Chromic salt production and extracting and reducing method of hexavalent chromium from chromic slag left behind society

A technology of hexavalent chromium and hexavalent chromium solution, which is applied in cement production, sustainable waste treatment, solid waste management, etc., can solve secondary pollution and other problems, and achieve the goal of reducing consumption, reducing hexavalent chromium content, and high efficiency Effect

Inactive Publication Date: 2008-10-22

李兴

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

(3) Calcium chromate in the chromium slag is soaked and dissolved in acid water and converted into an aqueous solution of hexavalent chromium, and the chromium slag is fully soaked through high temperature and high pressure, so that the acid-soluble hexavalent chromium in the chromium slag is fully extracted, and the crystalline chromium in the chromium slag is solved. Secondary pollution caused by calcium acid;

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

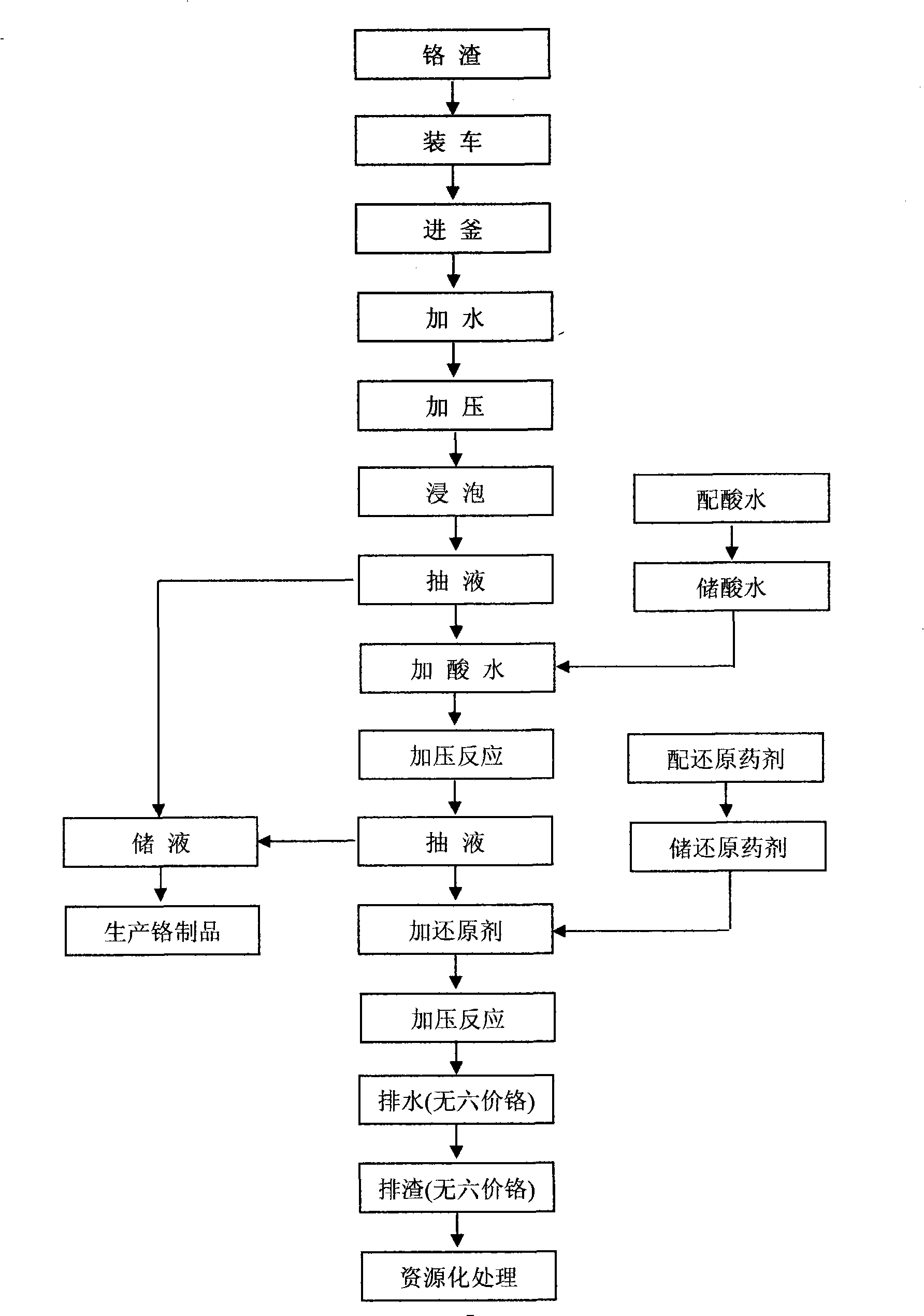

The invention discloses a method for extracting and reducing sexivalent chrome in chromium residue which is produced in chromate production and remained in the society. The method of the invention adopts a porous slot to load chromium residue (needing no grinding disposal); the sexivalent chrome liquor in the chrome residue is extracted under the conditions of pressurizing high-temperature saturation, high-pressure and vacuum by adding water in an autoclave; acid water is then added in the autoclave to dip and dissolve calcium chromate in the chrome residue, which is then converted into sexivalent chrome solution; the sexivalent chrome liquor is then extracted under the conditions of high pressure and vacuum; reduction reagent (ferrous sulfate) is added in the autoclave to reduce the sexivalent chrome residual in the chrome residue and converts the sexivalent chrome residue into trivalent chromium which is then fixed in the chrome residue; the gained sexivalent chrome can be used for preparing chrome products; the disposed non-toxic chrome residue can be used for auxiliary materials of cement and concrete, brick aggregate used for building and natural filling and disposal.

Description

A method for extracting and reducing hexavalent chromium in chromium salt production and chromium residue left over from society technical field The invention relates to a method for extracting and reducing hexavalent chromium in chromium salt production and chromium slag left over from society. Background technique The production of chromium salt is based on chromite, limestone and soda ash as raw materials. After calcination, trivalent chromium is oxidized to hexavalent chromium, and then hexavalent chromium is leached with water to make sodium dichromate (called chromium salt). The discharged residue called chrome residue. Chromium slag generally contains 1% to 2% of sodium chromate and calcium chromate (hexavalent chromium), and the hexavalent chromium in it will be leached out when exposed to water, polluting water and soil, and endangering life. Therefore, chromium slag is classified as hazardous waste by the national environmental protection department, and the nat...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): A62D3/37A62D101/43C04B7/24C04B18/14

CPCY02P40/10Y02W30/91

Inventor 李兴

Owner 李兴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com