Patents

Literature

201 results about "Tin can" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A steel can, tin can, tin (especially in British English, Australian English and Canadian English), steel packaging or a can, is a container for the distribution or storage of goods, composed of thin metal. Many cans require opening by cutting the "end" open; others have removable covers. Cans hold diverse contents: foods, beverages, oil, chemicals, etc. Steel cans are made of tinplate (tin-coated steel) or of tin-free steel. In some dialects, even aluminium cans are called "tin cans".

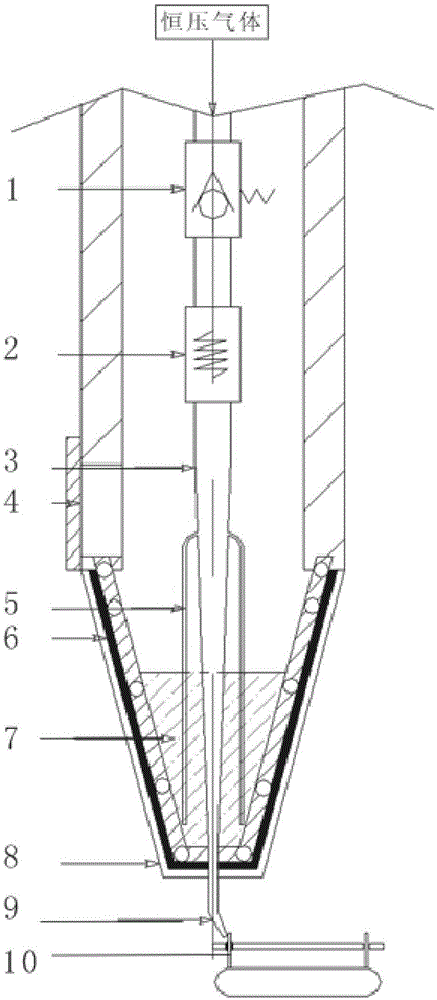

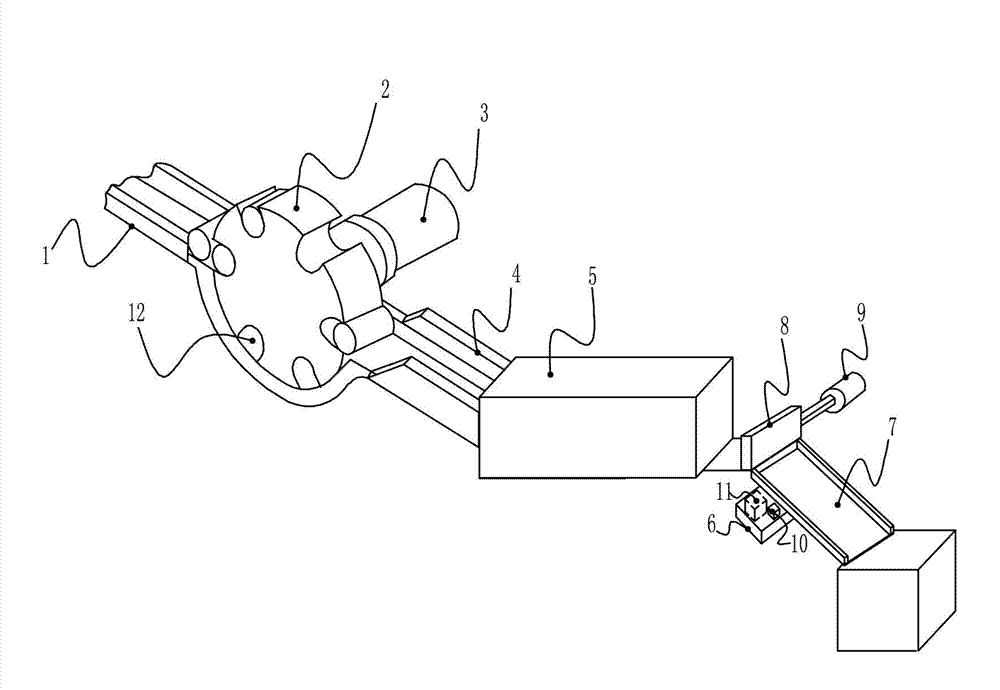

Method and device for disassembling electronic components from waste printed circuit boards and recovering soldering tin

InactiveCN101537522AAchieve separationSpeed up circulationSolid waste disposalElectronic waste recyclingElectricityAutomatic control

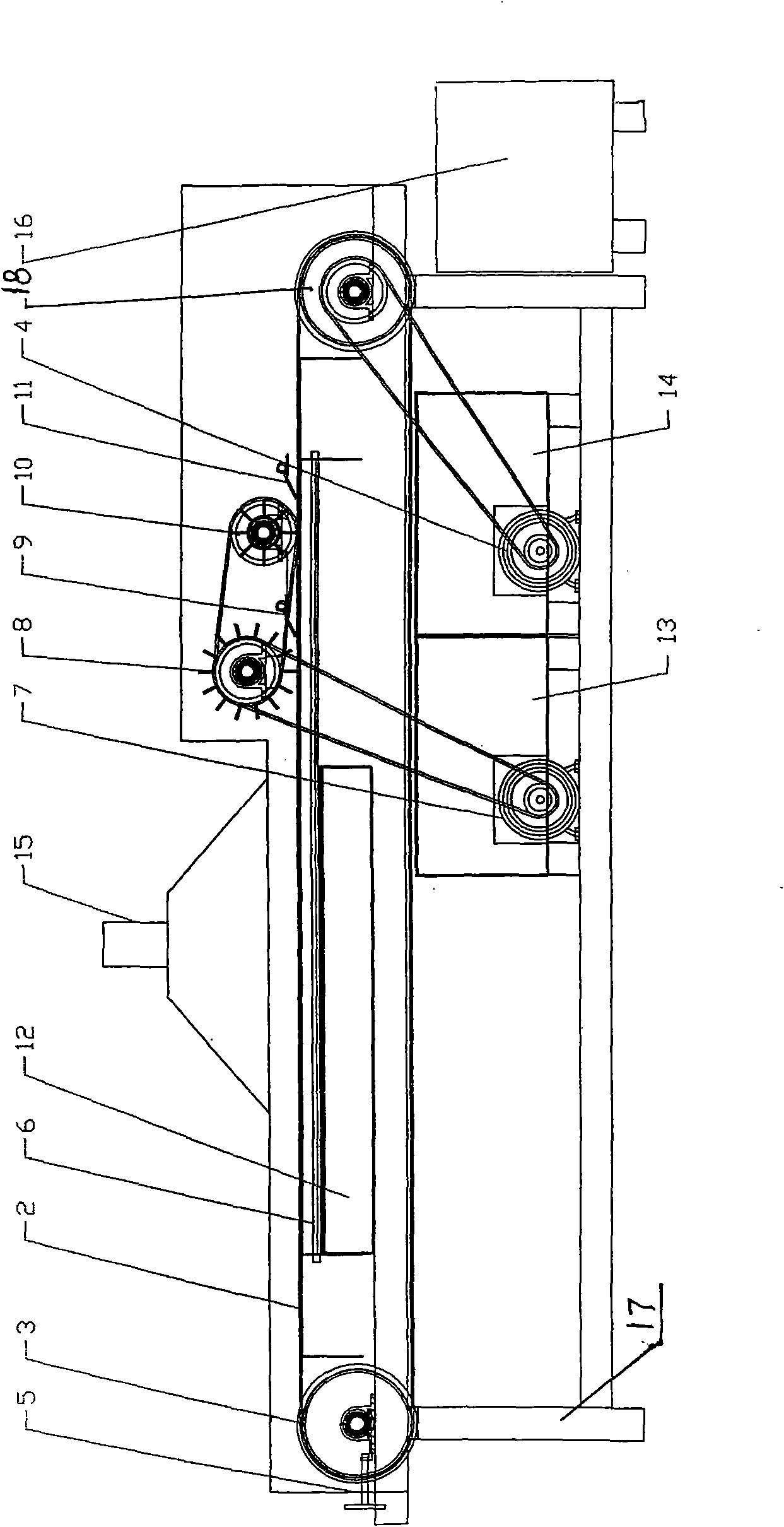

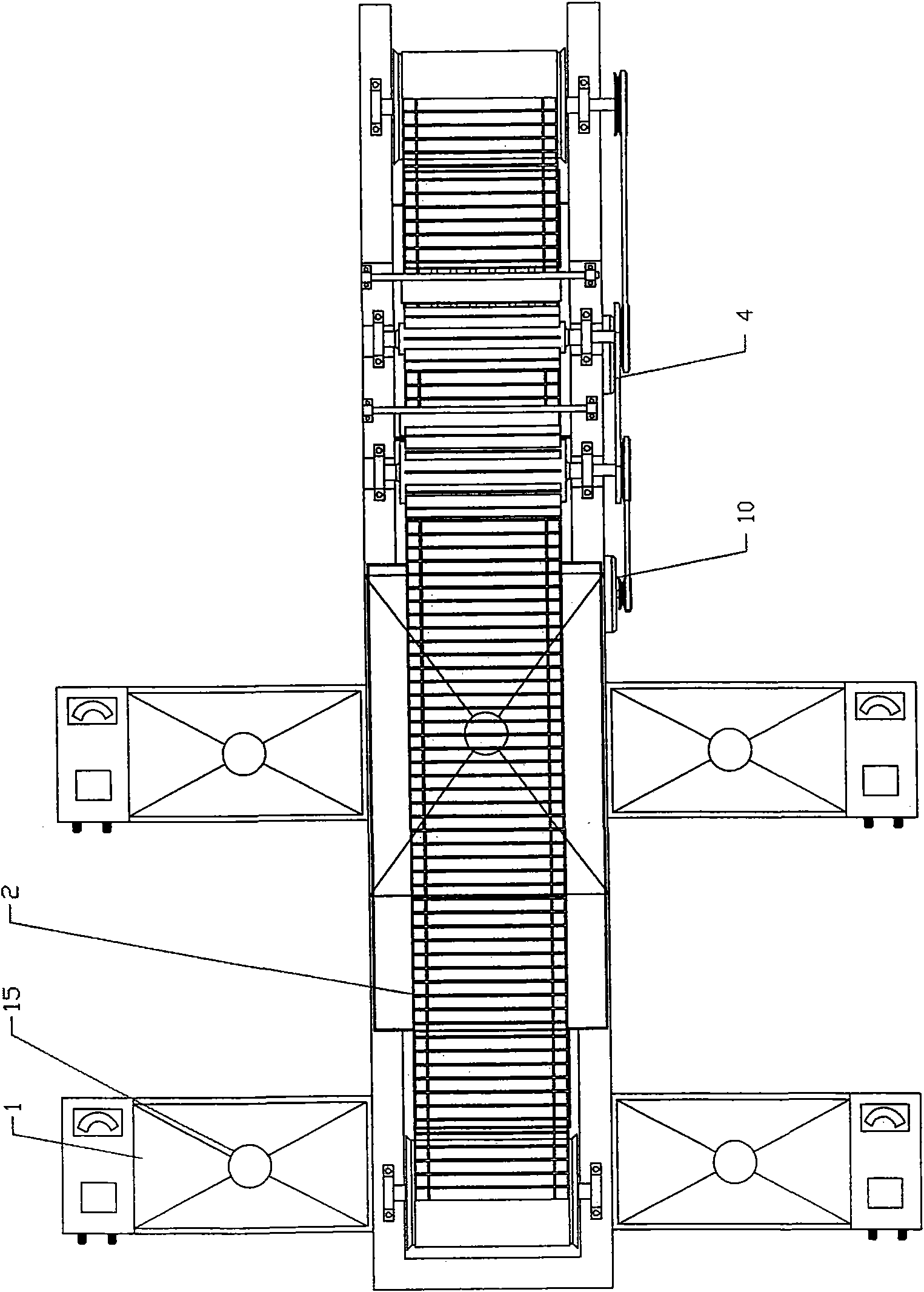

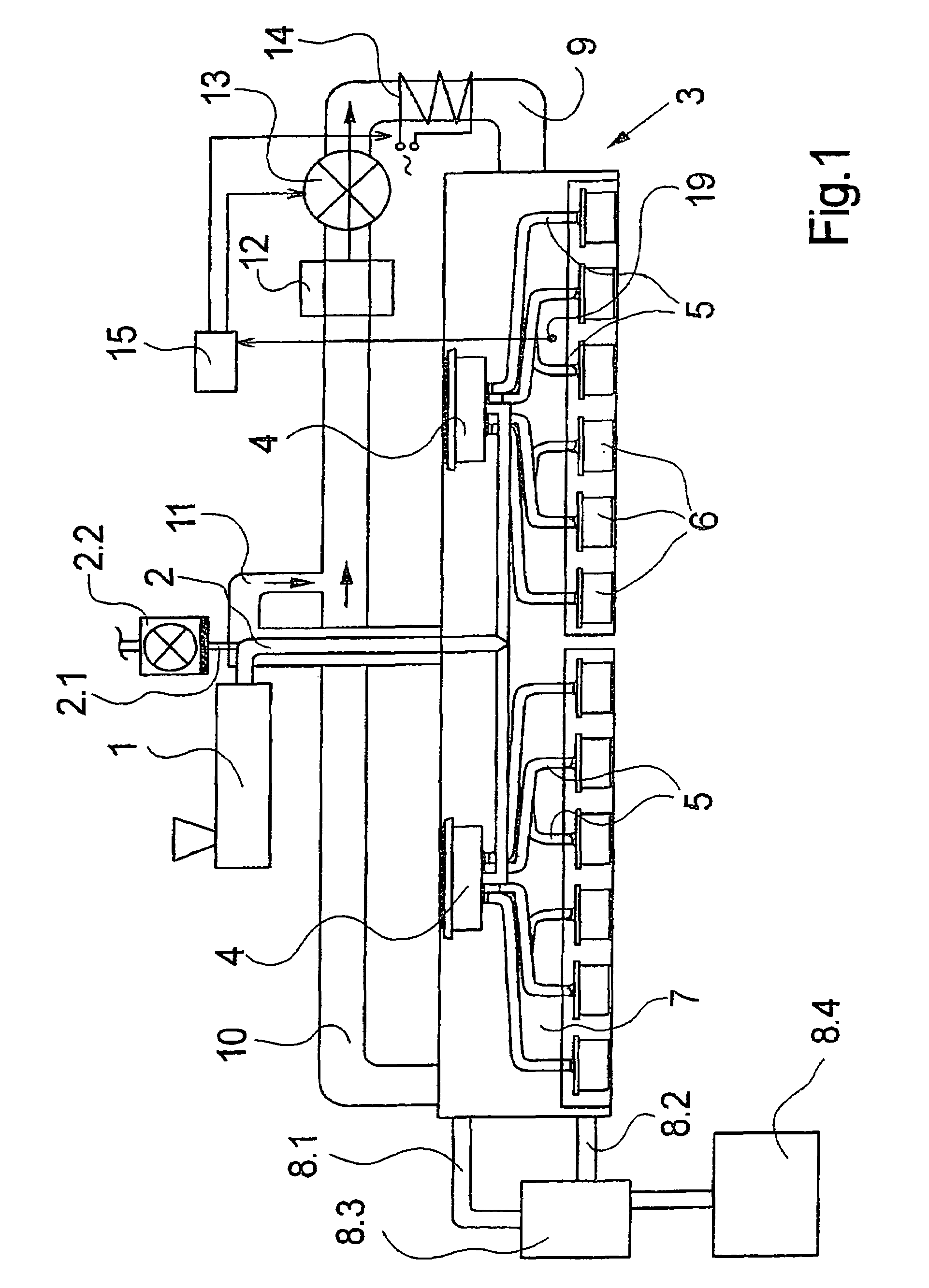

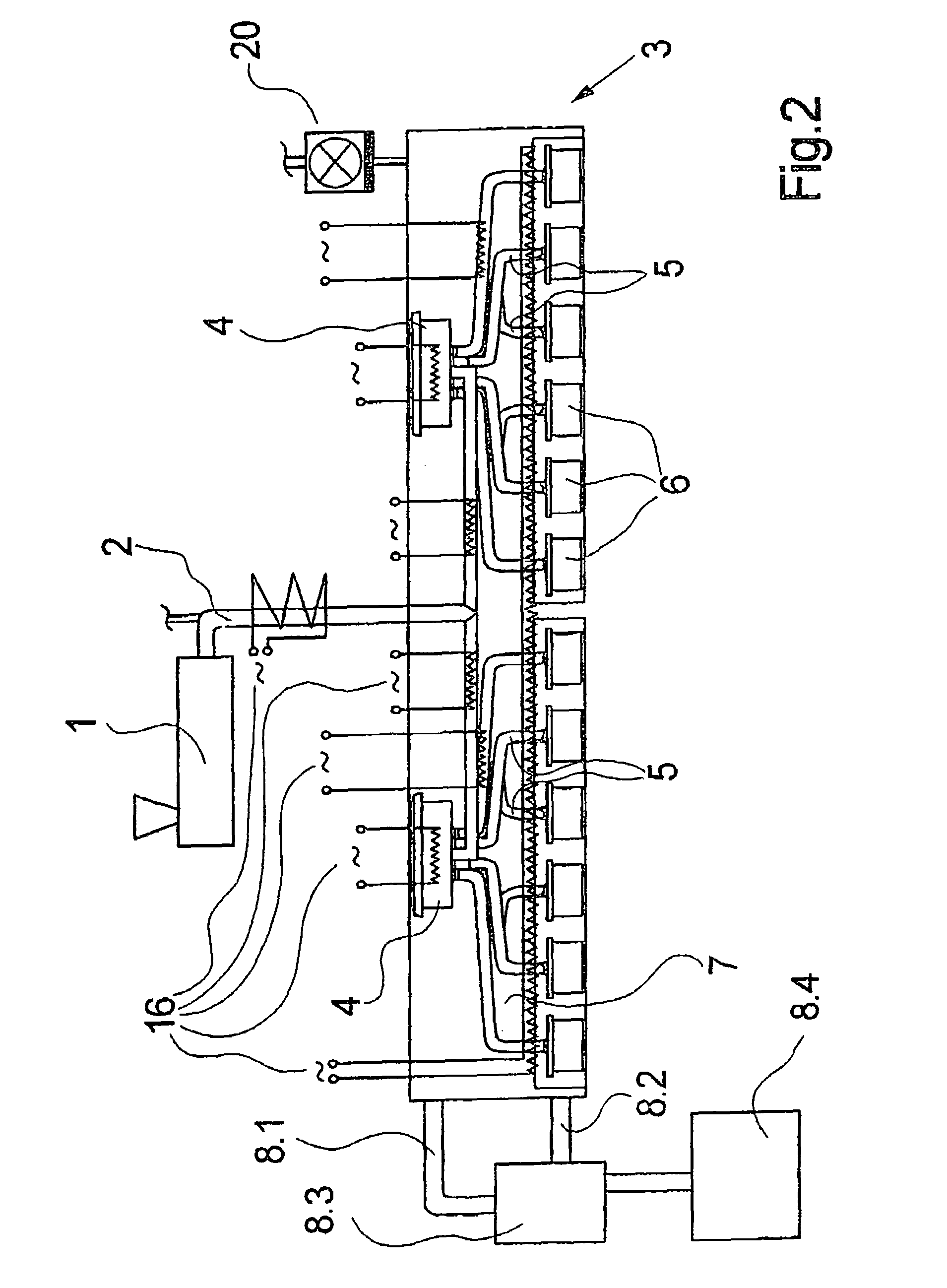

The invention provides a method and a device for disassembling electronic components from waste printed circuit boards (PCB) and recovering soldering tin. The method comprises the following steps: placing the PCB with the electronic components in a temperature-setting tin-melting furnace in a manner that the PCB faces up; grabbing larger electronic components manually and feeding the PCB containing smaller electronic components and soldering tin to the conveyor belt after the soldering tin is melted by heat, wherein, an automatic-control electrical heating and warming device is additionally arranged at the bottom of the conveyor belt; pinning down the PCB by a hob and forwarding the PCB, and eliminating the electronic components and the soldering tin by a scraper arranged on the rear side of the hob, so that the soldering tin can be separated from the electronic components on the PCB through the successive coordinating operation of hobs and scrapers in a plurality of groups; recovering the soldering tin by a material-receiving pot; and subjecting the peculiar smell and harmful gases generated by heating the PCB to negative-pressure air draft and absorption treatment and discharging the gases until the discharge standards are met. The invention is suitable for treating PCBs with various thicknesses and recovering electronic components of various types and models; the invention has the advantages of high speed, high efficiency, no pollution, high operability and advanced technology; and the invention contains a novel and environment-friendly method and an equipment for disassembling the waste printed circuit boards and recovering treatment of soldering tin.

