Method and device for disassembling electronic components from waste printed circuit boards and recovering soldering tin

A technology for waste printed circuit boards and electronic components, which is applied in the field of dismantling of waste printed circuit boards and electronic components and recycling of solder, which can solve the problems of complex components, poor operation effect, difficult recovery of precious metals, etc. Circulation, quality assurance, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

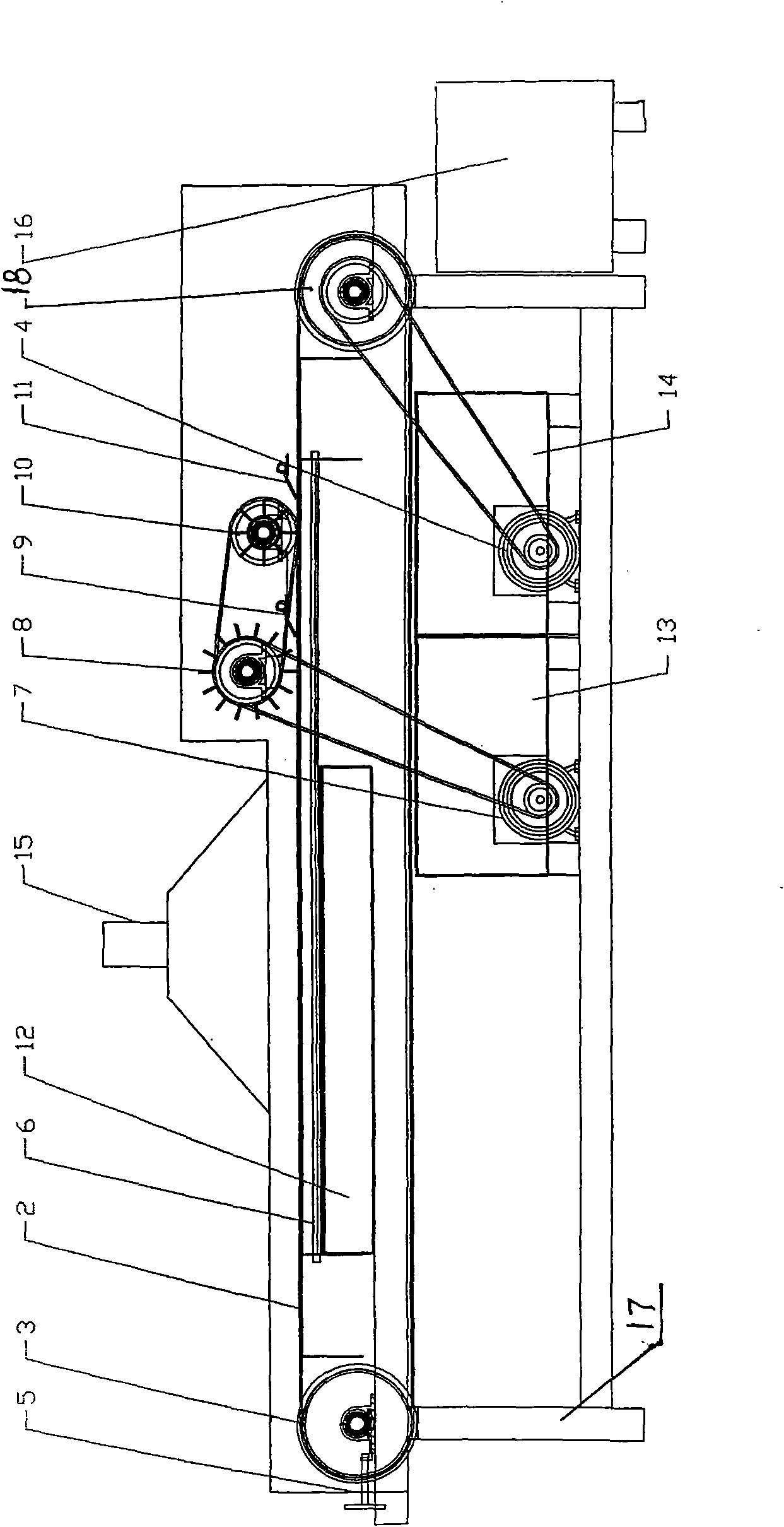

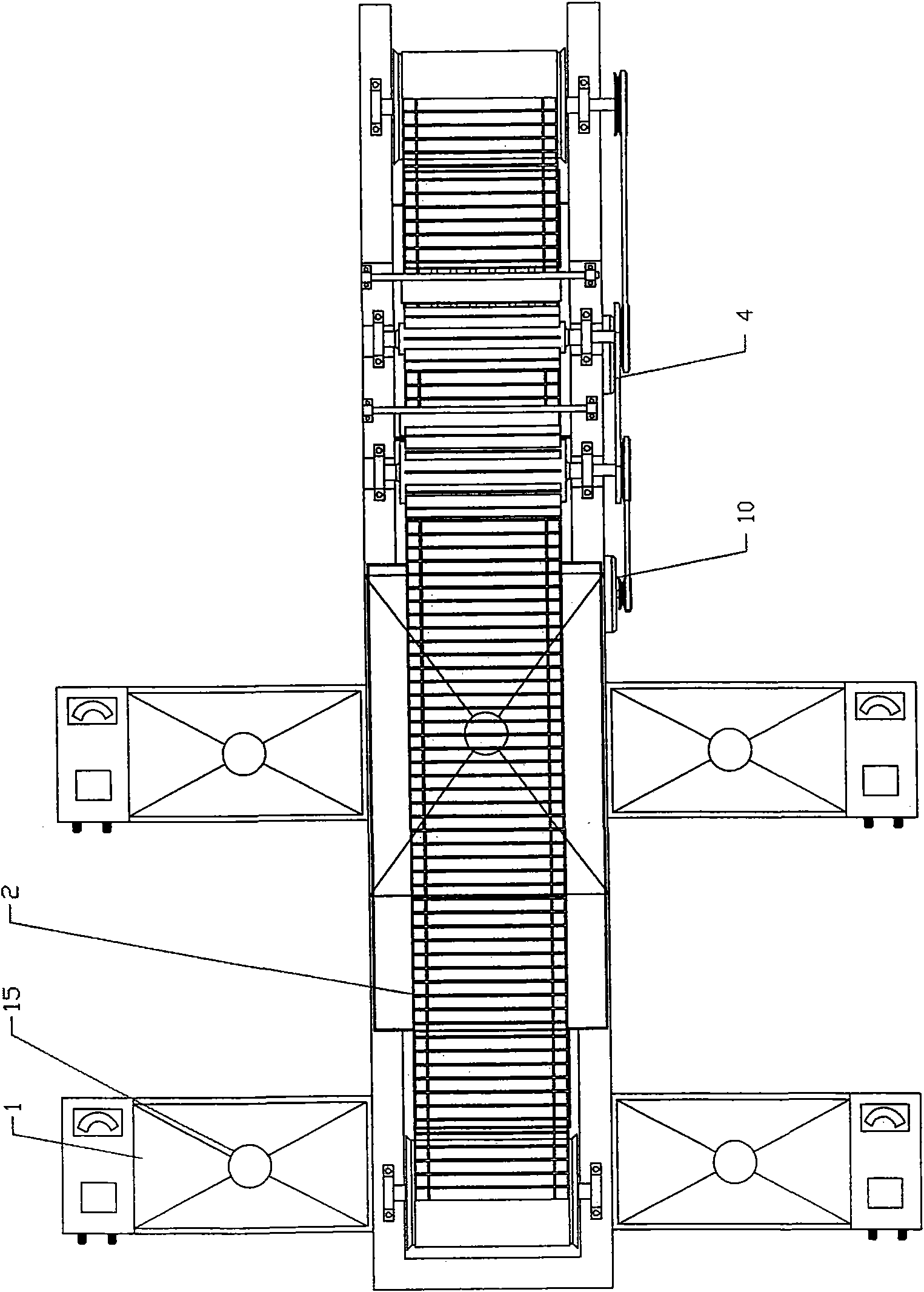

[0026] Referring to the accompanying drawings, the dismantling and solder recovery method of this waste printed circuit board electronic components of the present invention is: place the circuit board with the components face up in the melting tin furnace 1, and the wire leg tin is heated slowly Melt, remove larger components manually, send the circuit board containing small components and solder to the conveyor belt 2 with a self-controlled electric heating device 6 at the bottom, use the hob 8, 10 to suppress the circuit board and move forward For conveying, there are front scraper 9 and rear scraper 11 on the rear side of the hob to shave off components and solder, and through the sequential cooperation of one, two or more sets of hobs and scrapers, the components and solder on the circuit board are separated. The solder is recovered from the receiving basins 12, 13, and 14 under the tin melting furnace and the conveyor belt; the high temperature, peculiar smell, and harmful...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com