Patents

Literature

1817 results about "High-speed camera" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high-speed camera is a device capable of capturing moving images with exposures of less than 1/1,000 second or frame rates in excess of 250 frames per second. It is used for recording fast-moving objects as photographic images onto a storage medium. After recording, the images stored on the medium can be played back in slow motion. Early high-speed cameras used film to record the high-speed events, but were superseded by entirely electronic devices using either a charge-coupled device (CCD) or a CMOS active pixel sensor, recording, typically, over 1,000 frames per second onto DRAM, to be played back slowly to study the motion for scientific study of transient phenomena.

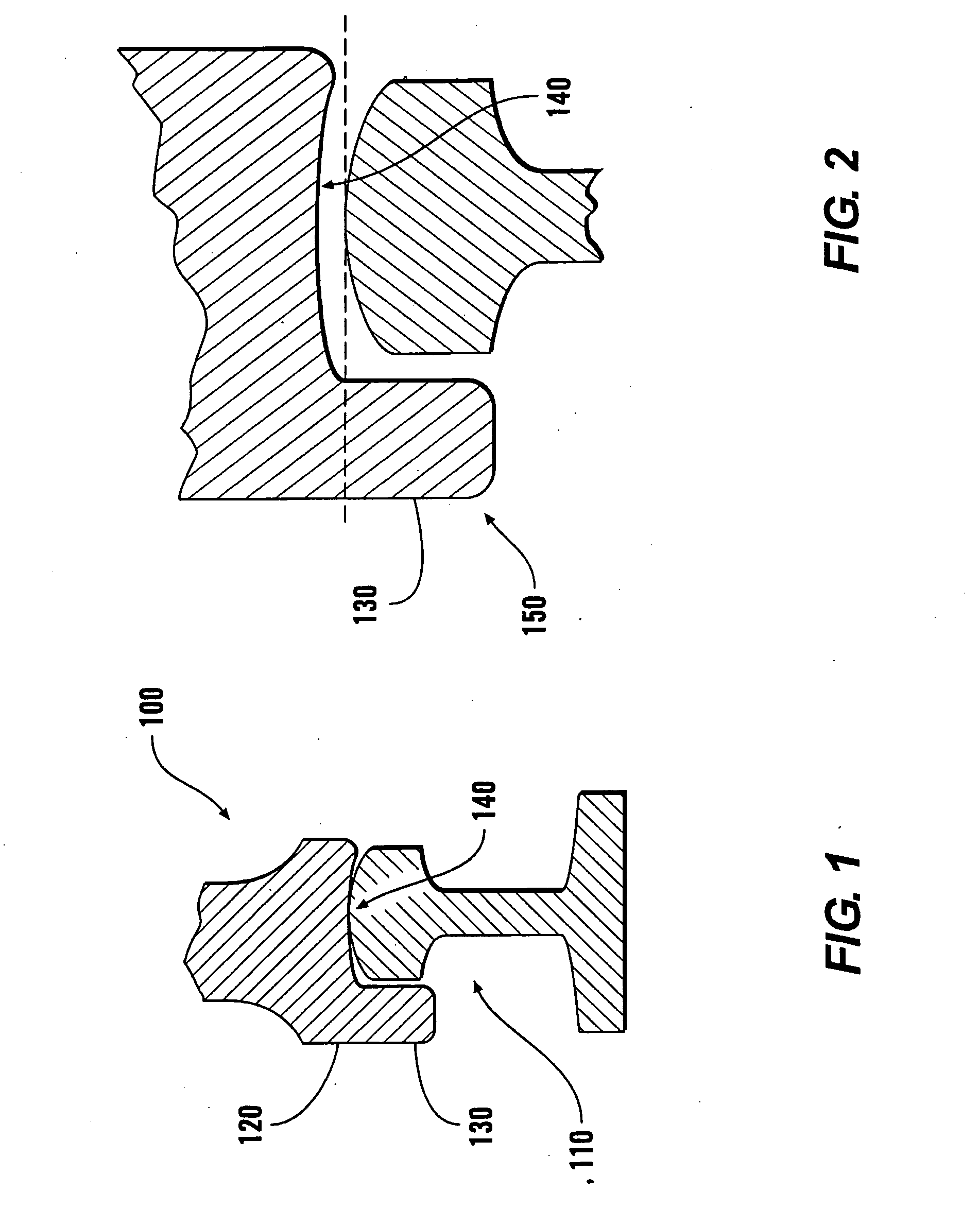

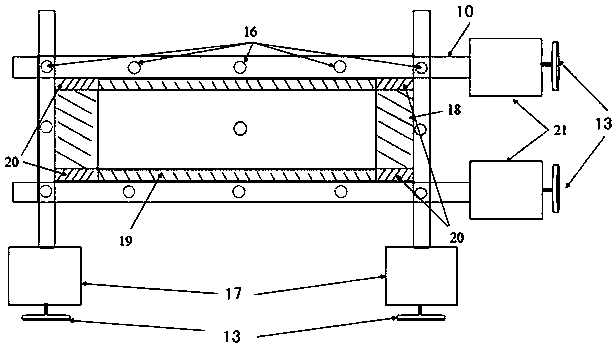

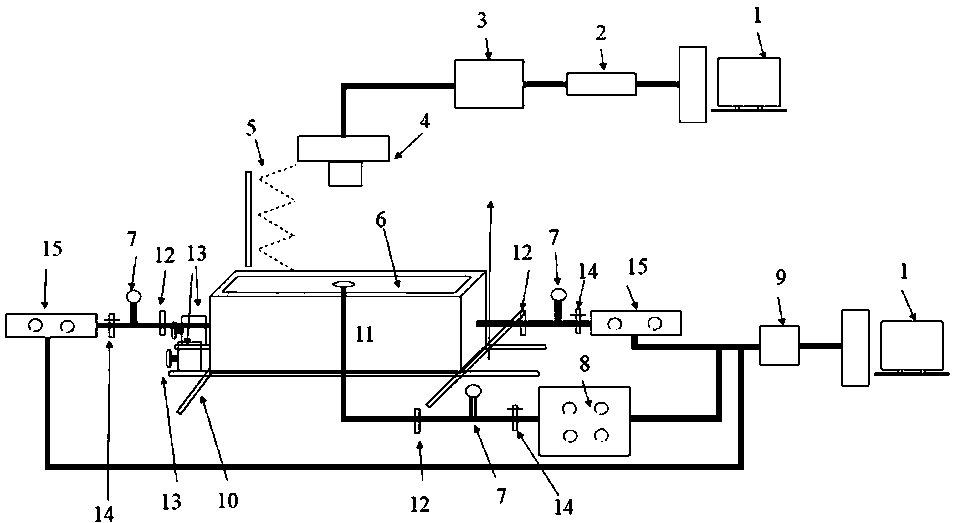

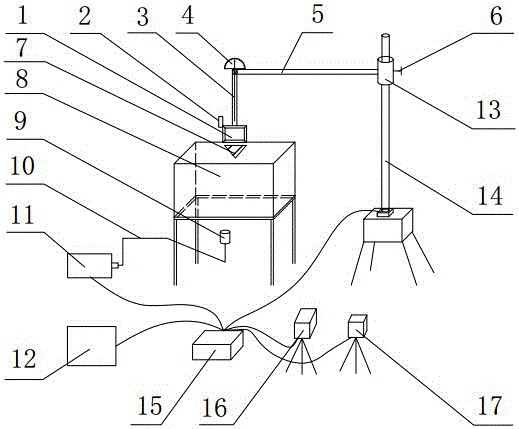

Oil-gas well hydraulically-created-fracture expansion visualization experiment method and oil-gas well hydraulically-created-fracture expansion visualization experiment device

ActiveCN103485759AFor the purpose of visualizationSurveyEarth material testingEpoxyHigh pressure water

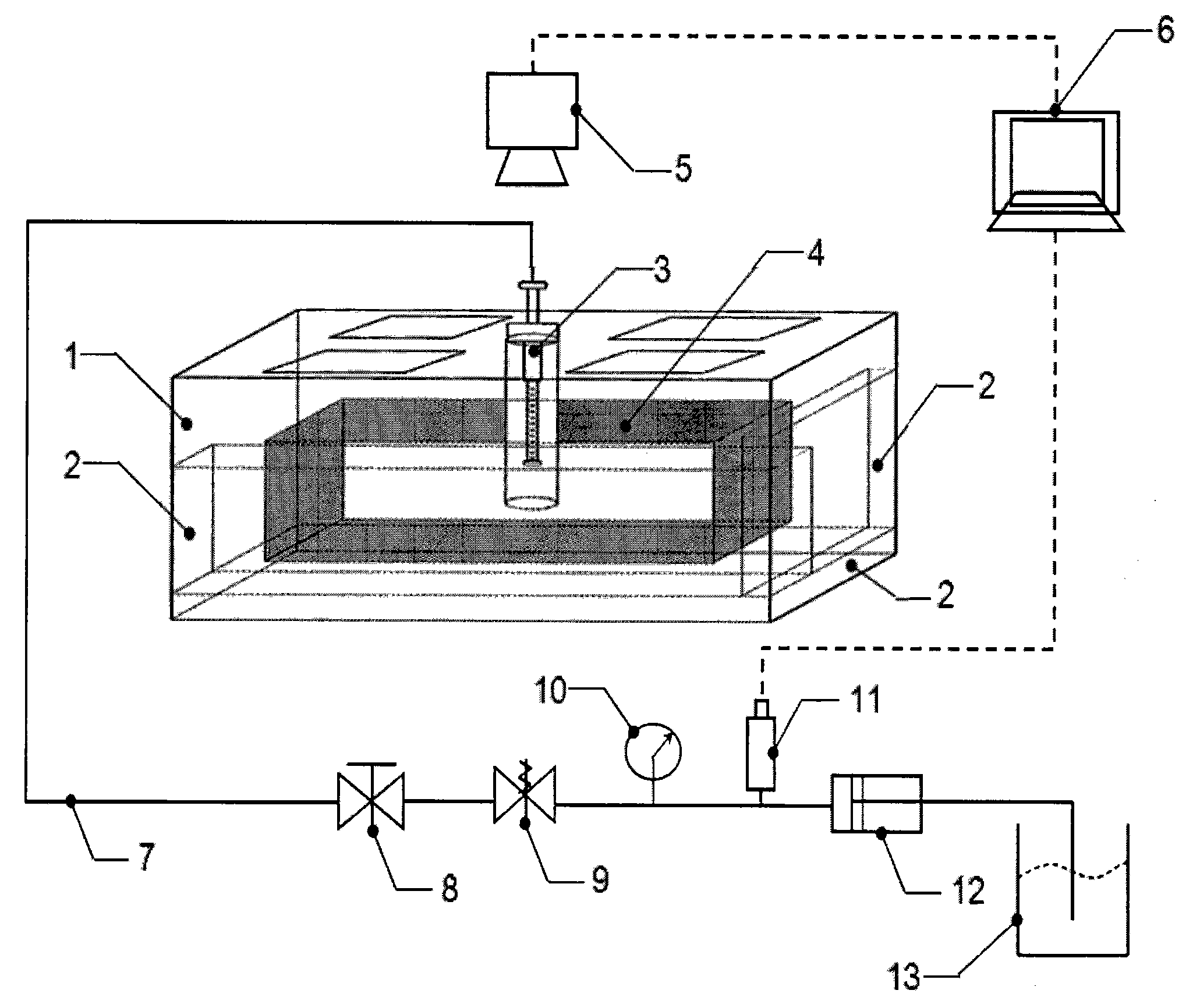

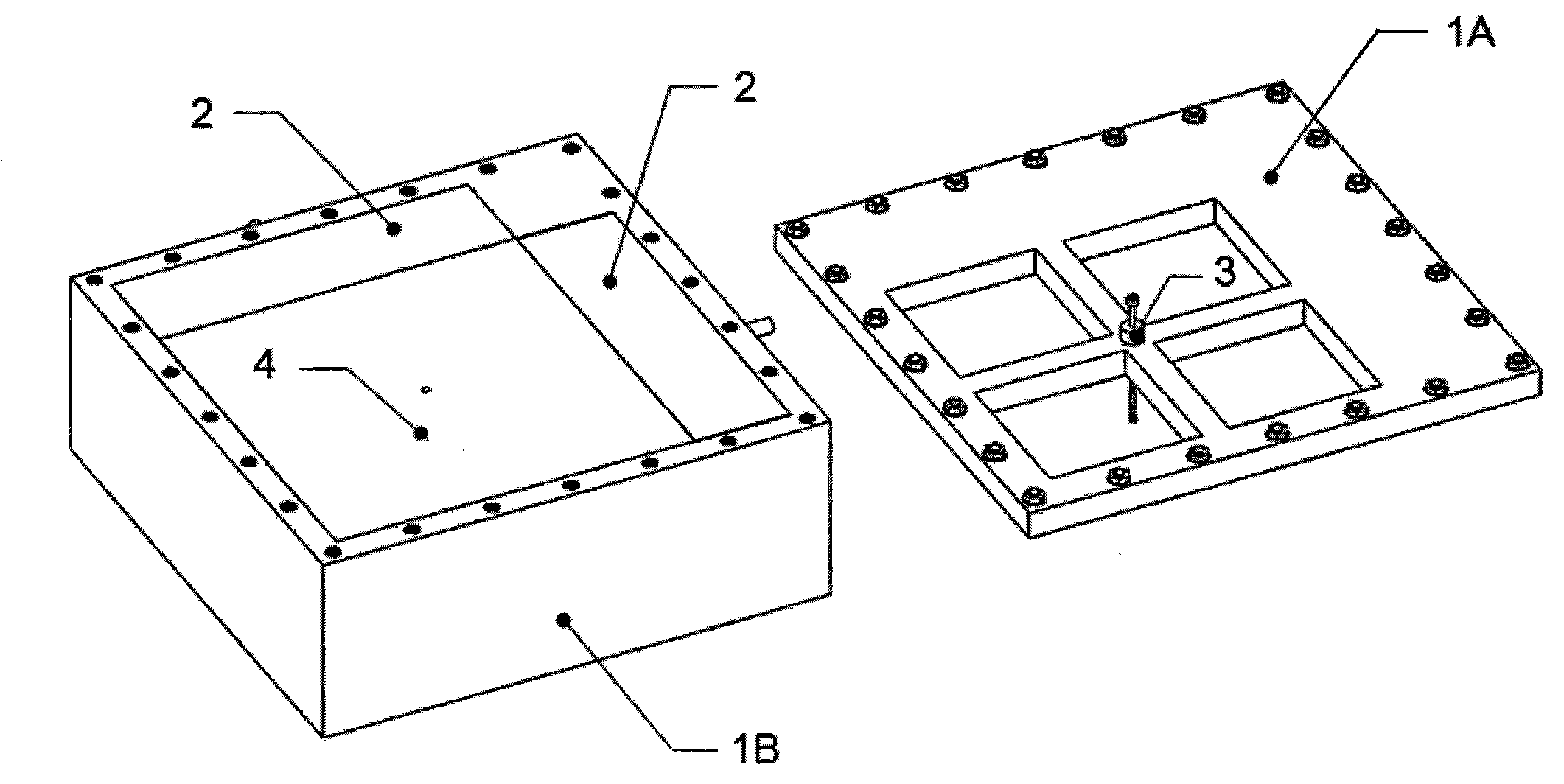

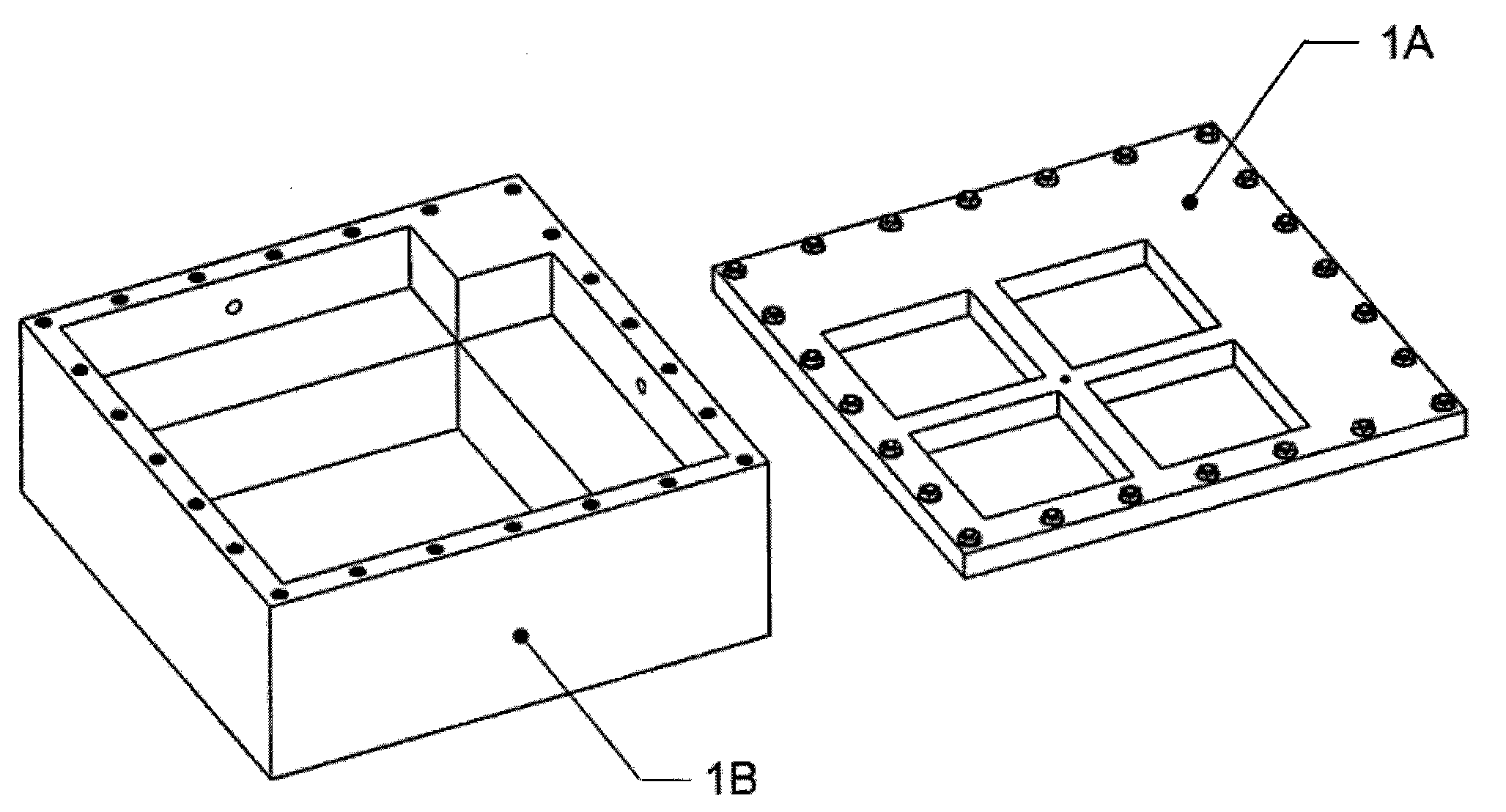

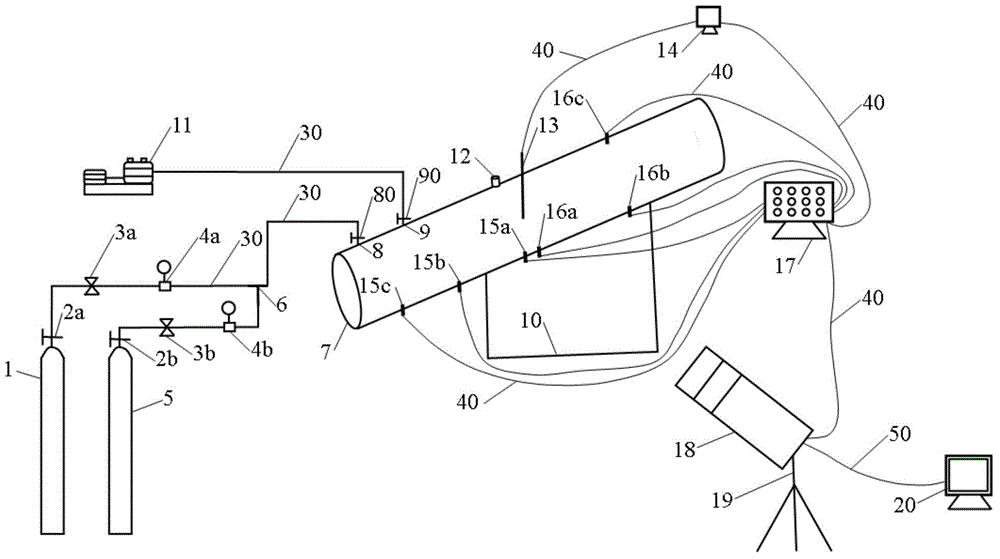

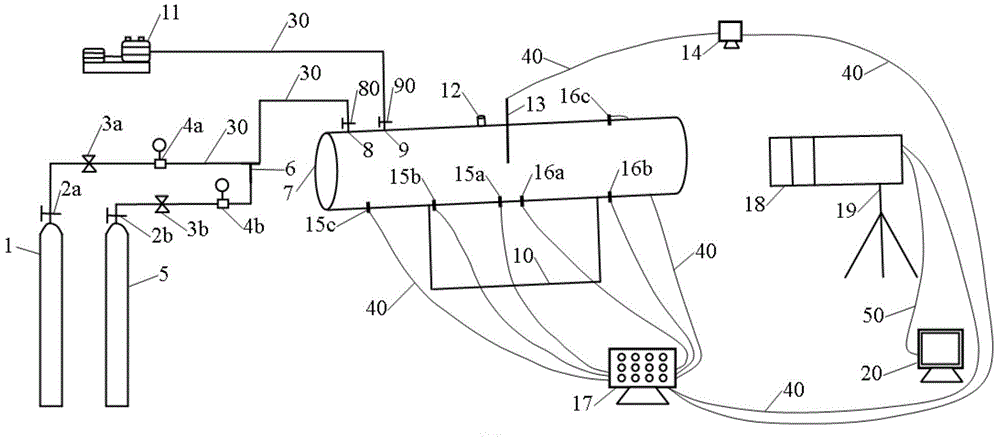

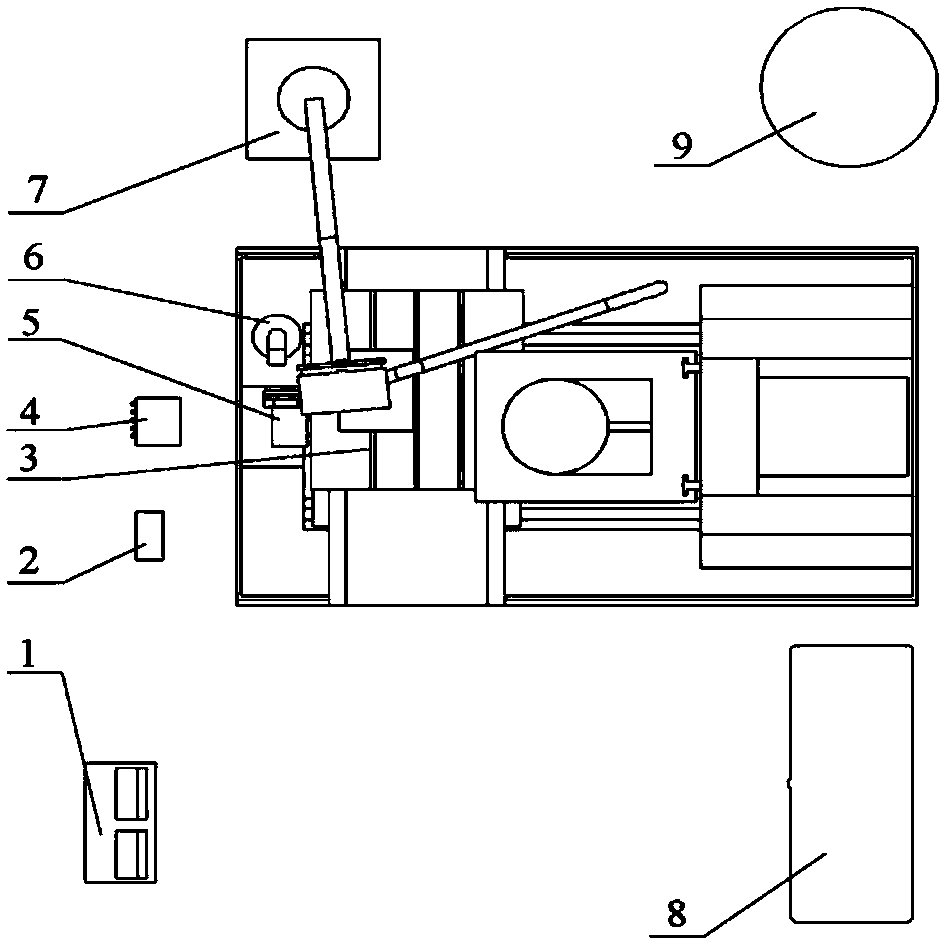

The invention relates to an oil-gas well hydraulically-created-fracture expansion visualization experiment method and an oil-gas well hydraulically-created-fracture expansion visualization experiment device. The device is composed of a rock sample chamber, a crustal loading unit, a simulation fracturing string, a high-speed camera, a high-pressure pumping unit, a data measuring and collecting unit and the like, and four transparent observation ports are formed on a top cover of the rock sample chamber. The method includes firstly, preparing a flat-plate-type rock sample, performing high-pressure-water cutting to preform a natural fracture, and filling the natural fracture with epoxy resin to form a filled-type fracture; secondly, performing water saturation on the rock sample for 3-5 days, and using epoxy resin to wrap the rock sample after water saturation; thirdly, loading three-axis stress on the rock sample, drilling a borehole under the condition that the three-axis stress is applied on the rock sample, and mounting the simulation fracturing string; finally, connecting a high-pressure pipeline with a constant-flux pump, pumping fracturing liquid, recording a fracture expansion path by the high-speed camera, and measuring pumping pressure changes by a pressure transmitter. By the method and the device, the hydraulically-created-fracture expansion path can be visualized on a plane, and a novel experiment method is provided for studying on a hydraulically-created-fracture expansion mechanism.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Vehicle component real object collision test method and tester

ActiveCN101430251ADetermination of impact forceDetermination of transient accelerationRailway vehicle testingShock testingComplete dataSpeed test

