Patents

Literature

71results about How to "Enhanced Far Infrared Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compound and preparation method thereof and high-molecular material and preparation method thereof

ActiveCN105504341AEnhanced Far Infrared PerformanceGood antibacterial effectArtificial filaments from viscoseArtifical filament manufactureMolecular materialsGraphene

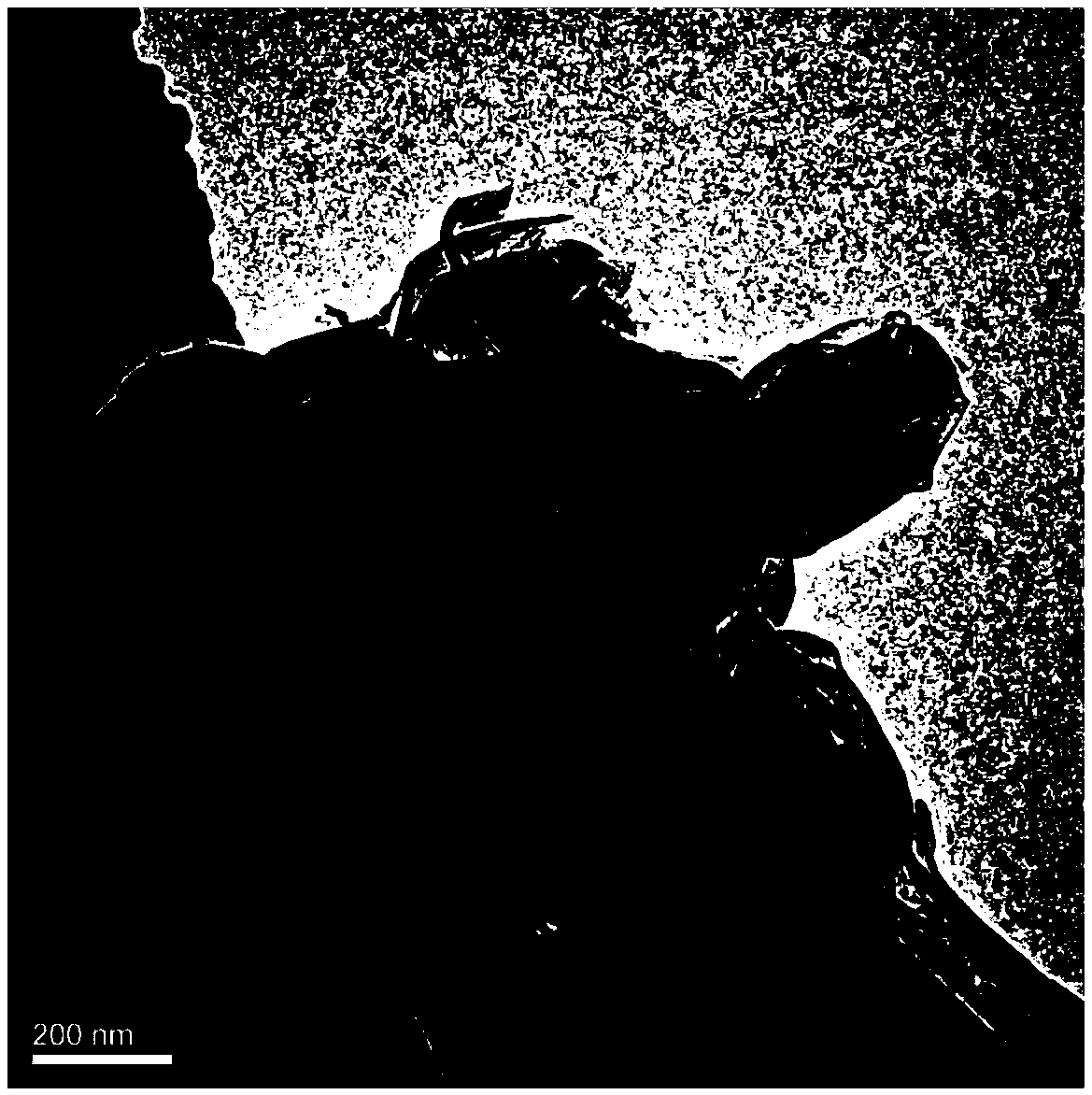

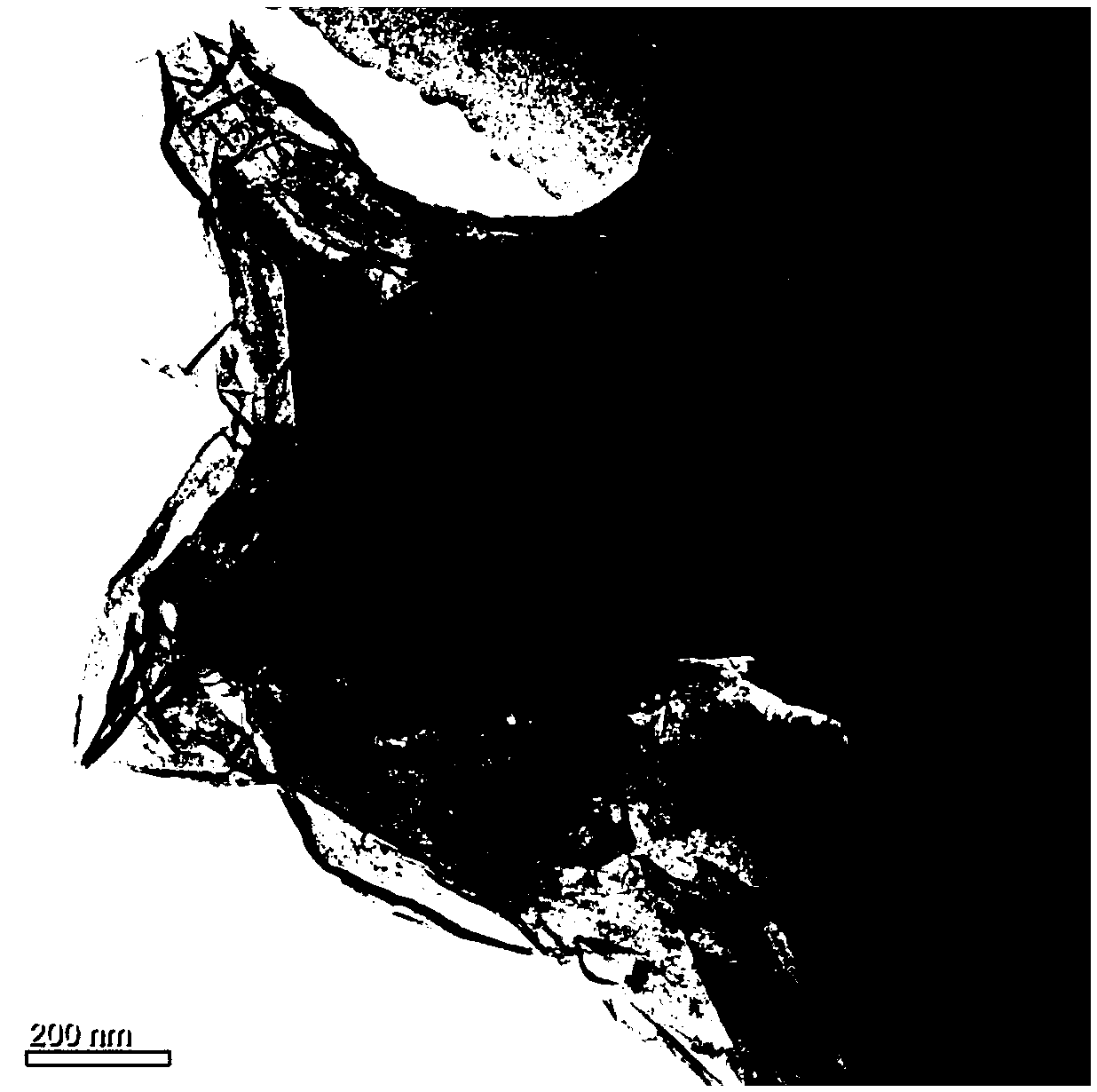

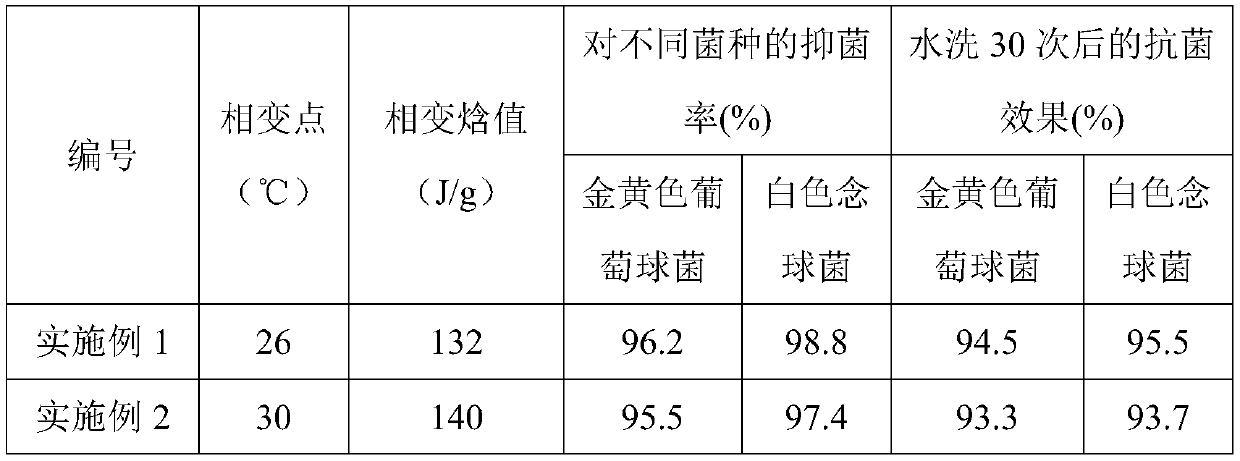

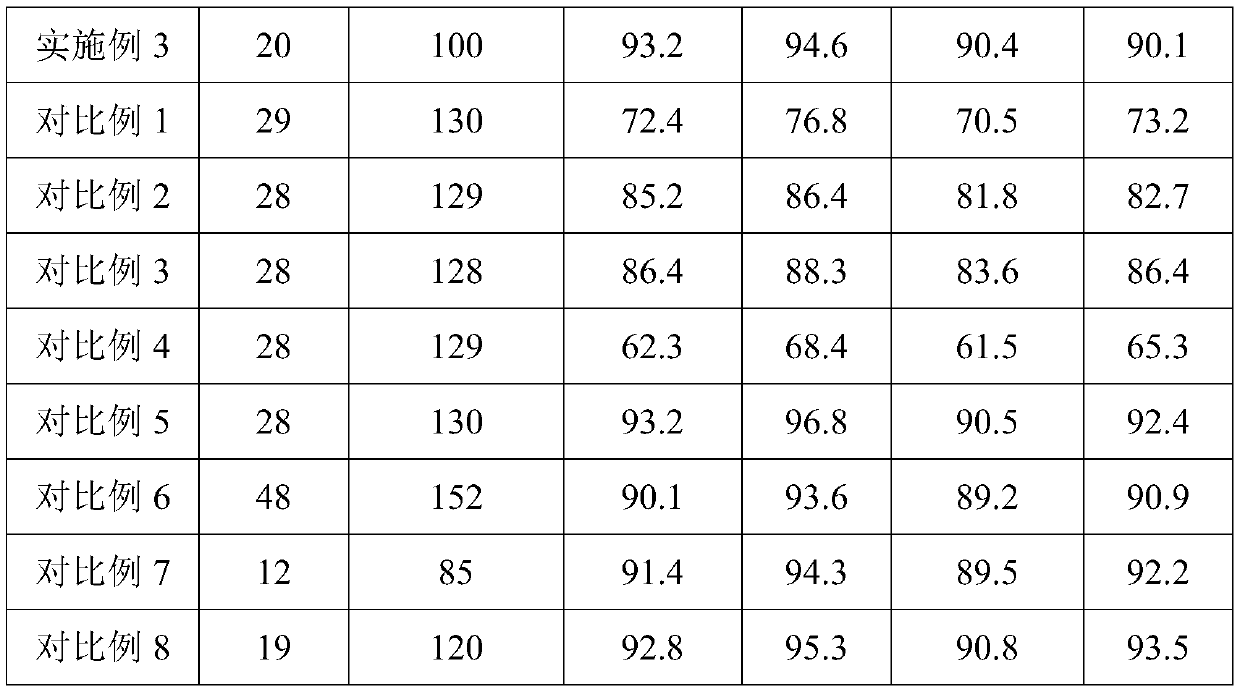

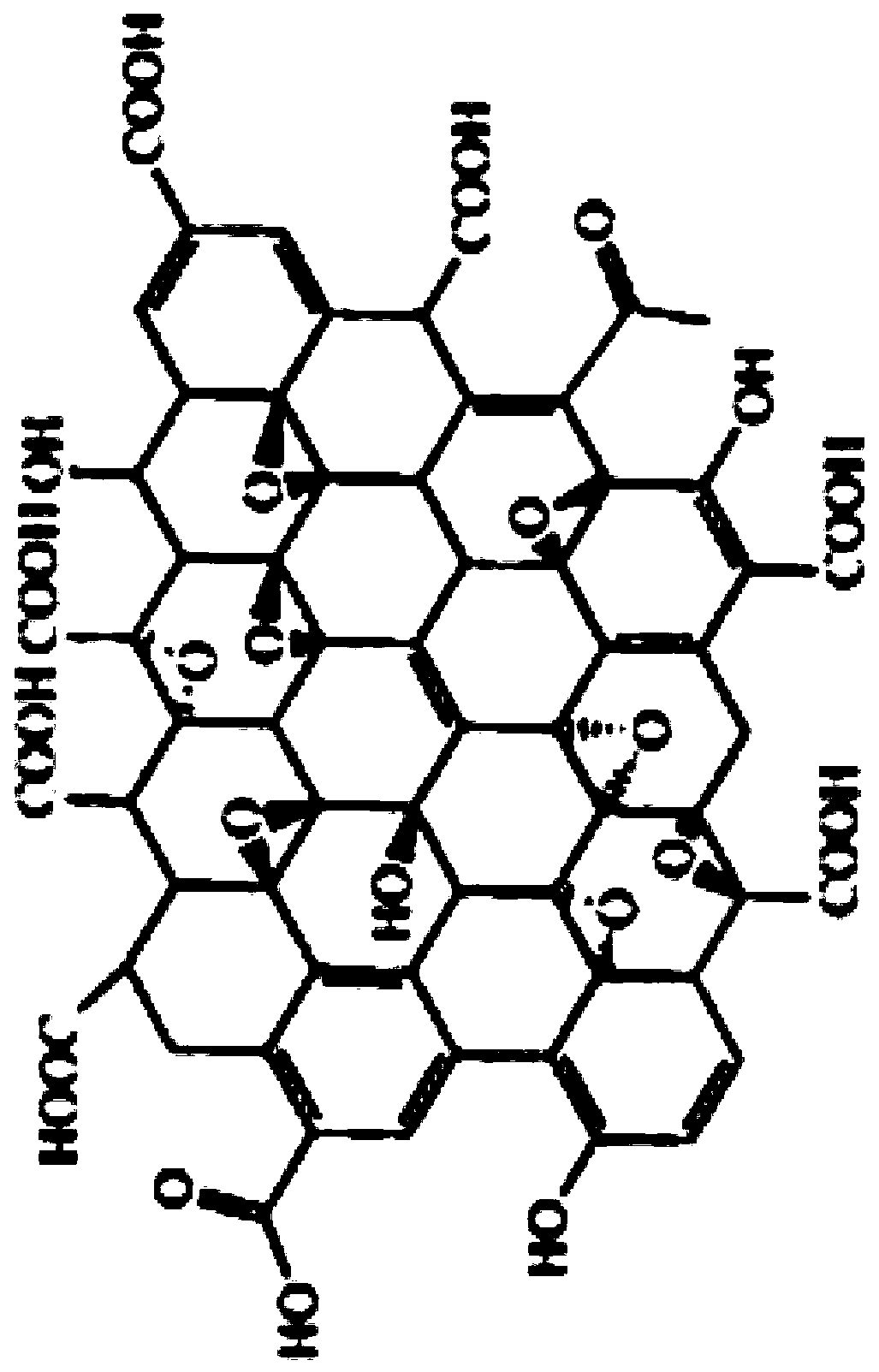

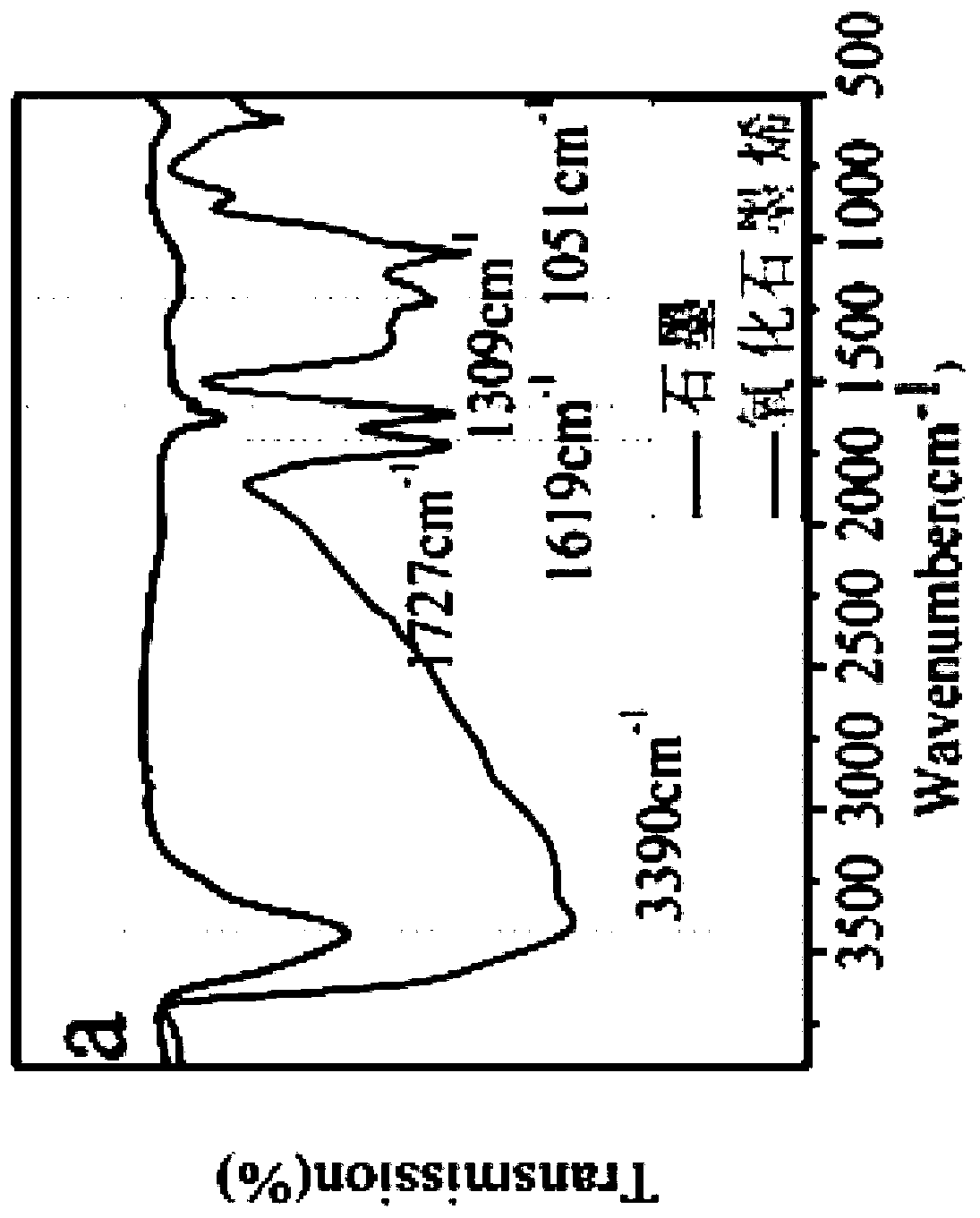

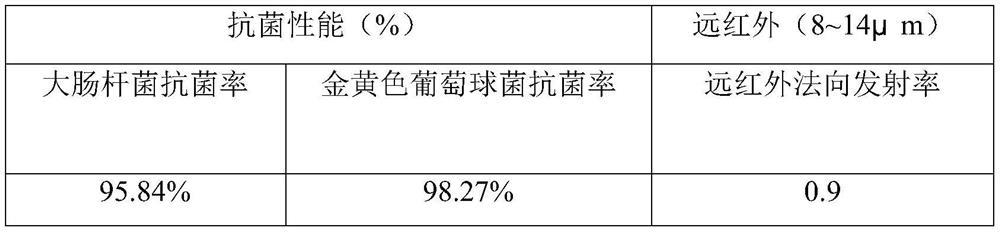

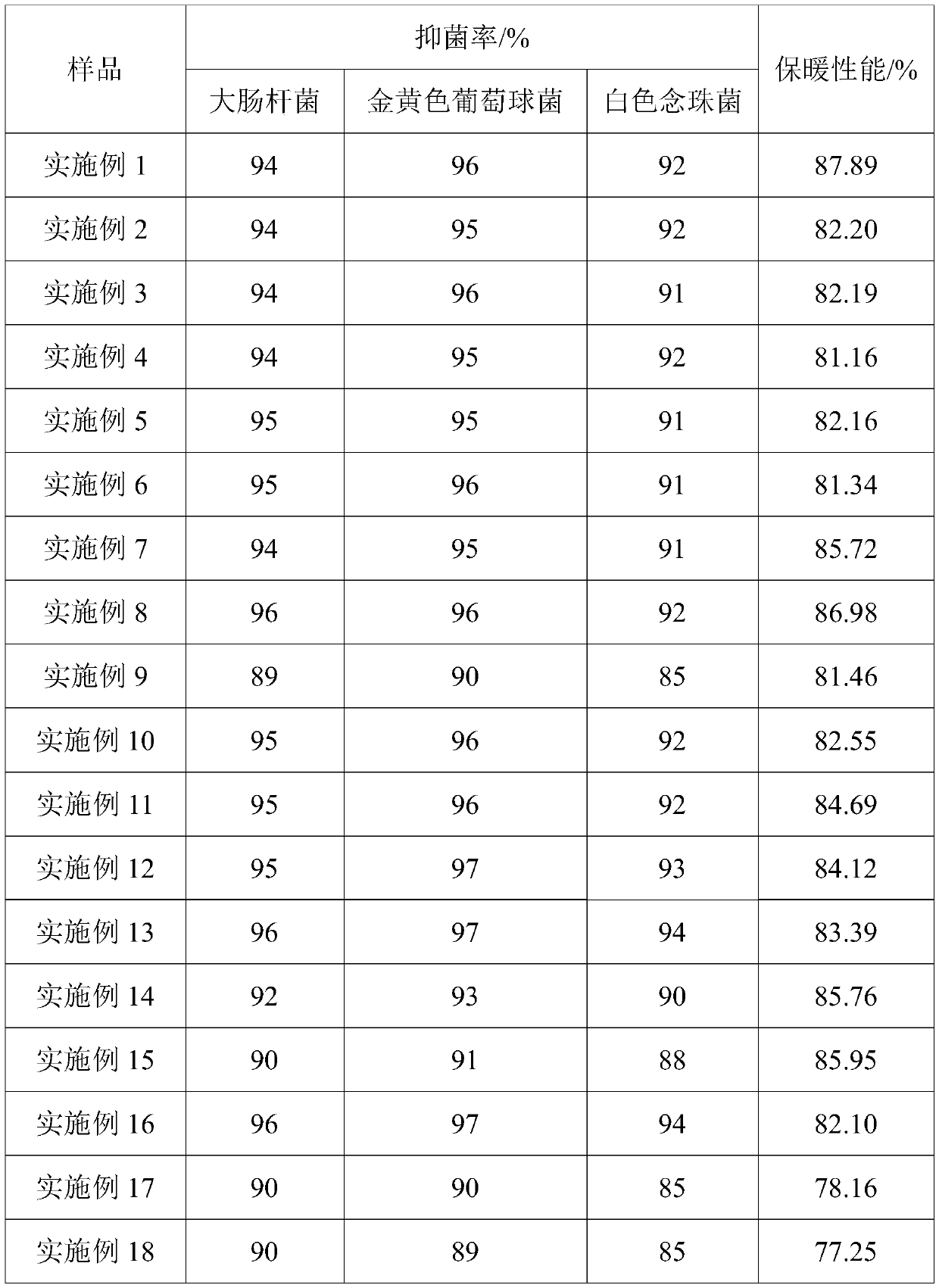

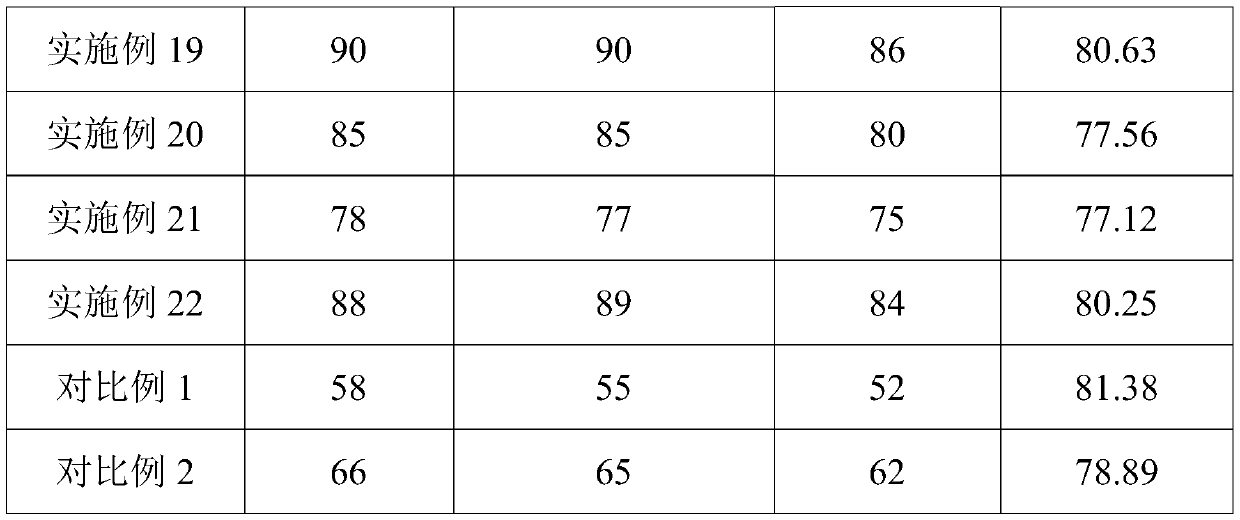

The present invention provides a carbon-nanostructure-containing compound comprising graphene, amorphous carbon and a non-carbon non-oxygen element, and the non-carbon non-oxygen element accounts for 0.5wt%-6wt% of the compound. Through controlling of content of the non-carbon non-oxygen element in the carbon-nanostructure-containing compound, excellent far infrared effect and antibacterial bacteriostat effect can be obtained, far-infrared property normal emittance can reach 0.85 or more, and the bacteriostasis rate can reach more than 95%. At the same time, the carbon-nanostructure-containing compound can be used in a high-molecular material in a lower amount for modifying of the high-molecular material without pre-modification and activation for achievement of significant far-infrared and antibacterial bactericidal properties.

