Patents

Literature

129 results about "Dual tree" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

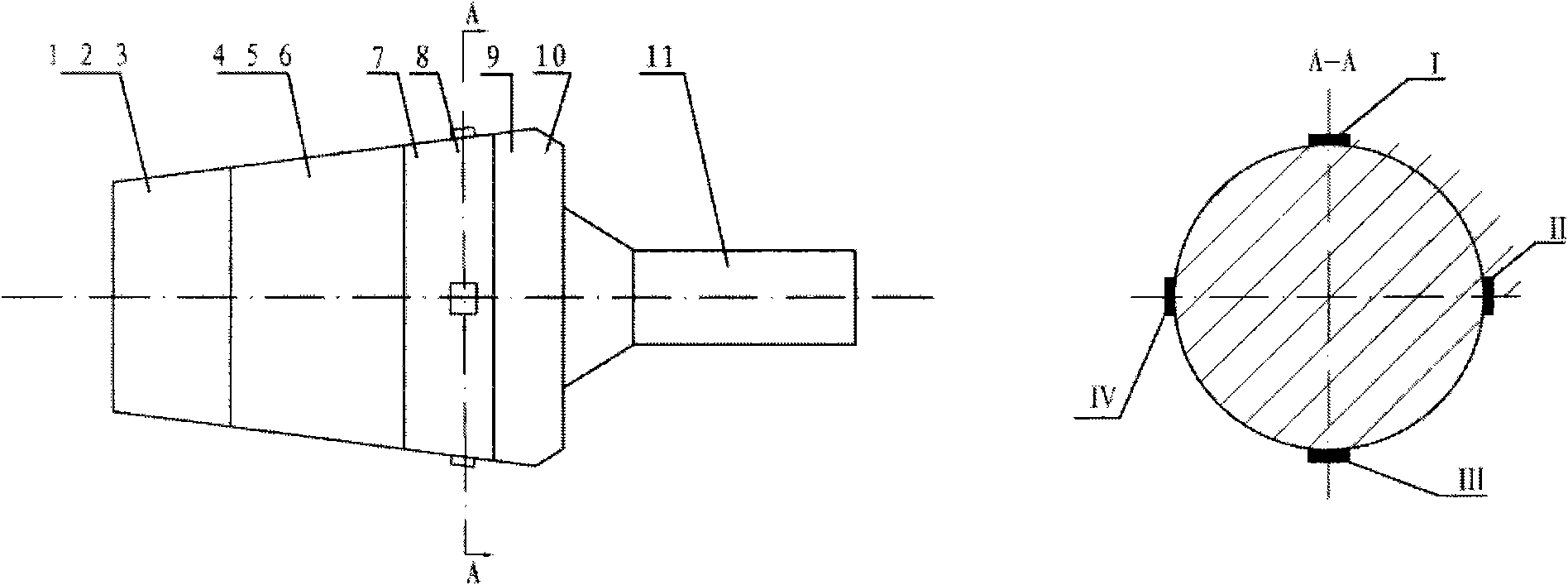

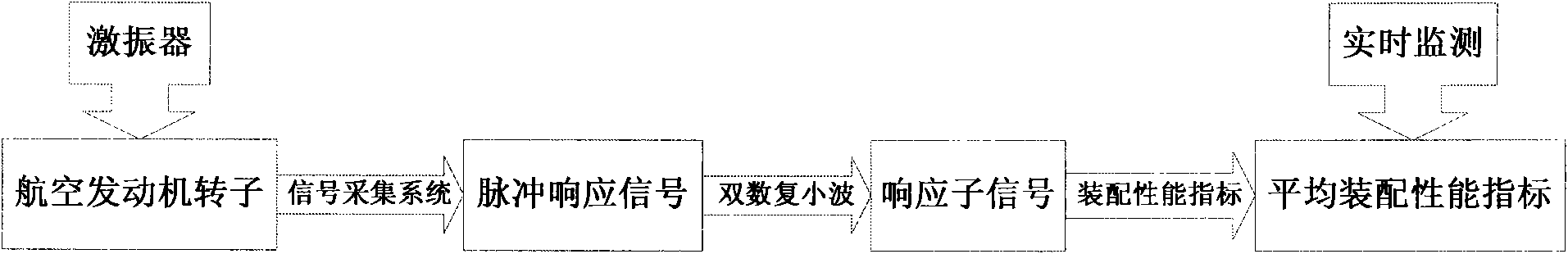

Method for testing assembly performance of rotor of aircraft engine

ActiveCN101799354AQuality improvementSave assembly timeEngine testingVibration testingAviationCarrier signal

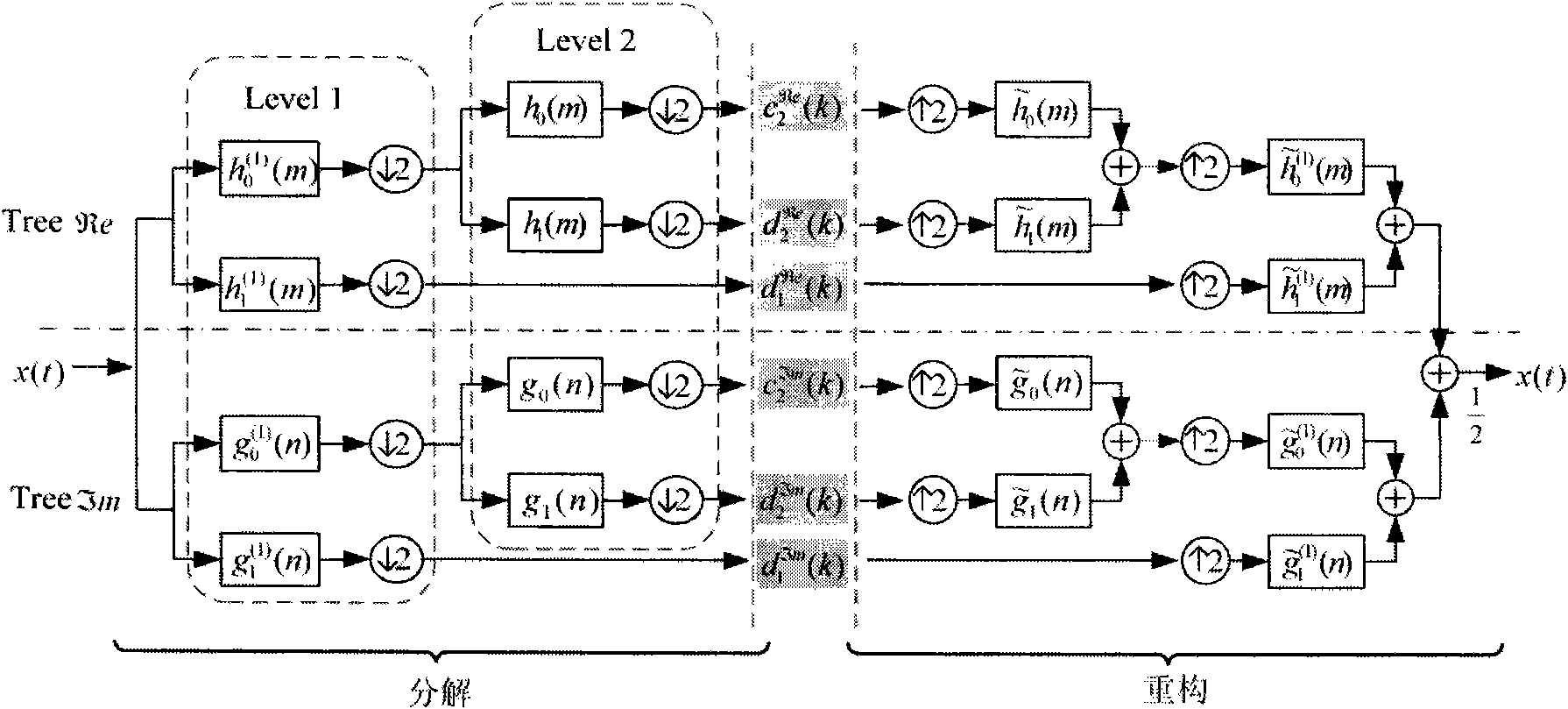

The invention discloses a method for testing the assembly performance of a rotor of an aircraft engine, which comprises the following steps of: firstly exciting and vibrating a rotor of an aircraft engine with a vibration exciter; obtaining a multiple carrier-coupled impulse response signal of the rotor of the aircraft engine with a vibrating sensor and signal-acquiring system software; analyzing the obtained multiple carrier-coupled impulse response signal of the rotor of the aircraft engine by means of dual-tree complex wavelet transform to obtain eight signal carrier-coupled impulse response signals of the rotor of the aircraft engine; and distilling the average assembly performance index of the obtained eight signal carrier-coupled impulse response signals of the rotor of the aircraft engine, wherein the assembly performance of the rotor of the aircraft engine is judged to be qualified if the obtained average assembly performance index is larger than or equal to 10, and the assembly performance of the rotor of the aircraft engine is judged not to be qualified if the obtained average assembly performance index is less than 10, so that the rotor needs to be repaired.

