Experimental device and method for simulating extension influence of hydraulic fracturing cracks and natural cracks

A technology of hydraulic fracturing and natural fractures, applied in the direction of earthwork drilling, mining fluid, measurement, etc., to achieve the effect of low economic cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

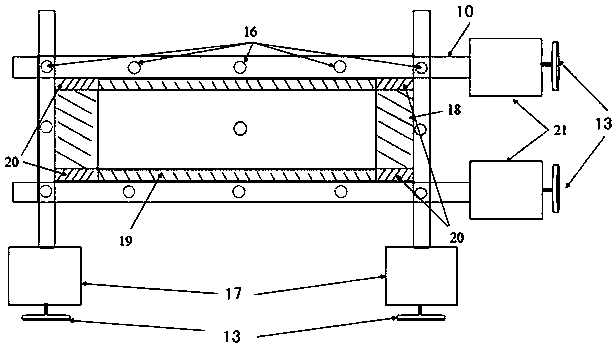

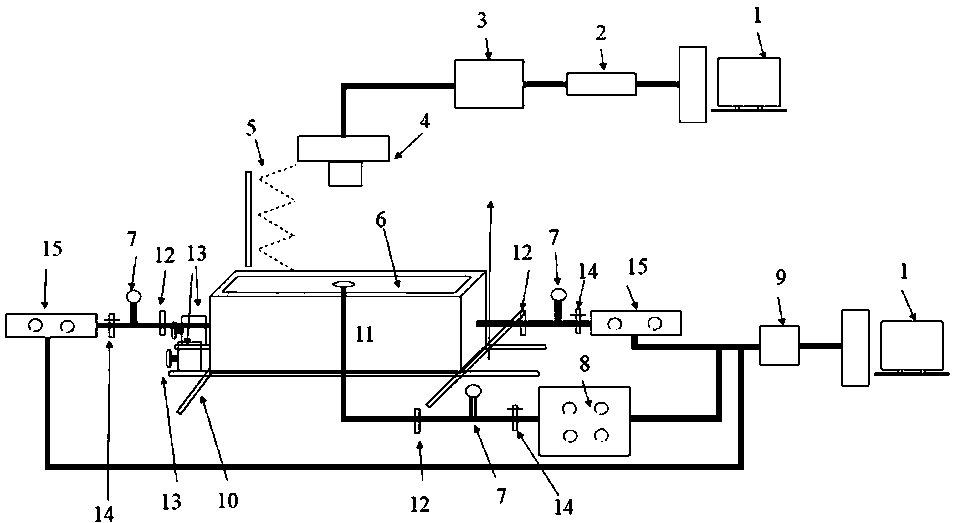

[0026] Embodiment 1, with reference to attached figure 1 and 2, the present invention mentions an experimental device for simulating the influence of hydraulic fracturing fractures and natural fracture propagation, and its technical scheme is: comprising a data processing computer terminal (1), an image monitoring module (2), a data acquisition module (3), High-definition high-speed camera (4), white light source (5), hydraulic fracturing physical simulation experiment chamber (6), servo control injection pump (8), analog-to-digital conversion module (9), simulated fracturing wellbore (11), confining pressure The pump (15), the high-definition high-speed camera (4) is installed above the hydraulic fracturing physical simulation experiment chamber (6), and is connected to the data processing computer terminal ( 1); the two sides of the hydraulic fracturing physical simulation experiment chamber (6) are respectively connected to the confining pressure pump (15), and the confini...

Embodiment 2

[0039] Embodiment 2, a more specific method of use in the present invention, comprises the following steps:

[0040] (1) According to the requirements of the experiment, select cement, quartz sand, clay, water and other materials of different components, add shredded A4 printing paper, oatmeal, or shredded kraft paper, mix them into the mold, and place the specimen in the mold for 72 hours Finally, remove the mold, and then put it into a constant temperature and humidity box for 14 days of maintenance;

[0041] (2) After the fracturing sample reaches the predetermined strength, use a drilling machine to drill in, insert a high-pressure resistant metal pipe to simulate the fracturing wellbore, and use a sealing ring and sealant to seal it. At the same time, one end is closed and the other end is open. To connect the hydraulic fracturing fluid injection manifold, the side is simulated perforation;

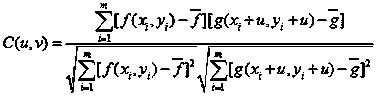

[0042] (3) First, use white self-spray paint to spray the surface of the cut fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com