Owner:营口圣泉高科材料有限公司

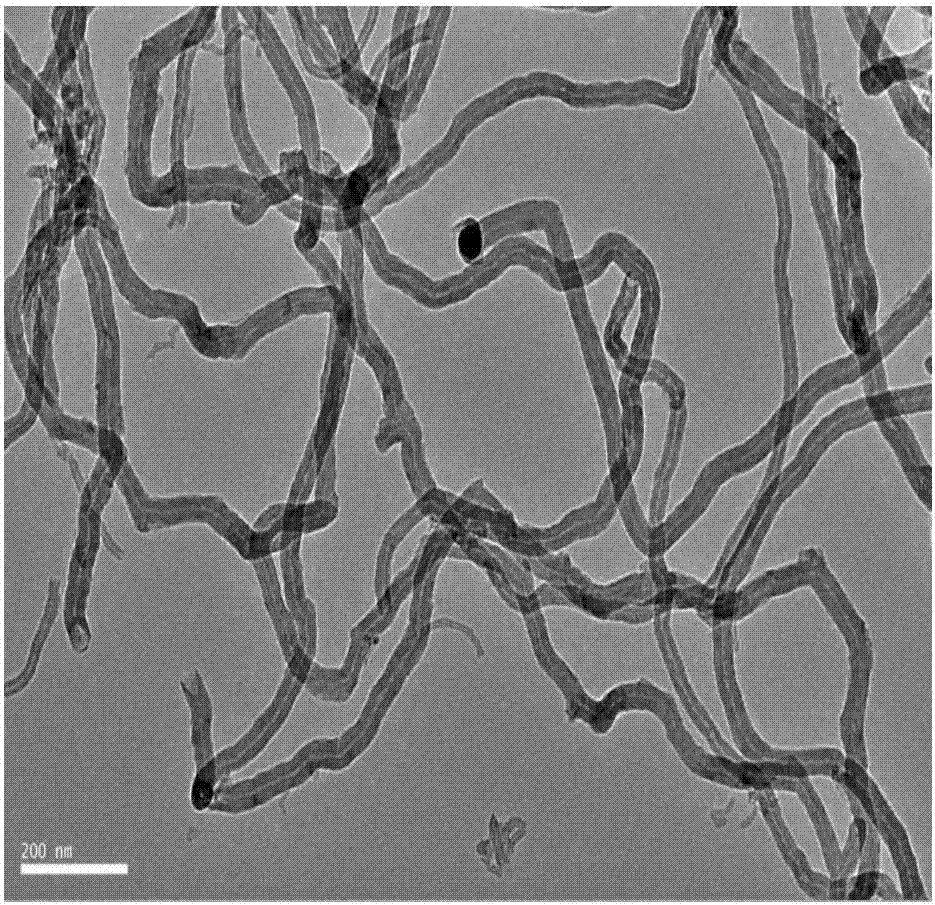

Carbon nanostructure composite and preparation method thereof

InactiveCN105502330AEasy to operateEnhanced Far Infrared PerformanceMaterial nanotechnologyEmissivityFar infrared

The present invention relates to a carbon nanostructure composite, the composite comprises carbon element and a first non-carbon and non-oxygen element material, the first non-carbon and non-oxygen element material is any one or a combination of at least two of first non-carbon and non-oxygen elements and compounds, and peak height ratio of carbon element G peak to carbon element D peak in a Raman spectrum of the composite is 1 to 20, the first non-carbon and non-oxygen elements in the composite are P, Si, Ca, Al and Na, the mass percentage of the first non-carbon and non-oxygen elements is 0.5-4wt%, and the far-infrared detection normal emittance of the composite is greater than 0.85. The composite has far infrared performance and antibacterial bacteriostat properties more obvious than that of the prior art, the composite is simple in preparation method and operation, some non-carbon and non-oxygen elements are retained by control of temperature-programmed stepping temperature and insulation temperature, and more excellent far infrared effect and antibacterial bacteriostat effect can be obtained.

