Patents

Literature

53results about How to "Control contact time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

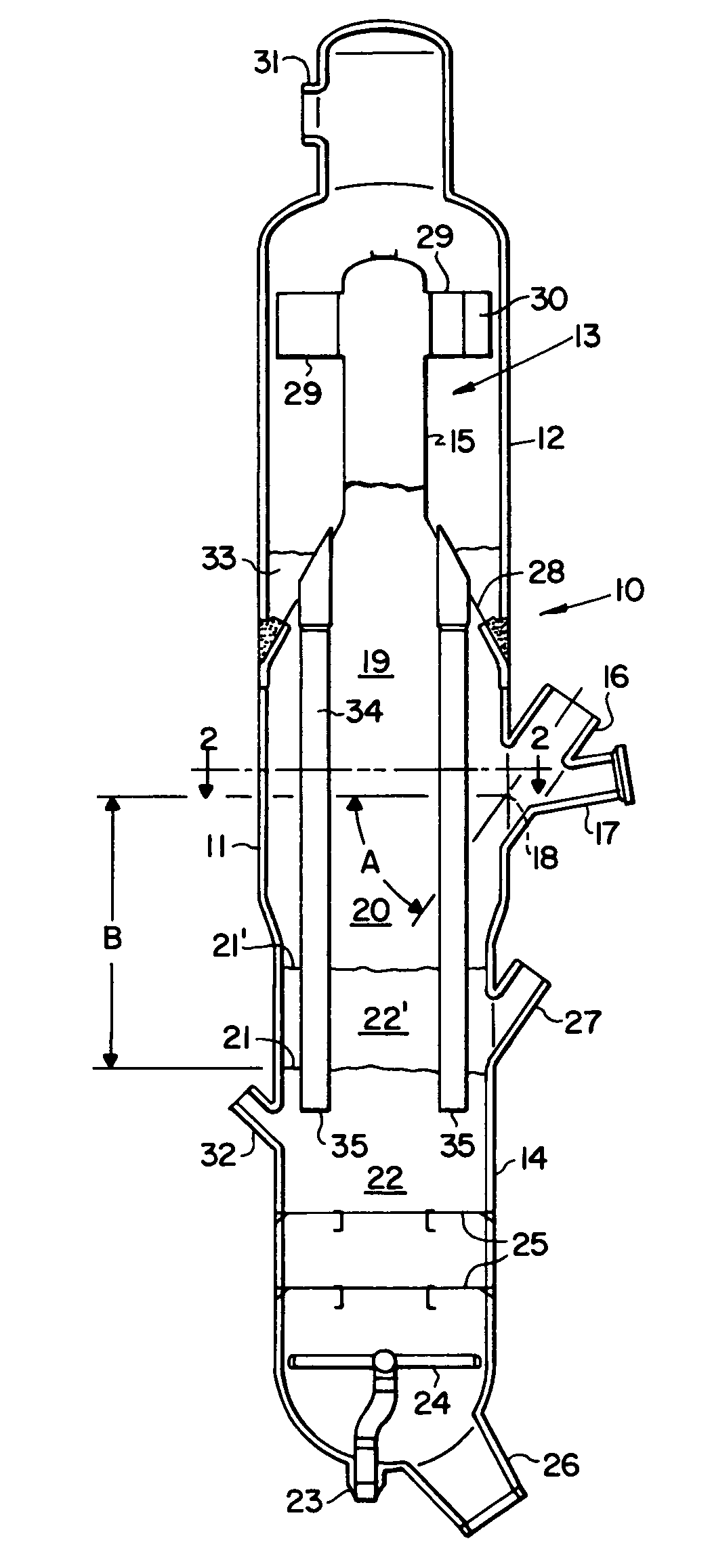

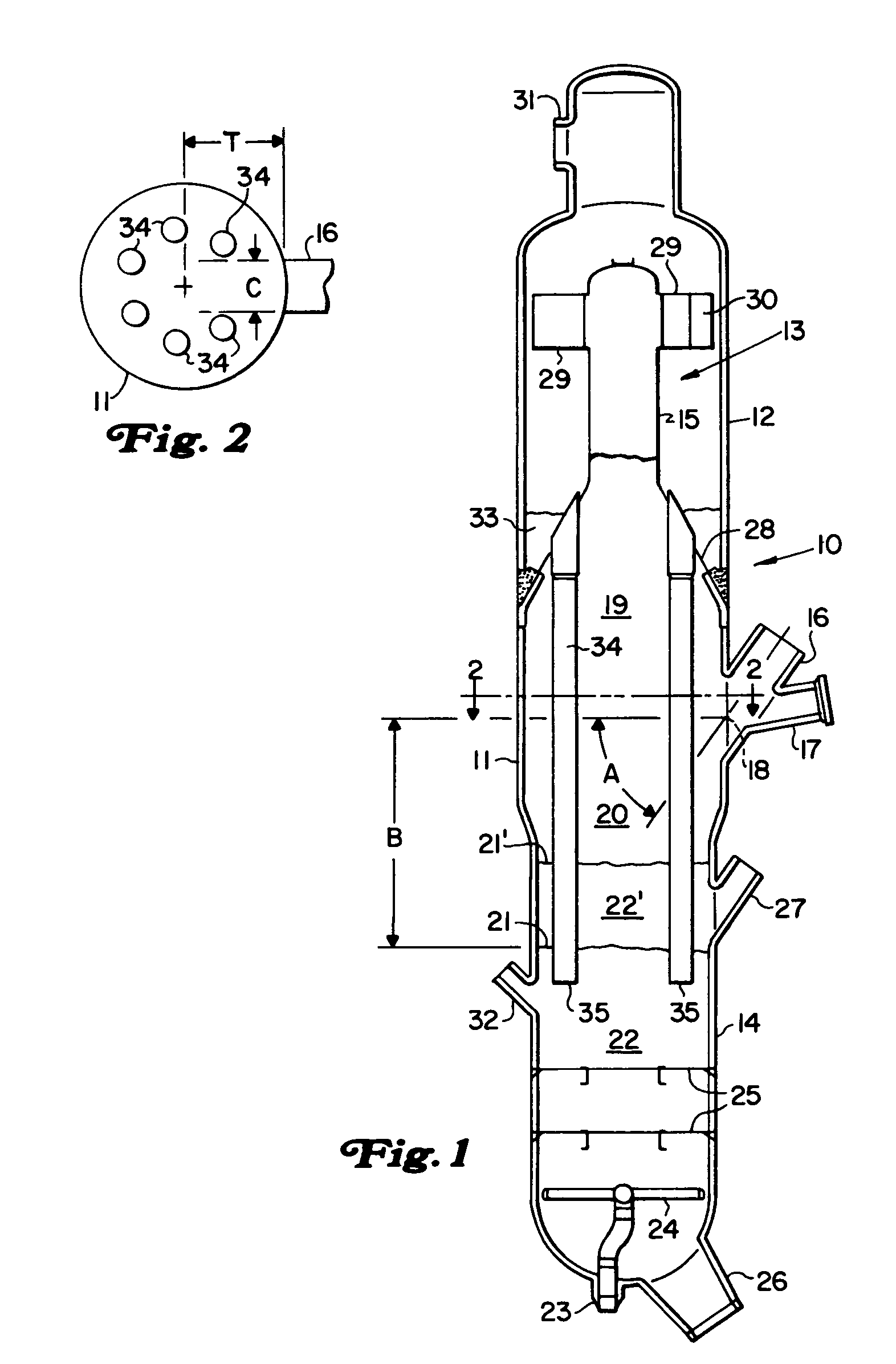

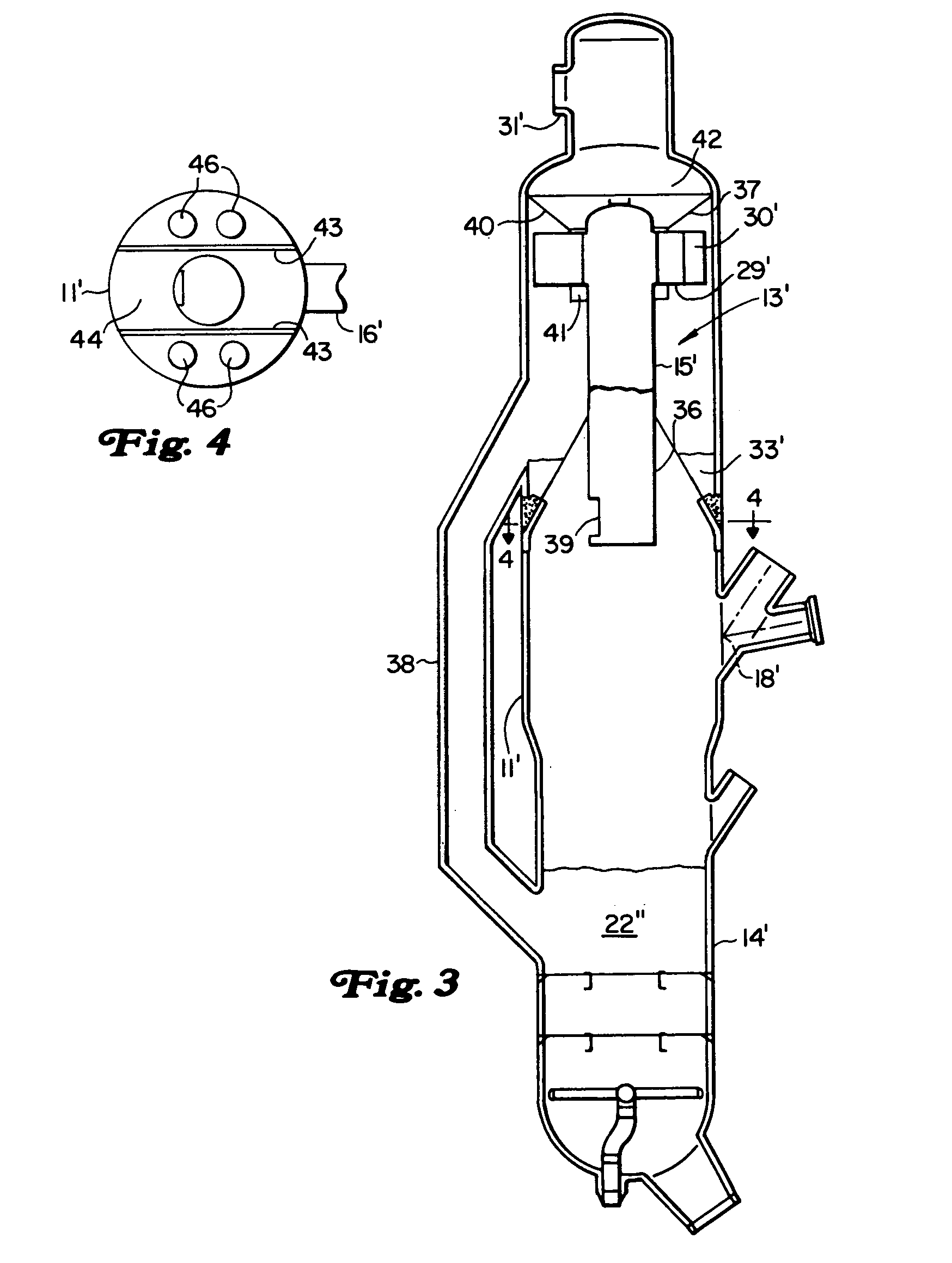

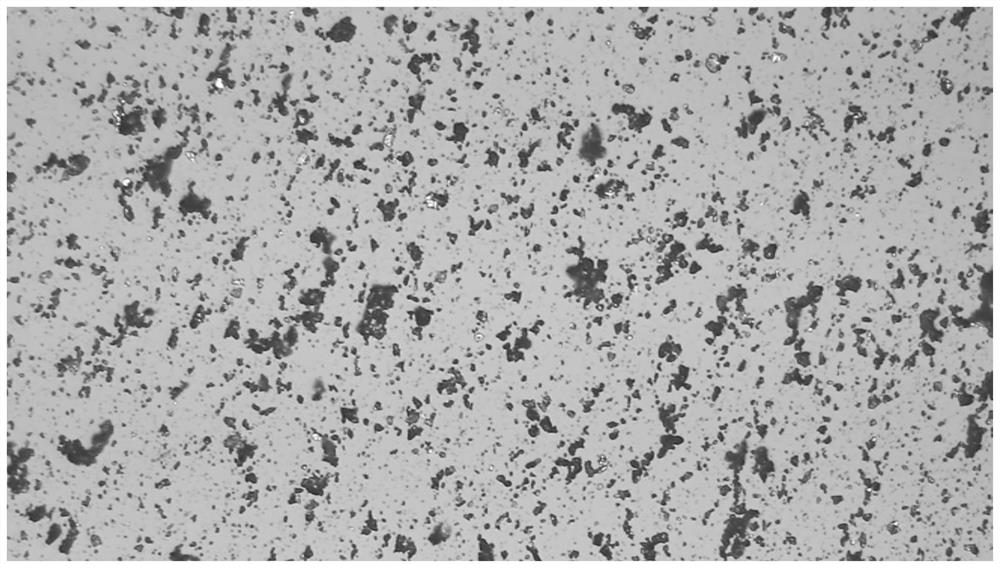

Apparatus for feed contacting with immediate catalyst separation

InactiveUS7135151B1Control contact timeTimely controlCatalytic crackingChemical/physical/physico-chemical nozzle-type rreactorsHigh elevationContact time

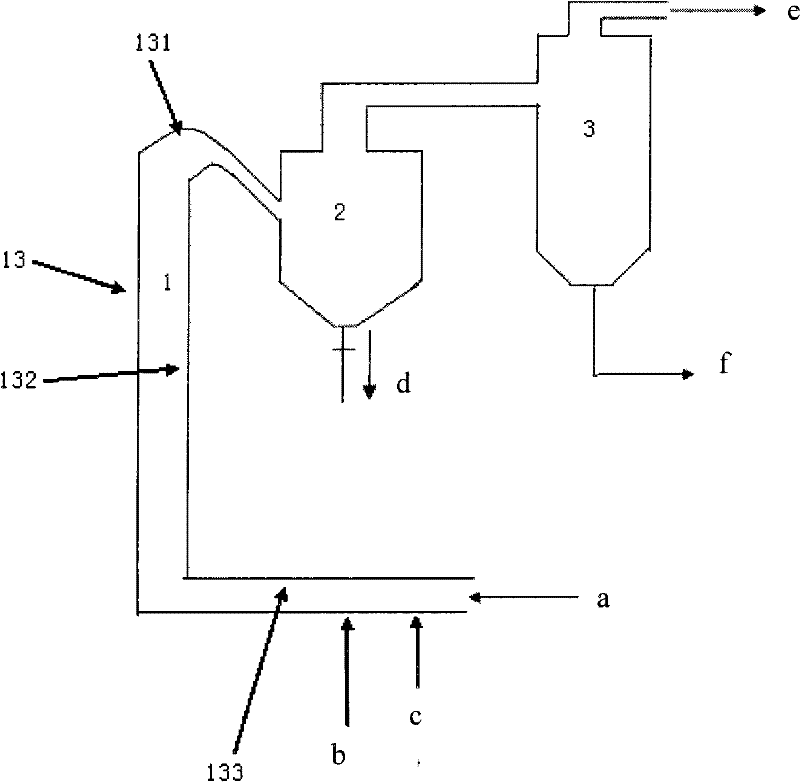

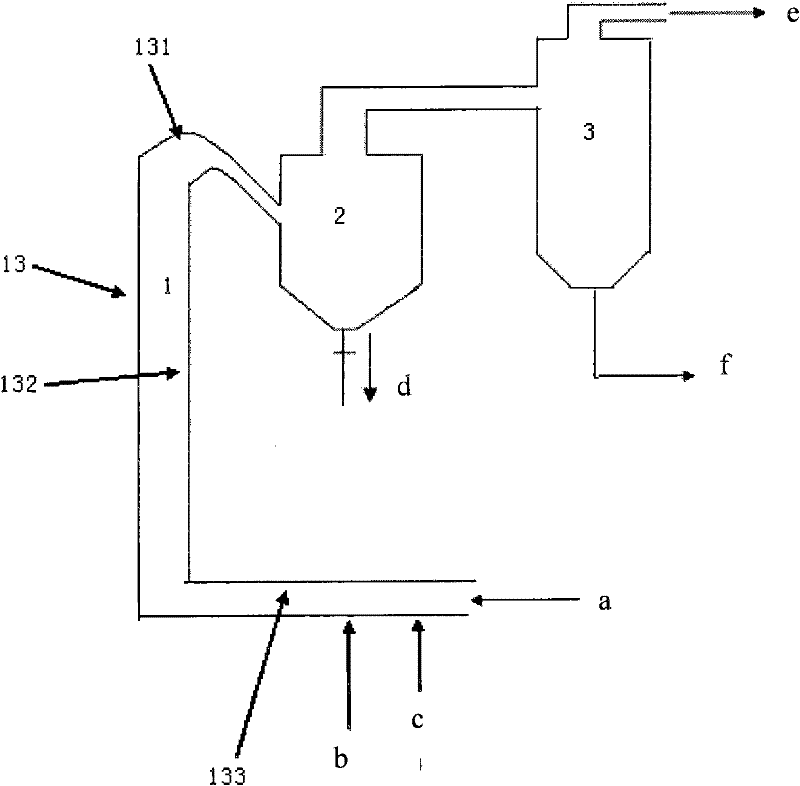

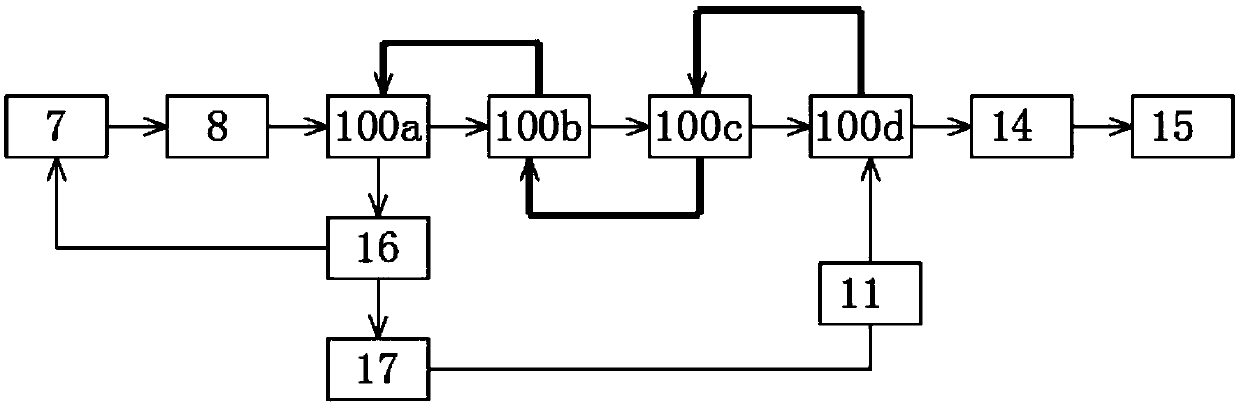

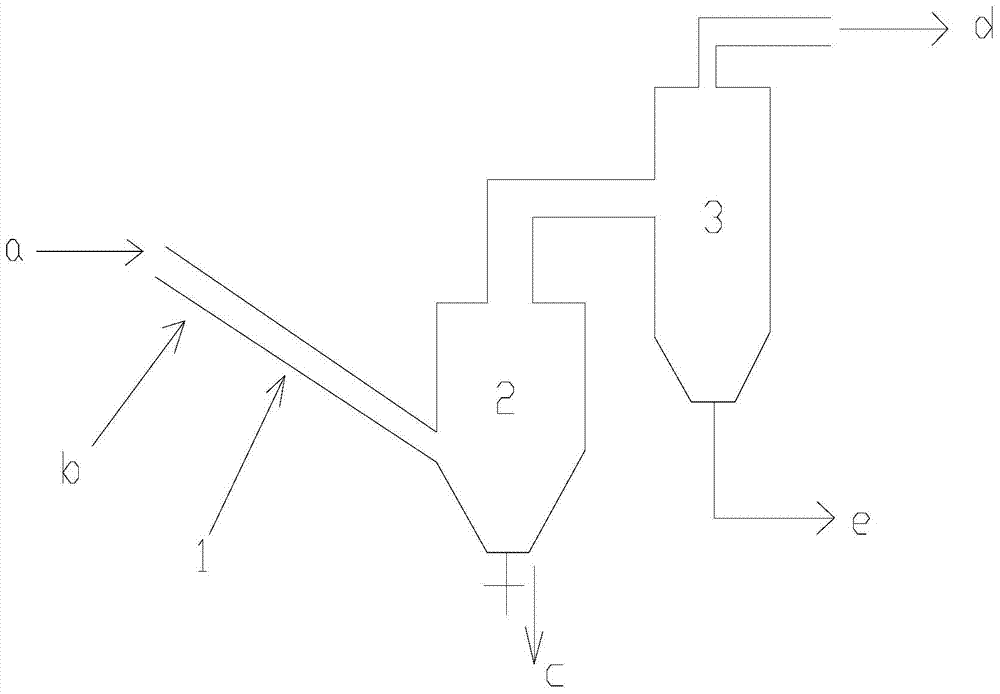

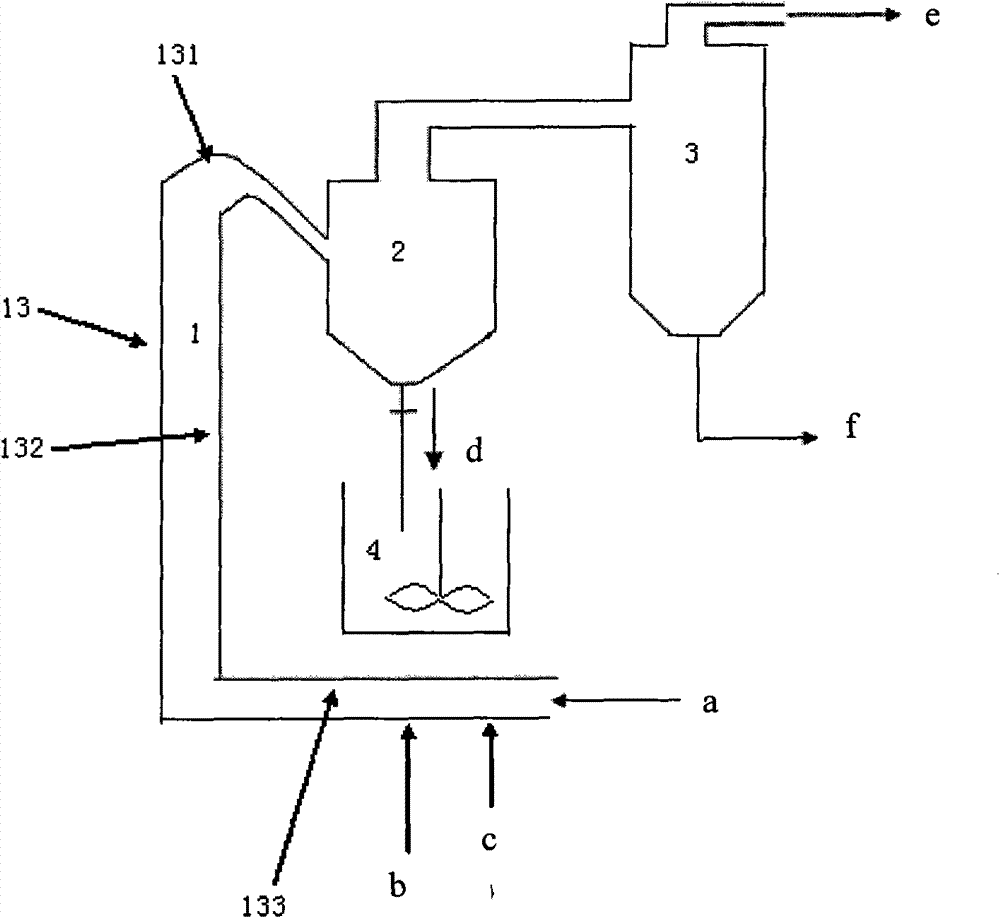

A particular arrangement of an FCC unit creates an immediate and sustained gravity separation of catalyst and hydrocarbon vapors in short contact time cracking operation. A transverse feed contactor ejects the mixture of catalyst and hydrocarbon vapors transversely into a central portion of a separation vessel for vertical disengagement of catalyst from vapors. The vapors travel upwardly in the vessel into an inertial separator that quickly segregates entrained catalyst from the hydrocarbon vapors and collects separated catalyst at a higher elevation for stripping of adsorbed hydrocarbons from the catalyst.

