Patents

Literature

407results about "Chromium compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

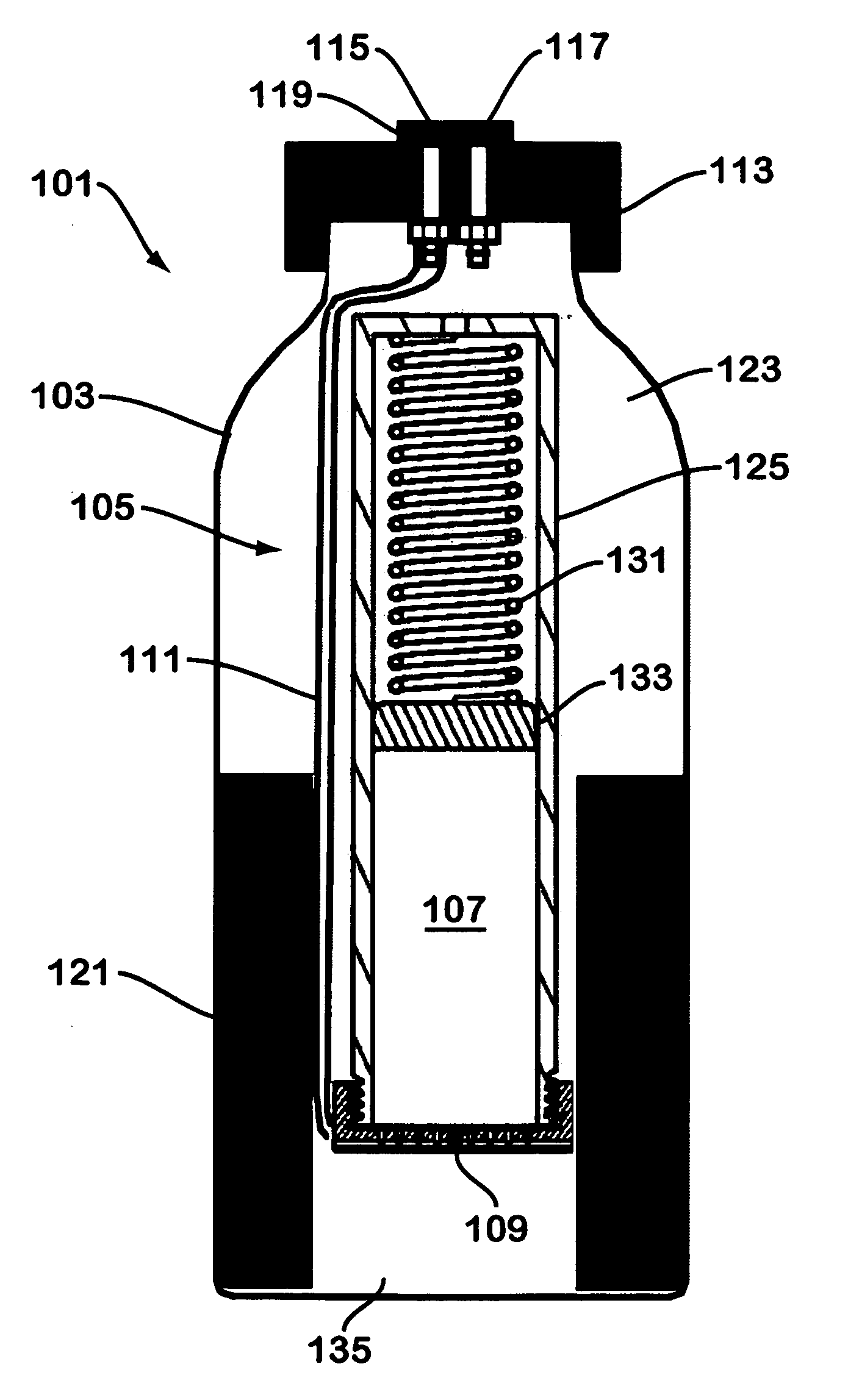

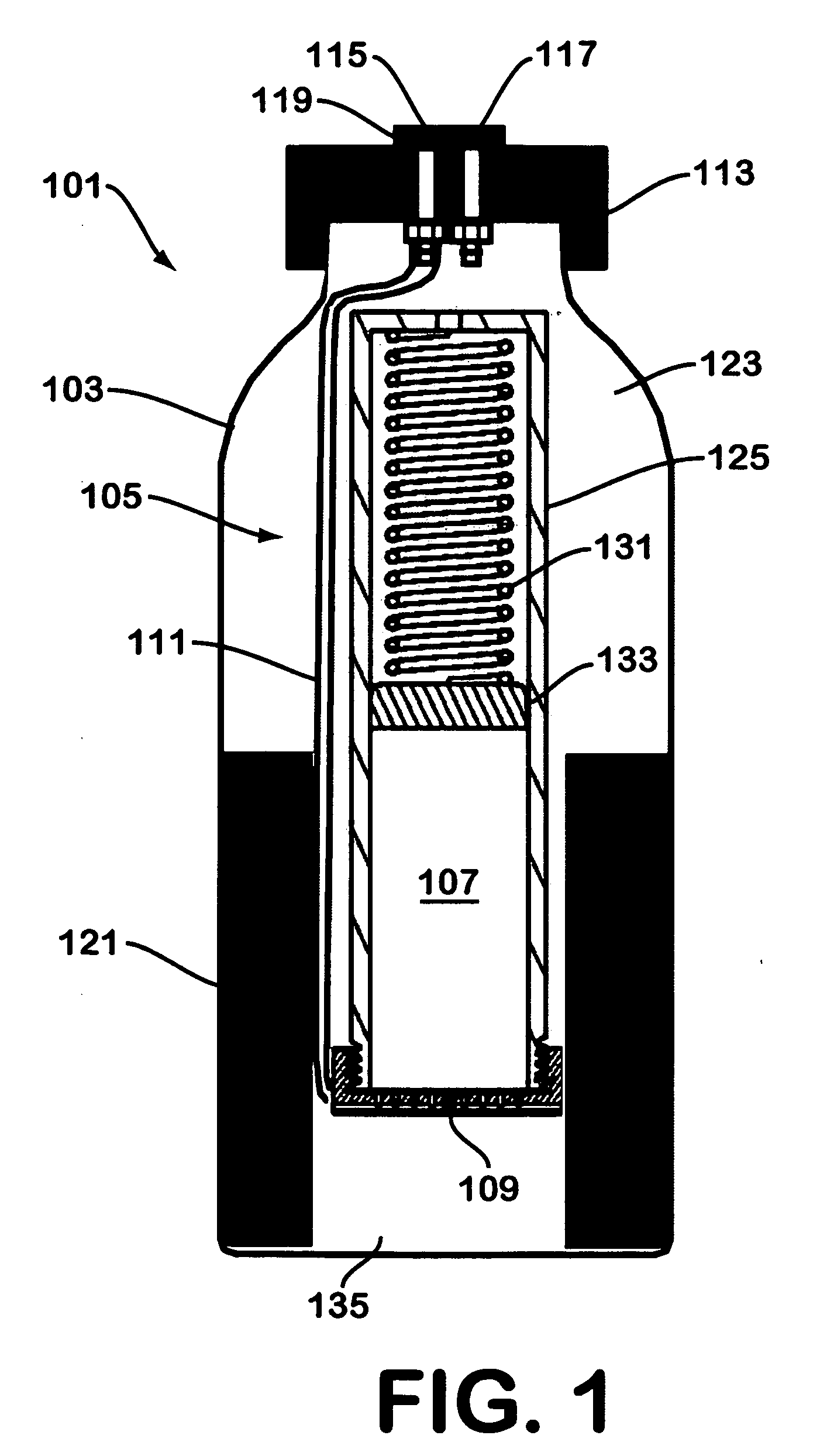

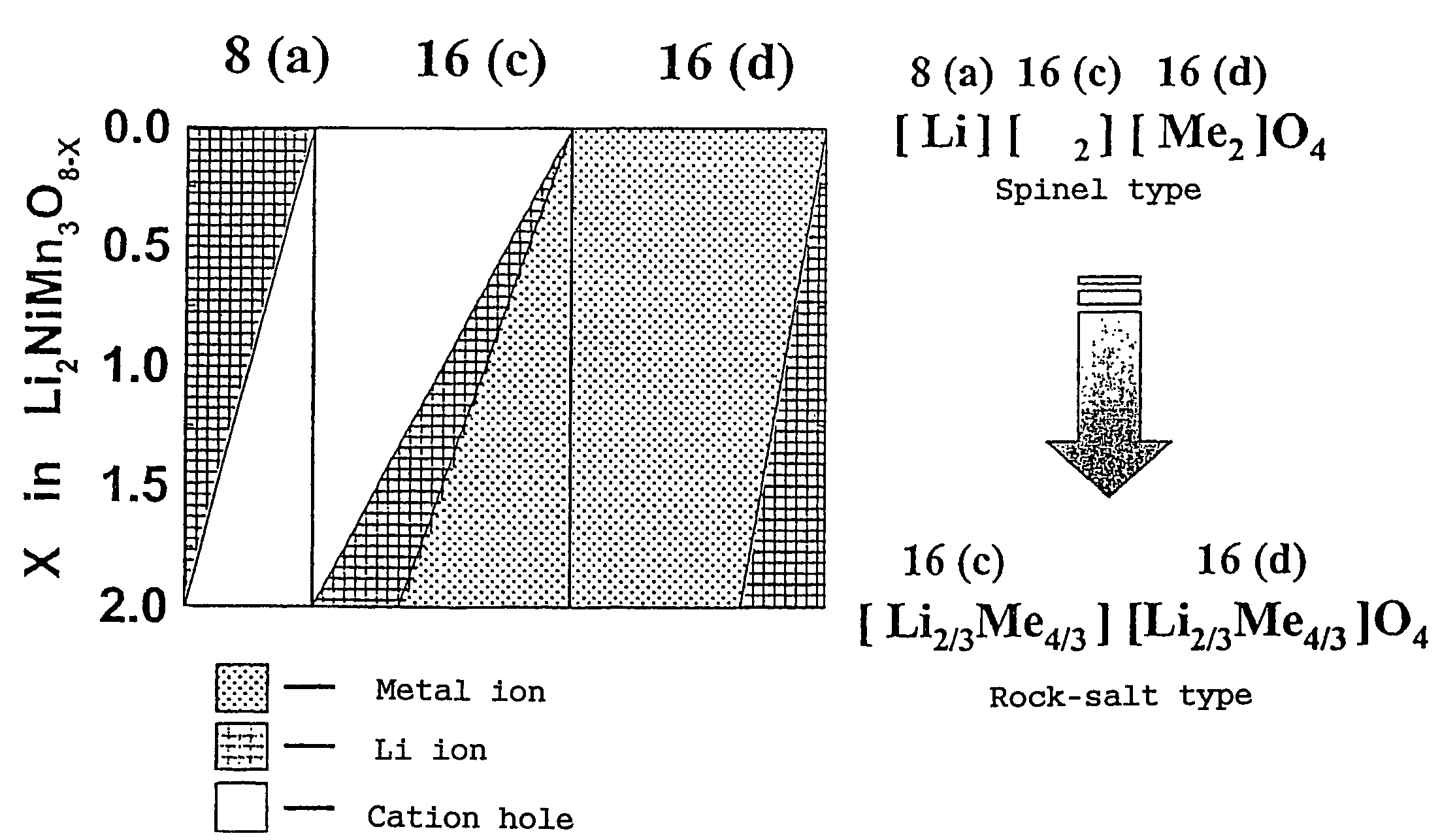

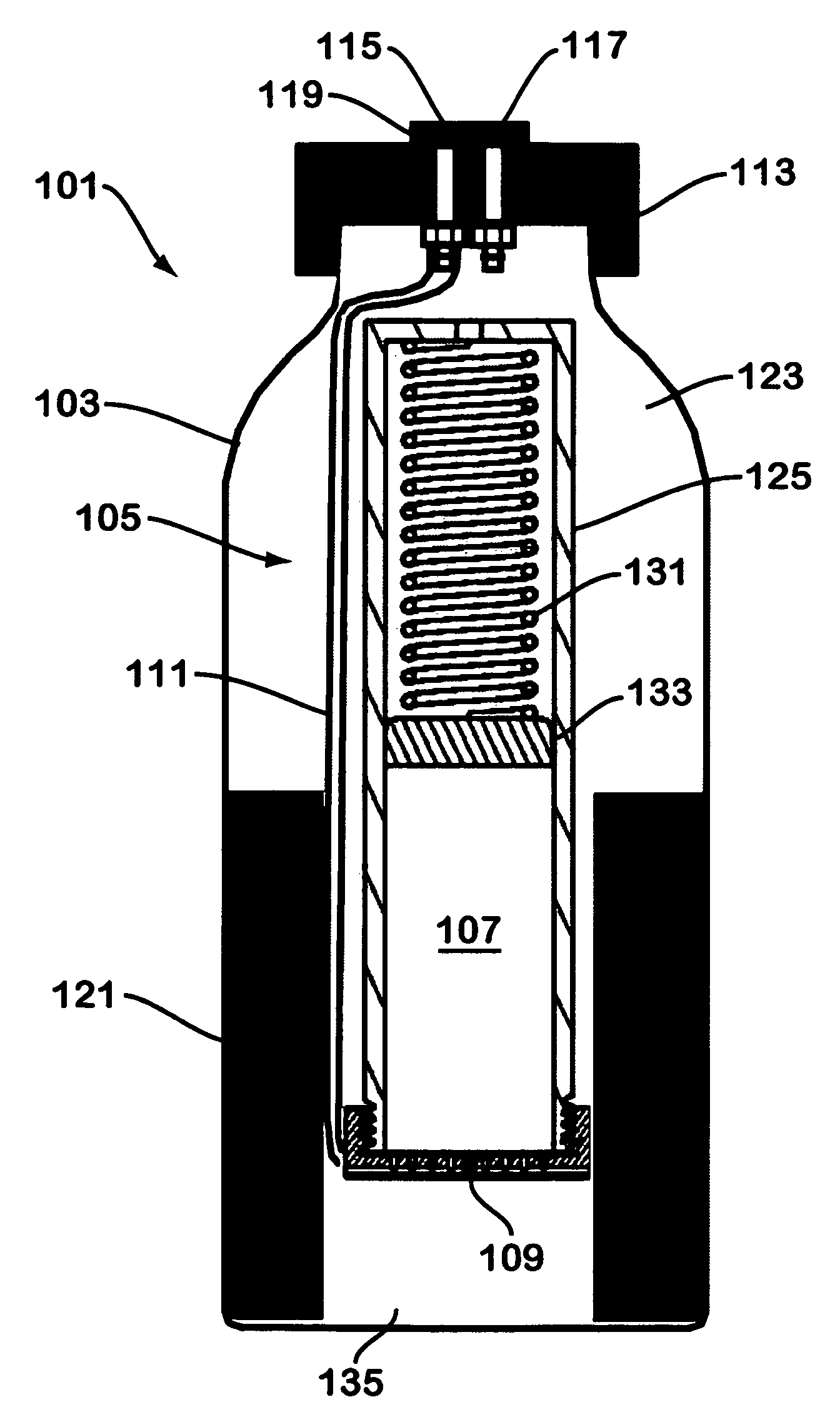

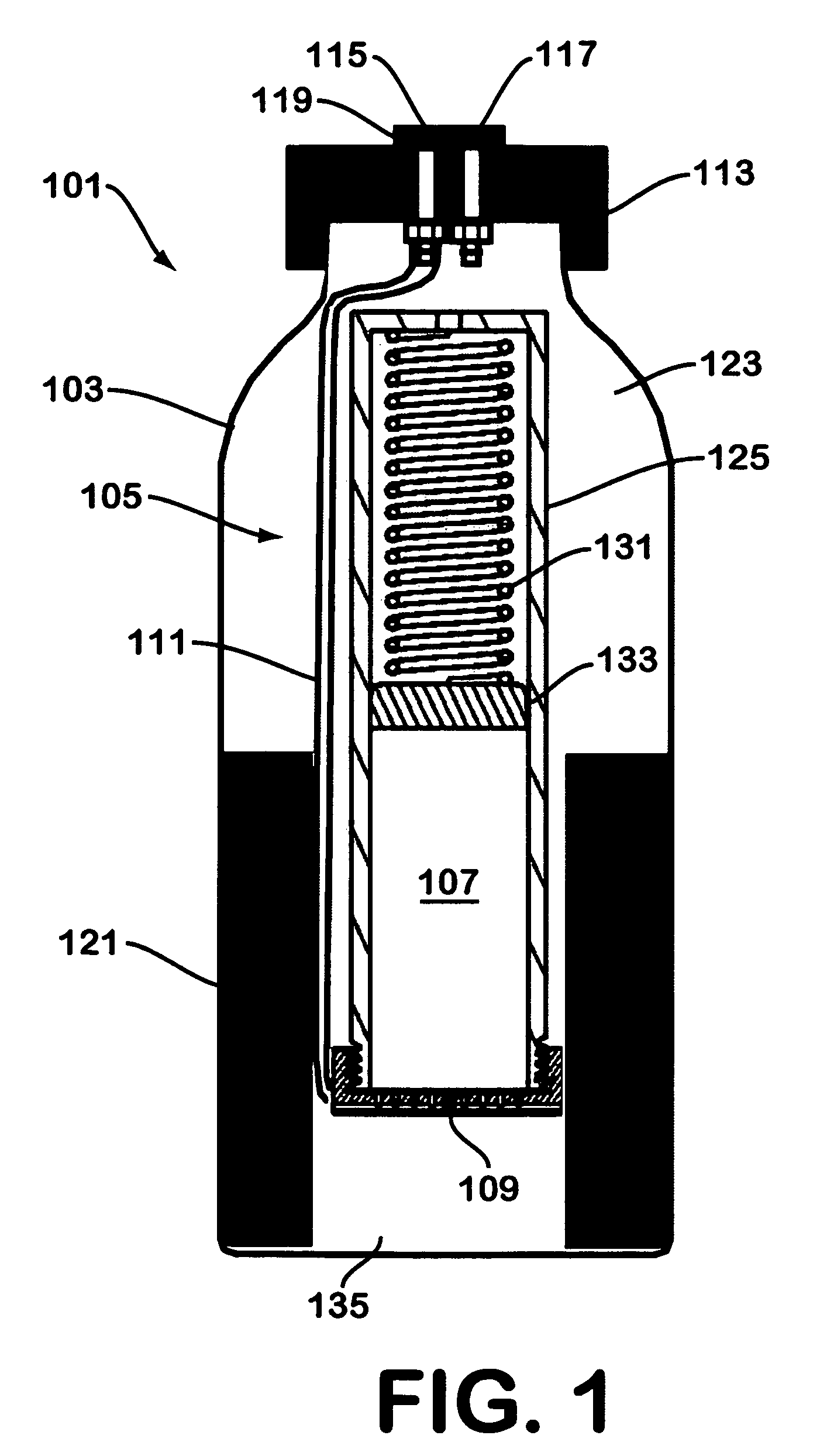

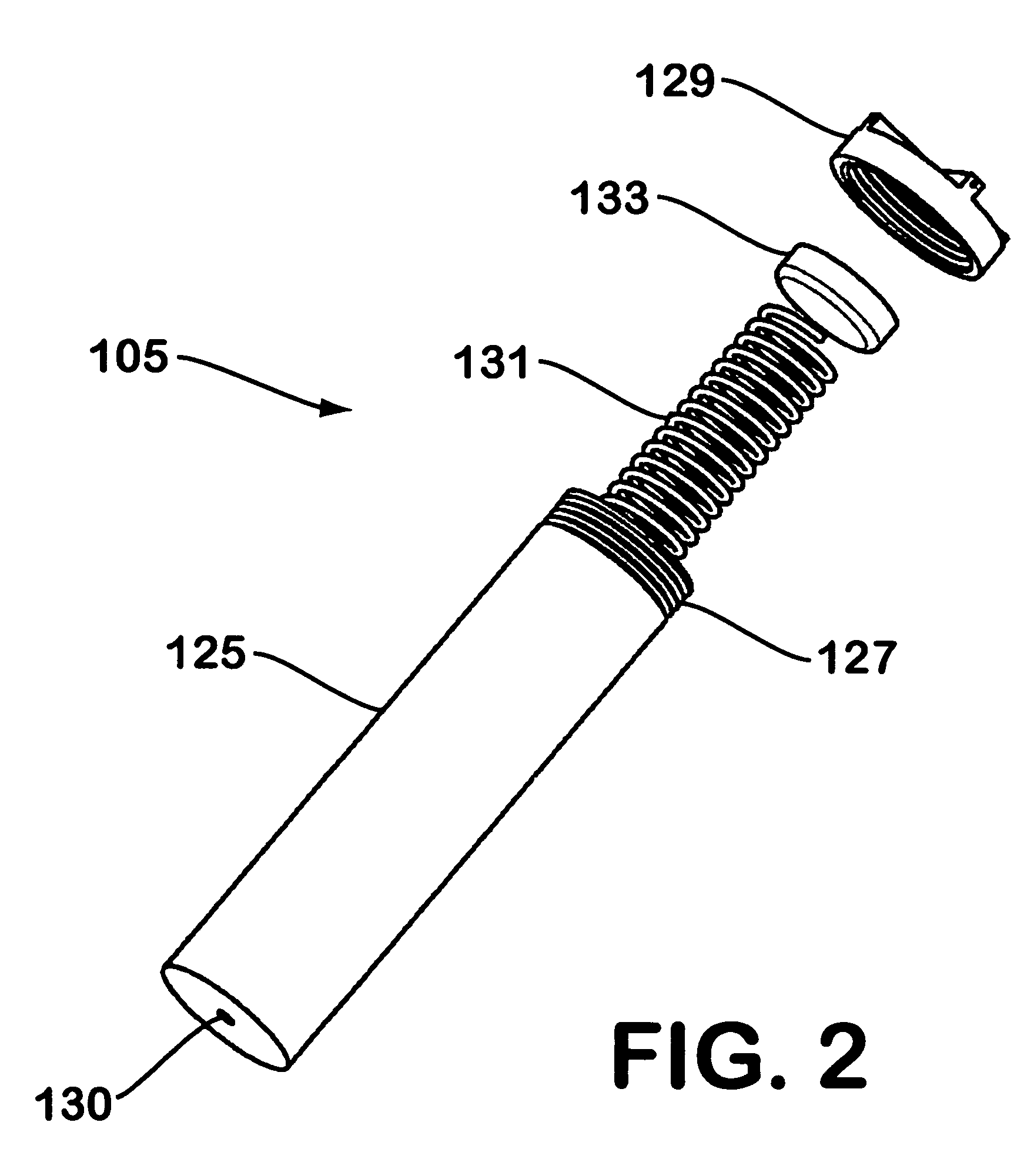

Solid chemical hydride dispenser for generating hydrogen gas

InactiveUS20070020172A1Molybdeum compoundsSynthetic resin layered productsCompound (substance)Hydrogen evolution

A device for generating hydrogen gas is provided. The device (101) comprises a first hydrogen-containing composition (107) that reacts with a second composition to evolve hydrogen gas; a dispenser (105) adapted to apply the first composition to a first porous member (109); and a conduit (111) adapted to supply the second composition to the first porous member. In a preferred embodiment, the first composition is selected from the group consisting of hydrides, borohydrides and boranes, the second composition is water, and the dispenser is spring-loaded and is charged with the first composition. As the first composition reacts with water at the interface to evolve hydrogen gas, the dispenser forces the reaction product across the interface and out of the dispenser, where it will not interfere with the progress of the hydrogen evolution reaction.

