Patents

Literature

497results about How to "High recycling value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recycling processing method for stainless steel processing process wastewater grading precipitation

InactiveCN101648757AHigh recycling valueSludge treatment by de-watering/drying/thickeningPhotography auxillary processesThree levelAcid washing

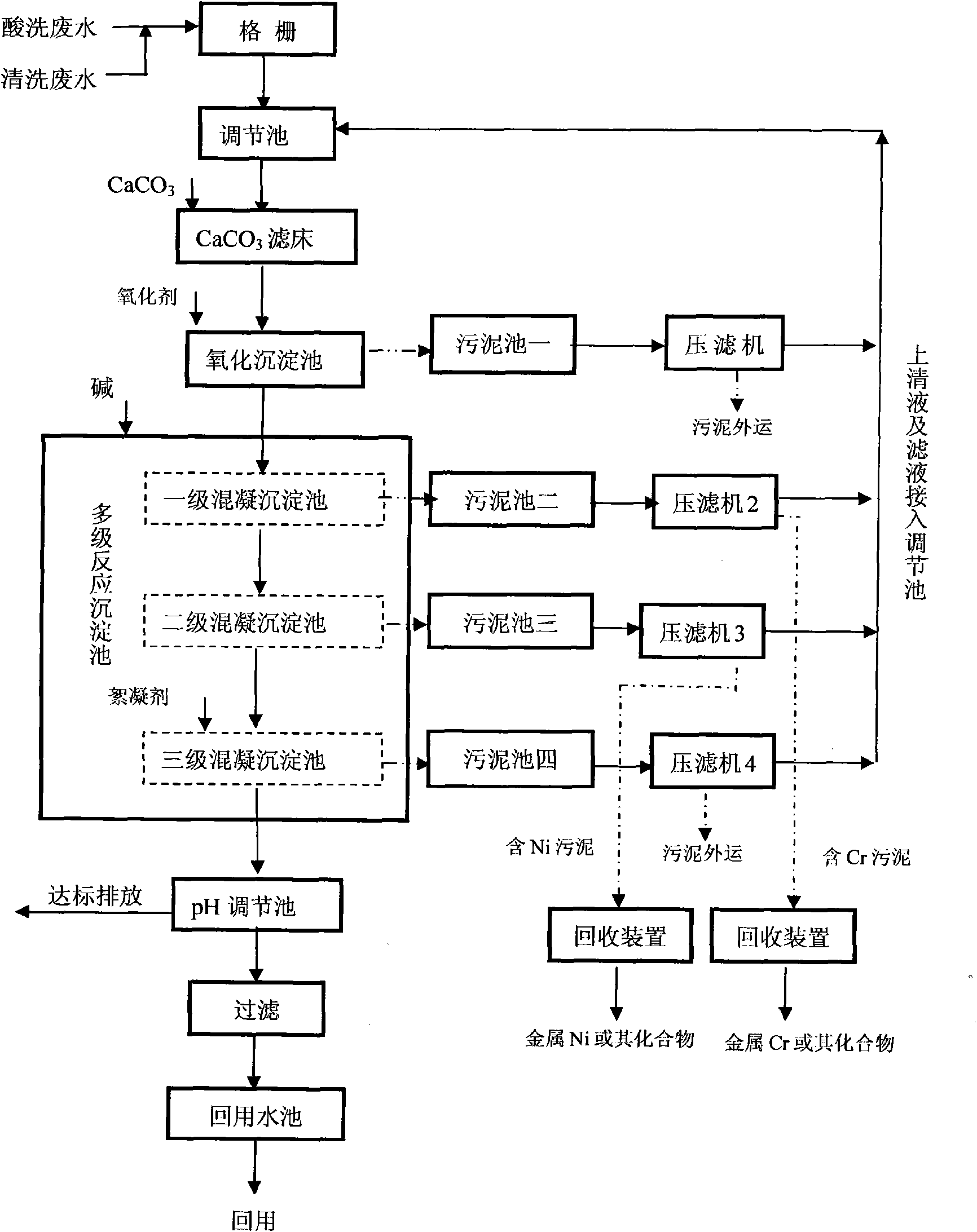

The invention relates to a recycling processing method for a stainless steel processing process wastewater grading precipitation, which comprises the following steps: (1) deslagging and homogenizing acid-washing residual liquid and washing wastewater; (2) adjusting the pH to 4.0-5.5 by a CaCO3 filter bed to generate CaF2; (3) oxidizing Fe<2+> into Fe<3+> by an oxidizing agent to generate sedimentsof Fe(OH)2 and Fe(OH)3; after the Fe(OH)2 , the Fe(OH)3 and the CaF2 are deposited, recovering; (4) carrying out three-level alkali adding coagulation precipitation on the supernatant liquid of an oxidation precipitation pool; adjusting the pH to obtain a Cr sediment in the first-level alkali adding coagulation precipitation; acquiring a Ni sediment in the second-level alkali adding coagulation precipitation; carrying out the third-level alkali adding coagulation precipitation and adding a flocculating agent to remove residual heavy metal ions so that discharge water reaches the standard, wherein the alkali added into a grading reaction precipitation pool is NaOH, Ca(OH)2, CaO or Na2 CO3; (5) regulating the pH of the discharge water of the grading reaction precipitation pool to 6.0-8.0; discharging 0-20 percent of wastewater and filtering residual F<-> and suspended matters of 80-100 percent of wastewater to reach the standard and recycle; and (6) recycling the Cr-Ni metal or the compound thereof from the Cr sediment and the Ni sediment acquired by a third-level coagulation precipitation pool by a recycling device.

Owner:ZHEJIANG UNIV

Recycling harmless treatment method of stainless steel pickling waste water

ActiveCN102659274AHigh recovery rateSmall footprintSludge treatmentSolid waste disposalIndustrial waste waterSS - Stainless steel

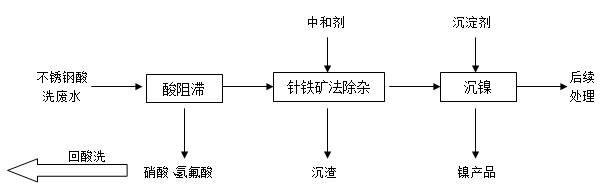

The invention discloses a recycling harmless treatment method of stainless steel pickling waste water, belonging to the toxic and harmful industrial waste water treatment field. The method comprises the following steps of: 1) recycling inorganic acids by an acid separation method: pumping stainless steel pickling waste water in which suspended matters are removed through filtering into a resin column so that the inorganic acids are absorbed on the resin; 2) removing impurities by a goethite method: pumping heavy metal ion solution into a reaction kettle, adjusting pH to a range from 3.5 to 5.0, and continuing reacting for 30-90 min, thereby removing iron, chromium and fluorine in the heavy metal ion solution in the form of dregs; 3) recycling nickel by a neutralized sedimentation method: feeding an alkaline liquor to nickel solution to adjust pH to a range from 9.5 to 12.5, and filtering and washing the filter residues, thereby obtaining nickelous hydroxide; and 4) performing harmlesstreatment on the dregs: after washing the dregs, adding lime powder to the dregs to realize stabilization treatment of harmful elements. The method is simple in operation and convenient for management; the high-concentration inorganic acids and nickel and the like contained in the waste water are all recycled, and simultaneously the generated dregs are harmlessly treated; and therefore the integration of economic benefit,environmental benefit and social benefit is realized.

Owner:NANJING UNIV

Recycling processing method for wastewater produced by processing stainless steel

InactiveCN101648759AHigh recycling valueIron oxides/hydroxidesCalcium/strontium/barium fluoridesStrong acidsOxidizing agent

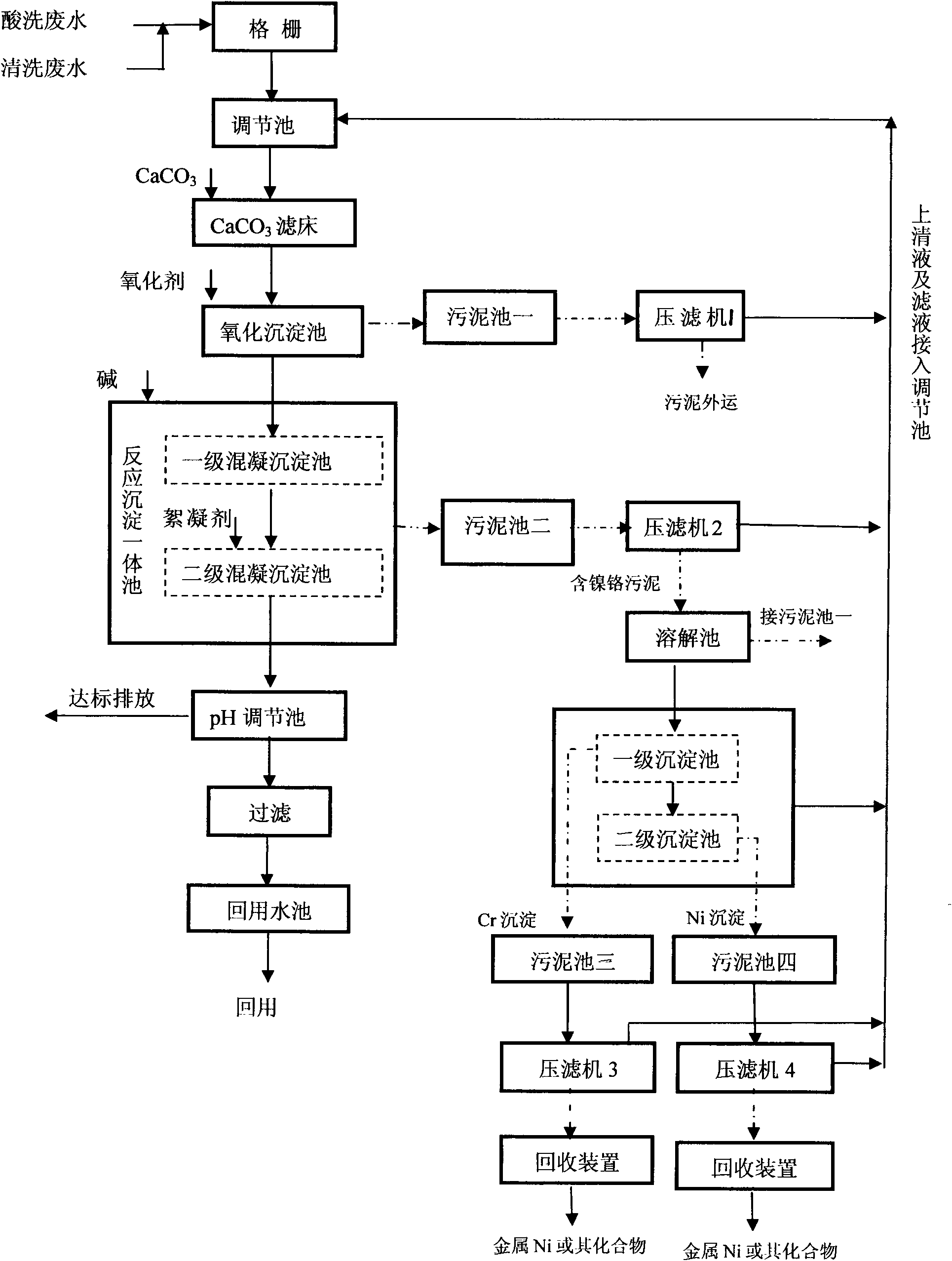

The invention relates to a recycling processing method for wastewater produced by processing stainless steel, which comprises the following steps: after acid-washing residual liquid and washing wastewater are carried out wastewater deslagging, homogenizing; pumping into a CaCO3 filter bed to adjust the pH to 4.0-5.5 and removing F<->; adding an oxidizing agent into discharge water, oxidizing Fe<2+> into Fe<3+> and generating Fe(OH)2 and Fe(OH)3; after the Fe(OH)2, the Fe(OH)3 and CaF2 are deposited, recovering; adopting two-level coagulating sedimentation on supernatant liquid; adding alkali to adjust the pH to 8.0-9.5 in the first level; continuously adding the alkali to adjust the pH to 10.0-11.0 in the second level and adding CaCl2 and a flocculating agent to deposit sludge containing chromium and nickel; adding acid liquor into the discharge water to adjust the pH to 6.0-9.0 and filtering residual F<-> and suspended matters to reach the standard and recover; carrying out dehydration separation on the sludge containing ferrum and the sludge containing chromium and nickel; adding strong acid into the sludge containing chromium and nickel to dissolve; adopting two-level alkali adding coagulating sedimentation on the wastewater of a dissolving pool to obtain a Cr(OH)3 sediment and a Ni(OH)2 sediment or a NiCO3 sediment; carrying out sludge-water separation and recovering to obtain chromium and nickel metal or the compound thereof; and using supernatant liquid and the discharge water of a press filter for homogenization.

Owner:ZHEJIANG UNIV

Aluminum-plastic composite packing separating agent and method of separating and reclaiming the same

The invention discloses a release agent of aluminum composite packing and the recovery method thereof. Said aluminum composite packing release agent is composed of sulfuric acid or phosphoric acid with a concentration of 5-20% and oxidizer. It applies as following steps: soaking the aluminum composite packing material in the sulfuric acid or phosphoric acid with a concentration of 5-20% at 40-80 DEG C, 0.1-0.5% cationic surfactant or only in the release agent containing sulfuric acid or phosphoric acid with a concentration of 5-20%, stirring uniformly; feeding oxidizer, stirring; aluminium layer and plastic layer being automatically peeled off after soaking for 1-20 minutes; washing the packing material with water twice or three times, removing the surface residual release agent; releasing the aluminum foil and plastic layer. The invention can separate the aluminum composite packing quickly and has a high aluminum coefficient of recovery, meanwhile provides a good working environment to the operator.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

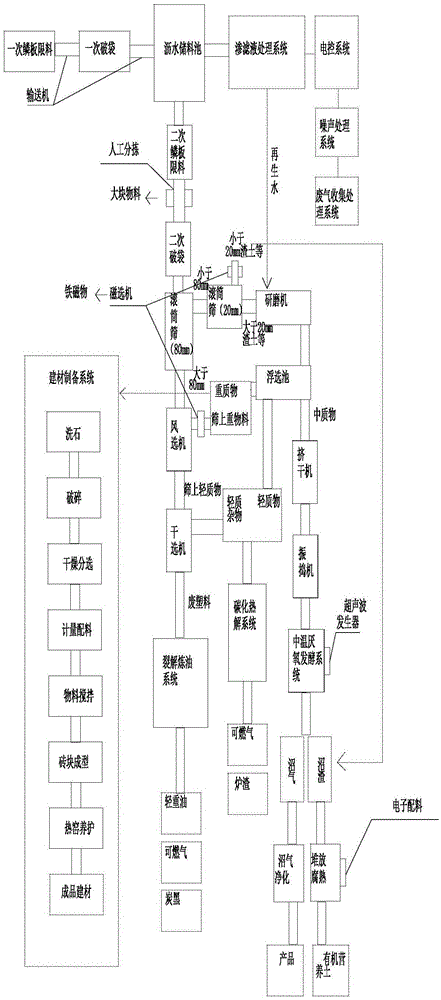

Household garbage fine separation and complete recycling comprehensive treatment process

InactiveCN105665410ARealize resourcesHarmlessWaste processingSolid waste disposalSoil organic matterLitter

The invention discloses a household garbage fine separation and complete recycling comprehensive treatment process and relates to a process for treating household garbage. According to the household garbage fine separation and complete recycling comprehensive treatment process, urban household garbage which is collected in a centralized manner can be recycled in a plurality of manners and enters all recycling systems, a plurality of products are produced and returned to the urban for use, and recycling, maximum reduction and harmlessness of the household garbage are truly and completely achieved. The household garbage fine separation and complete recycling comprehensive treatment process comprises following steps of bag breaking, leaching and material storage of the household garbage; separating, wherein waste plastic, unrecyclable combustible materials, organic matter, inert inorganic matter and ferromagnetic matter are separated out; treatment of the separated matter; collecting and treating of garbage leachate and waste water; collecting and treating of waste gas or bad smell; and treating of the noise.

Owner:BEIJING ZHENGSHI ENVIRONMENTAL PROTECTION ENG CO LTD

Waste power lithium battery automated splitting all-components clean recovery method

InactiveCN107086334AClean thoroughlyNothing producedWaste accumulators reclaimingBattery recyclingRecovery methodScreening method

A waste power lithium battery automated splitting all-components clean recovery method is characterized by comprising the following steps: conveying discharged waste single power batteries into a shell cutting device through a feeding conveyer, cutting off end caps of the single batteries, pushing out battery cells, cutting the battery cells into blocks through a battery cell cutting device, recovering shell materials, simultaneously sending the battery cell blocks into an organic solvent and rinsing, collecting the solvent and concentrating and recovering an electrolyte, distilling the solvent for recycling, drying the battery cell block materials, sorting out plastic diaphragms and positive and negative plates by an eddy current separation method, sorting out positive plates and negative plates continuously through a magnetic separation method, immersing positive plates with water and drying and carrying out material separation and sorting by a rolling mill screening method, recovering to obtain clean cathode material powder and cathode aluminium foils, and separating and sorting negative plates by the same method.