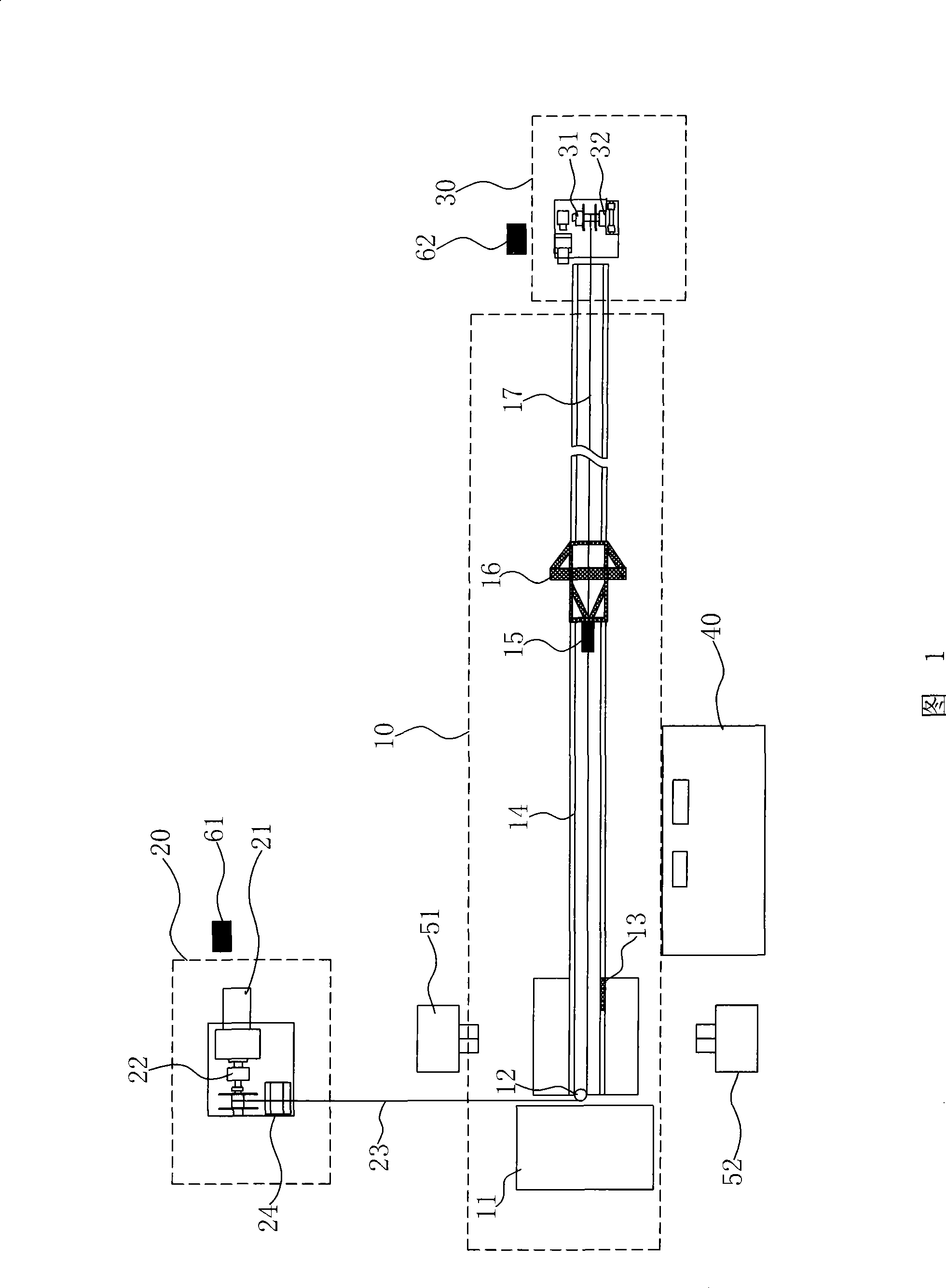

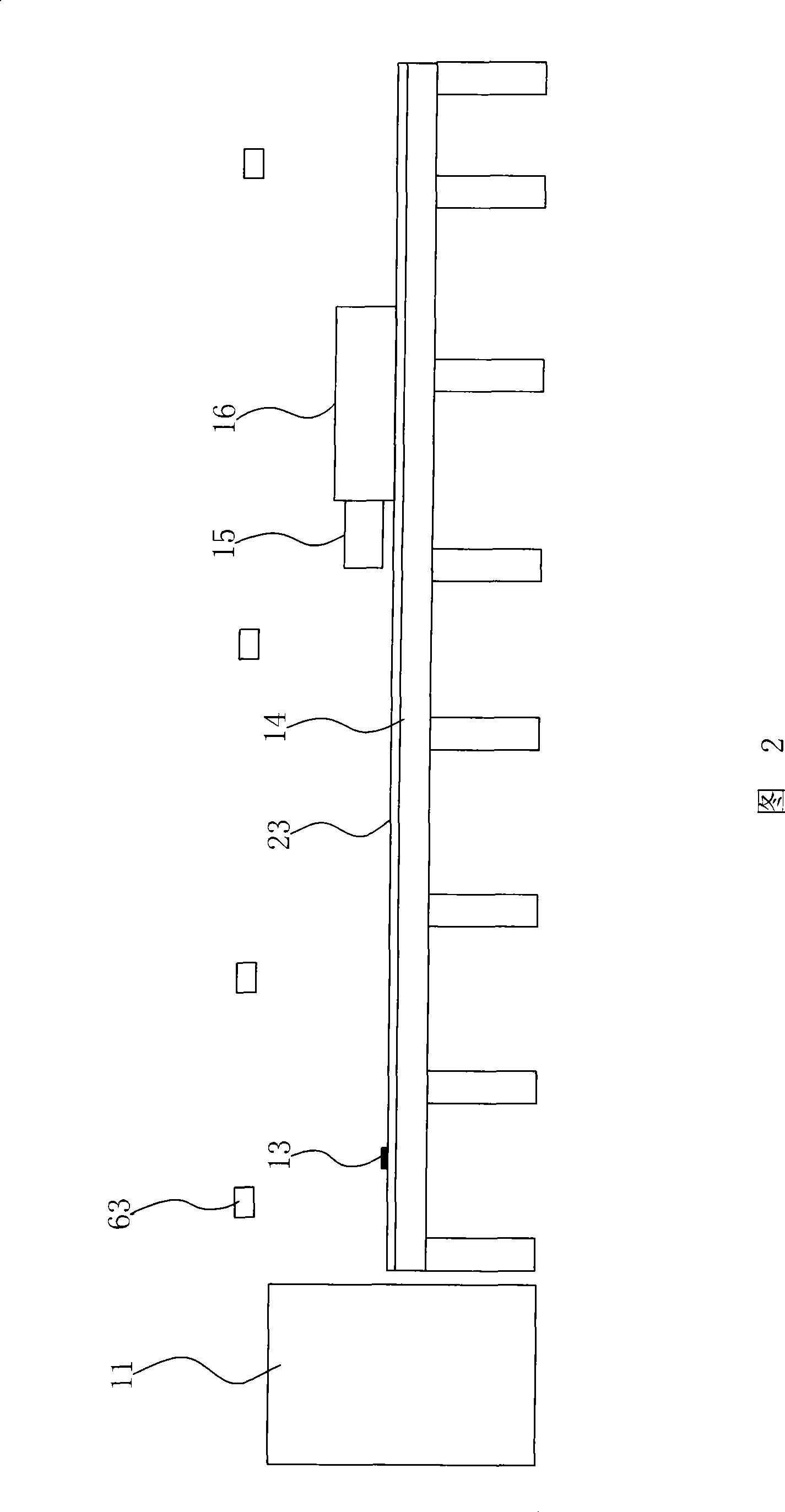

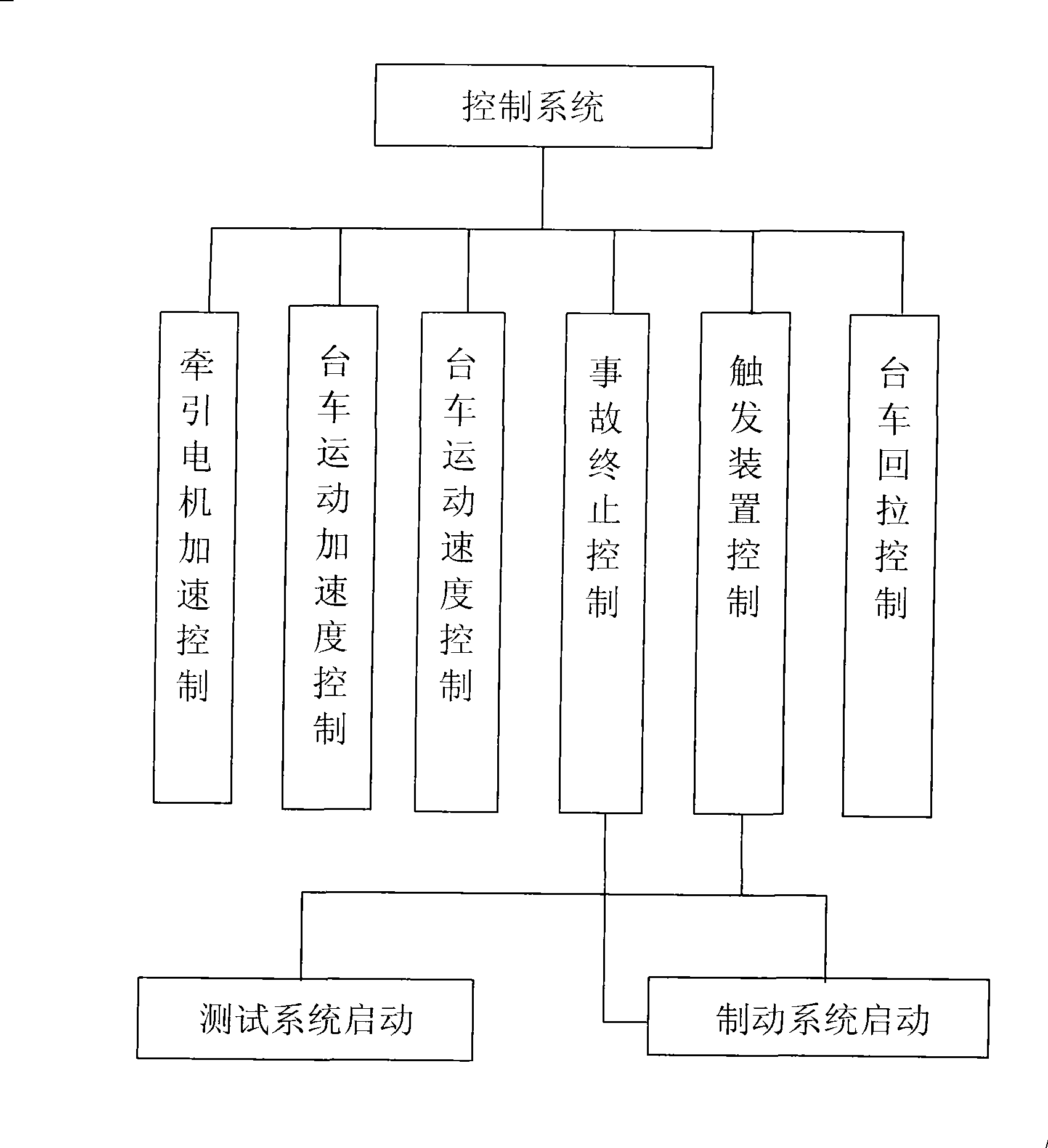

The invention discloses a test method for real object crash of vehicle components and a test device thereof. The test method comprises the following steps: the vehicle components are fixed on a carrying trolley which can move on a track, the speed of the trolley is increased to a test value by traction with a drive system before preparing for crash an impact wall; when the carrying trolley moves to a set position before the impact wall, a trigger device is started to detach the drive system from the carrying trolley, a test component and the carrying trolley are caused to crash the impact wall without drive power; a vehicle-borne acceleration test system is arranged on the carrying trolley so as to complete data acquisition in real time; and the trigger device triggers a speed test system, an impact force test system and a high-speed camera system at the same time. The test method of the real object crash of the vehicle components and the test device can help measure objective data in real time such as the impact force, a transient acceleration, component deformation and speed output at the moment of crash, and further can record deformation sequence images of the components during the whole crash course so as to get scientific and exact analysis results.

Owner:CENT SOUTH UNIV

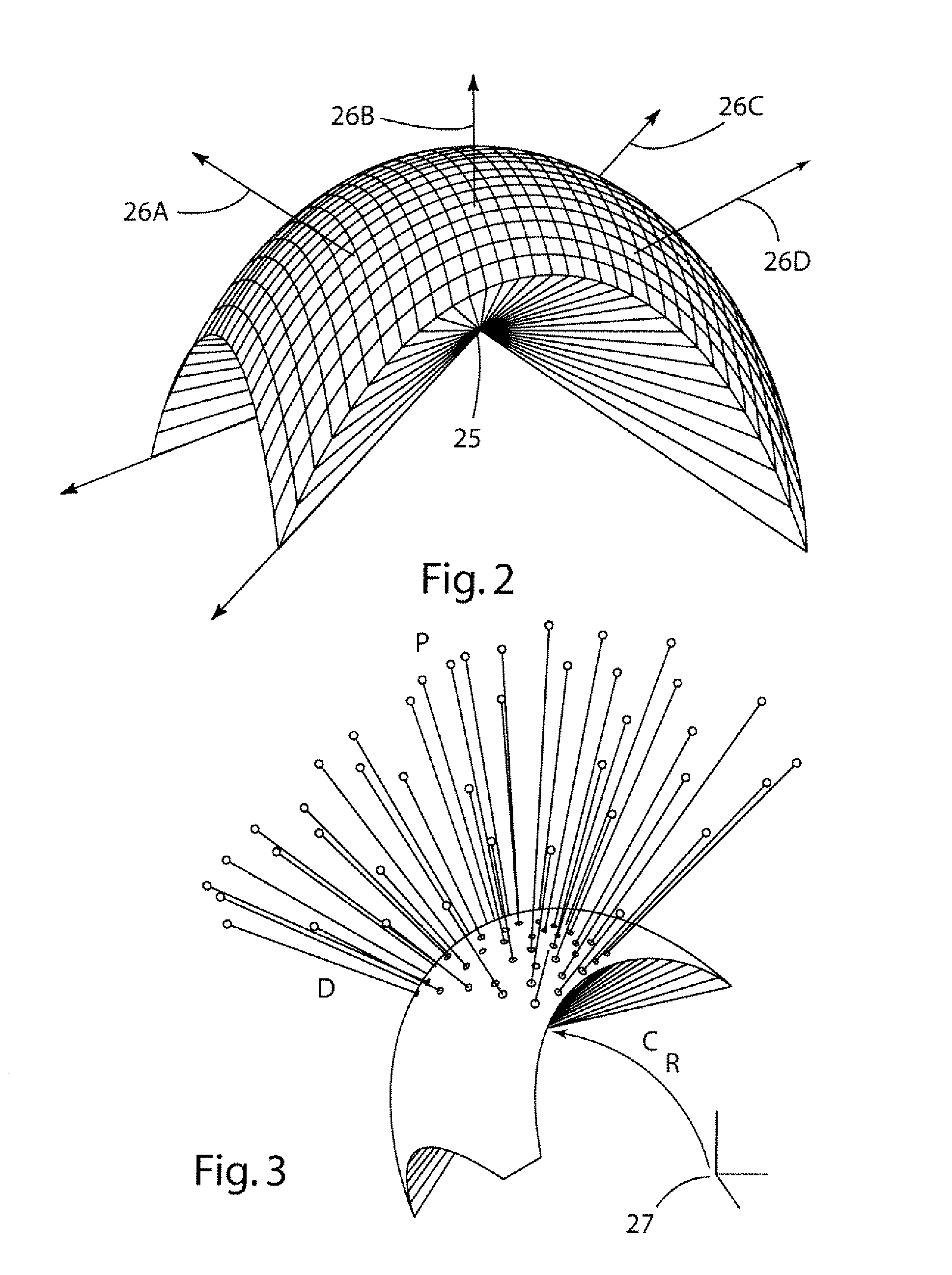

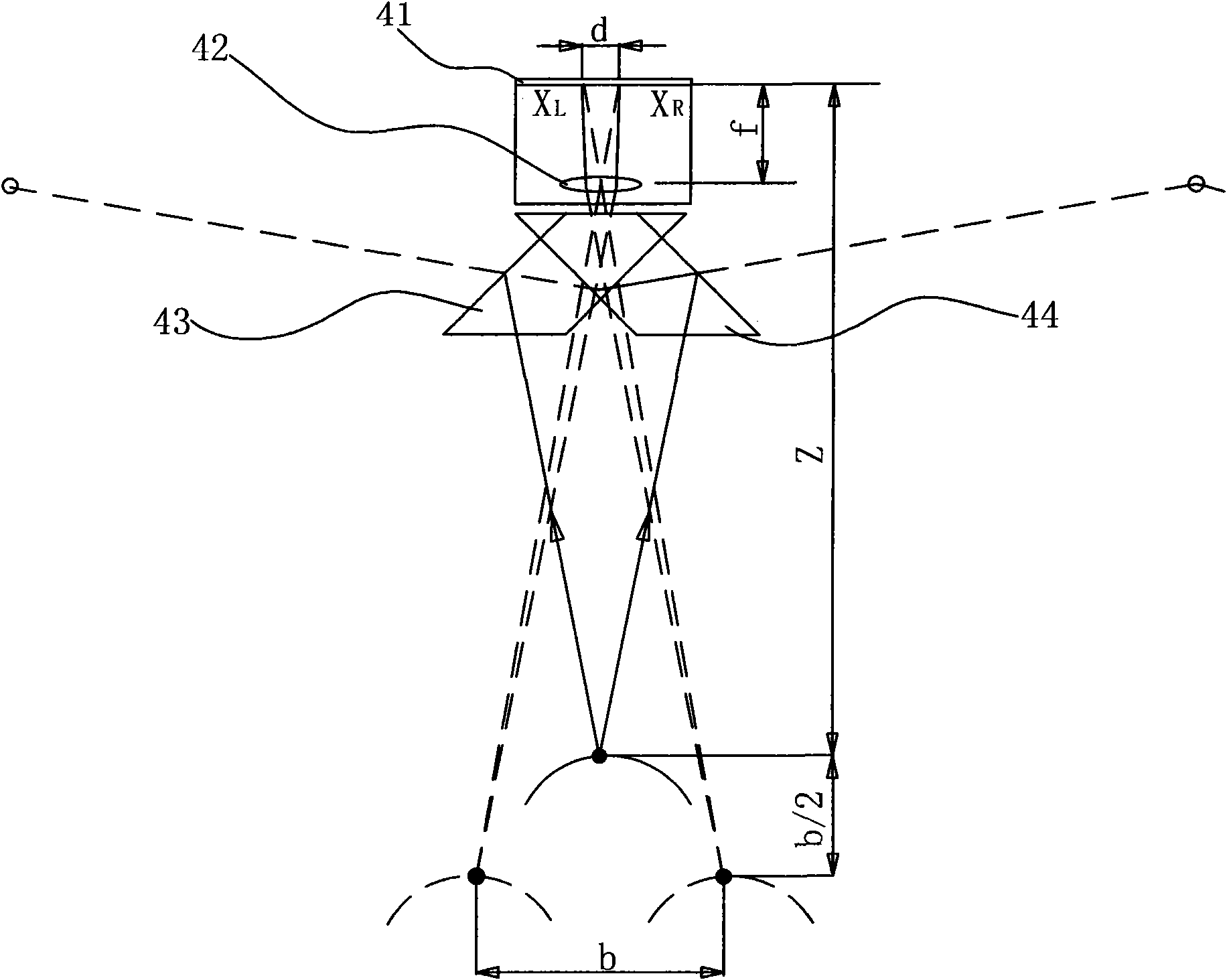

Shaft selection aiding apparatus for selecting optimum shaft for a golfer

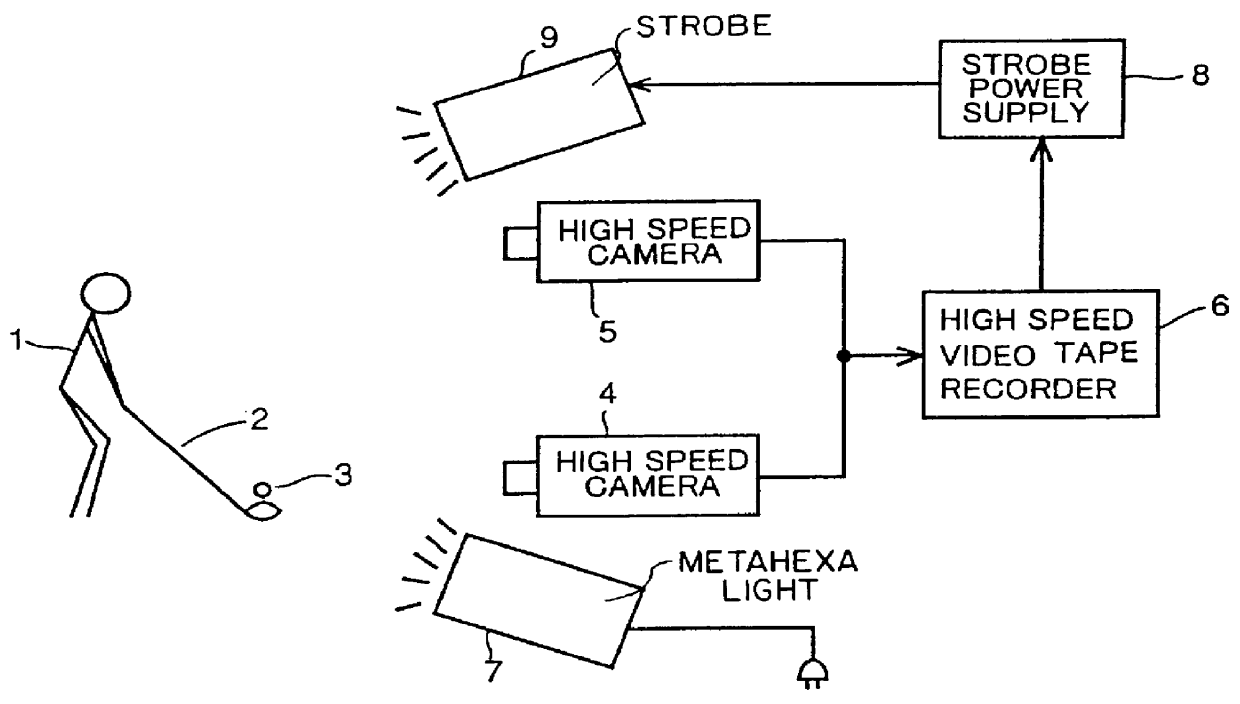

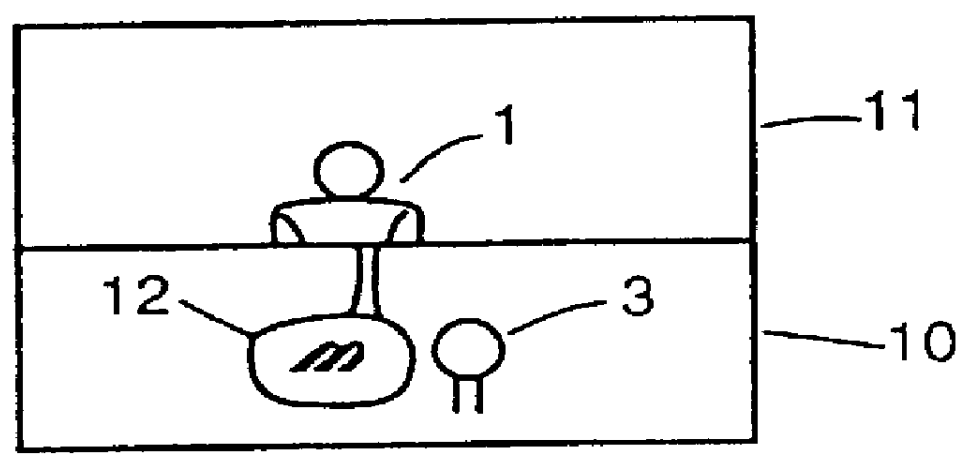

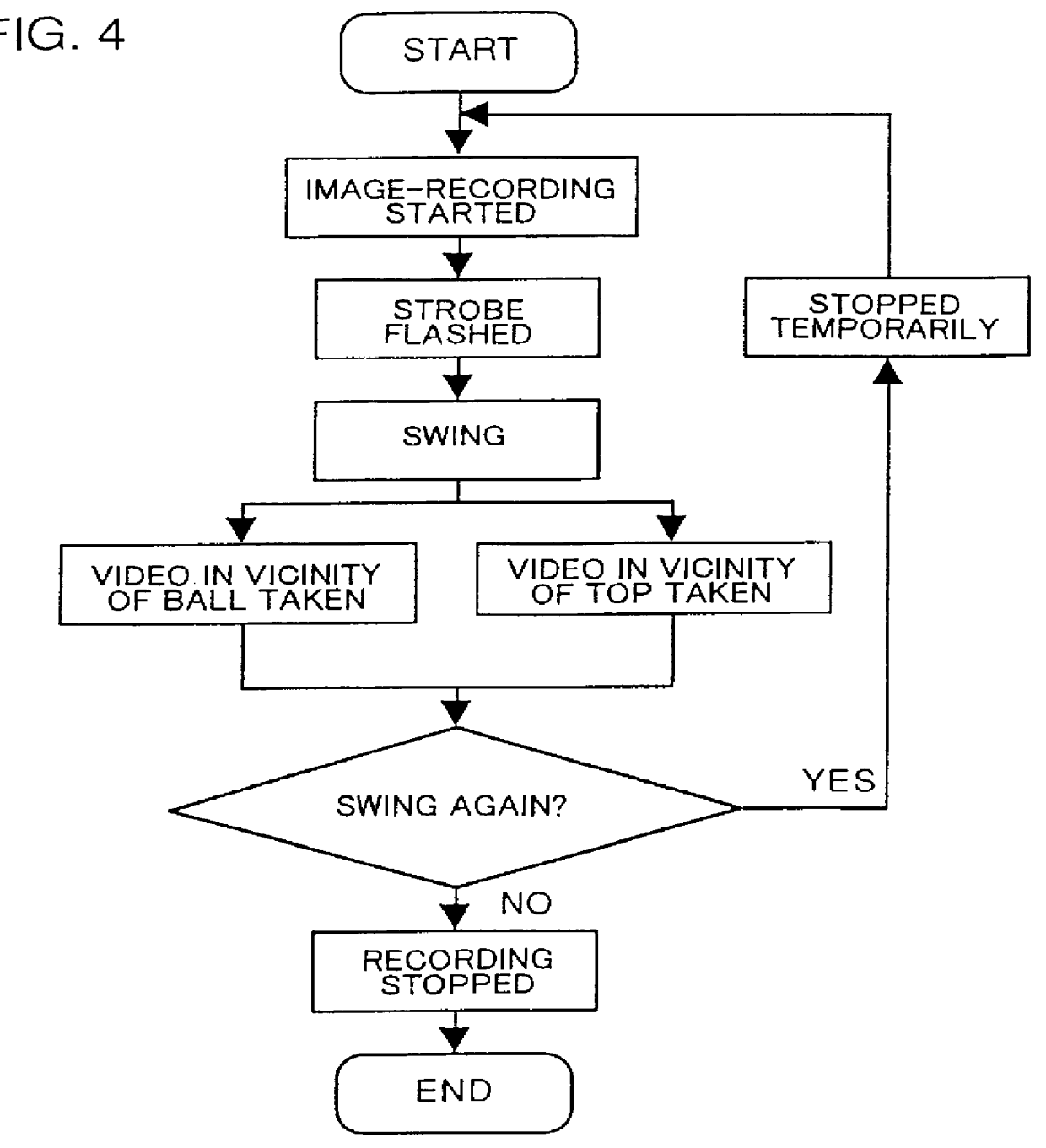

A high speed camera takes an image in the vicinity of a ball 3 and a club head 12, while a high speed camera 5 takes an image in the vicinity of the top of the swing of a golfer 1, and the images are recorded in a high speed video tape recorder 6. The recorded images are reproduced, swing time, a swing speed and a head speed are detected using a personal computer 15, and a shaft with an optimum flex for the golfer is selected based on the swing time, the swing speed, the swing time and the head speed, or the swing speed and the head speed.

Owner:MIZUNO CORPORATION

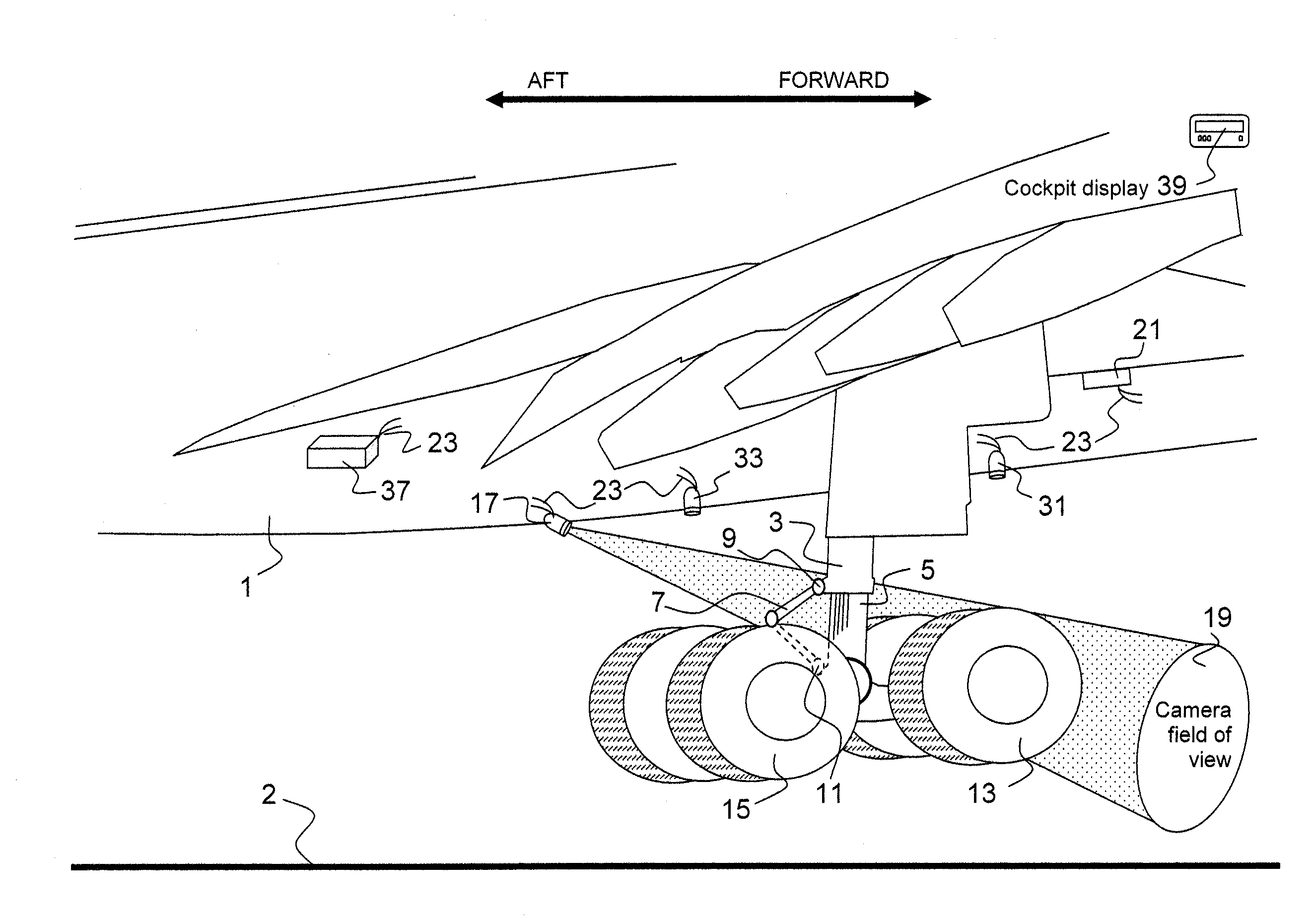

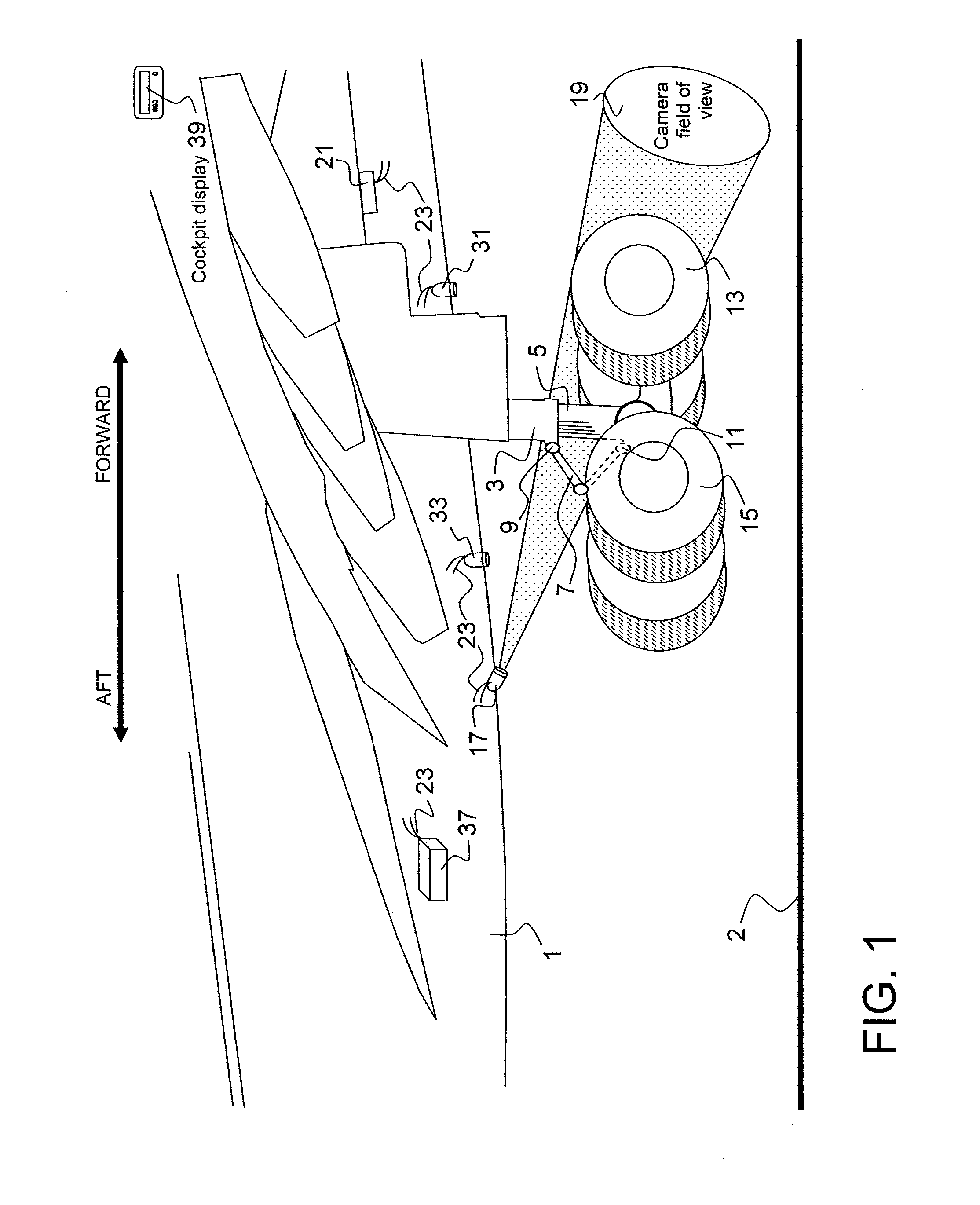

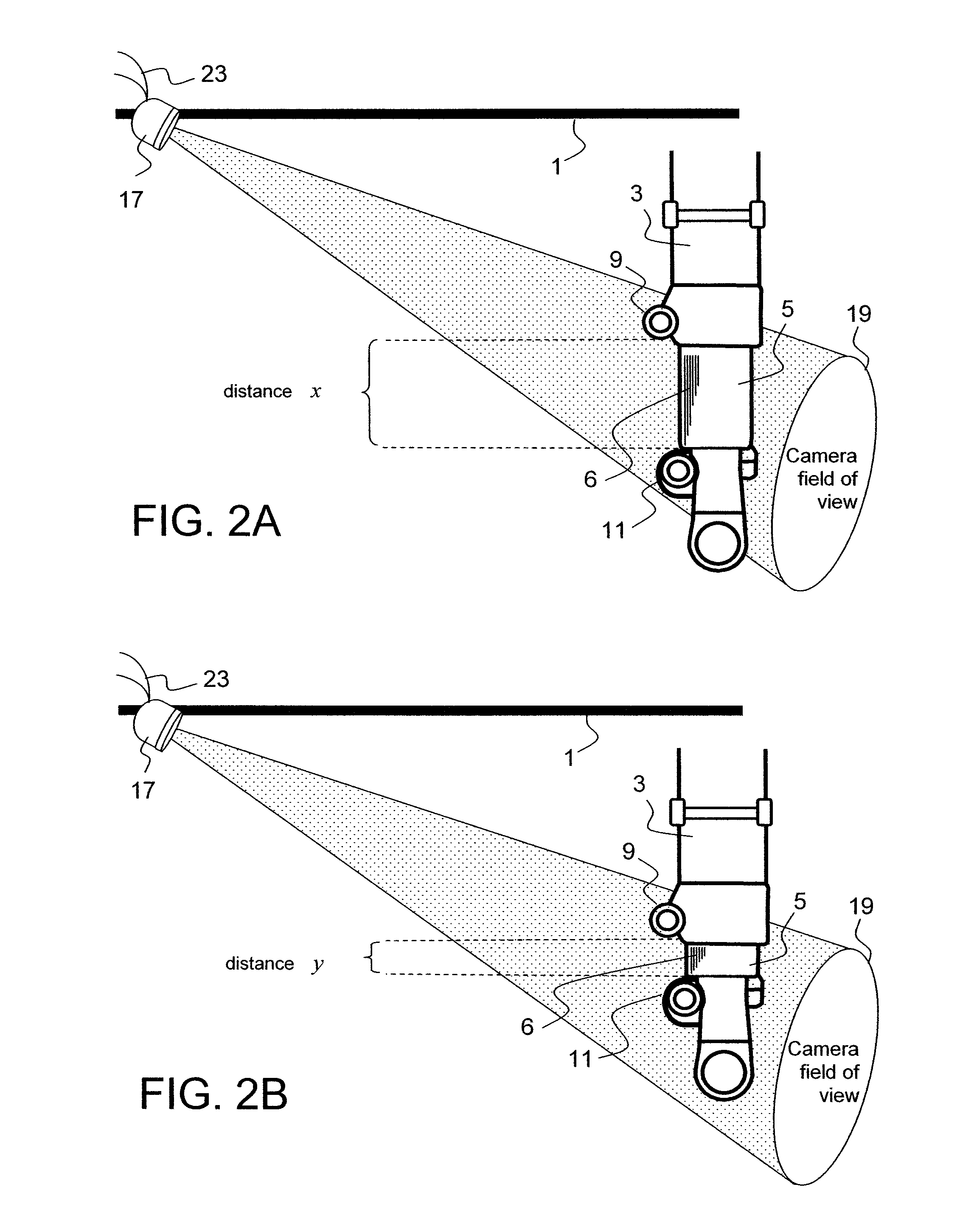

Aircraft landing gear compression rate monitor

ActiveUS8042765B1Aircraft health monitoring devicesSpeed measurement using gyroscopic effectsAircraft landingAirplane

A system for use in monitoring, measuring, computing and displaying the rate of compression of aircraft landing gear struts experienced while aircraft are executing either normal or hard landing events. A high speed computer attached to high speed cameras, or range-finders, mounted in relation to each of the landing gear struts are used to monitor, measure and record the landing gear compression rates and aircraft touch-down vertical velocities experienced by landing gear struts, as the aircraft landing gear initially comes into contact with the ground. The system also determines through landing gear strut compression rates if aircraft landing limitations have been exceeded.

