Patents

Literature

127 results about "Impact dynamics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and apparatus for embedded heater for desorption and ionization of analytes

ActiveUS20100078550A1Enhance spot resolutionSmall sizeTime-of-flight spectrometersSamples introduction/extractionDesolvationInstrumentation

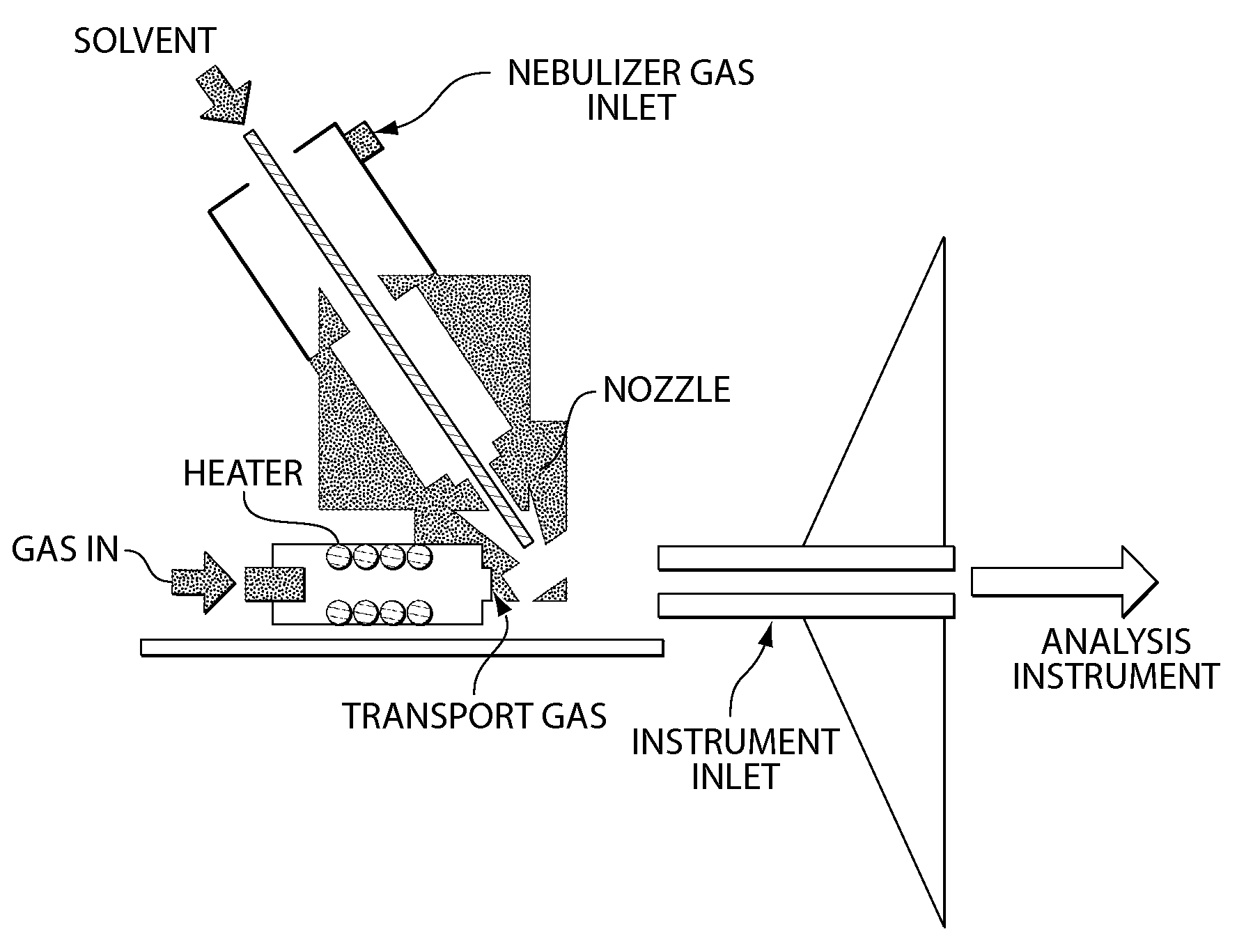

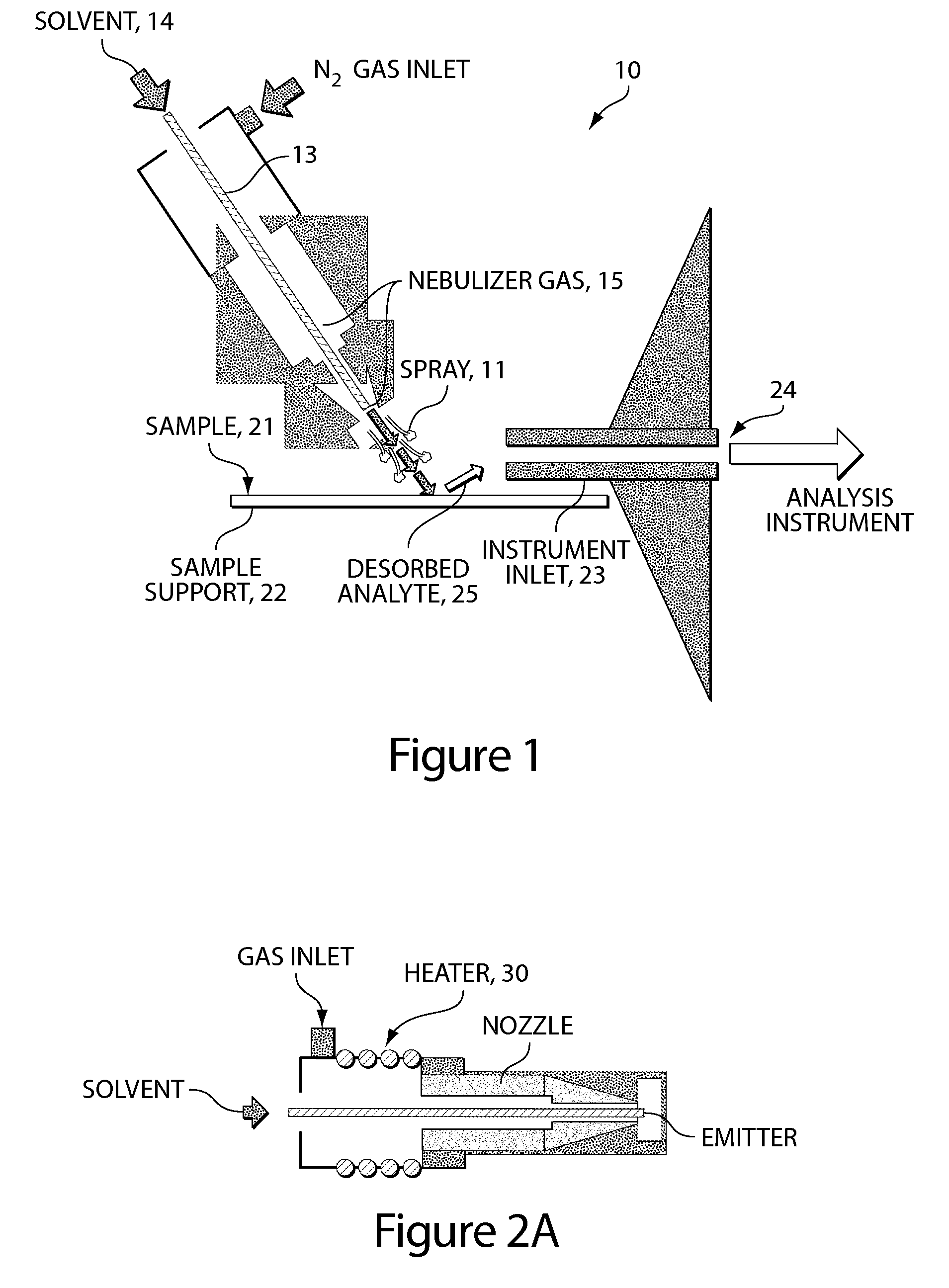

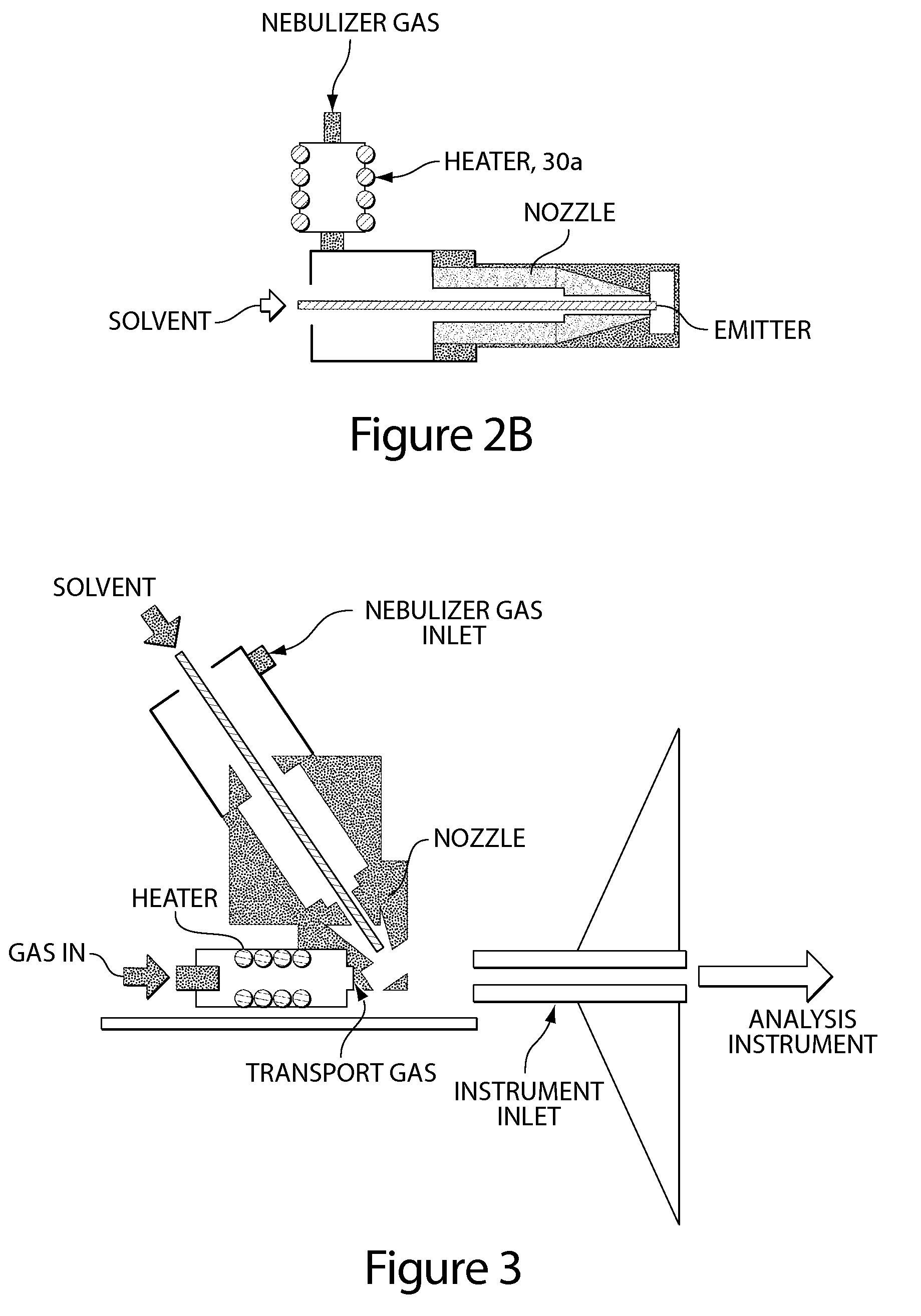

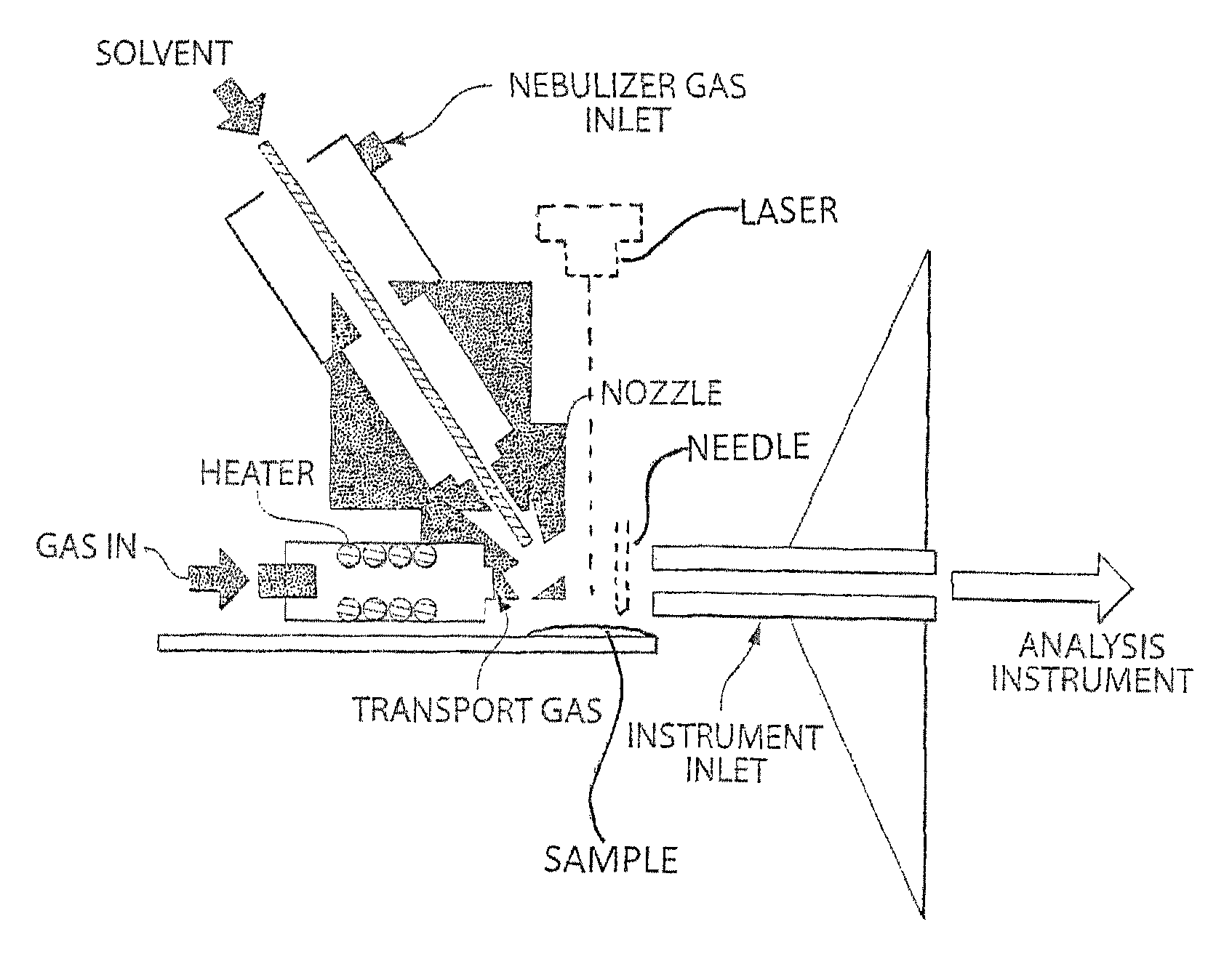

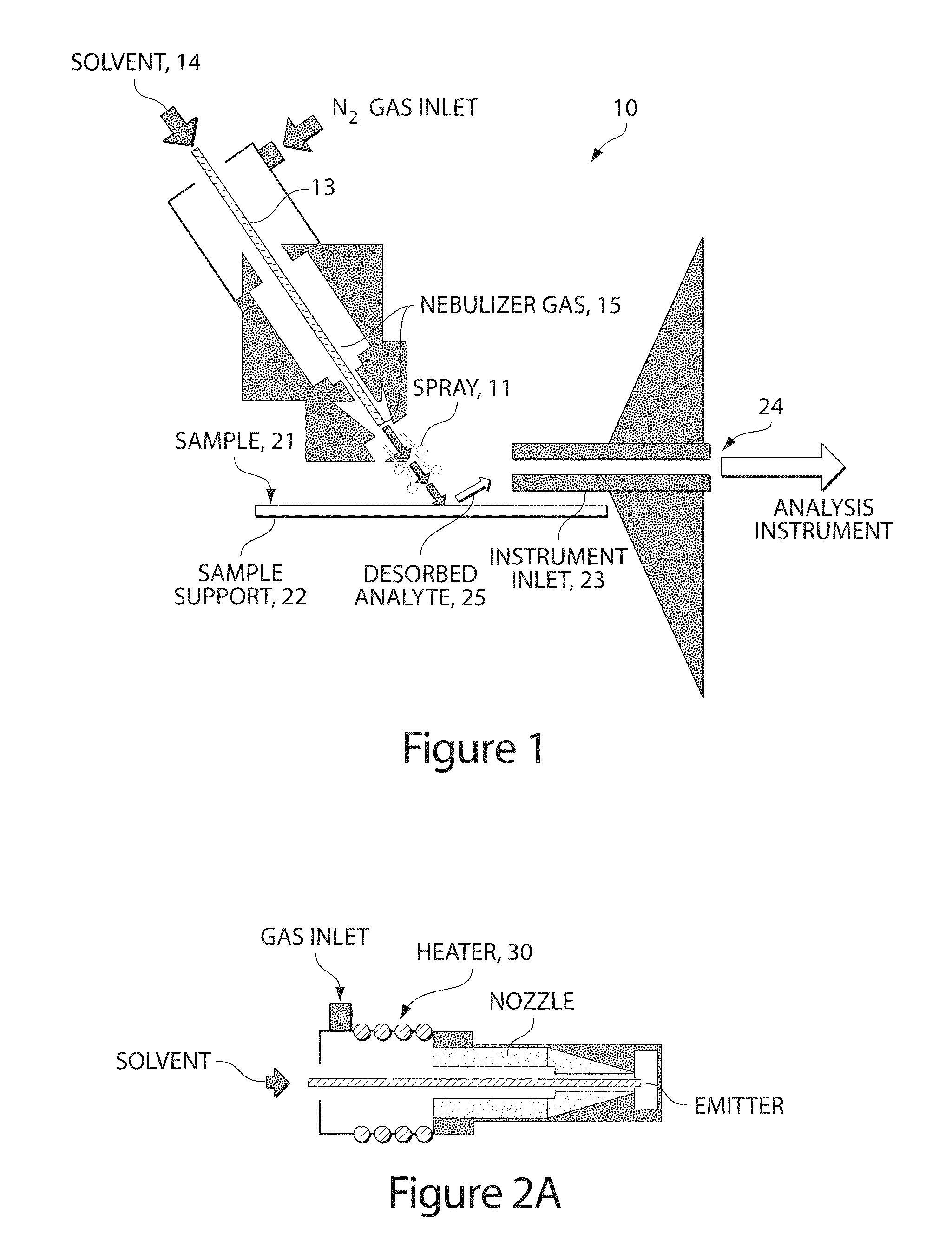

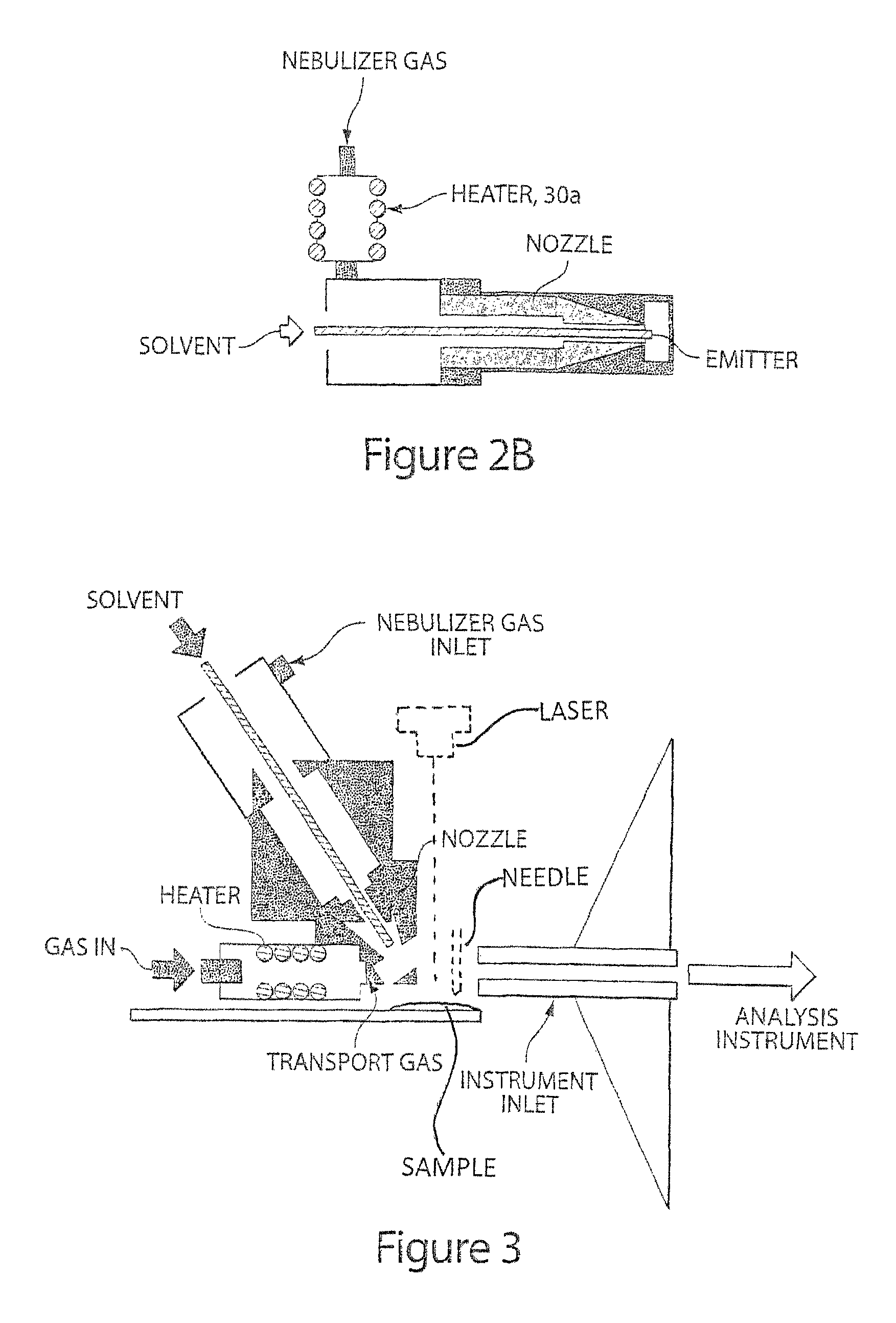

A heated DESI spray device provides improved resolution or control of analyte desorption at a target locus on a sample. Heating controls spot size and enhances resolution in an imaging mode without impairing signal level. Additionally or alternatively the heated DESI spray may control desorption kinetics of a target analyte or otherwise control analyte discrimination in detection mode. One embodiment of the DESI spray is heated by heating nebulizing gas that accompanies the electrosprayed solvent. Another embodiment heats a separate gas stream that transports or directs desorbed material to the ion aperture of an analysis instrument. Heating may reduce size of primary droplets, alter the impact dynamics or the energy delivered by the spray to the surface, reduce size of secondary droplets and / or assure desolvation, improve species selectivity or otherwise affect sampling and enhance the ion signal level.

