Regenerative circulating filtration system

A circulating filtration and filter material technology, applied in filtration separation, filter regeneration, other chemical processes, etc., can solve the problem of inability to achieve ozone utilization rate and regeneration effect, inability to adjust the contact time between ozone and activated carbon, and inability to change the size of ozone bubbles To achieve the effect of improving the water production index, increasing the use efficiency, and strengthening the cleaning degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

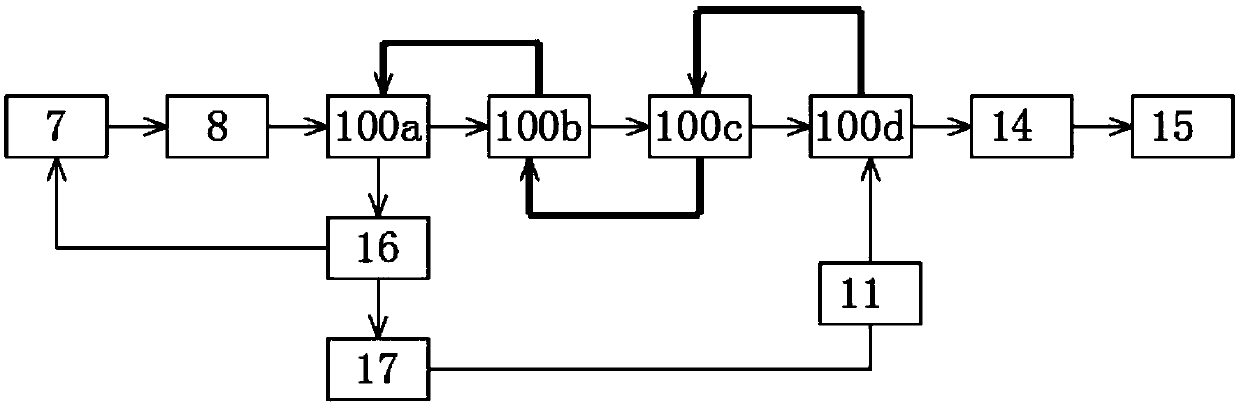

[0045] Such as figure 1 As shown, the present invention provides a regenerative circulation filtration system, at least comprising a regulating tank 7, a first intermediate pool 8, an activated carbon input unit 11, a V-shaped filter tank 14, a second intermediate pool 15, a waste hopper 16, and an activated carbon regeneration unit 17 And several washing devices 100 connected in series. Specifically, the regulating tank 7 is used for pretreatment of influent water such as flocculation and homogeneity. The downstream of the adjustment tank is connected to the first intermediate water tank 8, so that the primary water produced by the pretreatment of the adjustment tank 7 can enter the first intermediate water tank 8 for temporary storage. The downstream of the first intermediate pool 8 is connected with several washing devices connected in series. For example, the regenerative circulating filter system of the present invention includes four washers. The drain pipe 508 of the...

Embodiment 2

[0050] This embodiment is a further improvement on Embodiment 1, and repeated content will not be repeated here.