Owner:北京赛德美资源再利用研究院有限公司

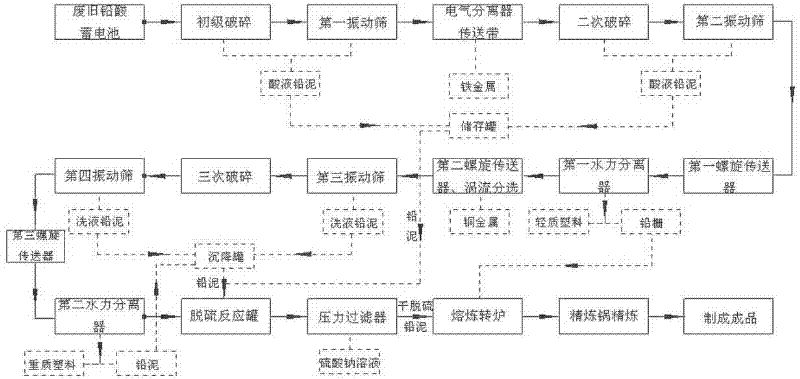

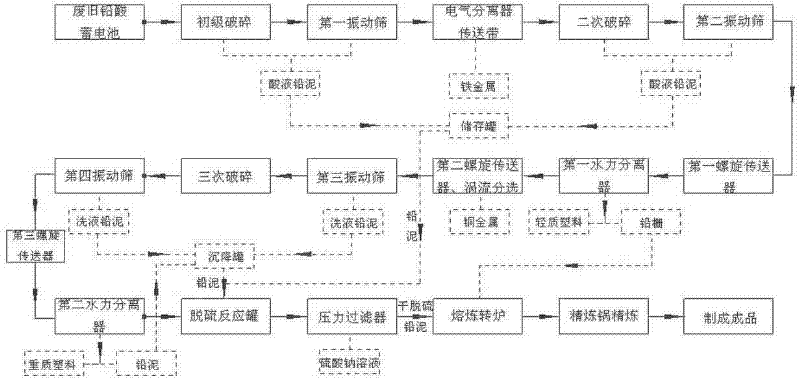

Closed circulating and recycling method of waste lead-acid accumulator

ActiveCN102534220ARealize pollution-free productionMethod environmentally friendlyProcess efficiency improvementFiltrationIngot

The invention relates to a closed circulating and recycling method of a waste lead-acid accumulator, and is used for solving the problem of low recovery efficiency, severe pollution and the like in the existing recycling aspect of the waste lead-acid accumulator due to lagging processing equipment, technical process production scale and the like. The method comprises the steps of: separating materials in the waste accumulator by crushing, oscillating screen sorting, magnetic separation, hydraulic sorting, vortex sorting and other methods, then carrying out desulfurization and pressure filtration treatment on obtained lead mud, then sequentially conveying obtained dried desulfurized lead mud and lead grid to a convertor and a refining kettle for smelting and refining, finally processing the refined molten lead into lead powder, lead grid or lead ingot, and storing for later use or selling as a finished product. The method has the advantages that the mechanical automation degree is high, pollution-free measures are adopted, the materials are thoroughly separated, the recovery rates of the materials are greatly improved, the total recovery rate of lead achieves 98%, the recovery rateof plastic achieves 95%, and the comprehensive utilization rate of resources achieves 98%.

Owner:阳煤集团山西吉天利科技有限公司

Methods to prepare stable electrolytes for all iron redox flow batteries

ActiveUS20140272493A1Low costHigh recycling valueRegenerative fuel cellsIndirect fuel cellsChemical reactionOxidation-Reduction Agent