Owner:HUNAN VARY TECH

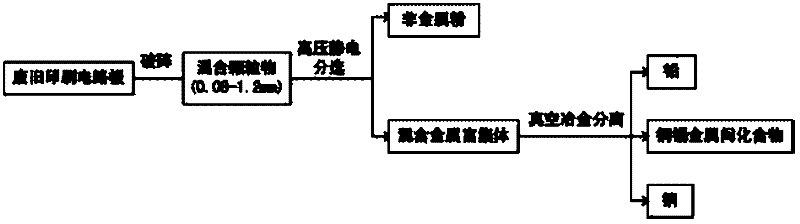

Method for synthetically recycling waste printed circuit board

InactiveCN101623698AAffect purificationImprove efficiencySolid waste disposalSoldering apparatusCrusherCopper

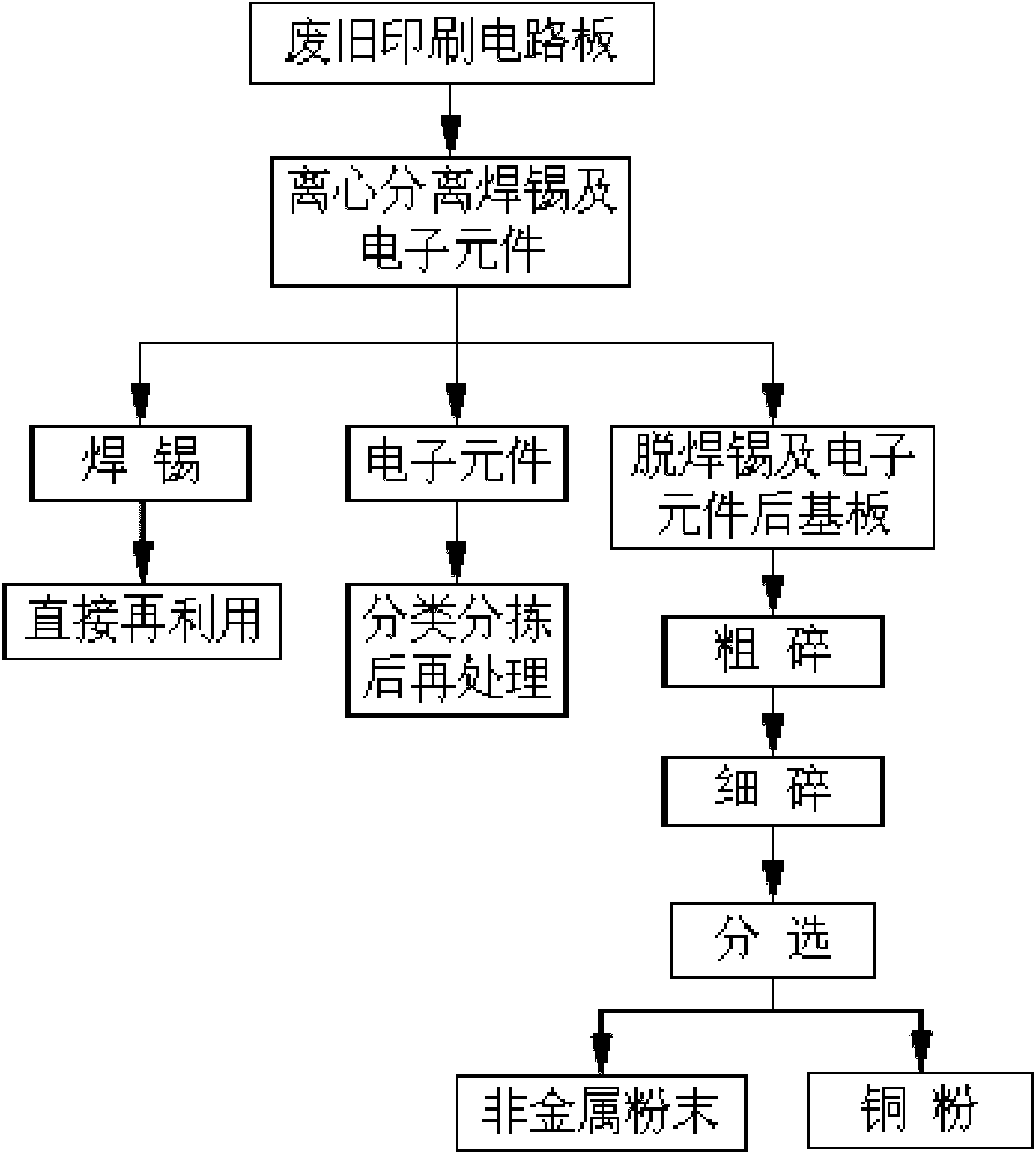

The invention provides a method for synthetically recycling a waste printed circuit board. The method comprises the following steps: (1) the waste printed circuit board with electronic elements is placed in a rotary drum and dipped in a liquid heating medium to melt soldering tin on the waste printed circuit board, the rotary drum is rotated, and the melted soldering tin can be filtered by passing through filtering holes on the wall of the rotary drum under the centrifugal effect of the rotation of the rotary drum; (2) the falling electronic elements are classified, sorted and further processed; and (3) the waste printed circuit board is coarsely crushed by adopting a cutting type crusher after the soldering tin and the electronic elements are removed, a fine crusher is adopted to fine crush the coarsely crushed printed circuit board to ensure that metal and nonmetal are mutually dissociated, and the dissociated mixing materials are separated by a pneumatic separator or a static separator to respectively obtain copper powder and nonmetal powder. The invention realizes scale treatment of the waste printed circuit board with low cost and high efficiency, and ensures that valuable substances such as nonmetal, soldering tin, copper and other metal are synthetically recycled.

Owner:CENT SOUTH UNIV

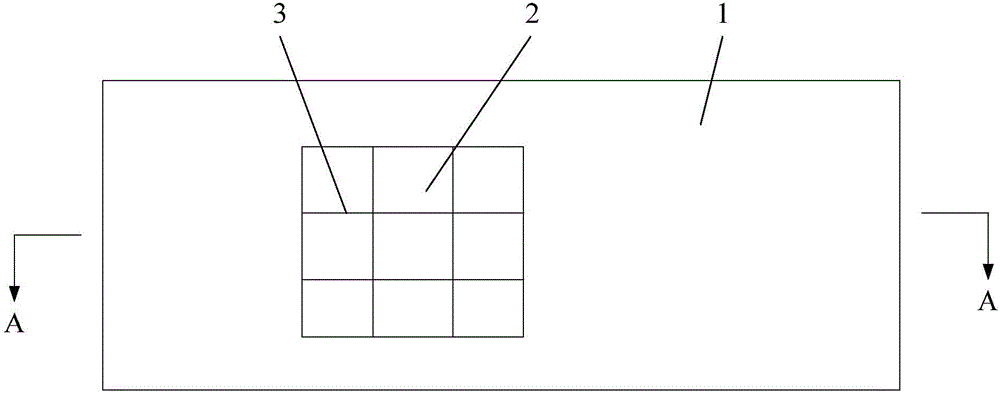

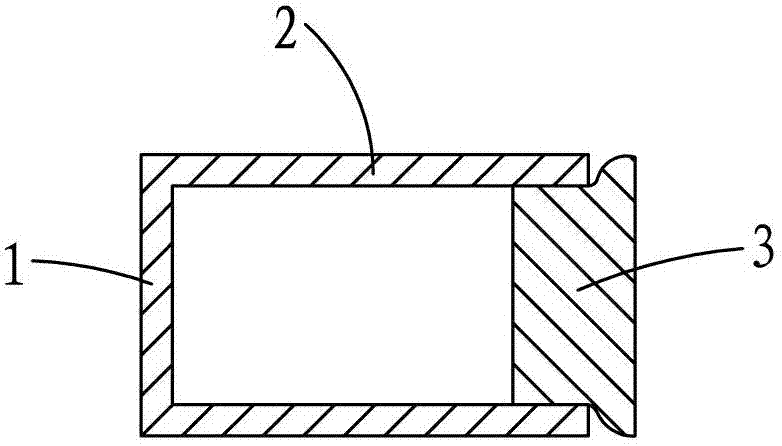

Half-tone phase shift mask blank and method for manufacturing half-tone phase shift mask

ActiveUS20130309598A1Increase etch rateDecrease in light-shielding propertyOriginals for photomechanical treatmentOptoelectronicsOxygen

