich sourcesReduce manufacturing costOrganic chemistrySodium bicarbonateSulfite salt

The invention discloses a preparation method of 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone, which is an intermediate for the synthesis of antiviral medicine carbonyl ring nucleoside, which is characterized in that, an aqueous solution prepared by anhydrous sodium sulfite and sodium bicarbonate is added to a reactor; the temperature is controlled between 0 to 60 DEG C; a fixed amount of methanesulfonyl chloride is added by dropping, and the temperature is maintained to react for 2 to 4 hours to prepare methyl sulfonate solution; a fixed amount of ether solvent is added to the solution, and under a temperature ranging from 10 to 60 DEG C, cyanogens chloride is added; after 4 to 6 hours reaction, cyclopentadienyl is added by dropping; the pH value of the reaction solution is controlled between 1.5 to 3 to react for 3 to 5 hours; then sodium hydroxide is used for regulating the pH value to 7 to 9; after standing, the ether solvent is separated, and a fixed amount of methyl chloride is used for separated extraction 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone; the methyl chloride is distilled and a crude product is obtained; the crude product is decolorized by activated carbon and recrystallized in ether solvent; 2-azabicyclo(2.2.1)hept-5-alkene-3-ketone with a purity of more than 99.6 percent is obtained after drying. The preparation method has the advantages of rich raw material sources, low cost, simple technological process, small emission of three wastes, benefits for industrial production and other advantages.

Owner:JILIN PURUITE BIOTECH CO LTD

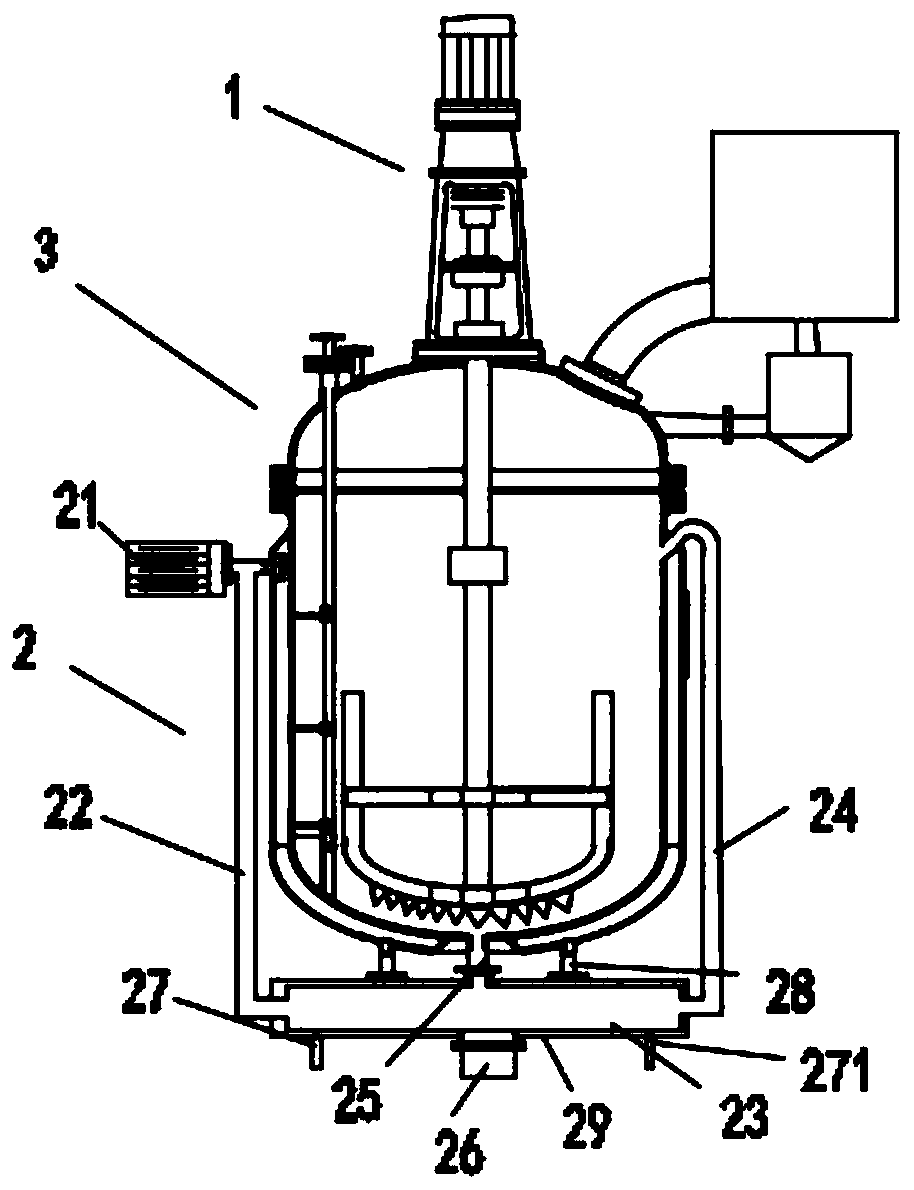

Esterification process of cyanate ester resin

ActiveCN110227401AQuality damageAvoid damageProcess control/regulationChemical/physical/physico-chemical stationary reactorsWater bathsEthylamine