Owner:WATERS TECH CORP

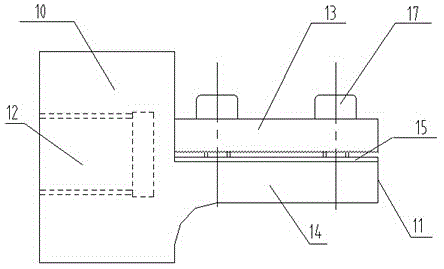

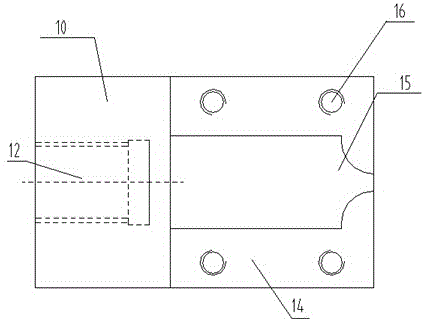

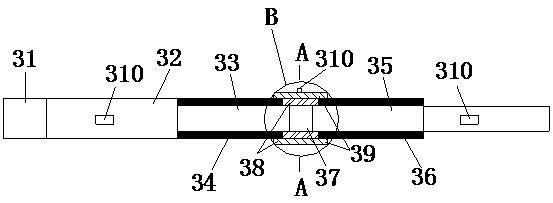

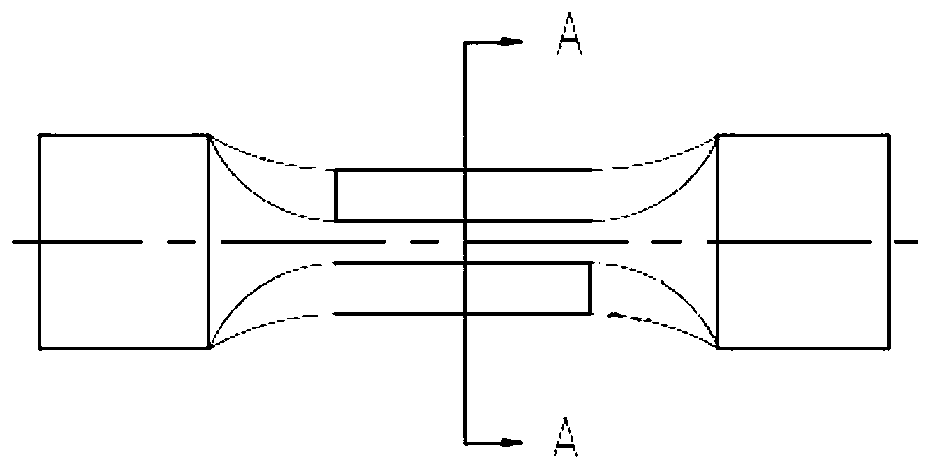

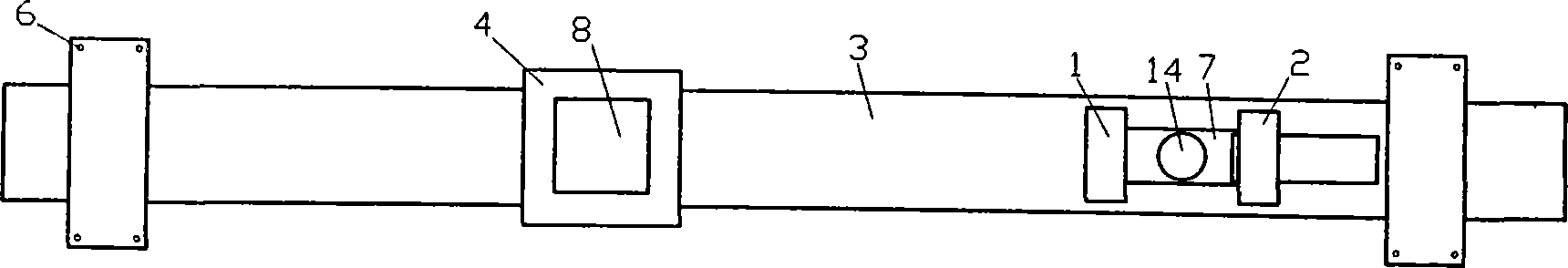

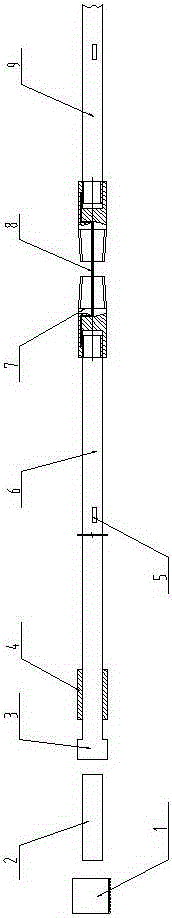

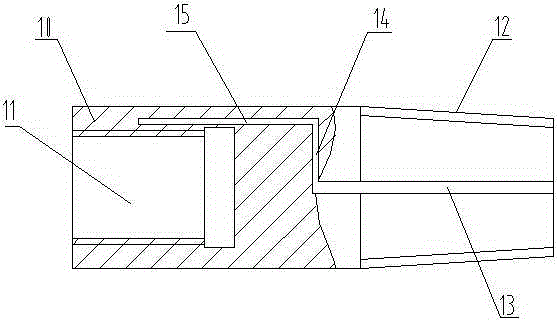

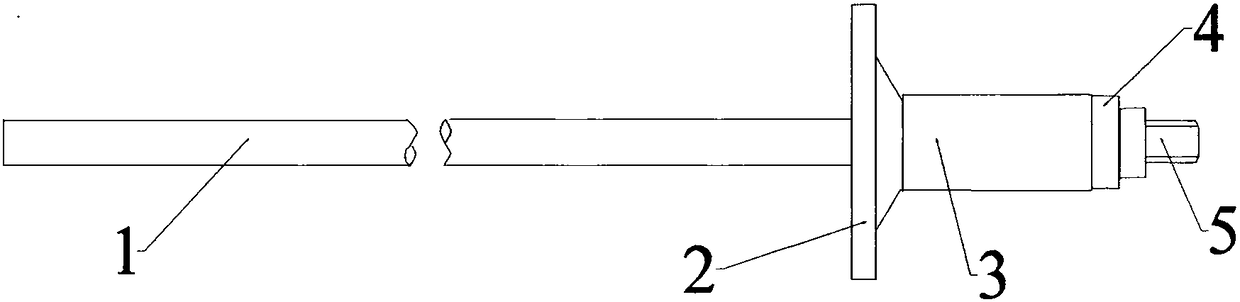

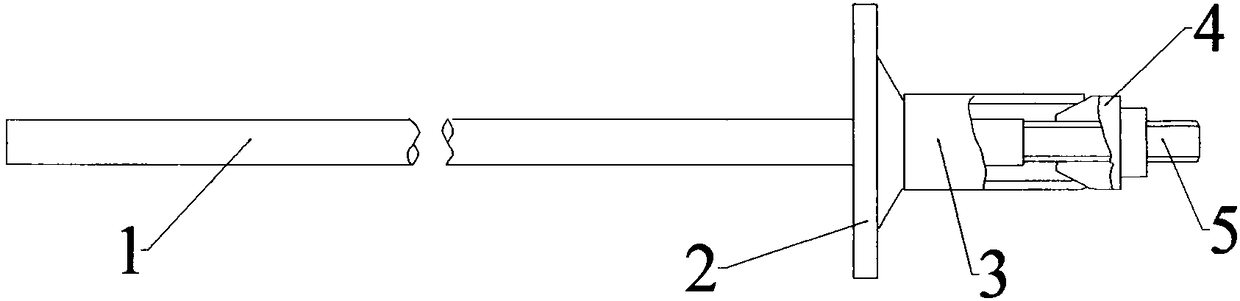

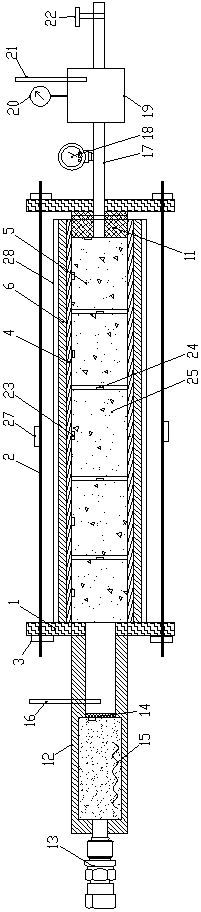

Clamping device and experiment method for split Hopkinson torsion bar test piece

InactiveCN105424470ANo need to disassembleConnectors are versatileMaterial strength using tensile/compressive forcesFibrous compositesScrew thread

The invention discloses a clamping device and an experiment method for a split Hopkinson torsion bar test piece, and belongs to the field of impact dynamics experiments. The clamping device comprises a connector and a clamping part. The connector is of a cylinder structure, a circular blind hole is formed in the connector, an internal thread is arranged in the hole, and the connector is connected with an incidence bar or a transmission bar through the thread. The clamping part comprises a pressing block and a base, the pressing block is arranged above the base in a buckled mode, the base and the connector are fixed into a whole, a groove is formed in the upper surface of the base and is of a flat structure, the body of the groove is square, the end of the groove is in a horn shape, the pressing block is of a hexahedron structure, the upper surface of the pressing block is parallel with the lower surface of the pressing block, screw holes are formed in the periphery of the pressing block, screw holes are formed in the portion, corresponding to the pressing block, of the base, and the pressing block and the base are connected and fixed through screws. By means of the clamping device and the experiment method for the split Hopkinson torsion bar test piece, the problems of difficulty of thread machining of a composite and nonuniformity in the high-strength adhesive bonding process are avoided, and a powerful foundation is laid for studying the constitutive relation of a fiber composite under dynamic tension.

Owner:TAIYUAN UNIV OF TECH

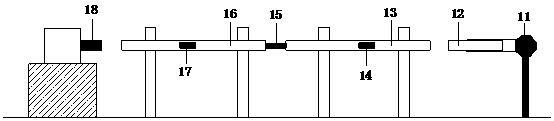

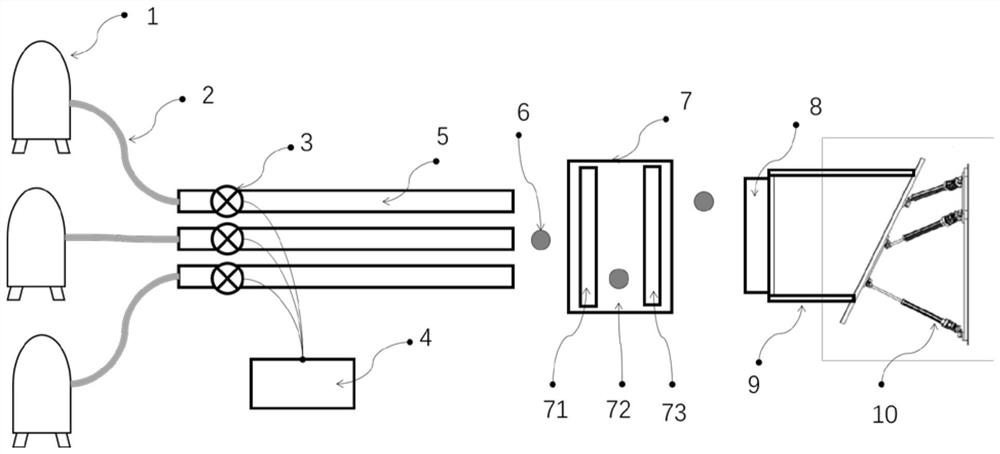

Three-dimensional impact loading experiment device

InactiveCN102169069AImprove accuracyAccuracy does not affectMaterial strength using repeated/pulsating forcesData acquisitionImpact loading

The invention discloses a three-dimensional impact loading experiment device, which belongs to the technical field of impact dynamics experiment devices. The three-dimensional impact loading experiment device is characterized by comprising a loading device, an incidence rod, a test piece and a transmission rod which are arranged sequentially; foil gauges are arranged on the incidence rod and the transmission rod respectively; the foil gauges are connected with a data acquisition and processing unit; the test piece is a cube; three incidence rods and three transmission rods are provided; one end of each of the incidence rods corresponds to a loading device, and the other end of the incidence rod is vertical to three vertical side faces of the test piece; the transmission rods are vertically arranged on the other three side faces of the test piece; and the incidence rods and the transmission rods correspond to each other one to one. The invention aims at providing the three-dimensional impact loading experiment device which is capable of really realizing three-dimensional dynamic loading and used for researching the dynamics performance of engineering materials under the three-dimensional dynamic loading.

Owner:浣石

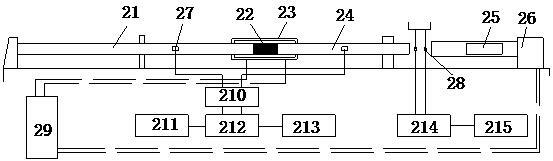

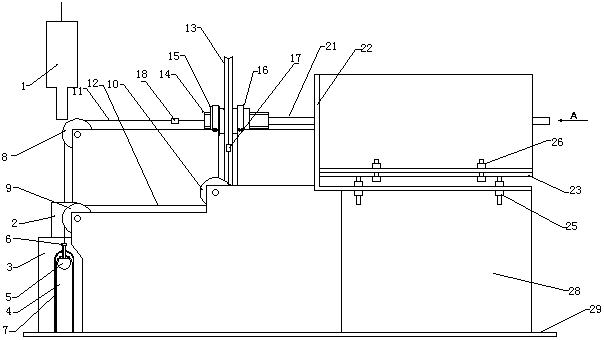

Experimental device and experimental method of impact drawing-twisting load

InactiveCN104181102ARealize dynamic impact tension and torsion experimentEasy to operateUsing mechanical meansMaterial analysisCircular discEngineering

The invention discloses an experimental device and an experimental method of impact drawing-twisting load, belonging to the field of impact dynamics experiments. The experimental device comprises a drop hammer, a test piece, an impact force transfer device, a loading disc, a measuring device and a test piece fixing device; the drop hammer drops down to impact a transmission target, the transmission target moves on a track after being impacted, a base is provided with a prestress loading device, the prestress is applied to an impact target through an adjusting threaded rod, two sides of the impact target are respectively connected to the loading disc through steel wire ropes, each steel wire rope is provided with a force sensor, the disc transfers the drawing force and twisting force to a reinforcing steel bar of the test piece, and a metal strain gauge is attached inside the reinforcing steel bar of the test piece and used for measuring the stress distribution along the anchoring length of the reinforcing steel bar. According to the experimental device and the experimental method, the bond stress distribution of a reinforcing steel bar concrete anchoring reinforcing steel bar under the drawing and twisting load effects of the impact is researched, and a powerful foundation is set for researching a constitutive relation of anchoring bond slip under the effect of complicated stress.

Owner:TAIYUAN UNIV OF TECH

Method and apparatus for embedded heater for desorption and ionization of analytes

ActiveUS8203117B2Small sizeHigh resolutionSamplingSamples introduction/extractionAnalyteImage resolution

A heated DESI spray device provides improved resolution or control of analyte desorption at a target locus on a sample. Heating controls spot size and enhances resolution in an imaging mode without impairing signal level. Additionally or alternatively the heated DESI spray may control desorption kinetics of a target analyte or otherwise control analyte discrimination in detection mode. One embodiment of the DESI spray is heated by heating nebulizing gas that accompanies the electrosprayed solvent. Another embodiment heats a separate gas stream that transports or directs desorbed material to the ion aperture of an analysis instrument. Heating may reduce size of primary droplets, alter the impact dynamics or the energy delivered by the spray to the surface, reduce size of secondary droplets and / or assure desolvation, improve species selectivity or otherwise affect sampling and enhance the ion signal level.

Owner:WATERS TECH CORP

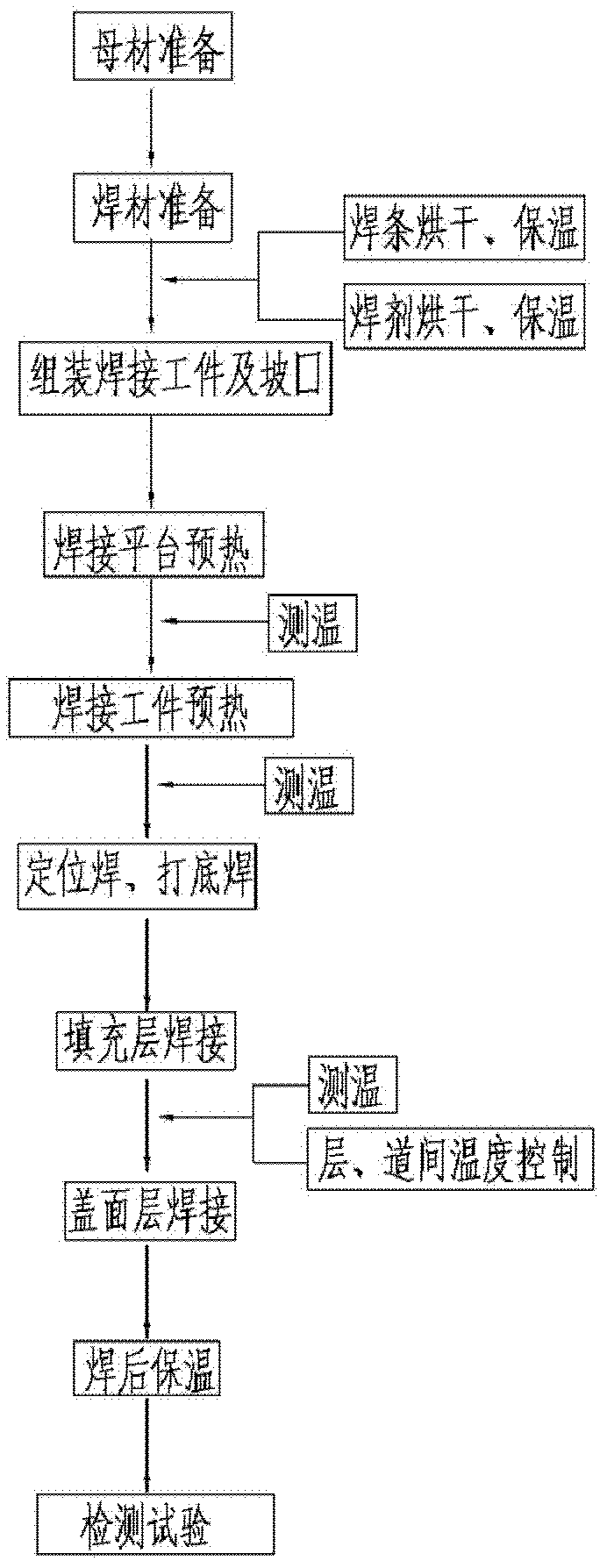

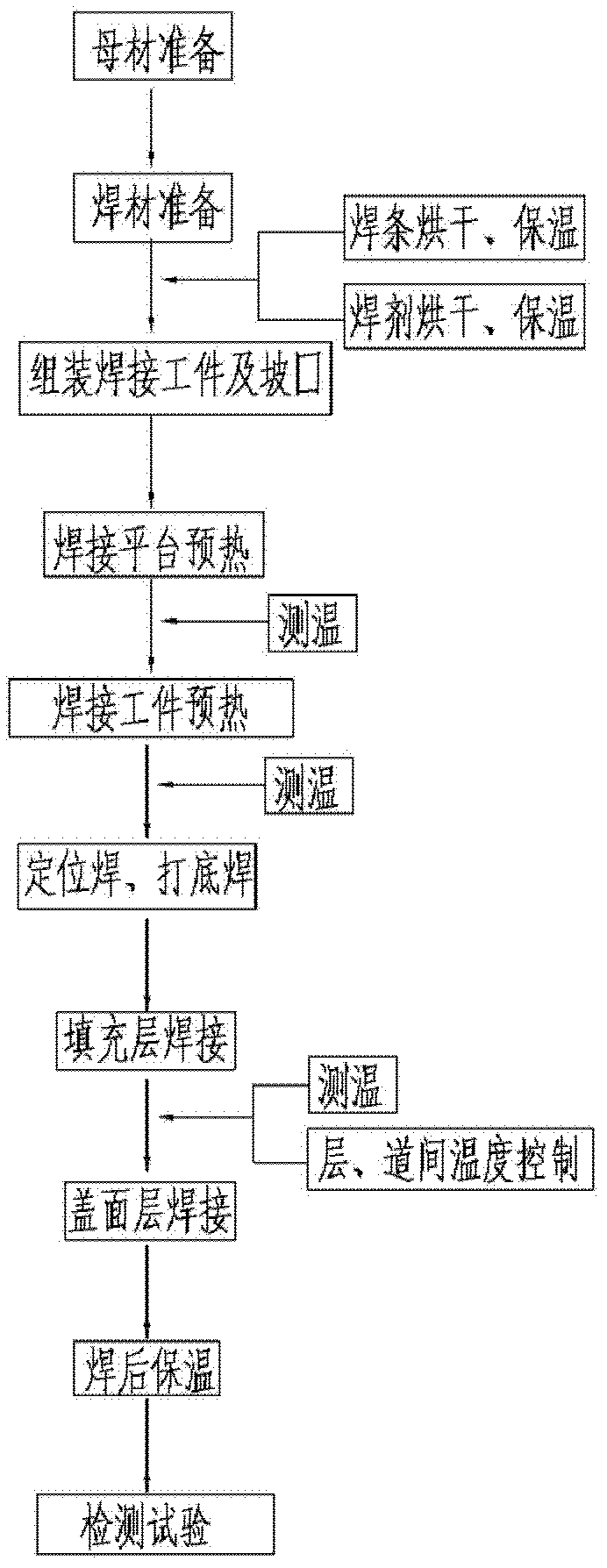

Low-temperature submerged-arc automatic welding method for Q370qE steel

InactiveCN102632328ATemperature controlThe temperature is simple and convenientWelding accessoriesEngineeringSlow cooling

The invention discloses a low-temperature submerged-arc automatic welding method for Q370qE steel and belongs to the field of welding methods. In the low-temperature submerged-arc automatic welding method, the temperature condition during the whole welding process of the Q370qE steel at environment temperature of 0-minus 15 DEG C is controlled by the steps as follows: dehumidification and pre-heating of a parent metal before welding, drying and temperature keeping of a welding rod and welding flux, and temperature keeping and slow cooling on the welding zone after welding. Especially, during welding, a crawler-type ceramic electric heater which needs electrifying before heating is laid on and covers a welding joint and 100-150mm parts at two sides of the welding joint, so that the temperature of welding joint layers and passes is controlled to 160-200 DEG C, and the crawler-type ceramic electric heater can be adjusted manually to control temperature, so that the temperature among the welding joint layers and passes can be simply and conveniently controlled. After the whole welding process is subjected to such-ordered temperature control, the welding process can be prevented from being influenced by low temperature environment as much as possible; the cooling speed of the welding joint during the welding process is slowed, so that the cold cracking, hardness and brittleness possibilities of the welding joint are reduced; and the low-temperature impact toughness of the submerged-arc automatic welding joint of the Q370qE steel is effectively ensured, the impact dynamic load performance of a bridge steel structure is enhanced and the service life of a bridge is prolonged.