Owner:XI AN JIAOTONG UNIV

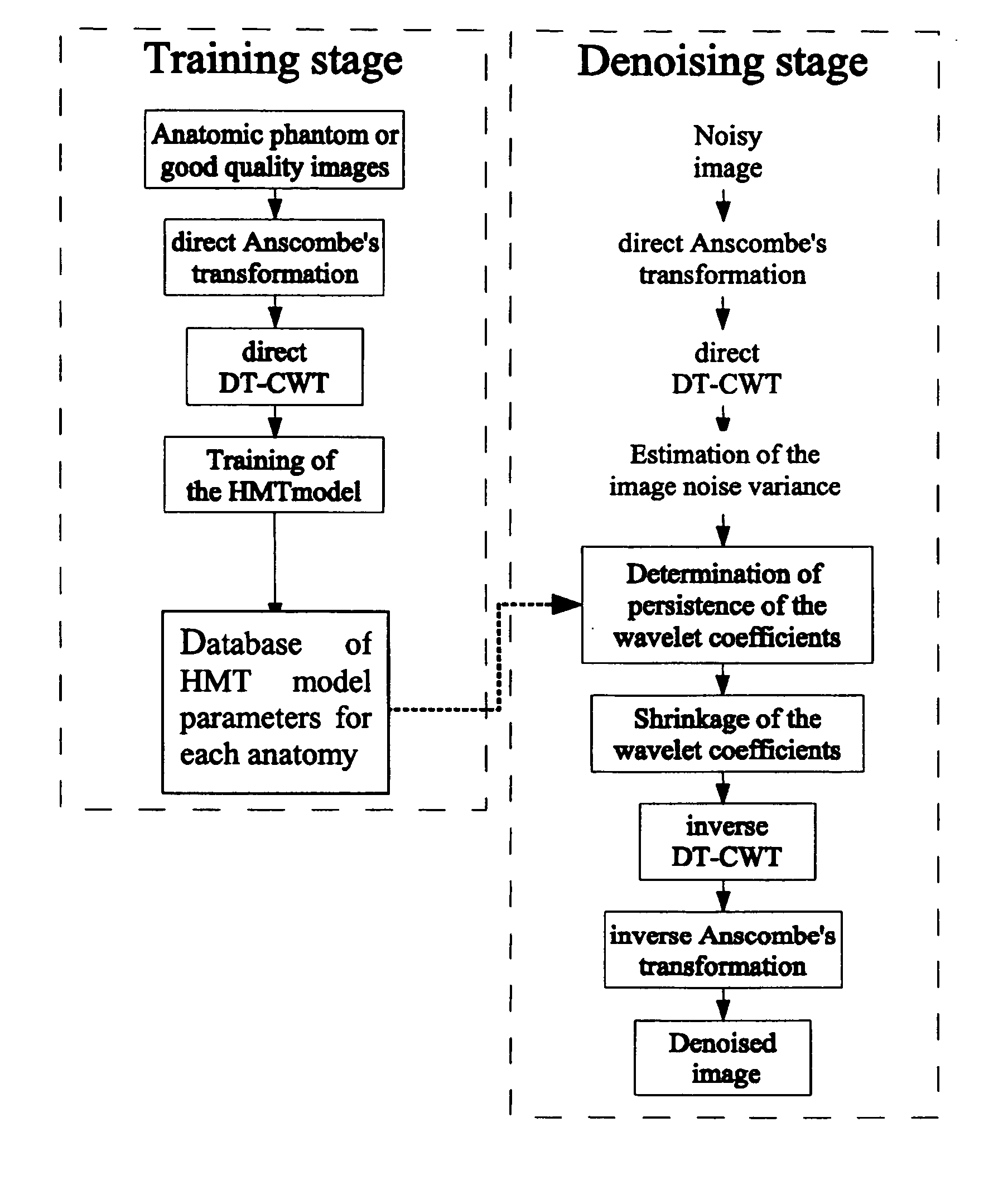

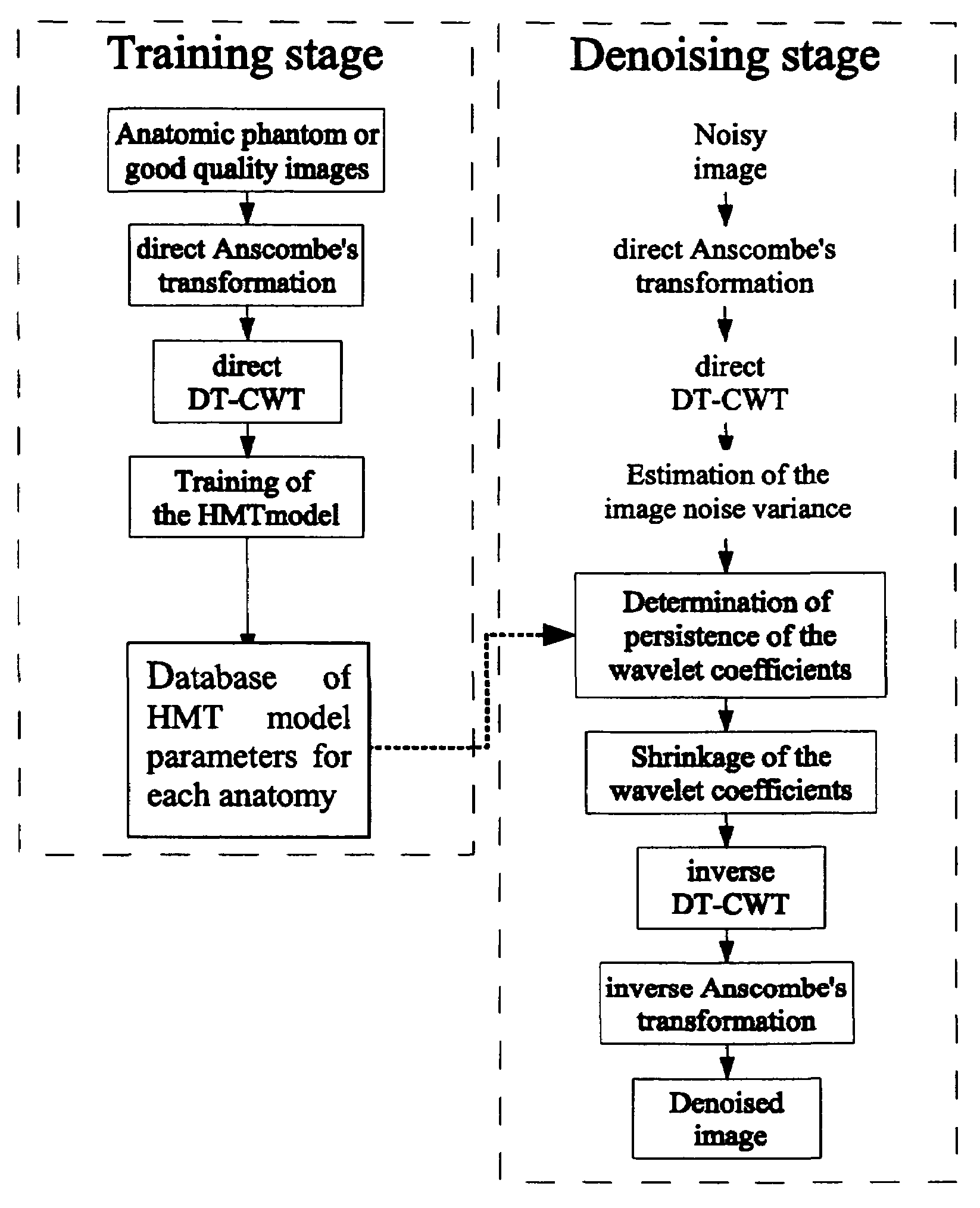

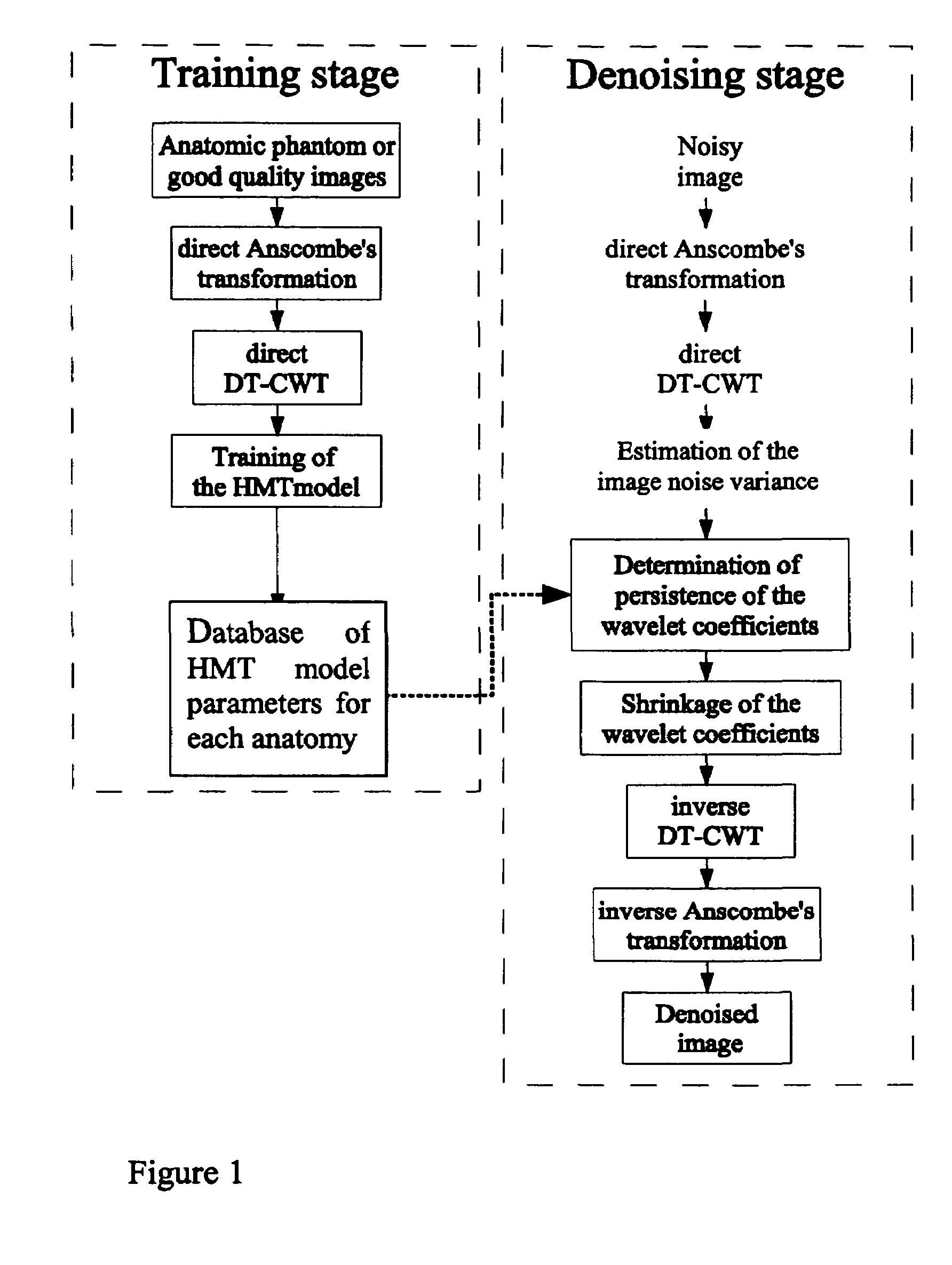

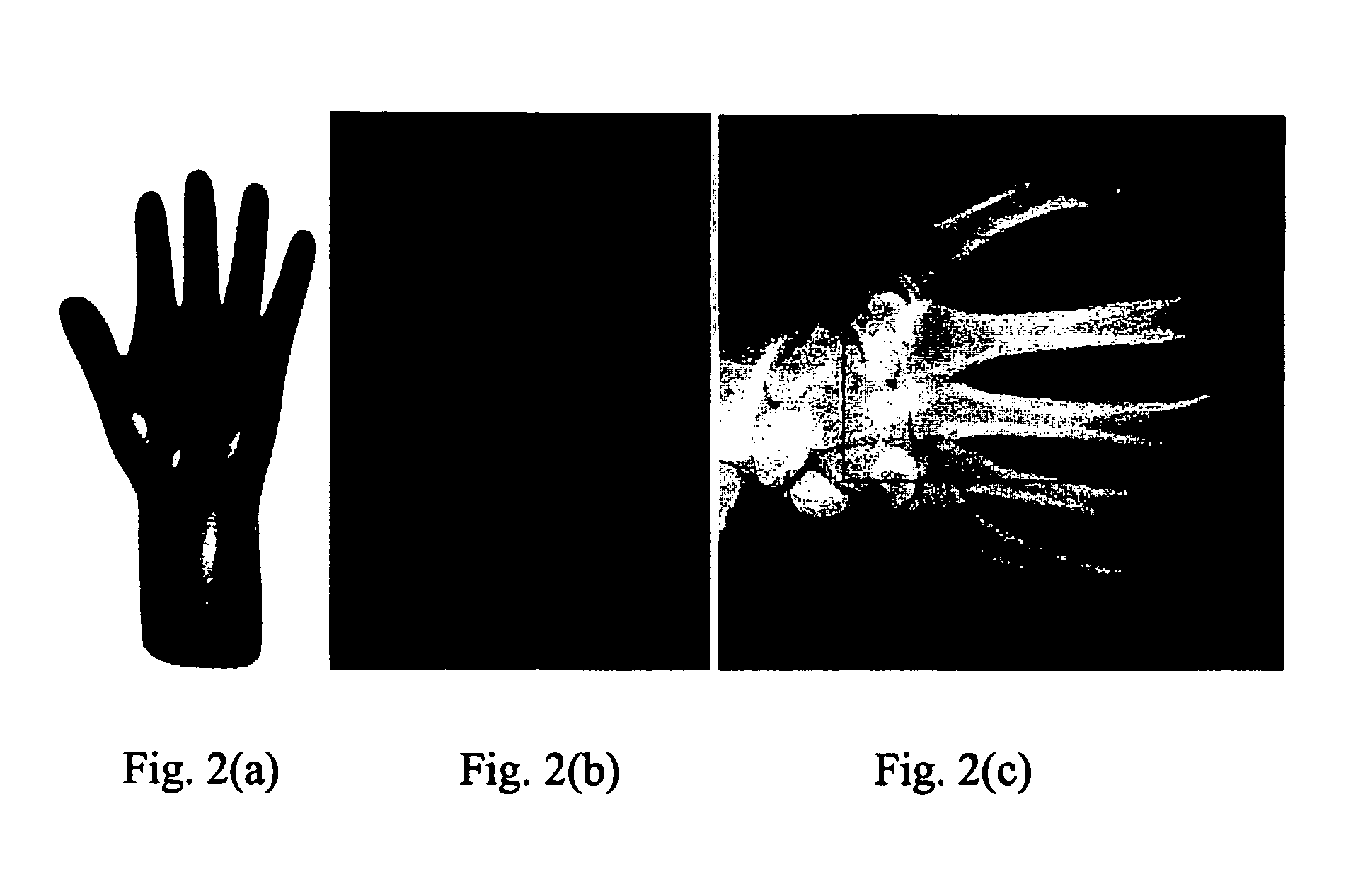

De-noising digital radiological images

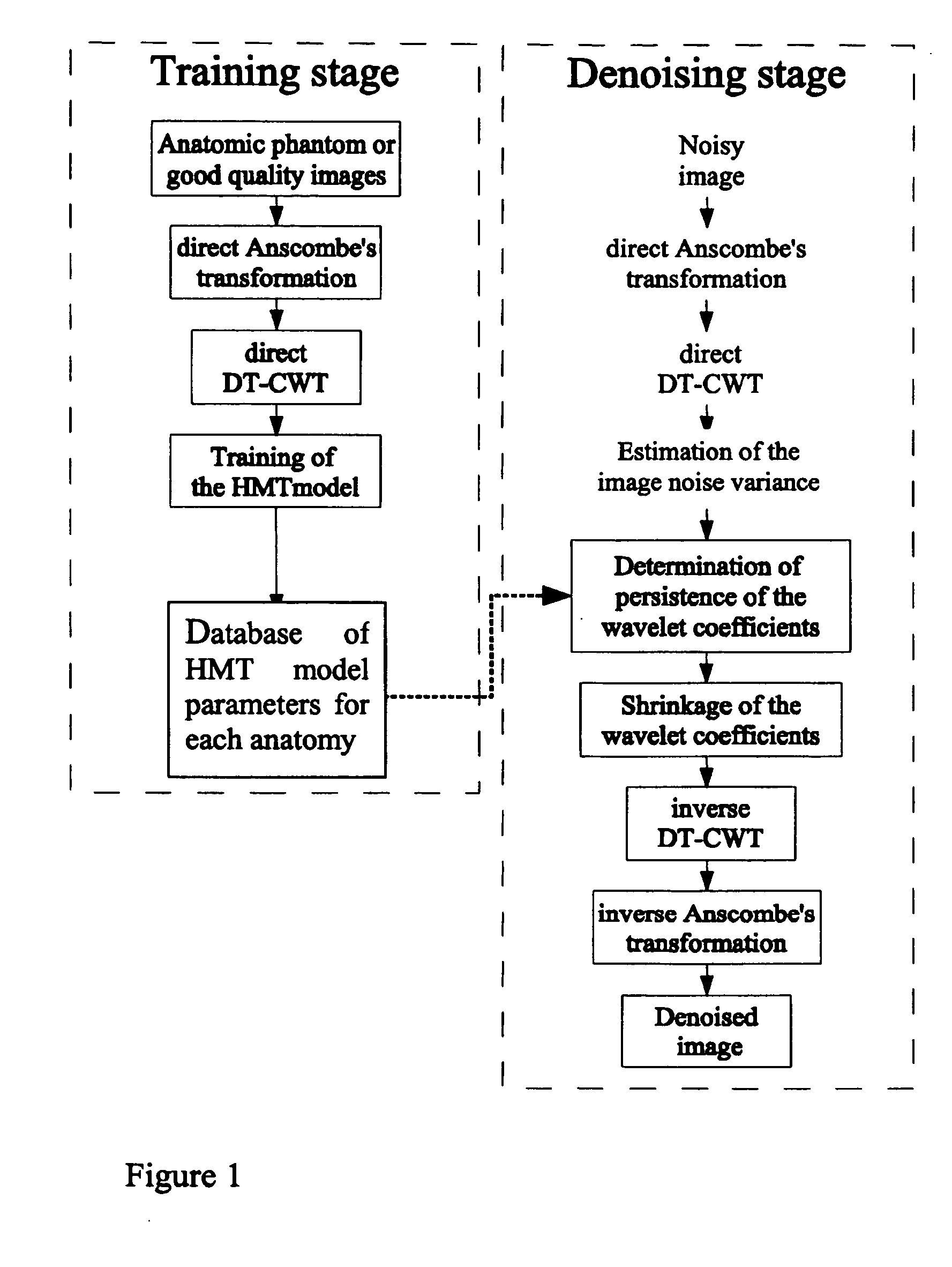

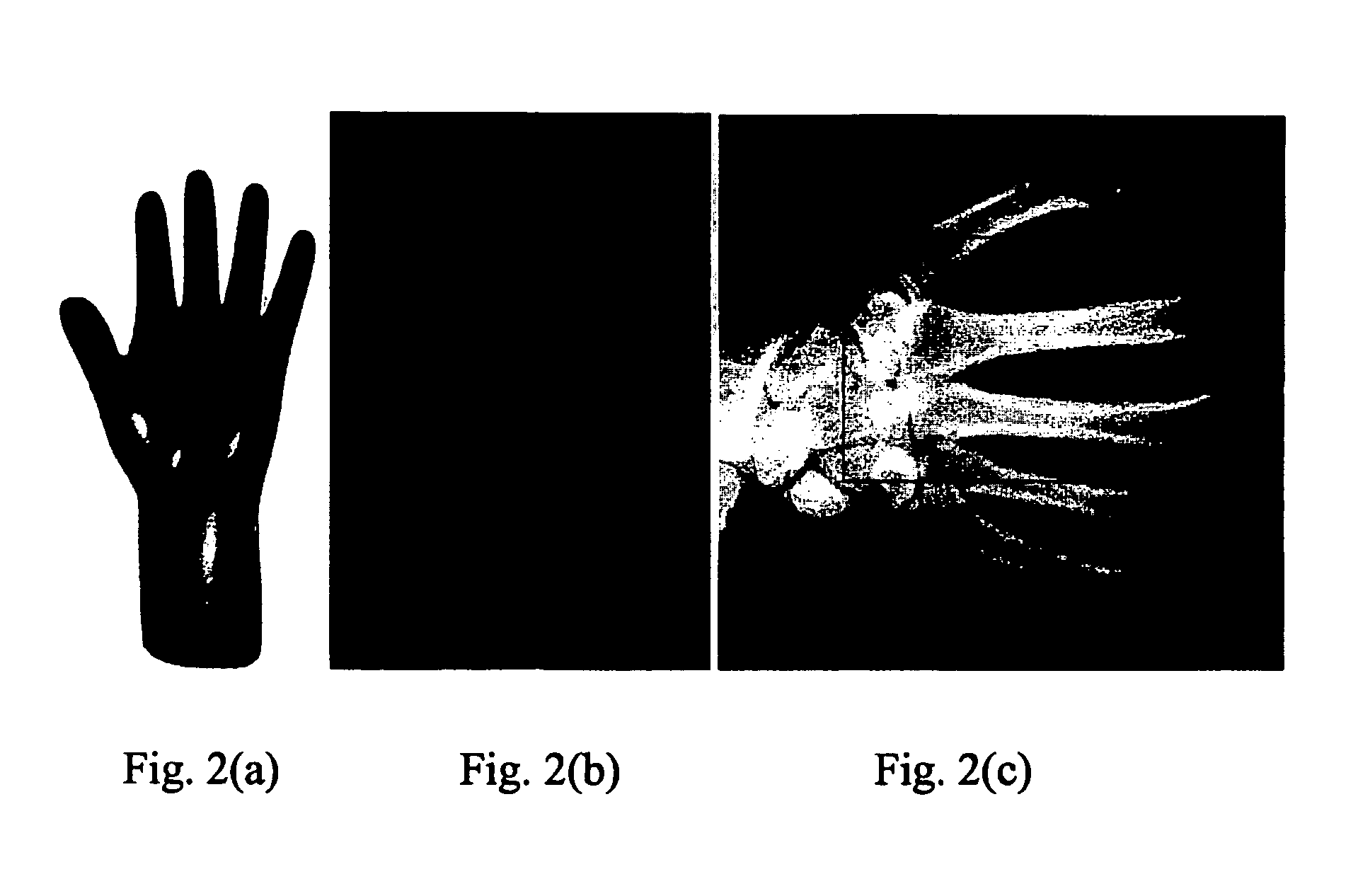

This invention relates to a method for de-noising digital radiographic images based upon a wavelet-domain Hidden Markov Tree (HMT) model. The method uses the Anscombe's transformation to adjust the original image to a Gaussian noise model. The image is then decomposed in different sub-bands of frequency and orientation responses using a dual-tree complex wavelet transform, and the HMT is used to model the marginal distribution of the wavelet coefficients. Two different methods were used to denoise the wavelet coefficients. Finally, the modified wavelet coefficients are transformed back into the original domain to get the de-noised image.

Owner:1370509 ALBERTA

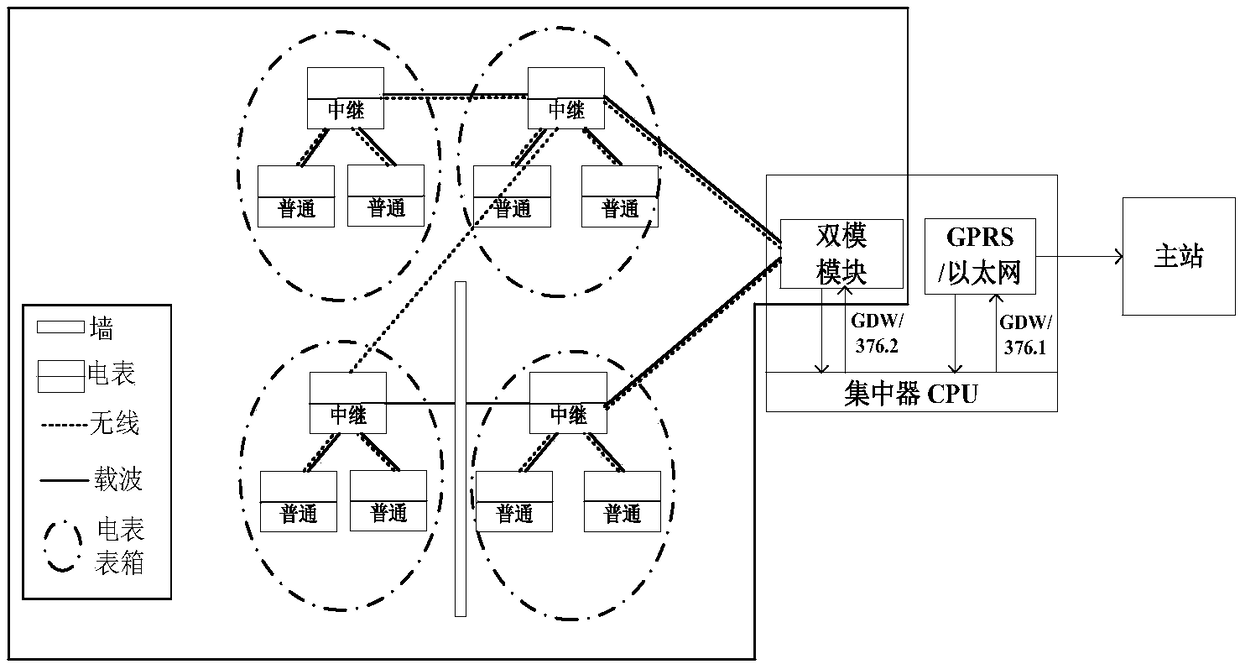

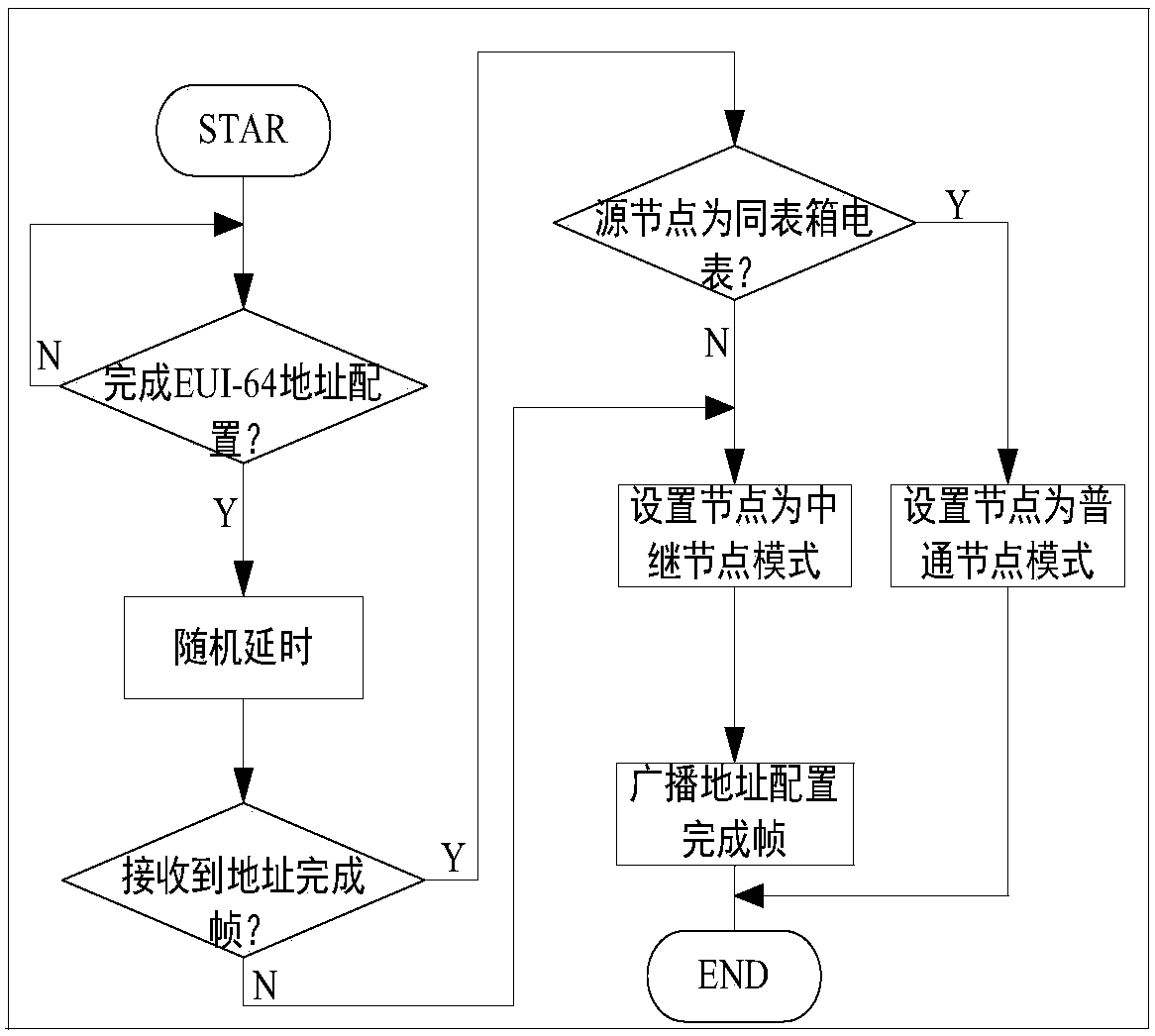

Dual-mode heterogeneous network networking communication method for power information collection system

ActiveCN108401041AImprove collection success rateIncrease success rateTransmission systemsTransmission monitoringDual modeCollection system

The invention relates to a dual-mode heterogeneous network networking communication method for a power information collection system, and belongs to the technical field of power consumption information collection. The method comprises the following steps: S1: constructing a dual-tree network for micro-power wireless and power carriers in combination with the distribution characteristic of power collection equipment and the difference between micro-power wireless and power carrier signal attenuation; S2: evaluating, by an equipment node, the communication performance of the power carriers and the a micro-power wireless channel, and performing postorder traversal on a routing forwarding tree to discover channel selection and routing addressing; and S3: collecting, by a concentrator node, power data according to the constructed dual-tree network. According to the method of the invention, the concentrator is ensured to collect the power data at a relatively higher success rate through a file updating mechanism and a retransmission mechanism. By adoption of the dual-mode heterogeneous network networking communication method provided by the invention, a dual-mode heterogeneous meter reading network can be reasonably constructed, the collection success rate of the power data is greatly improved, and a certain reference is further provided for cross-network transmission of the power data.

Owner:WUHAN SAN FRAN ELECTRONICS CO LTD

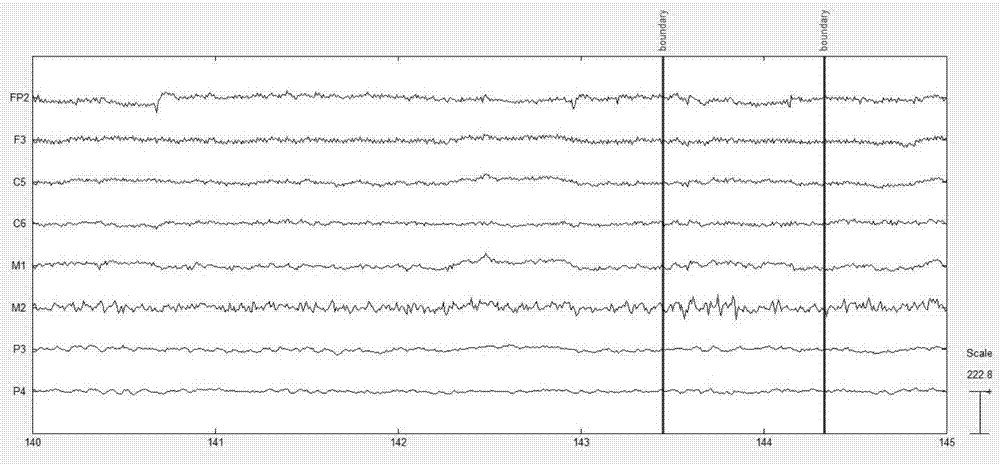

Method for Adaptive Complex Wavelet Based Filtering of Eeg Signals

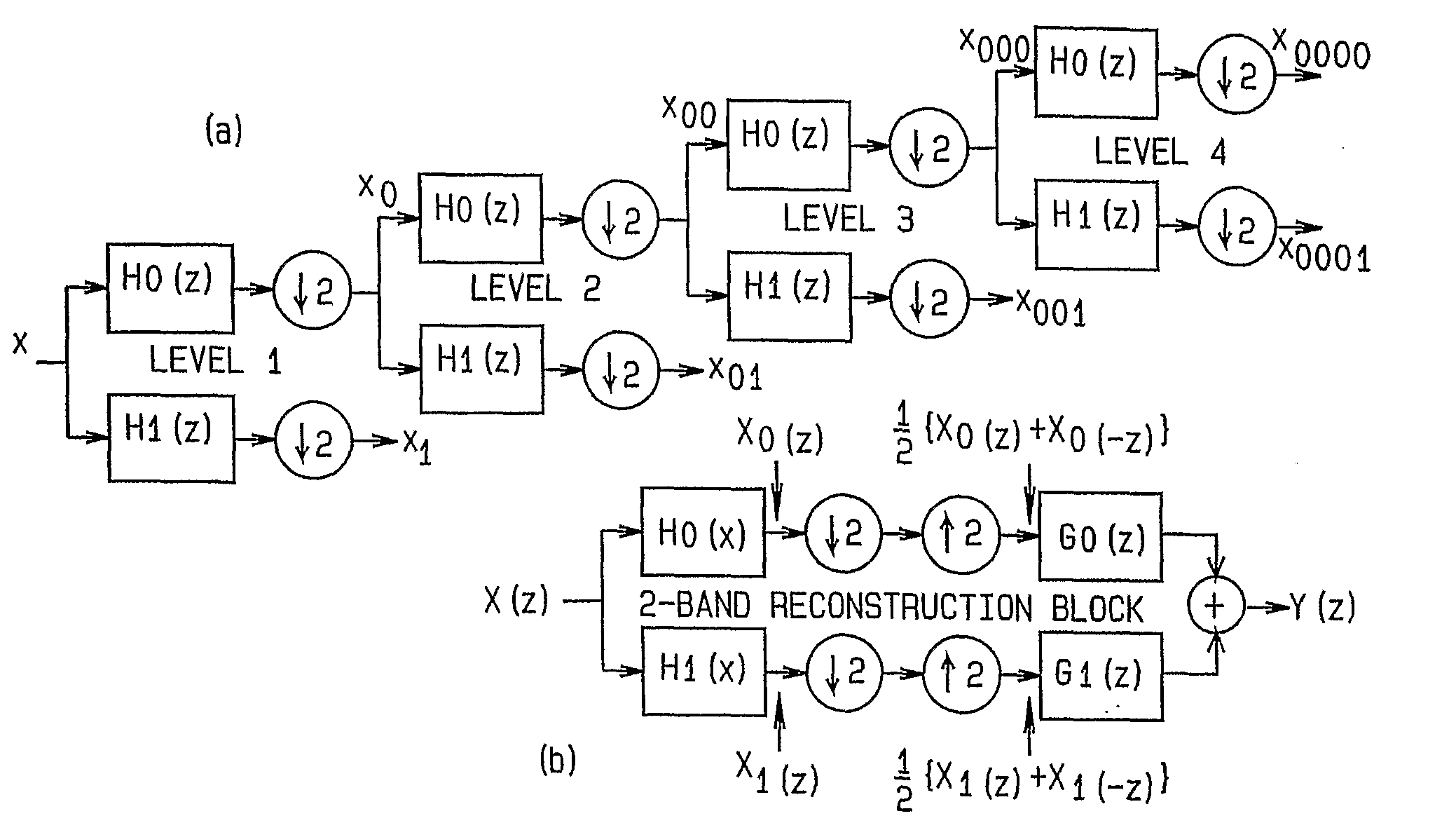

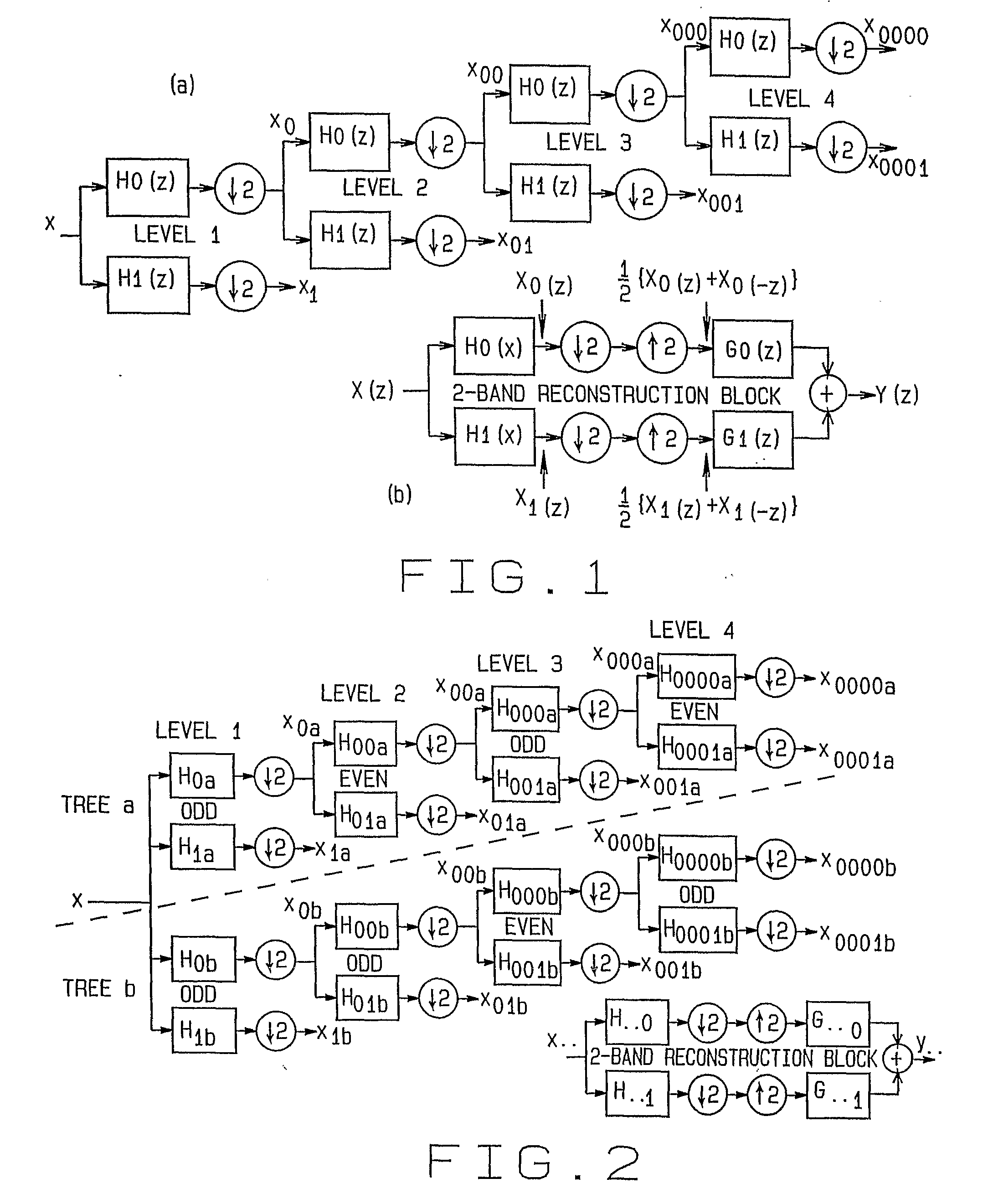

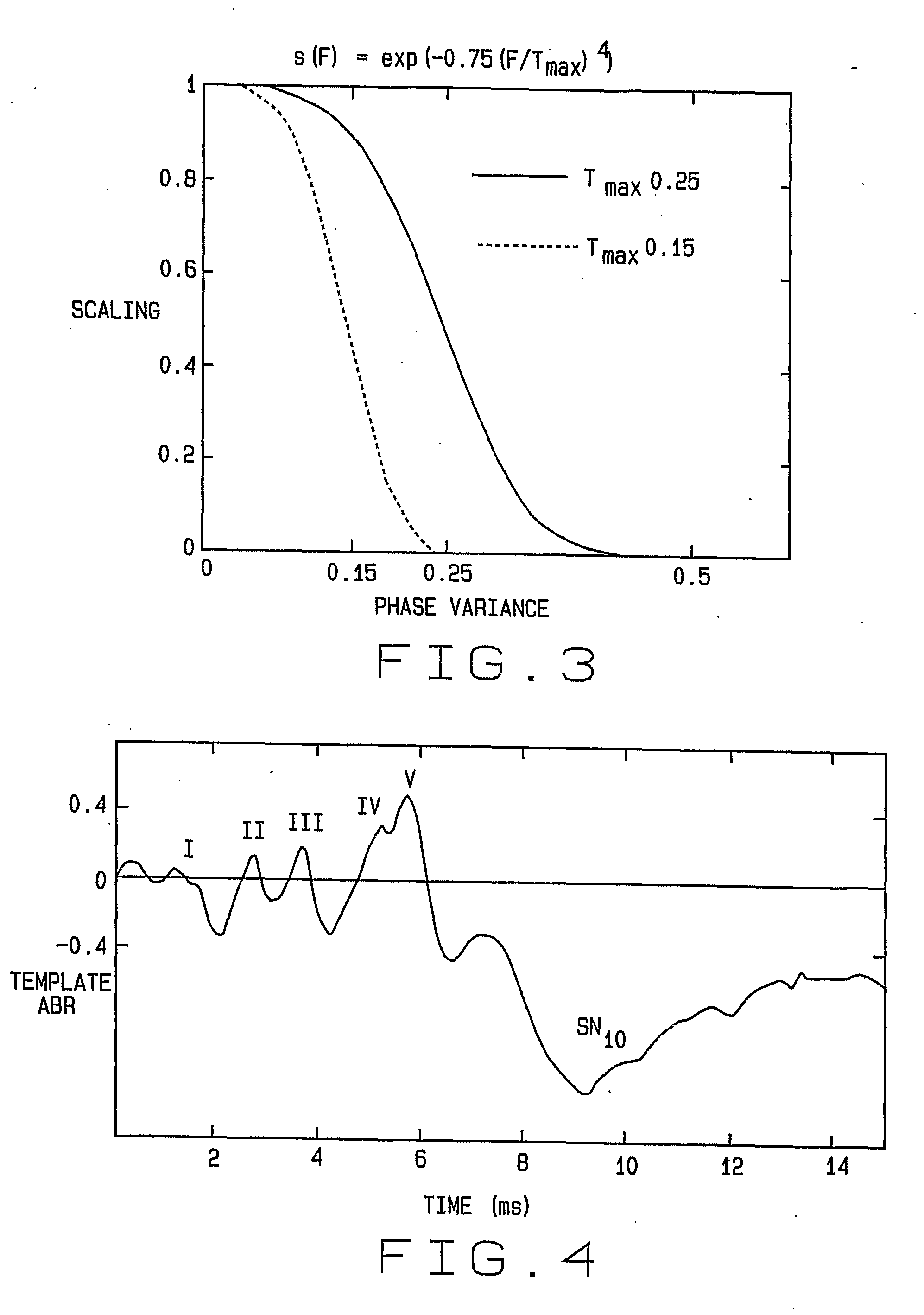

A method for adaptive filtering of EEG signals in the wavelet domain using a nearly shift-invariant complex wavelet transform. EEG signal data is segmented into a set of K “trials” or “light averages” of M-frames of data each. These trials are overlapped by a number of frames P, where P<M. A dual-tree complex wavelet transform is computed for each light average K of EEG signal data. Next, the phase variance of each resulting normalized wavelet coefficient is computed, and the magnitude of each wavelet coefficient is selectively scaled according to the phase variance of the coefficients. The resulting wavelet coefficients are then utilized to reconstruct the ABR signal extracted from the EEG data.

