Patents

Literature

624 results about "Online processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

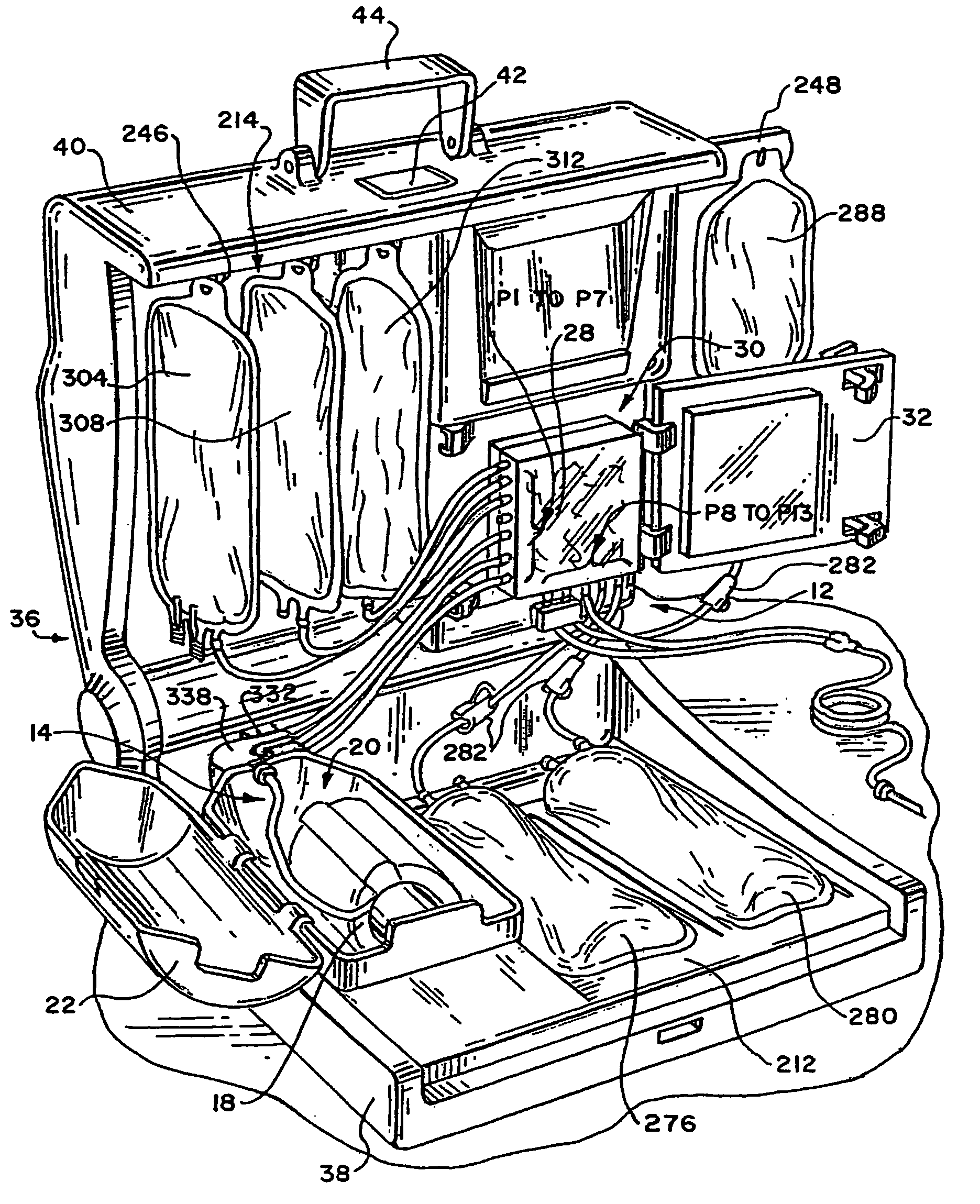

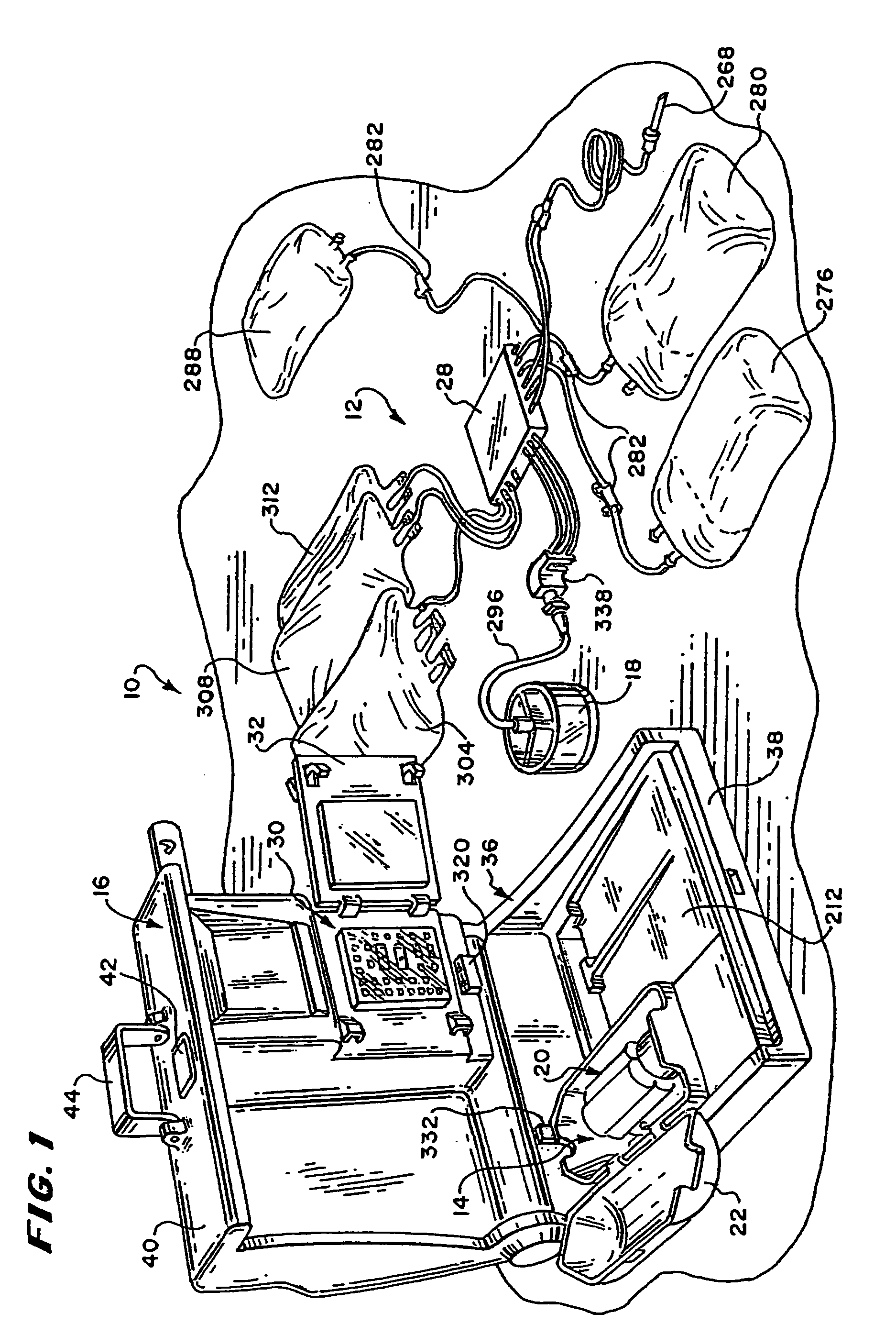

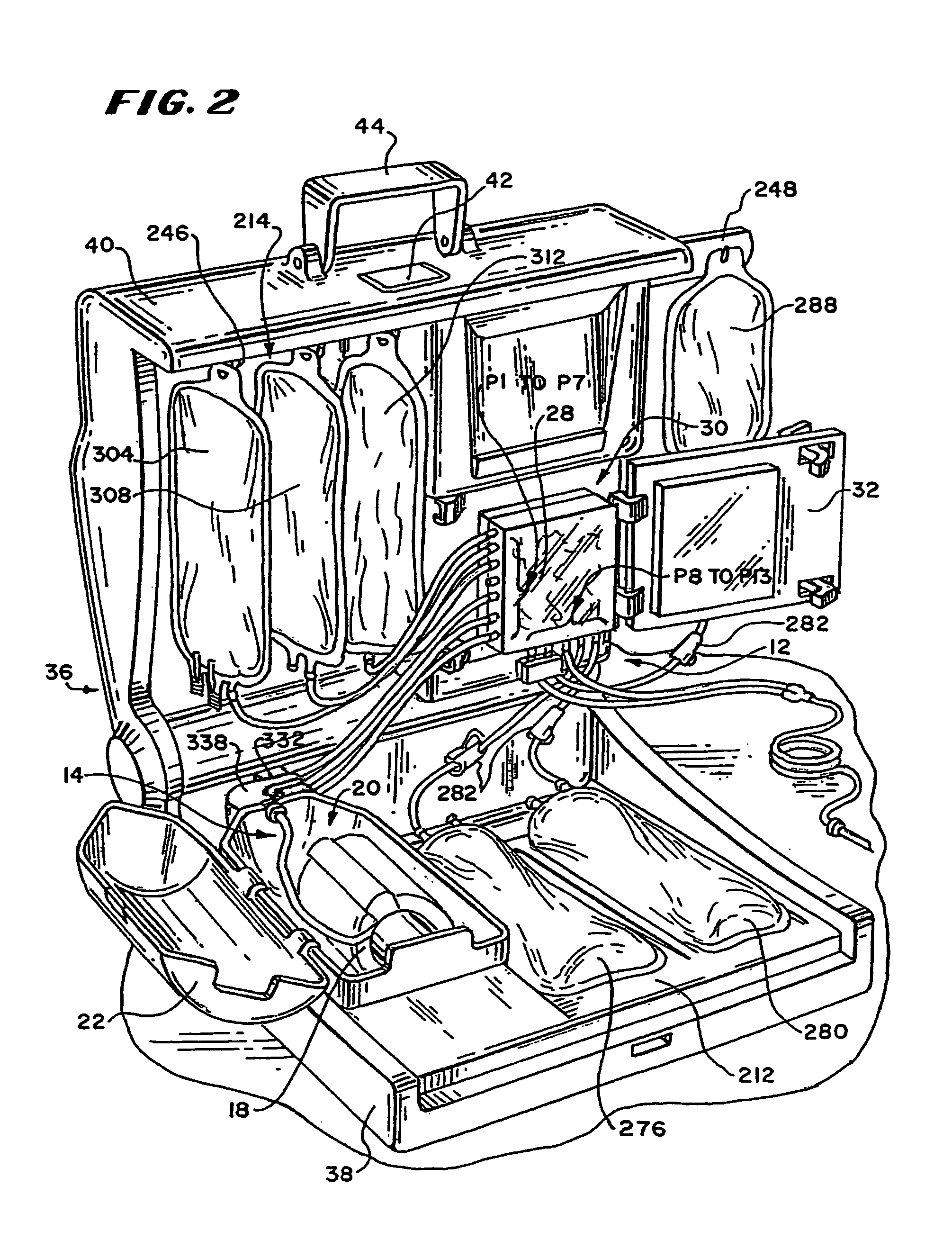

Blood separation systems and methods using a multiple function pump station to perform different on-line processing tasks

InactiveUS7041076B1Straightforward and accurate control functionReduce complexityOther blood circulation devicesRotary centrifugesBlood componentWhite blood cell

A multiple function pump station performs different on-line processing tasks. The pump station can be operated in one mode to draw blood from a donor can, in another mode, be operated to return blood to the donor. The pump station used to draw blood from a donor can also be used to perform subsequent blood processing tasks, such as mixing processing or additive fluids with the blood, or transfering a harvested blood component to a storage container, or finishing the processing of a harvested blood component, e.g., by passage through a filter to remove leukocytes.

Owner:FENWAL

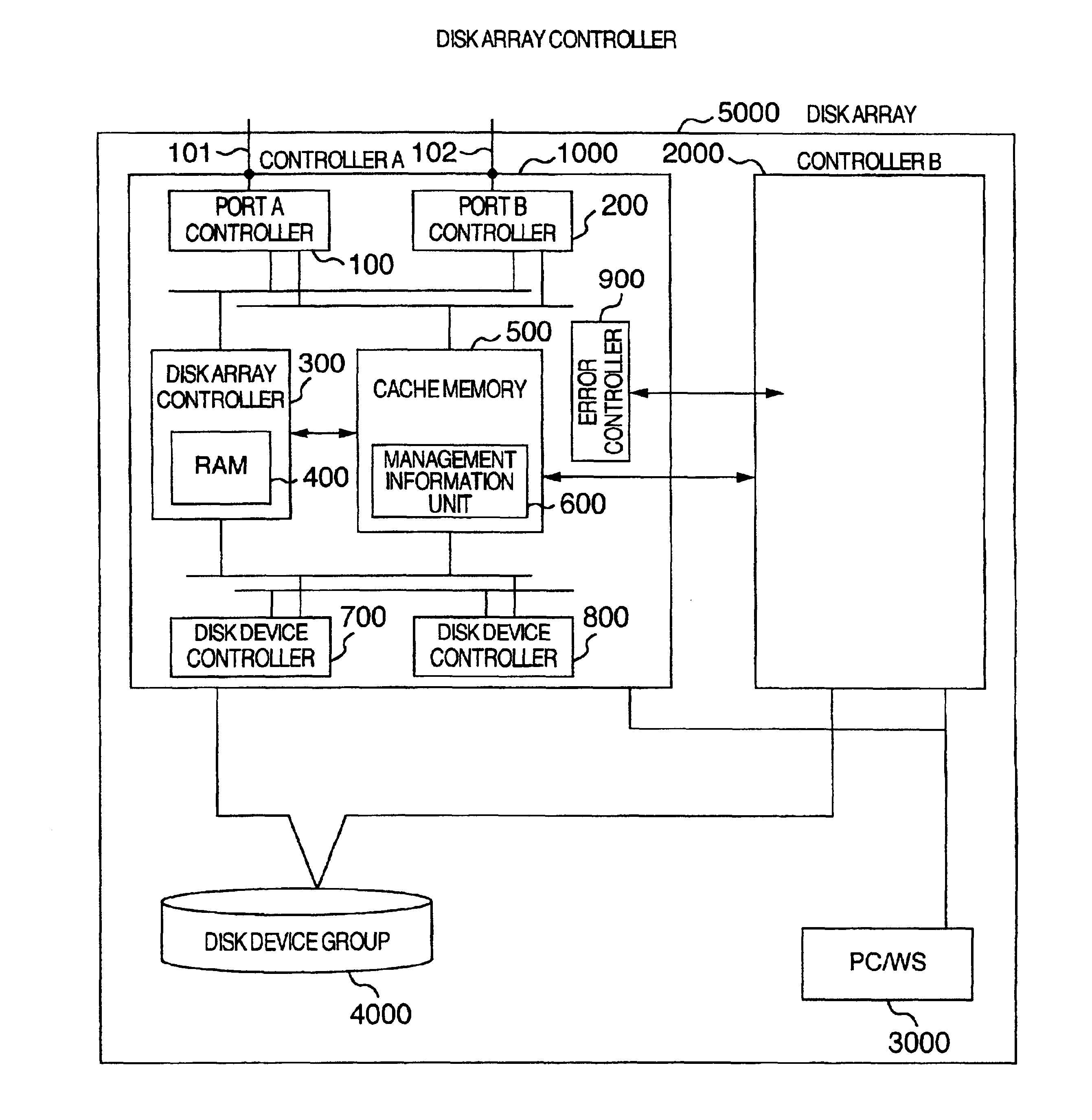

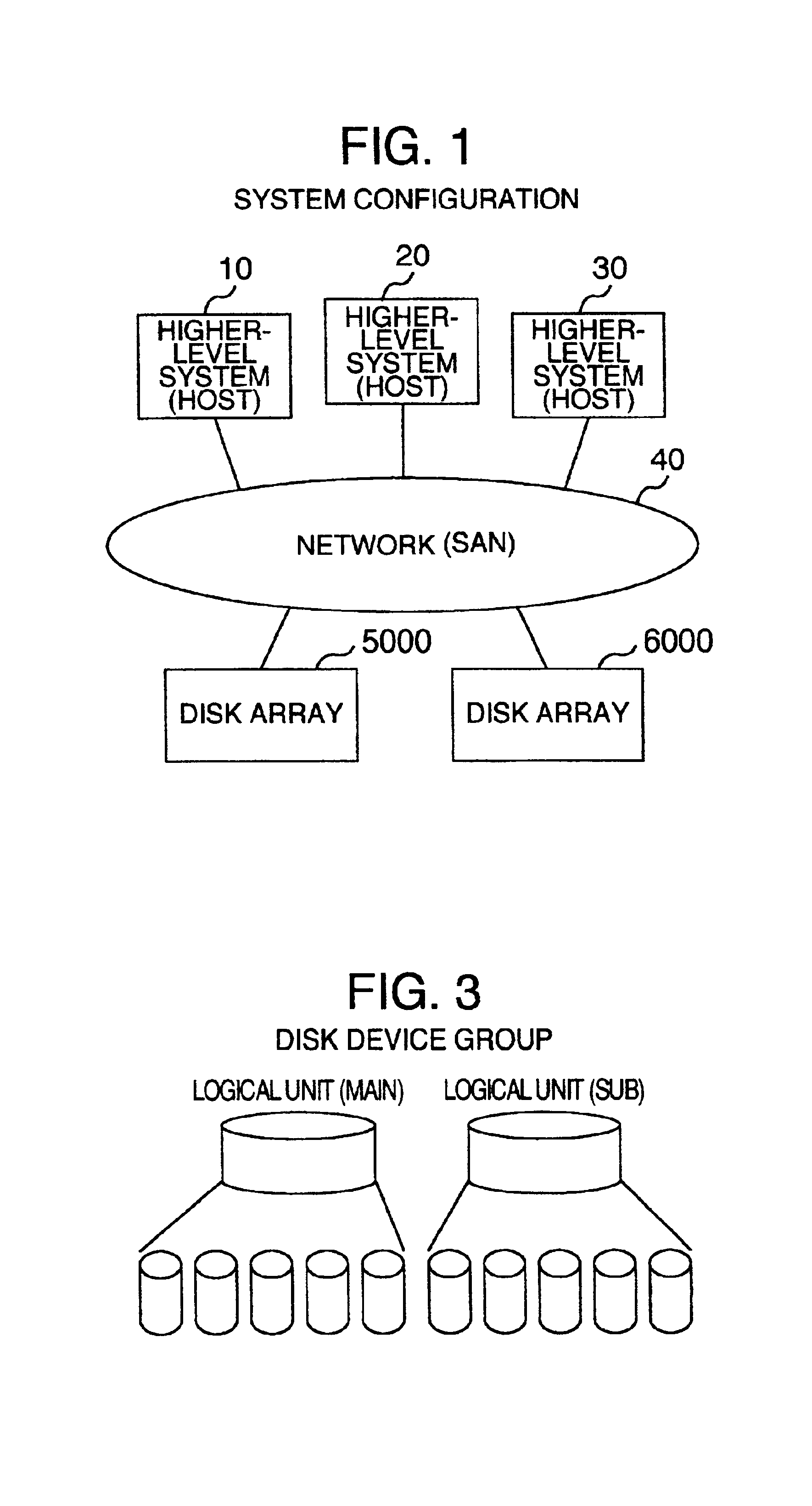

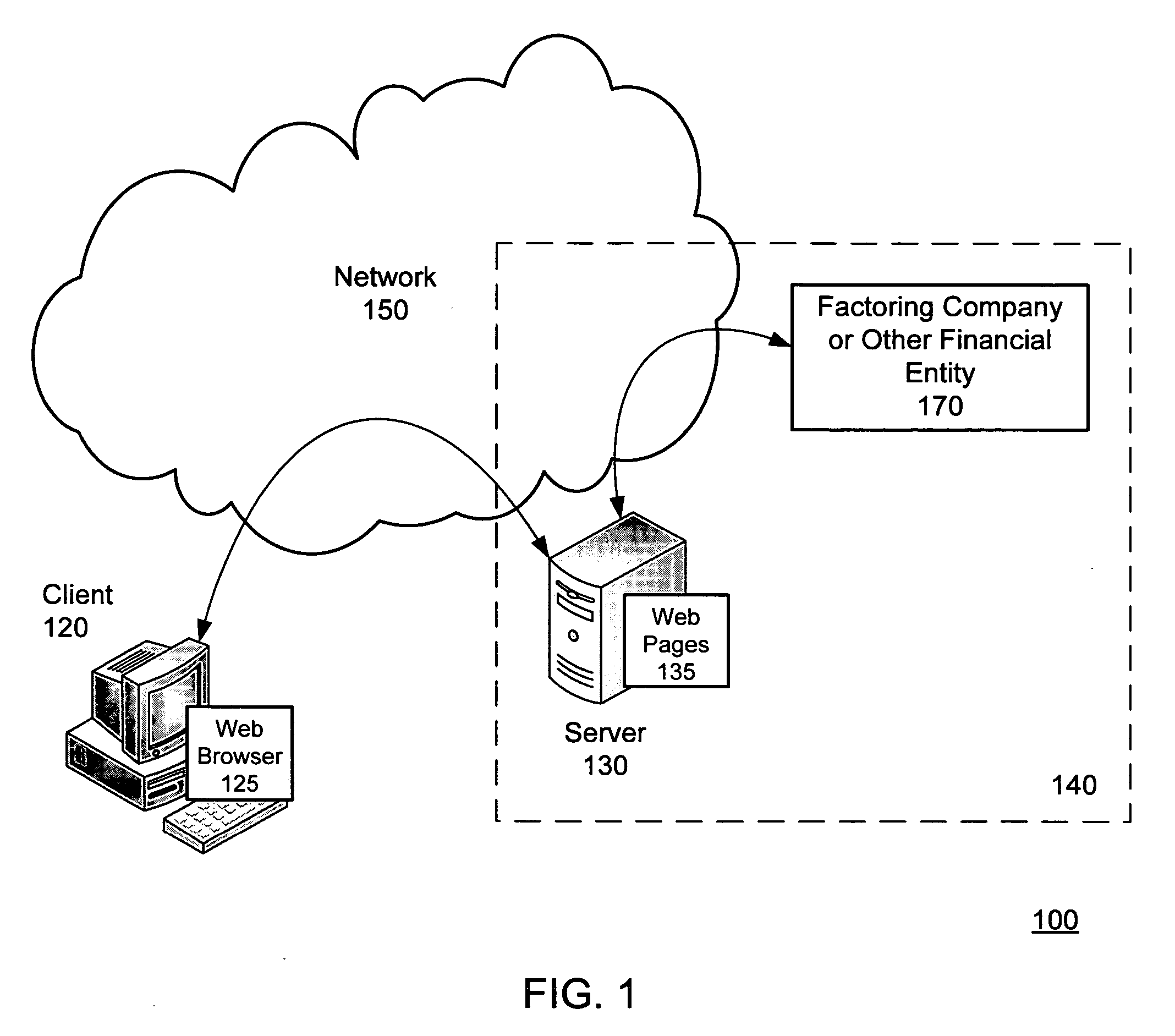

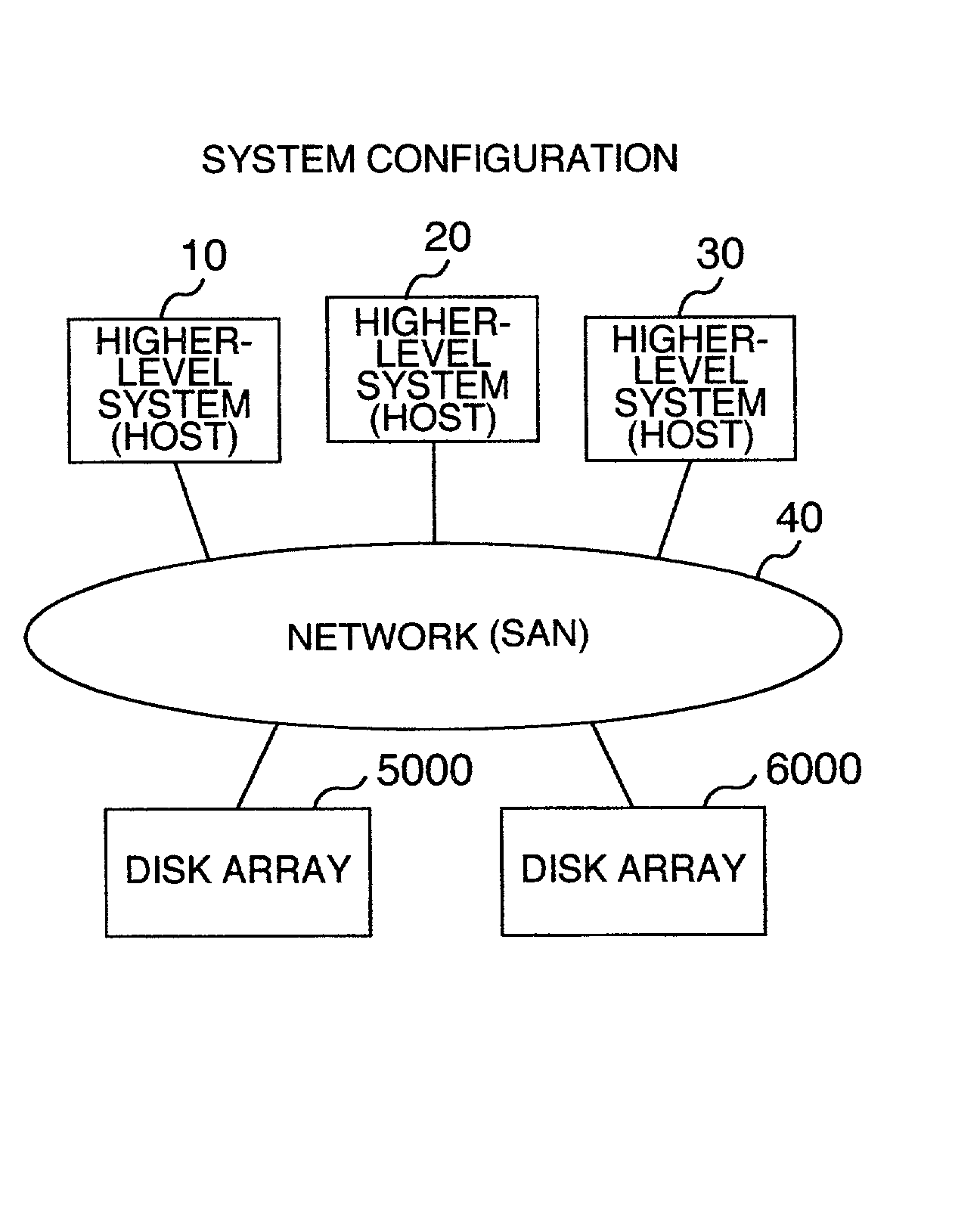

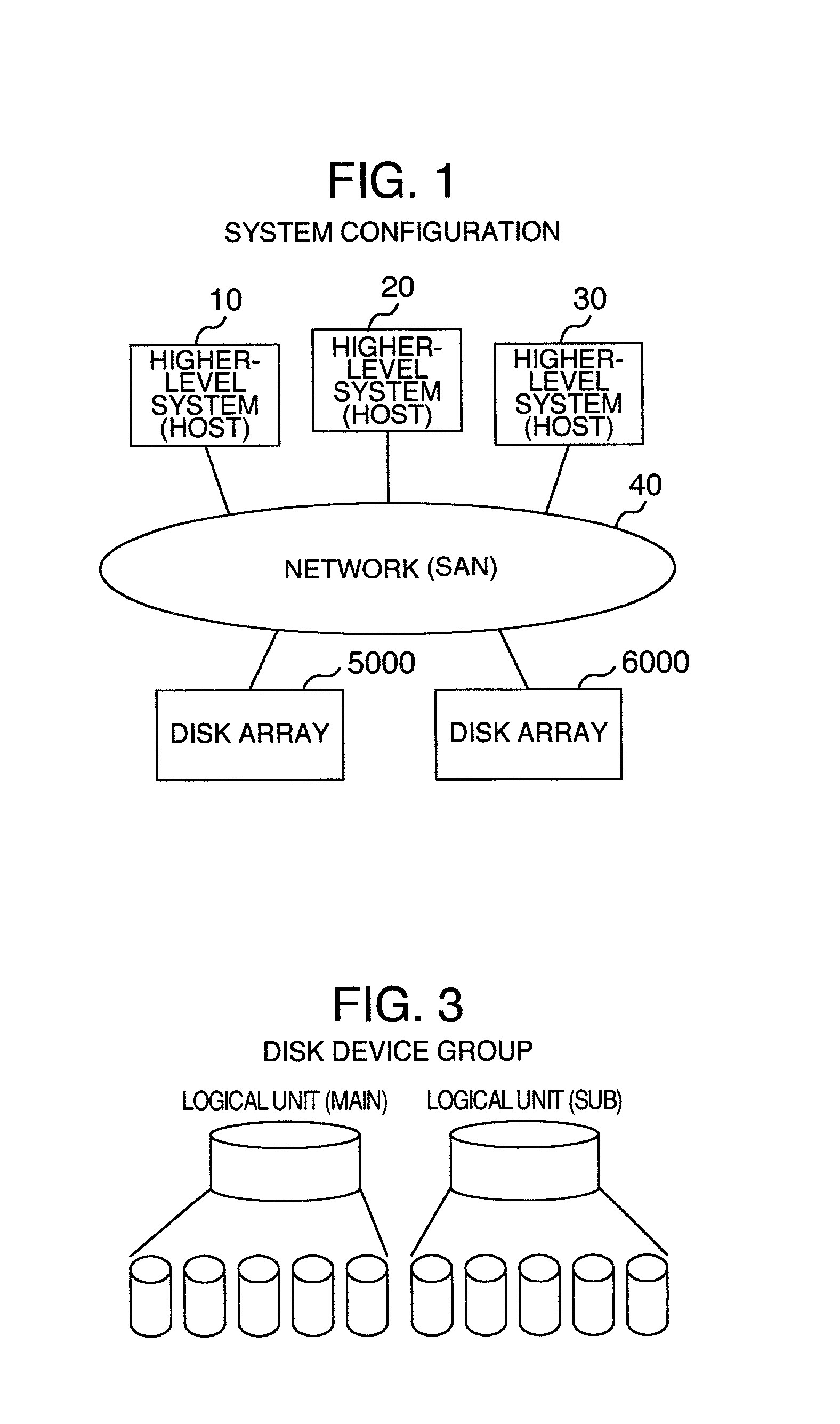

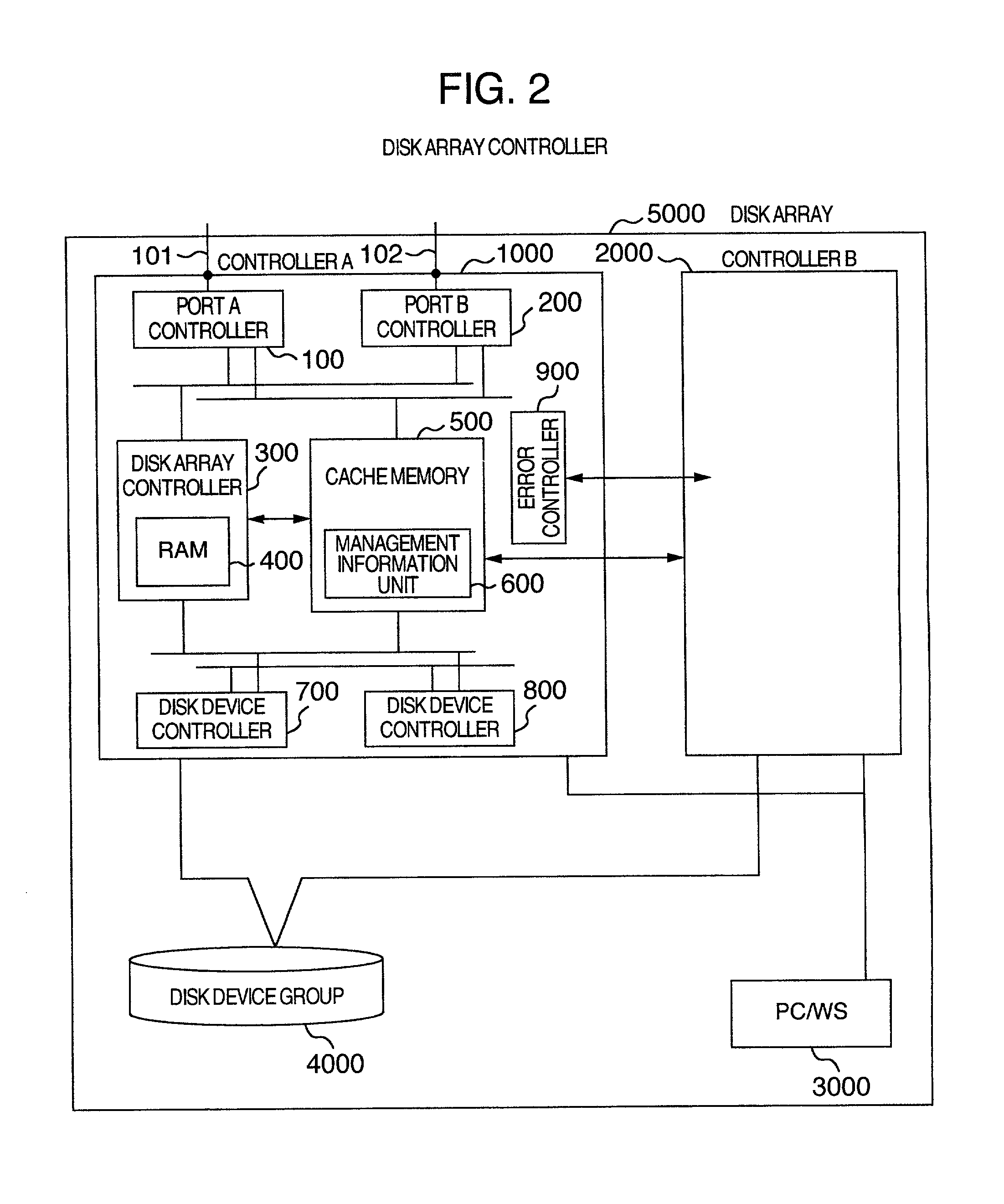

Storage subsystem that connects fiber channel and supports online backup

InactiveUS6851020B2Without degrading online processing performanceInput/output to record carriersMemory loss protectionFiberStorage area network

A disk array connected to a storage area network via a fiber channel has one or more ports each controlled by a processor. Even the disk array with one port and one processor executes online processing and backup processing at the same time while considering an online processing load. A port controller not only accepts a request from a host computer but issues a request to other storage controllers to allow online processing and backup processing to be executed at the same time. In addition, the disk array, if provided with a plurality of ports, selects ports or schedules processing depending upon the load to prevent backup processing from affecting online processing performance.

