Method for testing assembly performance of rotor of aircraft engine

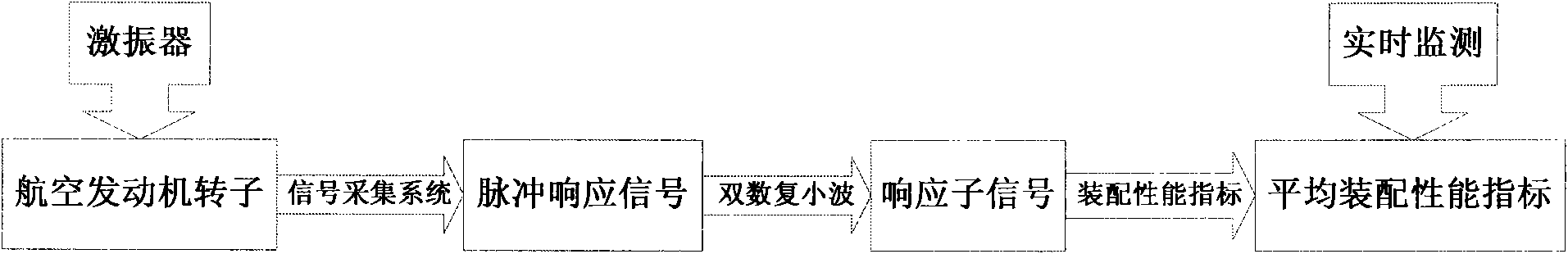

An aero-engine and rotor assembly technology, which is applied in the direction of engine testing, vibration testing, machine/structural component testing, etc., can solve problems that affect the quality and efficiency of aero-engine assembly, complex assembly process, poor accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

