Graphene-containing electric-conduction anticorrosive coating material and preparation method thereof

A conductive anti-corrosion and graphene technology, which is applied in the field of conductive anti-corrosion coating and its preparation, conductive anti-corrosion coating containing graphene and its preparation, can solve the effect of coating film-forming performance or conductive anti-corrosion, affect the effect of graphene materials, heavy metals Ion pollution environment and other problems, to achieve the effect of solving uneven mixing, good protection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

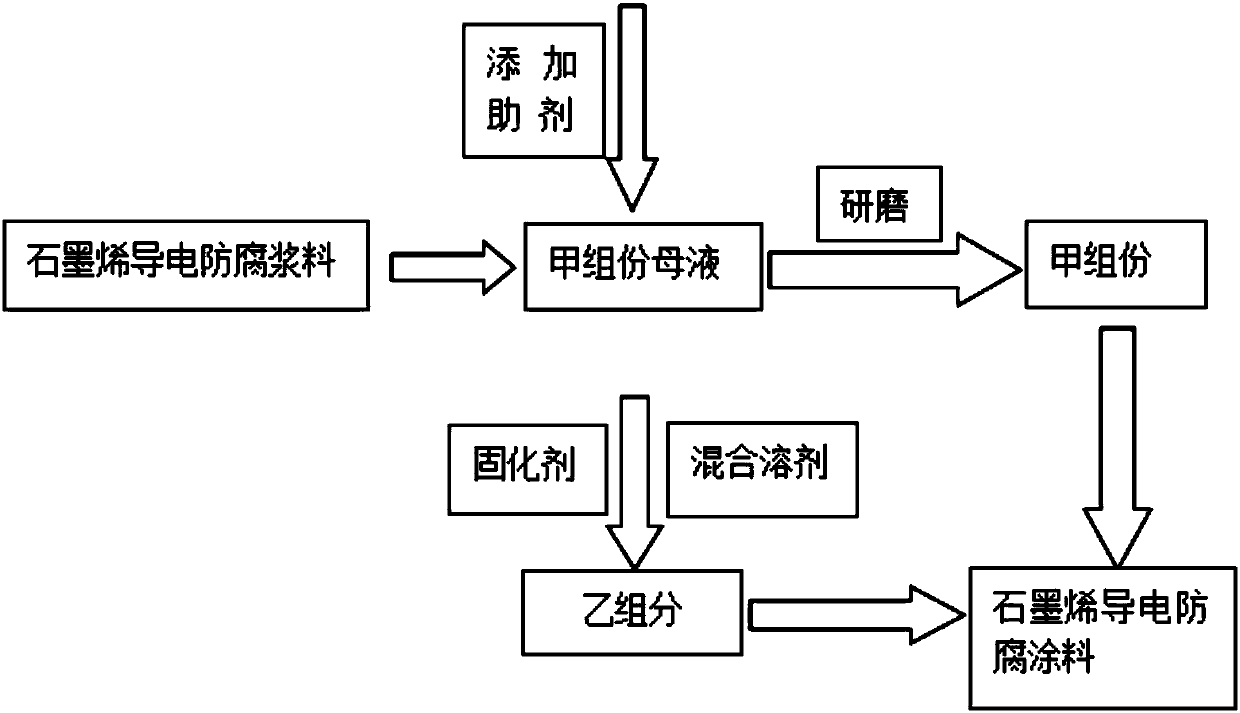

[0090] The present invention also provides a kind of preparation method of conductive anticorrosion paint, comprises the following steps:

[0091] 1) After mixing highly conductive graphene slurry, epoxy resin, anti-sedimentation agent, anti-rust agent, dispersant, coupling agent and solvent, and then grinding to obtain the first component of the conductive anti-corrosion coating;

[0092] After mixing the curing agent, accelerator and solvent again, the second component of the conductive anticorrosive coating is obtained;

[0093] The auxiliary agent includes one or more of a dispersant, an anti-settling agent, an antirust agent, a coupling agent, a curing agent and an accelerator.

[0094] The present invention can correspond to the selection and composition of the raw materials required in the above-mentioned preparation process, as well as the corresponding optimization principles, and the selection and composition of the corresponding raw materials in the aforementioned c...

Embodiment 1

[0146] Highly Conductive Graphene

[0147] The raw material is 1000 mesh natural graphite (Qingdao Dongkai Graphite Co., Ltd.). Mix and disperse 10 g of graphite and 50 g of sodium dihydrogen carbonate in 100 g of water, stir the mixture mechanically, react at room temperature for 20 hours, add 400 g of water to dilute, and centrifuge to obtain intercalated graphite. The intercalated graphite was placed in a muffle furnace at 1000 °C and expanded for 30 s. 5g of expanded graphite was dispersed in 5LN-methylpyrrolidone, 800W ultrasonic stripping for 8h, 300rmp ball milling for 2h, centrifugal washing and drying to obtain highly conductive graphene.