Owner:NANCE C KIRK

Vehicular image processing apparatus and related method

ActiveUS7171027B2Quality improvementImprove reliabilityTelevision system detailsGeometric image transformationImage extractionLow speed

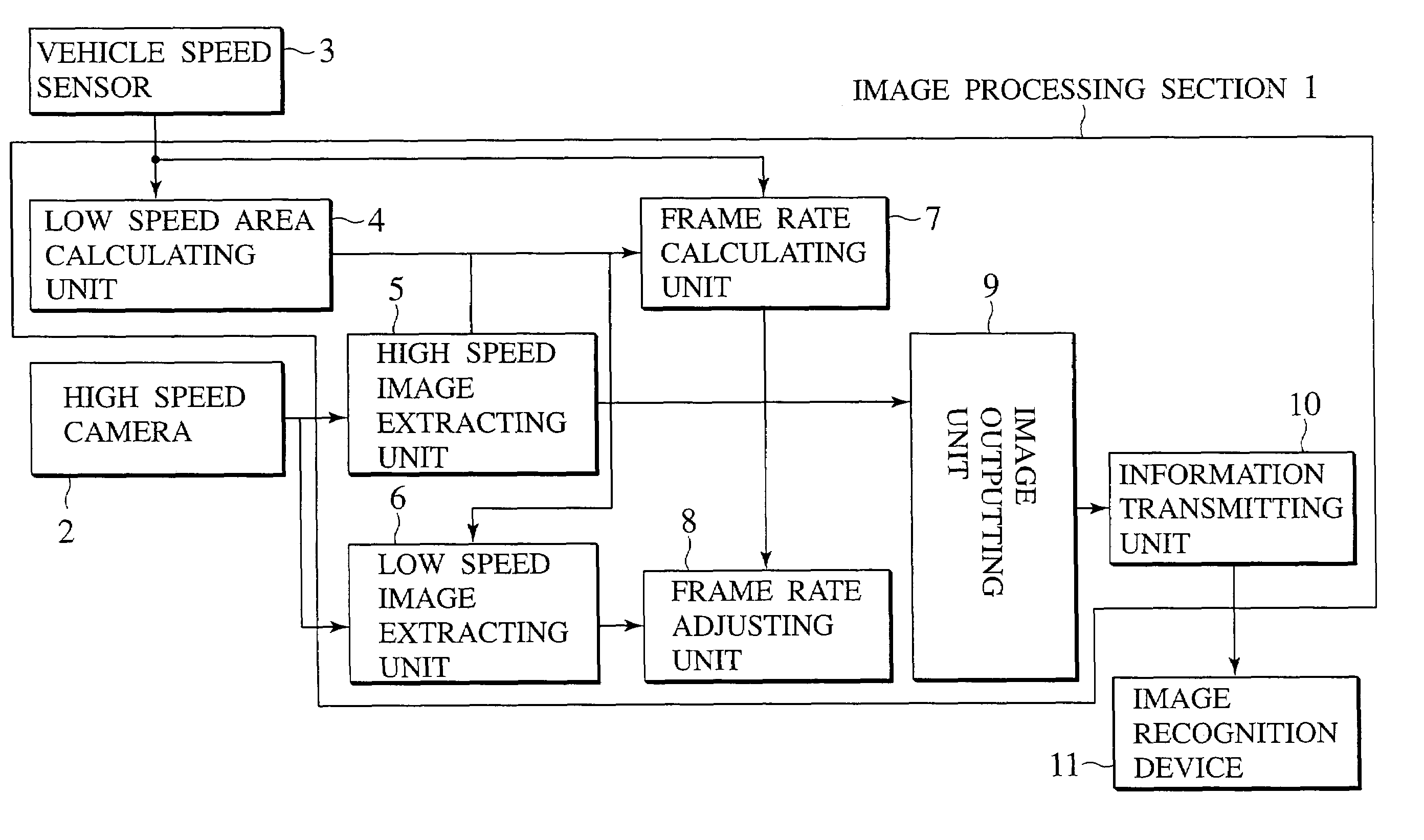

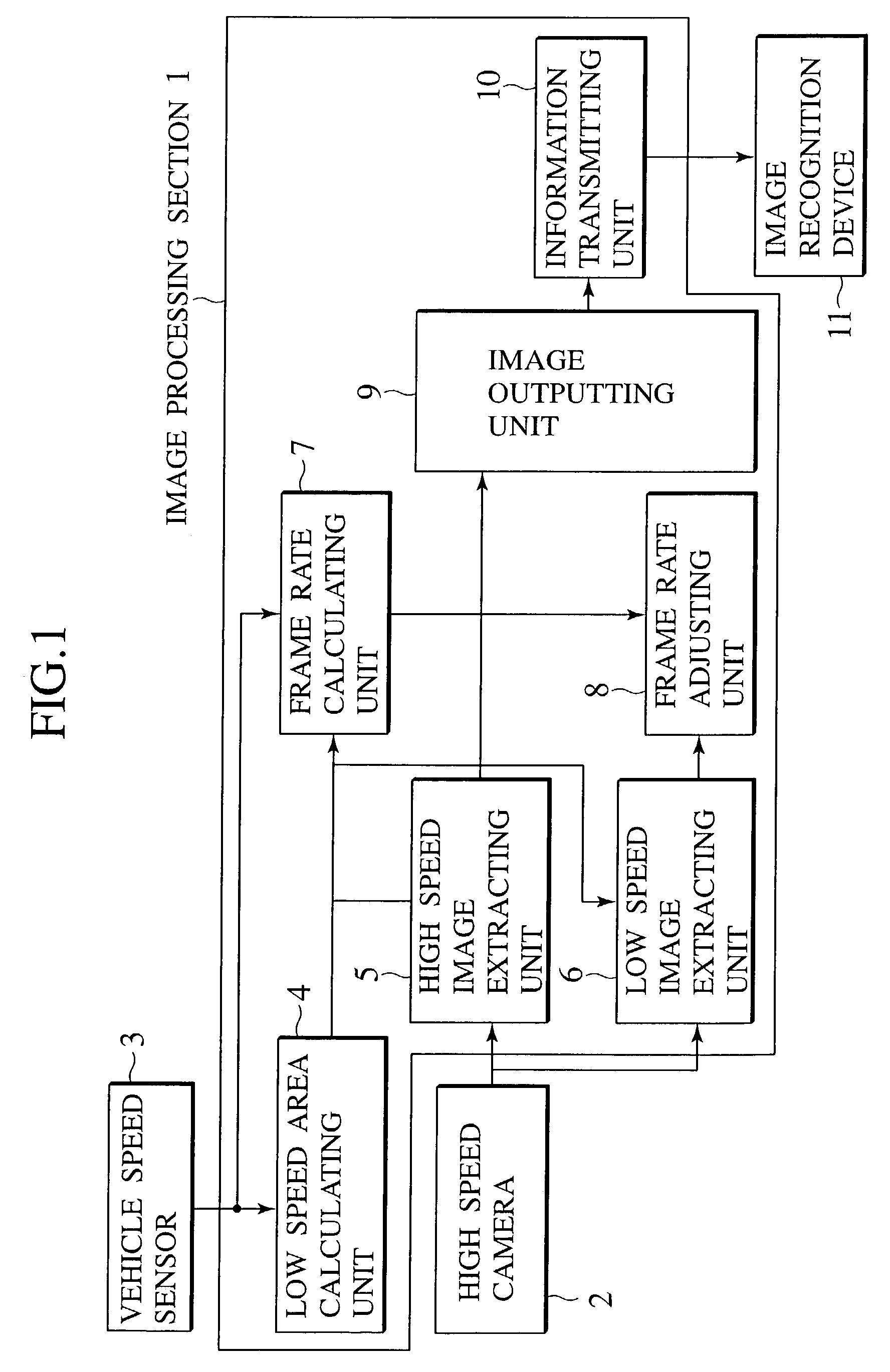

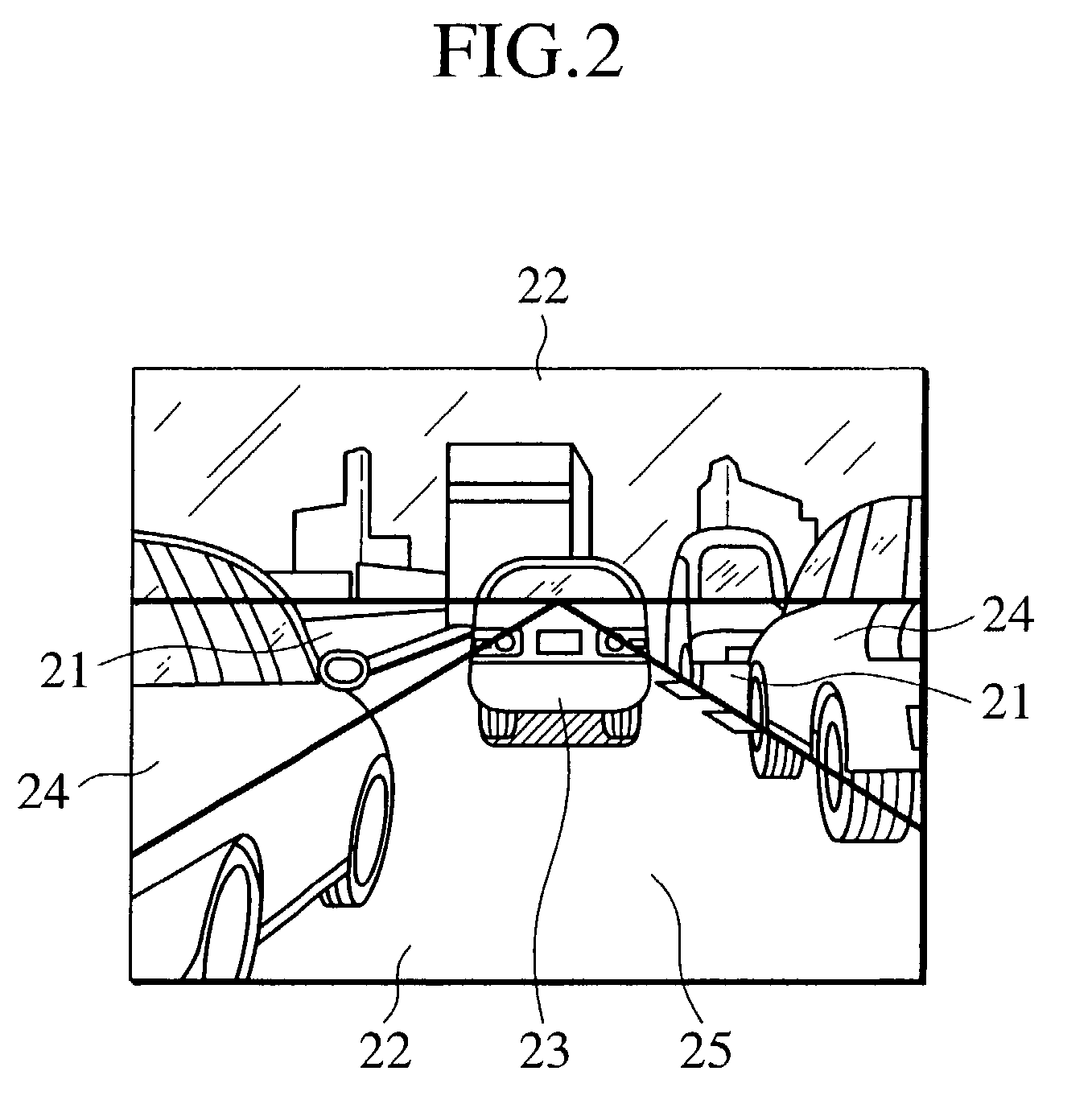

A vehicular image processing apparatus and related method are disclosed as having a high speed camera 2 that picks up an image of a surrounding of a vehicle, a low speed image extracting unit 6 extracting an image calculated with a low speed area calculating unit 4, a high speed image extracting unit 5 extracting other image than that calculated with the low speed area calculating unit 4, and an image outputting unit 9 synthesizing image information extracted with the high image extracting unit 5 and image information related to the image of the low speed area to provide an output which is applied to an image recognition device 11 to detect an obstacle around the vehicle or a road shape. A frame rate adjusting unit 8 enables the output image of the low speed image extracting unit 6 to be applied to the image outputting unit 9.

Owner:NISSAN MOTOR CO LTD

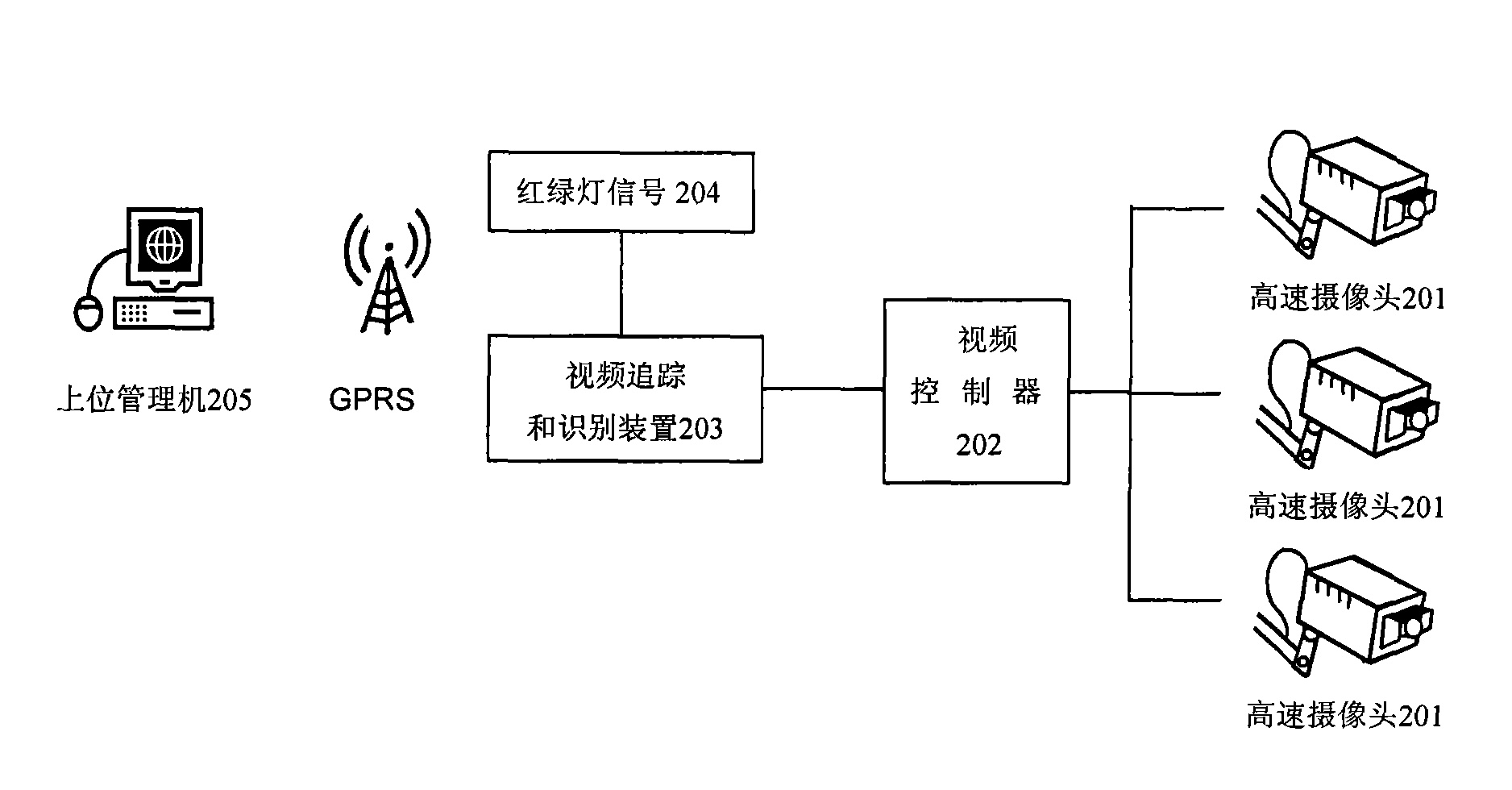

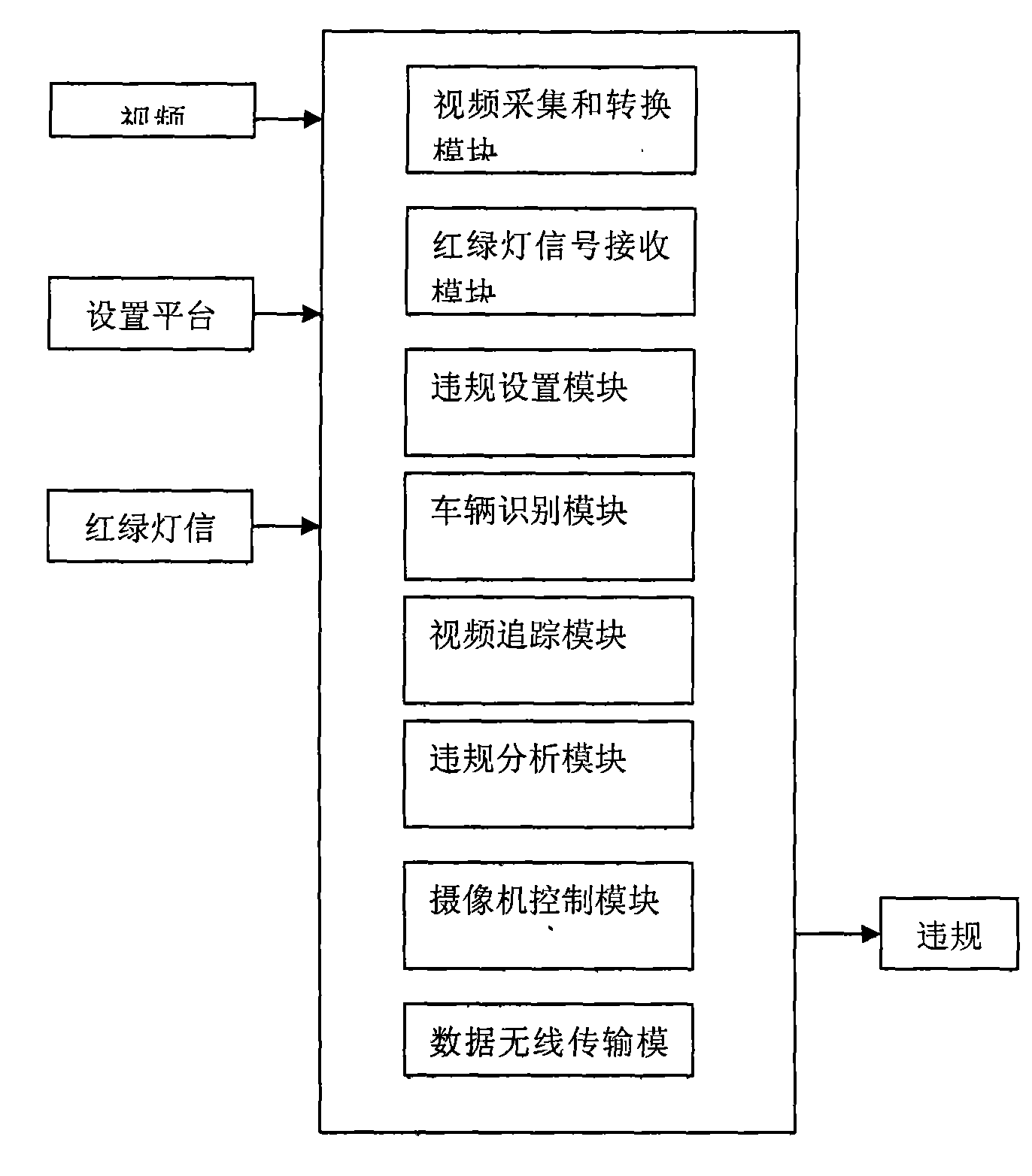

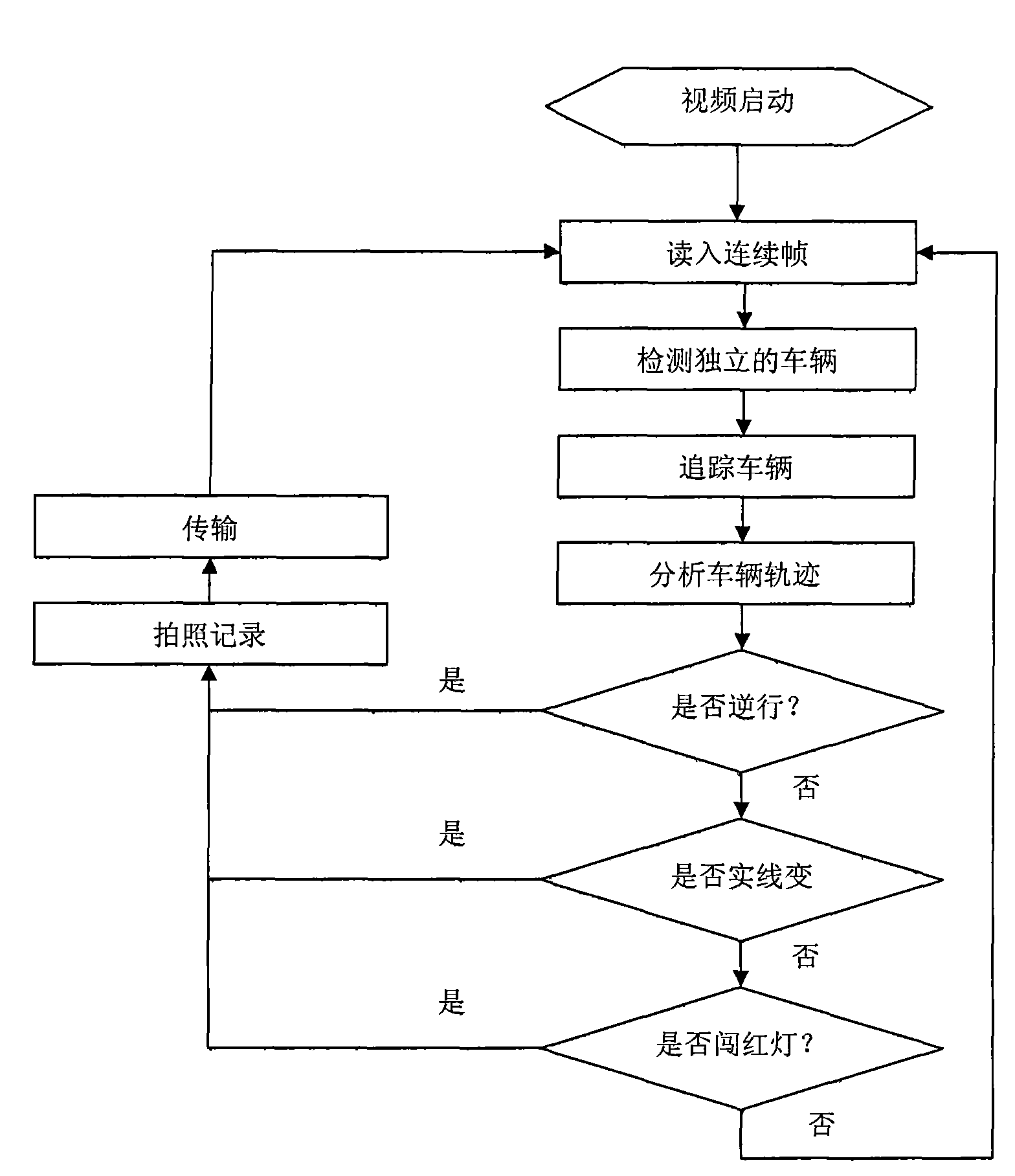

Traffic violation detection method based on video tracking and pattern recognition

ActiveCN101593422ALow implementation costImage analysisTransmission systemsCamera controlWrong direction

The invention discloses a traffic violation detection method based on video tracking and pattern recognition, and belongs to the technical fields of image recognition and pattern recognition. The method comprises the following steps: firstly, defining violation modes, namely defining traffic light stop lines, driving directions, and areas and directions of violation of course change; secondly, monitoring and controlling a camera to shoot video images of intersections; and thirdly, analyzing the video by an embedded system, performing detection and measurement by a pattern recognition method, using the video to track and acquire running tracks of vehicles, using the pattern recognition method to analyze behaviors of any one vehicle according to the running tracks, and immediately shooting the vehicle for recording if one of the following violation behaviors happens: going in wrong directions, violation of full line course change and running of a red light. A detection device used comprises a high-speed camera, a video controller, and a video tracking and pattern recognition device, wherein the video tracking and pattern recognition device comprises a traffic light signal receiving device, a video acquisition and conversion module, a violation setting module, a vehicle detection module, a video tracking module, a violation analysis module, a camera control module and a data wireless transmission module.

