Patents

Literature

840results about "Preparation by hydrogenation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fixed bed catalysts

InactiveUS6284703B1Promote hydrogenationHigh activityOrganic compound preparationPreparation by hydrogenationRheniumPowder mixture

A shaped, activated, fixed-bed Raney metal catalyst prepared by a method comprising preparing a mixture of powders comprising at least one catalyst alloy of (1) at least one catalytically active Raney process metal, a leachable alloy component and optionally a promoter, (2) at least one binder containing at least one pure Raney metal and (3) a moistening agent. Shaping, calcining and activating said catalyst and doping said catalyst with rhenium.

Owner:DEGUSSA AG

Hydroformylation process

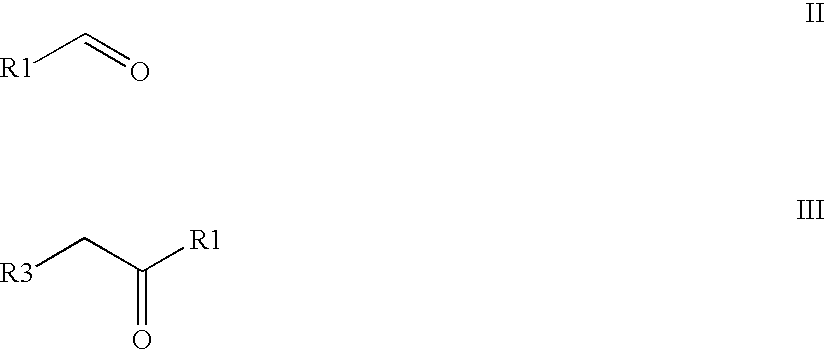

InactiveUS6049011AAvoid the needReduce processingPreparation by oxo-reaction and reductionPreparation by hydrogenationEthyleneHydrocarbon

PCT No. PCT / EP96 / 00163 Sec. 371 Date Oct. 15, 1997 Sec. 102(e) Date Oct. 15, 1997 PCT Filed Jan. 17, 1996 PCT Pub. No. WO96 / 22265 PCT Pub. Date Jul. 25, 1996A dilute ethylene stream, e.g., one produced by steam cracking, is oxonated to yield propanal, without the need to separate other lower hydrocarbons.

Owner:EXXON CHEM PAT INC

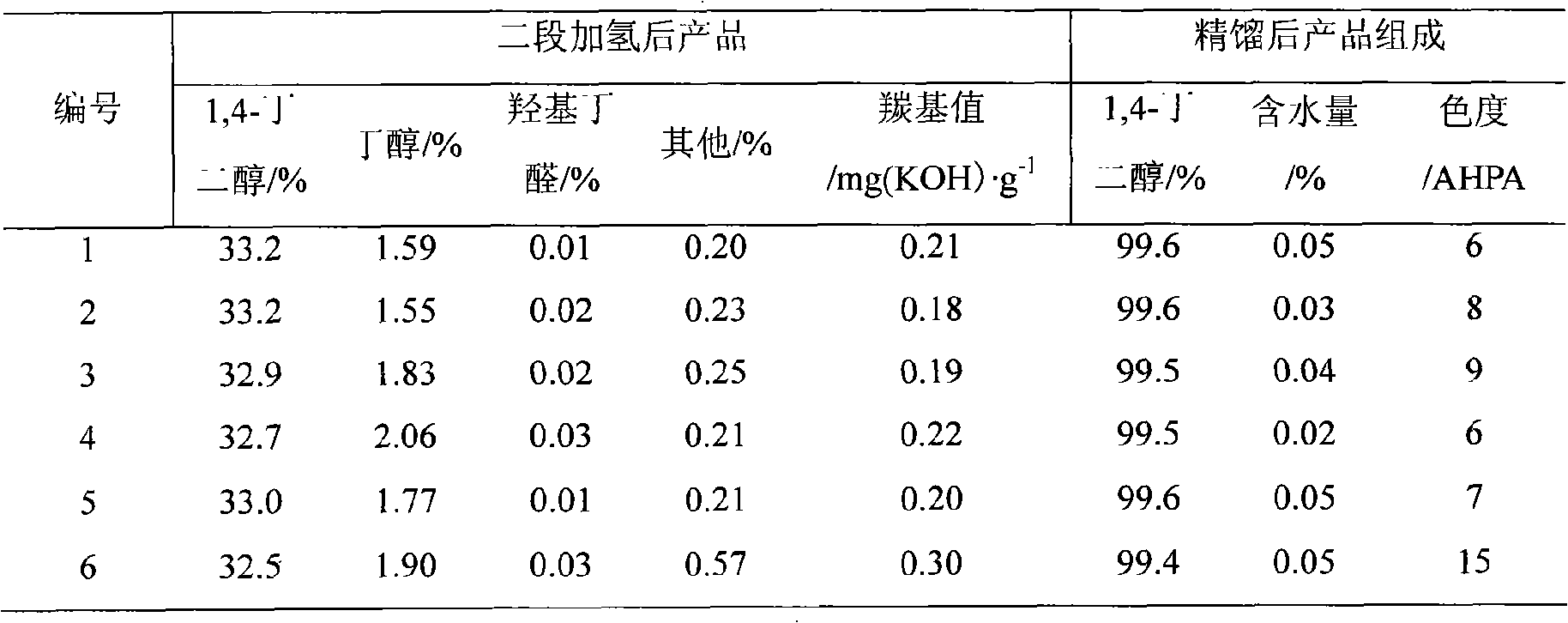

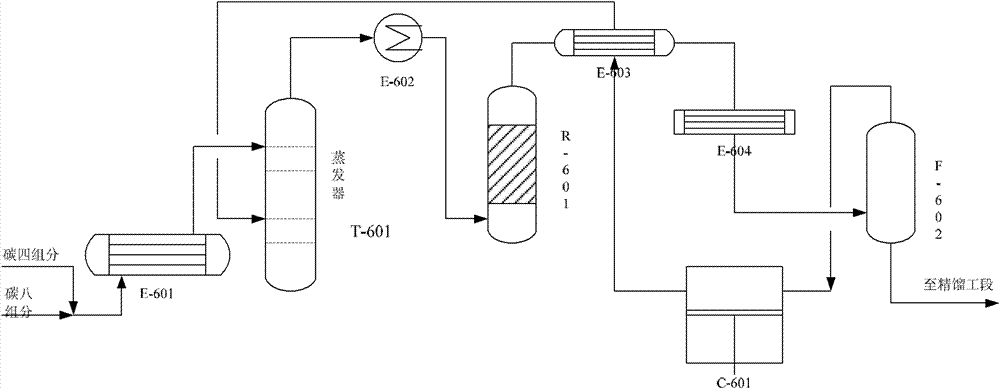

Preparation method of butanediol secondary hydrogenation catalyst by butynediol two-step hydrogenation

ActiveCN101306368AUniform depositionGood dispersionPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSURFACTANT BLEND

The invention provides a method for preparing a butanediol secondary hydrogenation catalyst through adopting the butynediol two-step hydrotreation, and the method comprises the following steps: an accelerant is introduced into an alumina carrier; the carrier is heated; mixed nickel complex solution containing organic nickel salt, inorganic nickel salt and surfactant is prepared; the mixed nickel salt solution is dipped on the heated carrier, and the catalyst product with the nickel content of 5-25 w% and the accelerant content of 0.001-6 w% can be obtained by drying, baking, deoxidizing and passivating. The catalyst can be used in the process of preparing the butanediol secondary hydrogenation by adopting the butynediol two-step hydrotreation, the carbonyl can be reduced to be lower than 0.2 mg (KOH)*g<-1>, and the contents of acetal and butylene glycol are enabled to be reduced to the lowest level. Through the subsequent rectification, the butylene glycol product with the purity more than or equal to 99.5 percent and the chromaticity lower than or equal to 10 AHPA can be produced.

Owner:SHANXI UNIV

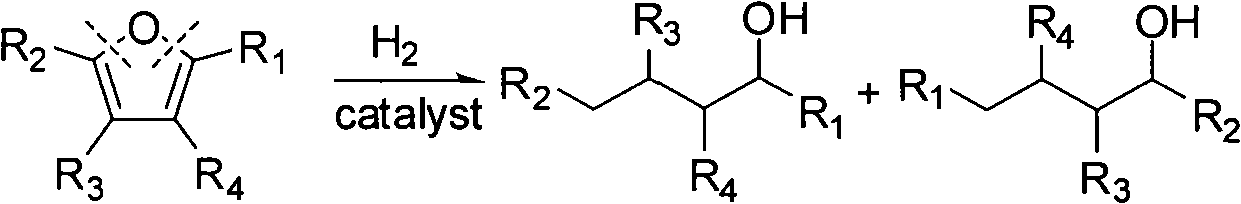

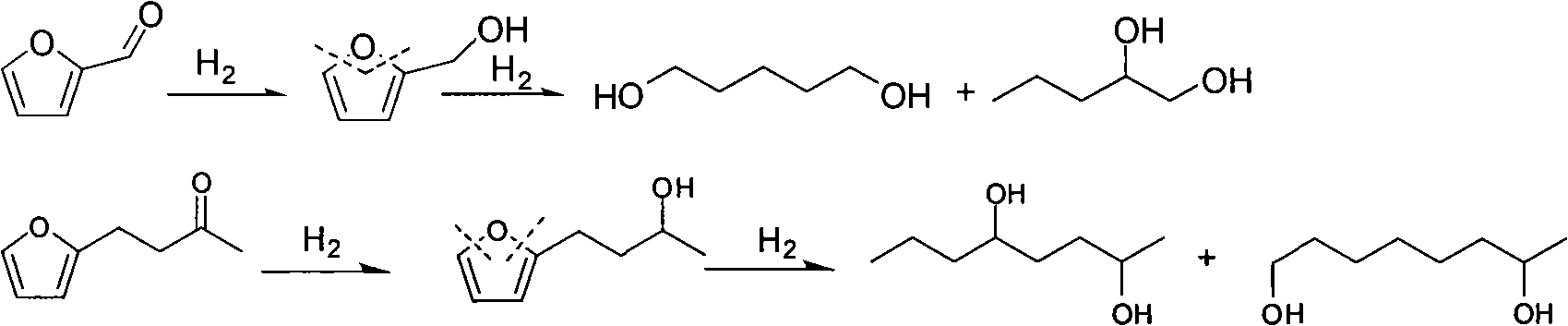

Catalyst used in ring-opening hydrogenation reaction of furan derivative

InactiveCN102068986AHigh activityGood choicePreparation by hydrogenationHydroxy group formation/introductionFuranHydrogenation reaction

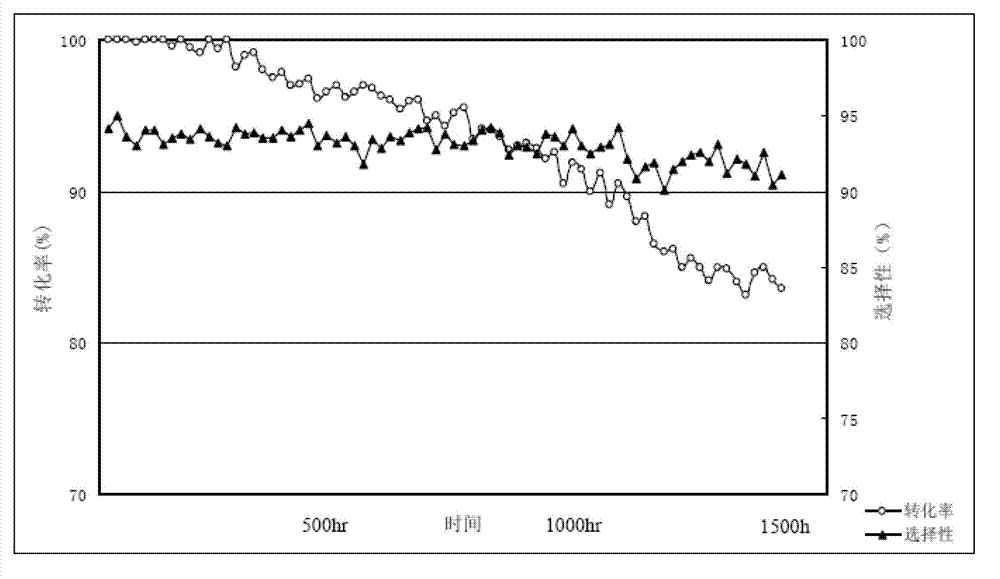

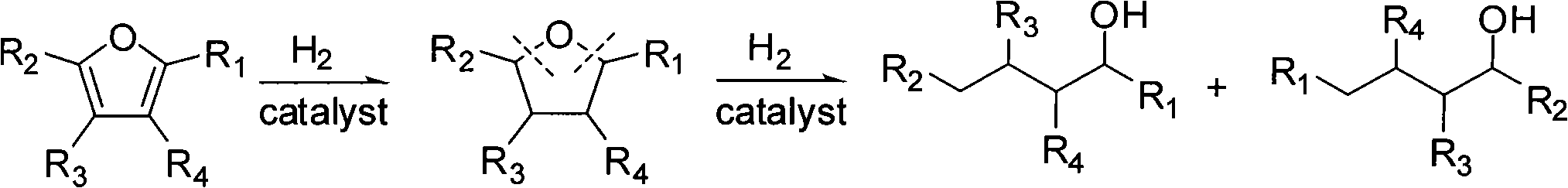

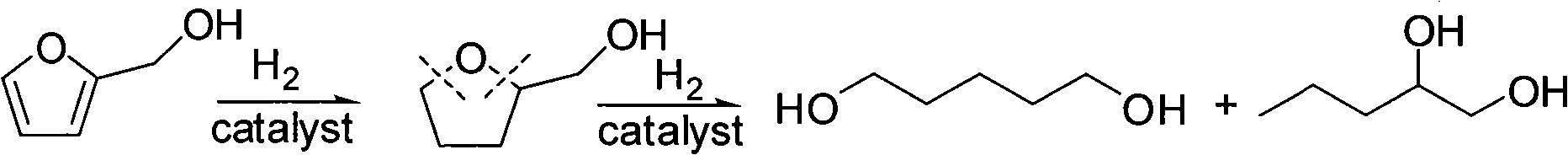

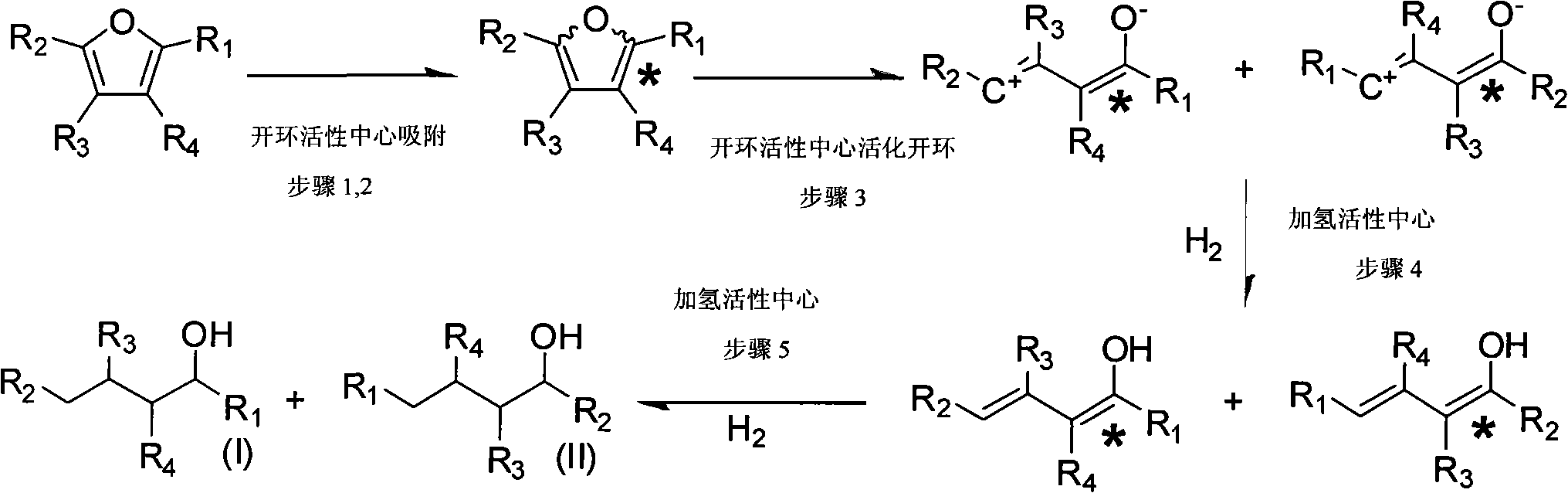

The invention relates to a catalyst used in a ring-opening hydrogenation reaction of a furan derivative. The catalyst is applied to direct preparation of one-step ring-opening hydrogenation of 1,5-pentanediol and 1,2-pentanediol by taking furfural or furfuryl alcohol serving as a raw material under a mild condition. The catalyst can provide two active ingredients, namely the ring-opening active center of a transition metal oxide and the hydrogenation active center of Pt, Pd, Rh, Ru, Co or Ni, wherein the active center of the transition metal oxide is mainly used for adsorbing furfural or furfuryl alcohol and directly hydrogenating a furan ring for opening the furan ring; and the hydrogenation active center of a noble metal or Co, Ni and the like is mainly used for quickly hydrogenating an intermediate material and hydrogenating subsequent enol so as to obtain 1,5-pentanediol and 1,2-pentanediol. An environmentally-friendly, reproducible, low-cost, mild and effective method is provided for producing 1,5-pentanediol and 1,2-pentanediol. The high-performance ring-opening hydrogenation catalyst is also suitable for the ring-opening hydrogenation reaction of other furan derivatives.

