Patents

Literature

38results about How to "Reduce the content of hexavalent chromium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment process for reducing content of hexavalence chromate in leather

InactiveCN1597993AIngenious ideaSimple process and operationTanning treatmentDamp environmentChemistry

The invention provides a treating method of reducing the content of the hexavalent chrome in fur. Its features that: spray the solution of the reducing agent with mass percent of 0.5% to 3.0% onto the leather and the semi-manufactured fur operated in damp environment or treat the semi-manufactured fur operated in damp environment in the drum. The inducing agent is once of the ferrous sulphate, ferrous chloride, amine ferrous sulphate, sodium sulfite, potassium sulfite and sodium thiosulfate. The invention can not only be used to treat the leather with the superscale hexavalent chrome, but also treat the semi-manufactured leather during the processing and prevent the formation of the hexavalent chrome in the leather. The invention simple technique and operation, richful resource of inducing agent, low cost, and no influence to the later procedure and quality of the fur.

Owner:SICHUAN UNIV

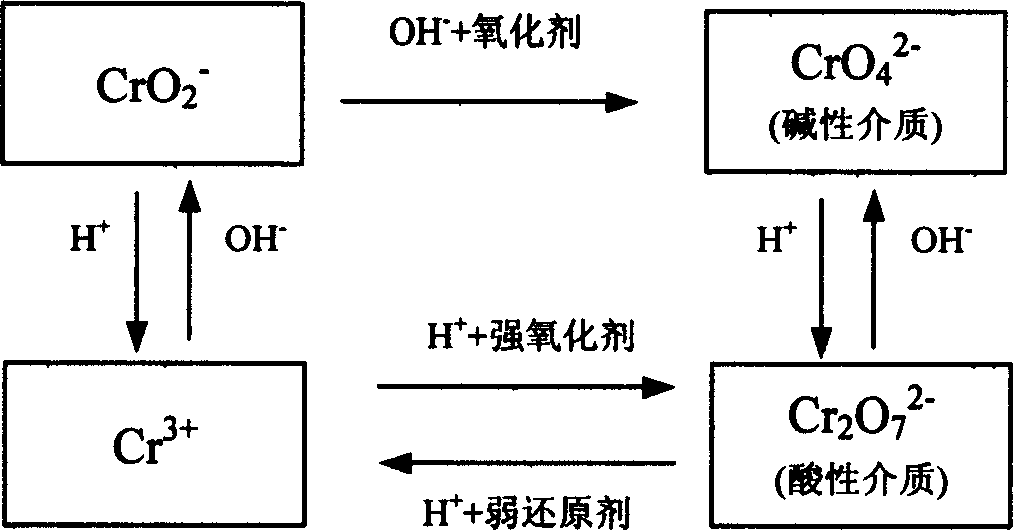

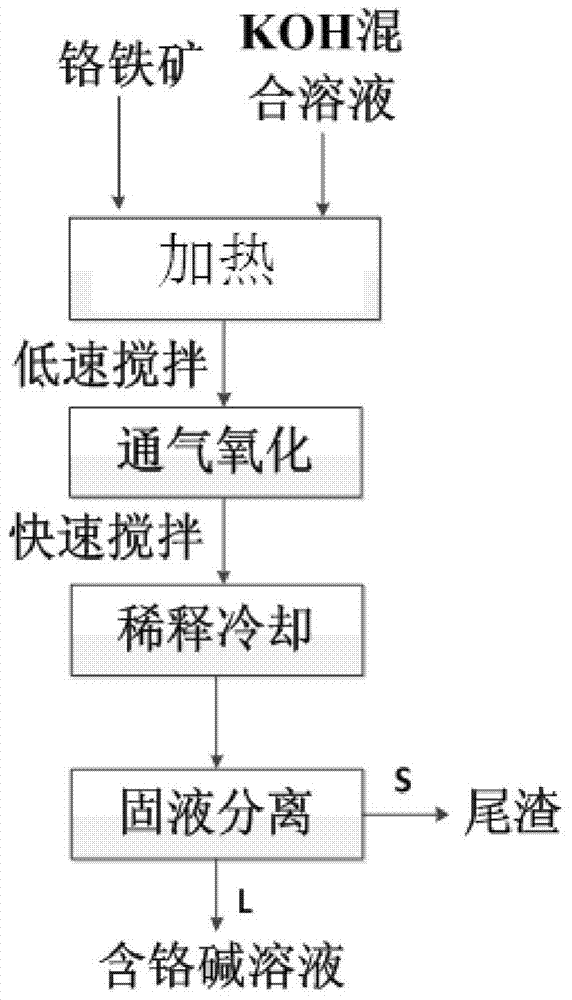

Method for extracting chromium from chromite by leaching

ActiveCN104726705ALow in chromiumEmission reductionProcess efficiency improvementPotassiumPotassium hydroxide

The invention relates to a method for extracting chromium from chromite by pressure leaching, which comprises the following steps: mixing chromite and / or pretreated chromite with a potassium hydroxide water solution, a potassium carbonate water solution and a potassium metaaluminate water solution to obtain an original slurry; adding the original slurry into a high-pressure autoclave, introducing oxidizing gas, and carrying out pressure leaching oxidizing reaction to obtain a reaction slurry; and carrying out solid-liquid separation to respectively obtain iron-rich tailings and a solution containing potassium chromate, potassium hydroxide, potassium carbonate, potassium aluminate and other water-soluble impurity components. The method has the advantages of greatly lower reaction temperature and low energy consumption, and effectively lowers the production cost, and the maximum chromium extraction yield can reach 97% above. Besides, the volume of the high-pressure autoclave can be 200L, and the reaction medium has the same proportioning as the industrial circulating liquor, so that the process is very close to the industrial process and can easily implement industrialization.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Alkali-acid double-cycle process for treating brown iron type nickel laterite ore

ActiveCN101691635AAchieve recyclingObvious superiorityProcess efficiency improvementAluminatePotassium hydroxide

The invention provides an alkali-acid double-cycle process for treating brown iron type nickel laterite ore. In the process, a brown iron type depleted nickel laterite ore is used as a raw material and undergoes roasting reaction with alkali such as sodium hydroxide, potassium hydroxide and the like or carbonate thereof at high temperature, and then the roasted materials are subjected to waster washing and liquid-solid separation to form alkali filter liquor rich in valent metal salts such as water-soluble chromate, aluminate and the like and insoluble filter cakes, wherein the filter liquor can be fully utilized to prepare chromium salt and aluminum salt and the recycle of alkali media is realized; and the filter cakes can be used for extracting nickel and cobalt through a subsequent pressurized and acid leaching process, the acid leaching dregs are high-grade fine iron powder, and acid media in the acid leaching liquor can be recycled.

Owner:河南永通不锈钢制品有限公司 +1

Method for preparing protein filling material for leather preparation by using leather preparation chromium-containing leftover material as raw material

InactiveCN101260141ASolve the pollution problemIncrease added valueConnective tissue peptidesTanning treatmentScrapChromium

The invention provides a method for preparing protein fillers used for tanning by taking tanning chrome containing scrap materials as materials. The invention is characterized in that chrome containing scrap materials obtained from pieced wet blue are ground, and 100 portions by weight of chrome containing scrap materials are picked up and soaked in an alkali compound solution with the concentration of between 0.1 and 2wt percent, which at least submerges chrome containing scrap materials, for 10 to 48 hours, and the chrome containing scrap materials are drained, and the pretreated chrome containing scrap materials are put in a reaction kettle provided with a stirrer, a thermometer and a reflux condenser, and 6 to 20 portions by weight of alkali compounds and water at least submerging chrome containing scrap materials are added, and the reaction kettle is heated to a temperature of between 50 and 95 DEG C and keeps the temperature for 2 to 20 hours, and the thick liquids with deep color are obtained, and the pH value of the thick liquids is adjusted to between 7 and 10 by an inorganic acid after the thick liquids are cooled, and the thick liquids are filtered, and the filtrate with the solid content of between 10 and 20 percent, which is rich in containing collagen polypeptides, and the filter residues are obtained, and finally the protein fillers for tanning are obtained after the filtrate is condensed and dried; the filter residues are added with 100 to 150 portions by weight of water and has the pH value adjusted to between 2 and 3 by the inorganic acid solution, which obtains a Cr2(SO4)3 green solution used for the chroming agent.

Owner:SICHUAN UNIV +1

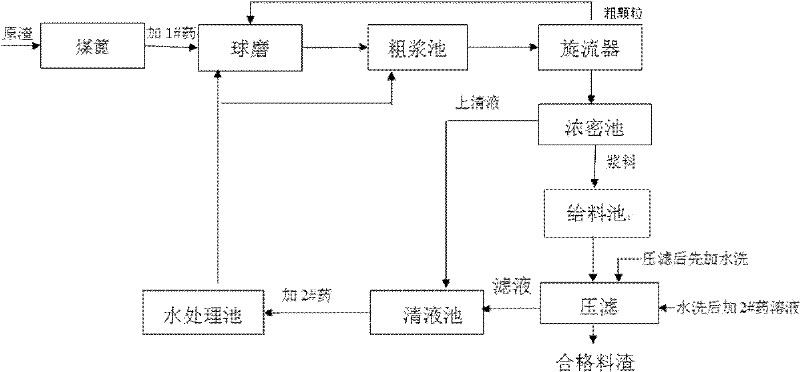

Chromium residue wet detoxication processing method

InactiveCN102210919ALow costGuaranteed detoxification effectChemical protectionChemistryHexavalent chromium

The invention discloses a chromium residue wet detoxication processing method which comprises the following steps: (1) using water to perform wet ball-milling on a chromium residue at a normal temperature; meanwhile, adding a soluble carobonat or a bicarbonate or a carbon dioxide which is 0.1-15wt% of the chromium residue; (2) carrying out fine particle and coarse particle separation on the residue liquid after the ball-milling by virtue of a hydrocyclone, repeatedly performing the ball-milling on the coarse particles with particle size more than 74 microns, and putting the fine particles with the particle size less than 74 microns in a reaction tank; and (3) reacting for 3-24 hours, performing the solid-liquid separation by using a plate-and-frame filter press with a rinsing function, rinsing repeatedly, adding barium chloride or lead acetate and lead nitrate into the filtrate to produce a chrome yellow, and adding a barium chloride or a ferrous solution sulfate in trace hexavalent chromium remained in a filter cake. Compared with the prior art, the chromium residue detoxication processing method has the obvious advantages and effects that a produced carbonate ion can be used for replacing an indissolvable chromate ion in the chromium residue so as to promote the indissolvable hexavalent chromium in the residue to be completely dissolved in a water solution without using acid; not only can the cost be reduced, but also the subsequent filter difficulty is not increased; and the content of the hexavalent chromium in the final residue is very low, and the detoxication effect is guaranteed.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

Clean production process for processing low-grade laterite-nickel ore by sodium hydroxide alkali fusion method

InactiveCN101864523AObvious superiorityImprove leaching rateProcess efficiency improvementEvaporationLaterite

The invention relates to a clean production process for processing low-grade laterite-nickel ore by a sodium hydroxide alkali fusion method. The process comprises the following steps: taking laterite-nickel ore as a raw material, carrying out roasting reaction on the laterite-nickel ore and sodium hydroxide at high temperature, washing and filtering the roasted material, and leaching valuable metal salts in the laterite-nickel ore, such as water-soluble chromium, aluminium and the like generated after the reaction. High-temperature roasting damages the crystal lattice structure of the laterite-nickel ore, thereby greatly improving the leaching rate of nickel and cobalt in the subsequent high-pressure acid leaching process and the grade of Fe in acid leaching dregs; filtrate is prepared into chromium salt, aluminium salt and recyclable sodium hydroxide by operations, such as evaporation, crystallization, separation and the like, so that the laterite-nickel ore product is diversified. The leaching rate of hexavalent chromium in the laterite-nickel ore is more than 90%, the leaching rate of trivalent aluminium is more than 75%, the leaching rate of the nickel is more than 98%, the leaching rate of the chromium is more than 94%, and the Fe content of fine iron powder in the acid leaching dregs is more than 61%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing anhydrous sodium sulfate from chromium-containing mirabilite

ActiveCN107934993AAvoid the problem of excessive hexavalent chromiumReduce the content of hexavalent chromiumChromium compoundsAlkali metal sulfites/sulfatesChemical industryChromium trioxide

The invention relates to the field of a chemical industry and particularly relates to a method for preparing anhydrous sodium sulfate from chromium-containing mirabilite as a by-product in the production process of sodium dichromate. The method comprises dissolving a certain concentration of chrome-containing mirabilite in chromium-containing waste water, adding quantitative sodium thiosulfate into the waste water to promote reduction of hexavalent chromium into trivalent chromium under 0.1-1 Mpa at 80-190 DEG C, wherein the trivalent chromium in a form of chromium trioxide hydrate is precipitated, adding a small amount of sulfuric acid to neutralize, filtering to acquire the chromium trioxide hydrate, removing impurities, carrying out decoloration, evaporating to precipitate anhydrous sodium sulfate crystals, and carrying out continuous centrifugal separation and drying. The method is simple and easy, utilizes cheap raw materials, has low energy consumption and a high automation degree and is suitable for large-scale production. The quality of the industrial anhydrous sodium sulfate product obtained by the method meets the requirements of class I products in the GB / T 6009-2014 industrial anhydrous sodium sulfate standard.