Owner:UOP LLC

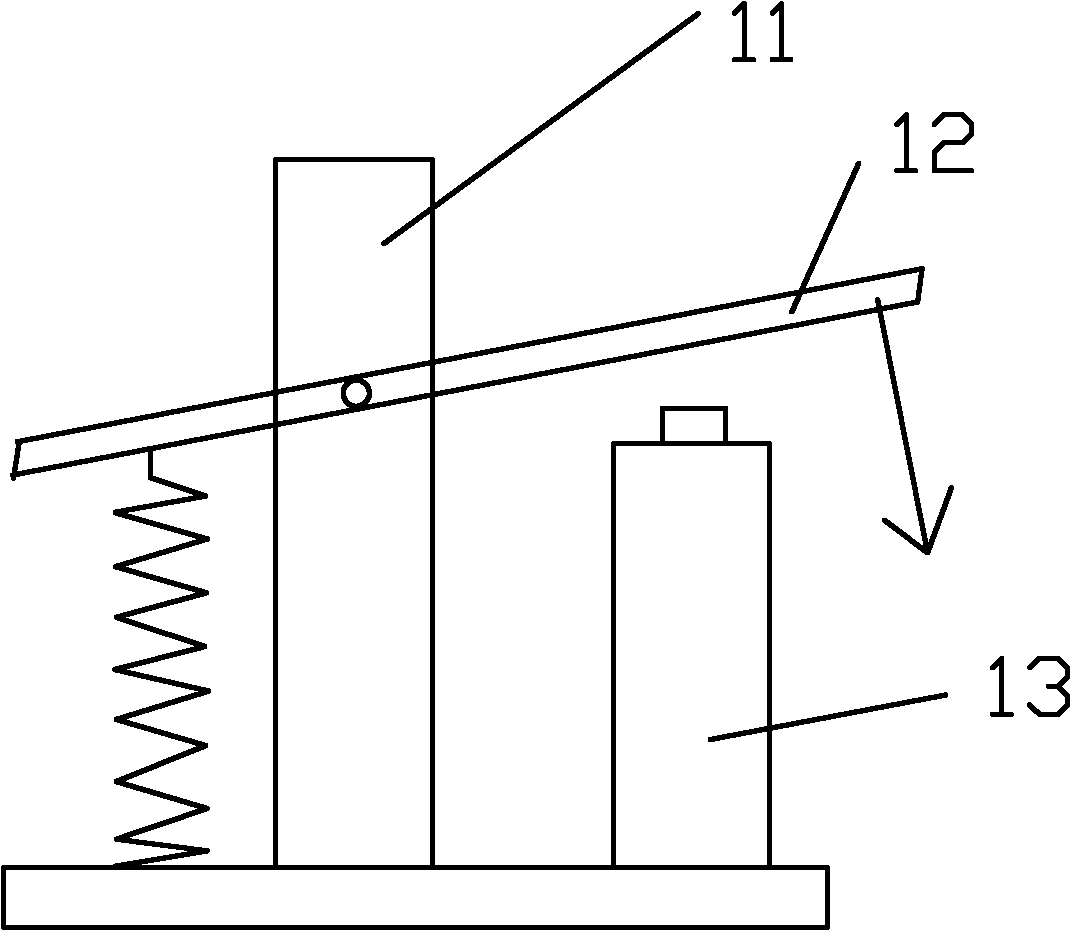

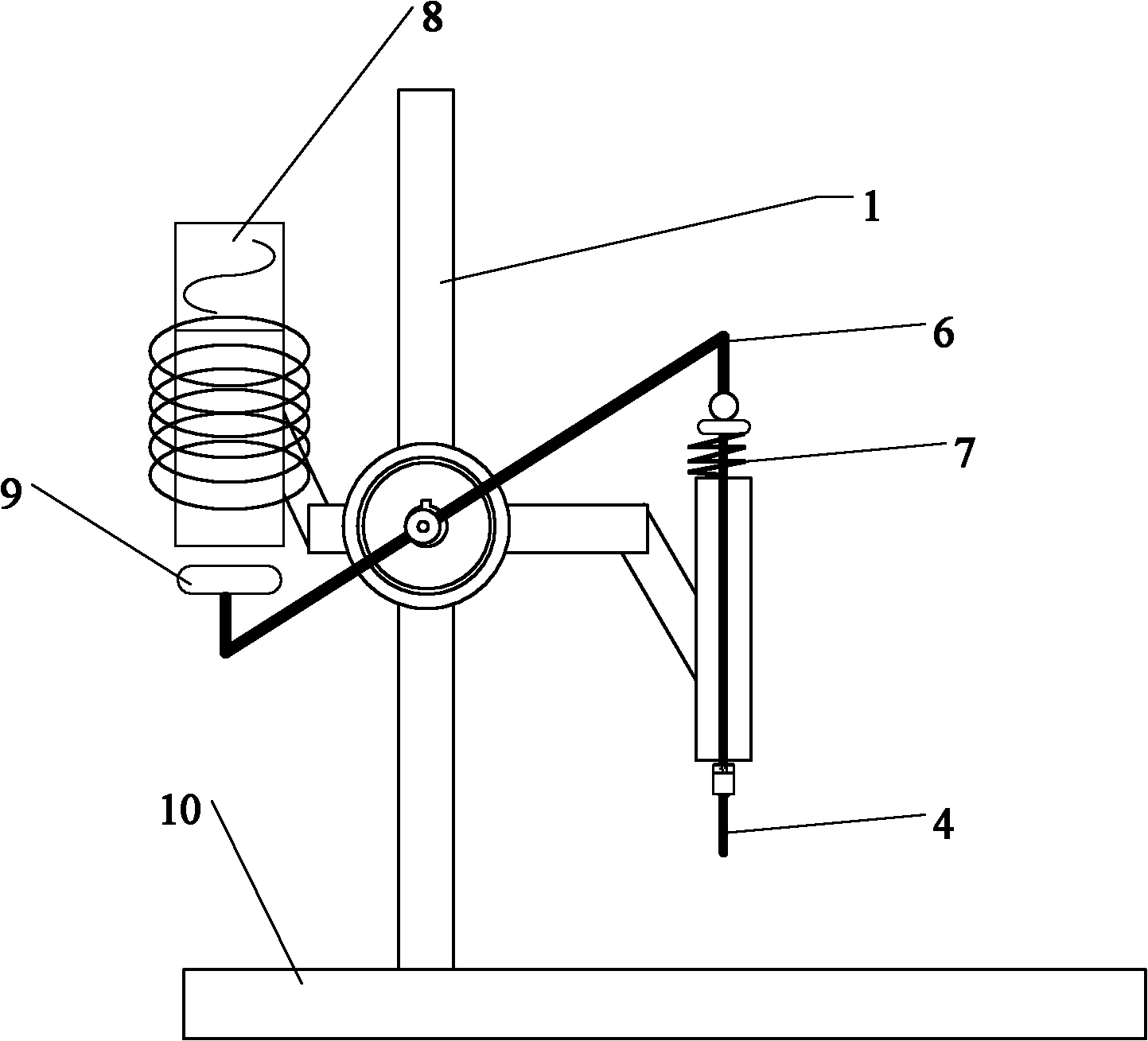

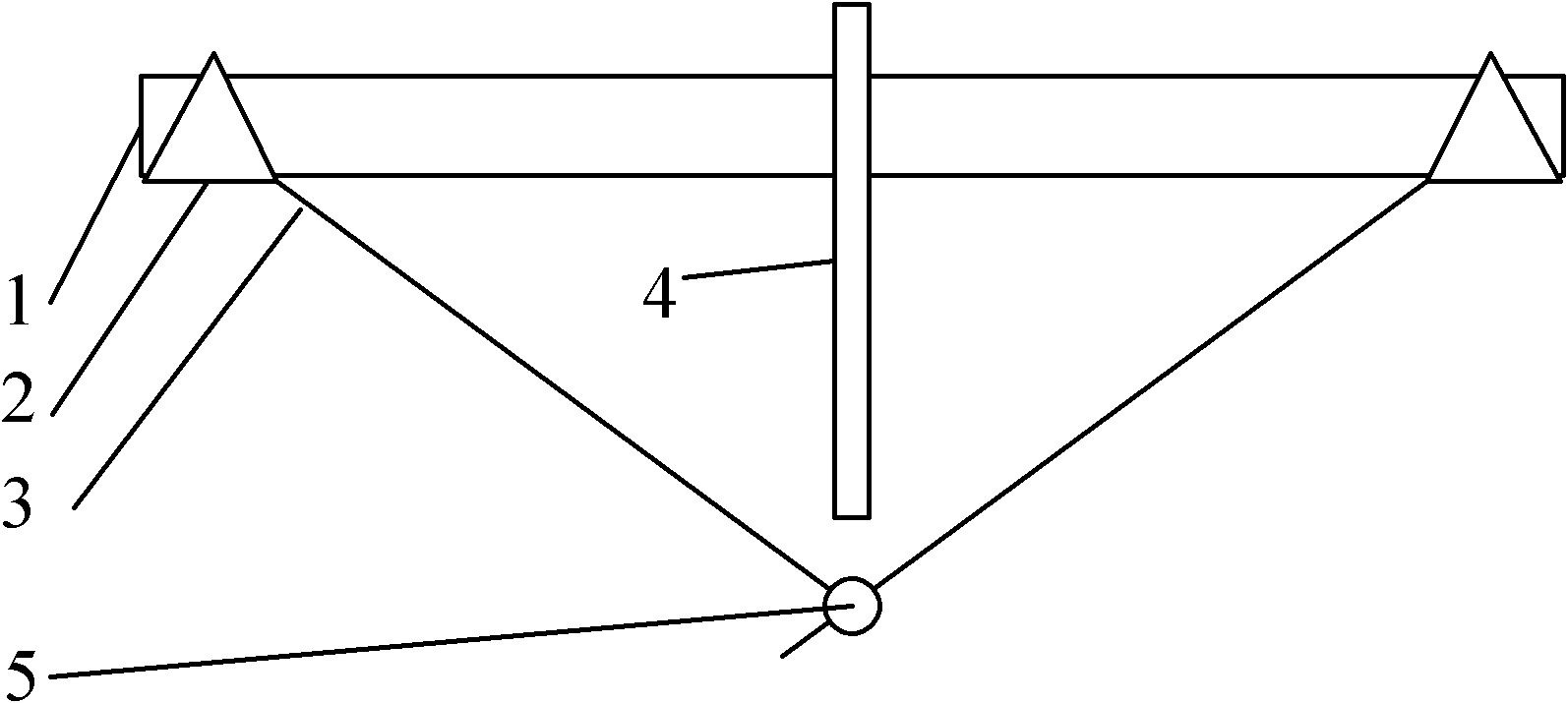

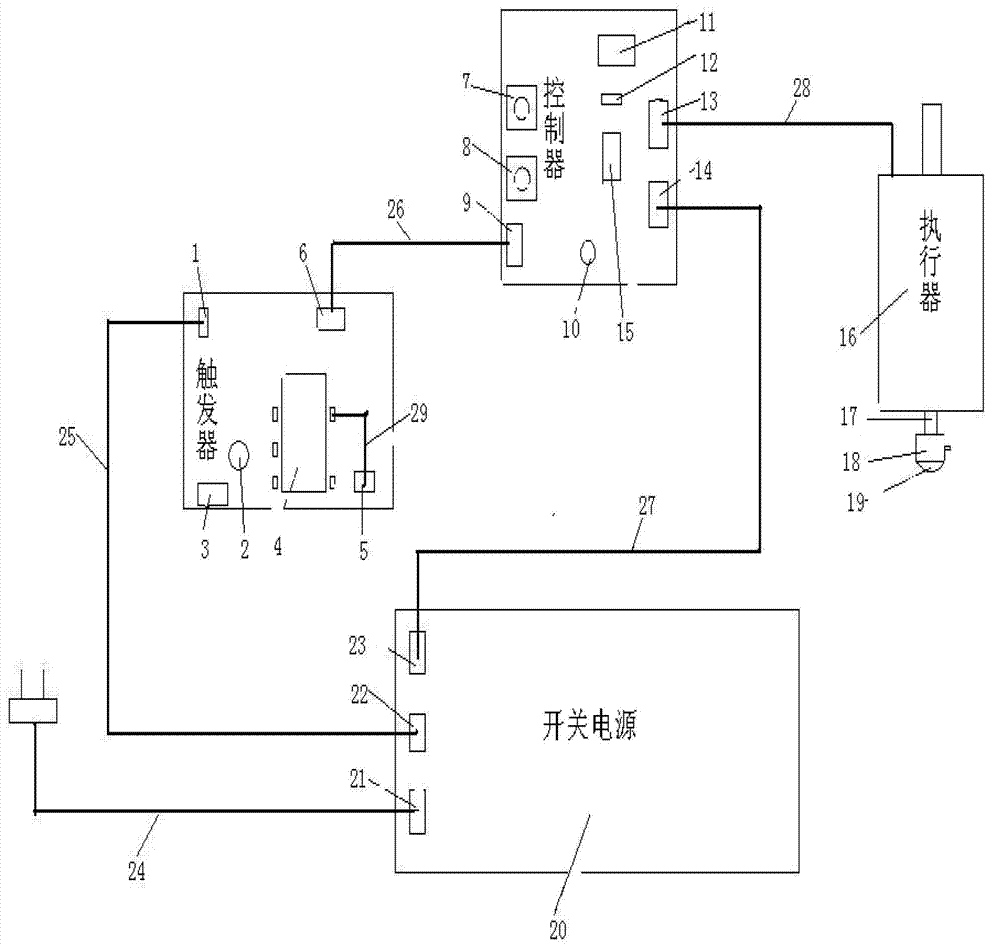

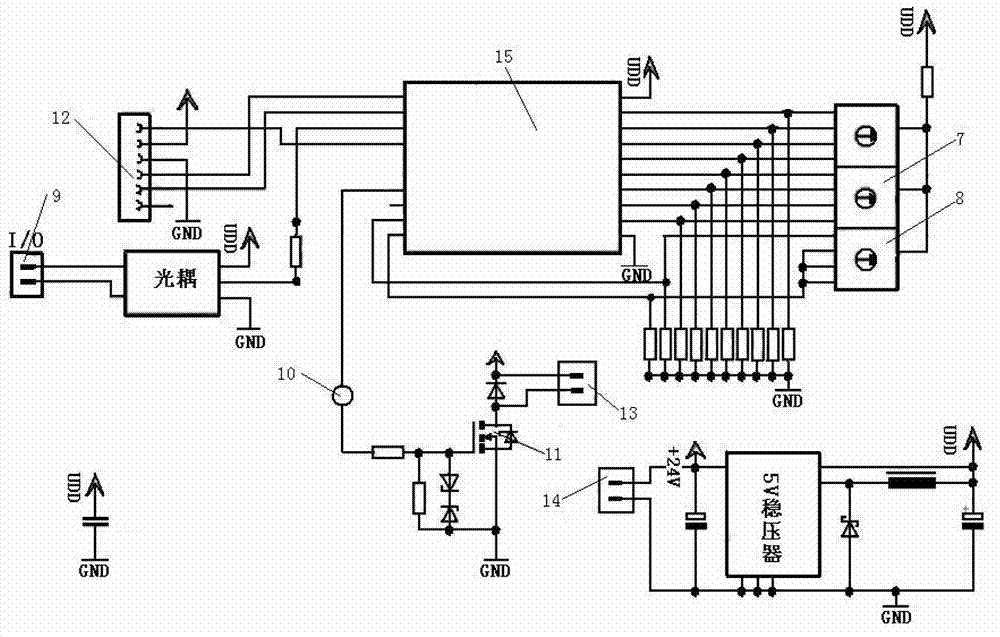

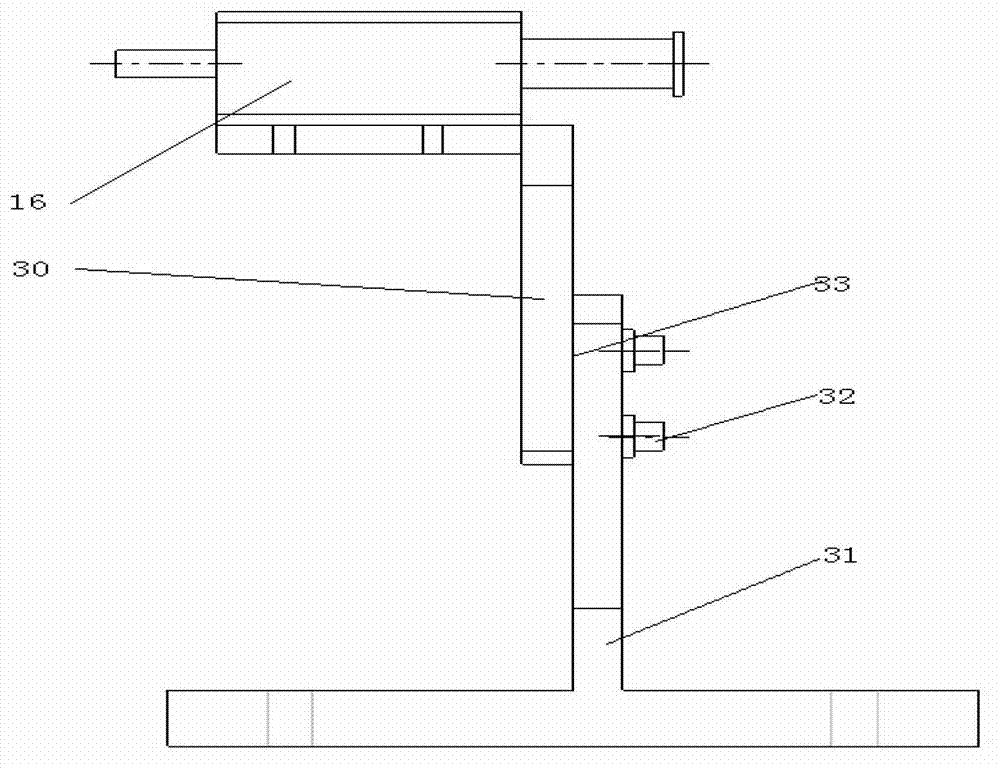

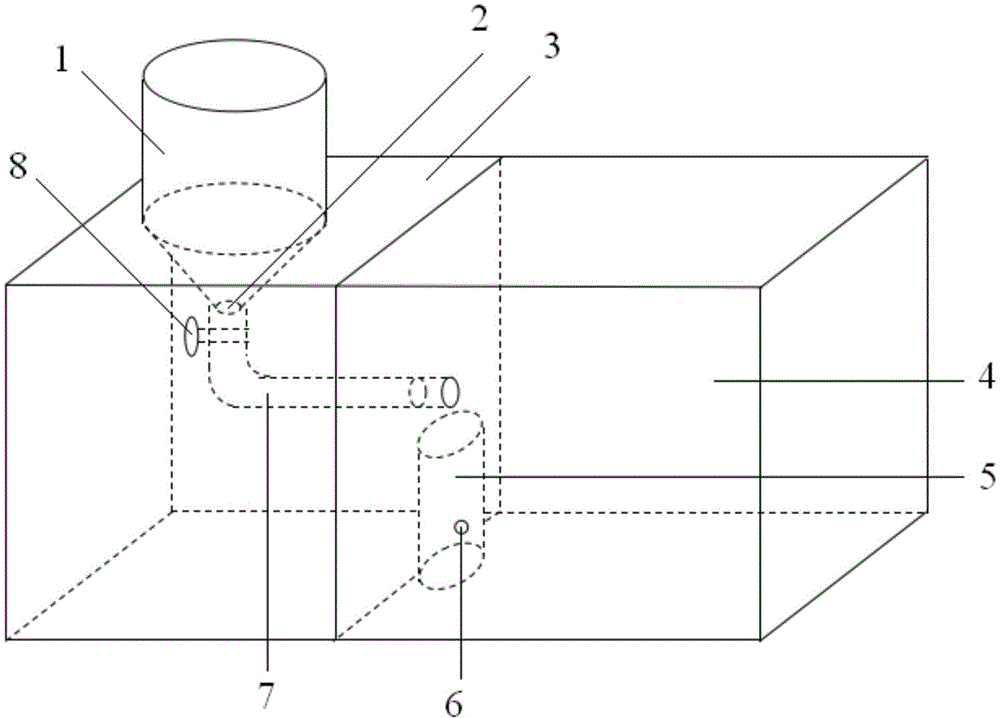

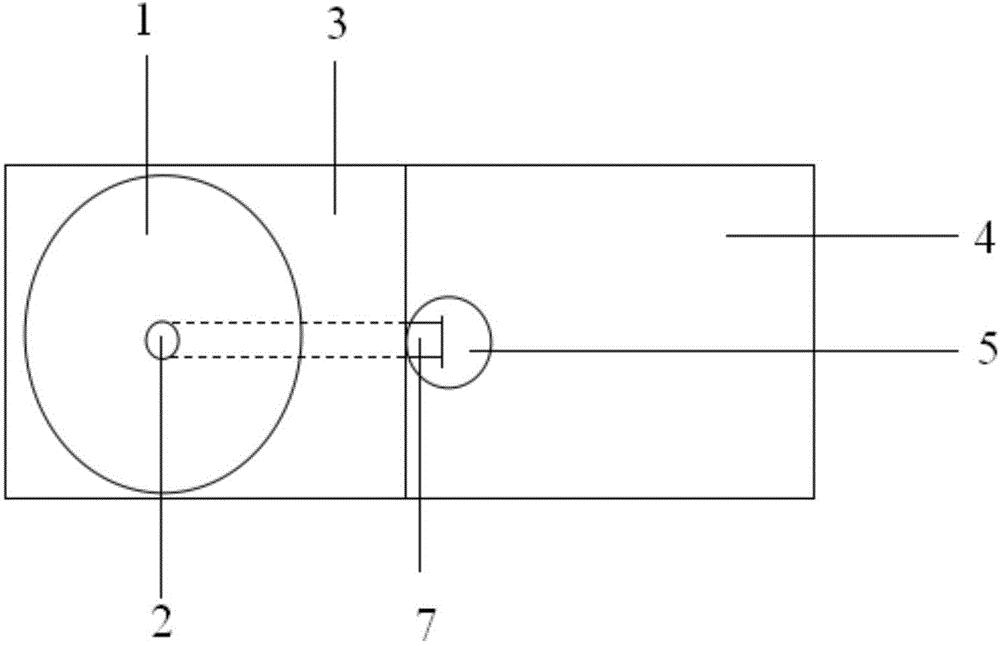

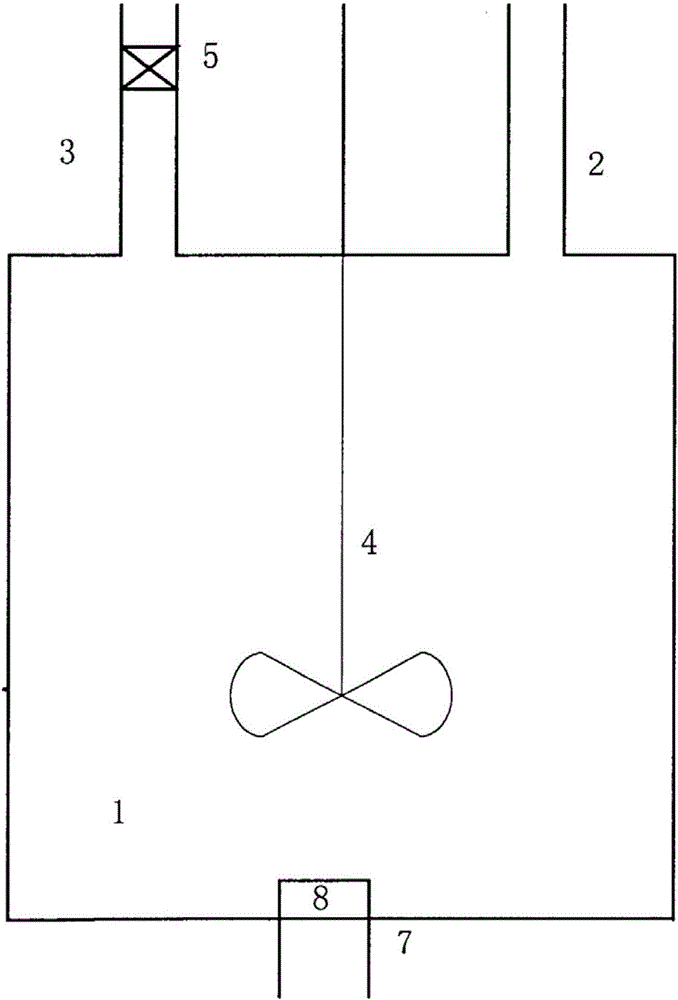

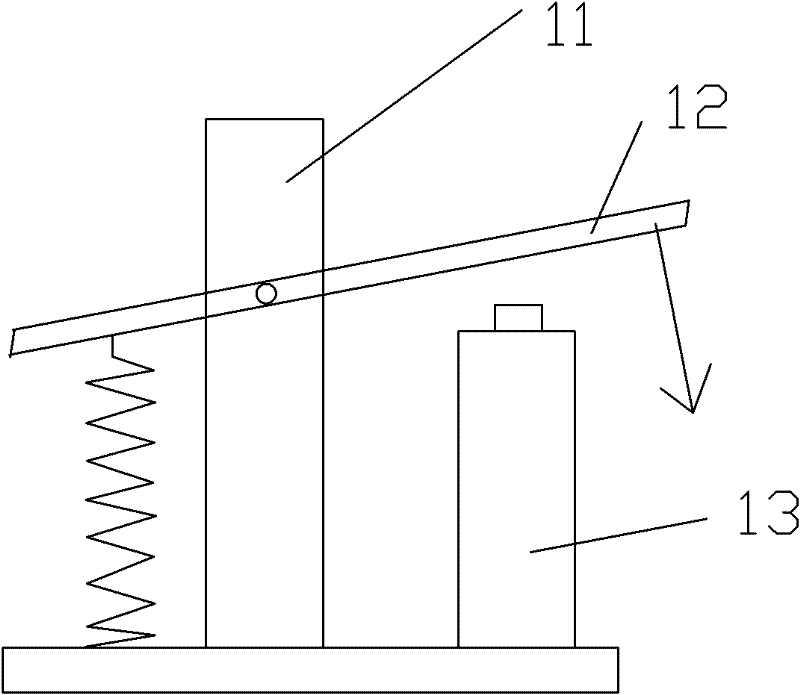

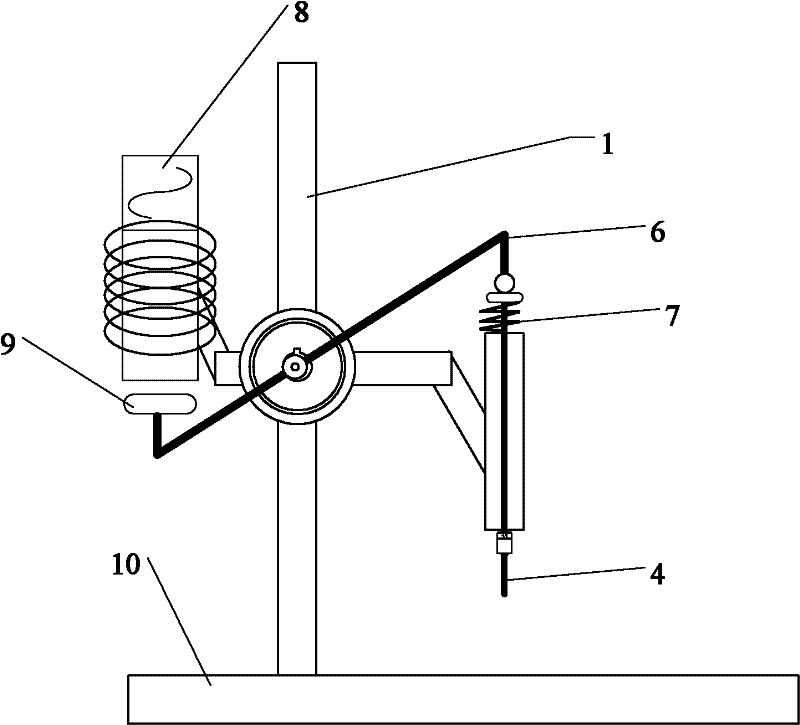

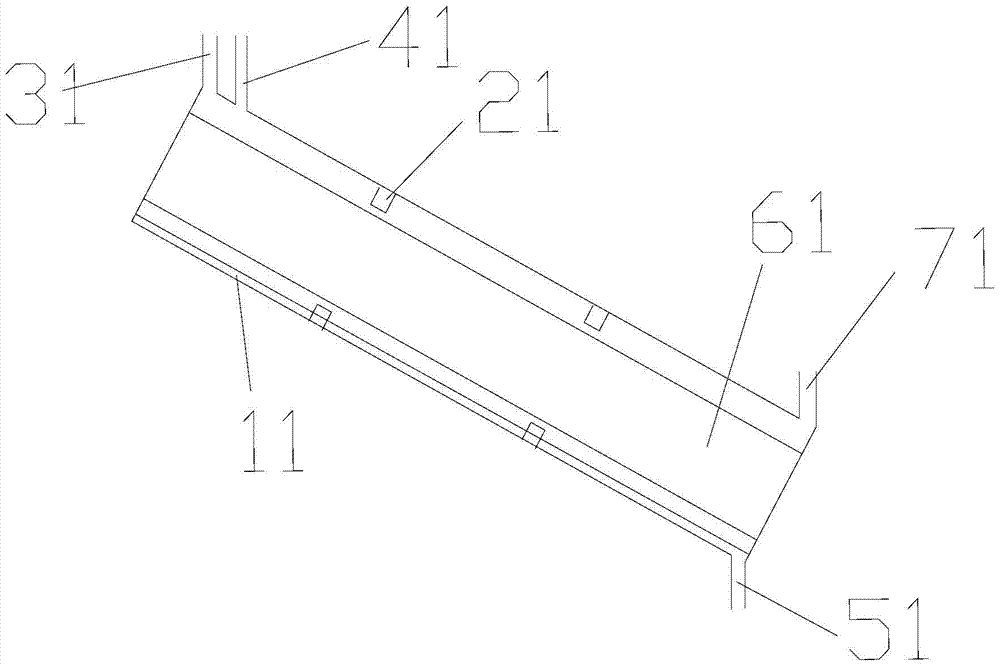

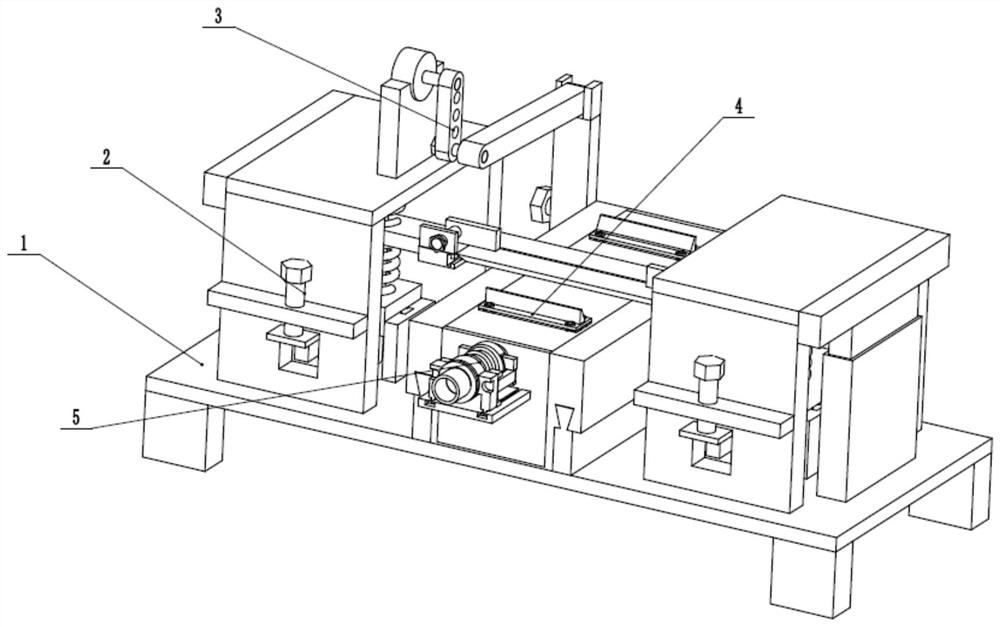

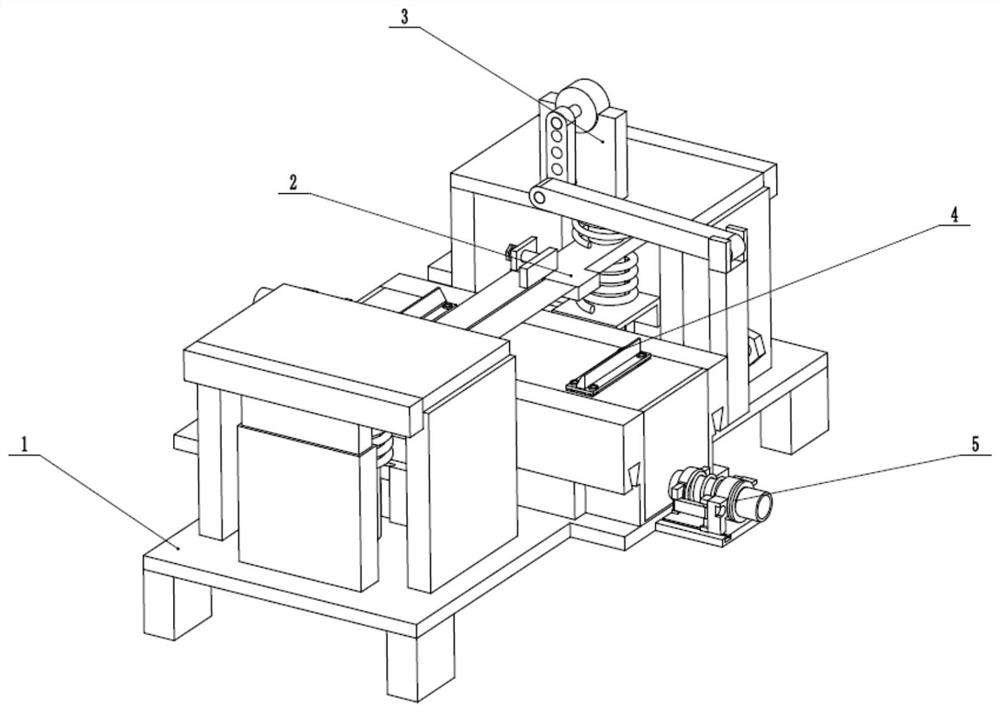

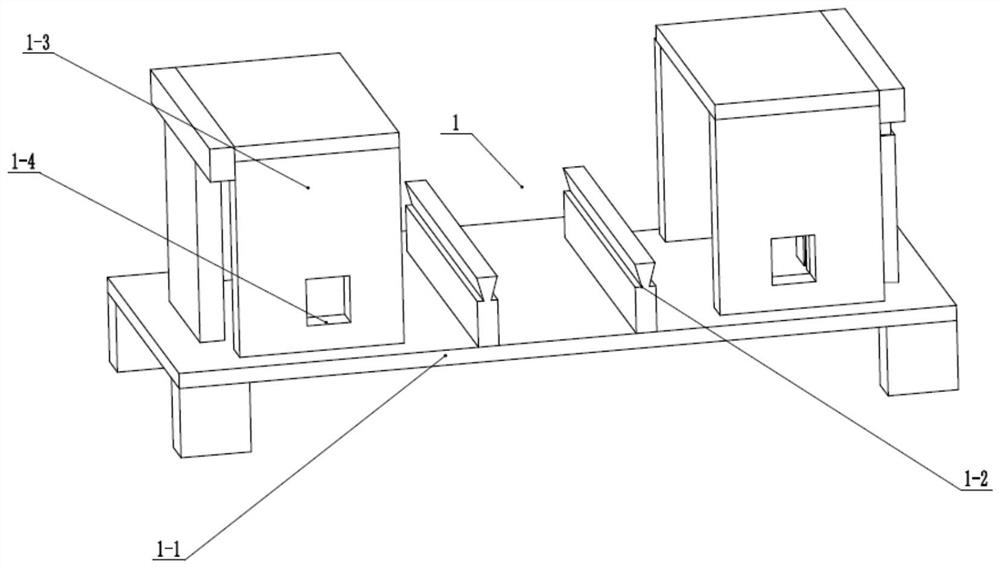

Acute spinal cord injury animal model modeling impactor

The invention discloses an acute spinal cord injury animal model modeling impactor, which is characterized by comprising a bracket, a lever, a guide rail, a probe and a relay device for driving the lever. A support point of the lever is arranged on the bracket; one end of the lever is provided with a sucking disc, the other end is connected with the upper end of the probe; the relay device and the guide rail are both fixed on the bracket along a vertical direction; the relay device is arranged above the sucking disc; the probe is arranged in the guide rail along the vertical direction; a return spring