Owner:HITACHI LTD

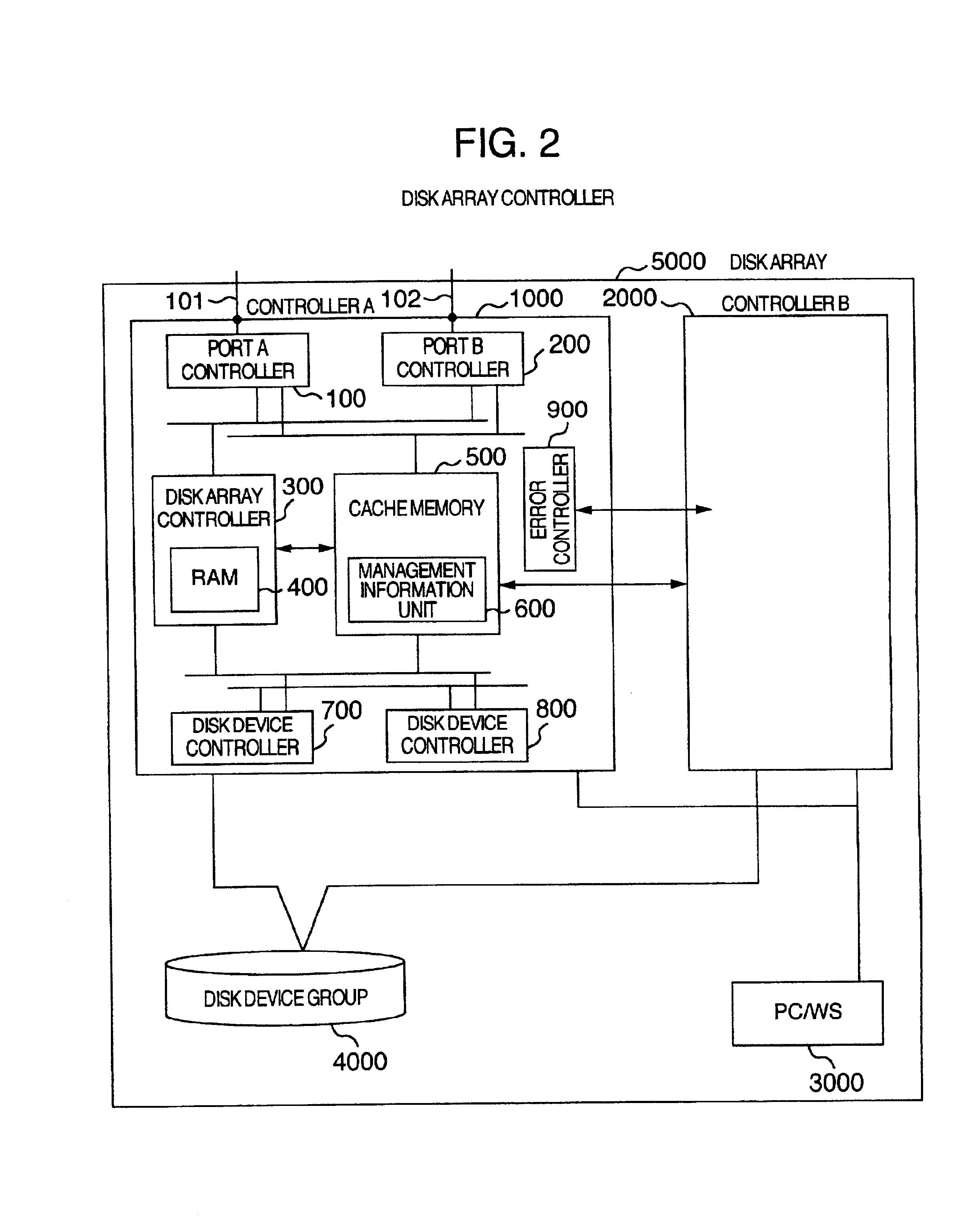

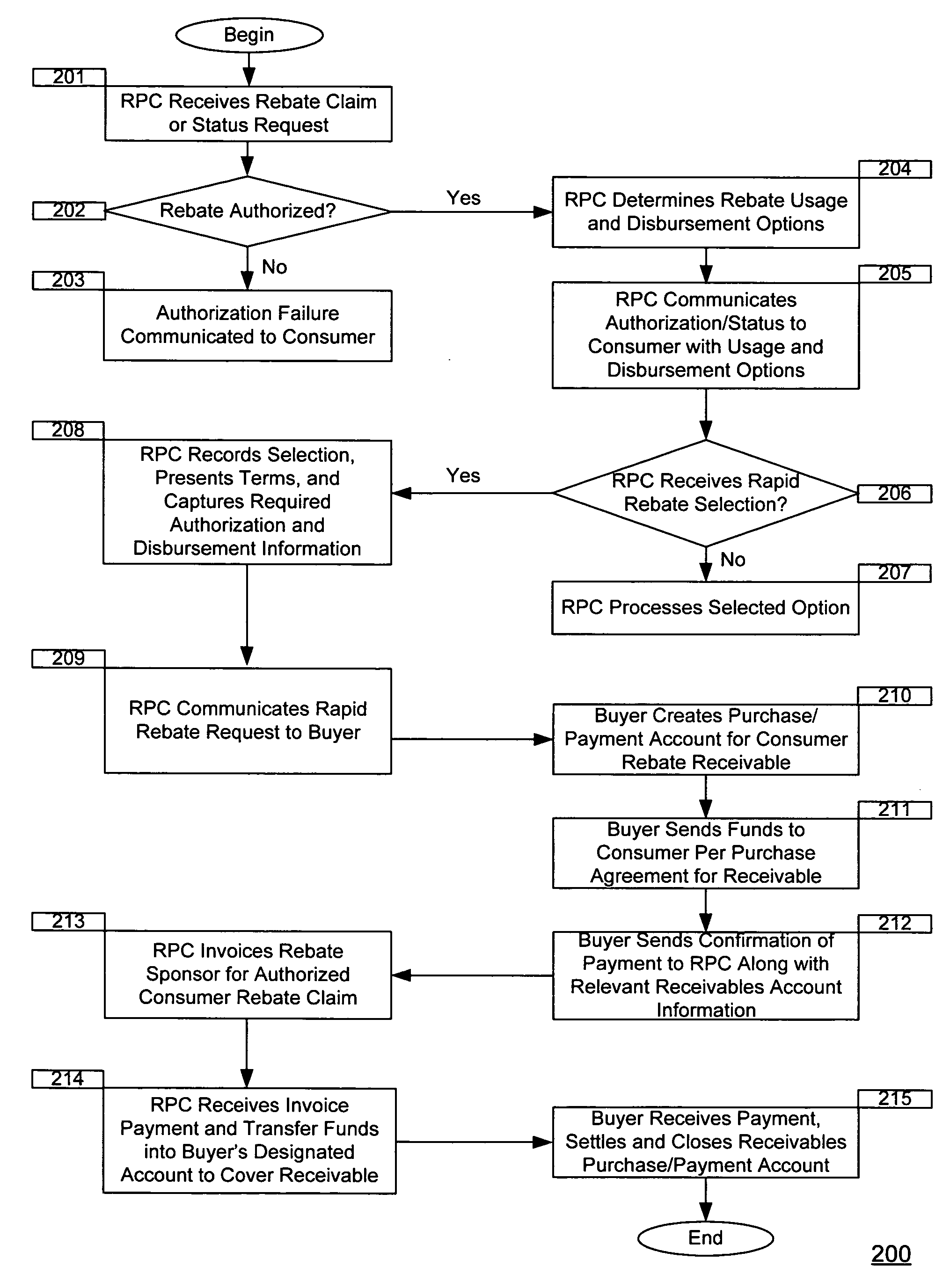

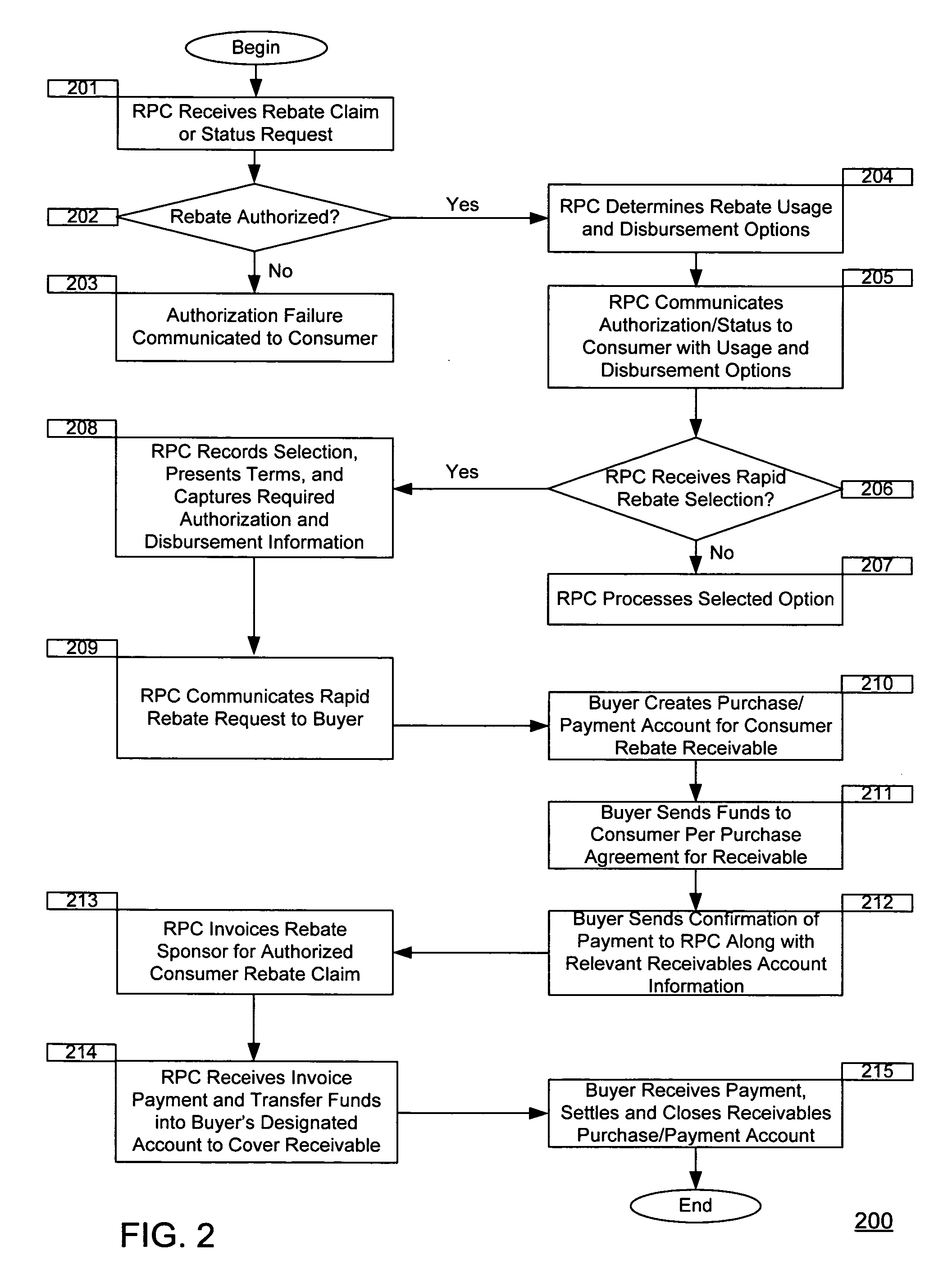

System and method for providing rapid rebate payments

Embodiments of the invention provide a method and system that has the ability to allow consumers to process rebates on-line and receive the rebate on an accelerated basis in exchange for assigning the rebate to a third party. One embodiment of the invention provides the consumer with a disbursement option to accept less than the original rebate amount from the rebate sponsor in exchange for a significant reduction in time to collect the rest. The exchange can be done transparent to the rebate sponsor. Another embodiment of the invention provides the consumer with an assignment option to transfer the right to collect the rebate to a third party in exchange for a rapid payment. In this embodiment, the third party manages the collection of the rebate from the rebate sponsor.

Owner:CROSSFILL

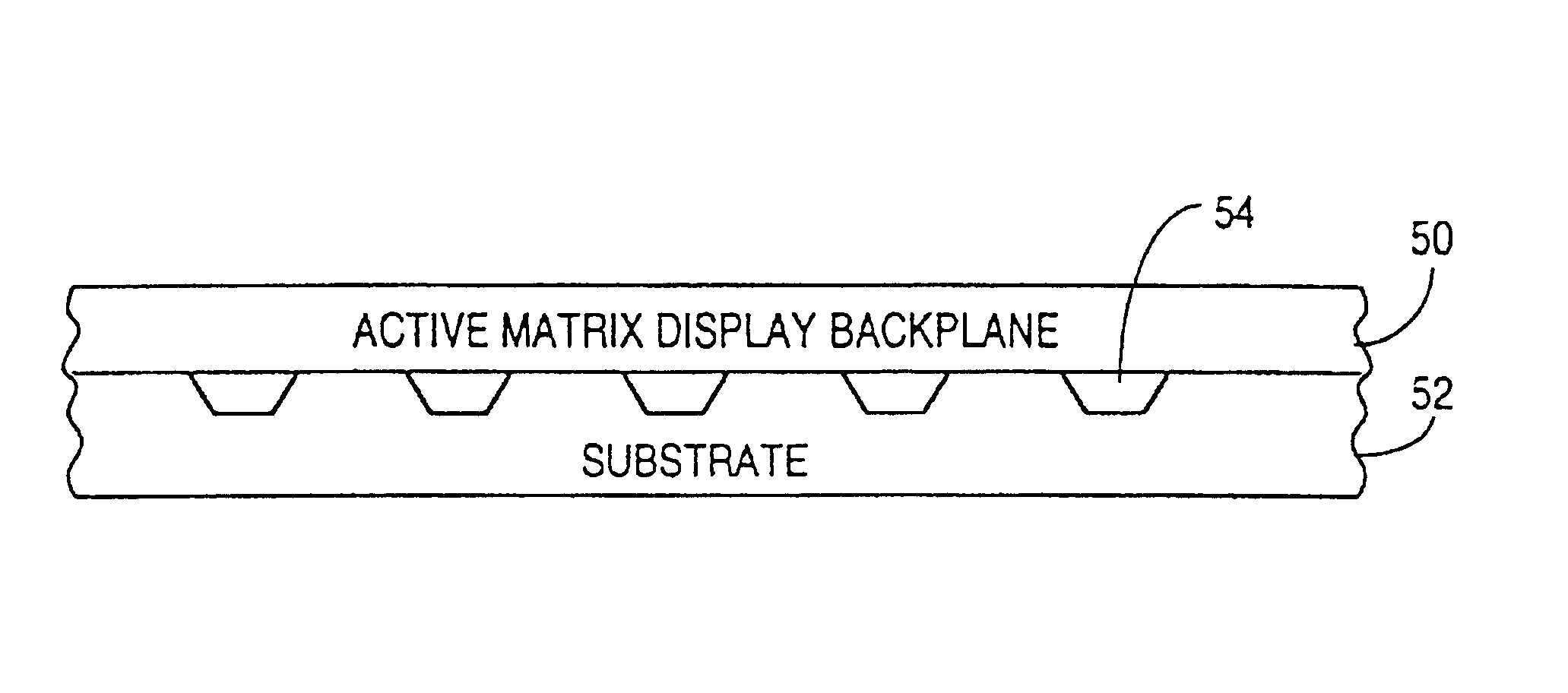

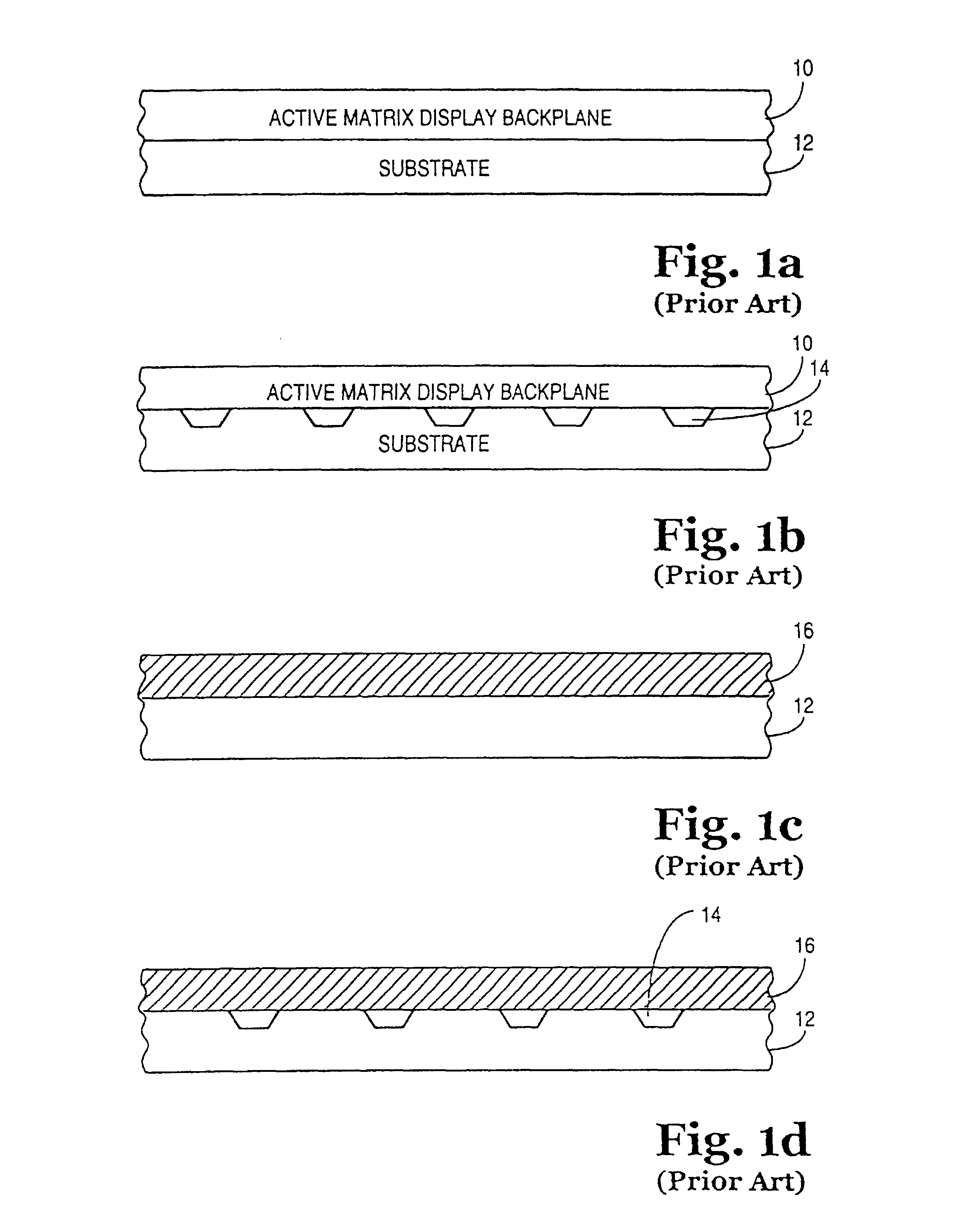

Apparatuses and methods for flexible displays

InactiveUS7046328B2Solid-state devicesSemiconductor/solid-state device manufacturingDeterministic methodActive matrix

Apparatuses and methods for forming displays are claimed. One embodiment of the invention relates to forming a flexible active matrix display along a length of flexible substrate. Another embodiment of the invention relates to forming multiple flexible displays along a continuous flexible substrate. Another embodiment of the invention relates to forming a flexible display along a flexible reflective substrate. Another embodiment of the invention relates to using FSA generally with a flexible web process material. Another embodiment of the invention relates to using FSA and a deterministic method such as “pick and place” to place objects onto a rigid substrate or onto a web process material. Another embodiment of the invention relates to using web processing to deposit and / or pattern display material through an in-line process.

Owner:RUIZHANG TECH LTD CO

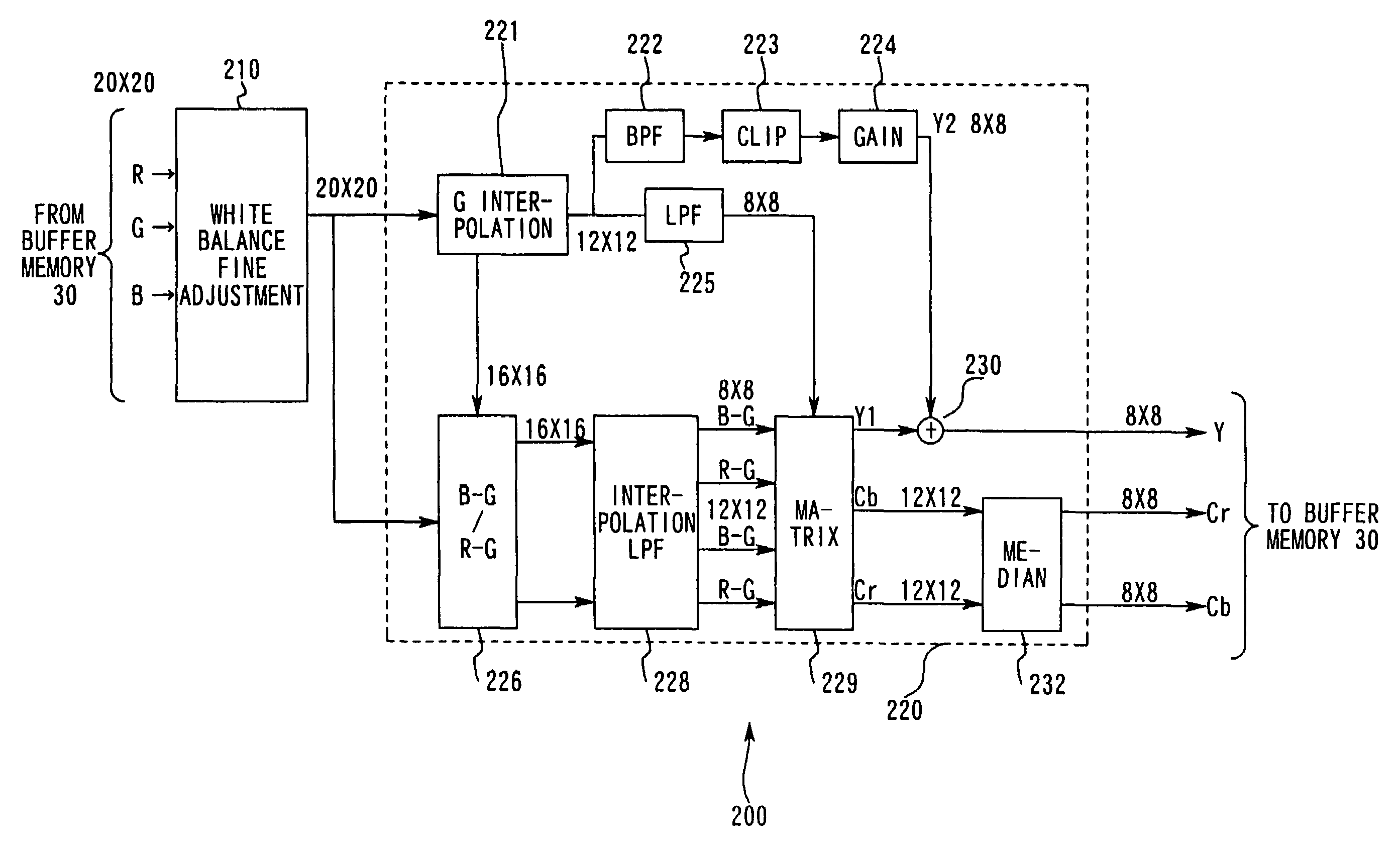

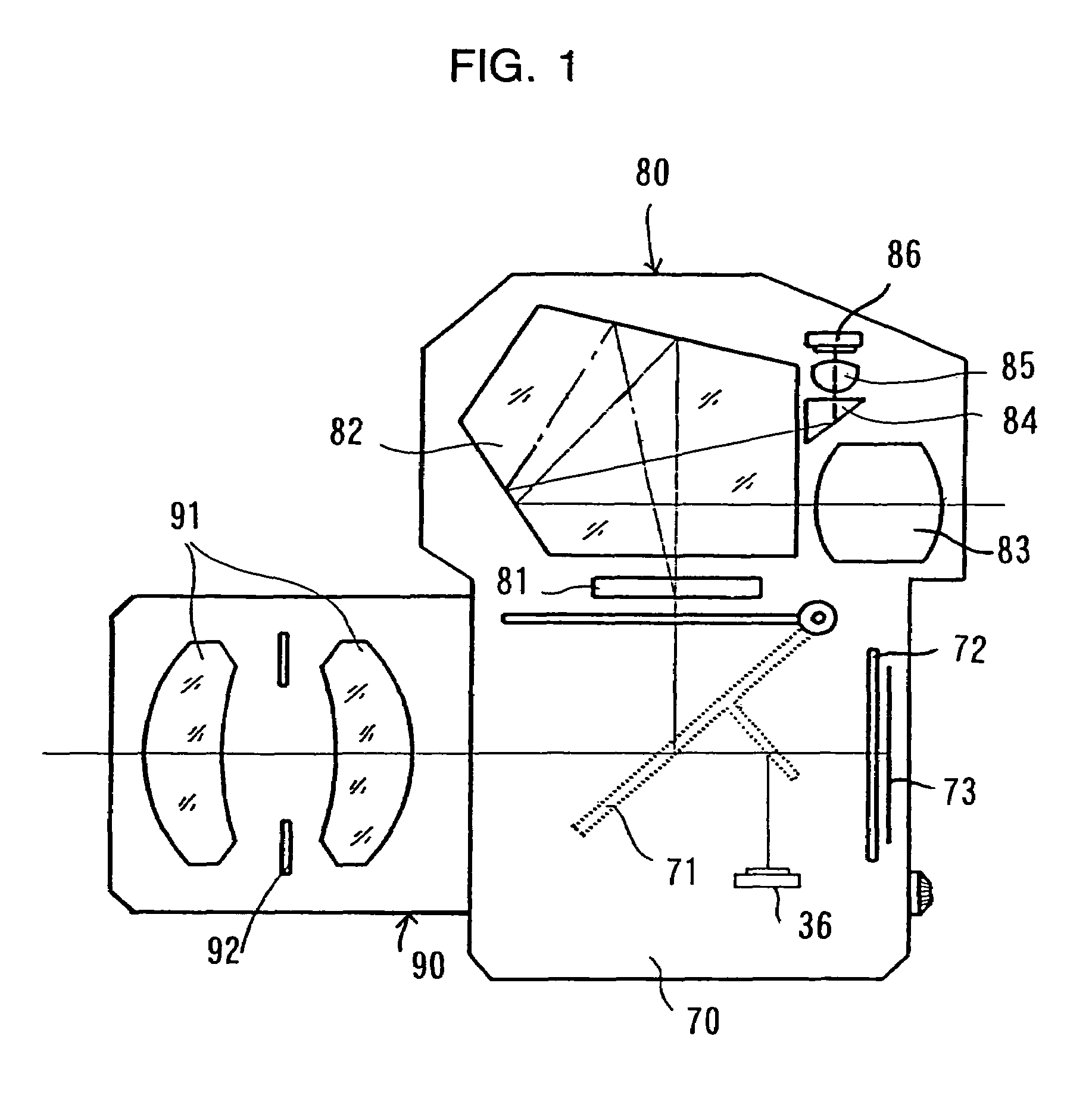

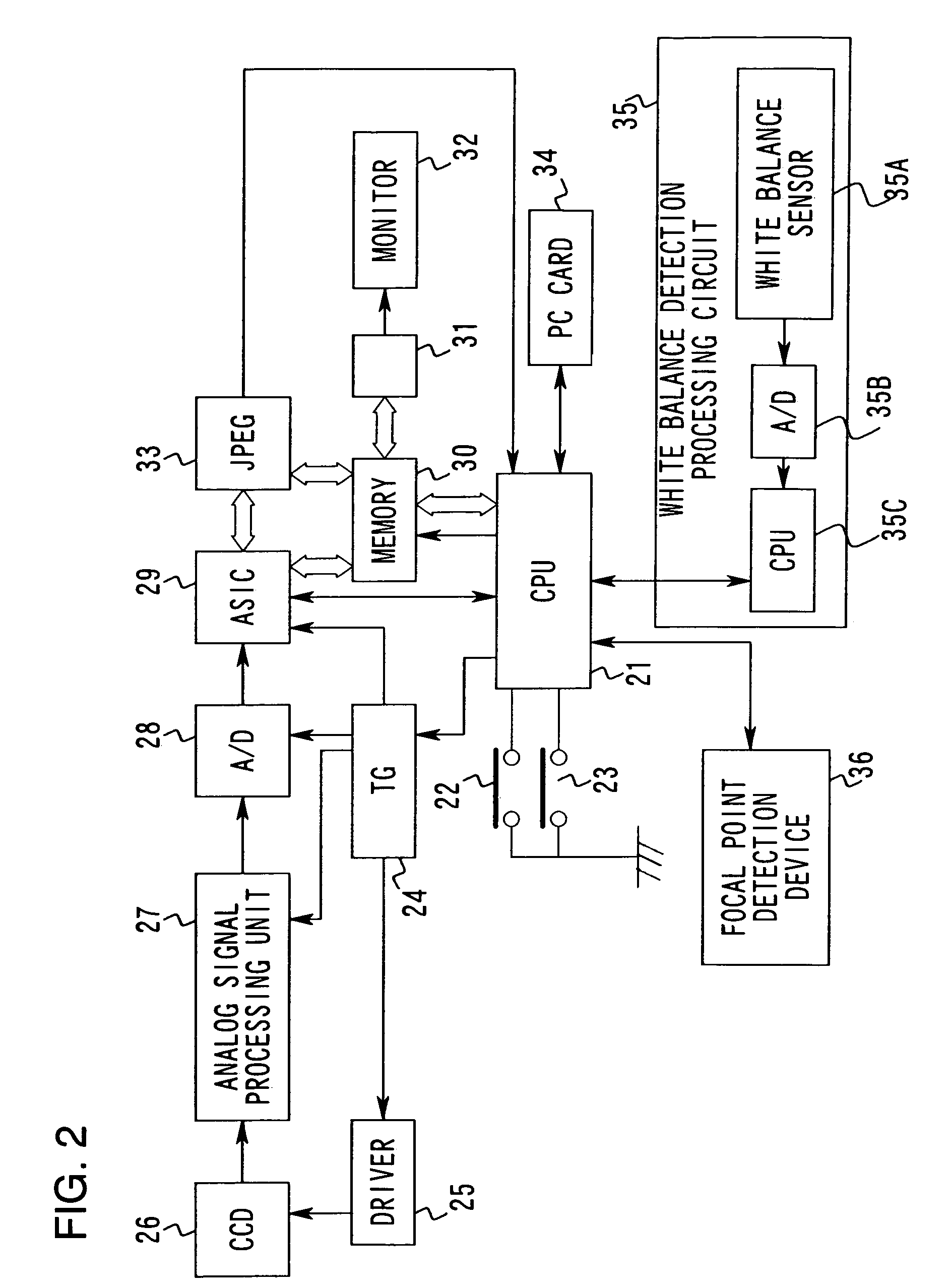

Digital camera, storage medium for image signal processing, carrier wave and electronic camera

InactiveUS7253836B1Increase capacityLow costTelevision system detailsColor signal processing circuitsCamera lensCarrier signal

A CCD captures a subject image having passed through a taking lens and an image processing circuit performs various types of image pre-treatment including gamma correction and white balance on image data corresponding to n lines×m rows output by the CCD. The image processing circuit also performs format processing on the data. The data are then compressed at a compression circuit. The white balance adjustment and the like are implemented in line sequence at a line processing circuit which engages in signal processing in pixel sequence in units of individual lines in the output from the CCD. The image data having undergone the pre-treatment are then subjected to format processing prior to JPEG compression, at a block processing circuit that engages in signal processing in units of individual blocks each ranging over an n×m (N>n, M>m) block. In other words, the signal processing is performed in block sequence.

Owner:NIKON CORP

Storage subsystem that connects fibre channel and supports online backup

InactiveUS20020124124A1Without degrading online processing performanceInput/output to record carriersMemory loss protectionFiberStorage area network

A disk array connected to a storage area network via a fiber channel has one or more ports each controlled by a processor. Even the disk array with one port and one processor executes online processing and backup processing at the same time while considering an online processing load. A port controller not only accepts a request from a host computer but issues a request to other storage controllers to allow online processing and backup processing to be executed at the same time. In addition, the disk array, if provided with a plurality of ports, selects ports or schedules processing depending upon the load to prevent backup processing from affecting online processing performance.

Owner:HITACHI LTD

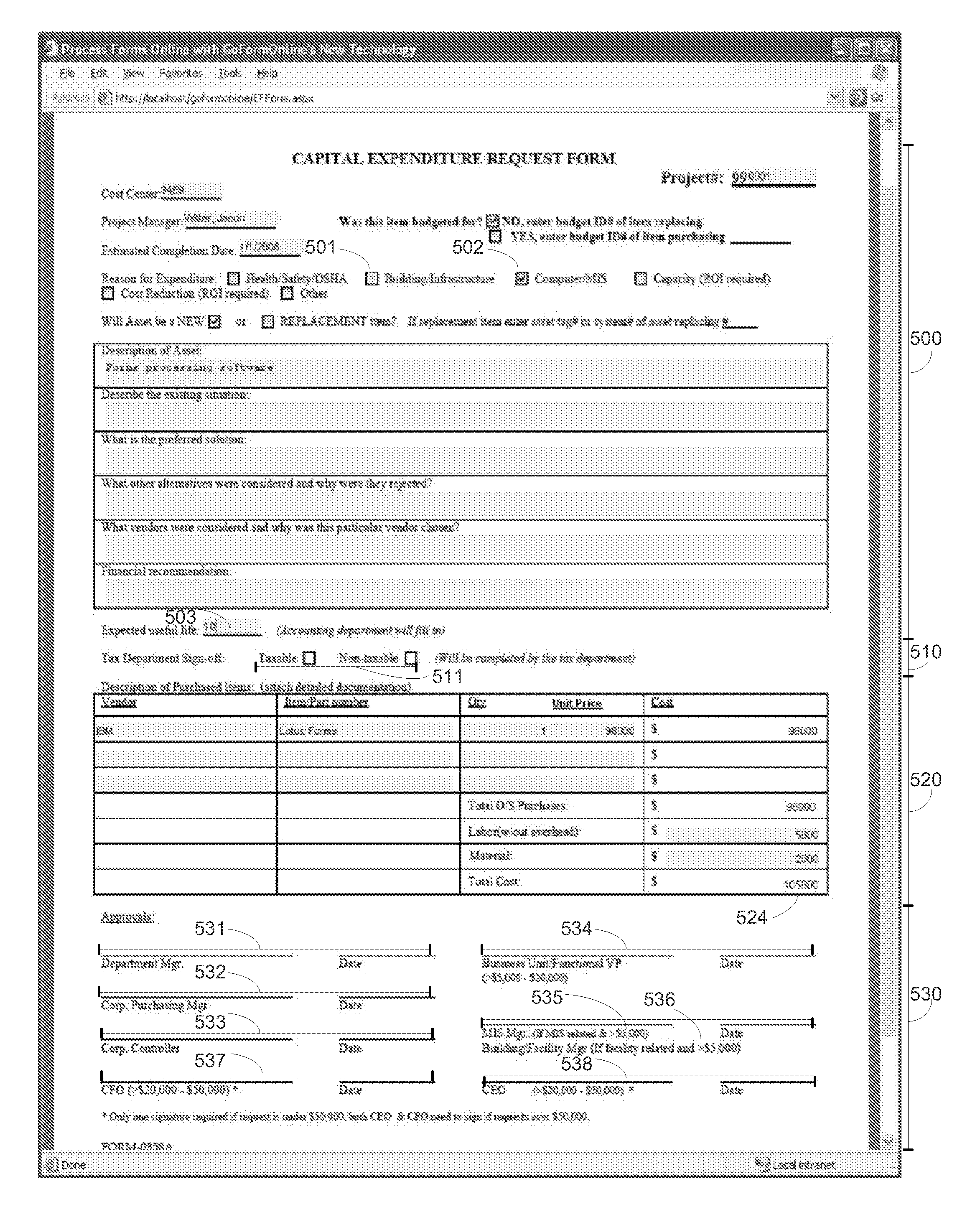

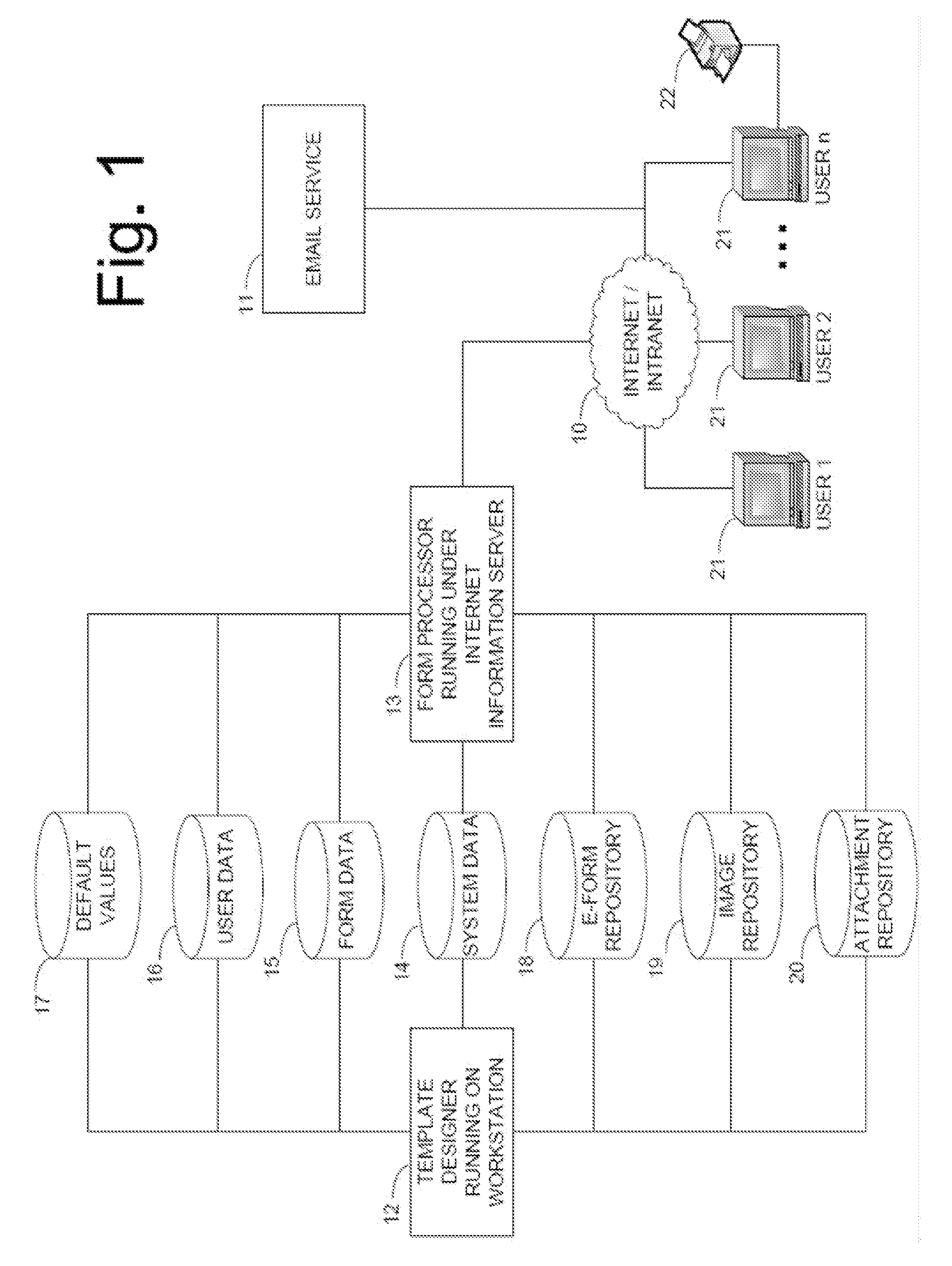

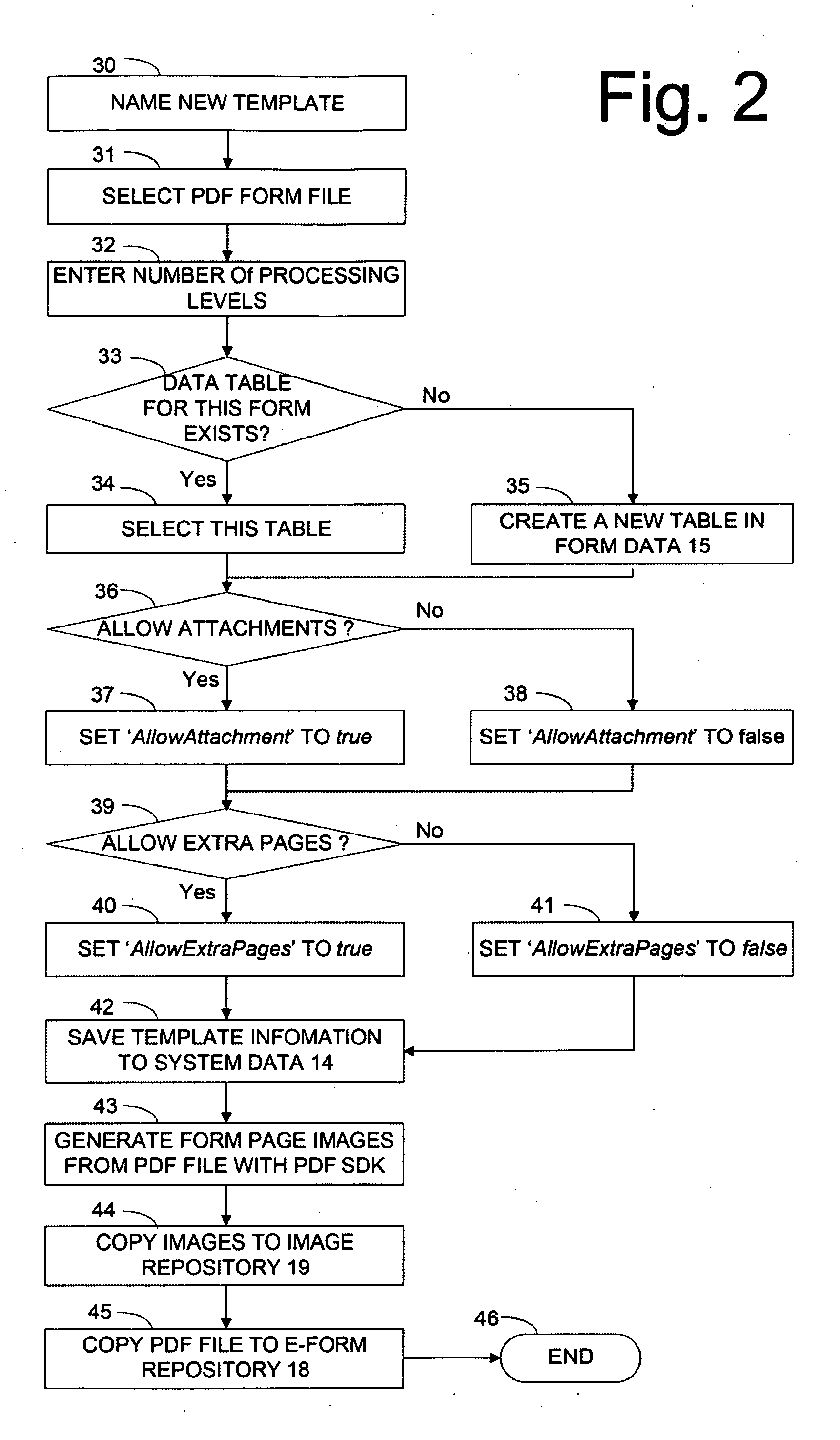

Method and System for Processing Fixed Format Forms Online

InactiveUS20100251092A1Simple processEasy to integrateNatural language data processingSpecial data processing applicationsElectronic formForm processing

A form processing system for processing electronic forms (e-form) forms while preserving the e-form fixed format is provided. The form processing system includes three functional modes or subsystems: the design mode, the edit mode and the view mode. The system, in design mode, designs form templates, manages permission and sets up dynamic workflow parameters. In the view mode, the form is read-only. The form looks like a regular PDF document. This mode is used for exporting data to e-form, printing form and sharing form by multiple users.

