Patents

Literature

442 results about "Flame propagation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flame propagation. The spread of a flame in a combustible environment outward from the point at which the combustion started.

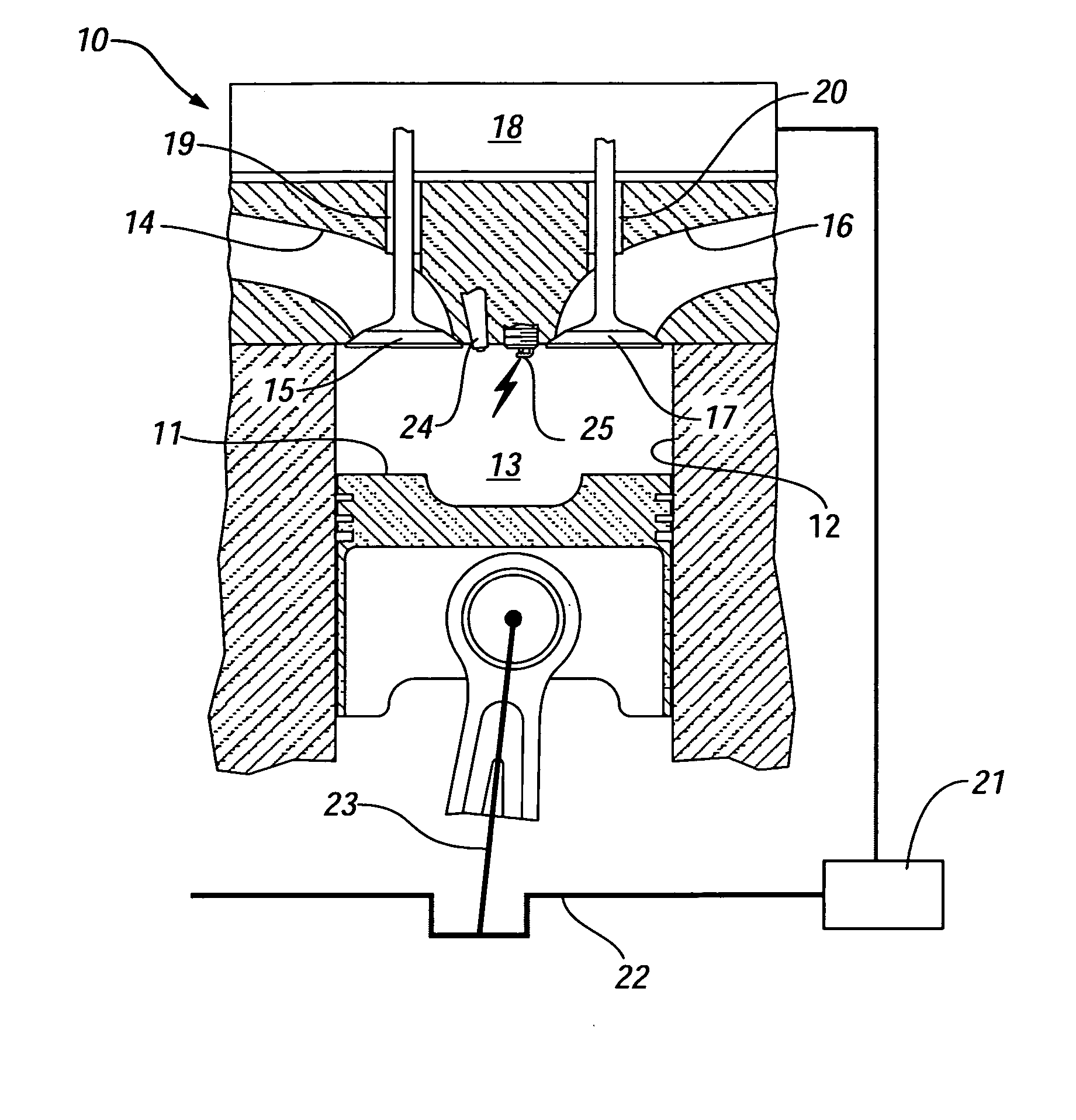

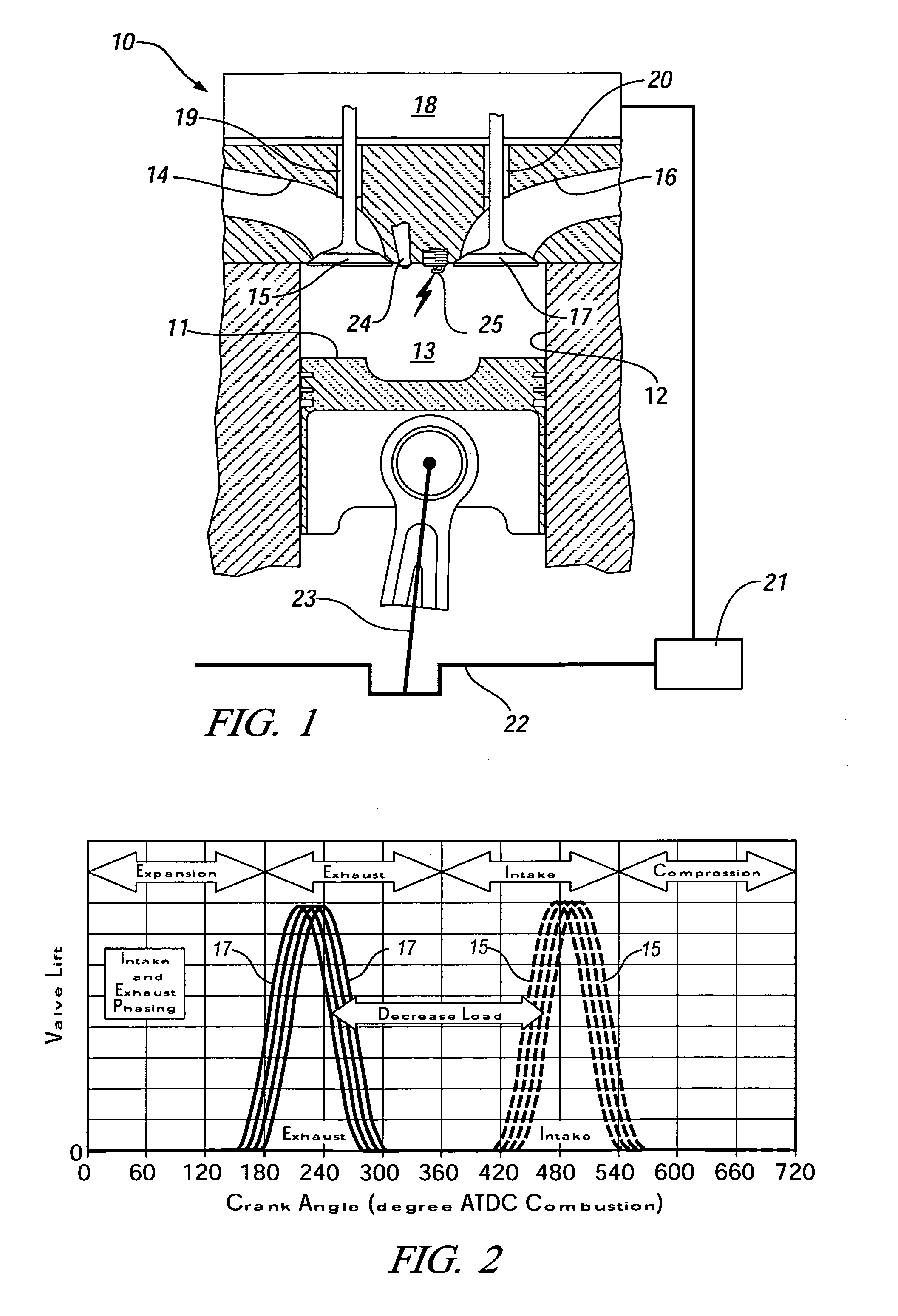

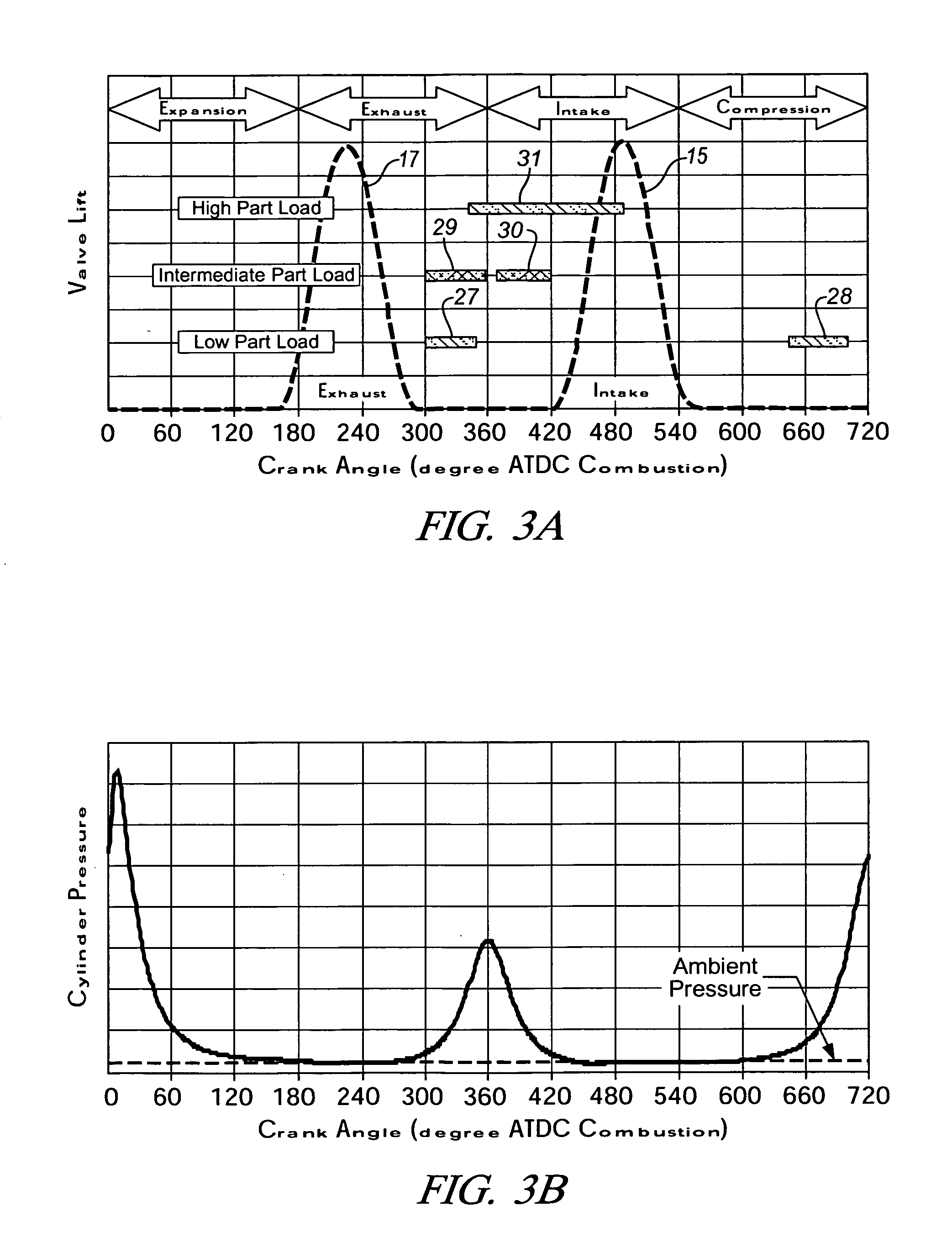

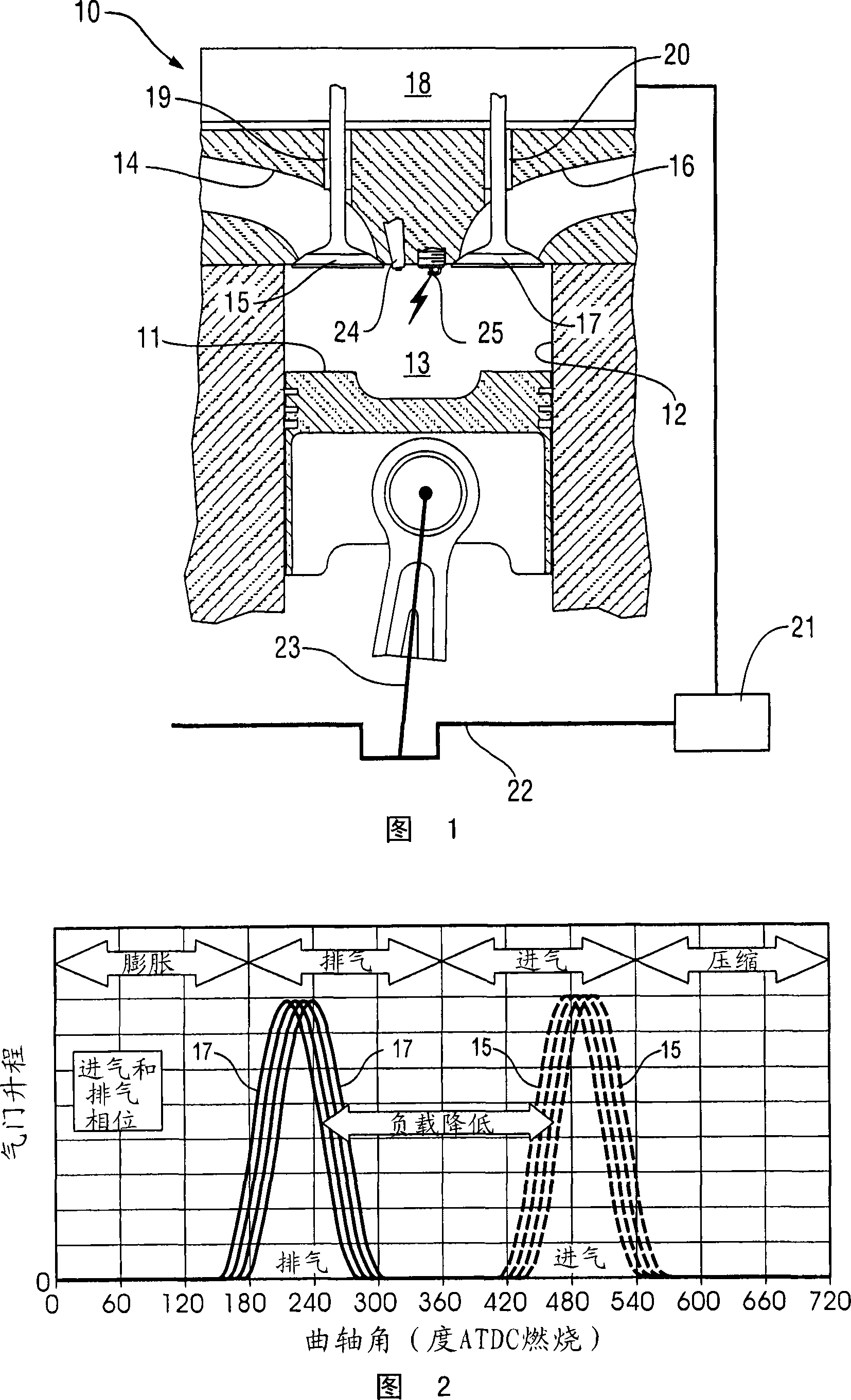

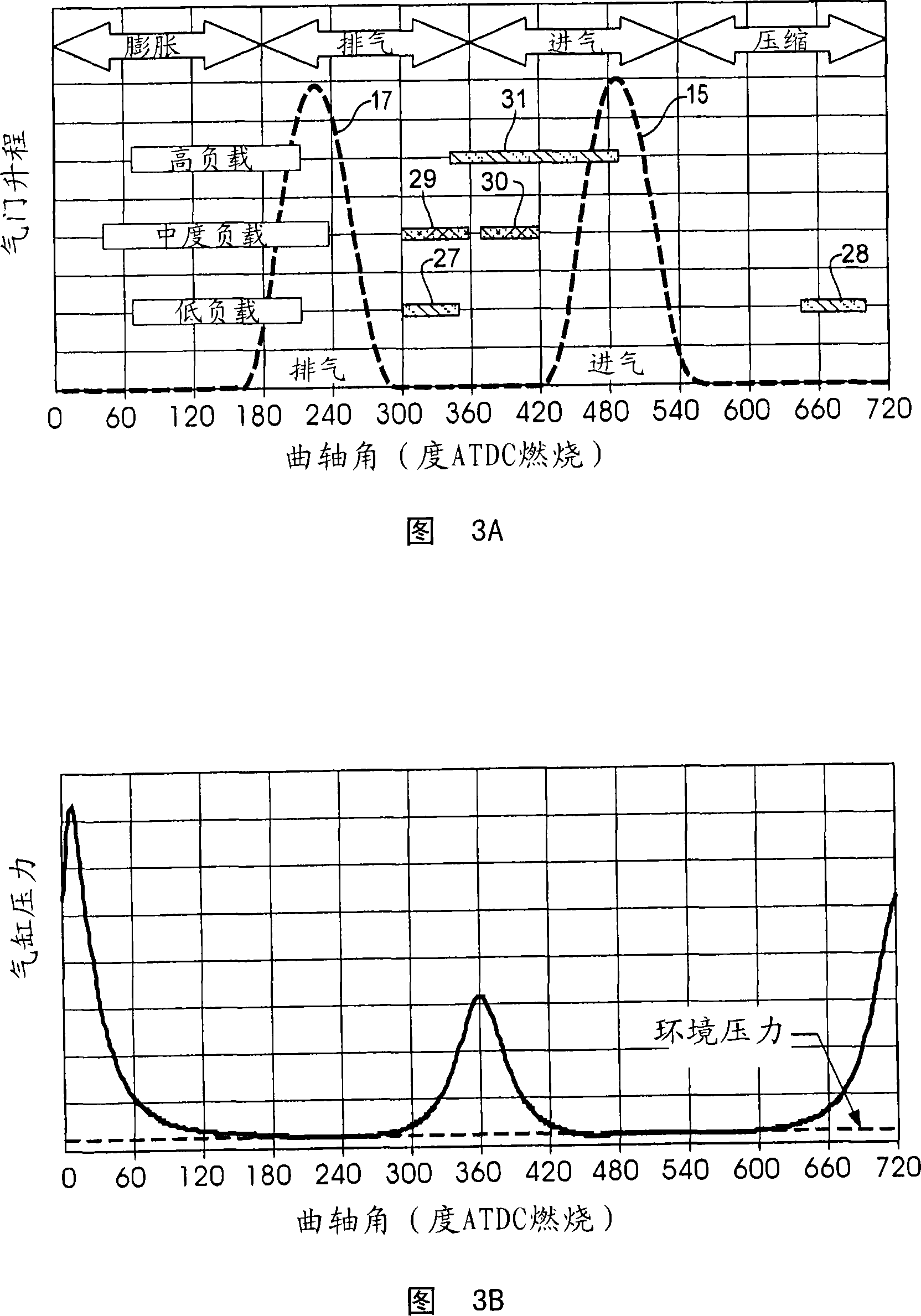

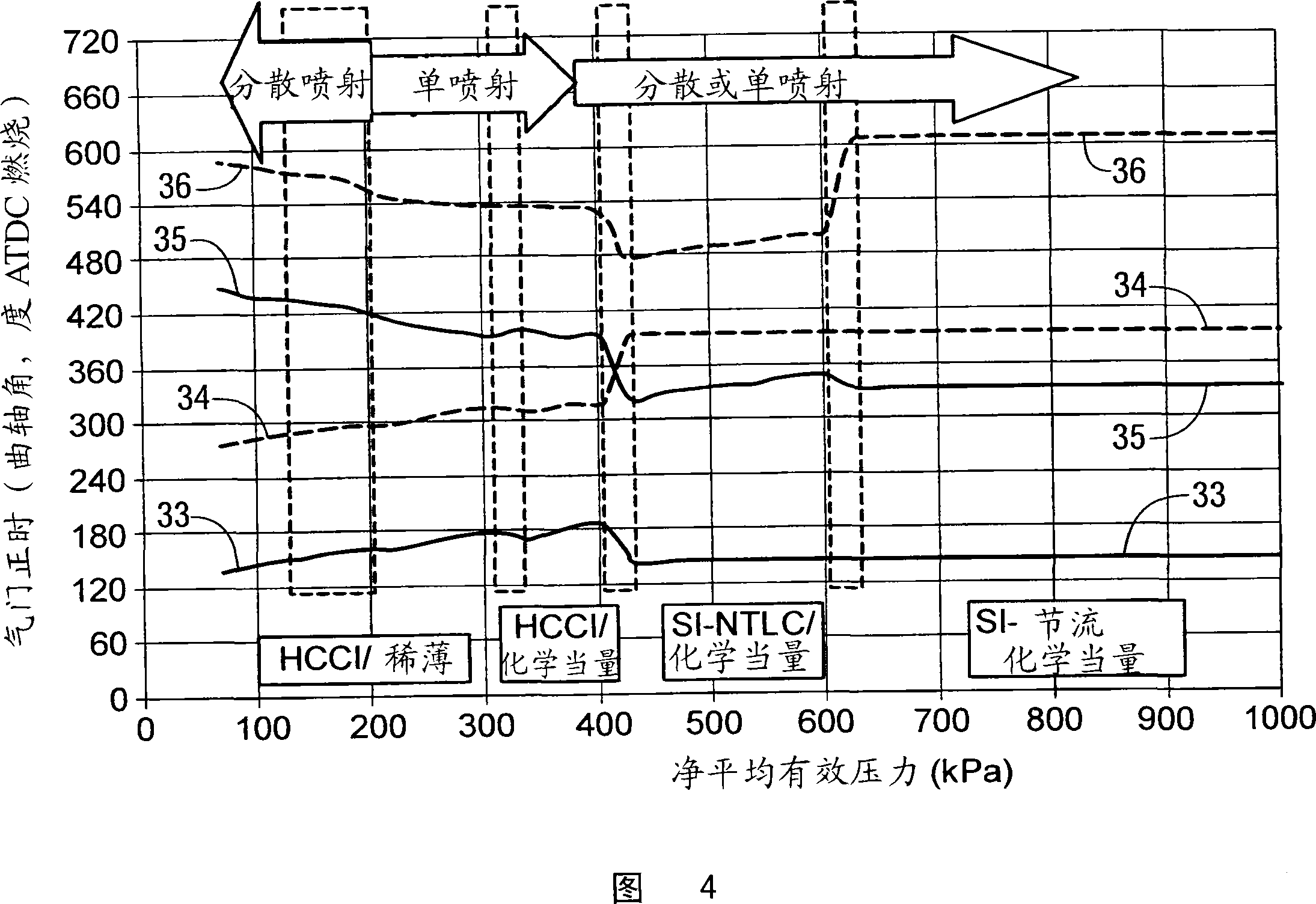

Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

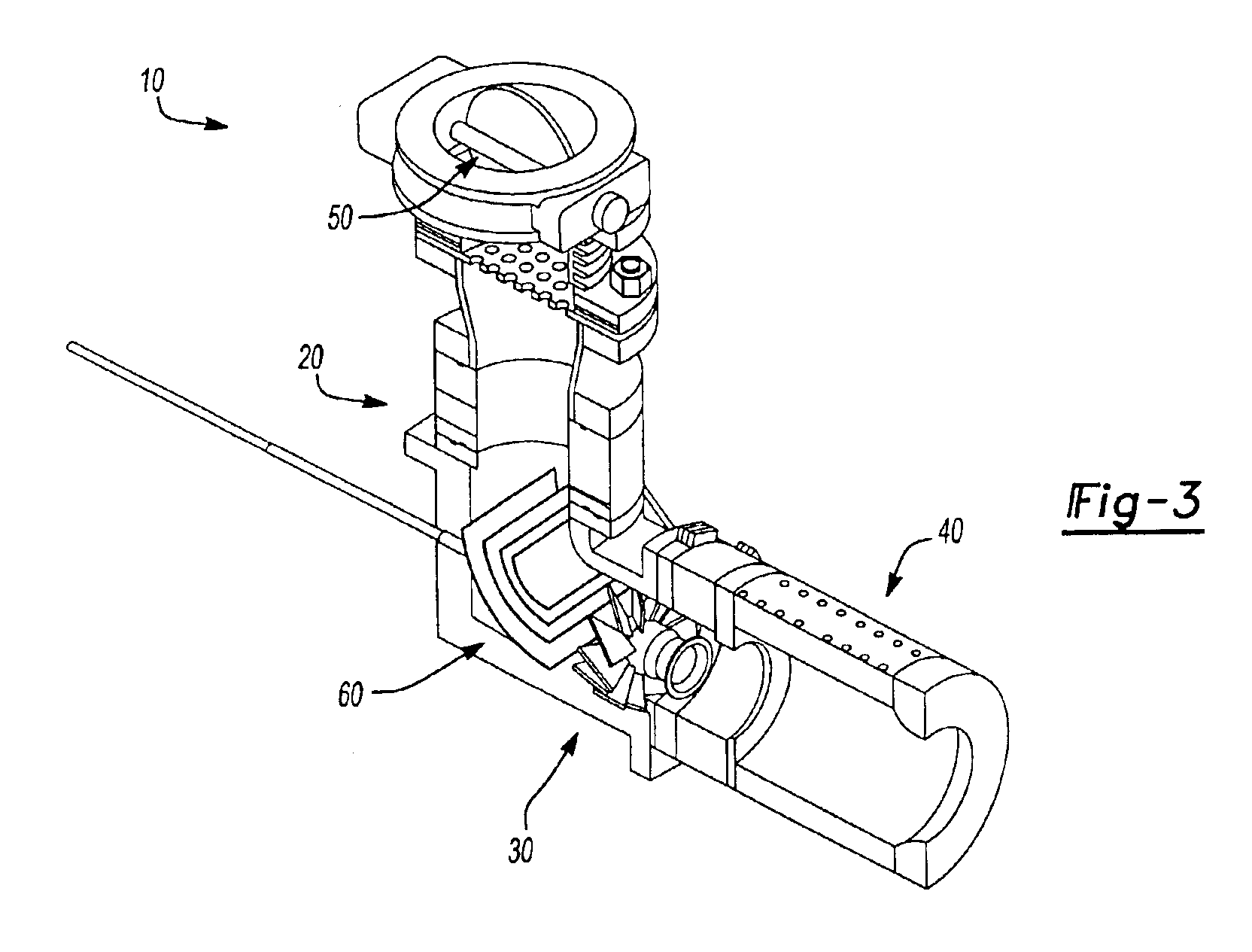

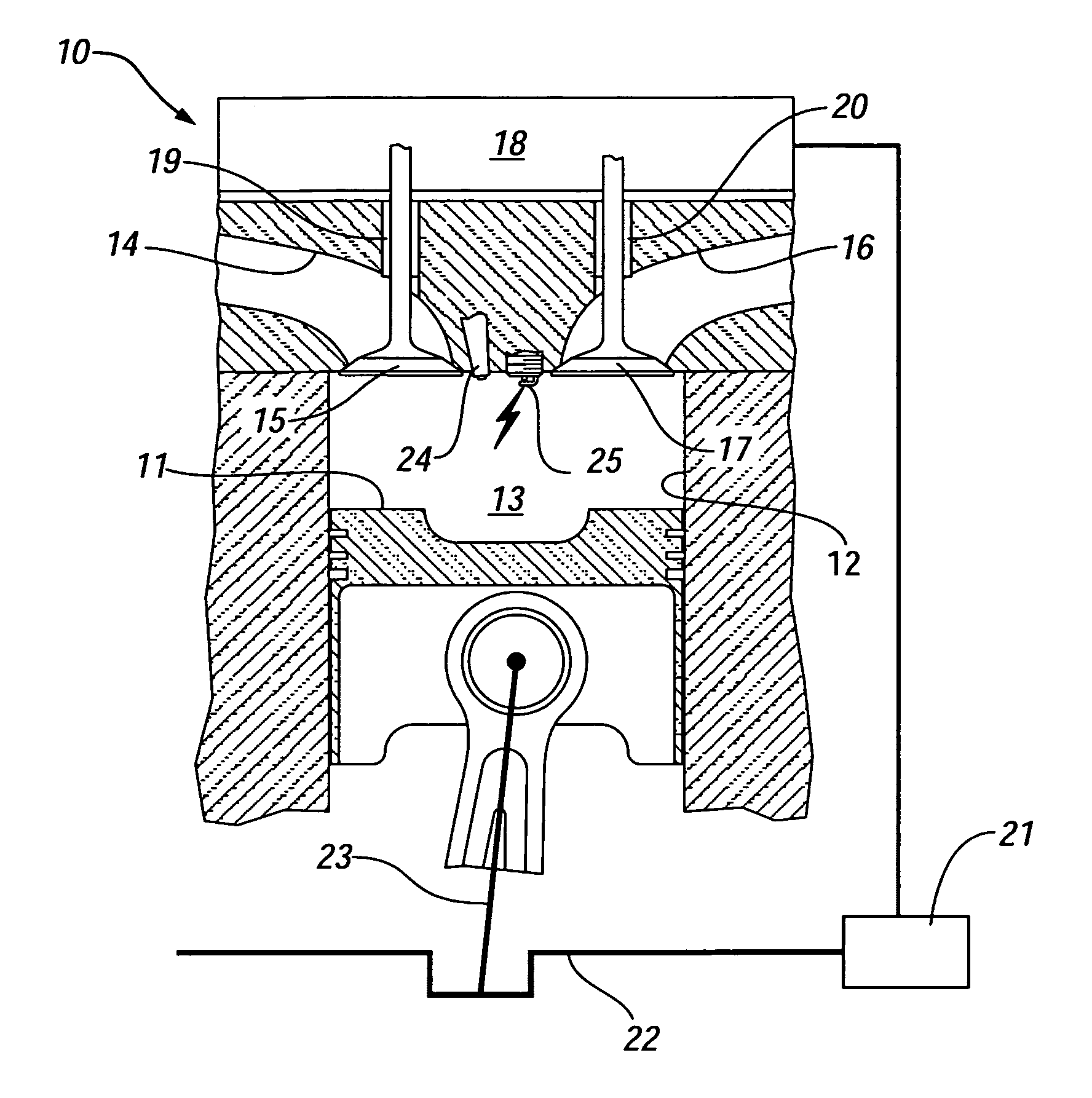

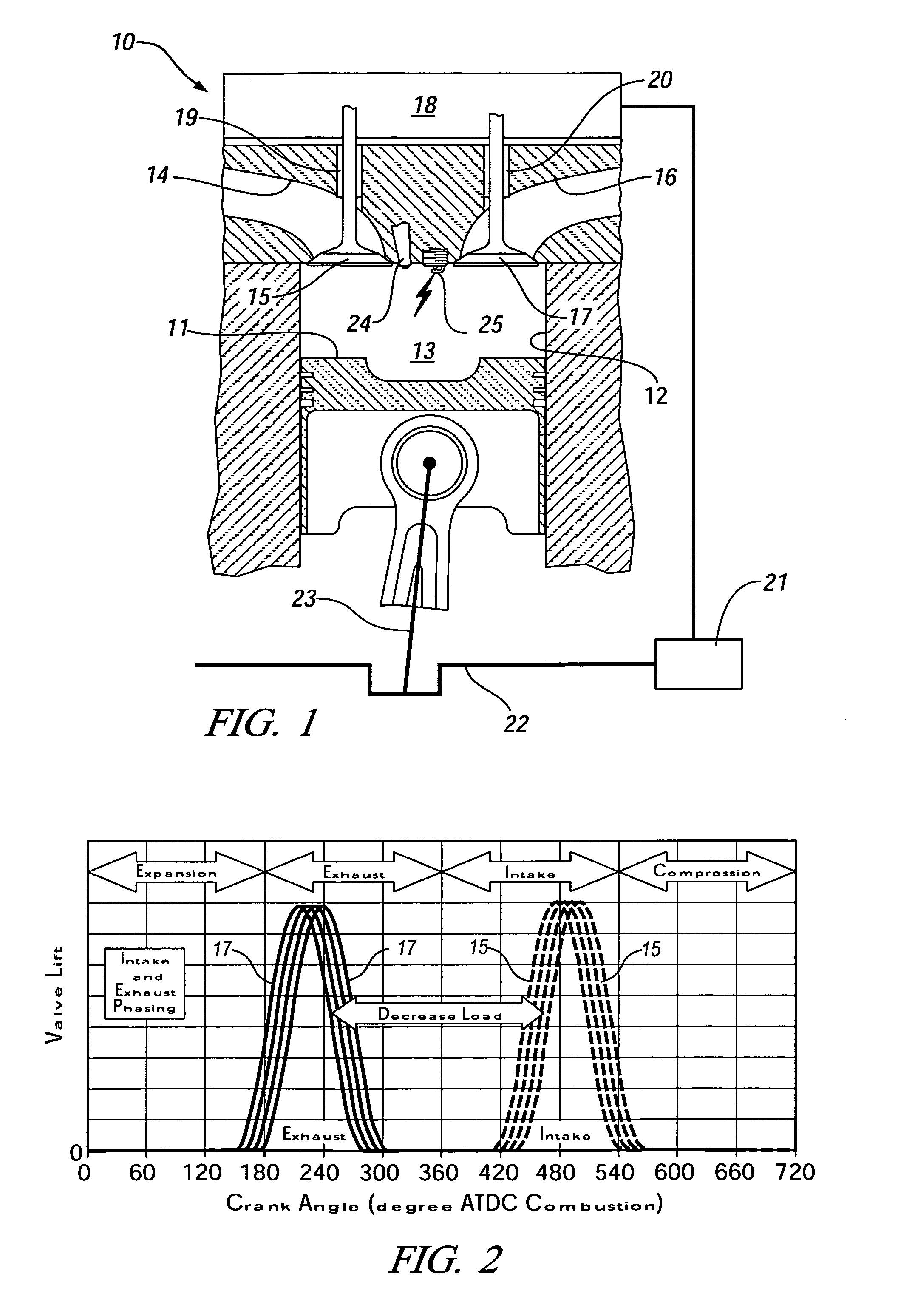

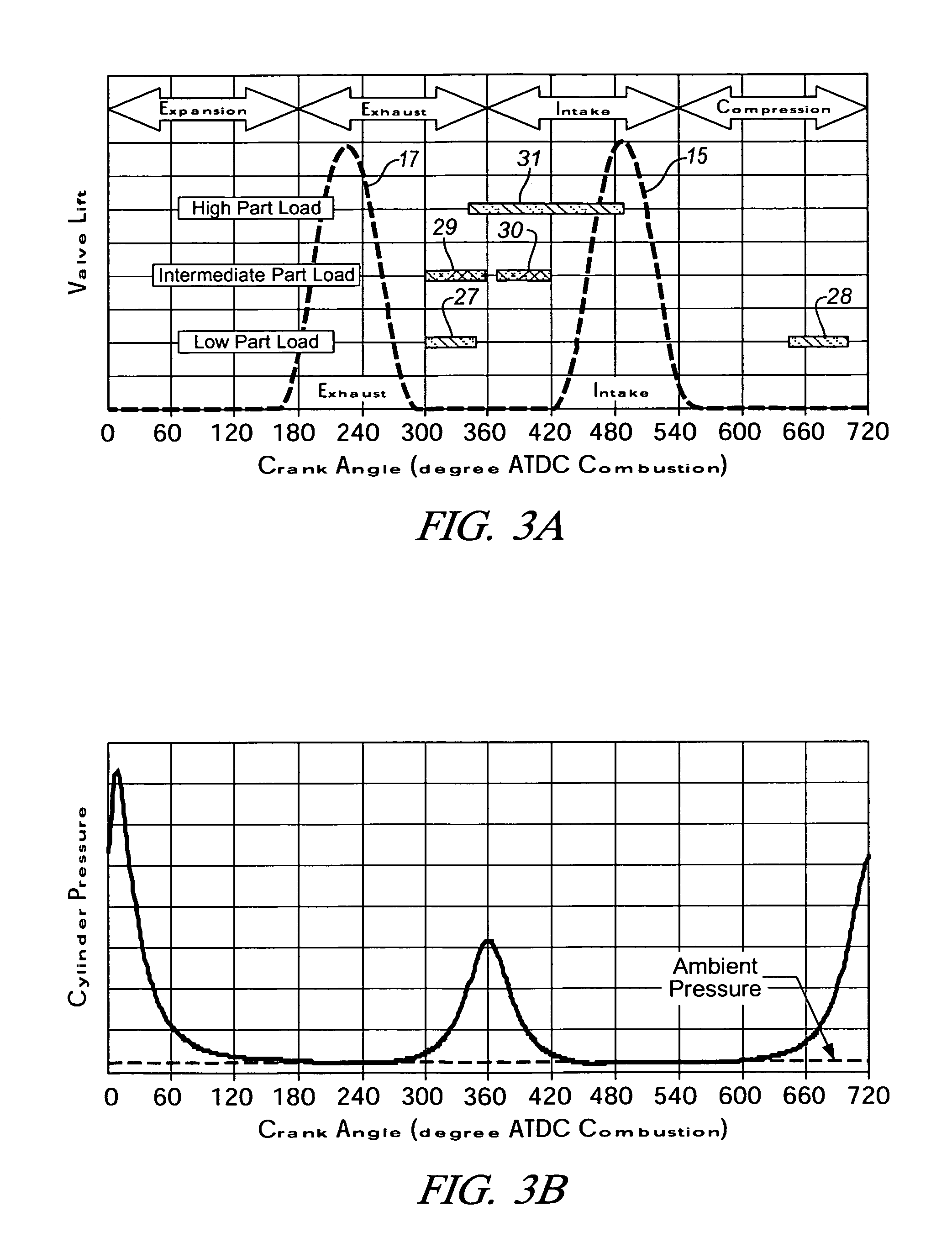

InactiveUS20060196466A1Eliminate misfiringEliminate partial burnValve arrangementsElectrical controlHomogeneous charge compression ignitionExhaust valve

