Patents

Literature

34 results about "Benzene vapor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Benzene is a chemical that is a colorless or light yellow liquid at room temperature. It has a sweet odor and is highly flammable. Benzene evaporates into the air very quickly. Its vapor is heavier than air and may sink into low-lying areas. Benzene dissolves only slightly in water and will float on top of water.

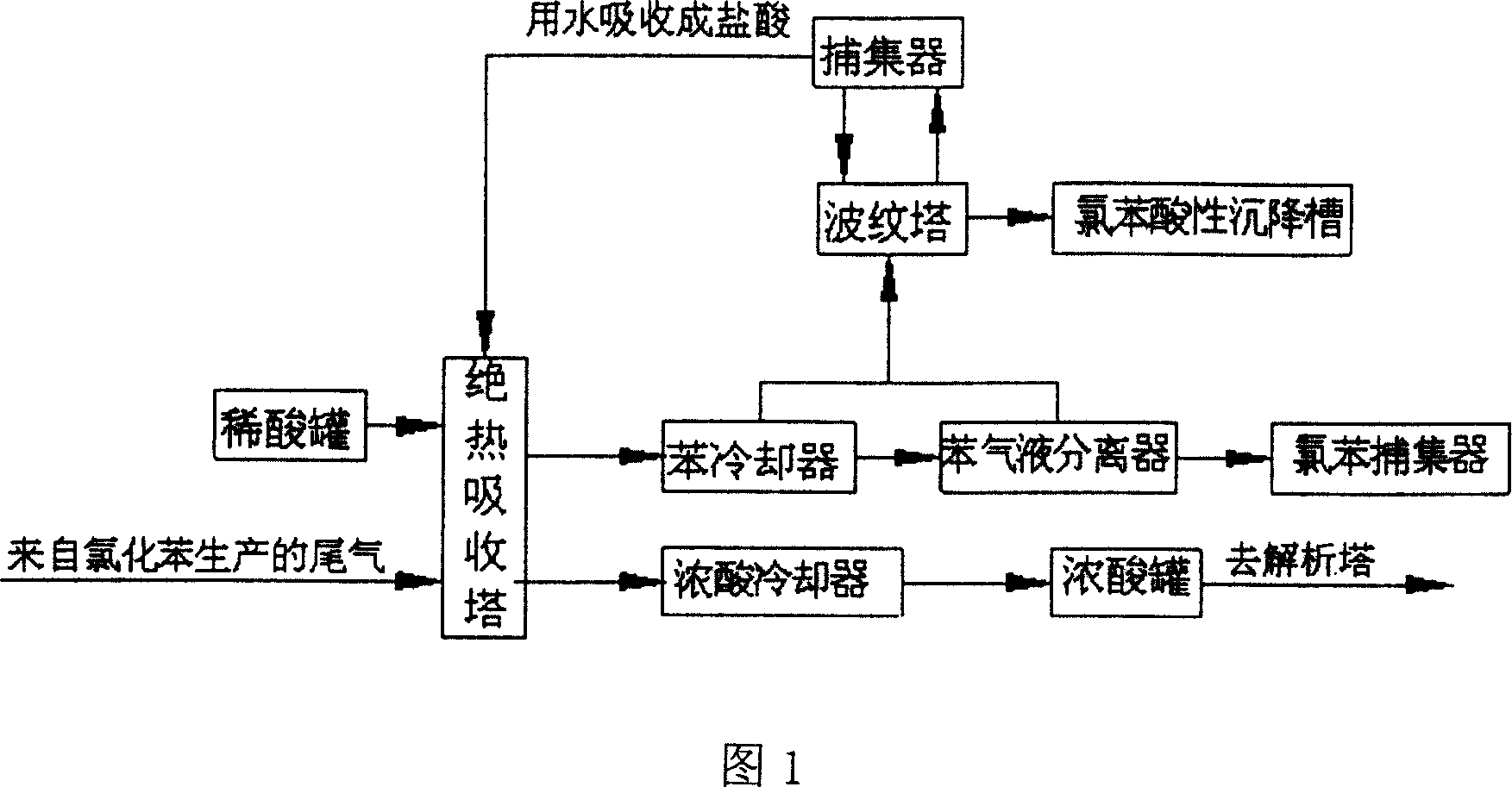

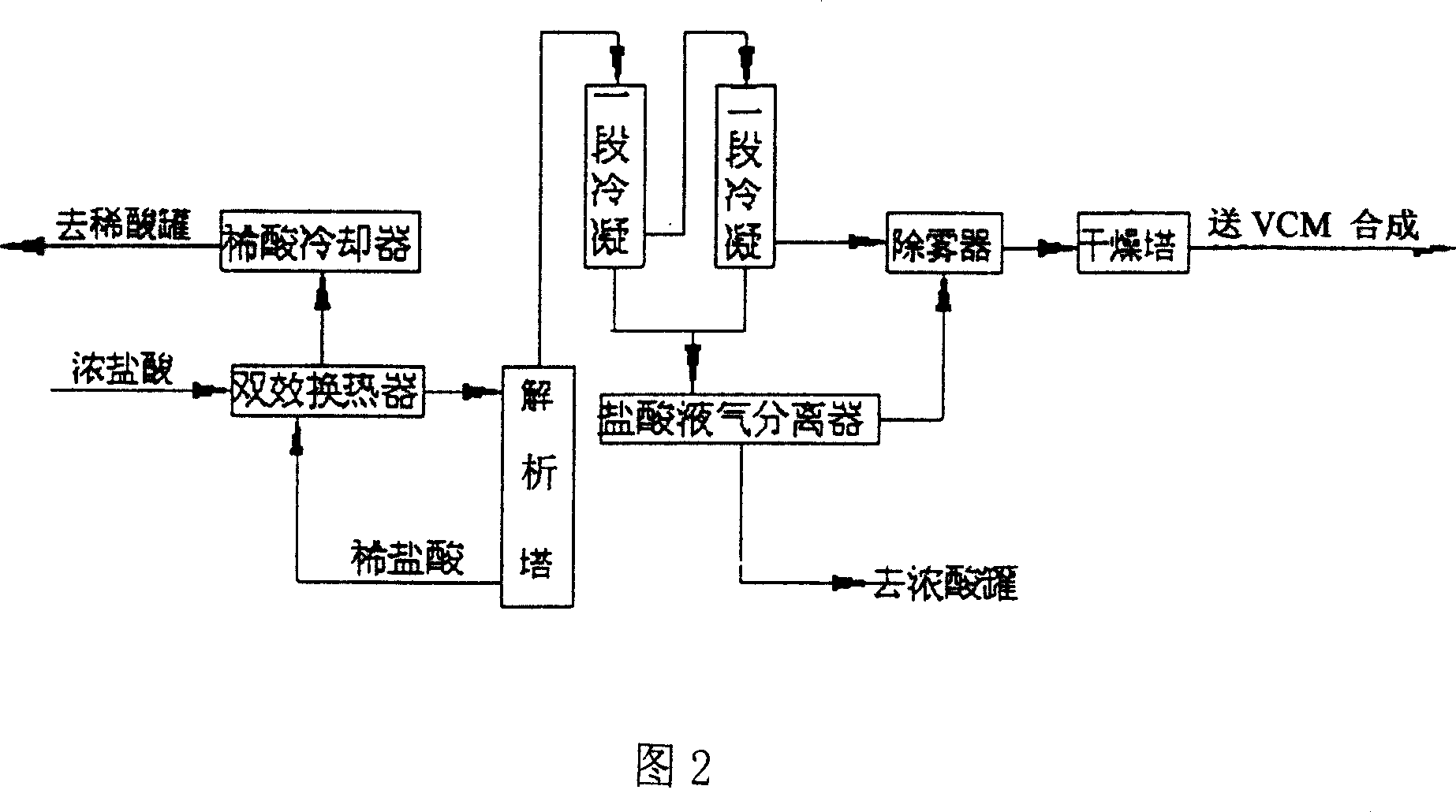

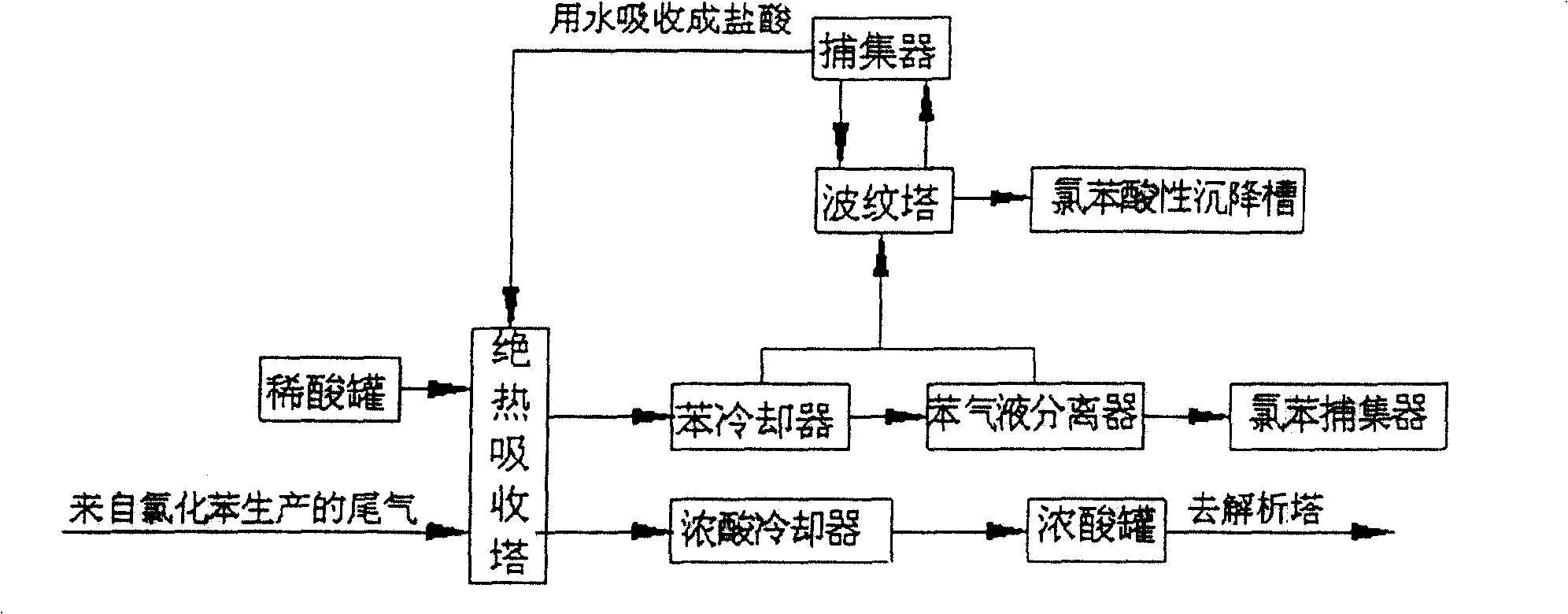

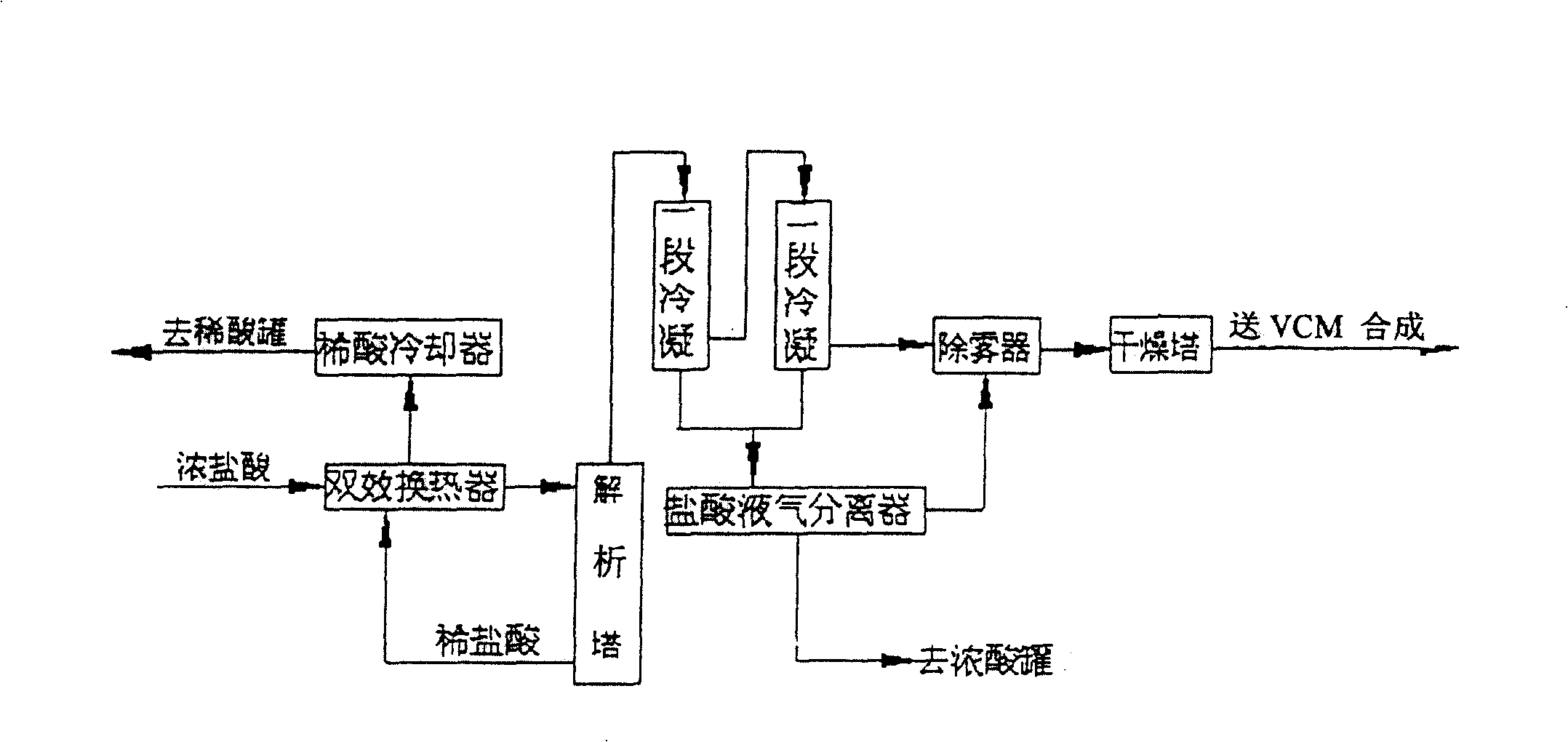

Method for reclamation and cyclic utilization of tail gas containing benzene and hydrogenchloride in chlorobenzene production

InactiveCN101077466AImprove analytical abilityGood effectDispersed particle separationVapor condensationBenzene vaporDesorption

The present invention is process of recovering benzene and hydrogen chloride from tail gas for reuse in benzene chloride production, and belongs to the field of chemical production effluent recovering and utilizing technology. The present invention is one absorption-desorption process, which includes the absorption of hydrogen chloride from the tail gas in an absorption tower at the temperature higher than the boiling temperature of benzene, 80.1 deg.c, with sprayed water or diluted hydrochloric acid to form concentrated hydrochloric acid, and the recovering of benzene from benzene vapor for reuse; and the desorption of concentrated hydrochloric acid in a desorption tower to obtain dry pure hydrogen chloride gas for reuse. The absorption-desorption process can recover benzene and hydrogen chloride from tail gas completely for reuse, and has saving of resource and environment friendship.

Owner:武汉祥龙电业股份有限公司

Fine purification system and method for carbonization crude benzol

InactiveCN101270027ALess investmentReduce energy consumptionDistillation purification/separationBenzene vaporReboiler

The present invention relates to a refining system of coked crude benzole and a refining method thereof. The basic equipment consists of two benzene towers, a primary tower, a first pure benzene tower, a second pure benzene tower, a toluene tower and a xylene tower. The heat of the reboiler of the primary tower comes from toluene vapor on the top of the toluene tower; the heat of the reboiler of the first pure benzene tower comes from the pure benzene vapor on the top of the second pure benzene tower. The refining method comprises pre-distillation, refining of the pure benzene and separation of the toluene and the xylene. The method not only saves energy but also reduces the cost of investment. The process is simplified. Compared with the traditional sulfuric acid washing process, the method eliminates the acid-alkali washing and benzene blowing processes. The whole process generates no waste acid, acid residue, caustic dross or waste water, which can cause serious damage to the environment. Compared with the catalytic hydrogenation, the method has the advantages of simplifying the process, lowering the energy consumption, reducing the cost of investment and production, and improving the benefit of production, and thus being an excellent method for steel enterprises and coking enterprises to further process and make use of by-products.