Owner:SUN JUN SHI

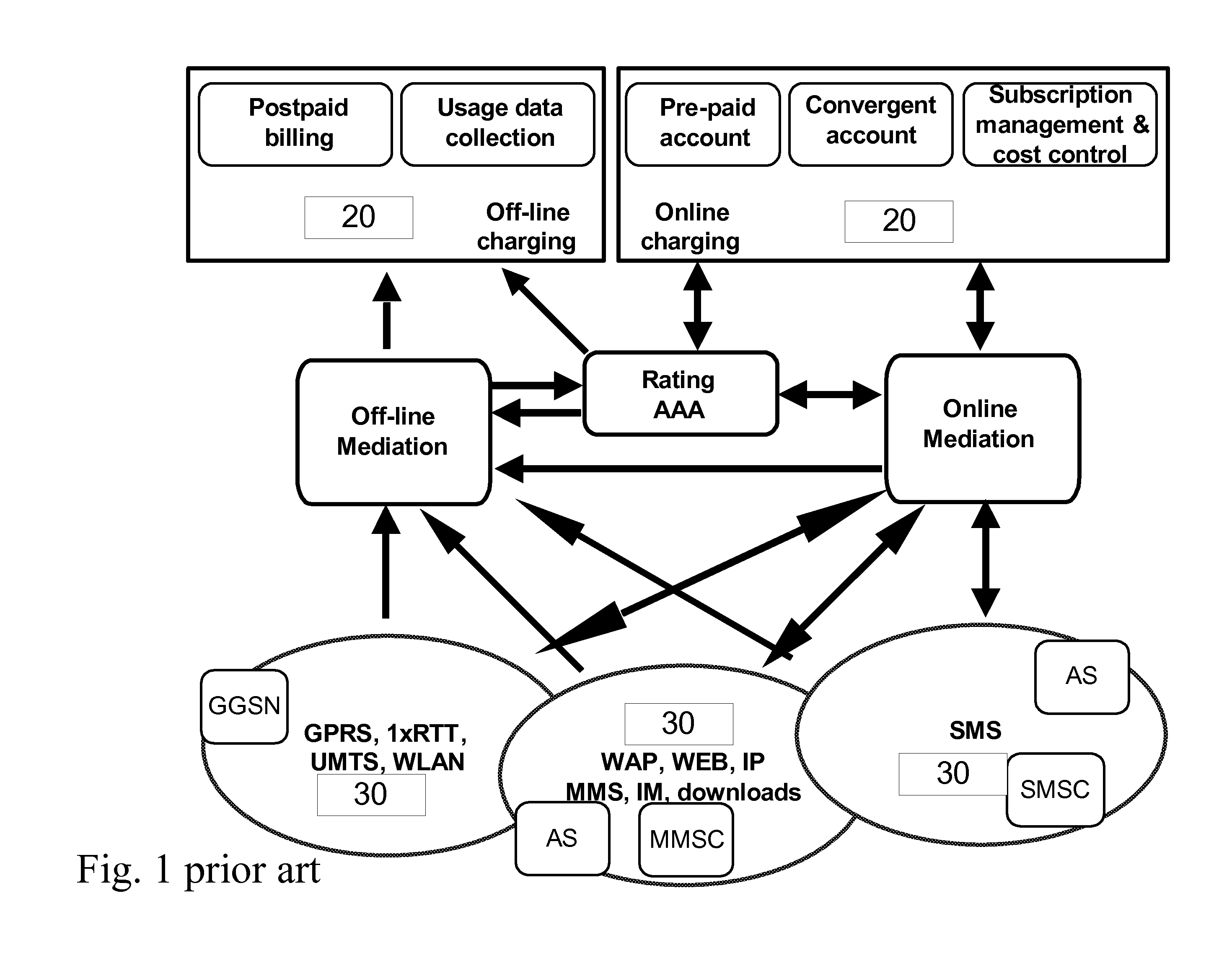

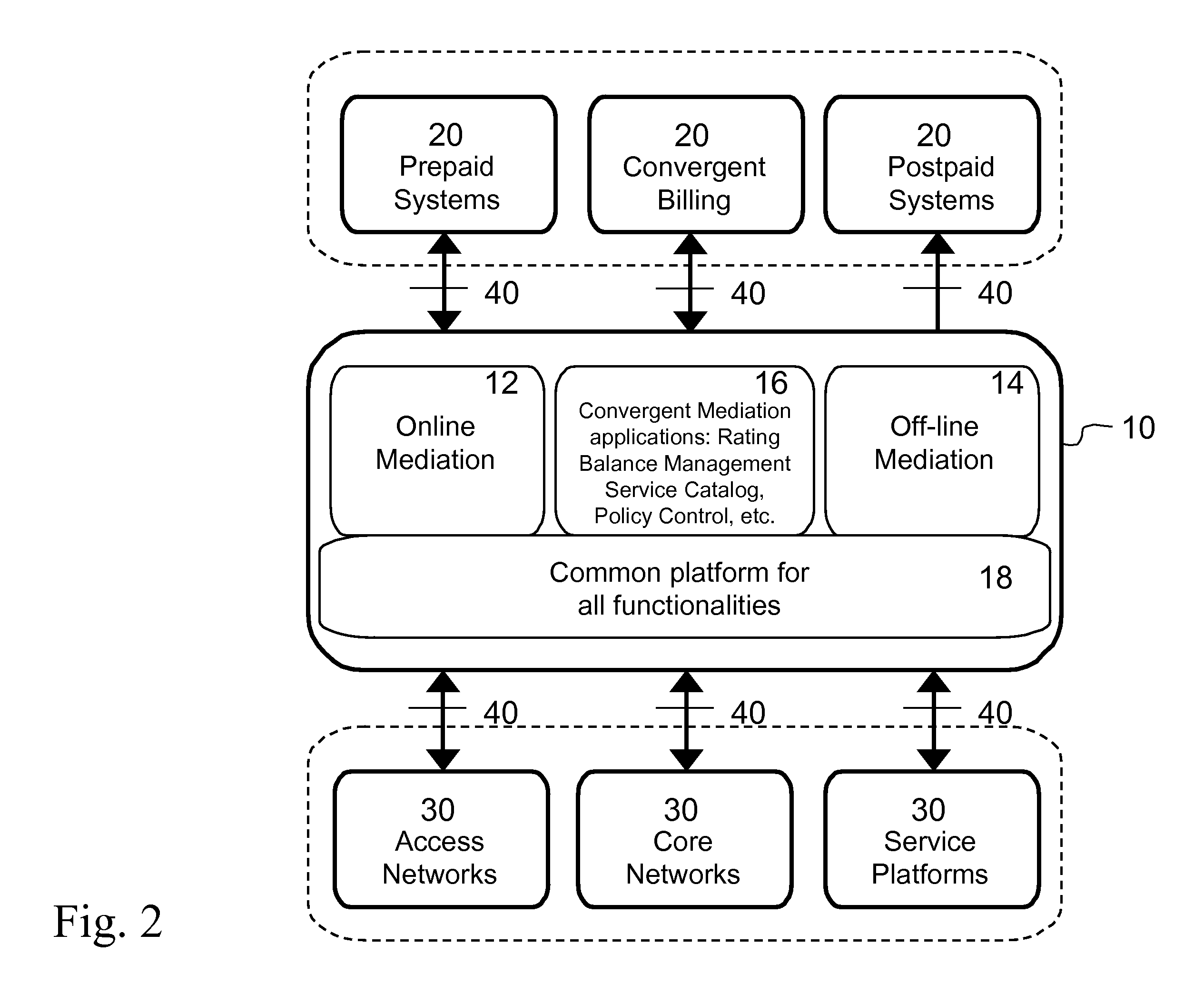

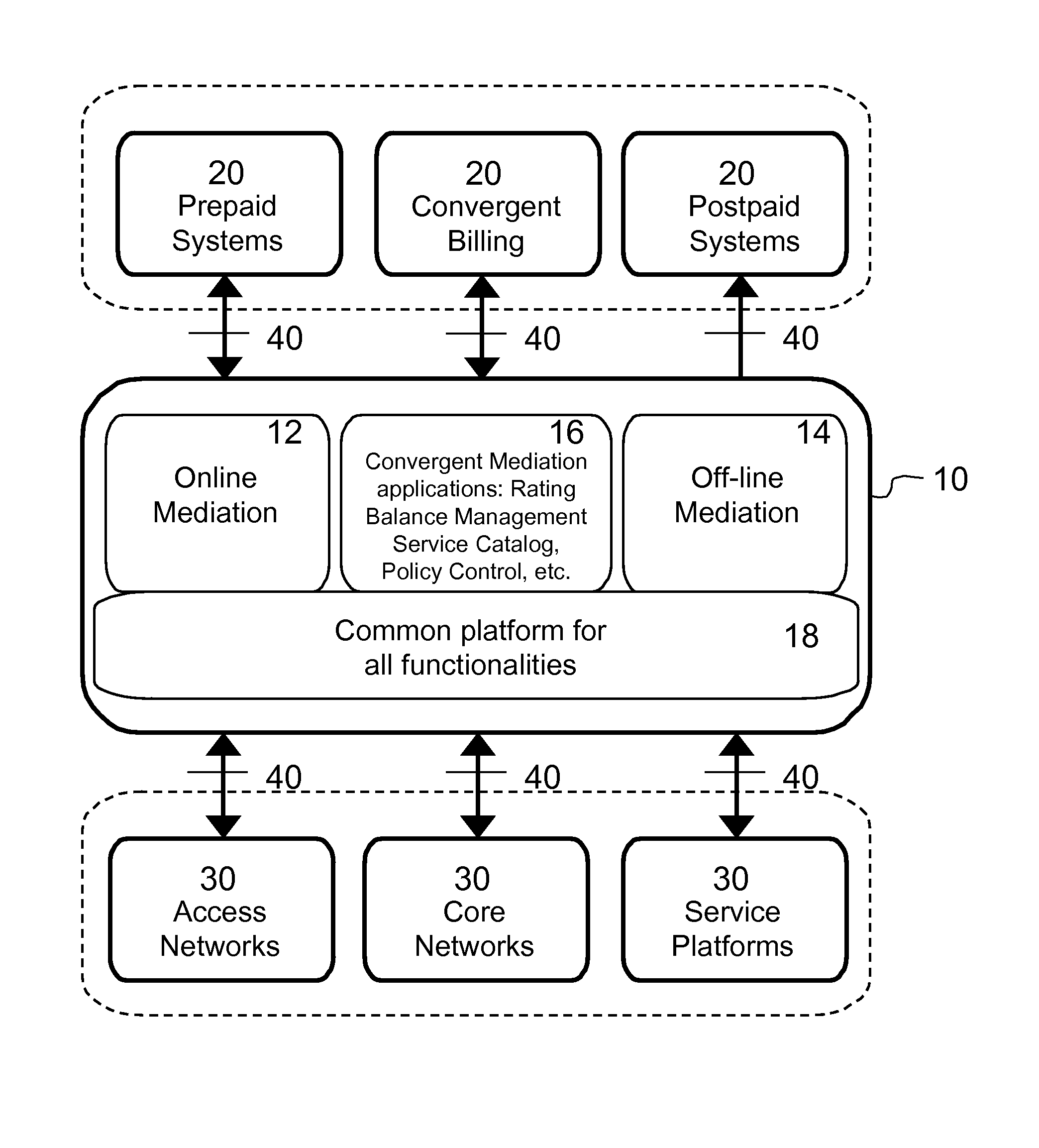

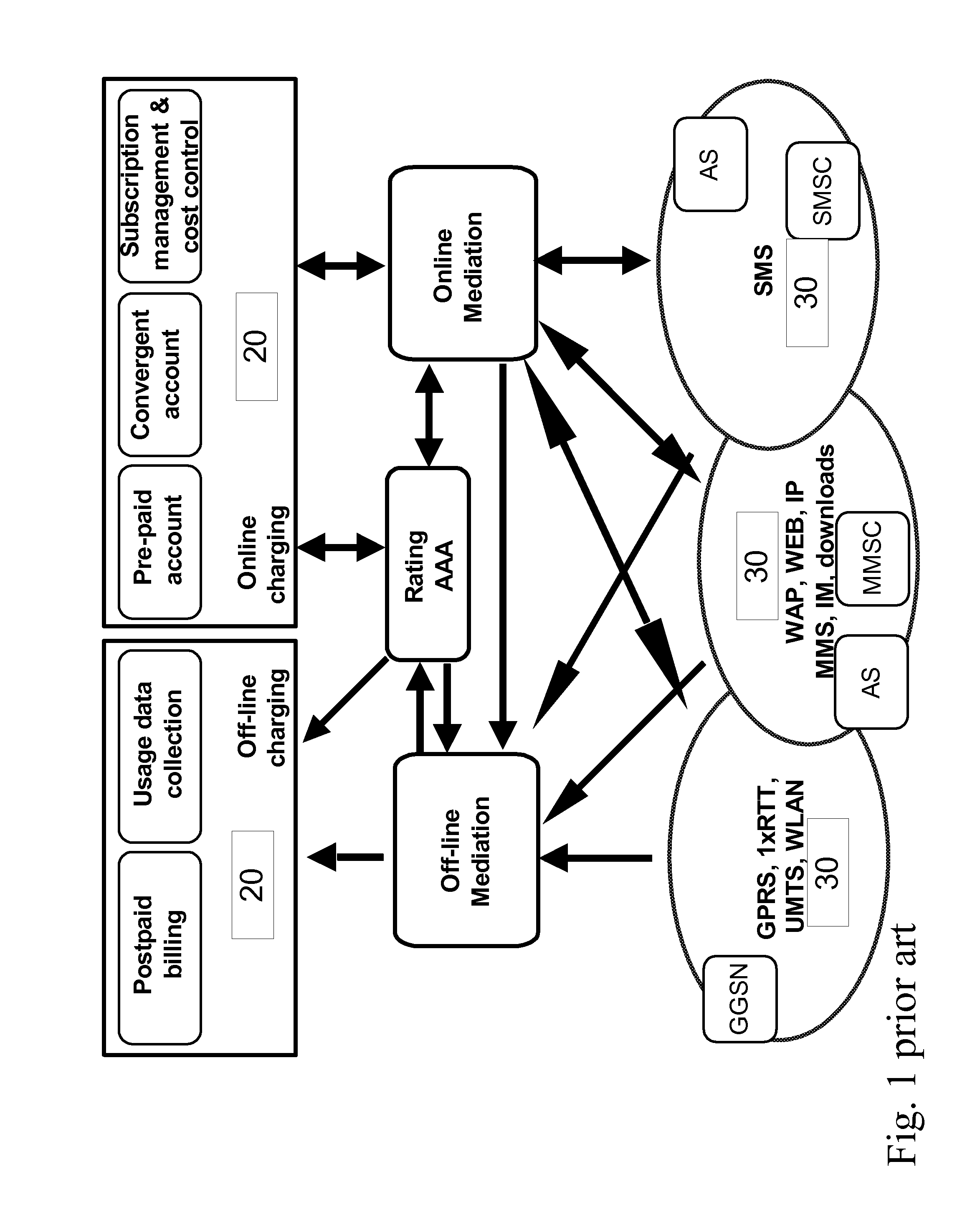

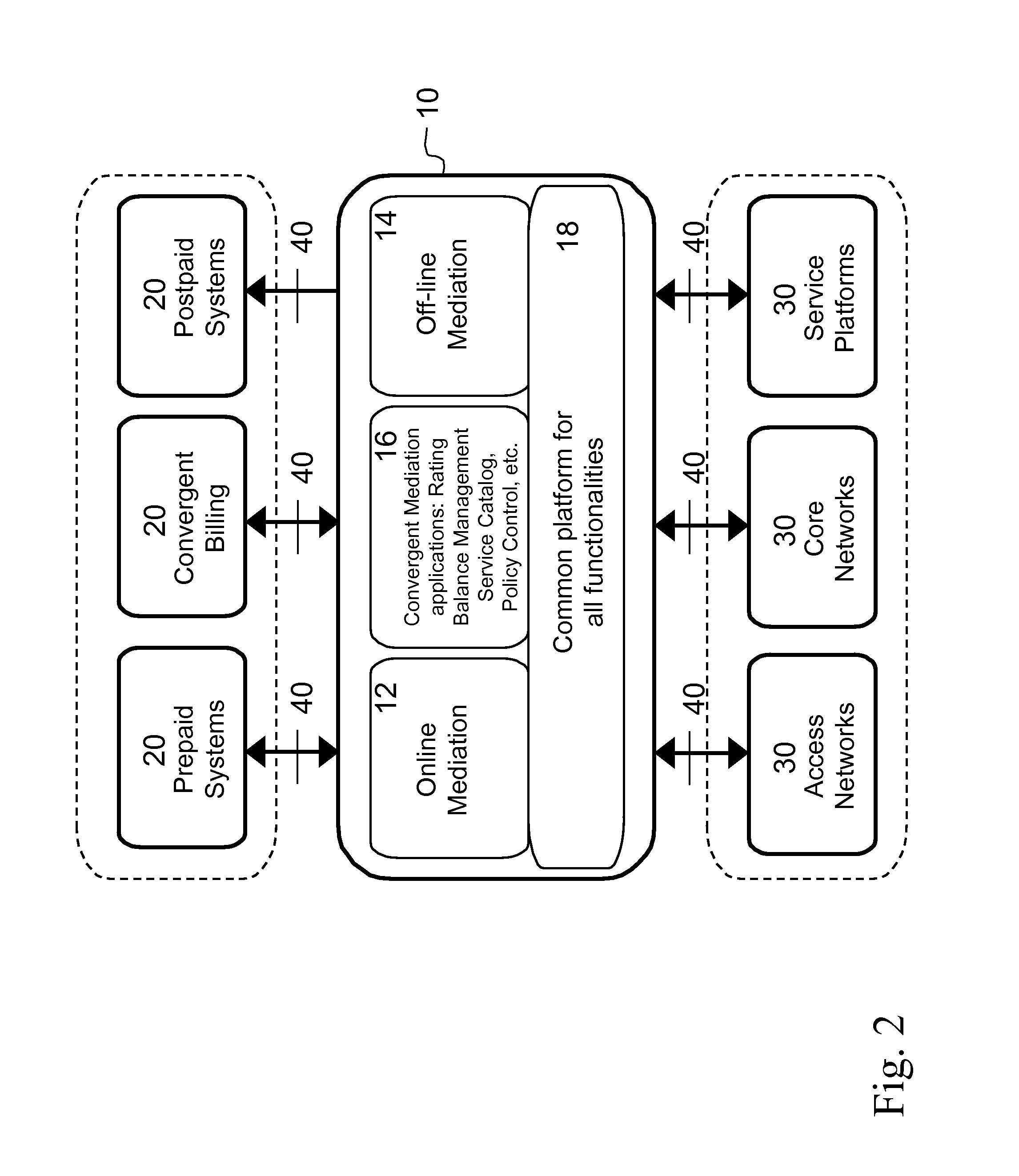

Convergent mediation system with dynamic resource allocation

InactiveUS20110010581A1Reliable and fast processHigh of administrationResource allocationTelephonic communicationDynamic resourceLatency (engineering)

An object is to create a convergent mediation system (10) and method that meet the technical requirements of low latency time and high throughput, without compromising the interoperability and ease of administration of the system. According an aspect of the invention, these objects are achieved by providing a convergent mediation system (10) that comprises a common platform (18) providing processing power for both online processing (12) and off-line processing (14) of data. The convergent mediation system (10) is also provided with a system controller (110) that is adapted to dynamically allocate the processing power of the common platform (18) for the online processing (12) and off-line processing (14) of data.

Owner:COMPTEL CORP

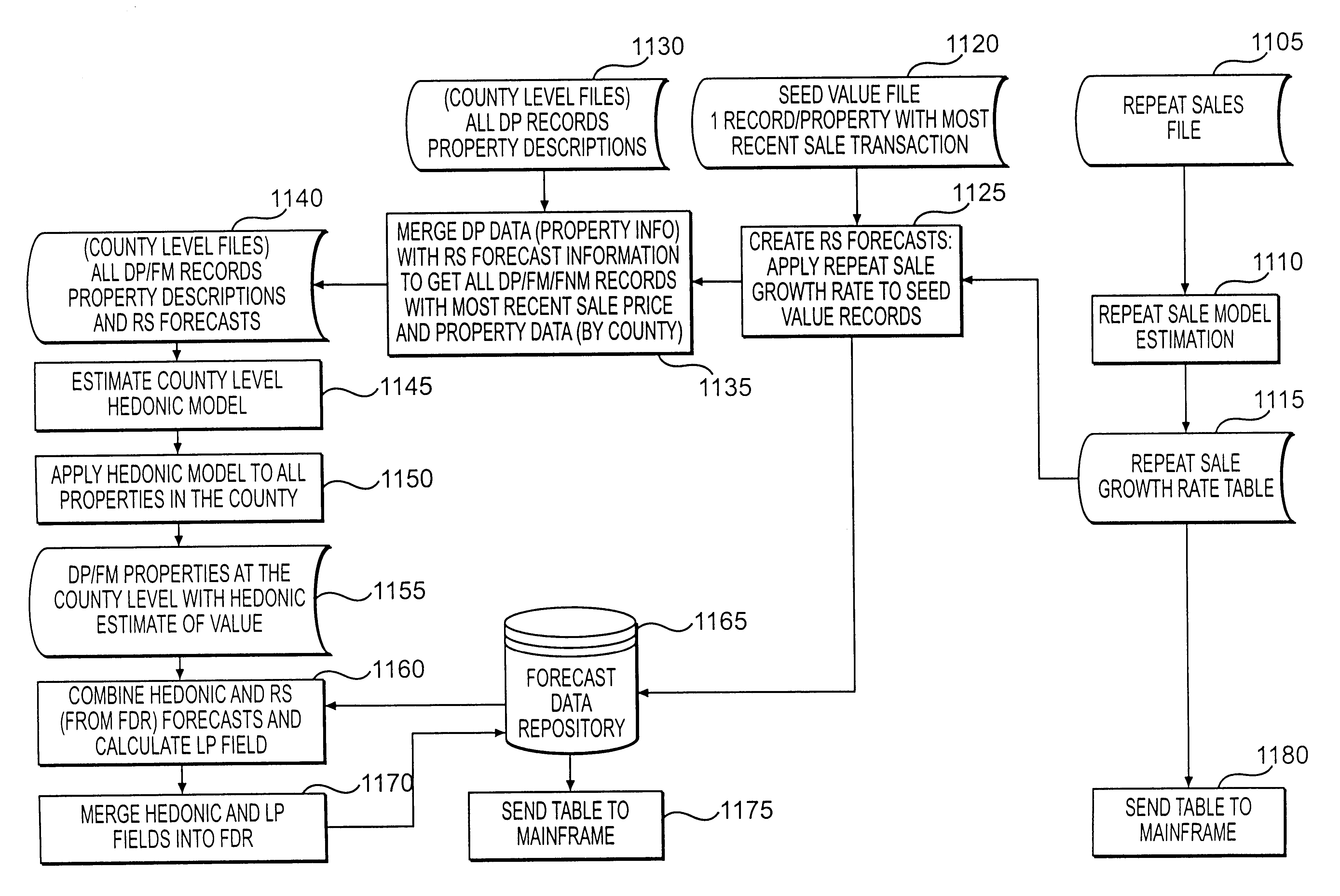

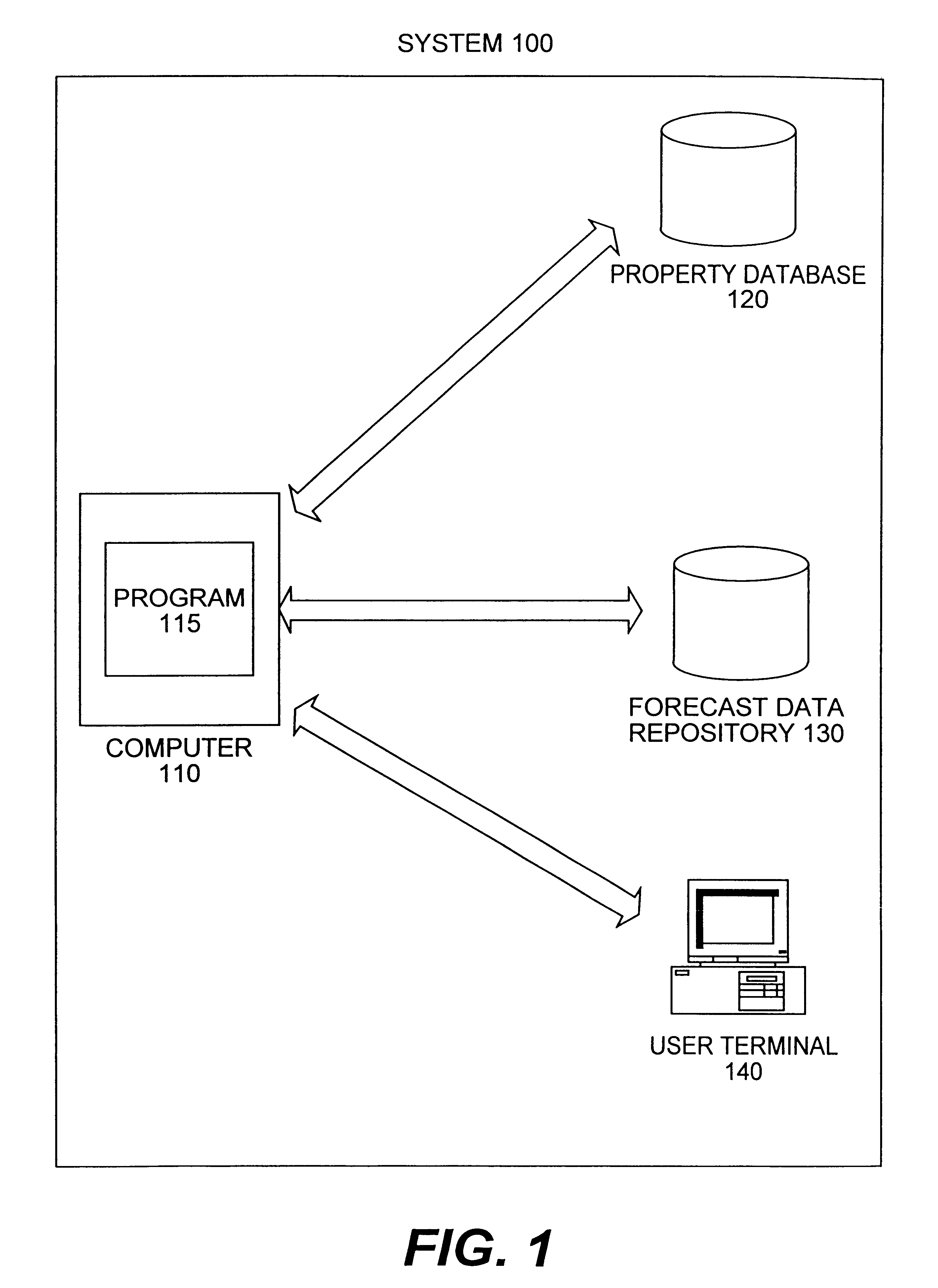

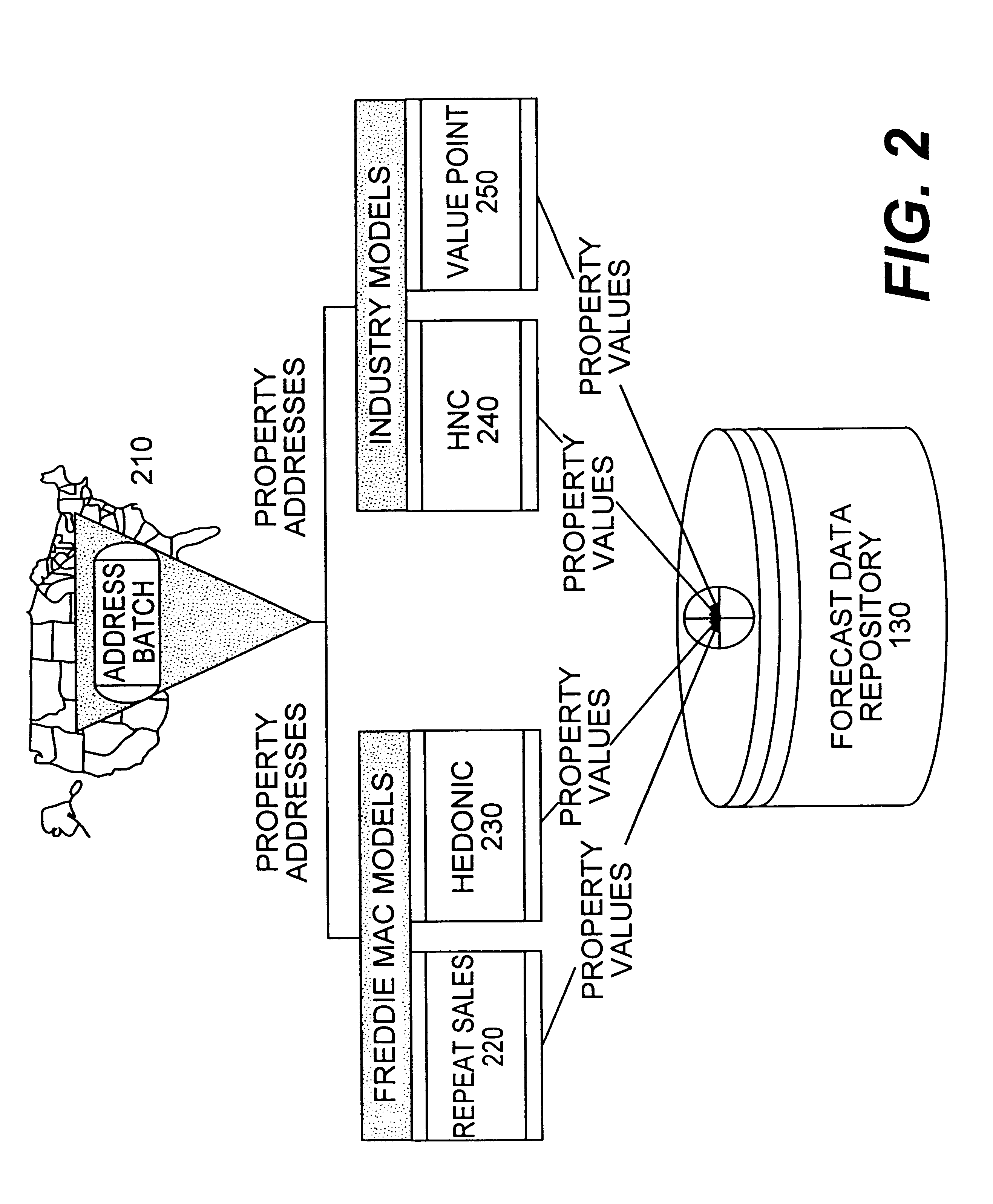

System and method for providing property value estimates

A system preprocesses property value estimates based on stored property data. It stores the computed property value estimates in a forecast data repository. The system obtains updates or new property data and computes new estimates according to a predetermined schedule. Users can instantaneously obtain property value estimates that have been preprocessed, thus eliminating a long wait period necessary for on-line processing.