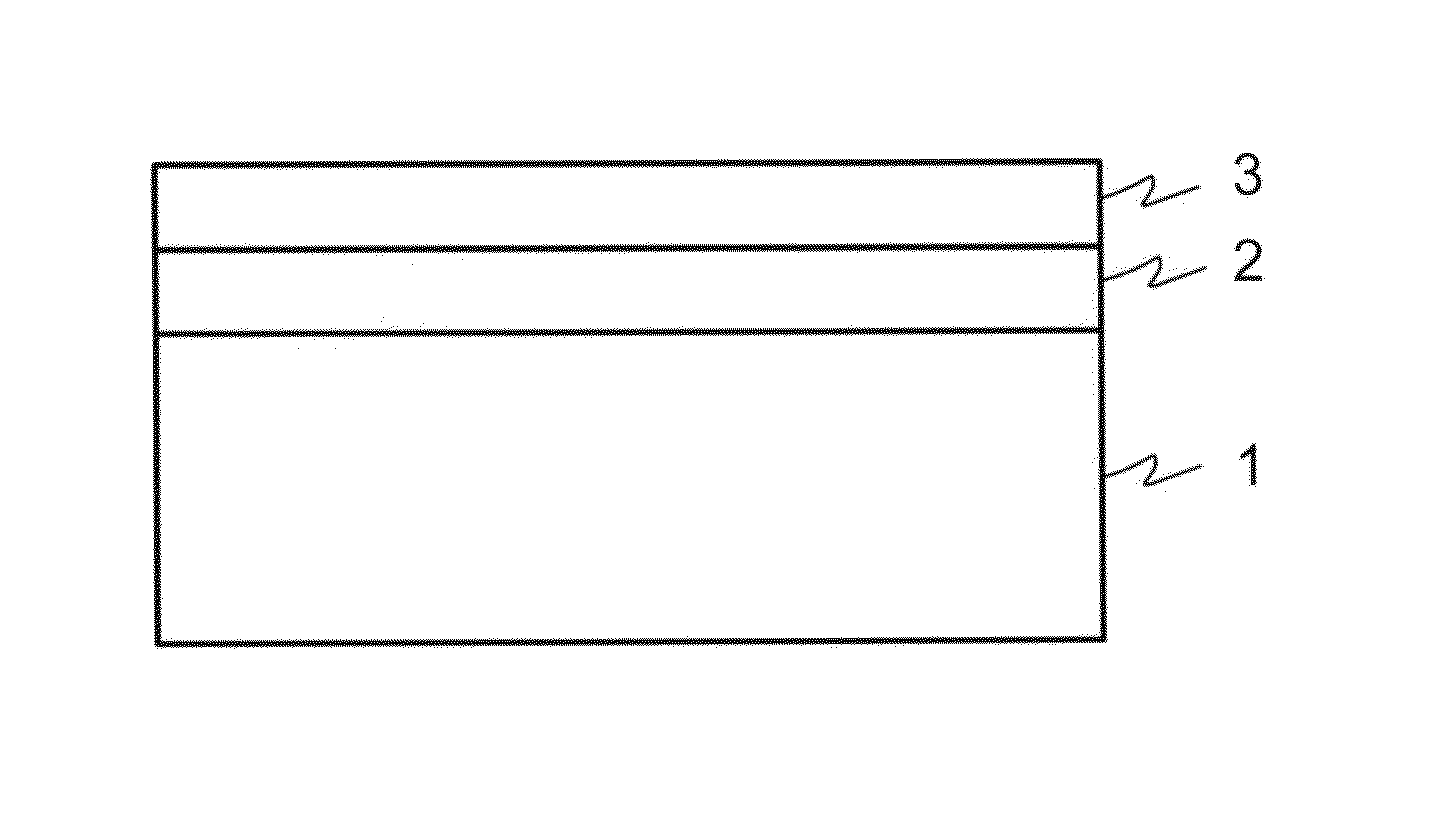

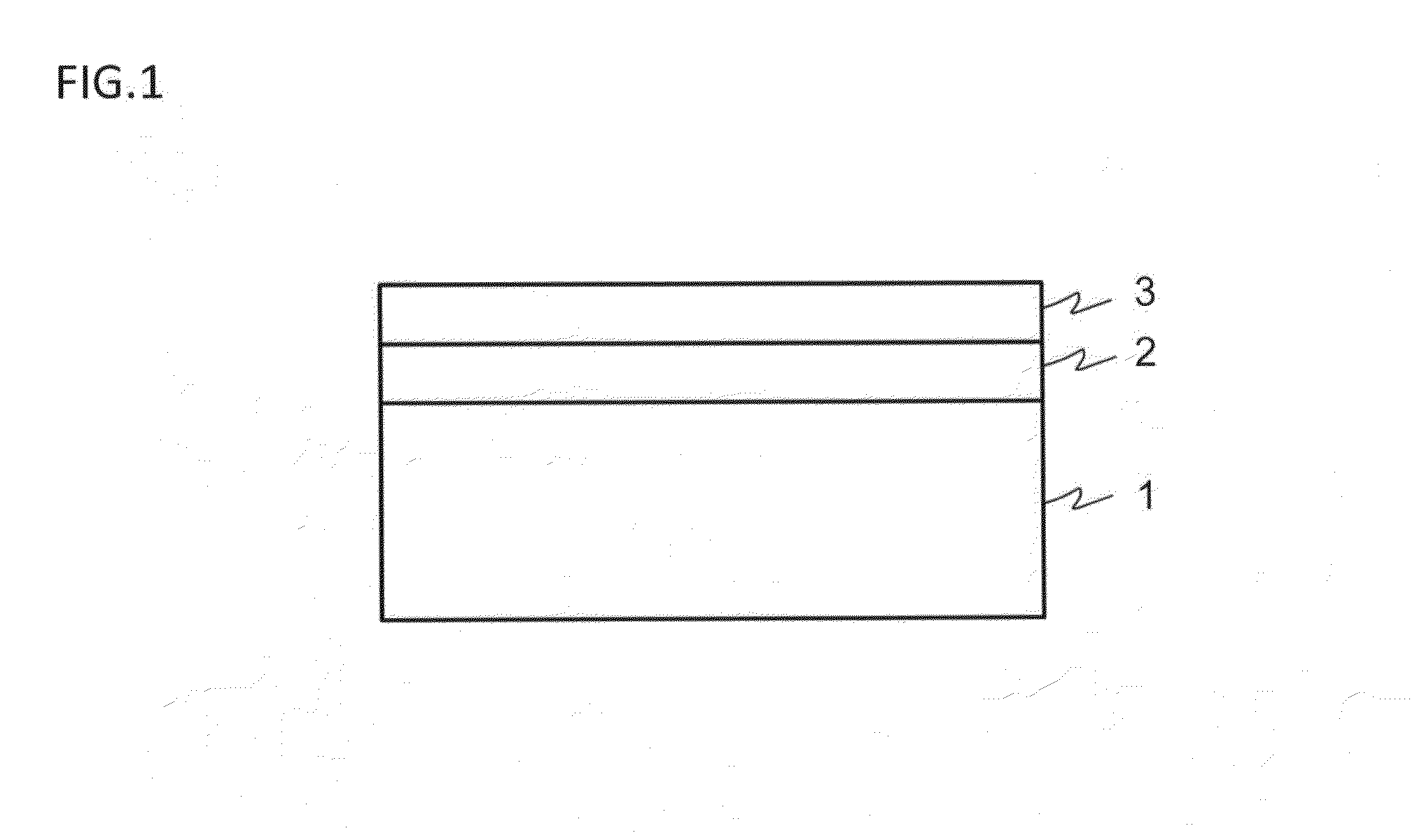

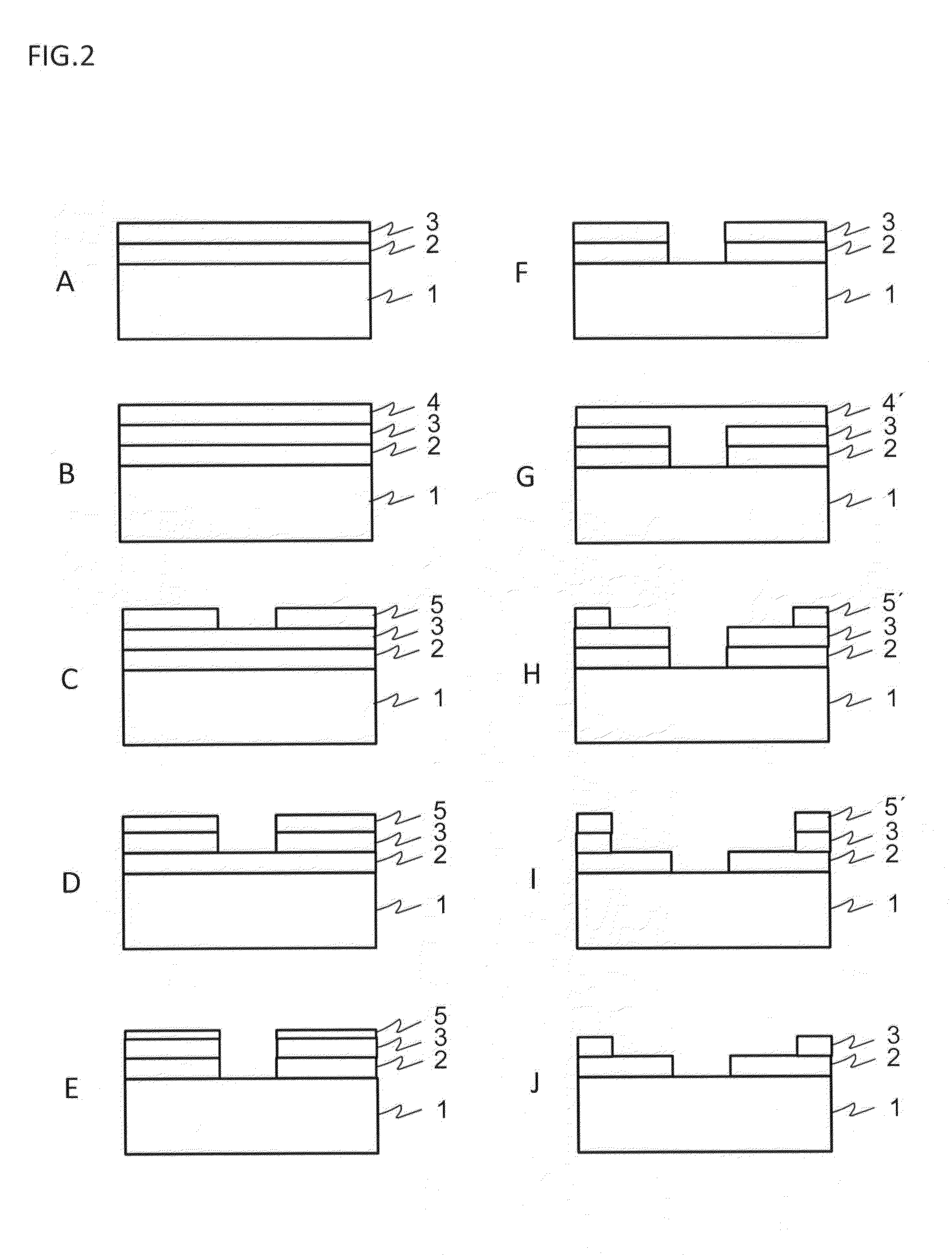

A half-tone phase shift film 2 and a light-shielding film 3 are stacked on transparent substrate 1. The light-shielding film 3 has a monolayer structure or a multilayer structure. At least one layer is formed by film-formation with a chromium-containing material including tin. The half-tone phase shift film 2 is made of a molybdenum silicon nitride oxide. The layer made of a chromium-containing material including tin can cause a significant increase in the etching rate at the time of chlorine-containing dry-etching including oxygen. Thus, burden on the resist pattern or hard mask pattern at the time of transferring a pattern on the light-shielding film is reduced, and therefore it is possible to carry out pattern transfer with high precision. The present invention provides a novel technique that can increase a dry-etching rate of a light-shielding film made of a chromium-containing material while assuring various characteristics required for the light-shielding film.

Owner:SHIN ETSU CHEM IND CO LTD

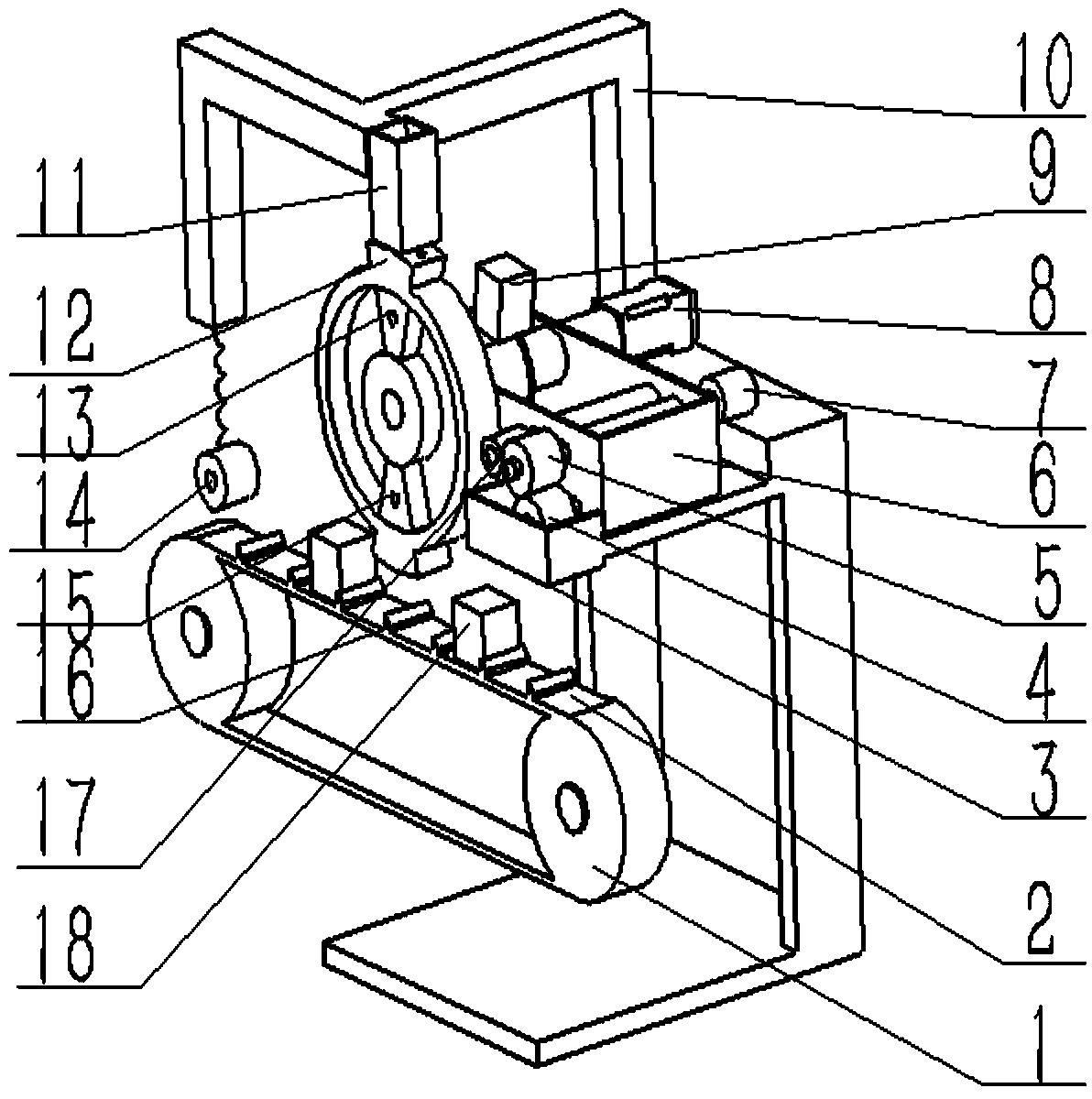

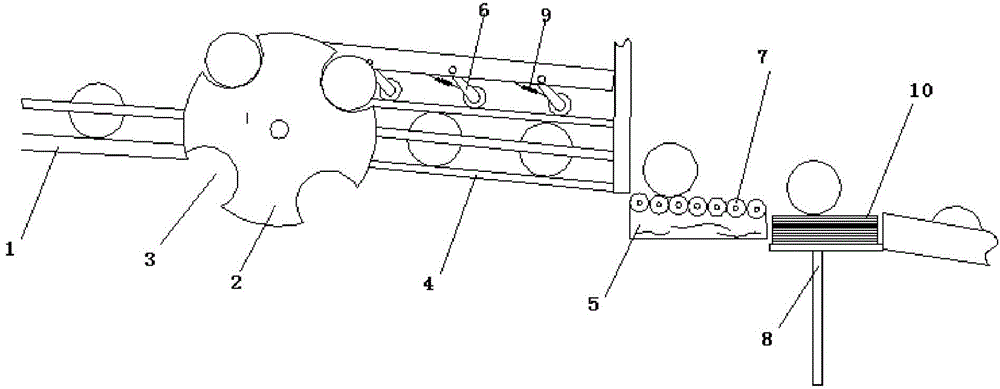

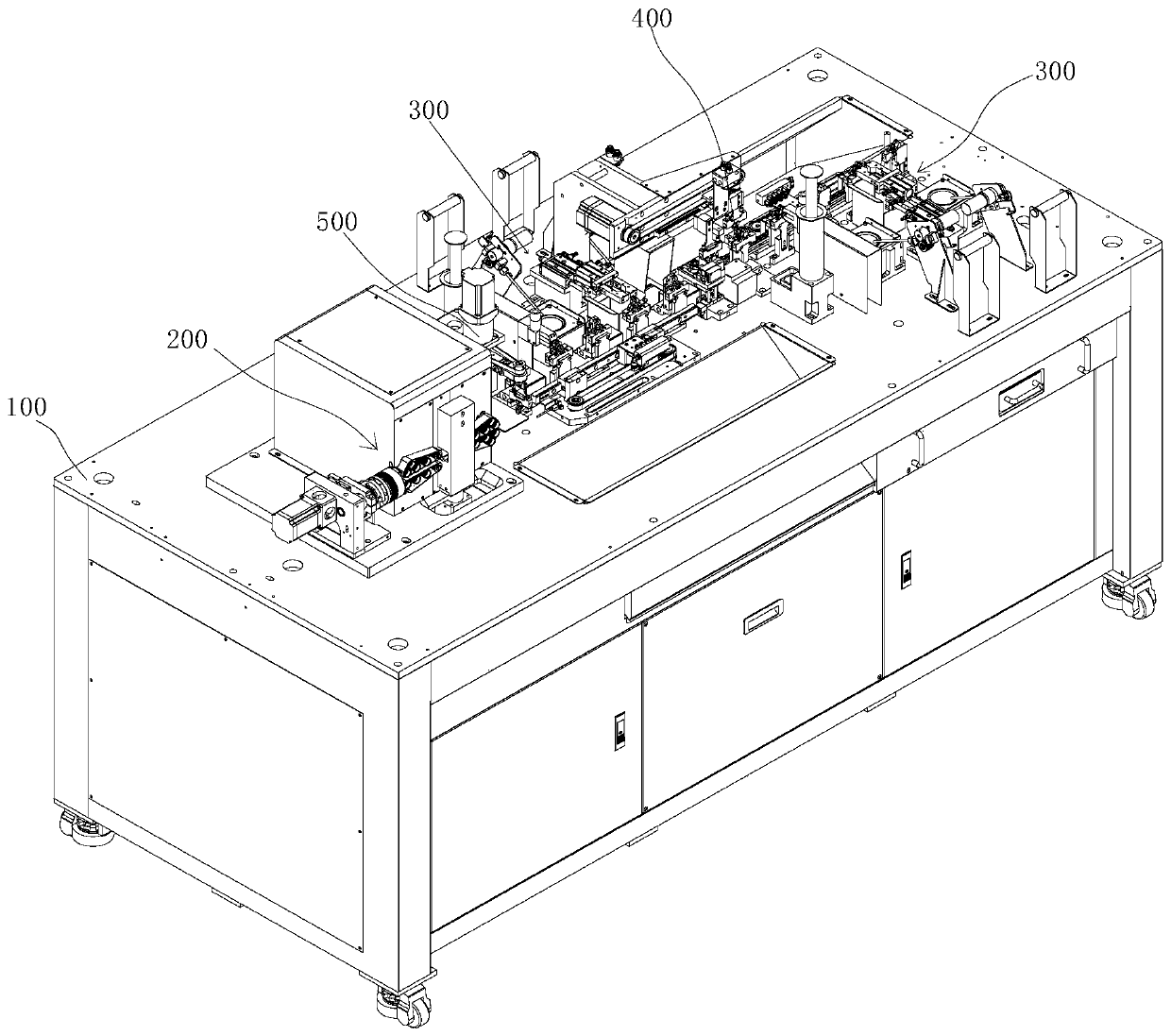

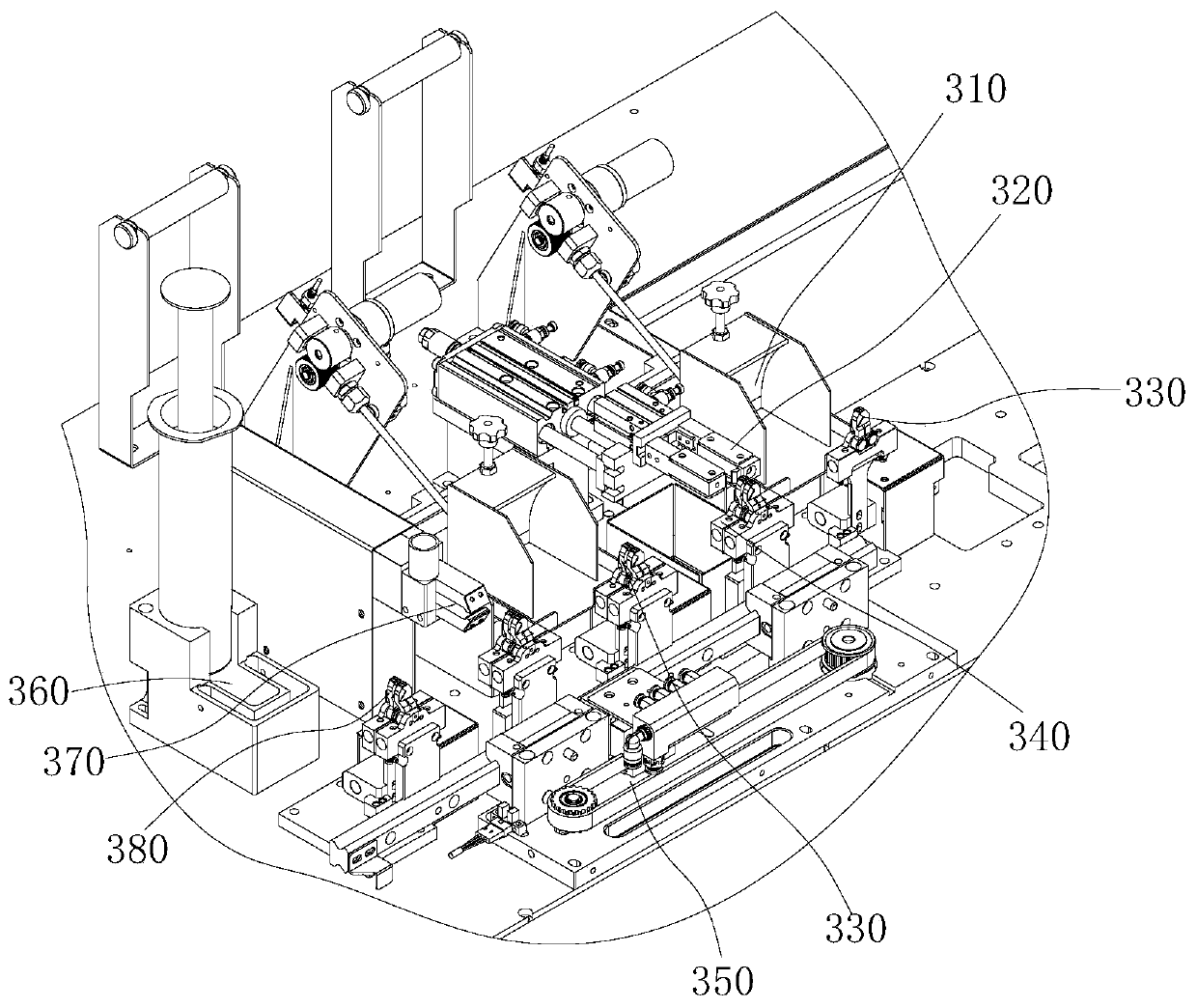

Automatic square tin can branding device

InactiveCN104139899APrecise positioningGuaranteed compactionLabelling short rigid containersLabelling machinesCouplingPulp and paper industry

The invention discloses an automatic square tin can branding device and belongs to electromechanical equipment. The automatic square tin can branding device comprises a belt pulley, a conveyor belt, a glue box, a first gluing roller, a second gluing roller, a bearing block, a motor, a stepping motor, an air pump, a rack, a paper box, a main wheel, an air suction hole, a pressure brush, an air-blowing hole, conveyor belt positioning blocks, a third gluing roller and tin cans, wherein the stepping motor arranged on a boss behind the rack is connected with the main wheel through a coupler and a shaft; the air pump is fixed on the shaft between the stepping motor and the main wheel; the motor arranged on the boss behind the rack is connected with the second gluing roller through a shaft; the glue box is welded in front of the rack; the paper box welded above the rack is positioned just above the main wheel; the air suction hole and the air-blowing hole are connected with a cylinder through an air pipe; the pressure brush is arranged at the left end of the rack; the conveyor belt is arranged under the main wheel and the pressure brush and is driven by the belt pulley; multiple positioning blocks are fixed on the conveyor belt. According to the automatic square tin can branding device disclosed by the invention, the automatic square tin can branding operation can be finished.

