Patents

Literature

125results about How to "Good thermoregulation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of thermoregulation cellulose fiber with intelligent thermoregulation function

InactiveCN1995497APrevent leakageHigher than the surfaceHeat-exchange elementsArtifical filament manufactureHeat stabilityCellulose fiber

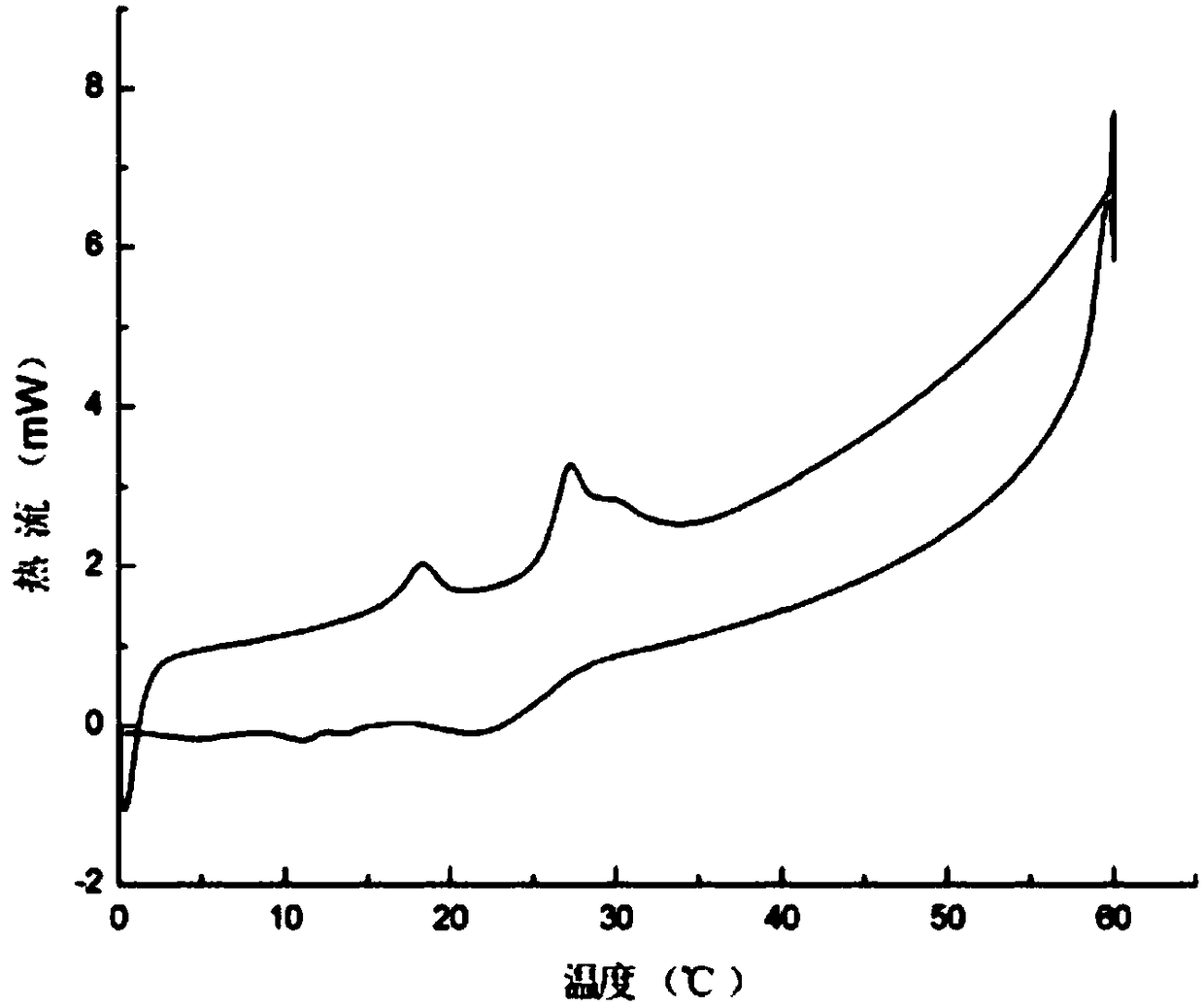

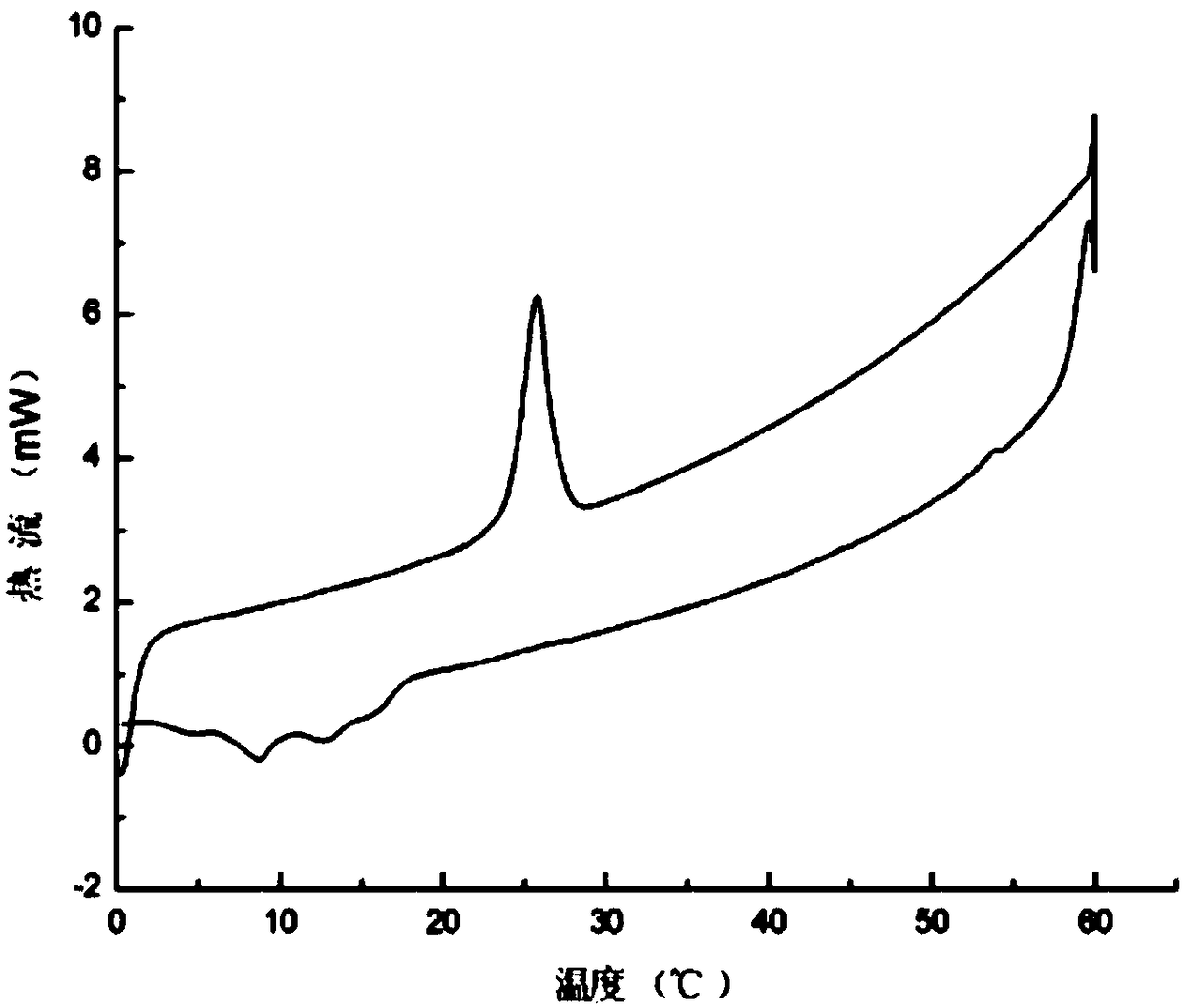

The invention relates to a manufacturing method for tempering cellulose fiber with intelligent tempering performance, characterized in that microcapsule grout of phase change energy storage materials with the weight of 10-230% of the fiber is put into the fiber stock solution of cellulose so as to form spinning dope by even mixture, which enters into the dilute caustic soda solution and dilute sulfate in turn to form the fiber; tempering cellulose fiber is formed by dilute acid decoppering, washing and drying. It is provided with simple process, low manufacturing cost and wide applicable range. The tempering cellulose fiber has the base material of cellulose fiber and the functional additive material of microcapsule of phase changer energy storage materials. The phase change energy storage materials are not easy to leak and is provided with good heat stability and tempering effect. When it is applied in down-proof fabric and duvay the phase change energy storage materials can strengthen the tempering performance.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

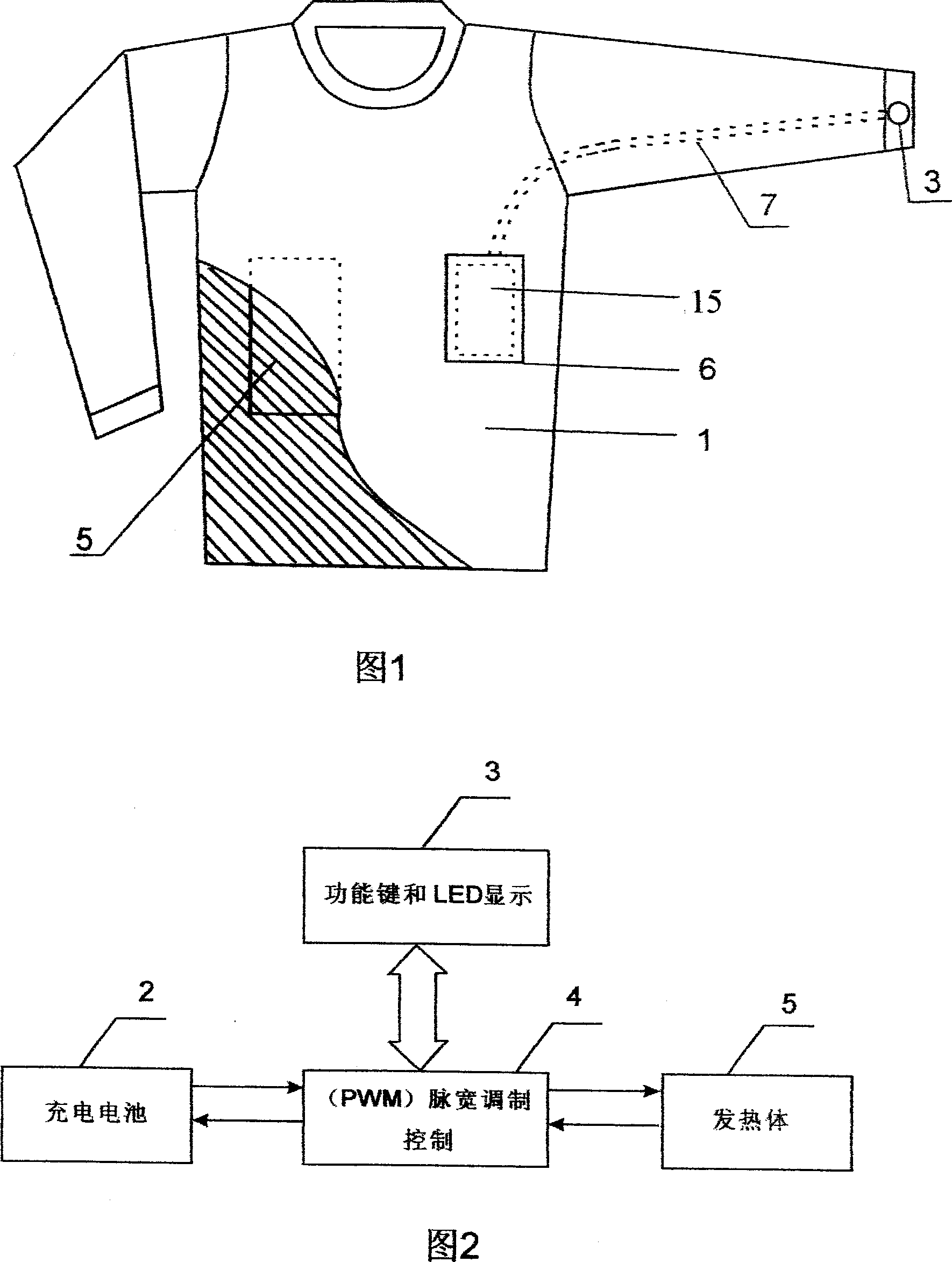

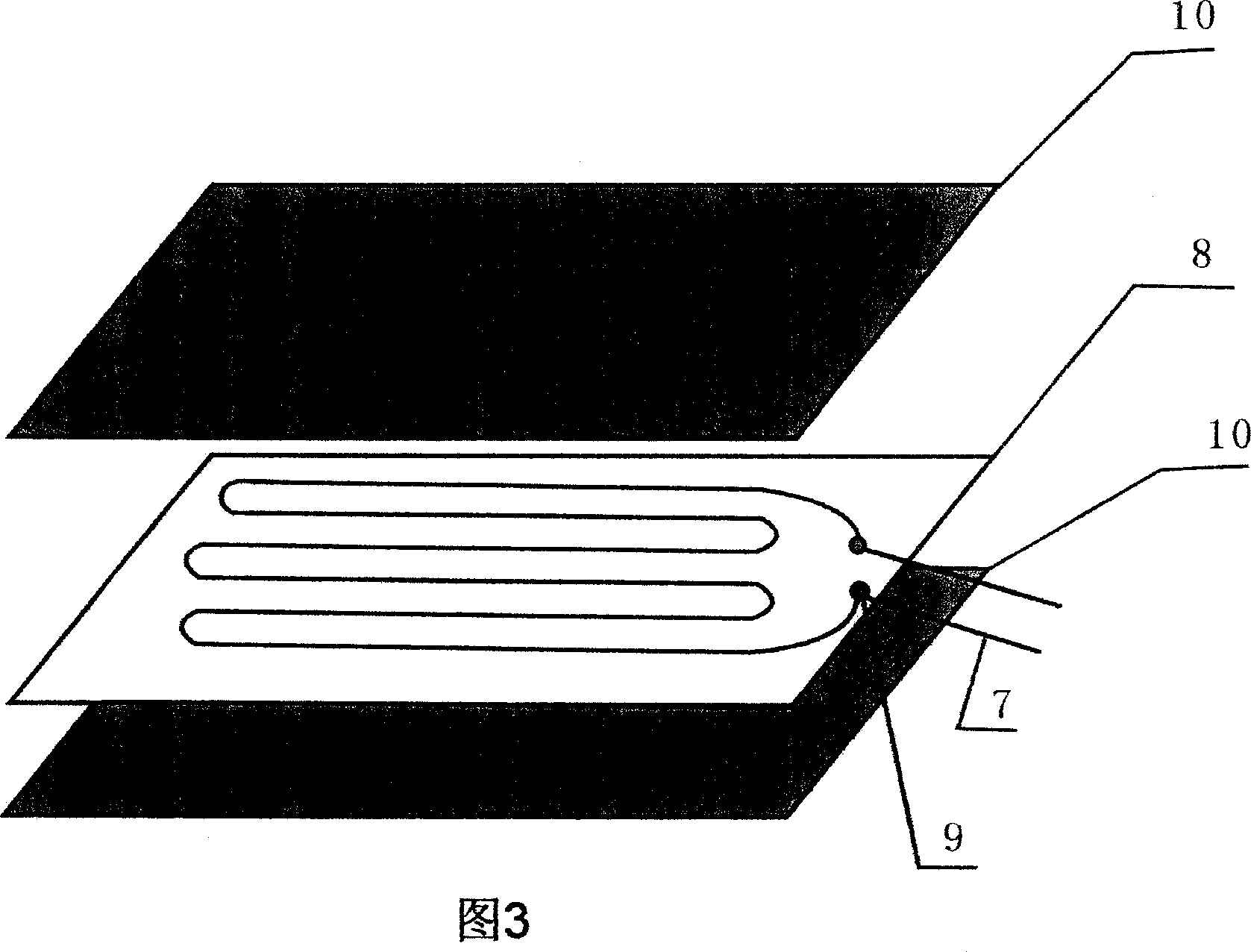

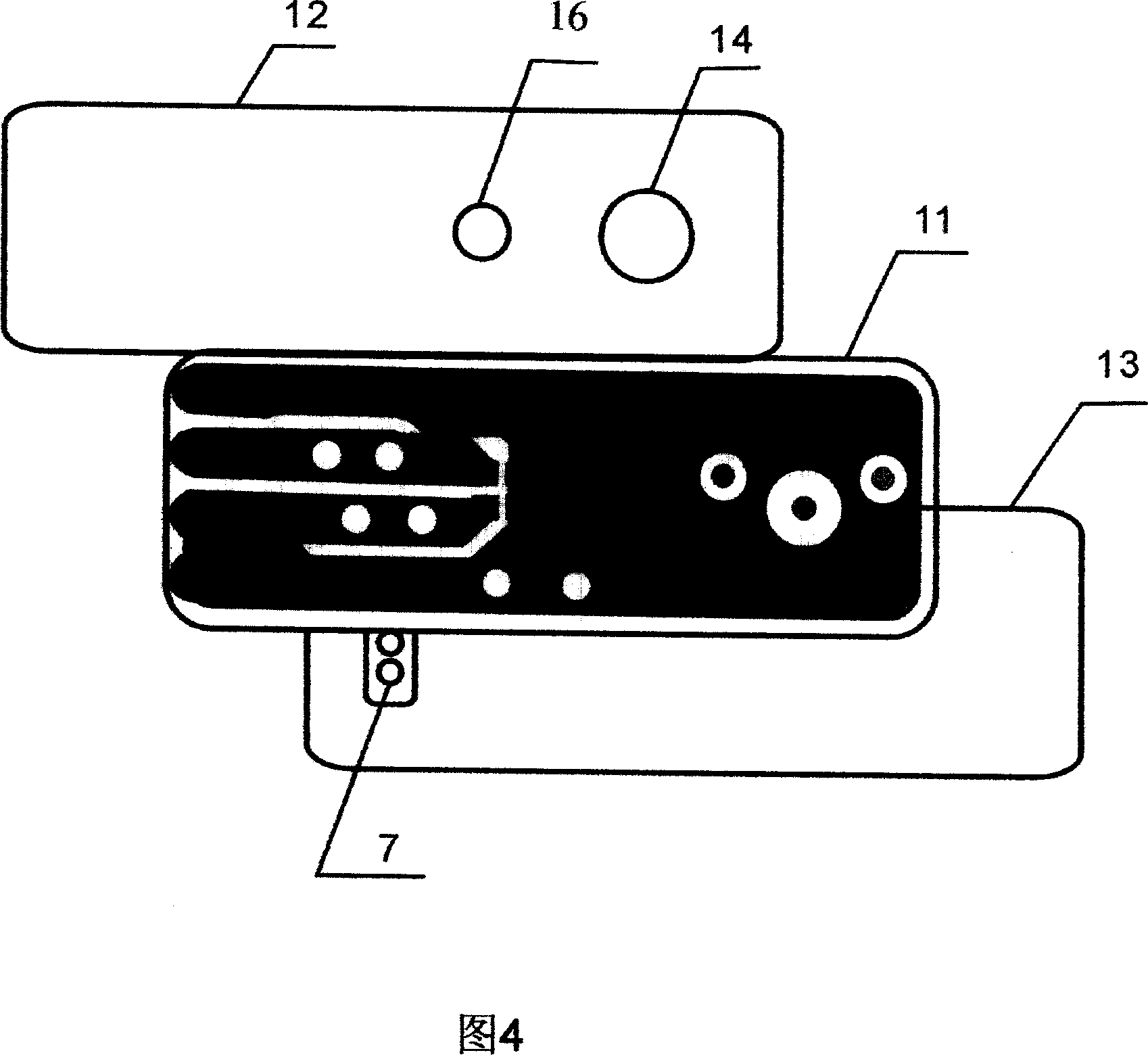

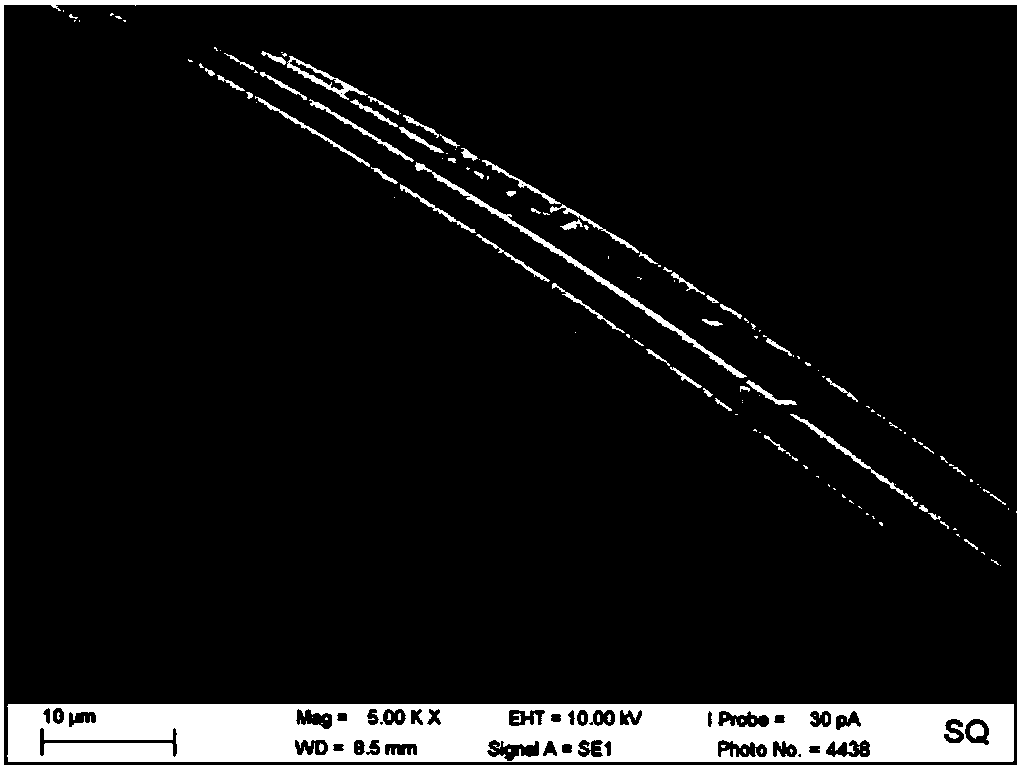

Far infrared Warm-keeping underclothes capable of generating heat

InactiveCN101081096AResistant to stretching and bendingExtended service lifeOhmic-resistance heatingTherapeutic coolingThermal energyLED display

The far infrared heating underwear is one sandwich structure including an inner layer and an outer layer, and has heating elements set inside the sandwich and in the places corresponding to the cool susceptible parts and important acupoints of body. The heating elements are connected through wires to power source box, functional key and LED display to constitute one electric loop for temperature regulation. The far infrared heating underwear has low power consumption and capacity of maintaining active heating for long term to make the body comfortable.

