Patents

Literature

7034 results about "Aero engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

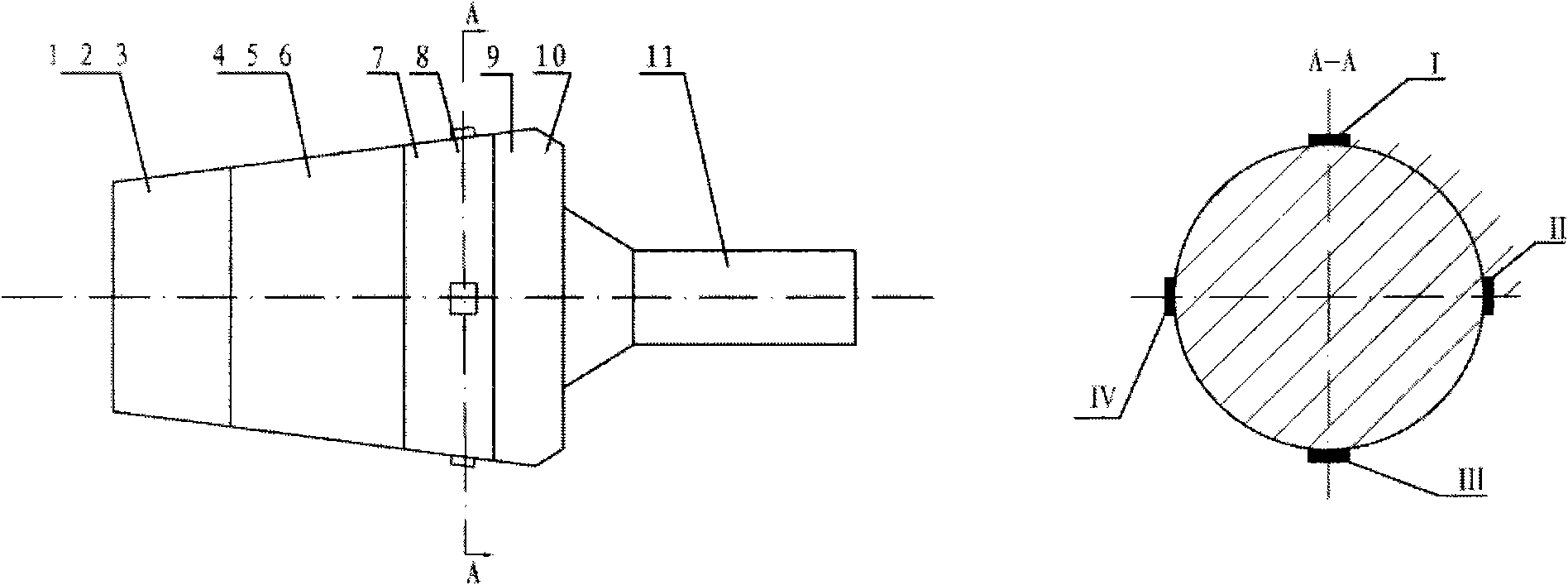

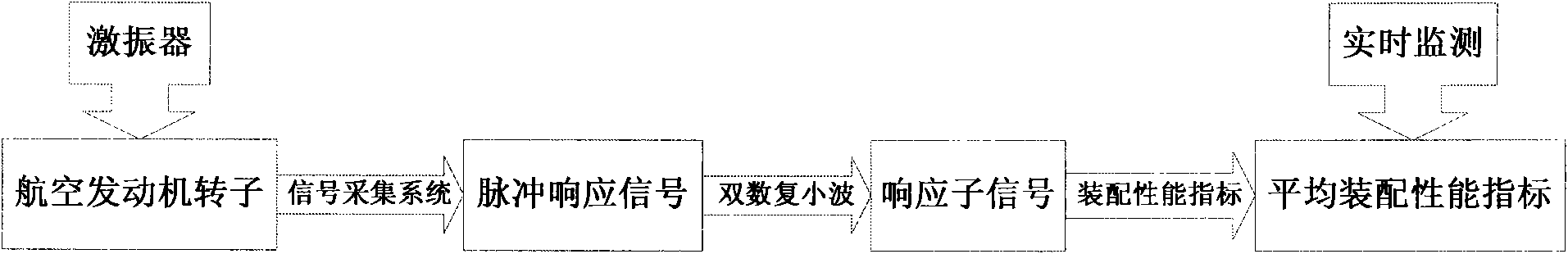

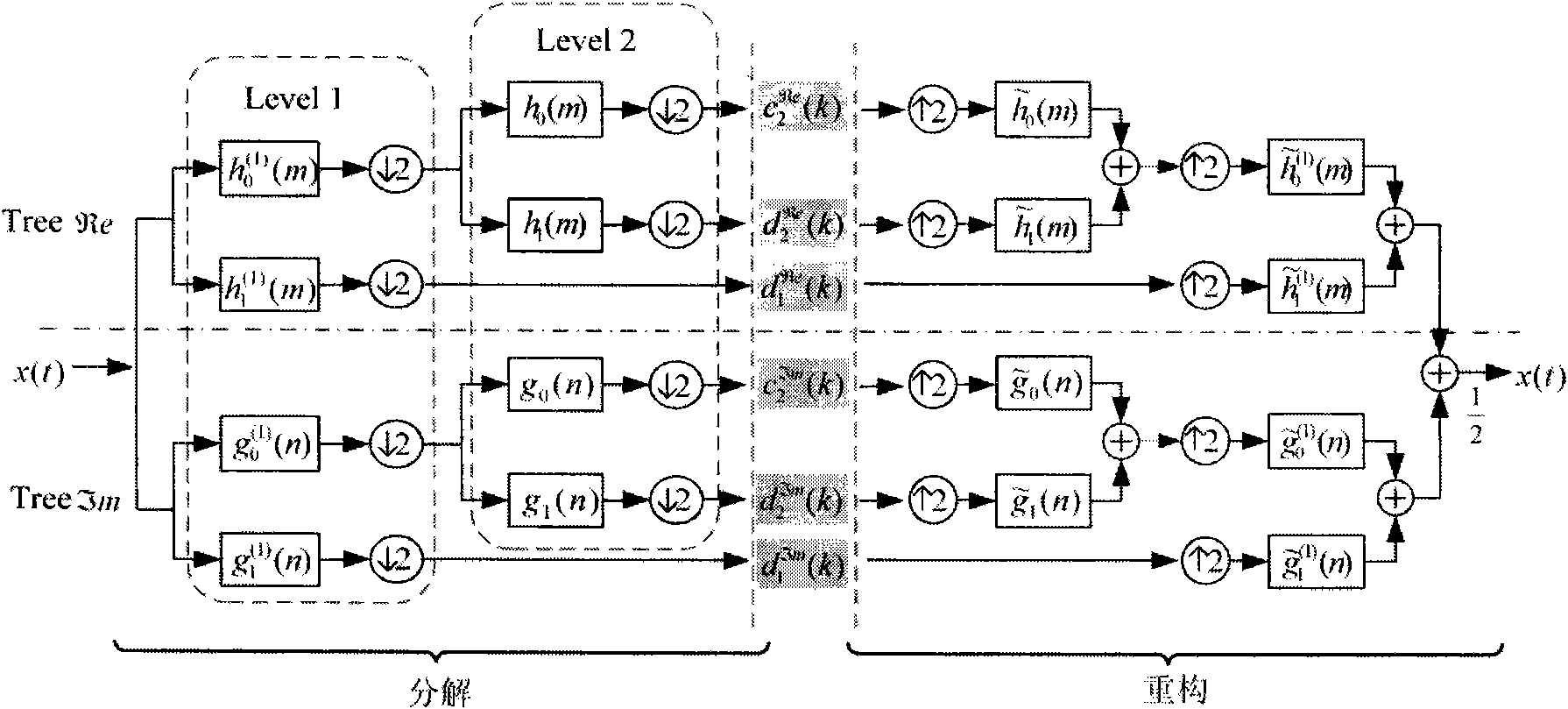

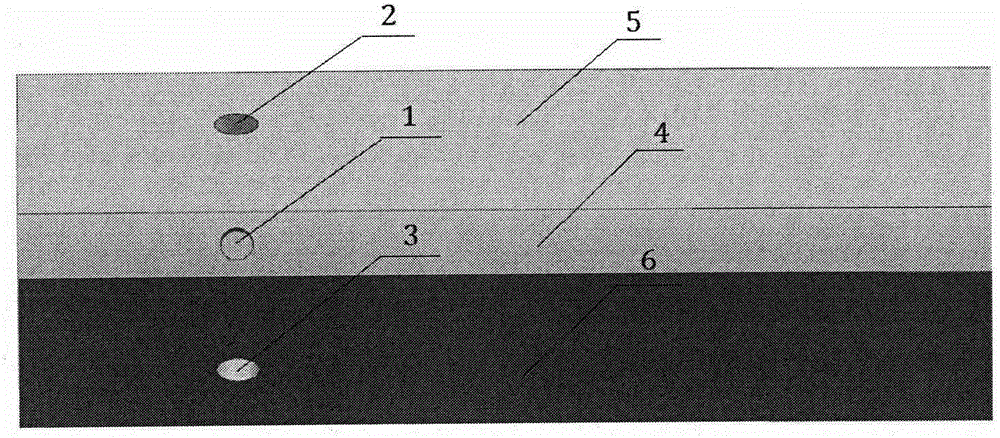

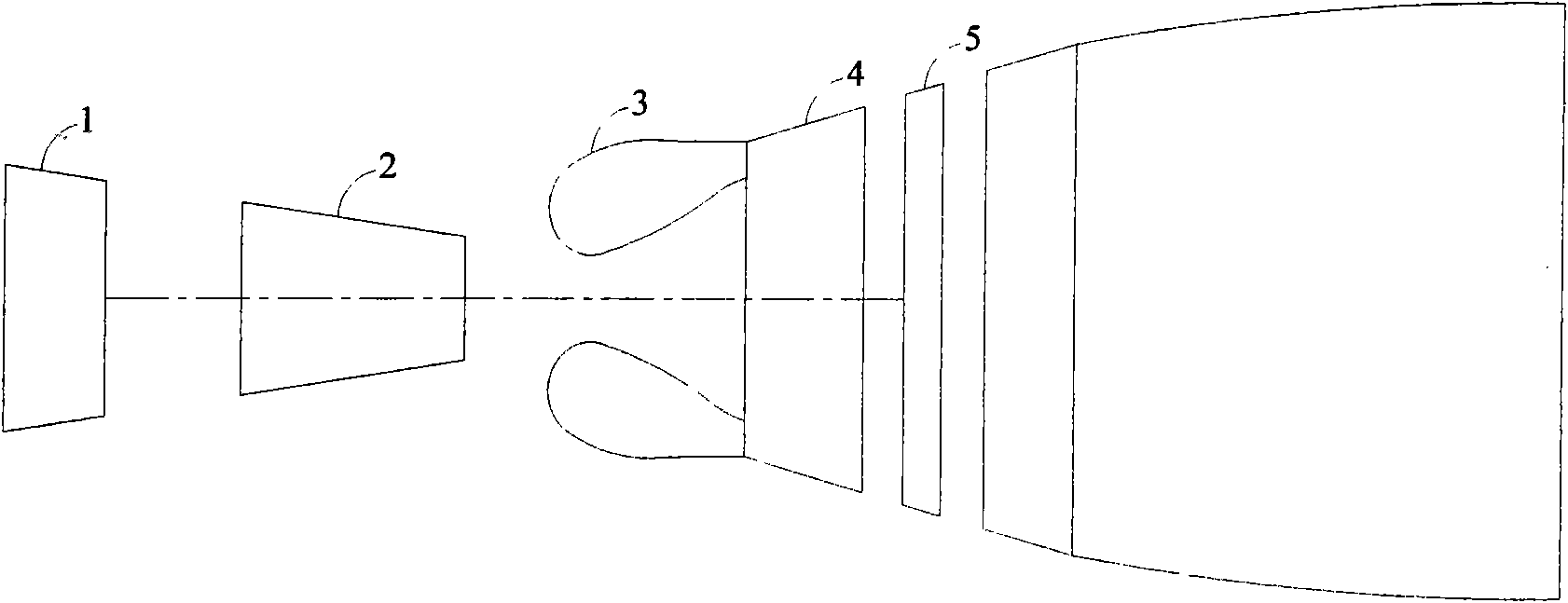

Method for testing assembly performance of rotor of aircraft engine

ActiveCN101799354AQuality improvementSave assembly timeEngine testingVibration testingAviationCarrier signal

The invention discloses a method for testing the assembly performance of a rotor of an aircraft engine, which comprises the following steps of: firstly exciting and vibrating a rotor of an aircraft engine with a vibration exciter; obtaining a multiple carrier-coupled impulse response signal of the rotor of the aircraft engine with a vibrating sensor and signal-acquiring system software; analyzing the obtained multiple carrier-coupled impulse response signal of the rotor of the aircraft engine by means of dual-tree complex wavelet transform to obtain eight signal carrier-coupled impulse response signals of the rotor of the aircraft engine; and distilling the average assembly performance index of the obtained eight signal carrier-coupled impulse response signals of the rotor of the aircraft engine, wherein the assembly performance of the rotor of the aircraft engine is judged to be qualified if the obtained average assembly performance index is larger than or equal to 10, and the assembly performance of the rotor of the aircraft engine is judged not to be qualified if the obtained average assembly performance index is less than 10, so that the rotor needs to be repaired.