Owner:LYNNTECH POWER SYST

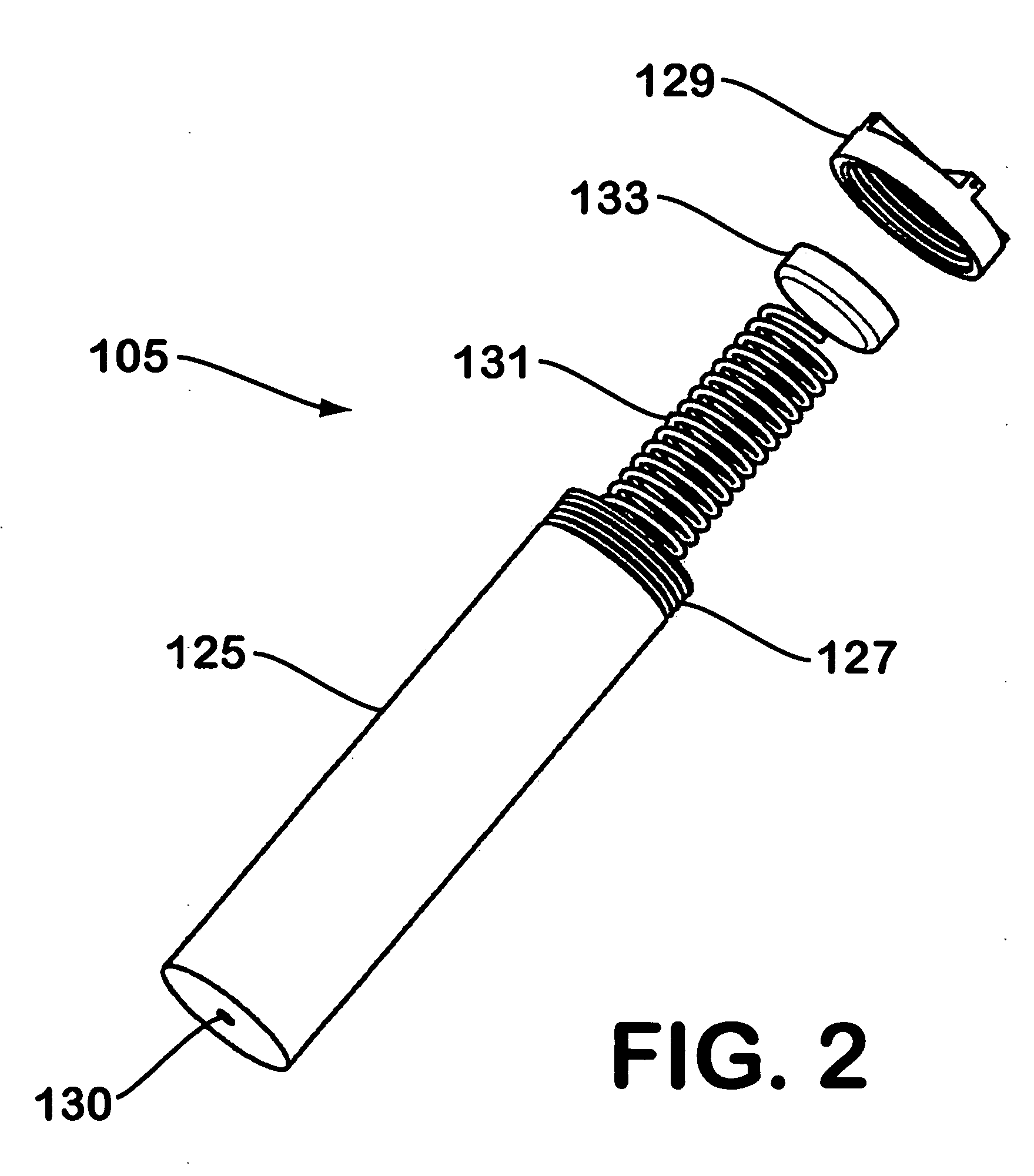

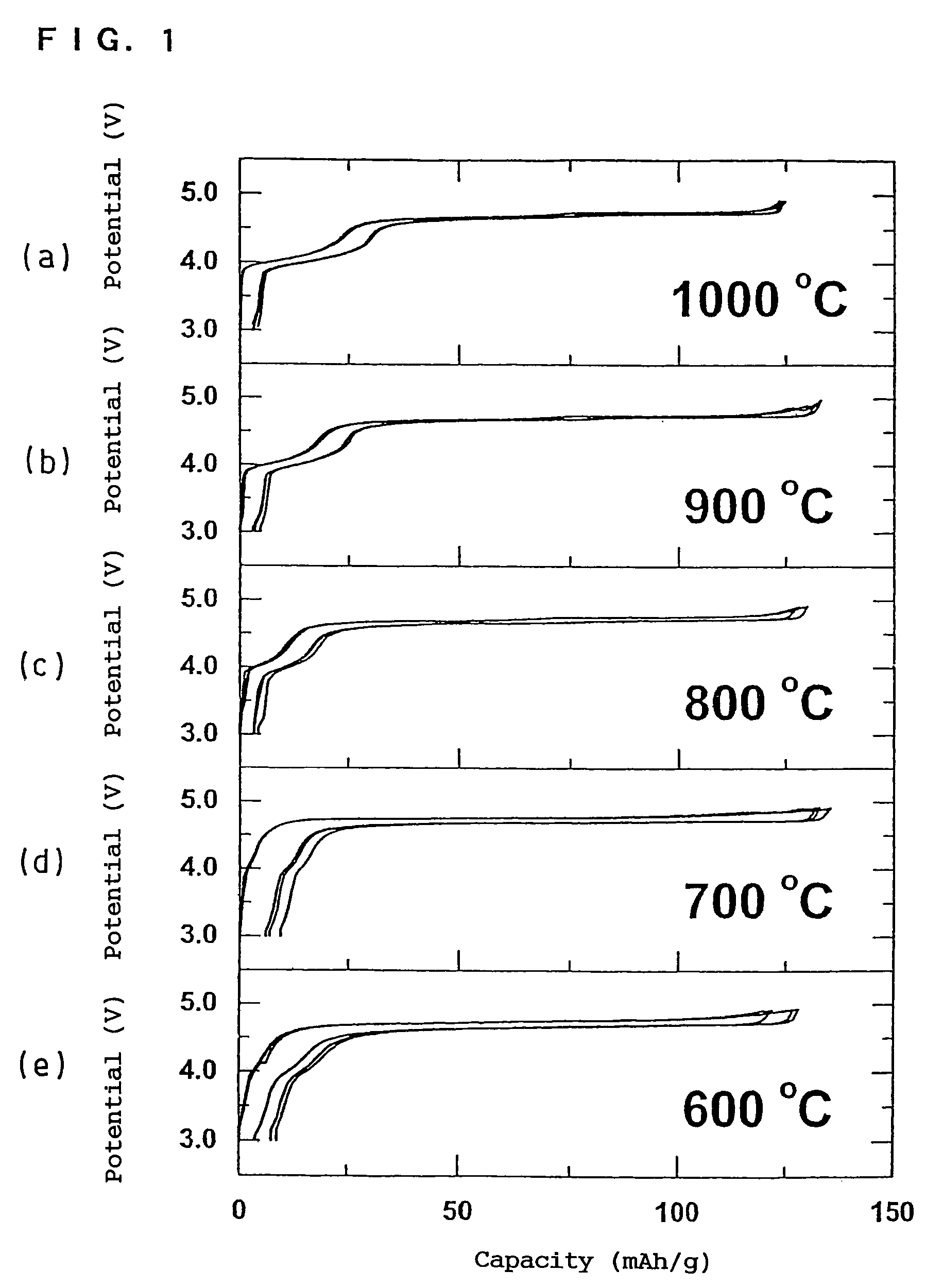

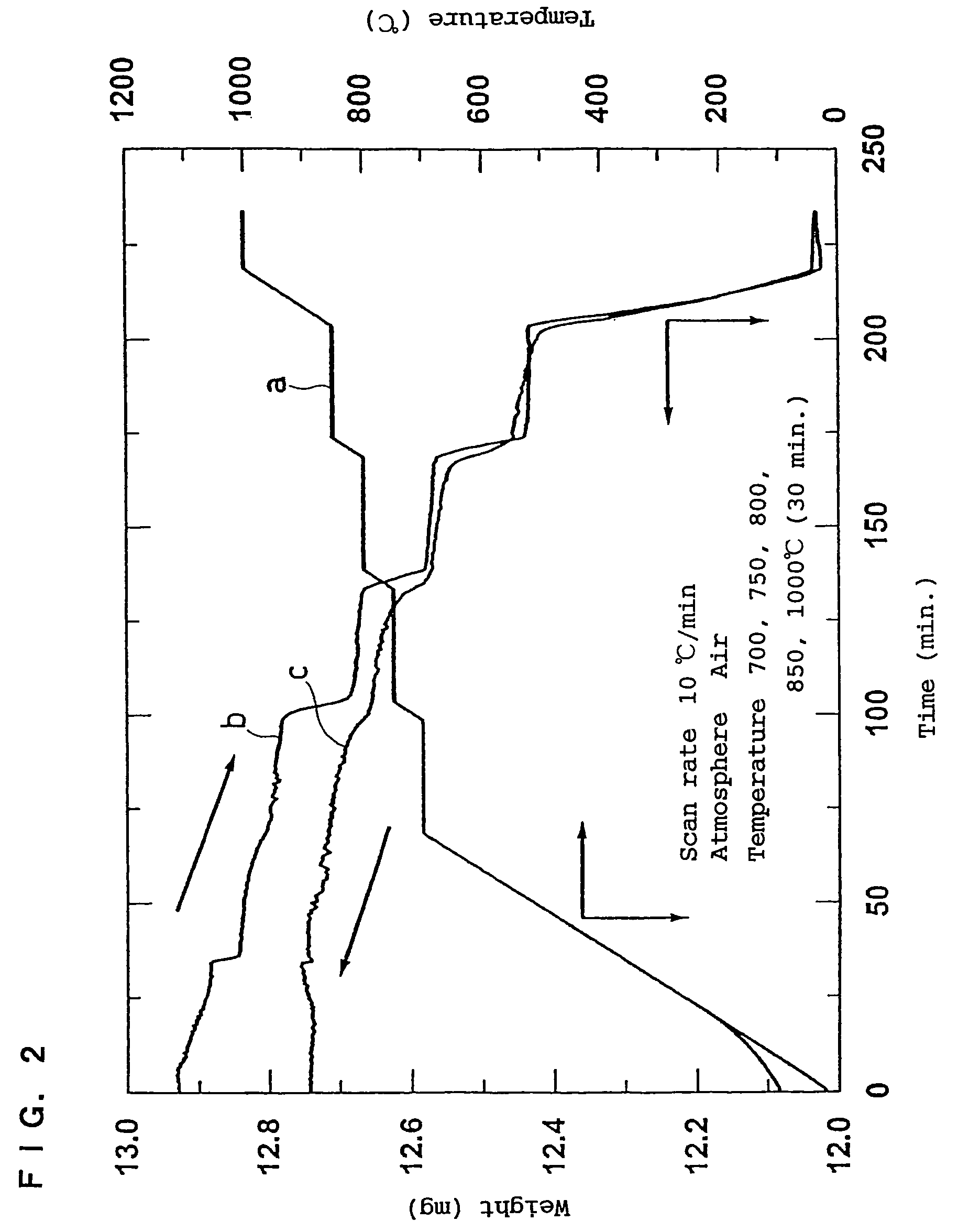

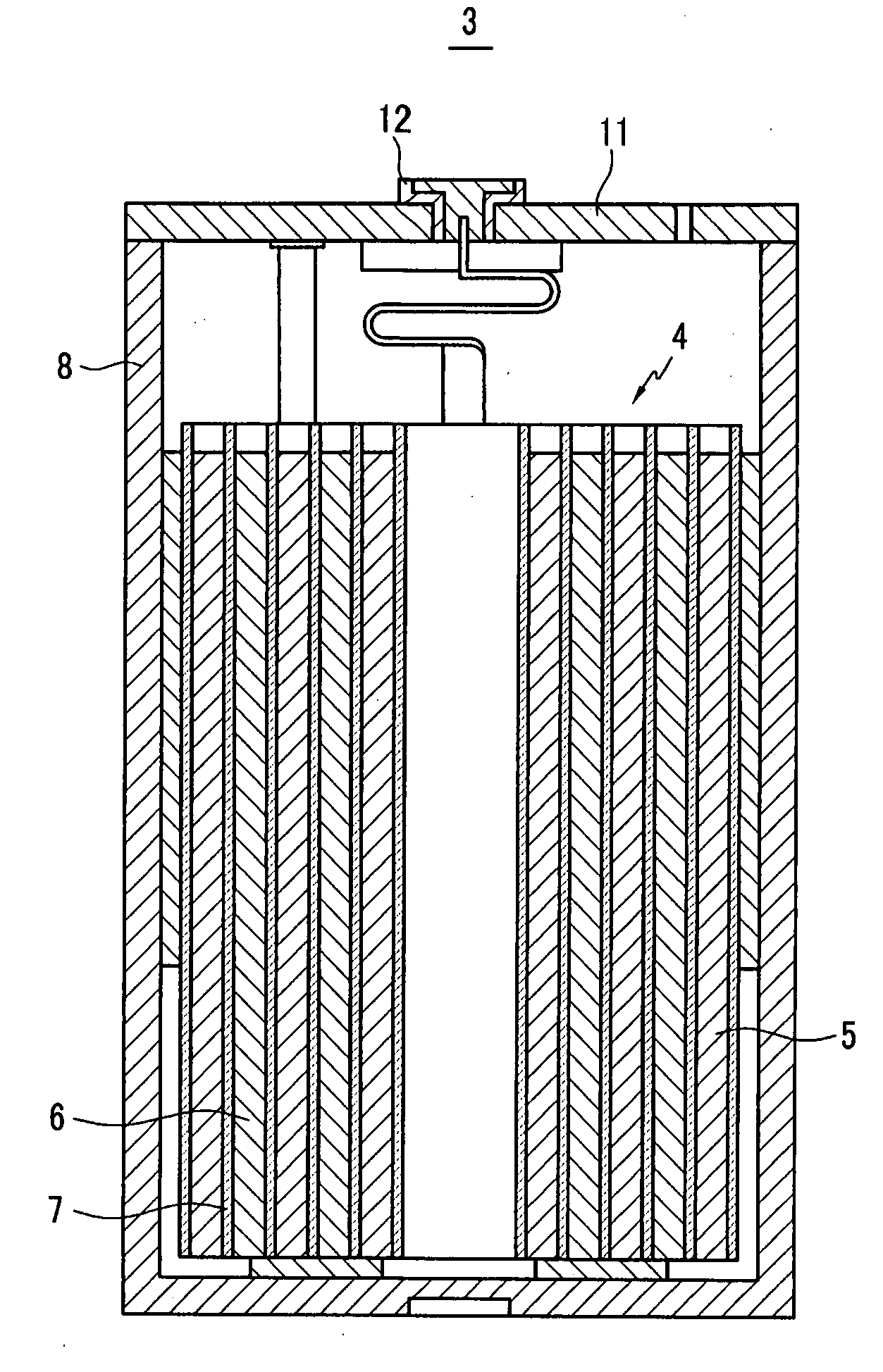

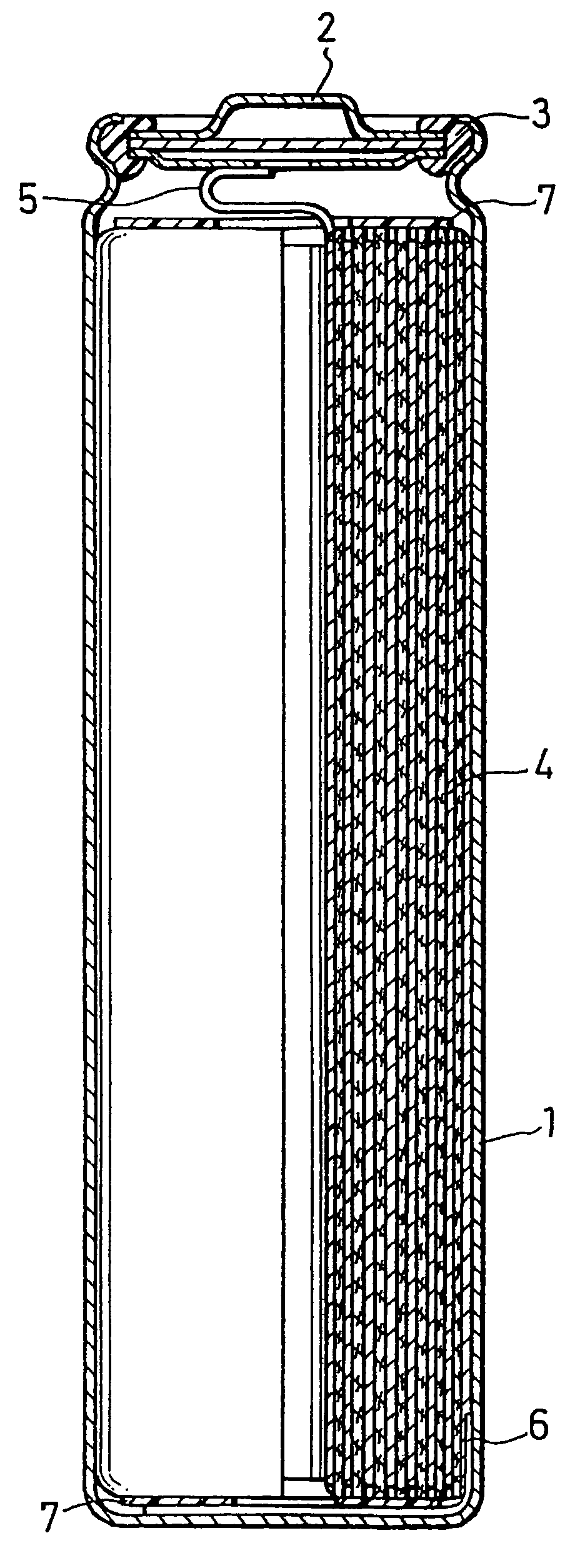

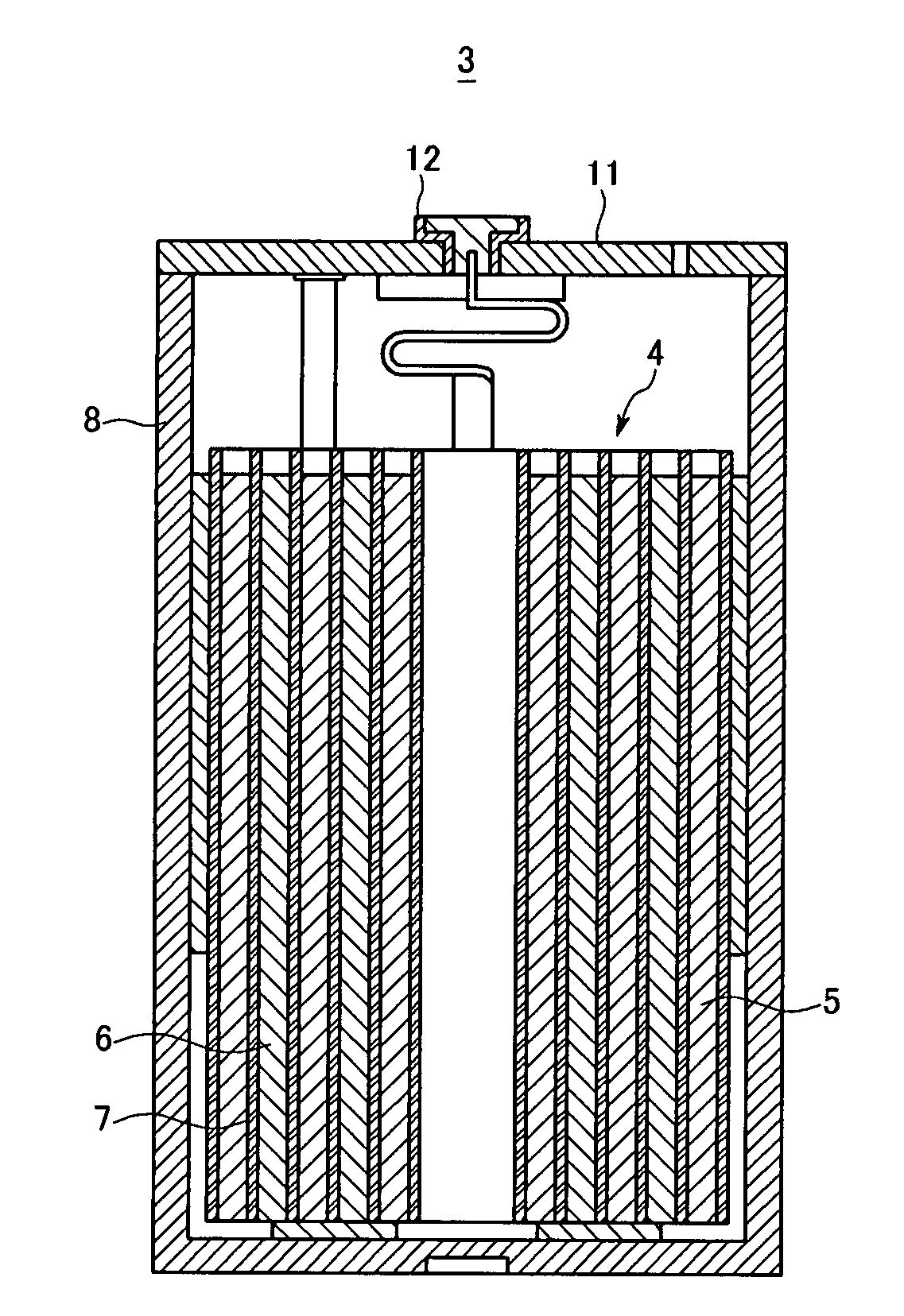

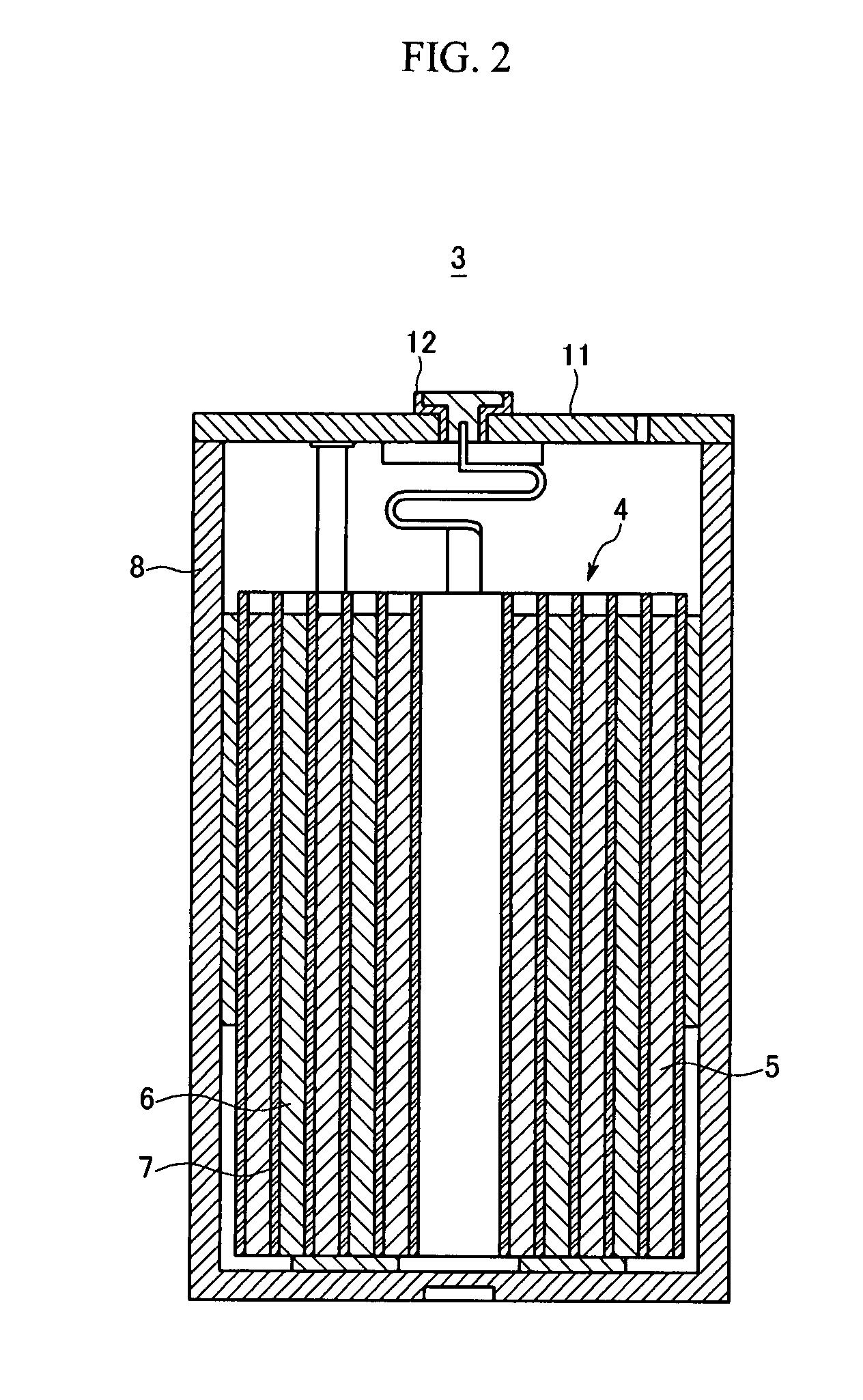

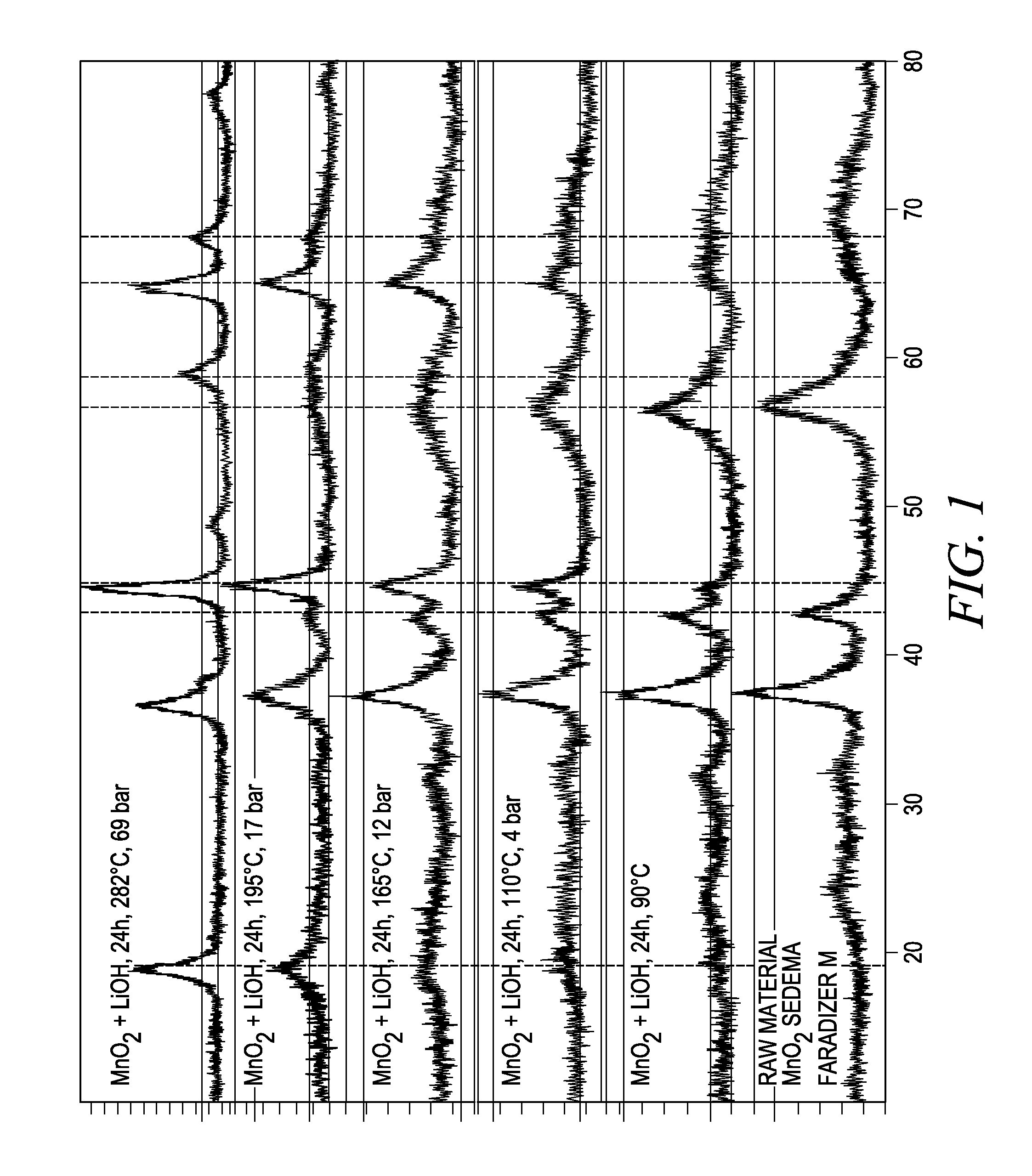

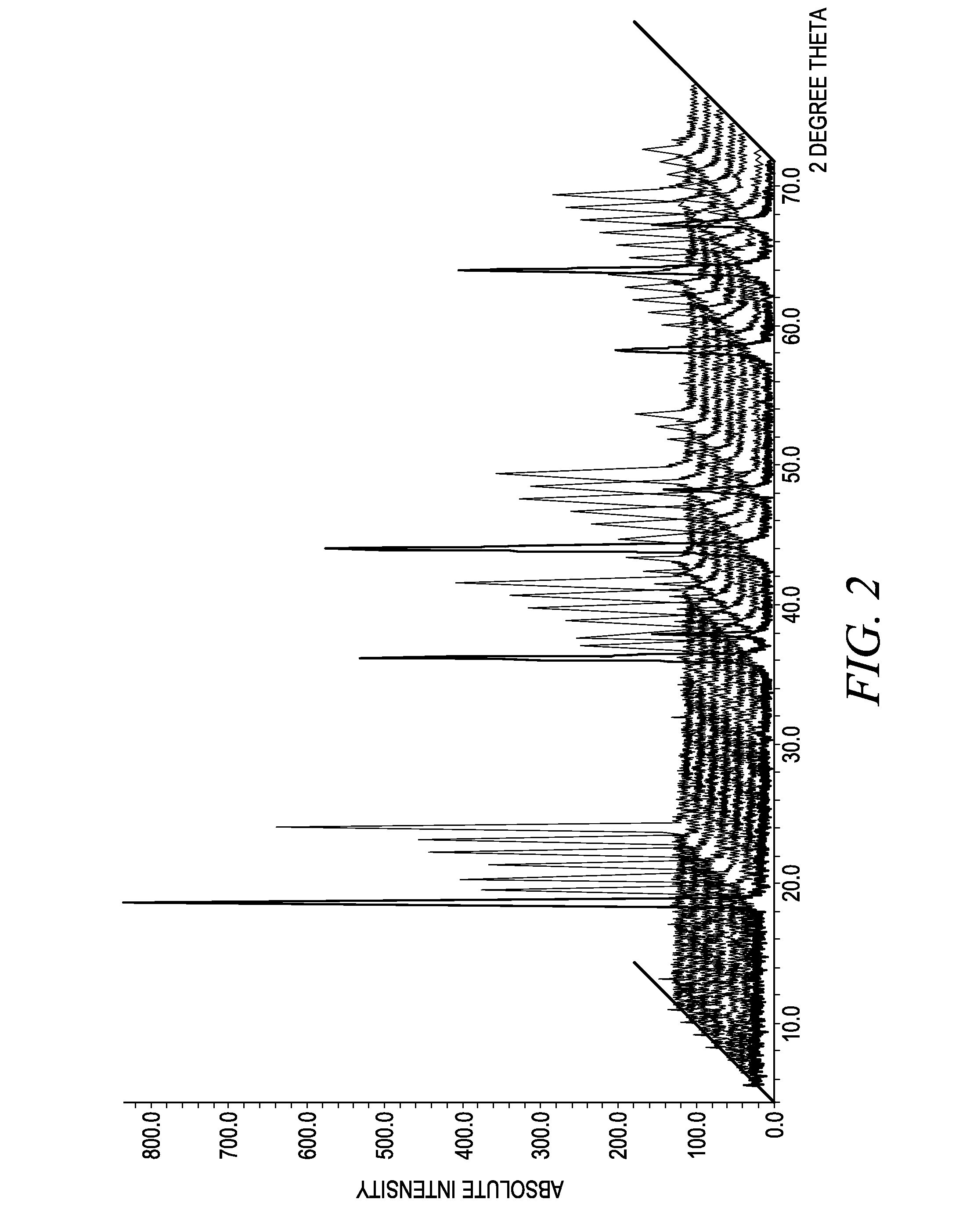

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

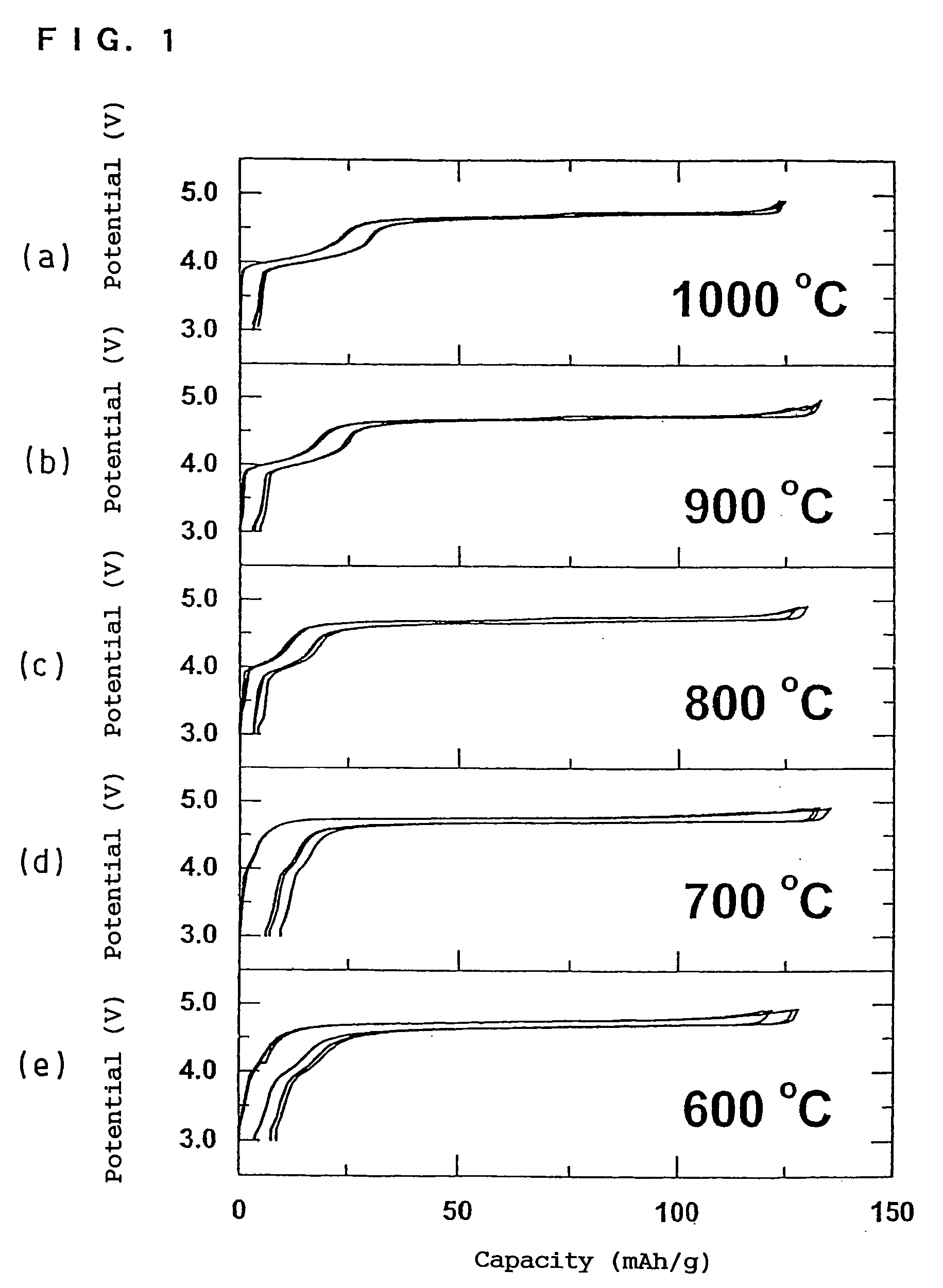

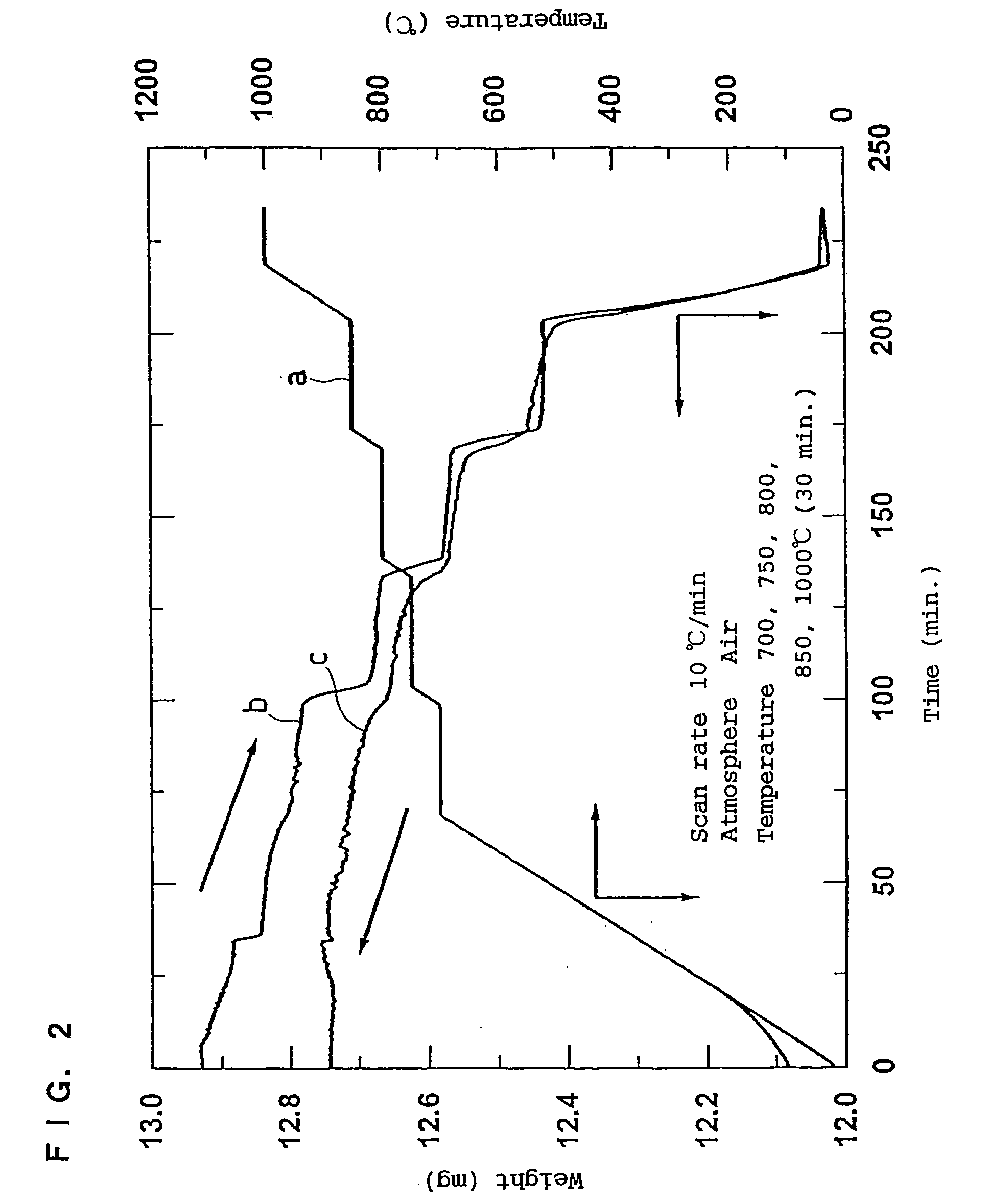

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIV +1

