Patents

Literature

395 results about "Carbon nanostructures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mass production of carbon nanostructures

InactiveUS20060121279A1Improve mechanical stabilityPigmenting treatmentMaterial nanotechnologyGraphiteGraphene

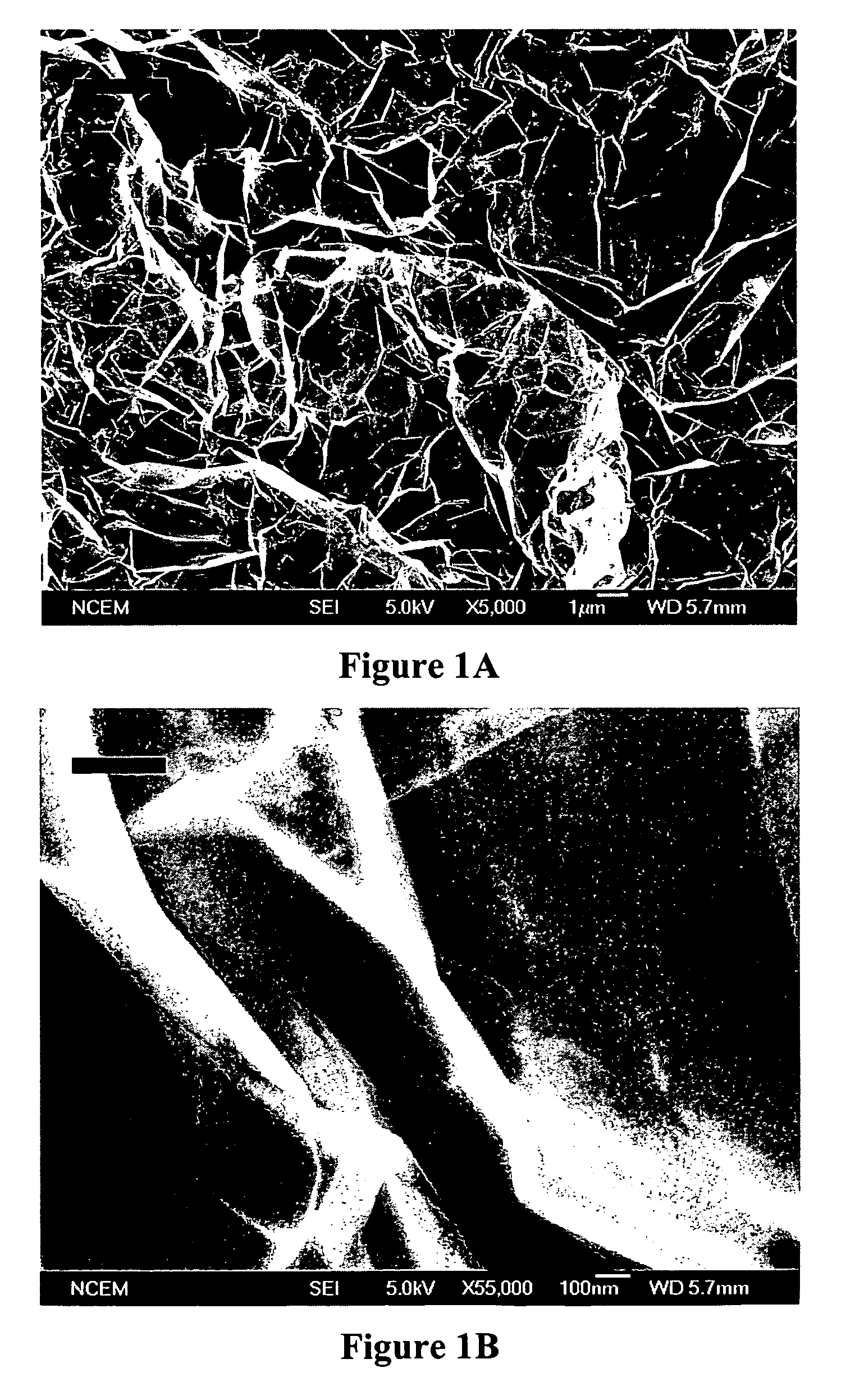

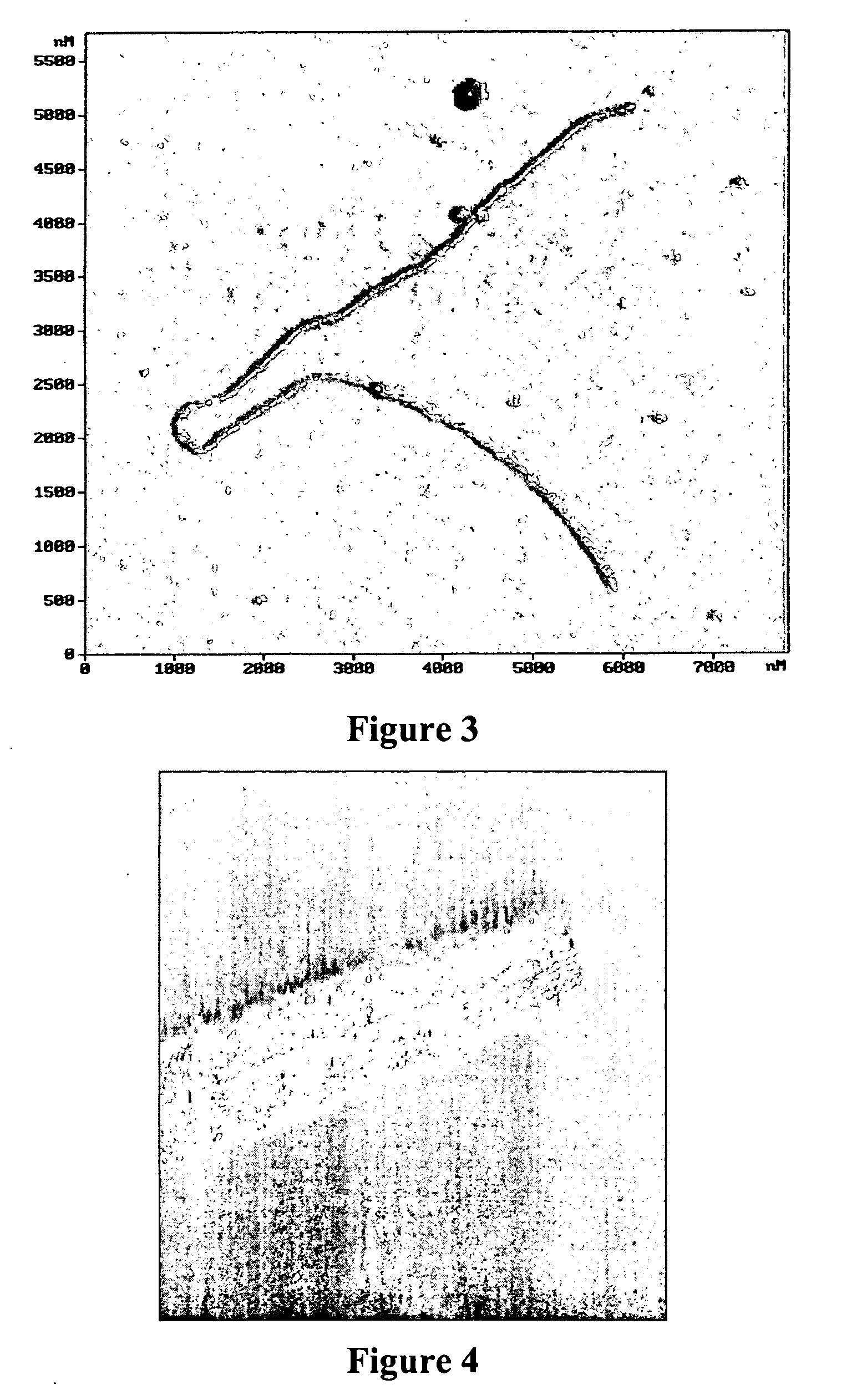

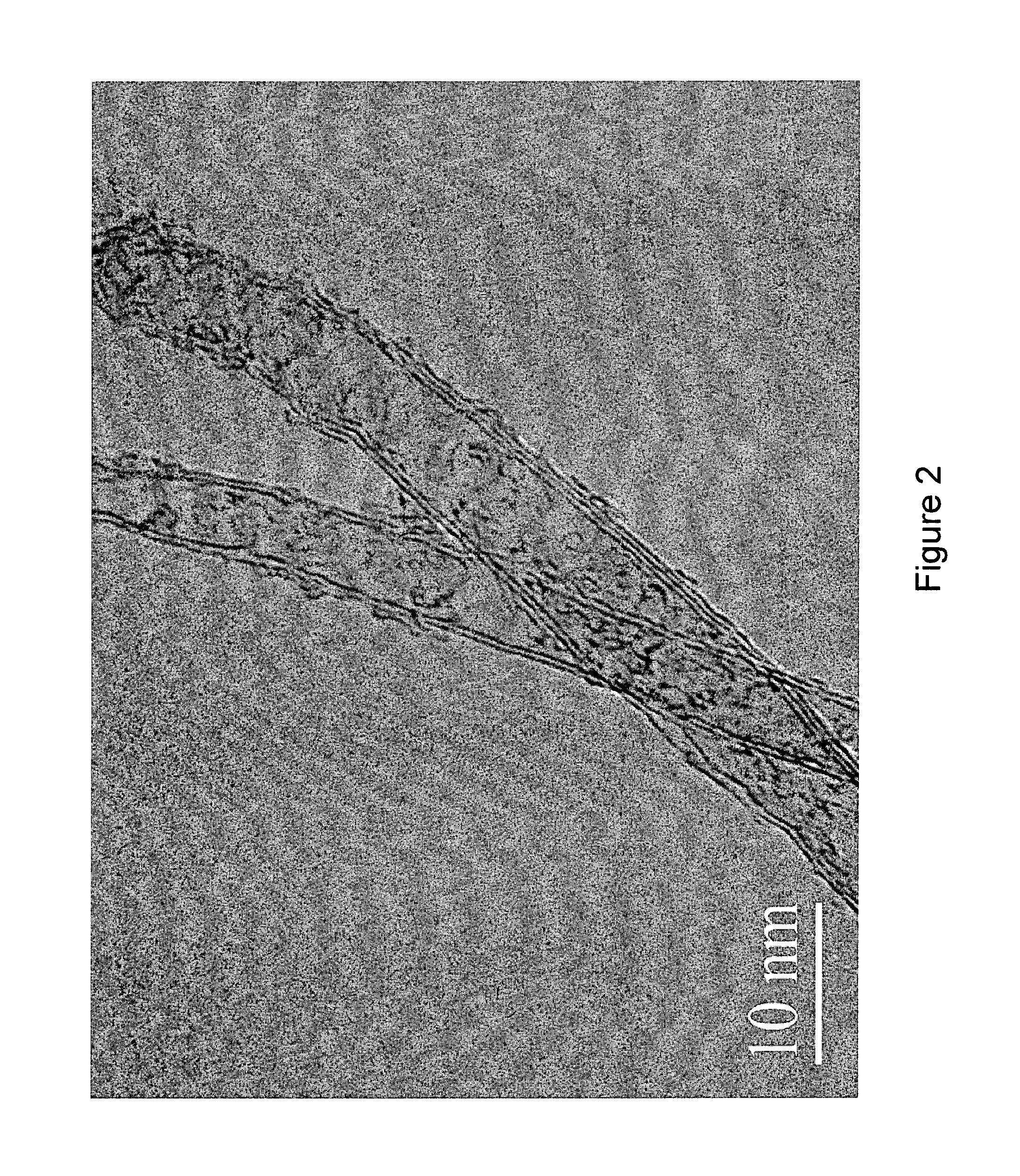

Carbon nanostructures are mass produced from graphite. In particularly preferred aspects, graphene is thermo-chemically derived from graphite and used in numerous compositions. In further preferred aspects, the graphene is re-shaped to form other nanostructures, including nanofractals, optionally branched open-ended SWNT, nanoloops, and nanoonions.

Owner:PETRIK VIKTOR I

Carbon nanostructures and process for the production of carbon-based nanotubes, nanofibres and nanostructures

InactiveUS20070183959A1Enhanced interactionImprove mechanical propertiesMaterial nanotechnologyFullerenesThermal insulationNanostructure

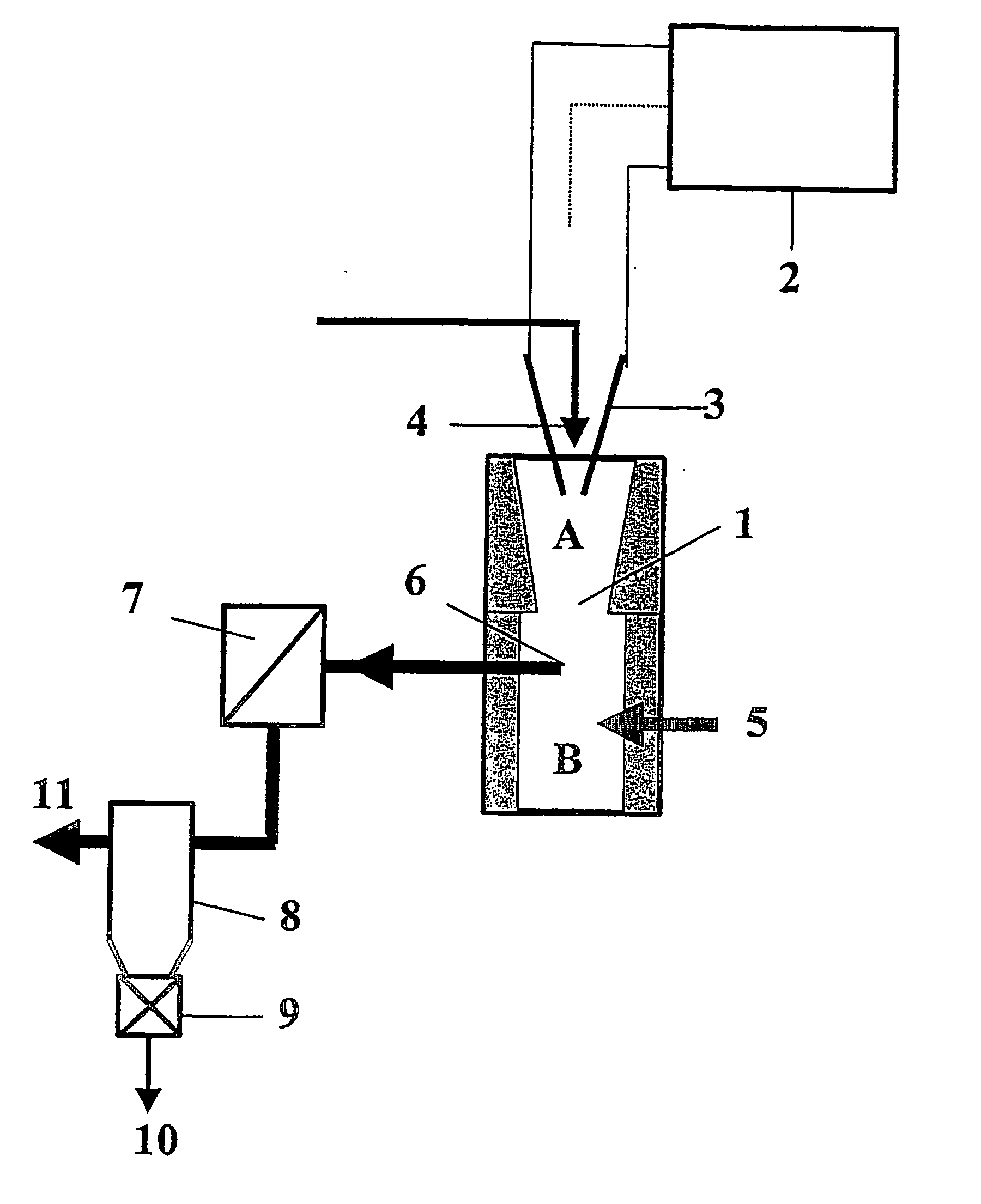

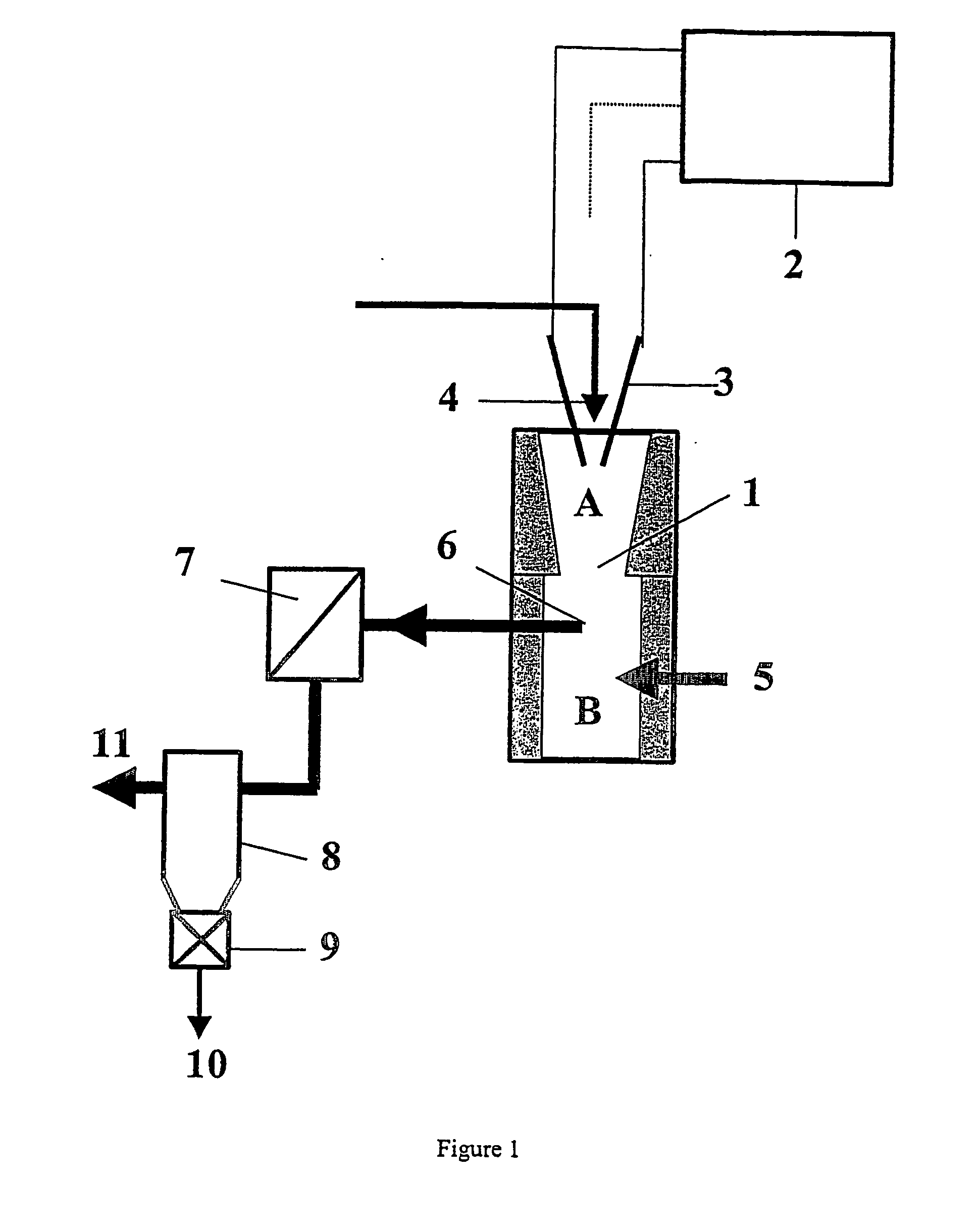

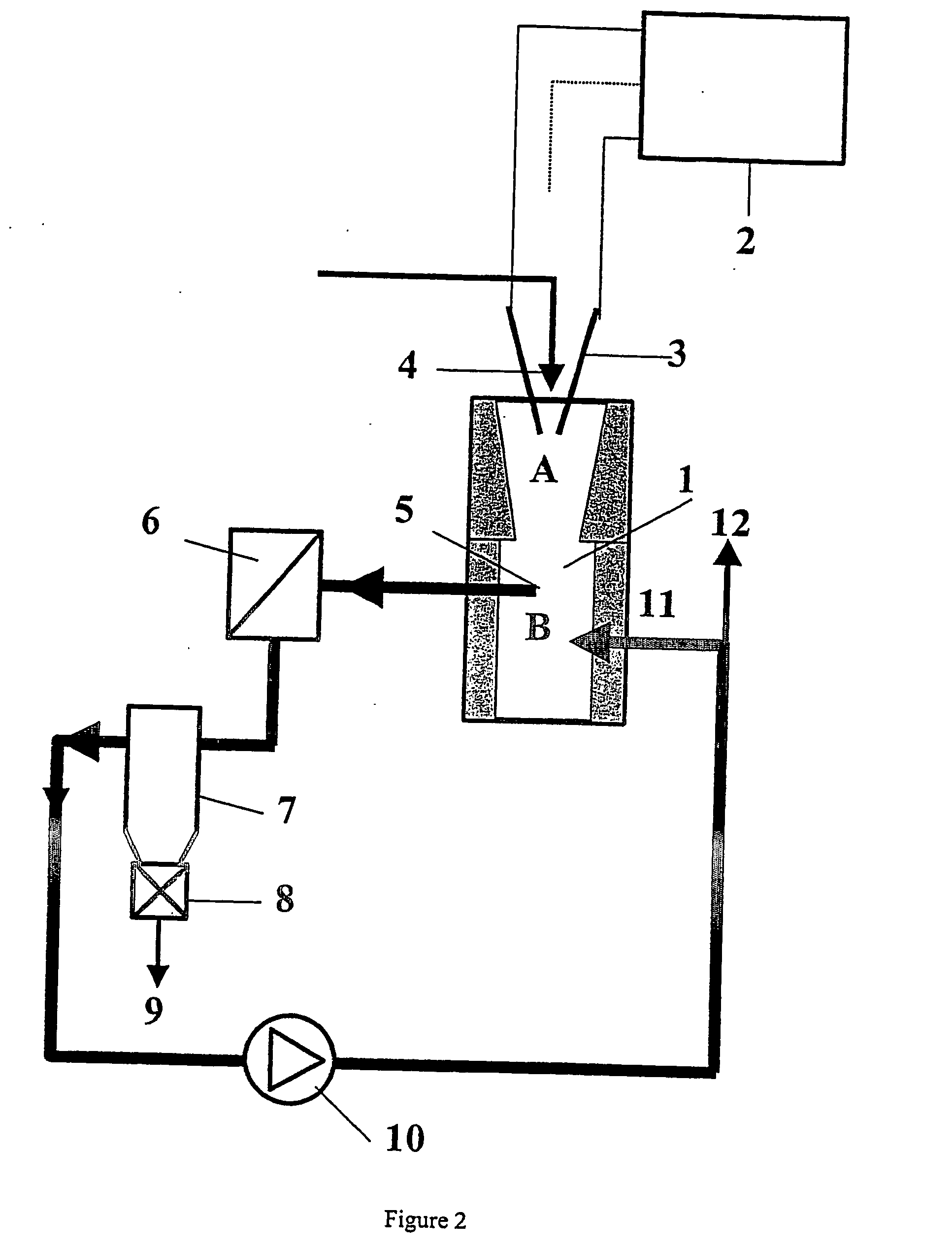

Continuous process for the production of carbon-based nanotubes, nanofibres and nanostructures, comprising the following steps: generating a plasma with electrical energy, introducing a carbon precursor and / or one or more catalysers and / or carrier plasma gas in a reaction zone of an airtight high temperature resistant vessel optionally having a thermal insulation lining, vaporizing the carbon precursor in the reaction zone at a very high temperature, preferably 4000° C. and higher, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyser through a nozzle, whose diameter is narrowing in the direction of the plasma gas flow, guiding the carrier plasma gas, the carbon precursor vaporized and the catalyses into a quenching zone for nucleation, growing and quenching operating with flow conditions generated by aerodynamic and electromagnetic forces, so that no significant recirculation of feedstocks or products from the quenching zone into the reaction zone occurs, controlling the gas temperature in the quenching zone between about 4000° C. in the upper part of this zone and about 50° C. in the lower part of this zone and controlling the quenching velocity between 103 K / s and 106 K / s quenching and extracting carbon-based nanotubes, nanofibres and other nanostructures from the quenching zone, separating carbon-based nanotubes, nanofibres and nanostructures from other reaction products.

Owner:ТІМКАЛ SА +1

Platinum-Based Electrocatalysts Synthesized by Depositing Contiguous Adlayers on Carbon Nanostructures

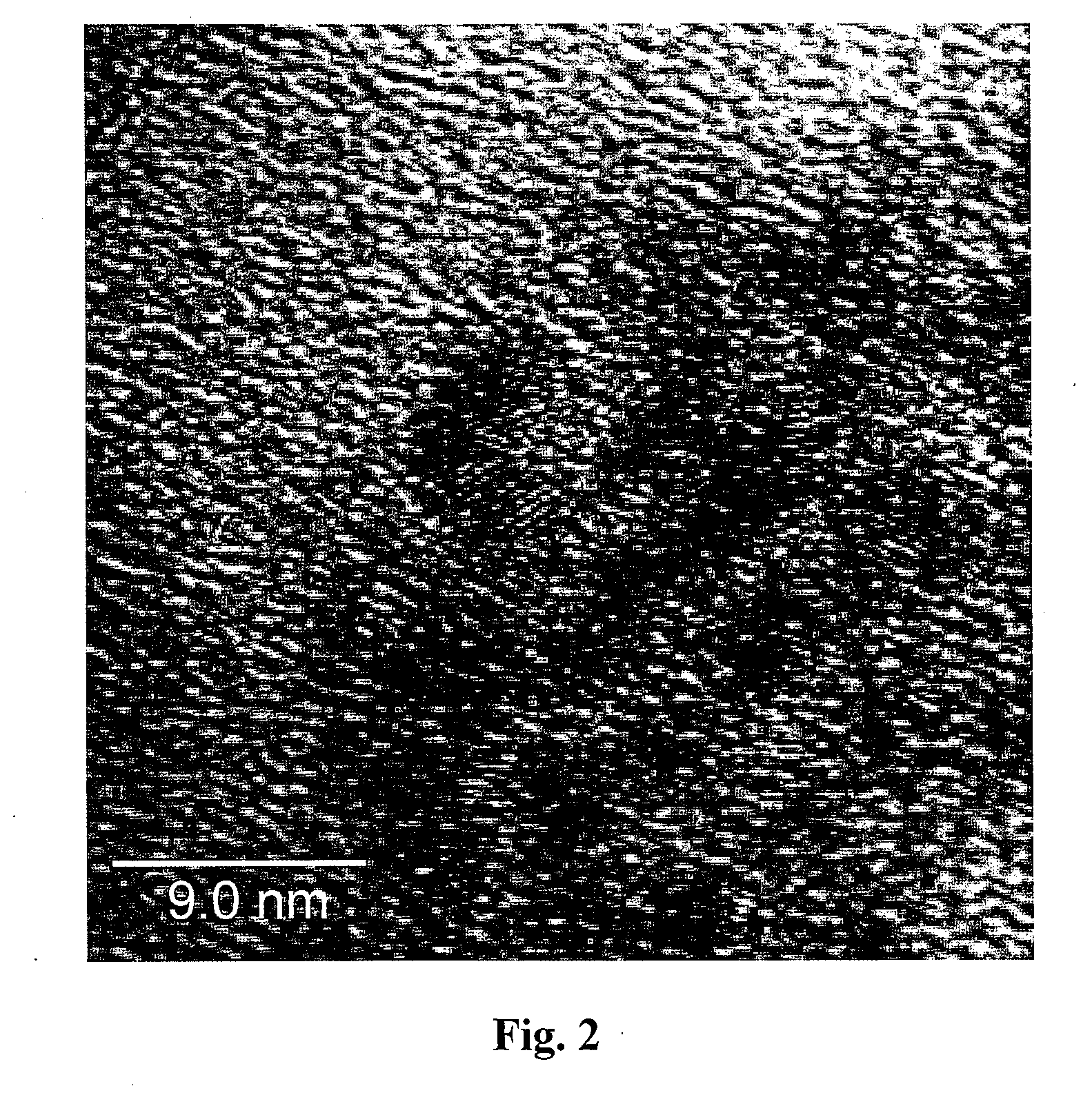

InactiveUS20100177462A1High catalytic activityImprove stabilityMaterial nanotechnologyCarbon compoundsNanostructurePt element

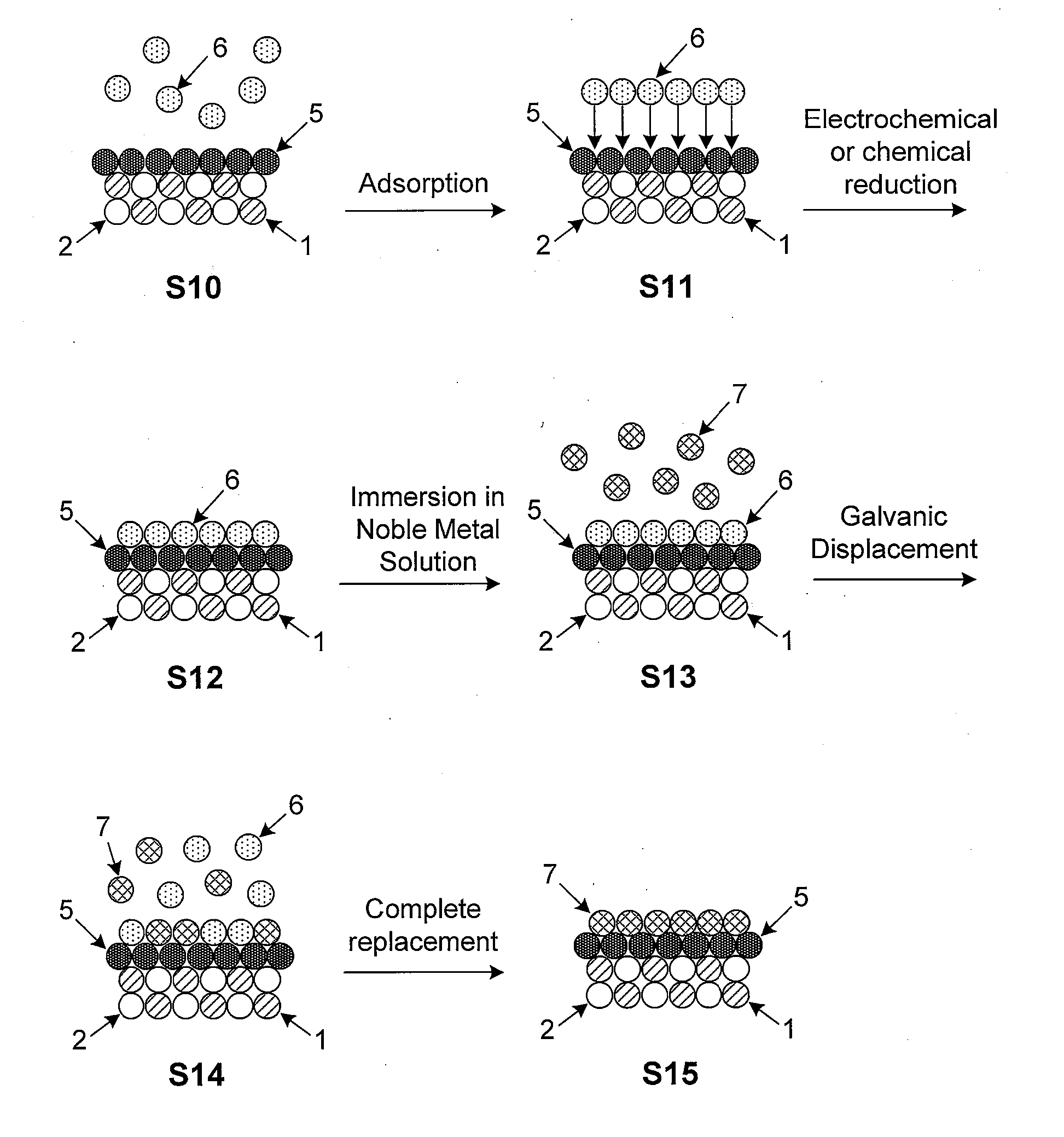

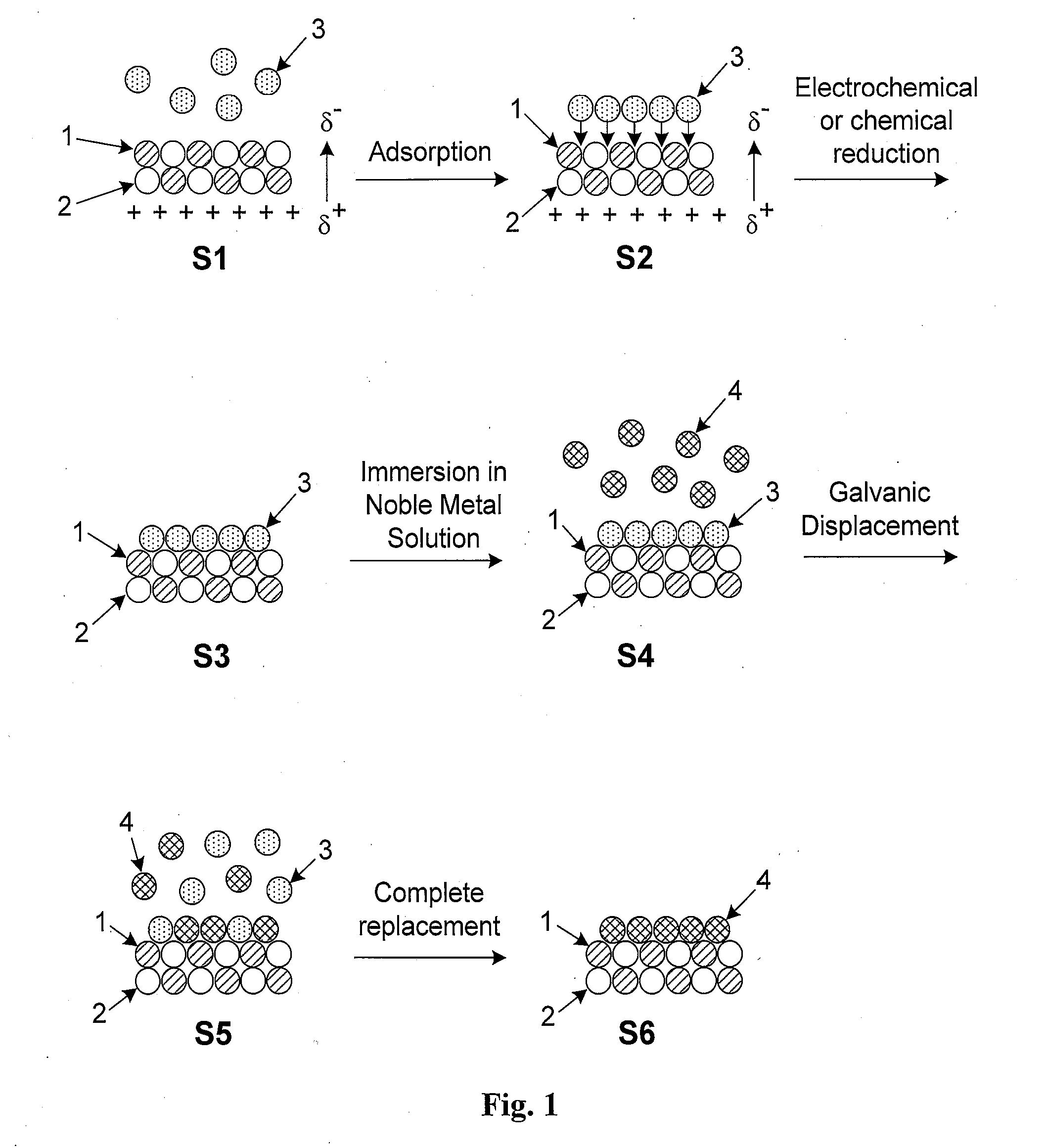

High-surface-area carbon nanostructures coated with a smooth and conformal submonolayer-to-multilayer thin metal films and their method of manufacture are described. The preferred manufacturing process involves the initial oxidation of the carbon nanostructures followed by immersion in a solution with the desired pH to create negative surface dipoles. The nanostructures are subsequently immersed in an alkaline solution containing non-noble metal ions which adsorb at surface reaction sites. The metal ions are then reduced via chemical or electrical means and the nanostructures are exposed to a solution containing a salt of one or more noble metals which replace adsorbed non-noble surface metal atoms by galvanic displacement. Subsequent film growth may be performed via the initial quasi-underpotential deposition of a non-noble metal followed by immersion in a solution comprising a more noble metal. The resulting coated nanostructures may be used, for example, as high-performance electrodes in supercapacitors, batteries, or other electric storage devices.

