Method for producing mixed butanol and coarse octanol by using waste liquid discharged from octanol device as raw material

A technology of crude octanol and butanol, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of difficult comprehensive utilization technology, pollute the environment and water sources, waste energy, etc., and achieve treatment costs Low, reduce treatment costs, improve the effect of water quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

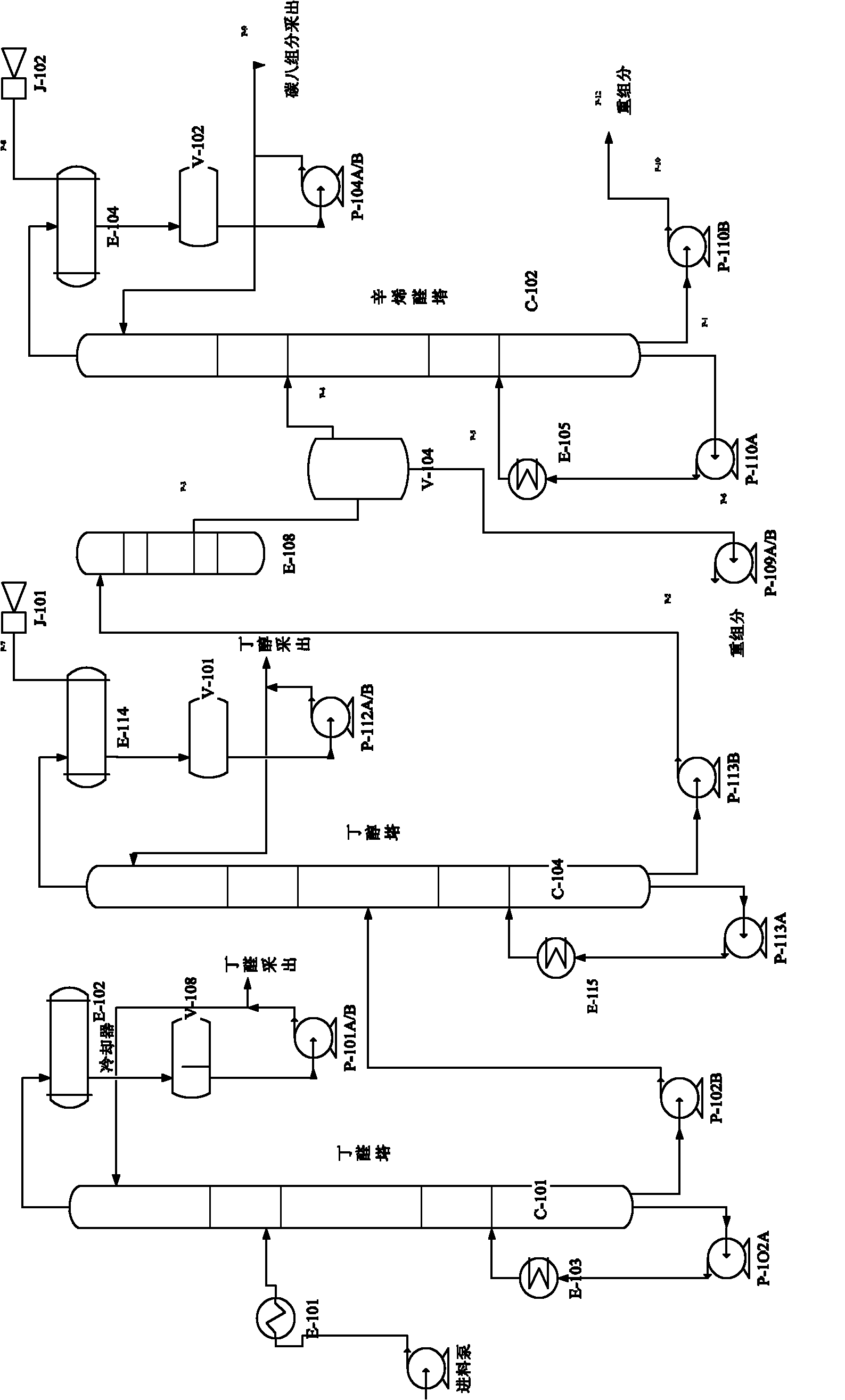

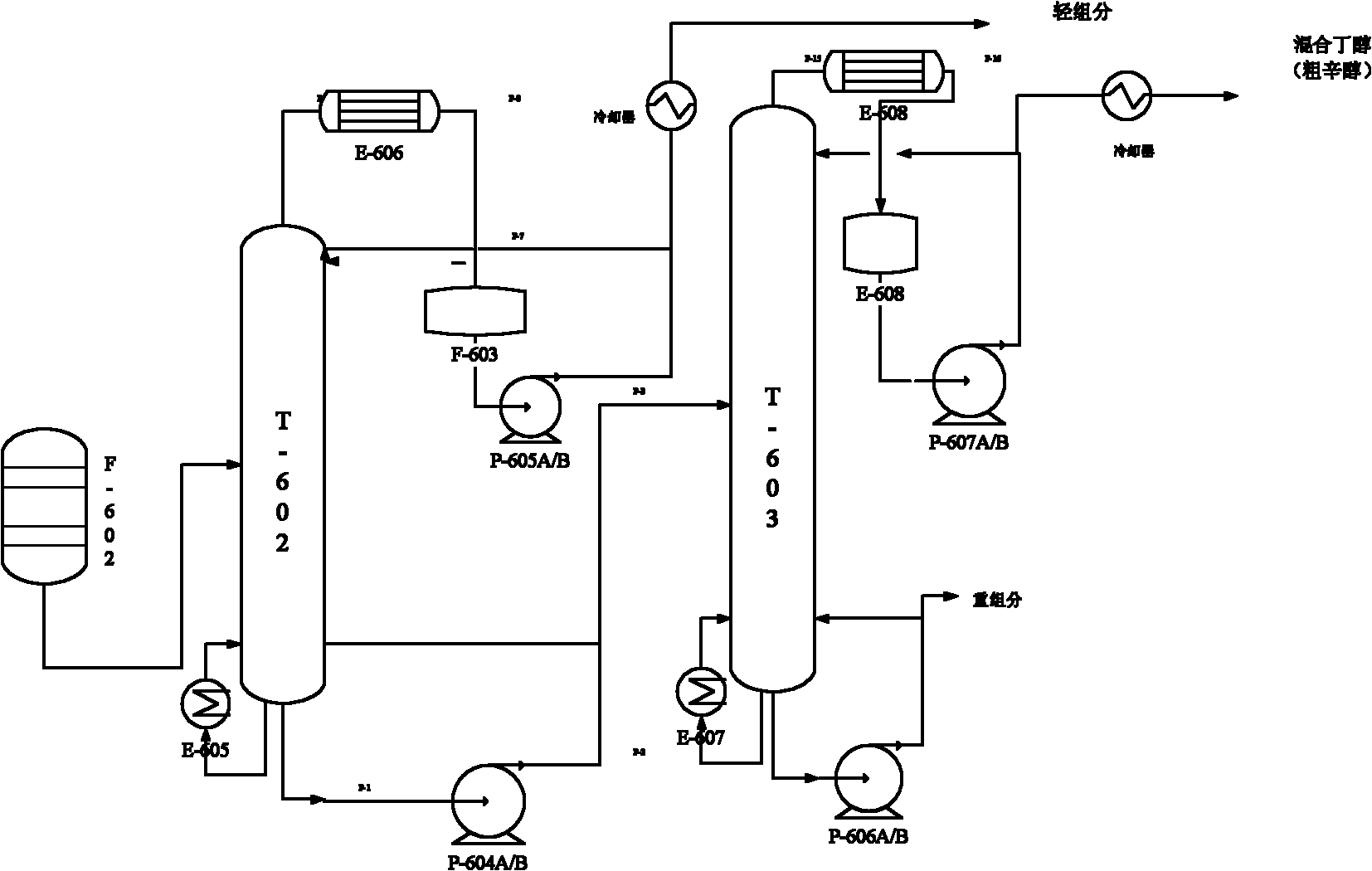