Owner:FREDDIE MAC

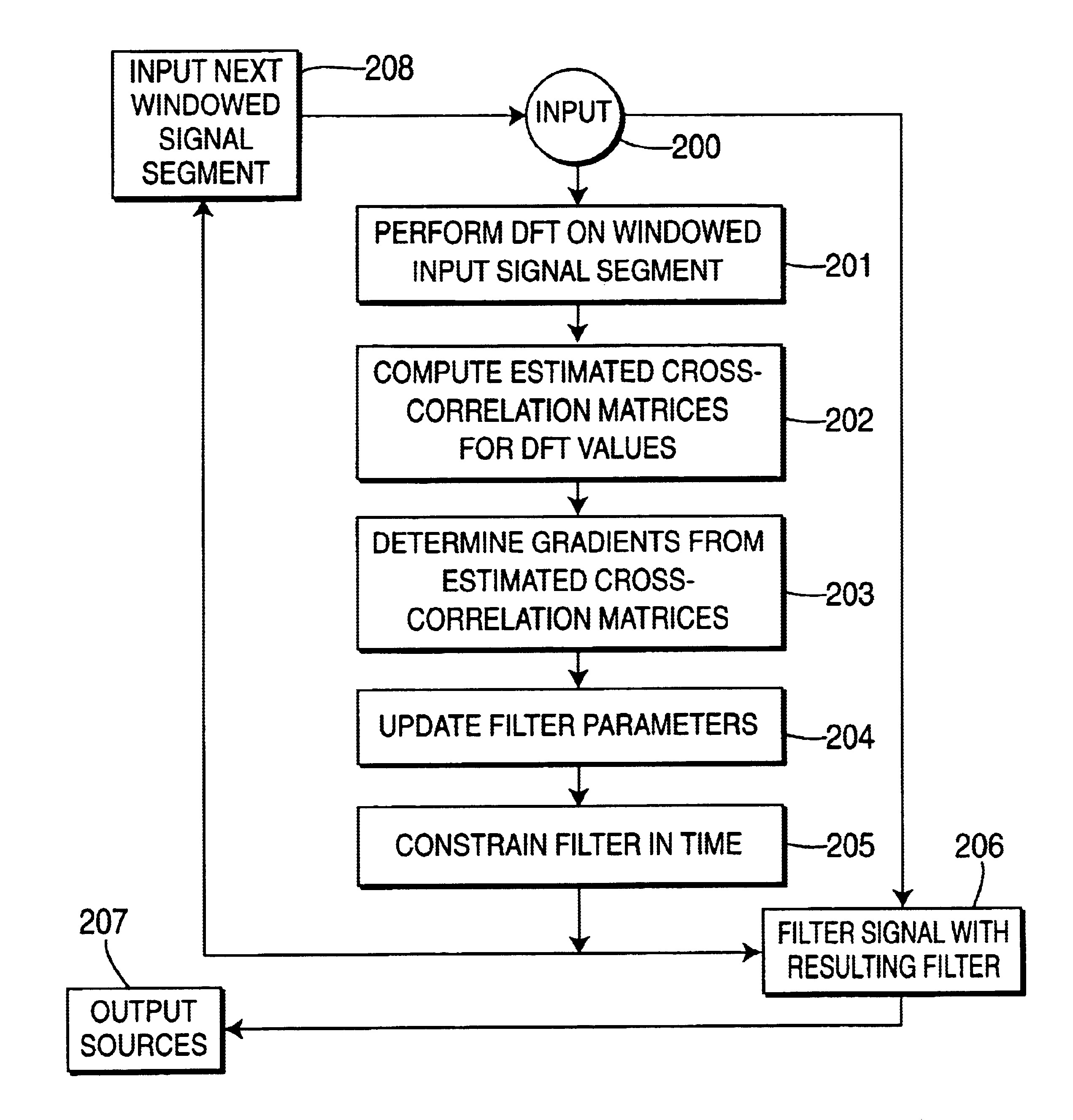

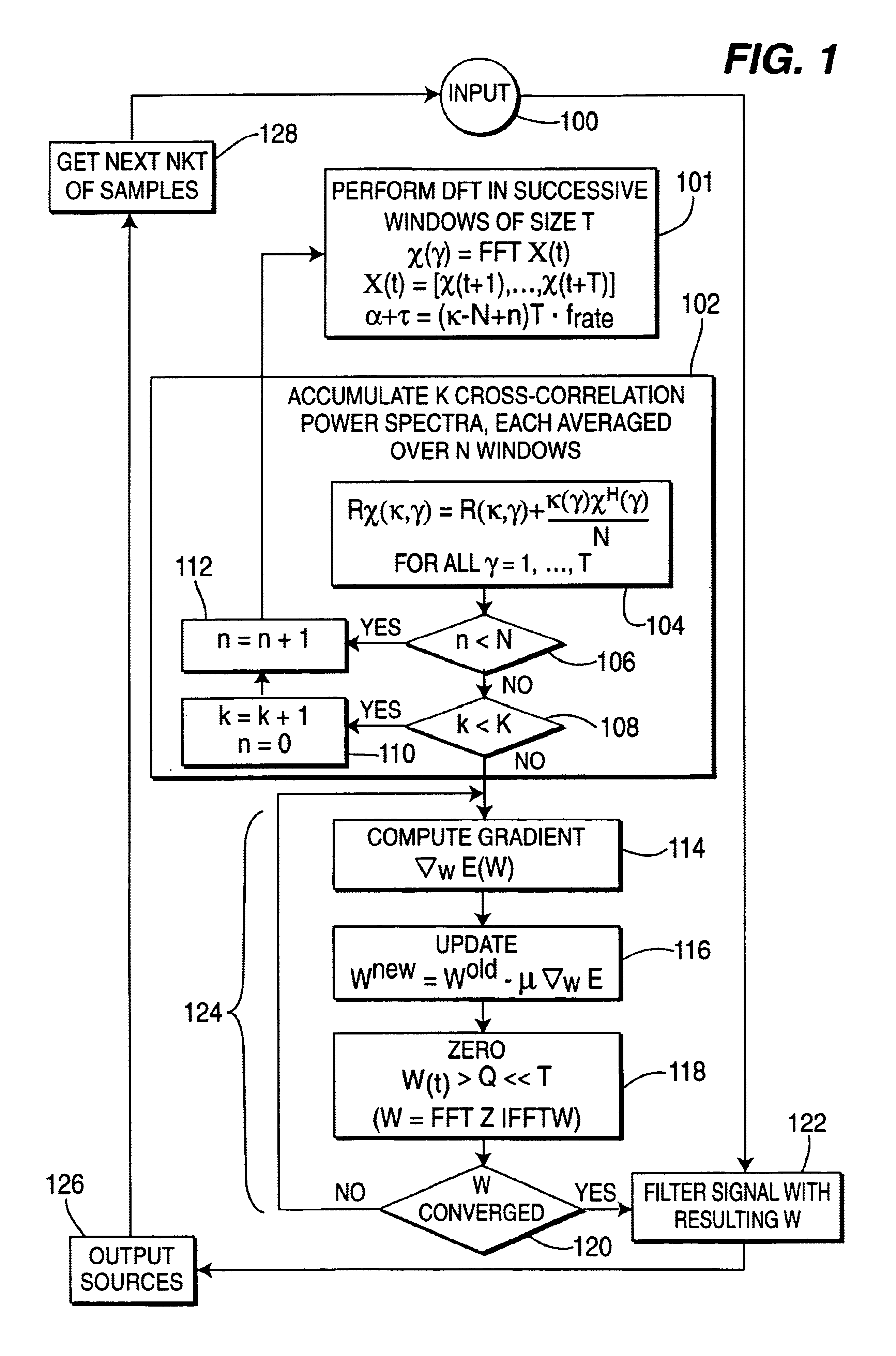

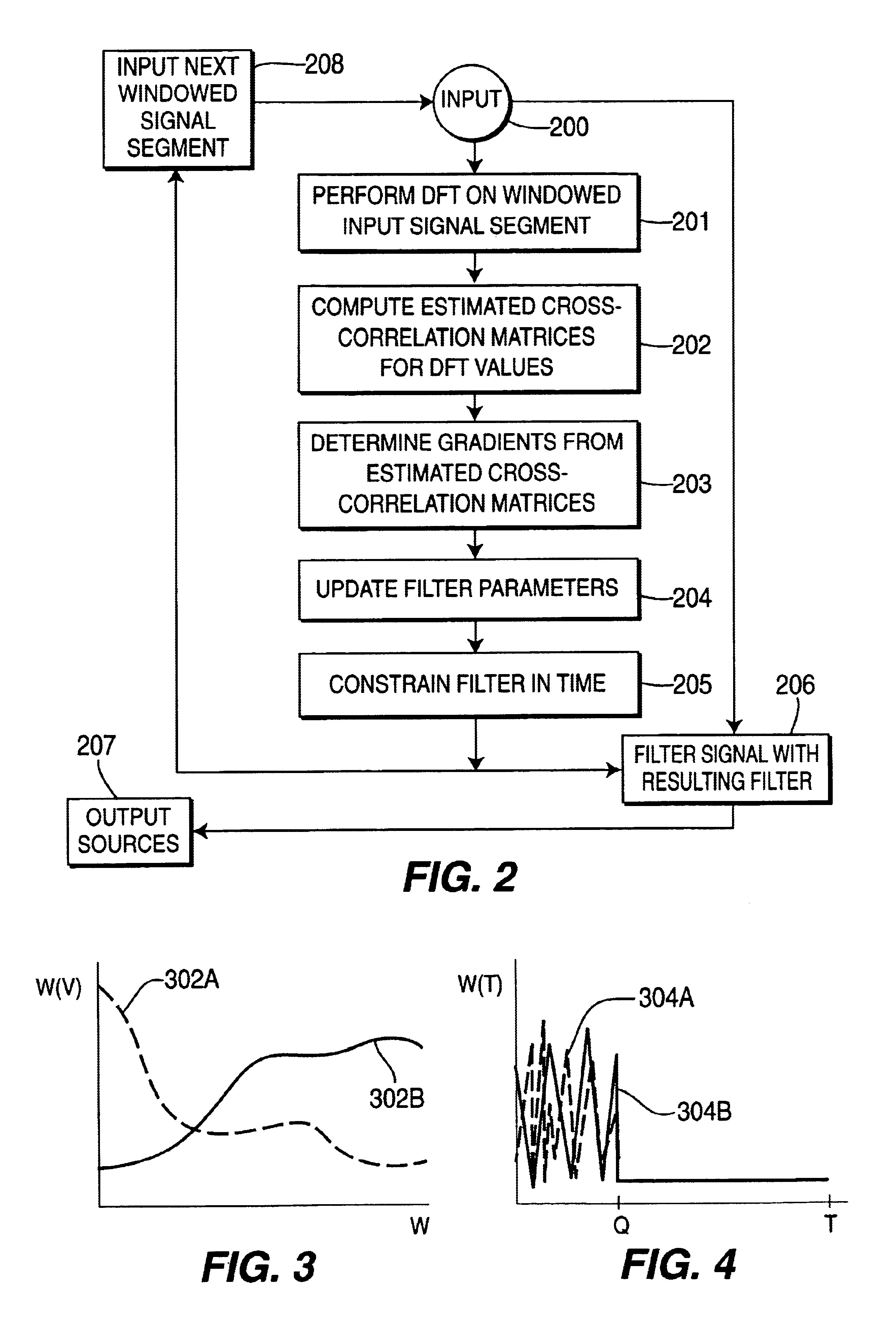

Method and system for on-line blind source separation

InactiveUS6898612B1Efficient separationAdaptive networkSpeech analysisNO storageFinite impulse response

A method and apparatus is disclosed for performing blind source separation using convolutive signal decorrelation. For a first embodiment, the method accumulates a length of input signal (mixed signal) that includes a plurality of independent signals from independent signal sources. The invention then divides the length of input signal into a plurality of T-length periods (windows) and performs a discrete Fourier transform (DFT) on the, signal within each T-length period. Thereafter, estimated cross-correlation values are computed using a plurality of the averaged DFT values. A total number of K cross-correlation values are computed, where each of the K values is averaged over N of the T-length periods. Using the cross-correlation values, a gradient descent process computes the coefficients of a finite impulse response (FIR) filter that will effectively separate the source signals within the input signal. A second embodiment of the invention is directed to on-line processing of the input signal—i.e., processing the signal as soon as it arrives with no storage of the signal data. In particular, an on-line gradient algorithm is provided for application to non-stationary signals and having an adaptive step size in the frequency domain based on second derivatives of the cost function. The on-line separation methodology of this embodiment is characterized as multiple adaptive decorrelation.

Owner:GOOGLE LLC

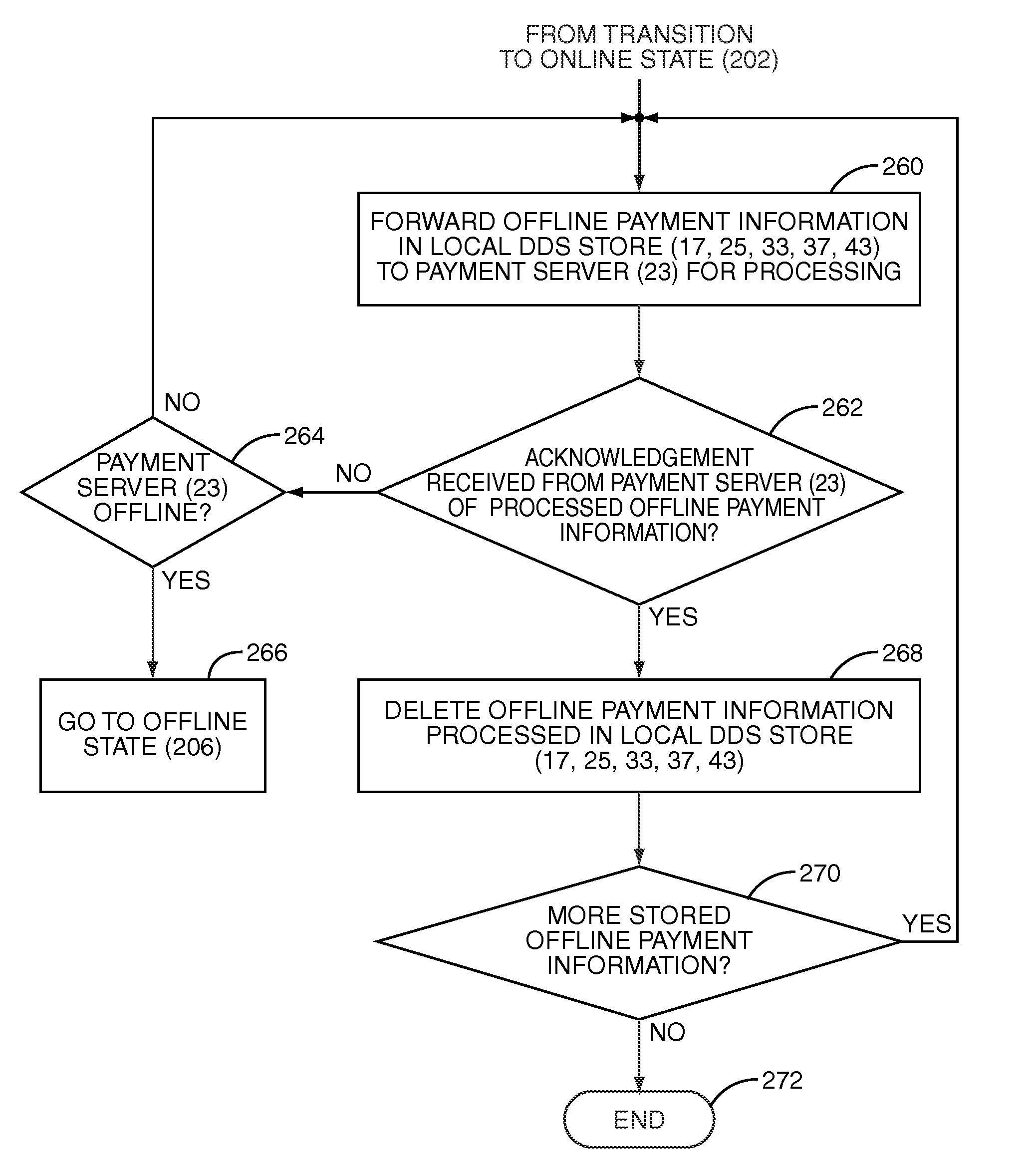

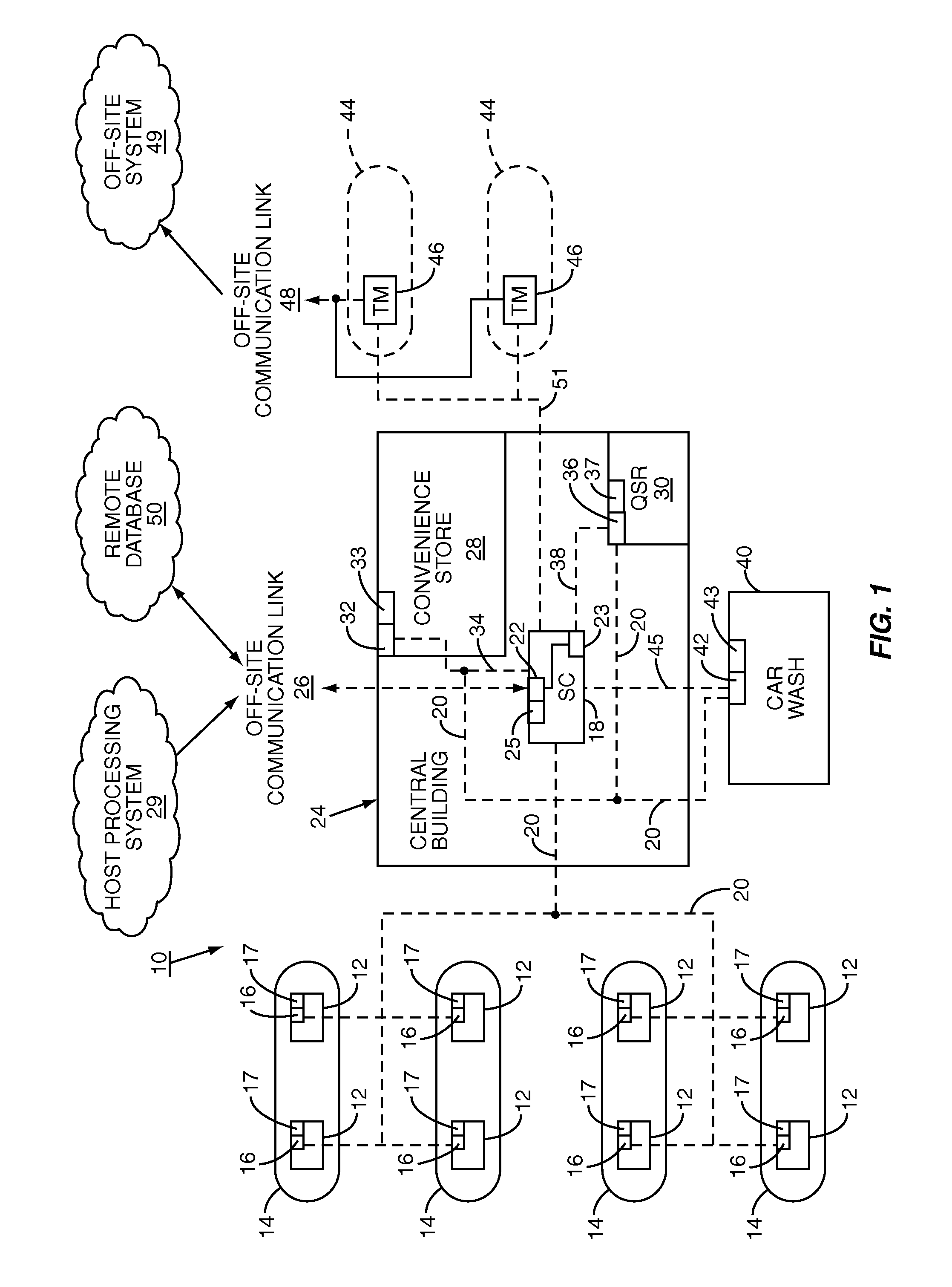

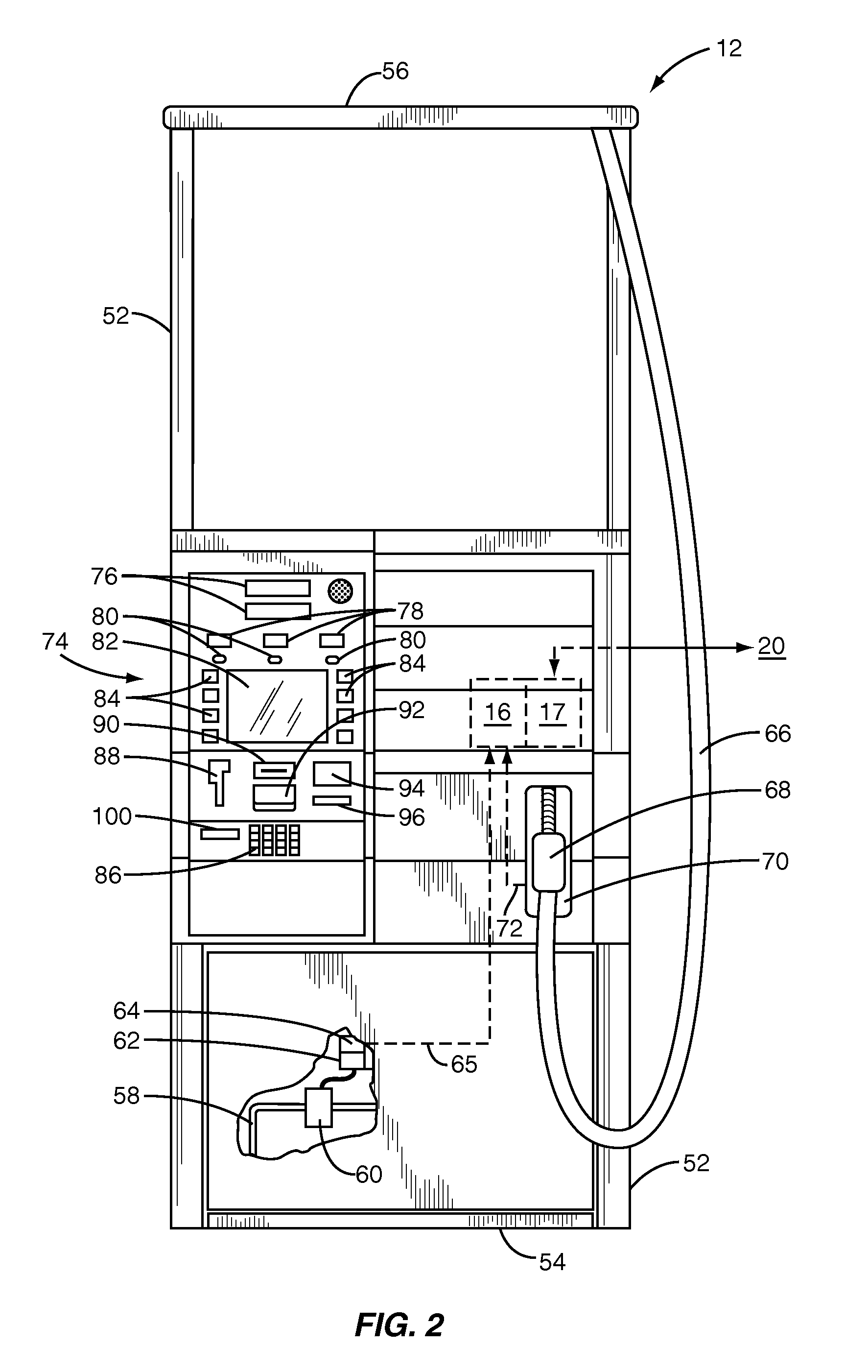

Peer-to-peer data replication for off-line transactions in a retail fueling environment

InactiveUS20080126213A1Hand manipulated computer devicesCash registersPayment transactionData storing

A failsafe, redundant storage system for storing additional copies of off-line transactional or payment information generated by service station forecourt devices. The forecourt devices accept customer payment information for carrying out transactions. The payment information is communicated to a payment server for processing. The forecourt devices may be configured to allow customers to initiate and carry out payment transactions even if payment processing is unavailable or off-line. In this instance, the off-line payment information is stored locally at the forecourt device and communicated to the payment server for processing once back online. The forecourt devices communicate with each other in a peer-to-peer fashion to provide another backup of off-line payment information stored locally at the forecourt device. In this manner, a failure of a forecourt device's local memory will allow another forecourt device to recreate the off-line payment data stored for payment processing once the payment server is back online.

Owner:GILBARCO

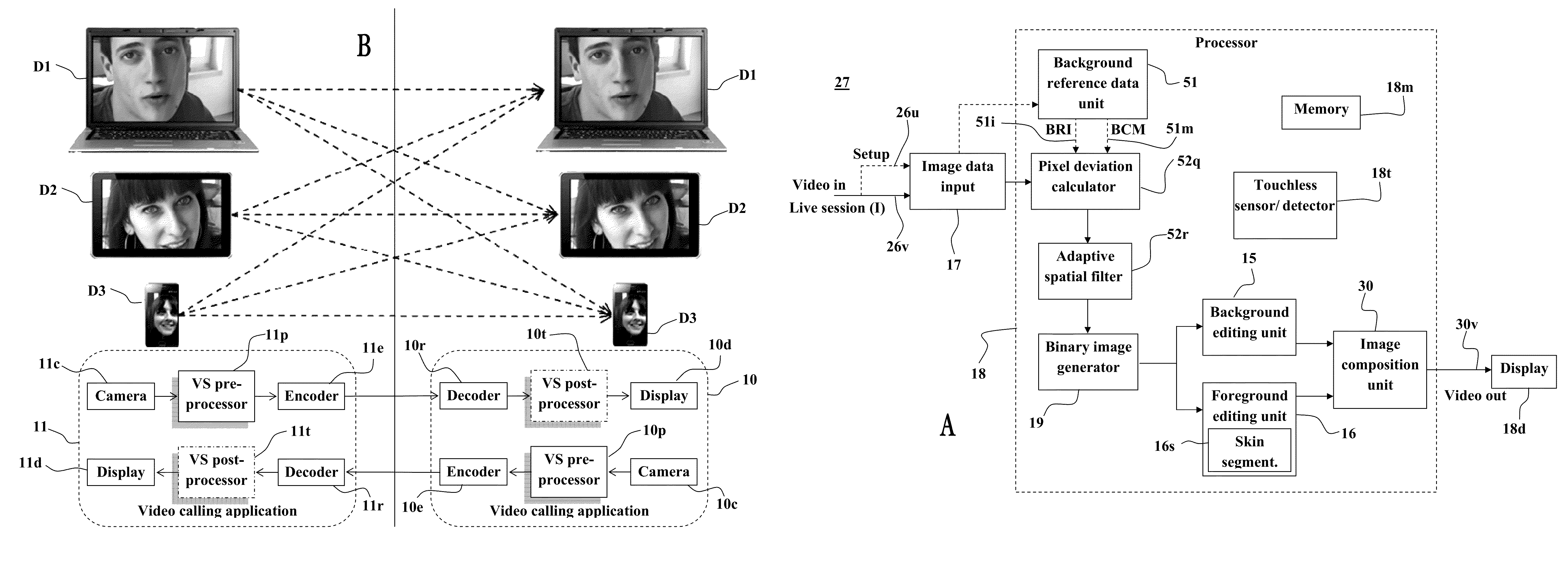

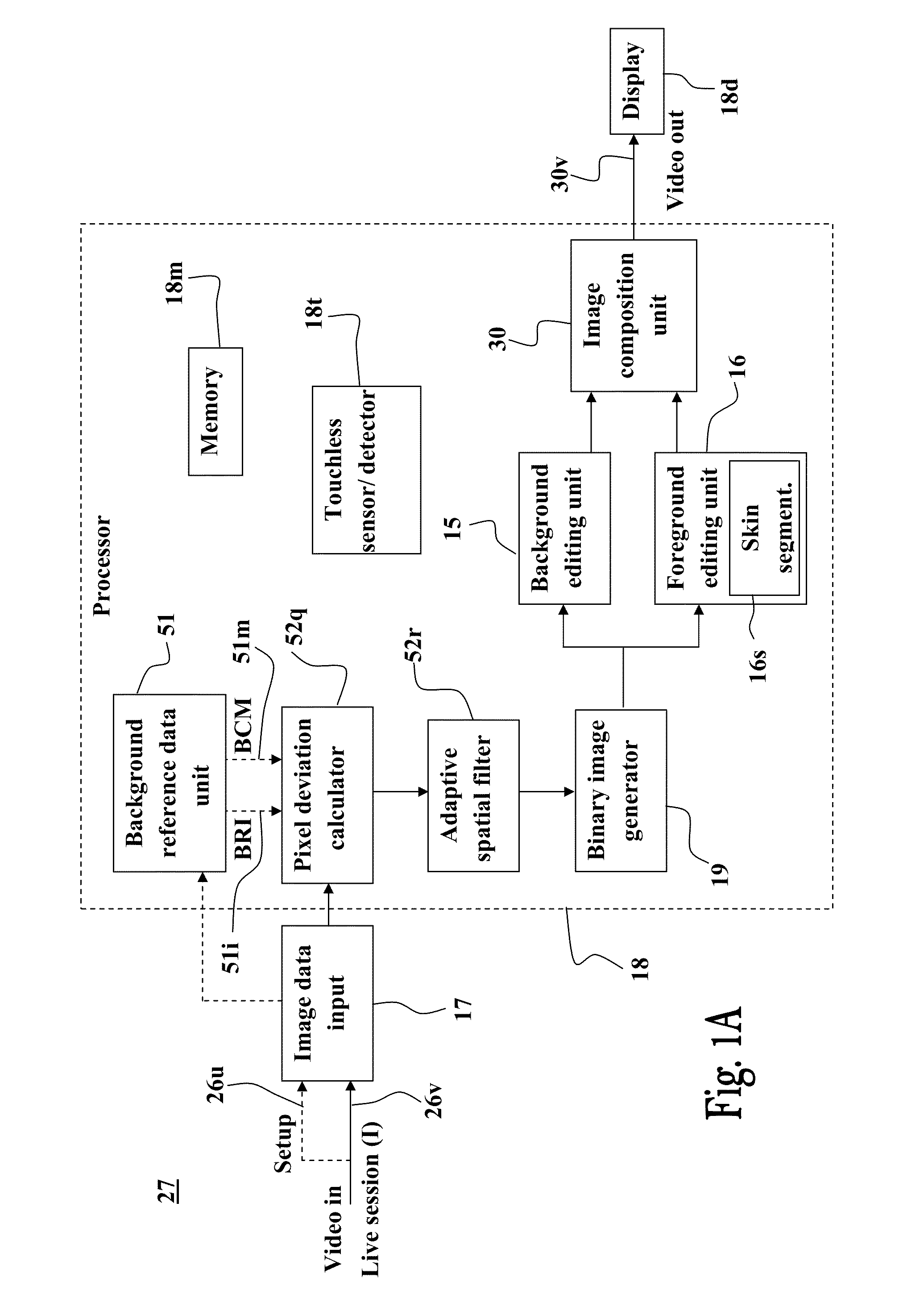

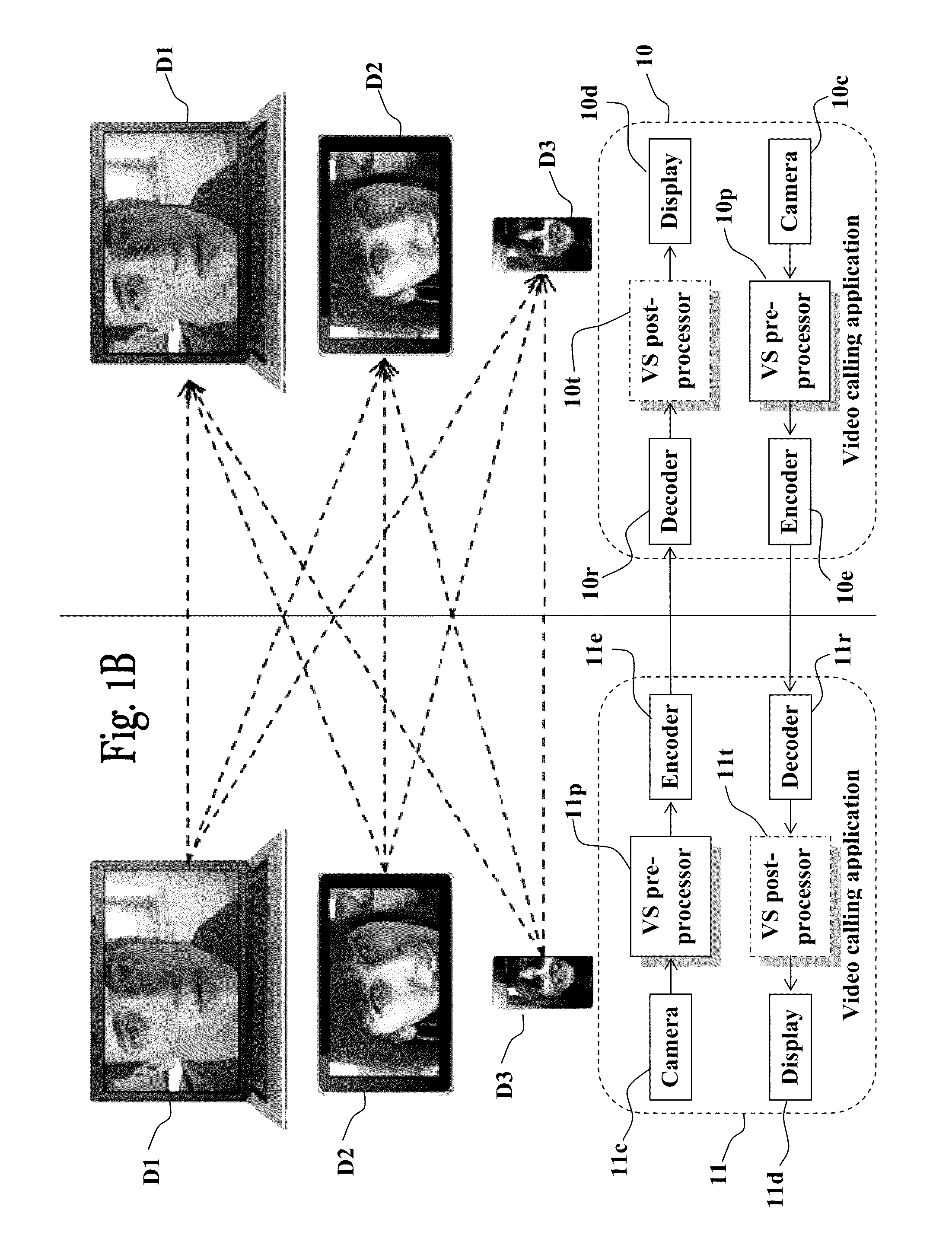

System and method for online processing of video images in real time

InactiveUS20160065864A1Efficiently manipulatedOptimize allocationTelevision system detailsImage enhancementReference imageVideo image

The invention is directed to real-time processing of video data. In some examples at least one image of the video data is processed utilizing reference data comprising reference image data of background within a region of interest and clutter image data indicative thereof, to determine a pixel deviation level of each pixel in the at least one image and generate pixel-deviation image data indicative thereof. The pixel-deviation image data is processed to enhance its tonal pixel distribution and generating enhanced image data, which is processed to determine a threshold level based on the tonal pixel distribution. A binary image map is then generated using the determined threshold level, the binary image map being indicative of the background and foreground components of the at least one image.