The invention discloses an esterification process of cyanate ester resin. The process comprises the following steps: step S1, weighing the following raw materials in parts by weight: 10-15 parts of diphenolyl propane, 0.5-1.0 part of triethylamine, 35-50 parts of acetone, 25-35 parts of absolute ethanol, and 20-30 parts of cyanogen chloride; step S2, adding diphenolyl propane and triethylamine toa beaker containing acetone, performing heating in a 45 DEG C water bath, performing stirring for 45 min at a rotation speed of 100 r / min, performing taking out, and performing standing for 30 min toobtain a mixed liquid A; and step S3, carrying out a reaction through a reaction kettle. In the process, the reaction kettle has high heat exchange efficiency and good heat exchange effect, reaction heat can be quickly taken away, and thus occurrence of side reactions is not easy to cause. Materials can be subjected to cutting during stirring to avoid uneven reaction due to increased viscosity ofthe materials along a reaction is carried out, and heat exchange efficiency can be further improved by mixing with remaining materials after heat exchange is completed.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

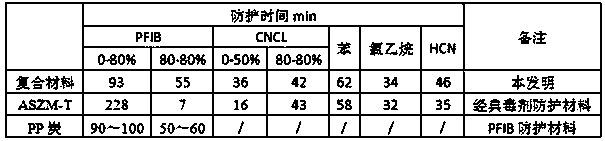

Cyanogen-containing electroplating wastewater treatment process

InactiveCN105174566ALow in cyanideSimple processing methodWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteCyanide ion

The invention provides a cyanogen-containing electroplating wastewater treatment process. The cyanogen-containing electroplating wastewater treatment process comprises the following steps that 1, the cyanogen-containing electroplating wastewater is fed into an electrolytic cell to be subjected to electrolytic cyanogen removal treatment; 2, the cyanogen-containing electroplating wastewater subjected to electrolytic cyanogen removal treatment in the electrolytic cell is fed into a wastewater reaction tank, sodium hypochlorite is added to oxidize cyanide ions in the cyanogen-containing electroplating wastewater into cyanogen chloride; 3, NaOH is added into the wastewater reaction tank, the cyanogen chloride produced in the step 2 is converted into sodium cyanate; 4, industrial dilute sulfuric acid is added into the wastewater reaction tank, the pH value of the wastewater is regulated to be 7-8; 5, sodium hypochlorite is added into the wastewater reaction tank again to convert the sodium cyanate generated in the step 3 into NaOH and NaCl; 6, the wastewater treated through the step 5 is fed into a sedimentation tank, and a flocculating agent is added into the sedimentation tank. The cyanogen-containing electroplating wastewater treatment process is simple in treatment mode, the electrolytic time is short, the content of the cyanide ions in the treated wastewater is low, and the A-level standard of Integrated Wastewater Discharge Standard (GB8978-1996) is met.

Owner:TAICANG DONGNENG ENVIRONMENTAL PROTECTION EQUIP

Cyanogen chloride preparation method

The invention discloses a cyanogen chloride preparation method, which comprises: 1, mixing sodium cyanide and water according to a certain ratio, and uniformly stirring to prepare a 30% sodium cyanidesolution; 2, respectively spraying the 30% sodium cyanide solution obtained in the step 1 and liquid chlorine into a tubular reactor at a certain feeding speed, wherein the gas outlet of the tubularreactor is connected with a condenser; 3, introducing the mixed gas obtained from the gas outlet of the condenser in the step 2 into a desorption tower, and carrying out desorption treatment; and 4, feeding the gas desorbed in the step 3 into a rectifying tower, and purifying. According to the invention, the mixing effect of the 30% sodium cyanide solution and the liquid chlorine in the tubular reactor is good, and the desorbed material liquid is rectified, so that the purity of cyanogen chloride is improved, and the content of the obtained cyanogen chloride can reach more than 97%.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

