Catalyst for preparation of hydrogenated bisphenol A

A hydrogenation bisphenol, hydrogenation catalyst technology, applied in the direction of physical/chemical process catalysts, hydrogenation preparation, organic chemistry, etc., can solve the problems of low load, aggravated dehydration by-product formation, unsuitable for industrial applications, etc., to improve activity and Effects of selectivity, life extension, and reduction of surface acidity of the carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

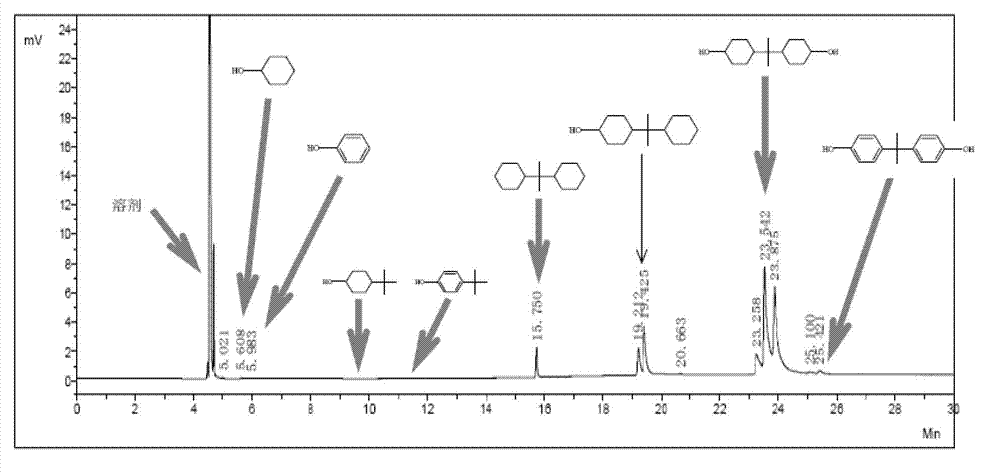

Image

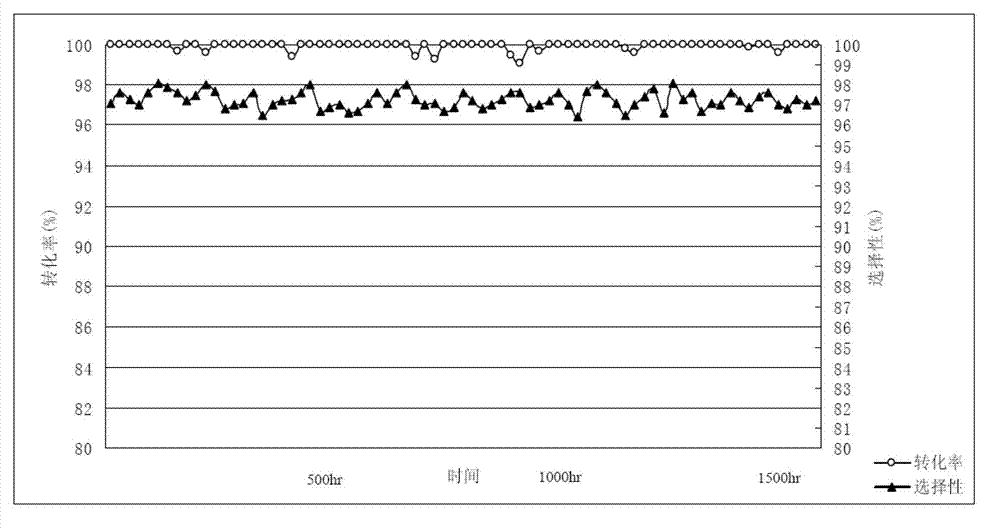

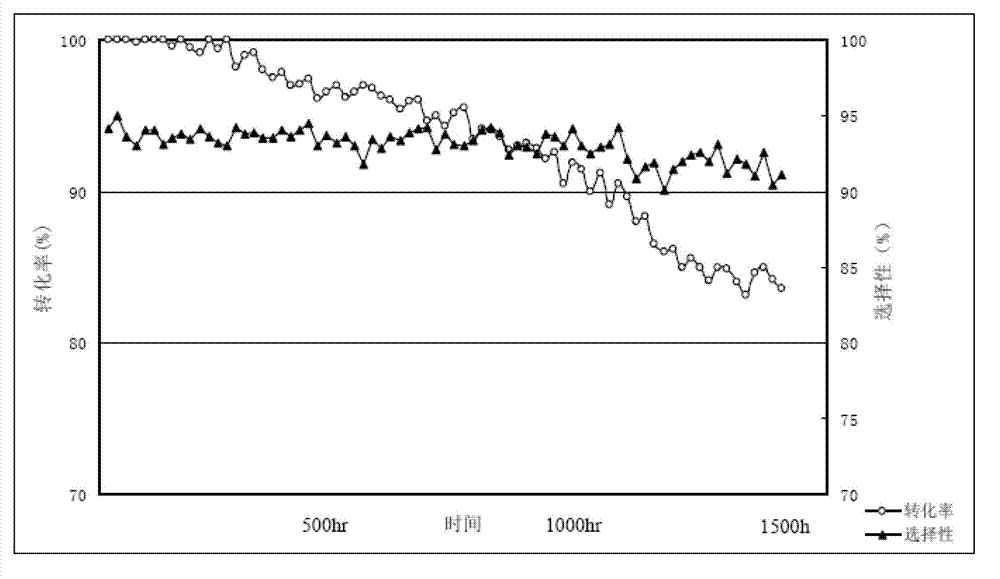

Examples

preparation example Construction

[0022] The preparation of the composite carrier is as follows:

[0023] Take commercially available pseudo-boehmite and aluminum hydroxide powder and mix them into a uniform powder in a certain proportion, weigh quantitative dilute nitric acid, phosphoric acid and alkali metal nitrate to make an aqueous solution, and spray the prepared solution evenly in a kneader In the powder, after aging for a certain period of time, it is extruded on a twin-screw extruder, and after drying, it is roasted under preset temperature control to obtain a strip-shaped composite alumina, which is pulverized and sieved to obtain a certain particle size carrier to obtain this product. The composite modified catalyst carrier used in the invention.

[0024] The loading of active ingredients is as follows:

[0025] The active component is impregnated and loaded by the conventional impregnation method. The catalyst carrier is impregnated with a metered concentration of palladium, ruthenium or rhodium c...