A method is provided for control of transition between combustion modes of a direct-injection engine operable in a homogeneous charge compression ignition (HCCI) mode at lower loads and a spark ignition flame propagation (SI) mode at higher loads. The engine includes a variable valve actuation system including two-step high and low lift valve actuation and separate cam phasing for both intake and exhaust valves. The method includes operating the engine at steady state, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during mode changes between the HCCI mode and the SI mode by switching the exhaust and intake valves between low lift for HCCI operation and high lift for SI operation. High load may be an SI throttled mode with an intermediate unthrottled mode (SI / NTLC} in which transition between HCCI and SI / NTLC modes requires switching only the exhaust valve lift and transition between SI / NTLC and SI throttled modes requires switching only the intake valve lift, with predetermined phase adjustments in the valve timing phasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

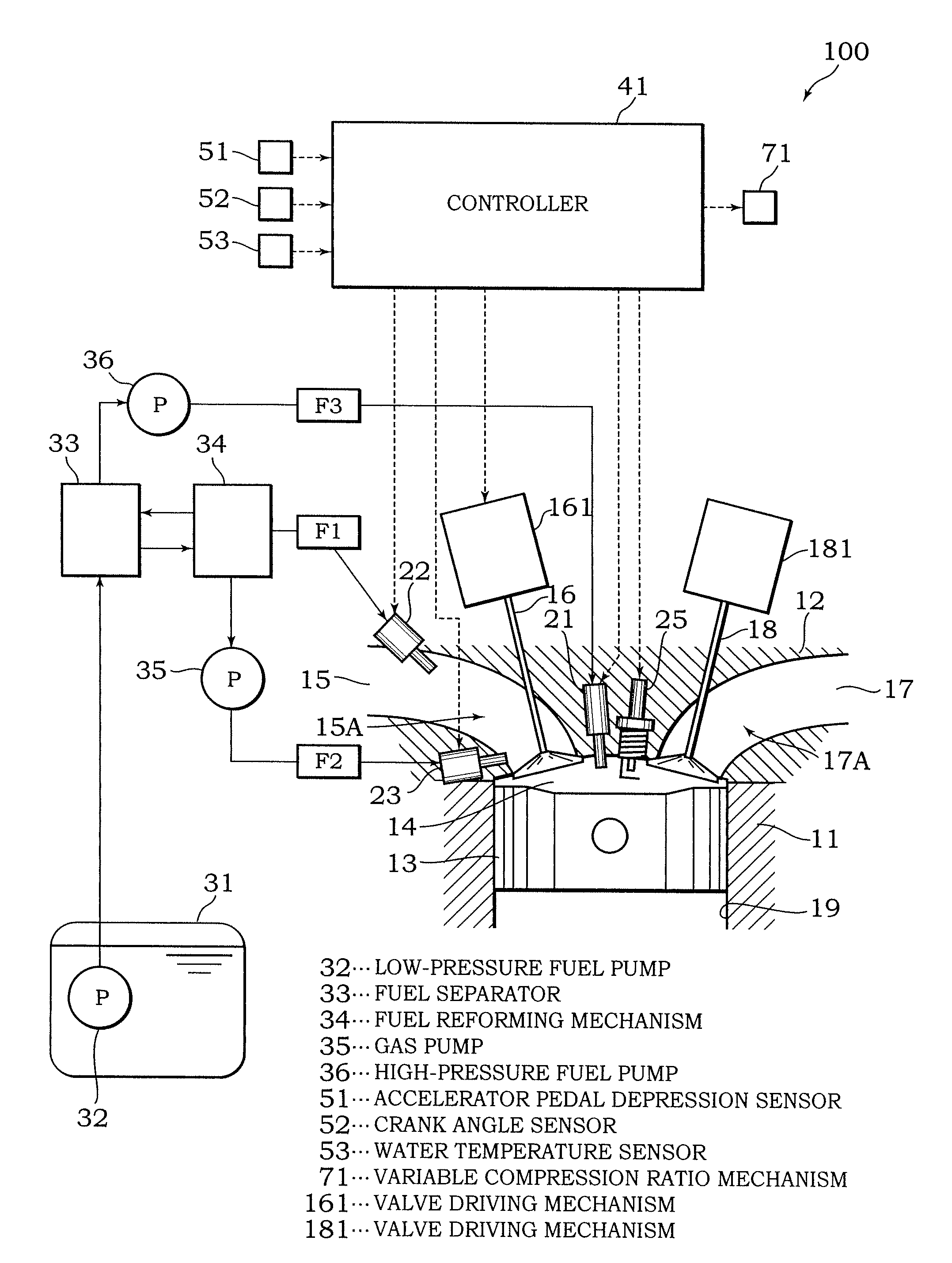

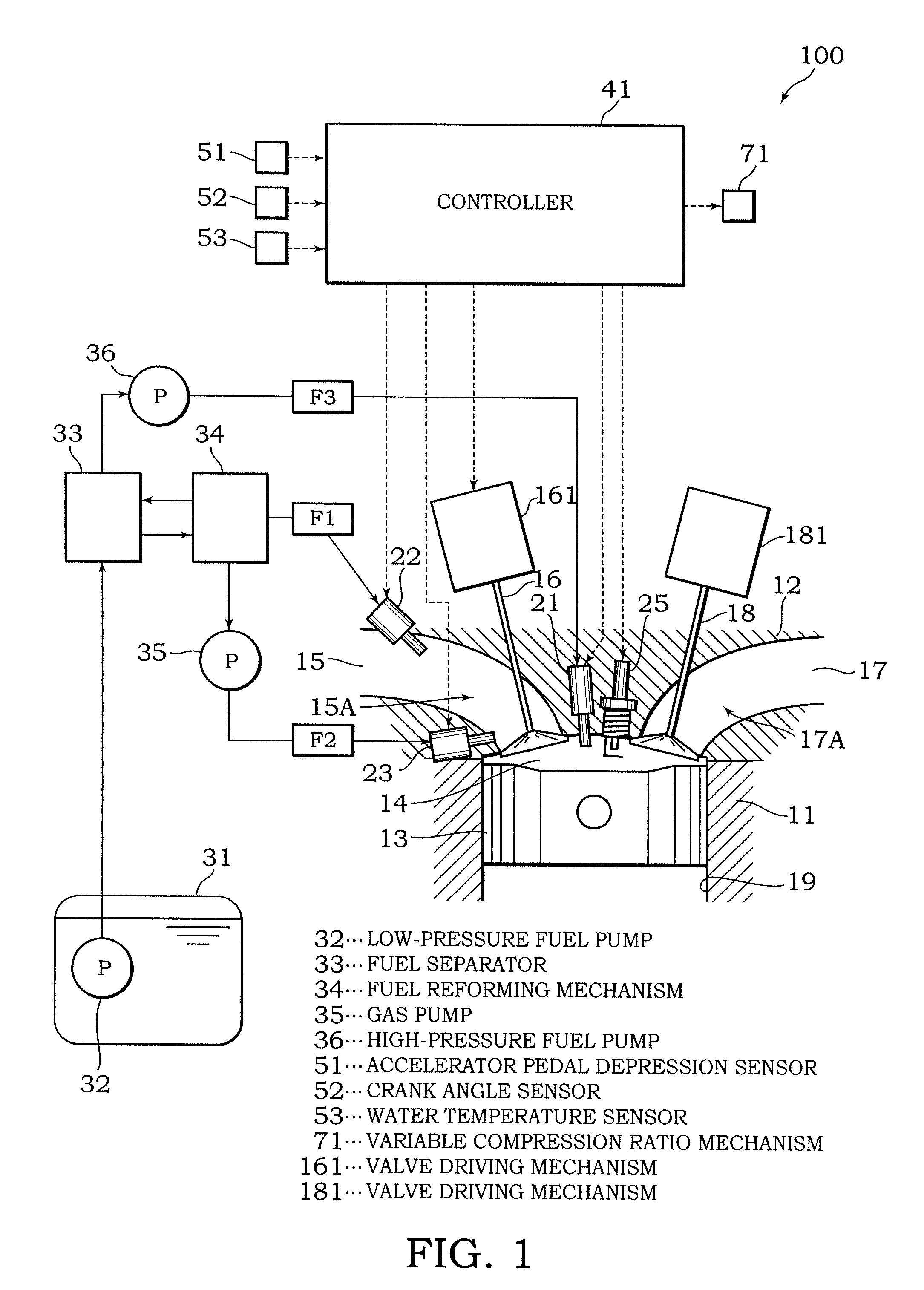

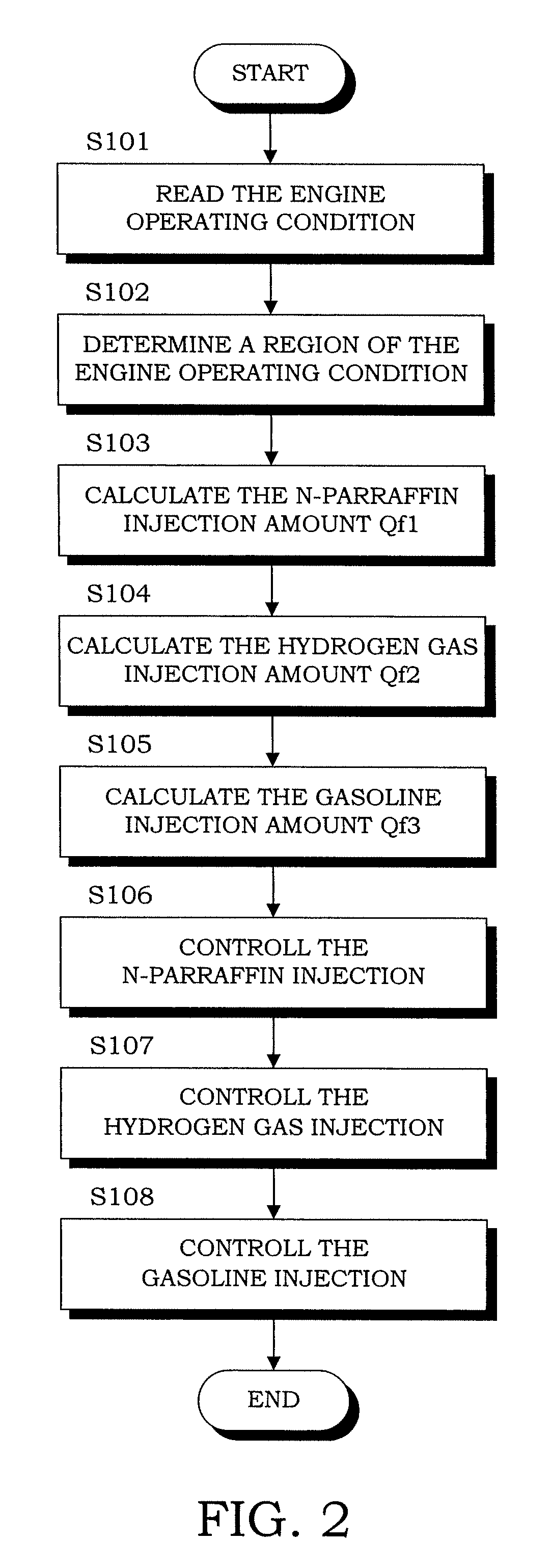

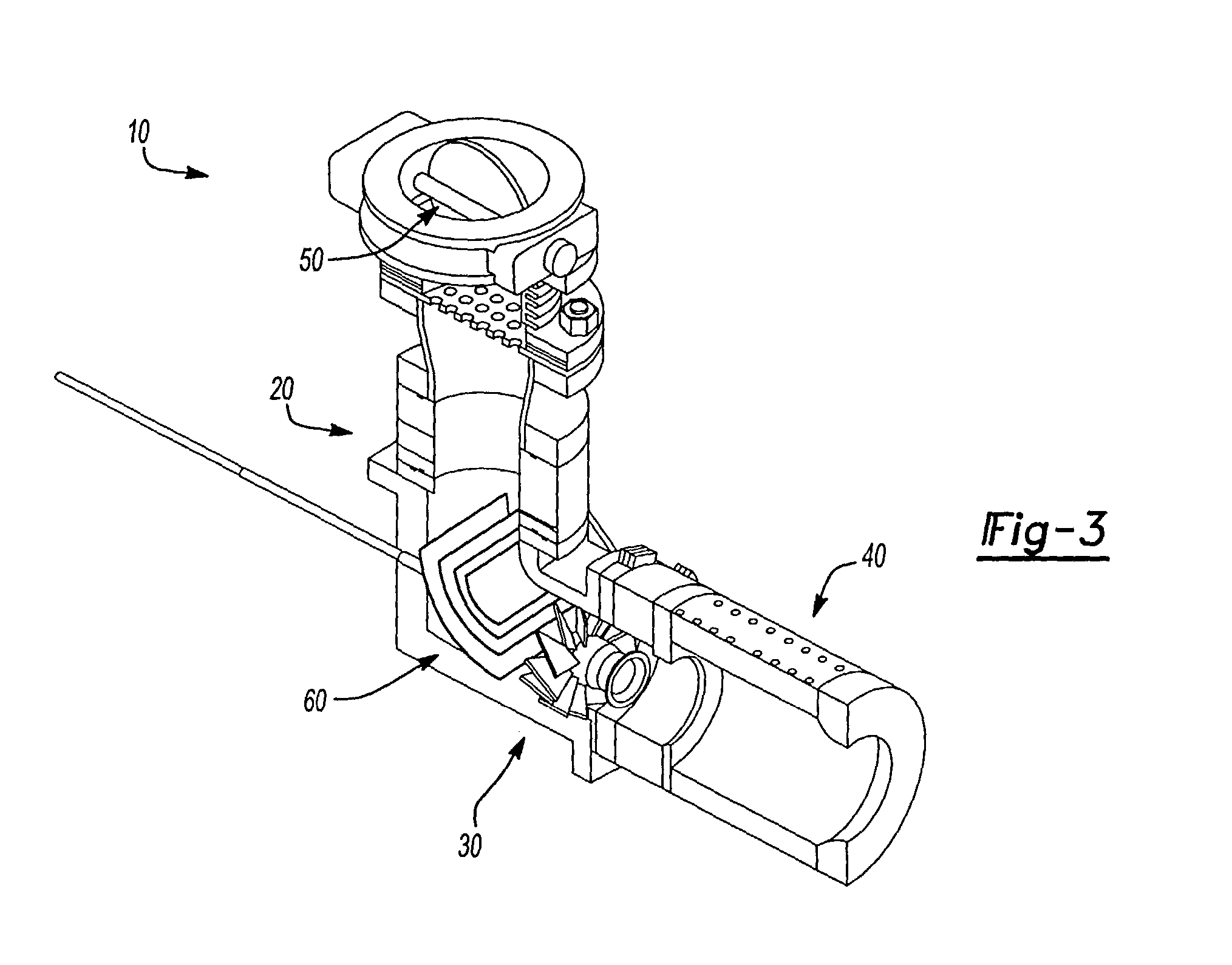

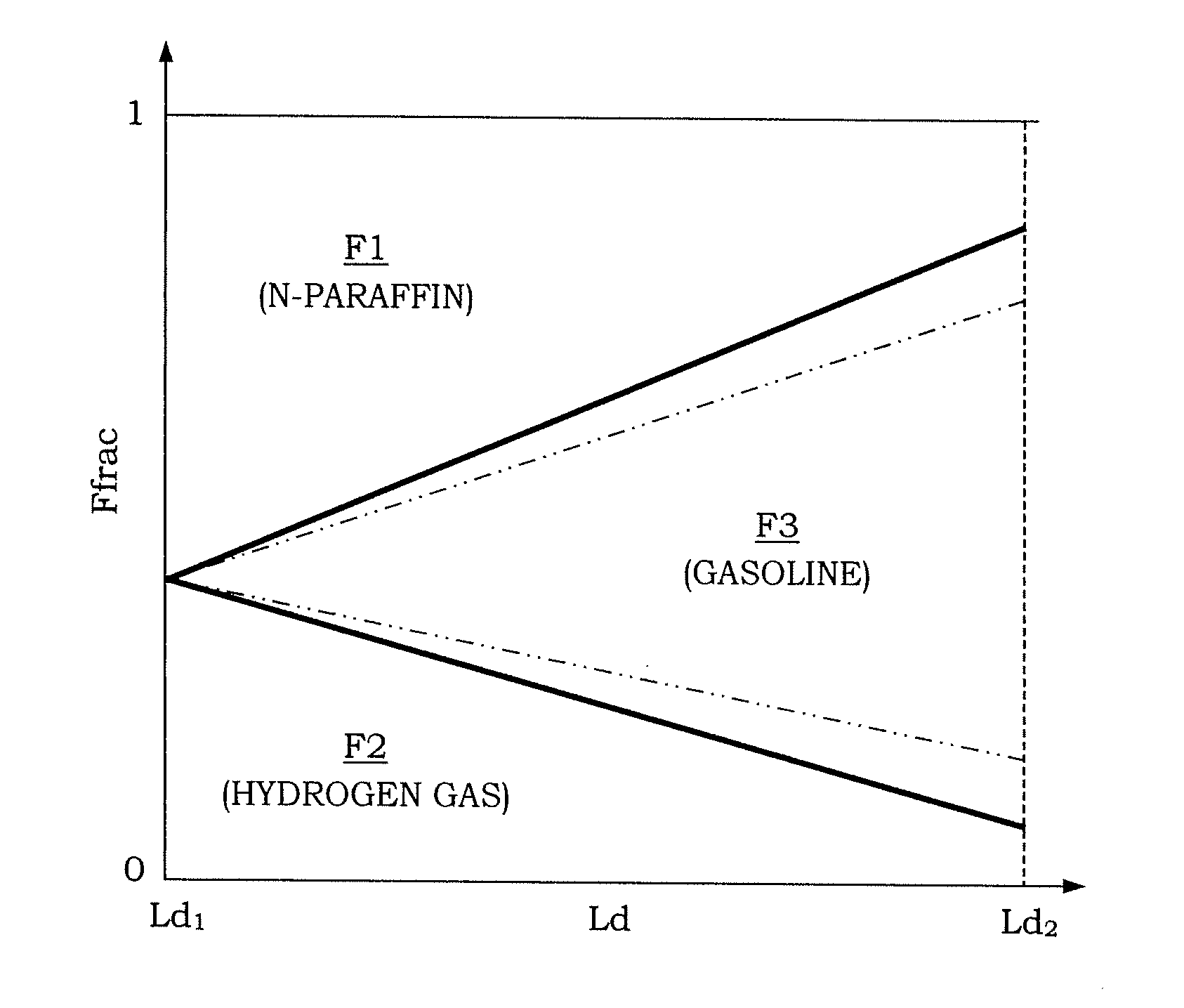

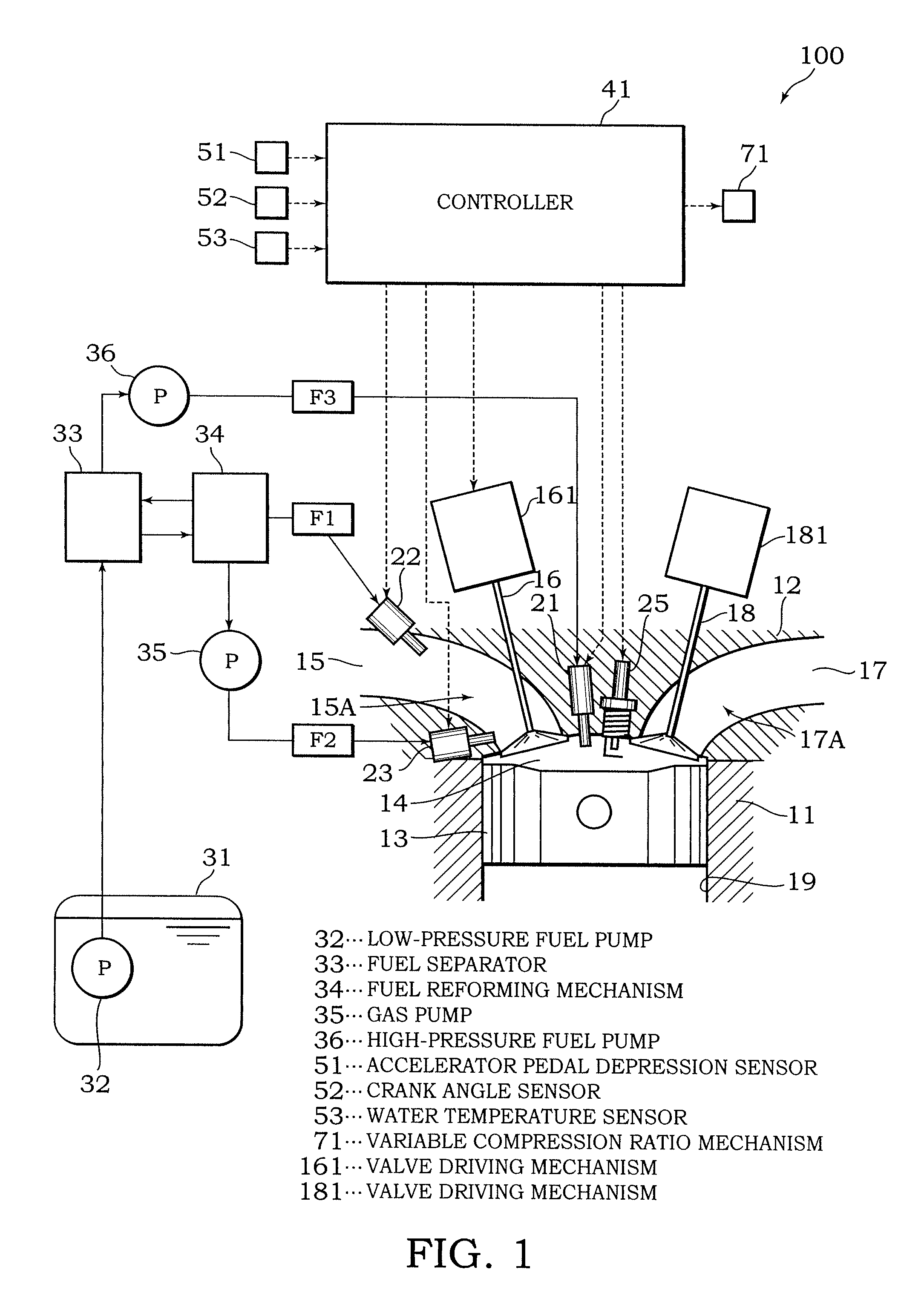

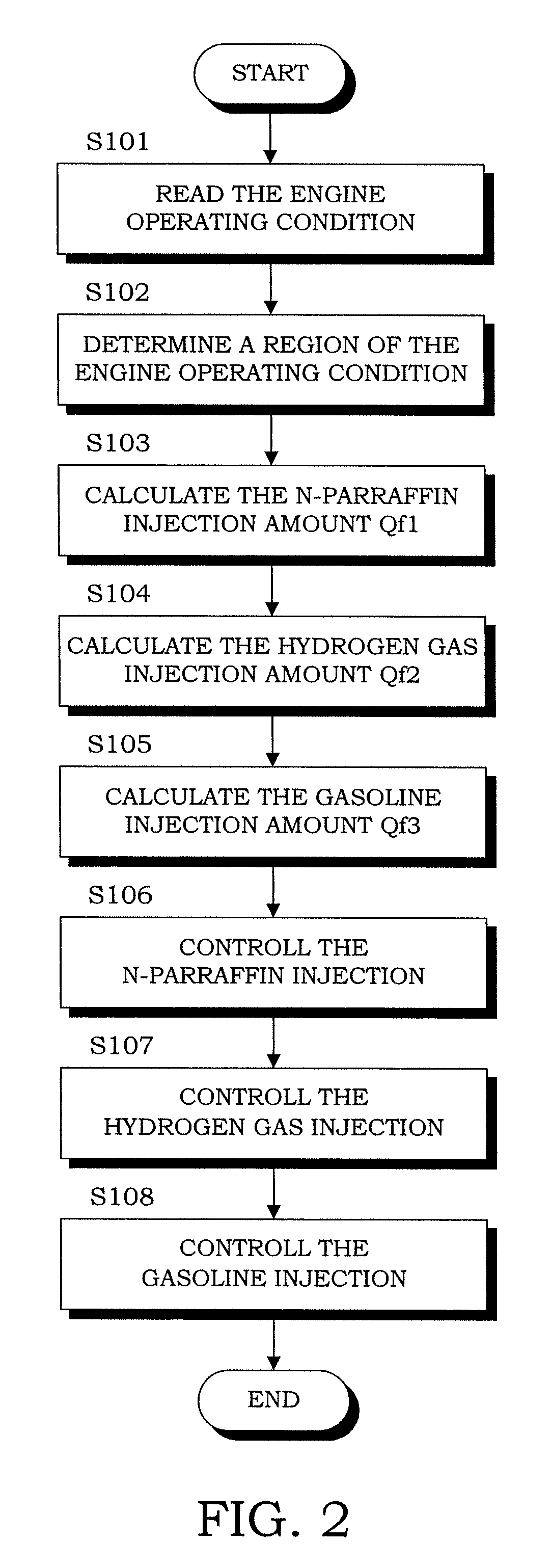

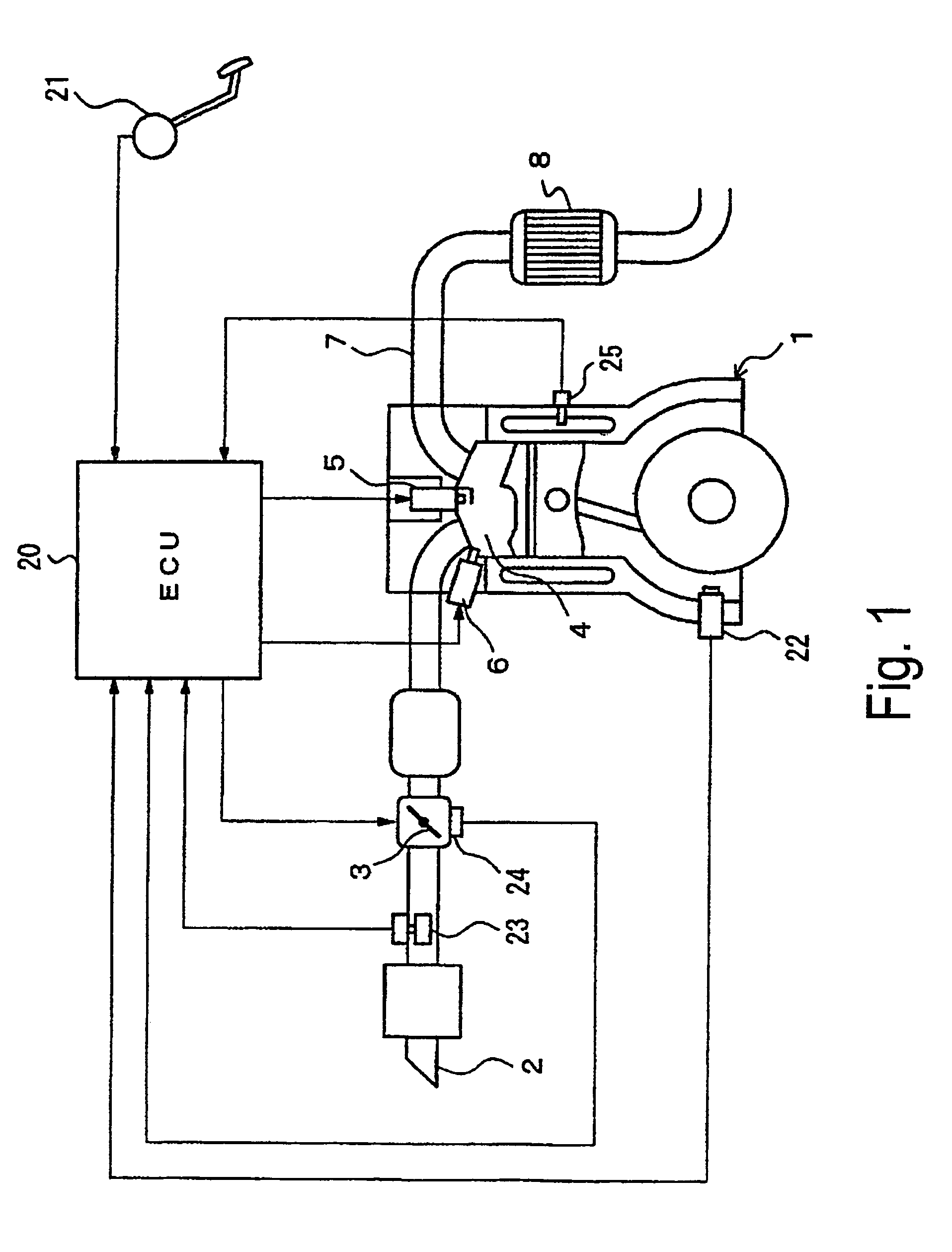

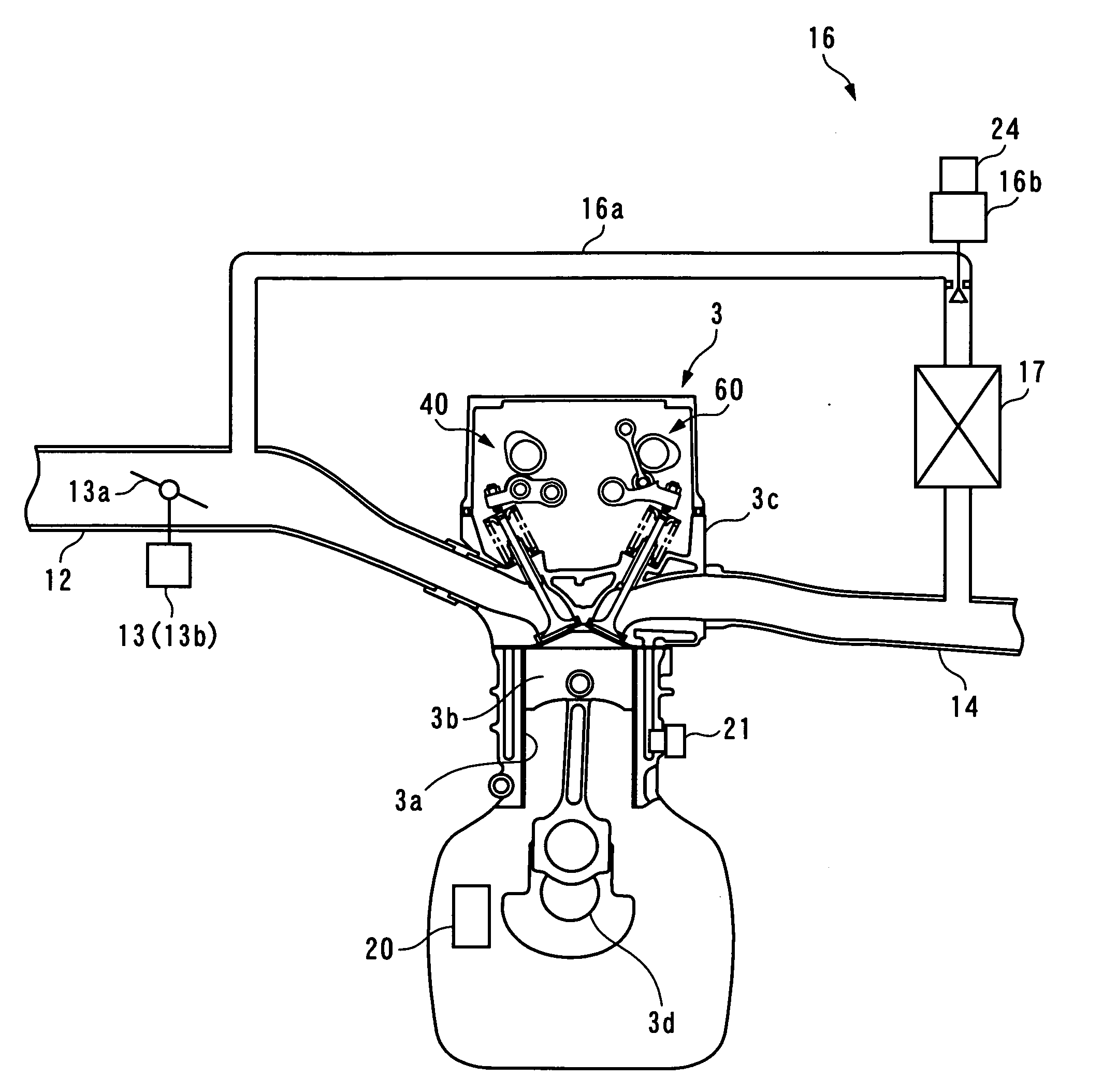

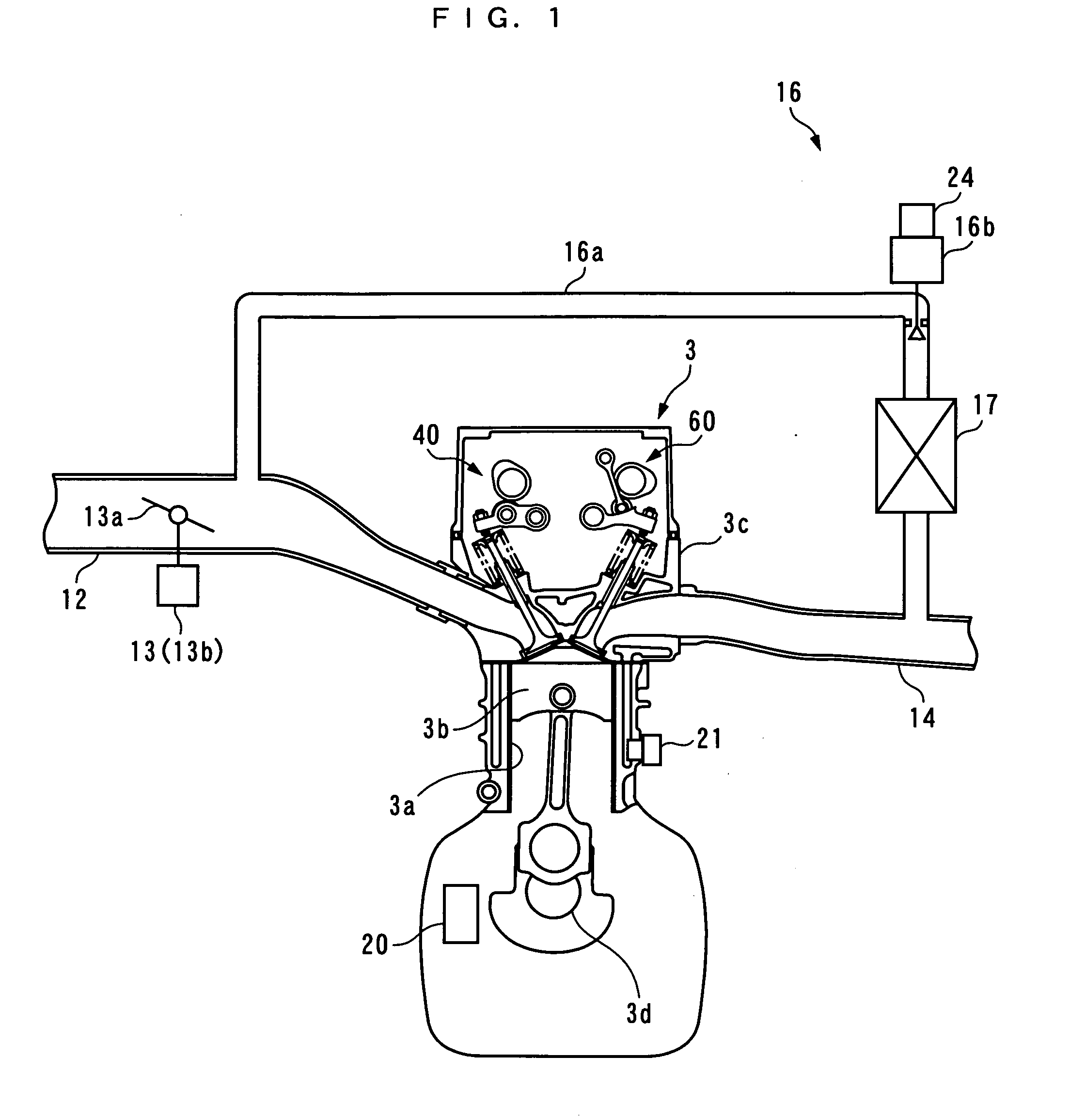

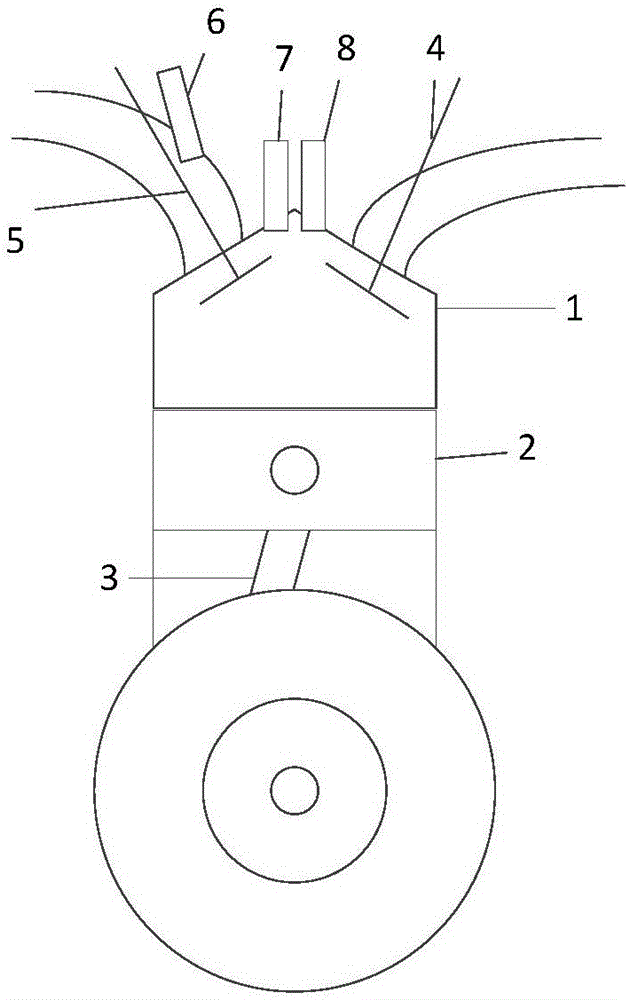

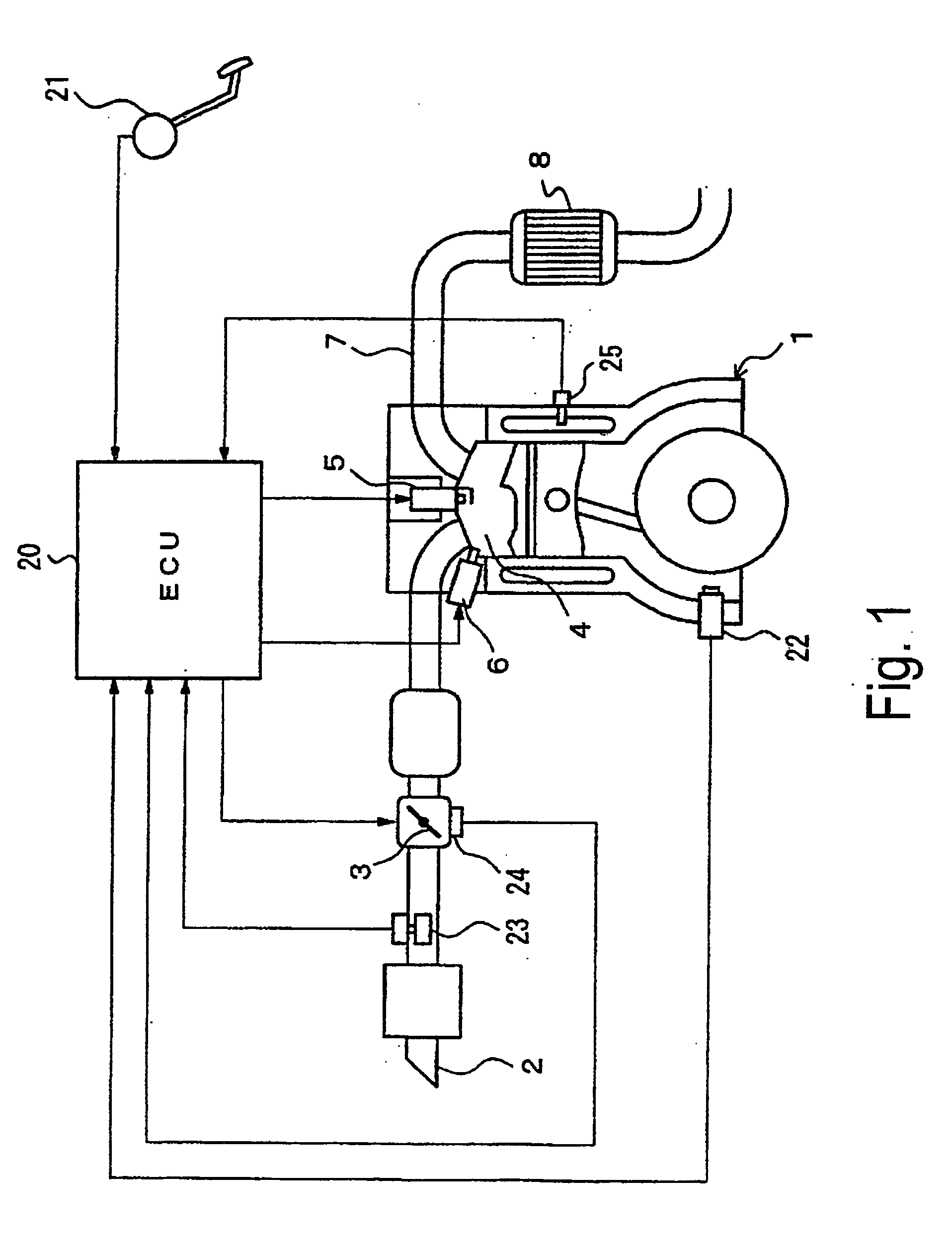

Internal combustion engine

InactiveUS20090043479A1High-temperature combustionIncrease temperatureElectrical controlInternal combustion piston enginesCombustion chamberFlame propagation

An internal combustion engine (100) comprises a fuel injection valve (21, 22) which supplies a first fuel having a higher self-ignitability than gasoline and a second fuel having a higher combustion speed than gasoline such that an air-fuel mixture containing the first fuel and the second fuel is formed in a combustion chamber (14), a spark plug (25) which ignites the air-fuel mixture, and a programmable controller (41) programmed to control supply proportions of the first fuel and the second fuel such that the ignited air-fuel mixture undergoes flame propagation combustion and then undergoes self-ignition combustion. Thus, a reduction in emissions can be achieved, and high thermal efficiency can be realized through the self-ignition combustion.