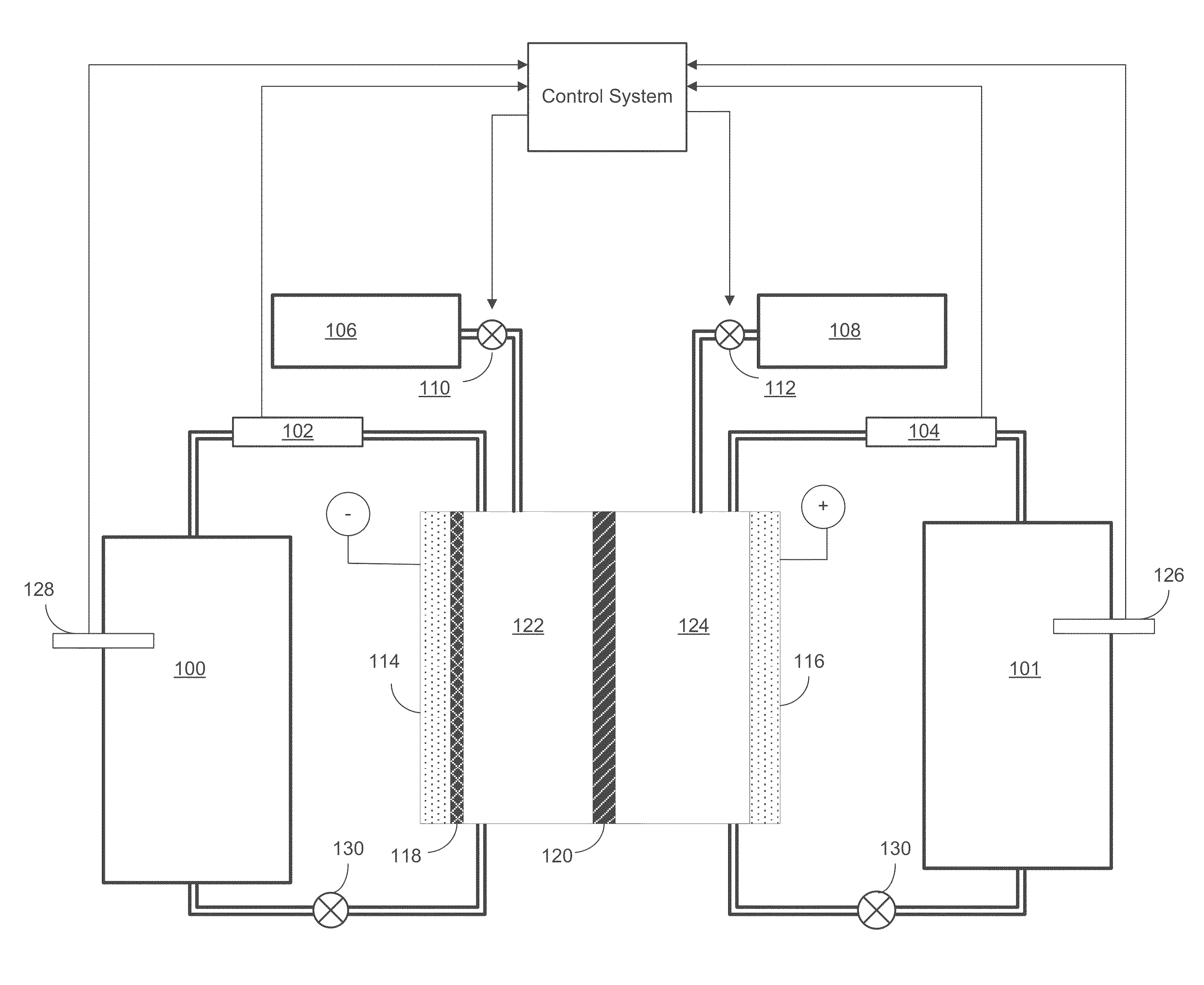

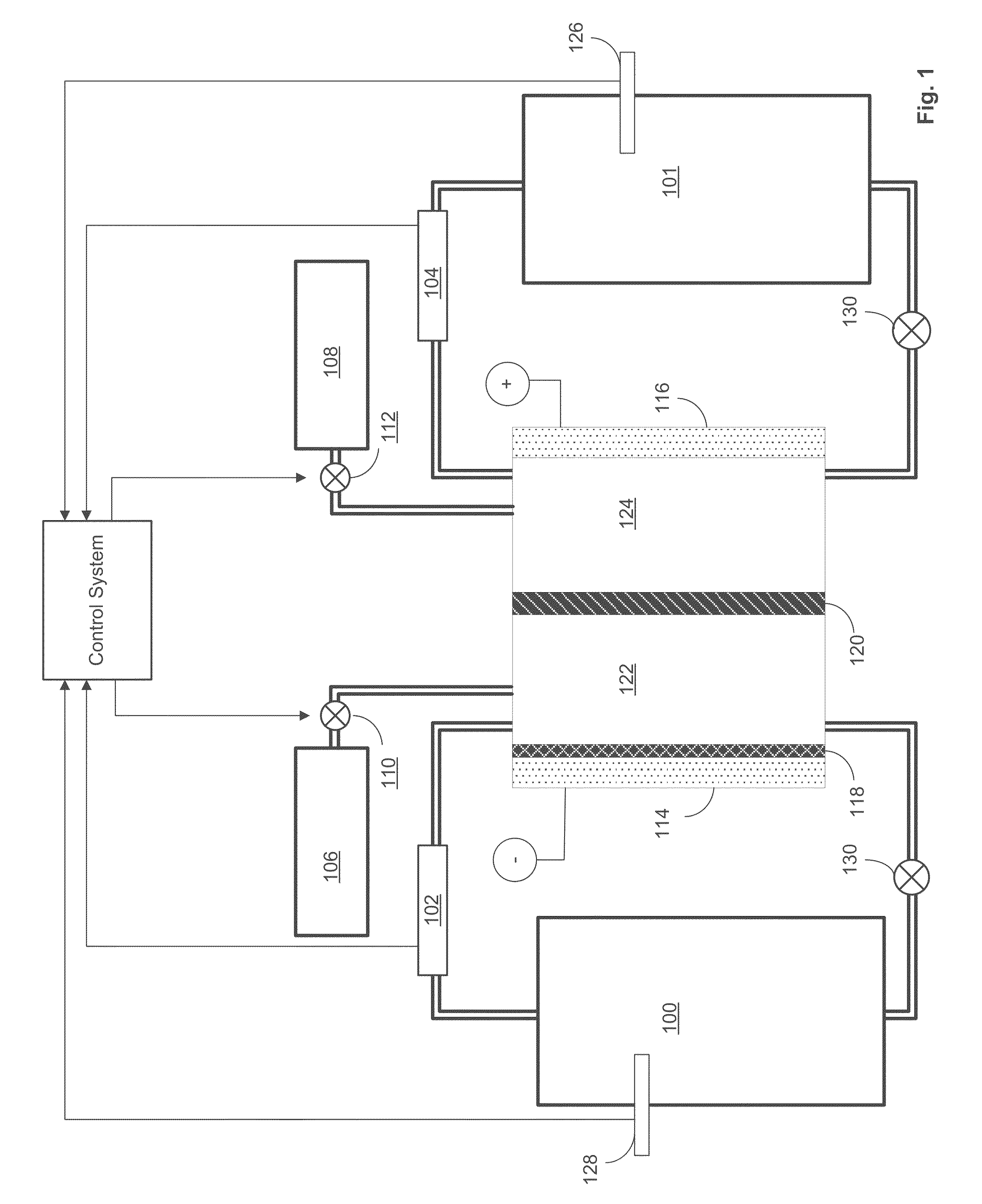

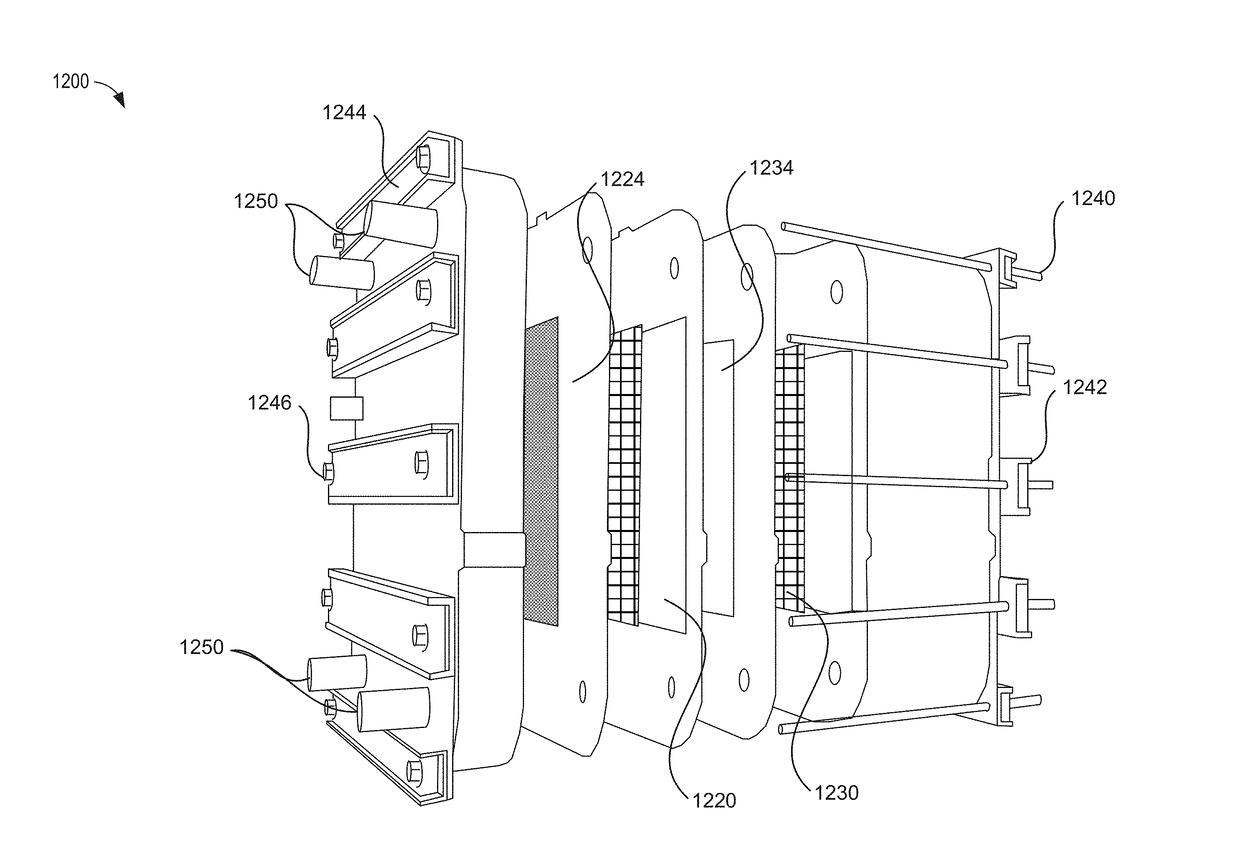

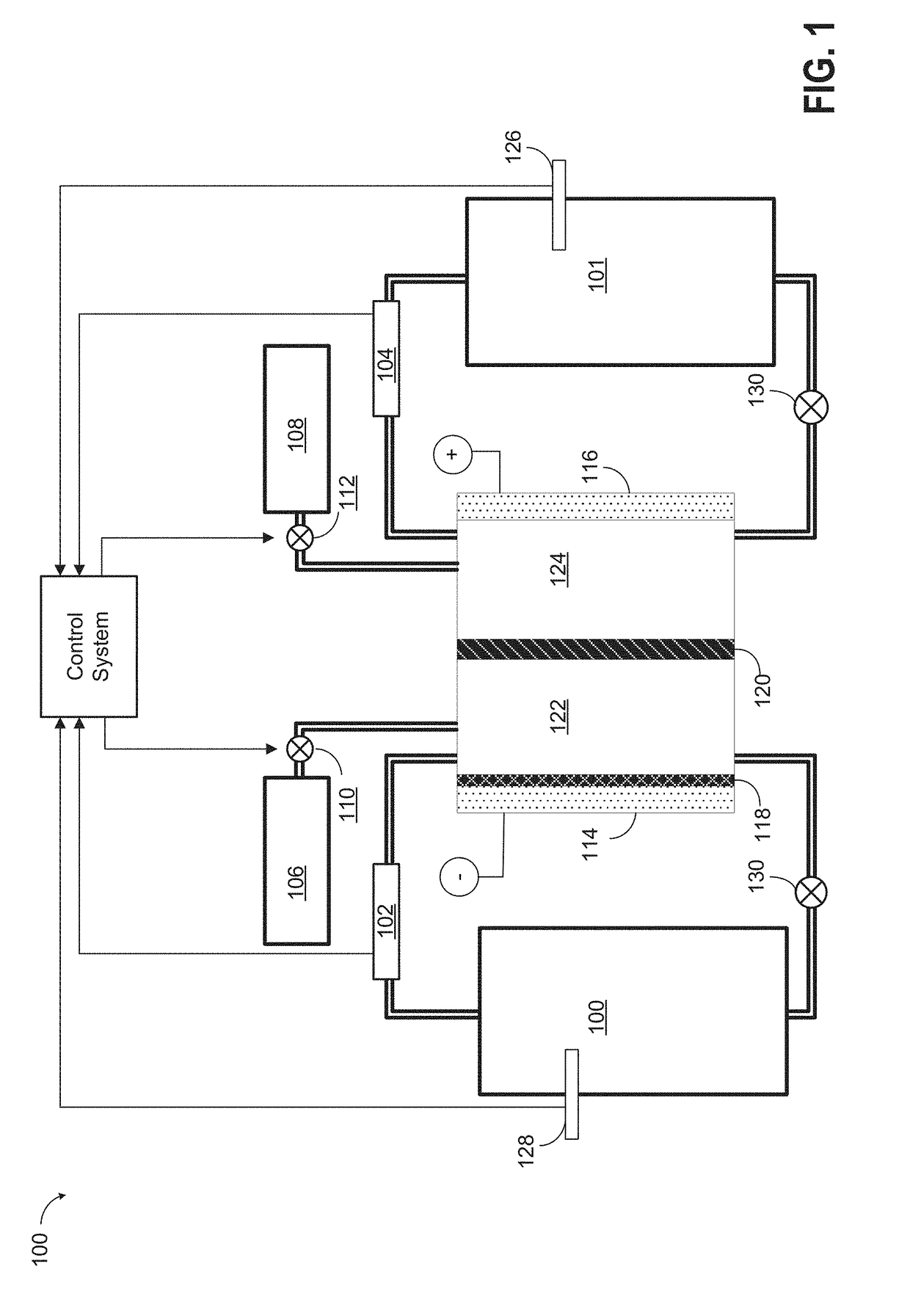

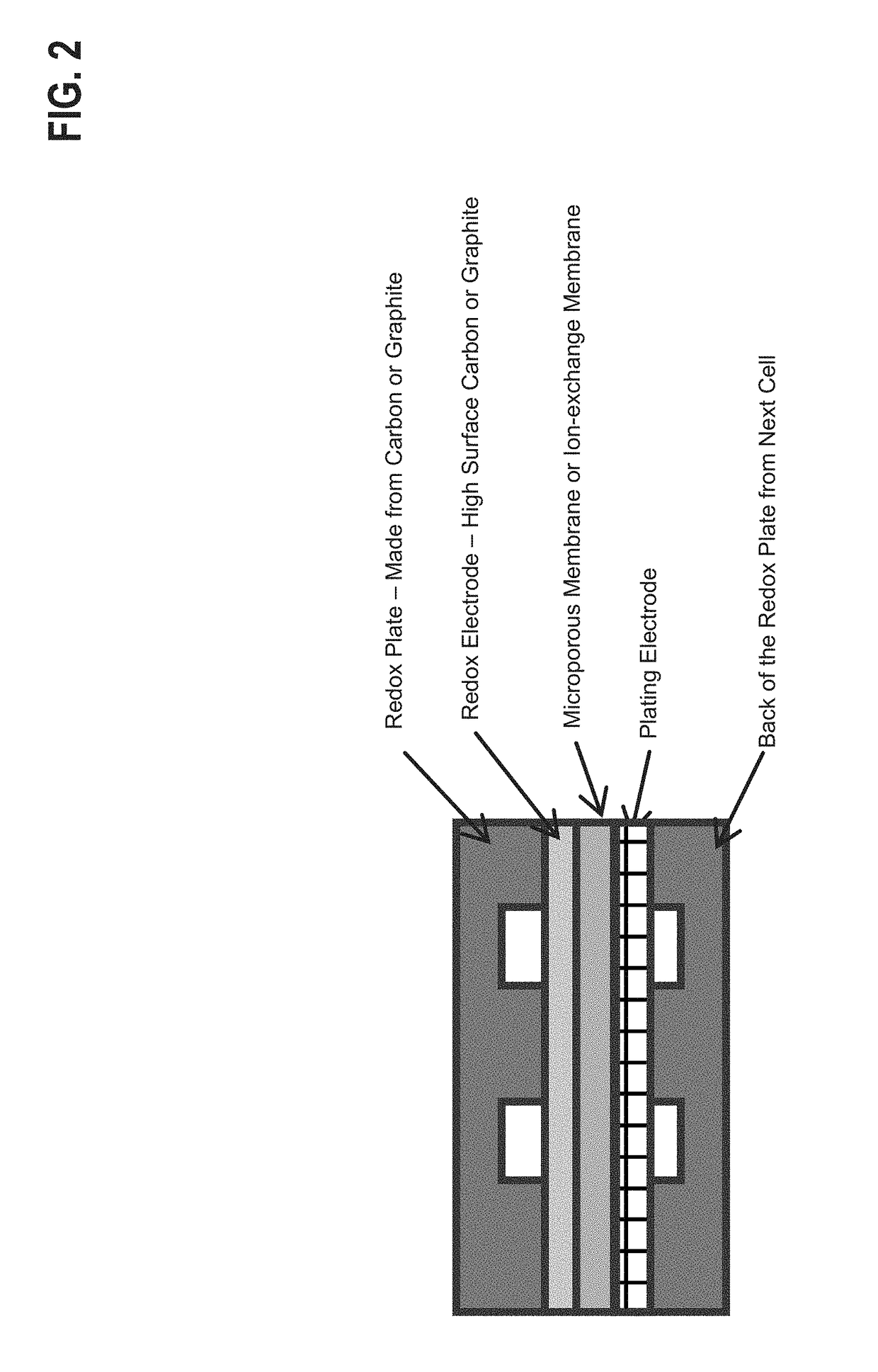

An iron redox flow battery system, comprising a redox electrode, a plating electrolyte tank, a plating electrode, a redox electrolyte tank with additional acid additives that may be introduced into the electrolytes in response to electrolyte pH. The acid additives may act to suppress undesired chemical reactions that create losses within the battery and may be added in response to sensor indications of these reactions.

Owner:ESS TECHNOLOGY

Novel process for co-production of liquefied synthesis gas, pure hydrogen and methanol from coke-oven gas

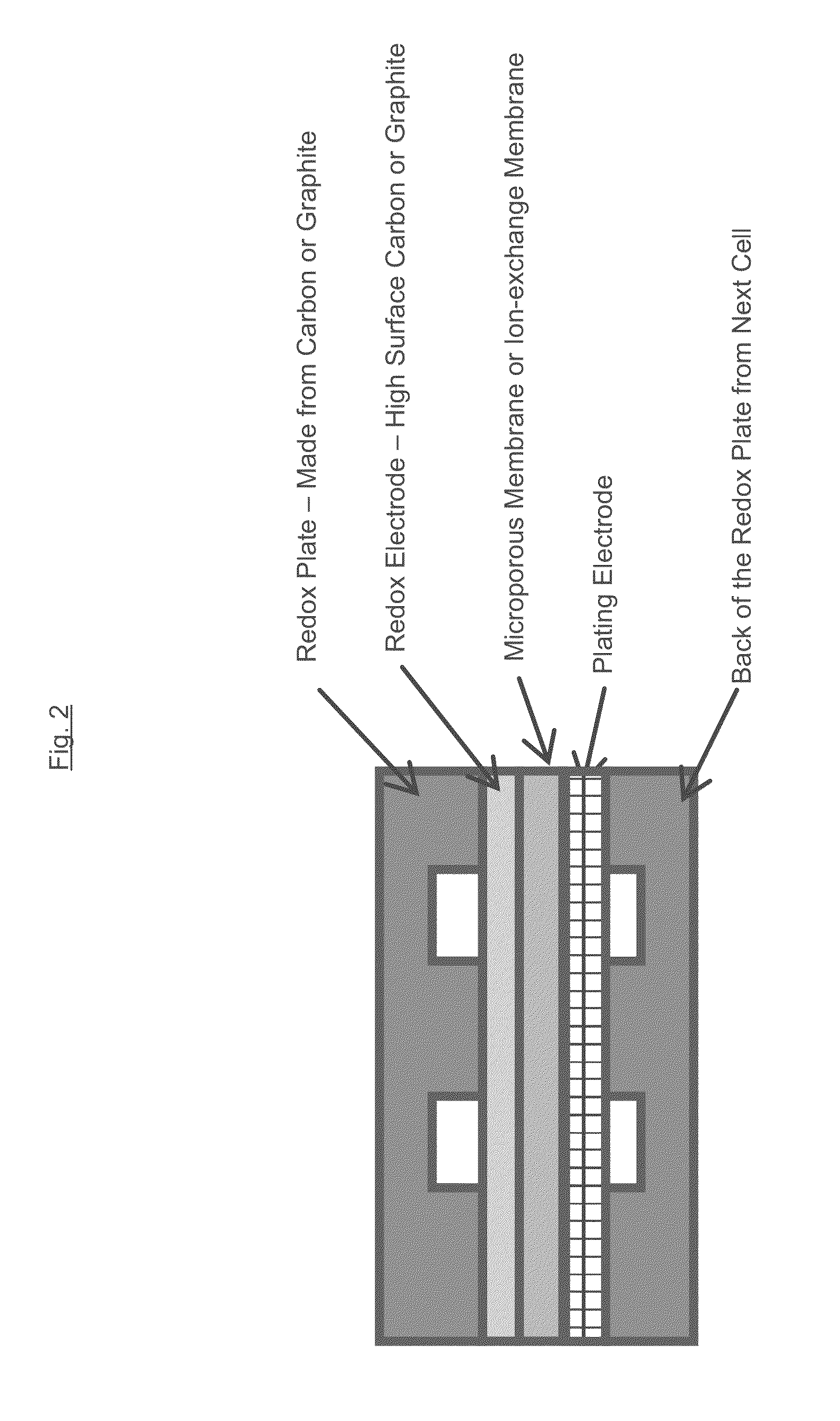

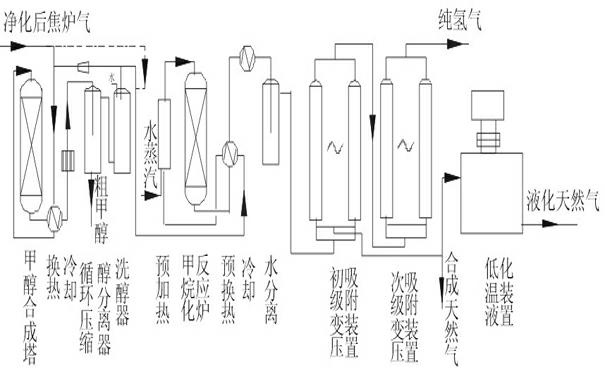

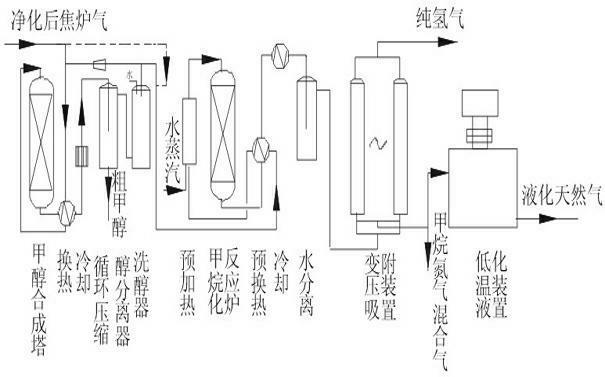

InactiveCN102585951AReduce contentLow carbon oxide contentGaseous fuelsHydrogen productionMethanationMethanol

The invention discloses a process for co-production of liquefied synthesis gas, pure hydrogen and methanol from coke-oven gas. The process comprises the steps of: (a) firstly, purifying and compressing the coke-oven gas, then enabling the gas after being subjected to the heat exchange of a heat exchange device to enter into a methanol synthesis tower for a methanol synthesis catalytic reaction, exchanging heat of discharged gas by a heat exchanger, and enabling the gas after being cooled by a cooler to enter into a methanol separator so as to obtain crude methanol; and (b) preparing refined methanol, enabling the gas to enter into a methanol washing machine, washing away trace methanol in the gas with water, enabling partial gas after being compressed by a circular compressor to turn back to the heat exchanger for methanol synthesis and enabling other gas to enter into a heat exchanger for methanation, enabling the gas to enter into a pre-heater after heat energy is recycled, adding a small amount of aqueous vapor in the pre-heater and then enabling the gas to enter into a methanation reaction furnace. According to the process disclosed by the invention, content of oxycarbide in the gas is reduced and the methanol product is obtained through resource recycling, residual small amount of oxycarbide is removed thoroughly and hydrogen resource with high value is recycled, and the obtained liquefied natural gas is convenient to transport.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Electrolytes for iron flow battery

ActiveUS20170179516A1Rapidly produceHigh charge rateRegenerative fuel cellsIndirect fuel cellsChemistryIron redox

A method of operating an iron redox flow battery system may comprise fluidly coupling a plating electrode of an iron redox flow battery cell to a plating electrolyte; fluidly coupling a redox electrode of the iron redox flow battery cell to a redox electrolyte; fluidly coupling a ductile plating additive to one or both of the plating electrolyte and the redox electrolyte; and increasing an amount of the ductile plating additive to the plating electrolyte in response to an increase in the plating stress at the plating electrode. In this way, ductile Fe can be plated on the negative electrode, and the performance, reliability and efficiency of the iron redox flow battery can be maintained. In addition, iron can be more rapidly produced and plated at the plating electrode, thereby achieving a higher charging rate for all iron flow batteries.

Owner:ESS TECHNOLOGY

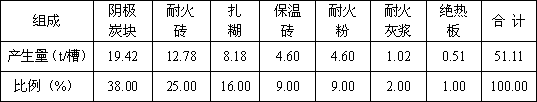

Method for recycling overhauling slag waste cathode carbon blocks of electrolytic bath

ActiveCN102992298AHigh fluorine and sulfur contentAchieve recyclingCarbon preparation/purificationElectrolysisSlag

The invention discloses a method for recycling overhauling slag waste cathode carbon blocks of an electrolytic bath. The method is characterized by comprising the following steps: separating the overhauling slag of the electrolytic bath to obtain waste cathode carbon blocks; respectively conducting water leaching to the separated waste cathode carbon blocks, conducting secondary smashing and water leaching to the separated blocks, recycling the separated blocks, grinding and floating the rest powder, and separating carbon powder from the rest powder. According to the method, fluoride salt difficultly removed from the overhauling slag waste cathode carbon blocks of the electrolytic bath can be separated, the recycling value of the overhauling slag waste cathode carbon blocks of the electrolytic bath can be improved, the overhauling slag waste cathode carbon blocks of the electrolytic bath can be changed into valuables, the overhauling slag waste cathode carbon blocks of the electrolytic bath can be economically recycled without pollution, thereby fundamentally removing the hidden pollution hazard.