[0039] a. Raw material fractionation

[0040] The waste liquid discharged from the butanol unit first passes through the butyraldehyde fractionation unit to fractionate the butyraldehyde component contained therein from the top of the butyraldehyde column, and then passes through the butanol fractionation unit to extract the butanol component contained therein from the butanol Alcohol is fractionated from the top of the tower, and finally, the carbon eight components octenal and octanol contained in it are fractionated from the top of the carbon eight tower through the carbon eight fractionation tower device; the fractionated butyraldehyde is stored in the butyraldehyde storage tank, fractionated The produced butanol is stored in the C4 storage tank, and the octenal and octanol are stored in the C8 storage tank;

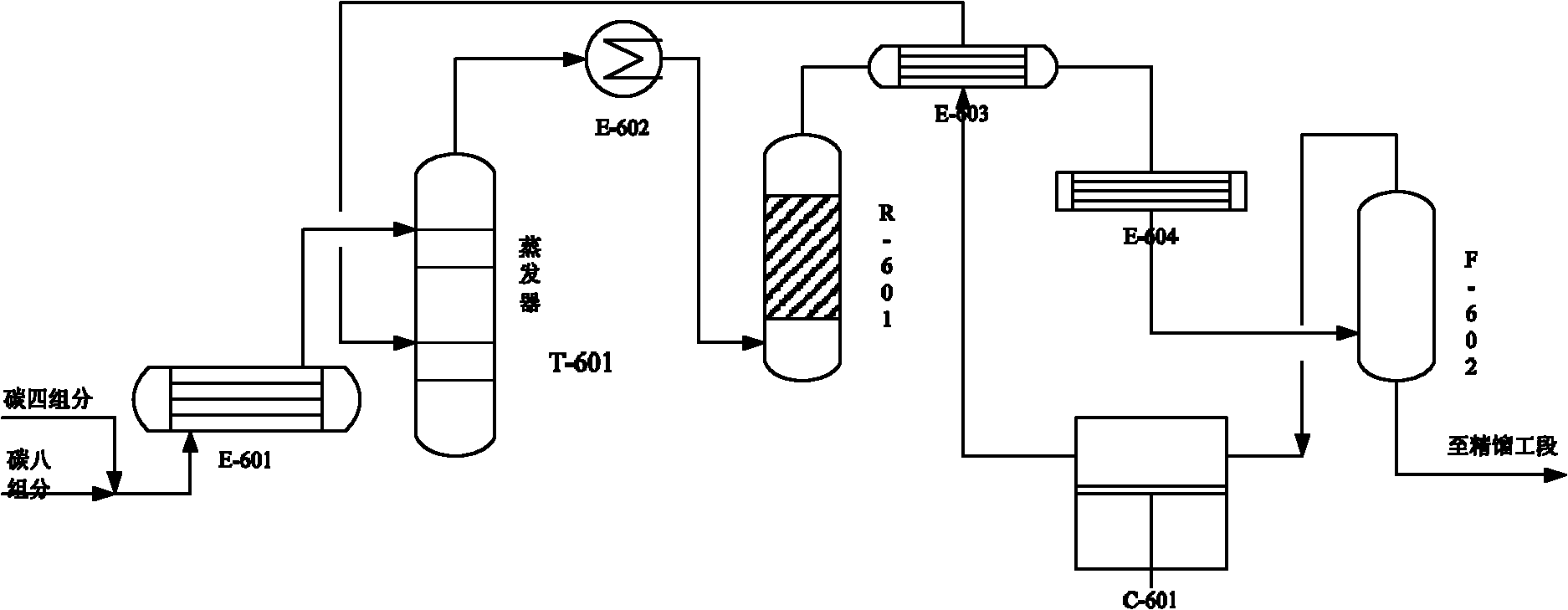

[0041] b. Hydrogenation synthesis

[0042] The butyraldehyde cut from the butyraldehyde storage tank in step a or the octenal and octanol cuts from the C8 storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com