Owner:BRAINSCOPE SPV LLC

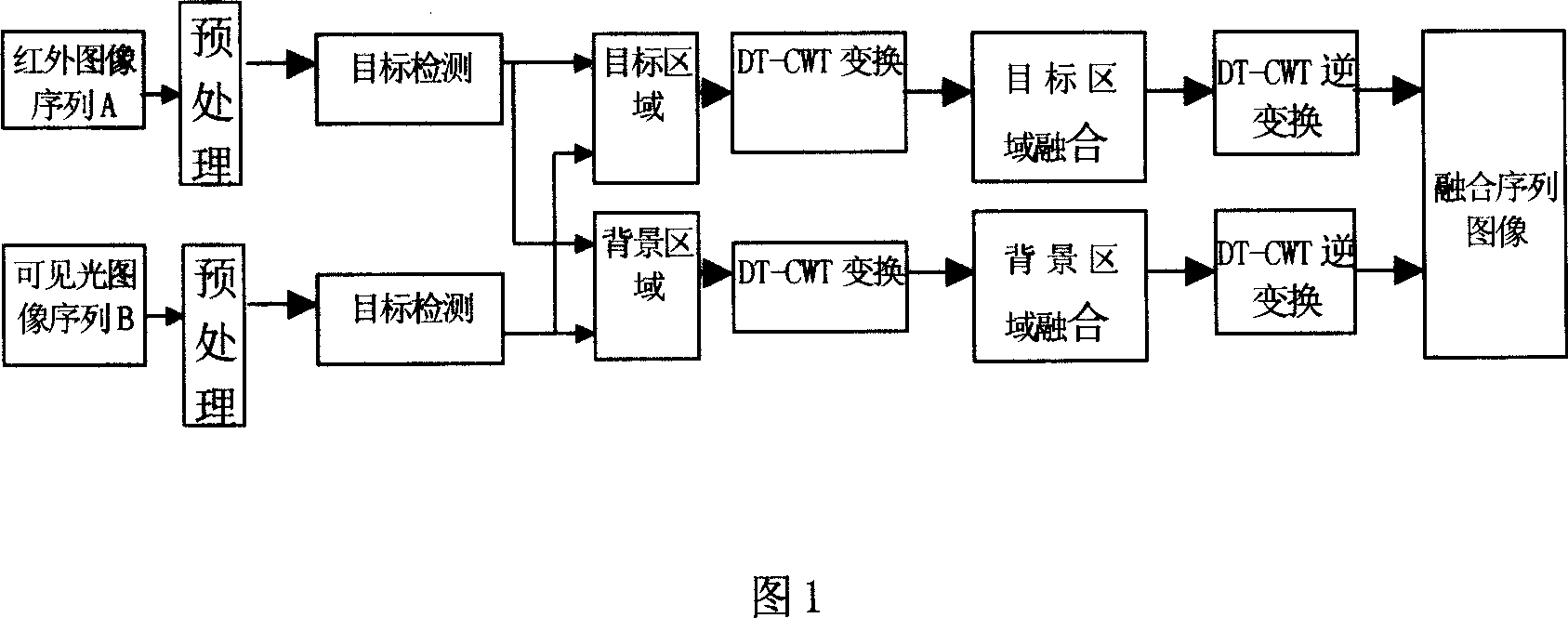

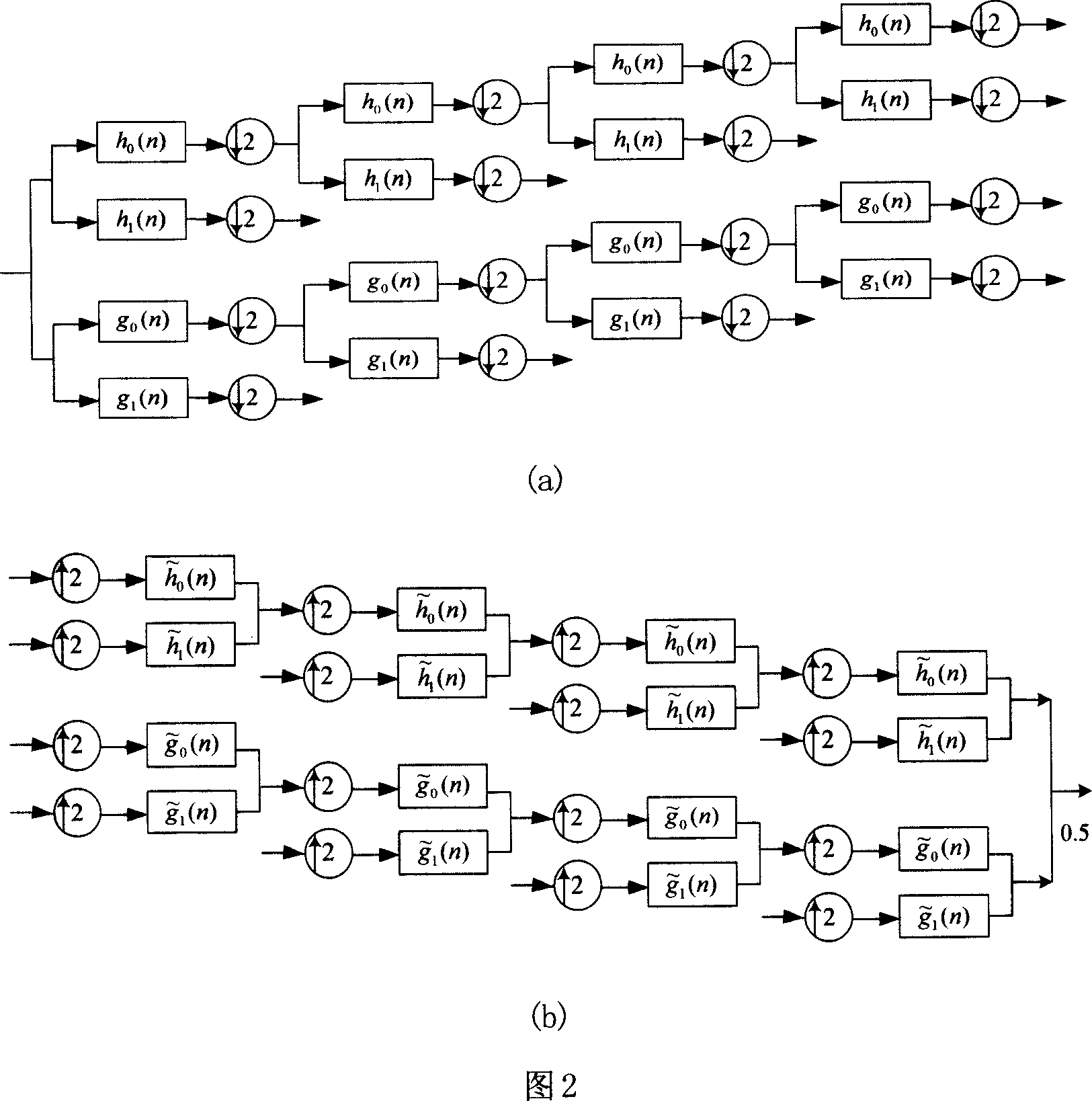

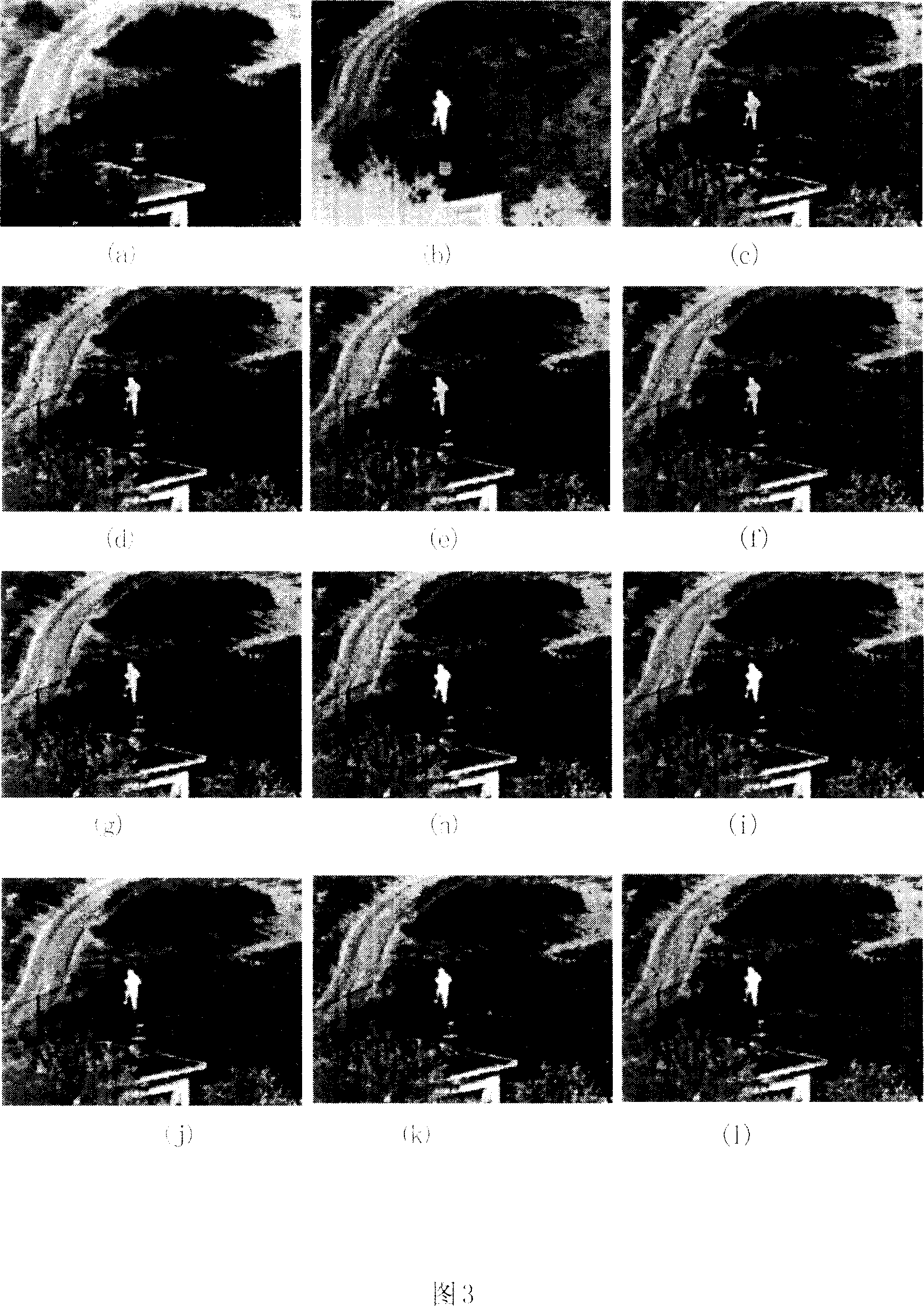

Infared and visible light sequential image feature level fusing method based on target detection

InactiveCN1932882AImprove clarityImprove perceptionImage enhancementImaging FeatureActive measurement

An infrared and visible light sequence image character level amalgamation method based object detecting belongs to image amalgamation technology field. It uses area growth method to divide up each frame fountain image and automatically get background area and object area according to effective detecting method and takes dual-tree complex wavelet transform method to the fountain image list. After the transform, apply different amalgamation rules for object and background area to realize the list image amalgamation with character level. After get the wavelet amalgamation coefficient of different area, use dual-tree complex wavelet inverse transform to get amalgamation list image. It uses different amalgamation rules to keep interesting goal information as more as possible. The amalgamation list image owns good inflexibility, stability of time and coherence, and high calculating efficiency for using the application with dual-tree complex wavelet transform.

Owner:SHANGHAI JIAO TONG UNIV

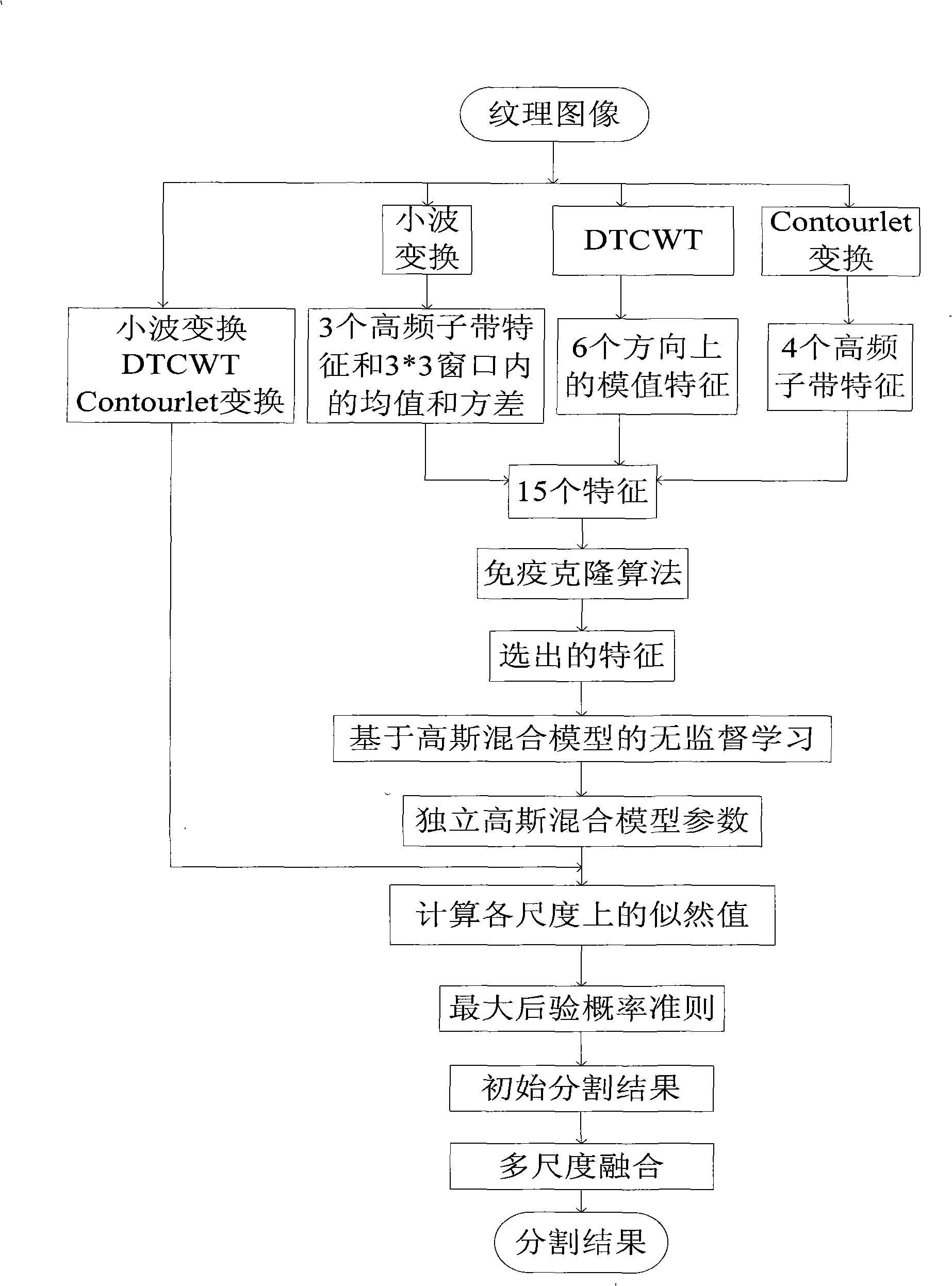

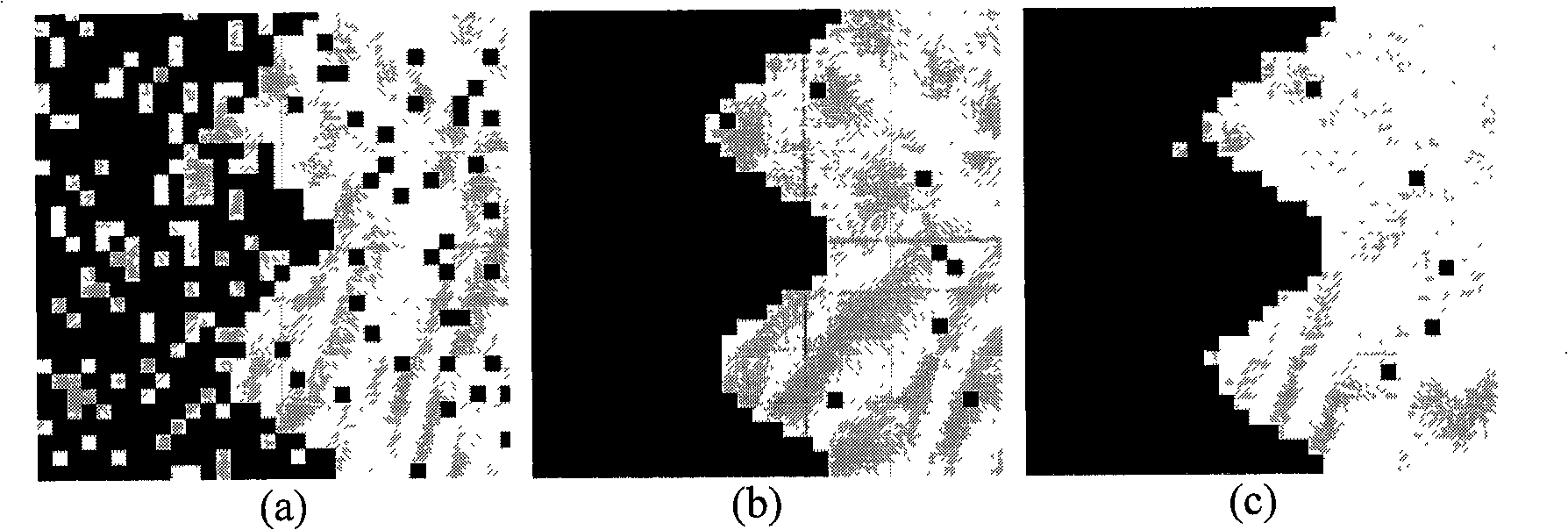

Texture image segmentation method based on independent Gaussian hybrid model

InactiveCN101540047AEffective training featuresOvercoming the disadvantage of being sensitive to initializationImage analysisCharacter and pattern recognitionUnsupervised learningSelf adaptive

The invention discloses a texture image segmentation method based on an independent Gaussian hybrid model, which comprises the following segmentation steps: simultaneously performing three-layer wavelet transformation, dual-tree complex wavelet transformation and Contourlet transformation to training texture images; extracting the characteristics of the corresponding training texture images; selecting the characteristics by adopting an immunity clone algorithm on each layer; performing unsupervised learning of the Gaussian hybrid model to each layer of each training image, adaptively obtaining the corresponding component number, and thus obtaining the parameter of the Gaussian hybrid model; simultaneously performing wavelet transformation, dual-tree complex wavelet transformation and Contourlet transformation to test texture images; calculating the corresponding final likelihood value of each layer according to the transformation coefficient and the component number; obtaining the primary segmentation result through comparing the corresponding likelihood value of each texture; and obtaining the segmentation result through multi-scale fusion of the primary segmentation result. The invention has the characteristics of good consistence of segmentation area, complete information retaining, and accurate edge positioning, and can be used for the image texture recognition.

Owner:XIDIAN UNIV

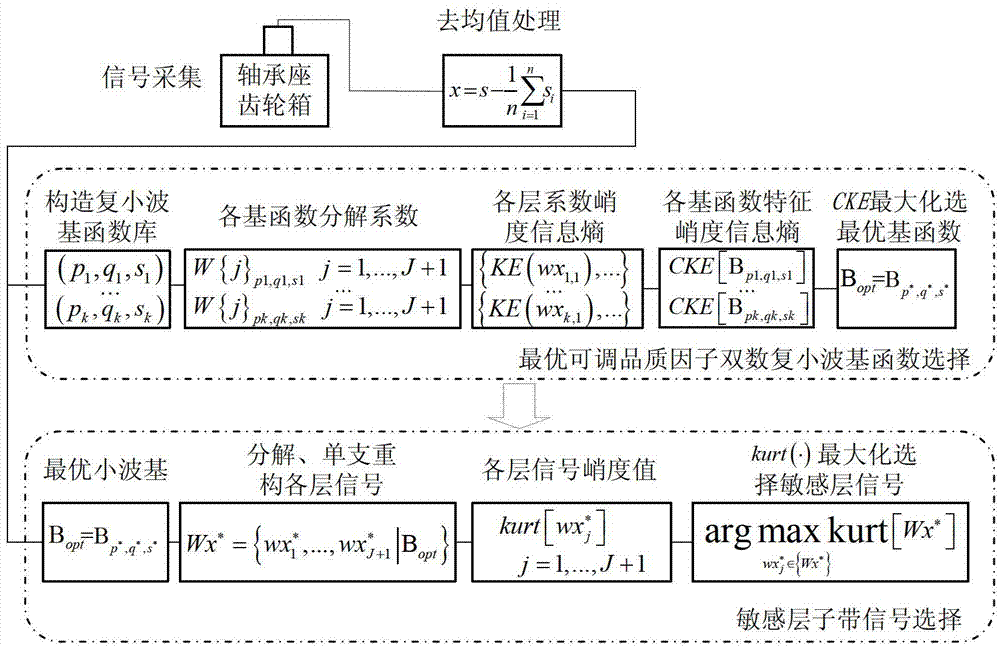

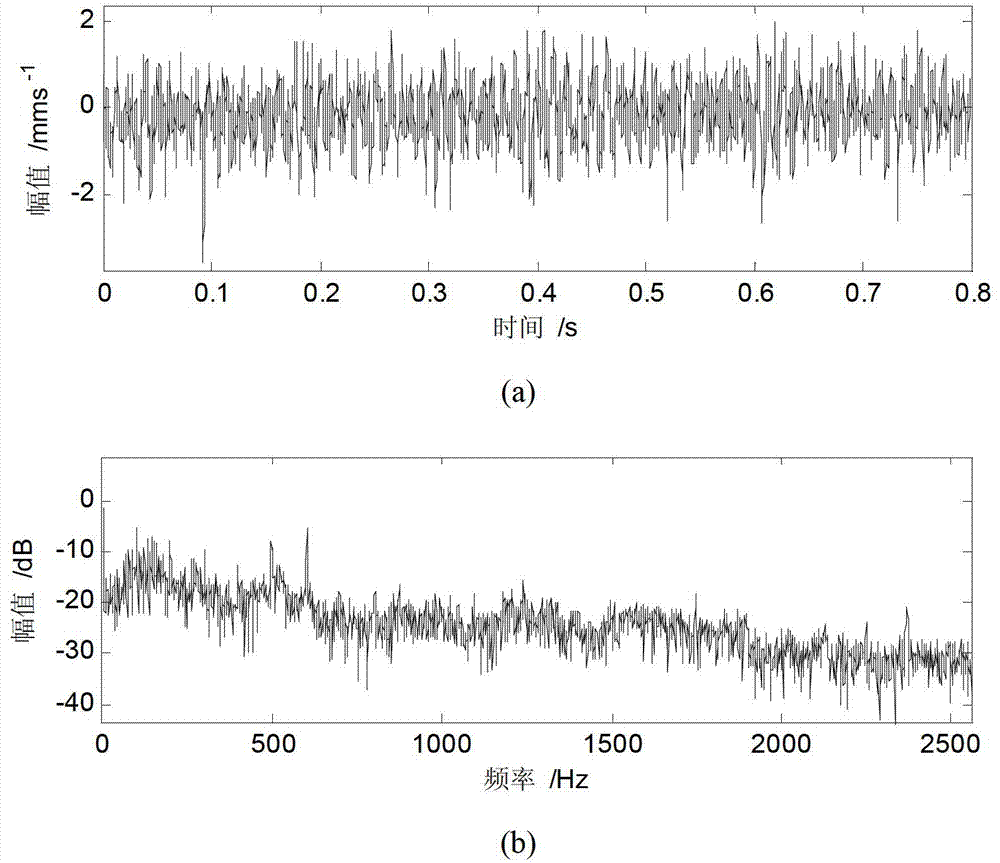

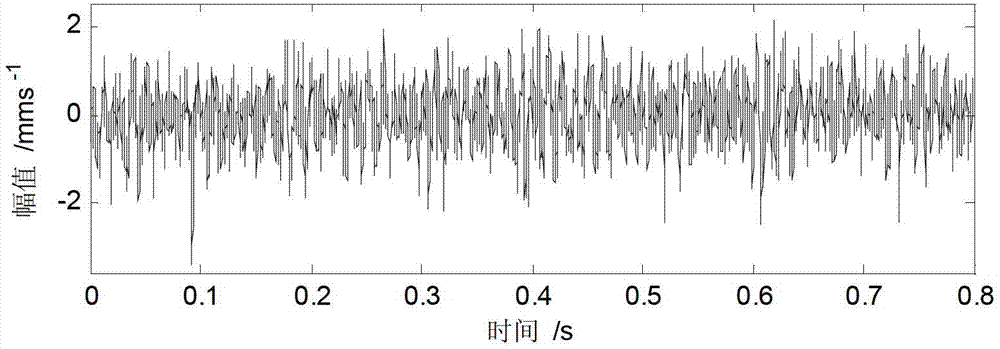

Rotary machine fault detection method of dual-tree complex wavelet transformation with adjustable quality factors

InactiveCN103499437AAdjustable quality factorEfficient detectionVibration measurement in solidsMachine part testingAlgorithmBase function

The invention discloses a rotary machine fault detection method of dual-tree complex wavelet transformation with adjustable quality factors. The rotary machine fault detection method of dual-tree complex wavelet transformation with the adjustable quality factors comprises the steps of (1) building a reasonable sampling parameter set, building dual-tree complex wavelet base functions with different quality factors, (2) using each built dual-tree complex wavelet base function to carry out time-scale analysis on a vibration response signal of a rotary machine, calculating kurtosis information entropy of wavelet coefficients of each layer with participation of each dual-tree complex wavelet base function, selecting a dual-tree complex wavelet base function corresponding to the maximum feature kurtosis information entropy as the dual-tree complex wavelet base function which is in optimal matching with an impact component of the vibration signal, and (3) analyzing the vibration signal through the optimal dual-tree complex wavelet base function, and carrying out fault diagnosis. According to the rotary machine fault detection method of dual-tree complex wavelet transformation with the adjustable quality factors, the dual-tree complex wavelet base functions with any frequency-band focusing performance and time-domain oscillation performance can be built, the base function with the optimal matching performance can be selected in a self-adaptation mode, and accurate detection of periodicity impact type fault features and information of the impact period of a rotary machine device can be achieved.