Owner:周俊和 +1

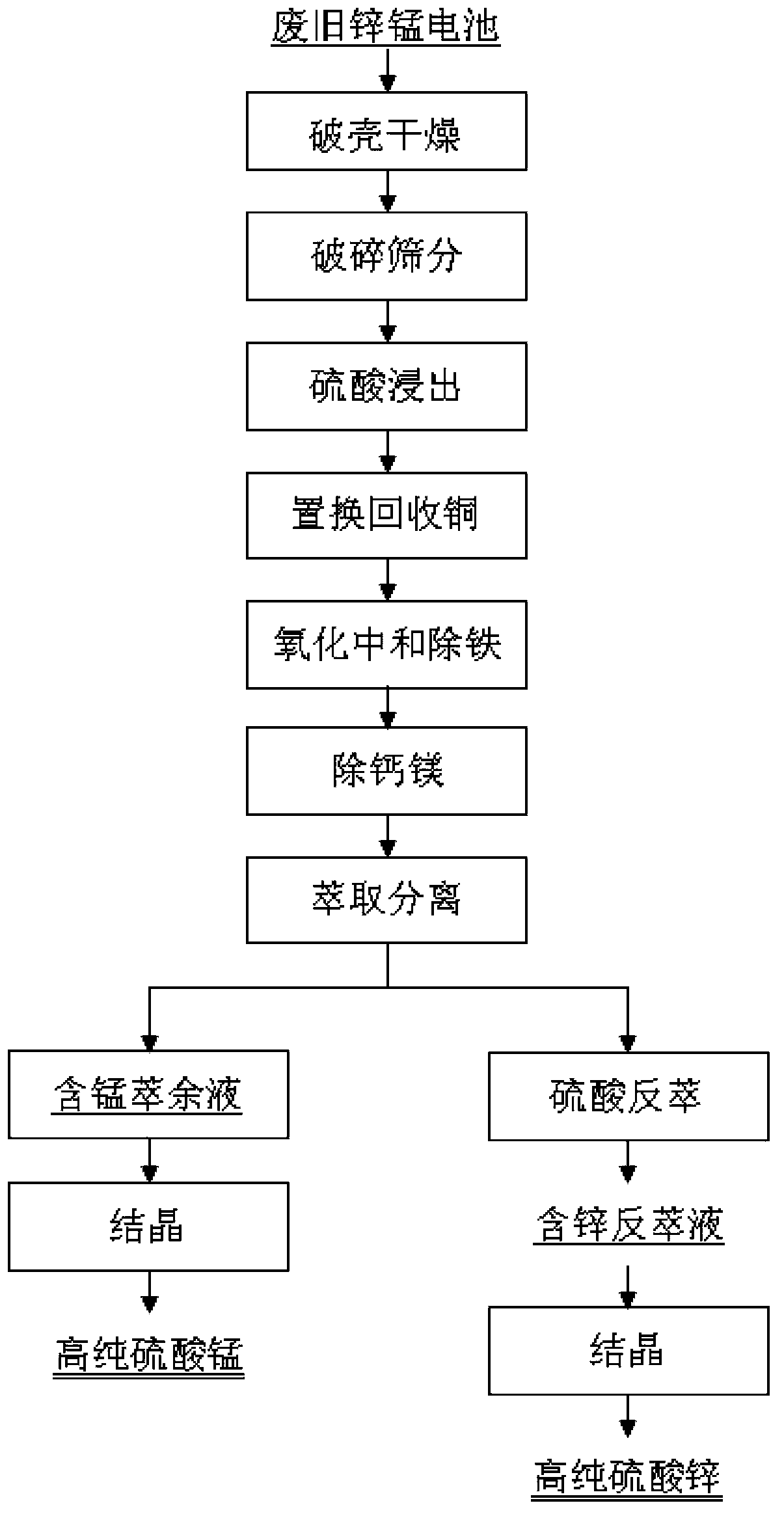

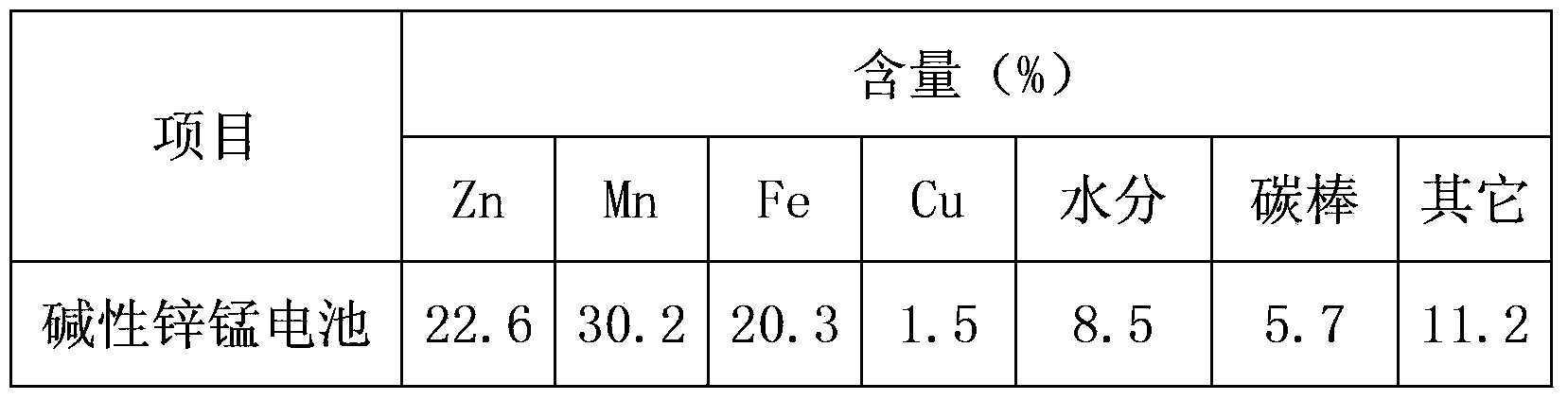

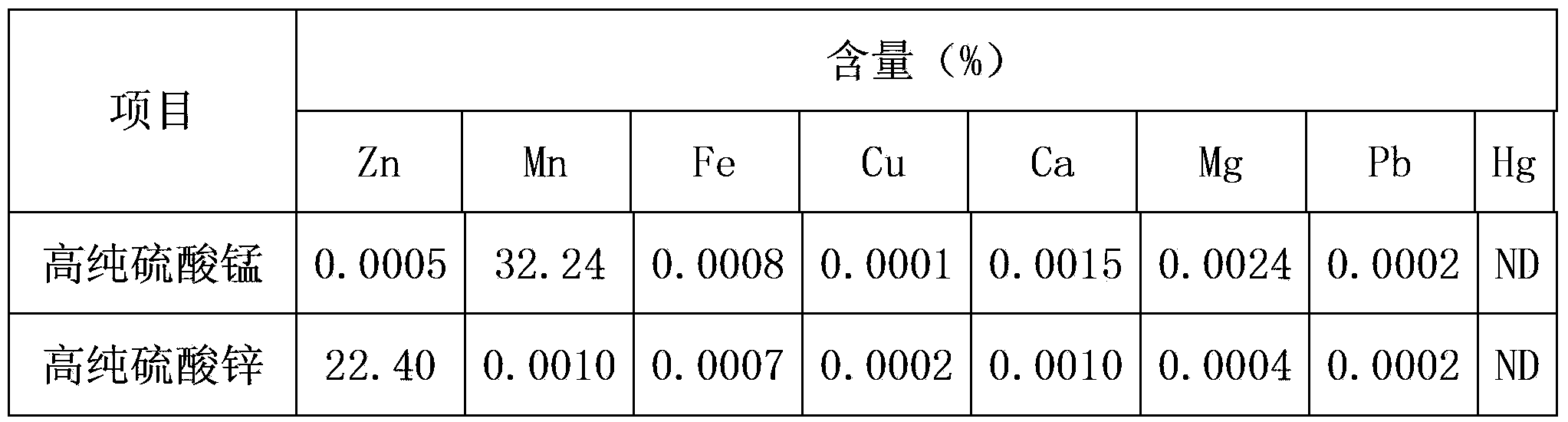

Method for preparation of high purity manganese sulfate and zinc sulfate from waste zinc-manganese batteries

ActiveCN104229898AStrong ability to useEfficient recyclingZinc sulatesManganese sulfatesChemical industryResource utilization

The invention discloses a method for preparation of high purity manganese sulfate and zinc sulfate from waste zinc-manganese batteries. Zinc-manganese batteries mainly contain manganese, zinc, iron, copper and other valuable metal components, and by means of sulfuric acid dissolution, iron powder replacement, oxidation neutralizing for iron removal, extraction purification and separation, crystallization and other processes, high purity manganese sulfate and zinc sulfate products can be prepared. The high purity manganese sulfate obtained by the invention can be used for preparation of battery materials, and the high purity zinc sulfate can be used for medicine, feed, food, chemical industry and other fields. The method provided by the invention has the characteristics of high resource utilization and recovery rate, and high product quality, etc.

Owner:HUNAN BRUNP RECYCLING TECH +1

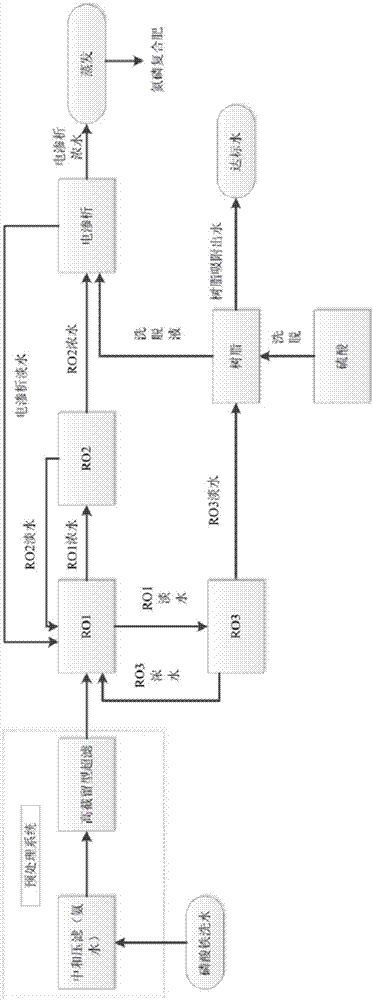

Ferric phosphate wastewater treatment process and treatment device

InactiveCN107082522ARealize resource processingIncreased efficiency of subsequent evaporationGeneral water supply conservationWater contaminantsPhosphatePhosphoric acid

The invention discloses a ferric phosphate wastewater treatment process and treatment device, wherein the treatment process comprises the following steps of (1) membrane concentration: ferric phosphate wastewater is subjected to membrane concentration to obtain concentrated water and fresh water, wherein the membrane concentration includes reverse osmosis and / or electroosmosis; (2) evaporation: the concentrated water is evaporated to recycle a nitrogen and phosphorus compound fertilizer; the evaporated concentrated liquid flow backs to the membrane concentration front end for circulation treatment; (3) resin treatment: the fresh water and evaporated condensed liquid are subjected to resin absorption treatment; resin absorption effluent is discharged in a standard reaching way or is reused for production; resin analytical liquid is subjected to membrane concentration treatment. Multistage reverse osmosis and resin absorption treatment are combined; ferric polyphosphate wastewater is subjected to desalination and ammonia and nitrogen removal step by step, so that the insulation capability of the whole treatment process on ammonia and nitrogen is higher; the ammonia and nitrogen discharging standard exceeding of effluent can be effectively avoided.

Owner:绍兴齐英膜科技有限公司

Method for recovering rare earth in neodymium-iron-boron waste by high-temperature and high-pressure leaching

The invention relates to a method for recovering rare earth in neodymium-iron-boron waste by high-temperature and high-pressure leaching. The neodymium-iron-boron waste is subjected to oxidation roasting, hydrochloric acid high-temperature and high-pressure leaching, and oxidation and impurity removal purification on Fe2+ in a leachate so as to obtain a rare-earth chloride leachate; and the rare-earth chloride leachate can be used as a subsequent process and a product raw material, rare earth is obtained through extraction and separation, rare earth carbonate is prepared through precipitation,or rare earth oxide is prepared through precipitation-roasting. According to the method, a closed high-pressure reaction kettle is adopted as leaching equipment, so that the dynamic condition of theleaching process is excellent, the requirement for the particle size of the leached raw materials is low, a large amount of dust generated by the fine grinding process of the raw materials is avoided,the leaching rate of rare earth in the leaching process is high, the utilization rate of hydrochloric acid is high, no acid gas is discharged, energy is saved, and the environment is protected; and in addition, the method has the advantages of being short in process flow, simple in process conditions and low in recovery cost, and the method has considerable economic, social and environmental protection benefits for large-scale recovery of the neodymium-iron-boron waste.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

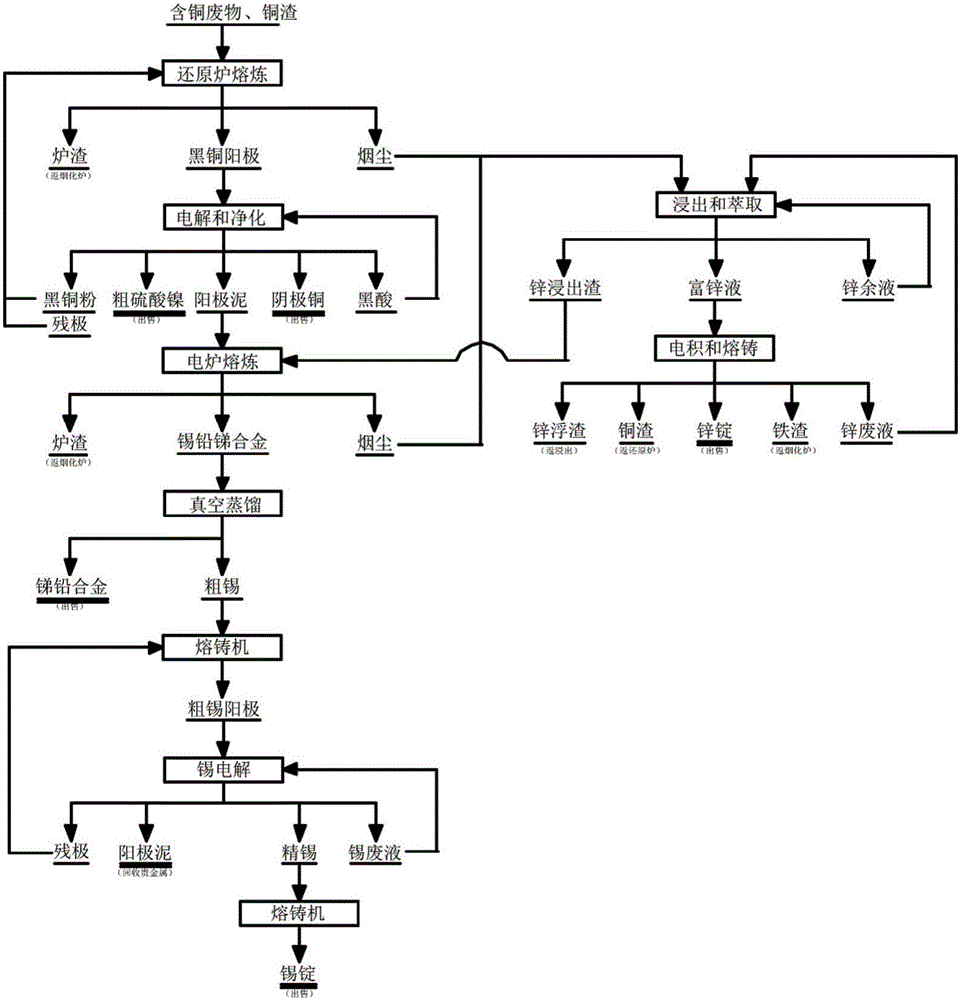

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

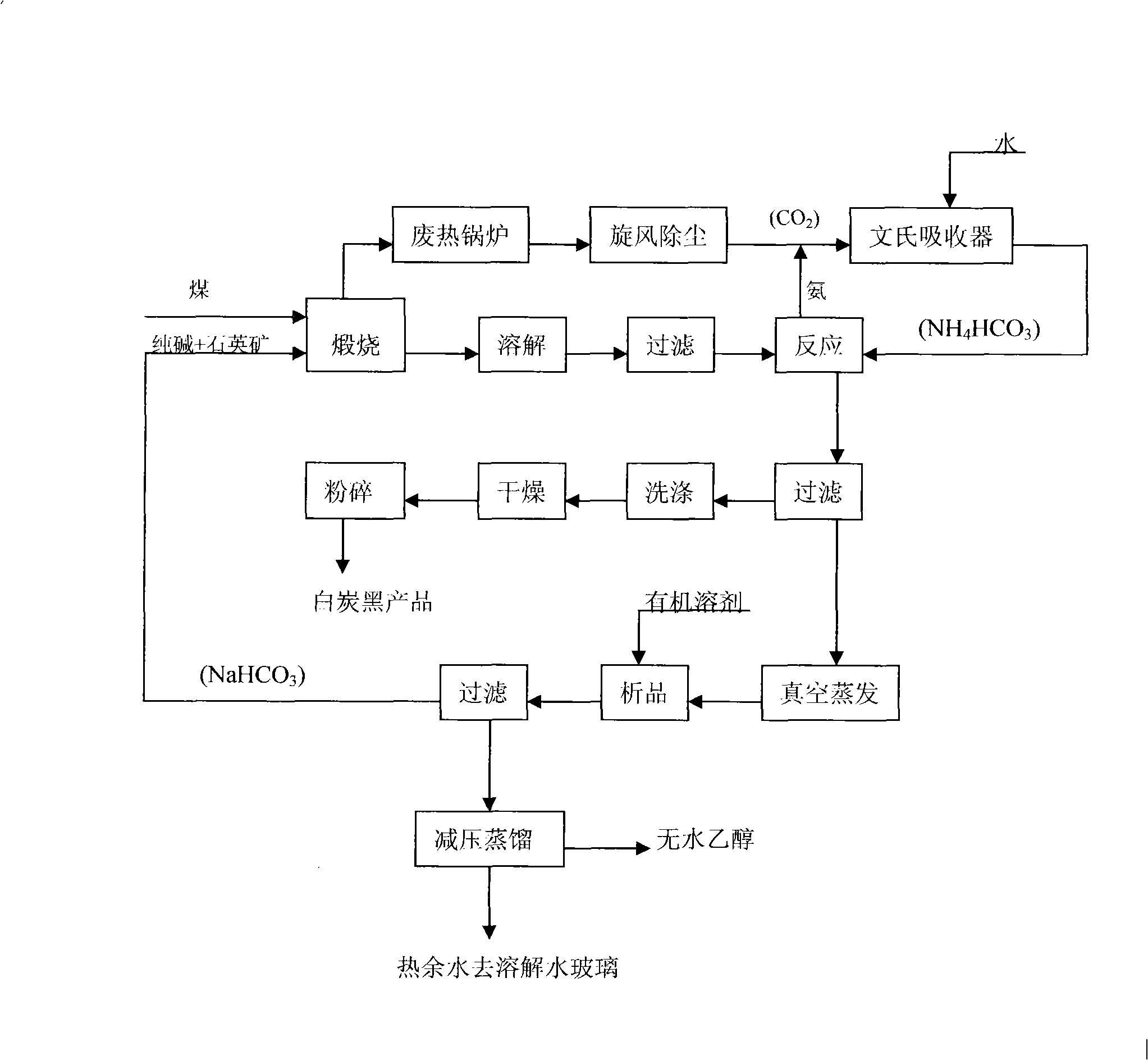

Circulation novel process for preparing white carbon black

InactiveCN101323453AAddressing effective recyclingHigh recycling valueSilicaSodium bicarbonateOrganic solvent

