Patents

Literature

42results about How to "Long salt spray resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc-rich epoxy anticorrosion paint and preparation method thereof

ActiveCN103173095AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene

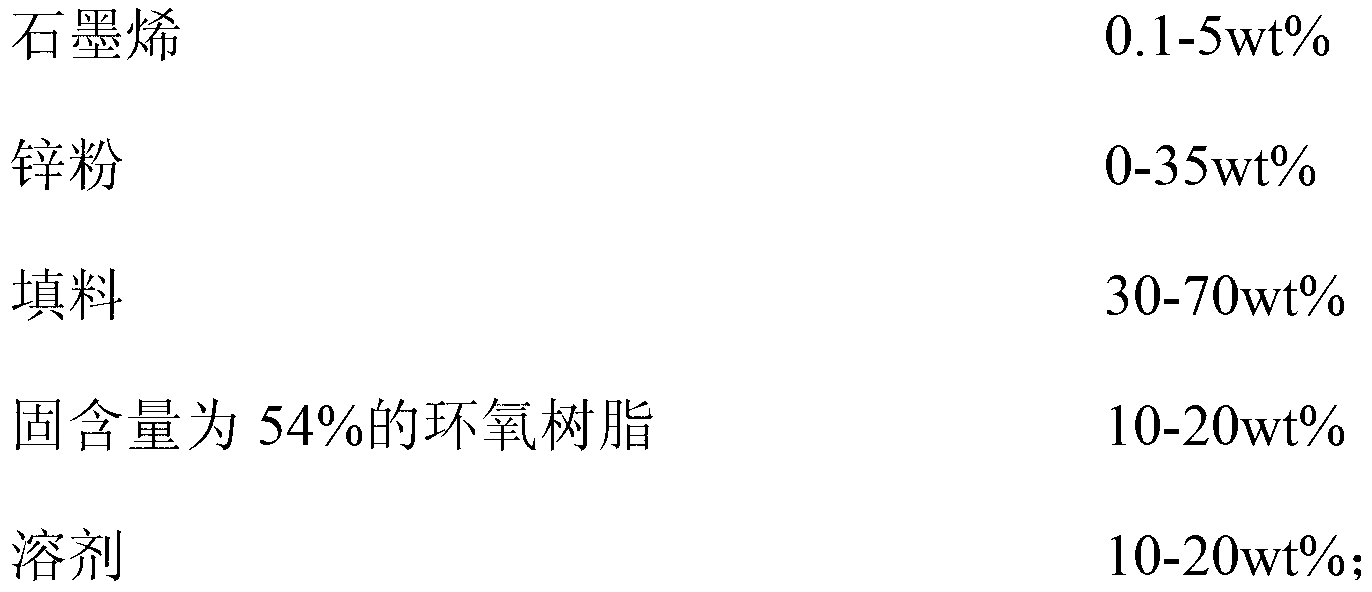

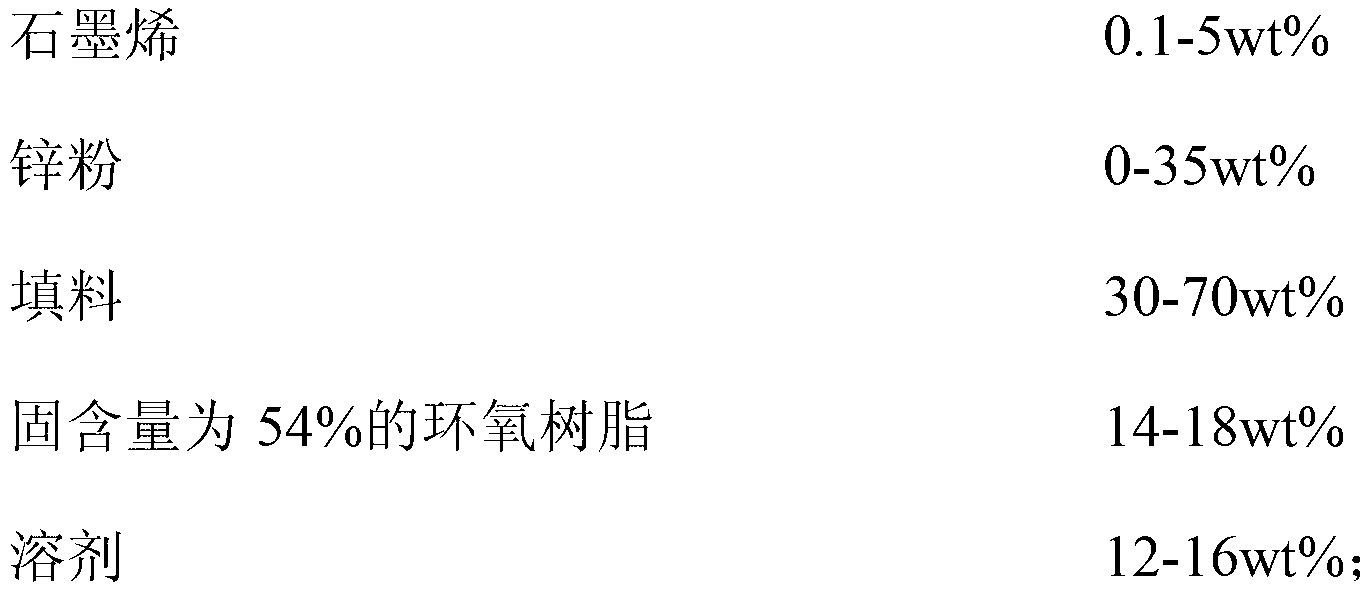

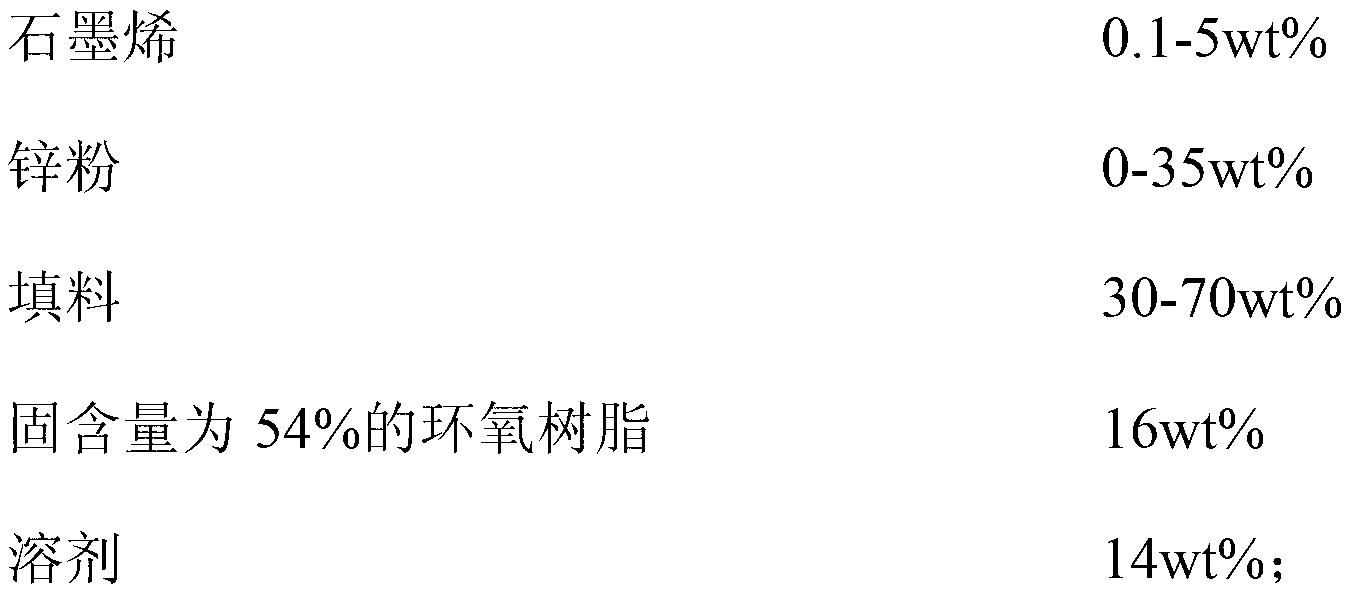

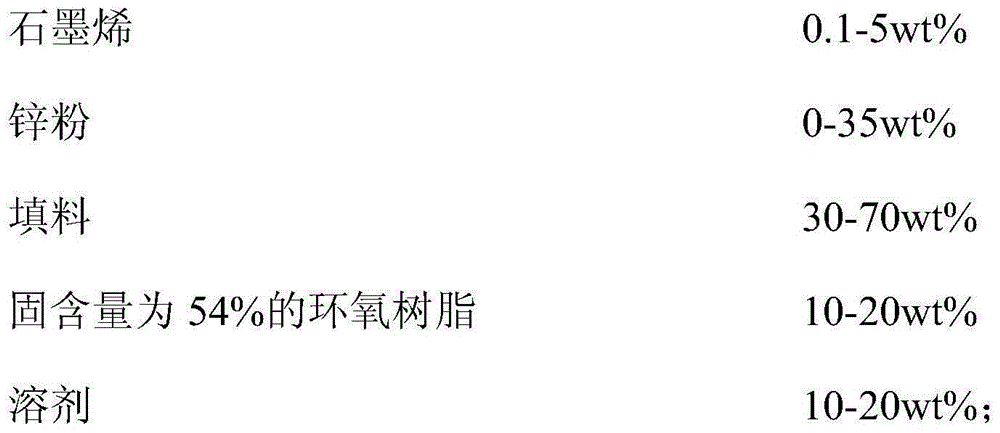

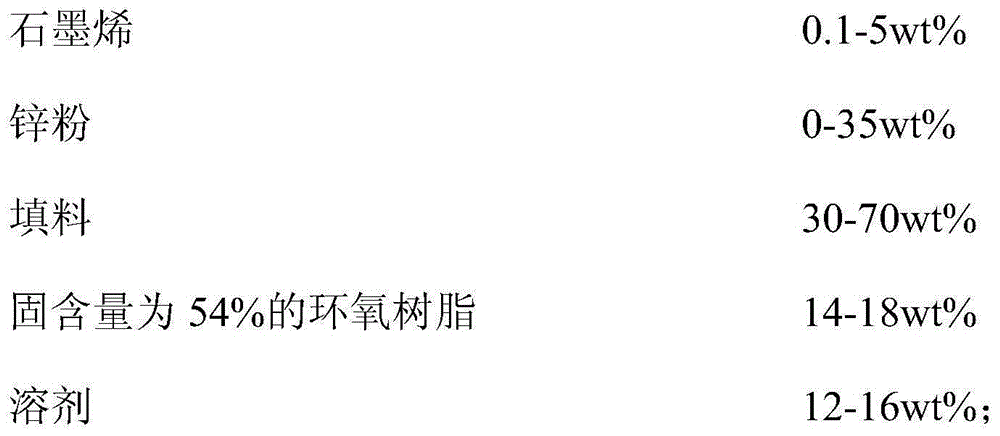

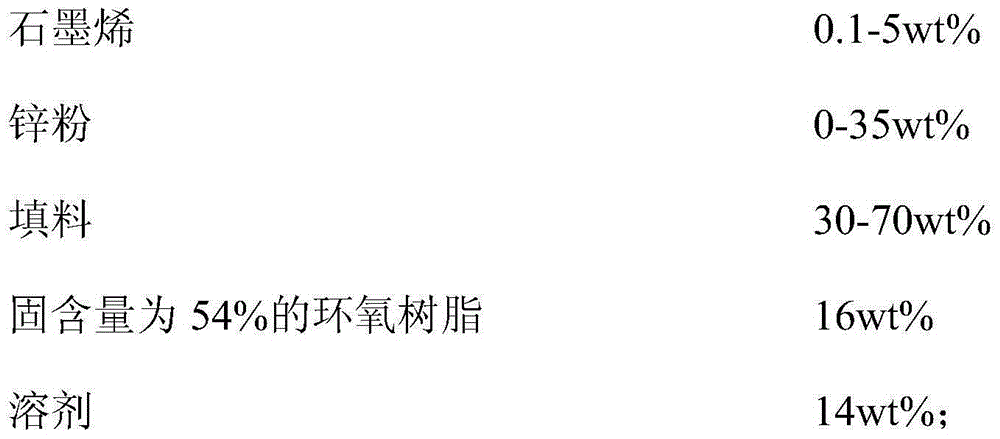

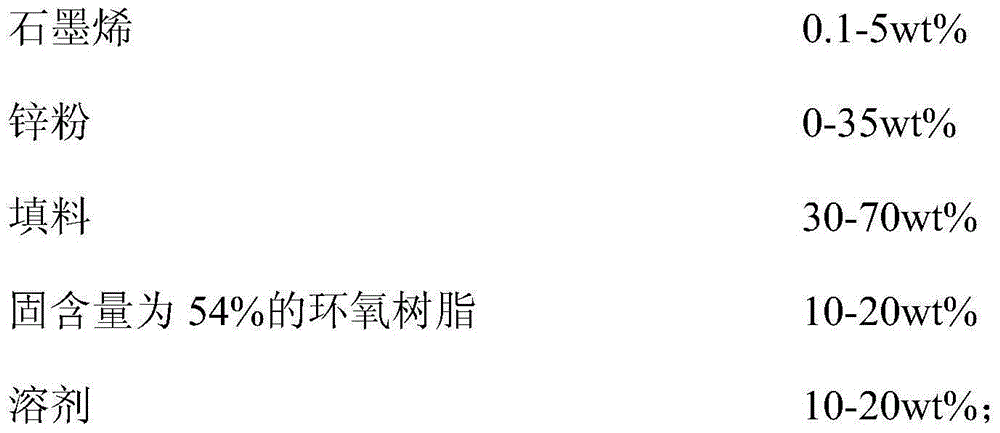

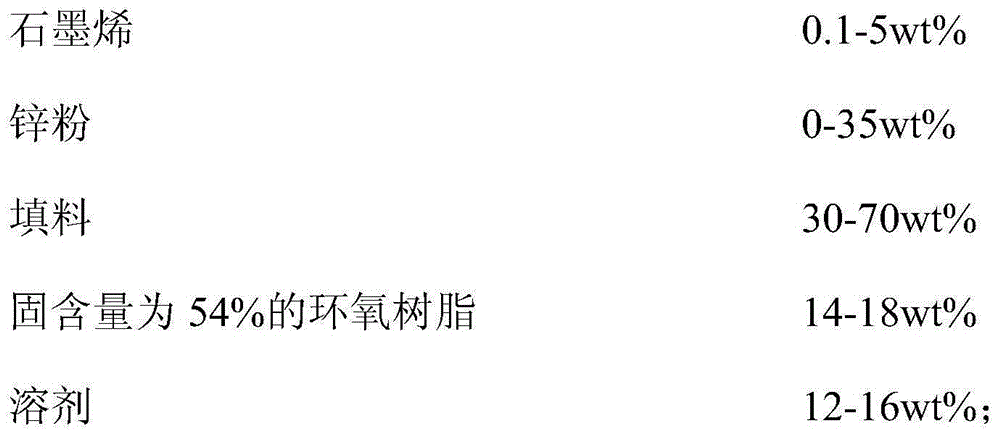

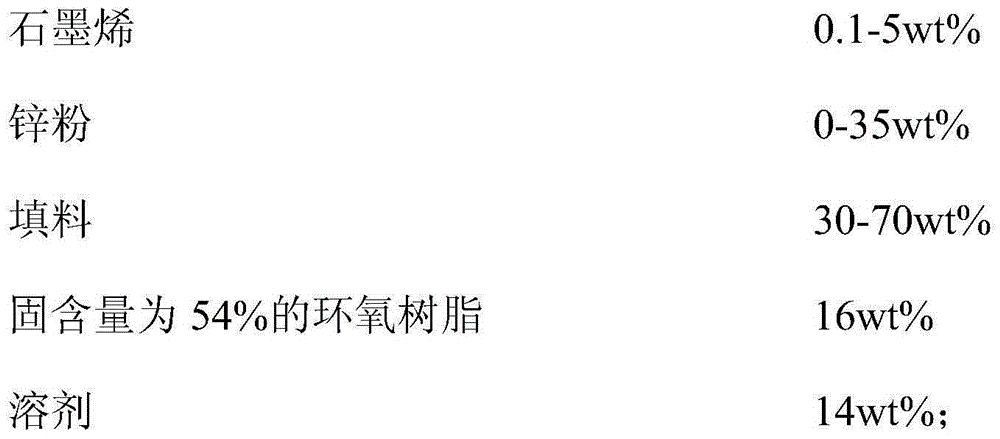

The invention relates to a zinc-rich epoxy anticorrosion paint. The paint comprises a component A which can be cured into a film and a component B comprising a curing agent. The component A comprises the components of, by mass, 0.1-5wt% of graphene, 0-35wt% of zinc powder, 30-70wt% of a filling material, 10-20wt% of epoxy resin with a solid content of 54%, and 10-20wt% of a solvent, wherein a total mass percentage of graphene, zinc powder, and the filling material is 60-80wt%, and a total mass content of the component A is 100wt%. According to the invention, graphene is added into the anticorrosion paint, such that paint film thickness is greatly reduced. Through the selection of the components, the anticorrosion effect is improved, and zinc powder content is greatly reduced. Therefore, a zinc-rich paint anticorrosion manner with the cost of sacrifice of zinc powder is overcome, and zinc oxide mist produced during welding is greatly reduced. The paint is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Double-component graphene anticorrosive coating

ActiveCN105086754AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