Owner:营口圣泉高科材料有限公司

Composite polyurethane foam containing graphene, and preparation method and application thereof

The invention relates to composite polyurethane foam containing graphene. The polyurethane foam contains a graphene structure and non-carbon non-oxygen non-hydrogen elements. According to the invention, a specific carbon nanostructured compound is selected and used, so compounding of p-polyurethane is realized through simple mixing of the specific carbon nanostructured compound with polyether polyol and polymerization of the obtained mixture with polyisocyanate; so the step of compounding of the carbon nanostructured compound is omitted, process is simple, and seamless linkage with conventional equipment is realized.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

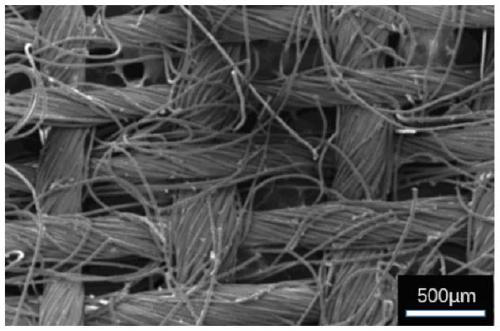

Composite fiber, preparation method and applications

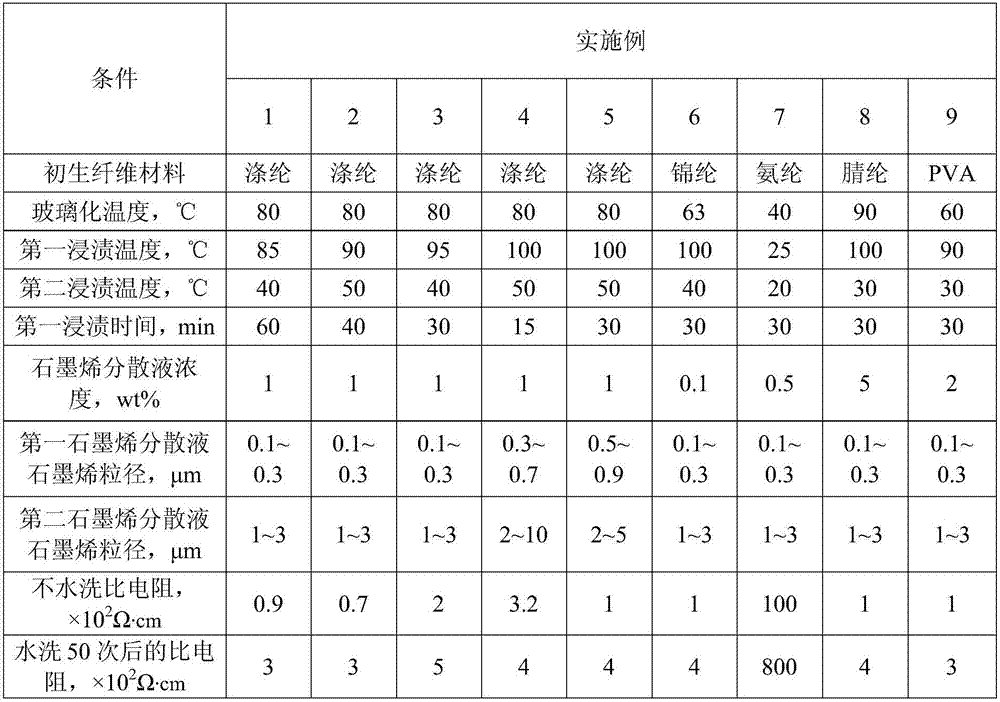

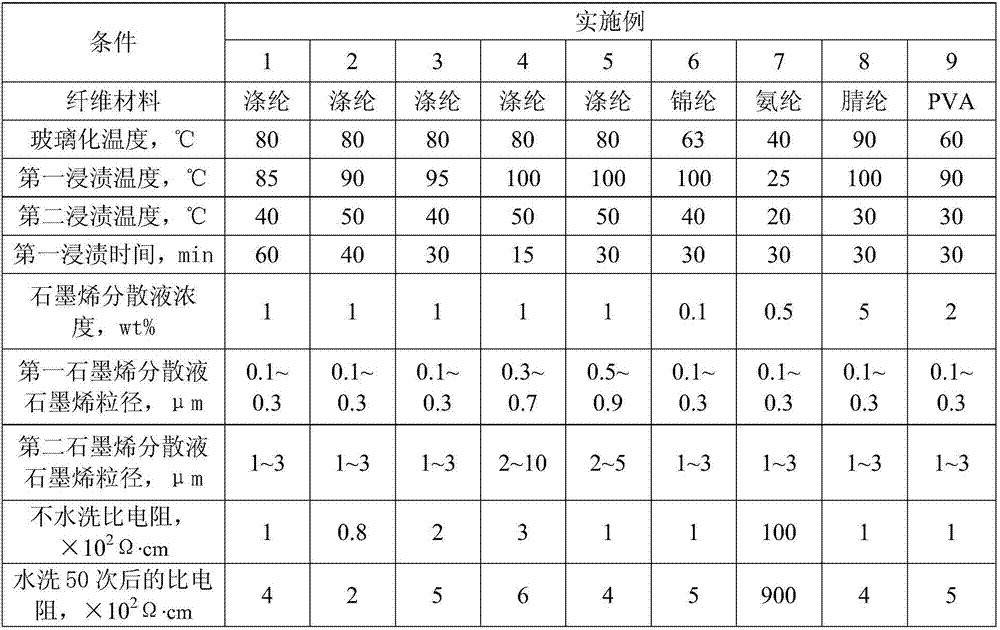

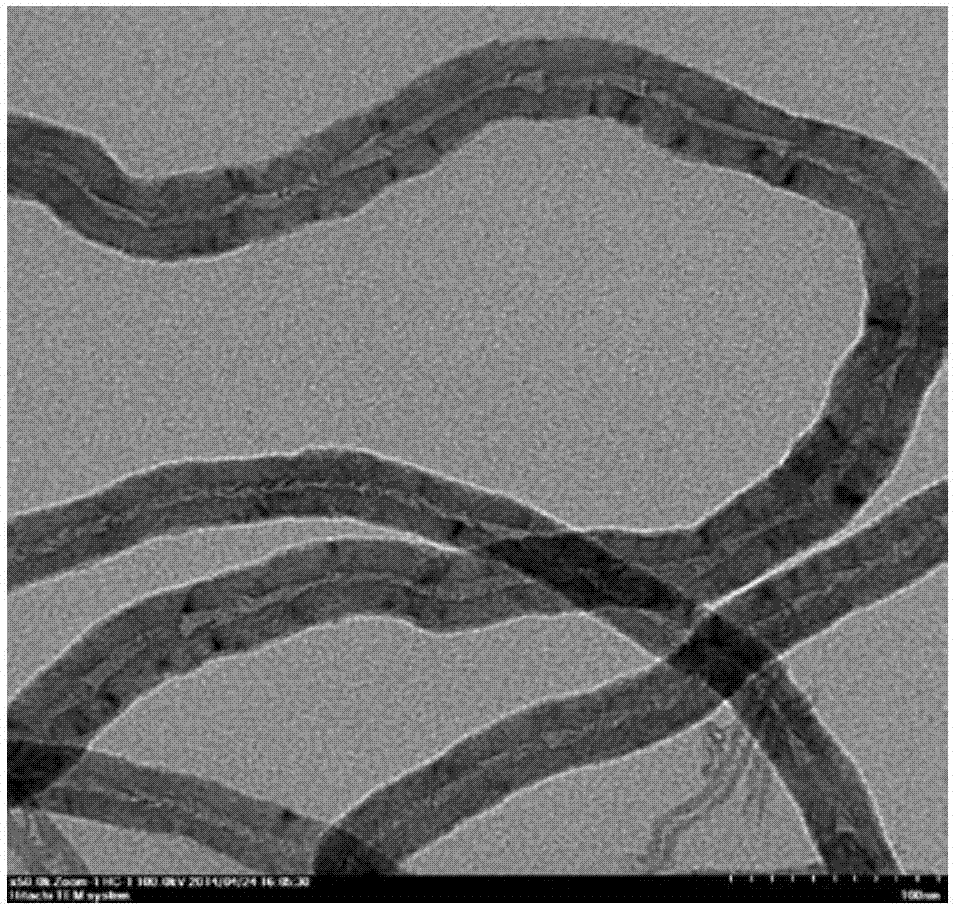

The invention relates to a preparation method of composite fiber. The preparation method comprises the following steps: immersing nascent fiber in graphene substance dispersing solution and then cooling and drying to obtain composite fiber, wherein the range of immersing temperature is at high-elastic-state temperature of the nascent fiber material. By immersing nascent fiber into graphene substance dispersing solution at the high-elastic-state temperature, the compounding of the graphene substances inside and outside the fiber can be realized, and the evenness and firmness of the graphene substances in the fiber can be increased; the conductivity of the fiber can be enhanced by adding graphene and / or biomass graphene; the far infrared performance of the fiber can be further strengthened by adding graphene oxide and / and biomass graphene; and the graphene substances can be effectively added inside the fiber by adopting the preparation method, and the fiber is externally cladded with the graphene substances.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Modified fiber product, preparation method and applications thereof

InactiveCN106930097AImprove firm performanceImprove segment uniformityFibre typesFiberOptoelectronics

The invention relates to a modified fiber product. The modified fiber product contains modified fiber, wherein graphene substances are contained inside the modified fiber, and graphene substances are also contained outside the modified fiber. A method comprises the following steps: immersing the non-modified fiber product into a graphene substance dispersing solution, and then cooling and drying to obtain the modified fiber product, wherein the range of the immersing temperature is at high-elastic-state temperature of a fiber material in the non-modified fiber product. Graphene are adhered or filled inside and outside the fiber, so that the evenness of the graphene can be increased, and the conductivity of the fiber can be improved; and by using the preparation method, the graphene can be effectively filled inside the fiber, and the fiber is externally cladded with graphene substances, so that the even distribution of graphene in the fiber can be realized.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Antibacterial and light textile fabric and preparing method thereof

ActiveCN110484994AEnhanced Far Infrared PerformanceWith negative ion therapyMonocomponent polyesters artificial filamentArtifical filament manufactureTemperature controlPolyester

The invention relates to the field of textile fabrics, in particular to an antibacterial and light textile fabric and a preparing method thereof. The antibacterial and light textile fabric is formed by weaving antibacterial and temperature-adjusting aerogel fibers, wherein the antibacterial and temperature-adjusting aerogel fibers are prepared by means of the steps of fusing polyester chips to prepare a polyester spinning solution, then adding modified aerogel and a negative-ion temperature-adjusting material into the spinning solution, after the materials are uniformly mixed, spraying out themixture from spinneret holes, and then conducting fiber forming, nascent fiber drafting orientation, fiber heat setting and winding. The prepared antibacterial and light textile fabric is simple in structure, reasonable in preparation of raw materials, and soft and smooth in texture, and has the function of intelligent temperature control, and the temperature in the fabric can be freely adjustedwithin a certain temperature range according to the temperature change of the outside environment; meanwhile, the antibacterial and light textile fabric also has lasting antibacterial performance andlarge application value.

Owner:JIANGSU DAMAONIU NEW MATERIAL TECH CO LTD

Yarn made by blending fiber having anions and far-infrared function and hemp-cotton fiber

InactiveCN106049070AVigorousMeet needsLight resistant fibresBiochemical treatment with enzymes/microorganismsYarnUltraviolet

The invention relates to yarn made by blending fiber having anions and a far-infrared function and hemp-cotton fiber. The yarn is prepared by blending the composite fiber having the anions and the far-infrared function and the hemp-cotton fiber. A preparation method of the composite fiber having the anions and the far-infrared function comprises the following steps: 1) preparing mixed fiber; 2) preparing anion and far-infrared functional nano slurry; 3) preparing anion and far-infrared functional composite fiber. The yarn provided by the invention is prepared by blending the fiber having the anions and the far-infrared function and the hemp-cotton fiber; because the yarn contains the hemp fiber, the anions and a far-infrared additive, the product has the characteristics of a good far-infrared effect, an anion health function, a good natural antibacterial property, a good uvioresistant function and the like; when people wear clothes made of the yarn, anions can be continuously excited to human bodies, then the human bodies can be always full of energy, and requirements of people on high-class textiles can be met.

Owner:YIWU MASHANGSHENG KNIT GOODS CO LTD

Modified polyester fiber production method

The invention discloses a modified polyester fiber production method. Graphene sheet layers exist inside and outside polyester fiber of a modified polyester fiber product; the polyester fiber productcomprises polyester fiber, polyester yarn and polyester fabric. Graphene is attached or added to the inside and outside of the polyester fiber and the uniformity and firmness of graphene are improved.The conductivity of the polyester fiber is improved by adding graphene and / or biomass graphene. The far infrared performance of the polyester fiber is further reinforced by adding graphene oxide and / or biomass graphene. With the adoption of the production method, the graphene can be effectively added to the inside of the polyester fiber, meanwhile, the outside of the polyester fiber is coated with the graphene sheet layer, and graphene can be uniformly distributed on the polyester fiber by impregnating the polyester fiber product with a graphene solution.

Owner:江阴市博帆化纺有限公司

Preparation method of regenerated cellulose fiber with surface being coated with graphene oxide

ActiveCN108193298AGood mechanical propertiesHigh strengthElectroconductive/antistatic filament manufactureArtificial filaments from cellulose derivativesUreaRegenerated cellulose

The invention relates to a preparation method of regenerated cellulose fiber with the surface being coated with graphene oxide. A coating mother solution is prepared by mixing regenerated cellulose, urea, NaOH and water, regenerated cellulose fiber is subjected to same-substrate coating, and thus the problem that in the process that fiber is coated with graphene oxide, graphene oxide is prone to being peeled off to affect the property of complex fiber due to the cohesiveness of different-substrate coating is poor is solved. In addition, because the regenerated cellulose can easily dissolve inthe urea and water solution of NaOH, a certain degree of etching is conducted on fiber by controlling the coating time, a rough surface is formed on the surface of fiber, the regenerated cellulose inthe mother solution can form a very strong hydrogen bond with a fiber substrate, and the cohesiveness of the coating mother solution and fiber is further enhanced through the two effects. Multi-functionalized graphene oxide is prepared to coat the regenerated cellulose fiber, the regenerated cellulose fiber is endowed with an excellent anti-static property, an excellent mechanical property, and properties such as sterilization, ultraviolet resistance and far infrared resistance.

Owner:HANGZHOU GAOXI TECH CO LTD

Preparation method of self-cleaning multifunctional graphene sponge

ActiveCN107474307AHigh strengthImprove antistatic performanceCarbon compoundsPolymer scienceAdhesive

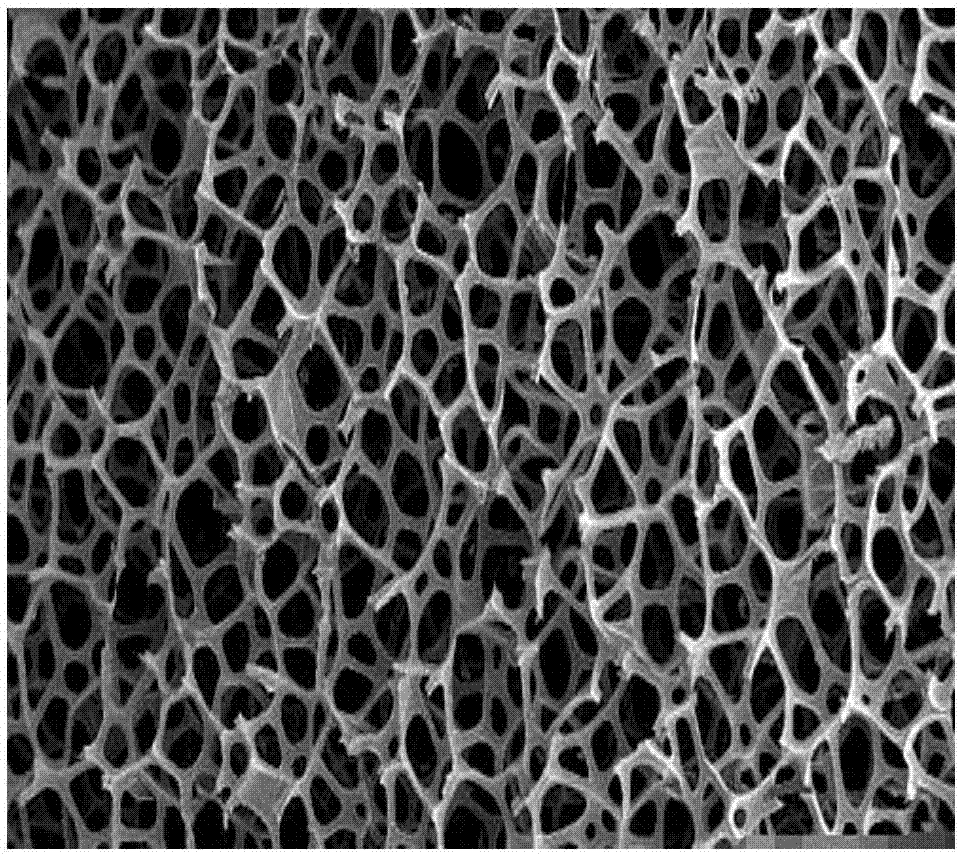

The invention belong to the technical field of preparation of multifunctional materials and relates to a preparation method of self-cleaning multifunctional graphene sponge. A technological process comprises three steps of preparation, mixing and foaming. Graphene, a photocatalyst, a flame retardant, an adhesive and a foaming aid are weighed according to set requirements, mixed with polyurethane and subjected to reaction crosslinking, and the sponge is prepared on the basis of polyurethane as a carrier with a one-step box foaming technology; the sponge has good absorption and ventilation properties, feels soft, and also has characteristics of ultrahigh strength, antistatic property, far infrared property, bacteria resistance, instantaneous deodorization property, negative ion property and the like of graphene; compared with traditional sponge, the graphene sponge has the advantages that electrical conductive and thermal properties are improved, functions of bacteria resistance, far infrared, negative ion and instant deodorization are added; the preparation process of the graphene sponge is simple, preparation efficiency and yield are high, environment-friendliness and energy conservation are achieved, and the graphene sponge can be widely applied to household products such as women's lingerie, shoes, seats of maglev trains, high-speed trains and high-grade automobiles, high-grade sofas, mattresses and the like.