Owner:WUHAN BRIDGE HEAVY INDS GROUP

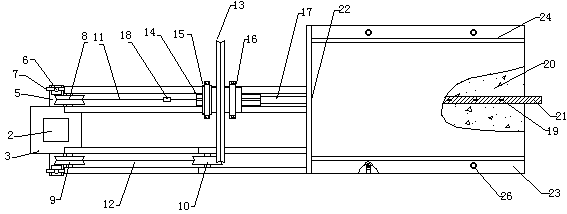

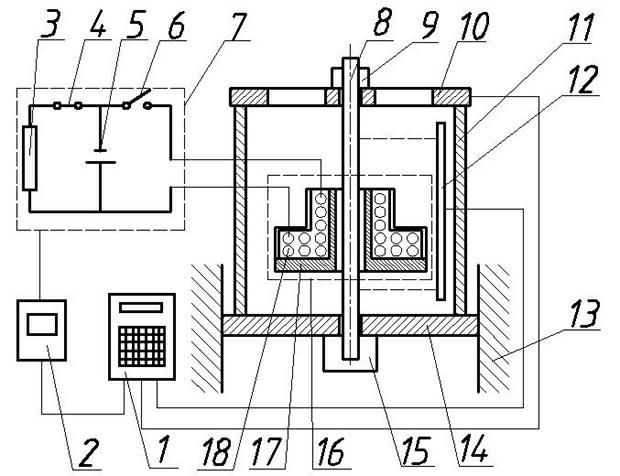

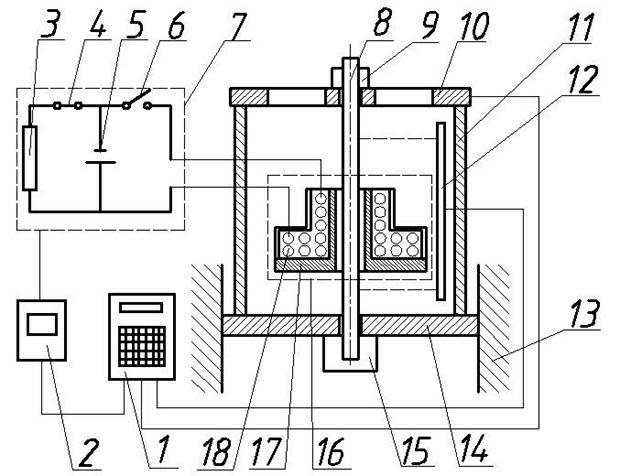

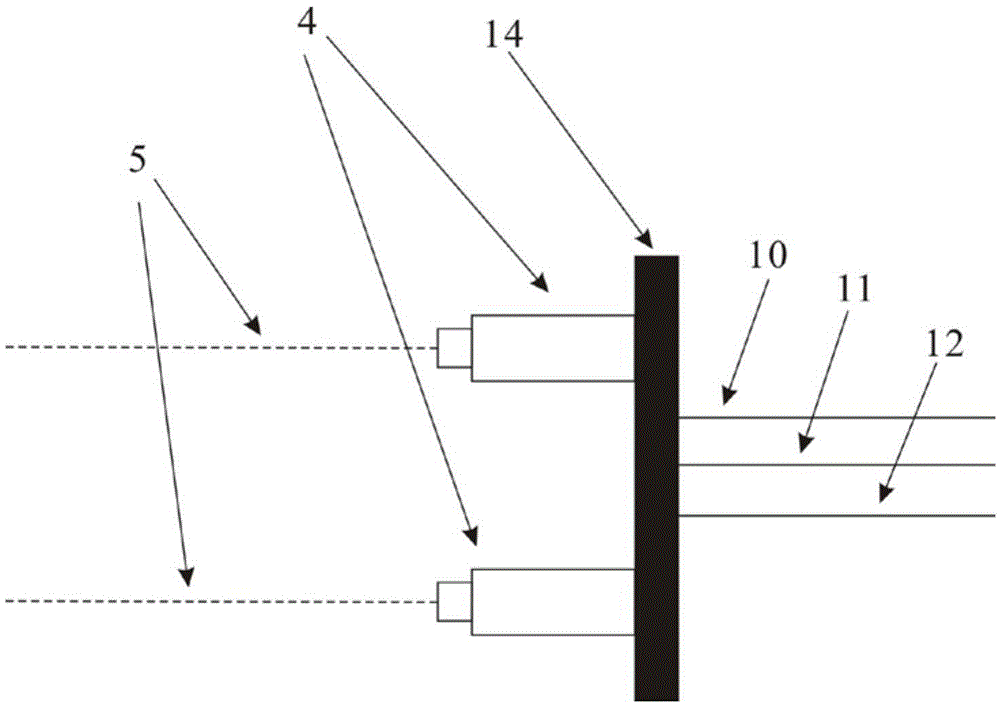

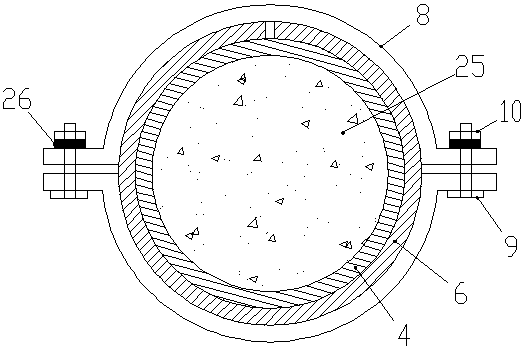

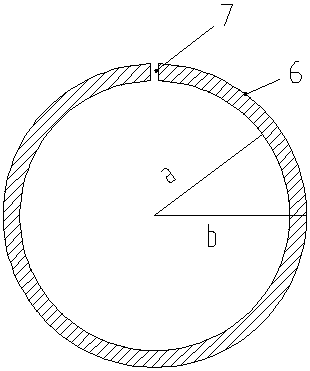

Electromagnetic impact dynamic tensile test method and device

ActiveCN102109436AAchieving Dynamic StretchEasy to controlMaterial strength using tensile/compressive forcesStrong pulseElectromagnetic pulse

The invention relates to an electromagnetic impact dynamic tensile test method and a device, and belongs to the technical field of dynamic tensile mechanical property test of materials. The device adopts an electromagnetic pulse to load; a tensile test piece (8) passes through a central hole of an electromagnetic pulse device (16); the electromagnetic pulse device (16) is used for arousing a strong-pulse magnetic field; the action of electromagnetic force is generated between a target (14) and an electromagnetic pulse coil (18), so that the tensile test piece (8) mounted between the target (14) and a bracket (10) obtains direct instantaneous tensile force to finish the dynamic tensile test of the tensile test piece (8). The method and the device are used for measuring the dynamic stress and strain relationship of the materials in a high strain state; and the device has simple structure and simple test process, can be used for carrying out direct dynamic tensile test as well as the dynamic tensile test of the materials under the conditions of different high strain rates and ultrahigh strain rates, and has low cost and good application prospect.

Owner:JIANGSU UNIV

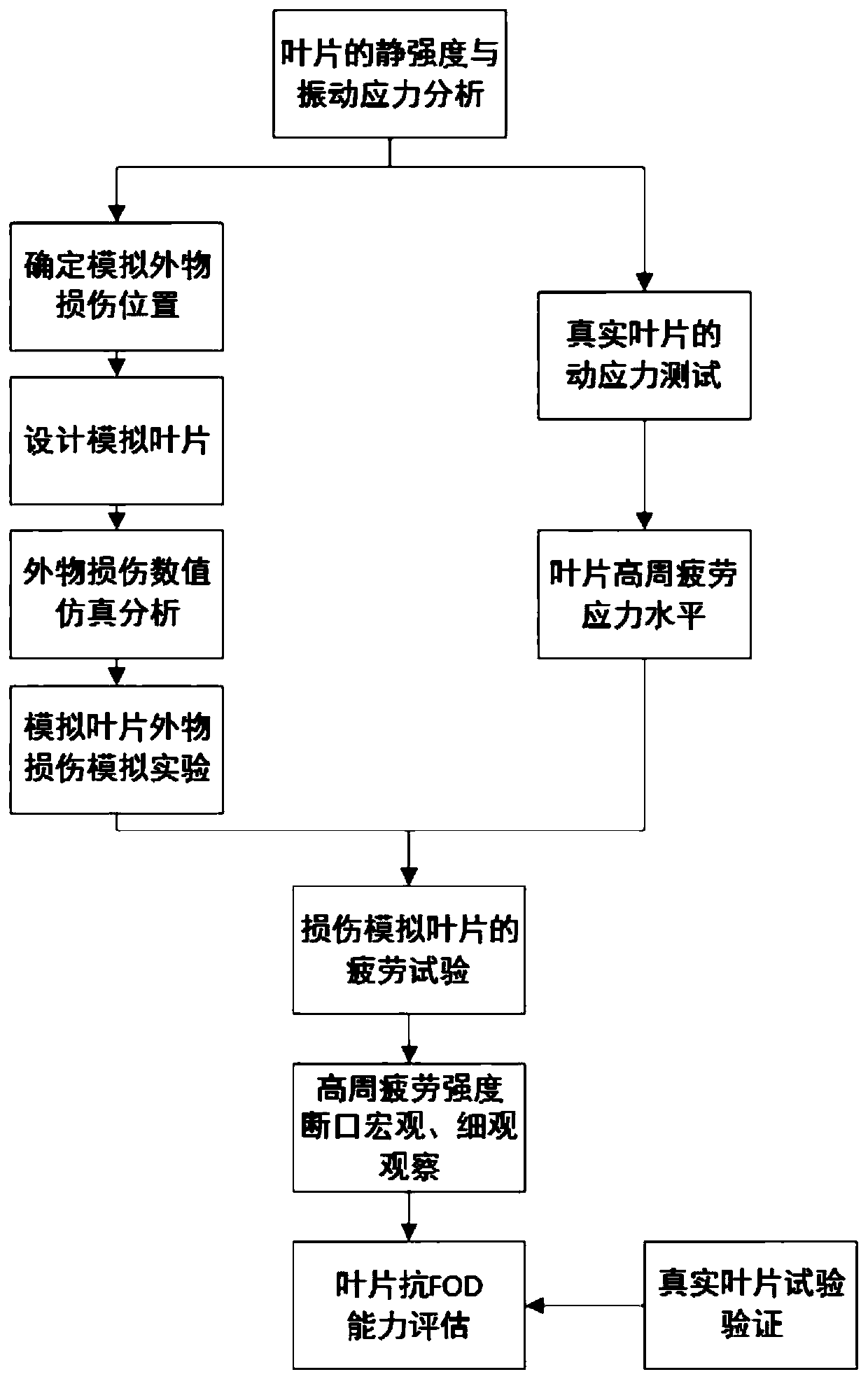

A method for evaluating the FOD resistance of an aero-engine blade

ActiveCN109815521AHigh cycle fatigue strengthAssessing the ability to resist FODSpecial data processing applicationsForeign object damageForeign object

The invention relates to a method for evaluating the FOD resistance of an aero-engine blade. The method comprises steps of carrying out impact dynamics simulation of foreign object damage on a simulated blade numerical model; obtaining the relation between the macroscopic characteristics of the notch and the foreign object type, the impact speed and the impact angle, determining foreign object damage test conditions on the basis of the relation, carrying out an external simulated object damage test on the simulated blade by using an air cannon, and observing the macroscopic characteristics ofthe impact notch; Taking the static stress and the dynamic stress under the working load at the dangerous position of the front edge of the blade as the initial static load and the dynamic load of thehigh-cycle fatigue test, carrying out the high-cycle fatigue test on the damaged simulated blade, obtaining the high-cycle fatigue strength of the blade through a stepping method, and evaluating theFOD resistance of the blade according to the result of the high-cycle fatigue test; And carrying out foreign object damage simulation and high-cycle fatigue test on a small number of real blades to obtain the high-cycle fatigue strength of the real blades so as to verify the conformity of the simulated blades and the real blade test result.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Loading and testing synthetic experimental device

The present invention discloses a load-applying and test synthetic experiment device. The long steel column, the measured structure model and the short steel column are vertically fixed on the bearing table, the long steel column is arranged with a hole with height corresponding with the measured structural model, the bearing hole at two sides of the hole is installed with a steel axis with sprocket wheel arranged wherein, one end of the steel axis is installed with an encoder connected with the data collecting case, the steel plate is fixed with an upright lifting cylinder and the upper end of the short steel column is arranged with a horizontal extension cylinder, the servo valve is connected with two cylinders and is electrically connected to the controller and the air pump, one end of the chain is connected with the measured structure model through the sprocket wheel and the other end is connected with the weight seat which is arranged with weights, the weight seat is arranged on the right upper side of the vertical lifting cylinder piston and the side surface is arranged at the front side surface of the horizontal extension cylinder piston. The device can be used for the side horizontal static load and the lateral impact dynamic load of the structure and executing the corresponding displacement test.