A zinc-rich epoxy anti-corrosion coating, including a component A, capable of being cured into a film, and a component B containing a curing agent; component A contains, by weight percentage, graphene (0.1-5wt%), zinc powder (0-35wt%), filler (30-70wt%), 10-20wt% epoxy resin having 54wt% solids content, and solvent (10-20wt%), wherein the sum of the weight percentages of the graphene, zinc powder and filler is 60-80wt% and the sum of the weight percentages of all components of compenent A is 100wt%. The present invention adds graphene into an anti-corrosion coating, thus decreasing the thickness of the coating film, increases the anti-corrosion effect while decreasing zinc powder contents, reduces the amount of zinc oxide vapor generated during welding, and is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Epoxy resin-graphene-zinc powder anticorrosive coating and preparation method thereof

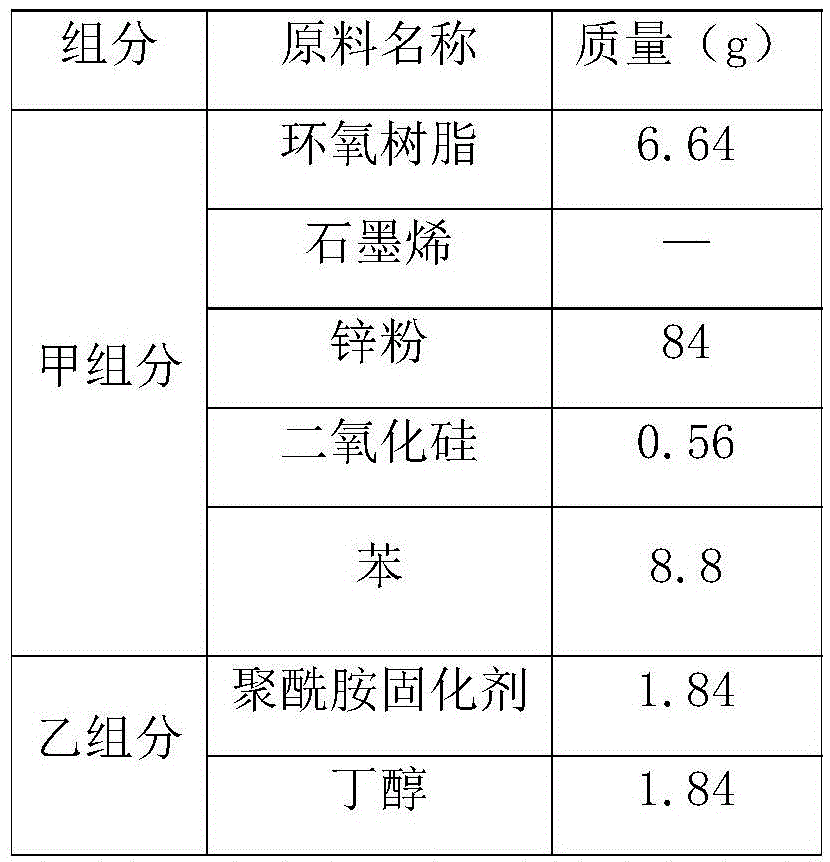

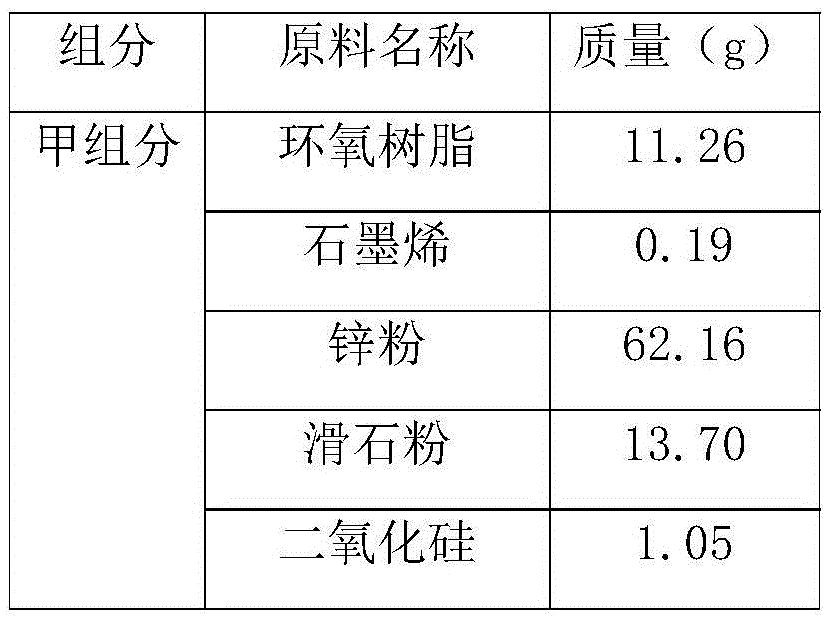

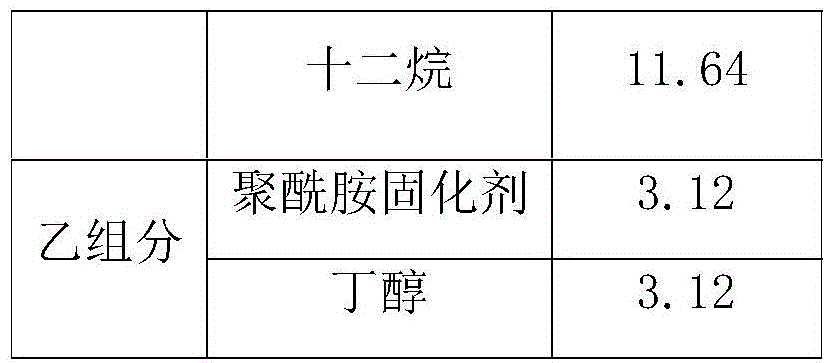

InactiveCN105623471AReduce contentWays to overcome corruptionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

The invention relates to epoxy resin-graphene-zinc powder anticorrosive coating and a preparation method thereof. The coating comprises a component A capable of forming a film in a curing mode and a component B containing a curing agent, wherein the component A is prepared from 14.64-20.24% of epoxy resin, 0.33-0.56% of graphene, 19.63-37.67% of zinc powder, 23.74-40.37% of filler, 1.41-2.0% of silicon dioxide and the balance a solvent. The component B is prepared from 50% of polyamide and 50% of butanol. Graphene is added into the anticorrosive coating, the anticorrosive effect is improved and the content of the zinc powder is greatly reduced by means of selection of the components, the anticorrosive mode, at the cost of zinc powder, of zinc-rich coating is avoided, zinc oxide fog generated during welding is greatly reduced, and the coating is environmentally friendly. The novel composite coating is good in anti-corrosive effect, free of toxin and pollution and wide in application range.