is arranged between the upper end of the guide rail and the upper end of the probe; the relay device comprises a multiple-turn coil and an iron core; the iron core is inserted in the multiple-turn coil; and the terminal of the multiple-turn coil is connected with a controllable current output interface of an external circuit. The impact degree and time of the impactor can be controlled, the impact position is more correct, and the repeatability of the impact operation is strong.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

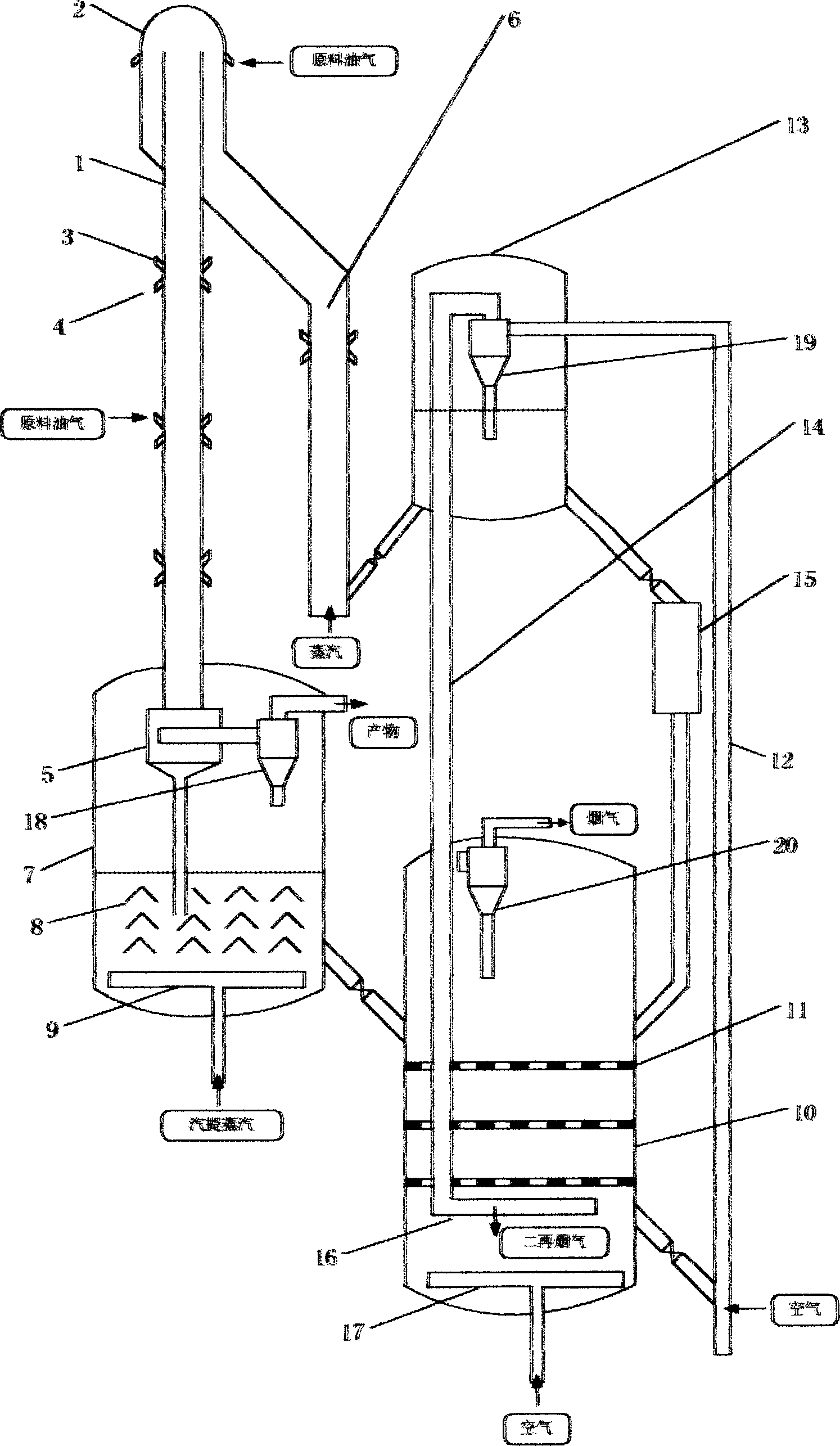

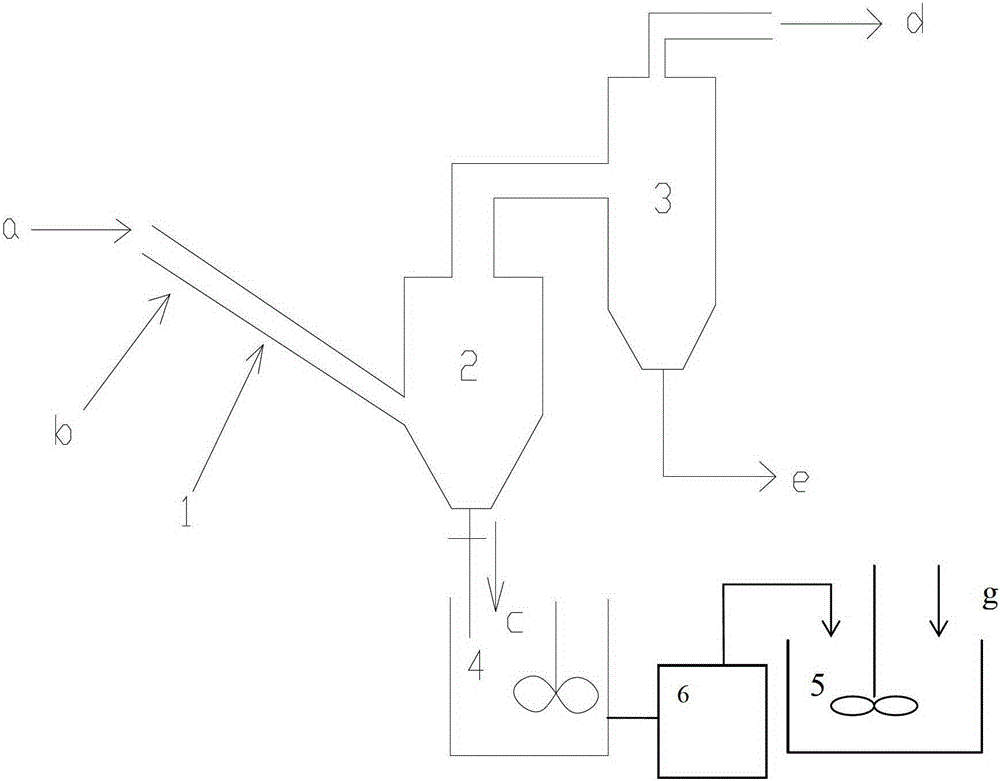

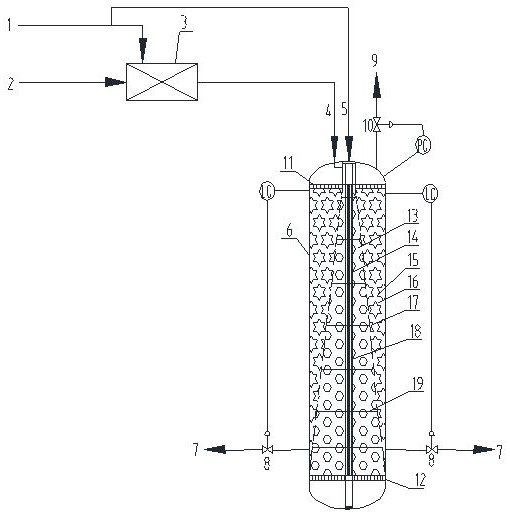

Down-flow catalytic cracking/ cracking reactor for processing heavy raw oil

InactiveCN1546610AImprove carbon burning conversion rateControl contact timeCatalytic crackingProcess engineeringPetroleum

The invention discloses a down-flow catalytic cracking / cracking reactor for processing heavy raw oil, comprising a gas-solid parallel flow descending super short contact catalytic reactor, a steam stripping device, a cascade turbulent fluidized bed form first section regenerator and a lift tube form second section regenerator, wherein the second section regenerator is connected to the main unit of the reactor through a pre-lift tube.