Owner:ZHEJIANG UNIV

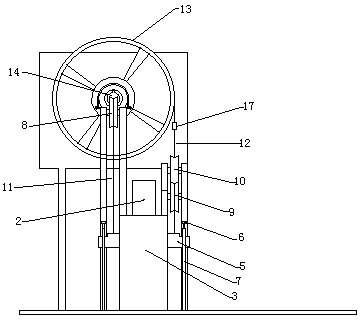

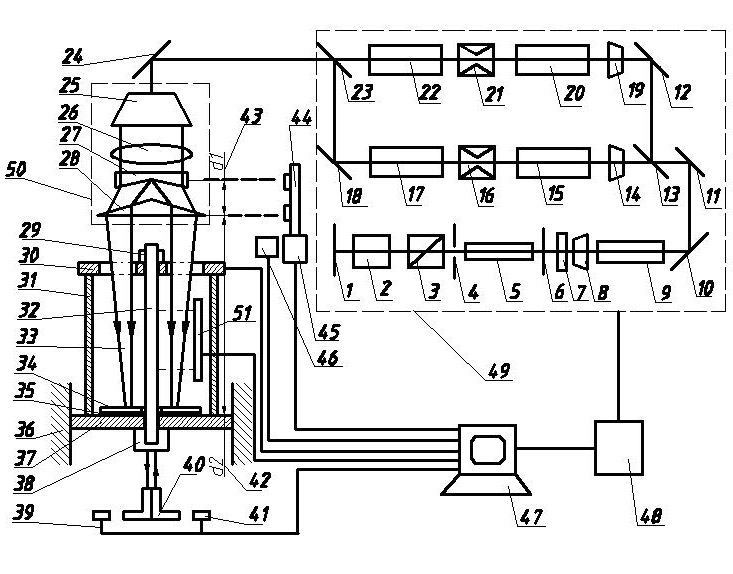

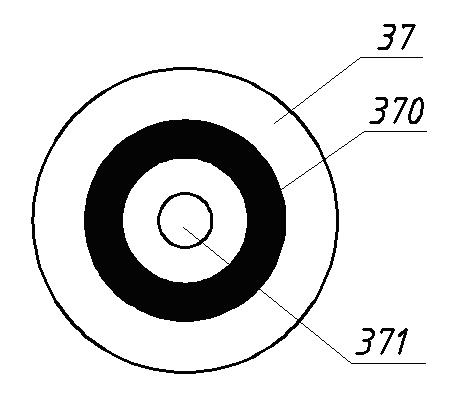

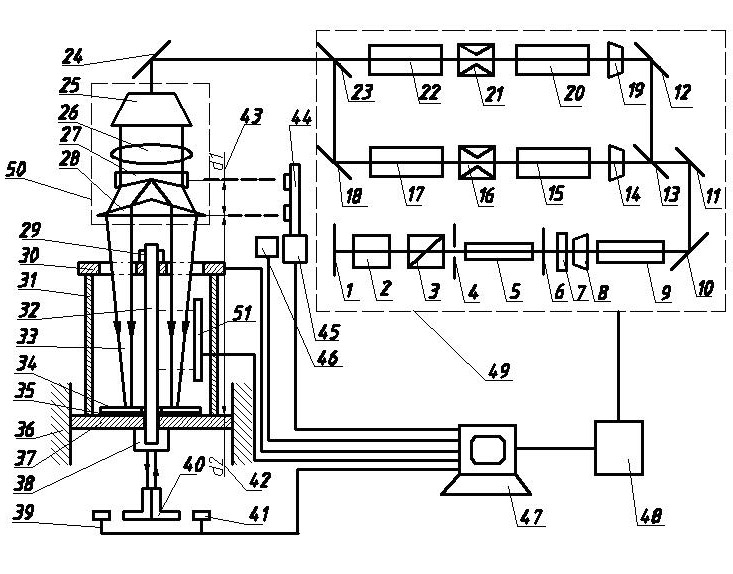

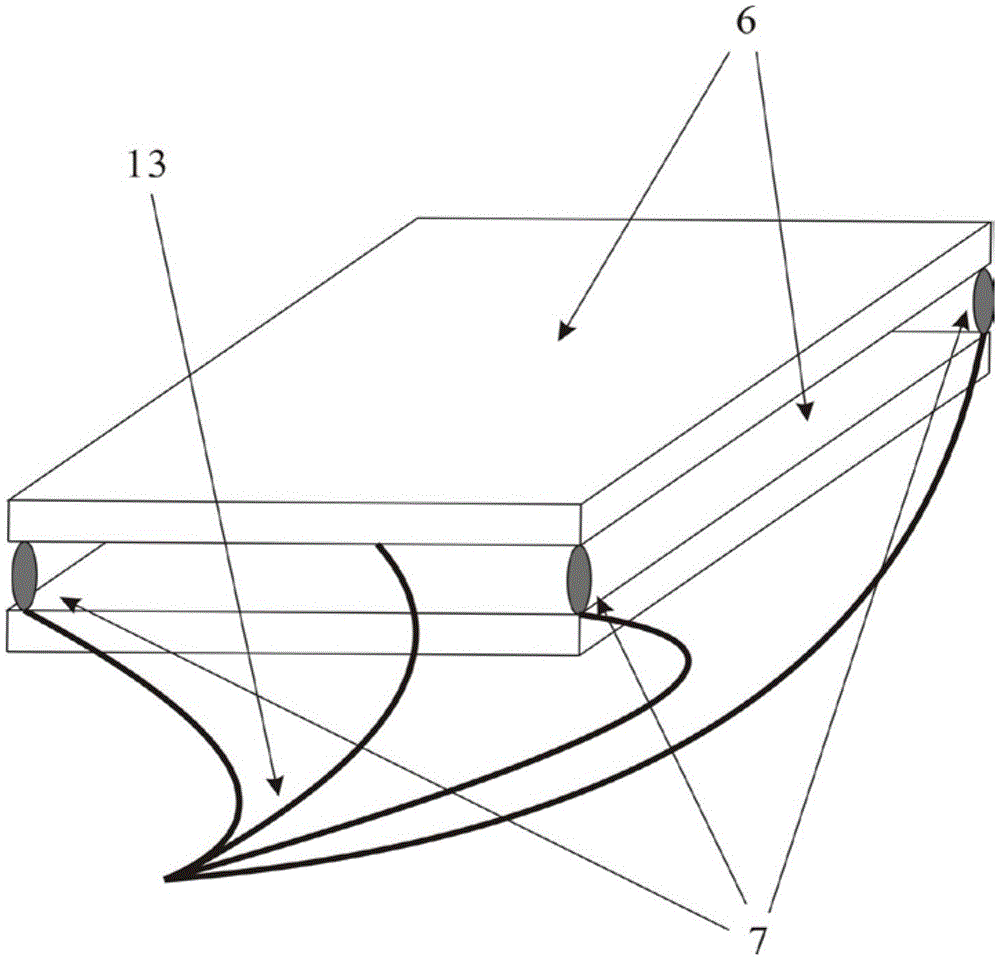

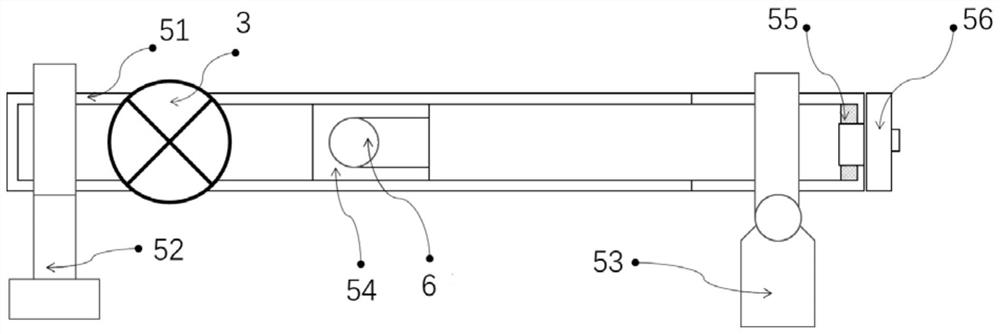

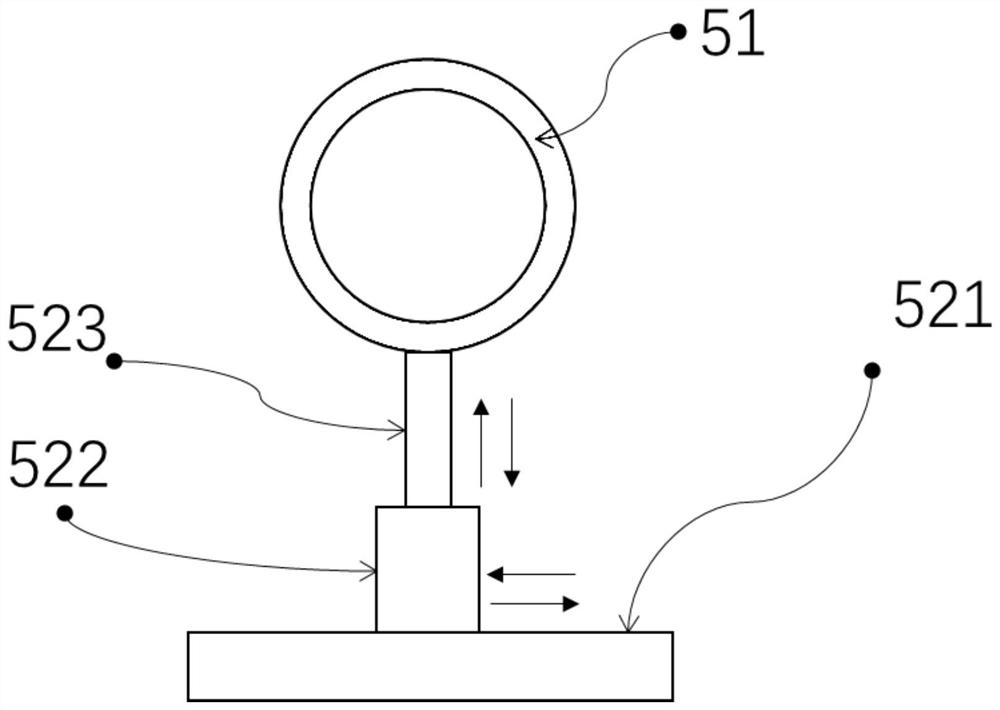

Impact dynamic tension test method and device thereof of ring laser

InactiveCN102072841AEasy clampingThe testing process is simpleStrength propertiesRing laserEngineering

The invention relates to an impact dynamic tension test method and a device thereof of a ring laser, relating to the technical field of dynamic tension mechanics performance test of materials. In the invention, a high power ring pulse laser is adopted to contain a test-piece in a hollow part of a laser beam; and a ring pulse laser gets through the test-piece via the hollow part and impacts a target, so that the test-piece arranged between a bracket and the target acquires instant tension so as to complete the impact dynamic tension test of the test-piece. The method and the device of the invention are used for for measuring dynamic stress strain relation of the materials under ultrahigh strain state, the device has simple structure, simple and convenient test process, and can perform direct dynamic tension test; and the method and the device can perform the dynamic tension test of the materials under the conditions of different high strain rates and ultrahigh strain rates, thereby having low cost and good application prospect.

Owner:JIANGSU UNIV

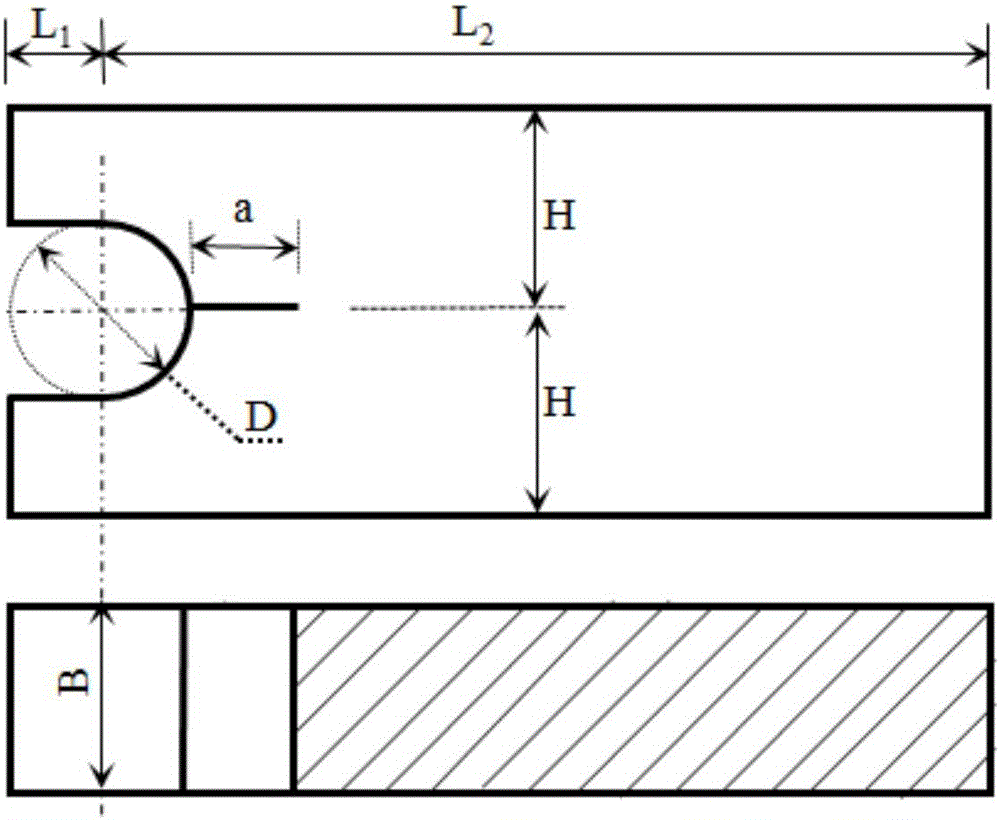

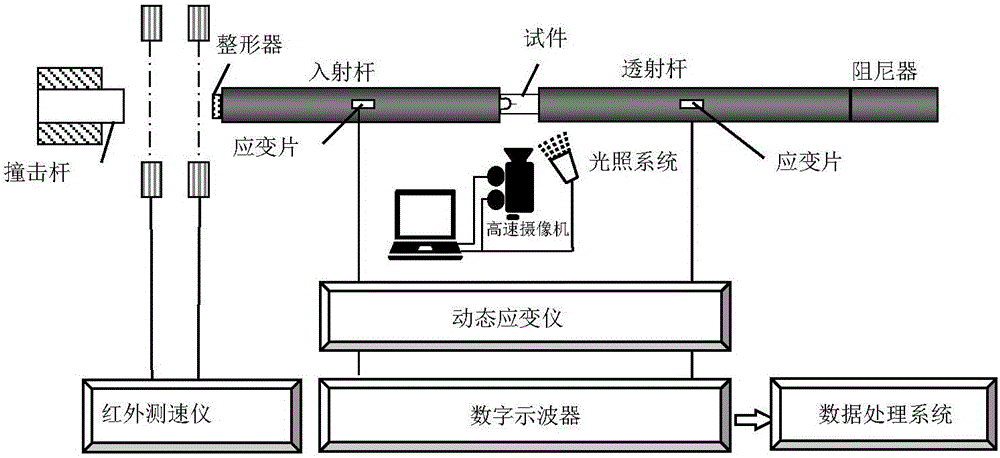

Testing method for dynamic crack arrest toughness of I-type crack under impact load

InactiveCN106290012ASimple methodEasy to operateMaterial strength using single impulsive forceConfiguration designStress intensity factor

The invention discloses a testing method for the dynamic crack arrest toughness of an I-type crack under the impact load, and belongs to the technical field of geotechnical engineering. The method includes the steps of conducting impact test research through a large-diameter separated type Hopkinson pressing rod and a test configuration designed by an inventor, determining the dynamic crack toughness of a sample through an experiment-numerical value method, calculating the load borne by the sample and the moment of crack arrest through strain signals obtained through a test, inputting an obtained time travel curve to a finite element program Ansys, calculating the near-field displacement of a crack tip through a 1 / 4 node unit, obtaining the time travel curve of the I-type dynamic rupture stress strength factor of the sample through a displacement extrapolation method, obtaining the strain strength factor value corresponding to the crack arrest moment as the dynamic crack arrest toughness of the material, and then obtaining the pure I-type crack dynamic crack arrest toughness under the effect of the impact load. The method is simple and convenient to operate and should have more practical application meaning in research of the dynamic crack arrest characteristic of rock under the impact dynamic load.

Owner:SICHUAN UNIV

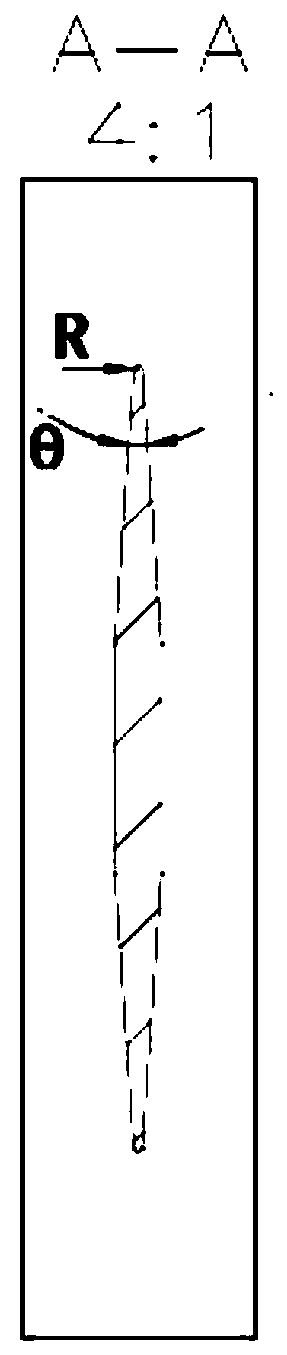

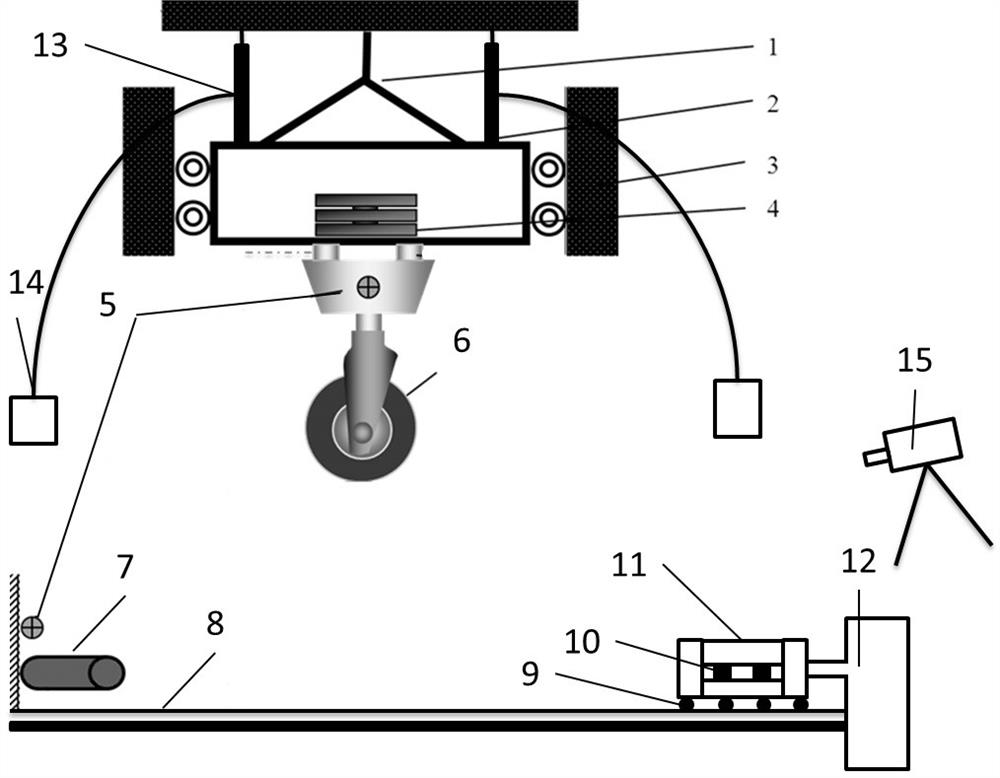

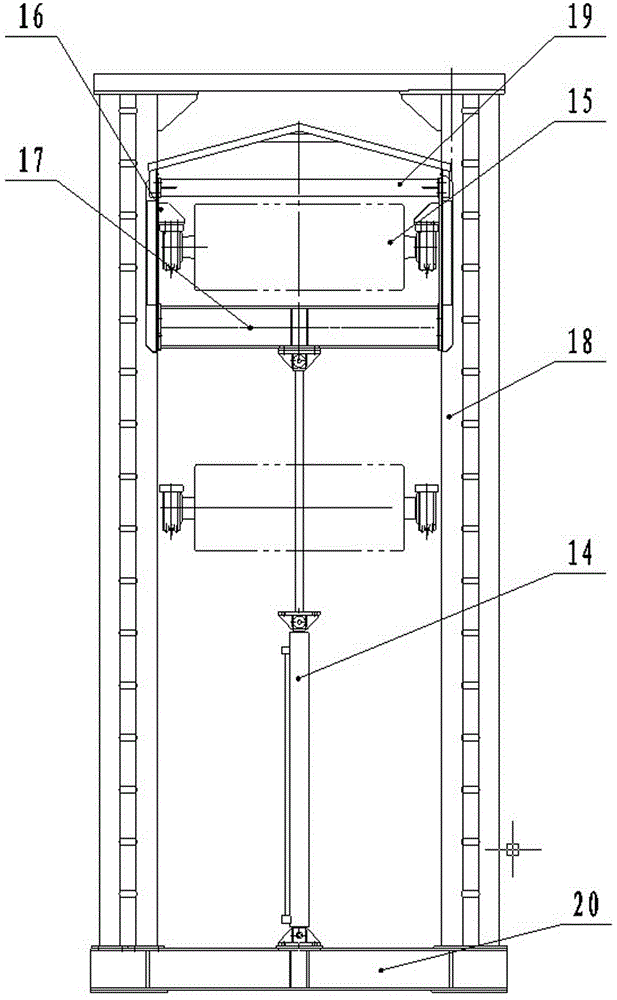

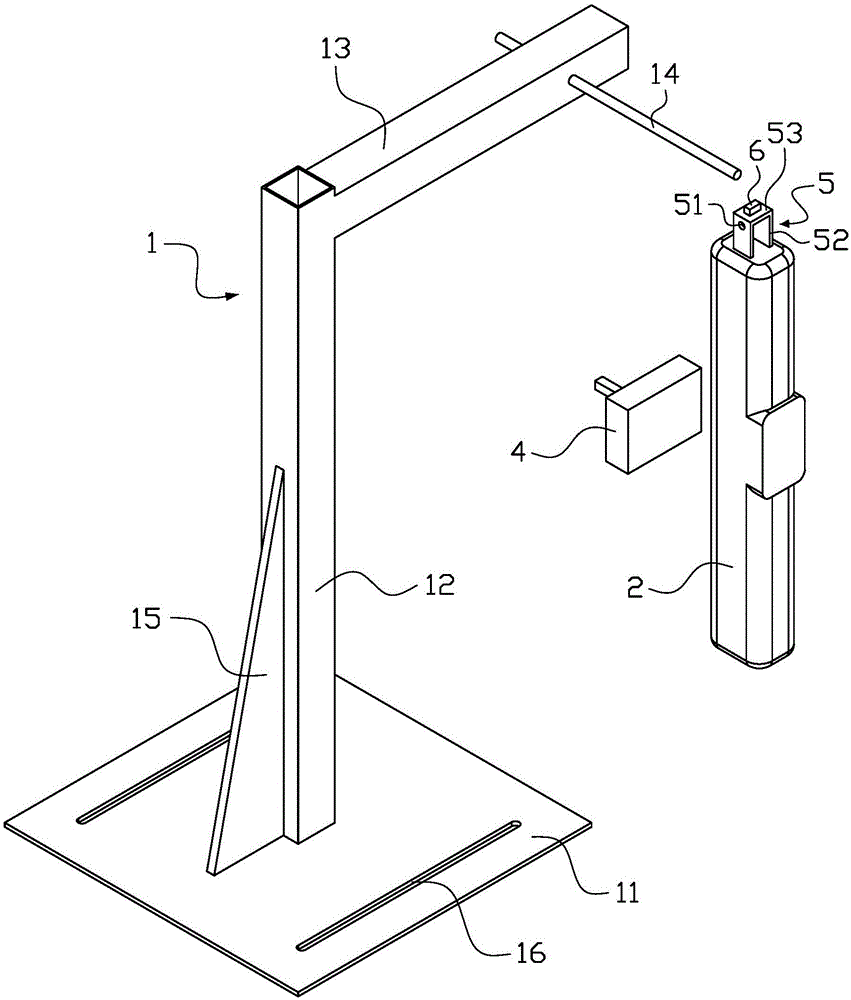

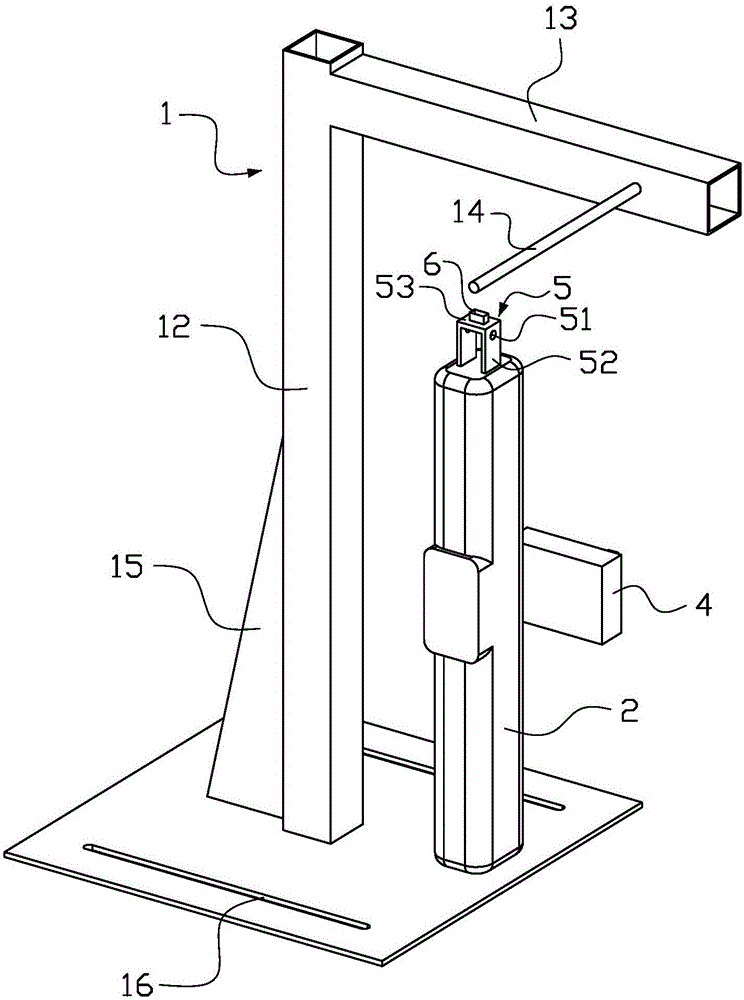

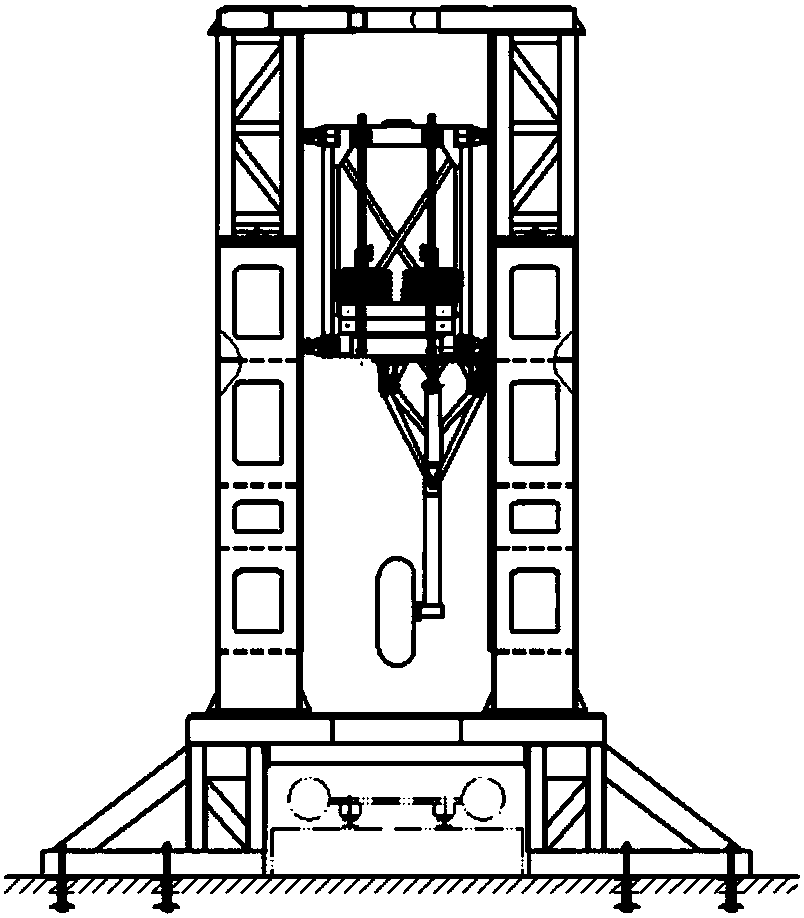

Ground test device for simulating landing impact process of shipboard aircraft landing gear

InactiveCN111929019ASatisfy the requirements of landing impact testAchieve obstructionAircraft components testingShock testingControl systemData acquisition

The invention belongs to the field of impact dynamics, and particularly relates to a ground test device for simulating the landing impact process of a shipboard aircraft landing gear, and the device comprises a hanging basket which is vertically and slidingly arranged among a plurality of experiment table stand columns; a lifting mechanism, the bottom end of which being movably connected to the top end of the hanging basket; an aircraft landing gear which is arranged at the bottom end of the hanging basket; a tackle table track which is horizontally laid on the ground; a tackle table which isslidably arranged on the tackle table rail, and a top plate of the tackle table serving as a tackle force measuring platform; a tackle table propelling device which is used for providing thrust for the tackle table; a release control system which is used for controlling the lifting mechanism and the tackle table propelling device; and a data acquisition system which is used for data acquisition. The ground test device for simulating the landing impact process of the shipboard aircraft landing gear can meet the landing impact test requirements of the shipboard aircraft landing gear, ensures theconsistency of the ground working condition and the actual engineering working condition, can realize simulation tests of arresting, obstacle crossing and the like of the shipboard aircraft on the ground, and has a wide application prospect.