Owner:宋金栋

Modified acrylic fibre product, as well as preparation method and application thereof

The invention relates to a modified acrylic fibre product. Graphene flakes exist in and out of acrylic fibres of the modified acrylic fibre product; the acrylic fibre product comprises acrylic fibres, acrylic yarns or acrylic fabric. According to the modified acrylic fibre product, graphene is adhered to or added into the interiors and the exteriors of the acrylic fibres simultaneously, so that the uniformity and the firmness of the existence of the graphene are improved; the electrical conductivity of the acrylic fibres is improved by adding the graphene or / and biomass graphene; the far infrared performance of the acrylic fibres is further enhanced by adding oxidized graphene and / or the biomass graphene; according to the preparation method provided by the invention, the graphene can be effectively filled into the interiors of the acrylic fibres, meanwhile, the exteriors of the acrylic fibres are coated with the graphene flakes, and uniform distribution of the graphene on the acrylic fibres is realized by soaking the acrylic fibre product with a graphene solution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

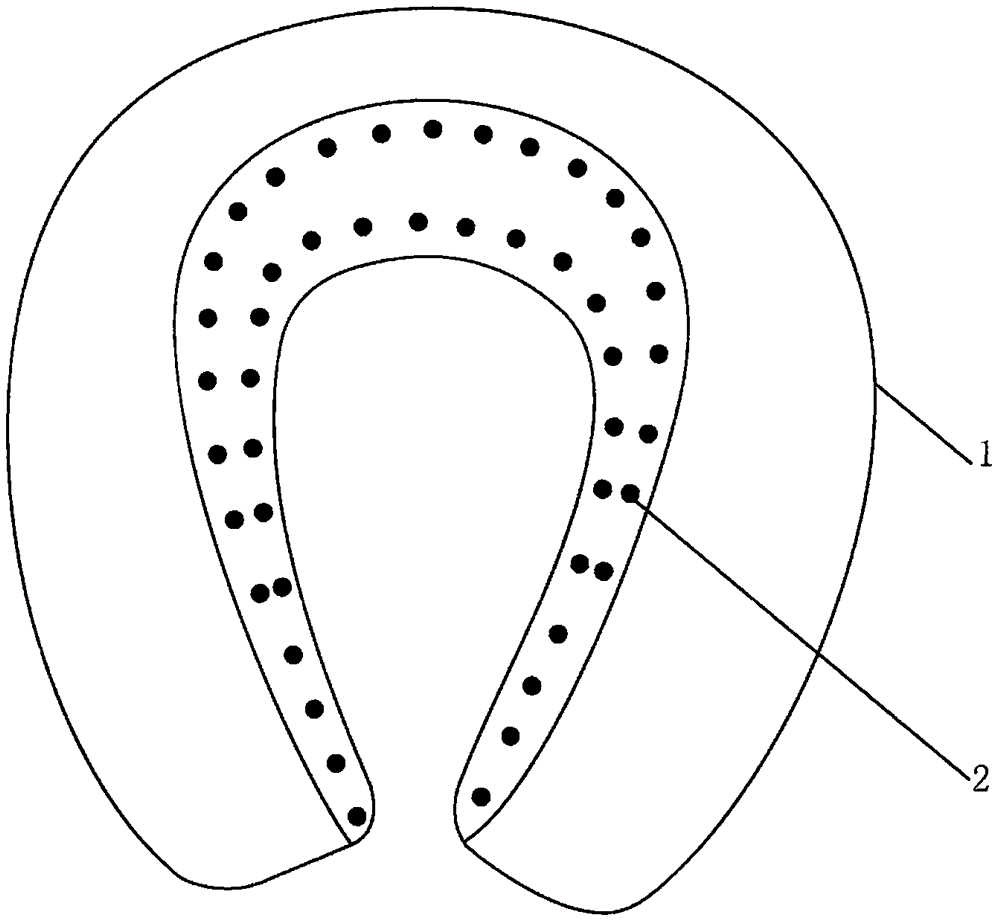

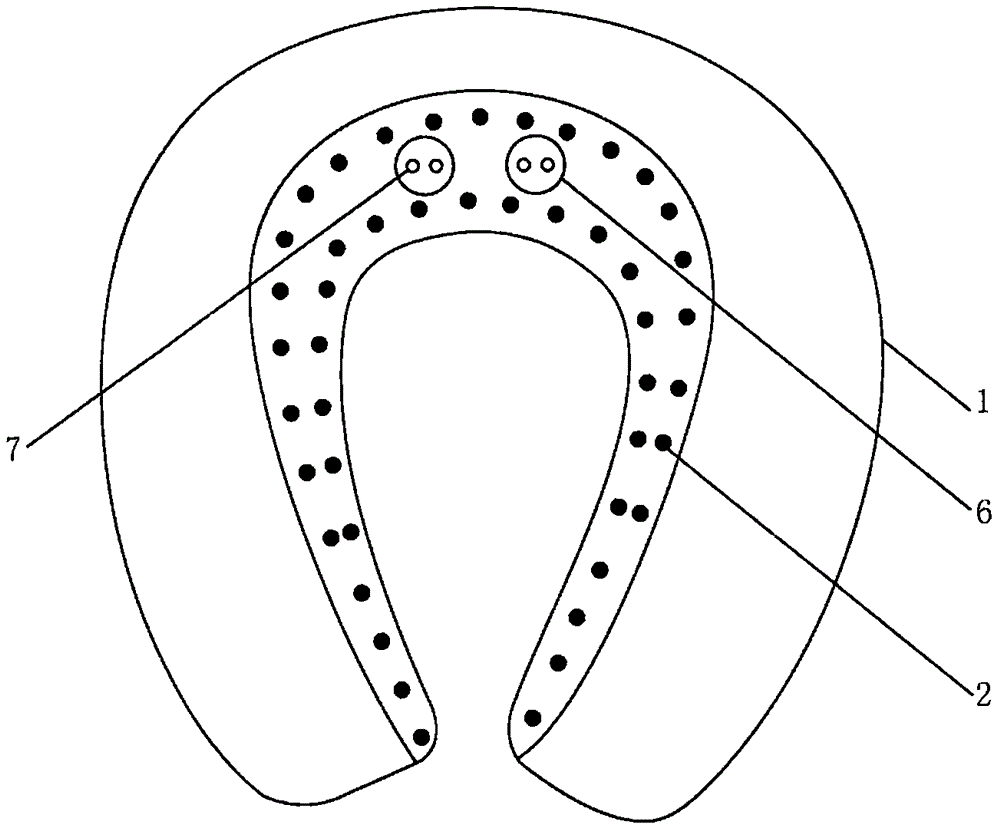

Natural self-heating health-care physiotherapy neck-protecting pillow and preparation method thereof

The invention discloses a natural self-heating health-care physiotherapy neck-protecting pillow. The natural self-heating health-care physiotherapy neck-protecting pillow comprises a filling pillow inner core, a pillow inner core cover and a pillow cover. The filling pillow inner core is of U shape, and the pillow inner core cover is detachably disposed outside the filling pillow inner core in a sleeved mode and is in close contact with the filling pillow inner core; The pillow cover is provided with an opening, and a zipper is arranged at the opening; the pillow cover is disposed outside the pillow inner core cover in a sleeved mode, a plurality of self-heating far infrared functional adhesive particles are distributed on the outer surface of the pillow cover which is in contact with the neck of the human body; the self-heating far infrared functional adhesive particles are made by heating and drying self-heating far infrared functional adhesive pastes; the self-heating far infrared functional adhesive pastes contain 5-40 % of raw ore slurry, 0.01-10% of far infrared functional additives, 50-80% adhesives and 0.1-5% of dispersant. The natural self-heating health-care physiotherapy neck-protecting pillow has better self-heating effect and far-infrared effect, and is more ideal for patients with cervical spondylosis.

Owner:QINGDAO UNIV

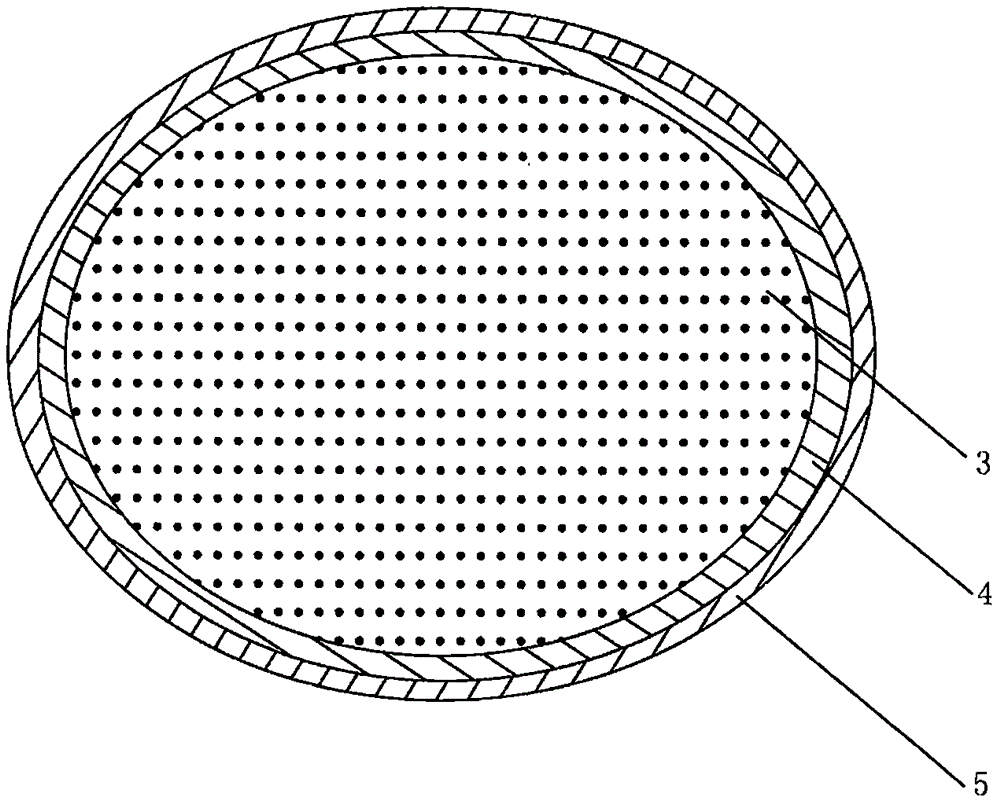

Natural self-heating health-care physiotherapeutic kneepad and production method thereof

InactiveCN106418794AImprove microcirculationPromote blood circulationLight therapyTherapeutic coolingCotton clothCushion

The invention discloses a natural self-heating health-care physiotherapeutic kneepad, comprising a kneepad body fitting a human body knee area; a first layer of the kneepad body and a third layer, fitting the human body knee area, of the kneepad body are of spandex stretch mesh, a second layer of the kneepad body is a stretch cotton cloth layer, the kneepad body is provided with a shell having a cavity and fitting the human body knee in shape, a cushion is arranged in the cavity of the shell, the outer surface of the cushion fitting the human body knee and the outer surface of the third layer are provided with a plurality of self-heating far-infrared functional adhesive particles, the self-heating far-infrared functional adhesive particles are made by heating and drying self-heating far-infrared functional adhesive slurry, and the self-heating far-infrared functional adhesive slurry comprises raw ore slurry, a far-infrared functional aid, an adhesive and a dispersant. The natural self-heating health-care physiotherapeutic kneepad and the production method thereof have the advantages that the kneepad is capable of improving human body microcirculation and promoting human body blood circulation, and the kneepad is significantly effective in easing pain, dispelling cold and relieving knee pain.

Owner:QINGDAO UNIV

Modified polyester fiber and preparation method thereof

InactiveCN105951208AGood far infrared effectGood antibacterial propertiesMonocomponent polyesters artificial filamentArtifical filament manufactureEtherUltraviolet

The invention belongs to the technical field of a textile material, and particularly relates to modified polyester fiber and a preparation method thereof. The polyester fiber is prepared from the following materials in percentage by weight: 90 to 95% of polyester chips and 5 to 10% of far infrared anion nano functional slurry, wherein the far infrared anion nano functional slurry is prepared from the following materials in parts by mass: 5 to 15 parts of nano titania, 5 to 15 parts of nano zinc oxide, 20 to 30 parts of ethyl alcohol, 20 to 35 parts of far infrared ceramic powder, 20 to 35 parts of tourmaline powder and 10 to 20 parts of hydroxymethyl cellulose ether. The modified polyester fibers prepared by the formula and the preparation method which are provided by the invention are developed for meeting the requirement of people for high-end textures; the obtained polyester fiber has functions of good far infrared effect, anion physiotherapy, excellent antibacterial property, heat insulation, ultraviolet resistance and the like.

Owner:SUZHOU YUXI NEW MATERIAL TECH

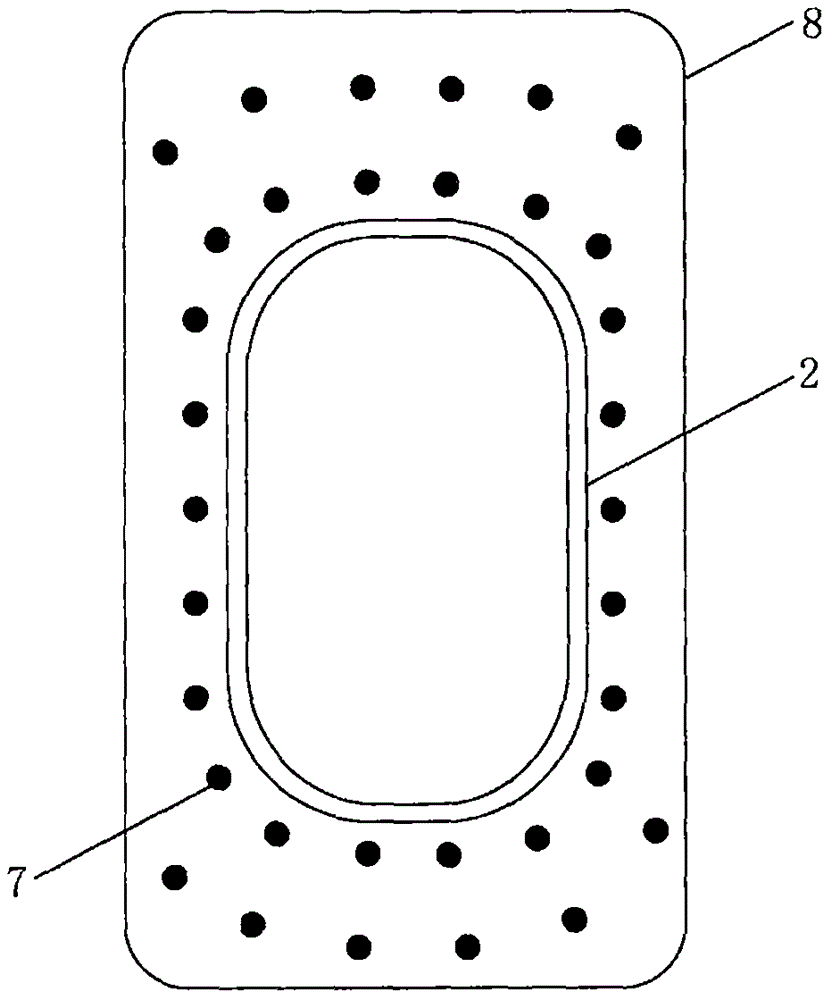

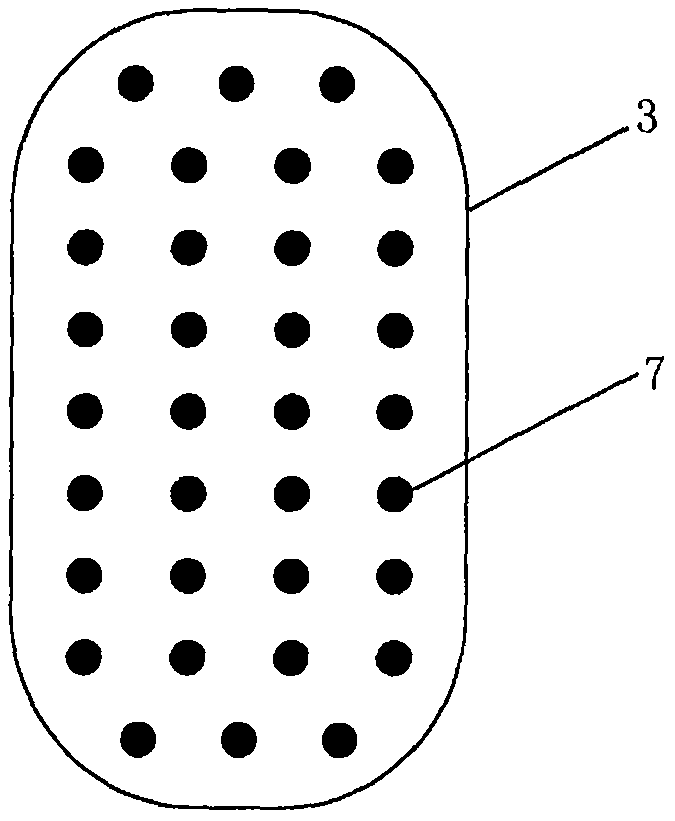

Preparation method of multifunctional graphene regenerated cellulose fibers

InactiveCN107354526AEnhanced Far Infrared PerformanceImprove antibacterial propertiesElectroconductive/antistatic filament manufactureArtificial filaments from viscosePolymer scienceMoisture absorption

