Worktable type electronic impact hammer

A technology of impact hammer and worktable, applied in the field of hammer device, can solve the problems such as difficulty in keeping the size and direction of hammering force consistent, difficult control of excitation time, difficulty in excitation force pulse, etc., to ensure repeatability and firm design , to ensure the effect of adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

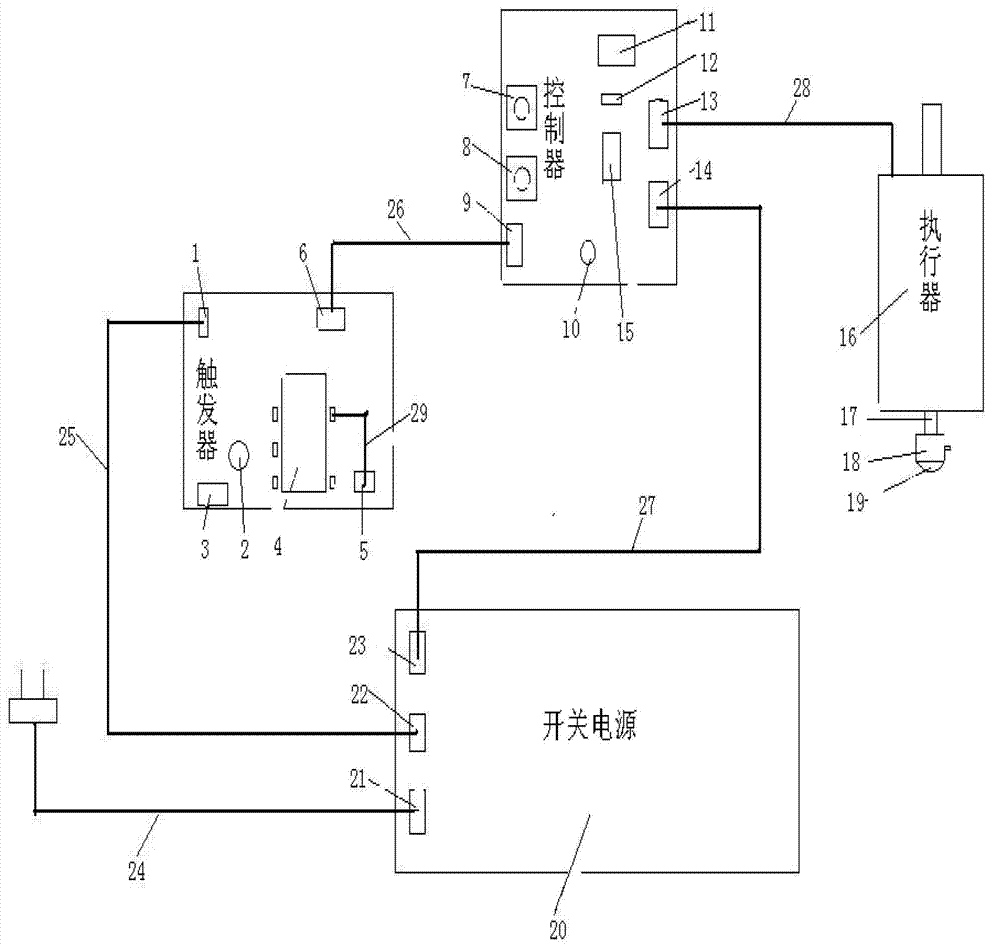

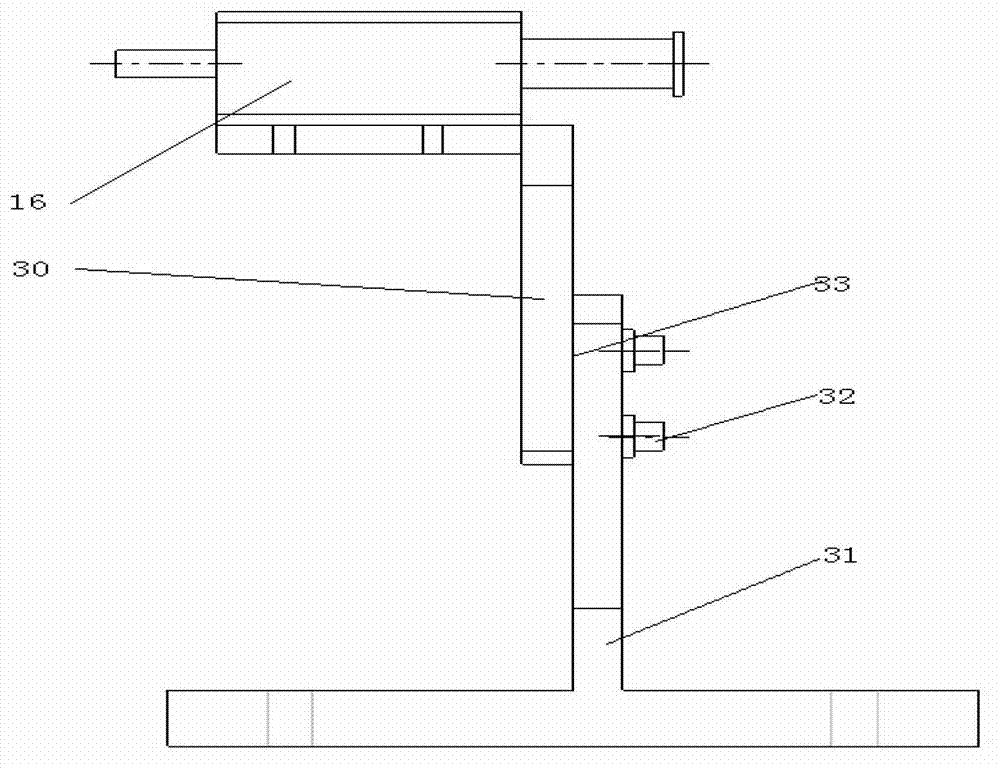

[0028] A workbench type electronic impact hammer, combined with Figure 1 to Figure 3 , including a workbench, a controller, a trigger, and a DC power supply, the controller and the trigger are respectively connected to