Owner:DIGITAL MAKEUP

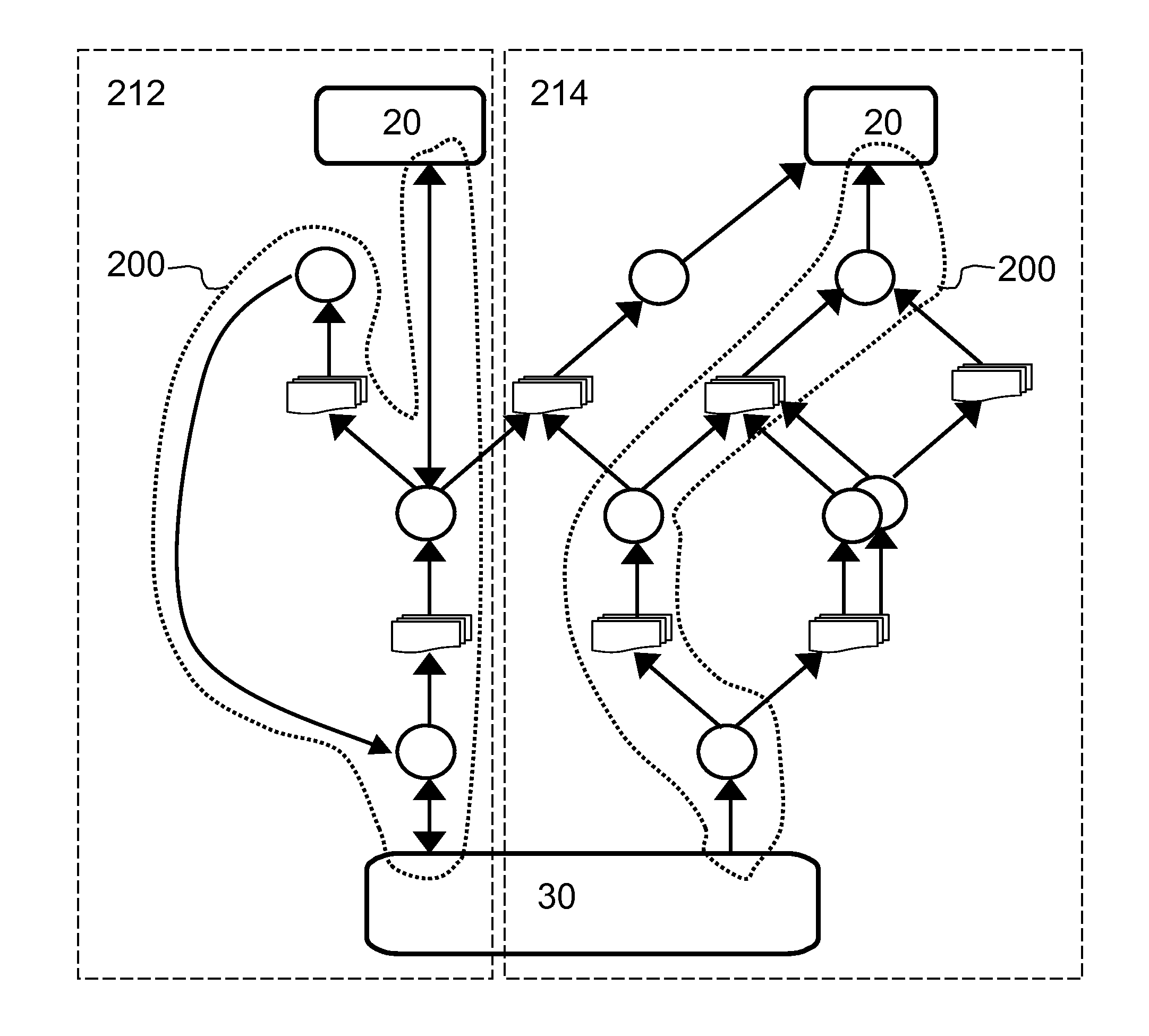

Convergent Mediation System With Improved Data Transfer

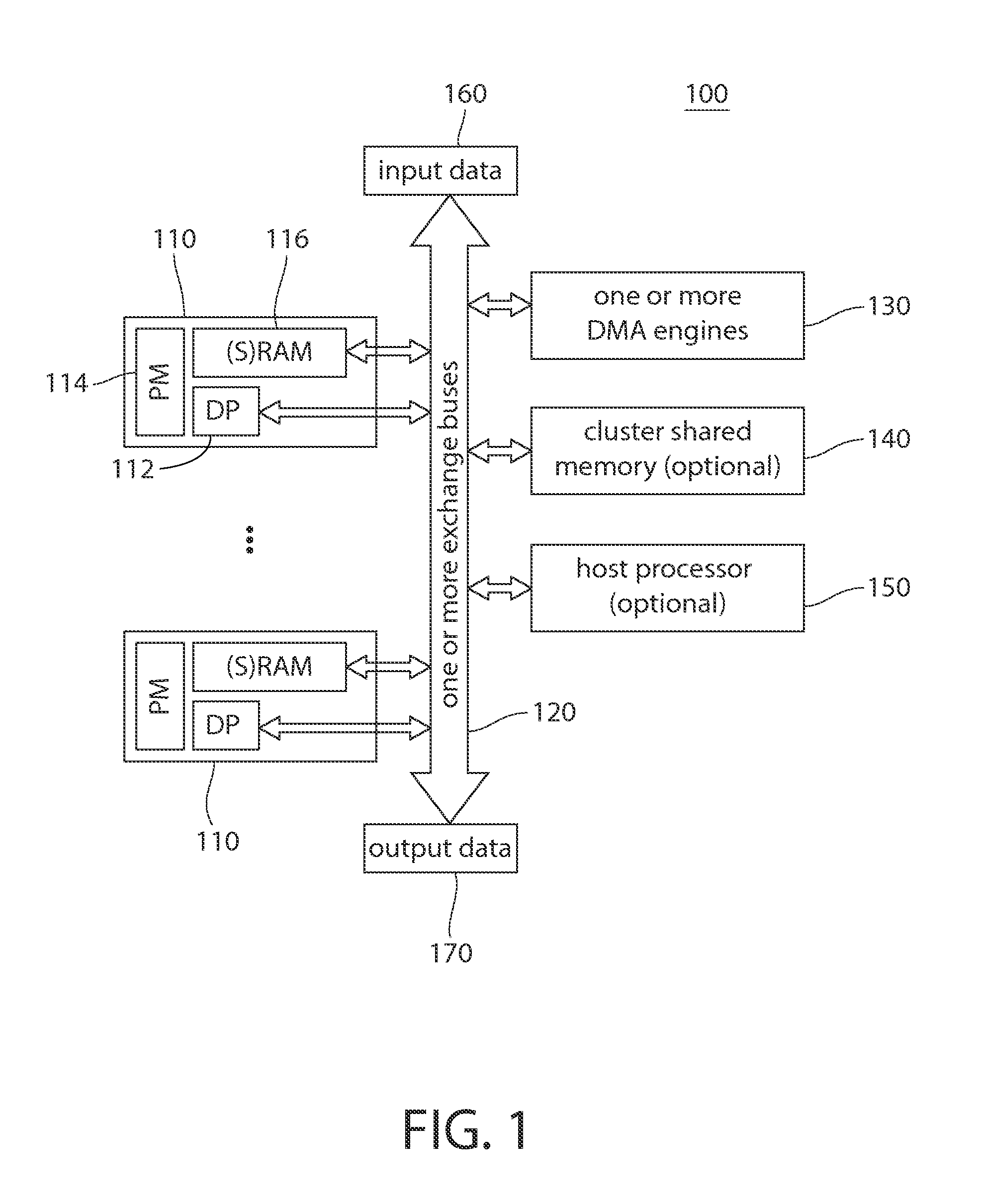

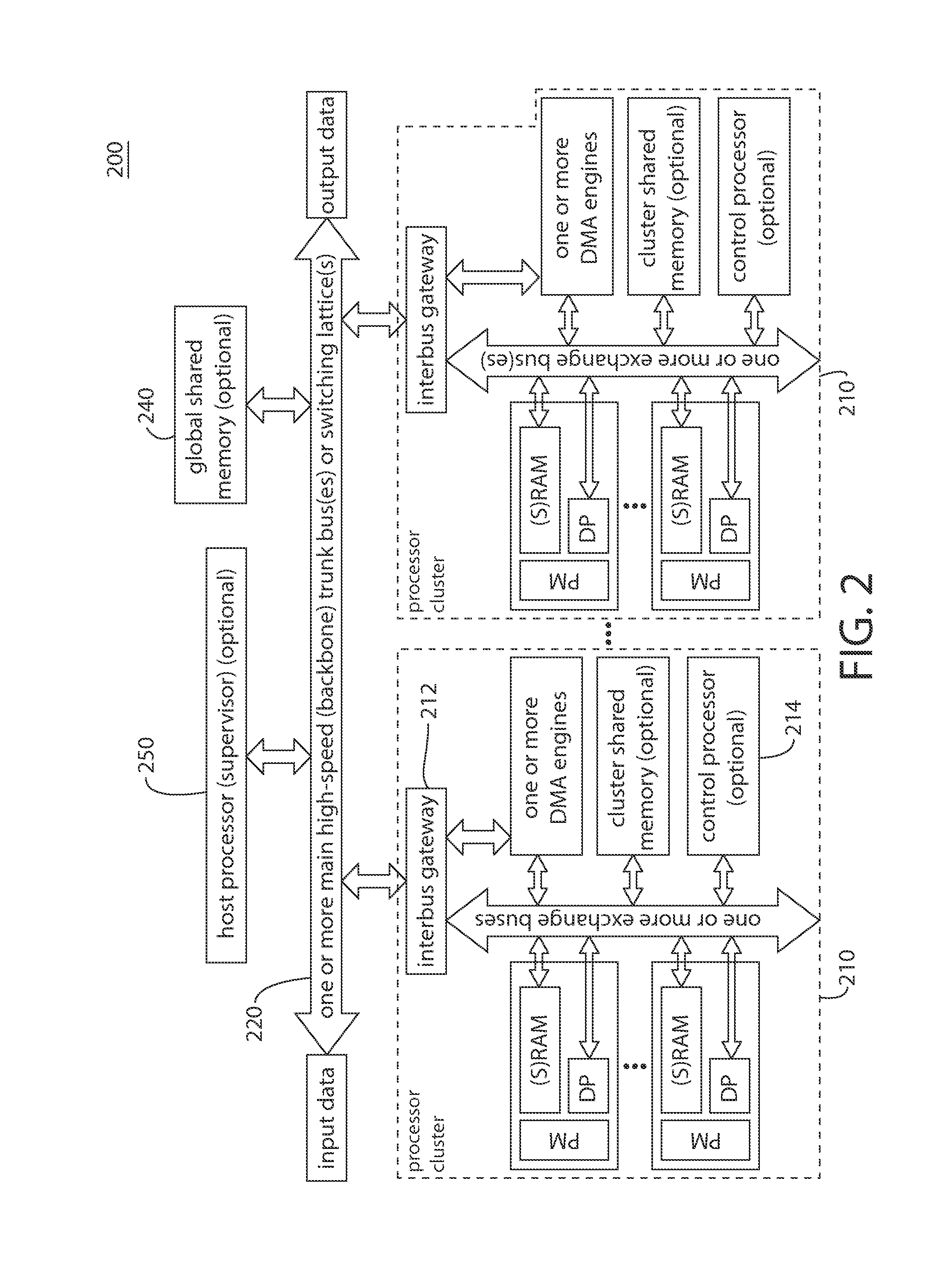

InactiveUS20110010461A1Reliability problemReduce latencyMetering/charging/biilling arrangementsMultiple digital computer combinationsStatic random-access memoryRandom access memory

An object is to create a convergent mediation system (10) and method that meet the technical requirements of low latency time and high reliability. According an aspect of the invention, these objects are achieved by providing a convergent mediation system (10) that comprises a plurality of independent processing nodes (120, 125) adapted to form processing streams (200) for the online processing (12) and off-line processing (14) of data. Each of the processing streams (200) comprises at least two independent nodes (120, 125) in sequence and buffers (145) between the nodes (120, 125). Furthermore, random access memory is utilized such that at least one of the buffers (145) in each of the online processing streams (212) is formed by a dedicated memory area in the random access memory.

On-line quality evaluation and real-time intelligent control method for tobacco process parameter

InactiveCN101488024ACorrected intelligent dynamic controlImprove matchTotal factory controlProgramme total factory controlData managementQuality assessment

The invention discloses a method for online quality evaluation and real-time intelligent control of a parameter during a process for processing tobacco. The method comprises the following steps: a parameter value between an operating parameter of raw material processing equipment and inner quality of a processed product is preset through a data management system; online acquisition is carried out in real time through a data management acquisition system; a parameter acquired by real-time online acquisition is compared with the preset parameter value through an intelligent control system of a data management layer; a valve, a draught fan and an air door power element on the equipment and parameter regulation of tobacco strip remoistening and rotating speed of a conditioning cylinder can be controlled through regulating the operating parameter of the PLC control system and a setting value of a PID open-close loop automation control parameter, thereby realizing accurate and dynamic control of raw material quality variation tendency during a tobacco online processing process and ensuring that the inner quality of the product can be controlled in an excellent and stable range in real time. The method is applicable to control of inner index in a tobacco primary processing line, a tobacco beating and redrying line, a CO2 swelling tobacco line and a rolling, connecting and packaging processing process.

Owner:QINHUANGDAO TOBACCO MACHINERY

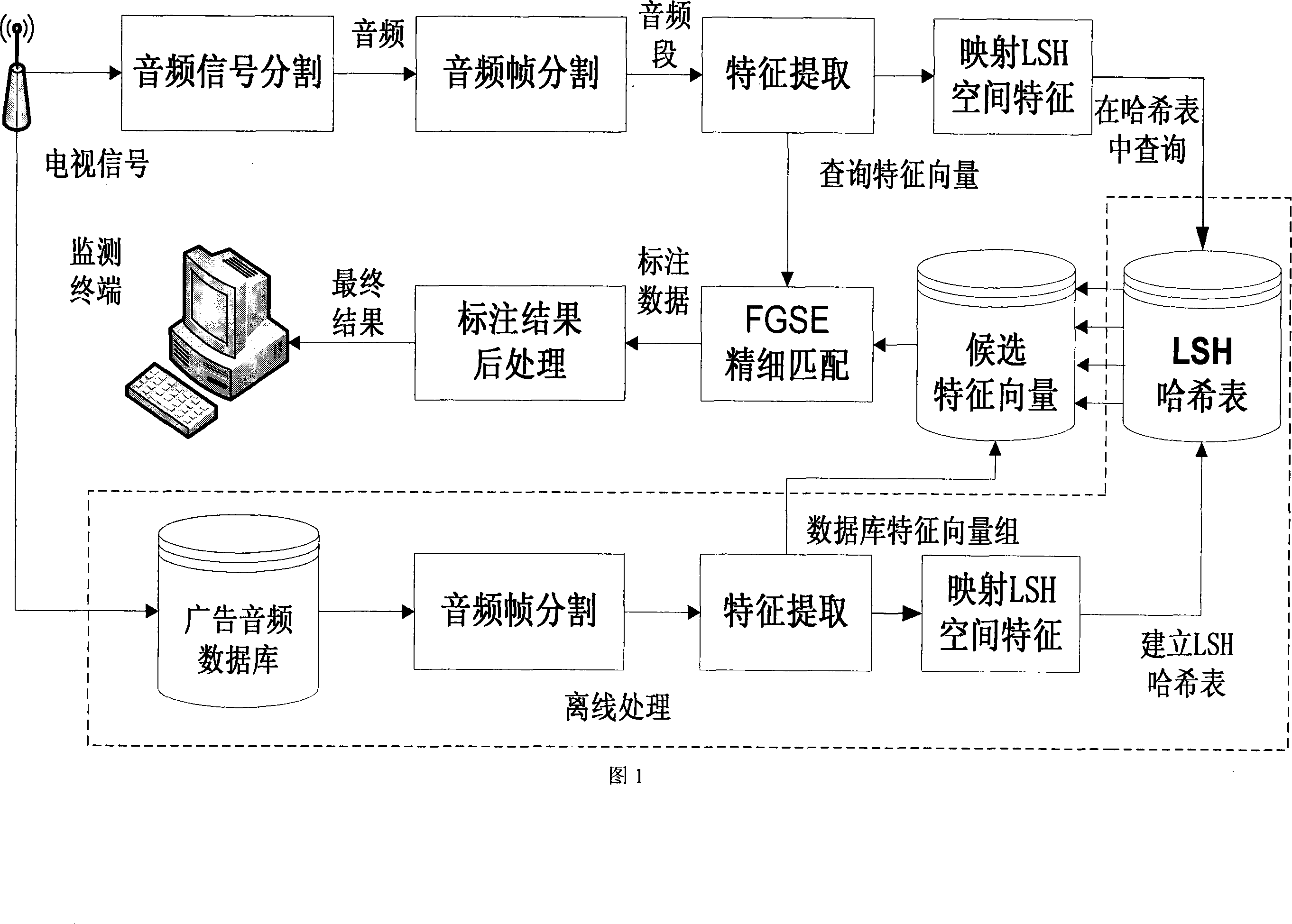

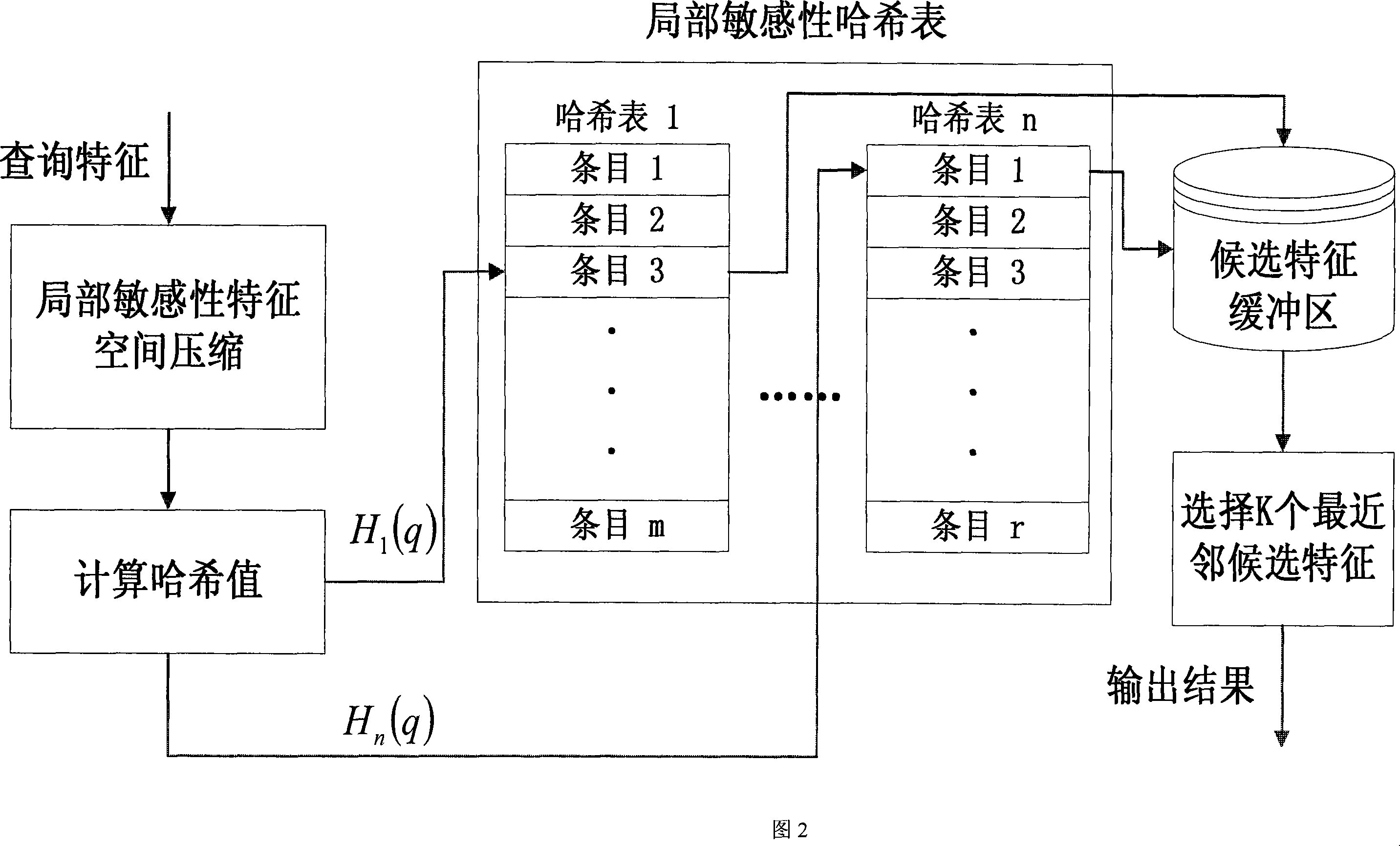

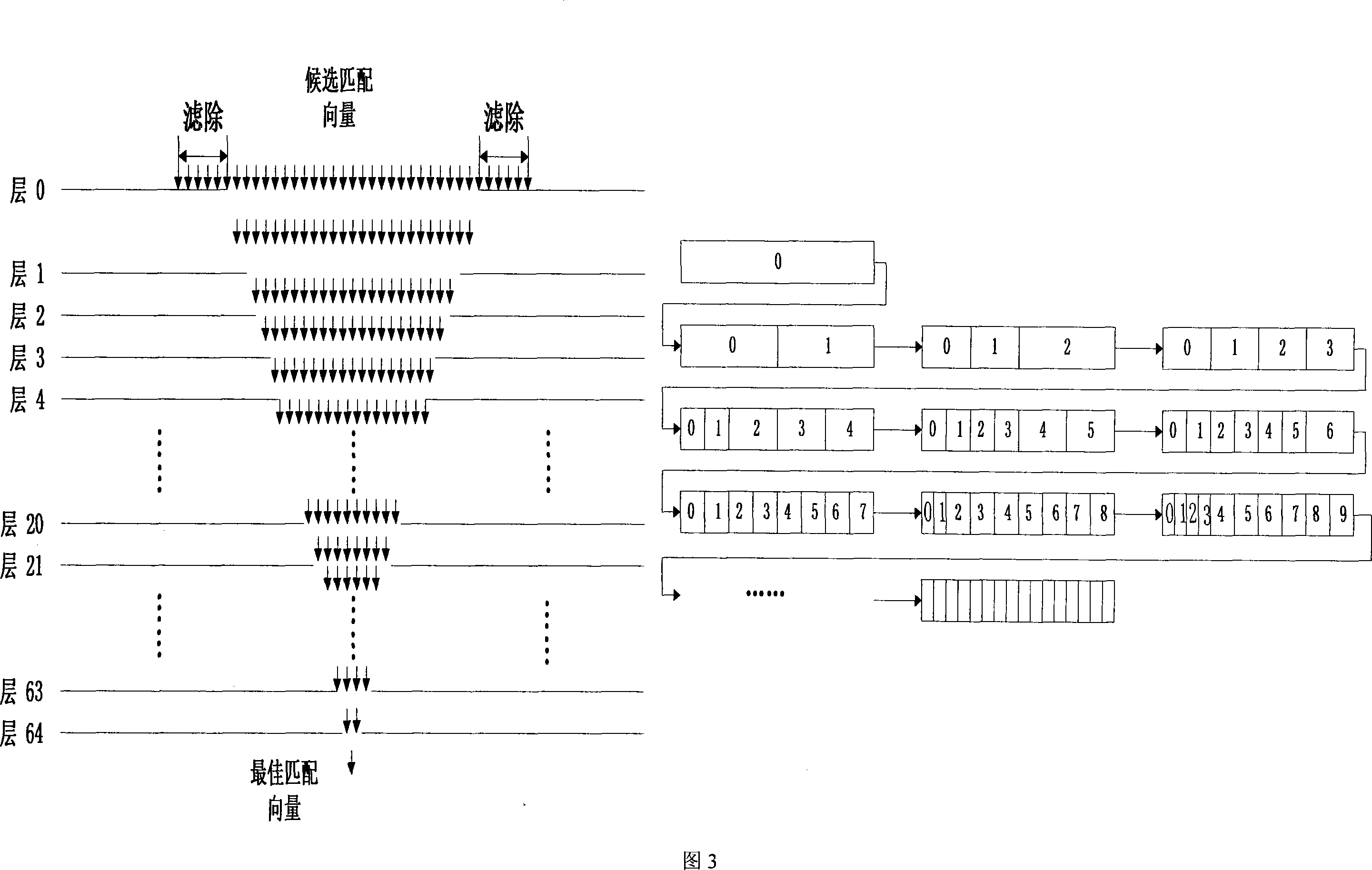

Quick-speed audio advertisement recognition method based on layered matching

InactiveCN101158967AReduce the amount of calculationReduce computational complexitySpeech recognitionSpecial data processing applicationsPattern recognitionAudio frequency

The invention relates to a rapid advertisement identification method which can rapidly detect whether TV or broadcast programs have the advertisements in a data base and is based on layered distribution. The invention is characterized in that the method comprises the following steps: construct an off-line data base and detect on-line, wherein the construction of the off-line data base is composed of an off-line preprocessing and a hash table construction; the on-line processing part is composed of the three parts which are an on-line preprocessing, a two-grade match from roughness to fineness and a post-processing.

Owner:BEIJING JIAOTONG UNIV

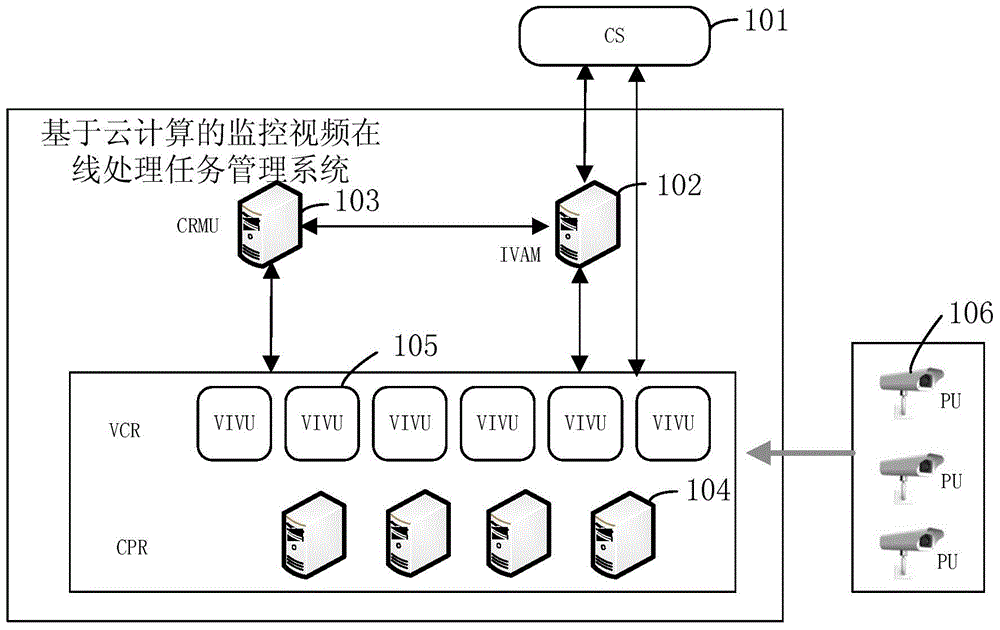

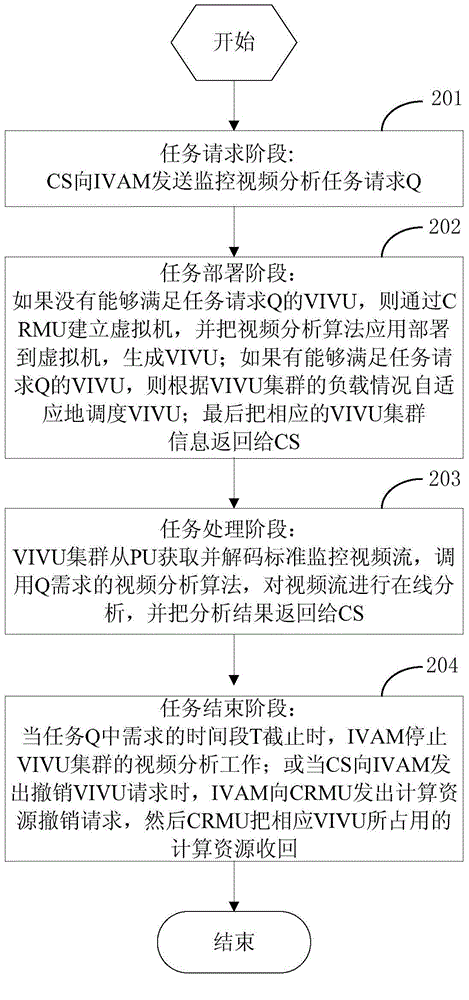

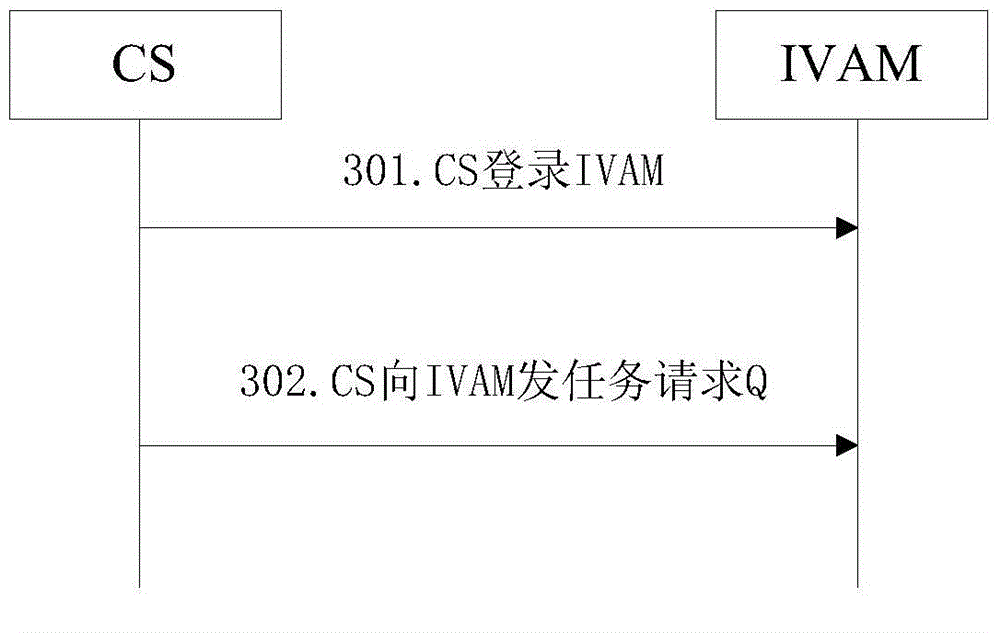

Cloud computing based online processing task management method and system for monitoring video

ActiveCN104618693ALoad balancingImprove flexibilityClosed circuit television systemsTransmissionResource utilizationData center

The invention discloses a cloud computing based online processing task management system for monitoring video. The system is respectively connected with a client and a front end camera and comprises an intelligent video analyzing algorithm management module, a cloud resource management module, a cloud computing physical resource model and a virtual intelligent video analyzing server. The invention further discloses a cloud computing based online processing task management method for monitoring video. According to the method and system, a group of interconnected server groups in a data center is unified to be managed by the cloud computing technology, and the server groups coordinate to provide a user the intelligent monitoring video online processing task management service; the system is high in telescopic performance; the intelligent video analyzing algorithm can be dynamically configured as requirement, thus the management is convenient, and the cost is greatly reduced; in addition, the video processing task provided by the user can be reasonably dispatched to enable balanced load of the computing groups, and therefore, the resource utilization rate is increased, and efficient cloud computing service is provided to the user.

Owner:BEIJING UNIV OF POSTS & TELECOMM

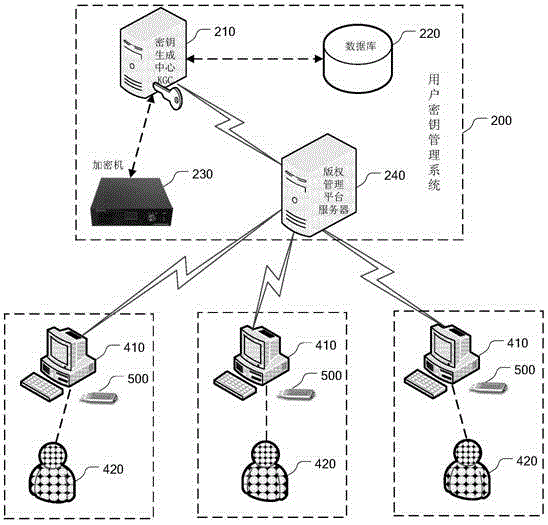

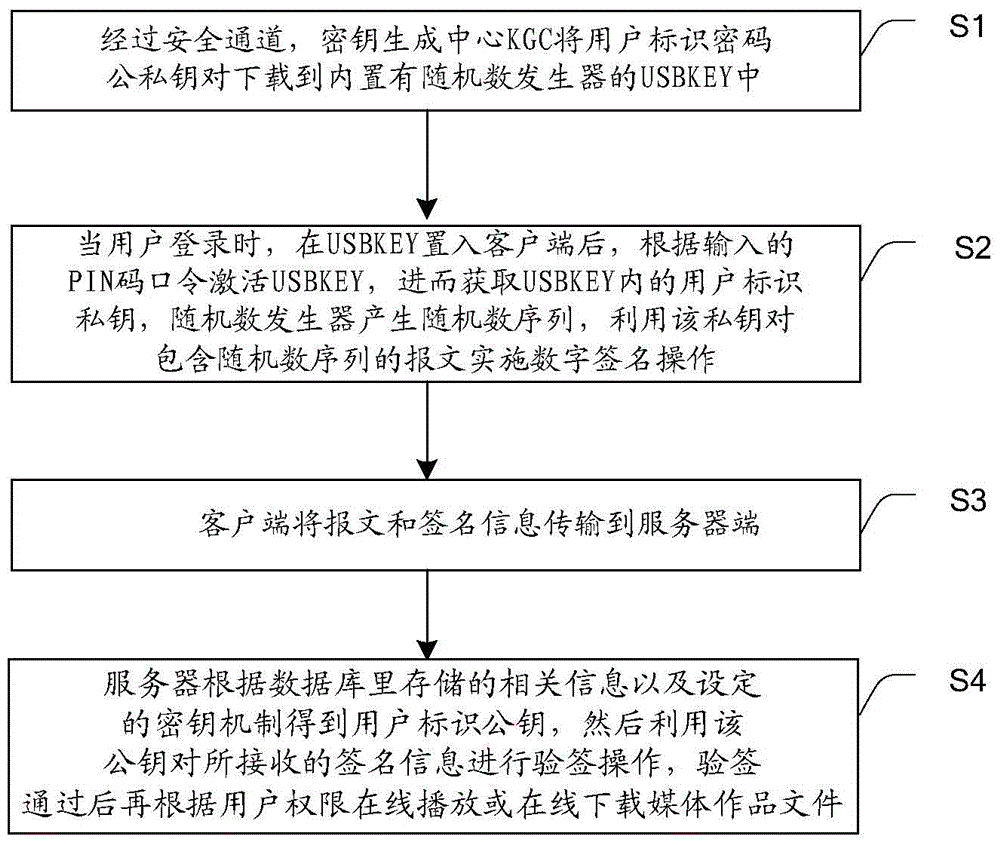

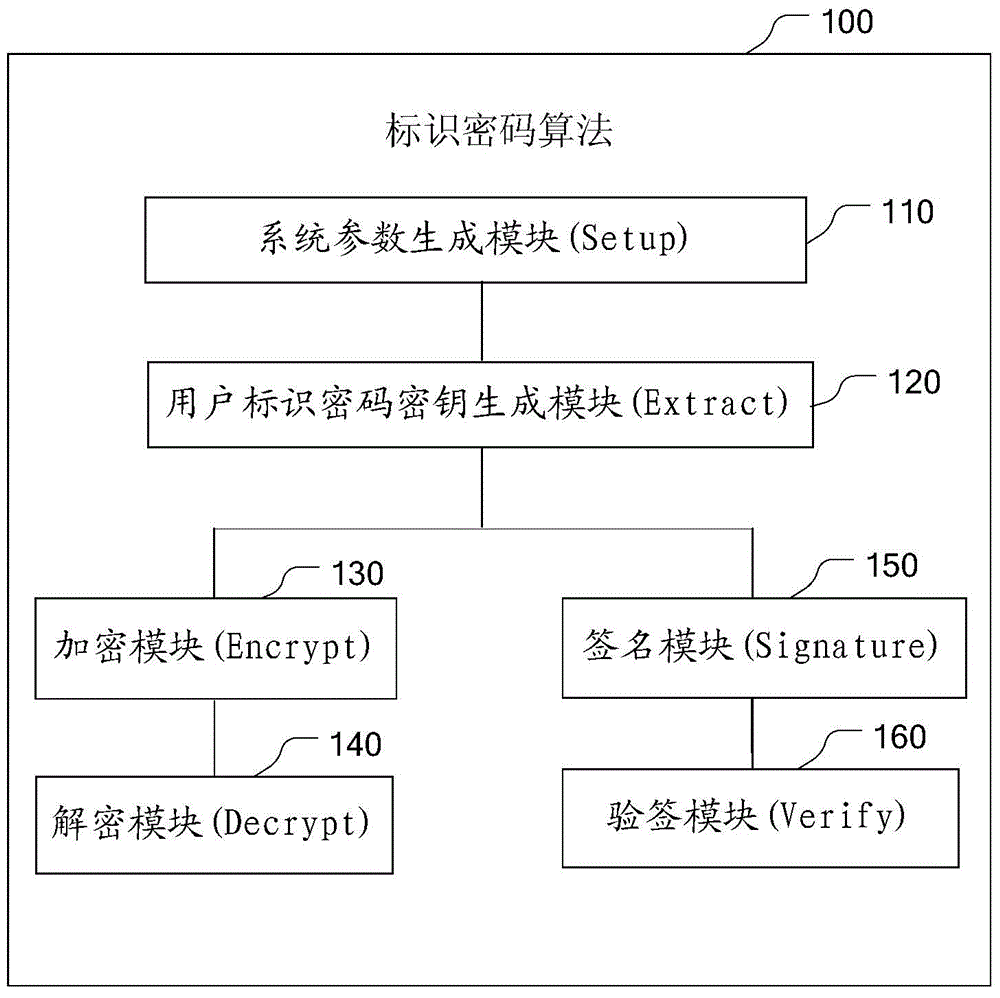

Dynamic digital right management method and system based on identification password

ActiveCN105553662ASolve management problemsReduce operating costsPublic key for secure communicationUser identity/authority verificationUser inputPassword

The embodiment of the invention provides a dynamic digital right management method and a system based on an identification password. The method mainly includes: a KGC generates identification password public and private key pairs of a user and sets the key pairs in a USBKEY; a client activates the USBKEY according to a personal identification password PIN password inputted by the user, and obtains an identification password private key of the user set in the USBKEY; digital signature operation of a message is performed by employing the identification password private key of the user, signature information is obtained, and the message and the signature information are transmitted to a right management platform server; the right management platform server obtains an identification password public key of the user via the KGC, signature verification operation of the signature information is performed, and after the passing of the signature verification, media files are processed online according to the authority of the user. According to the method and the system, identity authentication and data encryption operation of dynamic digital right safety protection can be performed by employing the identification password public and private key pairs of the user, the client does not adopt a digital certificate, the problem of complicated management of the digital certificates is avoided, and the operation speed of the system is increased.