Owner:陆思烨

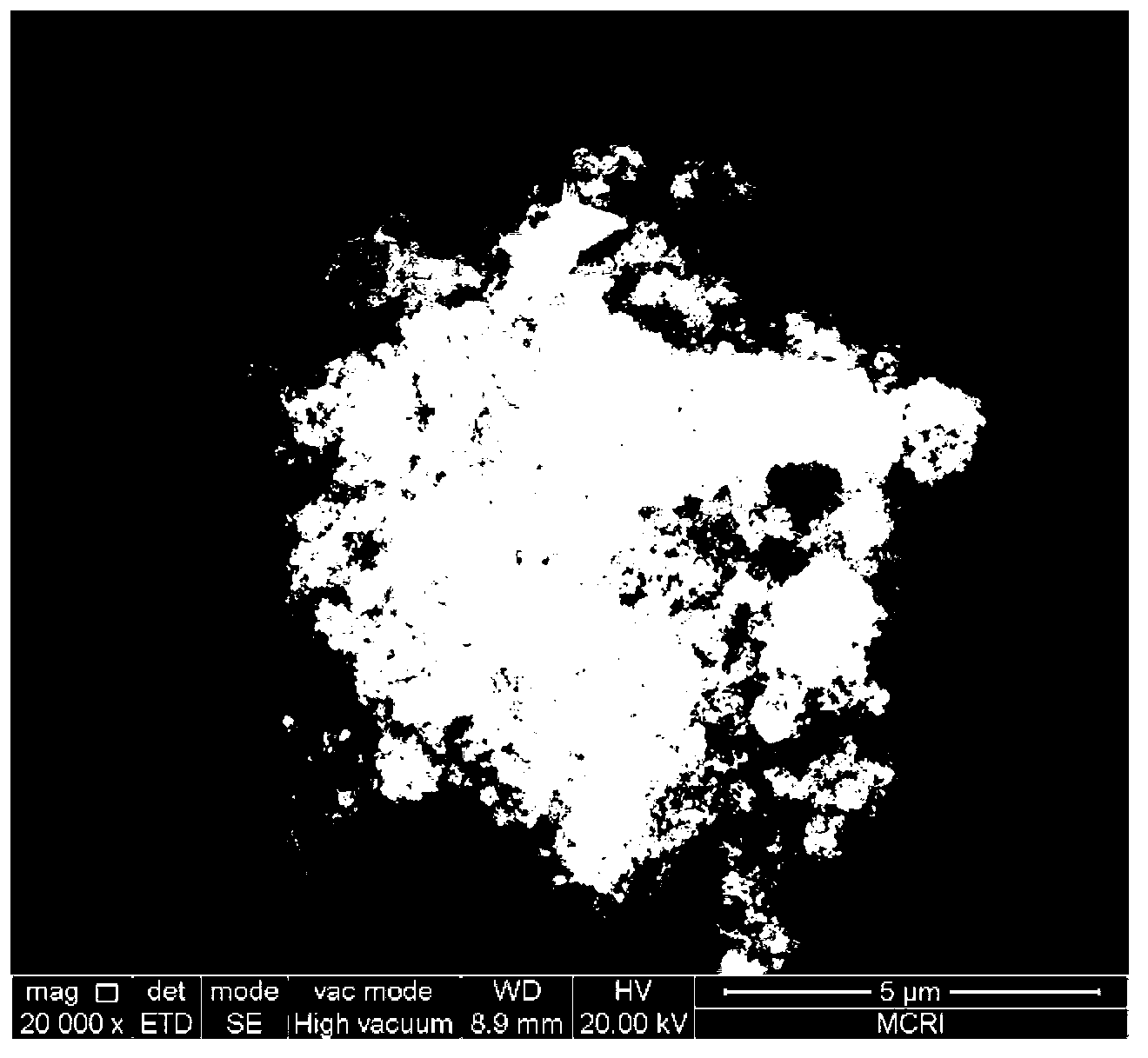

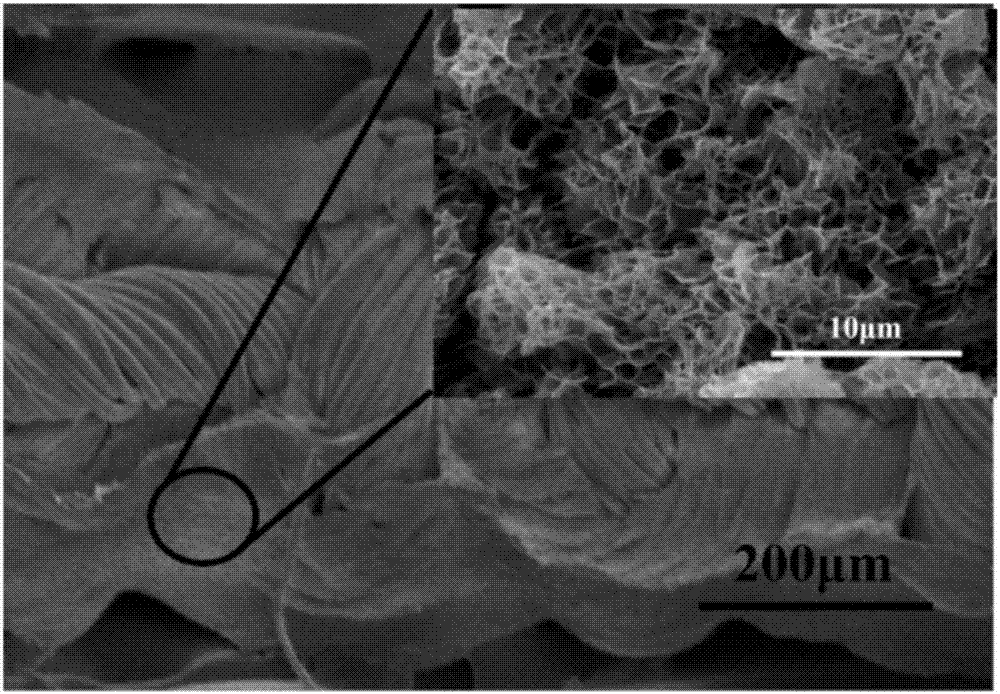

Graphene microcapsules, intelligent thermoregulation fibers and preparation methods thereof

InactiveCN108499497AAvoid complex process problemsGood dispersionArtificial filaments from viscoseMonocomponent synthetic polymer artificial filamentFiberDispersity

The invention provides graphene microcapsules, intelligent thermoregulation fibers and preparation methods thereof. The graphene microcapsules comprise a core material and a shell material, wherein the core material is a graphene material, and the shell material is a synthetic polymer or natural polymer material; the content of the core material is 15wt%-60wt% preferably. The preparation method ofthe graphene microcapsules comprises the following steps: an aqueous dispersion of the graphene material and a shell material raw material are mixed and emulsified, and a suspension is formed, the aqueous dispersion of the graphene material is prepared from deionized water, graphene and a surfactant; the shell material raw material is a prepolymer of a synthetic polymer or the natural polymer material; a curing agent or an initiator is added to the suspension, a curing reaction is performed, filtering and drying are performed, and the graphene microcapsules are obtained. By graphene microencapsulation, not only are dispersity and compatibility of graphene in a substrate improved, but also heat conduction and storage performance of the microcapsules is improved, a spinning process is optimized, and smoothness of surfaces of graphene modified fibers is improved.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Temperature-regulating quilt core

The invention discloses a temperature-regulating quilt core, which comprises a quilt cover and a quilt core covered in the quilt cover. The quilt cover is formed by sewing temperature-regulating fabric, the temperature-regulating fabric is formed by spinning temperature-regulating blended yarns, 100g of temperature-regulating blended yarns contain 40-70g of temperature-regulating fiber, and the quilt core is made of temperature-regulating filler. Therefore, since the temperature-regulating fiber is used in the spinning yarns of the quilt cover and the filler of the quilt core, and the spinning yarns of the quilt cover are blended yarns with the temperature-regulating fiber, the quilt core can automatically irradiate heat in summer and absorb heat in winter, thereby forming the 'air-conditioning quilt', meeting the life needs of people, simultaneously reducing the air conditioning cost, and saving the energy. In addition, the invention not only achieves the 'air conditioning' function of the quilt core, but also reduces the production cost.