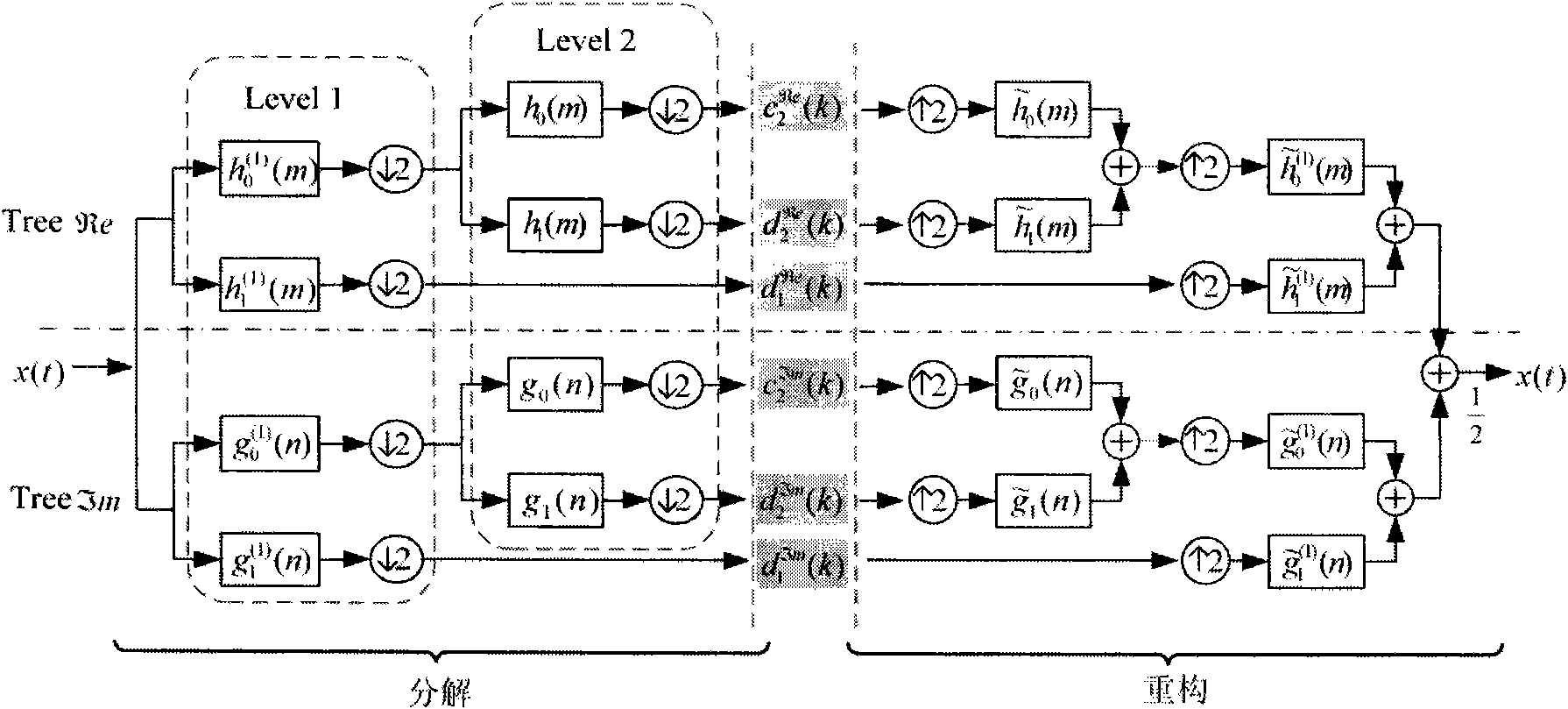

Method used

Image

Examples

Embodiment

[0100] This embodiment provides the specific implementation process of the present invention in engineering practice, and at the same time verifies the effectiveness of the present invention.

[0101] The three-state test and analysis of the vibration exciter for the high-pressure compressor rotor of an aero-engine:

[0102] (1) The 24 bolts of the high-pressure compressor rotor of the aero-engine are assembled in a qualified state;

[0103] (2) The 24 assembly bolts of the high-pressure compressor rotor of the aero-engine are loosened by half a turn;

[0104] (3) The 24 assembly bolts of the high-pressure compressor rotor of the aero-engine are loosened by one circle each;

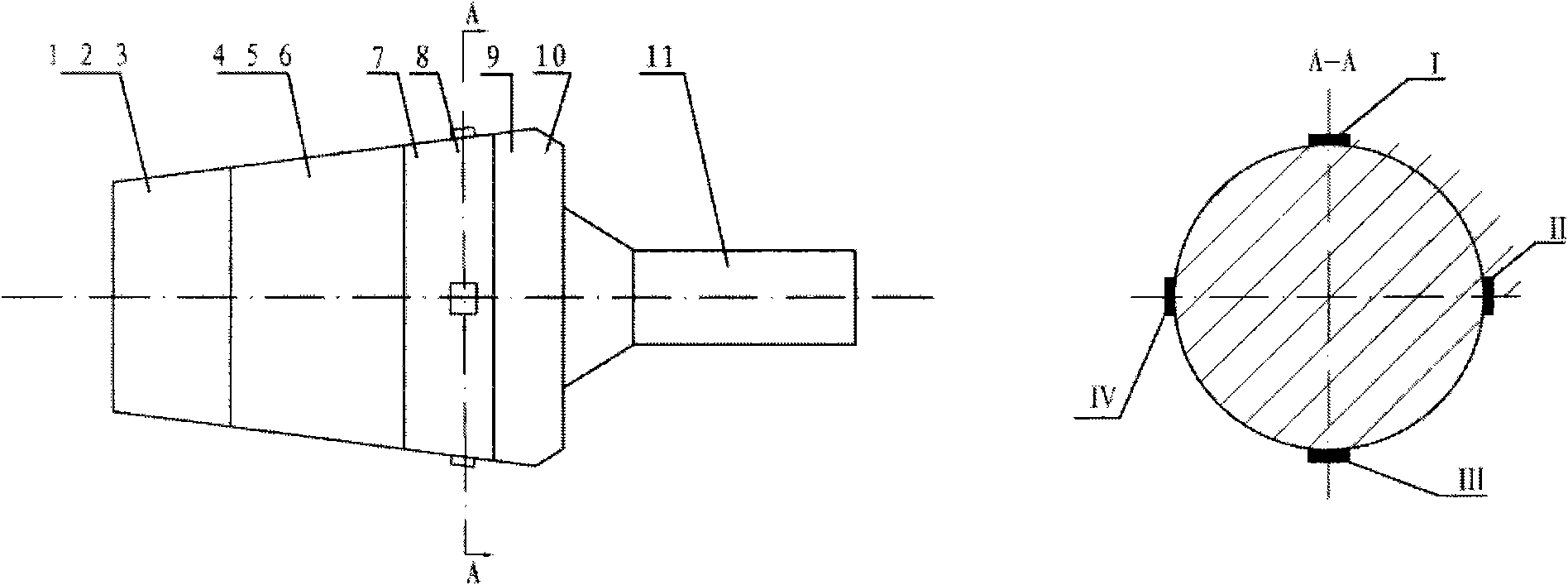

[0105] The vibrator is the LC series hammer produced by Beijing Appruite Technology Development Co., Ltd. The vibrator acts on figure 1 Different positions of the high pressure compressor rotor shaft 11 are shown. The vibration sensor is a 333B32 type ICP acceleration sensor vibration sensor produced b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com