Catalyst for preparing 1,4-cyclohexane dimethanol from hydrogenation of 1,4-cyclo hexane diformic acid

A technology of cyclohexanedimethanol and cyclohexanedicarboxylic acid, which is applied in the field of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

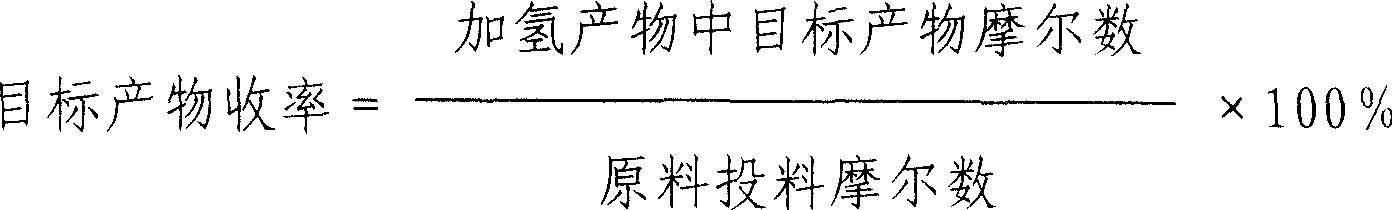

Image

Examples

Embodiment 1

[0015] 4.53gRuCl 3 ·3H 2 O was dissolved in 24.5ml of deionized water, and then 3.91g of SnCl was added 2 2H 2 O dissolved, then add 35g carrier Al 2 o 3 Stir evenly to obtain a dark green paste, leave it to age for 15 hours, dry it at 70-100°C for 2 hours, take the particles with a particle size of 80-200 mesh as the catalyst precursor after grinding, and use hydrogen to reduce it by heating, and the flow rate of hydrogen is 150ml / min, the catalyst for the reaction was obtained.

Embodiment 2~10

[0017] Change the consumption of each starting material and carrier of each catalyst carrier, all the other are the same as embodiment 1. The composition and content of the catalyst active components prepared in each embodiment are shown in Table 1.

[0018] Ru / Sn

(The molar ratio of)

Ru+Sn content

(wt%)

Example 1

1 / 0.7

11.5

Example 2

1 / 1.0

8.0

Example 3

1 / 1.0

9.5

Example 4

1 / 1.0

9.5

Example 5

1 / 1.0

10.0

Example 6

1 / 1.0

10.0

Example 7

1 / 1.0

10.5

Example 8

1 / 1.0

10.5

Example 9

1 / 1.3

12.5

Example 10

1 / 1.5

15.0

[0019] The catalyst that above-mentioned each embodiment obtains carries out active evaluation with following condition:

[0020] 150 g of water as a solvent and 15 g of 1,4-cyclohexanedicarboxylic acid were placed in a 300 ml autoclave, and the requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com