The invention relates to a new cycle technique for preparing white carbon black, comprising the following steps: 1) a water glass solution reacts with an ammonium hydrogen carbonate solution or solid ammonium hydrogen carbonate in the condition of the temperature of 30 to 50 DEG C, the white carbon black is obtained and ammonia escapes simultaneously; 2) the ammonia escaped from the step 1) is mixed with CO2 gas produced in the process of the preparation of the water glass solution and the obtained mixture is absorbed by water to obtain the ammonium hydrogen carbonate; 3) the white carbon black produced by reaction is filtered under the condition of vacuum to obtain a mother liquid A and a filter cake A, the mother liquid A is recovered and the filter cake A is washed, dried and crushed so as to obtain the white carbon black. The invention 1) solves the effective recovery of by-products in the production process, is used for self-production, improves the utilization value of materials, without three wastes discharge in the production process, and has high material utilization rate, good effect of discharge reduction and stable and reliable quality of products; 2) recovery of sodium bicarbonate is carried out after the mass concentration is increased by the evaporation in vacuum at low temperature, thus reducing the usage of organic solvent.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of reed-based biochar adsorption material

InactiveCN108970583AStrong pollutant adsorption capacityRealize the utilization of waste resourcesOther chemical processesAlkali metal oxides/hydroxidesChemistryNitrogen gas

The invention relates to a preparation method of a reed-based biochar adsorption material. The preparation method is technically characterized by comprising the following steps of cleaning the reed stalk, drying and crushing; soaking the crushed reed stalk into a KOH (potassium hydroxide) solution to activate, and drying; putting the dried crushed reed stalk into an atmosphere furnace, and performing oxygen-free high-temperature cracking under the nitrogen or inert gas protection atmosphere; after high-temperature cracking treatment, cooling to room temperature, and cleaning the cracked material to be neutral by an acid solution, so as to prepare the reed-based biochar adsorption material. The preparation method has the advantages that the problems of pollution to environment and waste ofresources due to irresponsible disposal of the wetland plant wastes are solved; compared with the prior art, the specific surface area is large, the pollutant adsorption ability is strong, the environment-friendly value is greatly increased, and the resource utilization of the wastes is realized.

Owner:SHENYANG ACAD OF ENVIRONMENTAL SCI

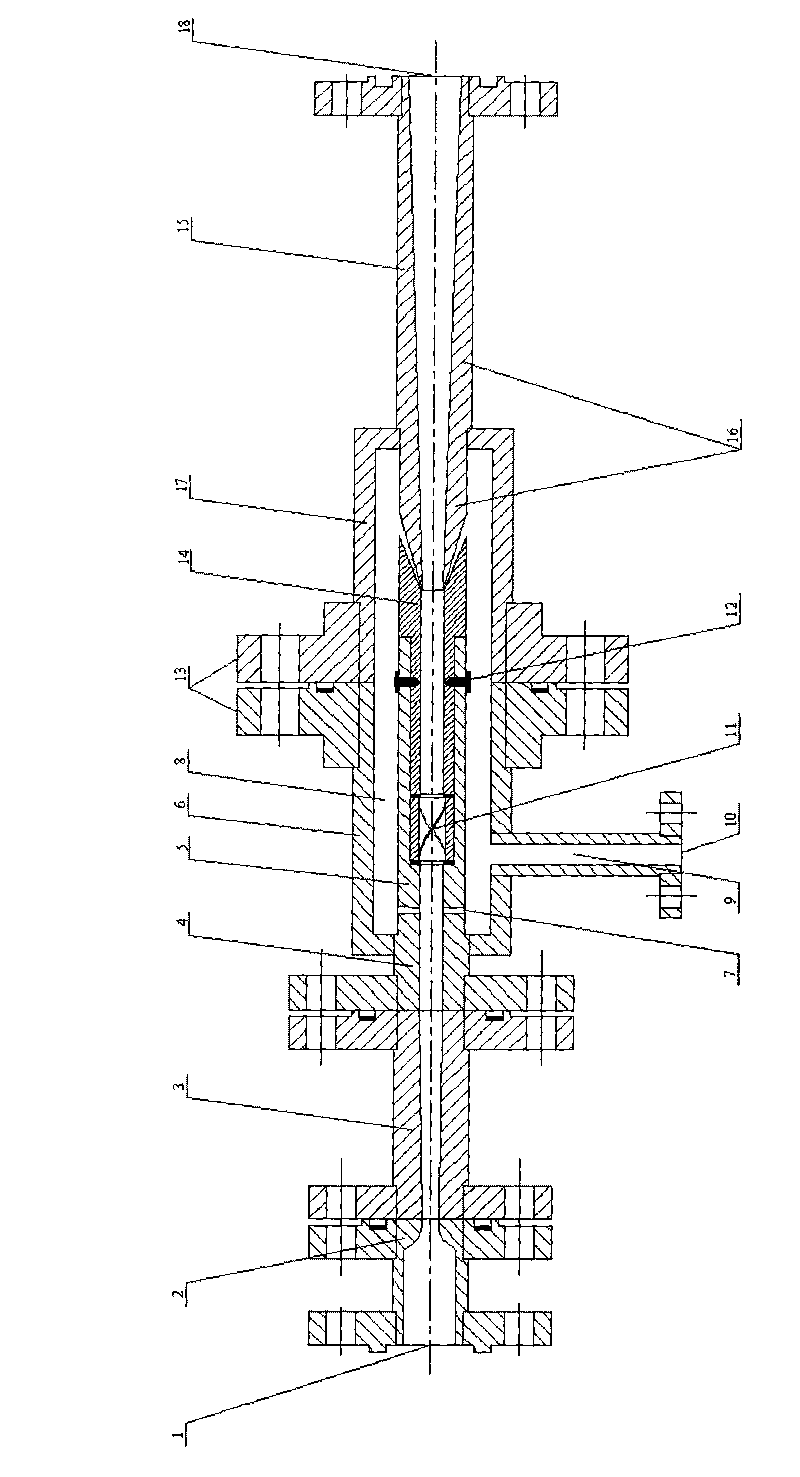

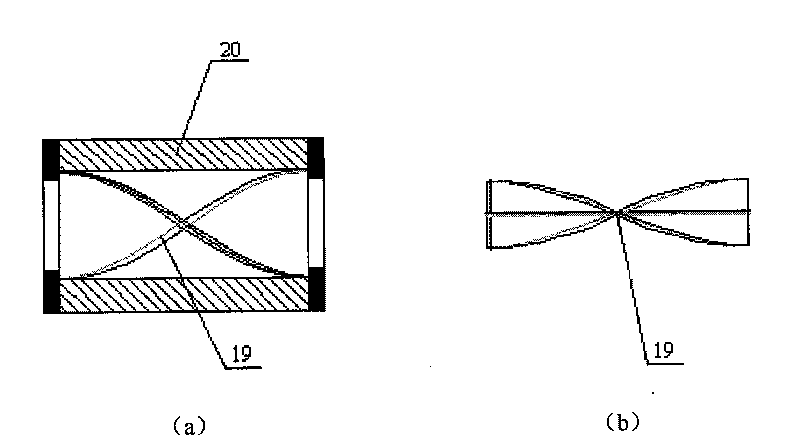

Moisture recycling supersonic speed gas-purification separation device

InactiveCN101690865AEfficient purificationEfficient separationDispersed particle separationFluid removalEngineeringMoisture recycling

The invention relates to a moisture recycling supersonic speed gas-purification separation device for moisture recycling, dehydration, liquid removal, purification and separation; the device comprises a convergent divergent nozzle, a recycling port, a recycling separation cavity, a straight length and a diffuser pipe; the left end of a tapering section of the convergent divergent nozzle is provided with a moisture inlet, the right end thereof is connected with an inner shell body in the straight length by the diverging section of the convergent divergent nozzle, a swirler is arranged in the inner shell body of the straight length, and the right end of the swirler is provided with a swirler fixed sleeve which is hollow, and the right end of the swirler fixed sleeve and the left end of the inner shell of the diffuser pipe form a ring-shaped channel. The recycling separation cavity is formed between the straight length and the diffuser pipe, the recycling port is arranged on the wall surface of the inner shell body of the straight length, so as to effectively lead liquid drops in the remaining recycling gas to be separated out in a swirling way. The device realizes moisture recycling, purification and separation, so as to improve the separation efficiency and environmental-protection benefit; furthermore, the device has the advantages of no chemical pollution, environmental protection and energy saving, compact structure and high circulating and utilizing value.

Owner:SICHUAN ZHONGKEDA OIL&GAS NEW TECH

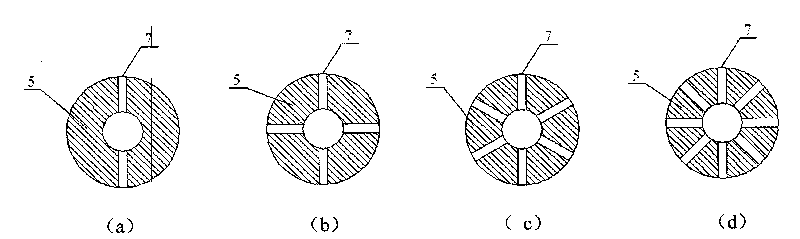

Red mud superconducting high-gradient magnetic separator

InactiveCN101837321AHigh in ironHigh recycling valueHigh gradient magnetic separatorsChemical industryRed mud

The invention discloses a red mud superconducting high-gradient magnetic separator which aims to solve the problem of low magnetic separation efficiency of the traditional magnetic separator. The red mud superconducting high-gradient magnetic separator comprises a superconducting magnet, a separator and a drive device, wherein the superconducting magnet is used for generating a background magnetic field; the separator is provided with two separating chambers connected into a whole, and each separating chamber is a closed container provided with a slurry inlet, a slurry outlet, a rinse water inlet and a rinse water outlet; both ends of the separator are respectively provided with a supporting guide rail; and the drive device is used for driving the two separating chambers to alternately enter and exit the background magnetic field along the guide rails. The red mud superconducting high-gradient magnetic separator can be used for various occasions such as the iron removal of kaolin, the iron removal before smelting metallic ores, the iron removal of chemical industry raw materials, and the like and is broad-spectrum equipment for removing iron by utilizing a strong magnetic field.

Owner:王小军

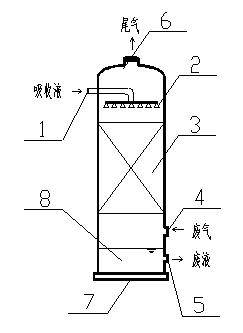

Method for preparing ammonia water and calcium chloride solution through decomposition recovery of ammonium chloride waste liquor

InactiveCN104876383ASimple processEmission reductionCalcium/strontium/barium chloridesWater contaminantsHigh concentrationLiquid waste

The invention discloses a method for preparing ammonia water and calcium chloride solution through the decomposition recovery of ammonium chloride waste liquor. The method comprises the following steps: the waste liquor is pretreated, and ammonium chloride and calcium oxide or calcium hydroxide powder is added into the pretreated ammonium chloride waste liquor; ammonia is distilled from the treated ammonium chloride waste liquor and is transferred into an ammonia absorption tower after being condensed, and a reaction liquid flows out from the bottom of a distillation tower; ammonia is absorbed from the condensed ammonia in the absorption tower by using desalted water, and the tail gas is exhausted after residual ammonia is washed by a tail gas washing tower; reaction liquid out of the bottom of the distillation tower is subjected to flash vaporization for recycling the energy and then is transferred into a clarifying barrel, and the clarified calcium chloride supernatant is used as the target product. According to the invention, the method is particularly suitable for the transformation of ammonium chloride wastewater treatment technology of enterprises in the existing rare earth industry, potassium carbonate industry and baking soda industry, and is simple in process; the ammonia is recycled by using desalted water through multi-stage absorption, and the recovery rate is up to 99%; the high-concentration calcium chloride solution can be used for producing calcium chloride products and the products can be recycled so as to have better economic benefits.