Owner:XI AN JIAOTONG UNIV

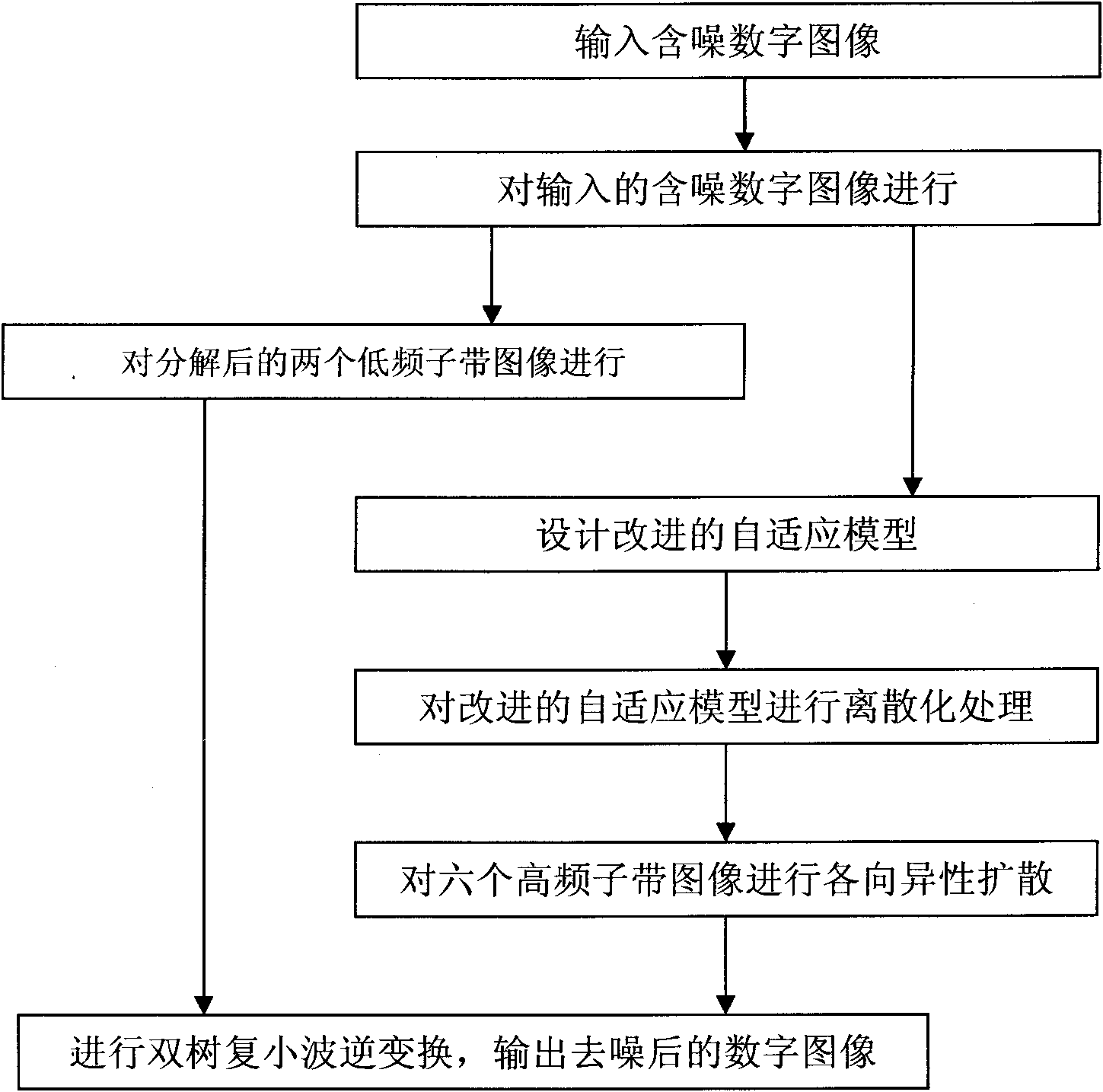

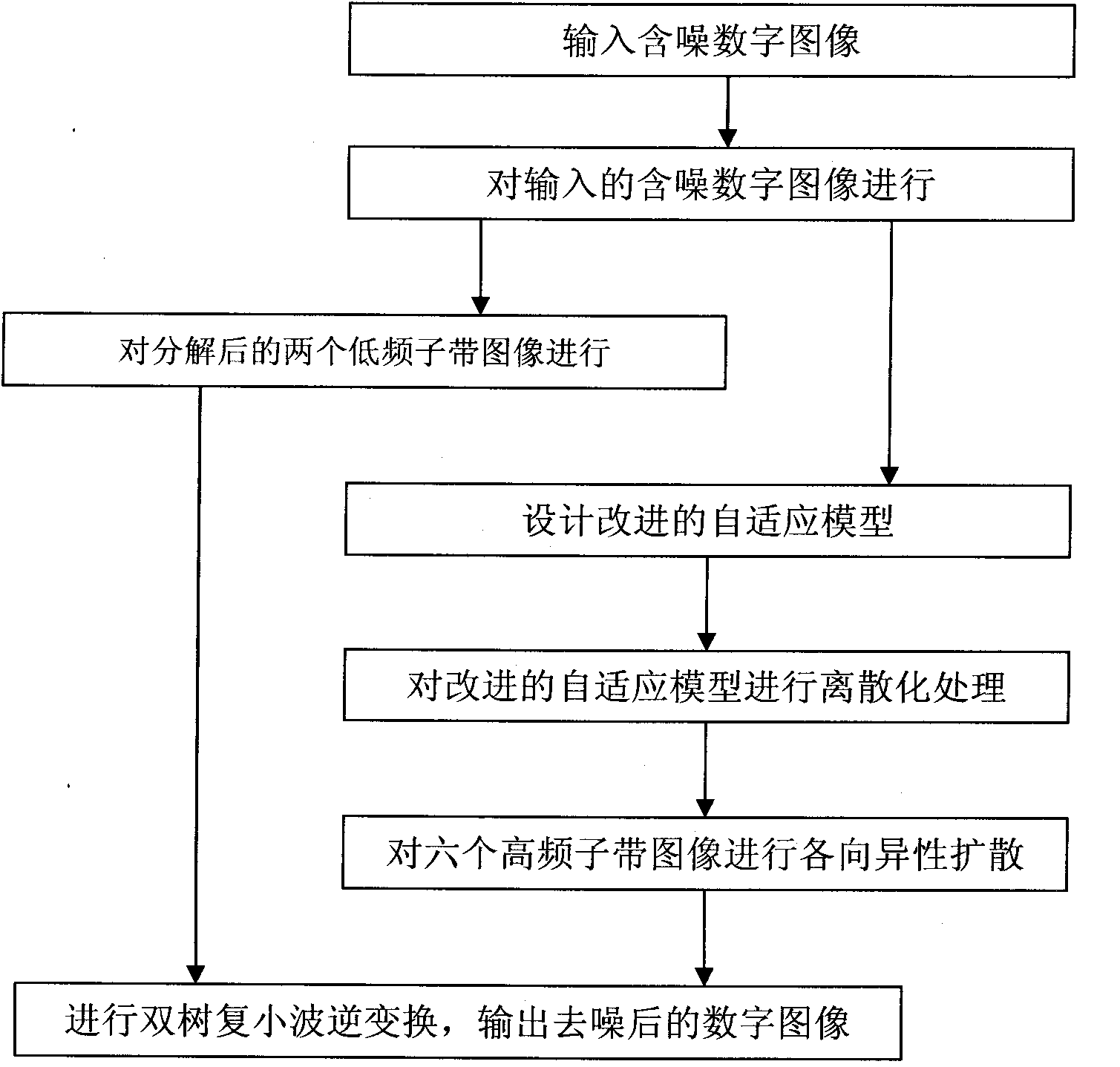

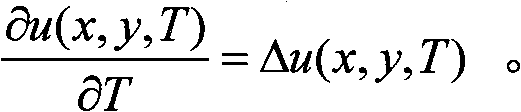

Method for de-noising dual-tree complex wavelet image on basis of partial differential equation

InactiveCN101777179AHigh denoising speedSuppression of Pseudo-Gibbs PhenomenoImage enhancementHigh rateDecomposition

The invention relates to a method for de-noising a dual-tree complex wavelet image on the basis of partial differential equation. The method comprises the following steps: inputting a noised digital image; carrying out the dual-tree complex wavelet transform decomposition on the inputted noised digital image to obtain two low-frequency sub-band images and six high-frequency detailed sub-band images; carrying out the isotropic diffusion on the two decomposed low-frequency sub-band images; designing an improved adaptive model; calculating the dual-tree complex wavelet transform modulus and gradient modulus of the high-frequency detain sub-band images on each direction, and designing an adaptive diffusion coefficient function to improve the P-M (Perona-Malik) model (i.e., the isotropic diffusion model) by using the weighted average of the dual-tree complex wavelet transform modulus and gradient modulus; carrying out the diffusion processing on the improved adaptive model; carrying out the isotropic diffusion on the six high-frequency sub-band images; and carrying out the dual-tree complex wavelet transform, and outputting the de-noised digital image. The invention has the beneficial effect that more detailed information of the image can be preserved on the premise that the higher rate of image de-noising is maintained.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

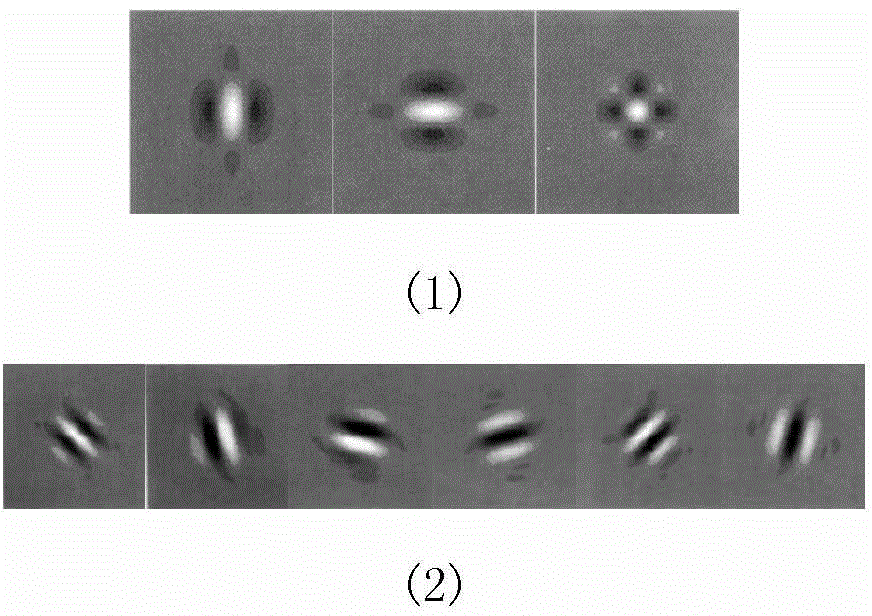

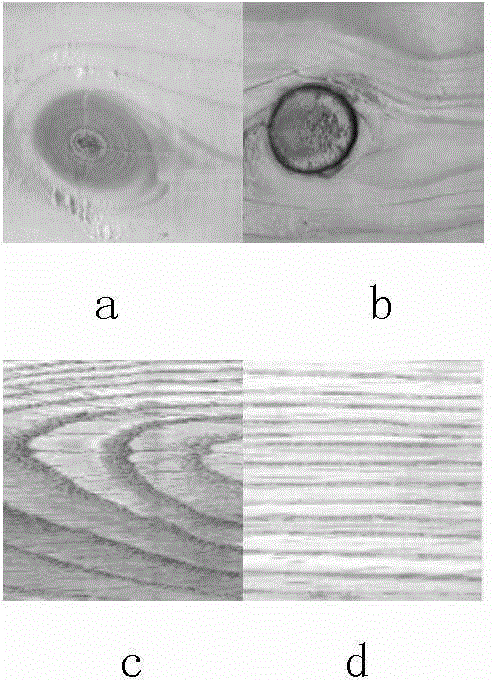

Method for cooperatively classifying perceived solid wood panel surface textures and defects by feature extraction and compressive sensing based on dual-tree complex wavlet

InactiveCN104392242AImprove classification accuracySimple structureCharacter and pattern recognitionFeature DimensionClassification methods

The invention discloses a method for cooperatively classifying perceived solid wood panel surface textures and defects by feature extraction and compressive sensing based on dual-tree complex wavlet, and relates to the field of solid wood panel surface defect detecting. The method is used for solving the problems of low classifying precision, low classifying efficiency, and the like of the existing solid wood panel surface texture and defect classifying method. The method comprises the following steps: performing feature dimension reduction after performing feature extraction by dual-tree complex wavelet transform on solid wood panel images; classifying optimized feature vectors based on a compressive sensing theory; using the optimized feature vectors as a sample row, and establishing a data dictionary matrix by a training sample matrix; linearly representing a measuring sample by using training samples, calculating a sparse representation vector on a data dictionary of a test sample, and determining the category with smallest residual error as the category of the test sample. Due to good directionality of the dual-tree complex wavlet, complex information of the panel surface can be expressed, and the classifying efficiency can be further improved based on feature selection of a particle swarm algorithm. Compared with the conventional classifier, the compressive sensing classifier is simple in structure and relatively high in classifying precision.

Owner:NORTHEAST FORESTRY UNIVERSITY

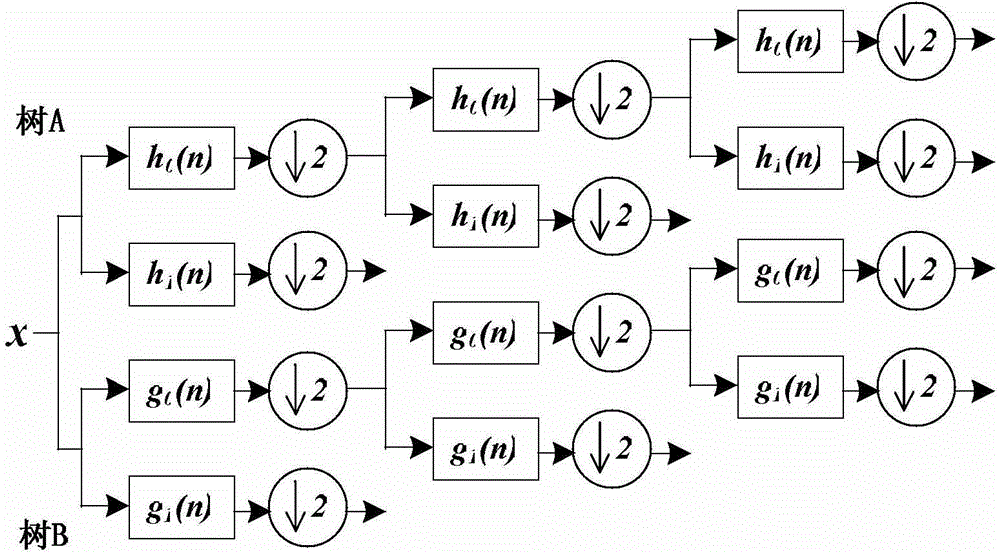

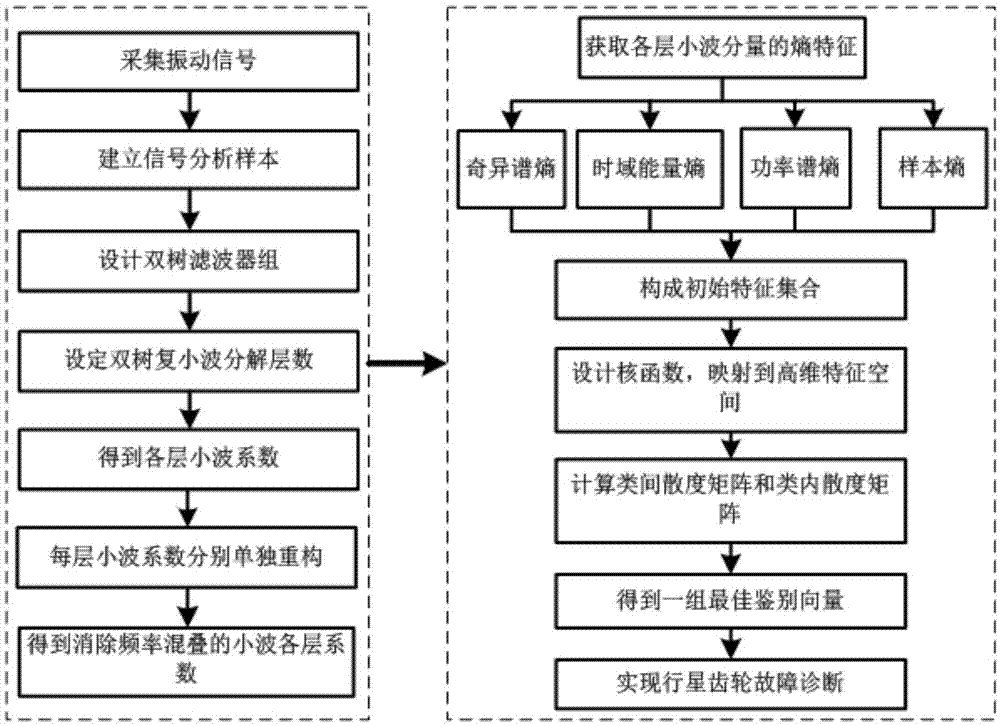

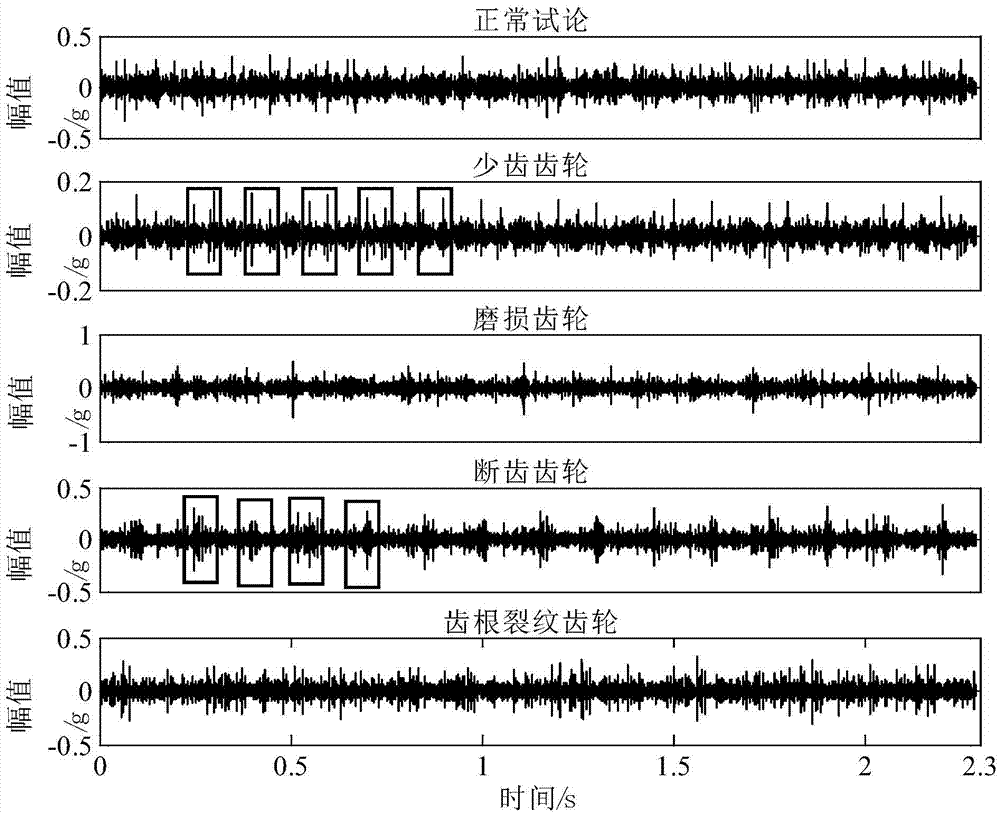

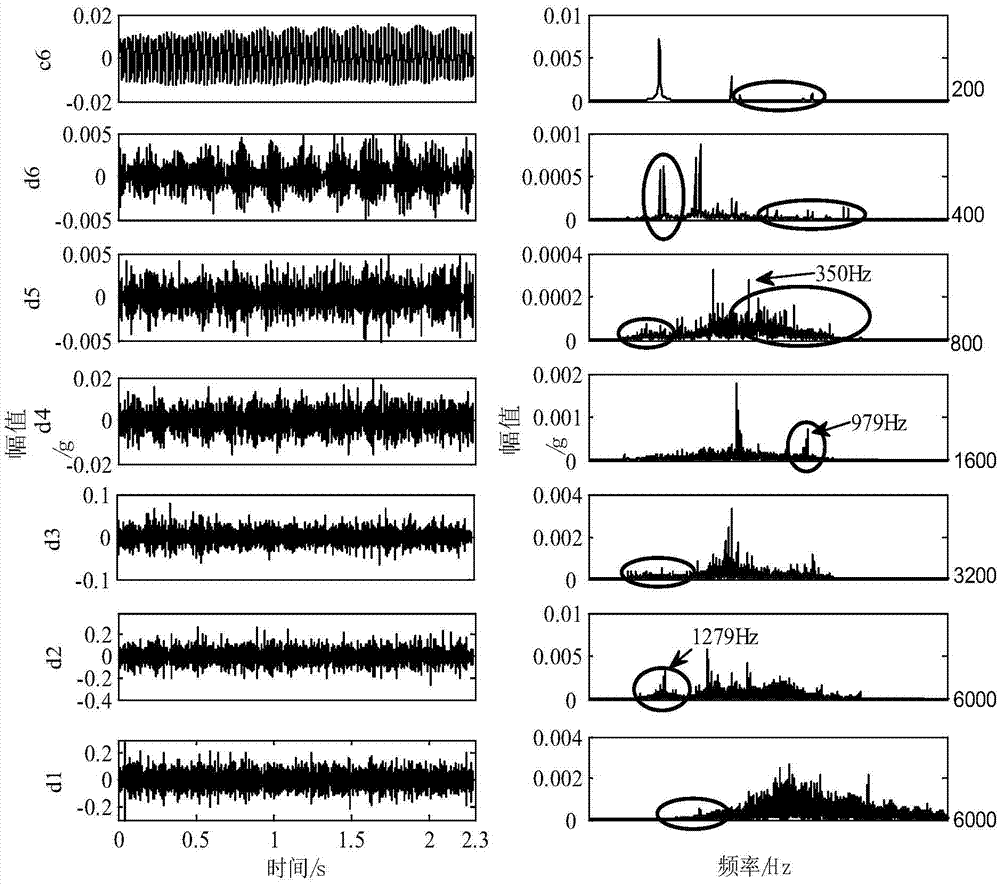

Planetary gear fault diagnosis method based on dual-tree complex wavelet transform-entropy feature fusion

ActiveCN105445022AAccurate diagnosisEnrich and improve fault diagnosis methodsMachine gearing/transmission testingFeature setFeature Dimension

The invention discloses a planetary gear fault diagnosis method based on dual-tree complex wavelet transform-entropy feature fusion. The method comprises the following steps of collecting integration simulation experiment table data and acquiring a planetary gear shell original vibration signal; using dual-tree complex wavelet transform to decompose an original vibration signal and extracting a signal component of each frequency band; constructing an entropy feature extraction model from multiple angles and acquiring a high-dimension original feature; using a nucleus Fisher discriminant analysis method to carry out dimension reduction processing on an original feature set formed by a plurality of entropy features, determining a group of optimum discriminant vectors, extracting a projection of the original feature in the optimum discriminant vectors and taking as a sensitive fault feature so as to determine a fault type; verifying a necessity of describing feature information from the multiple angles and multiple spaces and validity of carrying out feature dimension reduction by using a KFDA method based on that. The method is suitable for the non-linear and non-stable planetary gear vibration signal with a high coupling feature. By using the method, the sensitive fault feature can be effectively extracted and accurate diagnosis of the planetary gear is realized.

Owner:CHINA UNIV OF MINING & TECH

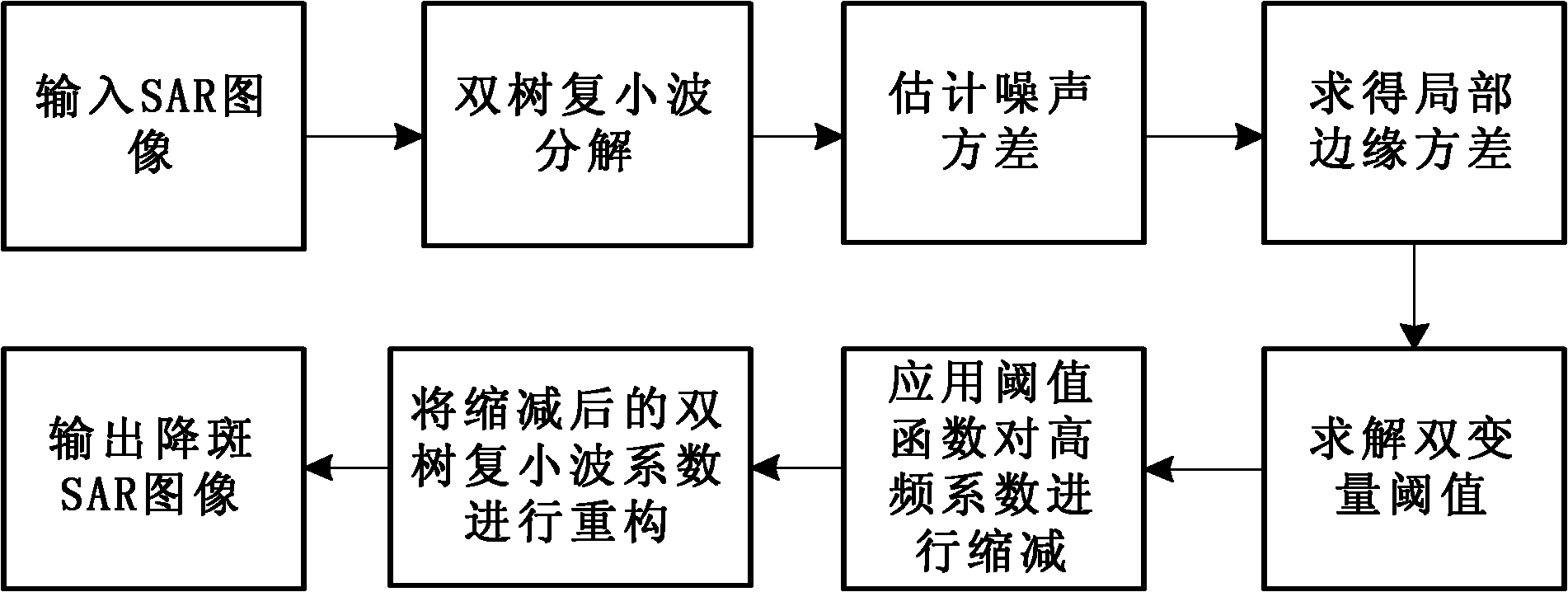

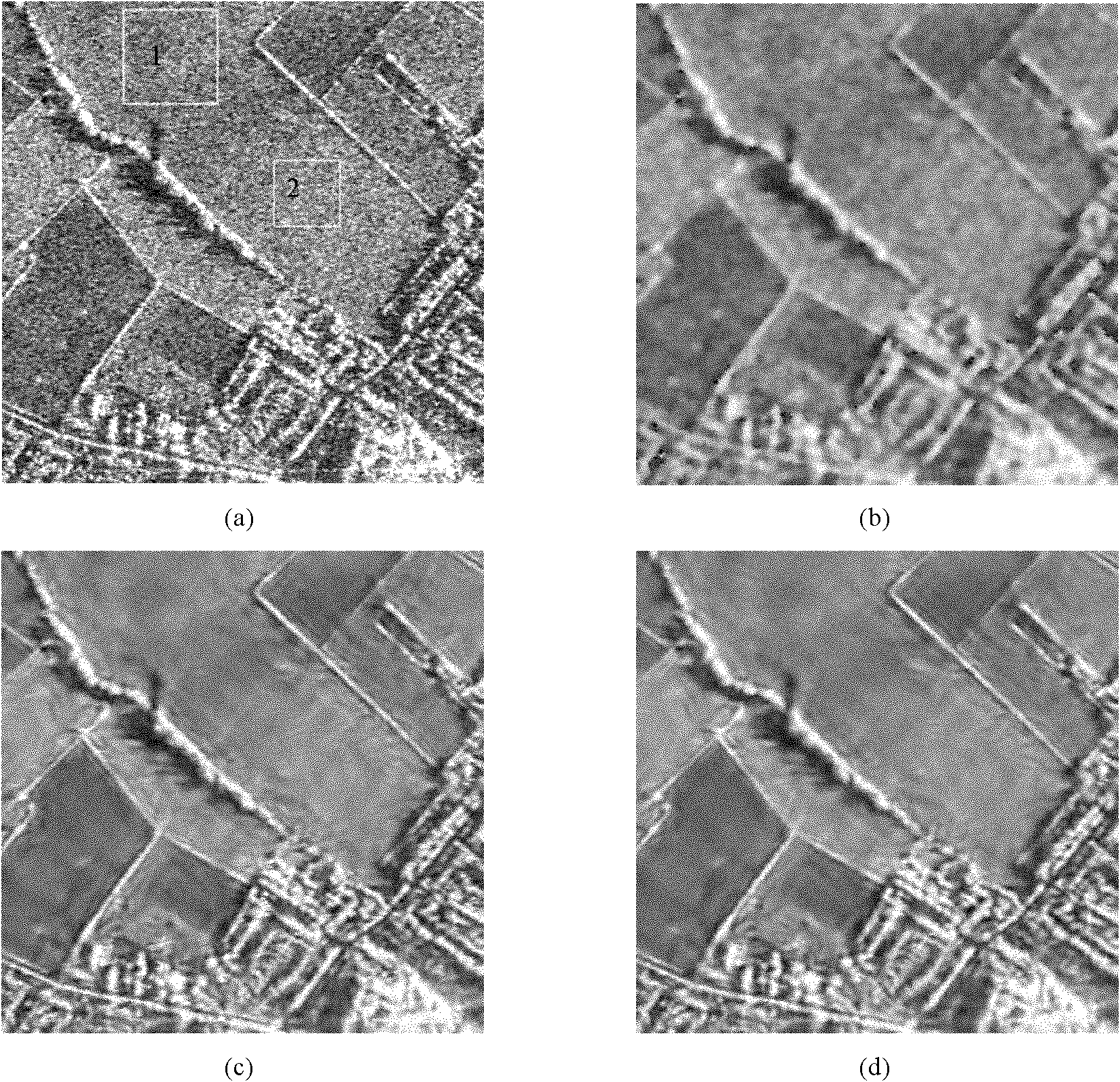

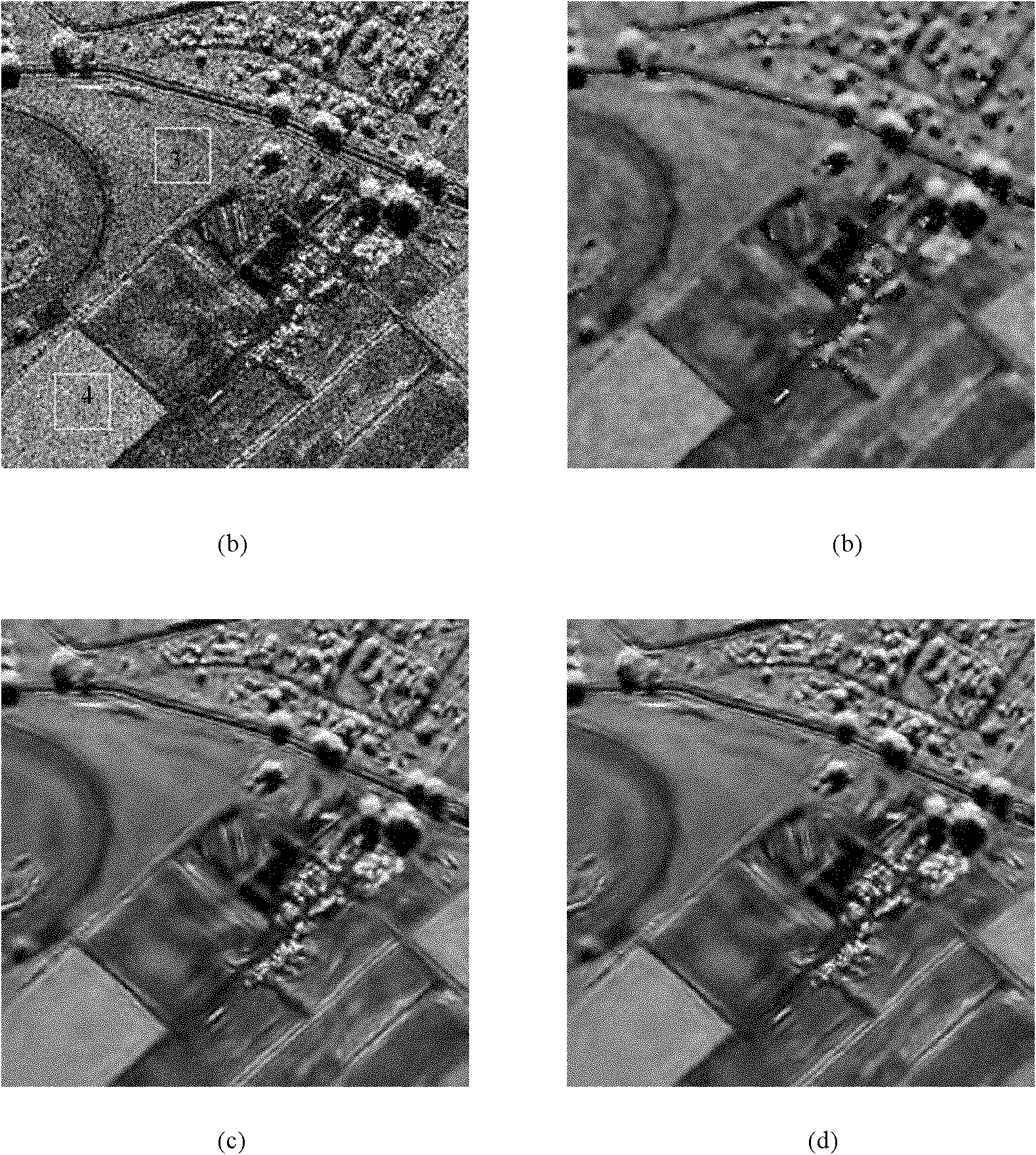

Method for reducing speckles of synthetic aperture radar (SAR) image by combining dual-tree complex wavelet transform with bivariate model

