Patents

Literature

52 results about "DIMETHYL SEBACATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature-resistant, oil-resistant and flame-retardant soft polyvinyl chloride cable material and preparation method thereof

InactiveCN104927229AImprove oil resistance (ASTM No. 2 oil) performanceImprove low temperature resistancePlastic/resin/waxes insulatorsPolyesterDIMETHYL SEBACATE

The invention relates to a low-temperature-resistant, oil-resistant and flame-retardant soft polyvinyl chloride cable material which has a low-temperature resistance characteristic, is high in oil resistance and can meet the UL American standard and the European standard and a preparation method thereof. The low-temperature-resistant, oil-resistant and flame-retardant soft polyvinyl chloride cable material consists of the following components in parts by mass: 50 parts of PVC resin, 28 to 35 parts of a plasticizer, 3 to 6 parts of a stabilizing agent, 3 to 6 parts of a flame retardant, 15 to 25 parts of a filling agent, 0.3 to 0.8 parts of a lubricating agent and 0.5 to 1 part of a modifying agent. The low-temperature-resistant, oil-resistant and flame-retardant soft polyvinyl chloride cable material has the advantages that 1, by adoption of acrylate trimer serving as the modifying agent, the polyester type plasticizer and a dimethyl sebacate composite, the oil resistance (ASTM2 oil) and the low-temperature resistance of soft PVC are improved; 2, the soft PVC plastic meets the requirement on the environment friendliness of the ROHS standard and meets the index requirement of the UL American standard; 3, on the premise of low-temperature resistance, oil resistance and flame retardancy, the low-temperature-resistant, oil-resistant and flame-retardant soft polyvinyl chloride cable material has the advantage of low cost and meets the market demand.

Owner:HANGZHOU GAOXIN RUBBER & PLASTIC MATERIALS CO LTD

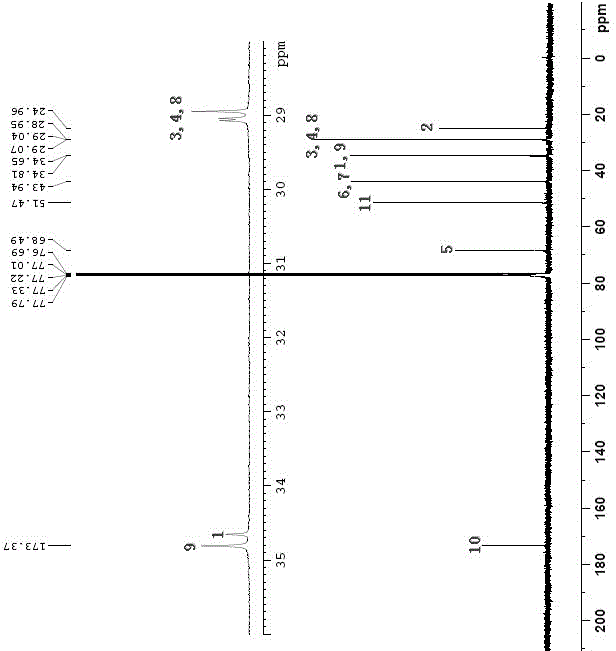

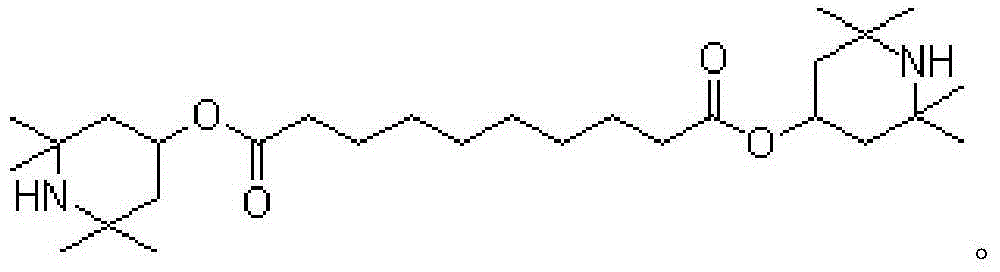

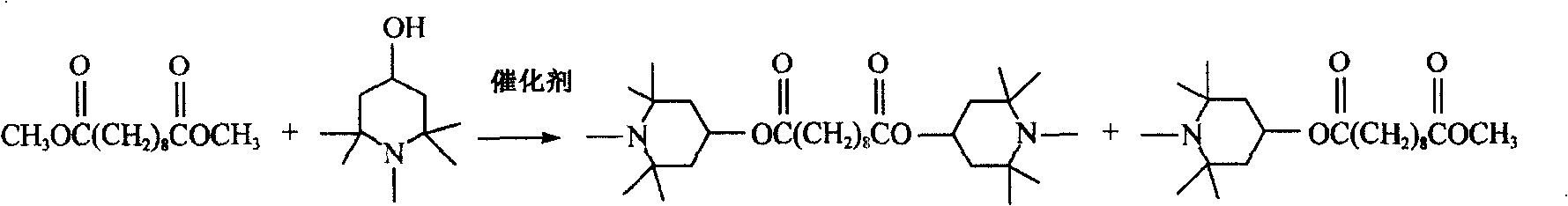

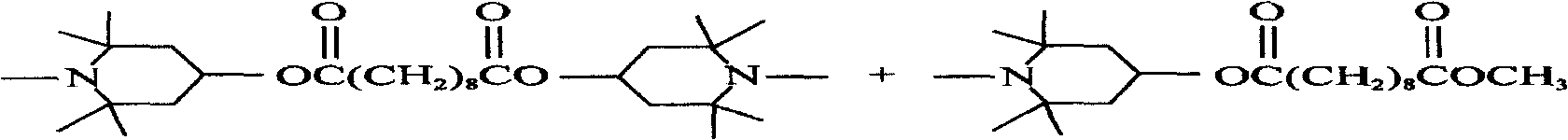

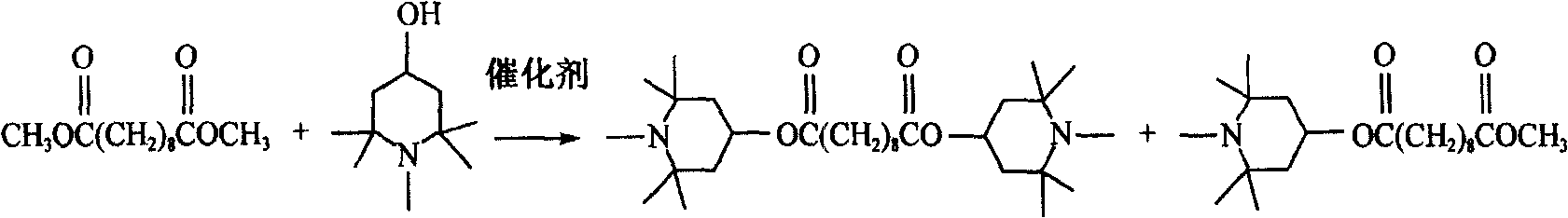

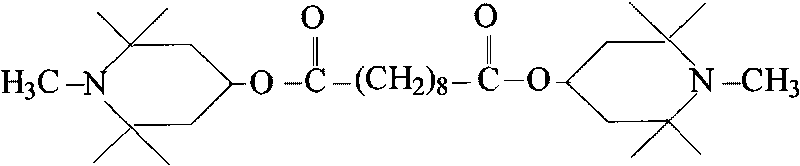

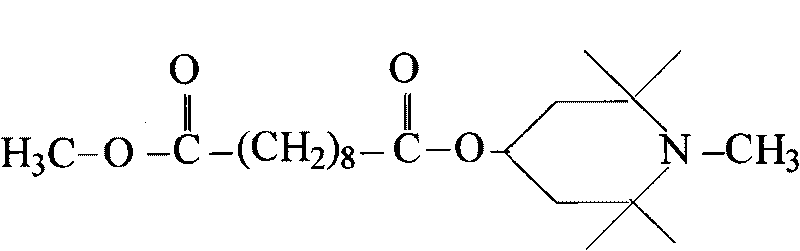

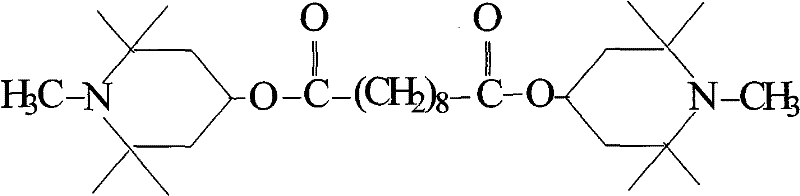

Synthesizing technology of hindered amine light stabilizer Tinuvin-770

InactiveCN102382039ALow costNo pollution in the processOrganic chemistryOrganic solventHindered amine light stabilizers