Owner:NISSAN MOTOR CO LTD

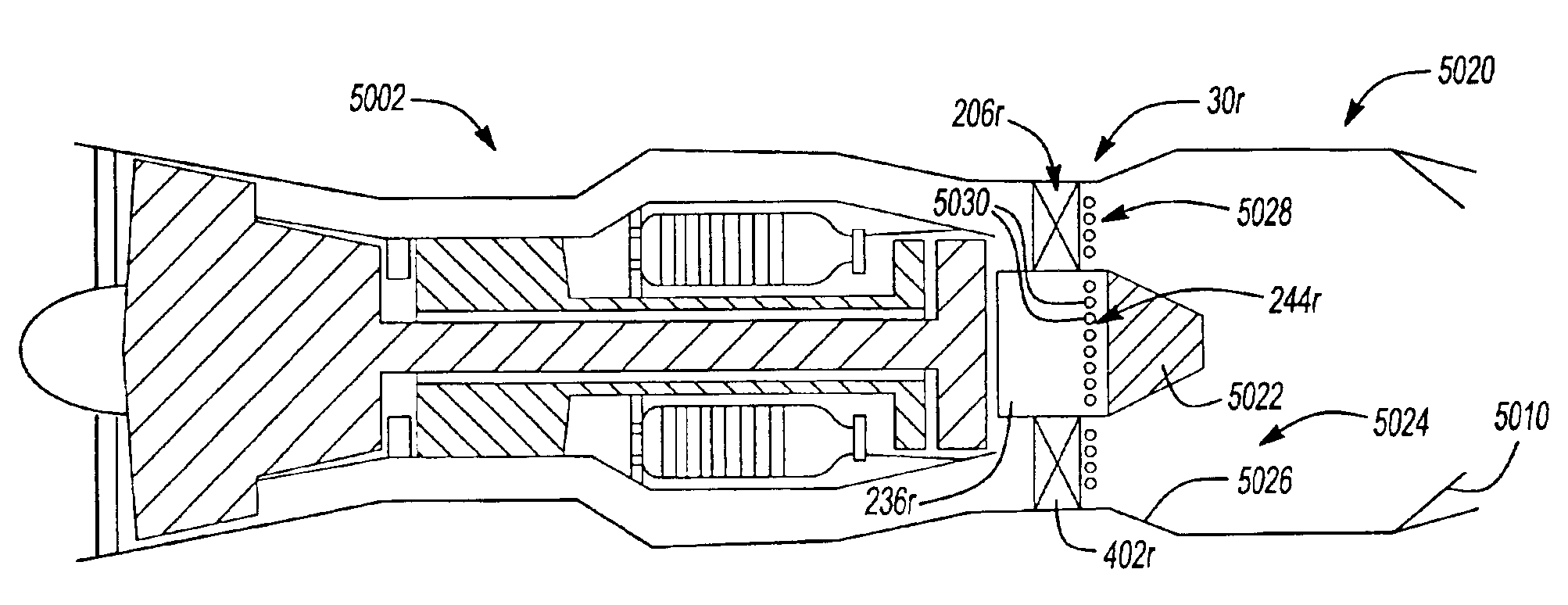

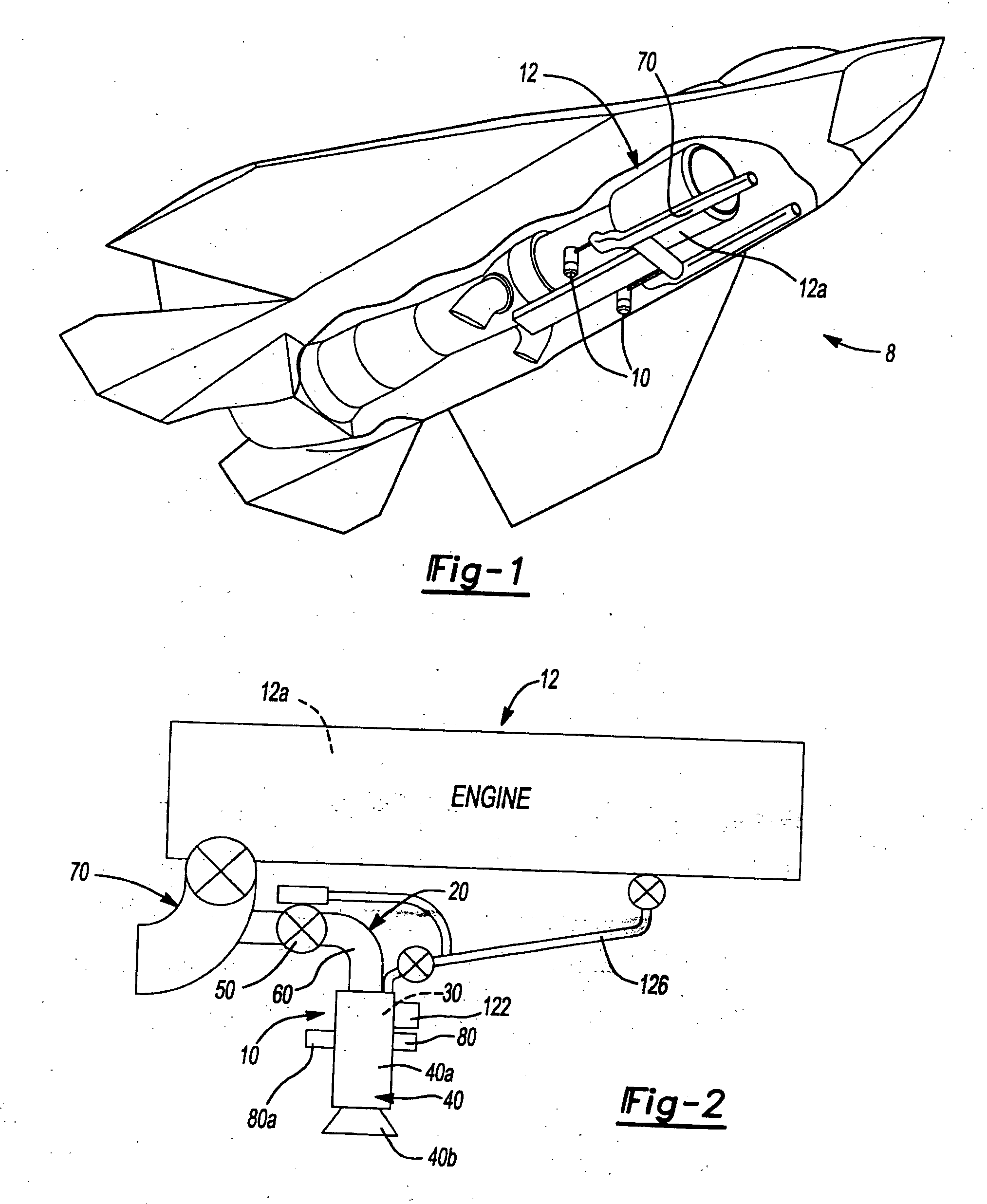

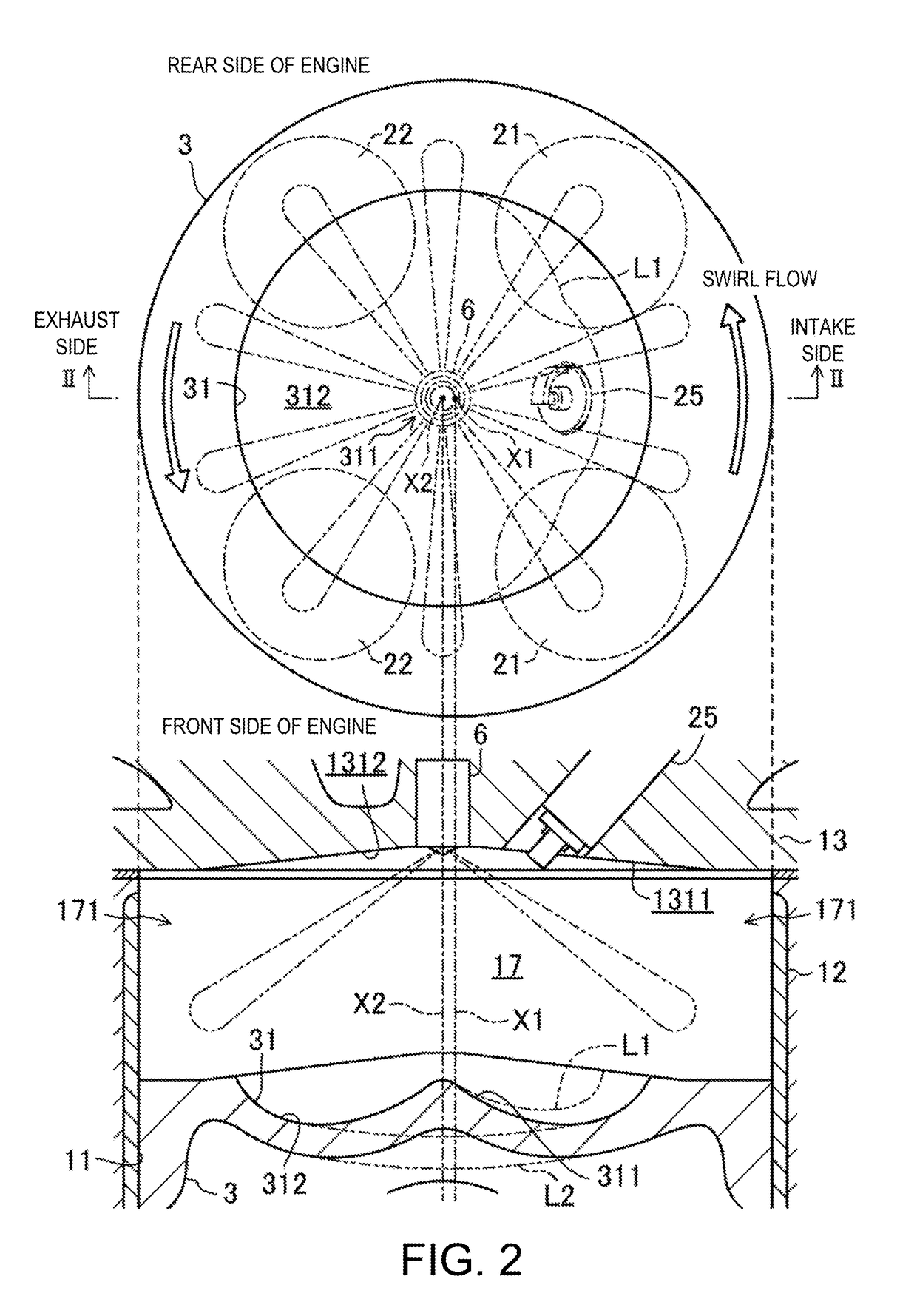

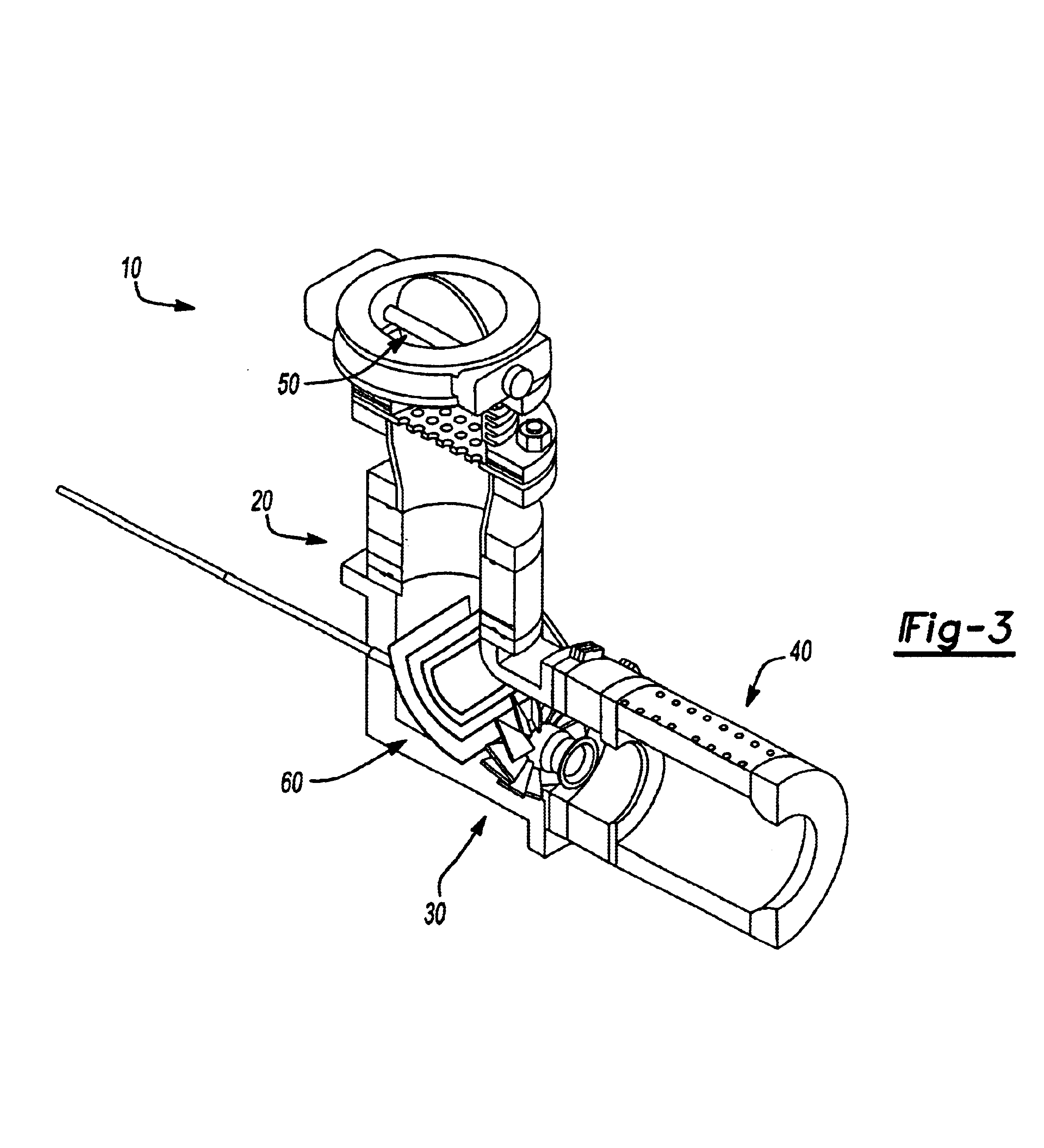

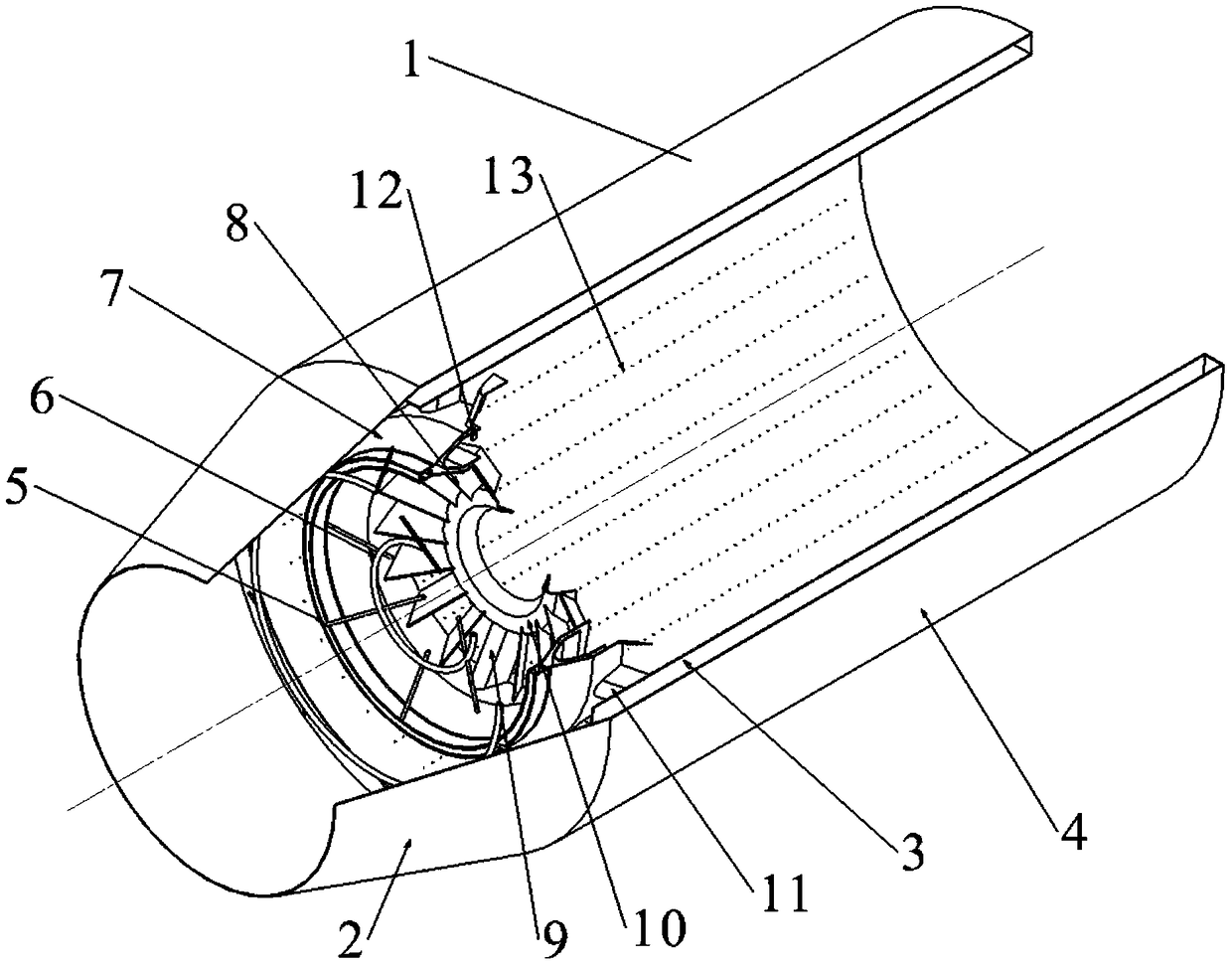

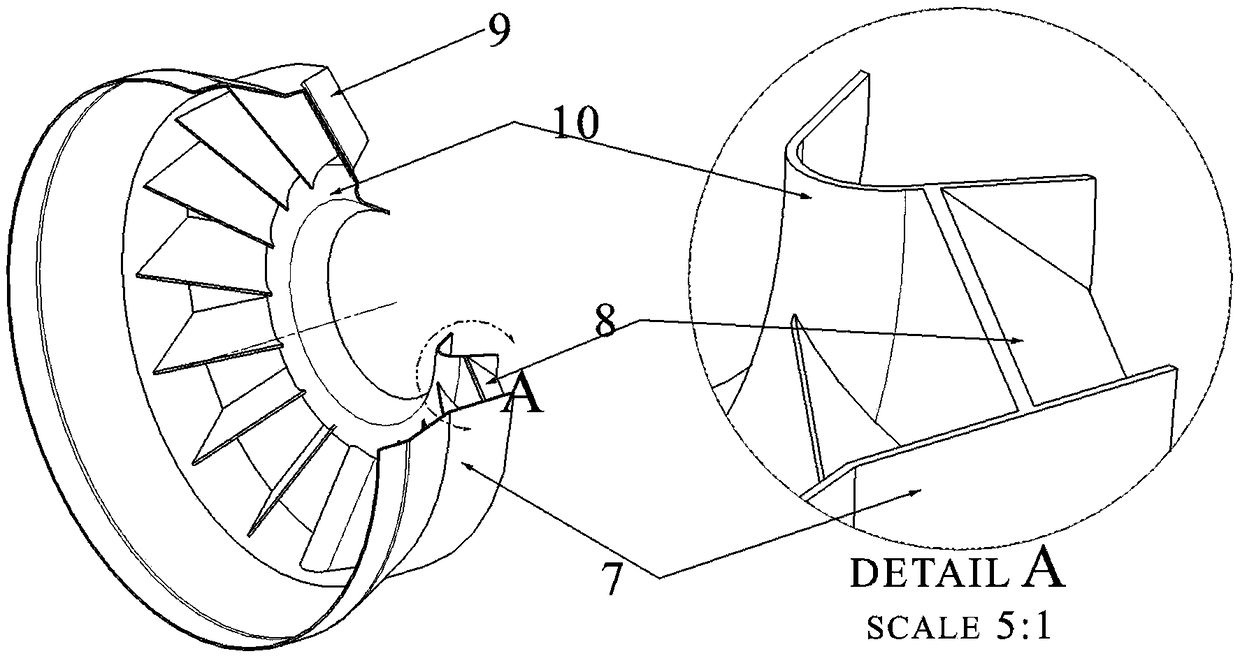

Compact swirl augmented afterburners for gas turbine engines

InactiveUS6895756B2Efficient flame propagationBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityCombustion chamber

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:THE BOEING CO +1

Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

InactiveUS7370616B2Eliminate misfiring and partial burnsValve arrangementsElectrical controlHomogeneous charge compression ignitionExhaust valve

A method is provided for control of transition between combustion modes of a direct-injection engine operable in a homogeneous charge compression ignition (HCCI) mode at lower loads and a spark ignition flame propagation (SI) mode at higher loads. The engine includes a variable valve actuation system including two-step high and low lift valve actuation and separate cam phasing for both intake and exhaust valves. The method includes operating the engine at steady state, with fuel-air-exhaust gas mixtures at predetermined conditions, for each speed and load, and controlling the engine during mode changes between the HCCI mode and the SI mode by switching the exhaust and intake valves between low lift for HCCI operation and high lift for SI operation. High load may be an SI throttled mode with an intermediate unthrottled mode (SI / NTLC} in which transition between HCCI and SI / NTLC modes requires switching only the exhaust valve lift and transition between SI / NTLC and SI throttled modes requires switching only the intake valve lift, with predetermined phase adjustments in the valve timing phasing.

Owner:GM GLOBAL TECH OPERATIONS LLC

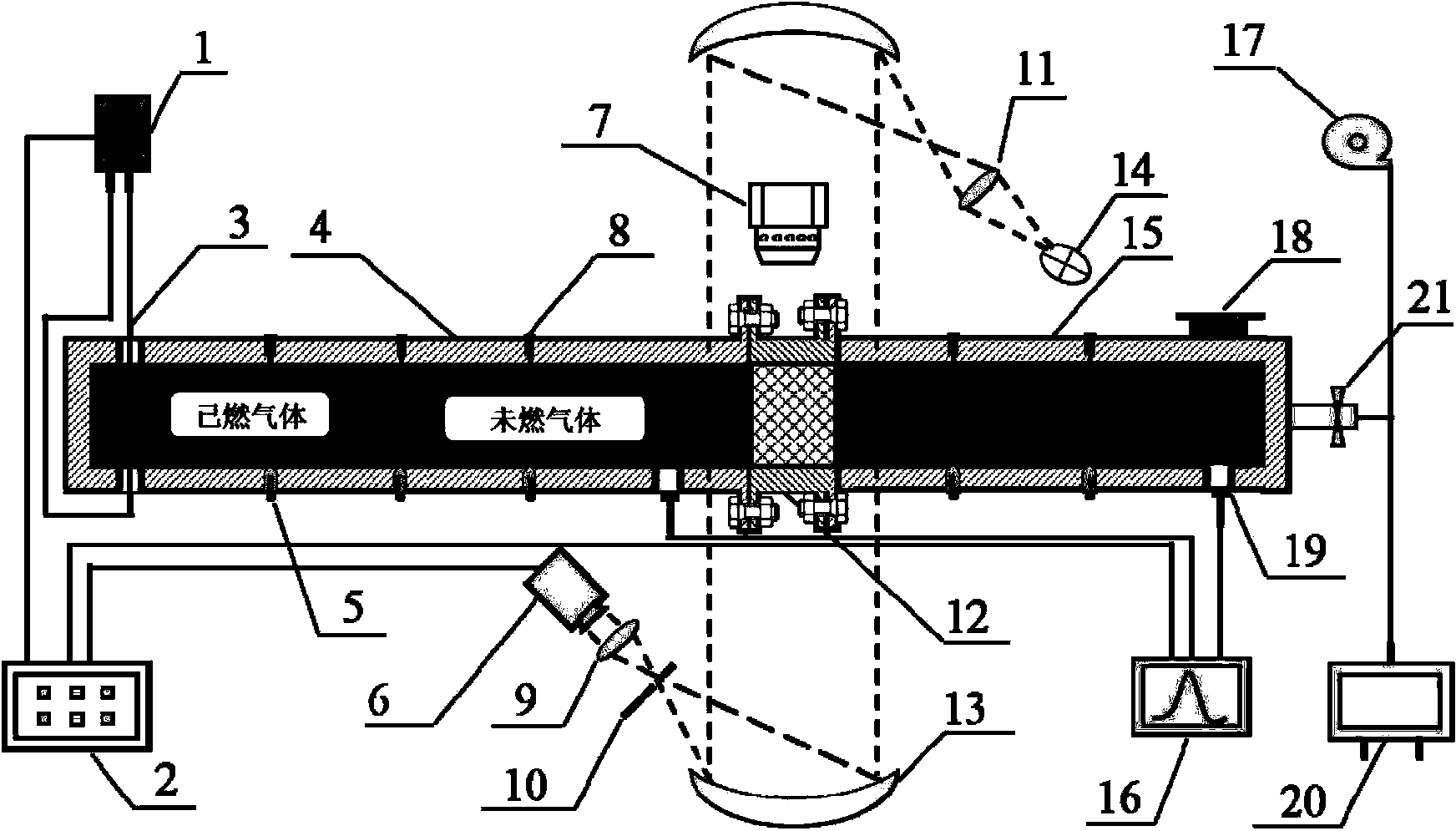

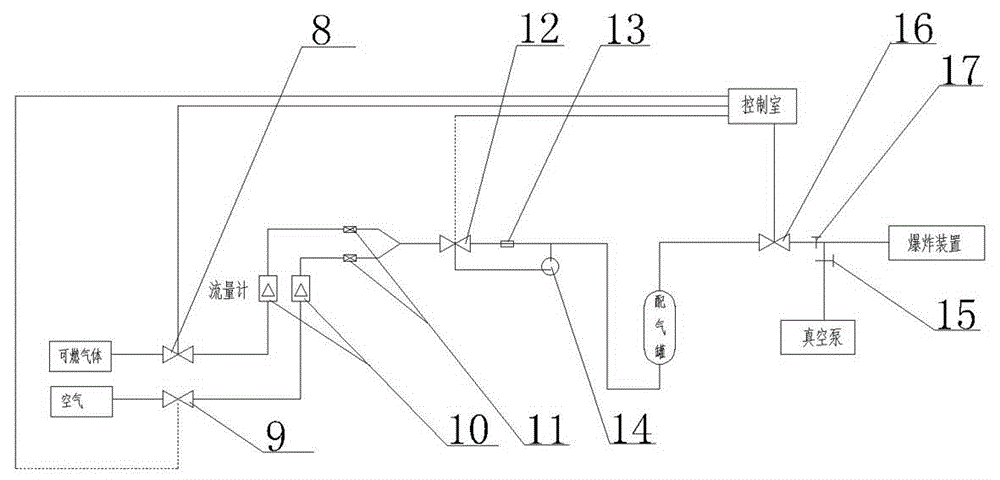

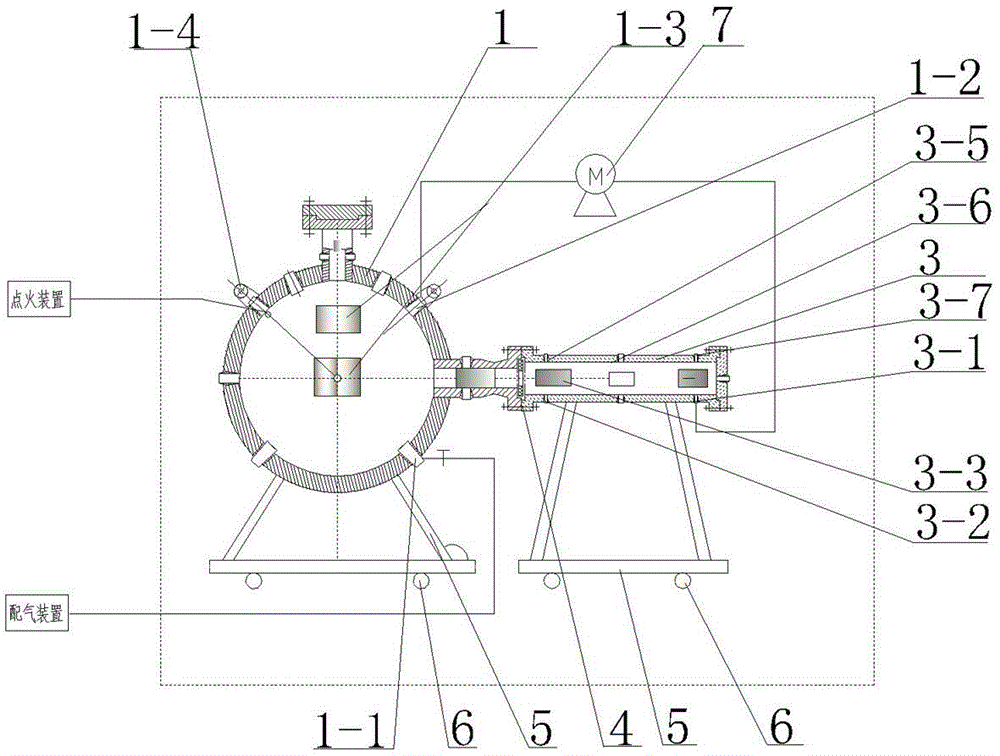

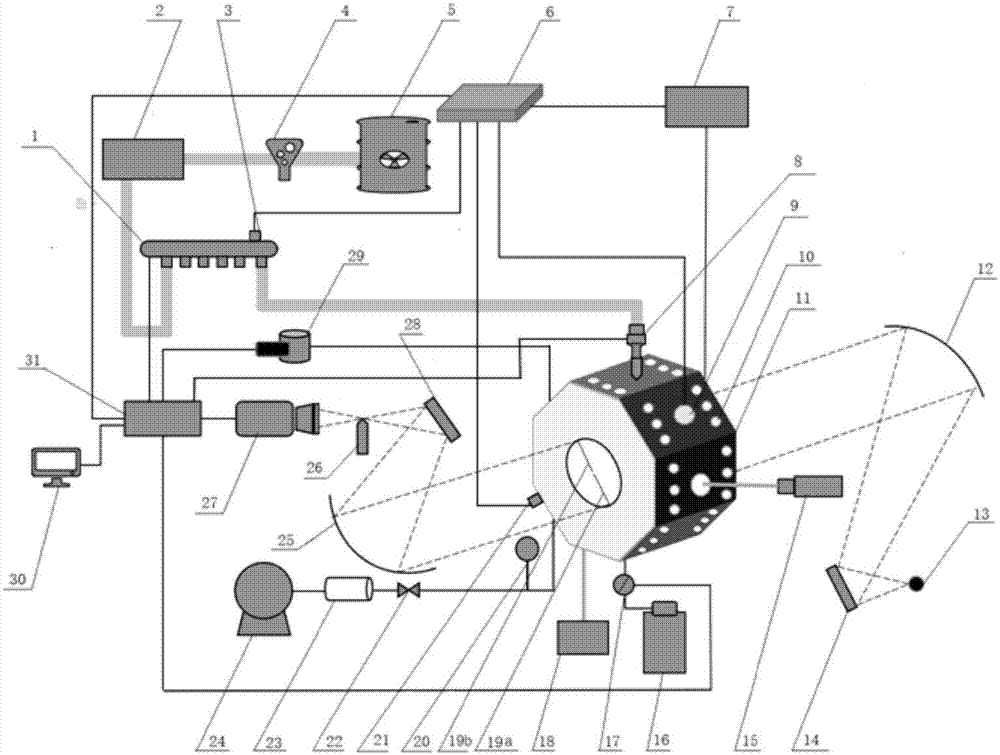

Apparatus for testing flame propagation and flame suppression in flammable gas and air premixed gas explosion process

ActiveCN103454308AAccurate and intuitive recordReveal inhibitionMaterial exposibilityData acquisitionInstability

The invention provides an apparatus for testing flame propagation and flame suppression in the flammable gas and air premixed gas explosion process. The whole apparatus comprises a combustion pipeline, a water mist generating device, a metal net fire retardance device, a high-speed camera, a schlieren system, a pressure testing system, an automatic gas distribution system, a temperature testing system, an ion probe detection system, a data acquisition instrument, a high-tension ignition system and a synchronous controller. Through the apparatus, flame propagation characteristics and flame propagation rules are researched in the premixed gas explosion process under the influences of factors such as different flammable gas components, different opening states, different ignition positions and different types of flame instability, the effects of stopping agents, fire-retardant metal nets, water mist and the like on controlling and restraining flame propagation are researched, a method and technology for restraining premixed gas flame propagation are developed under the physical-chemical coupling effect, and the inner mechanism of the apparatus is explained.

