Epoxy resin-graphene-zinc powder anticorrosive coating and preparation method thereof

A technology for epoxy resin and anti-corrosion coatings, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of difficulty in industrialized mass production and promotion, complicated steps of adding graphene, etc., and achieve the reduction of zinc oxide mist, Guaranteed anti-corrosion effect and long-term resistance to salt spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: a kind of preparation method of epoxy-zinc powder anticorrosion paint, comprises the steps:

[0052] (1) according to table 3, the epoxy resin of component A formula quantity is added in the stirring container, stir under the rotating speed of 1500r / min;

[0053] (2) Then add the solvent (benzene) of the formula amount of component A in turn, and continue to stir under the 2500r / min rotating speed until the dispersion is uniform;

[0054] (3) Add the mixture obtained in step (2), zinc powder, and silicon dioxide into a high-speed disperser for high-speed dispersion.

[0055] (4) Configure the mixed solution of component B according to Table 3

[0056] (5) Mix the prepared component A and component B to obtain the anti-corrosion coating.

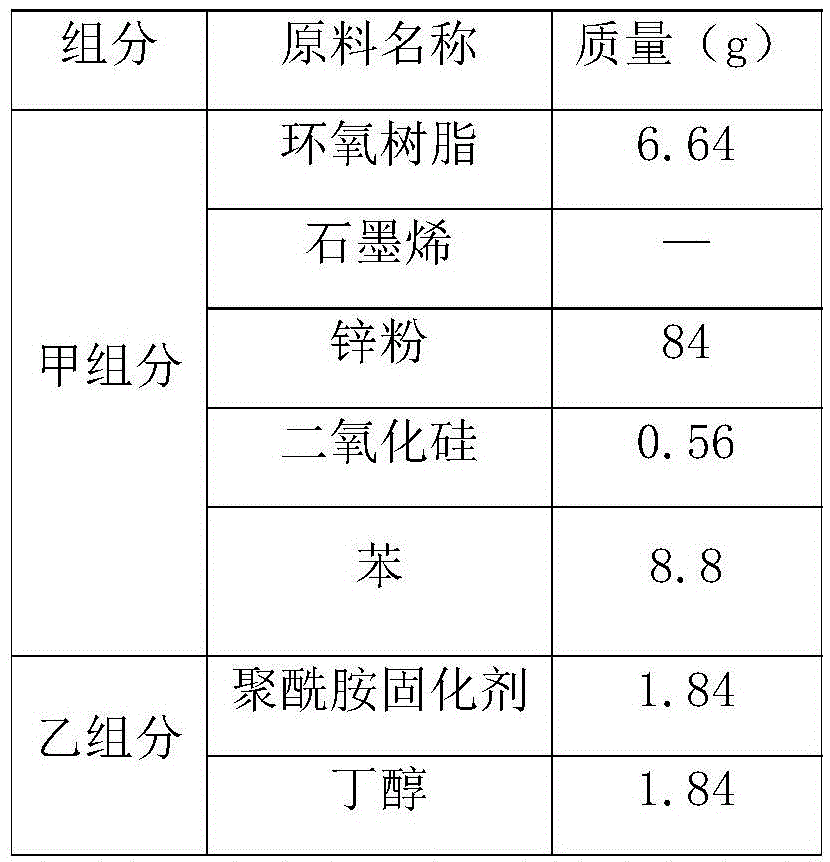

[0057]

[0058] Table 3: Components of the epoxy-zinc powder anticorrosion paint that embodiment 1 provides

Embodiment 2

[0059] Embodiment 2: a kind of preparation method of epoxy-graphene-zinc powder anticorrosion coating comprises the steps:

[0060] (1) according to table 4, the epoxy resin of component A formula quantity is added in the stirring container, stir under the rotating speed of 1200r / min;

[0061] (2) Then add the solvent (dodecane) and filler (talcum powder) of the formula amount of component A in sequence, and continue to stir at 1800r / min until the dispersion is uniform;

[0062] (3) Add the mixture obtained in step (2), zinc powder, silicon dioxide, and graphene into a high-speed disperser for high-speed dispersion.