ActiveCN101980286ARadiation properties preservedSufficiently filter out speckle noiseImage enhancementDecompositionSynthetic aperture radar

The invention discloses a method for reducing the speckles of a synthetic aperture radar (SAR) image by combining dual-tree complex wavelet transform with a bivariate model, which mainly solves the problems that speckle noise cannot be well inhibited and part of edge information and detailed information are lost in the conventional method for reducing the speckles of the SAR image. The method comprises the following steps of: performing dual-tree complex wavelet decomposition on the original SAR image to obtain a real part and an imaginary part of a decomposition coefficient on each scale; solving the variance of a noise coefficient by using a non-logarithmic additive noise model; solving the edge variances of the real parts and the imaginary parts of the complex wavelet coefficient by using a local neighborhood window; solving a threshold contraction function by maximum posterior estimation and performing threshold contraction on the dual-tree complex wavelet decomposition coefficient; and performing dual-tree complex wavelet reconfiguration on the contracted coefficient to obtain an image of which the speckles are reduced. The method has the advantages of capability of effectively removing the speckle noise from the SAR image and high edge preserving performance, and can be used for reducing the speckles of the SAR images with abundant edge information and detailed information, particularly the airport, runway and road-containing SAR images.

Owner:XIDIAN UNIV

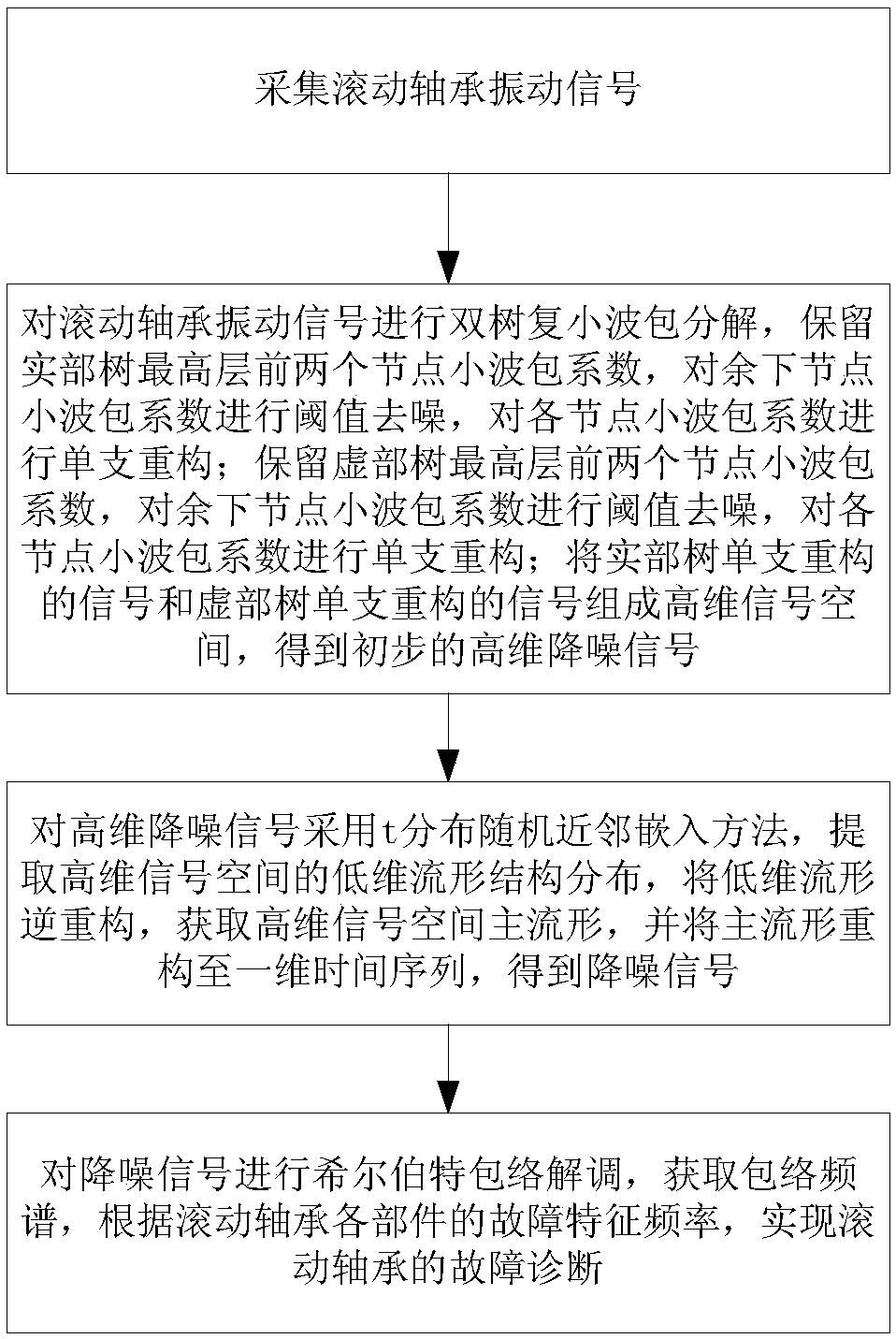

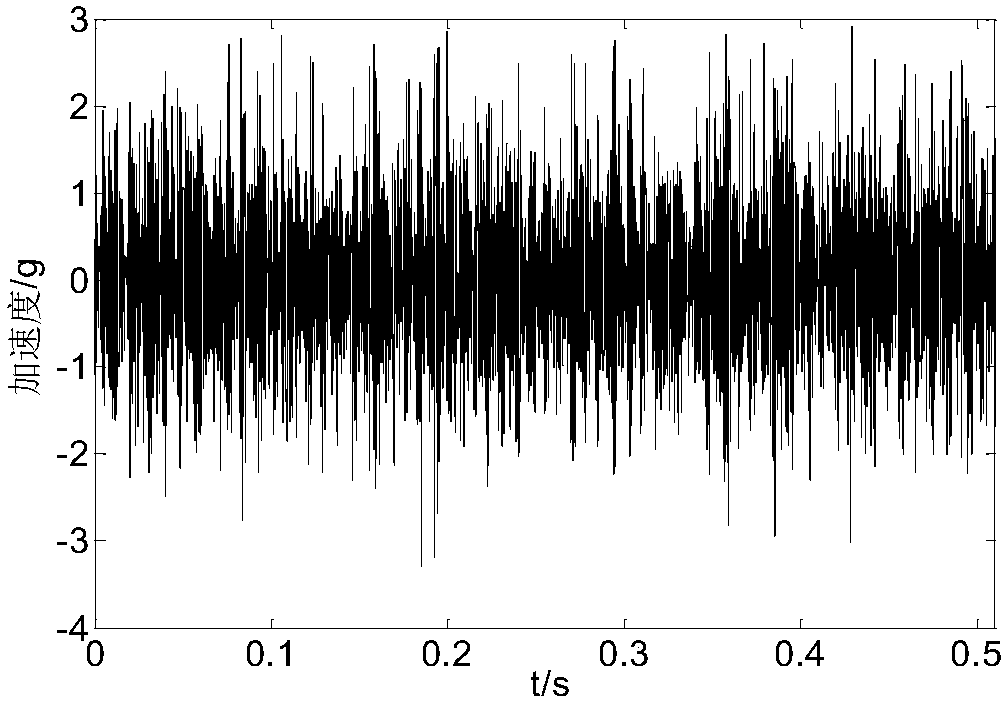

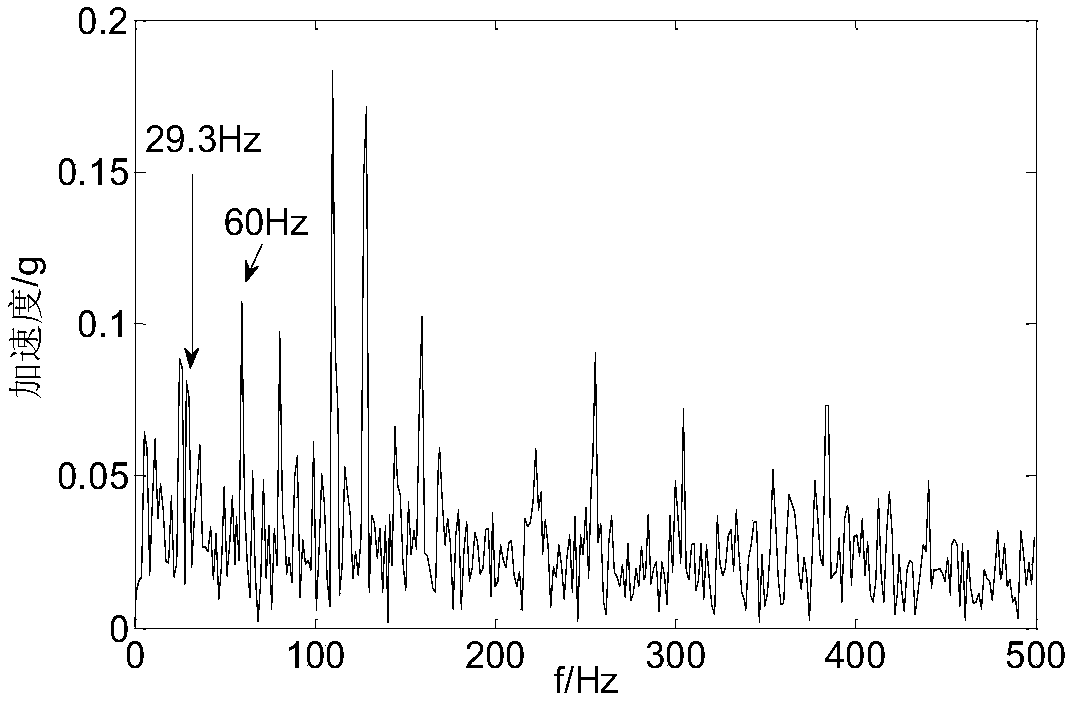

Rolling bearing fault diagnosis method based on dual-tree complex wavelet pack manifold domain noise reduction

ActiveCN107727399AAccurately obtain fault characteristic frequencyImplement fault diagnosisMachine bearings testingComplex mathematical operationsFrequency spectrumDecomposition

The invention relates to a rolling bearing fault diagnosis method based on dual-tree complex wavelet pack manifold domain noise reduction. The rolling bearing fault diagnosis method based on the dual-tree complex wavelet pack manifold domain noise reduction comprises steps of using an accelerated speed sensor to collect a vibration signal of the rolling bearing, performing dual-tree complex wavelet pack decomposition on the vibration signal, maintaining wavelet pack coefficients of first two nodes, performing threshold noise reduction on wavelet coefficients of the rest nodes, performing single branch reconstruction on the wavelet pack coefficient of each node to perform a high dimensional signal space, using a t distribution random neighbor embedding method to extract low a dimensional manifold, performing inverse reconstruction on the low-dimensional manifold to obtain a high-dimensional space main manifold, obtaining a signal after noise reduction, performing Hilbert envelope demodulation on the signal after noise reduction to obtain an envelope frequency spectrum of the vibration signal, and realizing fault diagnosis of the rolling bearing according to an inner ring fault characteristic frequency and an outer ring fault characteristic frequency of the rolling bearing, a rolling body fault characteristic frequency and a retainer fault characteristic frequency.

Owner:NAVAL UNIV OF ENG PLA

Human face recognition method based on anisotropic double-tree complex wavelet package transforms

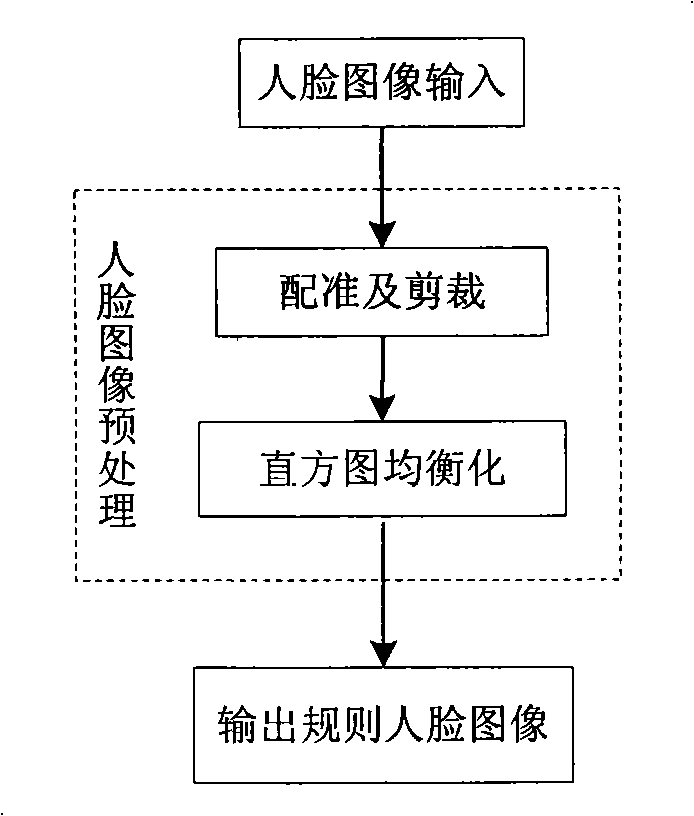

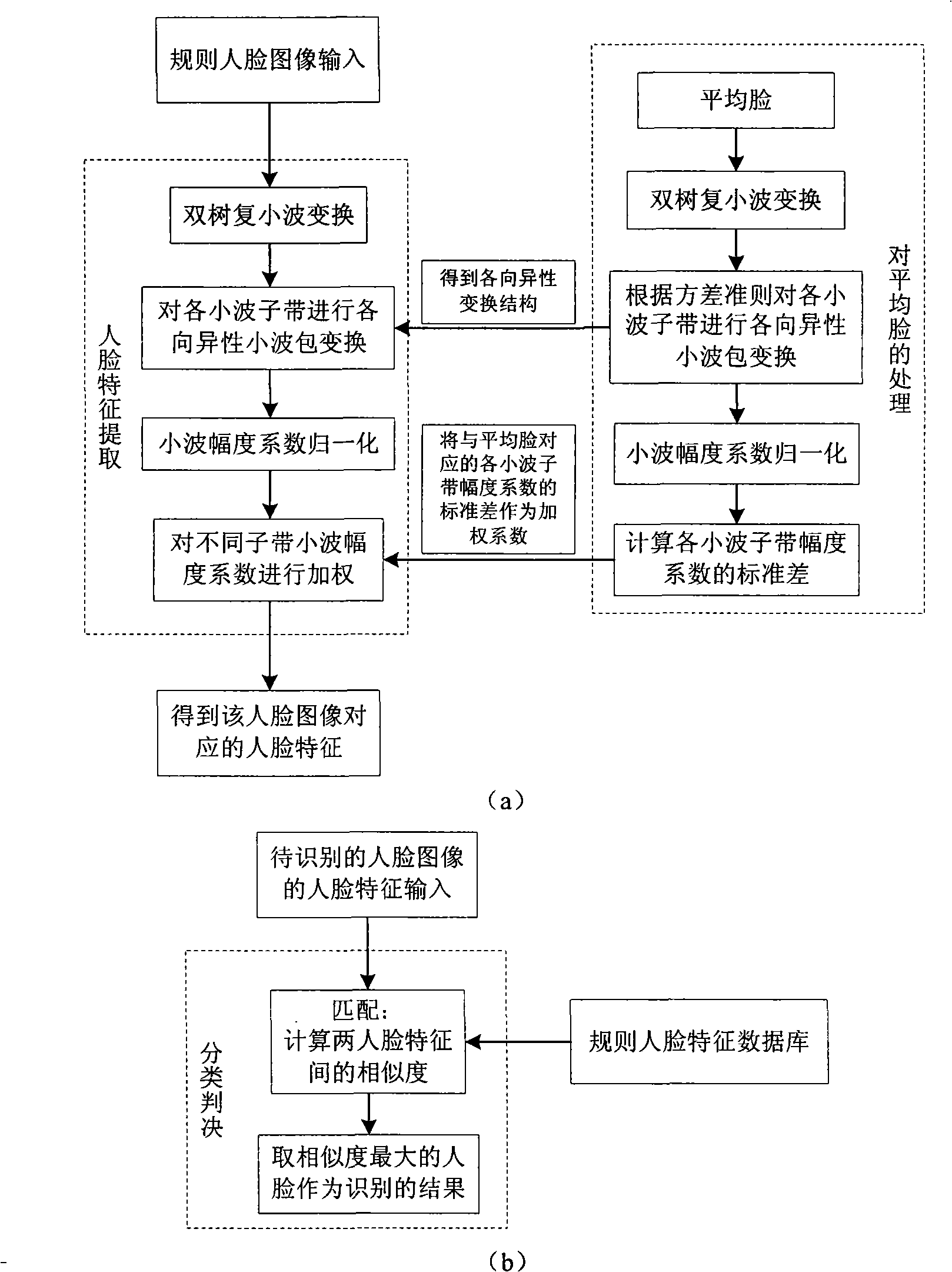

InactiveCN101271521AGood local texture featuresImprove stabilityCharacter and pattern recognitionFeature extractionWeight coefficient

The invention relates to a human face recognition method based on the anisotropy dual-tree complex wavelet packet transformation and belongs to a mode recognition technology field. The method includes that: firstly, an average face is processed; the characteristics of the face represented by a wavelet amplitude coefficient is obtained through a characteristic extraction of an input face image; a weight coefficient is used for the weighting of every wavelet sub-band amplitude coefficient, the same treatment is implemented on every regular front gray face image in a regular face database, and a standard face characteristic database is obtained; the face characteristics with wavelet amplitude coefficient corresponding to the input face image to be recognized matches one-to-one with the face characteristics with wavelet amplitude coefficient corresponding to every face image in the regular face characteristic database, and the face with the maximum similarity in the regular face characteristic database is used as the result of the face recognition. The face recognition method based on the anisotropy dual-tree complex wavelet packet transformation has the advantages of high face recognition accuracy as well as low computational complexity.

Owner:TSINGHUA UNIV

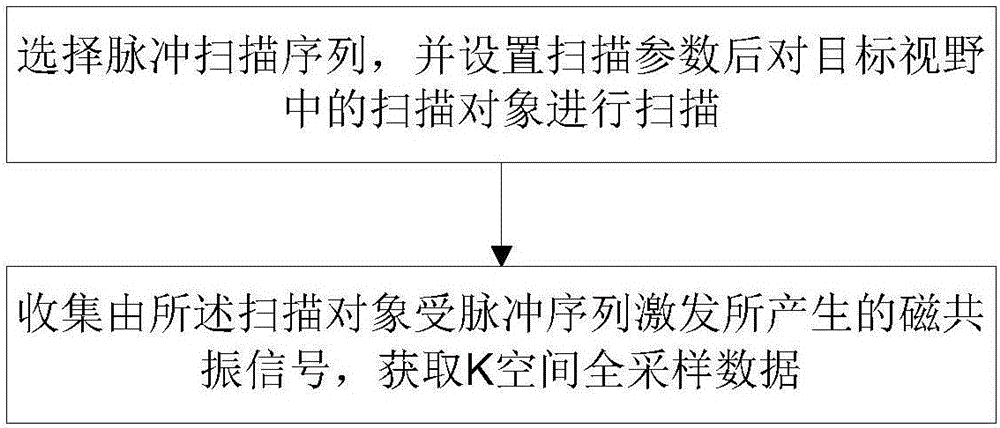

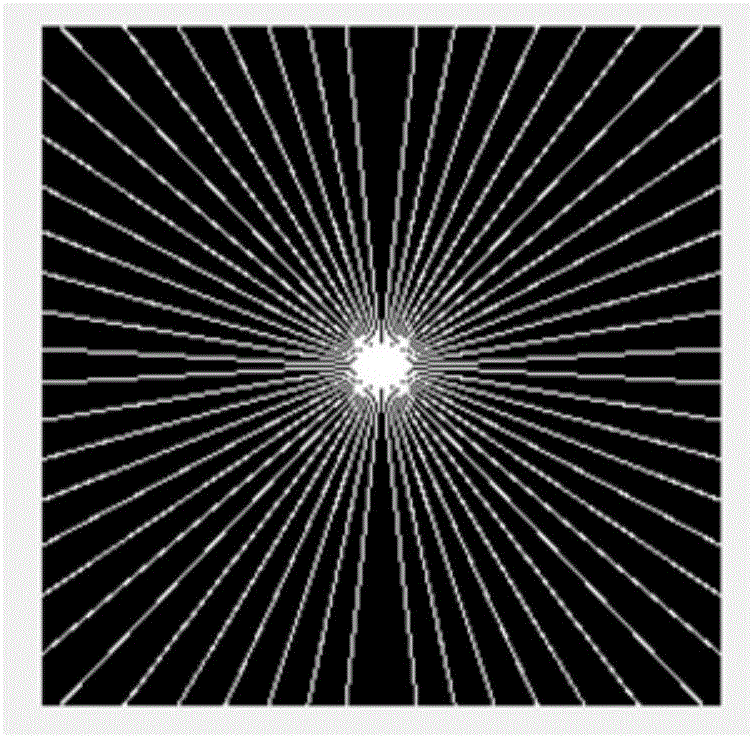

Fast and precise MRI (Magnetic Resonance Imaging) reconstruction method

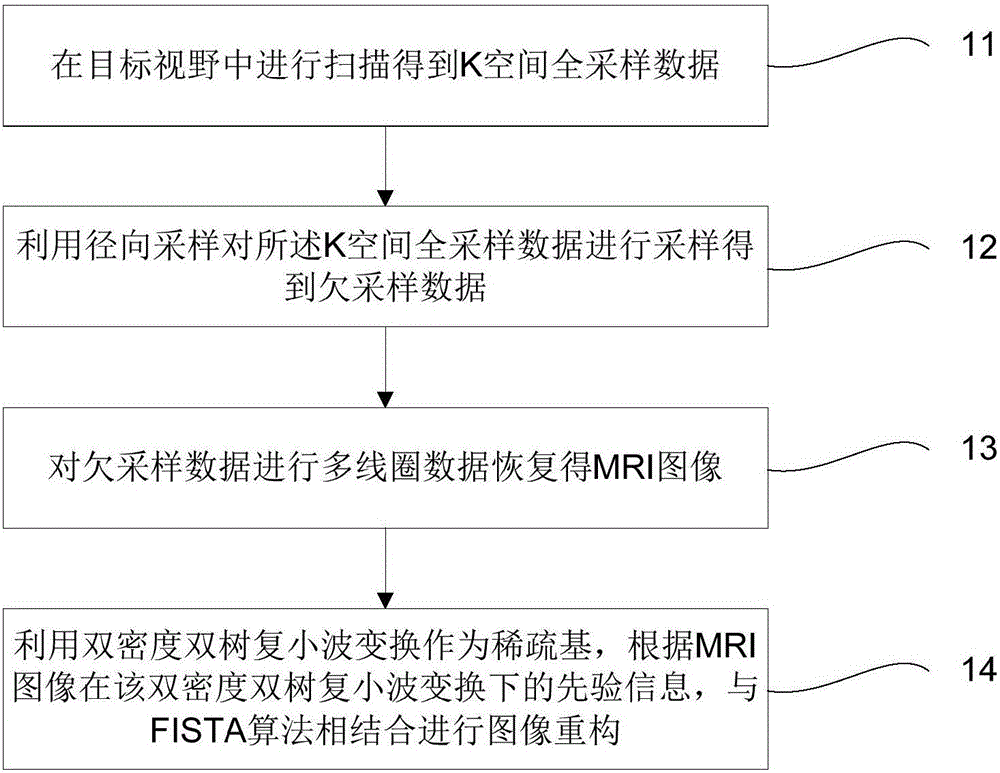

ActiveCN106485764AGood direction propertyReduce sensitivityReconstruction from projectionImage generationPattern recognitionVisual field loss

The invention discloses a fast and precise MRI (Magnetic Resonance Imaging) reconstruction method. The method comprises steps: scanning is carried out in a target visual field to obtain K space full sampling data; the K space full sampling data are sampled by using radial sampling to obtain under sampling data; the under sampling data are subjected to multi-loop data recovery to obtain an MRI image; and double-density dual-tree complex wavelet transform is used as a sparse basis, and according to the priori information of the MRI image under the double-density dual-tree complex wavelet transform, an FISTA algorithm is combined for image reconstruction. The reconstruction method can better depict image details and information, and the quality of the recovered image is improved.

