Test device for simulating protection time of canister to benzene vapor and use method

A test device and protection time technology, applied in the direction of simultaneous control of multiple variables, non-electric variable control, instruments, etc., can solve the problems of inability to change the temperature and humidity of benzene vapor, difficulty in changing the concentration of benzene vapor, high detection cost, etc., to save research Cost, comprehensive test conditions, and high safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

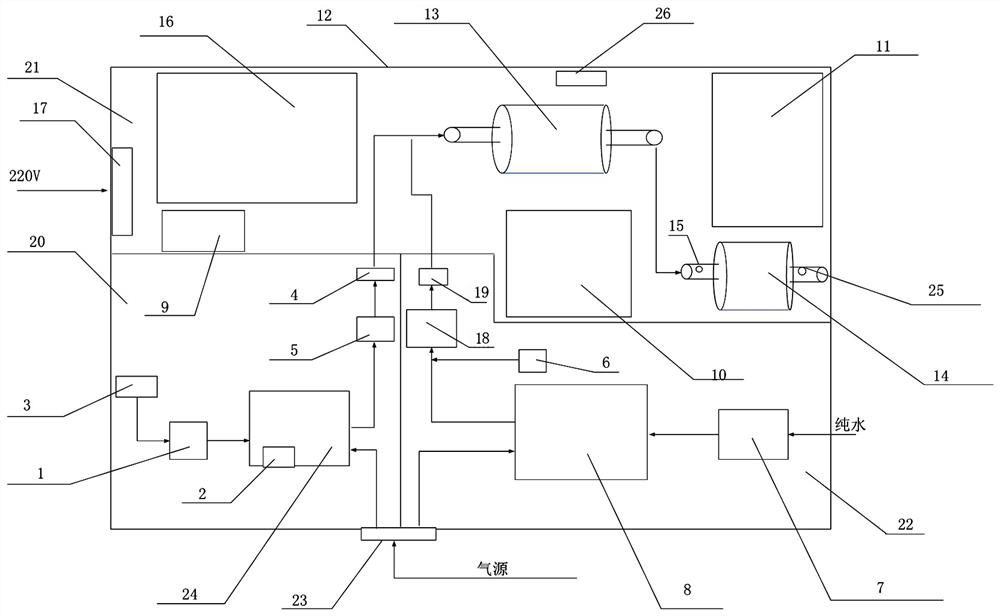

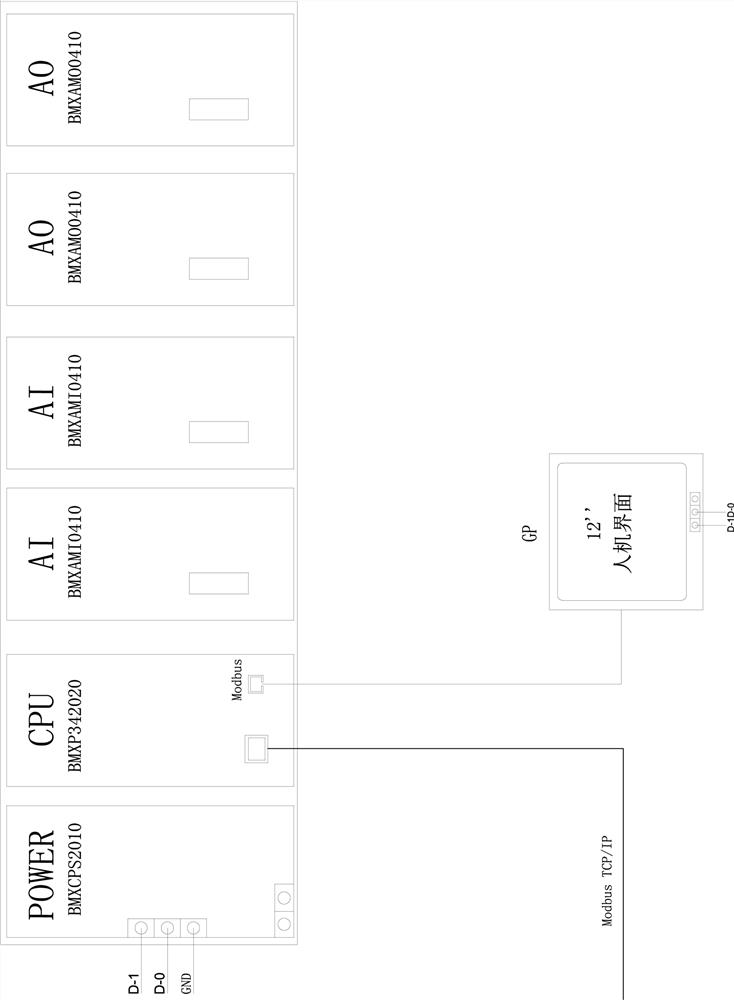

[0043] like Figure 1~Figure 8 Among them, a test device for simulating the protection time of a canister against benzene vapor comprises a box body 12, which is divided into a benzene generation chamber 20, a constant temperature chamber 21 and a humidity generation chamber 22; the benzene generation chamber 20 and the humidity generation chamber 22; Humidity generation chamber 22 is connected with air source interface 23; Benzene generation chamber 20 is provided with reagent bottle 3 and heating system; Humidity generation chamber 22 is provided with humidification system; Constant temperature chamber 21 is provided with mixing tank 13 and A simulated canister 14; a man-machine interface 16 and a switching power supply 17 are arranged outside the constant temperature chamber 21.

[0044] Further, the switching power supply 17 converts the 220V external power supply into a suitable voltage for use by the test device.

[0045] Preferably, the heating system includes a heatin...

Embodiment 2

[0058] A method for using a test device for simulating the protection time of a canister against benzene vapor, comprising the following steps:

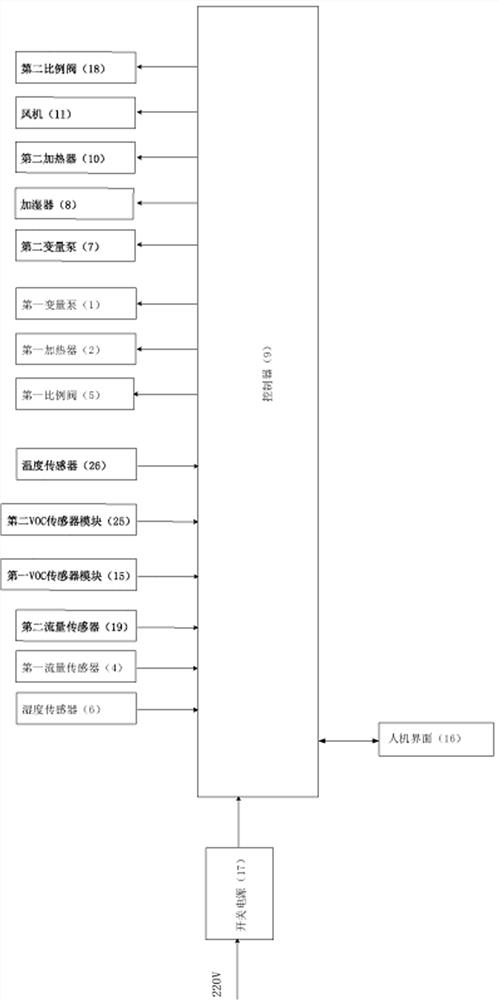