Owner:陕西省商南县东正化工有限责任公司

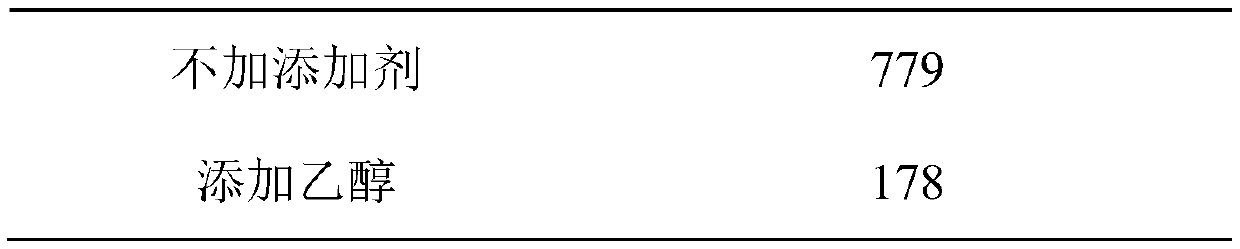

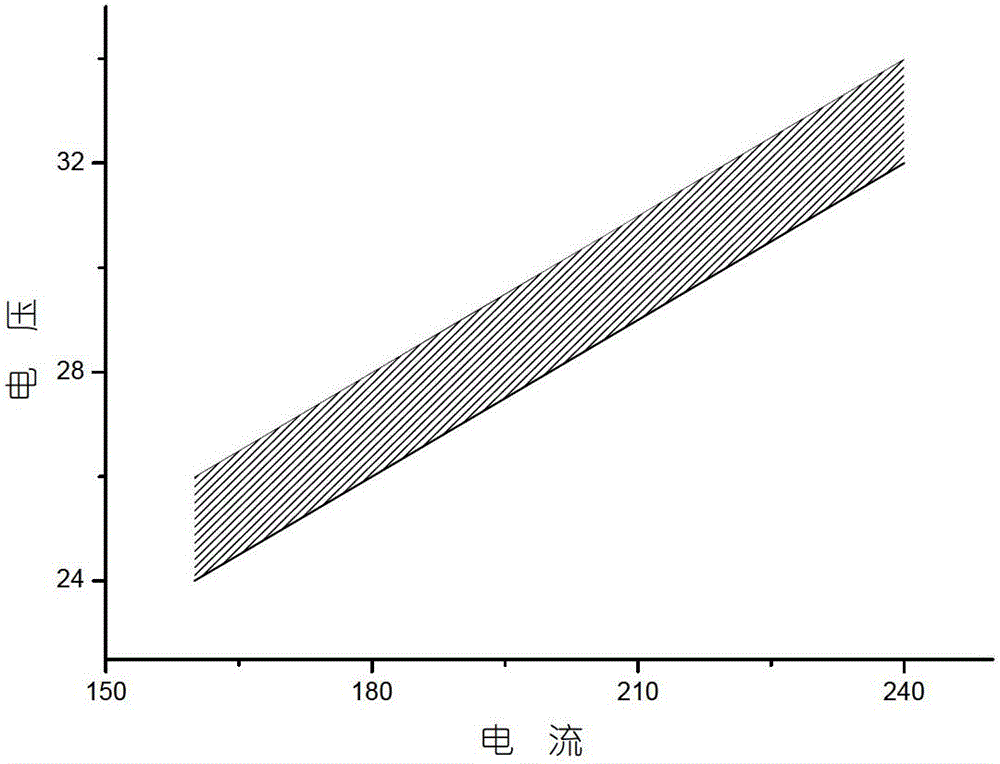

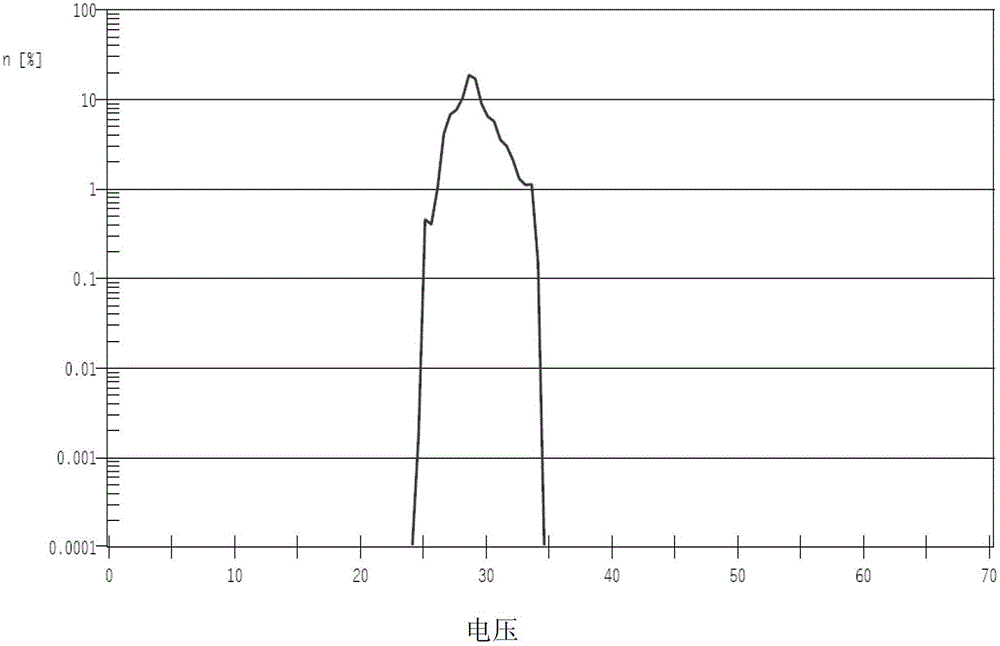

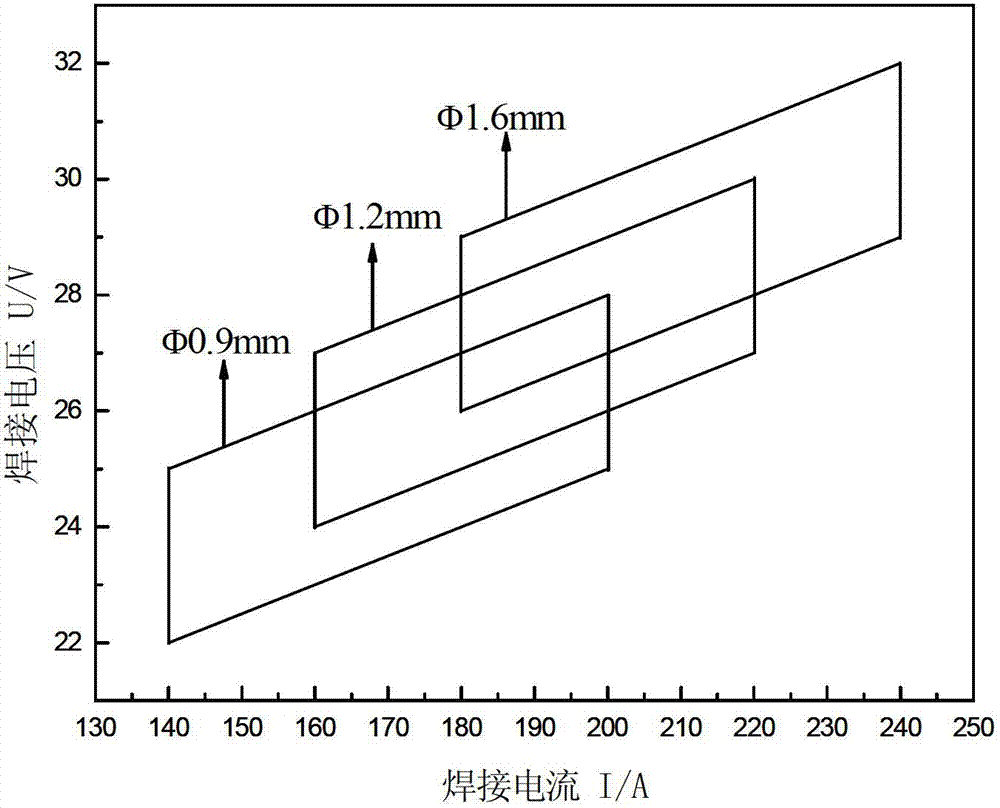

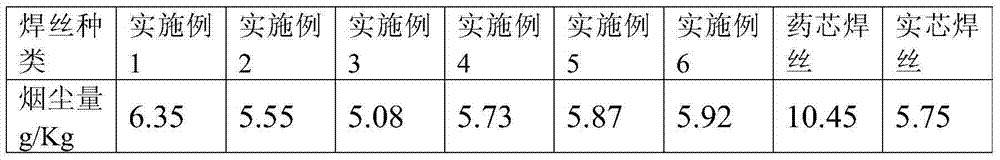

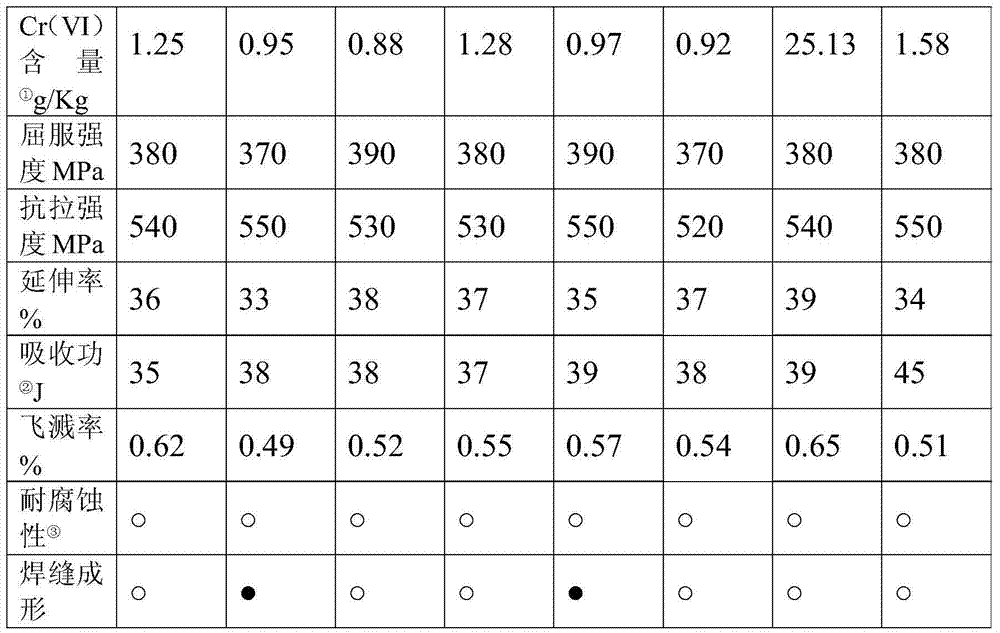

Stainless steel 347 metal core welding wire with low hexavalent chrome emission and preparation method of welding wire