Owner:EAST CHINA UNIV OF SCI & TECH

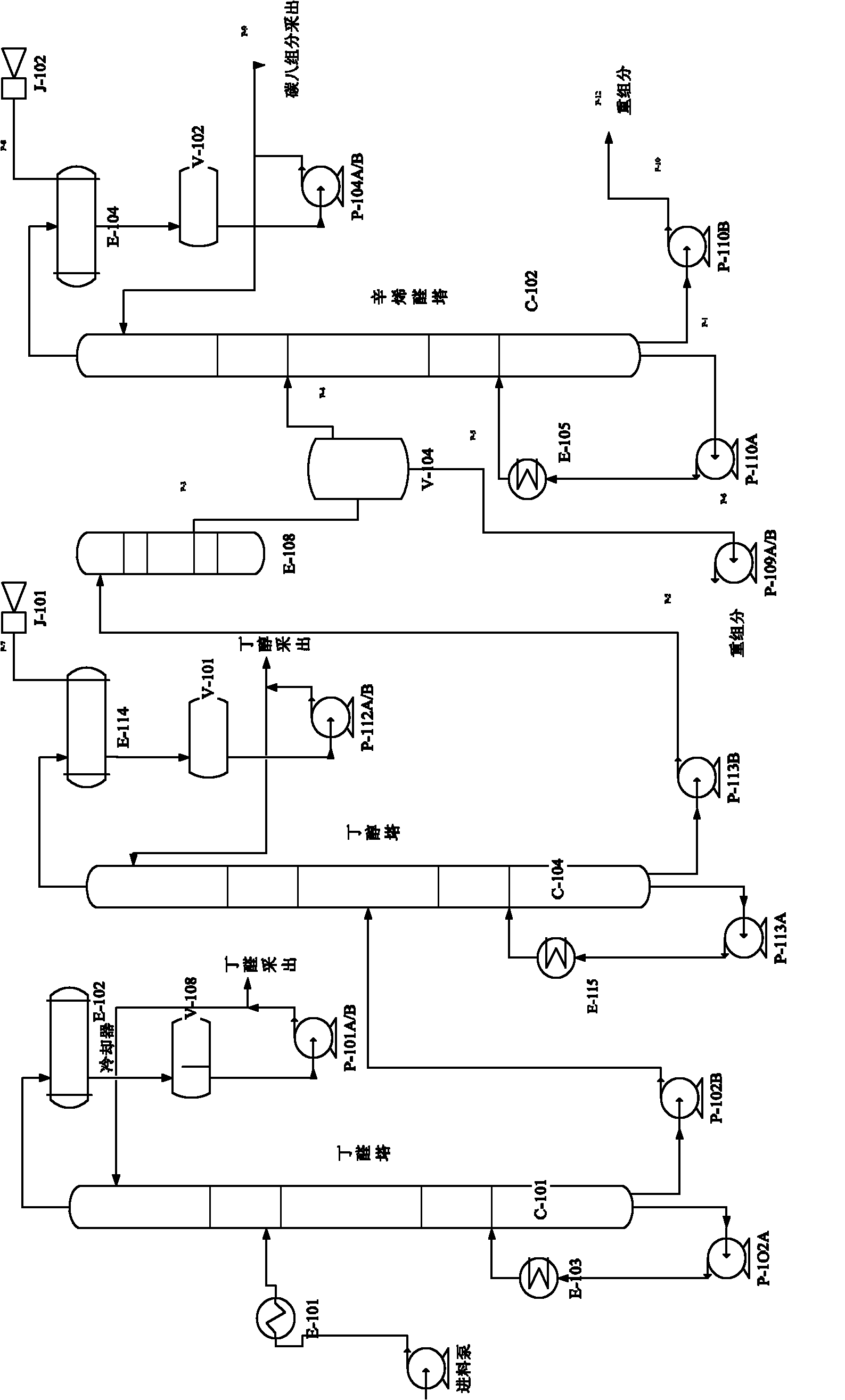

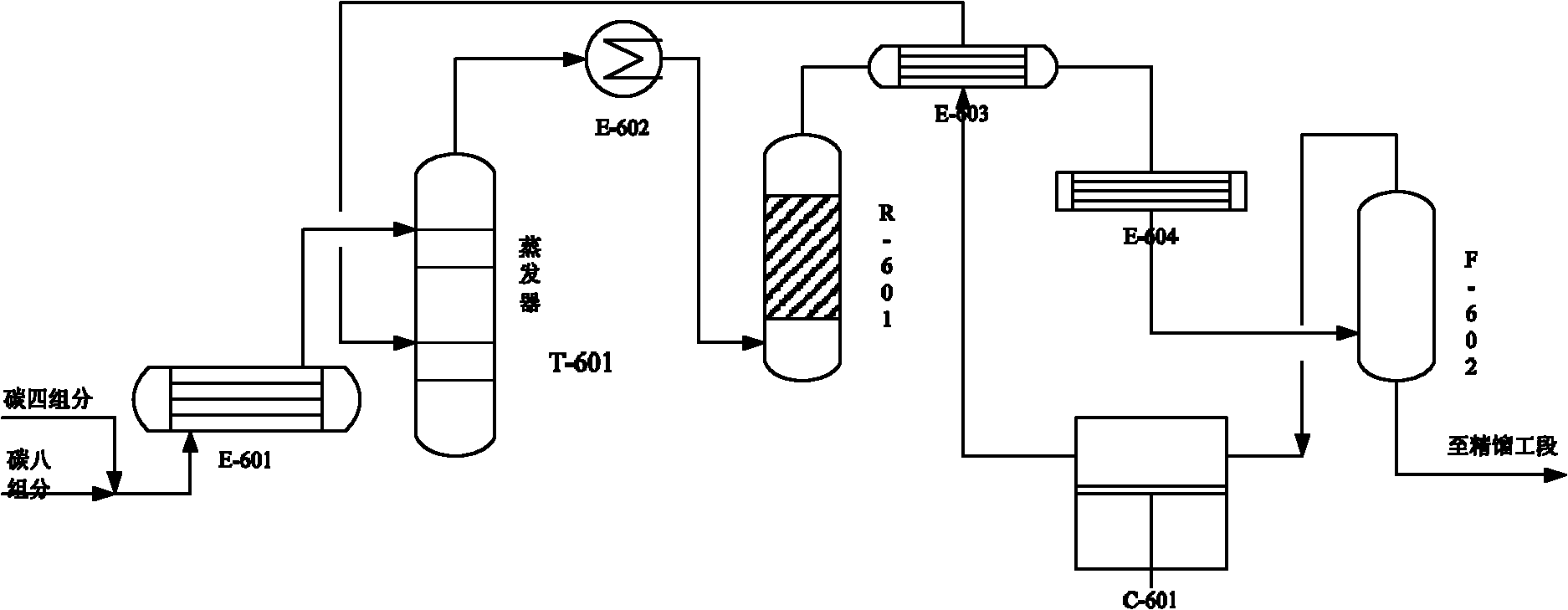

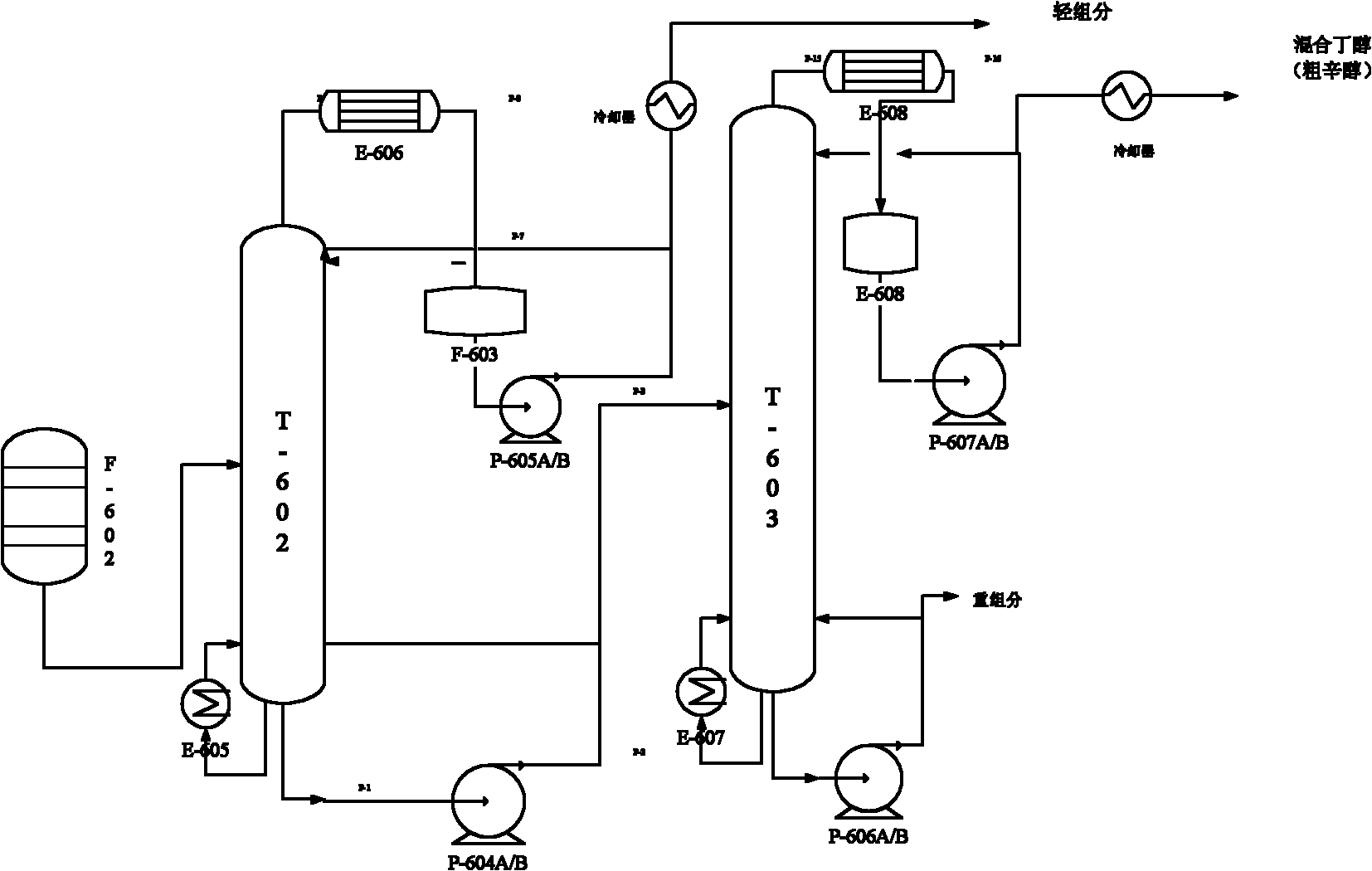

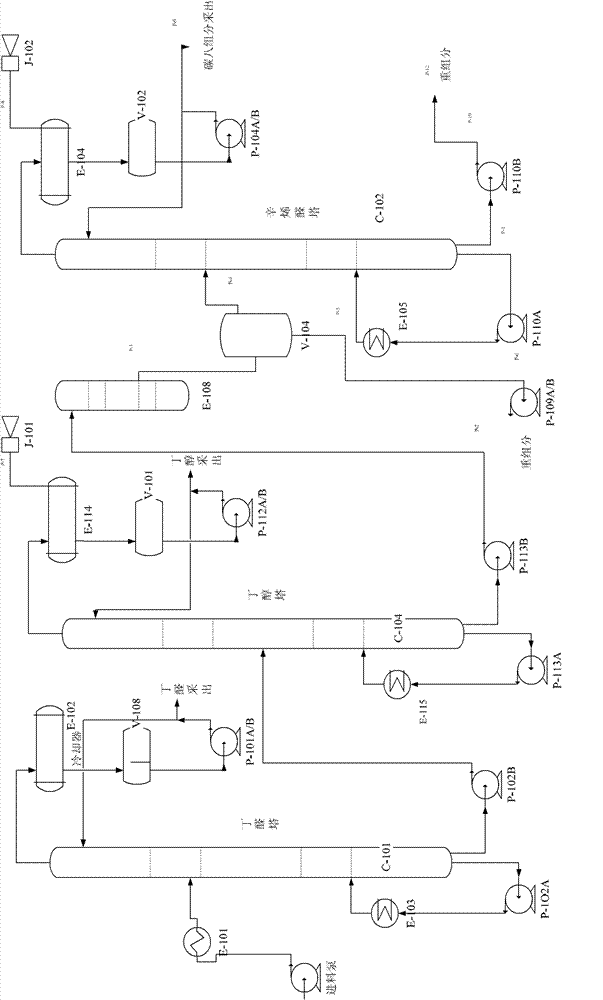

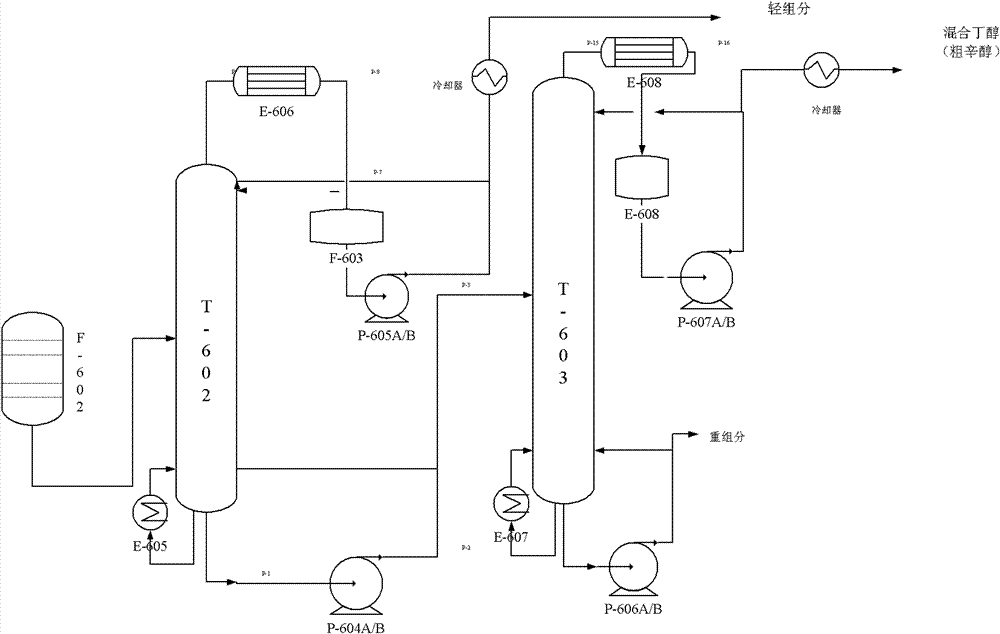

Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

ActiveCN101973846AReduce loadReduce processing costsOrganic compound preparationPreparation by hydrogenationLiquid wasteDistillation

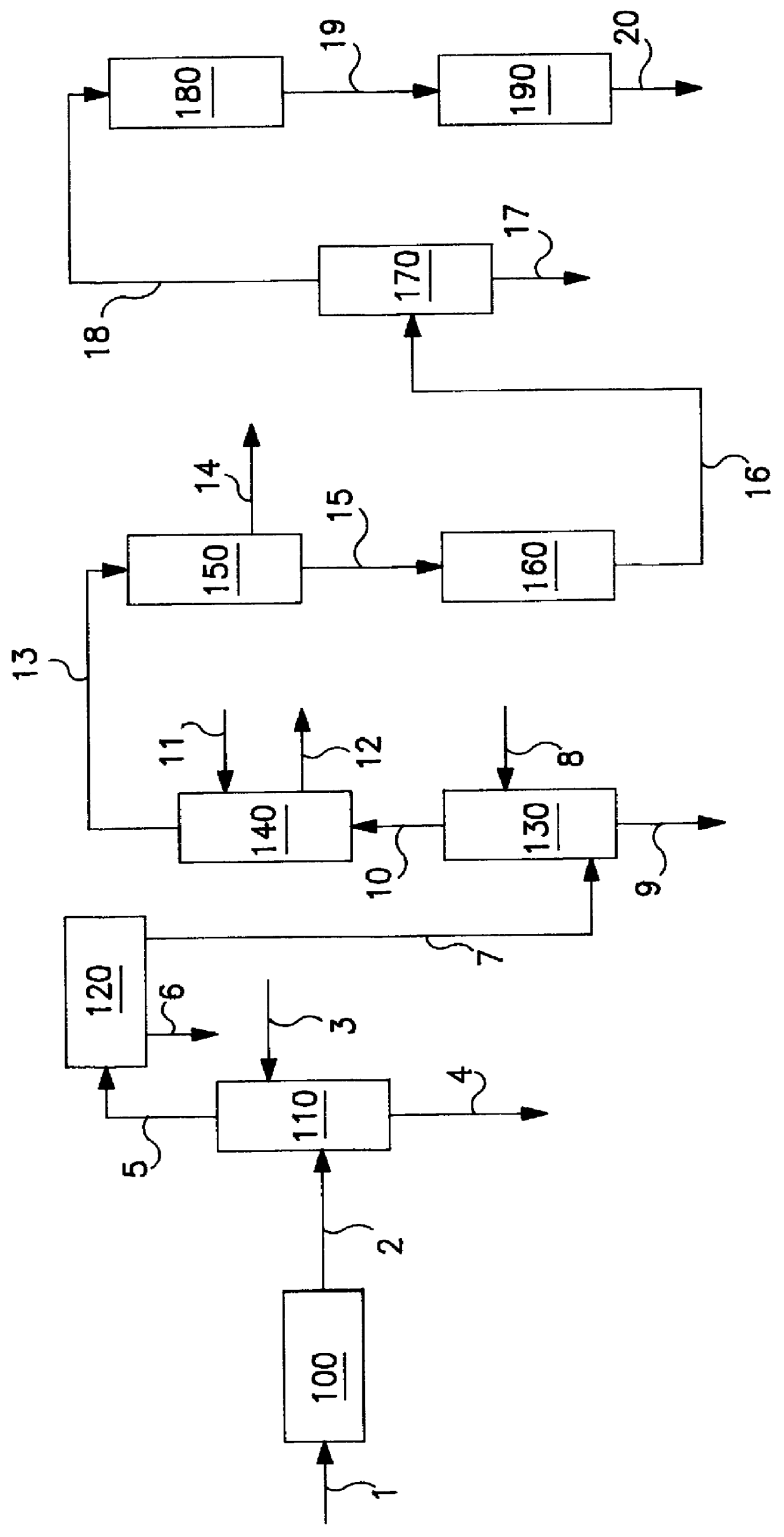

The invention discloses a method for producing mixed butanol and coarse octanol by using waste liquid discharged from an octanol device as a raw material, which belongs to a method for preparing acyclic monohydric alcohols, and is characterized by using a raw material fractionation unit, a hydrogenation synthesis unit and a product distillation unit, wherein the raw material fractionation unit comprises three fractionation devices: a butyraldehyde fractionation tower, a butanol fractionation tower and a C8 fractionation tower; the hydrogenation synthesis unit and the product distillation unit are suitable for hydrogenating and distilling a butyraldehyde fraction and a C8 fraction from the raw material fractionation unit alternately; and the product distillation unit comprises a light component removing tower device and a heavy component removing tower device. The method for producing the mixed butanol and coarse octanol by using the waste liquid discharged from the octanol device as the raw material, which is energy-saving and environmentally-friendly, can realize the recycling of the waste liquid discharged from the octanol device, reduce the waste water treatment cost of the octanol device and improves the technical indexes of treated water.