Owner:UNIV OF SCI & TECH OF CHINA

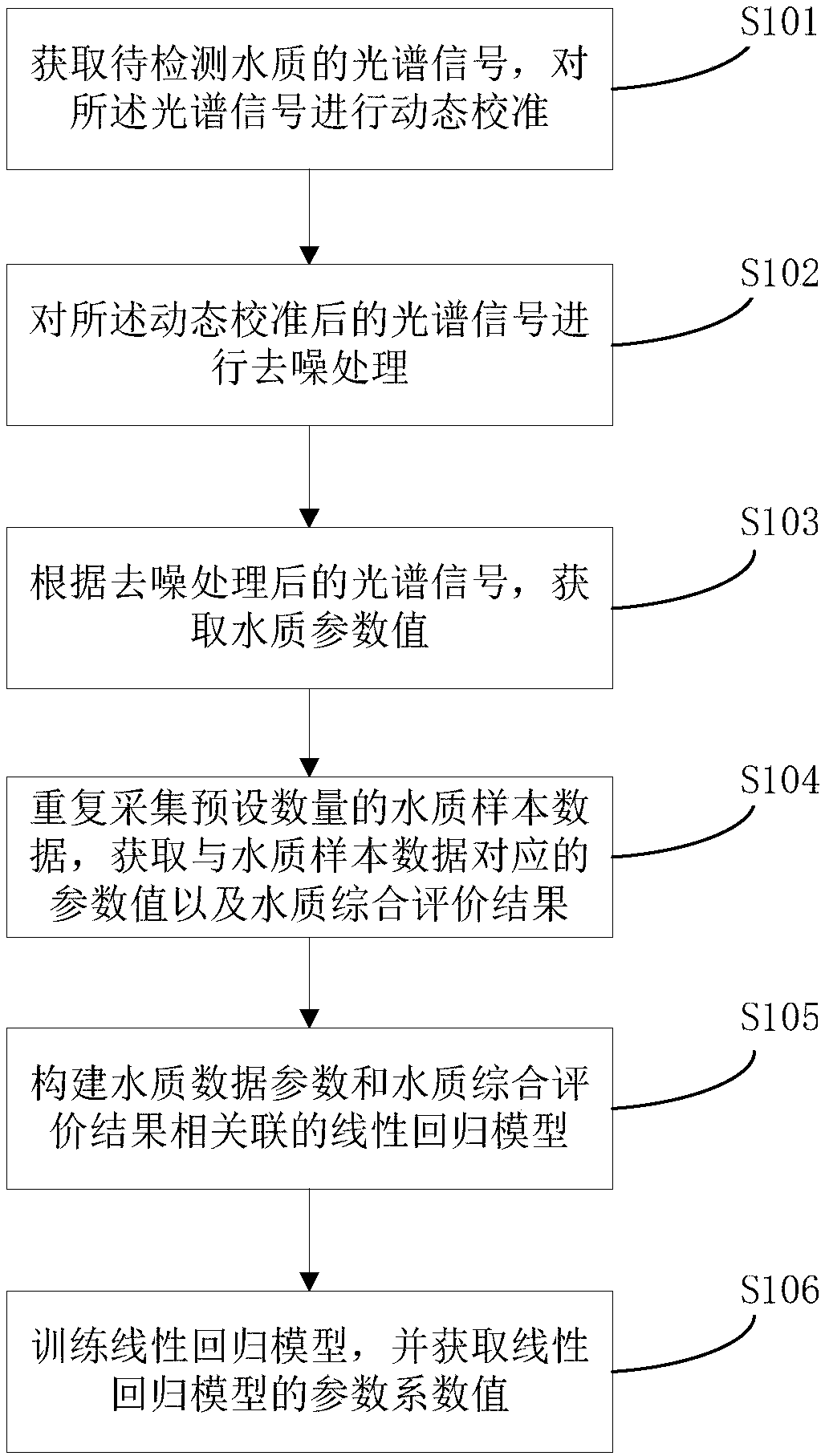

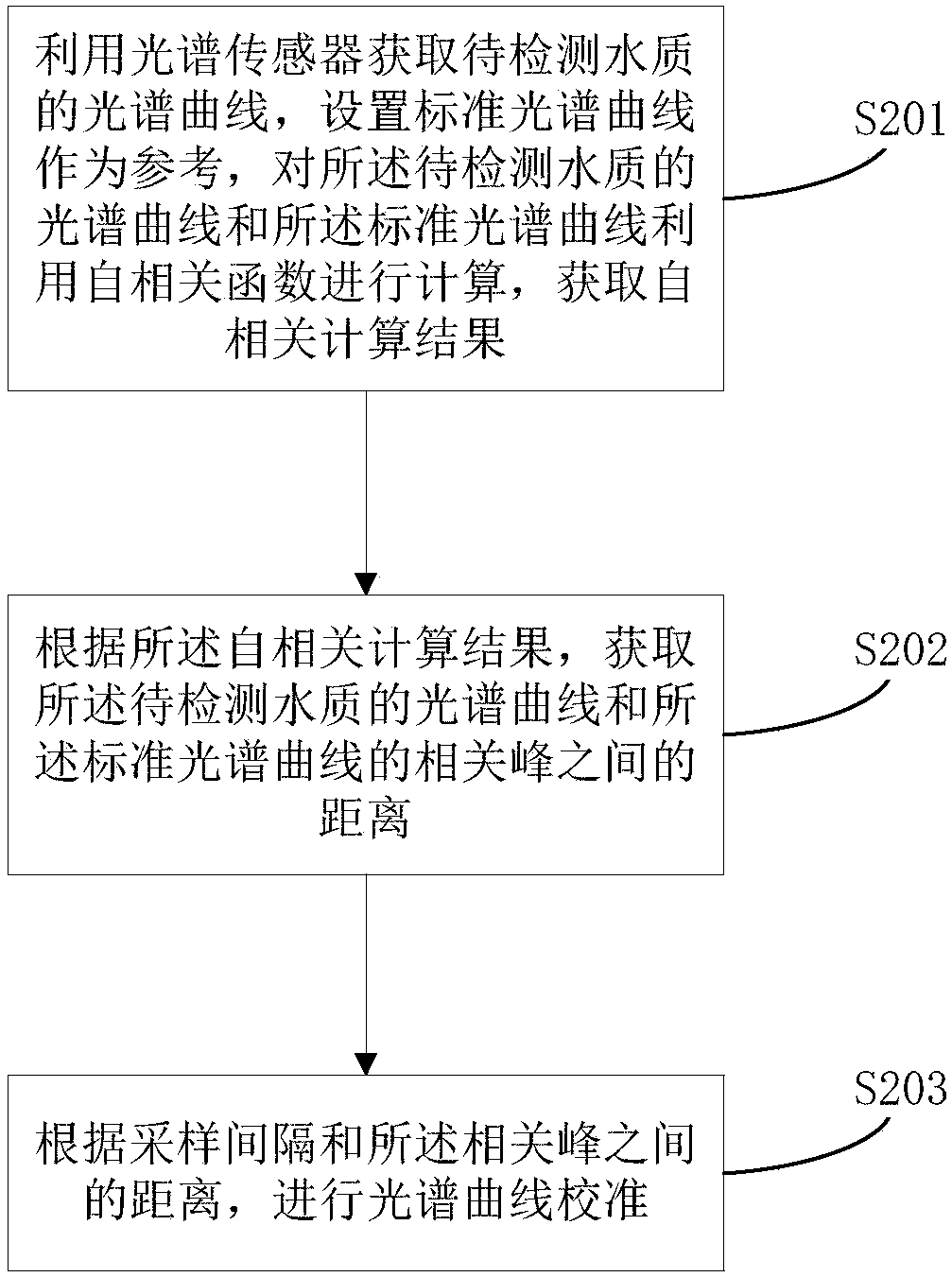

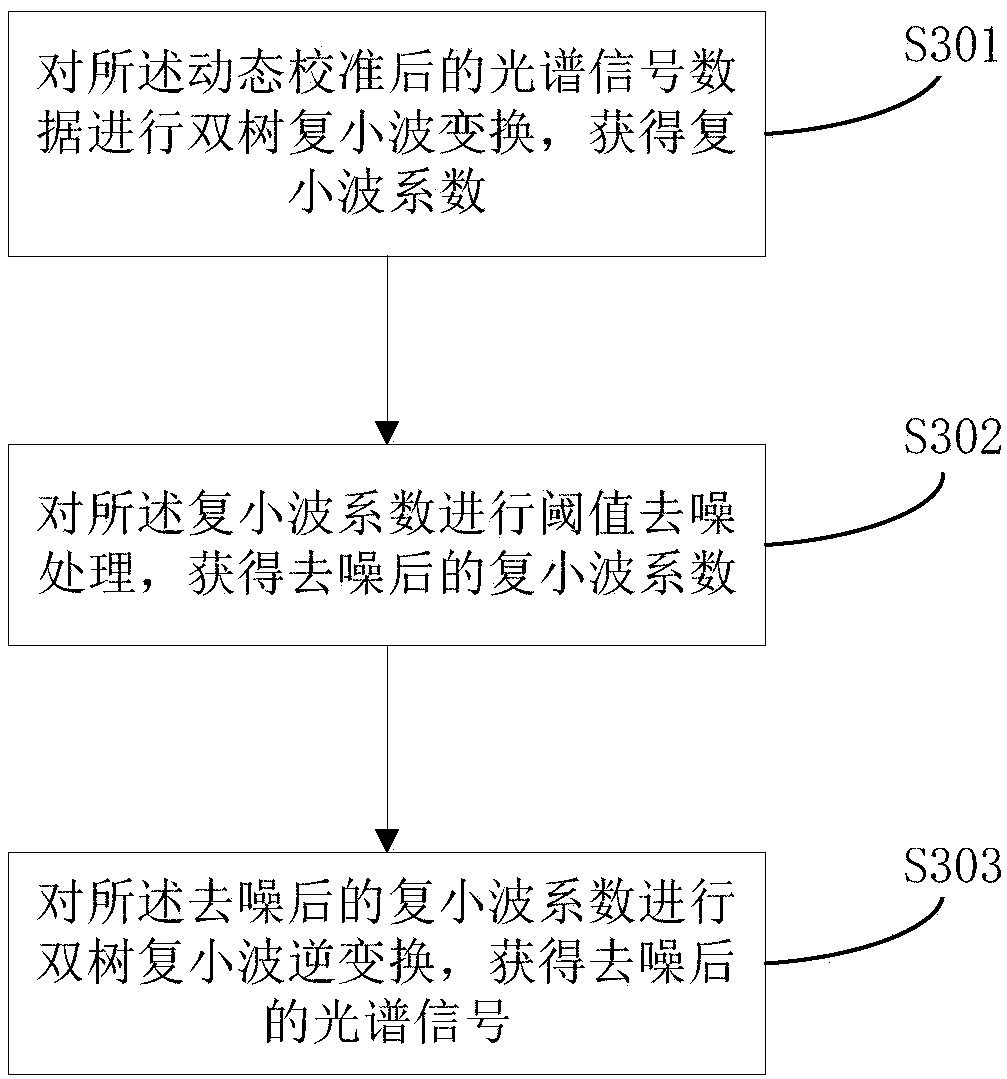

Water quality monitoring data online processing method and device

InactiveCN108108889ARealize dynamic calibrationGood repeatabilityGeneral water supply conservationColor/spectral properties measurementsEnvironmental noiseOptical spectrometer

The present invention provides a water quality monitoring data online processing method and device. The method comprises the steps of: obtaining a spectrum curve of water quality to be detected, setting a standard water quality spectrum curve as a reference, employing an autocorrelation function to calculate a related peak distance between the spectrum curve of water quality to be detected and thestandard water quality spectrum curve, and according to the related peak distance and sampling intervals, performing dynamic calibration of the spectrum curve of water quality to be detected; and performing noise removing processing of the spectrum curve after the dynamic calibration by employing a dual tree complex wavelet transform method, a threshold de-noising method and a dual tree complex wavelet inverse transform method, filtering the interference of noise signals, and finally, measuring a water quality reference value through a spectrometer according to the spectrum signals after noise removing process. Therefore, the spectrum signals with good repeatability can be obtained, the interference of water quality detection from outside environmental noise is avoided, and the accuracy of water quality detection is improved.

Owner:HANGZHOU DIANZI UNIV

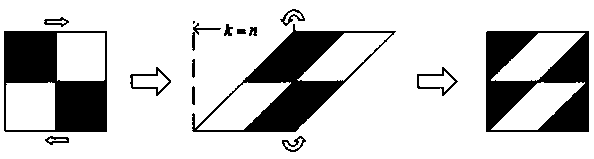

Image compression secure coding method based on multidirectional sparse representation

InactiveCN101848390AIncrease the number of directionsIncrease flexibilityTelevision systemsDigital video signal modificationObjective qualityNoise shaping

The invention discloses an image compression secure coding method based on multidirectional sparse representation, comprising the following steps of: performing discrete dual-tree wavelet transform on an image and then performing directional filtering on each obtained high-frequency sub-band to obtain fine image directional sparse representation; performing rarefaction process on an obtained directional sub-band coefficient by using a noise shaping technology; interleaving the coefficients of each layer to ensure that the sub-band coefficients of neighbor layers have a parent child relation, and then performing quantitative coding on the coefficients by using SPIHT (Set Partitioning in Hierarchical Trees); and finally encrypting the coefficient symbols in a code stream in an XOR (Exclusive OR) manner and encrypting other partial code streams by using random arithmetic coding. As the code stream obtained by coding is encrypted by using the random arithmetic coding, the encryption efficiency is high, the effect is good, the security is high and no influence is brought to the image compression performance. The high-frequency components of the image are decomposed by using a directional filter, and therefore the directional representation is more flexible, sparser image representation is obtained, the image coding compression process is favored and the decoded image has better objective quality and subjective effect.

Owner:SOUTHWEST JIAOTONG UNIV

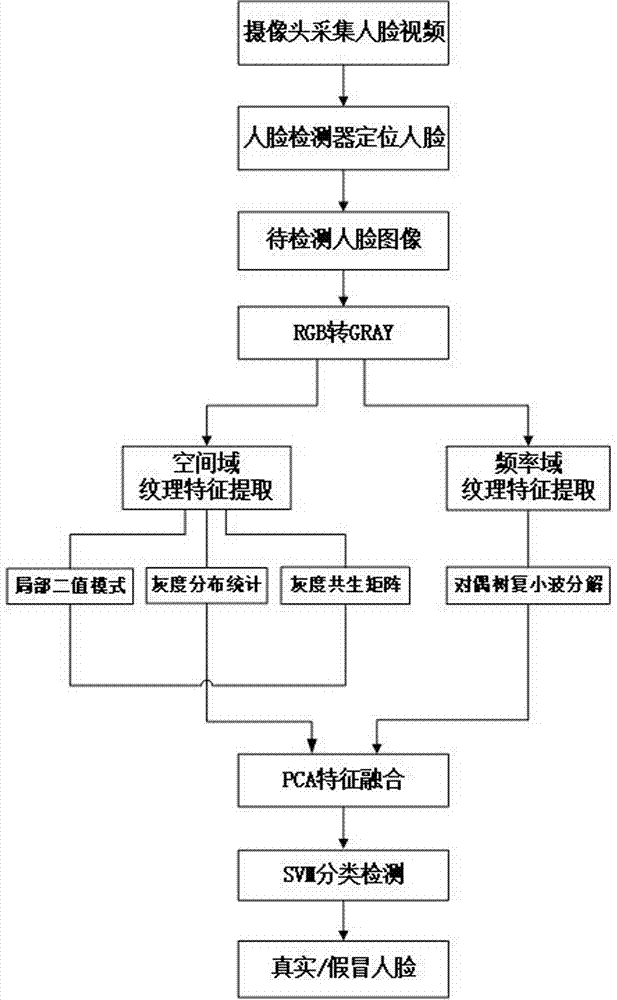

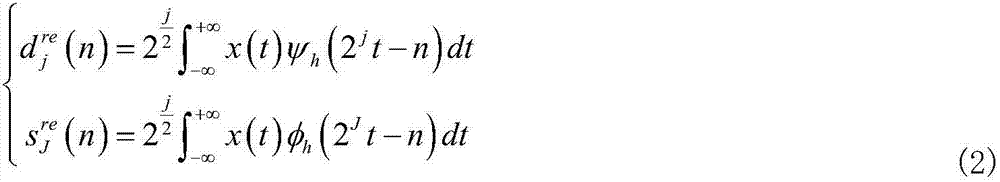

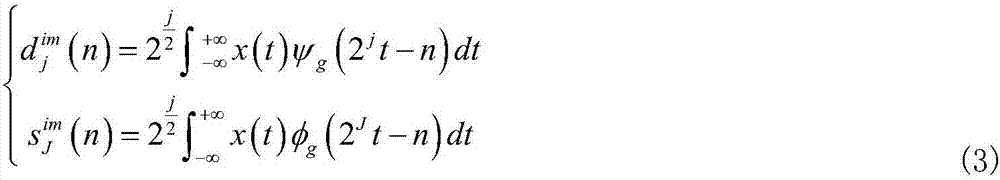

Anti-cheat detection method for human face in identity authentication system

InactiveCN107451575AReduce consumptionImprove accuracyCharacter and pattern recognitionPattern recognitionComputation complexity

The invention relates to an anti-cheat detection method for a human face in an identity authentication system, which comprises the steps of firstly, extracting spatial information of pixels by using a local binary pattern, grayscale distribution statistics and grayscale co-occurrence matrix to obtain texture features of a space domain; secondly, extracting a low frequency complex coefficient and a high frequency complex coefficient by using two-dimensional dual-tree complex wavelet decomposition to obtain texture feature of a frequency domain; then performing feature fusion by using PCA dimension reduction so as to fuse the texture features of the space domain and the texture features of the frequency domain; and finally, performing feature fusion on the texture features of the space domain and the texture features of the frequency domain, and detecting and judging a real / fake human face image by using an SVM classifier. According to the invention, the texture features of the space domain and the texture features of the frequency domain are fused, especially the texture features are extracted by using the time shift invariance and the direction selectivity of two-dimensional dual-tree complex wavelet decomposition in the frequency domain, and dimension reduction and decorrelation are performed on the fused features by using PCA, so that the calculation complexity is low, the redundancy is low, the consumption of time and space is saved, the accuracy of human face cheat detection is improved, and the security of human face cheating in the identity authentication system is enhanced.

Owner:UNIV OF JINAN

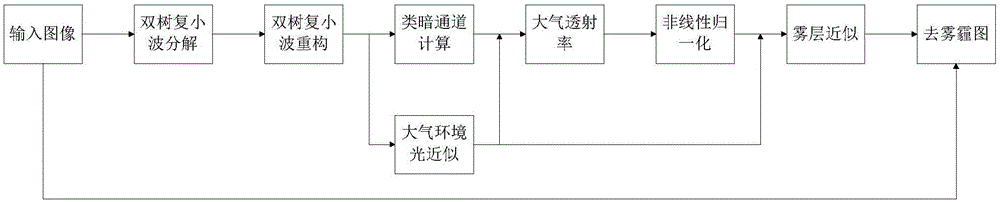

De-hazing method based on dual-tree complex wavelet

ActiveCN105096272AImprove the display effectQuality improvementImage enhancementImaging processingWavelet transform

The invention discloses a de-hazing method based on dual-tree complex wavelet and belongs to the technical field of image processing. The method comprises the following steps: to begin with, obtaining approximate value of atmospheric environment light through dual-tree complex wavelet transform; then, deducing a nonlinear normalized atmospheric transmissivity graph by utilizing an improved dark channel, and then, estimating a haze image; and finally, removing the haze to form a haze-free image according to the original image. The method has a better de-hazing effect for natural images of uniform haze and the like.

Owner:CHANGZHOU LEMENG PRESSURE VESSEL CO LTD

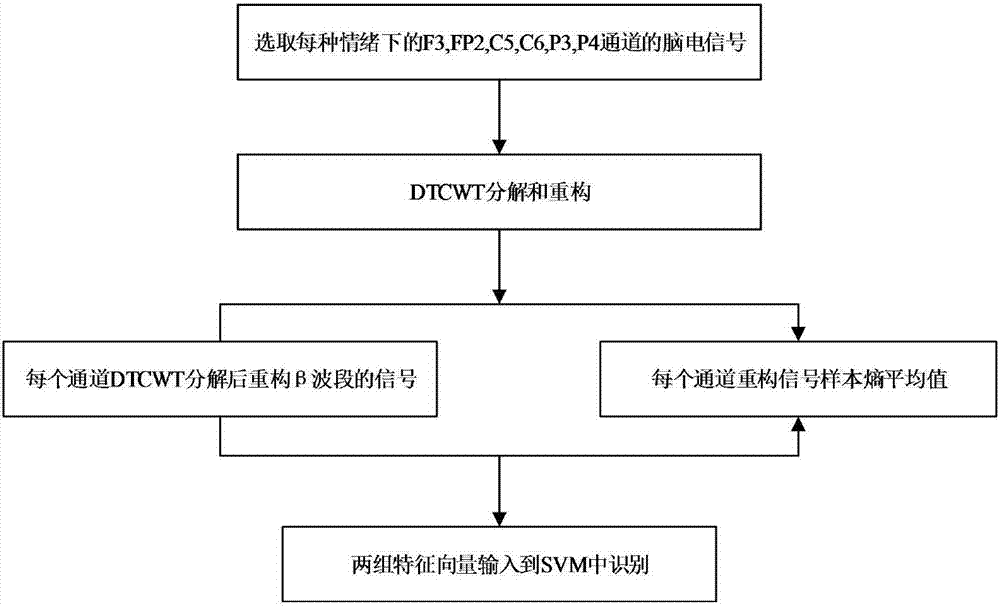

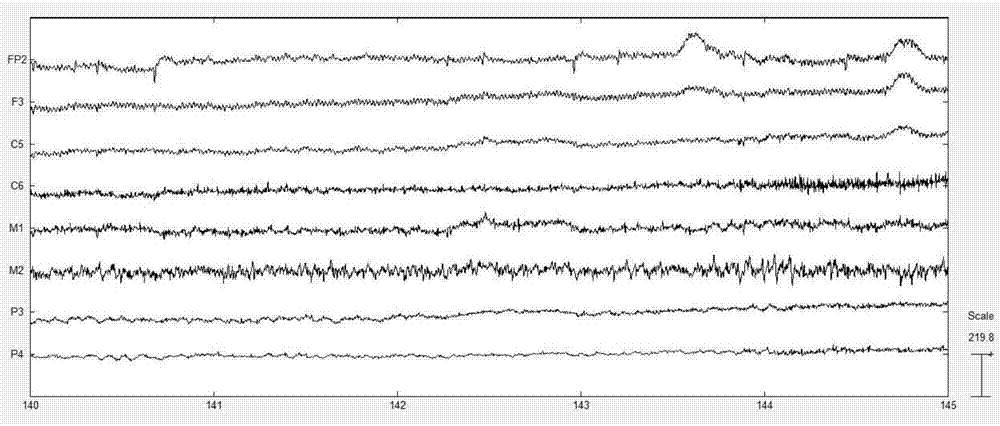

Emotional recognition feature extracting method based on electroencephalogram signal of dual-tree complex wavelet

InactiveCN107411739ASmall individual differencesOvercome the shortcomings of poor anti-aliasing and translation sensitivityDiagnostic recording/measuringSensorsFeature vectorDecomposition

The invention discloses an emotional recognition research method based on an electroencephalogram signal of dual-tree complex wavelet. Decomposition and reconstitution of dual-tree complex wavelet transform are adopted to calculate phase information and sample entropy value of different wavebands of the electroencephalogram signal, and the two features serve as feature vectors of different emotions to be input into an SVM classifier, so that three emotions of calmness, pleasure and sadness are recognized effectively. The results show that the defect that discrete wavelet transform is poor in aliasing resistance and high in translation sensitivity is overcome through dual-tree complex wavelet transform, the extracted feature vectors has a good classifying recognition result, and new thoughts are provided for later researching of emotional recognition of the electroencephalogram signal.

Owner:NANJING UNIV OF POSTS & TELECOMM

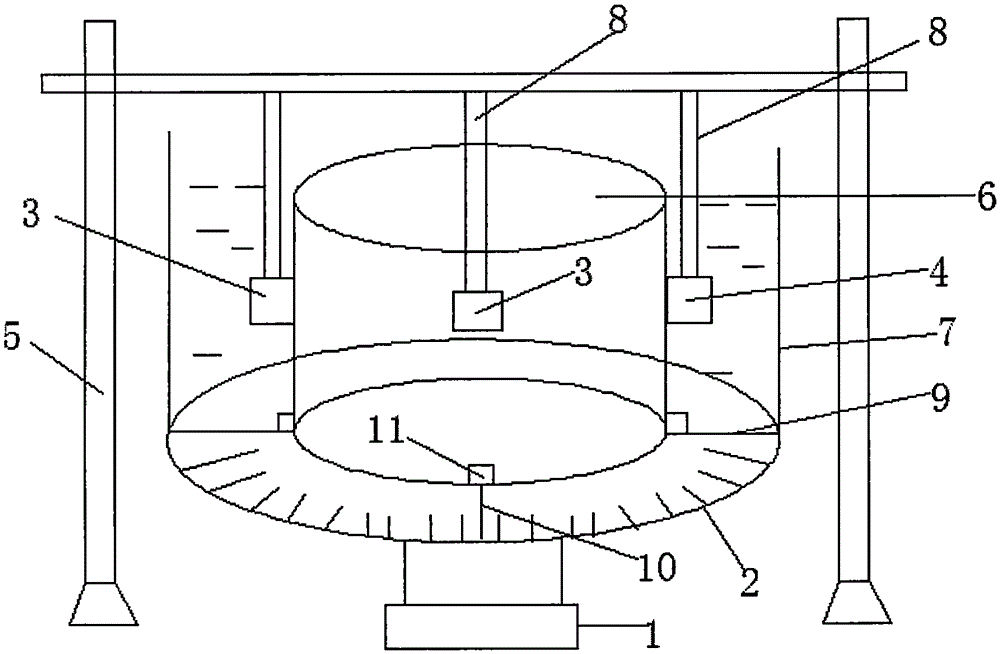

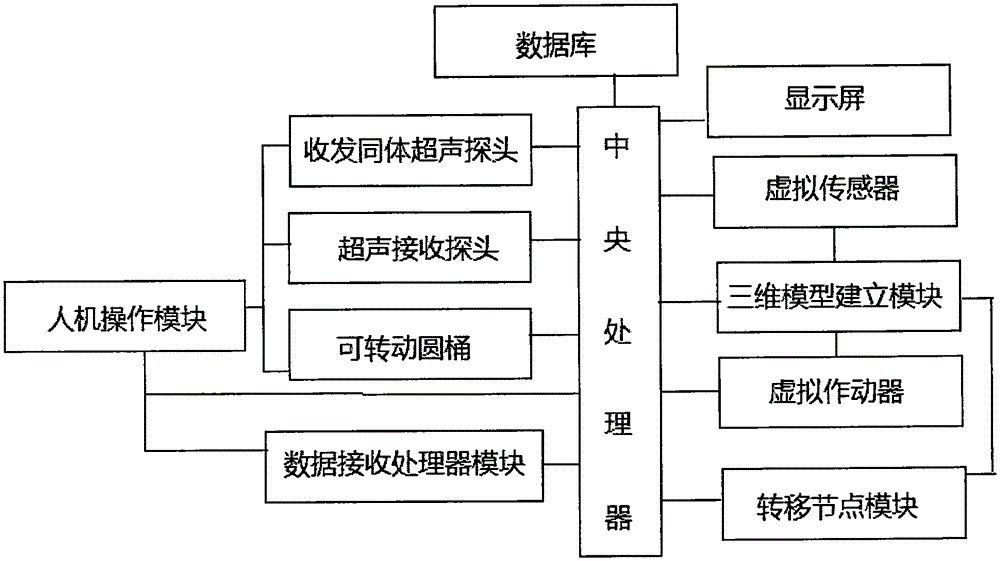

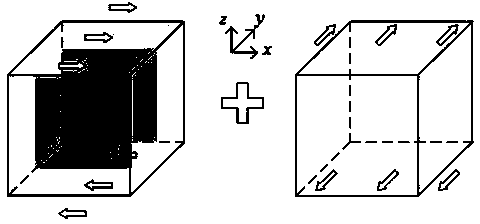

Ultrasonic testing system for defects of monocrystalline silicon sticks

InactiveCN105486748AHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalMultiscale decompositionUltrasonic testing

The invention discloses an ultrasonic testing system for defects of monocrystalline silicon sticks. Two receiving and transmitting integrated ultrasonic probes and two ultrasonic receiving probes are installed on the left and right sides and the front and back sides of a rotatable barrel respectively. A horizontal sliding rail and a vertical sliding rail which are perpendicular are arranged on the inner bottom face of the rotatable barrel. Clamping blocks with servo devices are arranged on both the horizontal sliding rail and the vertical sliding rail in a sliding mode. The receiving and transmitting integrated ultrasonic probes and the ultrasonic receiving probes are all connected with the upper ends of fixing supports through electric telescopic rods. The ultrasonic testing system further comprises a data receiving and processing module, a human-machine operation module, a three-dimensional model building module, a virtual actuator, a virtual sensor and a transfer node module. According to the ultrasonic testing system, multiscale decomposition and reconstruction are performed on received ultrasonic echo data through dual-tree complex wavelets, and accordingly, testing precision is improved, dynamic three-dimensional monocrystalline silicon sticks can be generated in the testing process, and the testing precision is further improved.

