Road phase-change temperature regulator and preparation method thereof

A phase change and temperature regulation technology, which is used in the preparation of microspheres, chemical instruments and methods, and microcapsule preparations. Production and other issues, to achieve significant technical feasibility and economic feasibility, eliminate adverse effects, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

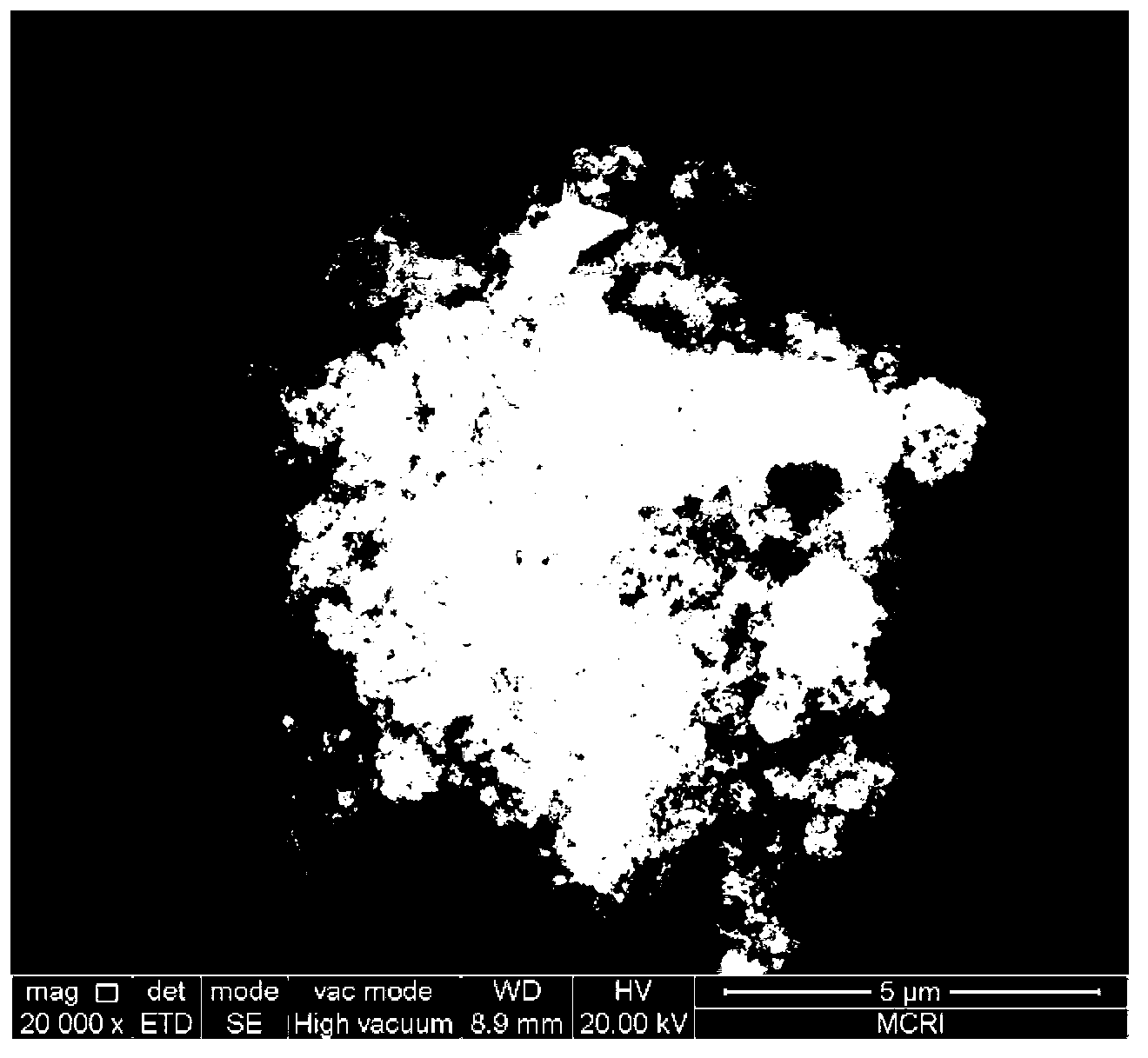

[0033] The highway phase-change temperature-regulating agent of this embodiment is made of the following raw materials in parts by weight: 25 parts of phase-change materials, 25 parts of white carbon black, 2 parts of ethyl cellulose, 0.3 parts of plasticizer, and 15 parts of organic solvents; The phase change material is paraffin or / and C 12 ~C 20 straight-chain alkanes, the paraffin wax has a melting point of 36°C to 50°C, and the plasticizer is an aliphatic dibasic acid ester or / and citrate; the preferred phase change material is n-tetradecane, and the preferred plasticizer The plasticizer is diisooctyl sebacate, the preferred organic solvent is dehydrated alcohol, and the preferred average particle size of white carbon black is 50nm.

[0034] The preparation method of the highway phase-change temperature-regulating agent of the present embodiment may further comprise the steps:

[0035] Step 1, stirring the plasticizer and the organic solvent uniformly by weight to obtai...

Embodiment 2

[0041]This embodiment is the same as Example 1, except that the preferred phase change material is n-tridecane, n-pentadecane or paraffin wax with a melting point of 36°C to 50°C, or n-tridecane, n-decadecane At least two of tetradecane, n-pentadecane, and paraffin waxes with a melting point of 36°C to 50°C; preferred plasticizers are dimethyl sebacate, di-n-octyl sebacate, triethyl citrate or Tri-n-butyl citrate, or at least two of di-isooctyl sebacate, dimethyl sebacate, di-n-octyl sebacate, triethyl citrate and tri-n-butyl citrate, The preferred organic solvent is absolute methanol, cyclohexane or acetone, or at least two of absolute ethanol, absolute methanol, cyclohexane and acetone.

[0042] The preparation method of the highway phase-change temperature-regulating agent of this embodiment is the same as that of Embodiment 1.

[0043] The phase-change temperature-regulating agent for roads in this embodiment has a micron-scale capsule structure.

Embodiment 3

[0045] The road phase change temperature regulating agent of this embodiment is made of the following raw materials in parts by weight: 10 parts of phase change material, 10 parts of white carbon black, 1 part of ethyl cellulose, 0.1 part of plasticizer, and 10 parts of organic solvent; The phase change material is paraffin or / and C 12 ~C 20 straight-chain alkanes, the paraffin wax has a melting point of 36°C to 50°C, and the plasticizer is an aliphatic dibasic acid ester or / and citrate; the preferred phase change material is n-tridecane, and the preferred plasticizer The plasticizer is dimethyl sebacate, the preferred organic solvent is anhydrous methanol, and the preferred average particle size of white carbon black is 100nm.

[0046] The preparation method of the highway phase-change temperature-regulating agent of the present embodiment may further comprise the steps:

[0047] Step 1, stirring the plasticizer and the organic solvent uniformly by weight to obtain a mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com