Owner:AEROSPACE INFORMATION

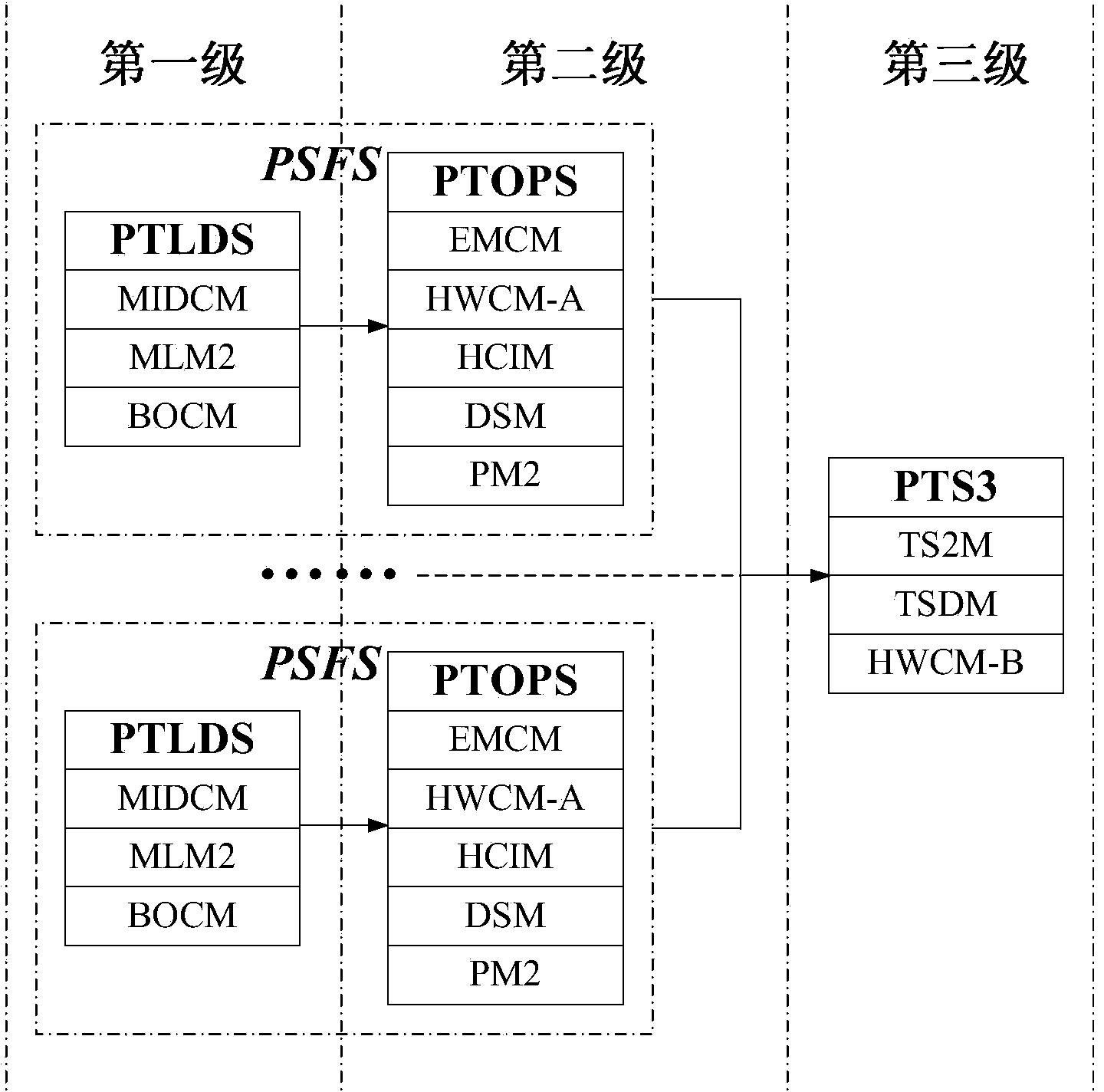

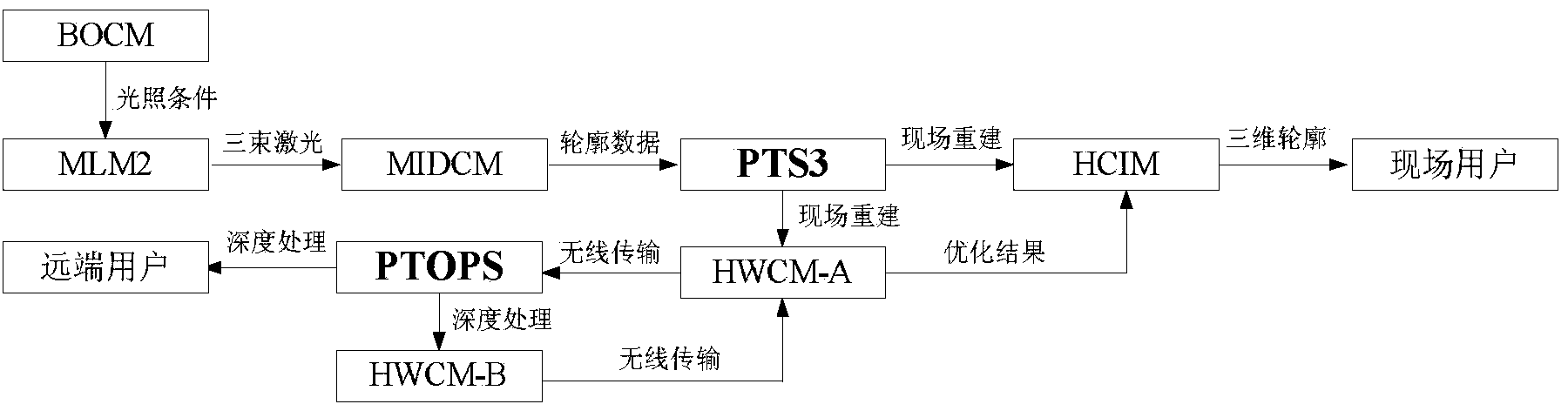

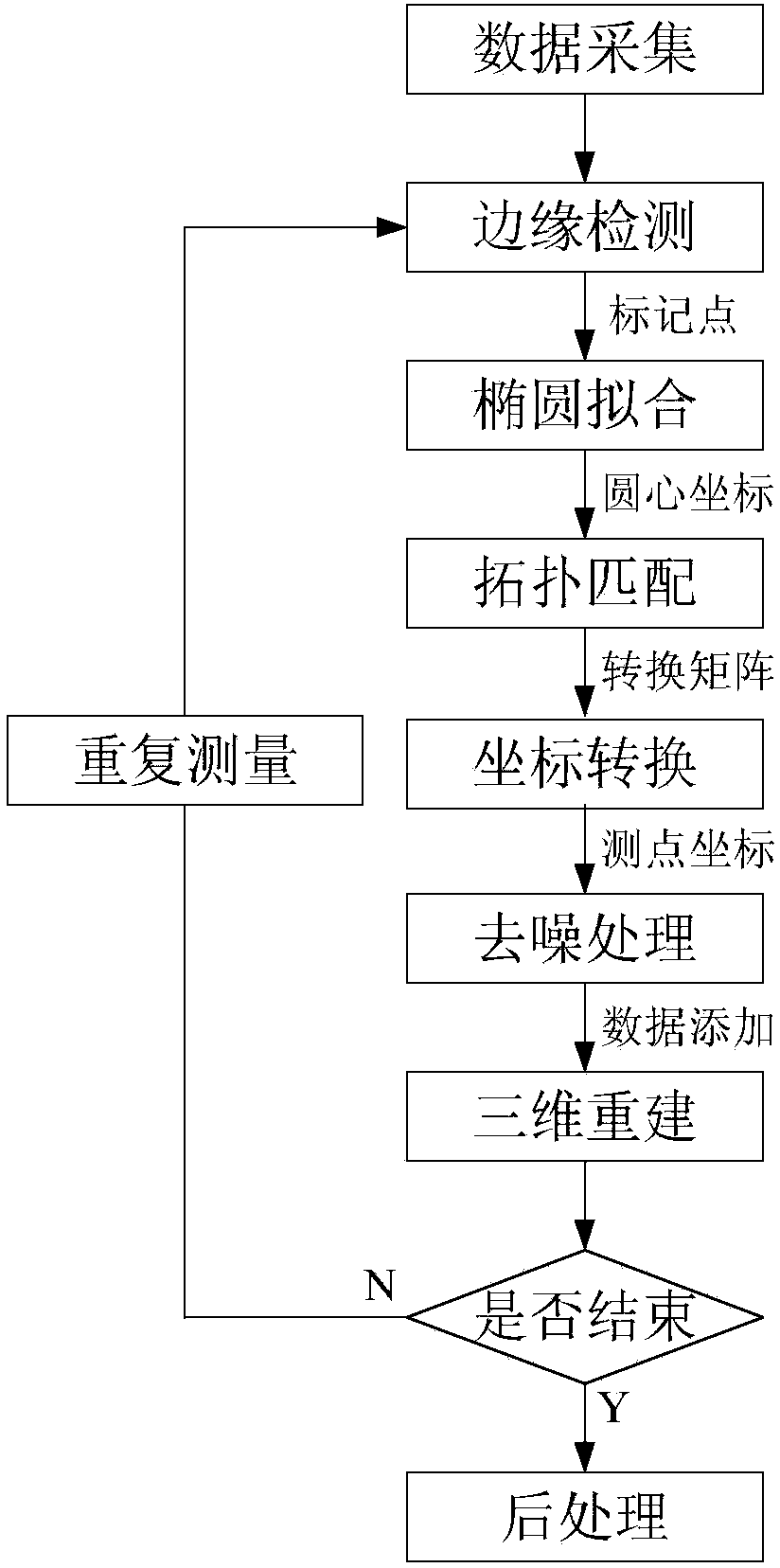

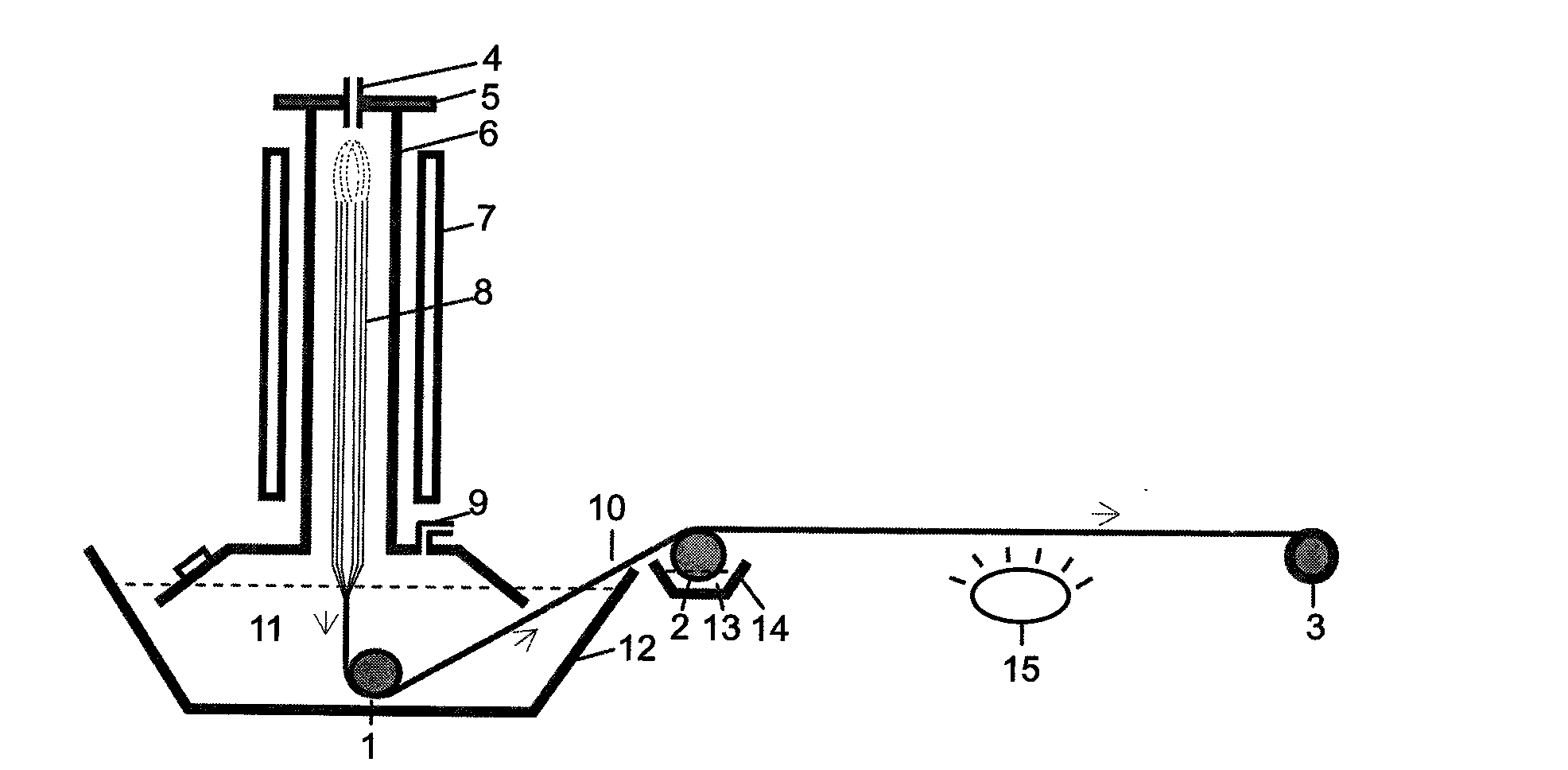

Wireless hand-held 3D laser scanning system

ActiveCN104165600AGuaranteed real-timeGuaranteed robustnessUsing optical meansLaser scanningHand held

The invention discloses a wireless hand-held 3D laser scanning system, comprising a hand-held 3D laser scanning data collection subsystem, a portable 3D data online processing display and control sub-system and a portable 3D data service terminal storage and analysis subsystem. The hand-held 3D laser scanning data collection subsystem is connected to the portable 3D data online processing display and control subsystem based on one-to-one correspondence, and the hand-held 3D laser scanning data collection subsystem and the portable 3D data online processing display and control subsystem are installed within a support frame to construct a portable subsystem which can independently perform 3D profile scanning. The portable 3D data online processing display and control subsystem is connected to the 3D data service terminal storage and analysis subsystem. The invention provides a wireless handheld 3D laser scanning system which is flexible, big in visual range and good in instantaneity.

Owner:SCANTECH (HANGZHOU) CO LTD

Lamellar carbon nanofibre and preparation method thereof

The invention relates to a lamellar fibre material and a preparation method thereof. The lamellar carbon nanofibre has multiple layers and a fibre structure of various cross-sectional shapes. The carbon nanofibre structure in the fibre is single-wall carbon nanotube, double-wall carbon nanotube and multi-wall carbon nanotube or a lamination carbon nanotube formed by the collapse of the carbon nanotubes. The macro structure of the fibre is hollow, solid, flat or crimp, and the like. Reaction carbon source, catalyst and promoter are mixed and added into high-temperature reaction airflow of a reactor, carbon nanotube for catalytic cracking growth is gathered into aggregate of lamellar carbon nanotube fibre in the reaction airflow, and the aggregate is spinned after liquid action or spinned through other online processing. The fibre with a multi-layer structure can be applied to structures, functional devices, knitting, and the like. The preparation method of the invention has simple process, is stable and reliable and can be used for preparing various multi-layer carbon nanofibre materials in industries.

Owner:TIANJIN UNIV

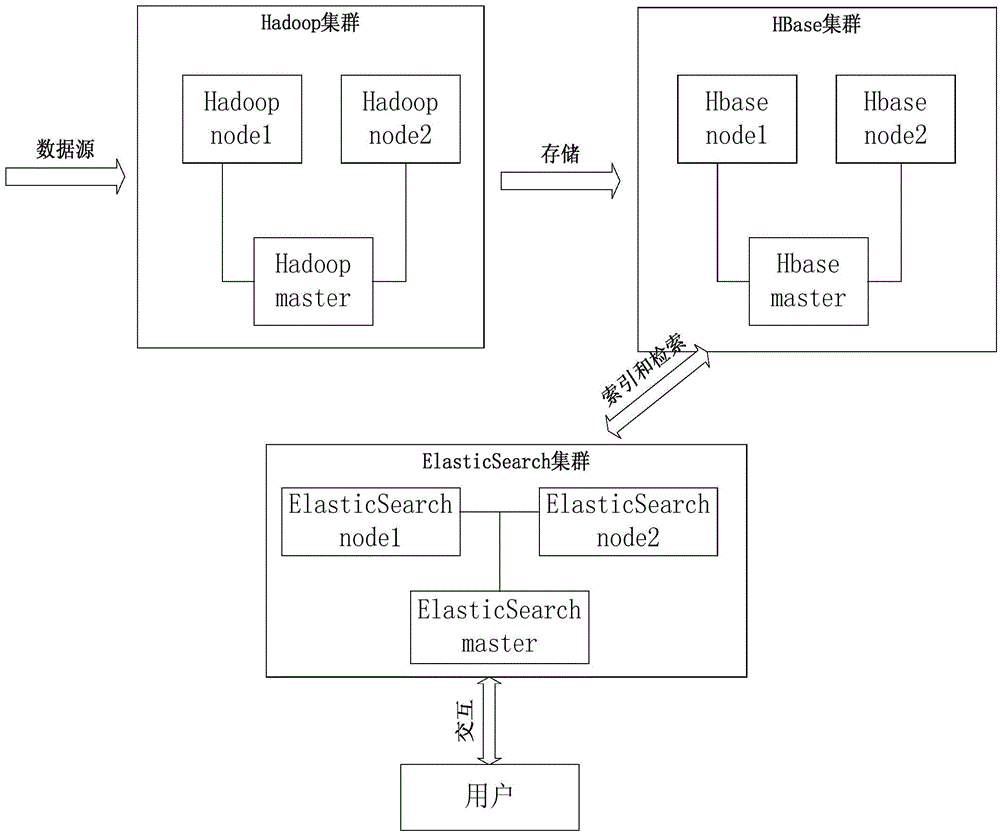

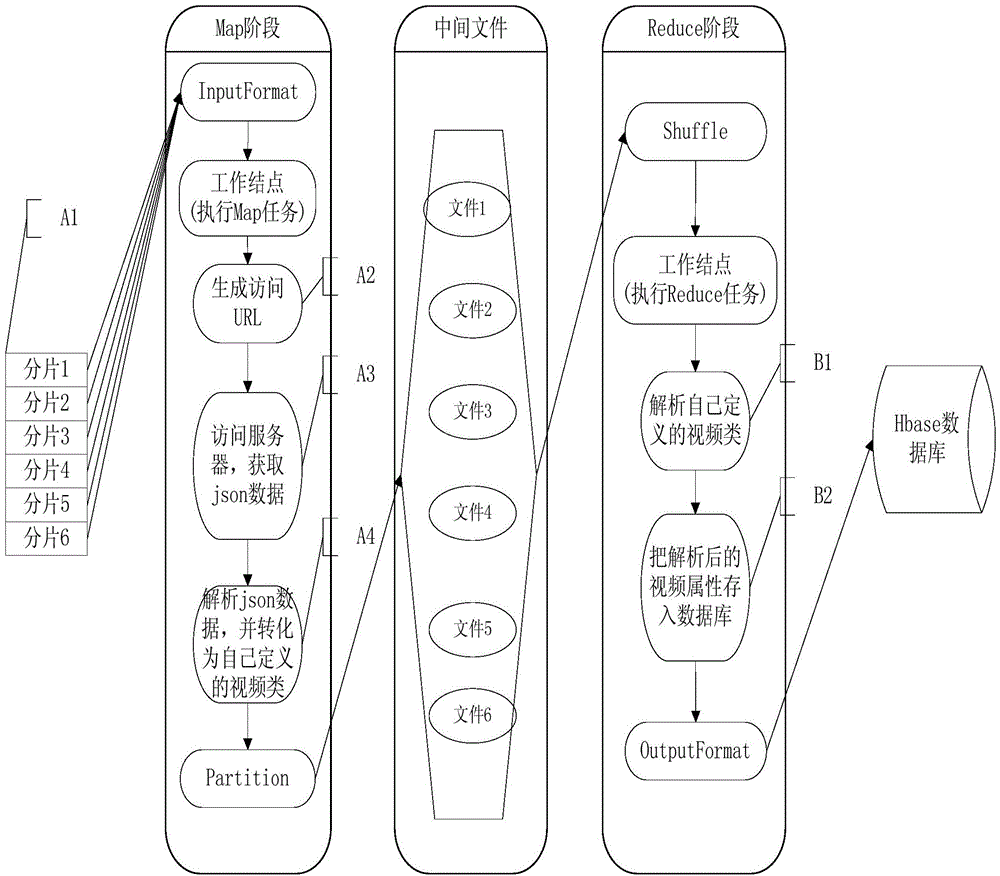

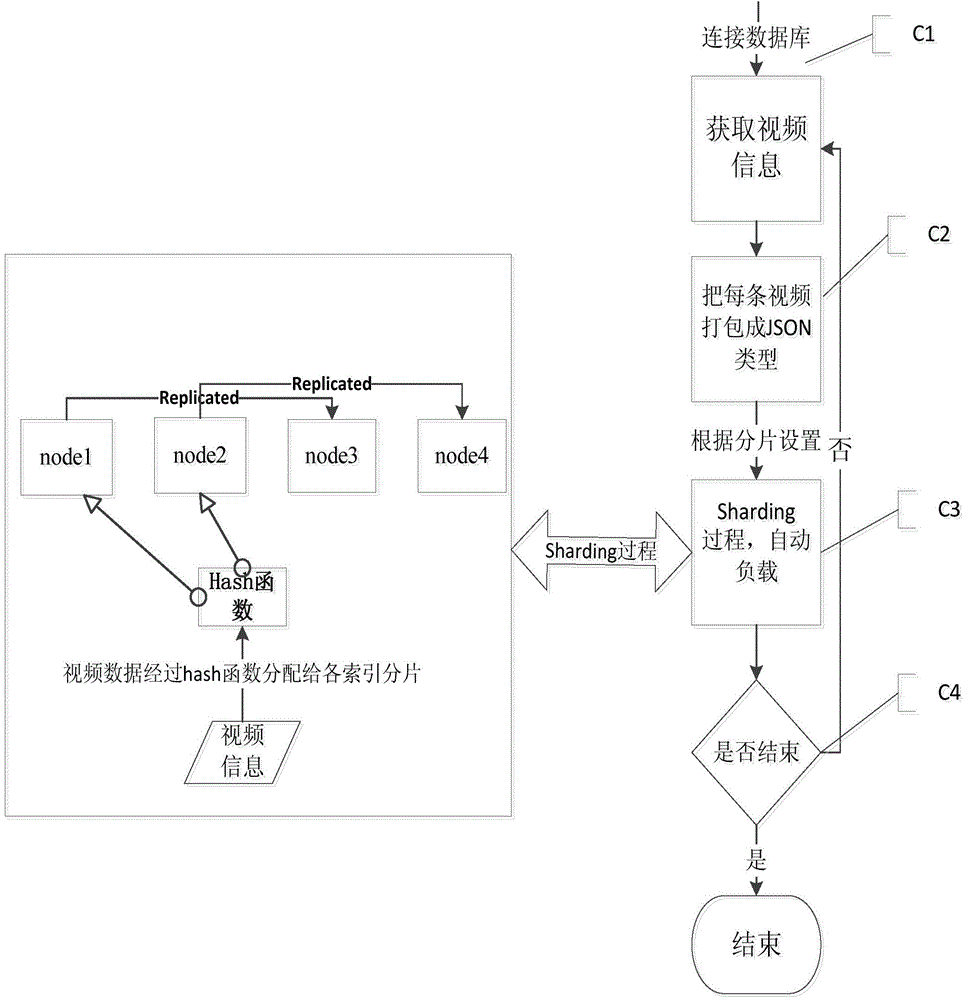

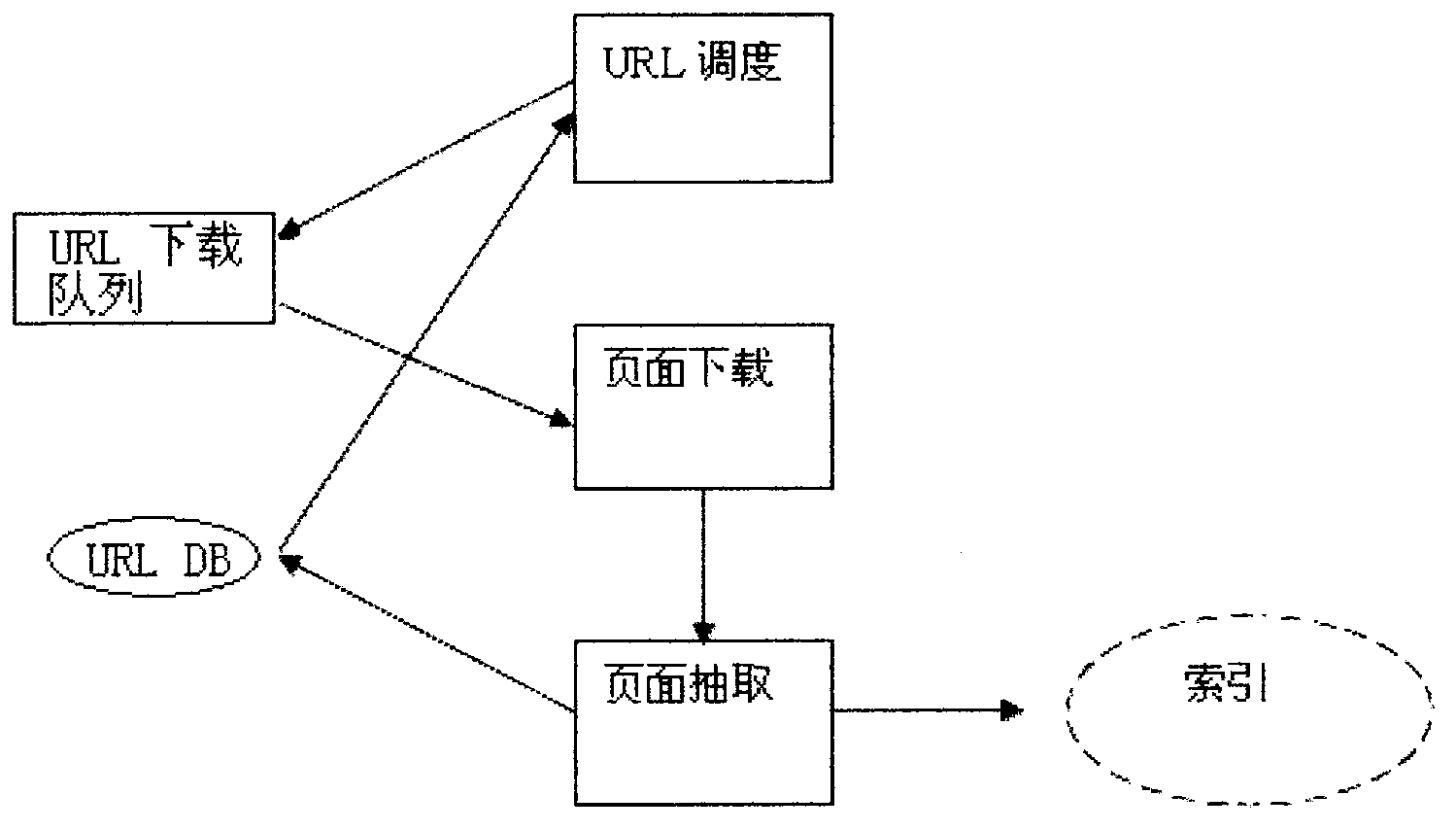

Distributed video vertical searching method and system

InactiveCN103984745AReal-time search is efficientQuick collection workVideo data indexingSpecial data processing applicationsVideo storageVideo retrieval

The invention provides a distributed video vertical searching method and system. The method includes an offline processing step and an online processing step. The offline processing step includes video capture, video storage and video information index building. The online processing step includes user interaction and video indexing. The method and system has the advantage that a distributed video vertical searching technical scheme based on Hadoop and Elastic Search is provided based on the video field, an effectively distributed searching scheme is provided for massive video data, batch fast collection, real-time searching and the like of massive videos are achieved, high-efficiency real-time search is achieved, and quick collection work for offline processing of the massive videos is achieved.

Owner:何震宇

Online control method for tobacco processing process parameters by using computer programs

InactiveCN102141804ARealize dynamic controlReal-time automatic correction of control system setting parametersTotal factory controlProgramme total factory controlProcess equipmentProcedural approach

The invention discloses an online control method for tobacco processing process parameters by using computer programs, which comprises the following steps of: acquiring temperature and humidity parameter values of a processed material, namely tobacco leaves or tobacco shreds through a temperature sensor and a moisture meter, acquiring running parameters of the real-time online acquisition processing process and the temperature or the humidity of the tobacco leaves or the tobacco shreds, comparing the running parameters of the real-time online acquisition processing process equipment and the temperature and humidity parameter values of the tobacco leaves or the tobacco shreds with the acquired parameter values of the temperature or the humidity of the tobacco leaves or the tobacco shreds before processing, transmitting modification instructions of control parameter setting provided by a data monitoring system to a programmable logic controller (PLC), and timely adjusting online control parameters and output instruction signals of the equipment to realize online real-time adjustment of the tobacco processing process parameters. Therefore, dynamic control of raw material change in the tobacco online processing process is realized. The method is suitable for controlling tobacco shredding, threshing and re-drying, CO2 expanded tobacco shred lines, rolling and packing.

Owner:QINHUANGDAO TOBACCO MACHINERY

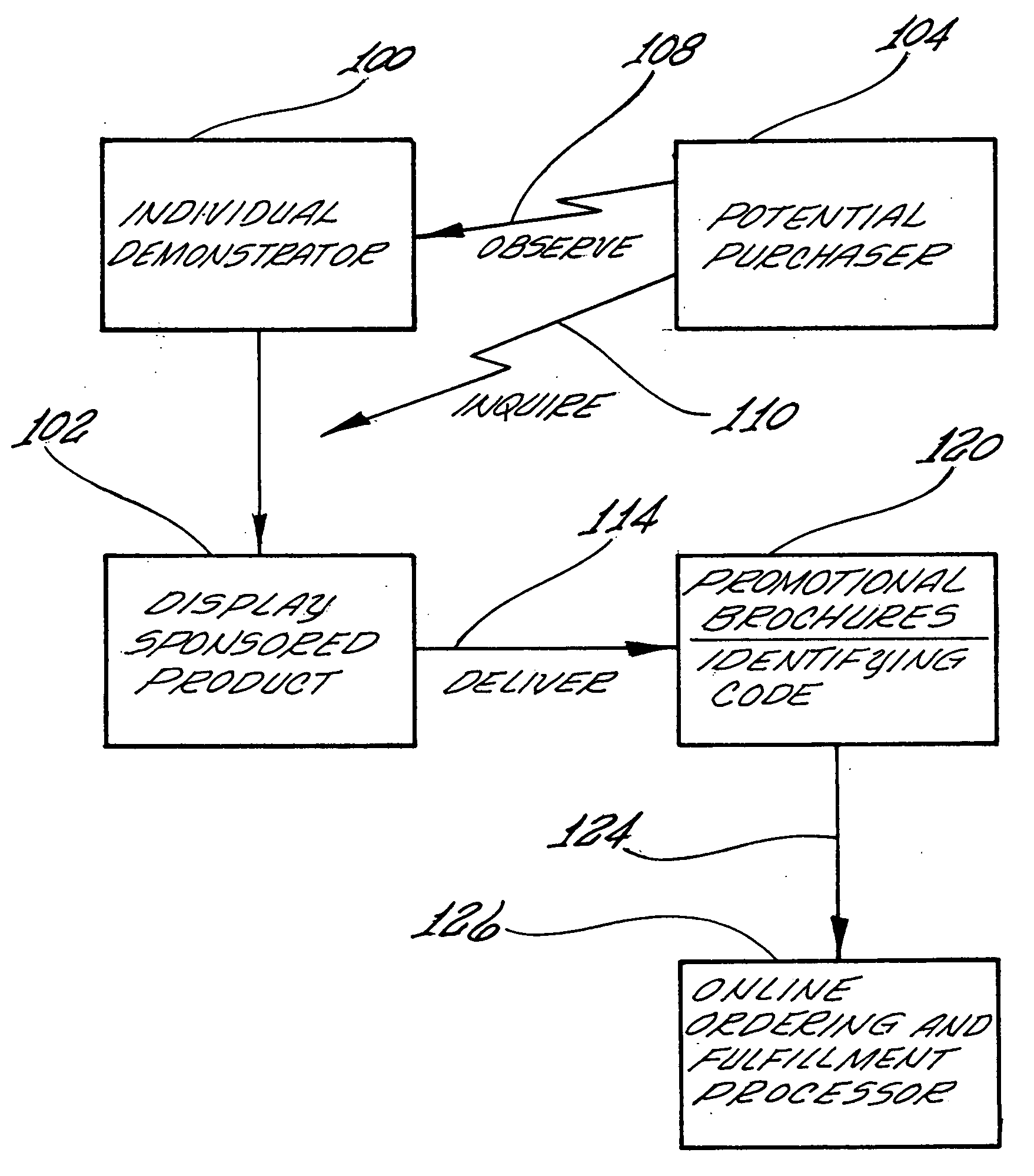

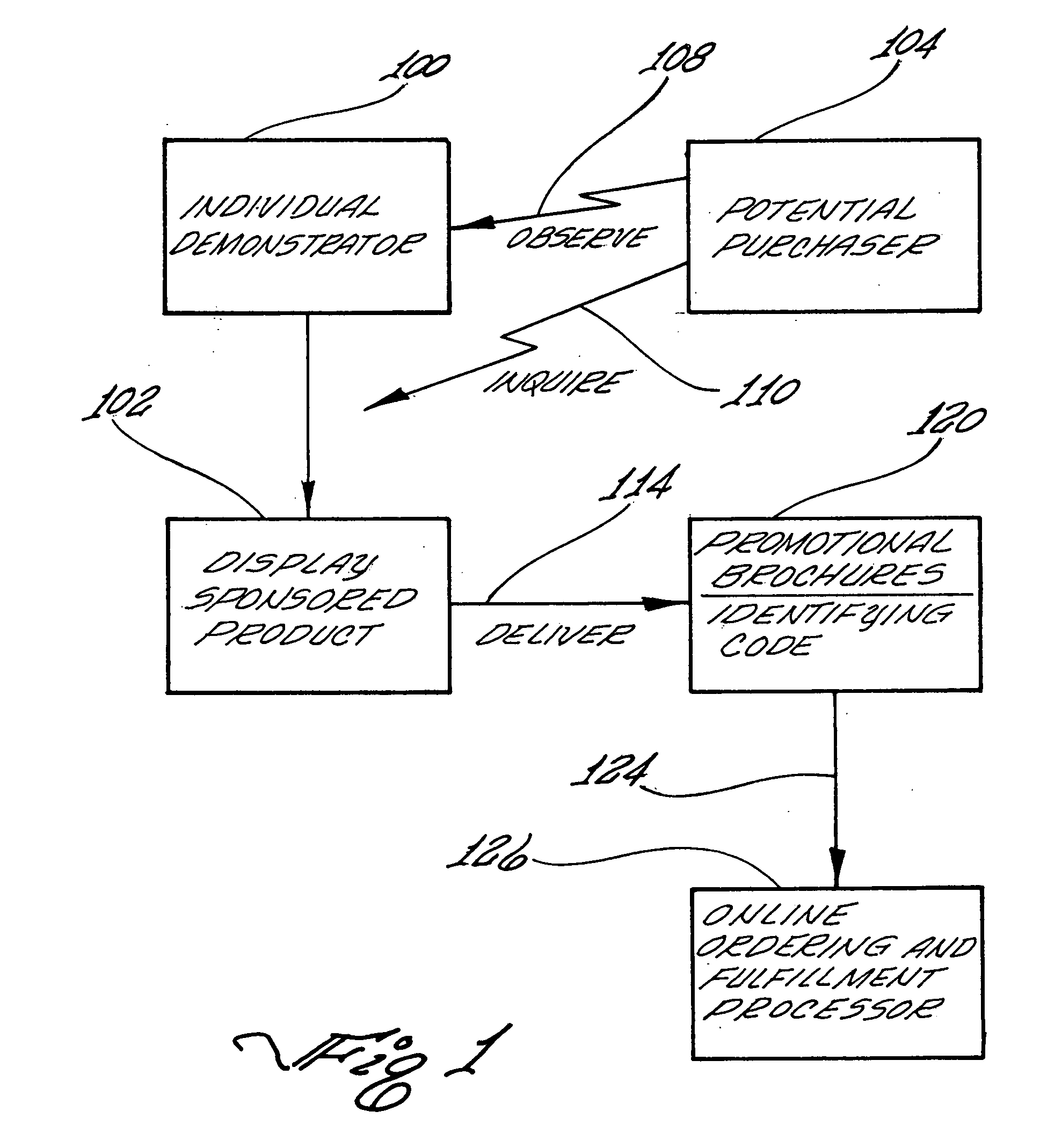

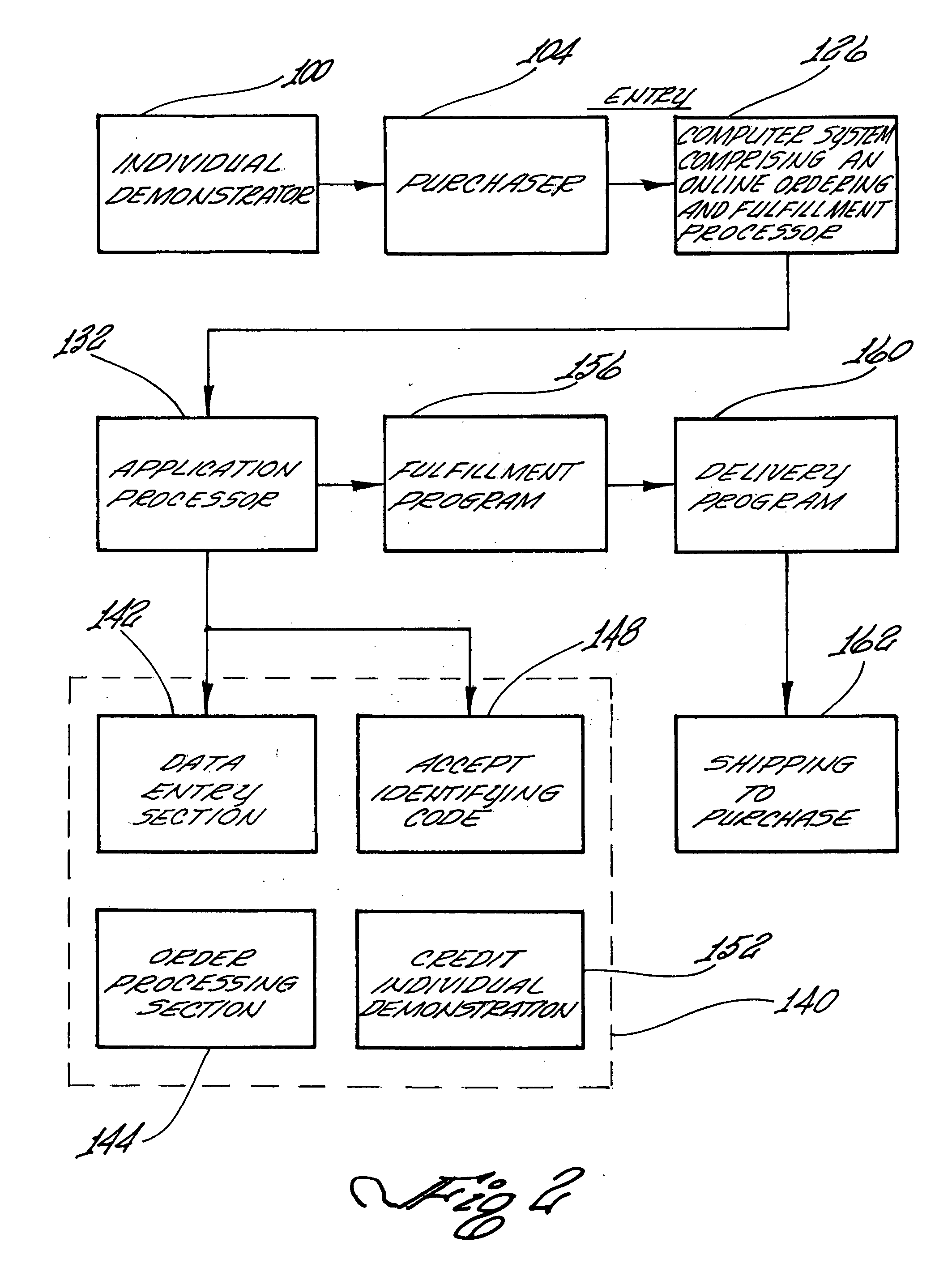

System for originating and consummating sales and method

A system for originating and consummating sales of products using an online processor or manual operation is shown. The system includes an individual demonstrator for displaying a sponsored product, as opposed to an overt demonstration thereof, which attracts interest of a potential purchaser. A promotional and informational document is delivered to a potential purchaser which includes pricing data, ordering information, a website address for a potential purchaser to place an order and to enter instructions together with an identifying code assigned to the individual demonstrator. An online ordering and fulfillment processor enables a purchaser to originate a purchase of the sponsored product, accepts the entry by the purchaser of the identifying code, accounts for the sale and disburses payments therefor.