Owner:天津凯赛特科技有限公司

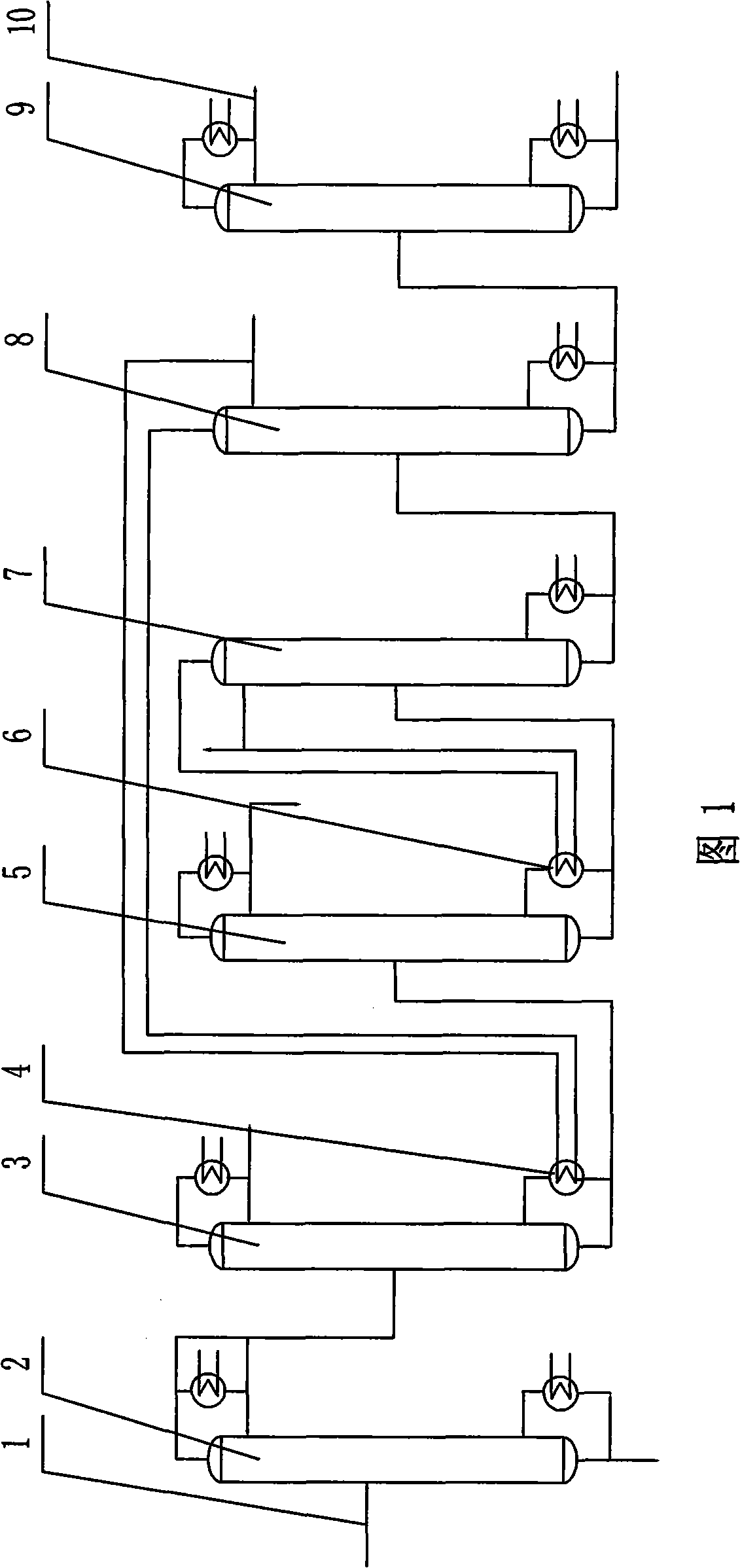

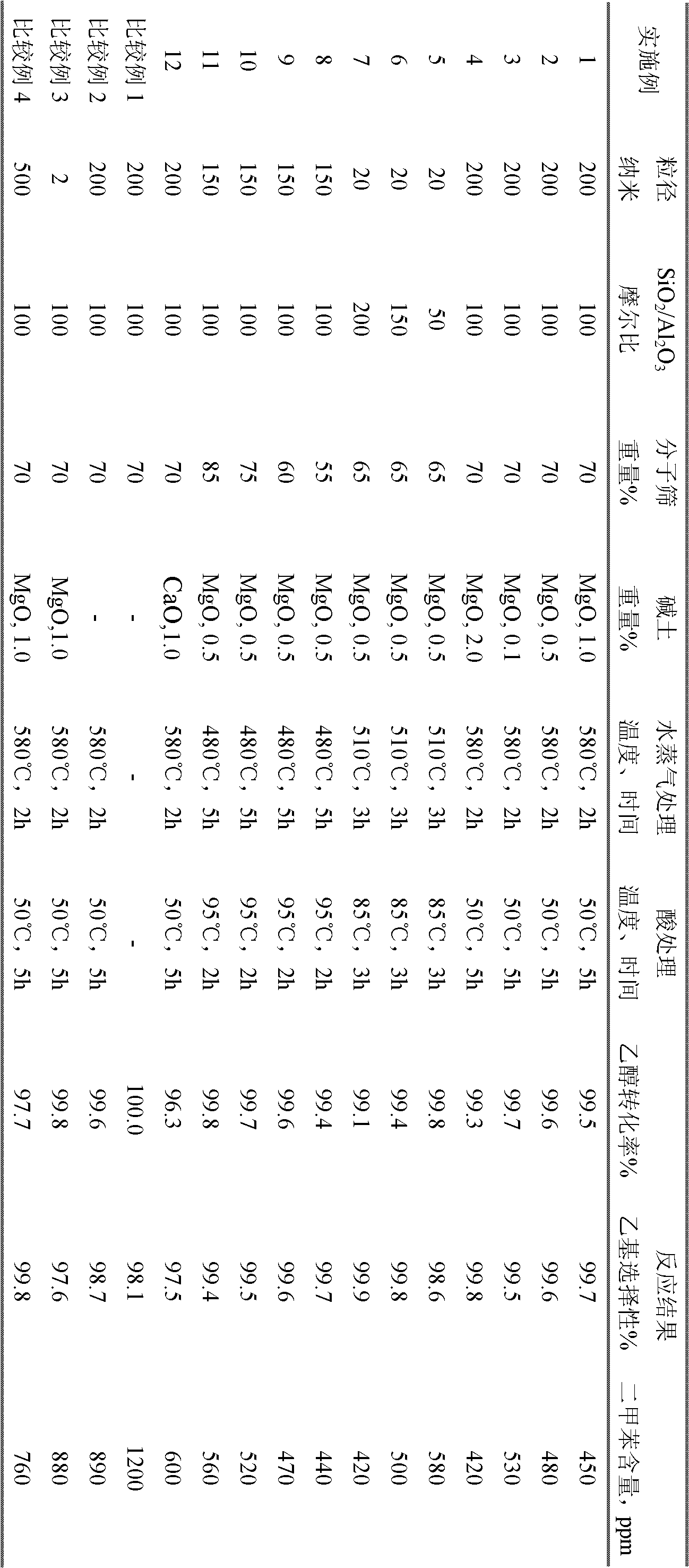

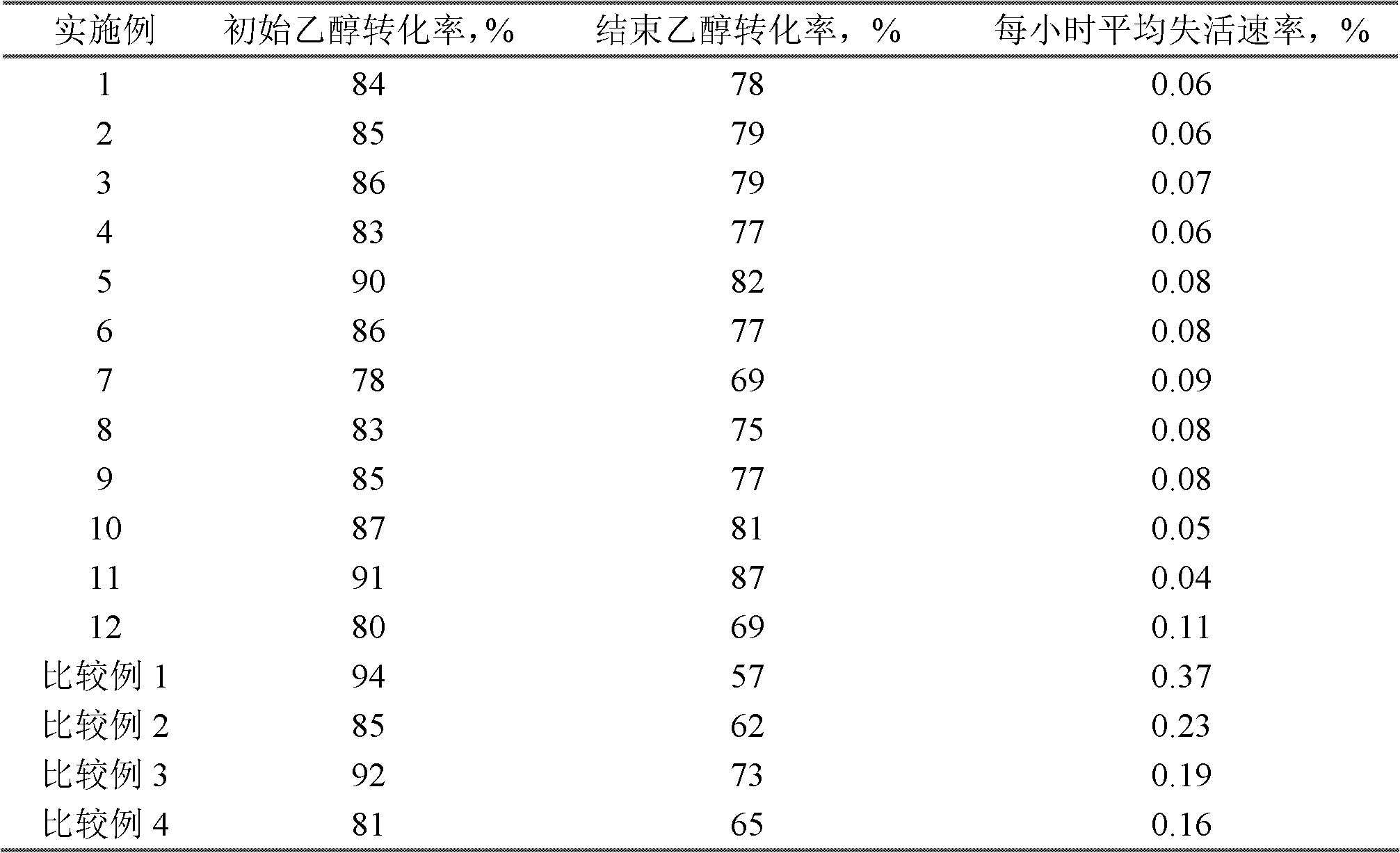

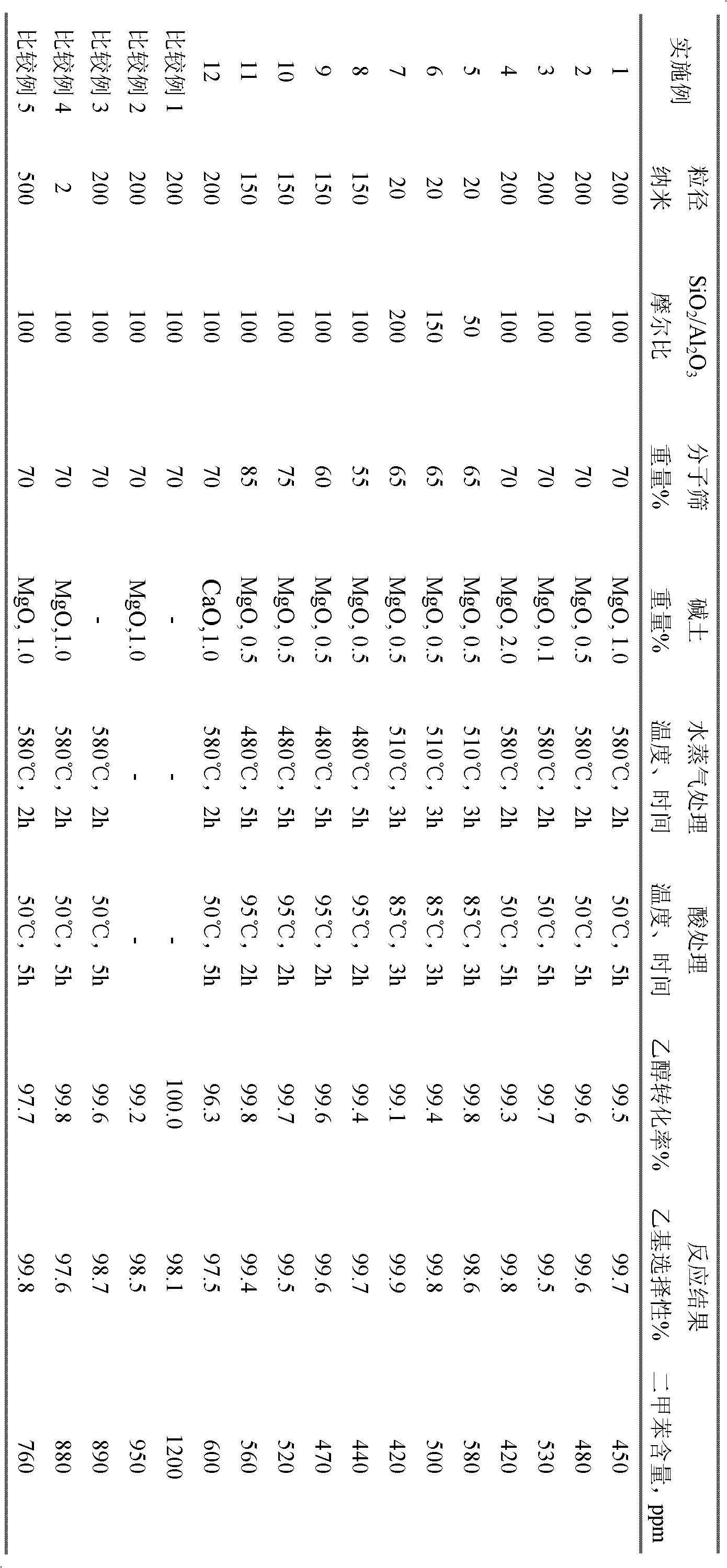

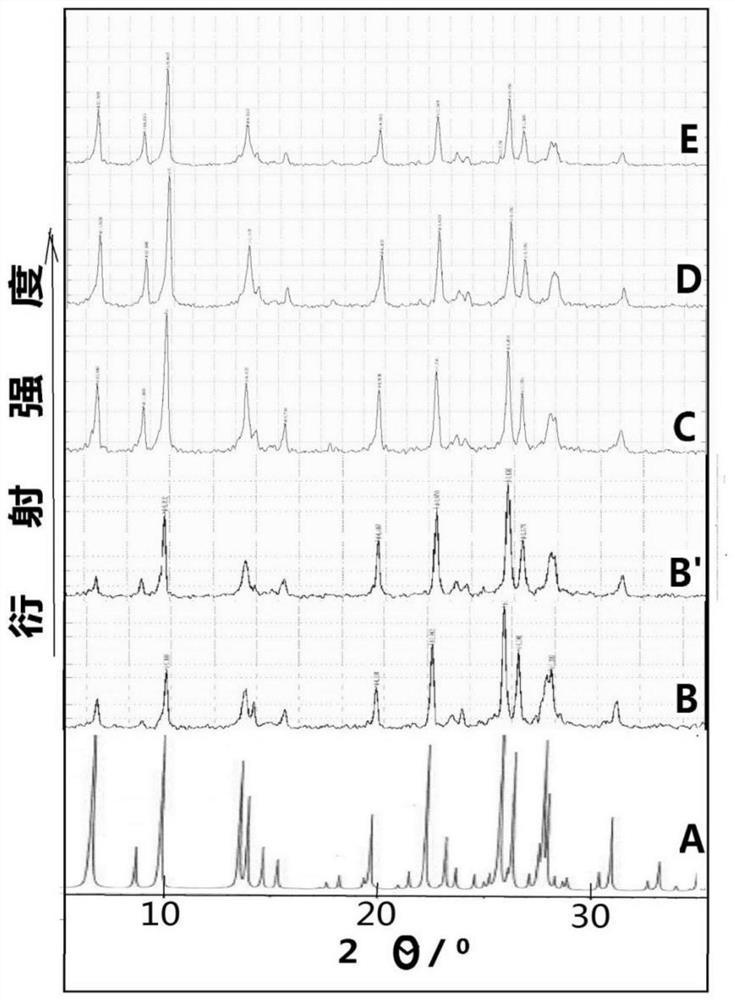

Catalyst for preparation of ethylbenzene by ethanol and benzene vapor-phase alkylation

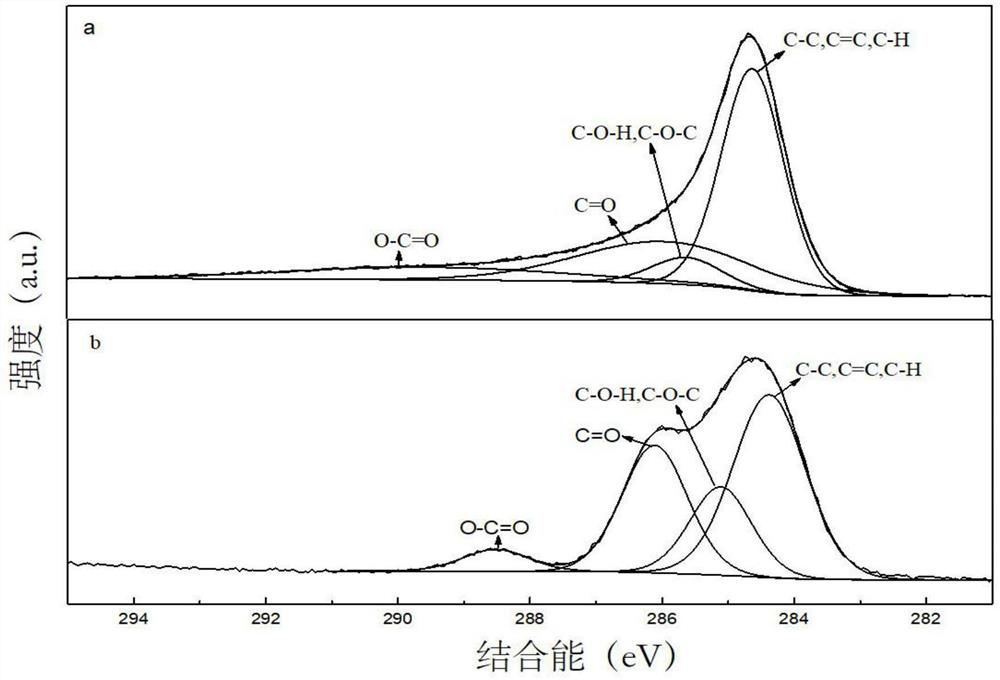

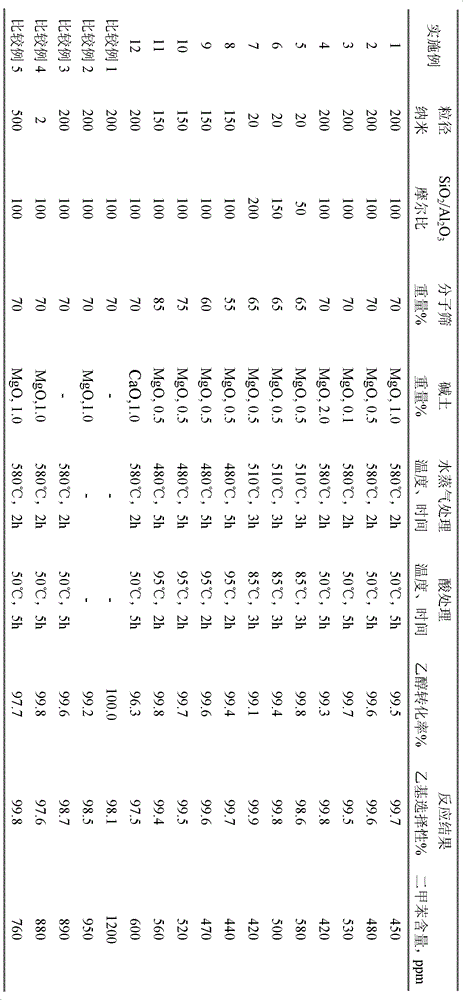

InactiveCN102872899AImprove technical effectMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationBenzene vaporSilicon dioxide

The invention relates to a catalyst for the preparation of ethylbenzene by ethanol and benzene vapor-phase alkylation and mainly solves the problem that the content of xylene impurity in the product ethylbenzene is high and a catalyst has poor stability and short regeneration period in the prior art. The catalyst provided by the invention comprises the following ingredients: by weight, a) 40-90% of a ZSM-5 molecular sieve with the silicon-aluminium mol ratio SiO2 / Al2O3 being 30-400 and grain size being 5-350 nm; b) 9-59% of a binder alumina or silicon dioxide; and c) 0.1-10% of alkaline earth oxide. By the adoption of the technical scheme, the above problem is well solved. The catalyst can be used in the industrial production of ethylbenzene prepared by ethanol and benzene vapor-phase alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