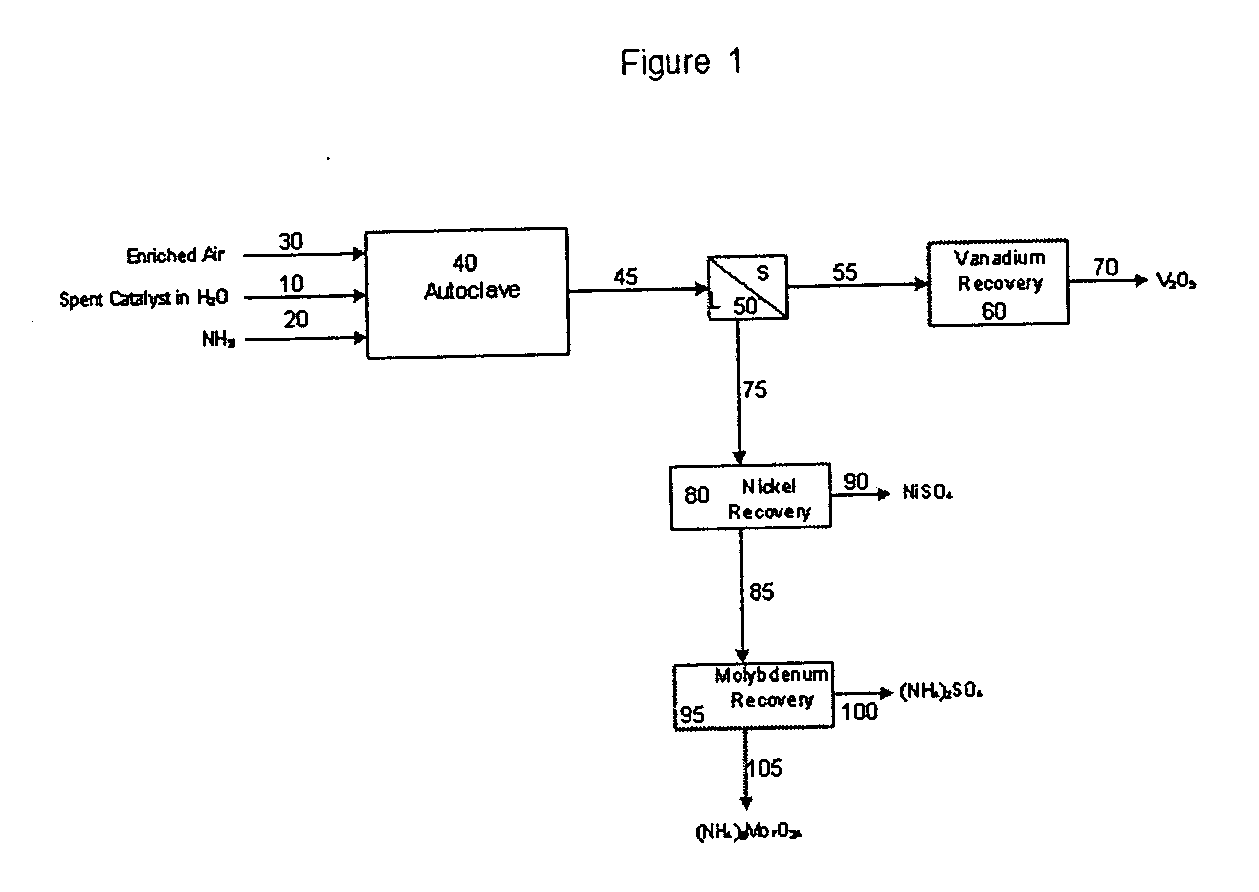

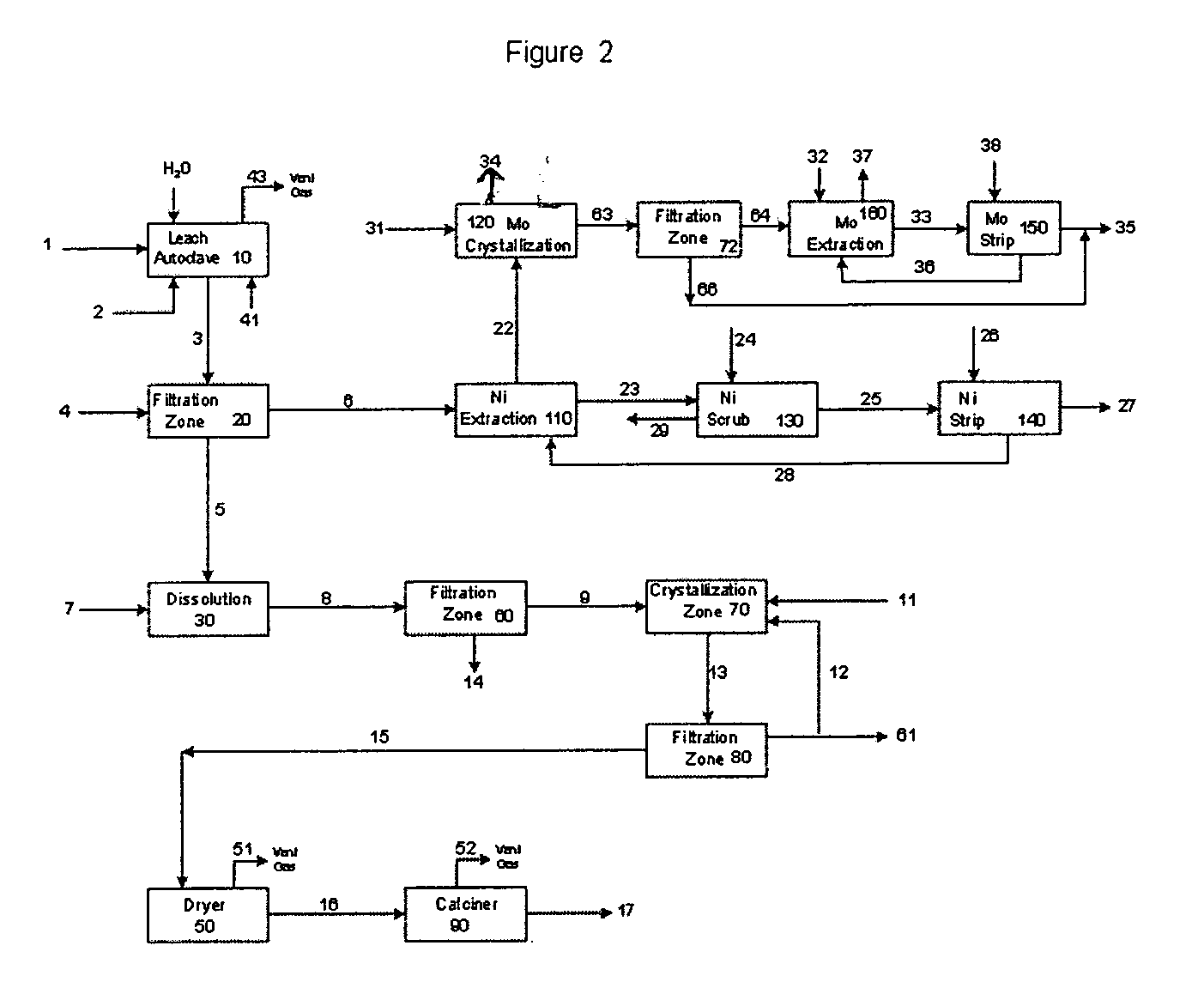

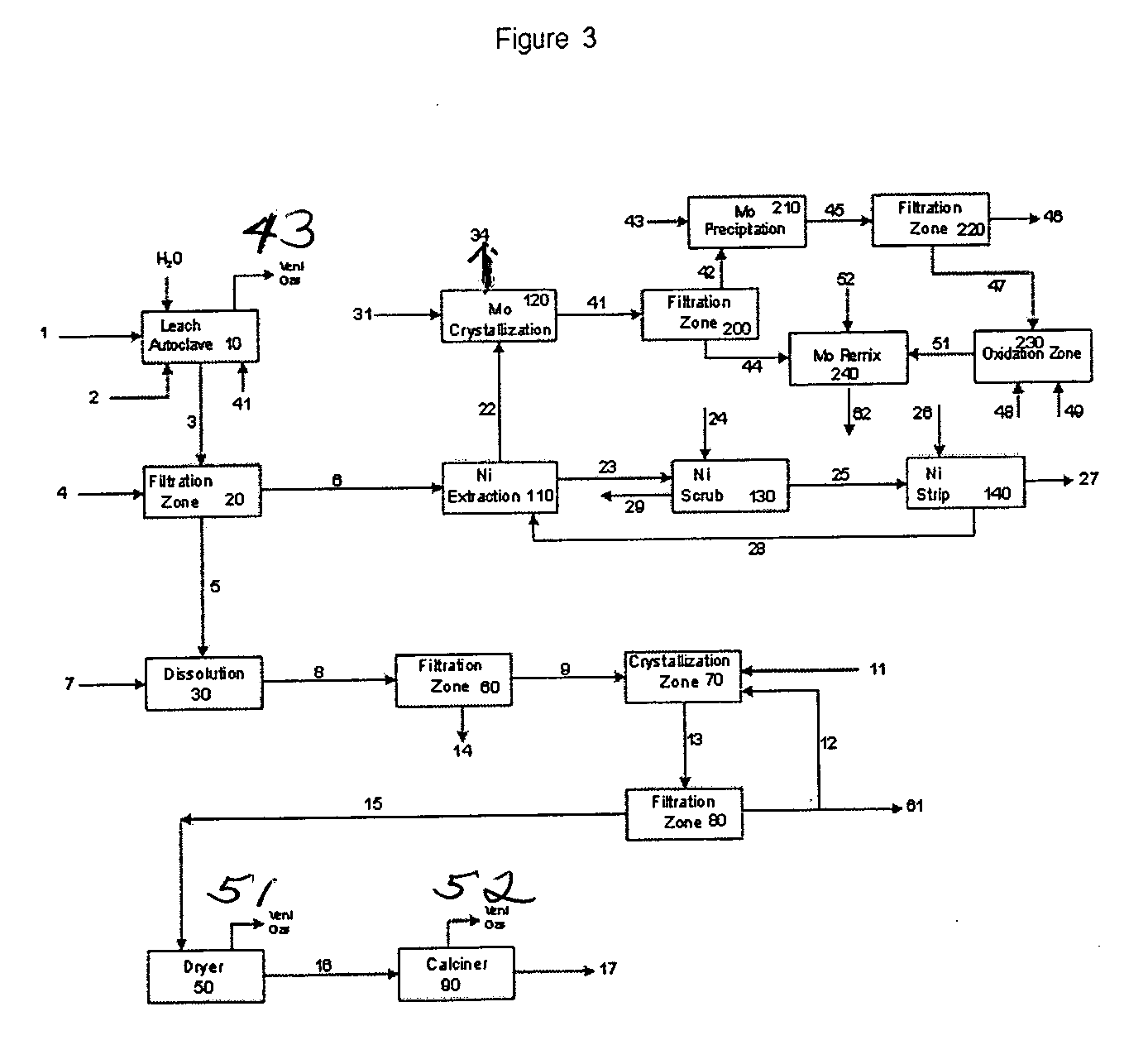

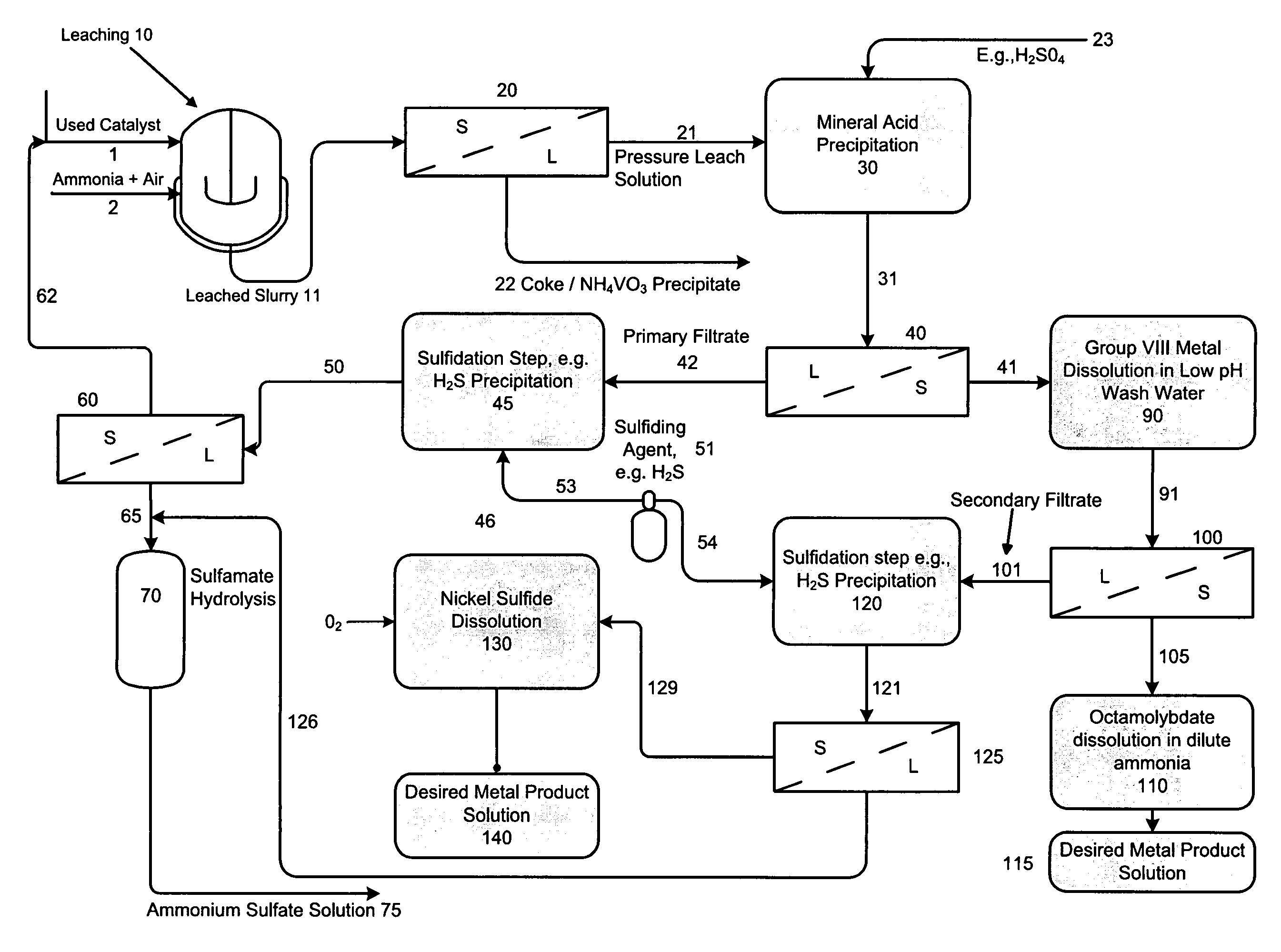

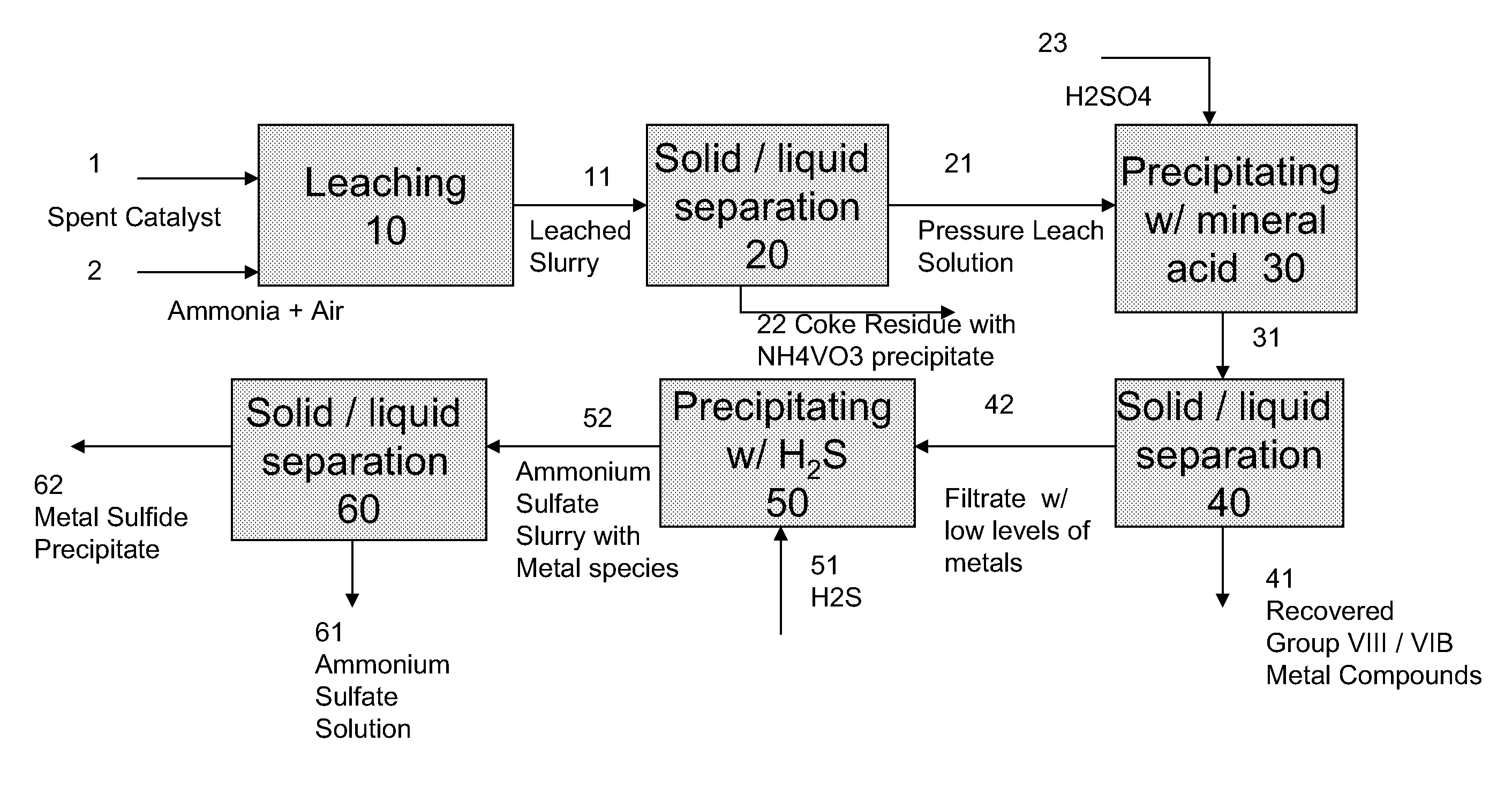

Process for metals recovery from spent catalyst

The process of this invention is directed to the removal of metals from an unsupported spent catalyst. The catalyst is subjected to leaching reactions. Vanadium is removed as a precipitate, while a solution comprising molybdenum and nickel is subjected to further extraction steps for the removal of these metals. Molybdenum may alternately be removed through precipitation.