Owner:BROOKHAVEN SCI ASSOCS

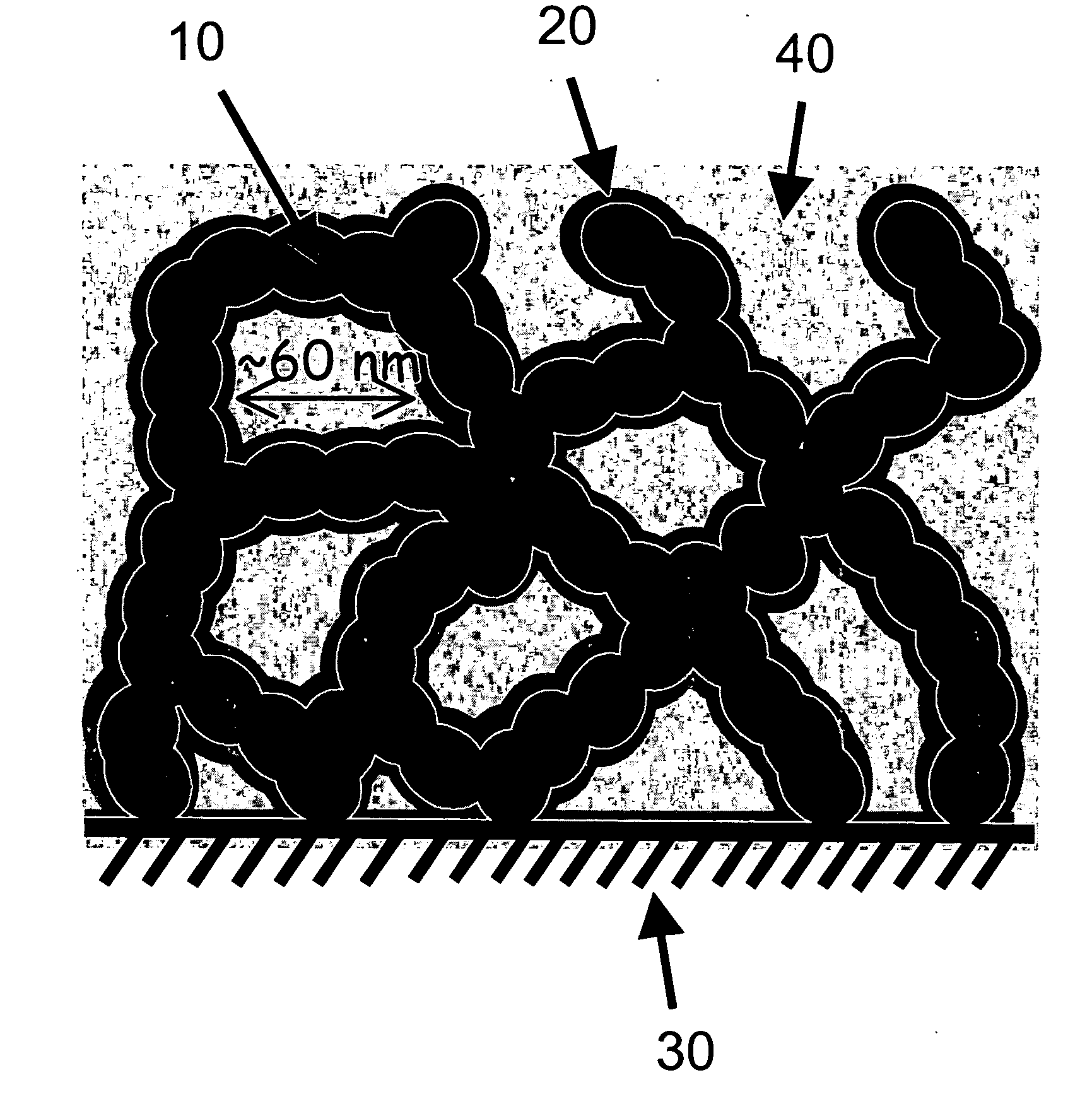

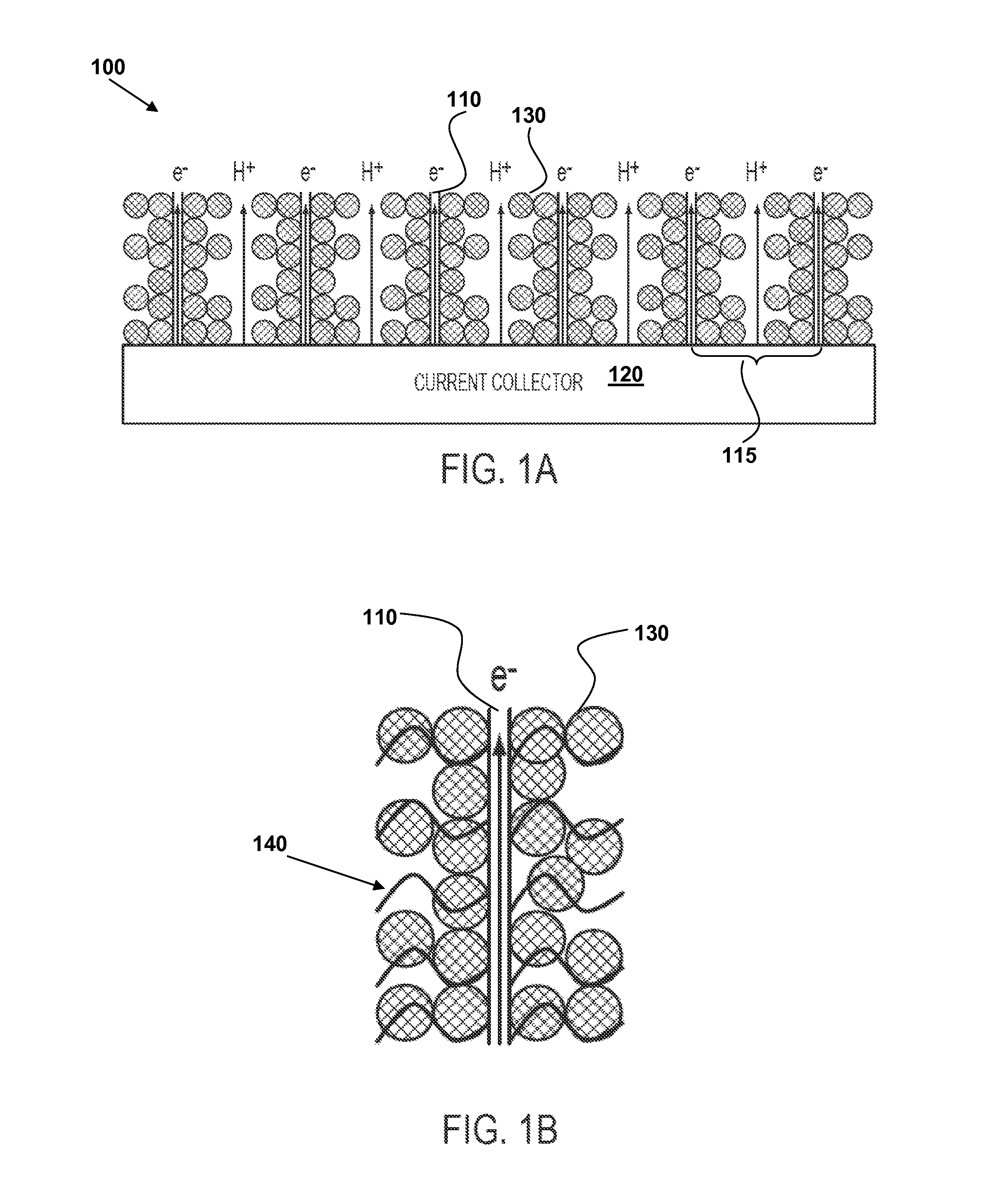

Interpenetrating networks of carbon nanostructures and nano-scale electroactive materials

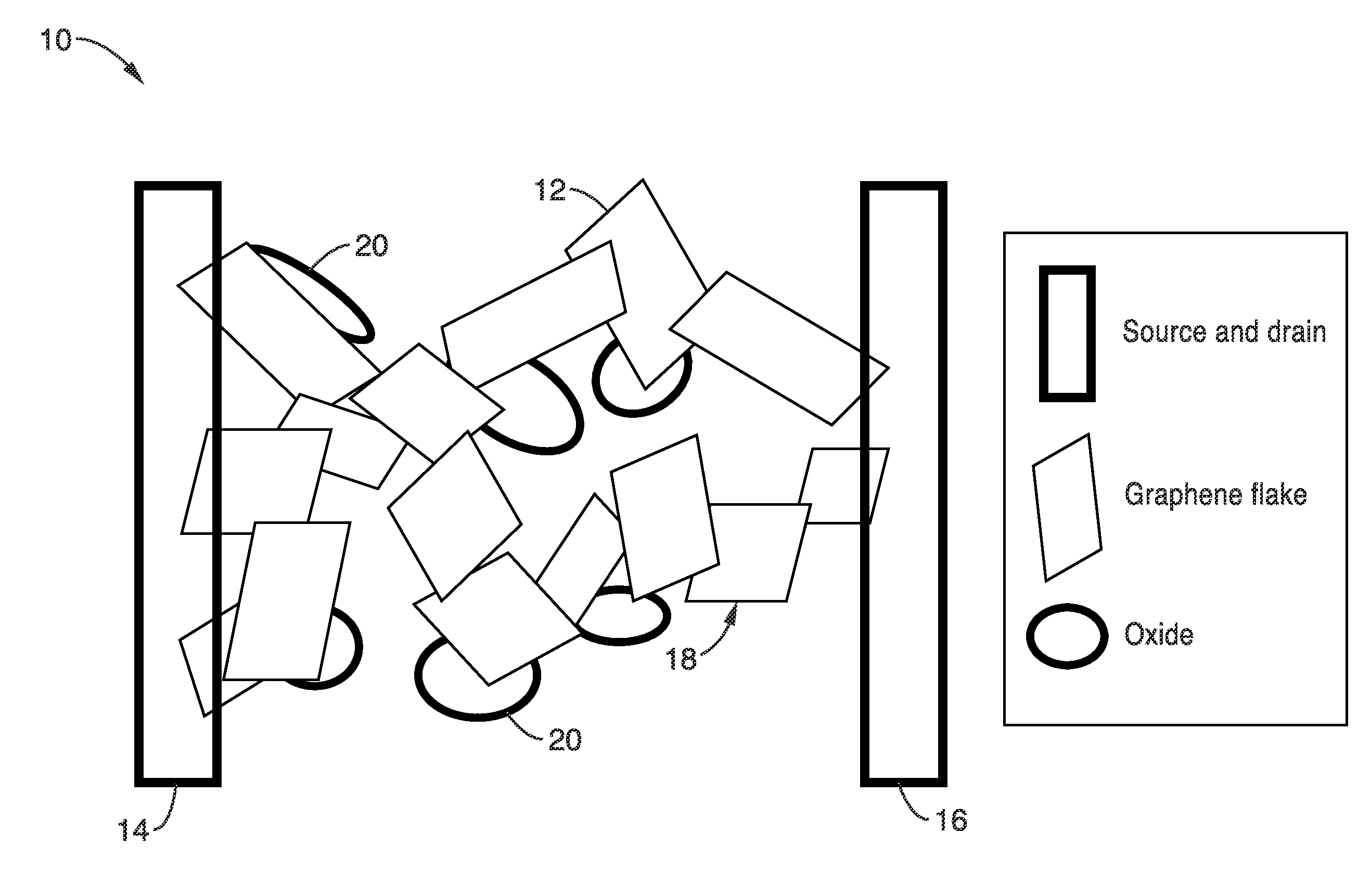

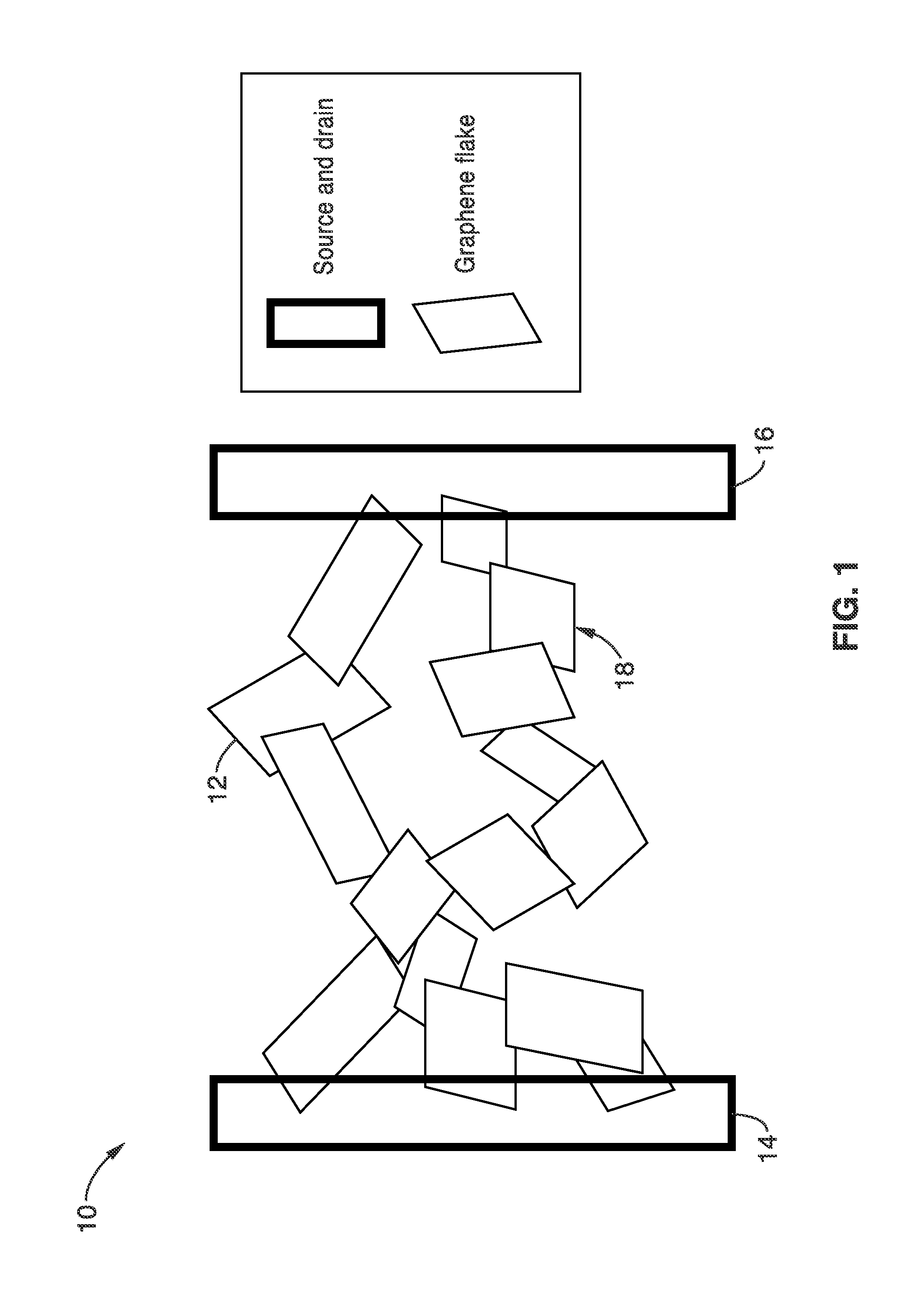

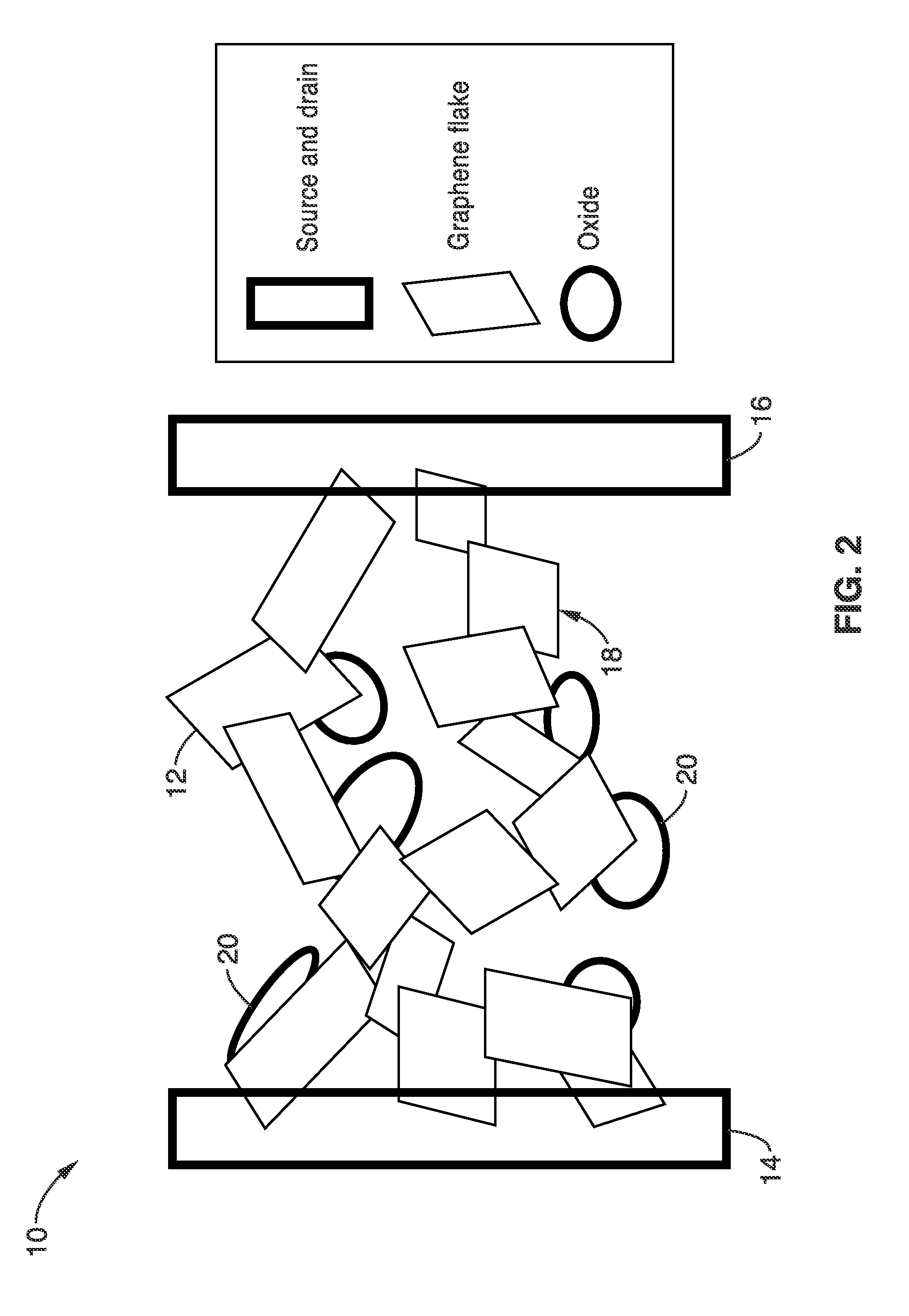

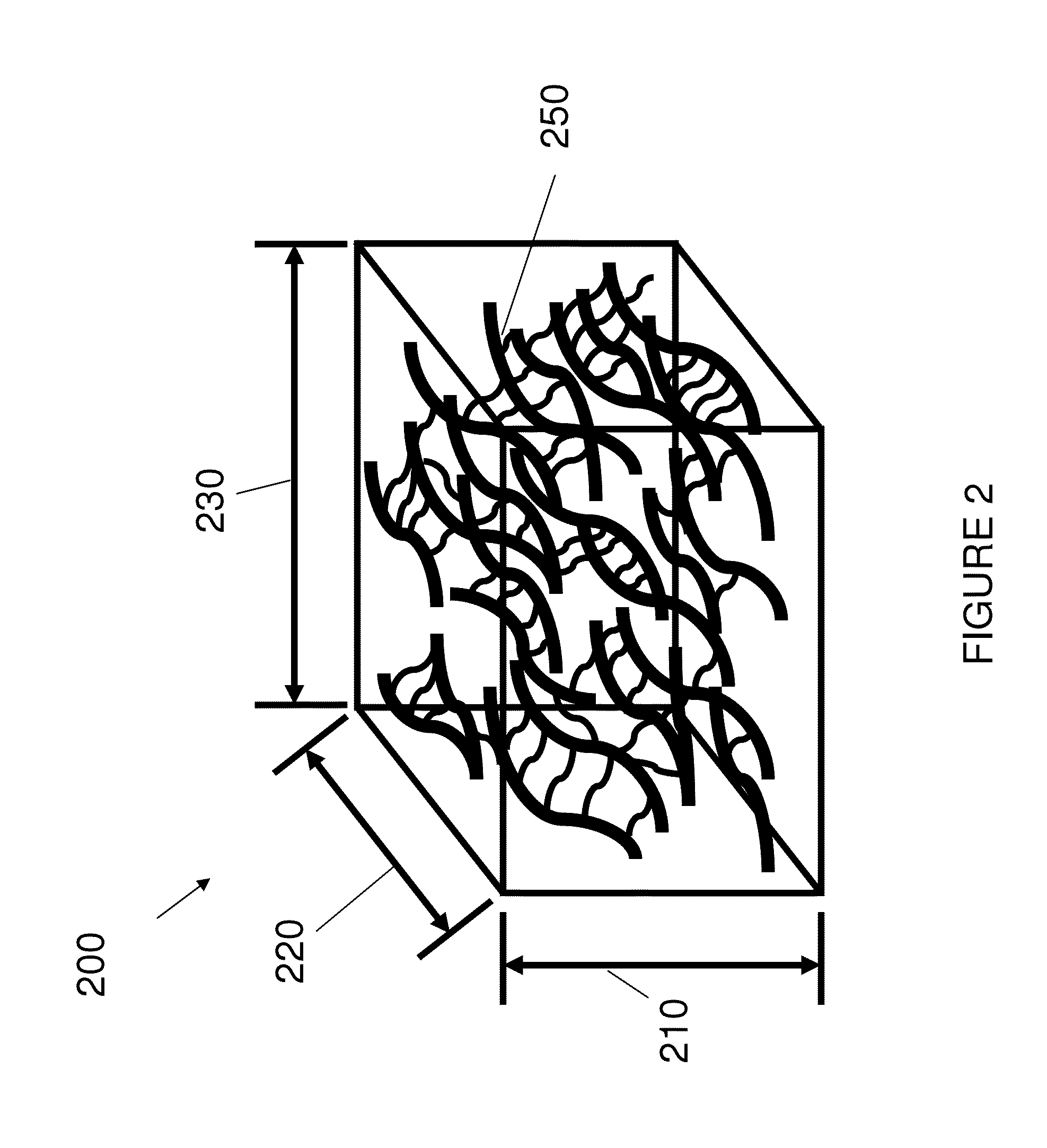

InactiveUS20140042390A1Improve conductivityLarge specific surface areaElectrolytic capacitorsHybrid capacitor electrodesActivated carbonGraphene flake

An interpenetrating network assembly with a network of connected flakes of nano-scale crystalline carbon and nano-scale particles of an electroactive material interconnected with the carbon flakes is provided. The network assemblies are particularly suited for energy storage applications that use metal oxide electroactive materials and a single charge collector or a source and drain. Interpenetrating networks of graphene flakes and metal oxide nanosheets can form independent pathways between source and drain. Nano-scale conductive materials such as metal nanowires, carbon nanotubes, activated carbon or carbon black can be included as part of the conductive network to improve charge transfer.

Owner:RGT UNIV OF CALIFORNIA

Carbon nanostructures and methods of preparation

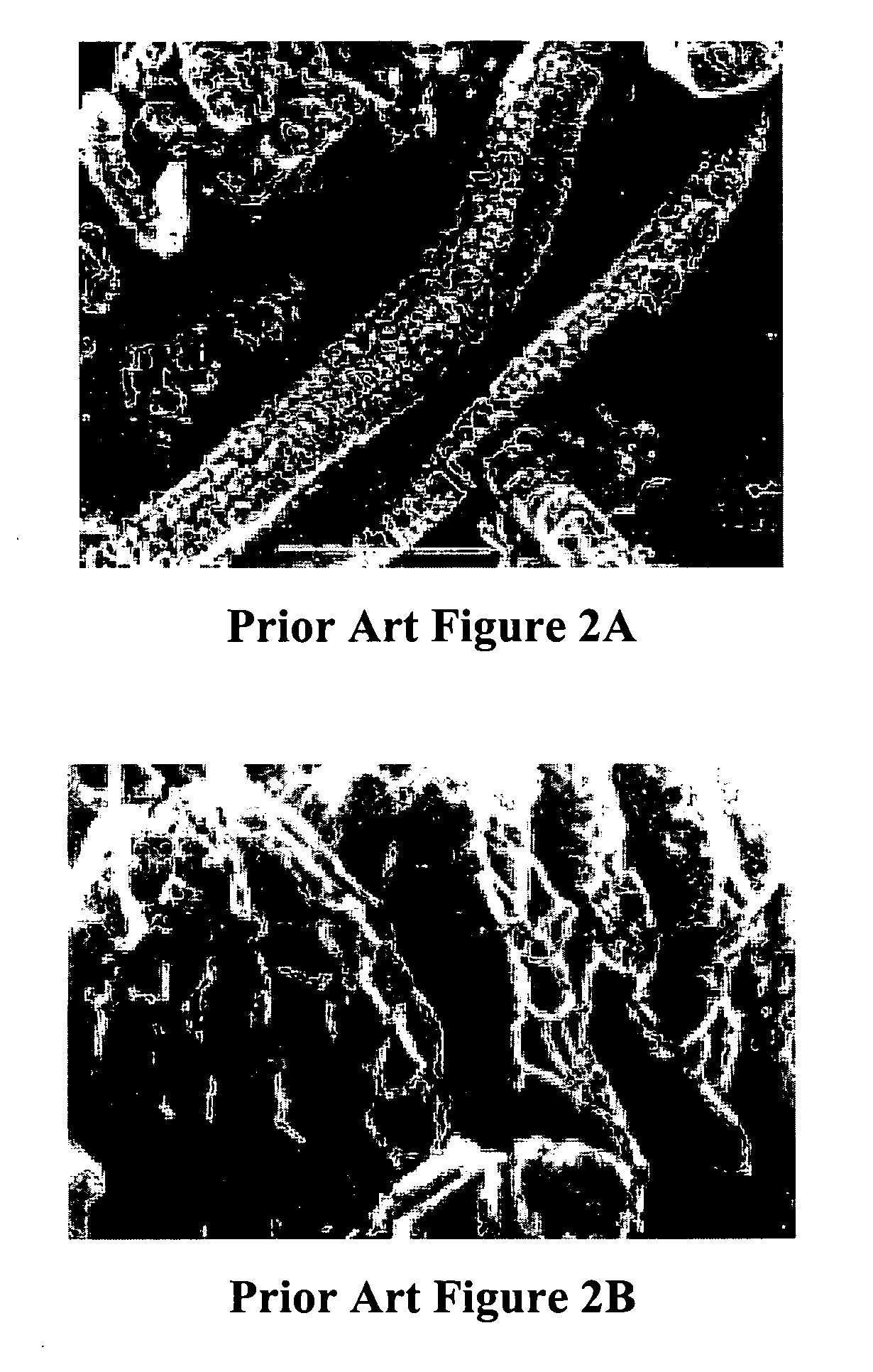

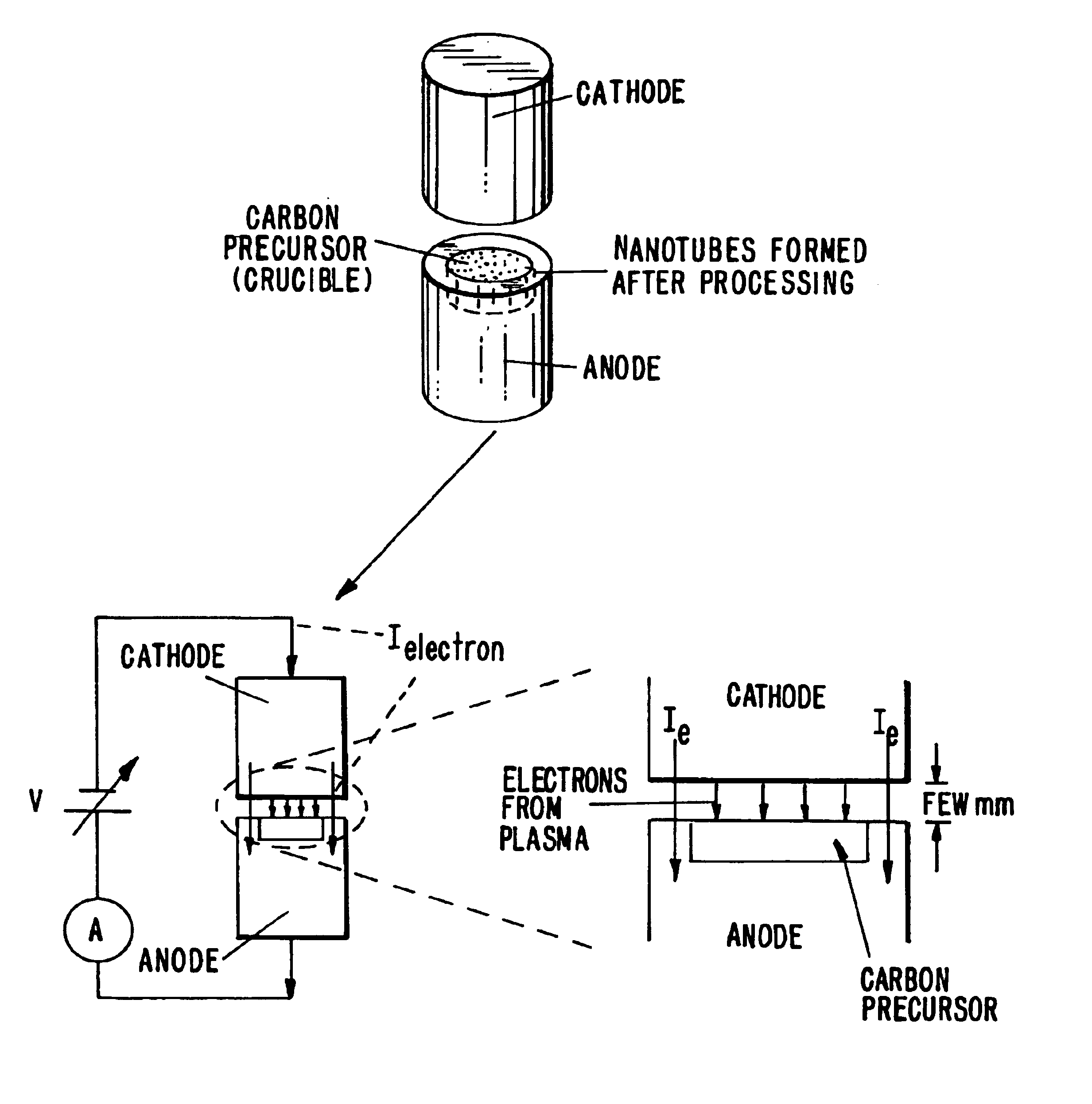

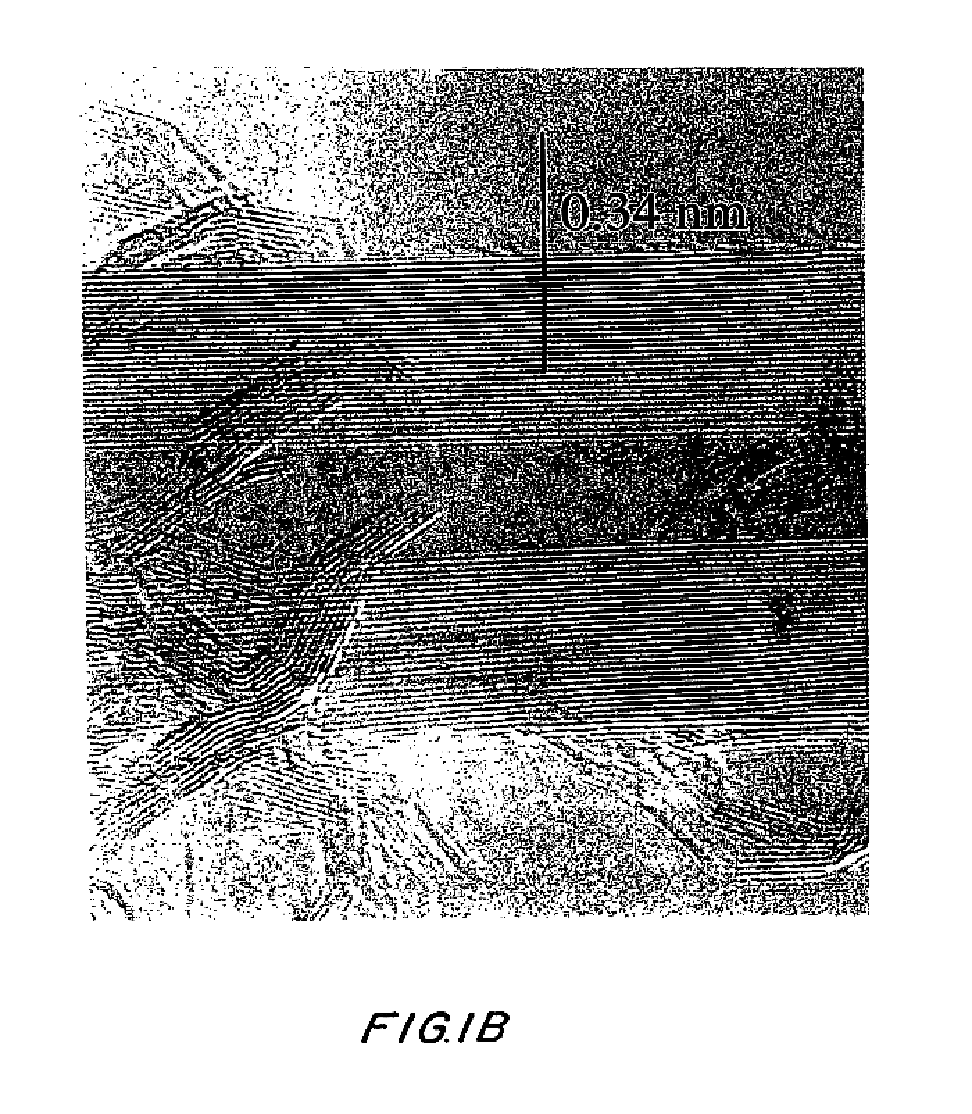

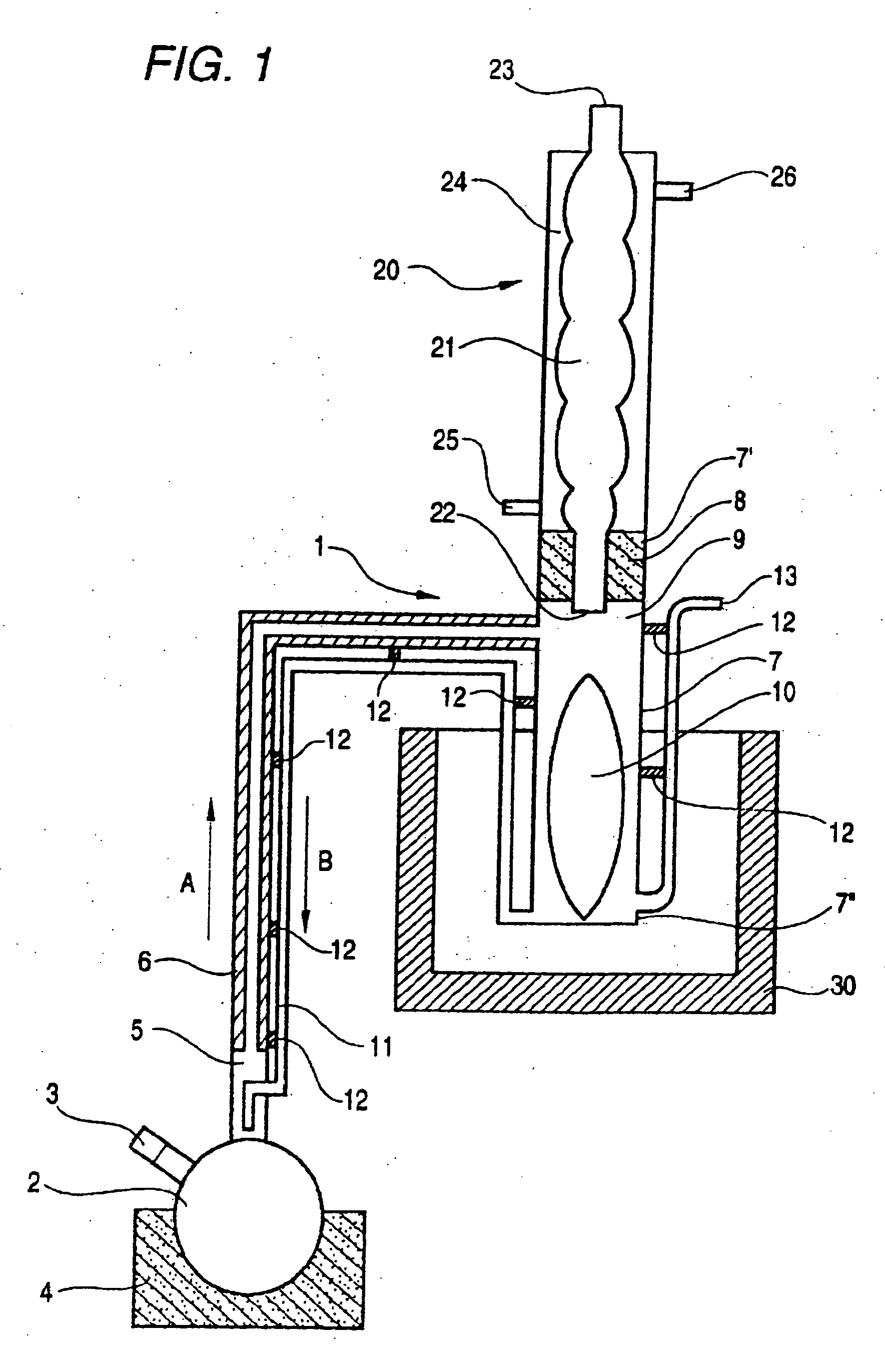

InactiveUS6765949B2Enhanced and superior structural and mechanical propertyImprove processing efficiencyMaterial nanotechnologyElectric discharge heatingSufficient timeElectric arc furnace

An electric arc furnace and method for forming tubular carbon nanostructures comprising a first electrode (cathode) and an a second electrode (anode) opposite the first electrode, sources of voltage (V) and current (A) to create charged particles (Ie) and produce an arch between the electrodes, a source of a gas to surround the arc, and a source of carbon precursor positioned adjacent the anode and within the arc, wherein the arc is maintained at a pressure and high temperature for a time sufficient to heat the carbon precursor to form carbon nonotubes upon the anode.