The invention belongs to the technical field of preparation of multifunctional materials and relates to a preparation method of multifunctional graphene regenerated cellulose fibers. The technological process comprises three steps of mixing, spinning and reducing, specifically, a multi-layer graphene dispersing solution and a regenerated cellulose fiber solution are mixed, a mixed solution is subjected to molding with a viscous wet spinning technology and subjected to reduction, and the multifunctional graphene regenerated cellulose fibers are obtained; the multifunctional graphene regenerated cellulose fibers utilize regenerated cellulose fibers as carriers, have good moisture absorption, breathability, soft hand feeling and dyeing property and further have the characteristics such as superhigh strength, antistatic property, far infrared performance, antibacterial property, instant deodorization performance and anionic property of graphene, electrical conductivity and thermal property of the fibers are improved when compared with those of conventional regenerated cellulose fibers, and the antibacterial property, the far infrared performance and the anionic function of the fibers are increased; the production technology of the fibers is simple, easy to operate, low in batch production cost, high in preparation efficiency and yield, environment-friendly and energy-saving and can be applied to the fields of textiles, clothing, woven goods and the like.

Owner:青岛中天嘉业国际贸易有限公司

Modified polyamide fiber product, preparation method and application thereof

InactiveCN107254774AImprove firm performanceImprove segment uniformityFibre typesYarnPolymer science

The invention relates to a modified polyamide fiber product. Graphene sheet layers are arranged inside and outside polyamide fiber of the modified polyamide fiber product, and the polyamide fiber product comprises polyamide fiber, polyamide yarn and polyamide fabric. Graphene is attached or filled both inside and outside the polyamide fiber, so that uniformity and firmness of the graphene are improved; by adding graphene and / or biomass graphene, conductive performance of the polyamide fiber is improved; by adding oxidized graphene and / or biomass graphene, far infrared performance of the polyamide fiber is further improved. By the preparation method, the graphene can be effectively filled into the inside of the polyamide fiber, the outside of the polyamide fiber is coated with the graphene sheet layer, and uniform distribution the graphene on the polyamide fiber is realized by soaking the polyamide fiber product in a graphene solution.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

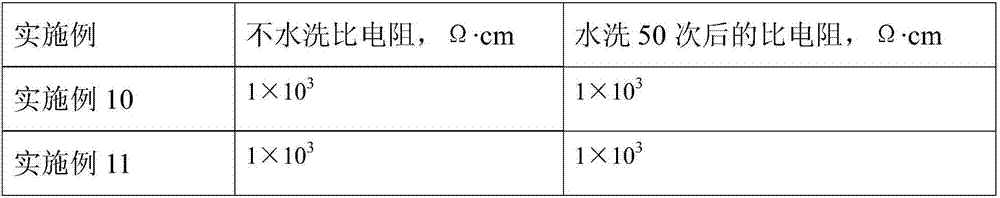

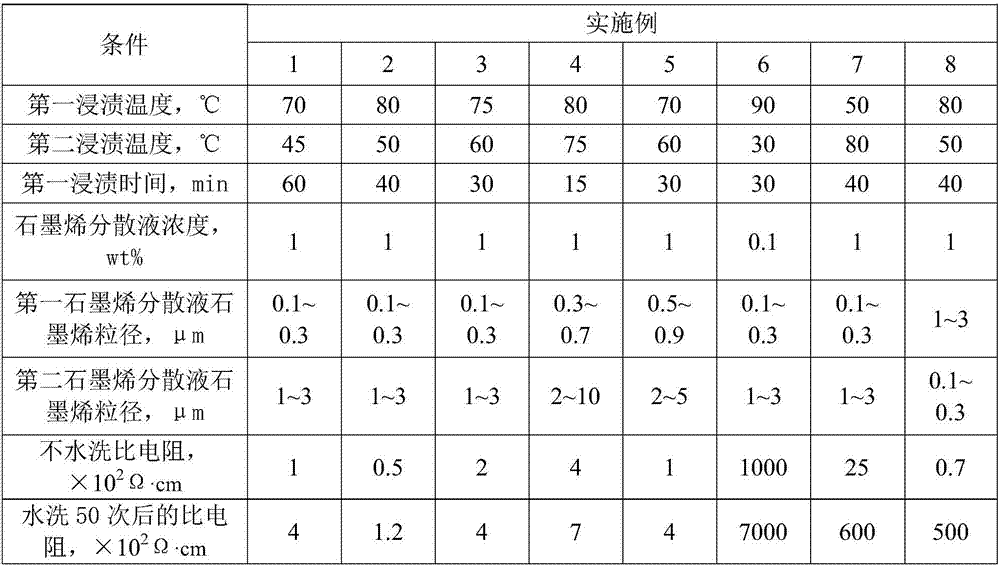

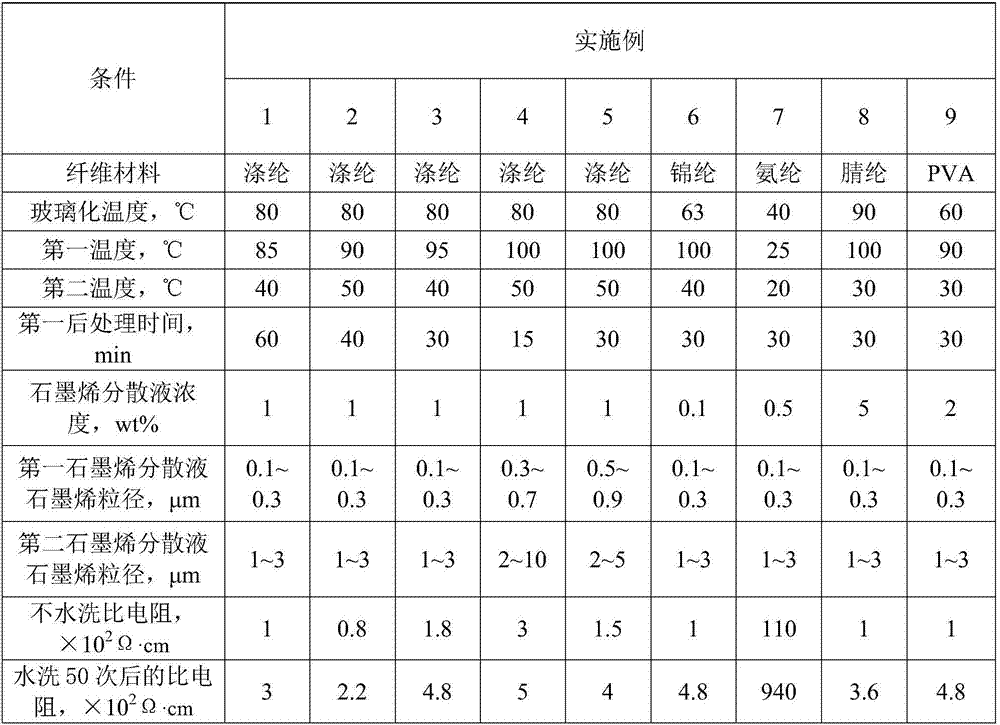

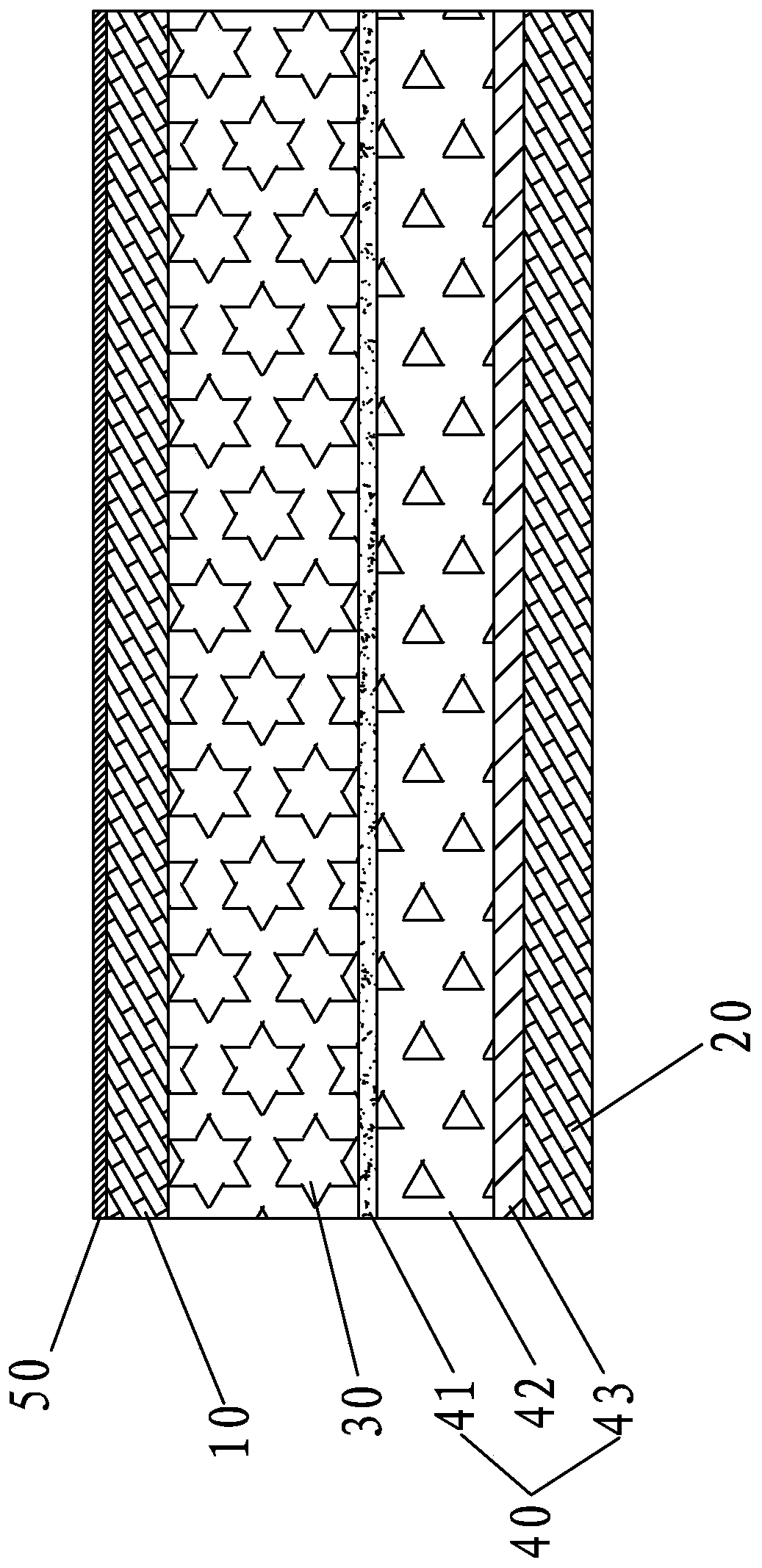

Post treatment method of fiber product, obtained modified fiber product and application thereof