Owner:TSINGHUA UNIV

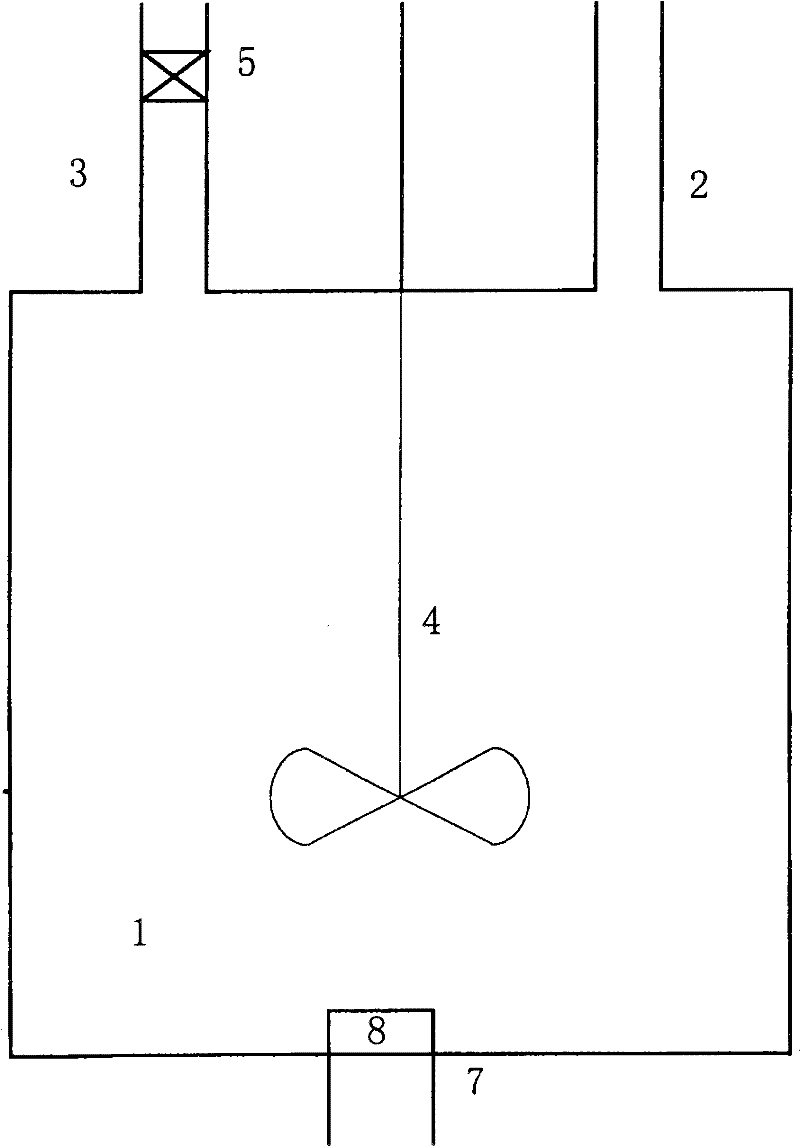

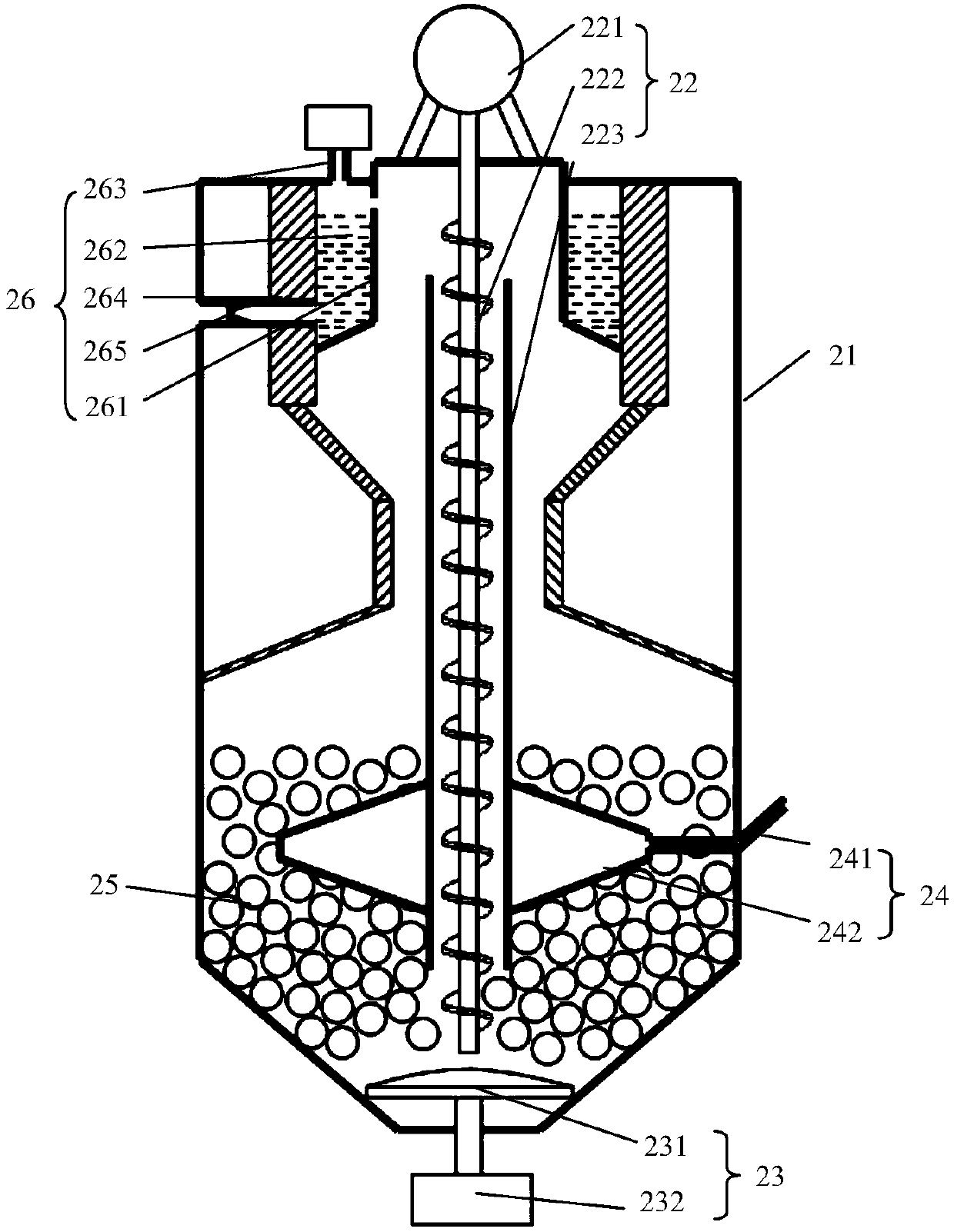

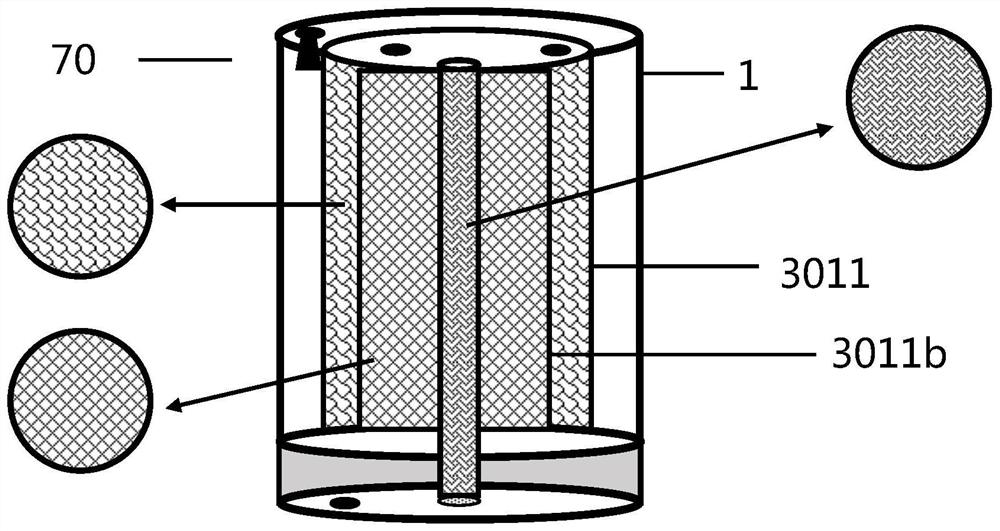

Equipment for preparing molecular sieve

ActiveCN102451655AFully contactedControl contact timeChemical/physical/physico-chemical stationary reactorsCrystalline aluminosilicate zeolitesMolecular sieveContact time

The invention provides equipment for preparing a molecular sieve. The equipment is characterized in that: the equipment comprises a tubular reactor, a gas-solid separator and an absorbing tower. The tubular reactor comprises a heater, a first feeding port, a discharging port and a tube body. The heater can be used for heating the tube body. With the molecular sieve preparing equipment provided by the invention, a contact reaction of the molecular sieve and SiCl4 can be continuously carried out. With the controlling over the length of the tubular reactor, the contact time of the molecular sieve and SiCl4 can be controlled, such that the contact reaction of the molecular sieve and SiCl4 can be sufficiently carried out in the tubular reactor. With the tubular reactor with the heating function, different reaction temperatures can be controlled, such that different reaction conditions and reaction degrees can be controlled. Therefore, molecular sieve products with different dealuminization depths can be obtained according to different requirements.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing molecular sieve

ActiveCN102452661AContinuous contact reactionAdequate contact responseMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveGas phase

The invention relates to a method for preparing a molecular sieve. The method comprises that: with carrying by inert carrier gas flow, a molecular sieve flows along with the inert carrier gas, and contacts gas phase SiCl4 for 10 s-100 min under a flowing state; the molecular sieve and the gas phase SiCl4 are heated during the contacting process, such that the contacting temperature of the molecular sieve and the gas phase SiCl4 is 250-700 DEG C. According to the method for preparing the molecular sieve, the molecular sieve can contact the gas phase SiCl4 under the flowing state, such that the contact reaction of the molecular sieve and the SiCl4 can be continuously performed; with controlling the flow rate of the carrier gas, the contacting time of the molecular sieve and the SiCl4 can be controlled, such that the contact reaction of the molecular sieve and the SiCl4 can be completely performed in a tubular reactor; with heating the molecular sieve and the gas phase SiCl4 during the contacting process, the molecular sieve can contact the gas phase SiCl4 at the different temperatures so as to obtain the molecular sieves with different silica alumina ratios.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of metallic oxide coated battery cathode material

InactiveCN106848321AFully contactedControl particle size distributionCell electrodesMetalMaterials science

The invention relates to a preparation method of a metallic oxide coated battery cathode material. The preparation method comprises the steps as follows: a cathode material substrate is coated with a coating liquid in an air-stream mill in an impinging stream manner, and a coated material precursor is obtained; the obtained coated material precursor is sintered and the metallic oxide coated battery cathode material is obtained. According to the preparation method, the battery cathode material is coated with a metallic oxide in the impinging stream manner by the aid of air-stream mill equipment, the coating rate and coating uniformity of the metallic oxide are increased, meanwhile, the coating process is controlled by adjusting parameters of the air-stream mill, and the preparation method is simple and can be applied to industrial production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Worktable type electronic impact hammer

The invention discloses a worktable type electronic impact hammer. The worktable type electronic impact hammer is characterized by comprising a worktable, a controller, a trigger and a direct-current power supply, wherein the controller and the trigger are respectively connected with the direct-current power supply; the controller is respectively connected with the trigger and an actuator; the actuator comprises a traction type electromagnet; an iron core extending part of the electromagnet is connected with a force sensor; an impact head with a protecting function is arranged at the front end of the force sensor; and the electromagnet is arranged on a platform of the worktable. The repeatability and the adjustability of impact force are guaranteed, the time for contact between the hammer and a mechanical structure to be measured is controlled reliably so as to obtain ideal force pulse, and the worktable type electronic impact hammer is particularly applied to modal analysis, automatic impact testing and finite element analysis (FEA) modal verification of the mechanical structure.

Owner:SHANDONG UNIV

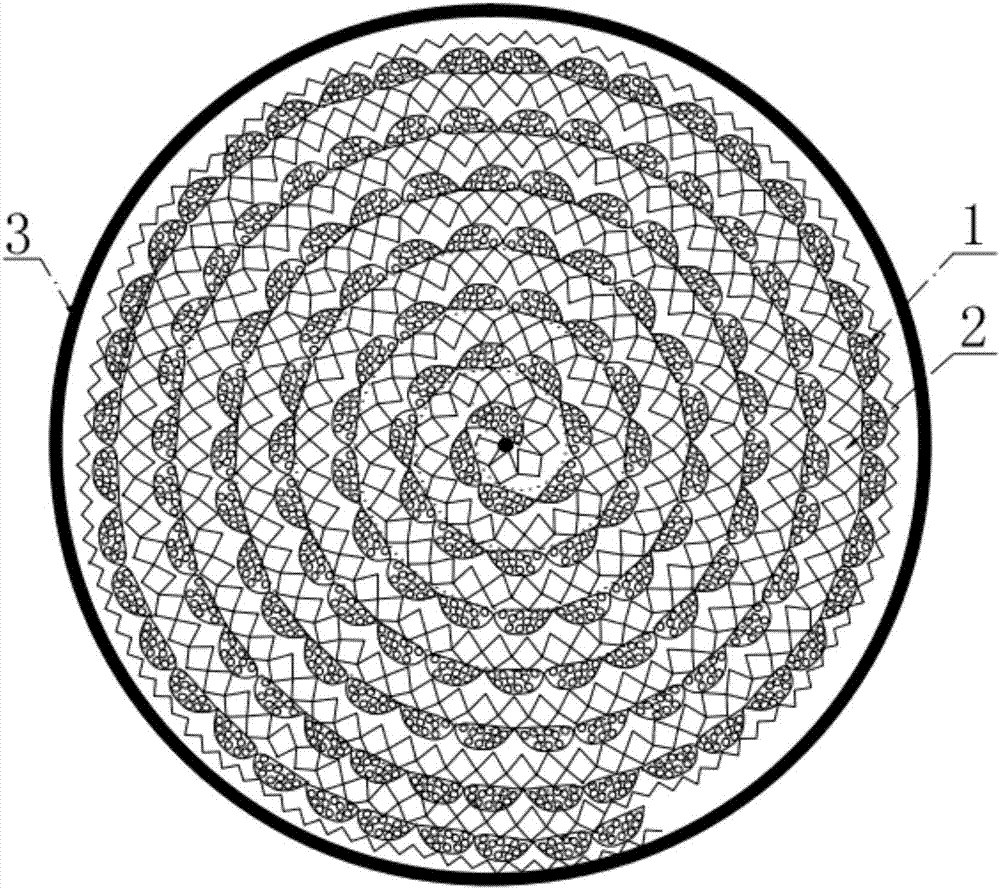

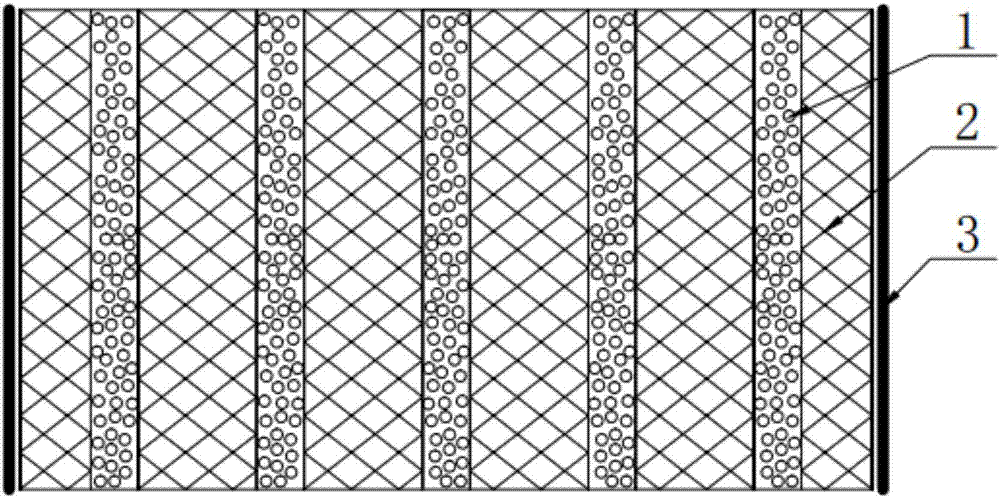

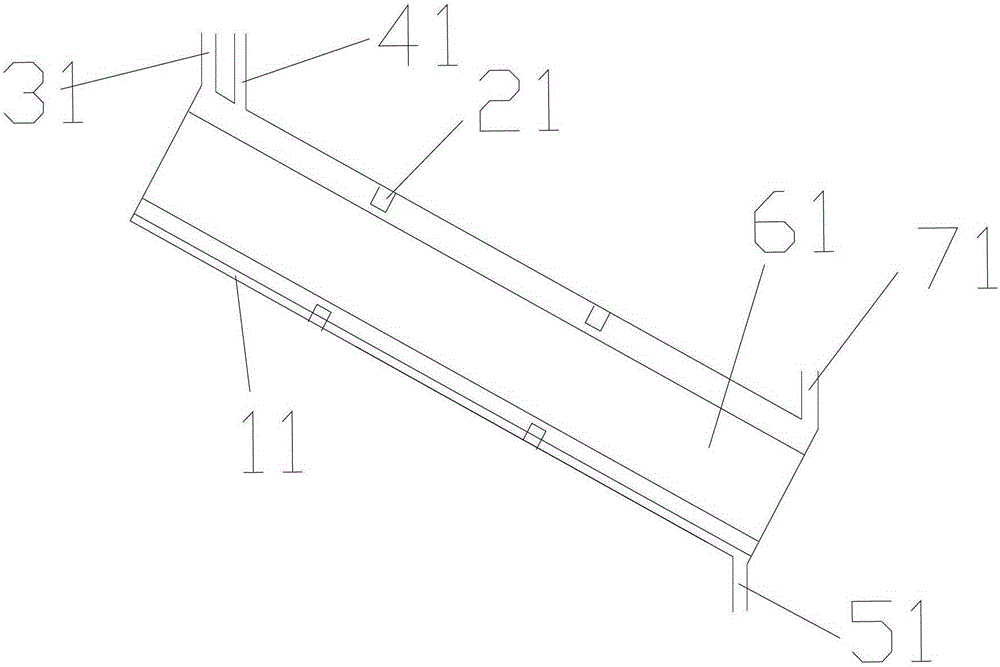

Disk-type assembled bagged catalytic distillation filler

PendingCN107051368AAdjustable seam sizeIncrease profitChemical/physical/physico-chemical processesFractional distillationComposite materialCatalytic distillation

The invention relates to a disk-type assembled bagged catalytic distillation filler, which structurally comprises an assembly A and an assembly B, wherein the assembly A is a rectangular catalyst bag formed through seaming and is filled with catalyst particles; the assembly B is a regular filler sheet; and the regular filler sheet of the assembly B and the catalyst bag of the assembly A are tightly stacked in parallel and are curled into a disk-type spiral structure and then fixed by using a banding sheet to form the catalytic distillation filler. The catalyst bag is adjustable in seaming size, the loading density of the catalyst is adjustable, the content of the catalyst is adjusted and the utilization rate of the catalyst is improved. The assembly A and the assembly B are alternately arranged, so that flowing of a liquid is improved by the regular filler sheet, uniform distribution of gas and liquid phases is ensured, a reactant and a product are continuously separated to the tower top and the tower bottom, the mass transfer process is promoted and the reaction rate is improved. The catalytic distillation filler is of the disk-type spiral structure and the catalyst bag and the regular filler sheet are arranged at an interval, so that uniform distribution of gas and liquid phases is improved, and meanwhile, the pressure drop can be reduced.