Embodiment 1

[0030] Mix commercially available pseudo-boehmite and aluminum hydroxide powder in a certain proportion to form a uniform powder, weigh 3% dilute nitric acid aqueous solution (wt%), 85% phosphoric acid aqueous solution (wt%) and alkali metal sodium nitrate to prepare into an aqueous solution, spray the prepared solution evenly in the powder in a kneader, after aging for a certain period of time, extrude on a twin-screw extruder, dry at 120°C for 12 hours, and roast at 650°C for 6 hours to obtain a strip-shaped compound Alumina is added, crushed and sieved to take particles with a certain particle size as the carrier for carrier characterization. Prepare the following 1-7 carriers according to different raw material ratios:

[0031] Table 1 Preparation and characterization of composite alumina carrier

[0032]

[0033] It can be seen from Table 1 that carriers 1 to 5 are modified by compounding, and alkali metal sodium and phosphorus elements are introduced. Carriers 6 and ...

Embodiment 2

[0036]According to the powder formulation of carrier 5 in Table 1 and the carrier preparation method in Example 1, the alkali metal is replaced by 30g, 60g, and 100g of potassium nitrate respectively, to obtain the following carriers 8a, 8b, 8c, and the specific surface area corresponds to 132.17m2 / g, 128.60m2 / g, 130.47m2 / g, pore volume corresponding to 0.48ml / g, 0.51ml / g, 0.53ml / g, L acid strength corresponding to 4.61mmol / g, 3.52mmol / g, 3.19mmol / g , B acid strength corresponding to 0.41mmol / g, 0.36mmol / g, 0.32mmol / g, for the following examples.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com