Owner:TIANJIN XITENG SCI & TECH CO LTD

Preparation method of graphene anticorrosive paint

ActiveCN105086758AImprove anti-corrosion performanceExtended service lifeAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

A zinc-rich epoxy anti-corrosion coating, including a component A, capable of being cured into a film, and a component B containing a curing agent; component A contains, by weight percentage, graphene (0.1-5wt%), zinc powder (0-35wt%), filler (30-70wt%), 10-20wt% epoxy resin having 54wt% solids content, and solvent (10-20wt%), wherein the sum of the weight percentages of the graphene, zinc powder and filler is 60-80wt% and the sum of the weight percentages of all components of compenent A is 100wt%. The present invention adds graphene into an anti-corrosion coating, thus decreasing the thickness of the coating film, increases the anti-corrosion effect while decreasing zinc powder contents, reduces the amount of zinc oxide vapor generated during welding, and is environmentally friendly.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

Electrostatic conductive and corrosion-resistant epoxy resin-graphene coating and preparation method thereof

InactiveCN105778709AGuaranteed long-term static conductive effectImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphene coating

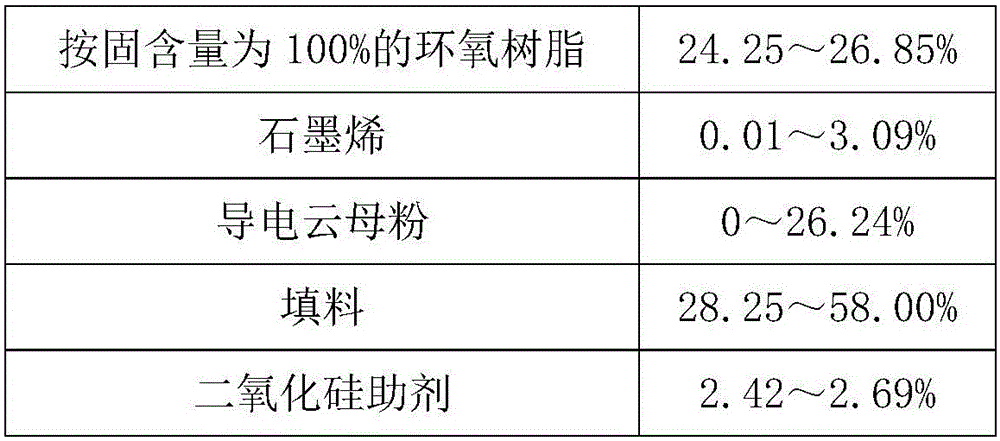

The invention relates to an electrostatic conductive and corrosion-resistant epoxy resin-graphene coating and a preparation method thereof. The coating consists of a component A and a component B, wherein the component A comprises the following components in percentage by mass: 24.25 to 26.85 percent of epoxy resin, 0.01 to 3.09 percent of graphene, 0 to 26.24 percent of conductive mica powder, 28.25 to 58.00 percent of a filler, 2.42 to 2.69 percent of a silicon dioxide auxiliary, and a solvent; the component B comprises 50 to 100 percent of a polyamide curing agent and 0 to 50 percent of butanol. The novel composite coating is prepared by utilizing a lamellar structure and high corrosion resistance, electrical conductivity and chemical stability of graphene, has a good electrostatic conduction effect and a good corrosion-resistant effect, and is long in service life, nontoxic and free of pollution. The phenomena of bubbles, cracks, spalling, chalking and digestion after 60-day acid leaching and 60-day alkaline leaching are avoided. A preparation process is simple, and a novel technology for application of graphene to electrostatic conduction and corrosion resistance is provided.

Owner:TIANJIN XITENG SCI & TECH CO LTD

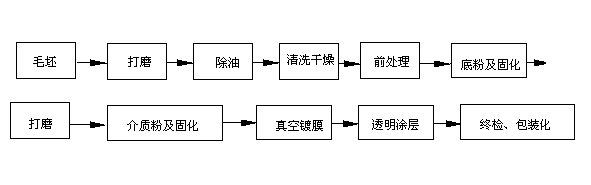

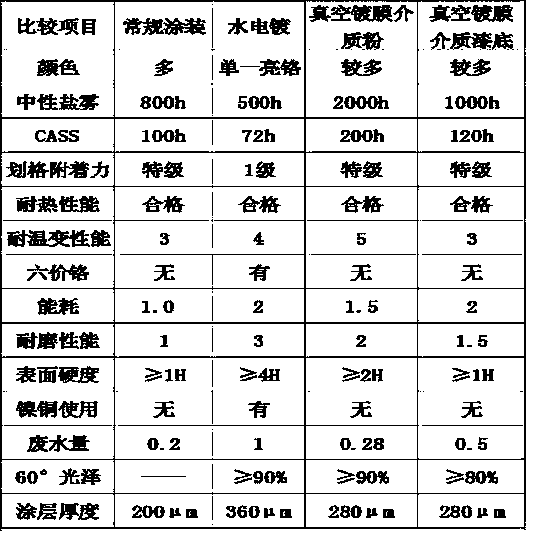

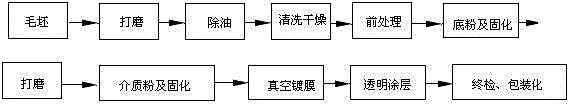

Vacuum coating production process of automobile hub with high physical and chemical properties

InactiveCN103572203AImprove flatnessAccelerated corrosionVacuum evaporation coatingSputtering coatingVacuum chamberVacuum coating

The invention relates to a vacuum coating production process of an automobile hub with high physical and chemical properties. The production process comprises the following steps: (1) processing a hub blank; (2) inspecting and polishing the hub blank; (3) removing oil; (4) cleaning and drying; (5) carrying out pre-treatment; (6) spraying body powder and curing; (7) polishing; (8) spraying medium powder and curing; (9) vacuum coating: spraying a metal coating on the treated hub in a vacuum chamber according to a vacuum sputter coating principle; (10) preparing a transparent coating; and (11) finally inspecting and packaging, wherein the passivation coating is a chromate-free passivation coating and the metal coating is an aluminum film. According to the production process provided by the invention, the surface evenness and the corrosion resistance of the hub are improved, the evenness, the gloss, the hardness and the corrosion resistance of the surface of the hub are increased, the surface of the hub is sealed and metallized, and the hub has glossiness of water electroplating. The transparent coating has an adhesive force of a high vacuum coating. The production process provided by the invention is concise and low in energy consumption, and the prepared hub is high in hardness and strong in corrosion resistance.

Owner:NORD WHEEL MFG

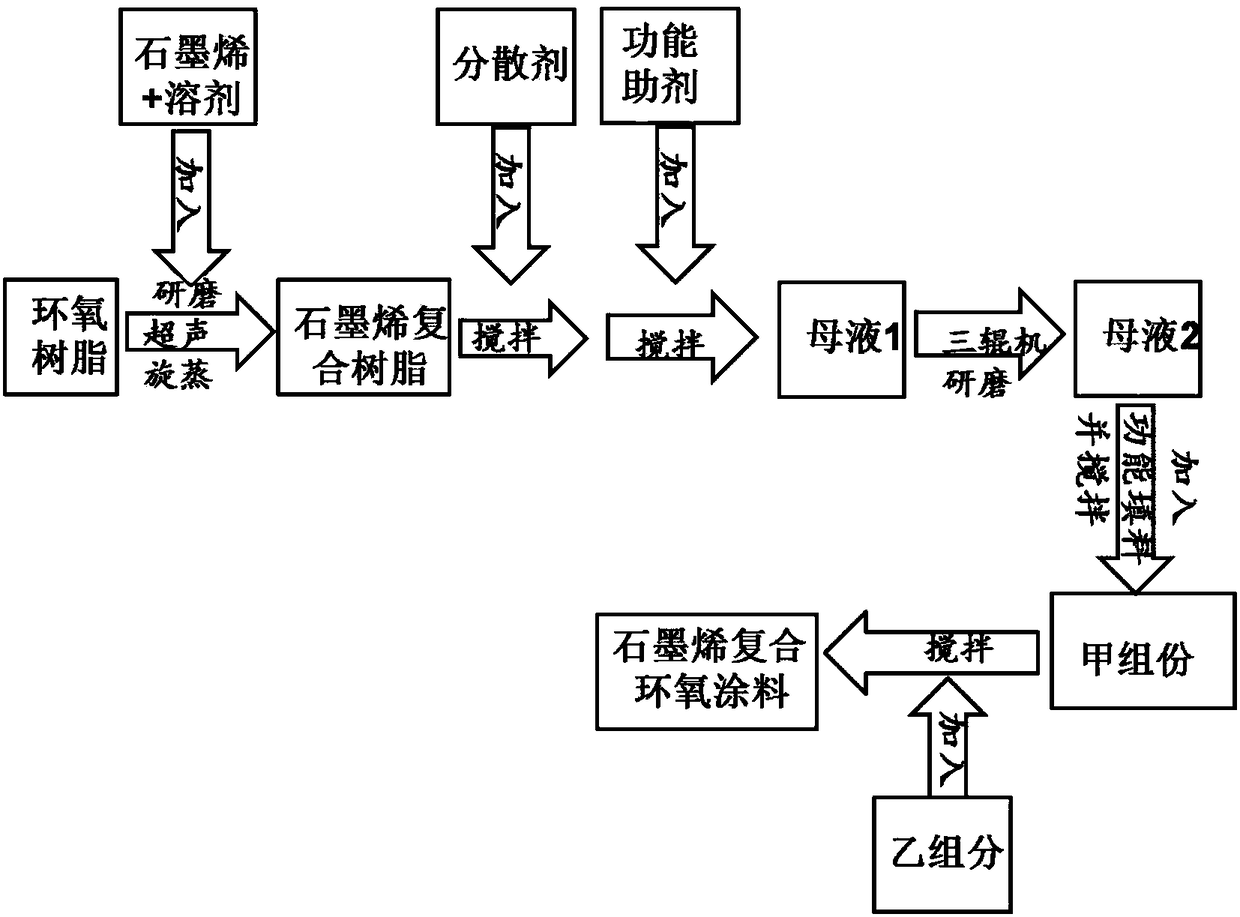

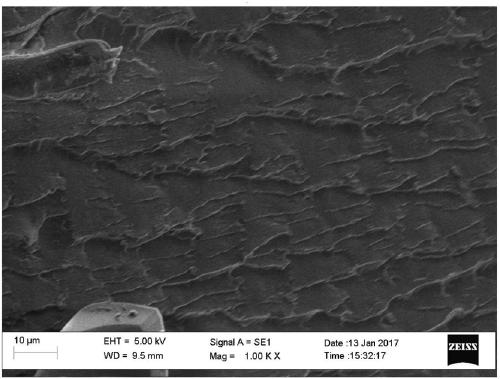

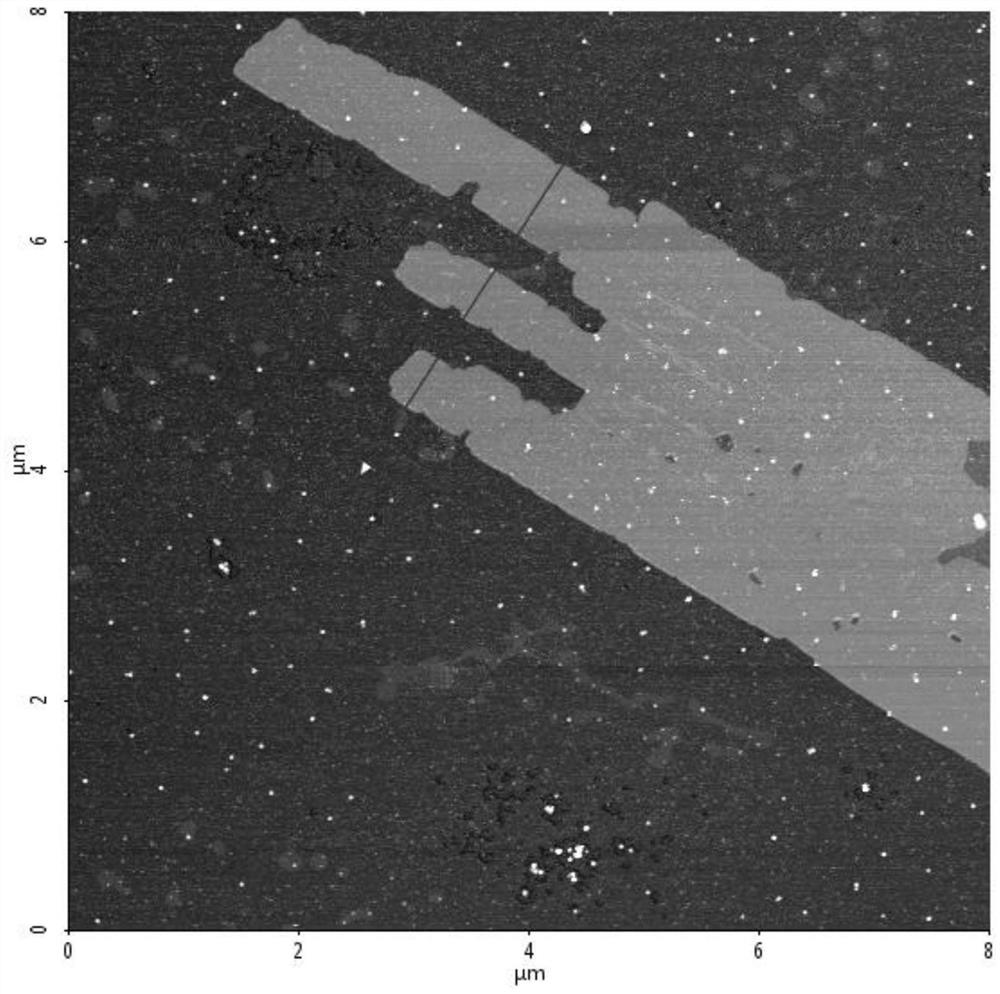

Resin anticorrosion paint containing graphene/epoxy resin composite material and preparation method thereof