Owner:NANTONG DREAMLA HOME TEXTILE

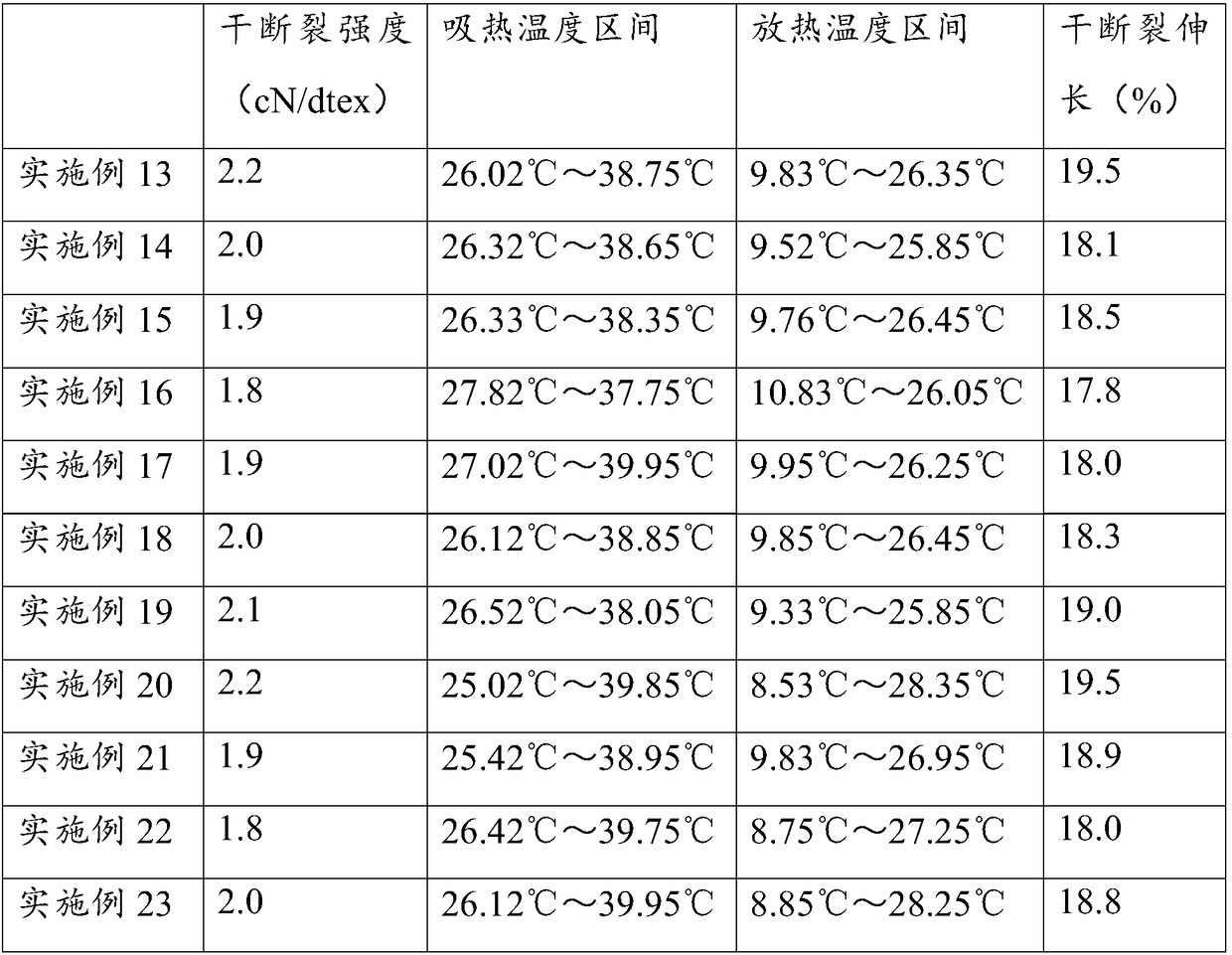

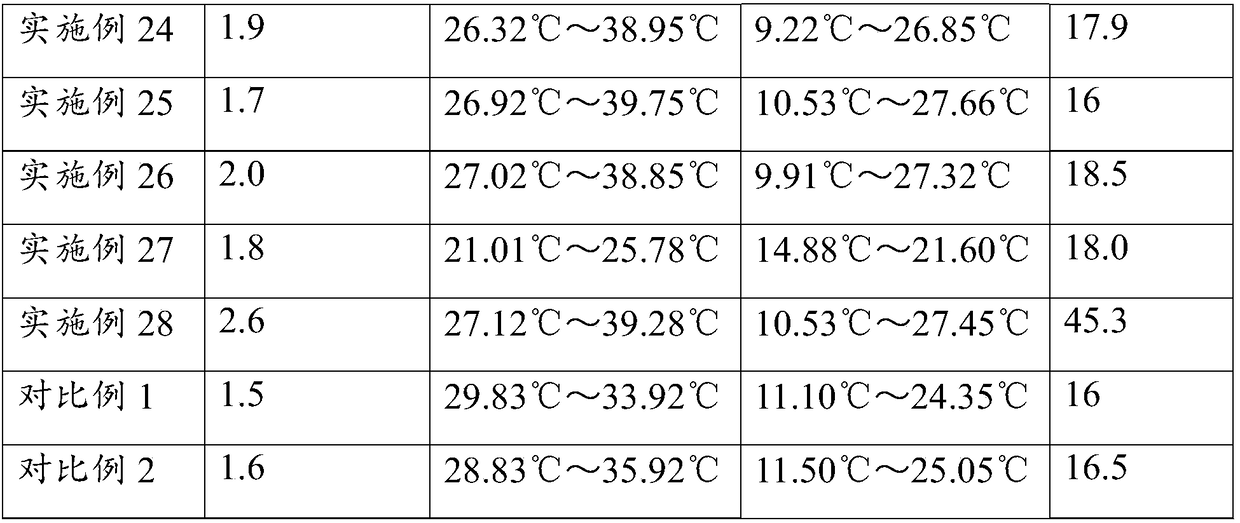

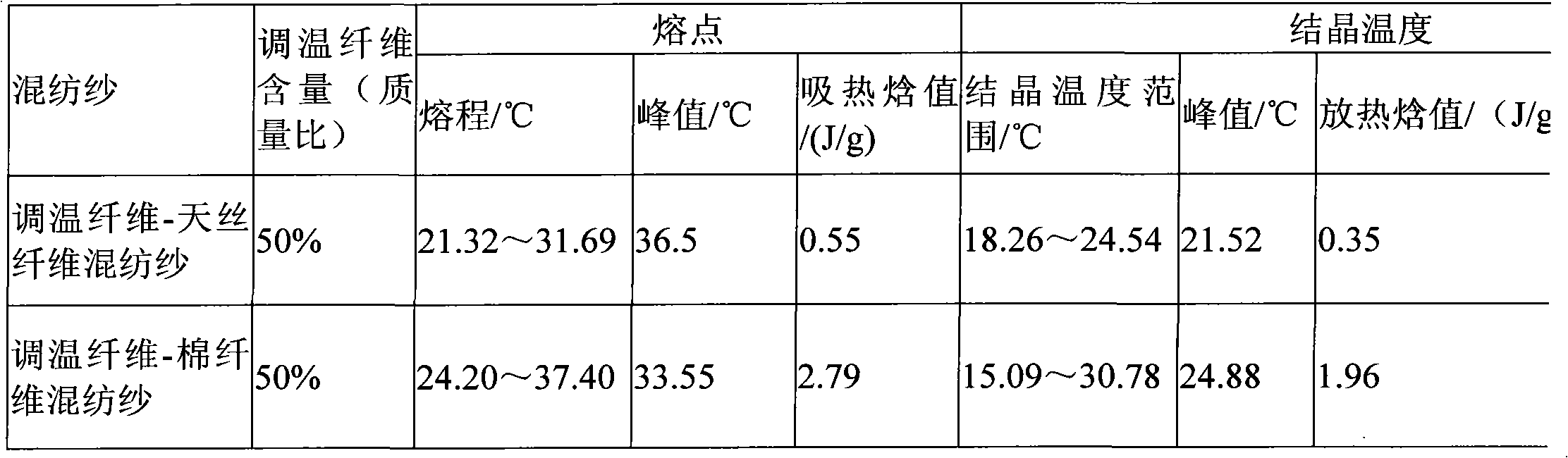

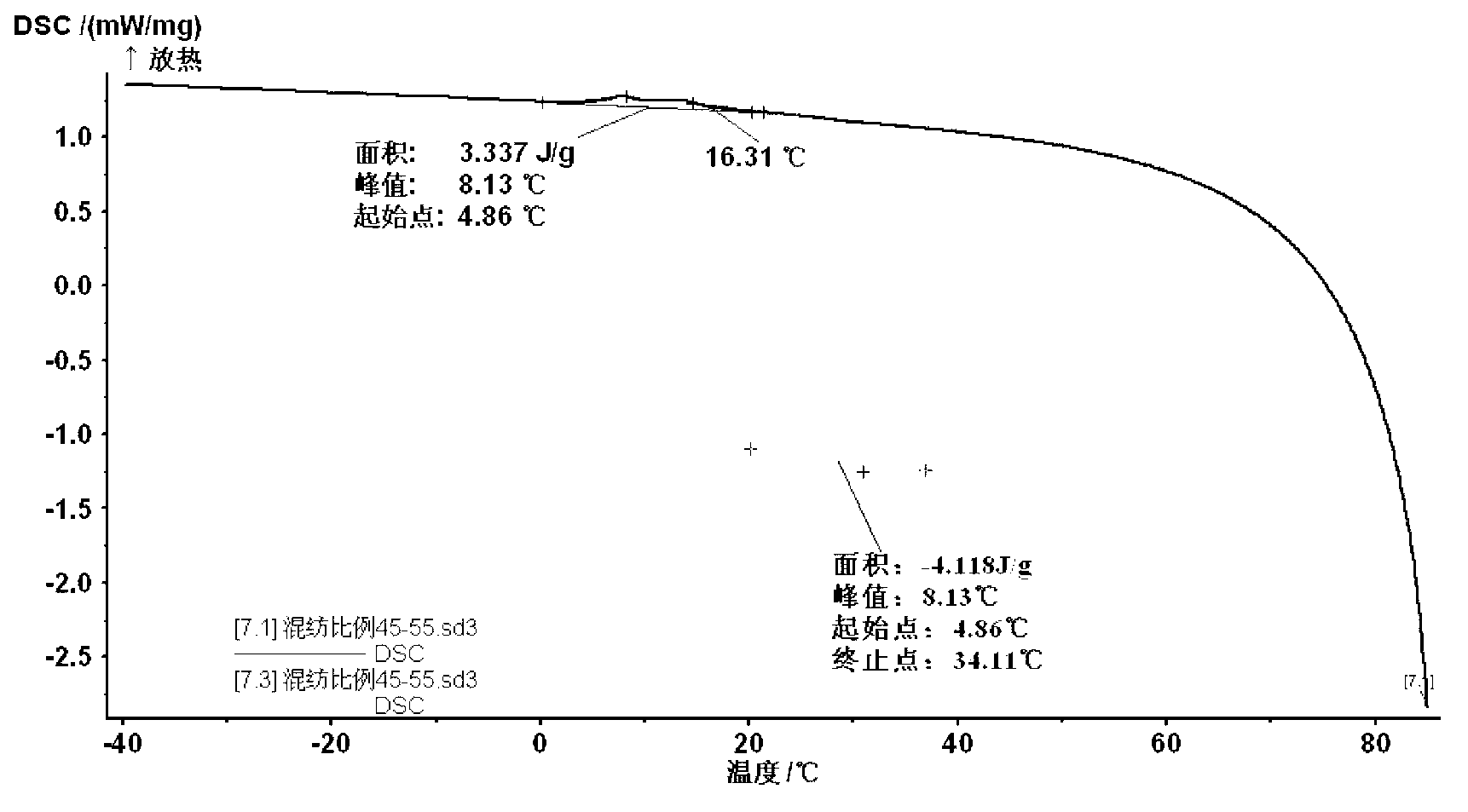

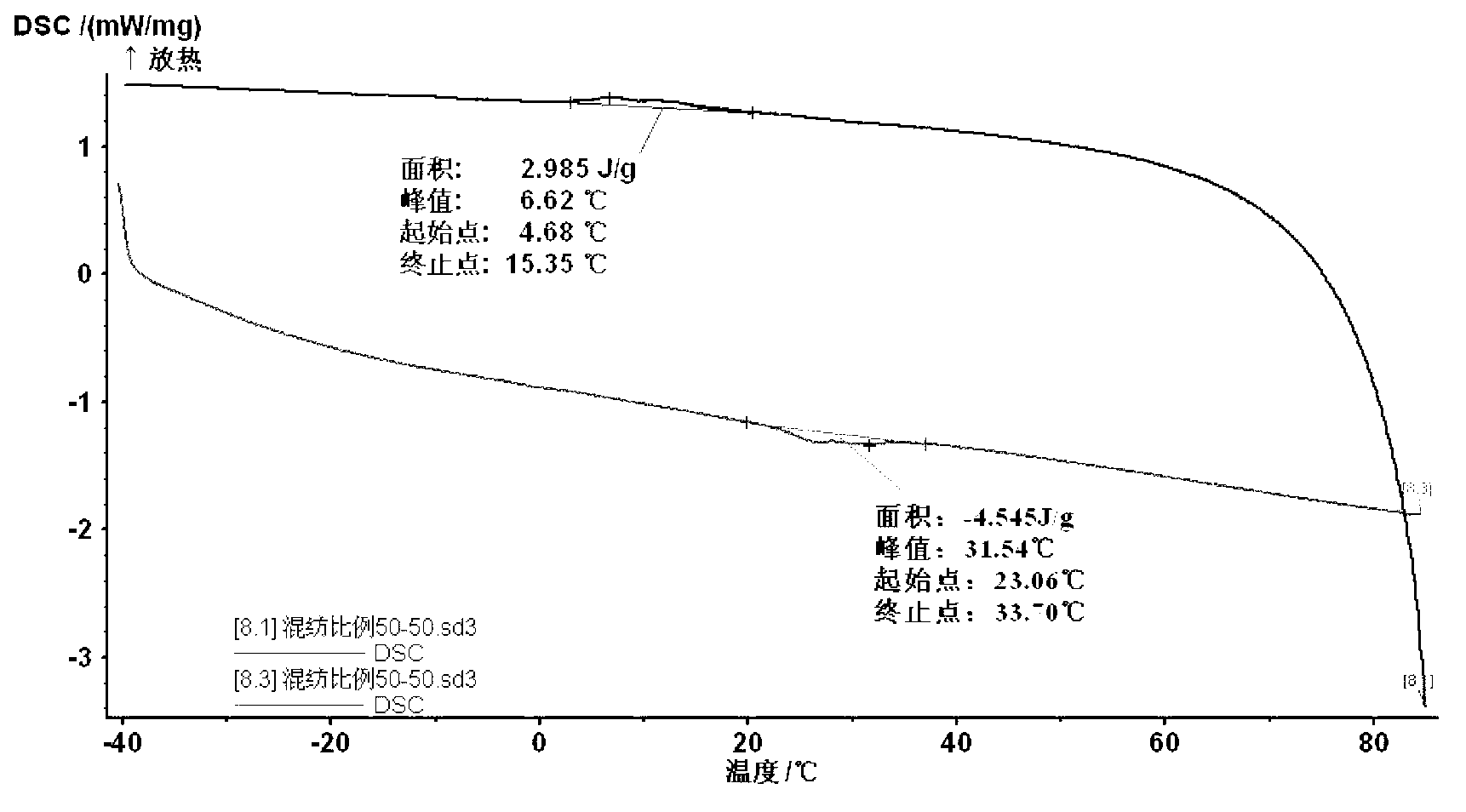

Blended yarn of air-conditioning fiber and cotton fiber/cotton-type chemical fiber and spinning method

The invention discloses a blended yarn of an air-conditioning fiber and a cotton fiber / a cotton-type chemical fiber. The blended yarn is composed of, by mass, 30-60% of the air-conditioning fiber, and 40-70% of the cotton fiber / the cotton-type chemical fiber. The invention further discloses a preparation method of the blended yarn. The method comprises the steps that the opening and picking process and carding process are conducted on the weighed air-conditioning fiber and the weighed cotton fiber / the cotton-type chemical fiber, then carding sliver of the air-conditioning fiber is obtained and carding silver of the cotton fiber / the cotton-type chemical fiber is obtained; a drawing frame is used for conducting drawing on all the carding silver, then drawn silver of the air-conditioning fiber is obtained, and drawn silver of the cotton fiber / the cotton-type chemical fiber is obtained; the drawn silver of the air-conditioning fiber and the drawn silver of the cotton fiber / the cotton-type chemical fiber are mixed to obtain a strip-shaped air-conditioning fiber and cotton fiber mixture or an air-conditioning fiber and cotton-type chemical fiber mixture; a coarse spinner and a spinning frame are used for processing the mixture to obtain the blended yarn. The blended yarn not only has the good temperature regulation effect, but also has a good mechanical property and yarn evenness.

Owner:XI'AN POLYTECHNIC UNIVERSITY

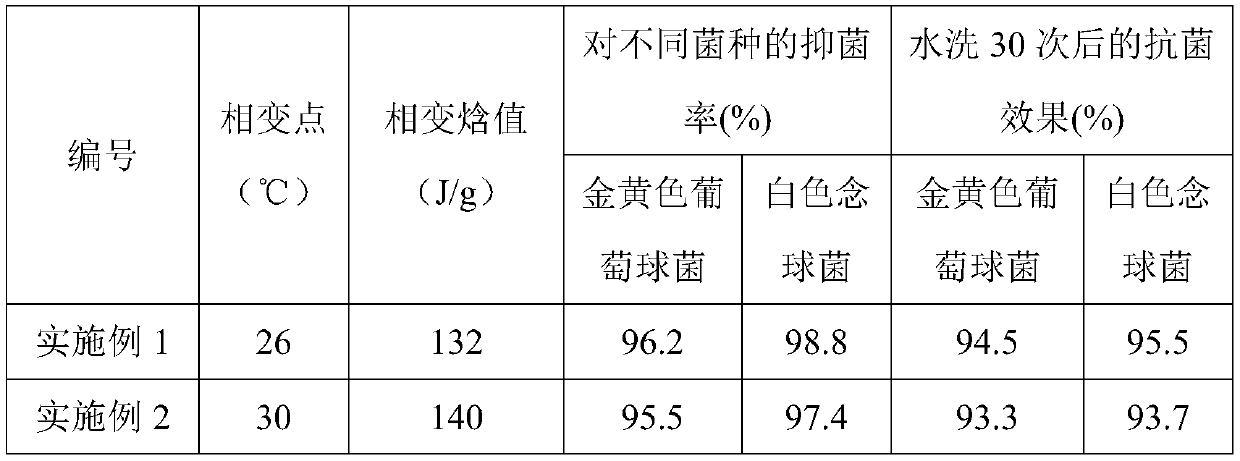

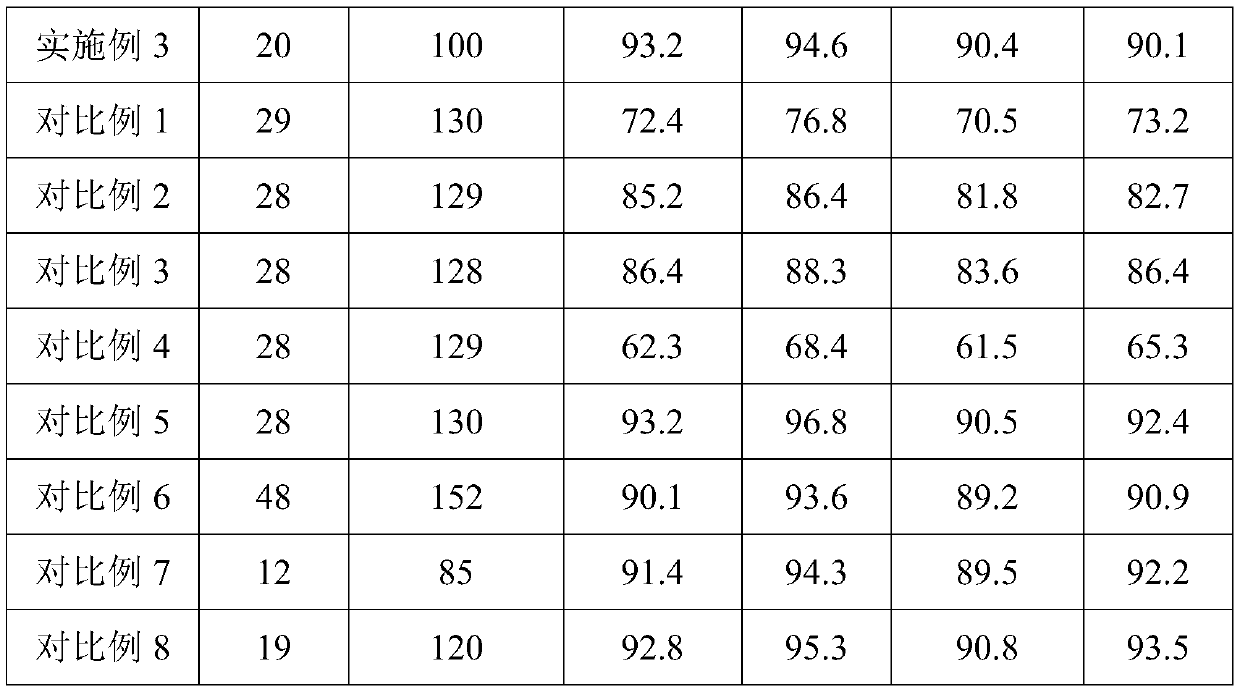

Antibacterial and light textile fabric and preparing method thereof

ActiveCN110484994AEnhanced Far Infrared PerformanceWith negative ion therapyMonocomponent polyesters artificial filamentArtifical filament manufactureTemperature controlPolyester

The invention relates to the field of textile fabrics, in particular to an antibacterial and light textile fabric and a preparing method thereof. The antibacterial and light textile fabric is formed by weaving antibacterial and temperature-adjusting aerogel fibers, wherein the antibacterial and temperature-adjusting aerogel fibers are prepared by means of the steps of fusing polyester chips to prepare a polyester spinning solution, then adding modified aerogel and a negative-ion temperature-adjusting material into the spinning solution, after the materials are uniformly mixed, spraying out themixture from spinneret holes, and then conducting fiber forming, nascent fiber drafting orientation, fiber heat setting and winding. The prepared antibacterial and light textile fabric is simple in structure, reasonable in preparation of raw materials, and soft and smooth in texture, and has the function of intelligent temperature control, and the temperature in the fabric can be freely adjustedwithin a certain temperature range according to the temperature change of the outside environment; meanwhile, the antibacterial and light textile fabric also has lasting antibacterial performance andlarge application value.

Owner:JIANGSU DAMAONIU NEW MATERIAL TECH CO LTD

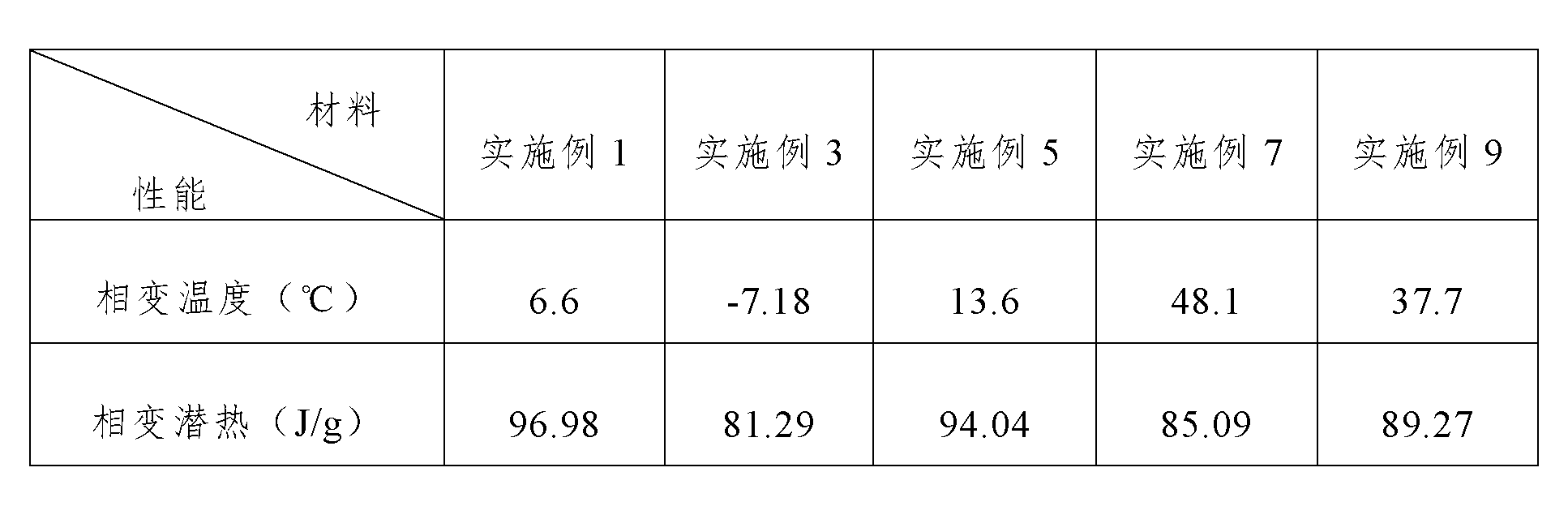

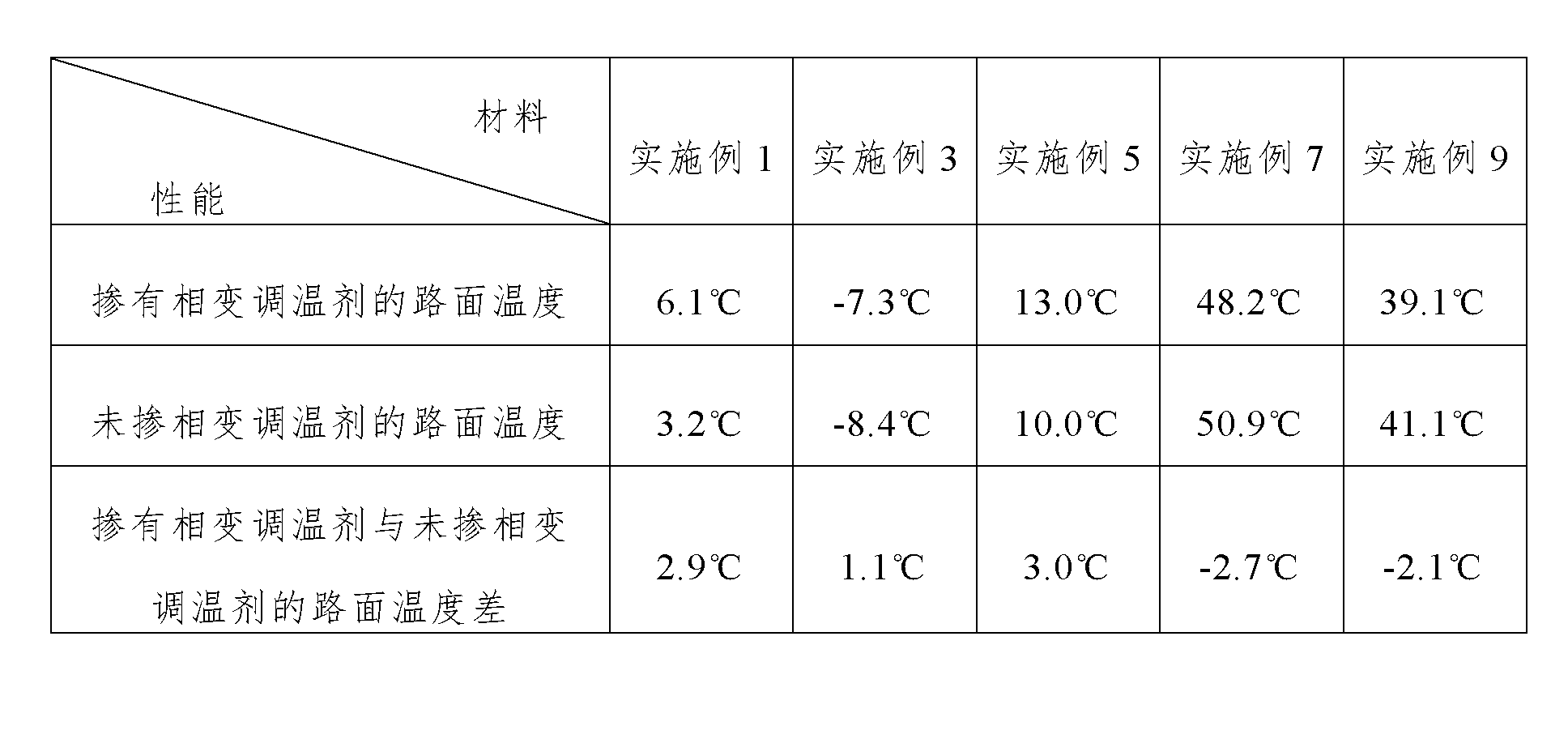

Road phase-change temperature regulator and preparation method thereof

InactiveCN102703035AWide variety of sourcesSimple preparation processHeat-exchange elementsMicroballoon preparationOrganic solventPlasticizer

The invention provides a road phase-change temperature regulator. The road phase-change temperature regulator is prepared from a phase change material, white carbon black, ethyl cellulose, a plasticizer and an organic solvent. The invention further provides a preparation method of the road phase-change temperature regulator. The preparation method of the road phase-change temperature regulator comprises the following steps: 1, uniformly stirring the plasticizer and the organic solvent to obtain a mixed solution; 2, adding the ethyl cellulose into the mixture to obtain a glue solution; 3, making the phase change material and the white carbon black into a moulded phase change material; and 4, uniformly stirring the moulded phase change material and the glue solution, and heating and drying to obtain the road phase-change temperature regulator. The road phase-change temperature regulator is wide in raw material source, simple in process and low in production cost and can be produced in batches on a construction site directly; and the road phase-change temperature regulator has a micro-scale capsule structure, can perform phase change along with change of the ambient temperature and store or release energy, can effectively regulate the surface temperature of a road and improve the capability of the road in responding to the change of the ambient l temperature.

Owner:CHANGAN UNIV

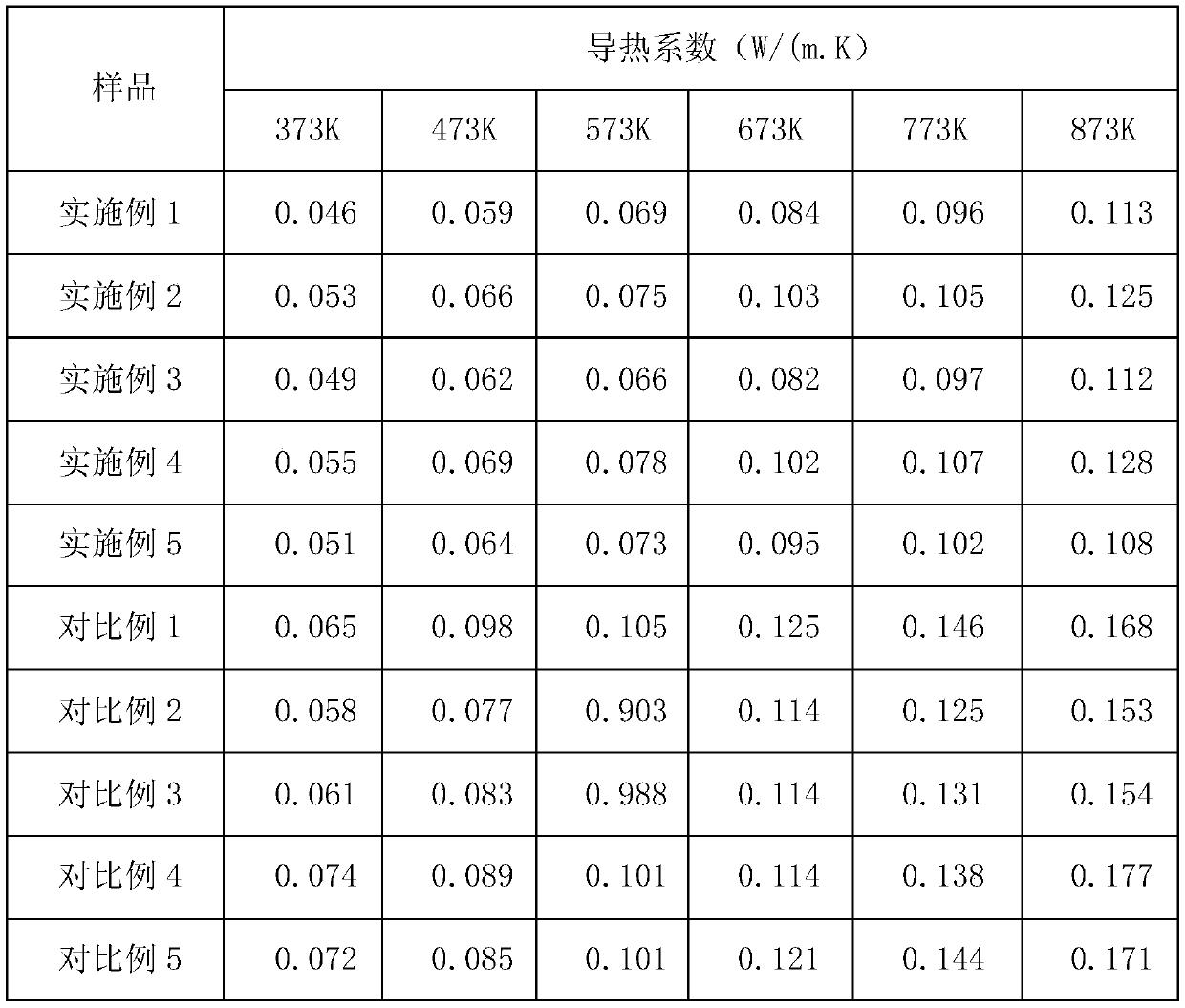

Nano-microporous thermal insulation material and preparation method thereof

The invention relates to a nano-microporous thermal insulation material, which includes a porous base layer and a heat insulation layer attached to the surface of the base layer. The base layer consists of the following raw materials by weight: 28-36 parts of polymer hollow microspheres, 1-5 parts of paraffin / porous perlite-urea-formaldehyde resin phase change microcapsules, 11-19 parts of nano-alumina hollow spheres, 5-12 parts of nano-silica sol, and 3-7 parts of alumina silicate fiber. The heat insulation layer is composed of the following raw materials by weight: 44-54 parts of silica aerogel, 14-18 parts of modified starch, 4-8 parts of hollow microspheres, 10-16 parts of nano-titanium oxide, 3-5 parts of mullite whisker, and 2-4 parts of a foaming agent. The nano-microporous thermalinsulation material provided by the invention has good heat insulation performance and high strength, does not shrink easily, and can meet the heat insulation requirements of building walls.