Owner:CHINA AIRPLANT STRENGTH RES INST

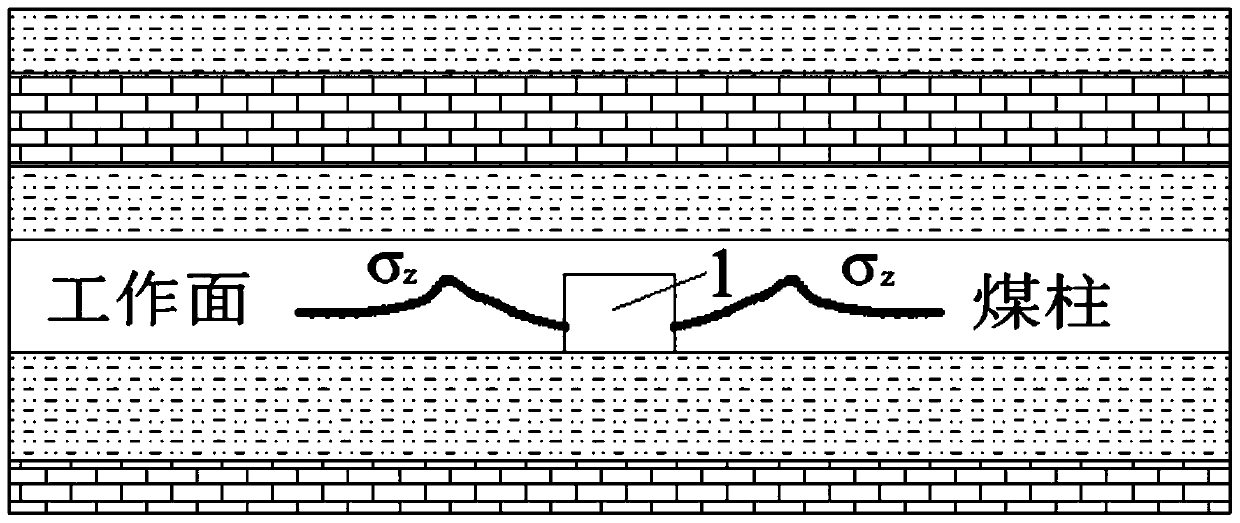

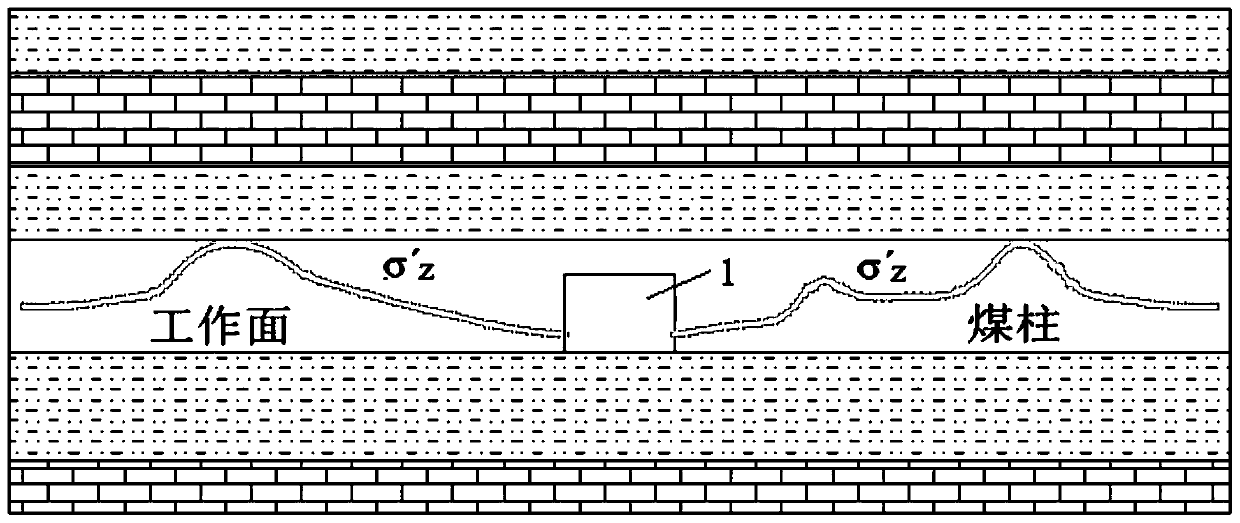

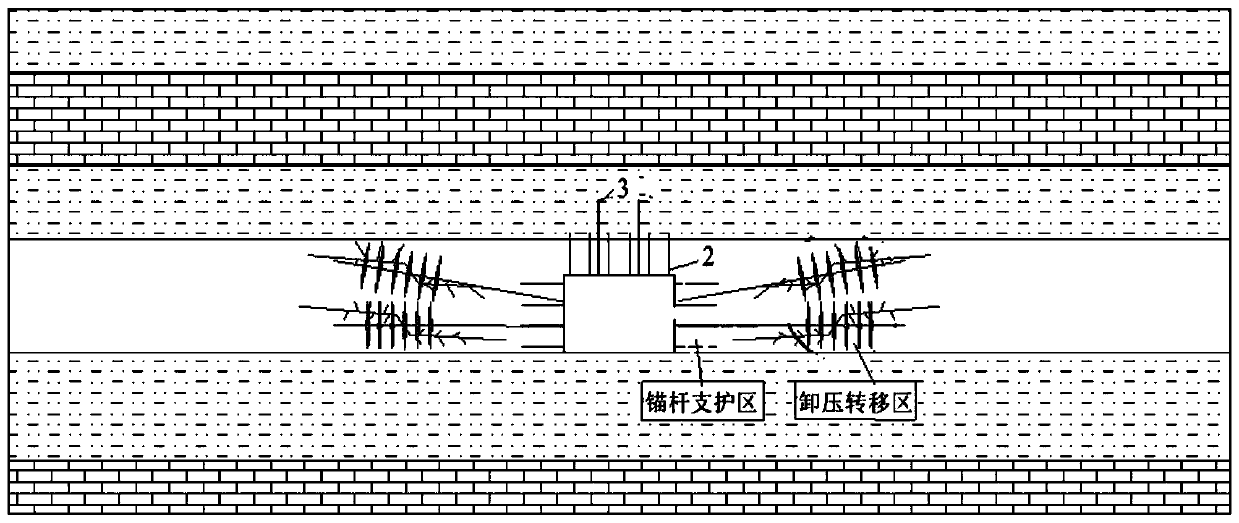

Construction method capable of controlling roadway deformation

ActiveCN110318761AReduce distortionGuaranteed escape spaceUnderground chambersTunnel liningStress concentrationDynamic pressure

The invention relates to the roadway surrounding rock control technology field, in particular to a construction method capable of controlling roadway deformation. The construction method capable of controlling the roadway deformation includes a roadway driftage and dynamic pressure influence preceding stage construction method and a back production constant dynamic pressure influence stage construction method, wherein the roadway driftage and dynamic pressure influence preceding stage construction method includes: drilling holes in a stress concentration area, and forming a pressure release area; and performing anchoring support on a roadway superficial layer surrounding rock area; and the back production constant dynamic pressure influence stage construction method includes: drilling holes in an area far away from the surface of a roadway to form a pressure release area; performing surrounding rock grouting modification on the other area closer to the surface of the roadway than the pressure release area; and performing anchoring support on the roadway superficial layer surrounding rock area. The construction method capable of controlling the roadway deformation enables multiple measures to jointly come into play, reduces influence from an impact dynamic load to the space in the roadway to the utmost, reduces the deformation of the roadway to the utmost, and guarantees a roadway escape space after dynamic disasters occur and reduces quantities of injuries and deaths of personnel on the premise of reducing occurrence rate of risk brought by the dynamic disasters of roadwayimpact ground pressure and the like.

Owner:天地(榆林)开采工程技术有限公司

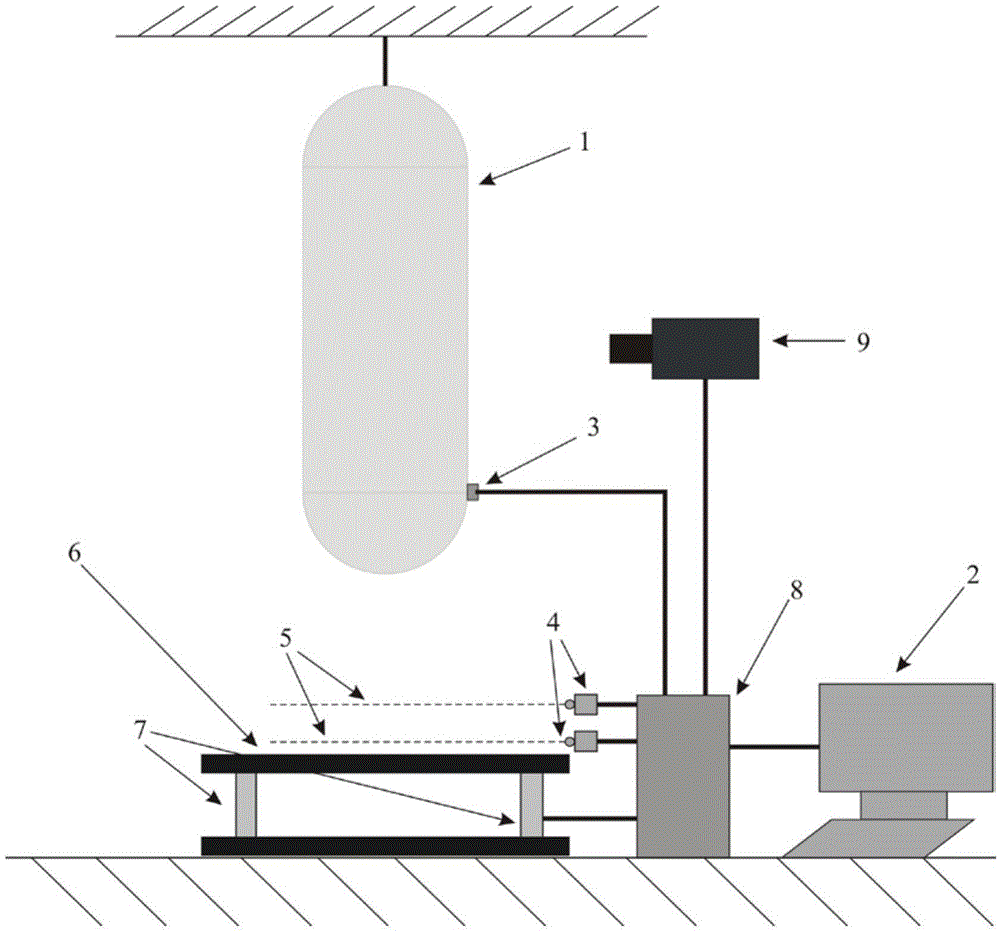

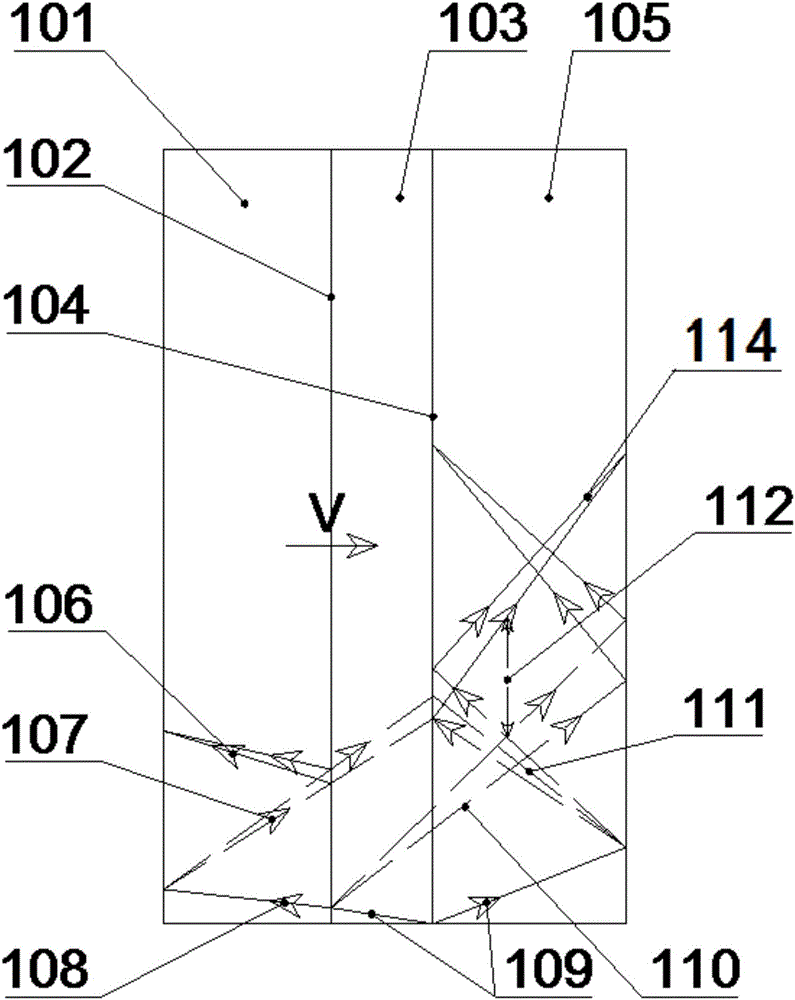

Impact dynamic characteristic test device and test method of inflatable flexible structure

ActiveCN105628321AContinuous adjustment of internal pressureEasy to adjustShock testingData acquisitionImpact velocity

The invention discloses an impact dynamic characteristic test device and test method of an inflatable flexible structure. An impact velocity value of the flexible structure is measured by a photoelectric sensing velocity-measuring system. An impact resultant force-time history curve of an impact process of the flexible structure is measured through a force-measuring platform. An accelerated speed-time history curve of the impact process is measured through an acceleration sensor which is adhered to the flexible structure surface and next to an impact region. An impact deformation process of the flexible structure is recorded by a high speed camera. Photoelectric signals, acceleration signals, and force signals are all transmitted to a data collection analyzer and converted to electronic signals through the data collection analyzer and input to a computer. The computer performs digital-to-analogue conversion on the signals to obtain a whole dynamic characteristic curve of a test object, and records the whole impact deformation process shot by the high speed camera. Thus the impact dynamic characteristic test device and test method of the inflatable flexible structure can provide verification and reference for the impact dynamics numerical simulation of the inflatable flexible structure. The structure device is simple and clear, is convenient to use, and has strong applicability.

Owner:BEIHANG UNIV +2

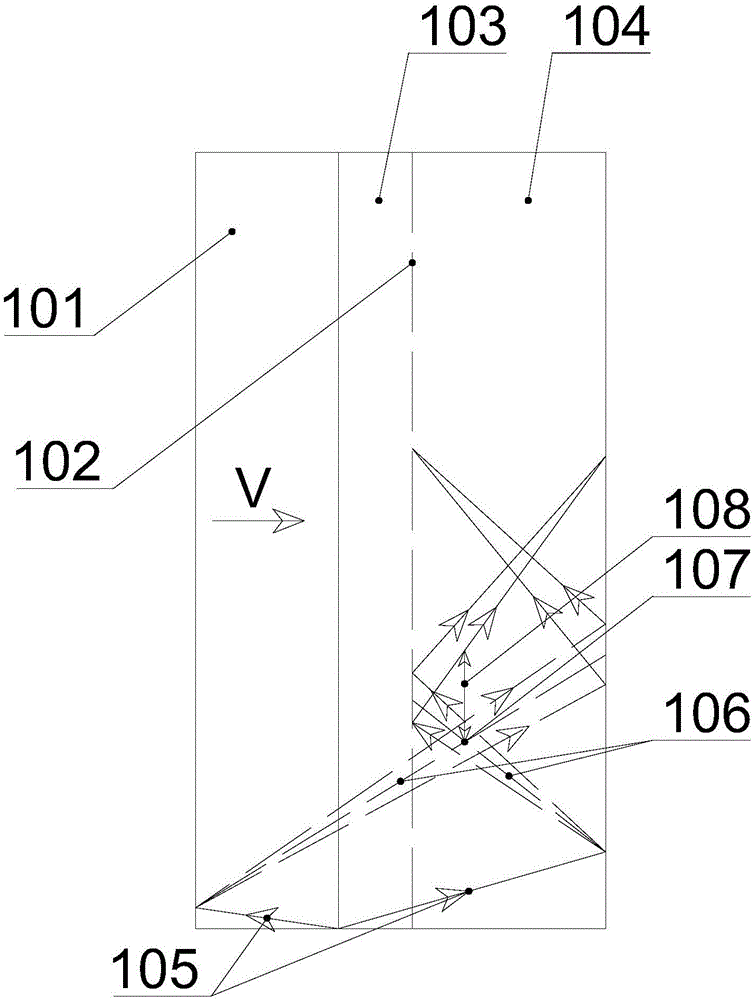

Dynamic damage experimental method based on dynamic tensile strain rate serving as single variable

InactiveCN105954120AClose to the research purposeReduce research difficultyMaterial strength using tensile/compressive forcesMaterial strength using single impulsive forceTensile strainExperimental methods

The invention provides a dynamic damage experimental method based on the dynamic tensile strain rate serving as a single variable, and relates to the field of impact dynamics. The dynamic damage experimental method includes S1, producing a plurality of flying sheets; S2, producing a plurality of sample targets, wherein the thickness difference value between a first sample target body and a second sample target body of each sample target is the same; S3, corresponding the flying sheets to the sample targets one to one to form a plurality of impact experiment groups, wherein the ratios of the thicknesses of the flying sheets in the impact experiment groups to the total thicknesses of the sample target bodies are the same, and the sums of the thicknesses of the flying sheets in the impact experiment groups and the total thicknesses of the sample target bodies are different; S4, performing impact experiments on the impact experiment groups; S5, measuring post-impact data and analyzing results. The dynamic damage experimental method has the advantages that the difficulty in strain rate effect theoretical analysis can be remarkably lowered, and the method is more suitable for research on dynamics processes and rules in the early stage of dynamic strain damage evolution.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

Clamping device of Hopkinson pull bar test-piece and experimental method

ActiveCN105300792AShorten experiment timeEasy to installStrength propertiesShock waveConnection type

The invention discloses a clamping device of a Hopkinson pull bar test-piece and an experimental method and belongs to the field of shock dynamics experiment. The experimental device is used in pairs. One end of an adapter is in threaded connection with an incident bar or transmission bar, and the threaded clearance is filled with thread seal tape so as to avoid the damage of shock wave to connecting thread; and the other end of the adapter is provided with a square groove to be connected to a flat test-piece. The square groove which matches the test-piece undergoes plane machining into tiny serrated teeth so as to increase frictional force during clamping. The outer rim of the adapter is processed into taper thread which matches a nut. When the clamping device is in use, clamping force perpendicular to the groove surface is provided by screwing-in the nut. According to the invention, the problem that screw thread is not easy to process in a composite material and high-strength glue is nonuniform during gluing process can be greatly avoided, connection type of a fibrous composite material under dynamic tension is studied, and a forceful foundation is laid for the constitutive relation of the fibrous composite material under dynamic tension.