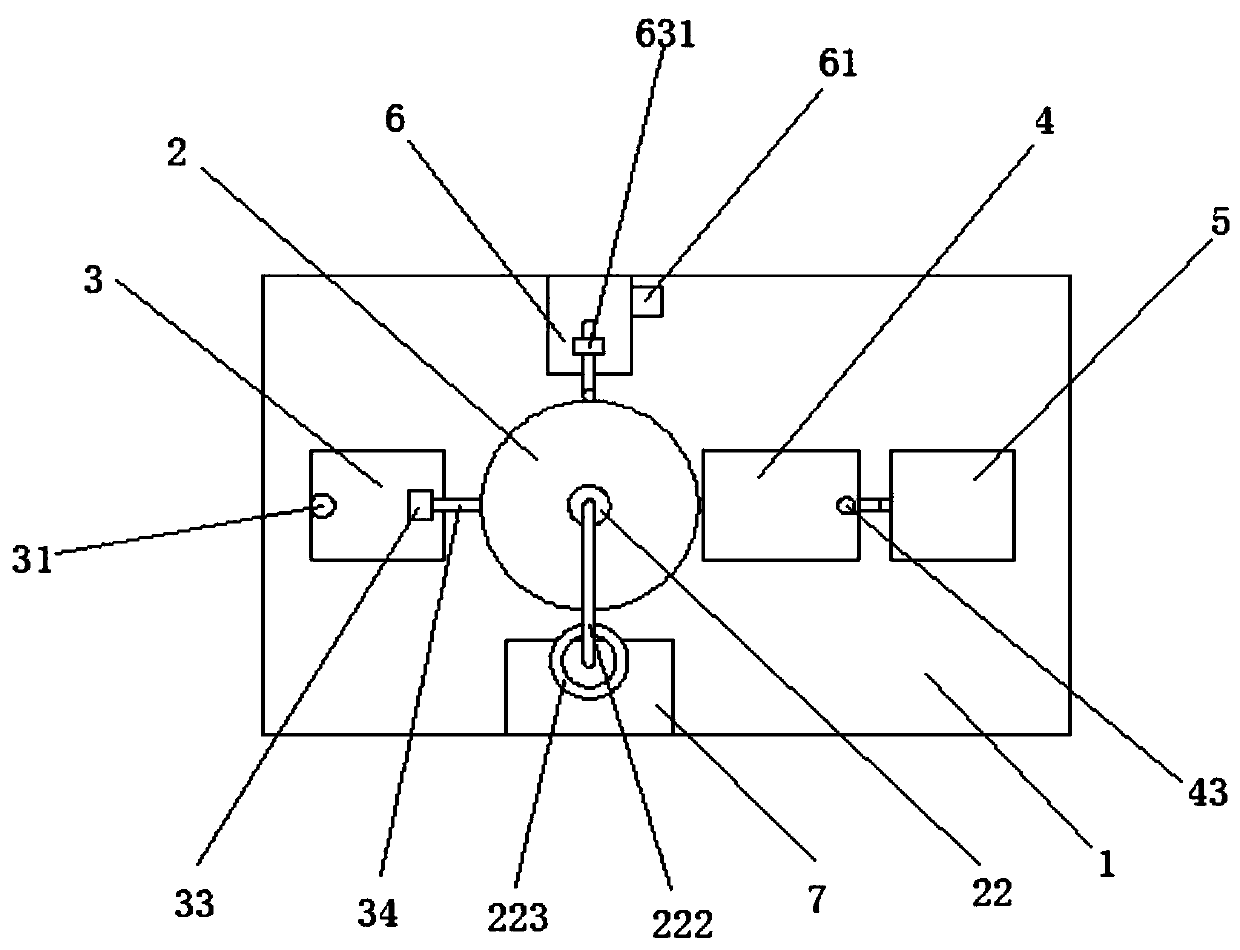

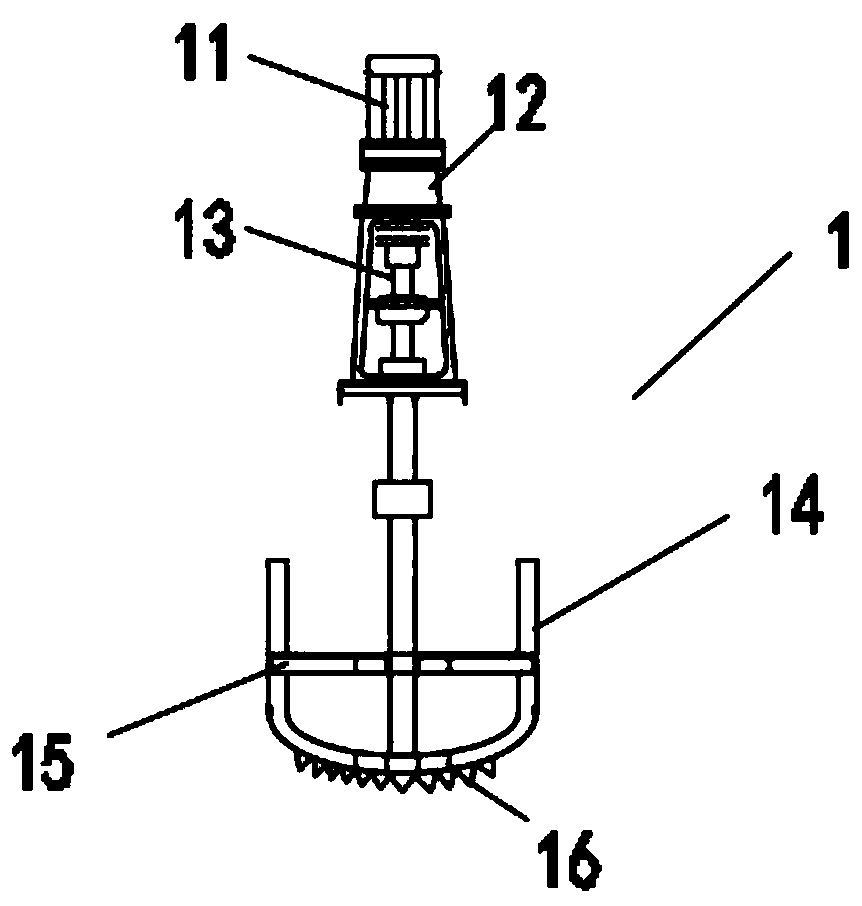

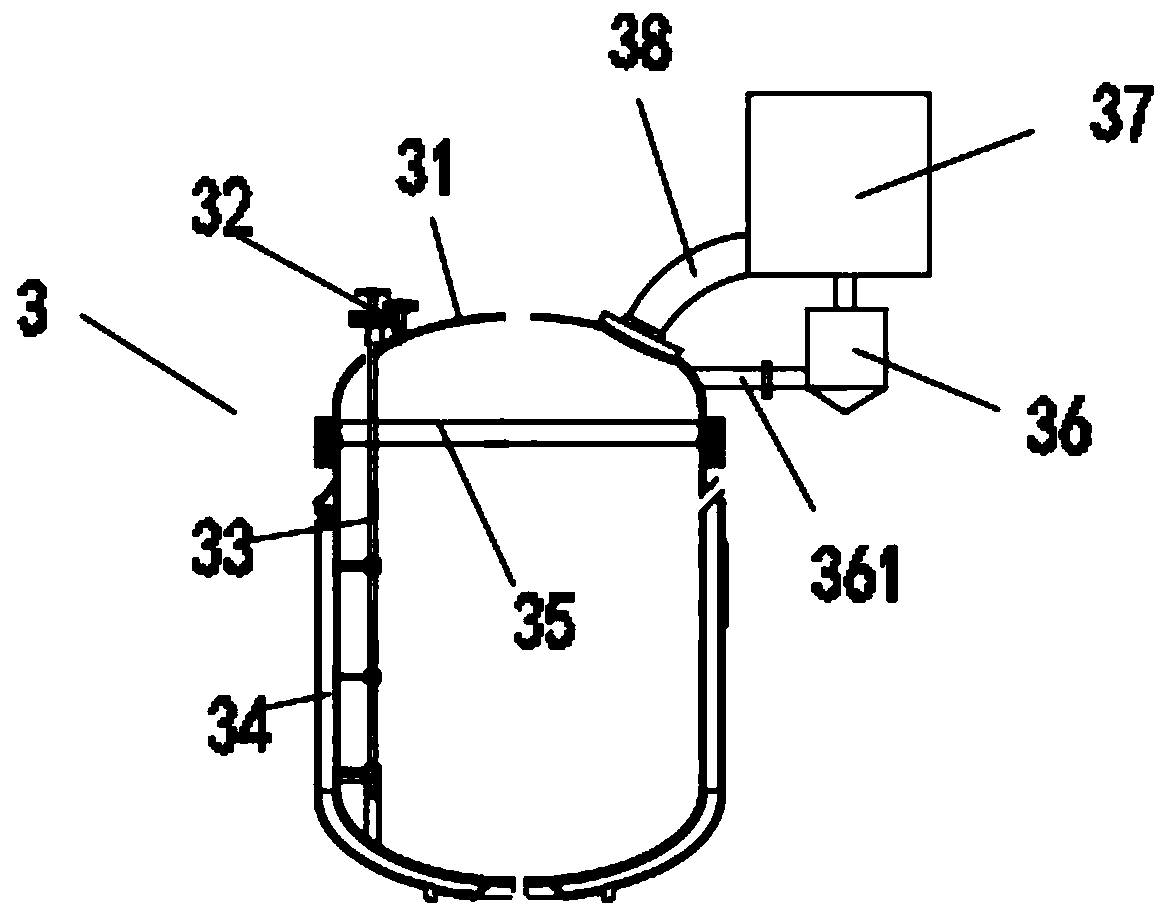

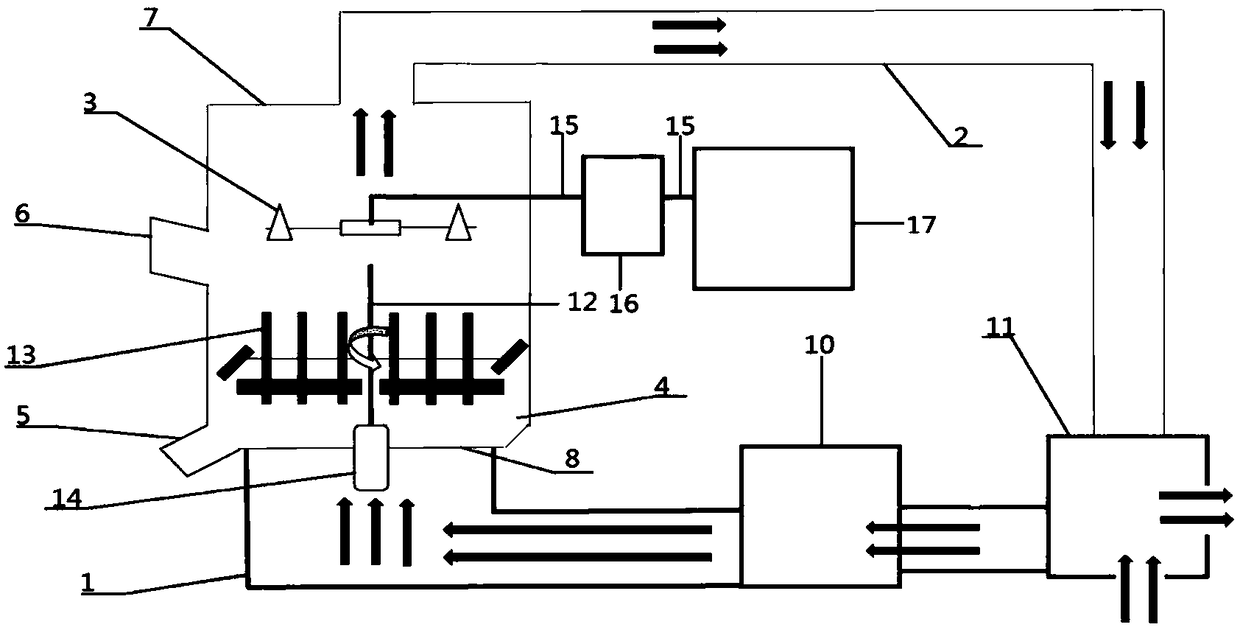

Metal nanoparticle loaded activated carbon and production equipment thereof

PendingCN109364947AReduce consumptionDry fastDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBenzene vaporActivated carbon

The invention discloses metal nanoparticle loaded activated carbon. According to the metal nanoparticle loaded active carbon, metal nanoparticle dispersion liquid and an activated carbon carrier are fully mixed and then are put into high-temperature airflow to be dried so as to obtain the metal nanoparticle loaded activated carbon, the loading capacity of metal nanoparticles is 2-14% of the mass of the activated carbon carrier, and the mass of the metal nanoparticle dispersion liquid is 48-70% of the mass of the activated carbon carrier. The invention further discloses related production equipment used for the metal nanoparticle loaded activated carbon and a preparation method for the metal nanoparticle