Owner:张凤仙

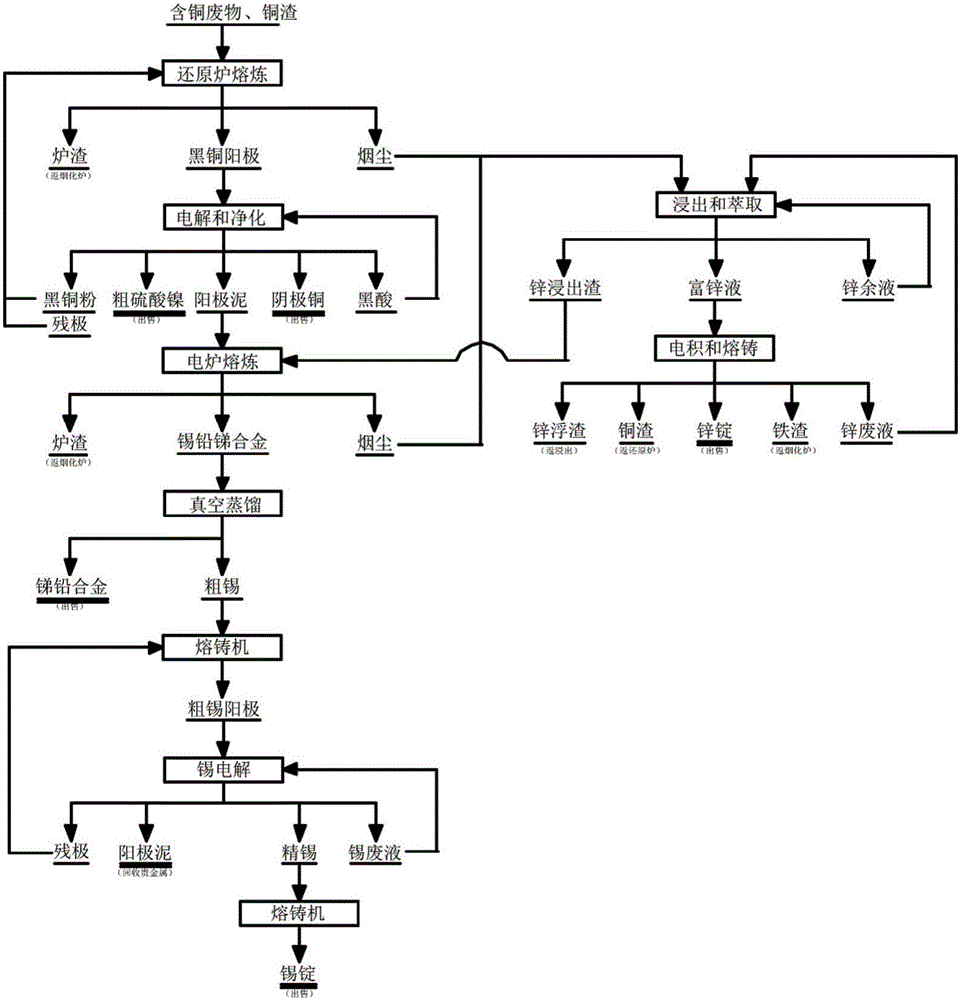

Full-path full-valence separation method for multifarious metal

ActiveCN105695744AInnovative technologyHigh recycling valuePhotography auxillary processesProcess efficiency improvementAntimonyRaw material

The invention discloses a full-path full-valence separation method for multifarious metal. Low-grade waste containing copper and copper slag serves as a raw material. The separation method comprises the following main steps that 1, the raw material is subjected to reduction smelting through a regeneration reduction furnace so that a black copper anode can be obtained, the raw material is subjected to electrolytic refining so that a metal cathode copper product and a crude nickel sulfate product can be obtained, and thus copper and nickel in the raw material are separated and recycled; 2, slag is leached out of copper anode mud and zinc and is subjected to reduction smelting through an electric furnace so that tin-lead-antimony alloy can be obtained, the tin-lead-antimony alloy is smelted through a vacuum furnace to be separated so that a antimony-lead alloy product and crude tin can be obtained, the crude tin is subjected to electrolytic refining so that refined tin can be obtained, that is, a tin ingot product is obtained, and hence tin, lead and antimony are separated and recycled; 3, a zinc ingot product is obtained by recycling smelting fume through a 'leaching- extraction- electrodeposition' method, so that the zinc, the tin and the lead are separated, and the zinc is recycled; and 4, tin anode mud is sent to a precious metal recycling factory as a precious metal enrichment material. According to the full-path full-valence separation method for the multifarious metal, the multifarious metal is completely separated, and remarkable economic benefits, environmental benefits and social benefits are achieved.

Owner:江西自立环保科技有限公司

Solder-reflow soldering method

InactiveCN101396751AReduces the chance of forming solder voidsEliminate Bubble ProblemsSoldering apparatusReflow ovenTin can

The invention is applicable to the field of reflow soldering, which provides a reflow soldering method comprising the following steps: a workpiece to be soldered is arranged into a reflow brazier, and processes are carried out in a preheating region, a reacting region, a reflow region and a cooling region of the reflow brazier in sequence. The ultrasonic wave is applied on the workpiece to be soldered in the reflow region to cause the workpiece to vibrate while being processed. As soldering tin in the reflow region is easy to generate bubbles and form voidages and the ultrasonic wave is applied in the reflow region to cause the workpiece to vibrate, a majority of bubbles generated by the soldering tin are eliminated, thereby effectively reducing the probability of forming soldering voidages at the soldering part, and the surface of the soldering tin can be cleaned so as to ensure that the soldering voidage ratio can be effectively controlled and the soldering performance can be improved.

Owner:BYD CO LTD

Method for plating tin on aluminum and aluminum alloy coiled material

The invention discloses a method for tinning aluminum and aluminum alloy coils. After the coils are unrolled, the following main steps are successively and continuously carried out: (1) degreasing, degreasing and pickling of the coil surfaces; (2) coiling Zinc immersion on the surface twice; (3) Nickel plating on the zinc layer and activation; (4) tin plating on the nickel layer, passivation after micro-etching; (5) use of organic matter to block micropores on the surface of the tin layer; (6) The coil is blown and dried. The invention realizes the continuous electroplating process of aluminum and aluminum alloy coils, that is, the tinning process of aluminum and aluminum alloy coils. The electroplated products have good electrical conductivity, strong weldability, fast heat dissipation, light weight, easy stamping, Low cost and other characteristics, the aluminum material after electroplating has the properties of tin material, which can achieve the purpose of replacing tin material.

Owner:尼尔金属(苏州)有限公司

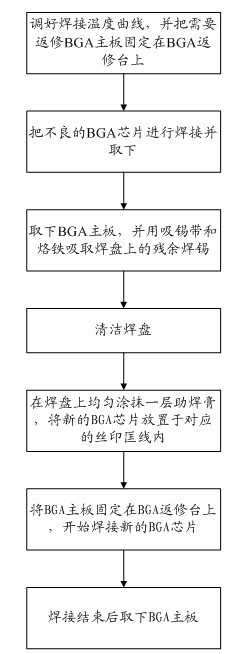

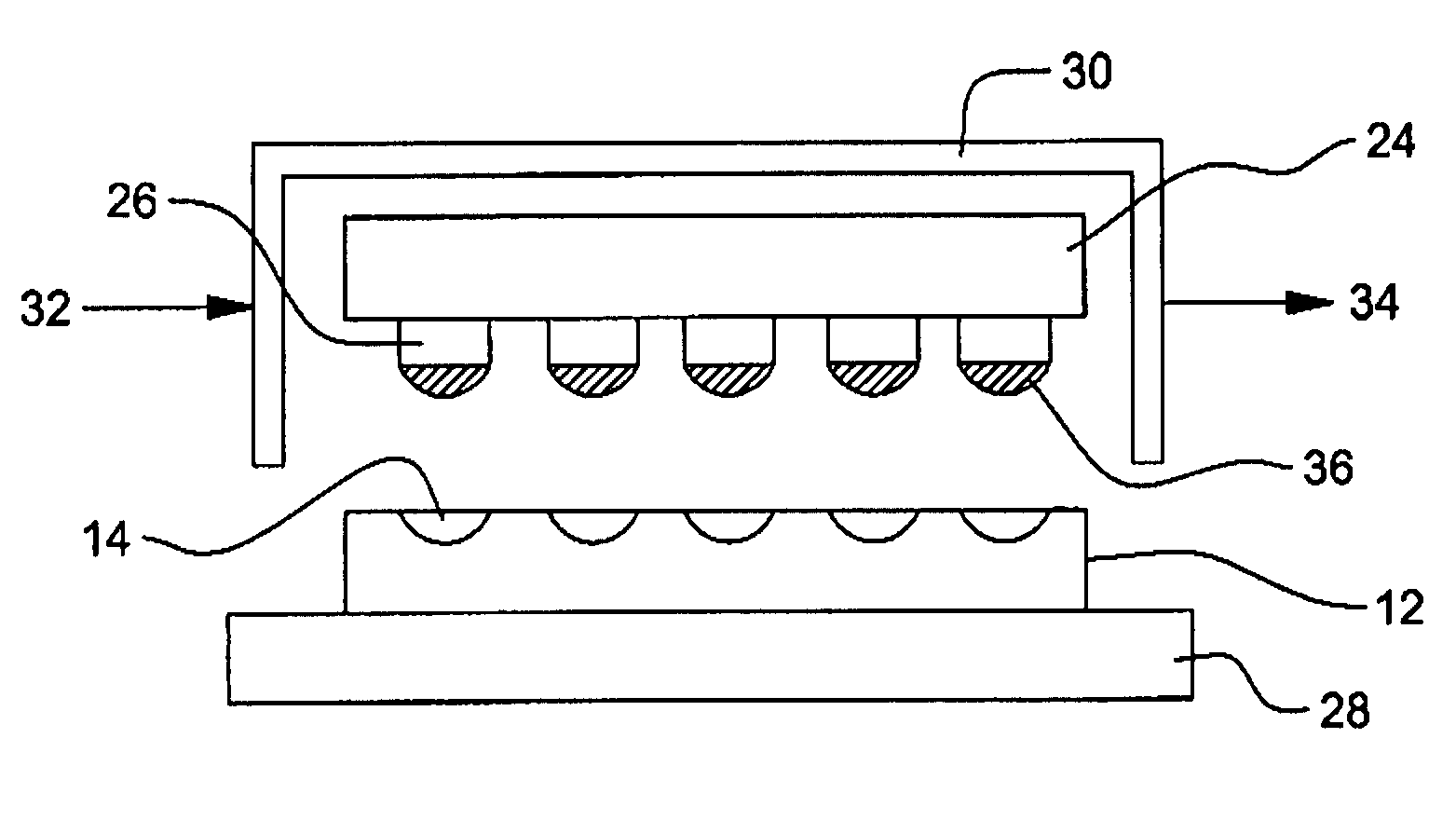

Method for removing residual solder tin from soldering-pan during repair and replacement of ball grid array (BGA) chip

InactiveCN102686044AImprove rework efficiencyImprove yield ratePrinted circuit assemblingScreen printingTemperature curve

The invention discloses a method for removing residual solder tin from a soldering-pan during the repair and replacement of a ball grid array (BGA) chip. The method comprises the following steps of: (a) well regulating a soldering temperature curve, and fixing a BGA mainboard to be repaired on a BGA repair station; (b) soldering a poor BGA chip, and taking the poor BGA chip down; (c) taking the BGA mainboard down, and sucking the residual solder tin from the soldering-pan by using a soldering wick and soldering iron; (d) cleaning the soldering-pan; (e) uniformly smearing a layer of flux paste on the soldering-pan, and placing a new BGA chip in a corresponding silk-screen printing frame wire; (f) fixing the BGA mainboard on the BGA repair station, and starting soldering the new BGA chip; and (g) after the soldering is finished, taking the BGA mainboard down. According to the method for removing the residual solder tin from the soldering-pan during the repair and replacement of the BGA chip, the residual solder tin can be effectively removed from the soldering-pan, the repair efficiency of the BGA chip is greatly improved, and the yield is also greatly improved.

Owner:JIANGSU LEMOTE TECH CORP

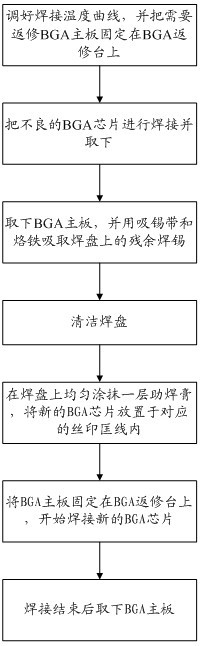

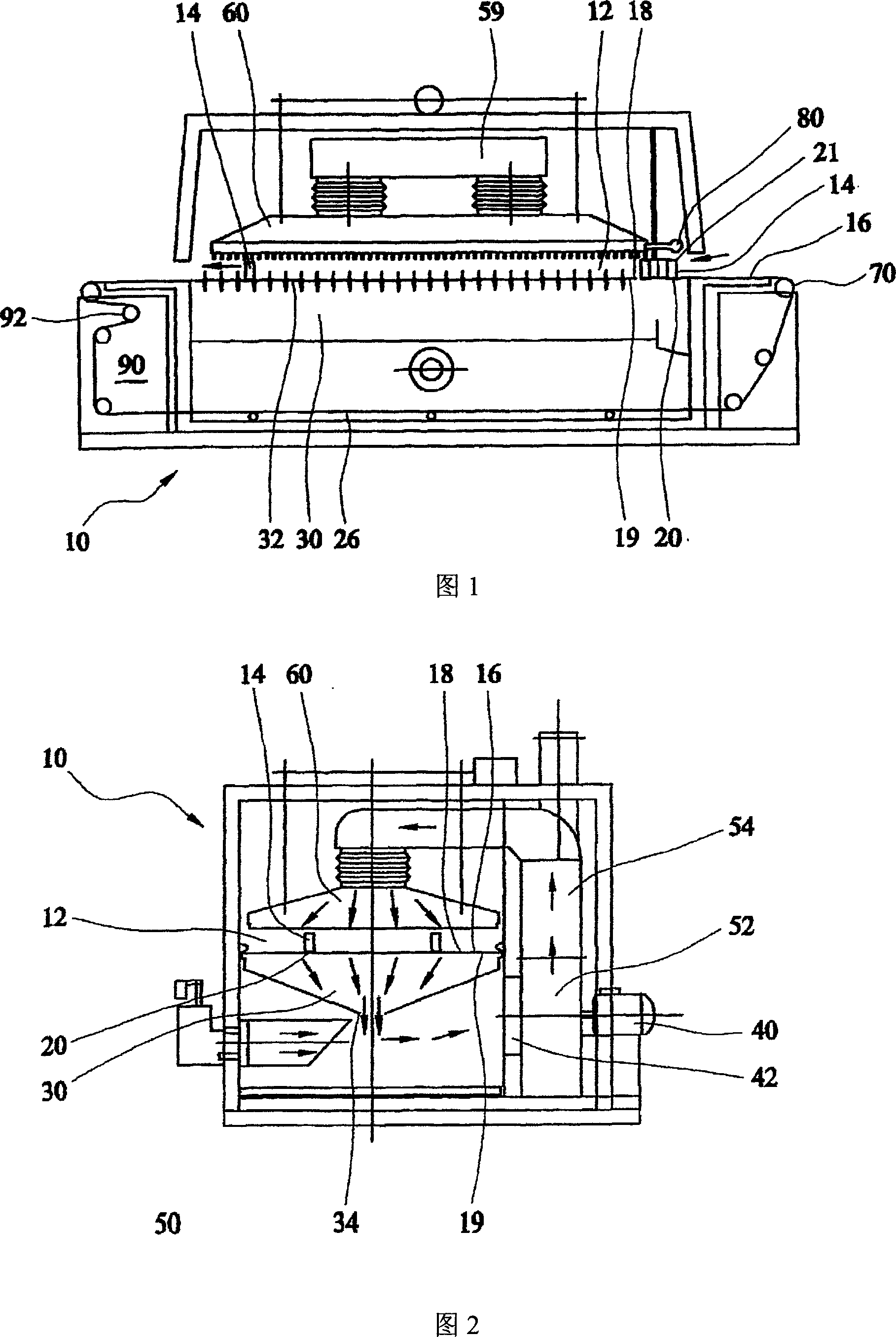

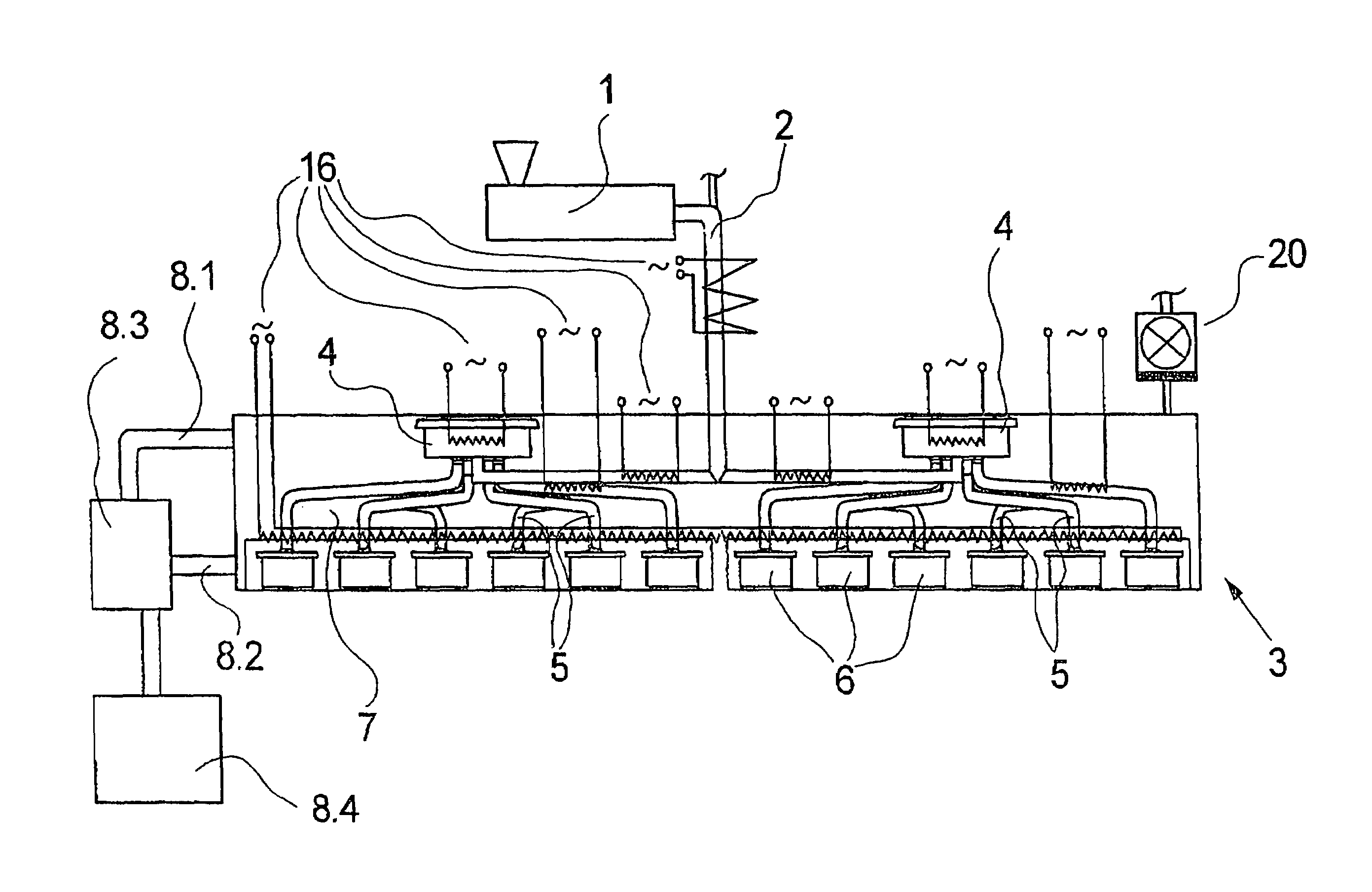

Drying apparatus and method

InactiveCN1981172ADrying solid materials without heatDrying machines with progressive movementsFiberProcess engineering

Drying apparatus (10) comprising an oven drying chamber (12) through which container and, in particular, metal beverage container cans (14) are arranged to pass through. The drying apparatus (10) is for use with in-line can producing apparatus and methods and is arranged to locate down-line from washing apparatus. The drying apparatus is arranged to remove water, chemicals, contaminants etc. from the cans prior to the further processing (e.g. printing) of the cans. The cans are supported on a Kevlar open mesh conveyor belt and a suction chamber is created to draw or attract the cans to the conveyor belt to increase the stability of the cans. Accordingly, this greater stability means that the air pressure of the convecting drying air can be greater when compared to prior art unstabilise drying apparatus.