Owner:XIAN UNIV OF TECH

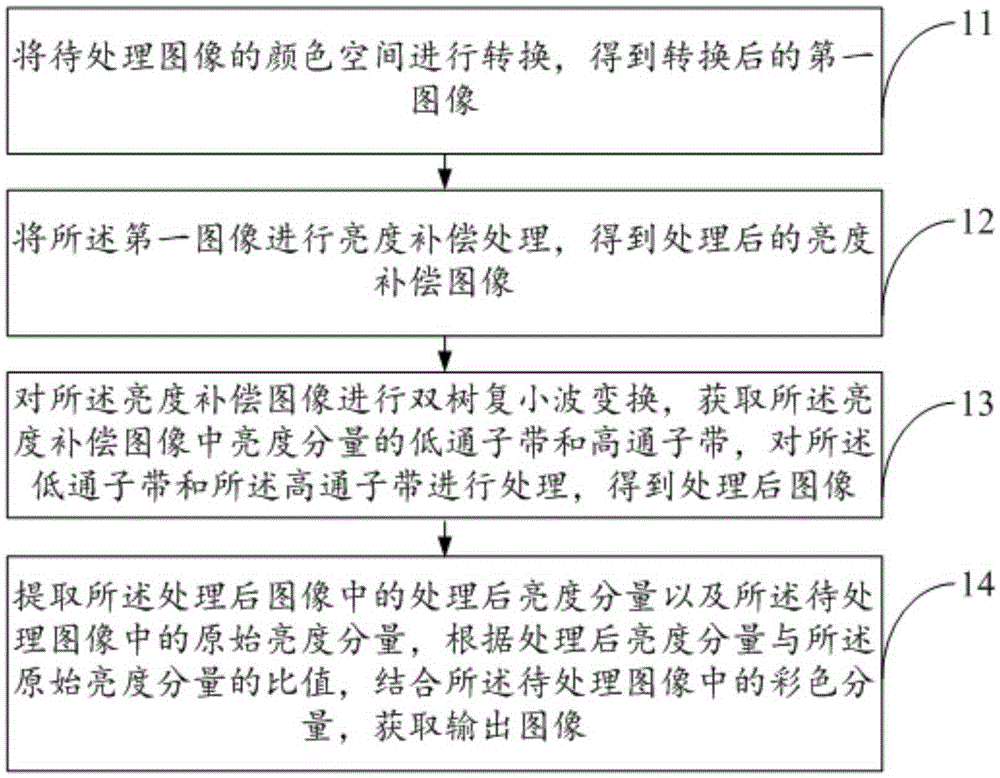

Low illumination image enhancement method based on dual-tree complex wavelet transform

The present invention discloses a low illumination image enhancement method based on dual-tree complex wavelet transform, belonging to the field of image processing. The method comprises a step of converting the color space of an image to be processed to obtain a first image, carrying out brightness compensation processing on the first image, and obtaining a processed brightness compensation image, a step of carrying out dual-tree complex wavelet transform on the brightness compensation image to obtain a processed image, and obtaining an output image according to the ratio of the brightness component in the processed image and the brightness component in the image to be processed. According to the method, through using the dual-tree complex wavelet transform to carry out contrast enhancement and image noise reduction in a wavelet domain in the processing process, due to shift invariance, good selectivity and remodeling characteristic, a guarantee is provided for low illumination image noise reduction, due to the classification of wavelet coefficients and the processing of the classified coefficients by using a nonlinear enhancement function, while the image contrast is enhanced, the noise is reduced, and the readability of a low illumination image is improved.

Owner:XIDIAN UNIV

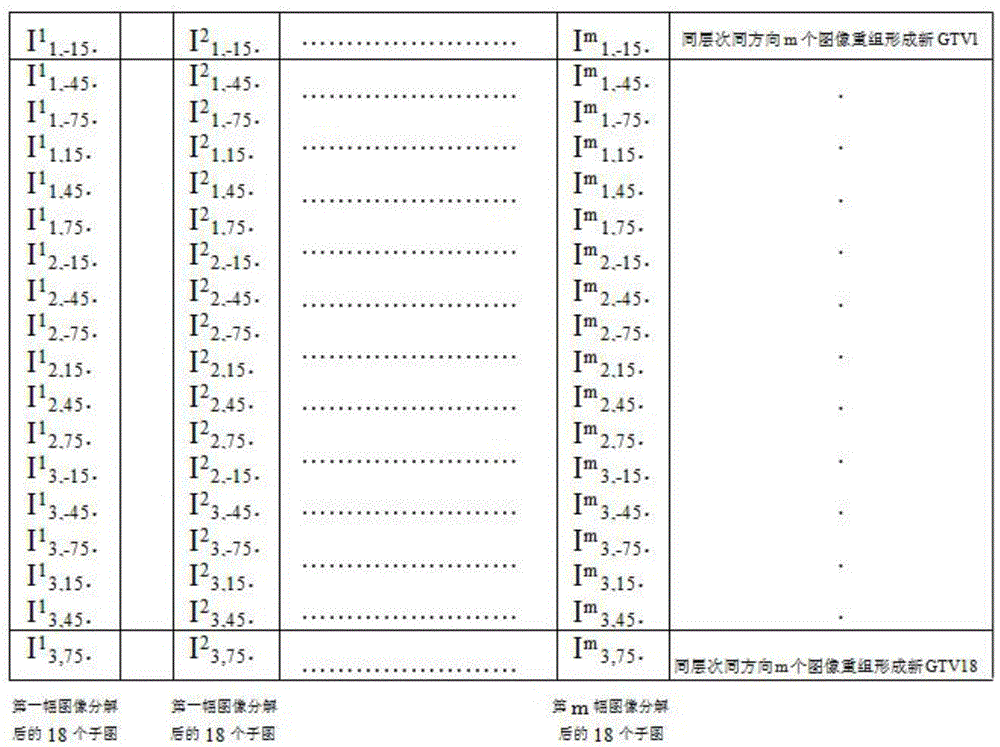

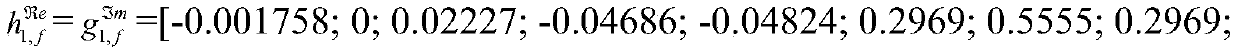

Multi-scale technology-based tumor texture feature extraction method

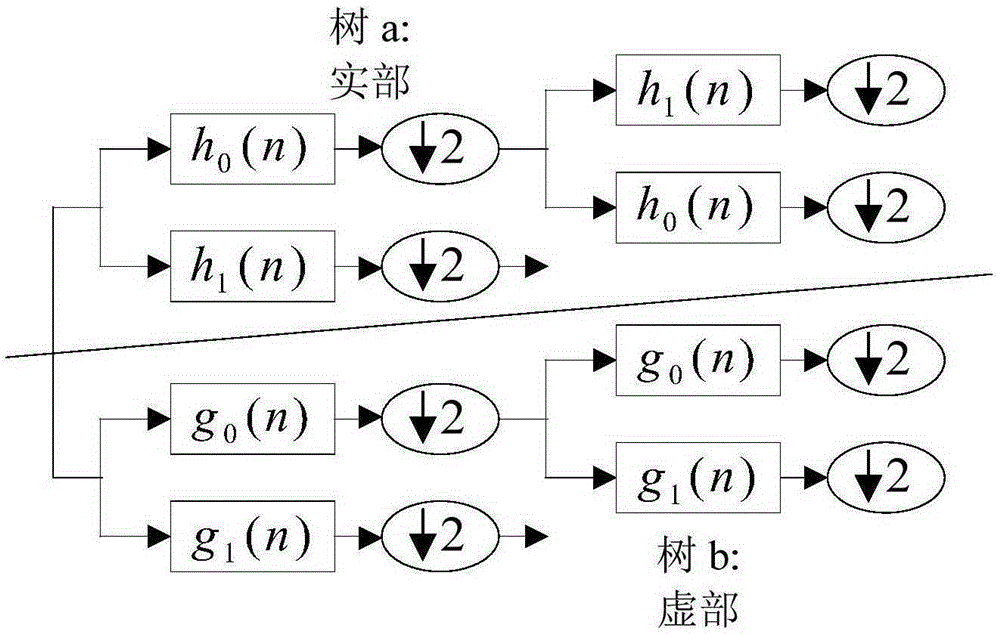

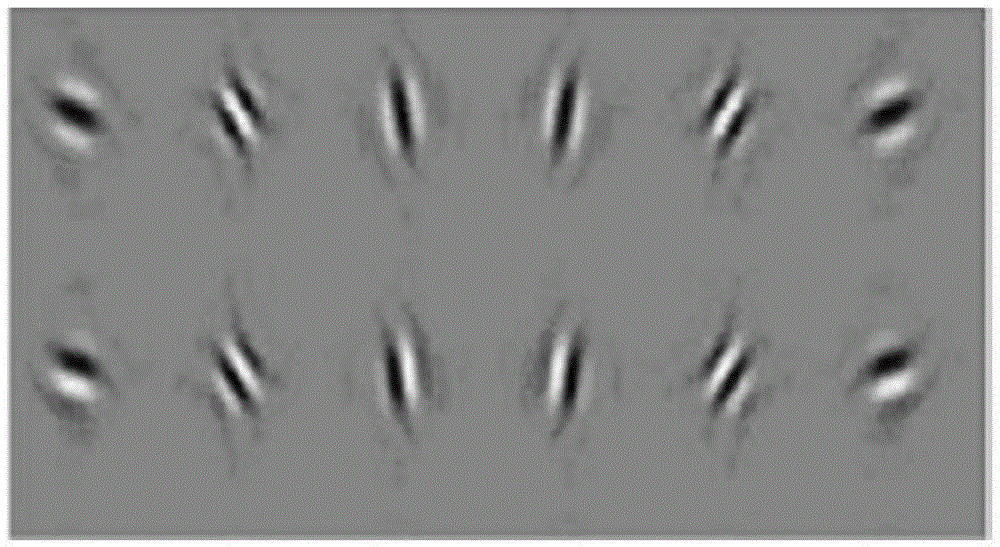

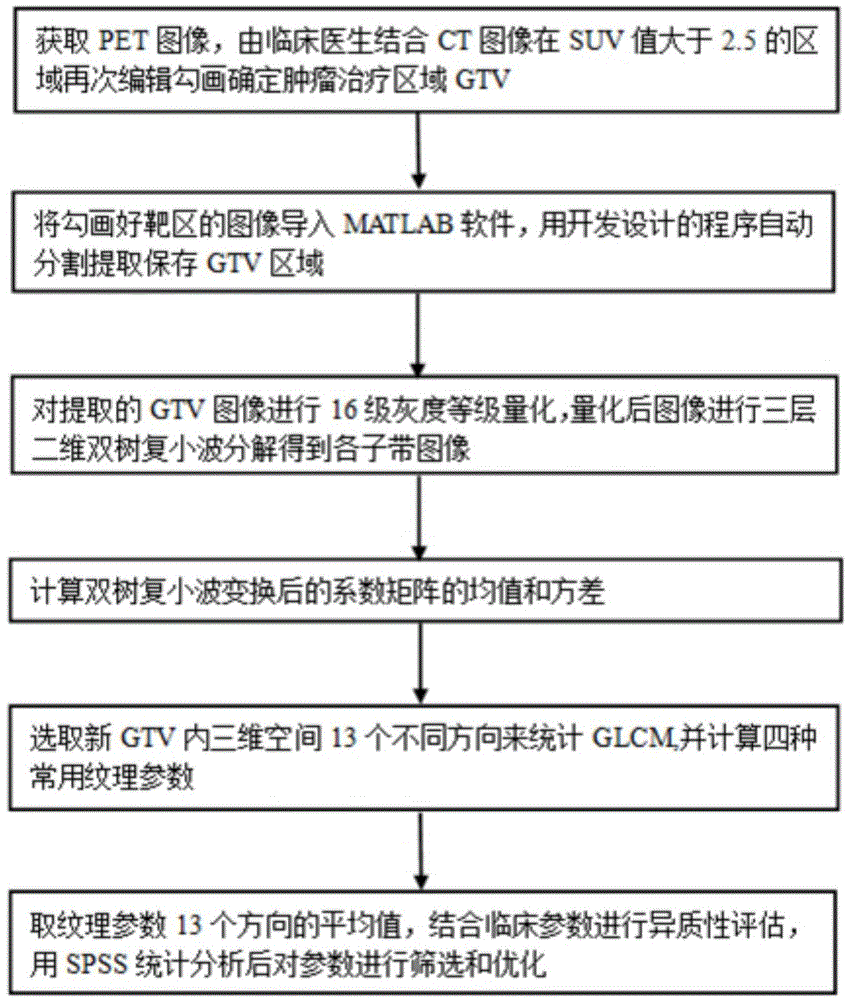

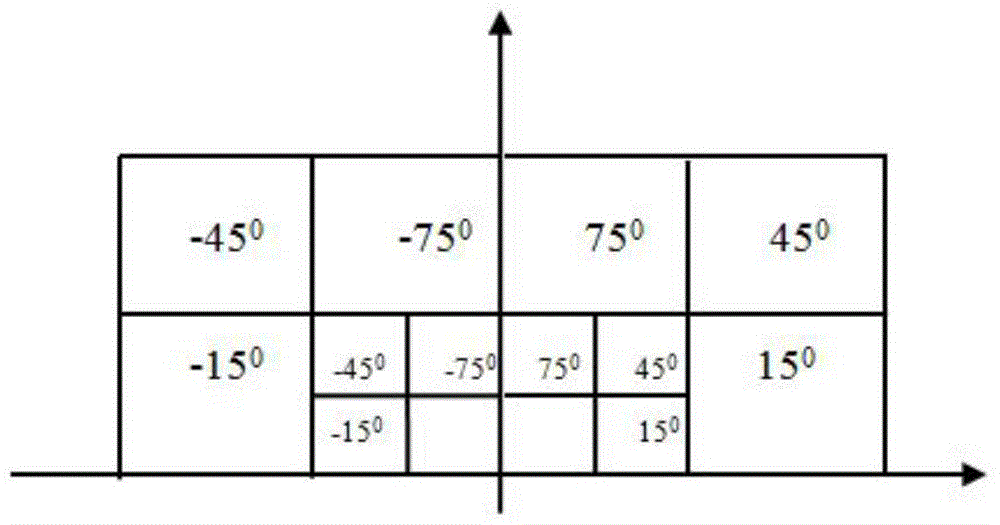

InactiveCN105869137AMeet the requirements of multi-scale and multi-resolutionEmbody all-roundnessImage analysisImaging dataDual tree

The invention discloses a multi-scale technology-based tumor texture feature extraction method. The method includes the following steps that: tumor PET image data are obtained from clinic, an ideal tumor treatment region is drawn; segmentation is carried out according to the boundary of the drawn target region, and gross tumor volume (GTV) is extracted, and PET images only containing the GTV are obtained; gray level quantization is performed on each PET image, and two-dimensional dual-tree complex wavelet transform is performed on the quantized images, and a plurality of sub-band images can be obtained from each image; all the sub-band images which are obtained by decomposing the PET images are re-combined into new stereo GTV; the mean and variance of a detail coefficient matrix obtained after two-dimensional dual-tree complex wavelet transform are calculated, and tumor texture feature values are calculated; and the relationships among the maximum values (SUVmax) of the tumor texture feature values and standardized uptake values, tumor TNM stages and infiltration depth are established, and the heterogeneous texture feature values of a quantized tumor are screened and optimized.

Owner:SHANDONG NORMAL UNIV

Non-stable signal multi-fractal feature extraction method based on dual-tree complex wavelet transformation

ActiveCN105426822AFast operationOvercoming translation invarianceCharacter and pattern recognitionFeature extractionAlgorithm

The invention discloses a non-stable signal multi-fractal feature extraction method based on dual-tree complex wavelet transformation. The steps include: performing integration processing on a non-stable signal to be analyzed; performing dual-tree complex wavelet transformation on the integrated signal, and using wavelet decomposition scale coefficients and detail coefficients to obtain fluctuation components of the signal under each scale; using the obtained wavelet coefficient of each scale to estimate the instantaneous frequency of each scale, and obtaining a time scale value of each scale; based on the scale values, performing segmentation on the fluctuation components under each scale; calculating a fluctuation function of each order of the signal, utilizing a double-logarithm relation of the fluctuation functions and the scale values, obtaining a generalized hurst index through least squares fitting, and obtaining scale index of each order; and utilizing legendre transformation to obtain a multi-fractal singular spectrum of the signal. The non-stable signal multi-fractal feature extraction method provided by the invention utilizes dual-tree complex wavelet transformation to perform signal decomposition, overcomes the problem that traditional wavelet transformation lacks translation invariance, ensures accuracy of multi-fractal feature extraction, the arithmetic speed is fast, and thus the method is in favor of online application.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

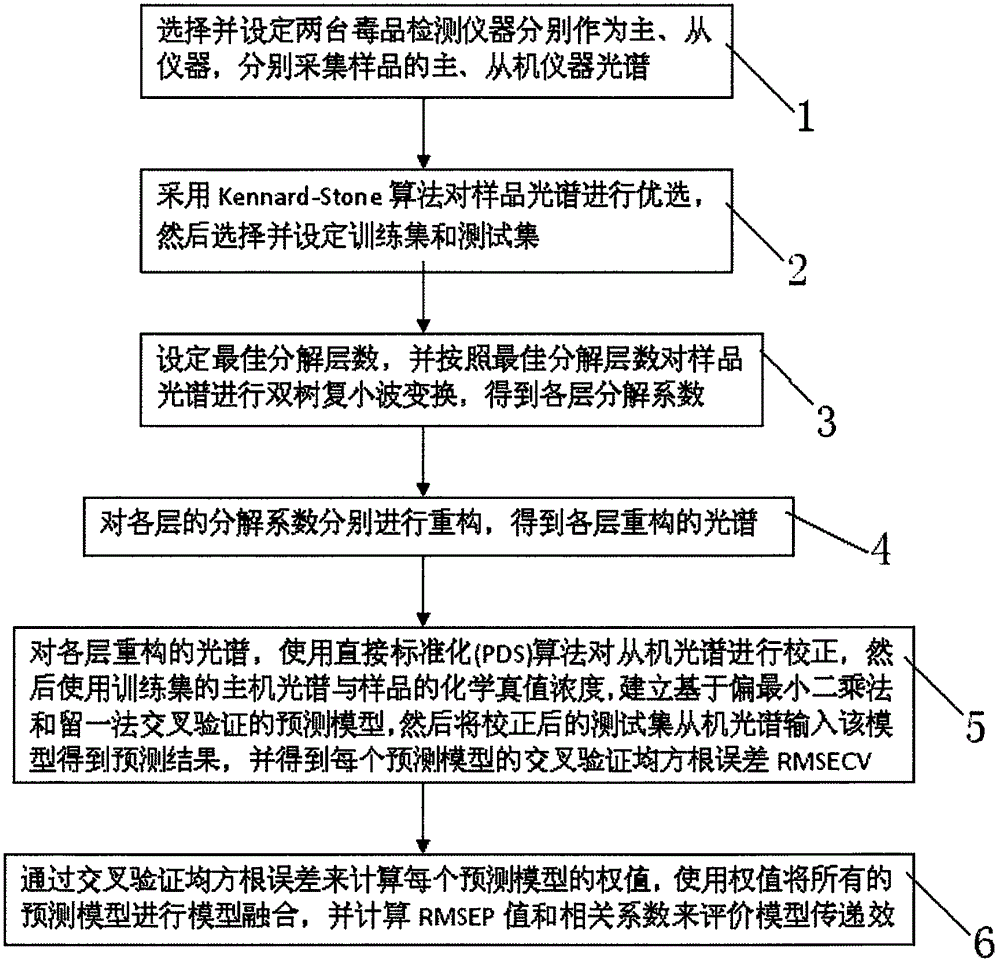

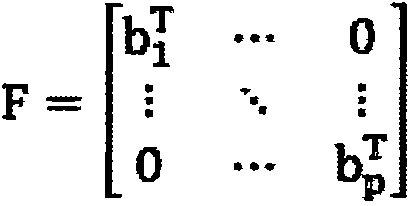

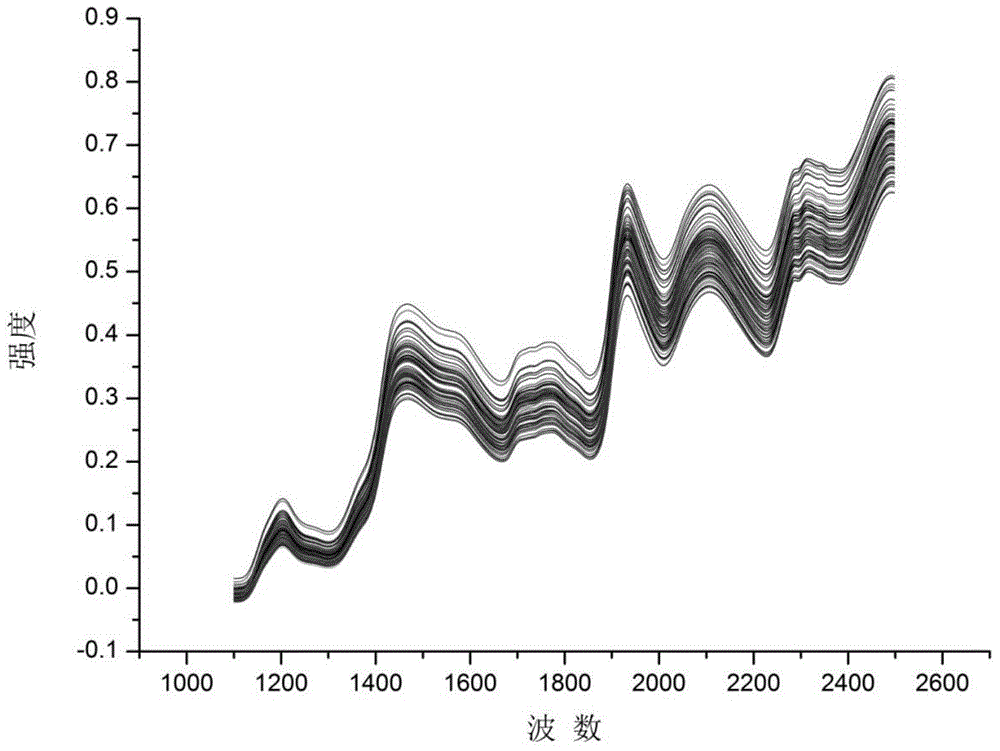

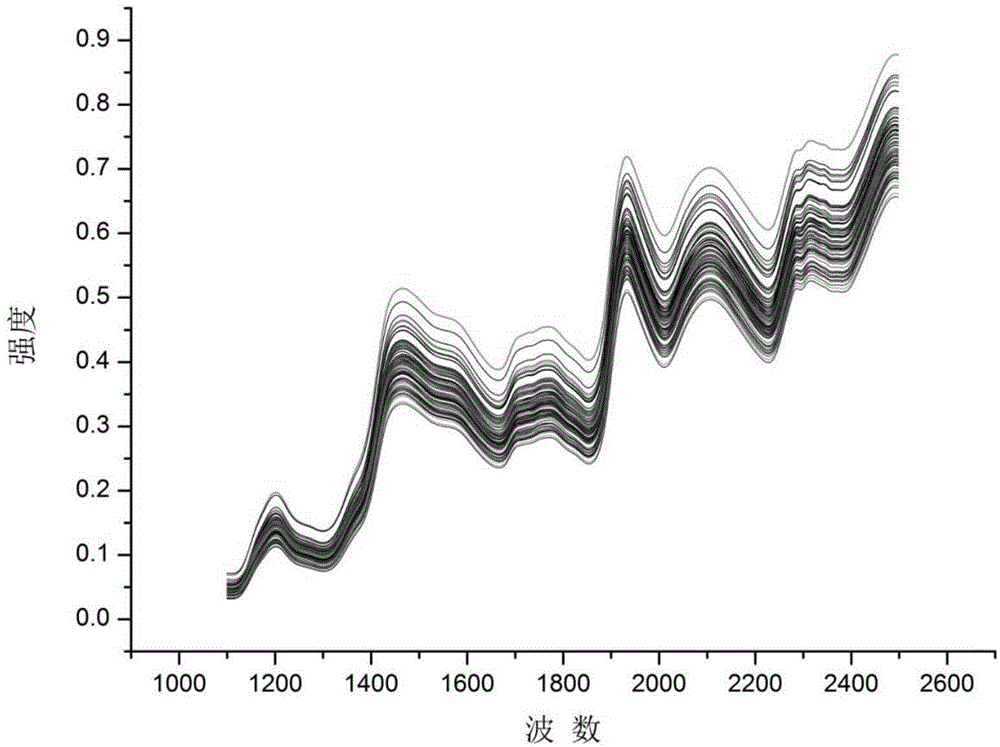

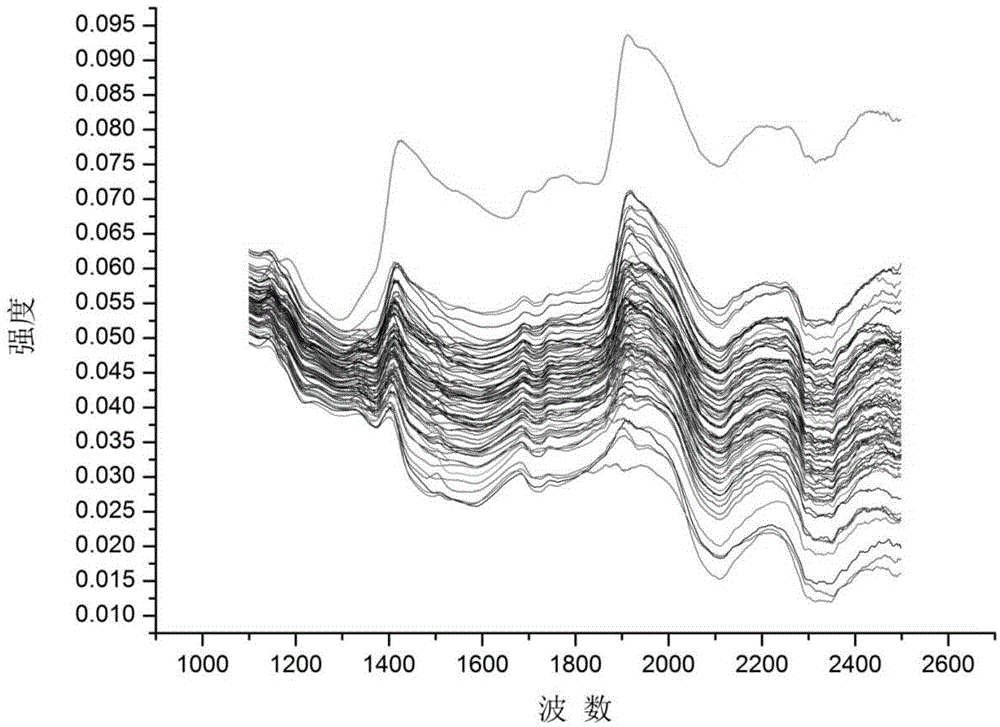

Drug detector standardization method based on dual-tree complex wavelet algorithm

InactiveCN105784672AExcellent ability to driftRaman scatteringComplex mathematical operationsMultiscale decompositionAlgorithm

The invention discloses a drug detector standardization method based on the dual-tree complex wavelet algorithm. Firstly, multi-scale spectrum decomposition and reconstruction are conducted with the dual-tree complex wavelet, then each layer of reconstructed spectrum is corrected through piecewise direct standardization, predication models based on partial least squares and leave one cross validation are established, and finally all the predication models are fused and evaluated according to a calculated weight. According to the dual-tree complex wavelet and direct standardization combined method, due to the translation invariance and multi-scale property of the dual-tree complex wavelet, the defects of existing model transfer methods are overcome, the capacity of correcting drifting in the X-axis direction and Y-axis direction is excellent, and the method also has the advantages of being exquisite, precise and efficient and can be widely applied to the fields including near-infrared and Raman spectrum.