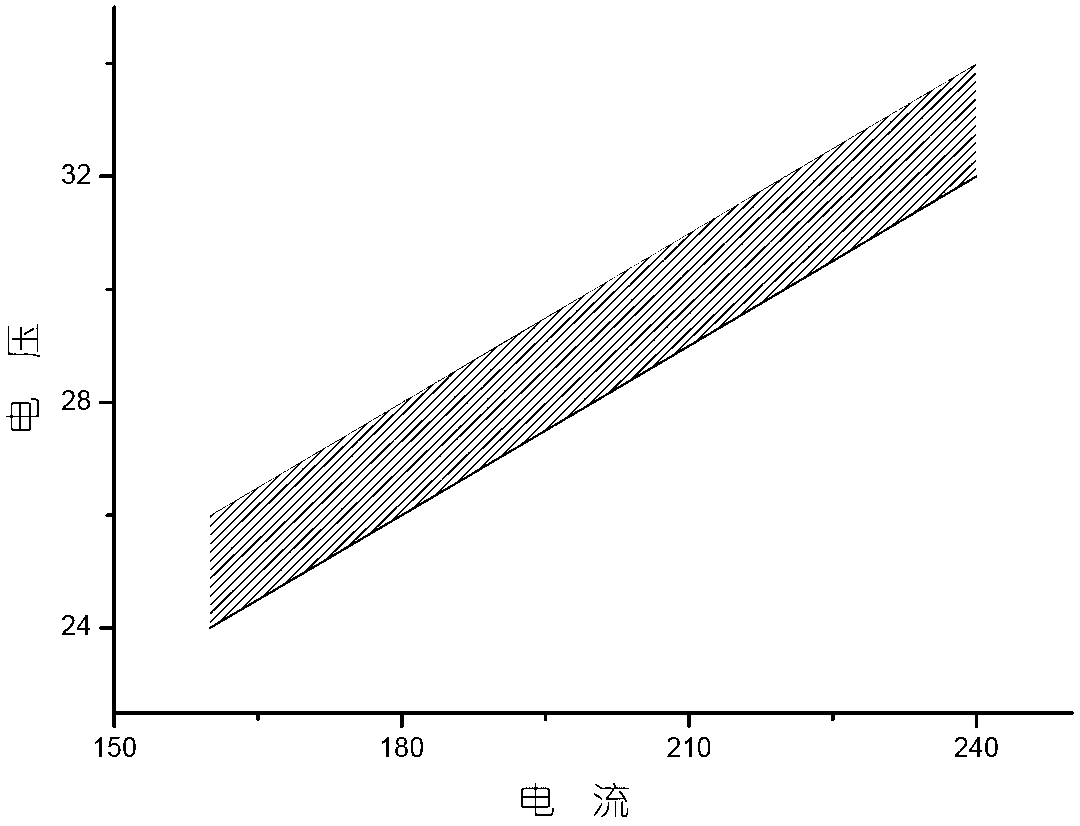

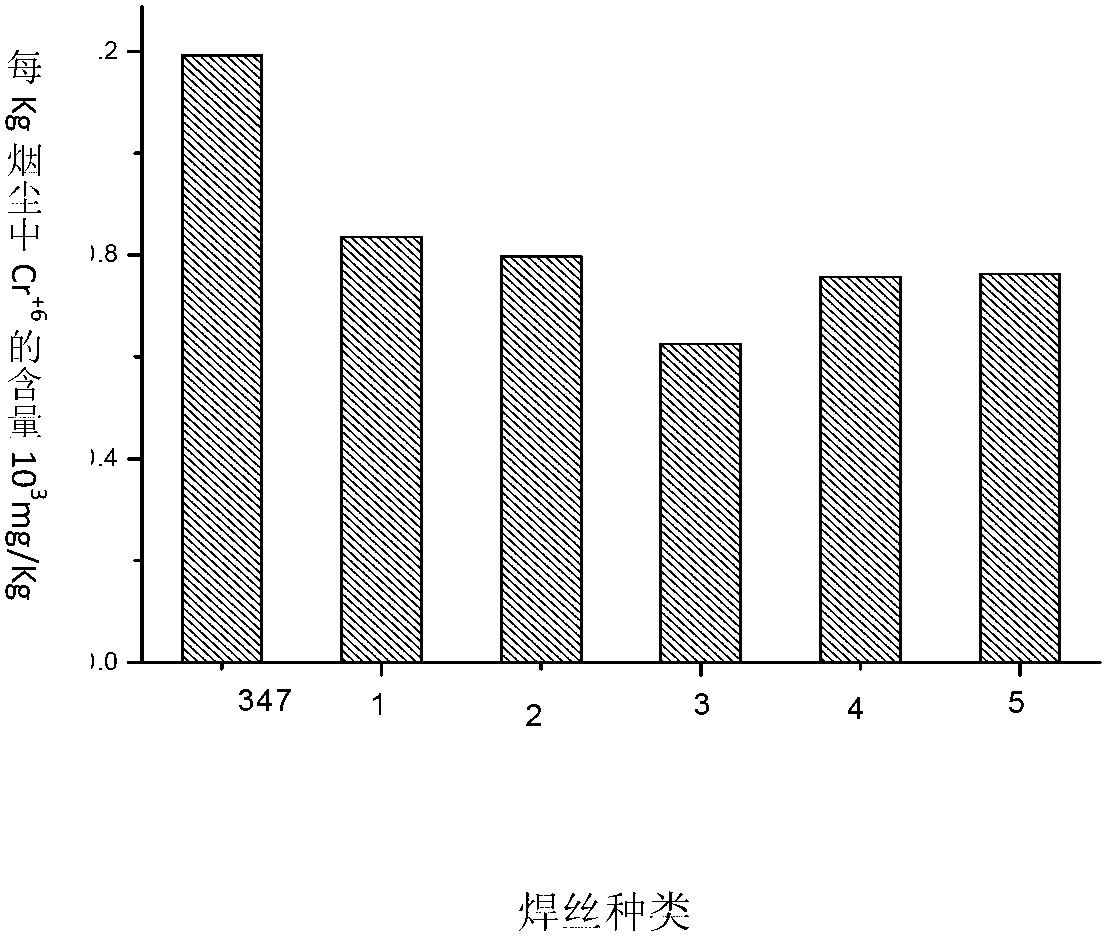

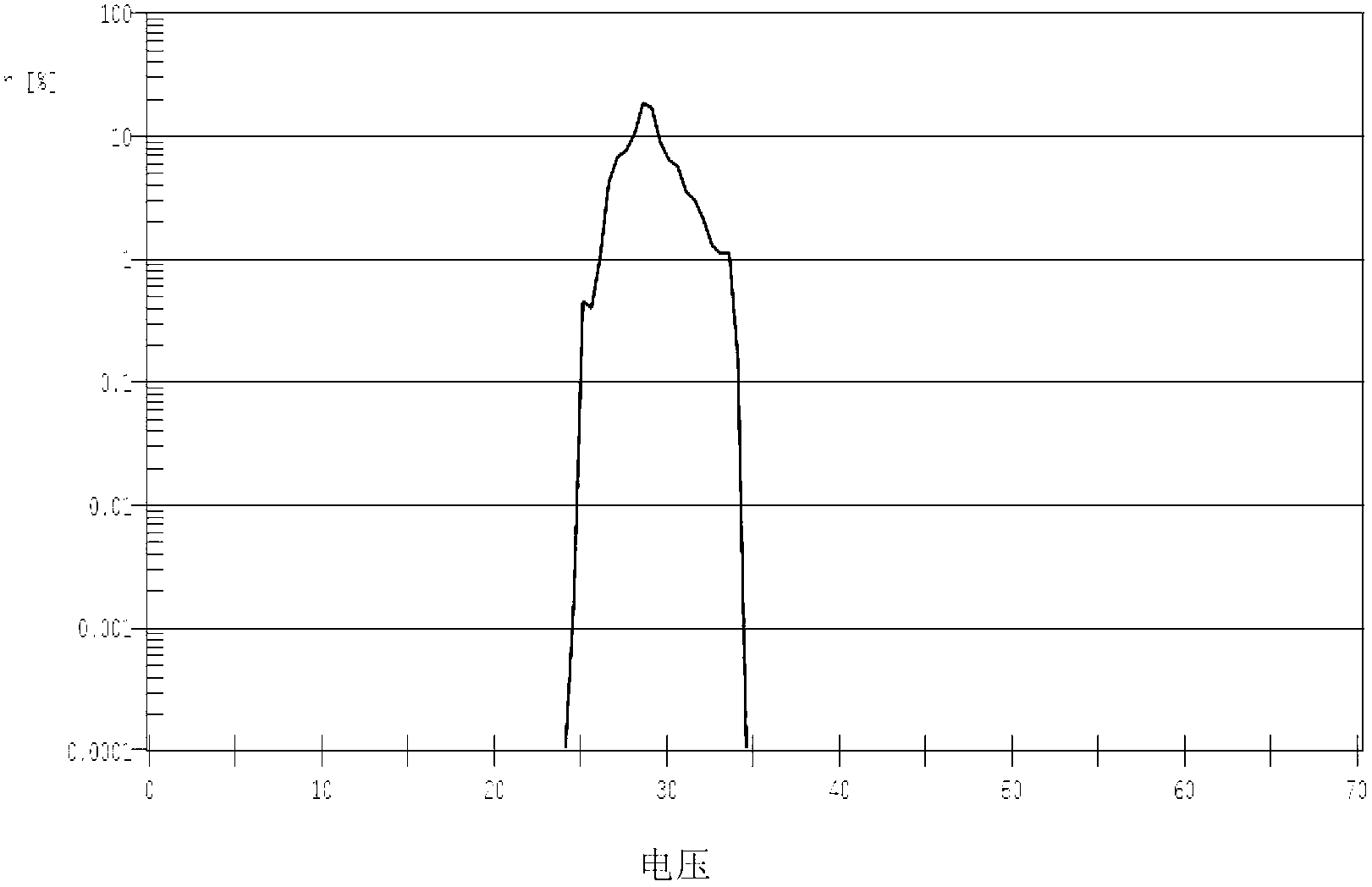

ActiveCN103223561AStable welding arcBeautiful weld shapeArc welding apparatusWelding/cutting media/materialsWelding fumeMechanical property

A stainless steel 347 metal core welding wire with low hexavalent chrome emission and a preparation method of the welding wire are suitable for the field of welding materials. The welding wire comprises the following components: 0.025-0.07wt.% of C, 45-60wt.% of Cr, 25-31wt.% of Ni, 4-7wt.% of Mn, 0.66-1.5wt.% of Si, 0.3-2wt.% of Ti, 0.3-2wt.% of Zn, 0.3-2wt.% of Zr, 0.25-1.2wt.% of Nb, and the balance of Fe and unavoidable impurities. The welding wire and the preparation method ensure that the mechanical property of welding wire deposited metal is matched with that of base metal, and a stainless steel belt is replaced with a carbon steel belt, so that the cost is lowered; 30-60% of the total amount of hexavalent chrome (Cr<+6>) in welding fume is reduced; a welding operation environment is improved; and in addition, the welding wire and the preparation method have the advantages that splattering is low, and the combination property of the formed deposited metal is excellent.

Owner:栗卓新

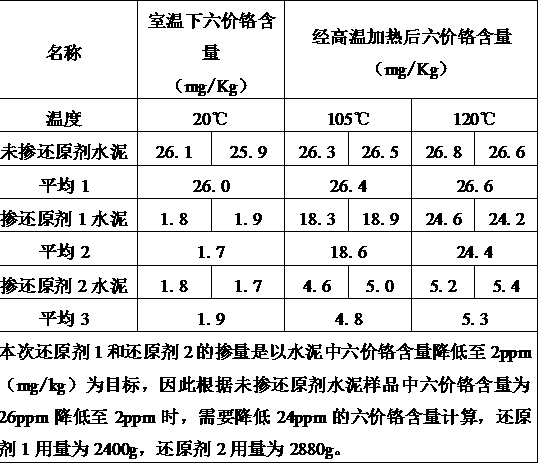

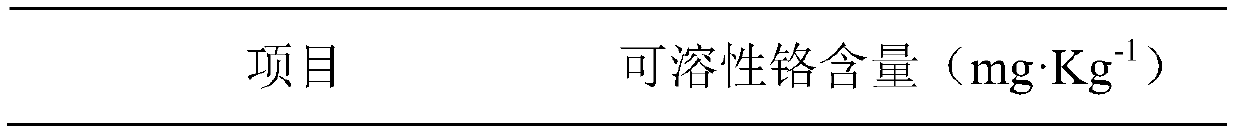

Method for measuring high-temperature stability of hexavalent chromium reducing agent for cement

InactiveCN110895241AReduce the content of hexavalent chromiumOptimized formulaColor/spectral properties measurementsMaterials scienceReducing agent

The invention discloses a method for measuring high-temperature stability of a hexavalent chromium reducing agent for cement. The method comprises the following steps: S1, measuring the content W1 ofhexavalent chromium in a cement sample which is not doped with the hexavalent chromium reducing agent at room temperature; S2, determining the content W2 of hexavalent chromium in the cement sample doped with the reducing agent at room temperature; S3, determining the content W3 of hexavalent chromium in the cement sample which is dried at high temperature and is not doped with the hexavalent chromium reducing agent; S4, determining the content W4 of hexavalent chromium in the cement sample doped with the hexavalent chromium reducing agent after high-temperature drying; and calculating to obtain the high-temperature stability of hexavalent chromium through a set formula. The method disclosed by the invention is simple to operate, and is beneficial to operators to select the hexavalent chromium reducing agent with good performance, so that the content of hexavalent chromium in cement is reduced, pollution is reduced, and the safety and reliability of operation are improved.

Owner:DONGYUAN HONGCHAO TECH

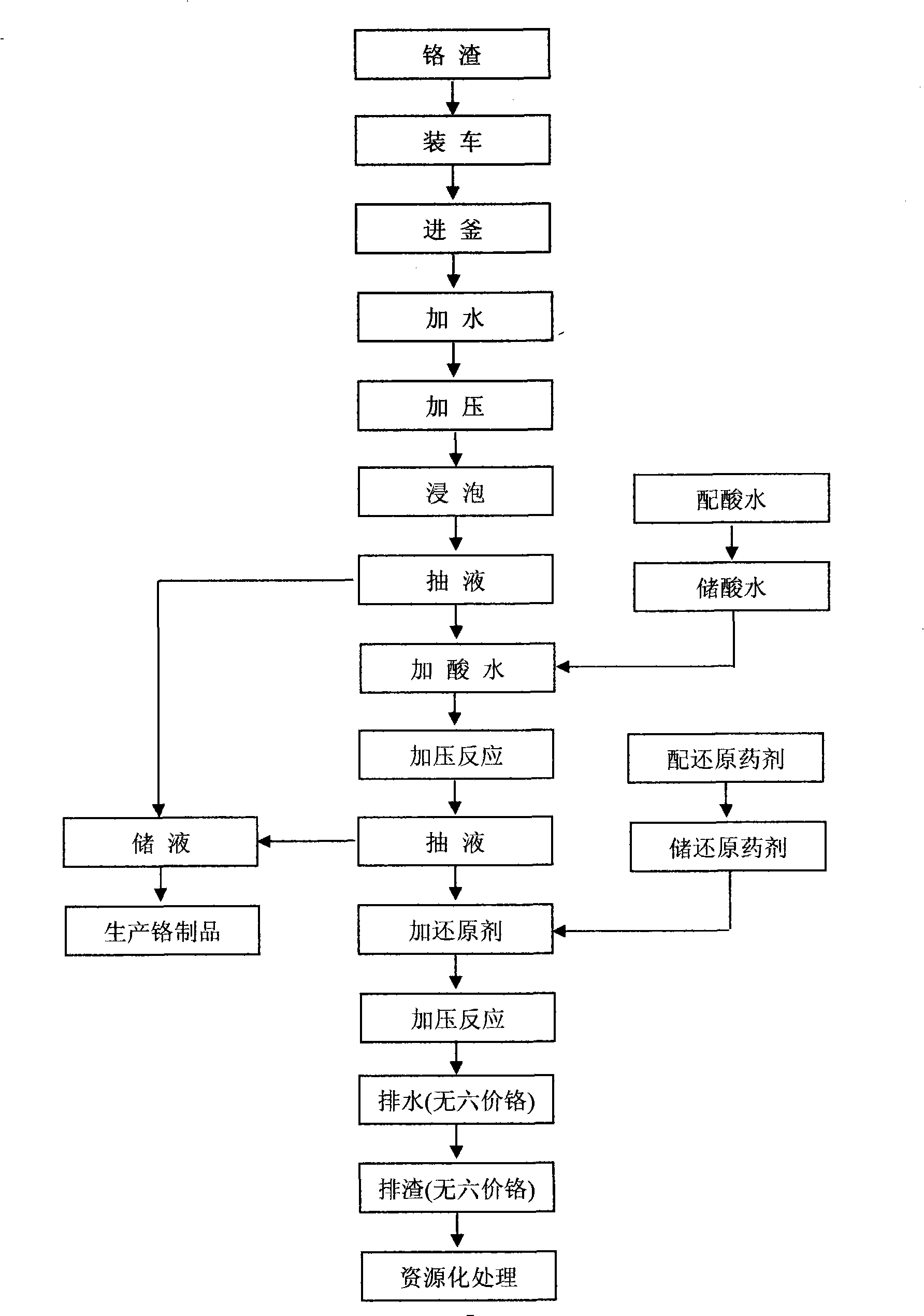

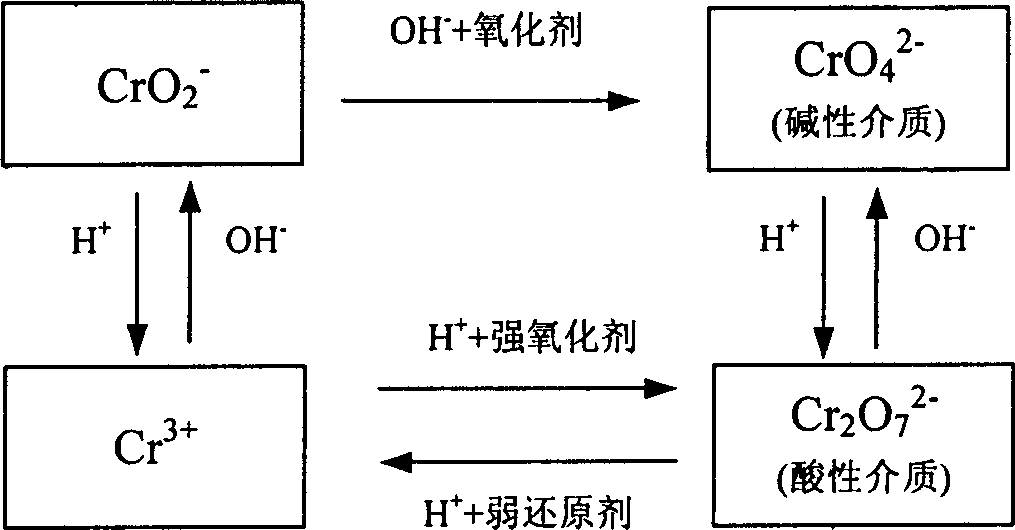

Chromic salt production and extracting and reducing method of hexavalent chromium from chromic slag left behind society

InactiveCN101288795AReduce the content of hexavalent chromiumReduce processing costsSolid waste managementCement productionBrickSlag

The invention discloses a method for extracting and reducing sexivalent chrome in chromium residue which is produced in chromate production and remained in the society. The method of the invention adopts a porous slot to load chromium residue (needing no grinding disposal); the sexivalent chrome liquor in the chrome residue is extracted under the conditions of pressurizing high-temperature saturation, high-pressure and vacuum by adding water in an autoclave; acid water is then added in the autoclave to dip and dissolve calcium chromate in the chrome residue, which is then converted into sexivalent chrome solution; the sexivalent chrome liquor is then extracted under the conditions of high pressure and vacuum; reduction reagent (ferrous sulfate) is added in the autoclave to reduce the sexivalent chrome residual in the chrome residue and converts the sexivalent chrome residue into trivalent chromium which is then fixed in the chrome residue; the gained sexivalent chrome can be used for preparing chrome products; the disposed non-toxic chrome residue can be used for auxiliary materials of cement and concrete, brick aggregate used for building and natural filling and disposal.