InactiveCN109423160ARealize layer overlayEvenly dispersedAnti-corrosive paintsEpoxy resin coatingsEpoxyEpoxy resin composite

The invention provides resin anticorrosion paint. The resin anticorrosion paint includes, by mass, 20-40 parts of graphene / epoxy resin, 70-130 parts of zinc powder, 45-75 parts of solvents, and otherauxiliary agents. The invention also provides a preparation method of the resin anticorrosion paint. The method changes an adding mode of graphene materials, firstly graphene and epoxy resin in the paint are compounded to obtain a composite material of the graphene and the epoxy resin, and then the treated graphene and epoxy resin are combined with other components of specific proportions to obtain the resin anticorrosion paint, and so, the problem of graphene dispersion can be better solved, perfect production of its excellent performance is ensured, other additives do not need to be added, introduction of impurities is reduced, the disadvantage of uneven mixing of flexible graphene materials in a paint system is fundamentally solved, uniform dispersion of the graphene can be ensured, thereby obtaining better performance.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Compound passivating fluid for mechanical zinc coating

InactiveCN102864447AImprove passivation effectMeet the requirements of corrosion resistancePolyurea/polyurethane coatingsMetallic material coating processesCompound (substance)Solvent

The invention belongs to the technical field of metal surface treatment and specifically relates to a compound passivating fluid for a mechanical zinc coating. The compound passivating fluid comprises a component A and a component B, wherein the component A is waterborne polyurethane, of which the weight percent is 8-18% in the compound passivating fluid; the component B is an inorganic passivator, of which the weight percent is 2.4-1.5% in the compound passivating fluid; and the balance is deionized water. The pH value of the compound passivating fluid is adjusted to 6-9 by using the sulfuric acid with the mass fraction of 98%. The compound passivating fluid has a better passivating function to a mechanical zinc coating workpiece; the environmental pollution caused by hexavalent chromium is avoided; a formed film is bright and transparent, is durable and excellent in flexibility, has a certain mechanical property, is excellent in water and chemical solvent resistance and is long in salt mist resisting time. The coating has the advantages of self-repairing function, high stability, low cost, simple preparation process and simple use method.

Owner:SHANDONG UNIV OF TECH

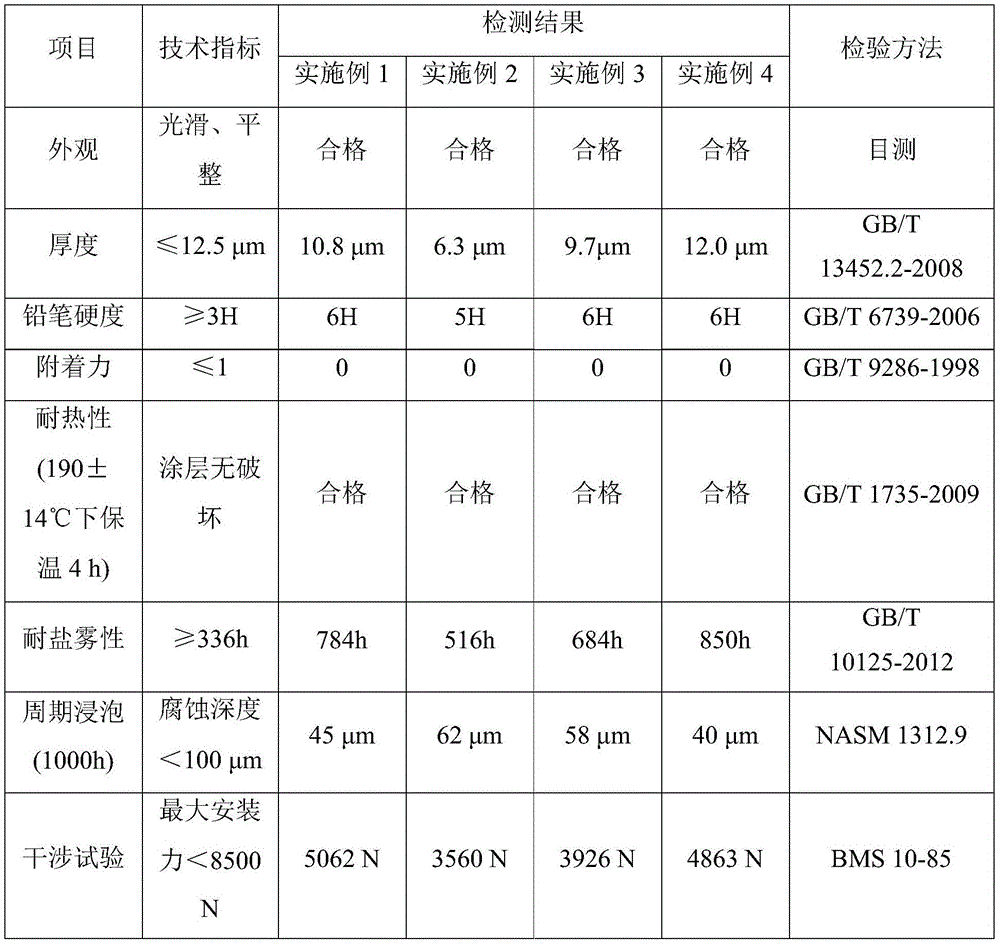

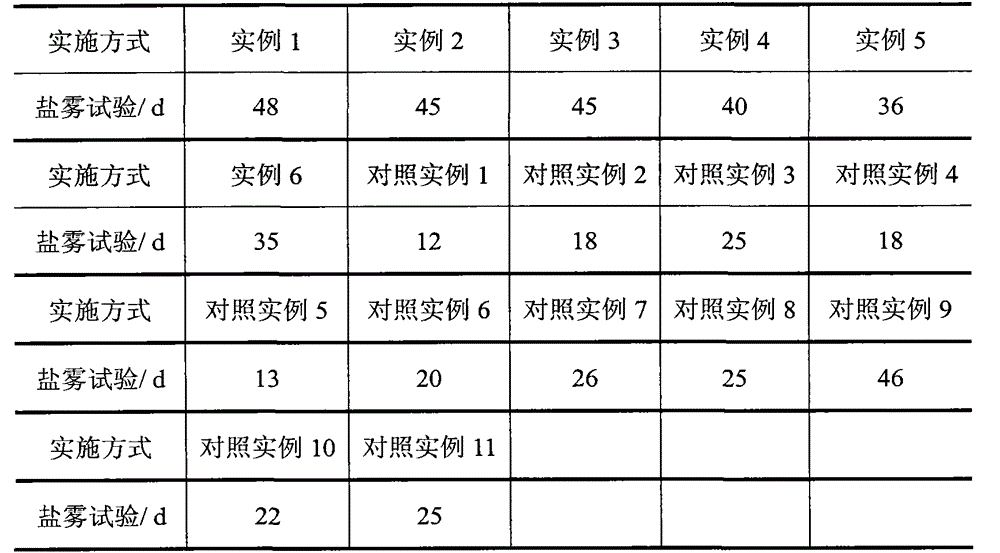

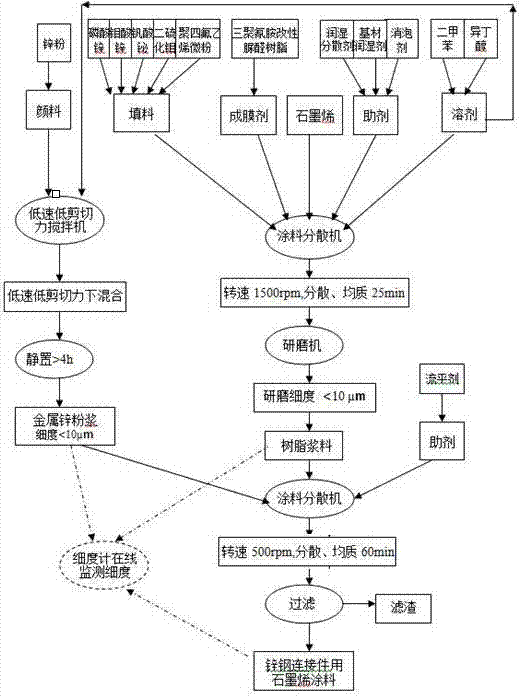

Graphene paint for steel fastening parts and preparation method of graphene paint

InactiveCN105585930ACorrosionReduce corrosionAnti-corrosive paintsFrictional coefficientMelamine formaldehyde resin

The invention discloses graphene paint for steel fastening parts and a preparation method of the graphene paint. The graphene paint is prepared from, by mass, 20-50 parts of urea formaldehyde resin, 1-10 parts of melamine-formaldehyde resin, 0.1-5 parts of graphene, 5-30 parts of aluminum paste, 5-30 parts of zinc powder, 2-10 parts of packing, 1-8 parts of an auxiliary and 10-70 parts of solvent. The paint can be applied to the surfaces of the steel fastening parts, a coating formed through heating curing has the advantages of being small in thickness, high in hardness, resistant to wear, good in adhesive force, low in frictional coefficient and excellent in corrosion resistance, therefore, corrosion of the steel fastening parts can be effectively delayed, and the service life of the steel fastening parts is prolonged.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