[0063] (4) Configure the mixed solution of component B according to Table 4

[0064] (5) Mix the prepared component A and component B to obtain the anti-corrosion coating.

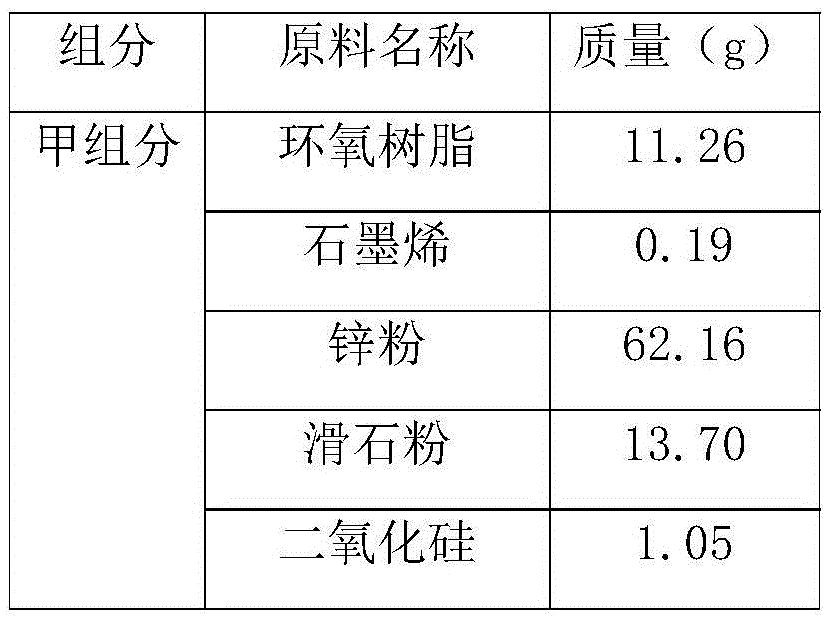

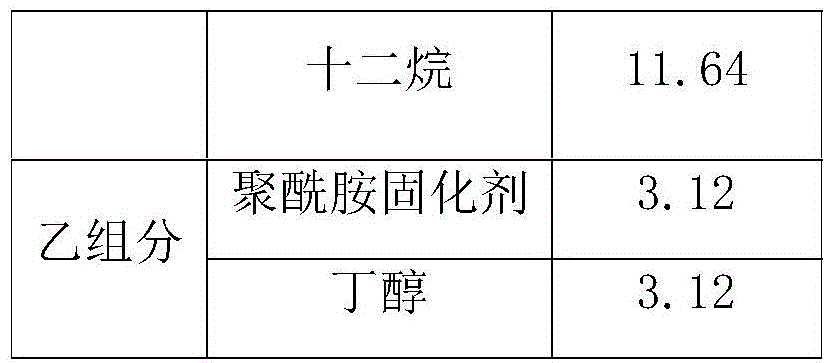

[0065]

[0066]

[0067] Table 4: The composition of the epoxy-graphene-zinc powder anticorrosion coating that embodiment 2 provides

Embodiment 3

[0068] Embodiment 3: a kind of preparation method of epoxy-zinc powder anticorrosion paint, comprises the steps:

[0069] (1) according to table 5, the epoxy resin of component A formula quantity is added in the stirring container, stir under the rotating speed of 1200r / min;

[0070] (2) Then add the solvent (methyl isobutyl ketone) and filler (titanium dioxide) in the formula amount of component A in sequence, and continue to stir at a speed of 2200r / min until the dispersion is uniform;

[0071] (3) Add the mixture obtained in step (2), zinc powder, silicon dioxide, and graphene into a high-speed disperser for high-speed dispersion.

[0072] (4) Configure the mixed solution of component B according to Table 5

[0073] (5) Mix the prepared component A and component B to obtain the anti-corrosion coating.

[0074]

[0075] Table 5: The composition of the epoxy-graphene-zinc powder anticorrosion coating that embodiment 3 provides

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com