Owner:UNIV OF SCI & TECH OF CHINA

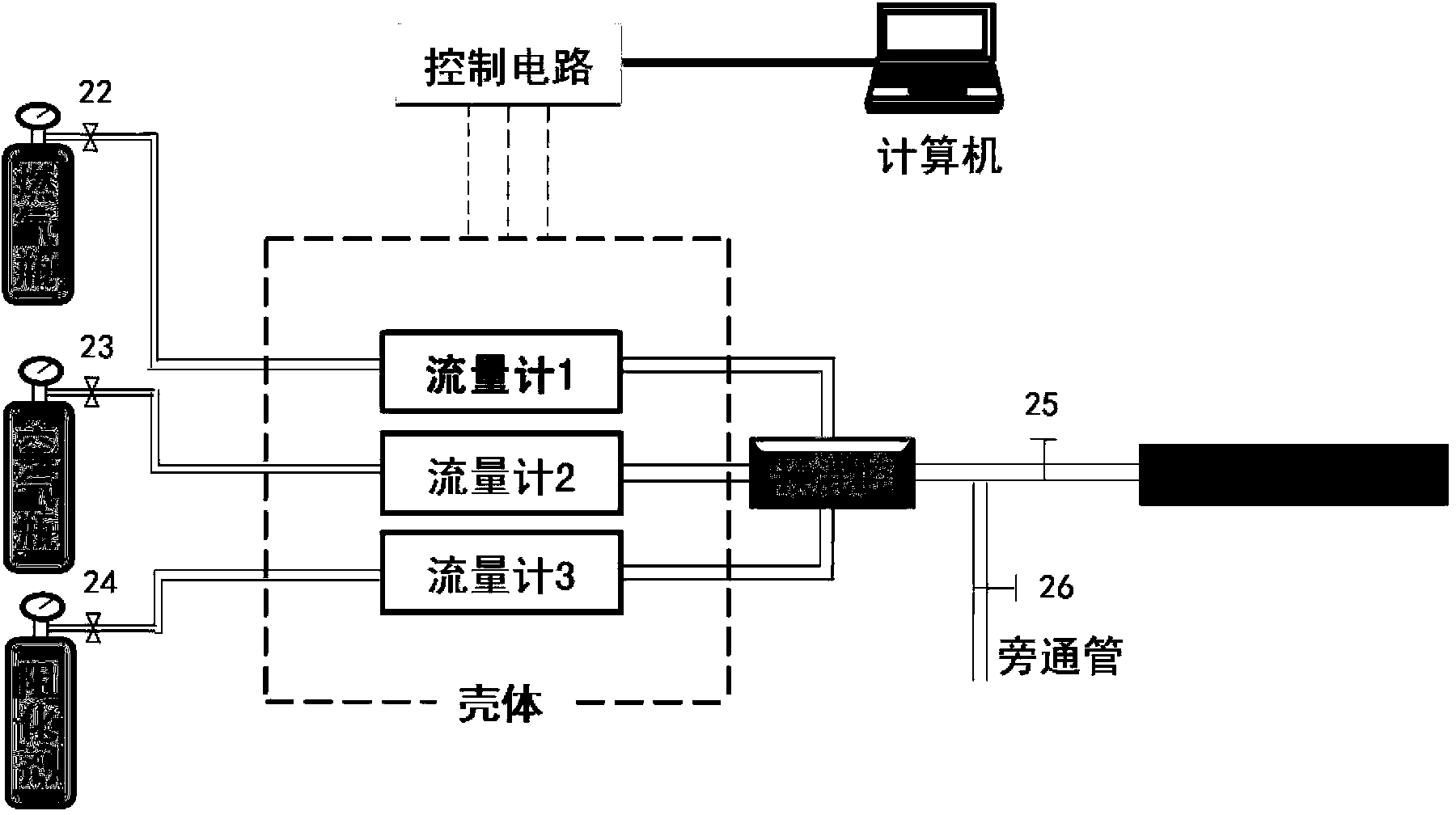

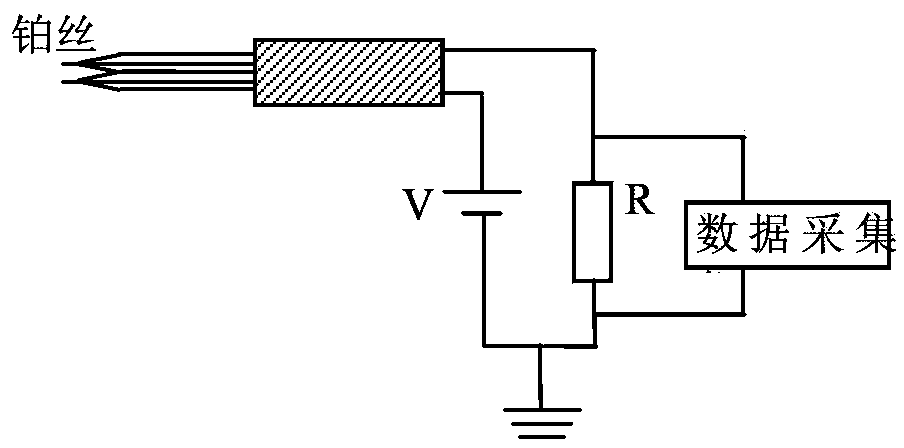

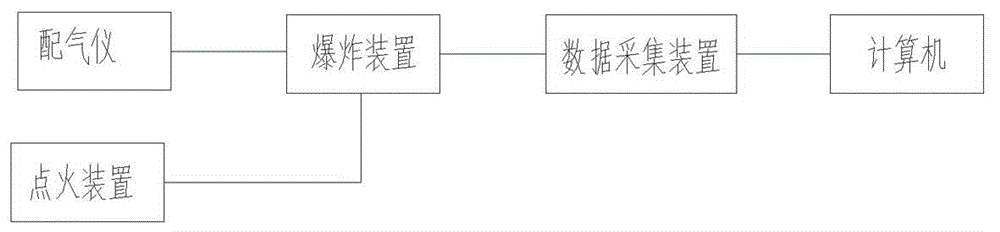

Testing system for gas explosion characteristic size effect

The invention discloses a testing system for a gas explosion characteristic size effect and relates to a testing system which studies on the gas explosion characteristic size effect. The device comprises a gas distribution device, an ignition device, an explosion device, a data collecting and processing device and a high-speed digital camera, wherein the gas distribution device comprises a combustible gas source, a distribution gas source and a gas distribution tank; the ignition device comprises a igniter, and the igniter is installed on the explosion device; the data collecting and processing device comprises a pressure sensor, a flame propagation rate sensor, a temperature sensor, a signal amplification circuit, a data collecting circuit and a computer, and the pressure sensor, the flame propagation rate sensor and the temperature sensor are installed on a spherical container, a cylindrical container and a pipeline; the explosion device is installed between the gas distribution device and the data collecting and processing device, and the explosion device comprises the spherical container, the cylindrical container and the pipeline; and the high-speed digital camera is used for shooting flames during explosion of the combustible gas inside the containers and the pipeline, and an output end of the high-speed digital camera is connected with the computer.

Owner:NANJING UNIV OF TECH

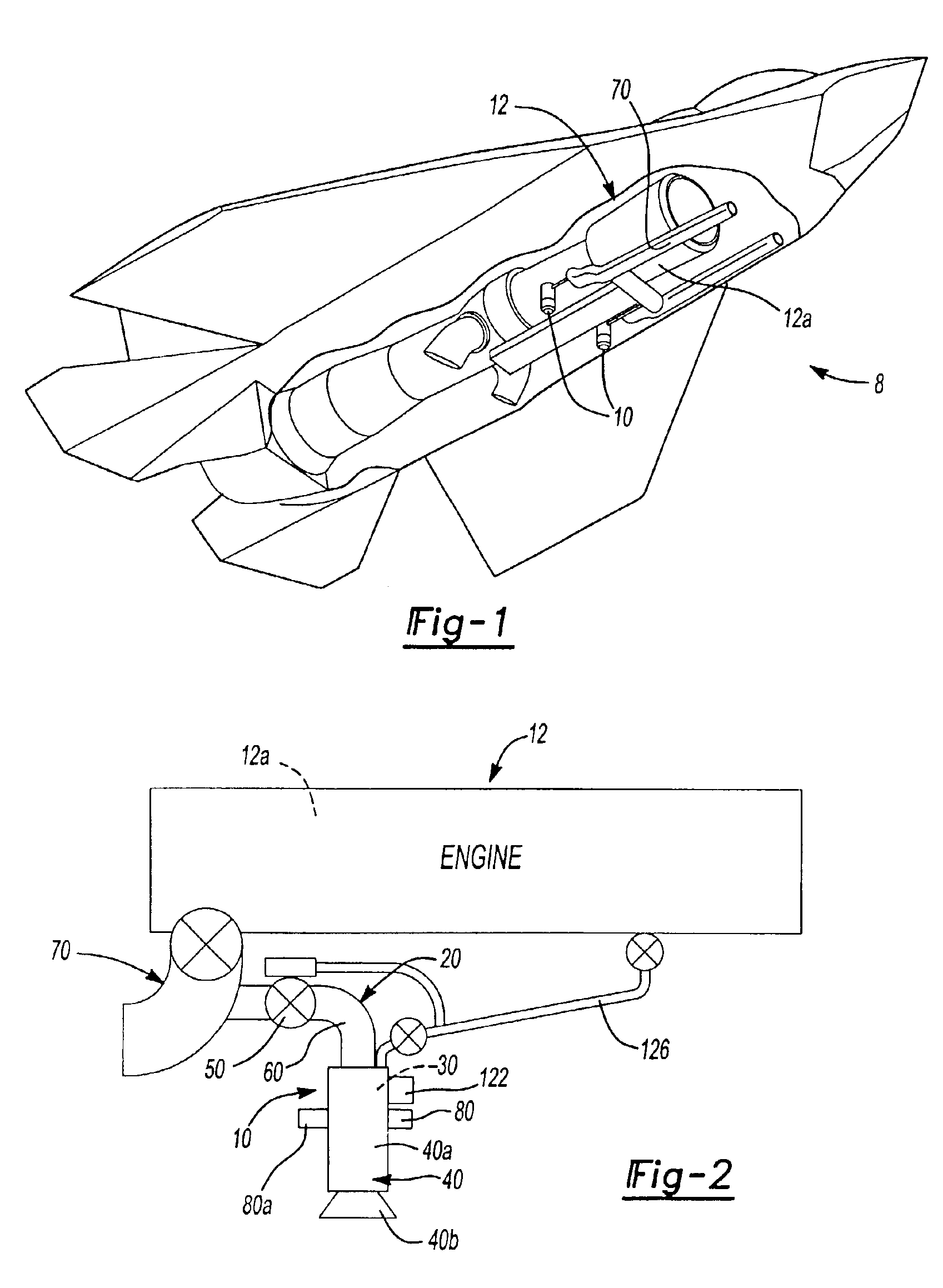

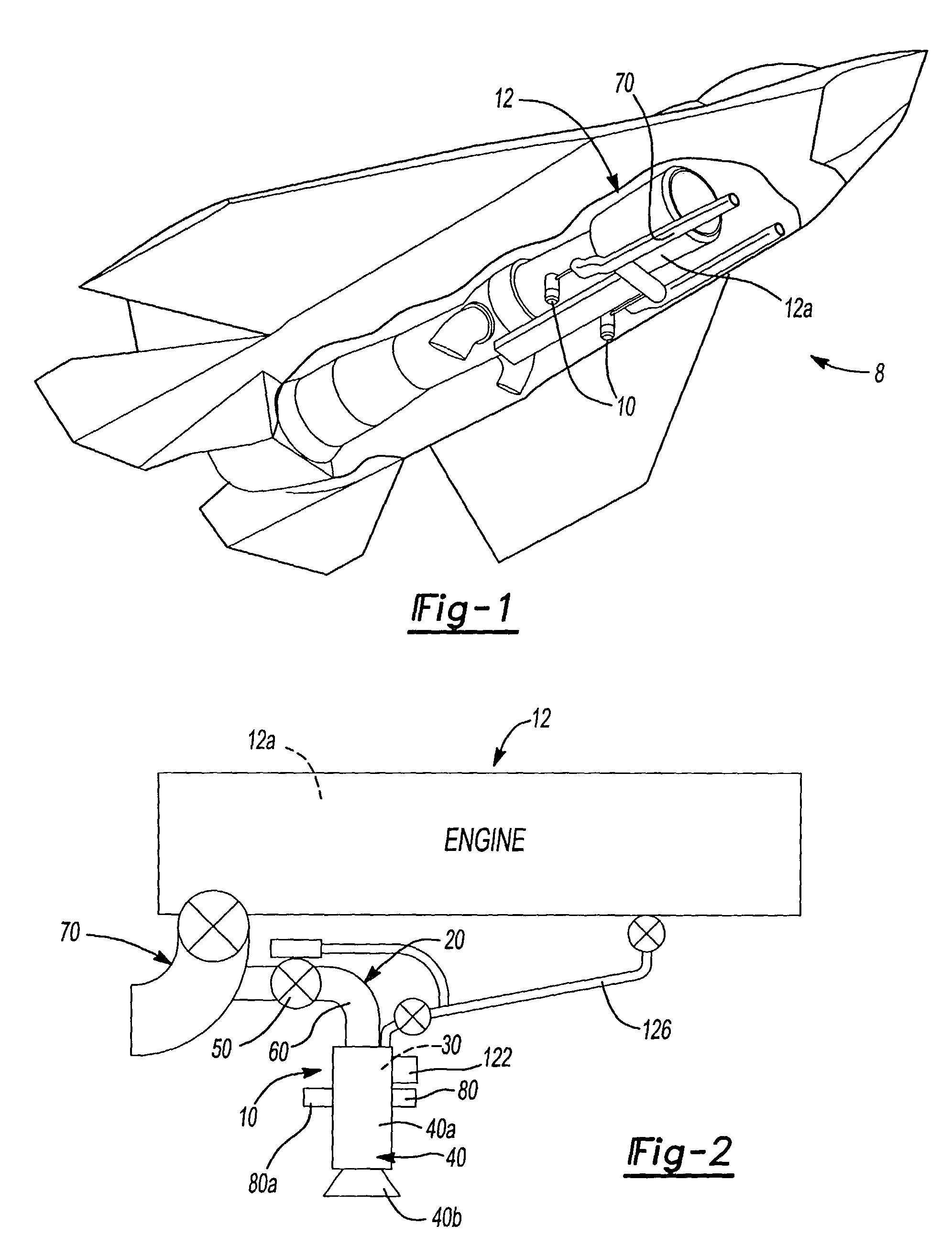

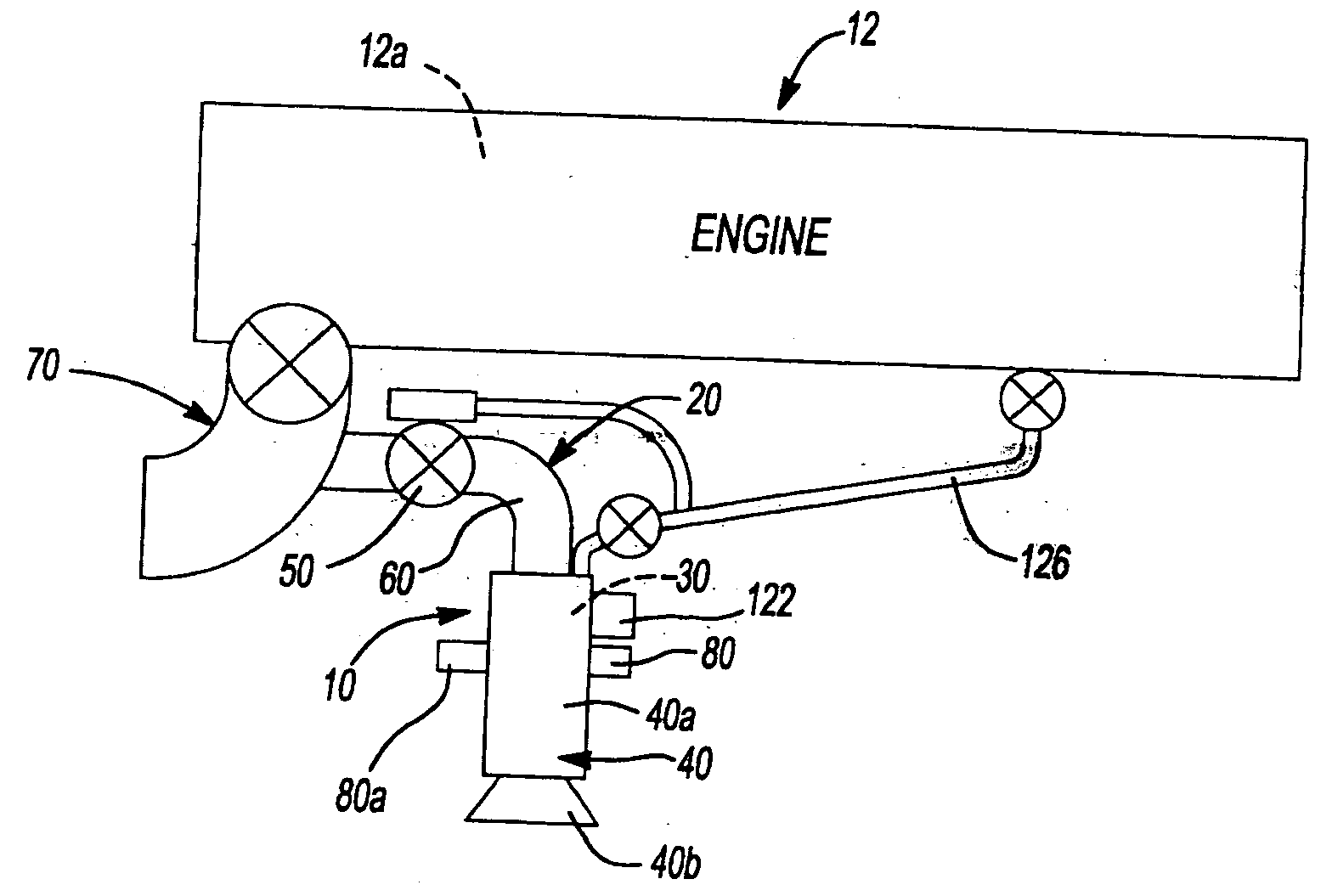

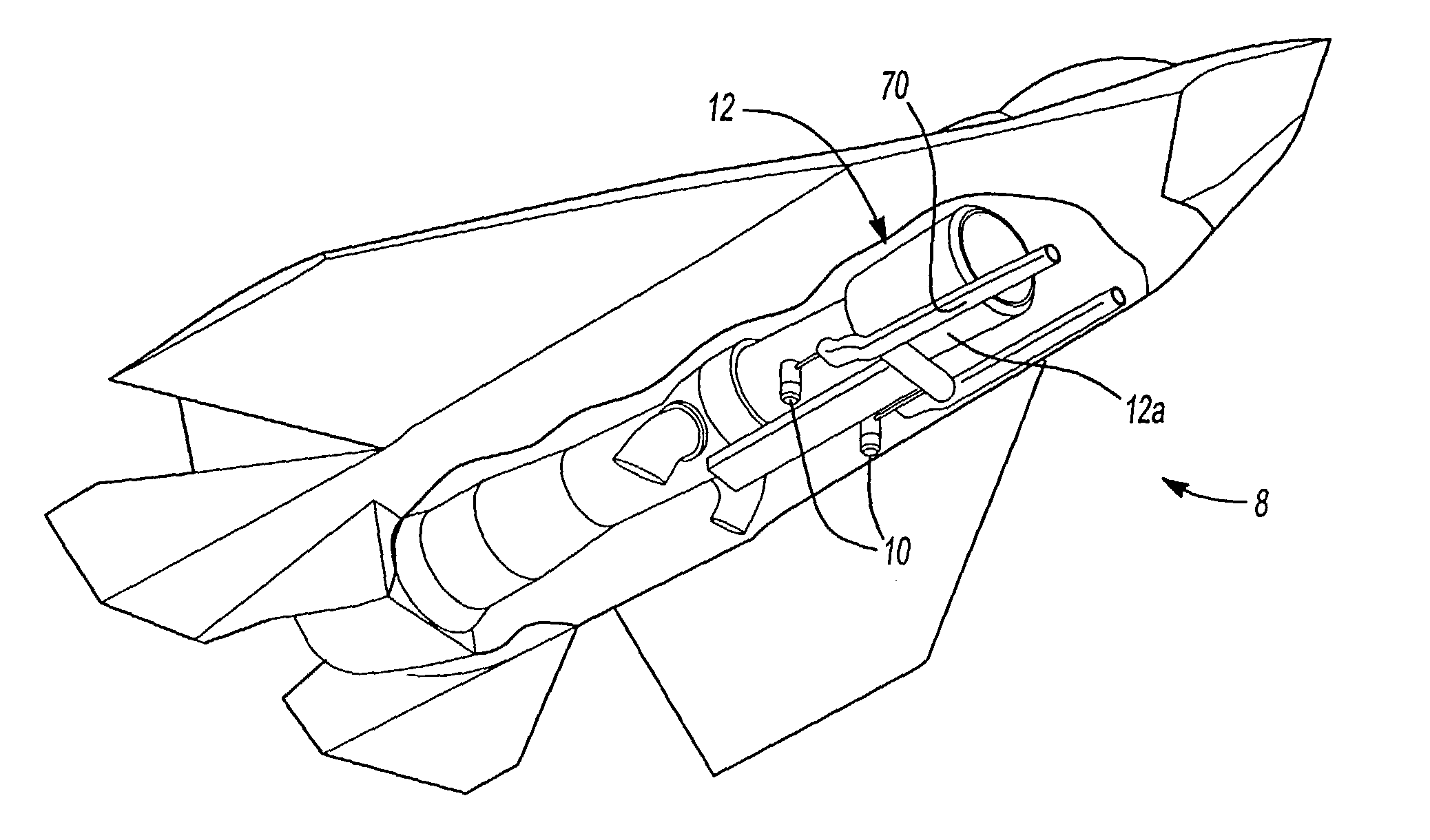

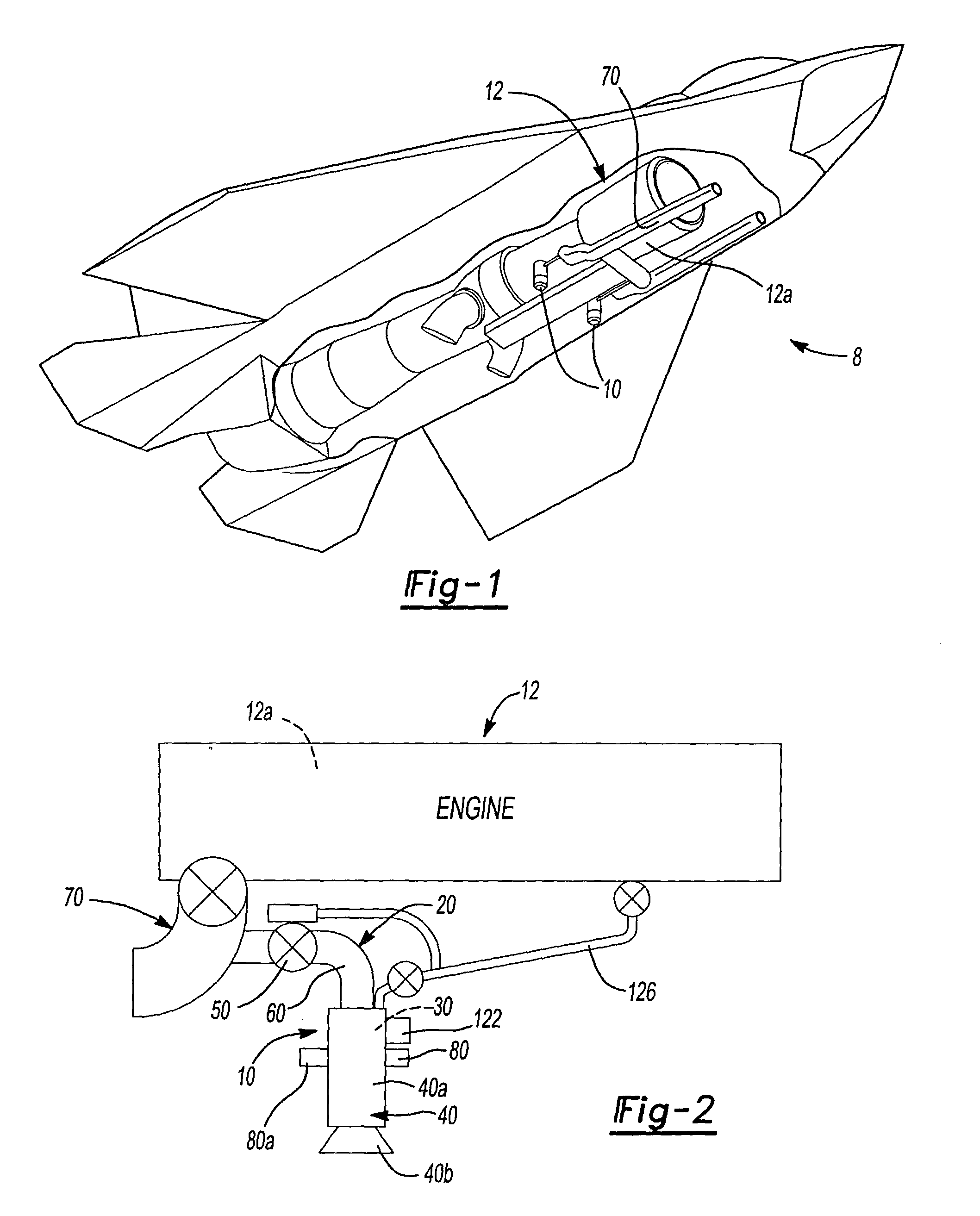

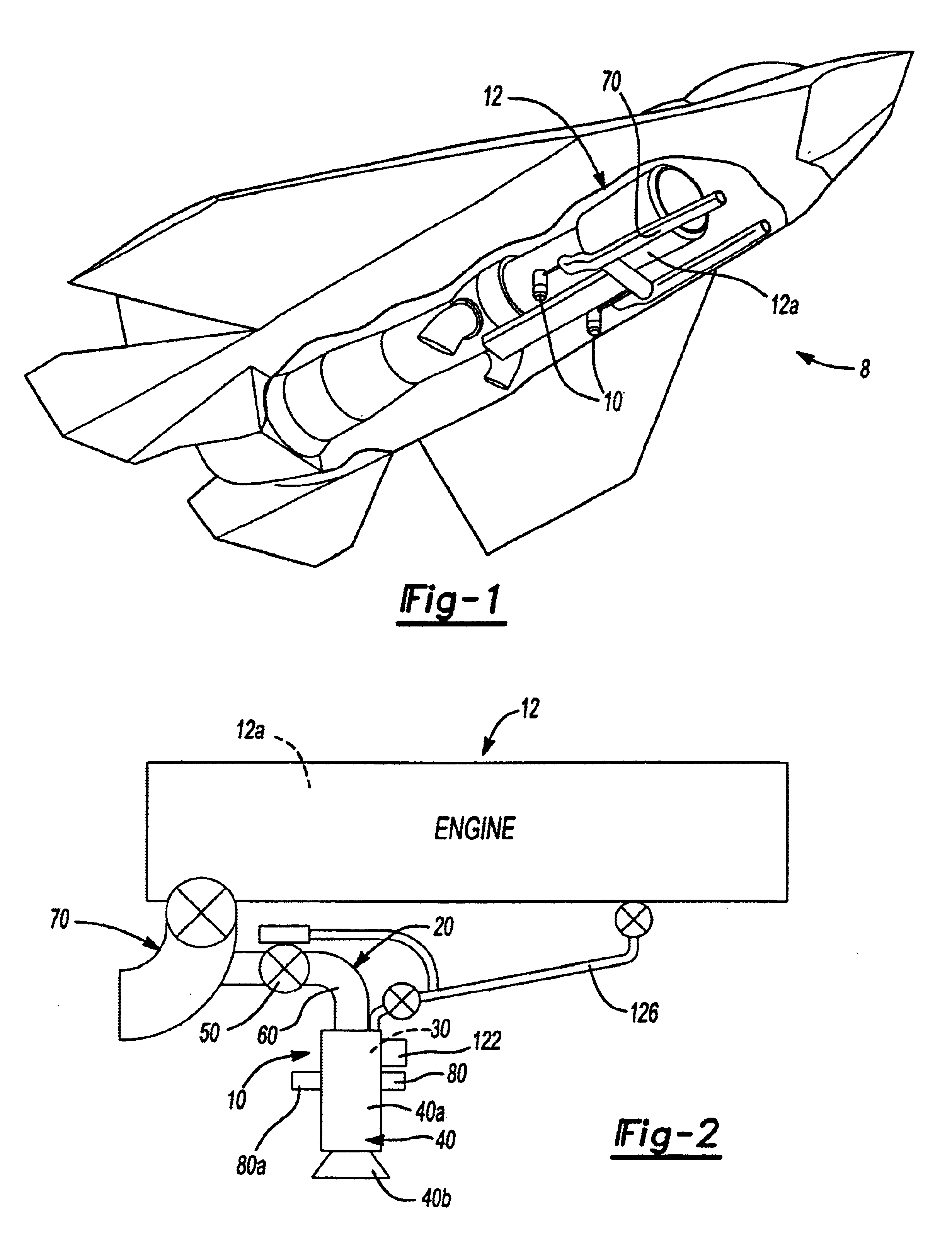

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS6907724B2Shorten the lengthFast atomizationContinuous combustion chamberJet type power plantsRamjetFlame propagation

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

Compact swirl augmented afterburners for gas turbine engines

InactiveUS20060230764A1Promotes rapid and efficient atomization and mixingBurn quicklyTurbine/propulsion fuel supply systemsContinuous combustion chamberCombustion instabilityFlame propagation

An afterburner apparatus that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel and an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and a central recirculation zone, which is positioned within the outer recirculation zone. These recirculation zones are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers. The recirculation zones accelerate flame propagation to allow afterburning to be completed in a relatively short length. Inherent with this swirl afterburner concept are design compactness, light weight, lower cost, smooth and efficient combustion, high thrust output, wide flammability limits, continuous operation at stoichiometric fuel / oxidizer mixture ratios, no combustion instabilities, and relatively low pressure losses.

Owner:UNITED TECH CORP

Water-based epoxy anti-corrosive coating and preparation method thereof

ActiveCN102311695AHas neutral salt spray resistanceLimit the spreadFireproof paintsAnti-corrosive paintsWater basedEpoxy

The invention discloses a water-based epoxy anti-corrosive coating and a preparation method thereof, and relates to a ship antirust and cabin inside and outside antirust fireproof paint. The invention provides a water-based epoxy coating with the VOC lower than 10g / l, and the coating belongs to an environment-friendly coating, which not only has the antirust performance of anti-corrosive coating,but also has low flame propagation of cabin inside finish paint, meets the requirement of cabin inside smoke and toxin, resists aging, and is a multifunctional water-based coating, and the bottom andthe surface are combined. Zhejiang Ampang AB-EP-20 is used as the epoxy resin, Zhejiang Ampang AD-HGF is used as the curing agent, and fluorocarbon emulsion (the model of which is Beijing Baowei PF-1) is used as the base material. Wetting dispersant, defoamer I, defoamer II, flash rust inhibitor, thickener, defoamer and substrate wetting agent are used as additives, rutile titanium white powder, compound zinc phosphate, ferrotitanium powder, talcum powder, ultra-fine aluminum hydroxide, precipitated barium sulfate, mica powder and aluminum tripolyphosphate are used as pigment fillers.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

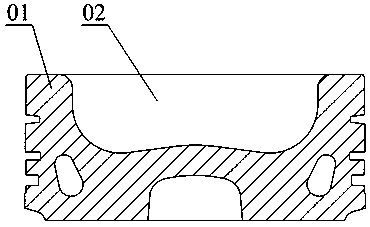

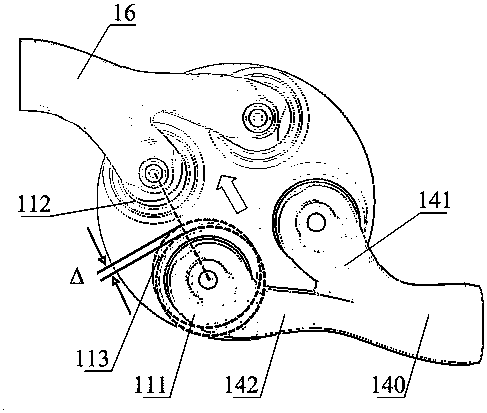

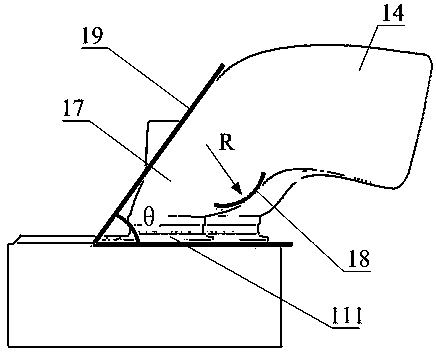

Weak tumble rapid combustion system and gas engine

ActiveCN111287860AImprove gas utilizationHigh feasibilityInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses a weak tumble rapid combustion system and a gas engine. The weak tumble rapid combustion system comprises a piston, a cylinder cover, an air intake channel and an exhaust channel, a combustion chamber is formed between the top of the piston and the cylinder cover, the cylinder cover is provided with an air intake throat and an exhaust throat, the section, close to the air intake throat, of the air intake channel is a tumble guide air channel, the axis of the tumble guide air channel is obliquely arranged relative to the bottom face of the cylinder cover, the upper sideface of the tumble guide air channel is an undershoot guide face obliquely arranged relative to the bottom face of the cylinder cover, the lower side face of the tumble guide air channel is an arc-shaped guide face sunken towards the bottom face of the cylinder cover, an eccentric chamfer is arranged at the lower end of the air intake throat, and the eccentric direction of the eccentric chamfer deviates along the direction of a central connecting line from the air intake throat to the air outlet throat. According to the weak tumble rapid combustion system, during air suction, fuel gas forms large-scale weak tumble motion in the air cylinder and is broken into small-scale turbulent flow in the last stage of compression, so that the flame propagation speed is increased, and the fuel gas utilization rate and the engine heat efficiency are improved.