[0059] S1, the first variable pump 1, the first heater 2, the first flow sensor 4, the first proportional valve 5, the humidity sensor 6, the second variable pump 7, the humidifier 8, the controller 9, and the second heater 10 , fan 11, first VOC sensor module 15, man-machine interface 16, second proportional valve 18, second flow sensor 19, second VOC sensor module 25 and temperature sensor 26 initialization;

[0060] S2, the controller 9 collects data from the humidity sensor 6, the first flow sensor 4, the first VOC sensor module 15, the second flow sensor 19, the second VOC sensor module 25 and the temperature sensor 26, so that the second heater 10 and the fan 11 start up;

[0061] S3, control the operation of the fan 11 through the feedback data of the temperature sensor 26, so that the temperature of the constant temperature ...

Embodiment 3

[0069] Work process and working principle of the present invention are:

[0070] When it is necessary to test the protection time of the canister against benzene vapor, the operator first fills the simulated canister with activated carbon of appropriate weight and thickness according to the actual canister, pours the benzene liquid reagent into the reagent bottle 3, and the gas source The interface 23 is connected to an external air source, and the second variable pump 7 is connected to pure water. During the working process, the controller 9 communicates with the man-machine interface 16, and the man-machine interface 16 can send commands to the controller 9 to adjust the humidity, concentration and flow of the intake air. The controller 9 collects data from the humidity sensor 6, the first flow sensor 4, the first VOC sensor module 15, the second flow sensor 19, the second VOC sensor module 25, and the temperature sensor 26; the controller 9 outputs signals to the second hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com