The invention discloses a synthesizing technology of a hindered amine light stabilizer Tinuvin-770, which comprises the steps of: step 1, adding 2,2,6,6-tetramethyl-4-piperidinol, sebacic acid, catalyst and solvent into a four-neck flask to mix; step 2, starting a stirrer, heating, backflow distributing through a water segregator until no water drop is generated, and keeping back flowing for 1h; step 3, after finishing the back flowing, cooling the four-neck flask to 30-40 DEG C, washing with water for two times, and then steaming the solvent through reducing the pressure; and step 4, adding water to stir, after cooling and recrystallizing, carrying out the filtering centrifuging washing technology, and obtaining white crystalline powder, i.e. the sebacic acid bis(2,2,6,6-tetramethyl-4-piperidinol). The technology utilizes the sebacic acid for esterification reaction to substitute dimethyl sebacate for interesterification reaction and uses water for recrystallization to substitute organic solvent, so the cost of raw materials is reduced, the Tinuvin-770 which is synthesized by the technology has high yield and purity, good color and quality, and the technology is convenient to operate and is easy to carry out.

Owner:SUQIAN UNITECHEM CO LTD

Preparation method for dimethyl sebacate

ActiveCN102351692AReduce dosageLow costOrganic compound preparationCarboxylic acid esters preparationPtru catalystSolid acid

The invention belongs to the field of chemical product preparation and particularly relates to a preparation method for dimethyl sebacate. A production method for the dimethyl sebacate comprises the following steps of esterification reaction and rectification process and has the concrete steps that: sebacic acid is mixed with methanol, then, solid catalysts are added, the esterification reaction is carried out, and then, products are purified through a rectification process. The method has the beneficial effect that the consumption mol ratio of the sebacic acid to the methanol is 1 / 0.9 to 1.2. Compared with the prior art, the method has the advantages that the consumption of the methanol is greatly saved, about 3 percent of the cost is saved, the solid acid is used as catalysts, the reaction efficiency is greatly improved, in addition, compared with the prior art adopting concentrated sulfuric acid as catalysts, the method has the advantage that the solid catalysts adopted by the method can be cyclically utilized, and compared with the method adopting liquid catalysts, the method has the advantage that about 5 percent of the cost is saved.

Owner:SHANDONG TIANXING BIOTECH

Sterilizing water-based antirust liquid and preparation method thereof

The invention discloses a sterilizing water-based antirust liquid comprising the raw materials in parts by weight: 10-20 parts of monoethanolamine, 4-6 parts of boric acid, 30-35 parts of dimethyl sebacate, 1-3 parts of sodium tungstate, 2-4 parts of sodium molybdate, 3-5 parts of ethylenediaminetetraacetic acid disodium salt, 0.2-0.4 part of a defoaming agent, 0.2-0.3 part of sodium dodecyl sulfate, 0.1-0.3 part of a bactericide, and 45-55 parts of water. The invention also discloses a preparation method of the sterilizing water-based antirust liquid. The sterilizing water-based antirust liquid has the advantages of good antirust performance, sterilization, corrosion prevention, and no pollution to the environment.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

Cat face pheromone and application thereof

PendingCN112516128AAlleviate or relieve stressful behaviorLow costNervous disorderEster active ingredientsMethyl linoleateDIMETHYL SEBACATE

The invention discloses cat face pheromone and application thereof. The cat face pheromone comprises a cat face pheromone analogue and a solvent, and the cat face pheromone analogue comprises methyl laurate, methyl myristate, methyl palmitate, methyl oleate, methyl linoleate and dimethyl sebacate. The cat face pheromone can be used for preparing a preparation for reducing and relieving anxiety andconflicts after a cat is blended into a new environment, is suitable for a scene that the surrounding environment of the cat is changed, and can ease or relieve stress behaviors of the cat in the newenvironment, such as abnormal emotion and even pathological diseases; and meanwhile, since dimethyl heptanedioate and dimethyl azelate which are relatively high in price are not adopted for the cat face pheromone analogue and the cat face pheromone, the cost of the used raw materials is relatively low, the product is suitable for mass production, the purity of the raw materials is improved, the product quality is improved, and the effect is exerted.

Owner:上海弗艾柏生物科技有限公司

Method for preparing 1,10-decanediol through supercritical dimethyl sebacate hydrogenation

The present invention discloses a method for preparing 1,10-decanediol through supercritical dimethyl sebacate hydrogenation. The method comprises that: (1) methanol is adopted as a supercritical fluid, the methanol and dimethyl sebacate are uniformly mixed, the obtained mixture is conveyed into a pre-mixer through a high-pressure injection pump, the pressure of hydrogen is increased through a hydrogen pressurization system to achieve a certain pressure, the pressurized hydrogen is conveyed to the pre-mixer and then is continuously conveyed into a fixed bed reactor loaded with a supported catalyst, and a hydrogenation reaction is performed at a reaction temature of 240-280 DEG C under a reaction pressure of 7-12 MPa according to a hydrogen to ester ratio of 30:1-150:1, wherein the reaction system is in the supercritical state of the methanol, and the used catalyst is a Cu / ZnO / Al2O3 catalyst; and (2) vapor-liquid separation is performed, the liquid phase product is collected, and the decanediol is rectified from the liquid phase product. According to the method of the present invention, the methanol is adopted as the supercritical fluid and does not have corrosion, the mass transfer resistance during the dimethyl sebacate reaction process can be eliminated, the hydrogen to ester ratio is low, and the conversion rate of the dimethyl sebacate and the selectivity of the 1,10-decanediol are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of hindered amine light stabilizer 770

InactiveCN103980185ASolve process problems such as low esterification rate and poor light transmittance of the final productLow equipment requirementsOrganic chemistryReaction temperatureDIMETHYL SEBACATE

The invention provides a preparation method of a hindered amine light stabilizer 770. According to the method, sebacic acid and tetramethylpiperidinol as reactants and an oxide and / or organic compound of the fourth main group element tin as a catalyst are subjected to a heating refluxing reaction in a solvent to obtain the hindered amine light stabilizer 770. The invention uses sebacic acid as raw material instead of dimethyl sebacate, and the sebacic acid under the effect of an appropriate catalyst performs a direct esterification dehydration reaction with tetramethylpiperidinol; and appropriate technology conditions such as an appropriate proportion of raw materials, reaction temperature adjustment and suitable solvent are employed to solve the technical problems of low esterification rate and poor light transmittance of a final product in a common direct esterification reaction, and to prepare the light stabilizer 770 product in line with the requirements of market quality standards. Compared with the ester exchange method in the prior art, the method has the advanategs of cheap raw materials, higher yield, low requirements for equipment, simple process and easiness for scale production.

Owner:新纶电子材料(常州)有限公司 +1

Manufacturing method of light-stability agent

The invention discloses a preparation method of a light stabilizer. Pent-amethyl and dimethyl sebacate conduct heating reaction under the function of a catalyst; the reaction product is cooled and added with measured petroleum ether; the mixture is washed by tap water into neutral for refining treatment, vacuum distillation is then conducted and qualified distillate is collected, thus obtaining the light stabilizer. The method adopts solvent-free transesterification reaction, conducts the reactions under the protection of inert gas while limitedly improving transesterification reaction temperature, ensuring fast reaction with less side reaction products; the post treatment purification adopts a combined rectification device, improving distillate producing rate and quality; the method eliminates chromogenic factors that can be produced, and can produce low-colority high-quality liquid light stabilizer GW508 products.

