Large straight-line joint submerged arc welding tube fast production process

A technology of straight seam submerged arc welding and production method, which is applied to arc welding equipment, welding equipment, workpiece edge parts, etc. Good effect and good molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

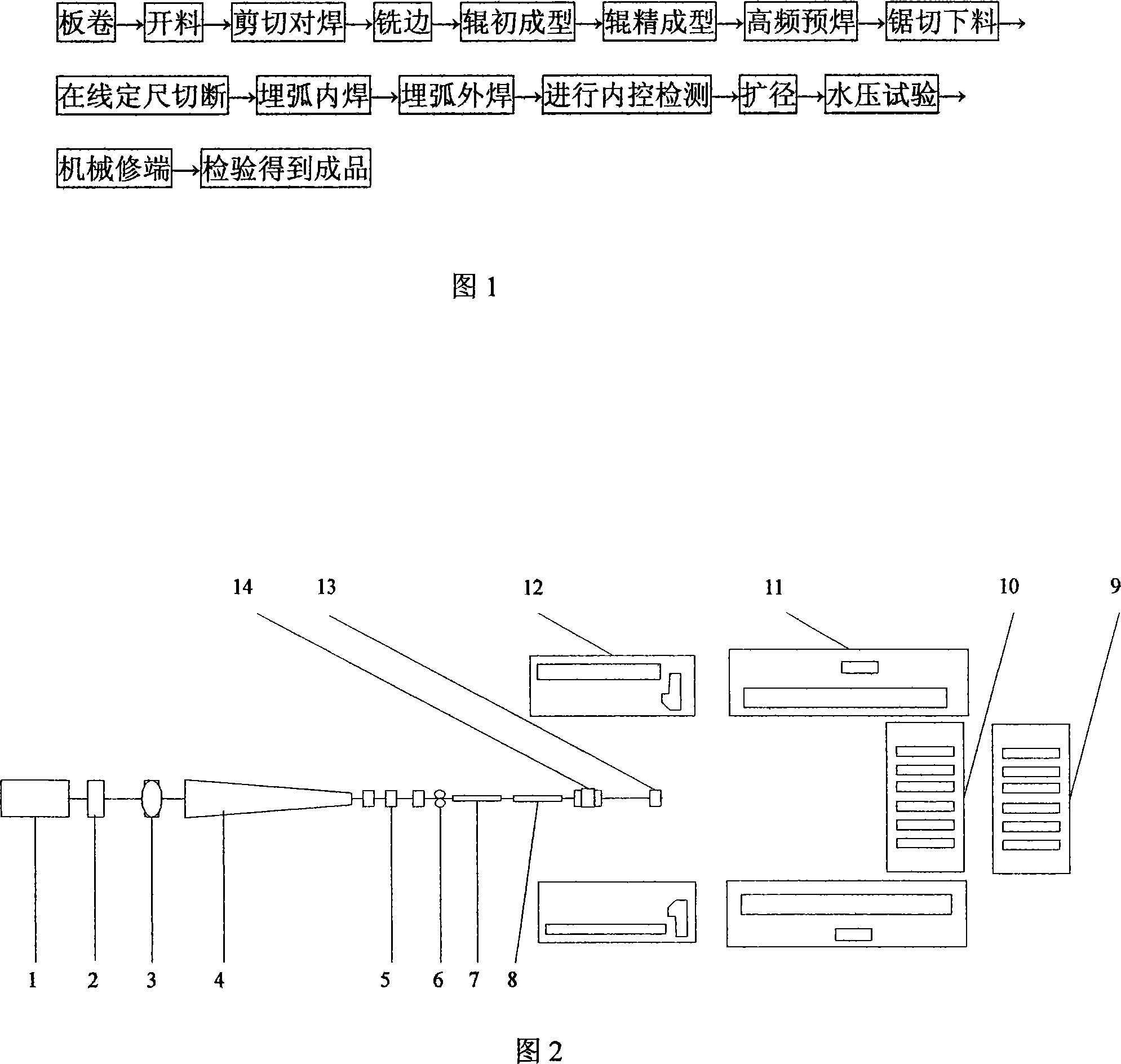

[0011] The present invention will be further described below in conjunction with accompanying drawing.

[0012] As shown in Figure 1, the coil feeding method of the present invention is cutting, shearing butt welding, using edge milling to complete the on-line processing of the plate edge bevel, initial forming of the rolls, fine forming of the rolls, and the high Frequency pre-welding, sawing and blanking, through online cut-to-length cutting, the steel pipe blank required for the submerged arc welding process can be obtained, the steel pipe blank is submerged arc internal welding, submerged arc external welding, internal control inspection, diameter expansion, water pressure Test, mechanical repair, inspection to get the finished product.

[0013] As shown in Figure 2, the process configuration of the present invention includes coil feeding 1, groove edge milling 2, rough rolling stand 3, roll forming stand 4, finishing rolling stand 5, high-frequency pre-welding 6, heat tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com