Owner:TAIYUAN UNIV OF TECH

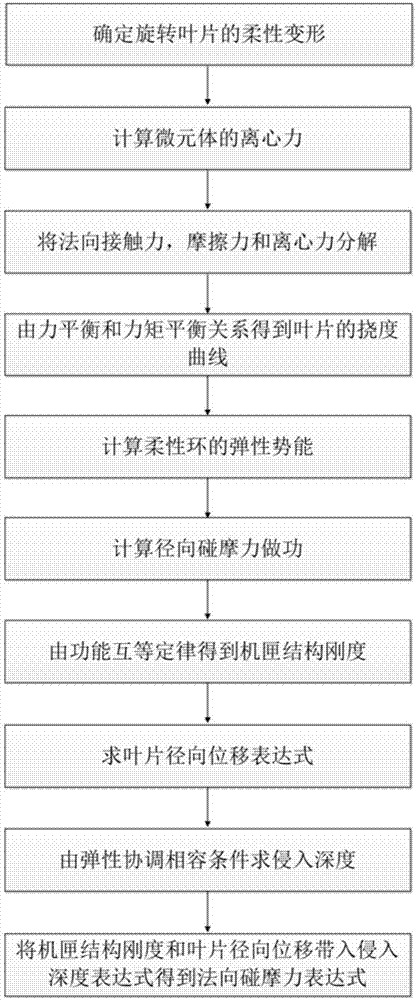

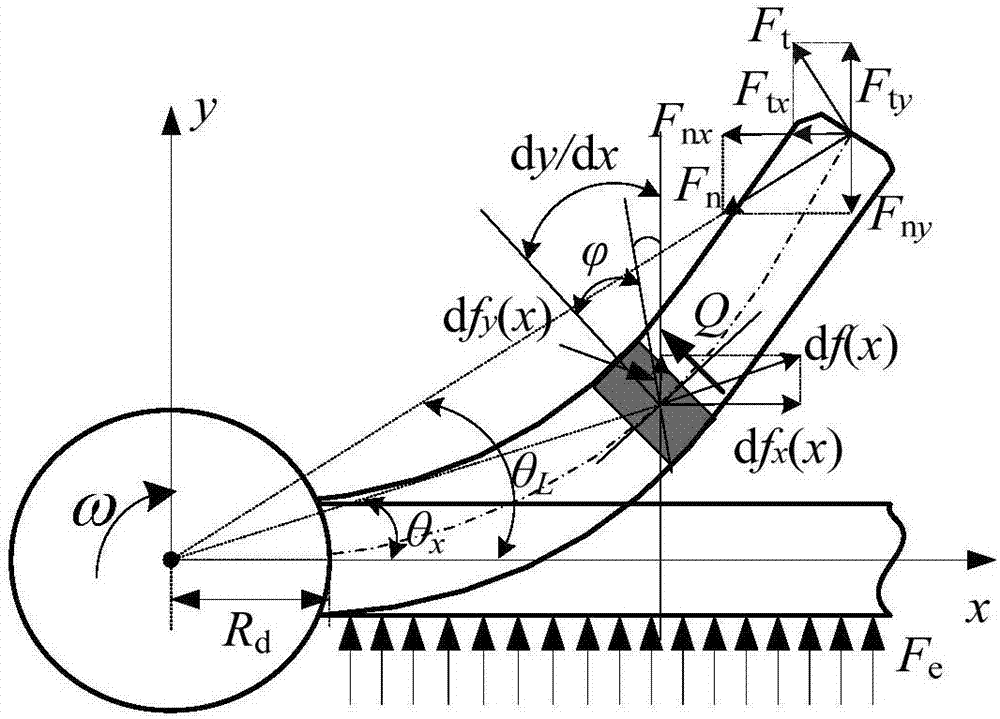

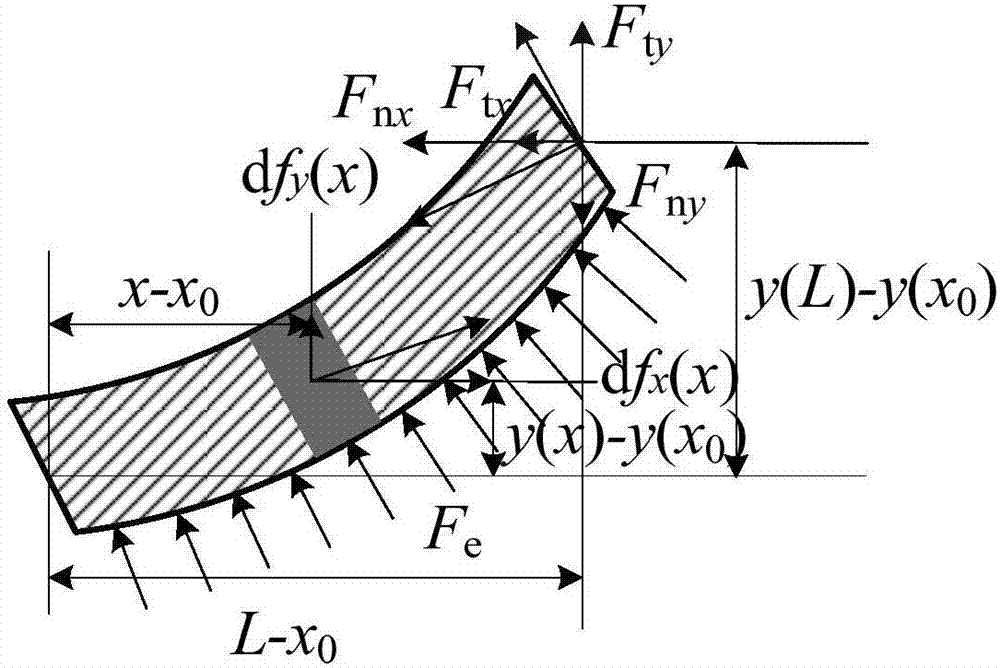

Improved rotating blade-flexible casing rub-impact force determination method

The invention relates to an improved rotating blade-flexible casing rub-impact force determination method, and belongs to the field of blade-casing system rub-impact dynamics modeling. The method is characterized in that centrifugal rigidifying, rotary softening, a Coriolis force effect and a rub-impact softening effect, which is caused by rub-impact with a casing, of a blade are considered, a flexible ring with spring supporting is used at the same time to simulate the casing, and overall and local deformation generated by the rub-impact can be considered. In addition, the invention also establishes a new rub-impact force characterization model of the blade-casing rub-impact. According to the method, influences of parameters such as a casing radius and thickness on a blade-casing rub-impact force can be reflected, and an actual blade-casing rub-impact mechanism can be more actually portrayed. Compared with using the traditional finite-element analysis, the method has the higher computational efficiency and precision. In addition, according to the method, test costs can also be greatly reduced, and reference is provided for designing of a blade-casing system structure to improve the performance and the safety of a system.

Owner:NORTHEASTERN UNIV

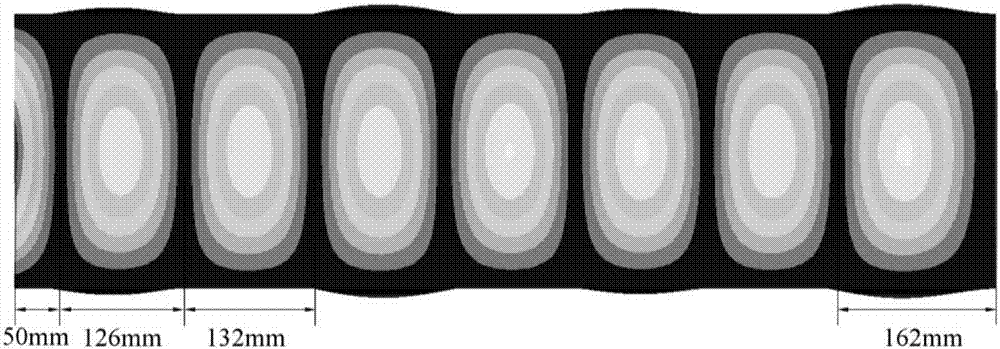

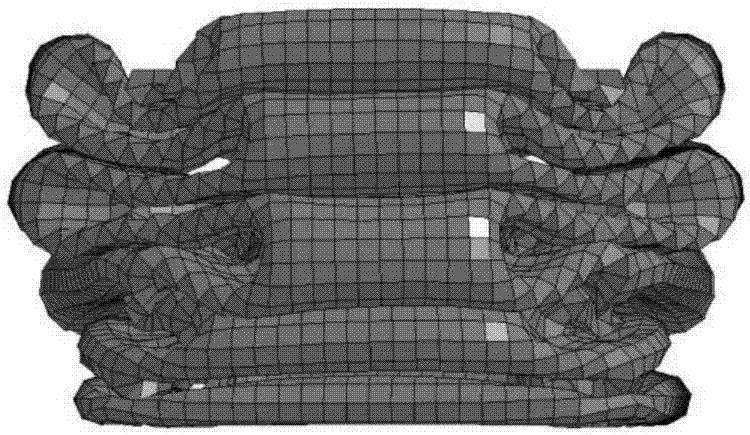

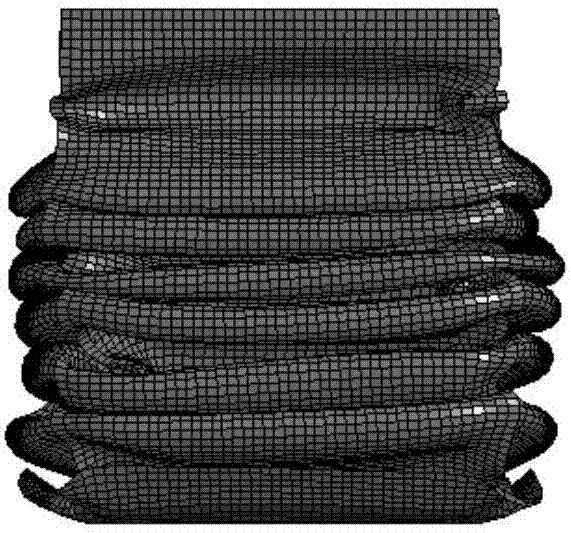

Active control method for inducting thin-walled pipe fitting to absorb energy

ActiveCN107451347AImprove energy absorptionConstant cushioning forceDesign optimisation/simulationSpecial data processing applicationsElement modelEnergy absorption

The invention relates to the technical field of structure modal analysis, and discloses an active control method for inducting a thin-walled pipe fitting to absorb energy in order to improve the energy-absorbing capability of an energy-absorbing structure and ensure a stable deformation mode. The active control method comprises acquiring a structure parameter of a thin-walled square pipe to be analyzed; predicting the number of telescoping buckling wrinkles of the thin-walled square pipe under the action of an impact load according to the structure parameter, and calculating the mean force of the thin-walled square pipe when the thin-walled square pipe generates telescoping deformation, the half wave length of an effective plastic hinge and original energy absorption; establishing a finite element model of the thin-walled square pipe, carrying out finite element modal analysis on the thin-walled square pipe, and determining the number of additionally-installed separator plates according to a convergence formula of the number of the additionally-installed separator plates and expected energy absorption; then respectively arranging the additionally-installed separator plates on corresponding vibration mode nodes of a vibration mode graph of a selected higher-order sine buckling mode; establishing a square pipe impact dynamics simulation calculation mechanical model for the improved structure with the additionally-installed separator plates, carrying out simulation analysis, and comparing the previous energy-absorbing characteristic with the optimized energy-absorbing characteristic.

Owner:CENT SOUTH UNIV

Avoidance buffering energy-absorbing anti-impact anchor rod

ActiveCN108119175ASimple structureWith constant resistance performanceAnchoring boltsSupporting systemRing block

The invention discloses an avoidance buffering energy-absorbing anti-impact anchor rod. The anchor rod includes a rod body, a tray, a constant resistance device and a nut; the right end of the rod body is provided with an external thread block, an external block is arranged on the external thread block, the external thread block and the rod body adopt integrated manufacture, the center of the trayis provided with a rod body installation hole, the rod body passes through the installation hole formed at the center of the tray, and the right end of the external thread block is provided with thenut; the constant resistance device is arranged between the tray and the nut and has a thin-wall circular tube structure, the middle of the constant resistance device is penetrated, and the rod body is sleeved with the constant resistance device. The nut includes a circular truncated cone block, a circular ring block and a square block, and the left side of the circular truncated cone block is inserted into an inner hole of the constant resistance device. The avoidance buffering energy-absorbing anti-impact anchor rod can adapt to the destroying characteristic that surrounding rock rapidly deforms in the impacting process, release and conversion of impact energy can be effectively guided and controlled, high energy is consumed in the avoidance buffering process, the influence of impact dynamic load can be effectively avoided, and the stability of the surrounding rock and a support system in a tunnel is ensured.

Owner:LIAONING TECHNICAL UNIVERSITY

Discrete source distributed impact test device and method

PendingCN113465862AImplement impact assessmentFlexible adjustmentAircraft components testingShock testingEngineeringAtmospheric sciences

Owner:CHINA AIRPLANT STRENGTH RES INST

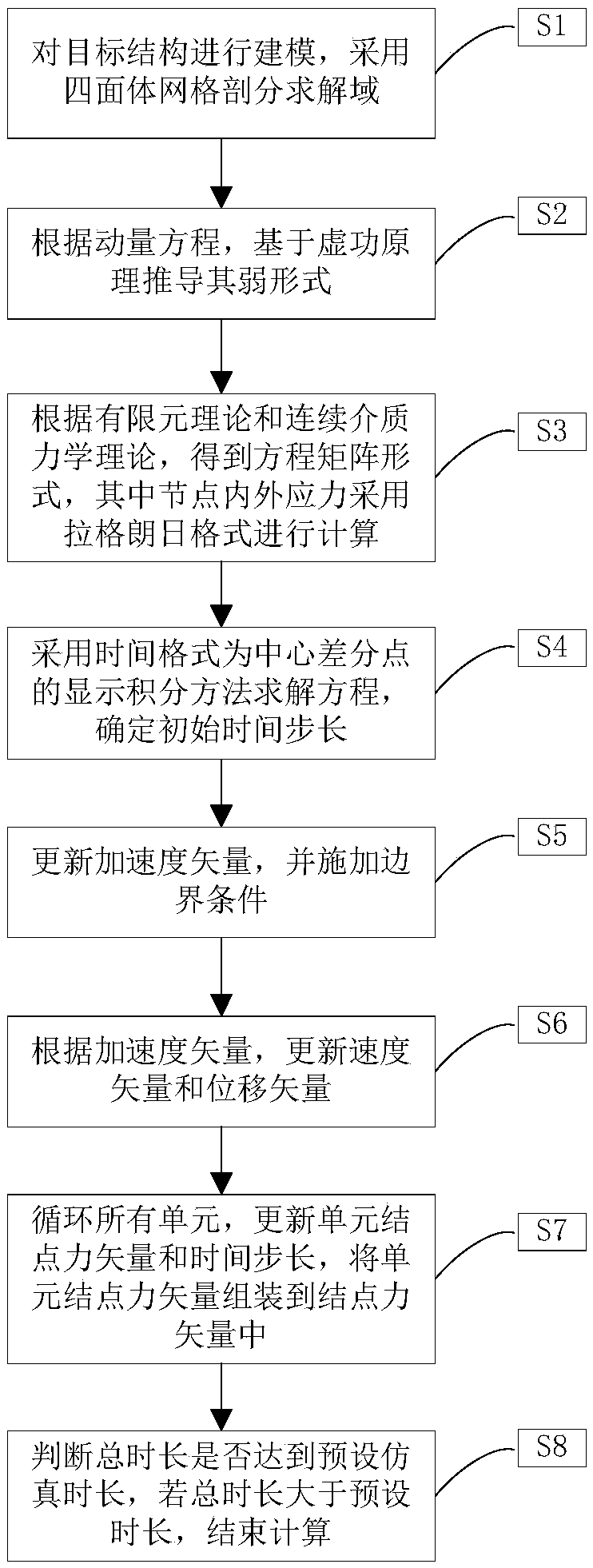

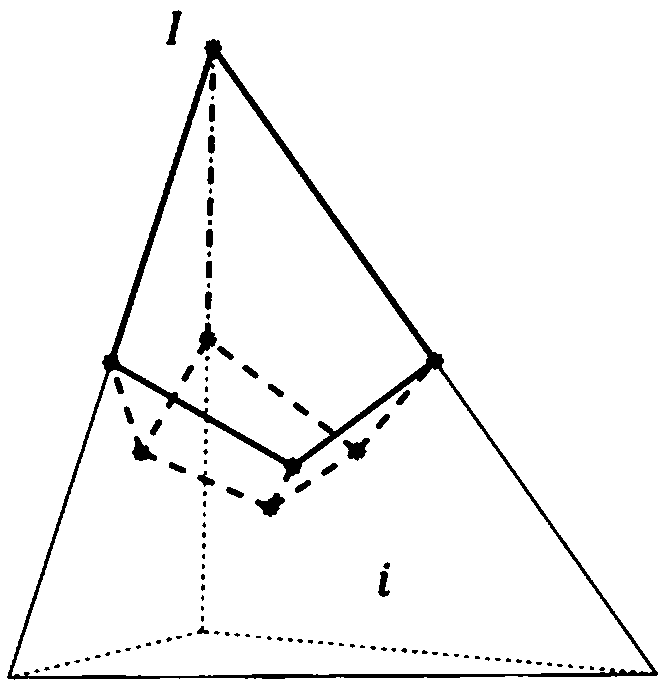

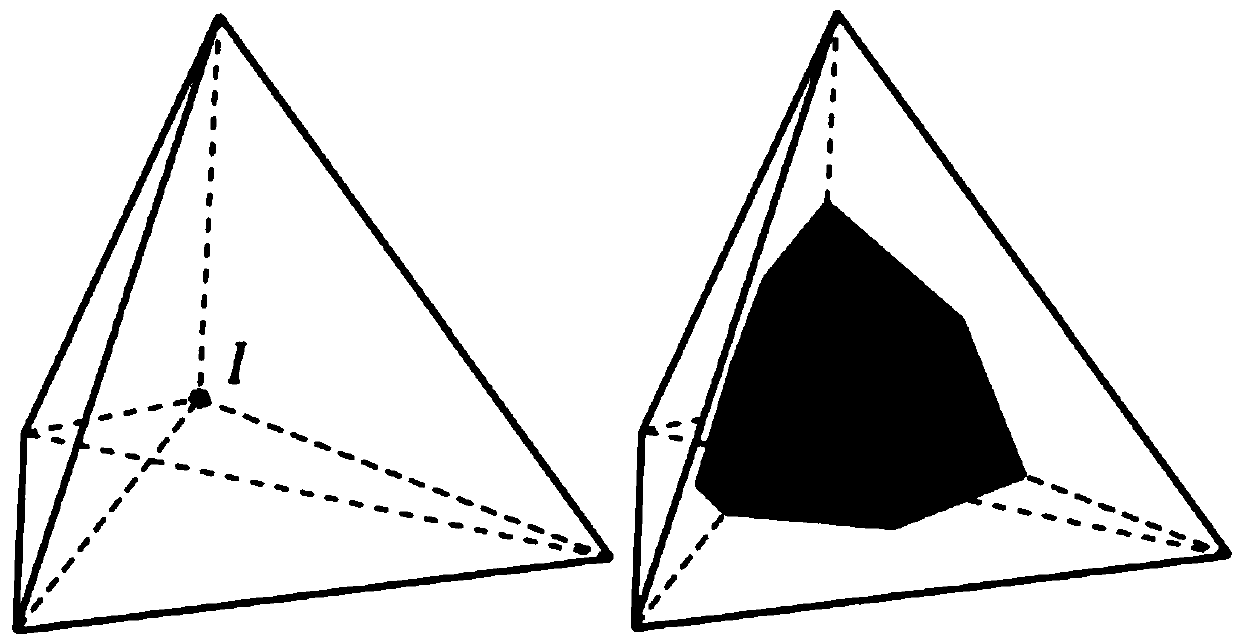

Impact response simulation analog method based on novel hybrid stress tetrahedron unit

ActiveCN108694280AFit closelyHigh precisionDesign optimisation/simulationSpecial data processing applicationsComputational mechanicsBest fitting

The invention provides an impact response simulation analog method based on a novel hybrid stress tetrahedron unit, and belongs to the field of computational mechanics. When the method solves an impact dynamics problem, the good fitting of a tetrahedron grid for a complex structure is kept, meanwhile, the accuracy of a stress field is improved, and the method is an explicit dynamics numerical value calculation method with good stability. Meanwhile, on the basis of a traditional tetrahedron unit, knot stress is subjected to smoothing, the complex model can be subjected to favorable fitting, inaddition, unit stress accuracy is greatly improved, and meanwhile, a calculated amount is small.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