Owner:淄博诺奥化工有限公司

Supported ruthenium catalyst and preparation method thereof

InactiveCN102476052ALow costEasy to prepareOrganic reductionMolecular sieve catalystsAlkaline earth metalSecondary component

The invention discloses a supported ruthenium catalyst and a preparation method thereof. The preparation method is characterized in that the preparation method comprises the following steps: 1, preprocessing a carrier with a soluble alkaline earth metal salt, wherein the mass of the soluble alkaline earth metal salt accounts for 0.1-20% of the mass of the carrier; and 2, dipping the alkaline earth metal salt processed carrier with a material which comprises a primary active component metallic ruthenium and an assisted catalytic component comprising one or several of Ni, Co, Pd and Pt, wherein the mass of the primary component metallic ruthenium accounts for 0.1-5% of the carrier, and the mass of the secondary component comprising one or several of Ni, Co, Pd and Pt accounts for 0.01-5% of the mass of the carrier. The catalyst of the invention is mainly applied to the selective hydrogenation process of an aromatic ring of an aromatic compound, wherein the aromatic ring of the aromatic compound has at least one alkyl group, one ester group, one hydroxyl group or an amino group and also has at least one C1-8 alkyl group. Compared with catalysts prepared with the prior art, the catalyst of the invention has the advantages of low cost, simple preparation method, high activity, good selectivity, high safety in the operation of the aromatic ring hydrogenation, realization of the operation of the aromatic ring hydrogenation under a low pressure, and good economy.

Owner:CHINA PETROLEUM & CHEM CORP +1

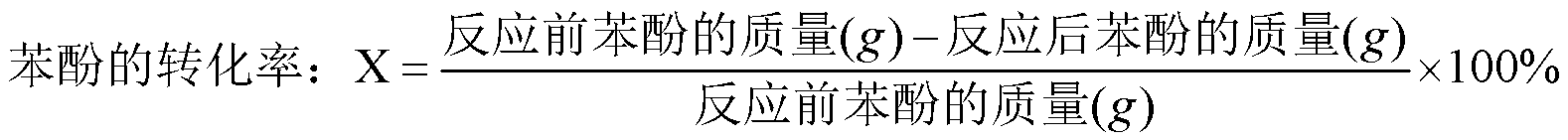

Method for preparing cyclohexanol by catalyzing by base metal catalyst

InactiveCN104447209AReduce use costLow costPreparation by hydrogenationHeterogenous catalyst chemical elementsFiltrationPorous carbon

The invention discloses a method for preparing cyclohexanol by catalyzing phenol hydrogenation by taking a porous carbon material loaded base metal as a catalyst. The synthetic route of the traditional two-step method comprises phenol hydrogenation and cyclohexanol dehydrogenation, and the catalysis of phenol hydrogenation in preparing cyclohexanol is mainly completed through metals, namely nanometer noble metal Pd, Ni radical and the like which have higher activated cracked hydrogen molecules. The method is characterized in that cyclohexanol is prepared in the presence of a solvent by using the porous carbon material loaded base metal as the catalyst, taking phenol or a phenol derivative as a raw material and catalyzing hydrogenation; a general formula of the catalyst is aM@CXy, wherein a indicates the weight percentage content of the metals contained in the catalyst, M indicates the base metal, C indicates carbon, X indicates a doped mixed element, and y indicates the weight percentage content of the mixed element. The method disclosed by the invention can be used for reducing the usage cost of the catalyst by recovering the catalyst by adopting a simple filtering method, and can obtain cyclohexanol by directly concentrating filter liquor obtained through filtration.

Owner:ZHEJIANG UNIV +1

Catalyst for preparation of hydrogenated bisphenol A

InactiveCN102921440AHigh activityHigh selectivityPhysical/chemical process catalystsPreparation by hydrogenationAluminium hydroxideBULK ACTIVE INGREDIENT

The invention relates to a catalyst for preparation of hydrogenated bisphenol A. The catalyst comprises: by mass, 100 parts of modified compound alumina carriers and 1 to 3 parts of precious metals as active ingredients. The modified compound alumina carriers comprise: by mass, 30 to 80 parts of pseudo-boehmite, 10 to 40 parts of aluminum hydroxide, 1 to 5 parts of an alkali metal and 1 to 5 parts of phosphorus. The active ingredients comprise two of Pd, Ru and Rh. The modified compound alumina carriers are adopted and are loaded with multiple precious metals to form the catalyst which is a hydrogenation catalyst having high activity, high selectivity and high loading capacity. The catalyst can realize preparation of a high trans-form / trans-form ratio isomer product under the condition of a trace amount of a stabilizer.

Owner:CHINA PETROLEUM & CHEM CORP

Preparation method and activation method of Raney nickel-aluminum-X catalyst specially for hydrogenation preparation of 1,4-butanediol from 1,4-butynediol

ActiveCN102744083APreparation by hydrogenationCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a preparation method and an activation method of a Raney nickel-aluminum-X catalyst specially for hydrogenation preparation of 1,4-butanediol from 1,4-butynediol. The Raney nickel-aluminum-X catalyst is characterized in that a mass ratio of nickel to aluminum is (0.5 to 1): 1; X of which mass is 0.1 to 2% of total mass of nickel and aluminum is adopted; and X represents Mg, B, Sr, Cr, S, Ti, La, Sn, W, Mo or Fe. The preparation method comprises the following steps of putting nickel, aluminum and X into a medium frequency induction smelting furnace according to the mass ratio, carrying out smelting, pouring out melt, cooling, crushing, and grinding to obtain powder which is the Raney nickel-aluminum-X catalyst. The activation method comprises the following steps that an alkali solution and the Raney nickel-aluminum-X catalyst which is powder are uniformly mixed according to a mass ratio of (2: 1) to (10: 1) and then undergo a reaction with stirring, wherein the alkali solution is a sodium hydroxide or potassium hydroxide solution having a concentration of 5 to 25wt%; after the reaction is finished, the reaction products are washed by distilled water and anhydrous ethanol until a pH value of the reaction products is 7; and the reaction products having a pH value of 7 are preserved in ethanol. In the presence of the Raney nickel-aluminum-X catalyst, in hydrogenation preparation of 1,4-butanediol from 1,4-butynediol, a conversion rate is in a range of 98 to 100% and selectivity of 1,4-butanediol is in a range of 90 to 98%.

Owner:HAISO TECH

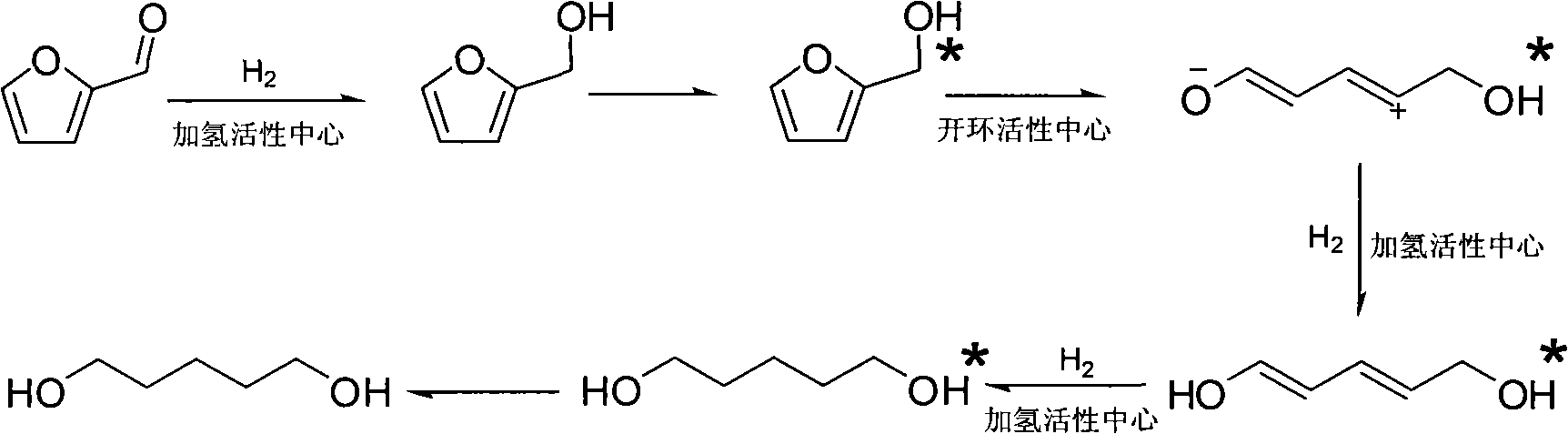

New loop opening hydrogenation reaction method for furan derivant

InactiveCN102134180ALower activation energyLow reaction pressureOrganic compound preparationThiol preparationFuranHydrogenation reaction

The invention aims at providing a new loop opening hydrogenation reaction method for furan derivant, which changes a reaction way by changing the traditional mechanism of catalytic reaction, realizes transformation from the traditional way of hydrogenation first and ring opening secondly to the way of ring opening first and hydrogenation secondly, and reduces the activation energy of reaction, thus greatly reducing reaction pressure and cost, alleviating operation difficulty, and have good industrial application prospect.

Owner:EAST CHINA UNIV OF SCI & TECH

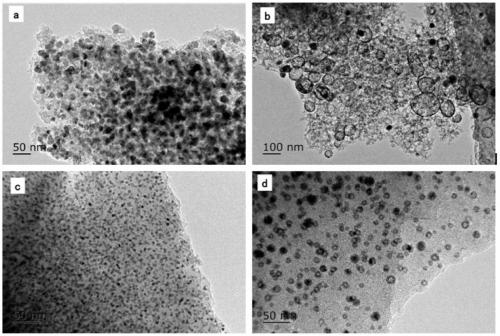

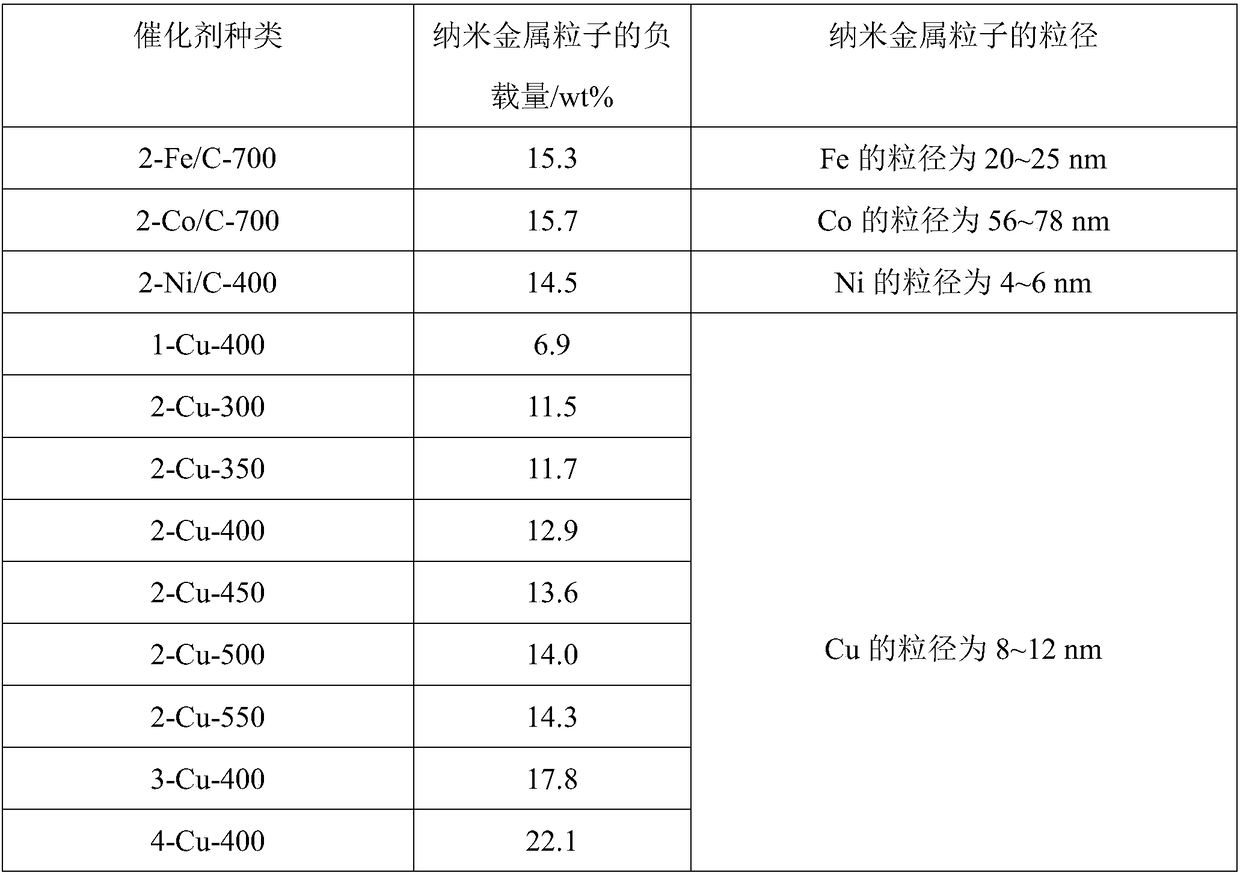

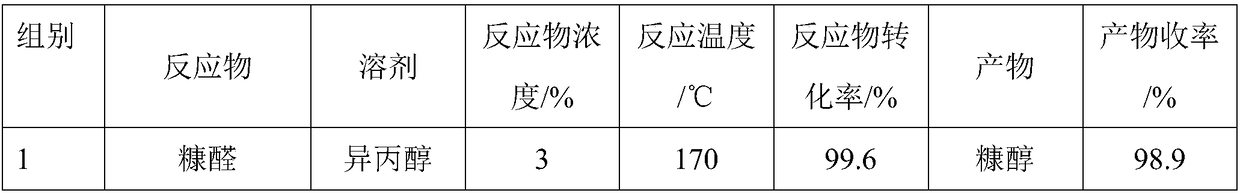

Biomass carbon-base material high-load nano-metal catalyst, as well as preparation method and application thereof

ActiveCN109364922ARaw greenEasy to makeMaterial nanotechnologyCatalyst carriersSimple componentCopper nitrate

The invention discloses a biomass carbon-based material high-load nano-metal catalyst, as well as a preparation method and application thereof. The catalyst is prepared by soaking shaddock peel powderin a nitrate solution having a certain concentration, drying and calcining, metal simple component serves as the active component, and organic carbon serves as the carrier; the nitrate is ferric nitrate, cobalt nitrate, nickel nitrate or copper nitrate; and the metal simple component is iron, cobalt, nickel or copper. The catalyst has the characteristics of environment-friendly raw materials, simple preparation process and high hydrogenation selectivity, has a good effect when being applied to a hydrogenation reaction of biomass derivatives, for instance, the furfuryl alcohol yield at a relatively low temperature of 170 DEG C can be 98,9 percent when the furfuryl alcohol is prepared by a furfuryl alcohol selective hydrogenation reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Organic compounds and processes for their manufacture

