Resin anticorrosion paint containing graphene/epoxy resin composite material and preparation method thereof

A technology of anti-corrosion coatings and epoxy resins, applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problems of easy agglomeration of graphene, difficulty in opening, poor effect, etc., achieve high-strength paint film thickness and improve performance , Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

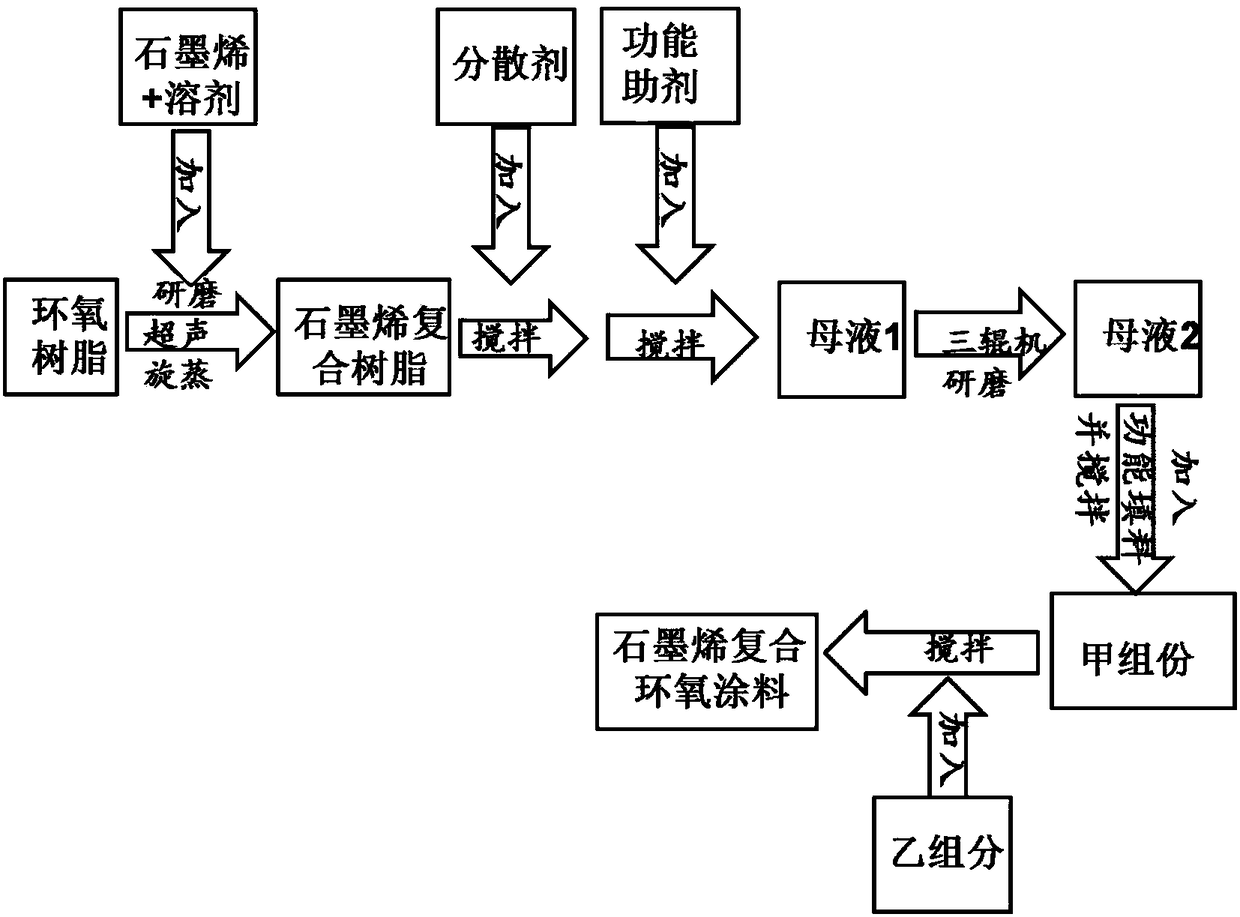

[0090] The present invention also provides a kind of preparation method of resin anticorrosion coating, comprises the following steps:

[0091] A) after mixing graphene and epoxy resin for the first time, obtain graphene composite epoxy resin;

[0092] B) the composite material, filler and solvent of graphene and epoxy resin obtained in the above steps are mixed, and after grinding again, intermediate products are obtained;

[0093] C) after the intermediate product obtained in the above steps, zinc powder, auxiliary agent and solvent are mixed again, the resin anticorrosion coating is obtained;

[0094] The auxiliary agent includes one or more of dispersant, anti-settling agent, defoamer, filler, curing agent and accelerator.

[0095] The present invention can correspond to the selection and composition of the raw materials required in the above-mentioned preparation process, as well as the corresponding optimization principles, and the selection and composition of the corre...

Embodiment 1

[0185] Graphene / epoxy composites

[0186] Weigh 40g of epoxy resin 601, 30g of xylene, and 3g of n-butanol and mix them uniformly under the condition of ultrasonic stirring, the stirring speed is between 200-500, and the ultrasonic frequency is 40kHz.

[0187] Then weigh 10 g of graphene slurry with a solid content of 2%, add 30 g of n-butanol and ultrasonically stir for 30 min to disperse the graphene evenly in n-butanol at a stirring speed of 200-500. The ultrasonic frequency is 40kHz.

[0188] Then, the dispersed graphene solution was added dropwise into the epoxy resin 601 solution under ultrasonic stirring to obtain a precursor solution.

[0189] The precursor solution obtained in the above steps was then subjected to wet ball milling at a ball milling speed of 300 r / s for 30 minutes, followed by ultrasonic stirring for 30 minutes to obtain a mixed solution.

[0190] Then, the graphene-epoxy resin mixed solution is processed by rotary evaporation until about 95% of the ...

Embodiment 2

[0193] 1) Graphene composite epoxy resin 601 was prepared with reference to the method of Example 1, wherein the graphene produced by Shandong Oupo New Materials Co., Ltd. was 0.56g, the solvent xylene was 22.8g, and the epoxy resin was 28g.

[0194] 2) Add the graphene composite resin obtained in step 1) into the stirrer; add propylene carbonate 11.3g, propylene glycol methyl ether 6.6g, defoamer 0.3g, and stir at a rotating speed of 1000r / min for 30min;

[0195] 3) In the graphene composite resin solution obtained in step 2), add calcium carbonate 40g, ferrophosphorus powder 28.3g, organoclay 2.15g, and stir to obtain mother liquor 1, rotating speed 3000r / min, stirring for 50min;

[0196] 4) Grinding with a three-roll machine for 30 minutes to obtain mother liquor 2;

[0197] 5) To the mother liquor 2 obtained in step 4), add 100.7g spherical zinc powder, 0.65g propylene carbonate, 1g Monoral3300, 5g aluminum powder slurry and stir for 30 minutes to obtain component A;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com