Owner:RUGAO DINGSHENG FINE CHEM IND

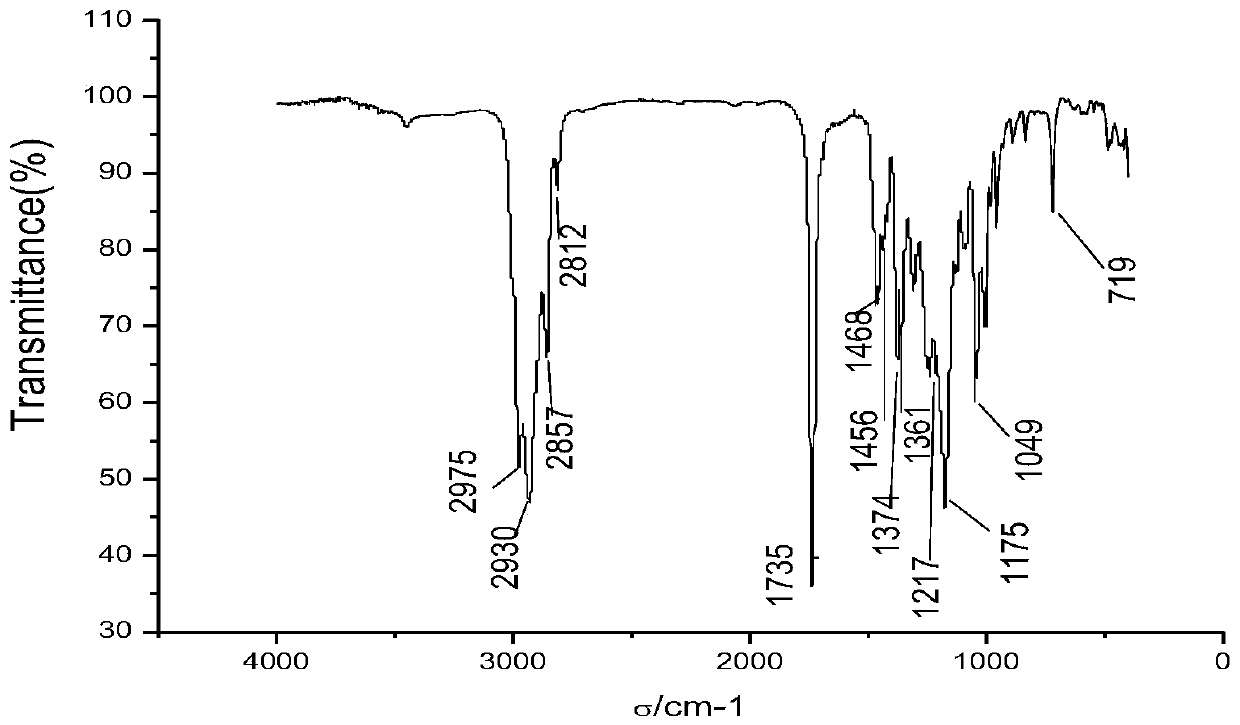

Light stabilizer and production method thereof

InactiveCN101712772AReduce pollutionEasy to separate and purifyOrganic chemistryDibutyltin oxideDIMETHYL SEBACATE

The invention discloses a light stabilizer-292 and a production method thereof. The light stabilizer-292 is prepared by taking dimethylbenzene, dimethyl sebacate and 1,2,2,6,6-pentamethyl-4-hydroxypiperidine as raw materialls and reacting in the presence of a catalyst. According to the method, the dimethylbenzene, the dimethyl sebacate and the 1,2,2,6,6-pentamethyl-4-hydroxypiperidine are used as the raw materials to synthesize the light stabilizer-292, and the dibutyltin oxide catalyst is adopted, so the method has the advantages of simplifying separation and purification processes, having short reaction time and high product yield, ensuring that the yield of products reaches over 96 percent, reducing energy consumption, and having less environmental pollution and low cost, which is an ideal process for realizing industrialized production.