Owner:龙元明筑科技有限责任公司

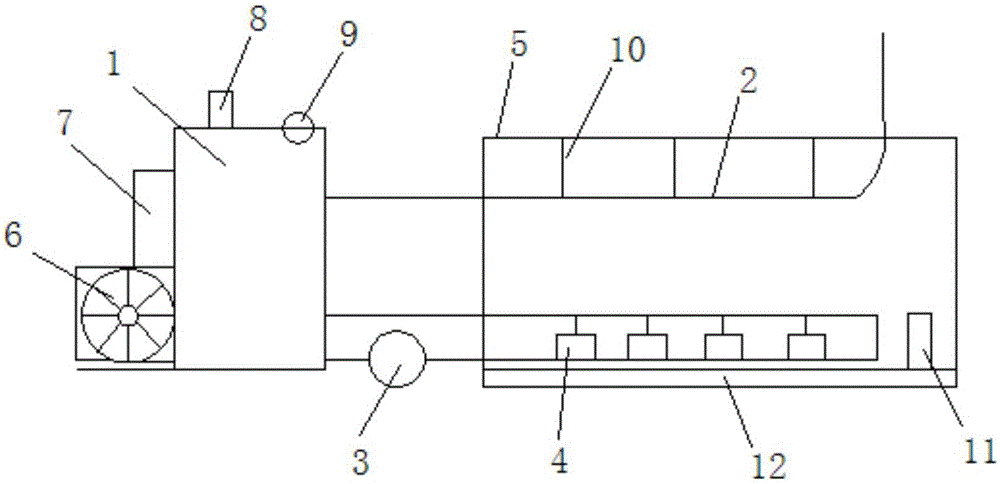

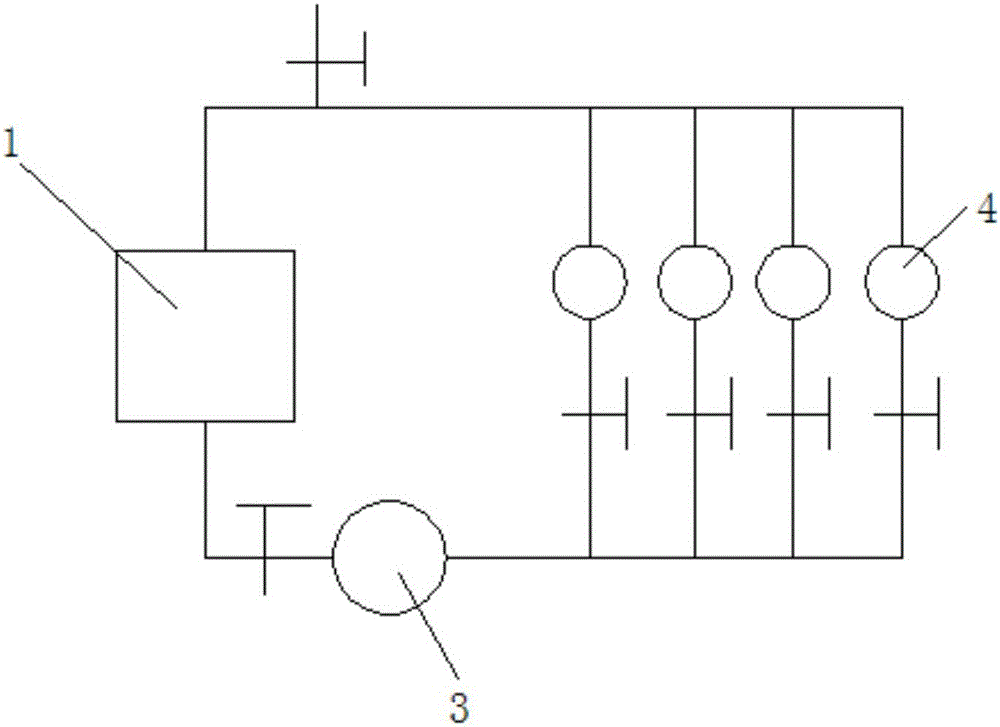

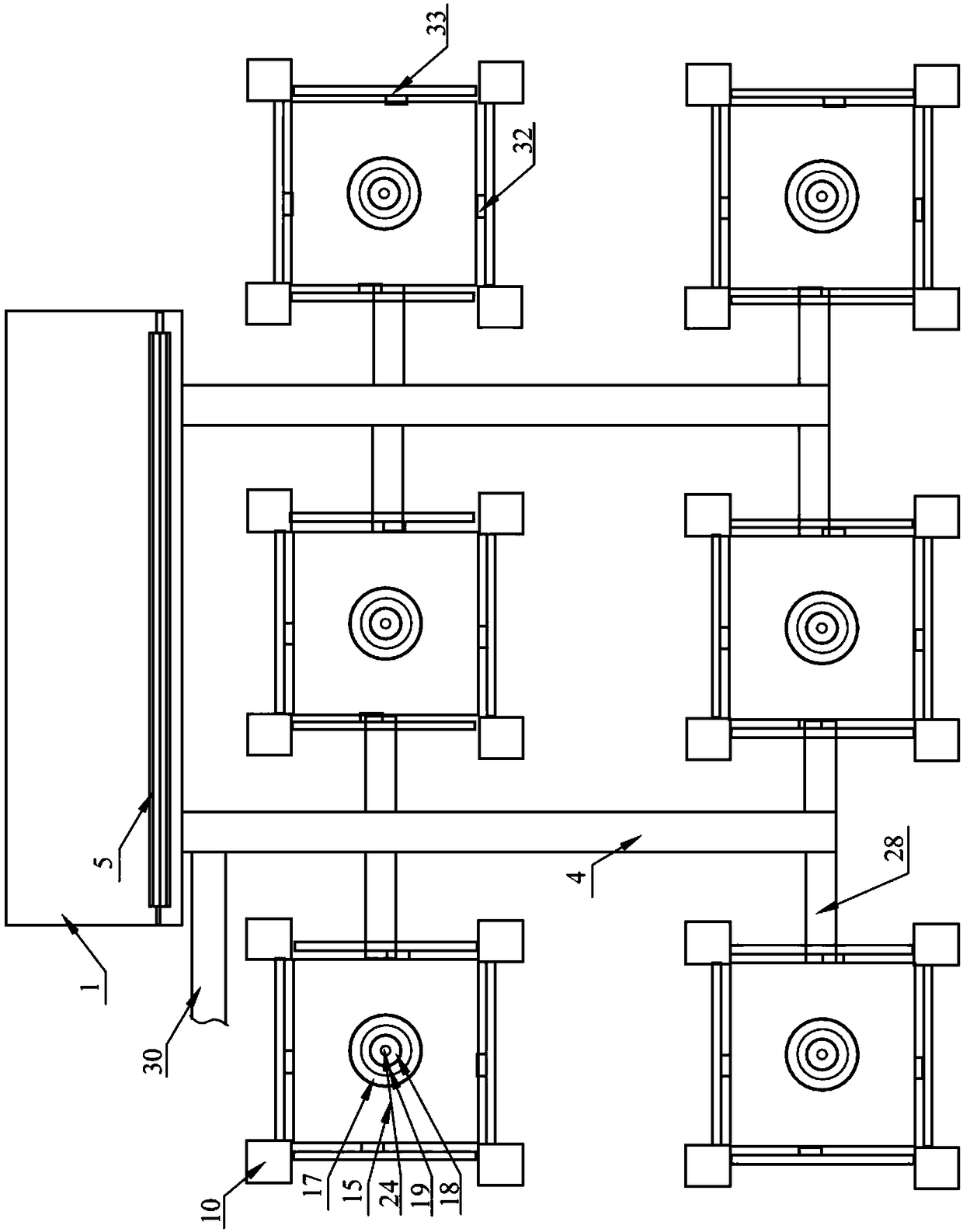

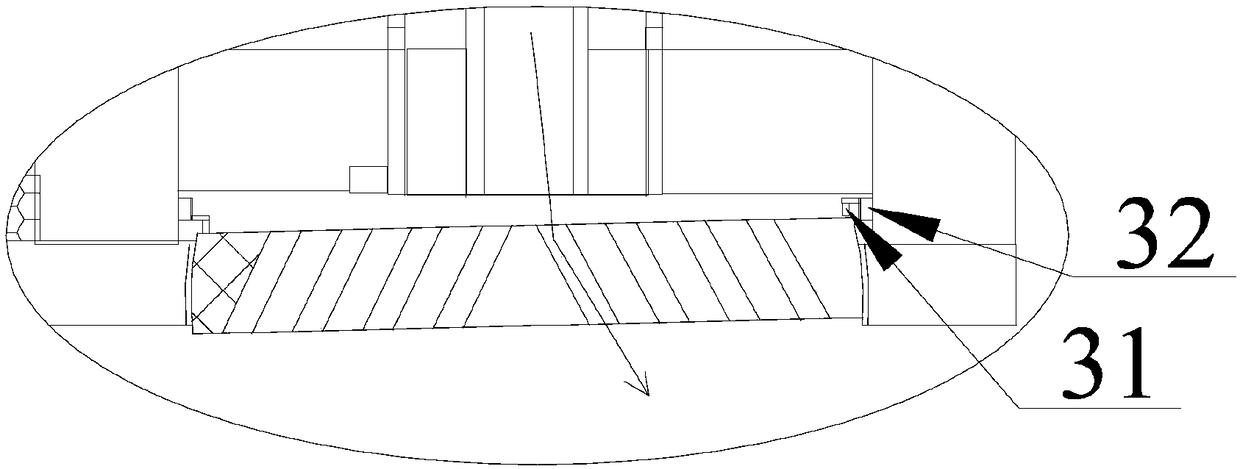

Automatic temperature regulating system for hen house heating

The invention discloses an automatic temperature regulating system for hen house heating. The automatic temperature regulating system comprises a boiler, a flue, a hot water pump and heating radiators. The boiler is arranged outside a henhouse. The side face of the boiler is provided with an air blower and a control relay. A water temperature probe and a water tank floating ball are arranged above the boiler. The flue is connected with the boiler and arranged on the upper portion of the henhouse. The lower portion of the henhouse is provided with the heating radiators. The heating radiators are connected with the boiler through pipes. The hot water pump is arranged between the heating radiators and the boiler. The henhouse is internally provided with a henhouse temperature probe. According to the automatic temperature regulating system for hen house heating, a novel environment-friendly efficient and energy-saving hot water boiler is adopted, the flue of the boiler passes through the henhouse, flue gas waste heat of the boiler is fully utilized, the temperature in the henhouse is even, the heat energy utilization rate is high, the utilization rate of coal is high, meanwhile the temperature regulating effect is good, and operation is simple.

Owner:合肥立华畜禽有限公司

Energy-storage heat-preserving building material

InactiveCN104529274AImprove stabilityGood thermoregulation effectSolid waste managementCoalReducing agent

The invention discloses an energy-storage heat-preserving building material in the field of building materials. The energy-storage heat-preserving building material comprises the following components: 300 to 380 parts of cement, 80 to 140 parts of coal ash, 3 to 5.5 parts of a plasticizer, 4 to 6 parts of a water reducing agent, 2 to 4 parts of polypropylene fibers, 8 to 11 parts of expanded polyphenyl granules, 55 to 65 parts of paraffin and 16 to 20 parts of expanded perlite. The energy-storage heat-preserving building material has the beneficial effects that as the paraffin exists in pores of the expanded perlite, the surface tension of the pores is relatively large, and the phase-changing energy-storage heat-preserving building material is still good in stability after working for a long time, so that the phase-changing energy-storage heat-preserving building material is good in thermoregulation effect and energy-saving effect and good in application prospect in the field of building energy-saving materials.

Owner:QINGDAO BAIZHONG CHEM TECH

Deodorization fabric

ActiveCN105040406AGood thermoregulation effectOutstanding styleWoven fabricsVegetal fibresFiberGraphene

The invention relates to a deodorization fabric. The deodorization fabric is formed by interweaving graphene modified composite fiber warps and shaping wefts, wherein composite fibers are woven by aupoz fibers, cotton fibers and silver fibers, and the outer surface of the fabric is coated with nano-zinc oxide and nano-titanium dioxide coatings. The deodorization fabric is low in cost, cloth produced by using the deodorization fabric has excellent temperature adjusting effect, and the deodorization fabric can be used for producing carpets, clothes, shoes, socks and the like, has deodorization and fungi-proofing functions and is in an excellent style.

Owner:吴江市孚华纺织品有限公司

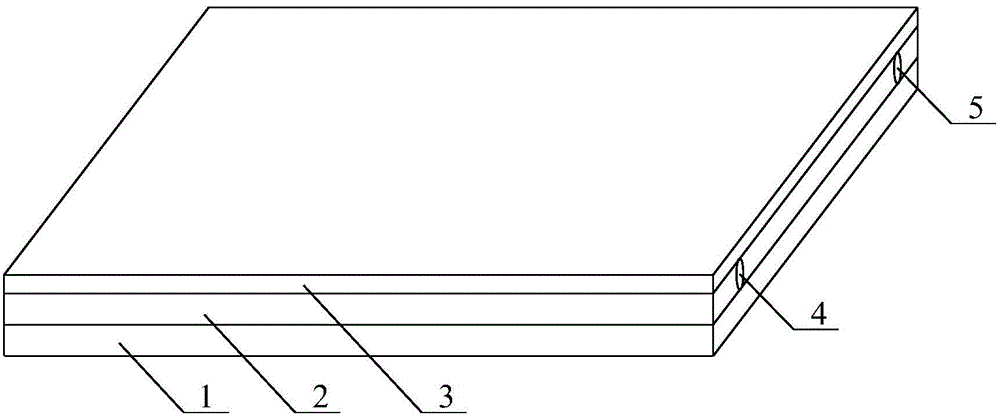

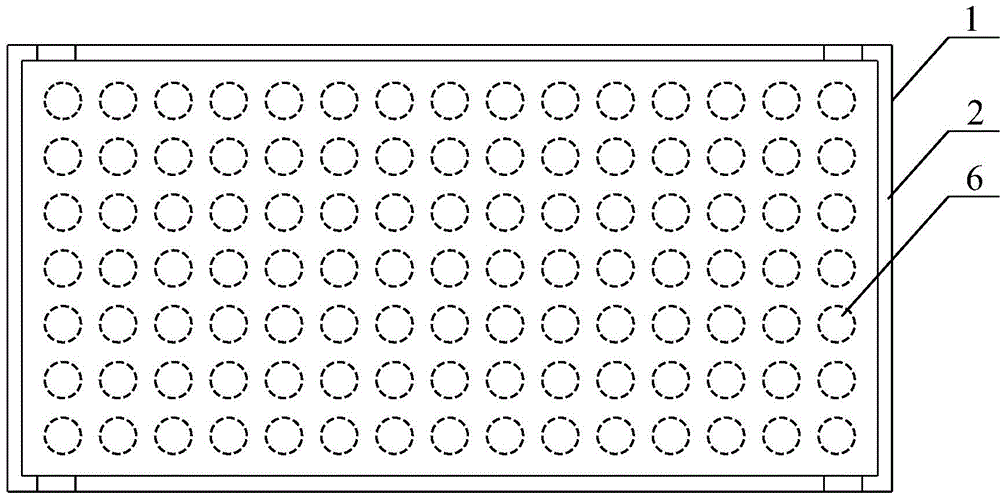

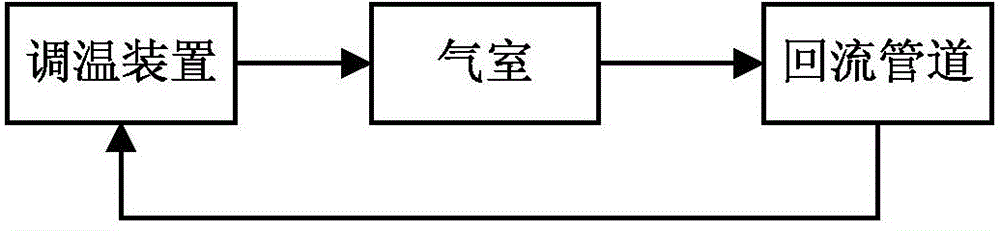

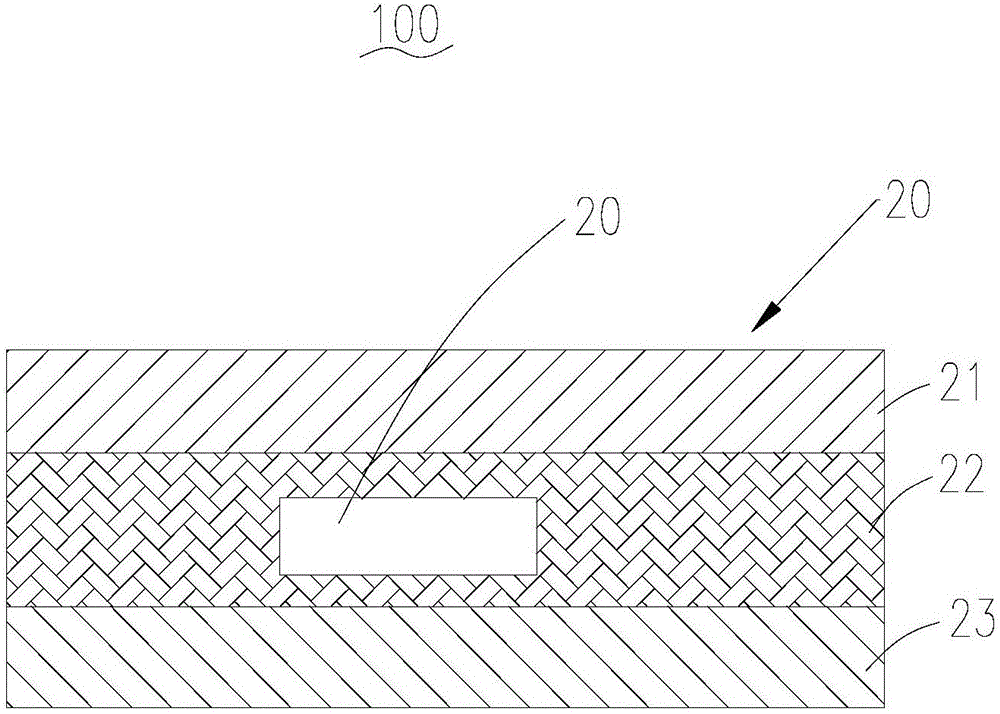

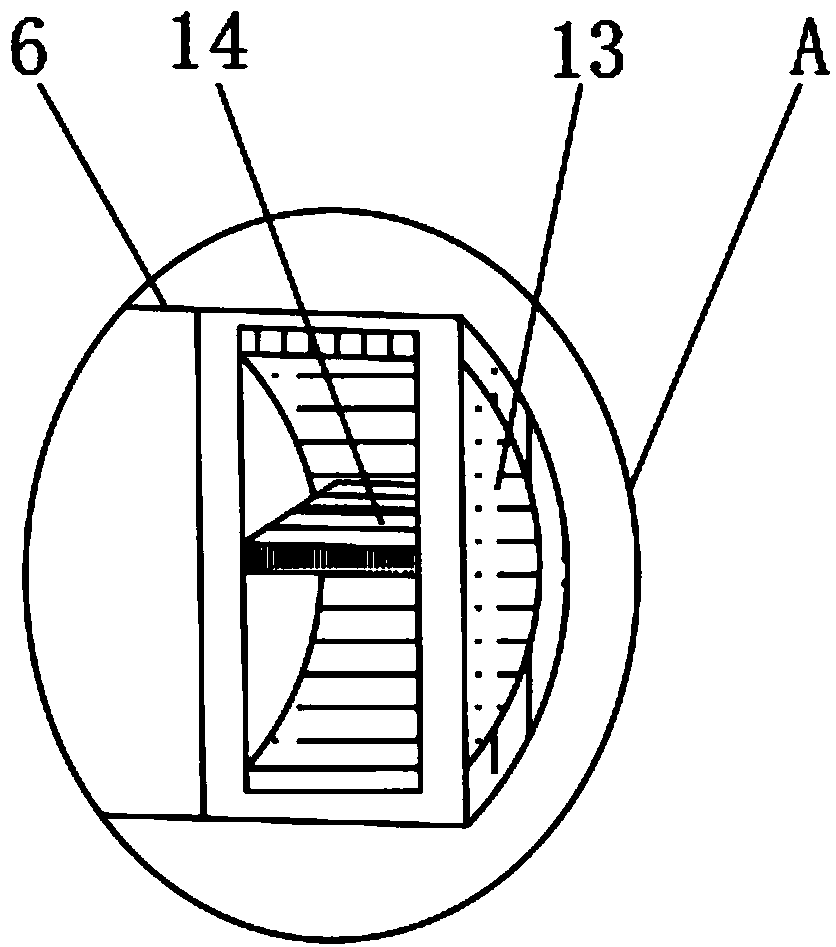

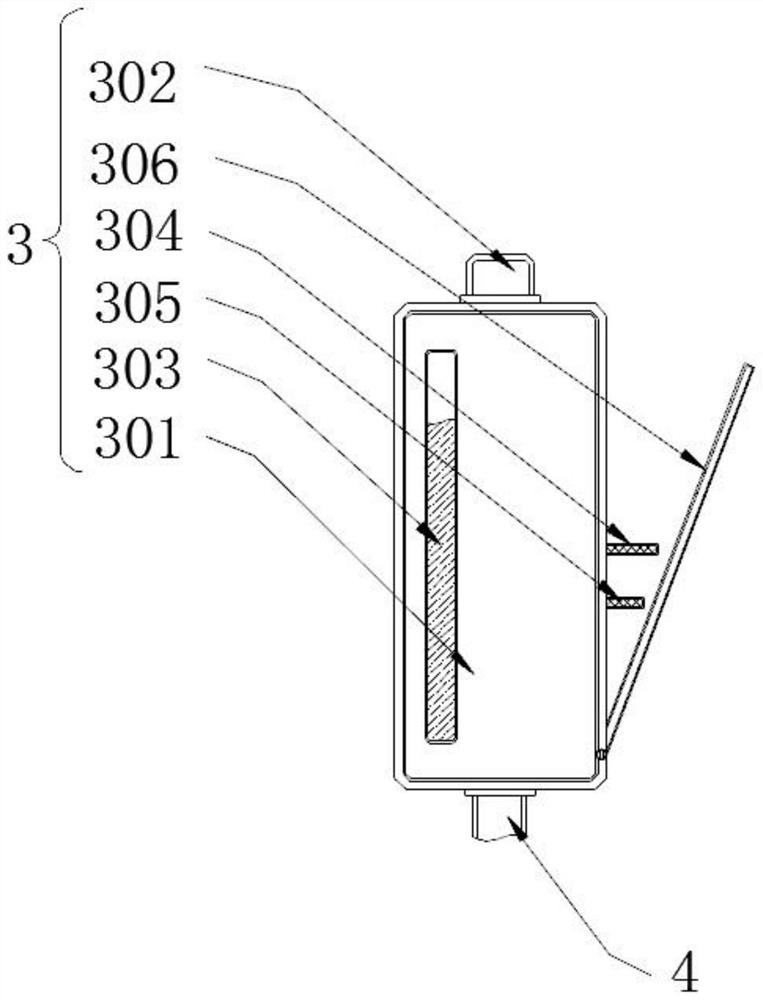

Contact type temperature control device for regulating temperature by gas

InactiveCN104664910ASimple structureGood thermoregulation effectGarment special featuresBlanketTemperature senseEngineering