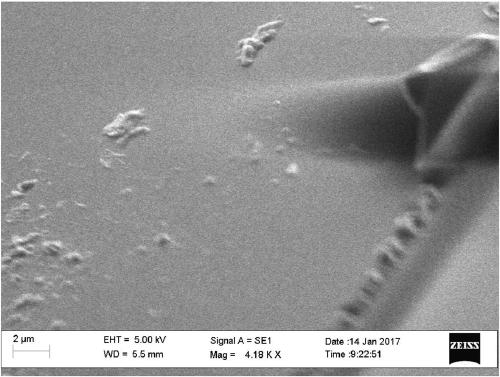

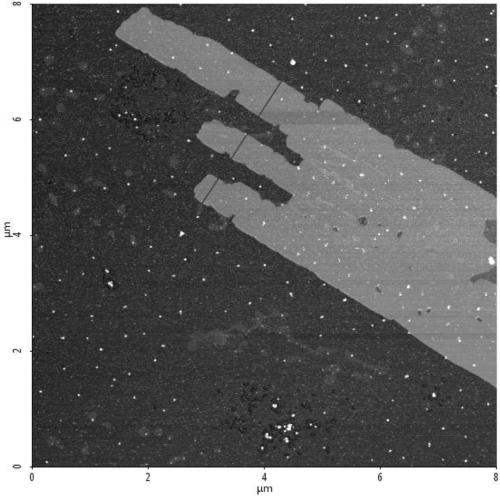

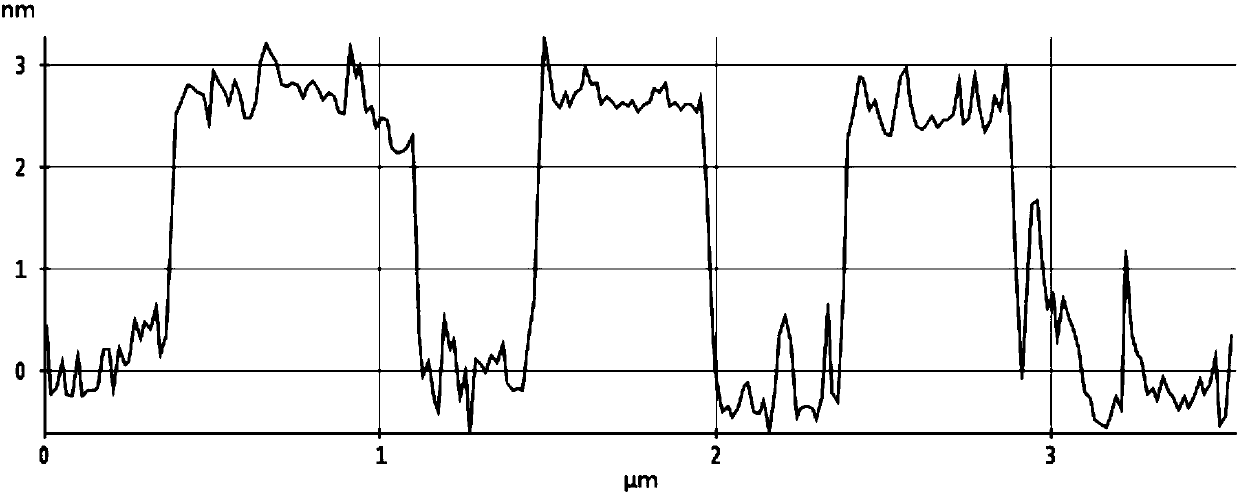

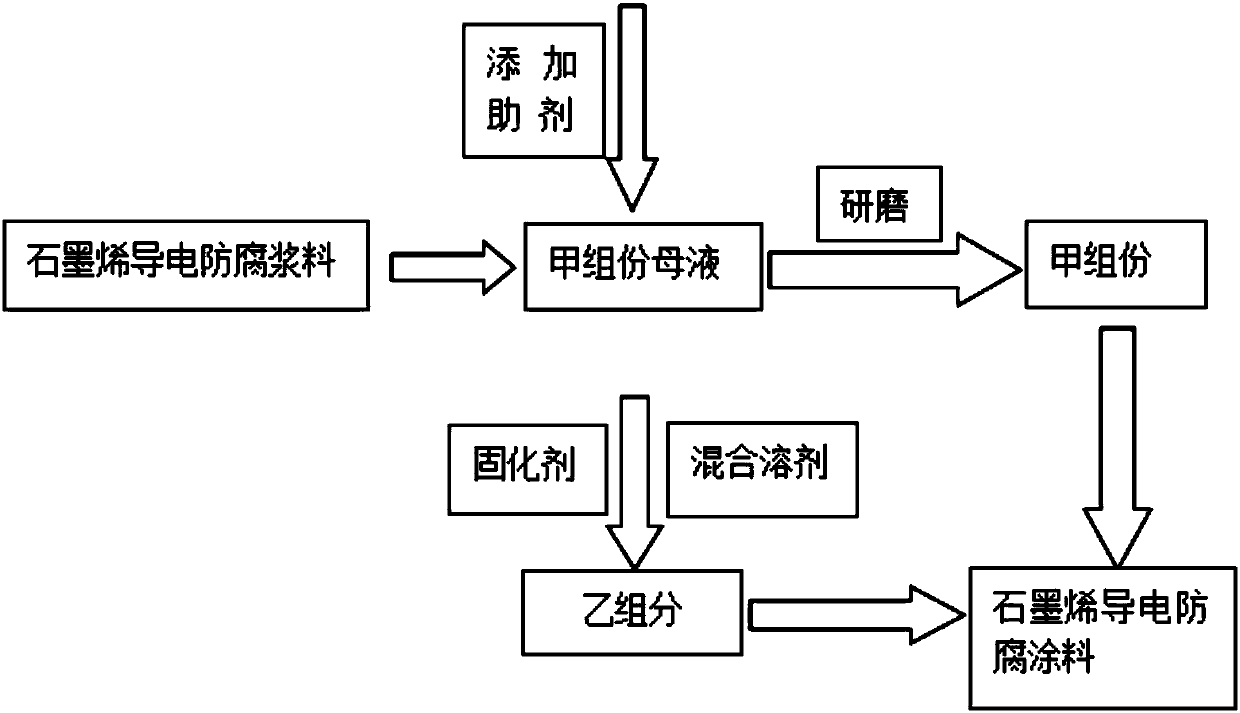

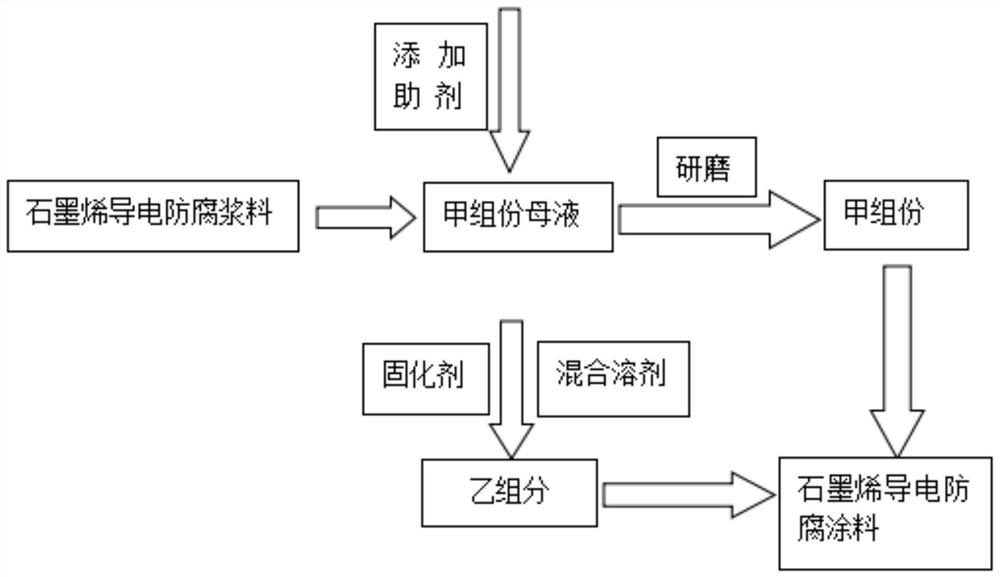

Graphene-containing electric-conduction anticorrosive coating material and preparation method thereof

ActiveCN109666370AImprove conductivityEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxySlurry

The present invention provides an electric-conduction anticorrosive coating material, which comprises, by mass, 15-25 parts by weight of an epoxy resin, 3-10 parts by weight of a highly conductive graphene slurry, 15-35 parts by weight of a solvent, and an auxiliary agent. The invention further provides a preparation method of the electric-conduction anticorrosive coating material. According to the present invention, the highly conductive graphene material is used, other components are combined, the specific ratio and the formula are supplemented, and the metal or metal ion-based filler is completely replaced, such that the highly conductive graphene can be uniformly dispersed in the coating material so as to substantially improve the electric conductivity and the performances of the coating material, and the layer-by-layer stacking of graphene can be achieved so as to provide the shielding effect and well protect; and the simple ultrasonic process and other physical compounding methods are used to uniformly distribute the graphene in the coating material without the adding of other auxiliary agents so as to reduce the introducing of impurities, such that the highly conductive andhighly anticorrosive graphene conductive anticorrosive coating material is prepared, and the method has characteristics of simple operation, safety and environmental protection.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

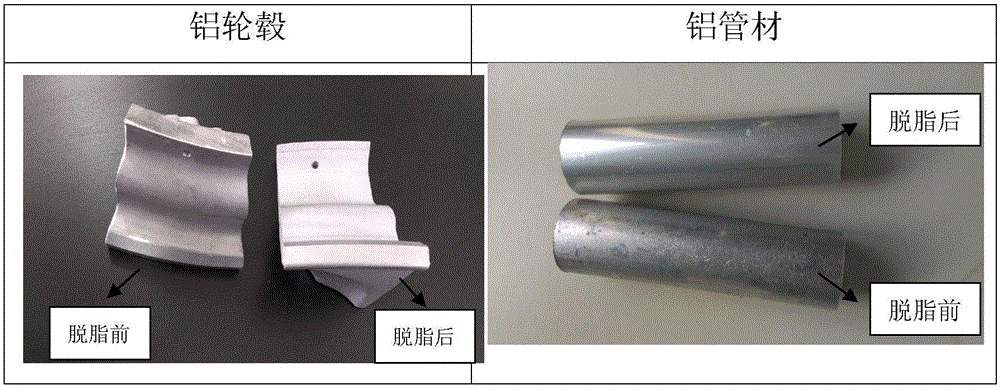

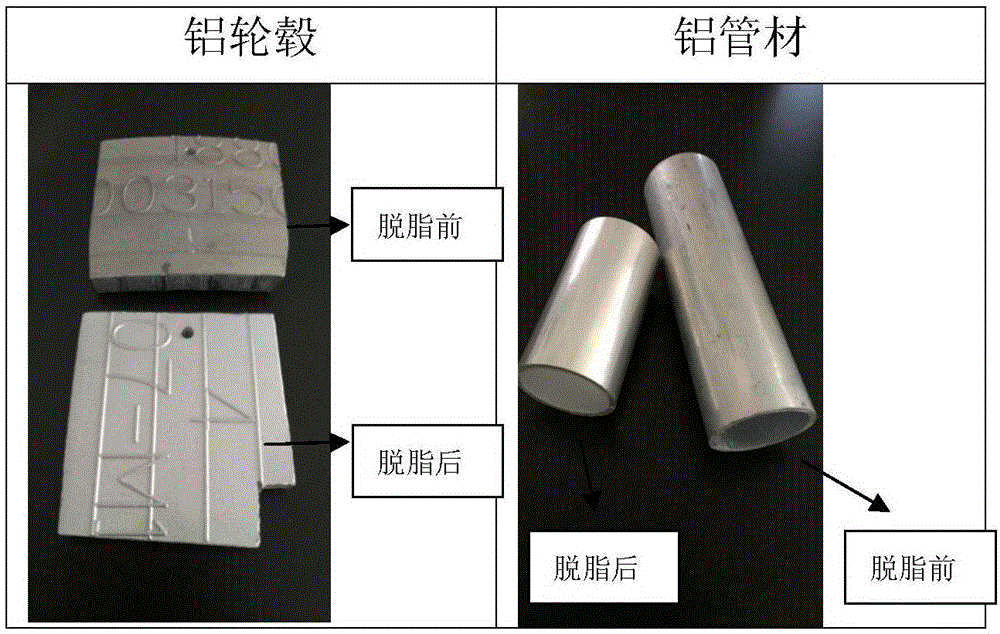

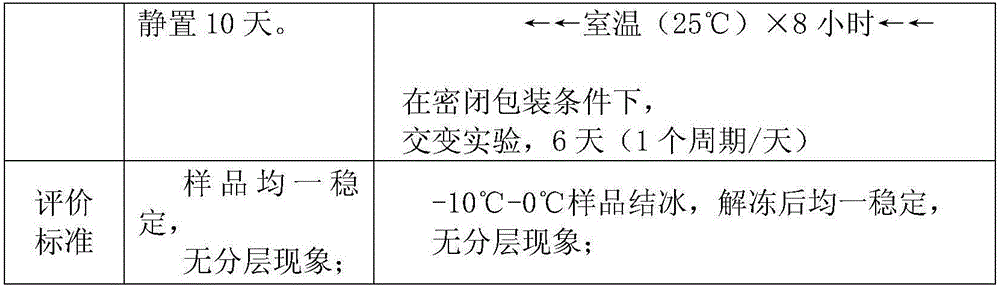

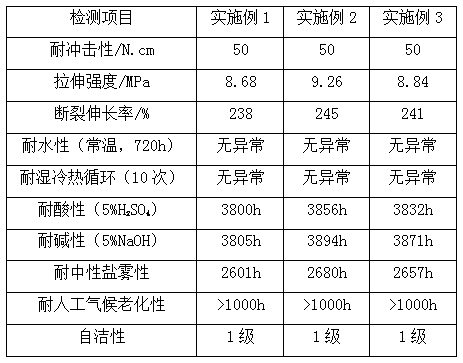

Metal surface degreasing agent and preparation method and application thereof

The invention relates to a metal surface degreasing agent. The metal surface degreasing agent is composed of an agent A and an agent B. The agent A is prepared from, by mass percent, 20%-30% of phosphate, 1%-10% of carbonate, 5%-15% of silicate, 1%-5% of a chelating agent, 1%-10% of a solubilizer and 30%-72% of deionized water. The agent B is a surface active agent. An aluminum material and an aluminum alloy subjected to degreasing and acid pickling can react with a passivation solution or a phosphating solution especially easily, a uniform and thin passivation film is formed, subsequent sealing treatment is facilitated better, and the salt mist resisting time of the passivation film is prolonged. The metal surface degreasing agent has the beneficial effects that operation is easy, no corrosion is generated, the treatment temperature is low, cost is low, and little foam is generated; and spraying and soaking can be both achieved in any place.

Owner:SHENYANG PARKERIZING

Anticorrosive tough coating material for outdoor communication tower, and preparation method thereof

InactiveCN110684440AGood dispersionGood chemical resistanceAnti-corrosive paintsEpoxy resin coatingsXylyleneFiber

The invention discloses an anticorrosive tough coating material for an outdoor communication tower, and a preparation method thereof, wherein the anticorrosive tough coating material is prepared fromthe following raw materials by weight: 12-18 parts of a polytrifluorochloroethylene resin, 35-45 parts of a bisphenol A type epoxy resin, 8-12 parts of polyphenylmethylsiloxane, 2-6 parts of alpha,omega-dihydroxy polydimethylsiloxane, 2-6 parts of amino-modified polysiloxane, 2-6 parts of hexamethyldisilazane, 2-6 parts of gas-phase nanometer silicon dioxide, 7-11 parts of silicon carbide short fibers, 12-16 parts of mica iron oxide powder, 2-8 parts of xylene, 10-20 parts of an acetone aqueous solution and 1-3 parts of a polyamine mixed curing agent. According to the invention, the prepared anticorrosive tough coating material has excellent anticorrosive performance, weather resistance and good elasticity; and by coating the communication tower with the anticorrosive tough coating material, the coating is compact, has excellent anticorrosive, anti-aging, hydrophobic, stain-resistant and impact-resistant effects, can well adapt to severe environments, and effectively prolongs the service life of the communication tower.