Owner:AVNER CORREY B

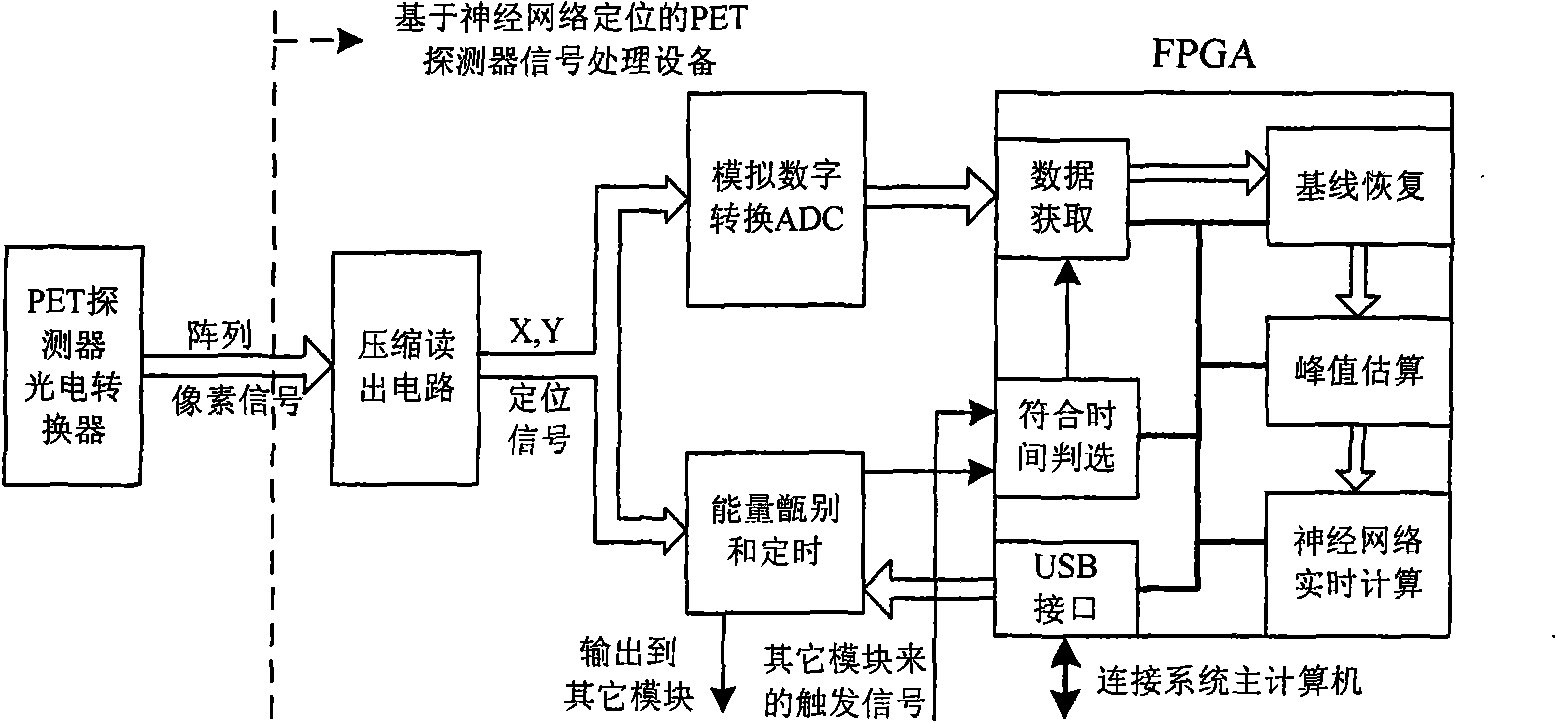

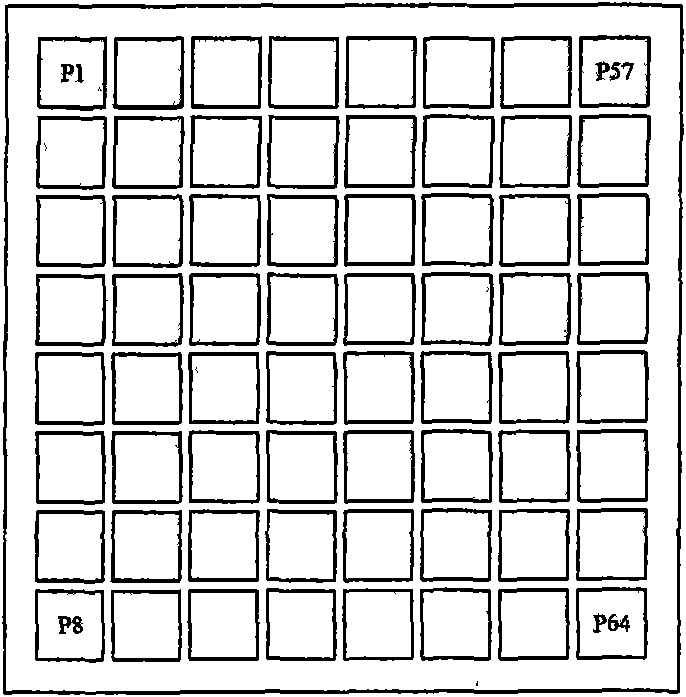

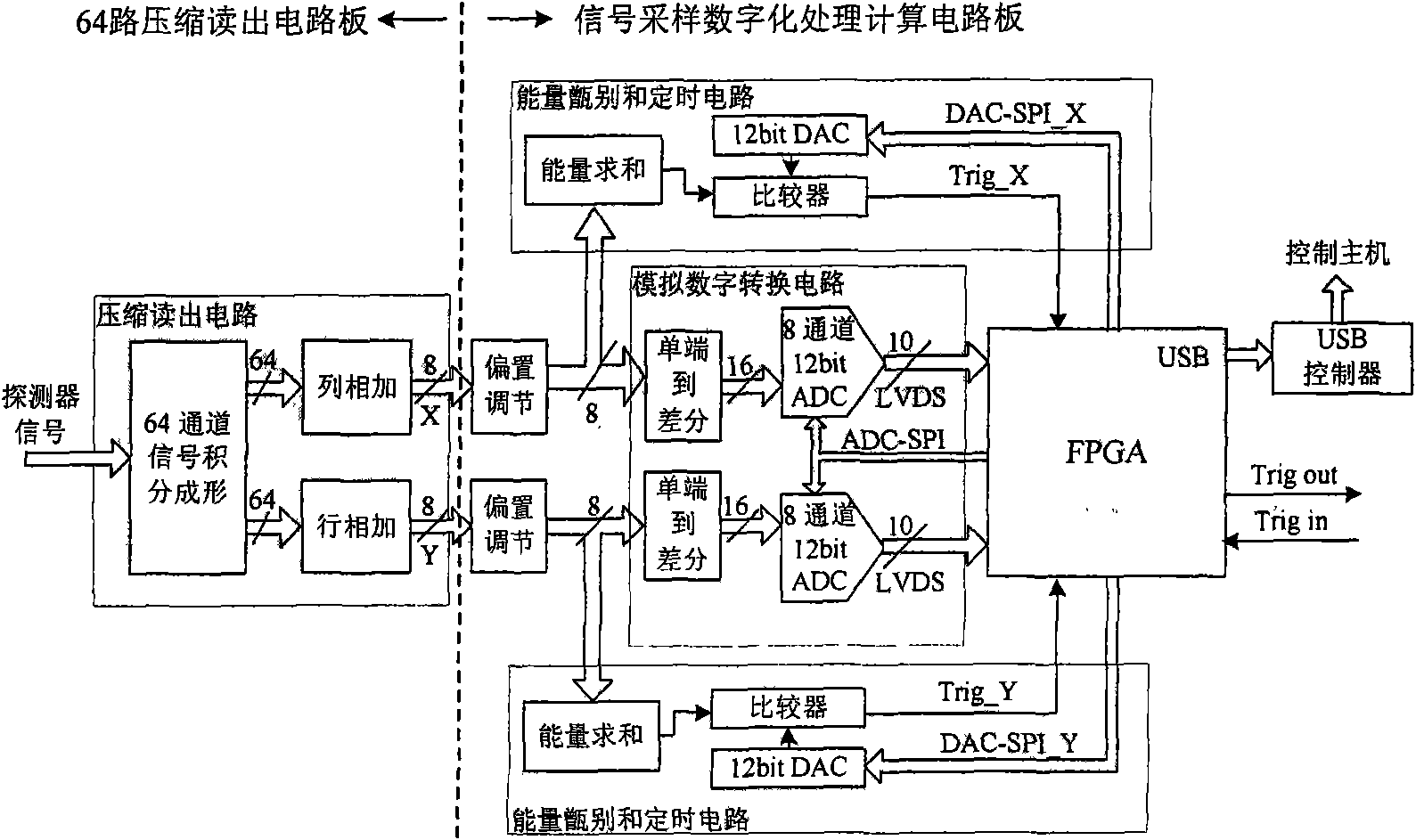

Signal processing equipment of PET detector based on neural network localizer

InactiveCN101606846AImproved real-time performance of signal processingHighly integratedComputerised tomographsTomographyPeak valueProper time

The invention provides signal processing equipment of a PET detector based on a neural network localizer. The equipment integrates and realizes procedures for processing a series of signals from a photoelectric switching signal outputted by a detector to the action position coordinate of the gamma ray counted by a neural network in real time. The equipment comprises a compression read processing circuit to an array pixel signal outputted by a photoelectric switching device, an analog-digital switching circuit, an energy identifying and timing circuit, a proper time judging circuit, a base line recovery circuit, a signal peak value estimating circuit, a neural network real-time computing circuit, a USB interface circuit, etc. Due to the realization of the technology for processing various digital nuclear signals based on FPCA and especially the real-time computing of the neural network, the instantaneity and the integration level of the system are greatly improved. The invention has compact structure, complete performance, strong on-line data processing performance, and can be conveniently assembled into an integral detector module with the PET detector, wherein the detector module is important intermediate equipment for researching and developing novel PET imaging equipment based on neural network positioning.

Owner:UNIV OF SCI & TECH OF CHINA

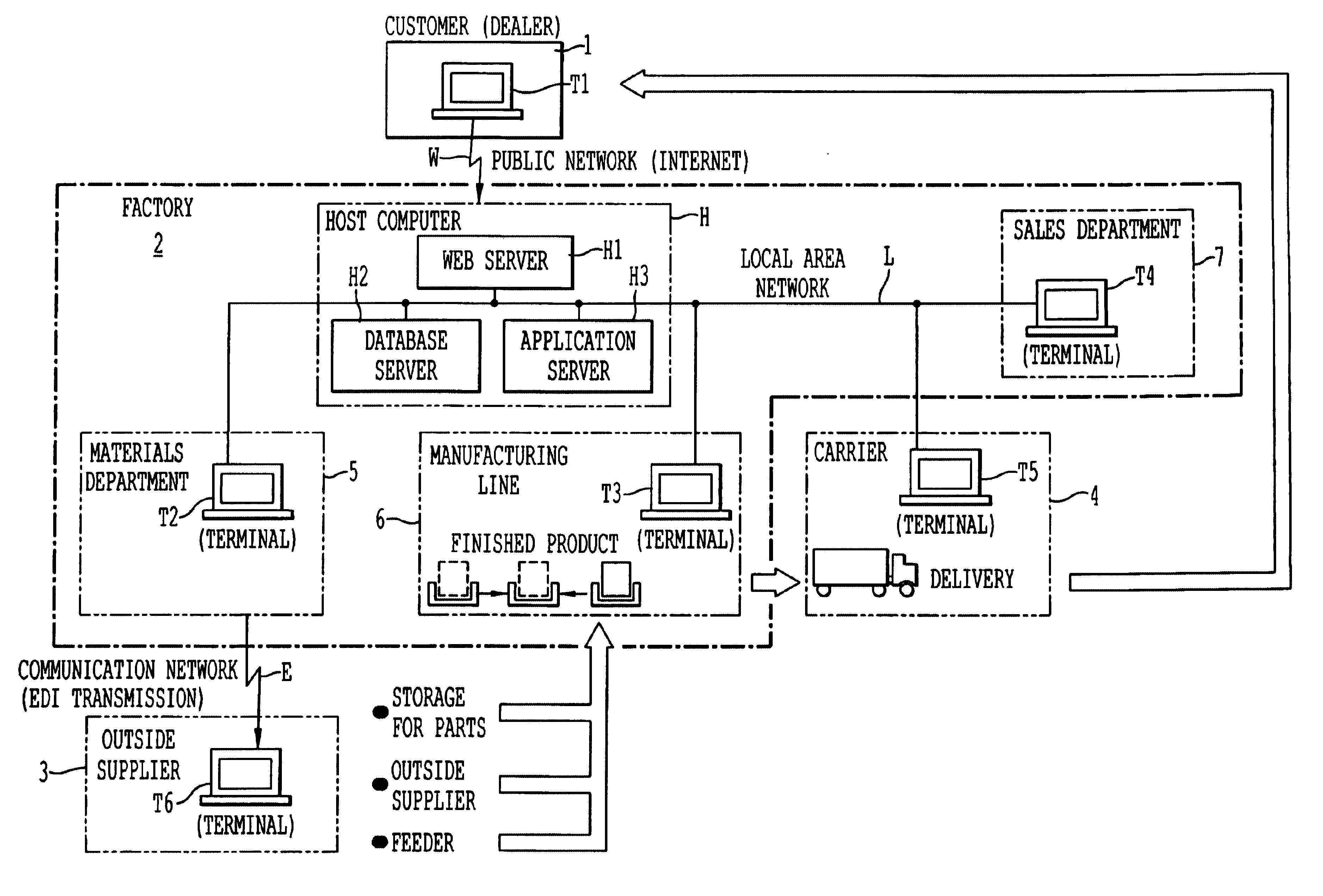

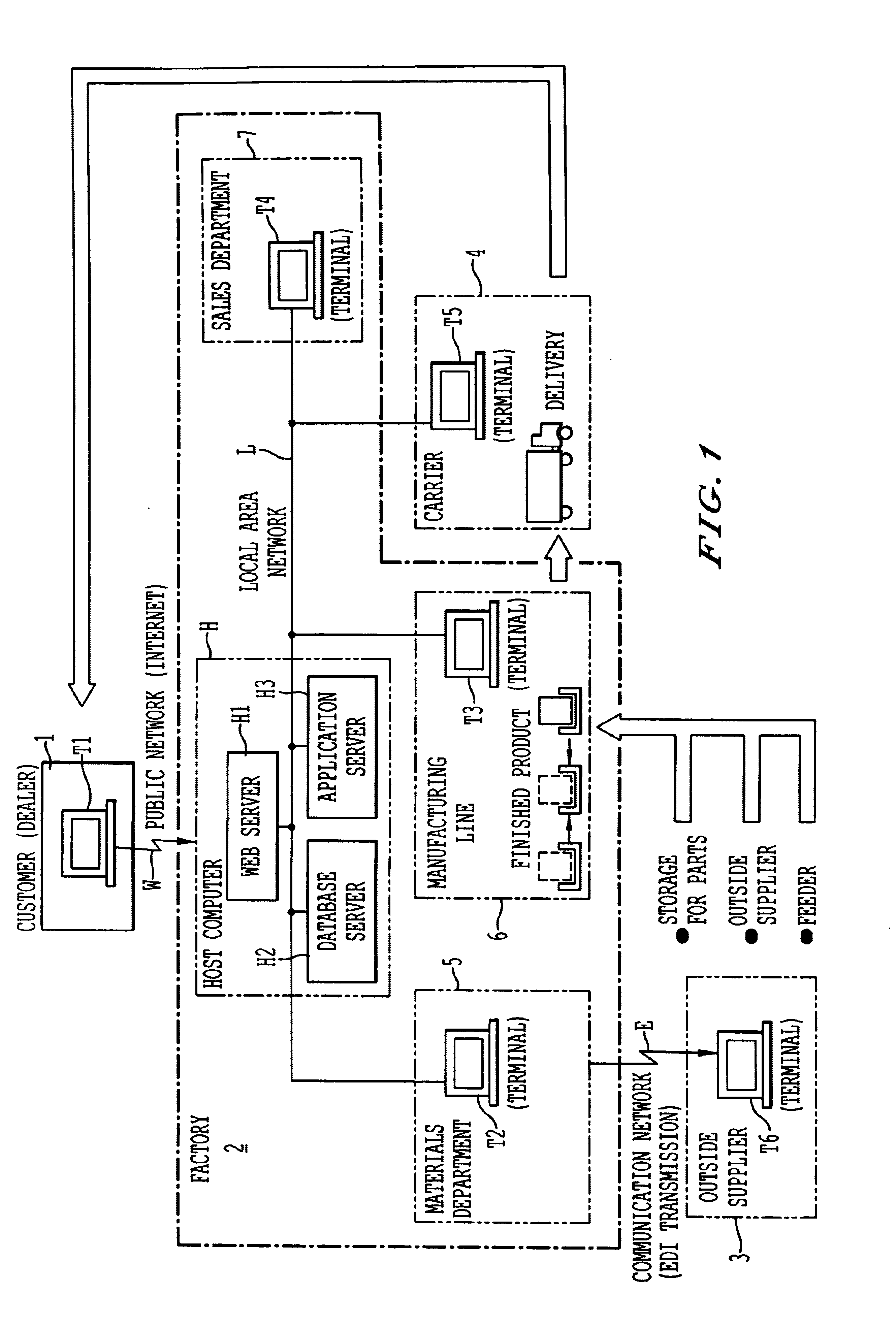

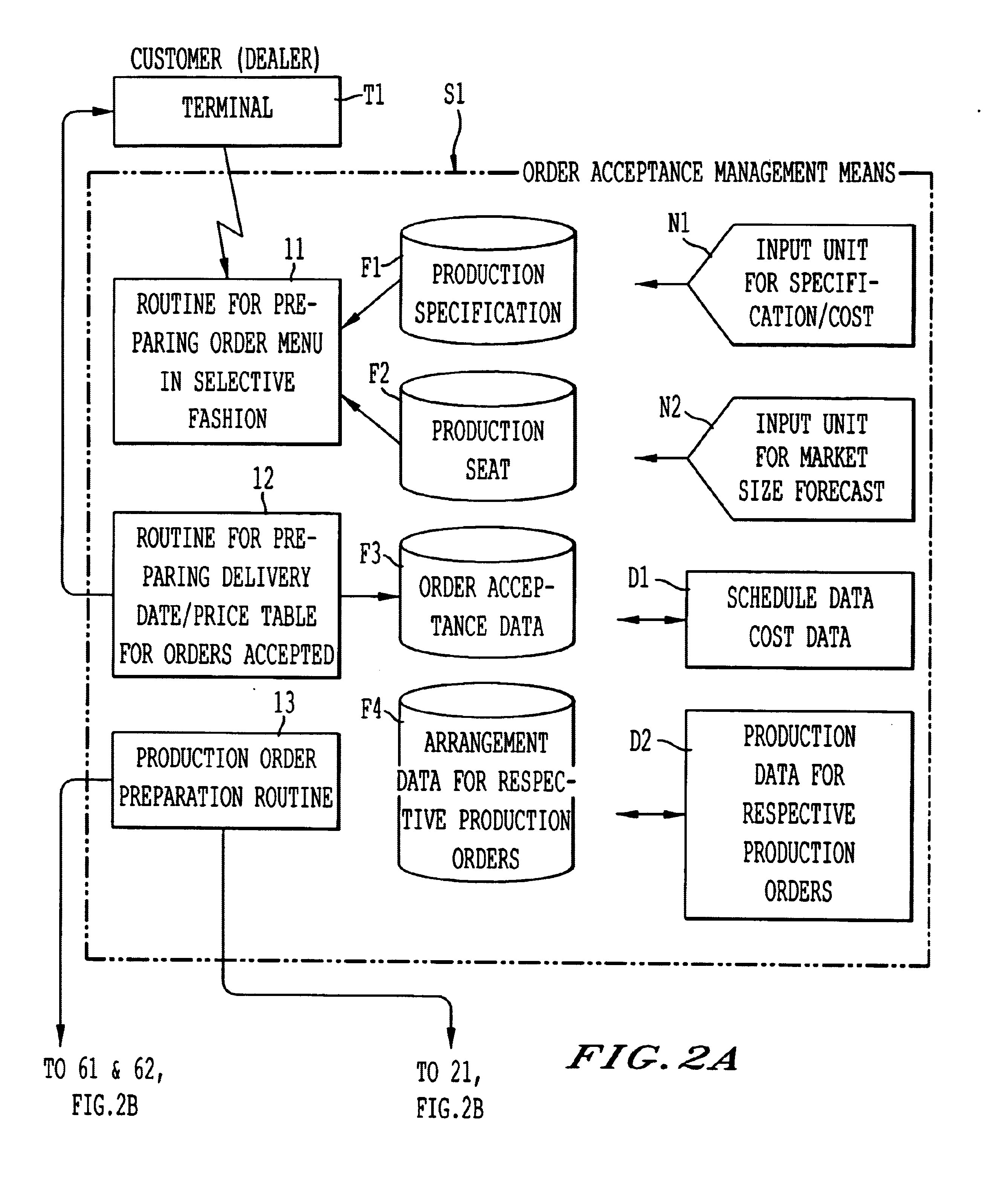

Production control system and method for producing air conditioners

InactiveUS6629008B2Preventing the stock of productsEfficiency acceptanceBuying/selling/leasing transactionsTransmissionControl systemThe Internet

An order menu that includes a plurality of specifications in respective functional blocks, into which a customized product is divided into, is provided from a factory through Internet. A customer selects a required specification from the order menu to determine the customized product. Based on data input through the order menu, material arrangement and directions for production can be dealt with on line, and data on the customized product are shared between the customer and a manufacturer.

Owner:MITSUBISHI ELECTRIC CORP

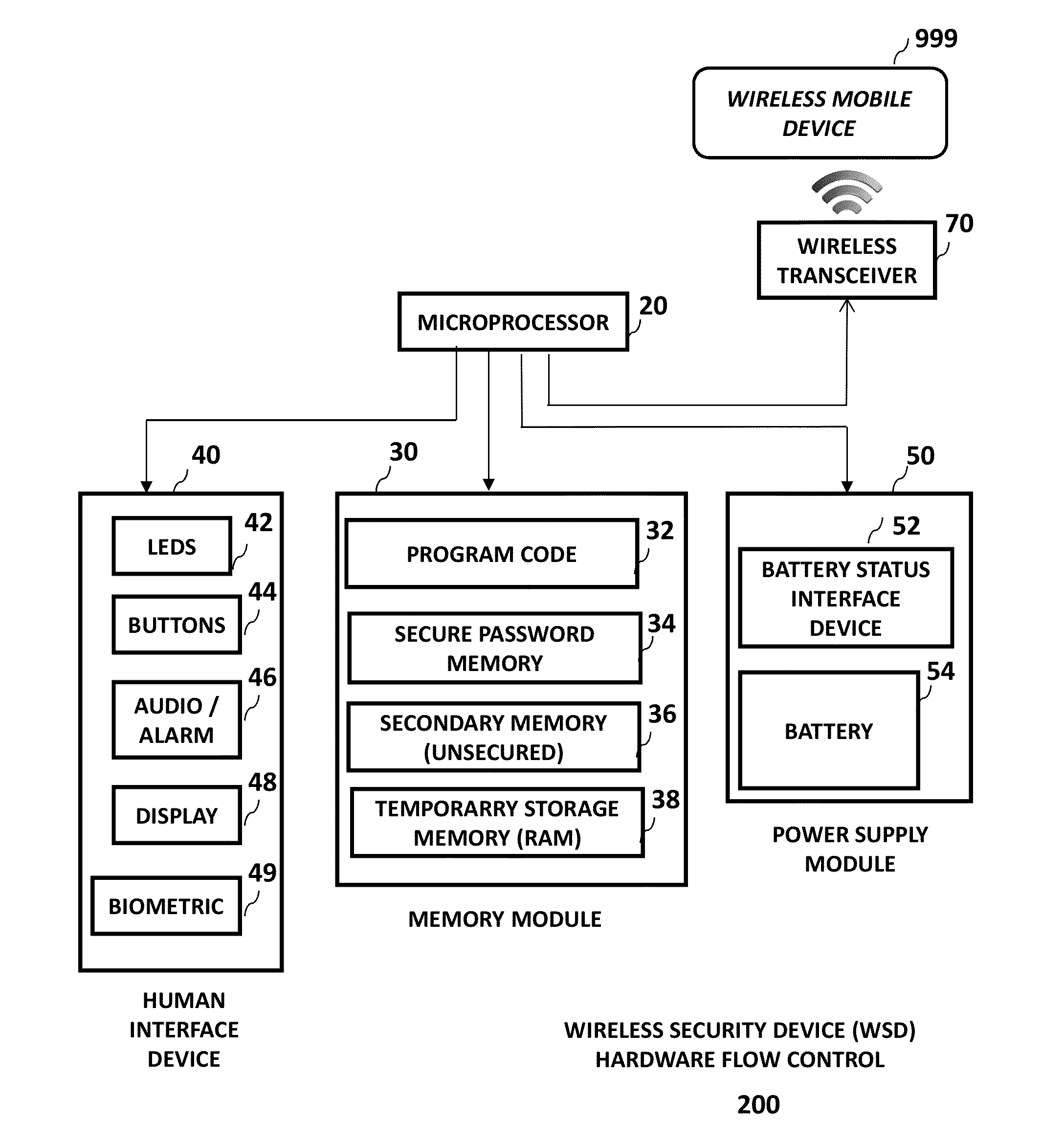

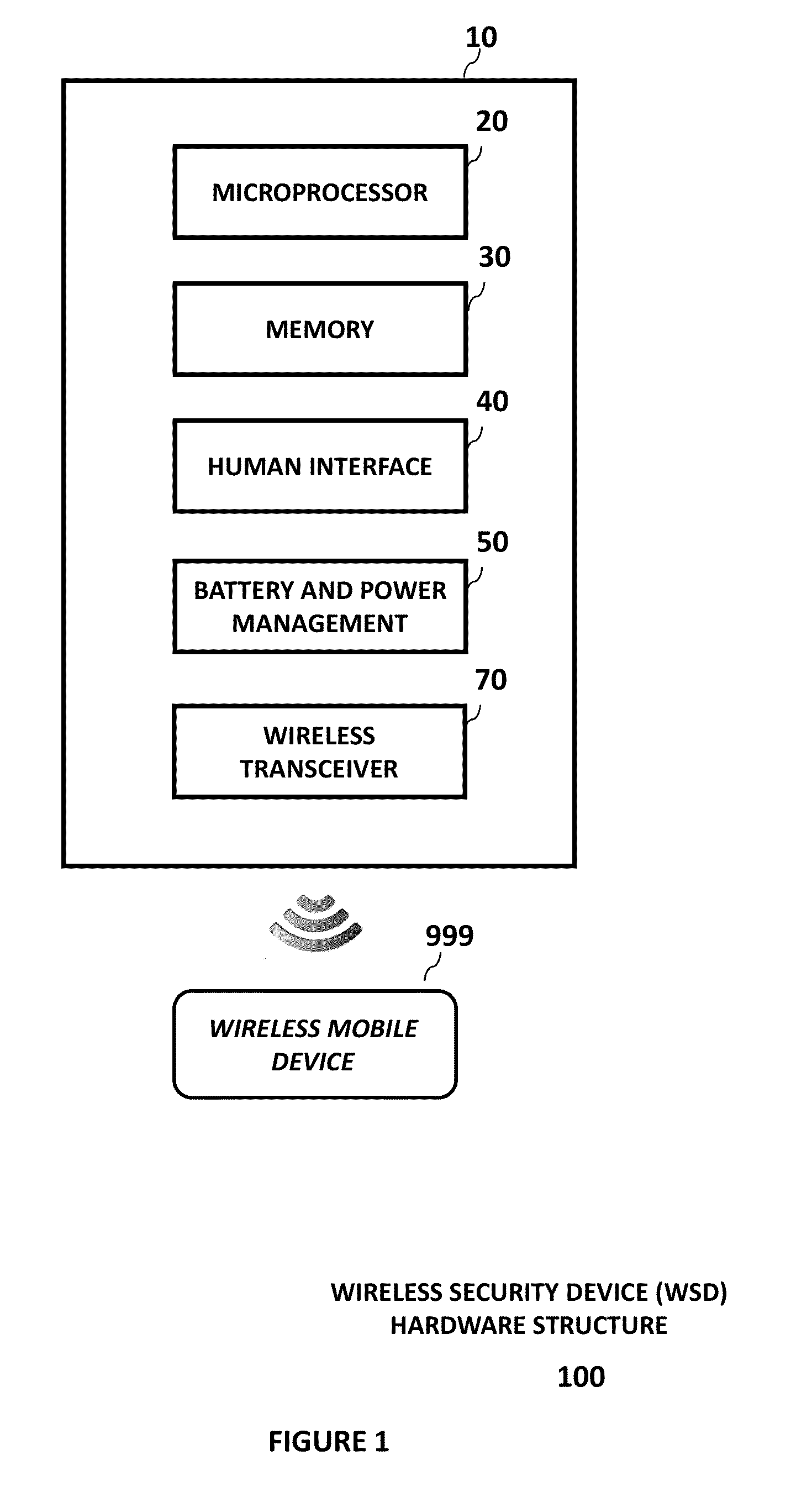

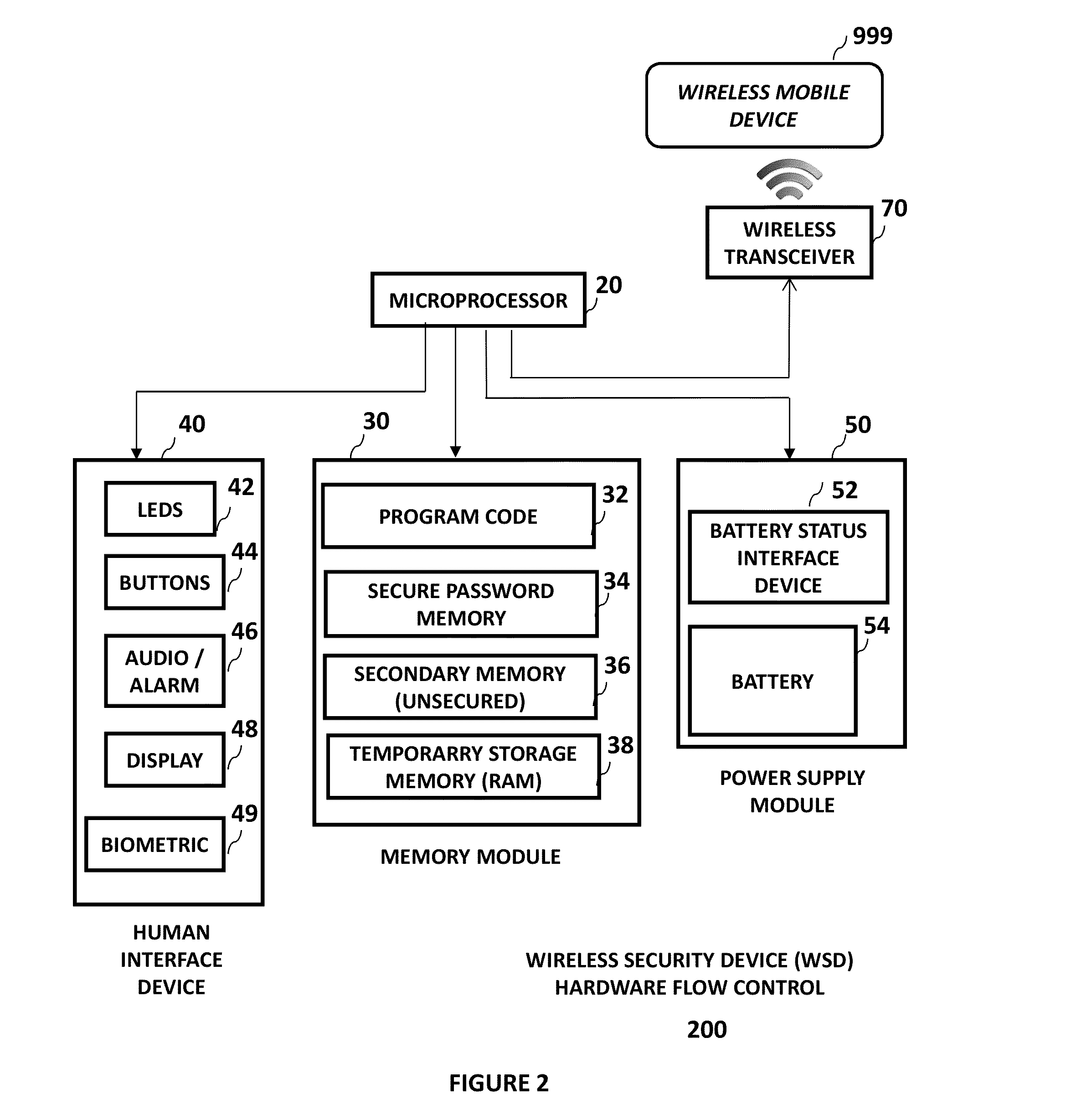

Method and apparatus for a portable wireless security device

ActiveUS20140123224A1Digital data processing detailsMultiple digital computer combinationsComputer networkPayment transaction

A portable wireless security device (WSD) along with methods of use for providing a multi-factor authentication process for authorizing RFID payment transactions, online processes and email correspondences made by a mobile device.