Owner:CHEVROU USA INC

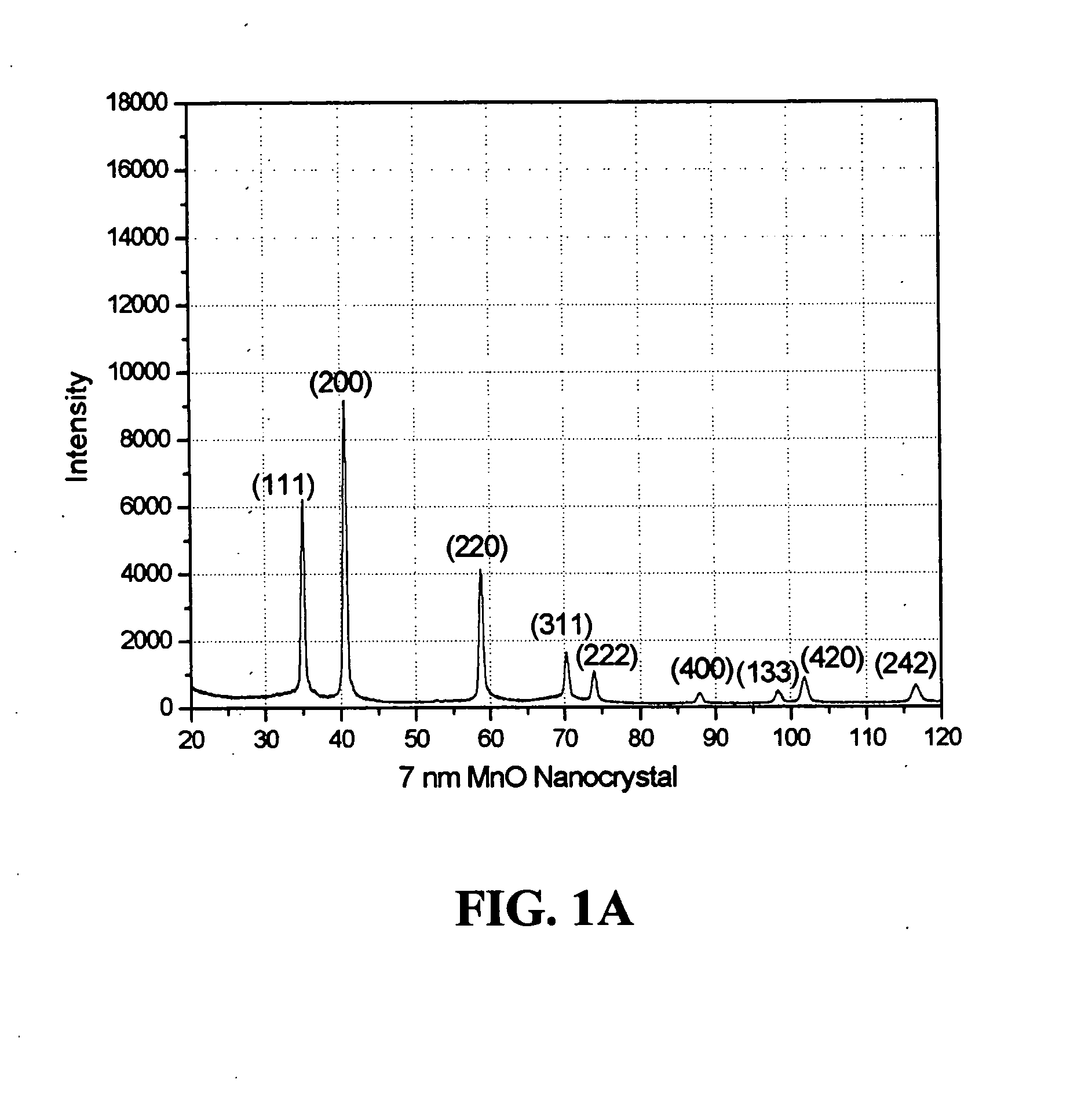

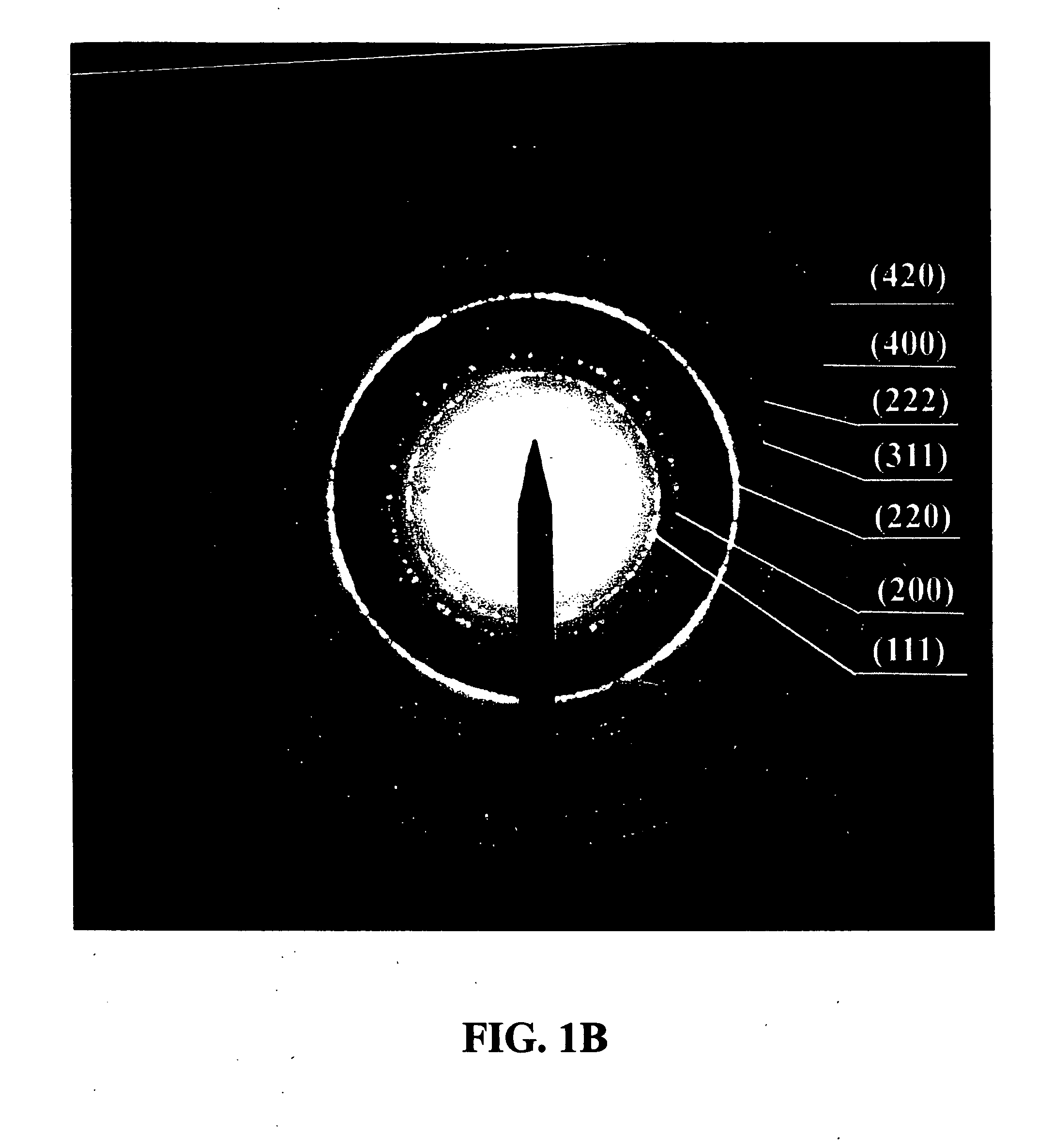

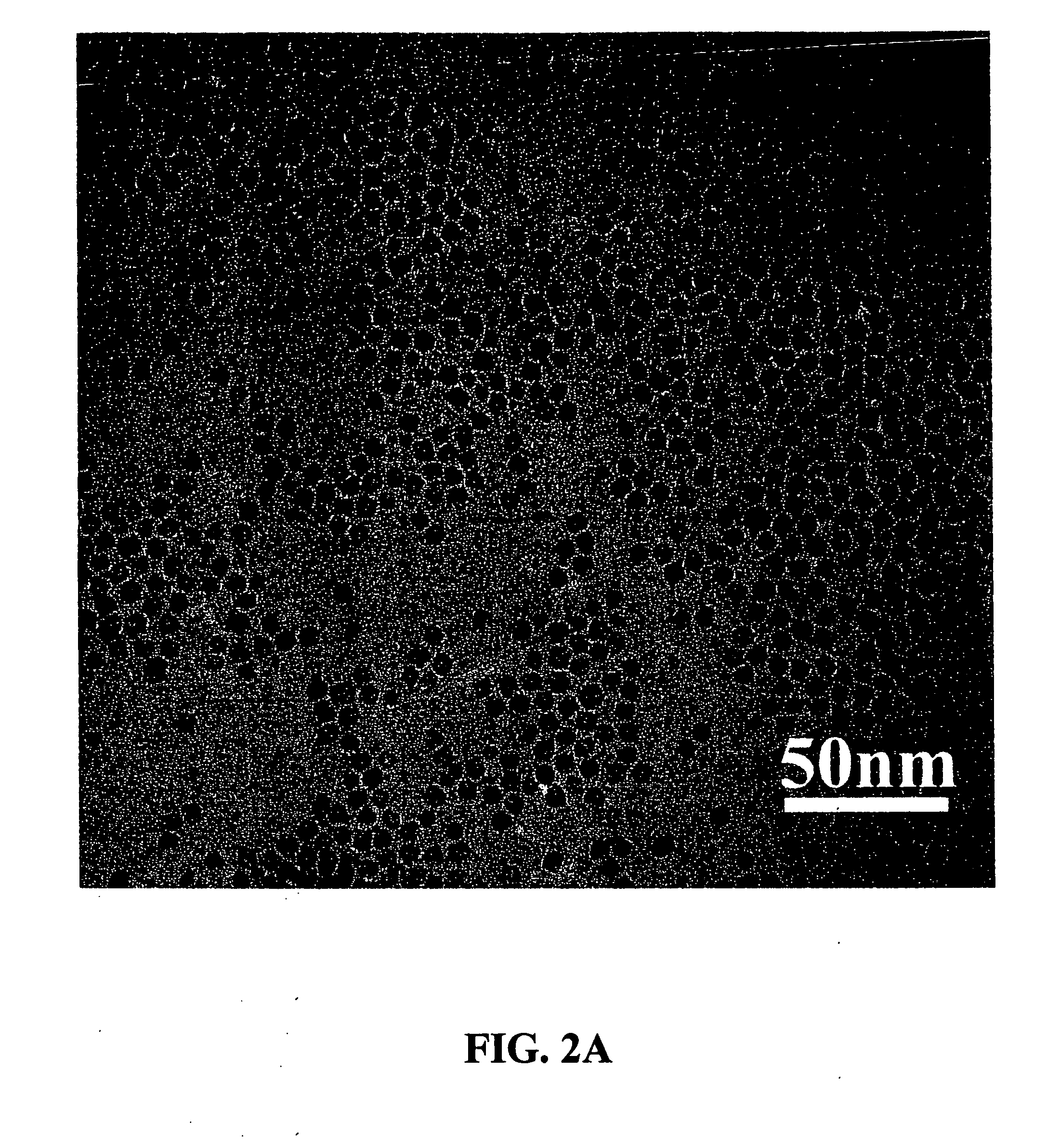

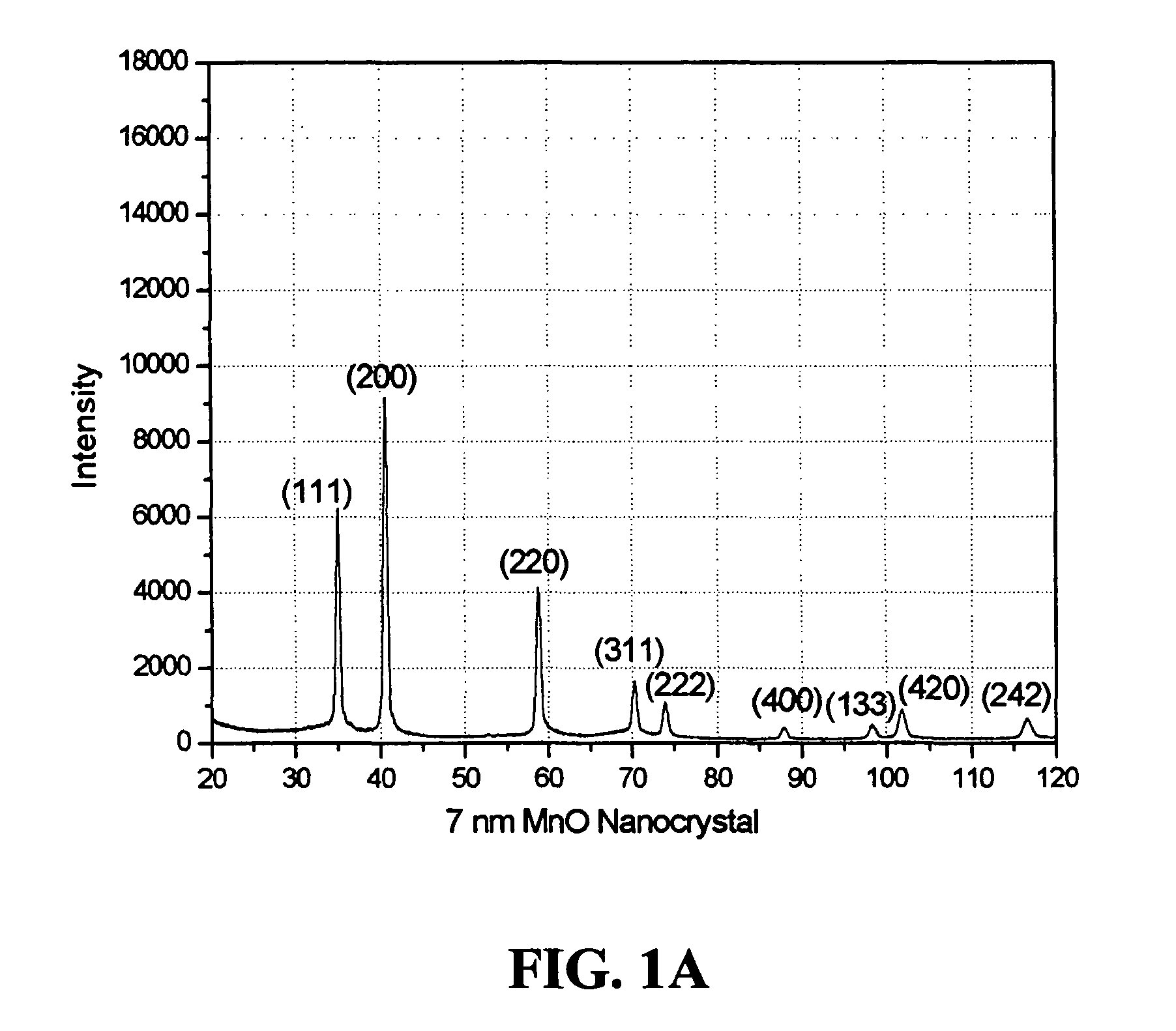

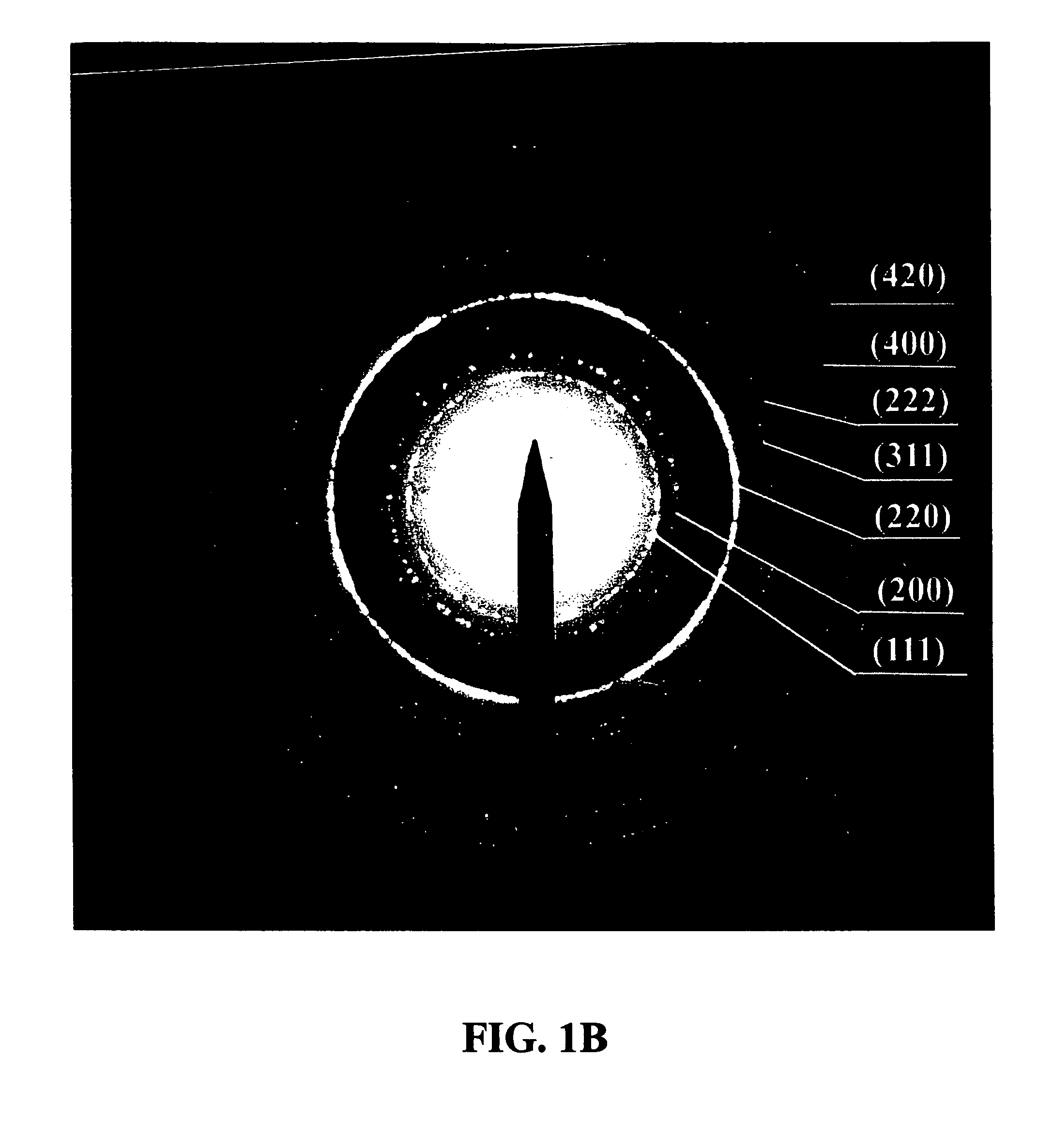

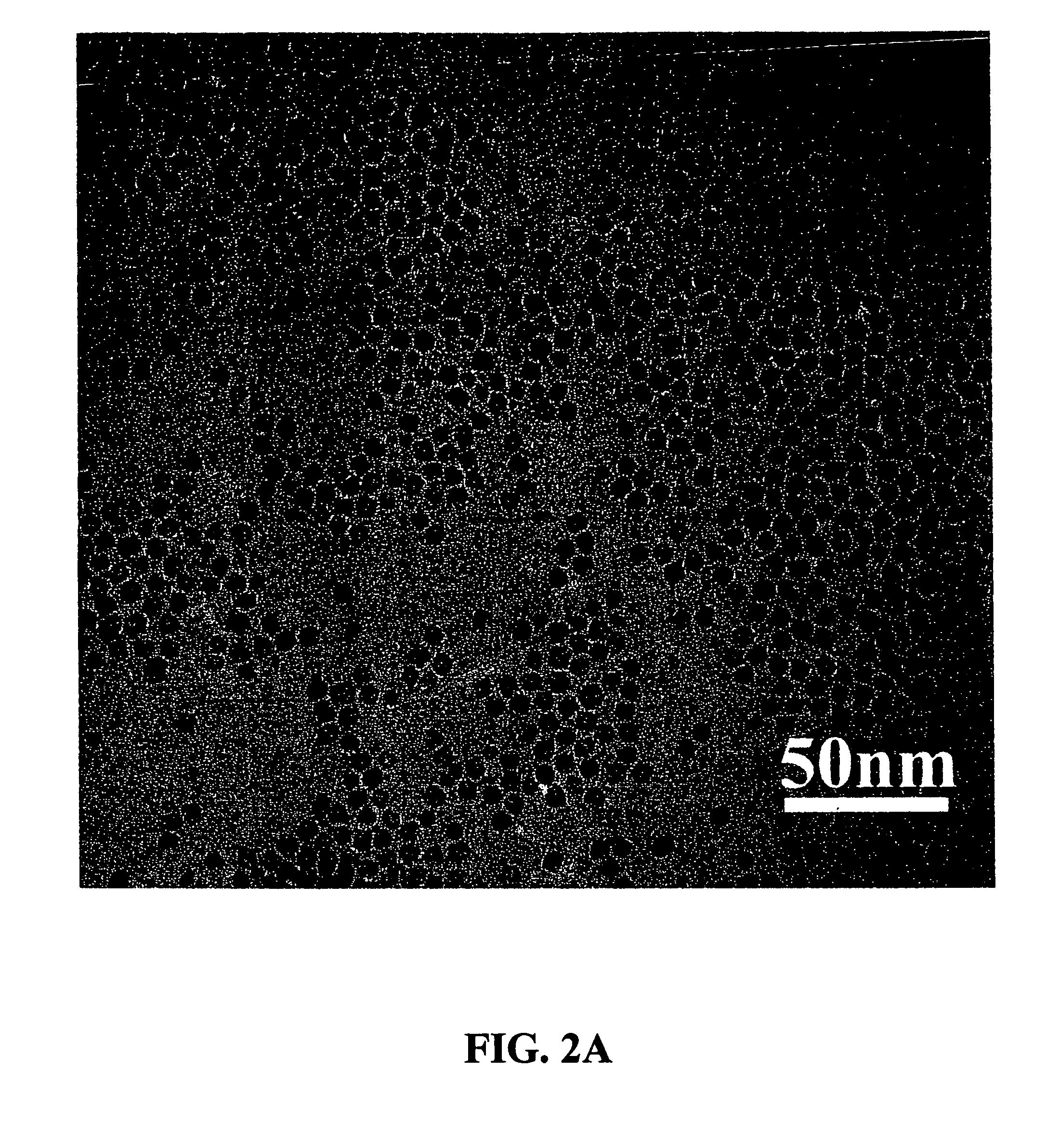

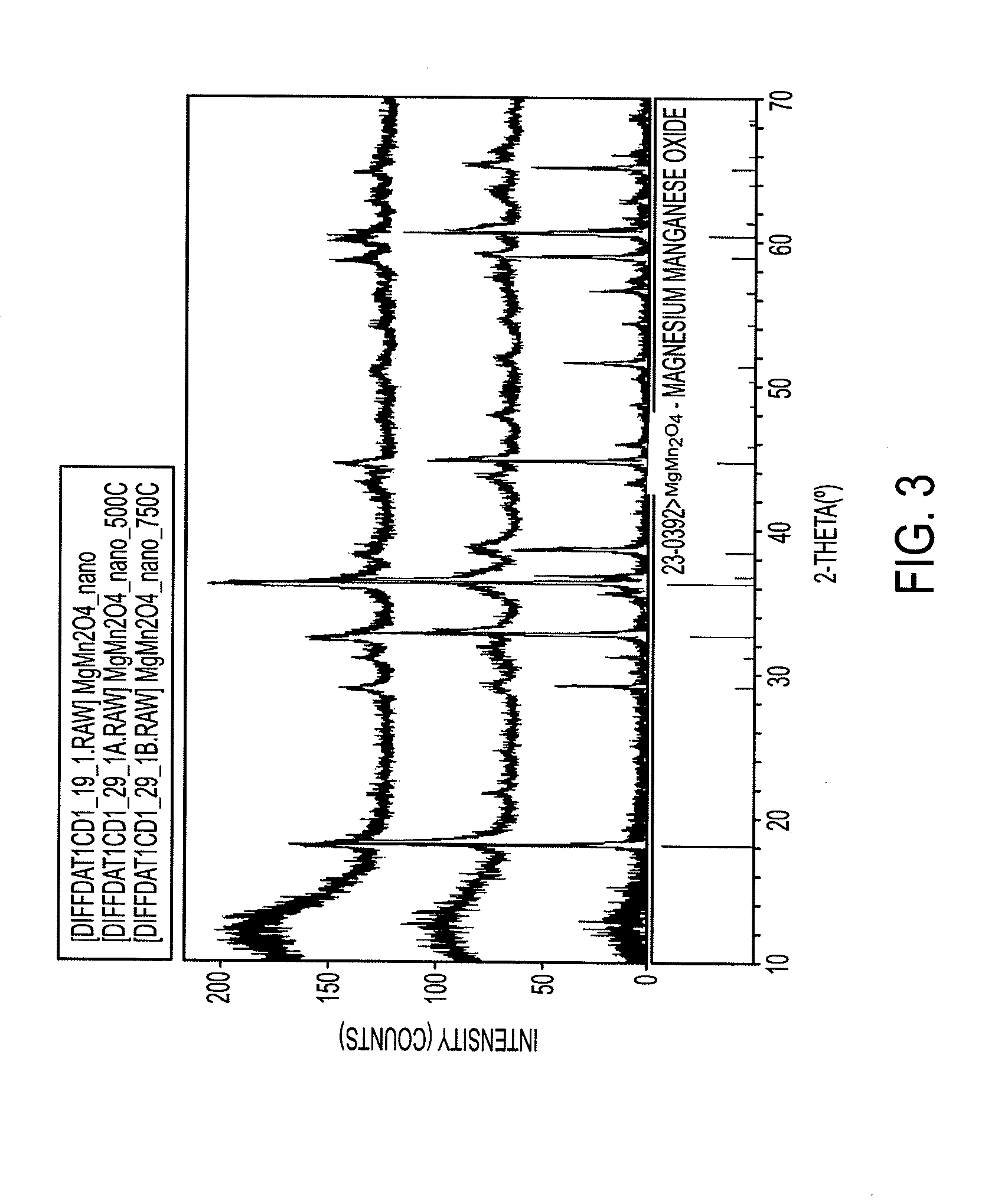

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS20070140951A1Economical and efficientQuality improvementMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

The present invention describes methods for preparing high quality nanoparticles, i.e., metal oxide based nanoparticles of uniform size and monodispersity. The nanoparticles advantageously comprise organic alkyl chain capping groups and are stable in air and in nonpolar solvents. The methods of the invention provide a simple and reproducible procedure for forming transition metal oxide nanocrystals, with yields over 80%. The highly crystalline and monodisperse nanocrystals are obtained directly without further size selection; particle size can be easily and fractionally increased by the methods. The resulting nanoparticles can exhibit magnetic and / or optical properties. These properties result from the methods used to prepare them. Also advantageously, the nanoparticles of this invention are well suited for use in a variety of industrial applications, including cosmetic and pharmaceutical formulations and compositions.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

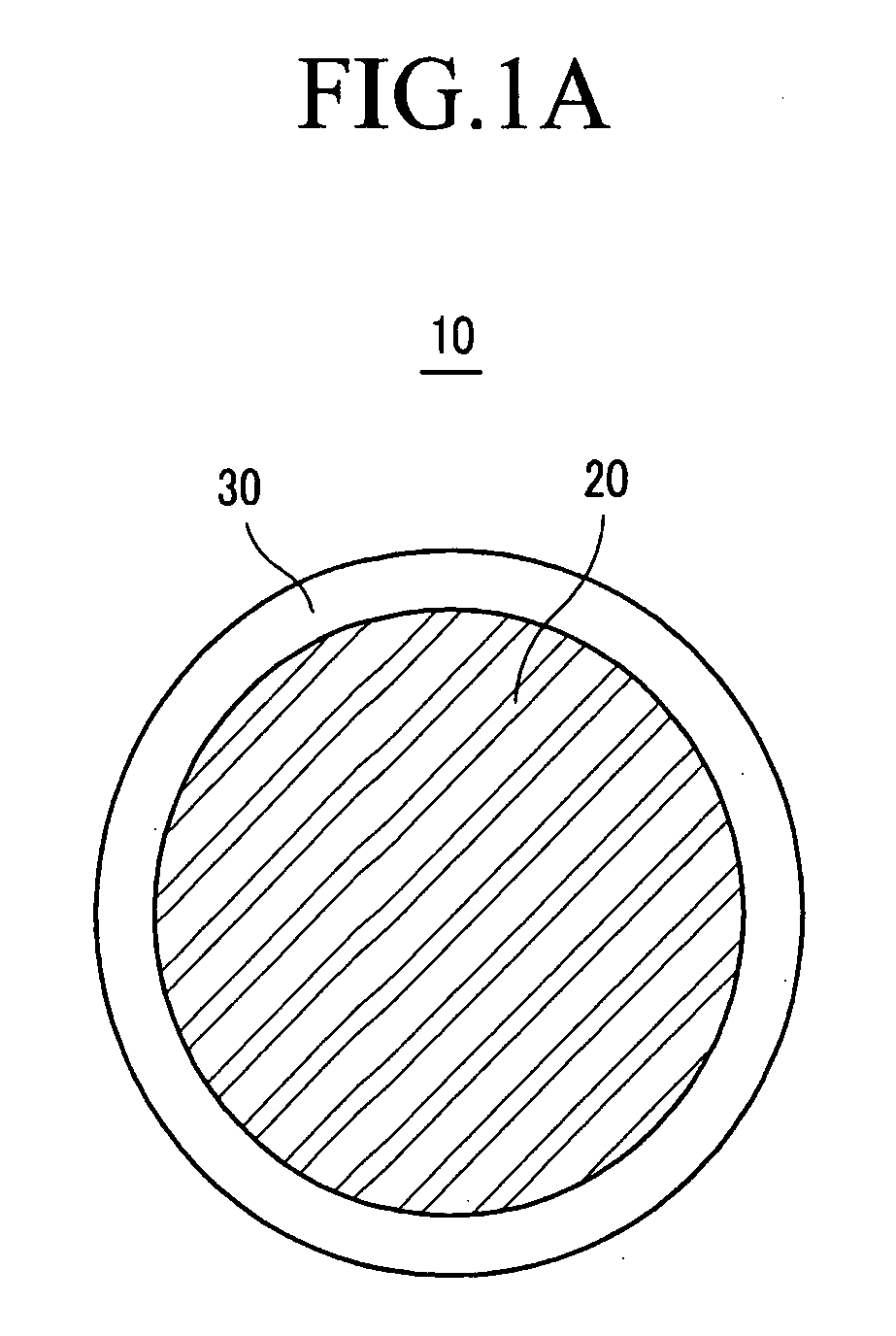

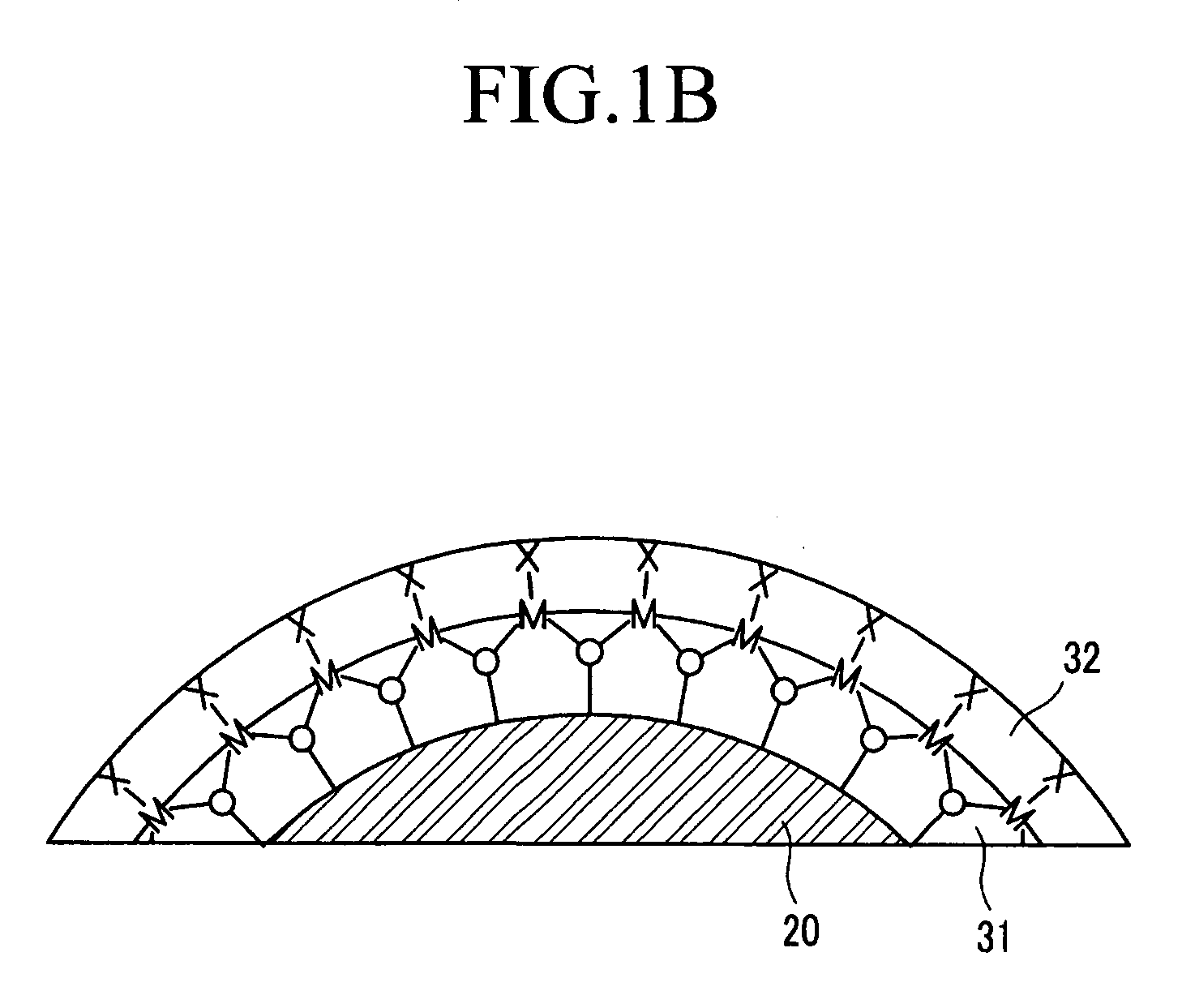

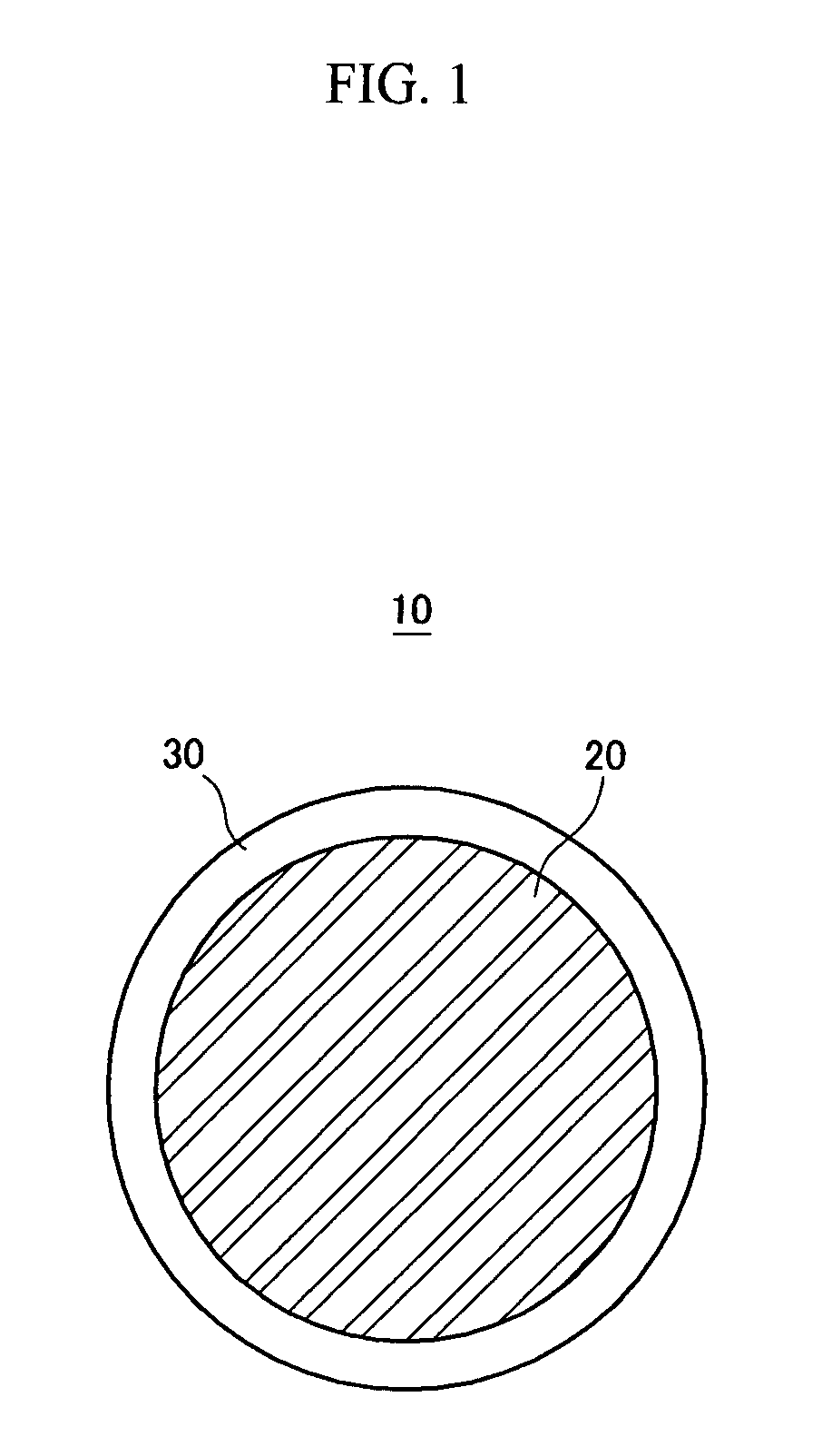

Negative active material for a rechargeable lithium battery,a method of preparing the same, and a rechargeable lithium battery including the same

ActiveUS20080118834A1Improve stabilityImprove cycle lifeElectrode manufacturing processesMolybdeum compoundsArylHigh rate

A negative active material for a rechargeable lithium battery includes a core including an active material being capable of performing reversible electrochemical oxidation and reduction, and a coating layer on the surface of the core. The coating layer includes a reticular structure including —O-M-O— wherein M is selected Si, Ti, Zr, Al, or combinations thereof and an organic functional group linked to the M as a side chain. The organic functional group is selected from the group consisting of an alkyl group, a haloalkyl group, a substituted or unsubstituted aryl group, and combinations thereof. The negative active material for a rechargeable lithium battery according to the present invention can be applied along with an aqueous binder, and improve high capacity, good cycle-life, and particularly high capacity during charge and discharge at a high rate.

Owner:SAMSUNG SDI CO LTD

Anode active material, manufacturing method thereof, and non-aqueous electrolyte secondary battery

In order to provide a 3V level non-aqueous electrolyte secondary battery with a flat voltage and excellent cycle life at a high rate with low cost, the present invention provides a positive electrode represented by the formula: Li2±α[Me]4O8−x, wherein 0≦α<0.4, 0≦x<2, and Me is a transition metal containing Mn and at least one selected from the group consisting of Ni, Cr, Fe, Co and Cu, said active material exhibiting topotactic two-phase reactions during charge and discharge.