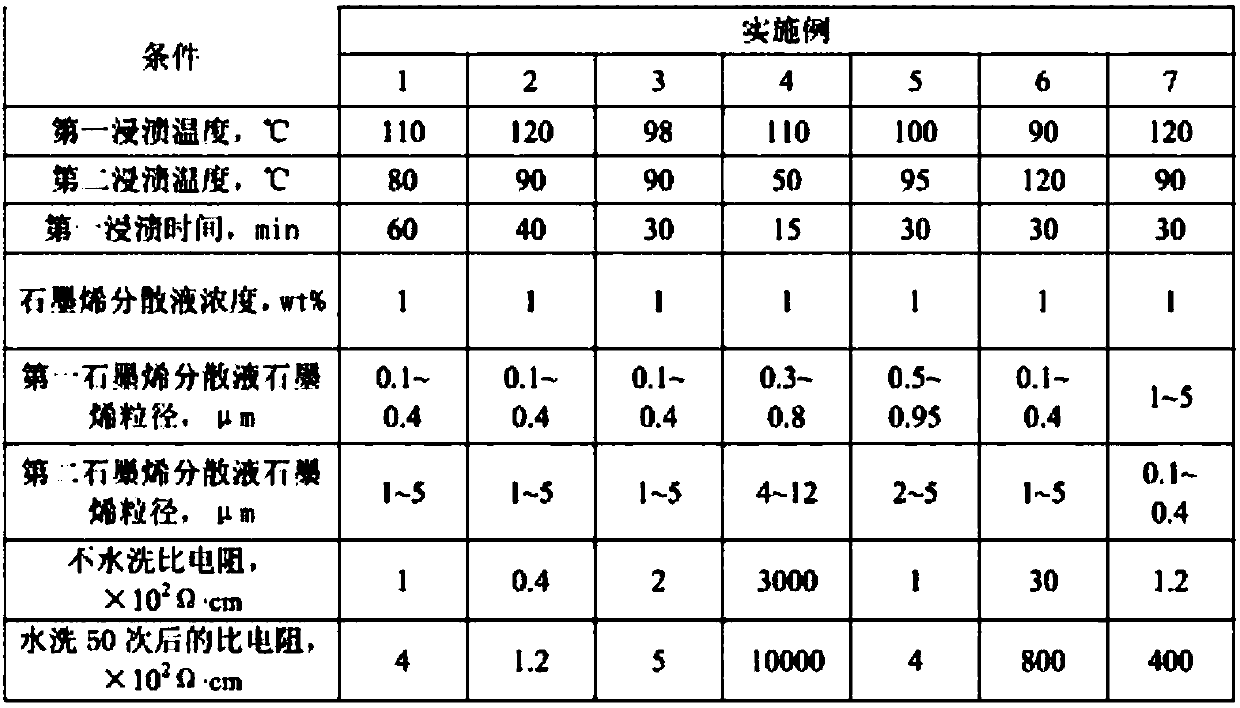

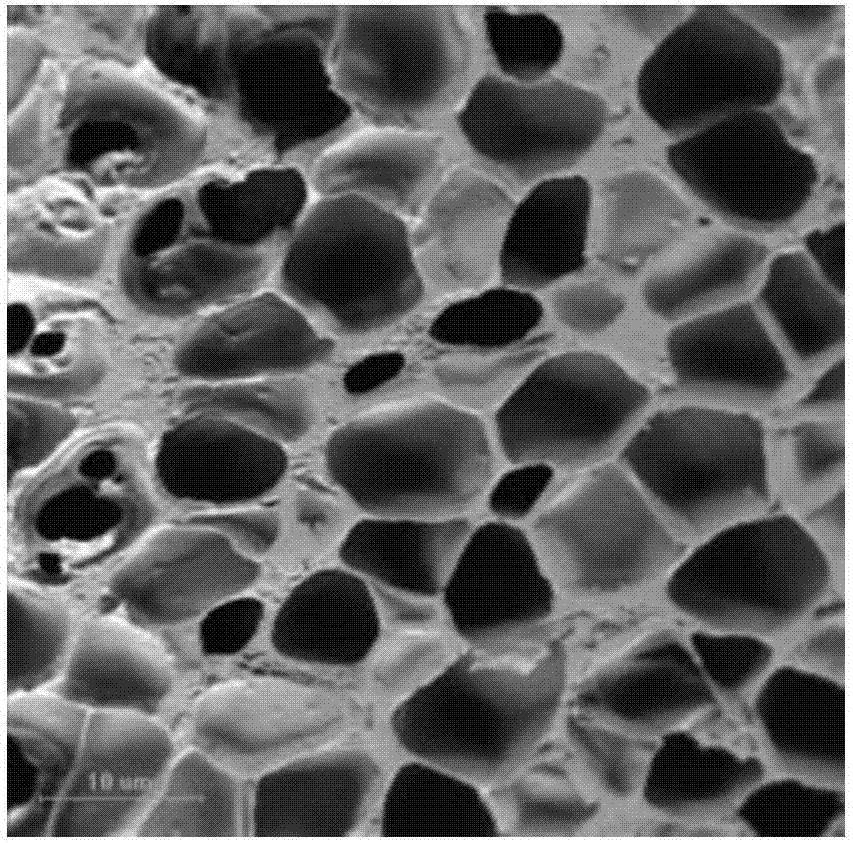

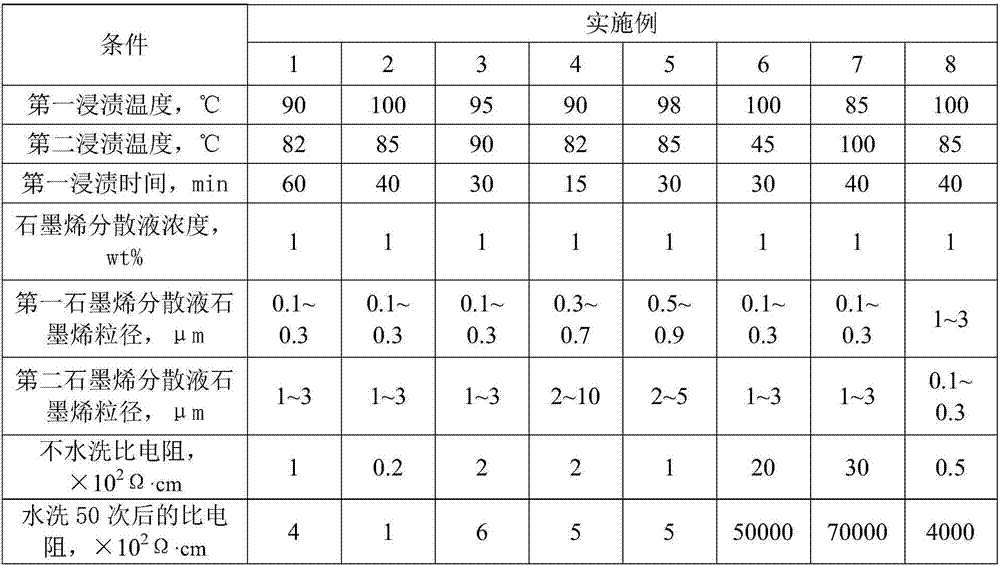

The invention relates to a post treatment method of a fiber product. The post treatment method of the fiber product comprises the following steps: (A1) impregnating the fiber product with first graphene type substance dispersion, taking out, then heating to the high-elastic state temperature of a fiber material, and carrying out primary compound treatment at a constant post-treatment temperature, wherein the particle size of graphene type substances in the first graphene type substance dispersion is less than 1mu m; and (A2) impregnating the fiber product subjected to the primary compound treatment into second graphene type substance dispersion, taking out, then heating to a second post treatment temperature, carrying out secondary compound treatment at a constant temperature, then cooling, and drying, so that a composite fiber product is obtained, wherein the particle size of graphene type substances in the second graphene type substance dispersion is 1-20mu m. The post treatment method provided by the invention has the advantages that adhesion firmness of the graphene type substances on fibers is improved; meanwhile, from the viewpoint of radial direction of the fibers, more graphene type substances with small particle size are distributed inside, and distribution uniformity of the graphene type substances in the radial direction of the fibers is improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Antistatic antibacterial far-infrared moisture-absorbing and quick-drying down fabric manufacturing method

ActiveCN110406213AGood touchSoft touchGarment special featuresElectroconductive/antistatic filament manufacturePolyesterYarn

The invention relates to an antistatic antibacterial far-infrared moisture-absorbing and quick-drying down fabric manufacturing method, wherein the down fabric comprises a fabric body, the fabric bodycomprises a surface layer, an inner layer and a down layer, and further comprises a windproof heat locking layer, the surface layer and the windproof heat locking layer are integrally sewn by suturesto form an accommodating channel for filling down, down is filled into the accommodating channel to form the down layer, the windproof heat locking layer comprises a separation cotton lining layer, asilk-like cotton layer and a lining cloth layer, the separation cotton lining layer, the silk-like cotton layer and the lining cloth layer are integrally compounded, the silk-like cotton layer is sandwiched between the separation cotton lining layer and the lining cloth layer, the lining cloth layer is attached to the inner layer, the weight of the silk-like cotton is 40-80 g, the surface layer and / or the inner layer are formed by interweaving with yarns, the yarns are graphene oxide polyester yarns, and the graphene oxide polyester yarn comprises 1-5% by mass of graphene oxide and 90-95% bymass of polyester. According to the present invention, the product has advantages of antistatic property, antibacterial property, far infrared property, moisture absorption, quick drying, low cost andgood warm keeping effect.

Owner:柯林(福建)服饰有限公司

High-performance alkenyl magnesium alloy material and preparation method thereof

The invention provides a high-performance alkenyl magnesium alloy material which mainly comprises the following components in percentage by mass: 5-8% of graphene substances, 1-2% of Co, 1-2% of Y, 4-7% of Al, 1-3% of Mn, 0.2-0.8% of Li, 0.2-1.0% of Zr, 0.1-0.5% of Ca, 0.1-0.5% of Zn, 0.2-1.0% of Cd, 0.3-0.7% of Yb, 0.3-0.7% of Ni, 0.1-1% of Sb, 0.1-1% of Mo and the balance Mg. A preparation method for the high-performance alkenyl magnesium alloy material comprises the following steps of: pre-heating pure magnesium metal, smelting the pure magnesium metal and other raw materials containing metal elements under protection of inert gases, and preserving the temperature after smelting; and increasing the temperature after preserving the temperature, adding graphene substance raw materials, standing after uniformly stirring, and filtering to obtain a crude magnesium alloy liquid. The alkenyl magnesium alloy material provided by the invention has relatively excellent performance indexes such as heat resistance, strength and hardness.

Owner:冯军 +1

Preparation method of graphene/polyacrylonitrile spinning solution

ActiveCN111321479AGood dispersionRealize industrializationElectroconductive/antistatic filament manufactureMonocomponent synthetic polymer artificial filamentPolymer scienceSpinning

The invention discloses a preparation method of a graphene / polyacrylonitrile spinning solution suitable for industrial production. According to the method, a conventional two-step process, including aqueous suspension polymerization and polyacrylonitrile resin dissolution in an inorganic solvent, is adopted, special equipment is not added, polyacrylonitrile filter cake dilution water in an original spinning process is switched into a stably dispersed graphene aqueous solution, graphene is uniformly dispersed in polyacrylonitrile slurry, then the slurry is mixed with NaSCN, and the graphene / polyacrylonitrile spinning solution is obtained through stirring and high shearing. The spinning solution prepared by the adoption of the method has good spinnability, and the graphene can be dispersed uniformly and stably in the spinning solution for 48 hours or above. Compared with pure polyacrylonitrile fibers, the specific resistance of graphene / polyacrylonitrile fibers prepared by the adoption of the spinning solution is increased by 3-5 orders of magnitudes, and strength is improved by 20% or above.

Owner:CHINA PETROLEUM & CHEM CORP +1

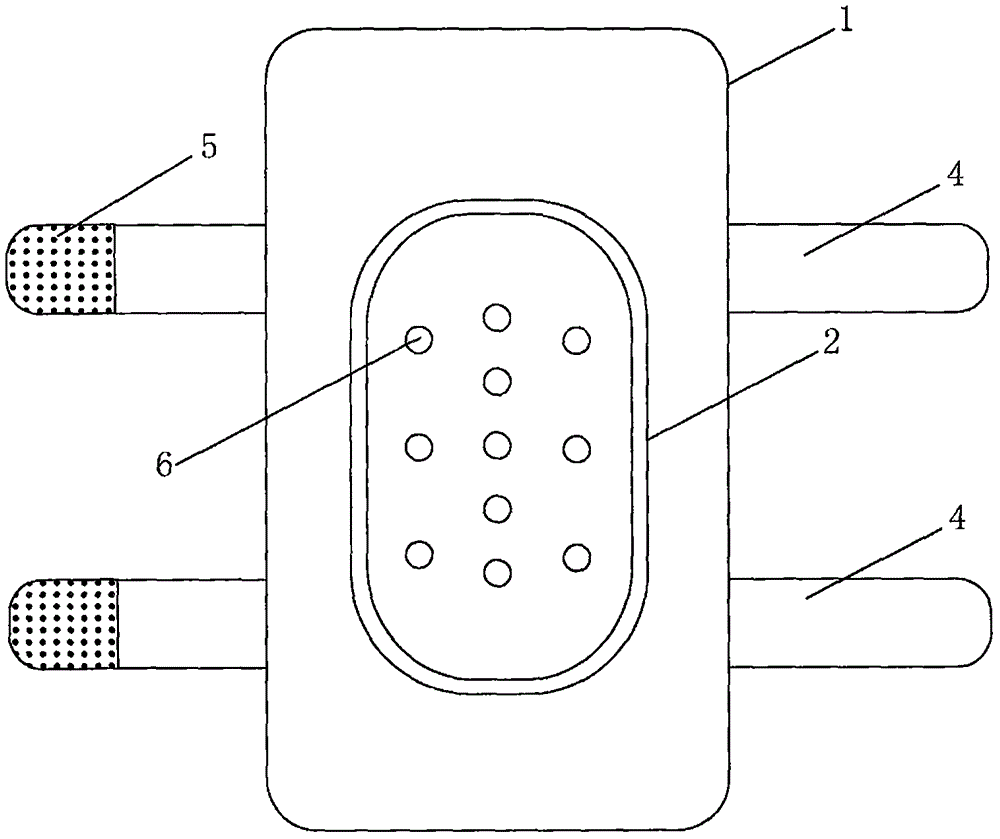

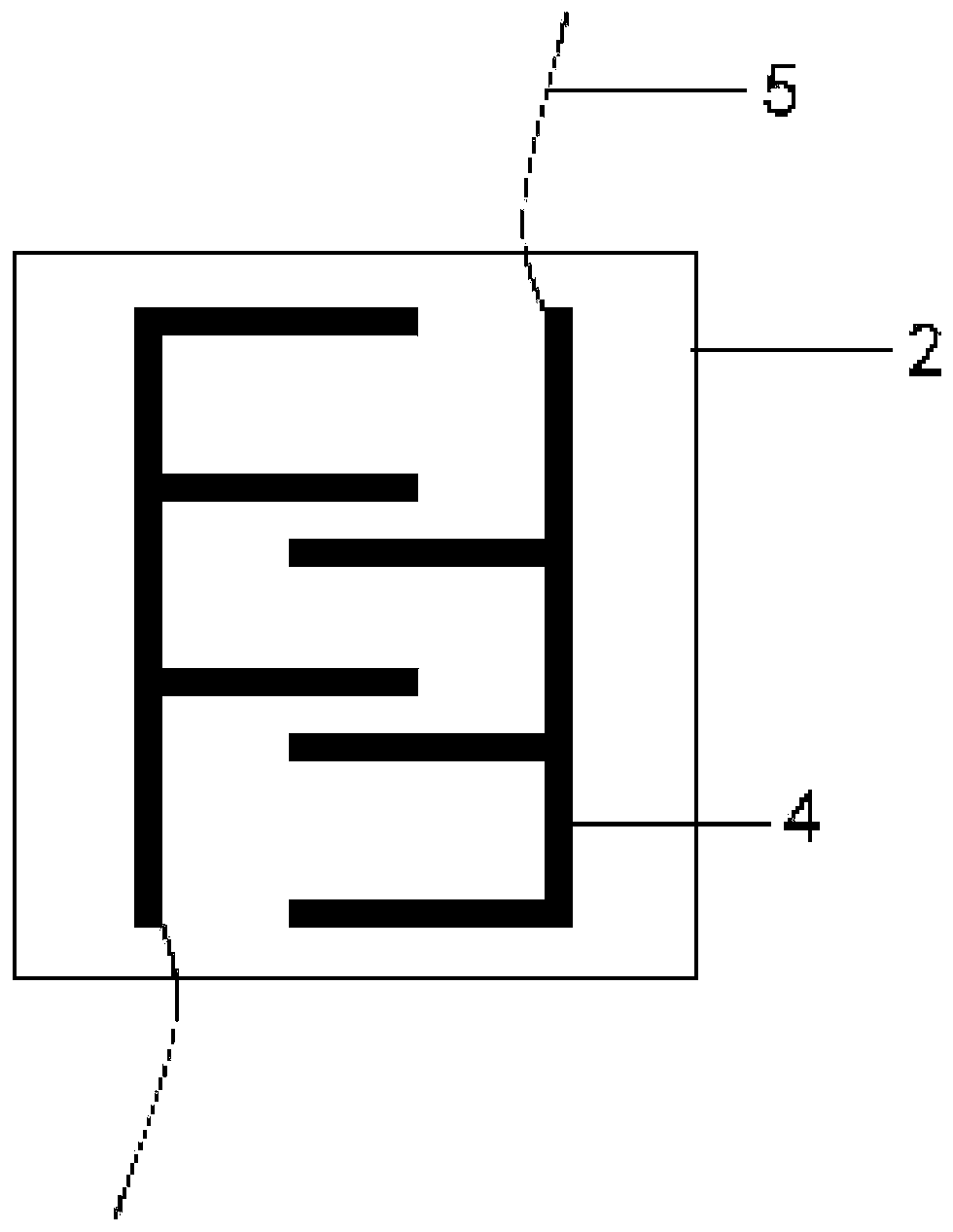

Far infrared radiation carbon fiber electric-thermal composite fabric and preparation method thereof

ActiveCN111186183AImprove heat resistanceImprove thermal stabilityOhmic-resistance electrodesCarbon fibresFiberCarbon fibers

The invention discloses a far infrared radiation carbon fiber electric-thermal composite fabric and a preparation method thereof. The composite fabric comprises a far infrared radiation carbon fiber fabric arranged between two layers of flexible fabric matrixes; and an electrode plate is arranged in the far infrared radiation carbon fiber fabric. The preparation method comprises the following steps: pretreating the carbon fiber fabric to obtain a desized carbon fiber fabric; dipping the carbon fiber fabric in a dopamine solution to obtain a dopamine biomimetic modified carbon fiber fabric; spraying far infrared slurry on the dopamine biomimetic modified carbon fiber fabric to obtain a far infrared radiation carbon fiber fabric; and compounding all the layers to obtain the far infrared radiation carbon fiber electric-thermal composite fabric. The composite fabric prepared by the invention not only ensures the electric-thermal stability and heating uniformity of the fabric, but also hasgood far-infrared radiation performance, and can realize the application of the electric-thermal fabric in the fields of human body clothing, intelligent wearable articles, cold-proof thermal insulation materials, greenhouse heat sources and the like.