Owner:CHANG ROBERT P H

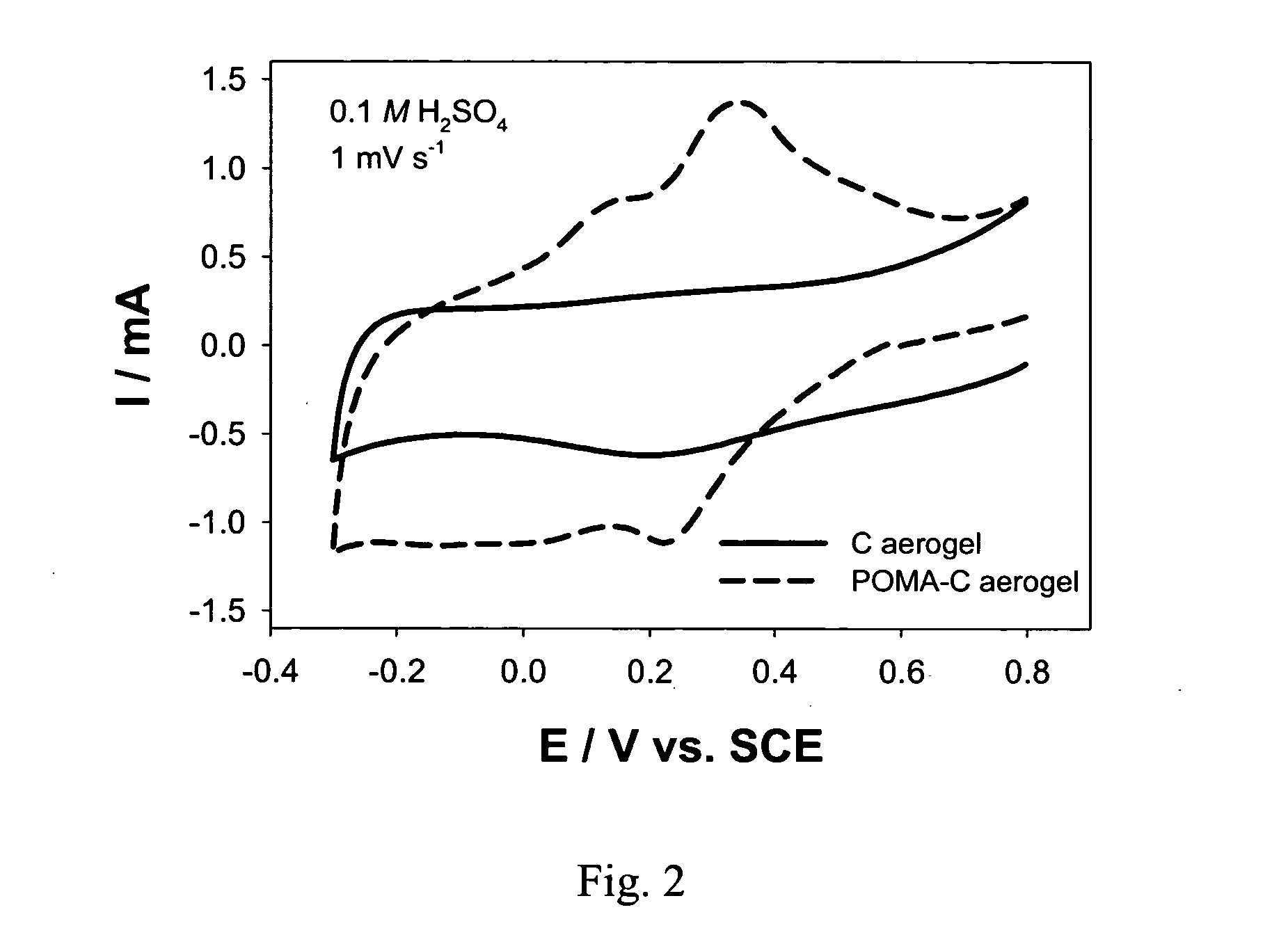

Carbon nanoarchitectures with ultrathin, conformal polymer coatings for electrochemical capacitors

ActiveUS20050153130A1Hybrid capacitor electrolytesElectrolysis componentsSelf limitingPolymer science

A composite having an electroactive polymer coating on a porous carbon structure is disclosed. The composite may be used in capacitor electrodes. The composite may be made by self-limiting electropolymerization of a monomer on the carbon structure.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

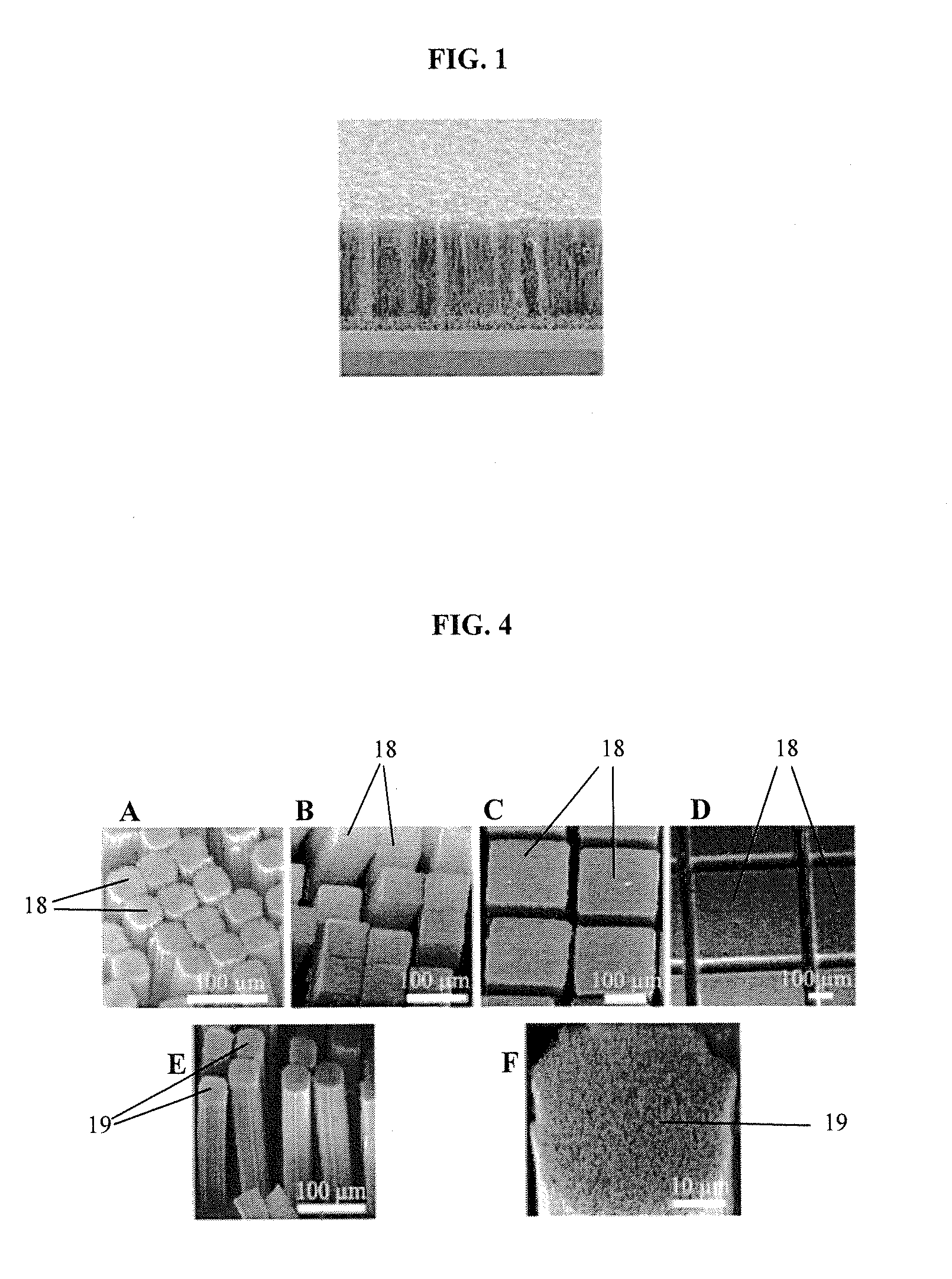

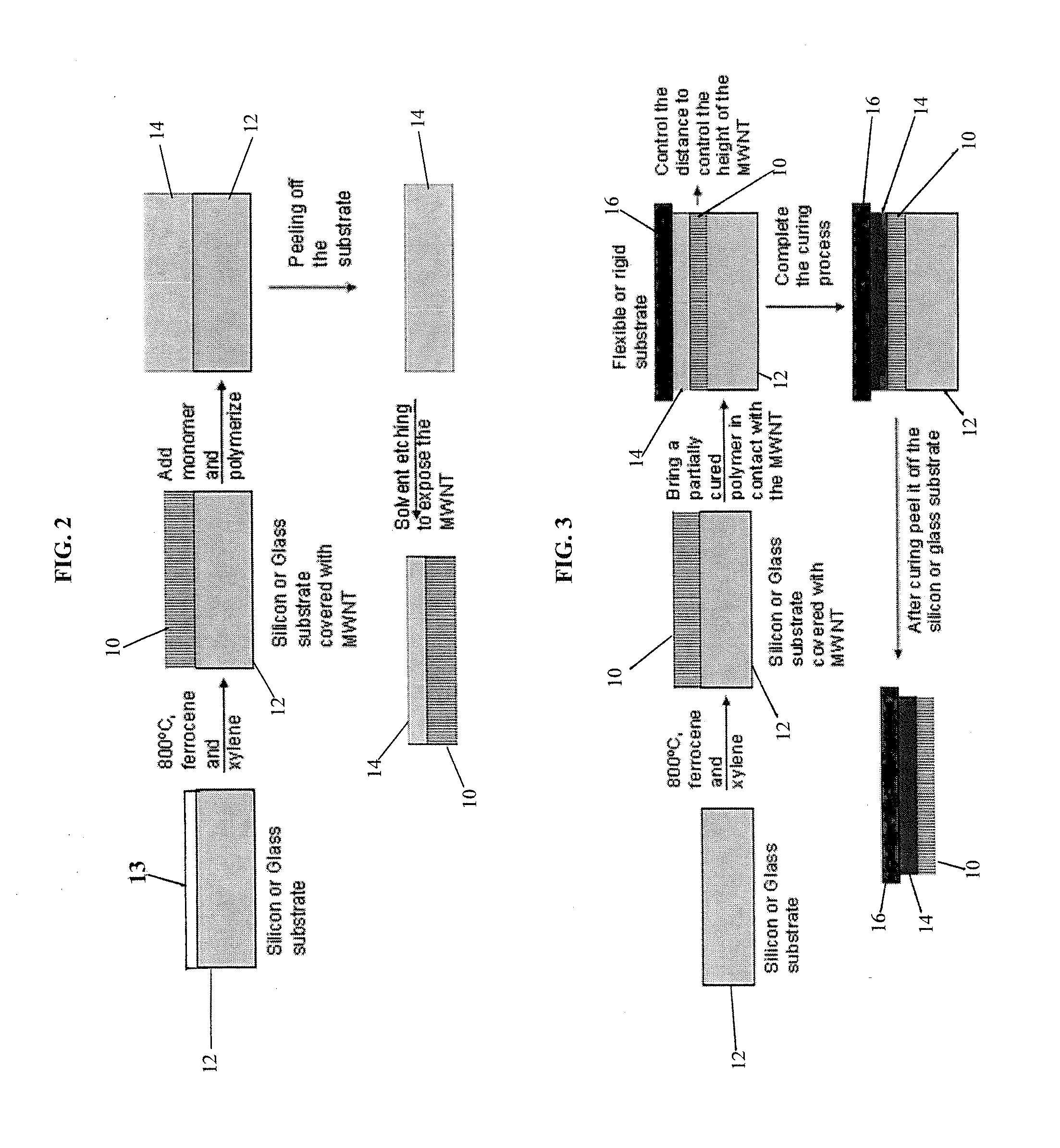

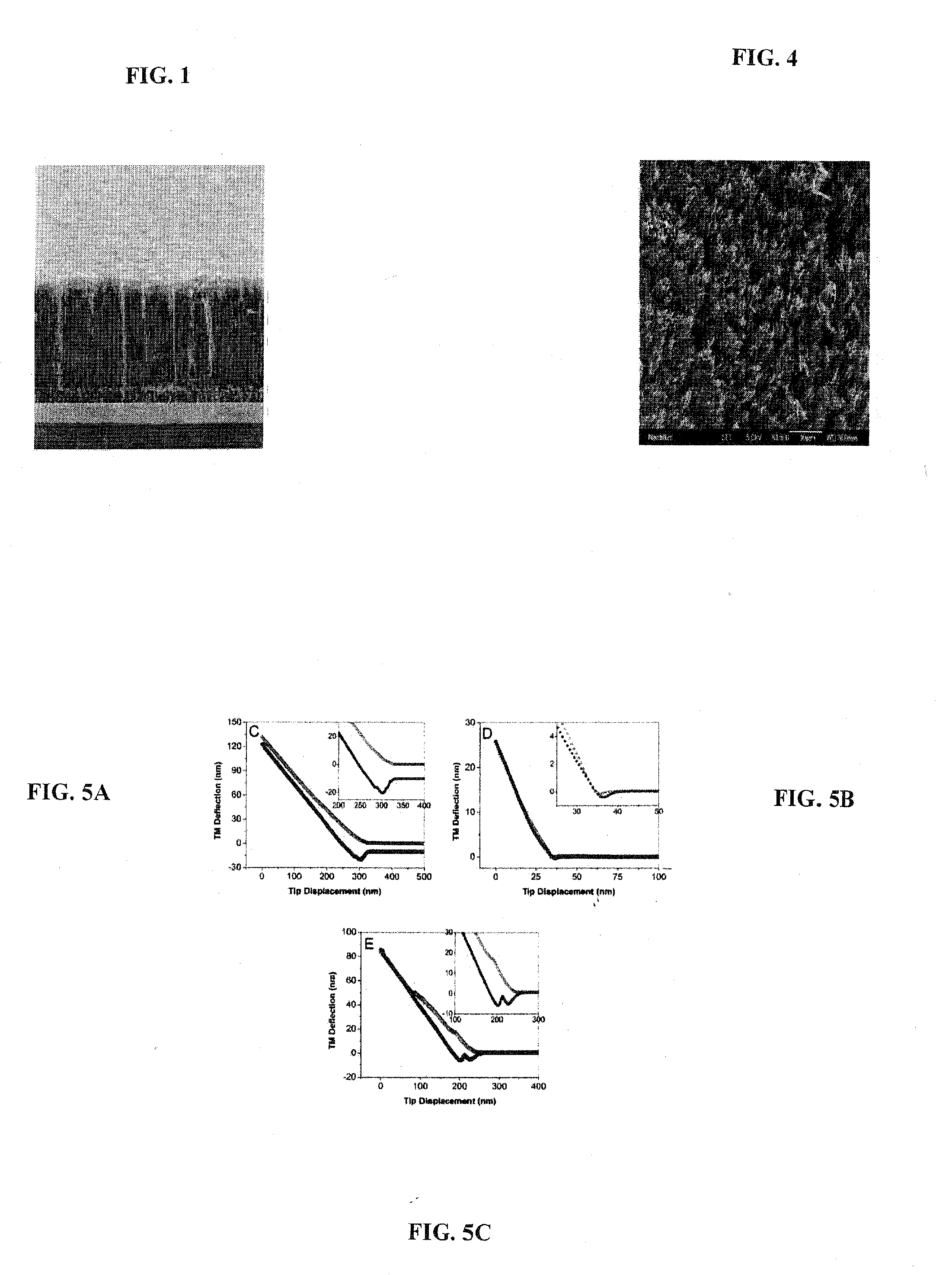

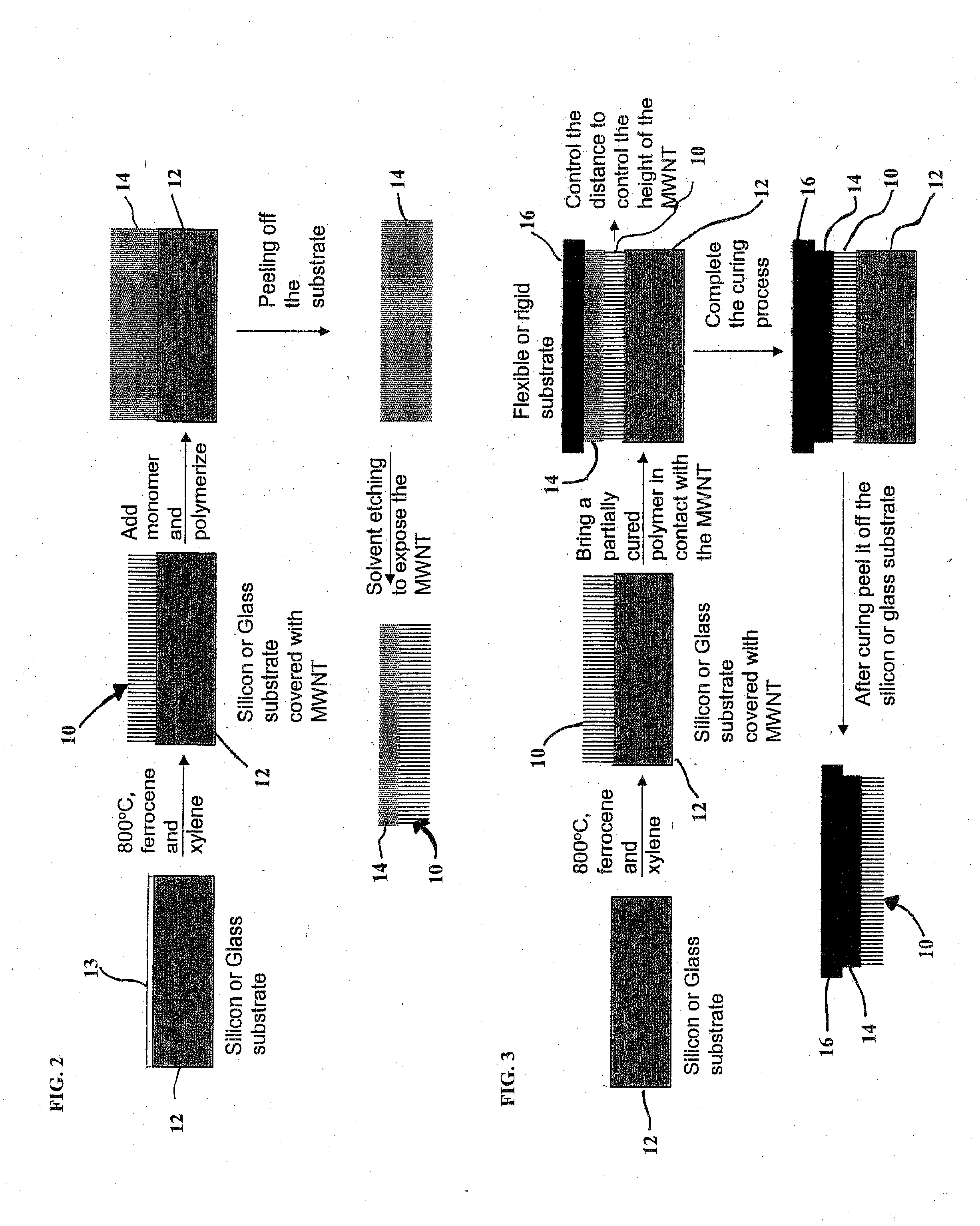

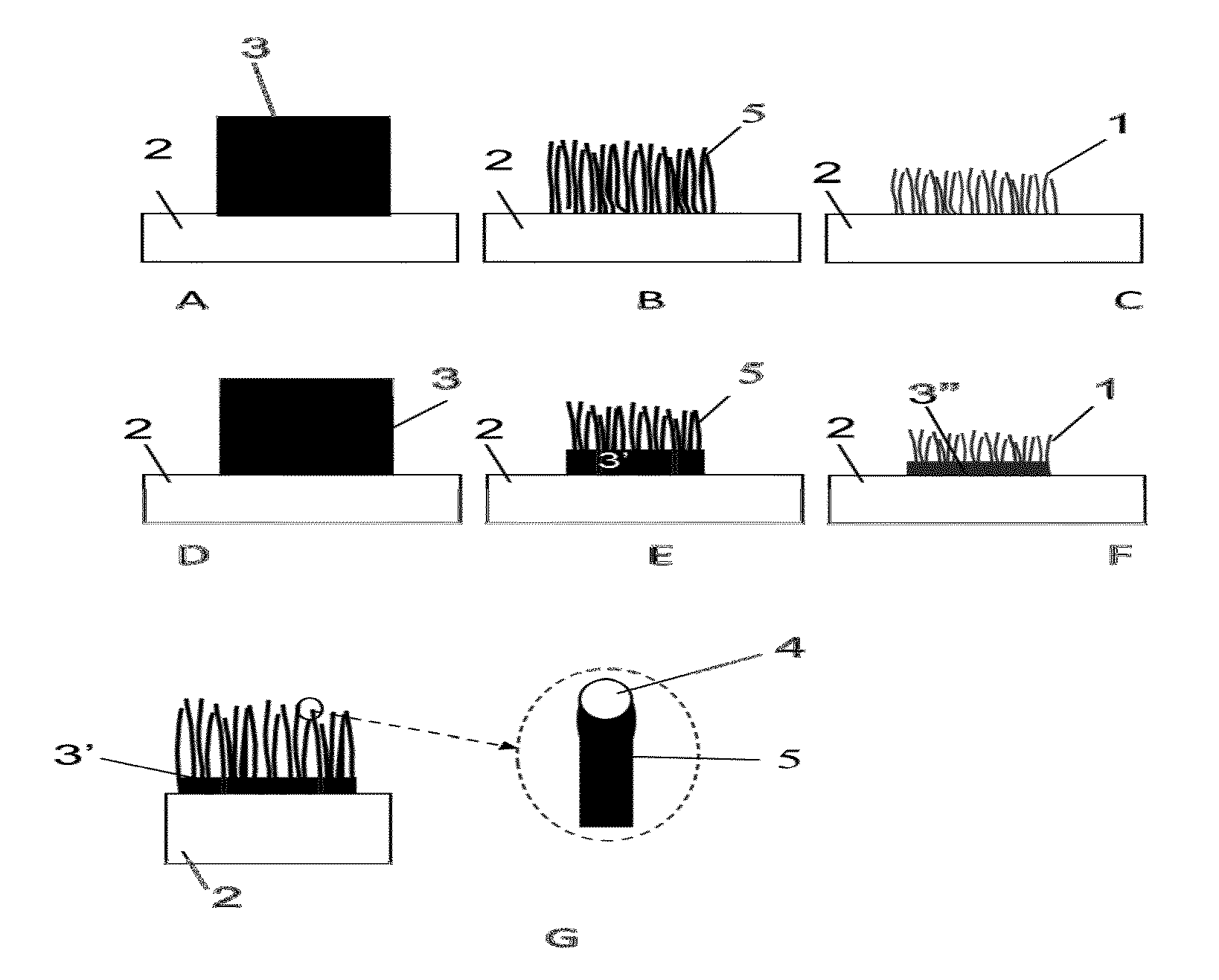

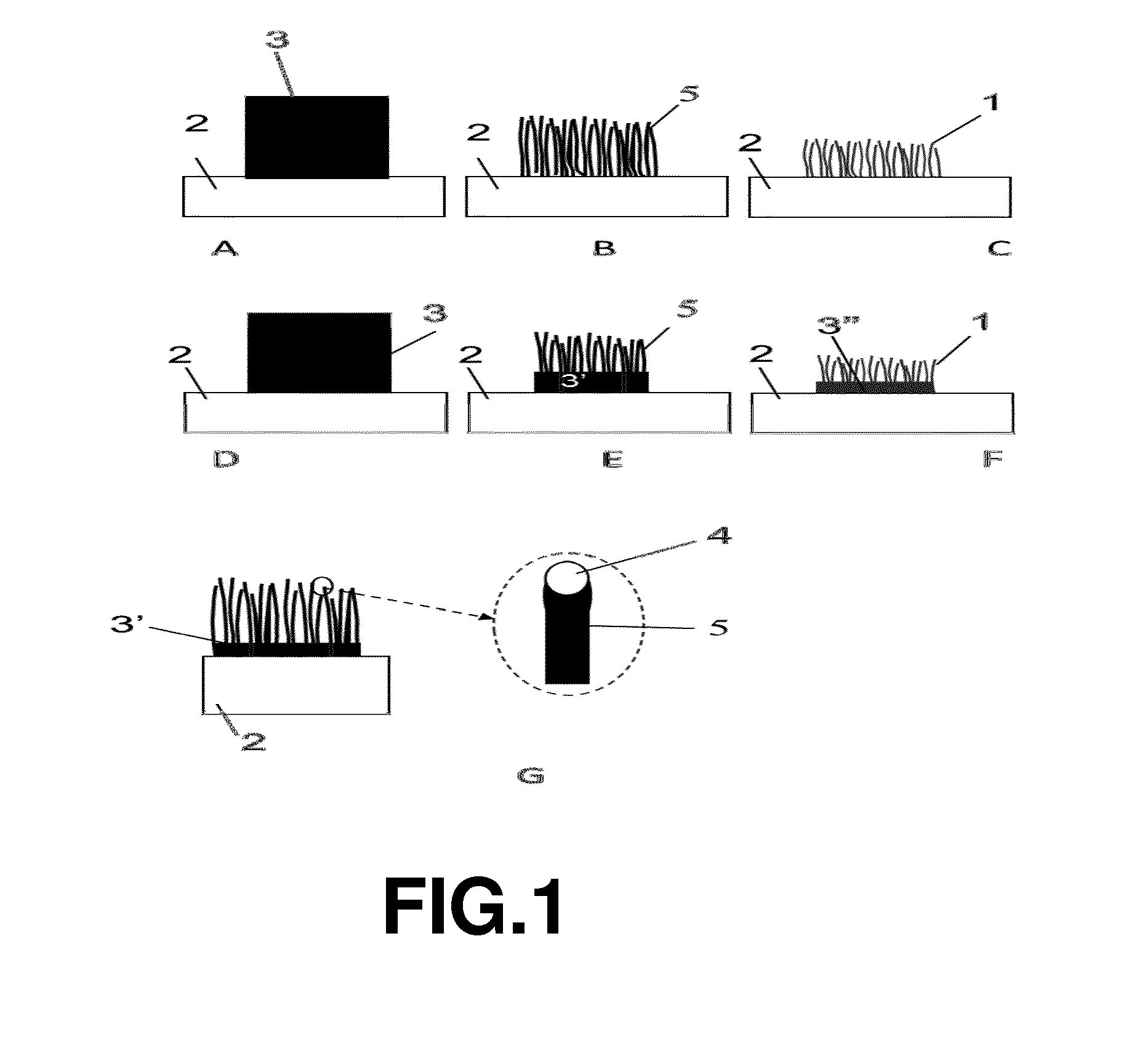

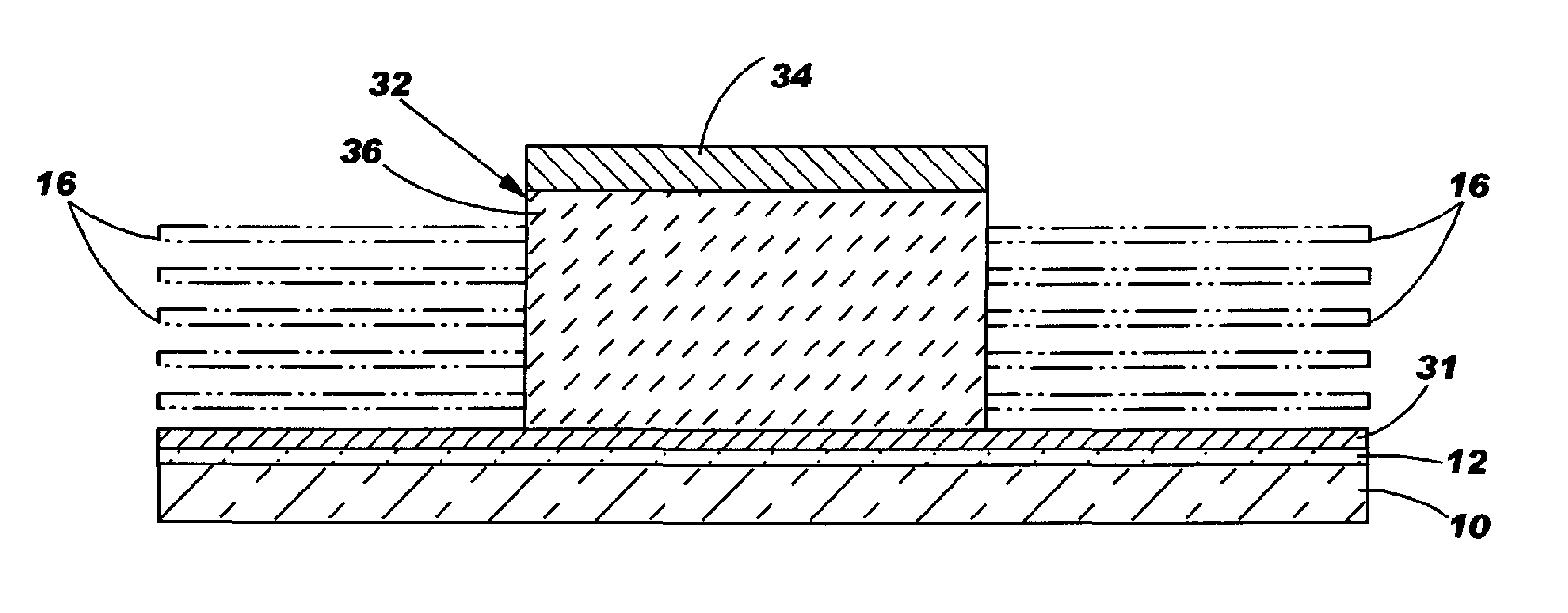

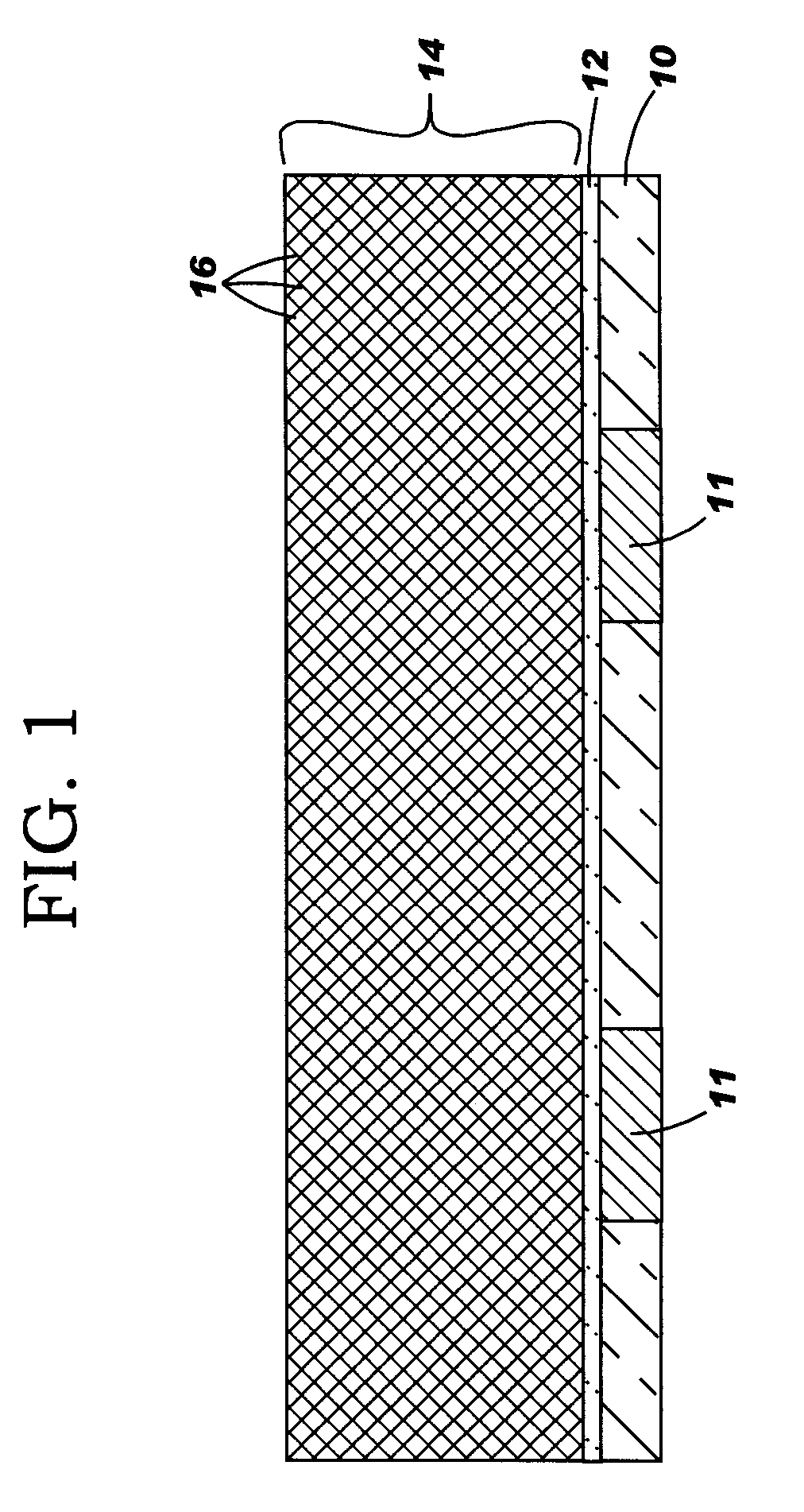

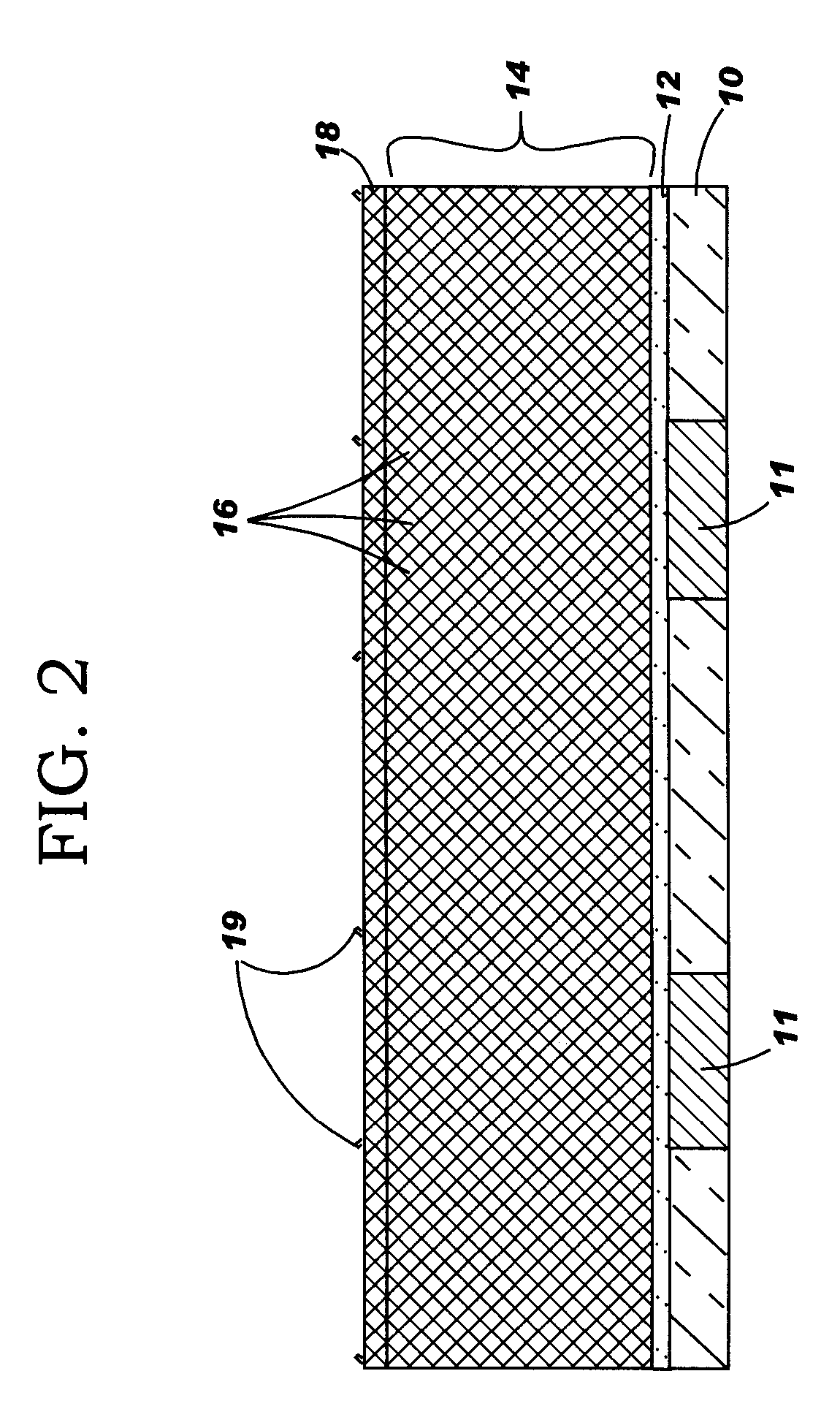

Aligned carbon nanotube-polymer materials, systems and methods

ActiveUS20080280137A1Stable positionMaterial nanotechnologySurgical adhesivesAdhesivePolymer composites