Owner:广西凯威铁塔有限公司

A kind of non-phosphorus and slag-free normal temperature coating agent

ActiveCN103397323BLong salt spray resistanceImprove compactnessMetallic material coating processesSlagPhosphate

The invention relates to a phosphorus-and-slag-free normal temperature coating agent. The phosphorus-and-slag-free normal temperature coating agent is suitable for the metal surface treatment of a plurality of metal materials, such as cold-rolled plates, hot-rolled plates, cast iron, galvanized plates, electrolytic plates, aluminum and aluminum alloys. The phosphorus-and-slag-free normal temperature coating agent is mainly composed of hexafluorozirconic acid, hydrofluoric acid, magnesium nitrate, hydrogen peroxide and water. The coating agent comprises a component A, a component B and a component C, wherein the component A comprises hexafluorozirconic acid, hydrofluoric acid and water; the component B comprises magnesium nitrate, hydrogen peroxide and water; and the component C comprises hexafluorozirconic acid, magnesium nitrate and water. A preparation method of the coating agent comprises the following steps: mixing the component A with the component B according to a certain ratio, fully stirring, and adding water to a constant volume; and adding the component C according to a certain proportion as a supplement to realize adjustment when the concentration of the above treatment liquid decreases. The phosphorus-and-slag-free normal temperature coating agent has the characteristics of strong adhesion capability, strong anticorrosion performance, simple operation method, and no need of the surface adjustment treatment or passivation enclosing, so the process flow is shortened, the coating agent can be repeatedly used for a long term, and the coating agent has a lower cost than traditional phosphatization liquids. Additionally, the environmentally-friendly coating agent contains no nitrites, phosphates, chromium ions or other toxic heavy metal ions or harmful volatile substances, so sewage can be directly discharged without sewage treatment.

Owner:广东东明新材科技有限公司

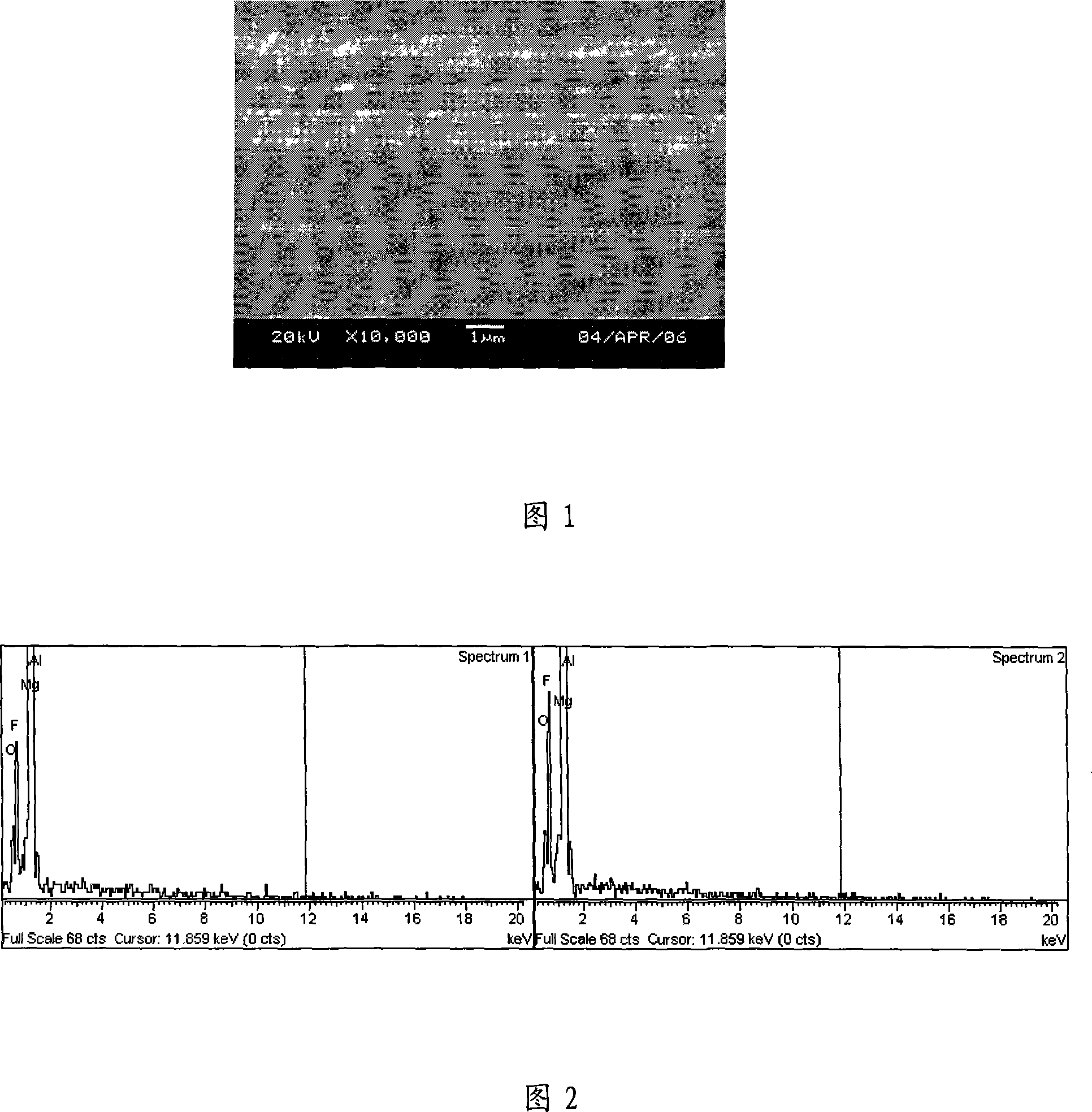

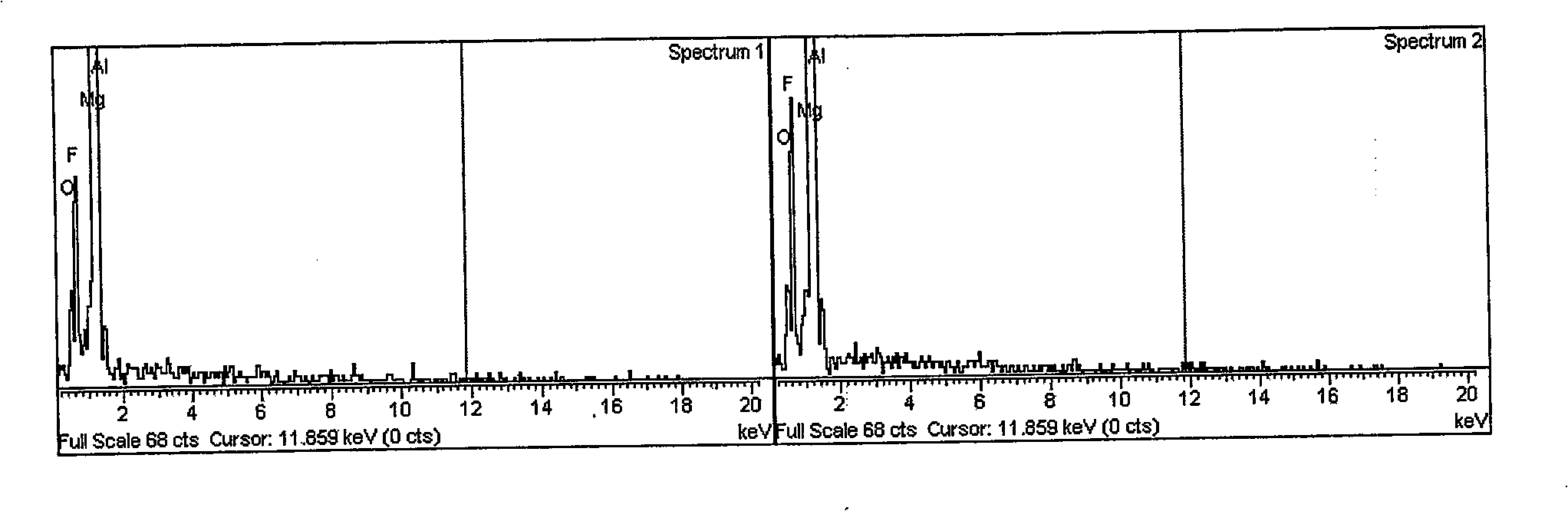

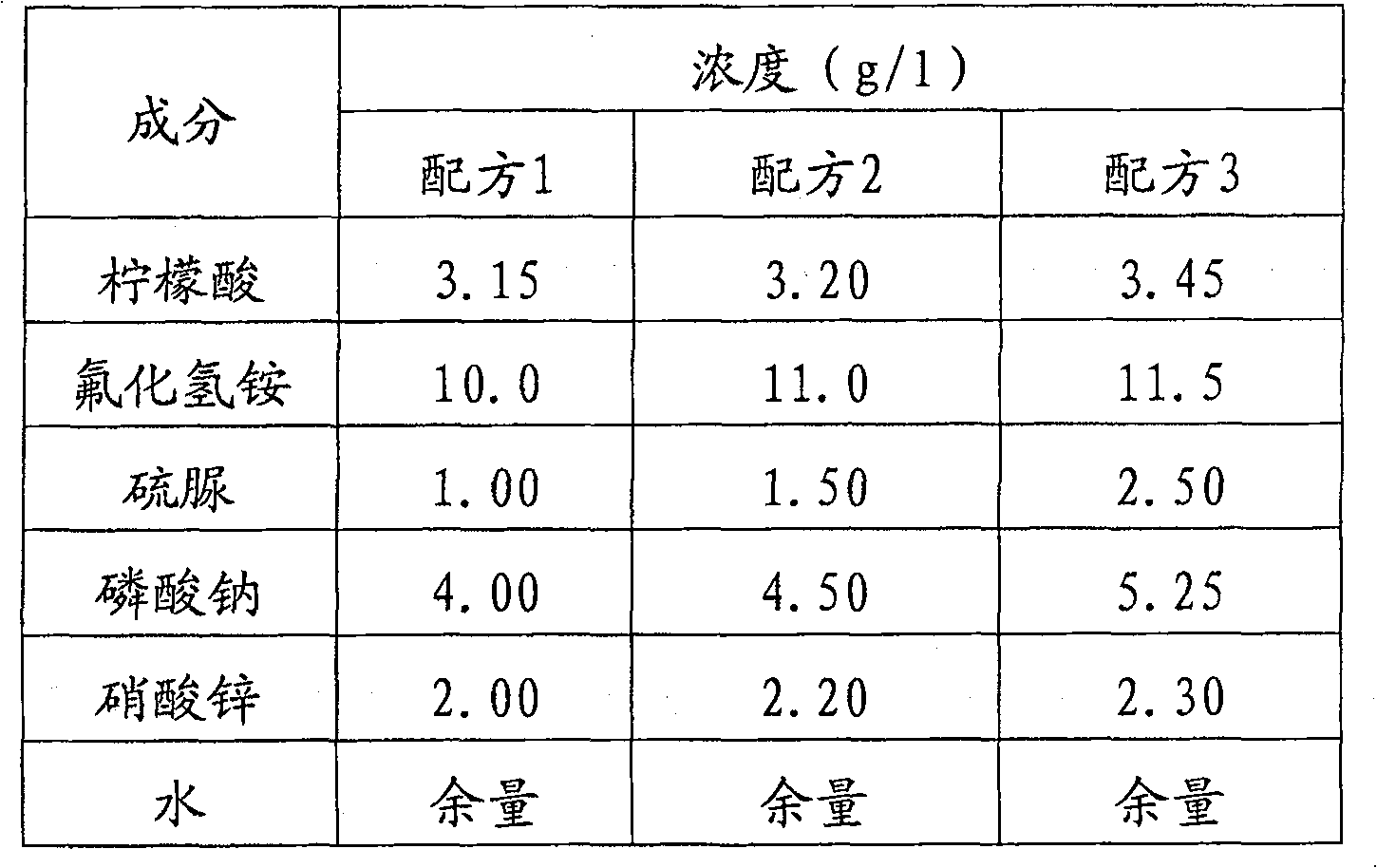

Surface treatment solution for magnesium alloy material and technique for processing magnesium alloy material surface

InactiveCN101161862APlay a protective effectDecorativeMetallic material coating processesSurface cleaningShort terms

The present invention relates to a magnesium alloy material surface treating solution and a magnesium alloy material surface treating technology, and is characterized by comprising the following procedures: the metal surface is cleaned according to the usual surface cleaning method of magnesium alloy; the magnesium alloy material is rapidly transferred to a treating solution to be immersed for 0.5 min to 1.0 min and is hot-air dried under the temperature between 50 DEG C and 70 DEG C; a protective film is formed on the surface of the magnesium alloy material. A layer of exquisite, tight and colorful film is formed on the surface of the magnesium alloy with the technique of the invention, thereby achieving a certain decorative effect. The invention can not only have short-term protection on magnesium alloy but also improve the binding force and the corrosion resistance between the organic coating layer and the magnesium alloy substrate.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Alkaline passivation solution

InactiveCN106521476AWon't change sizeDoes not change glossMetallic material coating processesSodium metasilicatePhosphate

The invention discloses an alkaline passivation solution. The alkaline passivation solution is composed of, by weight percentage, 3%-5% of benzotriazole, 1.5%-1.9% of potassium hydroxide, 1.8%-2.2% of sodium metasilicate pentahydrate, 3%-5% of pentasodium phosphate, 0.25%-0.5% of tetrasodium EDTA, 0.5% of monoethanolamine, 8%-10% of fatty alcohol-polyoxyethylene ether and 74.9%-81.95% of deionized water. The alkaline passivation solution is excellent in alkali resistance. An immersed workpiece does not need neutralization operation; in the using process of the alkaline passivation solution, the original size and glossiness of a stainless steel part cannot be changed; the circumstance that the alkaline passivation solution reacts with the stainless steel part to generate toxic substances cannot occur; the alkaline passivation solution does not contain phosphorus or organic pollutants or various types of heavy metal or toxic substances or irritative and volatile substances, and the working environment of operators is greatly improved; the alkaline passivation solution meets requirements of WEEE&RoHS directives of the European Union; cleaning efficiency is high; the alkaline passivation solution can be used repeatedly; production cost is lowered; corrosion encroachment against a container is small; the service life of the container can be prolonged, and salt mist resisting time of the stainless steel part is effectively prolonged; and the effect is remarkable.