Owner:江苏大江干燥设备有限公司

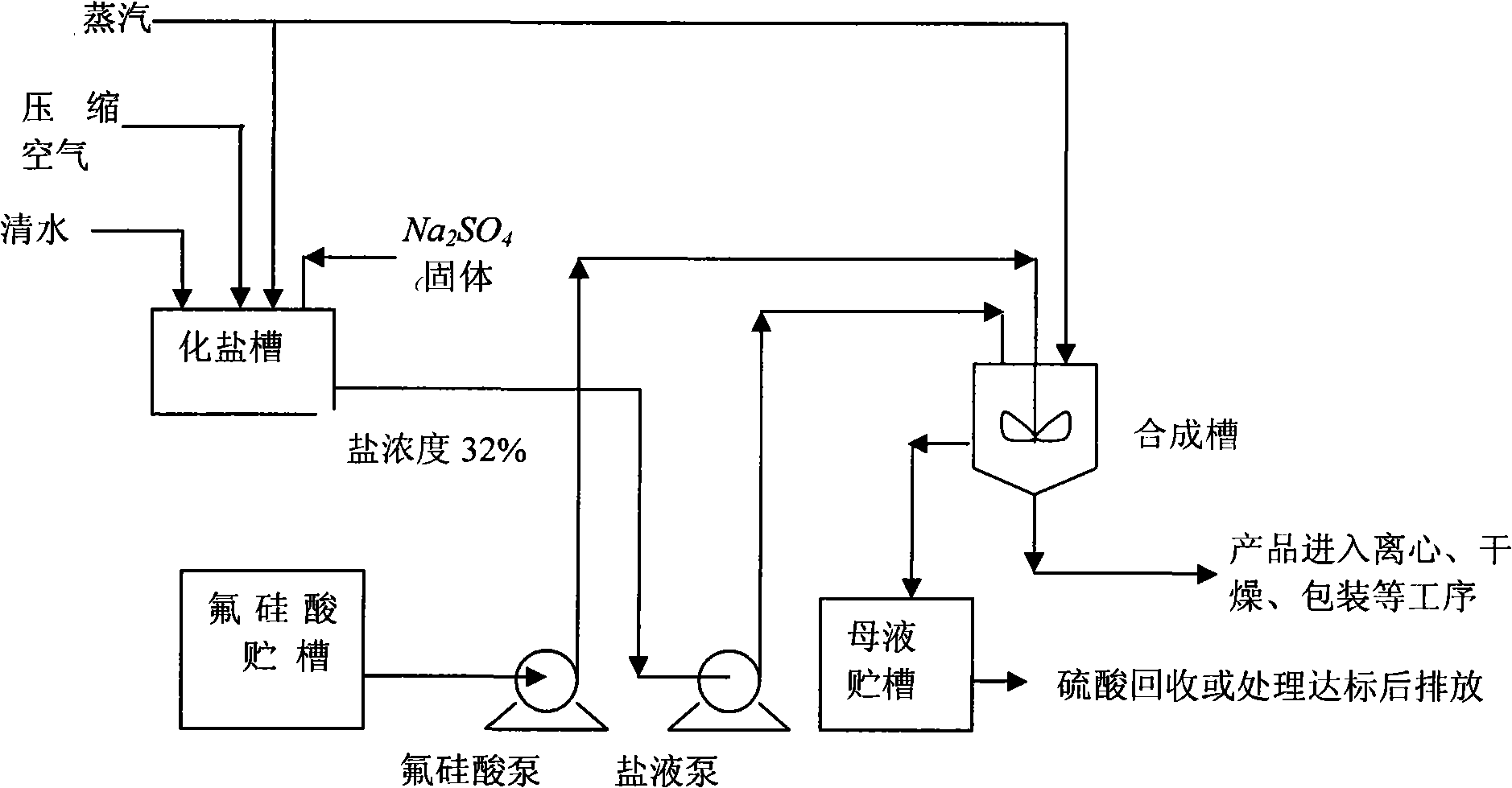

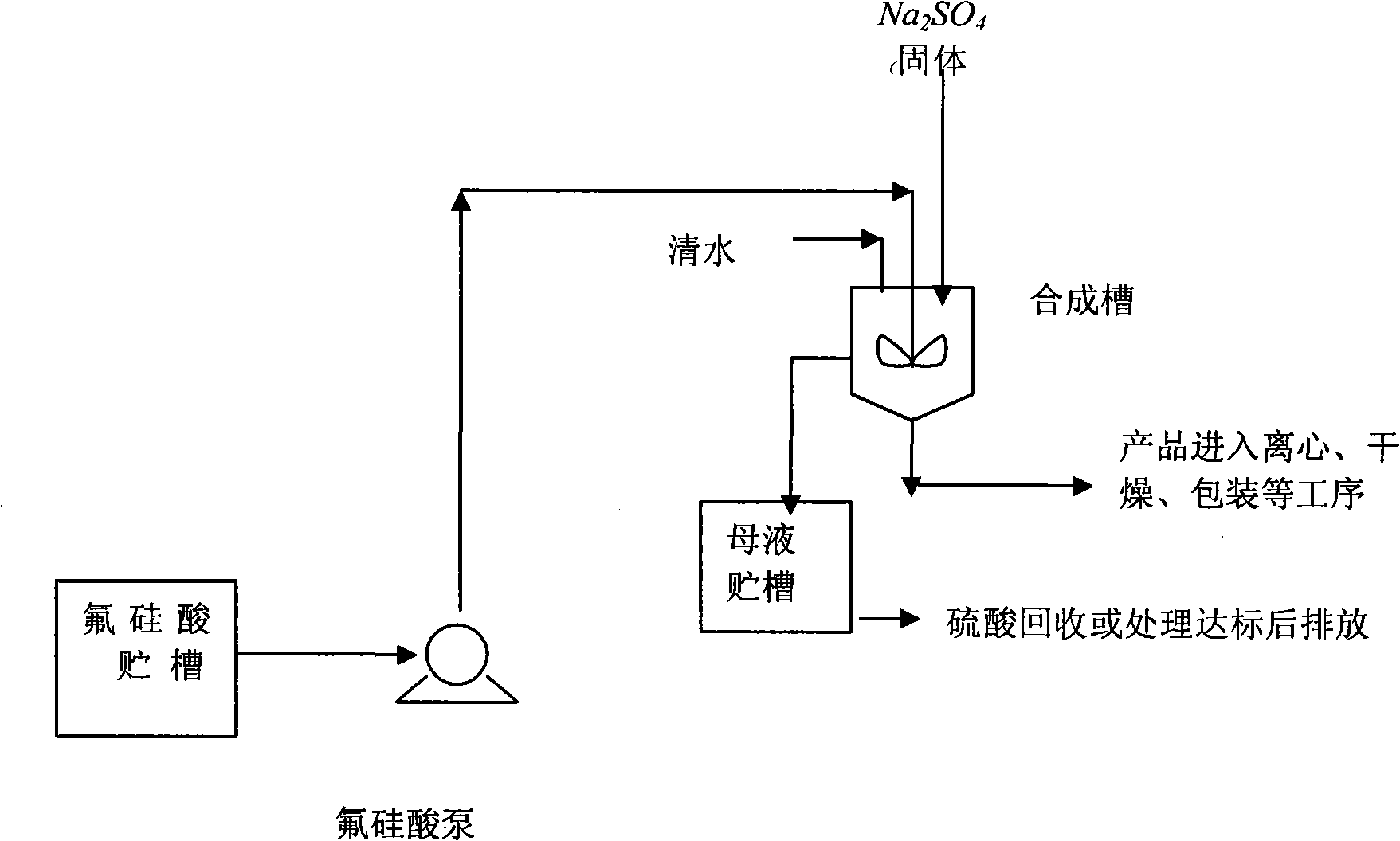

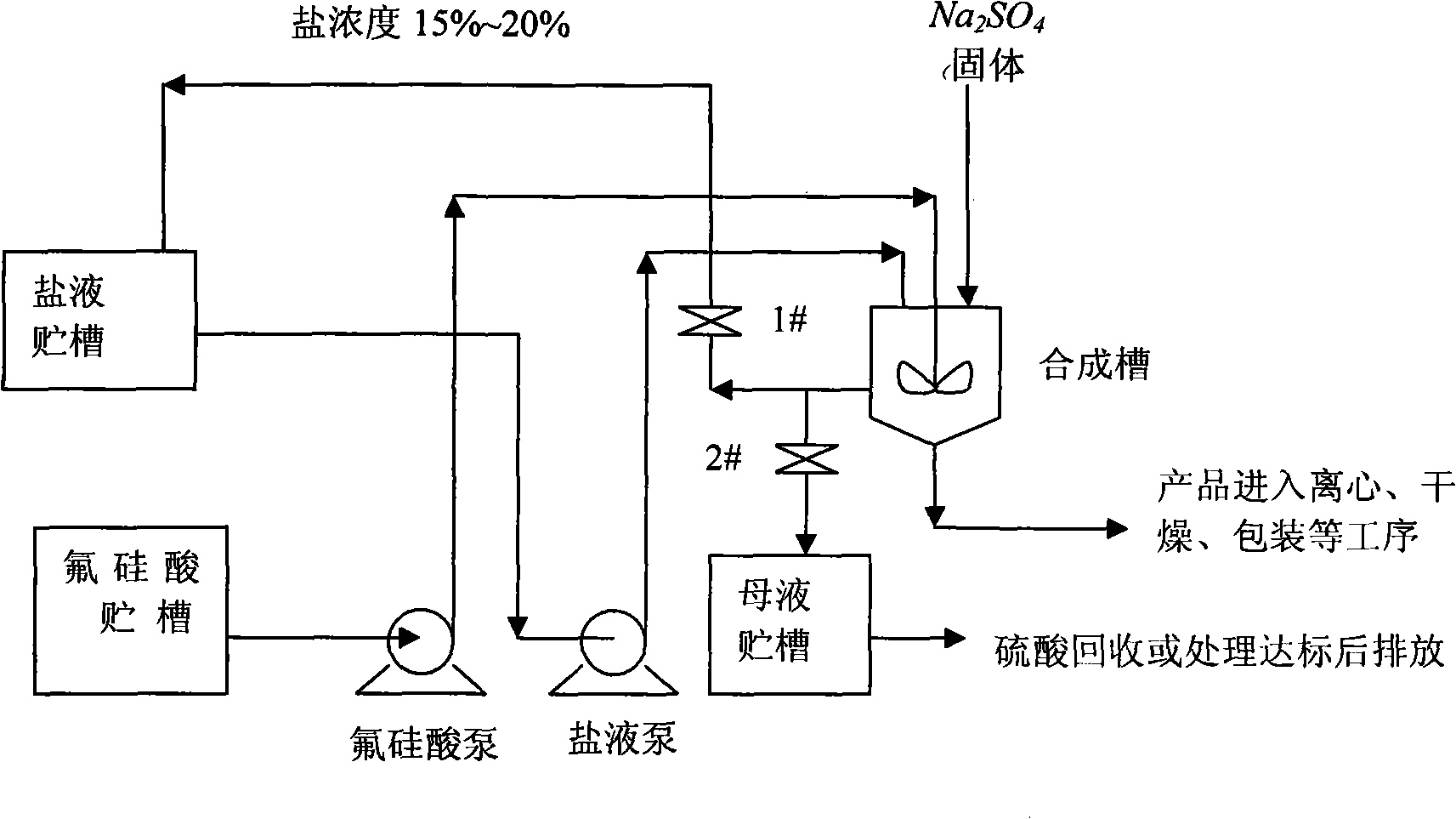

Preparation process of prodan by sodium sulfate method

InactiveCN101284669AHigh recycling valueSave compressed airAlkali metal silicatesChemistrySodium fluosilicate

The invention discloses a process for producing sodium fluosilicate by using sodium sulfate, which comprises the following steps: (1) subjecting the solution of hydrofluorosilicic acid and sodium sulfate with the mol ratio of 1:1.0 to 1.2 to reaction and crystallization; (2) adding solid sodium sulfate to the reaction solution for salt dissolution till the mass percent concentration of the sodium sulfate reaches 15 to 20%; (3) separating the sodium fluosilicate; (4) subjecting the mother solution slating liquid to a circulated process of salt dissolution and reaction. The method utilizes the water of the hydrofluorosilicic acid, saves a large part of water for the salt dissolution and reduces the production of sewage; the salt dissolution by the mother solution is to continue to add excess amount of salt so as to continue to enlarge the size of hydrofluorosilicic acid crystals and increase the precipitation quantity. The utilization rate of the hydrofluorosilicic acid can reach to above 96%, which is far higher than the level of around 80% by prior solution method.

Owner:NORTHWEST UNIV

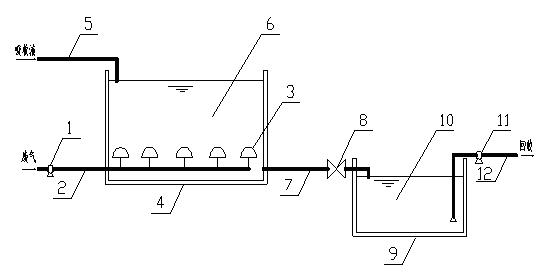

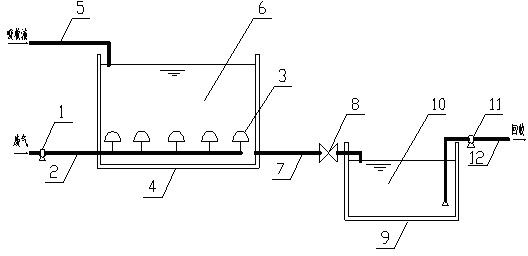

Method for exhaust gas purification

InactiveCN102319534AHigh saturation concentrationHigh recycling valueDispersed particle separationAbsorption cellHigh energy

The invention discloses a novel method for exhaust gas purification. The method comprises the following steps that 1) exhaust gas is fed into a microporous aerator 3 arranged at the bottom of an absorption cell 4 by a fan 1, is adequately diffused and then is fed to the absorption cell 4; 2) an absorption solution 6 matched with the exhaust gas is filled into the absorption cell 4; the exhaust gas passes through the microporous aerator 3, then forms tiny bubbles and enters the absorption solution 6; and the exhaust gas is diffused gradually in the absorption solution 6 from bottom to top to be absorbed fully in the absorption liquid 6 which is static relatively. The novel method for exhaust gas purification can absorb and treat exhaust gas efficiently and thoroughly, has high saturated concentration of an absorption solution and high recycle values, and overcomes the defects of high structure adopted by the existing spray absorption method, high energy consumption, low efficiency and incomplete absorption.

