An environment-friendly recovery system and process for releasing air from a chemical feed tank

A feeding trough, environmental protection technology, applied in the direction of organic chemistry, hydrogenation preparation, etc., can solve the problems of reducing the utilization rate of raw material benzene, polluting the air with benzene vapor, and unable to transport benzene vapor, reducing energy consumption, increasing utilization efficiency, reducing The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

[0035] The pressure in the feed tank is 7.0KPaG, and the temperature is 40°C. After testing, the mass of benzene vapor in the feed tank accounts for about 20% of the mass of liquid benzene in the feed tank. Based on this, the present invention improves the process of the feed tank.

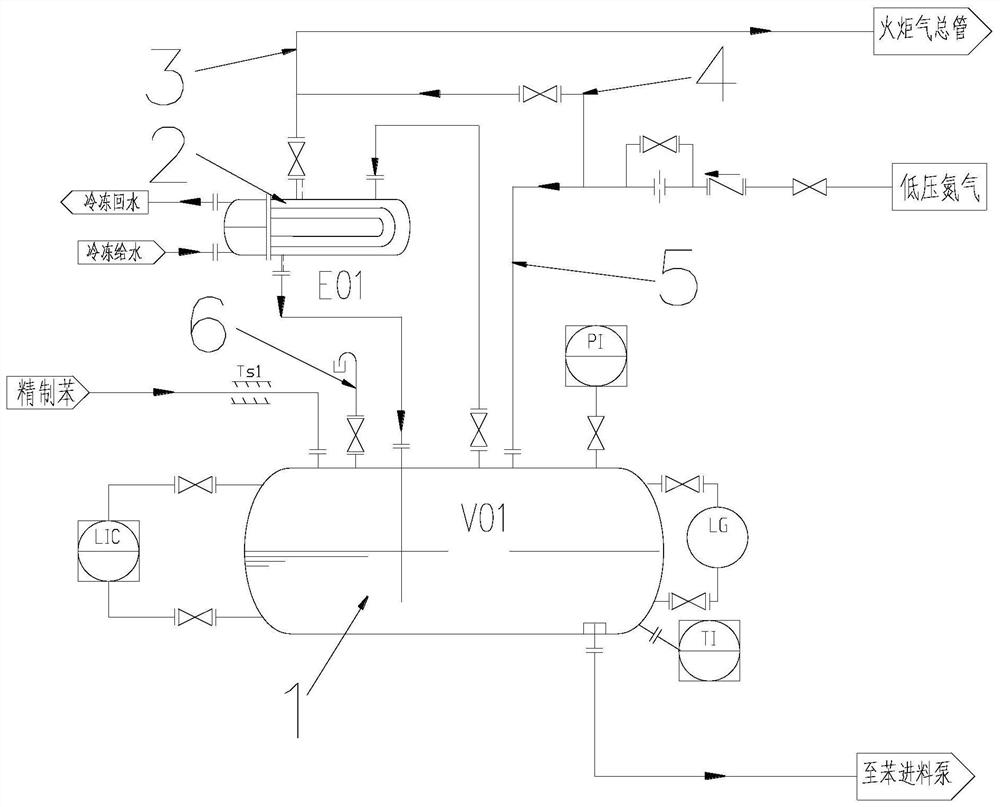

[0036] A kind of environment-friendly recovery system for releasing air from a chemical feed tank, such as figure 1 As shown, including feed tank 1 and condenser 2, raw material benzene enters feed tank 1 after being refined, and liquid benzene enters hydrogenation reactor benzene feed pump from the liquid outlet of feed tank 1, and the benzene in feed tank 1 The benzene vapor enters the condenser 2 from the gas outlet of the feed tank 1, and the condensed liquid benzene returns to the feed tank 1 from the liquid outlet of the condenser 2, and the gas outlet of the condenser 2 is connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com