Owner:OSAKA CITY UNIVERSITY +1

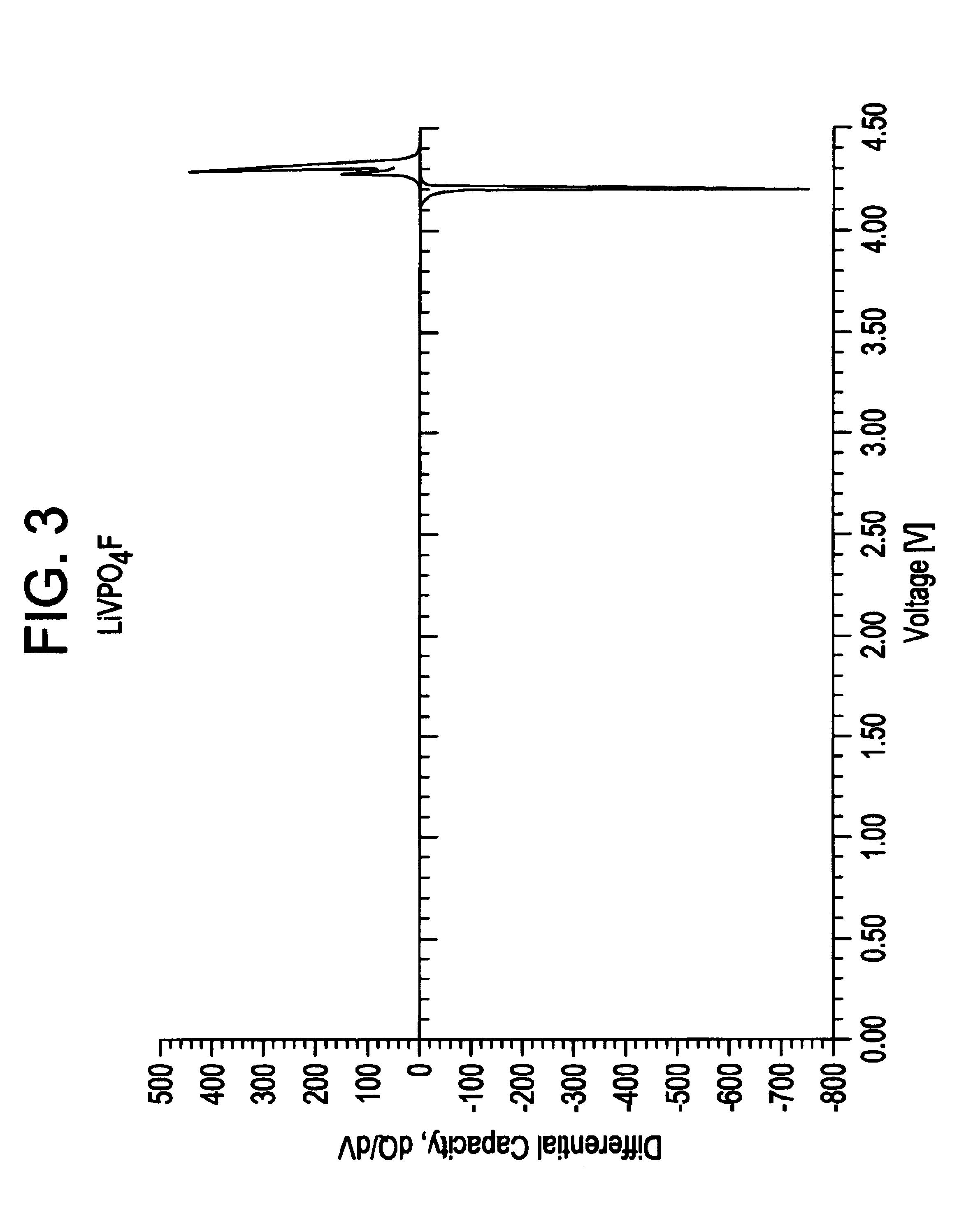

Methods of making lithium metal cathode active materials

The invention provides a novel method for making lithium mixed metal materials in electrochemical cells. The lithium mixed metal materials comprise lithium and at least one other metal besides lithium. The invention involves the reaction of a metal compound, a phosphate compound, with a reducing agent to reduce the metal and form a metal phosphate. The invention also includes methods of making lithium metal oxides involving reaction of a lithium compound, a metal oxide with a reducing agent.

Owner:LITHIUM WERKS TECH BV

Method for recycling copper, nickel, chromium, zinc and iron from plating sludge

The invention relates to a method for recycling copper, nickel, chromium, zinc and iron from plating sludge, belonging to the technical field of chemical engineering and metallurgy. The method comprises the following steps: acid leaching, vulcanizing for separation and enrichment, hot-pressure leaching, extracting for separation, hot-press oxidizing chromium, purifying chromium solution, extracting ferric chloride and the like. The method has obvious advantages of strong adaptability to different kinds of plating sludge, high utilization of metal resources, high value-added content of product,less process waste residue, thorough deintoxication and the like.

Owner:YANGZHOU NINGDA NOBLE METAL CO LTD

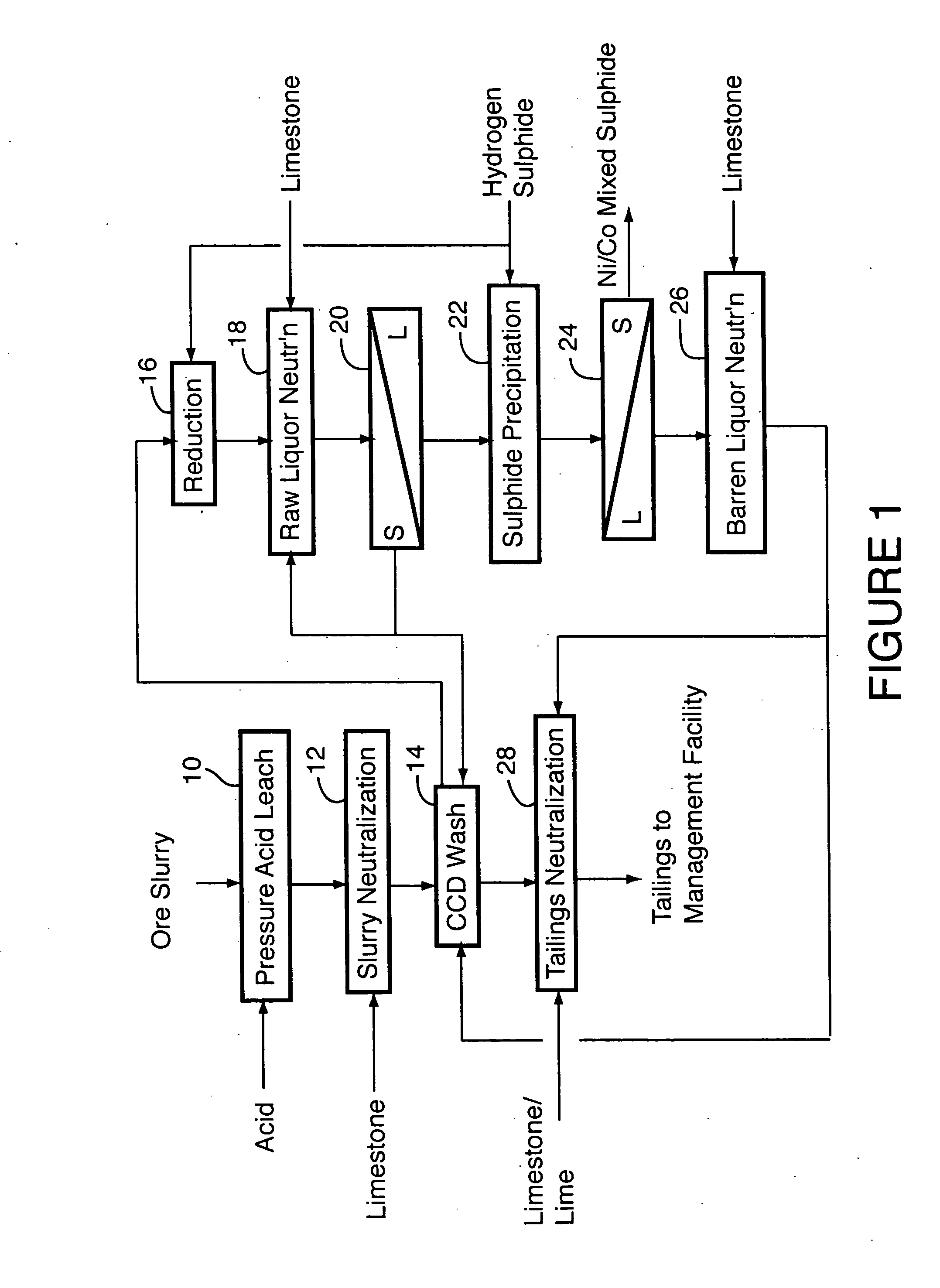

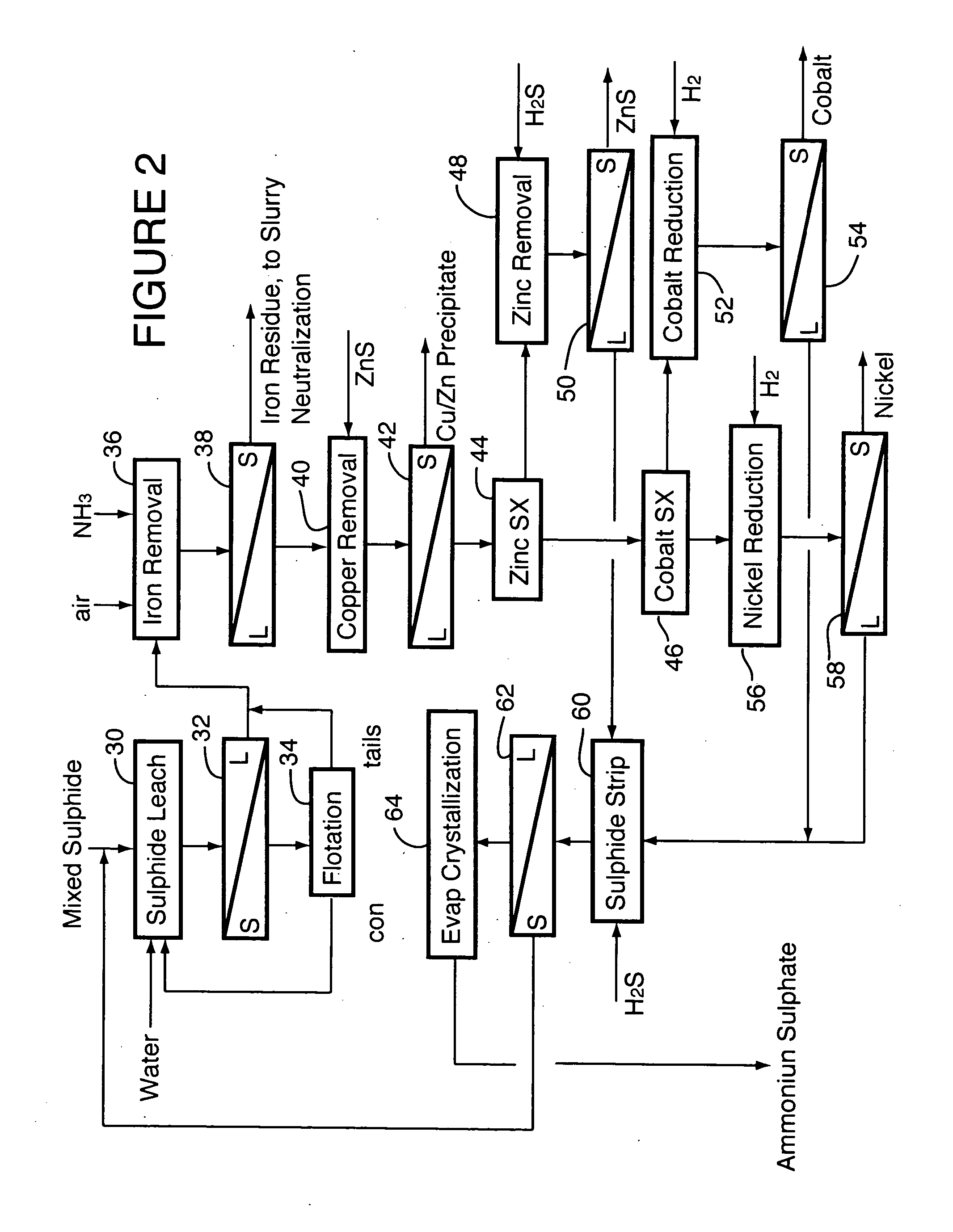

Process for recovery of nickel and cobalt from laterite ore

ActiveUS20060228279A1Efficient separation and recoveryHigh purityCobalt sulfidesSolvent extractionFree solutionSlurry

A process for recovering nickel and cobalt values from nickel- and cobalt-containing laterite ores as an enriched mixed nickel and cobalt sulphide intermediate and for producing nickel and cobalt metal from the nickel and cobalt sulphide intermediate. The laterite ore is leached as a slurry in a pressure acid leach containing an excess of aqueous sulphuric acid at high pressure and temperature, excess free acid in the leach slurry is partially neutralized to a range of 5 to 10 g / L residual free H2SO4 and washed to yield a nickel- and cobalt-containing product liquor, the product liquor is subjected to a reductant to reduce any Cr(VI) in solution to Cr(III), the reduced product liquor is neutralized to precipitate ferric iron and silicon at a pH of about 3.5 to 4.0, and the neutralized and reduced product liquor is contacted with hydrogen sulphide gas to precipitate nickel and cobalt sulphides. The precipitated nickel and cobalt sulphides can be leached in a water slurry in a pressure oxidation leach, the leach solution subjected to iron hydrolysis and precipitation, the iron-free solution contacted with zinc sulphide to precipitate copper, the iron- and copper-free solution subjected to zinc and cobalt extraction by solvent extraction to produce a nickel raffinate, the nickel raffinate contacted with hydrogen gas to produce nickel powder and the cobalt strip solution from the solvent extraction step contacted with hydrogen gas to produce cobalt powder.

Owner:SHERRITT INTERNATIONAL

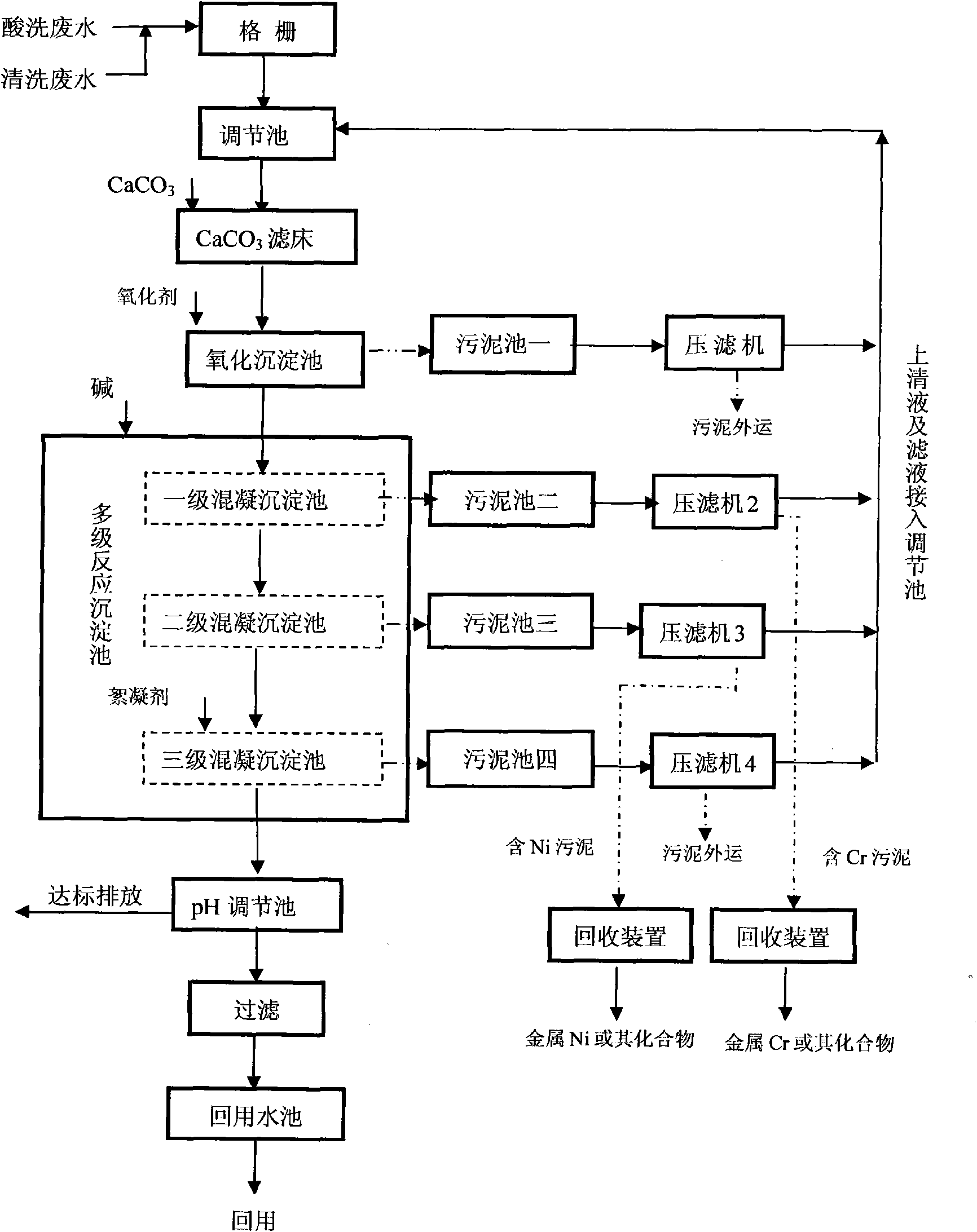

Recycling processing method for stainless steel processing process wastewater grading precipitation

InactiveCN101648757AHigh recycling valueSludge treatment by de-watering/drying/thickeningPhotography auxillary processesThree levelAcid washing

The invention relates to a recycling processing method for a stainless steel processing process wastewater grading precipitation, which comprises the following steps: (1) deslagging and homogenizing acid-washing residual liquid and washing wastewater; (2) adjusting the pH to 4.0-5.5 by a CaCO3 filter bed to generate CaF2; (3) oxidizing Fe<2+> into Fe<3+> by an oxidizing agent to generate sedimentsof Fe(OH)2 and Fe(OH)3; after the Fe(OH)2 , the Fe(OH)3 and the CaF2 are deposited, recovering; (4) carrying out three-level alkali adding coagulation precipitation on the supernatant liquid of an oxidation precipitation pool; adjusting the pH to obtain a Cr sediment in the first-level alkali adding coagulation precipitation; acquiring a Ni sediment in the second-level alkali adding coagulation precipitation; carrying out the third-level alkali adding coagulation precipitation and adding a flocculating agent to remove residual heavy metal ions so that discharge water reaches the standard, wherein the alkali added into a grading reaction precipitation pool is NaOH, Ca(OH)2, CaO or Na2 CO3; (5) regulating the pH of the discharge water of the grading reaction precipitation pool to 6.0-8.0; discharging 0-20 percent of wastewater and filtering residual F<-> and suspended matters of 80-100 percent of wastewater to reach the standard and recycle; and (6) recycling the Cr-Ni metal or the compound thereof from the Cr sediment and the Ni sediment acquired by a third-level coagulation precipitation pool by a recycling device.

Owner:ZHEJIANG UNIV

Negative active material for rechargeable lithium battery, method of preparing thereof, and rechargeable lithium battery including the same

ActiveUS20080118840A1Improve stabilityExcellent charge and discharge efficiency and cycle-lifeMaterial nanotechnologyMolybdeum compoundsDischarge efficiencyVanadium oxide

A negative active material for a rechargeable lithium battery of the present invention includes a lithium-vanadium oxide core material being capable of performing reversible electrochemical oxidation and reduction, and an inorganic oxide coating layer disposed on the surface of the core material. The negative active material can improve stability at the interface between a negative electrode and an electrolyte, charge and discharge efficiency, and cycle-life, and can be applied along with all kinds of aqueous and non-aqueous binders.

Owner:SAMSUNG SDI CO LTD

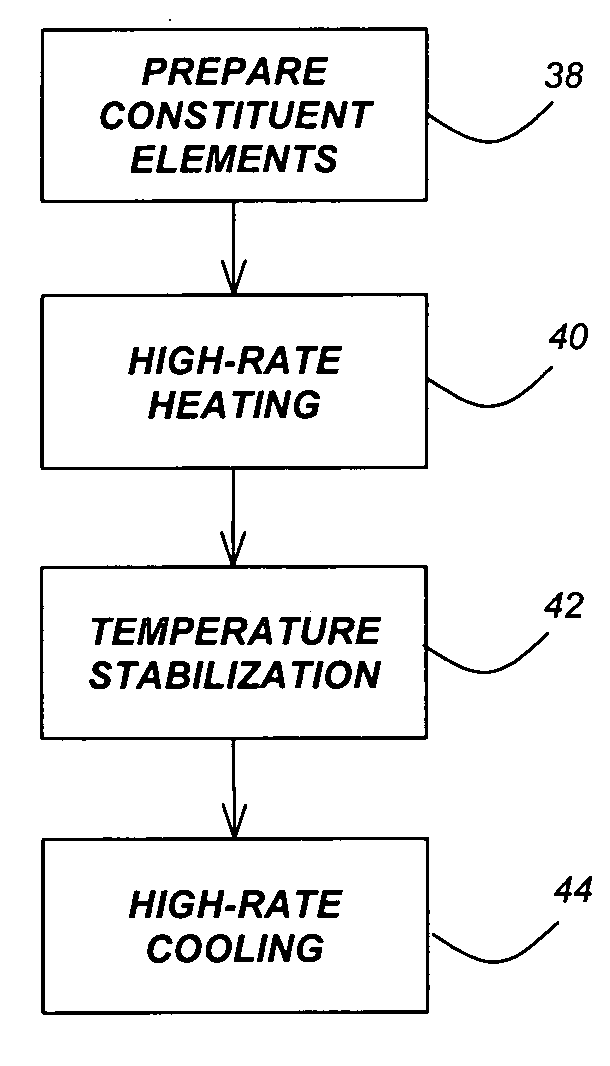

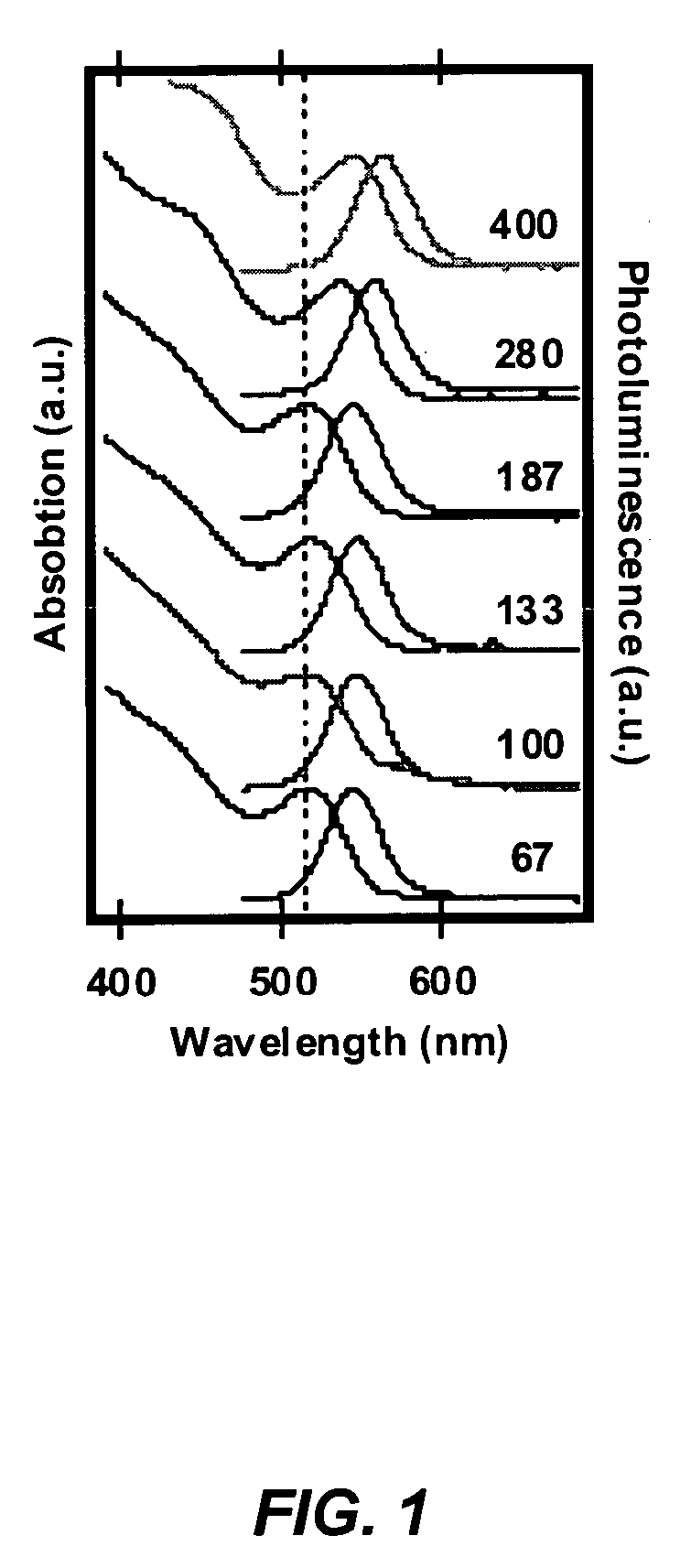

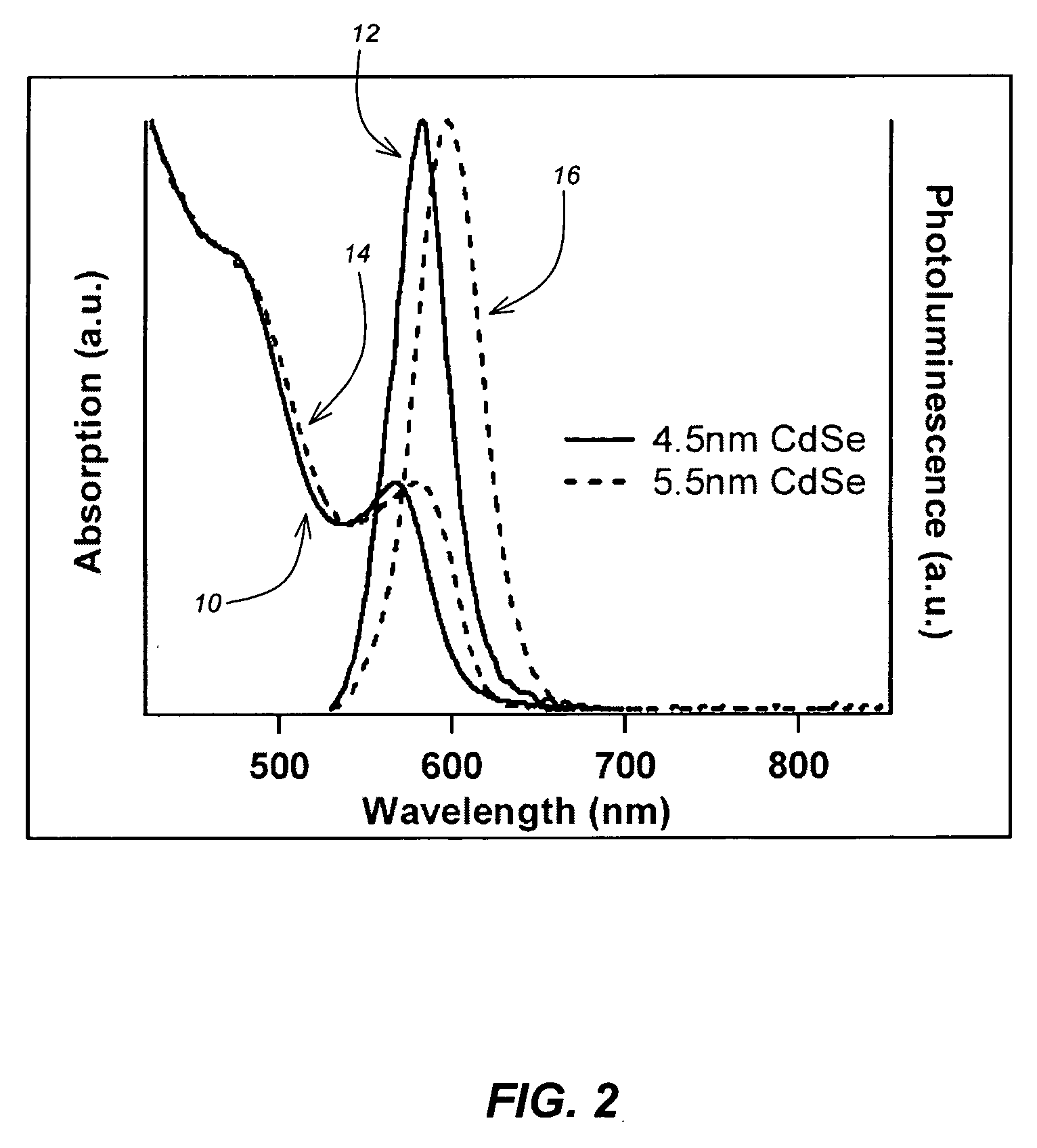

Method for synthesis of colloidal nanoparticles

InactiveUS20060060998A1Large-scale, safe, convenient, reproducible, and energy-efficient productionHigh crystallinityDielectric heatingNanoinformaticsColloidal nanoparticlesContinuous flow

A method for synthesis of high quality colloidal nanoparticles using comprises a high heating rate process. Irradiation of single mode, high power, microwave is a particularly well suited technique to realize high quality semiconductor nanoparticles. The use of microwave radiation effectively automates the synthesis, and more importantly, permits the use of a continuous flow microwave reactor for commercial preparation of the high quality colloidal nanoparticles.