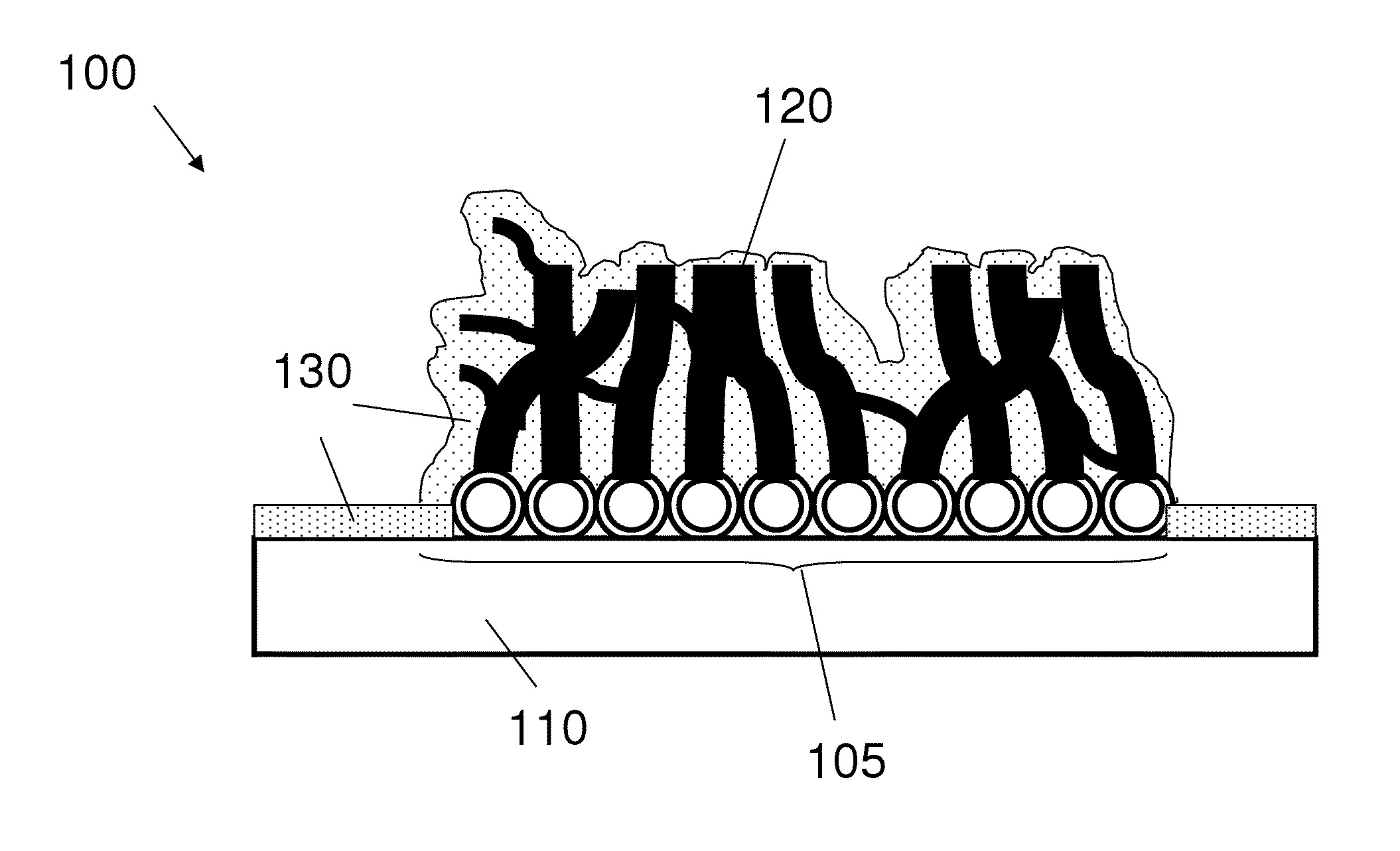

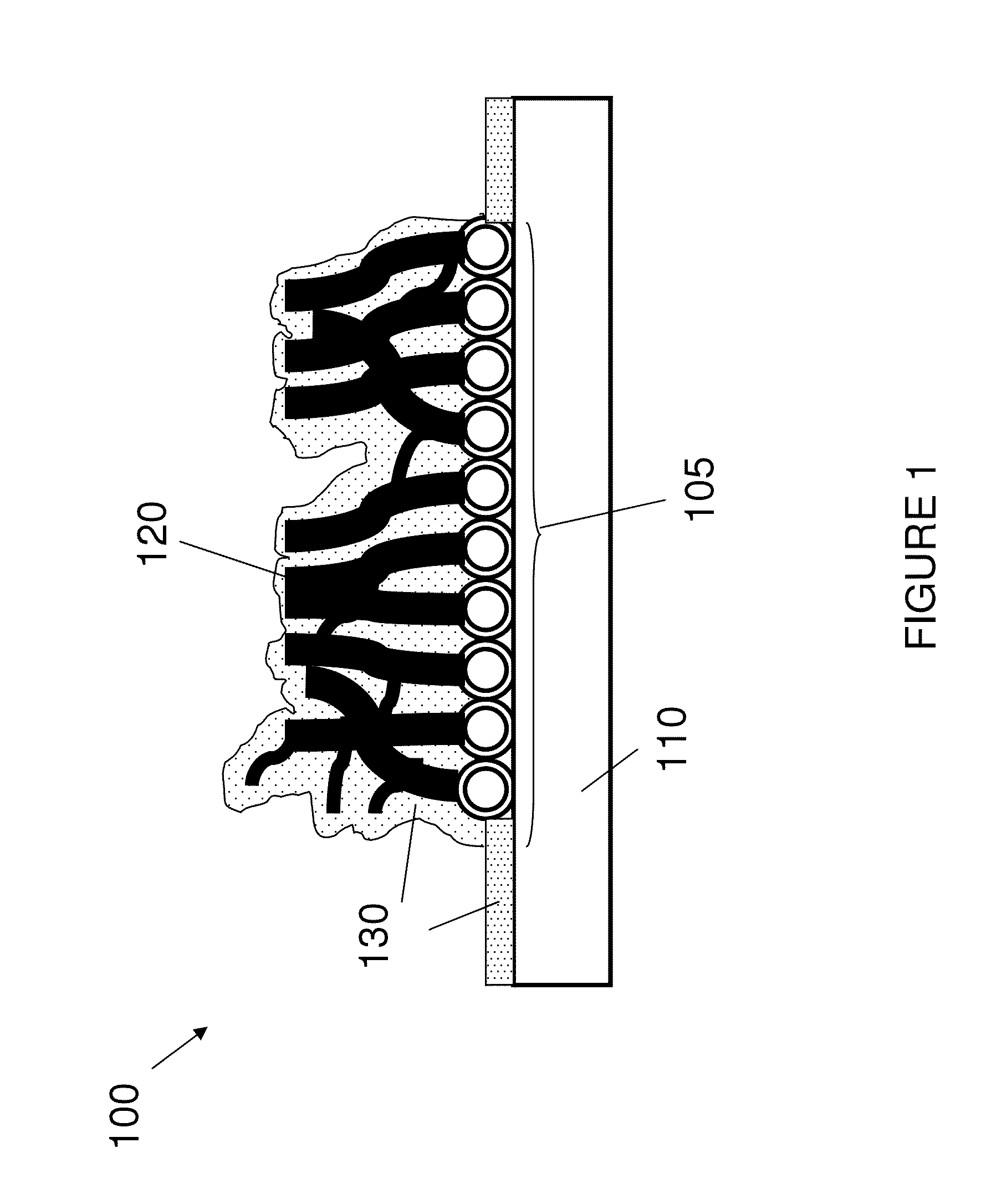

The invention is directed to carbon nanostructure composite systems which may be useful for various applications, including as dry adhesives, electronics and display technologies, or in a wide variety of other areas where organized nanostructures may be formed and integrated into a flexible substrate. The present invention provides systems and methods wherein organized nanotube structures or other nanostructures are embedded within polymers or other flexible materials to provide a flexible skin-like material, with the properties and characteristics of the nanotubes or other nanostructures exploited for use in various applications. In one aspect, the invention is directed to a carbon nanotube / polymer composite material having a plurality of carbon nanotubes formed into a predetermined architecture, with each of the plurality of nanotubes having a desired width and length. The architecture of the plurality of nanotubes defines at least one orientation for a plurality of nanotubes, and also defines the approximate spacing between nanotubes and / or groups of nanotubes. The carbon nanotube architecture is at least partially embedded with a polymer matrix in a manner that the architecture is stabilized in the predetermined architecture. The polymer matrix may also be formed to have a desired predetermined thickness.

Owner:THE UNIVERSITY OF AKRON +1

Aligned Carbon Nanotube-Polymer Materials, Systems and Methods

ActiveUS20100075024A1Stable positionLamination ancillary operationsArtificial flowers and garlandsAdhesivePolymer composites

The invention is directed to carbon nanostructure composite systems which may be useful for various applications, including as dry adhesives, electronics and display technologies, or in a wide variety of other areas where organized nanostructures may be formed and integrated into a flexible substrate. The present invention provides systems and methods wherein organized nanotube structures or other nanostructures are embedded within polymers or other flexible materials to provide a flexible skin-like material, with the properties and characteristics of the nanotubes or other nanostructures exploited for use in various applications. In one aspect, the invention is directed to a carbon nanotube / polymer composite material having a plurality of carbon nanotubes formed into a predetermined architecture, with each of the plurality of nanotubes having a desired width and length. The architecture of the plurality of nanotubes defines at least one orientation for a plurality of nanotubes, and also defines the approximate spacing between nanotubes and / or groups of nanotubes. The carbon nanotube architecture is at least partially embedded with a polymer matrix in a manner that the architecture is stabilized in the predetermined architecture. The polymer matrix may also be formed to have a desired predetermined thickness.

Owner:THE UNIVERSITY OF AKRON +1

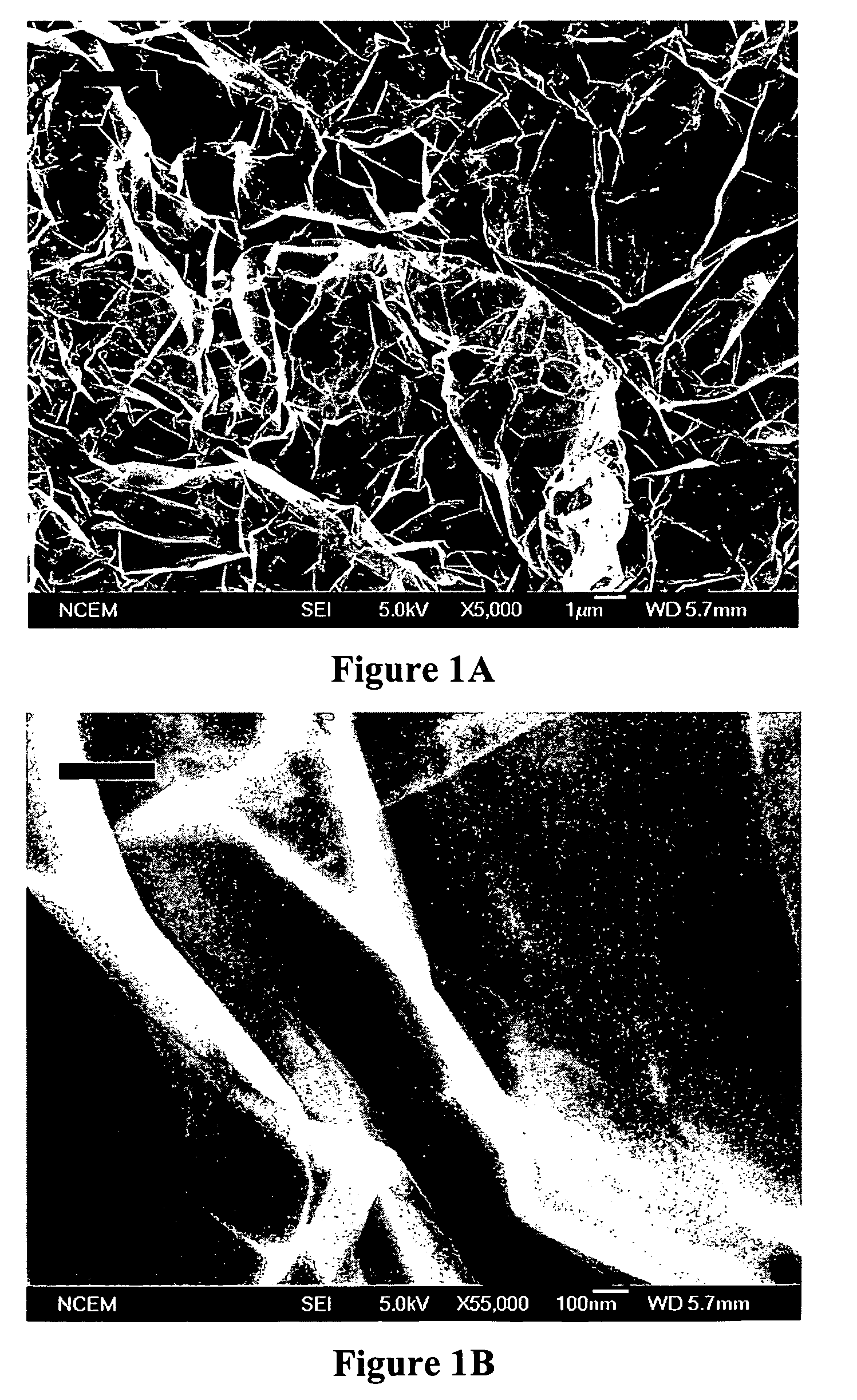

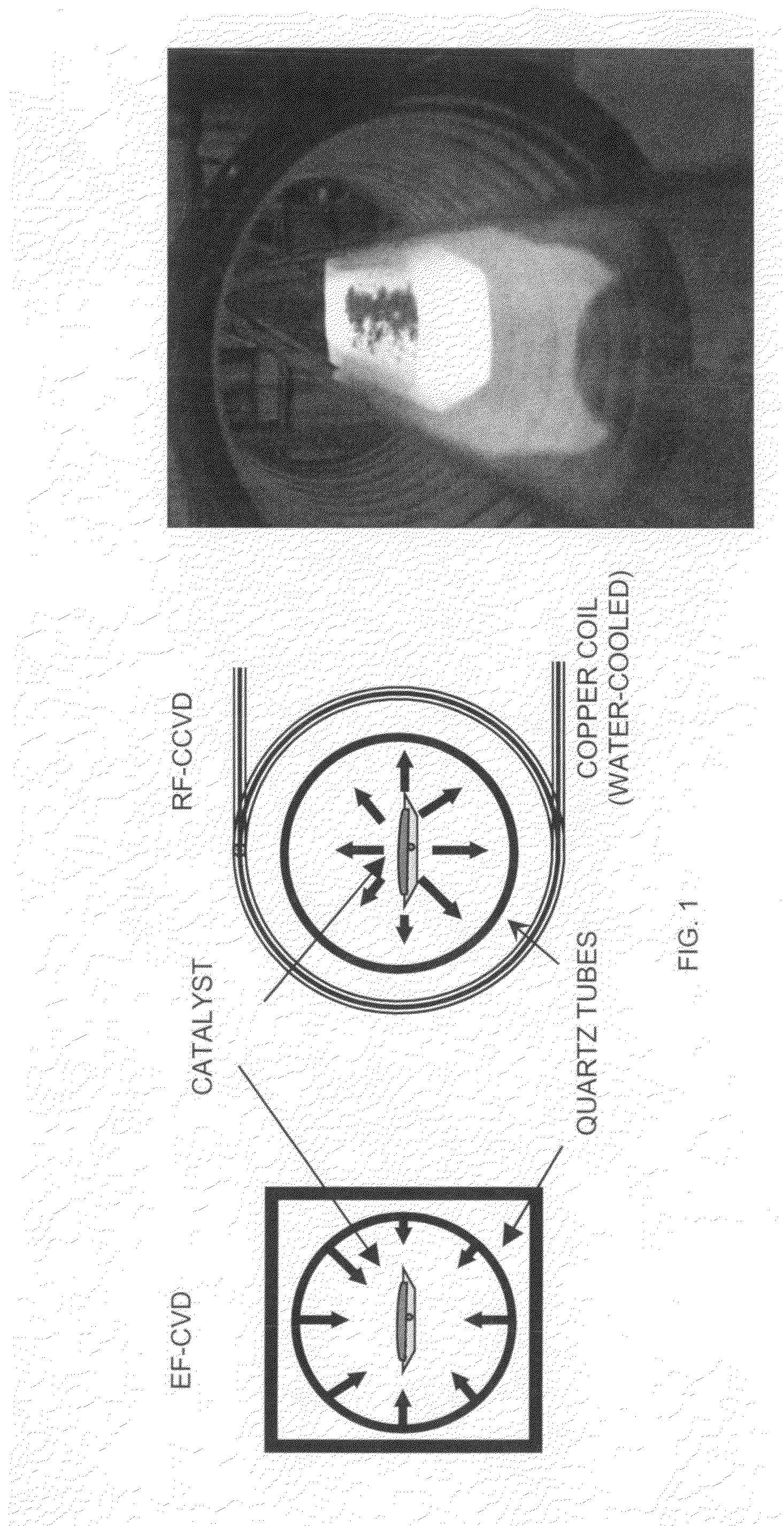

Carbon nanostructures and methods of making and using the same

ActiveUS20090011204A1Material nanotechnologySingle layer grapheneCatalyst supportCarbon nanostructures

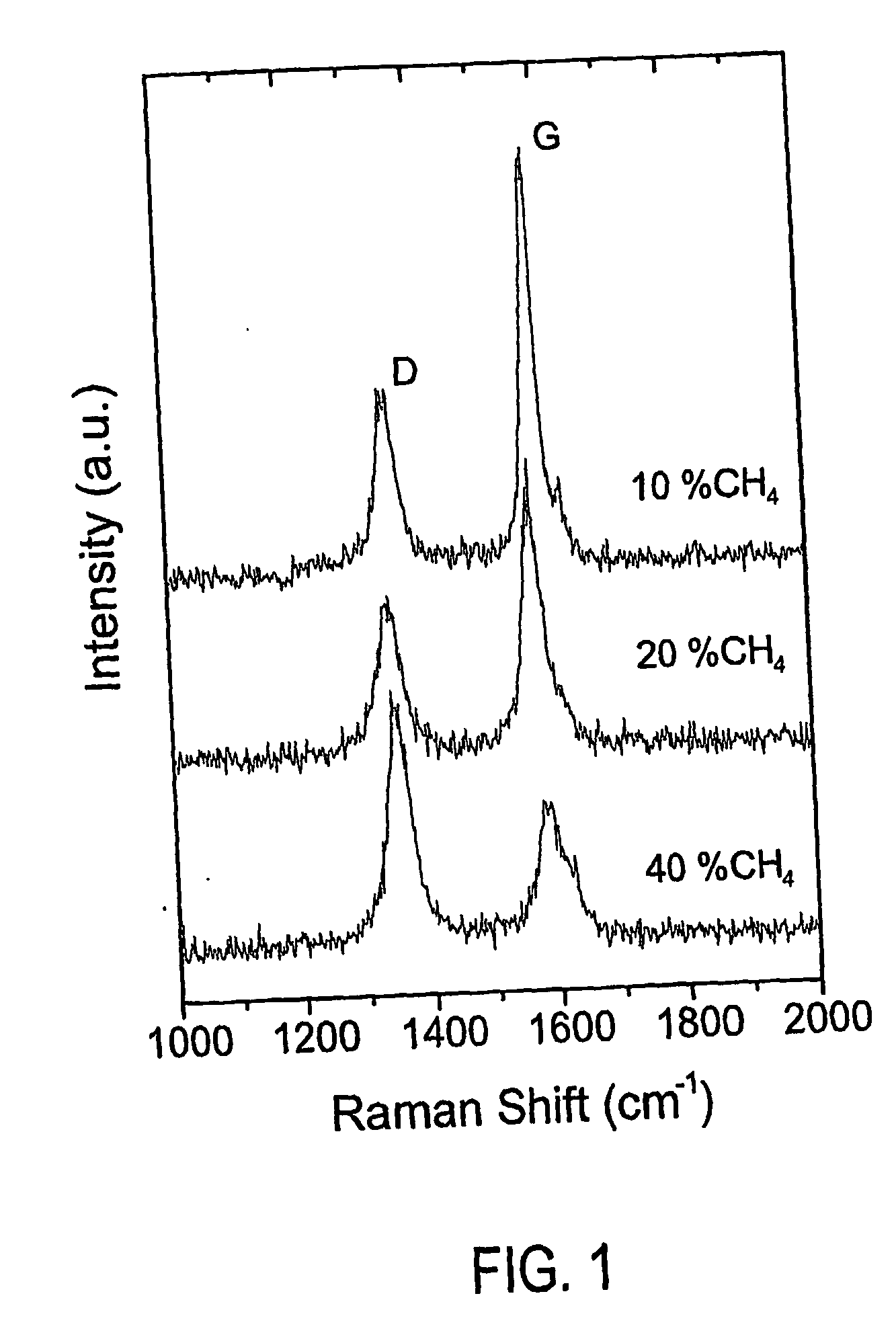

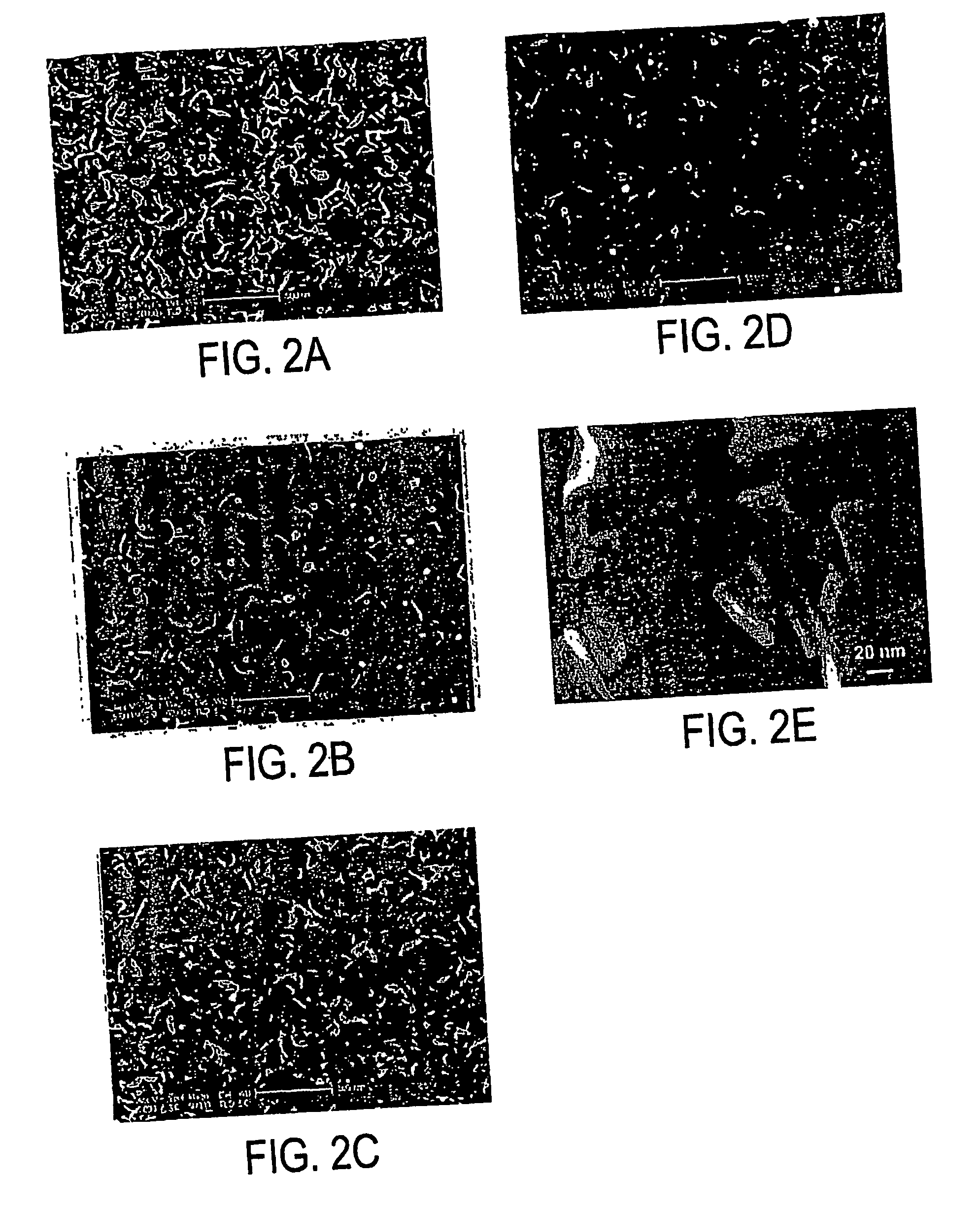

Carbon nanoflakes, methods of making the nanoflakes, and applications of the carbon nanoflakes are provided. In some embodiments, the carbon nanoflakes are carbon nanosheets, which are less than 2 nm thick. The carbon nanoflakes may be made using RF-PECVD. Carbon nanoflakes may be useful as field emitters, for hydrogen storage applications, for sensors, and as catalyst supports.

Owner:WILLIAM & MARY COLLEGE OF

Method for forming nanostructured carbons, nanostructured carbons and a substrate having nanostructured carbons formed thereby

InactiveUS20050106094A1Easy and quick to formMaterial nanotechnologyElectric discharge tubesAtmospheric pressureNanostructured carbon

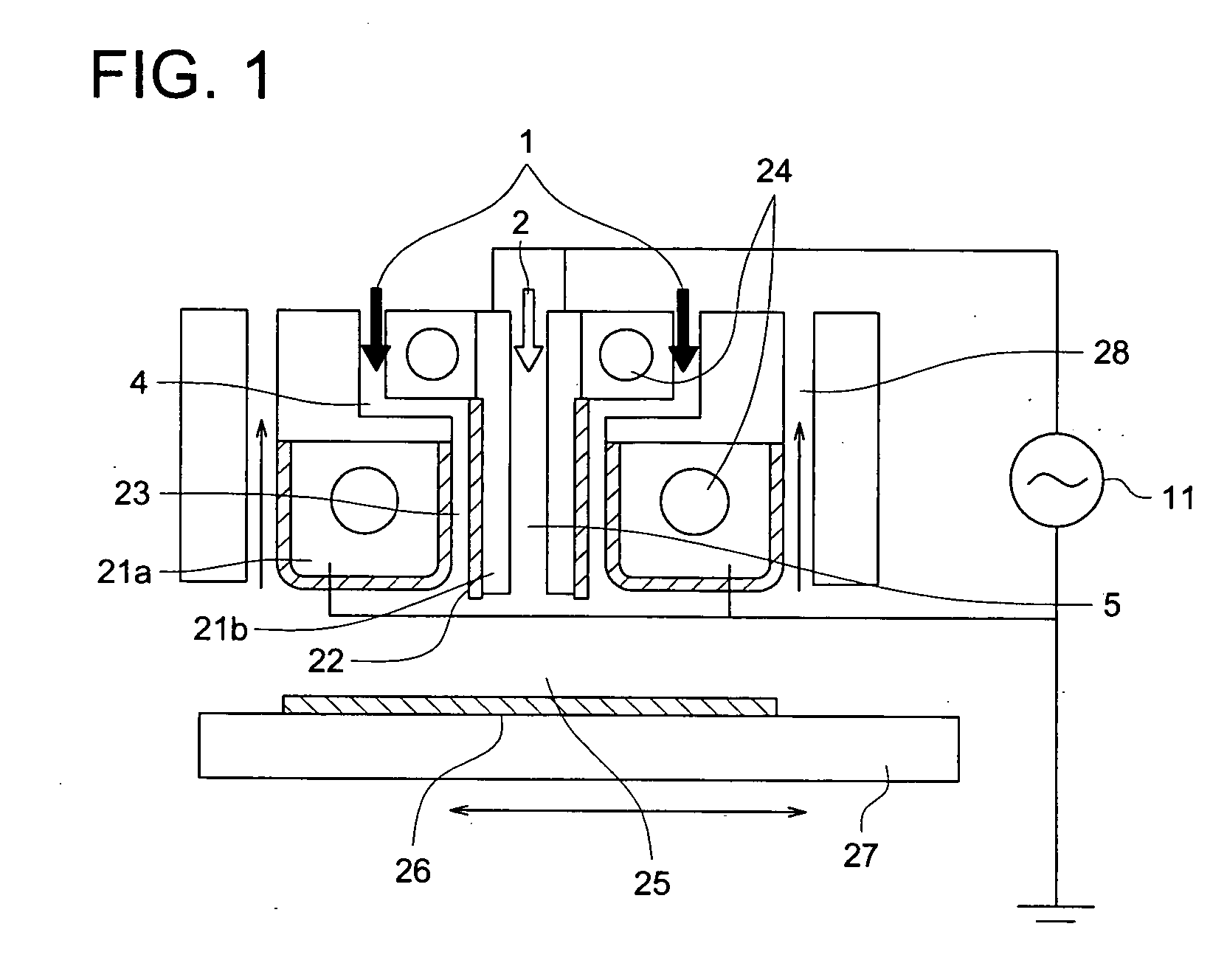

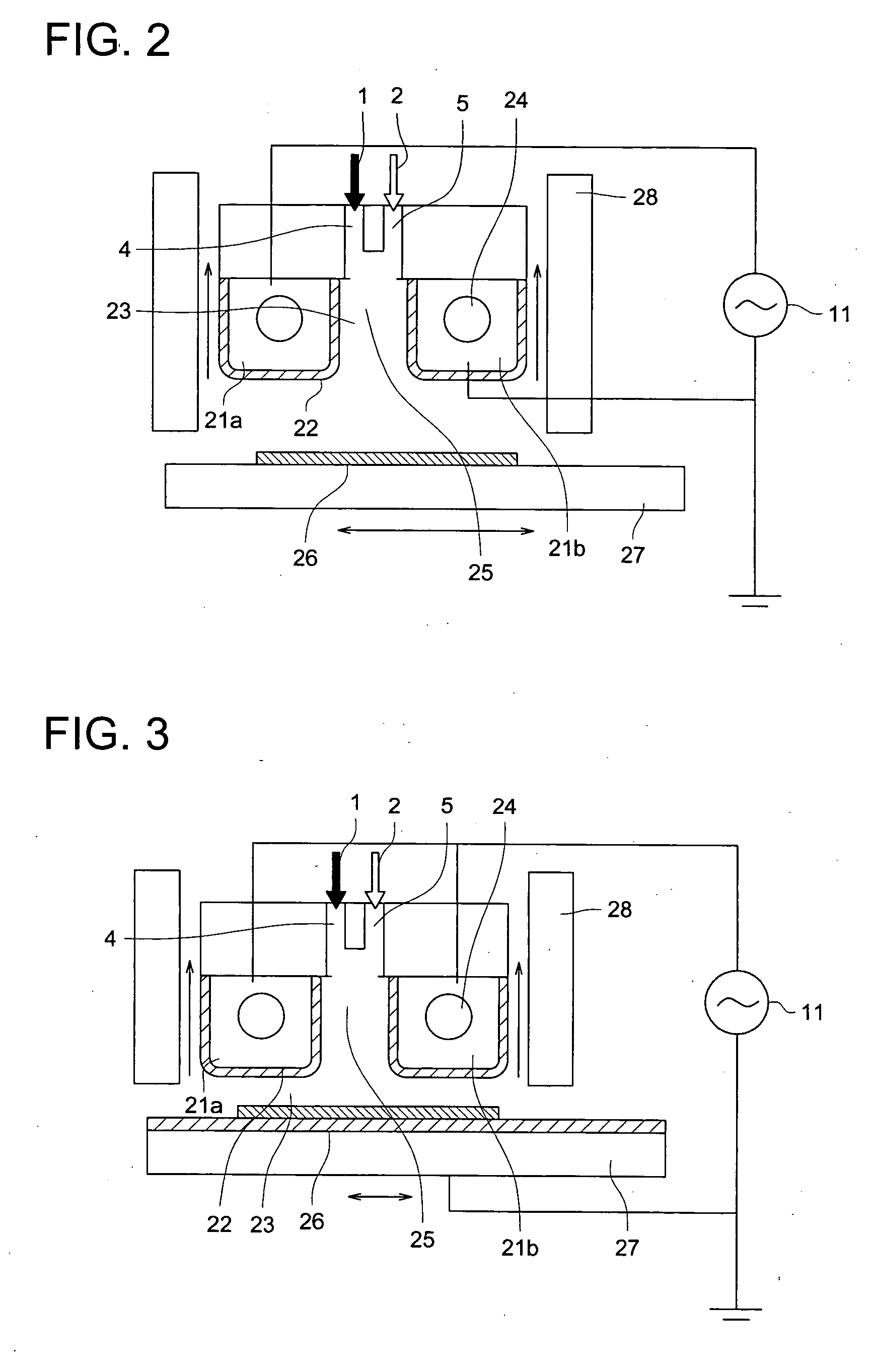

A method for forming nanostructured carbons comprising the steps of: generating a plasma by supplying at least a discharge gas between opposing electrodes and applying a high-frequency voltage between the electrodes under an approximately atmospheric pressure; existing a material gas for forming the nanostructured carbons with the plasma to generate an activated material gas; and exposing a substrate to the activated material gas.