Owner:南通惠康国际贸易有限公司

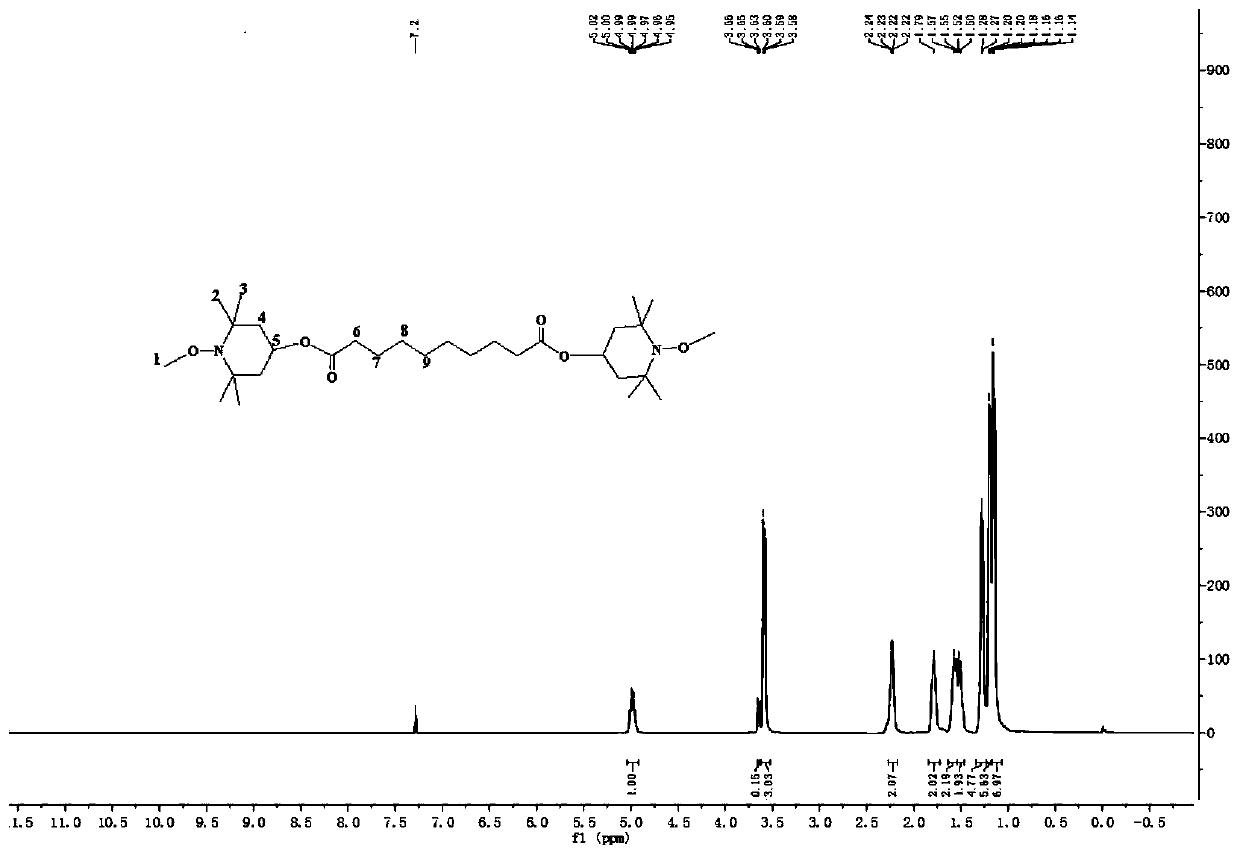

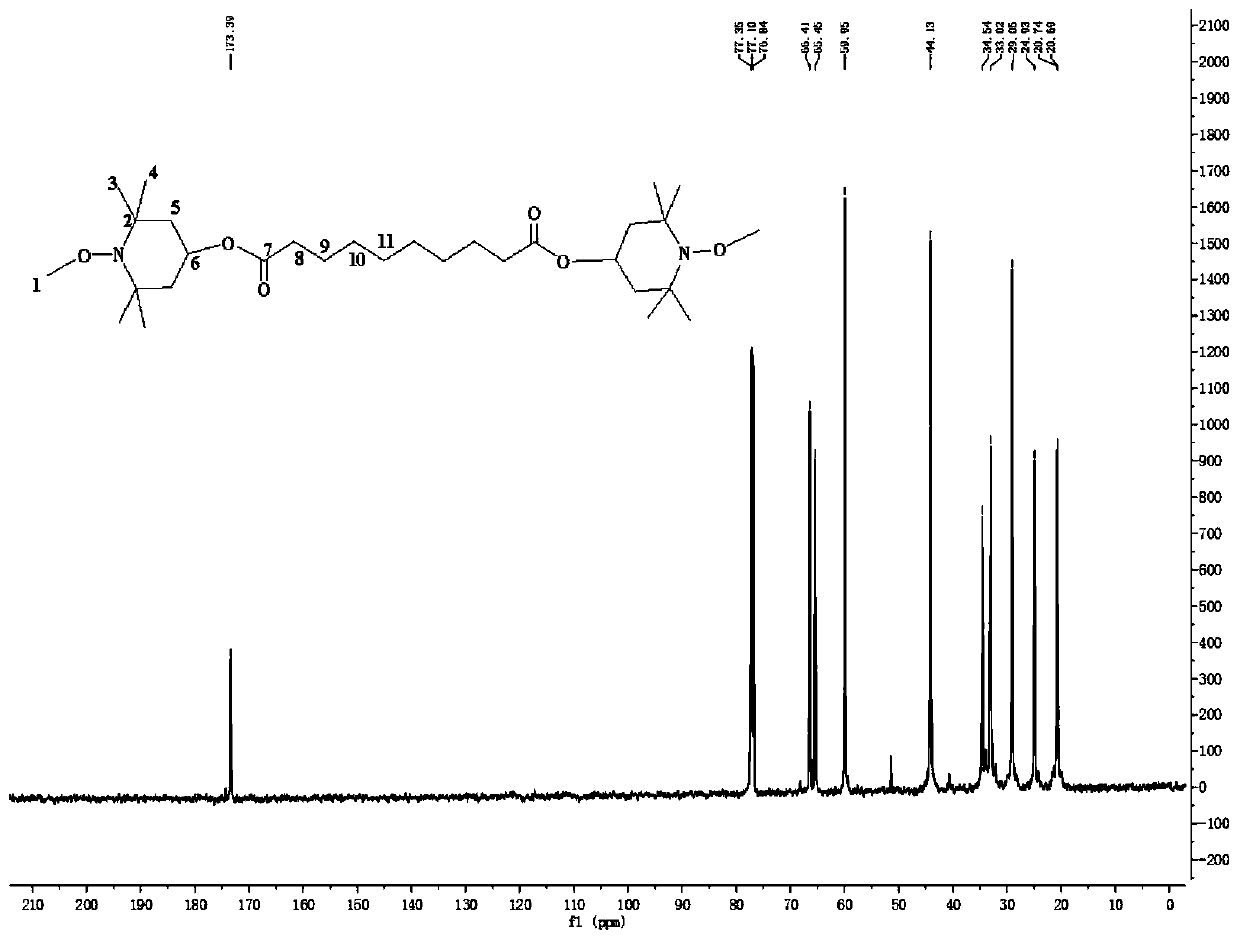

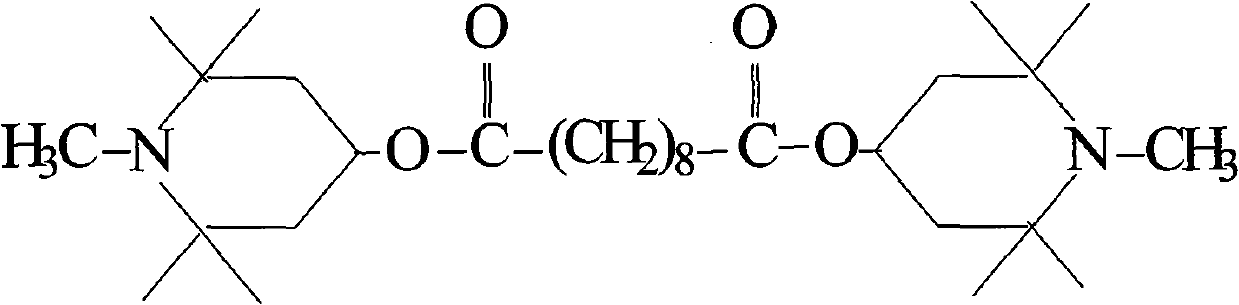

Method for preparing bis(1-alkoxy-2,2,6,6-tetramethyl piperidine-4-yl) sebate

The invention discloses a method for synthesizing bis(1-alkoxy-2,2,6,6-tetramethyl piperidine-4-yl) sebate. The bis(1-alkoxy-2,2,6,6-tetramethyl piperidine-4-yl) sebate is synthesized through transesterification by using dimethyl sebate and 1-alkoxy-2,2,6,6-tetramethylpipradrol as raw materials. According to the method, lithium hydroxide is adopted as a catalyst, a quaternary ammonium salt is adopted as a phase transfer catalyst, n-heptane is adopted as a methanol-carrying solvent, and methanol is separated continuously from the reaction system through a water knockout vessel. The process comprises the steps: adding dimethyl sebate, 1-alkoxy-2,2,6,6-tetramethylpipradrol, lithium hydroxide, the phase transfer catalyst and n-heptane to a reaction kettle with the water knockout vessel, performing heating to a reflux state so as to separate methanol continuously, stopping the reaction (about 5 hours later) until no separation of methanol, performing cooling to room temperature, performingwashing with deionized water, performing reduced pressure distillation on the oil phase so as to isolate the solvent and unreacted 1-alkoxy-2,2,6,6-tetramethylpipradrol and obtain a crude product, washing the crude product three times with a mixed solvent of methanol and water, and then performing distillation so as to isolate the solvent and obtain the final product. The method has the advantagesthat the process and the devices are simple, the catalyst has safe use, the product has easy separation, the product has high yield and high purity, and emission of three wastes is little.

Owner:山东兄弟科技股份有限公司 +1

Preparation method of carboxylated acrylonitrile butadiene rubber latex with high solid content

The invention discloses a preparation method of carboxylated acrylonitrile butadiene rubber latex with high solid content. The preparation method of the carboxylated acrylonitrile butadiene rubber latex with high solid content comprises that the carboxylated acrylonitrile butadiene rubber latex is prepared from the following raw materials: 20%-30% of carboxylated butadiene-acrylonitrile rubber, 15%-25% of phenolic rubber, 10%-20% of ethanedioic acid diethyl ester, 5%-15% of dimethyl sebacate, 5%-10% of an organosilicone waterproof agent, 15%-25% of modified starch and 5%-15% of deionized water. According to the preparation method of the carboxylated acrylonitrile butadiene rubber latex with high solid content, production and processing are carried out by adopting a reasonable material ratio; the technological process is simple and easy to control, and efficient production is facilitated; meanwhile, the solid content is improved by adding the modified starch, the quality and performanceof the latex are effectively improved, improvement of the alkali-resistant and antioxidant effects is facilitated, and application and popularization are facilitated.

Owner:DONGYING JIUZHOU AOHUA CHEM

Method for producing light stabilizer sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester

InactiveCN101768104AReduce pollutionEasy to separate and purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTetraisopropyl titanateSolvent

The invention discloses a method for producing a light stabilizer sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester. In the method, dimethyl sebacate, 1, 2, 2, 6, 6-pentamethyl-4-hydroxypiperidines serves as the raw material and reaction is carried out in the presence of solvent and catalyst at certain temperature to obtain sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester. In the invention, the dimethyl sebacate, 1, 2, 2, 6, 6-pentamethyl-4-hydroxypiperidines serve as raw materials for synthesizing sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester, active carbon loaded tetraisopropyl titanate catalyst is employed; as a result, separation and purification process is simplified, the reaction time is short, product yield is more than 97%, the catalyst can be repeatedly used; in addition, the method of the invention features high purity of obtained product, reduced energy consumption, little environmental pollution, low cost, thus being an ideal technology for industrialized production.

Owner:南通惠康国际贸易有限公司

Wear resistant and overpressure resistant terrace material

The invention relates to a wear resistant and overpressure resistant terrace material, and the terrace material is composed of the following components by weight: 32-36 parts of tetraphenolethane epoxy resin, 11-19 parts of clay, 6-9 parts of iron oxide, 10-12 parts of dimethyl sebacate, 2-4 parts of benzyl butyrate, 3-4 parts of butanone and 2-3 parts of magnesium bicarbonate. The prepared terrace material is used in the clean workshop and has good wear resistant and overpressure resistant performance.