Owner:WEICHAI POWER CO LTD

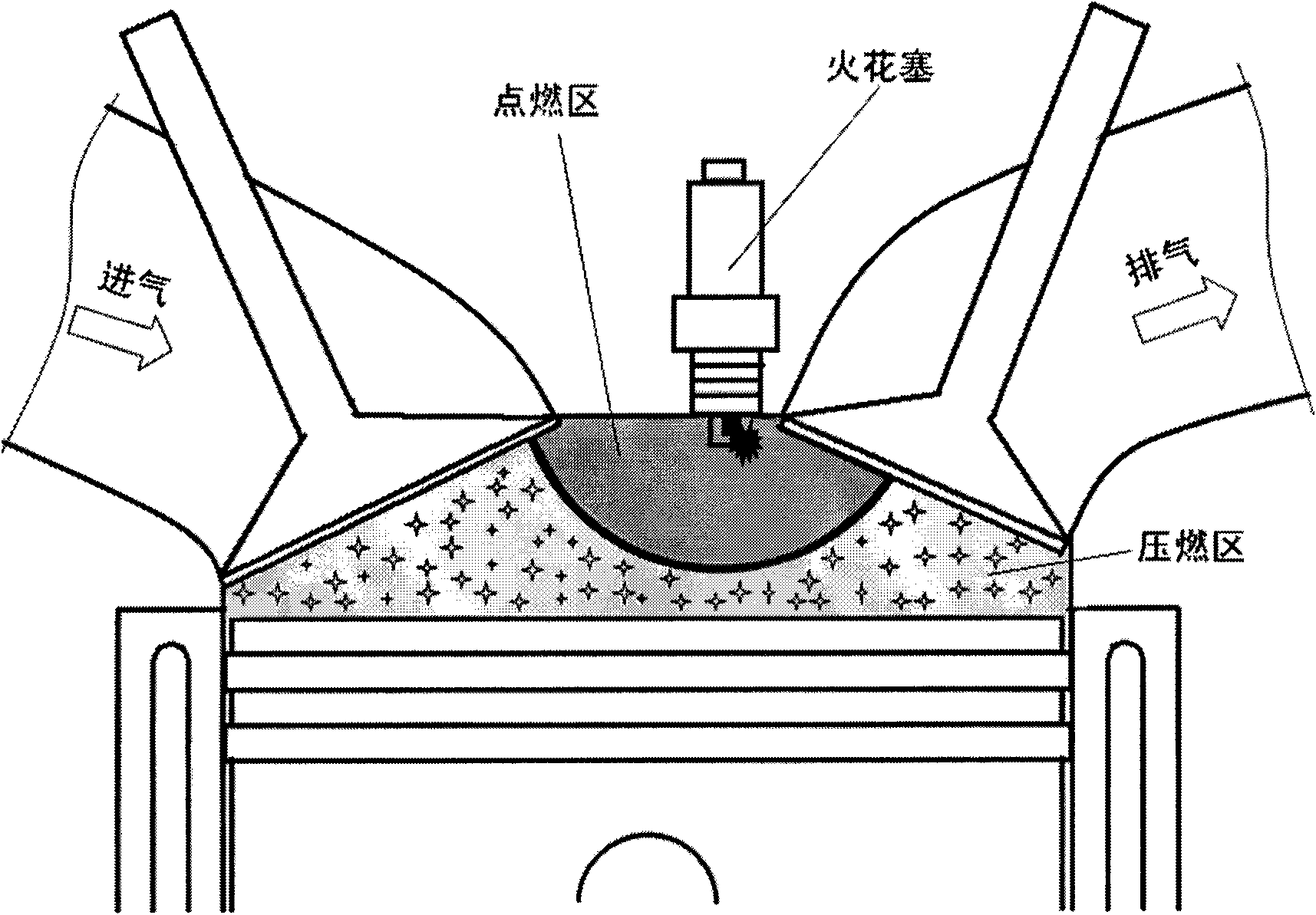

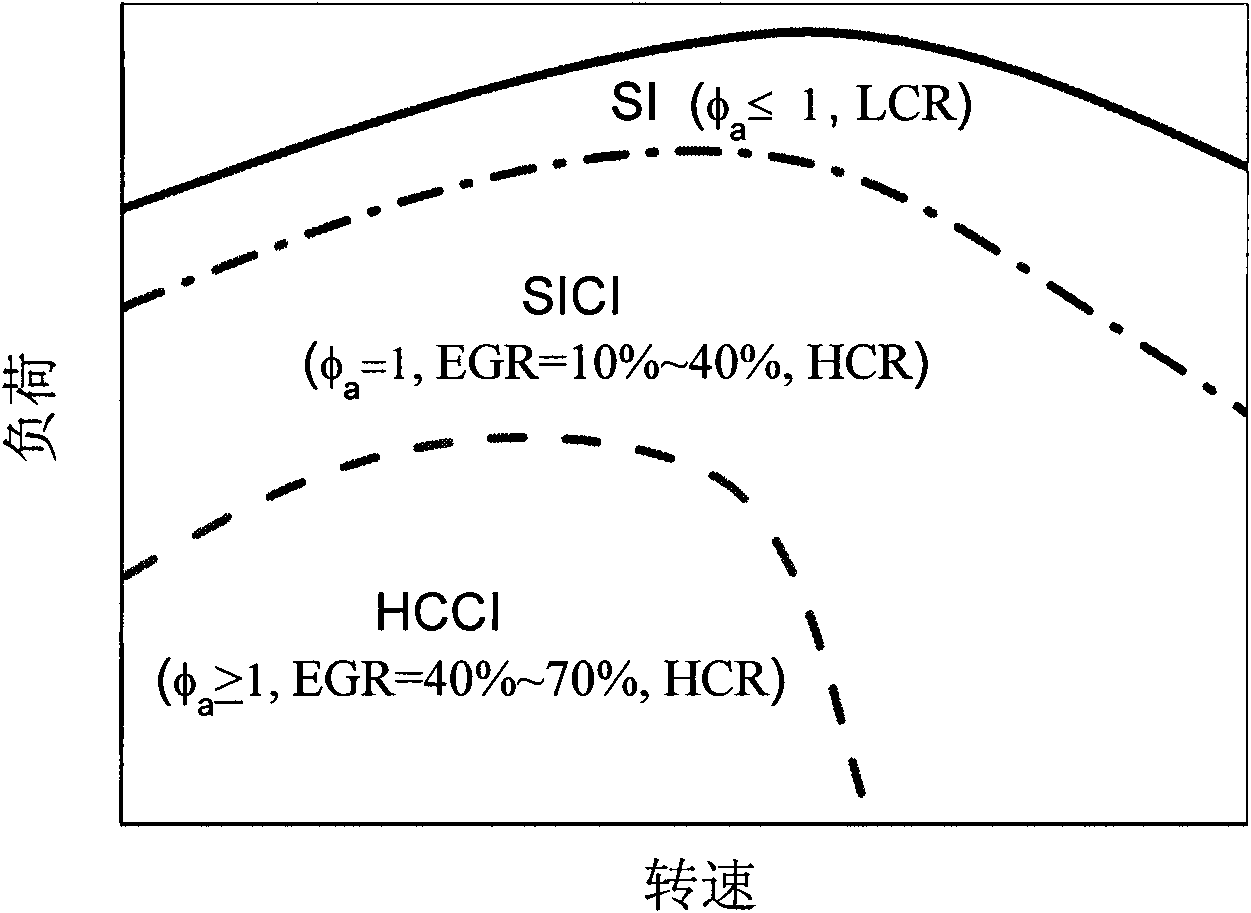

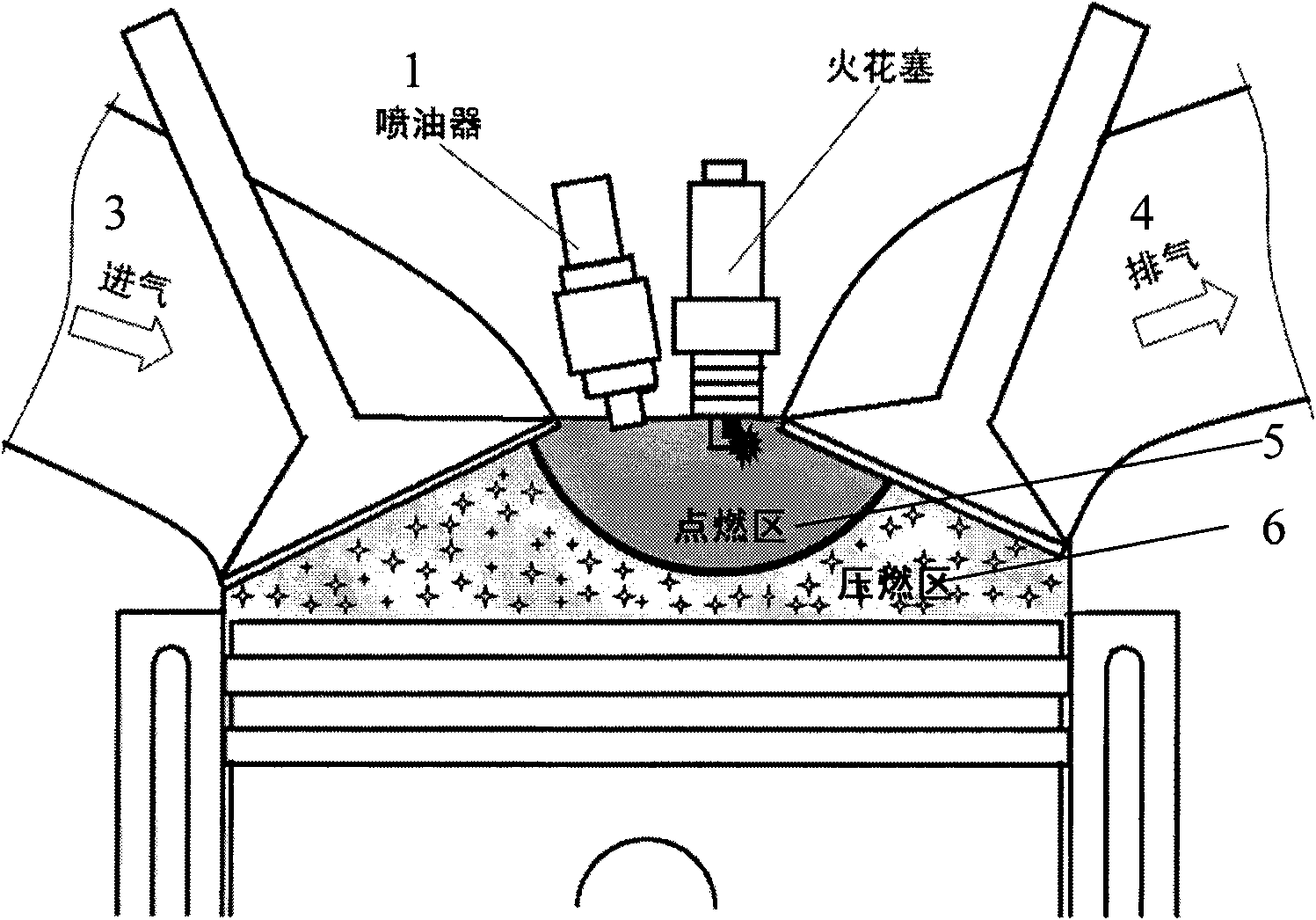

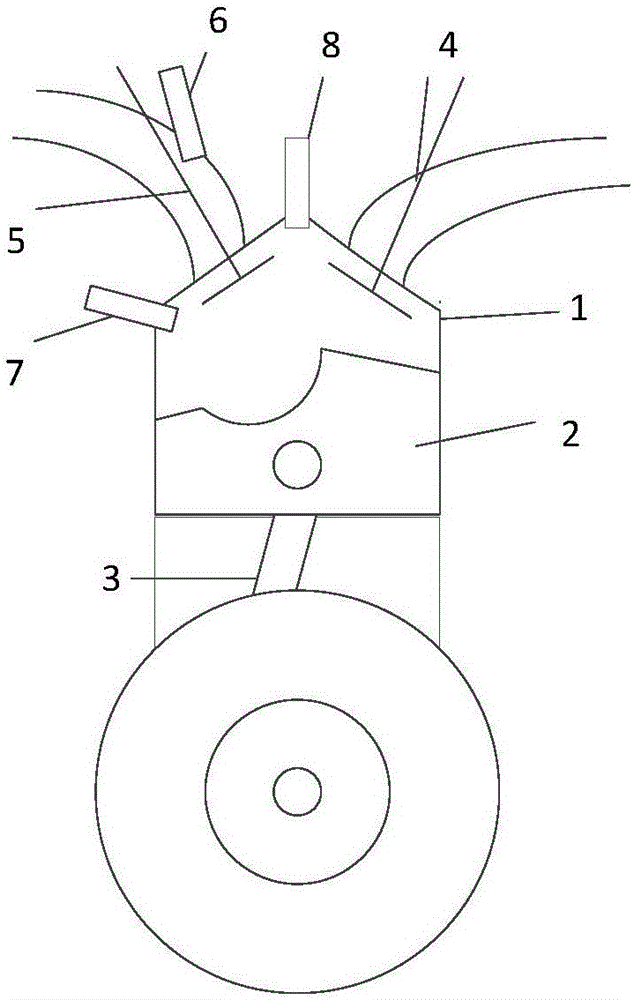

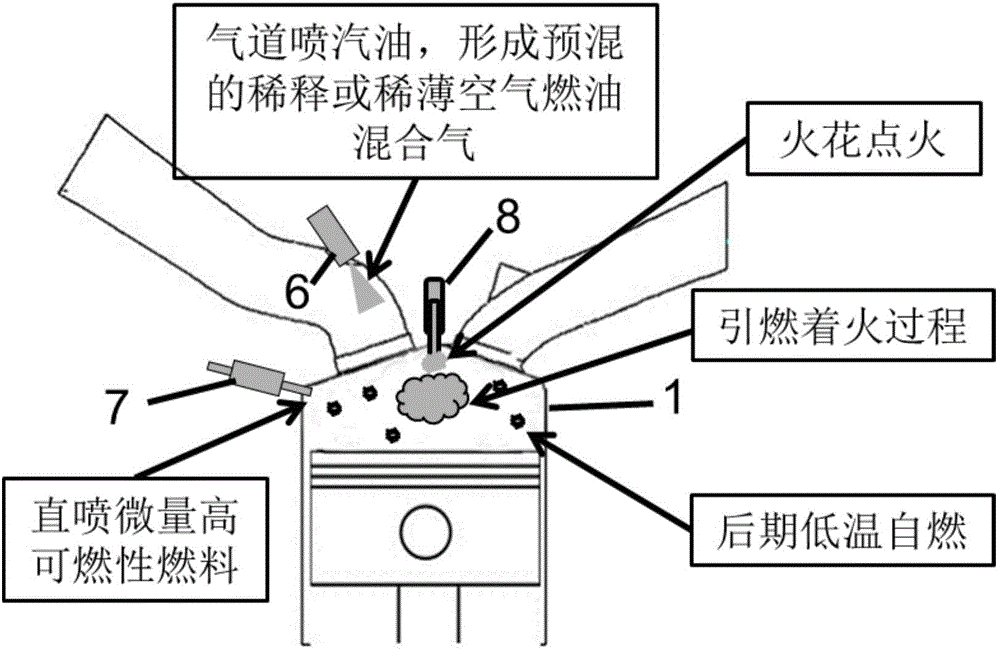

Petrol engine spark ignition excite homogeneous compression ignition combustion control method

ActiveCN101619670AReduced pressure rise rateControl the moment of fireElectrical controlInternal combustion piston enginesHomogeneous charge compression ignitionFlame propagation

The invention discloses a petrol engine spark ignition excite homogeneous compression ignition combustion control method which belongs to the technical field of internal combustion engines. In the control method, an ignition advance angle is used for controlling ignition moments, and a combustion rate is controlled by an EGR rate. The petrol engine spark ignition excite homogeneous compression ignition combustion control method comprises the following steps: spraying fuel firstly in an air inlet process to form homogeneous rarefied mixed gas when an upper dead center is compressed; spraying fuel secondly in a compression stroke to form local thicker mixed gas around a spark plug; igniting the local thicker mixed gas to produce flame propagation by the spark plug; releasing heat by the combustion of the local flame propagation; compressing the around large-area rarefied mixed gas to rise temperature and pressure to a self-ignite flammation state, thereby exciting the mixed gas in a whole cylinder to self-ignite in a large area in a multipoint mode, and quickly and completely burning the whole mixed gas; and otherwise, harmful emissions generated by burning the equivalent proportion mixed gas are effectively controlled by using a three-way catalyst of the traditional petrol engine.

Owner:TSINGHUA UNIV

Combined cycle engines incorporating swirl augmented combustion for reduced volume and weight and improved performance

InactiveUS20050081508A1Rapid fuel atomizationVaporization fastContinuous combustion chamberJet type power plantsRamjetFlame propagation

A combined-cycle engine having at least one core engine and at least one ramjet engine. The ramjet utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers, which accelerate flame propagation throughout the core flowfield. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits, high combustion efficiency and high specific thrust performance.

Owner:UNITED TECH CORP +1

Ticking Layers that Reduce Flame Propagation and Upholstered Articles Incorporating Same

InactiveUS20110283458A1Prevent and reduce flame propagationReduce riskLiquid surface applicatorsStuffed mattressesFlame propagationGas phase

A method of producing a ticking includes laminating a flame retardant backer to film material, wherein the backer releases flame retardant in the vapor phase that reduces the rate of flame propagation along the film material, when the ticking layer is exposed to flame. The backer is laminated in direct contact with the film material. In some embodiments, the laminated ticking is configured to release less than 15 MJ of heat in the first ten minutes when exposed to a flame in accordance with the testing protocol set forth in 16 CFR 1633. Upholstered articles, such as mattresses, mattress foundations, and articles of furniture, may incorporate the ticking layer.

Owner:PRECISION FABRICS GROUP

Internal combustion engine

InactiveUS7769527B2Leanness of the hydrogen-air mixture is limitedHigh-temperature combustionElectrical controlInternal combustion piston enginesFlame propagationCombustion chamber

Owner:NISSAN MOTOR CO LTD

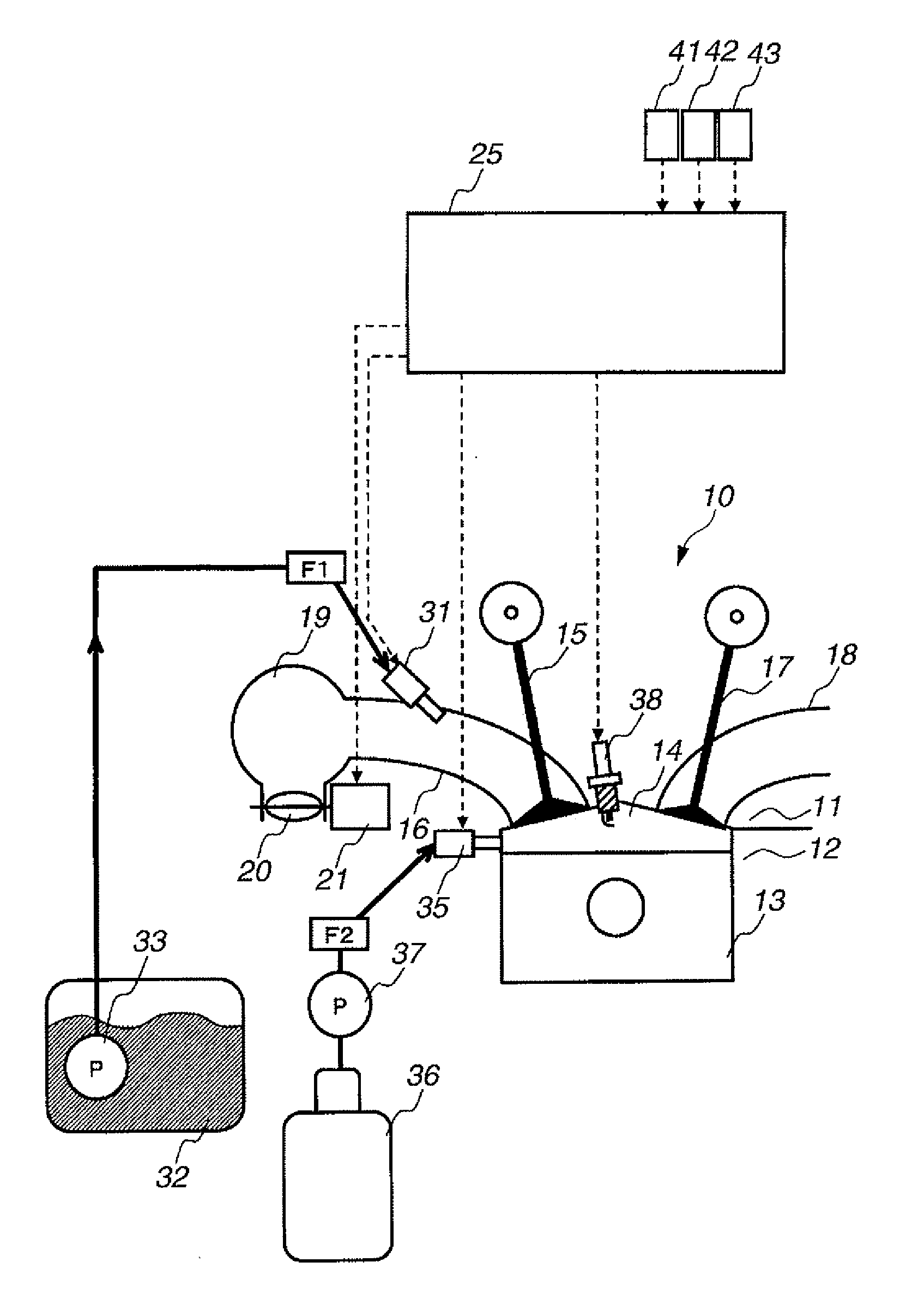

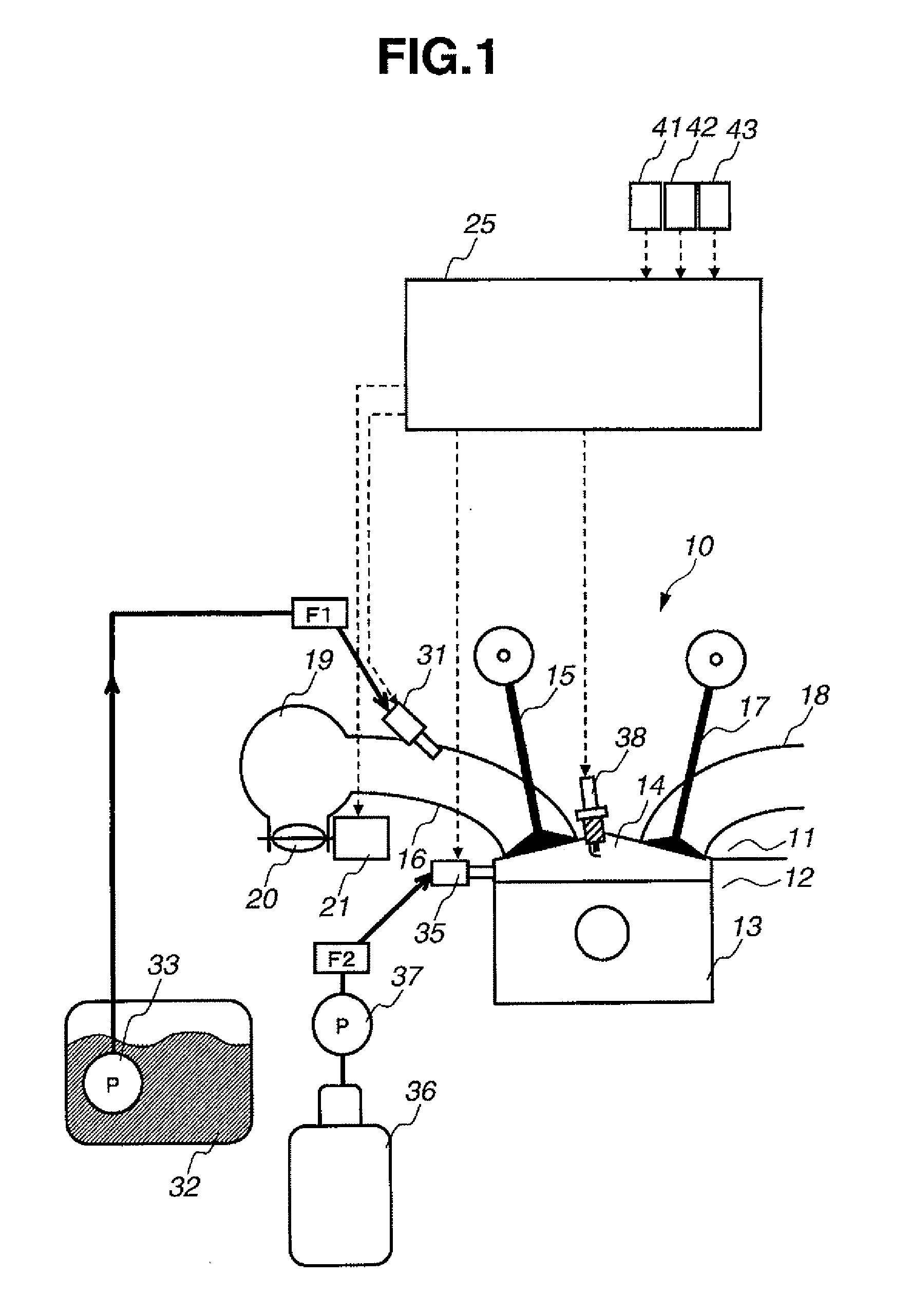

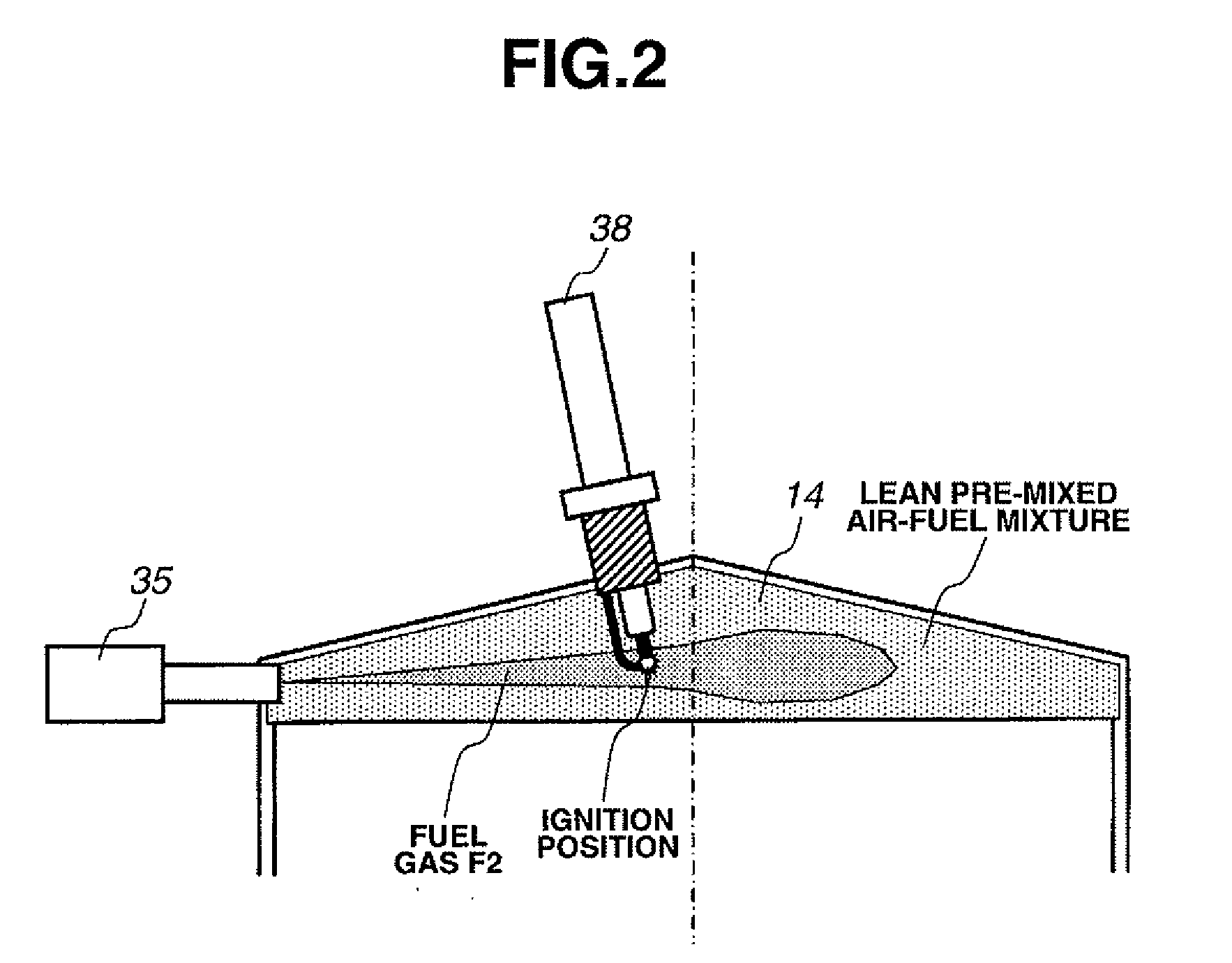

Internal combustion engine and combustion method of the same

InactiveUS20080257304A1Strong turbulent flowStrong flowValve arrangementsElectrical controlCombustion chamberTop dead center

An internal combustion engine, including a premixed mixture formation device that forms a premixed mixture of fuel and air in a combustion chamber, a fuel gas supply device that injects fuel gas directly into the combustion chamber, and an ignition device that ignites the fuel gas. The fuel gas supply device is configured to inject the fuel gas into the premixed mixture near a top dead center of a compression stroke such that a spray of the fuel gas passes through a firing position of the ignition device, to produce the spray of the fuel gas in a predetermined area substantially extending from one end of a cylinder bore to the other end as viewed in a cylinder-bore direction defined by a centerline of the cylinder bore. The ignition device is configured to directly ignite the spray of the fuel gas and to ignite and burn the premixed mixture by way of flame propagation along the spray of the fuel gas.

Owner:NISSAN MOTOR CO LTD

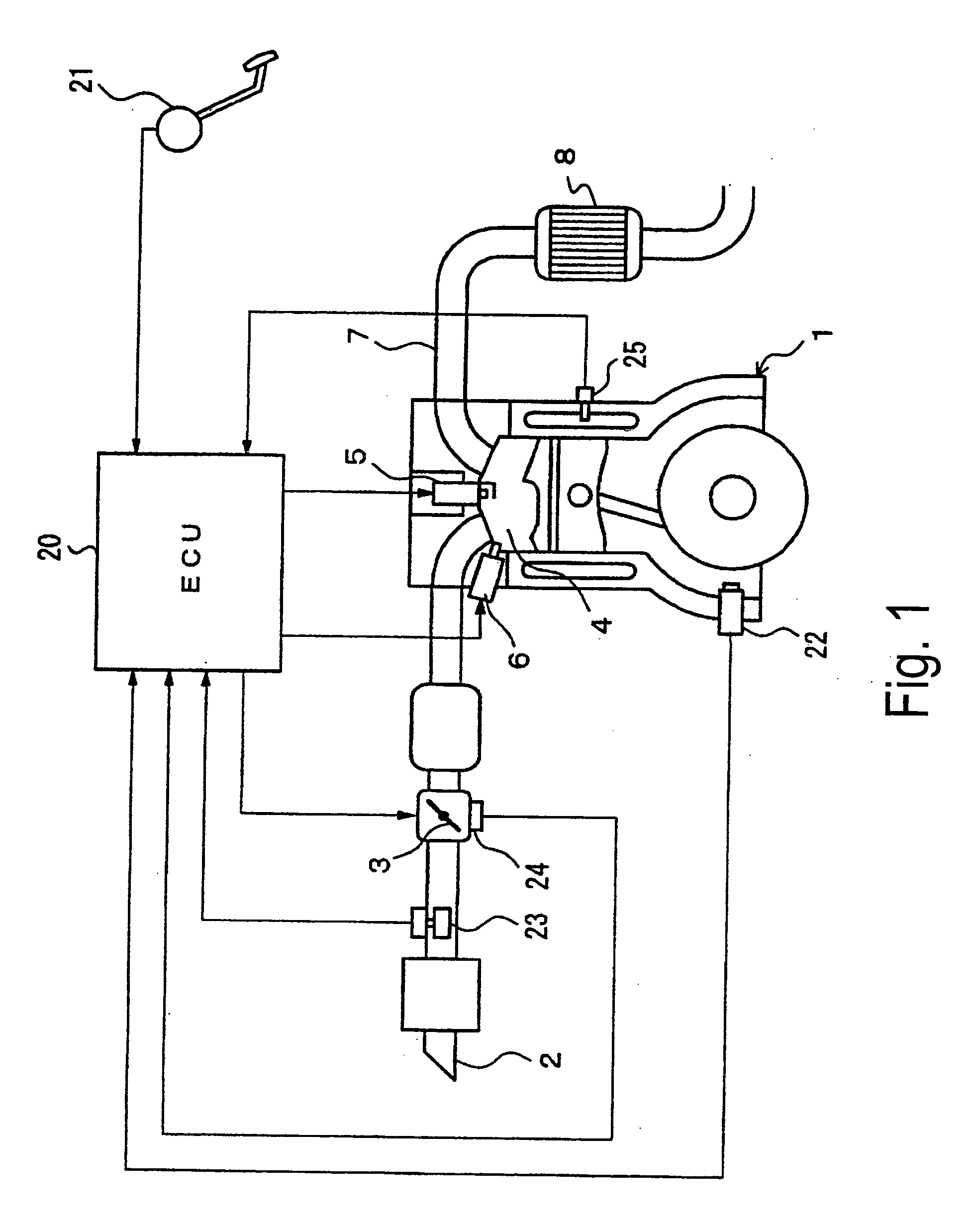

Direct fuel injection/spark ignition engine control device

InactiveUS7051701B2Promote combustionReduce turbulenceElectrical controlInternal combustion piston enginesFlame propagationTop dead center

Owner:NISSAN MOTOR CO LTD

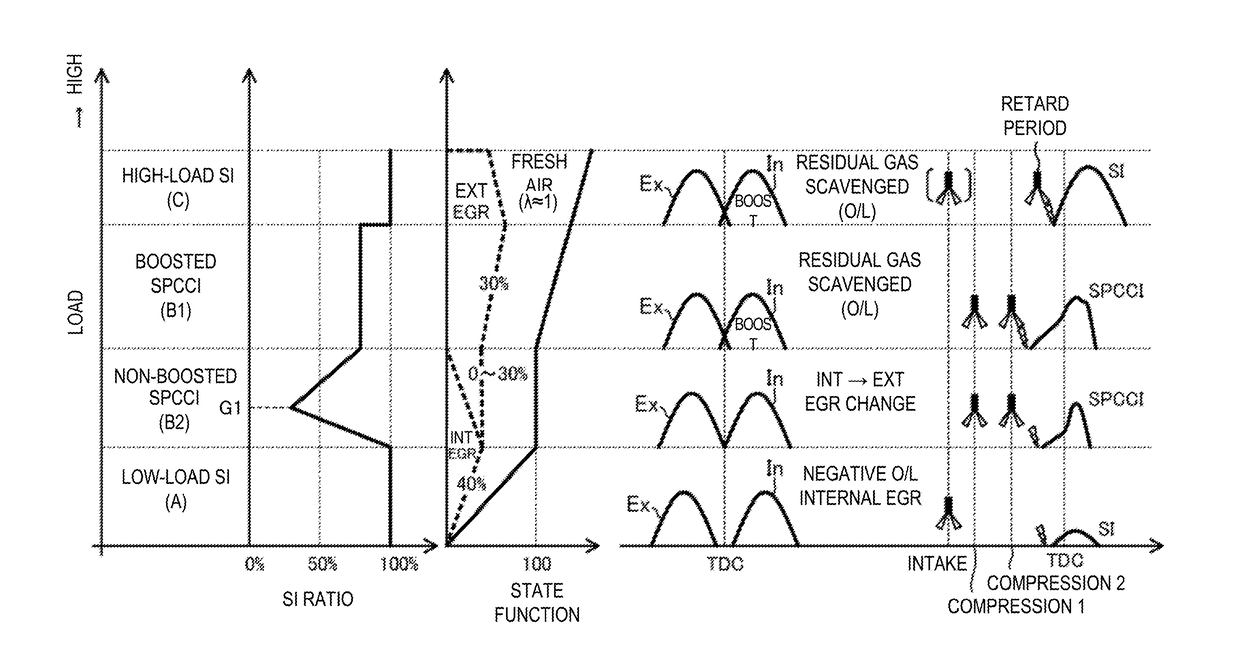

Control system of compression-ignition engine

ActiveUS20180334998A1Reduce variationTimely controlElectrical controlInternal combustion piston enginesCombustion chamberFlame propagation

A control system of a compression-ignition engine is provided, which includes an engine configured to cause combustion of mixture gas inside a combustion chamber, a spark plug, and a controller configured to operate the engine. The combustion is performed in a given mode in which, after the spark plug ignites the mixture gas to start combustion, unburned mixture gas combusts by self-ignition. The controller has a heat amount ratio changing module configured to change, according to an engine operating state, a heat amount ratio as an index relating to a ratio of a heat amount generated when the mixture gas combusts by flame propagation with respect to a total heat amount generated when the mixture gas inside the combustion chamber combusts. The controller causes the changing module to increase the heat amount ratio at a high engine speed than at a low engine speed.