Owner:KONICA MINOLTA INC

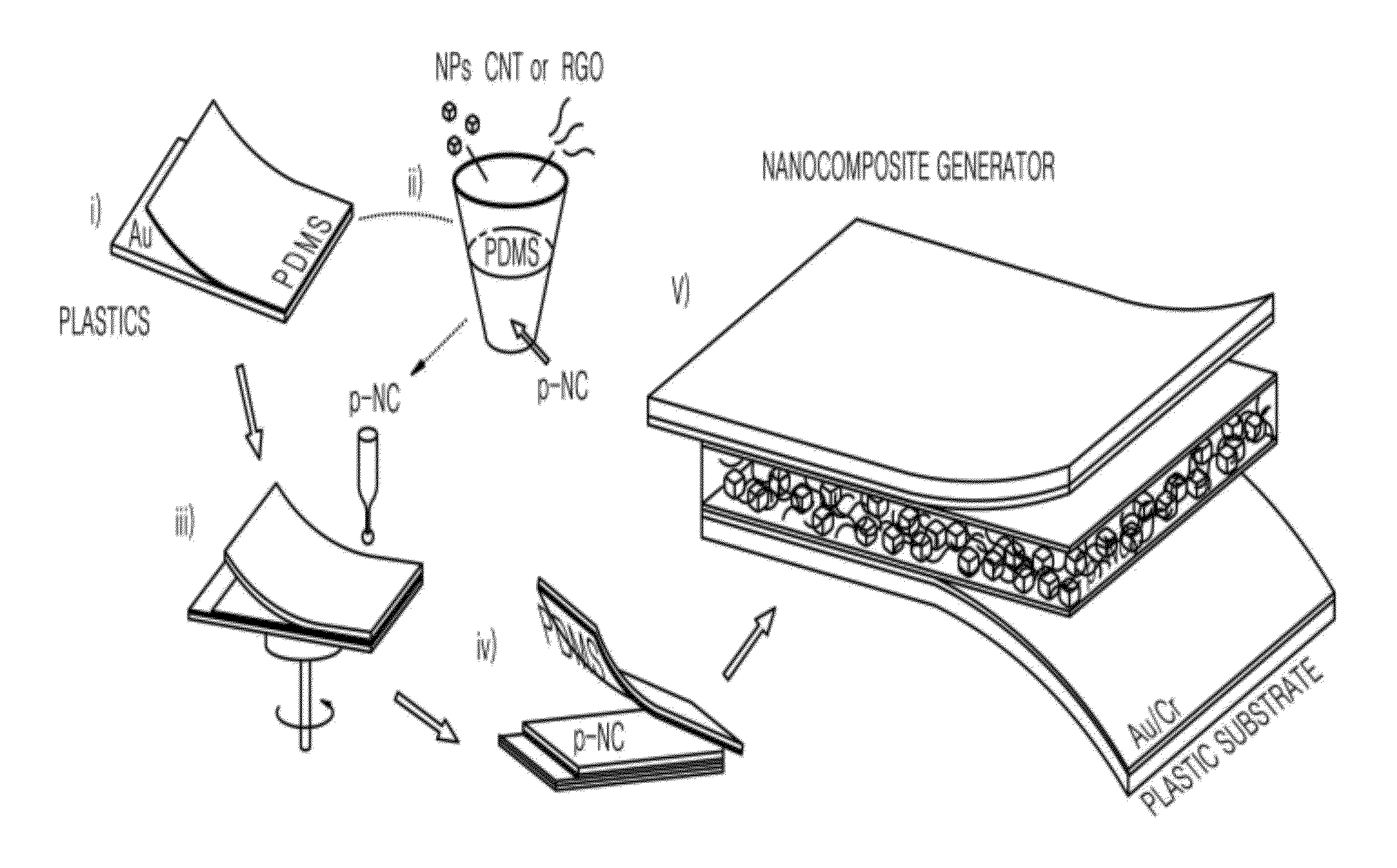

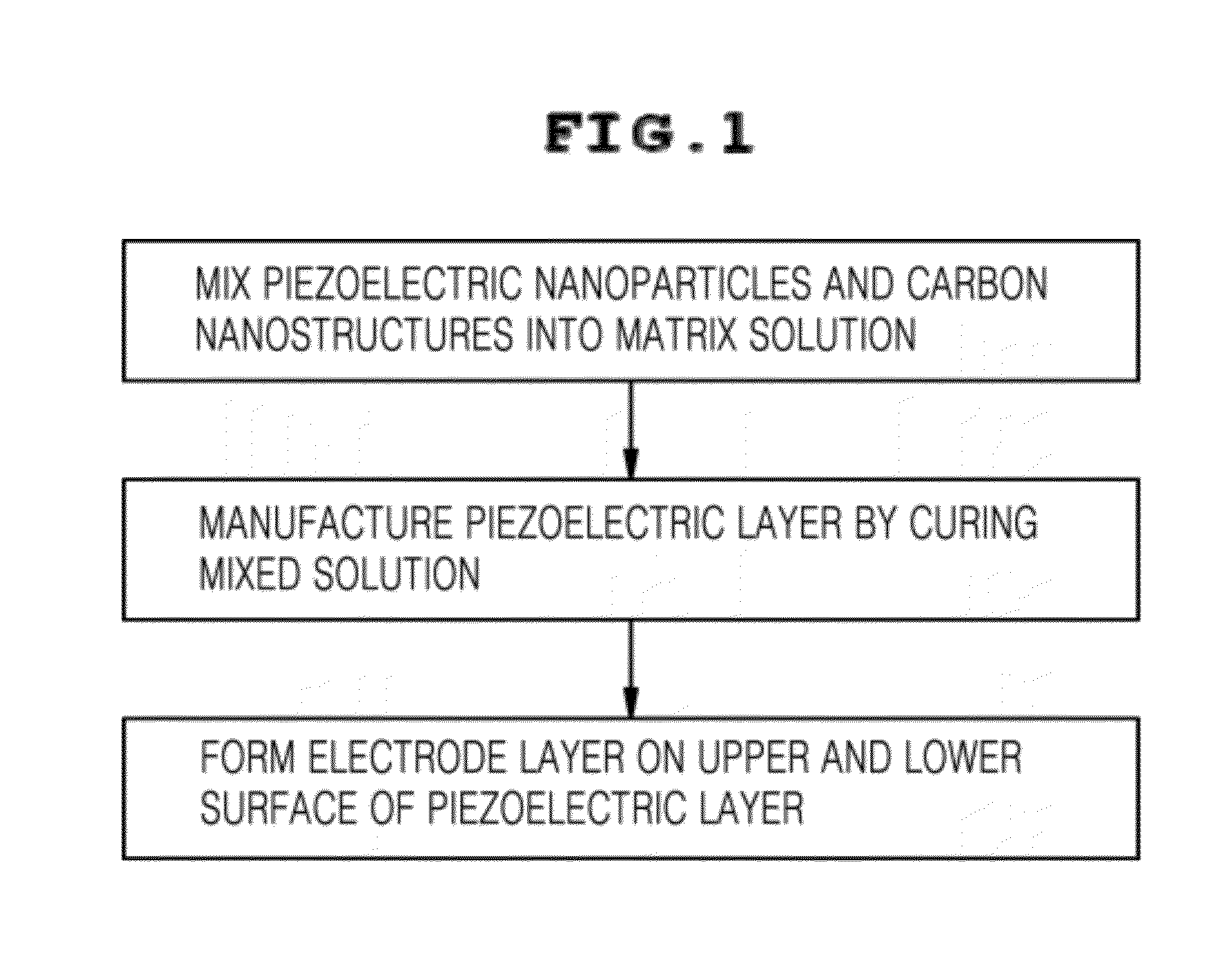

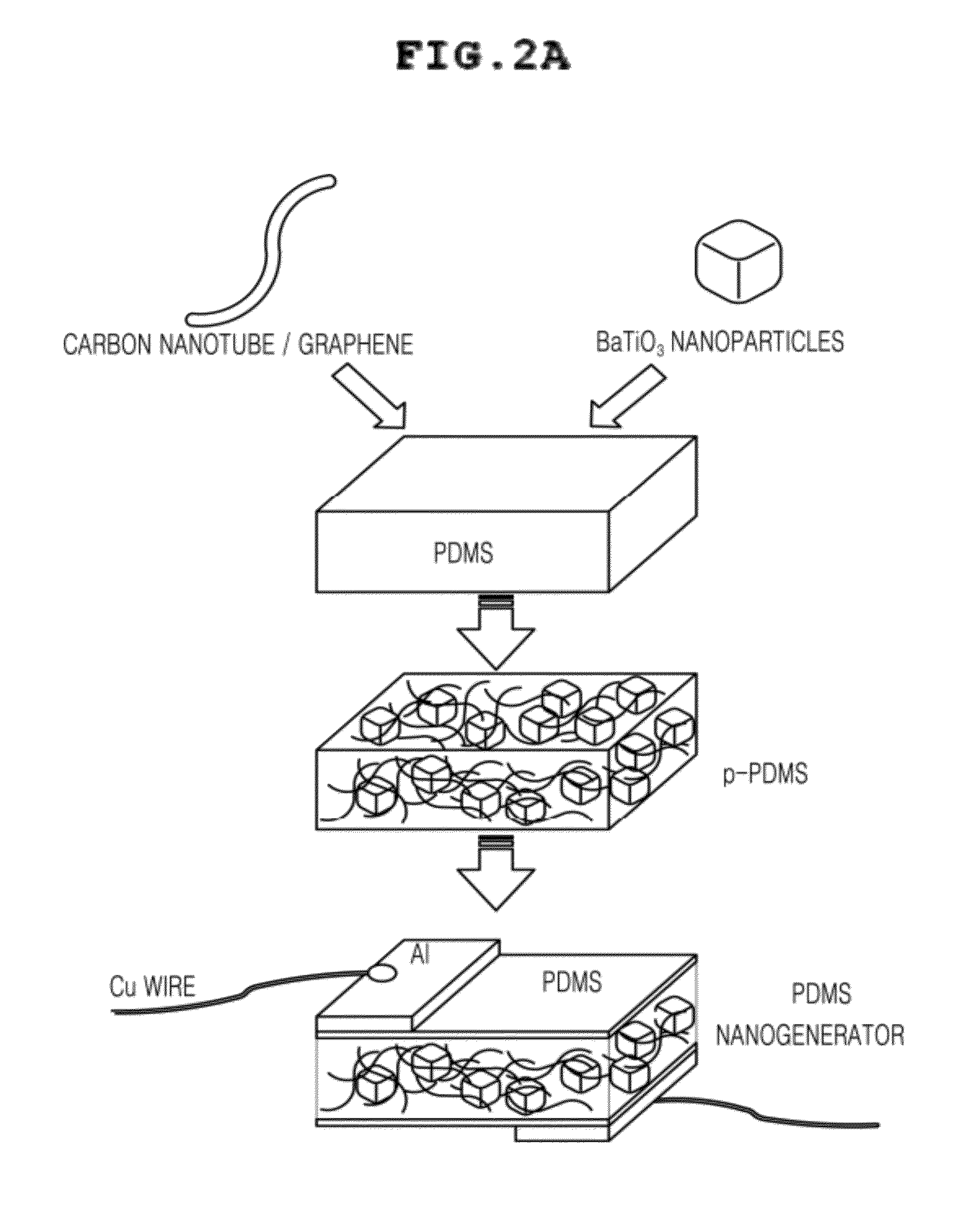

Flexible nanocomposite generator and method for manufacturing the same

ActiveUS20120133247A1Increase the areaSimple manufacturing processMaterial nanotechnologyPiezoelectric/electrostrictive device manufacture/assemblyFiberNanogenerator

There are provided a flexible nanocomposite generator and a method of manufacturing the same. A flexible nanocomposite generator according to the present invention includes a piezoelectric layer formed of a flexible matrix containing piezoelectric nanoparticles and carbon nanostructures; and electrode layers disposed on the upper and lower surfaces of both sides of the piezoelectric layer, in which according to a method for manufacturing a flexible nanocomposite generator according to the present invention and a flexible nanogenerator, it is possible to manufacture a flexible nanogenerator with a large area and a small thickness. Therefore, the nanogenerator may be used as a portion of a fiber or cloth. Accordingly, the nanogenerator according to the present invention generates power in accordance with bending of attached cloth, such that it is possible to continuously generate power in accordance with movement of a human body.

Owner:KOREA ADVANCED INST OF SCI & TECH

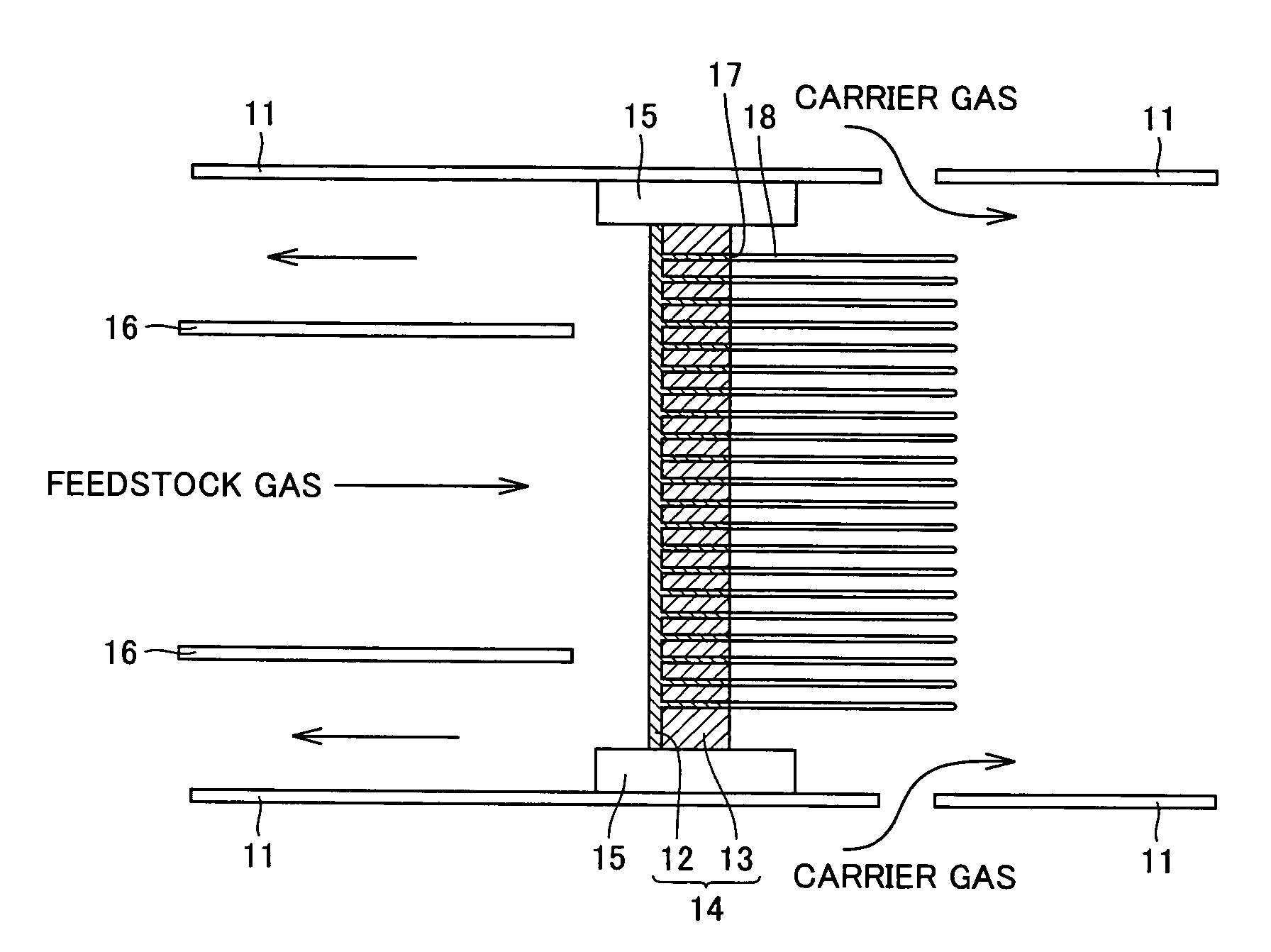

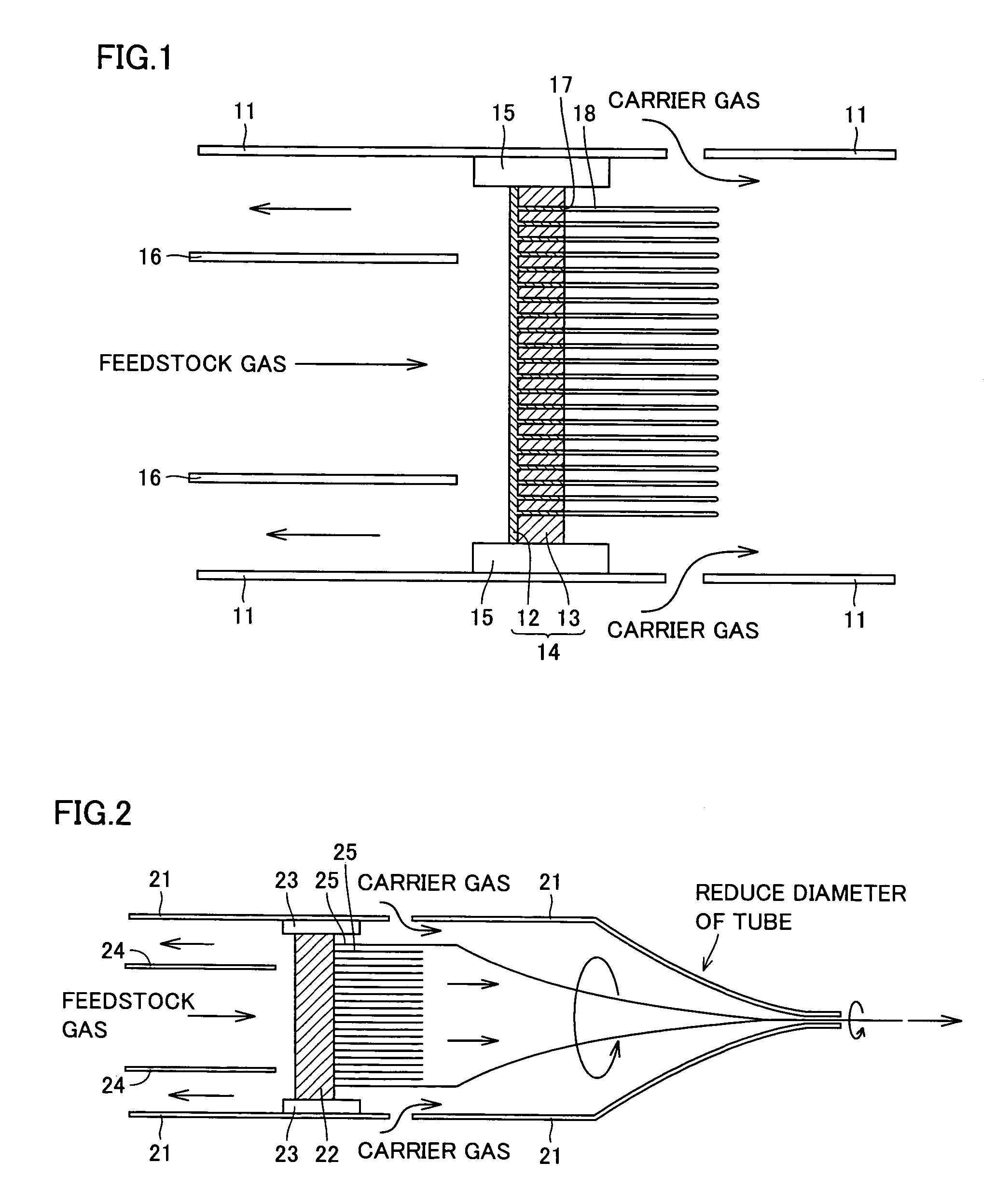

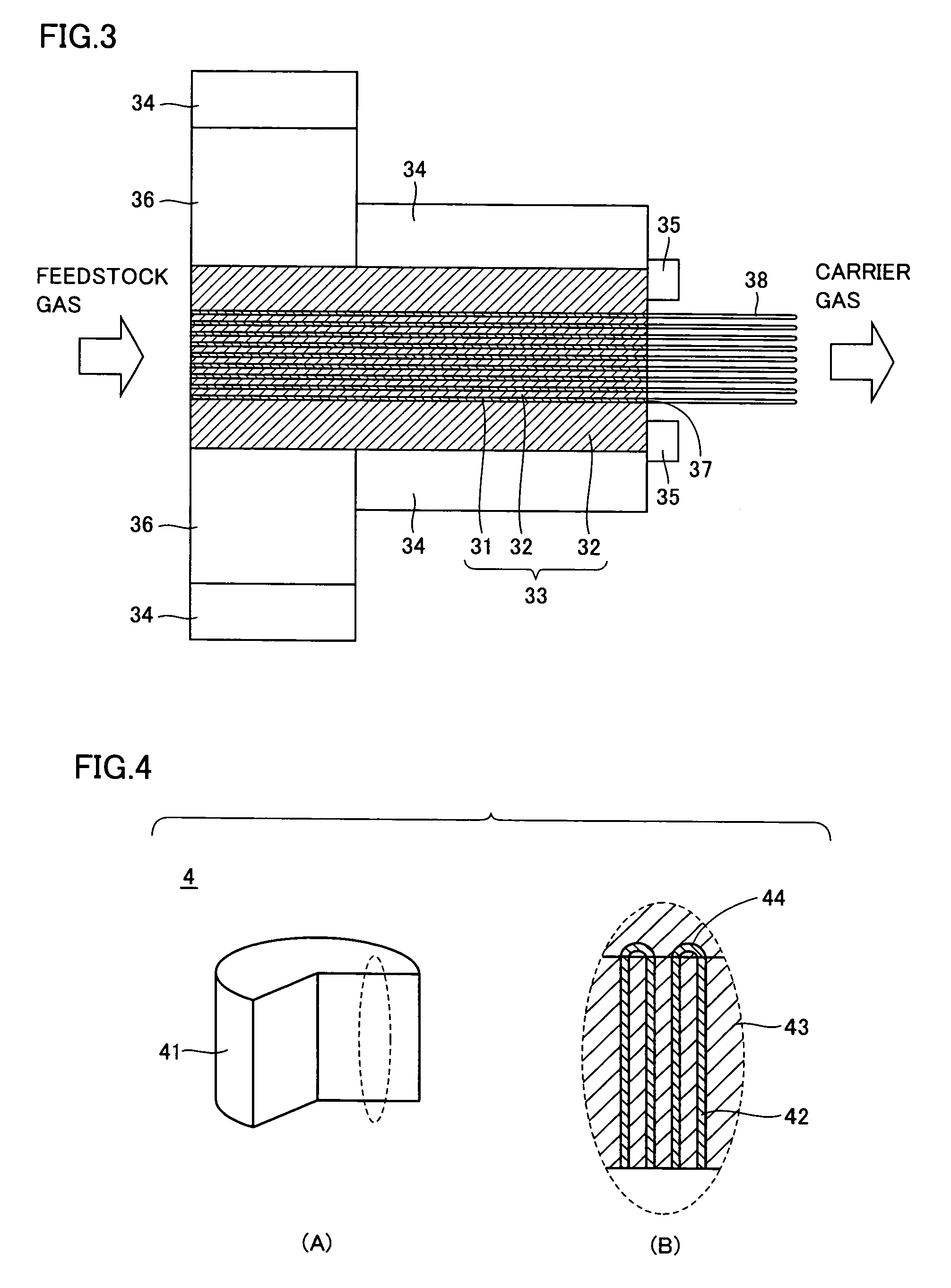

Method of manufacturing carbon nanostructure

ActiveUS7785558B2Uniform shapeHigh purityMaterial nanotechnologyPigmenting treatmentCarbon ionGas phase

The present invention relates to a method of manufacturing a carbon nanostructure for growing crystalline carbon by vapor deposition from a crystal growth surface of a catalytic base including a catalytic material, and in particular, to a method of manufacturing a carbon nanostructure where at least two gases including a feedstock gas are brought into contact with the catalytic base simultaneously. Preferably, the at least two gases are constituted by at least one feedstock gas and at least one carrier gas. Preferably, the carrier gas is brought into contact with the crystal growth surface, and the feedstock gas is brought into contact with at least a part of a region except for the crystal growth surface with which the carrier gas has been brought into contact. Preferably, the material gas contains an ion, and further preferably, it contains a carbon ion.

Owner:SUMITOMO ELECTRIC IND LTD

Carbon and electrospun nanostructures

InactiveUS20050025974A1Material nanotechnologyElectric discharge heatingIron saltsElectrospun nanofibers

The present invention is directed to the production of nanostructures, e.g., single wall carbon nanotubes (“SWNT”) and / or multi-wall carbon nanotubes (“MWNT”), from solutions containing a polymer, such as polyacrylonitrile (PAN). In particular, the invention is directed to the production of nanostructures, for example, SWNT and / or MWNT, from mixtures, e.g., solutions, containing polyacrylonitrile, polyaniline emeraldine base (PANi) or a salt thereof, an iron salt, e.g., iron chloride, and a solvent. In one embodiment, a mixture containing polyacrylonitrile, polyaniline emeraldine base or a salt thereof, an iron salt, e.g., iron chloride, and a solvent is formed and the mixture is electrospun to form nanofibers. In another embodiment, the electrospun nanofibers are then oxidized, e.g., heated in air, and subsequently pyrolyzed to form carbon nanostructures.

Owner:PHYSICAL SCI

CNS-shielded wires

A shielded wire includes a carbon nanostructure (CNS)-shielding layer including a CNS material in a matrix material, the CNS-shielding layer being monolithic and disposed about a dielectric layer and a conducting wire, wherein the dielectric layer is disposed between the CNS-shielding layer and the conducting wire. An extruded thermoplastic jacket includes a CNS material, the extruded thermoplastic jacket being configured to protect at least one wire. A thermoplastic article includes a CNS-infused fiber material and a flexible thermoplastic.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

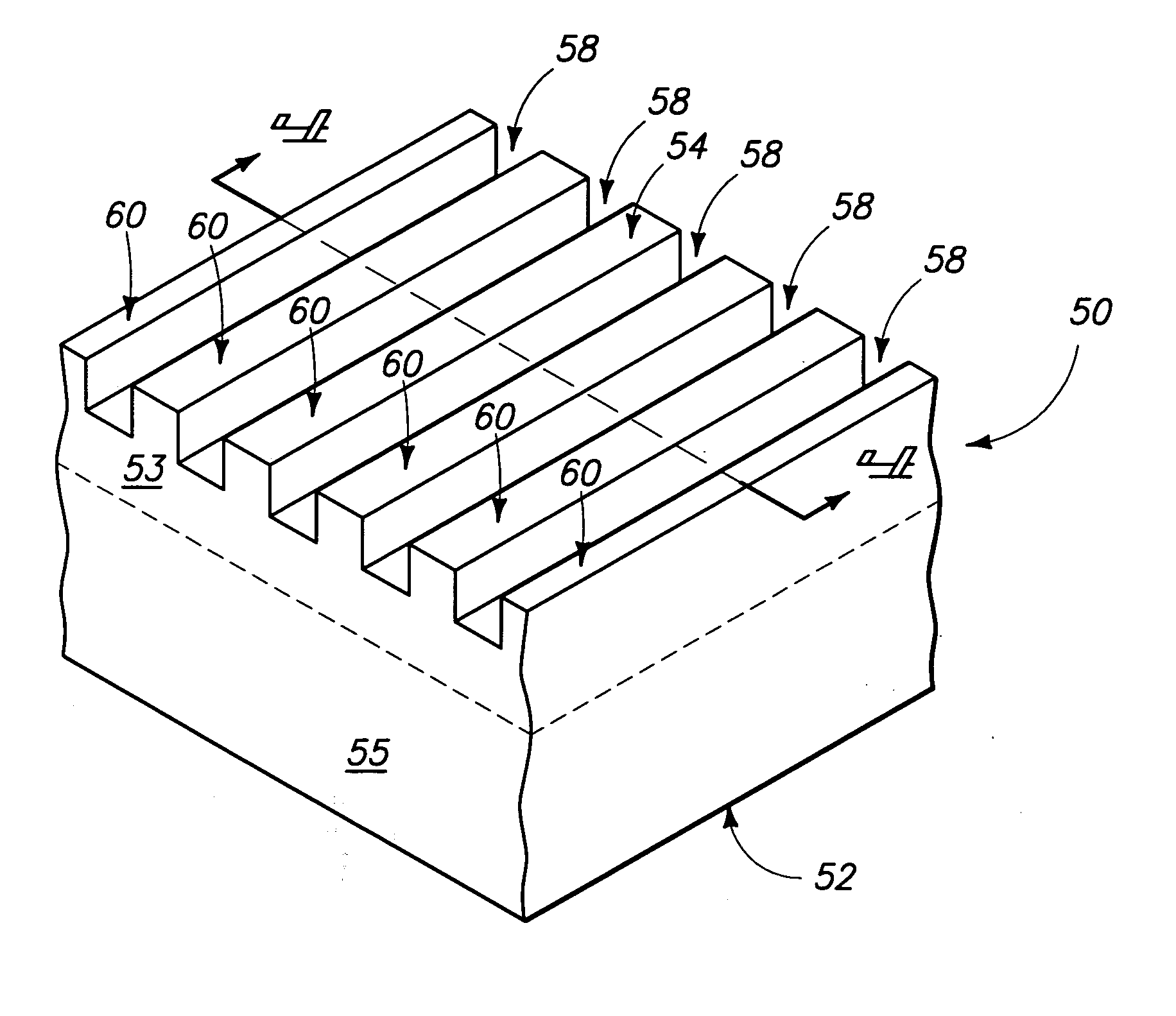

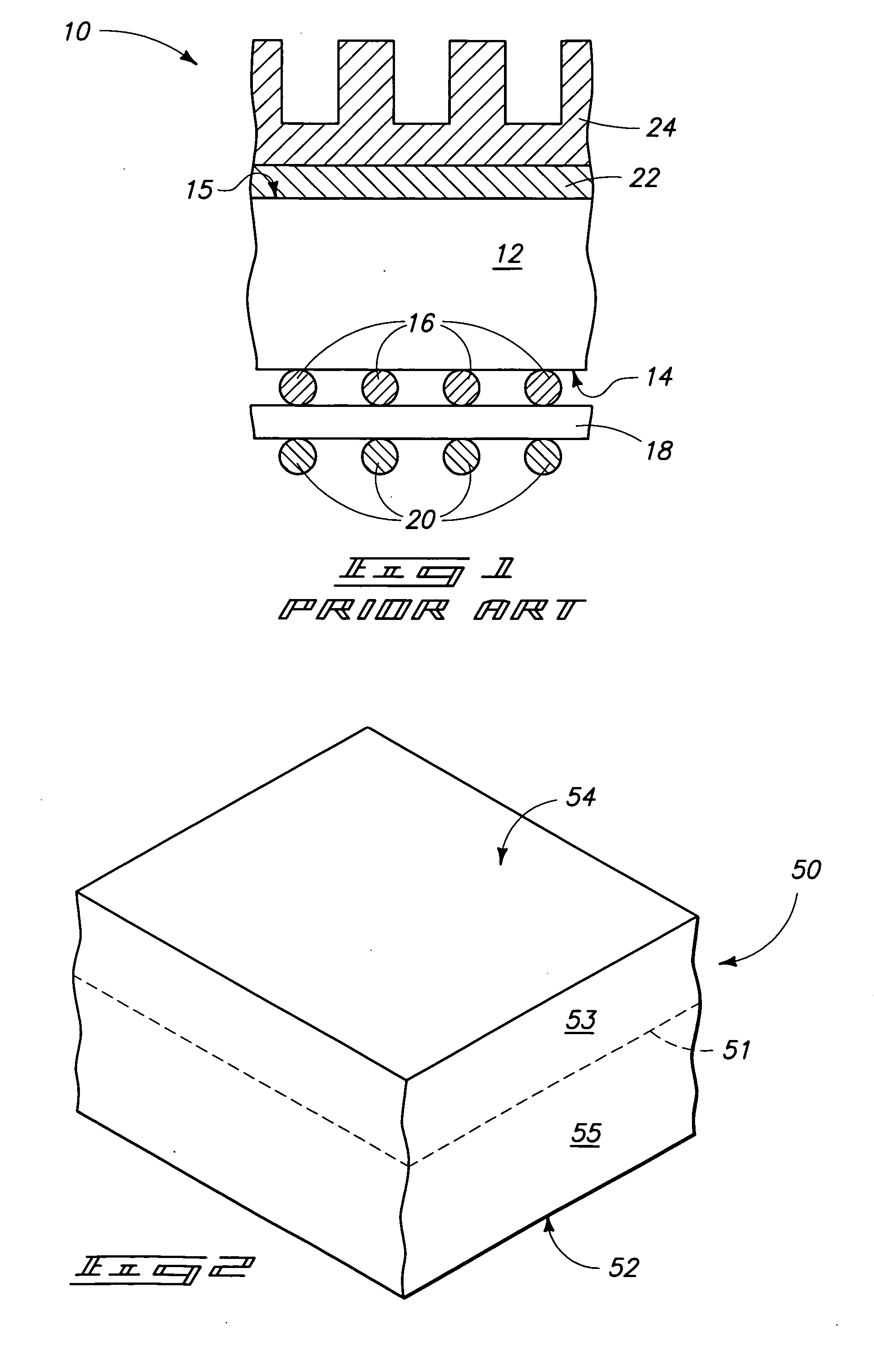

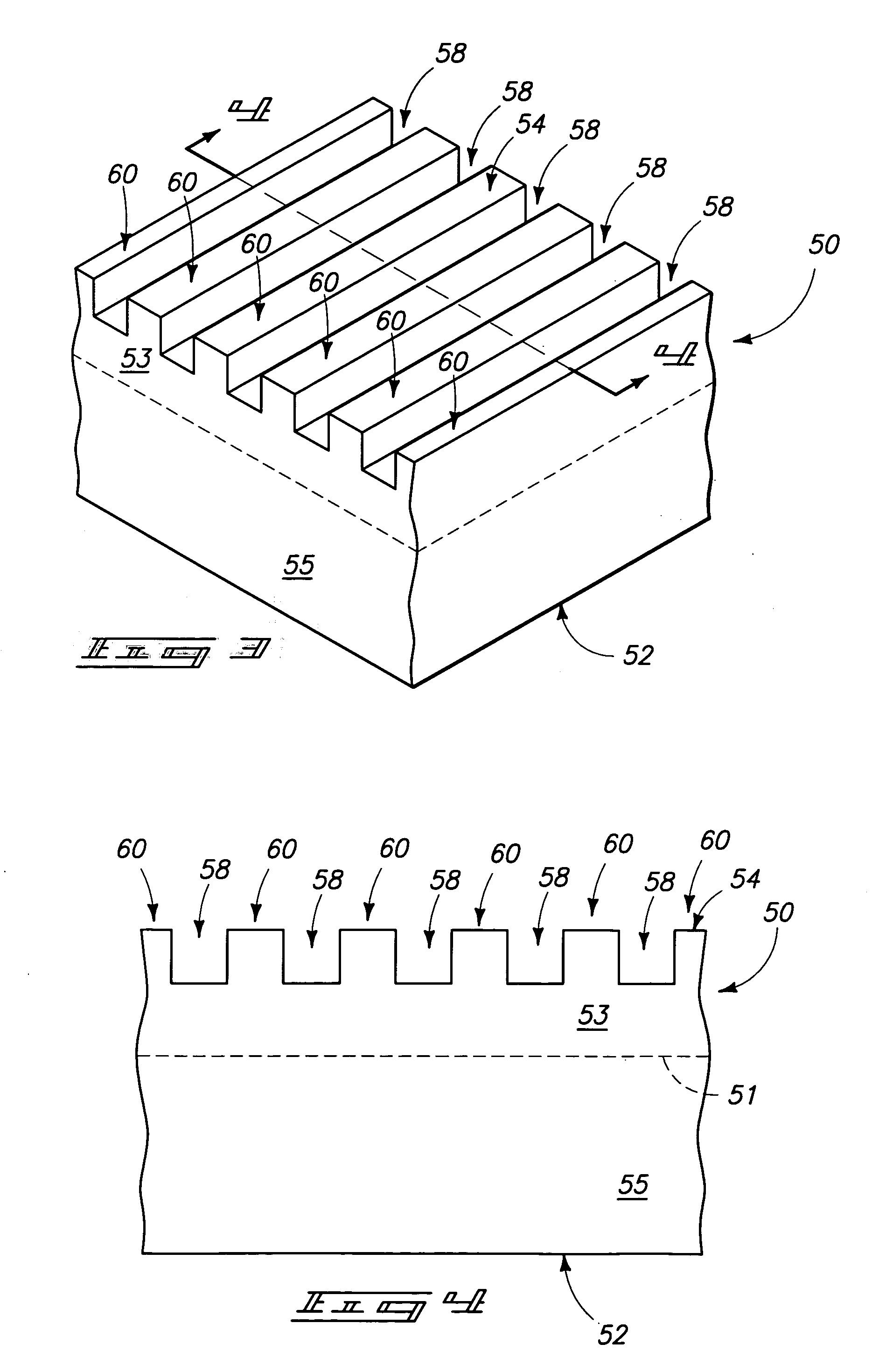

Semiconductor packages, methods of forming semiconductor packages, and methods of cooling semiconductor dies

The invention includes semiconductor packages having grooves within a semiconductor die backside; and includes semiconductor packages utilizing carbon nanostructures (such as, for example, carbon nanotubes) as thermally conductive interface materials. The invention also includes methods of cooling a semiconductor die in which coolant is forced through grooves in a backside of the die, and includes methods of making semiconductor packages.

