Rotational flow stress application/stamping combustion chamber

A stamping combustion chamber, swirl afterburning technology, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of high difficulty in flame stable structure installation, low total pressure loss, difficult structure, etc., and achieve weight Lightening, small total pressure loss, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical scheme of the present invention will be described in further detail below in conjunction with the accompanying drawings.

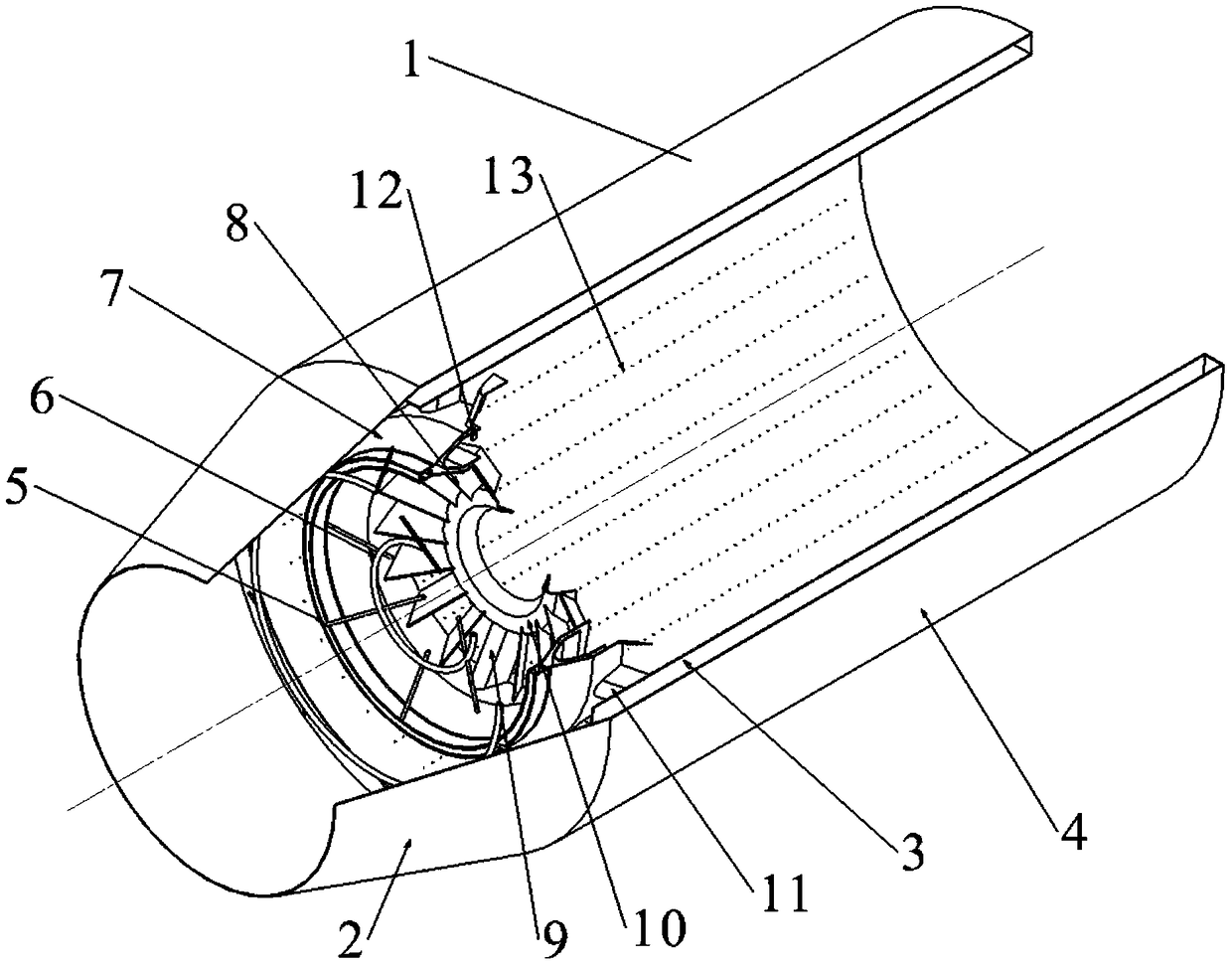

[0040] Such as figure 1 As shown, the swirl afterburner / ram combustion chamber 1 of the present invention is a full annular combustion chamber,