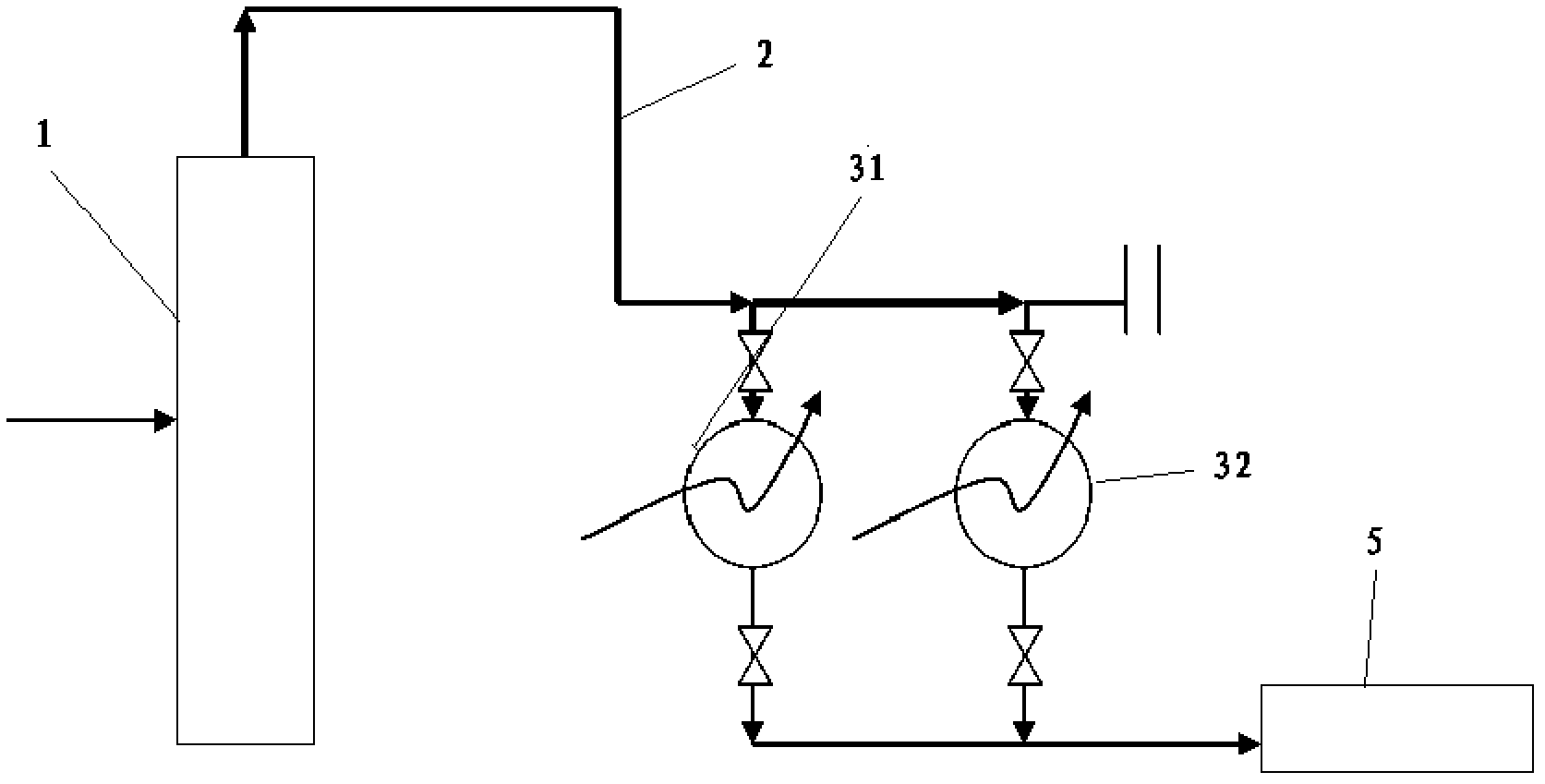

Activated carbon desorption method of activated carbon canister in benzene vapor recovery device

ActiveCN105080287AImprove desorption efficiencyDesorption efficiency, shortening the time required for vacuum desorptionDispersed particle separationCombustible gas purificationBenzene vaporActivated carbon

The invention relates to an activated carbon desorption method of an activated carbon canister in a benzene vapor recovery device. The method mainly solves the problem that activated carbon is prone to desorption at low temperature in the prior art. According to the technical scheme, the activated carbon desorption method comprises the steps that after adsorption of the activated carbon canister in the benzene vapor recovery device is saturate, an activated carbon bed layer is regenerated on the vacuum condition; after the pressure in the activated carbon canister is reduced to 5.0 kPa, air is blown into a heat exchanger to exchange heat with vapor to reach 40-60 DEG C and then enters the activated carbon bed layer in the activated carbon canister for replacement, and more benzene molecules are desorbed from the activated carbon bed layer and enter the follow-up treating process through a vacuum pump and a compressor. The activated carbon desorption method can be used for desorption of the activated carbon canister in the benzene vapor recovery device.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

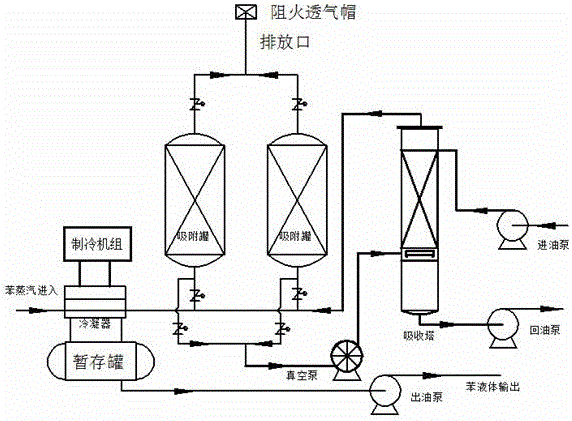

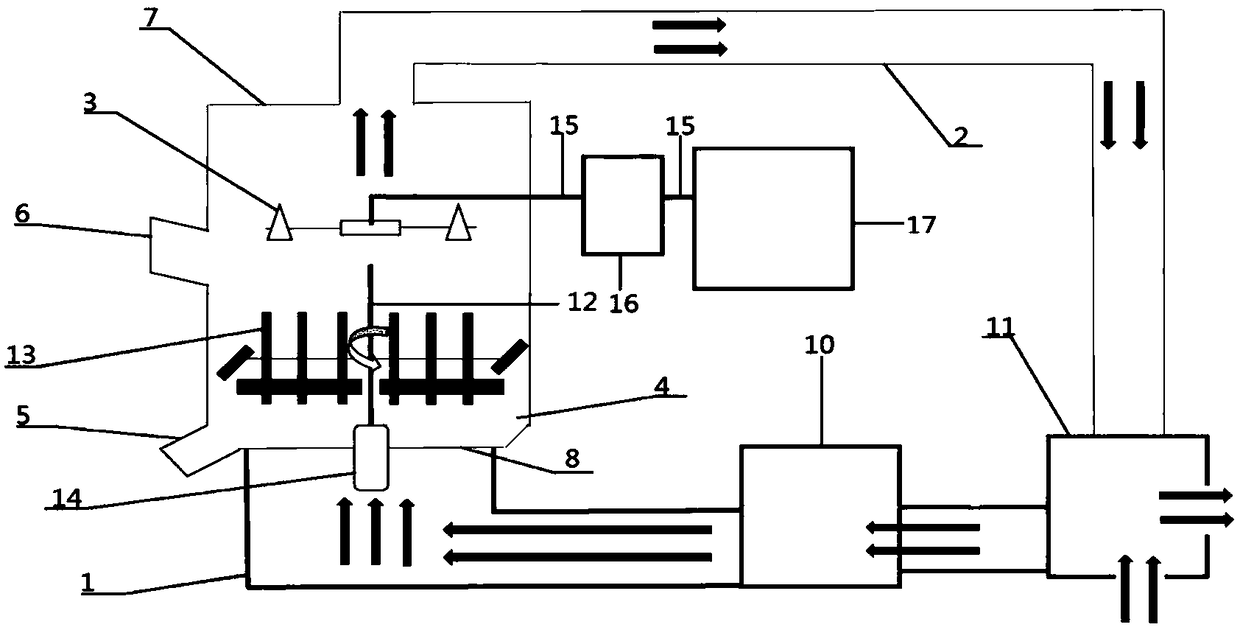

Benzene organic vapor recycling device and benzene organic vapor recycling method

ActiveCN104225951AExtended service lifeAvoid wastingDispersed particle separationVapor condensationBenzene vaporOrganic vapor

The invention discloses a benzene organic vapor recycling device and a benzene organic vapor recycling method. The benzene organic vapor recycling device comprises a low-temperature condensing device, a variable-temperature adsorbing device and a variable-pressure adsorbing device, wherein the low-temperature condensing device comprises a cold-box heat exchanger, a refrigerating compressor and a condensing heat exchanger which are sequentially connected; a vapor inlet of the cold-box heat exchanger is connected with a benzene organic vapor outlet; the condensing heat exchanger is connected with the cold-box heat exchanger through a valve to form a cooling circulating system; the condensing heat exchanger is further provided with a cooling water inlet and a cooling water outlet to form a water circulating system; the cold-box heat exchanger is further provided with a liquid outlet; the liquid outlet of the cold-box heat exchanger is connected with a layering trough and is used for recycling benzene liquid. The benzene organic vapor recycling device recycles and purifies benzene vapor through the low-temperature condensing device, the variable-temperature adsorbing device and the variable-pressure adsorbing device; finally, the benzene organic vapor achieves a concentration lower than 12 mg / m<3> and completely reaches the discharge standard; no secondary pollution is generated during operation of the benzene organic vapor recycling device.

Owner:NANJING DOULE REFRIGERATION EQUIP

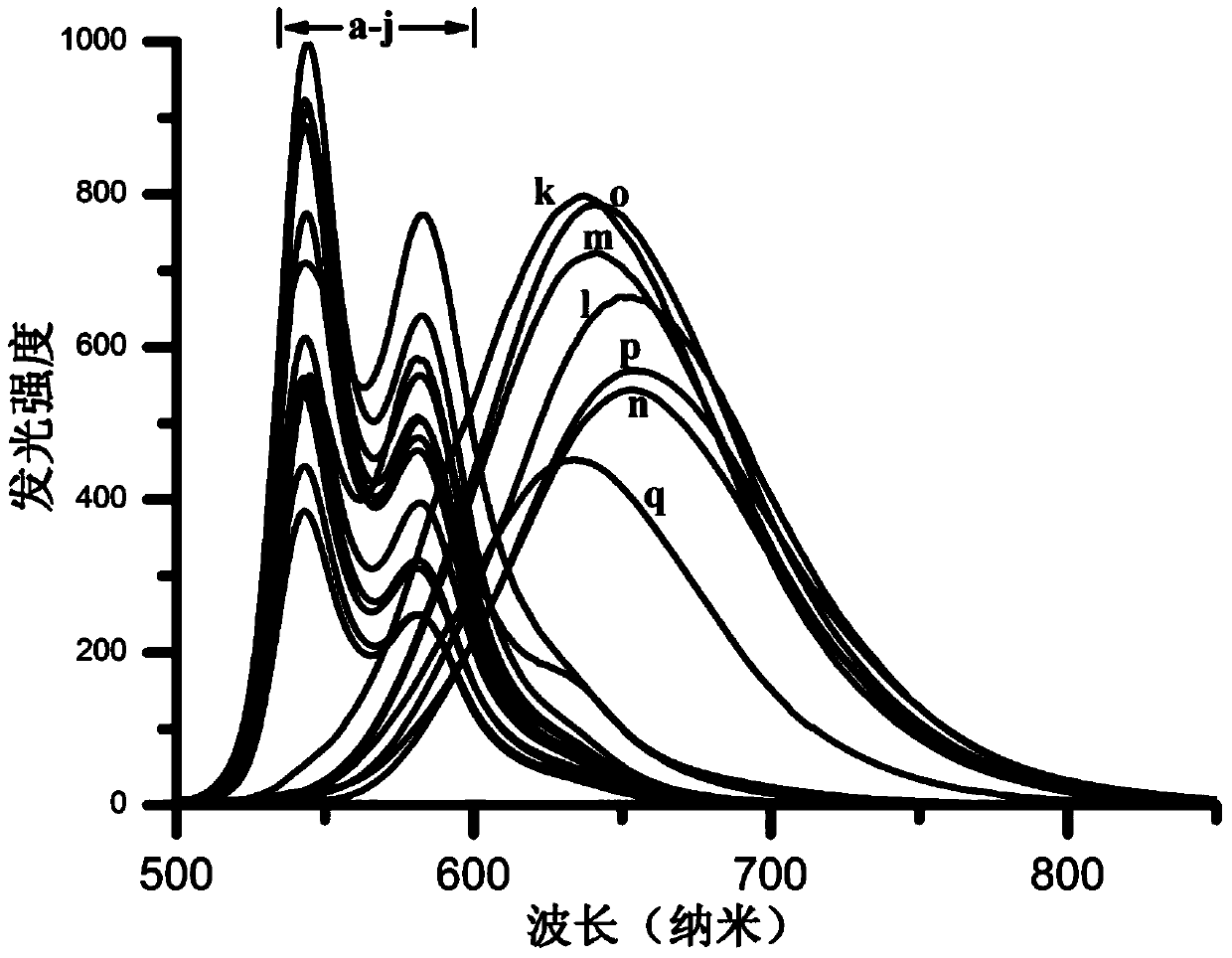

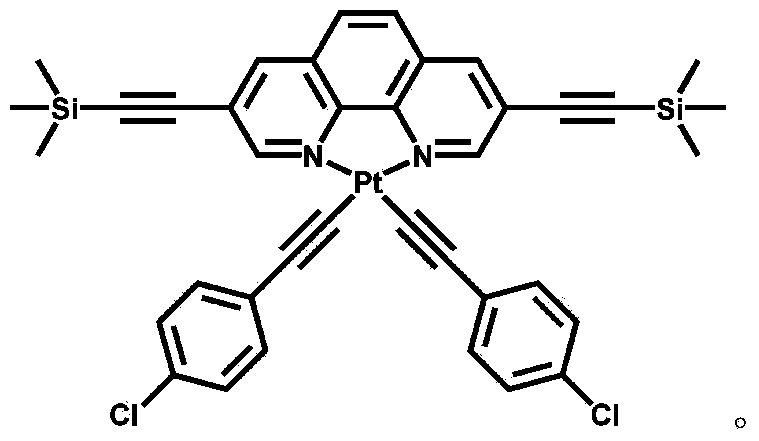

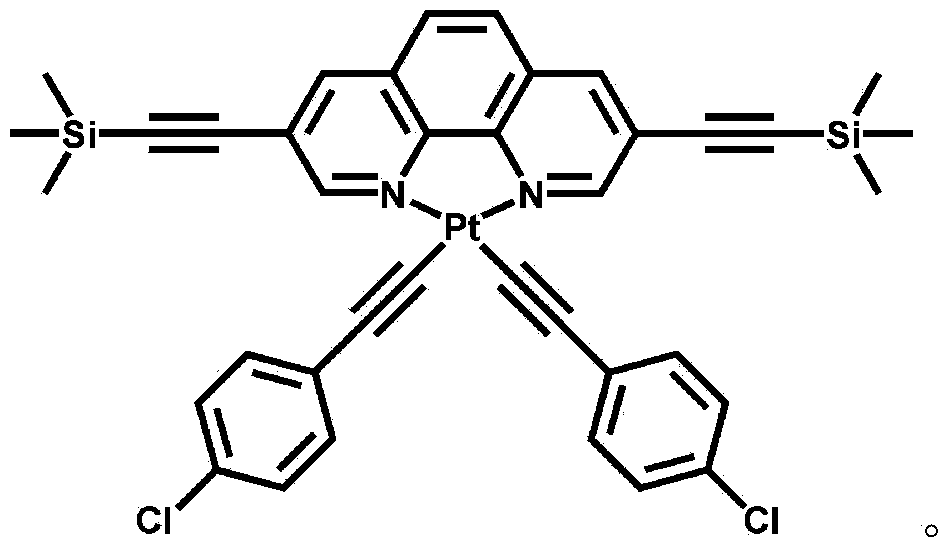

Luminescent probe with visual recognition effect for benzene steam as well as preparation method and application of luminescent probe

InactiveCN104194769AEasy to detectHigh sensitivityFluorescence/phosphorescenceTenebresent compositionsBenzene vaporChlorobenzene

The invention discloses a luminescent probe with a visual recognition effect for benzene steam as well as a preparation method and an application of the luminescent probe. The probe is a complex prepared from platinum (II), a 3, 8-bi(trimethylsilylacetylene)-1, 10-phenanthroline ligand and an auxiliary 4-chlorophenylacetylene ligand. When the probe is not in contact with benzene vapor, emission peaks of the probe are located at the wavelength positions of 543nm and 581nm under the excitation of light with the wavelength of 250-500nm, and the light is yellowish green. When the probe is in contact with the benzene vapor, an emission spectrum is subjected to bathochromic shift to a position near the wavelength of 630-660nm, and the color of the emitted light is remarkably changed from yellowish green to bright red. The probe disclosed by the invention not only has high sensitivity and high selectivity for the benzene vapor, but also has the advantages of high analysis speed, good repeatability, visualization, low detecting cost and simple detecting method so as to have a high application value in the field of environment detection. The probe has good reversibility, so that the performance of the probe is not influenced after the probe is repeatedly used.