Owner:GREENBANK TECH

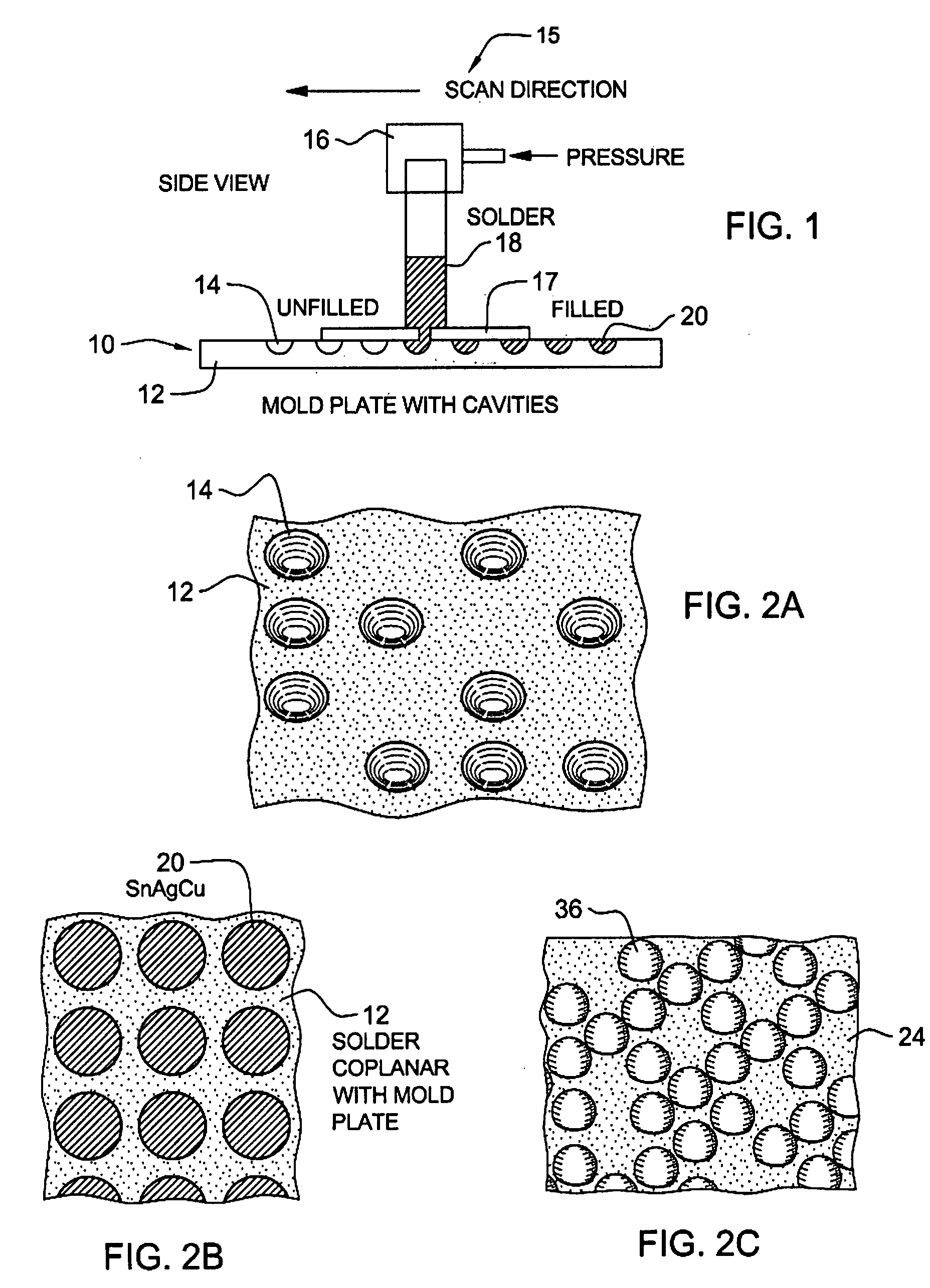

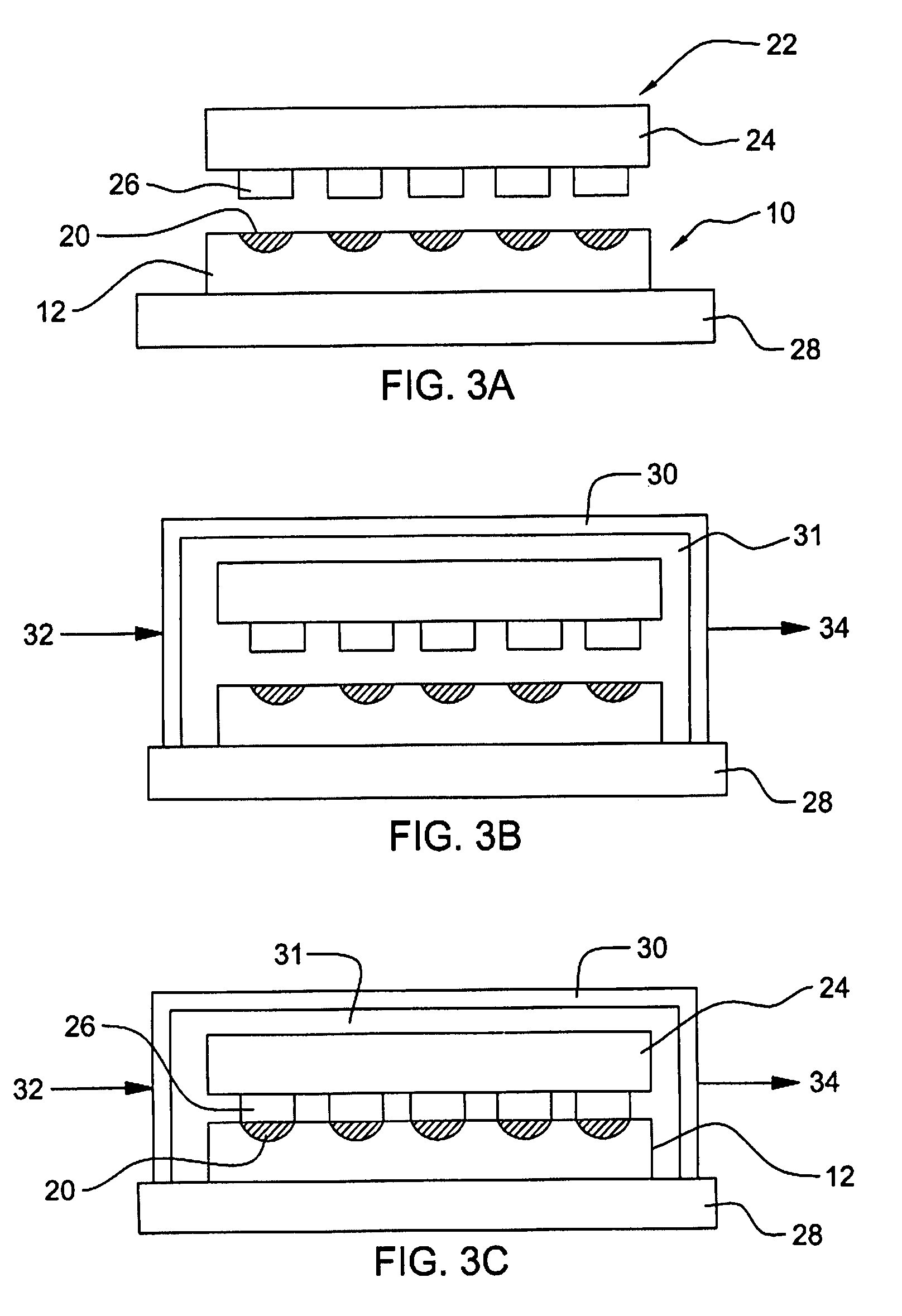

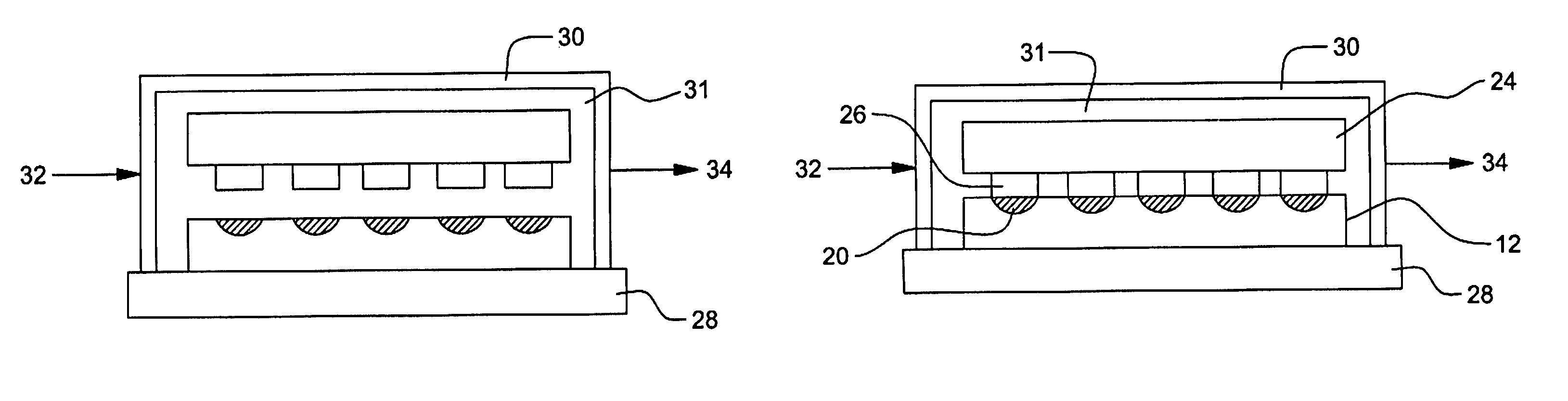

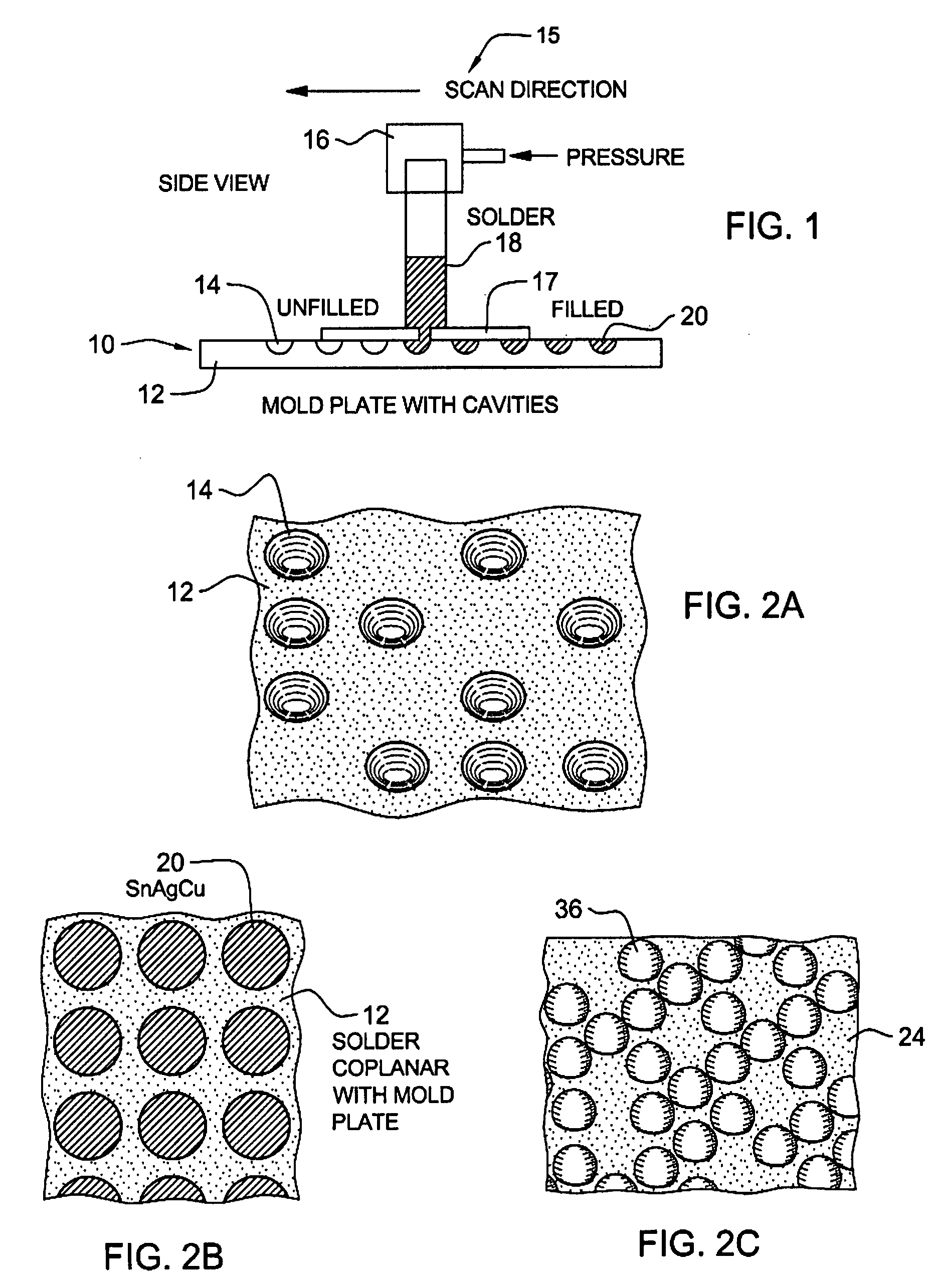

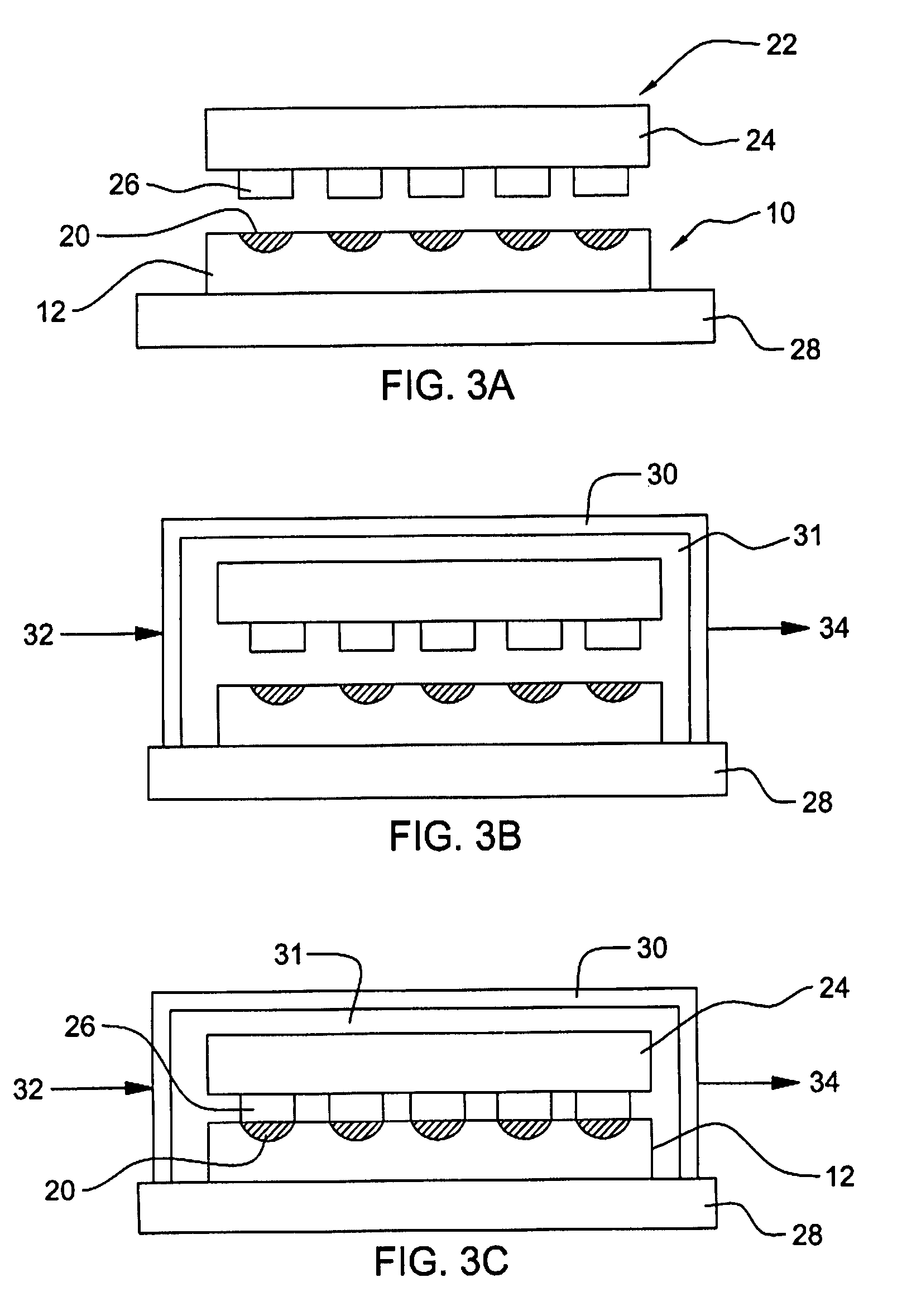

PROCESS FOR MAKING INTERCONNECT SOLDER Pb-FREE BUMPS FREE FROM ORGANO-TIN/TIN DEPOSITS ON THE WAFER SURFACE

InactiveUS20090020590A1Exhaust apparatusSilencing apparatusInterconnect technologyMelting temperature

A method is provided for making of interconnect solder bumps on a wafer or other electronic device without depositing any significant amount of tin or other solder component from the solder onto the wafer surface which tin can cause shorts or other defects in the wafer. The method is particularly useful for well-known C4NP interconnect technology. In one aspect of the invention, a reducing gas flow rate is used to remove oxides from the solder surfaces and wafer pad surfaces and is of a sufficient determined or pre-determined flow and / or chamber or mold / wafer spacing to provide a gas velocity across the solder surfaces and wafer pad surfaces so that Sn or other contaminants do not deposit on the wafer surface during solder transfer. In another aspect, the transfer contact is performed below the melting point of the solder and subsequently heated to above the melting temperature while in transfer contact. The heated solder in contact with the wafer pads is transferred to the wafer pads.

