Anticorrosion hard film inhibiter for oil tube

A technology of corrosion inhibitor and hard coating, applied in the field of hard coating corrosion inhibitor and anti-corrosion hard coating corrosion inhibitor, to achieve the effects of easy removal, long salt spray resistance and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

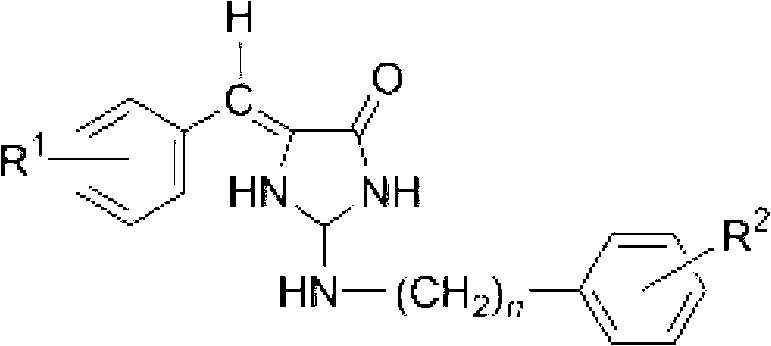

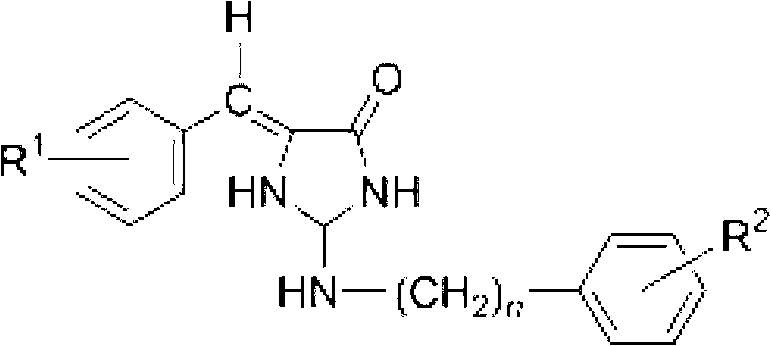

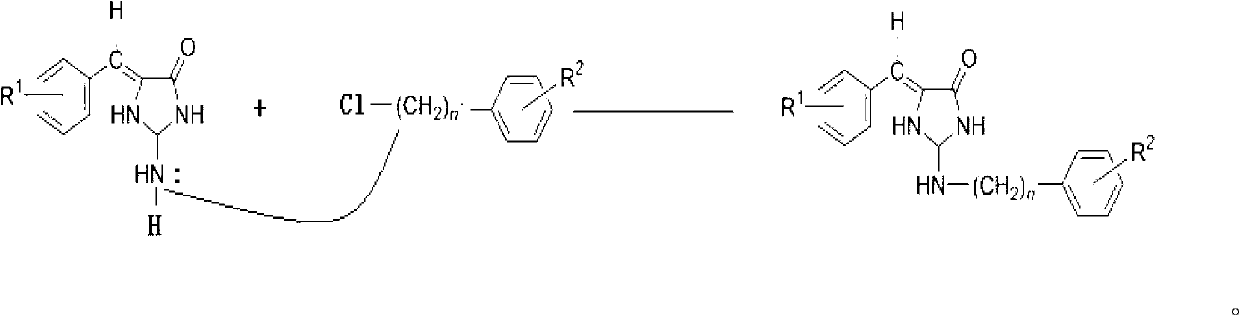

Method used

Image

Examples

Embodiment 1

[0021] This tubing dural corrosion inhibitor is prepared according to the following composition ratio (mass percentage content):

[0022] Perchlorovinyl resin 1%,

[0023] Cyclohexanone 30%,

[0024] Xylene 40%,

[0025] P-phenylenediamine 27%,

[0027] Imidazole derivatives 1%.

[0028] The preparation method of the present invention is as follows: directly add the above-mentioned substances into the reaction kettle to dissolve, stir uniformly, and pack; spray the hard film corrosion inhibitor directly on the surface of the tubing during construction and dry at room temperature.

[0029] The beneficial effects of this embodiment: the salt spray resistance time of the hard film corrosion inhibitor coated on N80 steel is 143 hours, the adhesion is level 3, and it is easy to remove.

Embodiment 2

[0031] This tubing dural corrosion inhibitor is prepared according to the following composition ratio (mass percentage content):

[0032] Perchlorovinyl resin 5%,

[0033] Cyclohexanone 30%,

[0034] Xylene 20%,

[0035] P-phenylenediamine 30%,

[0037] Imidazoline derivatives 10%.

[0038] The preparation method is the same as in Example 1.

[0039] Effect: The salt spray resistance of the hard film corrosion inhibitor coated on N80 steel is 155 hours, the adhesion is level 1, and it is not easy to remove.

Embodiment 3

[0041] This tubing dural corrosion inhibitor is prepared according to the following composition ratio (mass percentage content):

[0042] Perchloroethylene resin 3%,

[0043] Cyclohexanone 30%,

[0044] Xylene 40%,

[0045] P-phenylenediamine 20%,

[0046] Sodium tungstate 2%,

[0047] Imidazoline derivatives 5%.

[0048] The preparation method is the same as in Example 1.

[0049] The effect of the embodiment: the salt spray resistance time of the hard film corrosion inhibitor coated on N80 steel is 145 hours, the adhesion is level 2, and it is easier to remove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com