Conductor cleaning system and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

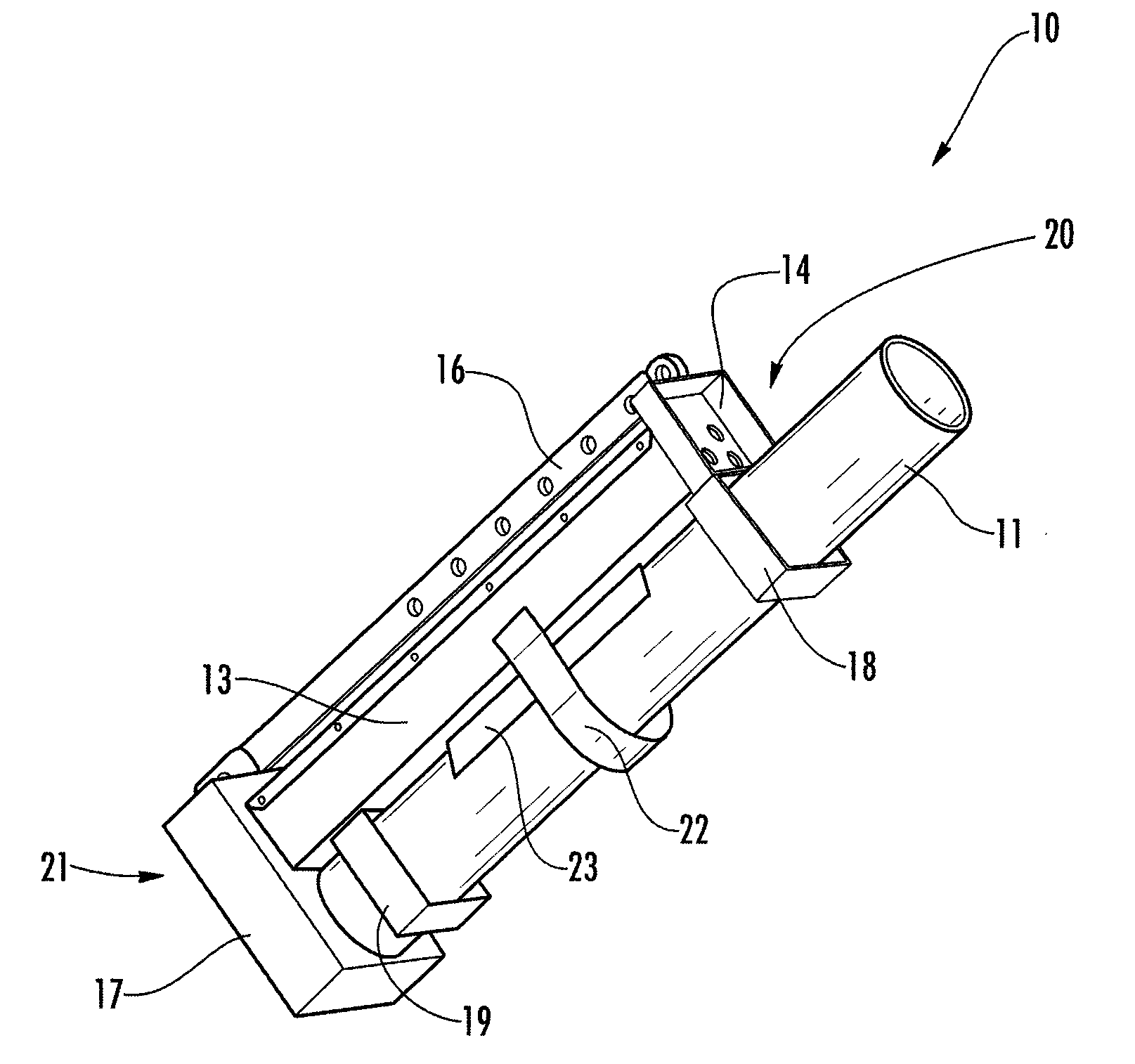

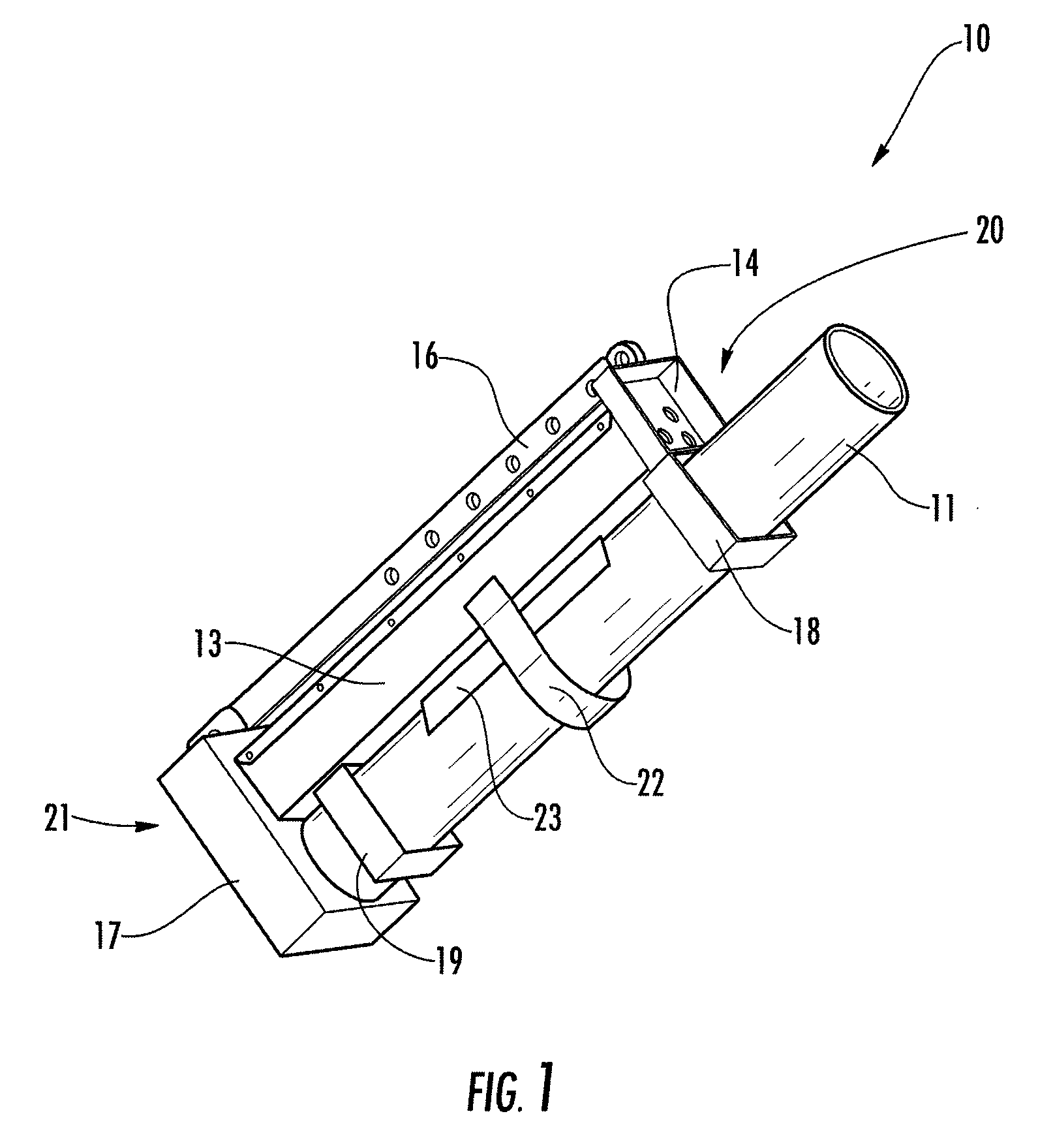

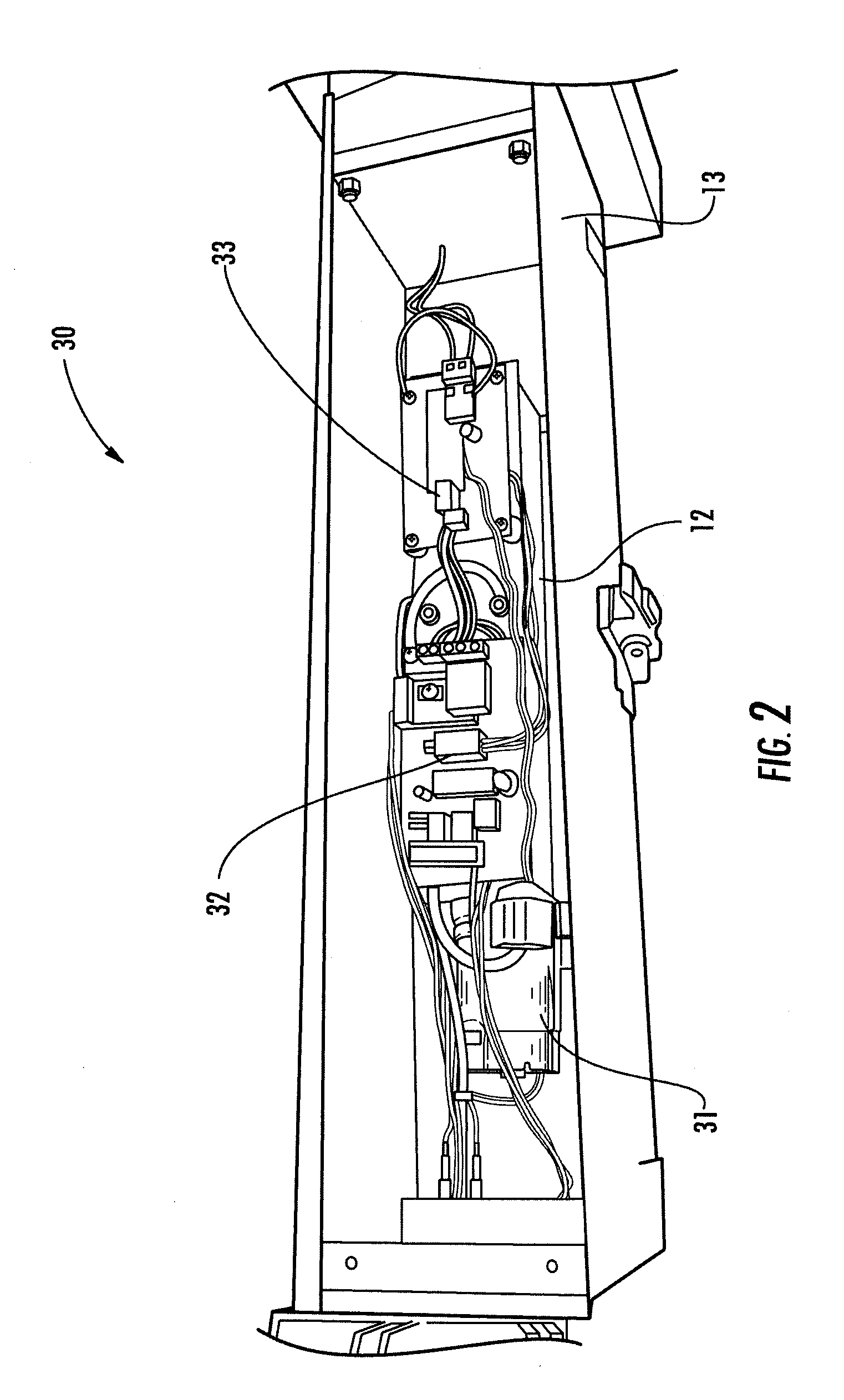

[0024]Referring to the drawings, an exemplary conductor cleaning system according to the present invention is illustrated in FIG. 1 and shown generally at reference numeral 10. The system 10 includes a container, such as tube 11 operably connected to an agitator, such as vibrator 12, FIG. 2, contained in a vibrator housing 13, and a control panel 14 for controlling the system 10. The container 11 may be disposable or permanently attached to the system 10.

[0025]The vibrator housing 13 is adapted to receive and support the container 11, and includes an attachment rail 16 to allow the system 10 to be attached to a support for easy operation or to allow a user to easily carry the system 10. Other attachments such as a hook-type attachment may also be used to attach the system 10 to a bucket of a bucket truck or other suitable support. A standing base 17 is disposed at one end of the housing 13 to allow the system 10 to be positioned in a stand-up position such that the tube 11 is in a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com