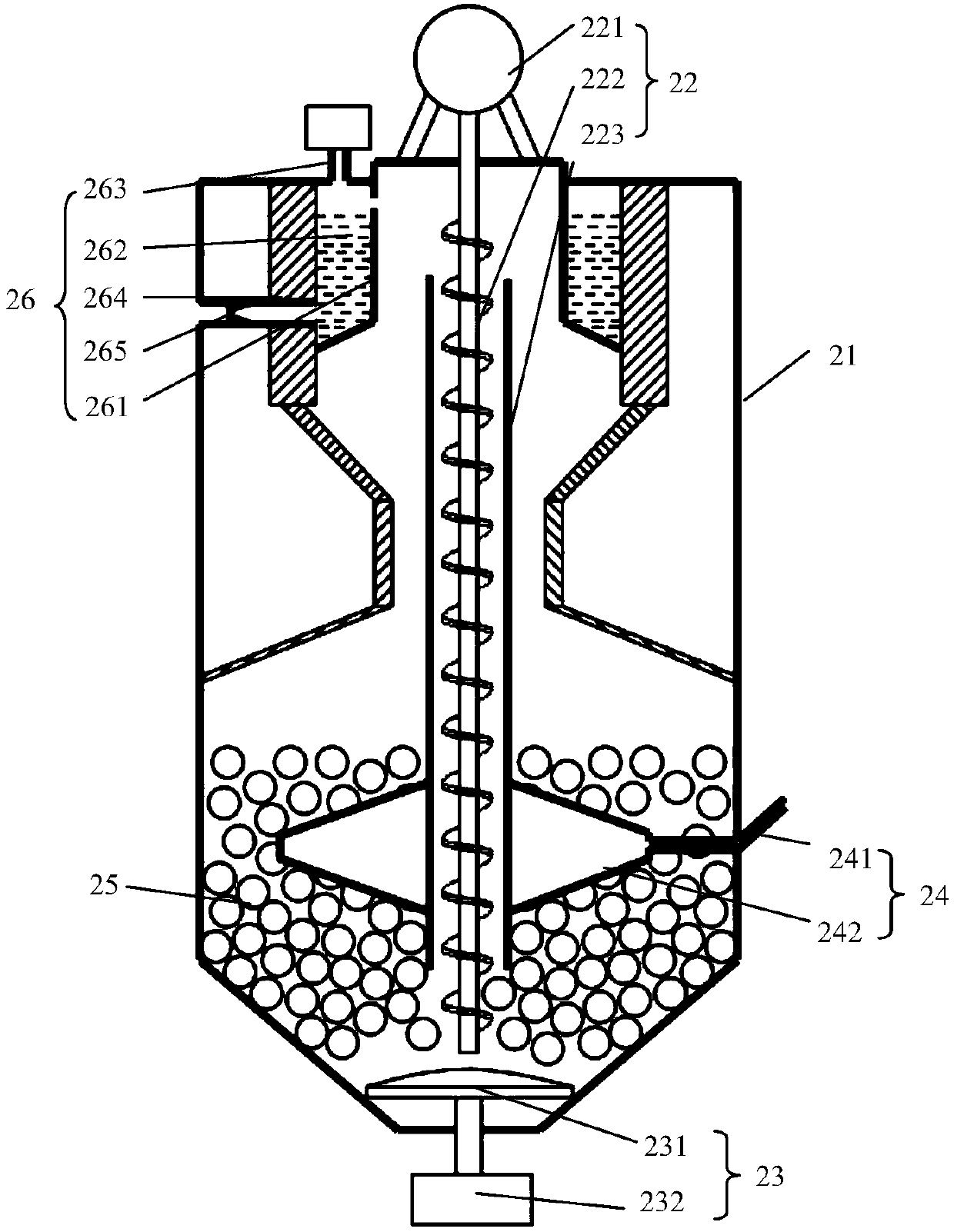

[0051] Such as figure 2 As shown, the activated carbon regeneration unit 17 at least includes a housing 21 , a lifting mechanism 22 , an aeration mechanism 23 , a first water inlet 24 , an aeration part 25 and a drainage part 26 . The shape of the housing 21 is defined by a columnar shape. A first water inlet 24 is provided on the outer wall of the casing 21, and the first water inlet 24 is used for introducing fluid-like activated carbon into the casing. An aeration mechanism 23 is arranged at the bottom of the casing, and the aeration mechanism 23 is used to inject bubble-shaped ozone into the casing, and then can aerate the activated carbon solution in the casing, and the activated carbon can be aerated by the oxidation of ozone. The adsorbed organic matter is decomposed, and the activated carbon can be regenerated. The casing 21 is provided with an aeratio...

Embodiment 3

[0059] This embodiment is a further improvement on the foregoing embodiments, and repeated content will not be repeated here.