Owner:XI AN JIAOTONG UNIV

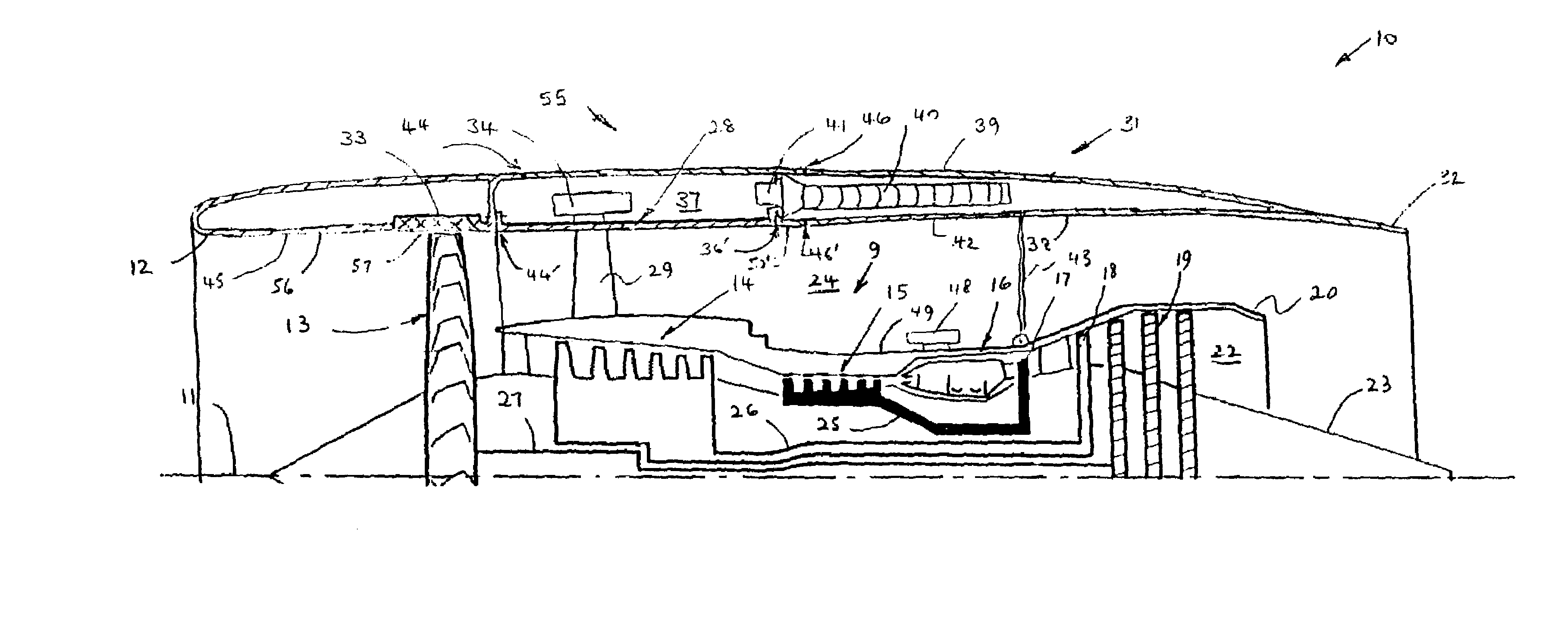

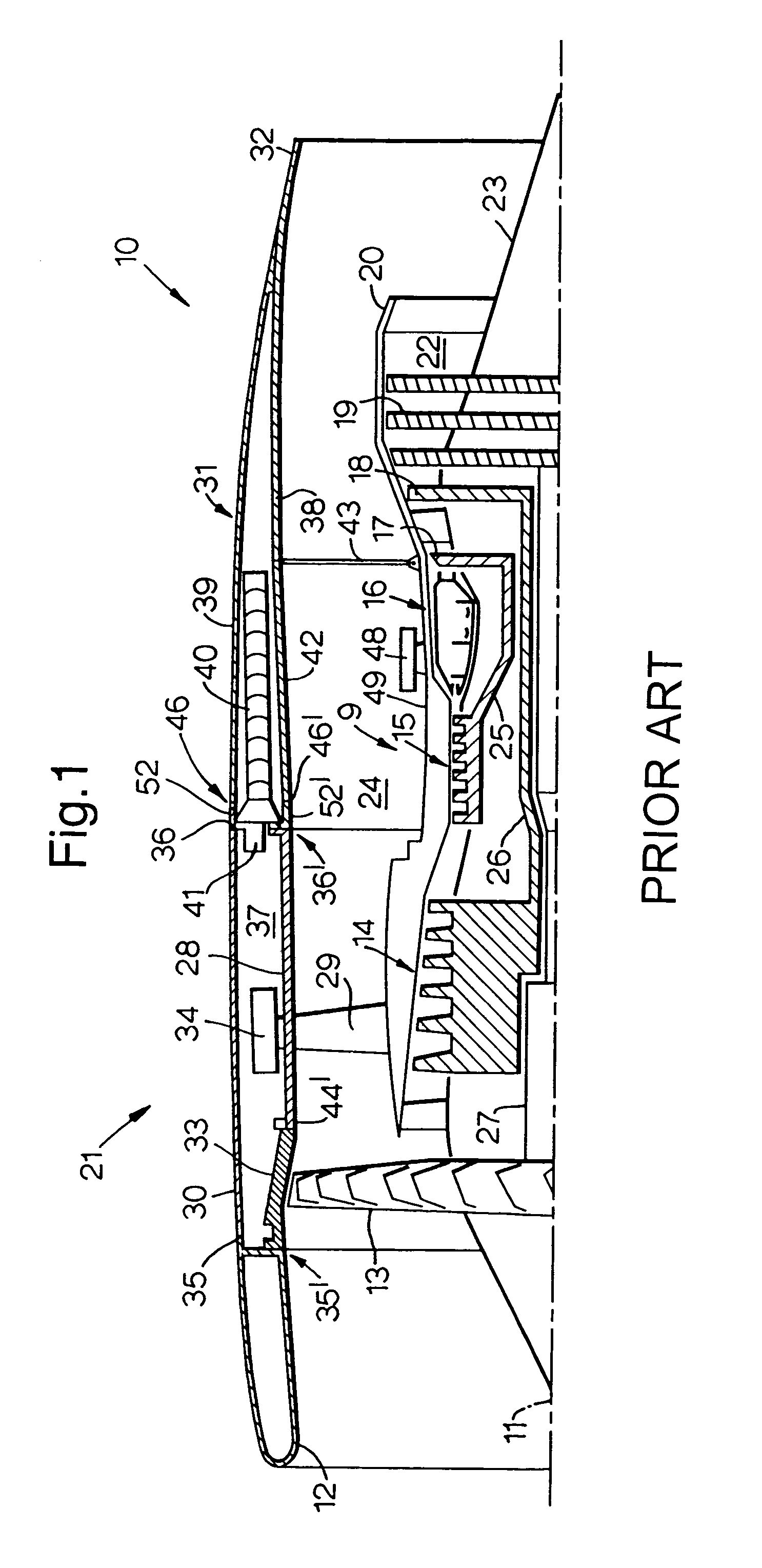

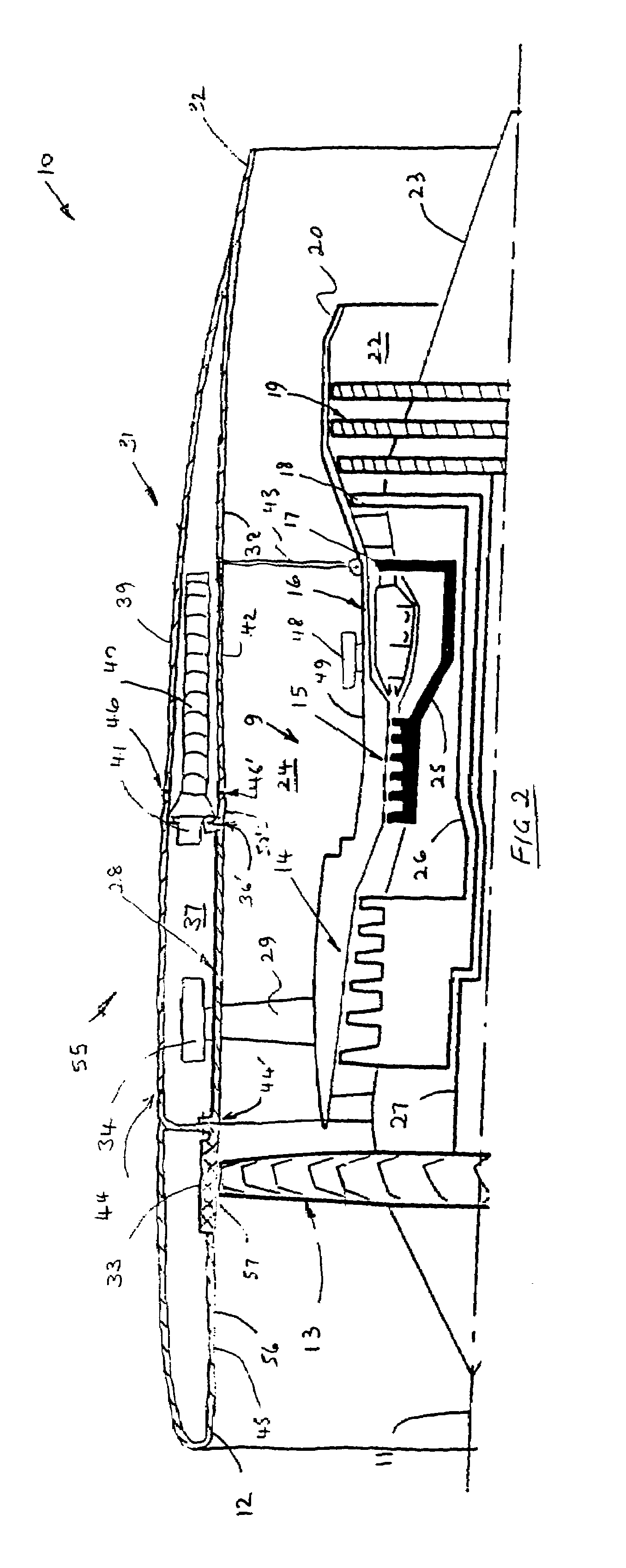

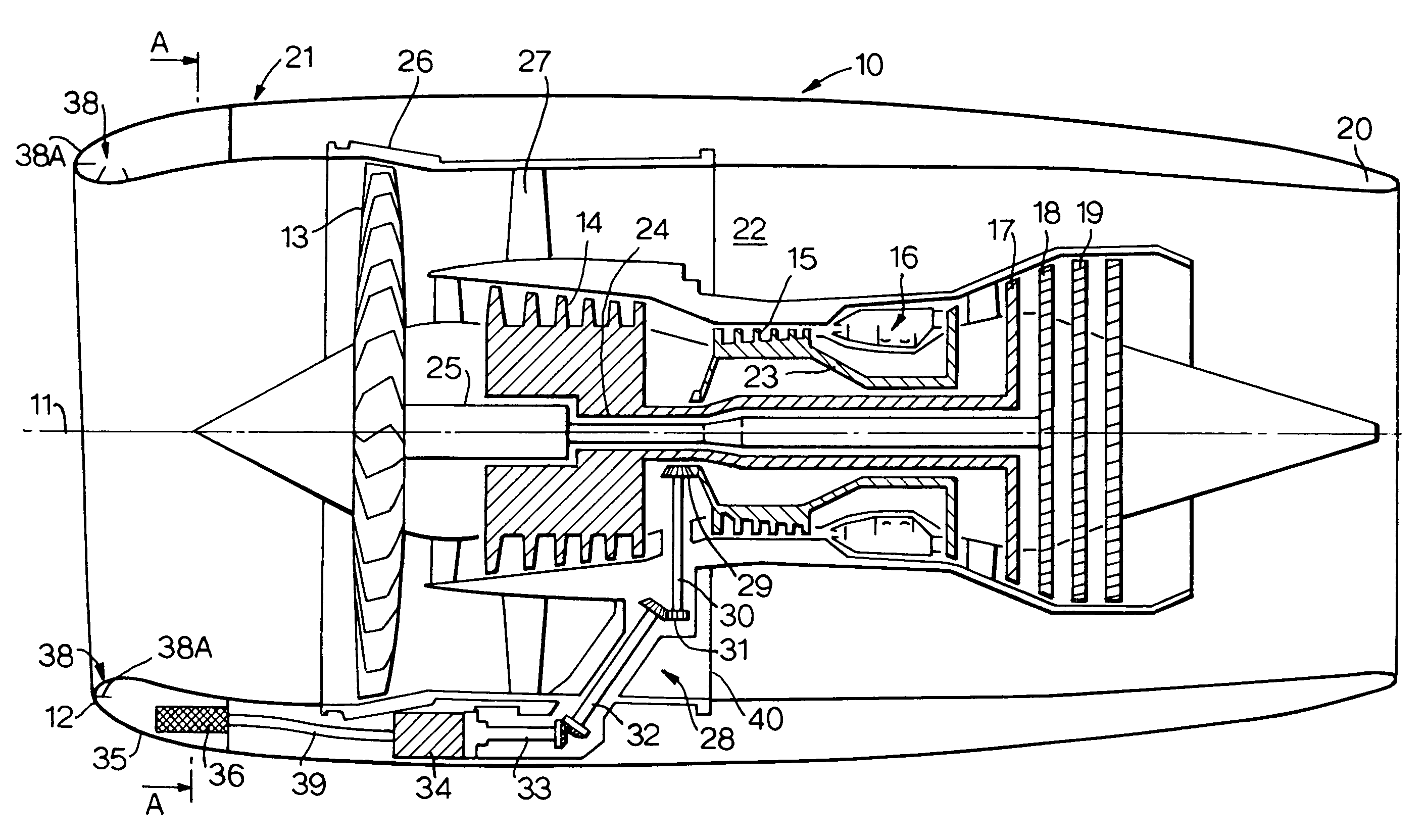

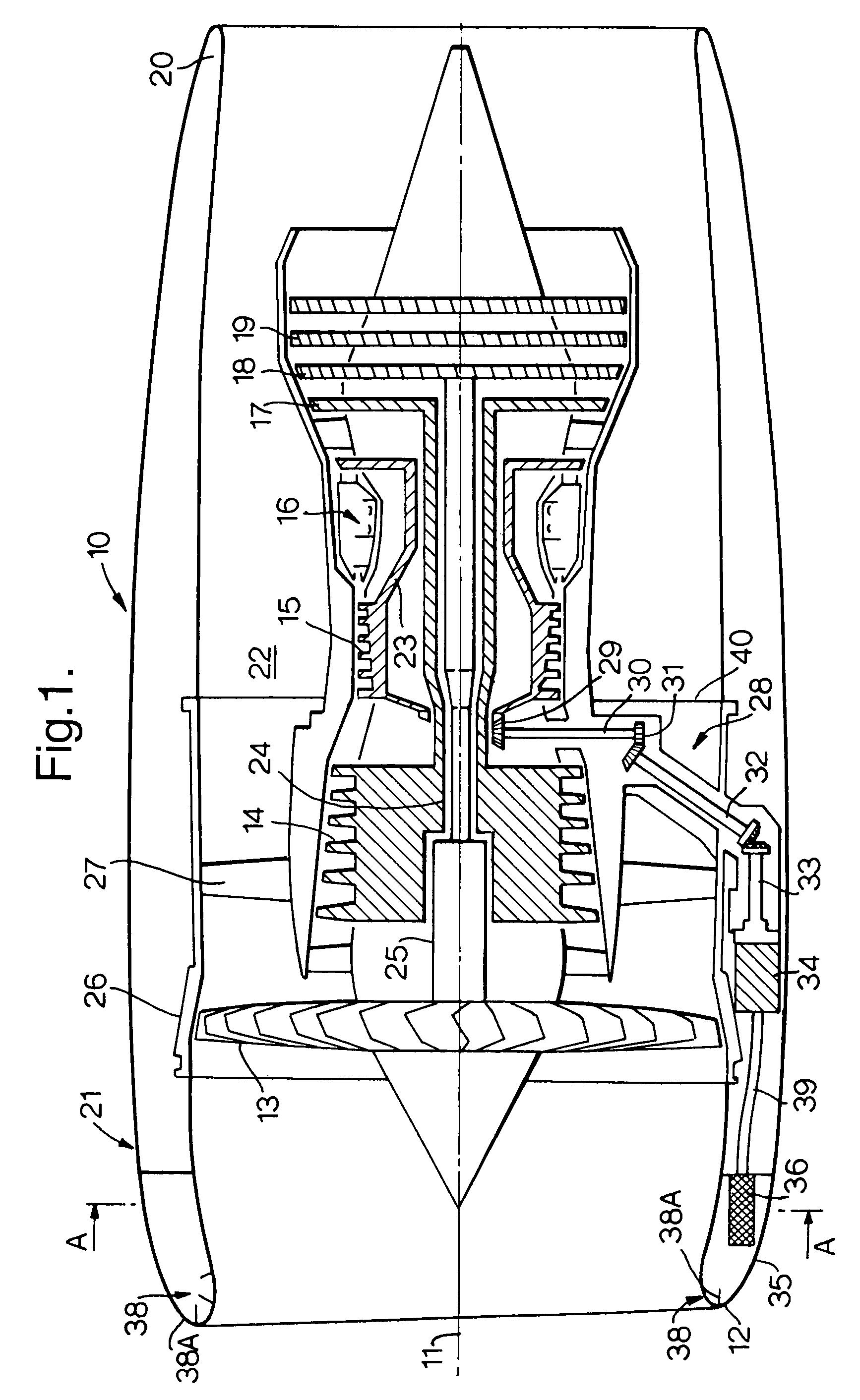

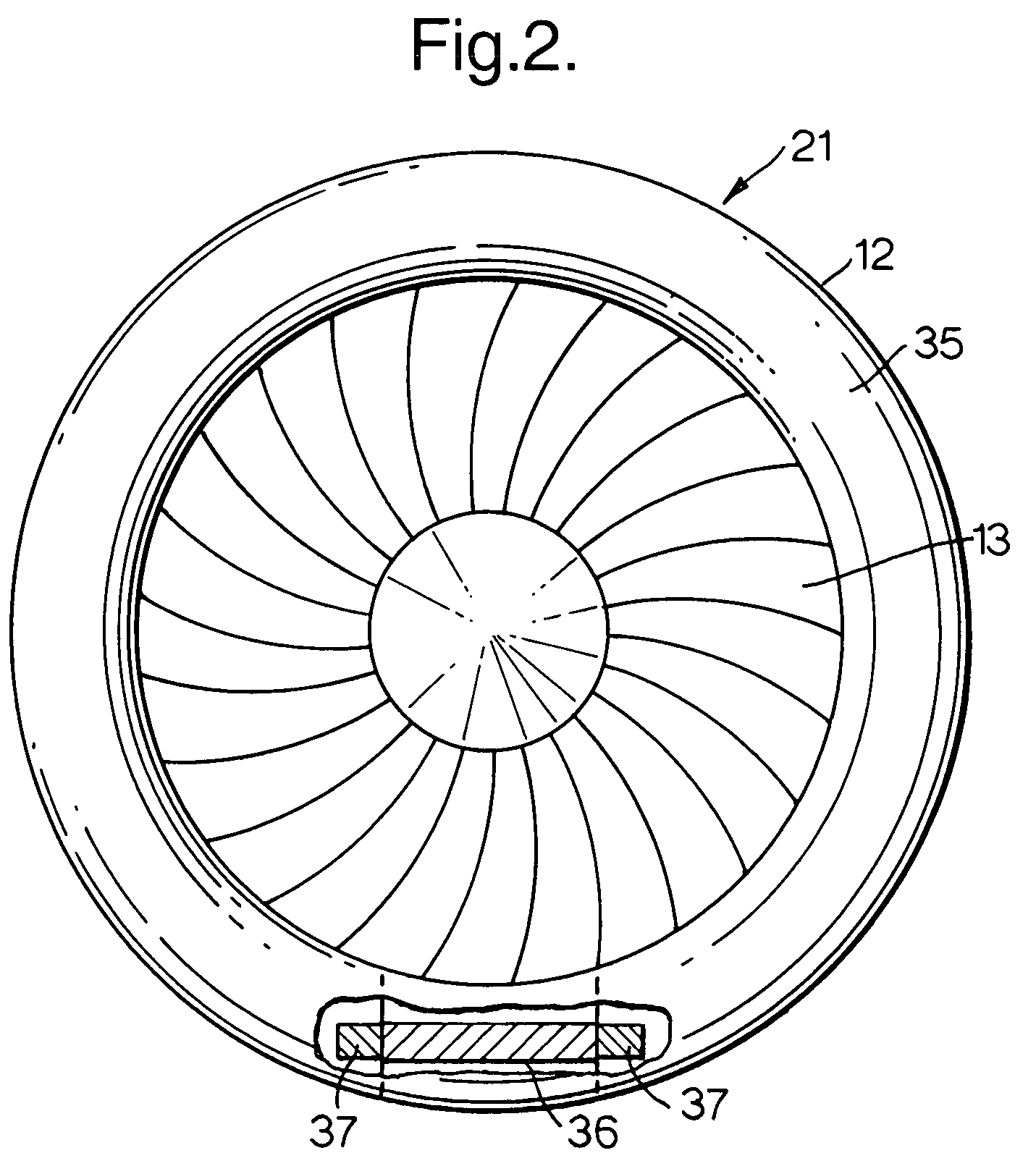

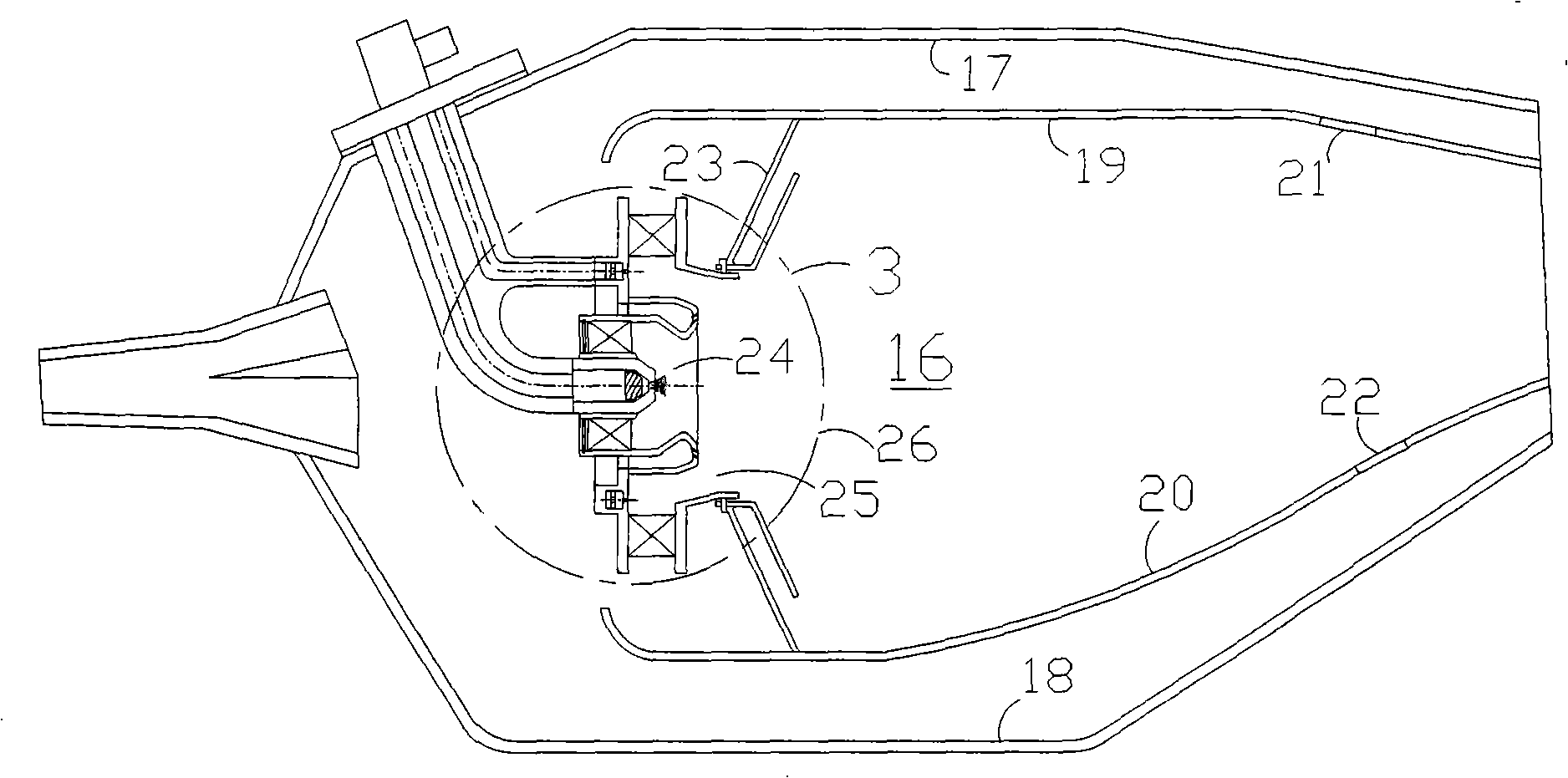

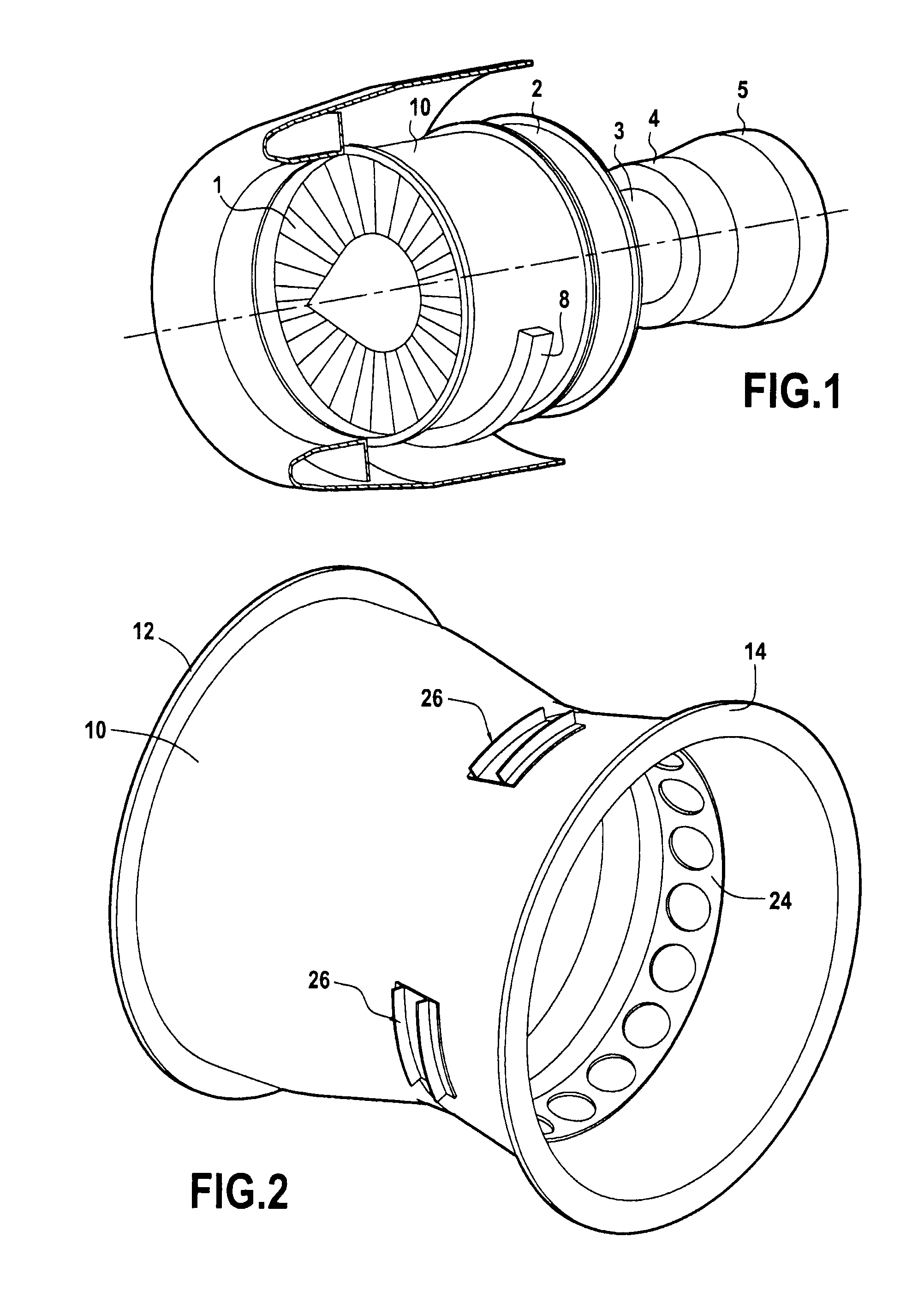

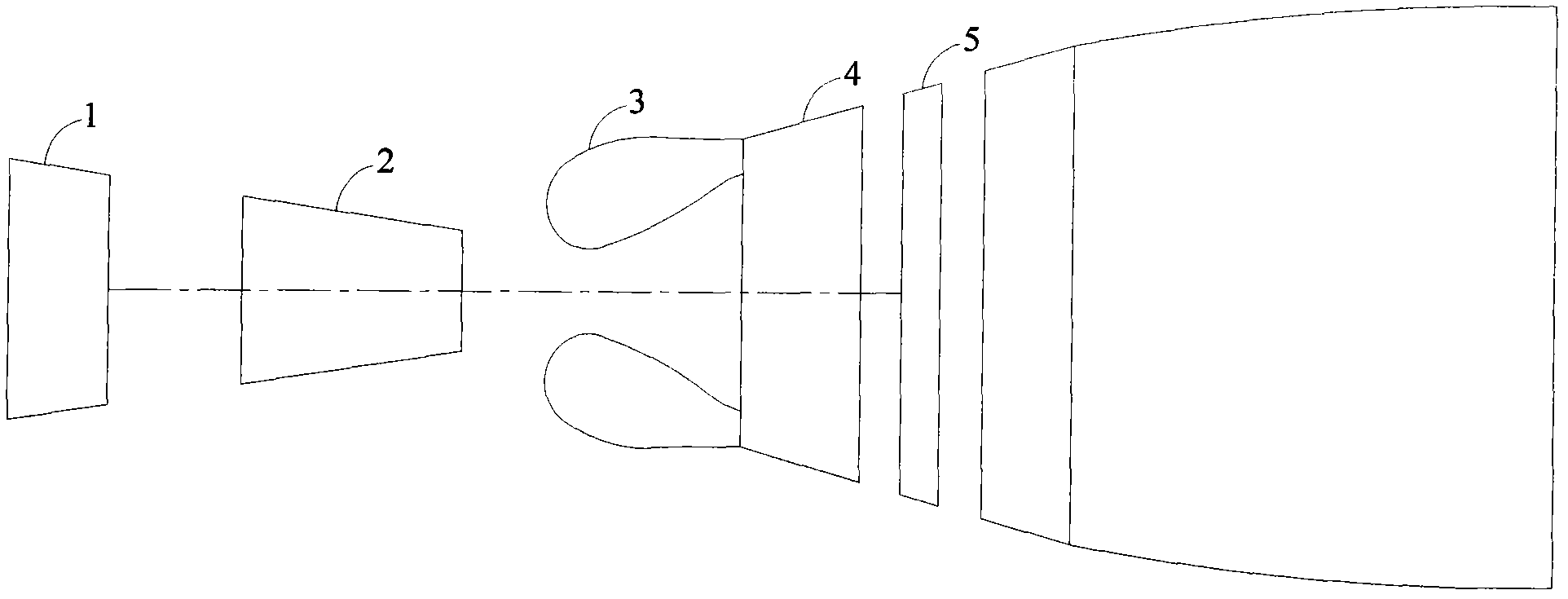

Aeroengine nacelle

ActiveUS7090165B2Reduce in quantityReduce assemblyPower plant arrangements/mountingPower plant inspection panelsAviationNacelle

A nacelle (55) for a gas turbine engine (10), the engine (10) comprising accessories (34) mounted to a fan casing (28) and a core engine (9), the nacelle (55) substantially surrounds the engine (10) and comprises an intake (12) and a thrust reverser unit (31). The thrust reverser unit (31) is formed by two generally C-shaped portions (31a, 31b). The thrust reverser unit (31) is openable to provide access to the accessories (34) and the core engine (9). The nacelle (55) further comprises a fan containment casing (33) that is integral with the intake (12).

Owner:ROLLS ROYCE PLC

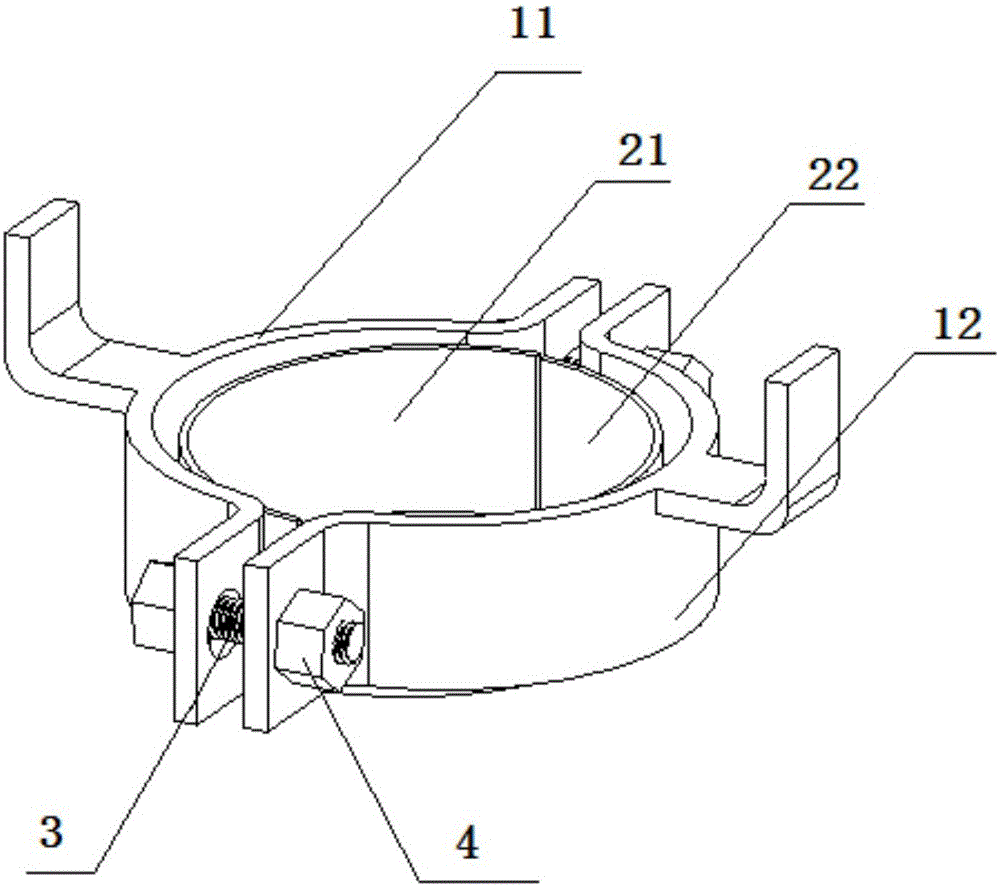

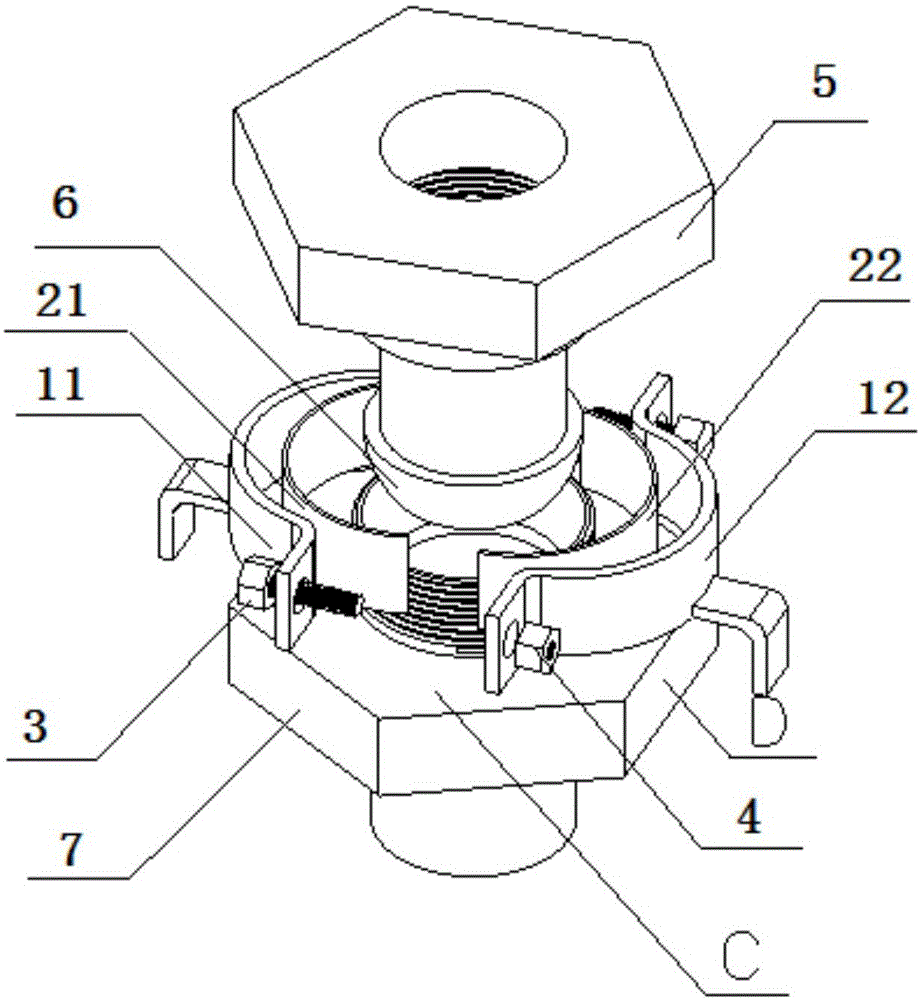

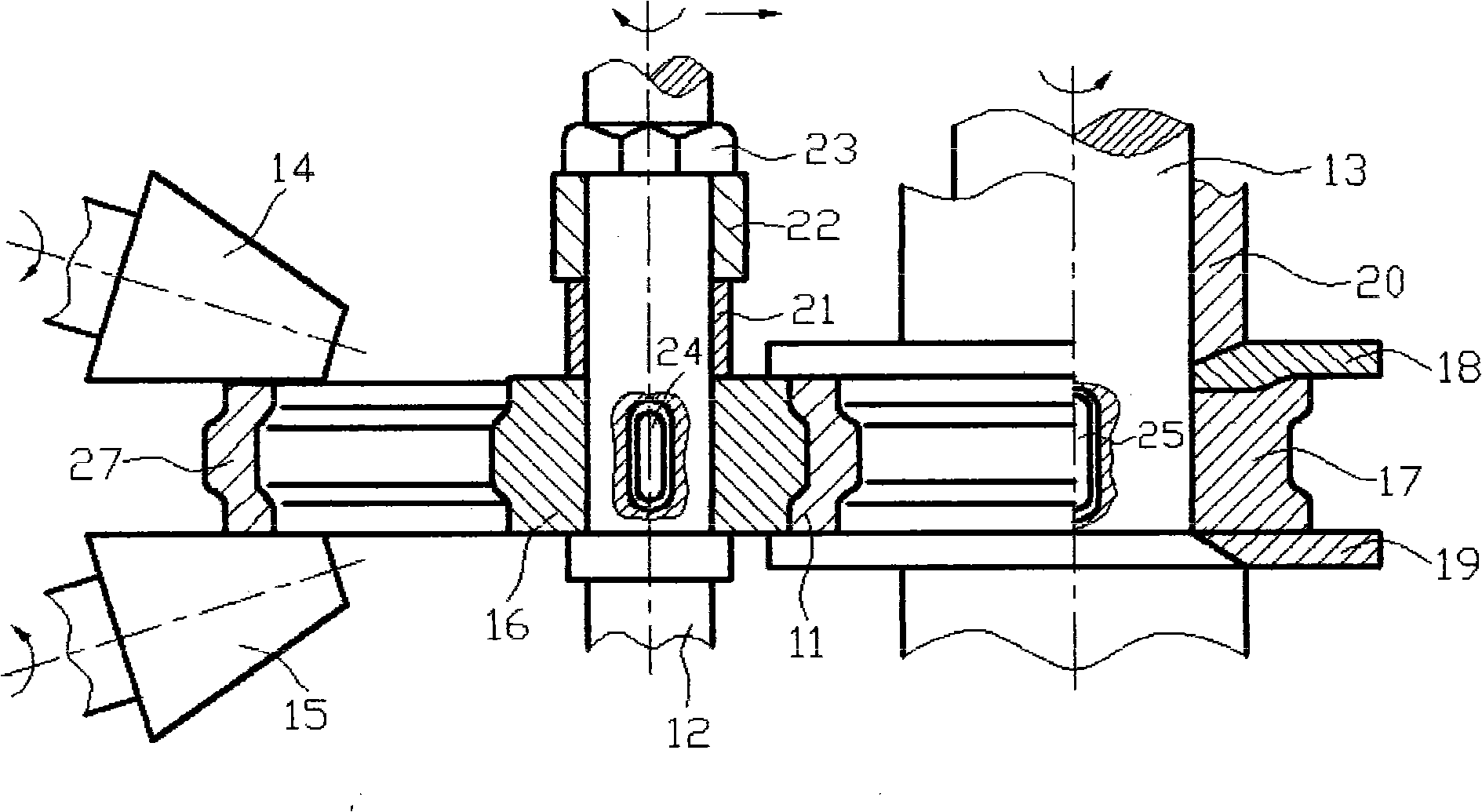

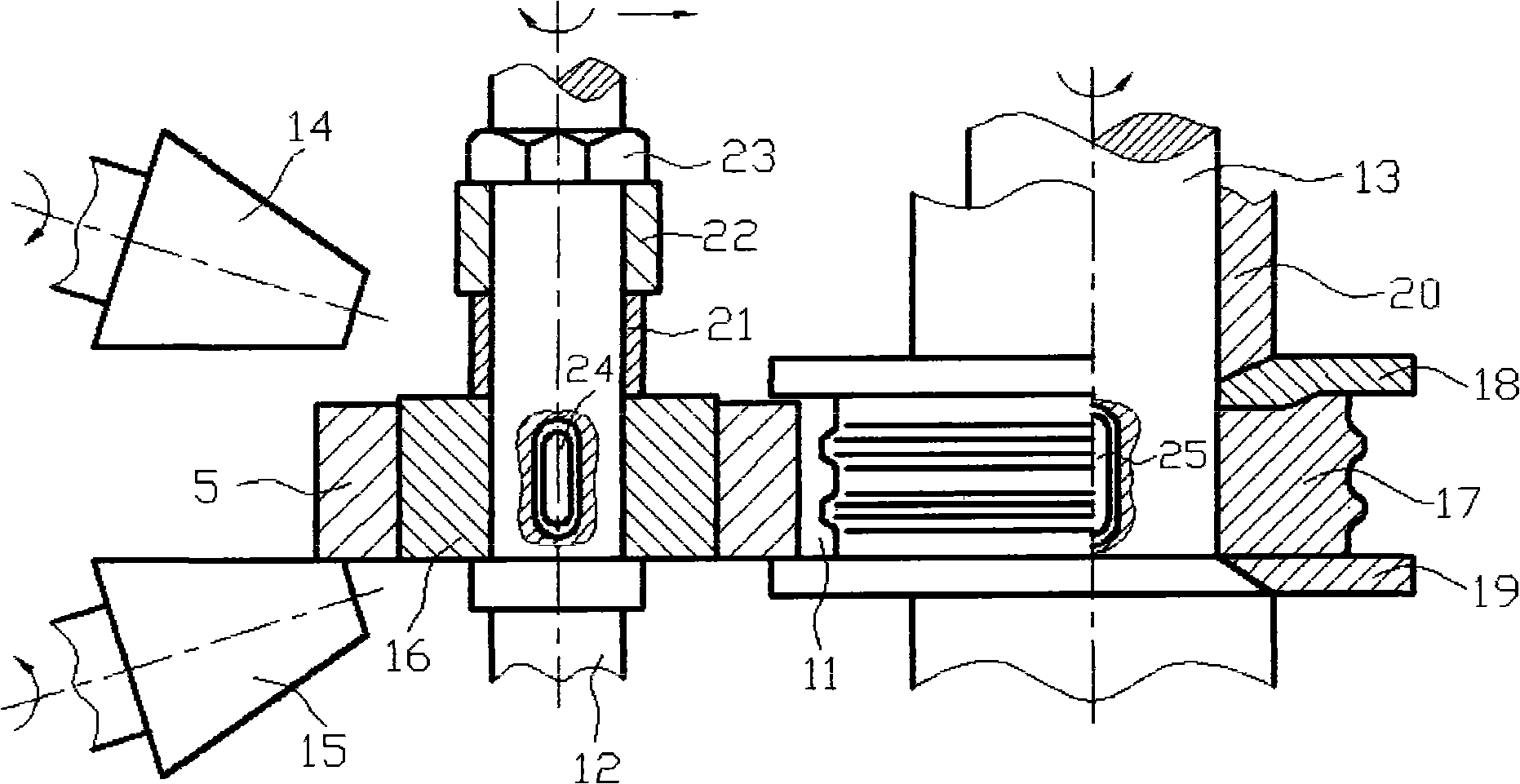

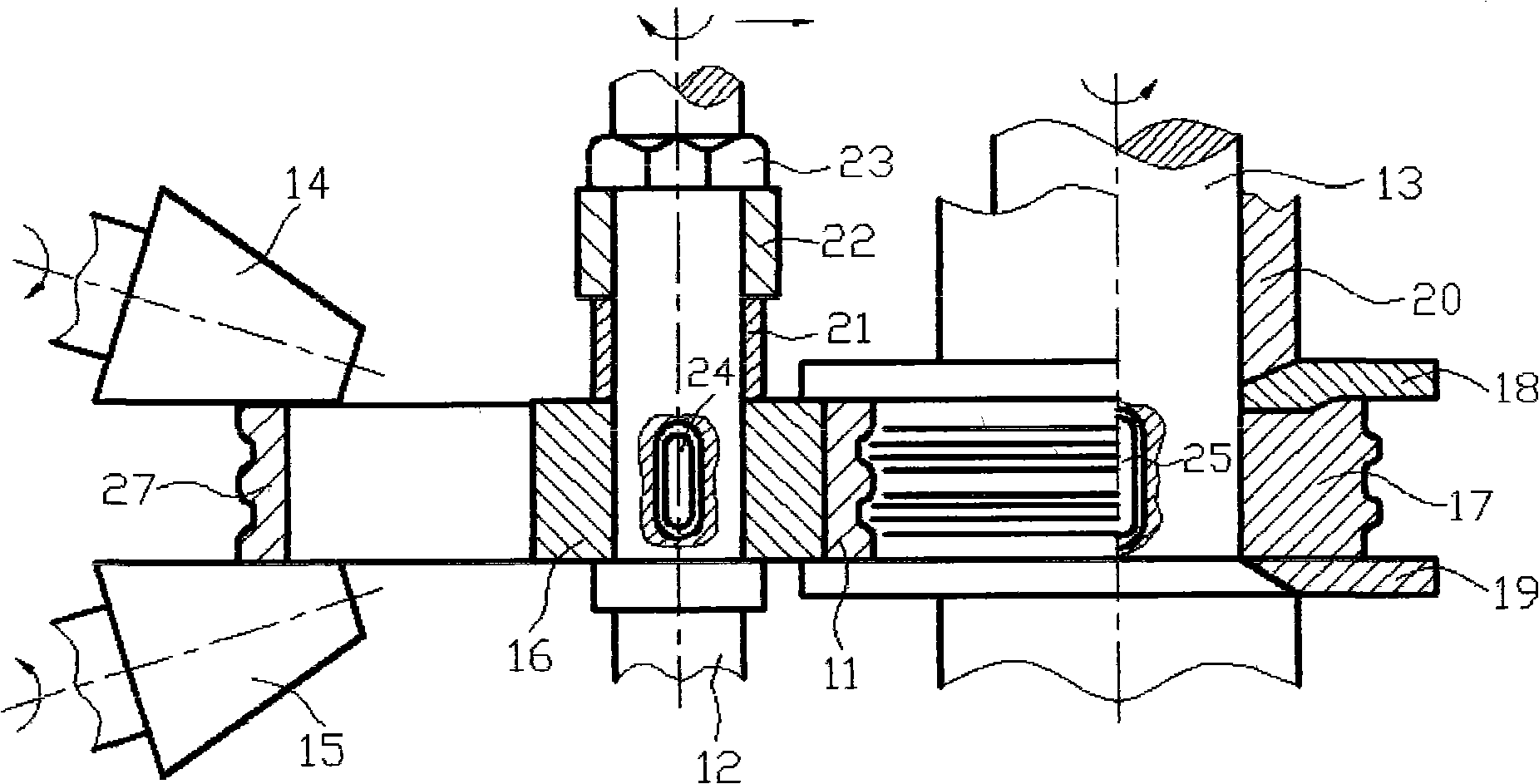

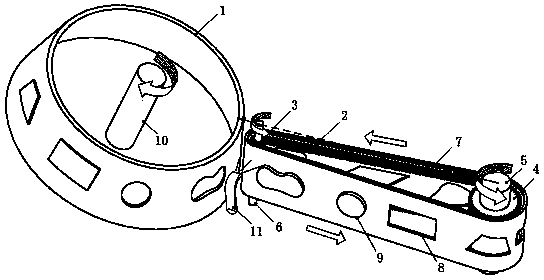

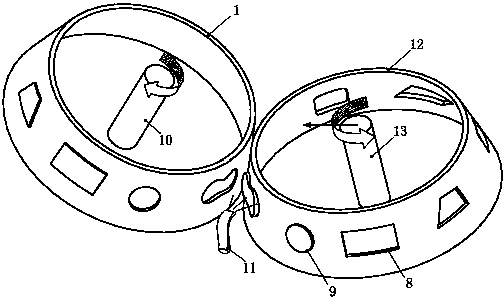

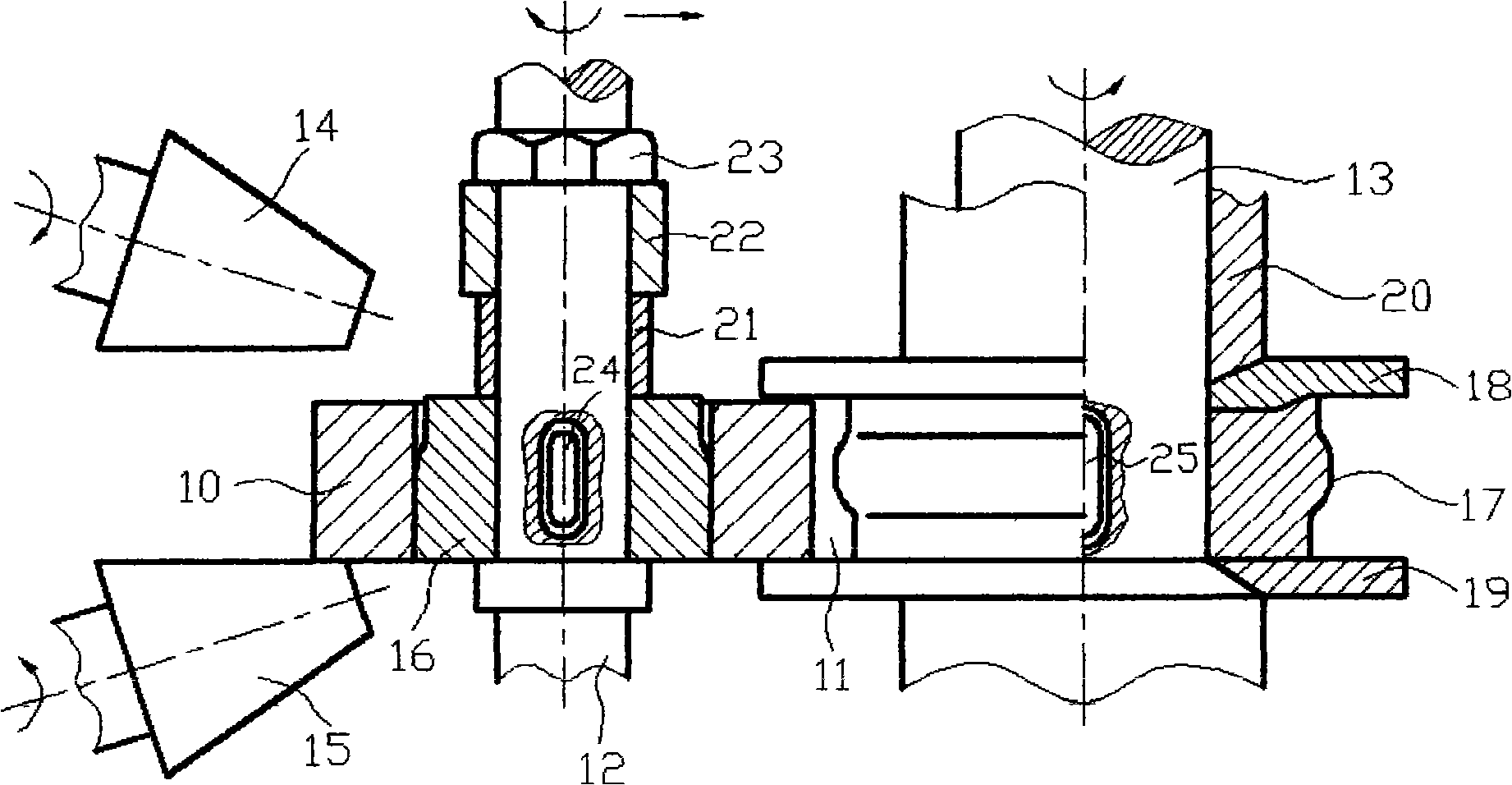

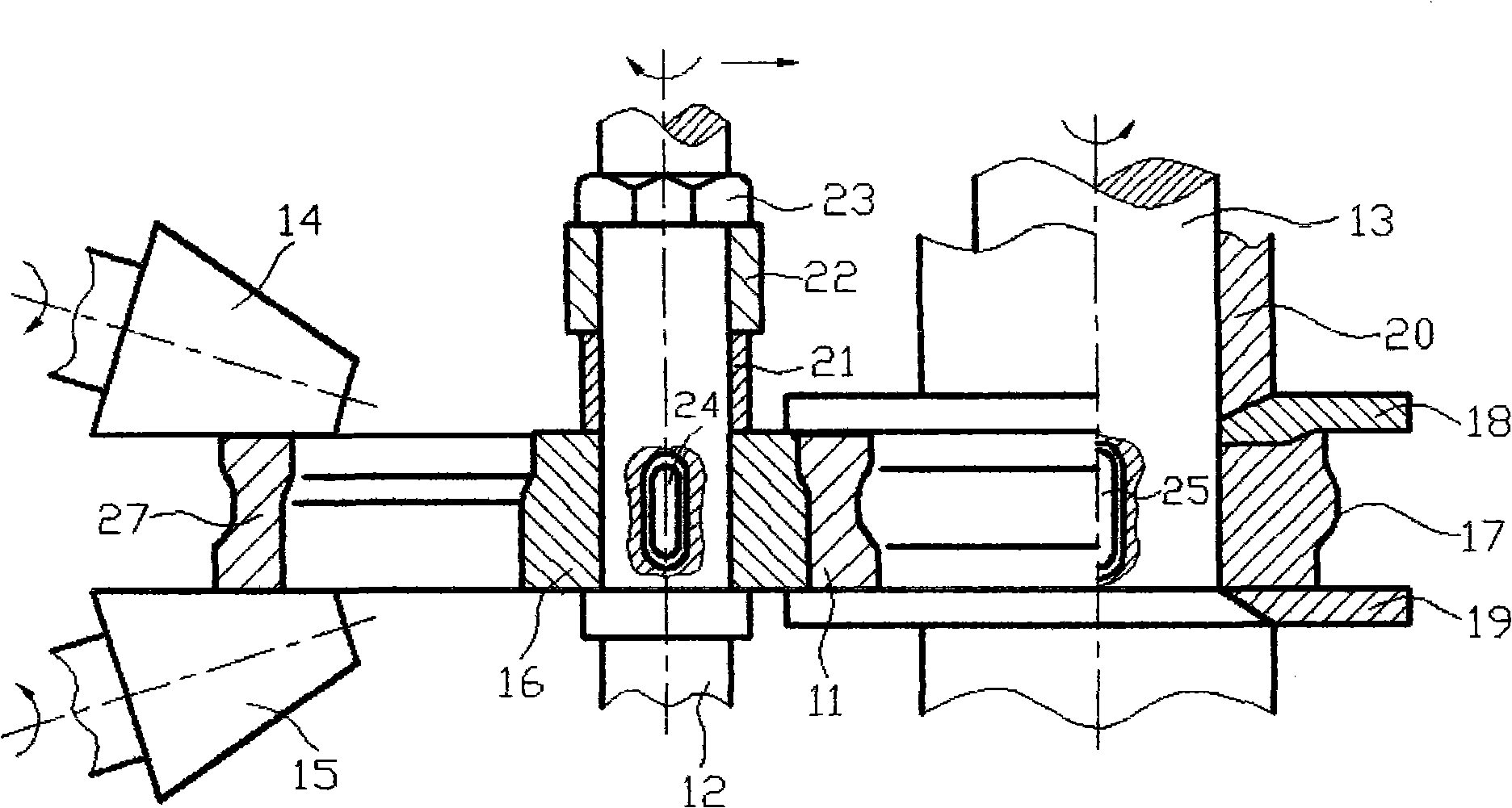

Pipeline joint locking device

ActiveCN105135101AImprove sealing effectEasy to assemble and disassembleSleeve/socket jointsAero engine