Owner:江苏悠谷未来科技有限公司

Medicinal adhesive and preparation method thereof

ActiveCN104368030ALess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideAdhesive

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

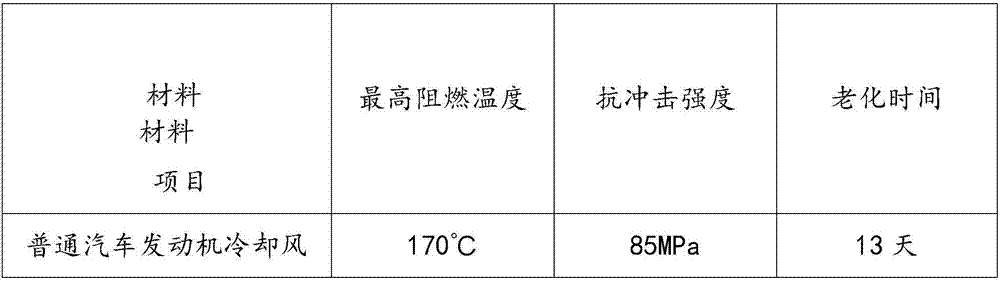

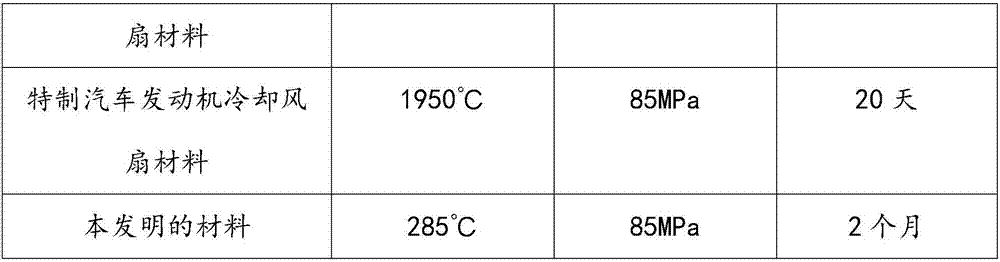

Cooling fan material of automobile engine and preparation method thereof

InactiveCN107057249AImprove structural strengthImprove flame retardant performanceMachines/enginesEngine cooling apparatusPolyvinyl alcoholFatty amine

The invention discloses a cooling fan material of an automobile engine. The material is prepared from the following materials in parts by weight: 17-25 parts of o-methyl phenyl diol, 16-20 parts of polyacrylamide, 8-14 parts of silicon dioxide, 9-16 parts of polybenzoate, 18-19 parts of polyaryletherketone, 20-24 parts of polybutylene terephthalate, 8-11 parts of polyphenyl ether, 7-18 parts of alkyl sodium sulfonate, 3-6 parts of ethyoxyl lauryluteramine, 5-11 parts of fatty amine polyoxyethylene ether, 6-7 parts of organic quaternary ammonium salt, 22-26 parts of glass fibers, 13-16 parts of dimethyl sebacate, 5-9 parts of benzotriazole, 10-15 parts of nano titanium dioxide, 22-26 parts of polyvinyl butyral and 6-7 parts of ammonium dihydrogen phosphate. The cooling fan material of the automobile engine, disclosed by the invention, is high in structural strength, good in flame retardant effect, resistant to ageing and long in service life.

Owner:芜湖天鸿汽车零部件有限公司

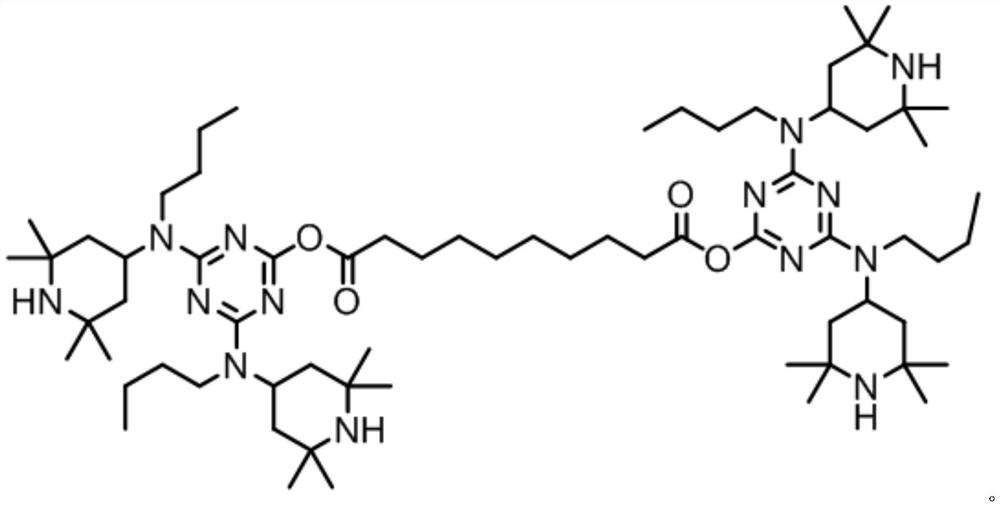

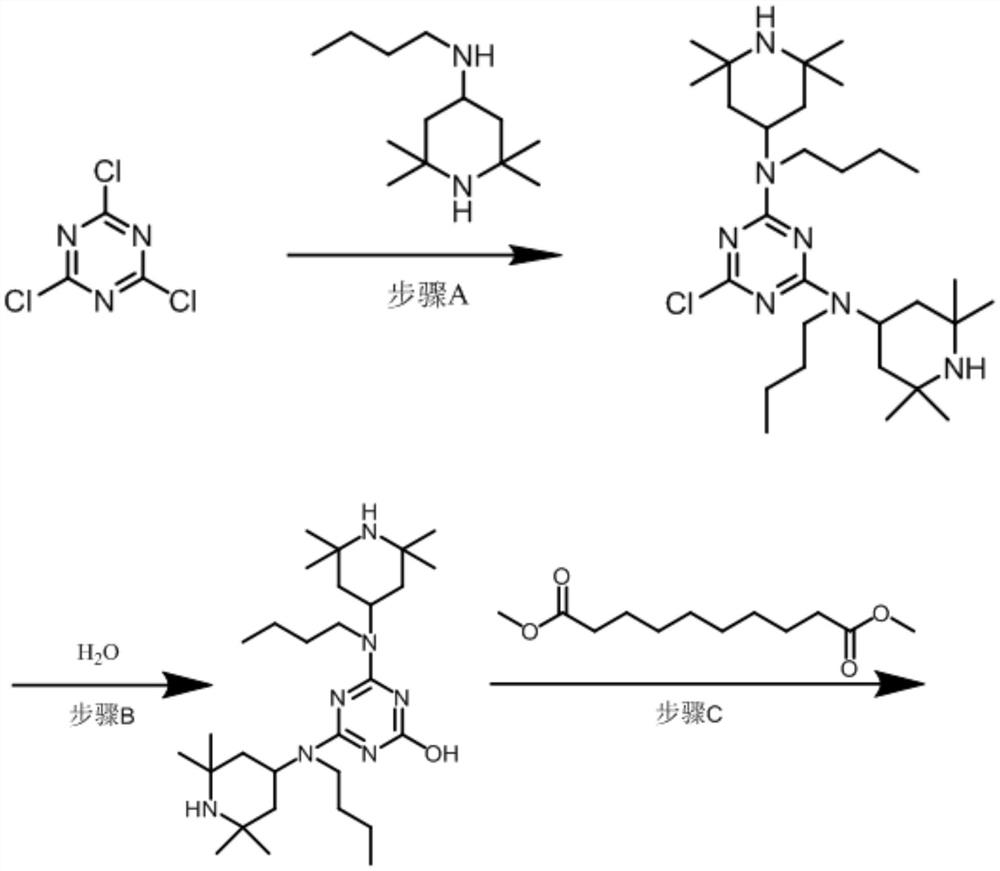

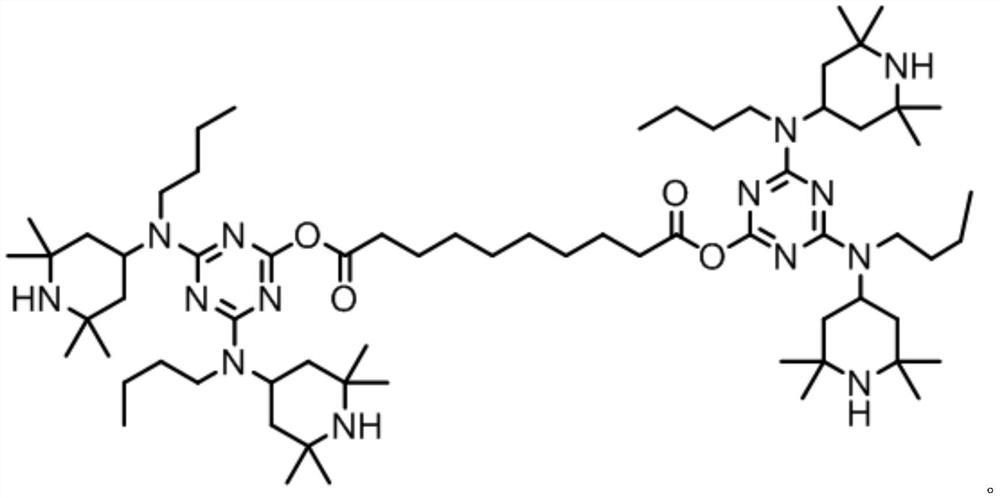

Hindered amine light stabilizer and preparation process thereof

The invention relates to a hindered amine light stabilizer and a preparation method thereof; the hindered amine light stabilizer is synthesized by taking cyanuric chloride, N-butyl 2, 2, 6, 6-tetramethyl- 4-piperidylamine, dimethyl sebacate and alkali as raw materials, and selecting xylene as a reaction solvent; the product is used as a light stabilizer, is suitable for polypropylene, polyethylene, polyurethane and the like, and has excellent light stability; The heat resistance of the product can be improved, and a synergistic effect can be generated with an ultraviolet light absorber and anoxidant to further improve the light stabilization effect of the product.