Owner:TIANJIN UNIV +1

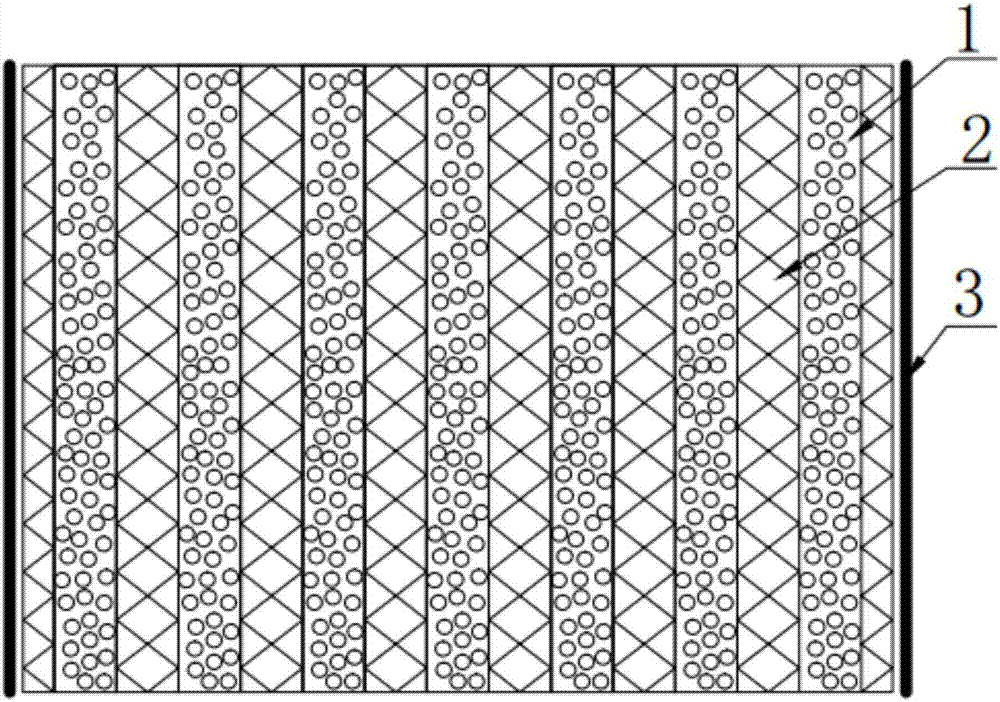

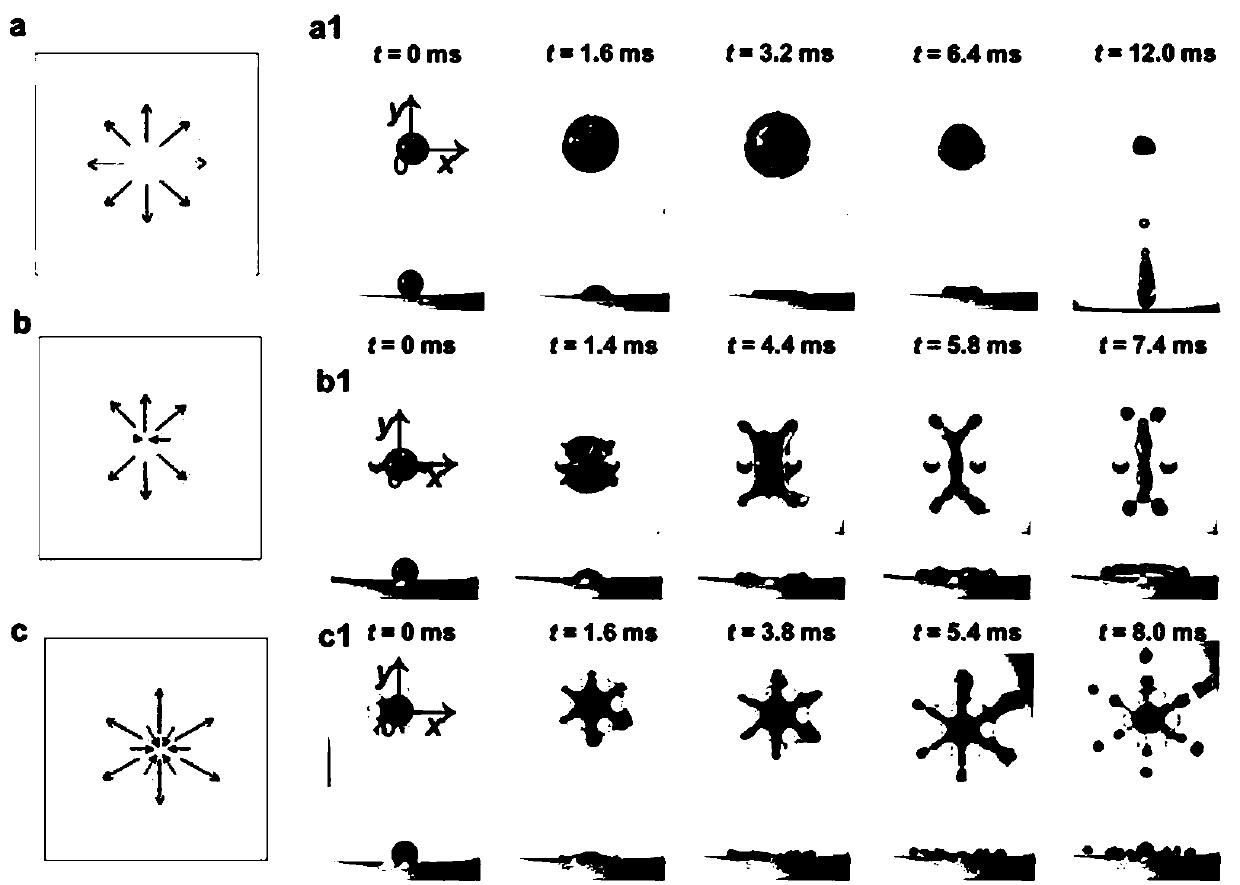

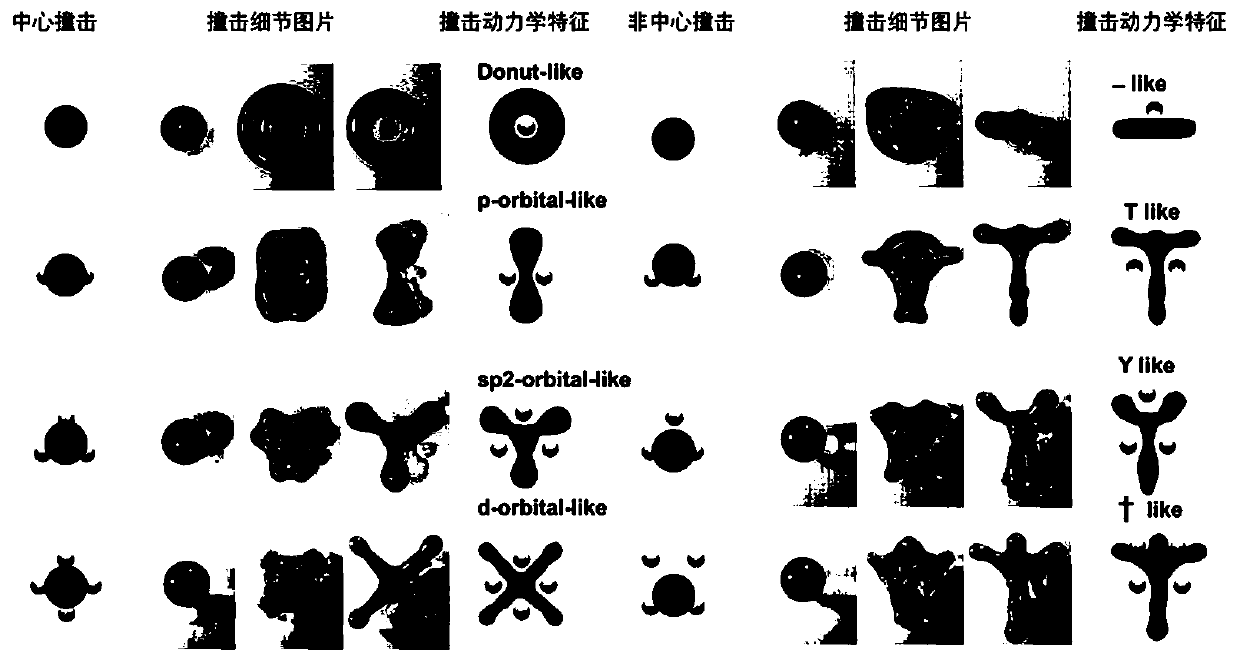

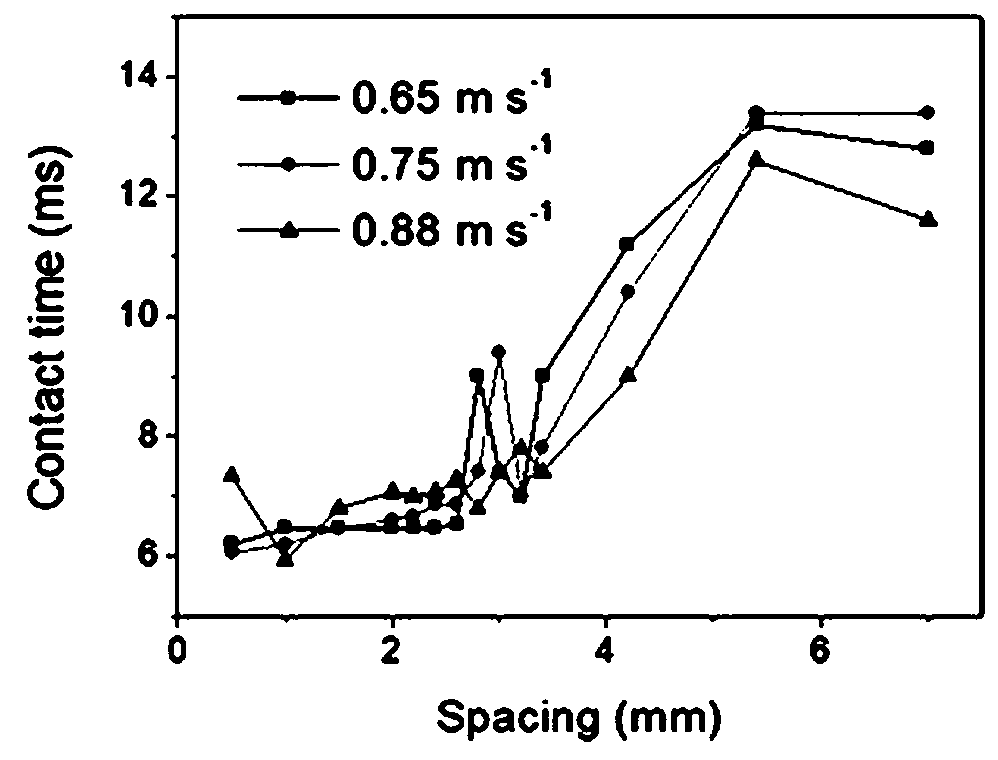

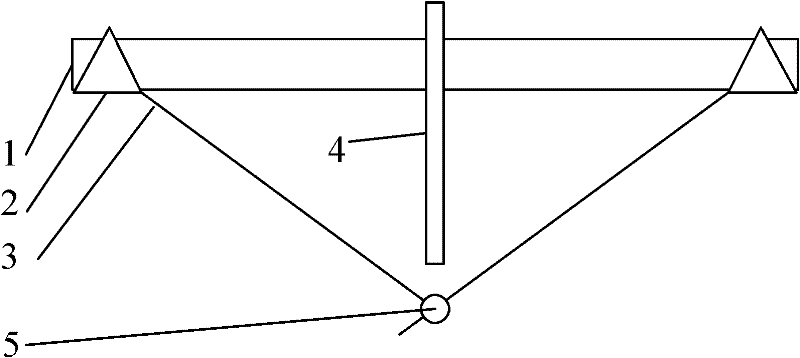

Method for controlling droplet impact form, contact time and droplet controllable splitting

ActiveCN111537398AControl impact shapeControl timeHydrodynamic testingSurface/boundary effectTemplate designPharmaceutical drug

The invention discloses a method for controlling droplet impact form, contact time and droplet controllable splitting. The method comprises the steps of 1 designing a template; 2 manufacturing the template; 3 treating the template surface; 4 carrying out liquid drop impact; and 5 observing and analyzing the impact form and dynamics. Impact dynamics with variable forms is obtained by changing the shape, size, number and position of obstacles on the template, the impact position of liquid drops and other factors. and the boundary between spreading and retreat are broken, so that spreading and retreating coexist in the process of droplet impact. The contact time is shortened, the impact form of a single droplet is variable and controllable, and the splitting of the droplet is controllable during impact by controlling the impact dynamics of different forms. The method is simple to operate, low in cost and good in effect, and can be applied to the fields of self-cleaning, printing, open microfluid, food and drug split charging and conveying and the like.

Owner:HENAN AGRICULTURAL UNIVERSITY

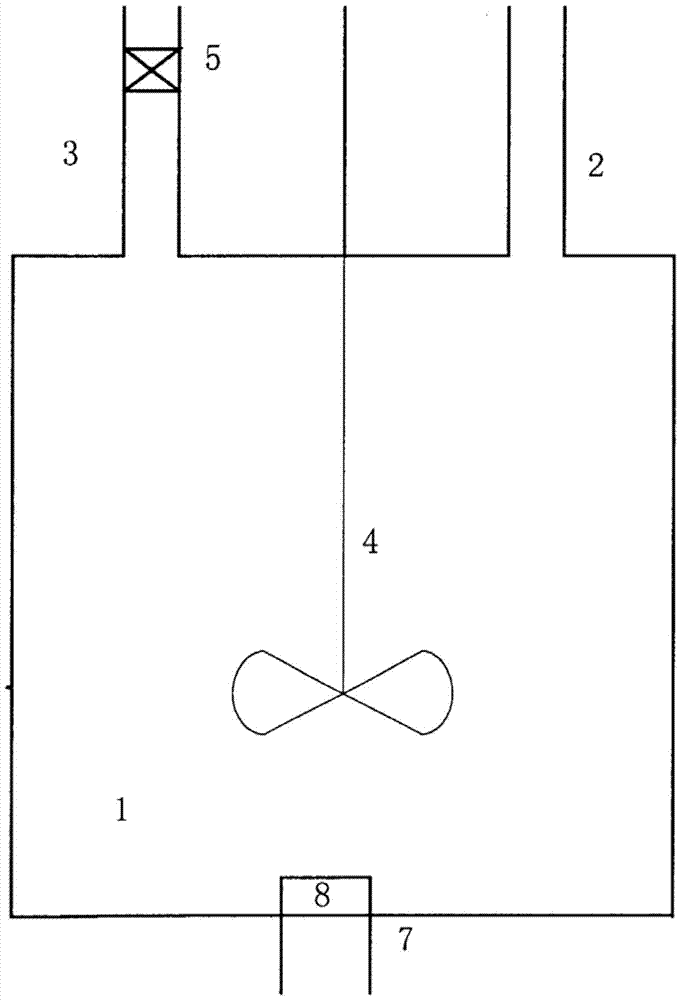

Formaldehyde fumigation method and formaldehyde fumigation device

ActiveCN104800872AControl contact timeEnsure safetyGaseous substancesChemicalsContact timeDisinfection methods

Owner:SHIJIAZHUANG NO 4 PHARMA

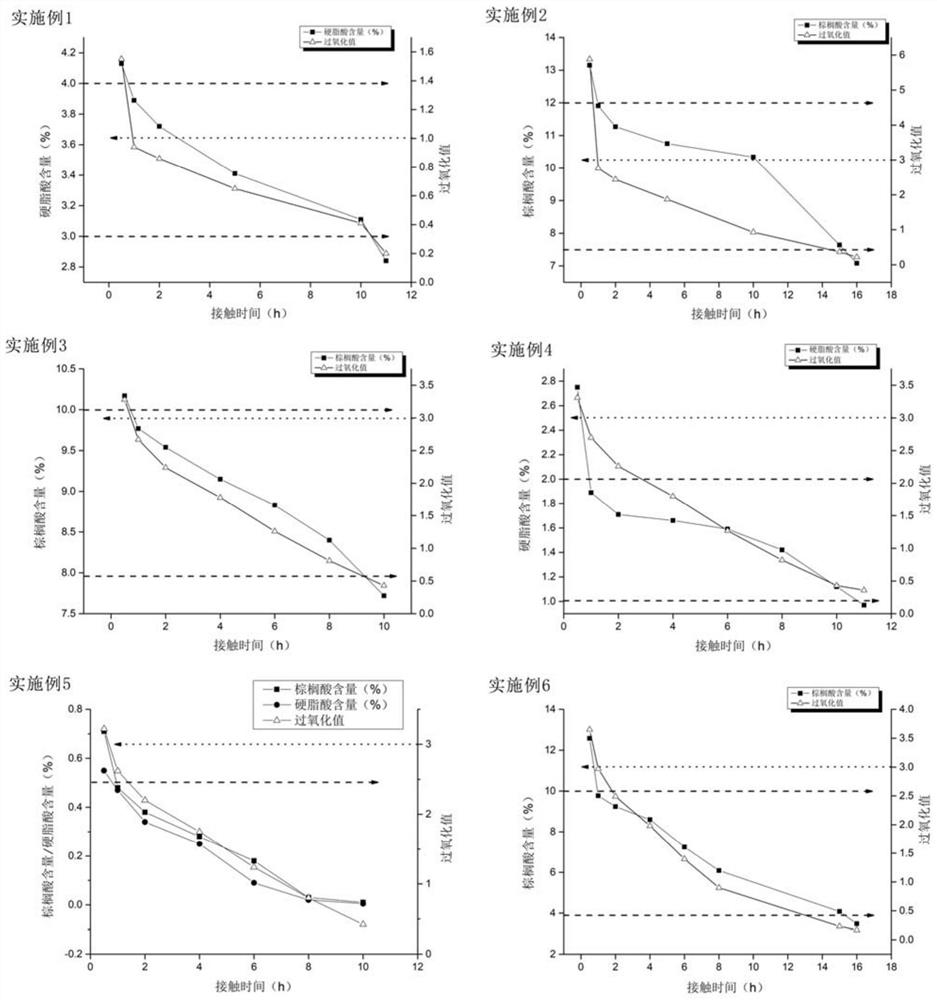

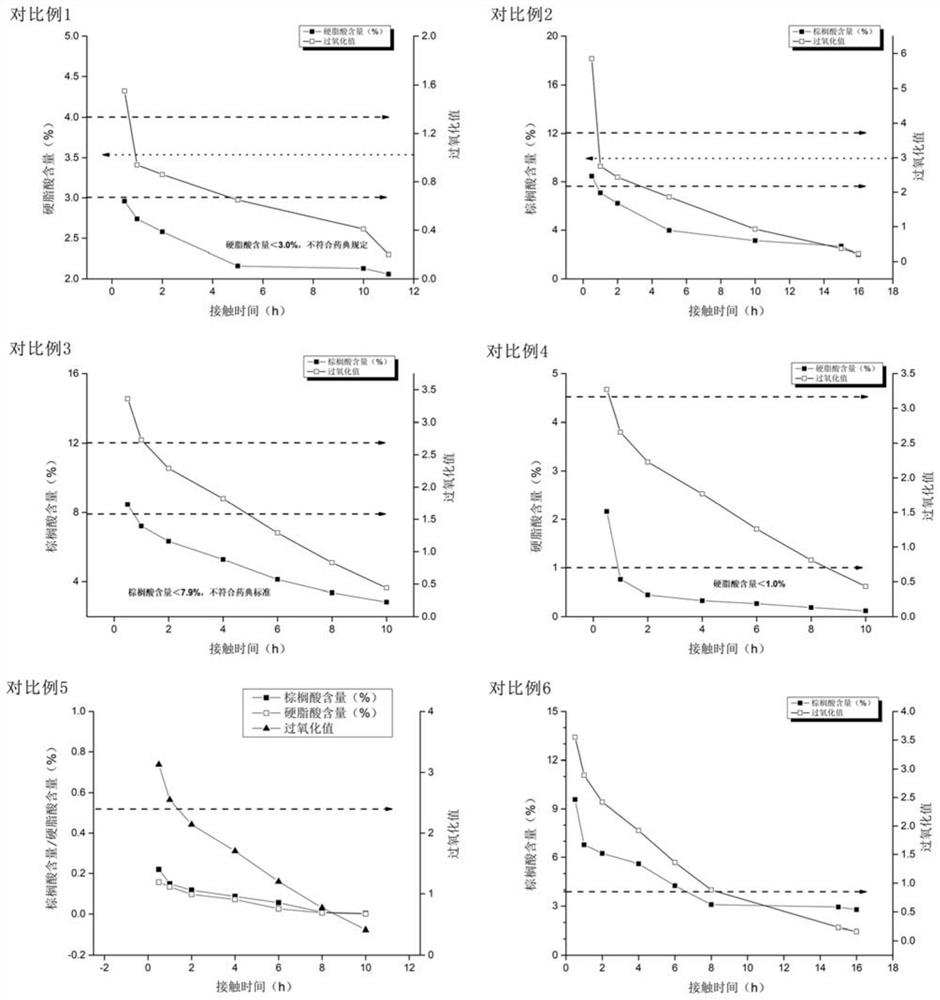

Method for accurately controlling proportion of specific fatty acid in oil by adopting microcirculation technology

ActiveCN112029580AExtend the duration of the refining processReduce the disadvantages of cumbersome industrialization stepsFatty-oils/fats refiningFermentationEngineeringDietary Oils