Owner:EXXONMOBIL CHEM PAT INC

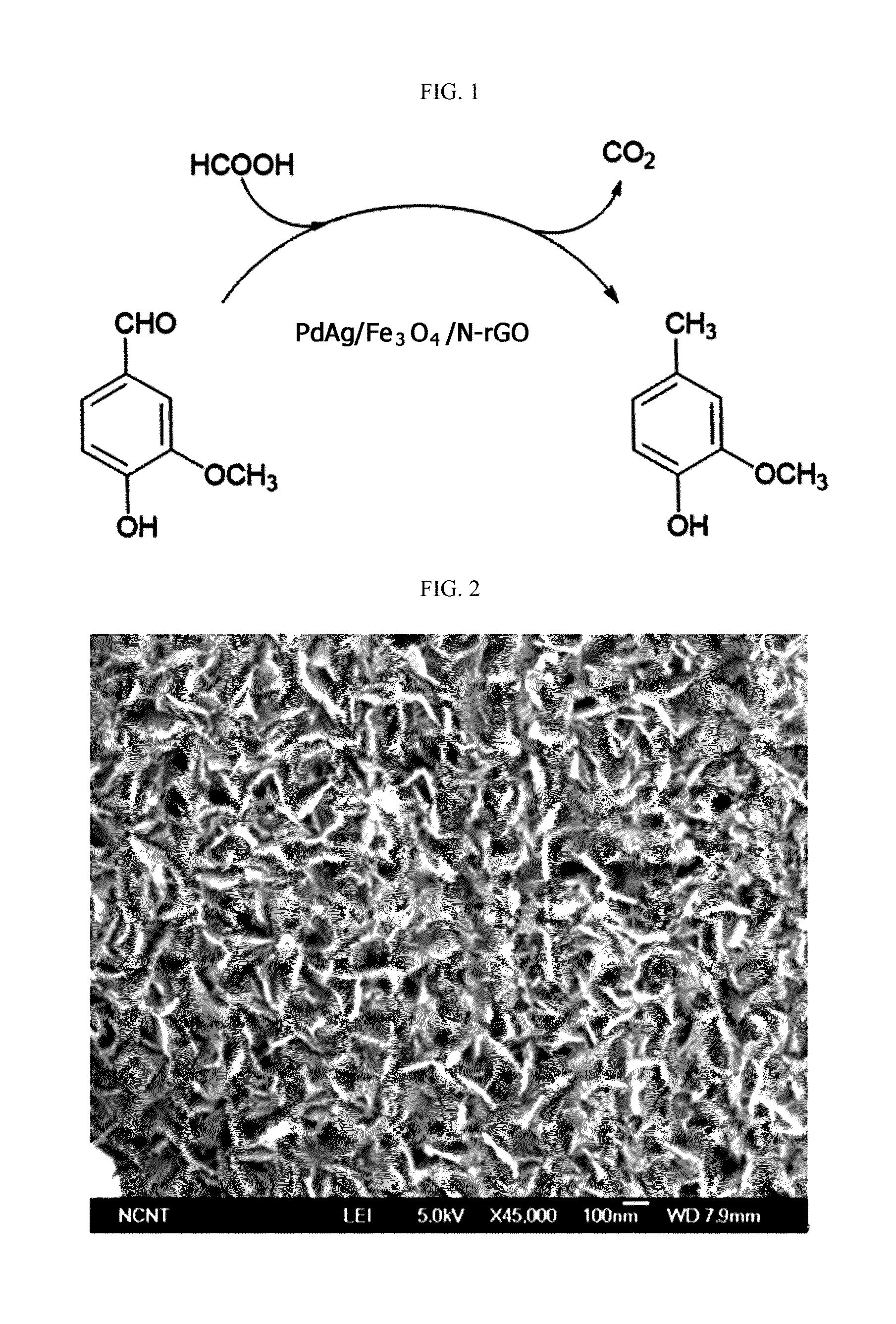

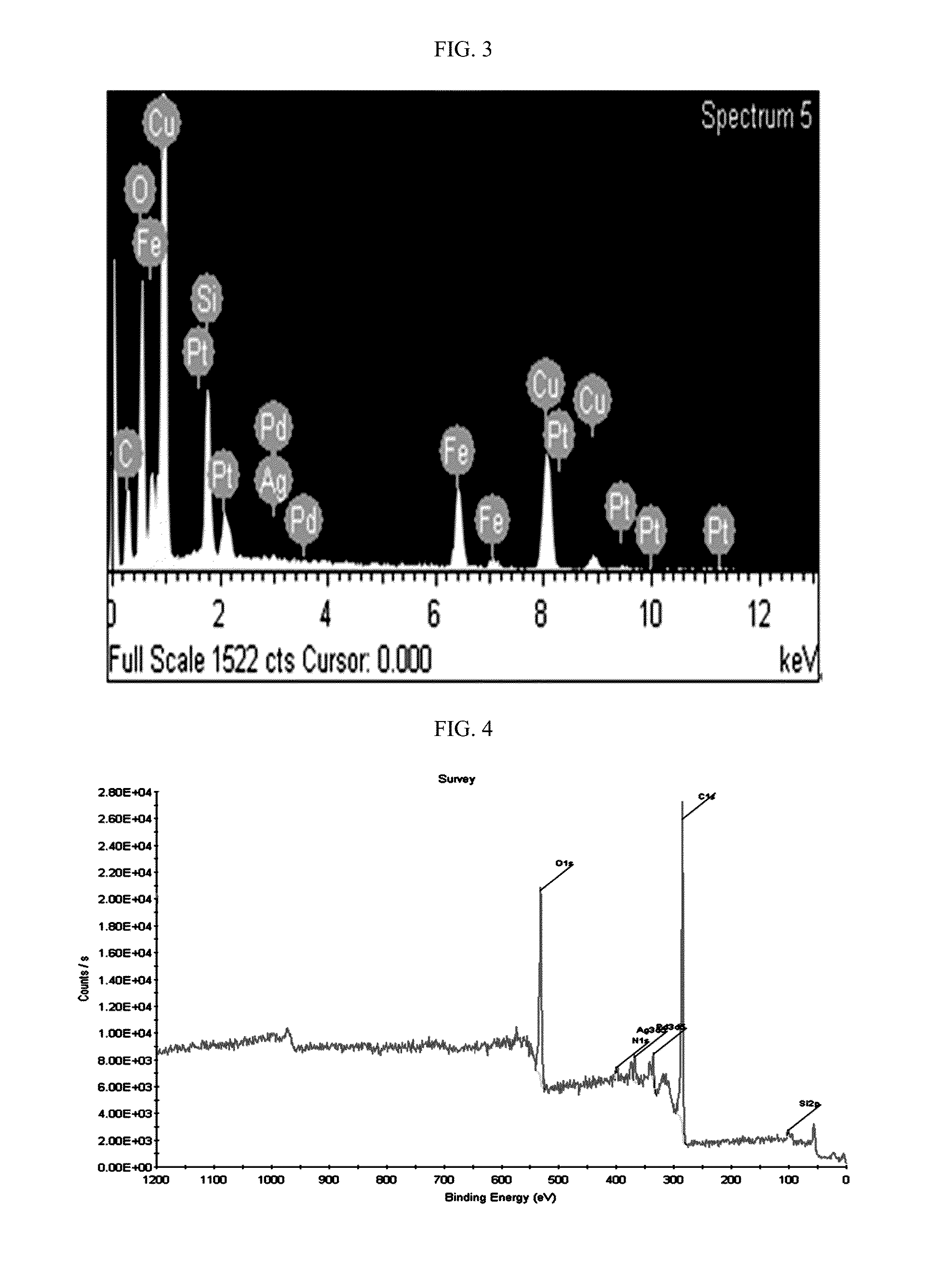

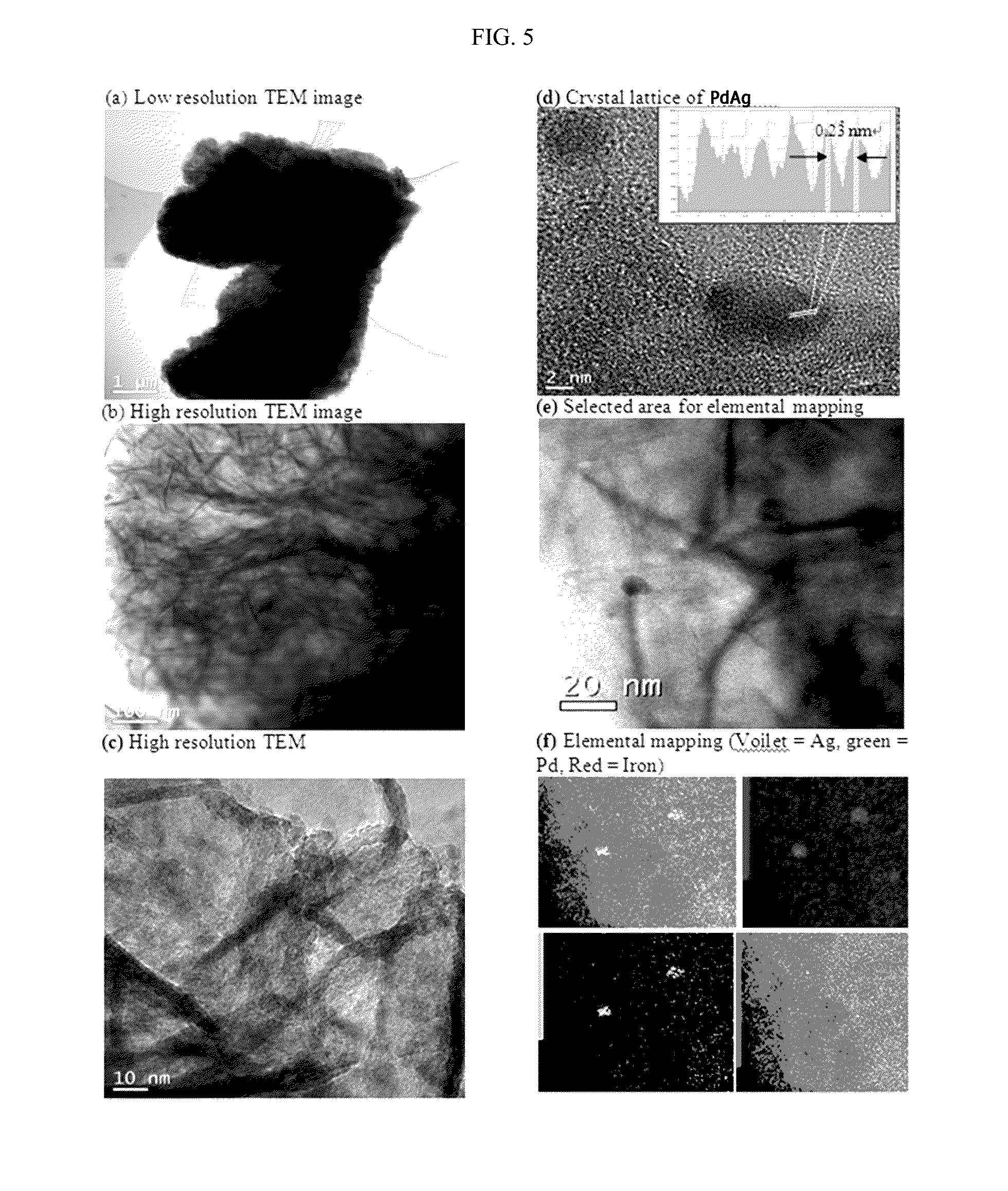

Inorganic Nanoparticle Deposited Catalyst For Hydrogenation And Manufacturing Method Of The Same, And Hydrogenation For Biomass Derived Hydrocarbon Compounds

InactiveUS20150224484A1Increase conversion rateHigh selectivityOxygen-containing compound preparationPreparation by hydrogenationCompound aHydrogenation reaction

A hydrogenation catalyst and a method of hydrogenating a hydrocarbon compound as a substrate using the same are provided. The hydrogenation catalyst includes inorganic nanoparticles and a nitrogen-doped reduced graphene oxide support for supporting the inorganic nanoparticles, and the hydrocarbon compound is derived from a biomass and contains a functional group. Therefore, the hydrogenation catalyst which exhibits a high conversion rate and high selectivity, is stable, and can be easily separated after a hydrogenation reaction, and whose catalytic activities are not significantly altered even when recovered and repeatedly recycled can be provided. The method of hydrogenating a hydrocarbon compound in which hydrogen can be directly produced in a reactor using formic acid as a hydrogen source without supplying additional hydrogen gas and simultaneously be used under normal pressure can also be provided.

Owner:POSTECH ACAD IND FOUND

Noble metal Raney catalysts and preparation of hydrogenated compounds therewith

InactiveUS6018048AOrganic compound preparationHydrocarbon by hydrogenationHydrogen pressureRuthenium

Noble metal, particularly ruthenium, Raney catalysts having the property of catalyzing the hydrogenation of (1) aromaticity-exhibiting ring portions of organic compounds, (2) carboxylic acids and their ester portions (carbonyl ester groups), (3) ring portions and carboxylic acid or their ester groups in compounds having such ring portions and carboxylic acid or their ester portions, and (4) ring portions and nitrile groups of aromatic nitrile compounds and methods for the preparation of corresponding hydrogenated compounds. The methods allow preparation of hydrogenated compounds having hydrogenated aromatic ring portions, hydrogenated carbonyl ester groups, hydrogenated aromatic ring and carbonyl ester groups, or hydrogenated aromatic rings and nitrile groups under milder hydrogen pressure and temperature conditions than the conventional catalysts.

Owner:SHOWA DENKO KK

Octanol hydrorefining catalyst and preparation method thereof

InactiveCN101791556AHigh surface active sitesIncreased surface active sitesOrganic compound preparationPreparation by hydrogenationRare-earth elementNickel salt

The invention discloses an octanol hydrorefining catalyst, which belongs to the field of hydrorefining catalytic materials. The prepared catalyst is used for modifying a carrier by using a rare earth element, reducing the amount of an active component of a nickel ion entering a carrier framework and improving the content of surface nickel species; the active component is loaded by adopting a hydrothermal deposition method, the dispersion of nickel salts on the surface of a carrier pore canal by using hydrothermal high-temperature and high-pressure conditions and forming nickel precipitation with proper size at the loading initial period of the active component by using a deposition reaction, so the invention can effectively control the amount of the nickel ions entering the carrier, improve the content of the surface nickel species and simultaneously can avoid the growth of nickel oxide particles; and the catalyst greatly increases the surface nickel active site, effectively improves the utilization rate of the active component of nickel and has higher catalytic reaction activity during hydrorefining the octanol at higher airspeed. The result shows that the hydrogenation rate of an unsaturated substance in crude octanol reaches over 90 percent when the temperature is 120DEG c, the pressure is 2.5MPa, the ratio of hydrogen to liquid for feeding is 8:1 and the airspeed is 30<-1>hour.

Owner:UNIV OF SCI & TECH BEIJING

Organic compounds and processes for their manufacture

InactiveUS6090986AOrganic compound preparationPreparation by hydrogenationSimple Organic CompoundsAlcohol

PCT No. PCT / EP96 / 00267 Sec. 371 Date Oct. 27, 1997 Sec. 102(e) Date Oct. 27, 1997 PCT Filed Jan. 17, 1996 PCT Pub. No. WO96 / 22268 PCT Pub. Date Jul. 25, 1996Esters of branched C9 alcohols suitable as plasticizers are formed by esterification of a C9 alcohol produced by the aldol condensation from propanal and a C6 aldehyde and hydrogenation, the propanal optionally having been made from natural gas streams.

Owner:EXXON CHEM PAT INC

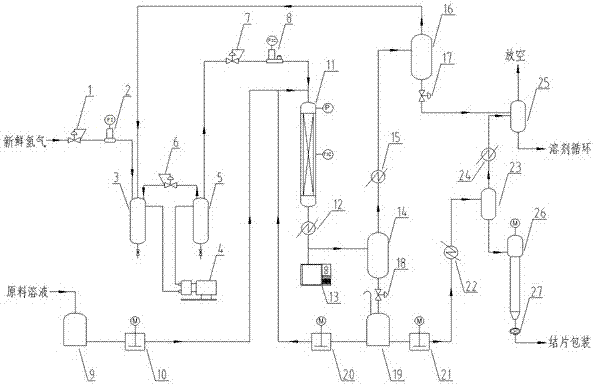

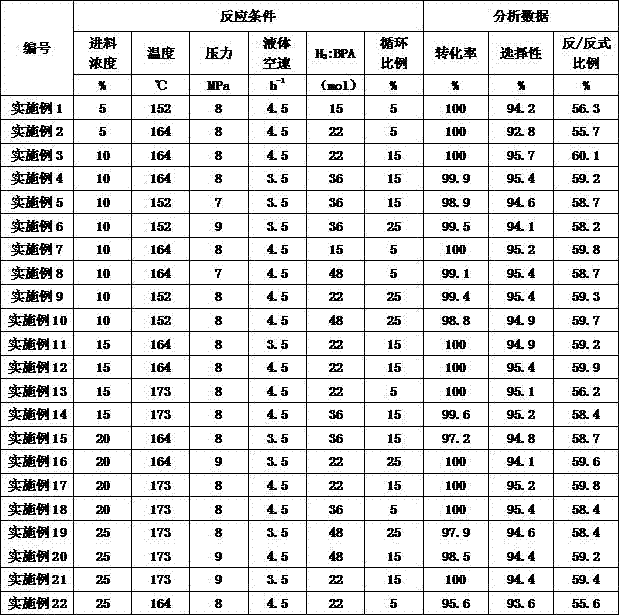

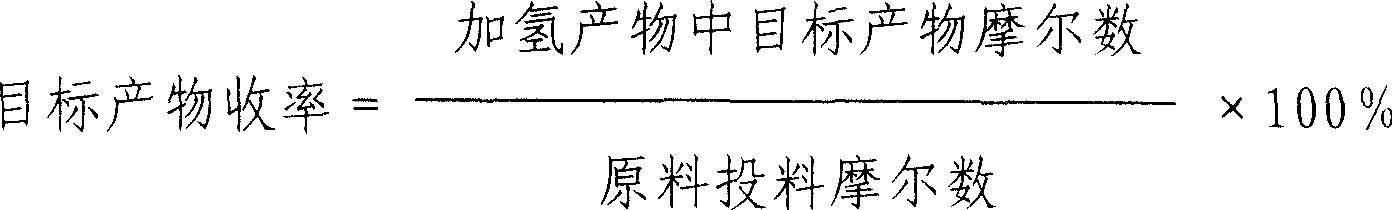

Continuous preparation method of hydrogenated bisphenol A

ActiveCN106866365AIncrease process linksRaise the ratioPreparation by hydrogenationHydroxy compound separation/purificationCyclic processHydrogenation reaction

The invention relates to a continuous preparation method of hydrogenated bisphenol A. The method comprises the following steps: carrying out a hydrogenation reaction on a prepared bisphenol A raw material in a fixed bed hydrogenation reactor under the action of a precious metal supported hydrogenation catalyst, returning the obtained hydrogenation products to the reactor according to a certain proportion in order to carry out cycle hydrogenation in order to control the ratio of the cis-trans structure in the hydrogenation product, and carrying out gas-liquid separation, normal pressure solvent removal, reduced pressure byproduct removal and sheeting treatment on the extracted partial hydrogenation products to obtain the final hydrogenated bisphenol A product, and recycling separated hydrogen and solvent. The method has the advantages of simple process flow, high controllability of the reaction process, realization of continuous preparation of the hydrogenation products, stable performances of the target product, and increase of the cis-trans isomer ratio in the hydrogenation products through the partial cycling process of the hydrogenation products, and allows the converstion rate of the hydrogenation reaction to reach 100%, the selectivity to be more than 95%, the purity of the product to be more than 97% and the cis-trans isomer ratio to reach 60%.