The invention discloses a contact type temperature control device for regulating the temperature by gas and relates to the field of gas temperature regulation. The contact type temperature control device comprises a bottom layer and a temperature sensing layer which are sequentially arranged from bottom to top, wherein a supporting outer frame is arranged between the bottom layer and the temperature sensing layer; a gas chamber is formed by spaces inside the bottom layer, the supporting outer frame and the temperature sensing layer; at least forty support members are arranged inside the gas chamber; all the support members are distributed at the top of the bottom layer in a disperse way; the sum of cross section areas of all the support members is 50-70 percent that of the gas chamber; the height of each support member is identical with the thickness of the supporting outer frame; at least one gas inlet and at least one gas outlet are formed in the wall of the supporting outer frame; a temperature regulating device is arranged in the at least one gas inlet and is provided with a fan for introducing gas. The contact type temperature control device disclosed by the invention has the advantages of better temperature regulating effect, convenience for use of people, safety and environment friendliness for use and wide application range.

Owner:胡斌

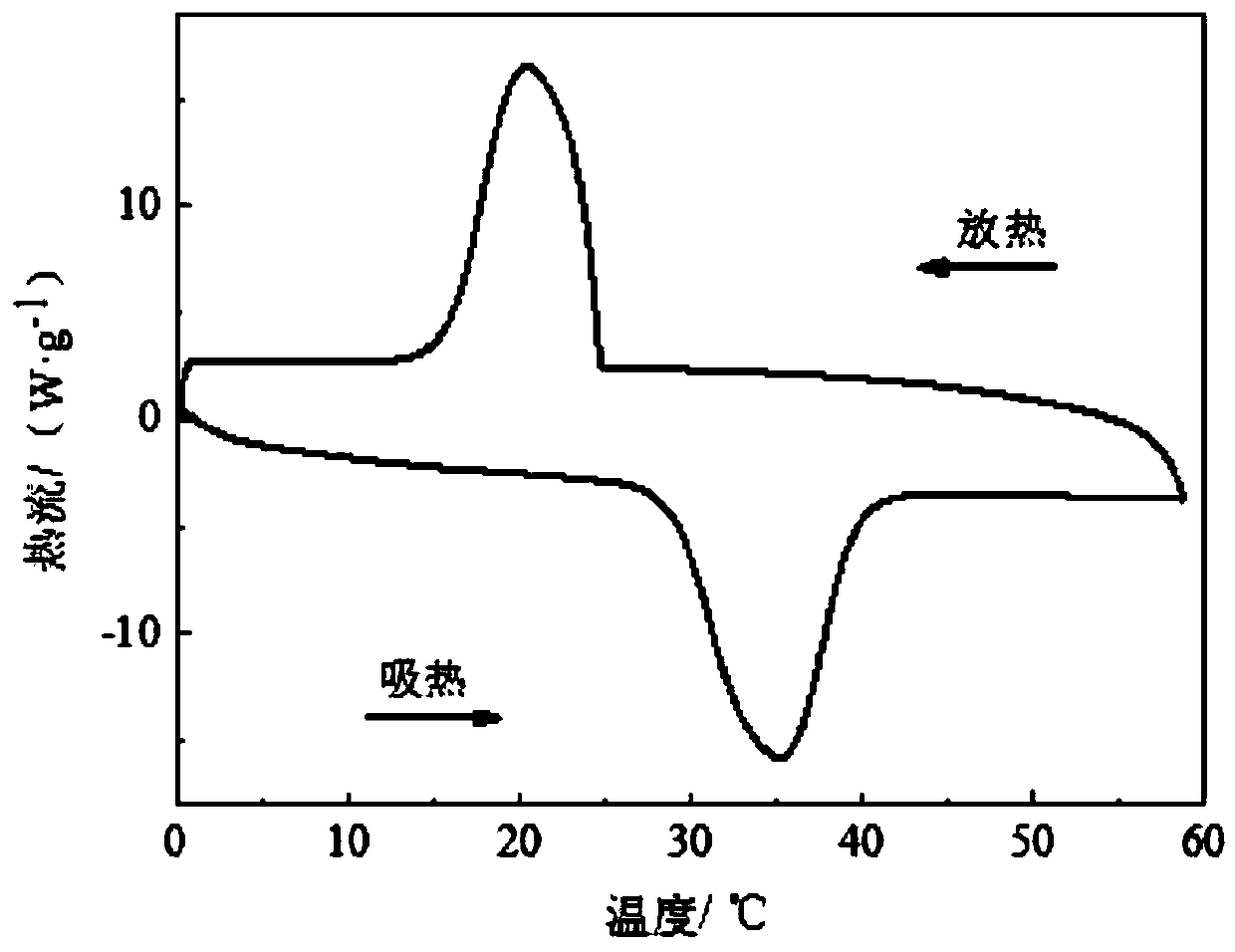

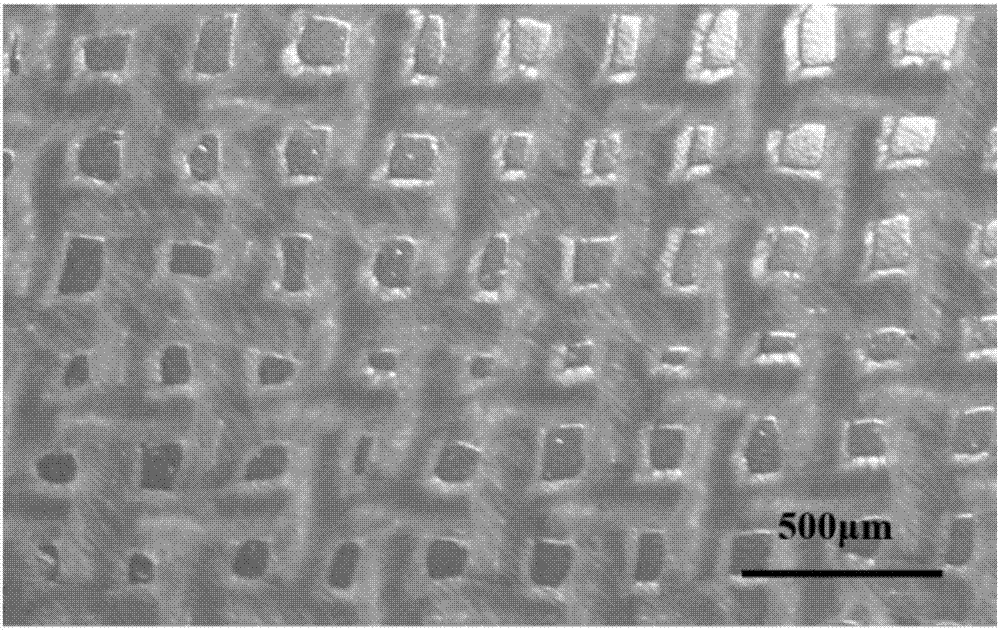

Coating finishing technology of intelligent temperature-regulating textile based on phase change microcapsules

InactiveCN110791971AIncrease coverageIncrease binding rateTextiles and paperPolyesterPolymer science

The invention discloses a coating finishing technology of an intelligent temperature-adjusting textile based on phase change microcapsules. The coating finishing technology comprises the following steps: (1) raw material preparation, wherein the used fabric is a polyester fabric; (2) preparation of the phase change microcapsules; and (3) a coating finishing process for combining the phase change microcapsules with the polyester fabric: firstly, uniformly mixing 40-50 parts of water and 1-3 parts of a dispersing agent, sequentially adding 10-15 parts of an aqueous polyacrylate coating agent under high-speed stirring, then stirring for 10 min at the rotating speed of 2000 r / min, then adding 25-30 parts of phase change microcapsule powder, finally stirring for 30 min at the rotating speed of800 r / min, then adding 2-5 parts of a crosslinking agent and 1-3 parts of a thickening agent, and uniformly stirring at low speed to form slurry for later use. The phase change microcapsules are environment-friendly, low in price and high in heat conductivity coefficient, the formed coating finishing fabric has the advantage of high bonding rate, and the problems of weak bonding fastness and low bonding rate of the phase change microcapsules and the fabric are solved.

Owner:ZHEJIANG SCI-TECH UNIV

Cool fabric with relatively high human body infrared permeability, and preparation method thereof

ActiveCN106948182AGood temperature regulationImprove penetrationTextiles and paperChemistryThermal conductivity

The invention relates to a cool fabric with relatively high human body infrared permeability, and a preparation method thereof. According to the preparation method, polyethylene and a diluent are mixed and are subjected to melting; the surface of a base cloth is coated with an obtained melted mixture; laminating is carried out at 140 to 170 DEG C under 0.2 to 0.8MPa; cooling is carried out; the diluent is removed; drying and setting are carried out; and surface plasma treatment is carried out so as to obtain the cool fabric with relatively high human body infrared permeability. Compared with conventional fabric, the cool fabric with relatively high human body infrared permeability possesses following advantages: dissipation of infrared thermal radicalization generated by human body can be realized preferably, thermal conductivity is high, dissipation of thermal energy generated by human body can be realized in time, blocking capacity on visible light is relatively high, human body is protected from sun light by the cool fabric, the cool fabric also possesses relatively high porosity and a certain degree of hydrophilic performance, so that sweat generated by human body can be discharged quickly, and the cool fabric possesses a certain degree of wearing resistance.

Owner:DONGHUA UNIV

Tencel fiber and linen fiber blended yarn and spinning process thereof

The invention provides a tencel fiber and linen fiber blended yarn which comprises tencel fiber with the blending ratio of 70% and linen fiber with the blending ratio of 30%, and further provides a spinning process of the tencel fiber and linen fiber blended yarn. The process includes the steps of blowing-carding, drawing, roving, spinning and winding. Compact siro spinning is adopted as the spinning mode and combines the advantages of siro spinning and compact spinning, the evenness CV value, the slub index and the fine index are quite good, the single yarn is high in strength, the structureis compact, the wear resistance is high, the yarn hairiness is lower, harmful hairiness with the length of 3 mm or above is quite low, the yarn is bright and clean, the fabric quality is high, and theyarn is a high-quality yarn raw material for jean fabrics. The prepared blended yarn is a high-quality yarn which is environmentally friendly, elegant, comfortable and rich in style.

Owner:上海纺织(集团)大丰纺织有限公司

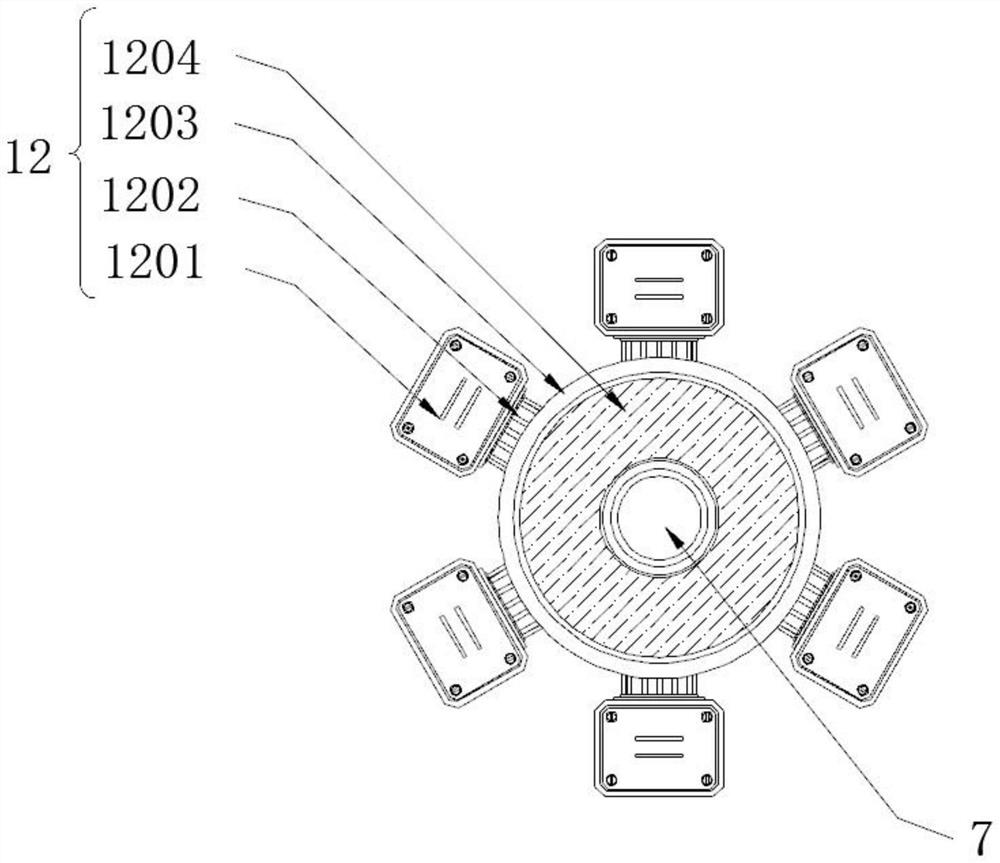

Exhaust port-movable temperature control system based on internet of things

InactiveCN108592354ASimple structureEasy to useMechanical apparatusSpace heating and ventilation safety systemsTemperature controlAir volume

The invention discloses an exhaust port-movable temperature control system based on an internet of things. The system comprises a condenser, an evaporator and a controller in an air conditioning system; exhaust ports and air return ports of the evaporator are arranged in temperature adjusting space; the exhaust ports communicate with one side of the evaporator through one end of a main exhaust pipe and an exhaust fan; the air return ports connected with the other side of the evaporator through one end of a main air return pipe; multiple air return ports are arranged at the outer periphery of an area to adjust the temperature and / or the periphery of each exhaust port through the other end of the main air return pipe; multiple exhaust ports are connected with a displacement driving mechanism; infrared human body induction sensors are arranged near the exhaust ports; control mechanisms for air volume adjustment, temperature adjustment and exhaust port opening and closing are arranged on the exhaust ports; and the control mechanisms are wirelessly connected with an infrared remote control emitter or a mobile phone with an infrared emitting head through an infrared remote control receiver and a controller.

Owner:HARBIN UNIV OF COMMERCE

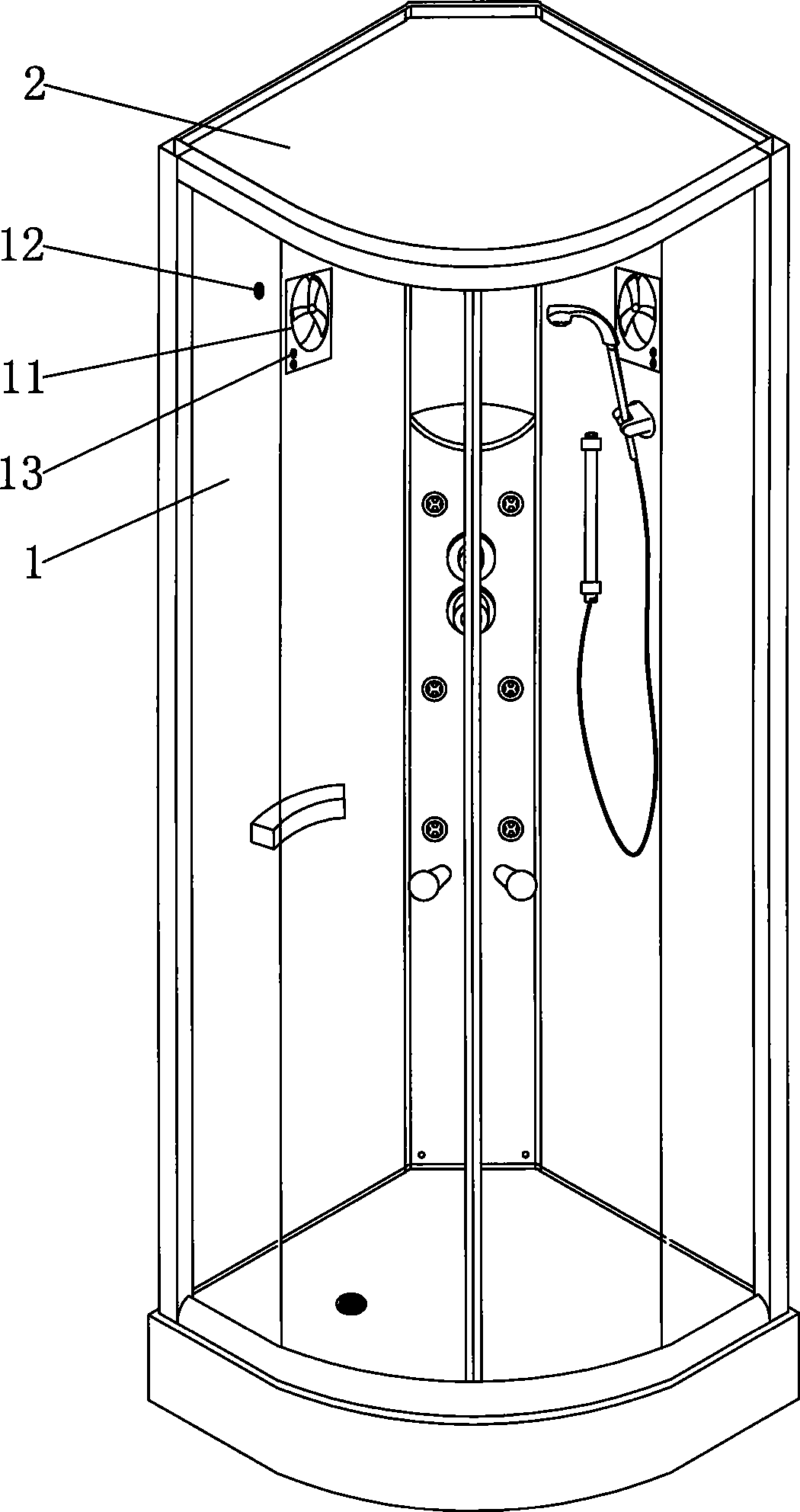

Bathing room with automatic air discharge

InactiveCN101502400AGood thermoregulation effectWith intake functionBathsDouchesFresh airEngineering

The invention discloses a shower house capable of automatically exhausting, comprising a shower house main body composed of a wall board and a sliding door, and a top cover on the top of the shower house main body, a plurality of automatic exhausting devices on the wall board and the top cover, a temperature controller on the wall board and connected with the automatic exhausting device, when the temperature in the shower house reaches the preset value, an exhausting fan automatically opens to exhaust. The exhausting fan has features of good effect and lower manufacture cost compared with the existing shower house ventilation mechanism and has air-admission function. Two relative exhausting fans are set in the shower house, thus the hot steam is exhausted and the fresh air is sucked, therefore the convection wind. The exhaust heat-dispersion effect is better and the human feels more comfortable when showering.

