Method for treating stainless steel cold rolling pickling waste water

A technology for pickling wastewater and treatment methods, which is applied in metallurgical wastewater treatment, neutralized water/sewage treatment, reduced water/sewage treatment, etc., and can solve the problems of inability to reuse raw materials for steelmaking furnaces, high cost of chemicals, and high treatment costs , to achieve the effect of stable fluoride ion concentration, lower drug costs, and lower total treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the examples.

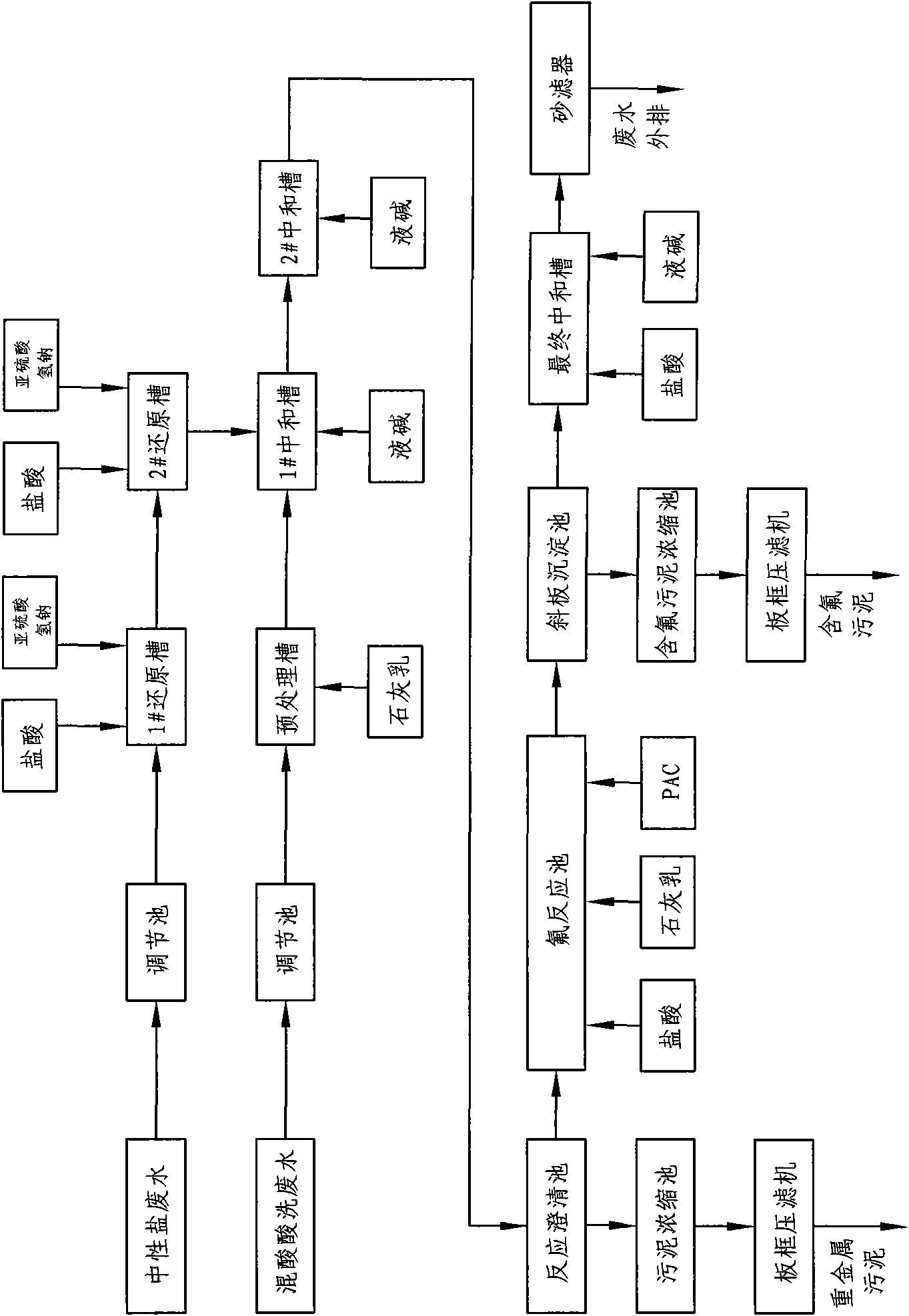

[0031] A treatment method for stainless steel cold-rolled pickling wastewater, characterized in that it comprises the following process steps in sequence:

[0032] 1) Put the mixed acid pickling wastewater into the acid wastewater regulating tank to adjust the water quality, then enter the pretreatment tank for preliminary neutralization, and control the pH value at 5-6 by adding lime milk;

[0033] 2) Put the neutral salt electrolysis wastewater or sulfuric acid electrolysis wastewater into the neutral salt wastewater adjustment tank to adjust the water quality, and then enter the first-level reduction tank and the second-level reduction tank in turn, and reduce the hexavalent chromium in the wastewater to three by adding a reducing agent. Valence chromium;

[0034] The reducing agent is hydrochloric acid and sodium bisulfite, the amount of reducing agent added is contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com