Owner:李兴

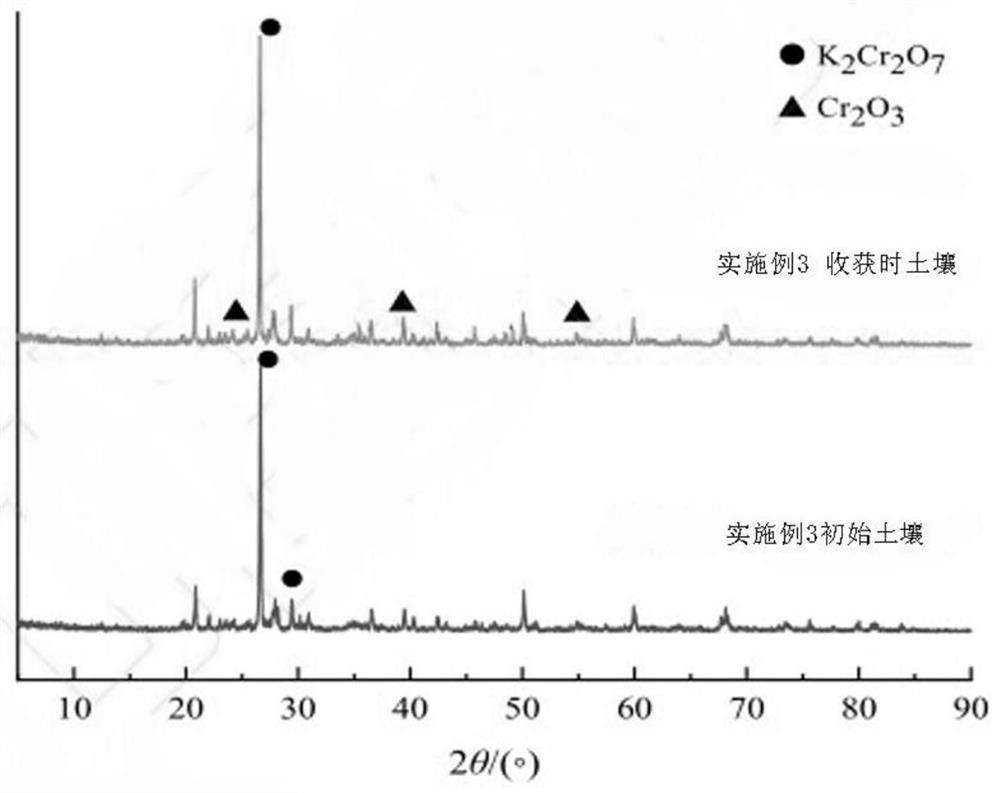

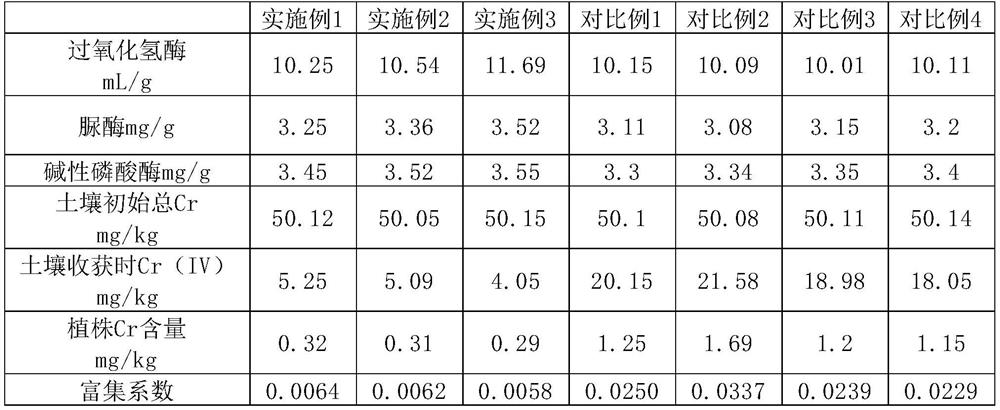

Bioactive soil conditioner for repairing chromium pollution of soil as well as preparation method and application of bioactive soil conditioner

PendingCN113980685AReduce the content of hexavalent chromiumHigh in nutrientsAgriculture tools and machinesBacteriaMicrobial agentBiology

The invention discloses a bioactive soil conditioner for repairing chromium pollution of soil as well as a preparation method and application of the bioactive soil conditioner, and belongs to the technical field of soil pollution treatment. The bioactive soil conditioner is prepared from the following raw materials in parts by weight: 30-50 parts of humic acid, 15-25 parts of attapulgite, 15-20 parts of biogas residues, 10-15 parts of urea, 5-10 parts of a solid fermentation microbial agent, 1-3 parts of a stabilizer and 0.5-1.5 parts of ferrous sulfate. The bioactive soil conditioner disclosed by the invention can effectively reduce the content of hexavalent chromium in soil, increase the content of nutrient substances in the soil and regulate the physicochemical properties of the soil, and the compound use of microorganisms can improve the disease resistance of crops and improve the yield and quality of the crops while regulating the soil environment; and the bioactive soil conditioner is safe, environment-friendly, pollution-free, high in chromium removal efficiency, convenient to use and particularly suitable for treatment of chromium-polluted soil, and has wide economic benefits and social benefits.

Owner:SHIKEFENG CHEM IND

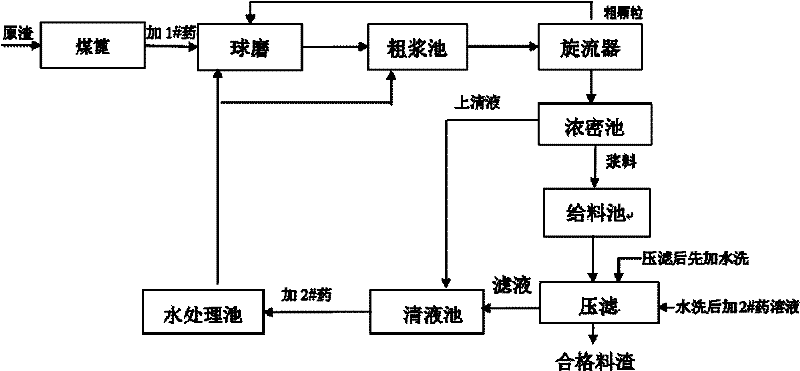

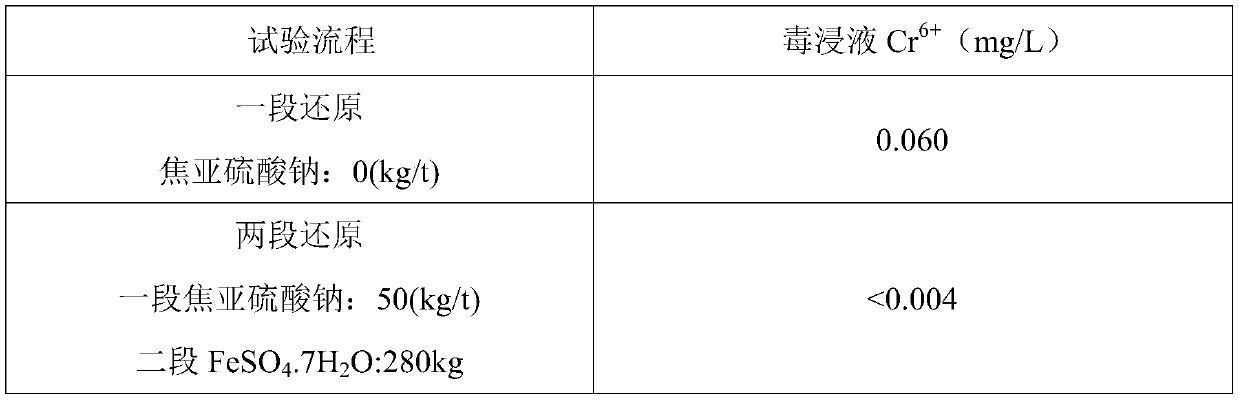

Two-stage deep wet detoxification method for industrial chromium slag

InactiveCN110812773AAvoid harmReach the standard of first disposal landfillChemical protectionSlagSlurry

The invention relates to a two-stage deep wet detoxification method for industrial chromium slag, and belongs to the field of treatment of industrial chromium slag. The grinding fineness of chromium slag ore is -0.074 mm%: 90; first stage water leaching solid-to-liquid ratio is 6: 1, constant-temperature water bath is carried out at 75-85 DEG C, and stirring is carried out for 1-2 hours at the speed of 90-110r / min; solid-liquid separation is carried out to obtain an orange red hexavalent chromium liquid; an obtained solid is subjected to second stage acid leaching, and sodium metabisulfite isadded into an obtained liquid until the liquid becomes dark green; calcium oxide is added into the dark green trivalent chromium liquid to form grey green chromium hydroxide precipitate, and a clearliquid obtained through filtering is recycled as return water; wherein the second stage acid leaching solid-to-liquid ratio is 3: 1, and constant-temperature water bath is carried out at 80-90 DEG C;concentrated sulfuric acid is added, the dosage of the concentrated sulfuric acid is 700-740 kg / t, and soaking is conducted for 4-6 h; excessive ferrous sulfate is added for treating for 4-6 hours; calcium oxide is added to adjust the pH value of an obtained slag slurry to be greater than 6; ore washing is conducted, washing water is recycled as return water, and waste residues are filtered and discharged. According to the two-stage deep wet detoxification method, the indexes after treatment are far lower than those in the national chromium slag landfill standards, the standard of first-time treatment landfill is achieved, the rebound risk is avoided, and the harm of chromium slag discharge treatment landfill to the environment is fundamentally avoided.

Owner:CHANGCHUN GOLD RES INST

Clean production technology for processing low-grade laterite-nickel ore by sodium carbonate alkali fusion

InactiveCN101864524AImprove leaching rateRaise the gradeProcess efficiency improvementEvaporationLaterite

The invention relates to a clean production technology for processing low-grade laterite-nickel ore by sodium carbonate alkali fusion. The invention takes laterite-nickel ore as a raw material, causes laterite-nickel ore and sodium carbonate to roast at high temperature, washes and filters the roasted material to leach valuable metal salts, such as water-soluble chromium, aluminum and the like generated in the laterite-nickel ore after reaction. High-temperature roasting damages the crystal lattice structure of the laterite-nickel ore so as to greatly improve the leaching rate of subsequent high-pressure acid leaching technical nickel and cobalt and improve the grade of Fe in acid leaching dregs; filtrate is prepared into chromium salt and aluminum salt by operations, such as evaporation, crystallization, separation and the like, so that the laterite-nickel ore product is diversified. The leaching rate of hexavalent chromium in the laterite-nickel ore is more than 90%, the leaching rate of trivalent aluminum is more than 65%, the leaching rate of nickel is more than 98%, the dipping rate of the chromium is more than 94%, and Fe content of fine iron powder in the acid leaching dregs is more than 61%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