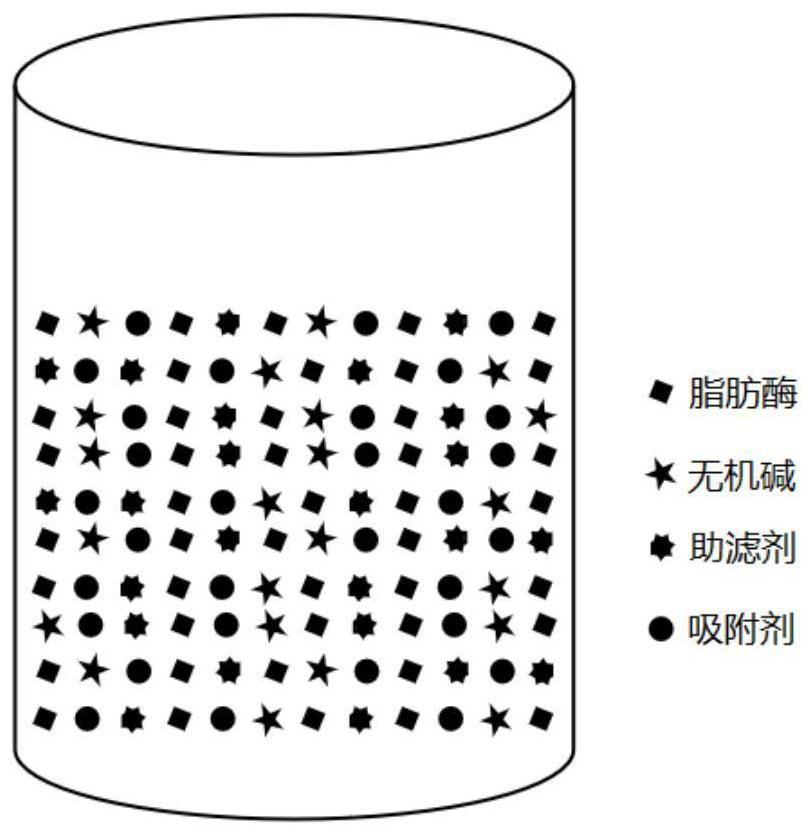

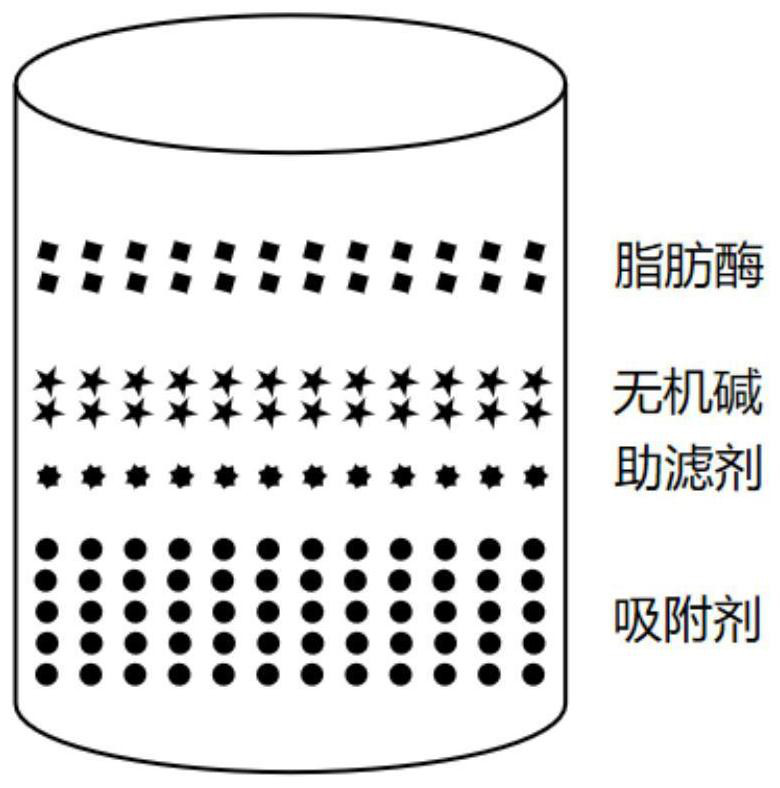

The invention belongs to the technical field of refiningof medicinal oil, and discloses a method for accurately controlling the proportion of specific fatty acid in oil by adopting a microcirculationtechnology. The method comprises the following steps: A, uniformly mixing lipase, inorganic base, a filter aid and an adsorbent in a physical mode to form a mixed filler, wherein the lipase is Sn-1,3-specific lipase; and B, enabling edible oil to flow through the mixed filler to obtain refined oil. The method solves the problems that the content of palmitic acid cannot be accurately controlled andthe requirement for preparing a high-quality fat emulsion preparation cannot be met in a traditional edible oil production process.

Owner:GUANGZHOU HANFANG PHARMA

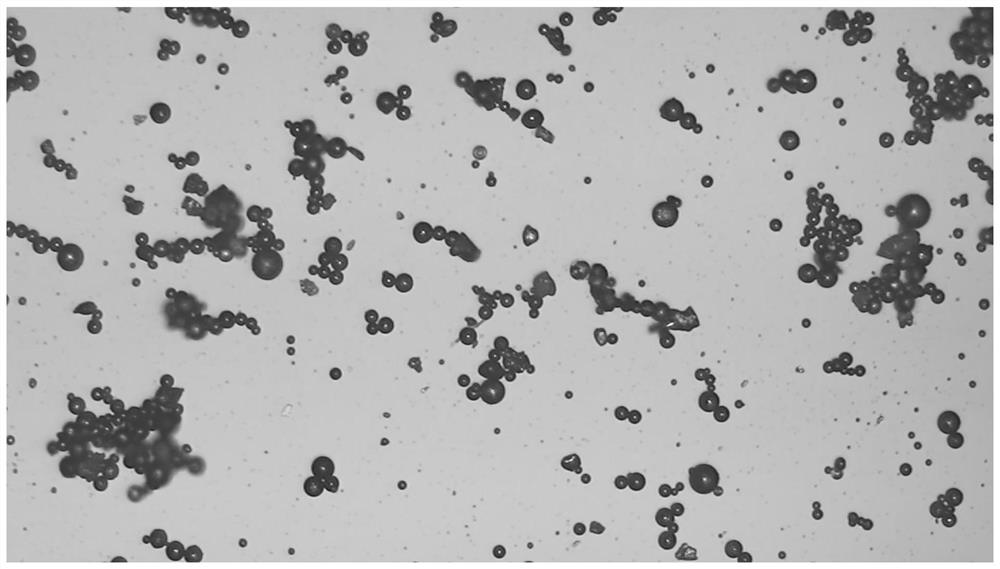

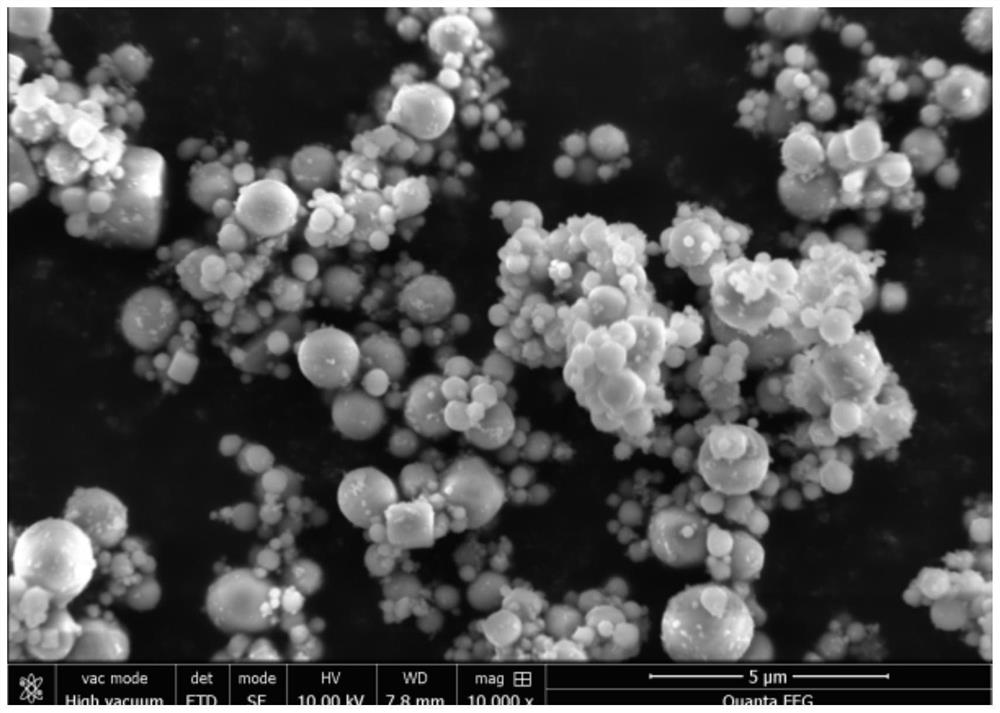

Spherical metal mineral powder, preparation method and application thereof and cement paste composition

PendingCN112276102AEnsure combustion heatingPrevent unsintered meltingTransportation and packagingMetal-working apparatusCombustorPhysical chemistry

The invention relates to the technical field of oil field drilling fluid and well cementation, and discloses a preparation method of spherical metal mineral powder. The preparation method comprises the following steps: (1) mixing the metal mineral powder with compressed gas in a venturi mixer to obtain a mixture, and the compressed gas is compressed gas with combustion supporting property; and (2)conveying the mixture into a combustor, spraying the mixture from a nozzle of the combustor, enabling the mixture to be in contact with fuel for combustion, and condensing to obtain the spherical metal mineral powder. According to the method, bonding and aggregation among metal ore particles can be prevented in the melting process, the particle size of the metal ore powder is remarkably reduced,the spheroidization rate and the spheroidization degree of the metal ore powder are improved, and the prepared spherical metal ore powder can be used as a weighting agent to be applied to the fields of cement paste, spacer fluid, drilling fluid and the like.

Owner:唐山龙源节能科技有限公司

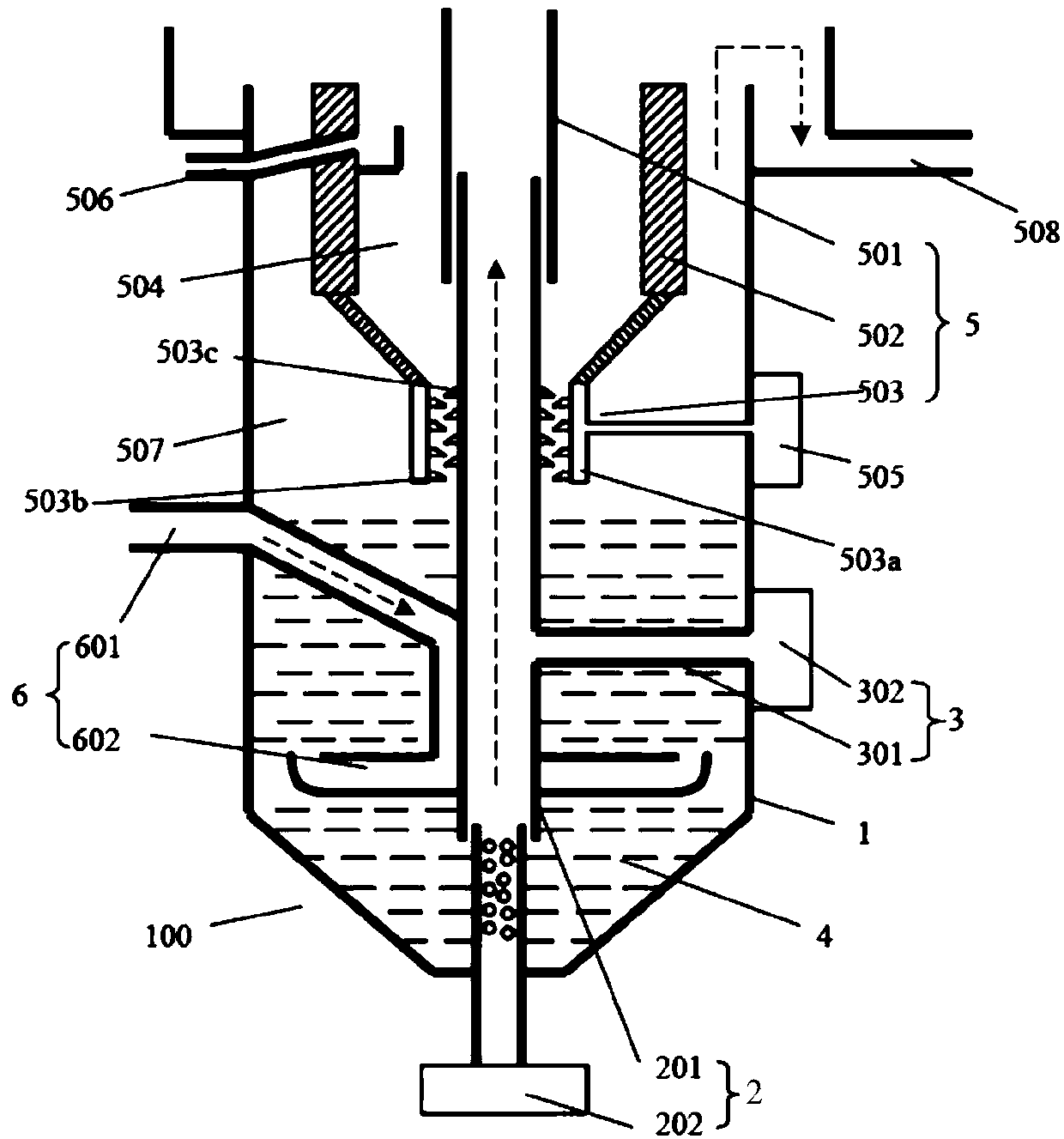

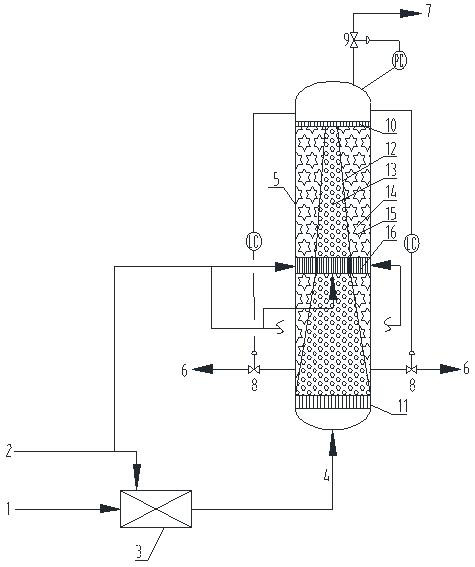

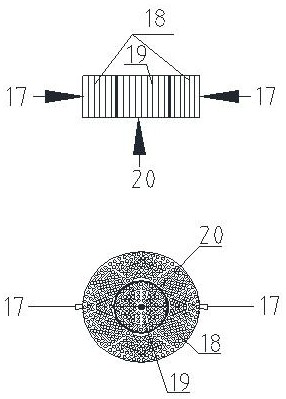

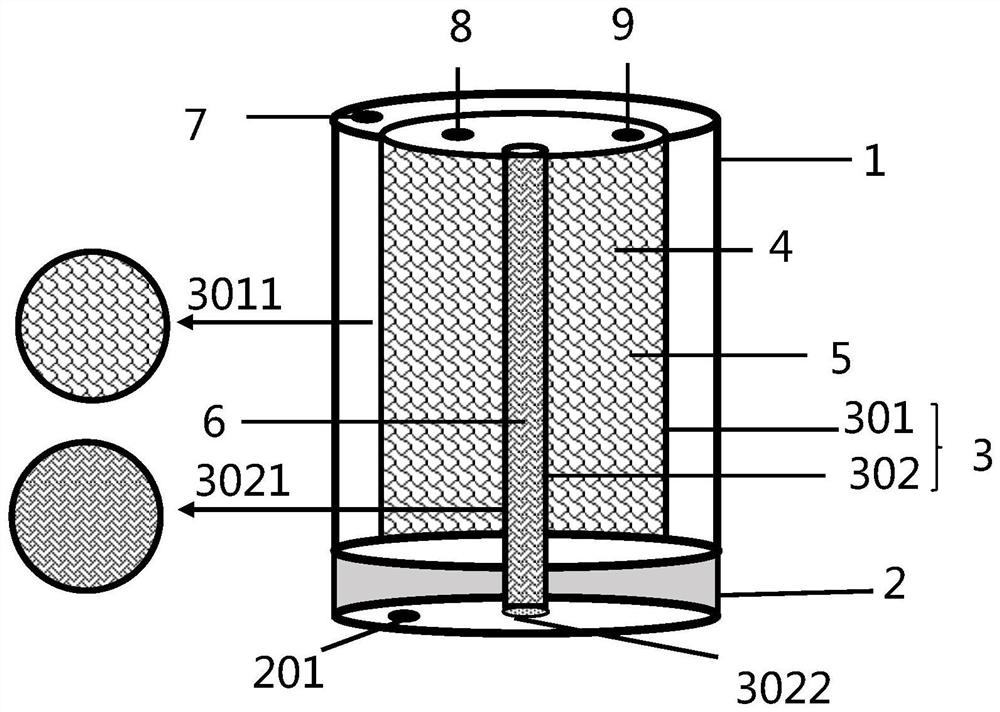

Liquid-phase hydrogenation reactor and hydrogenation process

ActiveCN112705117AControl contact timeControl temperature riseTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention relates to a liquid-phase hydrogenation reactor and a hydrogenation process, the liquid-phase hydrogenation reactor comprises an inner cylinder and a reactor shell, the inner cylinder is conical, the top and the bottom of the inner cylinder are open, the edge of the bottom of the inner cylinder is hermetically connected with the inner wall of the reactor, and a plurality of small holes are formed in the wall of the inner cylinder; a ceramic membrane tube bundle is vertically arranged in the axial direction of the reactor and is communicated with external hydrogen; the inner cylinder is filled with a hydrogenation catalyst I, the annular cavity is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than that of the hydrogenation catalyst II; the reactor raw material inlet communicates with the top of the inner cylinder; the materials flow in the inner cylinder from top to bottom; the materials flow in the annular cavity from top to bottom. According to the method, the contact time of the material and the catalyst in the whole hydrogenation reaction process can be effectively controlled, so that the temperature rise of a catalyst bed layer is more uniform, the problems of severe heat release and reaction conversion rate inhibition in the reaction process are solved, and higher hydrogenation reaction rate and conversion rate in the whole liquid-phase hydrogenation reaction process are achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Regenerative circulating filtration system

ActiveCN109603790AImprove cleaningExtend the life cycleOther chemical processesCombustible gas purificationActivated carbonFilter material

The invention relates to a regenerative circulating filtration system. The regenerative circulating filtration system at least comprises two or more material washing devices and an activated carbon regeneration unit which are communicated in sequence; inlet water flows through the material washing devices in sequence to be subjected to circulating filtration treatment, activated carbon flows through the material washing devices in sequence and enters the activated carbon regeneration unit to be regenerated, and the activated carbon regeneration unit at least comprises an aeration part in a shell; the aeration part is configured to conduct first-stage regeneration treatment on the activated carbon in the following modes that the aeration part forms multiple gaps for receiving the activatedcarbon according to a filter material stacking mode, and the activated carbon moves in the gaps to be regenerated.

Owner:BGT GRP CO LTD

Heavy oil hydrogenation reactor and hydrogenation method

ActiveCN112705116AReduce viscosityReduce transient responseTreatment with hydrotreatment processesChemical/physical processesMaterials scienceCracking reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation reactor and hydrogenation method thereof

ActiveCN112705123AControl contact timeReduce contact timeTreatment with hydrotreatment processesChemical/physical processesPtru catalystHydrogenation reaction

The invention discloses a hydrogenation reactor and a hydrogenation method thereof. The hydrogenation reactor comprises an inner cylinder and a reactor shell, the inner cylinder is conical, and an annular space is formed between the inner cylinder and the reactor shell; the edge of the bottom of the inner cylinder is connected with the inner wall of the reactor in a sealed manner; the inner cylinder is filled with a hydrogenation catalyst I, the annular space is filled with a hydrogenation catalyst II, and the activity of the hydrogenation catalyst I is higher than that of the hydrogenation catalyst II; a hydrogen supplementing assembly is horizontally arranged in the reactor; a reactor raw material inlet is communicated with the bottom of the inner cylinder; a reactor product outlet is communicated with the lower part of the annular space; the material flows in the inner cylinder from bottom to top; and the material flows in the annular space from top to bottom. The method can effectively control the contact time of the material and different active catalysts in different temperature sections in the hydrogenation reaction, realizes the purposes of rapid reaction in low and medium temperature sections and inhibition of side reaction in high temperature sections, and improves the hydrogenation reaction rate and reaction depth.