Owner:粟飞

Fishing hook and manufacturing method thereof

The invention relates to the field of fishing appliances, in particular to a fishing hook and a manufacturing method thereof. The fishing hook comprises, by weight, 60-80 parts of zirconium, 5-12 parts of carbon, 3-8 parts of copper, 5-10 parts of titanium, 3-8 parts of nickel and 0.2-0.5 part of aluminum. The fishing hook is light in weight, large in tensile force and high in strength, a fish mouth is easily fastened, so that fishes do not easily fall out, and fishing rate is increased. Besides, the fishing hook is high in penetrating force, long in salt-fog-resistant time and particularly suitable for sea fishing.

Owner:鄱阳县黑金刚钓具有限责任公司

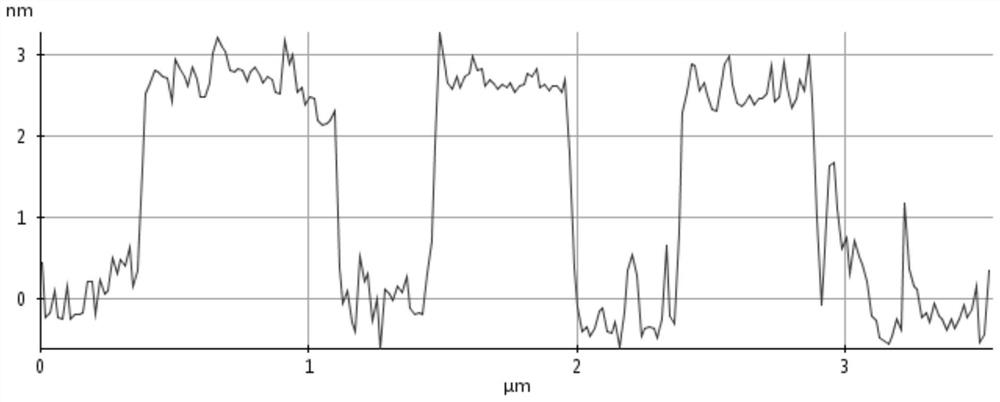

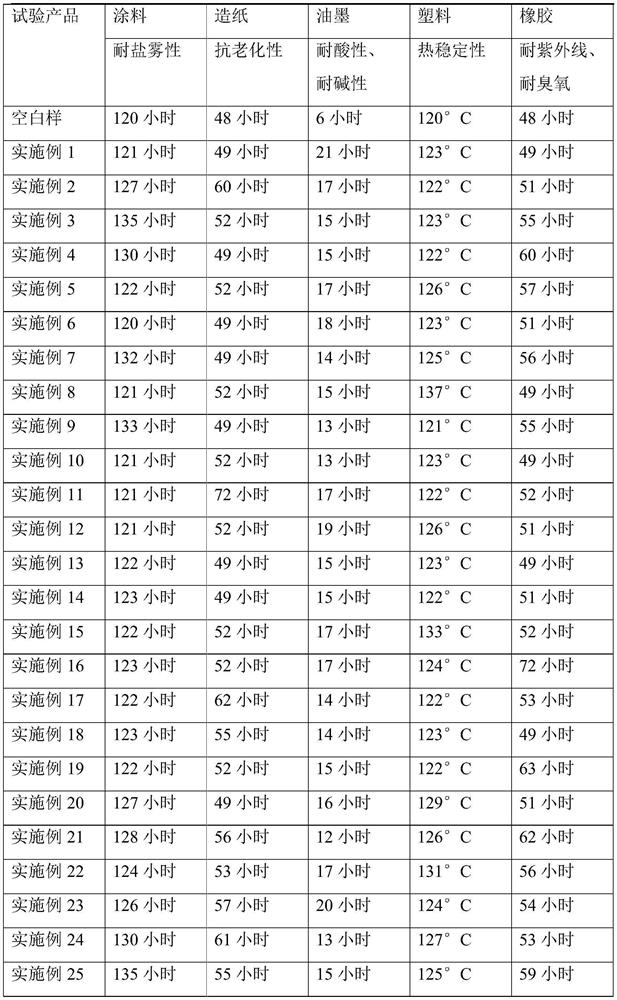

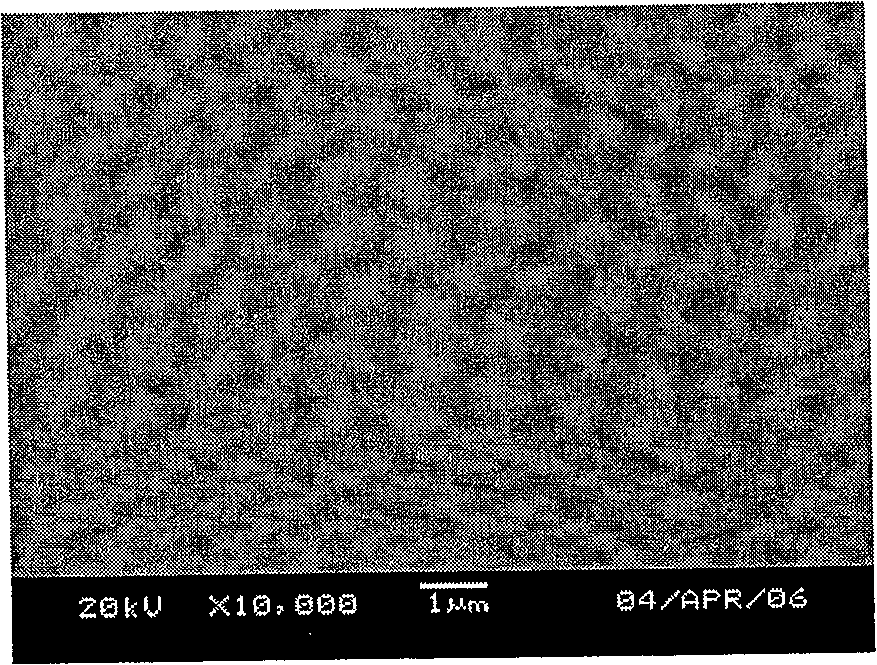

a ca 2+ /sio 2 Preparation method of ion exchange pigment

ActiveCN107722696BHigh purityImprove solubilityAgeing prevention agents additionInksSolubilityPapermaking

The invention provides a preparation method of a Ca<2+> / SiO2 ion exchange type pigment. The preparation method comprises the steps of dissolving a calcium source into an alcohol solvent I, dissolvinga silicon source into an alcohol solvent II, preparing gel by virtue of a sol-gel method, drying, grinding and sieving the gel, selecting dry gel particles with the particle sizes of 0.1-30 microns asa precursor, and maintaining the precursor at 200-1000 DEG C for 0.5-8 hours until the precursor is crystallized, so as to obtain the pigment. The preparation method is simple in process and operation and low in production cost, the prepared Ca<2+> / SiO2 ion exchange type pigment has good solubleness and is applied to the fields of coatings, papermaking, oil ink, plastic, rubber and the like, andthe performance of corresponding materials can be improved; and furthermore, the pigment is low in content of impurity heavy metal, so that the potential safety hazards of a user can be reduced, the environmental friendliness can be improved, and the pigment has good application prospects.

Owner:GUANGXI RES INST OF CHEM IND CO LTD

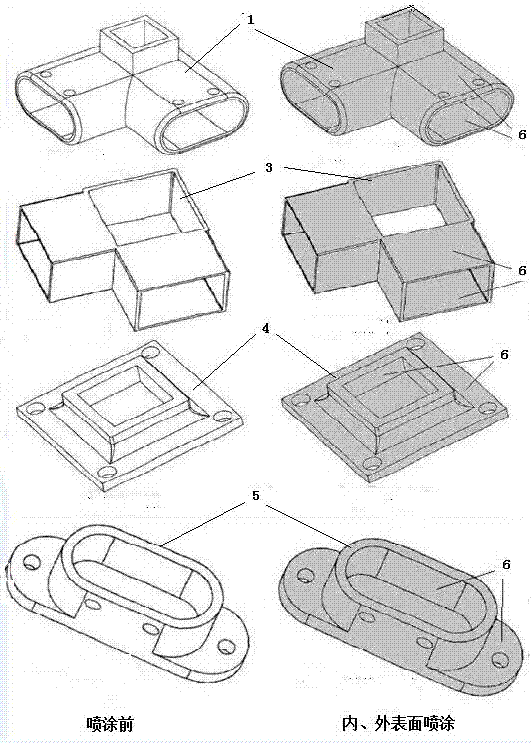

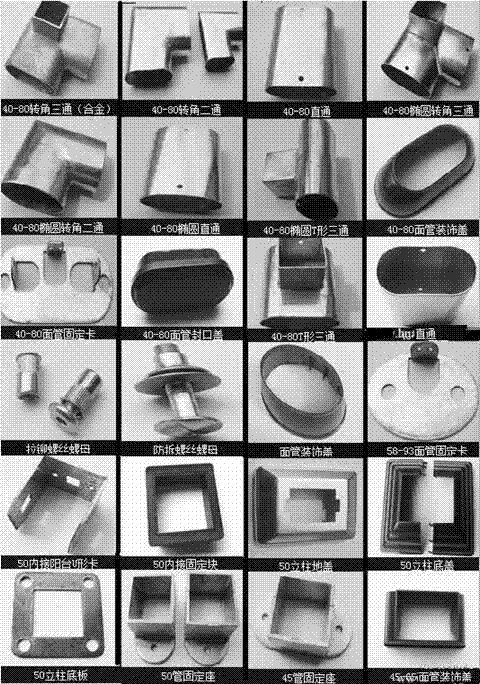

Zinc-steel fence connecting piece with surfaces sprayed with graphene coating

InactiveCN107313599AReduce performanceImprove performanceAnti-corrosive paintsBuilding material handlingConnection typeGraphene coating

A zinc-steel guardrail connector whose surface is sprayed with a graphene coating is characterized in that the prepared graphene coating suitable for the zinc-steel guardrail connector is applied on the outer surface of the zinc-steel guardrail connector or on the outer surface of the guardrail combined with the connector, Or the inner and outer surfaces of the connector, spray / brush the graphene coating with a thickness of 12µm±; for the connector that has been combined with the guardrail and is in use, spray the graphene paint with a thickness of 12µm± on its outer surface, or The outer surface of the combined guardrail is sprayed with a graphene coating with a thickness of 12µm±; for the new connecting piece that has not been combined with the guardrail, a graphene coating with a thickness of 12µm± is sprayed on the inner and outer surfaces; after testing, the thickness of the coating is only 12µm Under the condition of ±, a number of technical performances are superior to the existing surface-sprayed zinc-steel guardrail connectors.

Owner:湖南创新防护设施有限公司

Nickel passivation solution, preparation method thereof and method for passivating nickel surface

ActiveCN103805982AReduce the content of hexavalent chromiumWill not polluteMetallic material coating processesFluoroboric acidSilicon dioxide

The invention provides a nickel passivation solution and a preparation method thereof. The nickel passivation solution contains the following components: 1-5g / L of chromic anhydride, 20-50g / L of sulfuric acid, 0.5-2g / L of nano silica and 5-20g / L of fluoroboric acid. The invention also provides a method for passivating a nickel surface by adopting the nickel passivation solution. By adopting the nickel passivation solution provided by the invention, a stable and permanent passivation layer can be formed on the metallic nickel surface and the salt mist resistance time is greatly lengthened. Meanwhile, the nickel passivation solution provided by the invention has lower content of hexavalent chromium, is safe and environment-friendly and is suitable for plastic workpieces and workpieces with surfaces locally metalized.

