Method for synthesizing hexamethylenediamine key intermediate

An intermediate, the technology of hexamethylenediamine, which is applied in the field of synthesis of the key intermediate of hexamethylenediamine, 6-aminocapronitrile, can solve the problems affecting the reaction efficiency, affecting the normal operation of the reaction device, reducing the activity and service life of the catalyst, and achieving The process flow is simple, the effect of improving raw material utilization and product selectivity, and reducing surface coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

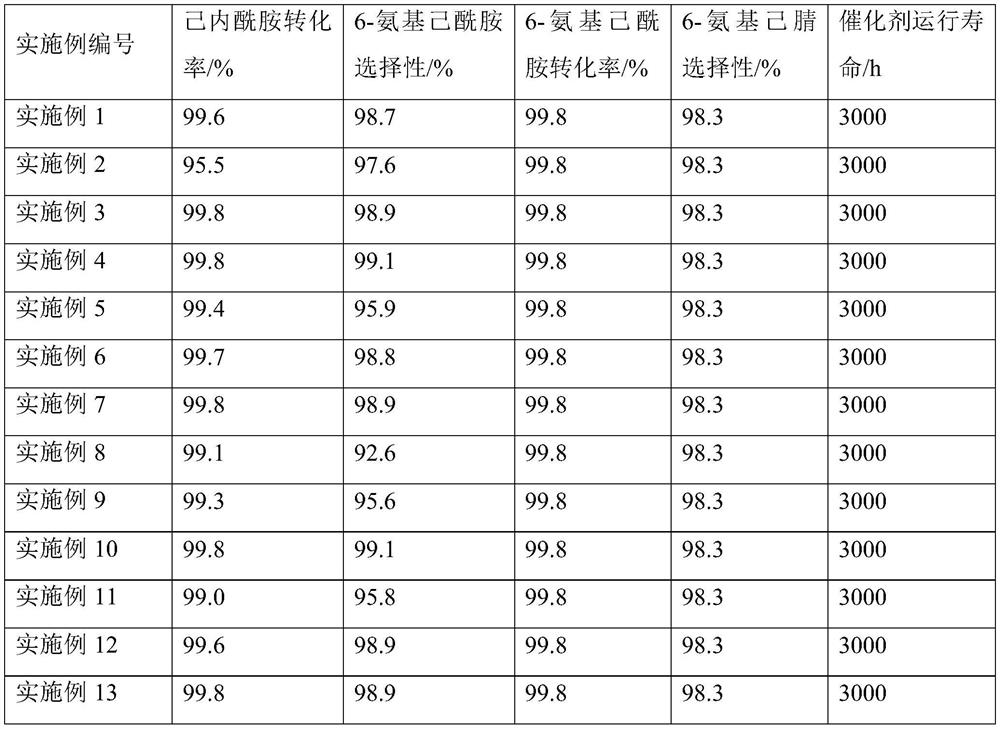

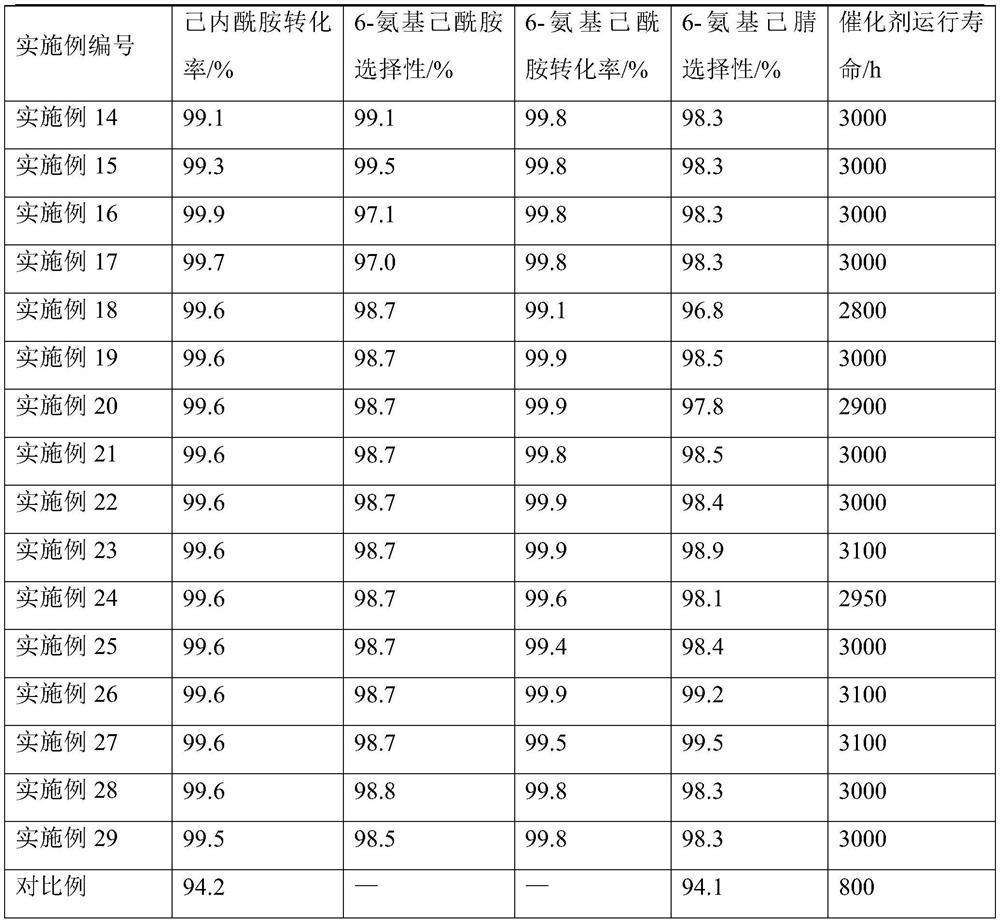

Examples

Embodiment 1

[0032] A kind of method of synthetic hexamethylenediamine key intermediate of the present invention, comprises the steps:

[0033] (1) The raw material caprolactam and ammonia water with a mass percentage concentration of 25% are transported to different preheaters with high-pressure pumps respectively for preheating. The final caprolactam and ammonia water are passed into the microchannel reactor at a molar ratio of 1:35, and the reaction is carried out at 500°C and 4MPa, and the reaction residence time is 8s;

[0034] (2) The material obtained after the reaction of step (1) is transported to the gas-liquid separator, and the gas-liquid separation is carried out at 120 ° C. The separated gas phase material ammonia and water are sent to step (1) to continue the reaction, and the separation is obtained The liquid phase material is 6-aminocaproamide;

[0035] (3) The 6-aminocaproic amide separated from the step (2) is pumped into the preheater with a high-pressure pump, and nit...

Embodiment 2

[0038] A method for synthesizing the key intermediate of hexamethylenediamine of the present invention, the basic method steps are the same as in Example 1, wherein, the difference is: in step (1), the molar ratio of the amount of raw ammonia and caprolactam is 1:1.

[0039] Result analysis method is the same as embodiment 1, specifically see table 1.

Embodiment 3

[0041] A method for synthesizing the key intermediate of hexamethylenediamine of the present invention, the basic method steps are the same as in Example 1, wherein, the difference is that in the step (1), the molar ratio of the amount of raw material ammonia and caprolactam is 50:1.

[0042] Result analysis method is the same as embodiment 1, specifically see table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com