Owner:RGT UNIV OF CALIFORNIA

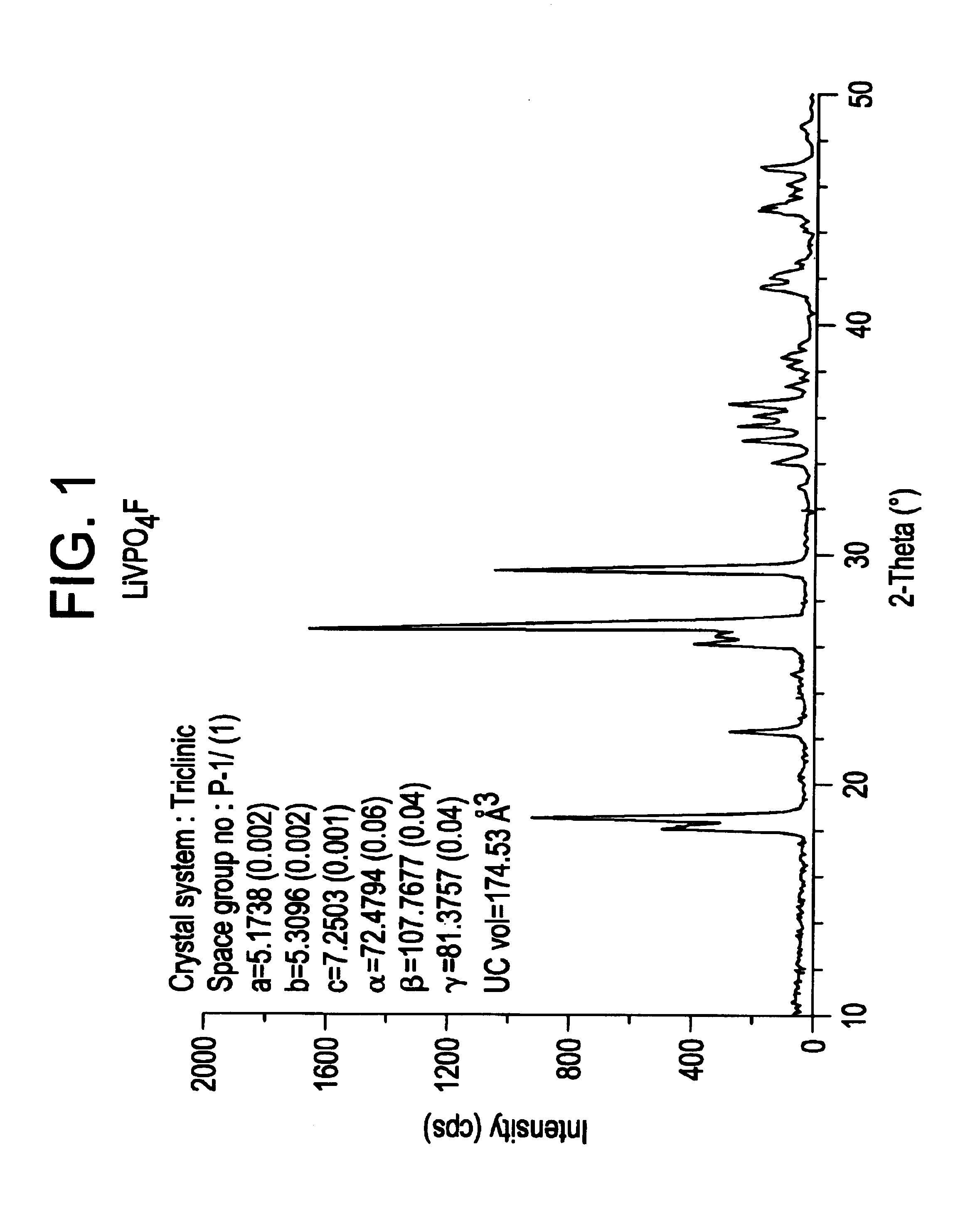

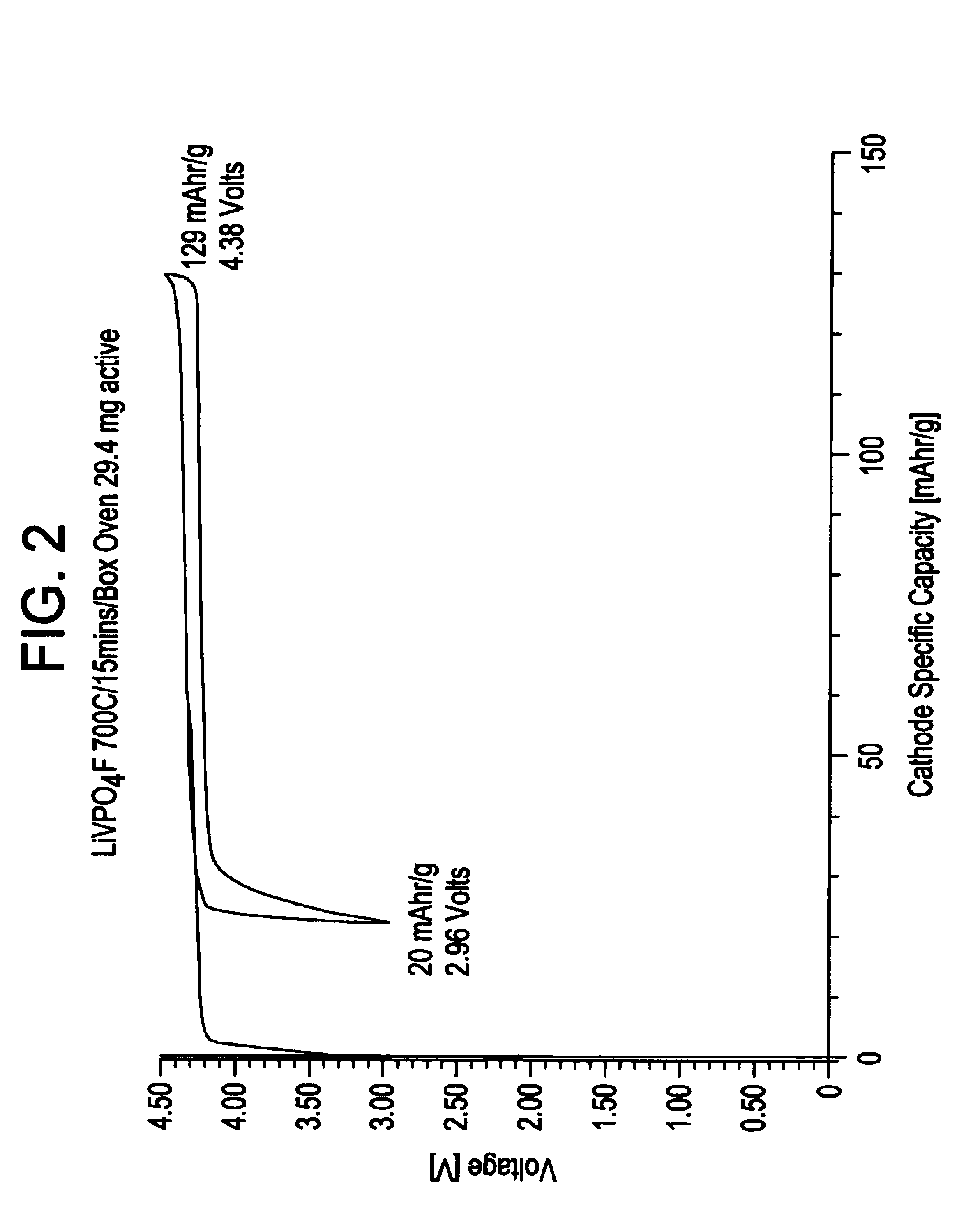

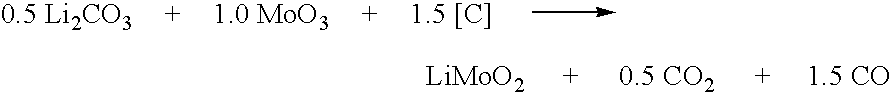

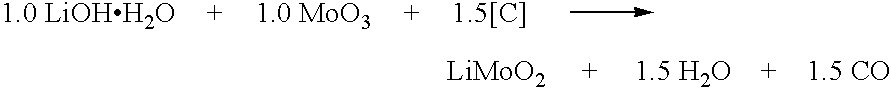

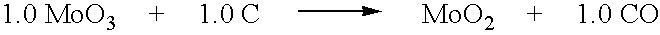

Synthesis of Metal Compounds Under Carbothermal Conditions

InactiveUS20050255026A1Economical and convenient processLower capability requirementsPhosphatesLithium compoundsOxidation stateGraphite

Active materials of the invention contain at least one alkali metal and at least one other metal capable of being oxidized to a higher oxidation state. Preferred other metals are accordingly selected from the group consisting of transition metals (defined as Groups 4-11 of the periodic table), as well as certain other non-transition metals such as tin, bismuth, and lead. The active materials may be synthesized in single step reactions or in multi-step reactions. In at least one of the steps of the synthesis reaction, reducing carbon is used as a starting material. In one aspect, the reducing carbon is provided by elemental carbon, preferably in particulate form such as graphites, amorphous carbon, carbon blacks and the like. In another aspect, reducing carbon may also be provided by an organic precursor material, or by a mixture of elemental carbon and organic precursor material.

Owner:LITHIUM WERKS TECH BV +1

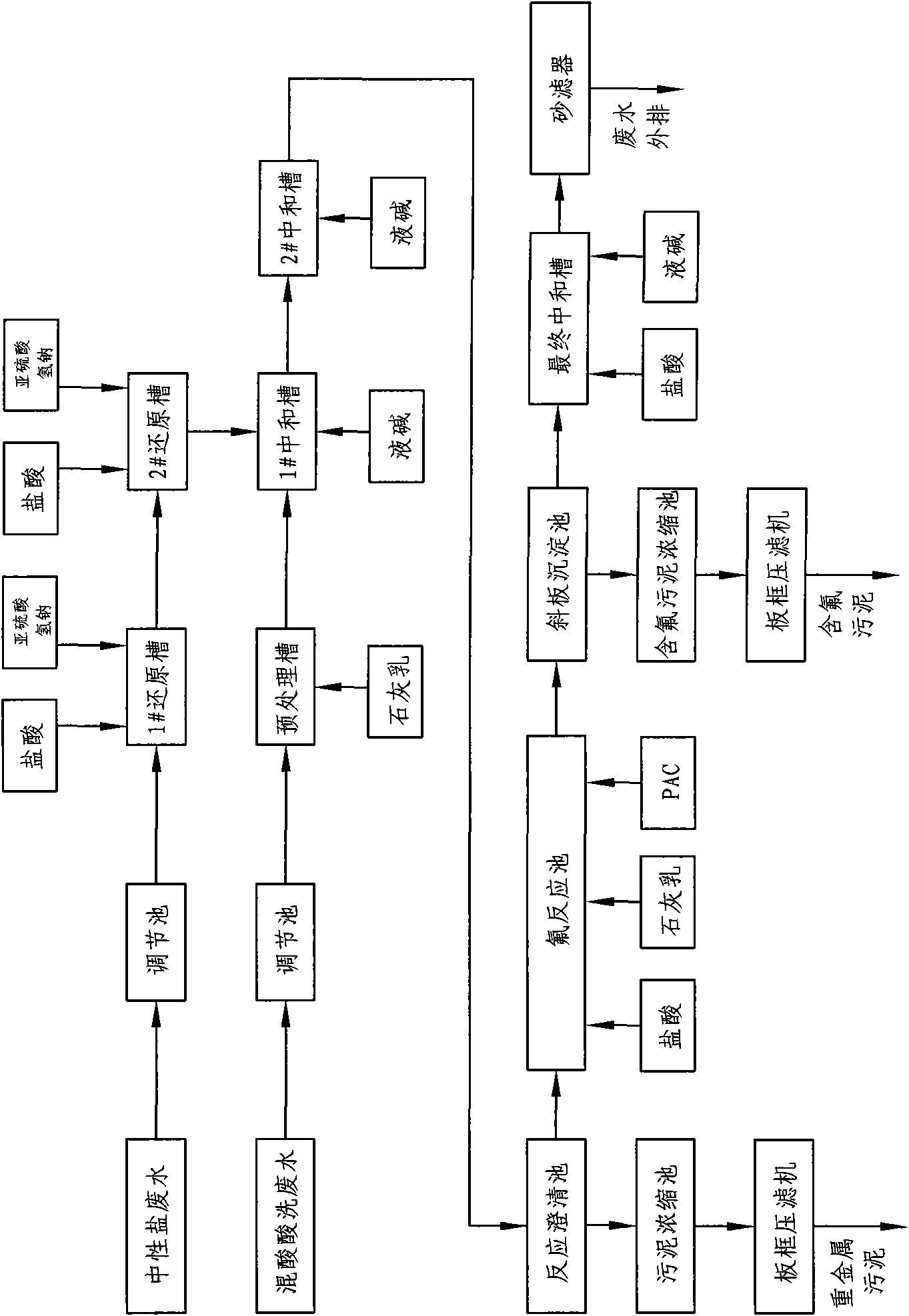

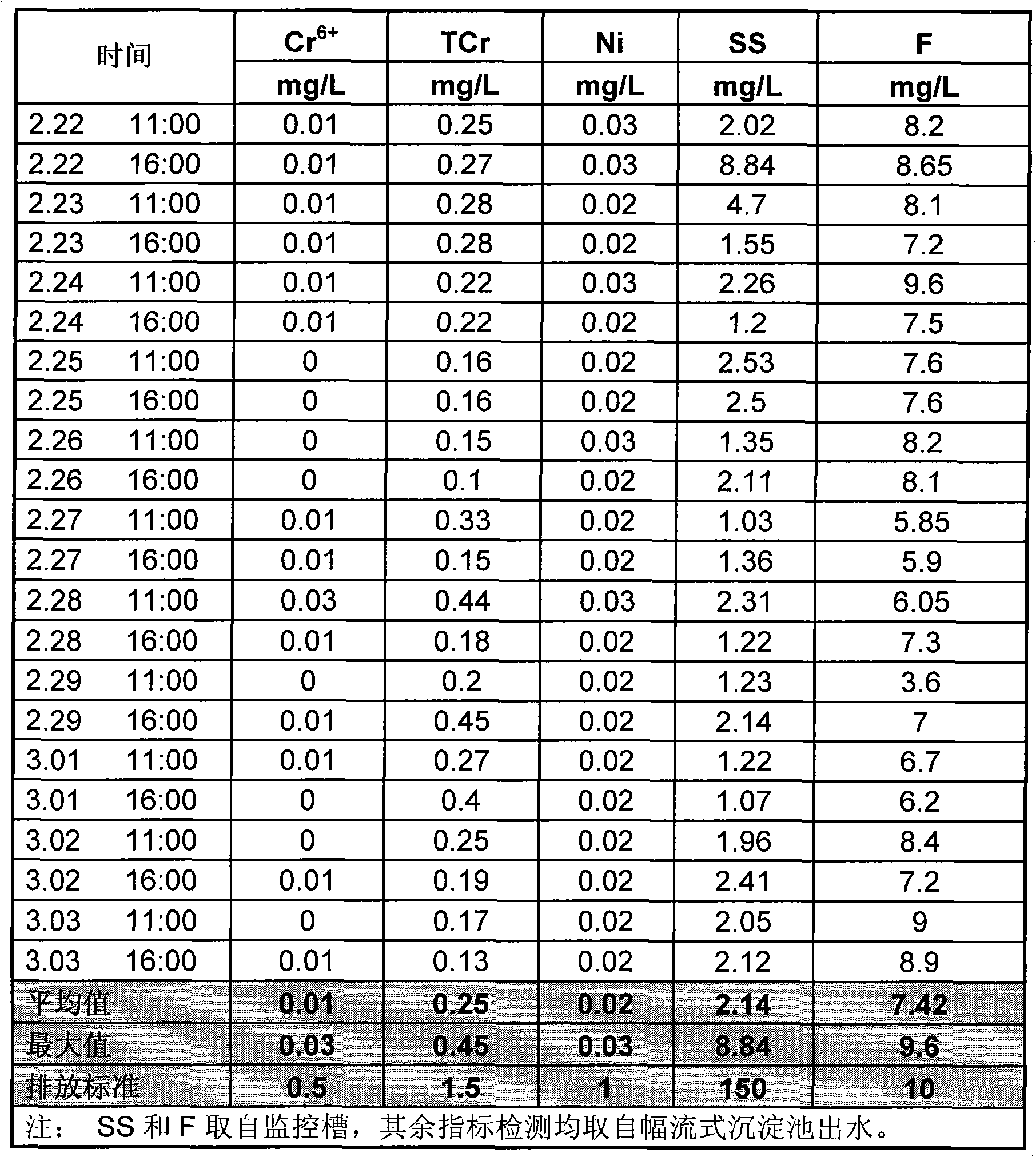

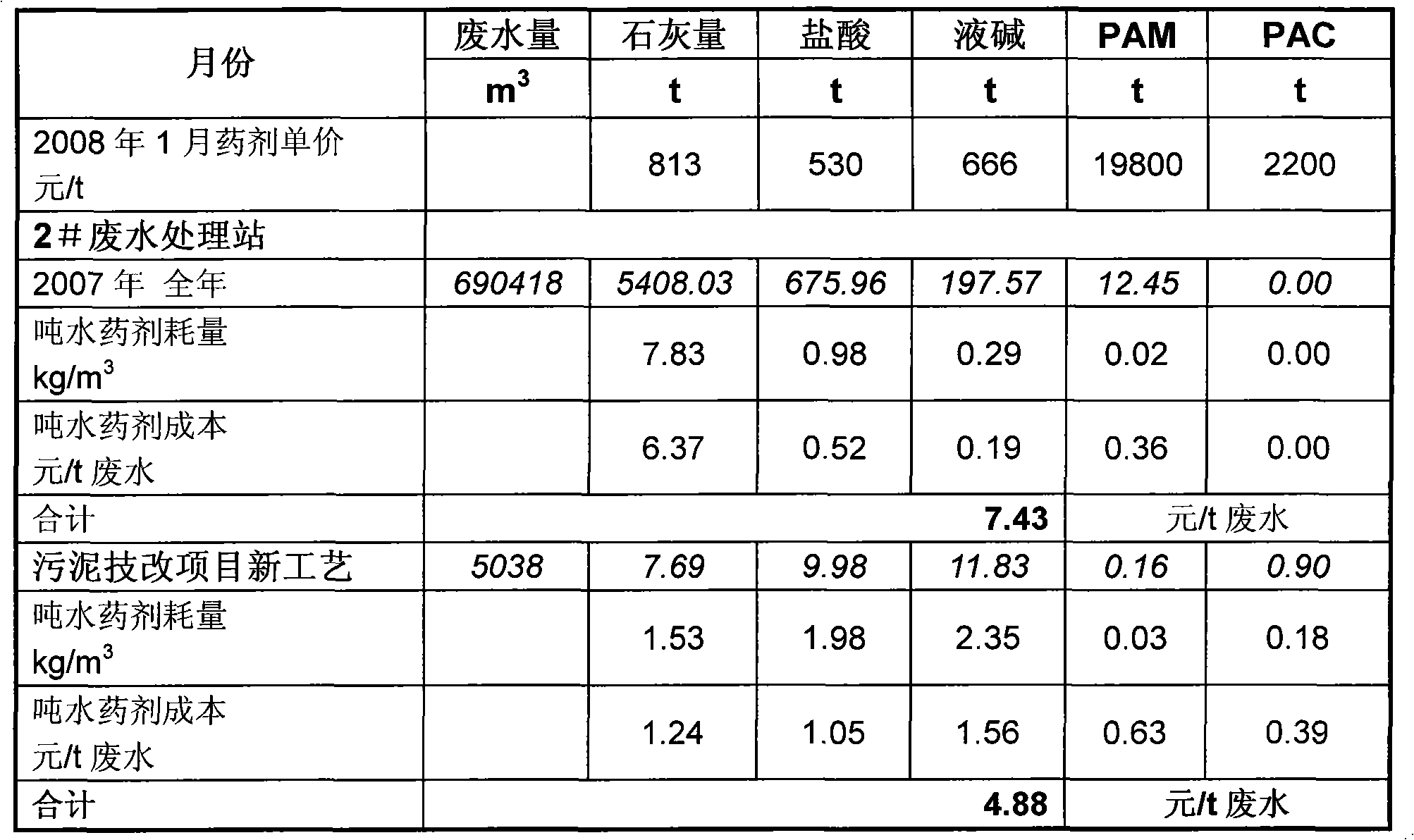

Method for treating stainless steel cold rolling pickling waste water

InactiveCN101993158AReduce consumptionStable fluoride ion concentrationIron oxides/hydroxidesWater contaminantsAluminium chlorohydrateSludge

The invention discloses a method for treating stainless steel cold rolling pickling waste water, which adopts a lime milk pretreatment process and a waste water segmental treatment process and comprises the following steps of: firstly, performing lime milk pretreatment on the waste water to control the pH value between 5 and 6; secondly, adding liquid caustic soda to remove heavy metal ions in the waste water so as to form a metal oxide precipitate; and finally, treating fluorine ions, namely adding polyaluminium chloride and lime milk to remove the fluorine ions, and filtering and discharging the waste water after adjusting the pH. The treatment method has good using effect, the waste water reaches the required standard and is stable, the sludge quantity is small, and the cost is low.

Owner:NINGBO BAOXIN STAINLESS STEEL

Synthesis of metal compounds under carbothermal conditions

InactiveUS7060206B2Economical and convenient processLower capability requirementsCell electrodesSulfur compoundsOxidation stateGraphite

Active materials of the invention contain at least one alkali metal and at least one other metal capable of being oxidized to a higher oxidation state. Preferred other metals are accordingly selected from the group consisting of transition metals (defined as Groups 4–11 of the periodic table), as well as certain other non-transition metals such as tin, bismuth, and lead. The active materials may be synthesized in single step reactions or in multi-step reactions. In at least one of the steps of the synthesis reaction, reducing carbon is used as a starting material. In one aspect, the reducing carbon is provided by elemental carbon, preferably in particulate form such as graphites, amorphous carbon, carbon blacks and the like. In another aspect, reducing carbon may also be provided by an organic precursor material, or by a mixture of elemental carbon and organic precursor material.

Owner:LITHIUM WERKS TECH BV

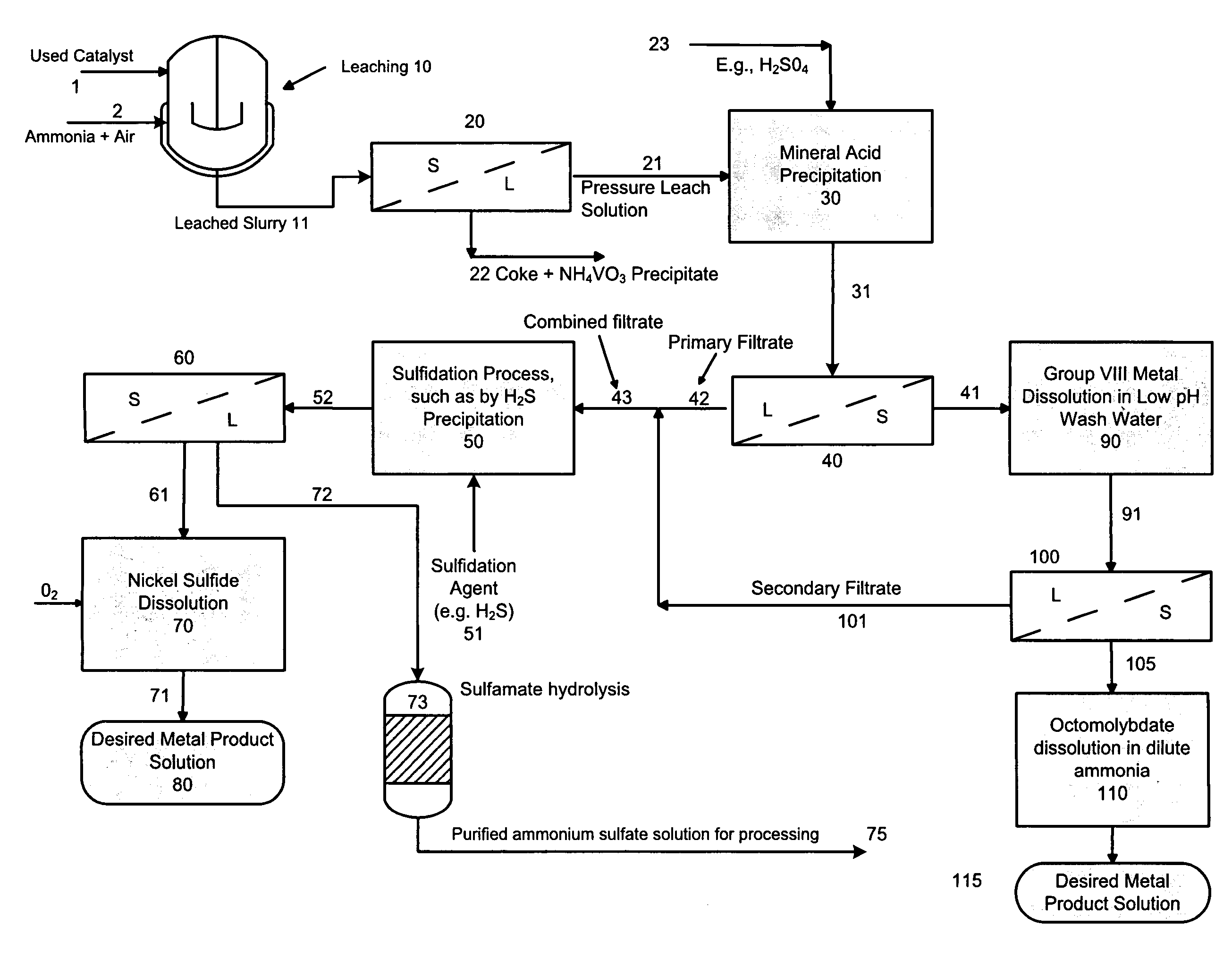

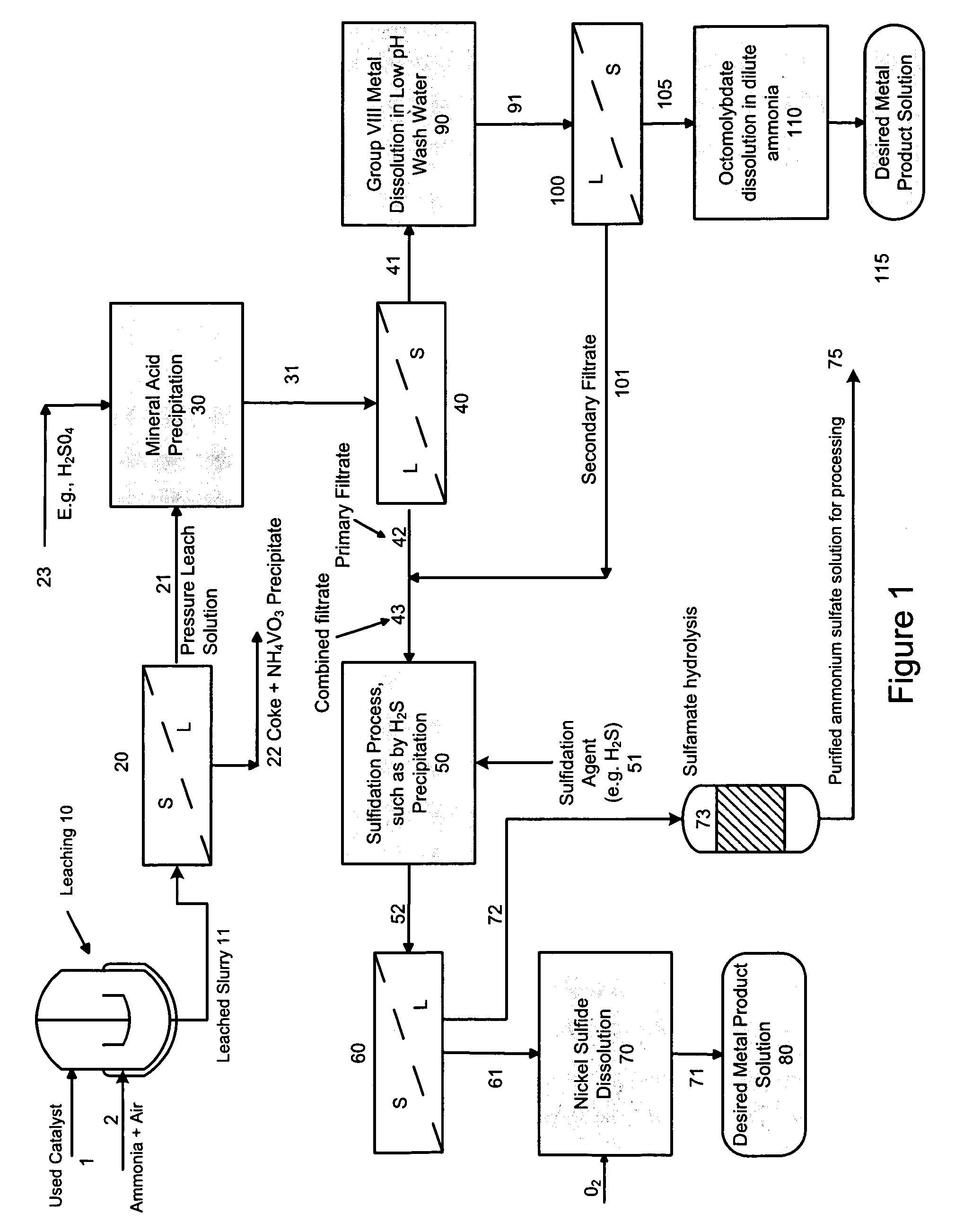

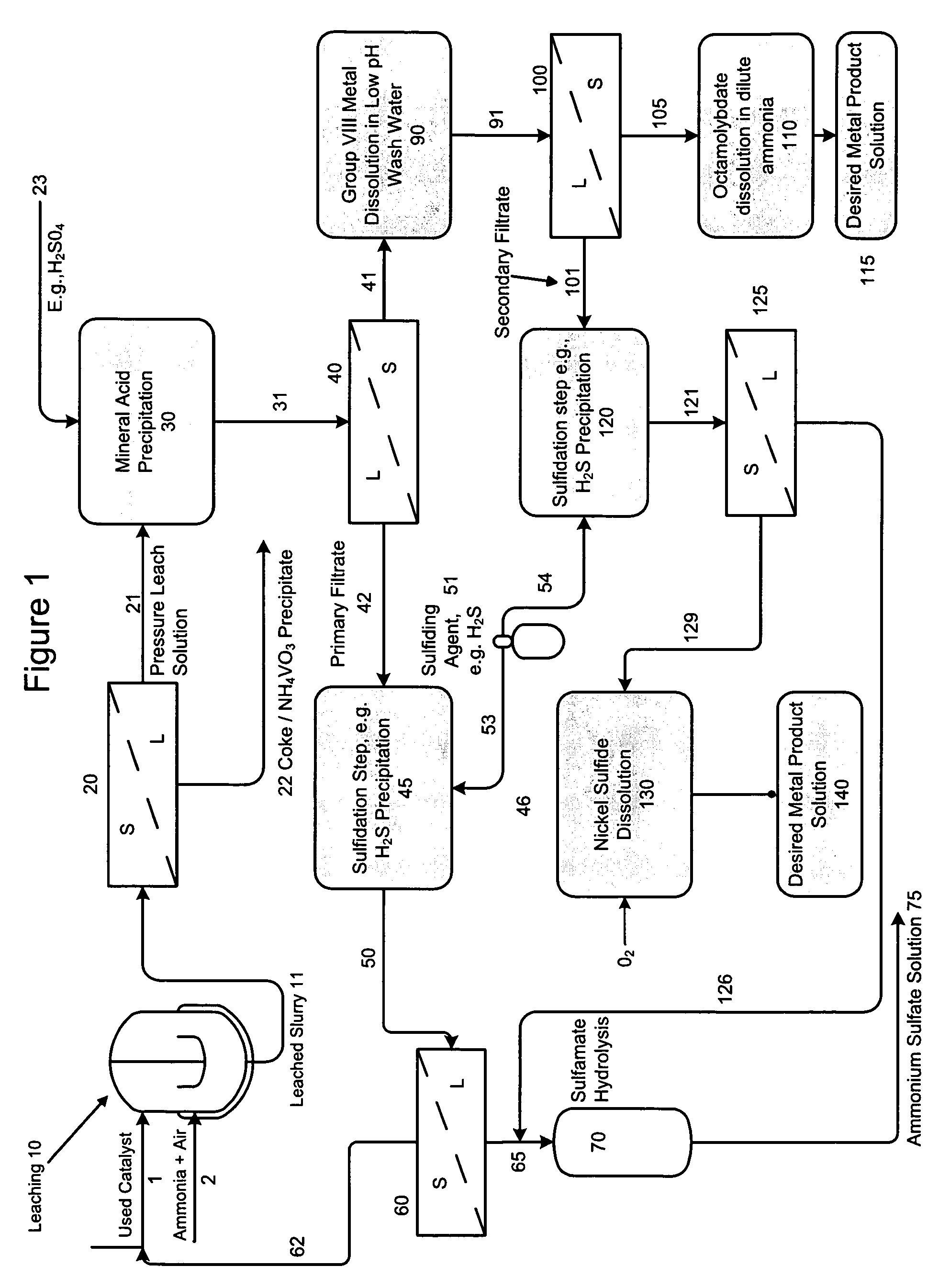

Process for separating and recovering base metals from used hydroprocessing catalyst

A method is disclosed for separating and recovering base metals from a used hydroprocessing catalyst originating from Group VIB and Group VIII metals and containing at least a Group VB metal. In one embodiment, the method comprises the steps of: contacting the used catalyst with an ammonia leaching solution under conditions sufficient to dissolve the group VIB metal and the Group VIII metal into the leaching solution; forming a leached slurry containing at least a group VIB metal complex and at least a group VIII metal complex, ammonium sulfate and a solid residue containing at least a Group VB metal complex and coke; separating and removing from the leached slurry the solid residue and coke; precipitating from the remaining solution at least a portion of the Group VIB metal complex and at least a portion of the Group VIII metal complex by controlling the pH to form a liquid material substantially free of Group VB, Group VIB and Group VIII metals and another solid material comprising substantially Group VIB and Group VIII metal complexes. Said solid material is further processed by dissolution, means of separation, further means of precipitation and oxidative dissolution to produce, separately, a Group VIB metal product solution, a Group VIII metal product solution and a purified ammonium sulfate product solution.