Owner:宿迁联盛科技股份有限公司

High-strength alloy material wear-resistant treatment material

InactiveCN110591646AReasonable formulaImprove wear resistanceOther chemical processesWear resistantCorundum

The invention discloses a high-strength alloy material wear-resistant treatment material. The wear-resistant treatment material is composed of the following components by weight: 2-5 parts of potassium titanate whisker, 3-7 parts of iron oxide, 6-14 parts of dimethyl sebacate, 7-11 parts of quartz sand, 6-15 parts of ferric hydroxide, 2-8 parts of benzyl butyrate, 7-11 parts of corundum, 2-5 partsof chromium oxide, 3-6 parts of limestone, 5-9 parts of silicon dioxide, 7-13 parts of butanone, 2-4 parts of magnesium oxide, 6-12 parts of graphite, 4-6 parts of magnesium bicarbonate, 2-7 parts ofaramid staple fiber, 9-14 parts of stannous octoate, 3-11 parts of hematite, 2-5 parts of barium stearate, 3-7 parts of vermiculite powder, 3-7 parts of metronidazole, 5-14 parts of ammonium dihydrogen phosphate, 3-14 parts of titanium diboride fiber and 2-10 parts of silicon nitride. The material provided by the invention has a reasonable formula, the wear resistance of the finished product material is greatly improved, the physical performance and chemical performance of the alloy material are greatly improved through reasonable proportioning of the alloy material and ingenious adding of various components, and the service life of the alloy material is fully guaranteed, therefore the high-strength alloy material wear-resistant treatment material is worthy of popularization and use.

Owner:马鞍山海华耐磨材料科技有限公司

A kind of medical adhesive and preparation method thereof

ActiveCN104368030BLess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideDIETHYL SEBACATE

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

Method for producing light stabilizer sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester

InactiveCN101768104BReduce pollutionEasy to separate and purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsTetraisopropyl titanateDIMETHYL SEBACATE

The invention discloses a method for producing a light stabilizer sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester. In the method, dimethyl sebacate, 1, 2, 2, 6, 6-pentamethyl-4-hydroxypiperidines serves as the raw material and reaction is carried out in the presence of solvent and catalyst at certain temperature to obtain sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester. In the invention, the dimethyl sebacate, 1, 2, 2, 6, 6-pentamethyl-4-hydroxypiperidines serve as raw materials for synthesizing sebacic acid (1, 2, 2, 6, 6-pentamethyl-4-piperidyl) diester, active carbon loaded tetraisopropyl titanate catalyst is employed; as a result, separation and purification process is simplified, the reaction time is short, product yield is more than 97%, the catalyst can berepeatedly used; in addition, the method of the invention features high purity of obtained product, reduced energy consumption, little environmental pollution, low cost, thus being an ideal technology for industrialized production.

Owner:南通惠康国际贸易有限公司

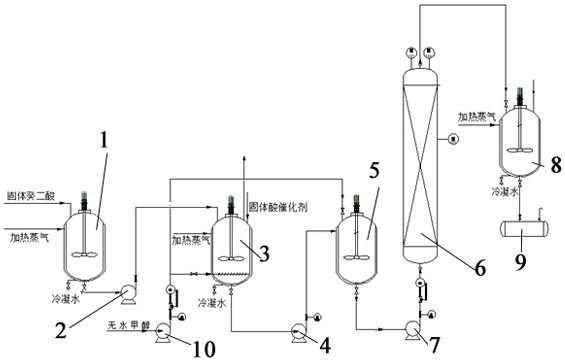

Dimethyl decanedioate separation continuous rectification method

ActiveCN103319340BContinuous distillation achievedRealize automatic controlOrganic compound preparationCarboxylic acid esters preparationReboilerProcess engineering

The invention belongs to the technical field of dimethyl decanedioate rectification, and particularly provides a dimethyl decanedioate separation continuous rectification method. According to the technical scheme, the dimethyl decanedioate separation continuous rectification method is characterized in that a dimethyl decanedioate crude product is pumped into a light-component removal tower, the temperature inside the light-component removal tower rises, and light components are distilled out through backflow; crude esters in the light-component removal tower enter a heavy-component removal tower to backwards flow, so that a product is collected, heavy components are discharged from the bottom of a reboiler, and the product collected through backflow is cooled to obtain the dimethyl decanedioate finished product. The technical scheme has the advantages of solving the problems of being high labor intensity and low production efficiency in a conventional batch production technology, and improving the product quality.

Owner:SHANDONG TIANXING BIOTECH

Stable rubber adhesive

InactiveCN104449463AChemically stableImprove adhesionNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer scienceAdhesive

The invention discloses a stable rubber adhesive, which is prepared from the following raw materials in parts by weight: 9-16 parts of dimethyl sebacate, 3-10 parts of phenolic resin, 10-15 parts of chloroprene rubber, 3-8 parts of rosin, 2-6 parts of an anti-ageing agent, 3-9 parts of zinc oxide, 8-11 parts of stearic acid, 4-10 parts of an ethylene propylene terpolymer, 2-8 parts of light calcium carbonate, 3-9 parts of white carbon black, 5-10 parts of methyl methacrylate, 1-5 parts of aluminum hydroxide and 2-6 parts of ethyl alcohol. The stable rubber adhesive disclosed by the invention has the beneficial effects of stable chemical property, and good caking property, and can play a good bonding role.

Owner:张桂华

Photo-curing adhesive and preparation method thereof

The invention discloses a photo-curing adhesive and a preparation method thereof. The adhesive comprises components in parts by mass as follows: 27-35 parts of epoxy resin, 4-12 parts of talcum powder, 14-29 parts of methacrylate phosphate, 2-11 parts of N-vinylpyrrolidone, 6-16 parts of tetrasodium pyrophosphate, 13-20 parts of dimethyl sebacate, 10-18 parts of polyethylene glycol, 2-13 parts of benzoin dimethyl ether and 3-12 parts of hydroxybenzophenone. The prepared adhesive can effectively shorten the photo-curing time while the adhesion strength is guaranteed, and the adhesive has important popularization and clinical application value.

Owner:SUZHOU JONATHAN NEW MATERIALS TECH

Dimethyl sebacate electrochemical synthesis method

ActiveCN113416969AReduce generationHigh selectivityElectrolysis componentsElectrolytic organic productionChemical synthesisOrganosolv

The invention discloses a dimethyl sebacate electrochemical synthesis method, which comprises: 1) mixing adipic acid and an ester compound thereof, an organic solvent and an electrolyte, placing in an electrolytic tank, introducing a carbon dioxide gas into the electrolytic tank to make the system pressure reach 0.5-4 Mpa (gauge pressure), heating the electrolytic tank to a temperature of 60-80 DEG C, and starting an electrolytic reaction; and 2) adding a mixture of haloid acid and peroxide into the electrolytic reaction system in the step 1), and obtaining the dimethyl sebacate after the electrolytic reaction is finished. According to the method, the generation of a byproduct methyl pentenoate can be remarkably reduced, and the selectivity of dimethyl sebacate is improved.