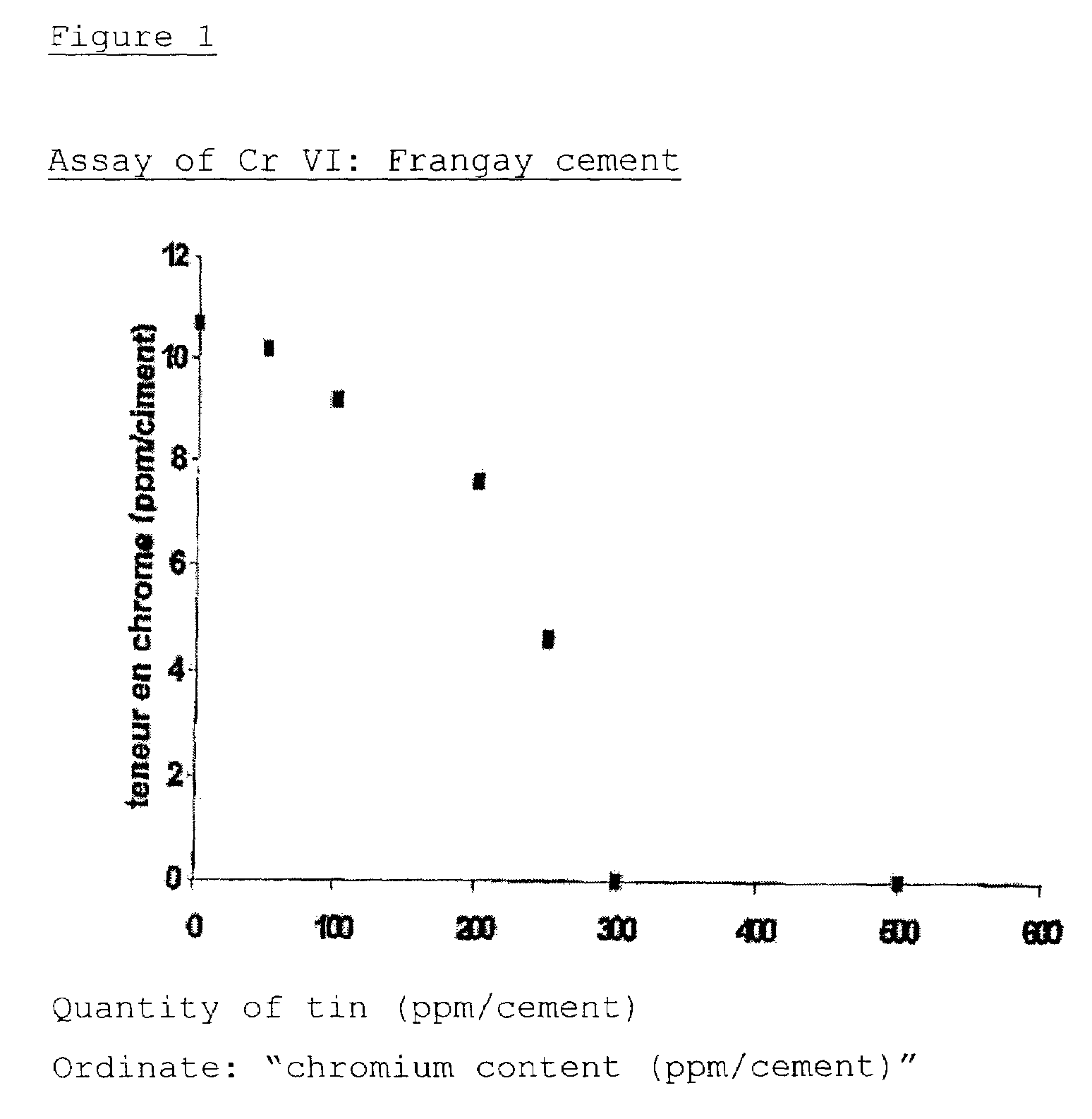

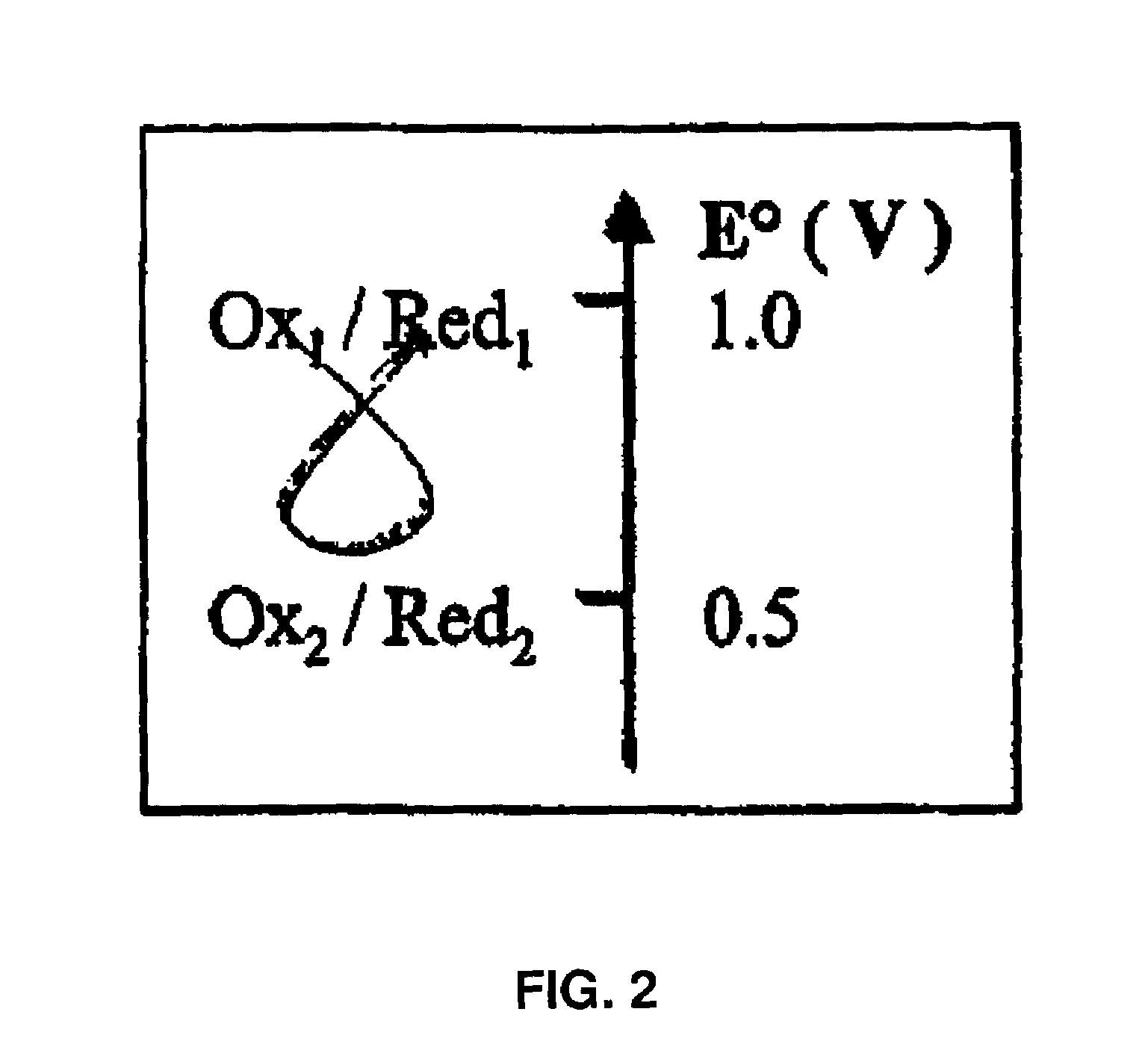

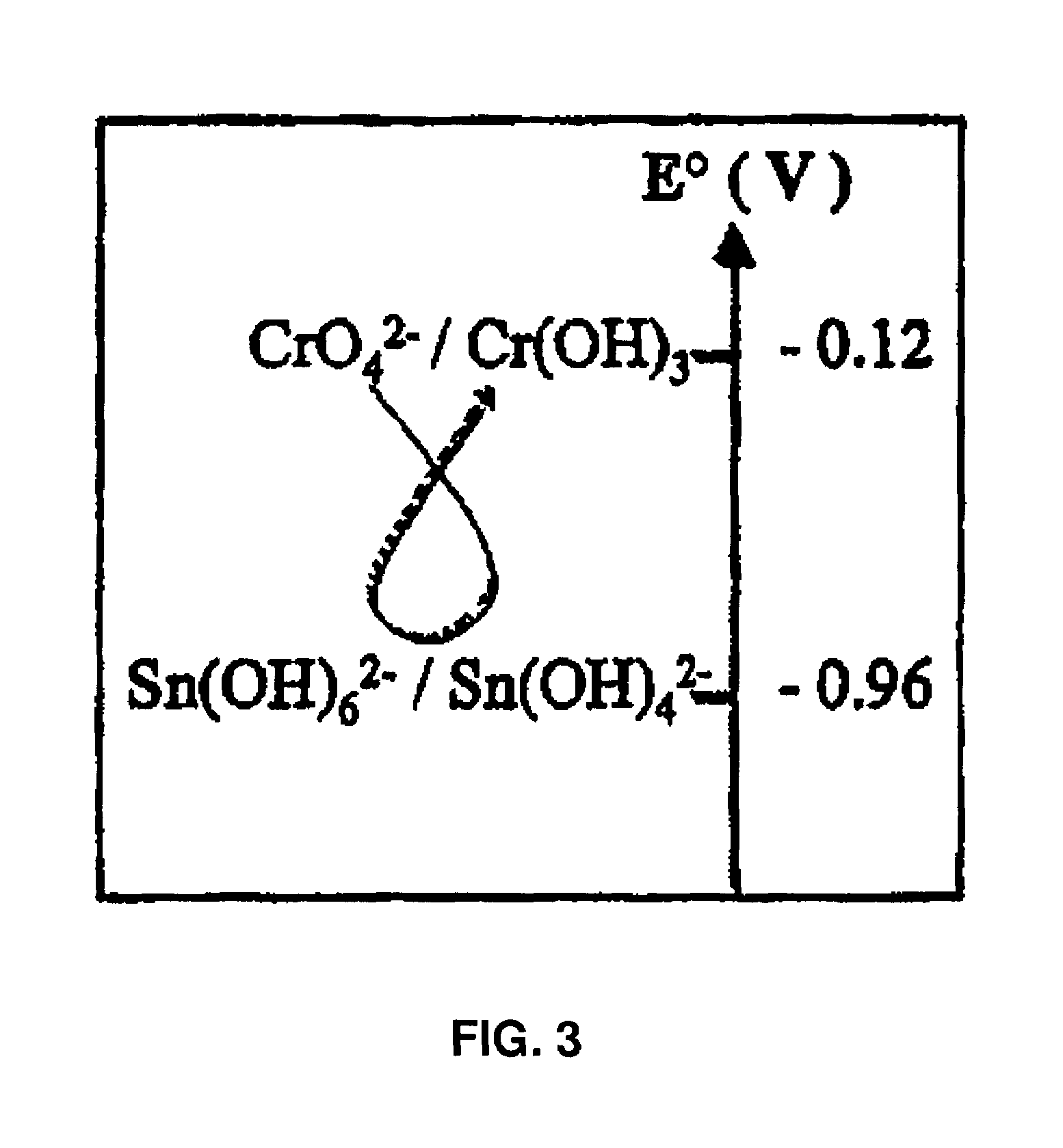

Colloidal hydroxide aqueous suspension of at least one transition element serving to reduce chrome in cement

InactiveUS7601328B2Improve stabilityReduce hydrosoluble hexavalent chromium compoundTransportation and packagingMixingOxidation reductionChromium

The invention relates to a hydroxide aqueous suspension of at least one selected transition element of which the potential oxidation reduction is less than that of the pair CrO72− / CrO42− (−0.12 V) having a pH between 2 and 11, limits excluded, for reducing the content of chrome VI of cement to a value no greater than 2 ppm. The suspension is characterized in that it contains 0.5 to 80% by wt. of dry material of hydroxide of at least one transition element with regard to the quantity of water and in that it is stabilized by a hydrosoluble stabilizer. This suspension makes it possible to reduce the content of chrome VI of cements to a value no greater than 2 ppm.

Owner:CHRYSO SA

A kind of method utilizing chromium-containing Glauber's salt to prepare anhydrous sodium sulfate

ActiveCN107934993BAvoid the problem of excessive hexavalent chromiumReduce the content of hexavalent chromiumChromium compoundsAlkali metal sulfites/sulfatesChemical industryChromium trioxide

The invention relates to the field of a chemical industry and particularly relates to a method for preparing anhydrous sodium sulfate from chromium-containing mirabilite as a by-product in the production process of sodium dichromate. The method comprises dissolving a certain concentration of chrome-containing mirabilite in chromium-containing waste water, adding quantitative sodium thiosulfate into the waste water to promote reduction of hexavalent chromium into trivalent chromium under 0.1-1 Mpa at 80-190 DEG C, wherein the trivalent chromium in a form of chromium trioxide hydrate is precipitated, adding a small amount of sulfuric acid to neutralize, filtering to acquire the chromium trioxide hydrate, removing impurities, carrying out decoloration, evaporating to precipitate anhydrous sodium sulfate crystals, and carrying out continuous centrifugal separation and drying. The method is simple and easy, utilizes cheap raw materials, has low energy consumption and a high automation degree and is suitable for large-scale production. The quality of the industrial anhydrous sodium sulfate product obtained by the method meets the requirements of class I products in the GB / T 6009-2014 industrial anhydrous sodium sulfate standard.

Owner:陕西省商南县东正化工有限责任公司

High-temperature-resistant cement hexavalent chromium reducing agent

The invention discloses a high-temperature-resistant cement hexavalent chromium reducing agent, which is prepared from the following components in parts by weight: 2-4 parts of stannous sulfate, 20-25parts of ferrous sulfate, 3-5 parts of montmorillonite, 2-4 parts of bentonite, 3-5 parts of magnesium fluoride and 3-5 parts of humic acid. The reducing agent has stronger high temperature resistance, and hexavalent chromium in cement can be more effectively reduced, so that the using amount of the reducing agent is relatively less, the cost is lower, and the cement performance is good.