Owner:王剑伟

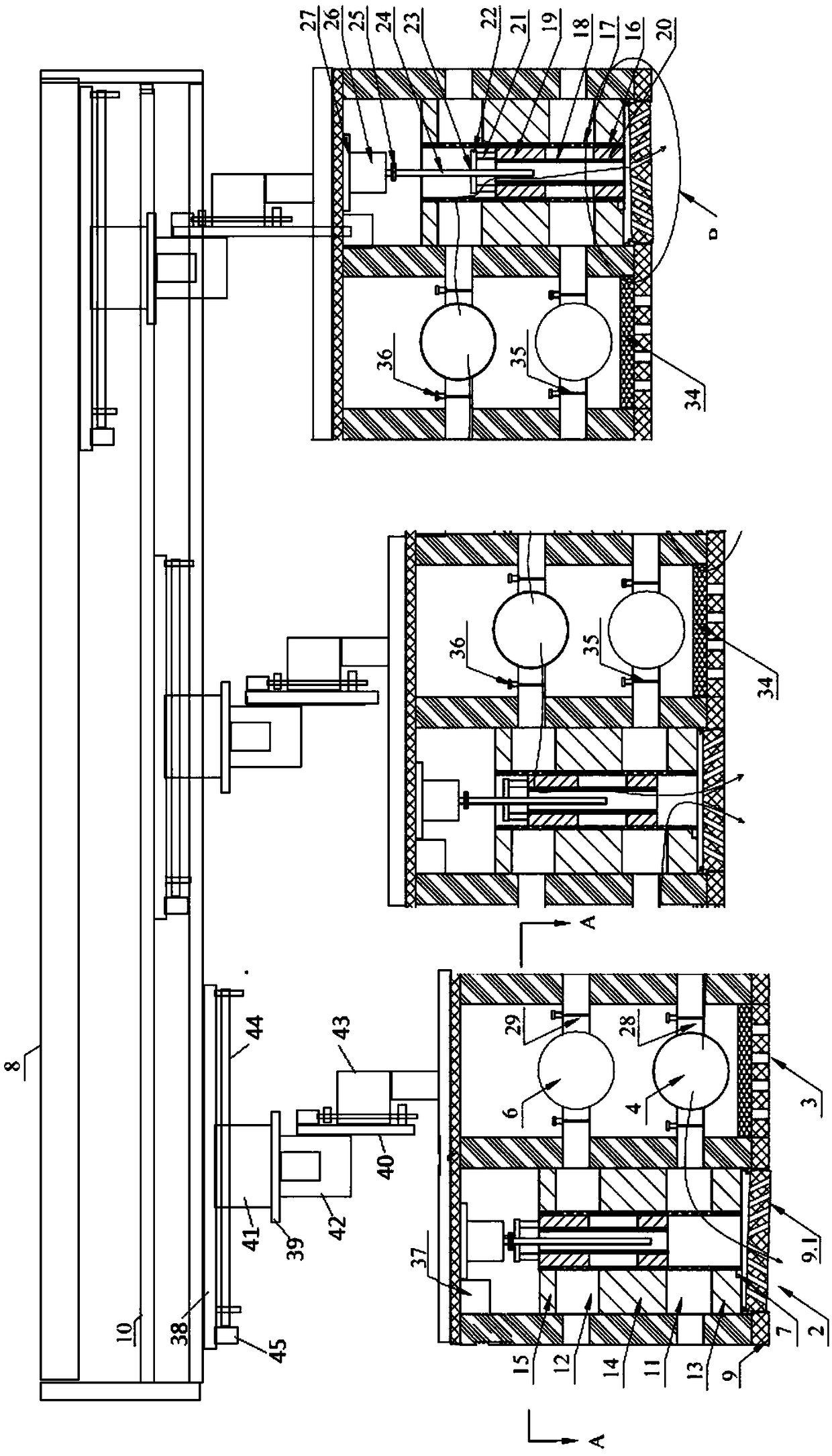

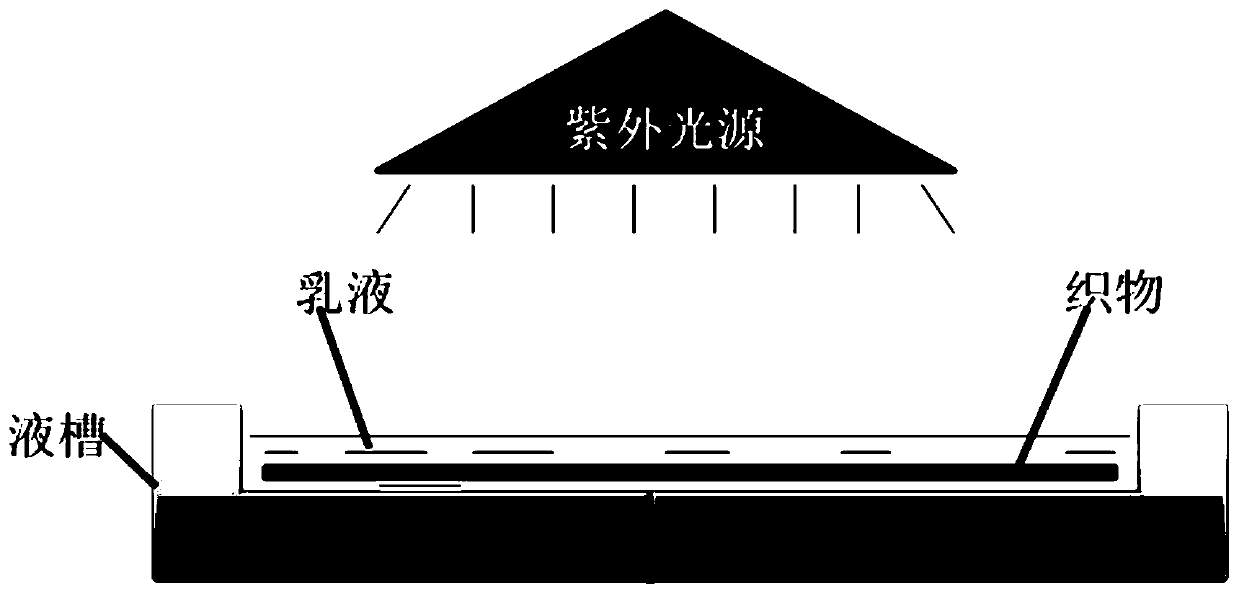

Preparation method of temperature-adjusting texture by in-situ photo-induced polymerization

ActiveCN107794770AGood adhesionHigh latent heat valueGrip property fibresMicroballoon preparationIn situ polymerizationOil emulsion

The invention relates to a preparation method of a functional temperature adjusting texture, and particularly relates to a high potential heat temperature-adjusting texture prepared by in-situ generation of a photo-induced phase change microcapsule on the texture. The preparation method of the functional temperature adjusting texture includes steps of (1), preparation of phase change core material, acrylic acid wall material, and other raw materials; (2), preparation of oil phase and water phase components; (3), evenly emulsifying oil and water phases to obtain water-coated-oil emulsion; (4),placing the emulsion and the texture in a specific device, and making the emulsion glue beam attached on the texture generate the phase change microcapsule through the photo-induced polymerization. The method has the advantages that the adhering force of the capsule on the texture is strong and the texture is wash resistance through in-situ polymerization of the phase change microcapsule on the texture; the preparation of the temperature-adjusting texture is completed by one-step method, the technique is simple and cost is low; the temperature-adjusting texture is high in potential heat value,and very suitable for using as the temperature-adjusting fabric, flocculus or filler for the clothes and other textiles; the temperature adjusting effect is obvious.

Owner:浙江中科微瑞新材料股份有限公司

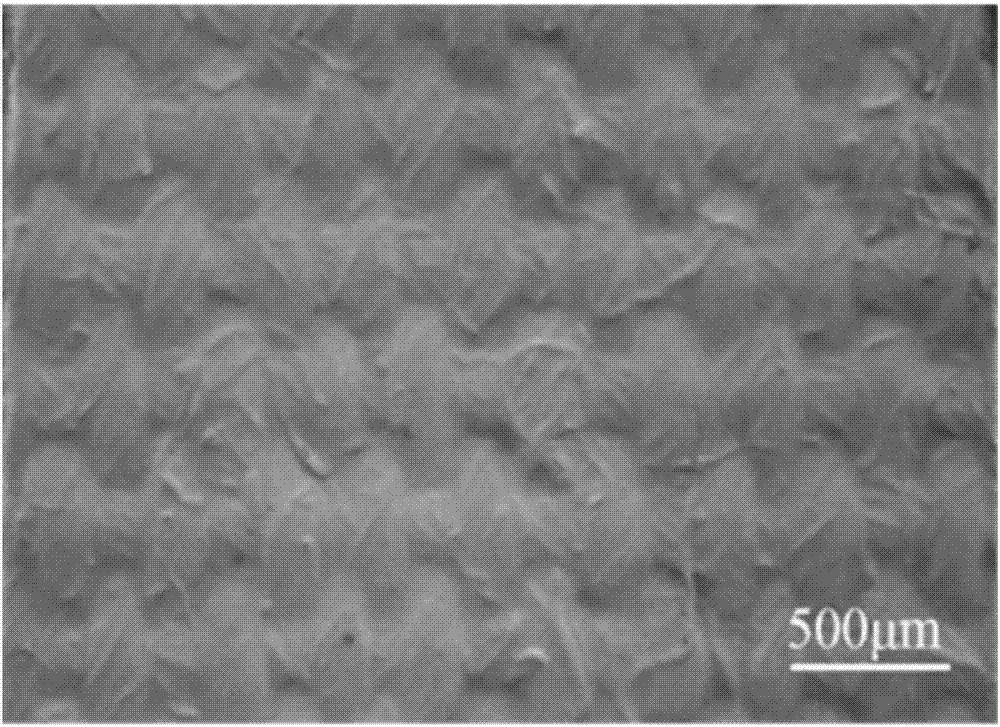

Elastic phase change energy storage polyurethane fiber and preparation method thereof

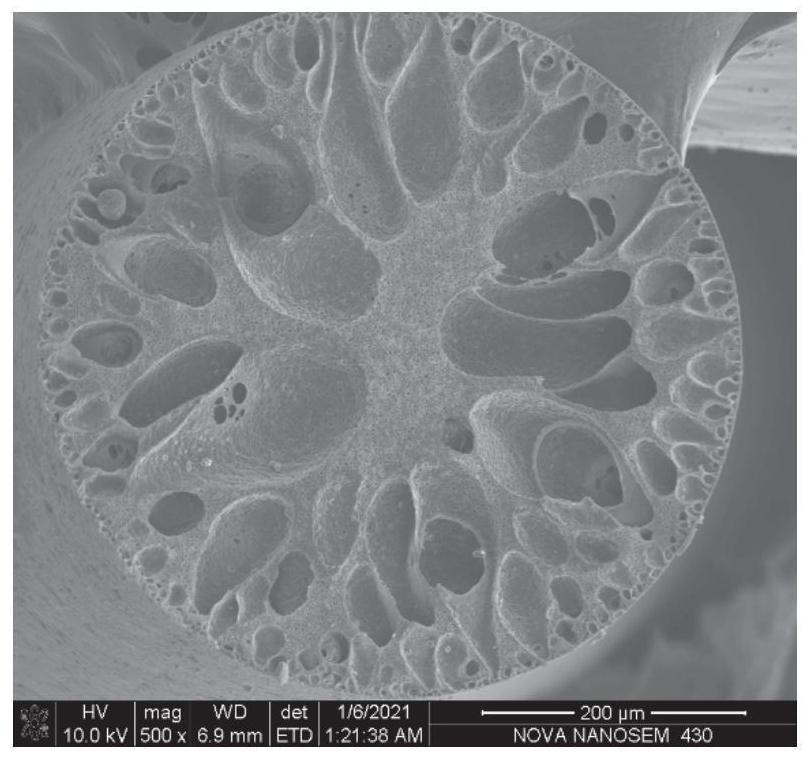

ActiveCN113235299AHigh phase change enthalpySimple processFibre typesHeat-exchange elementsFiberPolymer science

The invention belongs to the technical field of phase change fibers, and discloses elastic phase change energy storage polyurethane fiber and a preparation method thereof. The elastic phase change energy storage polyurethane fiber comprises elastic polyurethane fiber, a phase change material and a film layer; the elastic polyurethane fiber has a three-dimensional porous network structure; the phase change material fills the three-dimensional porous network structure; the film layer coats the surface of the elastic polyurethane fiber; and the film layer is a polyurethane film layer. The method comprises the following steps of dissolving polyurethane in an organic solvent or the organic solvent and ionic liquid to obtain a spinning solution; carrying out wet spinning on the spinning solution, performing soaking in water, and performing freeze-drying to obtain the porous polyurethane fiber; filling the porous structure with the liquid phase change material by adopting a vacuum impregnation method to obtain composite polyurethane fiber; and coating the surface of the composite polyurethane fiber with waterborne polyurethane, and performing film forming to obtain the elastic phase change energy storage polyurethane fiber. The fiber disclosed by the invention can be used for highly loading the phase change material, and has excellent flexibility and heat storage and thermal insulation properties.

Owner:SOUTH CHINA UNIV OF TECH

Temperature adjustable and insulating clothing

InactiveCN106120010AGood thermoregulation effectAvoid getting lostSynthetic resin layered productsCellulosic plastic layered productsFiberExternal energy

The invention discloses temperature adjustable and insulating clothing. The clothing includes a clothing body; the clothing body comprises an outer insulating layer, a core layer located on the inner side of the insulating layer; the core layer comprises fabric woven from heat-storage temperature adjustable fiber; the heat-storage temperature adjustable fiber is prepared by spinning a fiber-forming polymer and a solid-solid phase change material. According to the temperature adjustable and insulating clothing, the core layer comprises fabric woven from heat-storage temperature adjustable fiber; the solid-solid phase change material contained in the heat-storage temperature adjustable fiber can store heat, absorb heat in high temperature environment, and release heat in low temperature environment, so as to reach good temperature adjustable effect of the core layer; the thermal insulation layer can prevent the heat from entering the core layer from outer side of the clothing body and prevent heat loss to the outside, so that the clothing body has heat insulation effect. In addition, the heat-storage temperature adjustable fiber does not depend on external energy, so as to achieve the purpose of saving energy.

Owner:深圳市乐乐趣文化科技有限公司

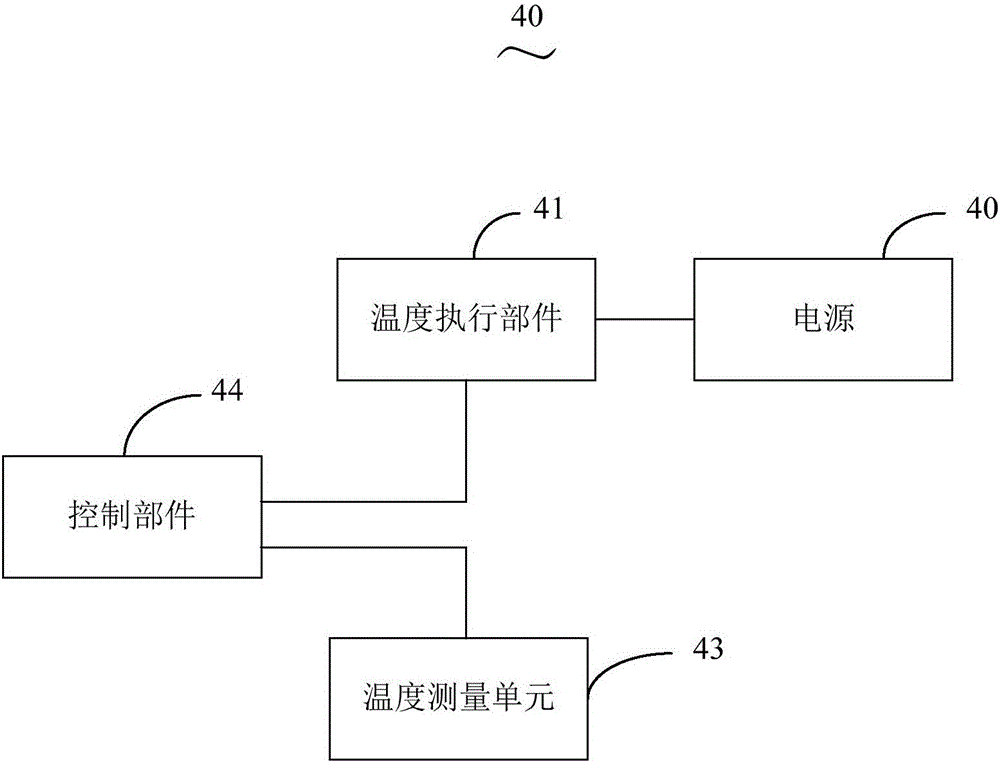

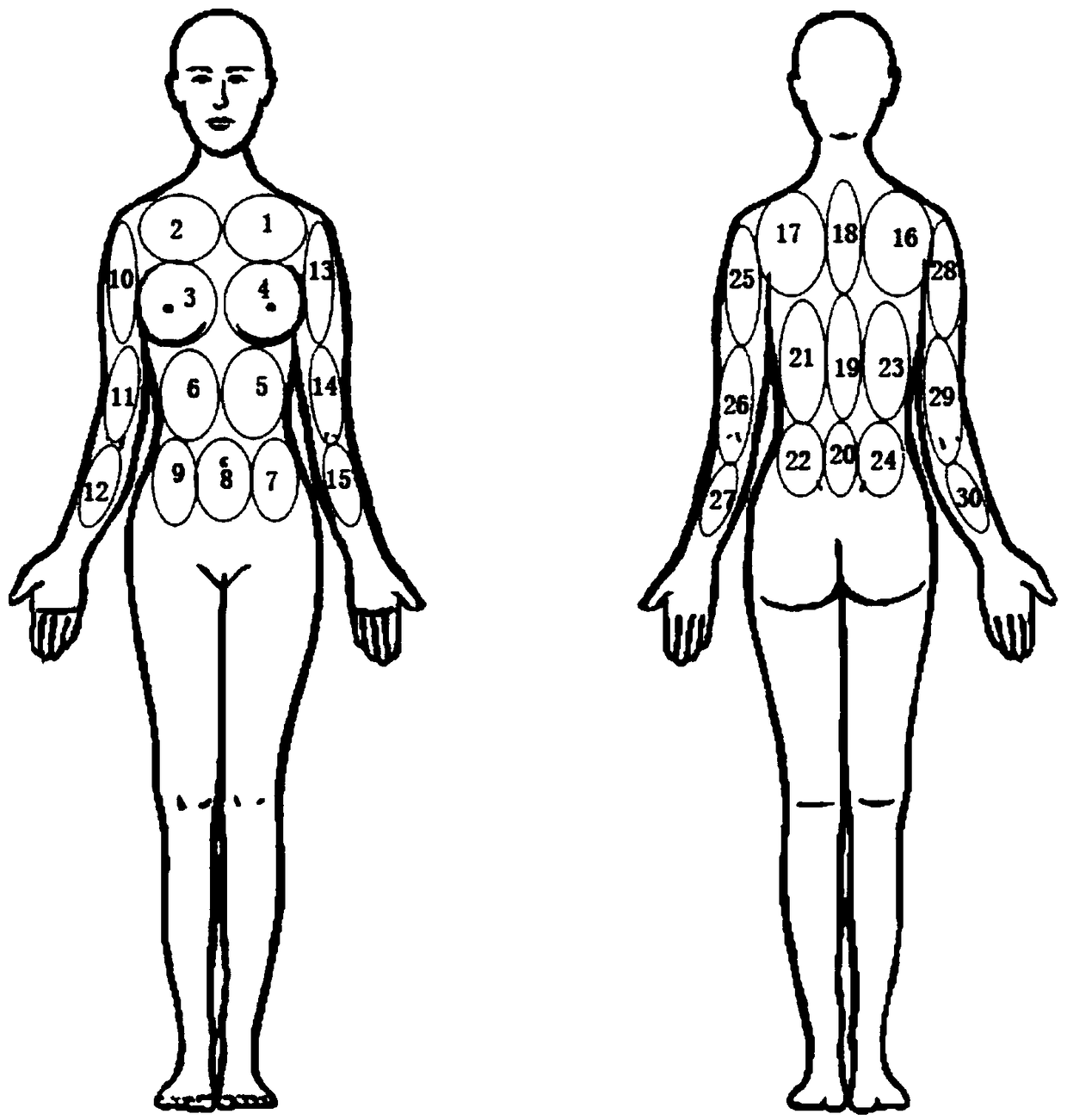

Temperature adjusting and controlling clothing

InactiveCN108497576AGood thermoregulation effectEasy to carryGarment special featuresProtective garmentEngineeringThermal sensation

The invention relates to temperature adjusting and controlling clothing, which comprises a clothing main body, wherein the clothing main body is divided into a clothing surface high-temperature area and a clothing surface low-temperature area, or a subjective thermal sensation high-value area and a subjective thermal sensation low-value area, or a clothing surface temperature high-change area anda clothing surface temperature low-change area, or a subjective thermal sensation value high-change area and a subjective thermal sensation value low-change area; the clothing surface low-temperaturearea, the subjective thermal sensation low-value area, the clothing surface temperature low-change area and the subjective thermal sensation value low-change area are made from a heat-insulating fabric; and the clothing surface high-temperature area, the subjective thermal sensation high-value area, the clothing surface temperature high-change area and the subjective thermal sensation high-changearea are made from a cooling fabric. According to the clothing provided by the invention, temperature can be automatically adjusted and controlled in accordance with temperature changes of a human body before and after motions.

