Vehicle component real object collision test method and tester

A crash test and vehicle component technology, which is applied in the direction of railway vehicle test, machine/structural component test, measuring device, etc., can solve the problems of lack of scientificity and objectivity of crash test, non-repeatable, large-scale vehicle test, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

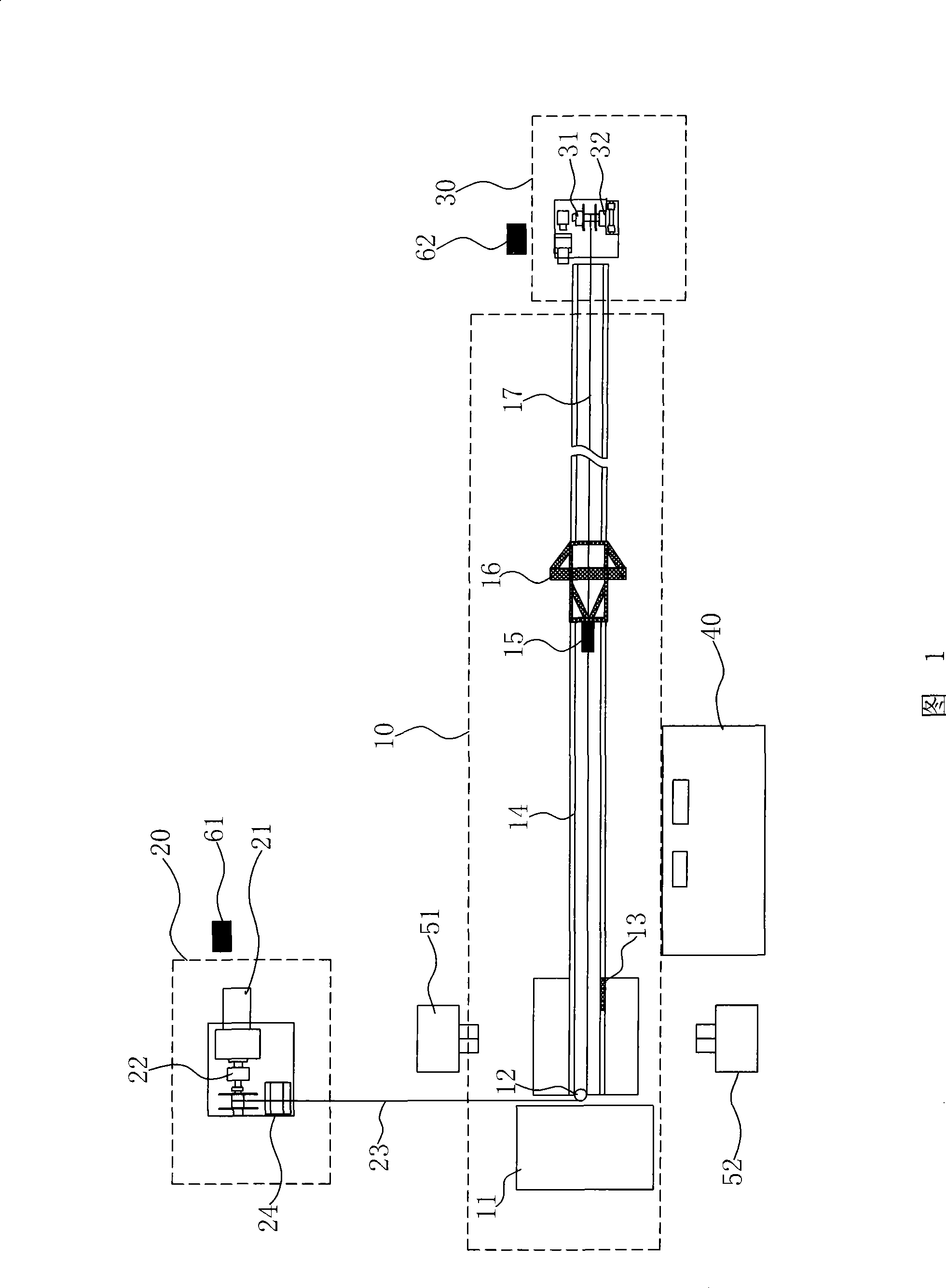

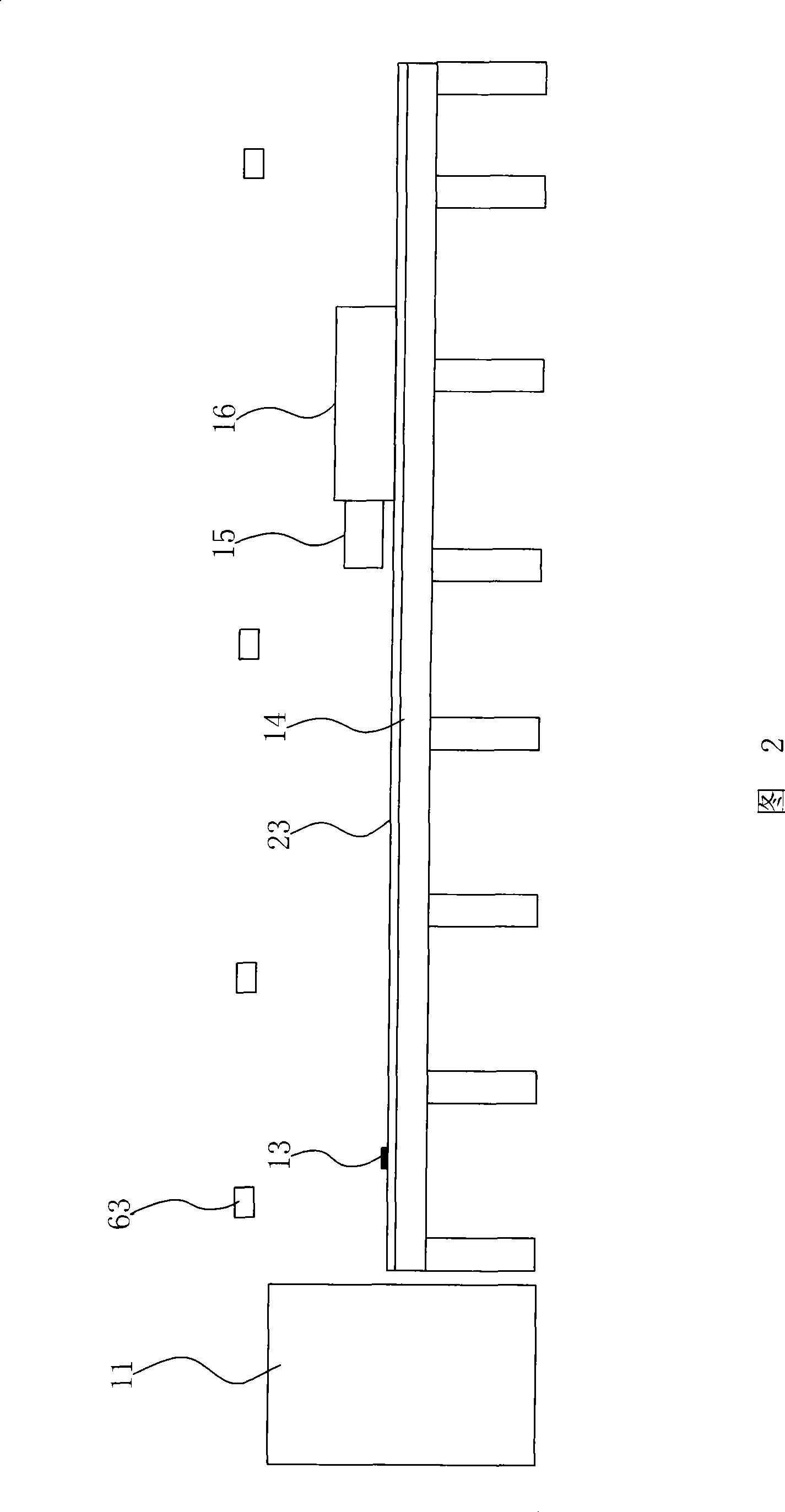

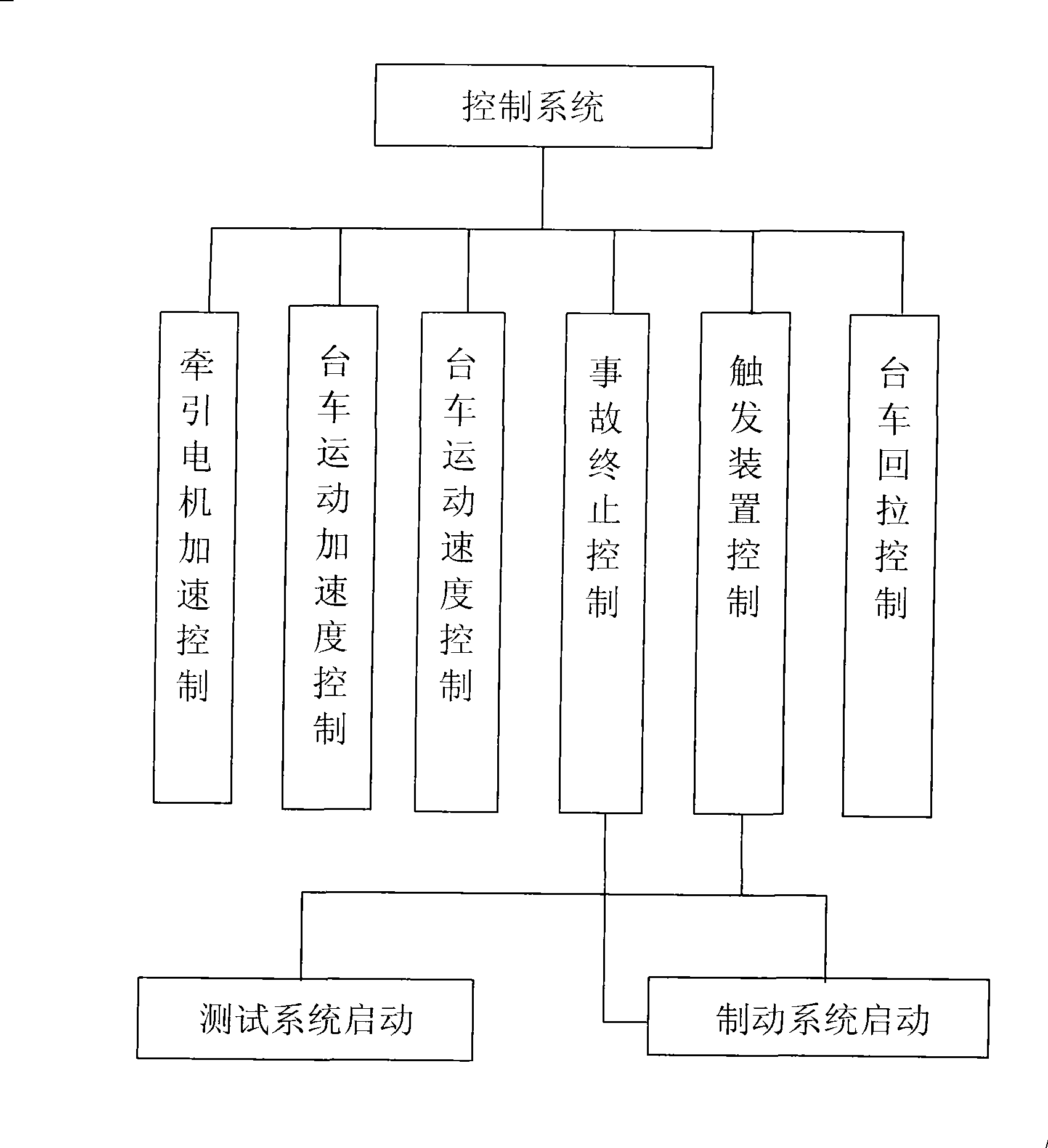

[0035] The vehicle component object collision test method is to carry out a collision test on the 1:1 vehicle component object, and obtain the deformation, acceleration, impact force versus time curve of the component during the collision process and the speed at the moment of impact contact. The vehicle parts to be impacted are fixed on the front end of the carrying trolley. The carrying trolley can be driven along a track by a drive system. The drive system can use an electromagnetic speed-adjustable motor as power, and the running speed of the carrying trolley can be controlled by acceleration control. keep improving. In this process, the PID controller can be used to continuously increase the power of the electromagnetic speed-adjusting motor, so that the input speed of the motor continues to increase, so that the running speed of the carrying trolley continues to increase. The running speed of the carrying trolley will be controlled by the speed controller or Other measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com