[0148] The highly conductive graphene prepared in Example 1 of the present invention was characterized.

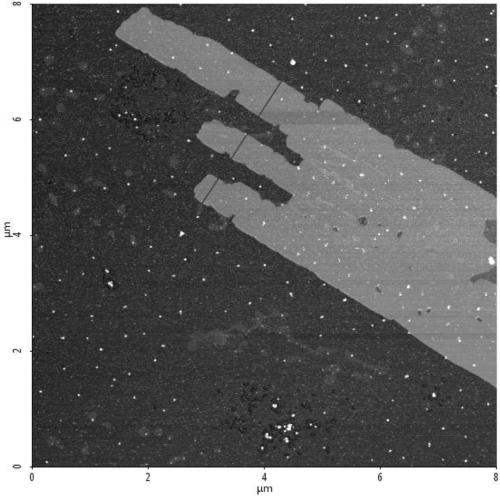

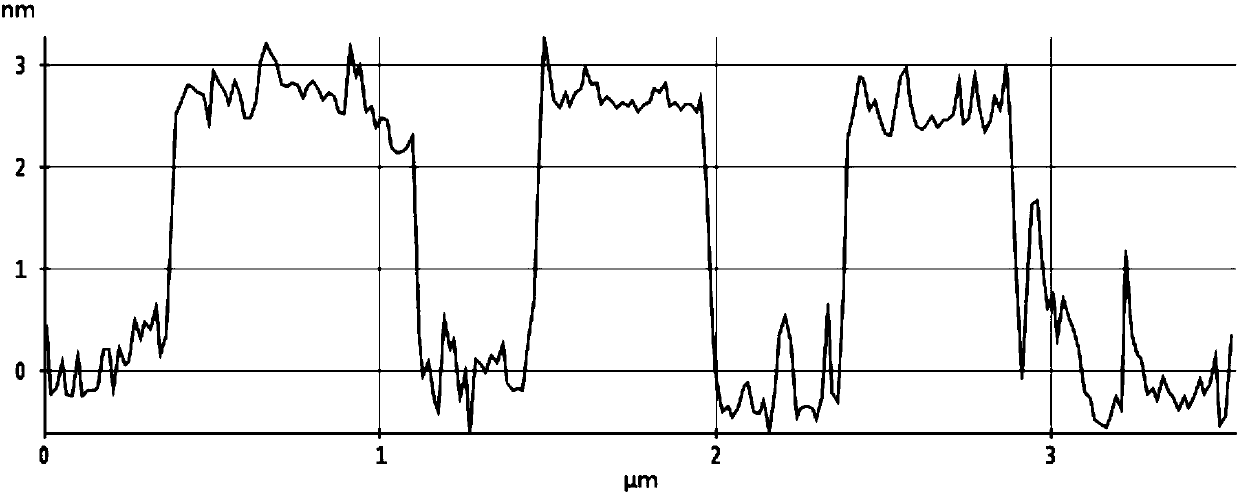

[0149] see figure 1 , figure 1 Atomic force microscope photo of the highly conductive graphene prepared in Example 1 of the present invention.

[0150] Depend on figure 1 The atomic force microscope photos show that the g...

Embodiment 2

[0165] 1, get the highly conductive graphene slurry 5g that embodiment 1 prepares, and mass concentration is 1%;

[0166] 2. Add 19.3g epoxy resin E20, 2.5g anti-settling agent 3300, 15.5g oily antirust agent, 0.3g dispersant propylene carbonate, 0.3g silane coupling agent, 9g of solvent (mixed solvent of xylene n-butanol), stirred at a speed of 1000-3000r / min until uniformly dispersed, and dispersed for 1h.

[0167] 3. Put the mixture obtained in step 2 into a three-roll machine and grind it to 25-55 μm to obtain component A.

[0168] The preparation method of component B of conductive anti-corrosion coating is as follows:

[0169] 4. Mix xylene and n-butanol in a weight ratio of 7:3 to make 15g of mixed solvent.

[0170] 5. Add 10g of polyamide 200 curing agent and 0.5g of DMP-30 accelerator to step 4 in sequence, and stir at a speed of 500-1000r / min until uniformly dispersed to obtain component B.

[0171] The paint film of the conductive anticorrosion coating containing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com