Owner:无锡乐骐科技股份有限公司

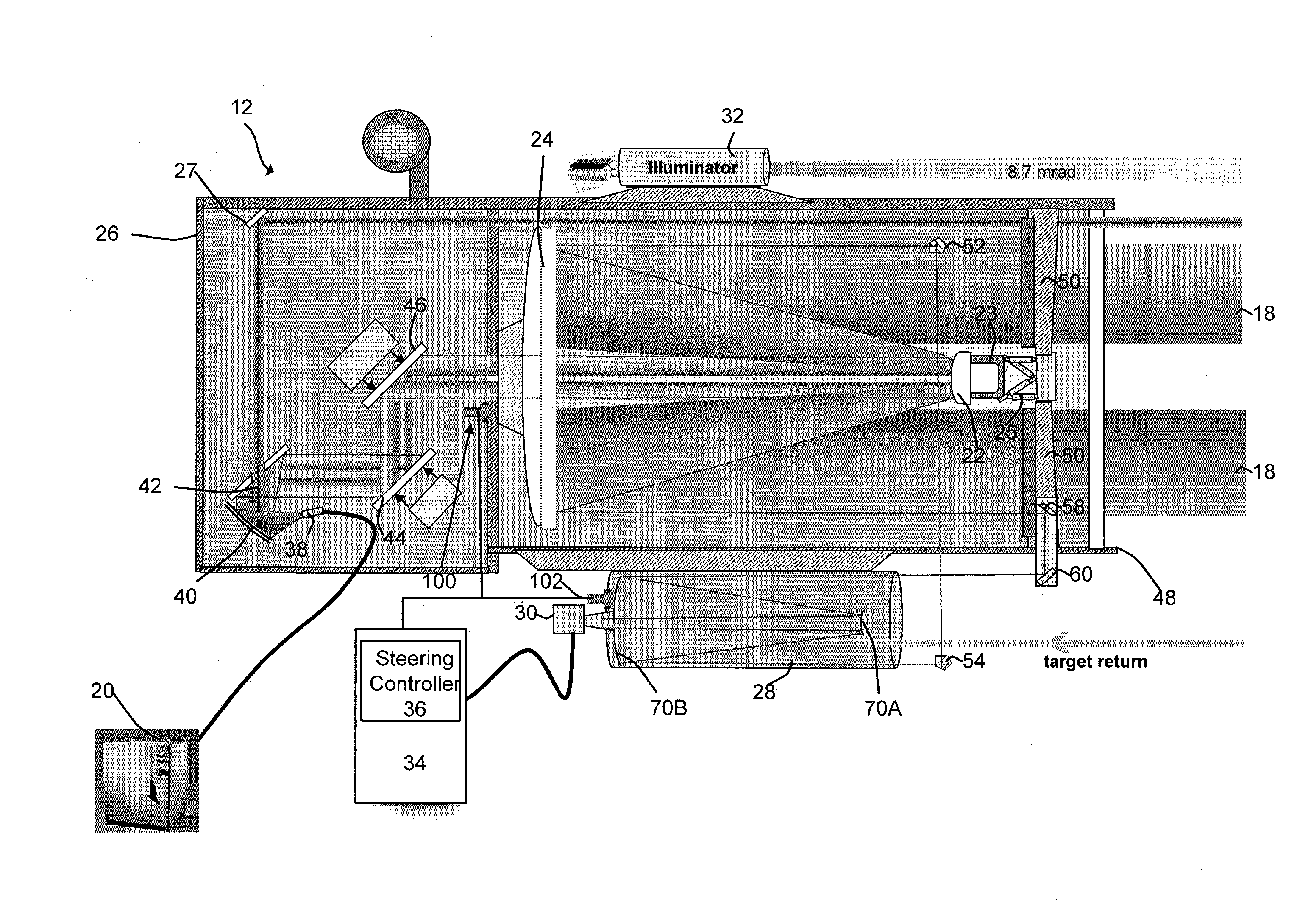

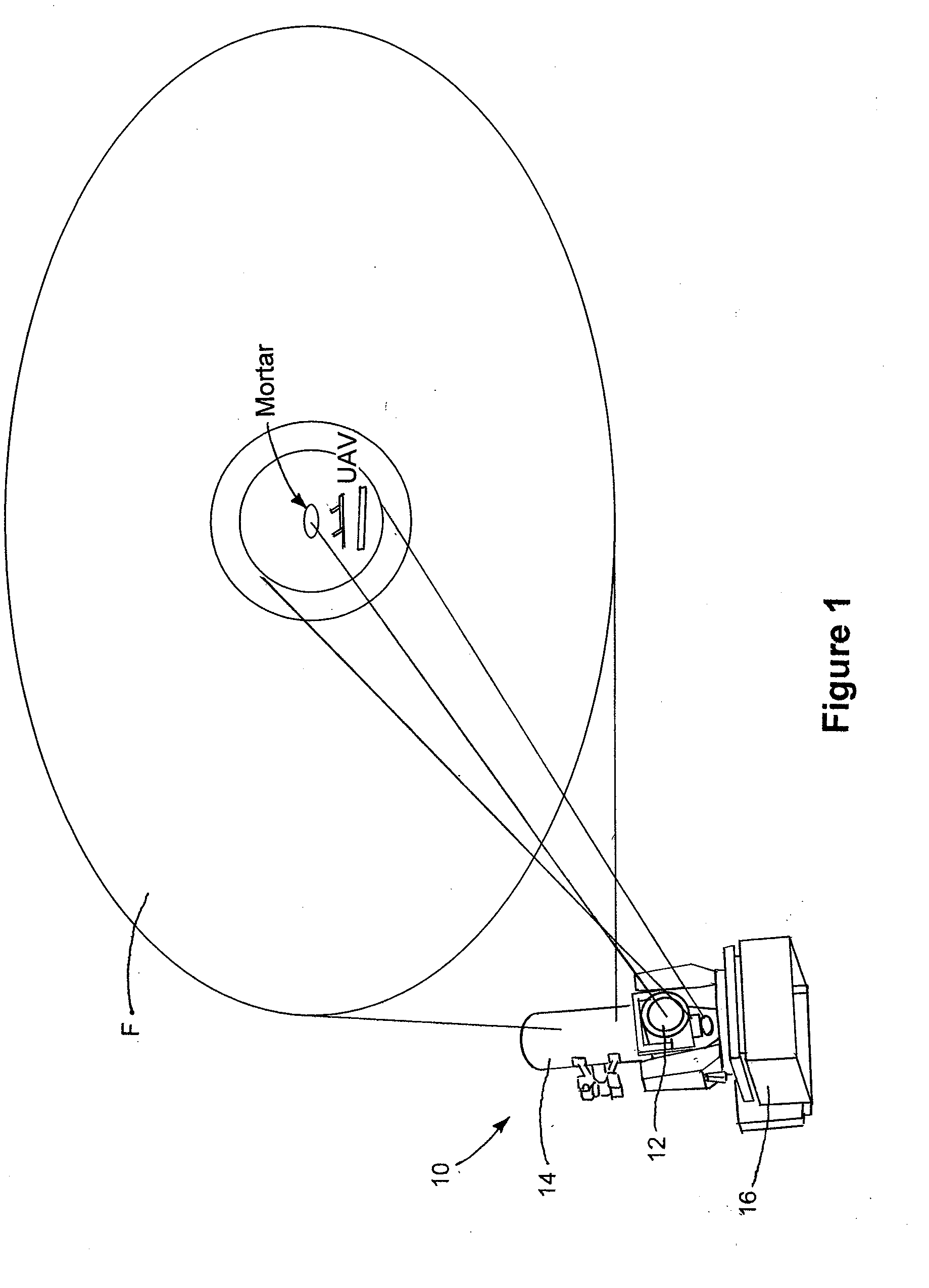

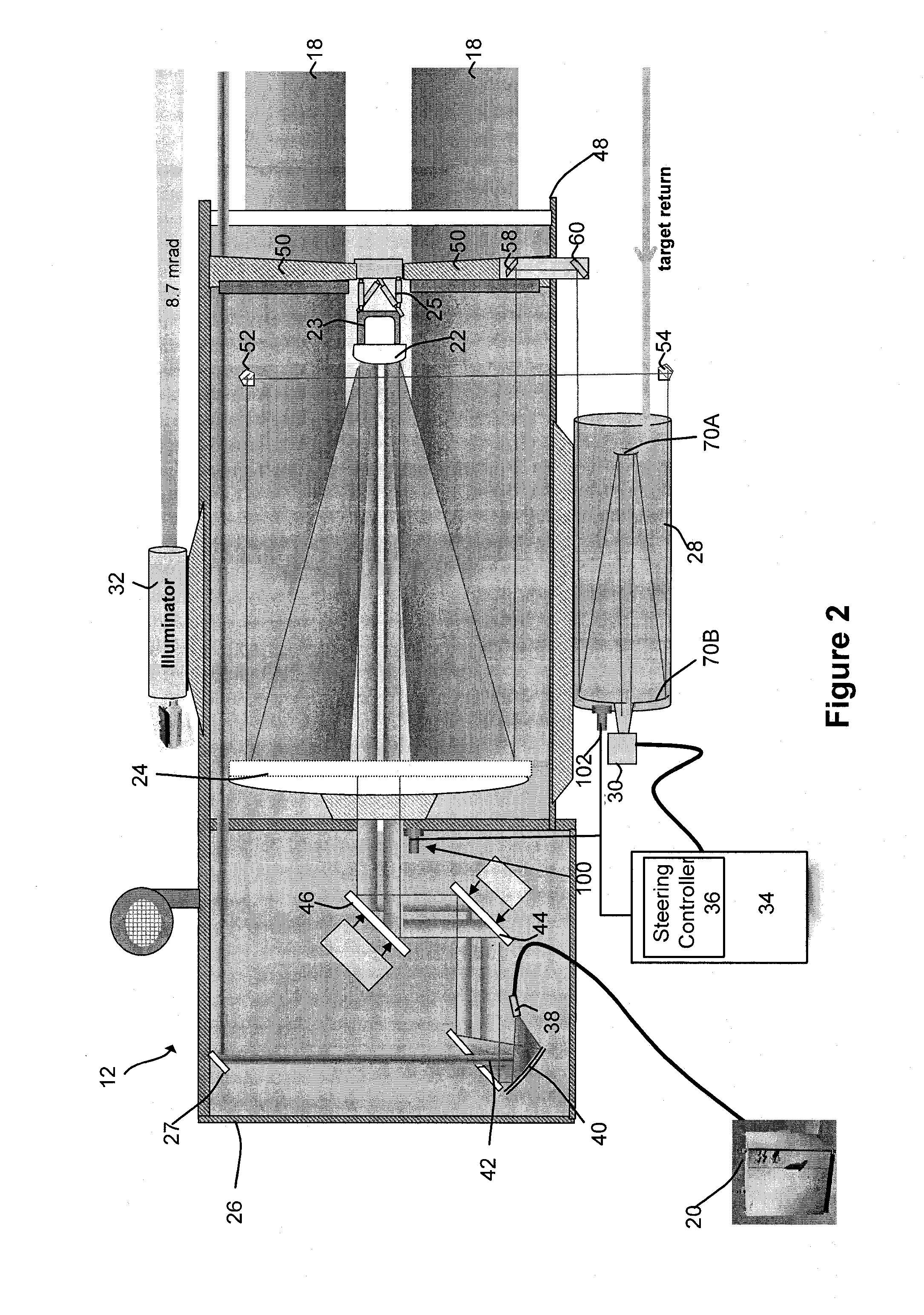

Semi-active optical tracking system

A system and method for tracking an airborne target including an illumination source (e.g., a diode laser array) is used to enhance a target signature and a detector (e.g., a passive high-speed camera) is used to detect to electromagnetic radiation (e.g., infrared radiation) reflected off the target. The received electromagnetic radiation may be processed by a digital computer and passed through a spatial filter that implements a band limited edge detection operation in the frequency domain. The filter may remove low spatial frequencies that attenuate soft edged clutter such as clouds and smoke as well as filter out artifacts and attenuated medium to high spatial frequencies to inhibit speckle noise from the detector as well as speckle from the laser return off the target.

Owner:RAYTHEON CO

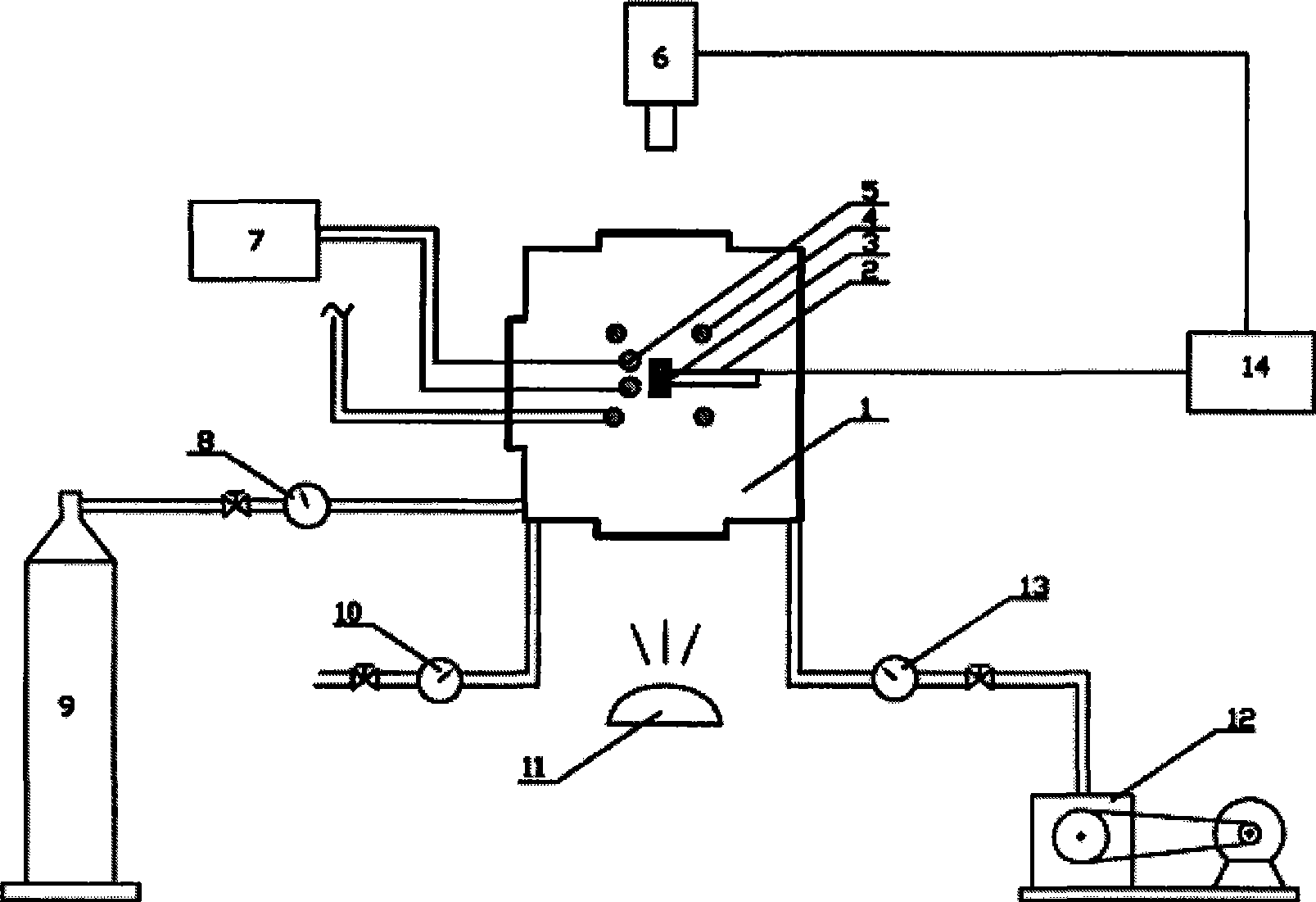

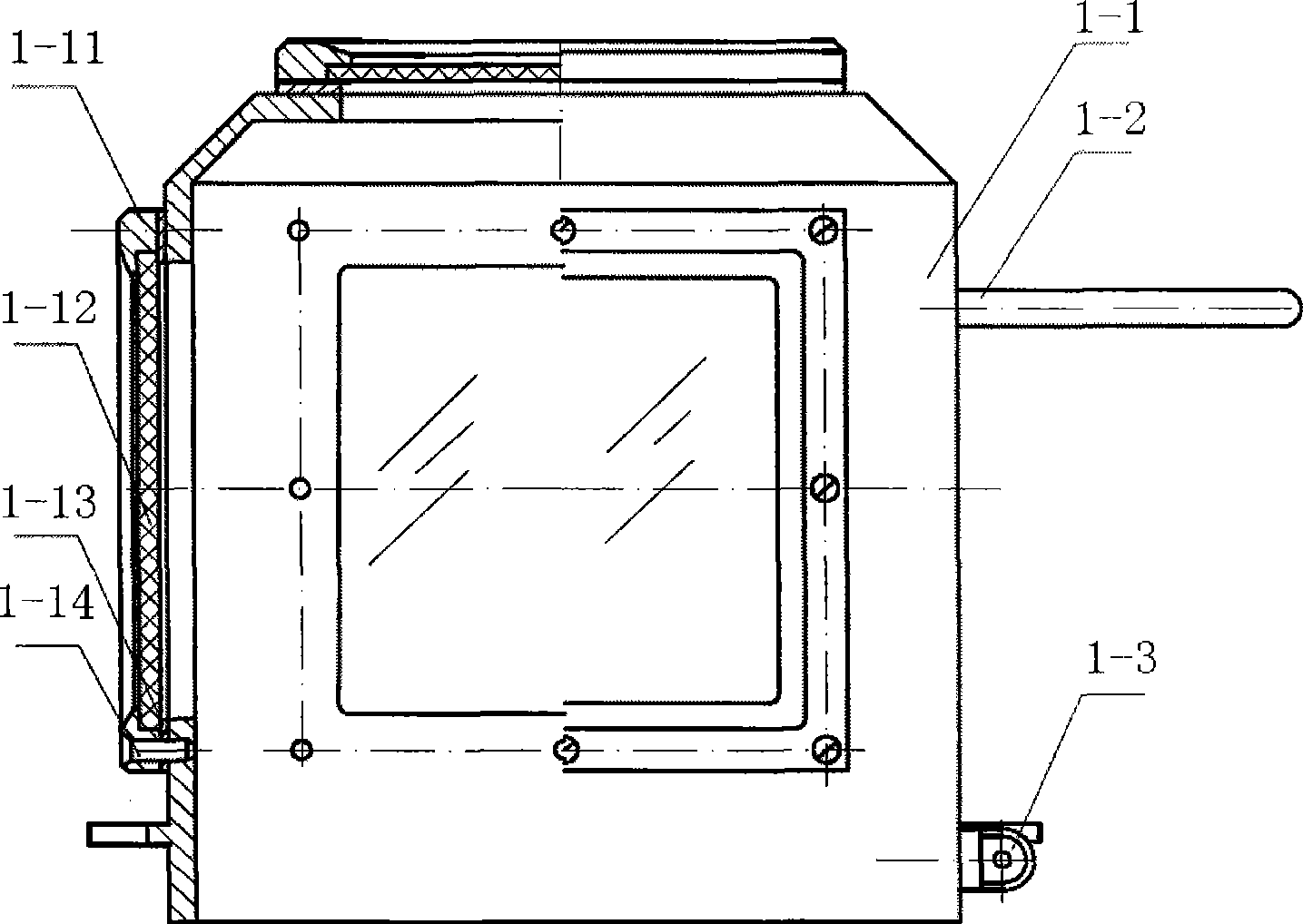

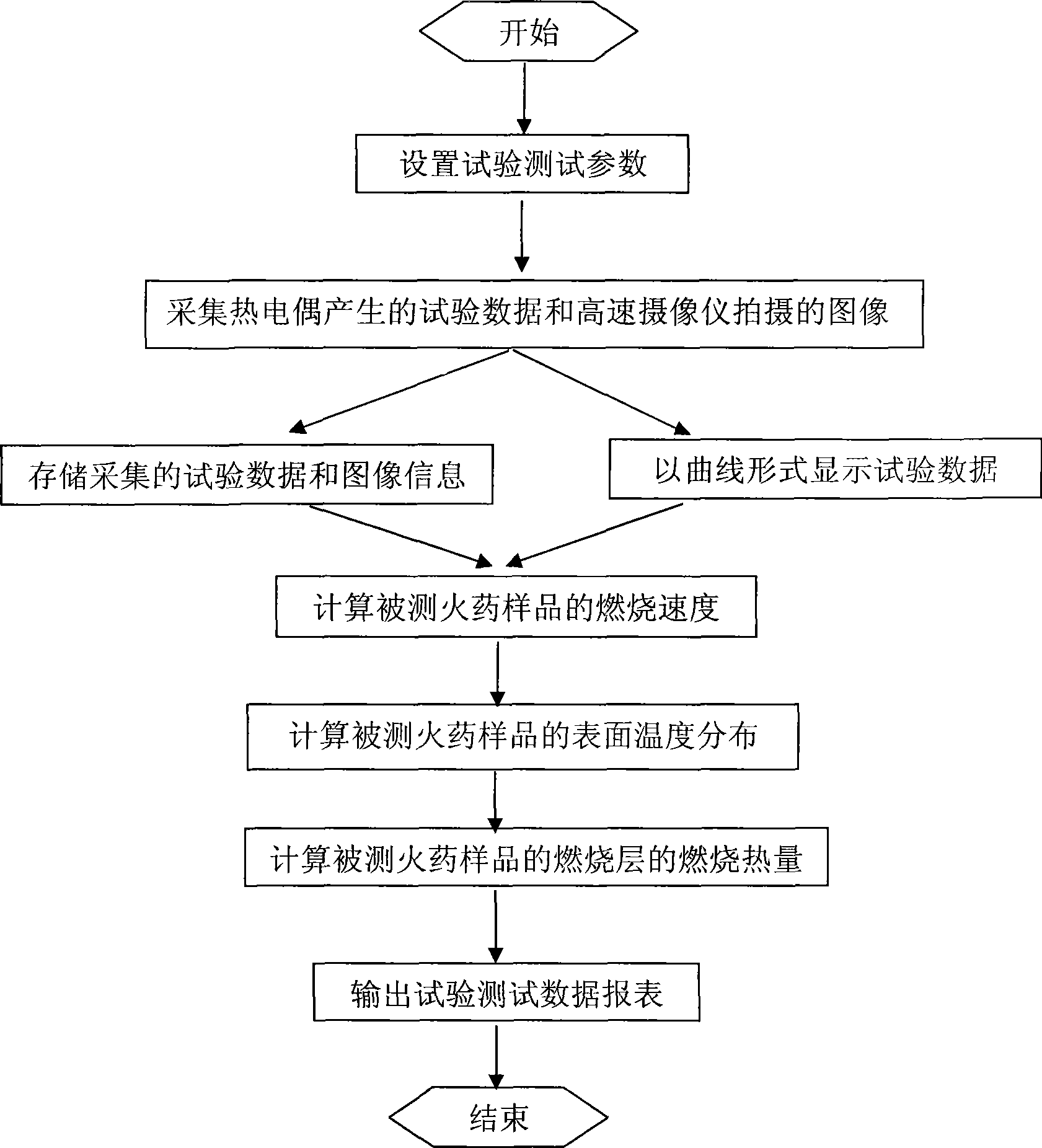

Device for testing powder combustion characteristics in vacuum condition

InactiveCN101382533ARealize measurementEfficient use ofChemical analysis using combustionFuel testingCombustion chamberHeating time

The invention discloses a testing device of gunpowder combustion characteristics in vacuum, which mainly comprises a combustion chamber, a vacuum pump, an electric heater, a thermoelectric couple, a high speed camera and a data acquisition and processing system; wherein, the vacuum pump provides vacuum environment for the combustion chamber; by controlling the heating current and the heating time of the electric heater, different ignition isoperibols can be provided for tested gunpowder samples in the combustion chamber; and the data acquisition and processing system collects the test data generated by the thermoelectric couple and the gunpowder combustion images shot by the high speed camera when the tested gunpowder samples combust, and finally obtains the combustion characteristics of the tested gunpowder samples through corresponding processing and calculation. The invention not only can be used for testing the parameters such as combustion speed, combustion surface temperature and combustion heat and the like of the gunpowder in vacuum, but also can be used for the generation and collection of the combustion products of the gunpowder under different vacuum conditions. The invention has the overriding advantages of high integration level, obtaining various parameters by one testing and low testing expenses.

Owner:XIAN MODERN CHEM RES INST

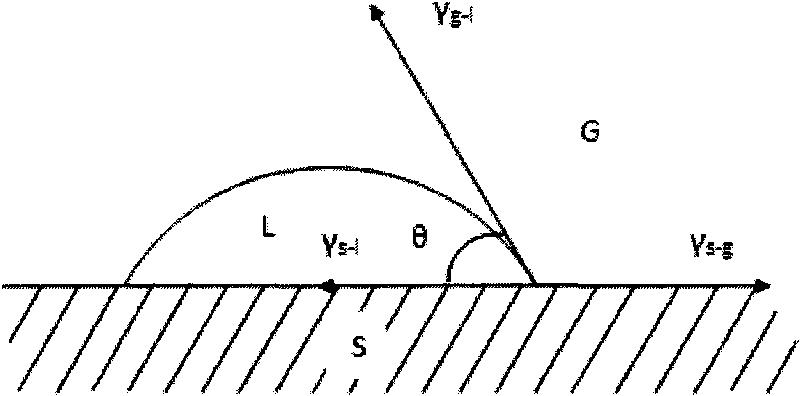

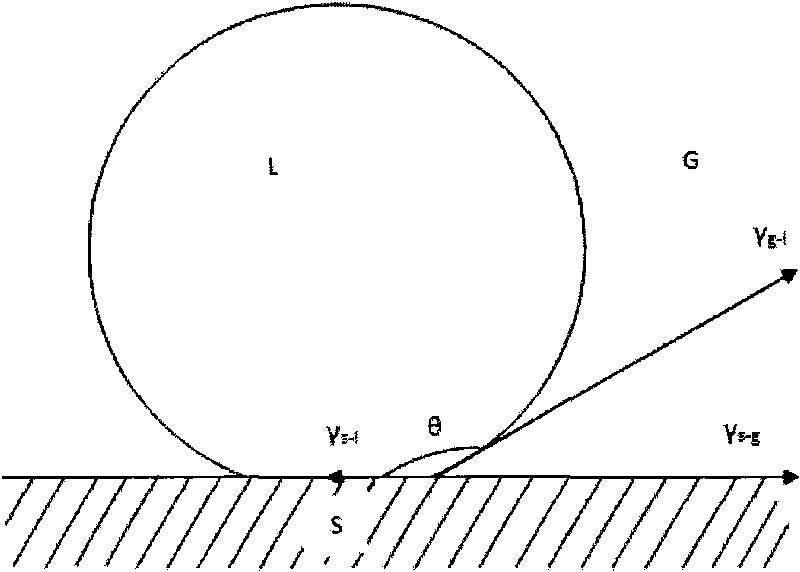

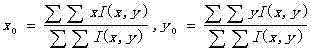

Method for synchronously measuring temperature, surface tension and contact angle of droplet by controlling temperature and humidity

InactiveCN101692012AGood repeatabilityHigh temperature control accuracyThermometers using electric/magnetic elementsUsing electrical meansData acquisitionChemical measurement

The invention belongs to the technical field of chemical measurement. A temperature and humidity control system is adopted to accurately control the environment in a sample case, namely the temperature ranges from minus 80 DEG C to plus 300 DEG C and the accuracy is + / -0.1 DEG C, the relative humidity ranges from 0%-100% and the accuracy is + / -2%-+5%. A high-speed data acquisition system and a high-speed camera system are adopted to synchronously measure the temperature and profile image of a droplet accurately. The sampling frequency of the temperature can be as high as 1MHz and the sampling speed of the image can reach 420 frames / s. Sample data are transmitted to a computing system through data lines and the temperature of the droplet is obtained. The image data are fitted according to the Bashforth-Adams equation and Yong-laplace equation to obtain such numerical values as surface tension and contact angle, etc. The device has simple operation, high testing accuracy and good repeatability of experimental results and is suitable for synchronously measuring the temperature, surface tension and contact angle under the conditions of wide temperature range and total humidity.