Owner:CHEVROU USA INC

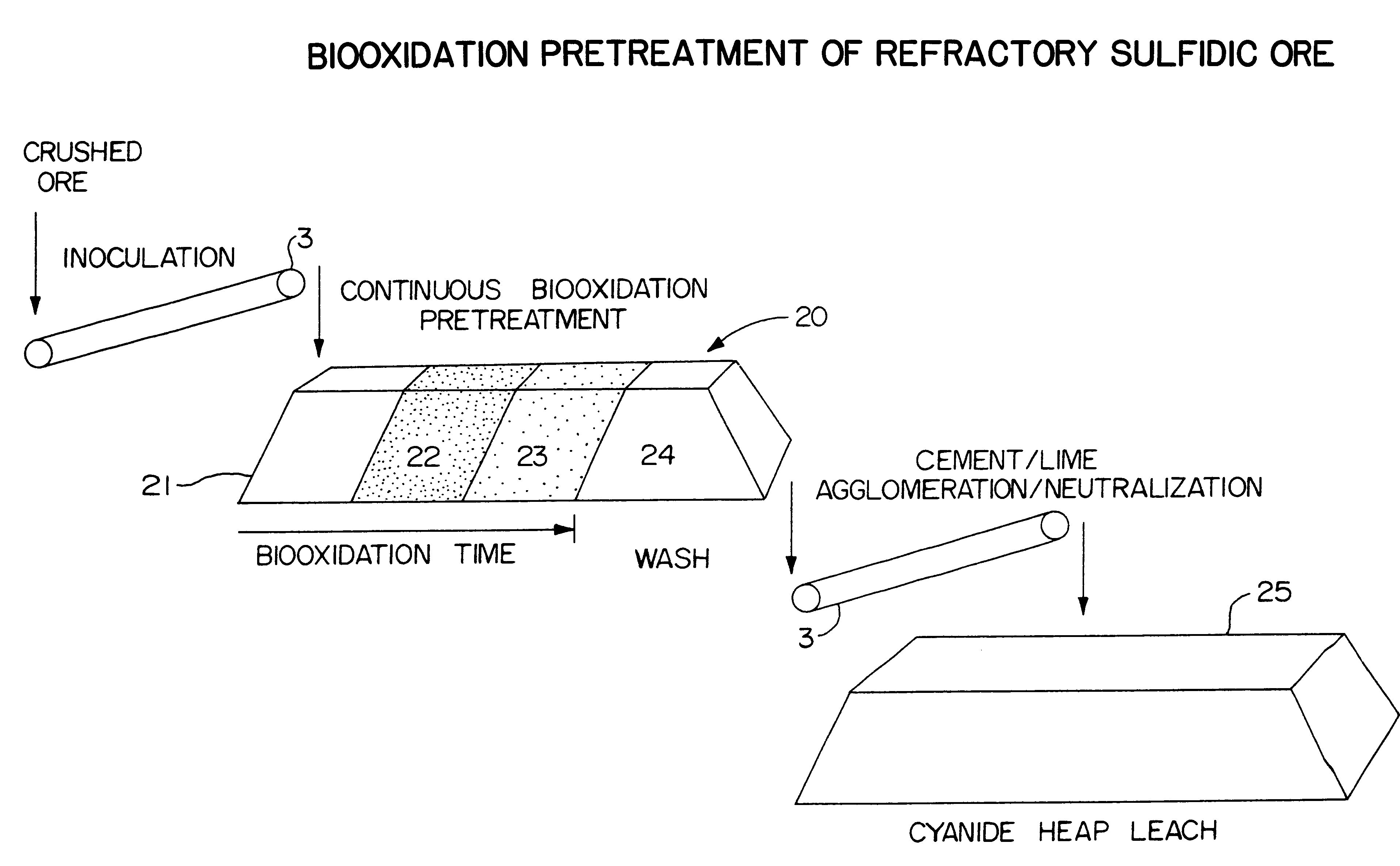

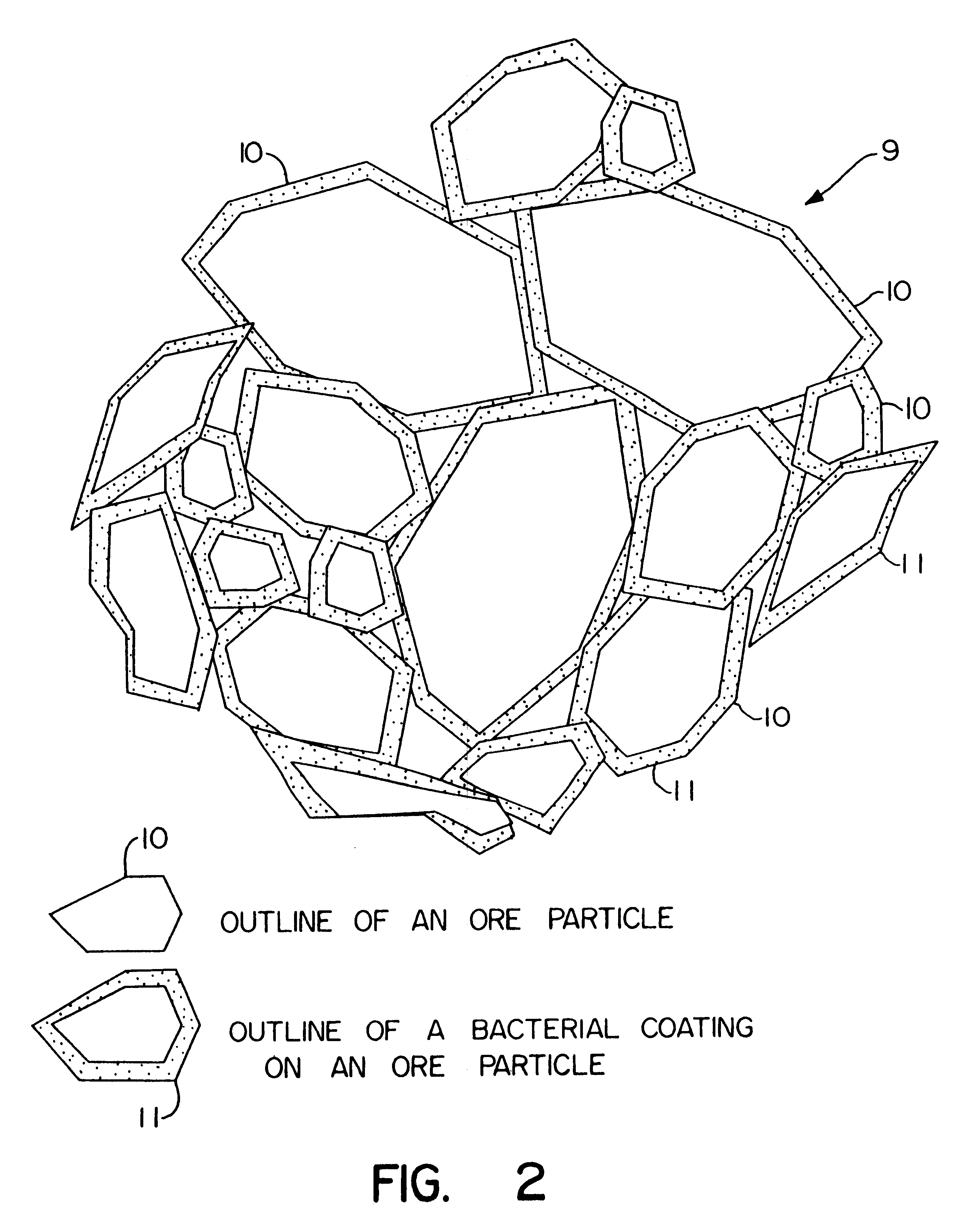

Biooxidation process for recovery of metal values from sulfur-containing ore materials

InactiveUS6383458B1Increase ratingsIncrease attractivenessTransuranic element compoundsSolvent extractionParticulatesPartial oxidation

A process for the recovery of one or more metal values from a metal ore material comprising those of one or more values and a matrix material having a sulfur content wherein the sulfur is present in an oxidation-reduction state of zero or less comprisinga. forming particulates from particles of said ore and an inoculate comprising bacteria capable of at least partially oxidizing the sulfur content;b. forming a heap of said particulates;c. biooxidizing the sulfur content andd. recovering those one or more metal values.

Owner:NEWMONT USA LTD

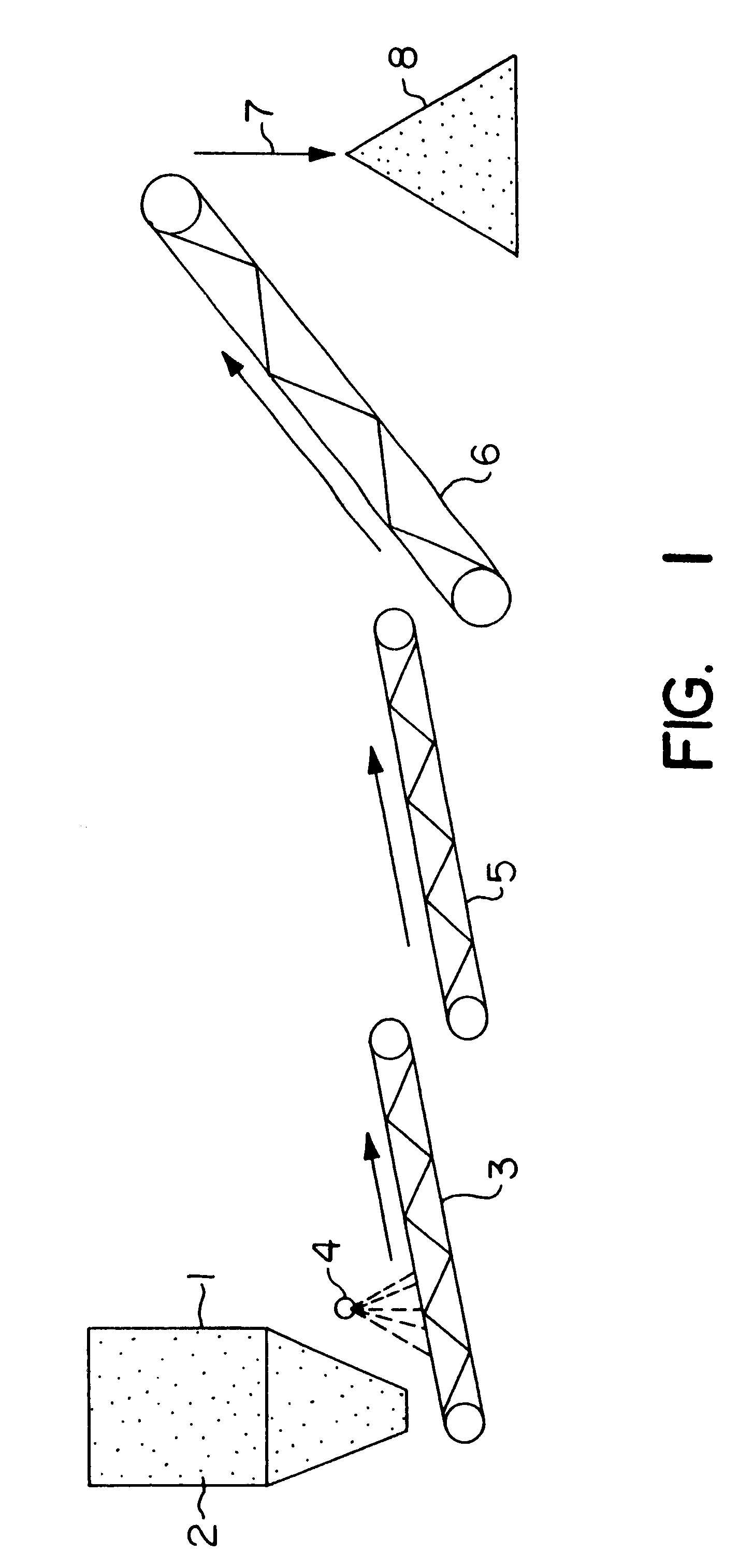

Solid chemical hydride dispenser for generating hydrogen gas

InactiveUS7666386B2Molybdeum compoundsSynthetic resin layered productsCompound (substance)Hydrogen evolution

A device for generating hydrogen gas is provided. The device (101) comprises a first hydrogen-containing composition (107) that reacts with a second composition to evolve hydrogen gas; a dispenser (105) adapted to apply the first composition to a first porous member (109); and a conduit (111) adapted to supply the second composition to the first porous member. In a preferred embodiment, the first composition is selected from the group consisting of hydrides, borohydrides and boranes, the second composition is water, and the dispenser is spring-loaded and is charged with the first composition. As the first composition reacts with water at the interface to evolve hydrogen gas, the dispenser forces the reaction product across the interface and out of the dispenser, where it will not interfere with the progress of the hydrogen evolution reaction.

Owner:LYNNTECH POWER SYST

Process for separating and recovering base metals from used hydroprocessing catalyst

A method is disclosed for separating and recovering base metals from a used hydroprocessing catalyst originating from Group VIB and Group VIII metals and containing at least a Group VB metal. In one embodiment, the used catalyst is contacted with an ammonia leaching solution to dissolve and separate the Group VIB and VIII metals from the Group VB metal complex and coke associated with the used catalyst. The resulting Group VIB and VIII metal containing solution is processed through at least two additional precipitation and liquid / solid separation steps to produce, in separate processing streams, a Group VIB metal product solution (such as ammonium molybdate) and a Group VIII metal product solution (such as nickel sulfate). Additionally, two separate filtrate streams are generated from liquid-solid separation steps, which filtrate streams are combined and subjected to hydrolysis and oxidation (oxydrolysis) to generate a purified ammonium sulfate solution for further processing, such as for fertilizer.

Owner:CHEVROU USA INC

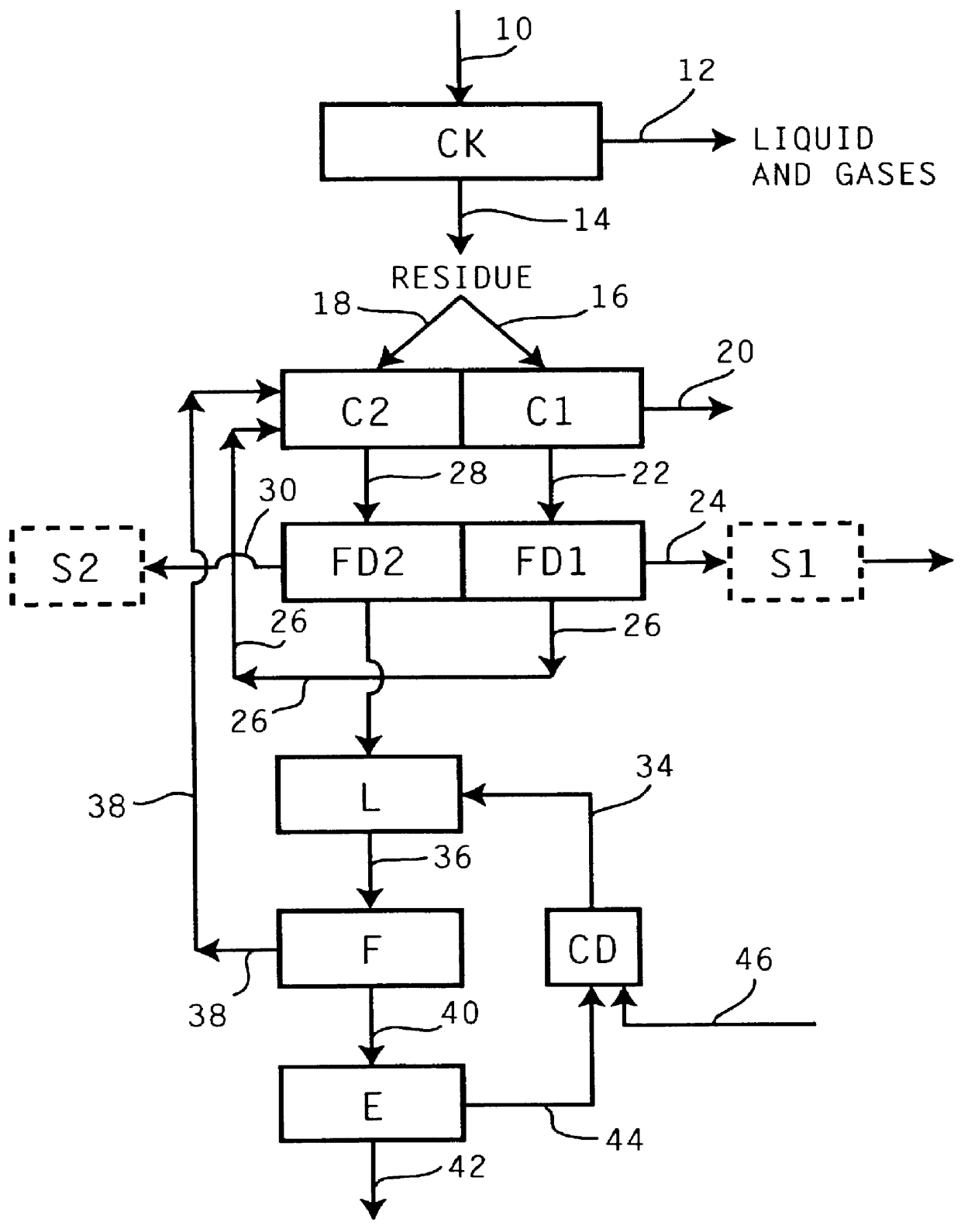

Recovery of the transition metal component of catalyst used in heavy feed hydroconversion

The invention relates to a process for recovering the transition metal component of catalysts used in the hydroconversion of heavy hydrocarbonaceous materials. In accordance with the invention, a slurry of a transition metal catalyst and hydrocarbon is catalytically desulfurized resulting in a desulfurized product and a solid residue containing the transition metal. The transition metal may be recovered by coking the residue and then dividing the coker residue into two portions are combusted with the flue dust from the first combustion zone being conducted to the second combustion zone. The flue dust from the second combustion zone is treated with ammonia and ammonium carbonate in order to obtain ammonium molybdate.

Owner:EXXON RES & ENG CO

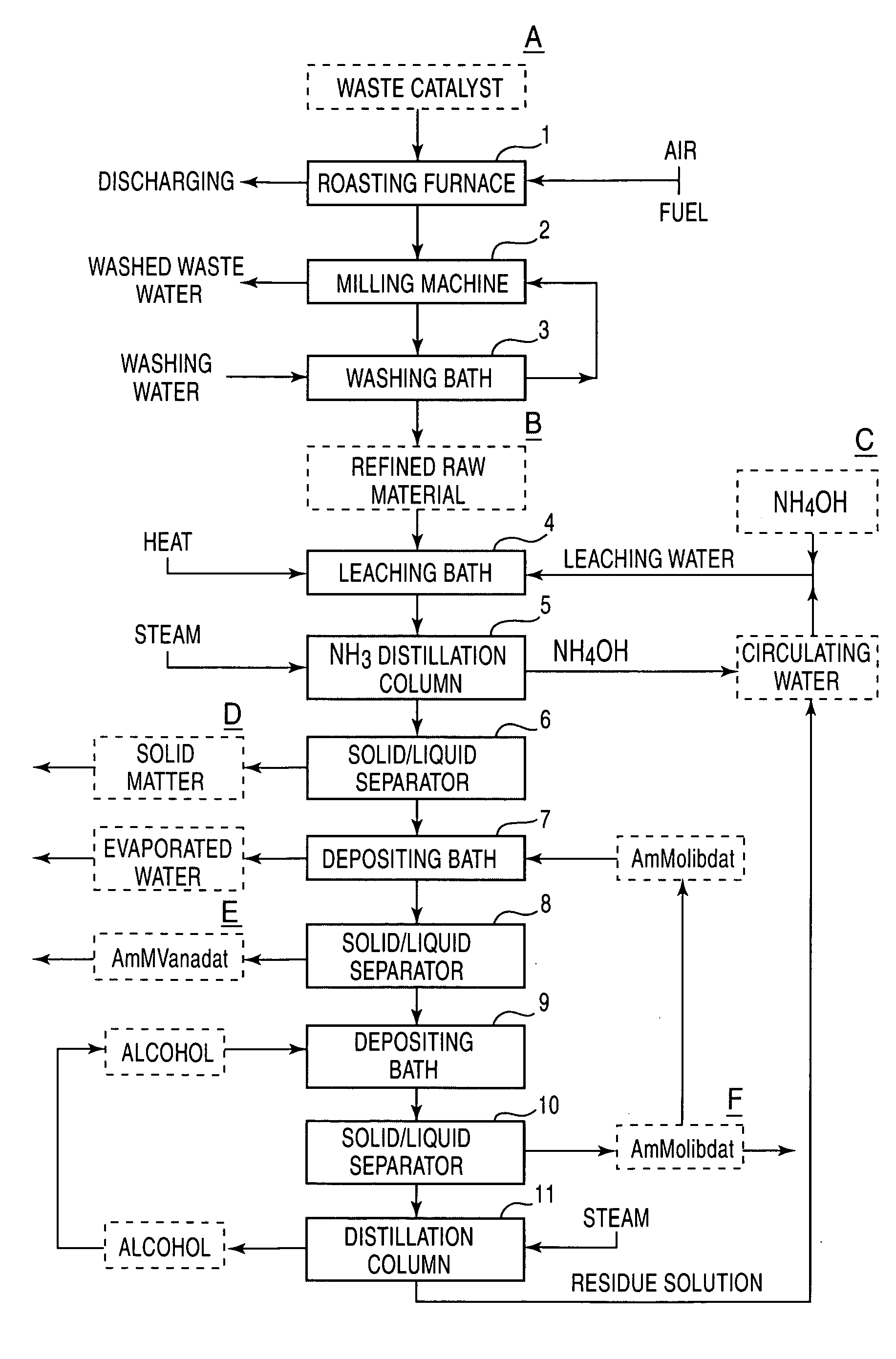

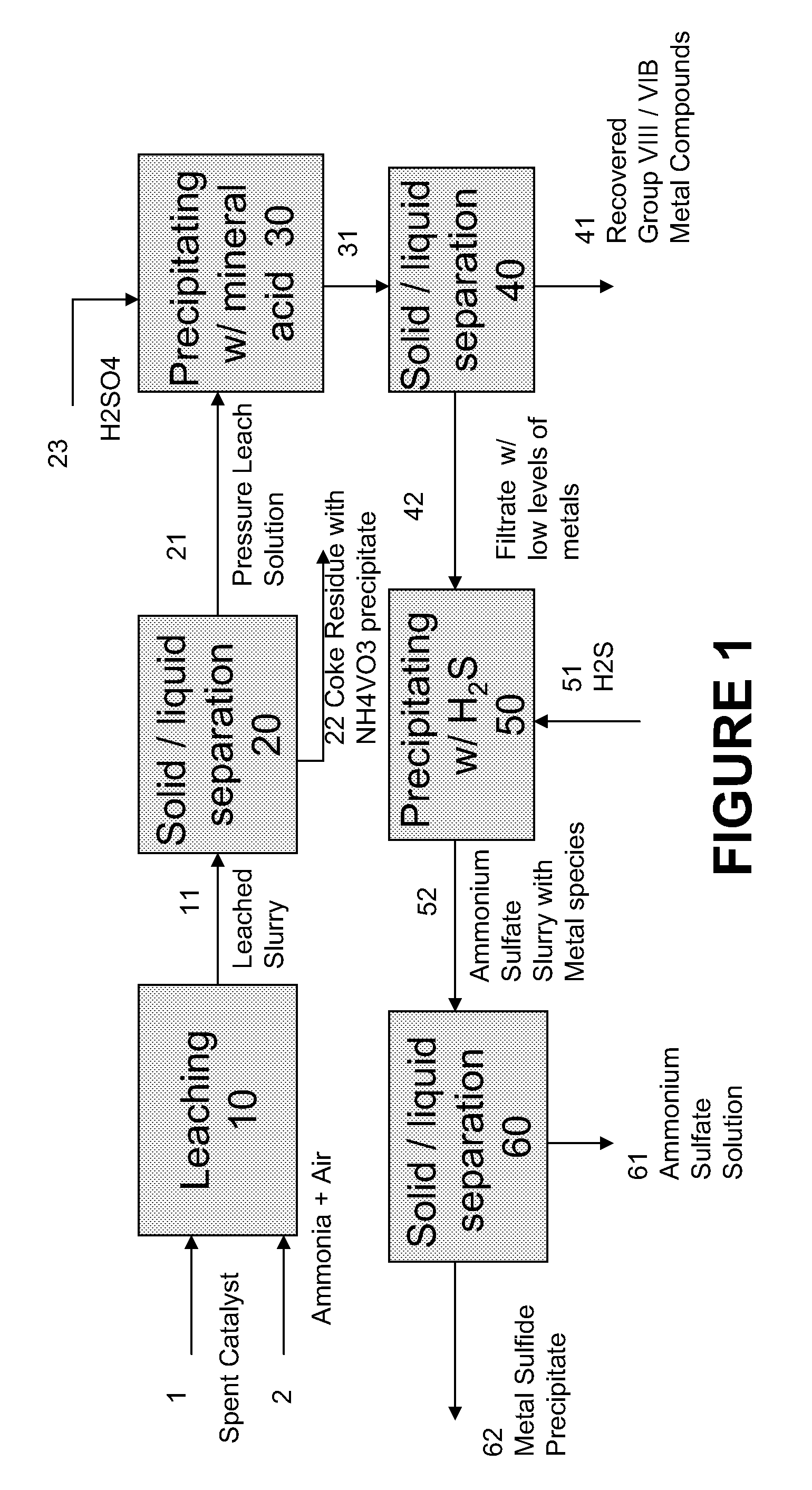

Process for separating and recovering valuable metals

InactiveUS20040213717A1Speed up leachingProceed efficientlyOther chemical processesTantalum compoundsVanadium CompoundsAlcohol

The present invention provides a process for economically separating and recovering valuable metal components, with no many kinds of chemicals being used, with no waste water that causes environmental pollution being discharged, and also perfectly no by-products being formed by means of simple steps. The present invention includes a step of leaching a raw material containing at least vanadium oxides and molybdenum oxides with ammonia-containing leaching water to obtain a leached solution containing a vanadium compound and a molybdenum compound, a step of adding ammonium orthomolybdate to the leached solution to separate and recover the deposited ammonium metavanadate from a first solution for separation, a step of adding a water-soluble alcohol to the separated solution to separate and recover the deposited ammonium orthomolybdate from a second solution for separation, a step of distilling the second solution for separation to separate and recover the water-soluble alcohol and a residue-solution, a step of adding at least a portion of the residue solution to the ammonia-containing leaching water as the portion thereof, and a step of returning a portion of the recovered ammonium orthomolybdate and a total of a recovered, water-soluble alcohol to the system for reusing.

Owner:Y K YSK TECHNOSYST

Process for recovering base metals from spent hydroprocessing catalyst

A method for recovering metals from a spent dispersed catalyst originating from a Group VIB metal sulfide catalyst containing at least a Group VB and Group VIII metal for hydrocarbon oil hydroprocessing is disclosed. In one embodiment, the method comprises the steps of: contacting the spent dispersed catalyst with a leaching solution containing ammonia and air to dissolve the group VIB metal and the Group VIII metal into the leaching solution at sufficient temperature and pressure; forming a slurry containing at least a group VIB metal complex and at least a group VIII metal complex, ammonium sulfate and solid residue containing at least a Group VB metal complex and coke; separating and removing the solid residue containing ammonium metavanadate and coke from the pressure leach solution (PLS); precipitating from the PLS at least a portion of the Group VIB metal and at least a portion of the Group VIII metal by controlling the pH at a pre-selected pH to selectively precipitate as metal complexes the Group VIB and Group VIII metals.

Owner:CHEVROU USA INC

Process for separating and recovering valuable metals

InactiveUS7182926B2Control generationSuitable for useOther chemical processesTantalum compoundsAmmonium orthomolybdateAmmonium metavanadate

A process for economically separating and recovering valuable metal components, with few kinds of chemicals being used, with no waste water that causes environmental pollution being discharged, and also perfectly no by-products being formed by means of simple steps. The process includes a step of leaching a raw material containing at least vanadium oxides and molybdenum oxides with ammonia-containing leaching water to obtain a leached solution containing a vanadium compound and a molybdenum compound, a step of adding ammonium orthomolybdate to the leached solution to separate and recover the deposited ammonium metavanadate from a first solution for separation, a step of adding a water-soluble alcohol to the separated solution to separate and recover the deposited ammonium orthomolybdate from a second solution for separation, a step of distilling the second solution for separation to separate and recover the water-soluble alcohol and a residue solution, a step of adding at least a portion of the residue solution to the ammonia-containing leaching water as the portion thereof, and a step of returning a portion of the recovered ammonium orthomolybdate and a total of a recovered, water-soluble alcohol to the system for reusing.