Owner:WANHUA CHEM GRP CO LTD

Glass adhesive and preparation method thereof

InactiveCN109181557AGood acid and alkali resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveDIETHYL SEBACATE

The invention discloses a glass adhesive and a preparation method thereof. The glass adhesive is prepared from ethyl cyanoacrylate, polyvinyl acetate, hydroxypropyl methylcellulose, stearic acid, pentamethyldiethylenetriamine, dimethyl sebacate, tricalcium phosphate, silica, glass frit, dioctyl phthalate and azodicarbonamide. The preparation method comprises the following steps: stirring and mixing the polyvinyl acetate, hydroxypropyl methylcellulose, dimethyl sebacate, tricalcium phosphate and glass frit to obtain a first mixture, adding the first mixture into a reactor, adding stearic acid and azodicarbonamide under a vacuum condition, and performing heating and stirring to obtain a first material; adding the ethyl cyanoacrylate, pentamethyldiethylenetriamine, silica and dioctyl phthalate to the first material, and performing heating and stirring under the protection of an inert gas to obtain the glass adhesive. The glass adhesive provided by the invention has the advantages of goodadhesion and good resistance to acids and alkalis.

Owner:江苏耀兴安全玻璃有限公司

UV292 preparing method

A UV 292 preparing method comprises the steps of S1, adding 2,2,6,6,-tetramethyl piperidine and dimethyl sebacate into a reactor to be molten and mixed; S2, adding tetrabutyl titanate into the reactor; S3, introducing nitrogen into the reactor and carrying out thermal-insulation reaction; S4, cooling a temperature of reactant to 80 DEG C to 85 DEG C after reaction is finished, adding water and sodium carbonate into the reactor and continuously carrying out thermal-insulation reaction for 1-2h; S5, adding methanol or methyl chloride into the reactor and carrying out thermal-insulation reaction for 30-45min; S6, separating liquid, filtering, washing and dewatering to obtain UV292 with the purity as 98% or above before cooling after the reaction is completely finished. The UV292 preparing method avoids a step of dissolving the reactant into solvent, so that collision between molecules of the reactant is facilitated, and the reacting efficiency is improved. Furthermore, the cost of the solvent is also saved, the reaction is always in alkalescence is guaranteed, reaction between the tetrabutyl titanate catalyst and water is facilitated, and purification of final products is facilitated.

Owner:杭州欣阳精细化工有限公司

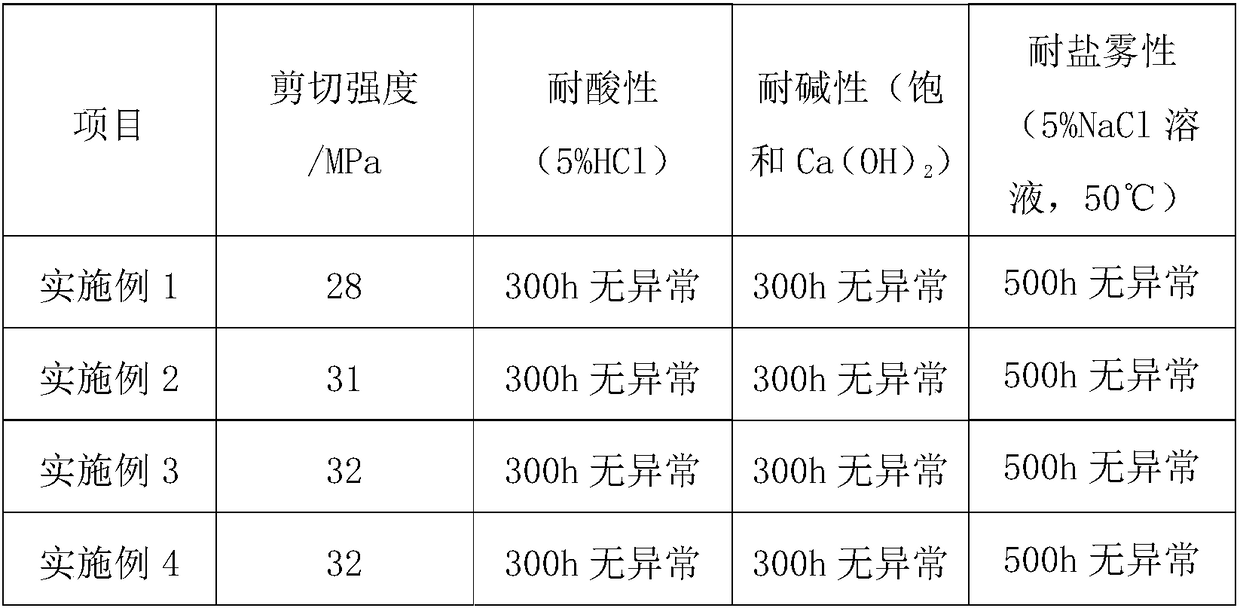

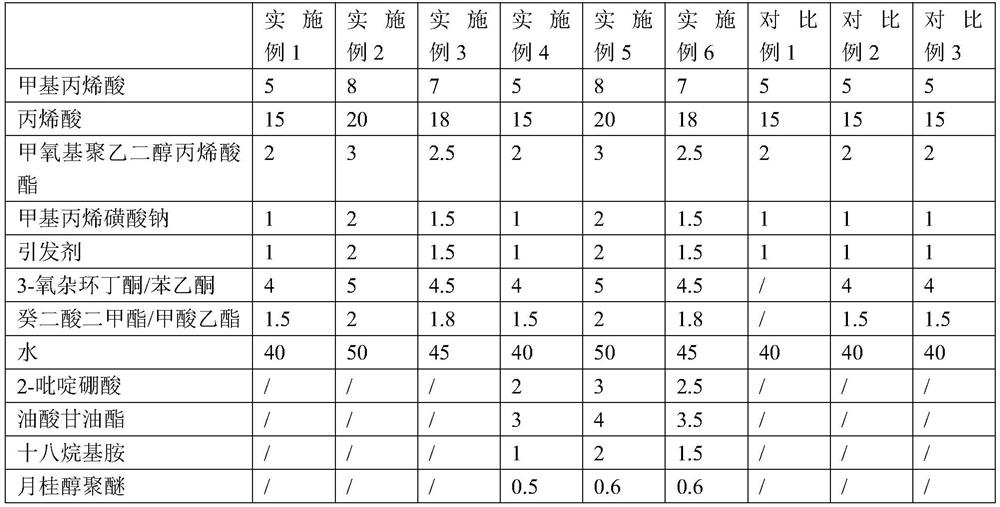

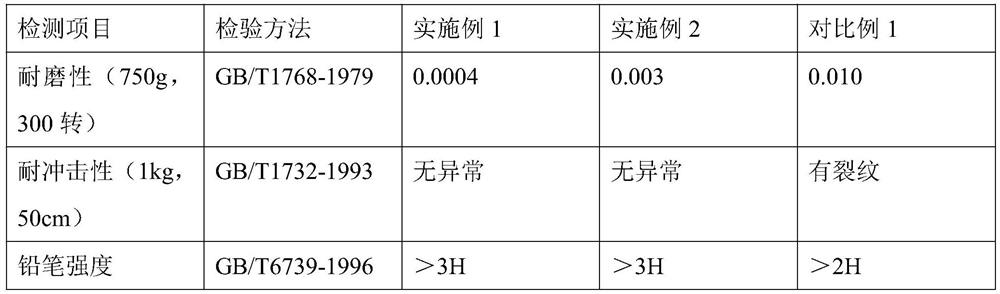

Viscosity reduction type polycarboxylic acid water reducing agent and preparation method thereof