Owner:威海新元科盛新材料有限公司

Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

ActiveCN101973846BSave energyReduce loadOrganic compound preparationPreparation by hydrogenationAlcoholDistillation

The invention discloses a method for producing mixed butanol and coarse octanol by using waste liquid discharged from an octanol device as a raw material, which belongs to a method for preparing acyclic monohydric alcohols, and is characterized by using a raw material fractionation unit, a hydrogenation synthesis unit and a product distillation unit, wherein the raw material fractionation unit comprises three fractionation devices: a butyraldehyde fractionation tower, a butanol fractionation tower and a C8 fractionation tower; the hydrogenation synthesis unit and the product distillation unitare suitable for hydrogenating and distilling a butyraldehyde fraction and a C8 fraction from the raw material fractionation unit alternately; and the product distillation unit comprises a light component removing tower device and a heavy component removing tower device. The method for producing the mixed butanol and coarse octanol by using the waste liquid discharged from the octanol device as the raw material, which is energy-saving and environmentally-friendly, can realize the recycling of the waste liquid discharged from the octanol device, reduce the waste water treatment cost of the octanol device and improves the technical indexes of treated water.

Owner:淄博诺奥化工有限公司

Preparation method of supported nickel catalyst

InactiveCN101733106AOrganic reductionHydrocarbon by hydrogenationSupercritical dryingNickel catalyst

The invention discloses a preparation method of a supported nickel catalyst, which comprises the following steps of: reacting soluble nickel salt solution and a precipitator to obtain a green precipitate, wherein the precipitator is mixed solution of sodium silicate and sodium carbonate, the Na<+> concentration is 0.1-1 mol / L, the amount of the sodium silicate is calculated according to the content of SiO2 in a carrier, and the amount of the sodium carbonate is 10-30 percent more than that of nickel nitrate based on a stoichiometric ratio; washing the precipitate by distilled water and carrying out supercritical drying or azeotropic distillation drying to obtain a supported nickel catalyst precursor; roasting the supported nickel catalyst precursor for 2-5 hours under N2 atmosphere at 200-600 DEG C, changing the N2 atmosphere into H2 atmosphere, and reducing the supported nickel catalyst precursor for 2-4 hours under H2 atmosphere at 300-550 DEG C to obtain the supported nickel catalyst with the surface area of high active metal nickel. The surface area of the obtained catalyst is 250-450m<2> / g, the average aperture is 4-16nm, and the pore volume is 1.0 -1.9cm<3> / g. The surface area of the active metal nickel of the obtained catalyst is 40-70m<2> / g. The catalyst prepared by using the method can be used for catalyzing hydrogenation of a benzene ring.

Owner:NANJING UNIV

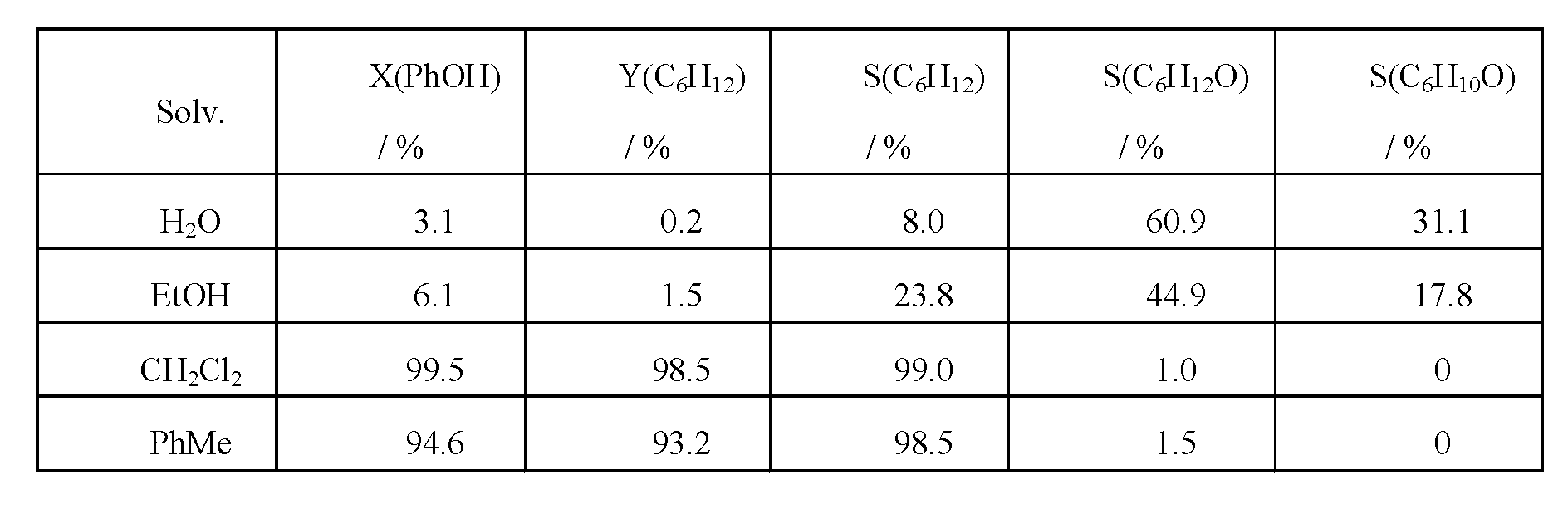

Synthesis process of cyclohexanone and cyclohexanol

InactiveCN1847206AImprove conversion rateFix security issuesOrganic compound preparationPreparation by hydrogenationCyclohexanonePalladium catalyst

The present invention relates to synthesis process of cyclohexanone and cycloexanol, especially through hydrogenating phenol. Phenol material, C1-C2 fatty alcohol and water in the weight proportion of 1 to 2.5-40 to 10-160 are reacted in one step at 100-300 deg.c temperature and 1-10 MPa pressure and in the action of Renny Ni catalyst or active carbon supported palladium catalyst to synthesize cyclohexanone and cycloexanol. The present invention features no need of outer hydrogen supply for hydrogenating phenol and the use of relatively cheap Renny Ni catalyst, and has the advantages of high safety, simplified technological process, low production cost, high phenol converting rate, high total cyclohexanone and cycloexanol selectivity near 100 %, no side product and easy product separation.

Owner:ZHEJIANG UNIV OF TECH

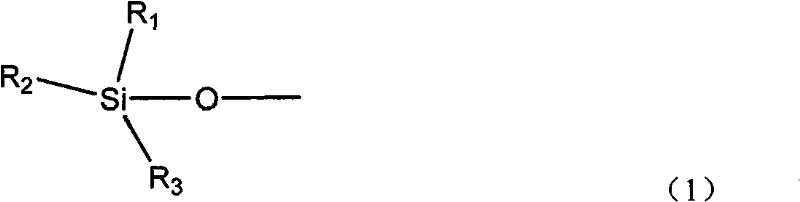

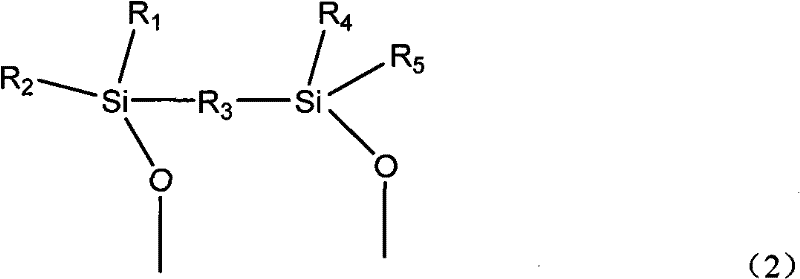

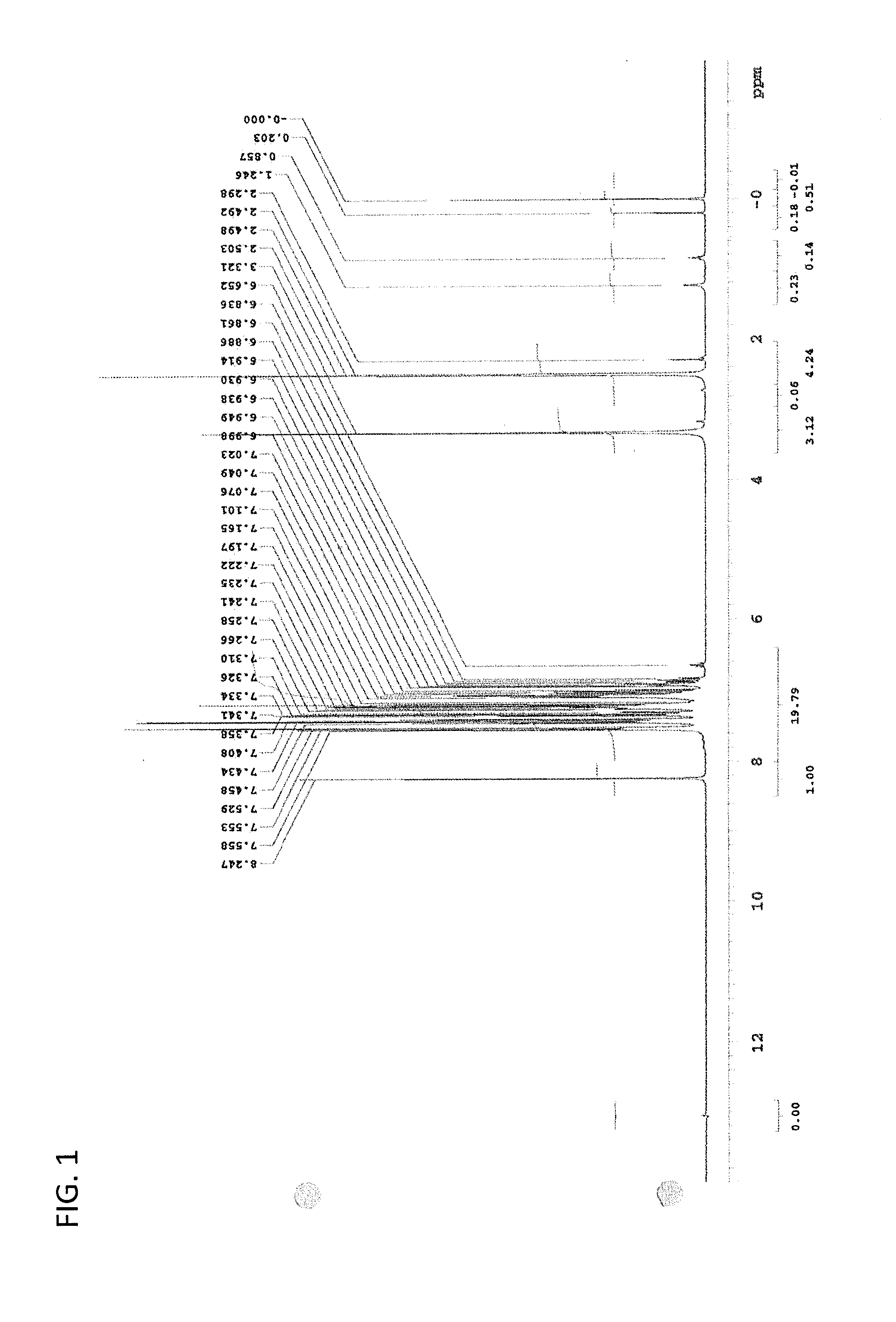

Method for preparing butanediol by carrying out two-stage catalytic hydrogenation on butynediol

ActiveCN102408307AHigh mechanical strengthNot easy to pulverizePreparation by hydrogenationSilanesCarbon deposit

The invention relates to a method for preparing butanediol by carrying out two-stage bed catalytic hydrogenation on butynediol. Aiming at the requirements on the suitability for a reaction system which contains water or fluctuating water content in a process for preparing the butanediol by carrying out two-step hydrogenation on the butynediol, and the inhibition on the generation of carbon deposit, the inventor proposes that: a hydrogenation catalyst A and a hydrogenation catalyst B in a two-stage bed respectively contains a carrier, a metal active component and silane groups, further, the silane groups are grafted through a silylanizing treatment, wherein the content of the silane groups in the total weight of the hydrogenation catalysts is 0.1-12 wt%. Compared with the prior art, under the premise of ensuring that the hydrogenation catalysts have better activity and better selectivity, the method provided by the invention has obvious raw material suitability, and the presence of water hardly influences on the catalytic performance of the hydrogenation catalysts; and meanwhile, the generation of the carbon deposit on the surfaces of the catalysts can be obviously inhibited, and the service life of the catalysts is prolonged, so that the hydrogenation reaction system can have a longer stable running cycle.