The invention relates to the field of aero-engine component test part pipeline structure design, in particular to a pipeline joint locking device to at least solve the problem of an existing locking device that a pipeline joint is hard to mount and dismount. The pipeline joint comprises a gland nut and a hexagonal conical port. The pipeline joint locking device comprises a first stop ring and a second stop ring which are arranged in a horizontally symmetrical mode and detachably connected, a first damping gasket and a second damping gasket which are arranged in a horizontally symmetrical mode, and stop fins, wherein the gland nut is fastened by the stop rings through the damping gaskets, and the stop fins are used for fixing the relative positions of the first stop ring, the second stop ring and the conical port. According to the locking device, the connected gland nut and hexagonal conical port are tightly pressed by means of the stop rings and the damping gaskets matched with the stop rings, so that sealing and fixing effects are better; the first stop ring and the second stop ring are detachably connected to facilitate assembly and disassembly and can be repeatedly used.

Owner:AECC SHENYANG ENGINE RES INST

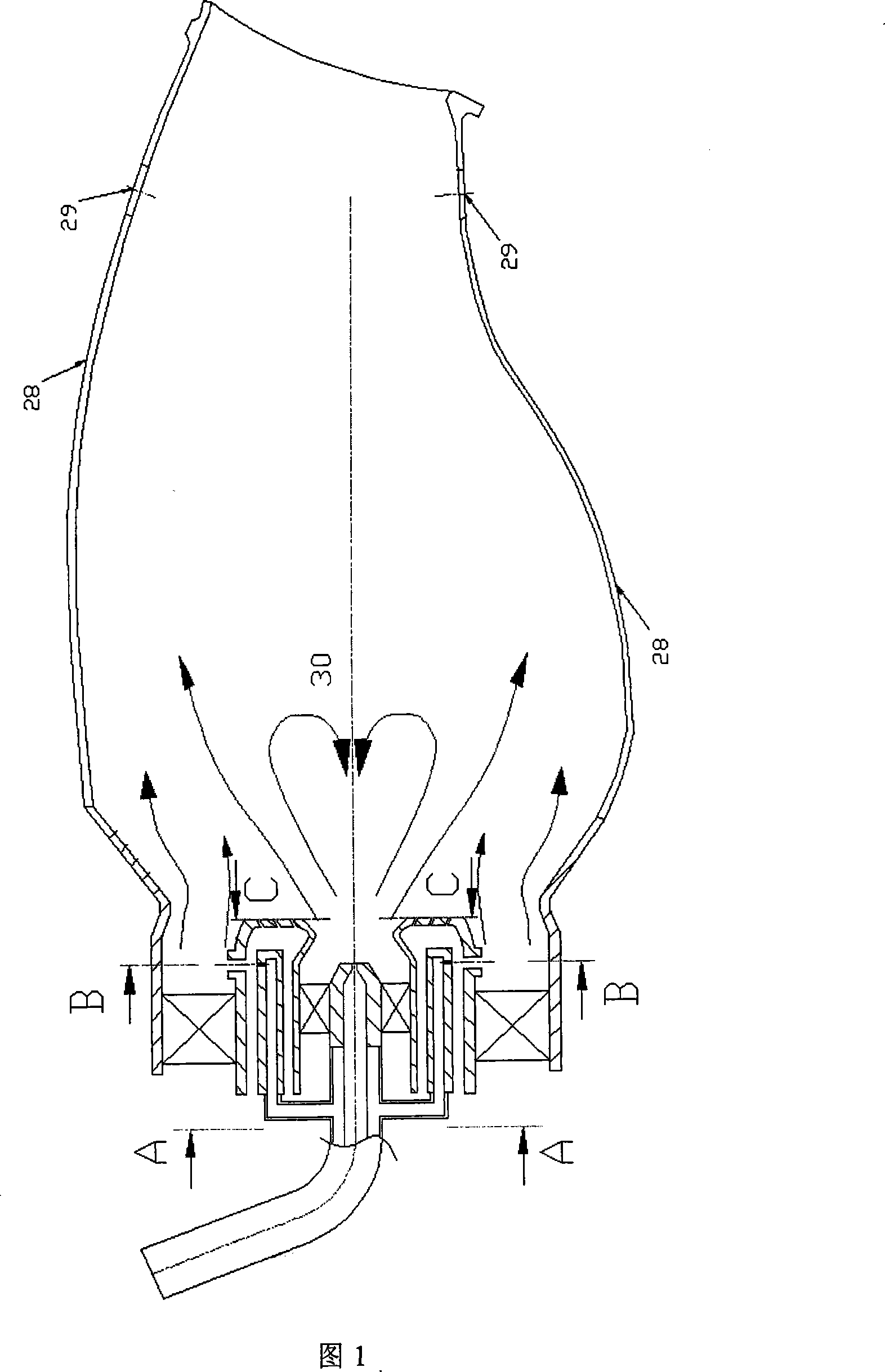

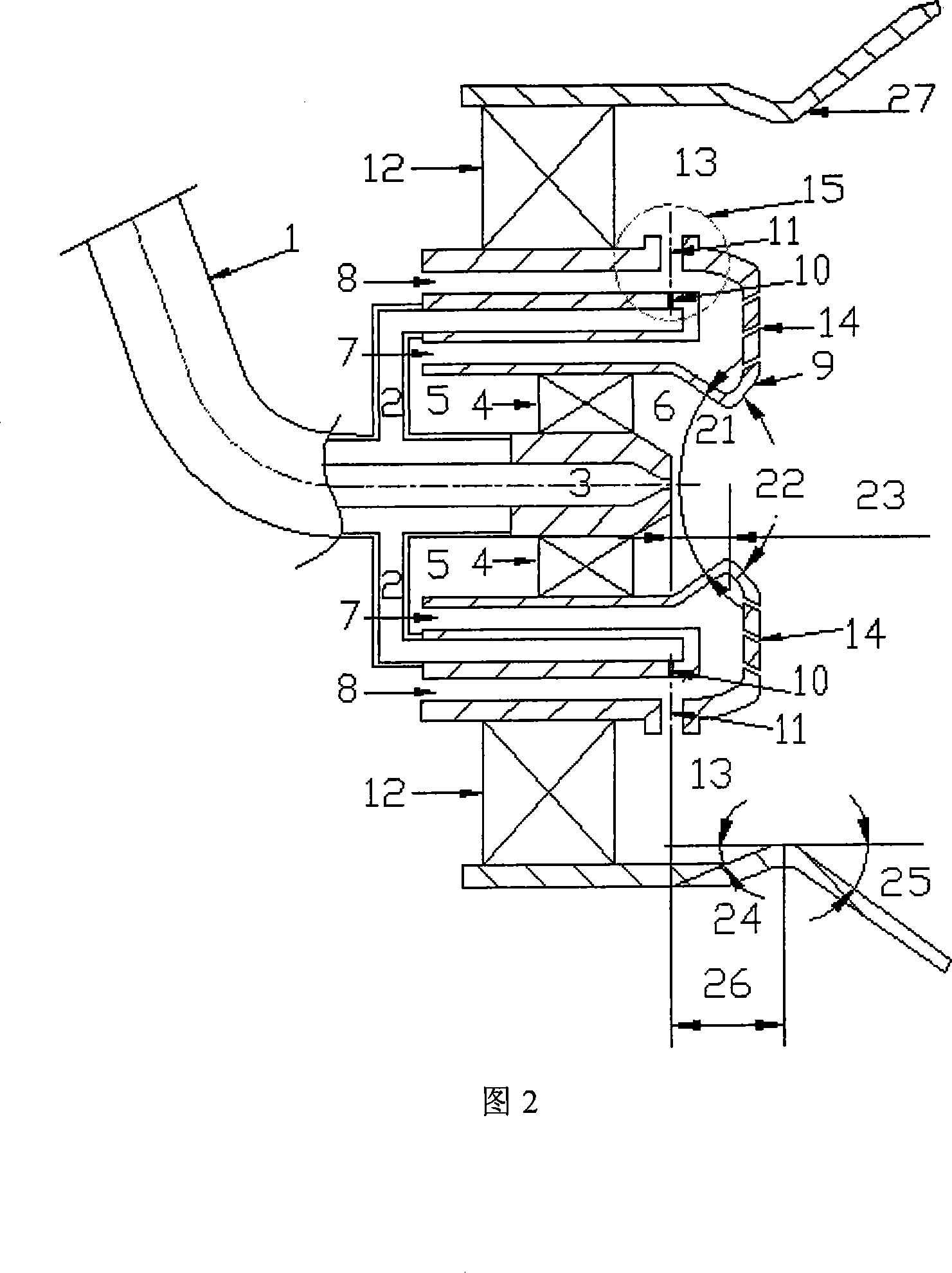

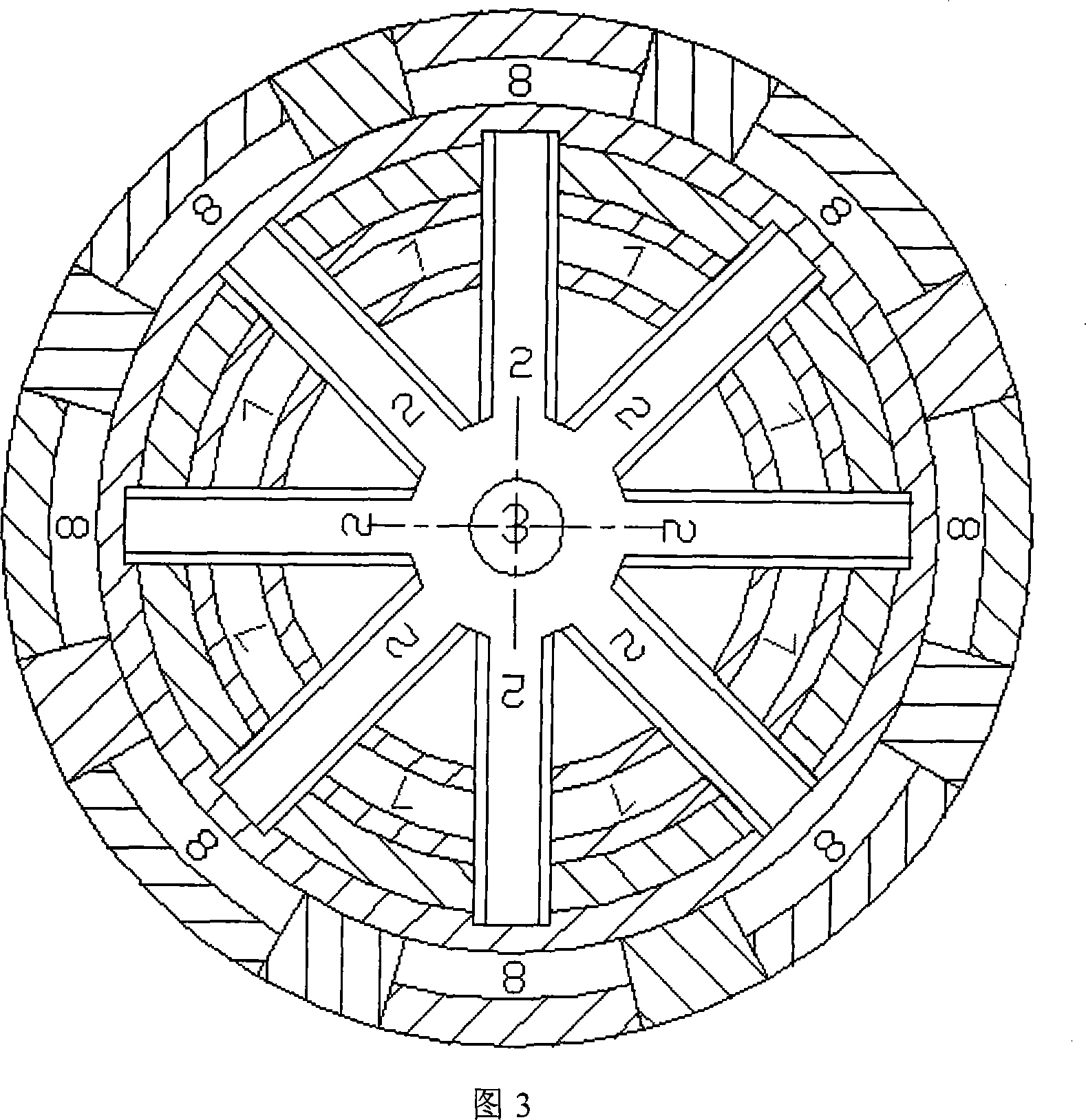

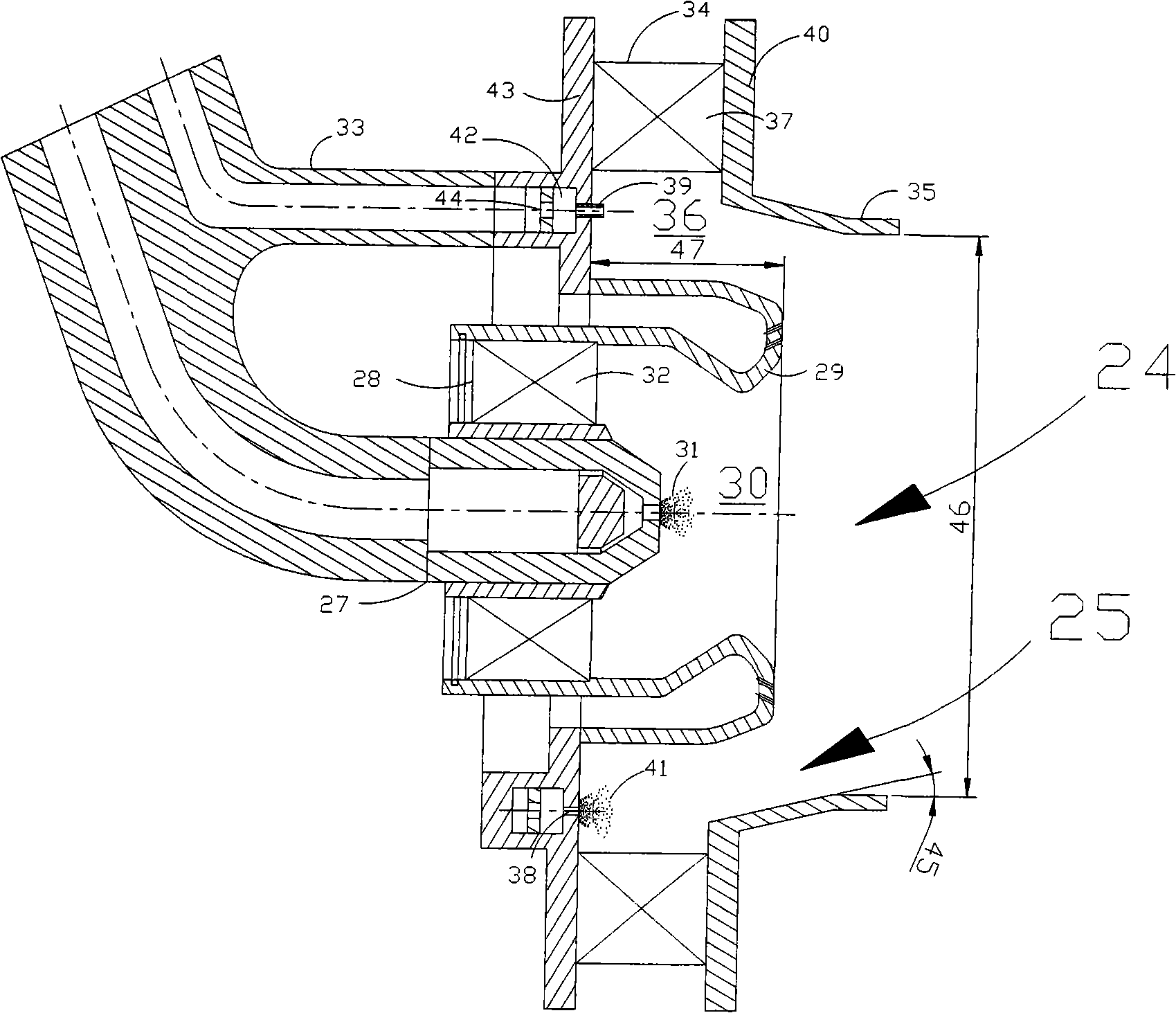

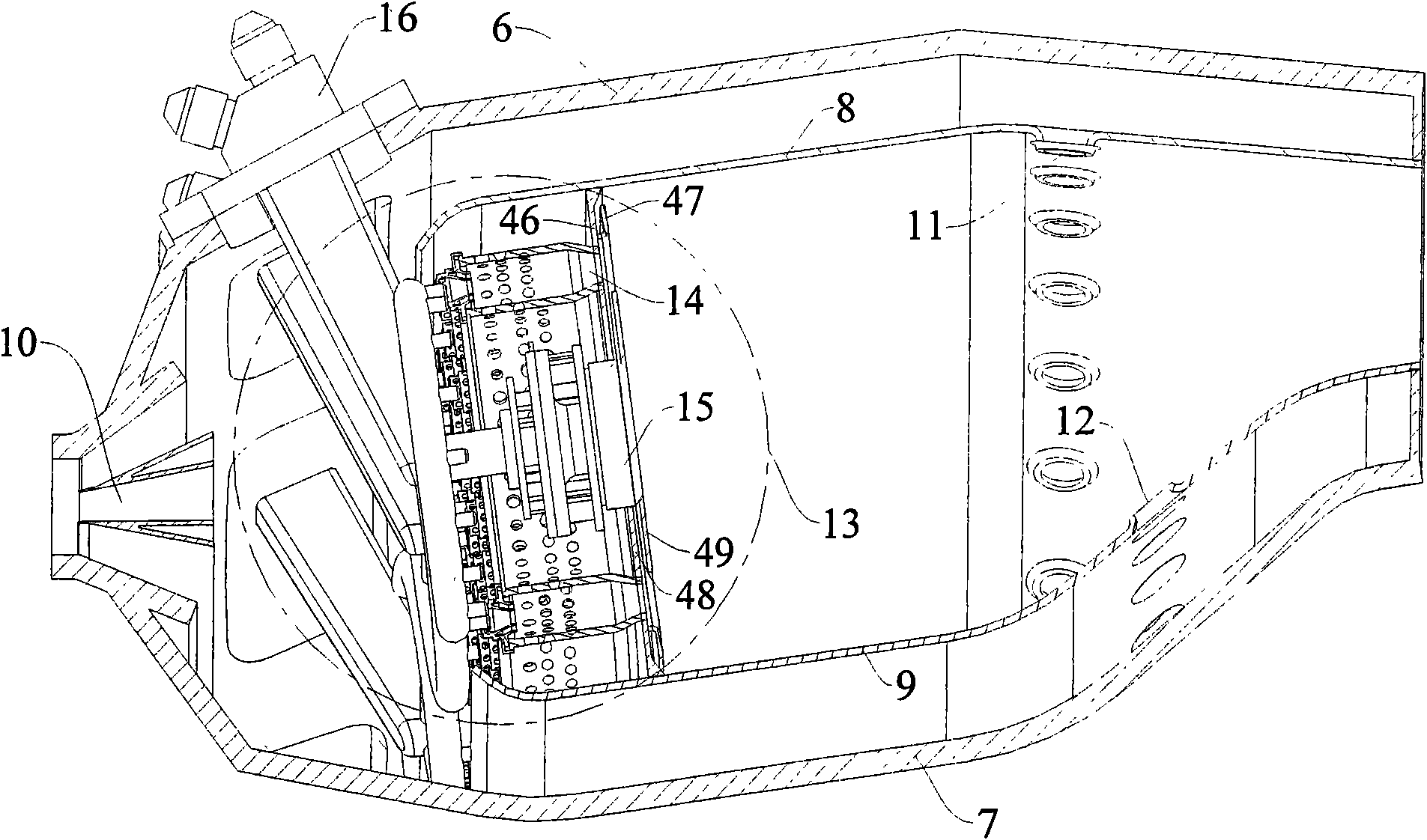

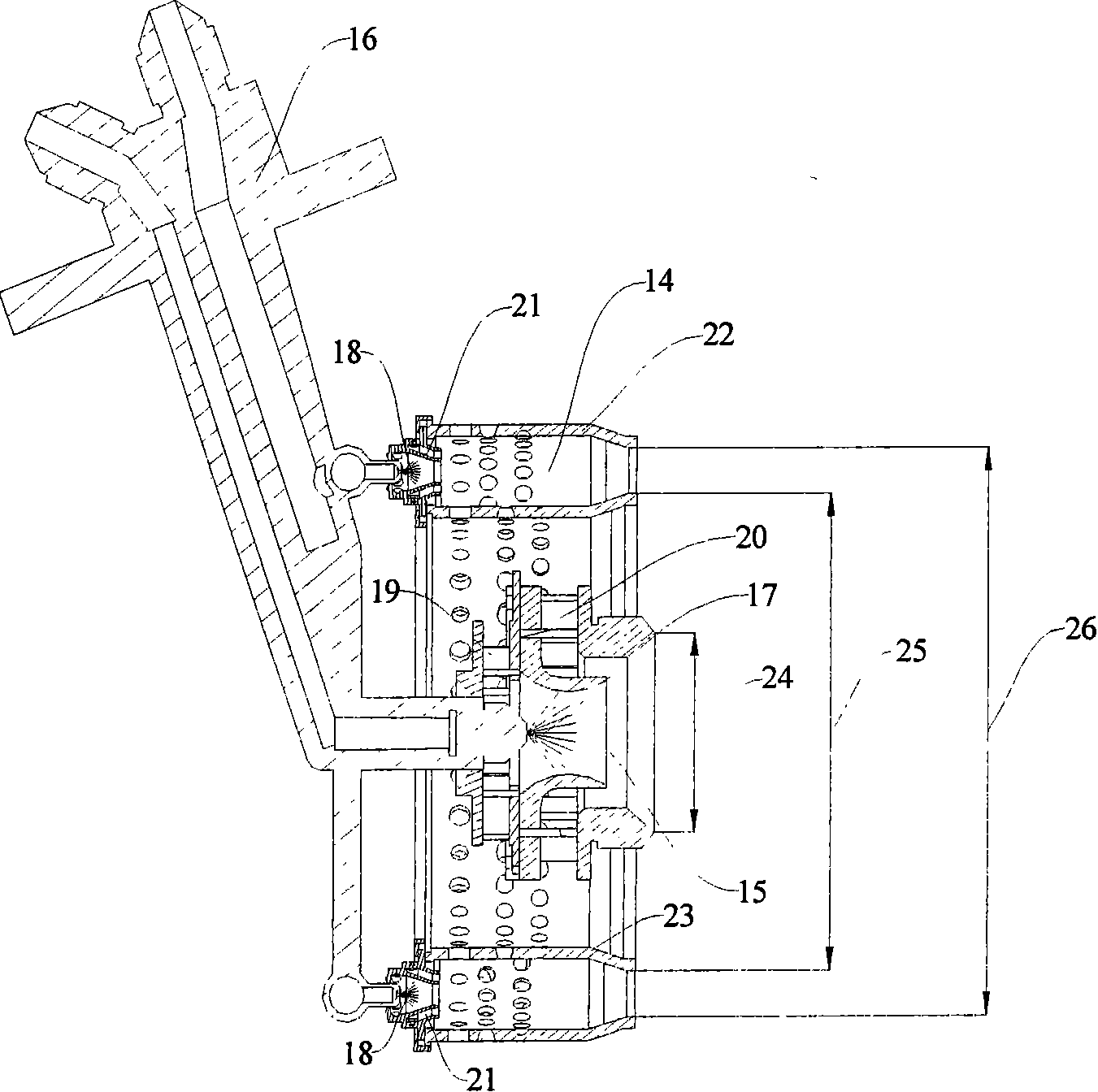

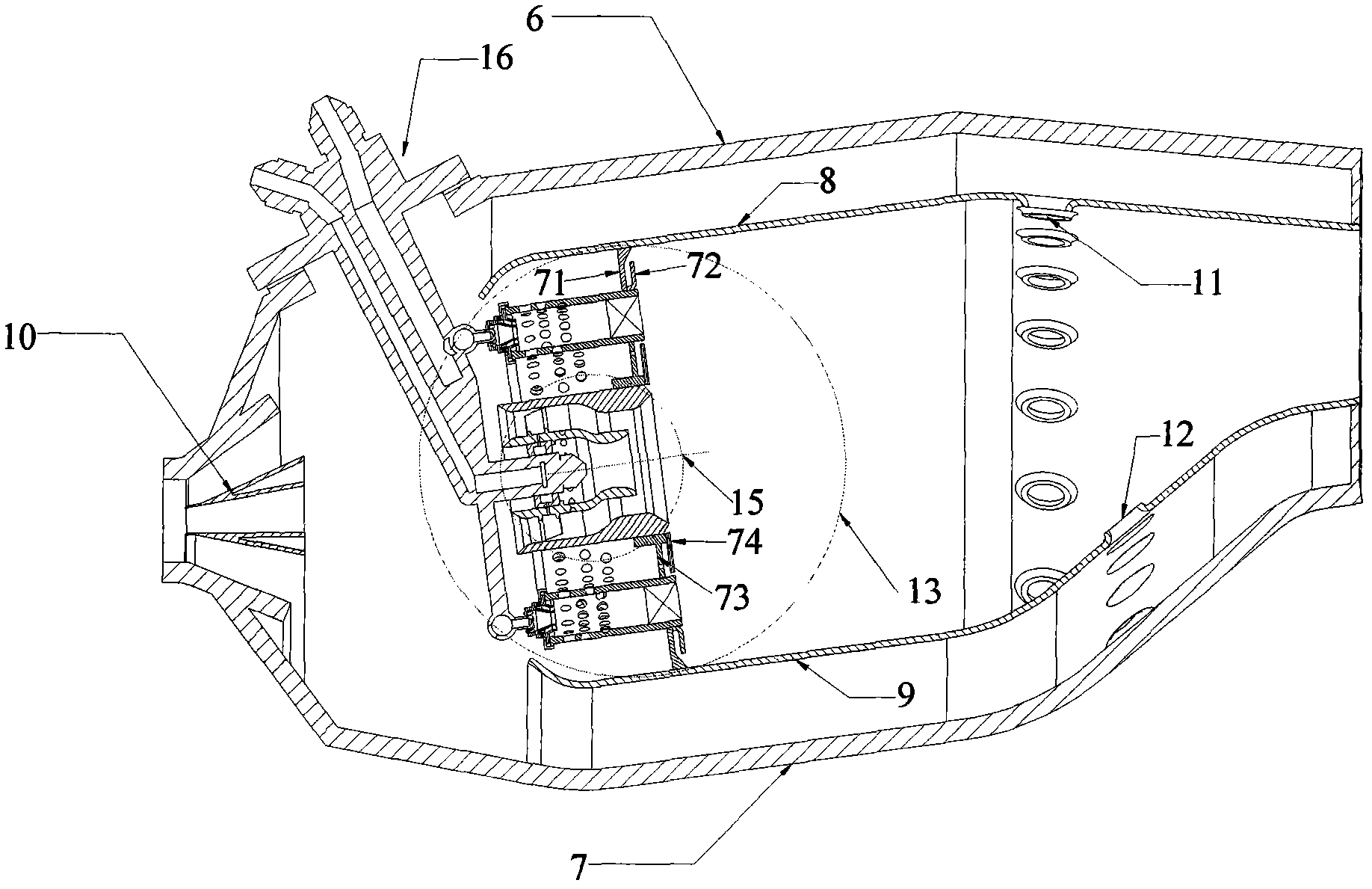

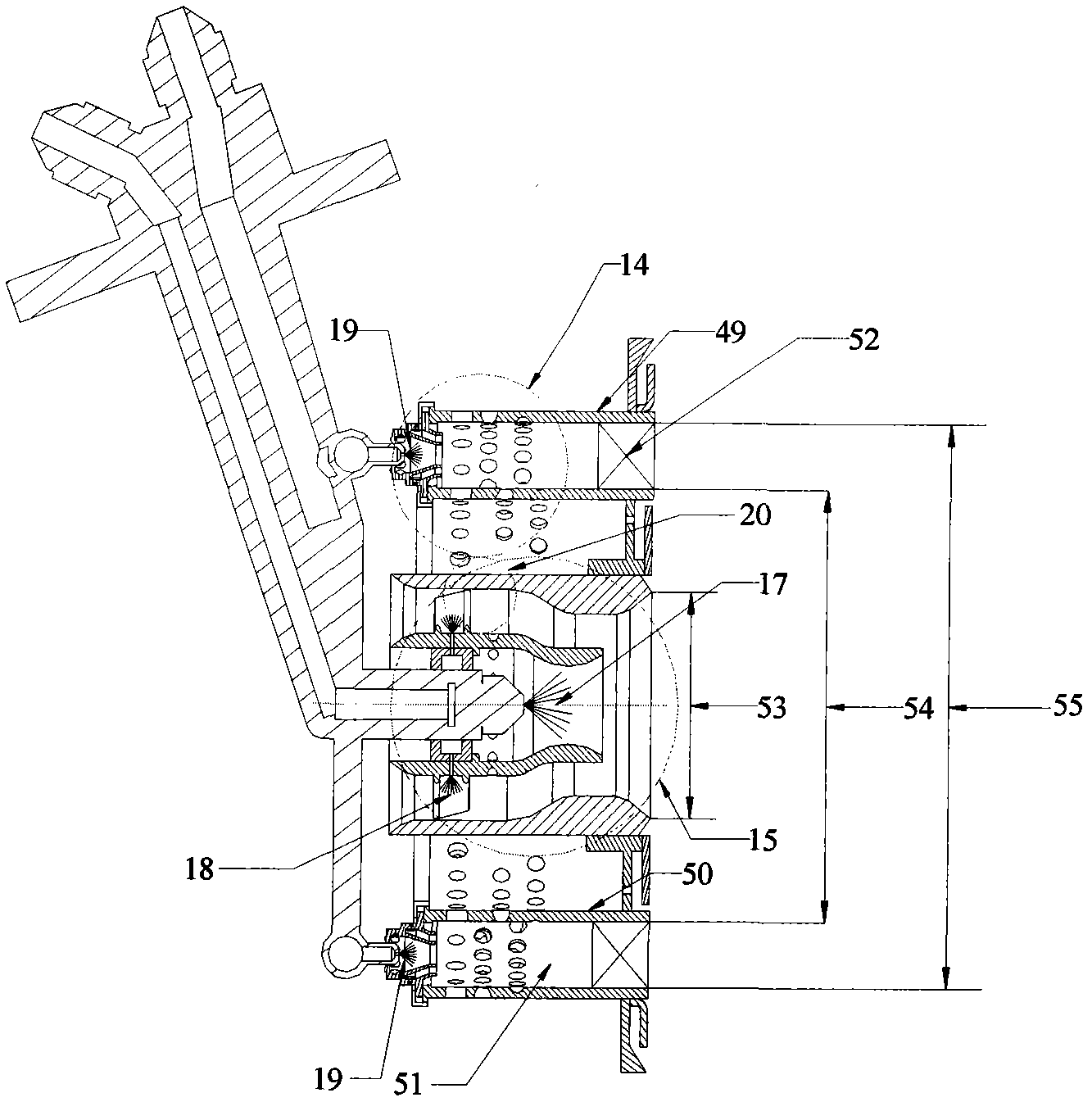

Aerial engine lean premixed preevaporated low contamination combustion chamber

An aero-engine lean-oil premixed pre-evaporation low-pollution combustor consists of a head and a flame tube, the combustion gas is all supplied from the head of the combustor, and the cooling gas and mixed gas enter from the flame tube; the head is The double-ring cavity structure is divided into two stages, the pre-combustion stage and the main combustion stage. The pre-combustion stage is included, and the main combustion stage surrounds the pre-combustion stage. The pre-combustion stage includes a centrifugal nozzle and a swirler surrounding the centrifugal nozzle. After being sprayed out from the centrifugal nozzle, the fuel is sheared and broken by the air swirl from the swirler, mixed in the mixing chamber area of the pre-combustion stage and then enters the combustion area Diffusion combustion is formed inside; the main combustion stage includes a direct air atomizing nozzle, a main swirler and a premixing ring chamber, the main swirler is located upstream of the nozzle, and the premixing ring chamber is located downstream of the nozzle, and the fuel goes first in the nozzle It is mixed and atomized with air, and then tangentially injected into the premixed ring cavity for premixed pre-evaporation, and enters the combustion area to form premixed combustion; in the downstream of the pre-combustion stage combustion and main combustion stage fuel outlets, contraction and expansion ports are used to prevent backflow fire and carbon buildup. The invention has a simple structure and can effectively reduce the pollution discharge of the aero-engine under the condition of ensuring the working state.