Owner:DALIAN UNIV OF TECH

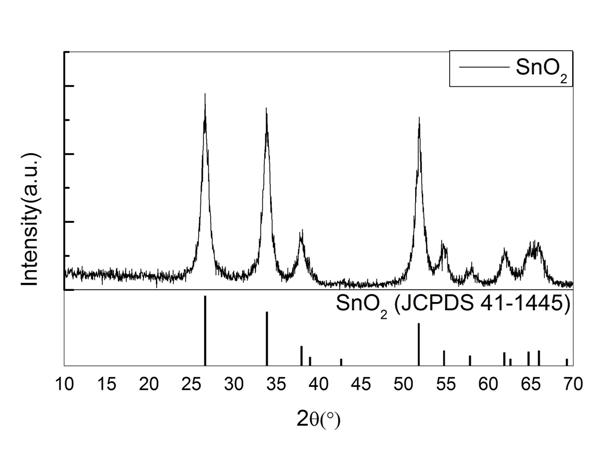

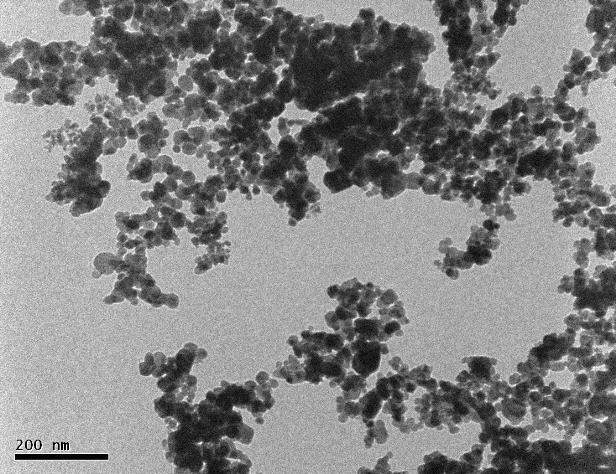

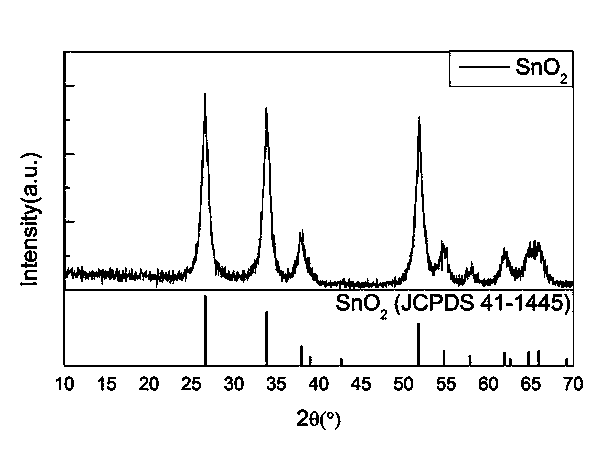

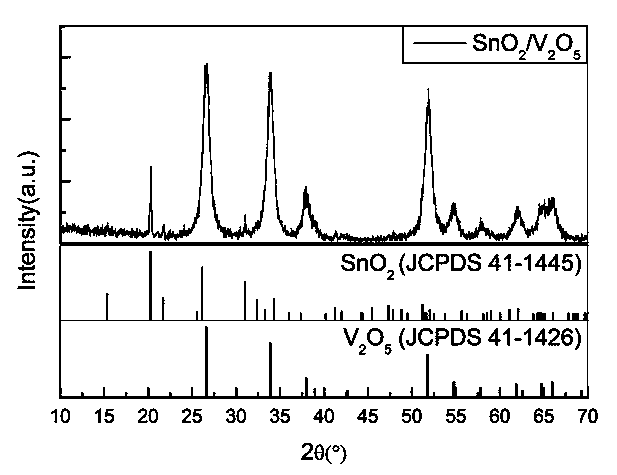

Sensitive material for benzene vapor detecting sensor and preparation method of gas sensor

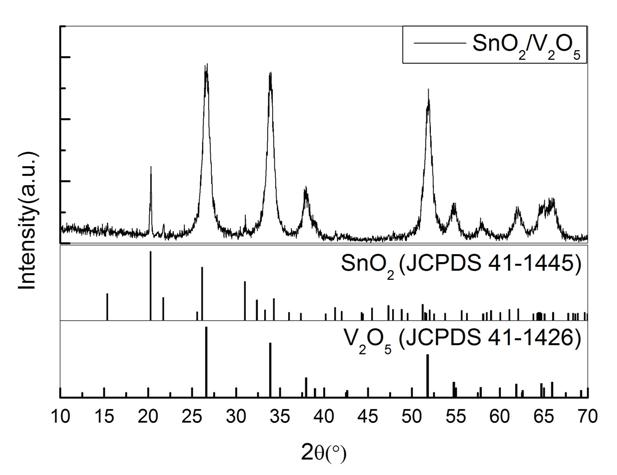

ActiveCN102661977ASimple preparation processLow costMaterial analysis by electric/magnetic meansNanotechnologyBenzene vaporPlatinum

The invention relates to a sensitive material for a benzene vapor detecting sensor and a preparation method of a gas sensor and belongs to the technical field of function materials, sensing technology and environmental monitoring technology. The preparation method includes: using SnO2 prepared by a sol-gel method and commercial V2O5 to prepare a composite material by means of solid-phase reaction, and using the composite material as the sensitive material to detect benzene vapor; subjecting the gas sensor coated with the SnO2 / V2O5 nano-composite material to calcination at 500 DEG C, and welding the gas sensor according to a thick-film semiconductor gas sensor manufacture process, namely, welding a quadrangular electrode lead platinum filament; and ageing and packaging after drying so that the gas sensor for detecting benzene vapor is prepared. The prepared gas sensor for detecting the benzene vapor has the advantages of high sensitivity, high selectivity, low power consumption and the like, and can be used for detecting benzene vapor and methylbenzene vapor in the atmosphere or indoor environment.

Owner:SHANGHAI UNIV

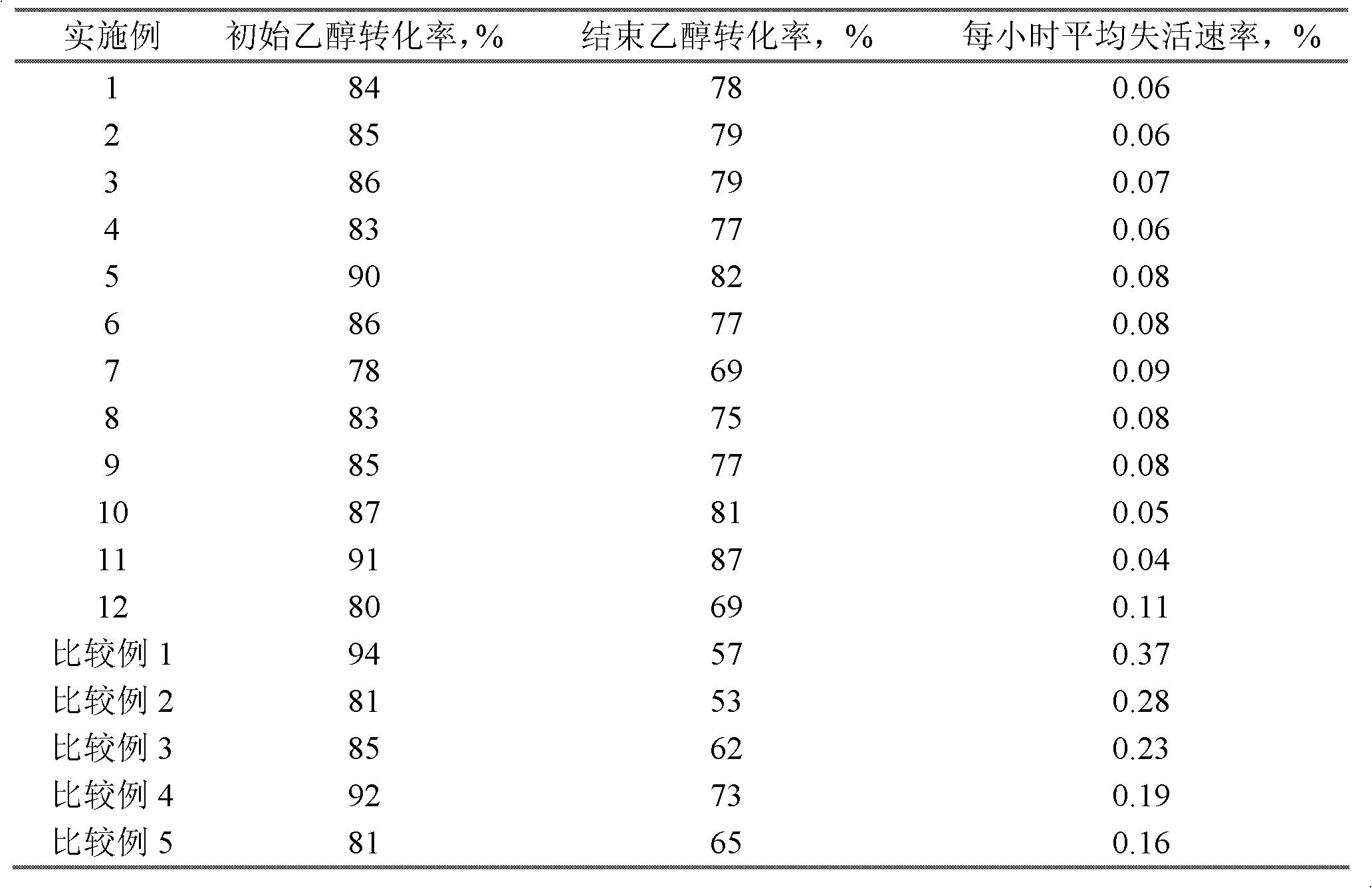

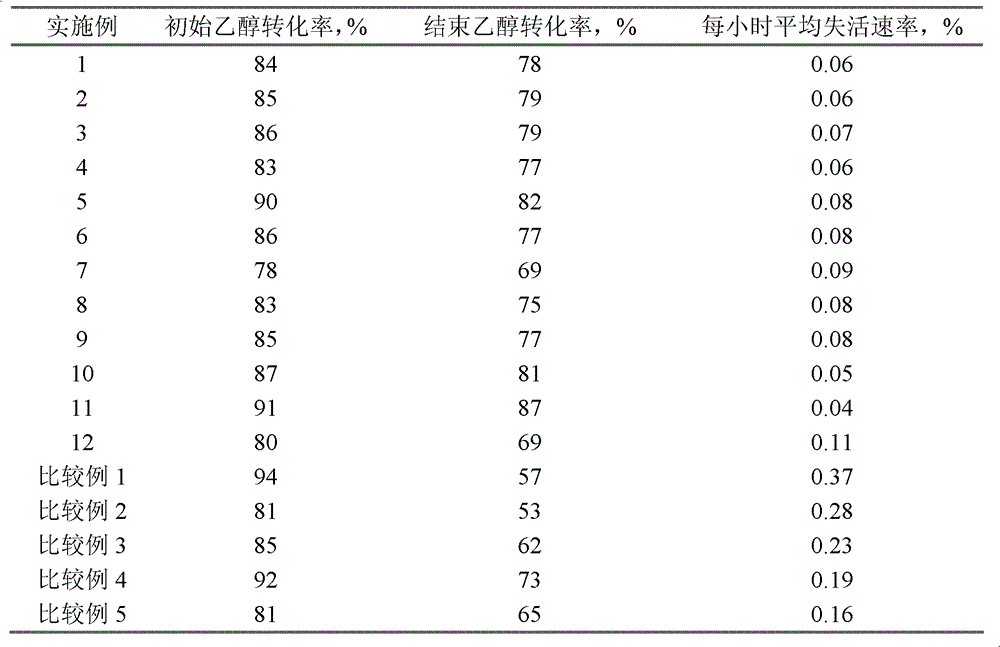

Method for preparing ethylbenzene by ethanol and benzene vapor-phase alkylation

ActiveCN102875315AImprove technical effectMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationBenzene vaporWater vapor

The invention relates to a method for preparing ethylbenzene by ethanol and benzene vapor-phase alkylation and mainly solves the problem that the content of xylene impurity in the product ethylbenzene is high and a catalyst has poor stability and short regeneration period in the prior art. According to the invention, ethanol and benzene are used as reaction raw materials. Under the condition that reaction temperature is 300-460 DEG C, reaction pressure is 0.5-2.8 MPa, ethanol WHSV is 0.1-5.0h<-1> and the benzene / ethanol mole ratio is 2-10, the reaction raw materials contact with a catalyst to carry out vapor-phase alkylation reaction so as to generate ethylbenzene. The catalyst used comprises the following ingredients of: by weight, a) 40-90% of ZSM-5 molecular sieve with the silicon-aluminium mol ratio SiO2 / Al2O3 being 30-400 and grain size being 5-350 nm; b) 9-59% of a binder alumina or silicon dioxide; and c) 0.1-10% of alkaline earth oxide. The catalyst successively undergoes high-temperature stream and phosphoric acid treatments before used. By the adoption of the technical scheme, the above problem is solved well. The method provided by the invention can be used in industrial production of ethylbenzene prepared by ethanol and benzene vapor-phase alkylation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Benzene recovering and treating device and treating method thereof

InactiveCN105879423AEfficient recyclingMeet emission standardsDispersed particle separationHydrocarbon purification/separationBenzene vaporTower

The invention relates to a benzene recovery and treatment device and its treatment method. The treatment device mainly includes a condenser, an adsorption tank and an absorption tower, and has the advantages of novel design, reasonable structure and convenient use, combined with the "condensation + adsorption + absorption" The treatment method can have a significant effect on the recovery and treatment of benzene vapor.

Owner:湖北楚天蓝环保设备工程有限公司

Method for removing thiophenic sulfur from coking benzene

InactiveCN102911003ASpecial catalyst structureHigh catalytic activityHydrocarbon purification/separationHydrocarbonsChemical industryBenzene vapor

The invention discloses a method for removing thiophenic sulfur from coking benzene, belonging to the field of chemical industry production of benzene. The method comprises the following steps: conveying fresh benzene to a benzene heat exchanger by a fresh benzene pump under the pressurizing action, exchanging heat, conveying to a benzene electric heater, mixing hydrogen gas with benzene steam, heating and gasifying, and conveying to a benzene desulfurization reactor; enabling the temperature to be 210-260 DEG C, the pressure to be 0.75-1.05MPa and the air velocity to be 2-3h<-1> in the benzene desulfurization reactor, adding thiophene with hydrogen to be converted into hydrogen sulfide under the action of a catalyst NHDS-8, and adsorbing onto the catalyst; enabling the benzene steam after desulfurization to enter into the benzene heat exchanger so as to convert gaseous benzene into liquid benzene; and carrying out gas-liquid separation on the liquid benzene and the hydrogen in a benzene separator, decompressing the liquid benzene through an adjusting valve, conveying to a benzene process tank, separating the hydrogen through a wire mesh demister, and conveying to a hydrogen circulator for further circulation. The method is better in thiophene removal performance, is capable of reducing the thiophene content in raw materials to be in PPb level, and is low in investment cost and simple to operate.

Owner:SHANXI YANGMEI FENGXI FERTILIZER IND GRPCO

Process for improving washing and removing efficiency of benzene in coal gas from coal

InactiveCN107760389AReduce pollutionKeep healthyCombustible gas purificationBenzene vaporCooling tower

The invention discloses a process for improving the washing and removing efficiency of benzene in coal gas from coal. The process comprises the following steps: cooling coal gas from an ammonium sulfate workshop section in a final cooling tower, then allowing the cooled coal gas to enter a benzene washing tower from the top of the benzene washing tower, to pass through packing layers in the benzene washing tower from bottom to top and to realize countercurrent contact with circulating washing oil sprayed from the top of the benzene washing tower, and after benzene in the coal gas is absorbed by the circulating washing oil, subjecting the coal gas to removal of droplets via a mist capturing section of the benzene washing tower and then allowing the coal gas to leave the benzene washing tower; subjecting the circulating washing oil to heat exchanging via an oil gas heat exchanger and a lean oil-rich oil heat exchanger, then heating the washing oil with a tubular furnace, allowing the heated washing oil to enter a benzene removing tower, carrying out steam stripping and distillation in the benzene removing tower in virtue of superheated steam from a regenerator, allowing crude benzenesteam to escape from the top of the benzene removing tower, subjecting the washing oil having undergone benzene removal to heat exchanging and cooling with the lean oil-rich oil heat exchanger, and then conveying the washing oil to the benzene washing tower for cyclic usage; and allowing oil gas to enter the oil gas heat exchanger and crude benzene to enter a condensation cooler, separating waterfrom obtained crude benzene by using an oil-water separator, then allowing the crude benzene to enter a reflux tank and conveying the crude benzene to the top of the benzene removing tower in virtueof a reflux pump. When the process is used for treating benzene included in coal gas, the content of benzene is allowed to reach a set safety value, little pollution is posed to environment, and humanhealth is guaranteed.

Owner:郭莉

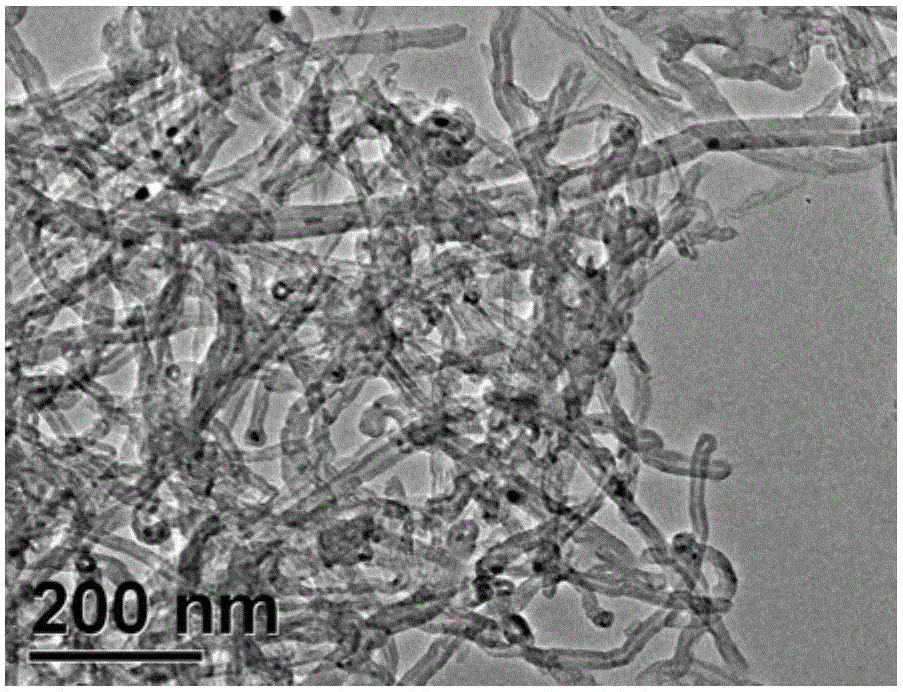

Preparation method of hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer/carbon nanotube conducting composite film

The invention discloses a preparation method of a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method comprises the following steps: carrying out in-situ coupling reaction on a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer and uniform hydroxy multiwall carbon nanotubes subjected to ultrasonic dispersion to form a polyurethane compound by using hexamethylene diisocyanate, coating a film, and drying at room temperature to obtain the hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method is simple to operate and easy for film formation, and has the advantages of low energy consumption, short operation time and favorable dispersibility of the carbon nanotubes; the obtained conducting composite film can implement detection on benzene and methylbenzene solvent vapor, has the advantages of short response time, high sensitivity and high selectivity, can not cause permanent damage to the conducting film, can implement the ppm-level detection on the benzene vapor, and can implement repeated use.