Owner:Y K YSK TECHNOSYST

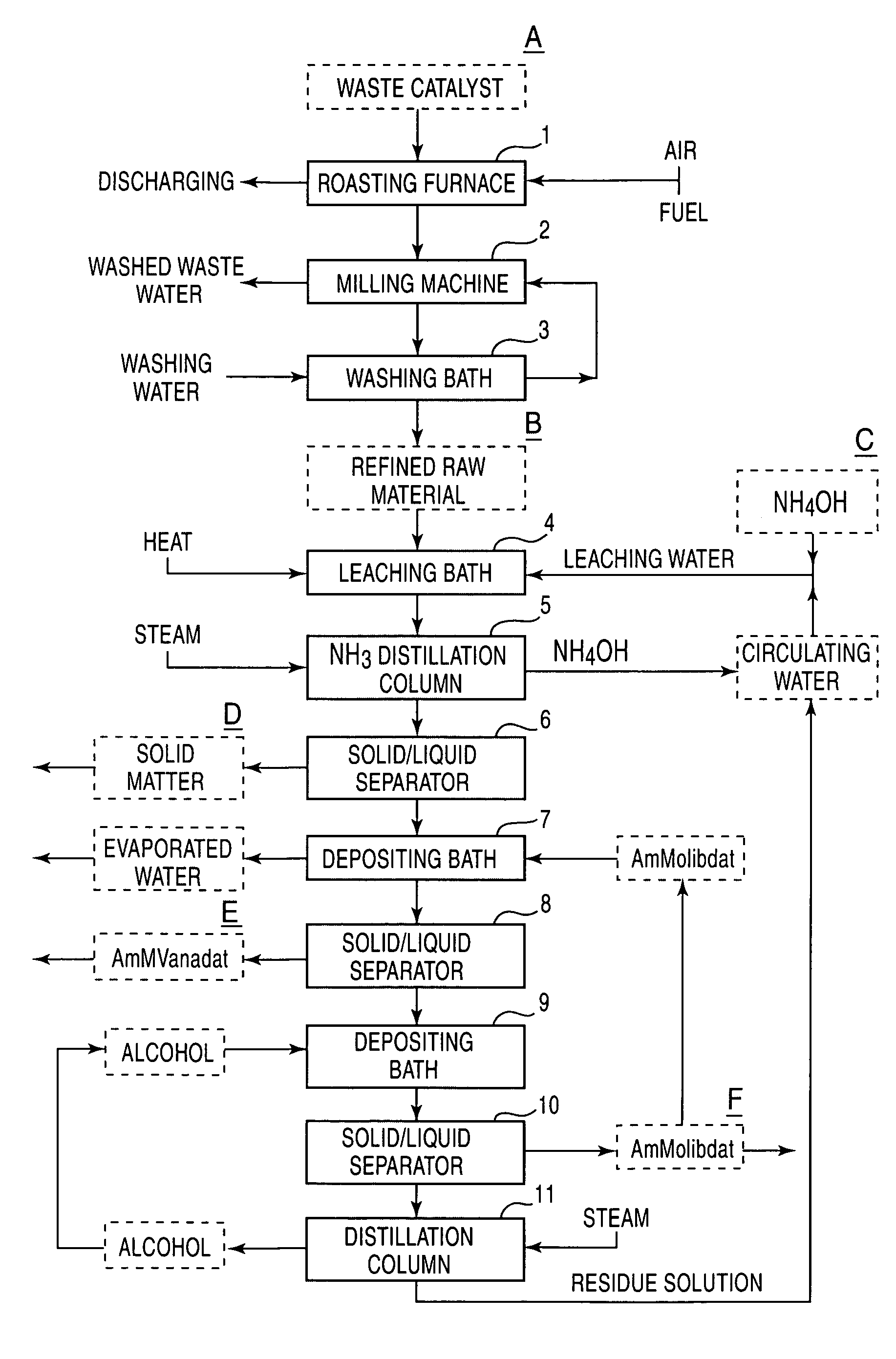

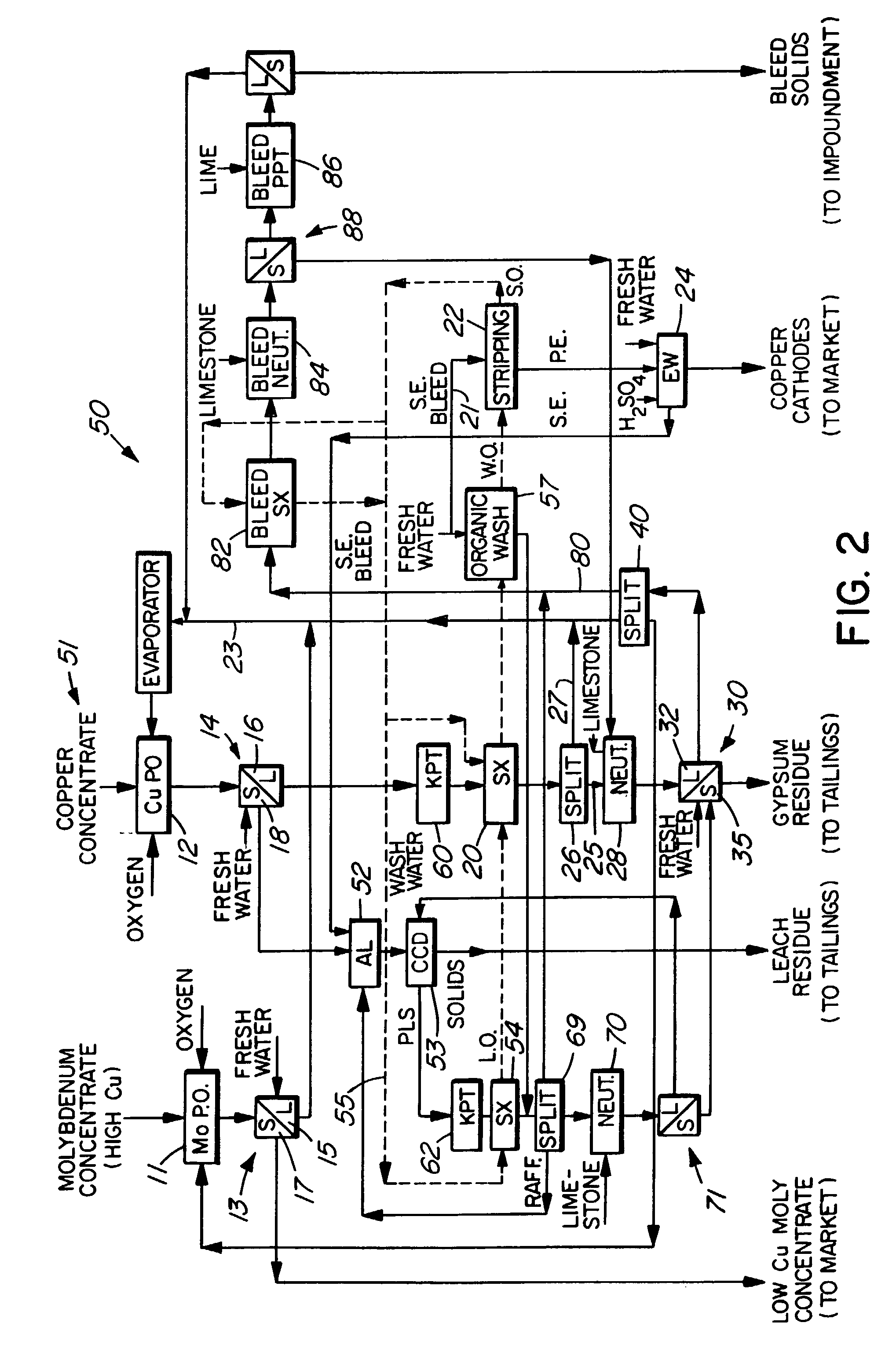

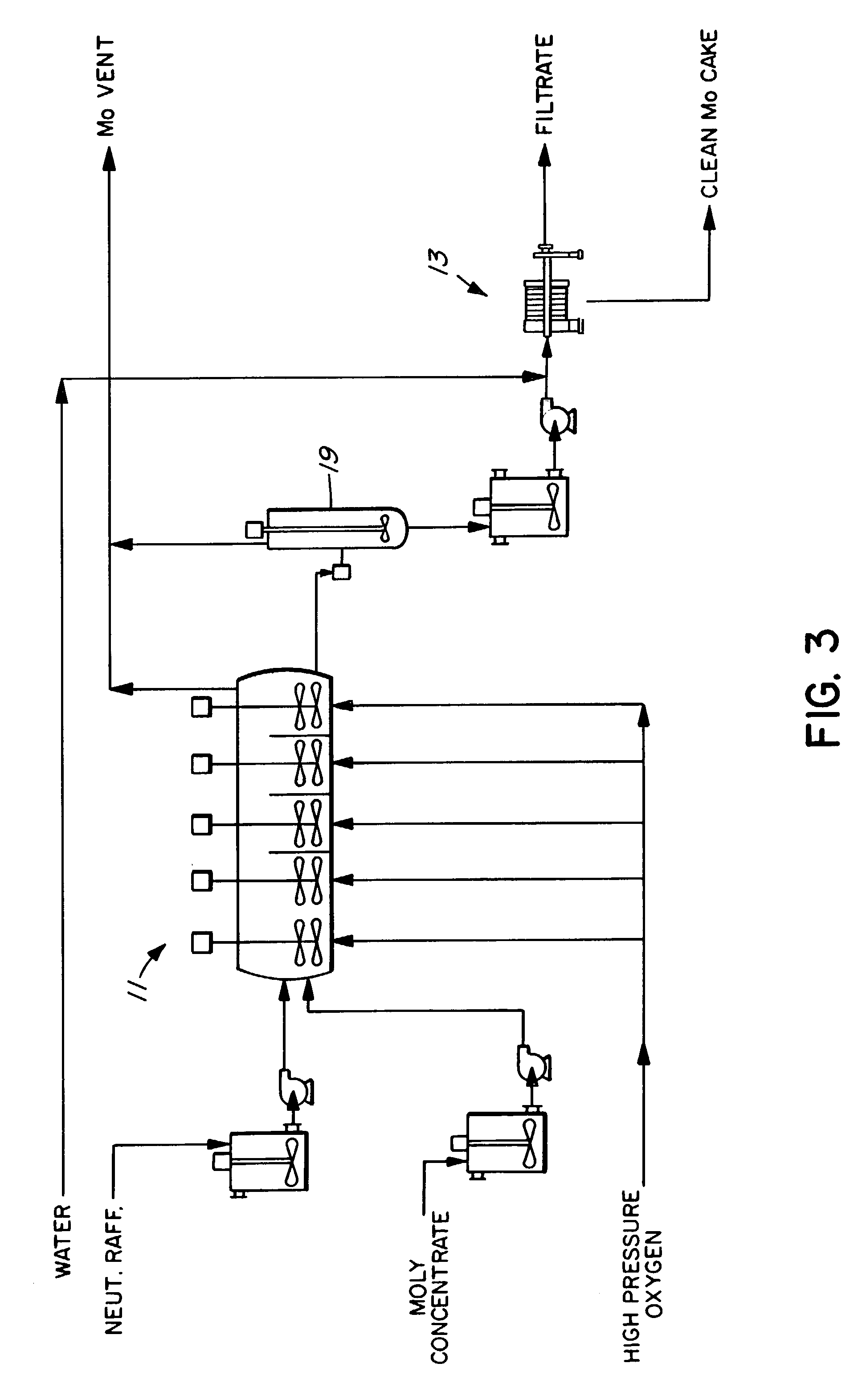

Process for the treatment of molybdenum concentrate

A method of treatment or purification of a molybdenum concentrate also containing copper, comprises the step of subjecting the molybdenum concentrate to pressure oxidation in the presence of oxygen and a feed solution containing copper (e.g. CuSO4) and halide (e.g. CuCl2) to produce a pressure oxidation solution containing copper and a solid residue containing molybdenum. The pressure oxidation solution may be combined with feed solution to a second pressure oxidation in which a copper concentrate is treated for the recovery of copper therefrom.

Owner:CESL LIMITED

Process for the preparation of lithium metal oxides involving fluidized bed techniques

A method of producing lithium metal oxides can include mixing lithium salt and a metal oxide to form a composition, heating the composition in a first reactor, transferring the composition to a second reactor, and passing the composition through the second reactor to anneal the composition to form lithium metal oxides. The second reactor can be a fluidized bed reactor. The lithium metal oxide can have an average crystal size of between about 5 microns and about 20 microns.

Owner:HONEYWELL INT INC

Nano-sized particles, processes of making, compositions and uses thereof

InactiveUS8182786B2Economical and efficientEfficiently tailoredMaterial nanotechnologyToilet preparationsSolventPharmaceutical formulation

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

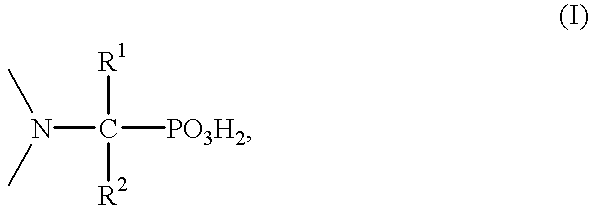

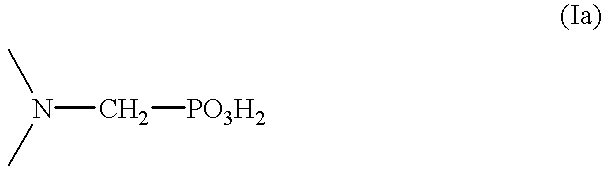

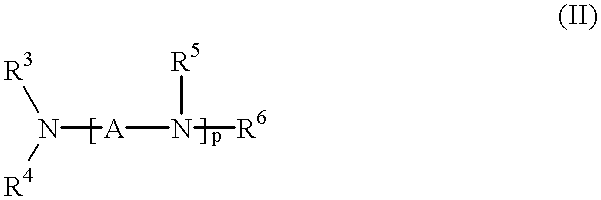

Method for effecting solvent extraction of metal ions using hydrocarbon soluble aminomethylene phosphonic acid compounds

Solvent extraction of one or more metal ions from an aqueous solution in the presence of hydrocarbon-soluble aminomethylenephosphonic acid derivatives.

Owner:BASF AG +1

Titanium composite, preparation method thereof and application thereof

ActiveCN101901905AImprove performanceEasy to preparePigmenting treatmentAlkali titanatesLithium chlorideHigh rate

Owner:BYD CO LTD

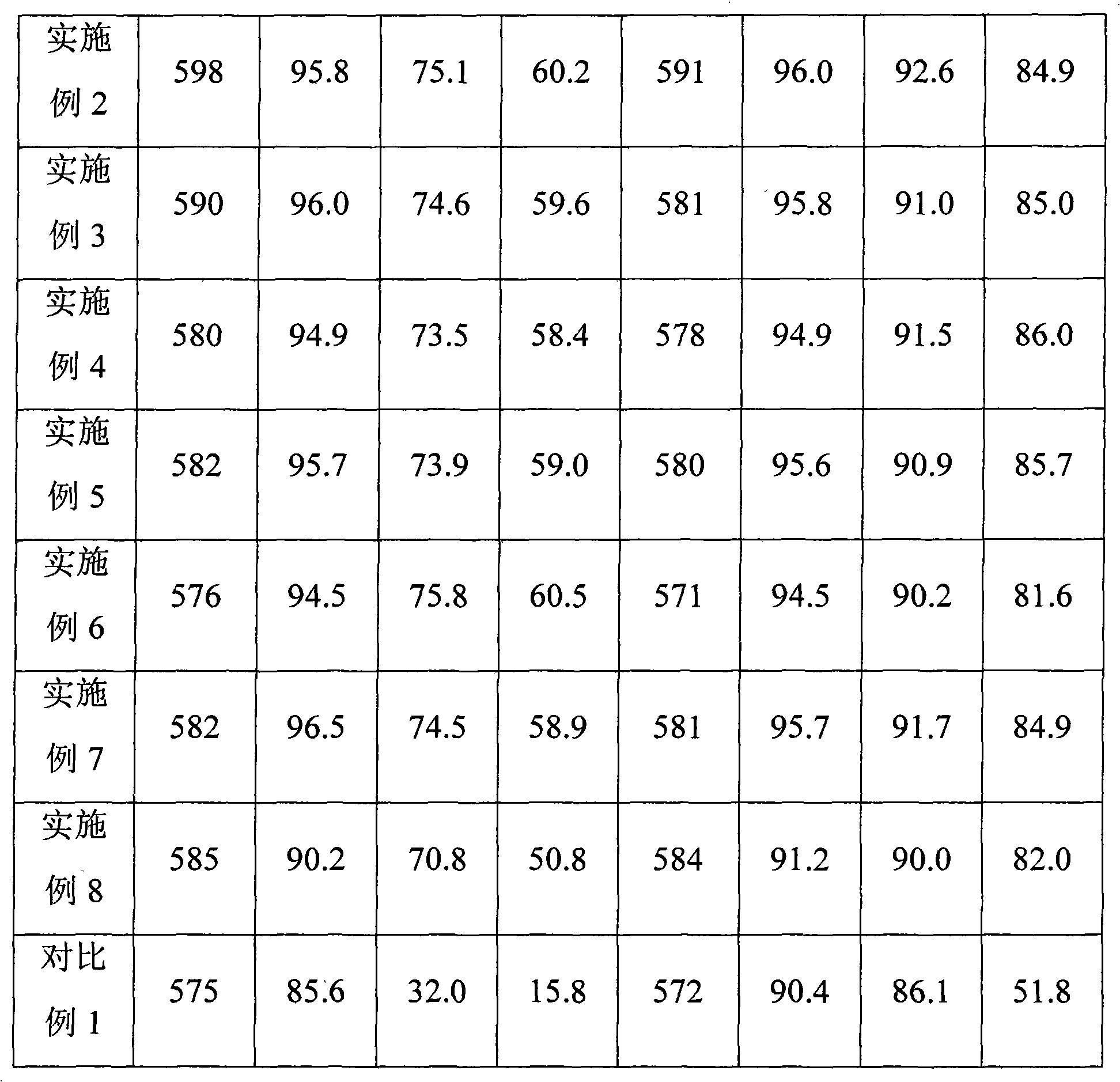

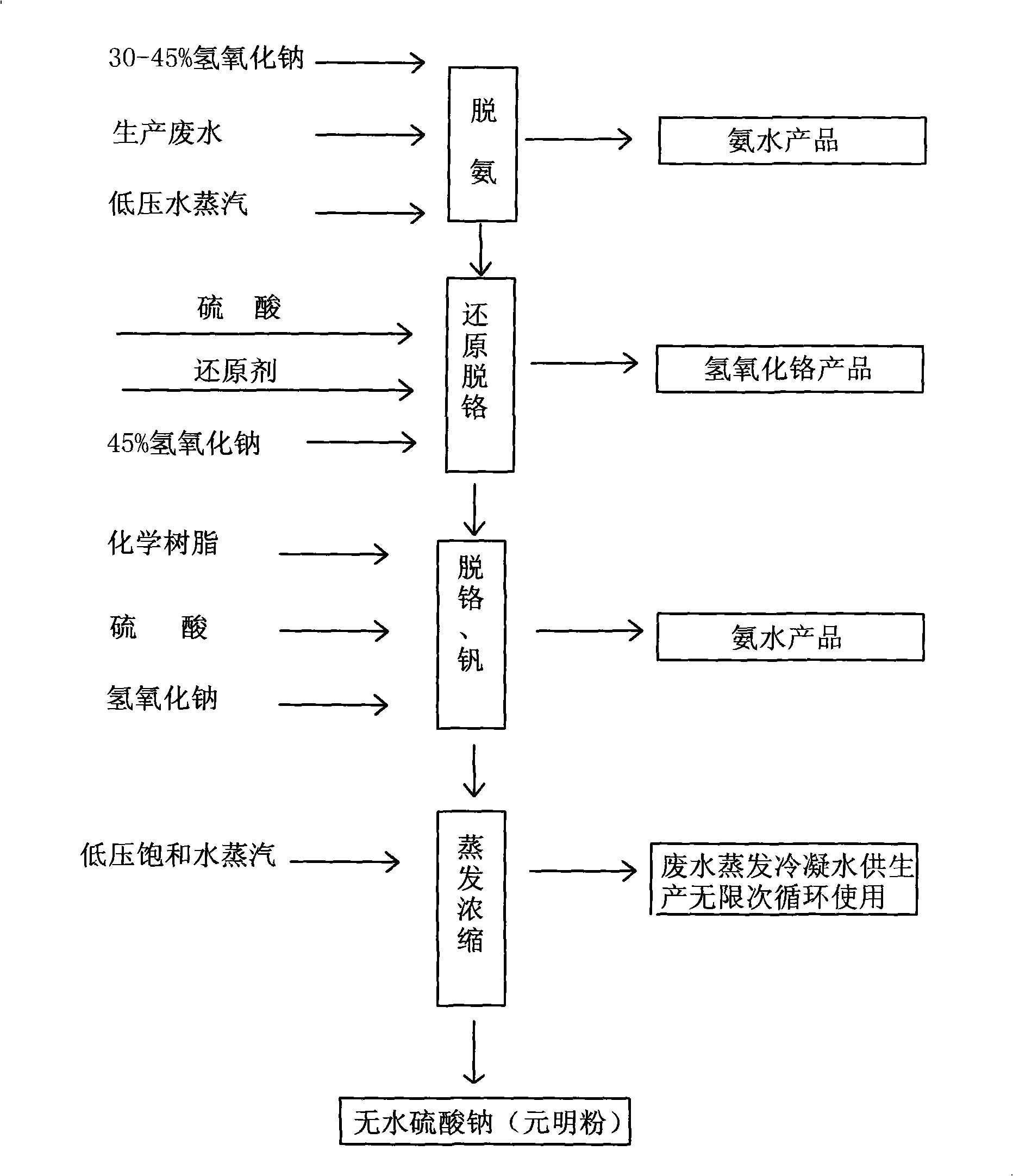

Method for treating wastewater containing ammonia, vanadium, chrome and sodium sulfate

ActiveCN101525189AProduce environmental effectWater contaminantsWater/sewage treatment by ion-exchangeSal ammoniacWastewater

The invention provides a method for treating wastewater containing ammonia, vanadium, chrome and sodium sulfate. The method comprises the following steps: step 1, deaminating to prepare ammonia; step 2, extracting chromic hydroxide; step 3, absorbing the vanadium and the chrome with resin columns; and step 4, extracting anhydrous sodium sulfate. The method can separate the ammonia, the vanadium, the chrome and the anhydrous sodium sulfate from the wastewater containing the ammonia, the vanadium, the chrome and the sodium sulfate to purify and recycle the wastewater, realize zero emission and generate environmental protection effect, thereby being suitable for extracting usable substances from the wastewater containing the ammonia, the vanadium, the chrome and the sodium sulfate while purifying and recycling the water.

Owner:辽宁虹京实业有限公司

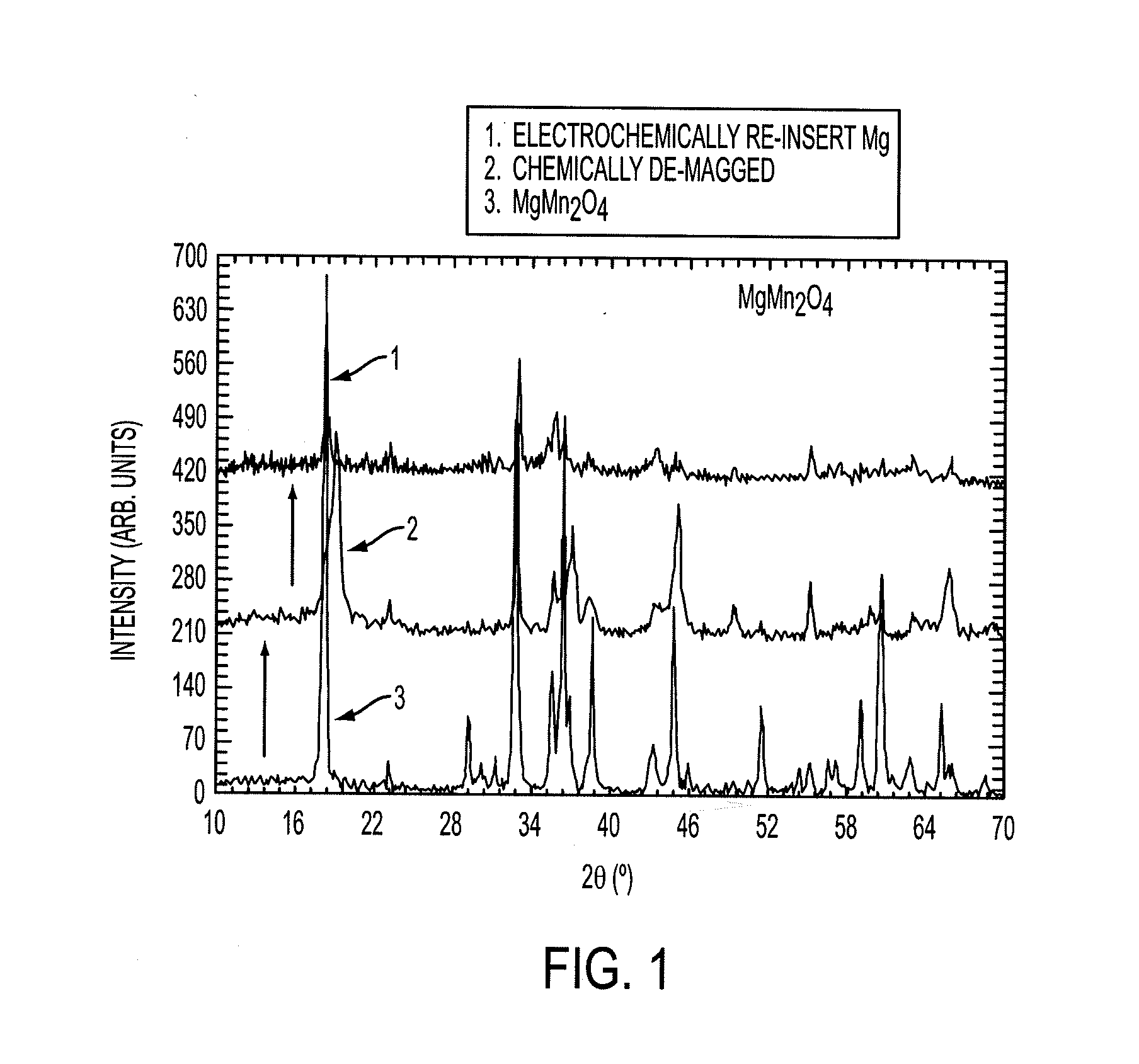

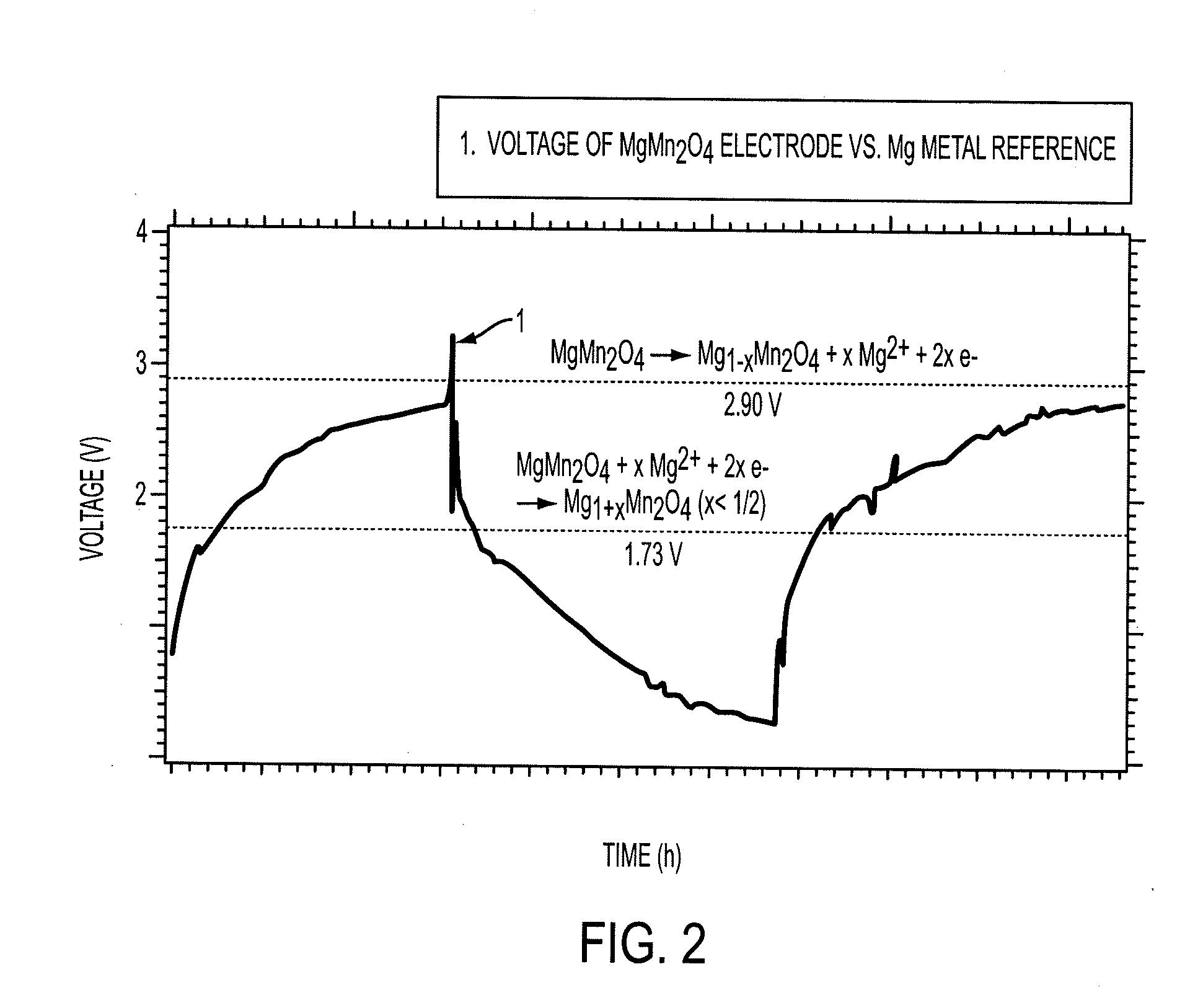

Electrode materials for magnesium batteries

InactiveUS20120219859A1Stable maintenanceReduce spreadSilver accumulatorsAlkaline accumulator electrodesMaterials scienceMagnesium battery

Owner:PELLION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com