Preparation method of graphene anticorrosive paint

A technology of anti-corrosion coatings and graphene, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex steps of graphene addition, achieve good chemical stability, wide application range, and reduce content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0075] A kind of preparation method of anticorrosion epoxy resin coating, comprises the steps:

[0076] 1, the preparation method of described anticorrosion coating first component is:

[0077] (1) Add the epoxy resin of the formula amount of component A into the stirring container, and stir at the speed of 1000-1500r / min;

[0078] (2) Then add the solvent, zinc powder, graphene and filler in the formula of component A in sequence, and continue to stir at a speed of 2000-3000r / min until the dispersion is uniform;

[0079] (3) Add the mixture obtained in step (2) into a three-stage grinder and grind it to 20-60 μm to obtain component A;

[0080] II, the preparation method of the second component of the anticorrosion coating is:

[0081] (4) A mixed solvent made of xylene and isobutanol in a weight ratio of 1:1 is used as the solvent for component B. Sequentially mix the curing agent and the solvent in the formulation amount of component B to obtain component B;

[0082] III...

Embodiment 5

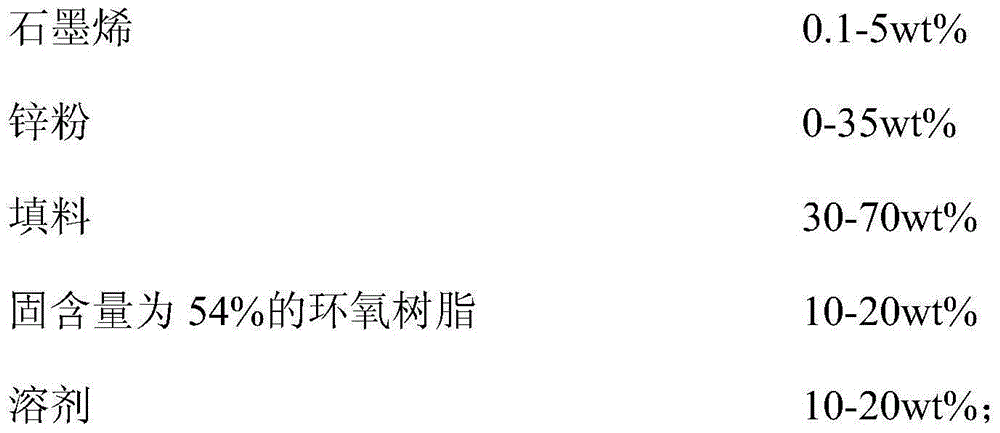

[0089] A kind of anticorrosion epoxy resin coating comprises following component by weight percentage:

[0090] Component A:

[0091]

[0092] Wherein, described epoxy resin is the SM-601 epoxy resin (dispersion solvent is xylene) that solid content is 54%, and the mass percent content sum of graphene, zinc powder and filler is 60wt%; Described graphene It is oxidized by the Staudenmaier method, and then obtained by pyrolytic expansion and peeling;

[0093] B component:

[0094] Polyamide resin curing agent 40wt%

[0095] Xylene and isobutanol m:m=1:1 (fixed) 60wt%;

[0096] Wherein, the sum of each component in the B component is 100wt%.

[0097] The preparation method of described anticorrosion epoxy resin coating comprises the steps:

[0098] (1) Add the epoxy resin of the formula amount of component A into the stirring container, and stir under the rotating speed of 1500r / min;

[0099] (2) Then add the solvent, zinc powder, graphene and filler in the formula amount ...

Embodiment 6

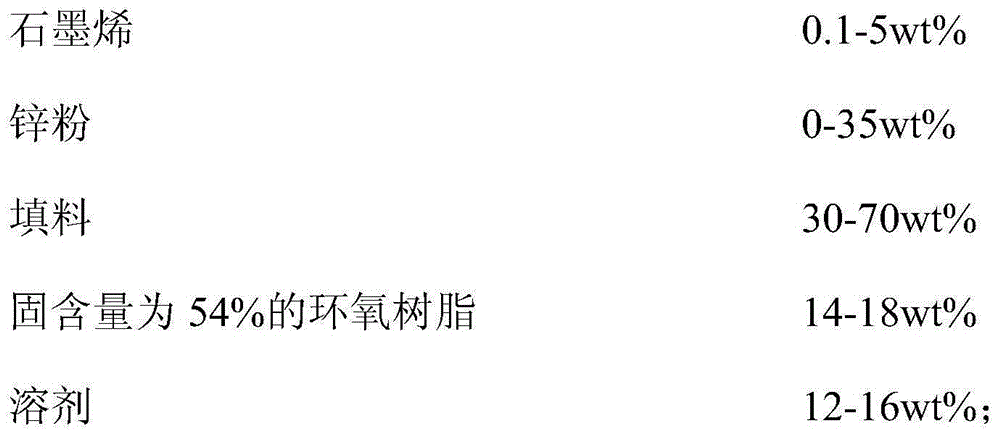

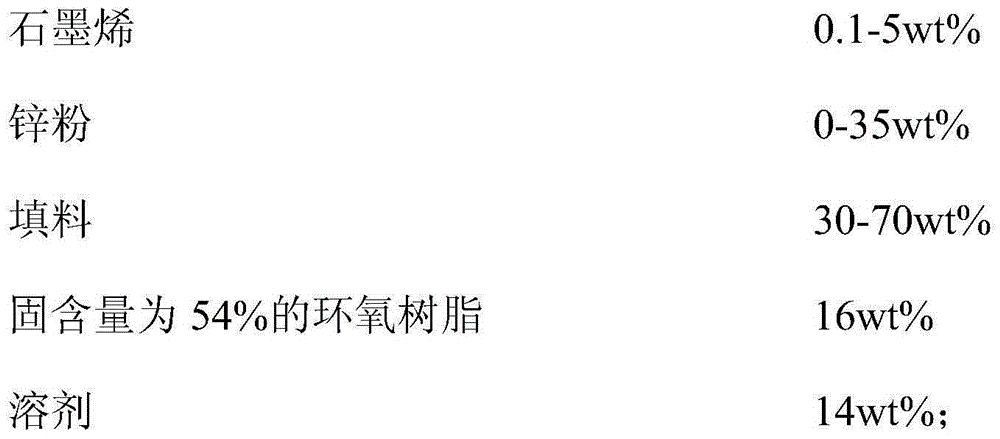

[0105] A kind of anticorrosion epoxy resin coating comprises following component by weight percentage:

[0106] Component A:

[0107]

[0108] Wherein, described epoxy resin is the SM-601 epoxy resin (dispersion solvent is xylene) that solid content is 54%, and the mass percent content sum of graphene, zinc powder and filler is 80wt%; Described graphene It is oxidized by Brodie method, and then obtained by ultrasonic dispersion;

[0109] B component:

[0110] Acrylic resin curing agent 60wt%

[0111] Xylene and isobutanol (m:m=1:1) 40wt%;

[0112] Wherein, the sum of each component in the B component is 100wt%.

[0113] The preparation method of described anticorrosion epoxy resin coating comprises the steps:

[0114] (1) Add the epoxy resin of the formula amount of component A into the stirring container, and stir under the rotating speed of 1000r / min;

[0115] (2) Then add the solvent, zinc powder, graphene and filler in the formula amount of component A in sequence...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com