Owner:DONGHUA UNIV

Graphene-modified polyamide-6 masterbatch material, fibers including same and application of fibers

InactiveCN108727808ASolve the problem of fragmentationEvenly dispersedArtifical filament manufactureMonocomponent polyamides artificial filamentChemical LinkageMasterbatch

The invention relates to a graphene-modified polyamide-6 masterbatch material. In the masterbatch material, a macromolecular chain of at least one polyamide-6 grows on a graphene lamella. A preparation method comprises the steps: adding functionalized graphene into hydrolysates obtained in a loop opening process and / or a polymerization process of caprolactam. A polyamide-6 macromolecular chain isgrafted on the graphene lamella, so that the dispersion problem of the graphene is effectively solved, and the polyamide-6 material with the uniformly-dispersed graphene is obtained; because the graphene lamella and the macromolecular chain of the polyamide-6 are connected through chemical bonds, in a preparation way process, the material has the advantages of good spinning performance and difficulty in breaking; through introduction and uniform distribution of the graphene, the far infrared performance and the antibacterial performance of the polyamide-6 material are improved.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

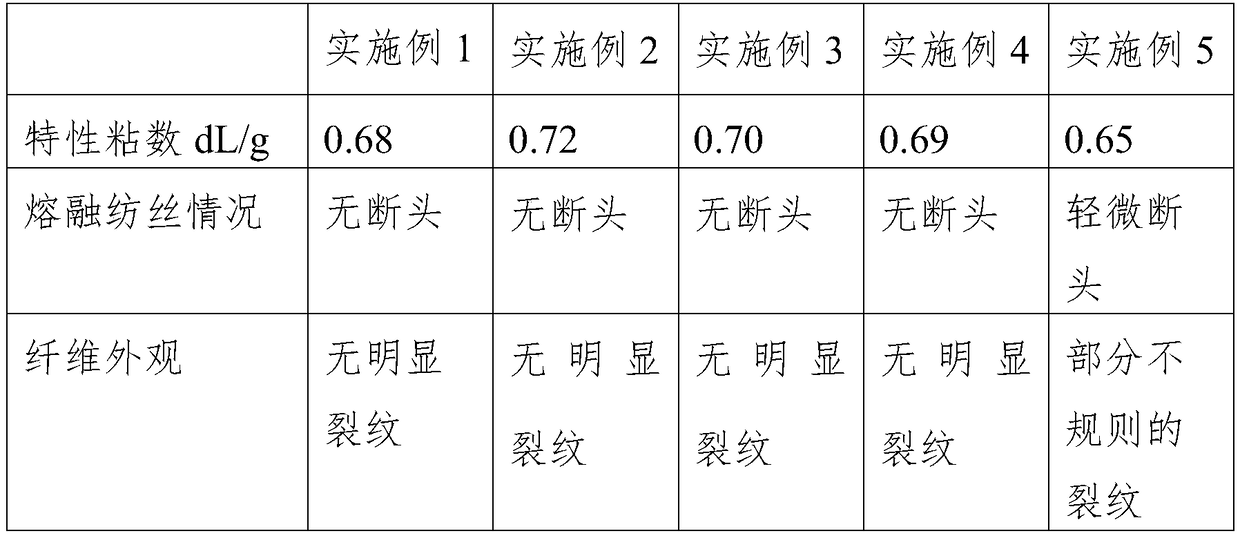

Preparation method of modified polyester chip, polyester chip and polyester fiber

ActiveCN109467683ALow viscosityGood dispersionMonocomponent polyesters artificial filamentArtifical filament manufactureOxygen ionsClick chemistry

The invention relates to the field of modification of synthetic fibers, in particular to a preparation method of a modified polyester chip. Nano-tourmaline is modified with a vinyl silane coupling agent and then subjected to a thiol-ene click chemistry reaction with 3-mercapto-1,2-propanediol, modified nano-tourmaline modified with polyhydroxyl on surface is prepared and added to purified terephthalic acid and ethylene glycol for condensation polymerization, and the modified polyester chip is obtained. Fabric woven from fibers obtained from the modified polyester chip by spinning has long-acting negative oxygen ion producing and far infrared effects, can purify the environment and brings health care and physiotherapeutic effects to human bodies.

Owner:福建省银河服饰有限公司

Ceramic digital glaze ink with sterilization and far infrared composite functions and preparation method thereof

ActiveCN112646416AEnhanced Far Infrared PerformanceImprove antibacterial propertiesInksFritFar infrared

The invention discloses ceramic digital glaze ink with sterilization and far infrared composite functions and a preparation method thereof. The ceramic digital glaze ink comprises the following components in percentage by mass: 30-60% of digital glaze powder, wherein the digital glaze powder is prepared from the following raw materials in percentage by mass: 30-70 percent of Ulan tea spar, less than 35 percent of high-temperature ceramic frit and less than 65 percent of low-temperature ceramic frit. By introducing the specific content of the Ulan tea spar and the ceramic frit in a proper proportion into the ceramic digital glaze ink, the obtained ceramic digital glaze ink not only has excellent far-infrared performance and antibacterial performance, but also can be applied to the surfaces of various types of ceramic green bricks, so that the production cost is greatly reduced, the application range of the ceramic digital glaze ink product is widened, popularization and application of the ceramic digital glaze ink with the far infrared and antibacterial composite functions are facilitated, and the ceramic digital glaze ink has very high practical value and application prospects.

Owner:佛山市三晶石陶瓷釉料有限公司

A kind of graphene modified color paste, preparation method and application thereof

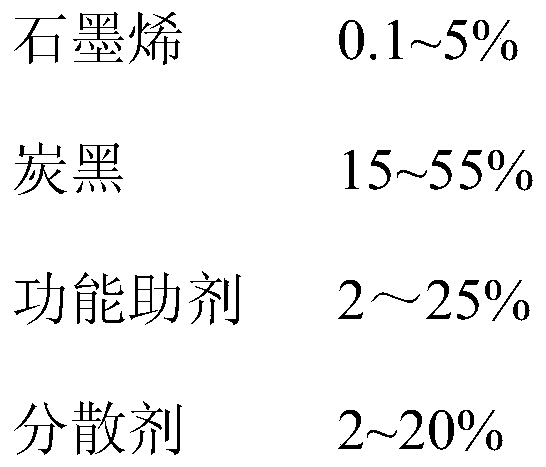

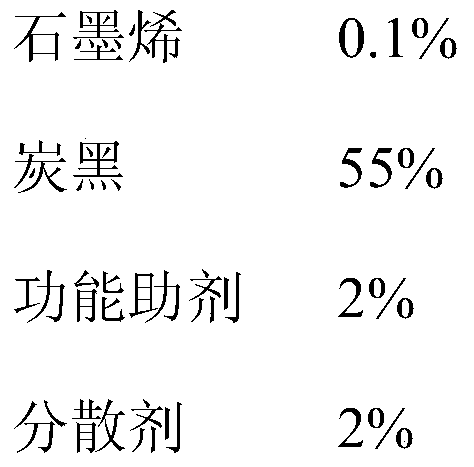

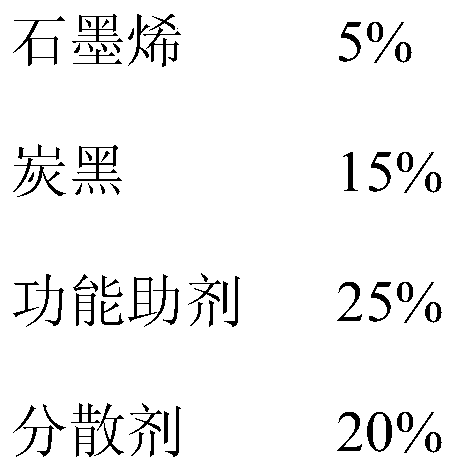

ActiveCN105543993BGood dispersionAvoid the defect of uneven dispersionPigment addition to spinning solutionSpinning solutions preparationPolymer scienceSpinning

The invention relates to graphene modified color paste. The graphene modified color paste is prepared from, by weight, 0.1-5% of graphene, 15-55% of carbon black, 2-25% of functional aids, 2-20% of a dispersing agent and the balance a solvent. By adding the specific amount of graphene into the color paste containing the specific amount of carbon black, the carbon block is attached to the surface of the graphene, dispersion of graphene can be facilitated because of the binding force between the carbon black and the graphene, and the defect that the graphene is not uniform in dispersion after being added into spinning liquid. Besides, the binding force between the specific amount of graphene and the specific amount of carbon black disappears in the spinning process, the functions of graphene in obtained textiles are give play to, and the textiles have the characteristics, such as excellent far infrared performance, bacteria resistance and the bacteriostasis and ultraviolet resistance, of graphene.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Electrothermal element

InactiveCN101925207AFill in the gapsHigh strengthOhmic-resistance electrodesHeating element materialsCarbon fibersAdhesive

The invention relates to a carbon fiber electrothermal element, which comprises a radiating layer at the lowest layer and also comprises a carbon fiber layer, a solidifying layer, a heat insulating layer and an outer housing arranged on the upper layer in sequence. The radiating layer is made of quartz glass or ceramic cloth. The solidifying layer adopts a curing agent resistant to a temperature up to 1200 DEG C and is mainly composed of a soluble adhesive, wherein ceramic fiber cloth or ceramic cellosilk prepared by ceramics containing silicon and zirconium components is distributed among the soluble adhesive. The strength and the anti-sheering force of the carbon fiber layer of the carbon fiber electrothermal element are enhanced, the surface becomes hard and durable as ceramics, the service life is prolonged, the solidifying layer contains ceramic fiber wires or ceramic fiber cloth which can further enhance the strength of carbon fiber electrothermal element, and in addition, the ceramics contains chemical elements, such as silicon, zirconium, and the like, and can further enhance the far infrared effect.

Owner:吴国栋 +1

Graphene hat

The invention discloses a graphene hat comprising a cap and a brim. The graphene has is characterized in that the cap is made of graphene fiber. There is a huge consumption market of hats and fashion is the vane of consumption. With the improvement of people's living standards, the role of hats is no longer what it was before; hats have become a mark of the love of beauty and fashion with the increase of consumption level and consumption taste. Therefore, if graphene is fit in the consumption trend, it will definitely promote the domestic demand of the industry of fashion hats just like graphene underwear does and therefore diverse development of graphene industry is promoted. In looking for a way out for the practicality of graphene difficultly through realizing popularization of the price of graphene by means of high-technology means, hundreds of millions of women can help. The graphene hat has lasting and unchangeable appearance and qualitative sense; the hat can be washed and dried at high or supper high temperature. The graphene hat has potential elements such as fashion and luxury which are highly sought after.