Owner:JIANGXI JDL ENVIRONMENTAL PROTECTION CO LTD

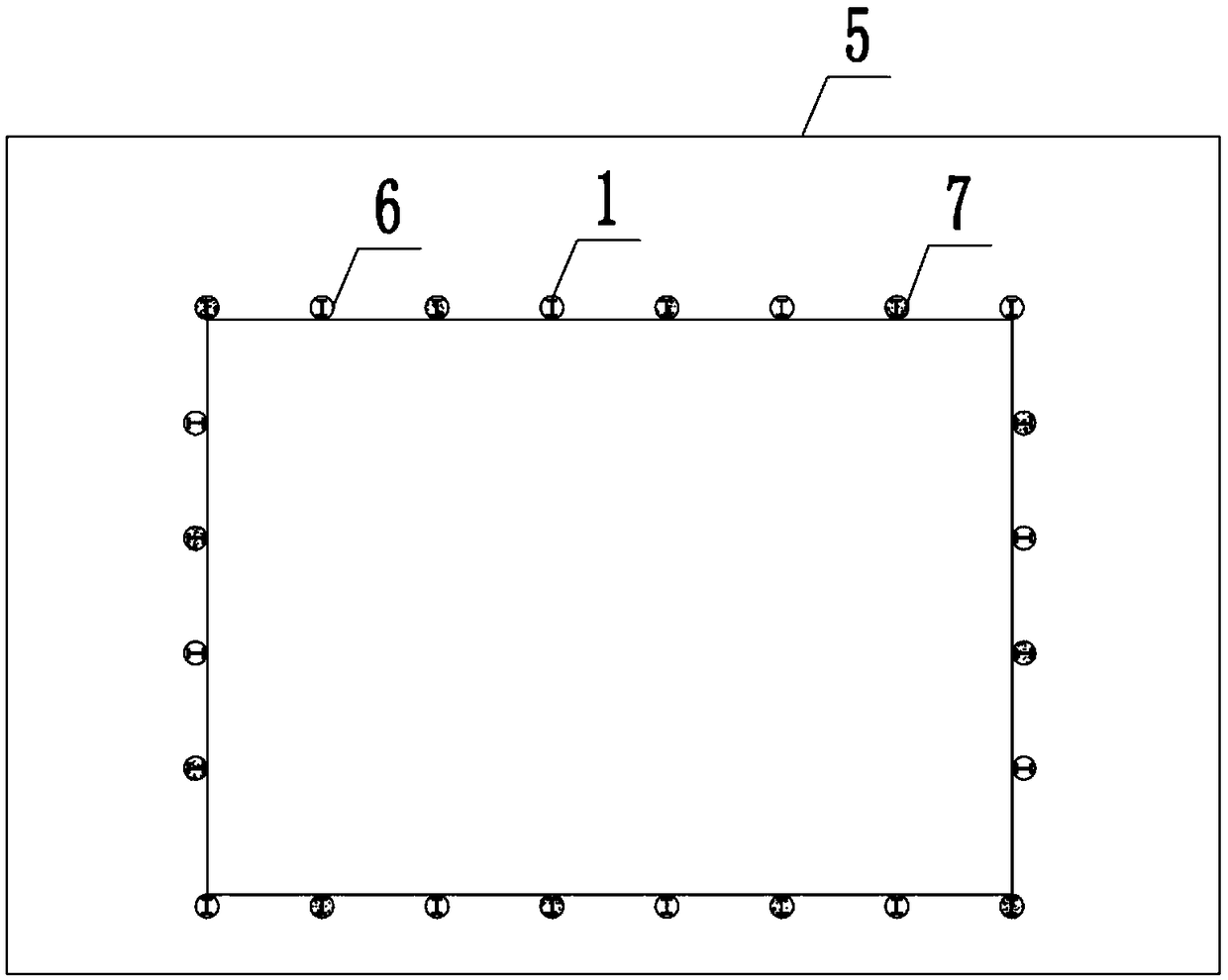

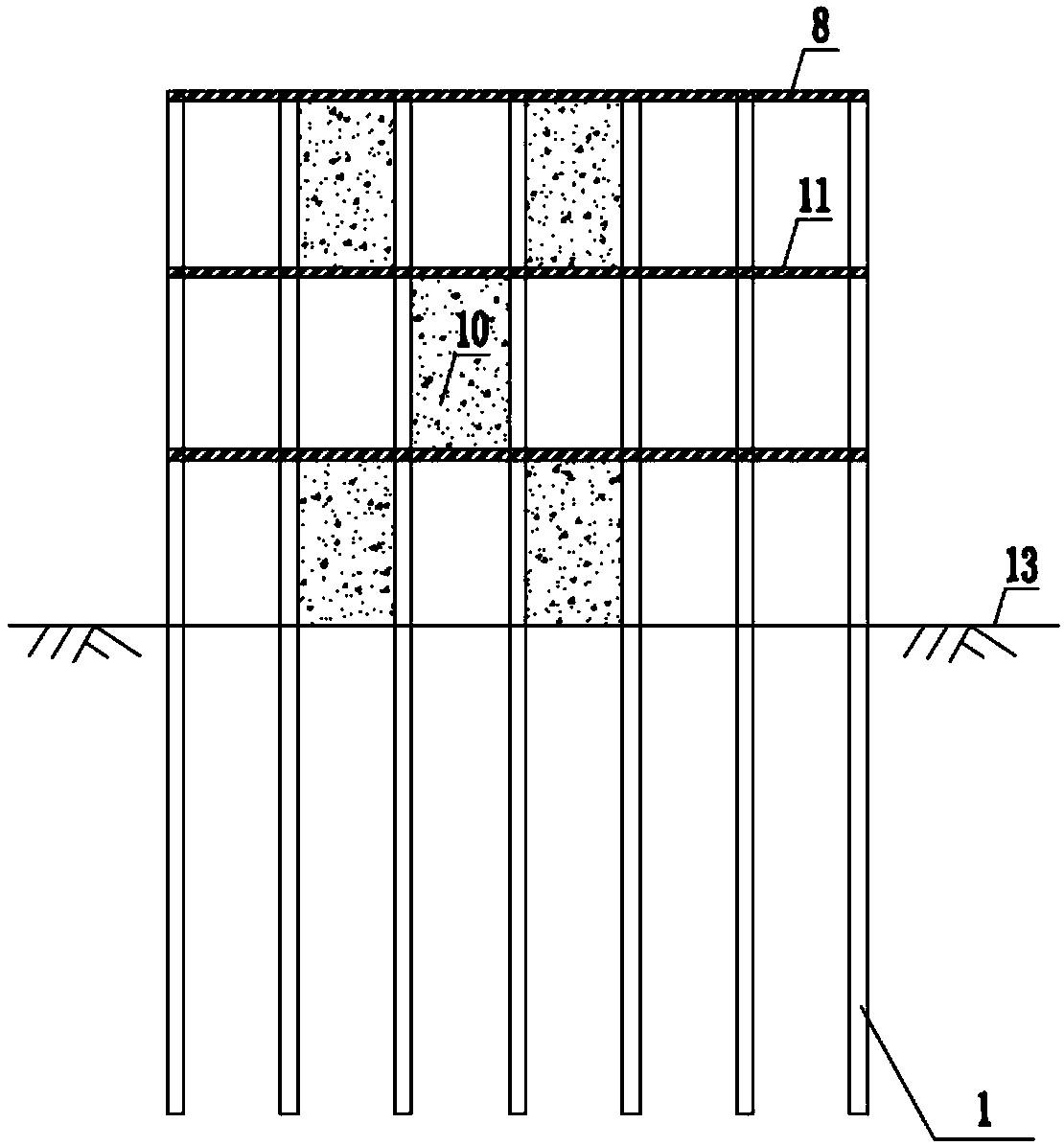

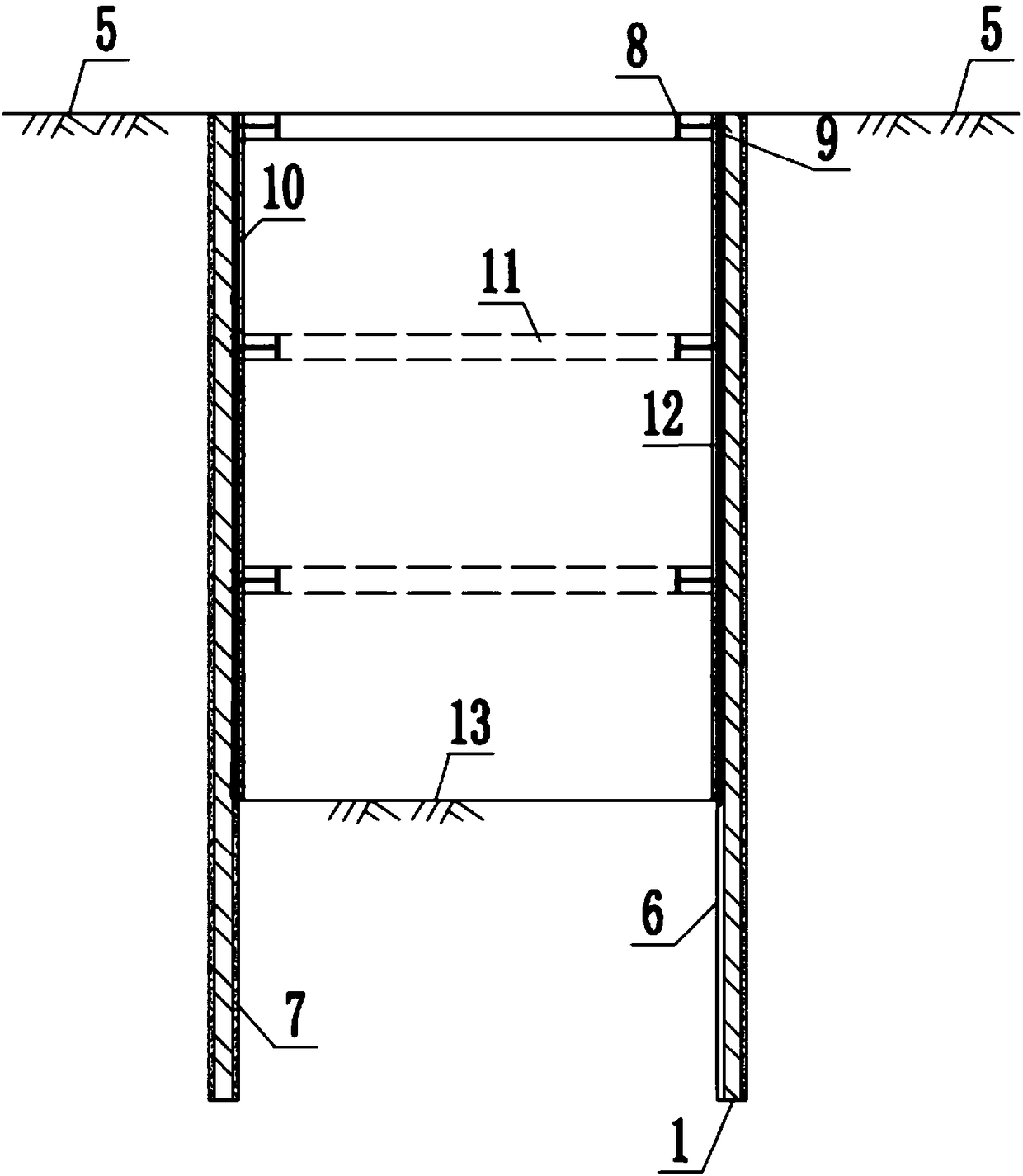

Design construction method of flexible compound fabricated recoverable rectangular working well supporting structure

InactiveCN109056746AMeet the positioning and installation accuracy requirementsAdvanced technologyExcavationsStructure systemHigh polymer

The invention relates to a standardized design construction method of a flexible compound fabricated recoverable rectangular working well supporting structure. The method comprises the following stepsthat (1) construction of minisize supporting piles is carried out; (2) construction of pile top crown beams; (3) a rectangular working well is excavated, panels and waist beams are installed, and high polymers are poured to side walls for sealing; (4) excavation is carried out layer by layer sequentially in the vertical direction, and the step (3) is carried out repeatedly till the design depth is met, that is, construction of the rectangular working well supporting structure is completed accordingly; and (5) after the supporting structure fulfills the usage function, the supporting structurerecovery work can be carried out as the backfilling work is started. Through standardized design construction of the established supporting structure system, one supporting structure can meet the construction requirement of most rectangular working wells in a region, the advantages of safety, reliability, quick and convenient construction, advanced technologies, high recoverability, superior economic indicators and the like are achieved, and the application and development prospects are considerable.

Owner:南方工程检测修复技术研究院

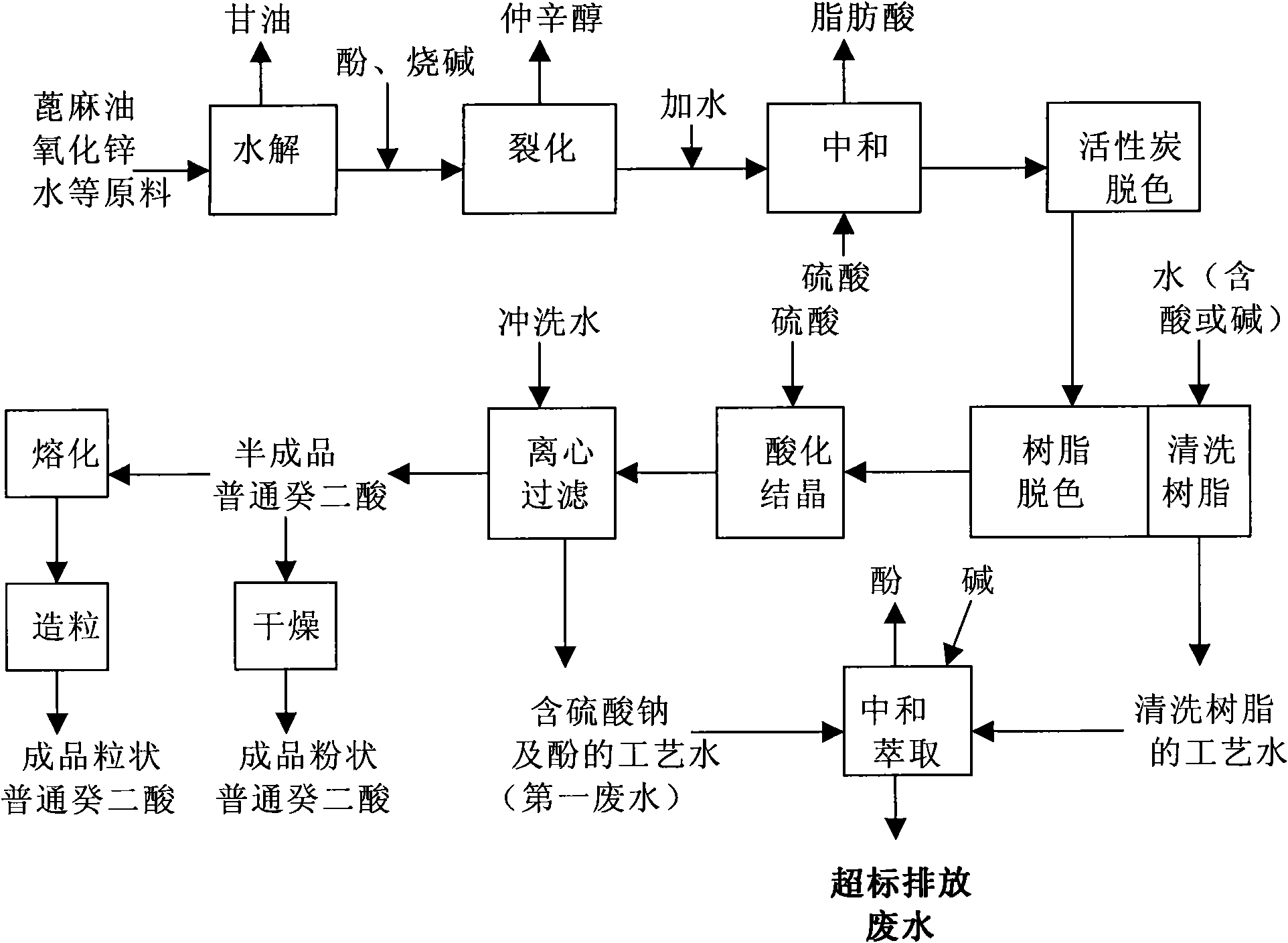

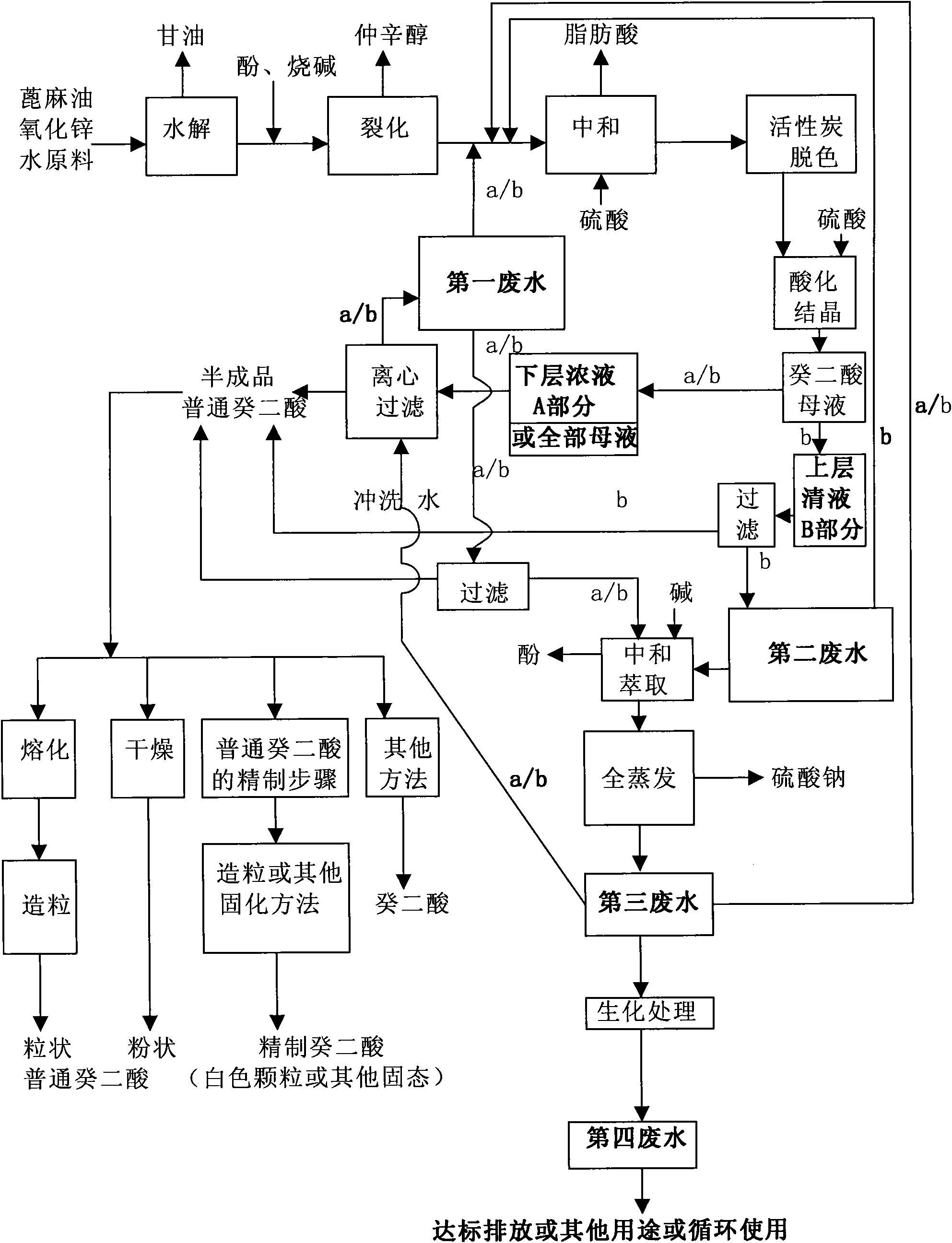

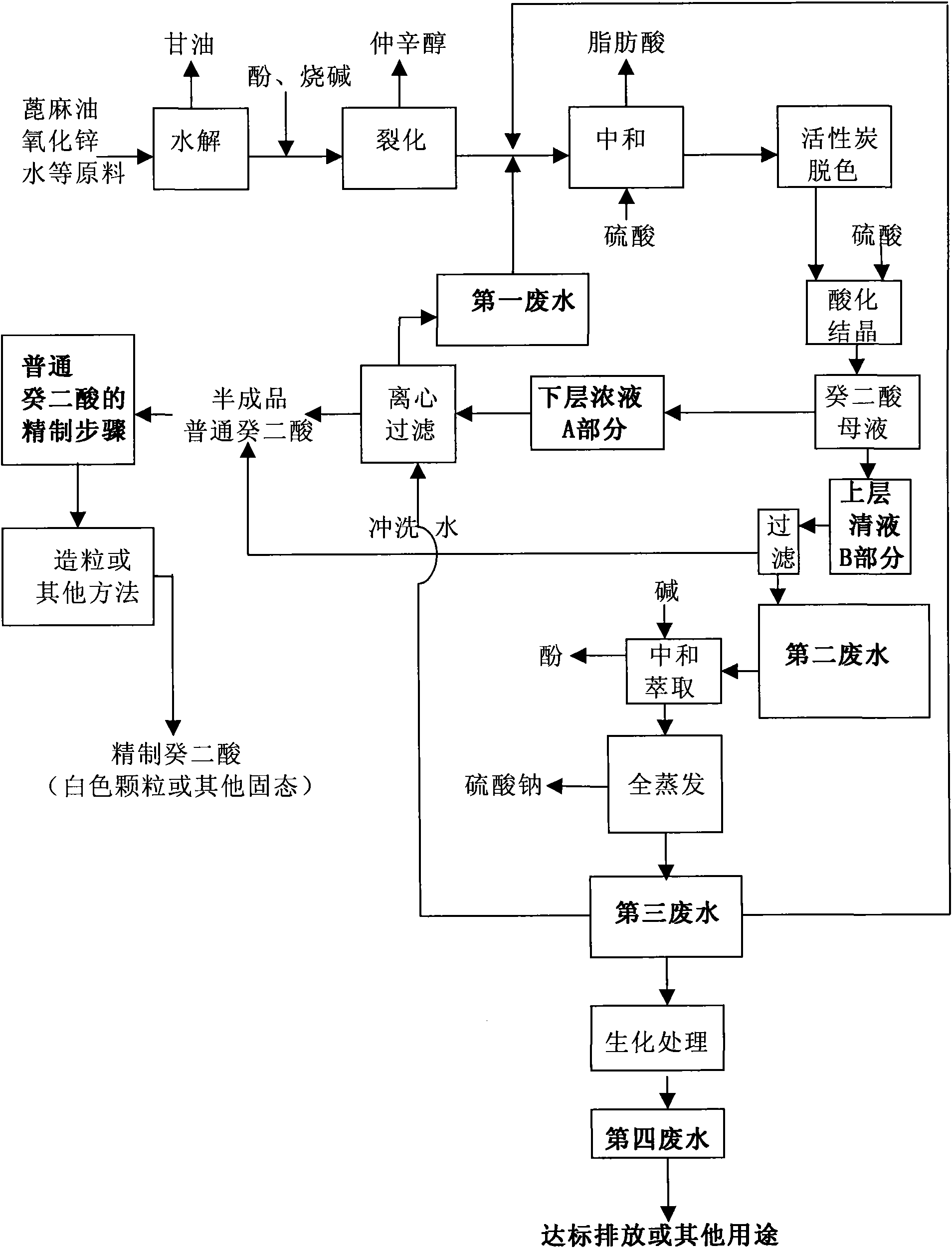

Reusable method of decanedioic acid phenol-containing wastewater

InactiveCN101575152AReduce water consumptionSave resourcesWater contaminantsMultistage water/sewage treatmentWastewaterPervaporation