Owner:ULTRATECH INT INC

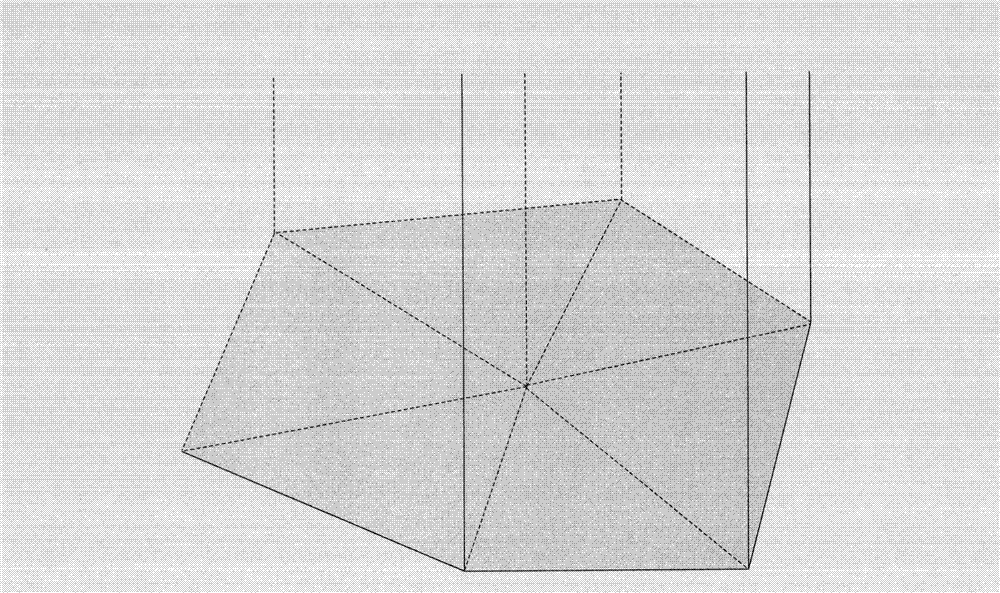

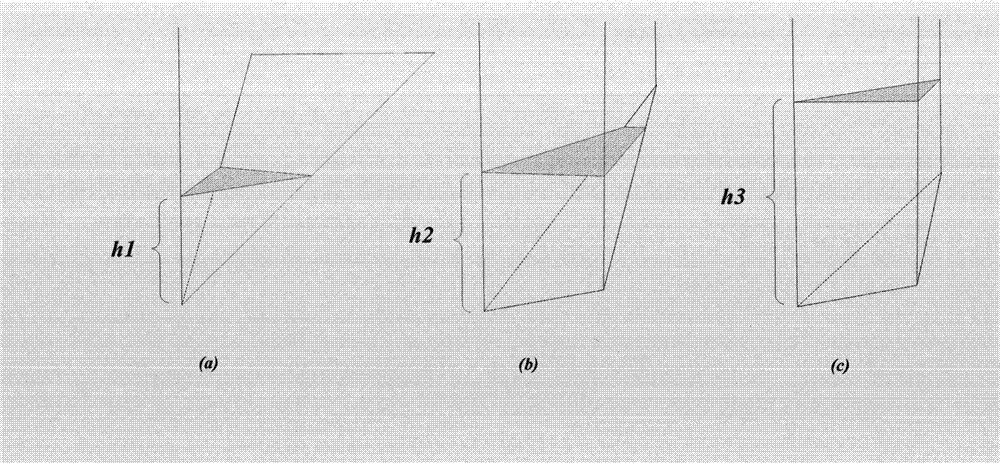

Urban area water logging flood processing simulation method based on CD-TIN

The invention discloses an urban area water logging flood processing simulation method based on a CD-TIN. The urban area water logging flood processing simulation method based on the CD-TIN takes a catchment area of an urban area based on a triangle surface patch partition as the basis of subsequent simulations. The urban area water logging flood processing simulation method based on the CD-TIN comprises (1) offering a calculation method of water volume runoff yield process in the catchment area based on inflow water volume and outflow water volume, (2) proposing a calculation method of dropsy water level in a flood area based on a triangular prism formed by a triangle which is taken as a bottom and three plumb lines which are made upwards from the three peak points of the triangle, and (3) designing a water volume confluence flow calculation method which takes characteristics of earth surface into consideration after the water volume of the catchment area reaches an water outlet. The urban area water logging flood processing simulation method based on the CD-TIN can effectively stimulate and analyze the range and the water depth of the urban area water logging flood, offers a new method for the research of an analysis software of the urban area water logging flood, and can supply technical support for urban area flood prevention, drainage scheme and emergency warning and rescue.

Owner:吴立新 +2

Automatic welding device and welding method of circuit board welding machine

ActiveCN105149719AAvoid stickingImprove welding qualitySolder feeding devicesEngineeringPressure difference

The invention relates to an automatic welding device of a circuit board welding machine. The automatic welding device comprises an outer shell, a guiding pipe, branch pipes and a nozzle. The outer shell of the welding device is fixedly mounted at the lower end of a sliding arm, and the guiding pipe is coaxially mounted in the outer shell; the upper end of the guiding pipe is communicated with a hot air input device in a sealed mode, and the lower portion of the guiding pipe is communicated with multiple branch pipes in a sealed mode; the lower end of the guiding pipe penetrates through the lower end face of the outer shell and is connected with the nozzle in a sealed mode. According to the nozzle of the automatic welding device, a high-temperature soldering tin spraying mode is adopted, the control over the amount of the soldering tin can be achieved by controlling the flow of high-pressure gas, and pressure difference generated by high-speed air flowing is used for spraying the soldering tin so as to weld direct-plugging elements, so that the soldering tin is prevented from being bonded to the nozzle, and the welding quality is improved.

Owner:天津天传电气传动有限公司 +1

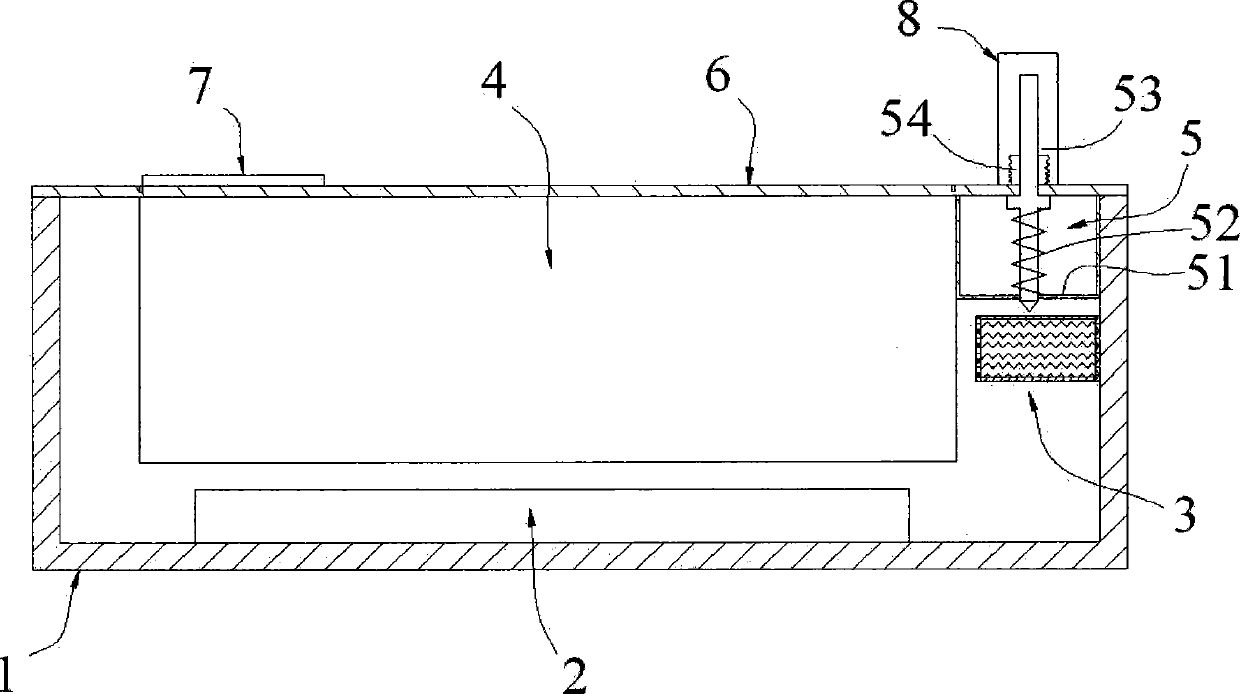

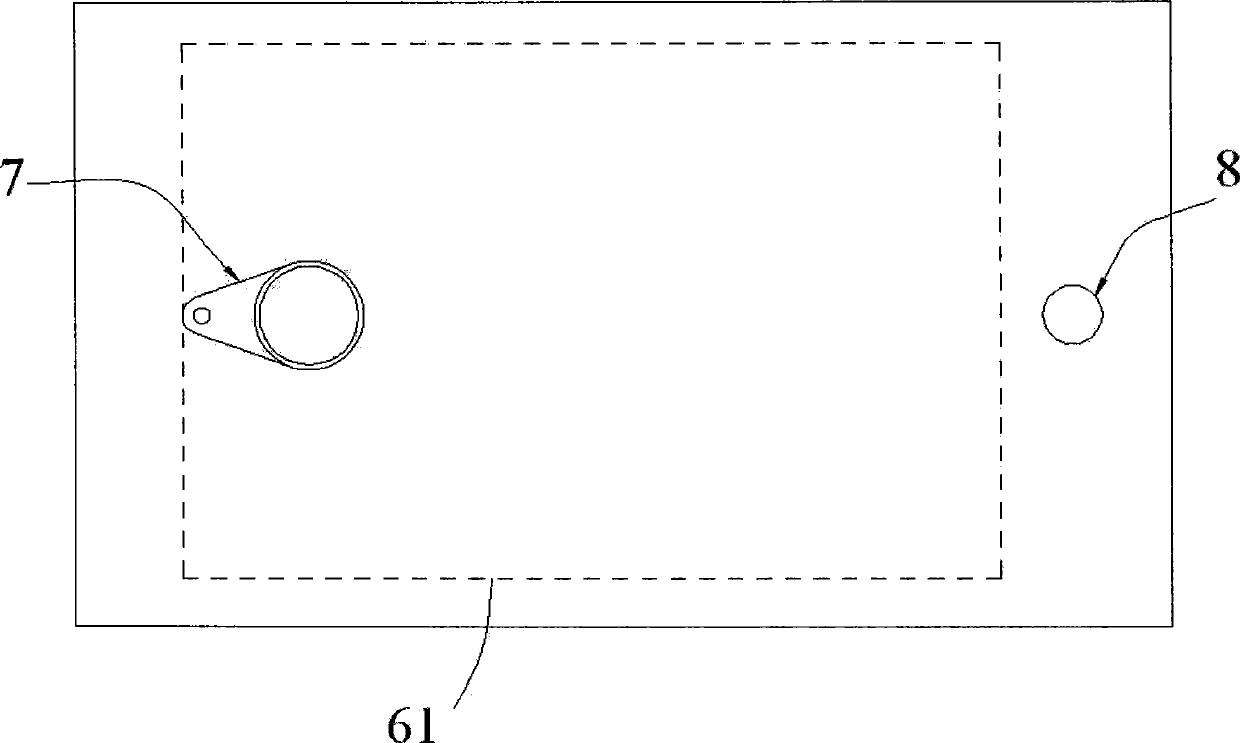

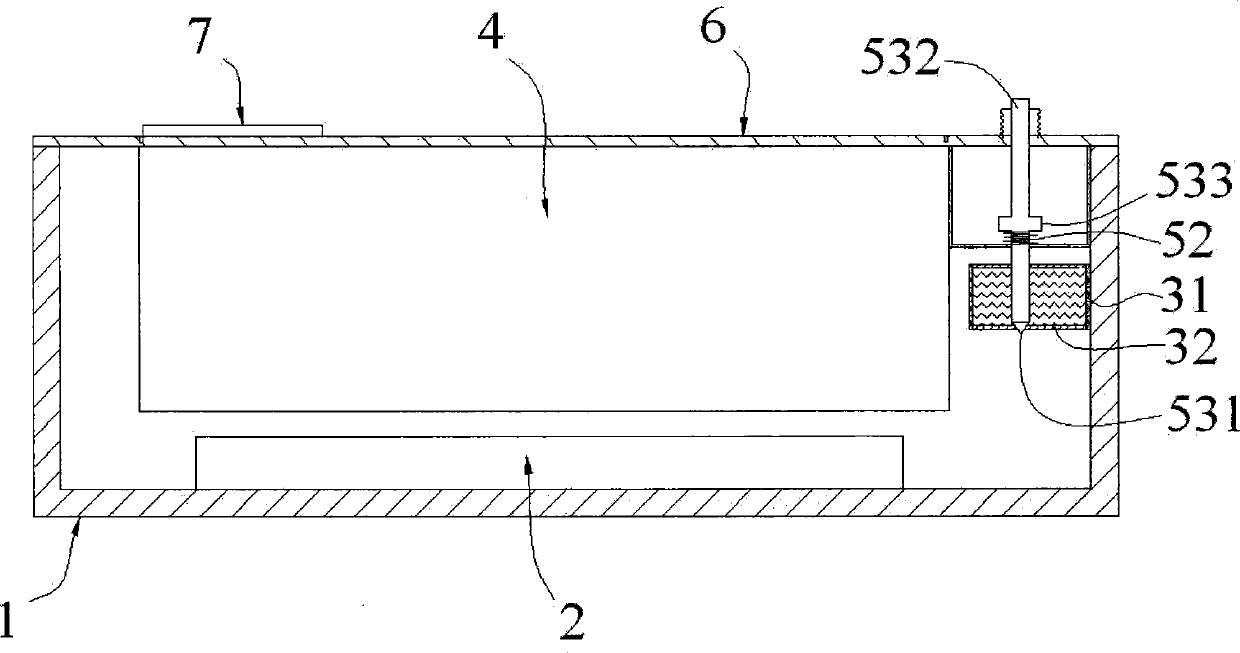

Tin can easy to heat and heating method thereof

InactiveCN104192433AIngenious structural designConvenient and quick heating methodContainers for heating foodPackaging foodstuffsHeating effectEngineering

The invention discloses a tin can easy to heat. The tin can easy to heat comprises an outer box, heating agents, a water container, an inner container and a puncturing device. The invention further discloses a heating method of the tin can easy to heat. The outer box, the inner container and the puncturing device are reasonably arranged for the tin can easy to heat, and the water container and the heating agents are arranged in the interlayer between the outer box and the inner container. When the tin can easy to heat needs to be used, what is only needed is to take down a safety cover, a puncturing rod is pressed downwards, and the tin can easy to heat can be automatically heated and food in the can is capable of being eaten after 13 minutes or so. Compared with an existing heating mode, more convenience and efficiency are brought, and convenience is brought to consumption by people; because of closed heating, the heating effect is better, the heating speed is higher, the application range is wide, the tin can is especially suitable for battlefields or outdoor activities, surrounding conditions can be observed once the puncturing rod is pressed downwards, and the situation that attention is influenced due to the complicated heating procedure is avoided. The tin can is simple and compact in integrated structure, easy to implement, convenient to store and carry, low in cost and suitable for wide application and popularization. The provided heating method is easy to achieve, convenient, fast and easy and convenient to carry out and brings convenience to life of people.

Owner:张延威

Leadless soldering tin paste

InactiveCN101112736AImprove performanceAvoid unrecognizableWelding/cutting media/materialsSoldering mediaFluorescenceUltraviolet

The invention belongs to a soldering tin in the electron and micro-electron circuit welding field, in particular to a novel soldering tin which increases the naked-eye discrimination by implementation from colorful conversion to colorless conversion after the soldering tin is melted. The soldering tin paste includes the tin powder which includes at least a fluorescent dye and at least a welding flux of the colorful dye; by the circumfluence melting, the colorful dye is changed into colorful dye, wherein, the fluorescent dye keeps the intrinsic characteristic and can emit the fluorescent under the irradiation of the ultraviolet radiation. The invention can provide a novel soldering tin which can be discriminated by the naked eyes and meanwhile by the emitting of the irradiation. The solid state of the invention has a certain color before using, the color appears after the soldering tin is melted, and different soldering tins can be discriminated by the fluorescent display of the invention by the irradiation of the ray.

Owner:KELITAISHENGZHEN ELECTRONICS

Rotary type tin can subpackaging counting mechanism

The invention belongs to the field of tinning equipment and particularly relates to a rotary type tin can subpackaging counting mechanism. The rotary type tin can subpackaging counting mechanism comprises a separating portion and a packaging portion, the separating portion comprises a feeding chute and a graduated plate which is radially embedded into the feeding chute, separating grooves are circumferentially and uniformly distributed on the graduated plate, and the graduated plate is connected with a rotating air cylinder; the packaging portion comprises a cooling bin, a counter and a loading chute, the cooling bin contains the feeding chute, the loading chute is installed at the tail end of the feeding chute, the counter is mounted on the loading chute, a baffle board is disposed at the initial end of the loading chute, and the baffle board is connected with a rotating air cylinder; the counter comprises a trigger and a processing control module, and the processing control module is respectively electrically connected with the trigger and the rotating air cylinder which is connected with the baffle board. By means of the separating portion and the counter, tin cans can be separated and meanwhile, counted and packaged, separating and packaging can be synchronously performed, thereby, separating and packaging processes can be combined on one machine tool, and the problem that a separating mechanism and a packaging mechanism in an existing structure are independent is avoided.