Owner:林惠花

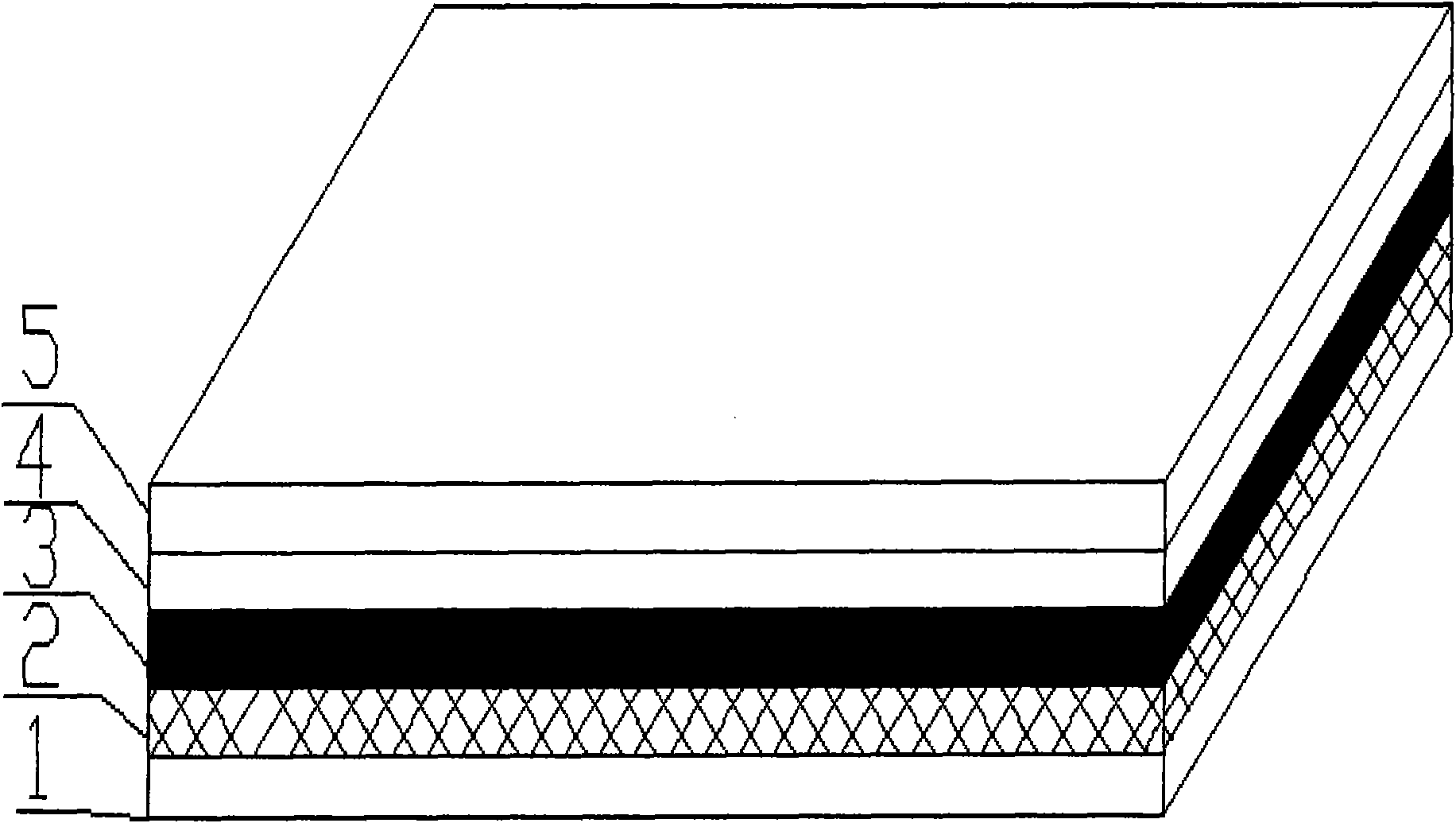

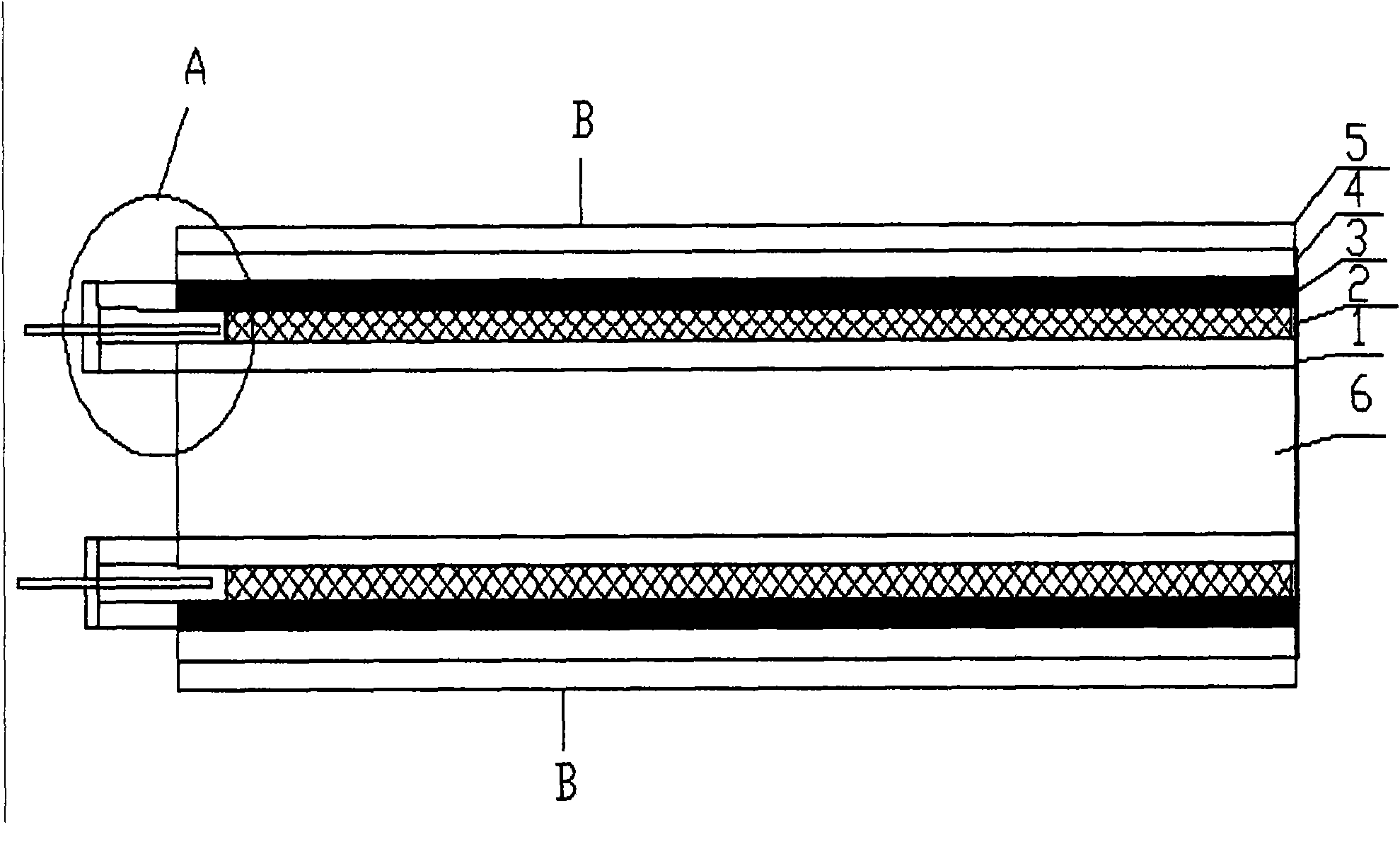

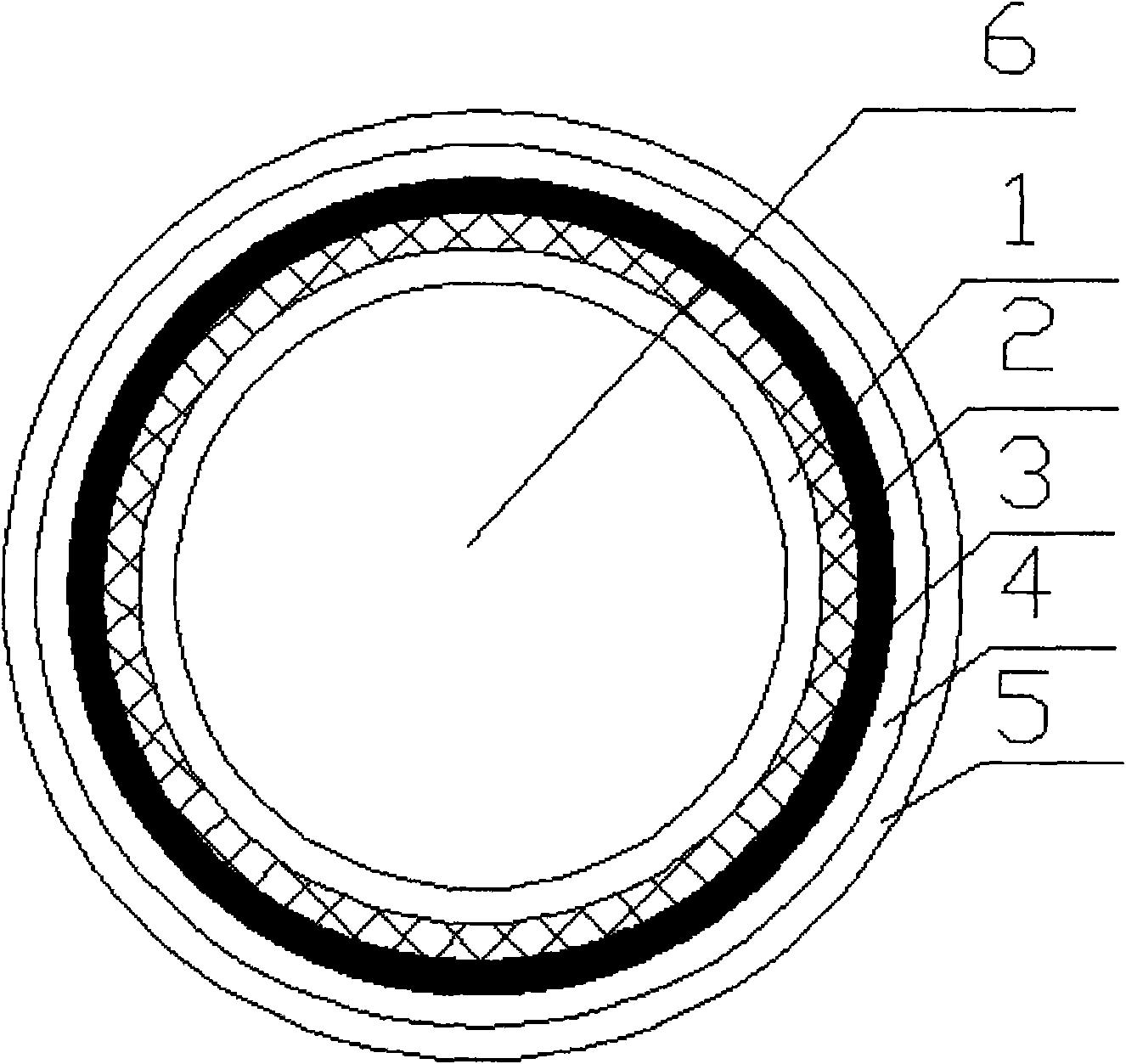

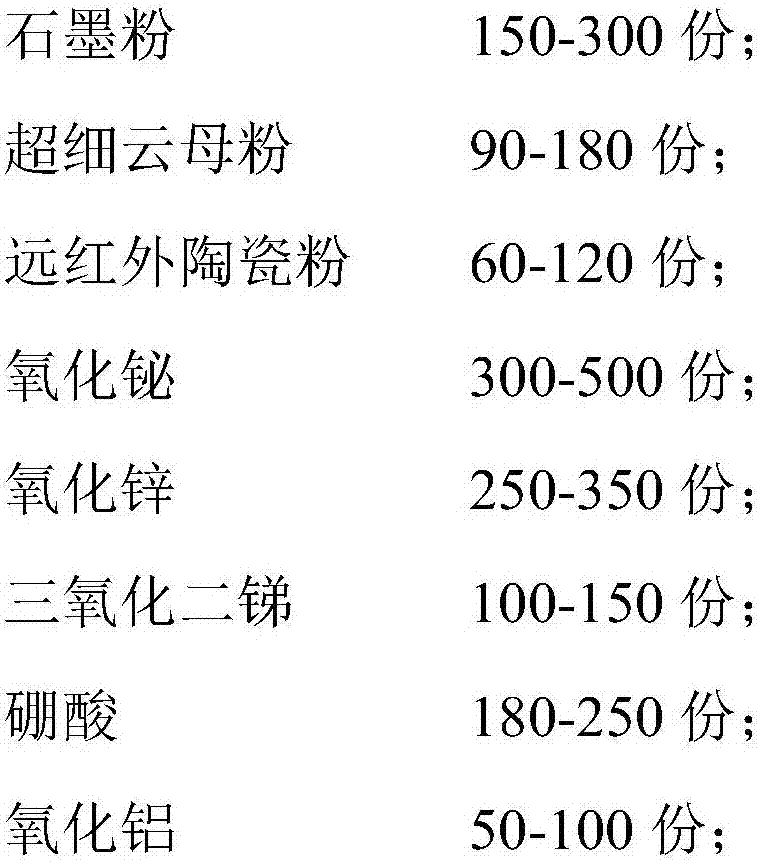

Inorganic non-metal far-infrared graphite resistive film, and preparation method and application thereof

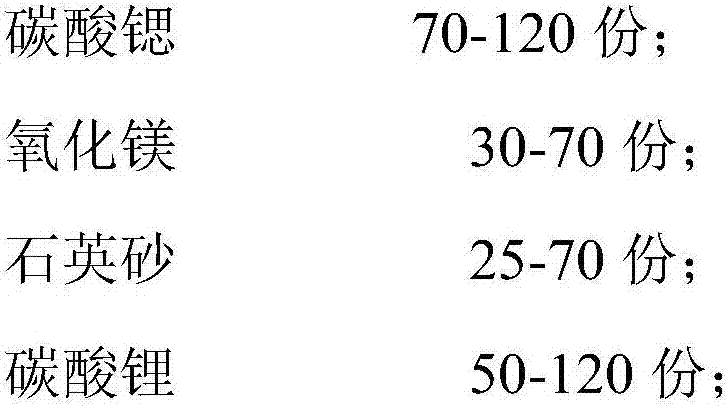

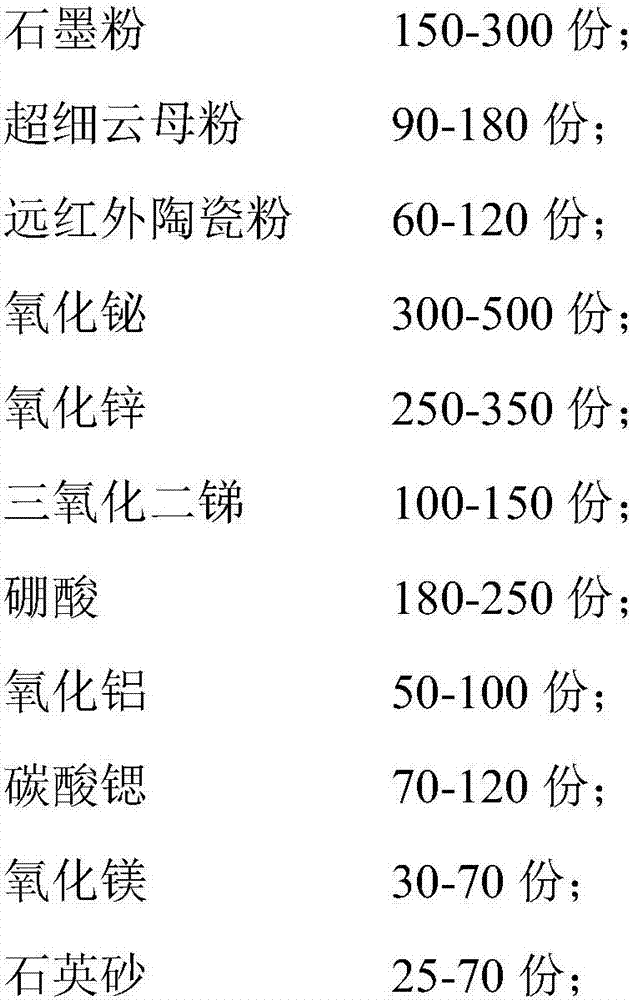

The invention provides an inorganic non-metal far-infrared graphite resistive film, which is prepared by using a base material and a liquid medium. The base material is composed of the following raw materials, by weight: 150-300 parts of graphite powder, 90-180 parts of ultrafine mica powder, 60-120 parts of far-infrared ceramic powder, 300-500 parts of bismuth oxide, 250-350 parts of zinc oxide, 100-150 parts of antimonous oxide, 180-250 parts of boric acid, 50-100 parts of aluminum oxide, 70-120 parts of strontium carbonate, 30-70 parts of magnesium oxide, 25-70 parts of quartz sand and 50-120 parts of lithium carbonate, wherein the far-infrared ceramic powder contains nano titanium oxide.

Owner:陶志斌

Single-sided transmission graphene film

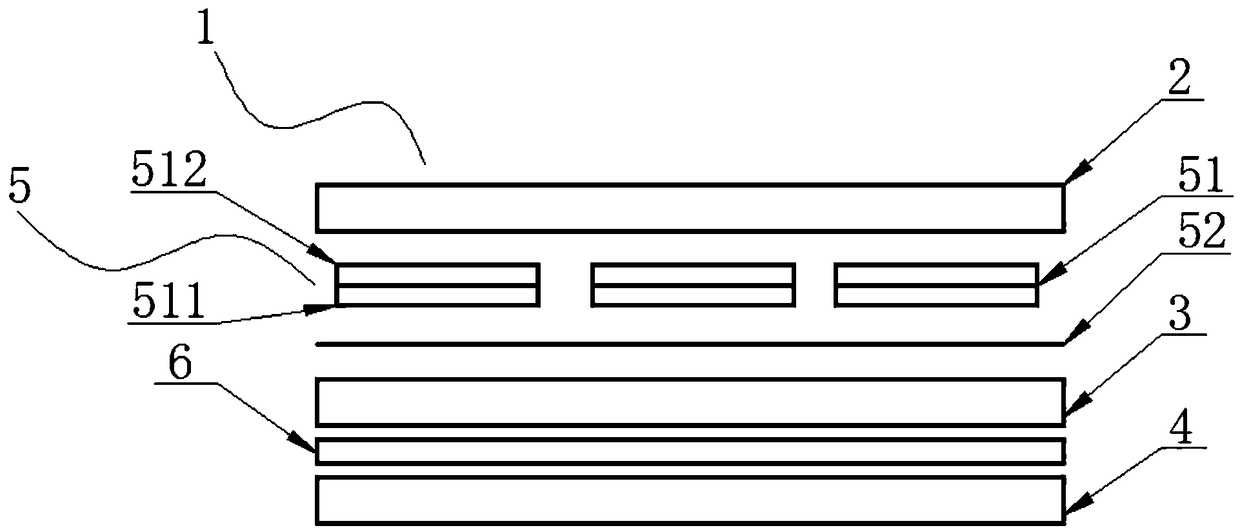

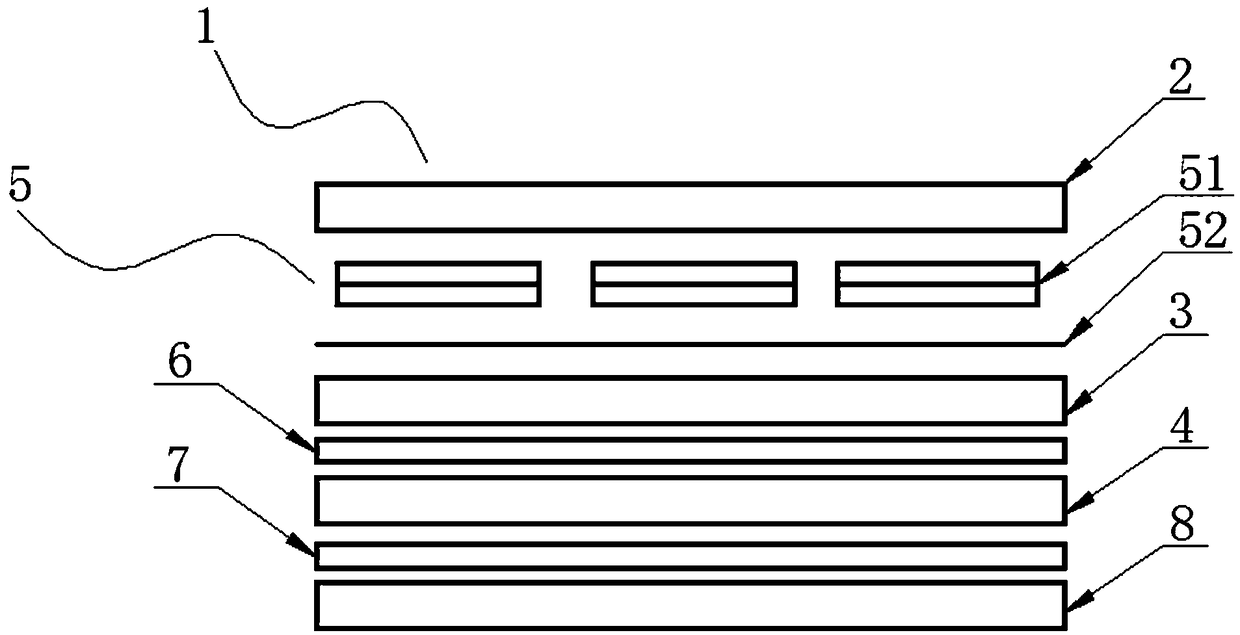

InactiveCN109049864AReduce thicknessEnhanced Far Infrared PerformanceSynthetic resin layered productsMedical devicesOptoelectronicsReflective layer

The application discloses a single-sided transmission graphene film. The single-sided transmission graphene film comprises a body, wherein the body comprises a first substrate layer, a second substrate layer, a heating layer and a reflective layer; the heating layer is arranged between the first substrate layer and the second substrate layer; the reflective layer is arranged on one side, deviatingfrom the heating layer, of the second substrate layer and is used for reflecting far infrared light emitted by the heating layer after electrifying. According to the application, the technical problem that the graphene film has no function of reflecting far infrared light and needs additional far infrared reflector in the actual application of a product, so that the thickness of the film is increased is solved.

Owner:张洁

Composite down material and preparation method and application thereof

InactiveCN110499554AGood antibacterial effectEnhanced Far Infrared PerformanceFibre mixingMonocomponent polyesters artificial filamentFar infraredFiber

The invention provides a composite down material and a preparation method and application thereof. The composite down material includes down and graphene-modified short fibers uniformly dispersed in the down. The provided composite down material has great antibacterial performance, far-infrared performance and anti-static performance; meanwhile, the graphene-modified short fibers and the down canbe supported by each other, more air storage space is provided, and therefore the composite down material has heat preservation performance. Moreover, down is likely to generate static electricity because of mutual friction and thus agglomerate together, and the graphene-modified short fibers contain graphene, have an antistatic function and can counteract the static electricity generated by the friction of the down to alleviate the agglomeration problem.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com