Owner:BYD CO LTD

Preparation method of coating composite material

ActiveCN109135525AReduce surface resistanceImprove conductivityAnti-corrosive paintsPolyether coatingsElectrical resistance and conductanceMetallic materials

The invention discloses a preparation method of a coating composite material. The preparation method has the advantages that the method is simple in process, low in production cost and suitable for industrial production; the prepared coating composite material is low in surface resistance, good in conductivity, lasting in salt mist resistance and capable of effectively avoiding metal rusting and corrosion; various metal materials can be coated with the coating material, and the metal materials with the coating material are applicable to fields such as petrochemical industry, cars, ships, engineering machinery and power industry.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Process method for improving salt mist resistance of electroplated steel shell lithium battery

PendingCN114094247ASo as not to damageLong salt spray resistanceCell component detailsMetallurgyMaterials science

The invention relates to a process method for improving salt mist resistance of an electroplated steel shell lithium battery. A compact protective film is added on the surface of the steel shell by replacing a cleaning solvent, so that the salt spray corrosion resistance grade of the lithium battery is improved. According to the technical scheme adopted by the invention, the method comprises the following steps of 1) completing production and sealing of the cylindrical lithium battery, confirming whether the product size meets the process requirement, and feeding qualified products into a cleaning machine, 2) preparing a water-based antirust agent solution with the concentration of 2%, setting the temperature of the solution to be 25 + / -2 DEG C, and cleaning for 20 + / -5 S, 3) after cleaning is completed, blow-drying by using the air pressure of 0.2 Mpa, and 4) baking residual water on the surface by using an oven.

Owner:陕西蓝湾进平新能源有限公司

Composite coating material and application

ActiveCN109181508AReduce surface resistanceImprove conductivityAnti-corrosive paintsPolyether coatingsElectrical resistance and conductanceMetallic materials

The invention discloses a composite coating material and an application. The composite coating material is low in surface resistance, has good conductivity and long salt-spray-resistant time, and caneffectively avoid corroding of metals. The coating material can be coated on multiple metal materials, and the obtained metal materials with the coating are applicable to the fields of petrochemical industry, cars, ships, engineering machines and power industry and the like. The invention discloses a preparation method of the composite coating material, and the preparation method is simple in process and low in production cost and is suitable for industrial production. The composite coating material is low in surface resistance, has good conductivity and long salt-spray-resistant time, and caneffectively avoid corroding of metals. The coating material can be coated on multiple metal materials, and the obtained metal materials with the coating are applicable to the fields of petrochemicalindustry, cars, ships, engineering machines and power industry and the like.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

A kind of conductive anticorrosion coating containing graphene and preparation method thereof

ActiveCN109666370BImprove conductivityEasy to operateAnti-corrosive paintsEpoxy resin coatingsEpoxyGraphite

The invention provides a conductive anticorrosion coating, which comprises 15-25 parts by weight of epoxy resin, 3-10 parts by weight of high-conductivity graphene slurry, 15-35 parts by weight of solvent and auxiliary agent in terms of mass fraction. The invention also provides a preparation method of the conductive anticorrosion paint. The present invention uses high-conductivity graphene material, combined with other components, supplemented with specific ratio and formula, completely replaces metal or metal ion fillers, so that high-conductivity graphene can be uniformly dispersed in the coating, greatly improving the Conductive properties and coating properties can also realize the layer-by-layer superposition of graphene, exert its shielding effect, and better protect. The present invention adopts physical composite methods such as ultrasound with simple process, so that the graphene is evenly distributed in the coating, without adding other additives, and reduces the introduction of impurities, thereby preparing a highly conductive and highly anti-corrosion graphene conductive anti-corrosion coating. Simple operation, safe and environment-friendly.

Owner:SHANDONG OBO NEW MATERIAL CO LTD

Composite passivation solution for mechanical zinc coating

InactiveCN102864447BImprove passivation effectMeet the requirements of corrosion resistancePolyurea/polyurethane coatingsMetallic material coating processesSolventZinc

The invention belongs to the technical field of metal surface treatment and specifically relates to a compound passivating fluid for a mechanical zinc coating. The compound passivating fluid comprises a component A and a component B, wherein the component A is waterborne polyurethane, of which the weight percent is 8-18% in the compound passivating fluid; the component B is an inorganic passivator, of which the weight percent is 2.4-1.5% in the compound passivating fluid; and the balance is deionized water. The pH value of the compound passivating fluid is adjusted to 6-9 by using the sulfuric acid with the mass fraction of 98%. The compound passivating fluid has a better passivating function to a mechanical zinc coating workpiece; the environmental pollution caused by hexavalent chromium is avoided; a formed film is bright and transparent, is durable and excellent in flexibility, has a certain mechanical property, is excellent in water and chemical solvent resistance and is long in salt mist resisting time. The coating has the advantages of self-repairing function, high stability, low cost, simple preparation process and simple use method.

Owner:SHANDONG UNIV OF TECH

A kind of coating composite material and application

ActiveCN109181508BReduce surface resistanceImprove conductivityAnti-corrosive paintsPolyether coatingsMetallic materialsPetrochemical

The invention discloses a coating composite material and its application. The coating composite material has low surface resistance, good electrical conductivity, long salt spray resistance time, and can effectively avoid metal corrosion. Moreover, the coating material of the present invention can be coated on various metal materials, and the obtained metal materials with the coating are suitable for fields such as petrochemical industry, automobile, ship, engineering machinery, electric power industry and the like.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

A kind of calcium/aluminum ion-exchange silica gel doped with rare earth element and preparation method thereof

ActiveCN109365008BHigh purityImprove friendlinessCation exchanger materialsAluminum IonRare-earth element

The invention discloses a calcium / aluminum ion-exchange silica gel doped with rare earth elements and a preparation method thereof. The calcium source, the aluminum source and the silicon source are respectively dispersed in water, and the calcium source dispersion liquid, the aluminum source dispersion liquid and the silicon source are dispersed. and then add rare earth element additives. After mixing evenly, adjust the pH to 4.0-12.0, then prepare the reactant by hydrothermal synthesis, dry and pulverize the reactant to obtain the precursor, and then crystallize the precursor Handling is obtained. The calcium / aluminum ion-exchange silica gel obtained in the present invention is used in the production of coatings, papermaking, printing inks, plastics, and rubber. has good performance.

Owner:GUANGXI XINJING TECH

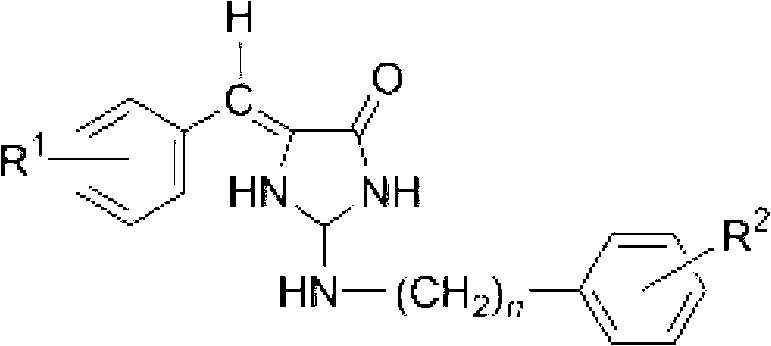

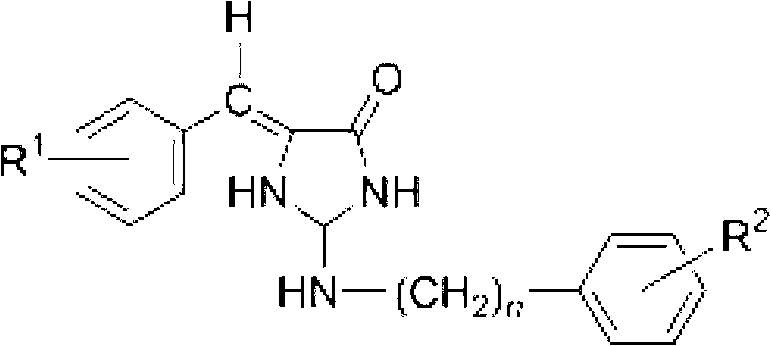

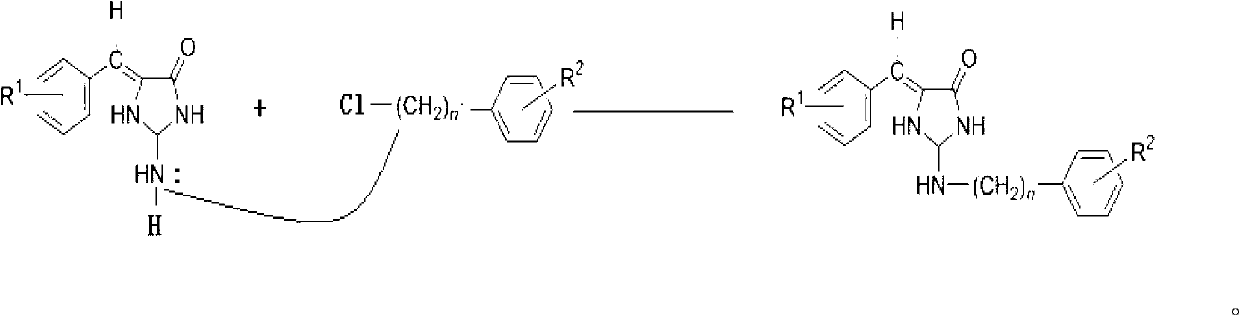

Anticorrosion hard film inhibiter for oil tube

InactiveCN102758206AImprove corrosion resistanceProtection against corrosionSalt resistanceCyclohexanone

The invention discloses an anticorrosion hard film inhibitor for an oil tube. The anticorrosion hard film inhibitor comprises components by weight percentage as follows: 1 to 5% of perchloro-ethylene resin, 15 to 30% of cyclohexanone, 20 to 40% of dimethylbenzene, 5 to 30% of p-phenylenediamine, 1 to 5% of sodium tungstate, and 1 to 10% of imidazoline derivative. The anticorrosion hard film inhibitor has high anticorrosion performance on protecting the oil tube in storing and transporting; and the salt spray resistance can last for 150 hours to the maximum; the hard film inhibitor is easy to remove; and the anticorrosion hard film inhibitor is simple in manufacture technology, convenient for construction, and low in production cost.

Owner:和盛包装科技(海宁)股份有限公司

Surface treatment solution for magnesium alloy material and technique for processing magnesium alloy material surface

InactiveCN100535186CStrong adhesionPlay a protective effectMetallic material coating processesSurface cleaningMetal

The present invention relates to a magnesium alloy material surface treating solution and a magnesium alloy material surface treating technology, and is characterized by comprising the following procedures: the metal surface is cleaned according to the usual surface cleaning method of magnesium alloy; the magnesium alloy material is rapidly transferred to a treating solution to be immersed for 0.5 min to 1.0 min and is hot-air dried under the temperature between 50 DEG C and 70 DEG C; a protective film is formed on the surface of the magnesium alloy material. A layer of exquisite, tight and colorful film is formed on the surface of the magnesium alloy with the technique of the invention, thereby achieving a certain decorative effect. The invention can not only have short-term protection on magnesium alloy but also improve the binding force and the corrosion resistance between the organic coating layer and the magnesium alloy substrate.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

A vacuum coating production process for high physical and chemical performance automobile hubs

InactiveCN103572203BImprove flatnessAccelerated corrosionVacuum evaporation coatingSputtering coatingVacuum chamberVacuum coating

The invention relates to a vacuum coating production process of an automobile hub with high physical and chemical properties. The production process comprises the following steps: (1) processing a hub blank; (2) inspecting and polishing the hub blank; (3) removing oil; (4) cleaning and drying; (5) carrying out pre-treatment; (6) spraying body powder and curing; (7) polishing; (8) spraying medium powder and curing; (9) vacuum coating: spraying a metal coating on the treated hub in a vacuum chamber according to a vacuum sputter coating principle; (10) preparing a transparent coating; and (11) finally inspecting and packaging, wherein the passivation coating is a chromate-free passivation coating and the metal coating is an aluminum film. According to the production process provided by the invention, the surface evenness and the corrosion resistance of the hub are improved, the evenness, the gloss, the hardness and the corrosion resistance of the surface of the hub are increased, the surface of the hub is sealed and metallized, and the hub has glossiness of water electroplating. The transparent coating has an adhesive force of a high vacuum coating. The production process provided by the invention is concise and low in energy consumption, and the prepared hub is high in hardness and strong in corrosion resistance.

Owner:NORD WHEEL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com