Method for reducing content of hexavalent chromium in chromium oxide green

A technology of chromium oxide green and hexavalent chromium, which is applied in the direction of chromium oxide/hydrate, can solve the problems of narrow application range of additives, increased energy consumption, high equipment and operation requirements, etc., to solve the yellowish color of the product and improve the recovery rate , The effect of reducing the content of water soluble matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

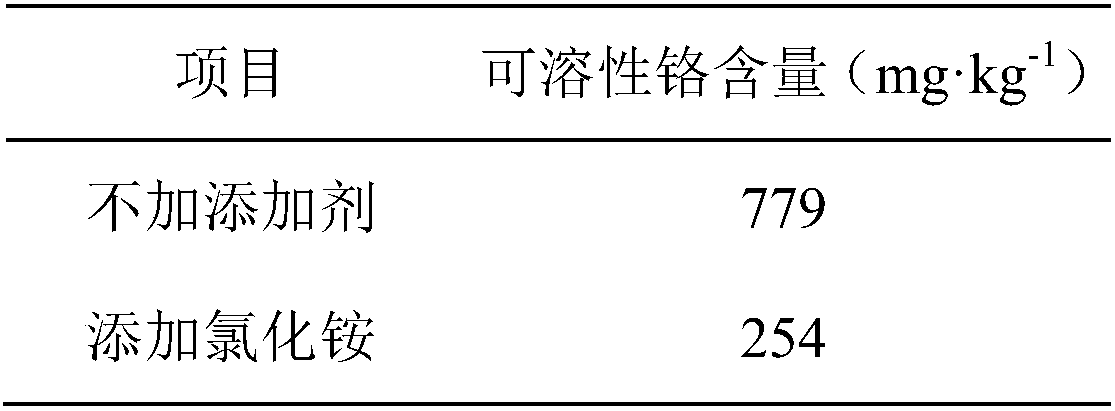

[0044] Raise the temperature of the muffle furnace to 950°C, put 15g of chromic anhydride 1 into it, and thermally decompose it for 1h. When the temperature of the muffle furnace is lowered to 400°C, add 2.5mL of saturated ammonium chloride solution, and cool naturally to room temperature. According to the methods of GB9760-88 and GB20785-2006, the hexavalent chromium in chromium oxide green was extracted and analyzed, and the results are as follows:

[0045]

[0046] ICP was used to analyze the chromium content. After adding ammonium chloride during the decomposition and cooling process of chromic anhydride, the soluble chromium content in the chromium oxide green product can be changed from 779 mg kg without adding -1 down to 254mg·kg -1 .

Embodiment 2

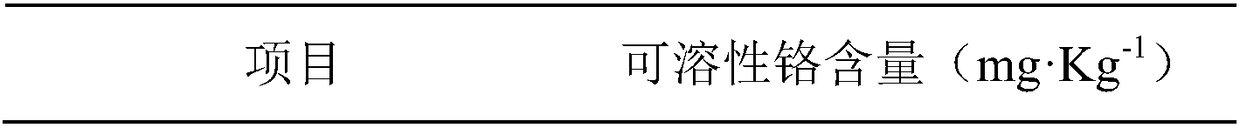

[0048] Raise the temperature of the muffle furnace to 950°C, put 15g of chromic anhydride 1 into it, and thermally decompose it for 1h. When the temperature of the muffle furnace is lowered to 100°C, add 0.2mL of ethanol solution and let it cool naturally to room temperature. According to the methods of GB9760-88 and GB20785-2006, the hexavalent chromium in chromium oxide green was extracted and analyzed, and the results are as follows:

[0049]

[0050]

[0051] ICP was used to analyze the chromium content. After adding ethanol in the process of decomposing and cooling chromic anhydride, the soluble chromium content in the chromium oxide green product can be increased from 779 mg kg without adding. -1 Dropped to 178mg·Kg -1 .

Embodiment 3

[0053] Raise the temperature of the muffle furnace to 950°C, put 15g of chromic anhydride 2 into it, and thermally decompose it for 1 hour. When the temperature of the muffle furnace is lowered to 400°C, add 2.5mL of saturated ammonium chloride solution, and let it cool naturally to room temperature. According to the methods of GB9760-88 and GB20785-2006, the hexavalent chromium in chromium oxide green was extracted and analyzed, and the results are as follows:

[0054]

[0055] ICP was used to analyze the chromium content. After adding ammonium chloride during the decomposition and cooling process of chromic anhydride, the soluble chromium content in the chromium oxide green product can be increased from 260mg kg without adding -1 down to 31mg·kg -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com