Owner:MAZDA MOTOR CORP

Method for transition between controlled auto-ignition and spark ignition modes in direct fuel injection engines

InactiveCN101218423AFully understandValve arrangementsElectrical controlHomogeneous charge compression ignitionExhaust valve

Owner:GM GLOBAL TECH OPERATIONS LLC

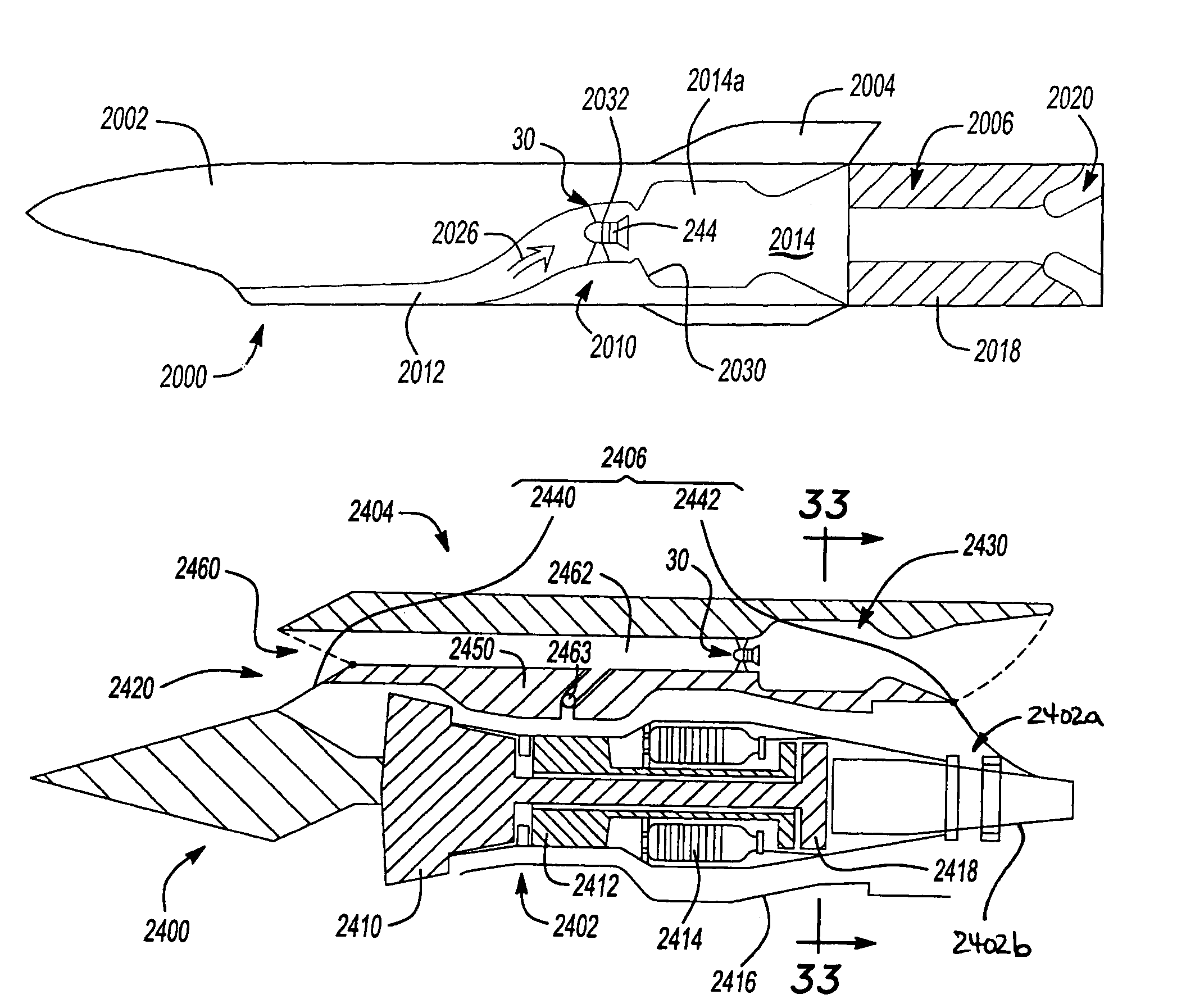

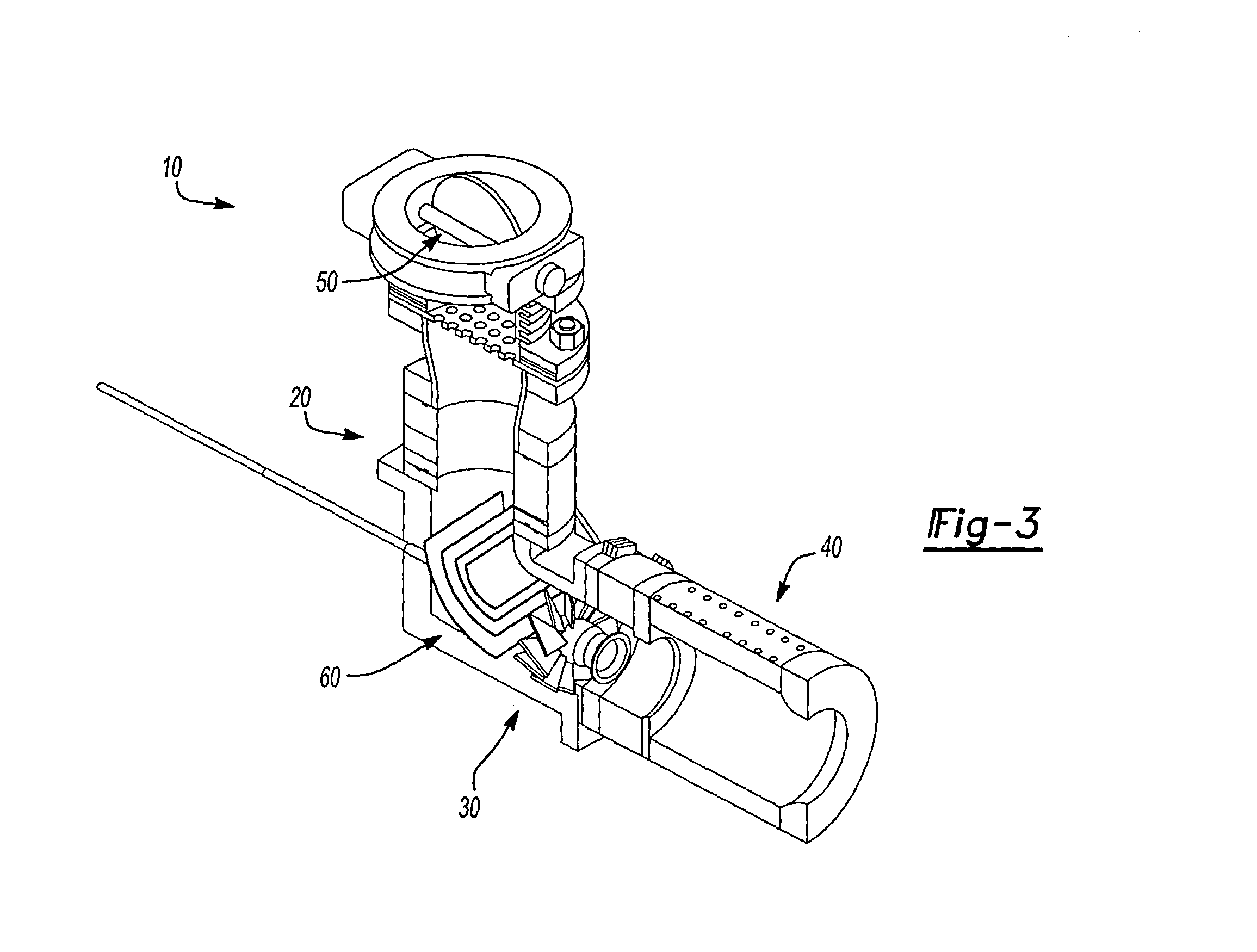

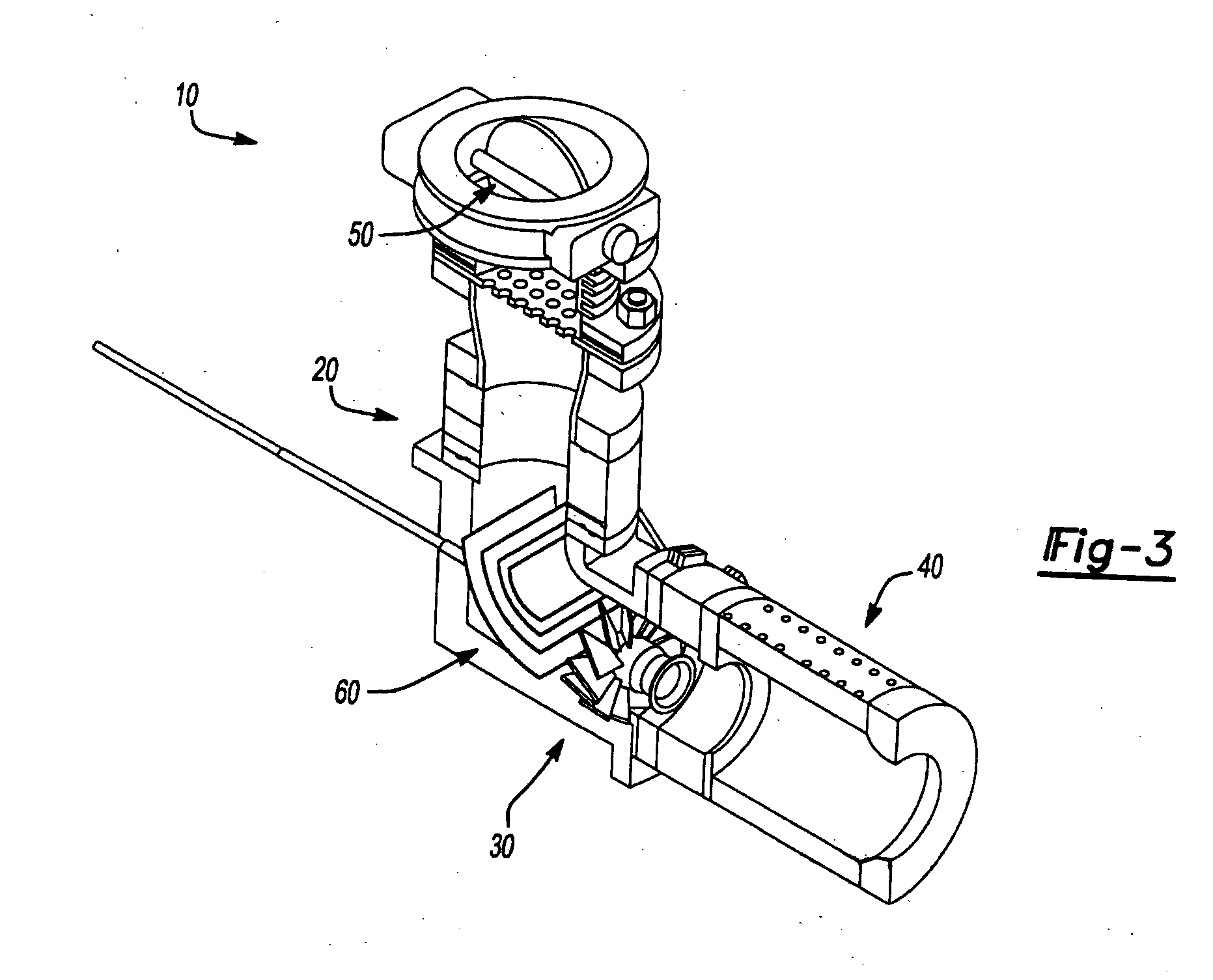

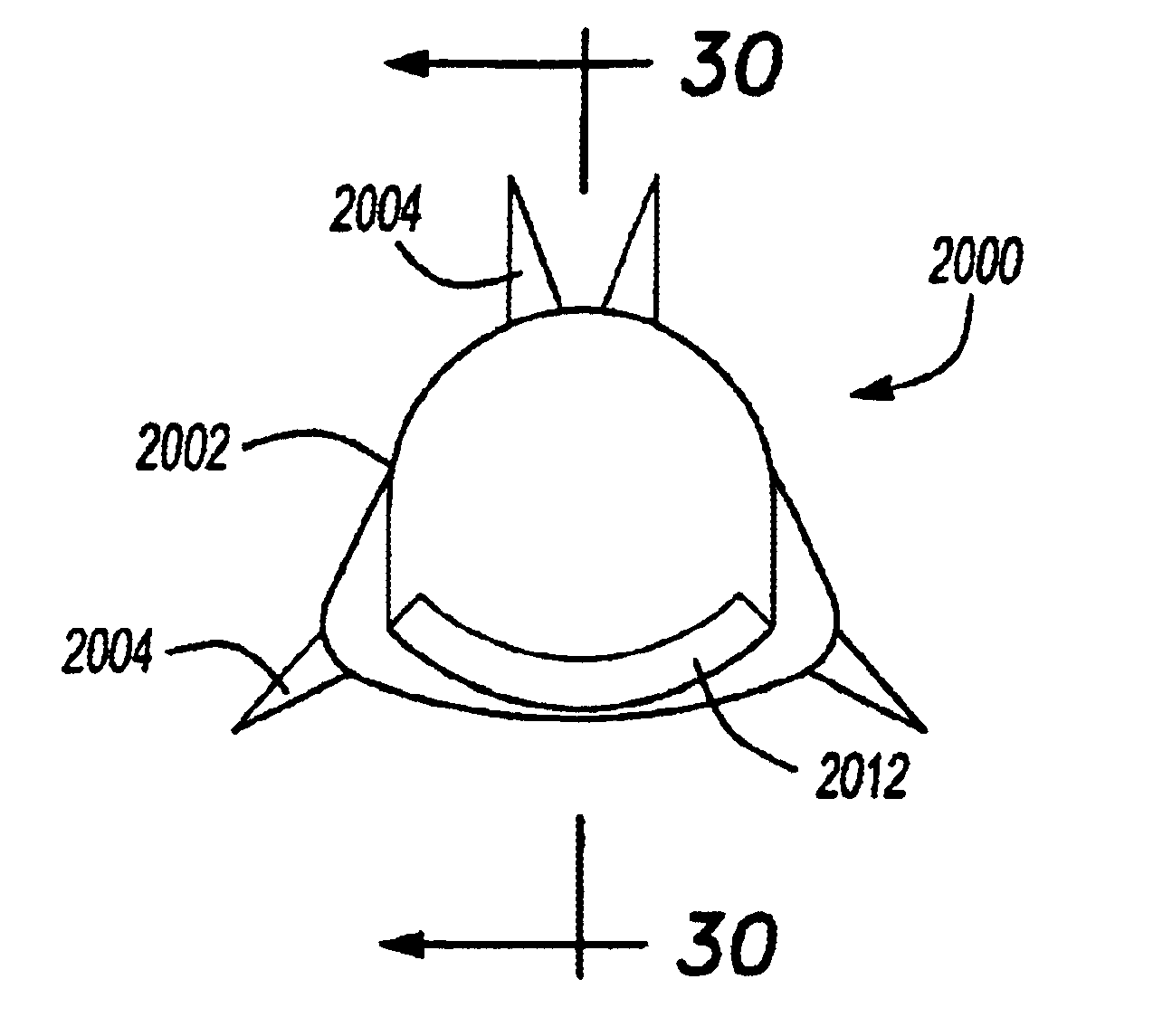

Compact lightweight ramjet engines incorporating swirl augmented combustion with improved performance

InactiveUS6968695B2Flame stabilizationEasy to operateContinuous combustion chamberEfficient propulsion technologiesRamjetFlame propagation

A ramjet powered device that utilizes a novel swirl generator for rapidly and efficiently atomizing, vaporizing, as necessary, and mixing a fuel into an oxidant. The swirl generator converts an oxidant flow into a turbulent, three-dimensional flowfield into which the fuel is introduced. The swirl generator effects a toroidal outer recirculation zone and an inner central recirculation zone, both of which are configured in a backward-flowing manner that carries heat and combustion byproducts upstream where they are employed to continuously ignite a combustible fuel / oxidizer mixture in adjacent shear layers and stabilizes flame propagation and accelerates combustion throughout the entire combustor. The swirl generator provides smooth combustion with no instabilities and minimum total pressure losses and enables significant reductions in the L / D ratio of the combustor. Other benefits include simplicity, reliability, wide flammability limits and high combustion efficiency and thrust performance.

Owner:THE BOEING CO

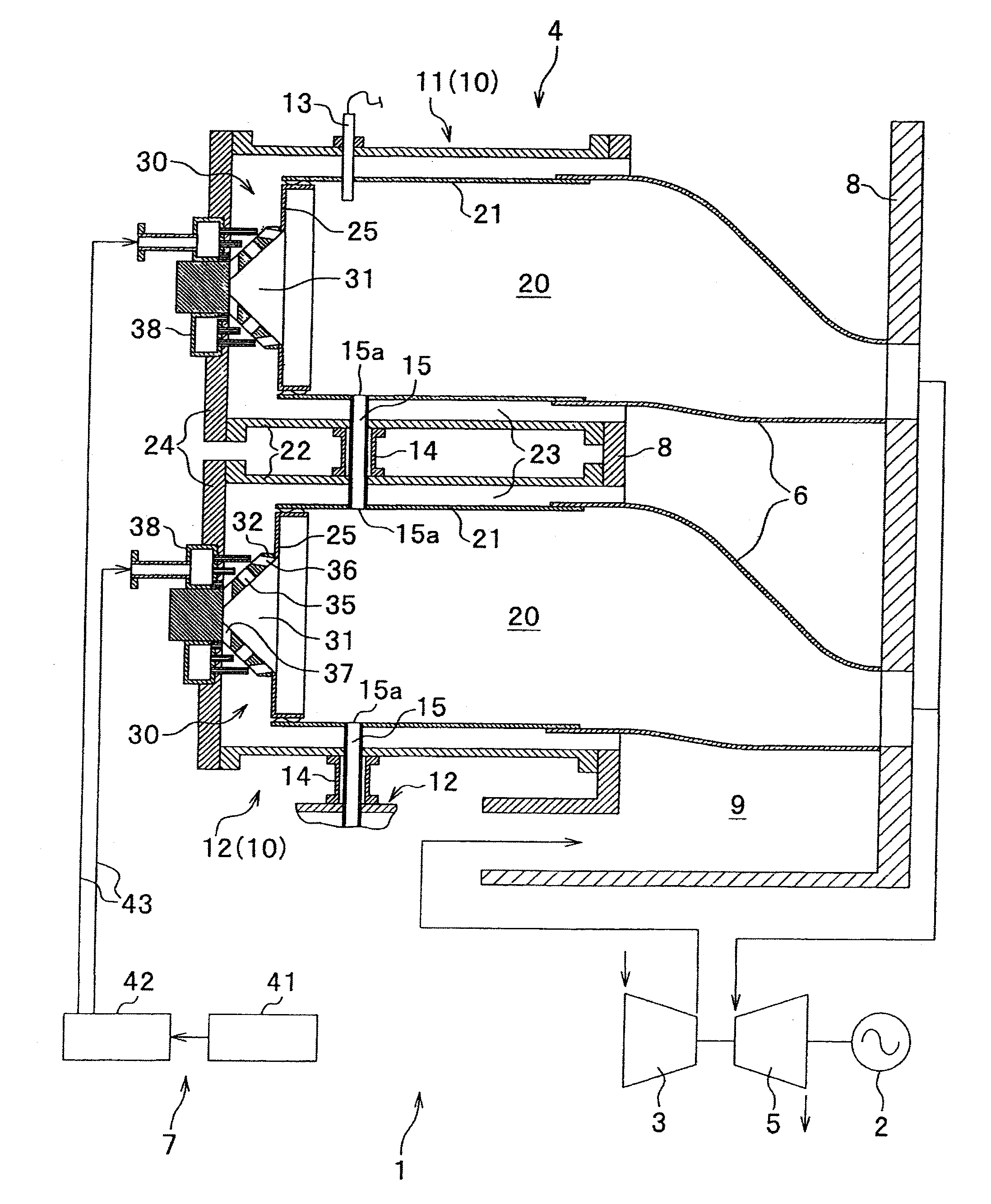

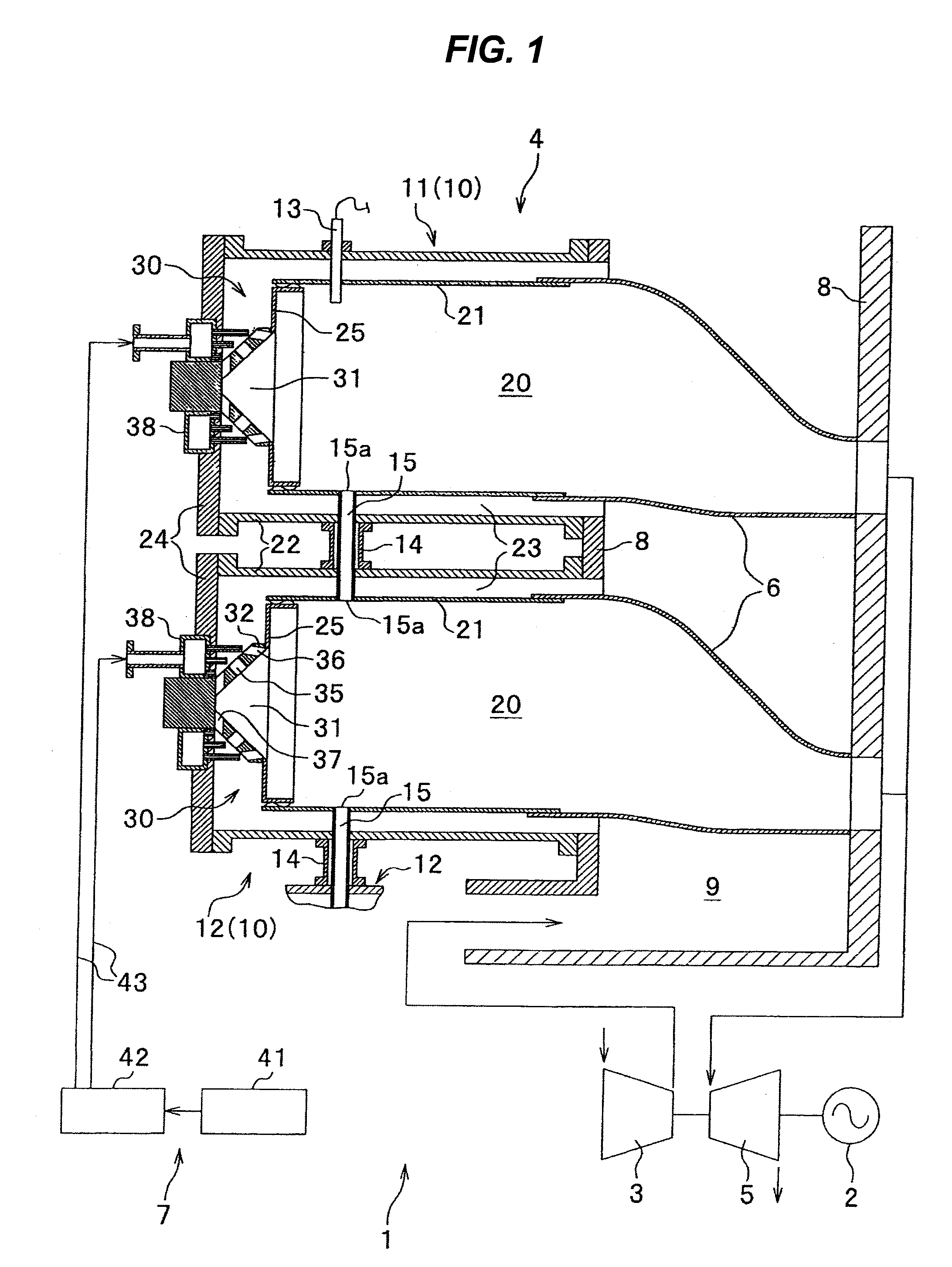

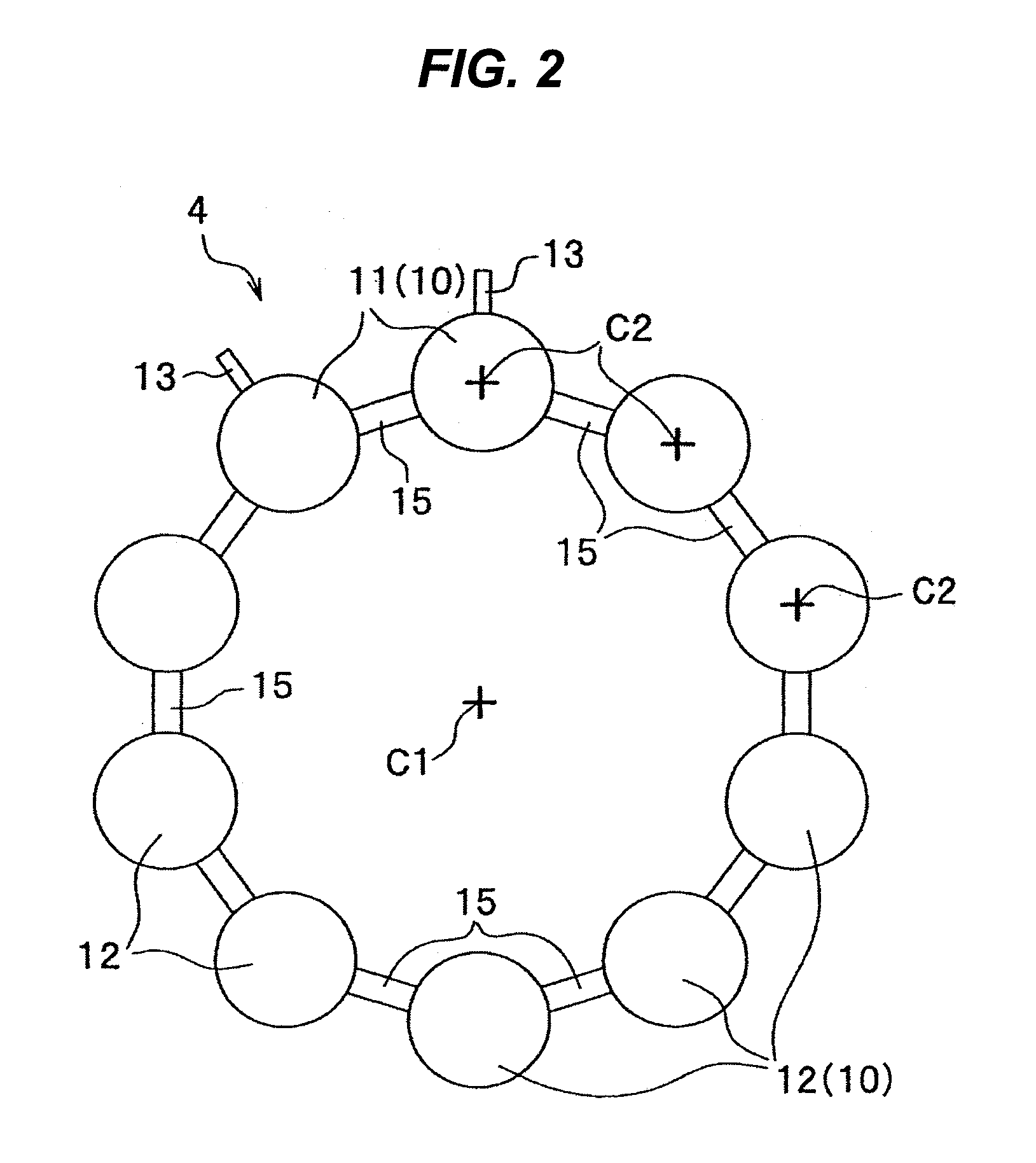

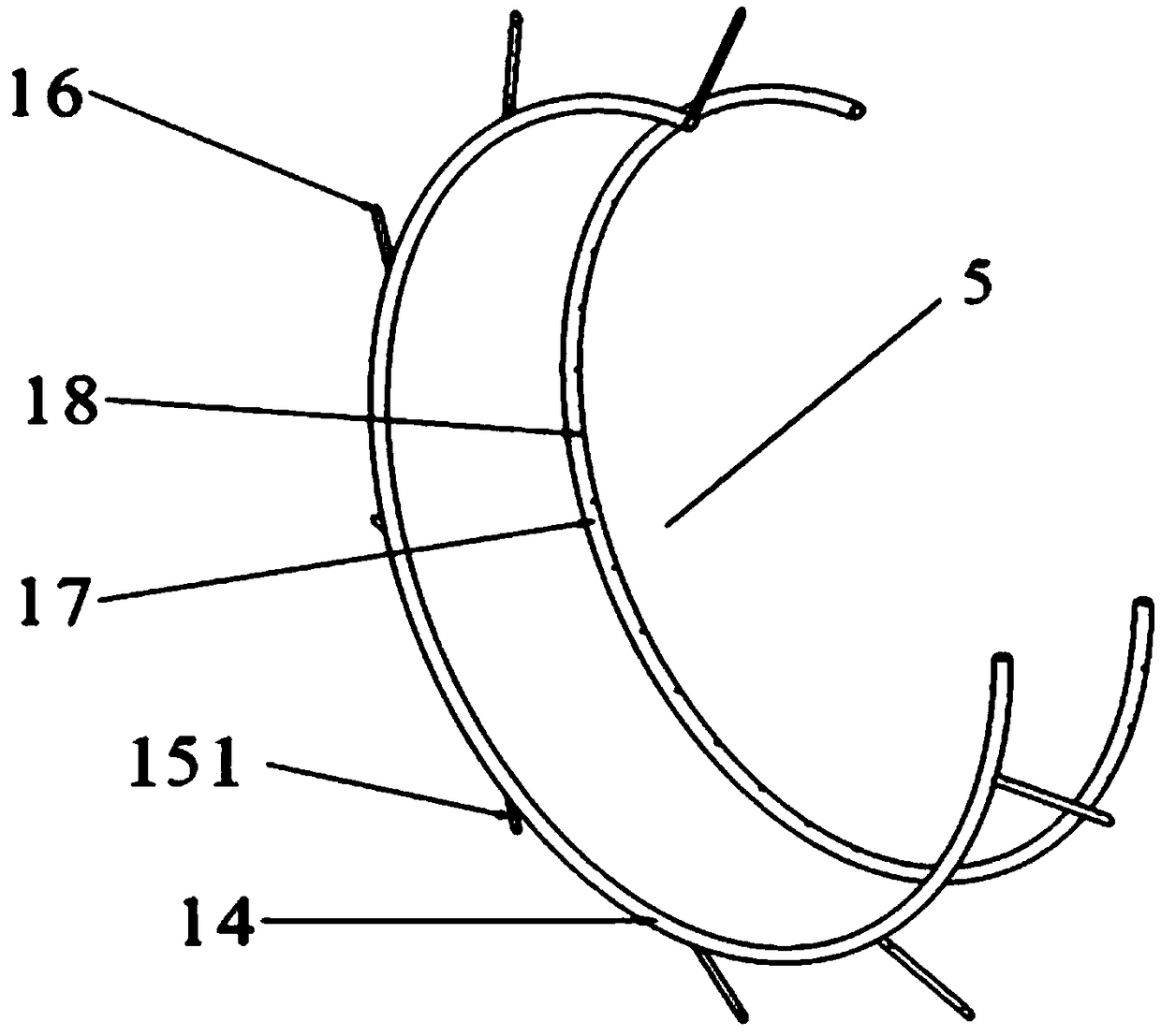

Gas Turbine Combustor

In a gas turbine combustor, mixing of a fuel and air is accelerated in a mixing chamber of a burner as well as in air introduction passages provided in a wall of the mixing chamber, whereby NOx emissions from premixed combustion are reduced while at the same time, ignition characteristics and flame propagation characteristics improve.The gas turbine combustor includes a plurality of combustors 10, a spark plug 13, and a cross-fire tube 15 that propagates a flame between the combustors 10. Each combustor 10 includes the burner 30 equipped with a fuel nozzle and the mixing chamber wall 32 forming the mixing chamber 31. A plurality of air introduction holes 35, 36 for introducing combustion air, along with the fuel from the fuel nozzle, into the mixing chamber 31, are provided in the mixing chamber wall 32. The combustion air and fuel jetted from the air introduction hole 35 into the mixing chamber 31 are mixed in the form of a mixture “m1”, “m2” and directed towards the spark plug 13 and the cross-fire tube 15.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

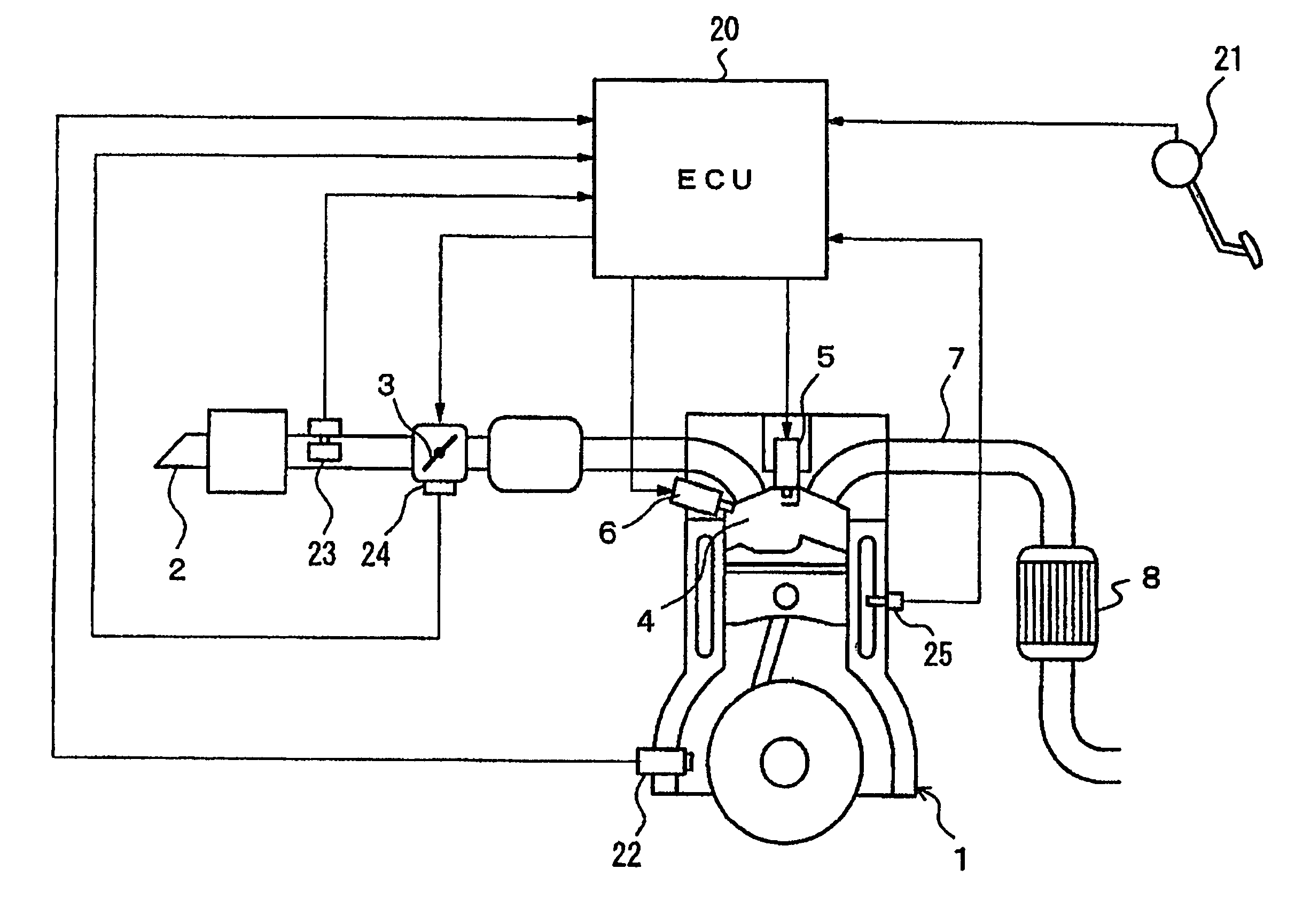

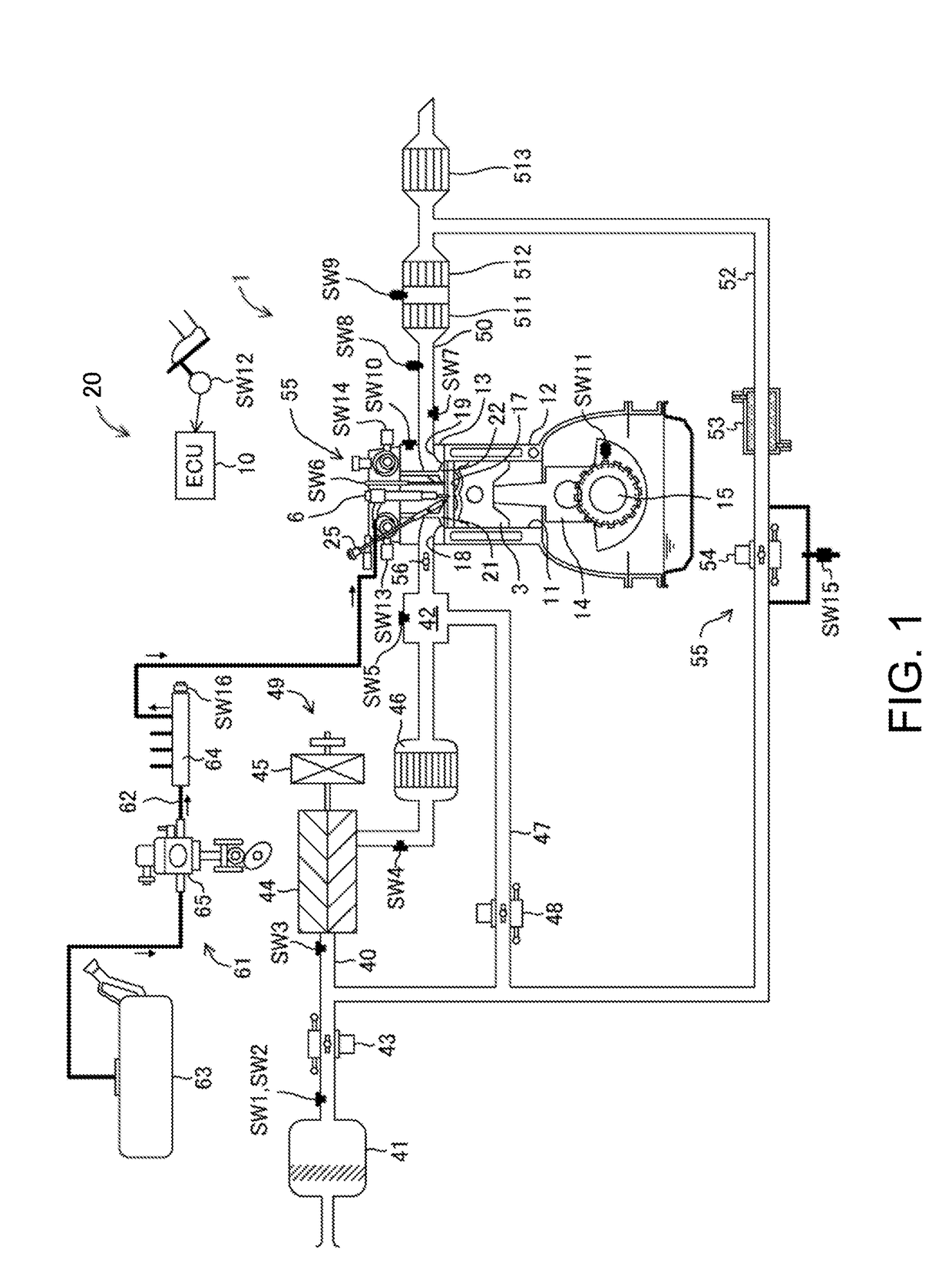

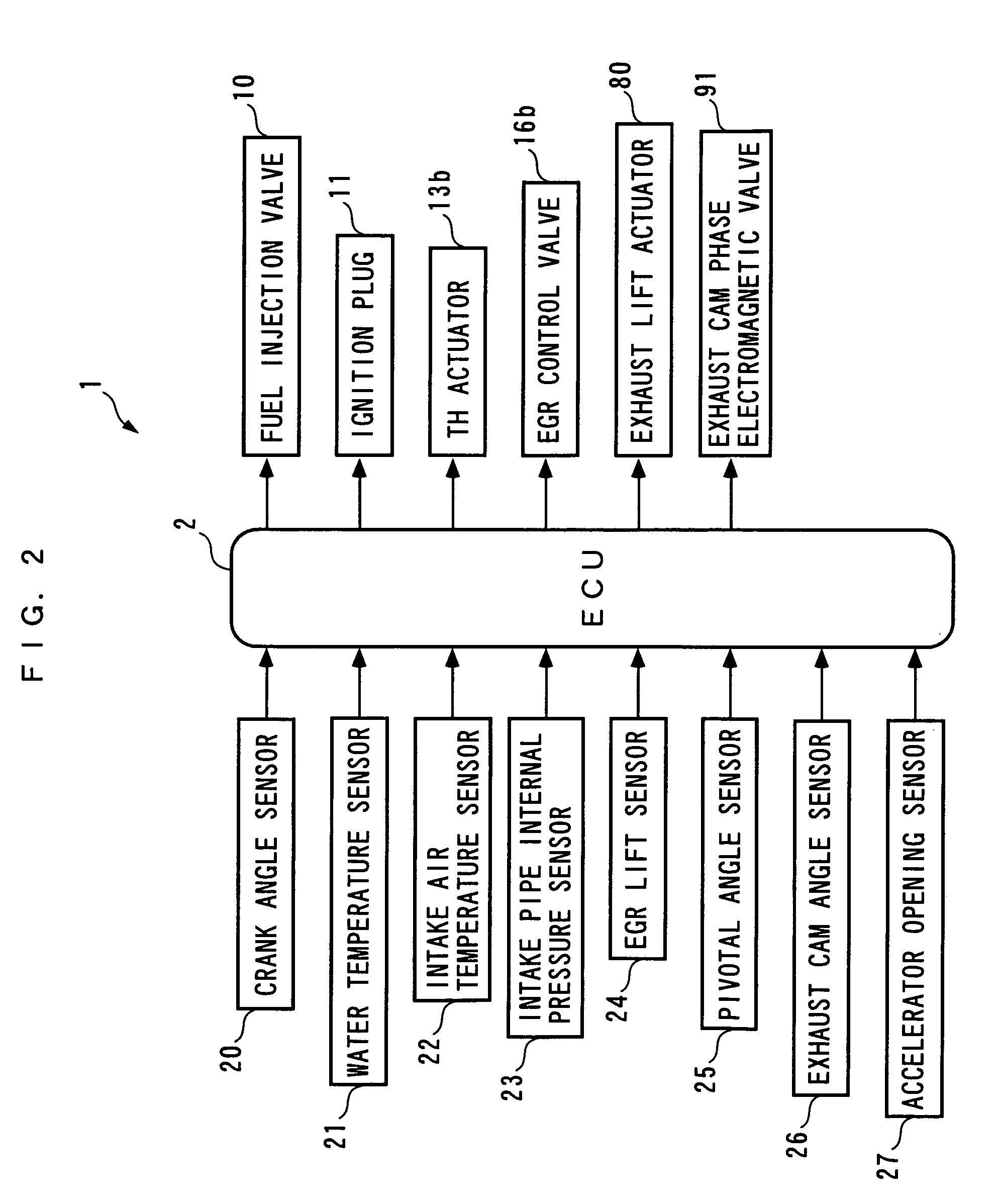

Egr control apparatus and method for internal combustion engine

InactiveUS20080162020A1Significant valueInternal combustion piston enginesExhaust apparatusFlame propagationExternal combustion engine

An EGR control apparatus and method for an internal combustion engine which burns an air-fuel mixture with self ignition in addition to a flame propagation combustion, are provided for improving the combustion efficiency, engine output, drivability, and exhaust gas characteristics in an internal combustion engine which involves a self ignition combustion of an air-fuel mixture in addition to a flame propagation combustion. The EGR control apparatus comprises an ECU which selects one of a stratified self ignition mode, a stratified flame propagation combustion mode, and a homogeneous flame propagation combustion mode, sets a total target EGR amount and a target in-cylinder gas temperature in accordance with the selected combustion mode, calculates a target internal EGR amount in accordance with the value, calculates a target external EGR amount by subtracting the target internal EGR amount from the total target EGR amount, and controls the internal EGR amount and the external EGR amount to be the target internal EGR amount and the target external EGR amount, respectively, by driving three mechanisms.