Owner:SHAANXI NORMAL UNIV

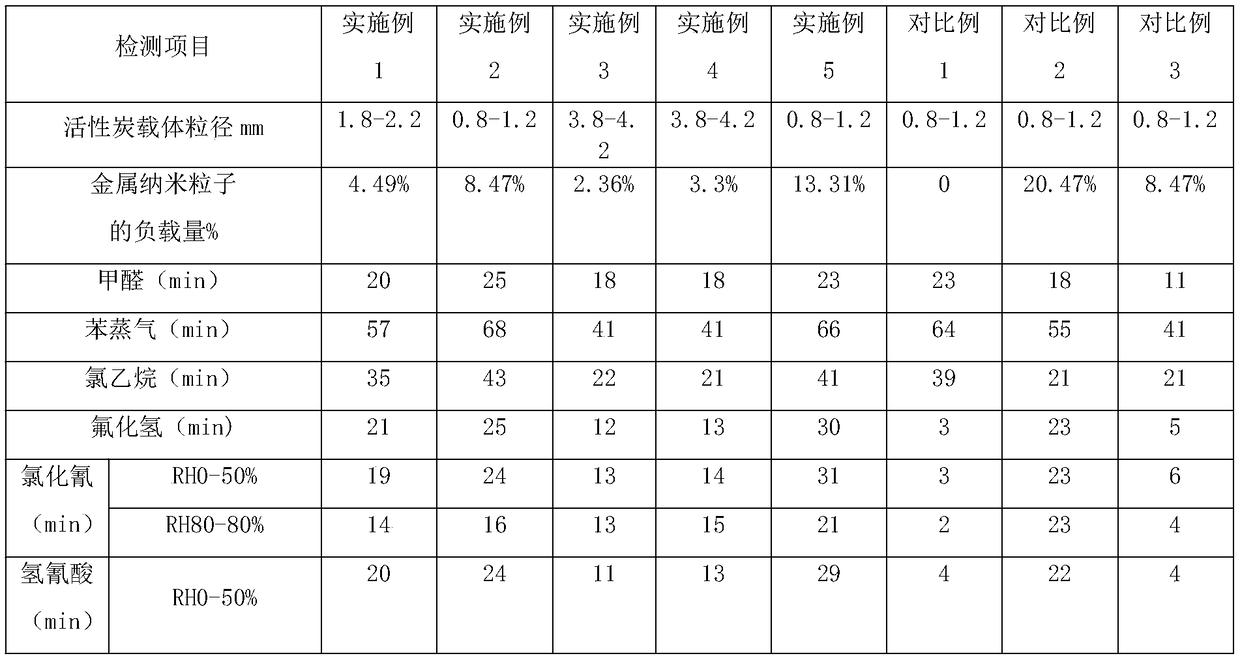

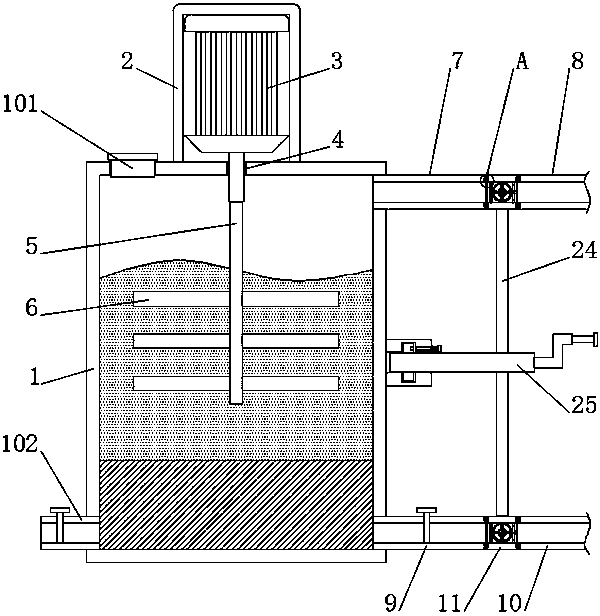

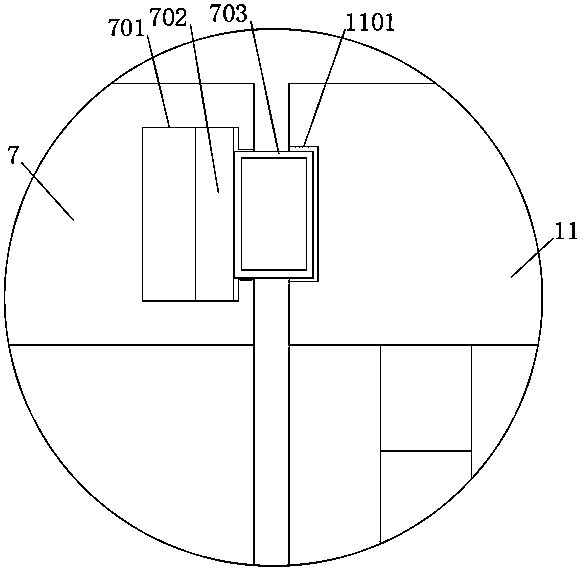

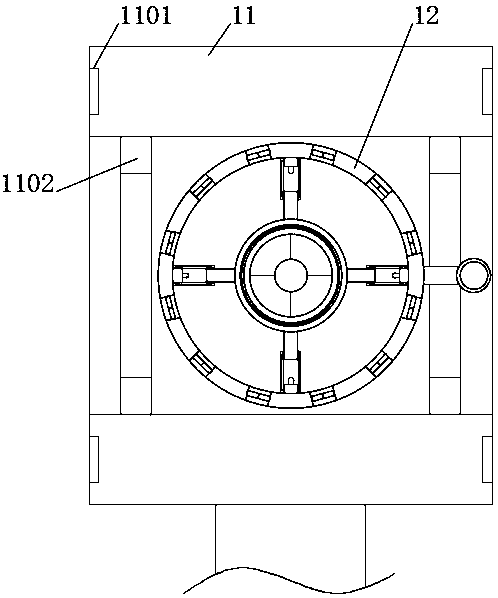

Metal nanoparticle loaded activated carbon and production equipment thereof

PendingCN109364947AReduce consumptionDry fastDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsBenzene vaporActivated carbon

The invention discloses metal nanoparticle loaded activated carbon. According to the metal nanoparticle loaded active carbon, metal nanoparticle dispersion liquid and an activated carbon carrier are fully mixed and then are put into high-temperature airflow to be dried so as to obtain the metal nanoparticle loaded activated carbon, the loading capacity of metal nanoparticles is 2-14% of the mass of the activated carbon carrier, and the mass of the metal nanoparticle dispersion liquid is 48-70% of the mass of the activated carbon carrier. The invention further discloses related production equipment used for the metal nanoparticle loaded activated carbon and a preparation method for the metal nanoparticle loaded activated carbon. The metal nanoparticle loaded activated carbon obtained by utilizing the preparation method for the metal nanoparticle loaded activated carbon has the advantages that the particle size distribution of the loaded metal nanoparticles is uniform, the physical adsorption performance and the chemical catalytic performance of the activated carbon are balanced and efficient, a preparation process is simple, and non-polar harmful gas such as benzene vapor, chloroethane vapor and formaldehyde and strong-polarity harmful gas such as cyanogen chloride and hydrocyanic acid can be effectively adsorbed.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

Method for reclamation and cyclic utilization of tail gas containing benzene and hydrogenchloride in chlorobenzene production

InactiveCN100446841CImprove analytical abilityGood effectDispersed particle separationVapor condensationBenzene vaporDesorption

The present invention is process of recovering benzene and hydrogen chloride from tail gas for reuse in benzene chloride production, and belongs to the field of chemical production effluent recovering and utilizing technology. The present invention is one absorption-desorption process, which includes the absorption of hydrogen chloride from the tail gas in an absorption tower at the temperature higher than the boiling temperature of benzene, 80.1 deg.c, with sprayed water or diluted hydrochloric acid to form concentrated hydrochloric acid, and the recovering of benzene from benzene vapor for reuse; and the desorption of concentrated hydrochloric acid in a desorption tower to obtain dry pure hydrogen chloride gas for reuse. The absorption-desorption process can recover benzene and hydrogen chloride from tail gas completely for reuse, and has saving of resource and environment friendship.

Owner:武汉祥龙电业股份有限公司

Waste gas treatment device and system for chemical reaction kettle

InactiveCN111569810AHigh purityImprove filtering effectCombination devicesDistillation purification/separationBenzene vaporChemical reaction

The invention discloses a waste gas treatment device and system for a chemical reaction kettle, and belongs to the technical field of chemical production; according to the scheme, the benzene steam isfiltered by the retractable filter ball; when the offset pull rod is in contact with the trigger switch, the first electromagnet and the second electromagnet attract each other, the whole retractablefiltering ball is temporarily retracted; when the offset pull rod is not in contact with the trigger switch, the retractable filter ball is continuously expanded, therefore, the retractable filter ball is continuously in a contracted and expanded state; the retractable filter balls are continuously contracted and expanded, so the filtering effect on distilled benzene steam can be improved; when the expansion balloon expands when heated, static electricity can be generated on the surface of the rubber ball through continuous friction of the fur layer on the rubber ball, so that the effect of collecting particles in benzene steam is improved, the content of the particles in the benzene steam can be reduced when coal tar containing benzene is separated, and the purity of the obtained benzeneis improved.

Owner:崔丽凤

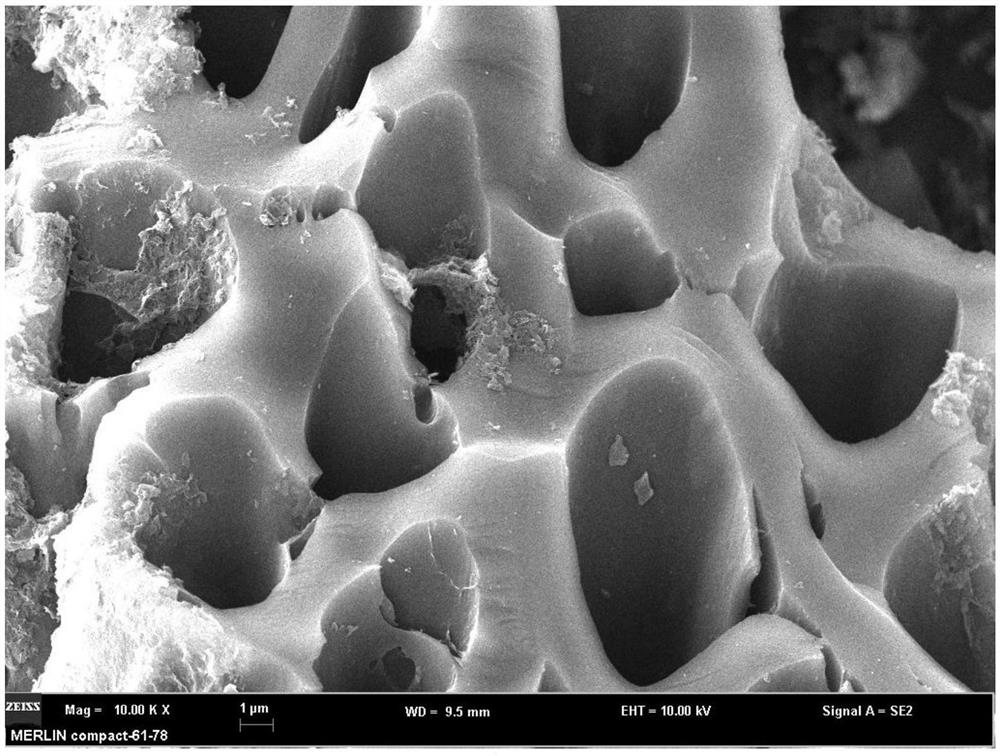

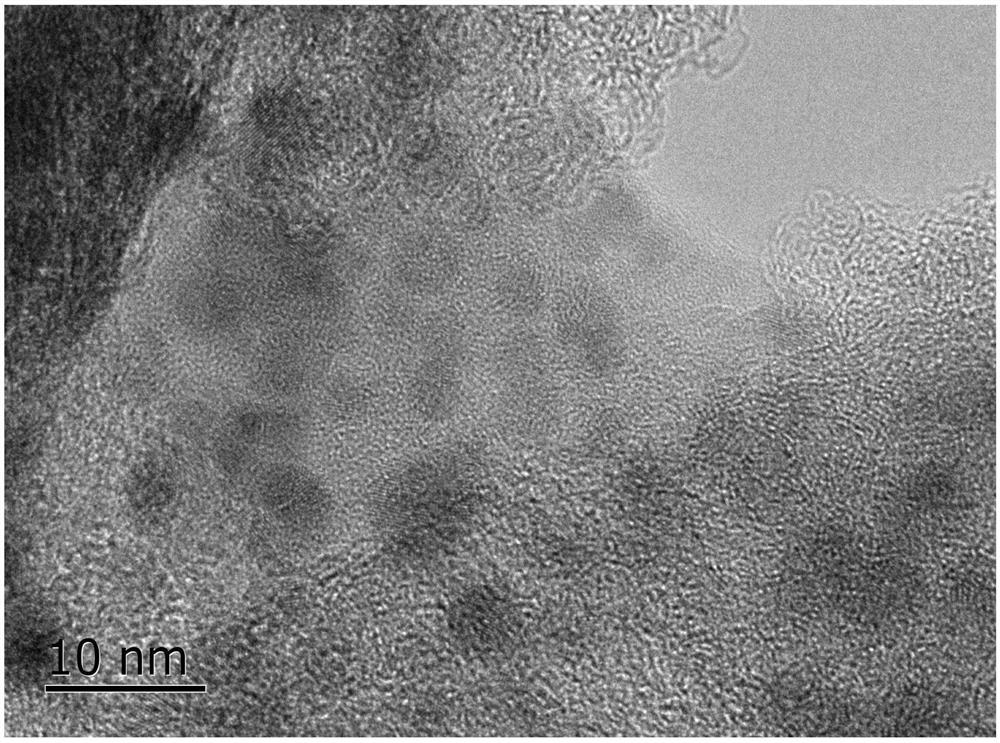

Hierarchical pore carbon material and preparation method and application thereof

InactiveCN111617737AImprove adsorption capacityHigh removal rateGas treatmentOther chemical processesBenzene vaporSorbent

The invention provides a hierarchical pore carbon material as well as a preparation method and an application thereof, and belongs to the field of porous materials. The hierarchical porous carbon material provided by the invention comprises micropores, mesopores and macropores, chlorine ions are loaded on the outer surface of the hierarchical pore carbon material and the surfaces of pore channels,and the outer surface of the hierarchical pore carbon material and the surfaces of the pore channels further contain carbon-oxygen functional groups. The hierarchical pore carbon material provided bythe invention is used as an adsorbent and can adsorb mercury vapor, arsenic vapor, selenium vapor and volatile organic pollutants. The results of embodiments show that the hierarchical pore carbon material provided by the invention can effectively adsorb elemental mercury vapor, VOCs (represented by benzene vapor and o-xylene vapor), arsenic vapor and selenium vapor.

Owner:HEBEI UNIV OF TECH

Method for producing ethylbenzene by vapor-phase alkylation of ethanol and benzene

ActiveCN102875315BMolecular sieve catalystsHydrocarbon by hydrocarbon and non-hydrocarbon condensationBenzene vaporGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