Owner:CHINA PETROLEUM & CHEM CORP +1

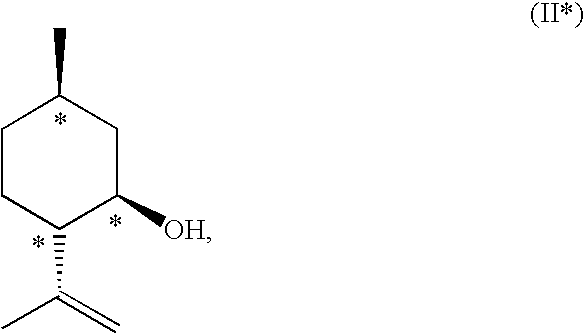

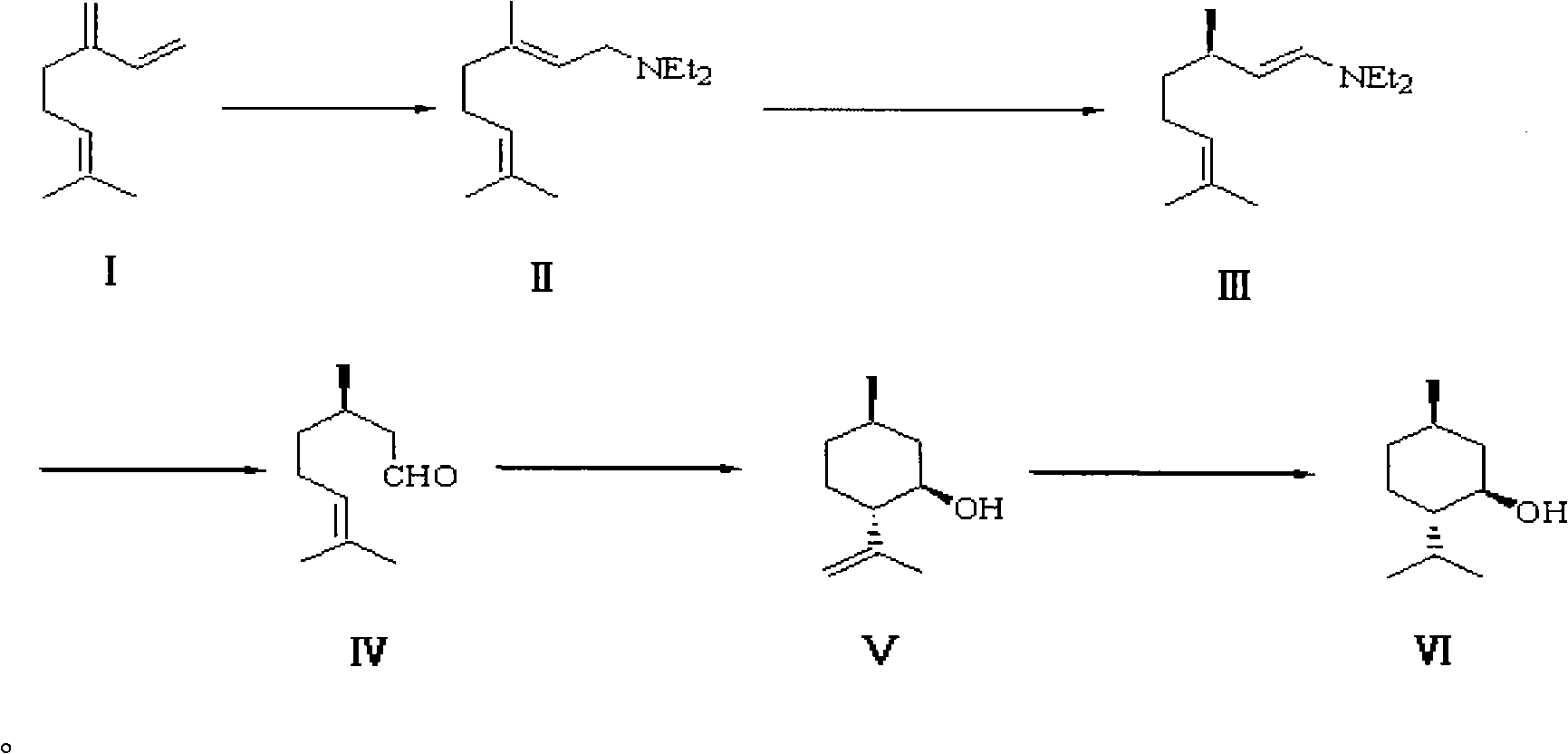

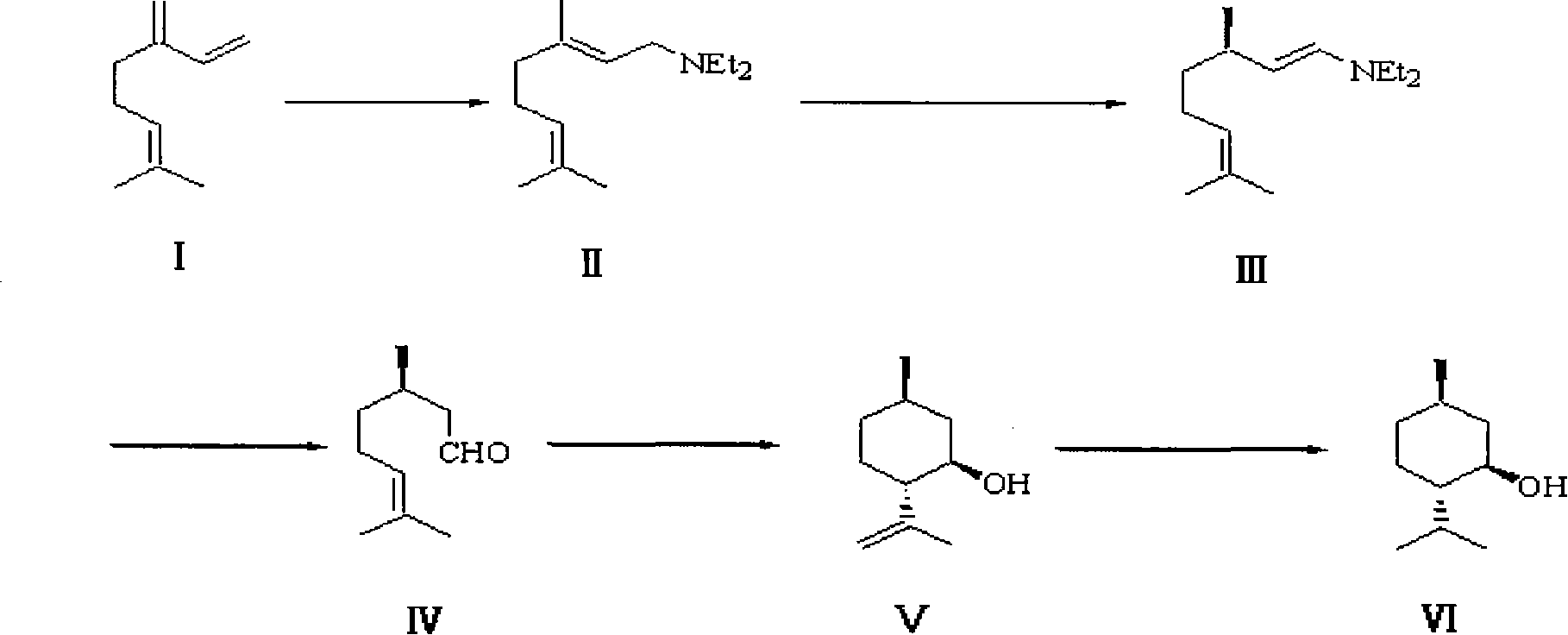

Method for manufacturing optically active menthol

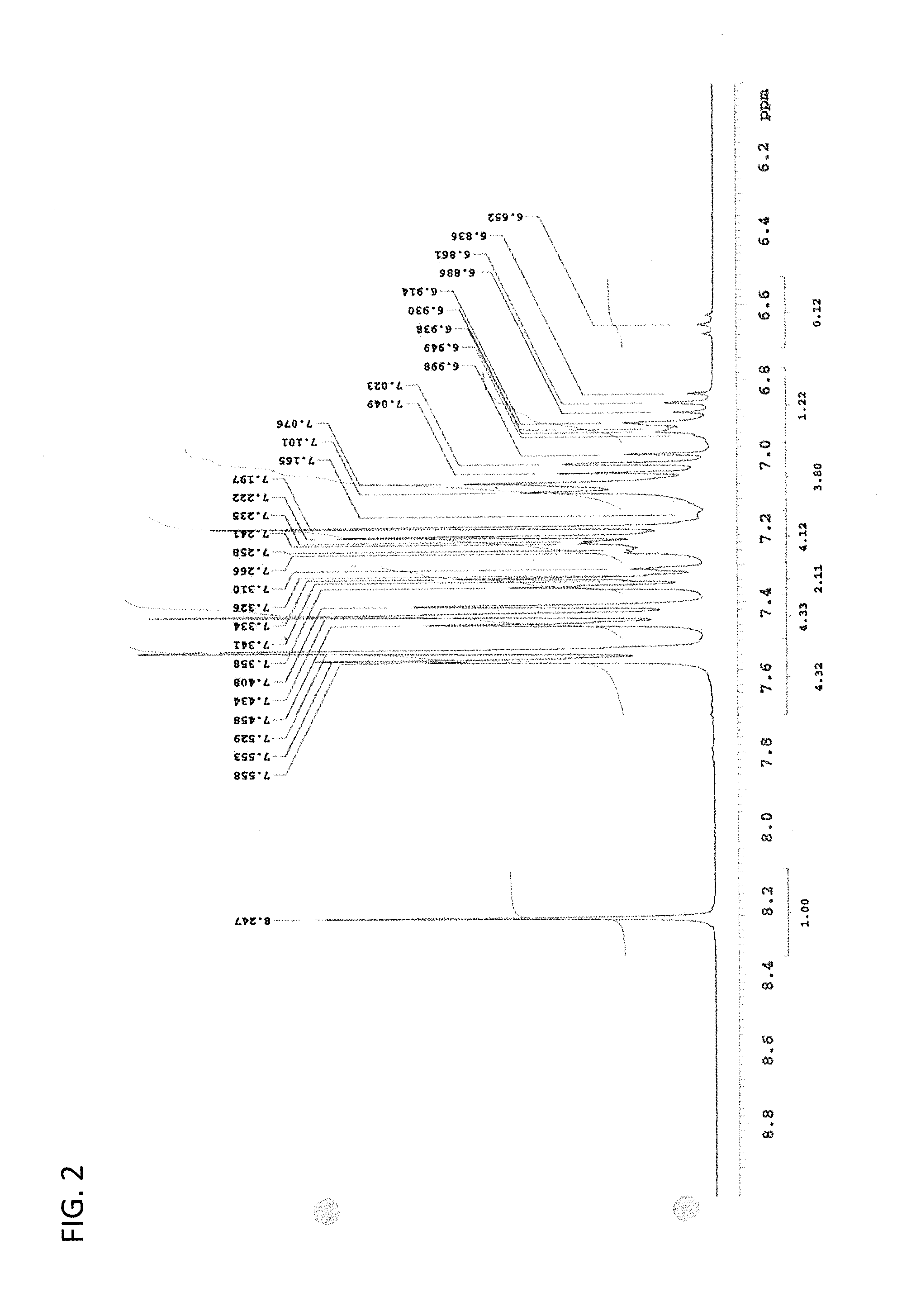

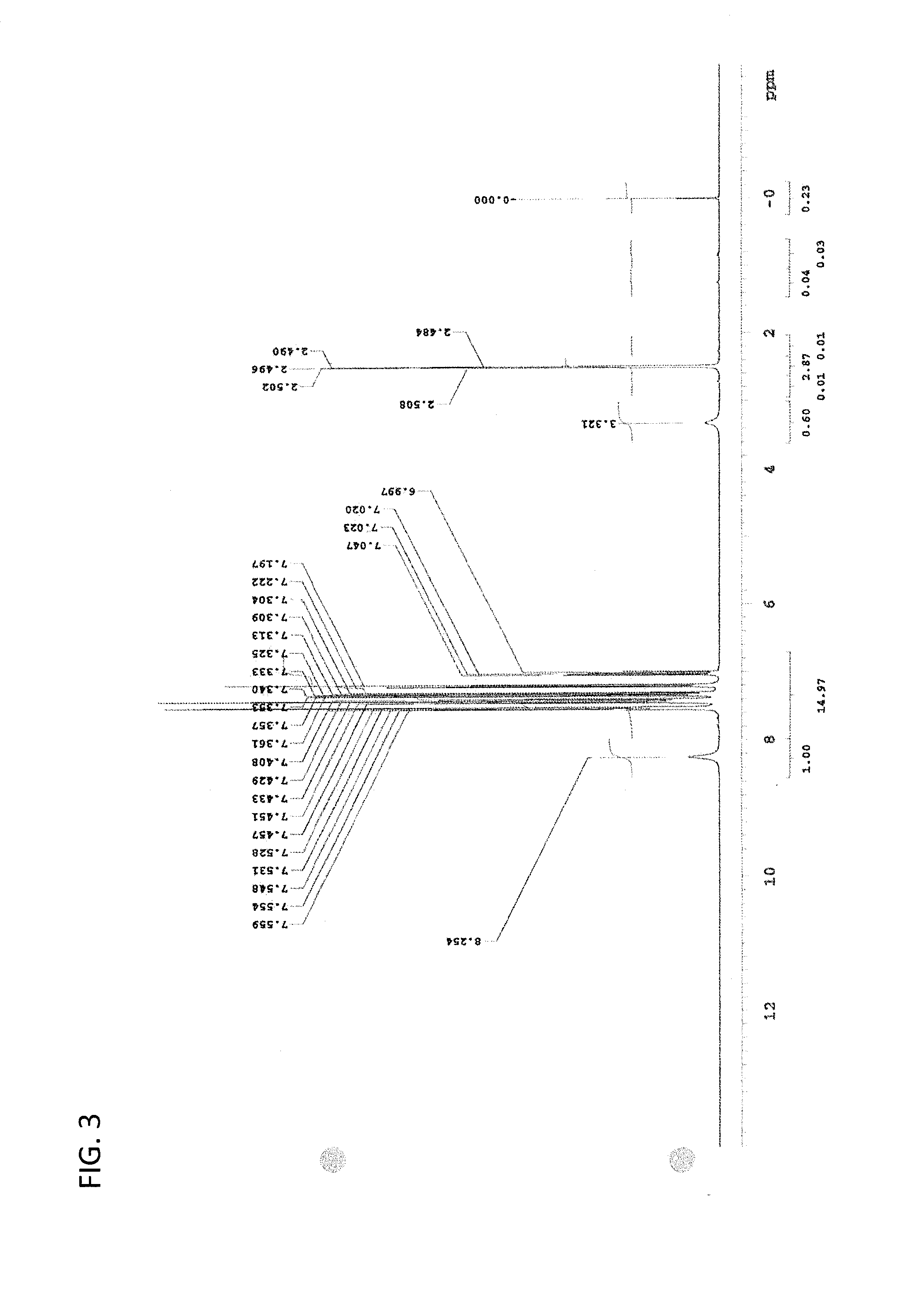

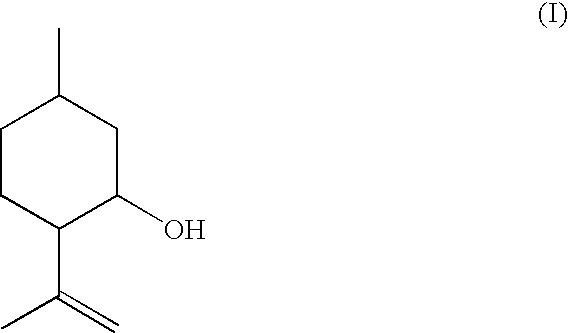

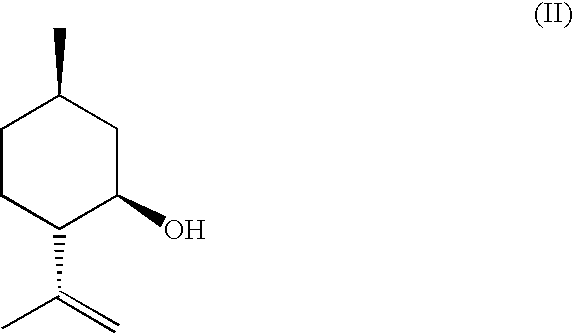

InactiveUS20130253228A1Easy to operateHigh selectivityOxygen-containing compound preparationPreparation by isomerisationMentholAsymmetric hydrogenation

An object of the present invention is to provide a method for manufacturing an optically active menthol having fewer steps, which generates less environmentally polluting waste because a catalytic reaction is involved in all of the steps, and is capable of saving a production cost. The present invention relates to a method for manufacturing an optically active menthol, including the following steps: A-1) asymmetrically hydrogenating at least one of geranial and neral to thereby obtain an optically active citronellal, B-1) conducting a ring-closure reaction of the optically active citronellal in the presence of an acid catalyst to thereby obtain an optically active isopulegol, and C-1) hydrogenating the optically active isopulegol to thereby obtain an optically active menthol.

Owner:TAKASAGO INTERNATIONAL CORPORATION

Method for the Production of Enriched Isopulegol

ActiveUS20080214877A1Easy to disassembleIncrease in the enantiomeric excessOxygen-containing compound preparationOrganic compound preparationMentholPolymer science

The present invention relates to a process for preparing enriched isopulegol by crystallization from a melt comprising isopulegol. The invention relates specifically to a process for preparing enantiomerically enriched n-isopulegol proceeding from optically active isopulegol having a relatively low enantiomeric excess by crystallization from the melt. The invention further relates to a process for preparing menthol proceeding from enantiomerically and / or diastereomerically enriched n-isopulegol prepared by crystallization from the melt.

Owner:BASF AG

Fixed bed catalysts

InactiveUS20020037808A1Promote hydrogenationHigh activityOrganic compound preparationPreparation by hydrogenationRheniumFixed bed