Owner:DONGHUA UNIV

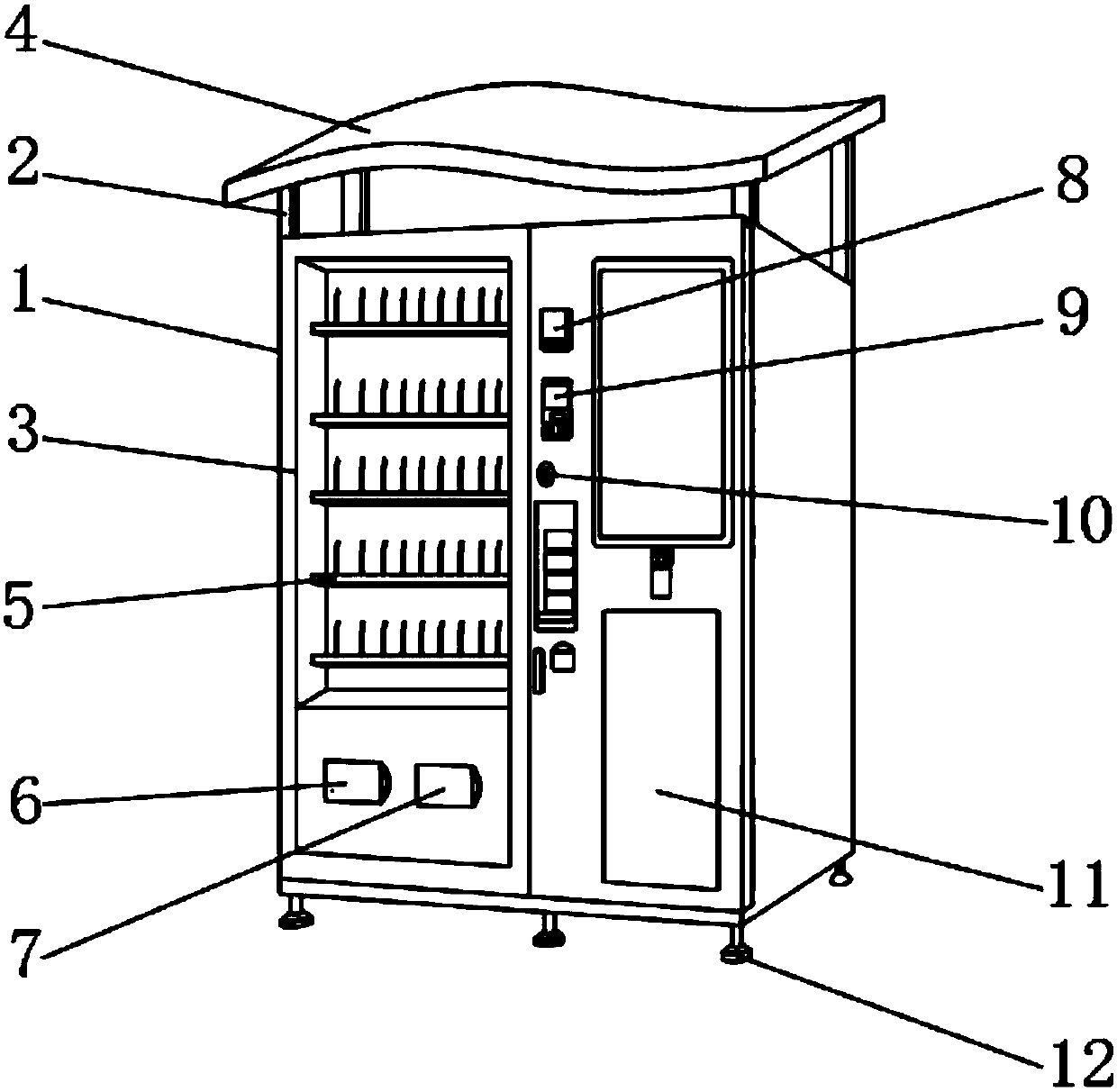

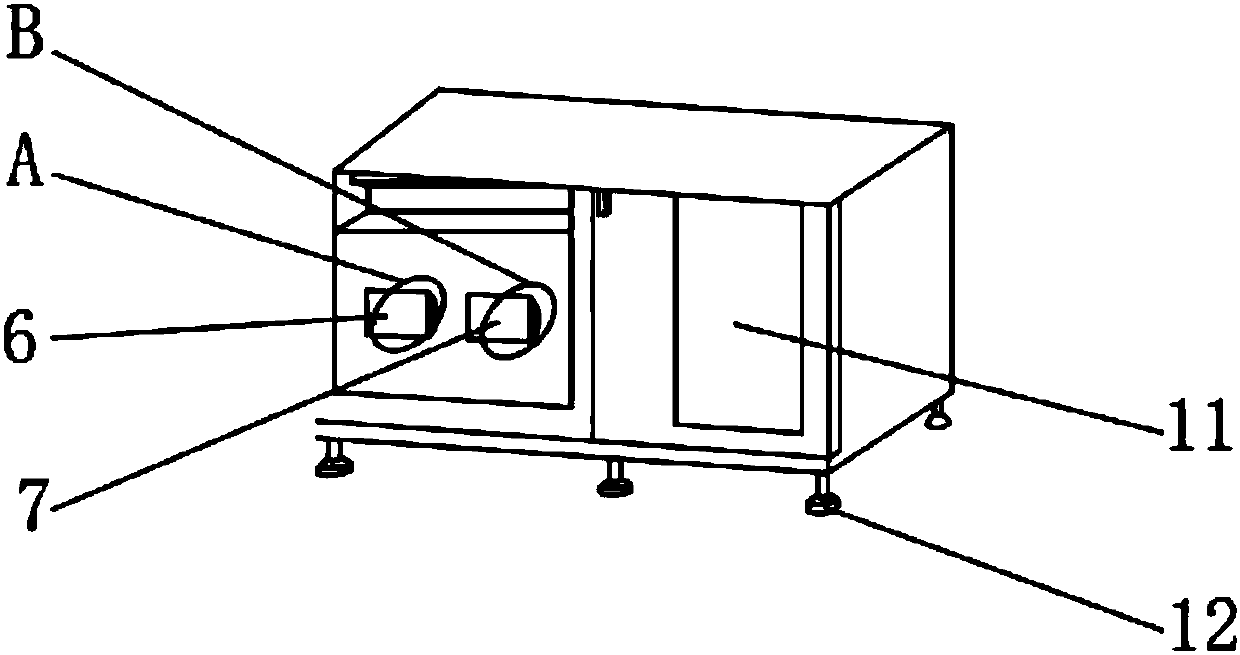

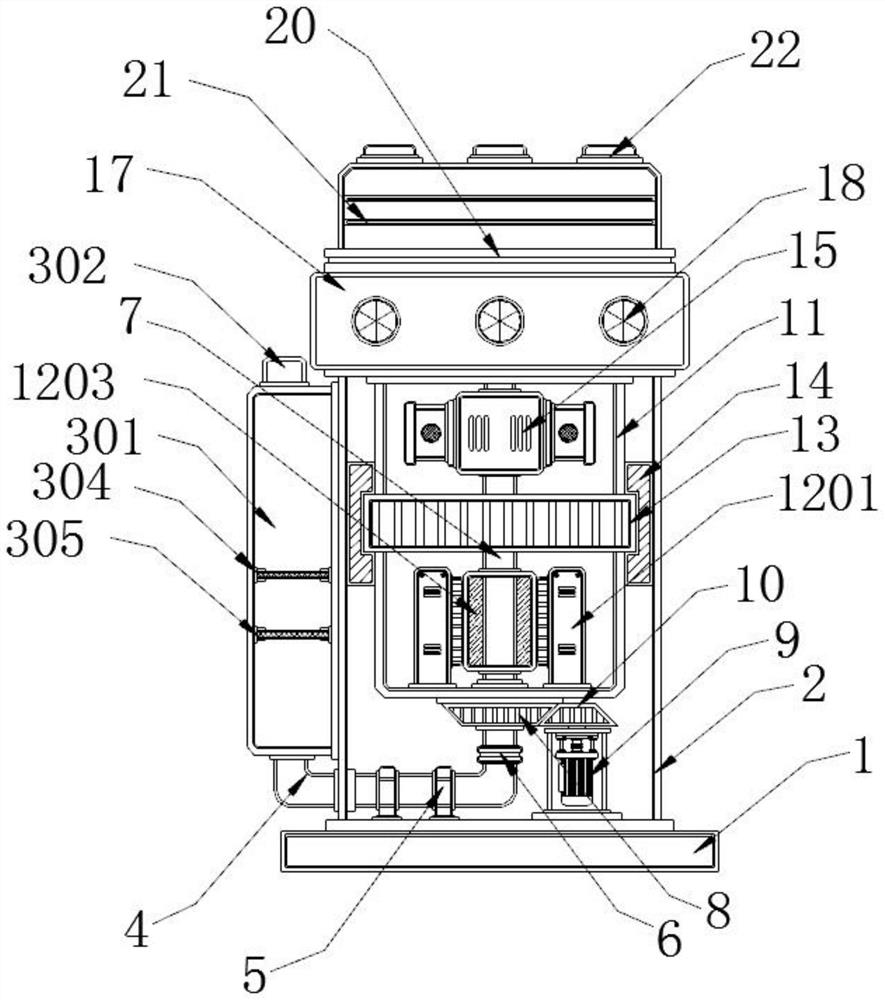

Life general merchandise unmanned vending device

InactiveCN107730721AIntegrity guaranteedAvoid the sun and windCoin-freed apparatus detailsApparatus for dispensing discrete articlesTemperature controlRoom temperature

Owner:WUXI DACHENG TIANXIA INTELLIGENT TECH CO LTD XISHAN BRANCH

Spliced cold-hot water circulation floor device

InactiveCN102748793AEfficient use ofThe main structure is novelLighting and heating apparatusFlooringButt jointEngineering

The invention belongs to the technical field of building decoration, and relates to a spliced cold-hot water circulation floor device. A water pipe groove parallel to long edges of each floor body is dug at the center of the bottom side of the floor body, a female groove and a male groove are arranged on two long edges respectively, a soft water pipe is placed in the water pipe groove on the bottom side of each floor body after a plurality of floor bodies are spliced to rotatably form a cold-hot water circulation loop, water pipe bending groove supports are arranged at the top ends of the floor bodies in a clamped and inserted butt joint manner, semicircular water pipe bending grooves are arranged on the upper sides of the floor bodies, a male clamp groove and a female clamp groove are arranged at two end edges of each floor body respectively, and wall passing water pipe groove supports are arranged at the top ends of the floor bodies penetrating through a wall in the clamped and inserted butt joint manner. The spliced cold-hot water circulation floor device is novel in structure, simple in process, attractive and practical in decoration, fine in temperature adjusting performance, is environment-friendly in use, low in cost and fine in energy conservation, and solar energy and underground energy are effectively used.

Owner:菏泽吴水木制品有限公司

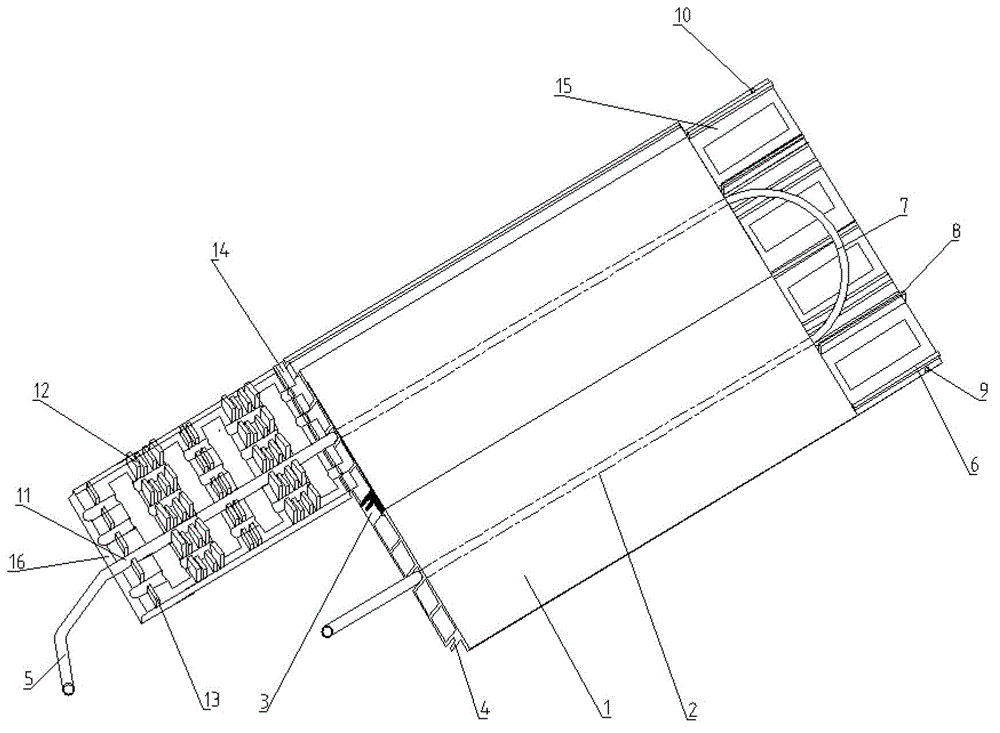

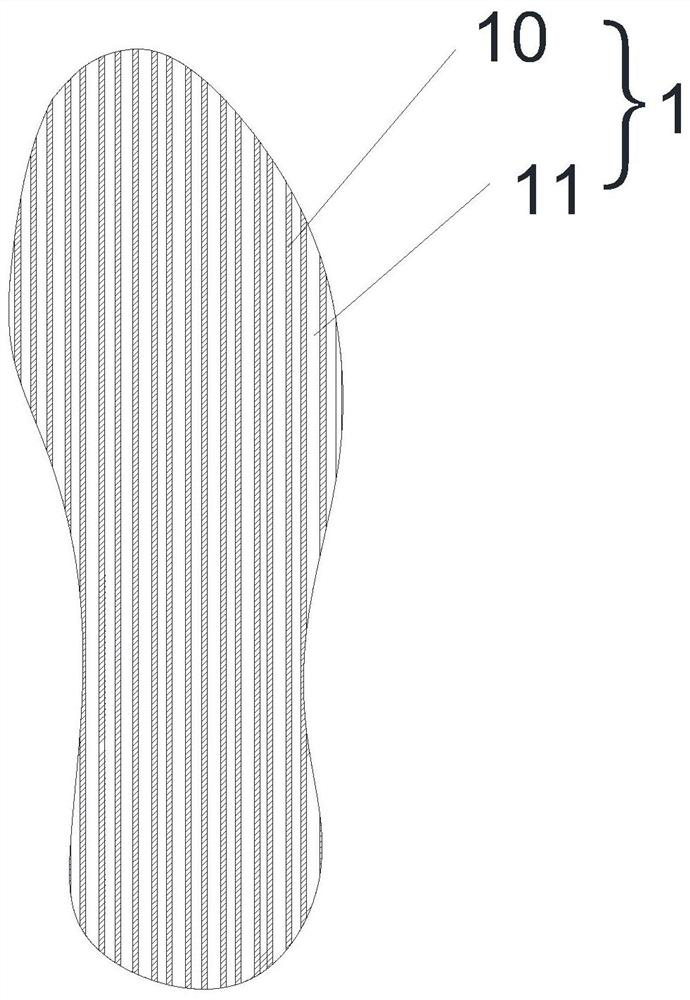

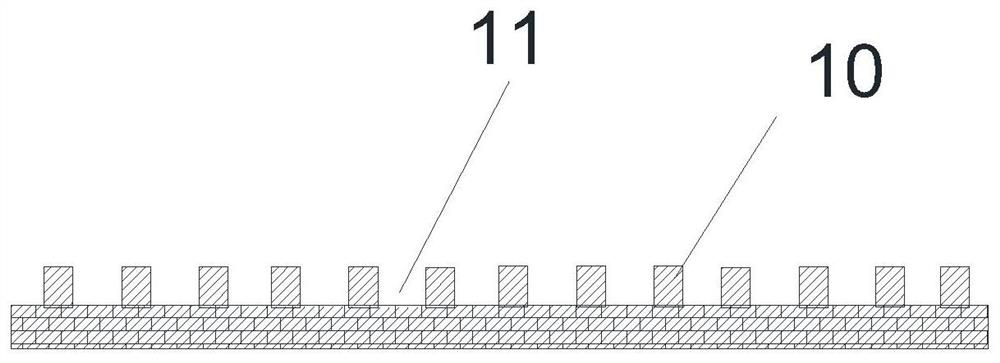

High-resilience ultralight insole and preparation method thereof

ActiveCN113733703AReduce cleaning timesExtended service lifeStain/soil resistant fibresInsolesYarnEngineering

The invention relates to the technical field of shoe materials, in particular to a high-resilience ultralight insole and a preparation method thereof. The insole comprises a fabric layer and a polyurethane layer, the upper surface of the fabric layer is of a concave-convex strip-shaped structure and comprises strip-shaped protruding parts and strip-shaped concave parts, the strip-shaped protruding parts and the strip-shaped concave parts are circularly arranged at intervals, the strip-shaped protruding parts are formed by weaving anti-fouling yarn, the width of each strip-shaped protruding part ranges from 0.5 mm to 1.5 mm, and the total area of the strip-shaped protruding parts does not exceed 30% of the area of the fabric layer. The strip-shaped concave parts are formed by weaving temperature adjusting yarns, and the width range of each strip-shaped concave part is 0.8-2mm; the polyurethane layer is prepared by a supercritical method, and the density of the polyurethane layer is 0.03-0.05 g / m < 2 >; the fabric layer and the polyurethane layer are compounded through dotted glue. The insole has a good antifouling effect and a good temperature adjusting effect, is prepared by adopting a supercritical method, and is low in density, light in weight and good in comfort.

Owner:FUJIAN HONGXING ERKE SPORTING GOODS CO LTD

Environment-friendly soft porcelain preparation method

ActiveCN109437855ARealize comprehensive utilizationWith moisture control effectCeramic materials productionClaywaresFiberEmulsion

The invention relates to an environment-friendly soft porcelain preparation method which comprises the steps of preparing nano silver fiber, modifying boron nitride nanotubes, preparing phase change microcapsules, preparing soft porcelain and performing surface treatment. The environment-friendly soft porcelain is prepared from 30 to 50 parts of inorganic powder, 15 to 35 parts of cement, 10 to 15parts of phase change microcapsules, 10 to 30 parts of acrylic polymer emulsion, 0 to 2 parts of pigment, 0.5 to 2 parts of a coupling agent, 0.5 to 1.2 parts of montmorillonite, 0.5 to 1.2 parts ofkieselguhr and 0.8 to 1.5 parts of wood fiber. The environment-friendly soft porcelain prepared by the preparation method disclosed by the invention has the advantages of good breathability and antifouling, self-cleaning, temperature-regulating and moisture-control performance.