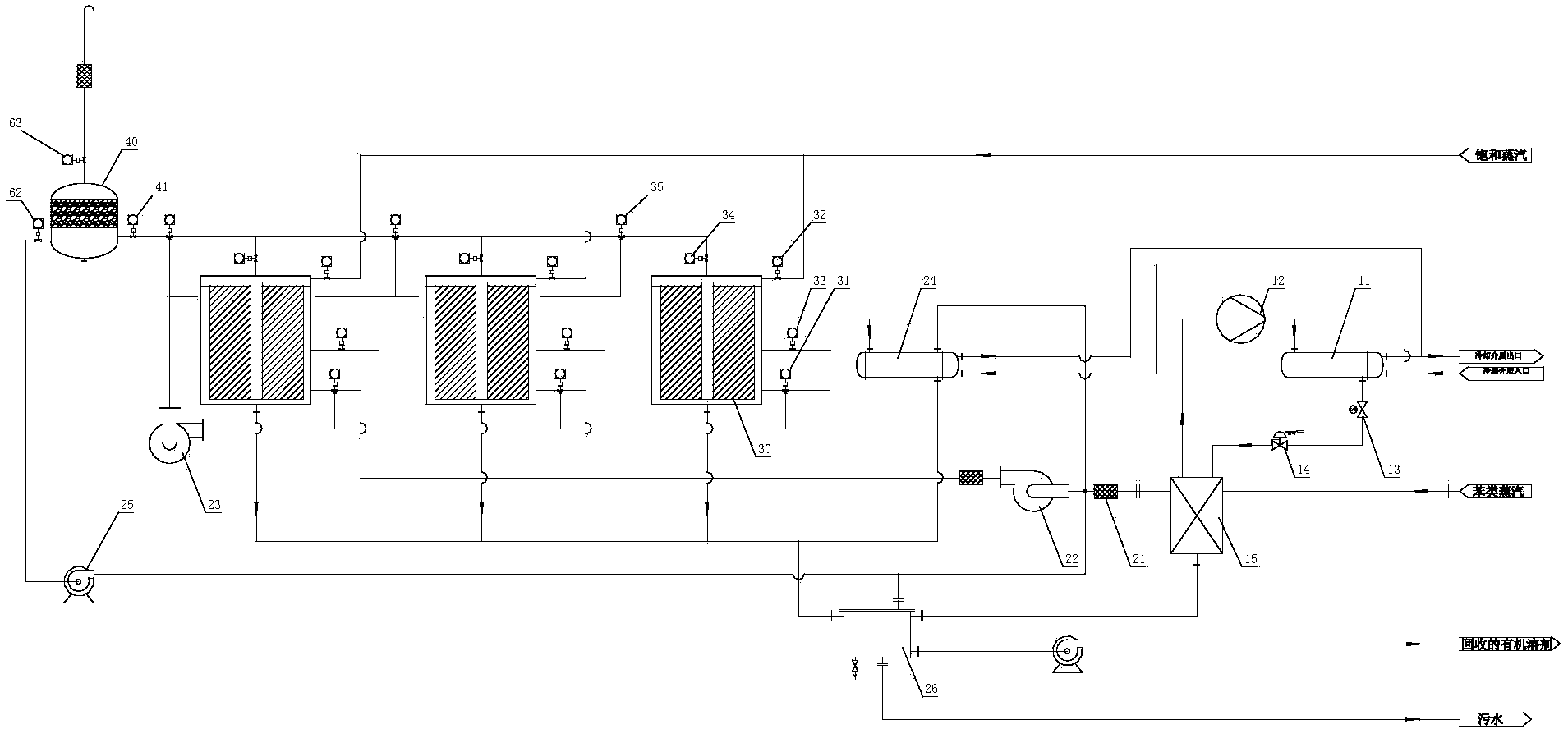

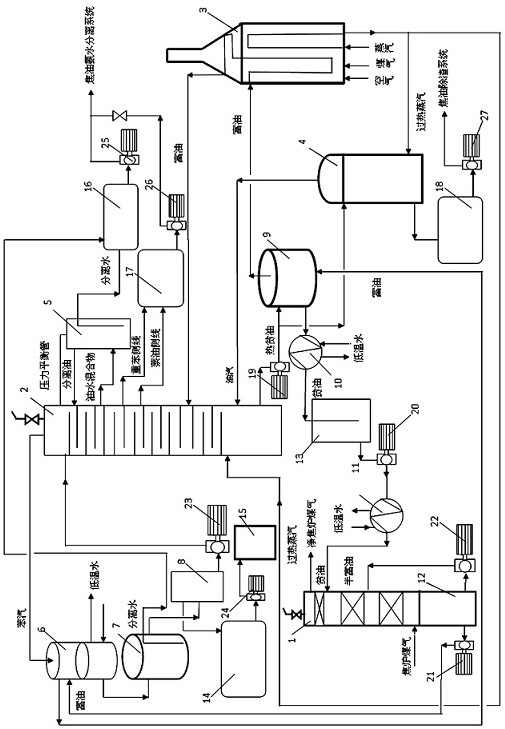

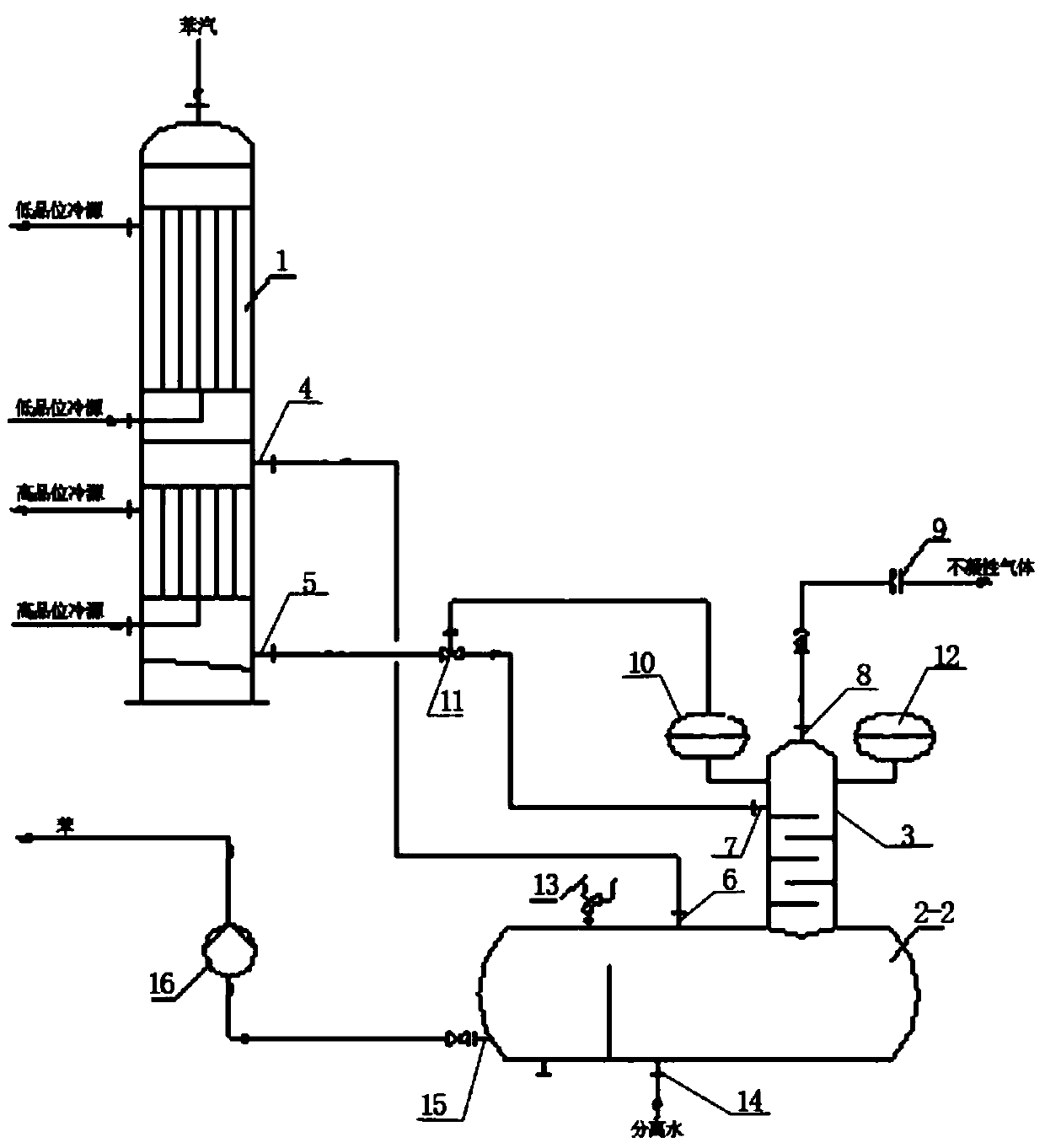

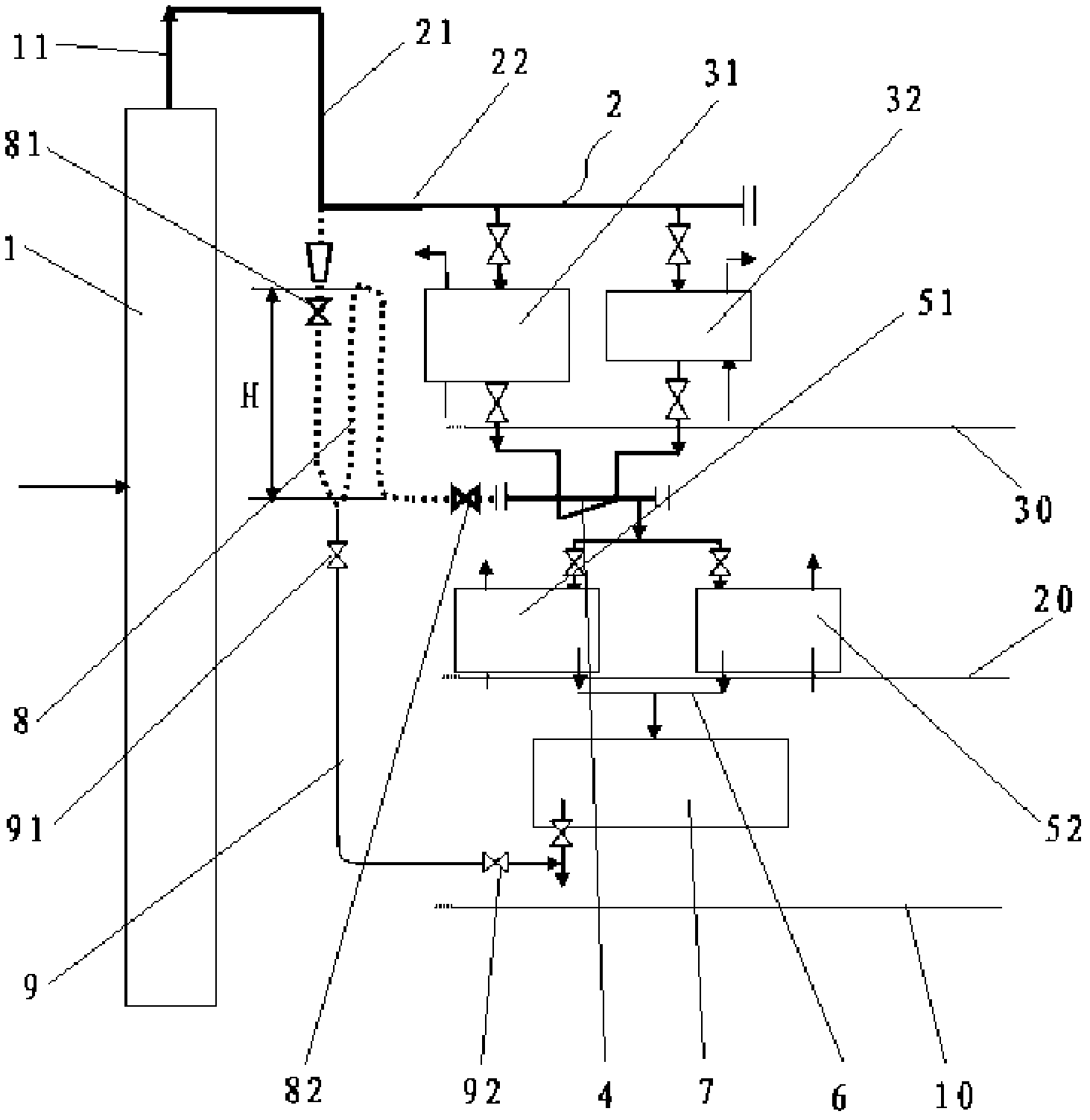

System and process for efficiently eluting benzene hydrocarbon in coke oven gas

PendingCN113999703AFully absorbedHigh spray densityEnergy recuperation in distillationGas contaminants removalBenzene vaporOil water

The invention relates to a system and a process for efficiently eluting benzene hydrocarbon in coke oven gas, and belongs to the technical field of coking chemistry in the coking industry. The system comprises a benzene washing tower (1), a benzene removal tower (2), a tubular furnace (3), a regenerator (4), a tower top oil-water separator (5), a benzene vapor condensation cooler (6), an oil-water separator (7), a reflux column (8), a lean and rich oil heat exchanger (9), a first-section lean oil cooler (10) and a second-section lean oil cooler (11). A cold lean oil pump (20) sends cold lean oil with the benzene content of less than 0.6% and the temperature of 22-30 DEG C to the top of the benzene washing tower (1) for spraying, and the semi-rich oil pump (22) sends semi-rich oil in the oil-rich tank (12) at the bottom of the benzene washing tower to the semi-rich oil circulating washing section in the middle of the benzene washing tower (1) for spraying, so that the benzene hydrocarbon in the coke oven gas is fully absorbed. The system and process has the beneficial effects that the benzene washing lean oil circulation volume is reduced while the absorption effect of the benzene hydrocarbon in the coke oven gas is improved, so that the debenzolization energy consumption is greatly reduced.

Owner:宣化钢铁集团有限责任公司

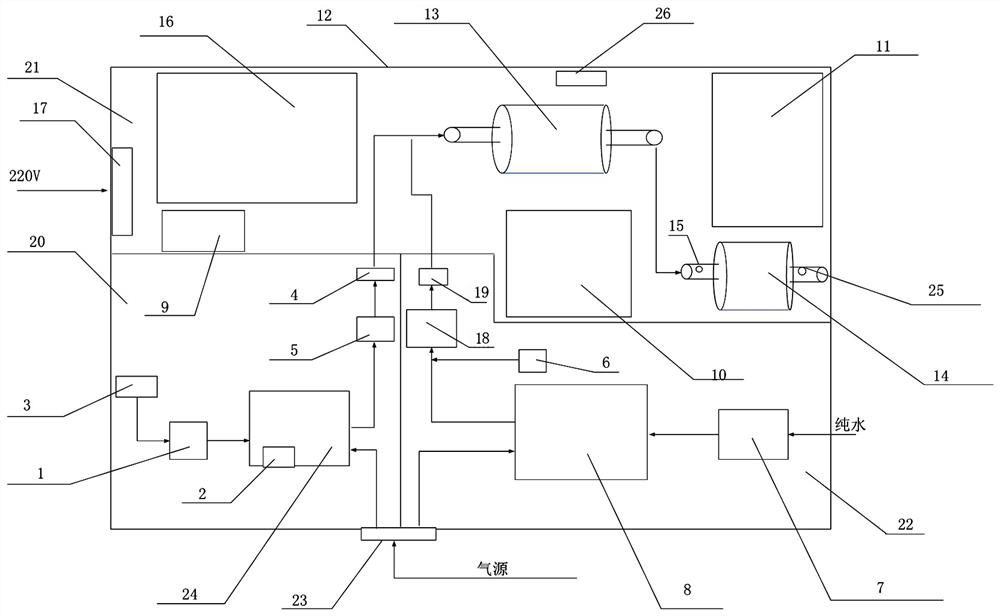

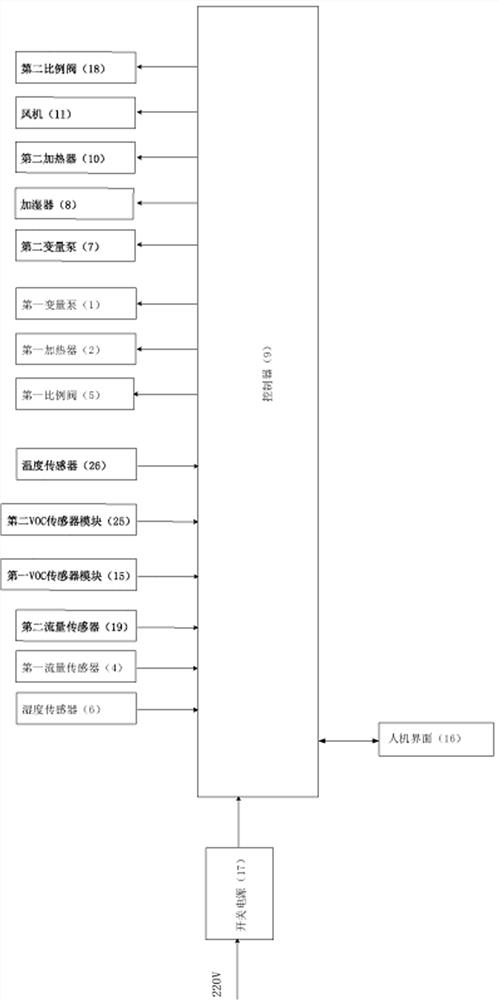

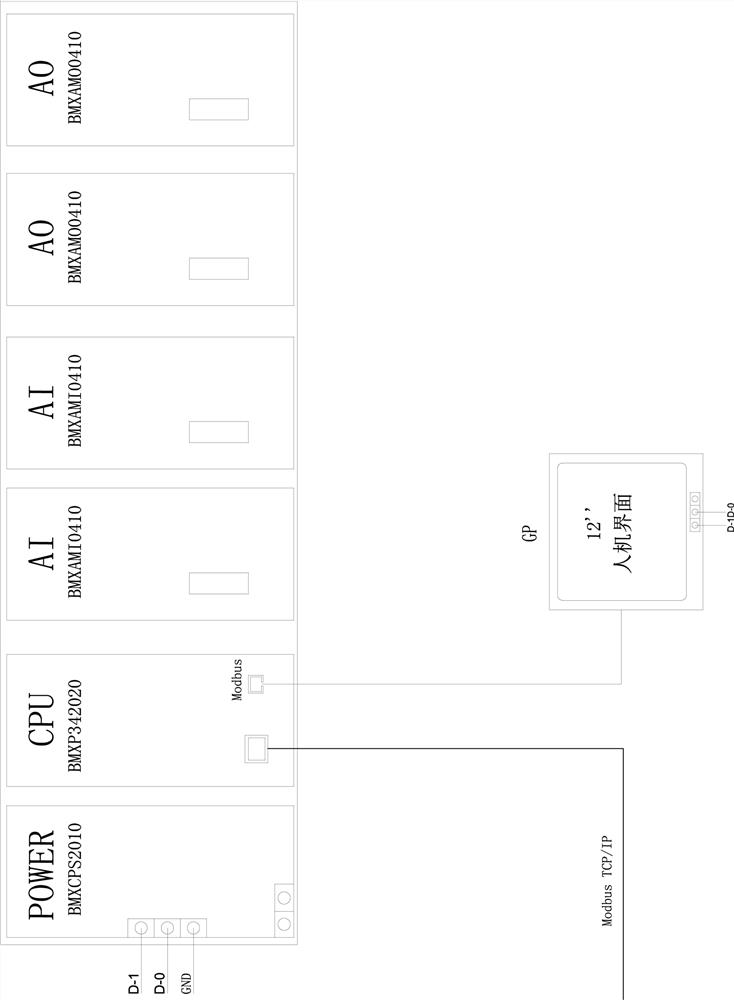

Test device for simulating protection time of canister to benzene vapor and use method

ActiveCN113220053AComprehensive test conditionsReduce research costsSimultaneous control of multiple variablesBenzene vaporCarbon layer

The invention discloses a test device for simulating protection time of a canister to benzene vapor and a use method. The test device comprises a box body, and the interior of the box body is divided into a benzene generation chamber, a constant-temperature chamber and a humidity generation chamber; the benzene generation chamber and the humidity generation chamber are both connected with the gas source interface; a reagent bottle and a heating system are arranged in the benzene generating chamber; a humidifying system is arranged in the humidity generating chamber; a mixing tank and a simulated canister are arranged in the constant-temperature chamber; and a human-computer interface and a switching power supply are arranged outside the constant-temperature chamber. The device can perform simulation test on benzene vapor protection time of different canister products, test the benzene vapor protection time of the canister under the conditions of different temperature and humidity, air inlet flow and concentration and different carbon layer thicknesses, does not need to use a canister finished product, saves research cost, is accurate and stable in test condition control, is integrally designed, the device can be integrally controlled, is simple to operate, and is suitable for scientific research on the protection time of the canister on the benzene vapor.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

Method for removing thiophenic sulfur from coking benzene

InactiveCN102911003BSpecial catalyst structureHigh catalytic activityHydrocarbon purification/separationHydrocarbonsChemical industryBenzene vapor

The invention discloses a method for removing thiophenic sulfur from coking benzene, belonging to the field of chemical industry production of benzene. The method comprises the following steps: conveying fresh benzene to a benzene heat exchanger by a fresh benzene pump under the pressurizing action, exchanging heat, conveying to a benzene electric heater, mixing hydrogen gas with benzene steam, heating and gasifying, and conveying to a benzene desulfurization reactor; enabling the temperature to be 210-260 DEG C, the pressure to be 0.75-1.05MPa and the air velocity to be 2-3h<-1> in the benzene desulfurization reactor, adding thiophene with hydrogen to be converted into hydrogen sulfide under the action of a catalyst NHDS-8, and adsorbing onto the catalyst; enabling the benzene steam after desulfurization to enter into the benzene heat exchanger so as to convert gaseous benzene into liquid benzene; and carrying out gas-liquid separation on the liquid benzene and the hydrogen in a benzene separator, decompressing the liquid benzene through an adjusting valve, conveying to a benzene process tank, separating the hydrogen through a wire mesh demister, and conveying to a hydrogen circulator for further circulation. The method is better in thiophene removal performance, is capable of reducing the thiophene content in raw materials to be in PPb level, and is low in investment cost and simple to operate.

Owner:SHANXI YANGMEI FENGXI FERTILIZER IND GRPCO

Sensitive material for benzene vapor detecting sensor and preparation method of gas sensor

ActiveCN102661977BSimple preparation processLow costMaterial analysis by electric/magnetic meansNanotechnologyBenzene vaporNanocomposite

The invention relates to a sensitive material for a benzene vapor detecting sensor and a preparation method of a gas sensor and belongs to the technical field of function materials, sensing technology and environmental monitoring technology. The preparation method includes: using SnO2 prepared by a sol-gel method and commercial V2O5 to prepare a composite material by means of solid-phase reaction, and using the composite material as the sensitive material to detect benzene vapor; subjecting the gas sensor coated with the SnO2 / V2O5 nano-composite material to calcination at 500 DEG C, and welding the gas sensor according to a thick-film semiconductor gas sensor manufacture process, namely, welding a quadrangular electrode lead platinum filament; and ageing and packaging after drying so that the gas sensor for detecting benzene vapor is prepared. The prepared gas sensor for detecting the benzene vapor has the advantages of high sensitivity, high selectivity, low power consumption and the like, and can be used for detecting benzene vapor and methylbenzene vapor in the atmosphere or indoor environment.