Owner:DEGUSSA AG

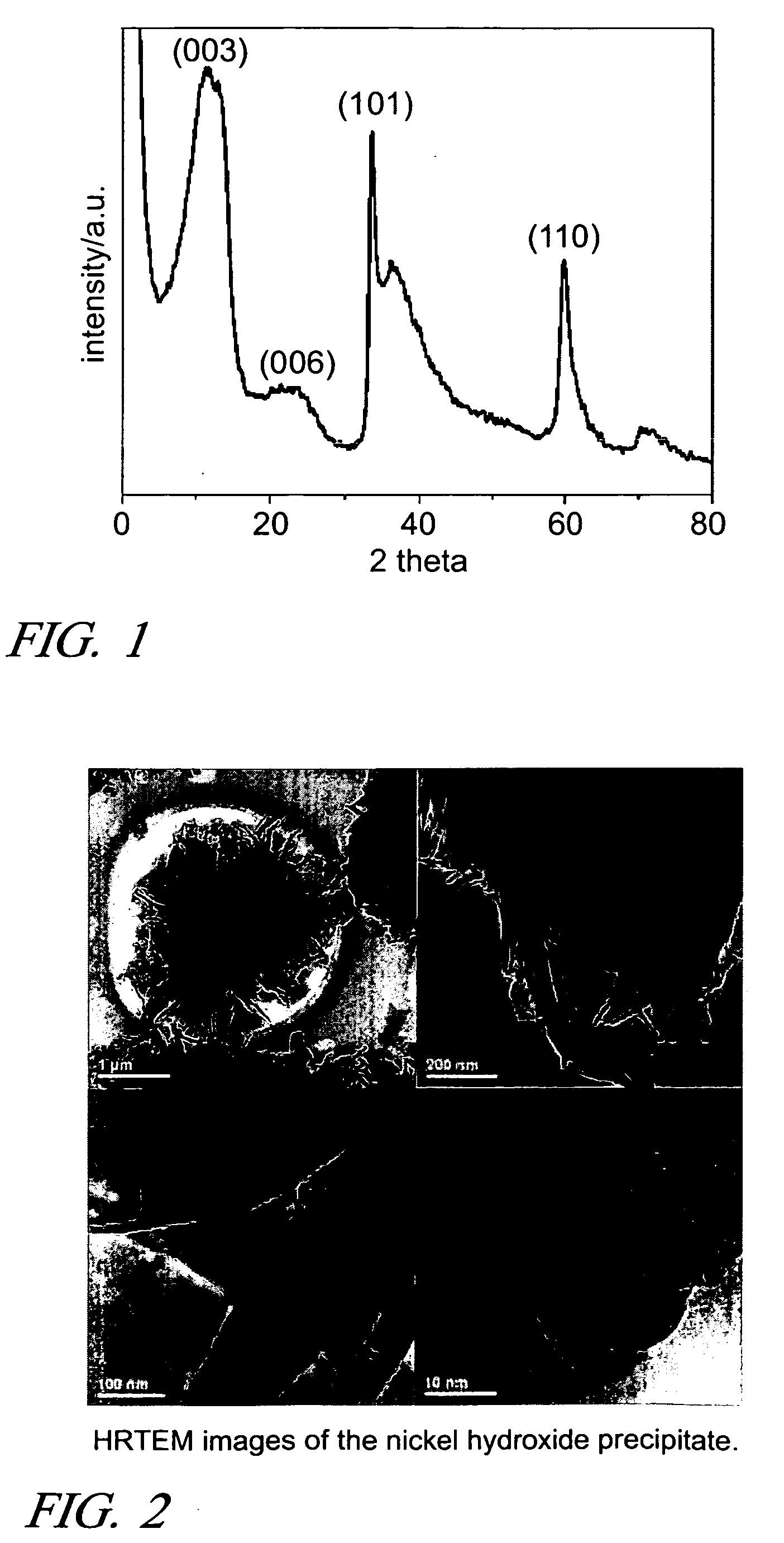

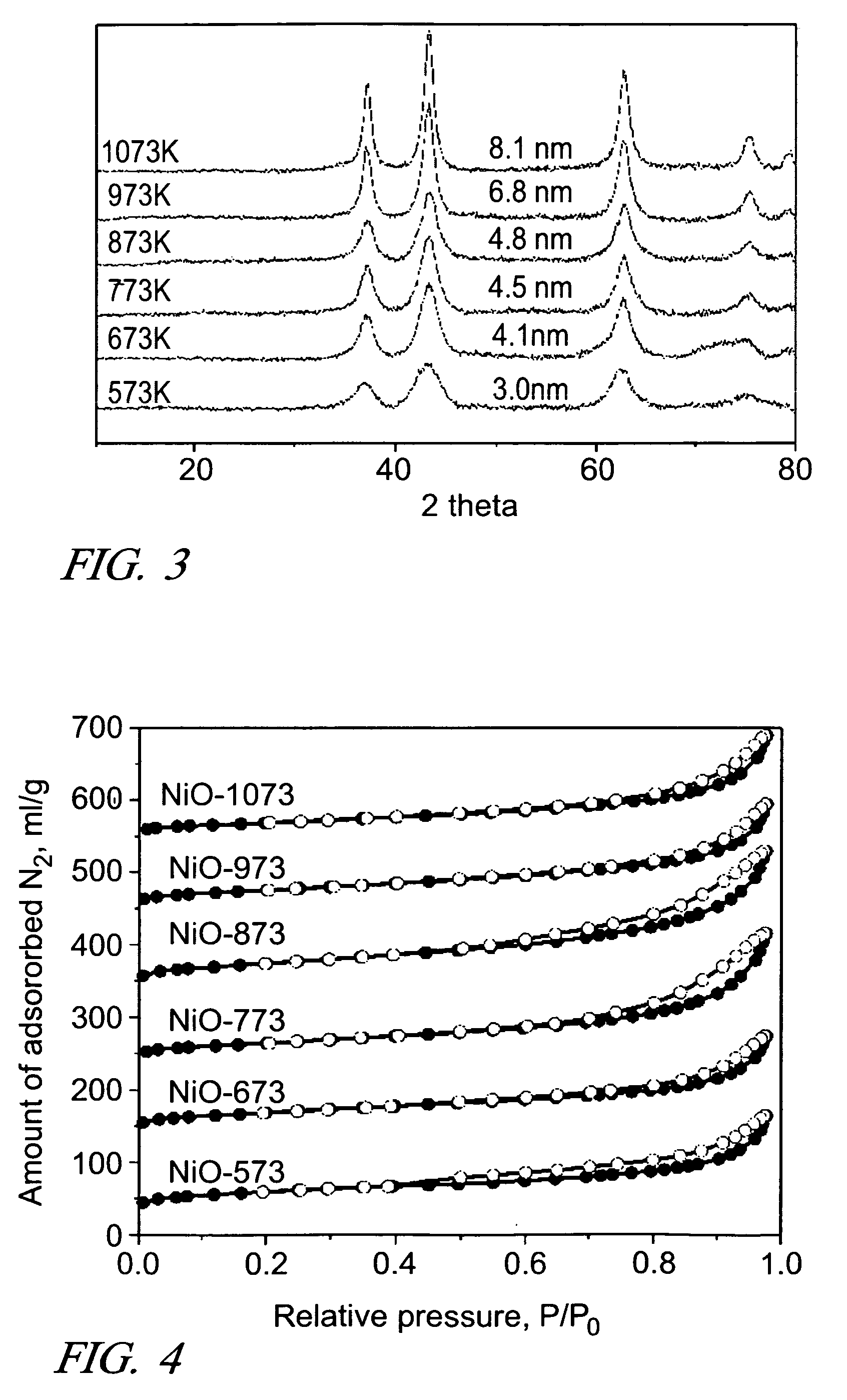

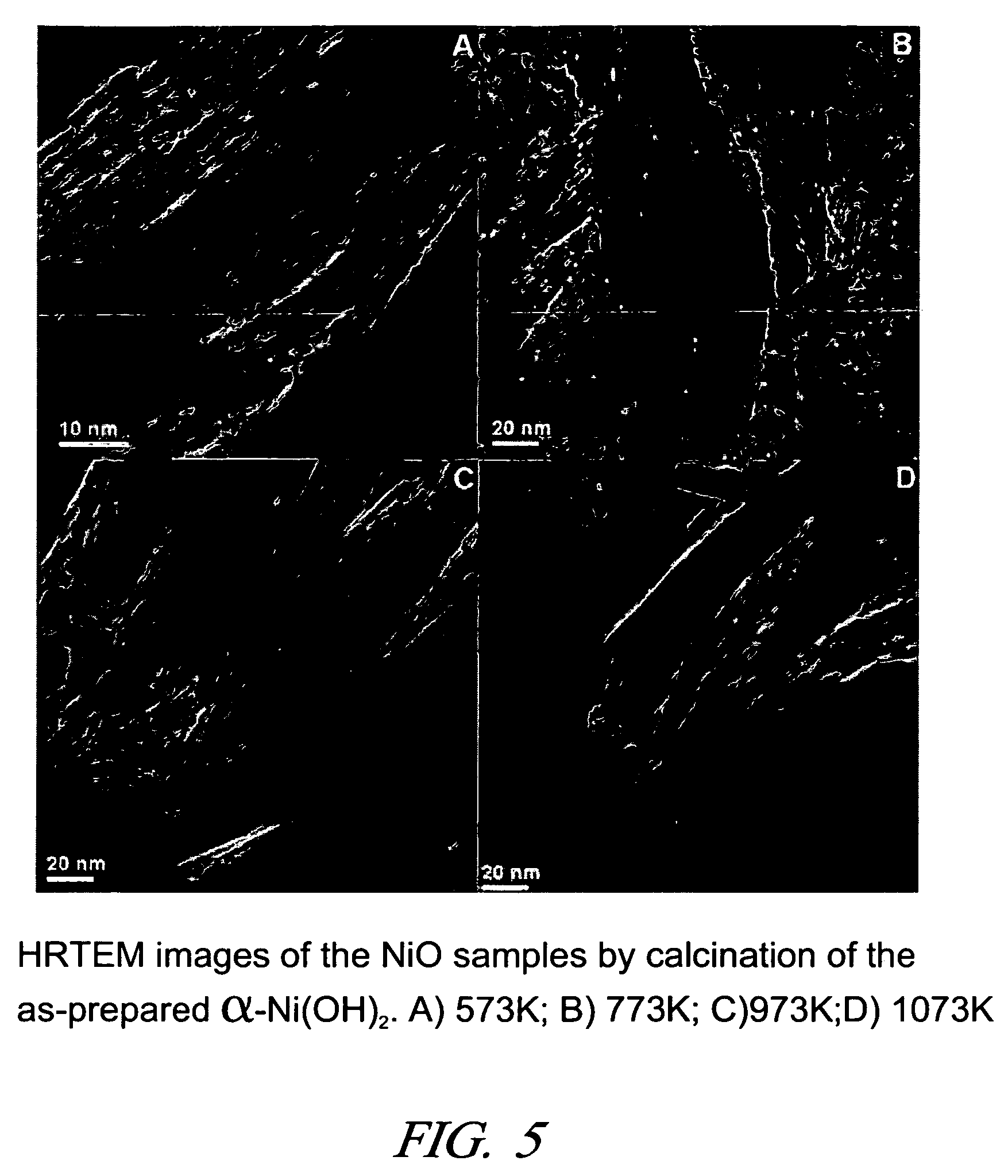

Method of making NiO and Ni nanostructures

ActiveUS20080019901A1Restore charge neutralityObvious advantagesMaterial nanotechnologyHydrogenFiberGlycol synthesis

The alpha form of nickel (II) hydroxide is formed by dissolving a compound of nickel (II), such as nickel acetate, in a water miscible dihydric alcohol (diol), such as ethylene glycol, propylene glycol and suitable oligomers, and adding a suitable base such as sodium carbonate. The α-Ni(OH)2 precipitate is separated from the diol-based mother liquor and dried. This stable α-Ni(OH)2 can be calcined at temperatures in the range of about 573K to about 1073K to form nanometer-size particles of NiO having, for example, fibrous shapes. And the small particles of NiO can be reduced with hydrogen to form small, fibrous nickel particles. Both the NiO particles and Ni particles have utility as catalysts and offer utility in applications requiring electronic and / or magnetic properties.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