Owner:BEIHANG UNIV

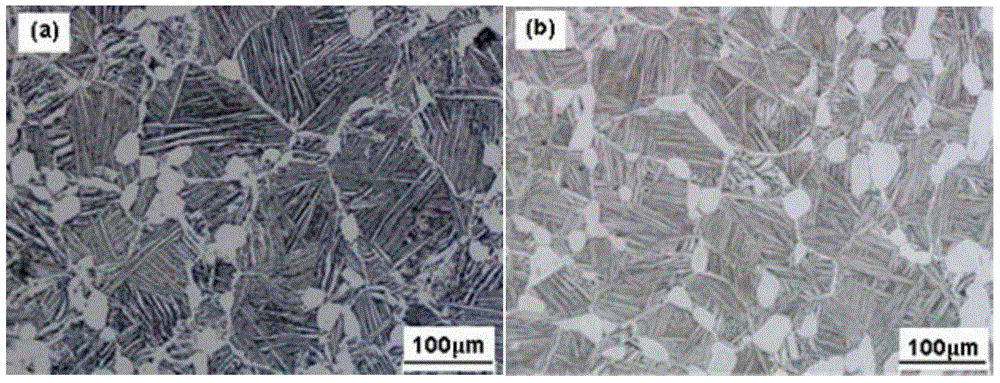

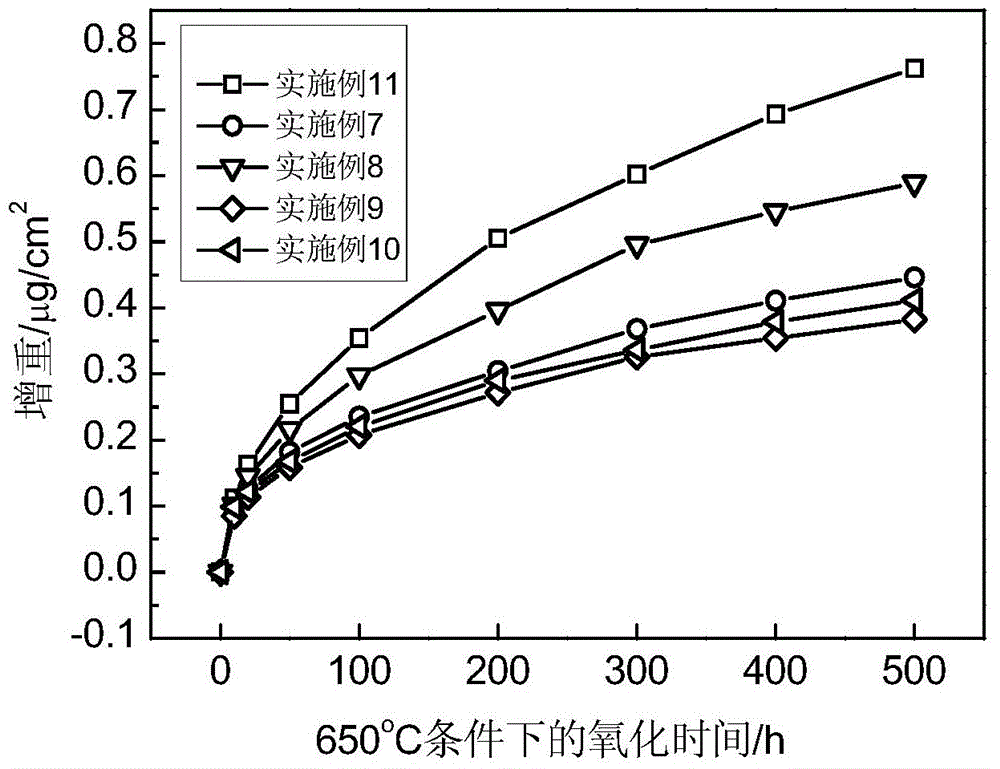

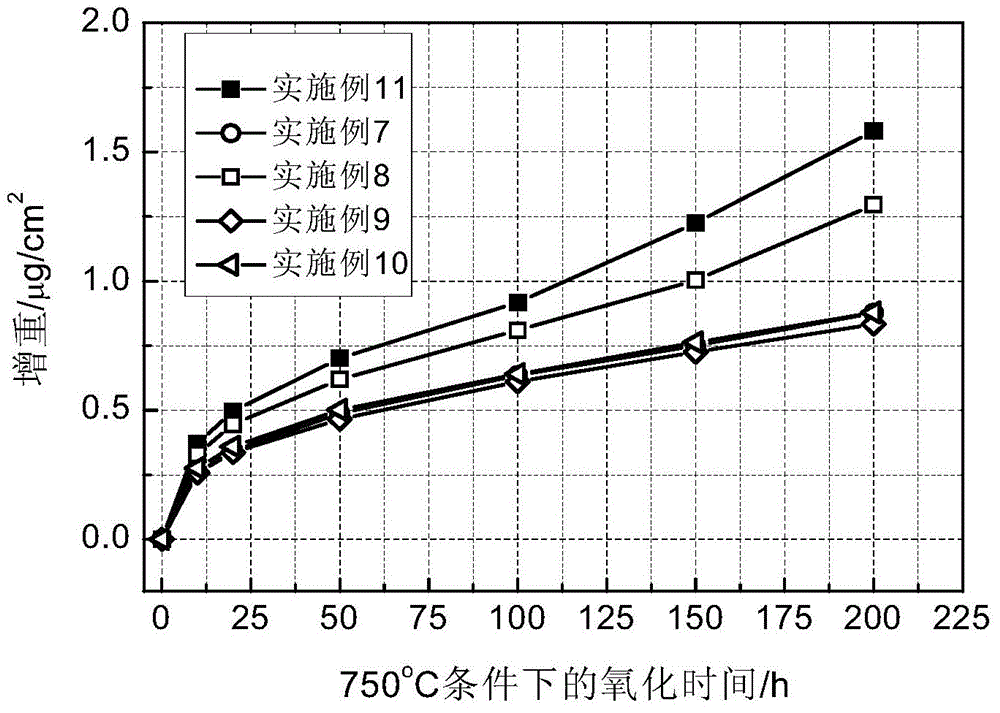

Novel heat-resisting titanium alloy and processing and manufacturing method and application thereof

The invention belongs to the field of titanium-based alloys, and particularly relates to a novel heat-resisting titanium alloy and a processing and manufacturing method and application thereof. The processing and manufacturing method comprises the composition elements of alloy components, smelting, heat processing, heat treatment and the like, wherein the alloy components are as follows (in percentage by weight): 5.4%-6.3% of Al, 3.0%-5.0% of Sn, 2.5%-6.4% of Zr, 0.0%-0.96% of Mo, 0.25%-0.5% of Si, 0.2%-0.5% of Nb, 0.3%-3.4% of Ta, 0.2%-1.6% of W, 0.0%-0.07% of C, less than or equal to 0.17% of O, less than or equal to 0.03% of Fe and the balance of Ti and inevitable impurity elements. The novel heat-resisting titanium alloy disclosed by the invention can obtain different matching of tensile strength, plasticity, permanence, creep strength and heat stability through the combination of different heat processing process and heat treatment processes, can be used for manufacturing parts, namely blades, coil assemblies and the like which are positioned on the high-temperature parts of an advanced aircraft engine, is used for a long time within a range of 600-650 DEG C, can also be used for manufacturing high temperature-resistant structural members, namely aerospace craft skin and the like, is used for a short time at about 700 DEG C and can be used as a material and the like used for high temperature-resistant corrosion-resistant valves of an automobile and a boiler.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aeroengine intake having a heat exchanger within an annular closed chamber

InactiveUS7398641B2Prevent freezingIncrease surface areaTurbine/propulsion engine coolingDe-icing equipmentsAviationNacelle

A gas turbine engine comprising a nacelle having an intake, the intake defining a generally annular chamber, an engine accessory and a heat exchanger for cooling a fluid of the accessory. The chamber is closed and the heat exchanger is disposed within the chamber operable to provide heat to prevent ice forming on the intake during engine operation.

Owner:ROLLS ROYCE PLC

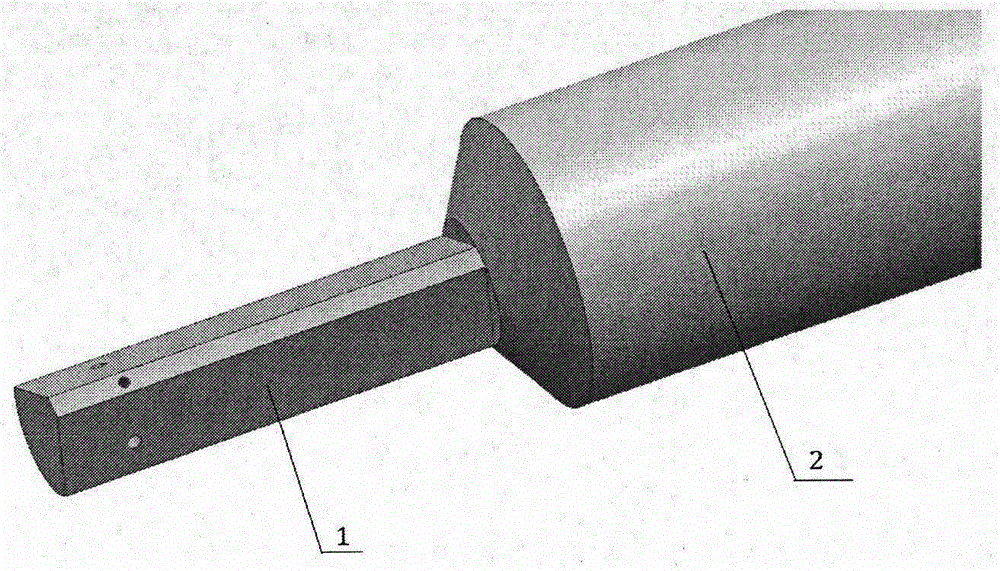

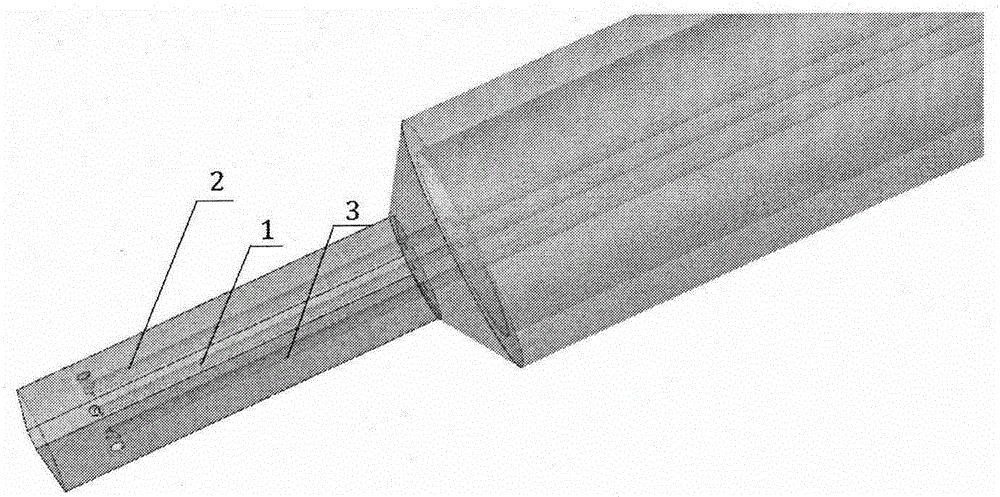

Three-hole transonic speed pressure probe

ActiveCN105716788AReduce resistanceNot easy to bendFluid pressure measurementTesting/calibration of speed/acceleration/shock measurement devicesShock waveEngineering

The invention discloses a three-hole transonic speed pressure probe. As a pneumatic technology develops, a transonic speed air flow appears more and more frequently, for instance, many air flows in an aeroengine reach a transonic speed state, so these transonic speed flow fields need to be measured and analyzed during development of engine components. Conventionally, the transonic speed flow fields are measured respectively by use of a total pressure probe and a direction probe so that total pressure and air flow directions can be obtained. When a flow speed reaches a transonic speed, the probes are under great resistance, and the probes are blown bent easily. When the flow speed reaches an ultrasonic speed, due to the existence of shock waves, there is large total pressure loss, and the influences exerted by the probes on the flow fields are quite large. Though these conventional probes can be used in an ultrasonic air flow, the influences exerted by the probes on the flow fields cannot be neglected, and the requirement for the strength of the probes is quite high. The novel three-hole transonic speed pressure probe provided by the invention is used for measuring the transonic speed flow fields. By use of the probe provided by the invention, the intensity of the shock waves in front of the probe can be weakened during measurement, the influences exerted by the probe on the flow fields are reduced, air-flow total pressure, static pressure, a Mach number and an air-flow deflection angle can be measured simultaneously, the resistance acting on the probe can be effectively reduced, and the firmness and reliability of the probe are guaranteed.

Owner:BEIHANG UNIV

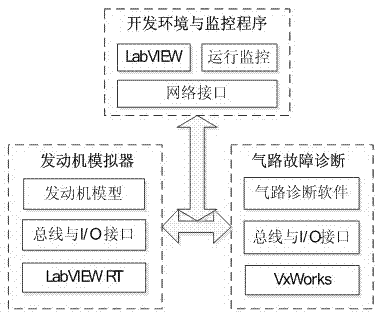

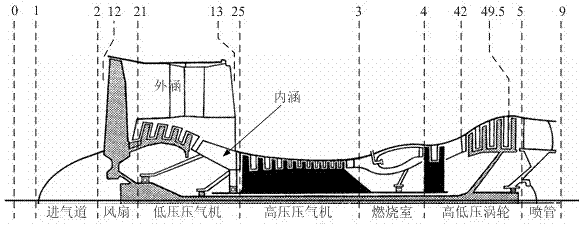

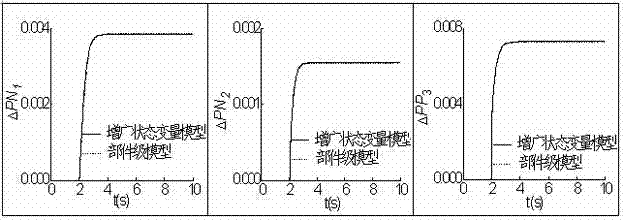

Quick prototype design method and platform for gas path fault diagnosis for aeroengine

InactiveCN102855349AHigh dynamic and steady state precisionRealize online estimationEngine testingSpecial data processing applicationsAviationOn board

The invention discloses a quick prototype design method for gas path fault diagnosis for an aeroengine. The quick prototype design method comprises the following steps of: building an adaptive model of the engine; designing a gas path fault diagnosis logic in the full service life of the aeroengine, and implementing abnormal monitoring and gas path performance on-line estimation; and designing a quick prototype design platform for gas path fault diagnosis for the engine, and checking abnormal monitoring and gas path performance on-line estimation functions of the platform. The adaptive model of the engine is built by a compound interference method; an engine on-board adaptive model is used for estimating performance parameters; an engine adaptive base line model is used for monitoring abnormities and performs off-line period updating; and the quick prototype design method is used for checking the engine gas path fault diagnosis logic. The invention also discloses a corresponding quick prototype design platform. The method and the platform are relatively high in capacity of monitoring abnormities and estimating the performance in the overall service life of the engine and have great significance for shortening the development period and reducing the test risk and the test cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Radial swirler turning zone direct injection premixing and prevapourising low pollution burning chamber

InactiveCN101275750AShorten the lengthWell mixedContinuous combustion chamberIndustrial gasCombustion chamber

Disclosed is a radial swirler turning area direct injection premixing pre-evaporation firebox, wherein the firebox composed of a burner head and a flame tube is a single ring structure. The burner head includes a preburning level in the center and a main burning level at the outer ring; Using the direct injection project in the back turning area of the main burning level radial swirler, the main burning level fuel forms the premixing pre-evaporation gas-oil mixture to enter the burning area for burning under the action of the swirling gas of the main burning lever radial swirler, wherein the burning way can effecctively reduce the discharge of the pollutants in the burning chamber, meanwhile, the direct injection in the back turning area and the turning flow for the main burning level radial swirler of the main burning level fuel can reduce the length of the burning chamber; the invention is mainly used in the airmortor firebox, also can be used in the firebox of the industrial gas turbine and the ship gas turbine.

Owner:BEIHANG UNIV

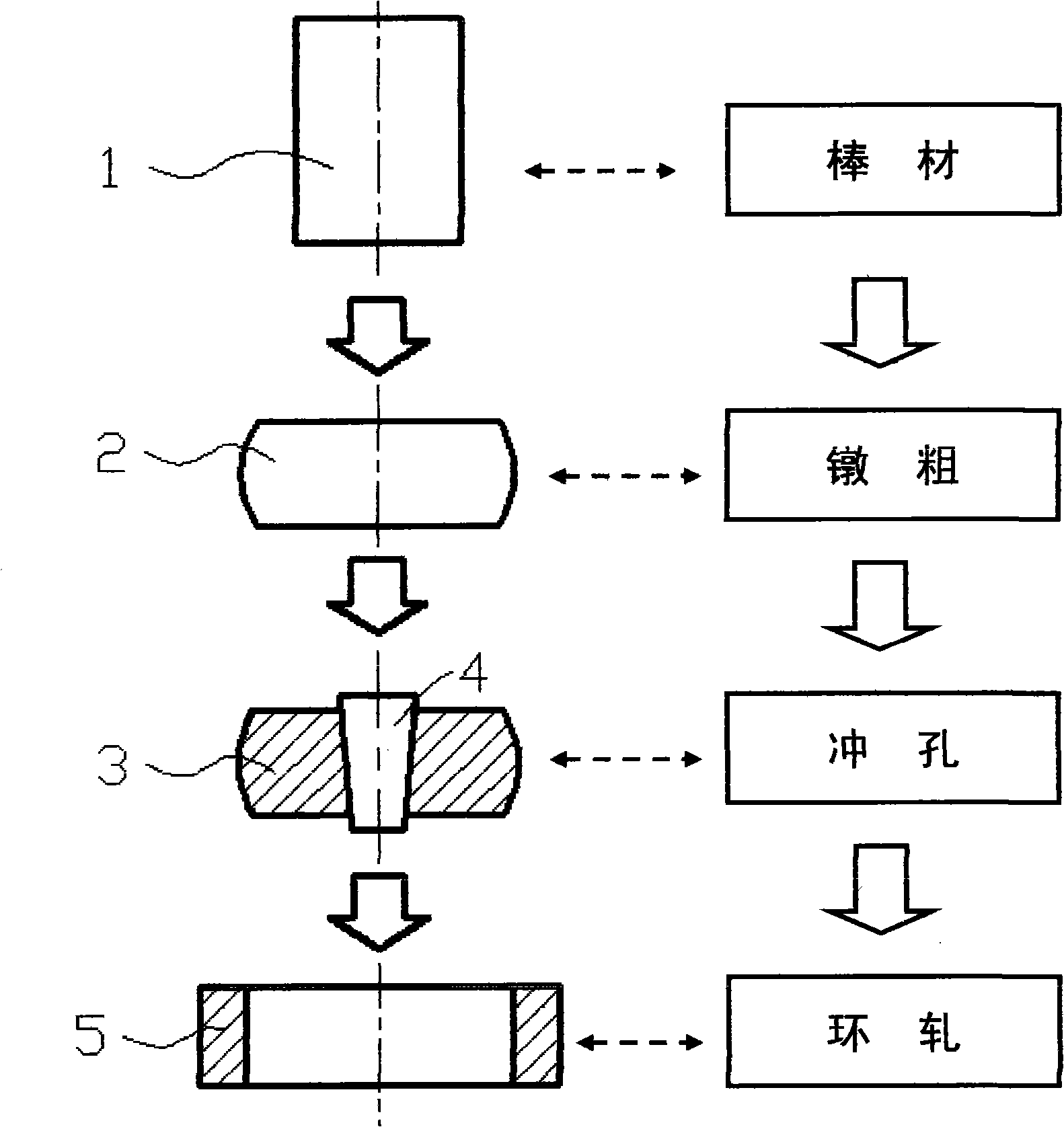

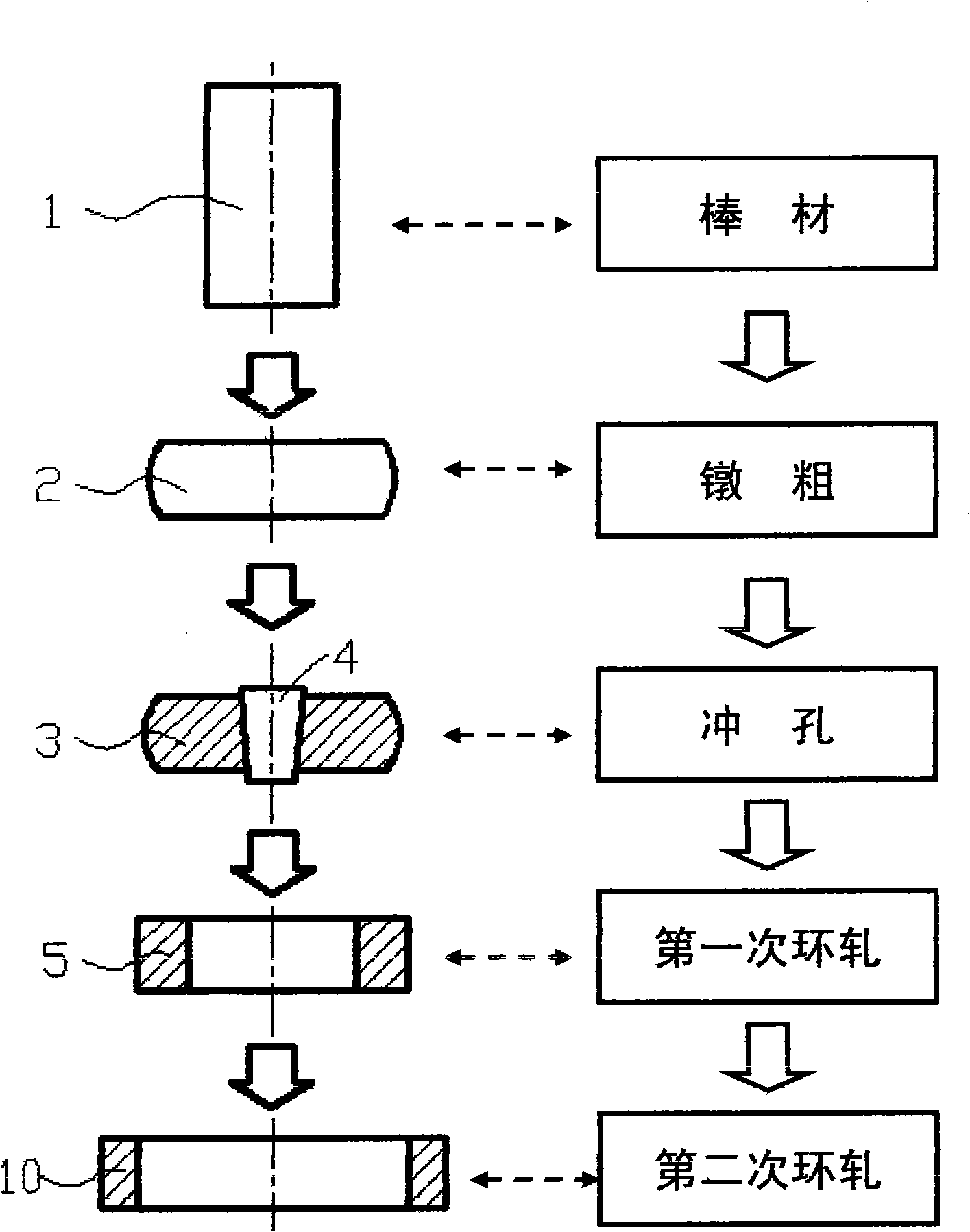

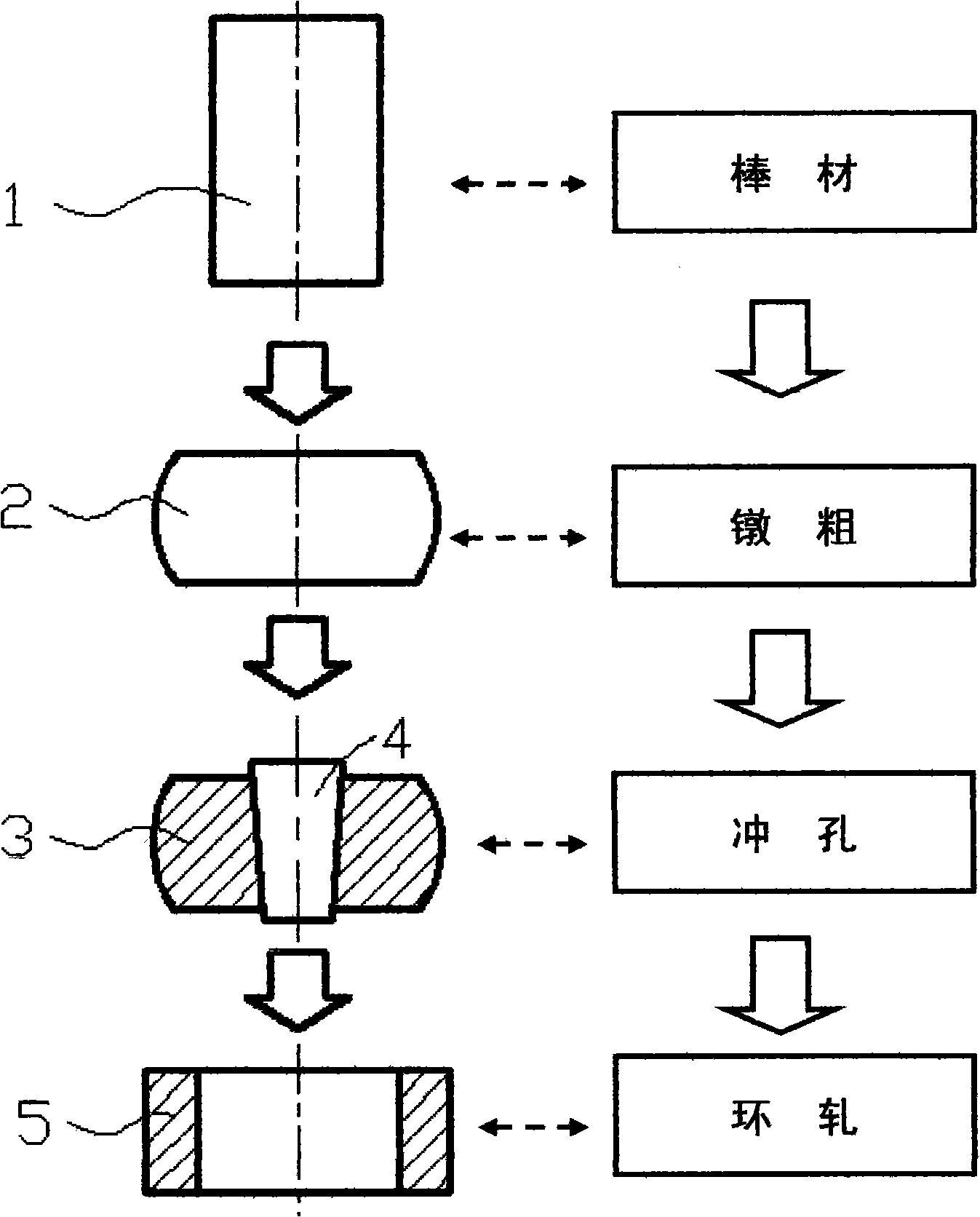

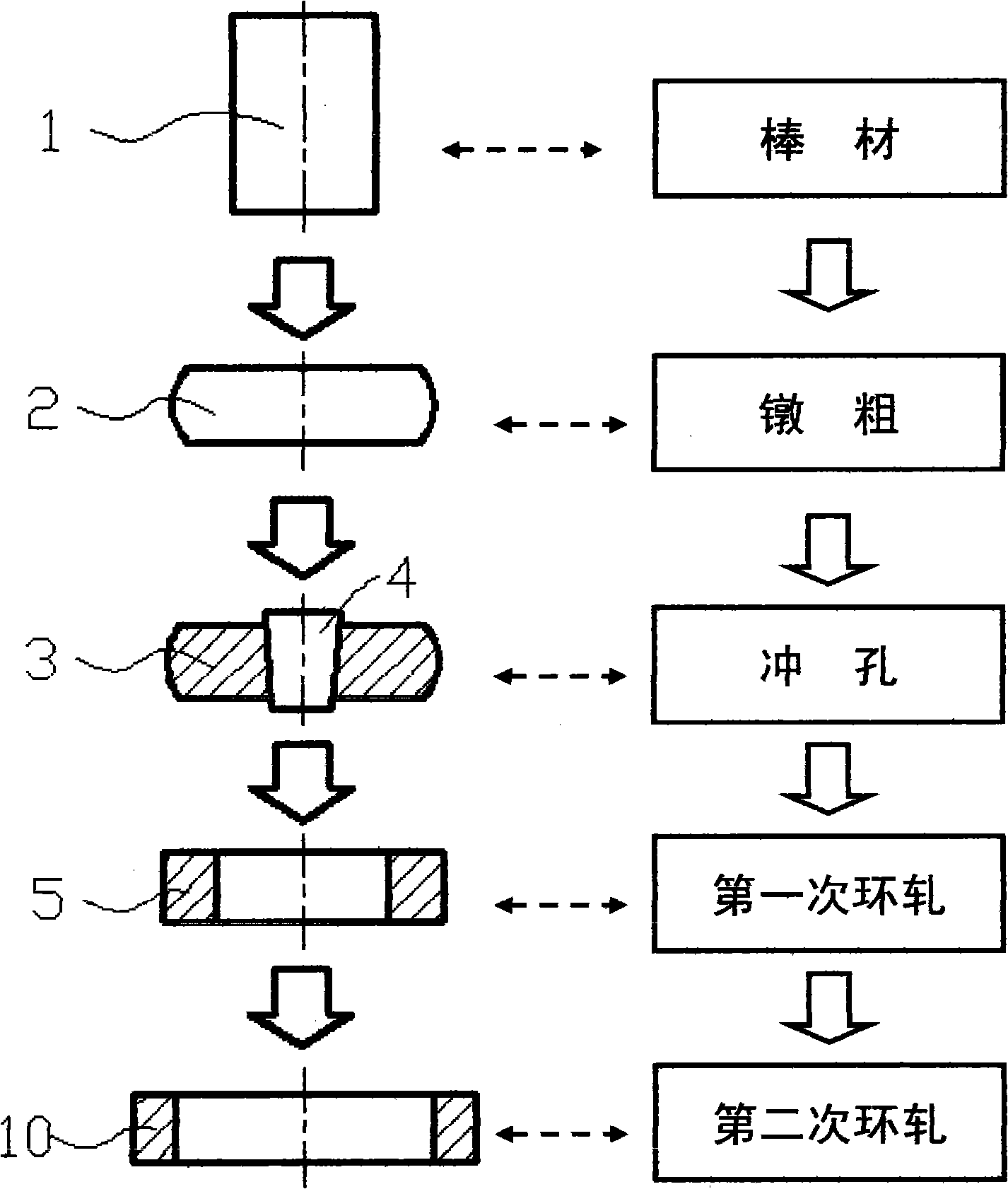

Method for rolling and shaping stainless steel special-shaped ring forging

The invention discloses a rolling and shaping method for a stainless steel heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