Owner:张凯

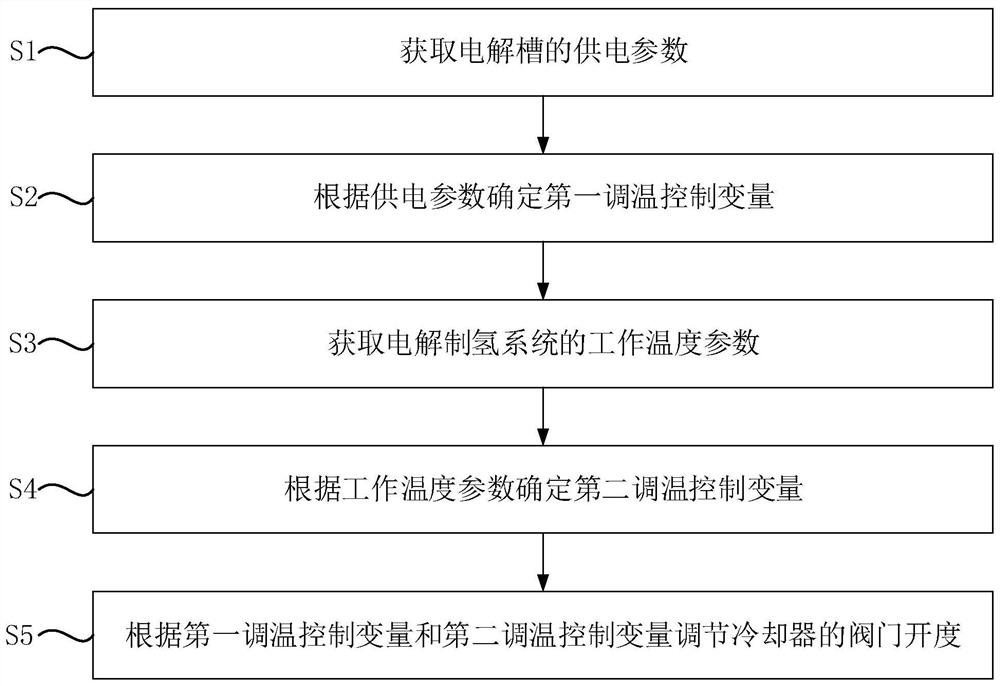

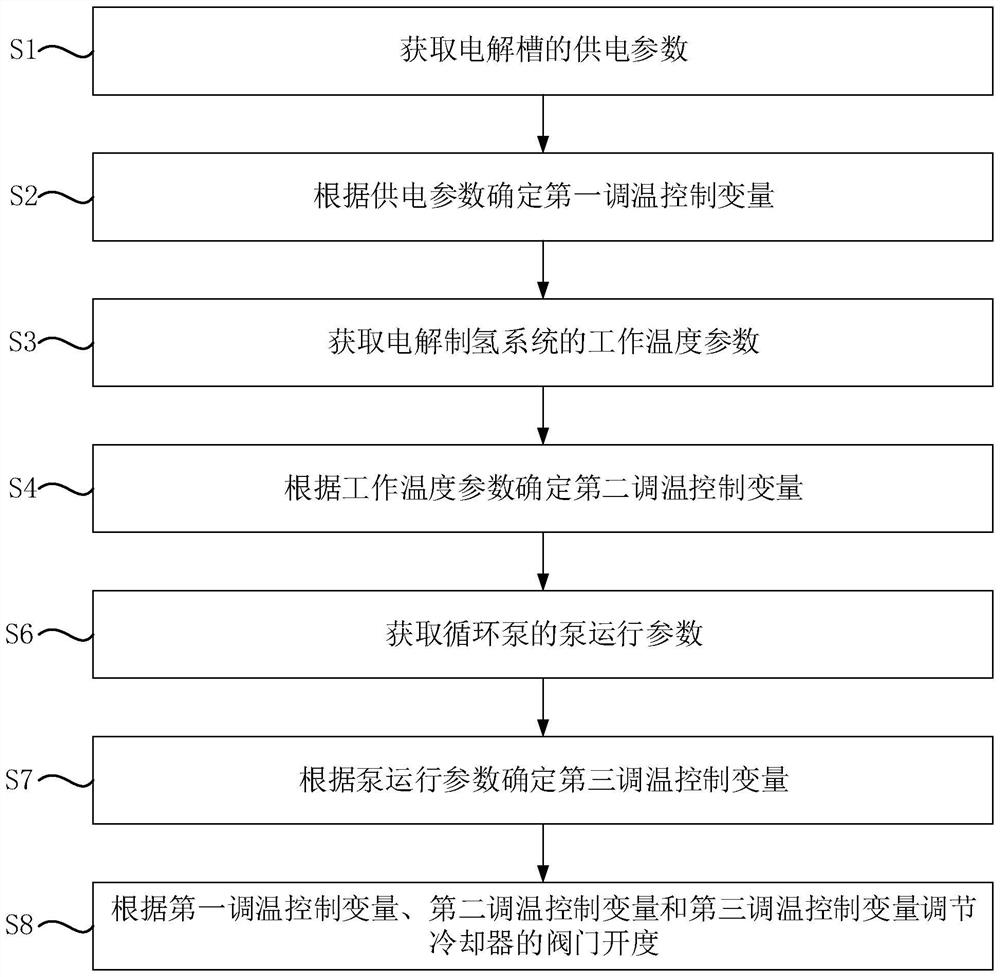

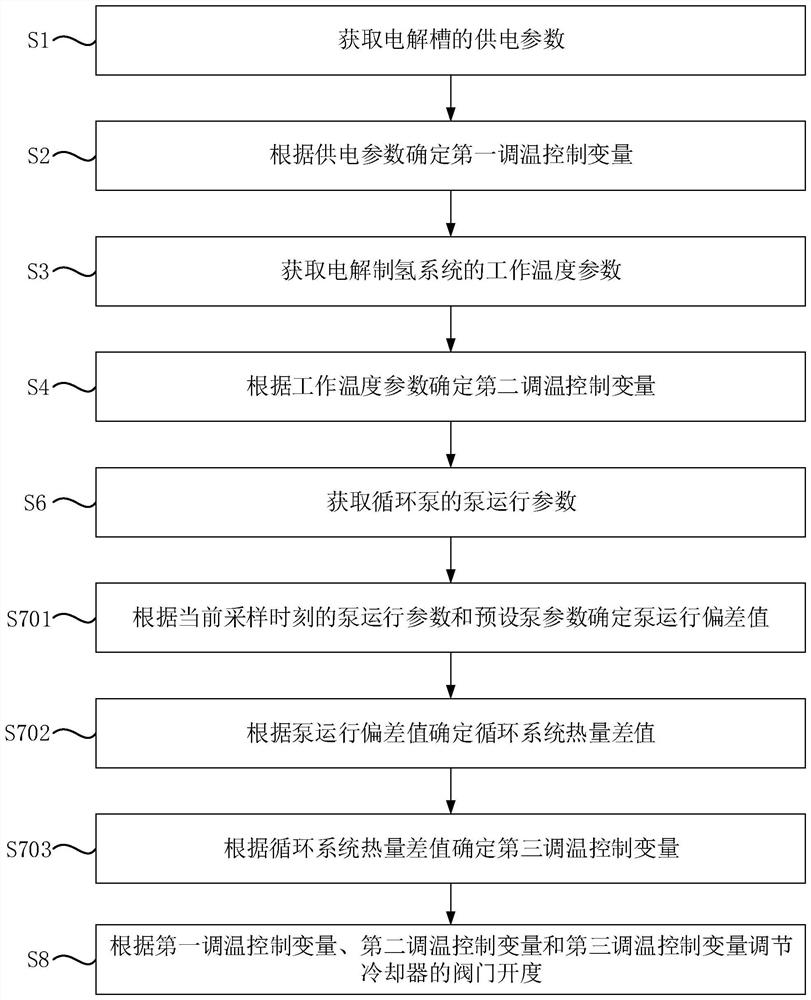

Electrolytic hydrogen production system and temperature control method and device thereof

PendingCN114059084AQuick responseOptimize the temperature adjustment effectCellsProcess engineeringValve opening

The invention discloses an electrolytic hydrogen production system and a temperature control method and device thereof. The method comprises the steps: obtaining a power supply parameter of an electrolytic bath; determining a first temperature regulation control variable according to the power supply parameter; obtaining a working temperature parameter of the electrolytic hydrogen production system; determining a second temperature regulation control variable according to the working temperature parameter; and adjusting the valve opening degree of the cooler according to the first temperature adjustment control variable and the second temperature adjustment control variable. The control variables required for temperature regulation are calculated through the power supply parameters of the electrolytic bath and the working temperature parameters of the system, the working temperature of the hydrogen production system is actively regulated, the temperature regulation response speed is increased, the temperature regulation effect is improved, and the safety performance and the operation reliability of the system are improved.

Owner:阳光氢能科技有限公司

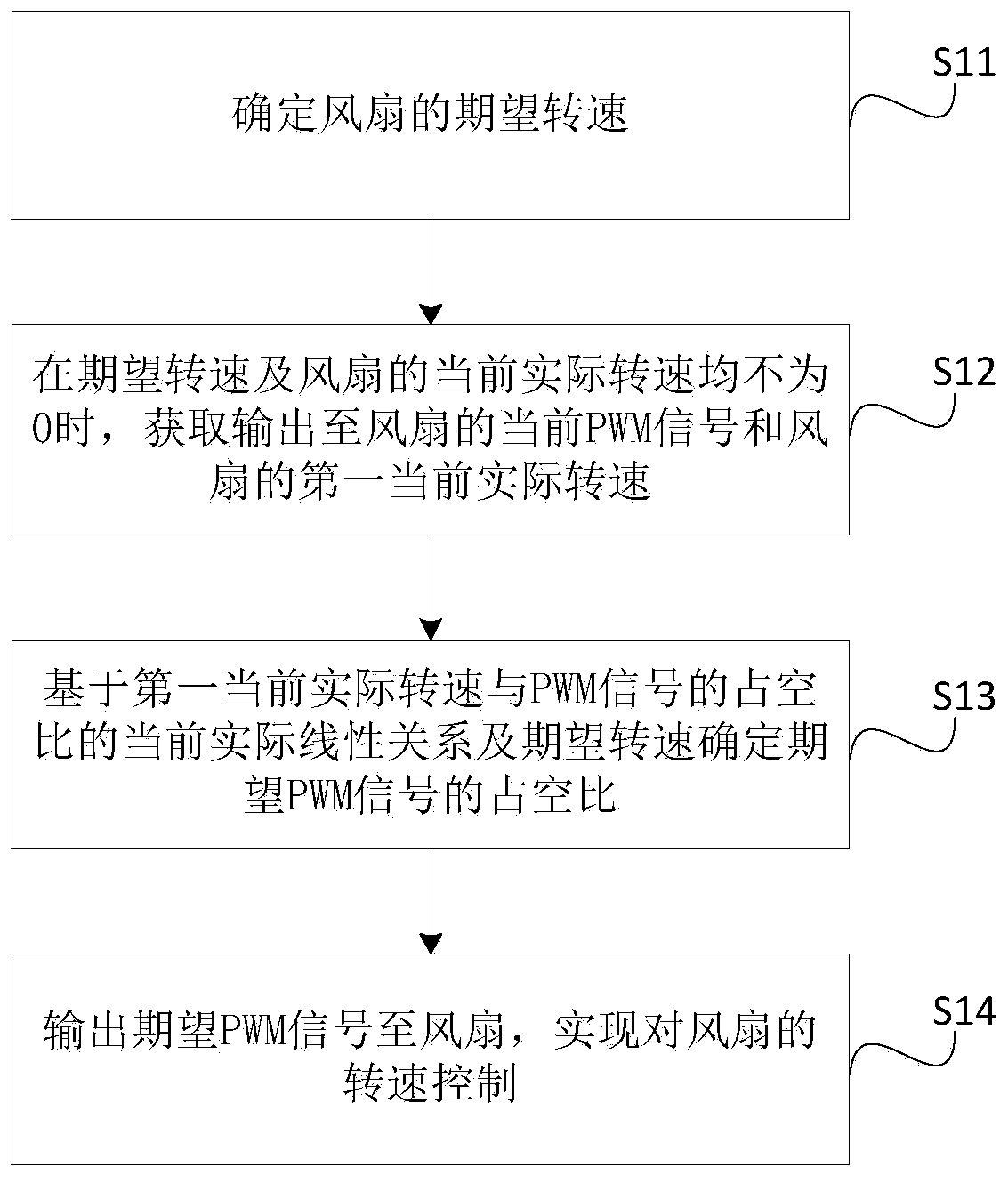

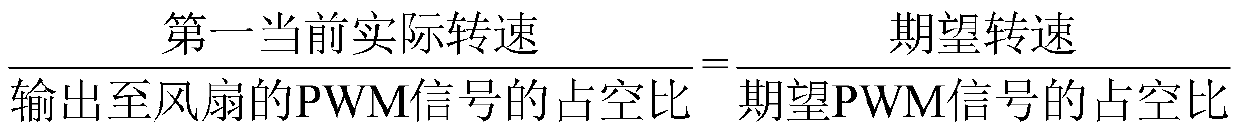

Fan rotating speed control method and device and wearing type equipment

ActiveCN111536068AHigh control precisionGood thermoregulation effectEfficient regulation technologiesPump controlControl mannerEngineering

The invention discloses a fan control method and device and wearing type equipment. After the expected rotating speed of a fan is determined, an expected PWM signal is not determined according to a preset mapping relation between rotating speed and a PWM signal, a current actual linear relation between two can be obtained according to an obtained PWM signal currently output to the fan and the first current actual rotating speed of the fan, then, based on the current actual linear relation and the expected rotating speed, a duty ratio of the expected PWM signal can be obtained, and according tothe expected PWM signal, the fan can be subjected to rotating speed control subsequently. Visibly, a fan control manner considers the influences of factors of an air outlet, an air inlet and the likeof the wearing type equipment on the rotating speed of the fan, through the current actual linear relation between the PWM signal obtained based on the first current actual rotating speed of the fanand the rotating speed, the expected PWM signal is determined, the fan control precision is improved, and the temperature adjusting effect is better.

Owner:WEIFANG GOERTEK ELECTRONICS CO LTD

Heat storage and temperature adjustment type reflective heat insulation coating and preparation process thereof

InactiveCN111647349AImprove reflectivityHigh emissivityWax coatingsAntifouling/underwater paintsParaffin waxALLYL SUCROSE

The invention relates to the technical field of coatings, particularly relates to a heat storage and temperature adjustment type reflective heat insulation coating, and further provides a preparationprocess of the coating. The coating specifically comprises an organic silicon emulsion, paraffin / zeolite-polyacrylic acid phase change microcapsules, a high-reflection type material, a heat radiationfiller, a heat insulation functional filler, a wetting dispersant, a mildew-proof antibacterial agent, a thickener, a defoamer, a coalescing agent and deionized water. The heat storage and temperatureadjustment type reflective heat insulation coating has high reflectivity and emissivity, is good in heat insulation effect, can effectively prevent heat conduction, is excellent in heat insulation performance and lasting in heat insulation performance, and automatically adjusts and stabilizes the indoor temperature by utilizing the reversible energy storage and release effects of the phase changemicrocapsules.

Owner:河南宣和钧釉环保材料有限公司

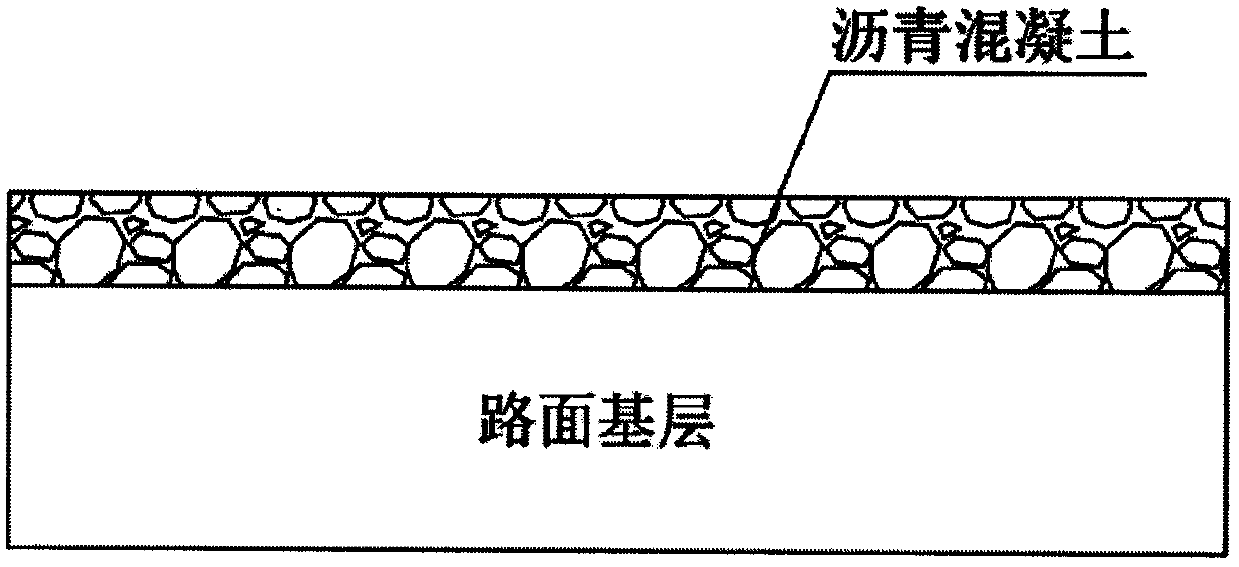

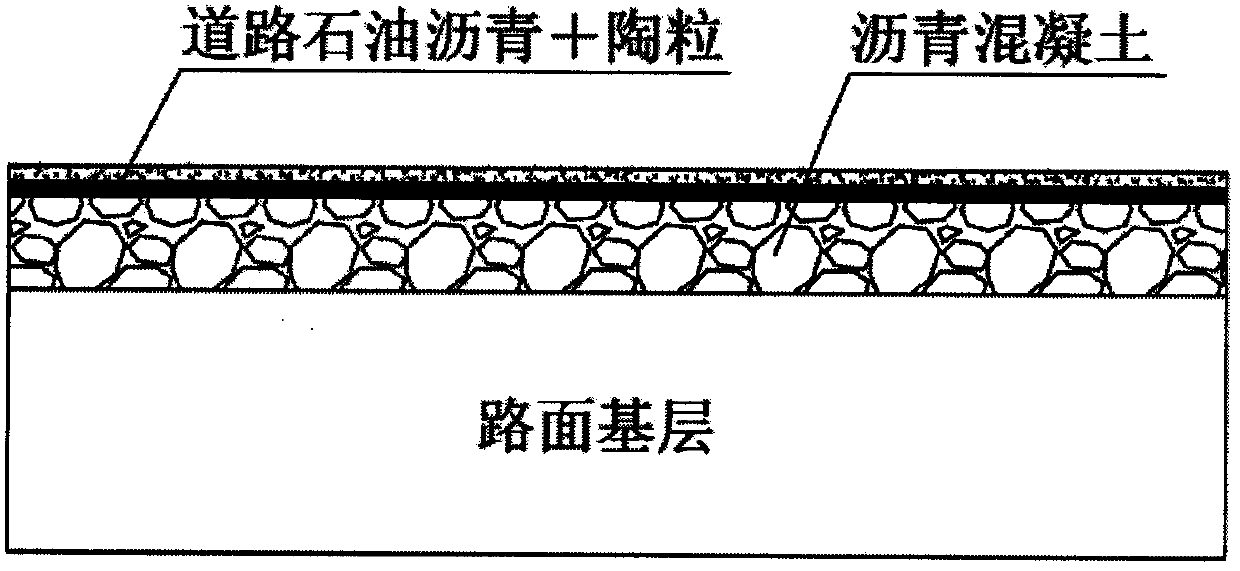

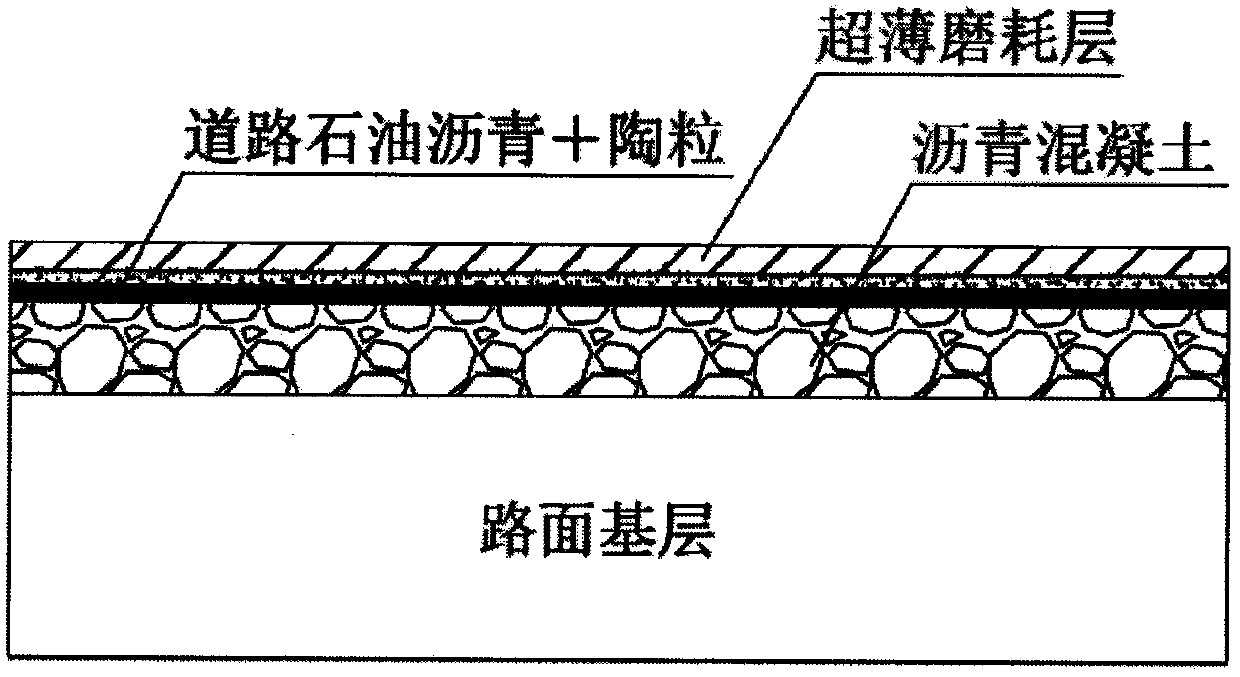

Heat insulation pavement structure and construction method

InactiveCN110344297ASlow down passGood thermoregulation effectIn situ pavingsInsulation layerStructural engineering

The invention discloses a heat insulation pavement structure and a construction method. The heat insulation asphalt pavement structure is a combined structure consisting of an ultrathin wearing layer,a heat insulation layer and asphalt concrete, and the thickness of the ultrathin wearing layer in the structure is not thicker than 2 cm, and the heat insulation layer is a sealing layer consisting of hot asphalt and ceramsite. The invention also discloses the construction method of the heat insulation pavement structure, which comprises following steps of firstly constructing asphalt concrete ona pavement base layer, then spreading road petroleum asphalt on the asphalt concrete, then spreading heat insulation particles on road petroleum asphalt to form the heat insulation layer, and finallyconstructing an ultrathin wearing layer on the heat insulation layer. Compared with the prior art, the invention has advantages of good heat insulation effect, excellent antiskid and durability performances and convenient construction.

Owner:NANJING FORESTRY UNIV

Adjustable humidifier with fragrance without essence mixing

InactiveCN114646110AFree from corrosionEasy to addMechanical apparatusLighting and heating apparatusProcess engineeringMechanical engineering

The invention discloses an adjustable humidifier with fragrance without essence mixing, and relates to the technical field of sound systems, the adjustable humidifier comprises a supporting base, a water inlet assembly and a humidifying seat, a fixed shell is arranged on the outer side of the top of the supporting base, and the water inlet assembly is arranged on the outer side of the left portion of the fixed shell; the outer side of the bottom of the water inlet assembly is connected with a water inlet pipe. A second suction pump works, the second suction pump can extract fragrance released by a flavoring agent stored in a fragrance box through an injection pipe and an injection port, the flavoring agent is a blocky fragrance block and can release the fragrance through gasification, the injection pipe can communicate with a humidification pipe through a butt joint port, and after the fragrance is extracted, the fragrance can be released through gasification. The fragrance can be mixed into mist in the humidifying pipe, so that the fragrance can be released in the humidifying process of the equipment, and the situation that the atomizer is corroded due to the fact that essence is directly added into water can be avoided since the fragrance is transmitted through an independent pipeline and mixed with the atomized clean water.

Owner:深圳市今日美创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com