Two-stage deep wet detoxification method for industrial chromium slag

A technology of wet detoxification and chromium slag, which is applied in the protection device against harmful chemicals, etc., can solve the problems of rebound and inability to restore hexavalent chromium more thoroughly, and achieve the effect of avoiding the risk of rebound

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

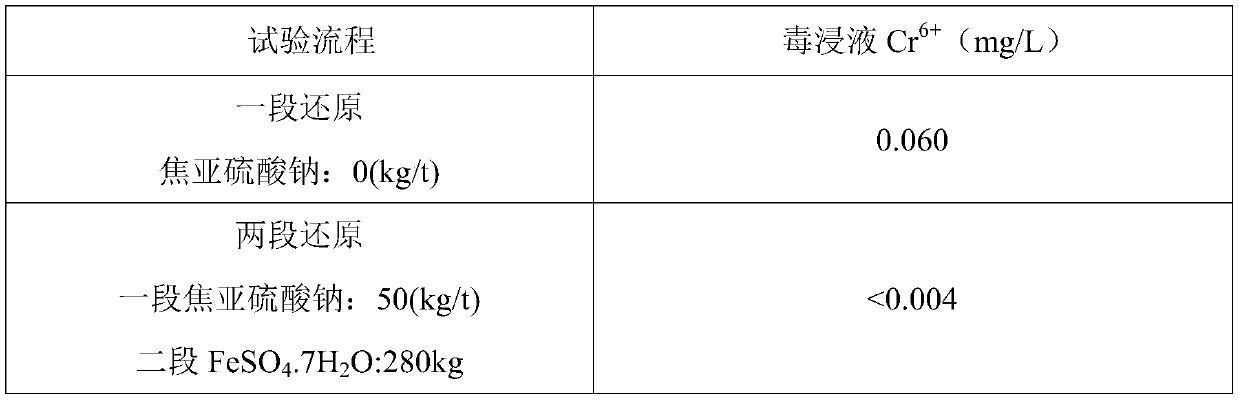

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0018] Include the following steps:

[0019] (1) Grinding fineness of chrome slag ore -0.074mm%: 90;

[0020] (2) A stage of water immersion with a solid-to-liquid ratio of 6:1, a constant temperature water bath at 75°C, stirring at 90r / min for 1 hour;

[0021] (3) Solid-liquid separation obtains orange-red hexavalent chromium liquid;

[0022] (4) The solid enters the second-stage acid leaching, and the liquid is added with sodium metabisulfite until the liquid turns dark green;

[0023] (5) Calcium oxide is added to the dark green trivalent chromium liquid to form a gray-green chromium hydroxide precipitate, and the filtered clear liquid is used as backwater;

[0024] (6) The solid-liquid ratio of the second-stage acid leaching is 3:1, and the constant temperature water bath is 80°C;

[0025] (7) Add concentrated sulfuric acid, the consumption of concentrated sulfuric acid is 700kg / t, soak for 4 hours;

[0026] (8) adding excess ferrous sulfate to process for 4 hours;

...

experiment example 2

[0030] Include the following steps:

[0031] (1) Grinding fineness of chrome slag ore -0.074mm%: 90;

[0032] (2) One stage of water immersion with a solid-to-liquid ratio of 6:1, a constant temperature water bath at 80°C, stirring at 100r / min for 1.5 hours;

[0033] (3) Solid-liquid separation obtains orange-red hexavalent chromium liquid;

[0034] (4) The solid enters the second-stage acid leaching, and the liquid is added with sodium metabisulfite until the liquid turns dark green;

[0035] (5) Calcium oxide is added to the dark green trivalent chromium liquid to form a gray-green chromium hydroxide precipitate, and the filtered clear liquid is used as backwater;

[0036] (6) The solid-liquid ratio of the second-stage acid leaching is 3:1, and the constant temperature water bath is 85°C;

[0037] (7) Add concentrated sulfuric acid, the consumption of concentrated sulfuric acid is 720kg / t, soak for 5 hours;

[0038] (8) adding excess ferrous sulfate to process for 5 hour...

experiment example 3

[0042] Include the following steps:

[0043] (1) Grinding fineness of chrome slag ore -0.074mm%: 90;

[0044] (2) A stage of water immersion with a solid-to-liquid ratio of 6:1, a constant temperature water bath at 85°C, stirring at 110r / min for 2 hours;

[0045] (3) Solid-liquid separation obtains orange-red hexavalent chromium liquid;

[0046] (4) The solid enters the second-stage acid leaching, and the liquid is added with sodium metabisulfite until the liquid turns dark green;

[0047] (5) Calcium oxide is added to the dark green trivalent chromium liquid to form a gray-green chromium hydroxide precipitate, and the filtered clear liquid is used as backwater;

[0048] (6) The solid-liquid ratio of the second-stage acid leaching is 3:1, and the constant temperature water bath is 90°C;

[0049] (7) Add concentrated sulfuric acid, the consumption of concentrated sulfuric acid is 740kg / t, soak for 6 hours;

[0050] (8) adding excess ferrous sulfate to process for 6 hours; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com