loaded activated carbon. The metal nanoparticle loaded activated carbon obtained by utilizing the preparation method for the metal nanoparticle loaded activated carbon has the advantages that the particle size distribution of the loaded metal nanoparticles is uniform, the physical adsorption performance and the chemical catalytic performance of the activated carbon are balanced and efficient, a preparation process is simple, and non-polar harmful gas such as benzene vapor, chloroethane vapor and formaldehyde and strong-polarity harmful gas such as cyanogen chloride and hydrocyanic acid can be effectively adsorbed.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

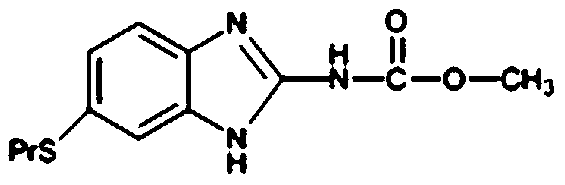

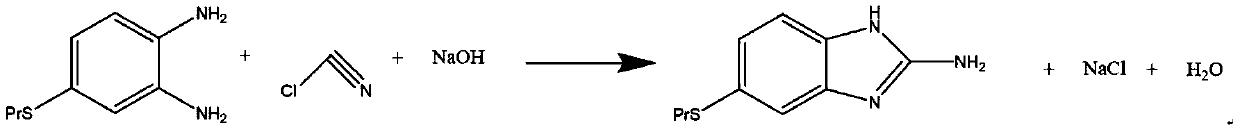

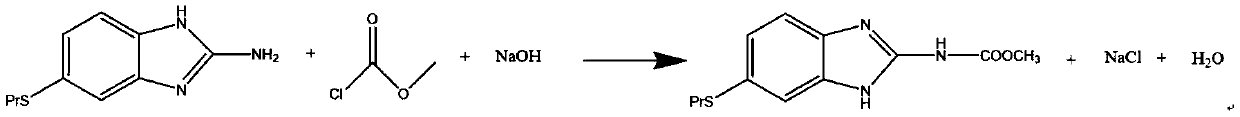

Preparation method of albendazole

The invention discloses a preparation method of albendazole, which comprises the following steps of: dissolving 4-propylthio-o-phenylenediamine in methanol, cooling, keeping the temperature at 0-5 DEGC, slowly dropwise adding cyanogen chloride for reaction under the condition of uniform stirring, and regulating and keeping the pH value at 4-5 in the process; heating to 35-45 DEG C after dropwiseadding is finished, carrying out heat preservation for 1-2 hours, then carrying out atmospheric distillation to recover methanol to obtain a solid-liquid mixed aqueous solution, and carrying out cooling, filtering and drying to obtain 6-propylthio-2-amino-1-hydrogen-benzo [d] imidazole; adding the obtained product into methanol, stirring, cooling, maintaining the temperature at 5-10 DEG C, slowlydropwise adding methyl chloroformate, and adjusting and maintaining the pH value at 6-7; after dropwise adding is finished, heating to 35-45 DEG C, keeping the temperature for 1-2 hours, distilling atnormal pressure to recover methanol, cooling to 15-20 DEG C, and performing filtering and drying to obtain an albendazole product. The method has the advantages of mild process conditions, low cost of used raw materials, water saving, strong reaction activity, good selectivity, high product yield and good product quality.