Owner:唐山冀东水泥外加剂有限责任公司 +2

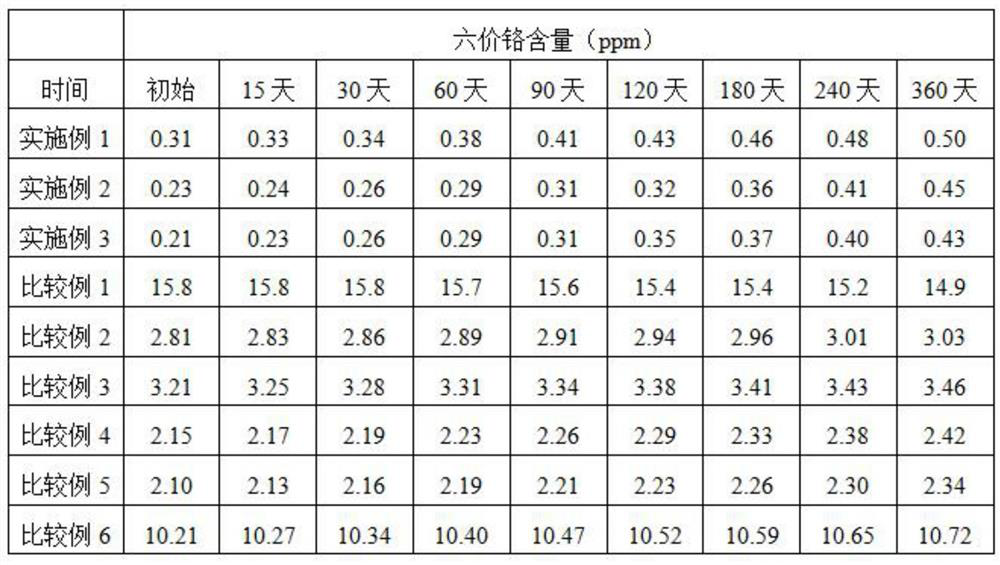

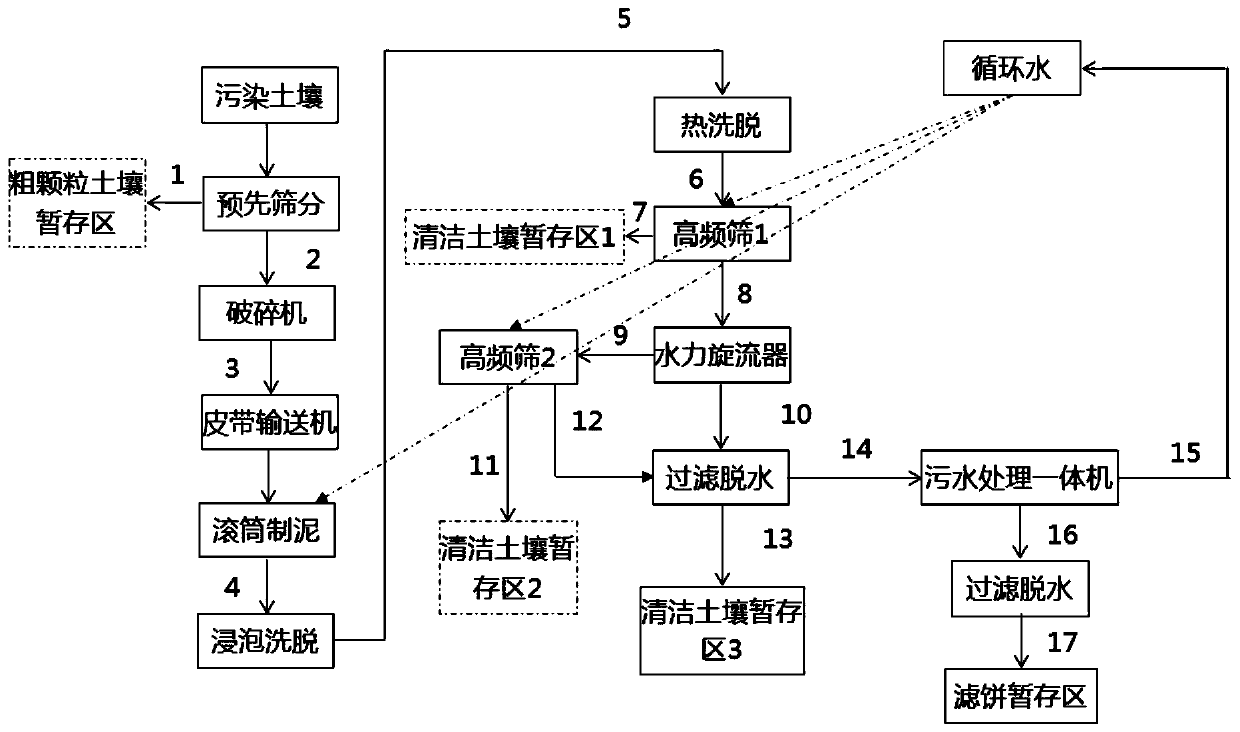

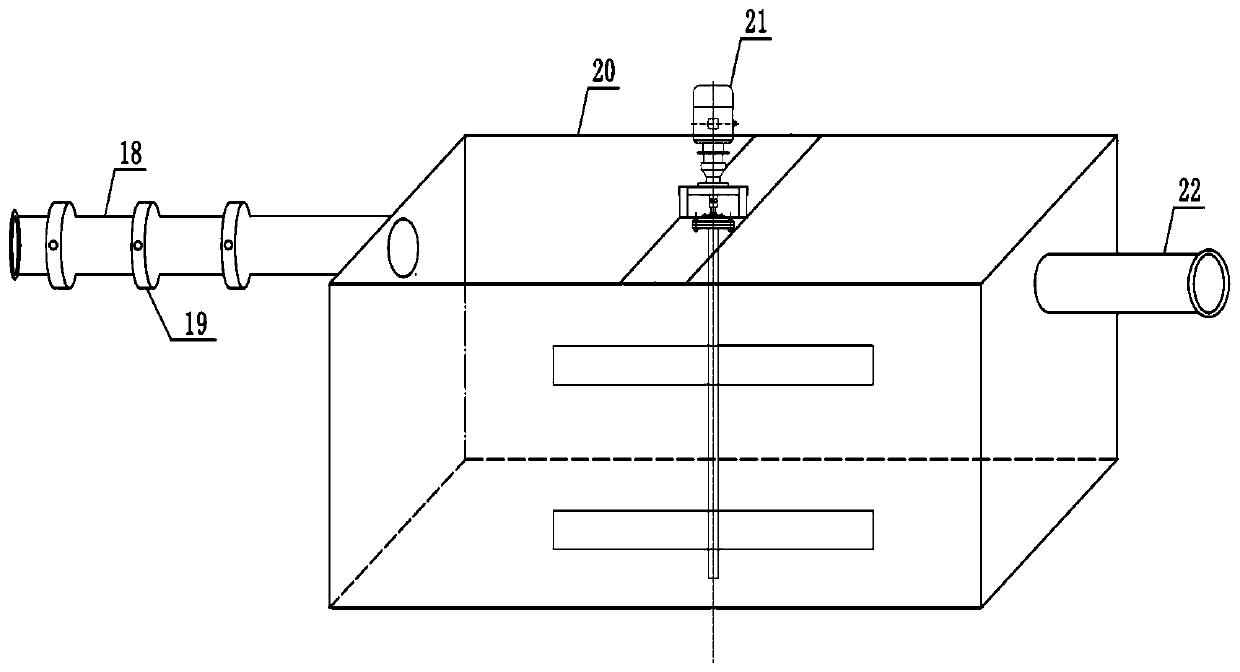

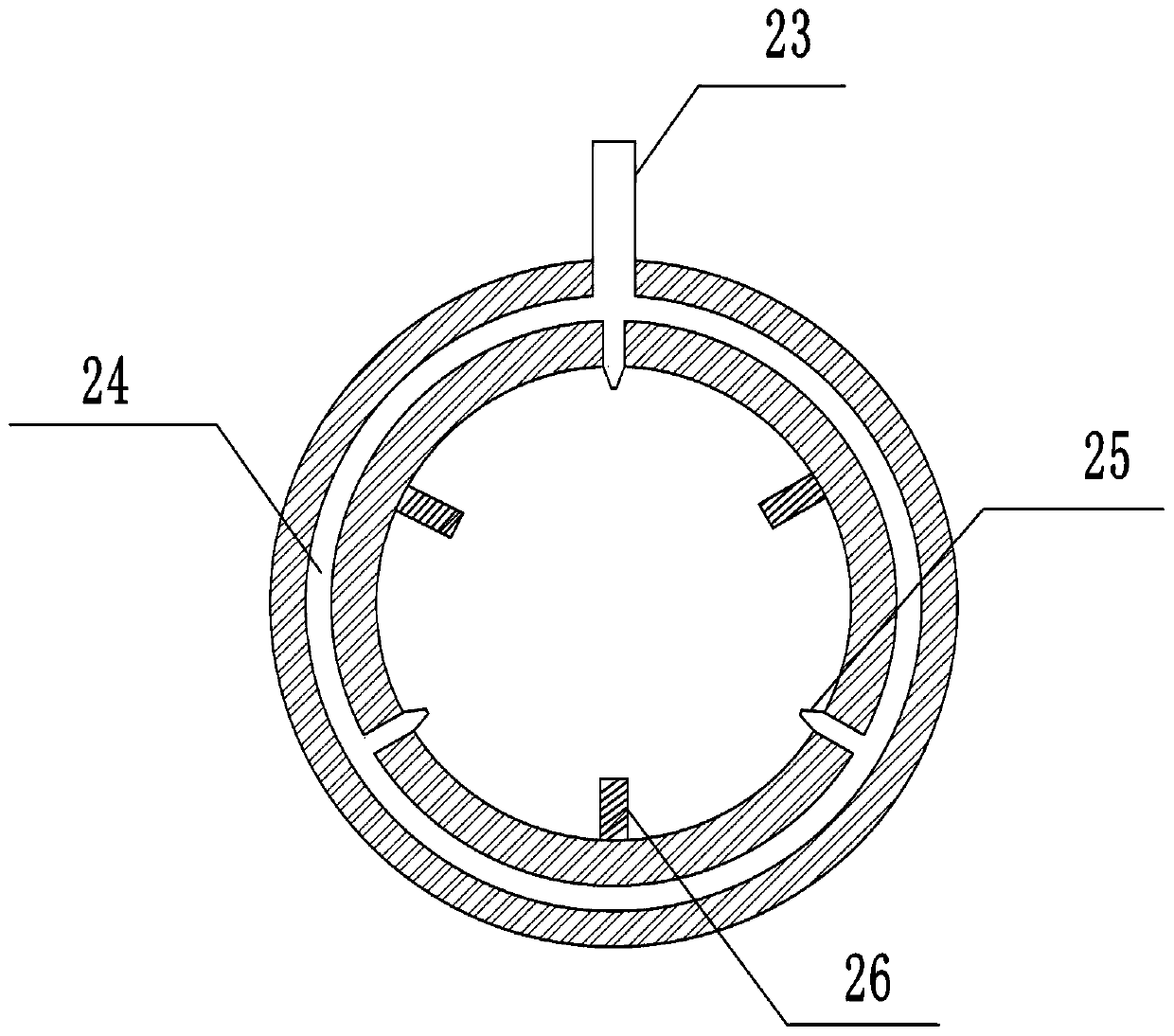

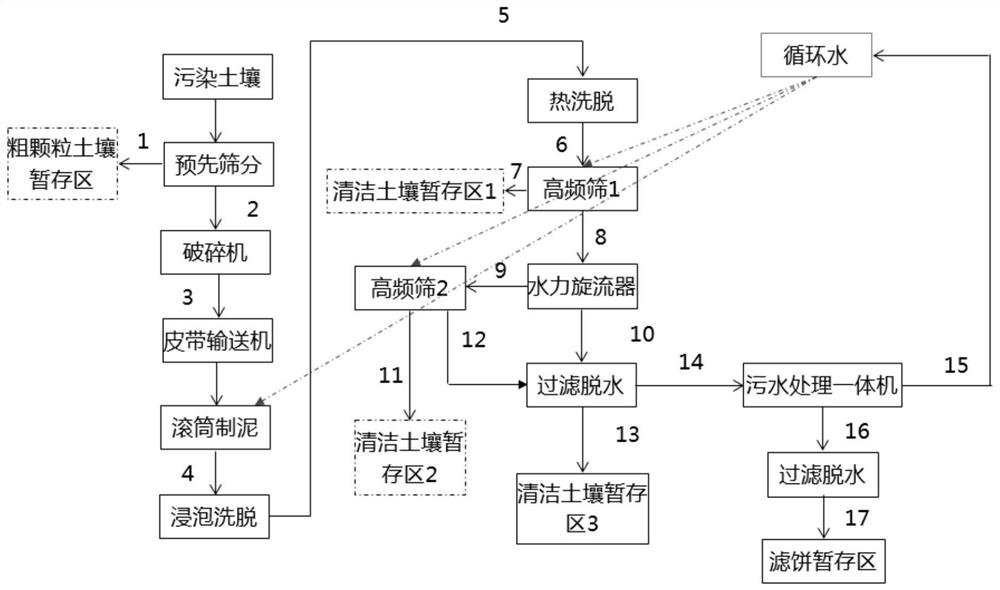

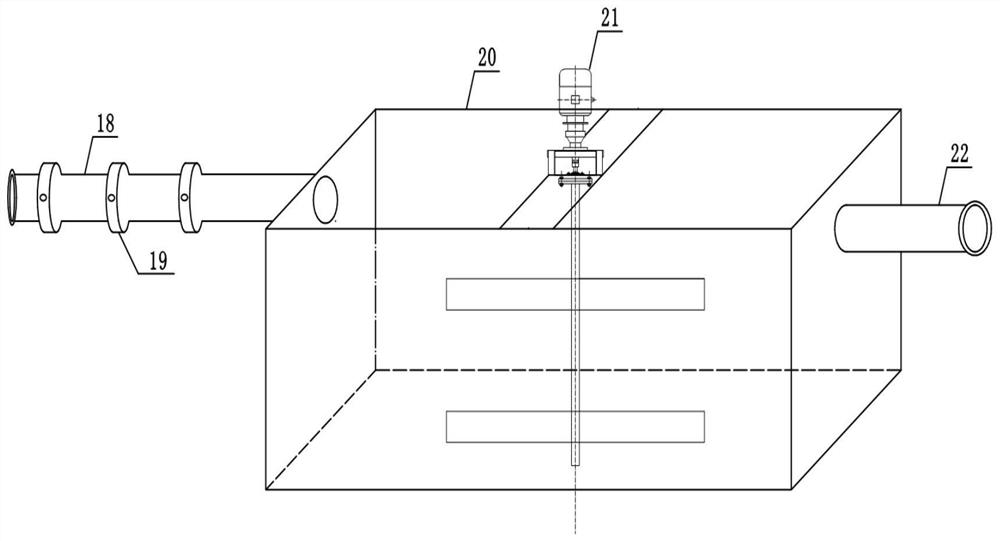

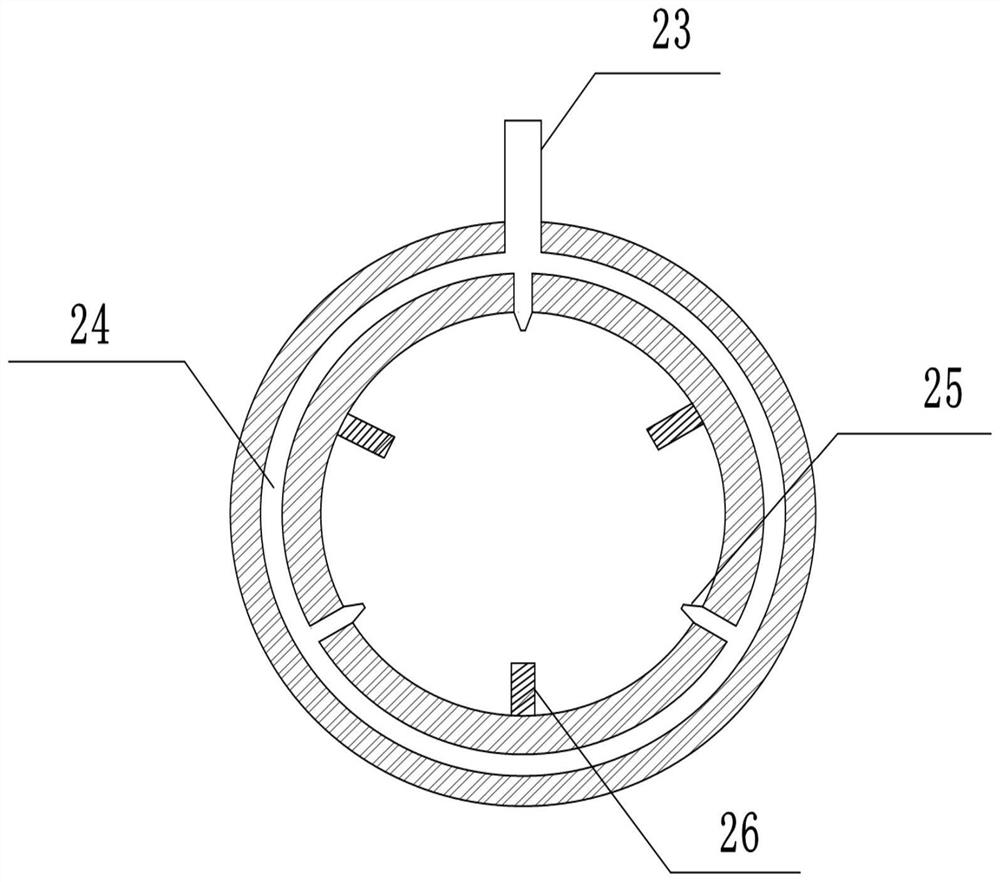

Hot elution equipment and method applicable to ex-situ remediation of chromium-contaminated soil

ActiveCN110170511AReduce the content of hexavalent chromiumAvoid secondary pollutionContaminated soil reclamationElutionEngineering

The invention discloses hot elution equipment and method applicable to ex-situ remediation of chromium-contaminated soil. The hot elution equipment comprises a heating pipe. A heater is mounted on theheating pipe; the heating pipe is connected with a hot elution pool; the heater is a circular ring consisting of a gas inlet pipe, a communicating pipe, a burner and a bracket; and a distance from the bracket to the circle center of the heater is equal to the outer diameter of the heating pipe. The chromium-contaminated soil is firstly dissociated by a crushing sieve and a drum mud machine. Afterbeing dissociated, the soil is immersed in the elution pool, and then immersed and eluted mud enters the hot elution pool after being heated; and the mud is subjected to leaching grading and solid-liquid separation after being subjected to hot elution remediation to obtain clean soil. The equipment disclosed by the invention is simple in structure, reasonable in design and high in operability. After the chromium-contaminated soil is treated by the hot elution equipment, the content of hexavalent chromium in the soil is substantially reduced, a field remediation goal is achieved, and secondarypollution of the hexavalent chromium to the surrounding environment is avoided; a foundation is laid for the ex-situ remediation and treatment of the soil in a chromium-contaminated site.