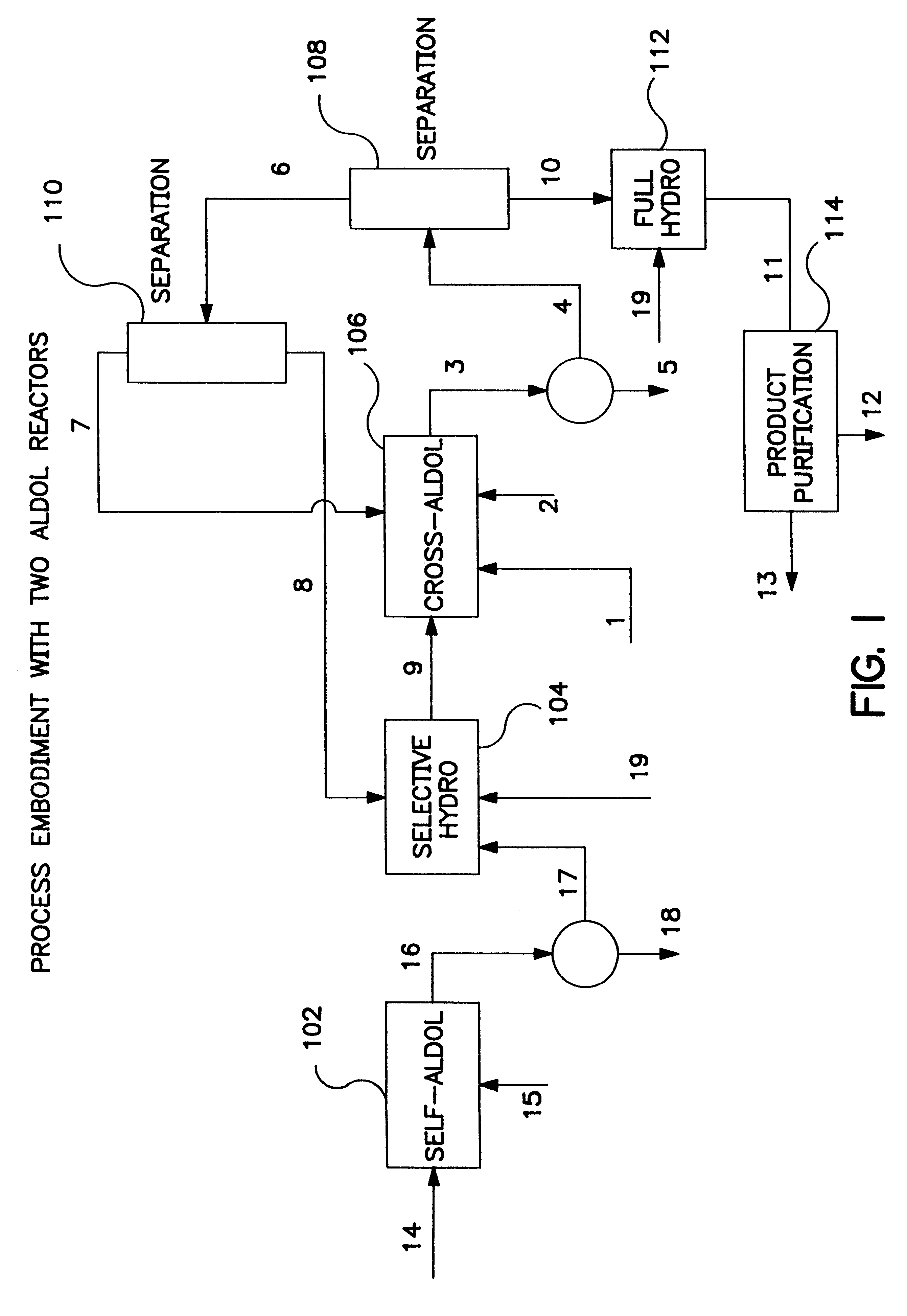

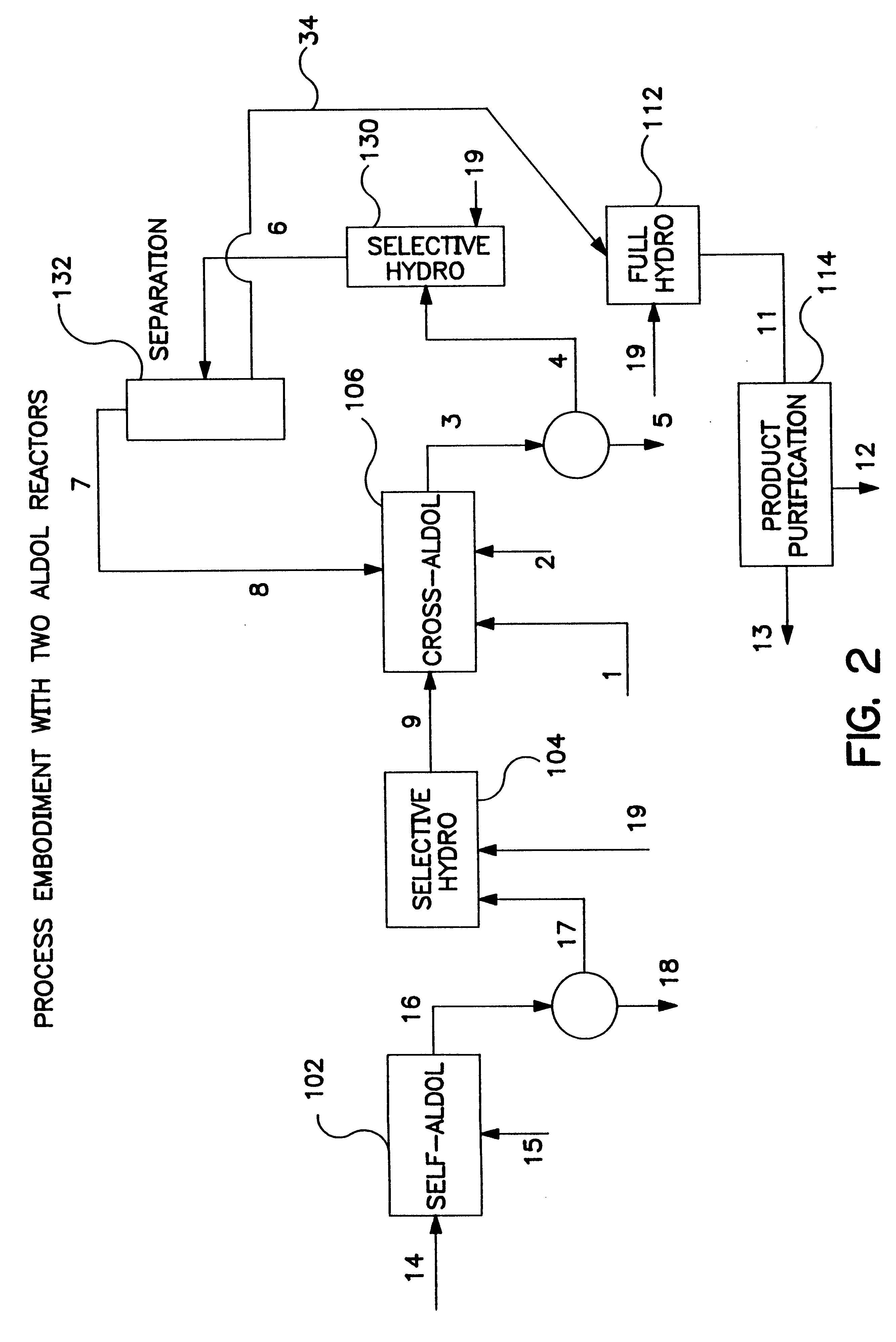

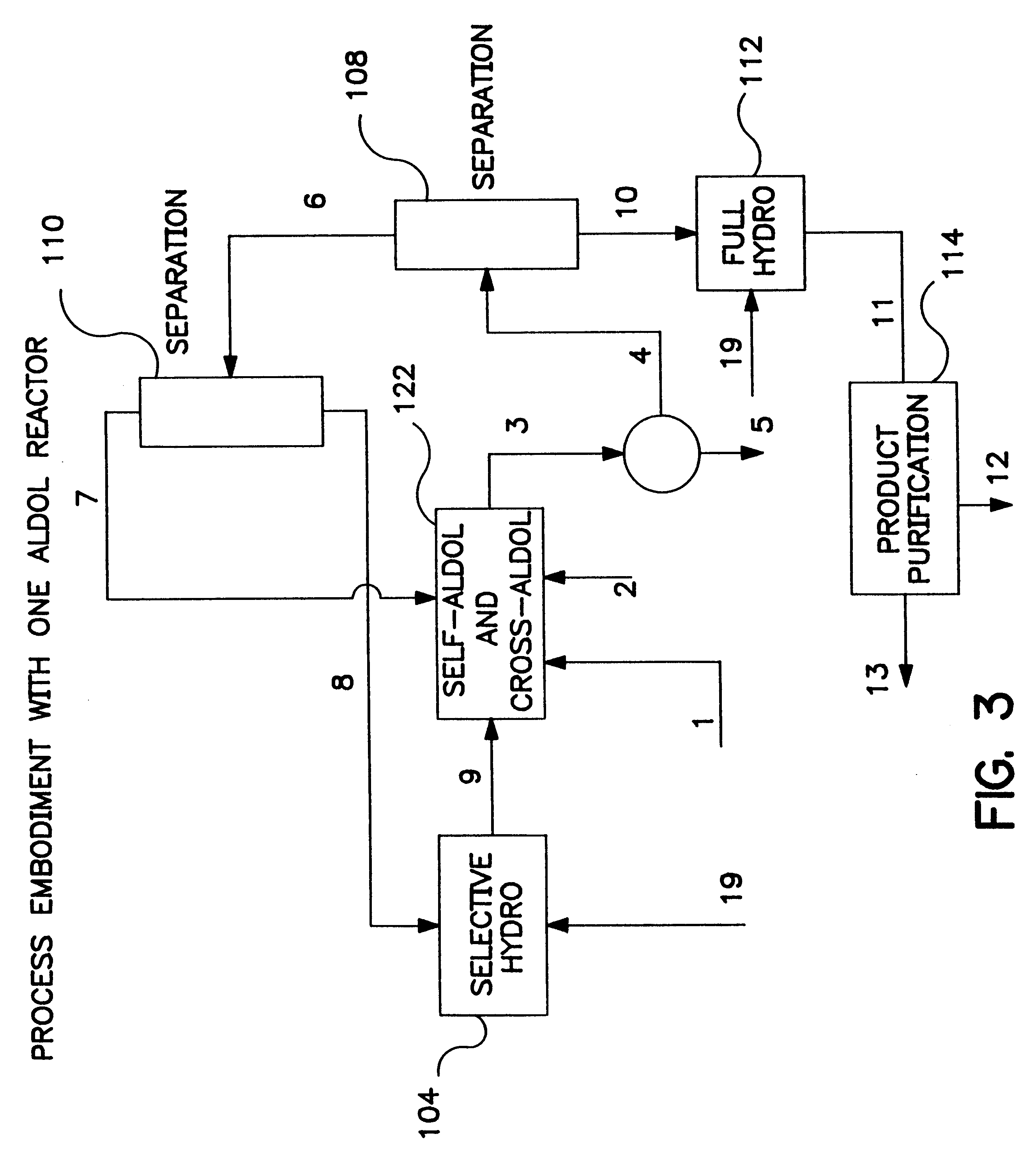

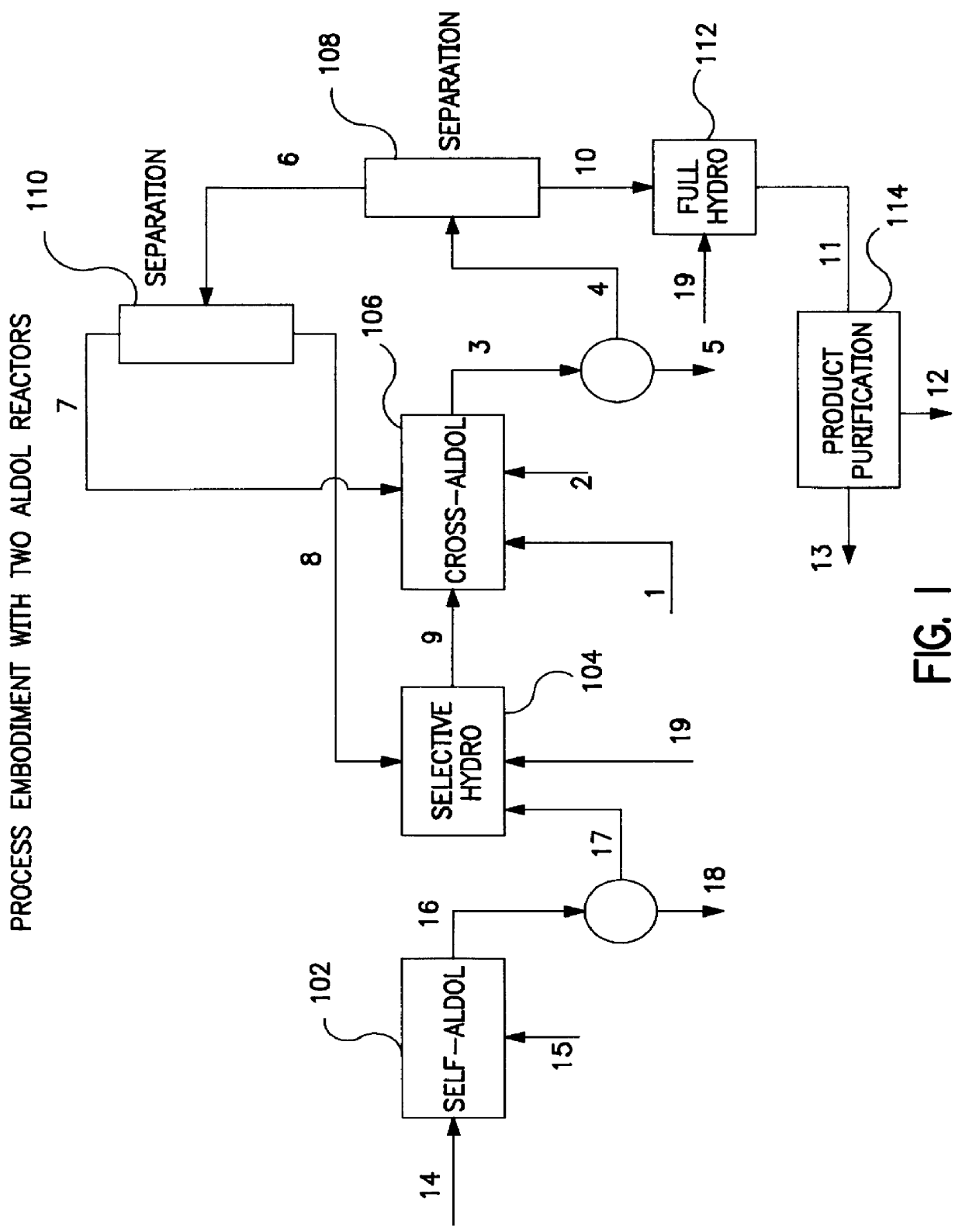

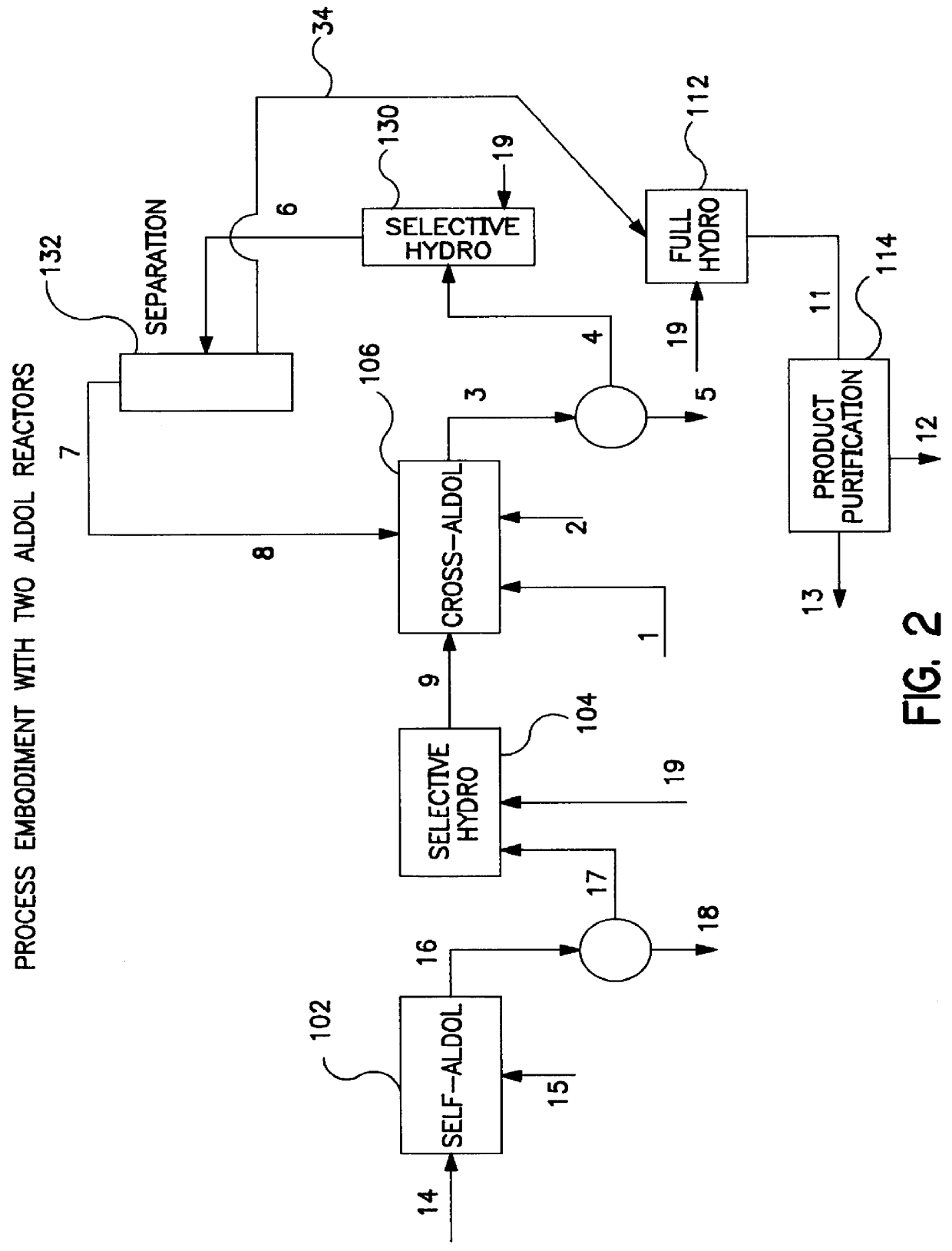

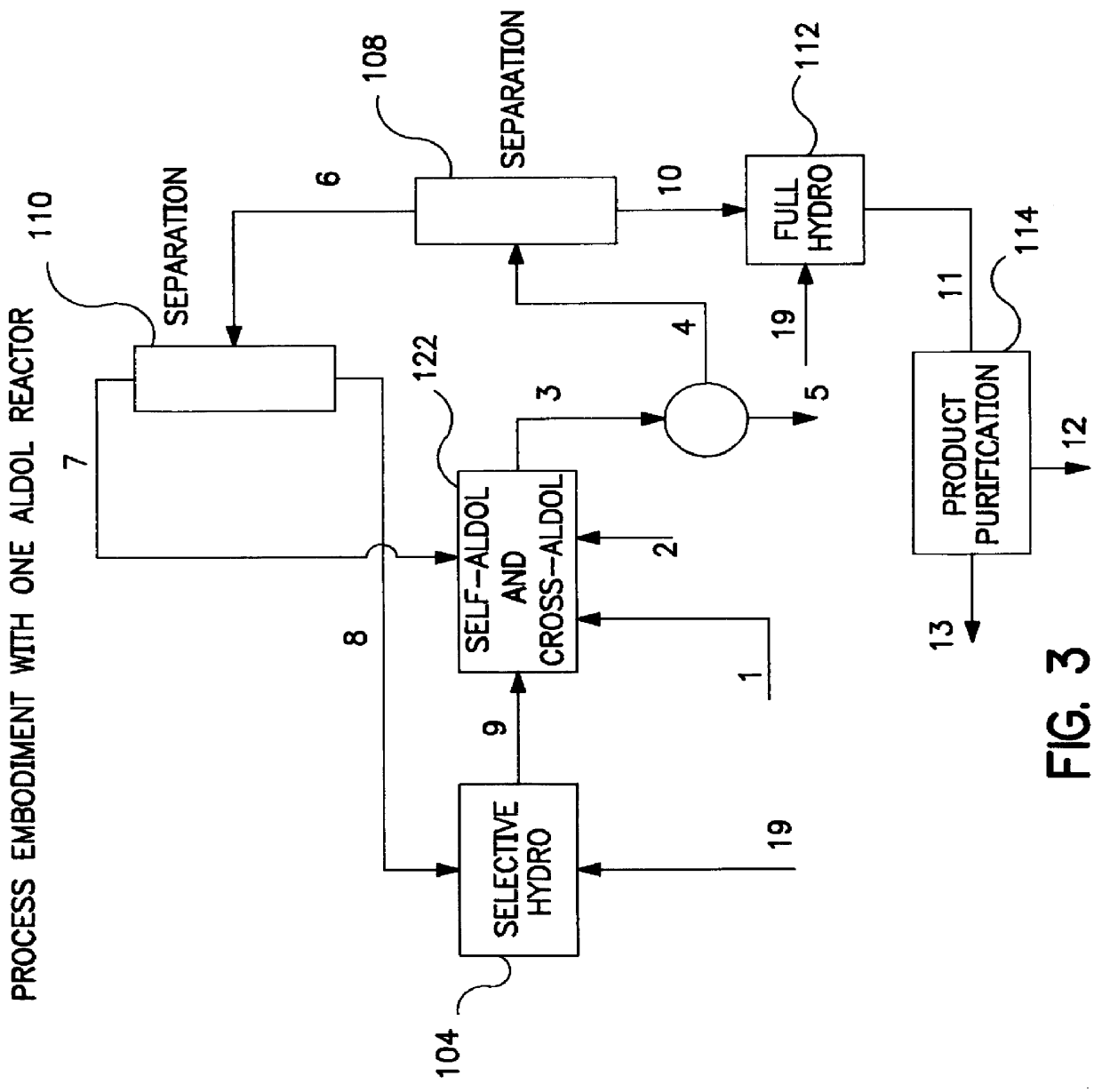

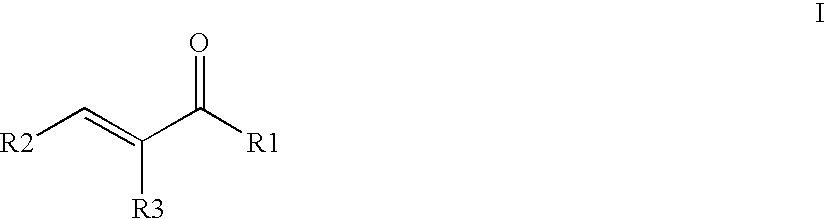

Condensation of aldehydes with ketones by multiphase reaction

InactiveUS6603047B2Improve responseHigh selectivityOrganic compound preparationPreparation by hydrogenationPhotochemistryUnsaturated ketone

Owner:OXENO OLEFINCHEMIE GMBH

Catalyst for preparing 1,4-cyclohexane dimethanol from hydrogenation of 1,4-cyclo hexane diformic acid

InactiveCN1911504AHigh product selectivityHigh reactivityOrganic compound preparationPreparation by hydrogenationActive componentHexane

The catalyst for hydrogenating 1, 4-cyclohexane diformic acid to prepare 1, 4-cyclohexane dimethanol consists of Al2O3 carrier and supported active components of metal Ru and Sn in the molar ratio of 1 to 0.5-2.0 and accounting for 5-20 wt%, and has grain size of 80-200 mesh. Compared with available technology, the catalyst of the present invention has the advantages of proper catalyst carrier, no use of noble metal Pt and Re, ideal activity and target product selectivity, low cost, etc.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

High-dispersion dual-functional catalyst for hydrogenating and deoxidizing phenol and preparation method of catalyst

InactiveCN102698788AImprove qualityRaise the pHMolecular sieve catalystsOrganic compound preparationAlkaneMolecular sieve

Owner:ZHEJIANG UNIV

Method of hydrogenating phenol

InactiveUS20060194989A1Drop in activity of catalyst can be preventedLow costPreparation by hydroxy compound hydrogenationOrganic compound preparationOrganic solventPHENOL LIQUID

The present invention provides a novel method of hydrogenating a phenol for hydrogenating a phenol industrially advantageously. The present invention relates, in the case of phenol hydrogenation in which carbon dioxide is made to participate in the reaction, to a method of hydrogenating a phenol characterized by using a supported rhodium and / or ruthenium catalyst, whereby the phenol is hydrogenated efficiently at a lower reaction temperature than with prior art; such a method characterized in that carbon dioxide having a temperature of 20 to 250° C. and a pressure of 0.1 to 50 MPa is used as the carbon dioxide; and such a method characterized in that hydrogen under conditions of a temperature of 20 to 250° C. and a pressure of 0.1 to 50 MPa is used. An environmentally friendly phenol hydrogenation process that uses no harmful organic solvents can be realized.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for synthesizing L-menthol

InactiveCN101602651AWide variety of sourcesLow pricePreparation by isomerisationPreparation by hydrogenationIsomerizationOrganic synthesis

The invention belongs to the technical field of organic synthesis, in particular to a method for synthesizing L-menthol. The method for synthesizing L-menthol takes myrcene as an initial raw material and comprises the following steps: amination reaction: diethylamine and myrcene carry out amination reaction to obtain geranylamine; isomerization reaction: the geranylamine carries out isomerization reaction under the catalytic action of chiral catalyst to obtain intermediate enamine; hydrolysis reaction: the enamine carries out hydrolysis reaction in an acidic medium to produce intermediate D-citronellal; cyclization reaction: the D-citronellal generates L-isopulegol by lewis acid catalyst and organic solvent; and hydrogenation reaction: the L-isopulegol is hydrogenated to obtain L-menthol. The method for synthesizing L-menthol has the yield of more than 90 percent, the GC purity of higher than 99.0 percent and the specific rotation of -49 degrees to -50 degrees, the raw material myrcene has wide sources and lower cost, and the whole method has simple technology, good repeatability and high yield and is quite suitable for large-scale industrialized production.

Owner:SHANGHAI WANXIANG FLAVORS & FRAGRANCES

Popular searches

Oxygen compounds preparation by reduction Raney catalysts Organic chemistry methods Essential-oils/perfumes Preparation by carbon monoxide reaction Oxygen compounds preparation by alkyne addition Base-materials Preparation by oxygen reduction Organic-compounds/hydrides/coordination-complexes catalysts Preparation by carbon monoxide or formate reaction

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com