Owner:HONDA MOTOR CO LTD

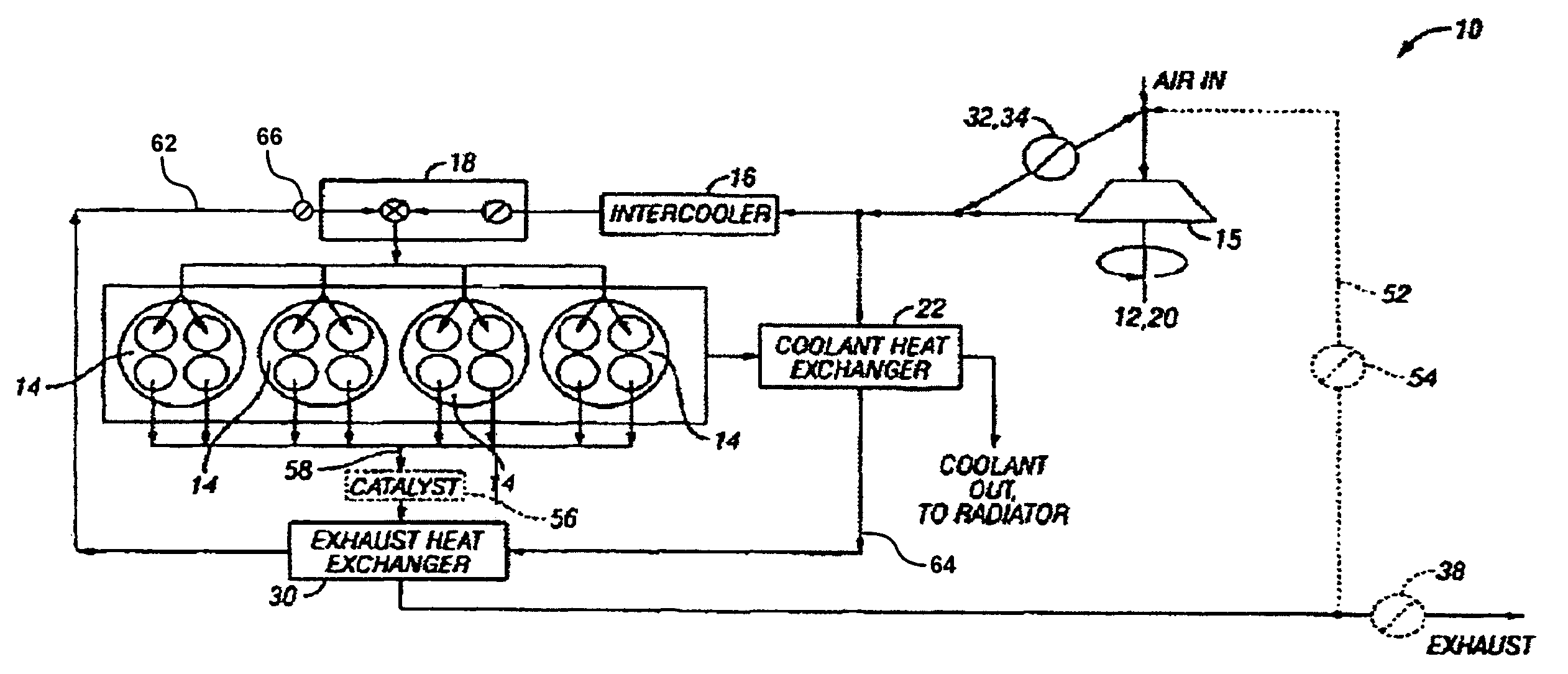

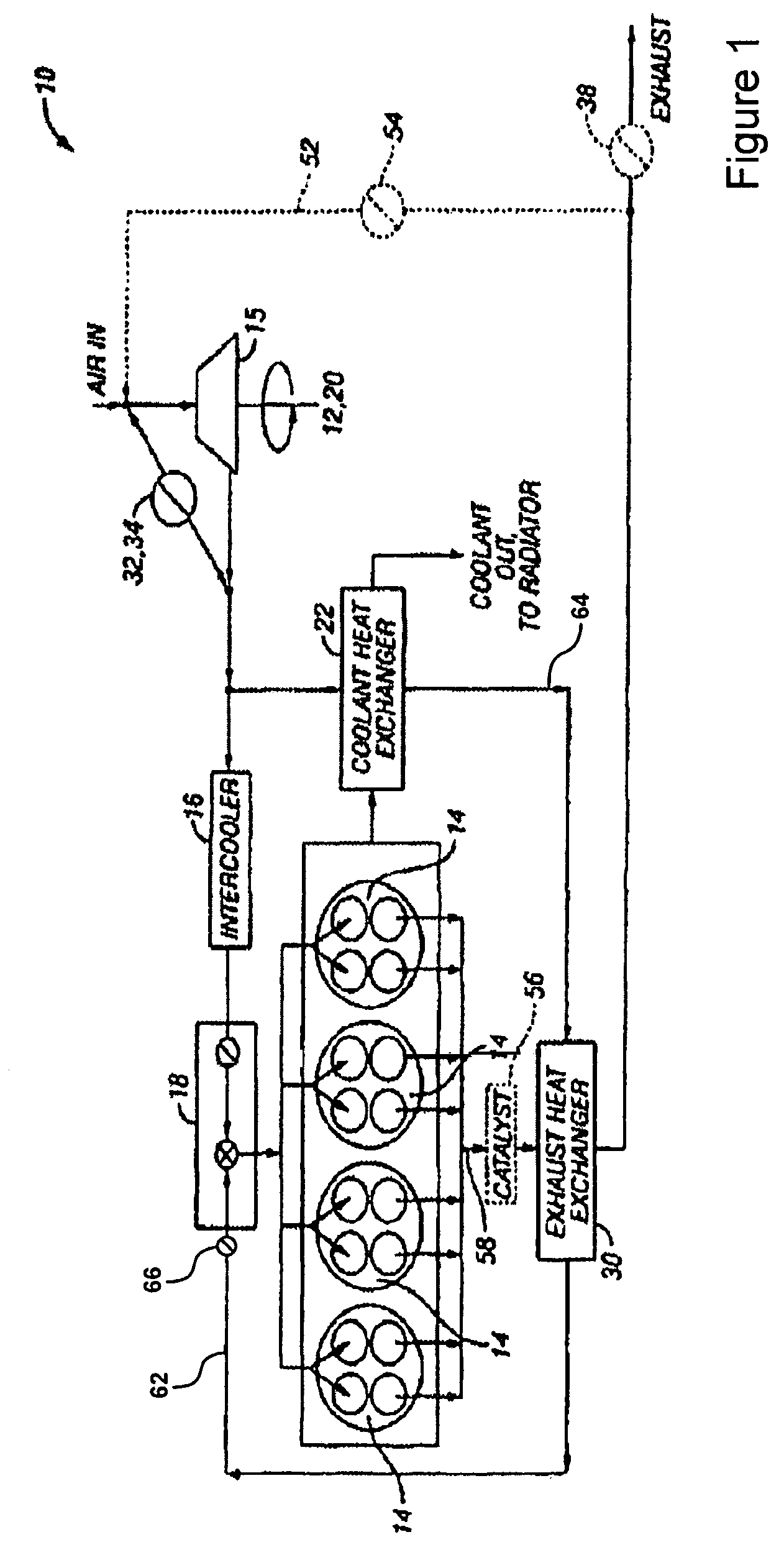

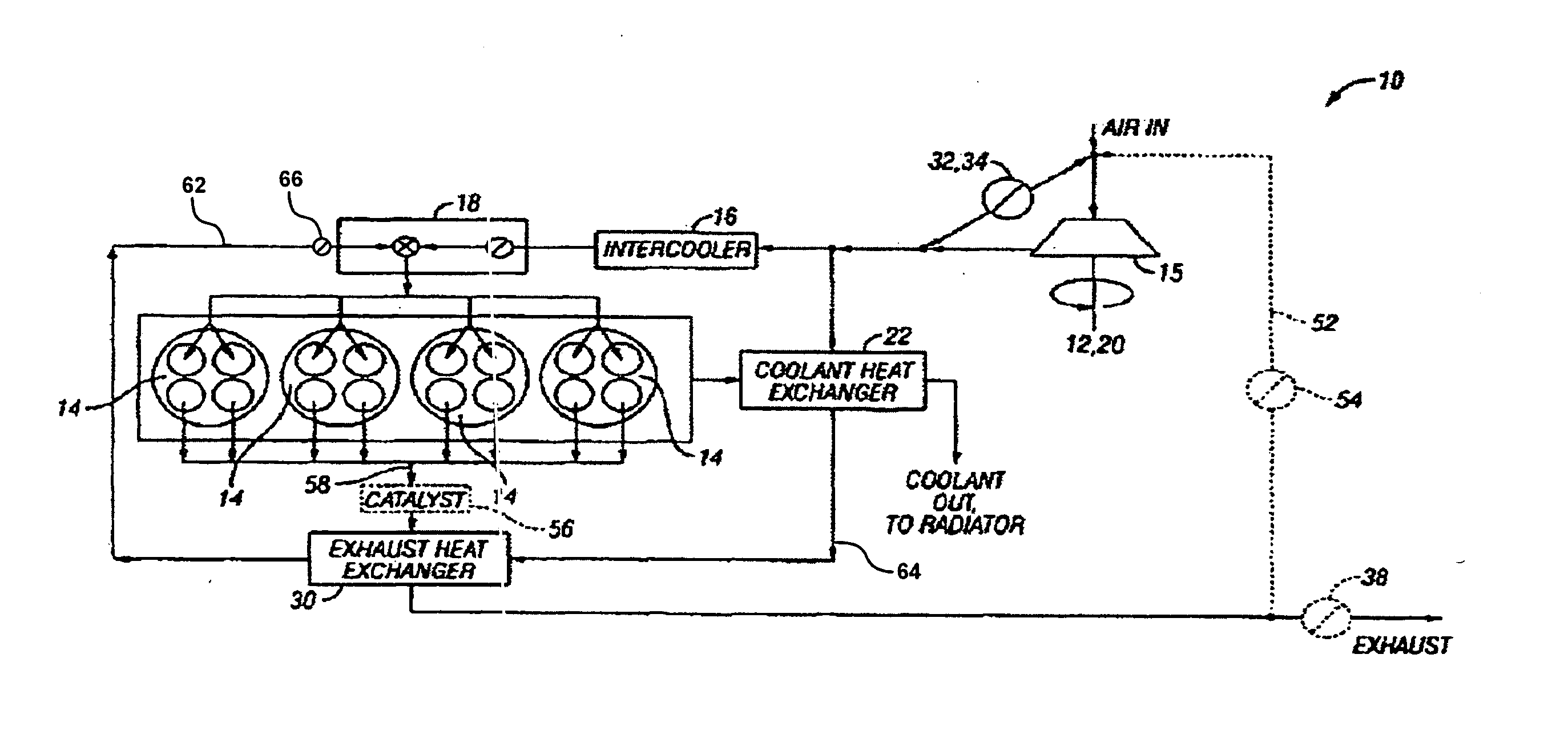

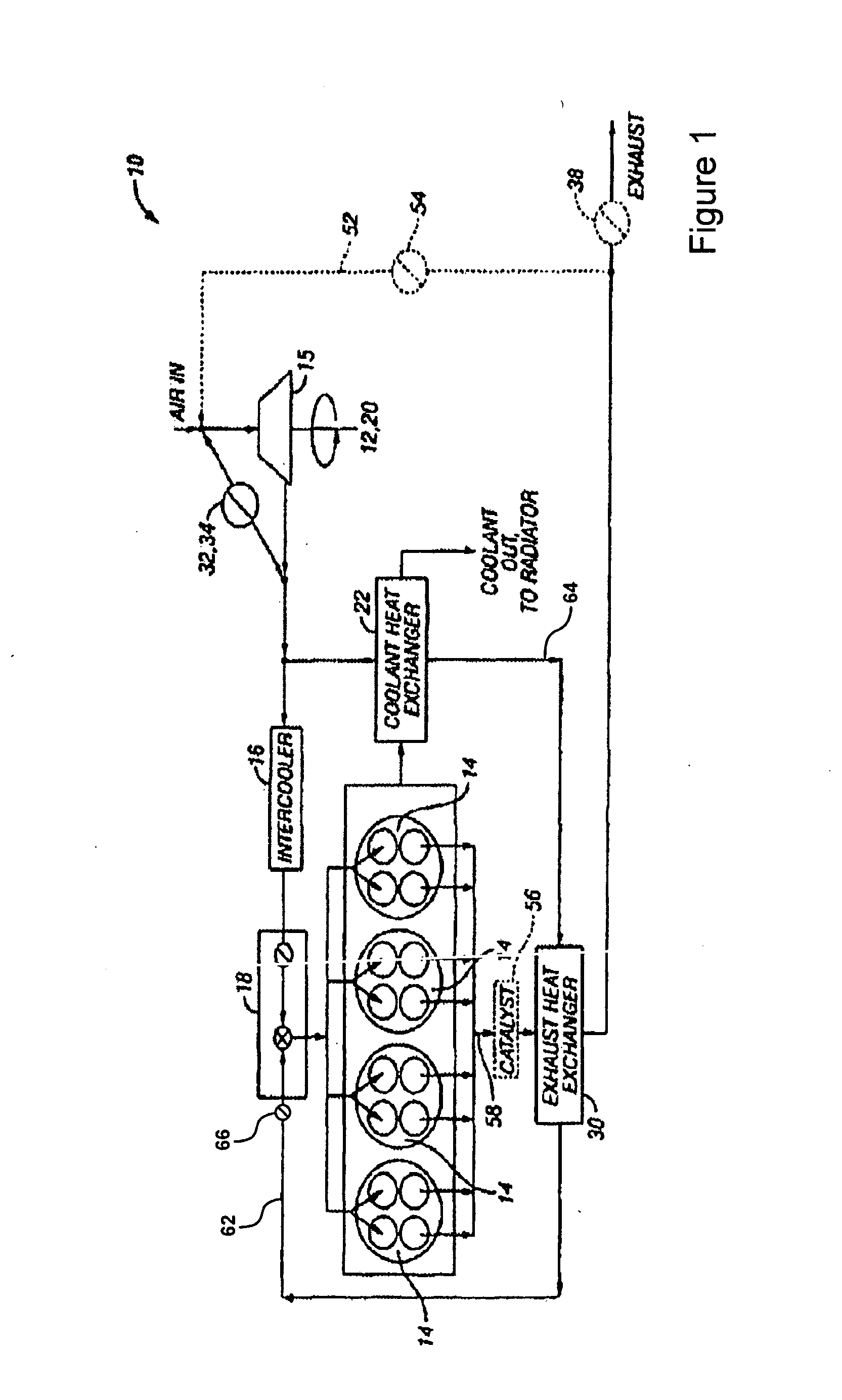

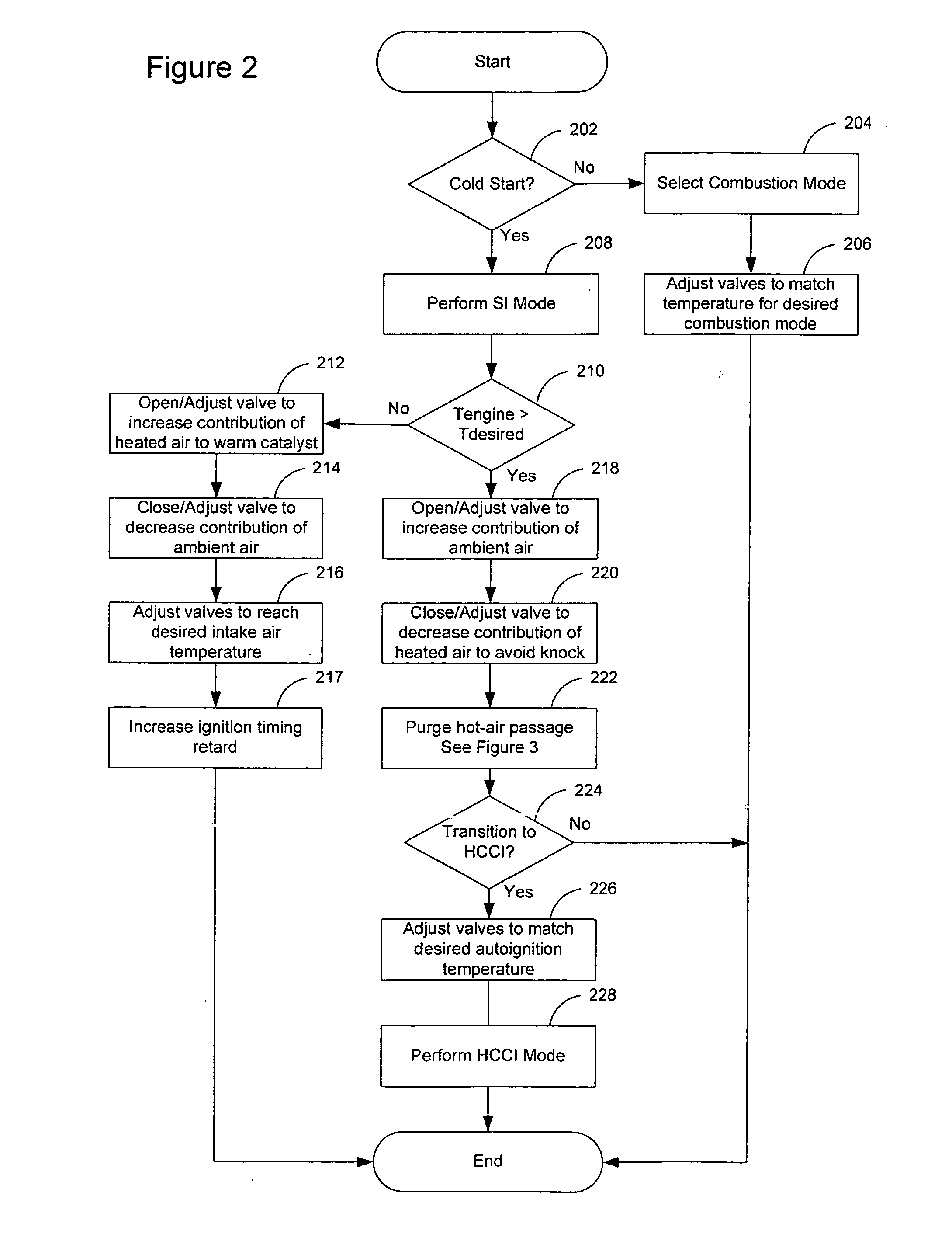

System and method for maintaining heated intake air

InactiveUS7213585B2Improve efficiencyReduce the production of nitrogen oxidesInternal combustion piston enginesThermal treatment of fuelFlame propagationInlet manifold

Owner:FORD GLOBAL TECH LLC

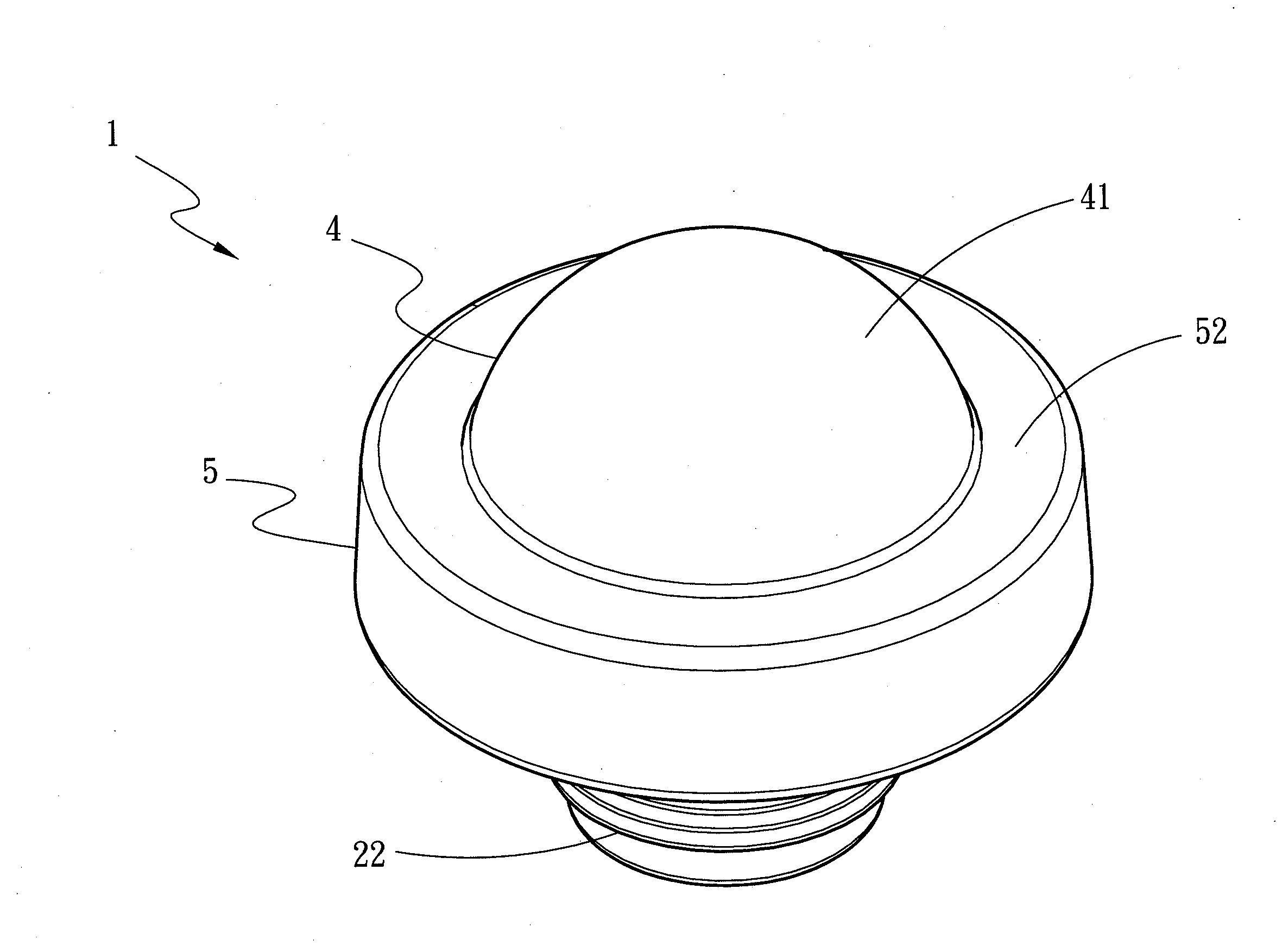

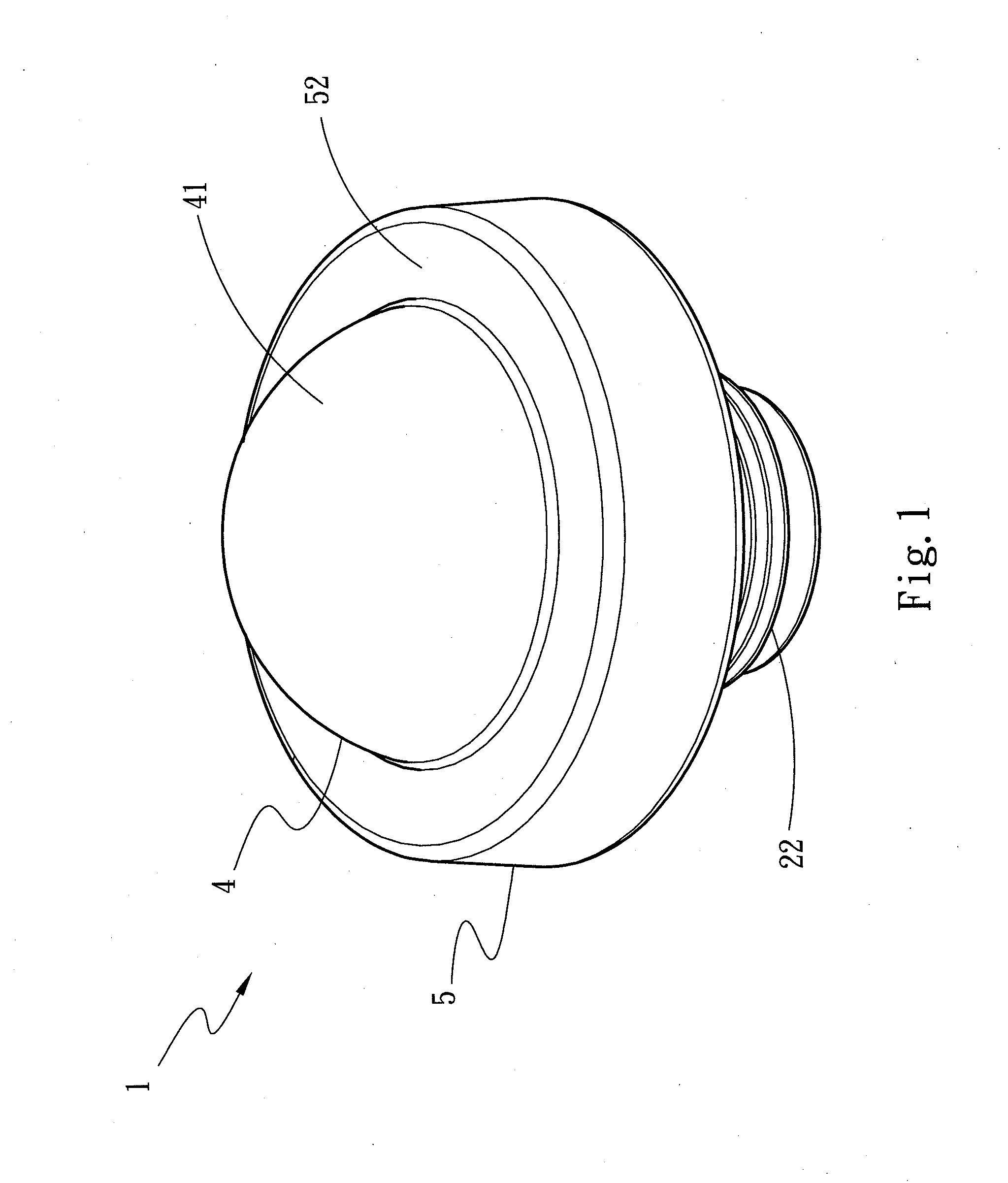

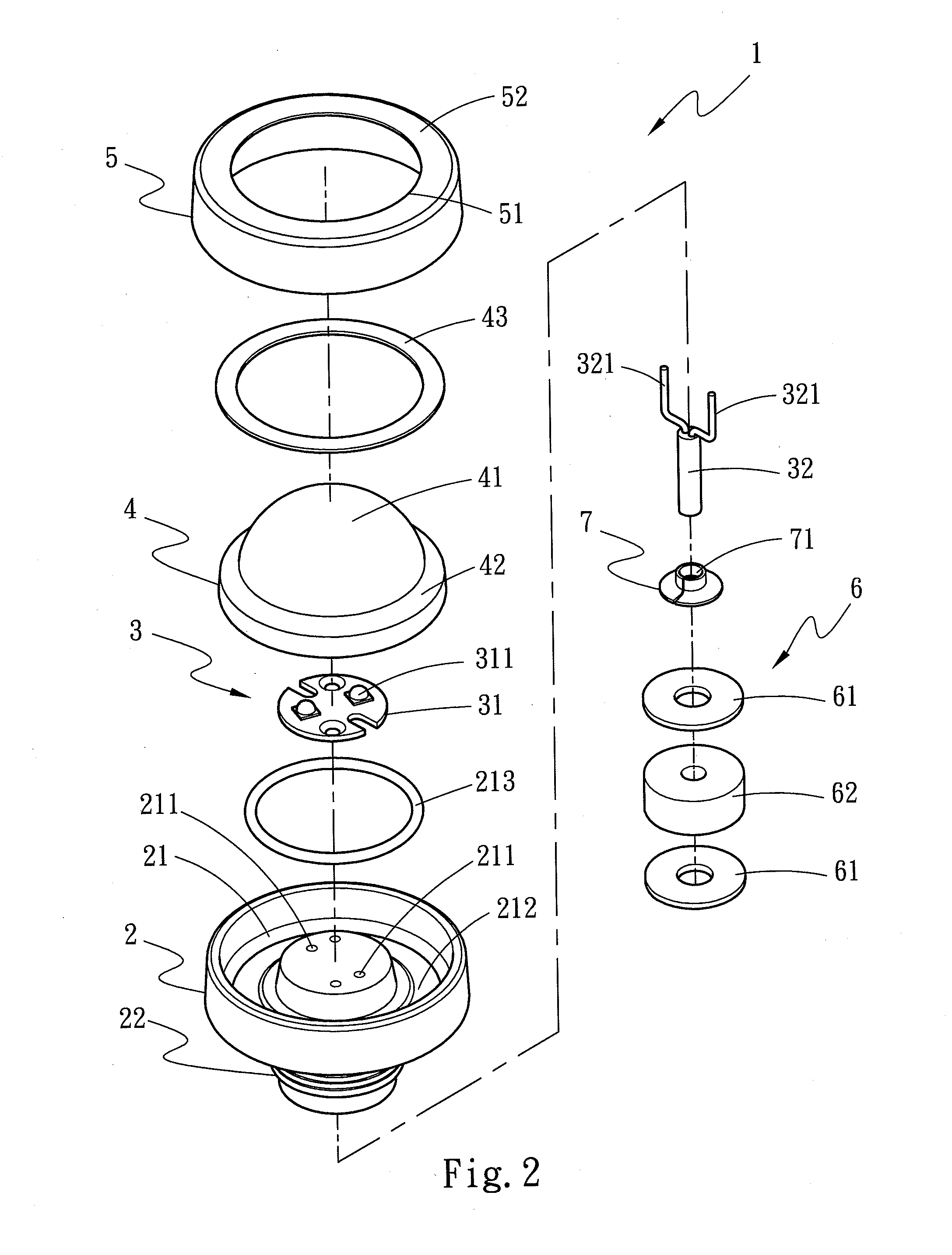

Energy-saving and explosion-proof LED lamp

InactiveUS20140211474A1Reduce consumptionImprove practicalityLighting heating/cooling arrangementsProtective devices for lightingFlame propagationEngineering

An energy-saving and explosion-proof LED lamp comprises a lamp socket, an LED element, a lamp shade and a ring cap. The lamp socket includes a housing chamber, a jutting coupling portion with a housing compartment at the bottom thereof to hold a washer assembly inside to seal the bottom of the lamp socket. The LED element is fixedly held in the housing chamber. The lamp shade is made of tempered glass and wedged in the housing chamber, and has a jutting lens in the center and an annular end extended outwards from the perimeter of the lens. The ring cap has a coupling opening mating the lens and a press portion at the rim thereof. The ring cap is coupled on the lamp socket with the press portion covering the annular end, thus forms a flame propagation distance complying with explosion-proof certification.

Owner:LI HONG TECHNOLOGICAL

System for researching spray diffusion combustion characteristics of liquid fuel

PendingCN106932527AResearch on Diffusion Combustion CharacteristicsChemical analysis using combustionFluorescence/phosphorescenceFlame propagationTop dead center

The invention discloses a system for researching spray diffusion combustion characteristics of liquid fuel. The system comprises a constant-volume combustion projectile body, an air inlet system, an exhaust system, an ignition module, a heating module, a high-pressure common rail system, a data acquisition module, a schlieren imaging system, a laser diagnosis system and an electric control unit. The spray diffusion combustion characteristics of different liquid fuel can be researched at different initial pressure and temperatures. In an experiment, a premixed combustible gas which is injected into the constant-volume combustion projectile body in advance can be ignited by using the ignition module; high-temperature and high-pressure environments are generated in the constant-volume combustion projectile body to simulate high-temperature and high-pressure environments, close to a top compression center, in a cylinder of a diesel engine; when the pressure of the constant-volume combustion projectile body is reduced to a set value, a control unit controls an oil atomizer to spray high-pressure fuel into the constant-volume combustion projectile body and the fuel is quickly atomized in the constant-volume combustion projectile body and ignited by compression; and the combustion flame propagation process of fuel compression ignition is synchronously recorded by using the schlieren imaging system and the spray diffusion combustion characteristics of different liquid fuel are researched by combining a laser diagnosis technology.

Owner:ZHEJIANG UNIV

Rotational flow stress application/stamping combustion chamber

ActiveCN108800205AIncrease the propagation speedImprove performanceContinuous combustion chamberFlame propagationCombustor

The invention discloses a rotational flow stress application / stamping combustion chamber and belongs to the technical field of rotational flow combustion of new concept aero-engines. In the structureof the combustion chamber, a diffuser carries out speed reduction and pressurization on airflow; a thermal insulating screen divides the incoming flow of a diffuser pipe into a main airflow and an outer duct airflow for cooling; a plurality of cooling holes are formed in the thermal insulating screen; a flame stabilizer transmits and stabilizes flame; a rotational flow blade is positioned in the flame stabilizer and forms a set included angle with the main airflow to rotate the downstream airflow; and an oil supply system comprises on-duty level oil supply, outer ring oil supply of a radial stabilizer and main combustion level oil supply and adopts the oil supply manners of combination of a direct-injection type fuel spray nozzle and an annular oil pipe, and a radial oil pipe of a main oilpipe. Compared with a traditional combustor, as the rotational flow combustion manner is adopted, the flame propagation velocity is not affected by pressure; in addition, the subregion oil supply manner is adopted, so that the oil and gas are mixed more fully, combustion is more efficient and stable, and pollution is less; and moreover, the flame transferring device of the flame stabilizer is eliminated, so that the structure of the combustion chamber is simplified, the length of the combustion chamber is shortened and the weight of the combustion chamber is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Method for controlling diluent or lean mixed gas burning and ignition through high-flammability fuel micro ignition

InactiveCN106321269AImprove economyExtended operating rangeElectrical controlInternal combustion piston enginesFlame propagationGasoline

The invention discloses a method for controlling diluent or lean mixed gas burning and ignition through high-flammability fuel micro ignition. The method comprises the steps that gasoline is ignited through spontaneous burning of a small amount of layered high-flammability fuel, and stable flame propagation is formed; the temperature inside a cylinder is increased through energy released by flame propagation and piston upward compression, meanwhile, multiple spontaneous burning points are formed in unburnt diluent or lean mixed gas under the assistance of a small amount of pilot injection high-flammability fuel, and then stable and rapid burning or multi-point spontaneous burning is formed. When an engine encounters knock or the largest explosion pressure exceeds limits, the burning process can be converted into rapid flame propagation type burning by introducing cooled burnt waste gas or excess air. When the heat state in the cylinder is not enough to form stable flame propagation or spontaneous burning heat release, the heat state in the cylinder is improved by introducing internal residual waste gas. The control problem in the ignition and burning process of premixed diluent or lean mixed gas can be solved.

