Wind power dedusting system for rolling process of cigarettes factory

A technology for dust removal system and cigarette factory, which is applied in the direction of cleaning method using gas flow, tobacco, application, etc. Pressure fluctuation and other problems, to achieve the standardization of pipeline design, improve the effective operation rate and output, and stabilize the wind pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

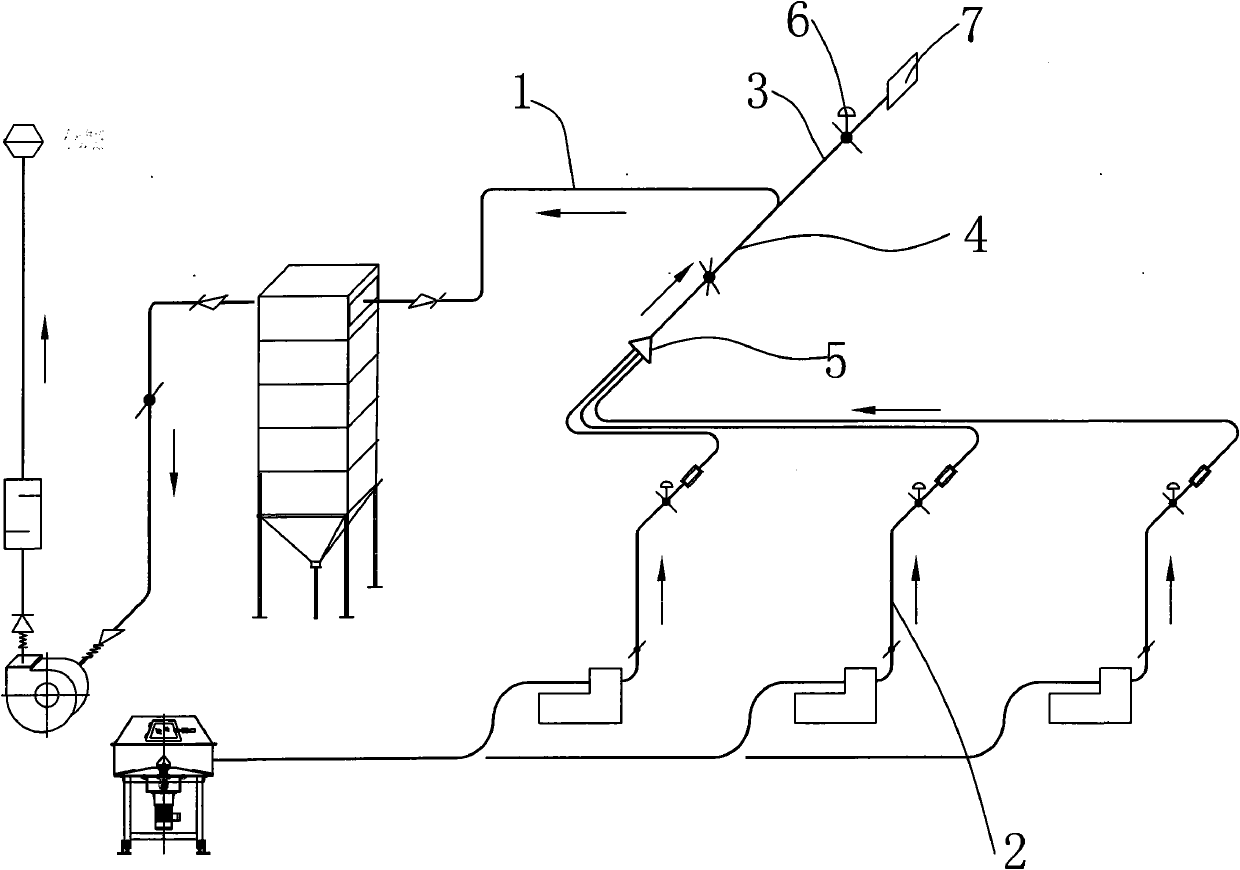

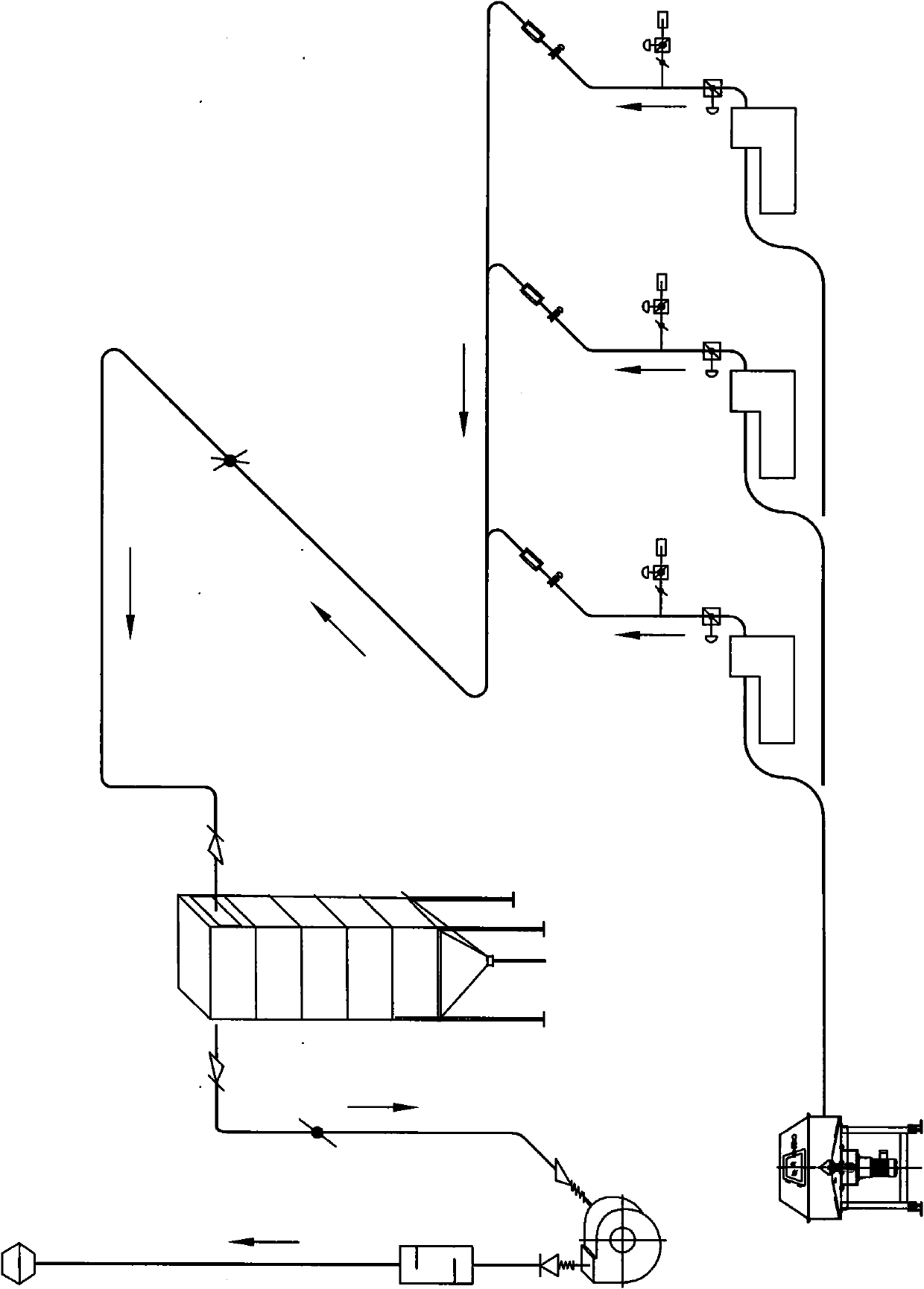