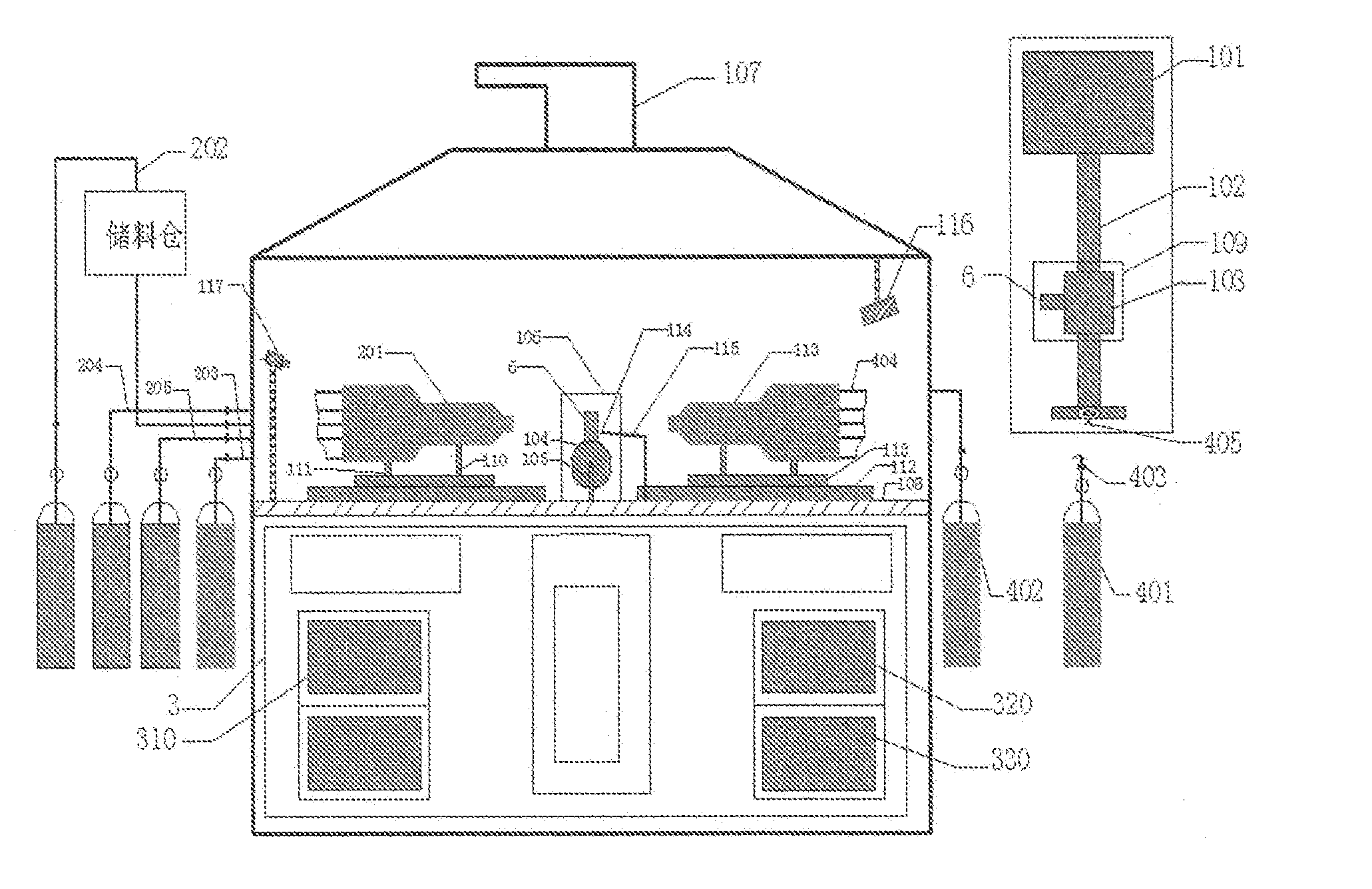

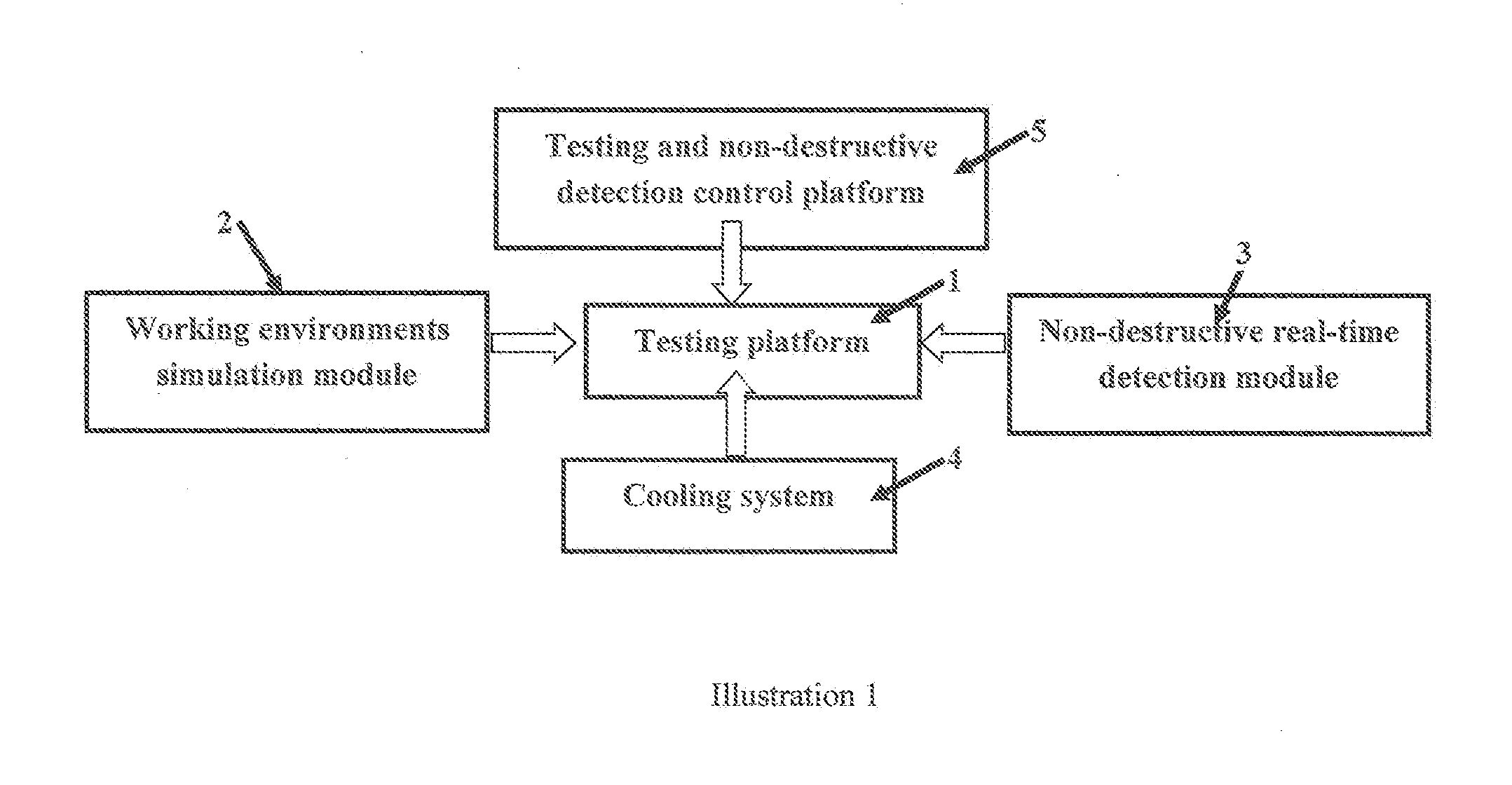

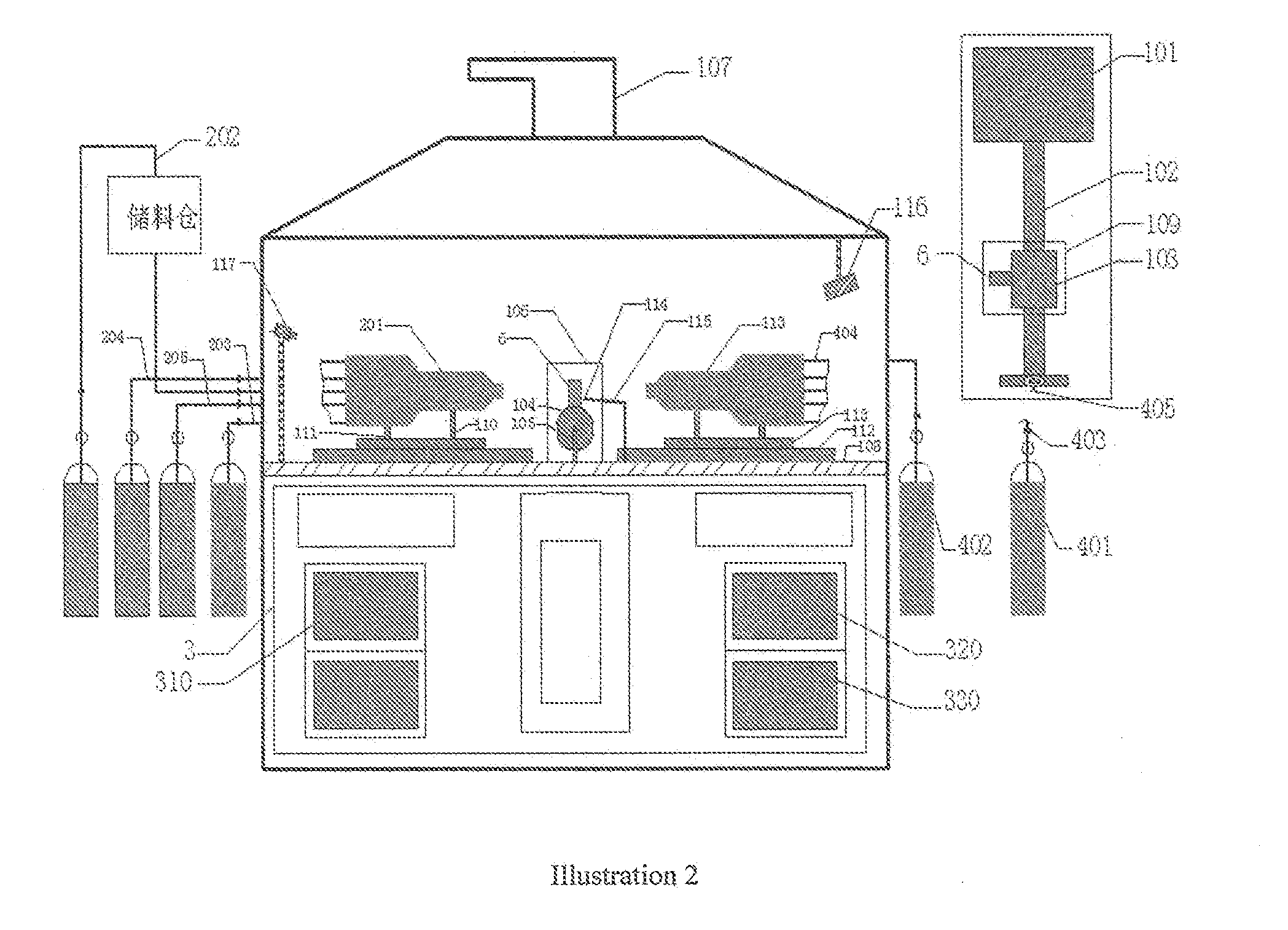

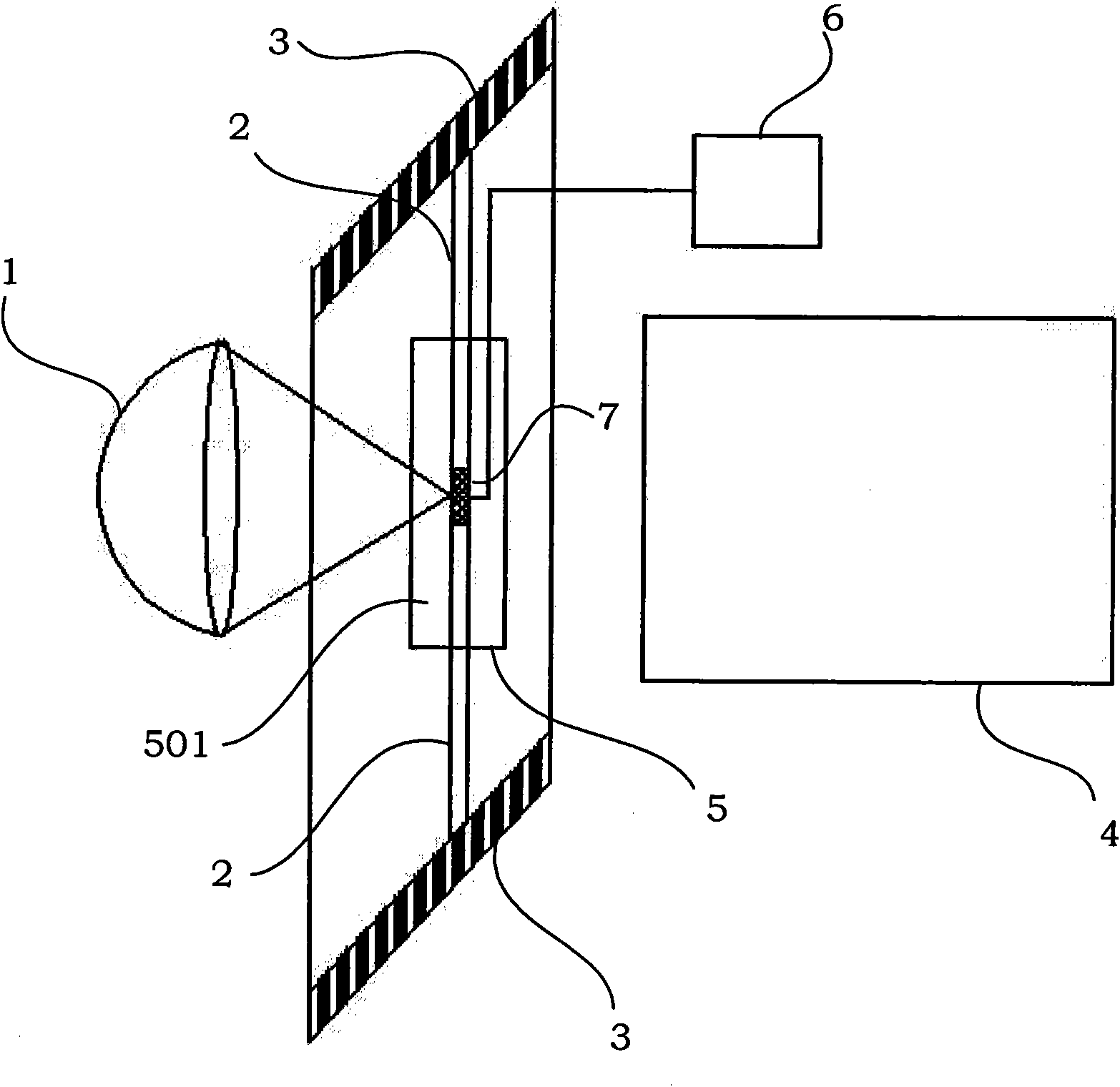

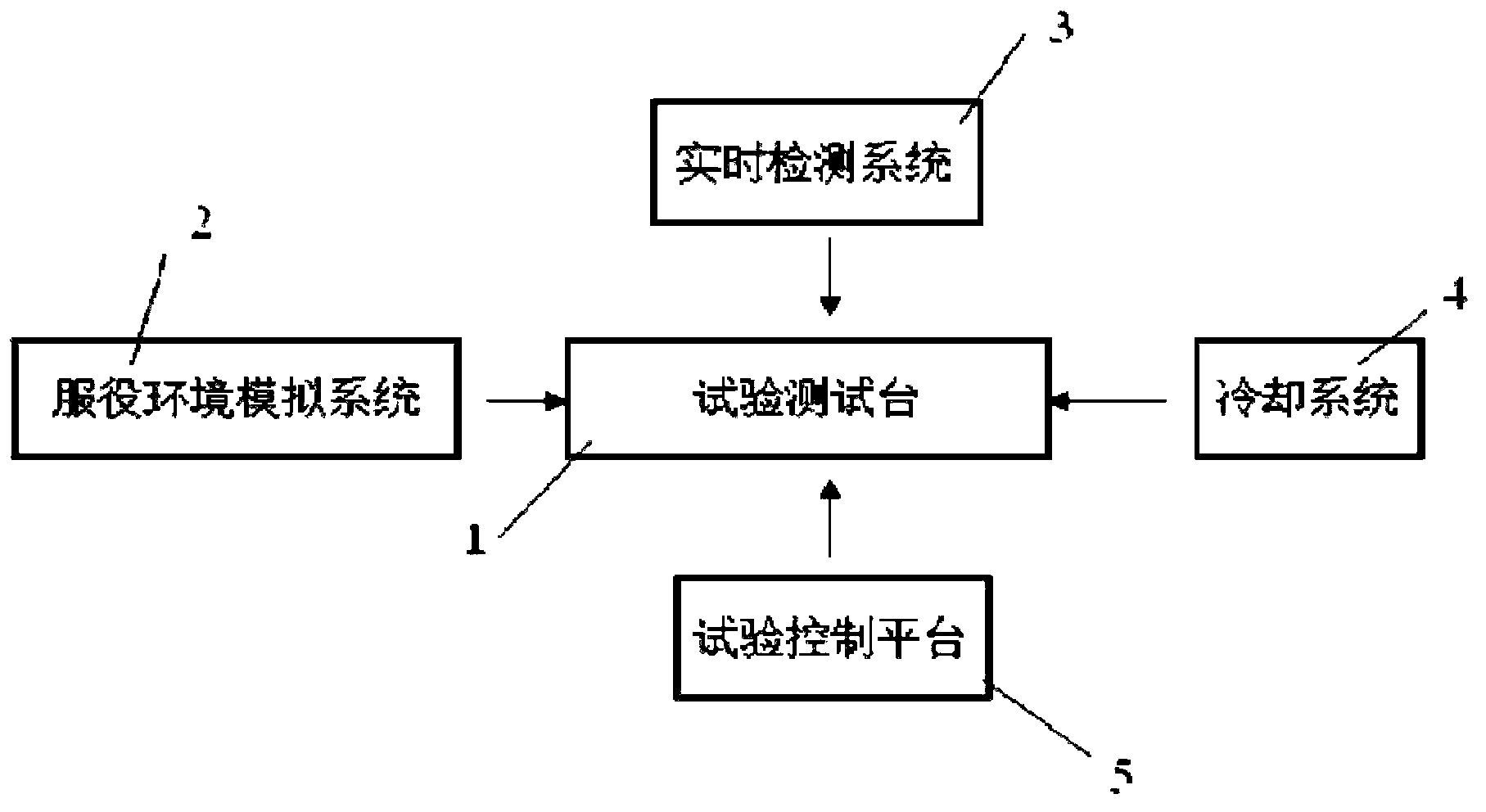

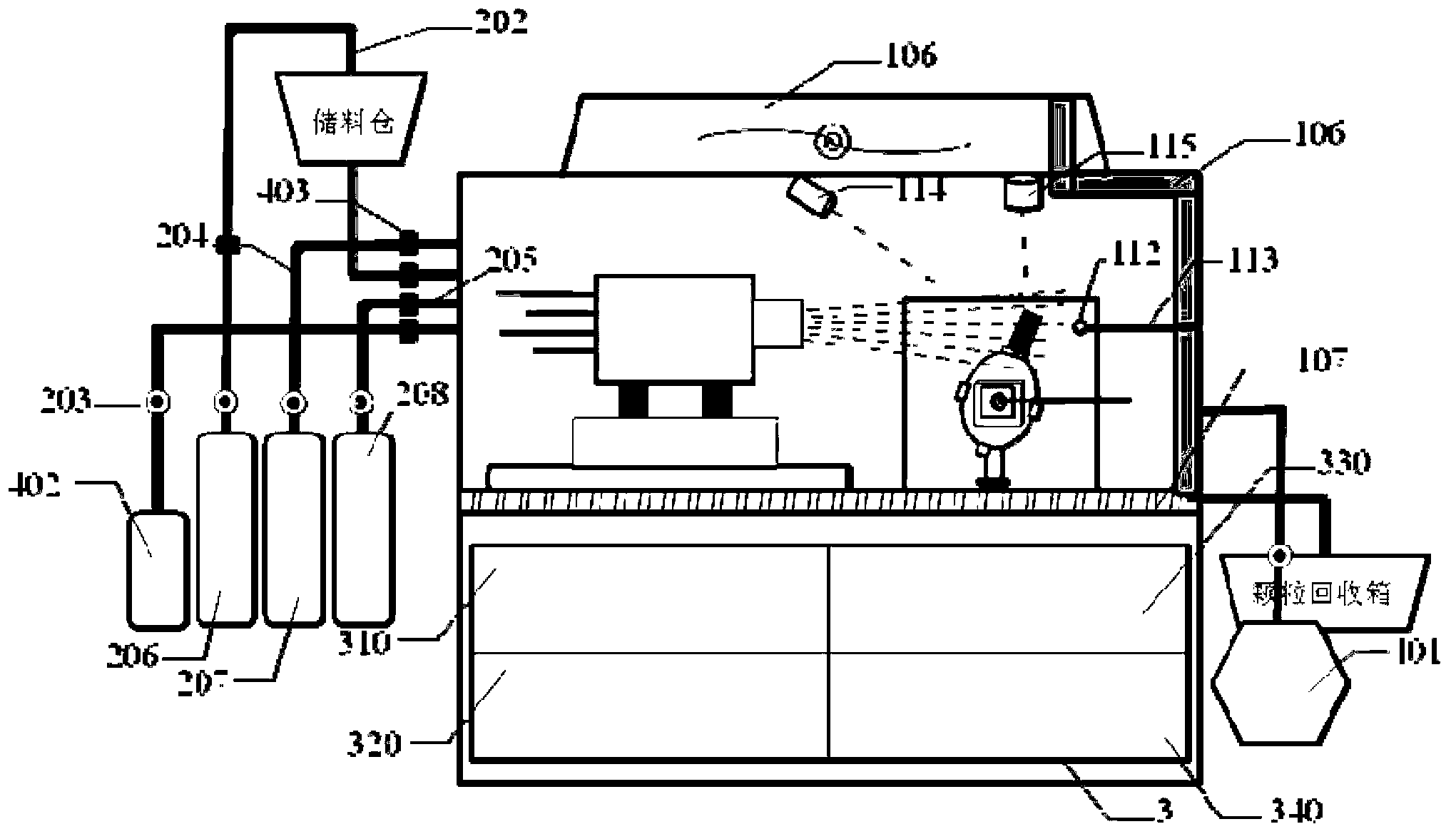

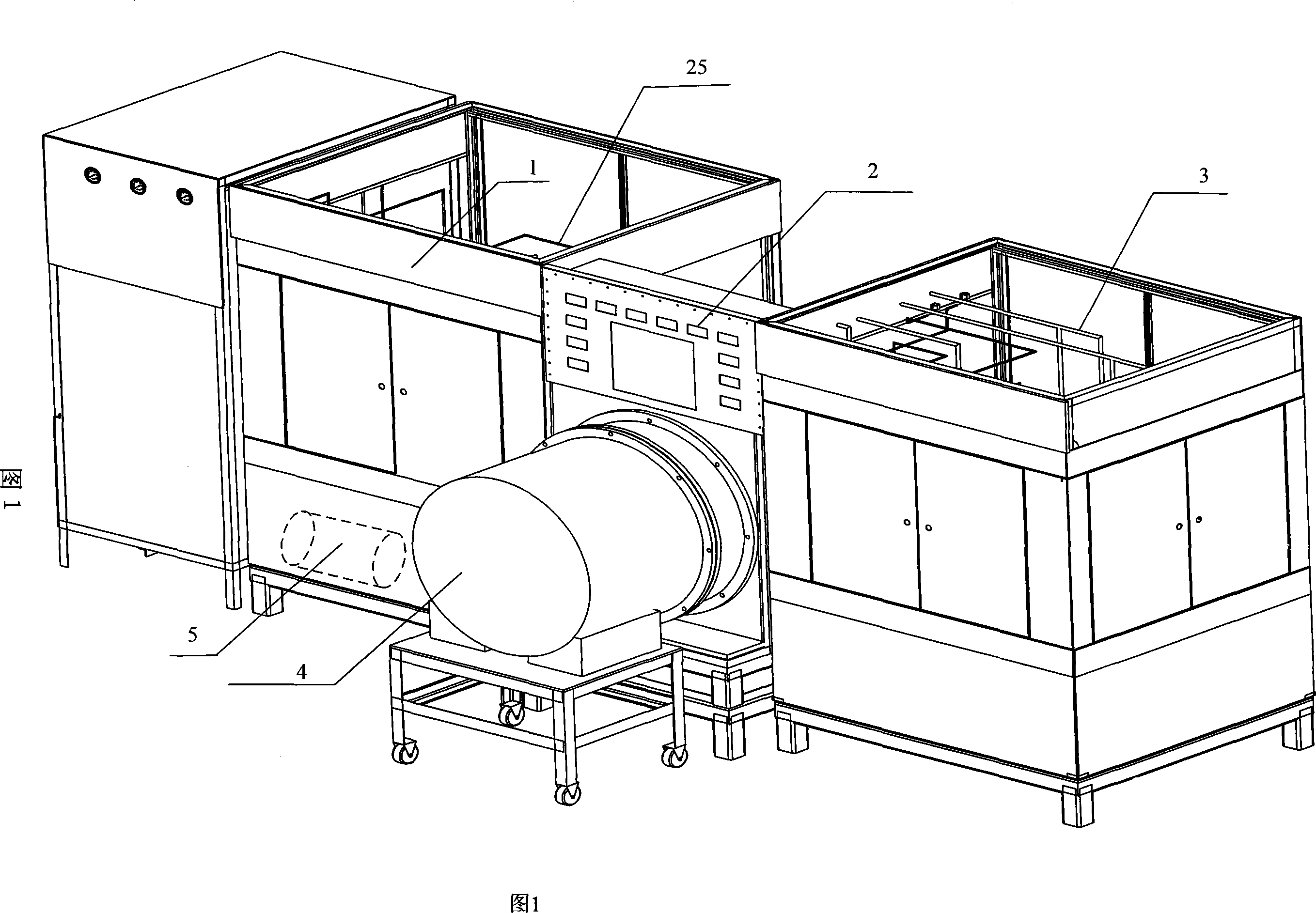

Type of testing equipment for detecting the failure process of thermal barrier coating in a simulted working environment

ActiveUS20150355074A1Better understandingReliable assessmentWeather/light/corrosion resistanceEngine testingSurface oxidationTurbine blade

A type of testing equipment for detecting the failure process of thermal barrier coating in a simulated working environment; it belongs to the field of simulated special working environment equipment. Testing equipment includes testing platform equipped with static or dynamic specimen holding apparatus, simulated module of working environment, real-time detection module, control panel. This invention is capable of simulating a high temperature, erosive, corrosive working environment for thermal barrier coated turbine blade of aero-engines; simulate high speed spinning working environment for thermal coated blade, simulate static working environment for guiding blade; perform real-time testing of temperature field, 3-D displacement field, crack initiation and expansion, surface oxidation, etc. This invention has achieved complete integration of high temperature, erosive, corrosive working environment for thermal barrier coating and complete integration static or dynamic working environment, complete integration of simulated working environment and real-time testing, thus providing a crucial testing platform and reference data to properly understand the failure mechanism of thermal barrier coated blade and to improve relevant designs; strong applicability.

Owner:XIANGTAN UNIV

Low-pollution combustion chamber provided with premixing and pre-evaporating ring pipe

ActiveCN101788157AReduce pollutionFast evaporation blendingContinuous combustion chamberCombustion chamberCombustible gas

The invention relates to a low-pollution combustion chamber provided with a premixing and pre-evaporating ring pipe, which adopts a single-ring cavity structure and consists of a combustion chamber outer casing, a combustion chamber inner casing, an outer flame tube, an inner flame tube and a combustion chamber head part, wherein air used for combustion completely enters into the flame tubes from the combustion chamber head part; the scheme of fractional combustion can be adopted, and pre-combustion stage and a main-combustion stage are divided; the main-combustion stage comprises the premixing and pre-evaporating ring pipe, a main-combustion stage nozzle and a main-combustion stage swirler; fuel oil is evaporated and mixed inside the premixing and pre-evaporating ring pipe and then enters into the flame tubes after forming even mixed combustible gas, belonging to premixed combustion; a fuel nozzle is used for supplying the fuel oil for the pre-combustion stage and the main-combustion stage; the stable working range of the combustion chamber is mainly controlled by the pre-combustion stage, so that the stable combustion can be ensured to be carried out in the combustion chamber within wider working range, and a stable ignition source can be provided for the main-combustion stage; the pollution emission is mainly controlled by the main-combustion stage, and the equivalent weight ration of the premixed gas of the main-combustion stage can be controlled within the low-pollution combustion range, so that the pollution emission of the whole combustion chamber cam be ensured to be greatly reduced. The premixing and pre-evaporating structure has small size, simple structure and modularized characteristic, can reduce the pollution emission of the combustion chamber of an aircraft engine, and ensures good combustion stability.