Owner:TIANJIN UNIV

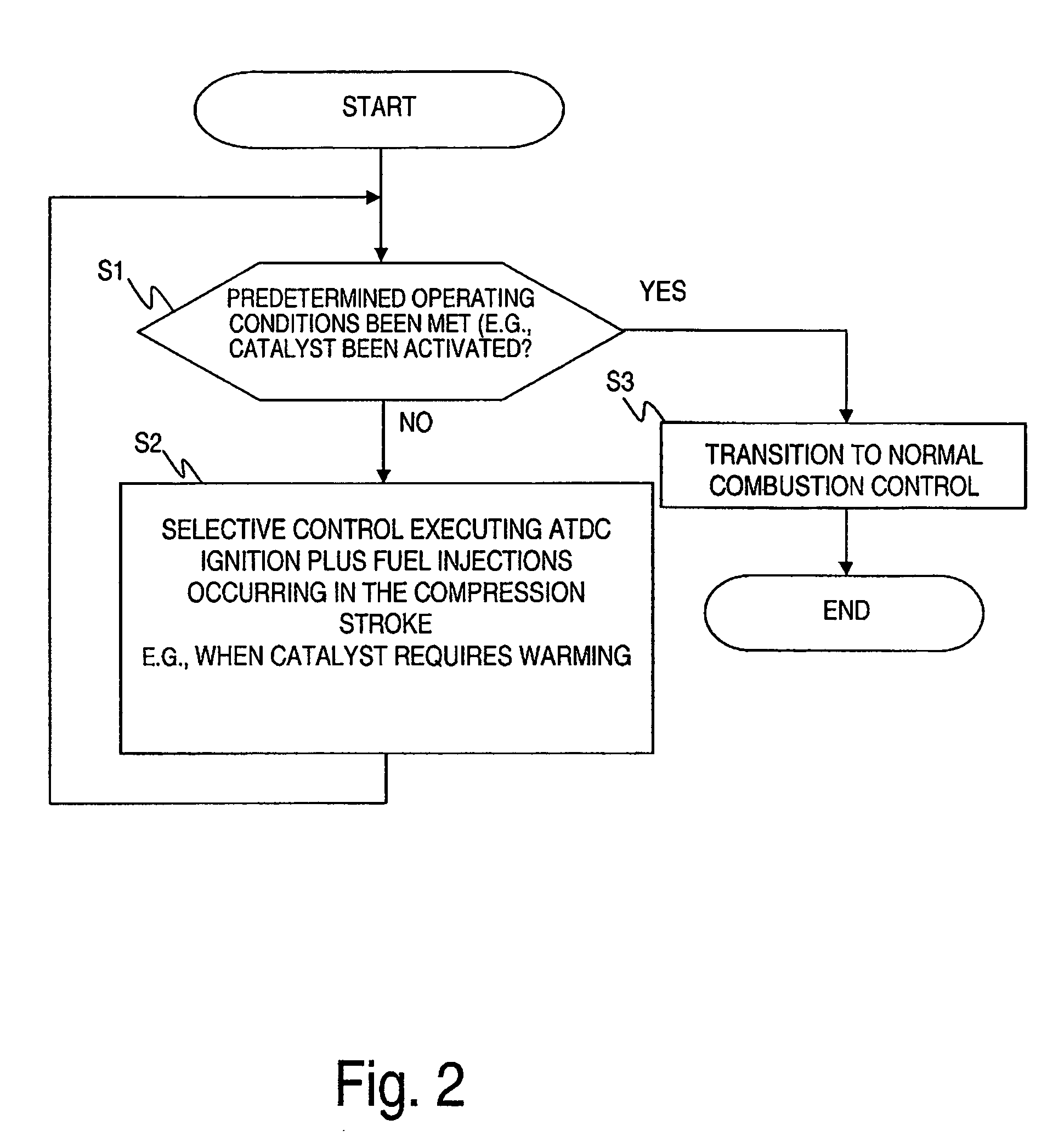

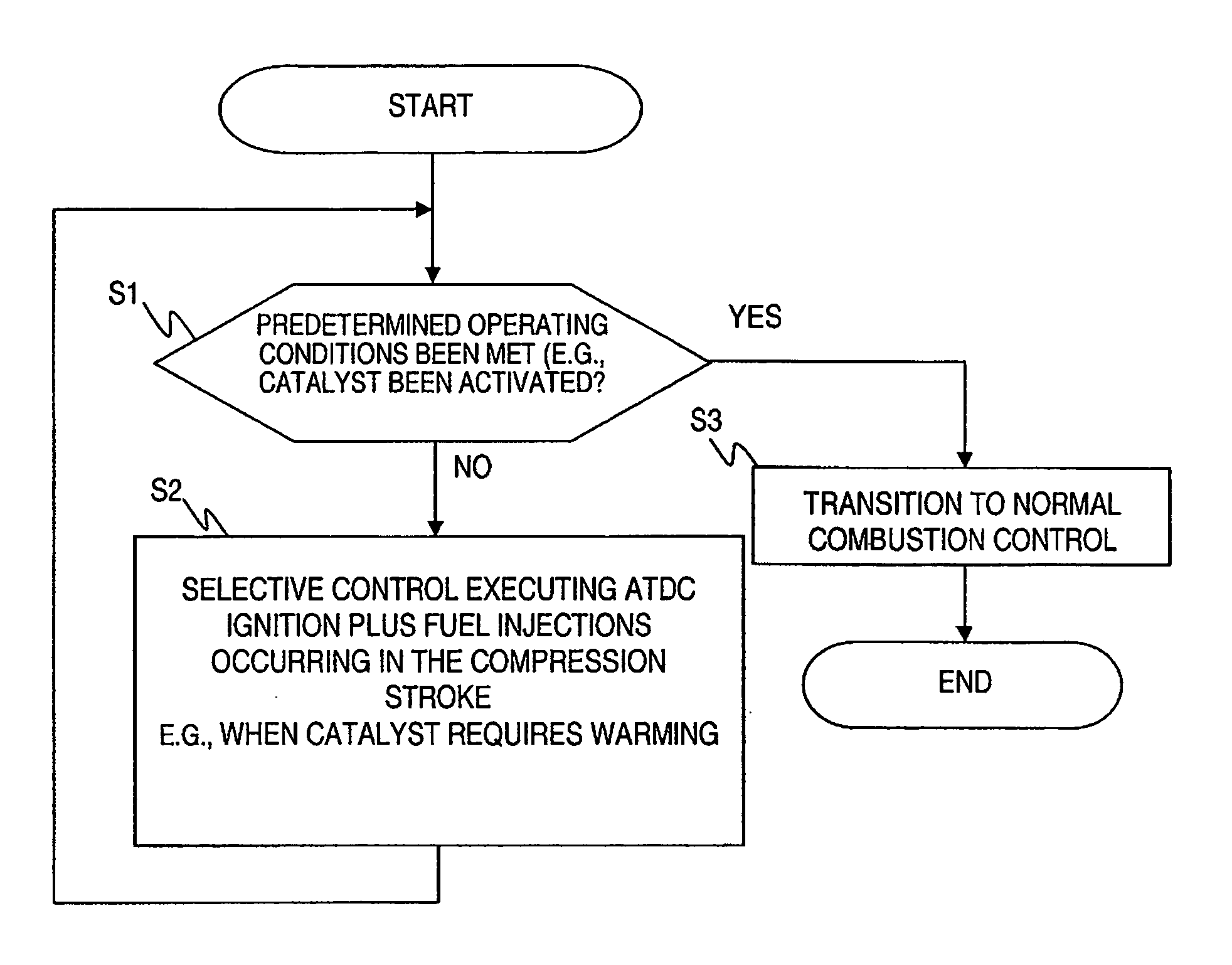

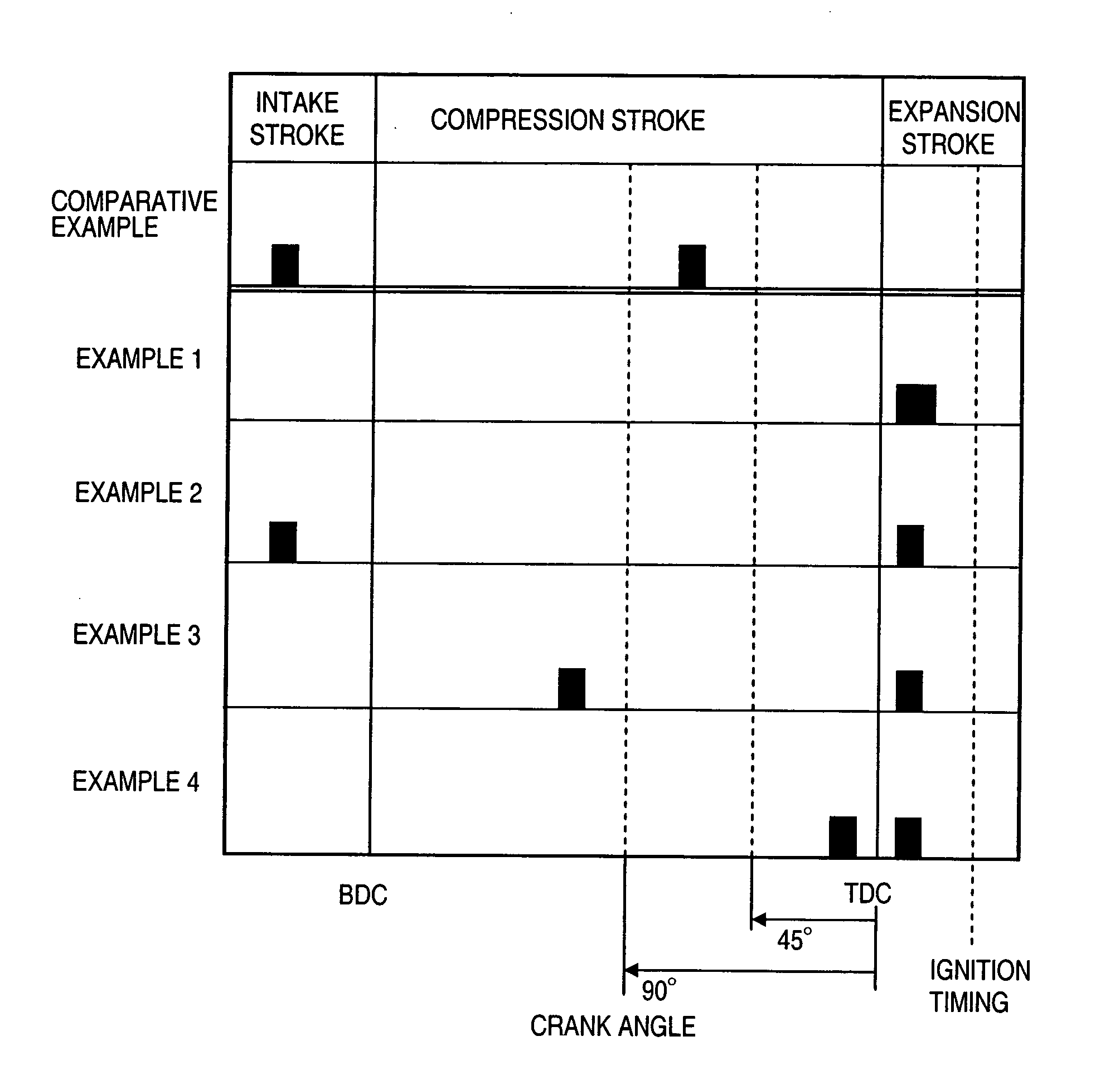

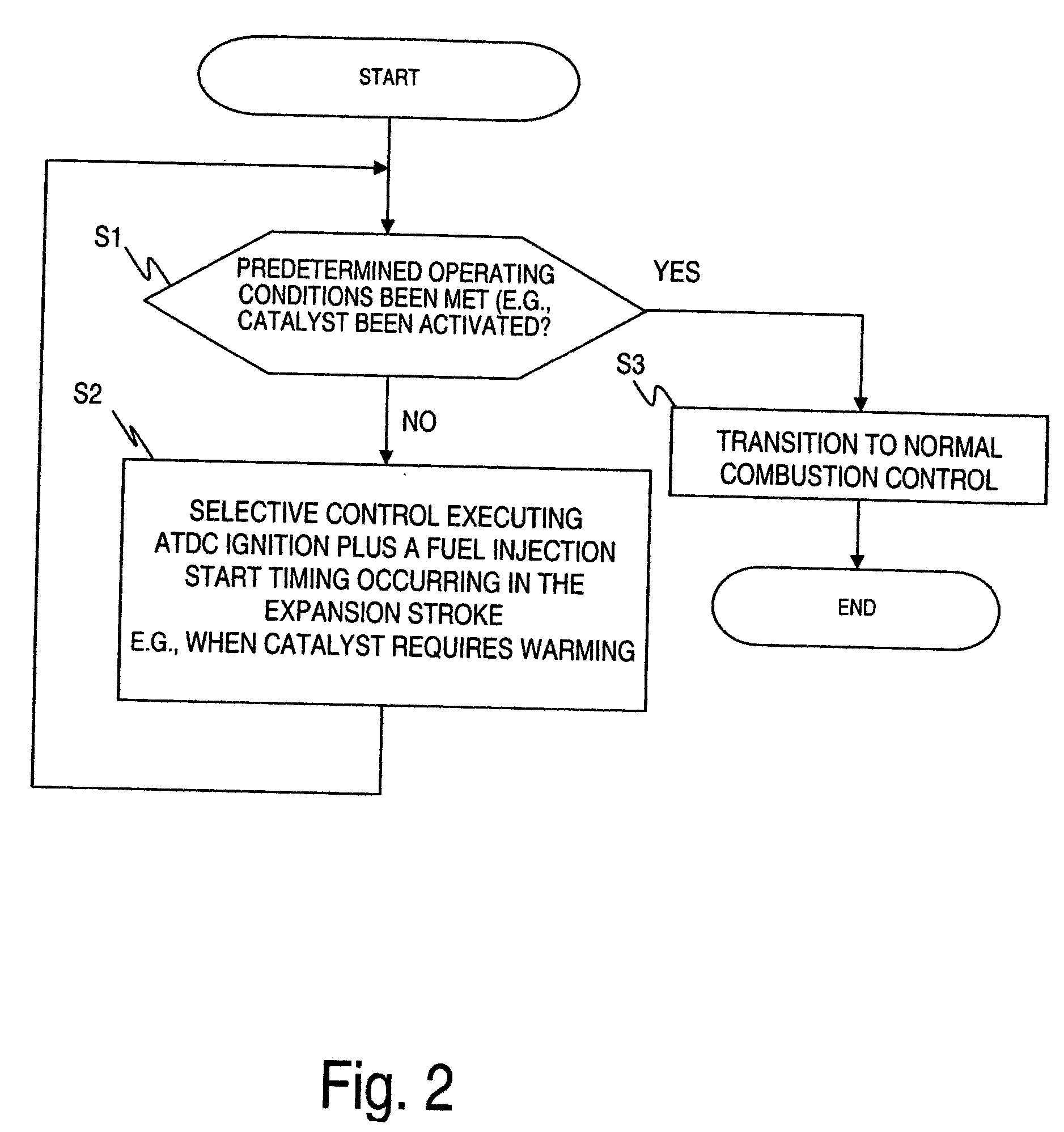

Direct fuel injection/spark ignition engine control device

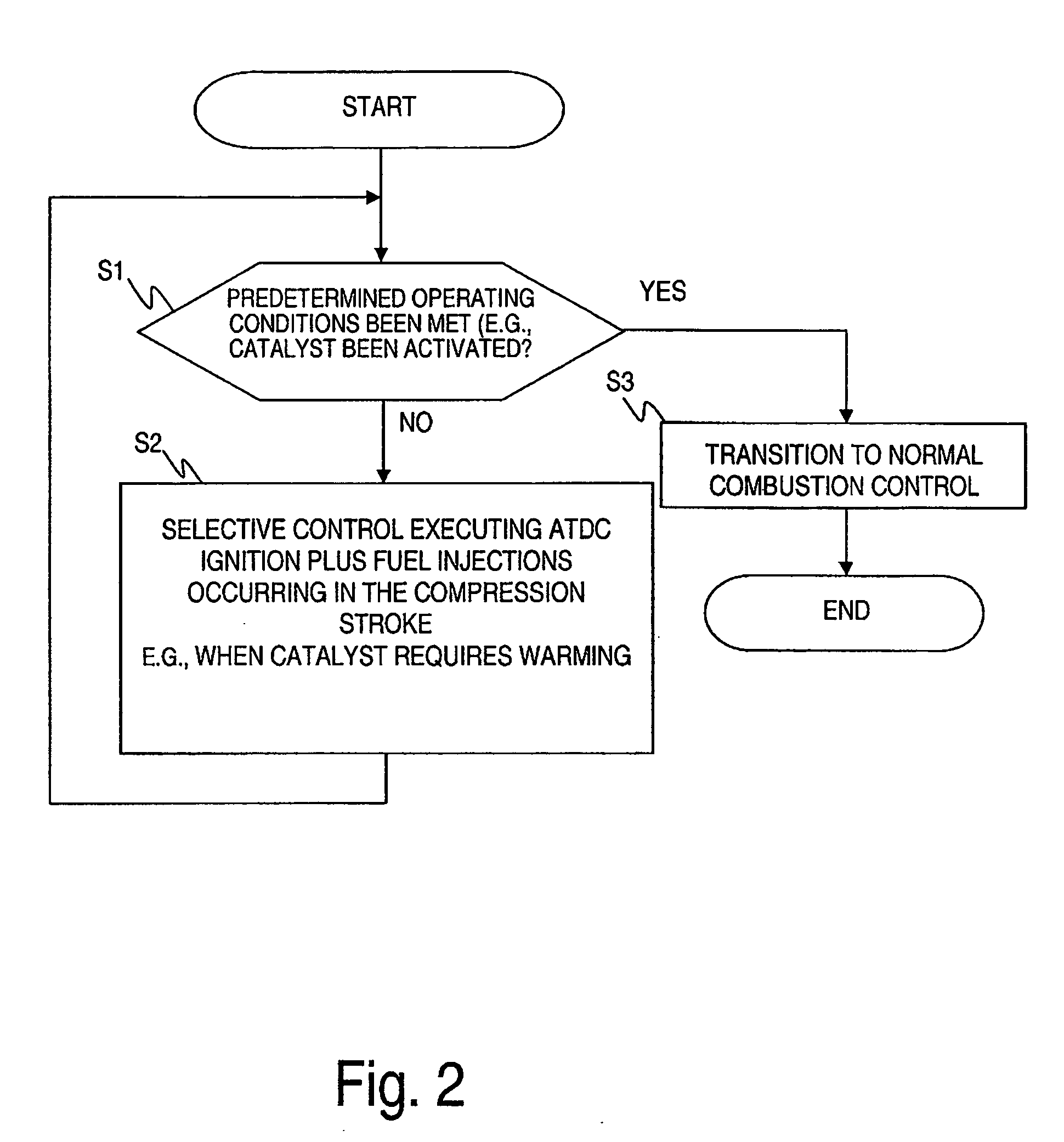

InactiveUS20050161018A1Promote combustionReduce turbulenceElectrical controlInternal combustion piston enginesFlame propagationTop dead center

A control apparatus is configured to enhance turbulence in the cylinder produced by the fuel spray, and to improve combustion stability (promote flame propagation) in an ATDC designed to reduce HC and / or achieve early activation of the catalyst. Ignition timing is set to compression top dead center (TDC) or later when needed such as when the catalyst requires warming. In one fuel injection timing, the fuel is injected in two fuel injections with a first fuel injection occurring during the compression stroke, and the second fuel injection being carried out at 45° BTDC or later.

Owner:NISSAN MOTOR CO LTD

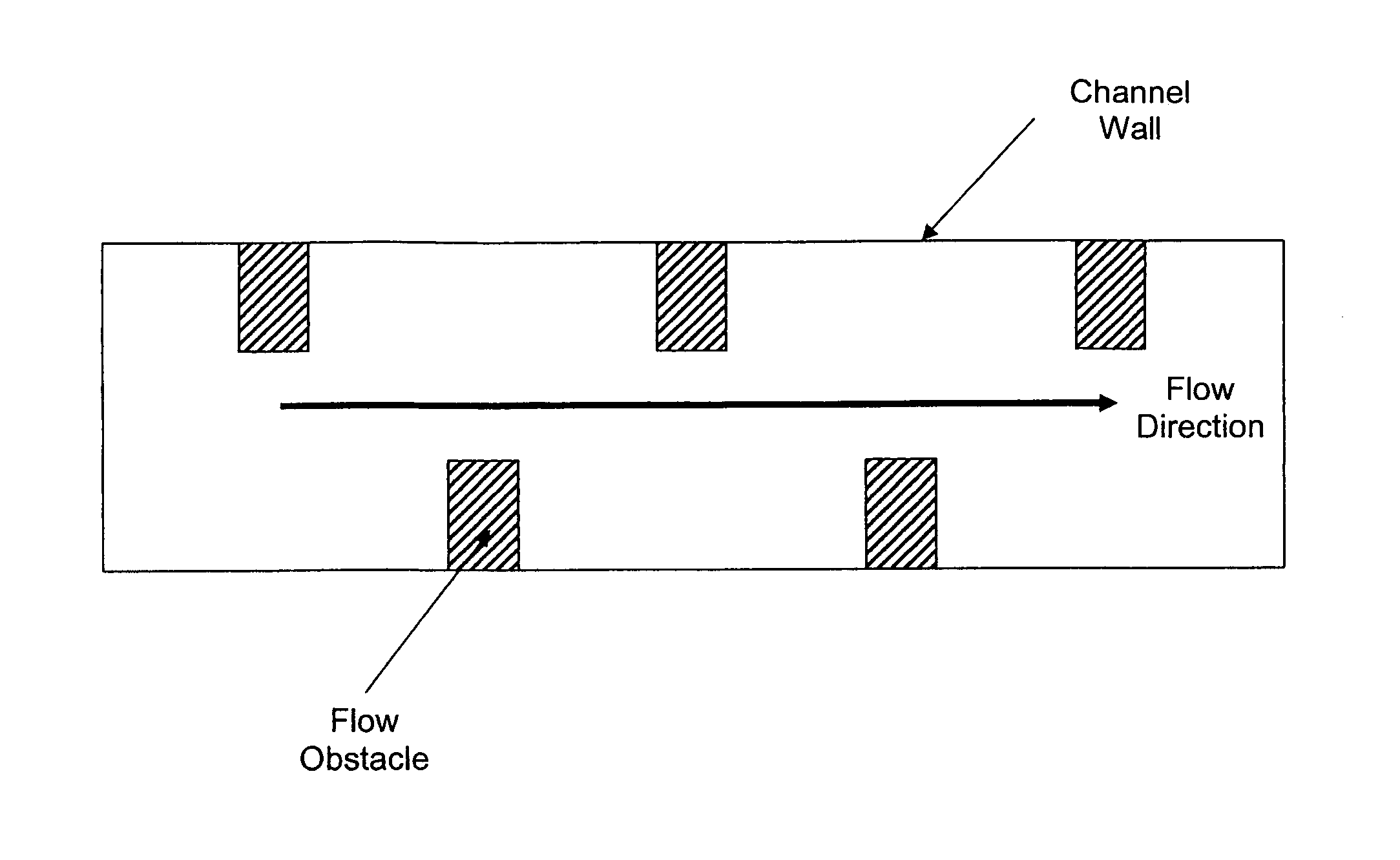

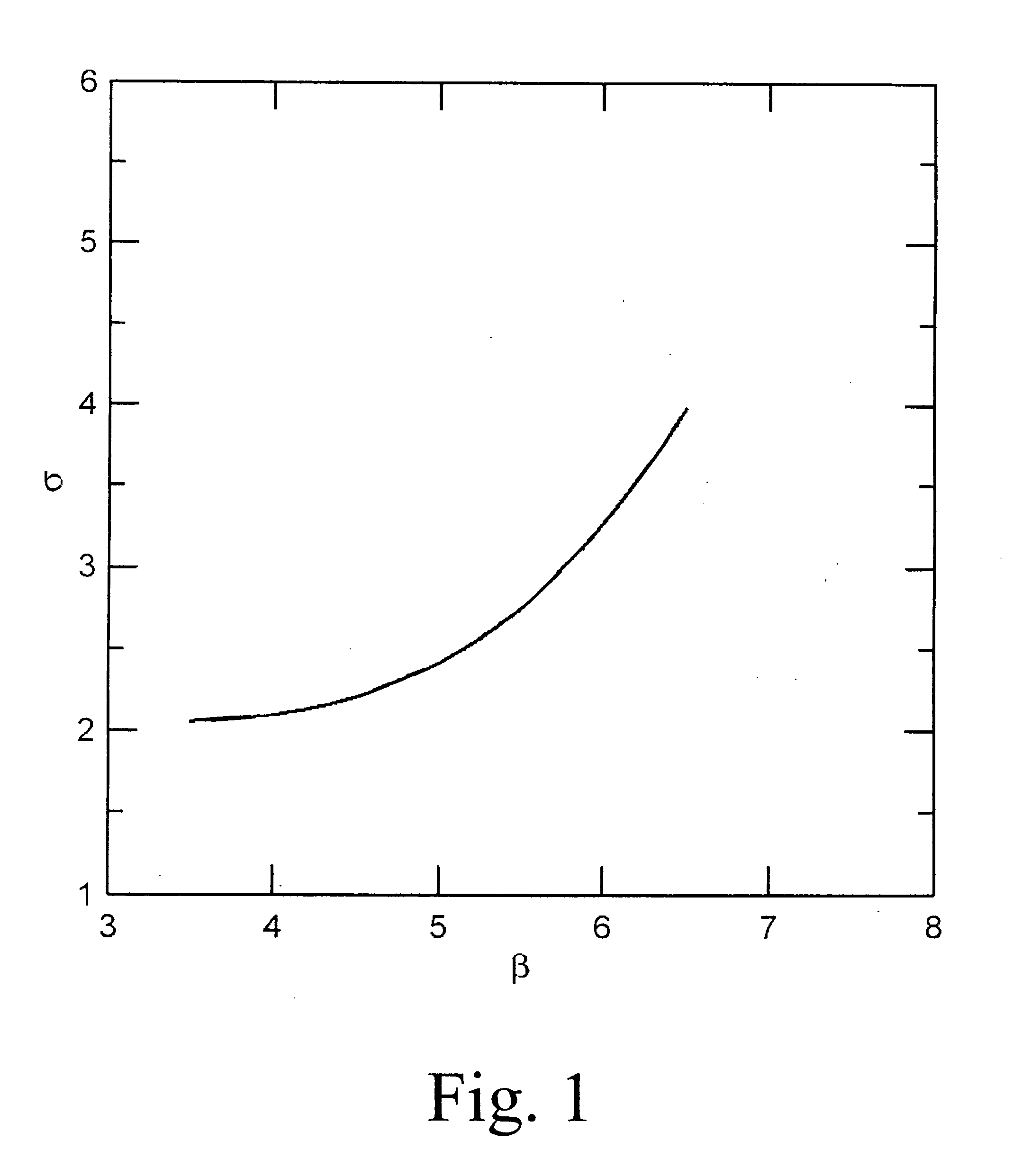

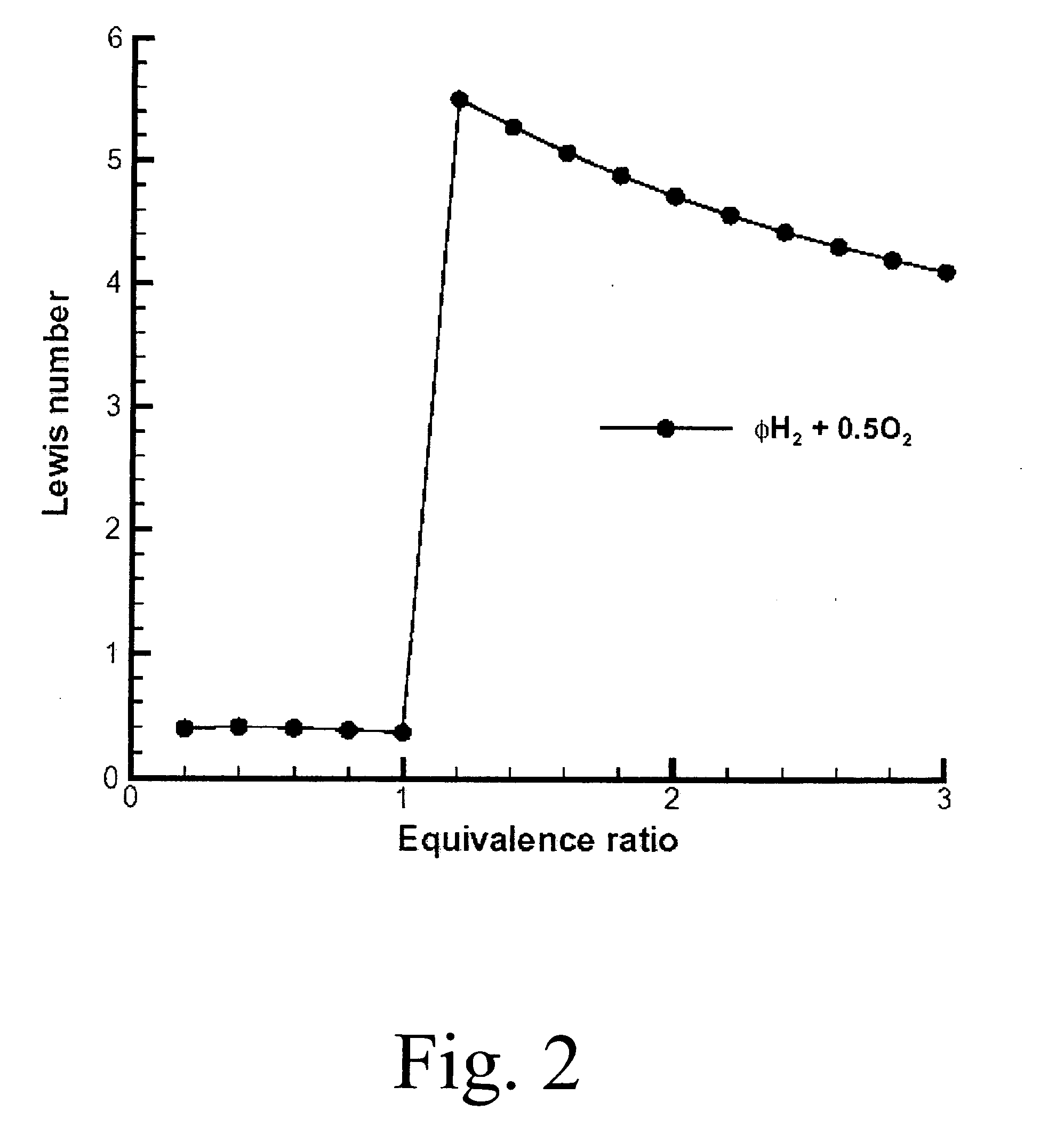

Detonation safety in microchannels

InactiveUS20060035182A1Increased flame speedProcess control/regulationFuel lightersInherent safetyFlame propagation

The proper sizing of microchannel dimensions and the management of internal features offer the possibility of inherently safe operation within the flammable limits of a combustible fluid stream while preserving the largest-possible flow dimensions for industrial-scale process capacity. Specifically, the microchannel dimensions need not be restricted to gap distances below the quenching distance to be operated safely. Microchannel performance can be engineered to provide adequate heat transfer for flame propagation. However, it is essential to maintain flame characteristics in such a manner that it cannot transition to a detonation flame front. A detonation takes place when the combustion wave propagates at supersonic speeds at the existing local temperature and pressure conditions in the system. It results in a much larger energy release over a much smaller period of time as compared to a laminar flame or deflagration, the later of which is a combustion wave propagating at subsonic speed. Detonations can be potentially highly destructive and very hazardous and therefore should be avoided for most industrial applications.

Owner:VELOCYS CORPORATION

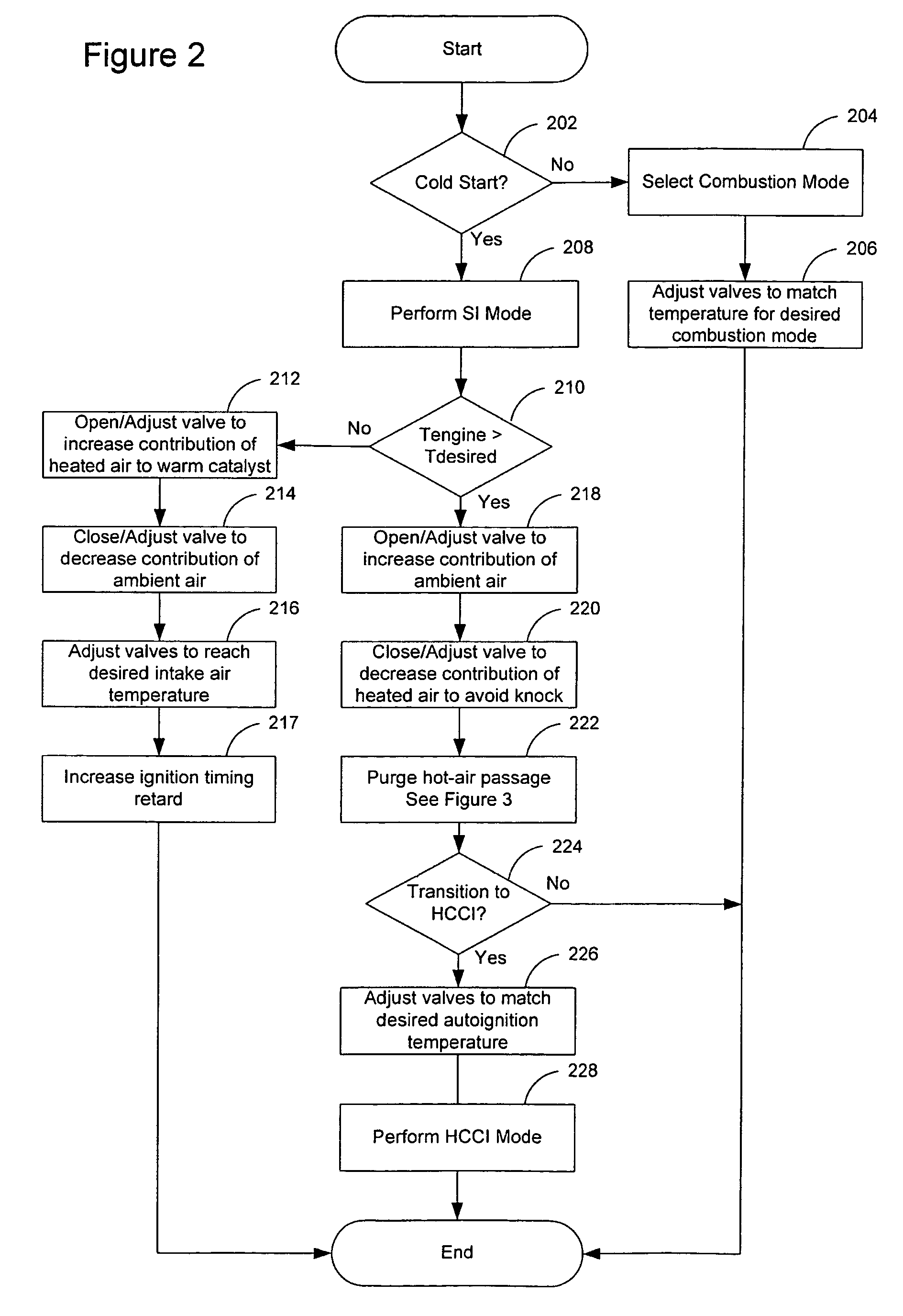

System and method for maintaining heated intake air

InactiveUS20070062490A1Improve fuel efficiencyReduce the production of nitrogen oxidesInternal combustion piston enginesEngine controllersFlame propagationSpark plug

A system for an internal combustion engine, the engine having an intake and exhaust manifold, the system comprising a heat exchanger configured to extract energy from at least a heat source that heats a first portion of intake air, a spark plug coupled to the engine, an intake passage configured to deliver said first portion of heated intake air to the engine and to deliver a second portion of intake air which bypasses said heat source, and a controller configured to direct said second portion of intake air to the engine at least when utilizing said spark plug to initiate combustion and flame propagation of an air-fuel mixture, and to at least temporarily cause said first portion of intake air to flow during said spark ignition combustion so that a temperature of said first portion of intake air is maintained above a selected value.

Owner:FORD GLOBAL TECH LLC

Direct fuel injection/spark ignition engine control device

InactiveUS20050161020A1Reduce HCIncrease exhaust temperatureElectrical controlCombustion enginesFlame propagationTop dead center

A control apparatus is configured to enhance turbulence in the cylinder produced by the fuel spray, and to improve combustion stability (promote flame propagation) in an ATDC designed to reduce HC and / or achieve early activation of the catalyst. Ignition timing is set to compression top dead center or later when for example the catalyst requires warming. In one fuel injection timing, a single fuel injection is injected prior to ignition timing at compression stroke top dead center or later. Alternatively, the fuel is injected in two fuel injections with a first fuel injection occurring during either the intake stroke or the compression stroke and the second fuel injection occurring at compression stroke top dead center or later.

Owner:NISSAN MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com