Owner:SHANDONG GUOBANG PHARMA +1

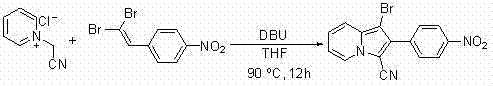

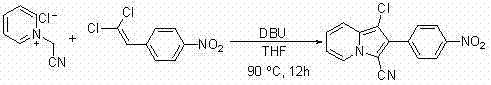

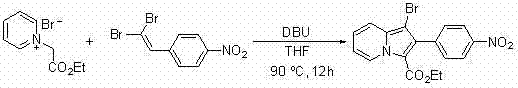

A method for synthesizing 1-halogen-2-aryl indolizine compounds

InactiveCN102295644AConvenient and effective synthesisMild reaction conditionsOrganic chemistryPyridiniumPtru catalyst

The invention relates to a method for synthesizing a 1-halo-2-aryl indolizine compound. According to the method, the 1-halo-2-aryl indolizine compound can be conveniently and effectively synthesized by using brominated N-ethyoxyl carbonyl methyl pyridinium salt (or chlorinated N-cyan methyl pyridinium salt) and 1,1-dibromo-2-arylethylene (or 1-halo-2-arylacetylene) as substrates under the action of alkali. Compared with the existing methods, the method provided by the invention has the advantages that the range of adaptable substrates is wide, reaction conditions are mild, no catalyst is needed, and reaction efficiency is high and is simple to operate, thus the method has an important application value.

Owner:TONGJI UNIV

Method for preparing (+/-)-2-azabicyclo[2, 2, 1]hepta-5-alkene-3-ketone

The invention relates to a method for preparing (+ / -)-2-azabicyclo[2, 2, 1]hepta-5-alkene-3-ketone. The method includes: using sodium sulfite and methyl sulfonyl chloride in the aqueous solution of sodium acetate to generate sodium methanesulfinate, adding fixed-quantity halogenated hydrocarbon solvent and cyclopentadiene monomer, dropwisely adding the solution formed by cyanogen chloride monomer and halogenated hydrocarbon into reaction liquid, using sodium acetate aqueous solution to regulate the pH of the reaction system so as to allow the pH to be in a specific range, and extracting, regulating pH and concentrating after the reaction to obtain the (+ / -)-2-azabicyclo[2, 2, 1]hepta-5-alkene-3-ketone with the purify not smaller than 98% and yield not smaller than 94%. The method is good in product quality, high in yield, low in raw material cost, simple in process, easy to operate, and the like, so that the method has better economic advantages and high competiveness in industrial production.

Owner:营口昌成新材料科技有限公司

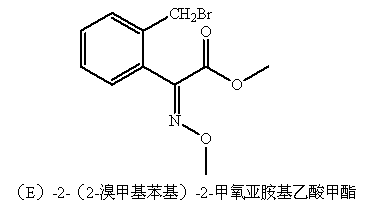

Preparation method of trifloxystrobin intermediate (E)-2-(2-bromomethyl phenyl)-2-methoxylimidomethyl acetate

The invention discloses a preparation method of a trifloxystrobin intermediate (E)-2-(2-bromomethyl phenyl)-2-methoxylimidomethyl acetate. According to the preparation method, the (E)-2-(2-bromomethyl phenyl)-2-methoxylimidomethyl acetate, which is obtained by performing chlorination, cyanation, hydrolyzation, esterification and oximation through O-methylbenzoic acid, is used as raw material; through analysis of a bromination reaction process, hydrogen bromide released in a bromination reaction process is converted to bromine by using an oxidizing agent; the bromine continuously takes part in reaction; and a synthetic process condition is optimized, so that the utilization rate of bromine atoms is improved, a content and a yield of bromide product are improved, the quality of trifloxystrobin product is improved, the discharge of bromide-containing wastewater is reduced, the corrosion to equipment and the pollution to the environment are reduced and the production cost is reduced.