Owner:NANJING UNIV

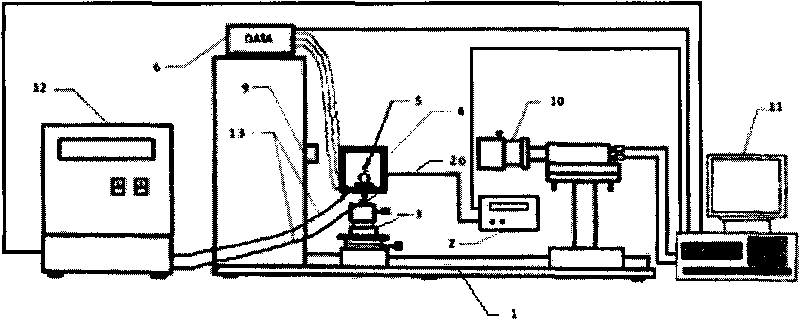

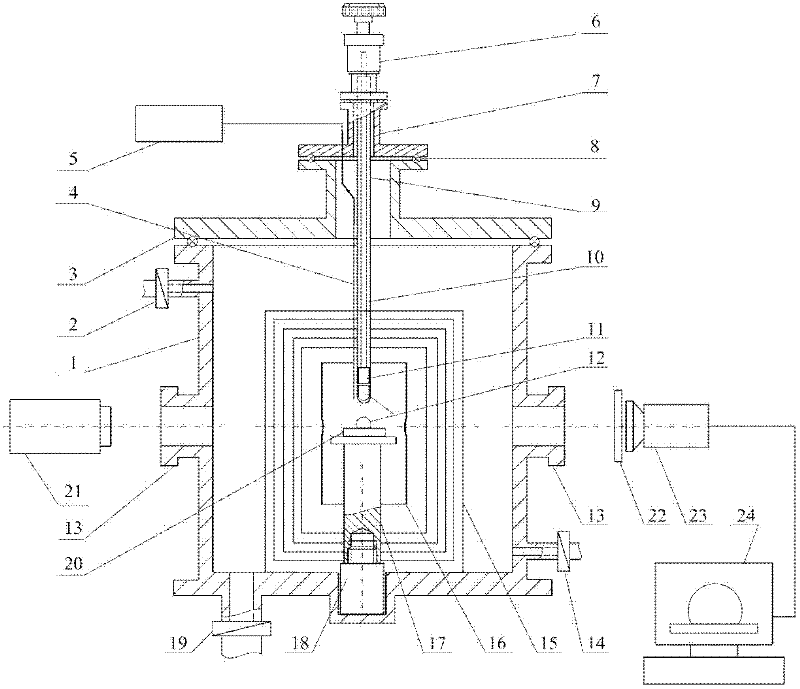

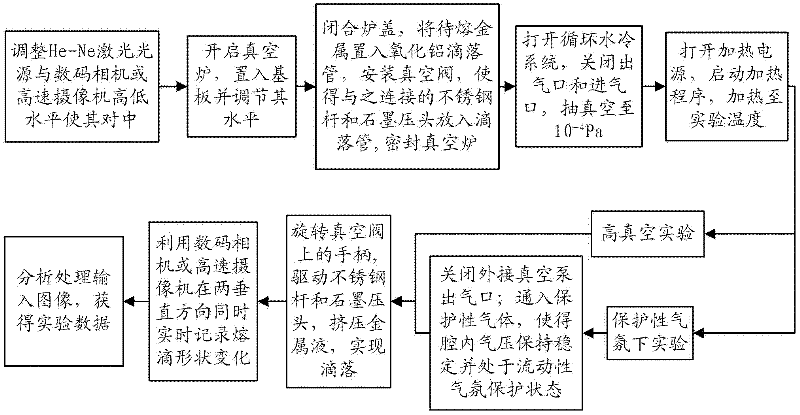

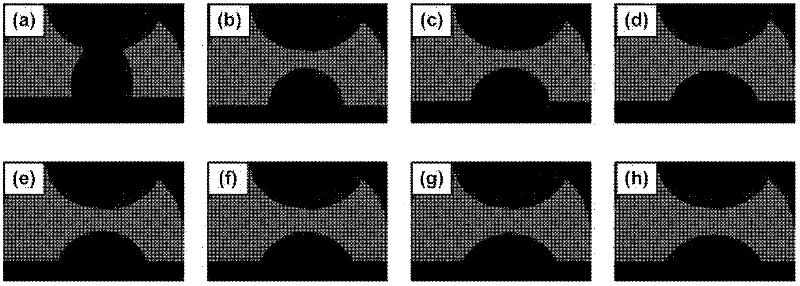

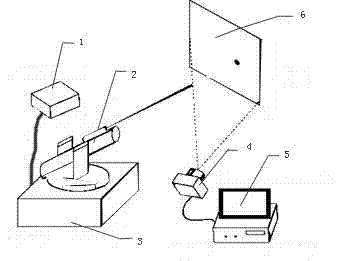

Apparatus and method for determining high temperature wettability

InactiveCN102353620ARealize separate heatingPrevent oxidationSurface/boundary effectFurnace typesRubber ringEngineering

Owner:JILIN UNIV

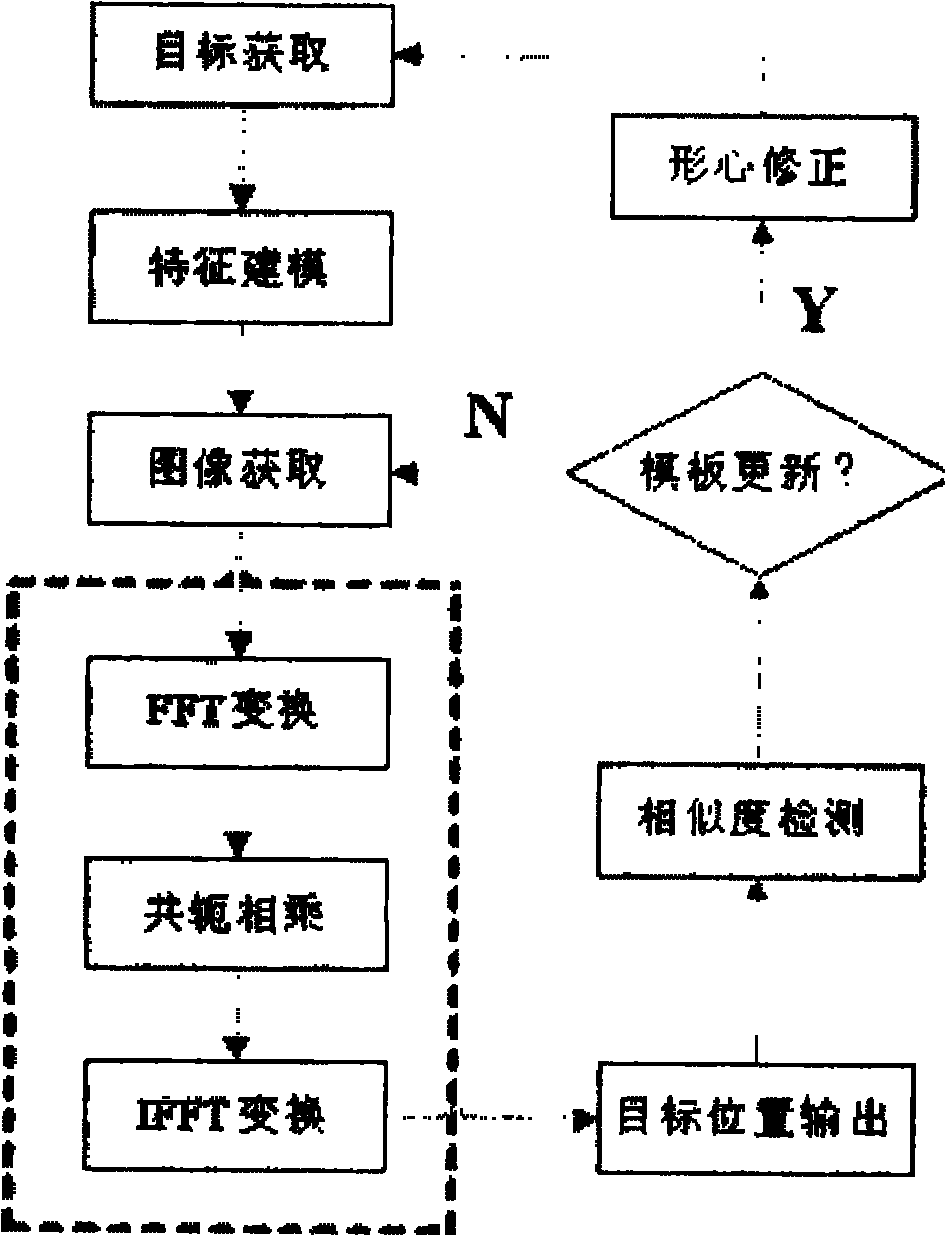

Device and method for calibrating dynamic tracking precision of photoelectric tracking system

The invention discloses a device and a method for calibrating the dynamic tracking precision of a photoelectric tracking system. The device comprises a beacon light subsystem used for generating beacon light, a high-speed image acquisition system and a processing subsystem, wherein the beacon light subsystem comprises a high-precision laser target simulator, a laser target controller, a first computer and a target plate; the high-speed image acquisition system comprises a high-speed camera; and the processing subsystem comprises a second computer. The beacon light subsystem consisting of a solid laser, a beam expander, a fast tilting mirror and a reflecting mirror is used for generating the beacon light to the target plate and can simulate targets with a plurality of motion modes and movement speeds through faculae, so that the precision of equipment can be tested persuasively. The faculae are acquired by the high-speed image acquisition system and the high test precision can be obtained by using a high-speed digital image processing technology, so that the photoelectric tracking system is quickly and accurately calibrated according to the measurement of the tracking precision.

Owner:NO 27 RES INST CHINA ELECTRONICS TECH GRP

Apparatus for testing flame propagation and flame suppression in flammable gas and air premixed gas explosion process

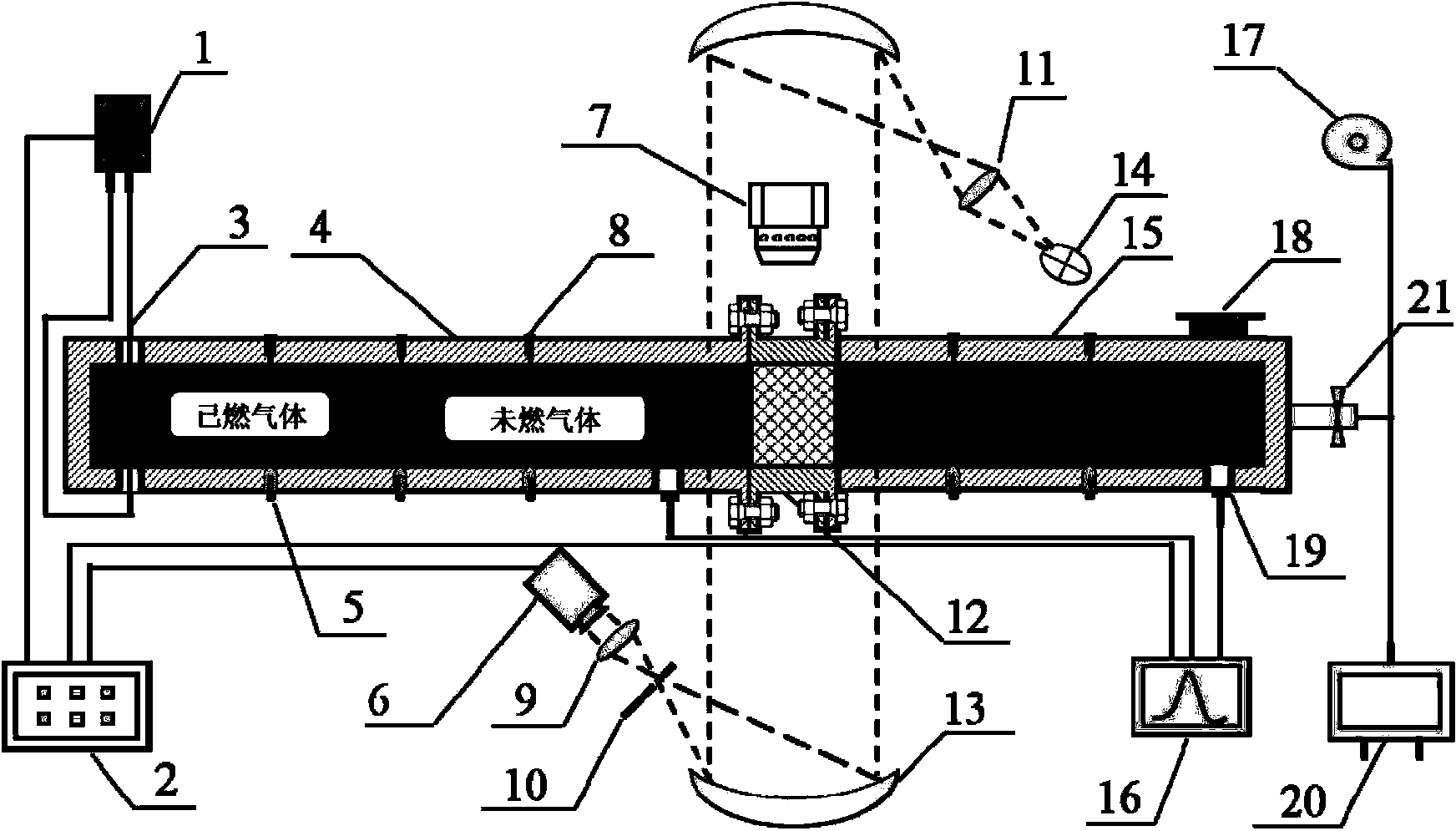

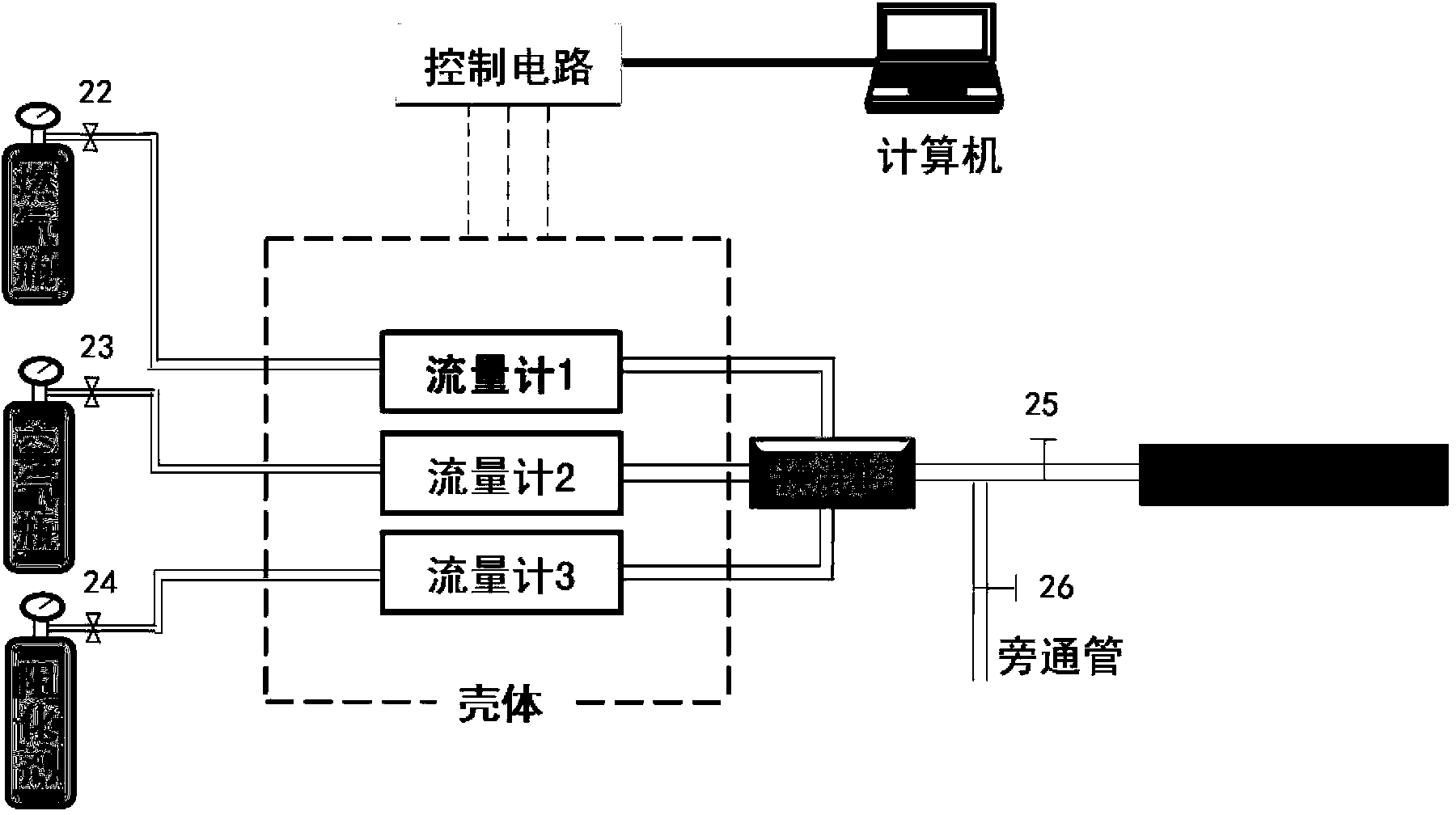

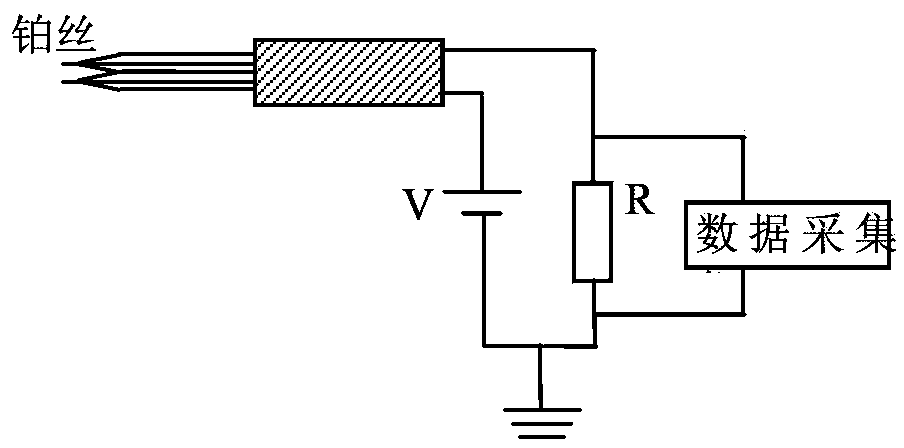

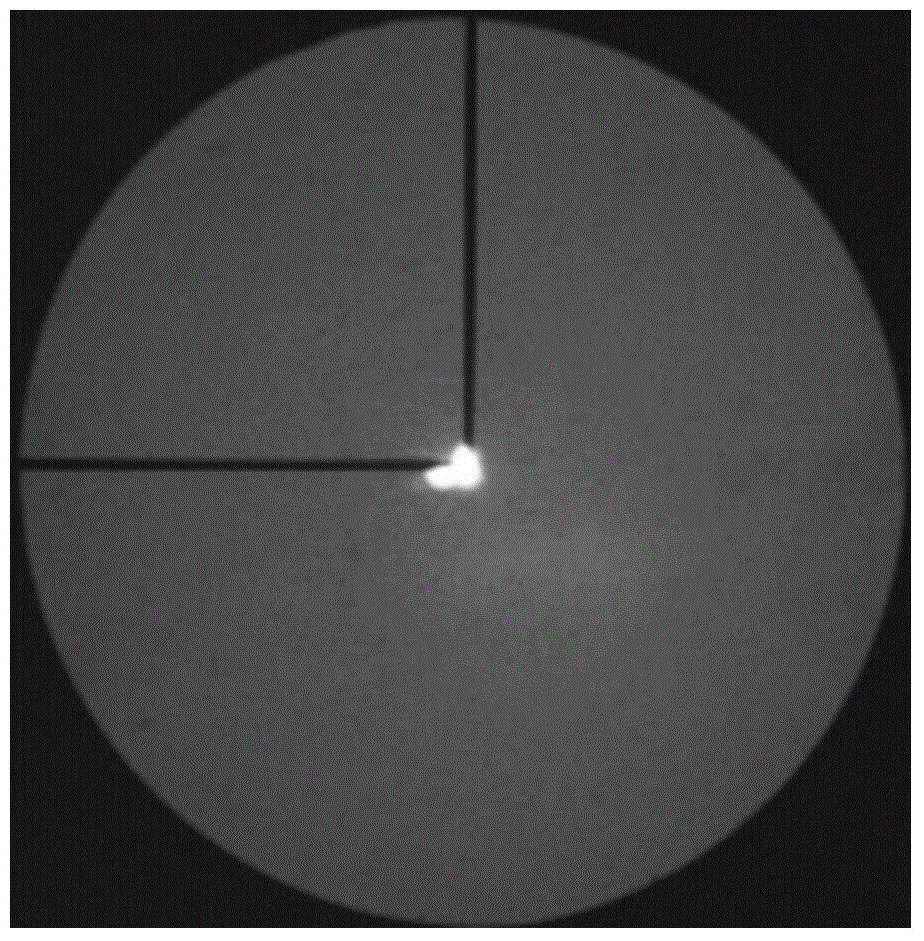

ActiveCN103454308AAccurate and intuitive recordReveal inhibitionMaterial exposibilityData acquisitionInstability

The invention provides an apparatus for testing flame propagation and flame suppression in the flammable gas and air premixed gas explosion process. The whole apparatus comprises a combustion pipeline, a water mist generating device, a metal net fire retardance device, a high-speed camera, a schlieren system, a pressure testing system, an automatic gas distribution system, a temperature testing system, an ion probe detection system, a data acquisition instrument, a high-tension ignition system and a synchronous controller. Through the apparatus, flame propagation characteristics and flame propagation rules are researched in the premixed gas explosion process under the influences of factors such as different flammable gas components, different opening states, different ignition positions and different types of flame instability, the effects of stopping agents, fire-retardant metal nets, water mist and the like on controlling and restraining flame propagation are researched, a method and technology for restraining premixed gas flame propagation are developed under the physical-chemical coupling effect, and the inner mechanism of the apparatus is explained.

Owner:UNIV OF SCI & TECH OF CHINA

Gas explosion simulation test system and method

Owner:ANHUI UNIV OF SCI & TECH

Online material biaxial static-dynamic performance test platform under service temperature

ActiveCN104502202AImprove reliabilityImprove stabilityMaterial strength using tensile/compressive forcesMaterial strength using repeated/pulsating forcesAlloyEngineering

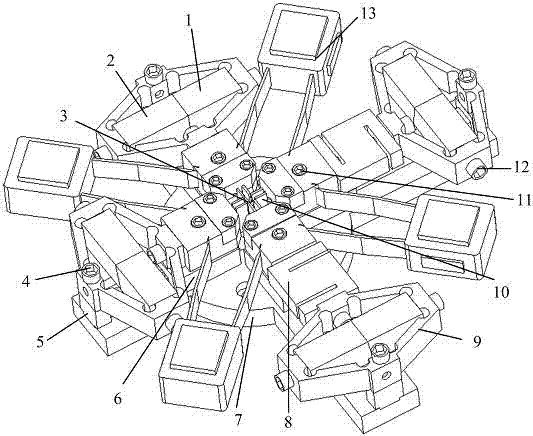

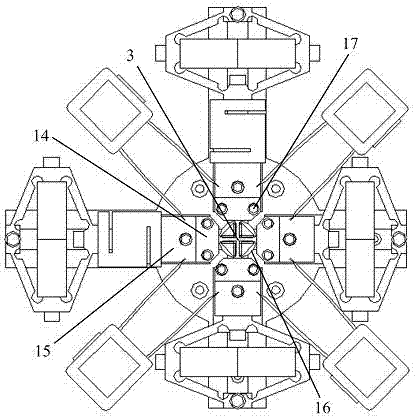

The invention relates to an online material biaxial static-dynamic performance test platform under service temperature, belonging to the field of precision drive. The large-stroke biaxial synchronous identical-speed or synchronous different-speed displacement output is realized by virtue of four groups of piezoelectric actuators which are orthogonally distributed, and the biaxial static tensile test or dynamic fatigue test for a block-shaped material or a film material with a characteristic size being in a millimeter scale can be carried out under a high / low temperature service condition by combining with an embedded high temperature electrothermal alloy sheet / parr patch. The online material biaxial static-dynamic performance test platform is likely to use in conjunction with a scanning electron microscope with a relatively-large vacuum cavity or other microimaging device with an open-type carrier space, such as an optical microscope, an atomic power microscope and a high speed camera, so that the multimode biaxial static tensile test or the large-frequency-range biaxial dynamic fatigue test can be carried out, and the research for the microstructure evolution behavior and fatigue failure mechanism of various structural materials or functional materials under a complicated service condition such as a high / low temperature condition and a static-dynamic plane stress condition can be facilitated.

Owner:JILIN UNIV

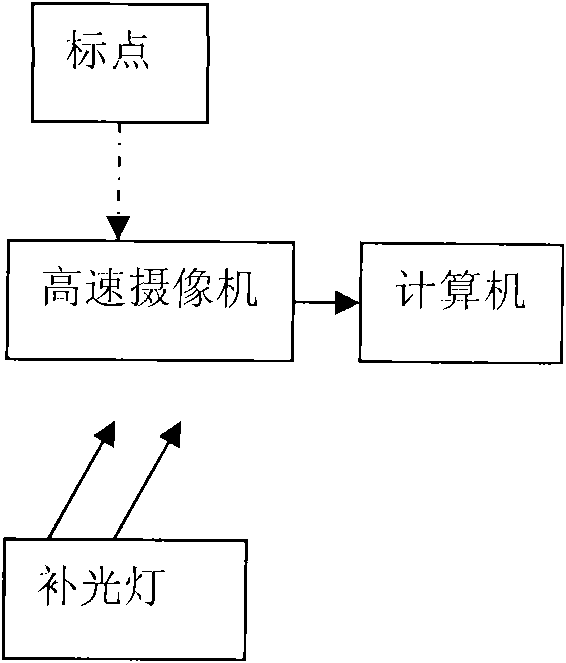

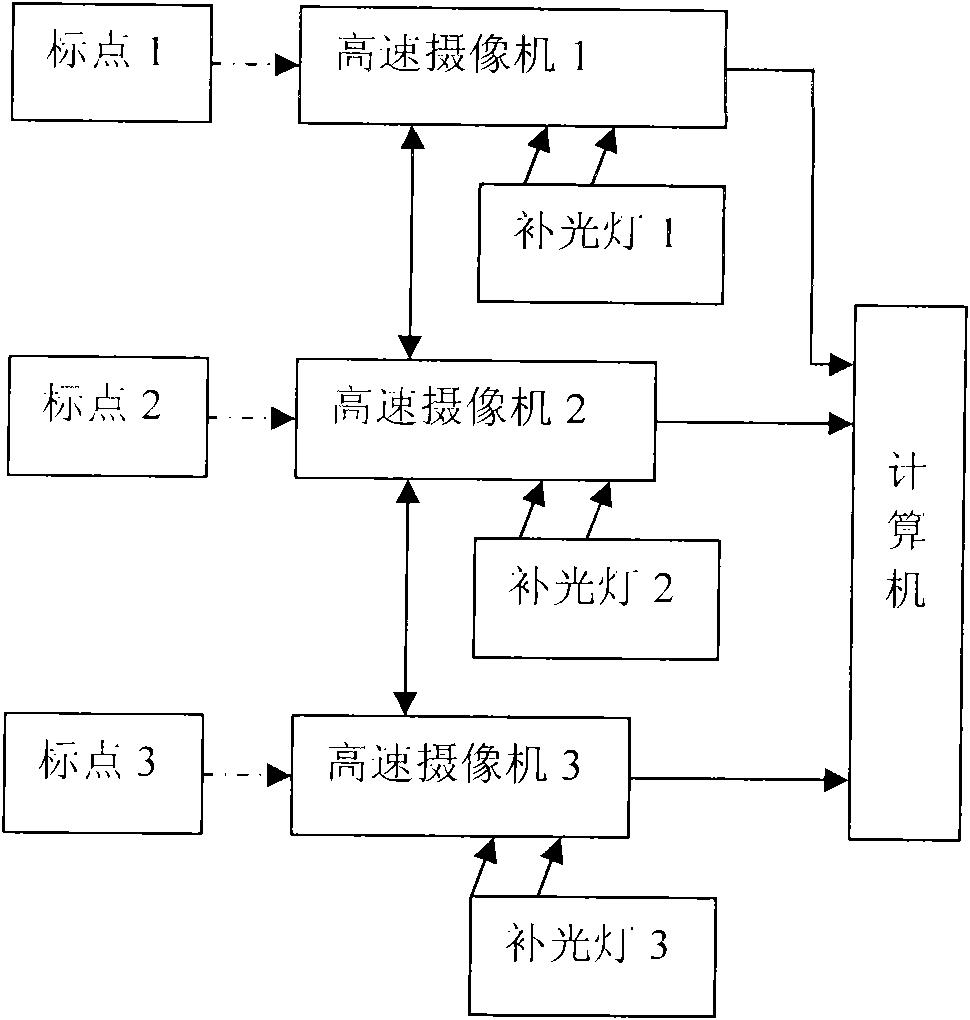

Digital radiography-based breaker operating characteristic on-line detection device and method

ActiveCN101893686AImprove reliabilityStrong analytical skillsCircuit interrupters testingElectric power systemDigital radiography

The invention discloses a digital radiography-based breaker operating characteristic on-line detection device and method. The device comprises a gage mark, an image acquisition device and a computer, wherein the gage mark is arranged on a breaker drive mechanism; the image acquisition device is arranged in a place corresponding to the gage mark on the breaker drive mechanism; and the signal input end of the computer is connected with the image output end of the image acquisition device. The device of the invention uses a high speed camera to shoot the motion process of the breaker drive mechanism and obtain a motion image and inputs the motion image in the computer; and the computer analyzes and processes the image to obtain the motion (travel time) curve of the gage mark and performs analysis according to the obtained motion curve to obtain the motion characteristic parameter of the breaker to be detected. The device and method of the invention can be used to realize the on-line detection of the motion characteristic of the breaker, lay a foundation for handling the operational state of the breaker and grasping the motion characteristic, play an important role in the improvement of the operational reliability and provide support for the reliable operation of the electric system.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