Owner:重庆信奇建材机械制造有限公司

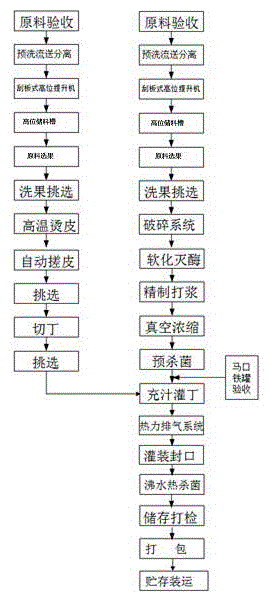

Method for preparing canned diced tomatoes

ActiveCN104982853AIndividual integrityReduce lossesClimate change adaptationFood preservationLycopenePre washing

The invention discloses a method for preparing canned diced tomatoes. The method specifically relates to raw material inspection, pre-washing drifting separation, a scraper type high-altitude lifting machine, an overhead storage tank, raw material selection, tomato washing and sorting in a bubbling tank, scald peeling, dicing and sorting, tin can inspection, a breaking system, preheating and softening enzyme deactivation, refining and pulping, vacuum concentration, pre-sterilization, juice and dice canning, a heating power exhaust system, filling and sealing, heat sterilization with boiled water, packaging, standing and checking, and storage and transportation. During scald peeling, peels are cured through high-temperature steam and then delivered to a vacuum section for condensation so as to shrink, crack and fall off, and tomatoes subjected to steam scald peeling are rubbed and rotated through rollers so that peels can completely fall off. According to the method, during peeling, after high-temperature steam scalding, tomatoes are rubbed and peeled through the rubber rollers, so that the effects of quick peeling, tomato integrity, and lycopene loss reduction are realized, fully-automatic mechanical continuous production is achieved, labor intensity is relieved, product competitiveness is improved, and market share is increased.

Owner:XINJIANG GUANNONG FRUIT & ANTLER GROUP +2

Spin beam

An apparatus for spinning melt-spun filament yarns including a spin beam is disclosed. A polymer melt fed to a spin beam is distributed within the spin beam to a plurality of spinning cans mounted on the spin beam. To reduce costs to the manufacturer for ensuring ease of disassembly of the spin beam, as well as to avoid the need for disassembling the spin beam and having a furnace on hand, the spin beam is provided with an integrated or removably attachable regenerative heater by which the melt-conducting components of the spin beam can be heated to a regeneration temperature of between about 450 to 550° C. to pyrolytically remove the deposits.

Owner:SAURER GMBH & CO KG

Hydrocarbons of carbon nano-tube loaded nickel-stannum and method of manufacturing the same and use thereof

InactiveCN101108351AImprove hydrogen storage performanceExcellent hydrogenation catalytic performanceOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeNitrophenol

The invention relates to fine chemical product technology field, in particular to a hydrogenation catalyst of CNT load nickel-tin and the preparation method and use. The invention is mainly composed of nickel, tin and CNT, wherein, the mass ratio of the above three substances are 5 to 10 / 1 to 5 / 20 to 80, and the nickel and the tin can be distributed on the surface and the gas of the CNT evenly. The catalyst of the invention can be used for the catalyzing and hydrogeneration processes aminophenol to nitrophenol, the process of hydrogenation aminophenol realizes short flow, large production ability, low labor intensity, high yield, small equipment investment and low composite cost, which is beneficial for protecting environment and saving energy and realizes the continuous clean production of hydrogenation aminophenol.

Owner:INST OF CHEM CHINESE ACAD OF SCI

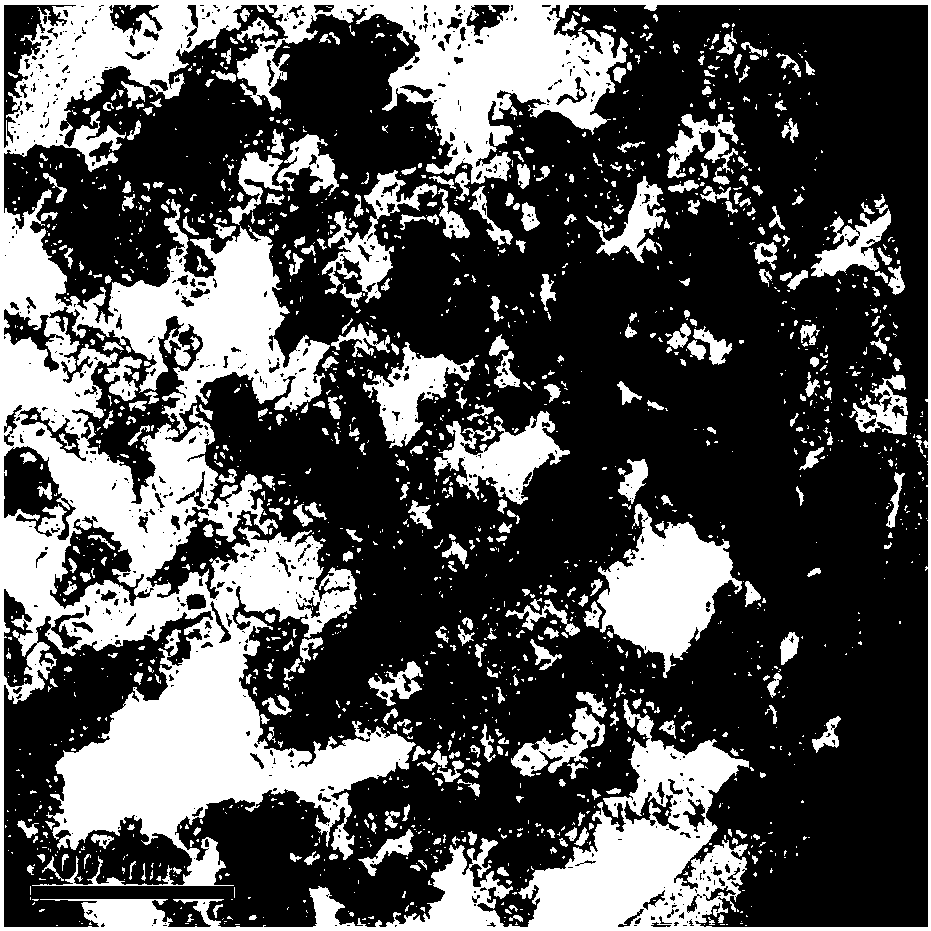

Nanometer tin/carbon composite material and preparation method thereof

InactiveCN108134091AAvoid bulky metallic tin situationsEvenly distributedMaterial nanotechnologyAlkaline accumulatorsCarbon compositesPotassium borohydride

The invention relates to a nanometer composite material, in particular to a nanometer tin / carbon composite material and a preparation method thereof. A nanometer tin and carbon compound is obtained bytaking various carbon materials as a substrate, tin nitrate, tin chloride, tin sulfate, tin acetate, tin citrate and the like as a tin source, water containing an organic complexing agent, ethylene glycol, propylene glycol or other mixture as a solvent and sodium borohydride, potassium borohydride, hydrazine hydrate and the like as a reducing agent and by an absorption-decomposition-reduction method. According to the method, a solution containing tin ions is absorbed to a surface of a carbon material, remaining solution is filtered, the tin oxide / tin and carbon compound is obtained after thermal treatment, and the nanometer tin / carbon composite material is finally obtained by reduction reaction. In the composite material obtained by the method, metal tin particles are uniformly distributed in surfaces of carbon particles in nanometer size, and a phenomenon that a large amount of tin can be agglomerated by a traditional tin reduction method is prevented.

Owner:CENT SOUTH UNIV

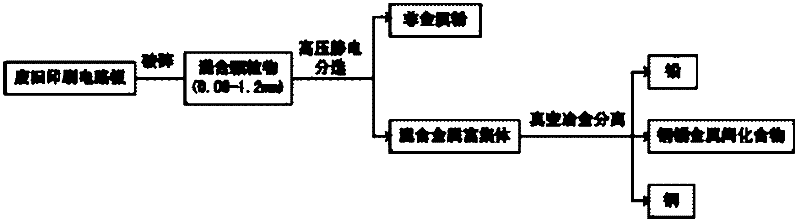

Recovery method of lead in waste circuit board

InactiveCN102357504AEasy to recycleLow costSolid waste disposalElectronic waste recyclingRecovery methodEvaporation

A recovery method of lead in a waste circuit board includes the steps as follows: first crushing the waste circuit board, the particle diameter ranging from 0.08mm to 1.2mm, and enabling metal materials (copper, soldering tin and the like) in the circuit board to be separated from non-metal materials in the circuit board; separating mixed materials obtained after crushing in high-voltage static mode, enabling metal parts to be separated from non-metal parts, and obtaining mixed metal enrichment bodies; performing lead evaporation in a vacuum furnace with mixed metal enrichment bodies containing lead serving as raw materials, and finally condensing lead steam on the condenser. Lead recovery can reach over 90%, and purity can reach over 99%. Therefore, lead is separated from mixed metal, tin can be enriched, simultaneously, purity of copper is improved, and mixed metal after vacuum separation can be continuously used in targeted purification separating in the next step. The recovery method of lead in the waste circuit board particularly has the advantages in the aspect of environment pollution decreasing, avoids secondary pollution of toxic heavy metal lead to the largest extent, and has the advantages of being low in cost, high in efficiency, free of pollution and the like.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method and application of durable super-hydrophobic finishing agent

The invention relates to a durable super-hydrophobic finishing agent. The finishing agent comprises components as follows: long-chain alkyl alkoxy polysiloxane, a self-prepared active cationic emulsifier and organic tin. The long-chain alkyl alkoxy polysiloxane is taken as a main active component, an organic tin catalyst and the self-prepared active cationic emulsifier are taken as auxiliary components, and three active groups exist in the structure of the long-chain alkyl alkoxy polysiloxane, are hydrolyzed through heating under the action of water and are interlinked to form a net structure, so that the hydrophilicity is greatly reducer, and meanwhile, the washability is improved; the organic tin can promote combination of organosilicon with fibers, so that the hydrophobicity and the washability are further improved; the self-prepared active cationic emulsifier can be decomposed under a heating condition to produce another hydrophobic substance, and the substance and the long-chain alkyl alkoxy polysiloxane have a synergistic waterproof effect, so that the super-hydrophobic effect is realized. The preparation method and the application have the characteristics that the technology is simple, the application cost is low and the like.

Owner:NANXIONG DING CHENG NEW MATERIAL TECH CO LTD

Production process of nickel tab of lithium ion battery

ActiveCN106356491ALess stableLess prone to false weldingCell component detailsSodium stearateInstability

The invention provides a production process of a nickel tab of a lithium ion battery. The process comprises the following steps of (1) processing solution preparation: mixing 1 to 2 weight percent of sodium carbonate, 10 to 15 weight percent of caustic soda, 0.5 to 1 weight percent of sodium stearate and 82 to 88.5 weight percent of water to prepare a processing solution, wherein the sum of the weight percentage of all ingredients of the processing solution is 100 percent; (2) passivation relieving treatment: putting a tab to be treated into the processing solution with a certain temperature to be soaked for a certain time to remove a passivation layer on the surface of the tab; (3) cleaning: putting the tab treated in the second step in water with the certain temperature; using ultrasonic waves for processing for a certain time to remove the processing solution on the tab. The tin can be easily soldered on the surface of the nickel tab on the premise of not influencing the performance of the tab glue, so that undesirable phenomena such as soldering instability, false soldering, insufficient soldering and the like cannot easily occur when the nickel tab is connected with a circuit board.

Owner:DONGGUAN ZHUOYUE NEW MATERIAL TECH CO LTD

Printed circuit board and mobile terminal

InactiveCN106231789AEnsure welding stabilityGuaranteed cooling effectPrinted circuit aspectsElectrical connection printed elementsEngineeringSoldering process

The invention discloses a printed circuit board and a mobile terminal. The printed circuit board comprises a board body having a first region for main welding plate arrangement, a main welding plate arranged at the first region, solder separation bars, soldering tin layers, and an electronic device. The solder separation bars arranged at the first region divide the main welding plate into a plurality of sub welding plates and are used for preventing the series flowing of soldering tin among the adjacent sub welding plates during the welding process. The soldering tin layers are arranged on the sub welding plates. The electronic device arranged at the first region is connected with the sub welding plates by the soldering tin layer. According to the provided printed circuit board, because the main welding plate are divided into multiple sub welding plates by the solder separation bars and the dimensions of the sub welding plates are smaller than that of the main welding plate, the soldering tin can be arranged on all sub welding plates during the welding process and welding bubbles and holes in the soldering tin layers are prevented, thereby guaranteeing stability and the heat radiation performance of the QFN packaging device welding.

Owner:NUBIA TECHNOLOGY CO LTD

Tin-bismuth alloy plating technology

The invention discloses a tin-bismuth alloy electroplating process. A tin-bismuth coating is plated on the pure tin coating of a plated part. The mass ratio of tin and bismuth in the tin-bismuth coating bath is 94:6. The pure tin layer and the tin-bismuth coating The total film thickness of the tin-bismuth coating is 7.5-12.5 μm, wherein the bismuth layer accounts for 5-10% of the total film thickness. The present invention adds a tin-bismuth layer on the basis of the pure tin layer, so that the obtained Sn-Bi alloy coating is uniform and dense, bright, has excellent bonding force and brazing property, and the tin-bismuth alloy coating of the present invention can not only prevent the formation of tin whiskers and The transformation of gray tin has higher quality and is non-toxic and environmentally friendly. The plating solution of the invention is stable, easy to operate, environmentally friendly and non-toxic.

Owner:ACKOTEC ZHONGSHAN ELECTRONICS PARTS

Labeling device used for round tin can

InactiveCN104443609ASolve efficiency problemsSolve the costLabelling machinesLabelling short rigid containersEngineeringIdler-wheel

The invention relates to the field of tin can processing, in particular to a labeling device used for a round tin can. The labeling device comprises a material feeding device, a separation device, a conveying device and a labeling device body, wherein the material feeding device is an oblique material feeding sliding chute; the separation device is arranged between the material feeding device and the conveying device and is a rotary indexing table, the rotation center of the rotary indexing table and a bottom plate of the material feeding sliding chute keep in the same plane, and grooves used for containing canned food are uniformly formed in the circumferential direction of the rotary indexing table; the conveying device comprises a tensioned conveying belt, the conveying belt is provided with speed-reduction idler wheels used for pressing the tin can; the labeling device body comprises an adhesive feeding groove, adhesive applying idler wheels and a labeling tray, the adhesive feeding groove is formed in an output port of the conveying device, the adhesive applying idler wheels are arranged in the adhesive feeding groove, and the labeling tray is arranged at the output end of the adhesive feeding groove. The labeling device used for the round tin can solves the problem that the efficiency of an existing labeling technique is low or the equipment cost is high.