Owner:CHINA PETROLEUM & CHEM CORP +1

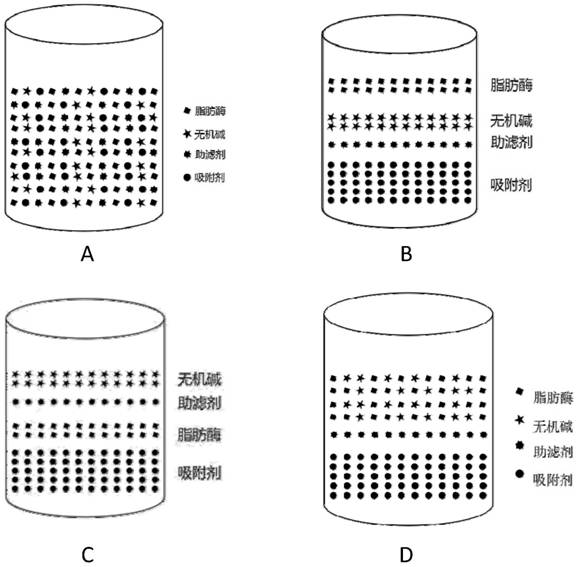

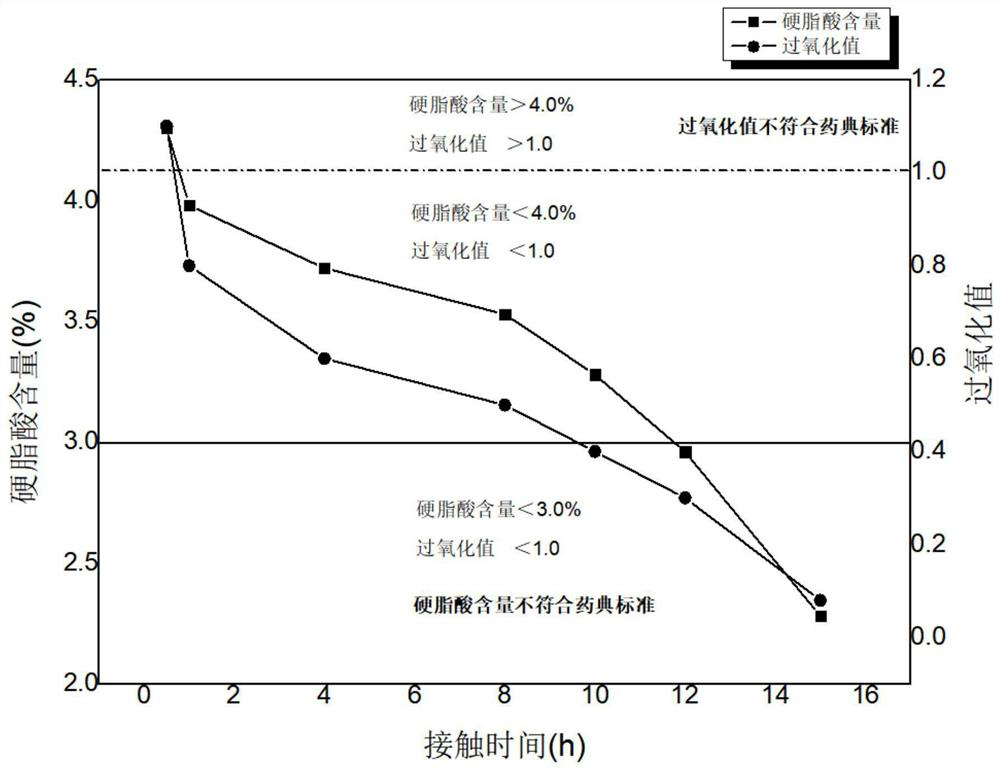

Method for accurately controlling content of stearic acid in soybean oil by adopting mixed filler

ActiveCN112048380AAvoid problems that are difficult to filterExtend the duration of the refining processFatty-oils/fats refiningProcess engineeringStearic acid

The invention belongs to the technical field of medicinal oil refining, and discloses a method for accurately controlling the content of stearic acid in soybean oil by using a mixed filler. The methodcomprises the following steps: A. physically and uniformly mixing lipase, inorganic base, a filter aid and an adsorbent to form a mixed filler, the lipase being Sn-1, 3-site specific lipase; B, enabling soybean oil to flow through the mixed filler to obtain refined soybean oil. The method solves the problems that the stearic acid content cannot be accurately controlled and the requirement for preparing a high-quality fat emulsion preparation cannot be met in the traditional soybean oil production process.

Owner:GUANGZHOU HANFANG PHARMA

Method for treating low-concentration VOCs (Volatile Organic Compounds) and achieving deodorizing through electrocatalytic oxidation

InactiveCN113144885AImprove processing efficiencyAchieve strengthGas treatmentDispersed particle separationElectrolytic agentCatalytic oxidation

The invention belongs to the field of waste gas VOCs treatment, and particularly relates to a method for treating low-concentration VOCs and achieving deodorizing through electrocatalytic oxidation, and the method specifically comprises the following steps: adding an electrolyte into water to prepare an ionic electrolyte with a certain concentration; conducting spraying in a mist form according to a certain direction; and enabling VOCs gas to reversely enter a special spray tower according to a certain flow rate, making the VOCs gas full contact with the electrolyte, keeping the spraying direction of the VOCs opposite to the direction of sprayed ionic liquid, and introducing direct current voltage into a mixed liquid tank where the VOCs gas is in contact with the ionic liquid. Therefore, the method for treating the low-concentration VOCs and deodorizing is obtained. According to the invention, by controlling the proportion of current to voltage, the intensity of an electric field is controlled, and the VOCs gas is electrically catalyzed; and the VOCs gas is effectively treated by controlling the contact time of the gas and the conductive liquid by adopting small-opening gas entering and large-opening gas flowing out.

Owner:江门市绿一茵环保科技有限公司

A kind of method for preparing catalytic cracking catalyst

ActiveCN103785437BControl dwell timeAdequate contact responseCatalytic crackingMolecular sieve catalystsMolecular sieveGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogen production device and system for fuel cell with controllable hydrogen production rate

PendingCN114524411AGuaranteed uniformityControl contact timeHydrogen productionFuel cellsThermodynamicsFuel cells

The invention belongs to the field of fuel cells and hydrogen production, provides a hydrogen production device, system and method for controlling the hydrogen production rate of a fuel cell, and solves the problems that the utilization rate of water in the system is reduced, the starting rate is slow, and the hydrogen production rate cannot be accurately controlled. According to the technical scheme, a water storage tank and a hydrogen production tank are connected in the mode that a pump or a pipe is filled with a wick, liquid water or steam slowly enters a system through an active matter filling tank hole, the good contact rate with active matter is kept in the process, and hydrogen is released; the surface of the water recovery tank is hollowed out to control the outflow rate of water and indirectly control the contact time with active substances; each space in the hydrogen production device can be filled with one or more water absorbing materials in advance, so that the stability of the reaction process rate is improved.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

A green synthesis device for 4-chloroacetoacetates

ActiveCN111203170BIncrease contact areaReduce generationPreparation from ketenes/polyketenesChemical/physical/physico-chemical stationary reactorsAcetoacetatesThermal insulation

The invention discloses a green synthesis device for 4-chloroacetoacetate, which comprises a sealed heat-insulating shell, a conductive cylinder is arranged inside the heat-insulating shell, and the upper and lower ends of the conductive cylinder are connected with the inner cavity of the heat-insulating shell. The upper and lower sides are sealed and fixedly connected. An electrostatic generator is installed outside the insulation shell. The output end of the electrostatic generator is connected to the side of the conductive cylinder through a cable, and the cable runs through the insulation shell. The upper part of the inner cavity of the conductive cylinder is equipped with an electrostatic Sprayer, a precooler is installed on the outside of the conductive cylinder; this green synthesis device of 4-chloroacetoacetates electrostatically atomizes the diketene solution to increase the contact area between the diketene solution droplets and chlorine gas, and double The downward movement distance of the diketene solution droplet determines the reaction time of the diketene solution droplet and chlorine gas, the reaction time of diketene solution and chlorine gas is easy to control, reduces the generation of by-products, and avoids the loss of raw materials.

Owner:山东昌邑灶户盐化有限公司

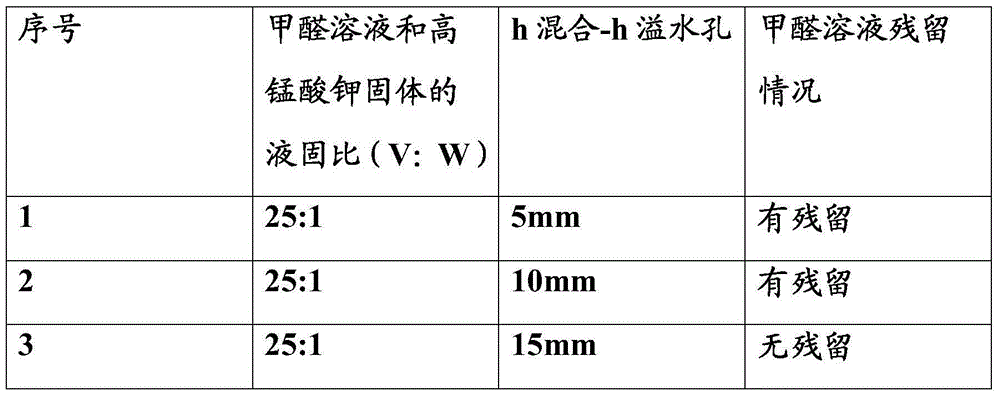

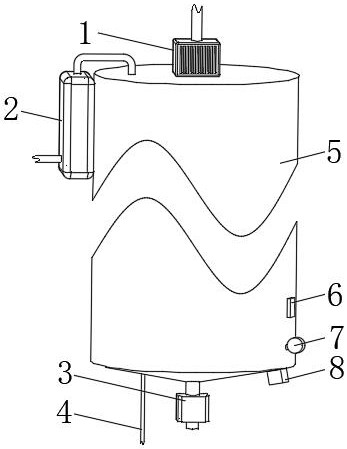

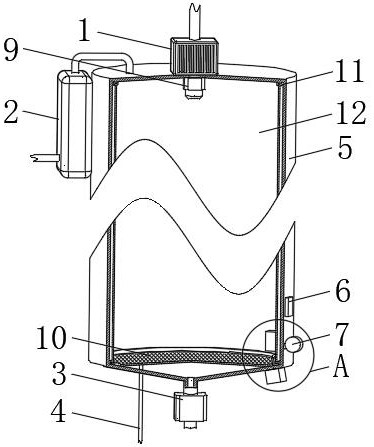

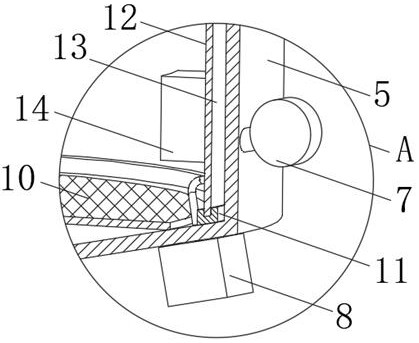

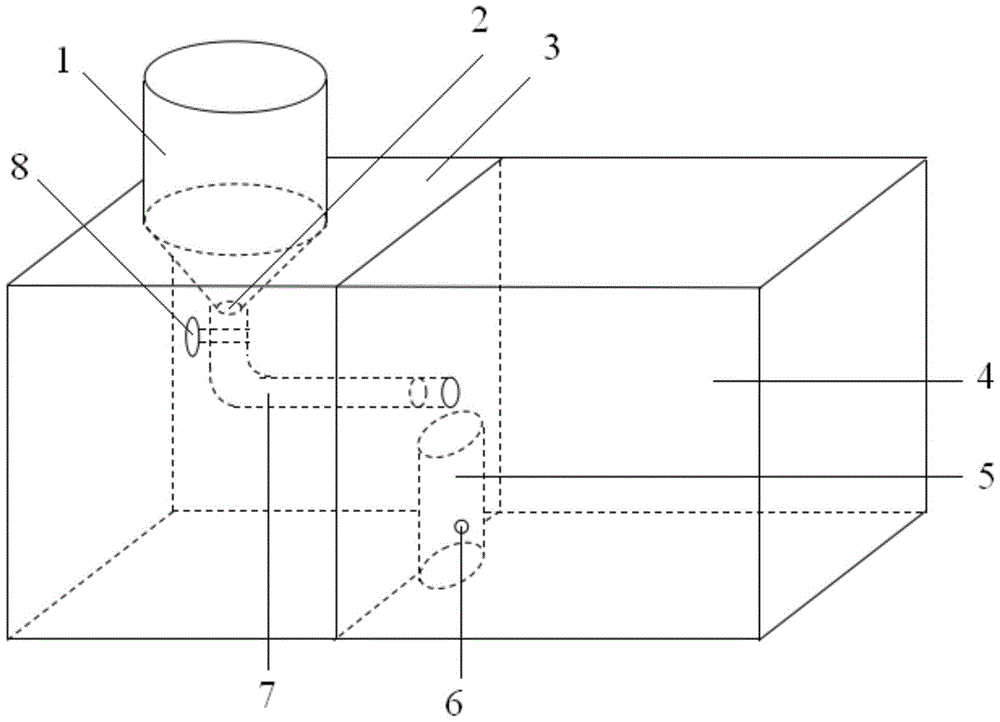

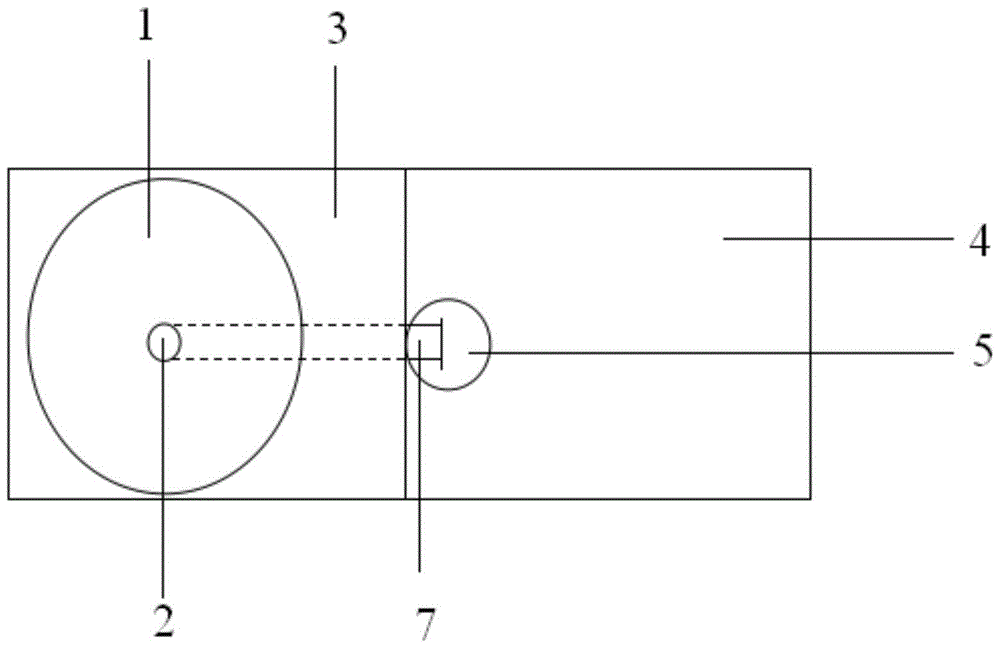

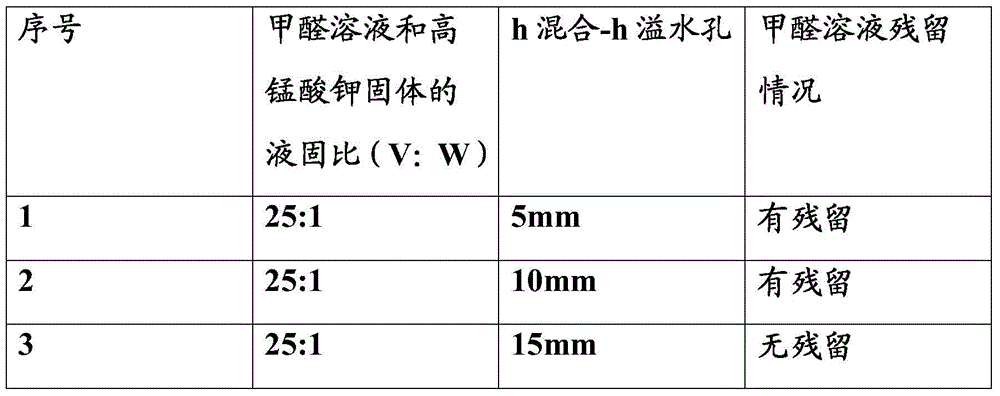

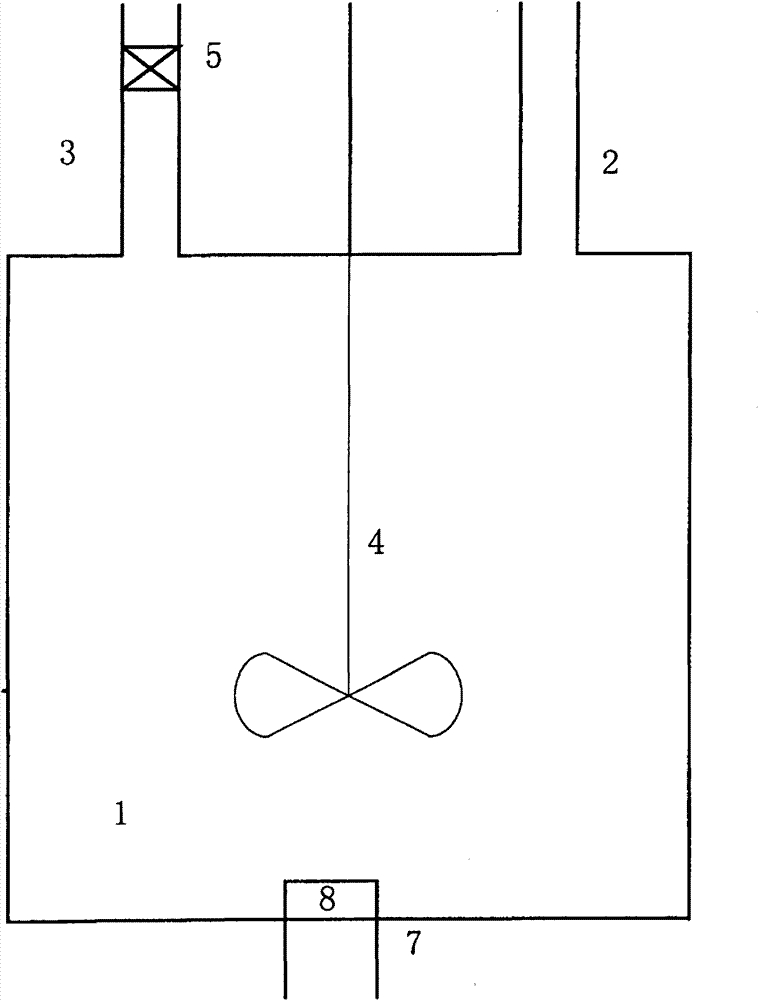

Formaldehyde fumigation and disinfection method and disinfection device thereof

ActiveCN104800872BControl contact timeEnsure safetyGaseous substancesChemicalsDisinfection methodsWell control

The invention discloses a method for fumigation and disinfection of formaldehyde and a disinfection device thereof, which can well control the contact time between formaldehyde and potassium permanganate, make the formaldehyde react completely, and ensure that there is no residual formaldehyde liquid so as to achieve the effect of fumigation and disinfection for airtight rooms ; Make formaldehyde and potassium permanganate react after the operator leaves the disinfection room; make the whole disinfection process avoid the generation of open flames and ensure the safety of the operator.

Owner:SHIJIAZHUANG NO 4 PHARMA

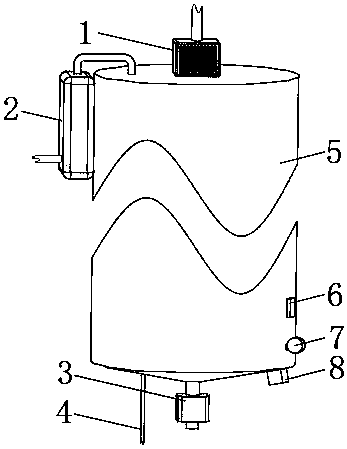

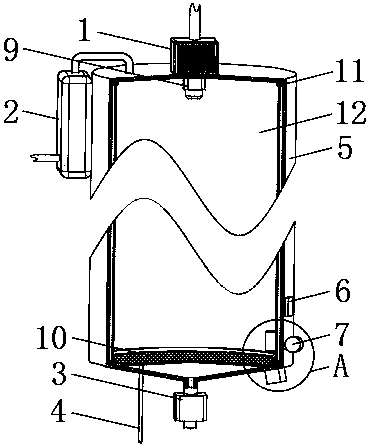

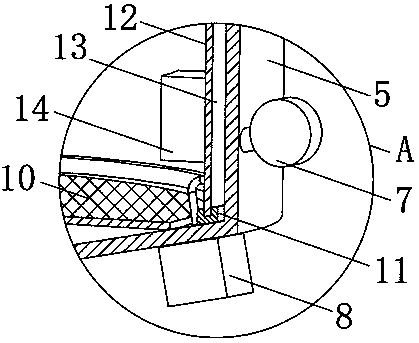

Acute spinal cord injury animal model modeling impactor

The invention discloses an acute spinal cord injury animal model modeling impactor, which is characterized by comprising a bracket, a lever, a guide rail, a probe and a relay device for driving the lever. A support point of the lever is arranged on the bracket; one end of the lever is provided with a sucking disc, the other end is connected with the upper end of the probe; the relay device and the guide rail are both fixed on the bracket along a vertical direction; the relay device is arranged above the sucking disc; the probe is arranged in the guide rail along the vertical direction; a return spring is arranged between the upper end of the guide rail and the upper end of the probe; the relay device comprises a multiple-turn coil and an iron core; the iron core is inserted in the multiple-turn coil; and the terminal of the multiple-turn coil is connected with a controllable current output interface of an external circuit. The impact degree and time of the impactor can be controlled, the impact position is more correct, and the repeatability of the impact operation is strong.