Owner:招商局生态环保科技有限公司

A kind of chromium slag biological detoxification and method for preparing bio-organic fertilizer

ActiveCN105237059BFast detoxificationReduce the content of hexavalent chromiumBio-organic fraction processingOrganic fertiliser preparationSlagResource utilization

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

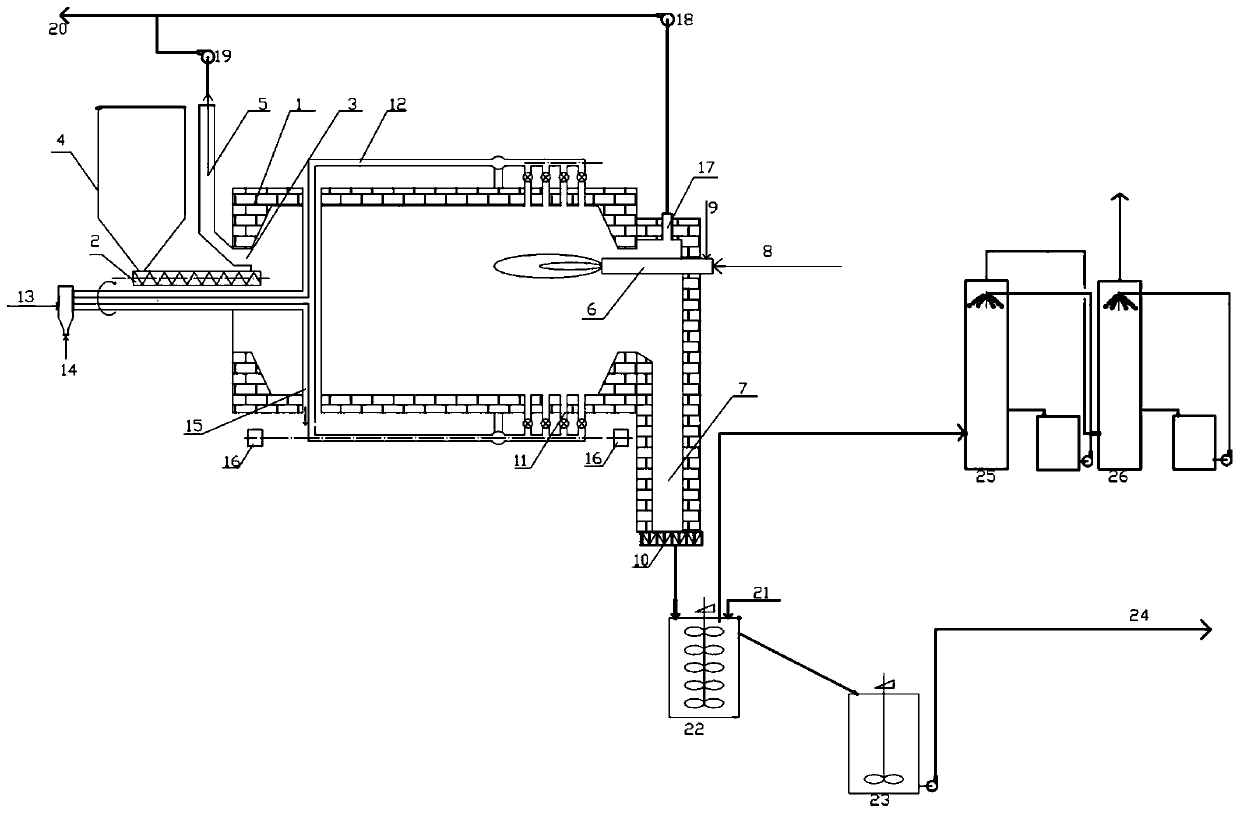

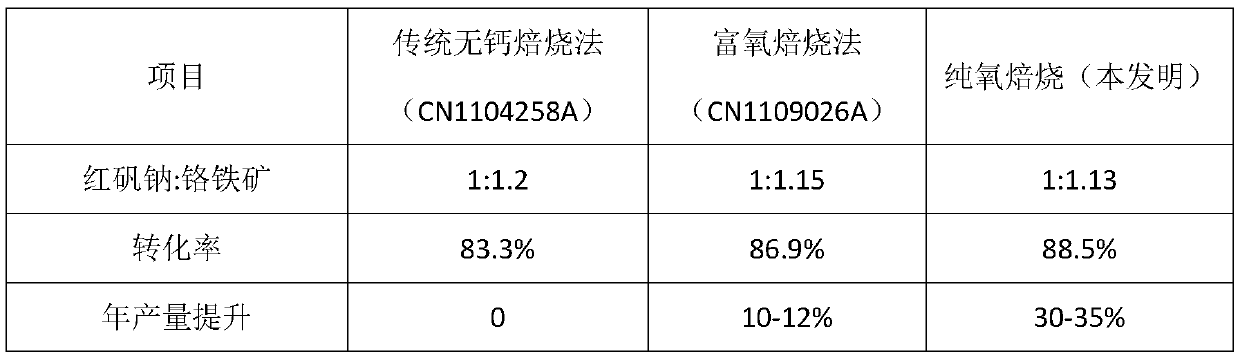

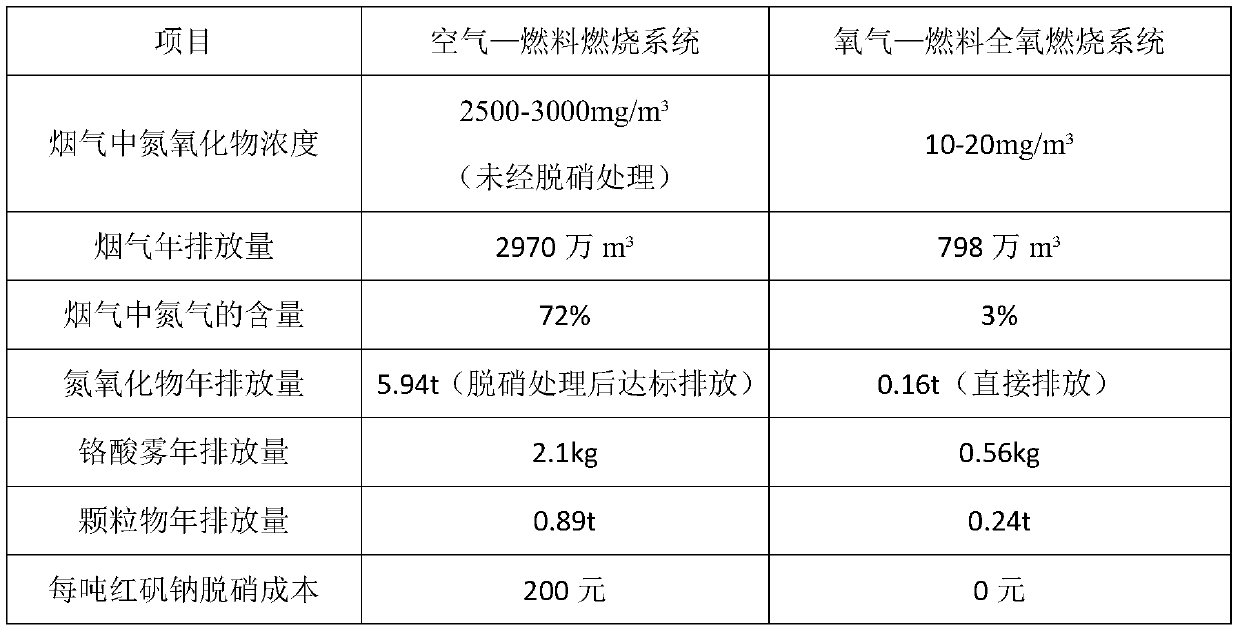

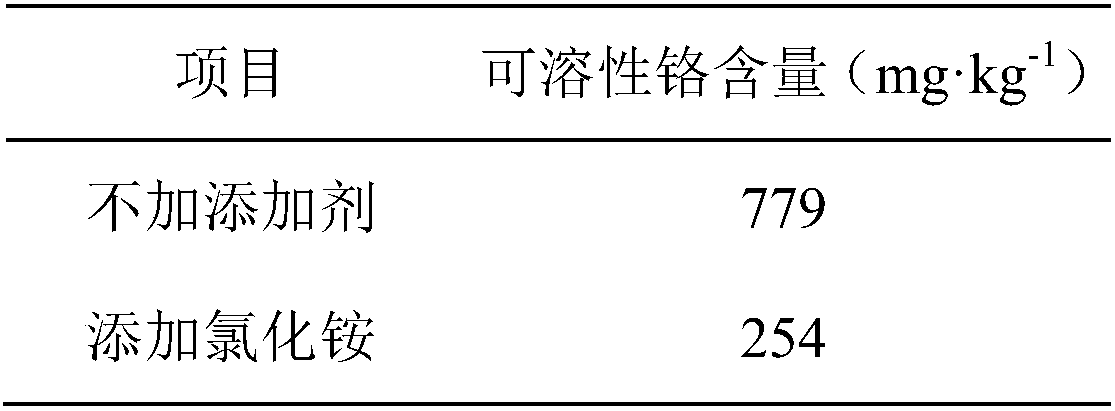

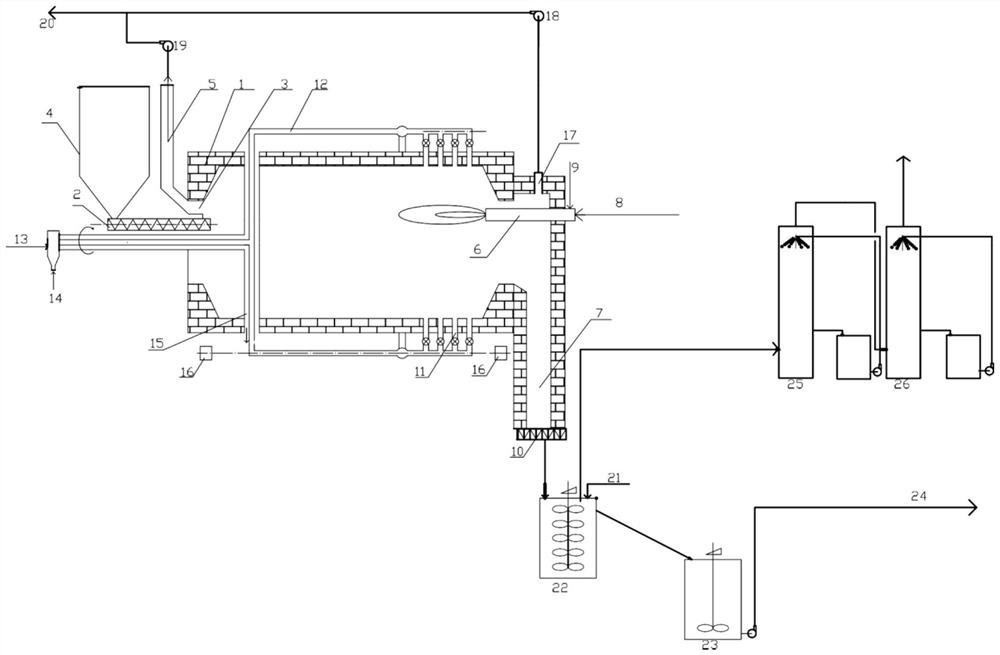

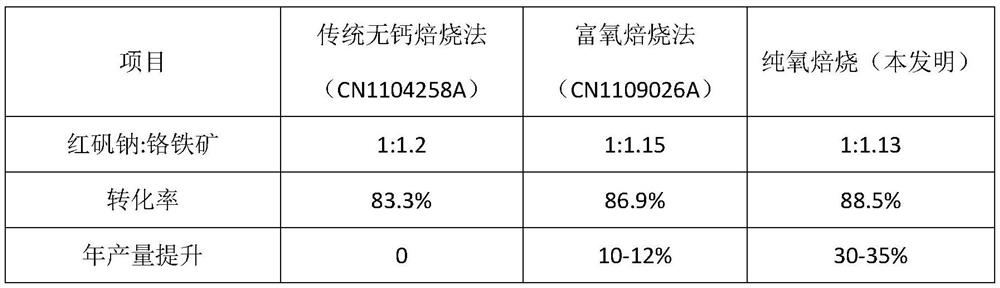

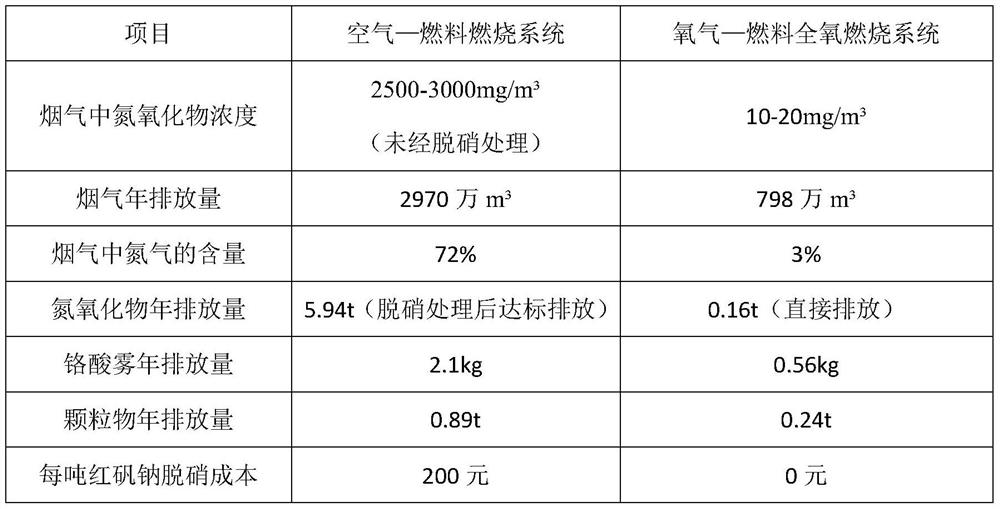

Method for preparation of sodium chromate by low-nitrogen roasting of chromite and continuous leaching of clinker

The invention discloses a method for preparation of sodium chromate by low-nitrogen roasting of chromite and continuous leaching of clinker. The method includes the steps of: (1) selecting chromium ore powder, sodium carbonate and return slag; (2) mixing the selected raw materials uniformly, then feeding the mixture into a rotary furnace, carrying out oxygen-fuel combustion through a total oxygen-fuel system, and controlling the temperature of the materials at 850DEG C-1150DEG C; (3) directly and uniformly injecting pure oxygen gas into the raw material under a material bed in the rotary furnace, and carrying out pure oxygen roasting reaction on the raw material in the rotary furnace; and (4) injecting the roasted clinker into a wet vertical mill, adding a sodium chromate dilute solution or pure water through a metering pump, stirring the substances uniformly, conveying the mixture to a belt filter through a transfer trough, and conducting continuous leaching and filtering to obtain sodium chromate. The method has the characteristics of low energy consumption, high sodium chromate yield, low chromium ore consumption, and low content of nitrogen oxide generated in the flue gas, canachieve continuous production, improves the production efficiency, and can realize clean emission.

Owner:成都铬科高化工技术有限责任公司

Method for reducing content of hexavalent chromium in chromium oxide green

ActiveCN108793252AWater soluble content decreasedSolve the yellowing of product colorChromium oxides/hydratesWater solubleHexavalent chromium

The invention provides a method for reducing the content of hexavalent chromium in chromium oxide green. The method includes the step: adding reducing agents into the chromium oxide green with the discharging temperature of 60-400 DEG C in a production process to obtain a chromium oxide green product. According to the method, the hexavalent chromium in the chromium oxide green can be reduced, thecontent of water soluble objects in the chromium oxide green product is reduced, the problem of yellowing of the product is solved, the recovery rate of chromium metal is increased, the method is simple to operate and less in reducing agent dosage, the reducing agents are added in the cooling process, an original process cannot be affected, and the reducing agents are volatilized and decomposed inthe reducing process, so that the purity of the chromium oxide green cannot be affected.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

Nickel passivation solution, preparation method thereof and method for passivating nickel surface

ActiveCN103805982AReduce the content of hexavalent chromiumWill not polluteMetallic material coating processesFluoroboric acidSilicon dioxide

The invention provides a nickel passivation solution and a preparation method thereof. The nickel passivation solution contains the following components: 1-5g / L of chromic anhydride, 20-50g / L of sulfuric acid, 0.5-2g / L of nano silica and 5-20g / L of fluoroboric acid. The invention also provides a method for passivating a nickel surface by adopting the nickel passivation solution. By adopting the nickel passivation solution provided by the invention, a stable and permanent passivation layer can be formed on the metallic nickel surface and the salt mist resistance time is greatly lengthened. Meanwhile, the nickel passivation solution provided by the invention has lower content of hexavalent chromium, is safe and environment-friendly and is suitable for plastic workpieces and workpieces with surfaces locally metalized.