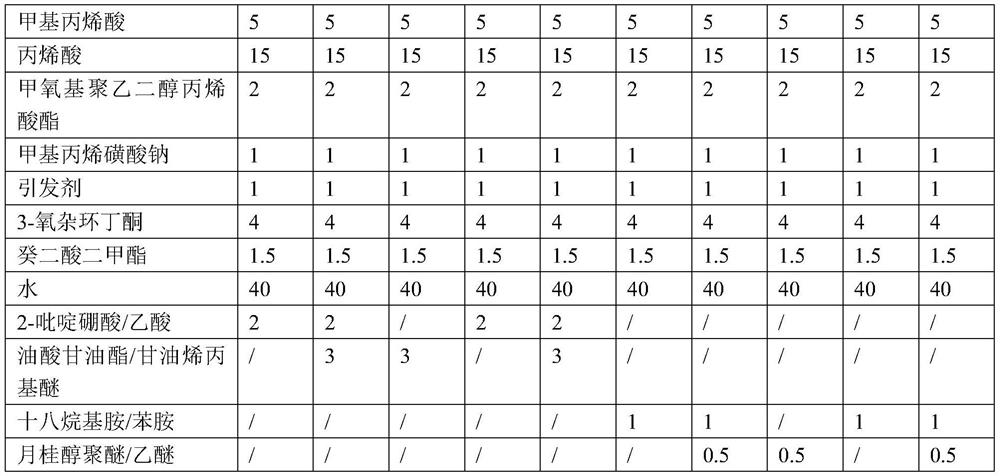

The invention relates to the field of water reducing agents, and discloses a viscosity reduction type polycarboxylic acid water reducing agent and a preparation method thereof. The viscosity reduction type polycarboxylic acid water reducing agent comprises the following raw materials in parts by weight: 5-8 parts of methacrylic acid; 15-20 parts of acrylic acid; 2-3 parts of methoxy polyethylene glycol acrylate; 1-2 parts of sodium methallyl sulfonate; 1-2 parts of an initiator; 4-5 parts of 3-oxetanone; 1.5-2 parts of dimethyl sebacate; and 40-50 parts of water. The preparation method comprises the following steps: mixing 3-oxetanone and dimethyl sebacate, and adding the mixture into a polycarboxylic acid product mixed with water to obtain the water reducing agent. The polycarboxylic acid water reducing agent has the following advantages and effects: a mixed product of 3-oxetanone and dimethyl sebacate is further added into a conventional polycarboxylic acid water reducing agent component, so that the mixed product is diffused among cement particles. Through combination of heterocyclic atoms with oily molecules and the special steric configuration of 3-oxetanone, the generation of a complex among cement particles is reduced. The aggregation among cement particles is reduced, the purpose of reducing the viscosity is achieved, and the viscosity of the concrete is reduced.

Owner:唐山冀东水泥外加剂有限责任公司 +1

Method for preparing hindered amine light stabilizer by adopting solvent method

PendingCN112661695AQuality controllableSimple processOrganic chemistryTrans esterificationPtru catalyst

The invention provides a method for preparing a hindered amine light stabilizer by adopting a solvent method. The method for preparing the hindered amine light stabilizer by adopting the solvent method comprises the following steps: under the action of a catalyst, carrying out transesterification on a 2, 2, 6, 6-tetramethylpiperidyl parent and dimethyl sebacate in an organic solvent to obtain a transesterification product; and sequentially washing, filtering and desolventizing the ester exchange product to obtain the hindered amine light stabilizer and wastewater. By adopting the preparation method to prepare the hindered amine light stabilizer, not only is the process cost reduced, but also the purity, the recovery rate and the light transmittance of the hindered amine light stabilizer are improved.

Owner:HENGSHUI KAIYA CHEM +1

Production method of dimethyl sebacate

ActiveCN113443983AAvoid problems such as acid refluxAvoid corrosionOrganic compound preparationCarboxylic acid esters separation/purificationPtru catalystSolid acid

The invention discloses a production method of dimethyl sebacate. The production method adopts a solid acid catalyst to catalyze esterification of sebacic acid and methanol to produce dimethyl sebacate. The method comprises the following specific operation processes: melting of sebacic acid, reaction in a primary esterification kettle, and fixed-bed final reaction. The process of the reaction in the primary esterification kettle adopts a methanol fed-batch coupled vaporization dehydration method, the reaction is carried out at a temperature slightly higher than the melting point of sebacic acid, and 95% or more of sebacic acid is converted into methyl sebacate; and the fixed-bed final reaction is carried out at a temperature lower than the boiling point of methanol, a small amount of residual carboxylic acid in a primary reaction product is subjected to a refined reaction, so an esterification rate is increased, the acid value of a product is reduced, and the purity of the product is improved. The method has the advantages of short reaction time, high esterification rate, high product purity, easy separation of the catalyst, long service life, less methanol consumption and low energy consumption.

Owner:ZHEJIANG UNIV OF TECH

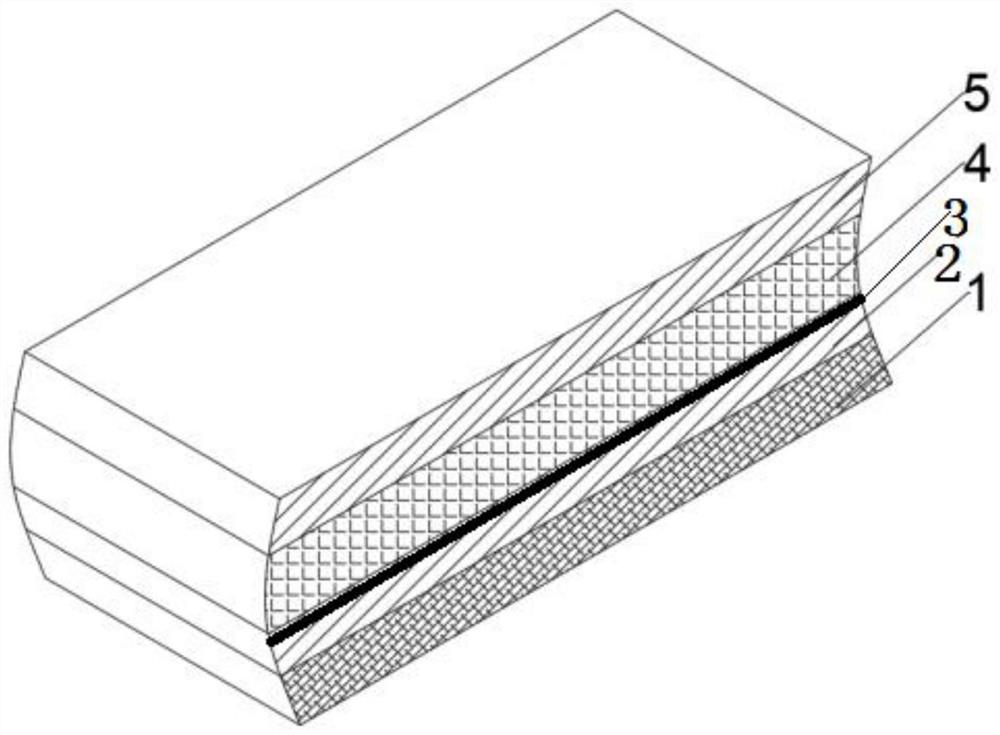

High-strength seamless terrace

PendingCN113738060AHigh strengthGuaranteed StrengthCoatingsFlooring insulationsAggregate (composite)Polyvinyl chloride

The invention discloses a high-strength seamless terrace. The high-strength seamless terrace structurally comprises a base layer, wherein an isolating layer, a slurry layer, a composite reinforcing layer and a surface layer are sequentially laid on the surface of the base layer from bottom to top; the composite reinforcing layer is prepared from the following raw material components in percentage by mass: 30 to 35 percent of urea resin, 4 to 6 percent of polyvinyl chloride, 10 to 15 percent of composite powder, 20 to 25 percent of functional mixture, 15 to 20 percent of dimethyl sebacate, 5 to 8 percent of benzyl butyrate and 4 to 6 percent of a mixture of phthalic acid and magnesium bicarbonate. The slurry layer is made of C10 concrete, and carborundum aggregate is doped in the slurry layer. The carborundum aggregate, the frosted balls, the quartz powder and other raw materials are added into the surface layer and the composite reinforcing layer and mixed to prepare special raw materials, the overall strength of the terrace after curing forming can be greatly improved, and the surface strength, toughness and abrasion resistance can be improved.

Owner:TIANJIN JUNJIE TECH CO LTD

High-performance corrugated paperboard adhesive

InactiveCN104388014AFast curing and dryingImprove adhesionNon-macromolecular adhesive additivesCellulosePolymer science

The invention relates to a high-performance corrugated paperboard adhesive. The high-performance corrugated paperboard adhesive is prepared from the following raw materials in parts by weight: 9-16 parts of butyl rubber, 4-8 parts of bentonite, 3-7 parts of ethyl acetate, 2-7 parts of an anti-aging agent D, 1-5 parts of dibutyltin dilaurate, 4-10 parts of cellulose ether, 2-8 parts of modified nano-powder, 1-5 parts of polycarbonate, 4-10 parts of dimethyl sebacate, 3-7 parts of fibrin glue, 1-5 parts of polypropylene fiber, 4-8 parts of potassium aluminum sulfate, 5-10 parts of calcium formate and 7-11 parts of natural tartaric acid. The high-performance corrugated paperboard adhesive has the beneficial effects of high curing-drying speed, good adhesion at a high temperature and long service life.

Owner:QINGDAO CHANGANDA PHARMA IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com