Owner:XIANGYA HOSPITAL CENT SOUTH UNIV

A kind of preparation method of ZSM-5 molecular sieve with high silicon-aluminum ratio

ActiveCN104556132BControl dwell timeControl contact timePentasil aluminosilicate zeoliteMolecular sieveGas phase

Owner:CHINA PETROLEUM & CHEM CORP +1

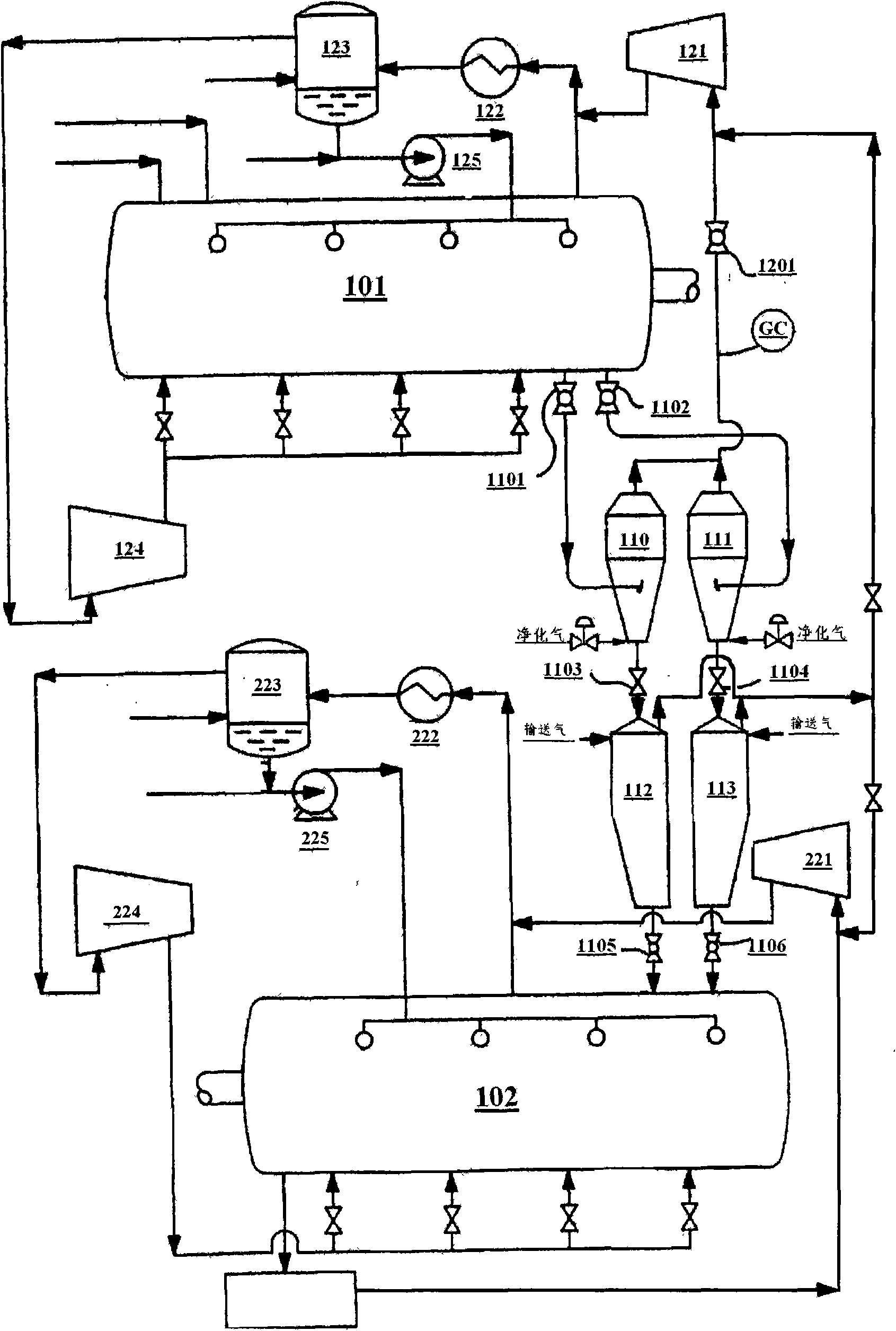

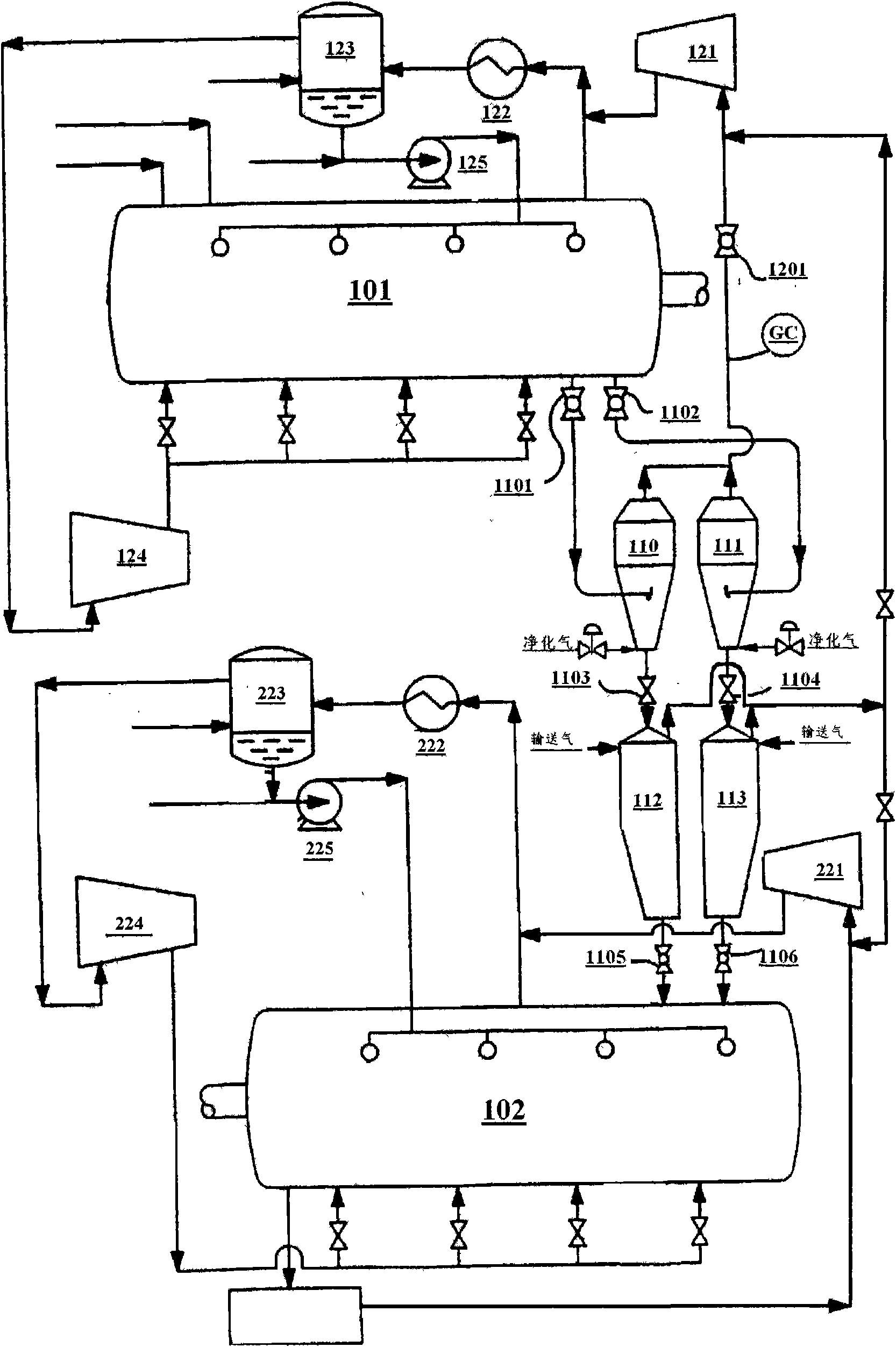

Method for transferring polymer particles among gas-phase polymerization reactors

ActiveCN101927141AImprove transfer efficiencyImprove purification efficiencyChemical/physical processesPolymer scienceFluidized bed

The invention provides a method for transferring polymer particles among gas-phase polymerization reactors, which is used for two or more gas-phase polymerization reactors connected in series, wherein the two or more gas-phase polymerization reactors connected in series continuously polymerize a polymer monomer or a mixture thereof, and each reactor contains a particle-quenching micro-fluidized bed for the polymer monomer. The transferring method shortens the cycle, simplifies the process and can effectively improve the transfer efficiency and the purification efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production device of metal surface treatment liquid

InactiveCN112642335AControl contact timeEffectively closed storageShaking/oscillating/vibrating mixersTransportation and packagingMechanical engineeringMaterials science

The invention relates to the field of metal surface treatment liquid, in particular to a production device of a metal surface treatment liquid. The device comprises a production rack, an adjusting dispenser, a motion adder, a flow mixing box and two quantitative discharge pipes, the adjusting dispenser is fixedly connected to the production rack, the motion adder is fixedly connected to the upper end of the production rack, the motion adder is fixedly connected with the flow mixing box through bolts, the flow mixing box is connected to the production rack in a front-back sliding mode, the two quantitative discharge pipes are fixedly connected and communicated to the front end and the rear end of the flow mixing box respectively, and the upper end of the flow mixing box is attached to the adjusting dispenser. The device has the beneficial effects that: in the process of producing the metal treatment liquid, the liquid contacts with and is mixed with dangerous materials for reaction in an adjustable intermittent manner, and the danger is reduced while effective reaction is achieved.

Owner:郑玉莲

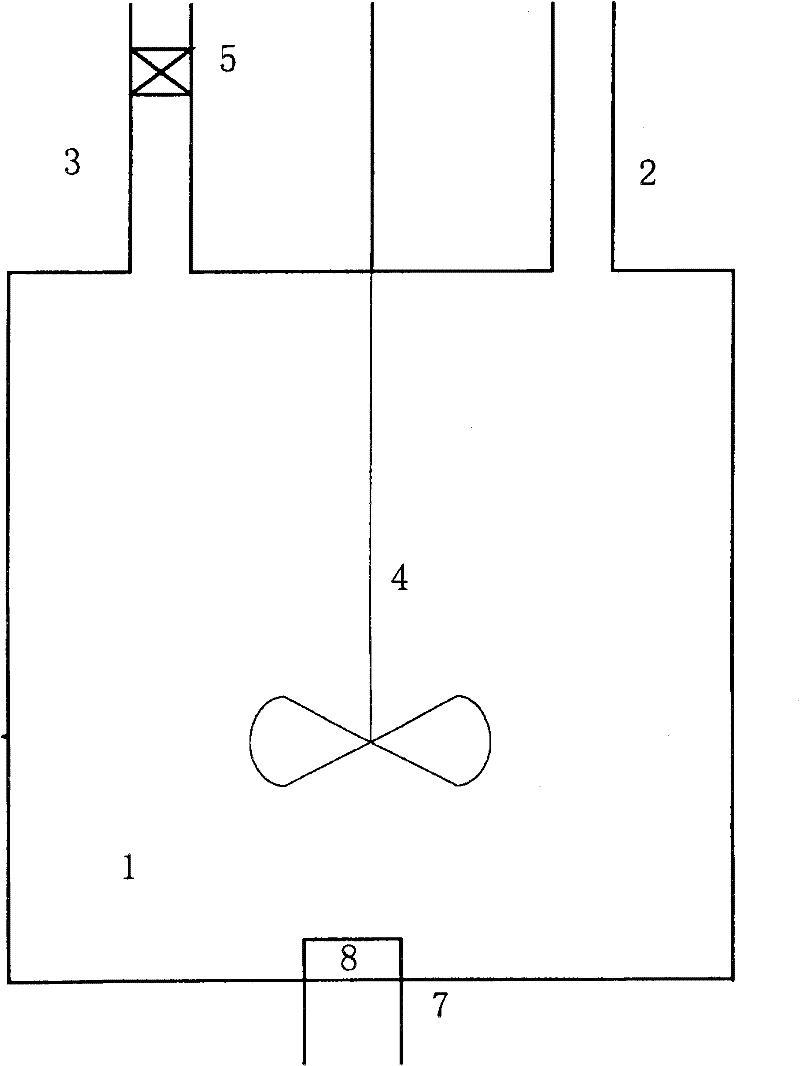

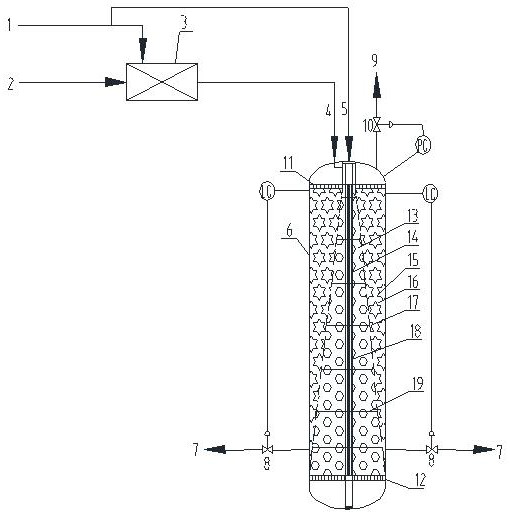

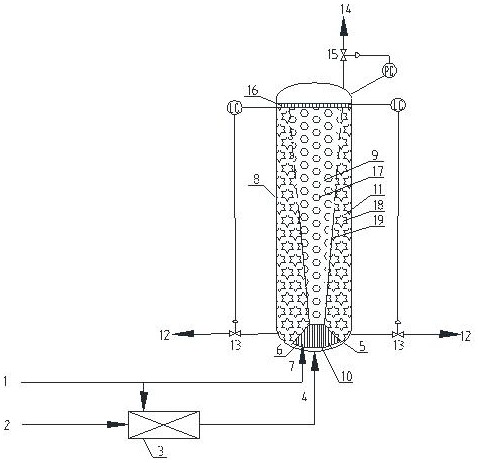

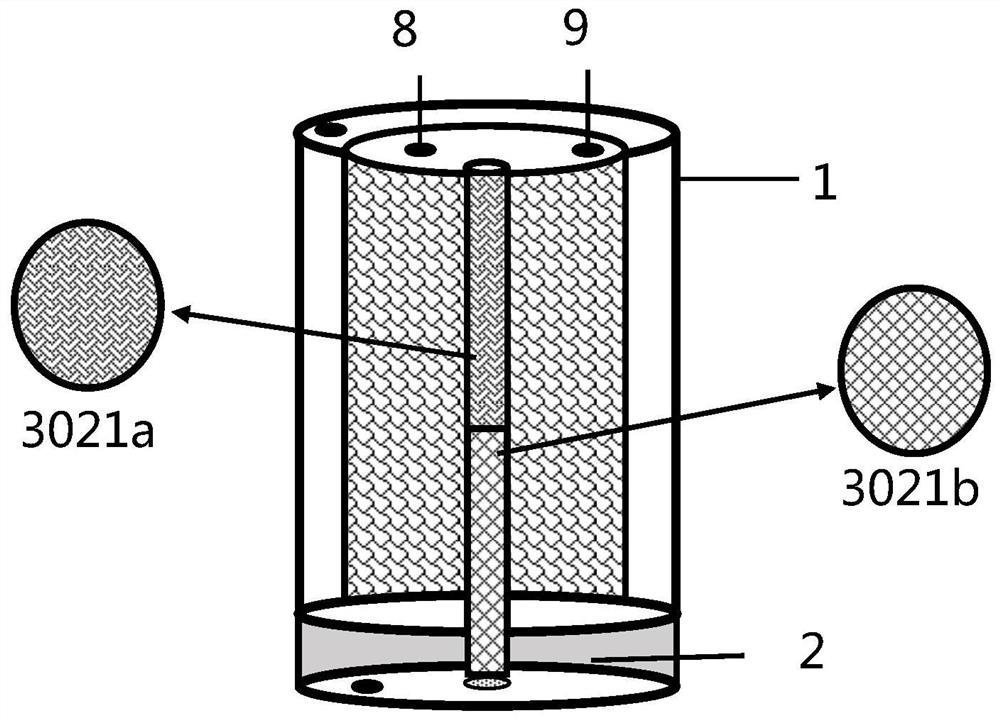

Equipment for preparing catalytic cracking catalyst

ActiveCN102049316BAdequate contact responseContinuous contact reactionCatalytic crackingMolecular sieve catalystsMolecular sieveAbsorption column

The invention relates to equipment for preparing a catalytic cracking catalyst, which comprises a tubular reactor, a gas-solid separator, an absorption column, a beating machine and a nodulizer, wherein the tubular reactor comprises a first feeding hole, a discharging hole and a tube body, and the first feeding hole and the discharging hole are respectively positioned at two end parts of the tubebody; the tubular reactor is communicated with the gas-solid separator through the discharging opening, the upper part and the lower part of the gas-solid separator are respectively communicated withthe absorption column and the beating machine, the position where the gas-solid separator is connected with the discharging hole is lower than that where the gas-solid separator is connected with theabsorption column, and the nodulizer is used for receiving materials from the beating machine. The equipment for preparing the catalytic cracking catalyst, provided by the invention, can realize continuous operation of the contact reaction of the molecular sieve and SiCl4, and can control the contact time of the molecular sieve and the SiCl4 through controlling the length of the tubular reactor and the flow speed of the carrier gas, thereby being capable of enabling the contact reaction of the molecular sieve with the SiCl4 to be fully carried out in the tubular reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

Green synthesis device of 4-chloroacetoacetate

ActiveCN111203170AIncrease contact areaEasy to controlPreparation from ketenes/polyketenesChemical/physical/physico-chemical stationary reactorsThermal insulationChemistry

The invention discloses a green synthesis device of 4-chloroacetoacetate. The synthesis device comprises a sealed thermal insulation shell; an electro-conductive barrel is arranged in the thermal insulation shell; the upper end and lower end of the electro-conductive barrel are hermetically and fixedly connected with the upper side and lower side of the inner cavity of the thermal insulation shellrespectively; an electrostatic generator is arranged outside the thermal insulation shell, the output end of the electrostatic generator is connected with the side face of the electro-conductive barrel through a cable, the cable penetrates through the thermal insulation shell, an electrostatic sprayer is arranged in the upper portion of the inner cavity of the electro-conductive barrel, and a pre-cooler is installed outside the electro-conductive barrel. The green synthesis device atomizes a diketene solution through static electricity, the contact area between liquid drops of the diketene solution and chlorine is increased, the time of reactions between the liquid drops of the diketene solution and chlorine is determined by the downward moving distance of the liquid drops of the diketenesolution, the time of reactions between the diketene solution and chlorine is convenient to control, byproducts are reduced, and raw material loss is avoided.

Owner:山东昌邑灶户盐化有限公司

A liquid phase hydrogenation reactor and hydrogenation process

ActiveCN112705117BControl contact timeControl temperature riseTreatment with hydrotreatment processesChemical/physical processesPtru catalystFluid phase

The invention discloses a liquid-phase hydrogenation reactor and a hydrogenation process, comprising an inner cylinder and a reactor shell, the inner cylinder is conical, the top and bottom of the inner cylinder are open, the bottom edge is tightly connected with the inner wall of the reactor, and the inner cylinder is open. A number of small holes are opened on the cylinder wall; a ceramic membrane tube bundle is vertically arranged on the axial direction of the reactor, and the ceramic membrane tube bundle communicates with external hydrogen; the inner cylinder is filled with hydrogenation catalyst I, the annular cavity is filled with hydrogenation catalyst II, and hydrogenation catalyst I The activity of the catalyst is higher than that of the hydrogenation catalyst II; the inlet of the raw material of the reactor is connected to the top of the inner cylinder; the flow mode of the material in the inner cylinder is from top to bottom; the flow mode of the material in the annular cavity is from top to bottom. The invention can effectively control the contact time between the material and the catalyst in the whole process of the hydrogenation reaction, make the temperature rise of the catalyst bed more uniform, solve the problems of severe exotherm and inhibit the reaction conversion rate in the reaction process, and realize the whole liquid phase hydrogenation reaction process Both achieve higher hydrogenation reaction rate and conversion.

Owner:CHINA PETROLEUM & CHEM CORP +1

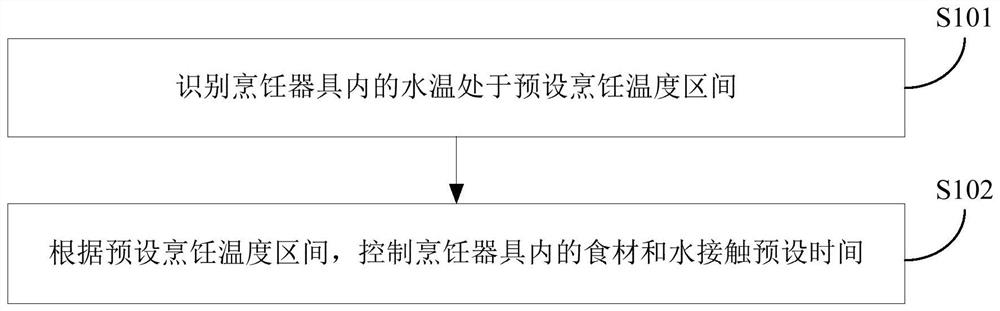

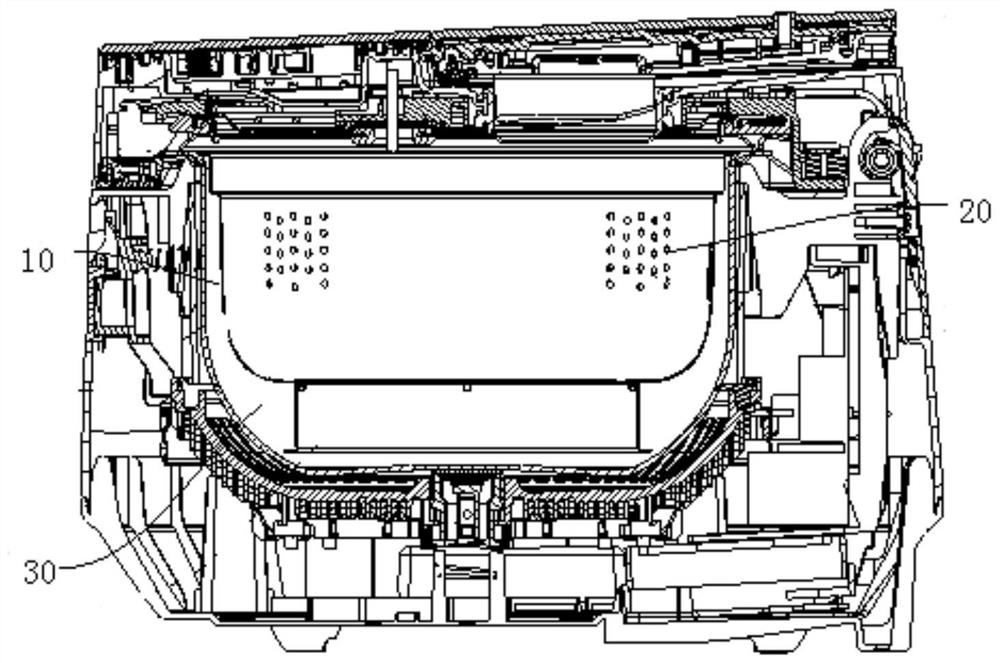

Cooking utensil and control method and device thereof

PendingCN112754251AControl contact timeLow in sugarVessels with intergral heatingTime-controlled ignitorsProcess engineeringRice dishes

The invention provides a cooking utensil and a control method and device thereof. The control method comprises the following steps that it is recognized that the water temperature in the cooking utensil is within a preset cooking temperature interval; and according to the preset cooking temperature interval, the preset contact time of food materials in the cooking utensil and water is controlled, so that the cooking utensil can control the contact time of the food materials and the water, and the sugar content in the rice is further reduced.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com