Owner:MICRON TECH INC

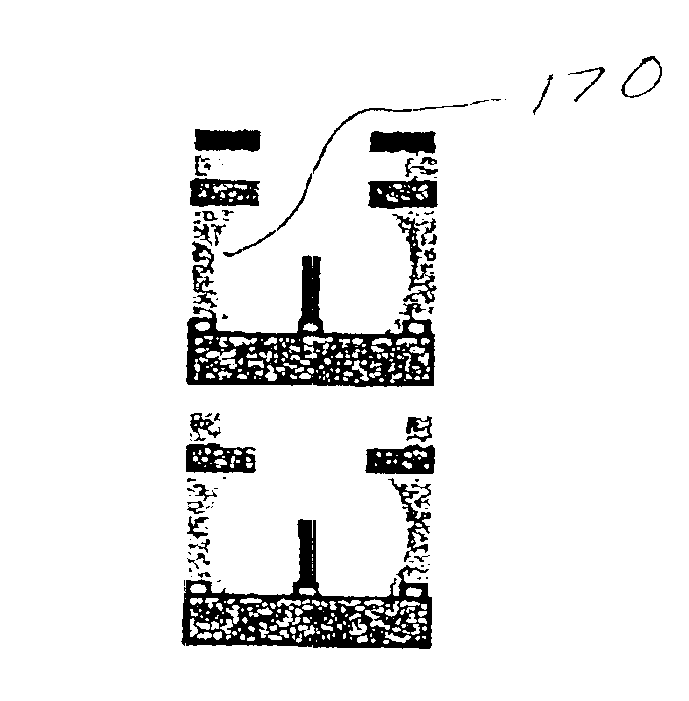

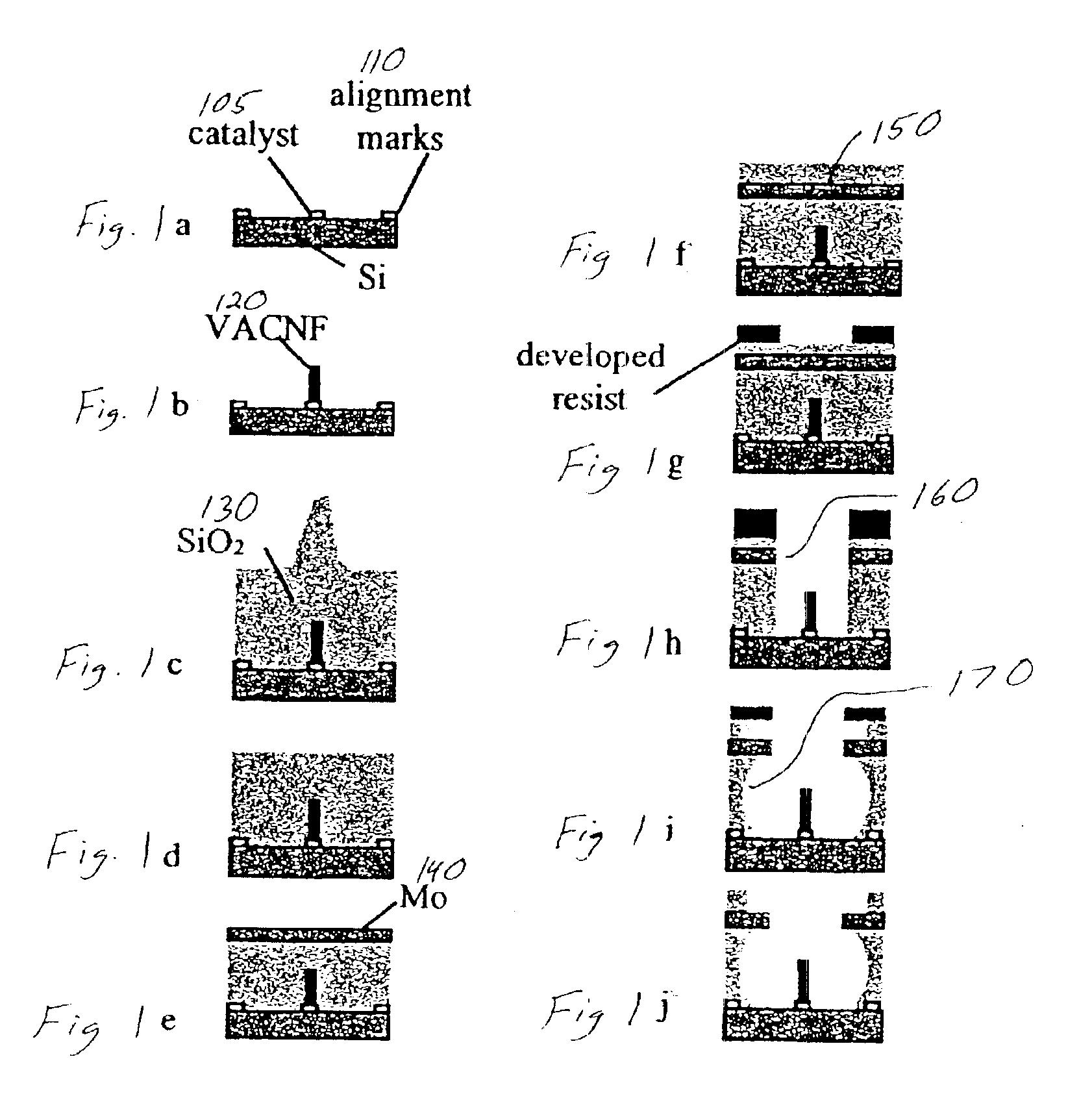

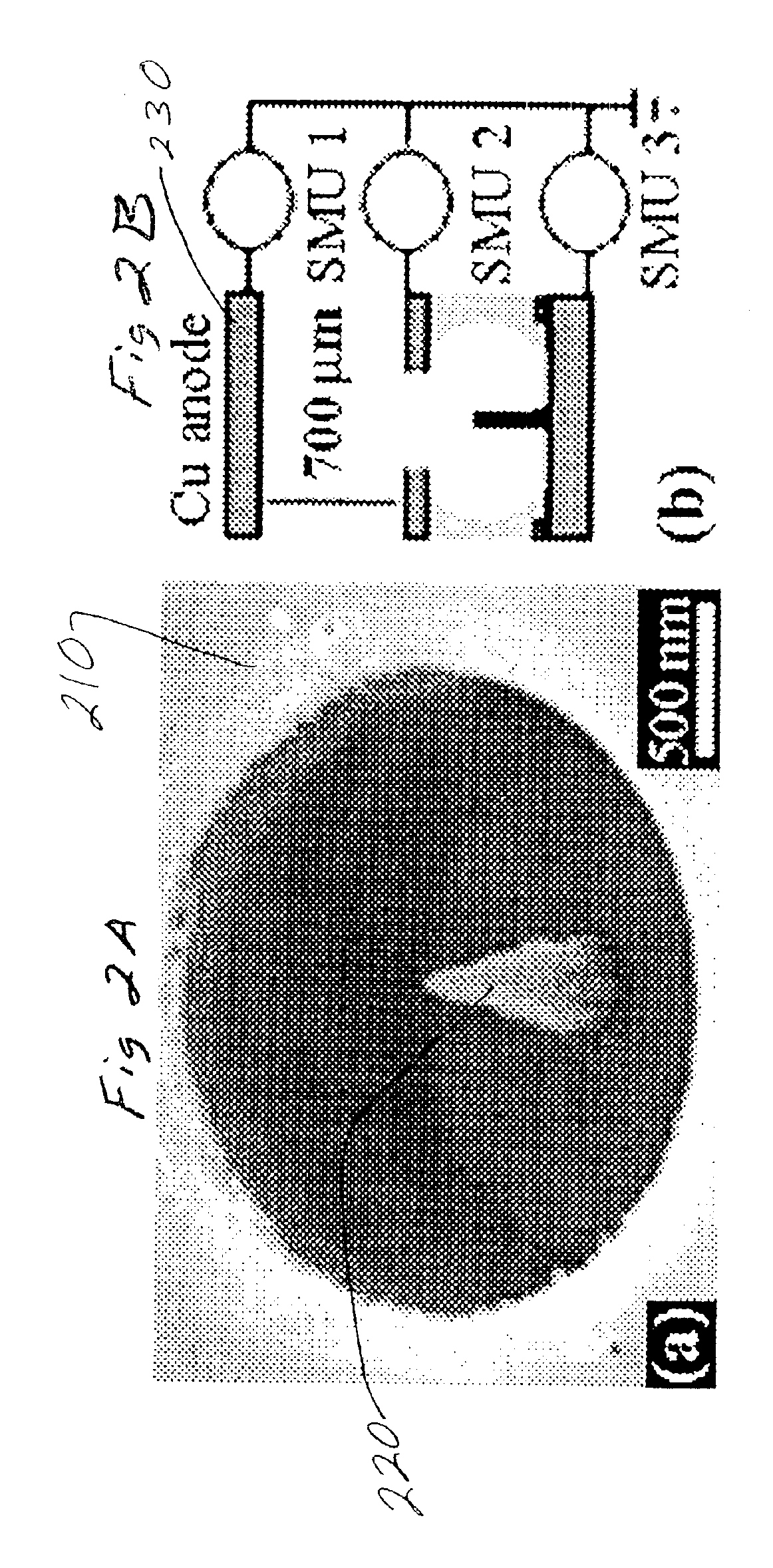

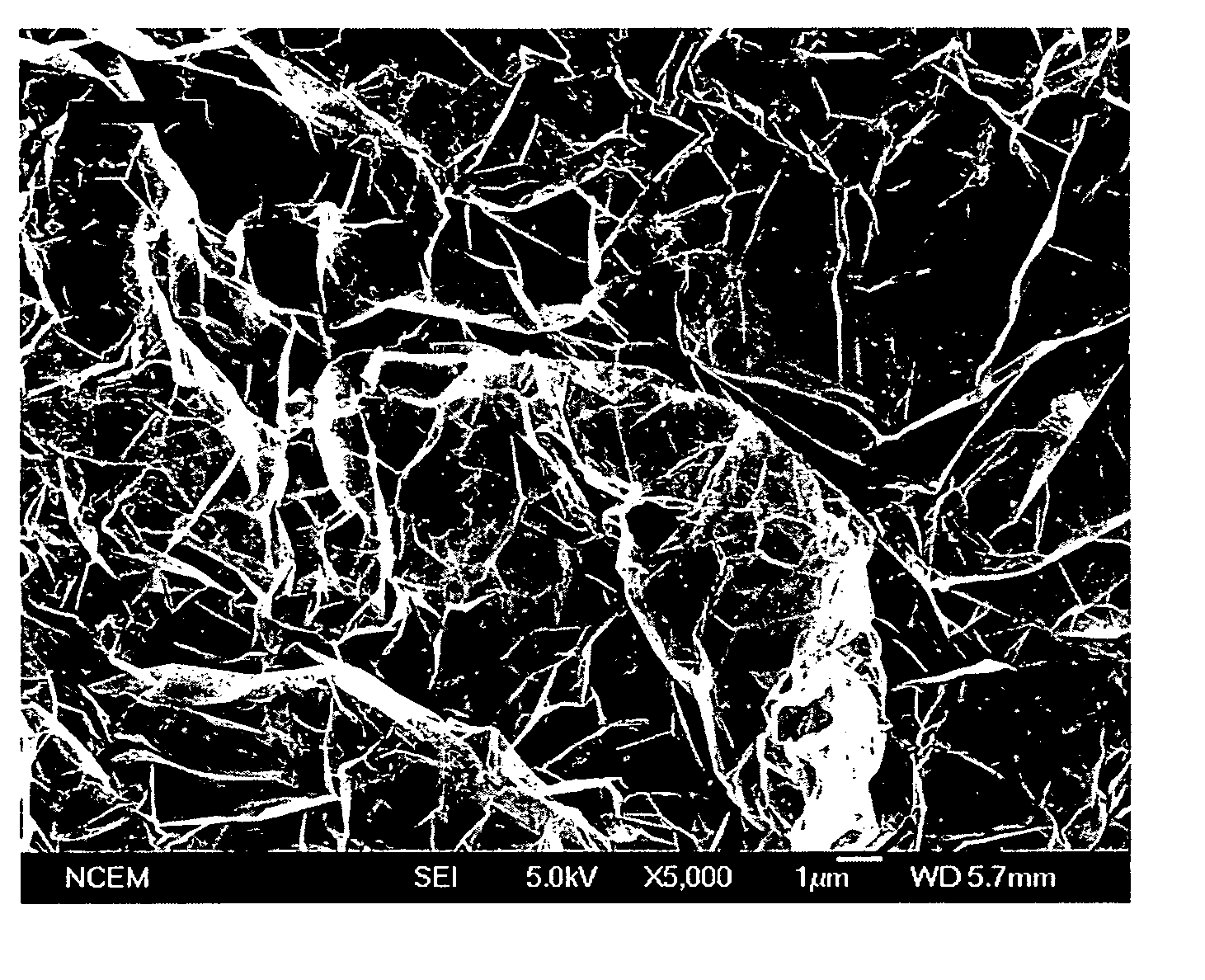

Gated fabrication of nanostructure field emission cathode material within a device

InactiveUS6858455B2Electric discharge tubesDecorative surface effectsField emission deviceDielectric

Gated field emission devices and systems and methods for their fabrication are described. A method includes growing a substantially vertically aligned carbon nanostructure, the substantially vertically aligned carbon nanostructure coupled to a substrate; covering at least a portion of the substantially vertically aligned carbon nanostructure with a dielectric; forming a gate, the gate coupled to the dielectric; and releasing the substantially vertically aligned carbon nanostructure by forming an aperture in the gate and removing a portion of the dielectric.

Owner:UT BATTELLE LLC

Mass production of carbon nanostructures

Carbon nanostructures are mass produced from graphite. In particularly preferred aspects, graphene is thermo-chemically derived from graphite and used in numerous compositions. In further preferred aspects, the graphene is re-shaped to form other nanostructures, including nanofractals, optionally branched open-ended SWNT, nanoloops, and nanoonions.

Owner:PETRIK VIKTOR I

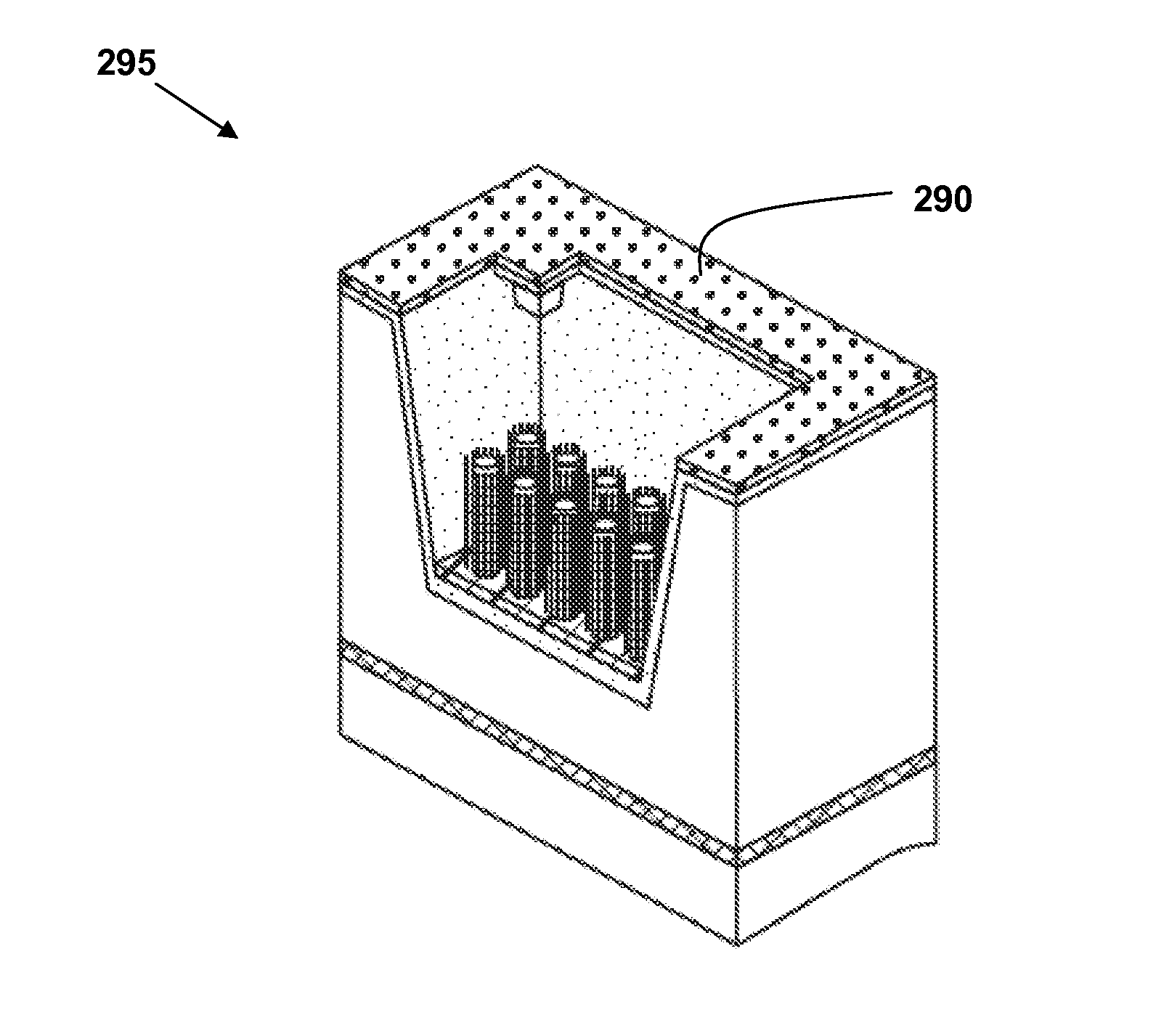

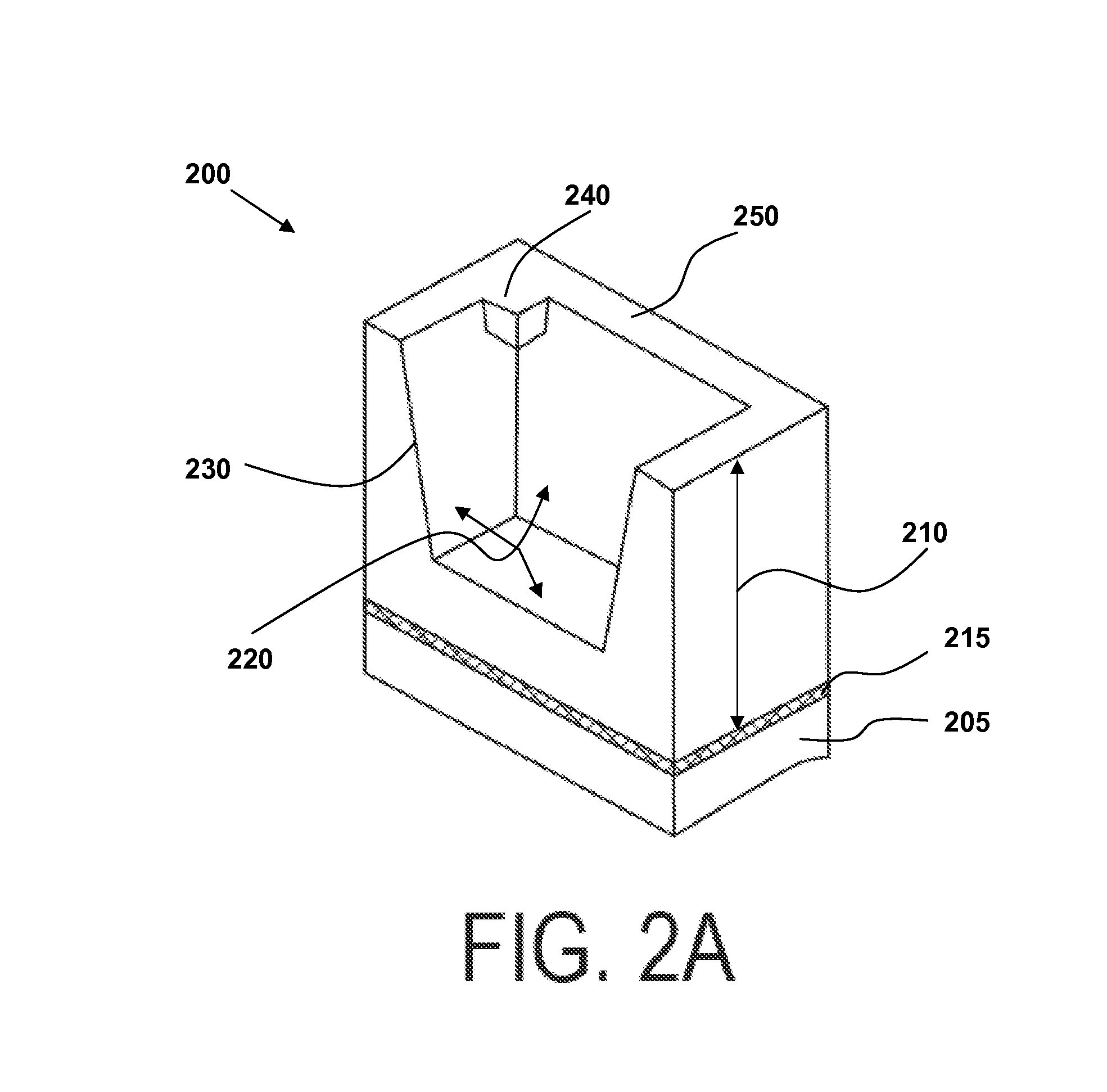

Supercapacitor cells and micro-supercapacitors

This invention provides a micro-supercapacitor with high energy density and high power density. In some variations, carbon nanostructures, such as carbon nanotubes, coated with a metal oxide, such as ruthenium oxide, are grown in a supercapacitor cavity that contains no separator. A lid is bonded to the cavity using a bonding process to form a hermetic seal. These micro-supercapacitors may be fabricated from silicon-on-insulator wafers according to the disclosed methods. An exemplary micro-supercapacitor is cubic with a length of about 50-100 μm. The absence of a separator translates to higher energy storage volume and less wasted space within the supercapacitor cell. The energy density of the micro-supercapacitor may exceed 150 J / cm3 and the peak output power density may be in the range of about 2-20 W / cm3, in various embodiments.

Owner:HRL LAB

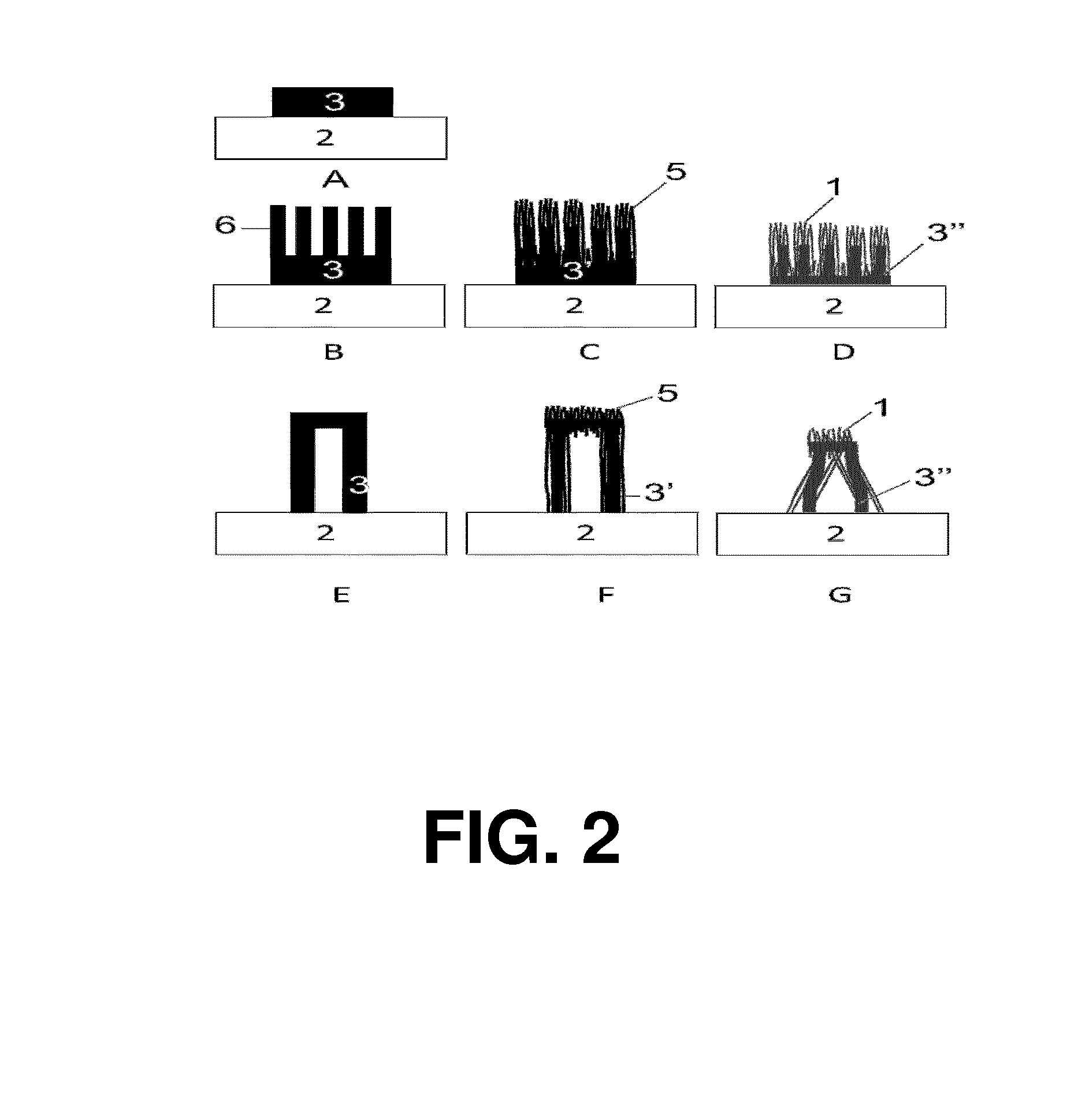

Hierarchical Carbon Nano and Micro Structures

ActiveUS20140079921A1Material nanotechnologyDecorative surface effectsMicro structureOxygen plasma etching

Disclosed are methods for fabricating pyrolysed carbon nanostructures. An example method includes providing a substrate, depositing a polymeric material, subjecting the polymeric material to a plasma etching process to form polymeric nanostructures, and pyrolysing the polymeric nanostructures to form carbon nanostructures. The polymeric material comprises either compounds with different plasma etch rates or compounds that can mask a plasma etching process. The plasma etching process may be an oxygen plasma etching process.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

Hybrid capacitor-battery and supercapacitor with active bi-functional electrolyte

InactiveUS20140065447A1High densityHigh pulse currentCapacitor and primary/secondary cellsHybrid capacitor electrodesSupercapacitorCapacitor

An electrode includes a substrate having a carbon nanostructure (CNS) disposed thereon and a coating including an active material conformally disposed about the carbon nanostructure and the substrate. The electrode is used in a hybrid capacitor-battery having a bifunctional electrolyte capable of energy storage.

Owner:GOOGLE LLC +1

Nanoporous films and method for manufacturing the same

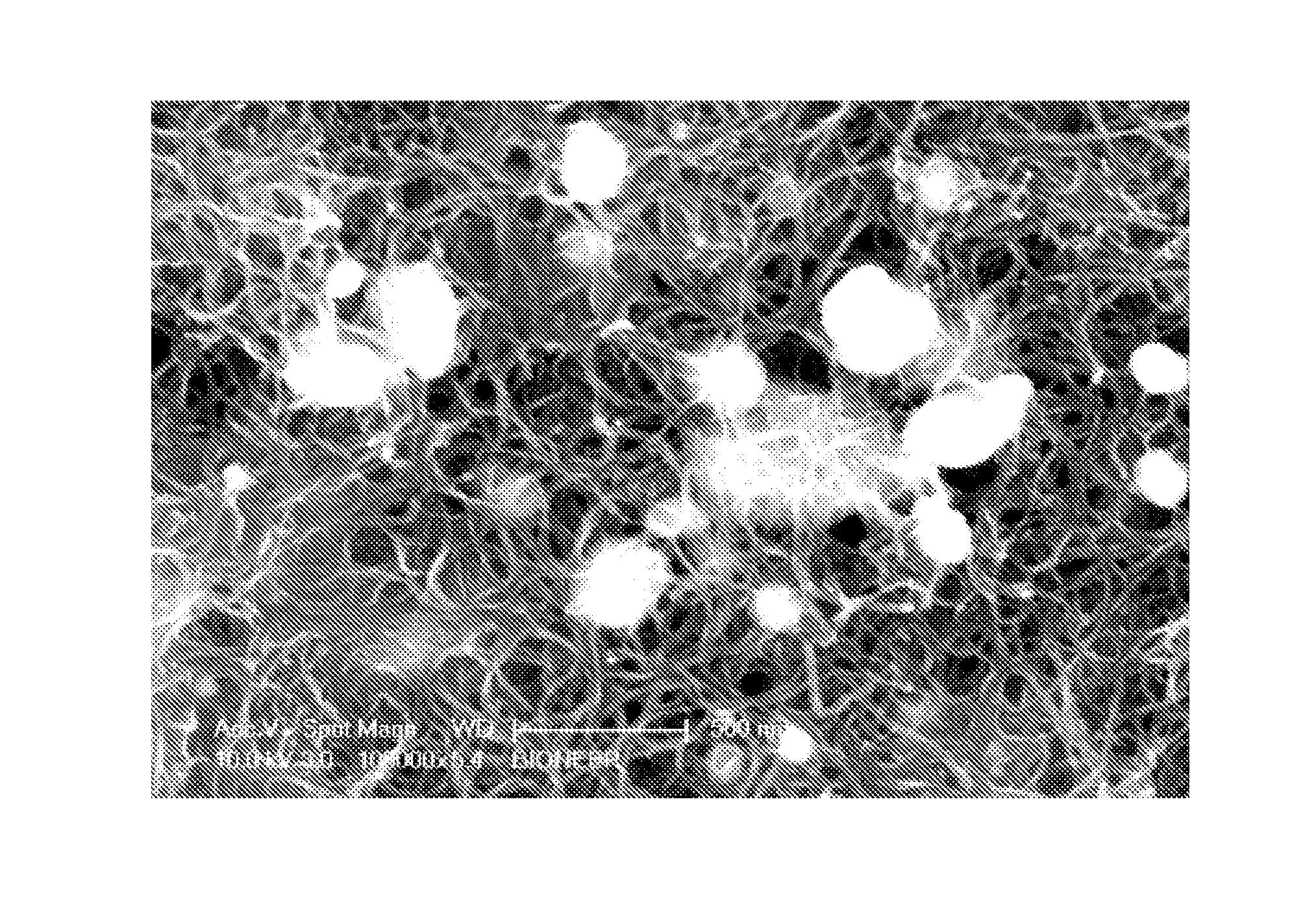

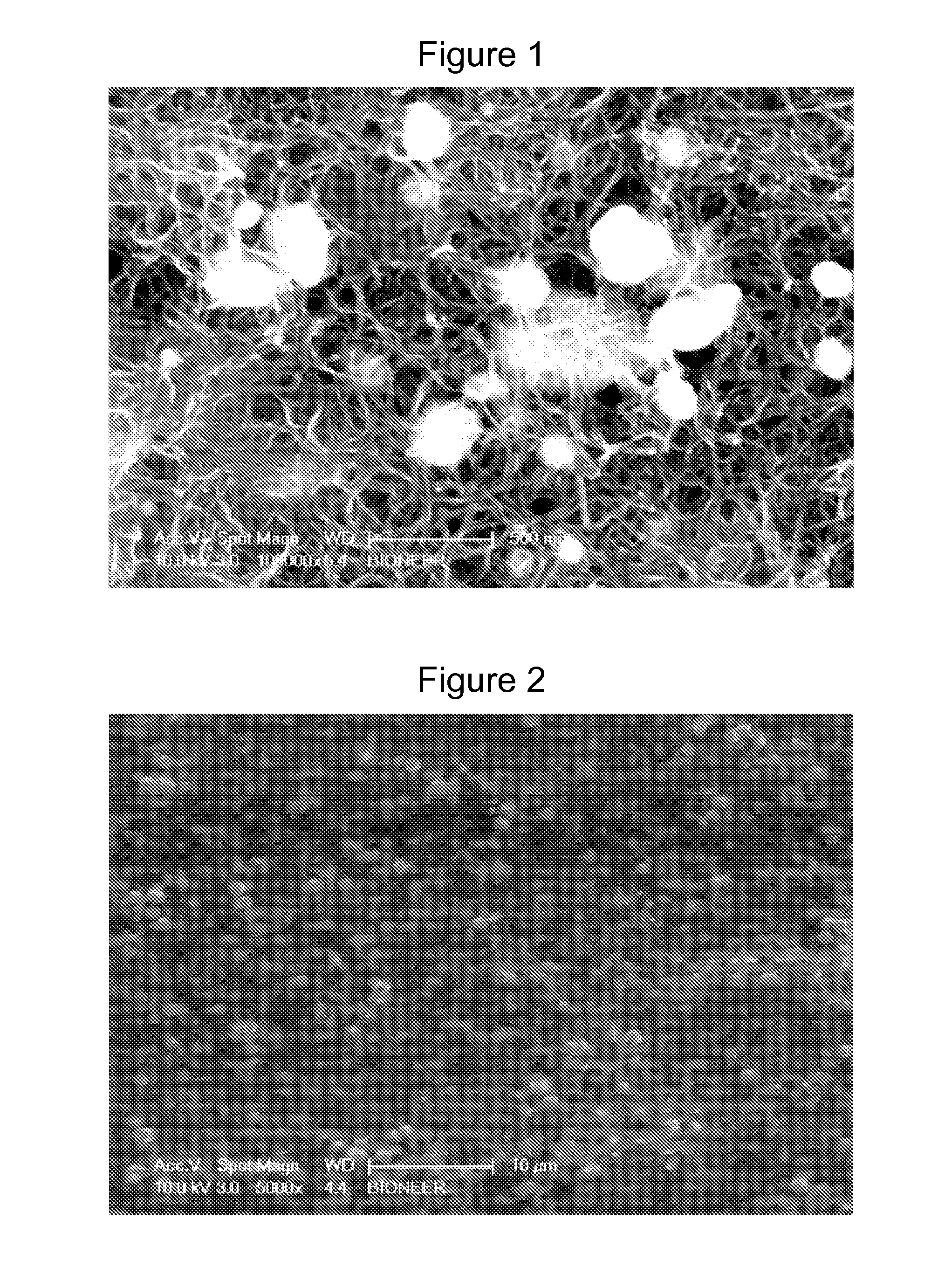

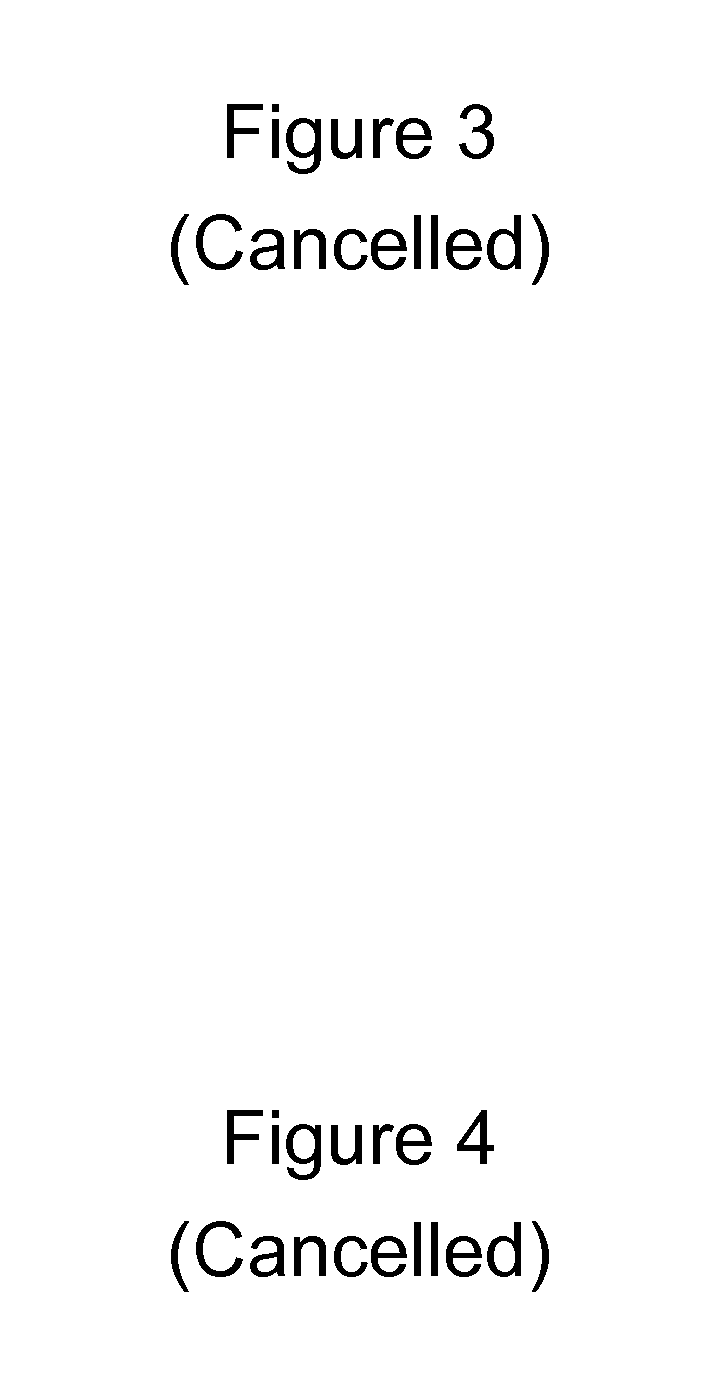

ActiveUS20120000845A1Small sizeEfficient removalMaterial nanotechnologySemi-permeable membranesCoated membraneNano size

Provided is a carbon nanostructure-metal composite nanoporous film in which a carbon nanostructure-metal composite is coated on one surface or both surfaces of a membrane support having micro- or nano-sized pores. A method for manufacturing a carbon nanostructure-metal composite nanoporous film, includes: dispersing a carbon nanostructure-metal composite in a solvent at the presence of a surfactant and coating the carbon nanostructure-metal composite on one surface or both surfaces of a membrane support; and fusing the metal on the membrane support by heating the coated membrane support. The metal in carbon nanostructure-metal composite nanoporous film melts at a low temperature since a size of a metal of the carbon nanostructure-metal composite is several nm to several-hundred nm.