Owner:JINGBO AGROCHEM TECH CO LTD

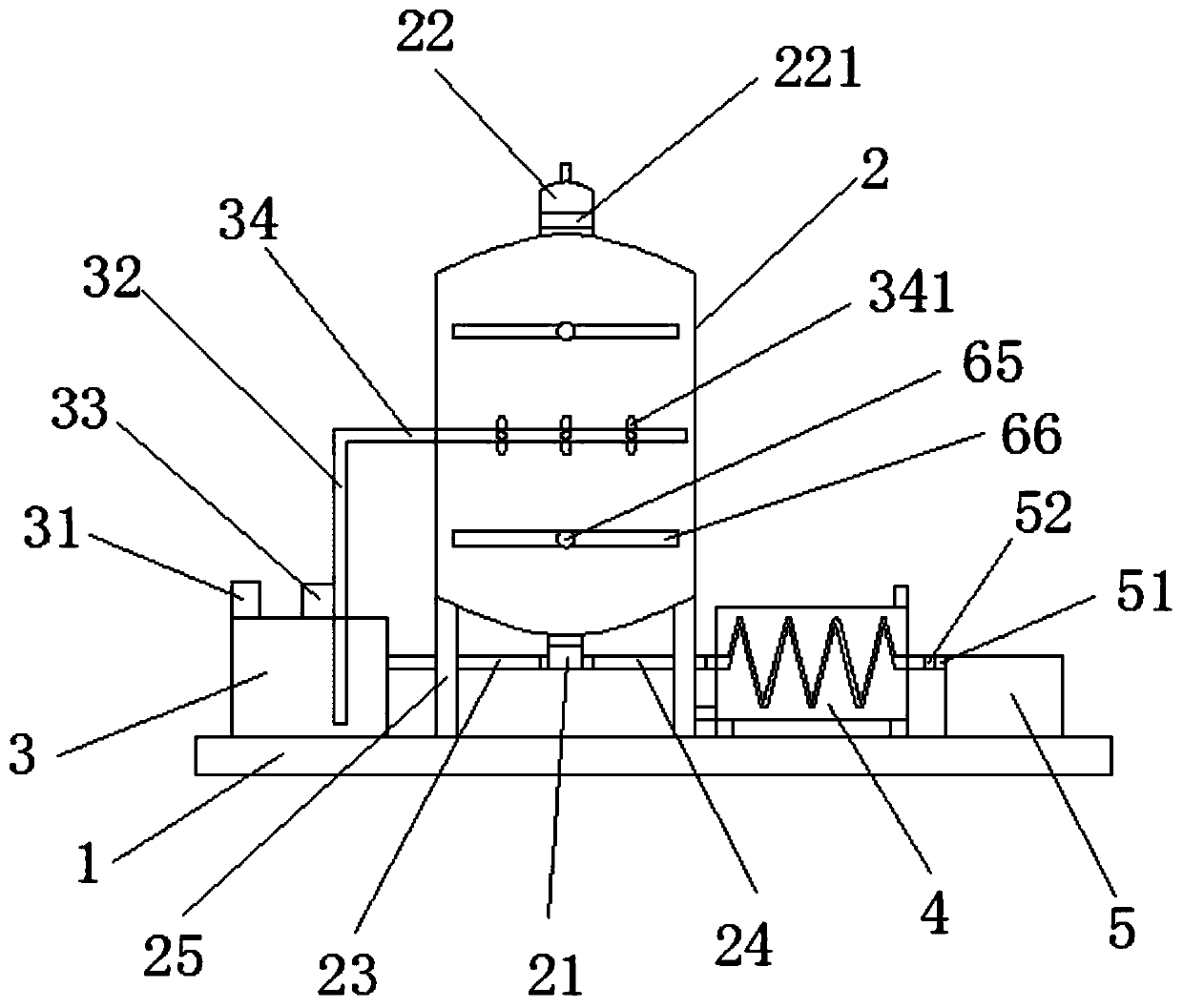

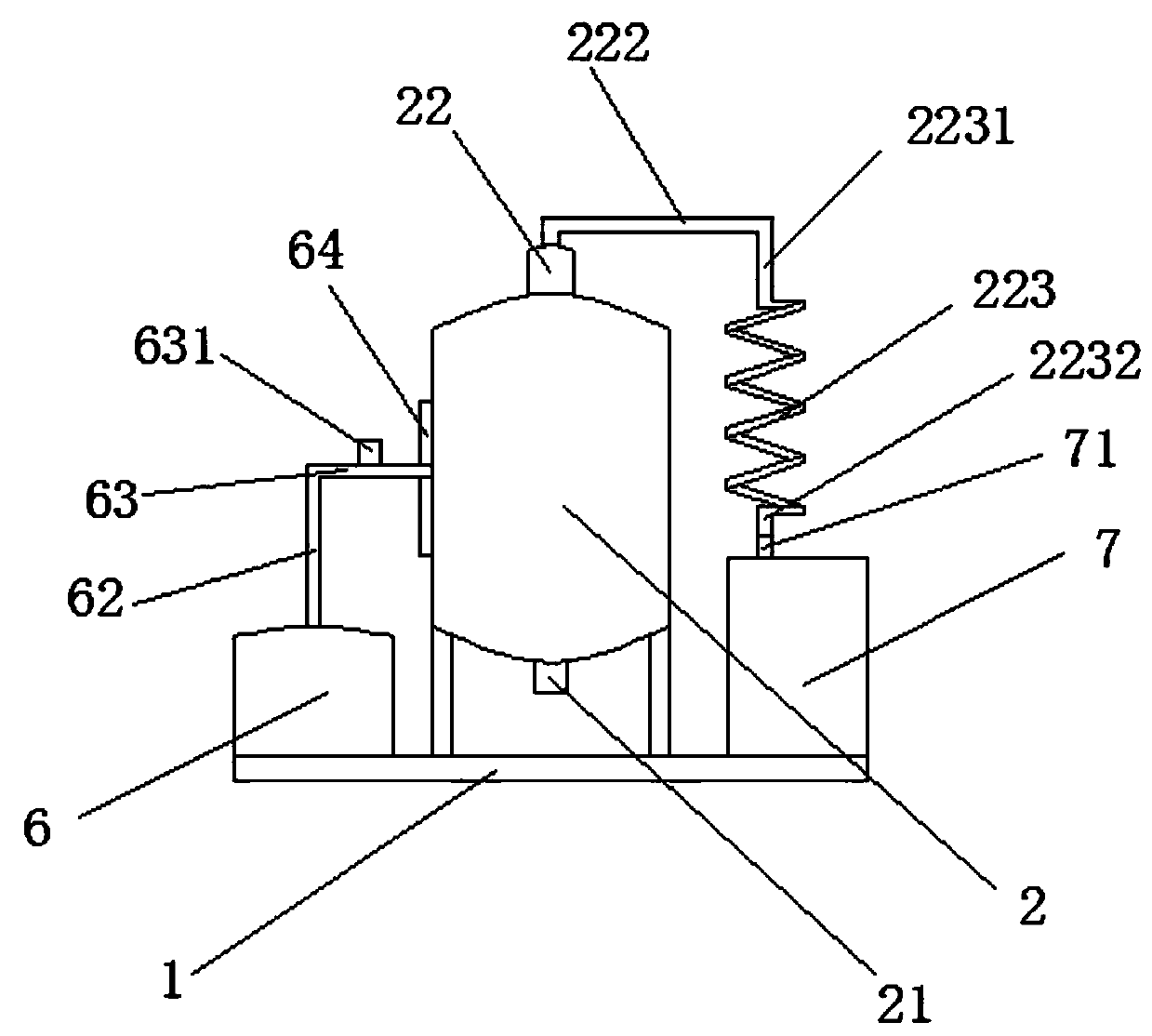

Cyanogen chloride preparation process for cyanate ester resin synthesis

ActiveCN111302360AImprove production efficiencyReduce processing difficultyCyanogen halogenidesSodium cyanideAqueous solution

The invention discloses a cyanogen chloride preparation process for cyanate ester resin synthesis. According to the process, a reactor is used in a cyanogen chloride preparation process, and comprisesa base, a reaction bin is arranged on the upper surface of the base, a discharging port is formed in the bottom end of the reaction bin, a material collecting port is formed in the top end of the reaction bin, and a first material storage bin, a condensation bin, a first material receiving bin, a second material storage bin and a second material receiving groove are further fixed to the upper surface of the base; a sodium cyanide aqueous solution in the first storage bin is pressed into a liquid spraying pipe from a liquid conveying vertical pipe through a booster pump and is sprayed out by liquid spraying heads, and the liquid spraying heads are arranged in a crossed manner, so that the sodium cyanide aqueous solution is completely atomized, and the whole reactor is filled with the sodium cyanide aqueous solution; gas spraying pipes are located on the upper side and the lower side of the liquid