Owner:CHONGQING GUANGHENG FOOD DEV

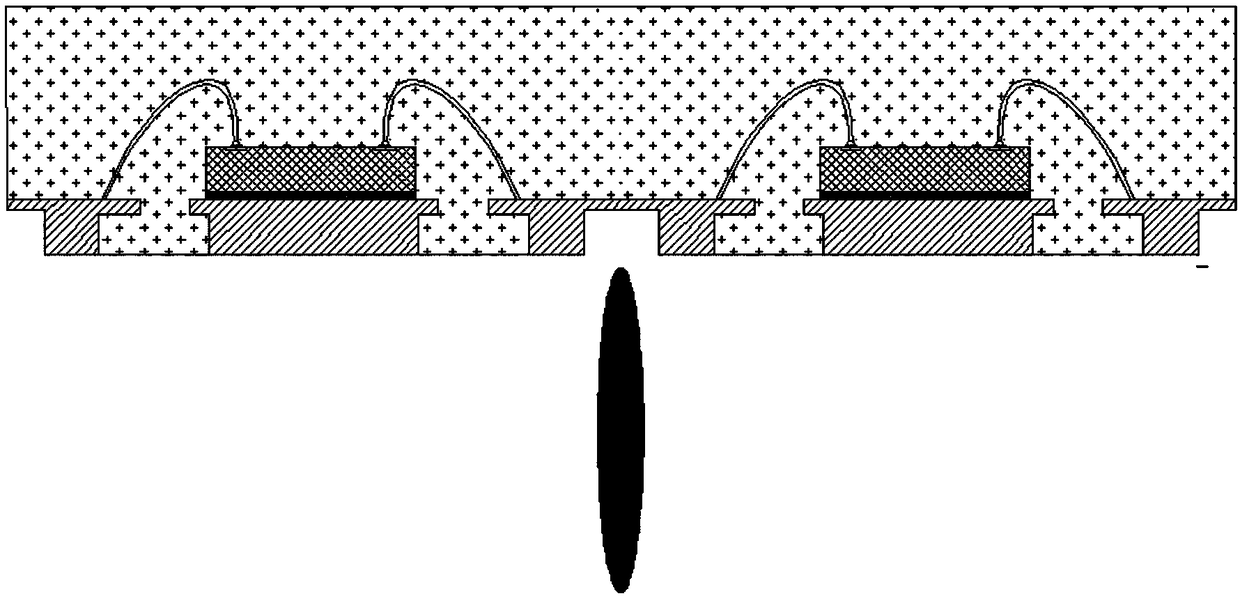

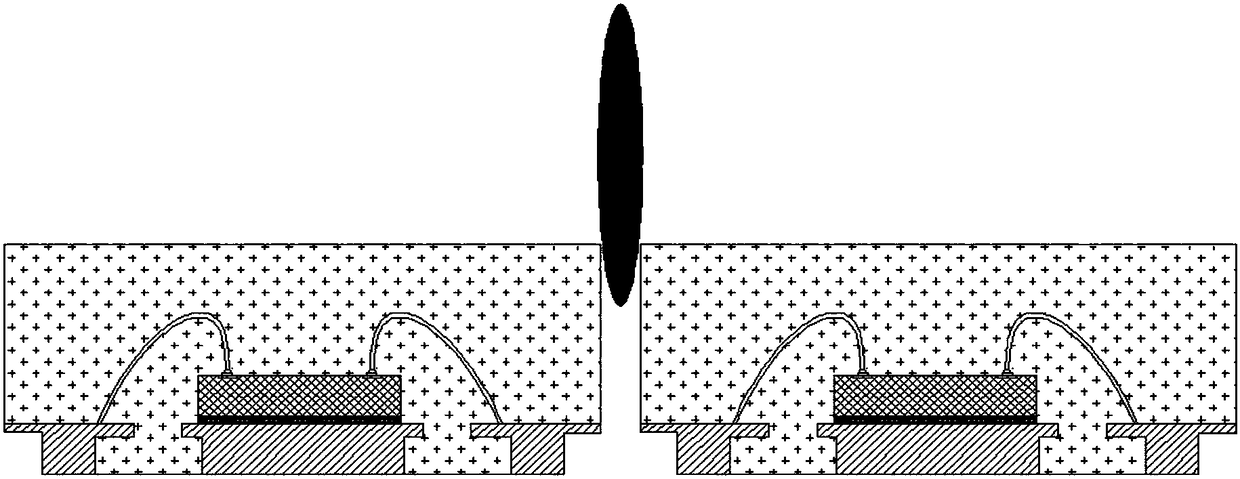

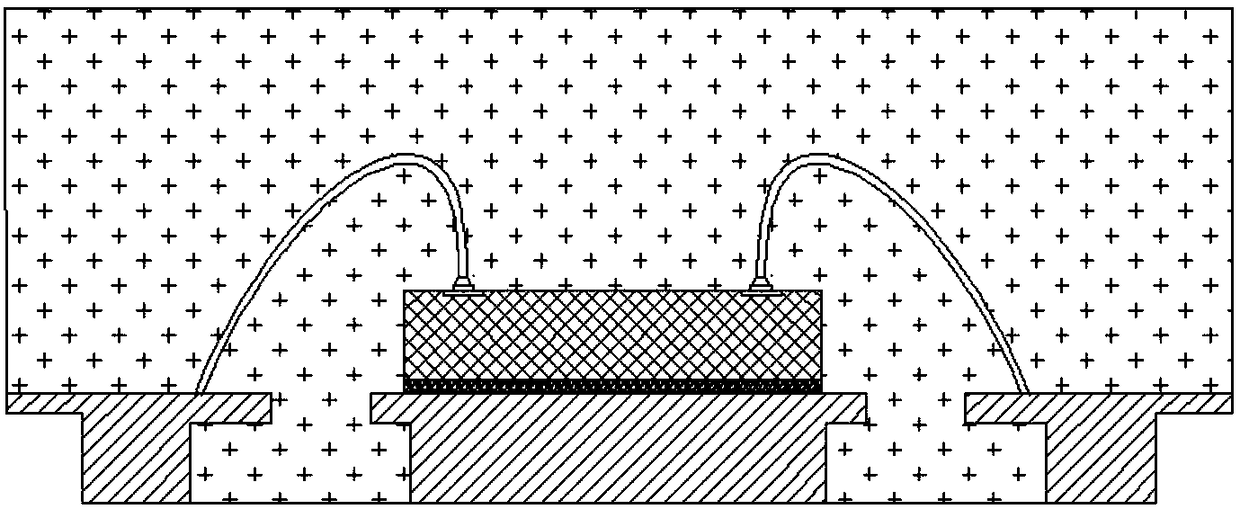

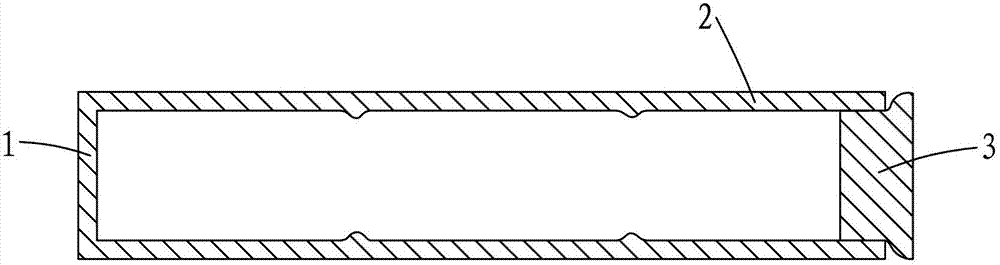

Lamination package structure having pin side wall tin climbing function and manufacturing process thereof

ActiveCN108198790AReduce cutting costsIncrease binding areaSemiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

The invention relates to a lamination package structure having a pin side wall tin climbing function and a manufacturing process thereof. The structure comprises a first paddle and a first pin, wherein the first pin comprises a planar part and a side wall part, the side wall part comprises a plurality of side wall surfaces, the planar part and the side wall part are in transition connection by anarc part, a first chip is arranged on a front surface of the first paddle, a first plastic sealing material wraps peripheral regions of the first paddle, the first pin and the first chip, a second paddle and a second pin are arranged on a surface of the first plastic sealing material, a second chip is arranged on a front surface of the second paddle, and a second plastic sealing material wraps peripheral regions of the second paddle, the second pin and the second chip. Welding tin can climb to a relatively high height along a vertical side wall during welding of a PCB, so that the bonding areaof the welding tin and the pins is expanded; and meanwhile, air at the pins can be discharged along protruding arcs, so that the welding performance and the welding reliability of a product are improved.

Owner:JCET GROUP CO LTD

Process for making interconnect solder Pb-free bumps free from organo-tin/tin deposits on the wafer surface

A method is provided for making of interconnect solder bumps on a wafer or other electronic device without depositing any significant amount of tin or other solder component from the solder onto the wafer surface which tin can cause shorts or other defects in the wafer. The method is particularly useful for well-known C4NP interconnect technology. In one aspect of the invention, a reducing gas flow rate is used to remove oxides from the solder surfaces and wafer pad surfaces and is of a sufficient determined or pre-determined flow and / or chamber or mold / wafer spacing to provide a gas velocity across the solder surfaces and wafer pad surfaces so that Sn or other contaminants do not deposit on the wafer surface during solder transfer. In another aspect, the transfer contact is performed below the melting point of the solder and subsequently heated to above the melting temperature while in transfer contact. The heated solder in contact with the wafer pads is transferred to the wafer pads.

Owner:ULTRATECH INT INC

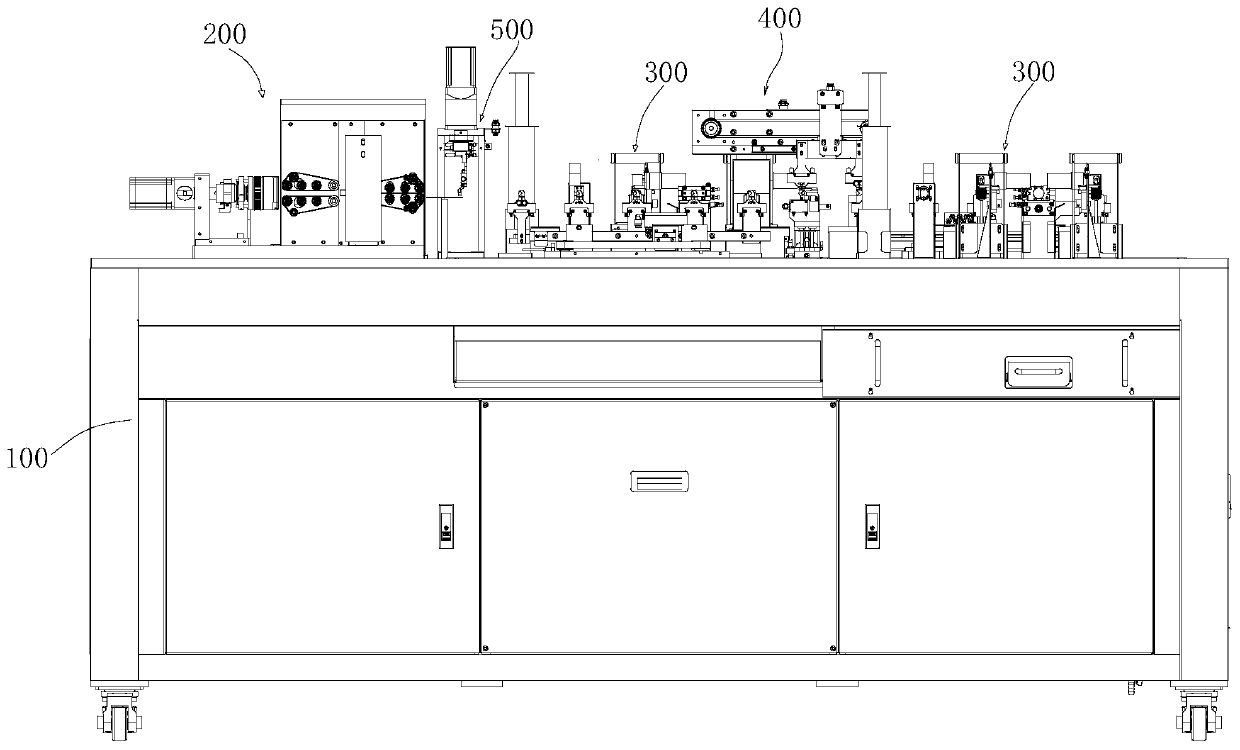

Cable double-end peeling and tin dipping integrated equipment

PendingCN110048290AEvenly distributedAvoid fried tinLine/current collector detailsElectronic waste recyclingCopper wireEngineering

The invention discloses cable double-end peeling and tin dipping integrated equipment which comprises a machine table, and the machine table is provided with a cable cutting and peeling device and twoopposite tin dipping devices; a transfer device is arranged between the two tin dipping devices, and a steering mechanical arm is arranged between the cable cutting and peeling device and the adjacent tin dipping device. Each tin dipping device comprises two sets of tin melting devices, a tin scraping mechanism, a tin dipping clamping mechanism, a tin scraping clamping mechanism and a tin dippingconveying mechanism. Each tin dipping conveying mechanism comprises a translation mechanism and at least three groups of conveying clamping mechanisms which are arranged on the translation mechanismat equal intervals; and the distance between the adjacent conveying clamping mechanisms is equal to or approximately equal to the distance between the tin scraping clamping mechanism and the tin dipping clamping mechanism. Tin can be uniformly distributed on the surface of the copper wire through two times of tin dipping, so that tin dipping is more attractive; and the equipment can meet double-head tin dipping of wires with different lengths.

Owner:广东银钢智能科技有限公司

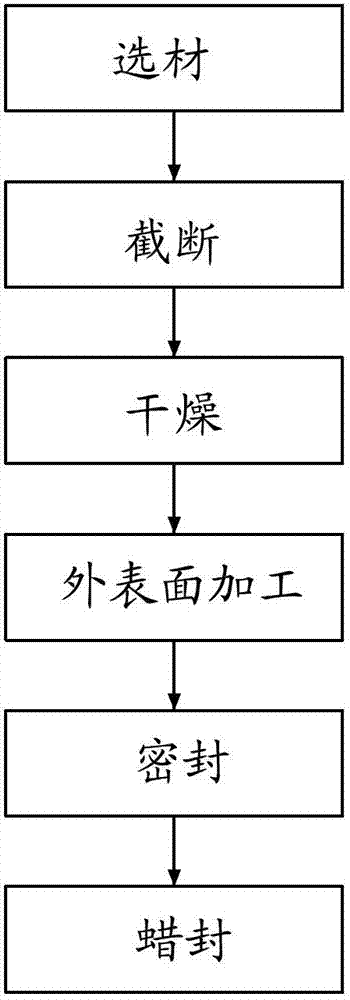

Manufacturing process of environment-friendly packaging tin

InactiveCN103043274AAvoid pollutionSimple processing technologyClosuresBio-packagingEnvironmental resistanceTea leaf

The invention provides a manufacturing process of an environment-friendly packaging tin. The manufacturing process includes: selecting bamboo growing over three years; cutting off the bamboo, reversing a bamboo joint to form a bamboo tube with an open end and a closed end; drying the cut bamboo at the temperature not higher than 80 DEG C until the water content is below 4%; and making a cork out of dried cork wood, ensuring the diameter of the cork to be slightly larger than that of the open end of the bamboo tube matching with the cork, clamping the cork to reduce the diameter of the cork, pushing the clamped cork to a preset position at the open end of the bamboo tube, and releasing to allow the cork to naturally expand and plug the bamboo tube. The manufacturing process is simple, airtightness is high, the manufacturing process is especially suitable for packaging tea, foods requiring vacuum package and the like, and pollution of the foods in the packaging tin can be prevented effectively. The environment-friendly packaging tin is truly environment-friendly.

Owner:杨兰钦

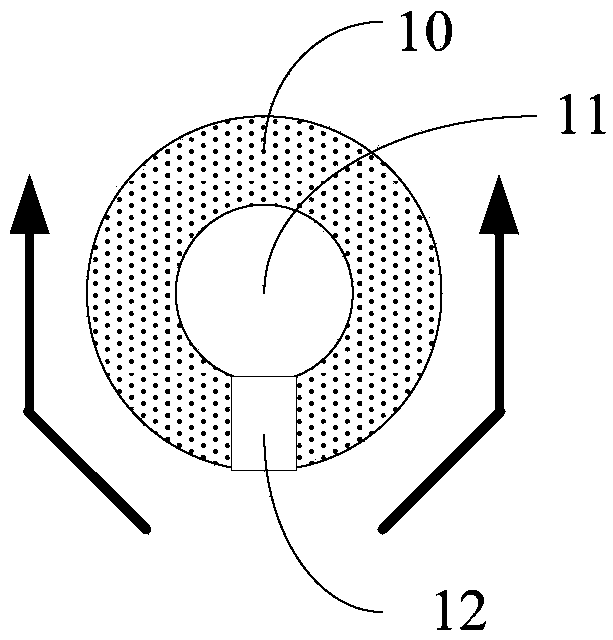

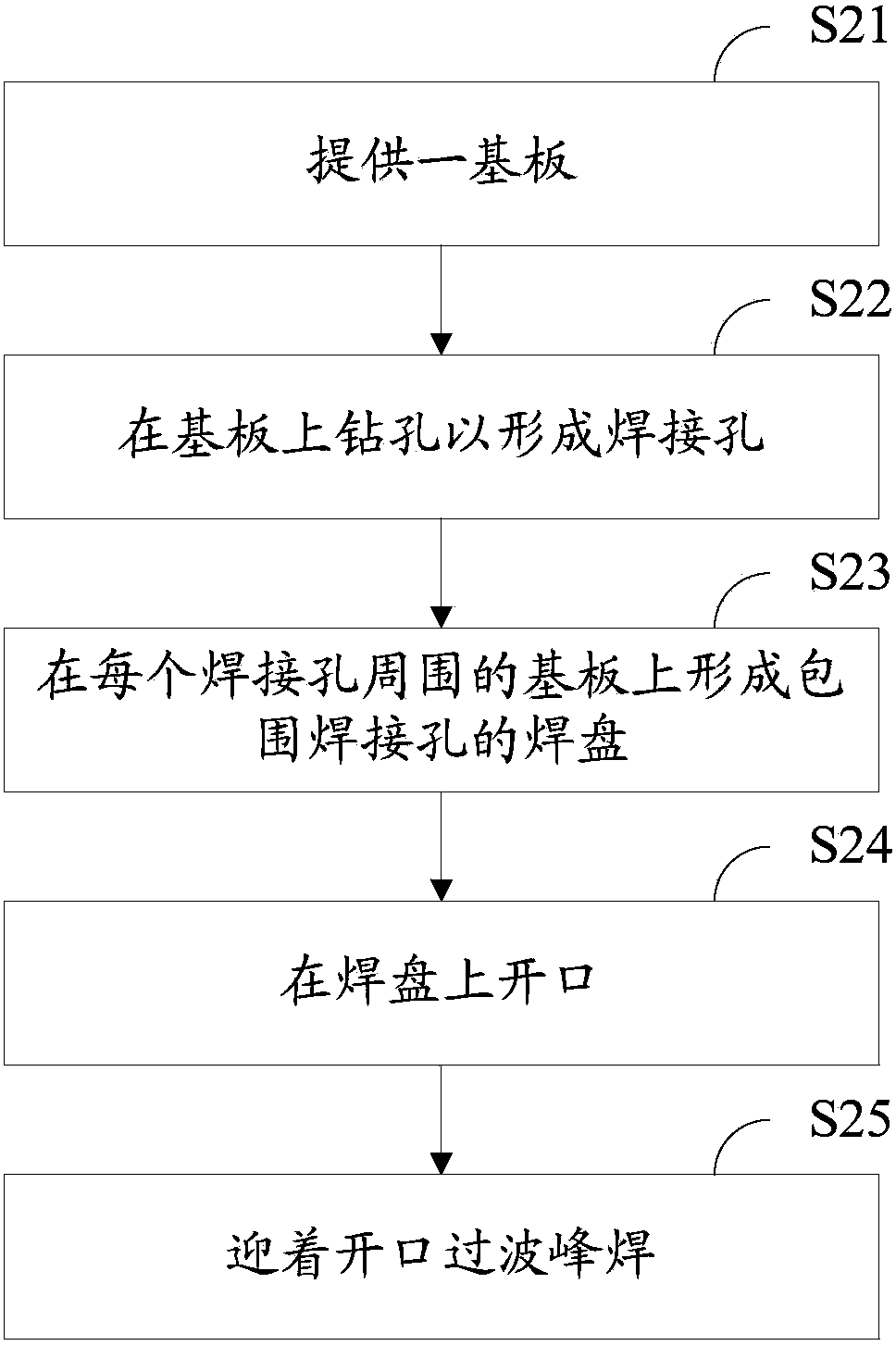

Method for preventing soldering holes from being blocked in wave soldering process and printed circuit board

InactiveCN104080277AAvoid easy cloggingNot easy to flow intoPrinted circuit assemblingElectrical connection printed elementsEngineeringMechanical engineering

The invention discloses a method for preventing soldering holes from being blocked in the wave soldering process. The method includes the following steps that a substrate is provided; holes are drilled in the substrate so as to form the soldering holes; a bonding pad enclosing each soldering hole is formed in the portion, around the soldering hole, of the substrate; an opening is formed in at least one bonding pad and covered with green oil; wave soldering is conducted towards the opening. The invention further relates to a printed circuit board. Because the opening of the bonding pad is covered with the green oil so that soldering tin cannot flow through in the wave soldering process, the soldering tin can only flow along the two sides of the opening and is not prone to flowing into the soldering holes, and thus it is guaranteed that the soldering holes without inserts cannot be blocked by the soldering tin easily in the wave soldering process.

Owner:SHENZHEN GONGJIN ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com