Glass adhesive and preparation method thereof

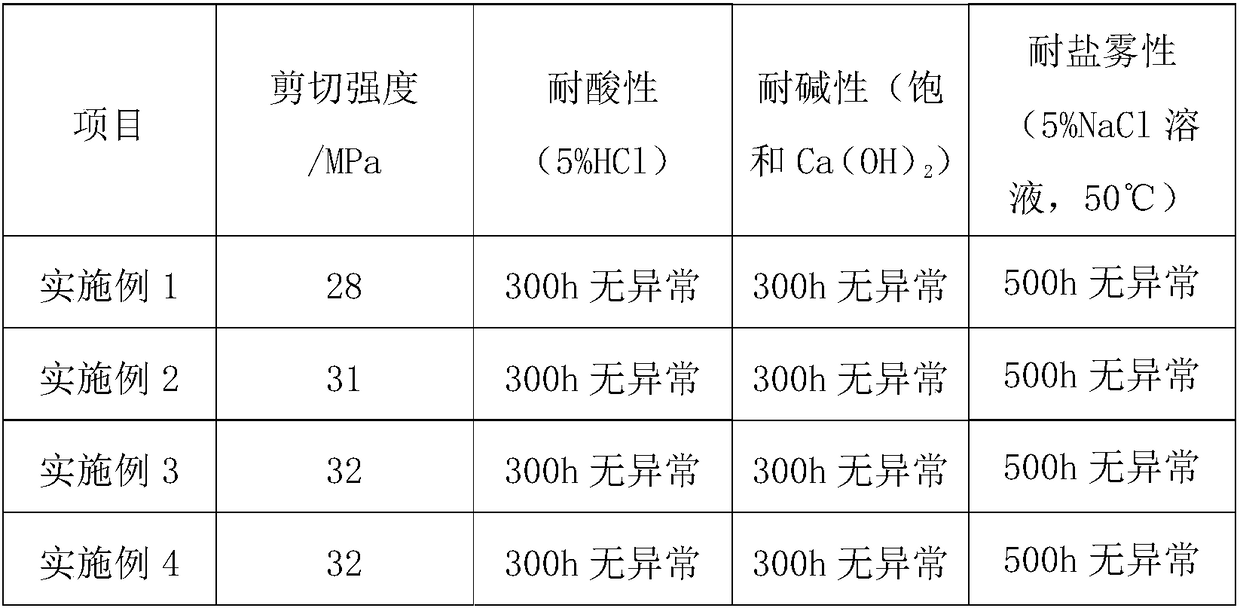

A technology of glass adhesive and ethyl cyanoacrylate, which is applied in the direction of non-polymer adhesive additives, adhesives, non-polymer organic compound adhesives, etc., can solve the problem of insufficient surface hardness of organic solvents, easy to rub hair, Poor adhesion effect and other problems, to achieve good acid and alkali resistance and neutral salt spray resistance, good adhesion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A glass adhesive, the preparation raw materials include the following components in parts by weight: 10 parts of ethyl cyanoacrylate, 3 parts of polyvinyl acetate, 2 parts of hydroxypropyl methylcellulose, 1 part of stearic acid, 1 part of pentamethyldiethylenetriamine, 2 parts of dimethyl sebacate, 1 part of tricalcium phosphate, 1 part of silicon dioxide, 1 part of glass powder, 1 part of dioctyl phthalate, azo Diformamide 1 part.

[0018] The preparation method of above-mentioned glass adhesive, comprises the steps:

[0019] Step 1, polyvinyl acetate, hydroxypropyl methylcellulose, dimethyl sebacate, tricalcium phosphate and glass powder are stirred and mixed, the stirring speed of stirring and mixing is 120 rpm, and the stirring time is 20 minutes to obtain mixture one;

[0020] Step 2, put the mixture 1 into the reaction kettle, add stearic acid and azodicarbonamide under the vacuum condition of 0.02 MPa, raise the temperature to 60°C, stir for 20 minutes, and ob...

Embodiment 2

[0023] A glass adhesive, the preparation raw materials include the following components in parts by weight: 12 parts of ethyl cyanoacrylate, 4 parts of polyvinyl acetate, 3 parts of hydroxypropyl methylcellulose, 2 parts of stearic acid, 1 part of pentamethyldiethylenetriamine, 3 parts of dimethyl sebacate, 2 parts of tricalcium phosphate, 1 part of silicon dioxide, 1 part of glass powder, 2 parts of dioctyl phthalate, azo Diformamide 1 part.

[0024] The preparation method of above-mentioned glass adhesive, comprises the steps:

[0025] Step 1, polyvinyl acetate, hydroxypropyl methylcellulose, dimethyl sebacate, tricalcium phosphate and glass powder are stirred and mixed, the stirring speed of stirring and mixing is 130 rpm, and the stirring time is 25 minutes to obtain mixture one;

[0026] Step 2, put the mixture 1 into a reaction kettle, add stearic acid and azodicarbonamide under a vacuum condition of 0.03MPa, raise the temperature to 65°C, and stir for 23 minutes to ob...

Embodiment 3

[0029] A glass adhesive, the preparation raw materials include the following components in parts by weight: 16 parts of ethyl cyanoacrylate, 5 parts of polyvinyl acetate, 4 parts of hydroxypropyl methylcellulose, 2 parts of stearic acid, 2 parts of pentamethyldiethylenetriamine, 4 parts of dimethyl sebacate, 3 parts of tricalcium phosphate, 2 parts of silicon dioxide, 2 parts of glass powder, 4 parts of dioctyl phthalate, azo Diformamide 2 parts.

[0030] The preparation method of above-mentioned glass adhesive, comprises the steps:

[0031] Step 1, polyvinyl acetate, hydroxypropyl methylcellulose, dimethyl sebacate, tricalcium phosphate and glass powder are stirred and mixed, the stirring speed of stirring and mixing is 140 rpm, and the stirring time is 27 minutes to obtain mixture one;

[0032] Step 2, put the mixture 1 into the reaction kettle, add stearic acid and azodicarbonamide under a vacuum condition of 0.05MPa, raise the temperature to 68°C, and stir for 25 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com