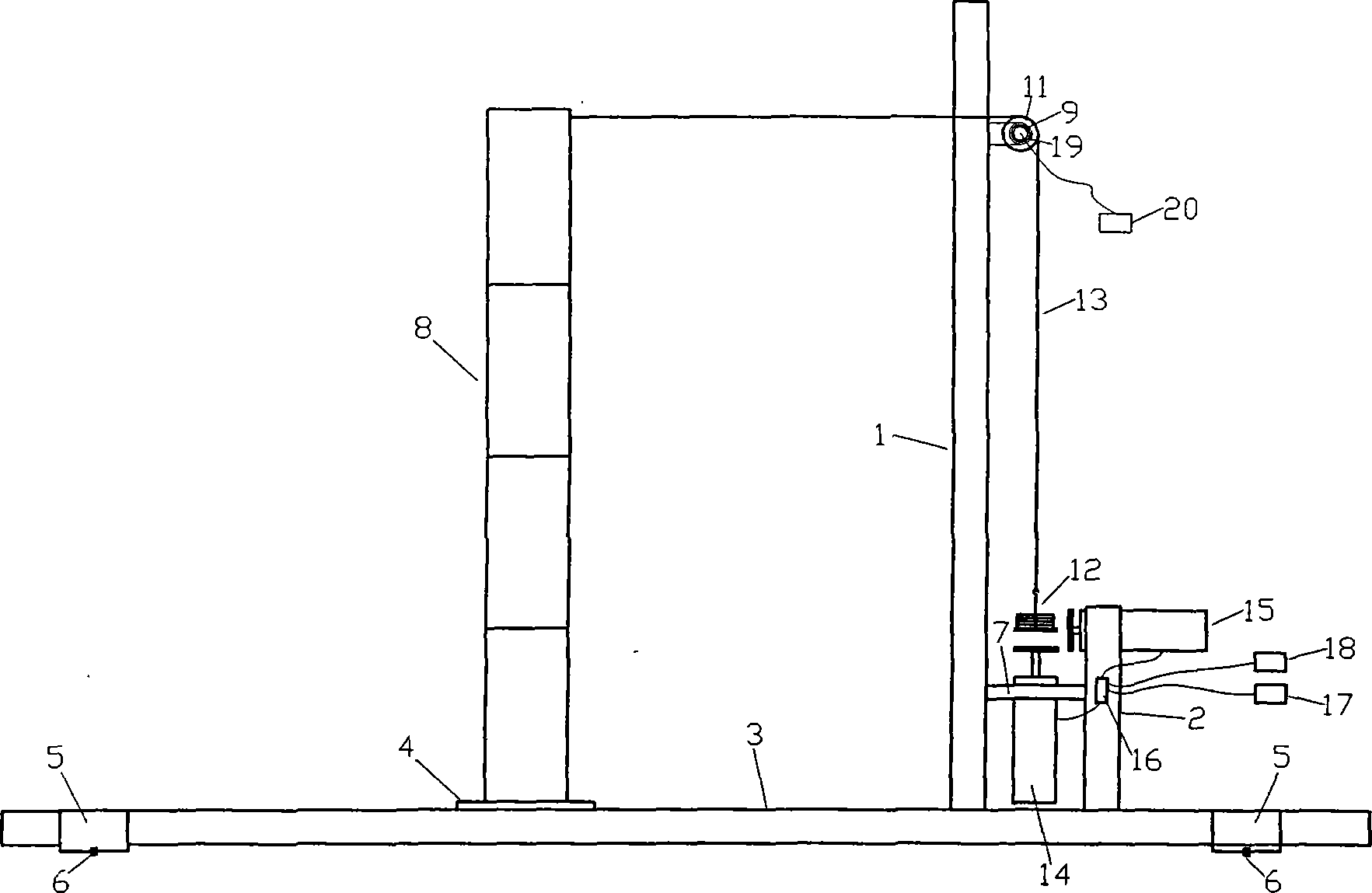

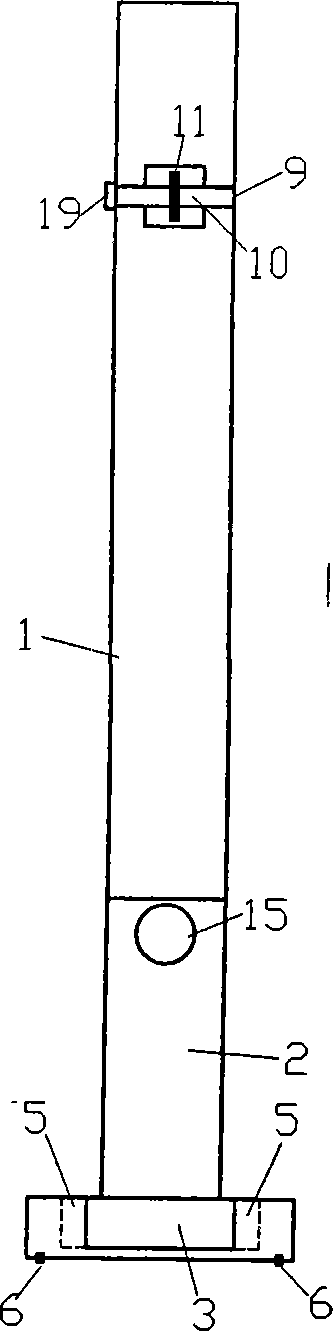

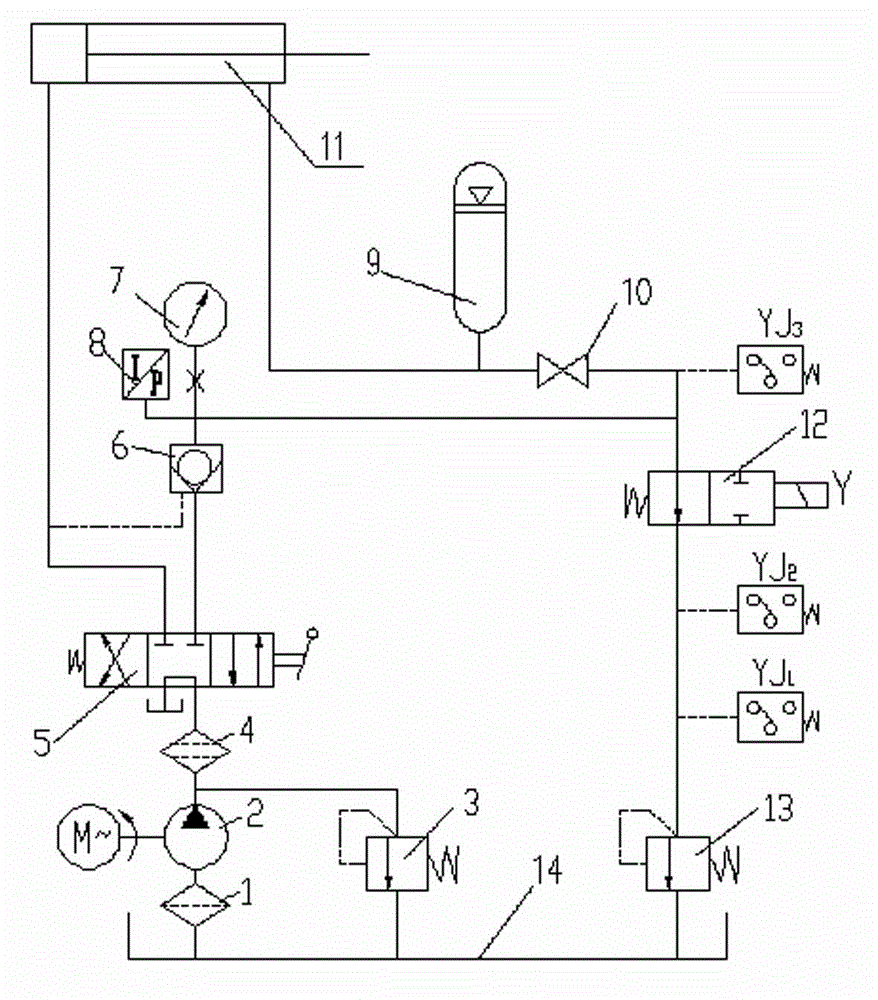

Vertical hydraulic tensioning device of round pipe belt conveyer

The invention belongs to the technical field of vertical tensioning devices of round pipe belt conveyers, in particular to a vertical hydraulic tensioning device of a round pipe belt conveyer, and provides a device for randomly adjusting tension according to the tension requirement of the round pipe belt conveyer. The vertical hydraulic tensioning device comprises a tensioning drum, guide rods and a tensioning oil cylinder; the tensioning drum is rotationally arranged in an integrated framework; each of two sides of the integrated framework is provided with a guide groove structure capable of sliding along each of the two guide rods; the bottom of the integrated framework is hinged with a piston rod end of the tensioning oil cylinder; and a rod cavity of the tensioning oil cylinder is connected with a hydraulic station through an energy accumulator. The vertical hydraulic tensioning device has the advantages that starting tension and normal operating tension can be randomly adjusted according to the tension requirement of the conveyer; and the device is quick in response and effectively realizes dynamic tensioning of the conveyer. The impacting dynamic load when the belt conveyer is started is reduced, so that the belt conveyer is started stably and reliably; the device is compact in structure and small in installation space; and remote control of the tensioning device can be realized.

Owner:太重集团向明智能装备股份有限公司

Experiment method taking dynamic tensile stress amplitude value as variable and impact experiment device

InactiveCN105784512AIndividual change controlEliminate distractionsPreparing sample for investigationStrength propertiesClassical mechanicsDynamic stretching

The invention provides an experiment method taking a dynamic tensile stress amplitude value as a variable and an impact experiment device and relates to the field of impact dynamics. The experiment method taking the dynamic tensile stress amplitude value as the variable comprises the following steps: S1. preparing a plurality of sample targets; S2. preparing a plurality of flying plate groups, wherein each flying plate group comprises a first flying plate layer and a second flying plate layer which is collided with the corresponding sample target; the first flying plate layers are fitted with the second flying plate layers and the resistance of each first flying plate layer is smaller than that of each second flying plate layer; S3. forming an impact experiment group by corresponding each flying plate group to one sample target; and S4. carrying out a collision experiment on each impact experiment group. In an experiment, experiment data of spallation caused by the single variable, which is controlled by the change of the dynamic tensile stress amplitude value, is only acquired, and the difficulty of theoretical analysis of a tensile stress amplitude value effect can be remarkably reduced. The invention further provides the impact experiment device.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

High-stress impact burst roadway anchor rod, design method and work method

ActiveCN110578542AImprove adaptabilityIncrease anchoring forceSpecial data processing applicationsBulkheads/pilesEngineeringHigh stress

The invention provides a high-stress impact burst roadway anchor rod, a design method and a work method. The anchor rod is suitable for being used under a coal mine. The anchor rod comprises a joint-like anchor rod body, an anchor rod tail lock, a force transmitting tray and a sleeve. Protrusions are arranged on the joint-like anchor rod body at intervals. A thread is arranged at the tail end of the joint-like anchor rod body. The force transmitting tray and the anchor rod tail lock are sequentially arranged on the thread. The sleeve is arranged outside the joint-like anchor rod body. A metalpipe provided with a penetration seam in the axial direction is adopted as the sleeve. A fine thread is arranged on the outer side of the metal pipe. An inner concave structure matched with the protrusions on the joint-like anchor rod body is arranged in the metal pipe. The anchor rod has the advantages that anchoring force is high, pre-tightening force is high, and the overall anchoring effect isnot influenced by local breakage, and the anchor rod can effectively avoid the problems that the anchoring condition of a current common anchor rod is rigorous, the whole loses efficacy easily due tolocal breakage, the allowable deformation amount is small, and the anchor rod cannot adapt to high stress, large deformation, strong impact dynamic pressure and rock crushing engineering environments.

Owner:CHINA UNIV OF MINING & TECH

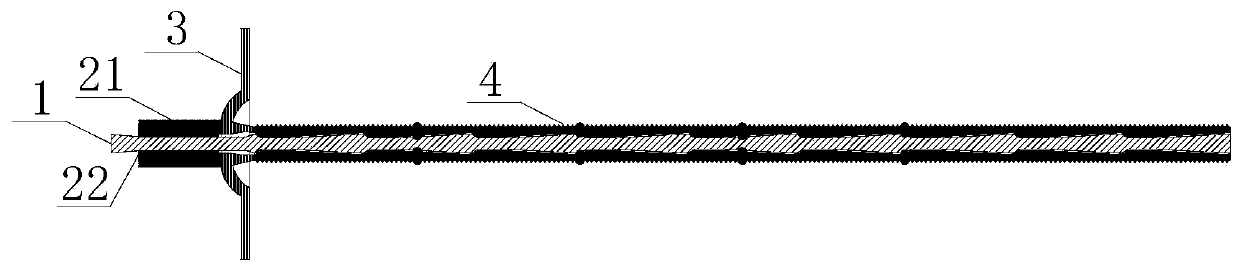

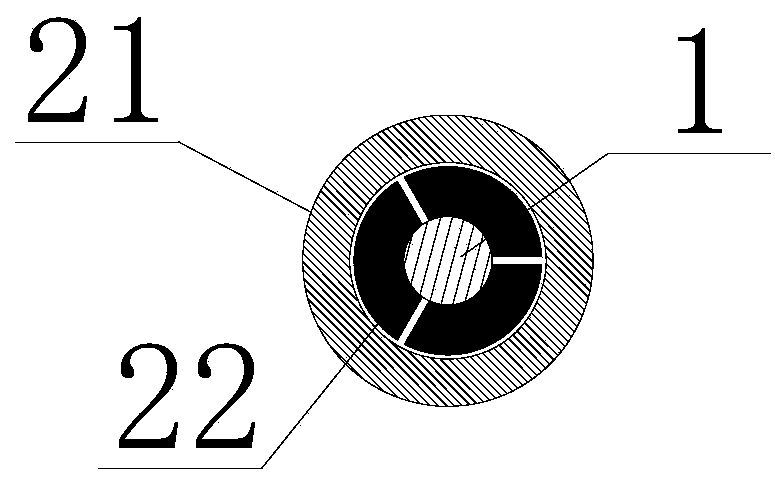

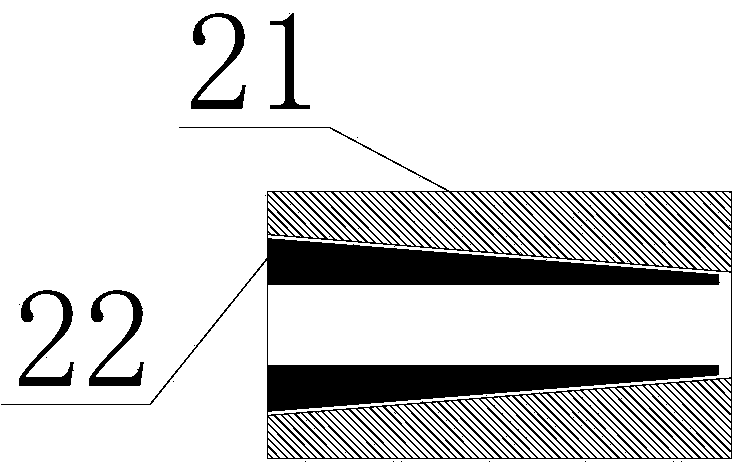

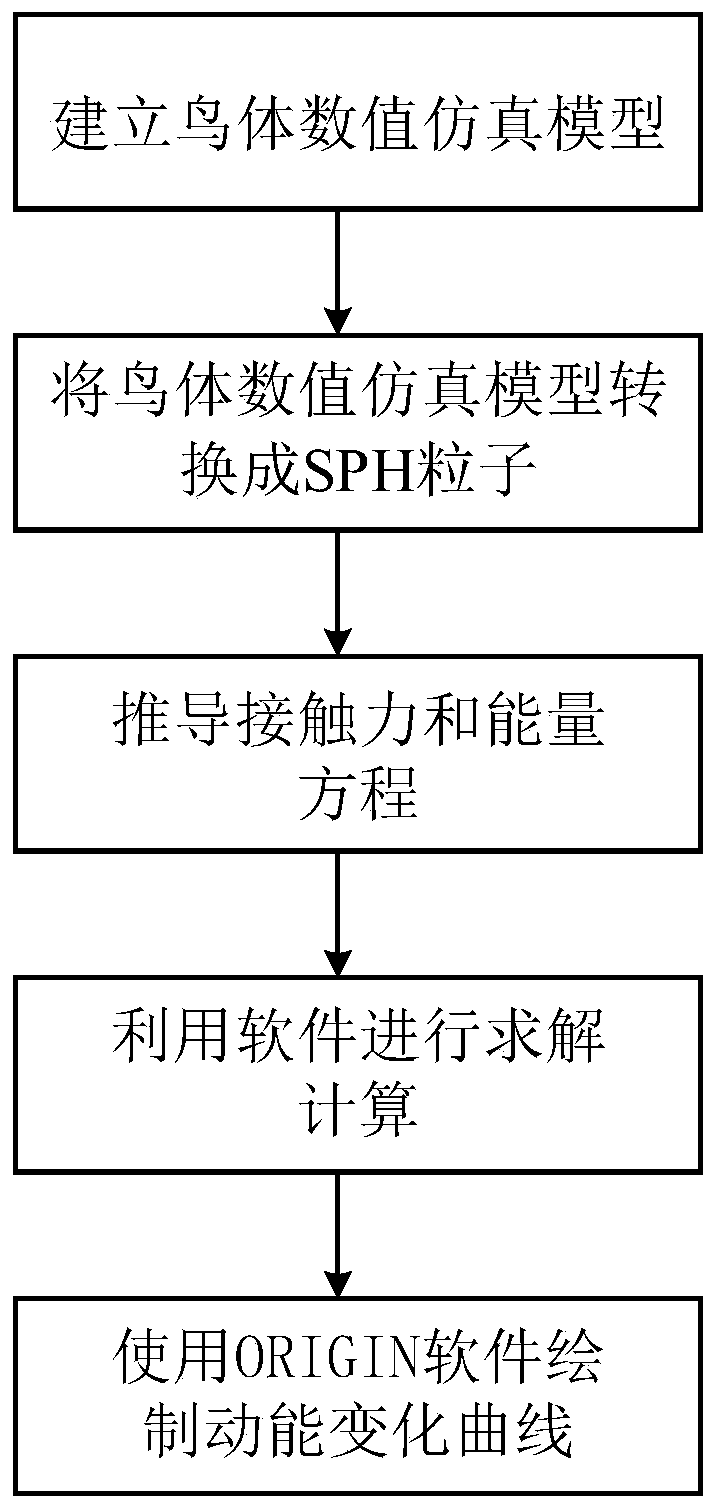

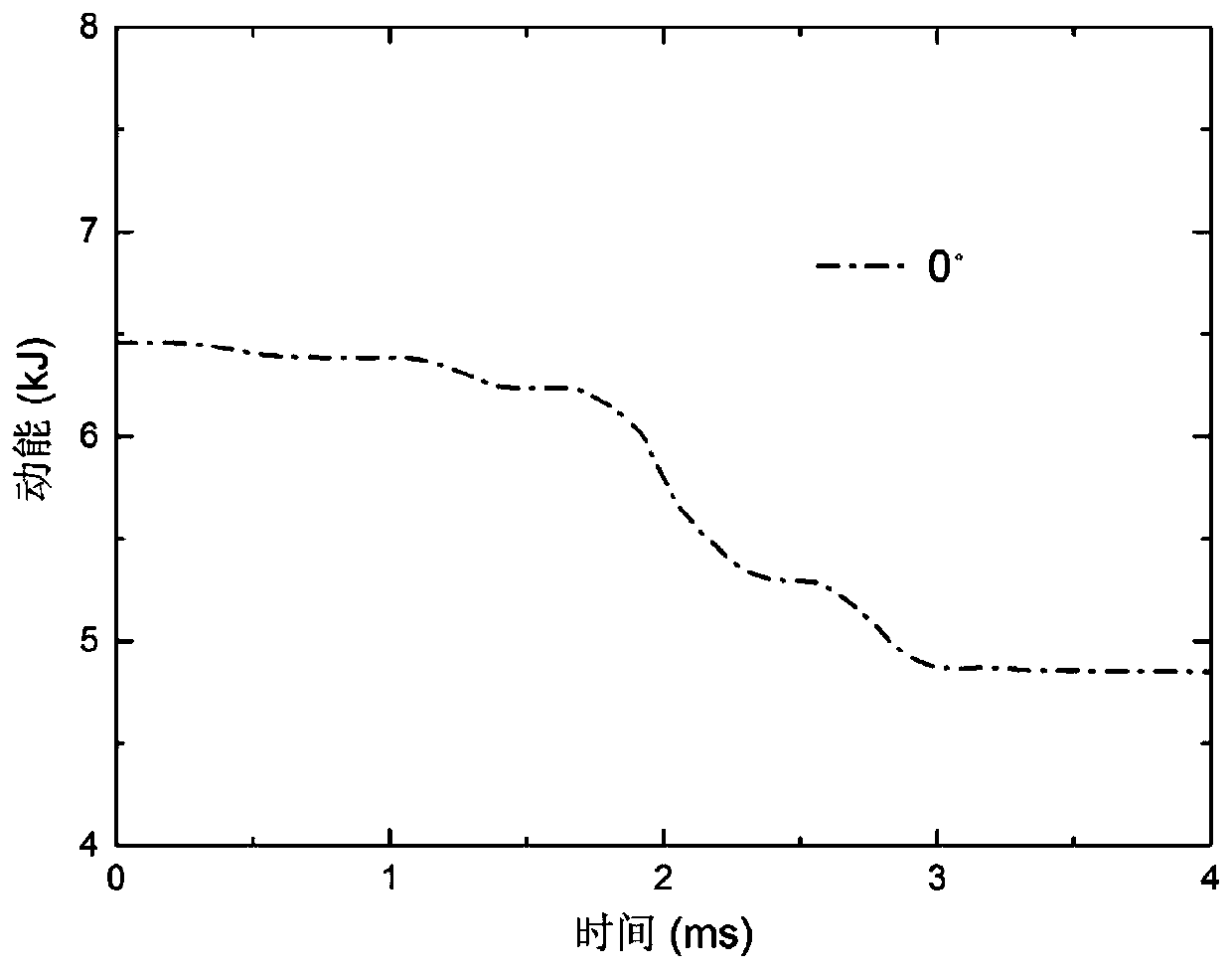

A method of calculating bird strike high speed rotation engine blade

The invention relates to a numerical simulation method for calculating response of bird strike on an engine blade. Based on a smooth particle method (Smoothed Particle Hydrodynamics SPH) and a finiteelement method (Finite Element Method FEM), a numerical simulation model considering the impact environment factor influence of the bird body attitude angle is established, and dynamic response simulation is carried out under the model. In addition, technicians in the field can more simply modify different parameters for research in the bird impact dynamics response research process, and a reference basis is provided for research on the design and optimization of the aero-engine structure.

