Lamellar carbon nanofibre and preparation method thereof

A layered carbon and fiber technology, applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve problems that have not mentioned the preparation of layered carbon nanofiber materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

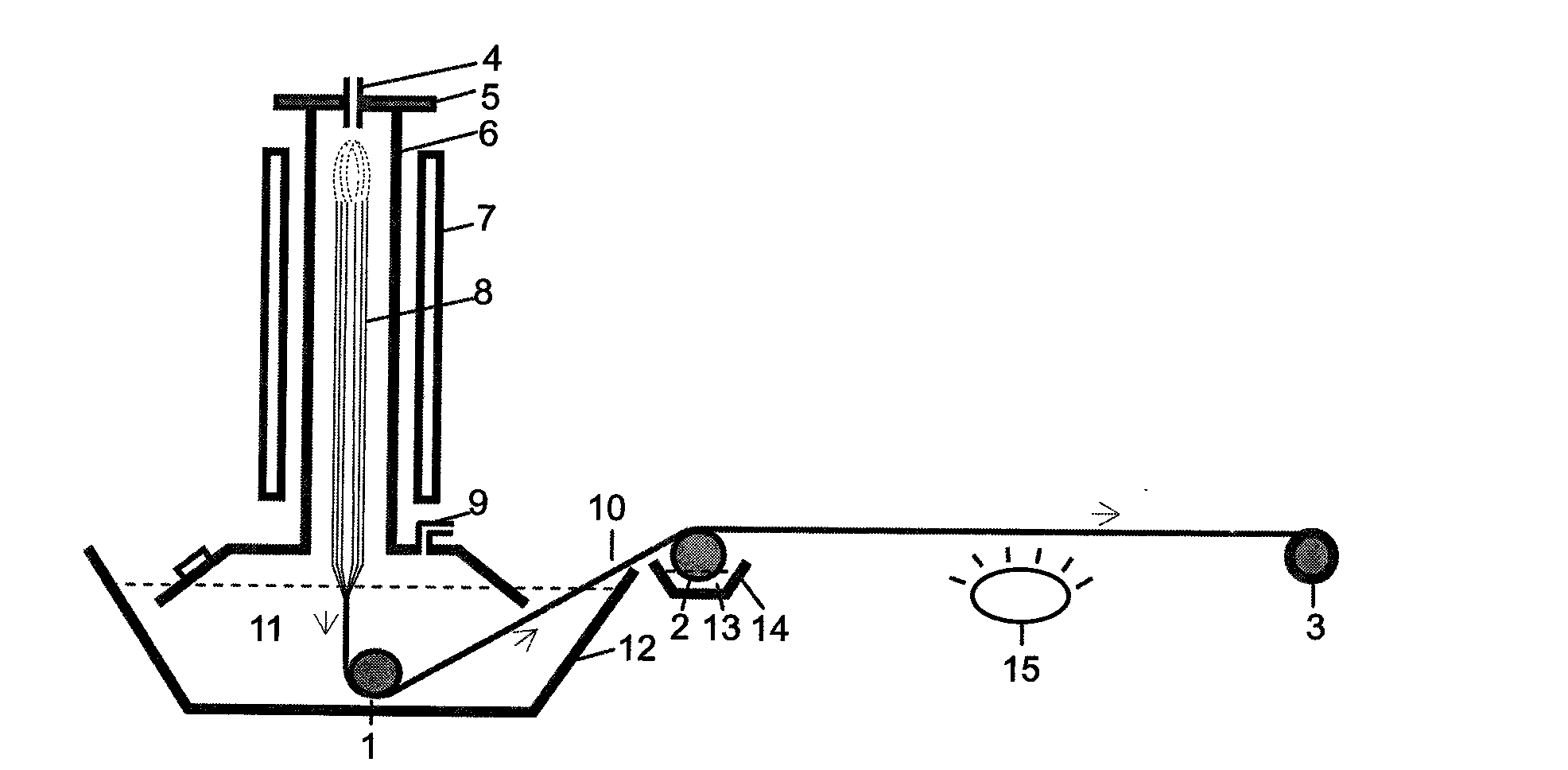

[0039] Based on the experimental equipment of the Chinese invention patent (CN101153413), plus a spinning device and an online processing device, layered carbon nanofibers were prepared as an example. The equipment includes tubular reactor, liquid sealing device, spinning device and on-line processing device. Using this device to prepare layered carbon nanofibers, the layered carbon nanofiber aggregates formed in the air flow enter the liquid medium to form layered carbon nanofibers, which are continuously spun in the liquid or outside the liquid medium to prepare continuous layered carbon nanofibers. Equipment principle such as figure 1: 1 Spinning Shaft-1, 2 Spinning-2, 3 Spinning-3, 4 Nozzle, 5 Flange, 6 Quartz Tube, 7 Tube Furnace, 8 Sleeve Packing Film Layer Aggregation, 9 Tail Gas Pipe, 10 Fiber, 11 Water, 12 liquid tank-1, 13 acetone, 14 liquid tank-2, 15 infrared oven lamp. The liquid tank 2 is filled with acetone to clean and compact the layered fibers; the infrare...

Embodiment 2

[0044] The section of the fiber prepared by scanning electron microscope observation embodiment 1 is hollow, and the fiber diameter is 120 microns ( Figure 7 a), containing 3 layers of carbon nanofiber membranes ( Figure 7 b), the fiber surface is composed of carbon nanofibers arranged along the fiber direction ( Figure 8 ). Transmission electron microscopy observes the layer in the fiber, which is made of carbon nanofibers ( Figure 9 ), carbon nanofibers are double-walled carbon nanotubes, which are collapsed ( Figure 9 a) and tubular ( Figure 9 b). Carrying out thermogravimetric analysis to described fiber the purity of carbon tube in the fiber is 96% ( Figure 10 ). The fiber is braided to prepare a layered carbon nanofiber braid ( Figure 11 ).

Embodiment 3

[0046] The fiber preparation process is the same as in Example 1, and a reciprocating wire rod is added between the spinning shaft 2 and the spinning shaft 3 to obtain a carbon nanofiber product arranged obliquely ( Figure 12 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com