Owner:BYD CO LTD

Composite liquid chromium removal agent as well as preparation method and application thereof

ActiveCN113480229AImprove reducibilityReduce the content of hexavalent chromiumOrganosolvPhysical chemistry

The invention provides a composite liquid chromium removal agent as well as a preparation method and application thereof. The composite liquid chromium removal agent comprises the following raw materials: 20-30% of ferrous sulfate heptahydrate, 10-30% of antimony oxychloride, 43-60% of water, 5-10% of an organic solvent and 2-10% of methyl cellulose, or 20-30% of ferrous sulfate heptahydrate, 10-30% of antimony trichloride, 43-60% of water, 5-10% of an organic solvent and 2-10% of methyl cellulose. The composite liquid chromium removal agent provided by the invention is a mixed phase of an organic phase and a water phase, ferrous sulfate heptahydrate and antimony oxychloride are combined through the organic solvent and methyl cellulose to jointly play a reduction role, and the chromium removal effect is better; and the addition of ferrous sulfate can prevent agglomeration of antimony oxychloride and methylcellulose, and ferrous sulfate in the system can be prevented from being oxidized by oxygen in air.

Owner:安徽精公检测检验中心有限公司

A method for reducing hexavalent chromium content in chromium oxide green

ActiveCN108793252BReduce hexavalent chromiumReduce the content of hexavalent chromiumChromium oxides/hydratesProcess engineeringReducing agent

The invention provides a method for reducing the content of hexavalent chromium in chromium oxide green. The method includes the step: adding reducing agents into the chromium oxide green with the discharging temperature of 60-400 DEG C in a production process to obtain a chromium oxide green product. According to the method, the hexavalent chromium in the chromium oxide green can be reduced, thecontent of water soluble objects in the chromium oxide green product is reduced, the problem of yellowing of the product is solved, the recovery rate of chromium metal is increased, the method is simple to operate and less in reducing agent dosage, the reducing agents are added in the cooling process, an original process cannot be affected, and the reducing agents are volatilized and decomposed inthe reducing process, so that the purity of the chromium oxide green cannot be affected.

Owner:HUBEI ZHENHUA CHEMICAL CO LTD

Stainless steel 347 metal core welding wire with low hexavalent chrome emission and preparation method of welding wire

ActiveCN103223561BStable welding arcBeautiful weld shapeArc welding apparatusWelding/cutting media/materialsCarbon steelMechanical property

A stainless steel 347 metal core welding wire with low hexavalent chrome emission and a preparation method of the welding wire are suitable for the field of welding materials. The welding wire comprises the following components: 0.025-0.07wt.% of C, 45-60wt.% of Cr, 25-31wt.% of Ni, 4-7wt.% of Mn, 0.66-1.5wt.% of Si, 0.3-2wt.% of Ti, 0.3-2wt.% of Zn, 0.3-2wt.% of Zr, 0.25-1.2wt.% of Nb, and the balance of Fe and unavoidable impurities. The welding wire and the preparation method ensure that the mechanical property of welding wire deposited metal is matched with that of base metal, and a stainless steel belt is replaced with a carbon steel belt, so that the cost is lowered; 30-60% of the total amount of hexavalent chrome (Cr<+6>) in welding fume is reduced; a welding operation environment is improved; and in addition, the welding wire and the preparation method have the advantages that splattering is low, and the combination property of the formed deposited metal is excellent.

Owner:栗卓新

Low hexavalent chromium 316 austenitic stainless steel metal core welding wire and preparation method thereof

ActiveCN103100804BLow costLow hexavalent chromiumArc welding apparatusWelding/cutting media/materialsManganeseSS - Stainless steel

The invention discloses a low hexavalent chromium 316 austenitic stainless steel metal core welding wire and a preparation method of the low hexavalent chromium 316 austenitic stainless steel metal core welding wire, and belongs to the field of welding material. Steel bands for the welding wire are low carbon steel bands with the following chemical components: carbon (C): 0.025-0.078 wt. %; silicon (Si): 0.06 wt. %; manganese (Mn): 0.33 wt. %; sulfur (S): <= 0.025 wt. %; and phosphorus (P): <= 0.03 wt. %. The chemical composition mass fraction of the welding wire powder includes: C: 0.025-0.078 wt. %; chromium (Cr): 48-57 wt. %; nickel (Ni): 28-33 wt. %; Mn: 4-6 wt. %; molybdenum (Mo): 2.8-5 wt. %; Si: 0.63-1.5 wt. %; titanium (Ti): 0.5-1 wt. %; zinc (Zn): 0.5-1 wt. %; zirconium (Zr): 0.5-1 wt. %; and ferrum (Fe): allowance. Compared with the prior art, the adopted steel bands are the low carbon steel bands, cost is reduced, at the same time welding dust content amount corresponds to that of a solid core welding wire, emission load of harmful Cr (VI) can be reduced by 20%-28% compared with the solid core welding wire, and welding electric arc is stable, spatter is small, weld forming appearance is attractive, and deposited metal is excellent in comprehensive performance.

Owner:山东高熵金属科技有限公司

A thermal elution method suitable for ex-situ remediation of chromium-contaminated soil

ActiveCN110170511BReduce the content of hexavalent chromiumAvoid secondary pollutionContaminated soil reclamationChromium contaminationSoil science

The invention discloses hot elution equipment and method applicable to ex-situ remediation of chromium-contaminated soil. The hot elution equipment comprises a heating pipe. A heater is mounted on theheating pipe; the heating pipe is connected with a hot elution pool; the heater is a circular ring consisting of a gas inlet pipe, a communicating pipe, a burner and a bracket; and a distance from the bracket to the circle center of the heater is equal to the outer diameter of the heating pipe. The chromium-contaminated soil is firstly dissociated by a crushing sieve and a drum mud machine. Afterbeing dissociated, the soil is immersed in the elution pool, and then immersed and eluted mud enters the hot elution pool after being heated; and the mud is subjected to leaching grading and solid-liquid separation after being subjected to hot elution remediation to obtain clean soil. The equipment disclosed by the invention is simple in structure, reasonable in design and high in operability. After the chromium-contaminated soil is treated by the hot elution equipment, the content of hexavalent chromium in the soil is substantially reduced, a field remediation goal is achieved, and secondarypollution of the hexavalent chromium to the surrounding environment is avoided; a foundation is laid for the ex-situ remediation and treatment of the soil in a chromium-contaminated site.

Owner:招商局生态环保科技有限公司

A kind of nickel passivation liquid and its preparation method and the method for nickel surface passivation

ActiveCN103805981BReduce the content of hexavalent chromiumImprove hydrophobicityMetallic material coating processesEnvironmental resistanceTriethoxysilane

Owner:BYD CO LTD

A method for preparing sodium chromate by low-nitrogen roasting of chromite ore and continuous leaching of clinker

Owner:成都铬科高化工技术有限责任公司

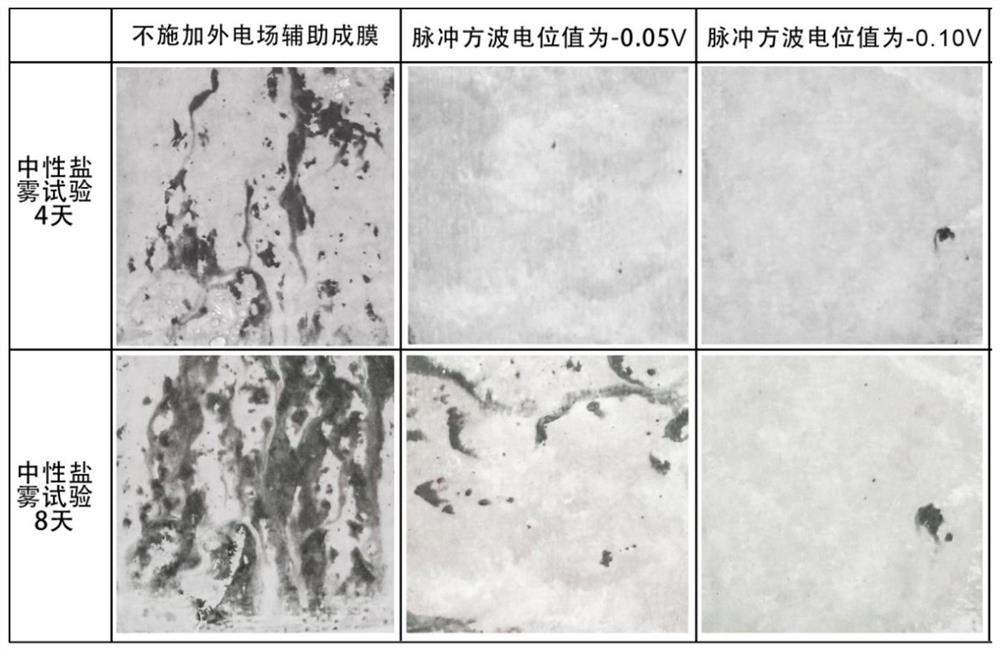

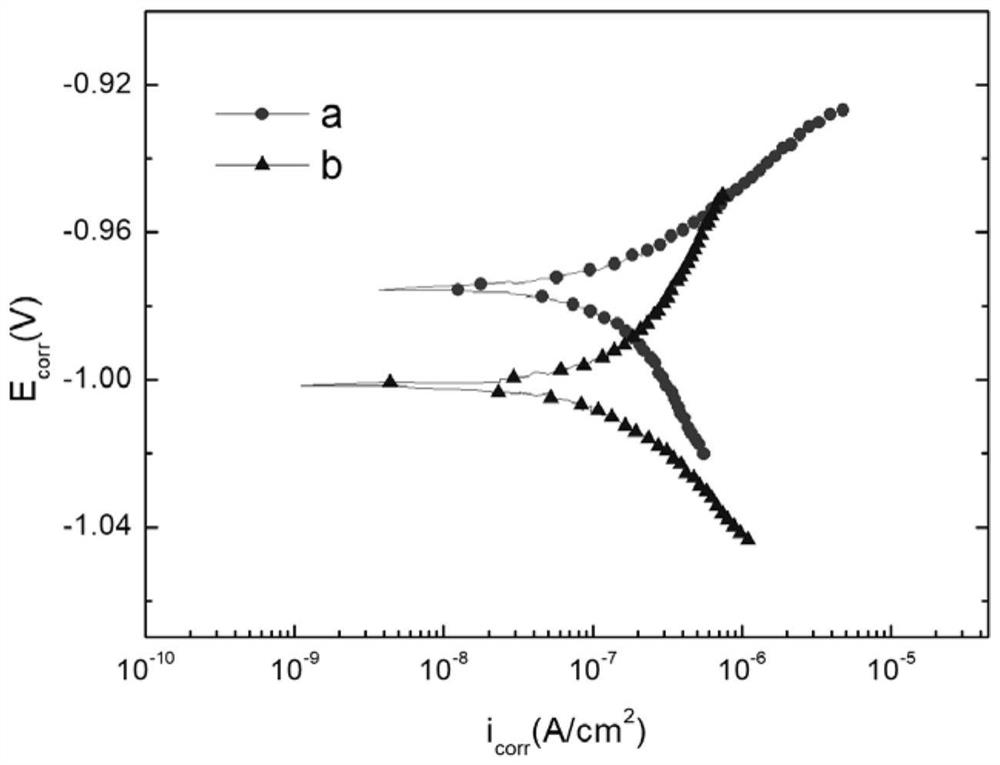

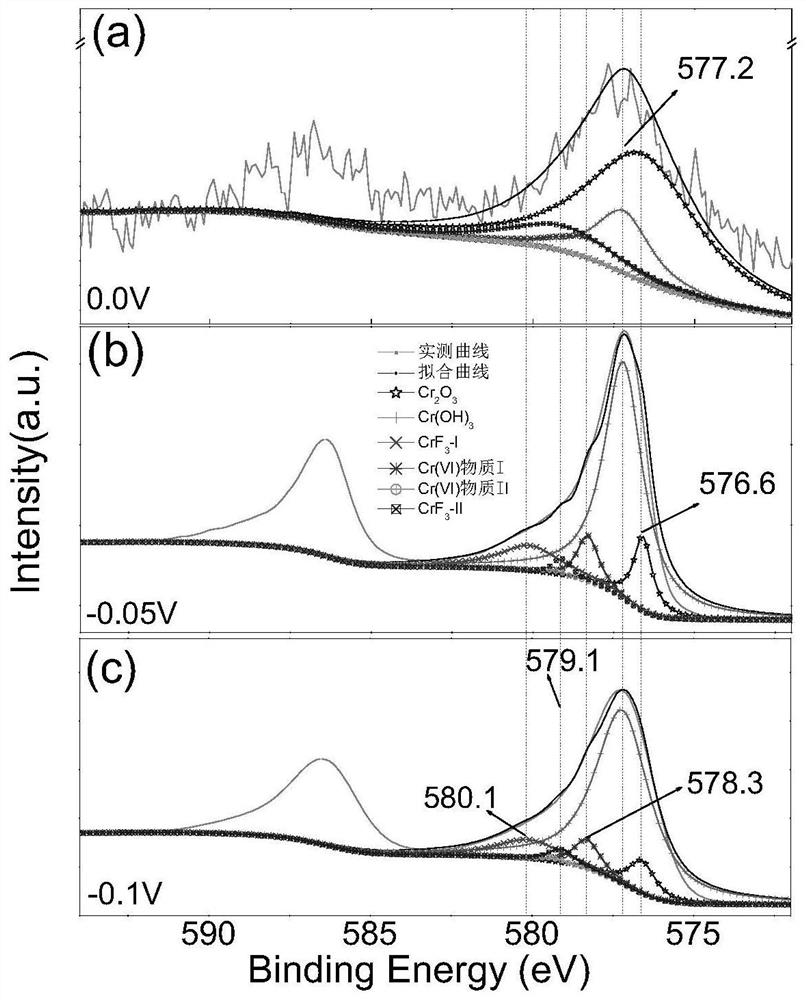

Film formation method for controlling the performance of trivalent chromium chemical conversion film on the surface of hot-dip galvanized aluminum alloy coating

ActiveCN111500962BPotential value is smallReduce energy consumptionHot-dipping/immersion processesSurface reaction electrolytic coatingHigh current densityAlloy coating

The invention proposes a film-forming method for adjusting and controlling the performance of a trivalent chromium chemical conversion film on the surface of a hot-dip galvanized aluminum alloy coating, which belongs to the field of chemical conversion film-forming technology, and can solve the problems of hexavalent chromium and film-forming quality that are prone to occur in existing film-forming methods Inhomogeneity and technical problems such as high voltage, high current density, and low efficiency used in auxiliary film formation. The film forming method includes putting the hot-dip galvanized aluminum alloy coating into the trivalent chromium chemical conversion diluent, and after standing still for a while, applying a pulsed cathode square wave potential to it to chemically convert into a film at a certain temperature, wherein the heat The galvanized aluminum alloy coating is the cathode, and the counter electrode is the anode; after the above-mentioned product is cleaned and dried at normal temperature, a trivalent chromium chemical conversion film is obtained on the surface of the hot-dip galvanized aluminum alloy coating. The invention can be applied to the structure and performance control of the trivalent chromium chemical conversion film on the surface of the hot-dip galvanized aluminum alloy coating, so as to be applied to the temporary protection of the hot-dip galvanized aluminum alloy coating.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com