Owner:BEIHANG UNIV

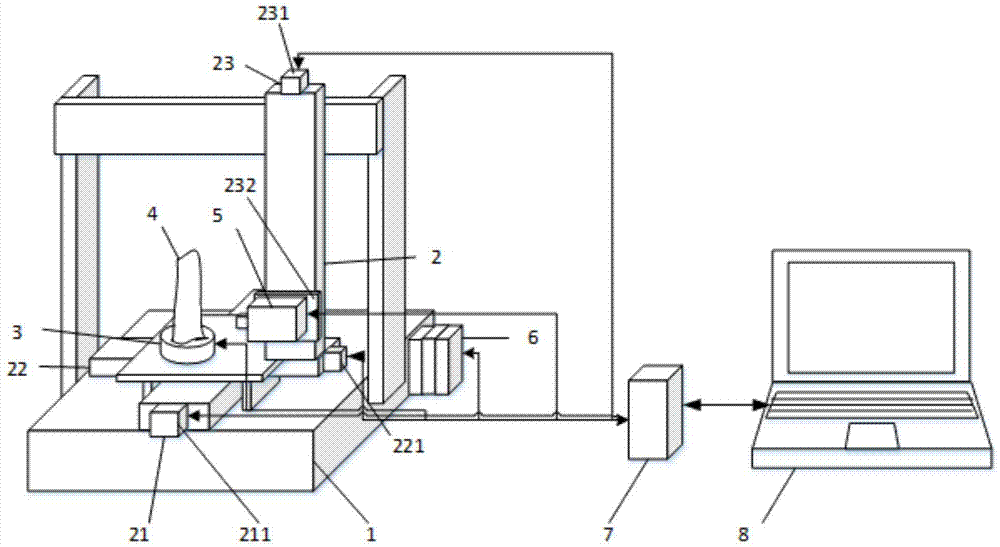

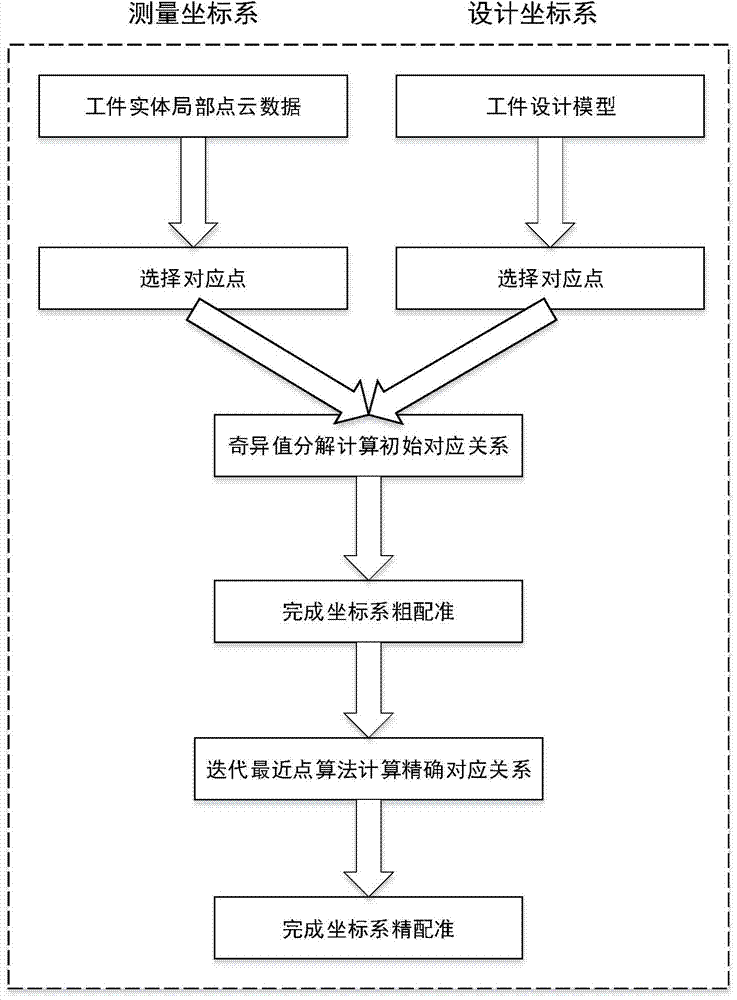

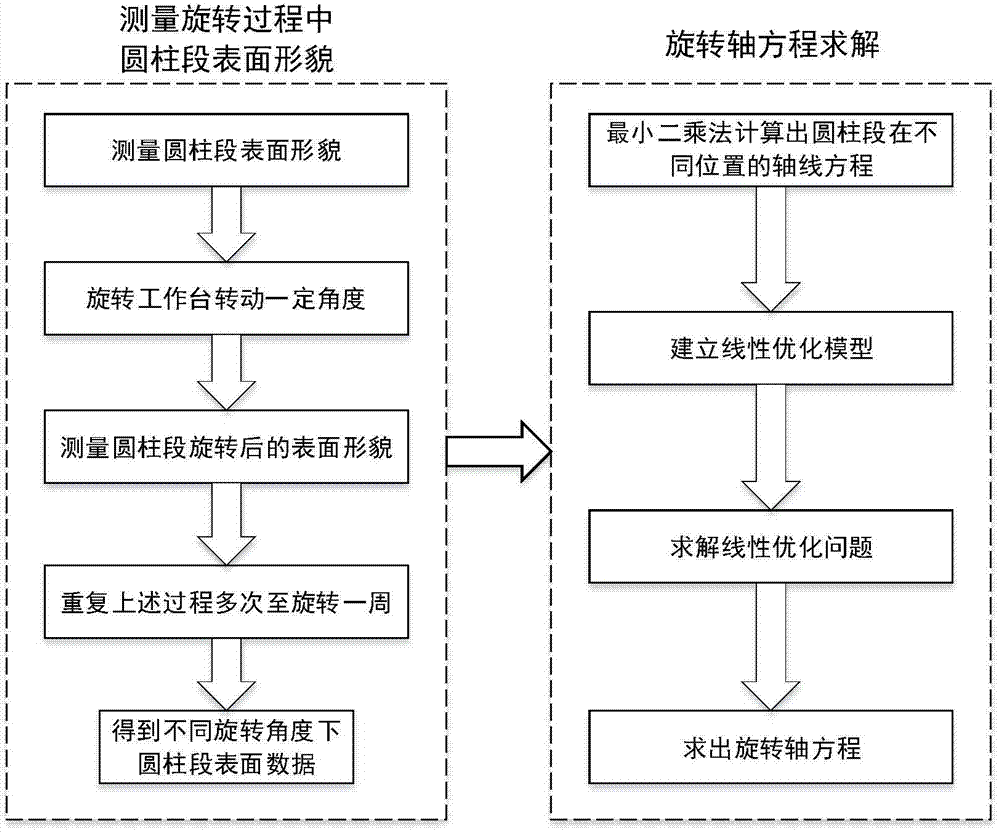

Automatic three-dimensional measuring method and automatic three-dimensional measuring system for high-precision blade of aviation engine

ActiveCN104515478AHigh measurement accuracyImprove measurement resolutionUsing optical meansAviationThree dimensional measurement

The invention discloses an automatic three-dimensional measuring method for a high-precision blade of an aviation engine. The automatic three-dimensional measuring method comprises the following steps of (1) rectification: performing rectification on a design coordinate system of a design model and a measurement coordinate system of a workpiece entity; (2) path planning: planning a motion path of a distance sensor in a measuring process by using a data processing device so that a measured region of the workpiece entity is in a measurement range of the distance sensor; and (3) automatic measurement: sampling a front region and a reverse region of the workpiece entity by using the distance sensor to obtain a complete surface profile of the workpiece entity. The distance sensor serves as a measuring terminal, and position information of surface points of the measured region can be acquired; and moreover, by a three-axis motion mechanism, measurement on different regions of the workpiece entity can be realized, measured cloud data of points of density of a local range are automatically fused to the same coordinate system, and complete precise measurement on a workpiece and quality testing operation on the workpiece entity are realized.

Owner:HUAZHONG UNIV OF SCI & TECH

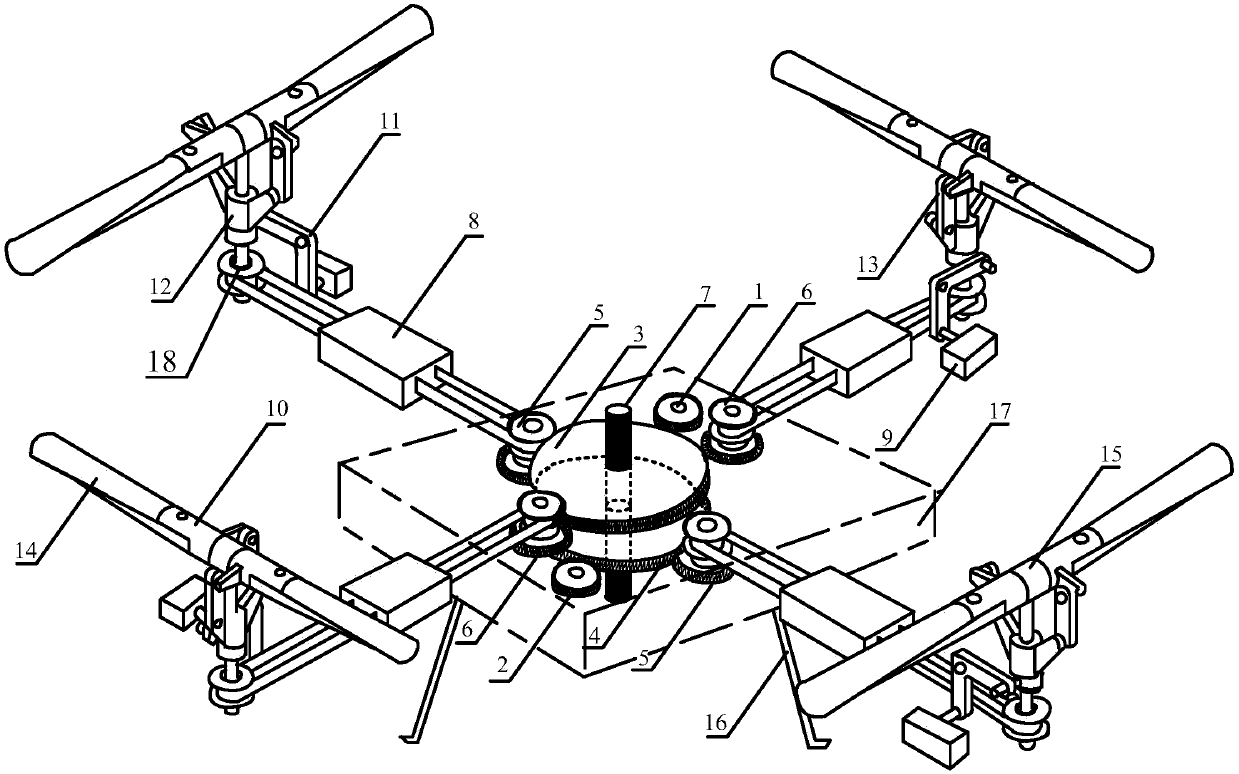

Unmanned aerial vehicle with double engines, four shafts and four rotors

The invention discloses a highly reliable unmanned aerial vehicle with double engines, four shafts and four rotors. The unmanned aerial vehicle is composed of aero-engines, a rotor machine body, a power distribution transmission system, a flying control system and four rotor assemblies, wherein the rotor machine rotors are pitch-variable rotors and each rotor comprises a rotor rotation driving part and a rotor blade angle adjusting part. According to the unmanned aerial vehicle, two aero-engines are used for driving four rotors; each engine drives a pair of blades on a symmetrical axis and a speed reducing mechanism is additionally arranged between the engine and the blades; the rotor blade angle adjusting mechanism drives the pitch-variable blade to change the pitch, so as to change lifting force; the engines work in a relatively high efficiency section; postures such as hovering, fly forwards and backwards are realized by adjusting the pitch; and the flying control system is composed of an ARM, GPS and a three-axis gyroscope and is accurate and reliable. By adopting the double-engine scheme, when one engine fails, the attitude of the vehicle can be maintained by improving the power of the other engine, so as to land safely; and the unmanned aerial vehicle has high reliability.

Owner:东营鹰视铁卫航空科技有限公司

Process for preparing self-sealing silicon carbide ceramic based composite material

The invention relates to a method for manufacturing a self-healing silicon carbide ceramic matrix composite. The method comprises the following steps: preparing fiber preform; filtrating a pyrolytic carbon interface layer by chemical gas phase; carrying out thermal treatment on the interface layer; infiltrating silicon carbide and boron carbide substrate by chemical gas phase alternately; and depositing three silicon carbide coatings by the chemical gas phase. The method has strong designability, simple process and good repeatability. The ceramic matrix composite manufactured by the method has good high temperature resistance and oxidation resistance, has excellent mechanical performance and thermal performance, and can meet the use requirement of a sealing strip / an adjustment sheet, an interior cone and other components of a high thrust-weight ratio aeroengine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for achieving high-melting-point material 3D printing through nanometer ink together with laser melting

InactiveCN103407296AWide range of choicesLarge specific surface areaOther printing apparatusDevice formInk printer

The invention discloses a method for preparing the nanometer ink through ceramics, metal, semiconductors, glass and other high-melting-point materials, carrying out 3D printing and utilizing the laser heating sintering in the process of printing to obtain 3D devices formed by combining the ceramics, the metal, the semiconductors and other composite. The method comprises the first step of processing raw materials needed to prepare the device into nanometer particles of 1-500nm, the second step of preparing the particles into ink jet printing ink, the third step of carrying out 3D printing by utilizing an improved ordinary ink printer and adopting the laser heating sintering in the process of printing, and the fourth step of achieving the melting and sintering molding of the nanometer particles. According to the method, micron-level precision devices with any complex shape can be directly prepared, the high surface energy of the nanometer particles is utilized, the sintering temperature is lowered, high density is achieved, and a superior property is obtained. The method can be used for manufacturing automobile metal ceramic composite pistons, aviation engine tail pipes, and ceramic bearings and ceramal composite precise components of watches and other precision instruments and for directly printing a circuit board.