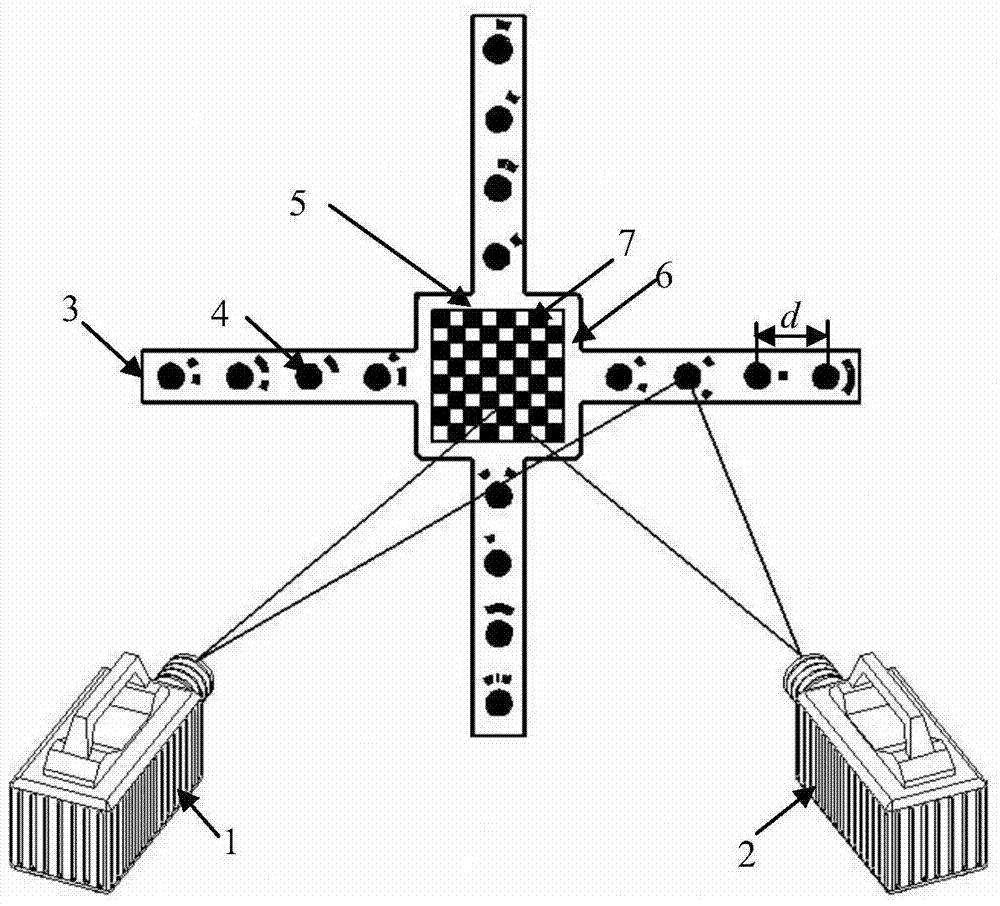

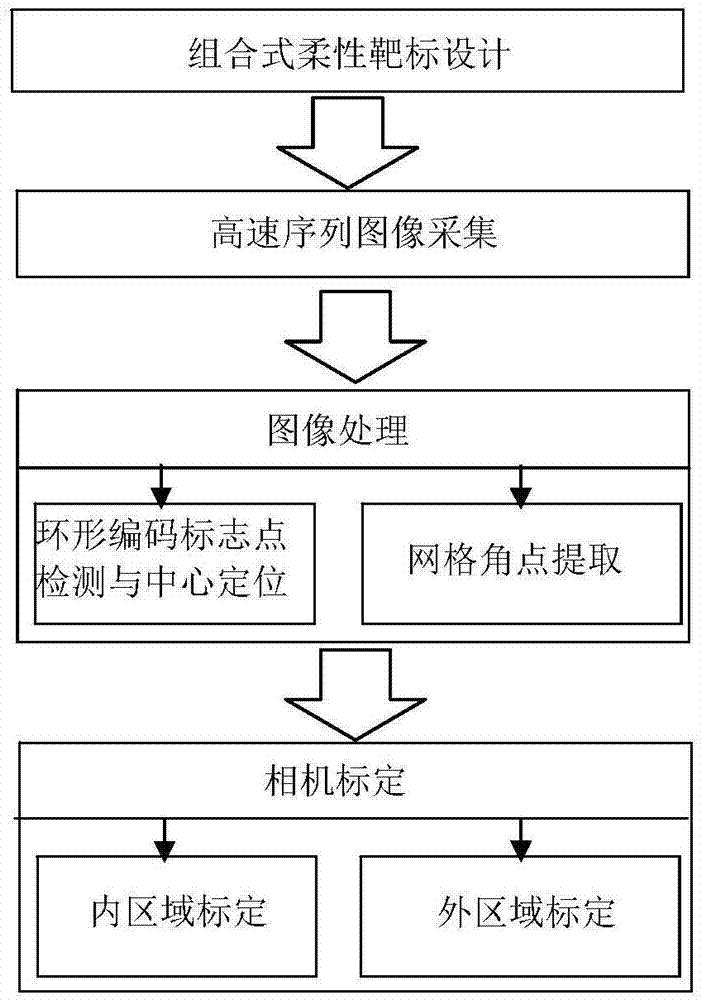

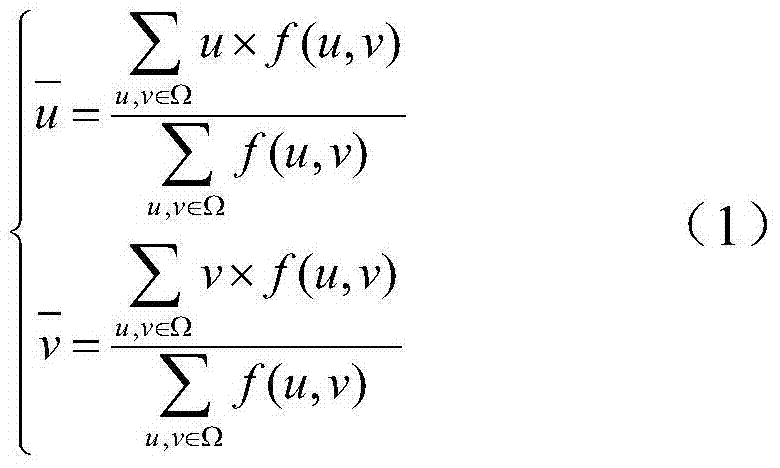

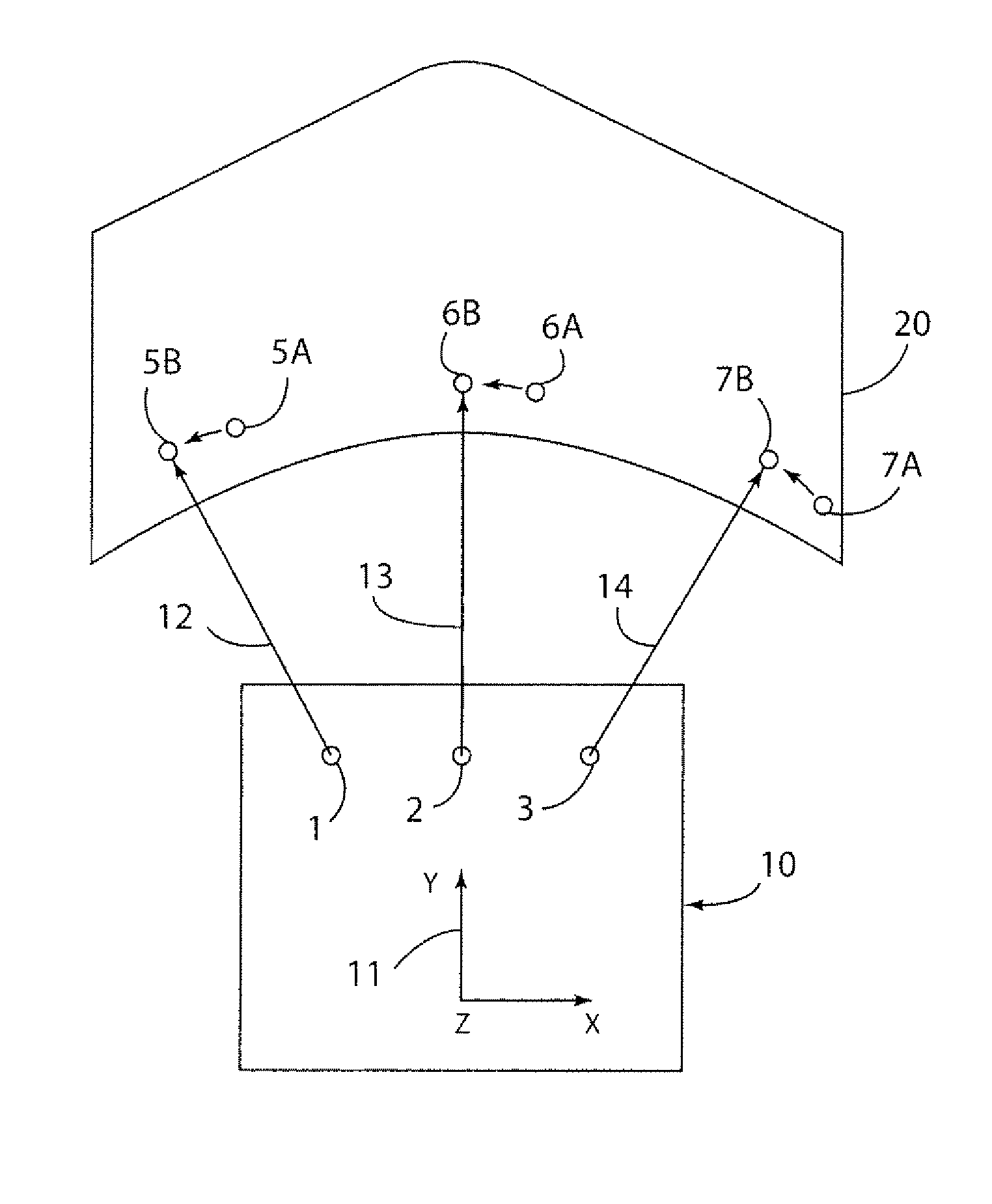

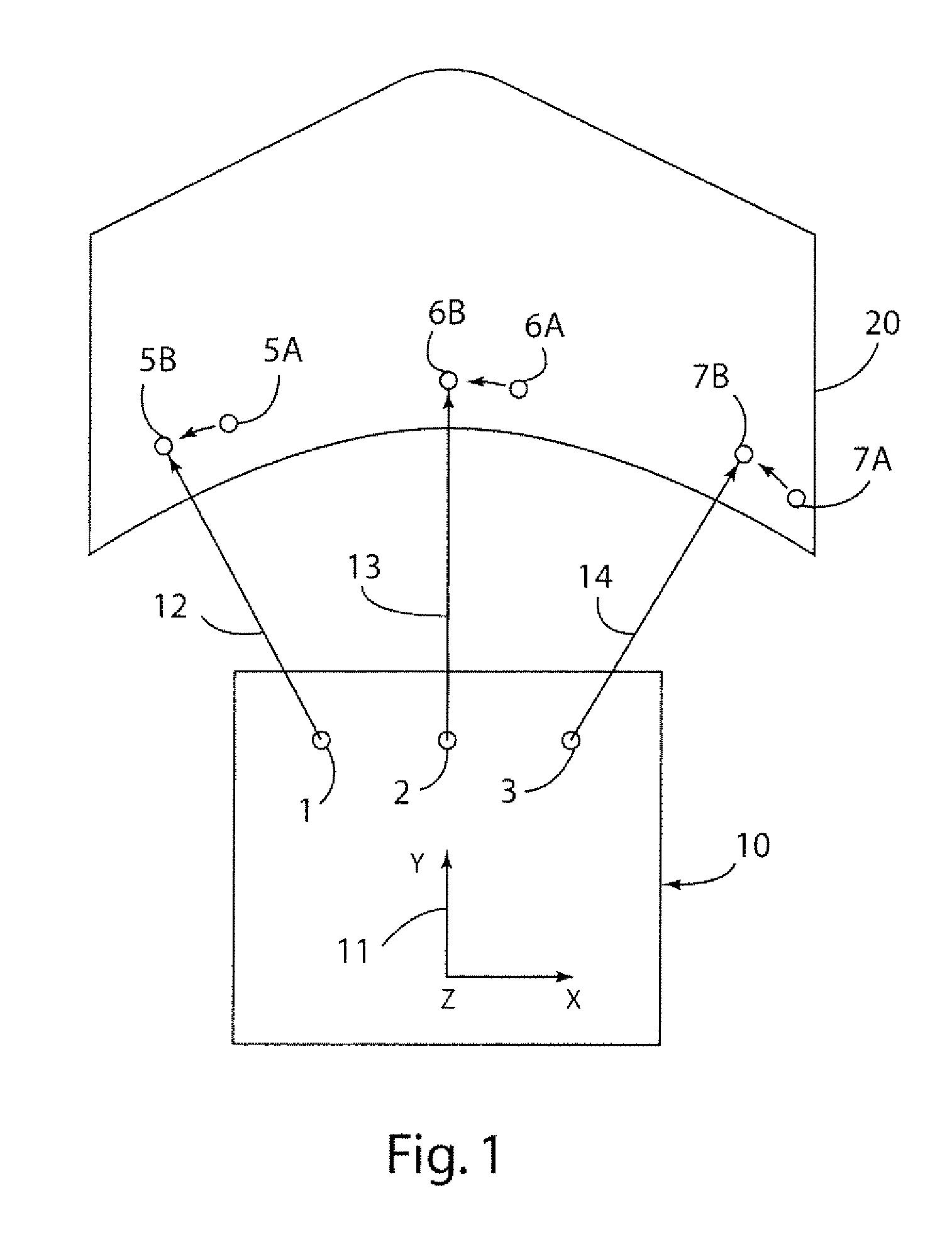

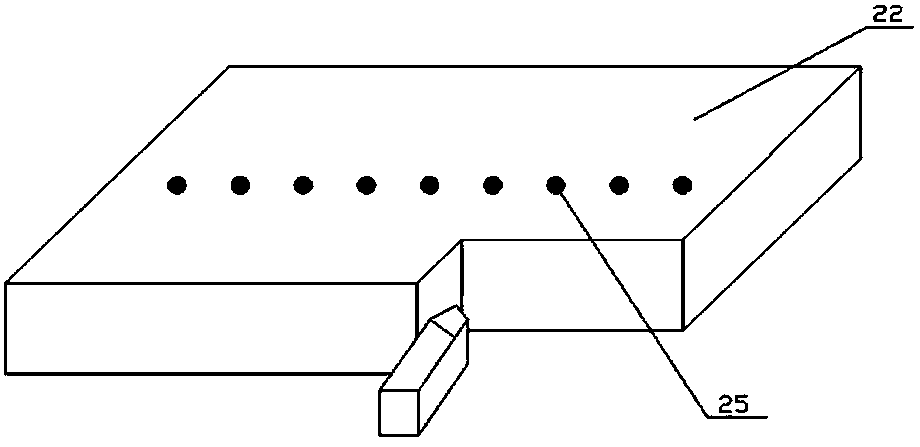

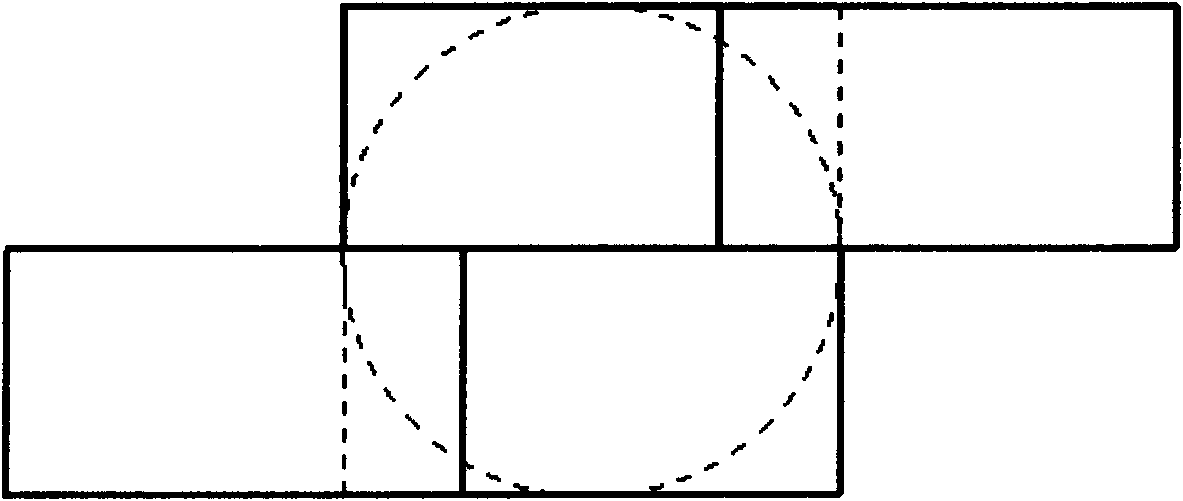

Flexible-target-based close-range large-field-of-view calibrate method of high-speed camera

The invention, which belongs to the computer vision field, provides a flexible-target-based close-range large-field-of-view calibrate method of a high-speed camera and relates to a close-range large-field-of-view binocular-visual-sense camera calibration method in a wind tunnel. According to the method, a flexible target is used for fill an overall calibration view field for calibration; the internal region of the target is formed by a planar chessboard mesh and distances between angular points of the chessboard mesh are known; the external region of the target is formed by cross target rods perpendicular to each other and a plurality of coding marking points with known distances are distributed on the target rods uniformly. During calibration, regional and constraint calibration is carried out on a high-speed camera by using different constraint information provided by different regions of the target. When the internal region of the target is calibrated, calibration is carried out by using a homography matrix; and the external region is calibrated by using distance constraints of the coding marking points. According to the invention, the cost is lowered and the operation portability is realized. During calibration, distortion of different regions is considered by using the regional and constraint camera calibration method, so that the calibration precision is improved.

Owner:DALIAN UNIV OF TECH

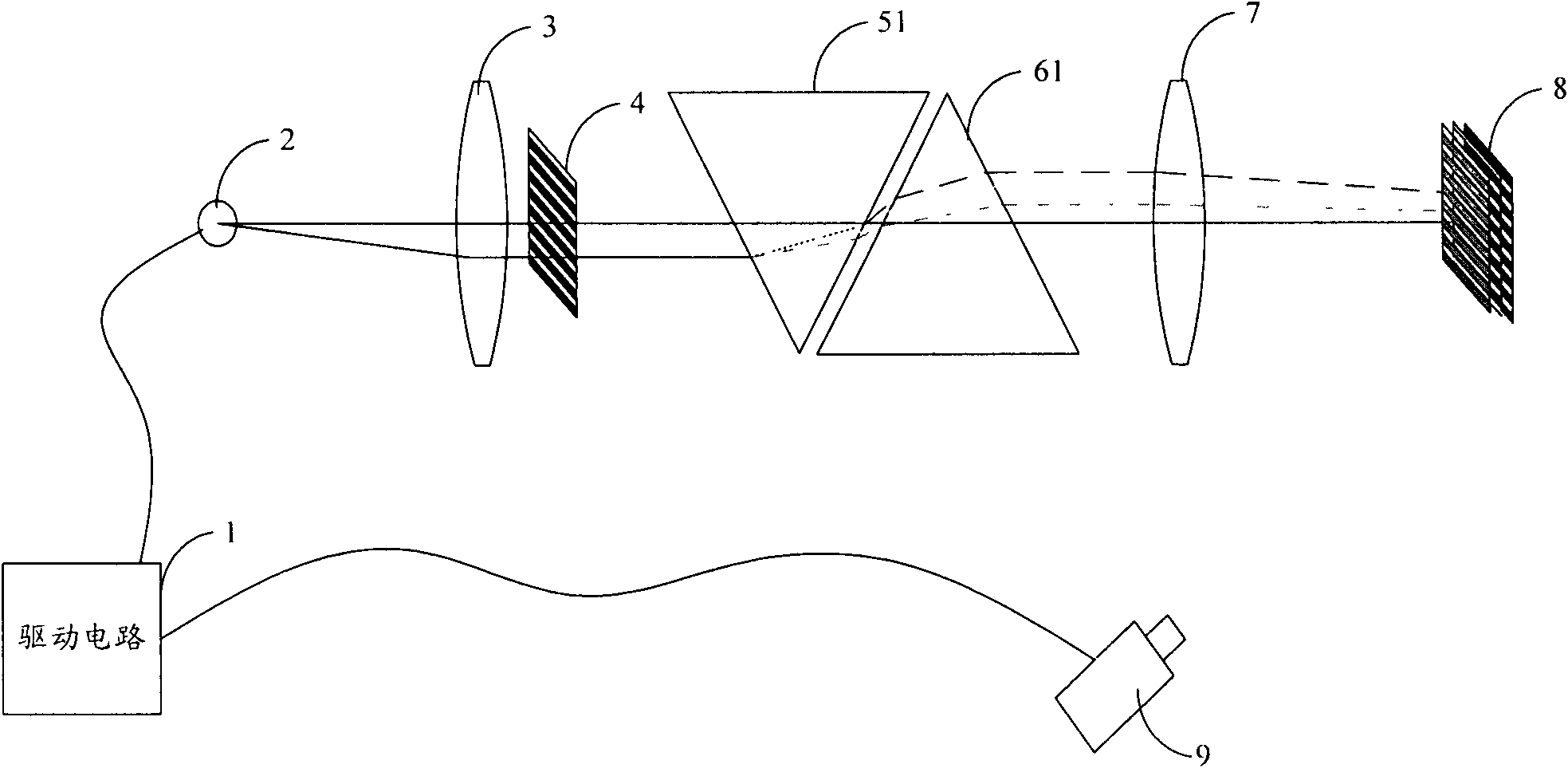

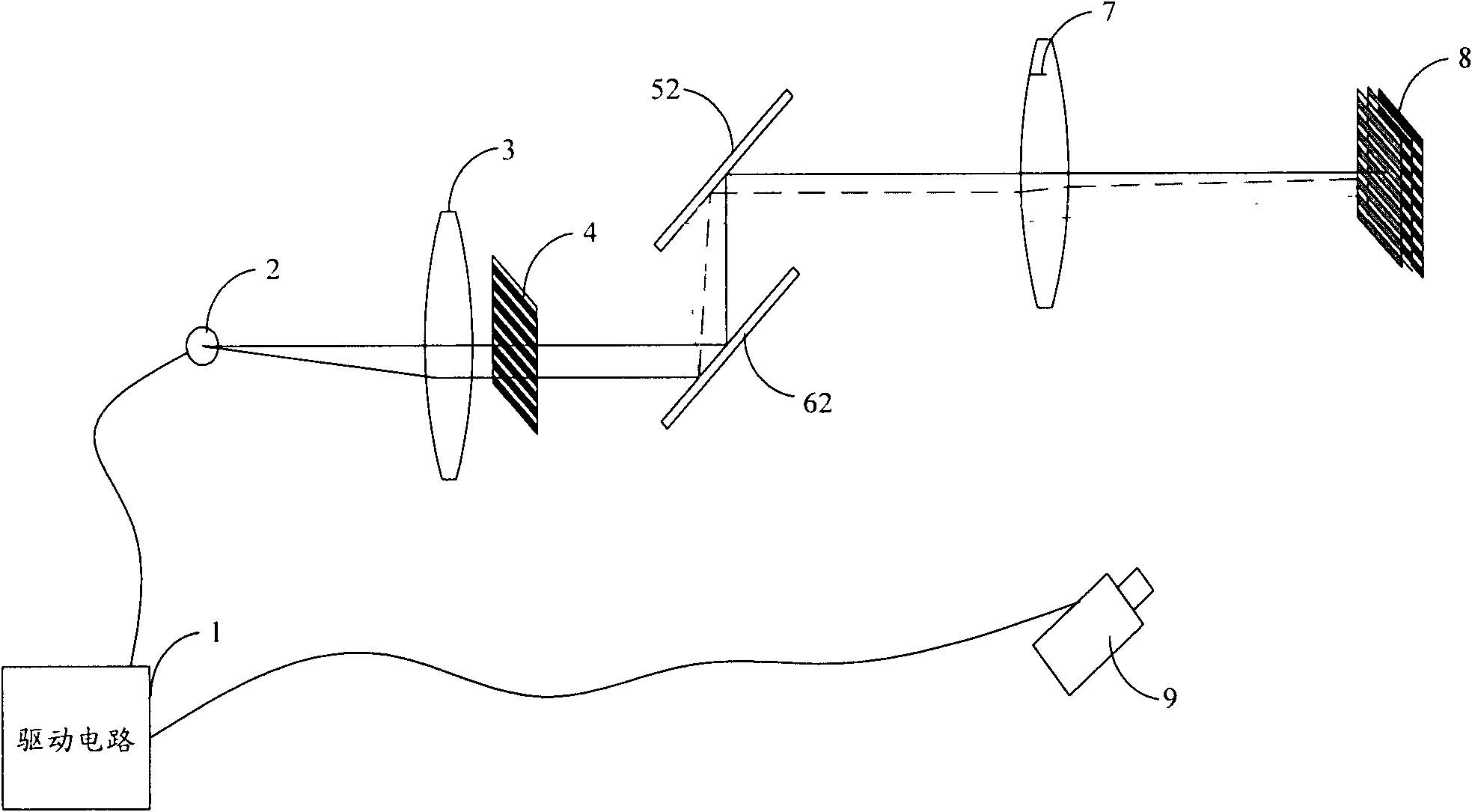

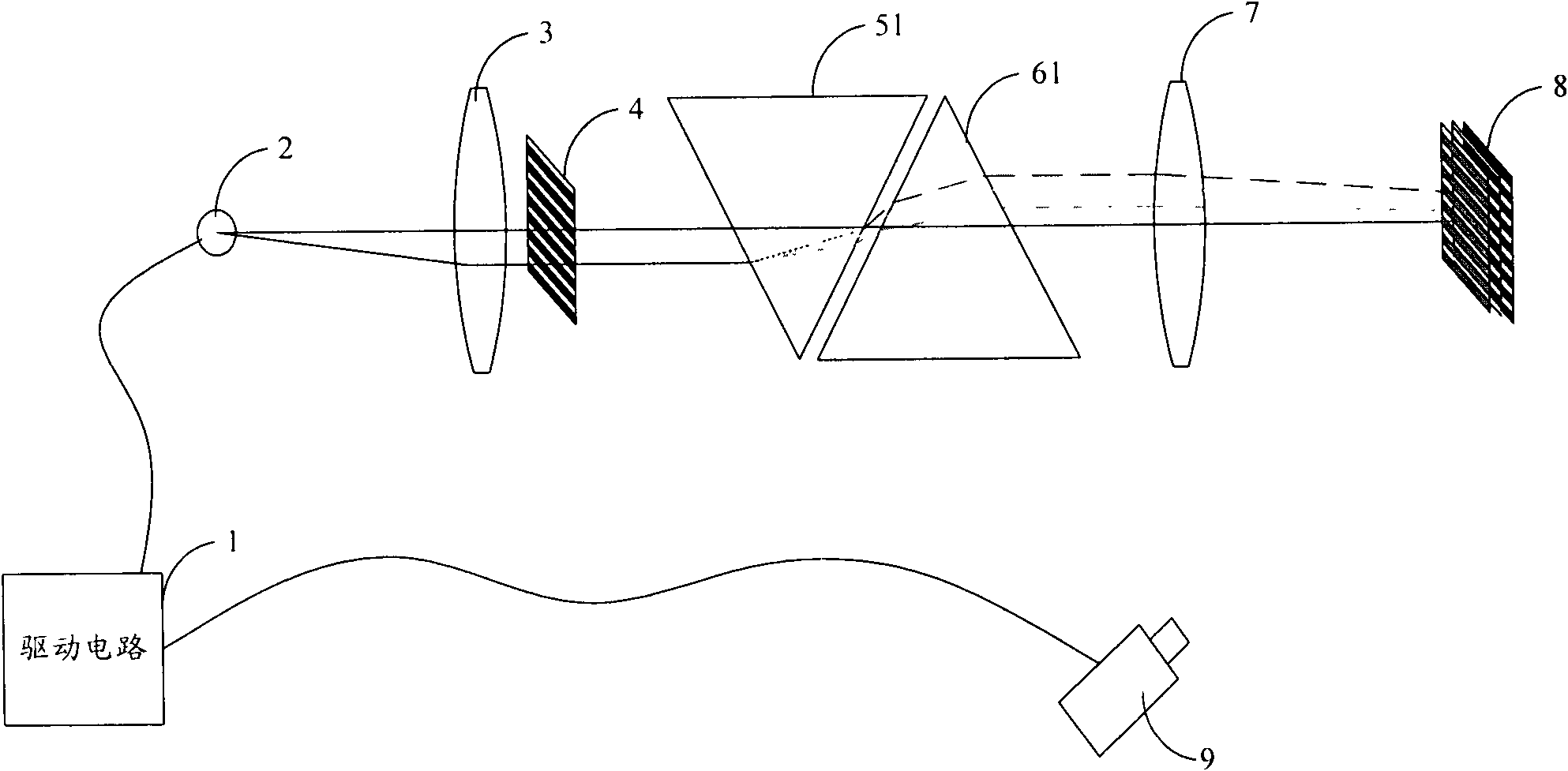

Structured light projection-based high-speed three-dimensional measurement system

InactiveCN101957183AHigh-speed 3D measurementMeet the needs of 3D data acquisitionTelevision system detailsColor television detailsGratingPhase shifted

The invention is applied in the technical field of three-dimensional sensing, and provides a structured light projection-based high-speed three-dimensional measurement system, which comprises a set of phase shifting image projection unit and a high-speed camera, wherein the phase shifting image projection unit comprises a multi-color LED point light source array; and along the emergent direction of the multi-color LED point light source array, the phase shifting image projection unit further comprises a collimating lens, a grating, a pair of reflection gratins arranged in parallel or a pair of inversely-arranged triple prisms, and a projection lens which are sequentially arranged. The structured light projection-based three-dimensional measurement system further comprises a drive circuit for driving the multi-color LED point light source array. The high-speed camera is used for shooting a projection image of the grating on the surface of a measured object, and has shutter frequency synchronous with the frequency of stroboflash of the multi-color LED point light source array. The structured light projection-based high-speed three-dimensional measurement system realizes the high-speed phase shift of the grating image by utilizing the quick frequency response characteristics of LEDs and the dispersion effect of the triple prisms or the reflection gratings, and then performs synchronous shooting by using the high-speed camera to realize high-speed three-dimensional measurement.

Owner:傅仕伟 +1

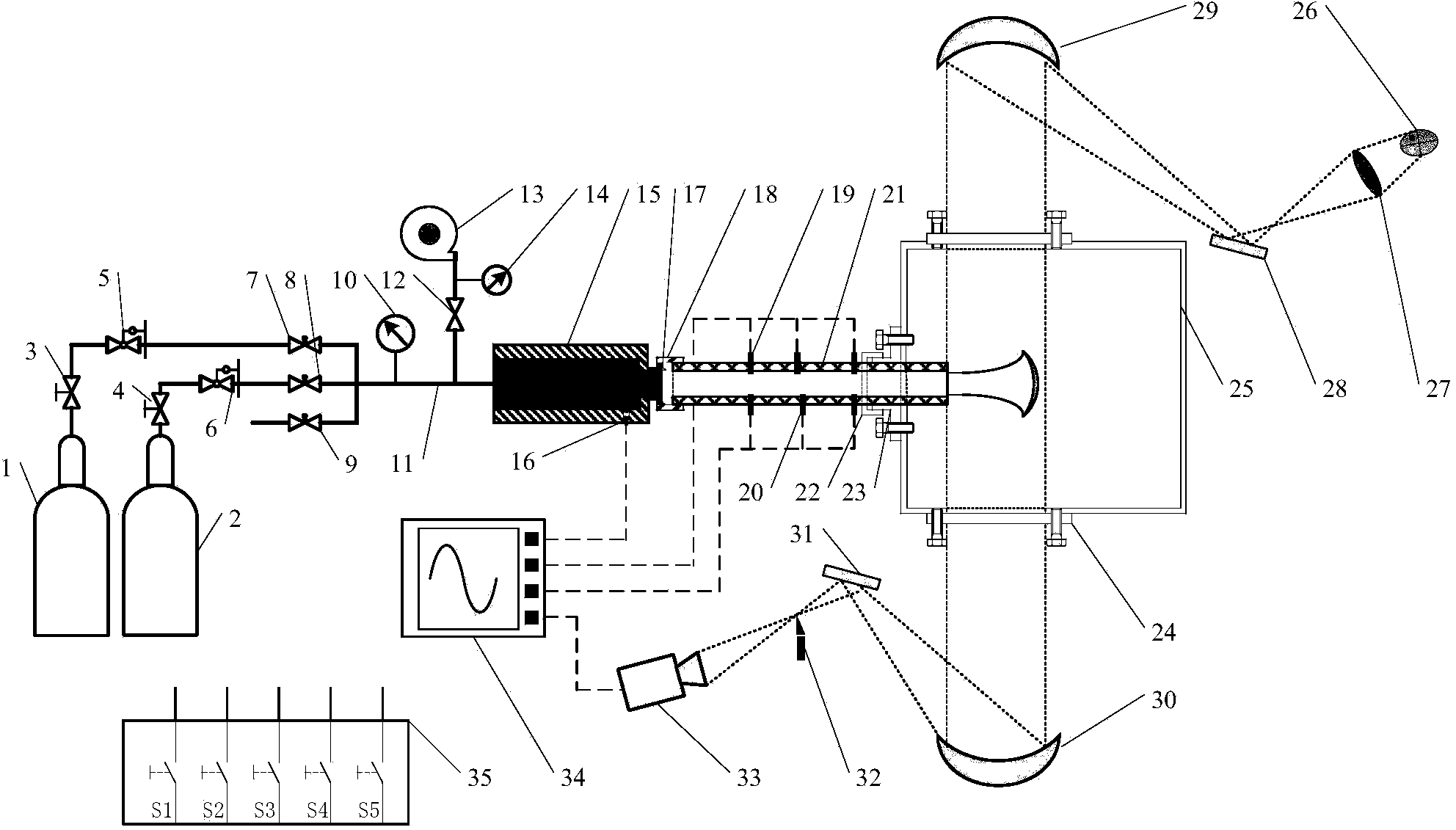

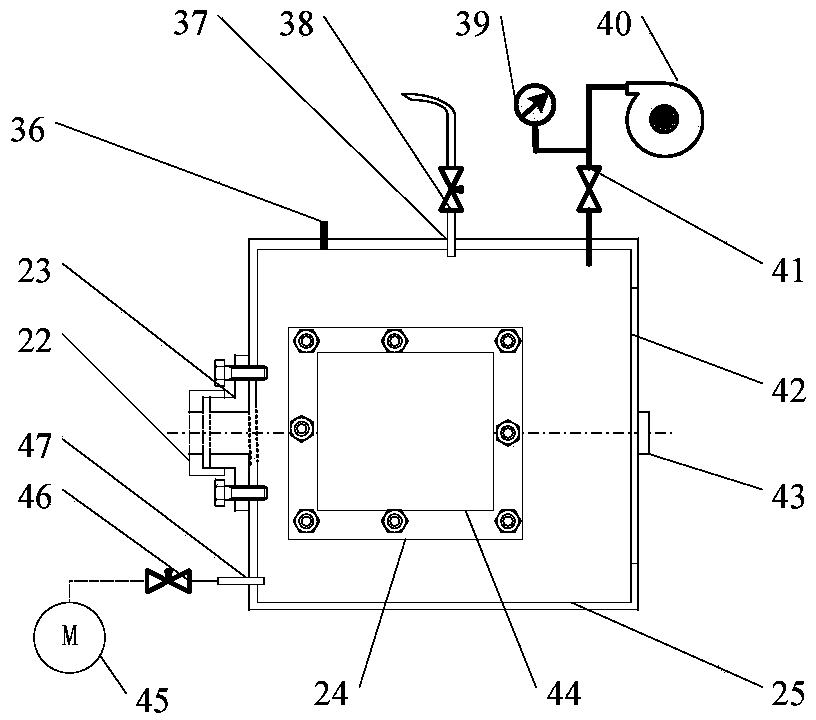

Test device for high-pressure combustible gas leakage spontaneous combustion and shock wave induction ignition

InactiveCN103454396APerfect spontaneous ignition mechanismEnable Visualization ResearchFuel testingSpontaneous combustionShock wave

The invention discloses a test device for high-pressure combustible gas leakage spontaneous combustion and shock wave induction ignition. The whole test device comprises a test gas bottle, a nitrogen gas bottle, a high-pressure ventilating pipeline, a pressure stabilization valve, an electromagnetic valve, a pressure gauge, a vacuum pump, a high-pressure storage tank, a pressure transducer, an ICP (inductively coupled plasma) pressure sensor, a photoelectric diode, a rupture disk clamp (in which a rupture disk is arranged), downstream pipelines, a schlieren, a high-speed camera, a protection box, an air compressor and the like. The device can be used for (1) researching the influence of factors, such as different leakage pressures, shapes, lengths and diameters of different downstream pipelines, the gas initial temperature, a breakage shape of the rupture disk and obstacles outside an orifice, on the spontaneous combustion ignition, and further completing a spontaneous combustion ignition mechanism; (2) researching a shock wave induction ignition process and disclosing a shock wave induction ignition mechanism and influence factors thereof; (3) realizing the visible research on spontaneous combustion ignition and shock wave induction processes.