Owner:SHANGHAI UNIV

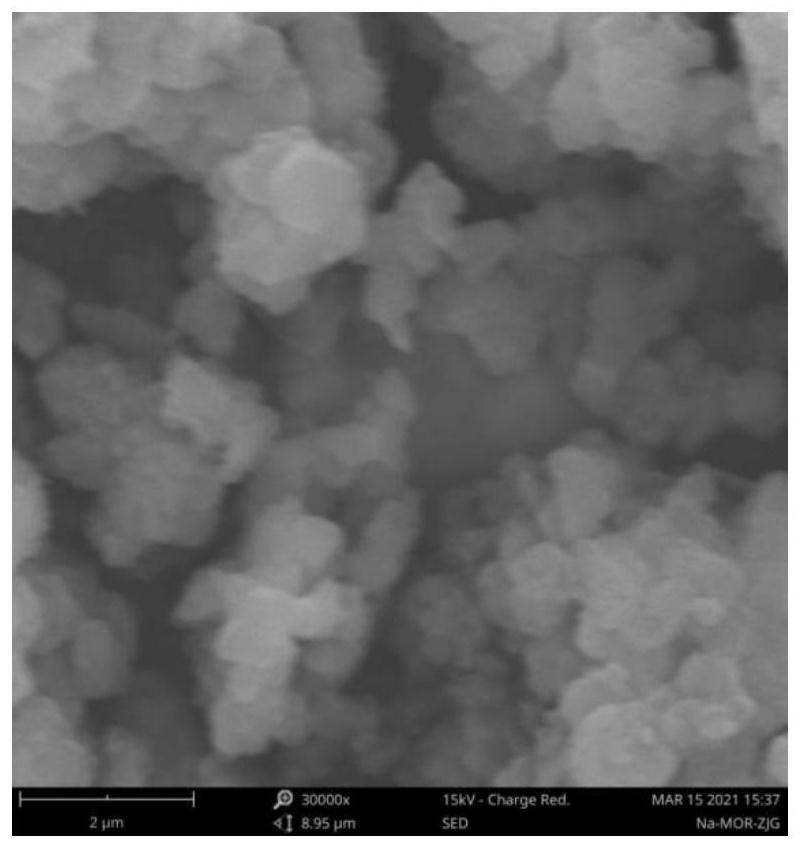

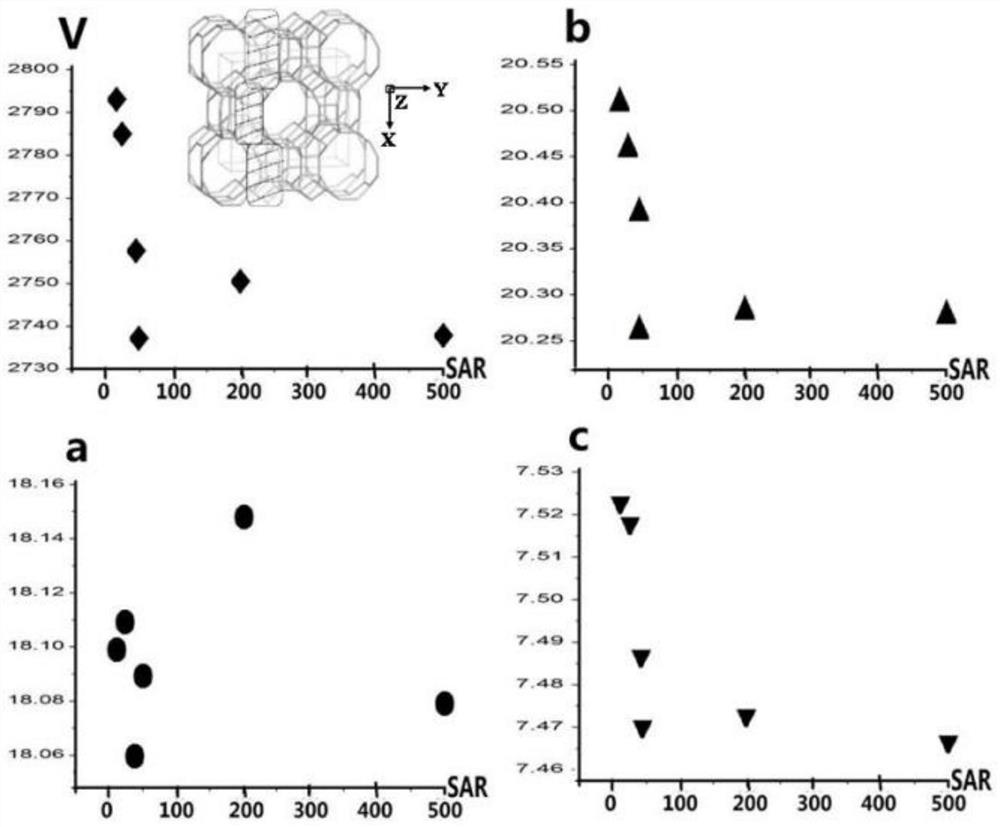

High-silicon mordenite and preparation method thereof

PendingCN114349020AImprove crystal structureGood microporous adsorption propertiesMordenite aluminosilicate zeoliteBenzene vaporMordenite

The invention relates to high-silicon mordenite and a preparation method thereof, and the preparation method comprises the following steps: step S1, treating Na-MOR with SAR = 14, which is hydrothermally synthesized in a fluorine-free all-inorganic silicon oxide-aluminum oxide-water reaction mixture system, with a sulfuric acid solution to prepare H-MOR zeolite; s2, carrying out high-temperature steam roasting on the H-MOR zeolite; step S3, carrying out acid solution treatment on the roasted H-MOR zeolite; and S4, washing the H-MOR zeolite treated by the acid solution, filtering, and drying to prepare the hydrophobic MOR zeolite. The high-silicon mordenite is hydrophobic MOR zeolite, the hydrophobic coefficient of the high-silicon mordenite is larger than 1, the benzene vapor adsorption capacity of the high-silicon mordenite is larger than 5.4%, the water vapor adsorption capacity of the high-silicon mordenite is smaller than 4.5%, the BET surface area of the high-silicon mordenite is larger than 530 m < 2 > / g, and the micropore volume of the high-silicon The hydrophobic MOR zeolite with the hydrophobic coefficient H larger than 1 is prepared through water vapor roasting and subsequent acid treatment modification, and the hydrophobic MOR zeolite has the good micropore adsorption property.

Owner:FUYU ZHANGJIAGANG NEW MATERIALS TECH CO LTD

Processing method of high-strength polyethylene twisted netting

InactiveCN107012582ALow shrinkageGuarantee product qualityHeating/cooling textile fabricsConjugated synthetic polymer artificial filamentsBenzene vaporPolymer science

The invention belongs to the technical field of fishing gear processing, and in particular relates to a processing method of high-strength polyethylene twisted net sheet, which includes primary benzene steam setting, cooling and secondary hot steam setting. Compared with the prior art, the present invention has the following advantages: in the present invention, when the linear density is slightly increased by adding compounding additives to the high-strength polyethylene monofilament raw material, the tensile mechanical properties are also improved to a certain extent, and at the same time The woven mesh is stretched once and the benzene steam is set for the first time to modify the mesh, so that the spatial structure is more complex, the molecular structure is tighter, and the strength is increased; the mesh is stretched twice and the hot steam is set, reducing The retraction rate of the mesh is improved, and the product quality of the fishing net is guaranteed. Compared with the mesh of the same specification, the breaking strength is increased by about 3.5%, and the scope of application is wider.

Owner:巢湖市强力渔业有限责任公司

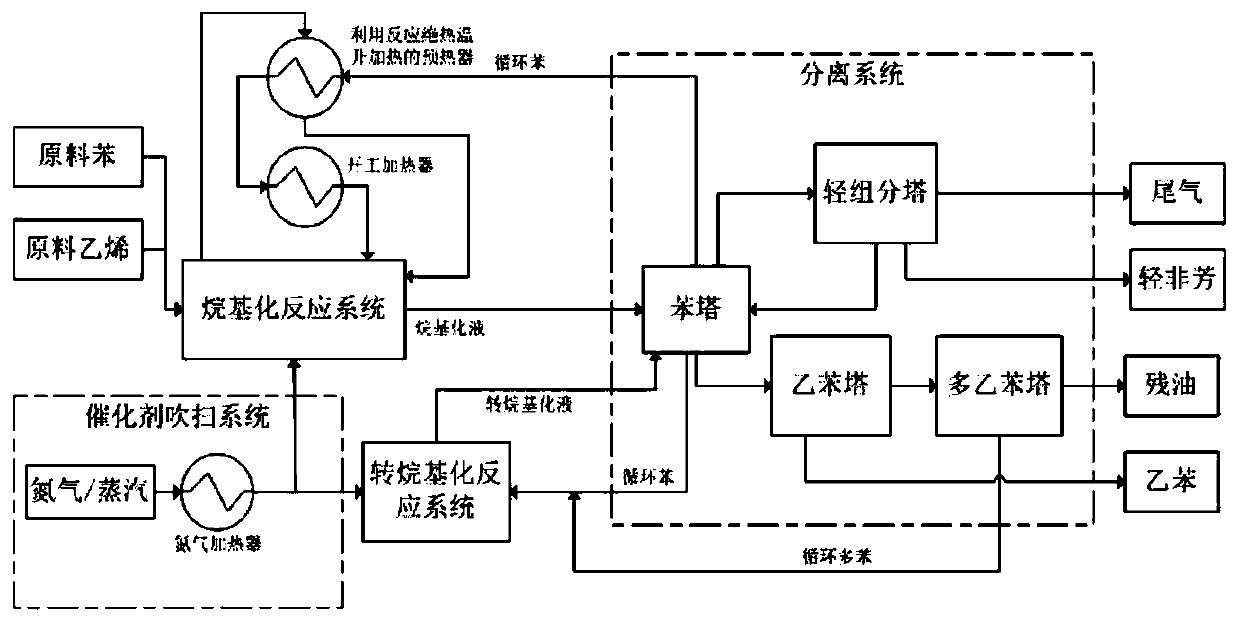

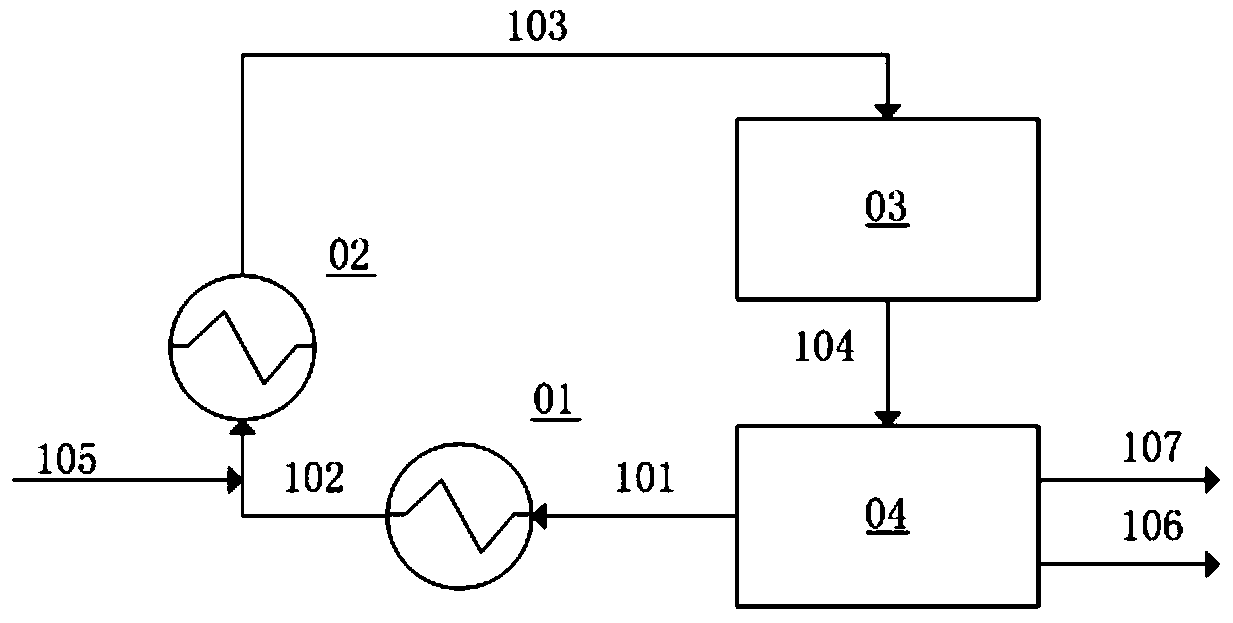

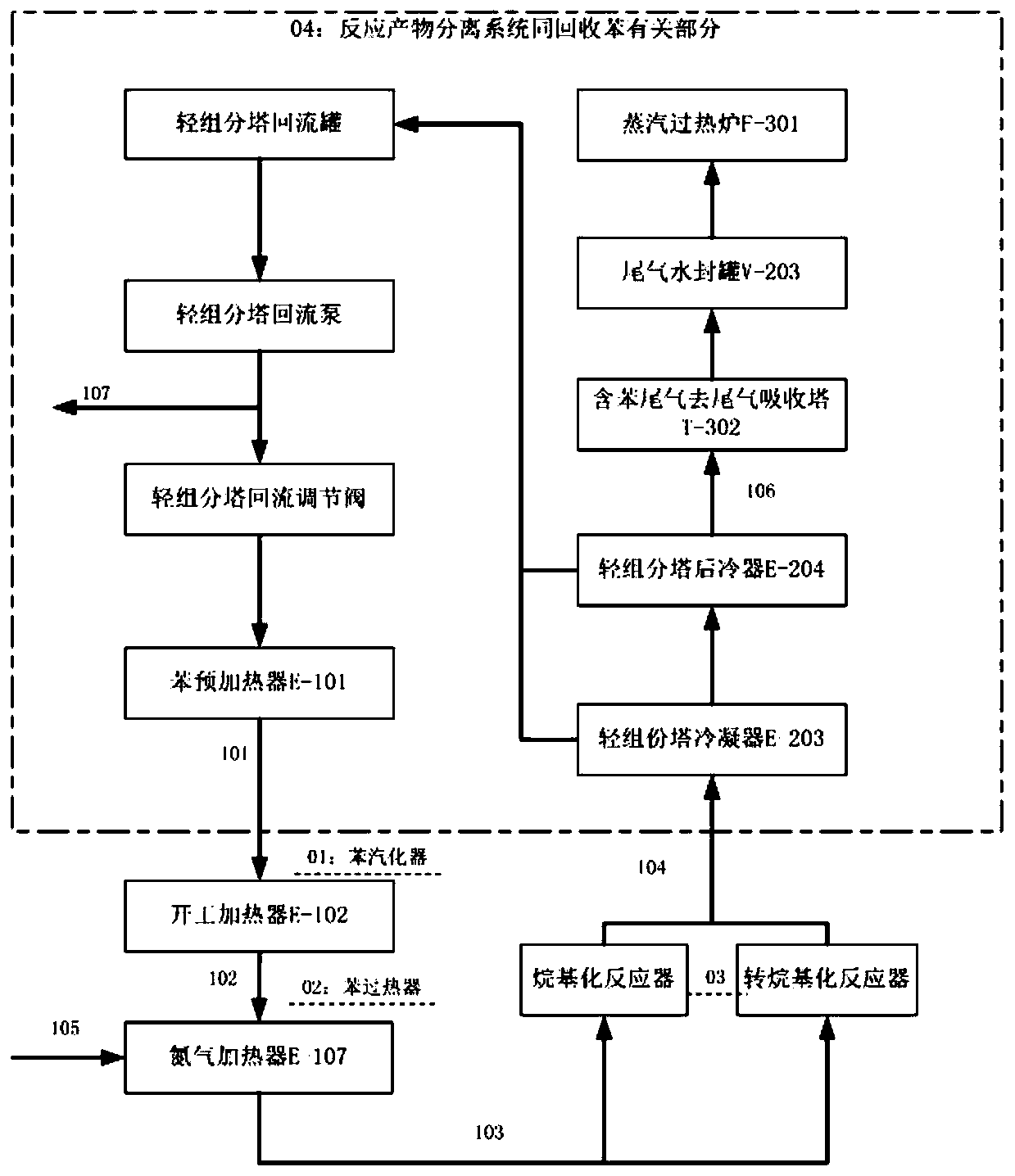

Method for removing liquid-phase benzene retained in catalyst of liquid-phase ethylbenzene alkylation and transalkylation reactor through superheated benzene steam purging

PendingCN111569954ASuccessful removalSolve the problem of damaging the aluminum skeleton of the catalystHydrocarbon purification/separationCatalyst regeneration/reactivationBenzene vaporPtru catalyst

The invention discloses a method for removing liquid-phase benzene retained in a catalyst of a liquid-phase ethylbenzene alkylation and transalkylation reactor through superheated benzene steam purging. The superheated benzene steam is used as a purging medium and can replace most of the existing steam purging methods for ethylbenzene production devices by a liquid phase method so that the servicelife of the catalyst of an ethylbenzene unit is prolonged, and the selectivity and the conversion rate of a regenerant are prevented from deteriorating; compared with a method for removing the liquid-phase benzene in the catalyst through hot nitrogen purging, the method is beneficial to reducing the equipment investment of a circulating nitrogen system and reducing the one-way purging consumptionof nitrogen, and the economic benefit is more outstanding.

Owner:CHANGZHOU RUIHUA CHEM ENG&TECH

Preparation method of hydroxyl-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer/carbon nanotube conductive composite film

The invention discloses a preparation method of a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method comprises the following steps: carrying out in-situ coupling reaction on a hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer and uniform hydroxy multiwall carbon nanotubes subjected to ultrasonic dispersion to form a polyurethane compound by using hexamethylene diisocyanate, coating a film, and drying at room temperature to obtain the hydroxy-functionalized carboxyl-terminated polybutadiene-acrylonitrile copolymer / carbon nanotube conducting composite film. The method is simple to operate and easy for film formation, and has the advantages of low energy consumption, short operation time and favorable dispersibility of the carbon nanotubes; the obtained conducting composite film can implement detection on benzene and methylbenzene solvent vapor, has the advantages of short response time, high sensitivity and high selectivity, can not cause permanent damage to the conducting film, can implement the ppm-level detection on the benzene vapor, and can implement repeated use.