Owner:NANJING UNIV OF SCI & TECH

Flexible-leg reverse-impact dynamic calibration device and test method

The invention provides a flexible leg reverse impact dynamic calibration device, which includes a flexible leg suspension device, a flexible leg, a launch system and an impact block, the flexible leg is vertically suspended on the flexible leg suspension device, and the launch system is used to launch the impact block and make The impact block with specified mass hits the predetermined impact point of the flexible leg head-on at a specified speed level, and the flexible leg can break away from the flexible leg suspension device and fly freely within a certain period of time after the impact. Further, the present invention also provides a flexible leg reverse impact dynamic calibration test method, which uses the flexible leg reverse impact dynamic calibration device as described above to perform the test, which includes the following steps: vertically hang the flexible leg on the flexible leg Suspension device; make the launch system horizontal and facing the predetermined impact point of the flexible leg; start the launch system to make the impact block hit the predetermined impact point of the flexible leg horizontally at a prescribed speed.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

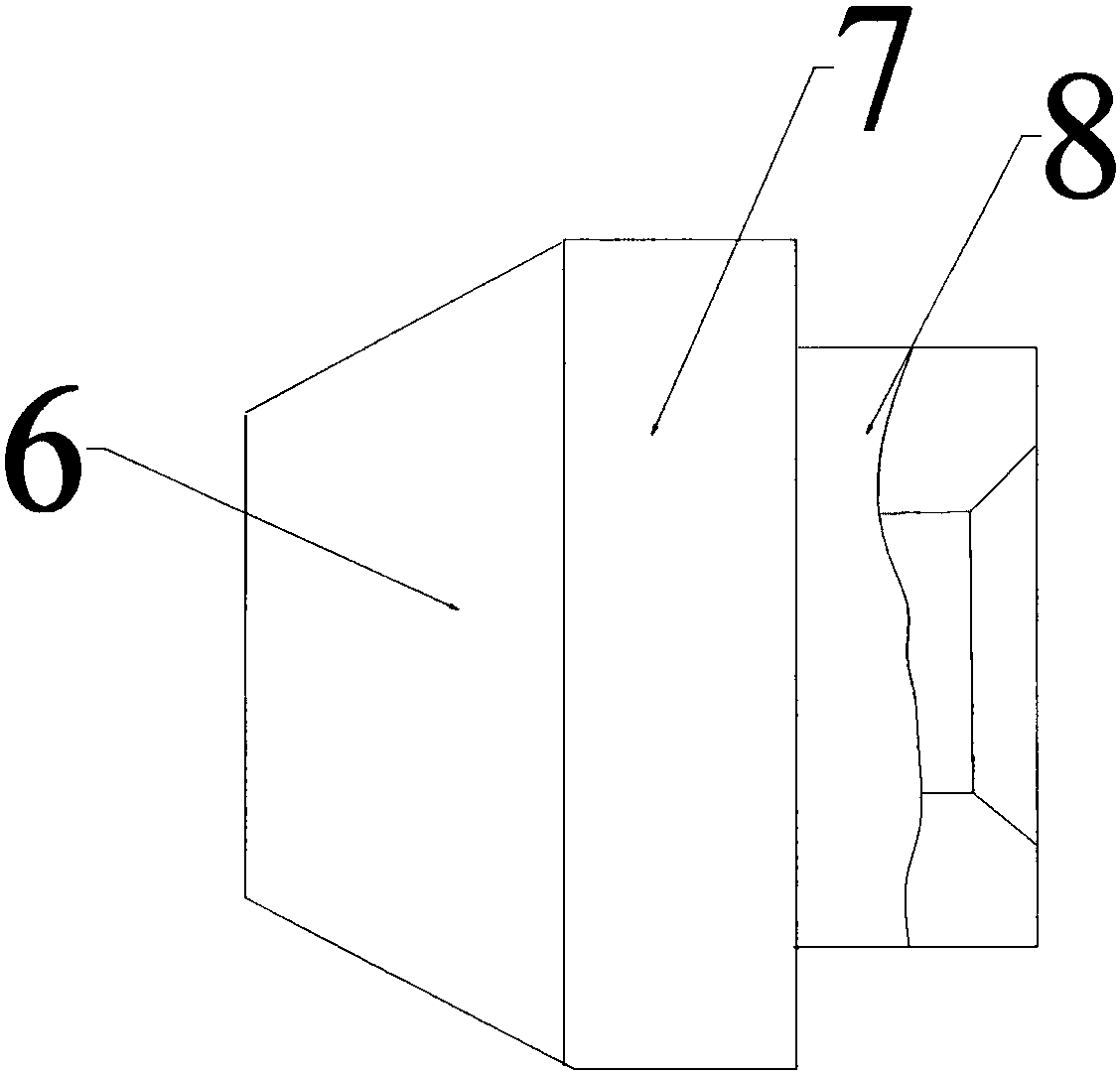

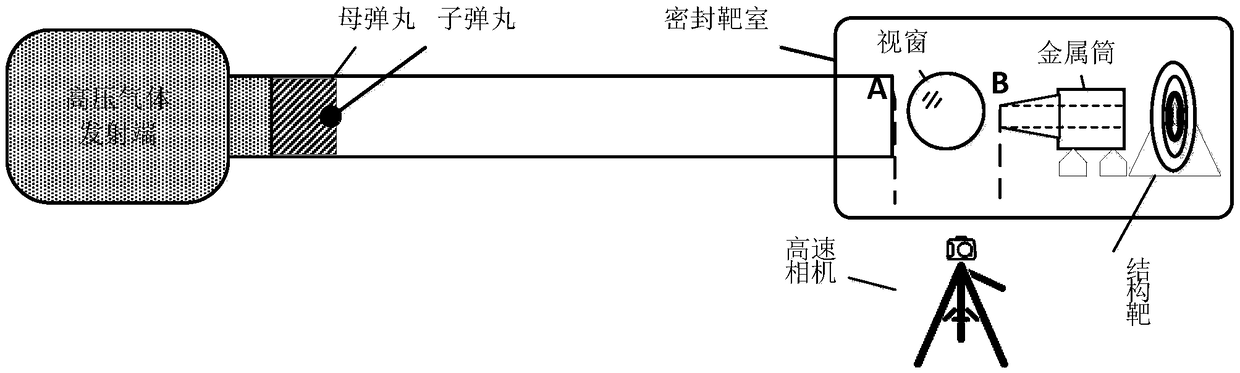

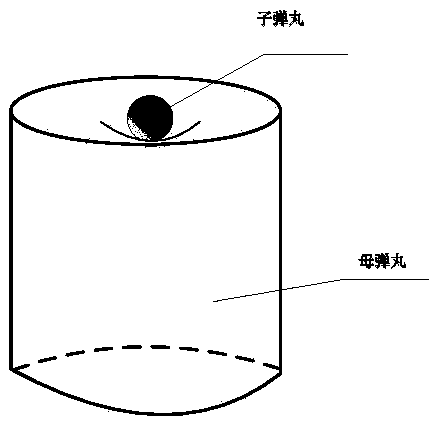

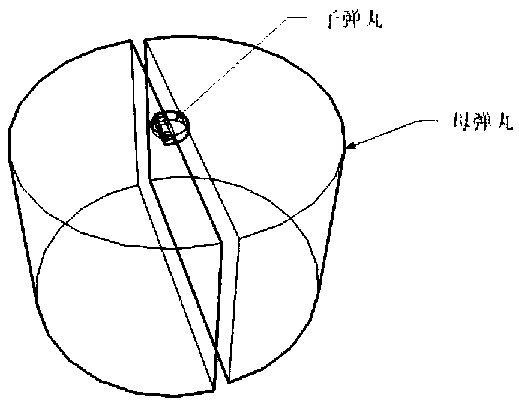

Pill for air-cannon-impacting mechanics experiment and device for testing speed of pill

ActiveCN108895932AImprove accuracyReduce contact timeAmmunition projectilesAmmunition testingEngineeringRepeatability

The invention relates to sub-master pills for an air-cannon-impacting mechanics experiment and a device for testing the speed of the pills, and belongs to the technical field of sub-master pill separation. According to the pill for the air-cannon-impacting mechanics experiment and the device for testing the speed of the pill, in an impacting dynamic experiment that abnormal pills collide a selected some-point structure, as for the problem that an internal sub-pill deviates from a designed flight route and the speed measurement aim of the sub-pill, by accurately designing the structure of the sub-master pills and pill speed measurement equipment, the two problems are solved. In the experiment process, pill sectioning is carried out without relying on friction between the master pill and air, and the master pill is reliably sectioned through heat generated by friction between the master pill and a gun barrel and the rotary inertia of the master pill. According to the technical scheme, the length of a target chamber can be reduced, the air-cannon building price can be reduced by 1 / 5, and meanwhile the pointing accuracy of the impact collision point and the experimental repeatability are greatly improved.

Owner:成都泰坦未来科技有限公司

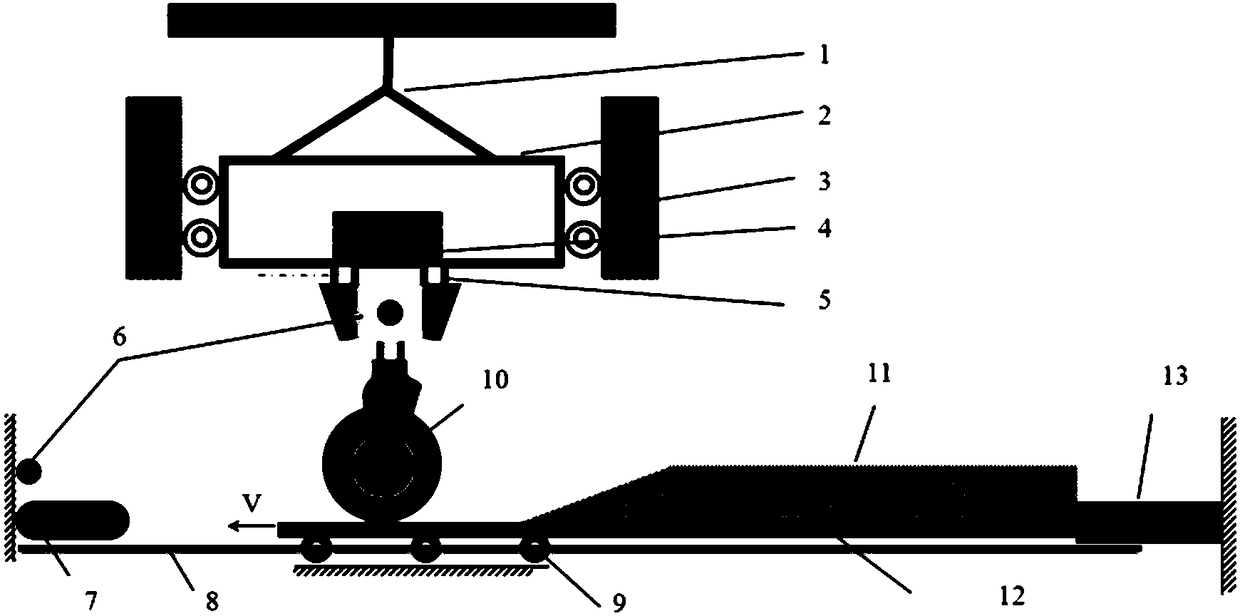

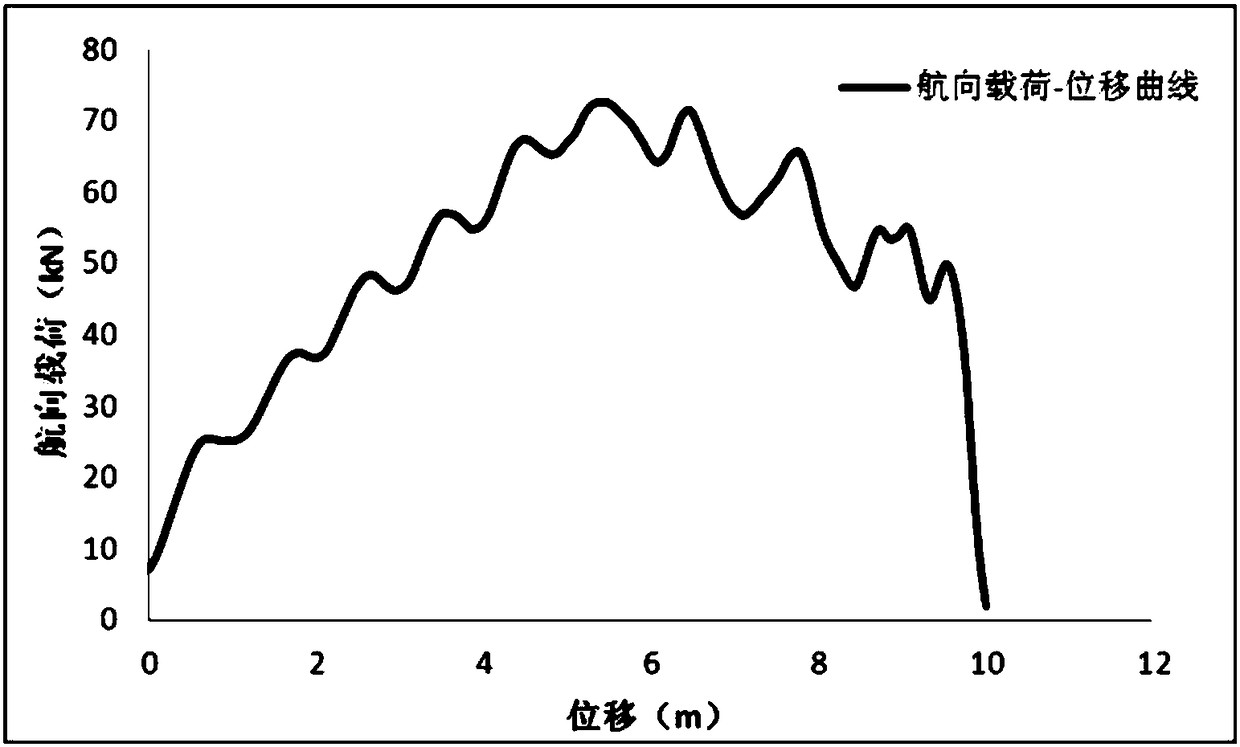

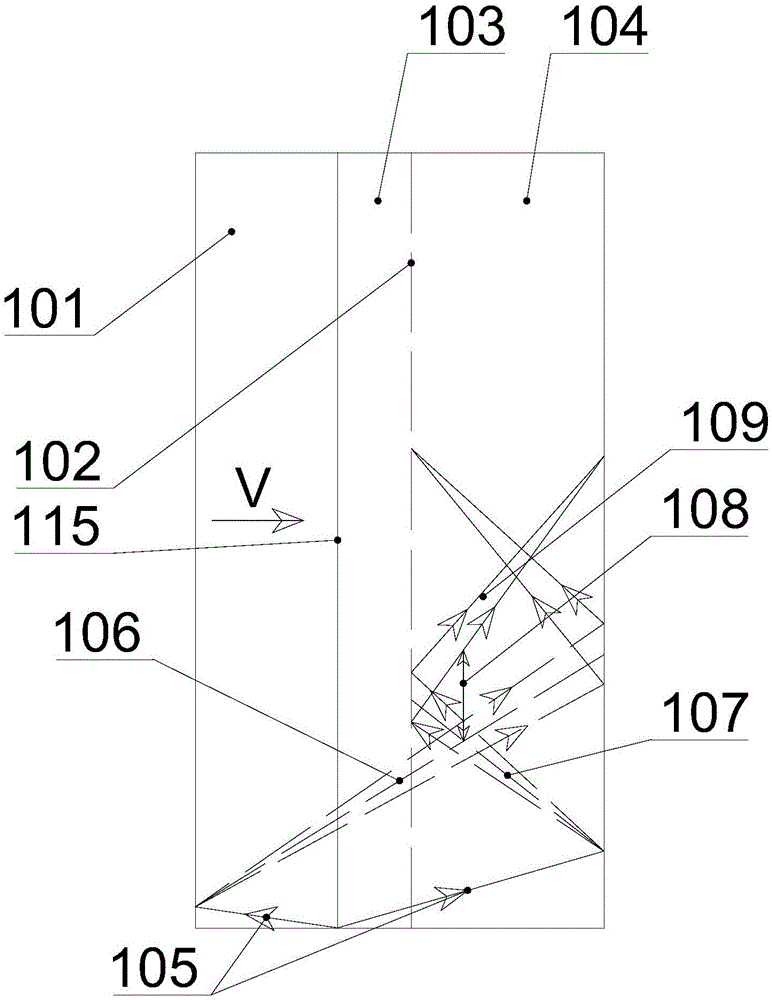

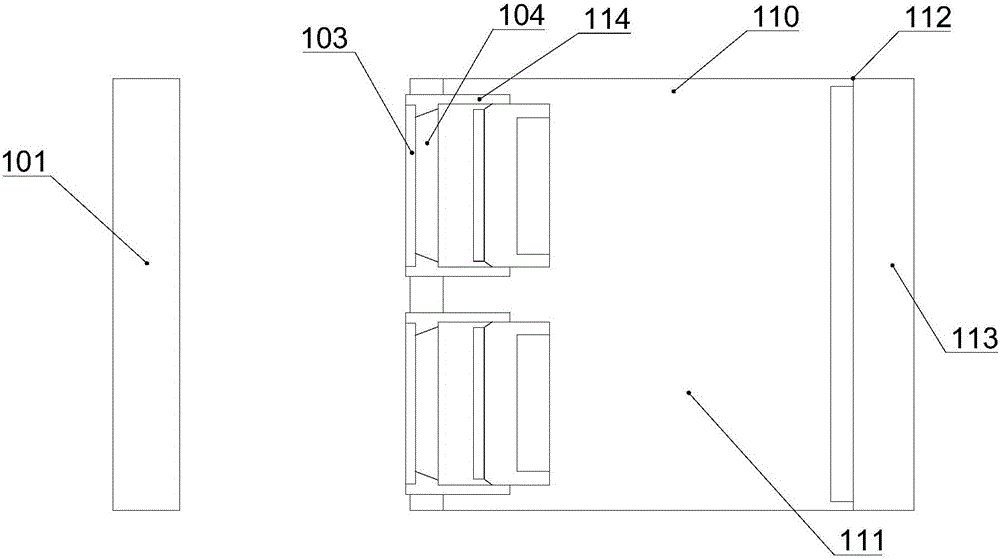

Experiment apparatus and experiment method for dynamic energy absorption characteristic of arresting system

InactiveCN108362638AComplete test parametersThe relative error of the test is smallMachine part testingUsing mechanical meansExperimental testingExperimental methods

The invention belongs to a structural impact dynamics experimental technology, and particularly relates to an experiment apparatus and an experiment method for the dynamic energy absorption characteristic of an arresting system. EMAS is a safety facility for blocking the safety hazard caused by the running of the large aircraft out of the runway and is spread at the end of the airport runway, andthe predictable blocking resistance can be produced for the aircraft through the aircraft wheel rolling material, such that the aircraft can reduce the speed and stay in the safe area under the premise of the safety so as to ensure the structure of the aircraft and the safety of the occupants. The invention provides an experiment test method for performing dynamic energy absorption characteristicsof EMAS, and designs a special experiment table frame for researching the influence of the type of an aircraft landing gear wheel, the vertical loading state of the wheel, the wheel rotation speed and other parameters on the arresting load of EMAS. According to the present invention, the support can be provided for the research and development of the emergency arresting system at the ends of civil aviation and military airport runways, the real aircraft verification experiment of the rushing of the real aircraft into the EMAS material can be partially replaced, and the apparatus and the method have advantages of economy, high efficiency, strong operability, wider application prospect and the like.

Owner:CHINA AIRPLANT STRENGTH RES INST

Experimental method based on tensile stress lasting time serving as variable, and impact experiment device

InactiveCN105954121ASame collision speedThe same collision speed is the same, and the efficiency of the experiment is improved at the same timeMaterial strength using single impulsive forceExperimental methodsTotal thickness

The invention provides an experimental method based on the tensile stress lasting time serving as a variable, and relates to the field of impact dynamics. The experimental method includes S1, producing a plurality of flying sheets; S2, producing a plurality of sample targets, wherein each sample target comprises a first sample layer and a second sample layer, the first sample layers are thinner than the second sample layers, the total thicknesses and textures of the sample targets are the same, and the thicknesses of the first sample layers of the target samples are different; S3, corresponding each flying sheet to the sample targets to form an impact experiment group, wherein the sample targets in each impact experiment group are arranged adjacently; S4, performing impact experiments on the impact experiment groups. The experimental method has the advantages that the tensile stress lasting time is taken as the single variable successfully, intermediate experiment information and data in the same damage evolution path are acquired, and the influence of taking the tensile stress lasting time as the single variable on the slabbing phenomenon is predicted accurately.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

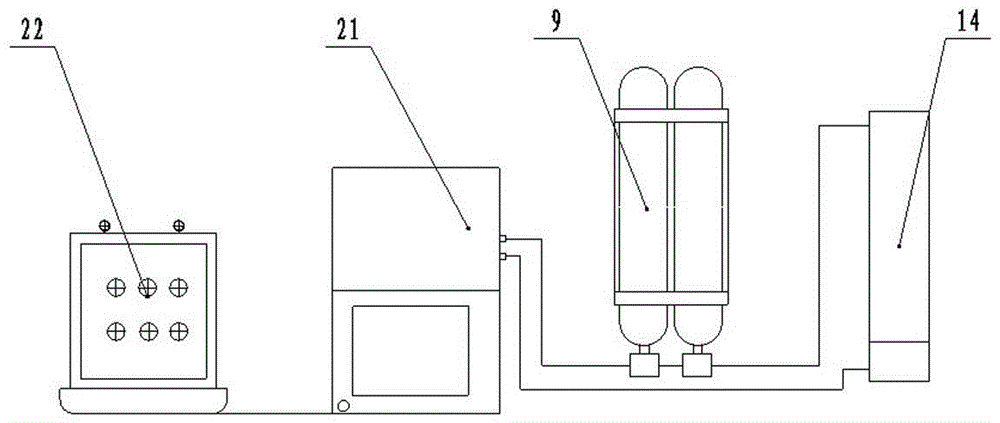

Carbon dioxide blasting impact dynamic monitoring test device and test method thereof

PendingCN109991148AAvoid disturbanceSolve bulkySurface/boundary effectPermeability/surface area analysisButt jointPhase change

The invention discloses a carbon dioxide blasting impact dynamic monitoring test device. The carbon dioxide blasting impact dynamic monitoring test device comprises a CO2 blasting impact test system,wherein the CO2 blasting impact test system is provided with a dynamic stress test system and a static stress test system; the CO2 blasting impact test system consists of a stress loading mechanism, ablasting impact mechanism and a gas collection mechanism; the stress loading mechanism comprises a test piece stress loading part and two ring flanges; the two ring flanges are arranged one after theother side by side; and the stress loading part is arranged between the two ring flanges. The carbon dioxide blasting impact dynamic monitoring test device can perform in-situ integral test on dynamic information of coal bodies under blasting impact, and has the beneficial effects that I, a cylindrical test piece adopted in the test can be directly taken from the site, so that the disturbance ofindoor machining on the original structure of the test piece is avoided; II, an impact source is provided by liquid CO2 phase change blasting, so that butt joint of the test piece is facilitated, andthe blasting performance parameters can be controlled conveniently; III, various observation sheets can be arranged conveniently; and IV, the problems of heaviness, high cost and inconvenience in thetest for large test pieces are solved.

Owner:HENAN POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com