Owner:河北伊诺光学科技股份有限公司 +1

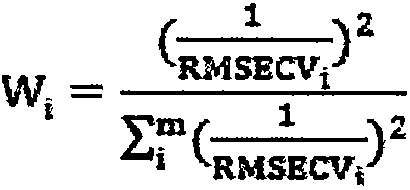

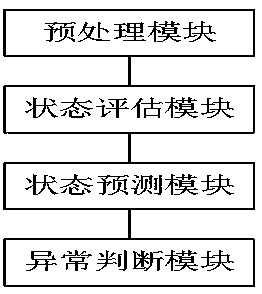

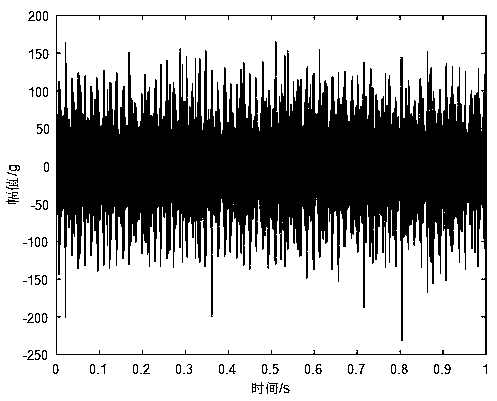

Rotating equipment state abnormity judgment method and system

ActiveCN111259717AImplement state predictionRemove noise signalSubsonic/sonic/ultrasonic wave measurementCharacter and pattern recognitionState predictionPrincipal component analysis

The invention relates to the field of rotating equipment fault diagnosis, and discloses a rotating equipment state abnormality judgment method and system. The method comprises: A) collecting a rotating equipment vibration signal, and carrying out the dual-tree complex wavelet packet transformation of the rotating equipment vibration signal; B) calculating the frequency band energy of the vibrationcomponent signal of the rotating equipment; C) processing the characteristic parameter matrix by adopting a principal component analysis method to obtain a dimension-reduced characteristic parametermatrix; D) obtaining a rotating equipment vibration signal sample state evaluation value time sequence; and E) establishing a rotating equipment state abnormity alarm mechanism, and predicting the rotating equipment state evaluation value by adopting an LSTM method. The rotating equipment state prediction and evaluation are realized, the rotating equipment abnormity early warning can be realized,and the false alarm rate of rotating equipment abnormity judgment is reduced.

Owner:HANGZHOU ANMAISHENG INTELLIGENT TECH CO LTD

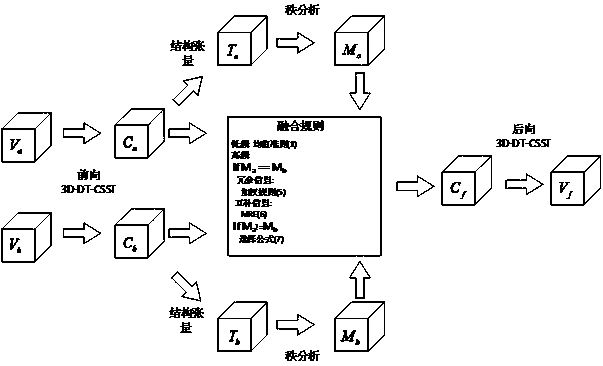

Feature-level medical image fusion method based on 3D (three dimension) shearlet transform

ActiveCN103985109AAccurate Direction InformationImprove fusion qualityImage enhancementGeometric image transformationImaging processingDual tree

The invention discloses a feature-level medical image fusion method based on 3D (three dimension) shearlet transform, belonging to the technical field of medical image processing and application. The feature-level medical image fusion method mainly comprises the following steps: 1, performing 3D-D-CSST (three dimensional-discrete-compact shearlet transform) or 3D-DT-CSST (three dimensional dual-tree compact shearlet transform) on two images to obtain transformation coefficient images Ca and Cb; 2, performing image fusion on transformation coefficients to obtain a fusion coefficient Cf; and 3, performing DWT or DTCWT inverse transformation, performing backward shear transformation on the transformed image to obtain a fusion image Vf. According to the feature-level medical image fusion method, the problems that the quality of a fused image is relatively low and information which is partially important and is not remarkable is easily ignored are solved.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

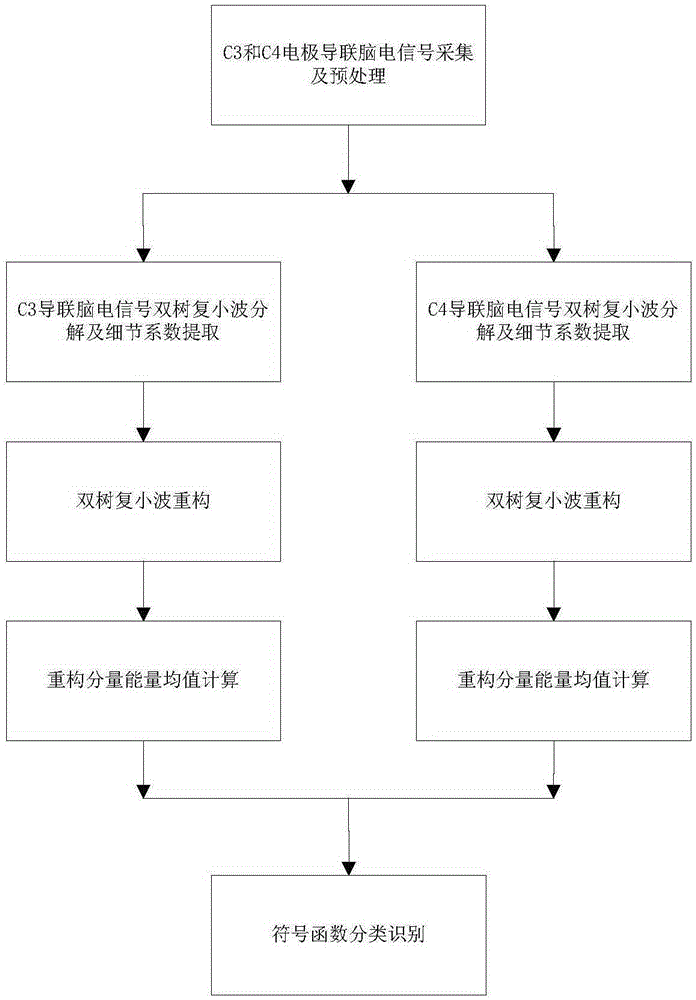

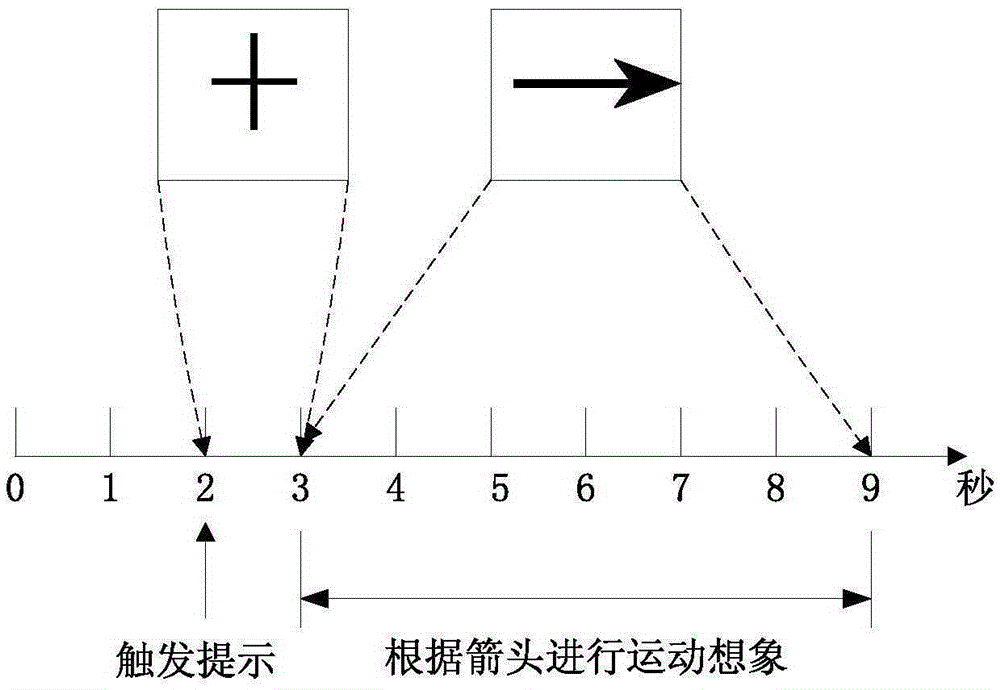

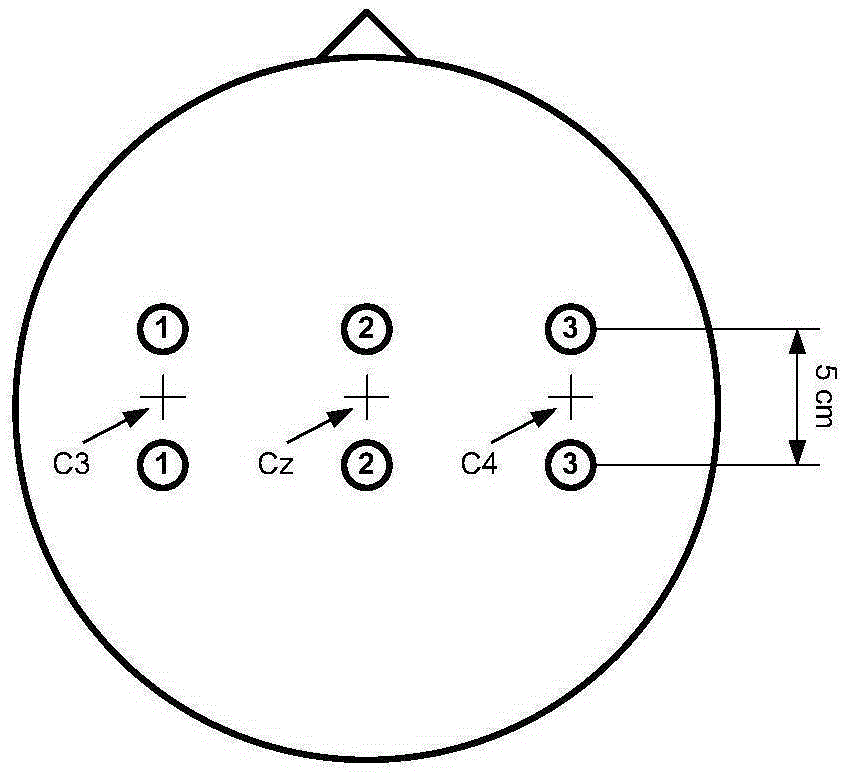

Motor imagery brain electrical signal recognition method based on dual-tree complex wavelet energy difference

InactiveCN105286860AEasy to use in real timeGuaranteed classification accuracyDiagnostic recording/measuringSensorsBrain computer interfacingAlgorithm

The invention discloses a motor imagery brain electrical signal recognition method based on dual-tree complex wavelet energy difference. Energy difference features of brain electrical signals are calculated mainly through dual-tree complex wavelet decomposition and reconstruction, and are classified and judged through a sign function. The method includes the steps of brain electrical signal collection and preprocessing, dual-tree complex wavelet decomposition and detail coefficient extraction, dual-tree complex wavelet reconstruction, reconstruction component energy averaged value calculation and sign function classification and recognition. Results show that dual-tree complex wavelet conversion effectively overcomes the defects of poor aliasing resistance, translation sensitivity and the like of discrete wavelet transformation, and good classification and recognition results can be obtained through extracted energy averaged value difference features. Compared with a traditional classification algorithm, the feature classification algorithm based on features of the sign function is easier to design, low in complexity, high in calculation speed, suitable for the development direction of a Brain-Computer Interface (BCI) system and favorable for real-time application of the BCI system.

Owner:SOUTHEAST UNIV

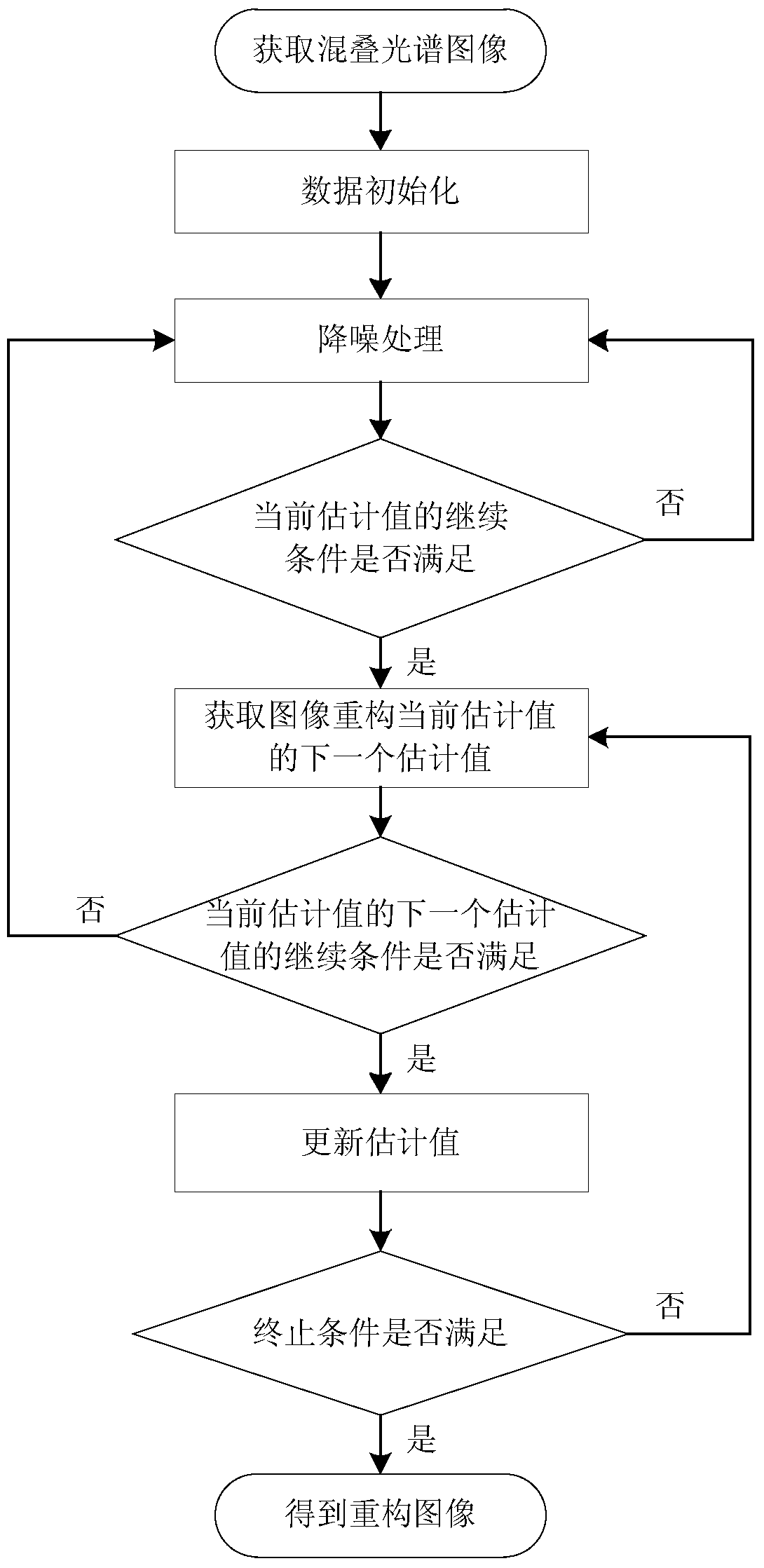

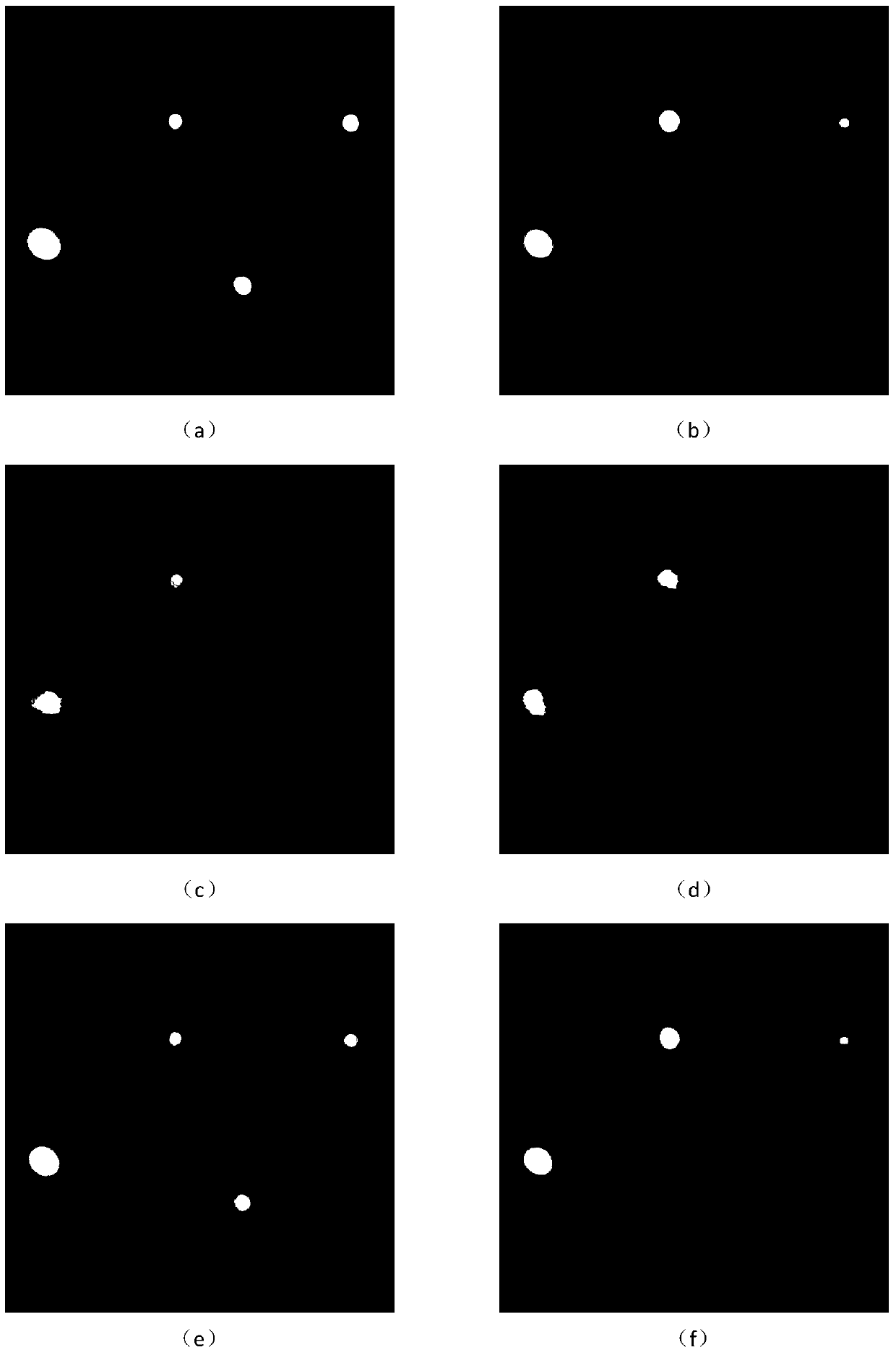

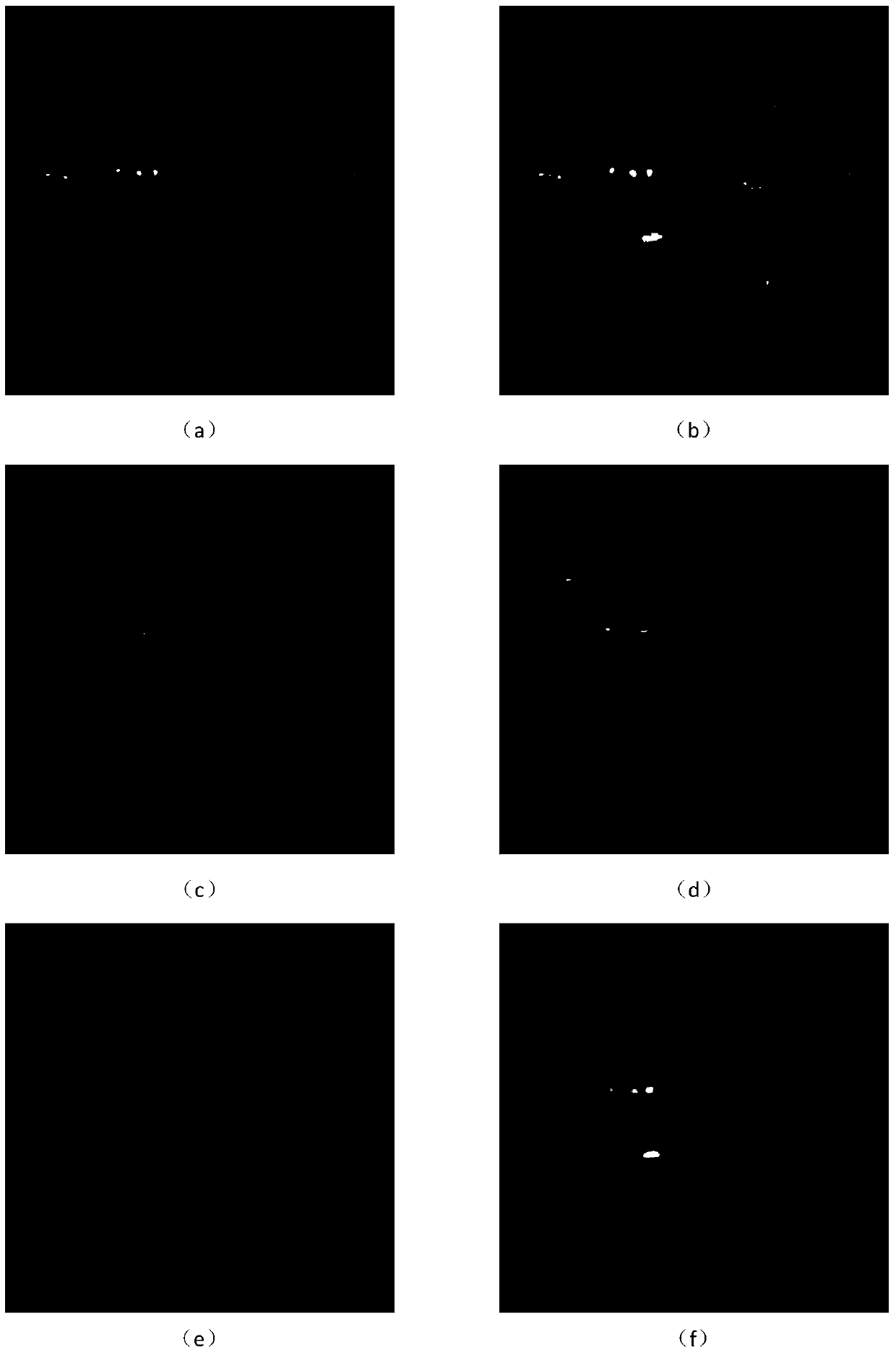

Multispectral image reconstruction method based on dual-tree complex wavelet transformation

The invention discloses a multispectral image reconstruction method based on dual-tree complex wavelet transformation and aims at solving the problems of unideal reconstruction effect and low reconstruction speed in the existing multispectral image reconstruction technology. The multispectral image reconstruction method based on dual-tree complex wavelet transformation comprises the steps of (1) obtaining an aliased spectral image, (2) performing data initialization, (3) performing noise reduction processing, (4) determining whether the continuing condition of a current estimated value is satisfied, (5) obtaining next estimated value of the current estimated value of image reconstruction, (6) determining whether the continuing condition of the next estimated value of the current estimated value is satisfied, (7) updating the estimated value, and (8) determining whether an end condition is satisfied. The multispectral image reconstruction method based on dual-tree complex wavelet transformation has the advantages that dual-tree complex wavelet transformation is adopted to realize noise reduction processing on the image, and a good multispectral image reconstruction result and a relatively high multispectral image reconstruction seed can be obtained in the reconstruction process of compressive spectral imaging.

Owner:XIDIAN UNIV

Model transferring method based on dual-tree complex wavelet and piecewise direct standardization

InactiveCN105631176AExcellent ability to driftSpecial data processing applicationsMultiscale decompositionAlgorithm

The invention discloses a model transferring method based on a dual-tree complex wavelet and piecewise direct standardization. The method comprises the steps of firstly adopting the dual-tree complex wavelet to perform multi-scale decomposition and reconstruction, then correcting each layer of reconstructed spectrum by using the piecewise direct standardization, then establishing prediction models based on cross validation of a partial least squares method and a leave-one-out method, and at last fusing all prediction models by computed weights and evaluating. According to the method combining the dual-tree complex wavelet with the piecewise direct standardization provided by the invention, as the dual-tree complex wavelet has the characteristics of translation invariance and multi-scale, the deficiencies of the existing model transferring method are overcome, the capability of correcting drifting in X-axis and Y-axis directions is very excellent, and meanwhile the advantages of being fine, accurate and efficient are provided, and thereby the method can be widely applied to the fields of near-infrared and Raman spectrum.

Owner:河北伊诺光学科技股份有限公司

De-noising digital radiological images

This invention relates to a method for de-noising digital radiographic images based upon a wavelet-domain Hidden Markov Tree (HMT) model. The method uses the Anscombe's transformation to adjust the original image to a Gaussian noise model. The image is then decomposed in different sub-bands of frequency and orientation responses using a dual-tree complex wavelet transform, and the HMT is used to model the marginal distribution of the wavelet coefficients. Two different methods were used to denoise the wavelet coefficients. Finally, the modified wavelet coefficients are transformed back into the original domain to get the de-noised image.

Owner:1370509 ALBERTA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com