Owner:南京鼎科纳米技术研究所有限公司

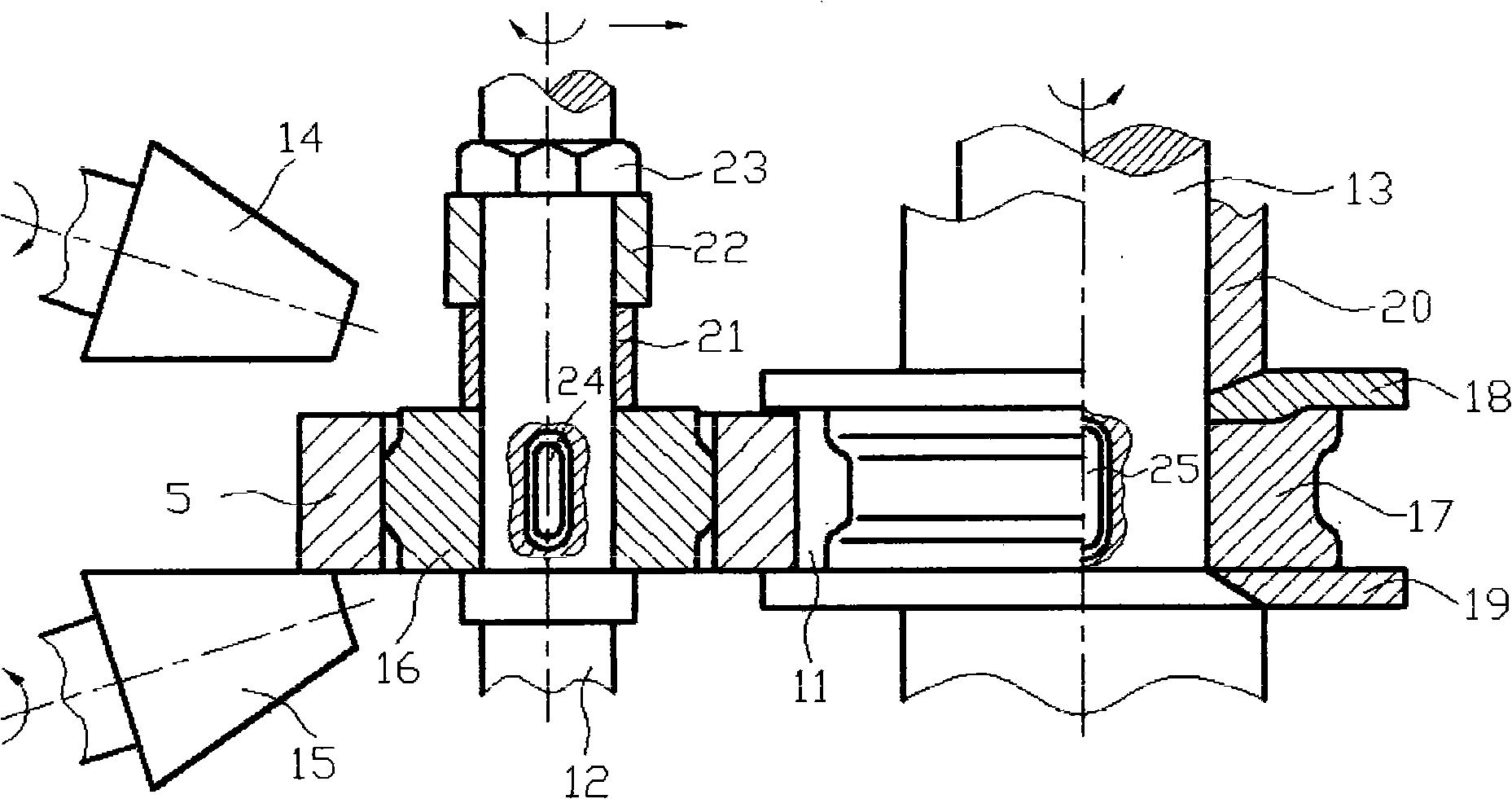

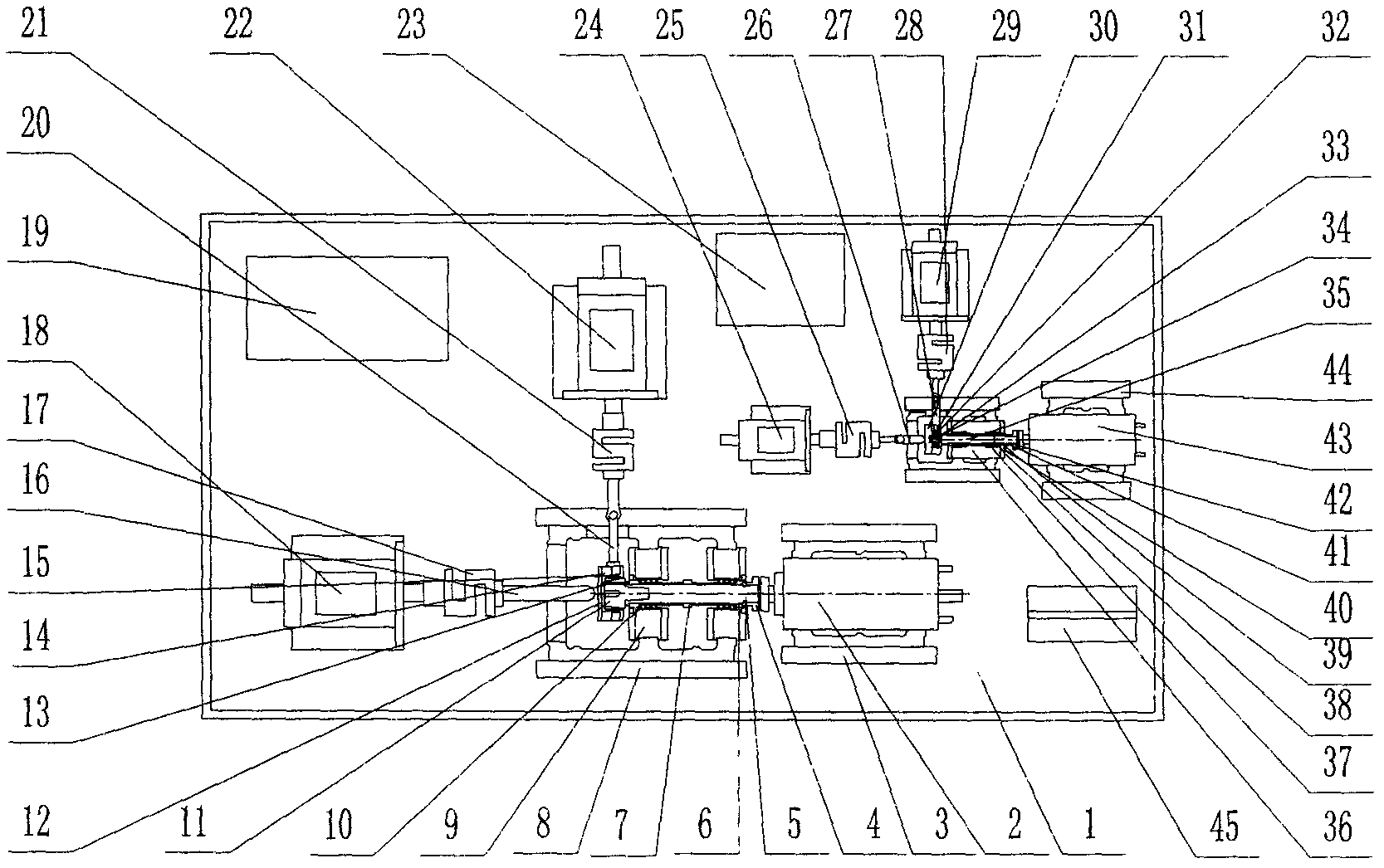

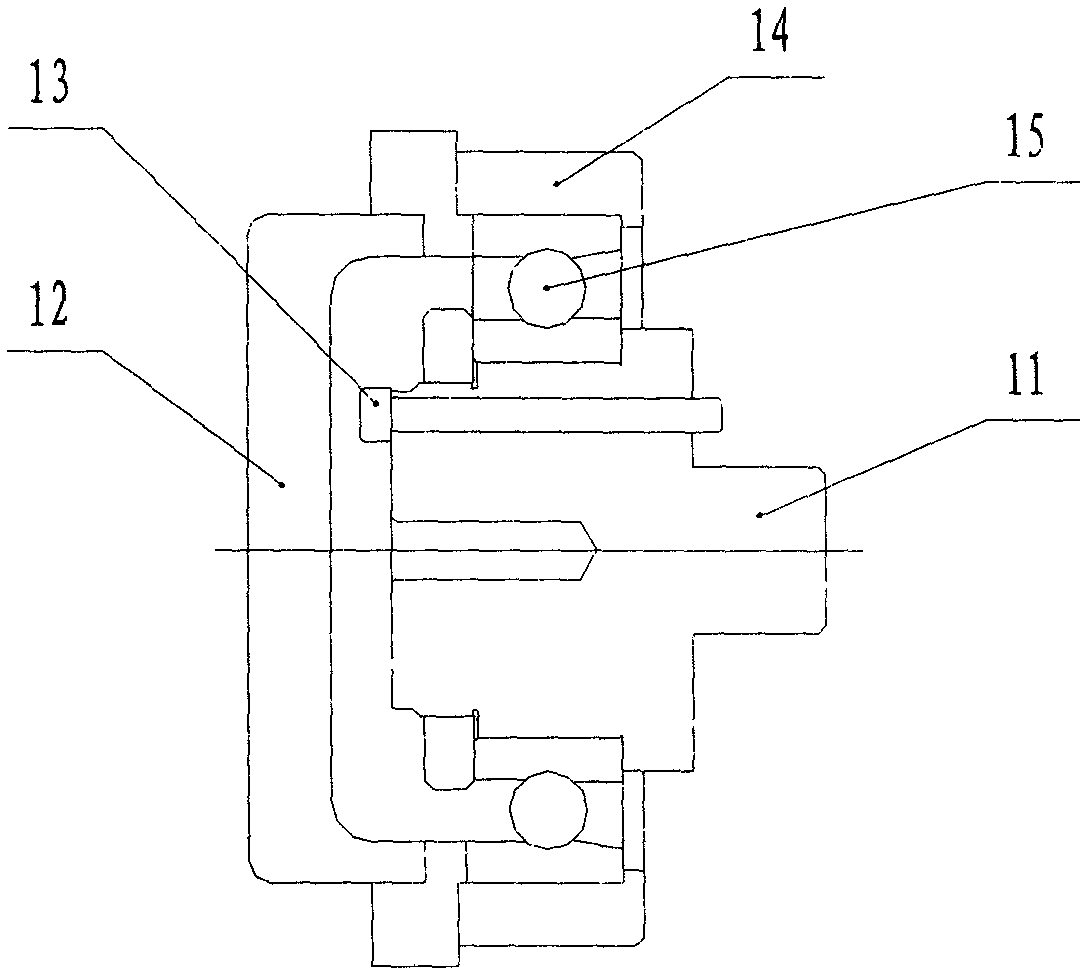

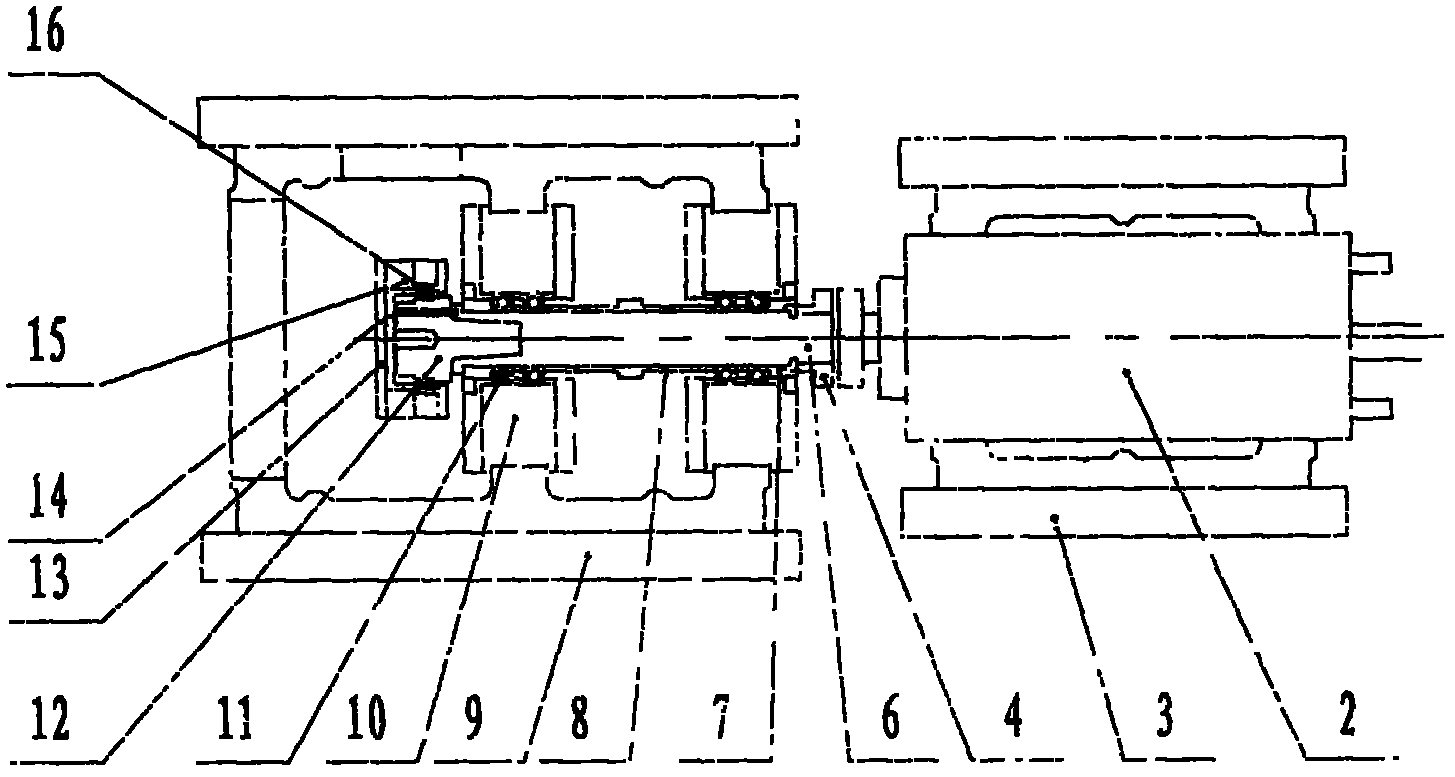

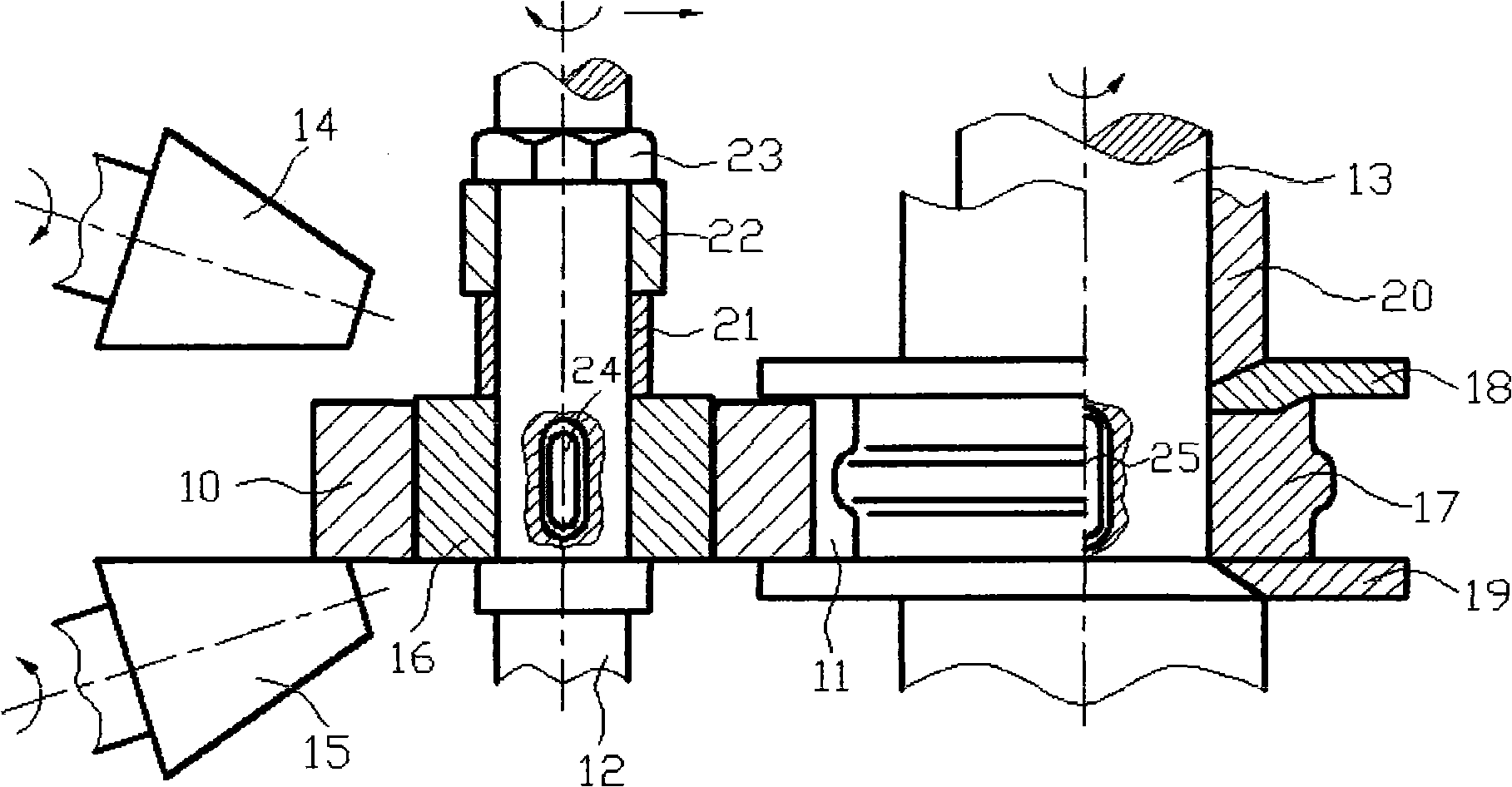

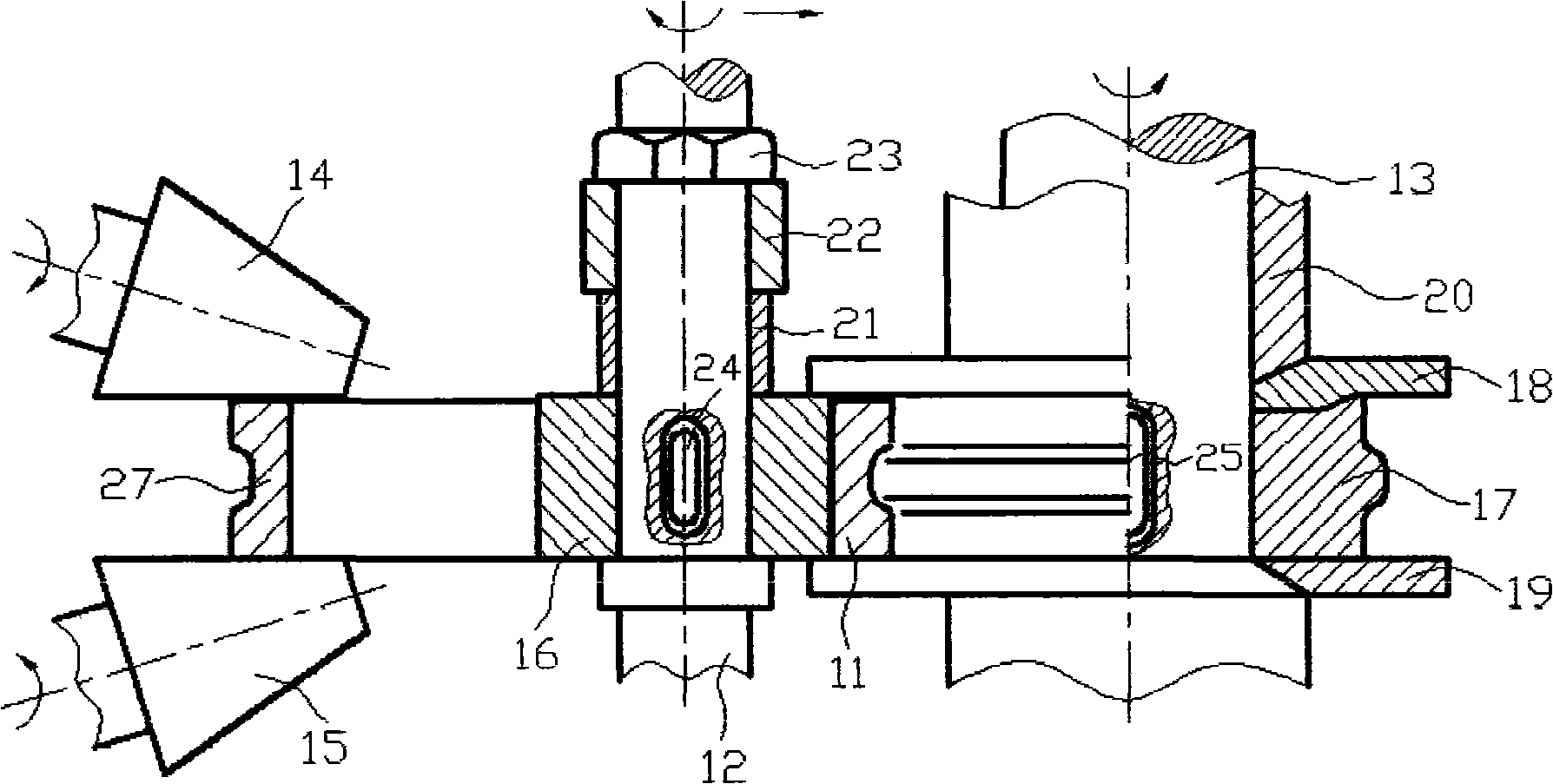

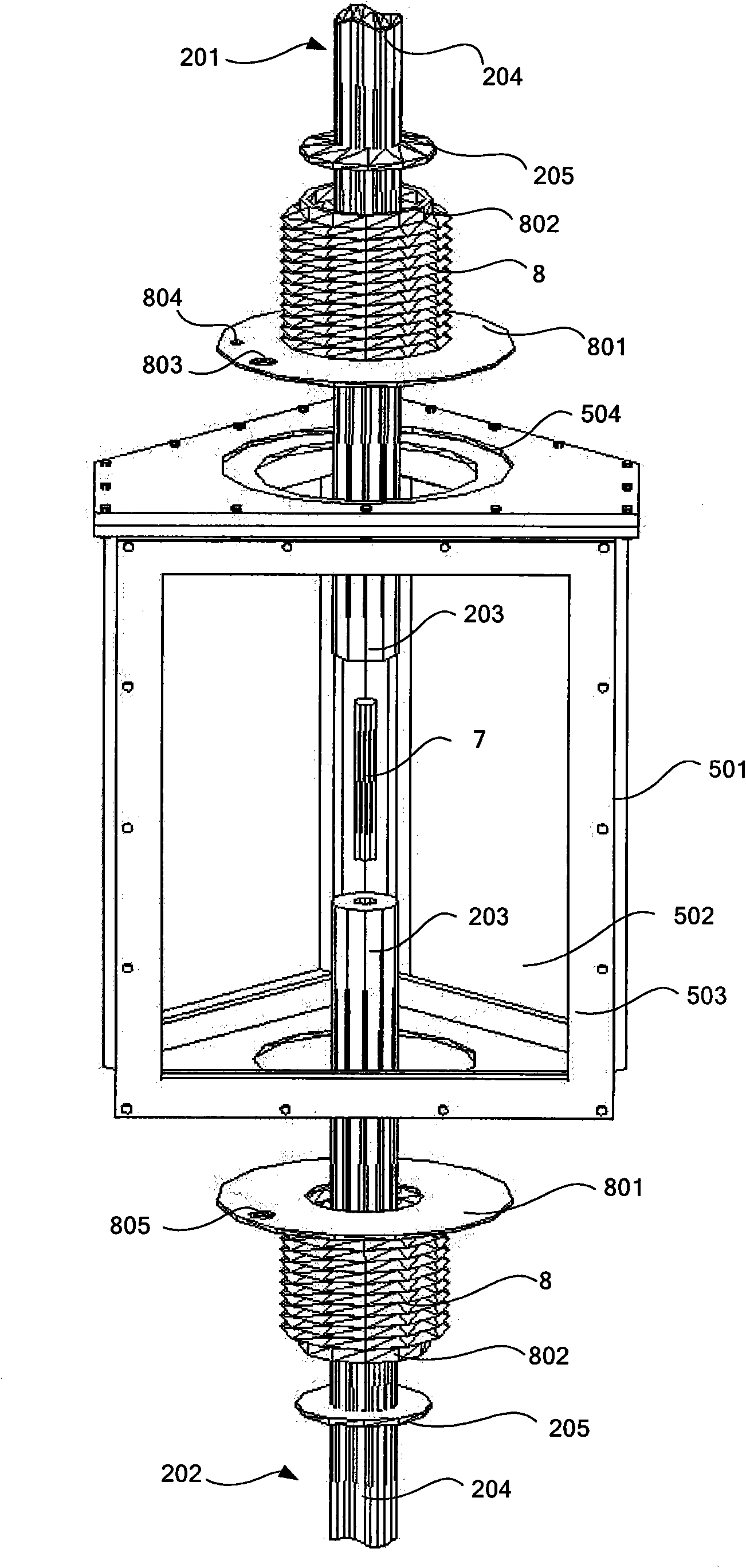

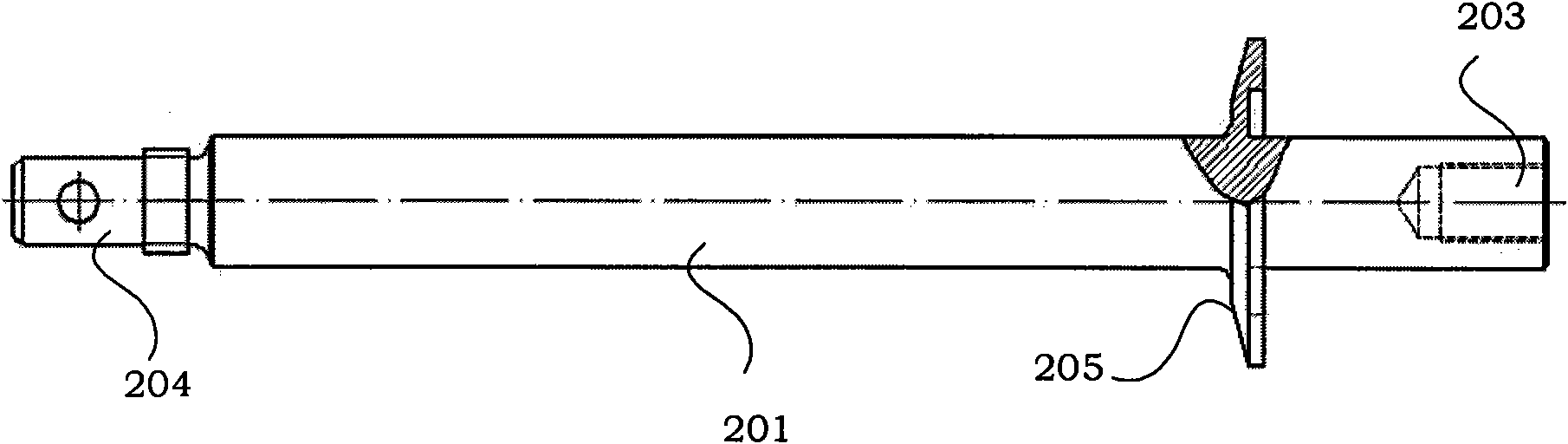

Aircraft engine spindle bearing testing machine

The invention belongs to the aircraft bearing detecting technology and provides an aircraft engine spindle bearing testing machine. a testing mechanism of the aircraft engine spindle bearing testing machine mainly comprises a cantilever supporting mechanism of a testing bearing (15), axial and radial loading mechanisms, a driving mechanism, a transmission mechanism and a heating device (23) as well as a detecting and collecting device, wherein the axial and radial loading mechanisms are used for applying changing torque and size alternation to the testing bearing (15); the heating device (23) is used for heating the testing bearing (15); two types of transmission shafts (5) are arranged; and one type of the transmission shafts is used for testing low load and high rotation speed of the testing bearing while the other type is a fixed structure used for testing bearings with diameters of more than 100 mm and bearings with rotation speeds of less than 25000 rpm in the testing bearings. According to the invention, through three groups of transmission shafts of two sets of testing mechanisms, the testing range of the testing bearing of the testing machine is enlarged.

Owner:洛阳工铭机电设备有限公司

Method for rolling and shaping titanium alloy special-shaped ring forging

ActiveCN101279345AReduce manufacturing costHigh dimensional accuracyMetal rollingTitanium alloyAbnormal shaped

The invention discloses a rolling and shaping method for a titanium alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 65 to 70 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 25 to 30 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 25 to 30 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

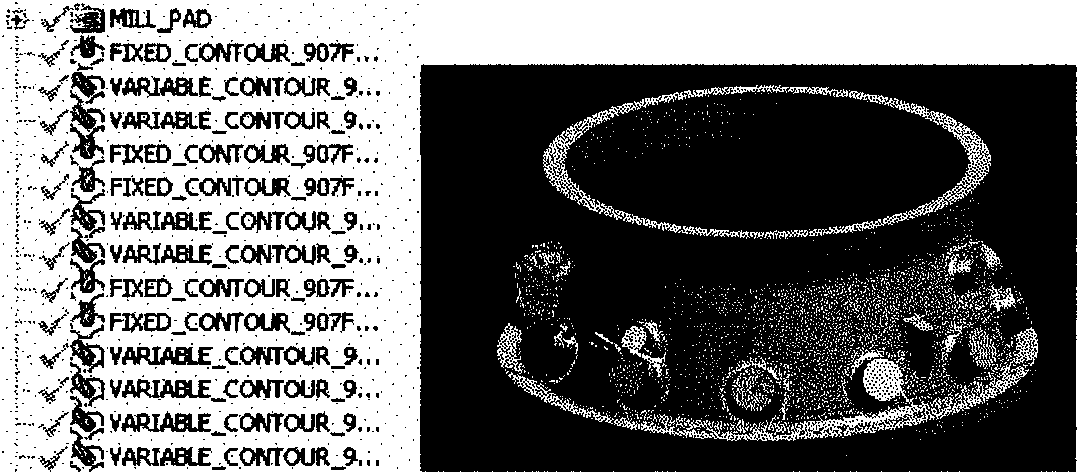

Five-axis plunge milling method of aeroengine crankcase

InactiveCN101767218AImprove processing efficiencyReduce processing costsMilling equipment detailsNumerical controlNumerical controlMilling cutter

The invention discloses a five-axis plunge milling method of an aeroengine crankcase, which is characterized by comprising the technical processes of part processing technology analysis, technology route formulation, cutter selection, cutting parameter selection, numerical control programming and processing. The invention overcomes the key technique of generating the paths of five-variable-axis plunge milling cutters of complex crankcase pieces, provides an effective means for crankcase processing, improves the crankcase processing efficiency and reduces the processing cost. The method can be used in the technical filed of numerical control processing of the parts of the aeroengine crankcases.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

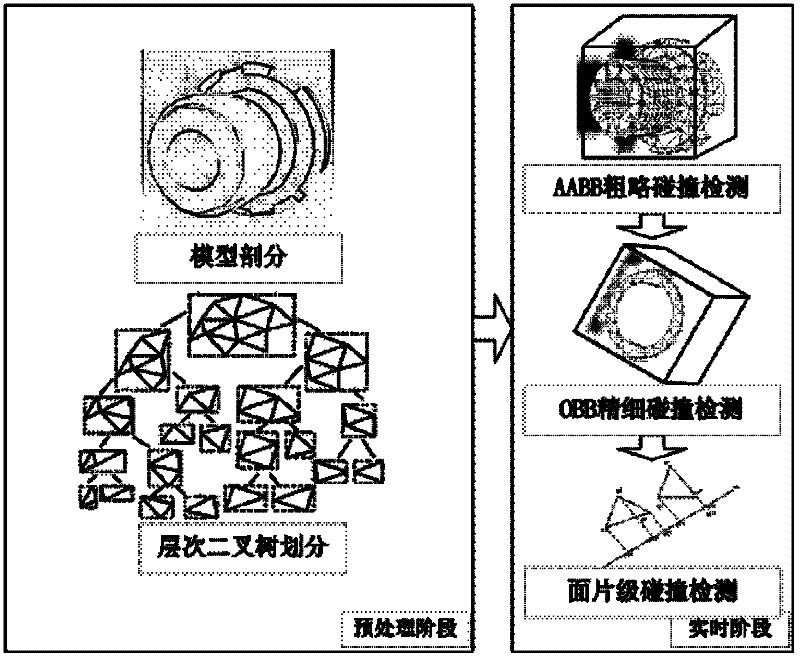

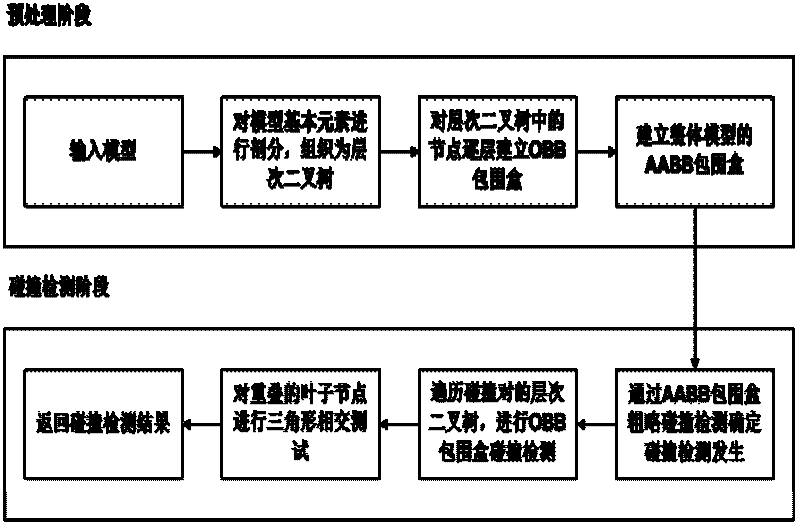

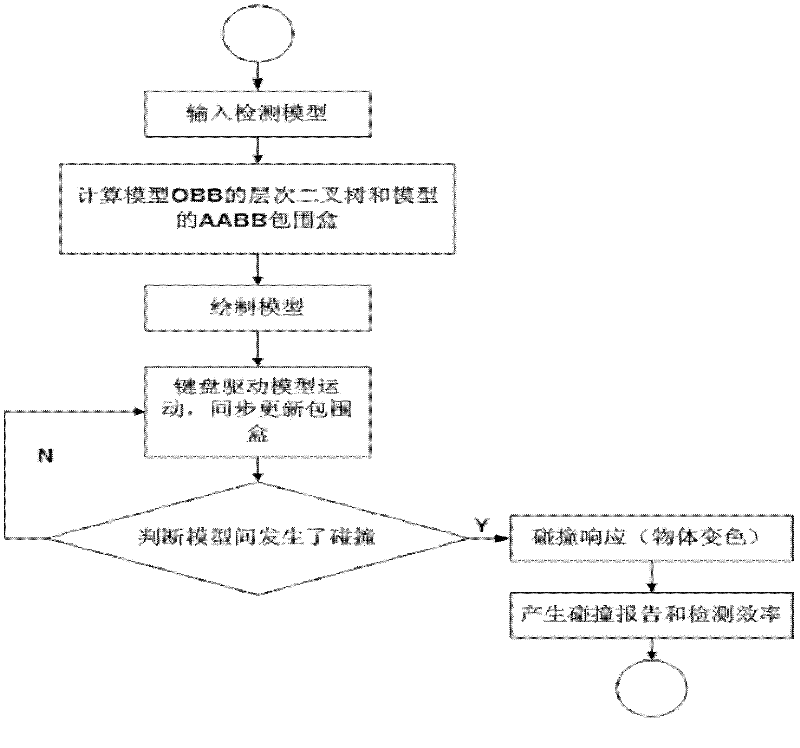

Virtual assembly-oriented collision detection method based on AABB (Axis Aligned Bounding Box)-OBB (Oriented Bounding Box) mixed bounding box

The invention provides a virtual assembly-oriented collision detection method based on an AABB (Axis Aligned Bounding Box)-OBB (Oriented Bounding Box) mixed bounding box. A pre-processing stage comprises the following steps of: splitting a model of a deformable object, establishing an OBB layered binary tree layer by layer, and establishing an AABB of the entire model. A real-time stage comprises the following steps of: maintaining the AABB at the peak of the binary tree, and carrying out rough collision detection on the entire model; maintaining an OBB at the other nodes, and carrying out accurate collision detection by using the OBB; and finally, carrying out patch-level collision detection. The method comprises the following steps of: loading a three-dimensional model; splitting the model, and establishing a layered binary tree; carrying out collision detection by using the AABB in the rough collision detection stage; carrying out collision detection by using the OBB in the accurate collision detection stage; and finally, carrying out patch-level collision detection. The method provided by the invention can ensure that in an aircraft engine assembling process, a spherical nut wrench is used for disassembling and assembling spherical nuts, and an internal hexagonal wrench is used for disassembling and assembling plug screws.

Owner:BEIHANG UNIV

Method for rolling and shaping aluminum alloy special-shaped ring forging

InactiveCN101279344AReduce manufacturing costHigh dimensional accuracyMetal rollingAbnormal shapedAero engine

The invention discloses a rolling and shaping method for an aluminum alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 50 to 55 percent, so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle pre-rolling blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 40 to 45 percent; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and forms a heterotypic ring forging after being rolled and deformed by 50 to 55 percent in a section groove. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 20000kg to 120000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

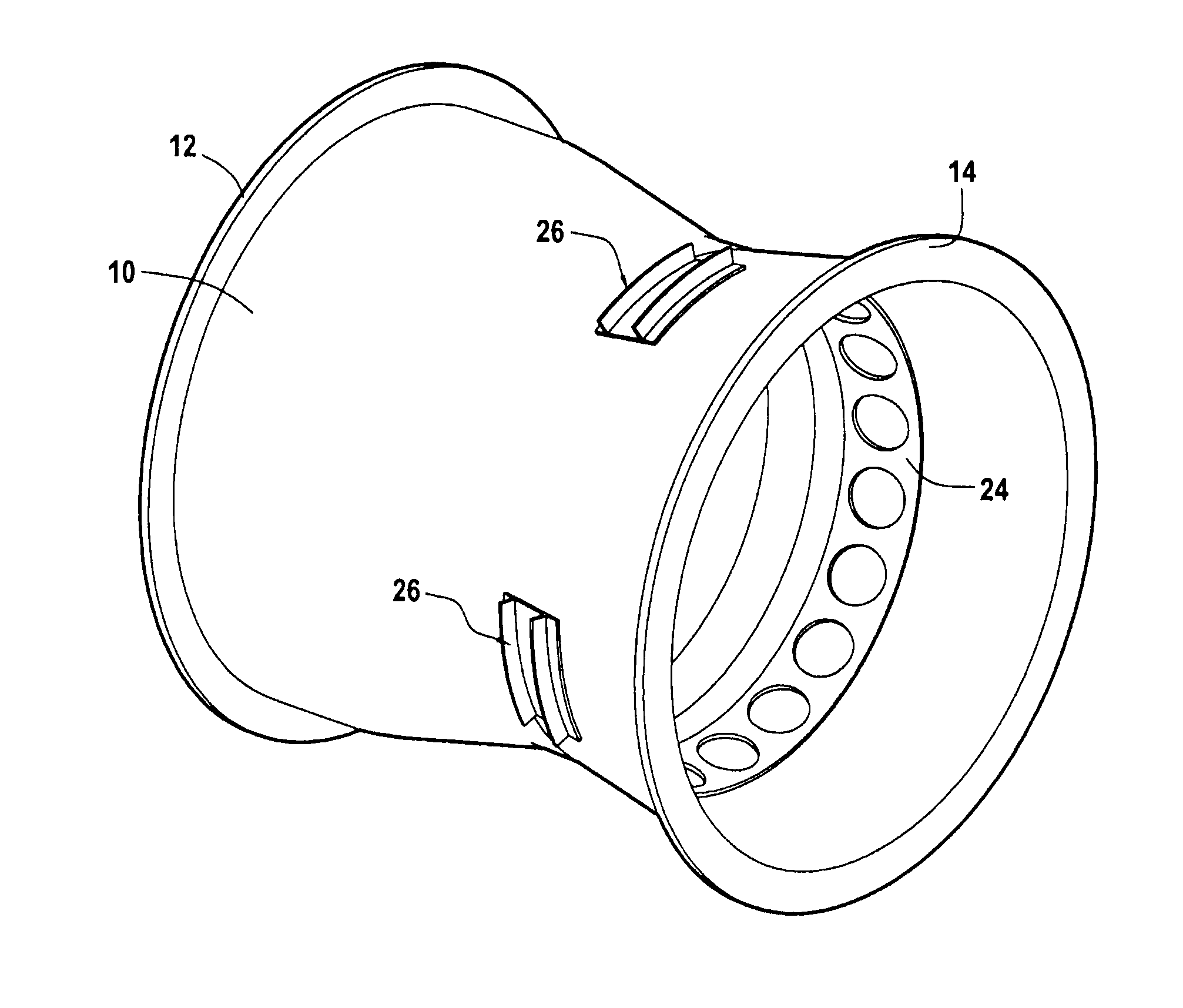

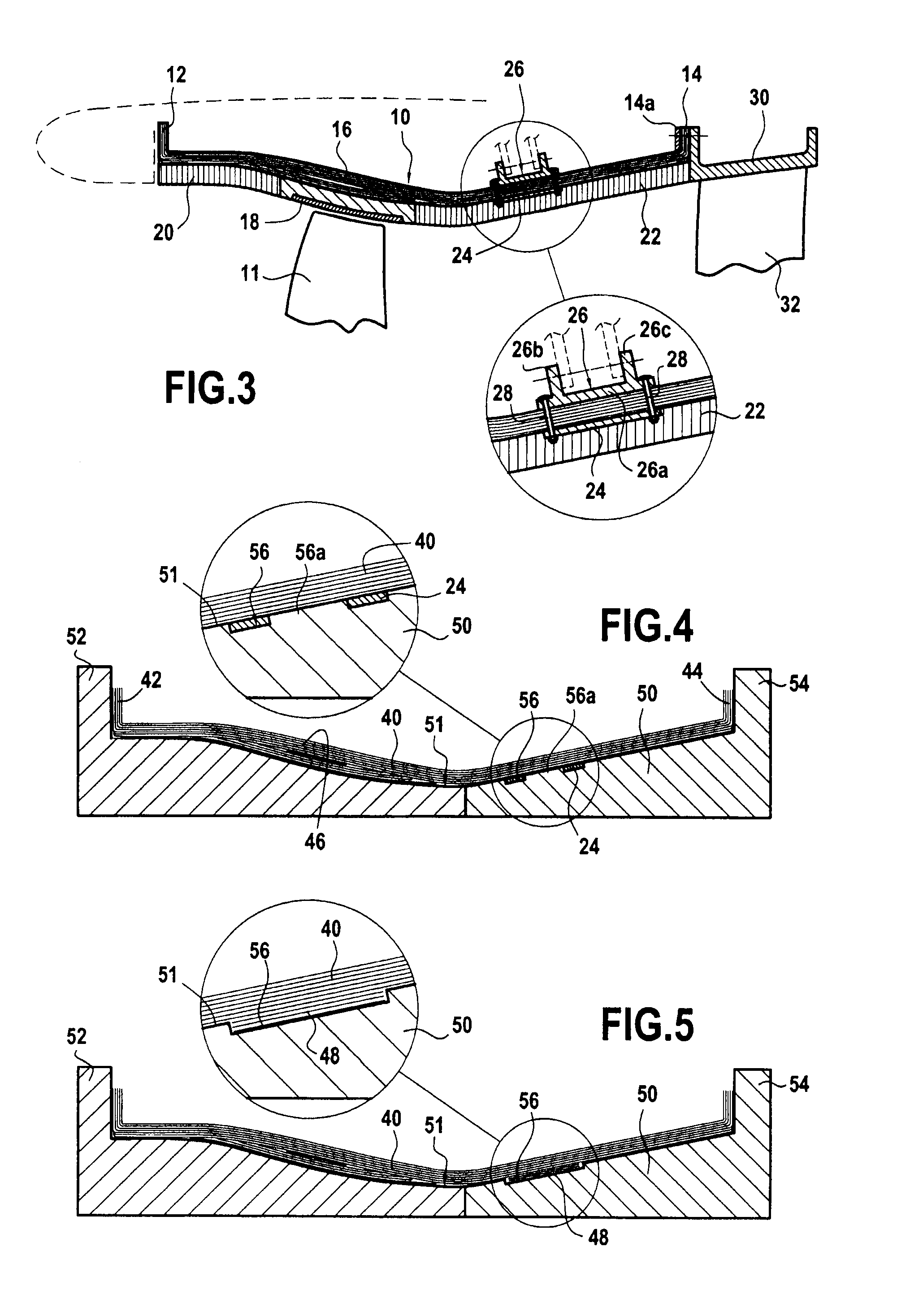

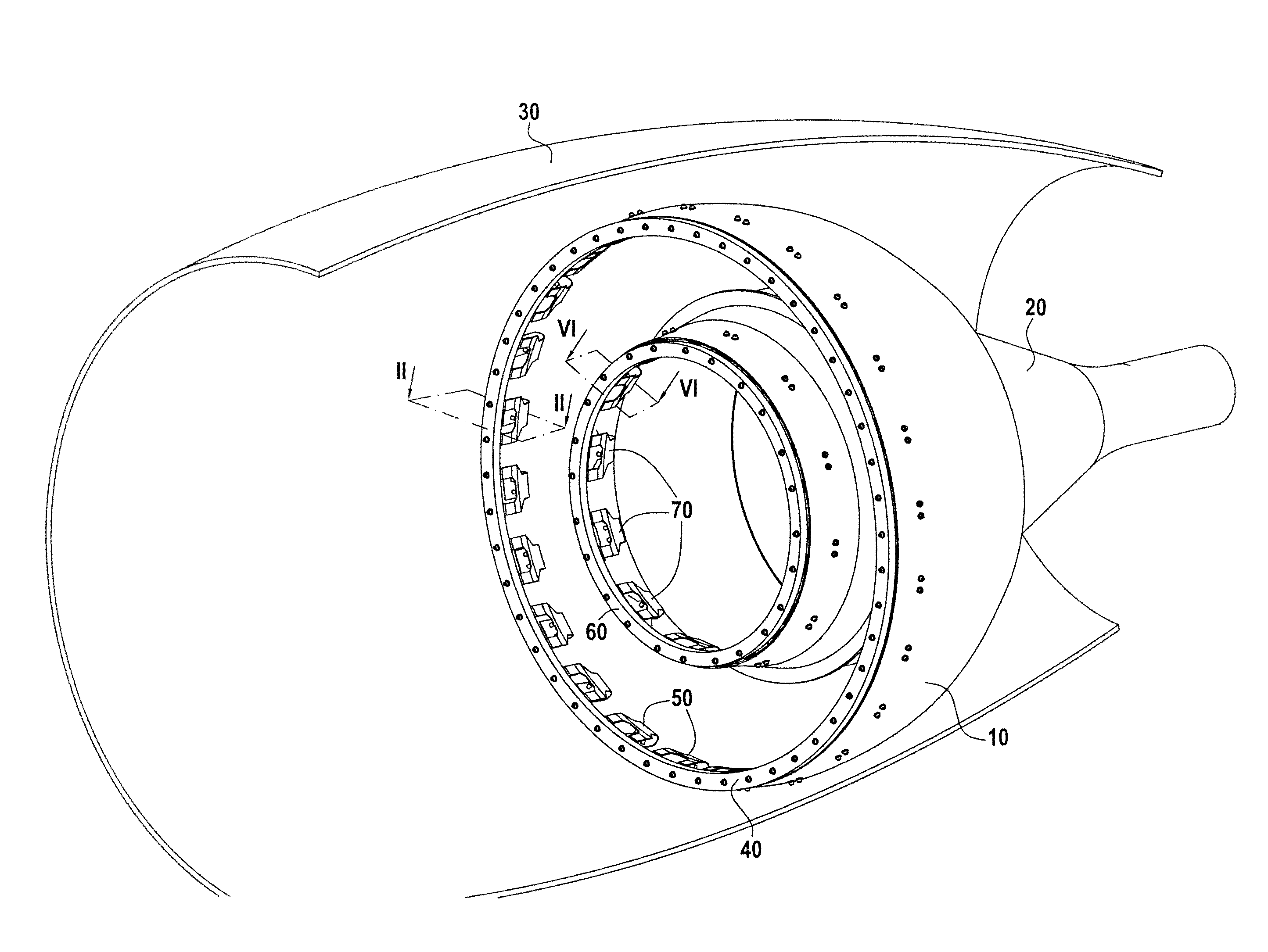

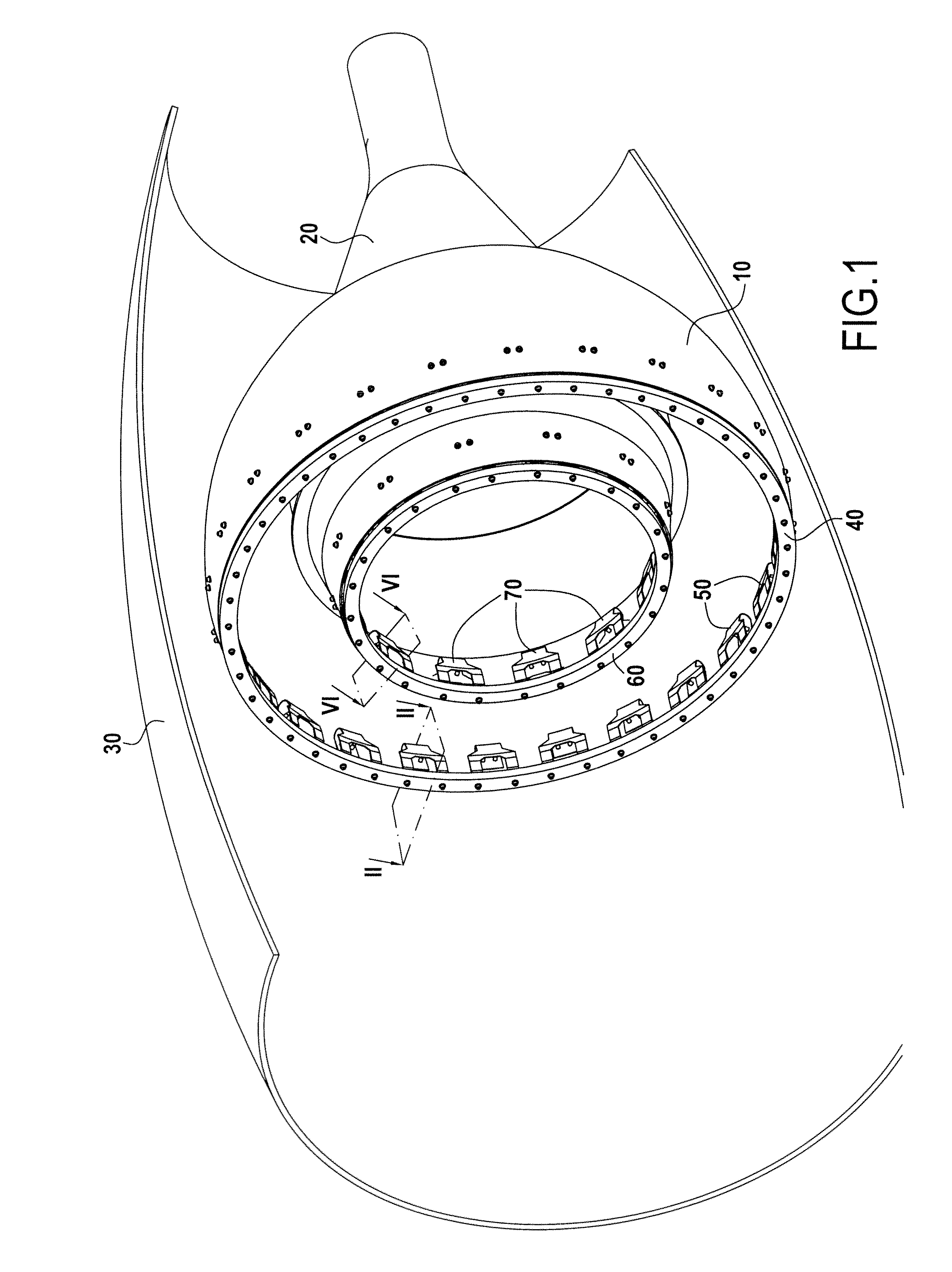

Aeroengine fan casing made of composite material, and a method of fabricating it

ActiveUS20120099981A1Avoid disadvantagesLess exposed to any riskPump componentsGas turbine plantsEngineeringAero engine

An aeroengine fan casing is made of composite material comprising fiber reinforcement densified by a matrix. The casing (10) is secured to at least one ring (24) or ring sector that is situated on the inside face of the casing and that is mechanically connected to an equipment fastener part (26) that is situated on the outside face of the casing, in particular for fastening an accessory gearbox.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