the DC power supply, and the controller is respectively connected to the trigger and an actuator, and the actuator includes a traction electromagnet 16, the electromagnet The overhanging part 17 of the iron core is connected with the force sensor 18, the front end of the force sensor 18 is provided with a protective impact head 19, and the electromagnet 16 is installed on the platform of the workbench. The extension part of the iron core and the force sensor are threaded, and different force sensors and impact heads are selected according to the needs to obtain the required excitation frequency.

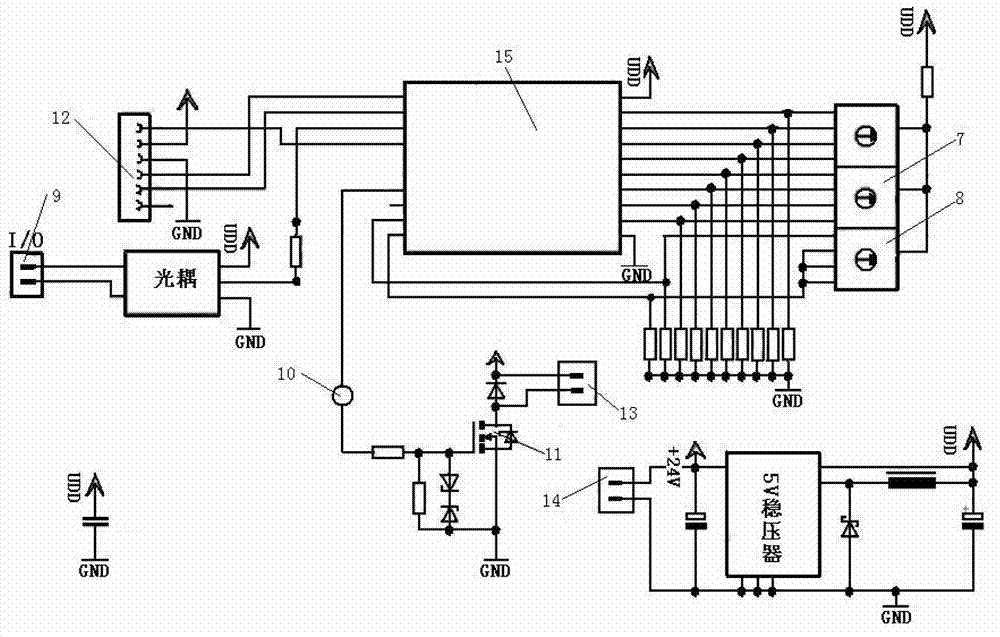

[0029] The controller includes an optocou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com