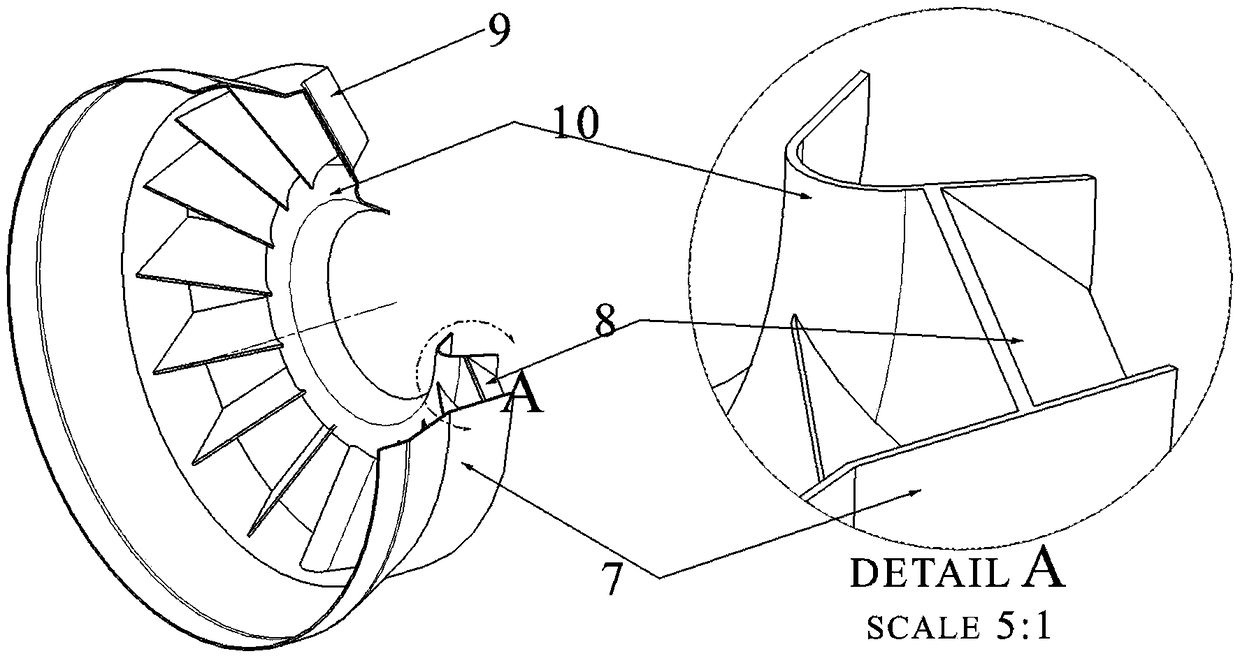

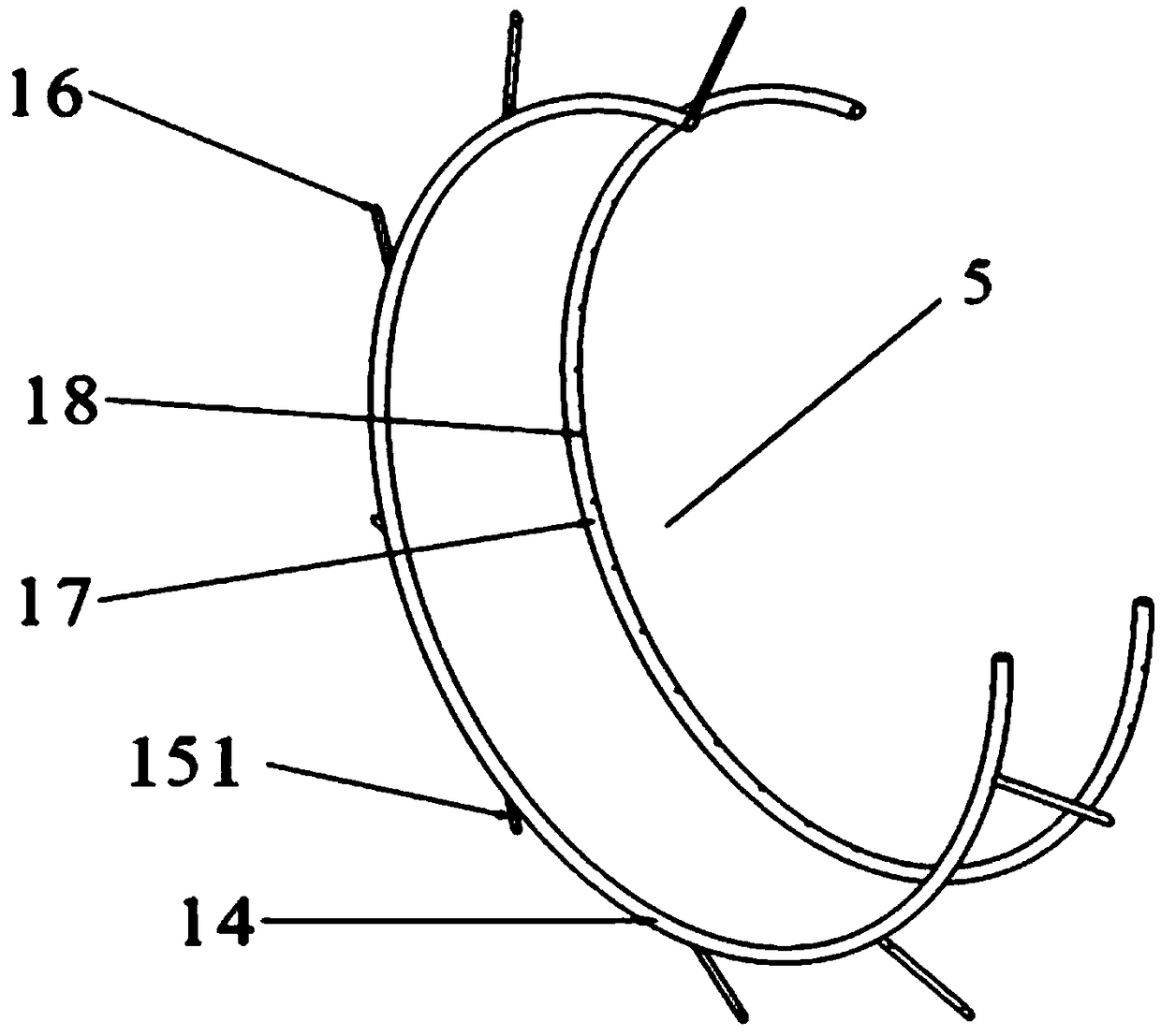

[0041] It mainly consists of diffuser 2, heat shield 3, outer casing 4, on-duty oil supply device 5, mainstream oil supply device 6, on-duty stabilizer 7, swirl vane 8, flame transfer groove 9, V-shaped stabilizer 10. It consists of a radial stabilizer 11 and a high-energy electric nozzle 12. The air flow enters the combustion chamber after being decelerated and pressurized by the diffuser 2, so as to facilitate the organization of combustion. The heat shield 3 is arranged in the outer casing 4, and the airflow flowing out from the diffuser 2 is divided into the main airflow and the external channel airflow for cooling through the heat shield 3, and several pairs of heat shield 3 walls are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com