Owner:UNIV OF SCI & TECH OF CHINA

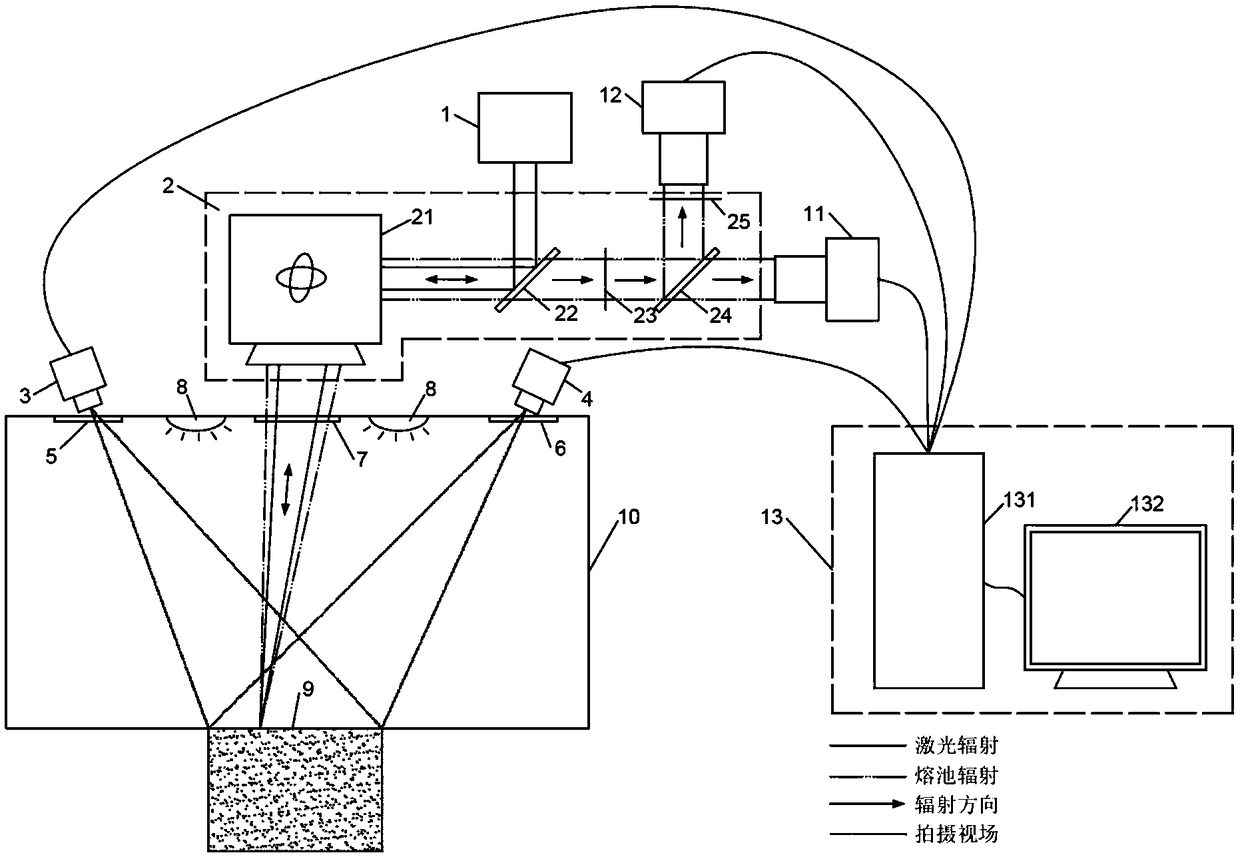

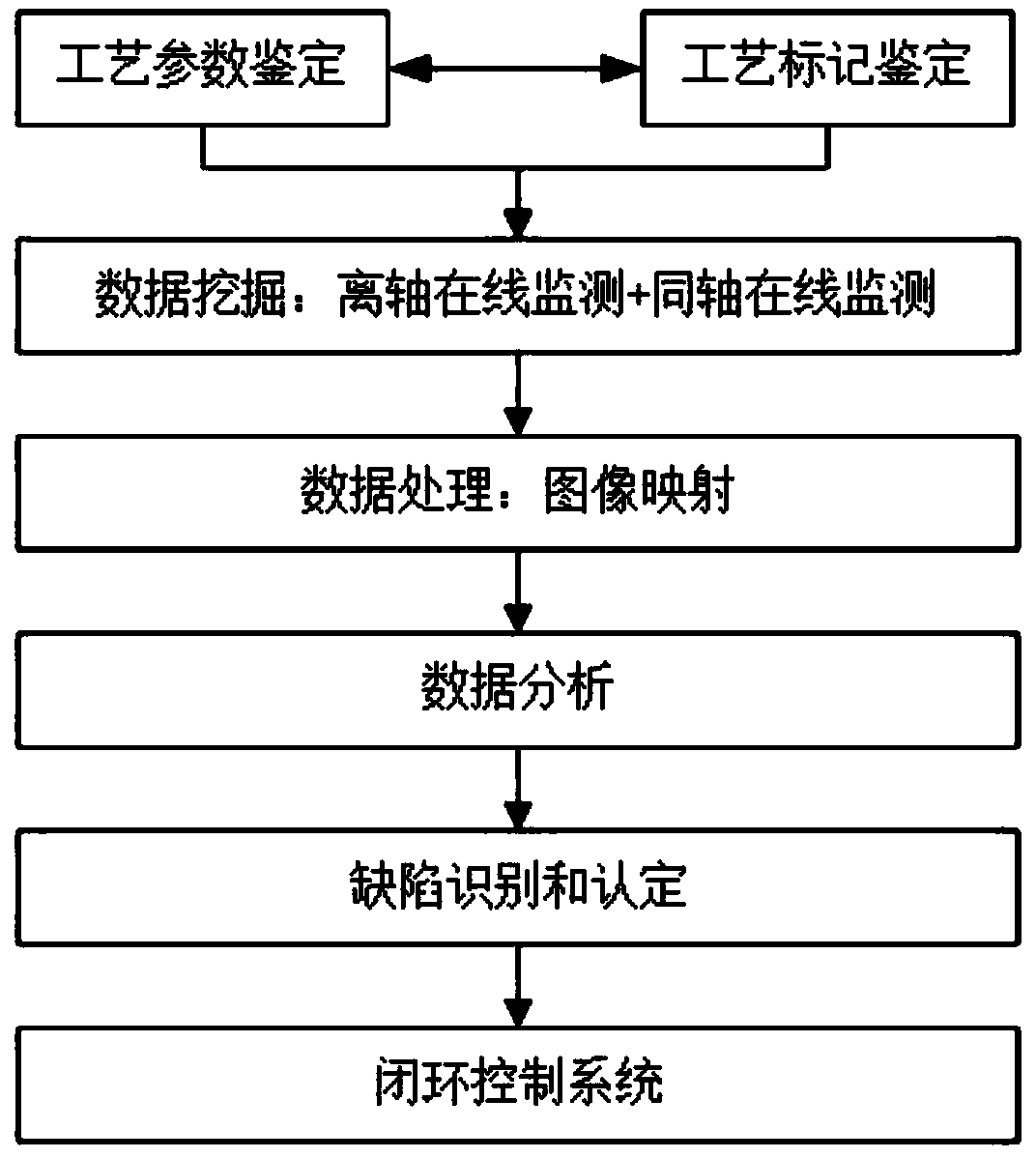

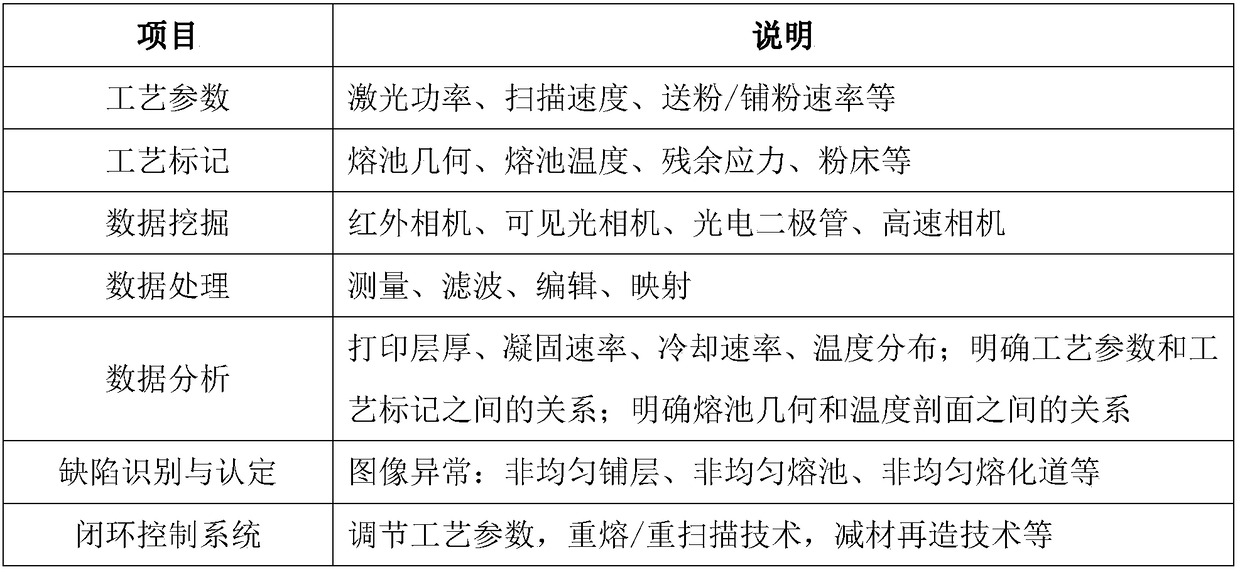

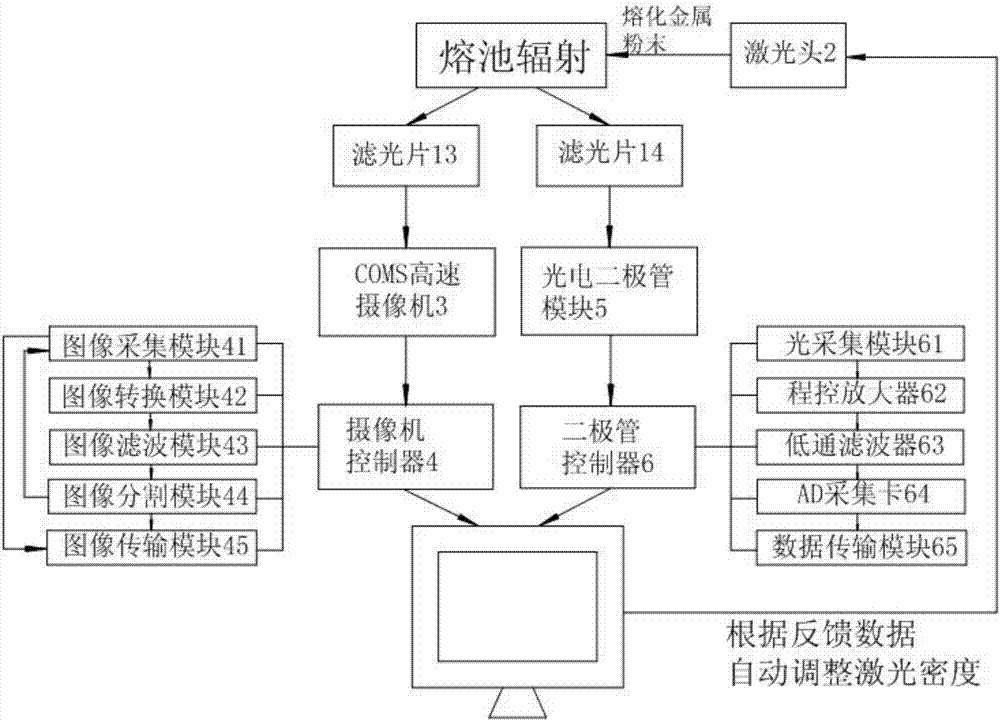

Real-time quality monitoring device and method for selective laser melting processing process

InactiveCN108788153ARealize online monitoringAvoid interferenceAdditive manufacturing apparatusIncreasing energy efficiencyMelting tankSelective laser melting

The invention discloses a real-time quality monitoring device and method for a selective laser melting processing process. Advantages of non-contact measurement means such as an industrial camera, aninfrared thermal imager, a high-speed camera and a photodiode are comprehensively utilized, and a set of complete monitoring method is formed. Through the on-line monitoring method combining an off-axis on-line monitoring device with a coaxial on-line monitoring device, the working condition of a printing work plane can be captured, and real-time molten pool data can also be collected. The meltingand condensation processes of metal powder can be monitored in a microcosmic manner, and a printer system and a workpiece layer-by-layer quality can also be monitored in a macroscopic manner. The industrial camera is adopted to monitor powder bed defects and printing defects, and the infrared thermal imager tracks the scanning path and captures the thermal stress; and the high-speed camera observes the geometrical morphology of a molten pool, and the photodiode captures the radiation strength of the molten pool. The process marks are made to correspond to printing process parameters, and on-line monitoring of the selective laser melting processing process can be realized more effectively.

Owner:西安智造人企业管理合伙企业(有限合伙)

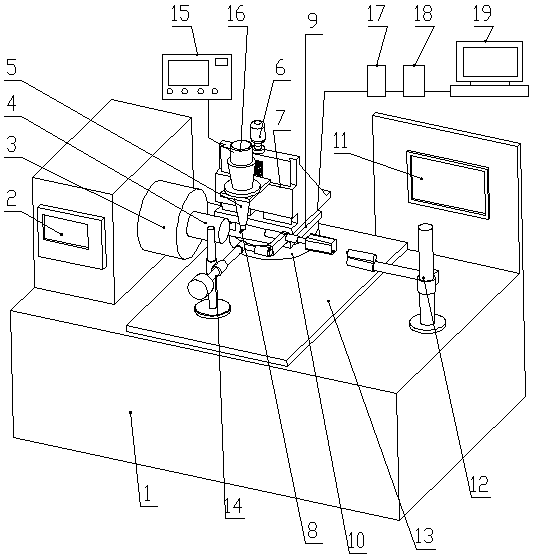

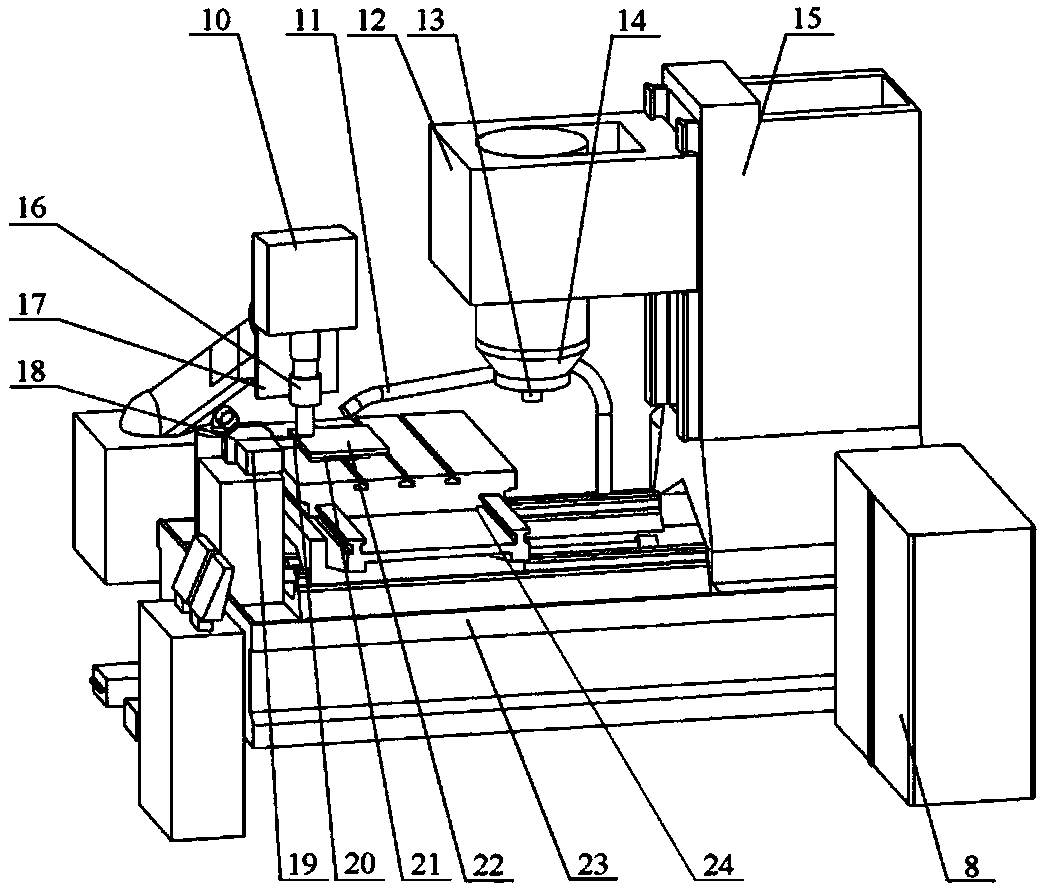

Device and method for single abrasive grain grinding experiments under assistance of ultrasonic vibration

ActiveCN104002220ASimulated machinabilityRealize online dynamic observationGrinding feed controlGrinding machinesData processing systemStress conditions

A device for single abrasive grain grinding experiments under the assistance of ultrasonic vibration comprises a super precision machine tool, a tool setting system, an ultrasonic vibration system, a force measurement system, a high-speed camera shooting system and a data processing system. A method for the single abrasive grain grinding experiments under the assistance of ultrasonic vibration comprises the steps of installing a workpiece in an air floatation spindle clamp of the super precision machine tool; utilizing the tool setting system to rapidly accurately perform tool setting; dismantling the tool setting system, starting the super precision machine tool and the ultrasonic vibration system, utilizing the force measurement system to perform on-line detection and recording on single abrasive grain stress conditions in the experiment processing, and transmitting data to a computer; and utilizing the high-speed camera shooting system to perform on-line observation and recording on a abrasive grain movement trail in the grinding process, the microscopic changing process and the material removing process. The device and the method genuinely reflect the grinding process of a whole grinding wheel and can particularly reflect the abrasive grain cutting process under the conditions of ultrasonic grinding and can provide valuable experimental data for manufacture and research of the grinding wheel and a cutting mechanism of the grinding wheel.

Owner:CONPROFE TECH GRP CO LTD +1

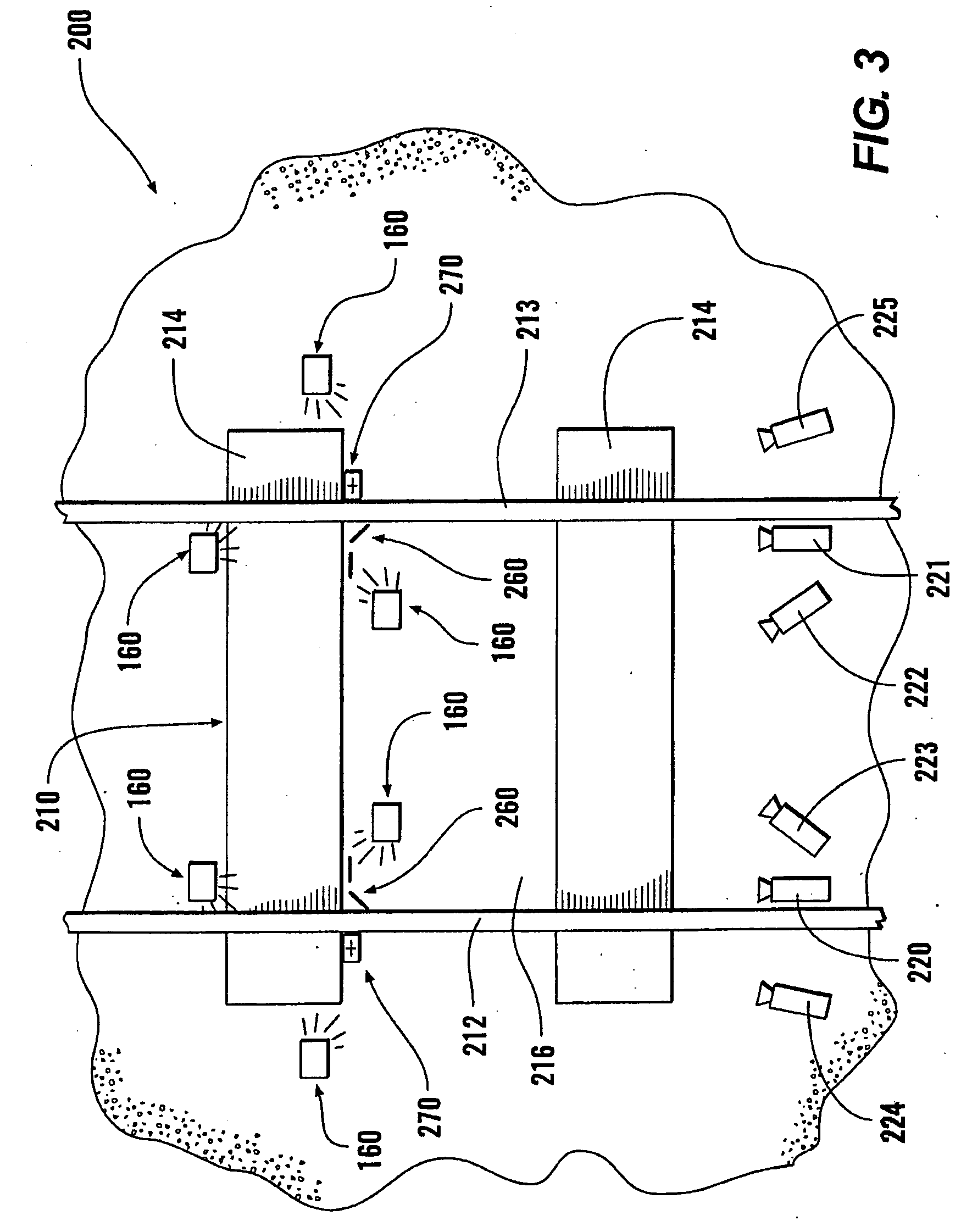

System and method for analyzing rolling stock wheels

An exemplary system and method for analyzing rolling stock wheels helps allow a wheel to be analyzed at speed, reducing any need for manual inspections or other related delays. An exemplary system may include one or more strobe lights and one or more high-speed cameras to capture images of the rolling stock wheel(s) at speed. The images may include one or more markers to assist in analyzing various parameters of the rolling stock wheel. The exemplary system may include one or more backface illumination plates to assist in illuminating the rolling stock wheel(s) and / or the one or more marker(s).

Owner:WABTEC CONTROL SYST PTY LTD

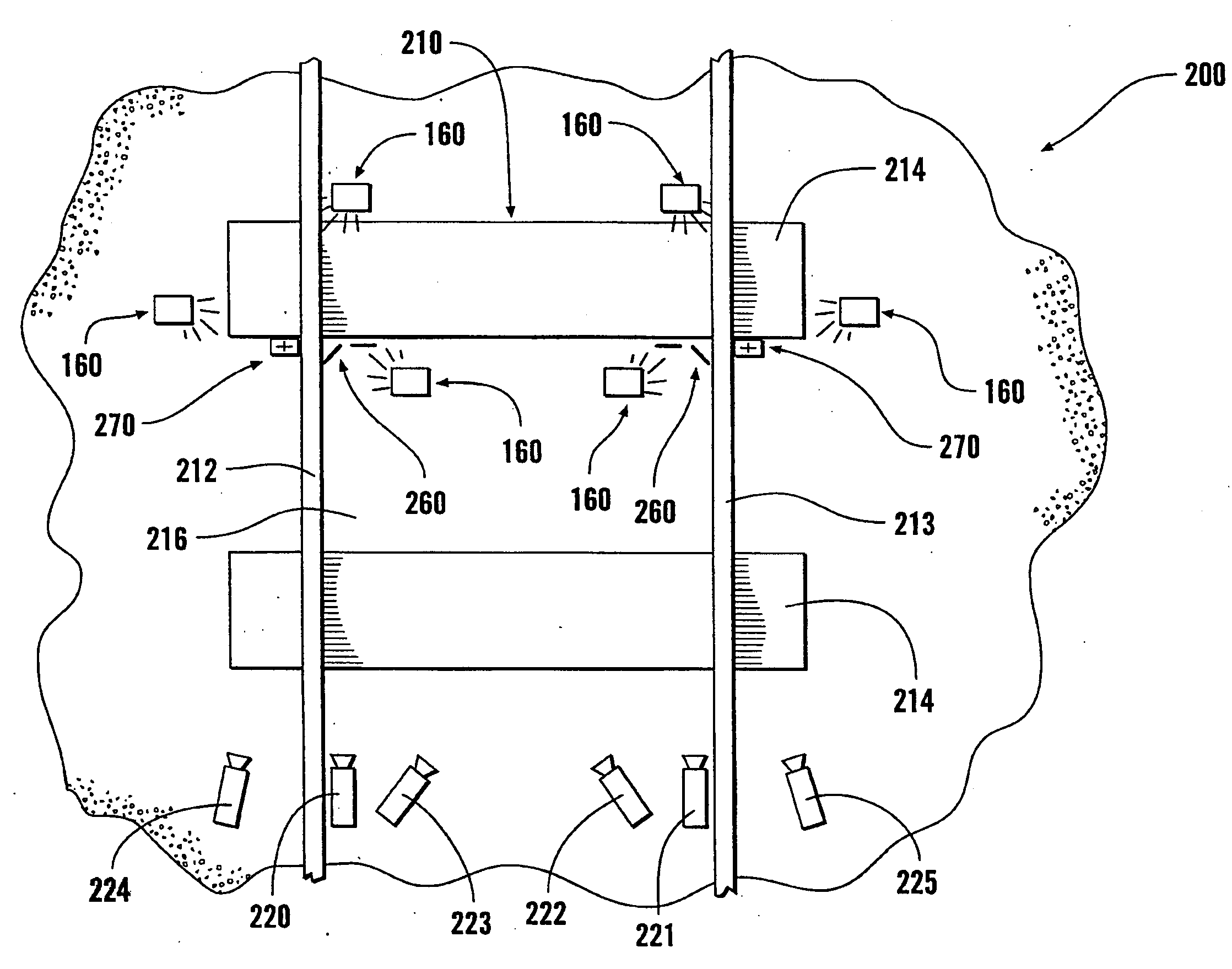

Experimental device and method for simulating extension influence of hydraulic fracturing cracks and natural cracks

ActiveCN107701160ADisadvantages such as high cost of customer service experiments and limited accuracySimple structureSurveyFluid removalHydraulic fracturingRock sample

The invention relates to an experimental device and method for simulating the extension influence of hydraulic fracturing cracks and natural cracks. Fracturing pipe columns are simulated through steelpipes, planar rock samples are formed through pouring and cured, and then rock samples with random spots are prepared; then the samples are placed into adjustable hydraulic fracturing cavities, unequal ground stress is applied to the two sides of the samples, and then fracturing liquid is injected through the fracturing pipe columns; and meanwhile a high-speed camera is utilized to shoot the crack extension condition in the hydraulic fracturing process, the rock body deformation condition in the hydraulic fracturing process is collected through a deformeter, and the pumping-in pressure and strain change are detected. According to the experimental device and method for simulating the extension influence of the hydraulic fracturing cracks and the natural cracks, the interplaying mechanicalrelation between the hydraulic fracturing cracks and the natural cracks can be intuitively analyzed, the distribution problem after a flow makes contact with the natural cracks can be accurately researched, and meanwhile the complex mechanical behavior such as cracking rules of hydraulic fracturing, rock body deformation caused by hydraulic crack extension and opening, re-starting or dislocation of the natural cracks at different strength is intuitively observed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