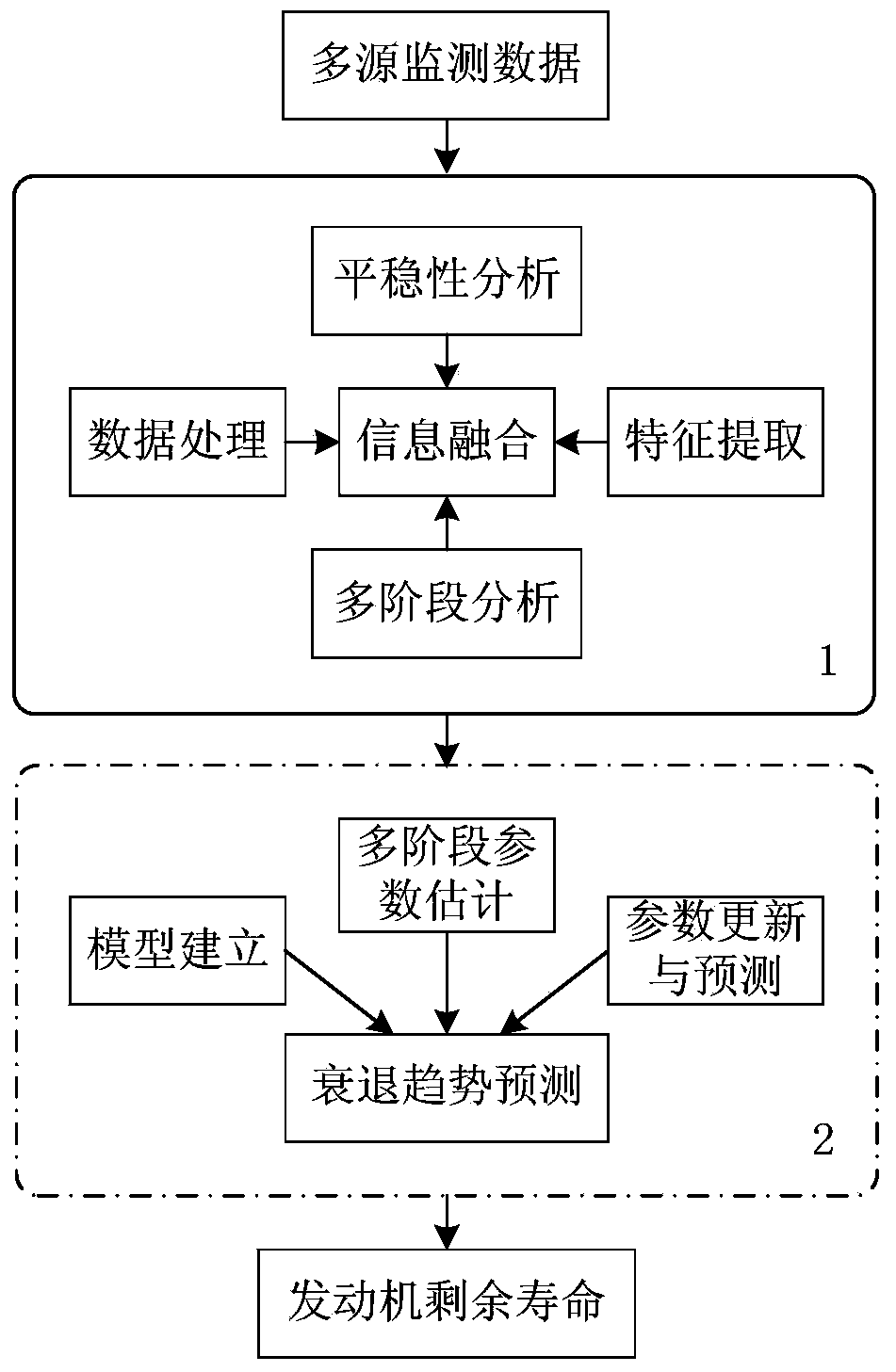

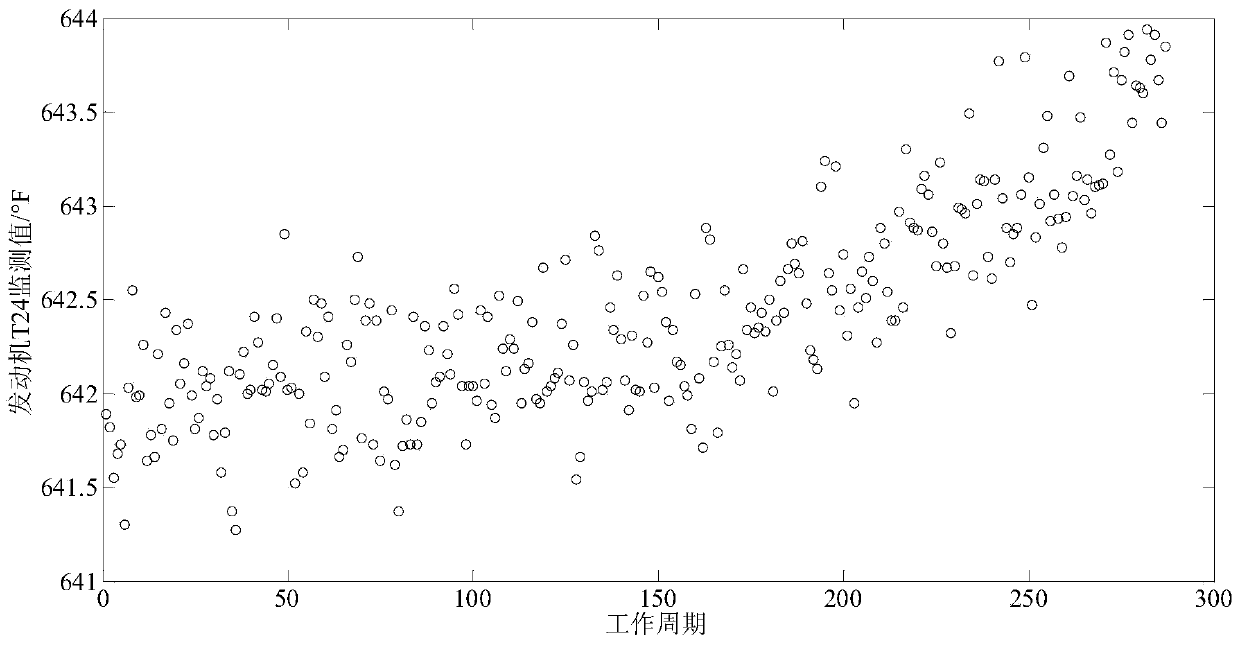

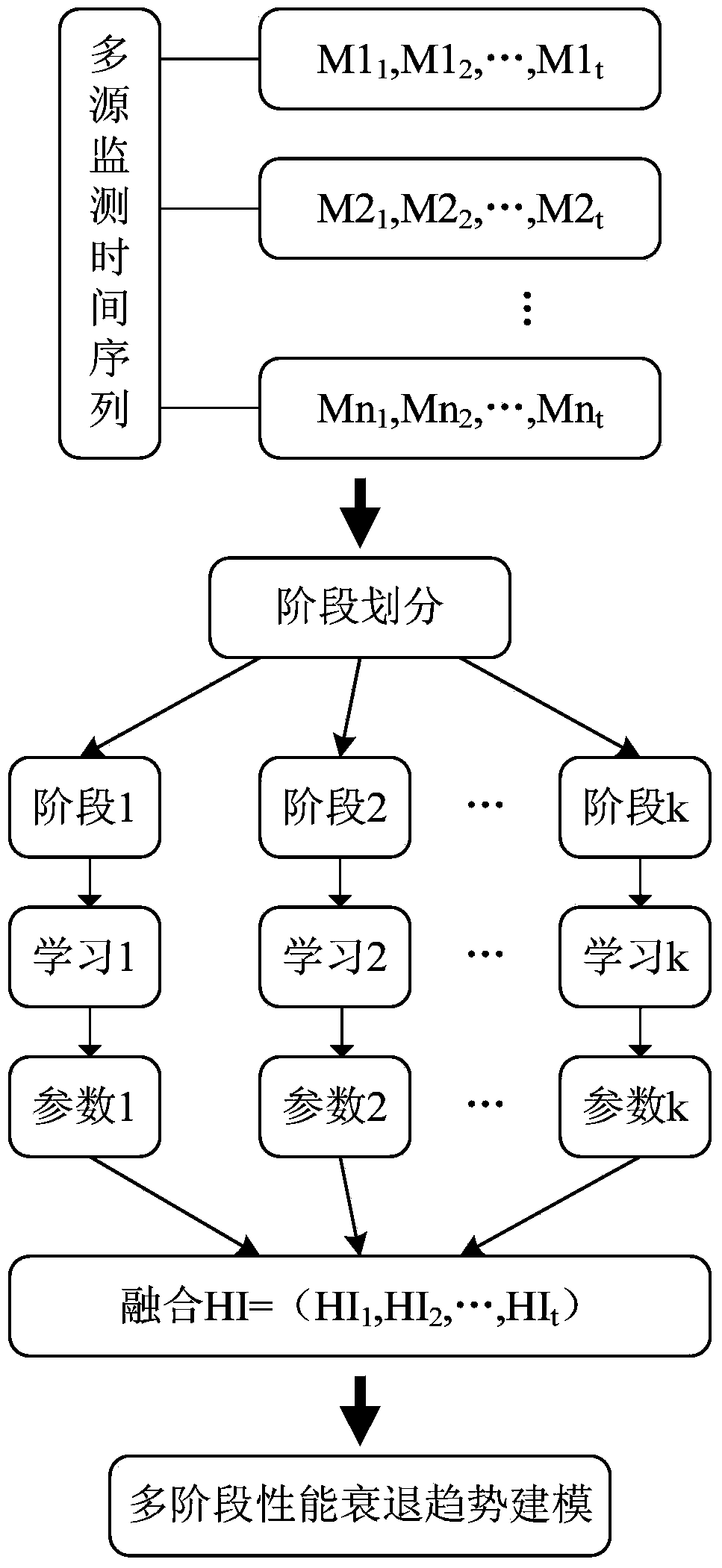

Aero-engine remaining life prediction method based on multi-stage information fusion

ActiveCN104166787AAchieve integrationRealistic representation of non-stationaritySpecial data processing applicationsAviationTest set

The invention discloses an aero-engine remaining life prediction method based on multi-stage information fusion. The method comprises the steps that multi-source monitoring parameter denoising processing and feature extraction are conducted; stable analysis is conducted on multi-source monitoring time sequences, sudden change points of all parameter monitoring time sequences are calculated and parameter degeneration proportions at the positions of the sudden change points are calculated; multi-stage division is conducted on multi-source parameters, a regression fusion model is established, sample training is conducted by using historical monitoring data and parameters, in multiple stages, of the fusion model are obtained; according to monitoring data in a training set, the multi-source monitoring parameters are fused and a health indicator HI is obtained; by using the Kalman filtering algorithm, best fit is conducted on an engine in the whole process that the performance fails from being complete, and the error of a prediction model is minimized; according to real-time monitoring data in a test set, the multi-source monitoring parameters are fused and a health indicator HI is obtained; time-varying parameters of the prediction model are estimated in real time by using the Kalman filtering algorithm; the prediction model is determined, the time mechanism is introduced and the failure time of the engine is estimated in real time.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Electrolytic machining method for thin-wall machine case of aero-engine

ActiveCN104384643AFix stability issuesSolve the costElectrical-based machining electrodesElectrochemical machining apparatusConvex structureAviation

The invention provides an electrolytic machining method for a thin-wall machine case of an aero-engine, belonging to the technical field of electrolytic machining. The electrolytic machining method mainly aims at the machining of a surface concave-convex structure of a complicated thin-wall rotary body part in the aviation field, and is characterized in that a tool cathode is of a thin-wall strip-shaped structure or a rigid rotary body structure; window or lug boss structures with different shapes are distributed on the surface of the cathode. In a machining process, a workpiece anode automatically rotates and the tool cathode is fed to the anode in a peripheral movement process. In the whole machining process, electrodes do not need to be replaced, and the surface concave-convex structure of the thin-wall rotary body part is machined and molded once through rolling sleeve electrolytic action of a cathode window.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Test device for surface deformation and material and test method thereof

InactiveCN101672749AHeating up fastFast mechanical loadingMaterial strength using tensile/compressive forcesUsing optical meansOptical testStrength of materials

The invention discloses a test device for surface deformation of a material and a test method thereof, wherein the device comprises a material mechanical property test machine, an infrared fast heating device, a surface deformation optical test system, a temperature collecting device, a vacuum system and a clamp. The clamp fixes a sample in a vacuum chamber of the vacuum system and is connected with the material mechanical property test machine, the infrared fast heating device supplies thermal load for the sample, and the surface deformation optical test system measures the surface deformation of the sample. The device and the test method can simultaneously heat, apply stress and synchronously test deformation field in the surface. The coupling simulation of an aero-engine under service environment with high temperature and loading level, and the surface deformation condition of the structural material with high temperature under the environment are tested.

Owner:BEIHANG UNIV

Low-pollution combustion chamber with premixed and pre-evaporated precombustion part

ActiveCN102022753ADoes not affect work stabilityReduce pollutionContinuous combustion chamberCombustion chamberPollutant emissions

The invention relates to a low-pollution combustion chamber with a premixed and pre-evaporated precombustion part, which adopts a monocylic cavity structure and comprises a pressure diffuser, an outer receiver of a combustion chamber, an outer wall of a flame tube, an inner wall of the flame tube and a combustion chamber head, wherein all air for combustion enters the flame tube from the combustion chamber head, a grade combustion scheme is adopted and comprises a precombustion grade and a main combustion grade ; the main combustion grade adopts a premixed combustion mode, and the precombustion grade adopts a mode of combining diffusion combustion with stable rotational flow and rotational-flow premixed combustion; and the precombustion grade adopts the mode of combining the diffusion combustion and the premixed combustion, and pollutant discharge under a small working condition is reduced without influencing stable combustion. In the invention, the precombustion grade structure is simple, and the pollutant discharge is reduced under a small working condition without influencing the combustion stability so as to ensure that the pollution discharge of the whole landing and take-off (LTO) of an aircraft engine combustion chamber is further reduced.

Owner:BEIHANG UNIV

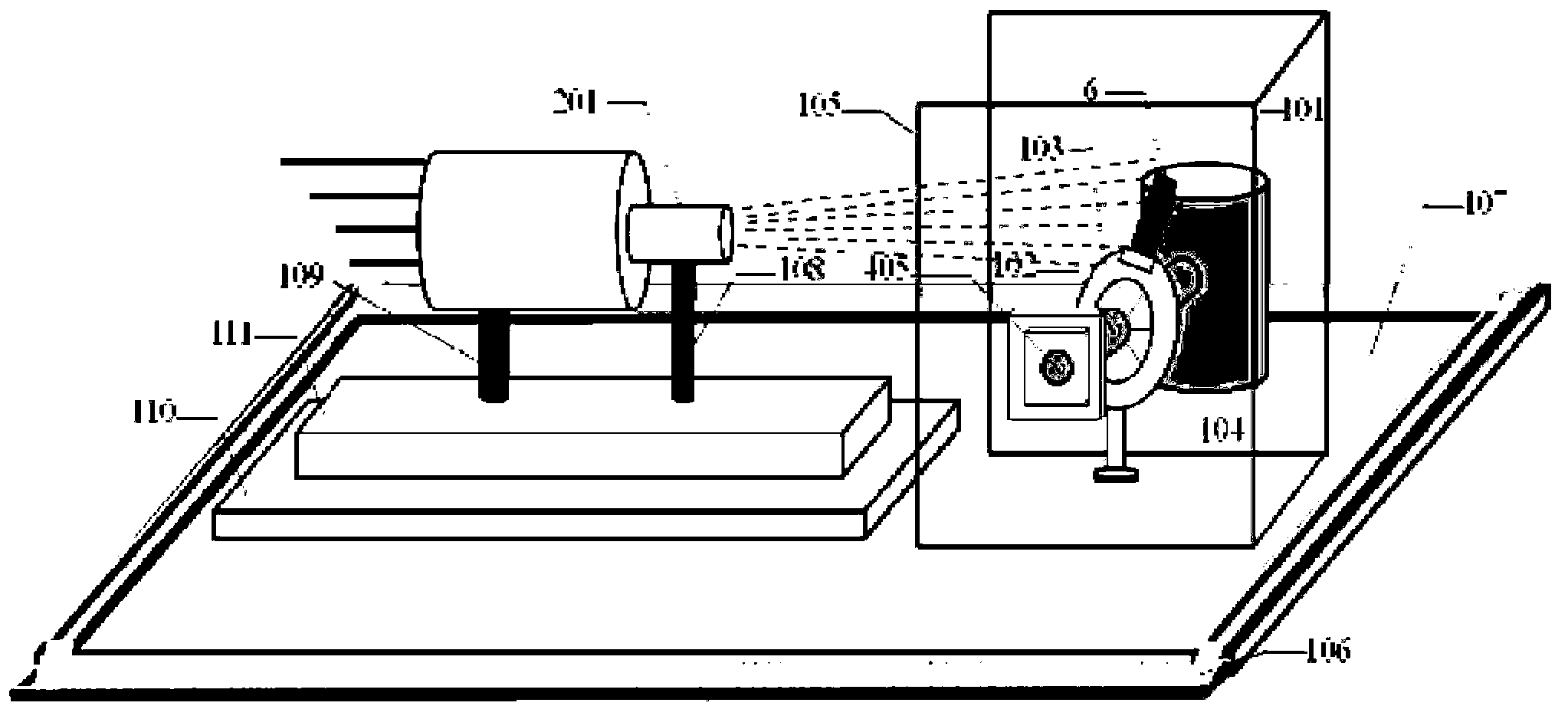

Testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades

ActiveCN103063534AEasy to realize included angleFast heating rateInvestigating abrasion/wear resistanceTest platformTopography

The invention discloses a testing device for simulation and real-time detection of erosion of thermal barrier coatings of turbine blades, belonging to the field of simulation devices in a special service environment. The testing device comprises an erosion particle feeding system, a test testing platform (1), a temperature test system, an acoustic emission nondestructive testing system, a control platform and the like. An erect fixed shaft (101) is arranged on the test testing platform (1) and is connected with a horizontal supporting shaft. The testing device can be used for simulating the erosion service environment in which hard particles in a high-performance aero-engine repeatedly impact thermal barrier coatings of turbine blades due to the driving of airflow. By controlling the parameters such as erosion speed, angle, size and the like of erosion particles, the process that the coatings are eroded by different hard particles in the service process is realized and the real-time test and analysis of data, such as the temperature, the surface topography evolution, the interfacial oxidation of a sample and the like can be synchronously realized. The device can provide an important test platform for effectively assessing the erosion failure process and the failure mechanism of coatings of turbine blades in the special service environment.

Owner:XIANGTAN UNIV

Method for rolling and shaping nickel-based high-temperature alloy special-shaped ring forging

The invention discloses a rolling and shaping method for a nickel-based high temperature alloy heterotypic ring forging in order to obtain the alloy heterotypic ring forgings with excellent tissues and properties as well as realize accurate rolling. The method includes the following steps: alloy bar material is heated, carried out continuous upsetting and deformed by 60 to 65 percent so as to be made into a solid cake and then is punched again to lead the alloy bar material to be made into a hollow round cake after the aperture dimension of the alloy bar material is 30 to 35 percent of the dimension of the outer diameter thereof; a rectangle ring blank is obtained after the hollow round cake is heated, rolled circularly and deformed by 20 to 25 percent; a rectangle pre-rolling blank is obtained after the rectangle ring blank is heated, rolled circularly and deformed by 20 to 25 percent again; the pre-rolling blank is heated and arranged in a rolling die of a ring rolling machine and becomes a heterotypic ring forging after being rolled and deformed by 40 to 45 percent in a section groove of the die. When in expansion, the broadening speed of the pre-rolling blank along the radial direction is 2mm / s to 15mm / s with a radial rolling force of 40000kg to 220000kg. The method is mainly used for the shaping of the heterotypic ring forging of an aeroengine or a gas turbine. The method can be adopted to obtain the heterotypic ring forging that is arranged in a flow line along the outline of a part.

Owner:GUIZHOU ANDA AVIATION FORGING

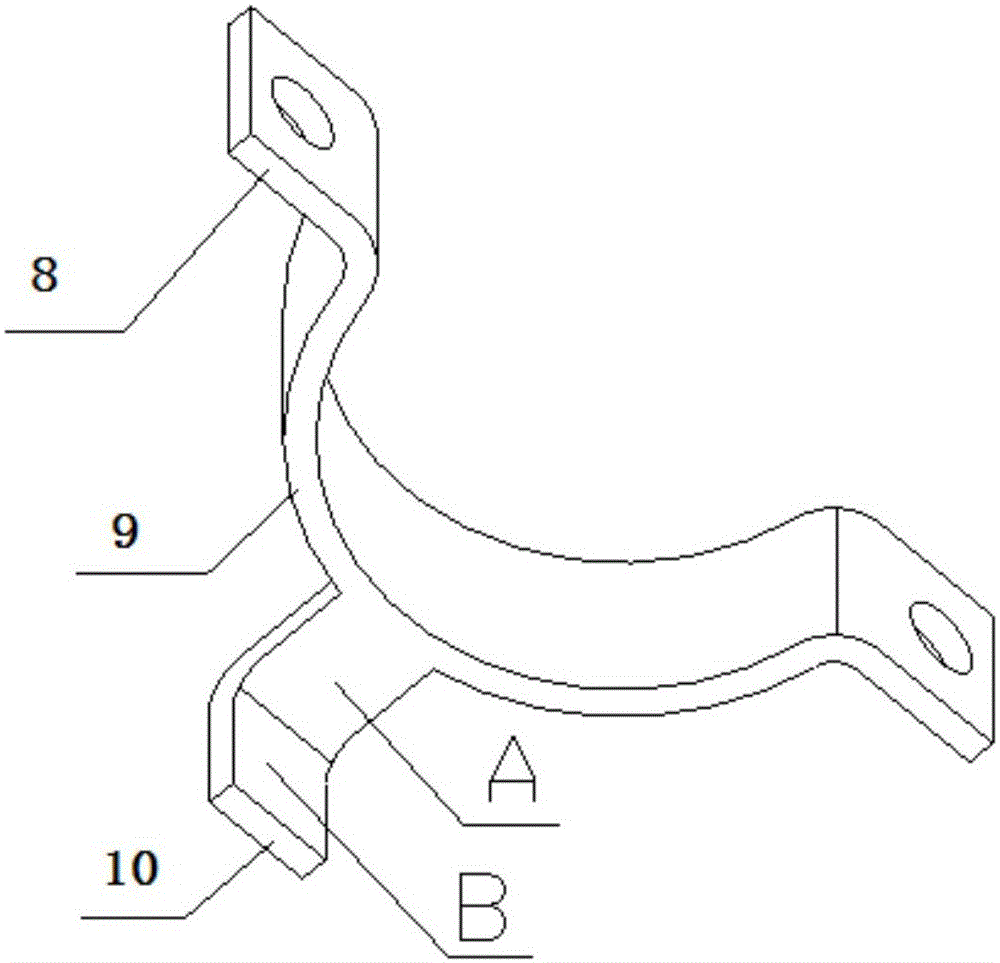

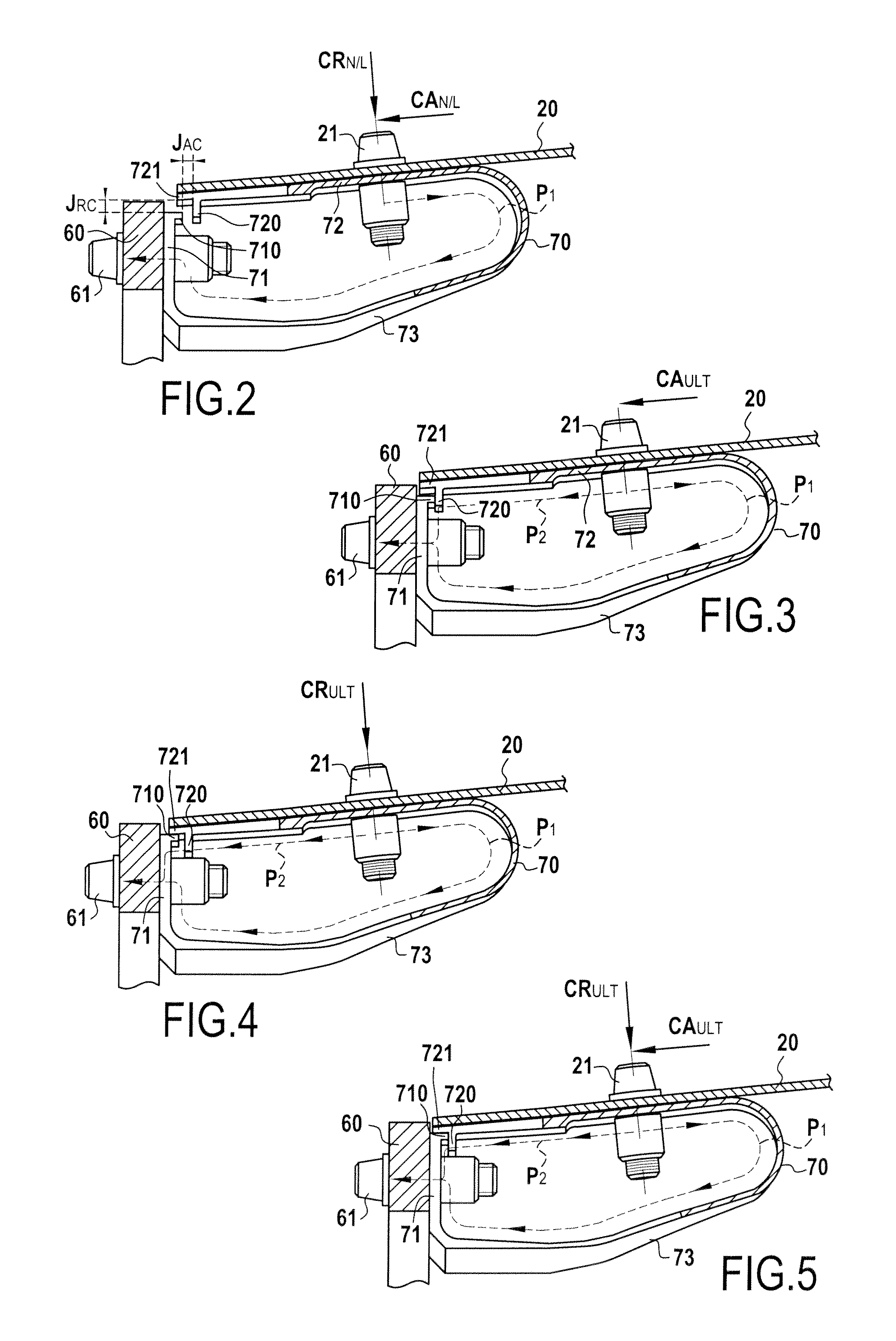

Flexible abutment links for attaching a part made of cmc

InactiveUS20110203255A1Without degrading flexibilityReduce weightPower plant exhaust arrangementsPropulsive elementsMetallic materialsEngineering

An after-body assembly for an aeroengine, the assembly including, in an axial direction, an annular part made of metallic material secured to the aeroengine and an after-body part made of ceramic matrix composite material presenting the form of a body of revolution at least in its upstream portion, the after-body part being mounted on the annular part by resiliently flexible fastener tabs, each fastener tab having a first end fastened to the annular part and a second end fastened to the upstream portion of the after-body part, wherein each fastener tab includes an axial abutment element extending radially from the second end of the tab, the axial abutment element facing the first end and a radial abutment element at the second end of the tab, the radial abutment element overlying the first end in a radial direction.

Owner:SAFRAN NACELLES

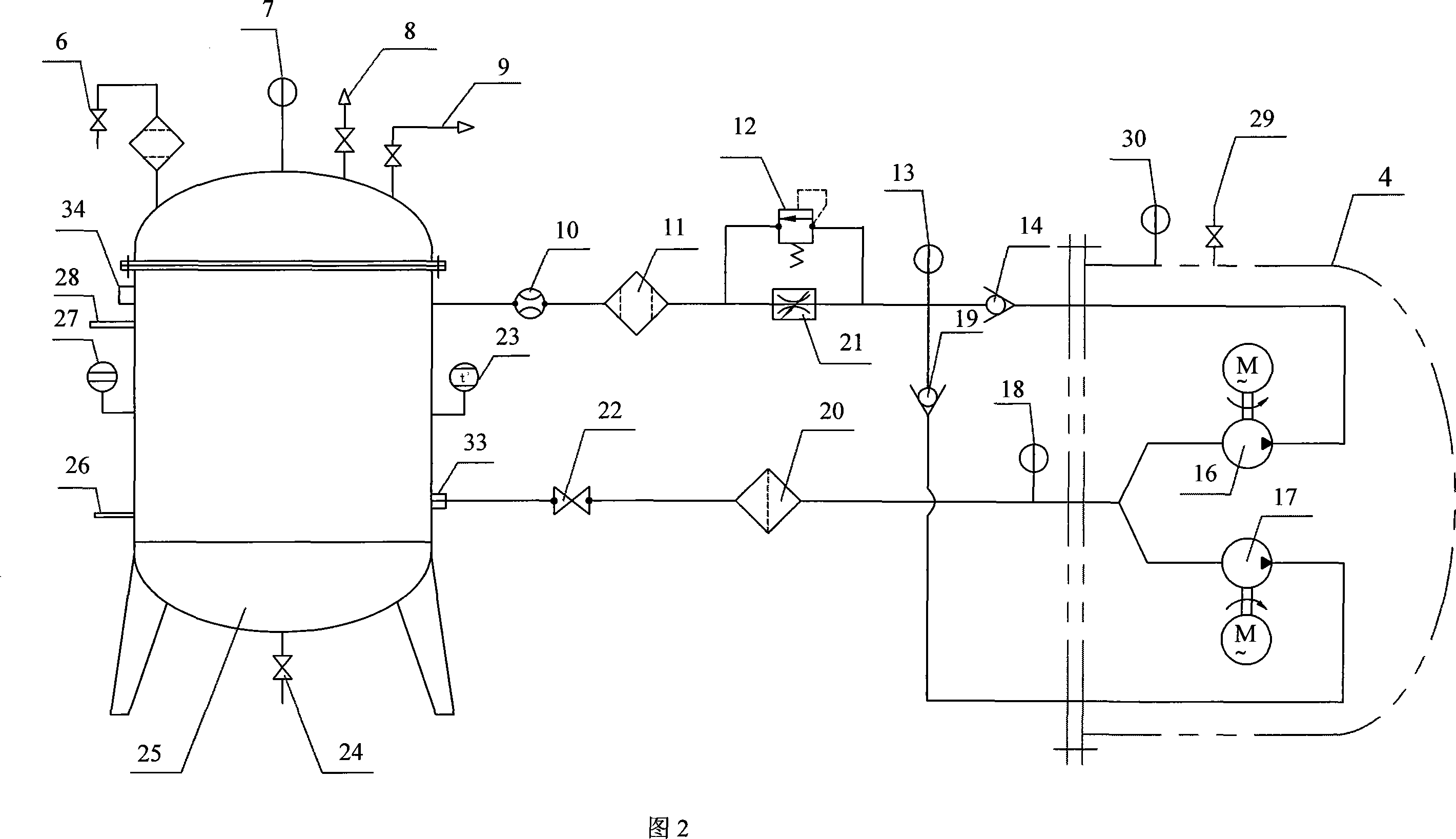

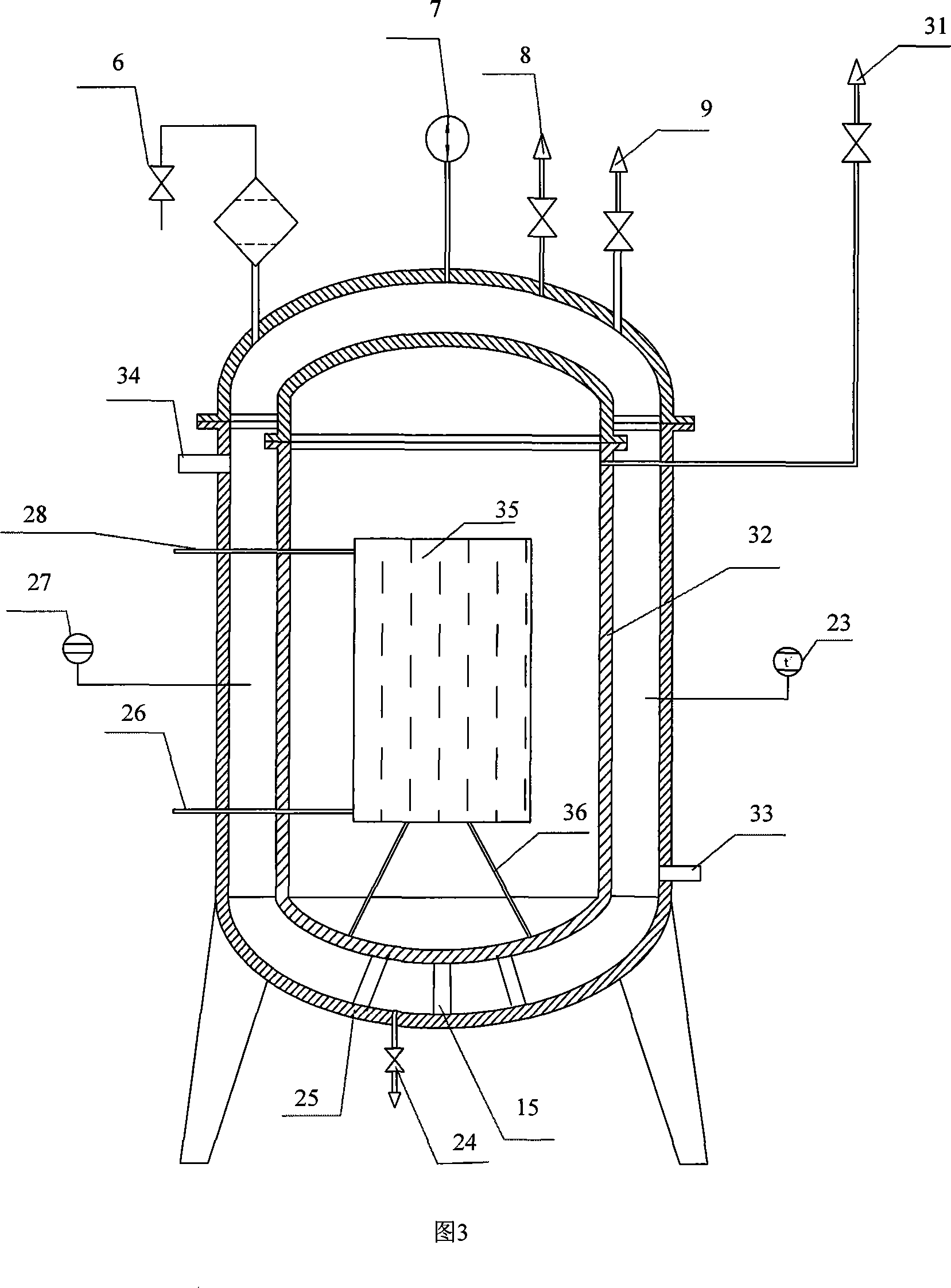

Device and method for testing upper air performance of aircraft engine fuel oil system

InactiveCN101231215AImplement performance testingAccurate control of fuel temperatureInternal-combustion engine testingAviationFuel tank

The invention discloses an aeroengine fuel system altitude performance testing unit and a test method thereof. The testing unit comprises an equipment cabinet, a control computer, a display instrument, a high altitude box, a fuel tank, an oil pipeline, a vacuum pump package and various valves, wherein, the inner part of the high altitude box is provided with a testing oil fuel pump which is connected with the fuel tank through the oil pipeline inside the equipment cabinet, the fuel tank has a structure with low temperature resistance and atmospheric depression resistance, can simulate the high altitude working environment of the fuel system of the aeroengine. The test method utilizes the fuel tank capable of simulating the atmospheric depression and the low temperature of the high altitude and a high altitude box capable of simulating the atmospheric depression, adopts the pipeline and the valves to adjust the oil inlet pressure and the oil return pressure, and uses a flowmeter, a thermometer and a pressure gauge to read the parameter values. The test of altitude simulations of an oil supply system of an electronic oil fuel pump of an aircraft piston engine can be performed by the method.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com