spraying pipe, so that chlorine can make full contact with the sodium cyanide aqueous solution when entering the reactor; and by arranging a discharge port valve and a first liquid guide valve, the unreacted sodium cyanide aqueous solution enters the reaction bin again, so that the sodiumcyanide aqueous solution and the chlorine react sufficiently.

Owner:YANGZHOU TECHIA MATERIAL CO LTD

Method for producing chlorosulfonyl isocyanate

ActiveUS7468174B2Easy to controlNitrosyl chlorideSulfonic acid amide preparationChlorosulfonyl isocyanateSulfur trioxide

Owner:NIPPON SODA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212c00021.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212c00031.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/112b2583-6a73-484f-a31c-39a0c3939d47/a200710056212d00061.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121C00011.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121C00021.PNG)

![Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one Method for preparing 2-azabicyclo[2.2.1]heptyl-5-ene-3-one](https://images-eureka.patsnap.com/patent_img/760f75f2-2d75-4f94-a716-ef866d0cbcfd/S2007100562121D00031.PNG)

![Method for preparing (+/-)-2-azabicyclo[2, 2, 1]hepta-5-alkene-3-ketone Method for preparing (+/-)-2-azabicyclo[2, 2, 1]hepta-5-alkene-3-ketone](https://images-eureka.patsnap.com/patent_img/4715ce15-4f3e-47b0-9083-5bd0cde70fb9/BSA0000132215480000021.PNG)