Owner:SHAANXI NORMAL UNIV

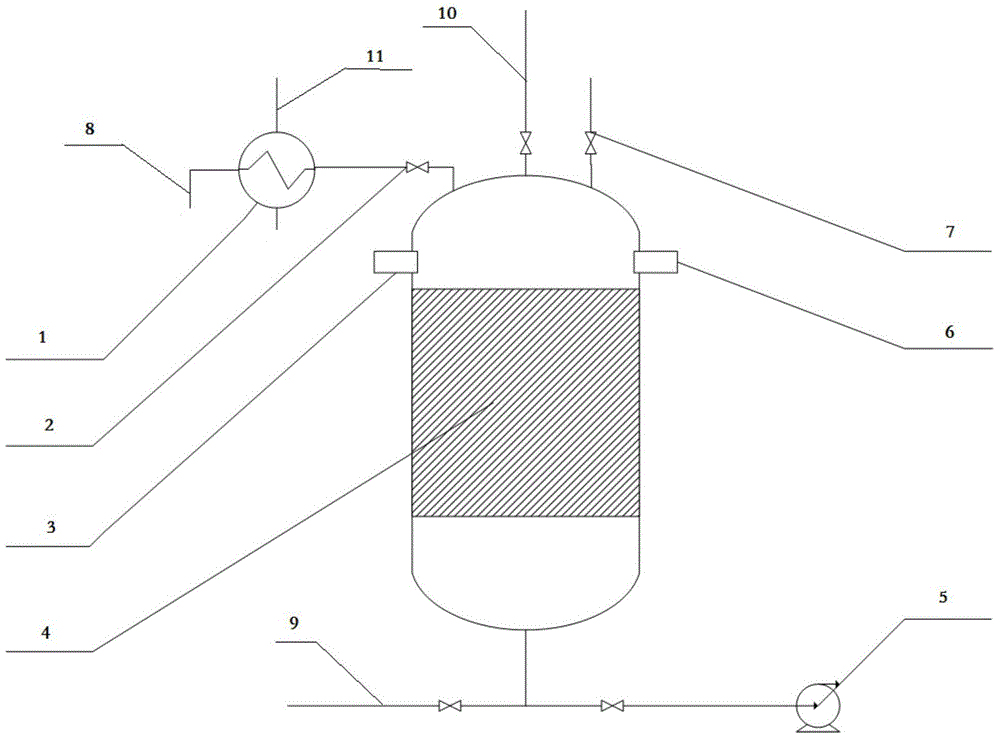

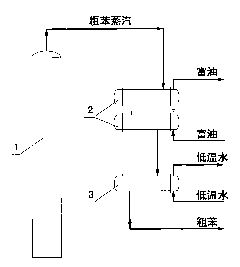

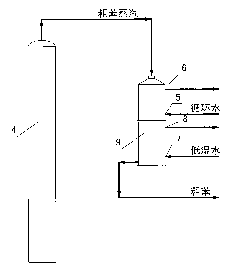

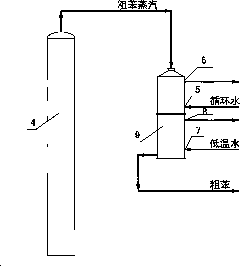

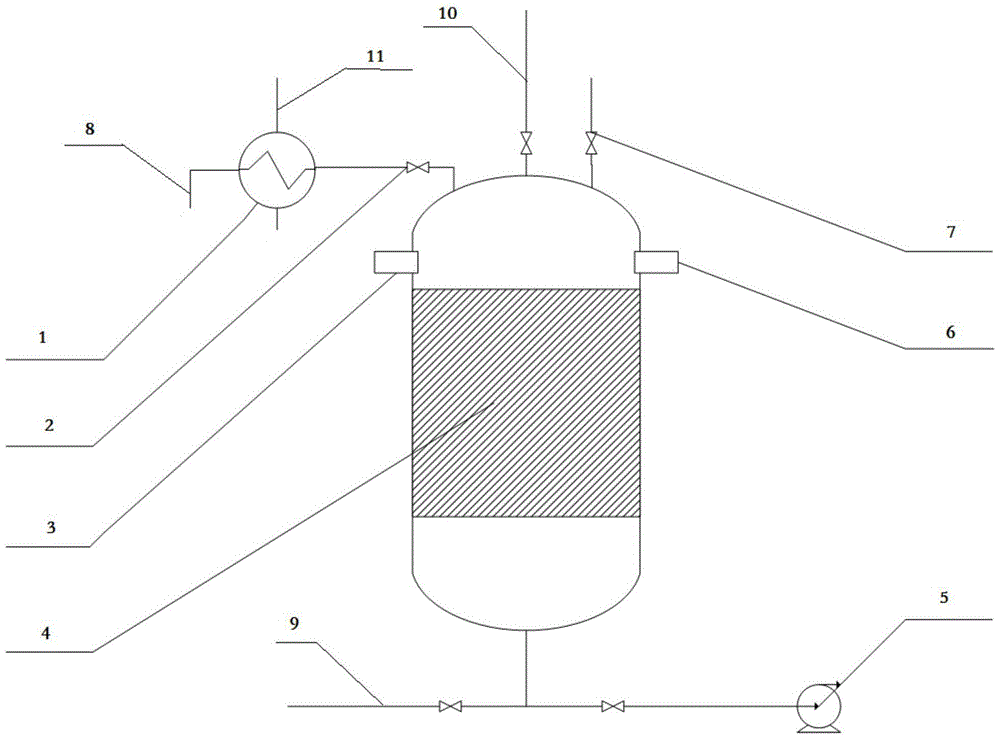

Process and device for condensing and cooling crude benzene vapor

InactiveCN101797443AReduce investmentReduce land occupationFractional condensation purification/separationVapor condensationBenzene vaporCoal chemical industry

The invention relates to the technical field of coal chemical industry and discloses a process and a device for condensing and cooling crude benzene vapor. The process comprises the following steps of: exchanging heat with crude benzene vapor coming from a benzole scrubber by using circulating water as a heat exchange medium and cooling the crude benzene vapor cooled by the circulating water by using low-temperature water, wherein the processes of circulating water cooling and cooling water cooling are carried out in the same condensation cooler. The device is of a tank body structure, and the interior of the tank body is divided into two communicated areas, wherein the upper area is a circulating water cooling area, and the side part of the area is provided with a circulating water inlet and a circulating water outlet; and the lower area is a low-temperature water cooling area, and the side part of the area is provided with a low-temperature water inlet and a low-temperature water outlet. The process is used for replacing a rich oil heat exchange process of an original process by using the circulating water, thereby lightening the load of an oil-gas heat exchanger, reducing the temperature of the crude benzene vapor, and saving the dosage of low-temperature water and the operating cost.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

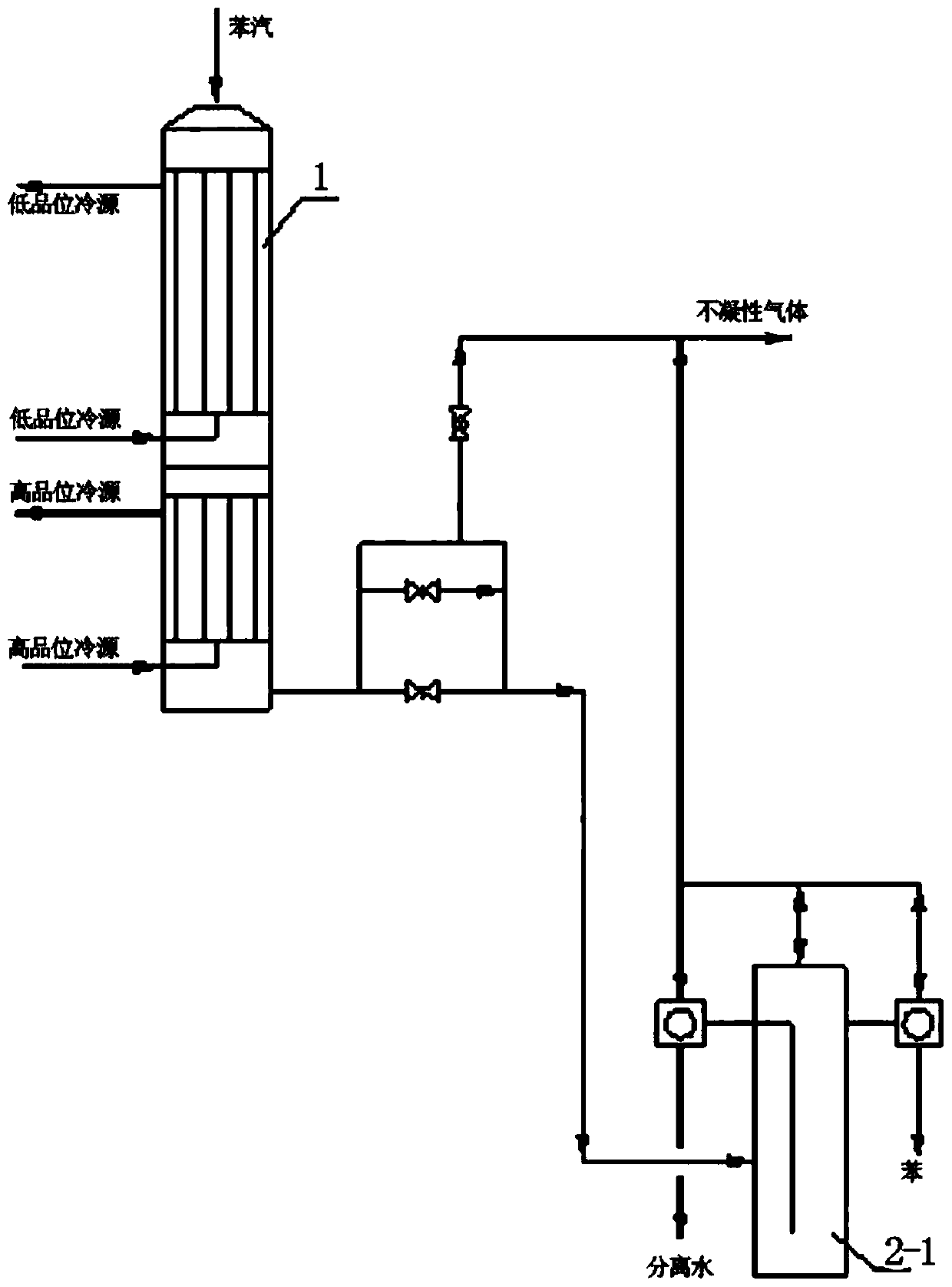

Technology and device for controlling continuous and stable discharge of non-condensable gas in benzene recovery system

ActiveCN105062575BImprove securityQuality assuranceCombustible gas purificationBenzene vaporGas phase

The invention relates to a process and device for controlling the continuous and stable discharge of non-condensable gas in a benzene recovery system. The benzene vapor generated at the top of the benzene removal tower enters a condensing cooler and is cooled by a low-grade cold source and a high-grade cold source in sections to obtain Benzene-water mixture; the benzene-water mixture flows into the gas-liquid mass transfer heat transfer device and flows to the lower benzene-water separator, and the gas phase in the condensing cooler enters the benzene-water separator and flows to the upper gas-liquid mass transfer heat transfer device Internal flow, the pressure inside the control system is ‑80kPa~45kPa; in the gas-liquid mass transfer heat transfer device, the gas-liquid two-phase countercurrent contact, the high-boiling organic components in the gas phase are condensed into the benzene-water separator, and the non-condensable gas is cooled Continuous and steady discharge from the top. The invention can continuously and stably discharge the non-condensable gas in the benzene recovery system, while ensuring the quality and yield of crude (light) benzene, it can eliminate the unstable factors in the operation of the benzene removal tower, and improve the safety of the benzene recovery system; and The process is simple, the equipment layout is reasonable and compact, and the installation and maintenance are convenient.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

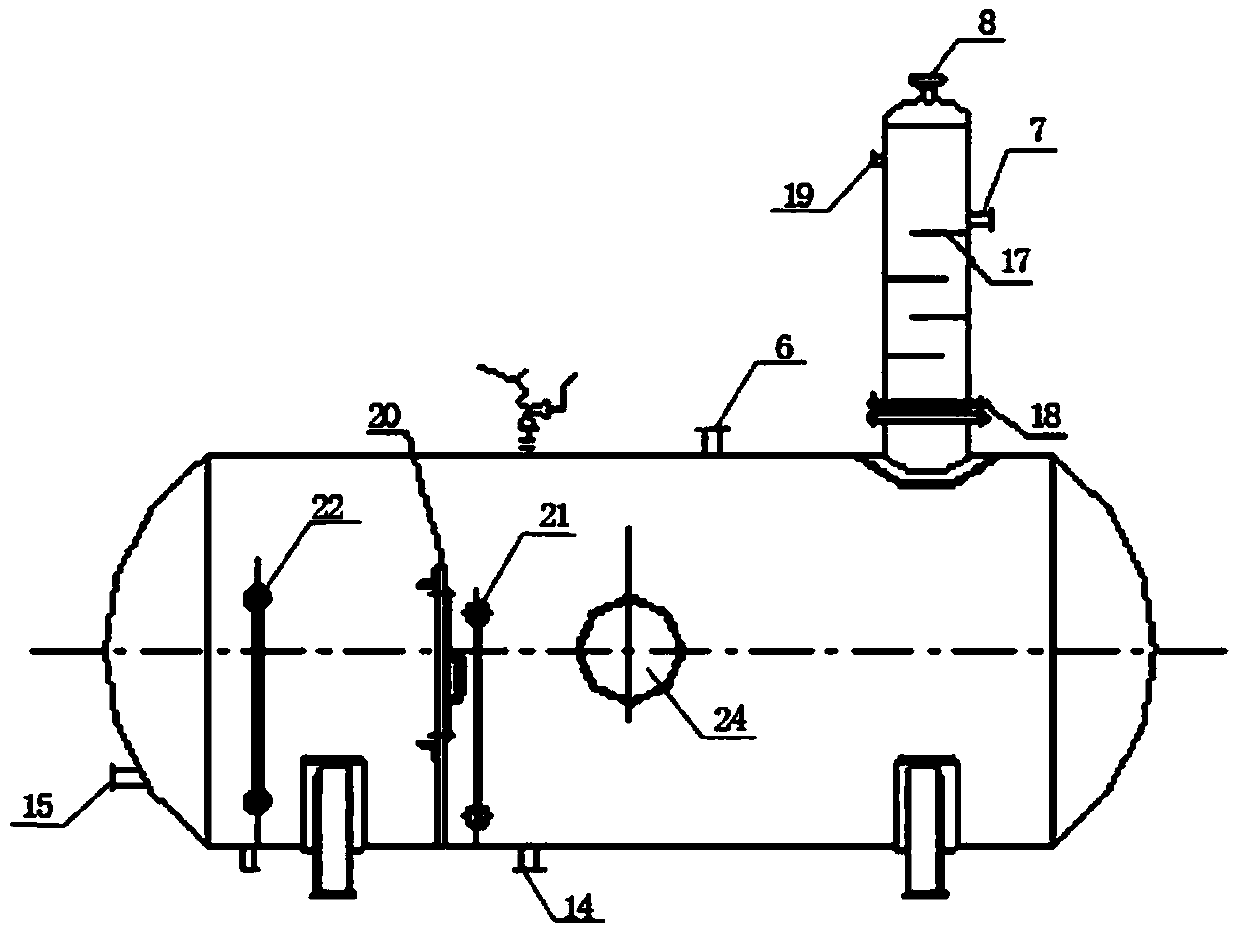

Separation system for reducing vapor-liquid entrainment of vapor phase tube of debenzolization tower

InactiveCN103032679AExtended service lifeReduce erosion corrosionPipeline systemsVapor liquidBenzene vapor

The invention discloses a separation system for reducing vapor-liquid entrainment of a vapor phase pipe of a debenzolization tower. The separation system for reducing the vapor-liquid entrainment of the vapor phase pipe of the debenzolization tower comprises a liquid sealing pipe and a liquid sealing discharge pipe, wherein the liquid sealing pipe is formed by connecting three straight pipes and two U-shaped elbow pipes and arranged below a vapor phase inlet main pipe, and the bottom end of one lower elbow pipe and the vapor phase inlet main pipe are located on the same level line. An upper end opening of the liquid sealing pipe is connected with the lower end of a vertical pipe of the vapor phase inlet main pipe, and a lower end opening of the liquid sealing pipe is connected on a vapor phase outlet main pipe. The liquid sealing height of the liquid sealing pipe is H, wherein H=U / rho * g, in the formula, U is pressure of crude benzene steam, rho is the density factor of the crude benzene steam, and g is acceleration of gravity. The upper end of the liquid sealing discharge pipe is connected with the lower end of the lower elbow pipe of the liquid sealing pipe, and the lower end of the liquid sealing discharge pipe is connected on a water discharge pipe at the bottom of a crude benzene separation groove. By means of the separation system for reducing the vapor-liquid entrainment of the vapor phase pipe of the debenzolization tower, vapor and liquid in the crude benzene steam escaping from the debenzolization tower can be effectively separated, liquid phase entrainment in a crude benzene vapor phase is greatly reduced after separation, and erosion corrosion of an inlet pipe of an oil-gas heat exchanger and erosion corrosion of a body of the oil-gas heat exchanger are lightened.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Activated carbon desorption method of activated carbon tank in benzene vapor recovery unit

ActiveCN105080287BImprove desorption efficiencyImprove desorption and desorption efficiencyDispersed particle separationCombustible gas purificationActivated carbonBenzene vapor

The invention relates to an activated carbon desorption method of an activated carbon canister in a benzene vapor recovery device. The method mainly solves the problem that activated carbon is prone to desorption at low temperature in the prior art. According to the technical scheme, the activated carbon desorption method comprises the steps that after adsorption of the activated carbon canister in the benzene vapor recovery device is saturate, an activated carbon bed layer is regenerated on the vacuum condition; after the pressure in the activated carbon canister is reduced to 5.0 kPa, air is blown into a heat exchanger to exchange heat with vapor to reach 40-60 DEG C and then enters the activated carbon bed layer in the activated carbon canister for replacement, and more benzene molecules are desorbed from the activated carbon bed layer and enter the follow-up treating process through a vacuum pump and a compressor. The activated carbon desorption method can be used for desorption of the activated carbon canister in the benzene vapor recovery device.

Owner:CHINA PETROLEUM & CHEM CORP QINGDAO RES INST OF SAFETY ENG +1

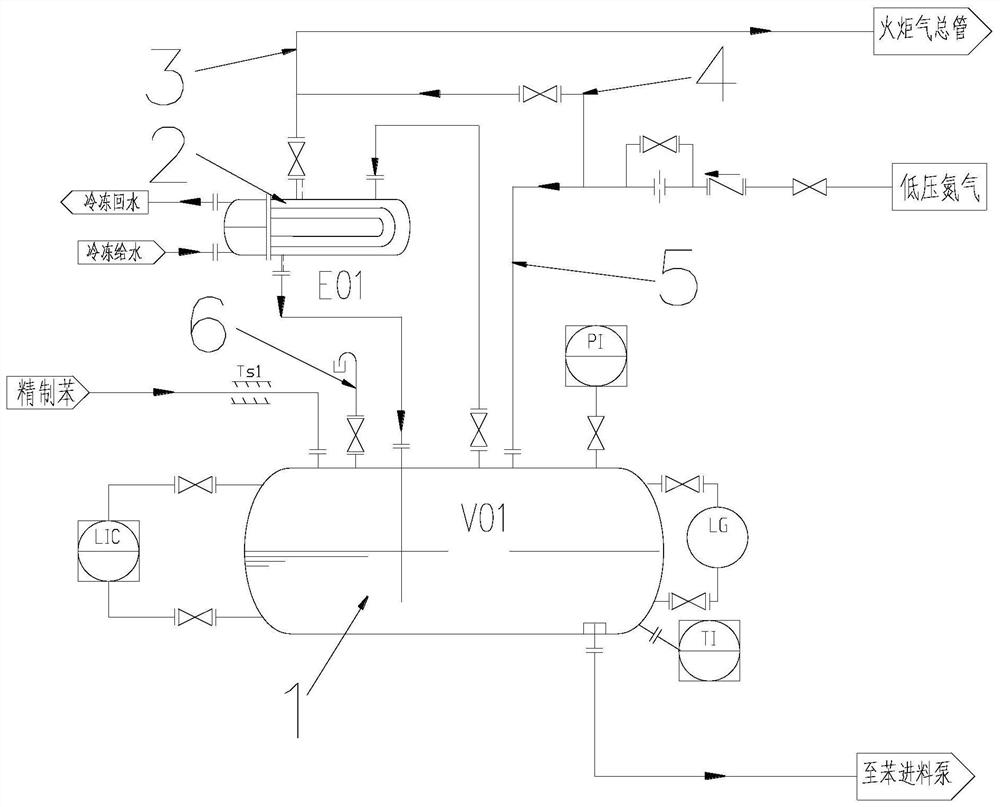

An environment-friendly recovery system and process for releasing air from a chemical feed tank

ActiveCN106831329BImprove utilization efficiencyAvoid pollutionPreparation by hydrogenationBenzene vaporEnvironmental engineering

The invention discloses an environment-friendly recycling system and process for air discharged from a chemical feeding trough. The environment-friendly recycling system comprises a feeding trough and a condenser, wherein after a raw material benzene enters the feeding trough, liquid benzene enters a benzene feeding pump of a hydrogenation reactor from a liquid outlet of the feeding trough, benzene vapor in the feeding trough enters the condenser from a gas outlet of the feeding trough, the condensed liquid benzene is returned into the feeding trough from a liquid outlet of the condenser, and a gas outlet of the condenser is connected to a flare gas main pipe. By adopting the environment-friendly recycling system, the benzene vapor in the feeding trough can be sufficiently utilized, and the utilization rate of the raw material benzene can be increased; and the air pollution can be reduced.

Owner:LIAOCHENG LUXI POLYCARBONATE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com