Owner:NOSRATI FARHAD DAVID

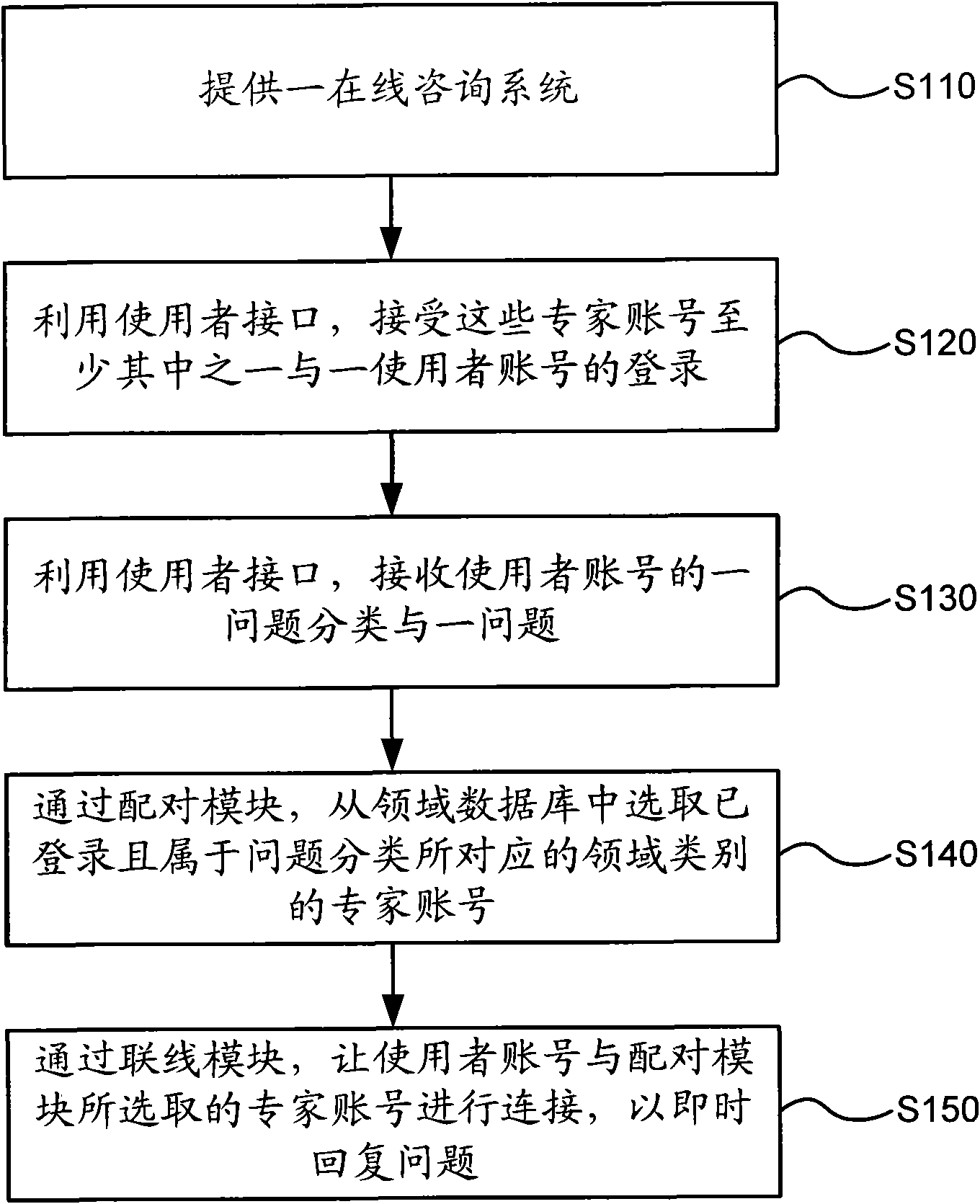

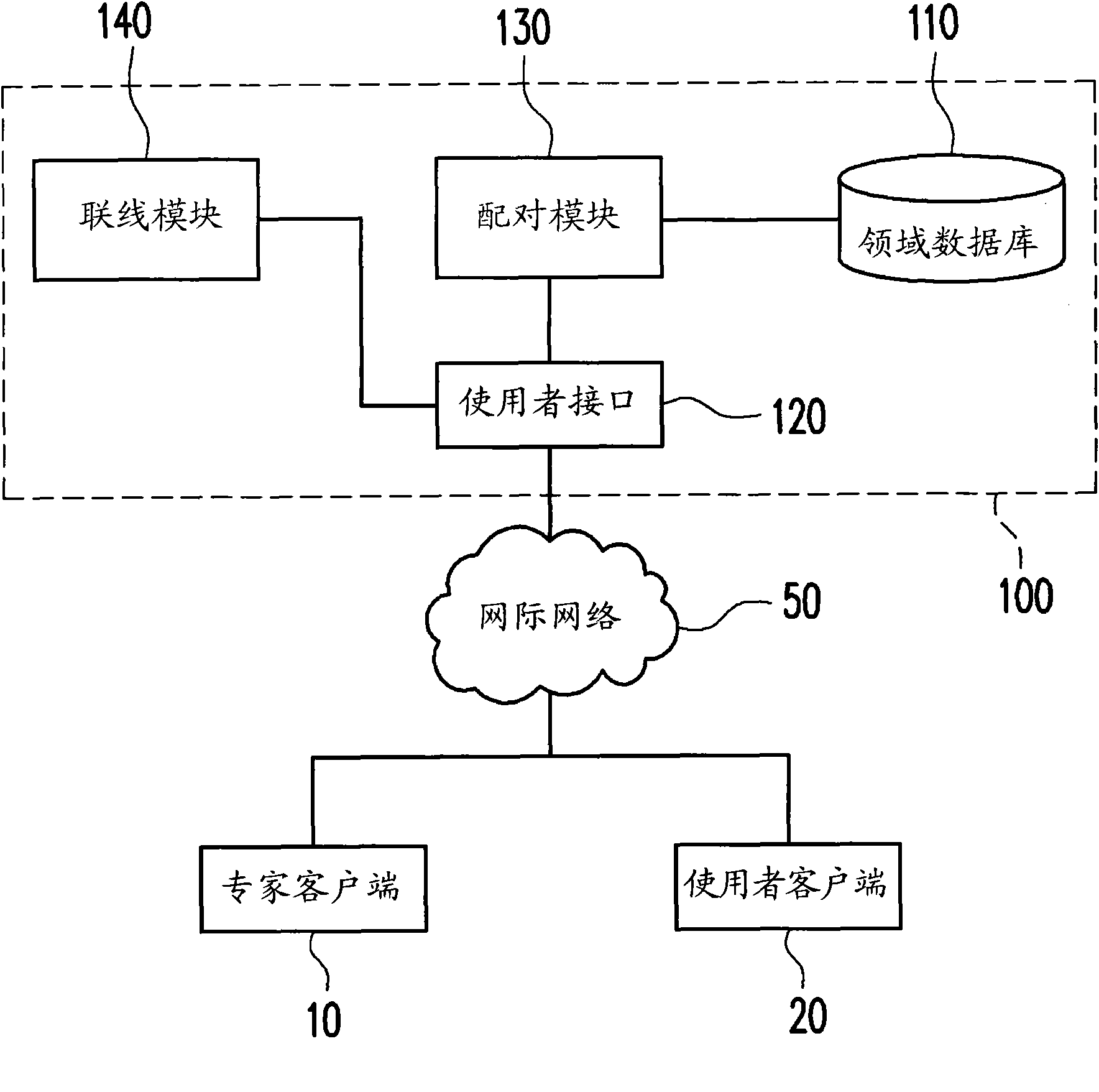

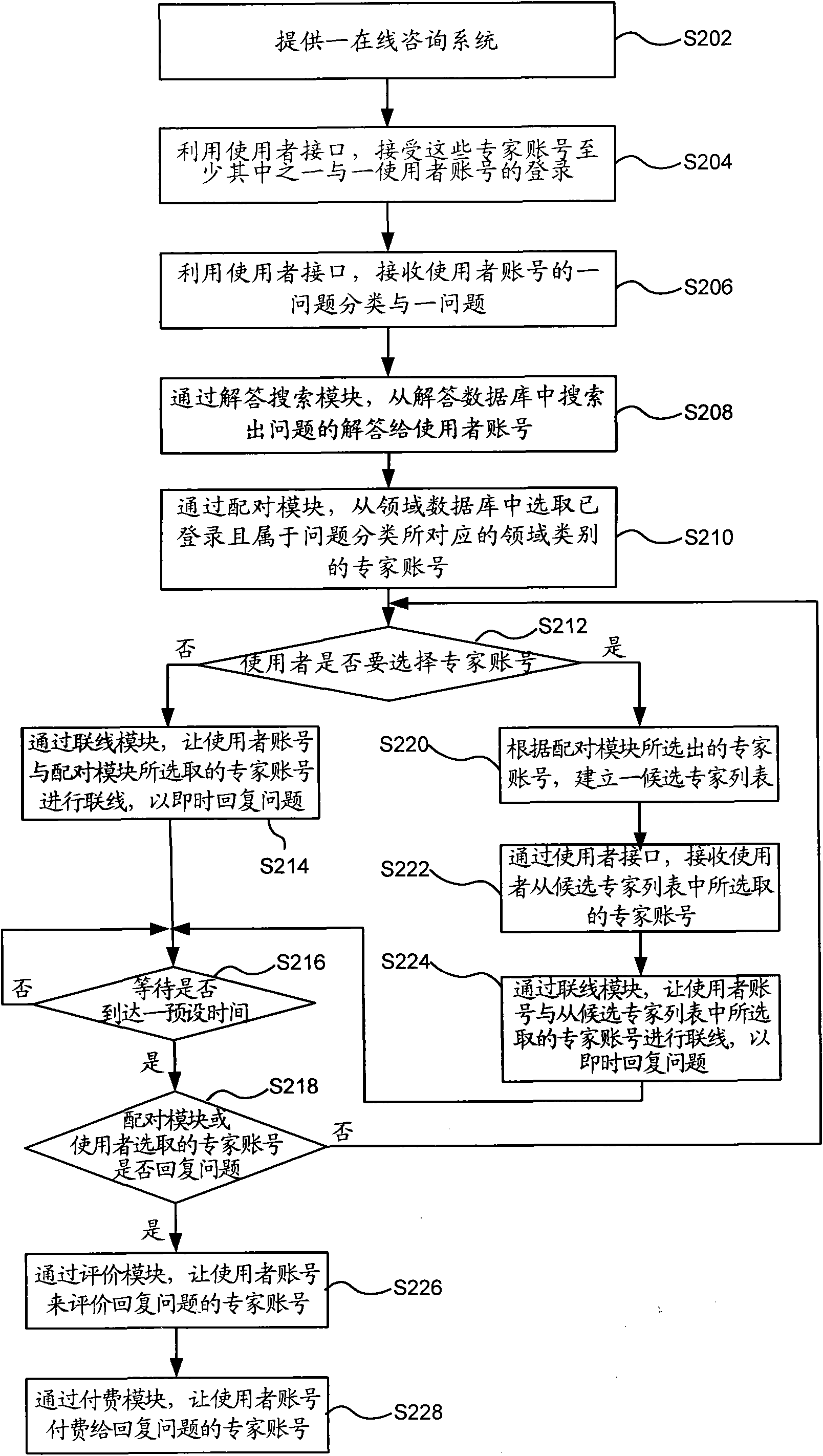

Online consultation method and system

The invention provides an online consultation method and system. The online consultation method comprises the following steps: firstly, providing an online consultation system, wherein the online consultation system comprises a user interface, a pairing module, a realm database and an online module, and a plurality of expert accounts and a plurality of realm classes are stored in the realm database; then, receiving the logining of at least one of the expert accounts and a user account by using the user interface; receiving a question classification and a question of the user account by using the user interface; selecting the expert account which is logged in and belongs to the realm class corresponding to the problem classification from the realm database through the pairing module; and finally, carrying out online processing on the user account with the expert account selected by the pairing module so as to immediately reply questions.

Owner:INVENTEC CORP

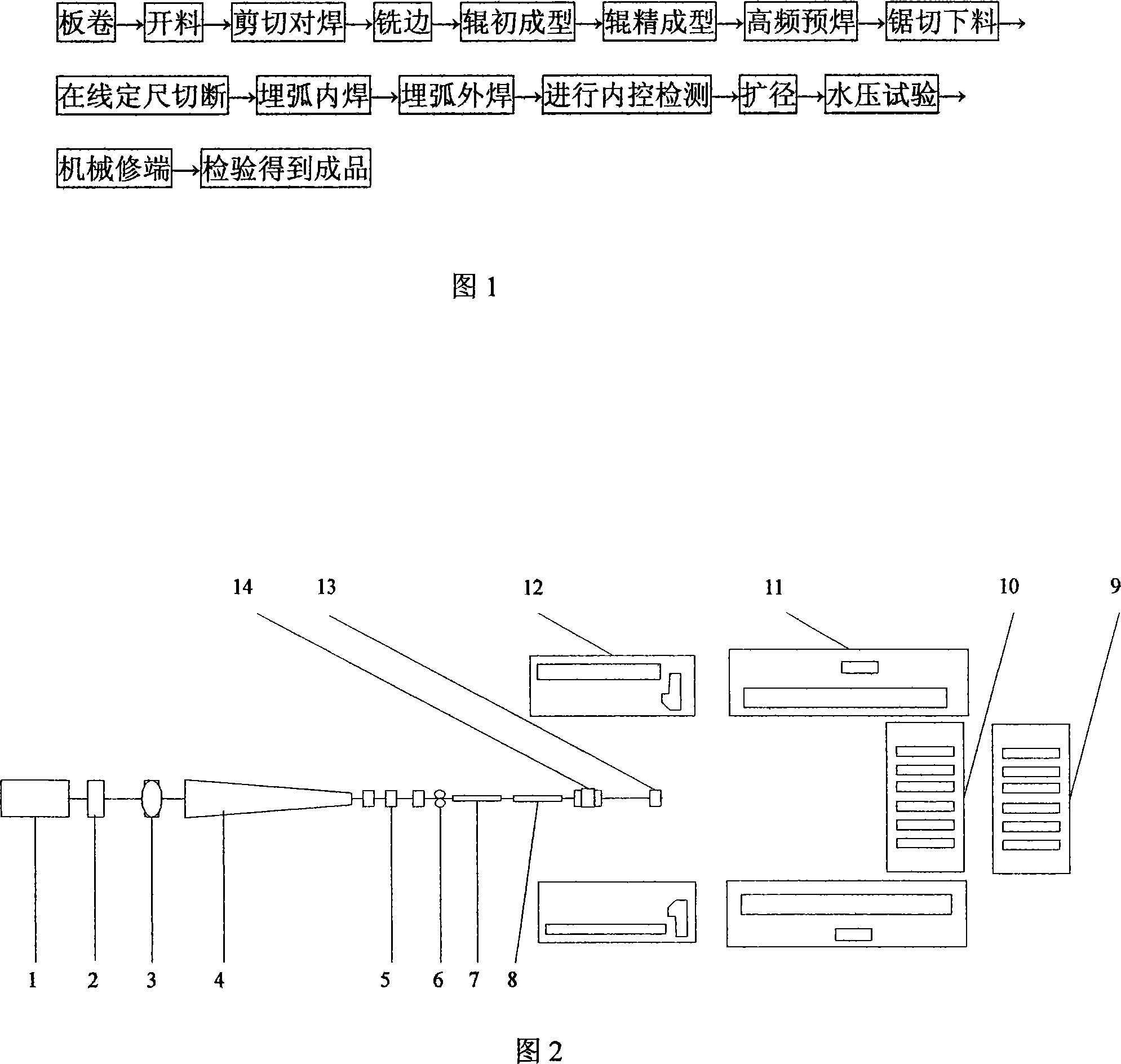

Large straight-line joint submerged arc welding tube fast production process

ActiveCN101214511ARapid productionIncrease productivityArc welding apparatusWorkpiece edge portionsButt weldingEngineering

The invention provides a big vertical masonry joint hidden arc welding tube fast production method belonging to the processing and forming fields of metal plate and relating to the bending processing and forming technology of metal plate which is mainly used for the fast production of the big vertical masonry joint hidden arc welding tube. The invention adopts continuous array rollers of a coil stock to form, high frequency prewelding on line, then utilizing a off-line automatic submerged arc welding to carry out the inner welding and outer welding of the welded pipe as well as expanding, water pressure and nondestructive examinations; thereby realizing the high efficiency production of the big vertical masonry joint hidden arc welding tube products. The invention adopts a plate-coiling mode to supply materials, cutting materials, shearing and butt welding, utilizes milling edge to finish the online-processing of a divided edge beside the plate, primary roller forming, fine roller forming, high frequency prewelding after a rough material is continuously formed by the array rollers and sawing as well as baiting and the steel tube rough material needed by a hidden arc welding working procedure can be acquired through online dimension fixing and cutting off; hidden arc inner welding and hidden arc outer welding, inner control examination, expending, water pressure test, repairing ends by machinery are carried out on the steel rough material to exam to acquire a finished product. The technique has a reasonable design and has the advantages of good steel tube forming quality and high production efficiency as adopting the array rollers to form and high frequency prewelding; thereby ensuring the overall production efficiency of the technique and the welding line quality can also be ensured reliably.

Owner:PANYU ZHUJIANG STEEL PIPE LIANYUNGANG

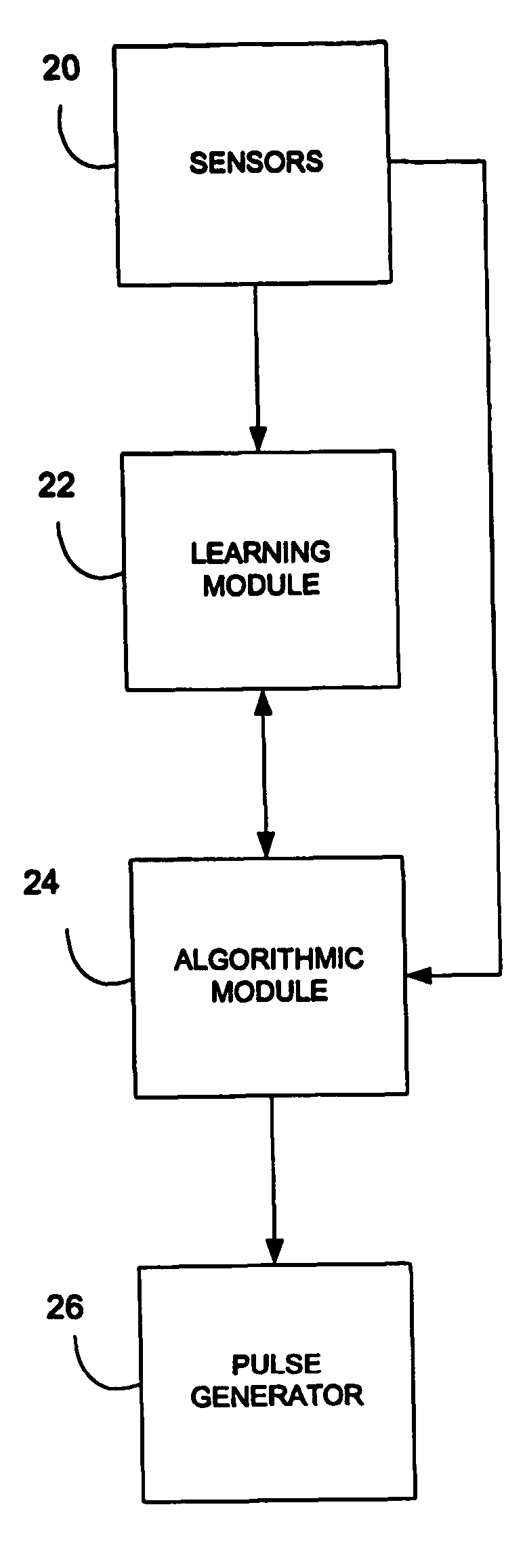

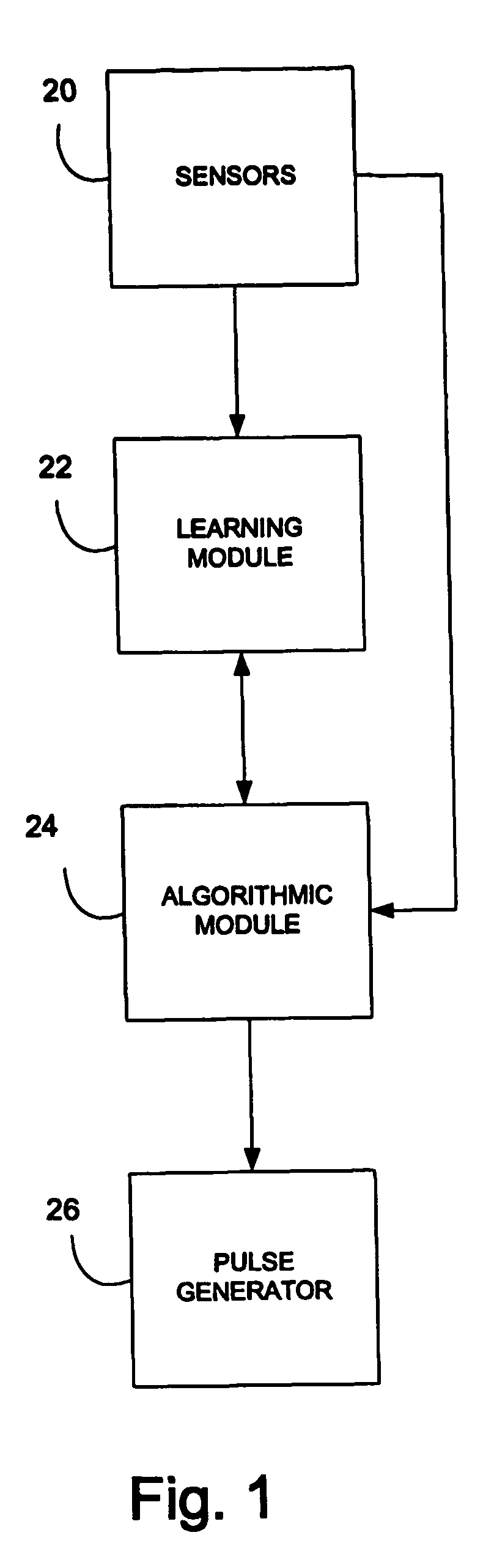

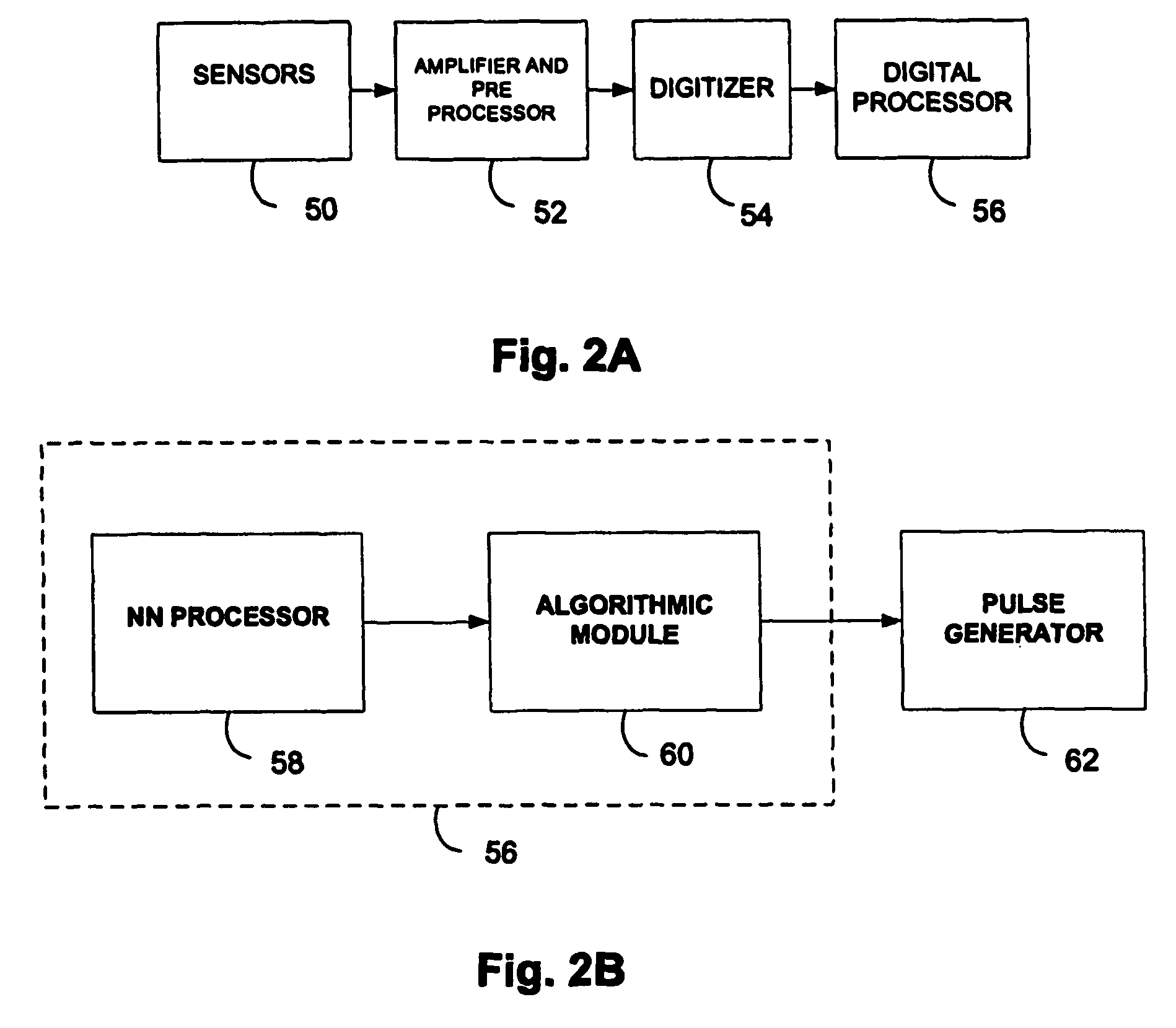

Adaptive resynchronization therapy system

A system including a learning module and an algorithmic module for learning a physiological aspect of a patient body and regulating the delivery of a physiological agent to the body. An embodiment of the invention is an adaptive CRT device performing biventricular pacing in which the AV delay and VV interval parameters are changed dynamically according to the information supplied by the IEGM, hemodynamic sensor and online processed data, in order to achieve optimal hemodynamic performance. A learning module, preferably using artificial neural network, performs the adaptive part of the algorithm supervised by an algorithmic deterministic module, internally or externally from the implanted pacemaker or defibrillator.

Owner:AI SEMI

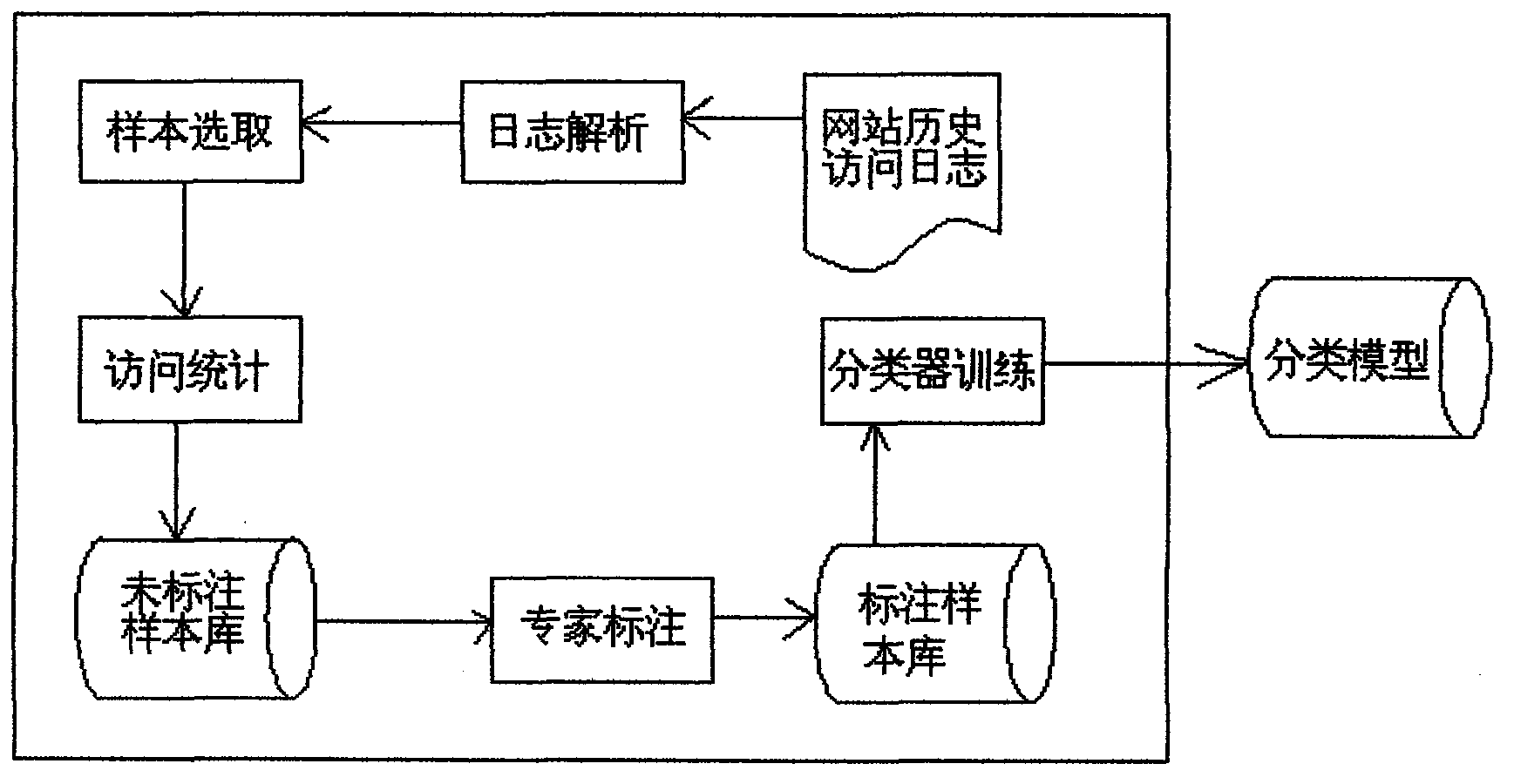

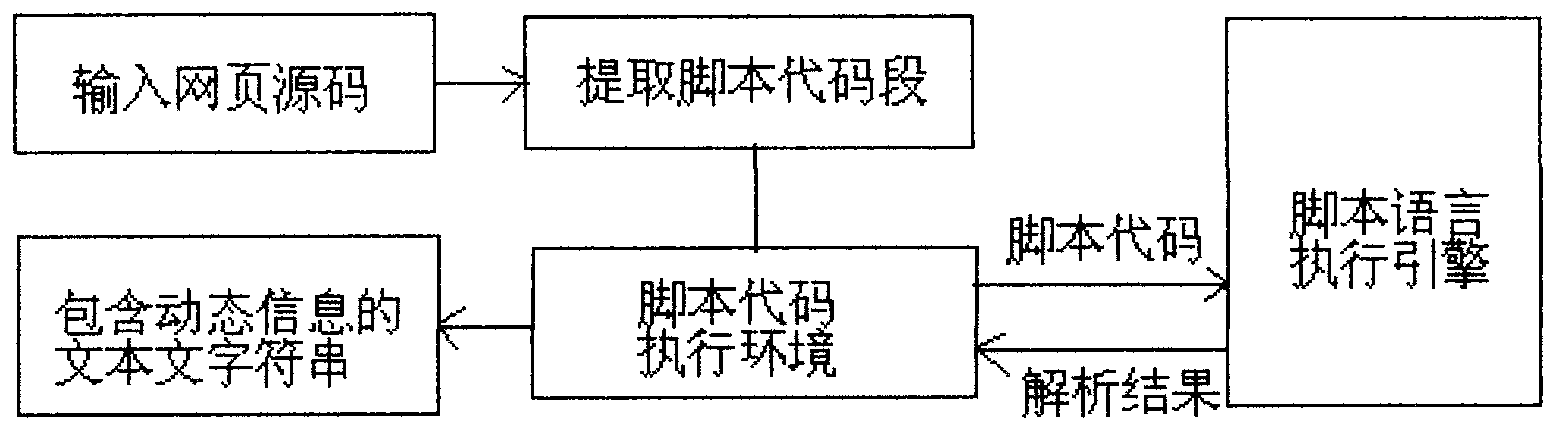

System and method for identifying and automatically acquiring webpage information

ActiveCN103218431AImplement anti-crawlingAvoid collectingSpecial data processing applicationsWeb pageOnline processing

The invention discloses a system and a method for identifying and automatically acquiring webpage information. The system comprises an anti-acquisition classifier constructing module, an automatic acquisition identifying module and an anti-acquisition online processing module, wherein the anti-acquisition classifier constructing module is mainly used for automatically acquiring history web information by using a computer program and learning and distinguishing normal webpage access behaviors; the automatic acquisition identifying module is used for automatically identifying the automatic acquisition behavior of a search engine program by using an anti-acquisition classifier in the previous step, and adding an IP (Internet Protocol) segment where the identified acquisition program is positioned into a blacklist; and the anti-acquisition online processing module is mainly used for automatically judging and processing accessing users on line. Due to the adoption of the system and the method, the deficiencies in the prior art are overcome; and in the system, the history webpage access behaviors of a website are analyzed, the automatic acquisition classifier is established, automatic acquisition of a robot is identified, and webpage anti-grabbing is realized through automatic robot acquisition and identification.

Owner:国科(上海)企业发展有限公司

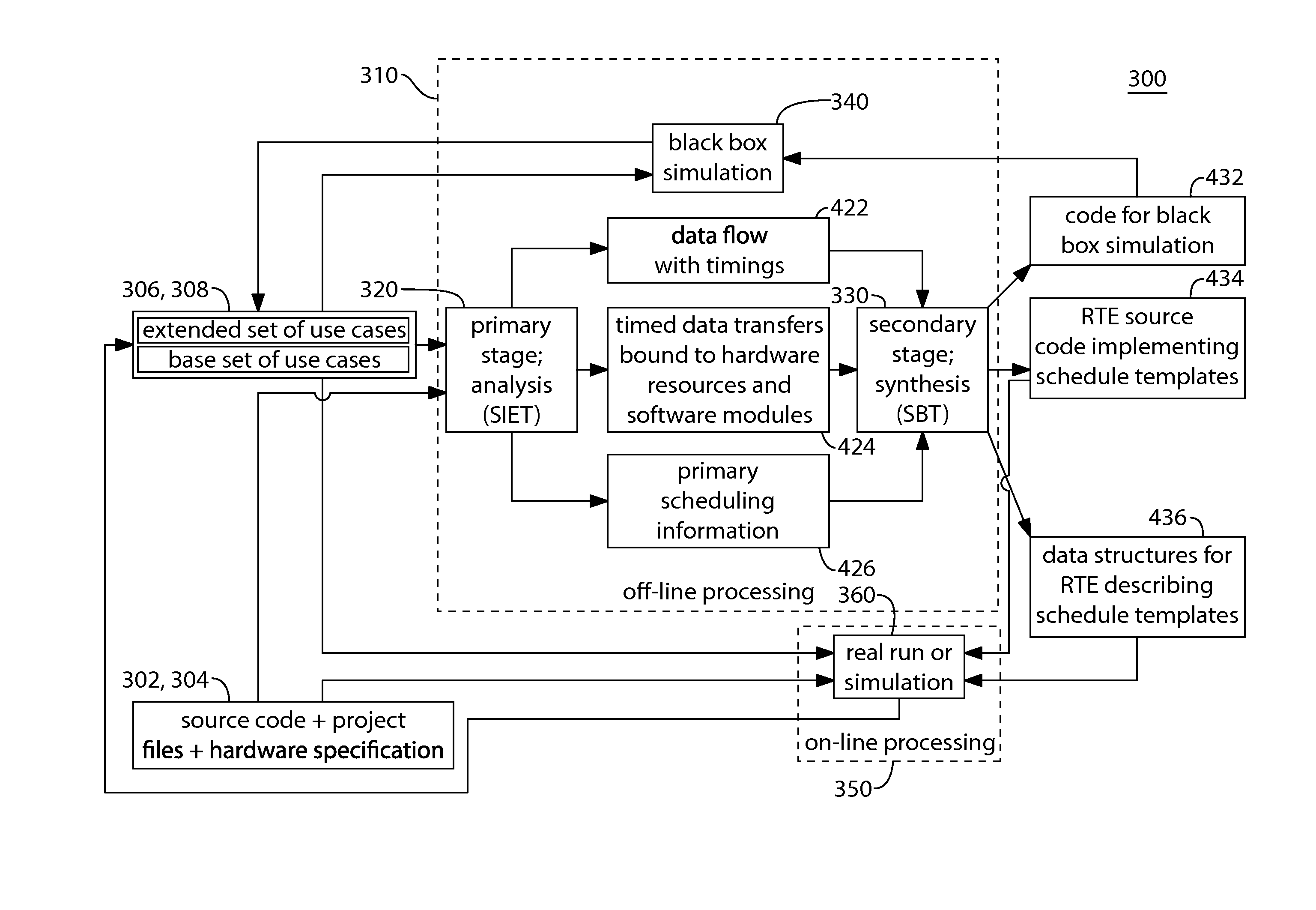

Program Module Applicability Analyzer for Software Development and Testing for Multi-Processor Environments

InactiveUS20140007043A1Error detection/correctionSoftware maintainance/managementReal-time dataMulti processor

In one embodiment, a machine-implemented method programs a heterogeneous multi-processor computer system to run a plurality of program modules, wherein each program module is to be run on one of the processors The system includes a plurality of processors of two or more different processor types. According to the recited method, machine-implemented offline processing is performed using a plurality of SIET tools of a scheduling information extracting toolkit (SIET) and a plurality of SBT tools of a schedule building toolkit (SBT). A program module applicability analyzer (PMAA) determines whether a first processor of a first processor type is capable of running a first program module without compiling the first program module. Machine-implemented online processing is performed using realtime data to test the scheduling software and the selected schedule solution.

Owner:AVAGO TECH INT SALES PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com