Owner:BIONEER

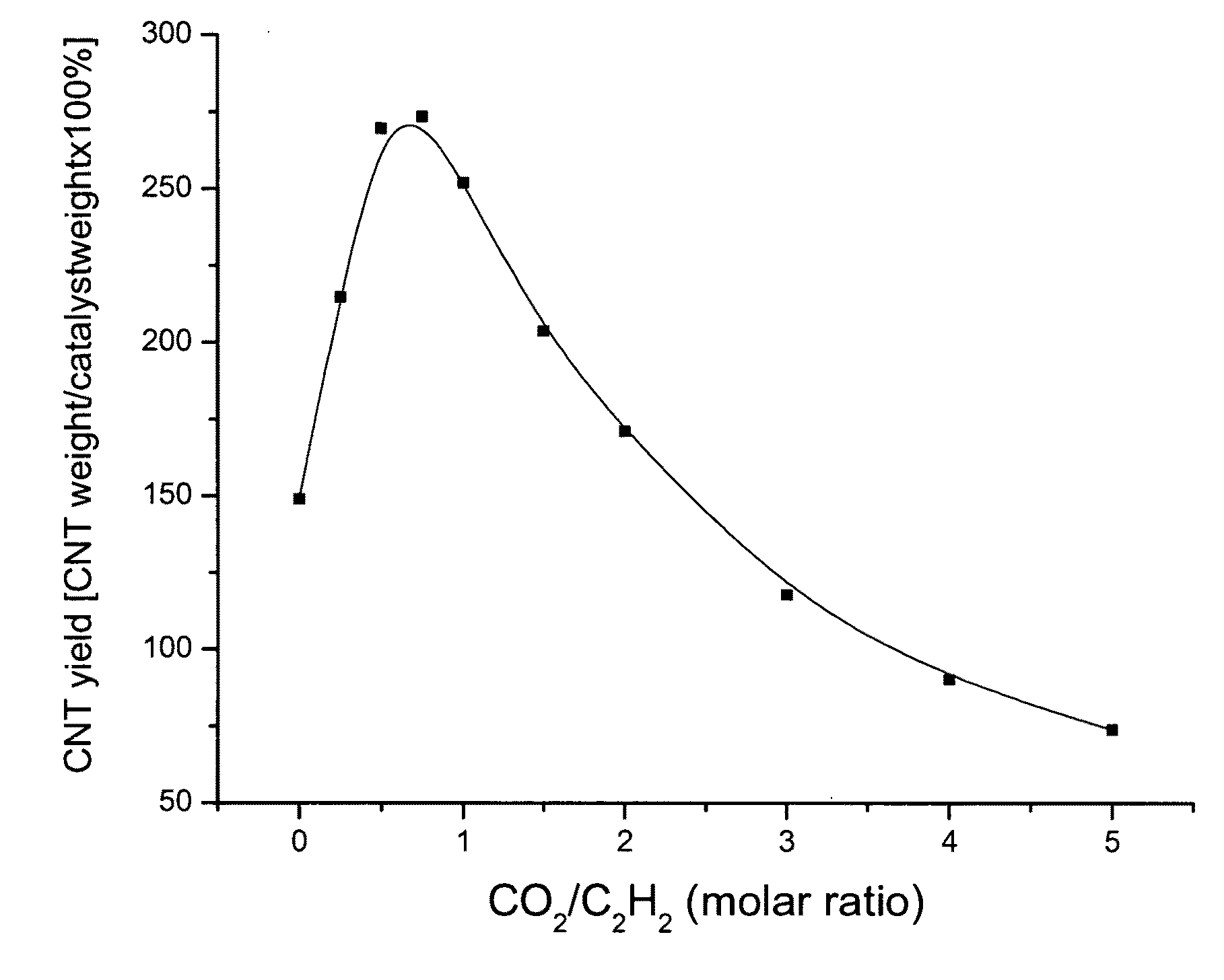

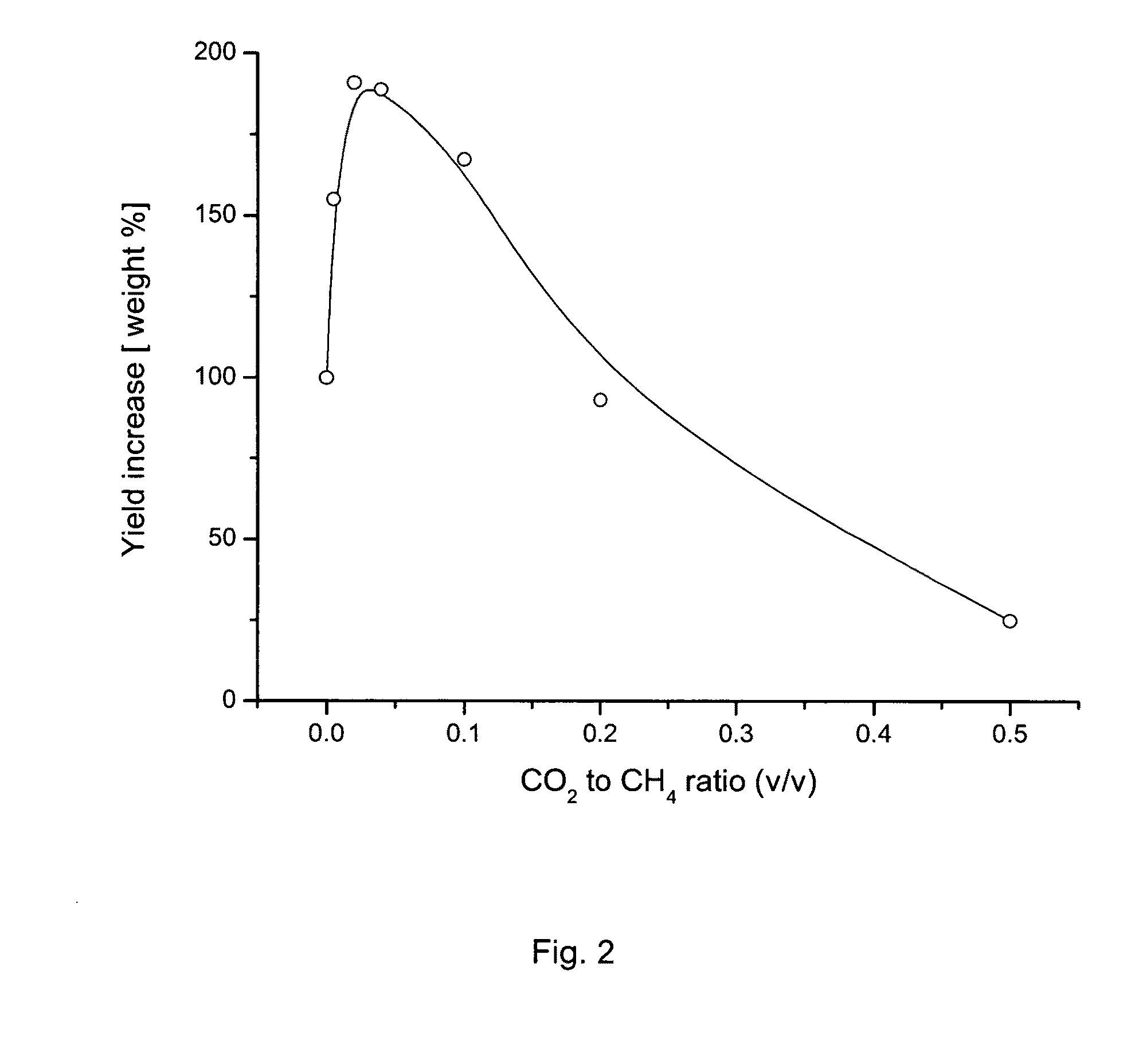

Method for enhanced synthesis of carbon nanostructures

A method of significantly improving carbon nanotube or carbon nanofiber yield from catalytic chemical vapor deposition of a carbon-containing gas comprising at least one hydrocarbon with the assistance of a proper amount of carbon dioxide (CO2). The catalytic particles preferably contain at least one metal from Group VIII (Fe, Co, Ni or the like) or / and one metal from Group VIb, including Mo, W, and Cr. The catalytic particles are preferably supported on oxide powders such as MgO, Al2O3, SiO, CaO, TiO, and ZrO, or a flat substrate such as, but not limited to, a Si wafer. The carbon nanotube or nanofiber product is preferably formed by exposing the catalyst to a mixture of a carbon-containing gas comprising at least one hydrocarbon with a proper amount of CO2 at a sufficiently high temperature. In an alternative embodiment, other oxygen-containing gases, such as alcohols, may be included in the mixture in addition to carbon dioxide.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

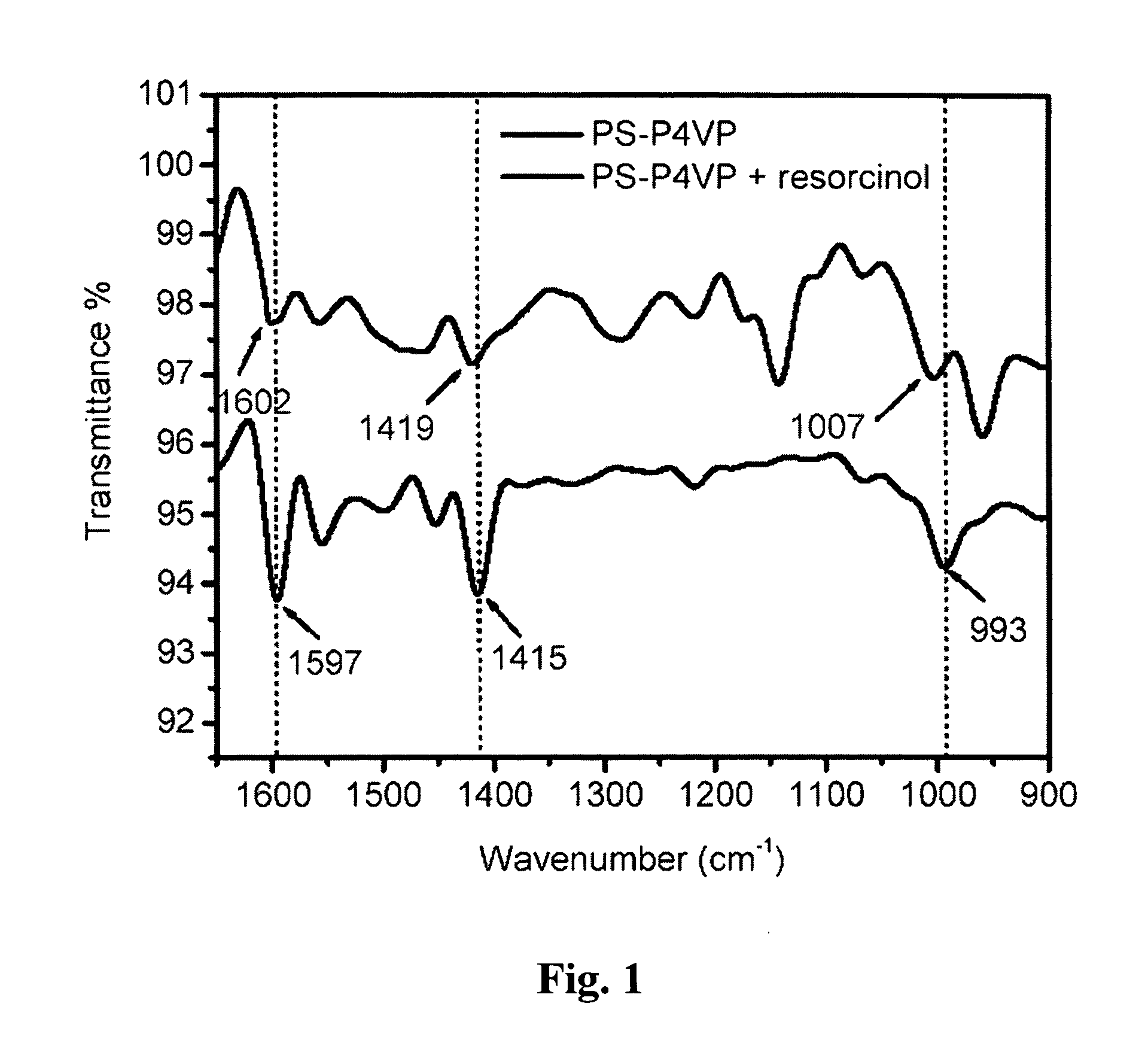

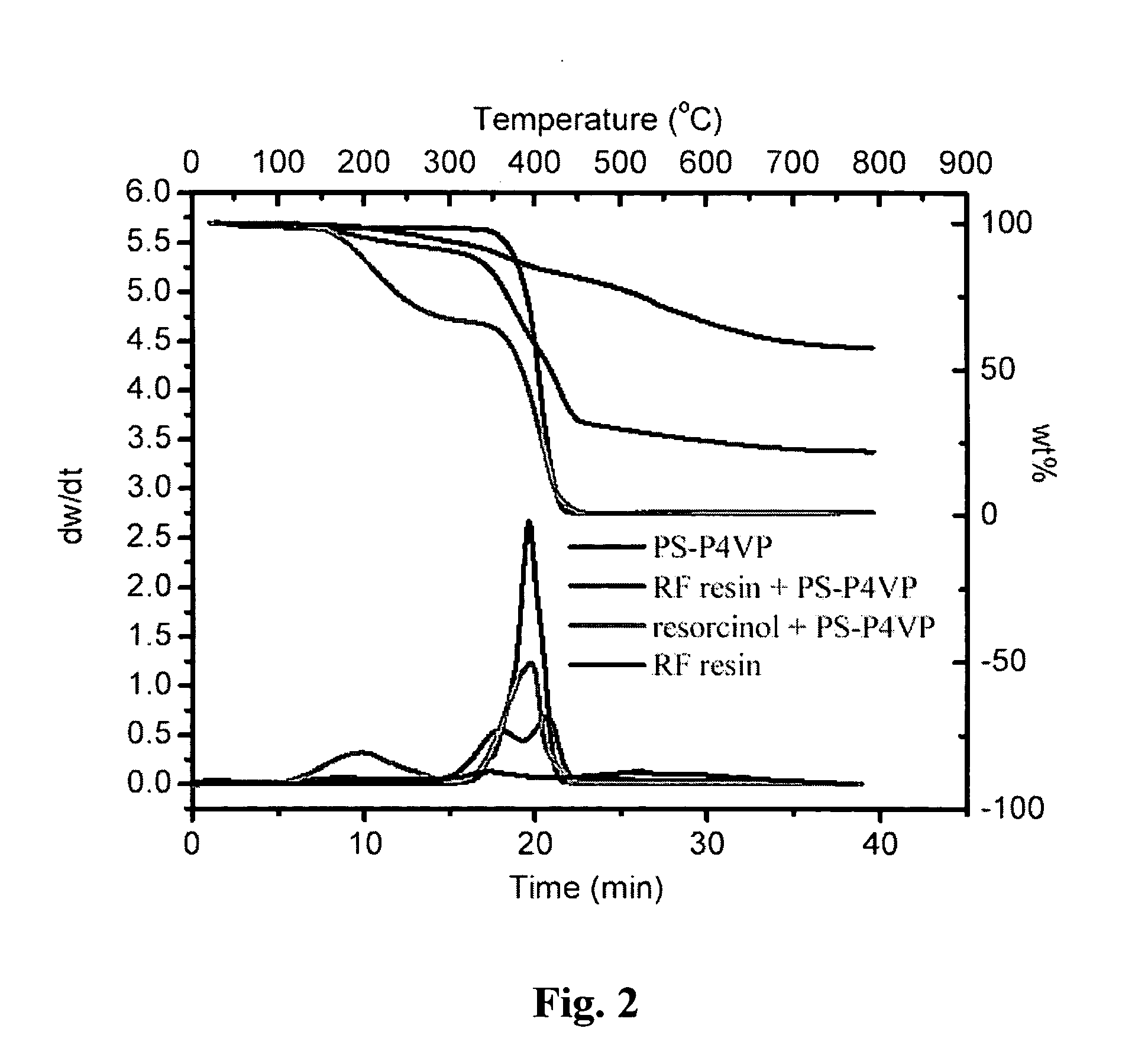

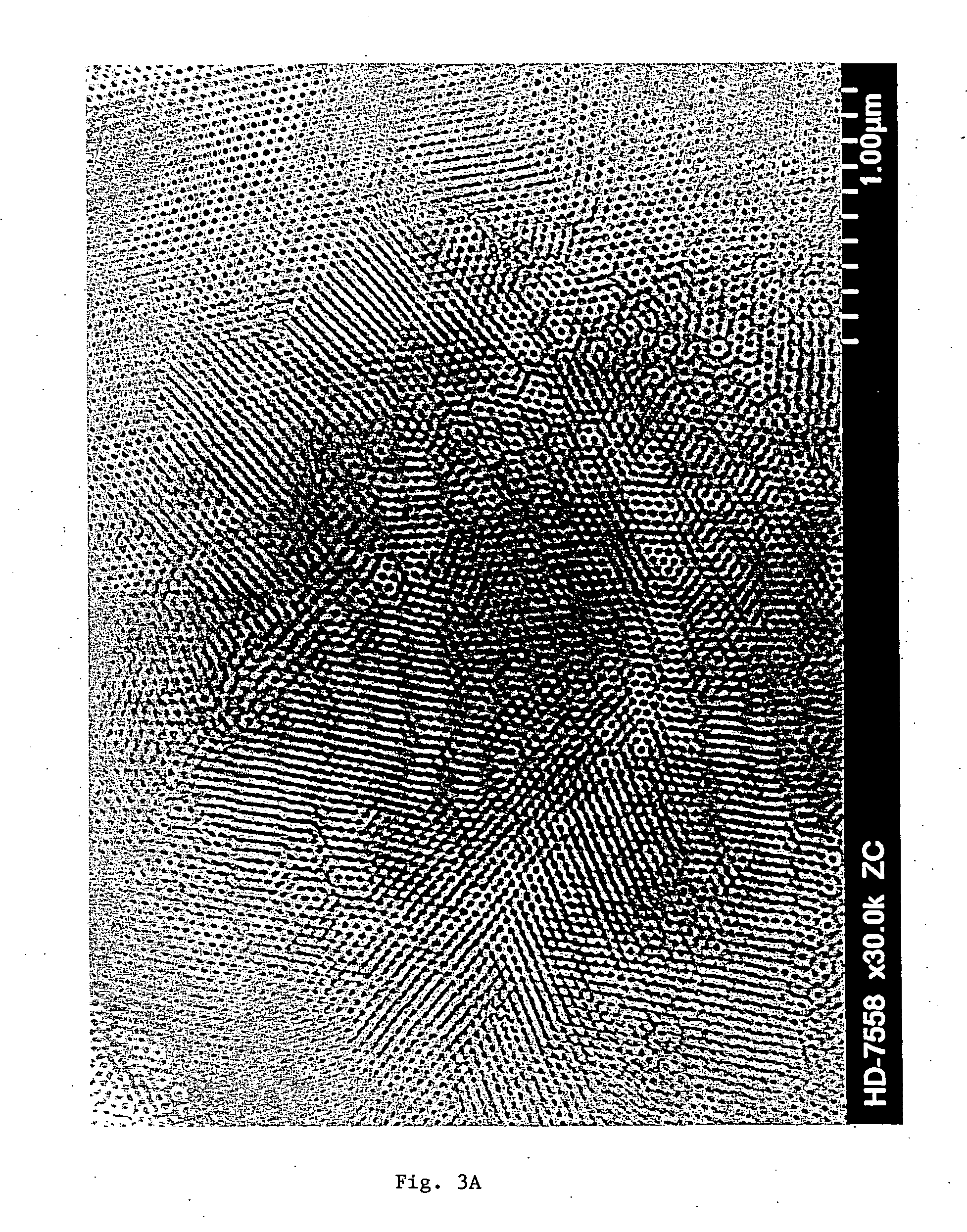

Highly ordered porous carbon materials having well defined nanostructures and method of synthesis

Applicant's present invention comprises a method for fabricating porous carbon materials having highly ordered nanostructures comprising the steps of first, forming a precursor solution comprising a block copolymer template and a carbon precursor; second, forming a self-assembled nanostructured material from the precursor solution; third annealing the nanostructured material thereby forming a highly ordered nanostructured material; fourth, polymerizing the carbon precursor to cure the nanostructured material; and pyrolyzing the nanostructured material wherein the block copolymer template is decomposed to generate ordered carbon nanopores and the nanostructured material is carbonized to form the walls of the carbon nanopores thereby forming a porous carbon material having a highly ordered nanostructure. In addition, the present invention further comprises a porous carbon material comprising a carbon nanostructure having ordered carbon nanopores that have uniform pore sizes ranging from about 4.5 nm up to about 100 nm.

Owner:UNIV OF TENNESSEE RES FOUND +1

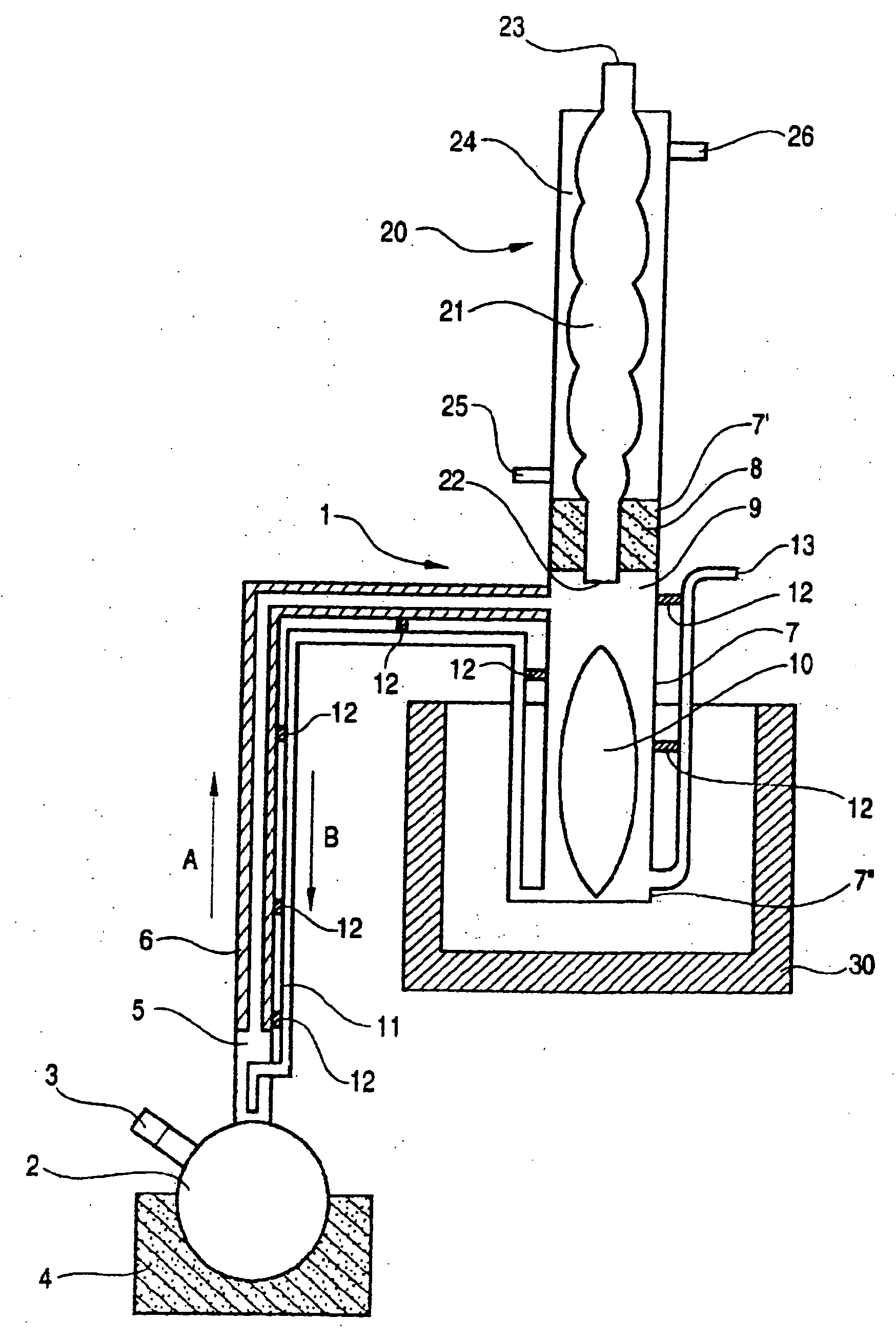

Gas accumulator

A gas accumulator for storing pressurized gases, in particular gaseous fuels such as hydrogen or the like, which gas accumulator has a sealed vessel which is provided with a valve-actuated feed line and outlet line for the pressurized gas and with a solid packing of carbon nanostructures. To increase the storage capacity of a gas accumulator of this type significantly, the particles of the carbon nanostructures are compacted to form larger coherent conglomerates having an apparent density which is increased in comparison with the apparent density of the originally loose particles. The compaction can be carried out, for example, by ordering the carbon nanostructures in their orientation to one another, or else by forming the conglomerates by pressing non-ordered carbon nanostructures. In each case, minimizing the interstices between the individual carbon nanostructures means that the amount of the carbon nanostructures which can be introduced into the vessel and thus the amount of the pressurized gas which can be stored in these can be increased.

Owner:MANNESMANN AG

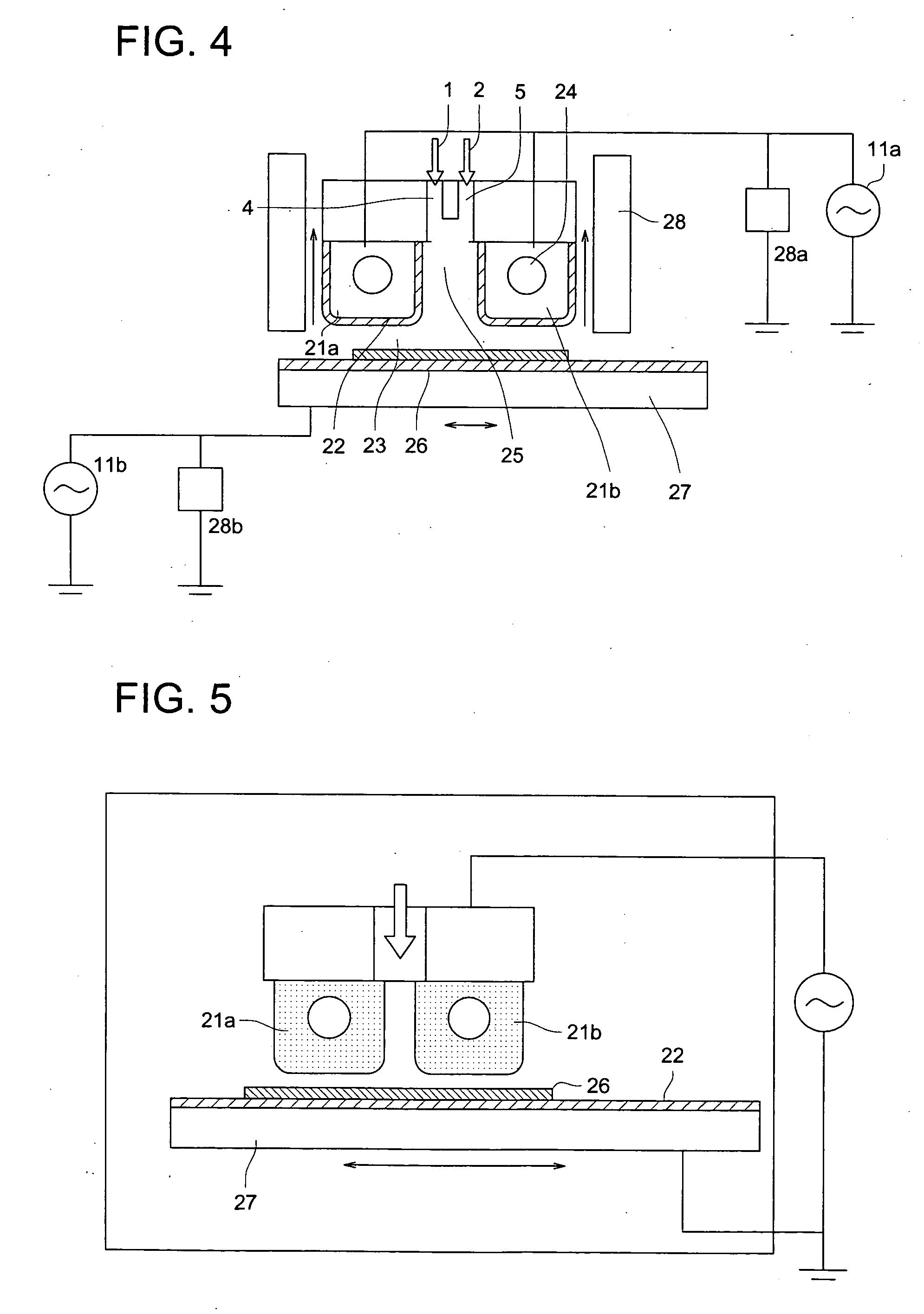

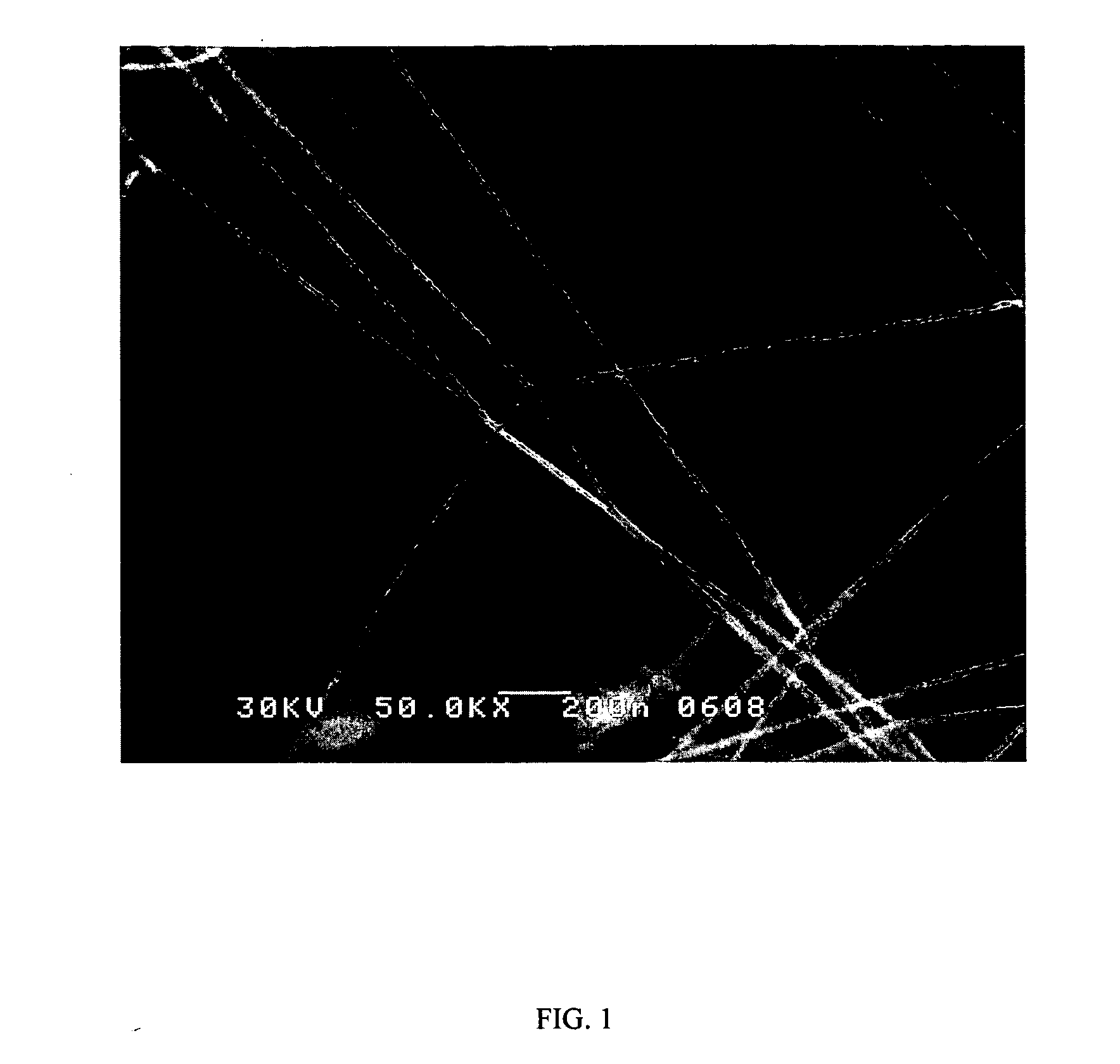

Highly Efficient Material Spraying Type Carbon Nanostructure Synthesizing Method and Apparatus

InactiveUS20070253890A1Reduce generationImprove efficiencyMaterial nanotechnologyFullerenesSynthesis methodsTar

Developed are a synthesizing method for carbon nanostructures where the generation of tar-like byproducts is reduced and carbon nanostructures are generated highly efficiently, and a unit therefor. A highly efficient material spraying type carbon nanostructure synthesizing apparatus according to the present invention is formed of a catalyst body that is placed inside a reaction tube, a heating unit that is provided in order to heat the vicinity of this catalyst body to the temperature range where carbon nanostructures are generated, a material gas supplying pipe for introducing a material gas into reaction tube which is provided in such a manner that an end of this supplying pipe is placed in proximity to catalyst body, and a preheating unit for preheating the material gas supplying pipe to a temperature range where no tar-like products are generated from a material gas. No tar-like substance is generated in the material gas supplying pipe, and the material gas is directly sprayed against the catalyst body, skipping the middle temperature range. Therefore, the probability of reaction occurring is high, and the yield in the generation of carbon nanostructures is high. Most of the material gas is consumed; thus, no tar-like substance is generated inside reaction tube.