The invention provides a reusable method of decanedioic acid phenol-containing wastewater, which comprises the following steps: providing decanedioic acid mother liquid which is prepared by neutralizing and acidating and crystallizing a sebacate solution; carrying out solid-liquid separation to the mother liquid to obtain a decanedioic acid solid and first wastewater, reusing the first wastewater, for example, part of the first wastewater is recycled to be used in a neutralization step; neutralizing and extracting balance of the first wastewater, removing phenol, performing pervaporation and removing by-product which is sodium sulfate to obtain third wastewater that is recycled to be used in the neutralization step or as flushing water in a centrifugal filtration step or is biologically treated to obtain fourth wastewater satisfying the discharge standard; or laminating the decanedioic acid mother liquid to obtain lower layer dope (part A) which contains crystallized decanedioic acid and upper clear solution (part B); carrying out solid-liquid separation to the lower layer dope (part A) which contains crystallized decanedioic acid to obtain the decanedioic acid solid and the first wastewater; carrying out solid-liquid separation to the upper clear solution (part B) to obtain the decanedioic acid solid and second wastewater; and reusing the first wastewater and the second wastewater.

Owner:上海芝东商务咨询有限公司

Method for preparing silk protein composite cellulose fibers

ActiveCN102505170AHigh recycling valueLow viscosityArtificial filaments from viscoseProtein solutionSulfonate

The invention discloses a method for preparing silk protein composite cellulose fibers, which includes steps: firstly, adding degummed waste silk into LiBr solution, dissolving the waste silk to prepare silk protein solution in which silk protein accounts for 3-15%, by weight; secondly, adding the silk protein solution into sodium hydroxide solution with cellulose sulfonate to obtain blended solution of silk protein and cellulose, wherein blended silk protein solution accounts for 5-50% of that of the sodium hydroxide with cellulose sulfonate by weight; and thirdly, spinning the blended solution by coagulating bath and obtaining the silk protein composite cellulose fibers by post-processing. By the method, recovery value of the waste silk is improved greatly, special effects of whitening and skin caring of the silk protein composite cellulose fibers can be realized, and the fibers are smooth and soft to touch as silk, and have the skin caring and whitening effects that the effects of protein powder fibers or blended fibers of protein powder and cellulose solution cannot match.

Owner:赛得利(盐城)纤维有限公司

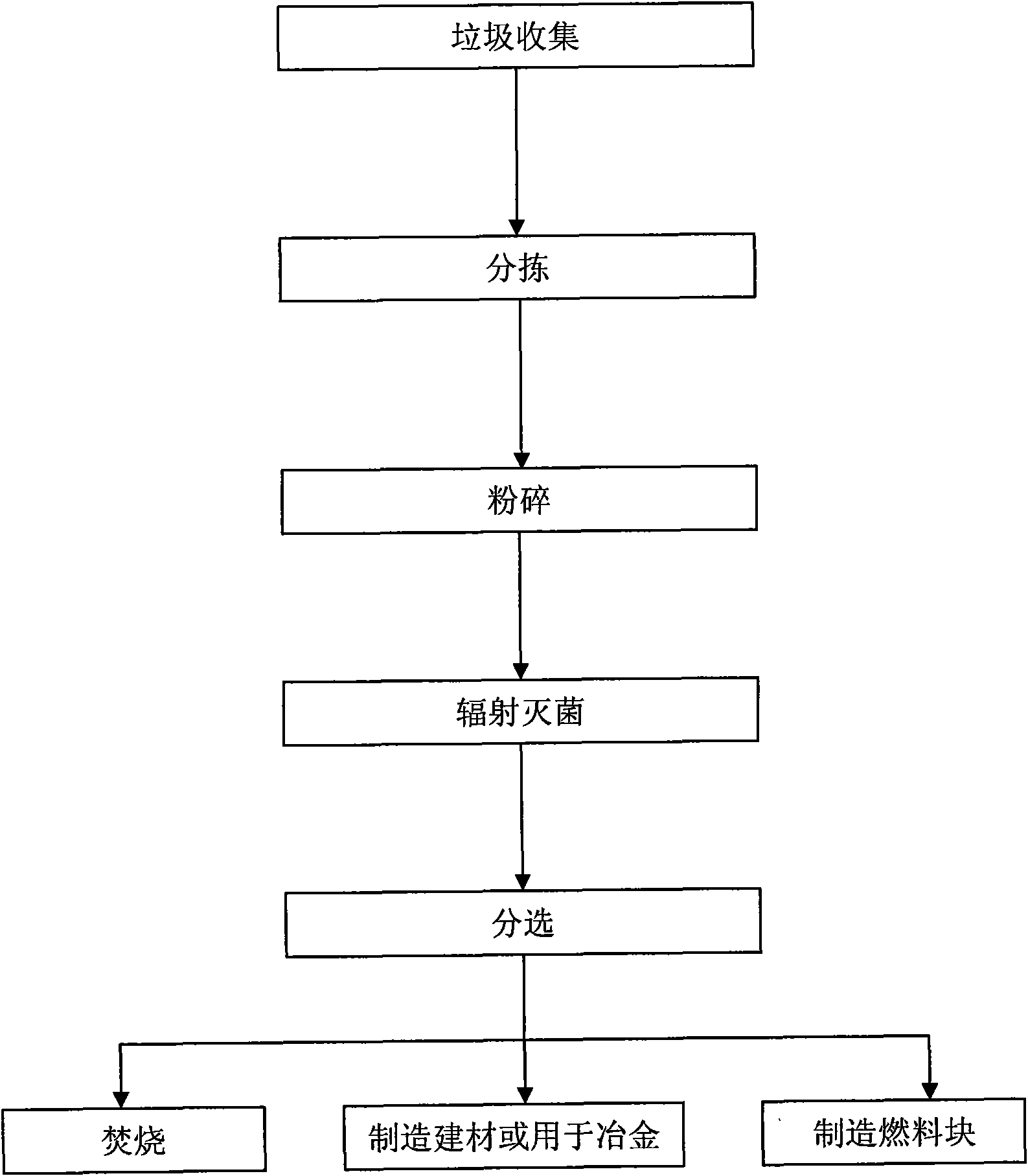

Medical garbage sorting harmless treatment and combustible recycling method

InactiveCN101590484AHigh recycling valueReduce processing costsSolid waste disposalBiofuelsRefuse collectionWaste collection

The invention relates to a medical garbage sorting harmless treatment and a combustible recycling method. The pre-treatment and separating of the medical garbage comprise the following steps: (1) garbage collecting; (2) sorting; (3) crushing; (4) radiation sterilization; (5) separating: according to the specific weight and magnetism of materials, separating the medical garbage into four types: lighter materials, heavier materials, magnetic materials and residual materials; recycling the lighter materials, the heavier materials and magnetic materials and sending the residual materials in a special garbage incinerator to burn. When recycling the lighter materials, the materials are crushed and mixed with smoke coal powder in 100:30-40 ratio, then proper binding agent and other additives are added, after adding water, the mixture is pressed and molded by a former and dried by air to form bulk fuel. The invention facilitates recycling of physical resources and reduces energy consumption and air pollution.

Owner:BEIJING JINAOHUARONG TECH

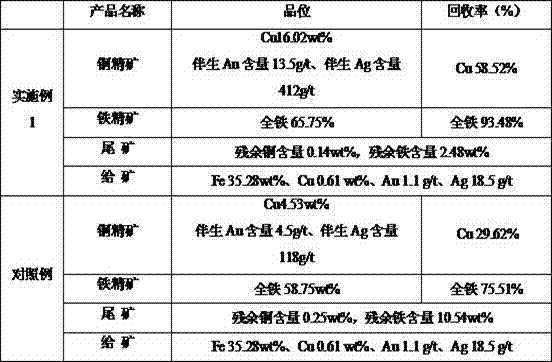

Method for step recycling of iron, copper and noble metal from copper smelting waste slag

InactiveCN103882235AReduce viscosityRealize Cascade RecyclingRecycling and recovery technologiesMagnetic separationSlagMagnetite

The invention discloses a method for step recycling of iron, copper and noble metal from copper smelting waste slag. The method comprises the following steps: firstly, respectively crushing and treating copper smelting waste slag, a reducing agent carbon powder and an alkali substance caustic soda and a sodium salt anhydrous sodium sulfate into certain granularity, sufficiently and uniformly mixing the raw materials, pelletizing, adding alkali and performing reduction roasting at a high temperature, wherein the functions of the caustic soda and the anhydrous sodium sulfate are to reduce the viscosity of the slag, and effective aggregation of copper particles in the slag and sufficient enrichment of an iron component to magnetite phase are facilitated; after roasting is accomplished, performing magnetic selection to obtain magnetic concentrate (iron-copper component); and subsequently performing Nelson reselection to separate the copper and the noble metal in the magnetic concentrate. The magnetic tailings can be applied to the building industry and high-quality abrasive preparation. According to the method, the caustic soda and the anhydrous sodium sulfate are innovatively added, and Nelson reselection is adopted, so that step recycling of noble metal in the copper smelting waste slag is achieved, the method has the advantages of simplicity and convenience in process, high applicability, low production cost, no emission and the like, a novel method is provided for comprehensive utilization of the copper smelting waste slag, and remarkable economic benefits and social benefits are achieved.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

High molecular clay material

The invention discloses a green, environment-friendly, and pollution-free high molecular clay material. The high molecular clay material is composed of deionized water, a PVPK30 solution, medical vaseline, glycerol, edible pigment, and a foaming agent; and is prepared by the following steps: mixing the raw materials mentioned above according to a certain weight ratio, evenly stirring, moulding, and cutting so as to obtain the high molecular clay material in a hand mould; wherein the material is novel, environment-friendly, and nontoxic, and is naturally dried in the air. The provided high molecular clay material has the advantages of lightness, environment-friendliness, long storage life, simple production technology, low cost, and high cyclic utilization value.

Owner:LUOHE LOUFOR STATIONERY MFG

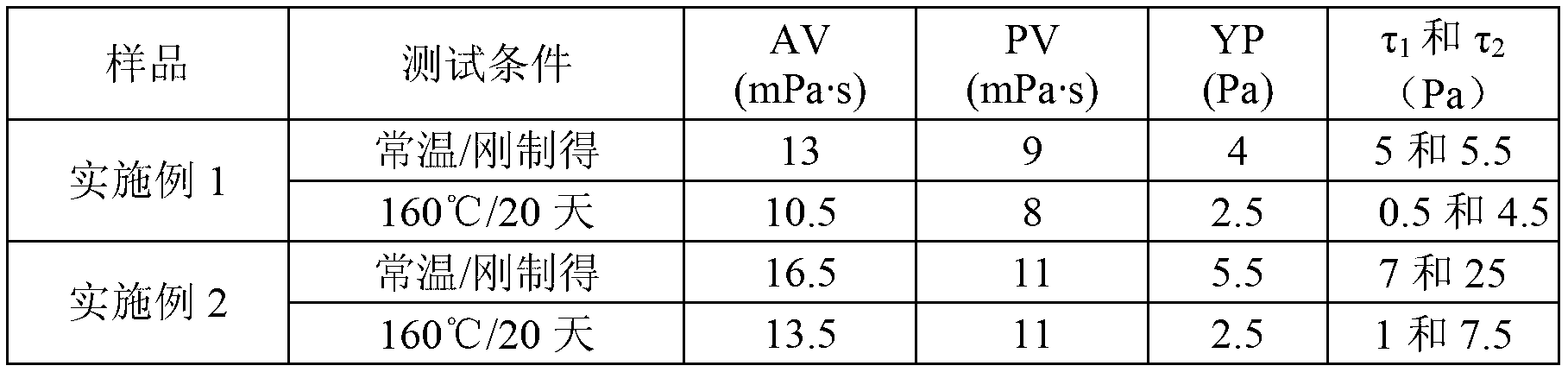

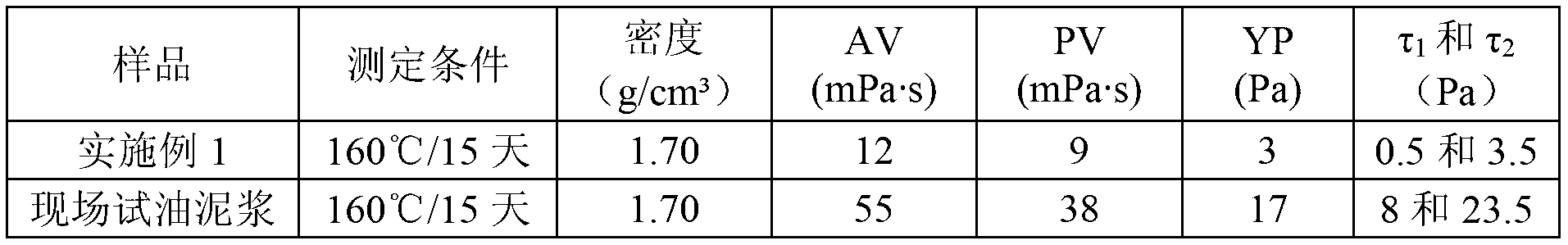

High density ultramicro formation testing working solution and preparation method thereof

ActiveCN103194186AImprove thermal stabilityReduce sedimentDrilling compositionHigh densityFiltration

The invention relates to a high density ultramicro formation testing working solution and a preparation method thereof. The high density ultramicro formation testing working solution comprises the following raw material components in parts by weight: 100-500 parts of water, 0.1-10 parts of high temperature resistance dispersing agent, 0.1-10 parts of high temperature resistance dispersion stabilizer, 0.6-2.0 parts of sodium hydroxide, 5-30 parts of anti-agglomerant, 0.1-10 parts of flow pattern modifier, 0.1-8 parts of filtration control agent, and a weighting agent, and the density of the high density ultramicro formation testing working solution is 1.5-2.5g / cm<3>. The preparation method comprises the following steps of: sequentially adding the raw materials into the water under the condition of stirring, and after uniform blending, obtaining the high density ultramicro formation testing working solution. The high density ultramicro formation testing working solution has excellent high temperature sedimentary stability and rheological property, and is applicable to formation testing working conditions of a deep well and an ultra deep well.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method utilizing hop residues to extract xanthohumol

InactiveCN101768068AHigh recycling valueHigh yieldCarbonyl compound separation/purificationBulk chemical productionAlcoholGradient elution

The invention provides a method utilizing hop residues to extract xanthohumol. The method includes the following steps: after a hop extractum is extracted by liquid and subcritical or supercritical CO2, hop raffinate (the hop residues) wasted is utilized to extract total polyphenols in hops; a total polyphenol extract is absorbed by an absorbent; then, gradient elution is carried out on the absorbent by an alcohol-water system so as to obtain hop polyphenols of different kinds; meanwhile, the collected xanthohumol is separated and purified to obtain the high-purity one.

Owner:刘玉英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com