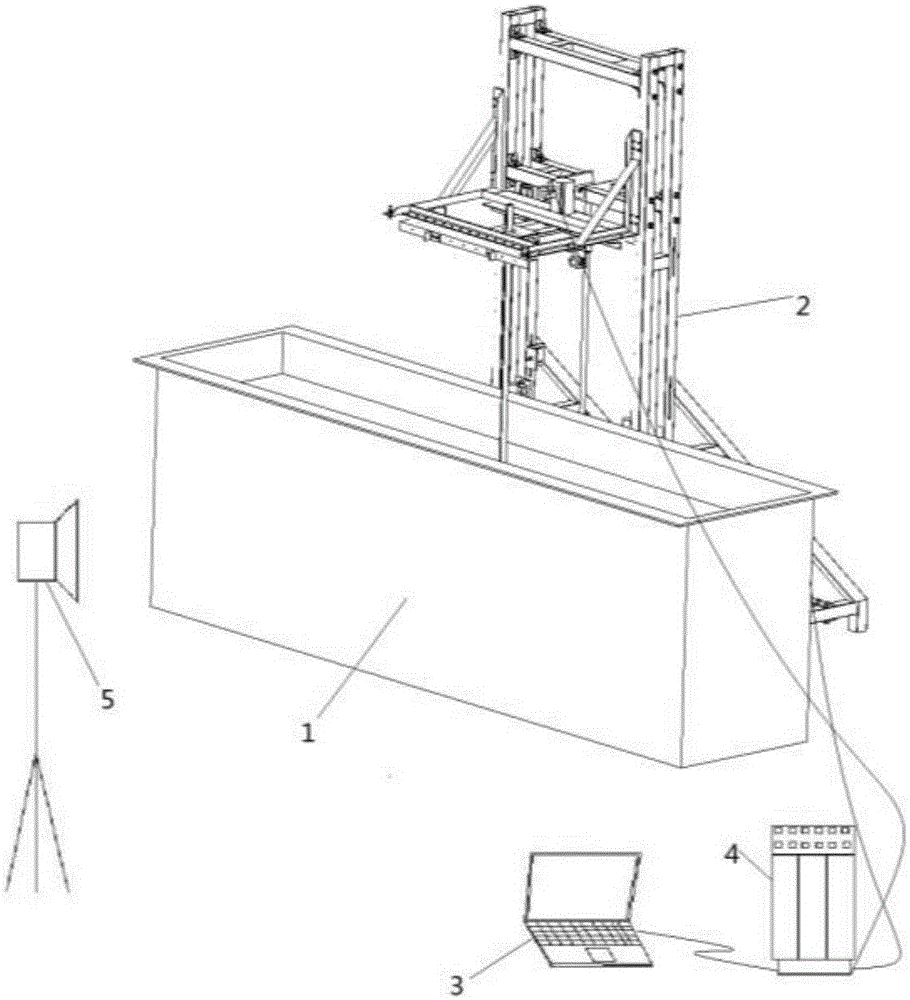

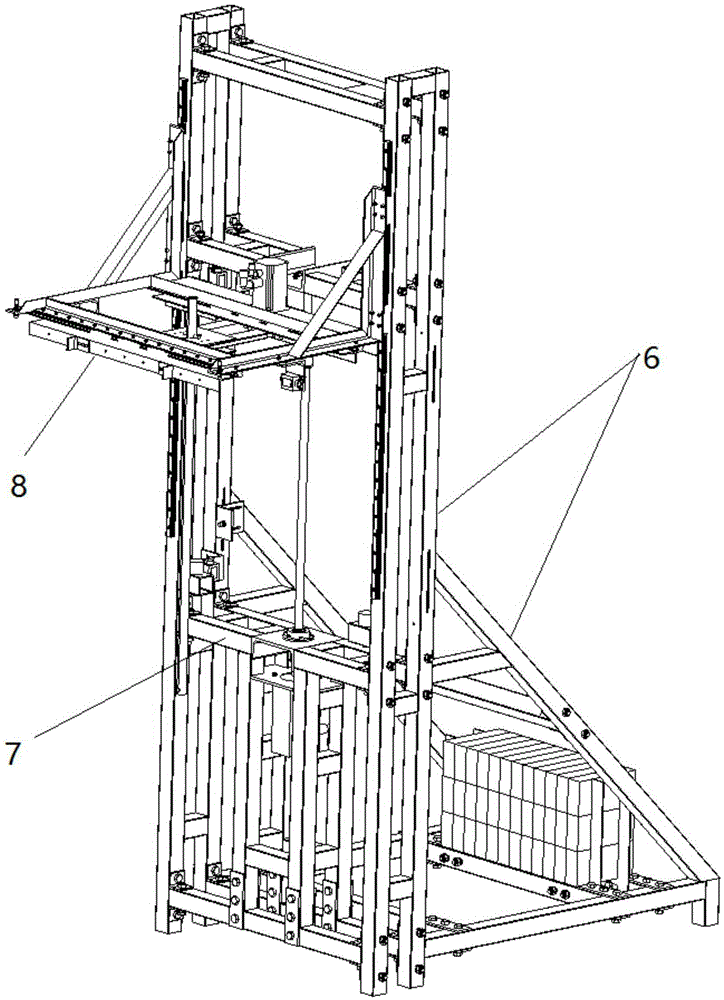

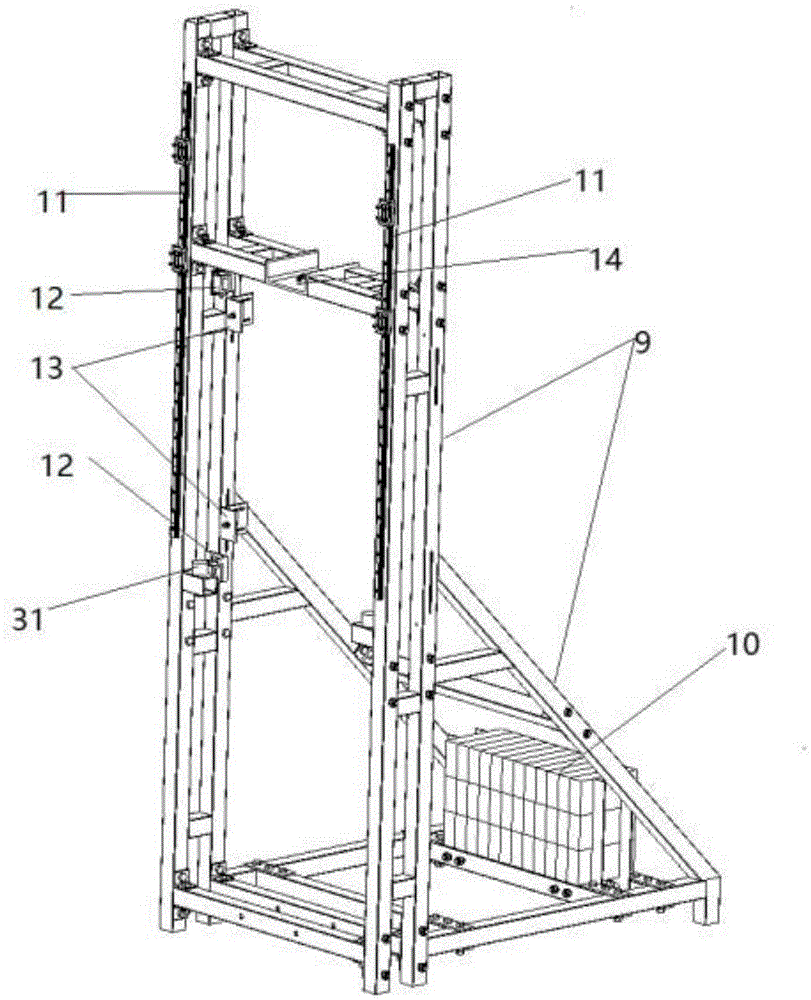

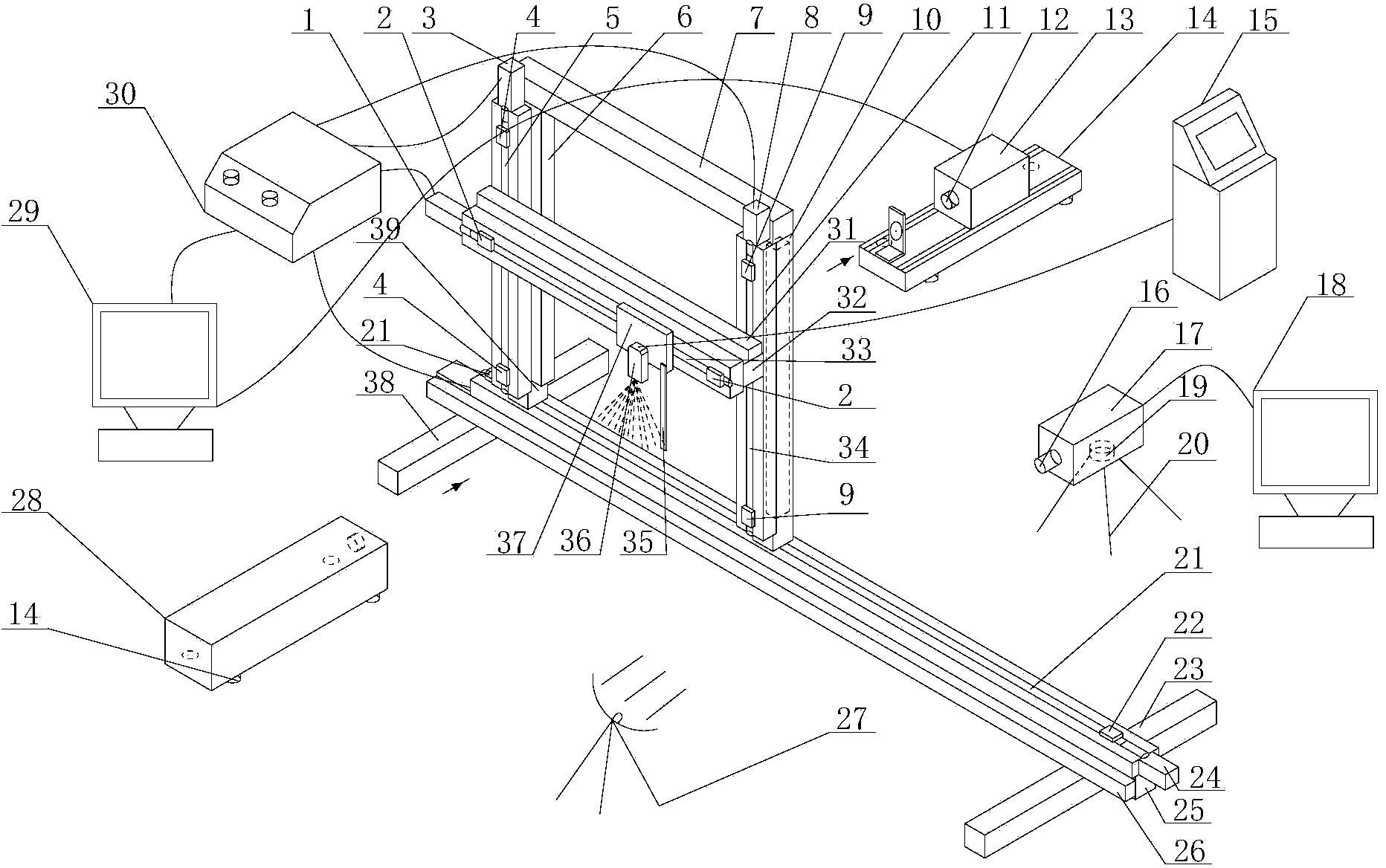

Multi-angle object water entry and wave-making motion experimental device

ActiveCN105334019AMeet the requirements of simulation of different water entry methodsMeet free entryHydrodynamic testingControl systemEngineering

The invention provides a multi-angle object water entry and wave-making motion experimental device, which is a novel water entry experimental device with various water entry modes, a controllable water entry angle and a controllable water entry speed. The device is applied to water and underwater wave-making experiments when a model has a different immersion depth. The device of the invention is composed of an experimental water tank, a driving system, a power cabinet, a control system and a high-speed camera system, wherein the driving system is composed of a supporting frame, a horizontal experimental table, a vertical experimental frame and an angle connector, and the angle connector is connected with the horizontal experimental table and the vertical experimental frame, thereby realizing linkage of a horizontal motion and a vertical motion of the system and adjusting a structure water entry depth. Through respectively controlling speed values of the horizontal experimental table and the vertical experimental frame, oblique water entry, variable speed water entry and wave-making motion experiment can be realized. The device has the advantages of various experimental means, high result accuracy, high device utilization rate, high equipment adaptability and the like.

Owner:HARBIN ENG UNIV

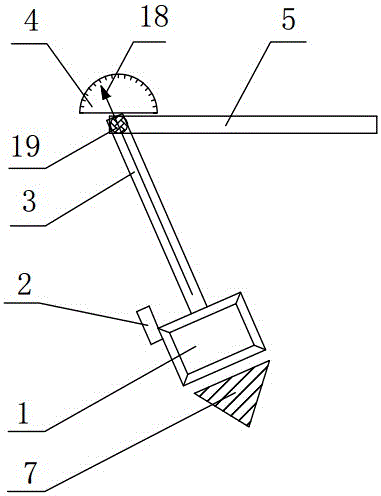

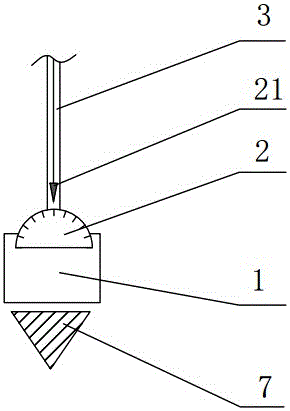

Experiment device for stable multi-angle entering-into-water of object

The invention belongs to hydraulic experiment model facilities, and particularly relates to an experiment device for stable multi-angle entering-into-water of an object. The experiment device comprises a transparent water tank, an electromagnetic releasing device and a data acquisition system. The electromagnetic releasing device comprises supporting columns and a vertical rod. One end of the vertical rod is hinged with a transverse supporting rod through a first hinge joint, and the other end is hinged with an electromagnet block through a second hinge joint, wherein a water entering object is attracted with the bottom of the electromagnet block. A transverse water entering angle adjusting pointer and a longitudinal water entering angle adjusting pointer are vertically fixed on different sides of the vertical rod. A transverse water entering angle protractor is fixedly arranged on the transverse supporting rod. A longitudinal water entering angle protractor is fixedly arranged on the electromagnet block. The electromagnetic releasing device is connected with an industrial control computer through a cable. The data acquisition system comprises a synchronization instrument, a laser transmitter, a high-speed image photographing instrument and a high-speed camera, wherein the synchronization instrument is controlled by the industrial control computer. The experiment device can stably release water entering objects with different shapes and furthermore can accurately control the water entering angles of the objects.

Owner:ZHEJIANG UNIV

Experimental device for cutting off carbon fiber composite material

InactiveCN103837422ASave spaceThe cutting experiment is orderly and accurateInvestigating machinabilityTemperature controlMaterial removal

The invention provides an experimental device for cutting off a carbon fiber composite material, and belongs to the field of research on hardly machined material cutting devices. The experimental device is provided with experiment functional devices by taking a cutting device as a basic structure, wherein the experiment functional devices comprise a work piece quick assembling-clamping and temperature control device, a high-speed micro-examination device, a temperature and cutting force online measuring device and a dust remover. In the high-speed micro-examination device, a lens is connected with a high-speed camera, the high-speed camera is arranged on a single-axis precision displacement platform pedestal which is arranged on a camera support, a light source is aligned to a cutting area and the high-speed camera is connected with a computer system. The experimental device for cutting off the carbon fiber composite material, which is disclosed by the invention, can effectively realize the observation on a cutting process, precisely measures the temperature and the cutting force in real time, controls the temperatures of a sample and a cutter, and studies on material breakage forms, material removal mechanisms and cutter abrasion mechanisms under different cutting conditions, so as to provide experimental support for the explanation of the carbon fiber composite material cutting basic theory.

Owner:DALIAN UNIV OF TECH

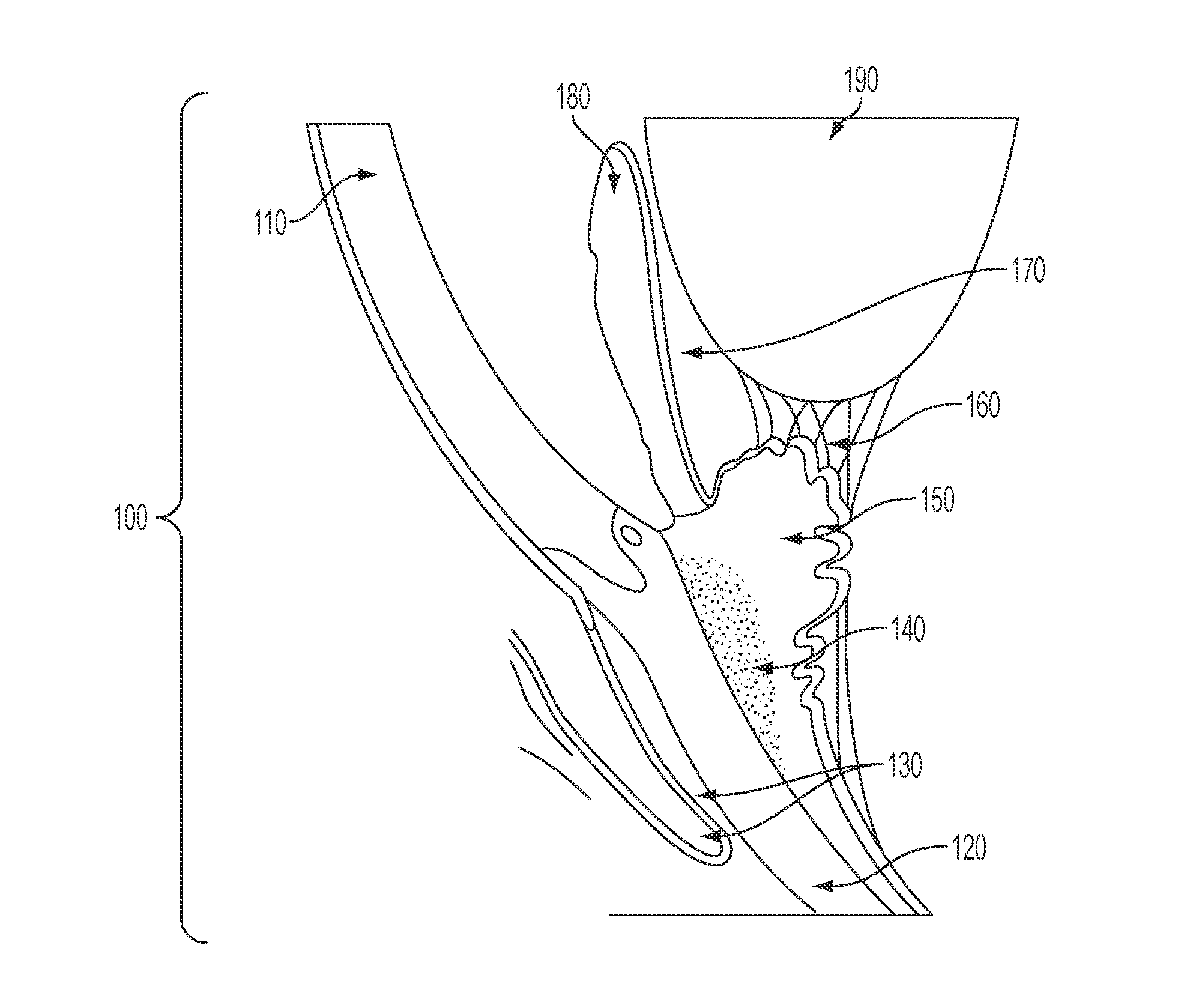

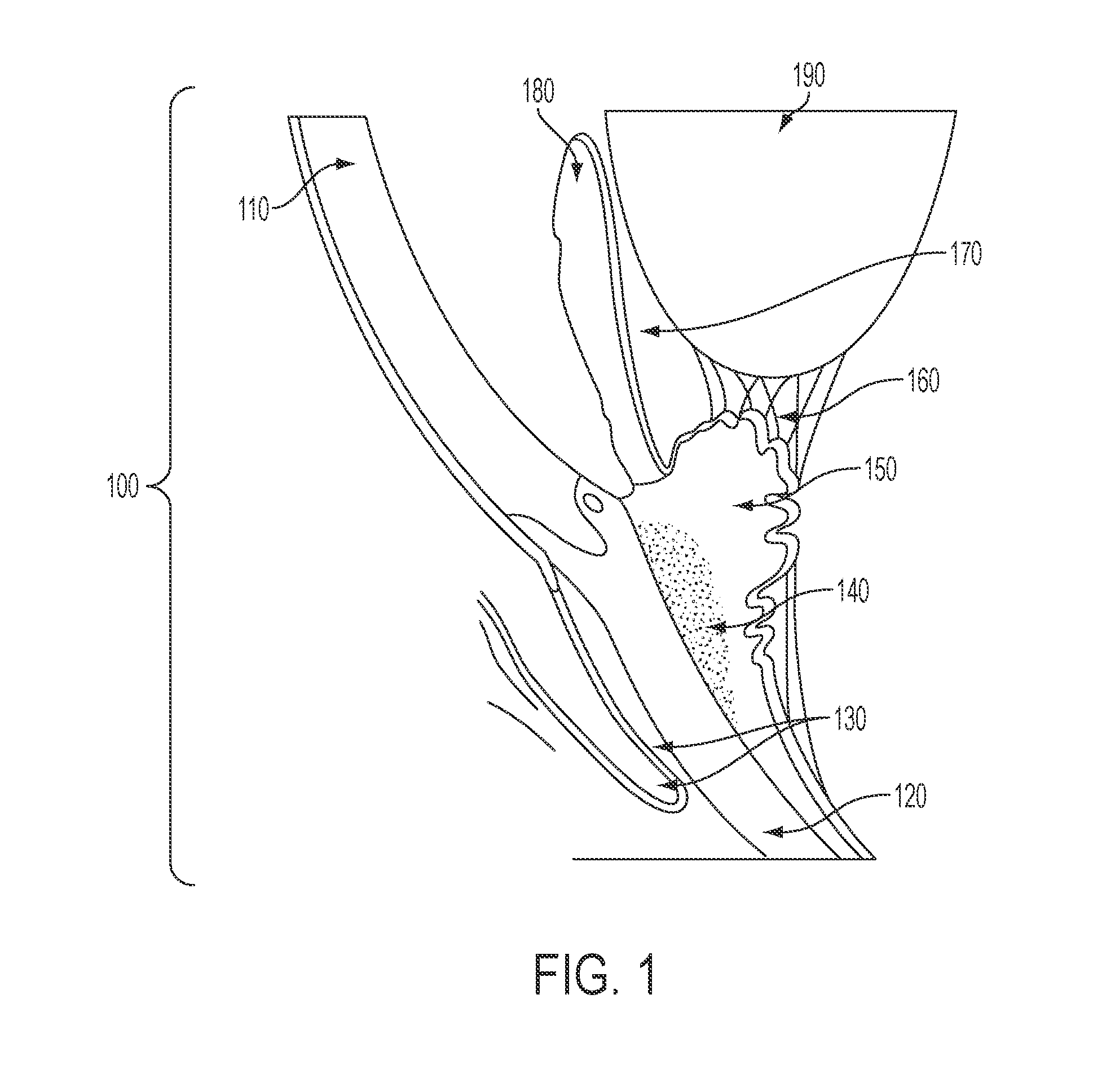

Assessment of microvascular circulation

InactiveUS20130070201A1Improve acquisitionMaterial analysis by optical meansSensorsConjunctivaIntervention design

Methods and compositions are disclosed to quantitatively measure in vivo blood vessel diameter, blood velocity, and other flow dynamics. Such methods and compositions can optimize therapeutic interventions designed to prevent or reduce the risk of cardiovascular and blood disorders. In one aspect, the methods and apparatus involve calculating blood vessel characteristics from a two dimensional image of a blood vessel in the conjunctiva of a subject's eye. In another aspect, a series of temporal images of a blood vessel are obtained to determine blood flow properties. The apparatus can include, for example, a biomicroscope, an illuminating light source and a high speed camera to acquire the series of temporal images with the data then analyzed by a programmed processor.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Spray characteristic parameter detection device and method

ActiveCN104181083AEasy to moveHigh degree of automationParticle size analysisControl systemEngineering

The invention discloses a spray characteristic parameter detection device and method. The spray characteristic parameter detection device comprises an integral support rack, a two-dimensional moving unit, a servo motor, a servo control unit, a spray control system, a pulse nozzle, a high-speed camera image acquisition system and a laser particle size analyzer system. On the basis of the device, the spray characteristic parameter detection method comprises the following steps: detecting an outline shape of spray, macroscopic two-dimensional distribution of spray and the flying speed of particles of spray by virtue of the high-speed camera image acquisition system; and detecting the particle size of spray with two-dimensional distribution in a spatial two-dimensional plane travel range by a two-dimensional precise servo driving system based on a laser particle size analyzer according to the outline and the macroscopic two-dimensional distribution of spray on the basis of a spray image acquisition result.

Owner:TIANJIN UNIV OF COMMERCE

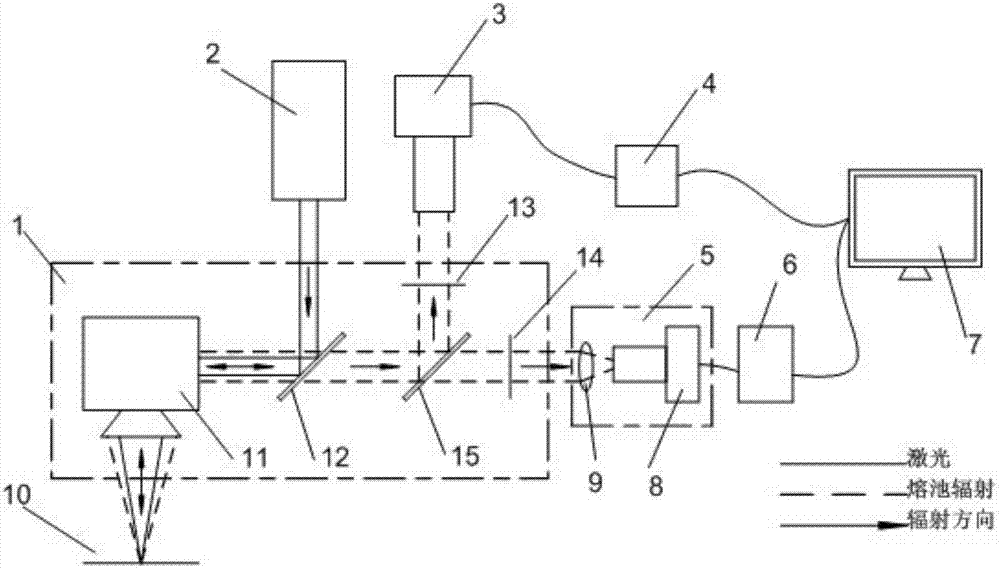

Coaxial monitoring method and device in selective laser melting process

ActiveCN106984813AEasy to detect and analyzeHigh local resolutionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMelting tank

The invention discloses a coaxial monitoring method and a device in a selective laser melting process. The device comprises a light path module, a photodiode module, a diode controller, a laser head, a COMS high-speed camera, a camera controller and a computer. Metal powder on a workbench base plate is melted selectively by a scanning galvanometer of the light path module, and molten pool radiation is reflected into the COMS high-speed camera 3 and a photodiode in the selective laser melting process; the COMS high-speed camera and the photodiode module are used for processing molten pool radiation data converted into image information transmitted to the corresponding controller; the camera controller is used for processing the image data converted into feedback information for controlling the laser; the diode controller is used for processing optical signals exempted from external electromagnetic interference, and the device is applicable for collection; in the selective laser melting process, by combining the COMS high-speed camera and the photodiode, the coaxial monitoring method is beneficial to improving the local resolution ratio and quick scanning rate.

Owner:SOUTH CHINA UNIV OF TECH

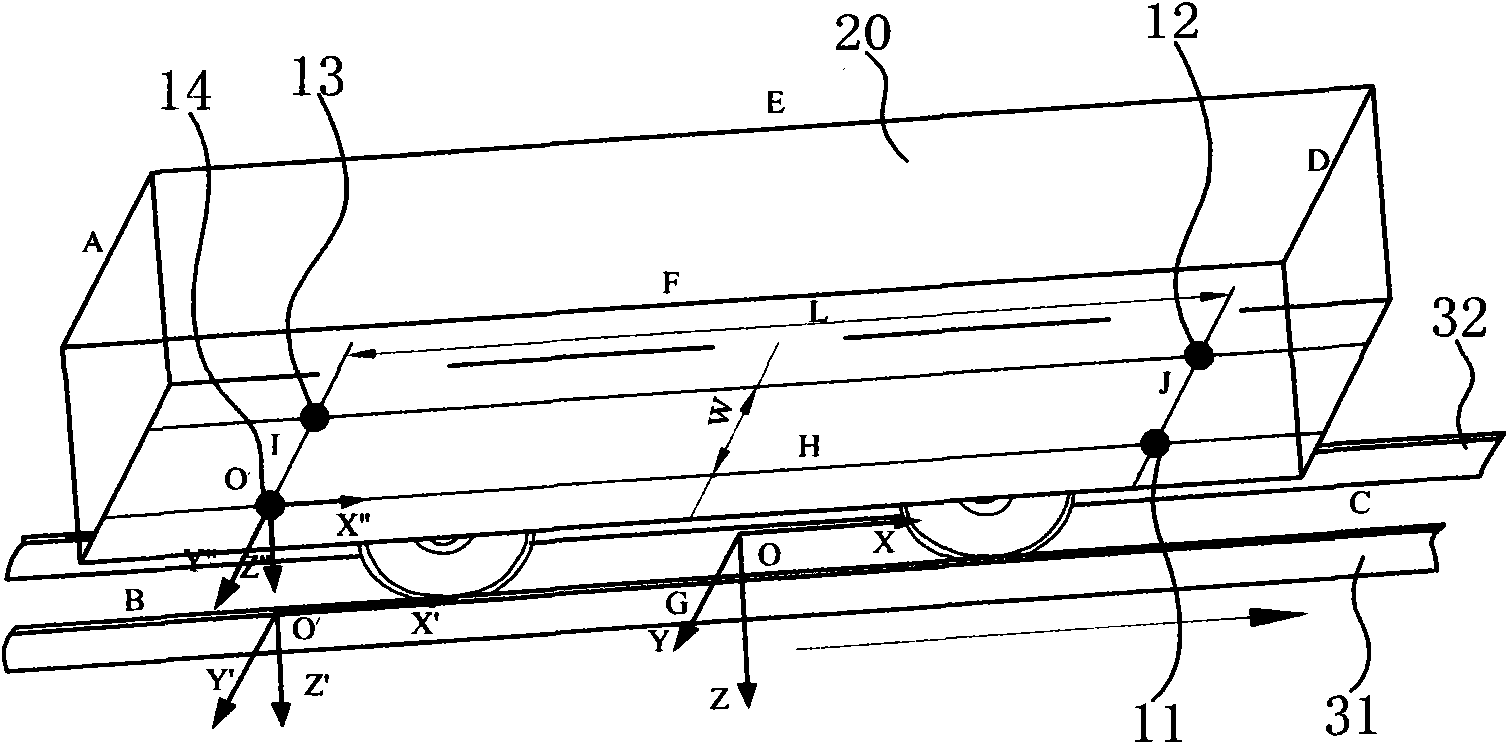

Railway locomotive running attitude measuring method

ActiveCN101666716AAcquisition stableGuaranteed measurement accuracyUsing optical meansRailway vehicle testingEngineeringImage sequence

The invention relates to a railway locomotive running attitude measuring method comprising the following steps: a high-speed camera is fixedly arranged on at least three non-colinear points of the railway locomotive under measurement by taking surfaces of rails as the measuring datum; along with the running of the railway locomotive under measurement, the high-speed camera shoots the running imagesequence of an counterpart camera arranged on the top surface of the rails; the running image sequence of the counterpart camera is processed and analyzed, and the offset of each point relative to the rails is obtained; the special attitude and the offset of the railway locomotive under measurement relative to the two rails are determined according to the offset of three measuring points, and accordingly the dynamic offset of any point which is fixedly connected with the railway locomotive under measurement is obtained; the dynamic envelop curve of the railway locomotive under measurement isobtained according to the dynamic offset of the key point on the profile of the railway locomotive under measurement; the dynamic envelop curve is compared with the building profile, and the ultralimit early warning and alarming is carried out if a monitoring point is close to or exceeds the building clearance. The invention ensures the railway locomotive running attitude measuring precision whenthe dynamic displacement of the railway locomotive is measured on line in real time.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com