Owner:JAPAN SCI & TECH CORP +3

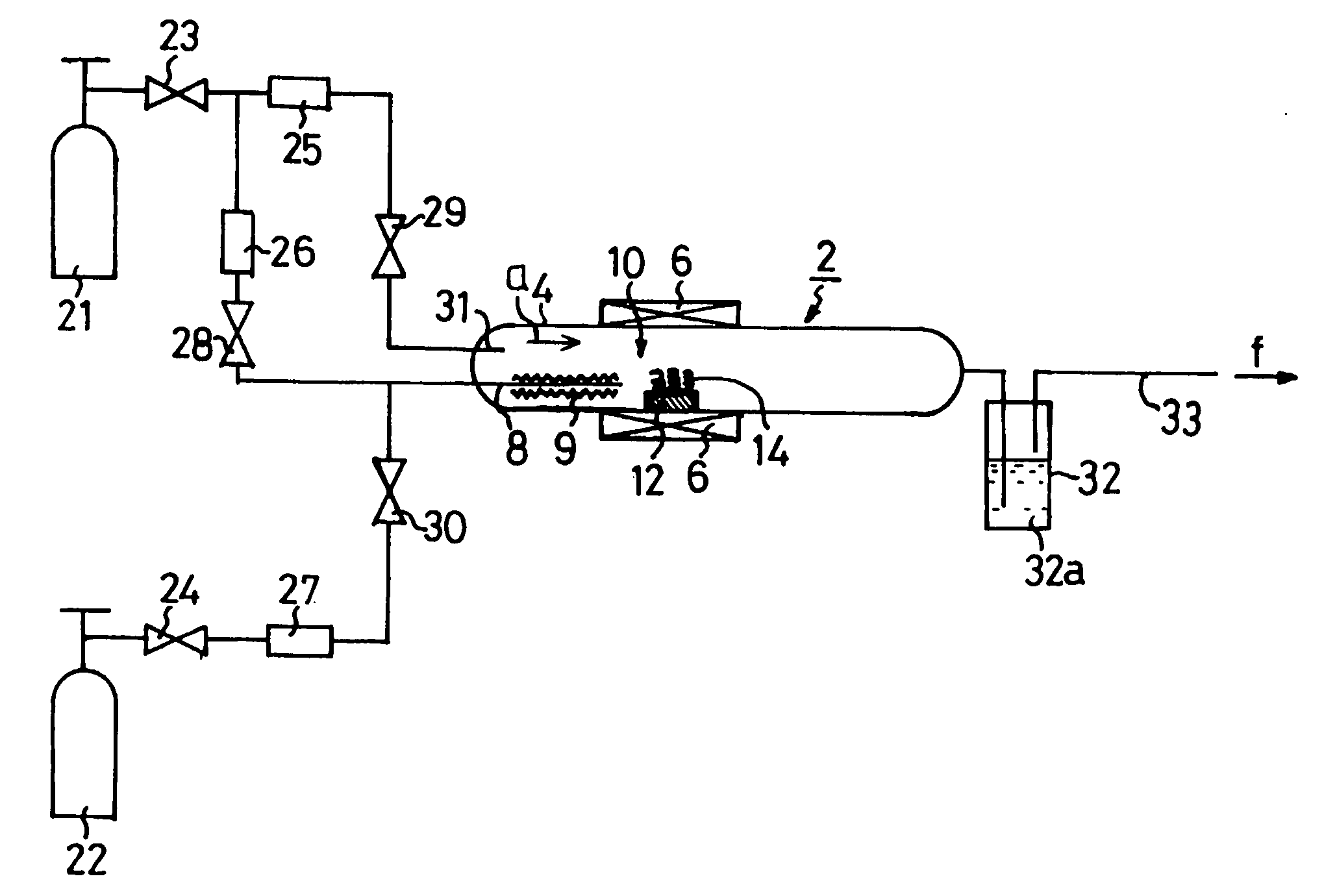

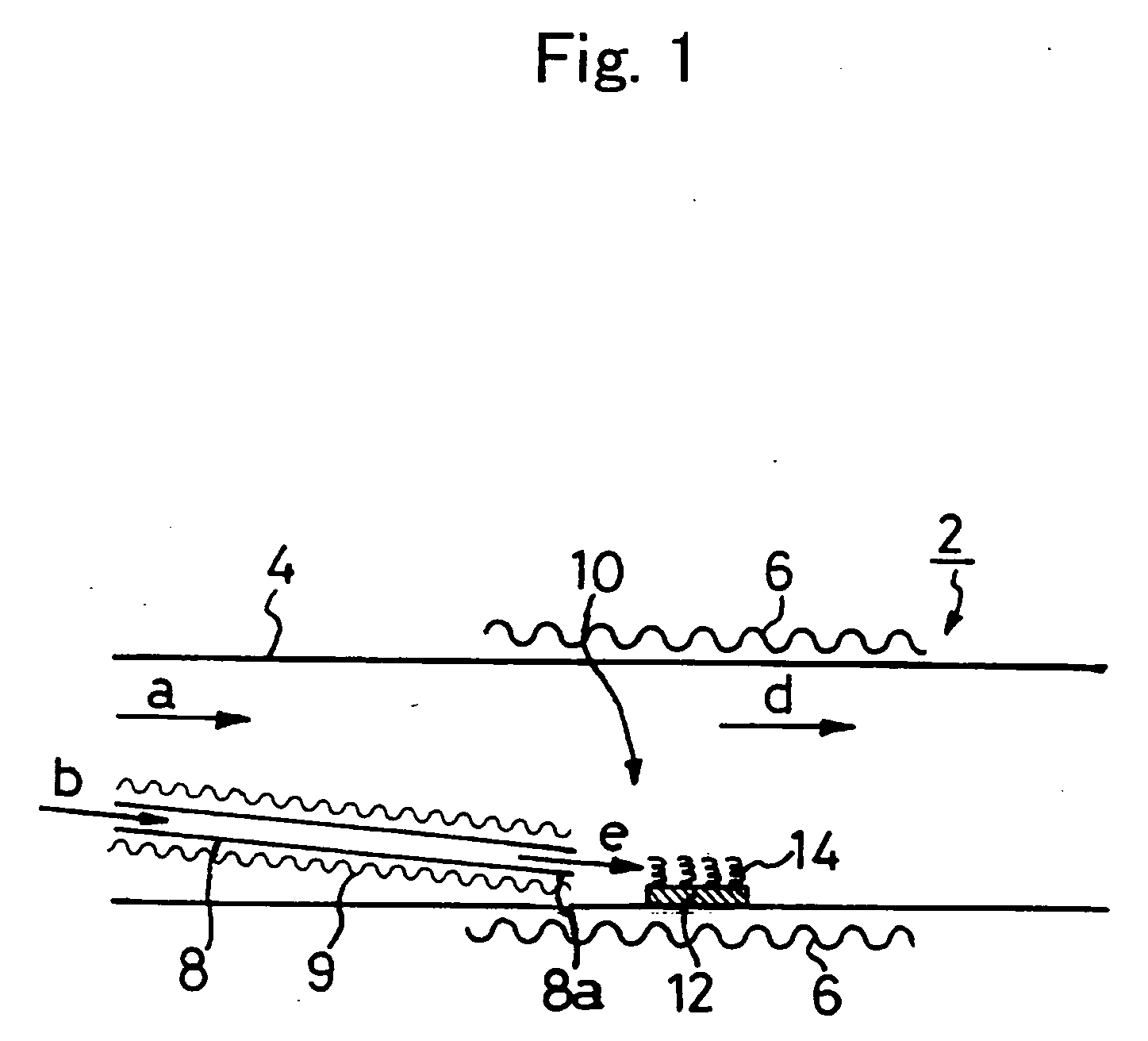

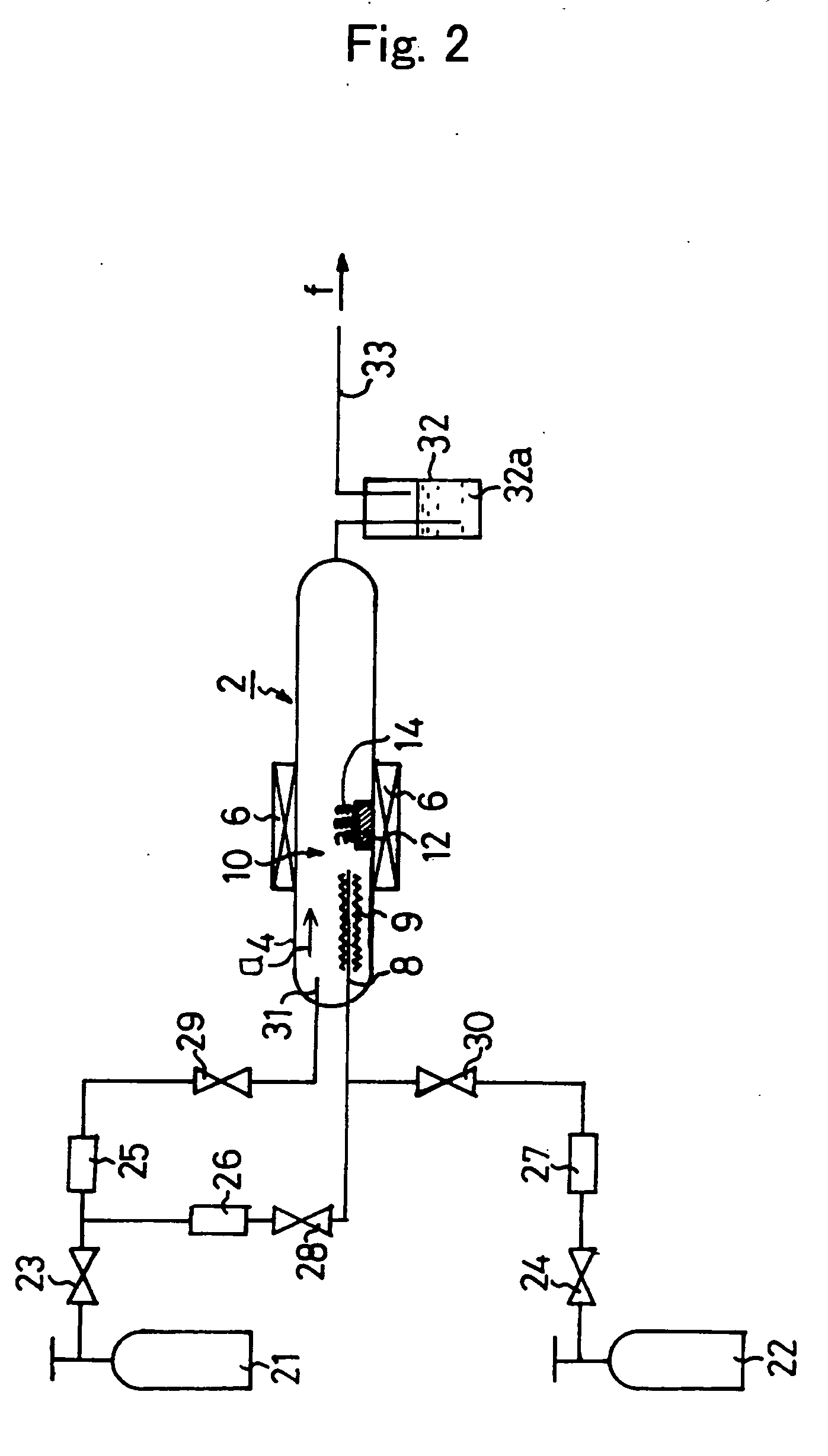

Ultrasonic reflux system for one-step purification of carbon nanostructures

InactiveUS20050069480A1Improve efficiencyIncrease percentageMaterial nanotechnologyNanostructure manufactureRefluxSolvent

Reflux systems and methods for purifying carbon nanostructures using same are provided. The reflux system includes a solvent flask, an extraction tube connected to the solvent flask by a siphon tube and a vapor tube each extending between the extraction tube and the solvent flask, and an energy application disposed around the bottom portion of the extraction tube. The reflux systems can be used in a one-step method of purifying carbon nanostructures that includes placing a soot sample that contains the carbon nanostructures and amorphous carbon in a filter and disposing the filter in the extraction tube.

Owner:SONY CORP

Compound and preparation method thereof and high-molecular material and preparation method thereof

ActiveCN105504341AEnhanced Far Infrared PerformanceGood antibacterial effectArtificial filaments from viscoseArtifical filament manufactureMolecular materialsGraphene

The present invention provides a carbon-nanostructure-containing compound comprising graphene, amorphous carbon and a non-carbon non-oxygen element, and the non-carbon non-oxygen element accounts for 0.5wt%-6wt% of the compound. Through controlling of content of the non-carbon non-oxygen element in the carbon-nanostructure-containing compound, excellent far infrared effect and antibacterial bacteriostat effect can be obtained, far-infrared property normal emittance can reach 0.85 or more, and the bacteriostasis rate can reach more than 95%. At the same time, the carbon-nanostructure-containing compound can be used in a high-molecular material in a lower amount for modifying of the high-molecular material without pre-modification and activation for achievement of significant far-infrared and antibacterial bactericidal properties.

Owner:营口圣泉高科材料有限公司

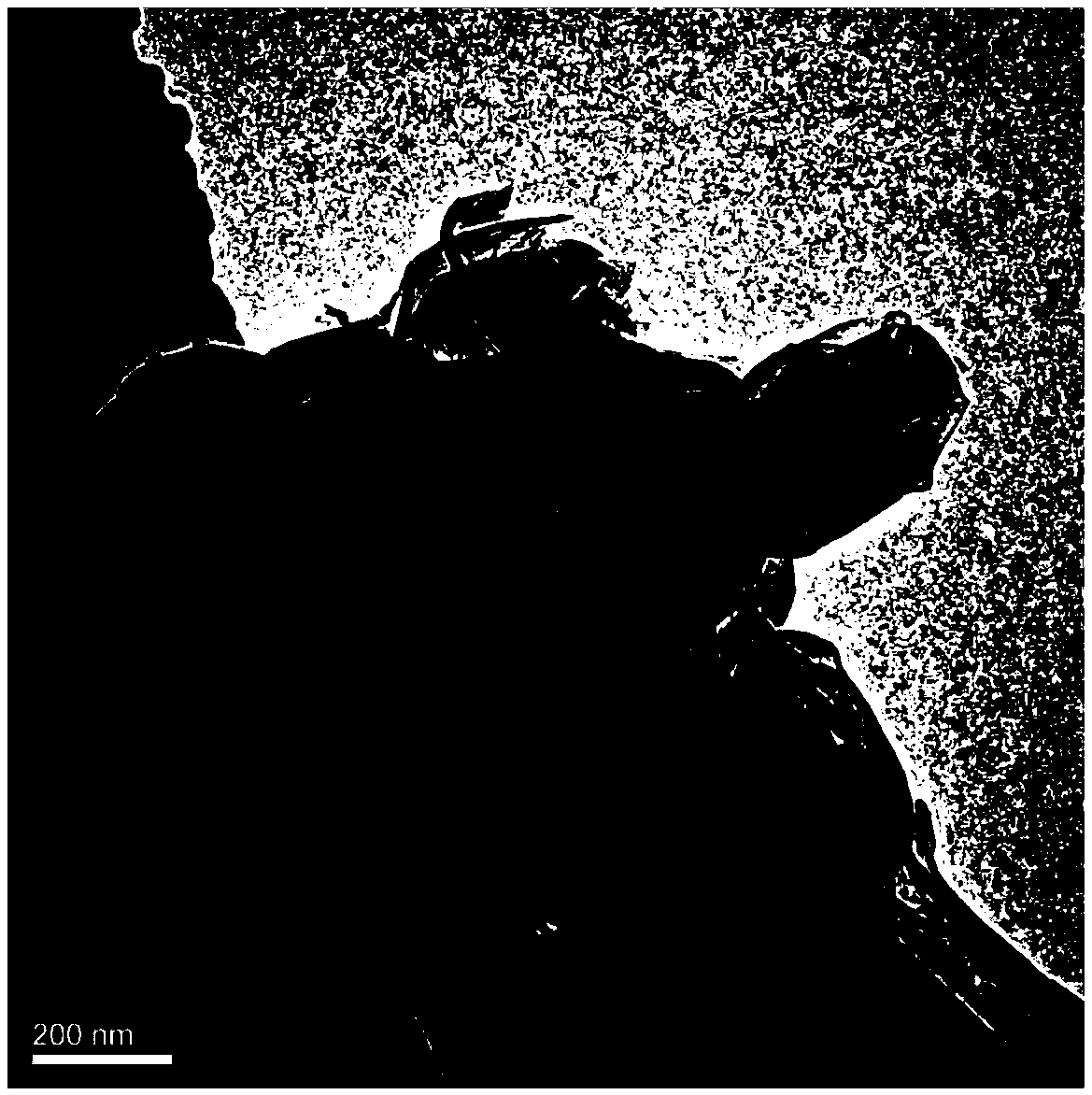

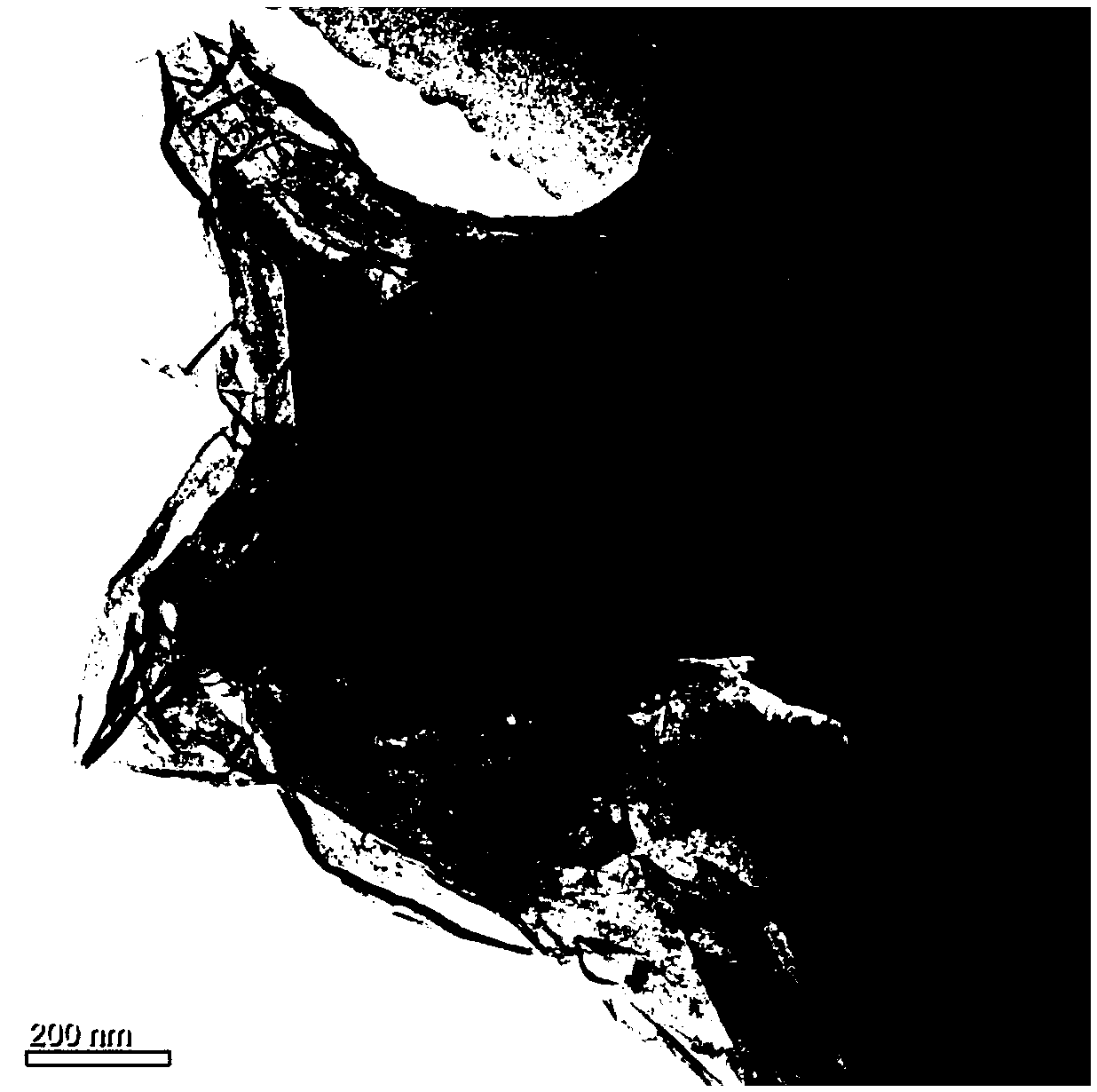

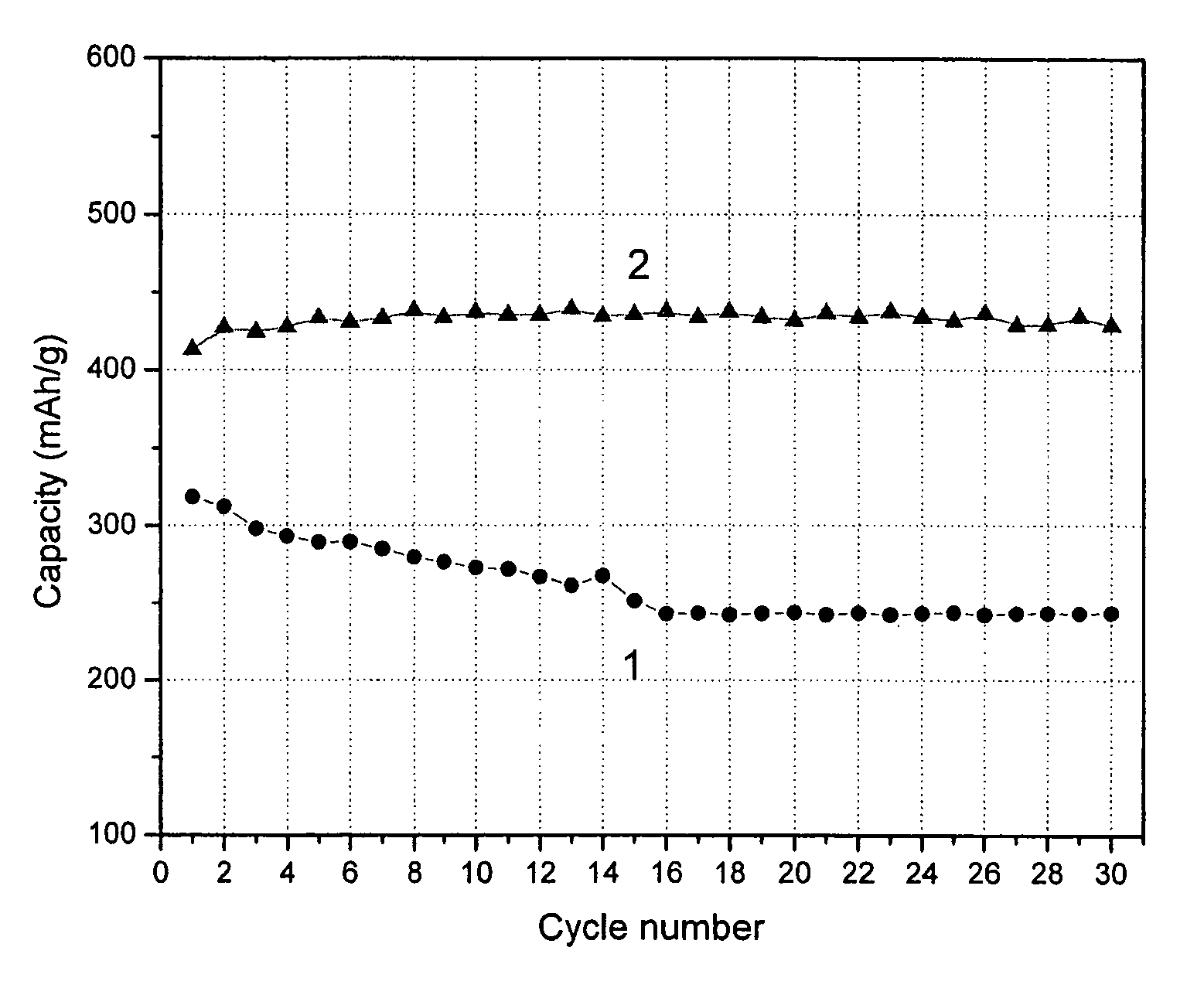

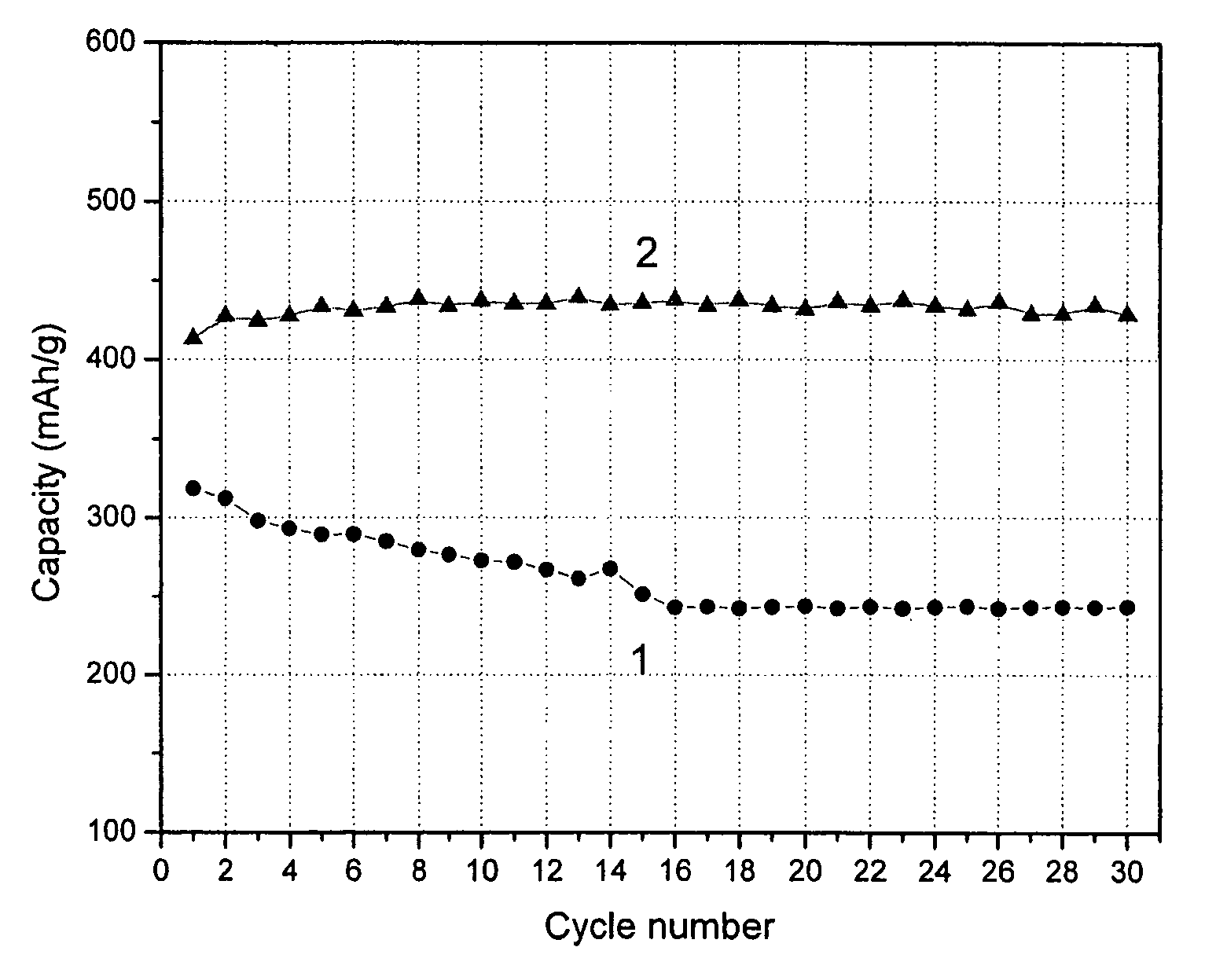

Lithium-ion battery incorporating carbon nanostructure materials

A lithium ion battery is disclosed in which the negative electrode material comprises carbon nanostructures having no dimension greater than 2 μm. The battery has a high reversible capacity of the order of 400 mAh / g to 500 mAh / g which can be maintained over a long cycle-life (at least 30 cycles). The carbon nanostructures may be mixed with graphite to improve conductivity. The carbon nanostructues may be synthesized using an AFI template material followed by calcination.

Owner:THE HONG KONG UNIV OF SCI & TECH

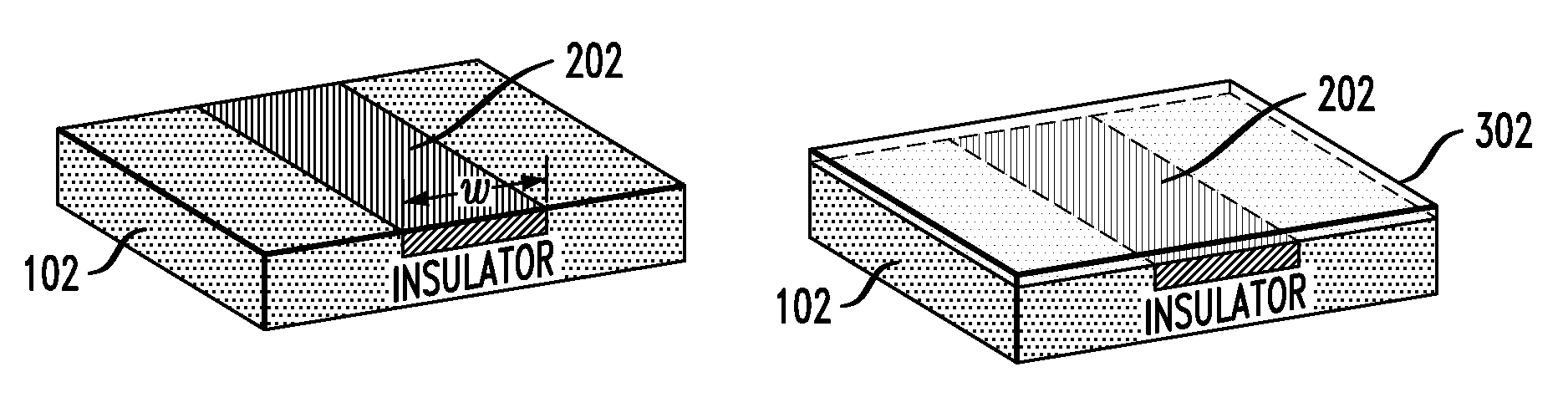

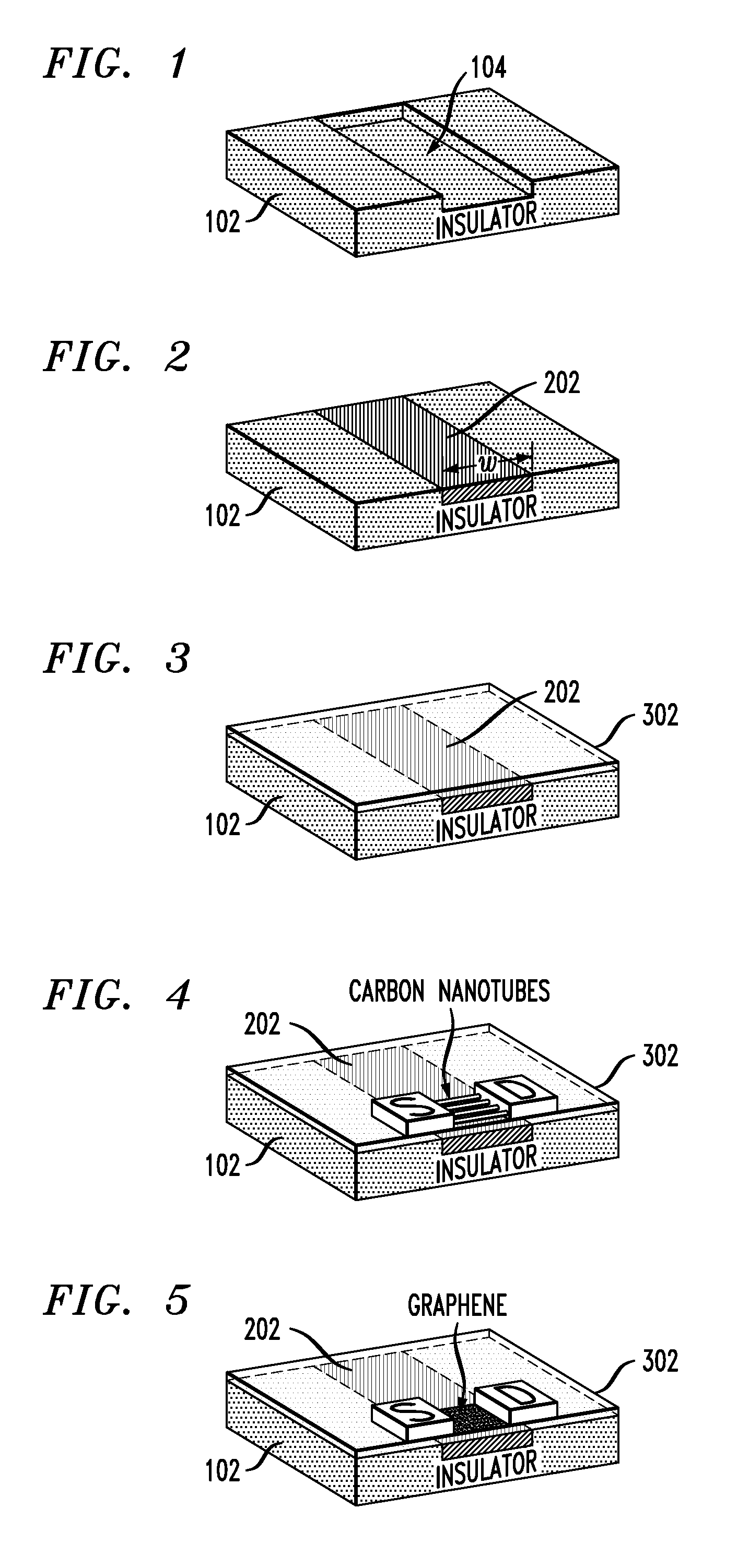

Local bottom gates for graphene and carbon nanotube devices

Owner:GLOBALFOUNDRIES U S INC

Low-k dielectric material based upon carbon nanotubes and methods of forming such low-k dielectric materials

ActiveUS20060073682A1Semiconductor/solid-state device detailsNanoinformaticsSemiconductor structureNanostructure

A low-k dielectric material for use in the manufacture of semiconductor devices, semiconductor structures using the low-k dielectric material, and methods of forming such dielectric materials and fabricating such structures. The low-k dielectric material comprises carbon nanostructures, like carbon nanotubes or carbon buckyballs, that are characterized by an insulating electronic state. The carbon nanostructures may be converted to the insulating electronic state either before or after a layer containing the carbon nanostructures is formed on a substrate. One approach for converting the carbon nanostructures to the insulating electronic state is fluorination.

Owner:GLOBALFOUNDRIES US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com