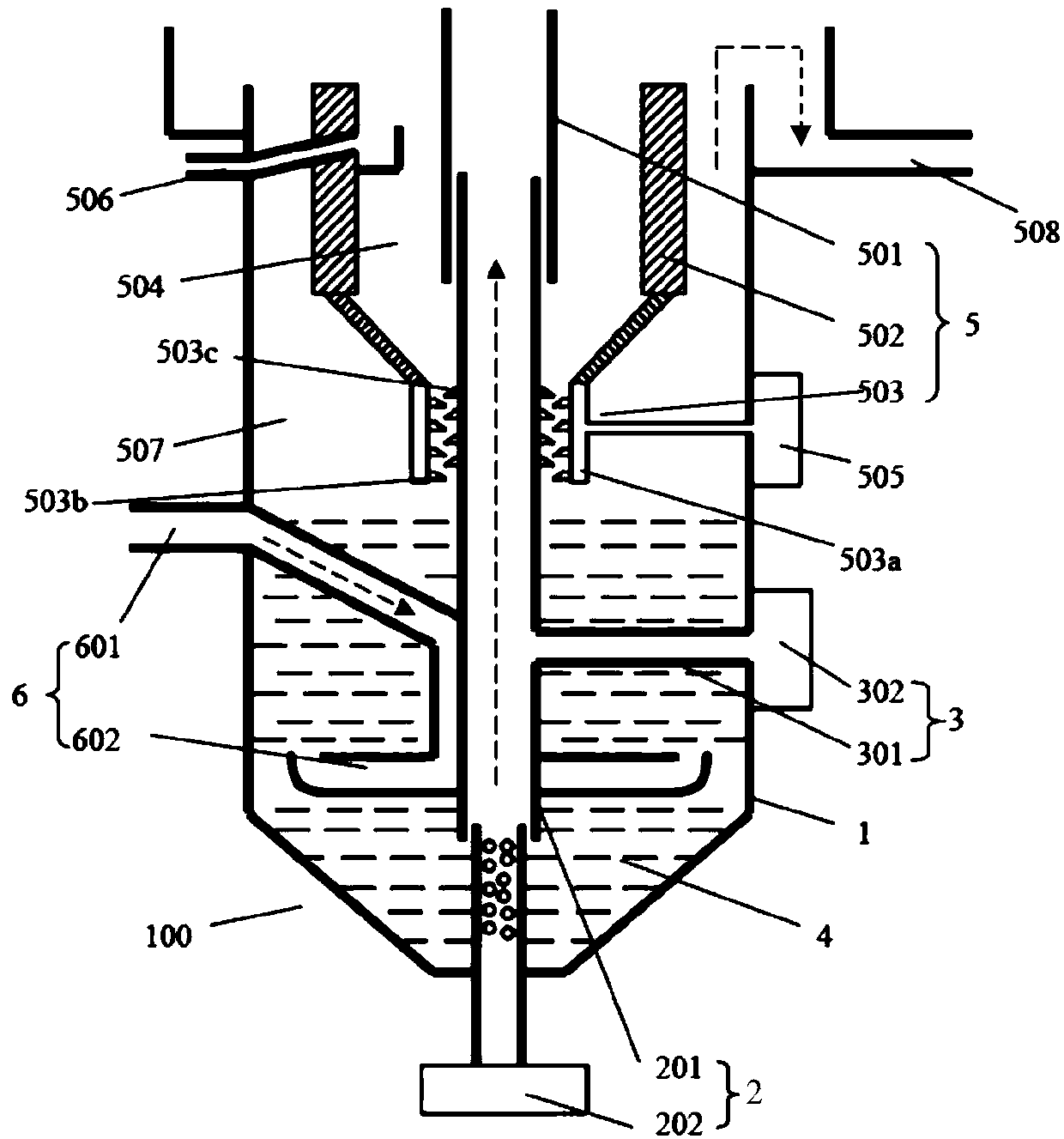

[0060] Such as image 3 As shown, the present invention provides a washing device 100, which at least includes a body 1 and a lifting part 2, a first flushing part 3, a filter part 4, a second flushing part 5 and a second water inlet part all arranged in the body 1 6. The main body 1 at least includes a first section in the shape of a hollow cylinder and a second section in the shape of a hollow cone, and the first section is located on the upper side of the second section. The second water inlet portion 6 is used for inputting external fluid into the main body 1 . The filter unit 4 is a filter layer composed of a filter medium. The second water inlet part 6 is located on the lower side of the filter part so that the input external fluid can pass through the filter part 4 in an upwardly moving manner, and then can filter out impurities or large par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com