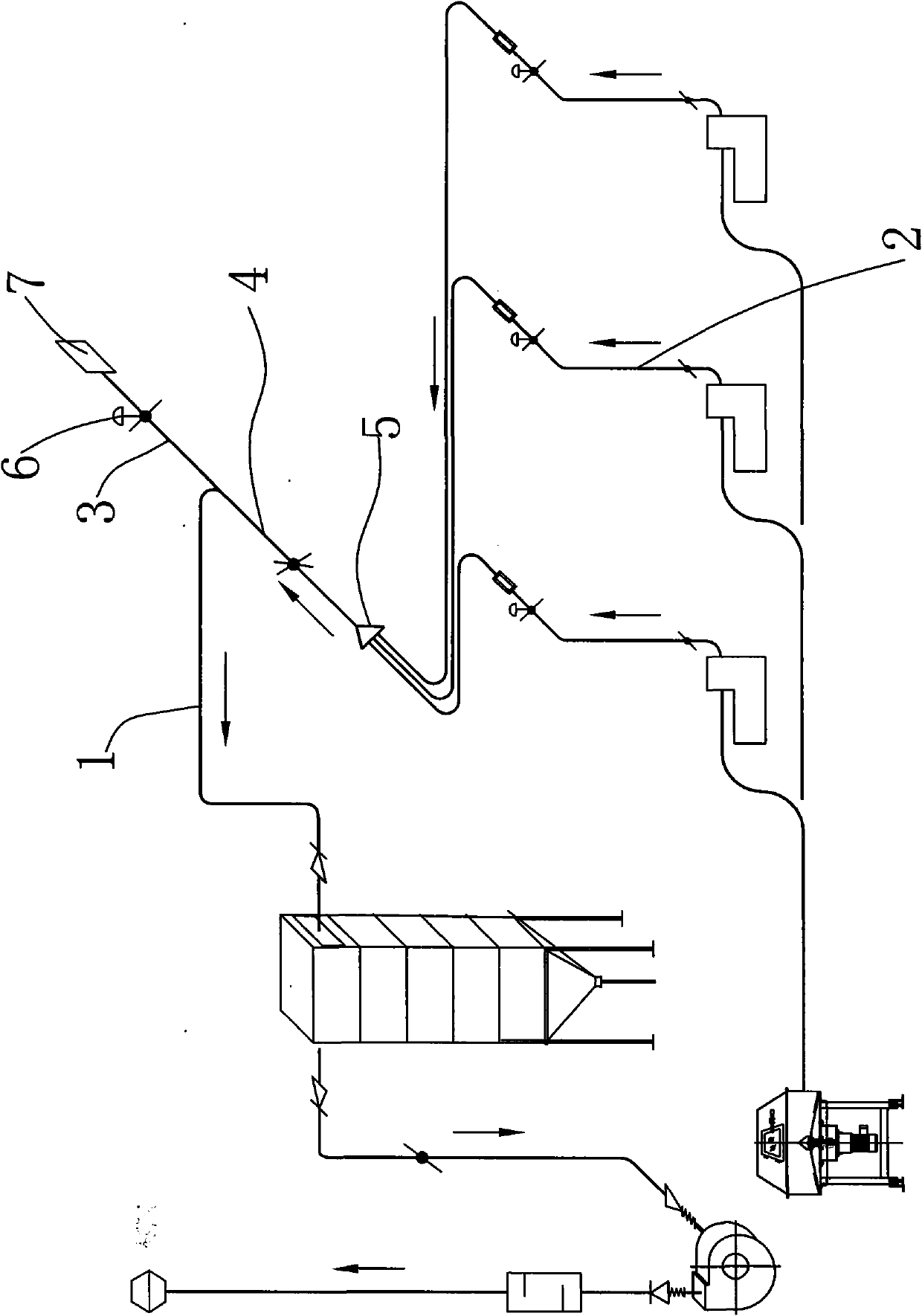

[0009] from figure 1 It can be seen that the air dust removal system used in the cigarette factory coiling process of the present invention includes a centrifugal high-pressure fan, a dust collector, a dust collector connecting pipe 1, several air distribution pipes 2, several coiling and packaging units, and an air supply pipe 3. The main air duct 4 and the header 5 are equipped with control valves and differential pressure orifice flowmeters on each branch air duct 2, and a pneumatic control valve 6 and an air supplement muffler 7 are installed on the supplementary air duct 3. A 70° fire damper is installed on the total air duct 4 . One end of the dust collector connecting pipe 1 is sequentially connected with the dust collector and the centrifugal high-pressure fan, and the other end is respectively connected with the supplementary air duct 3 and the main air duct 4. The root-dividing air duct 2 is connected with a crimping and wrapping unit.

[0010] When the wind-force...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com